Patents

Literature

80results about How to "Control deterioration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

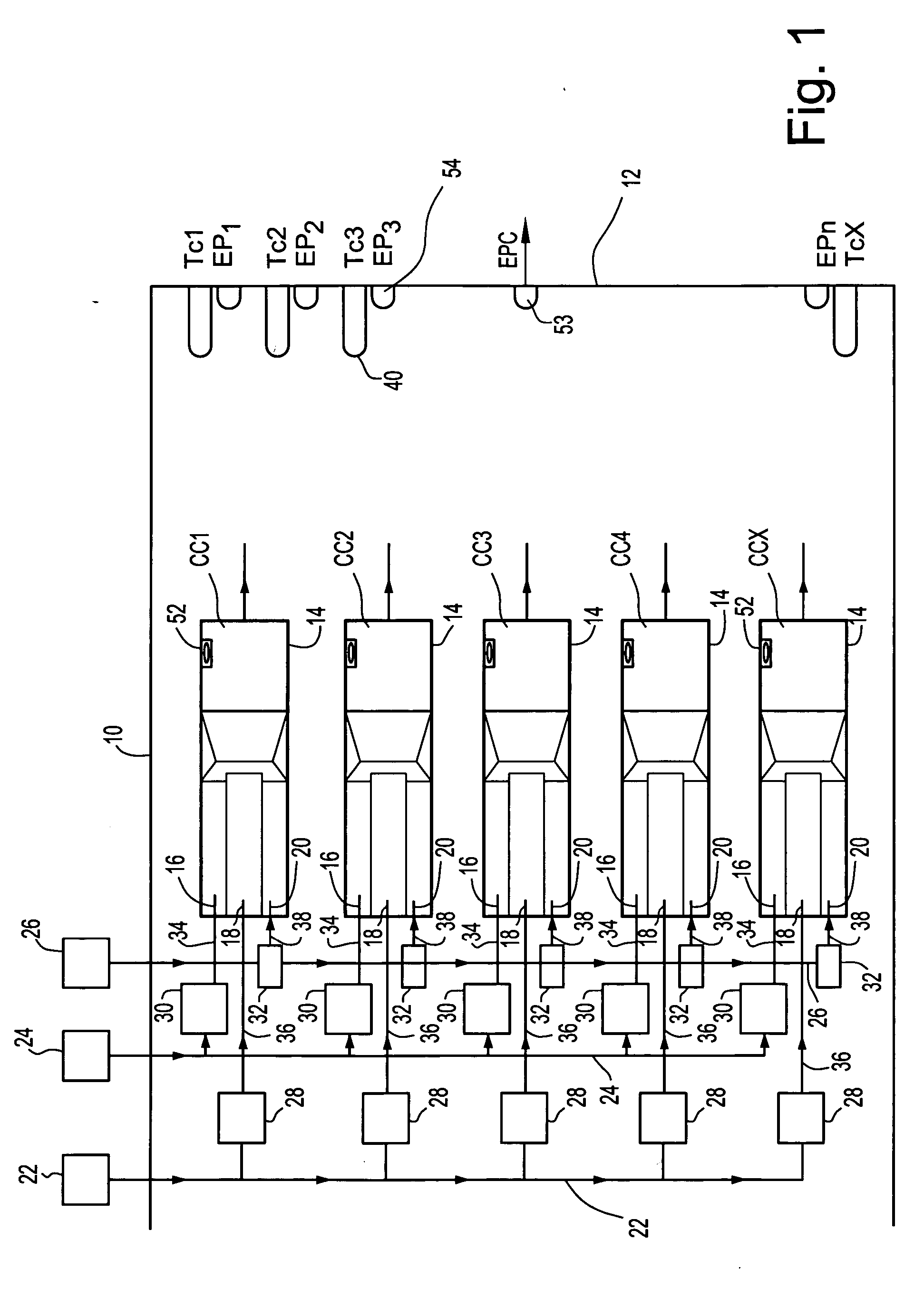

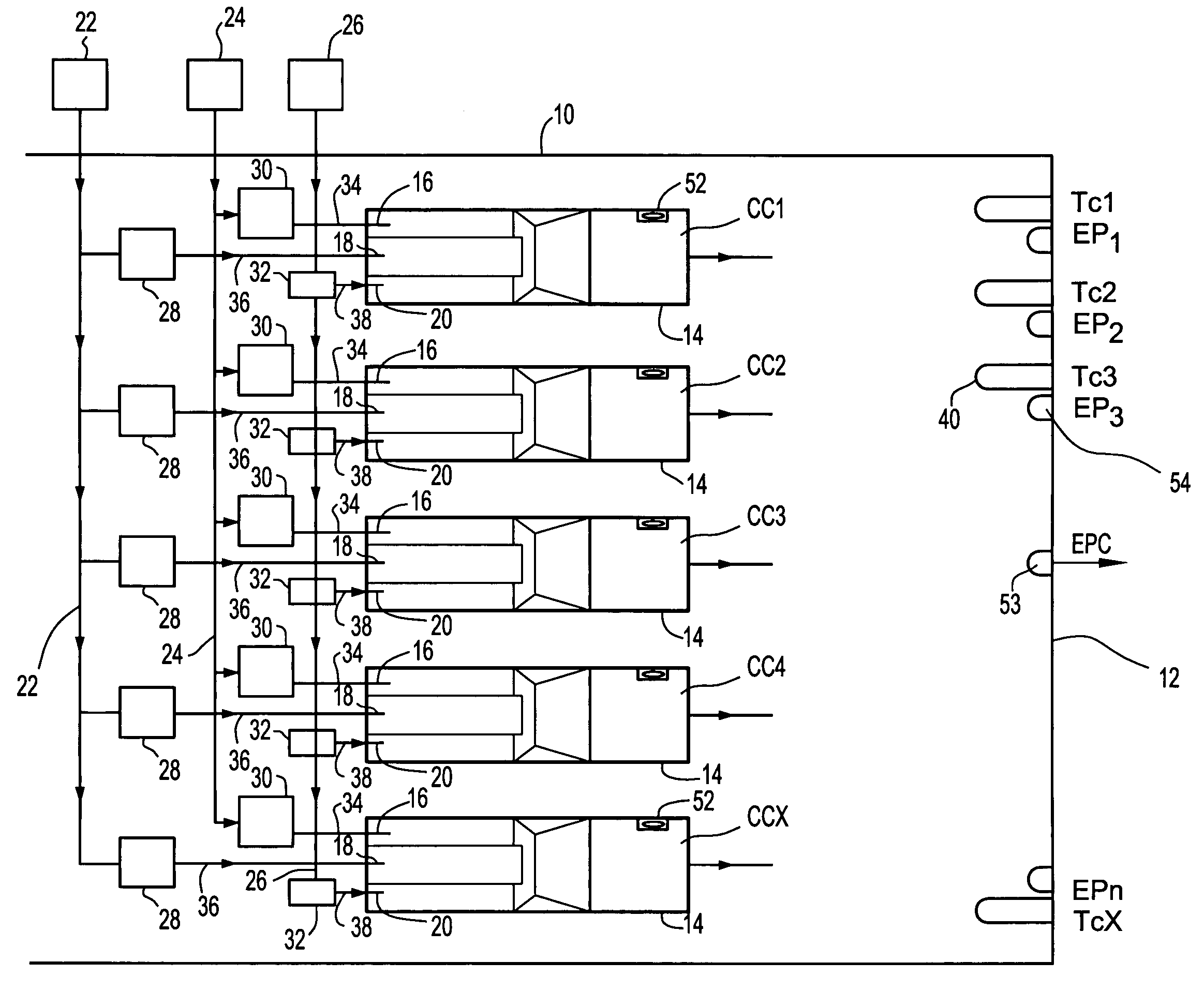

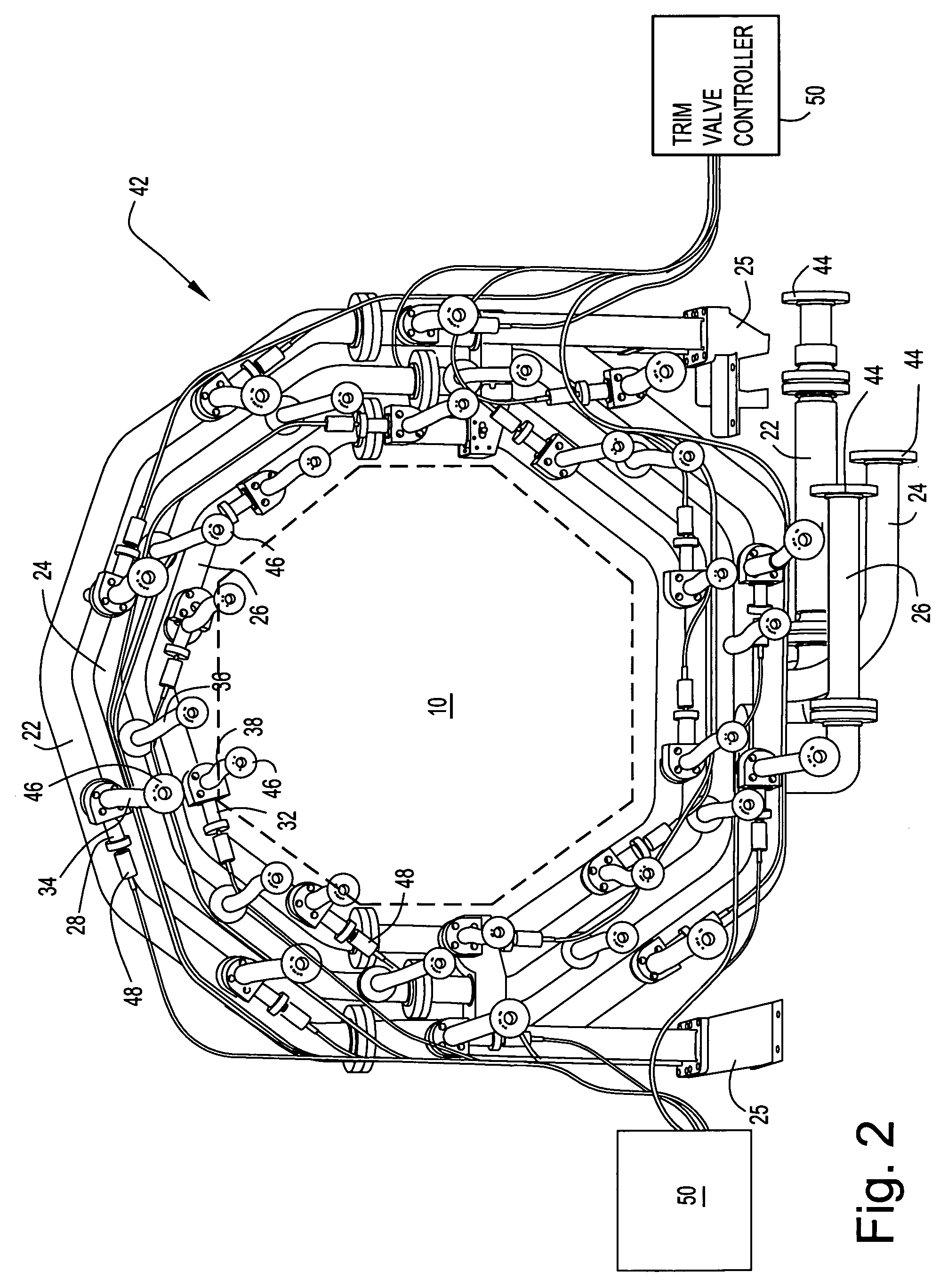

Method and apparatus for automatically actuating fuel trim valves in a gas

InactiveUS20060107666A1Minimized pressure dropClosely arrangedContinuous combustion chamberTurbine/propulsion fuel flow conduitsCombustion systemCombustion chamber

A gas turbine combustion system having: a plurality of combustion chambers; a plurality of fuel nozzles for each of combustion chamber; a plurality of manifolds for supplying fuel to at least one fuel nozzle in each of the combustion chambers; each of the manifolds having fuel trim control valves for the fuel nozzles, wherein the fuel trim control valves are mounted on the multiple manifolds for metering the fuel to the fuel nozzles in the combustion chambers, and a trim valve controller automatically actuates one or more of the fuel trim valves to adjust fuel to the fuel nozzles based on gas turbine operating conditions.

Owner:GENERAL ELECTRIC CO

Method and apparatus for automatically actuating fuel trim valves in a gas

InactiveUS7269939B2Control deteriorationClosely arrangedContinuous combustion chamberTurbine/propulsion fuel flow conduitsCombustion systemCombustion chamber

A gas turbine combustion system having: a plurality of combustion chambers; a plurality of fuel nozzles for each of combustion chamber; a plurality of manifolds for supplying fuel to at least one fuel nozzle in each of the combustion chambers; each of the manifolds having fuel trim control valves for the fuel nozzles, wherein the fuel trim control valves are mounted on the multiple manifolds for metering the fuel to the fuel nozzles in the combustion chambers, and a trim valve controller automatically actuates one or more of the fuel trim valves to adjust fuel to the fuel nozzles based on gas turbine operating conditions.

Owner:GENERAL ELECTRIC CO

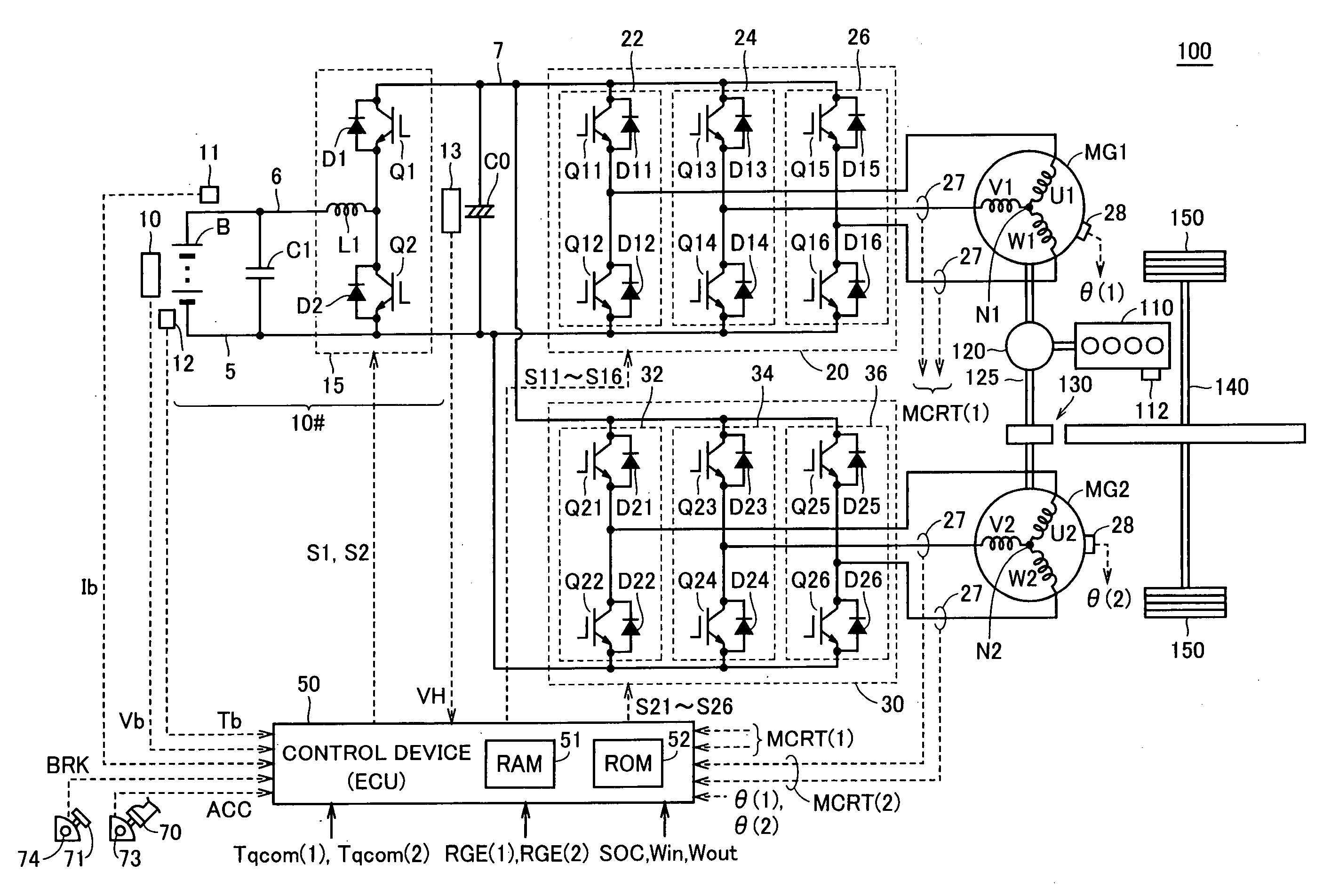

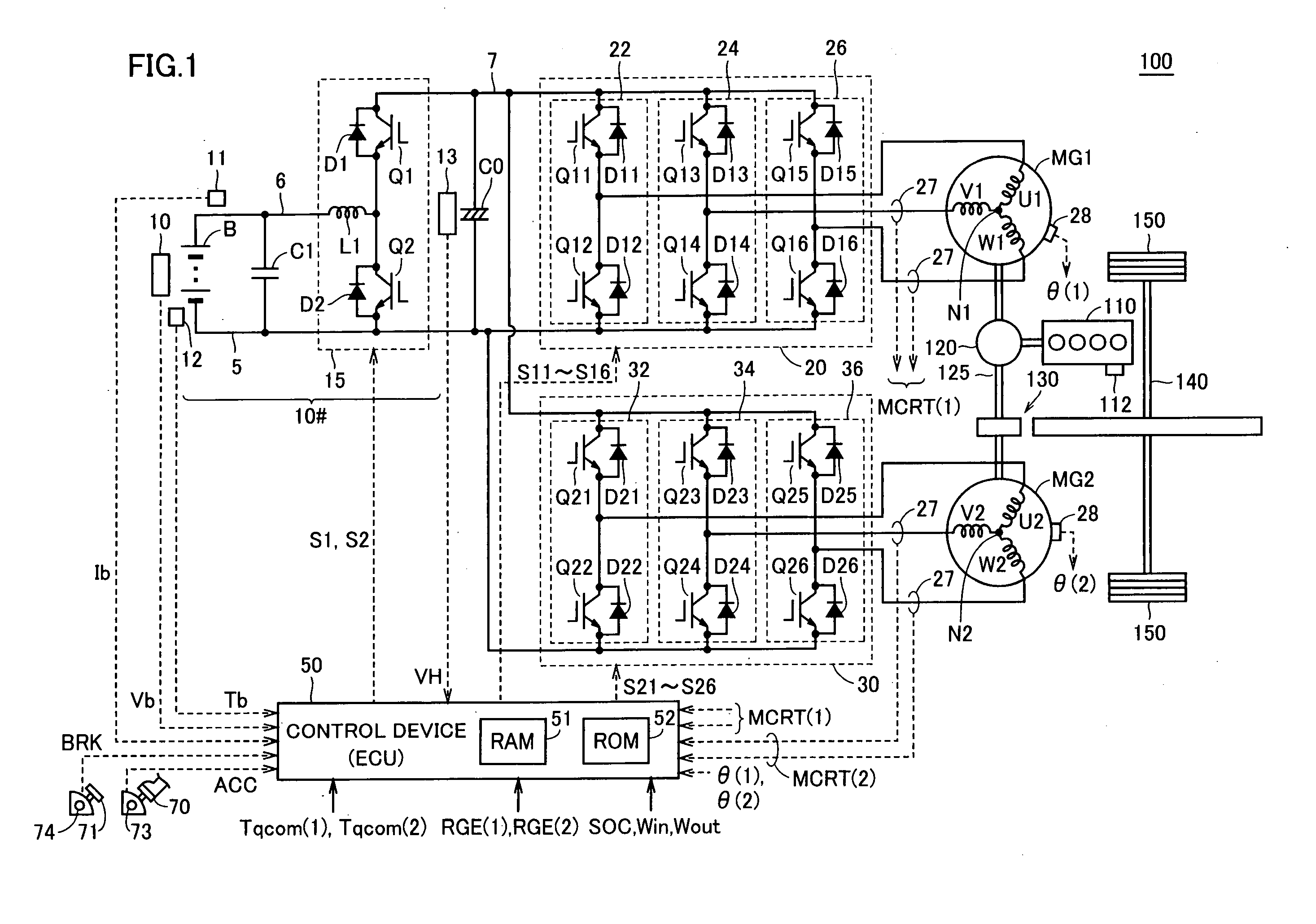

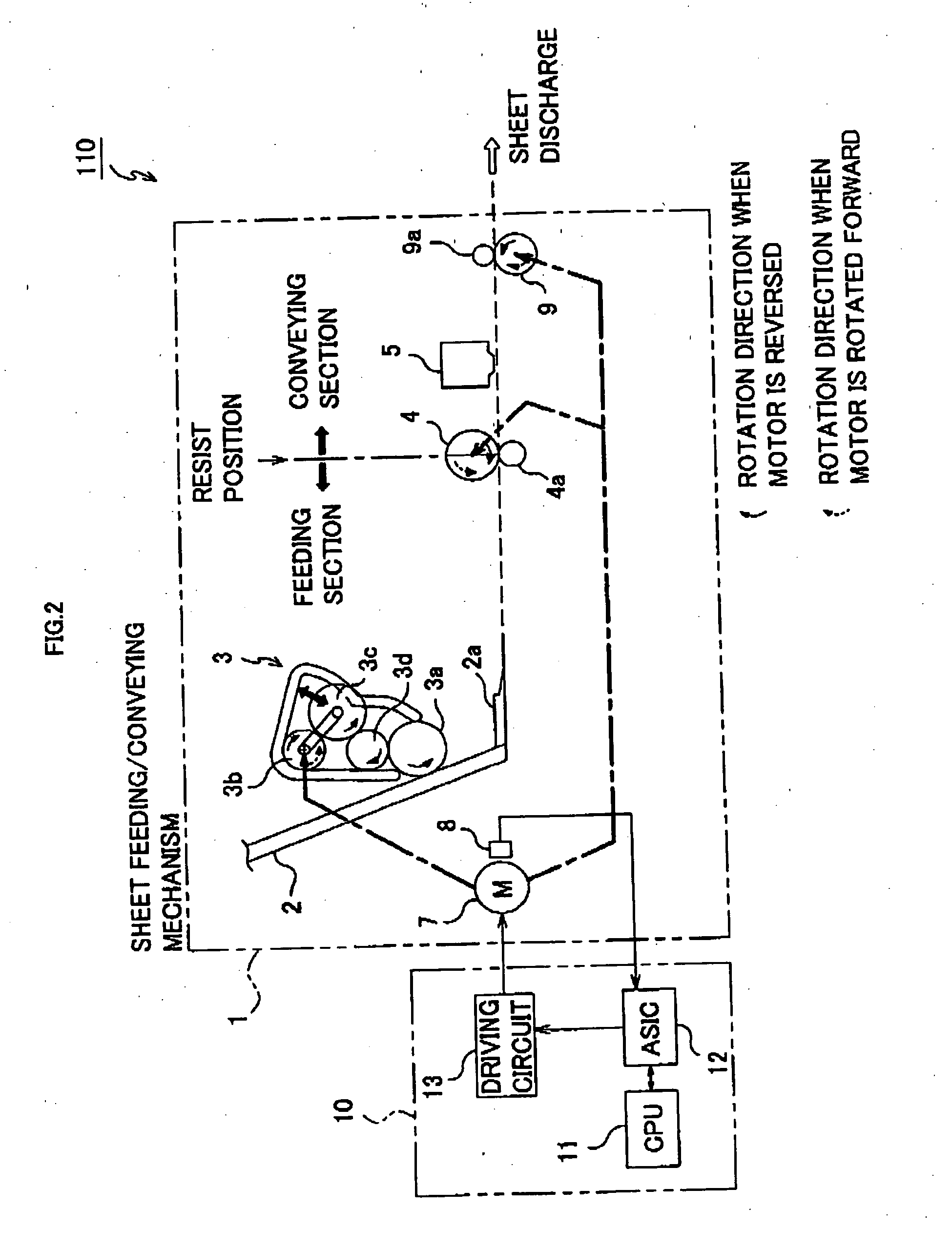

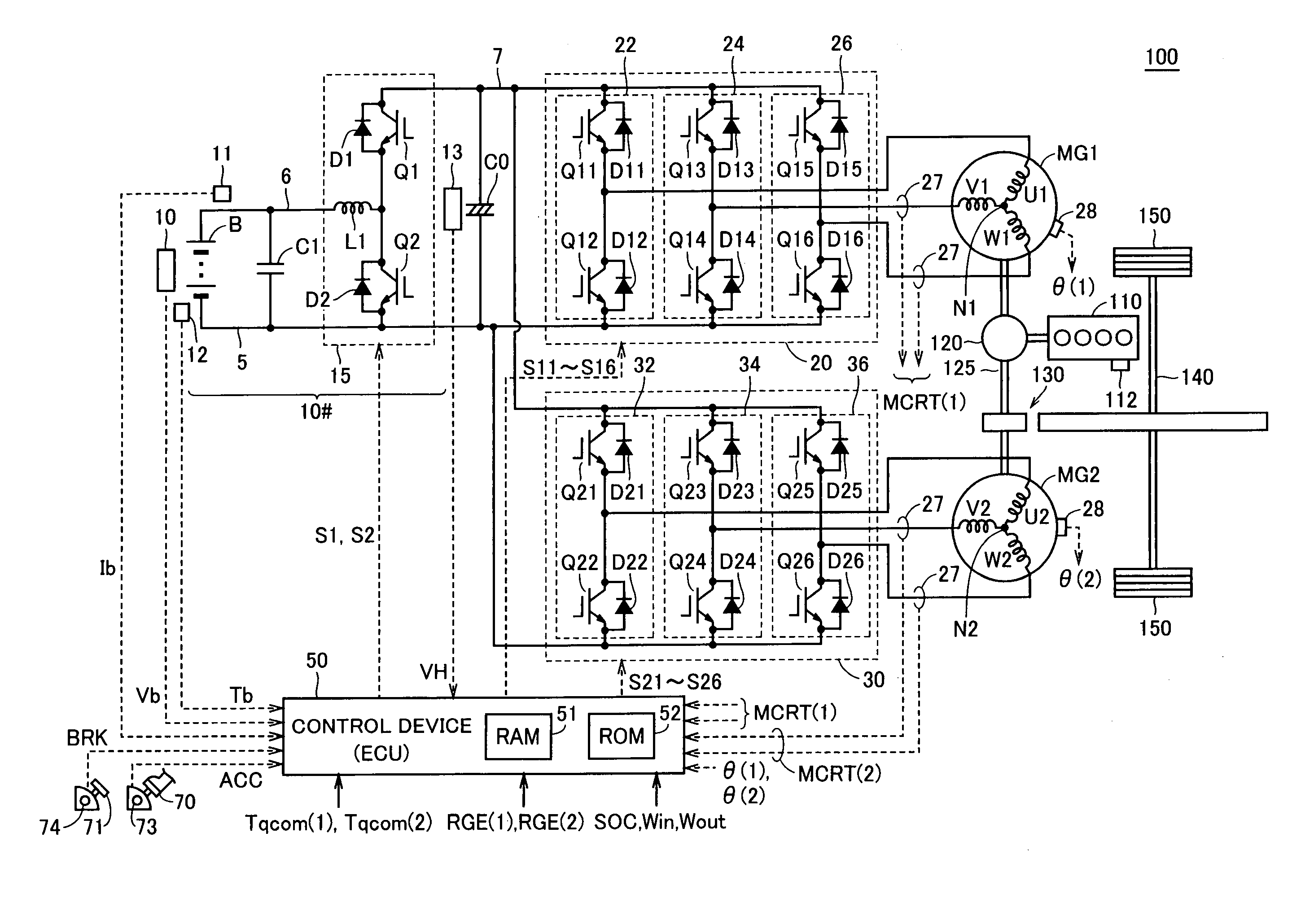

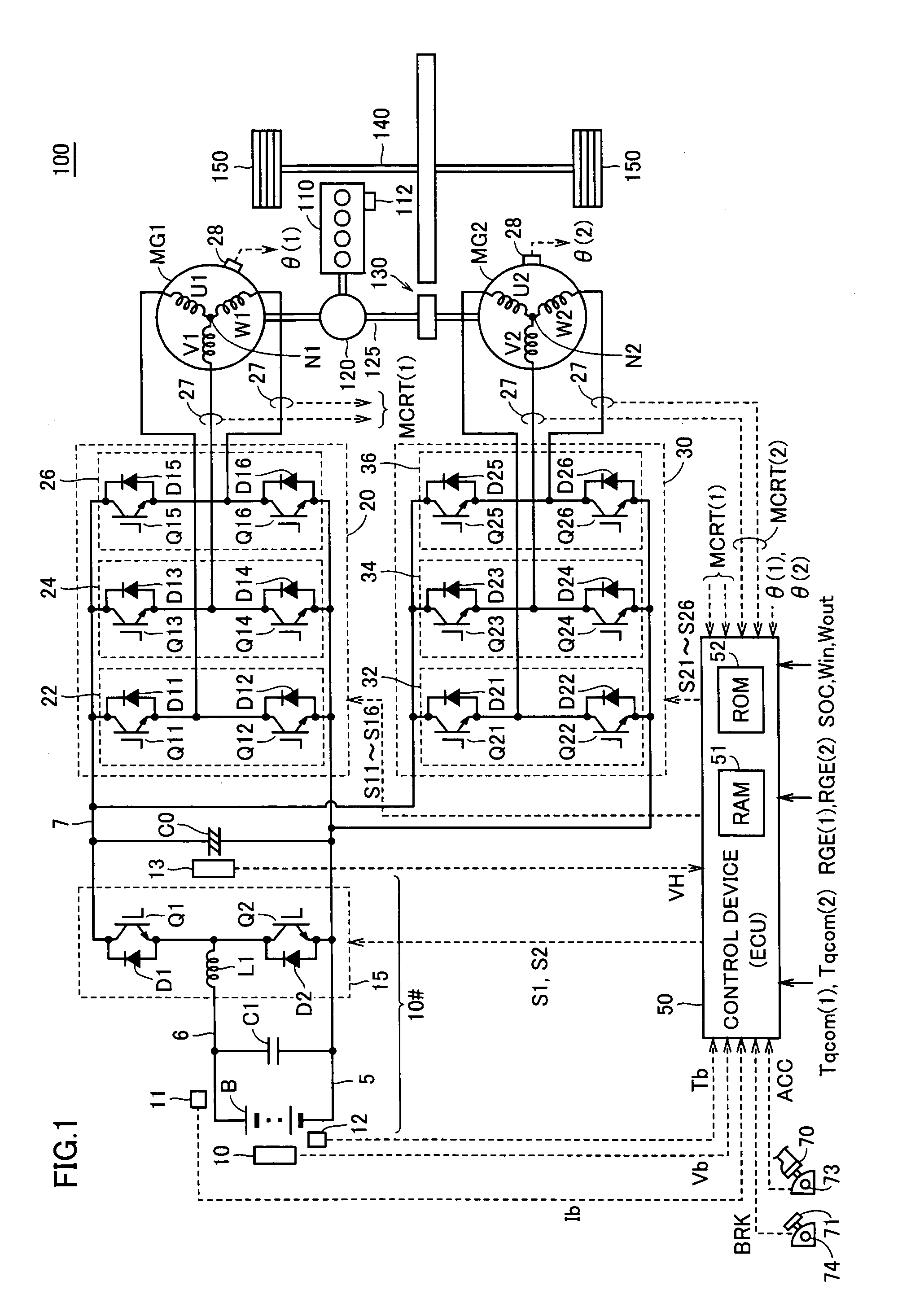

Motor Drive Control System and Method for Controlling the Same

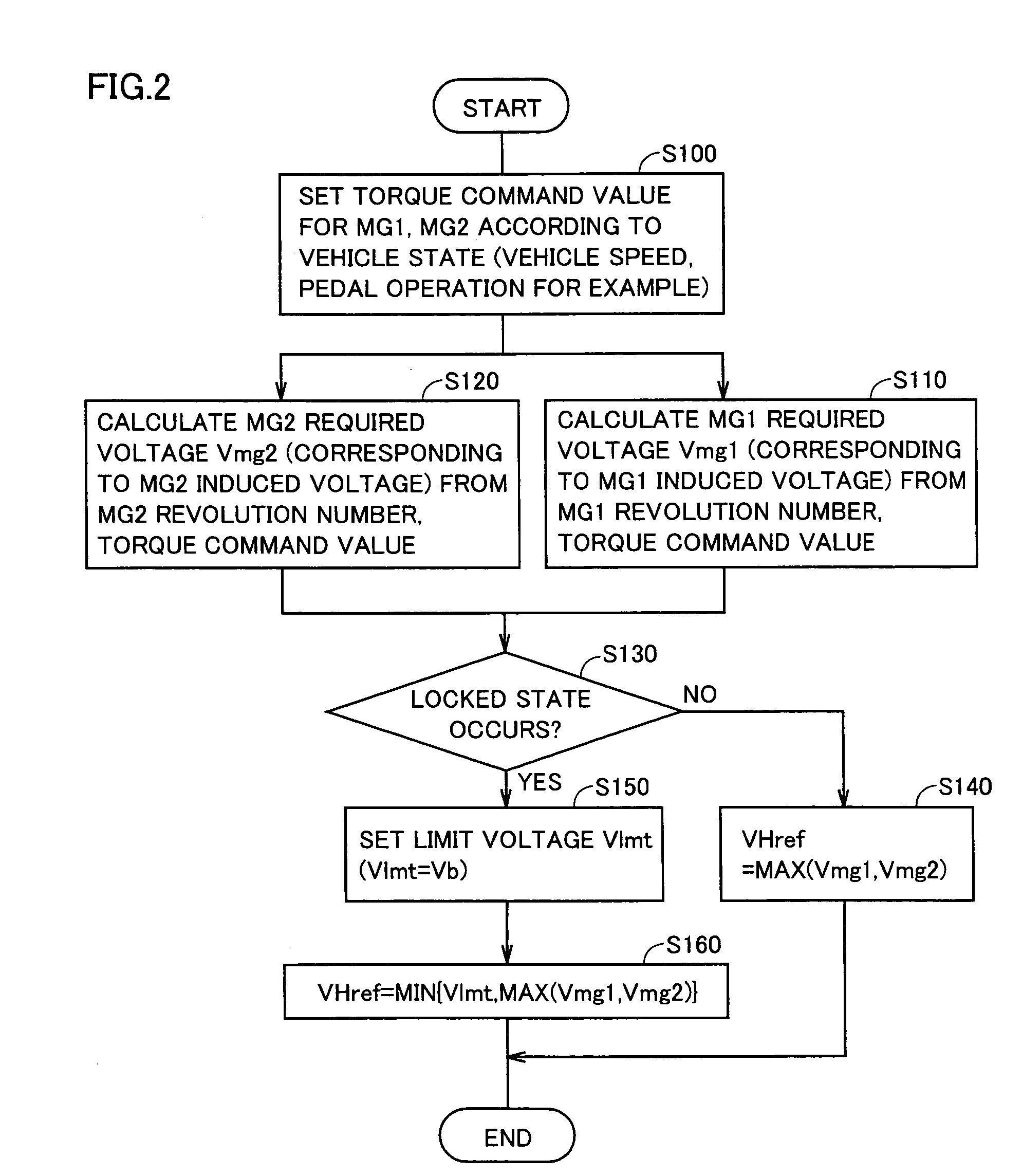

ActiveUS20090021198A1Control deteriorationAudible noise is generatedDC motor speed/torque controlAC motor controlControl systemDevice form

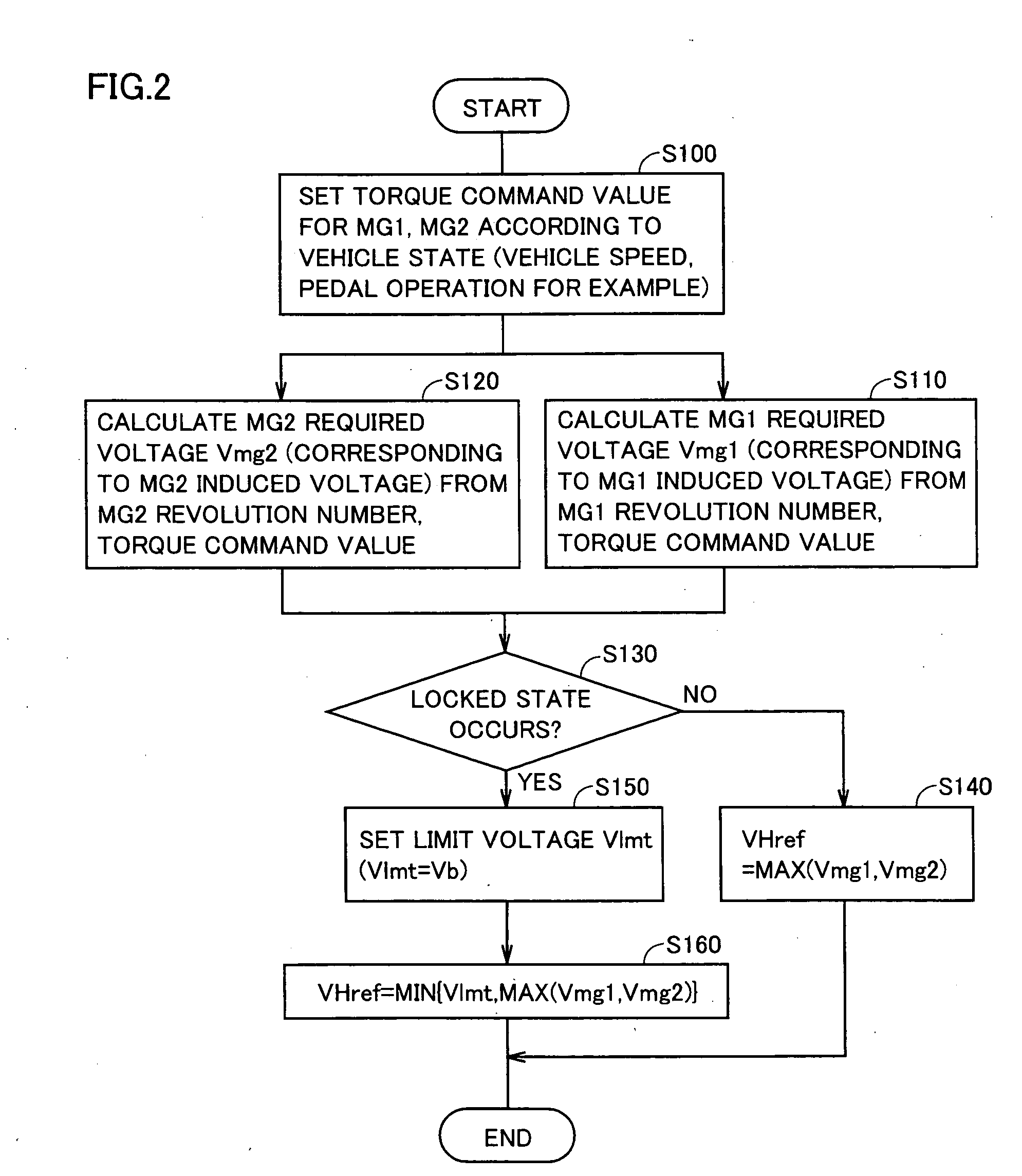

In a motor drive control system configured to include a converter capable of stepping up the voltage, when the locked state of MG2 operating as an electric motor does not occur (NO in S130), a voltage command value VHref for the converter output voltage is set according to respective required voltages of MG1 operating as an electric generator and MG2 (S140). In contrast, when the locked state of MG2 occurs (YES in S130), the voltage command value VHref is set to a limit voltage Vlmt or less for limiting the voltage step-up by the converter (S150, S180). When the locked state occurs, the converter output voltage is decreased and accordingly the DC voltage switched by the inverter is lowered, so that a switching loss at the switching device forming a part of the inverter is reduced and the temperature increase due to the heat generation can be suppressed.

Owner:DENSO CORP

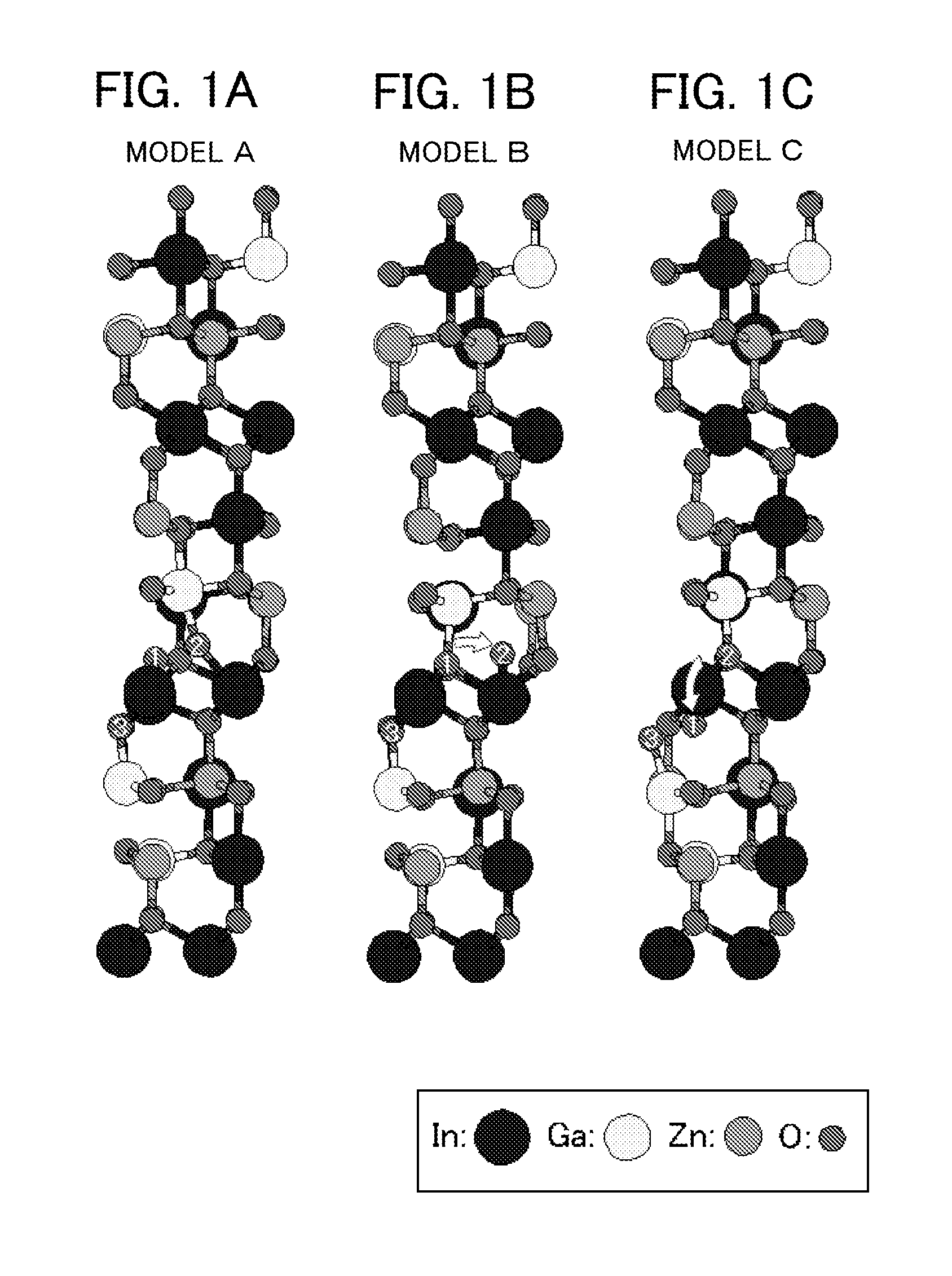

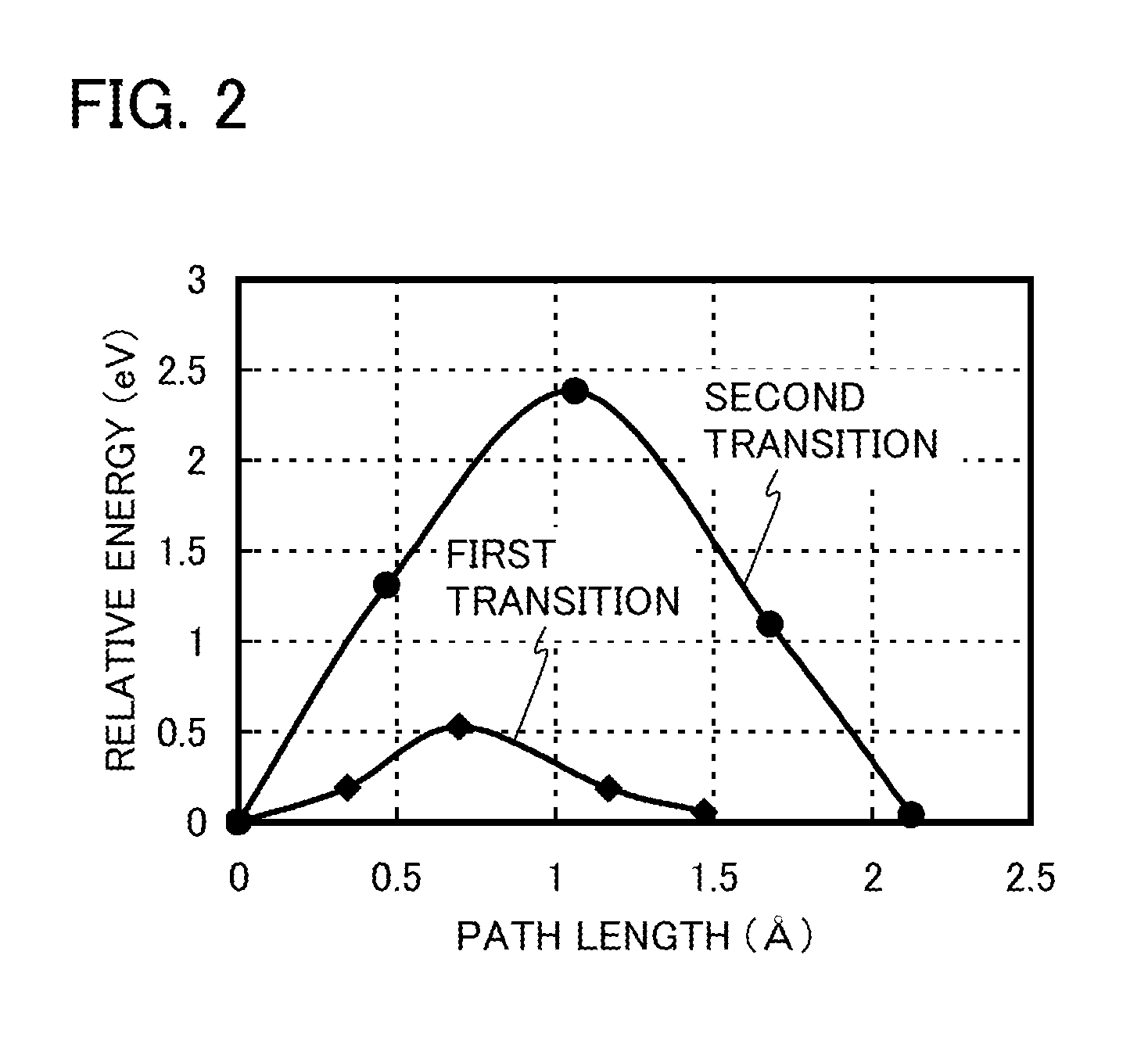

Semiconductor device and method for manufacturing the same

InactiveUS20130161611A1Improve reliabilityChange in electric characteristics of the transistorTransistorSemiconductor/solid-state device manufacturingDevice materialEngineering

Release of oxygen at a side surface of an island-shaped oxide semiconductor film is controlled and decrease in resistance is prevented. A semiconductor device includes an island-shaped oxide semiconductor film at least partly including a crystal, a first gate insulating film provided to cover at least a side surface of the island-shaped oxide semiconductor film, and a second gate insulating film provided to cover at least the island-shaped oxide semiconductor film and the first gate insulating film. The first gate insulating film is an insulating film that supplies oxygen to the island-shaped oxide semiconductor film, and the second gate insulating film is an insulating film which has a low oxygen-transmitting property

Owner:SEMICON ENERGY LAB CO LTD

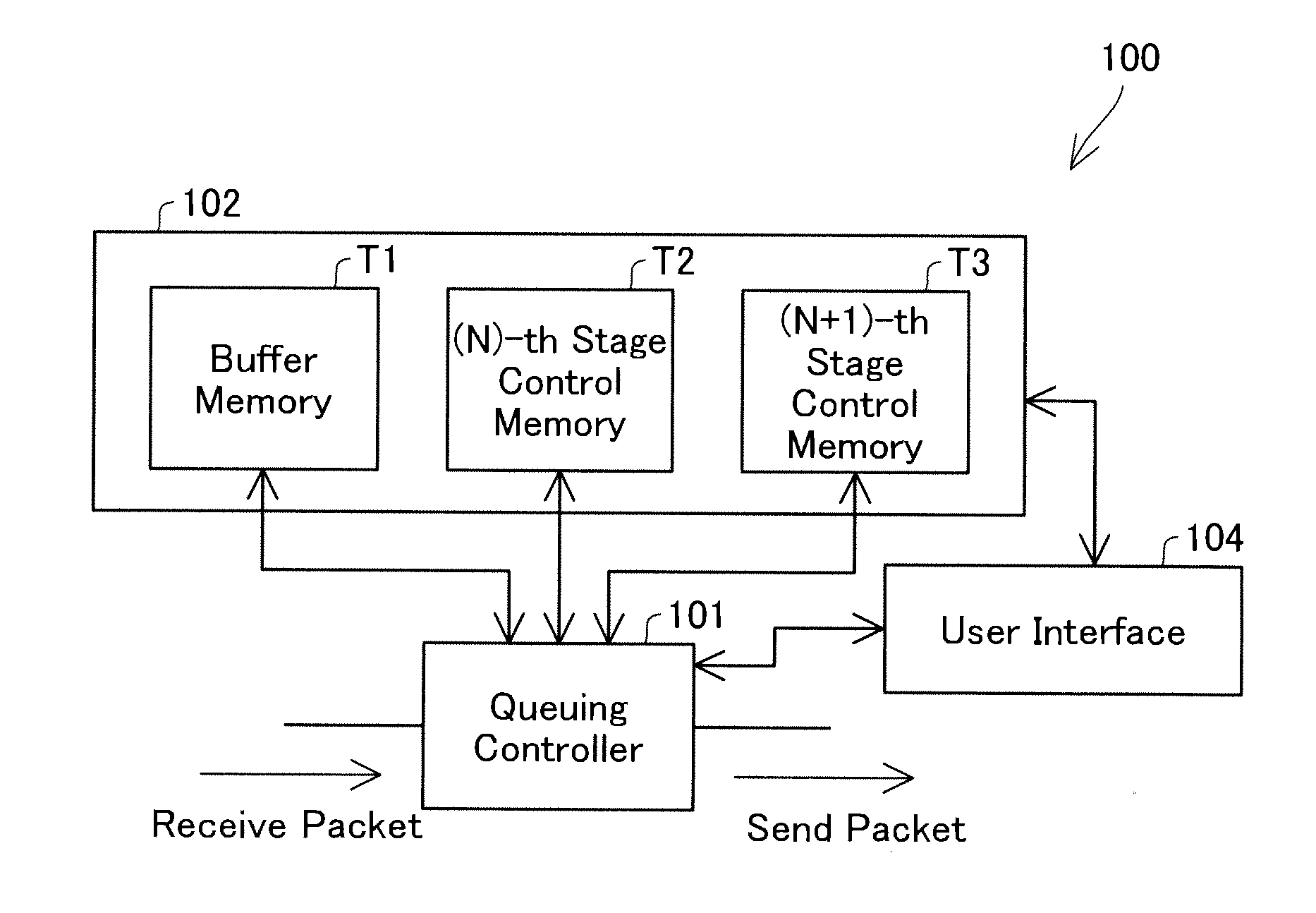

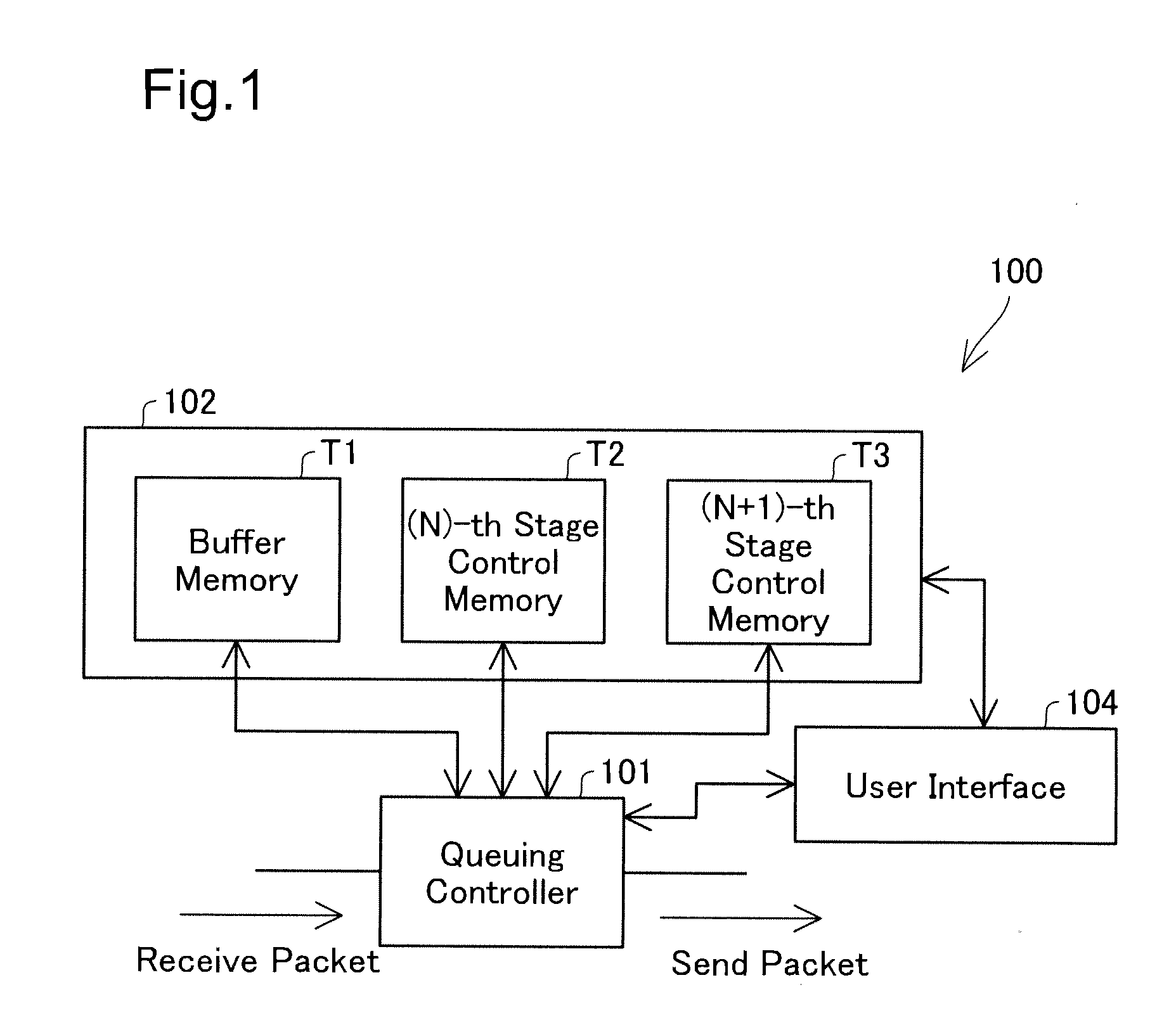

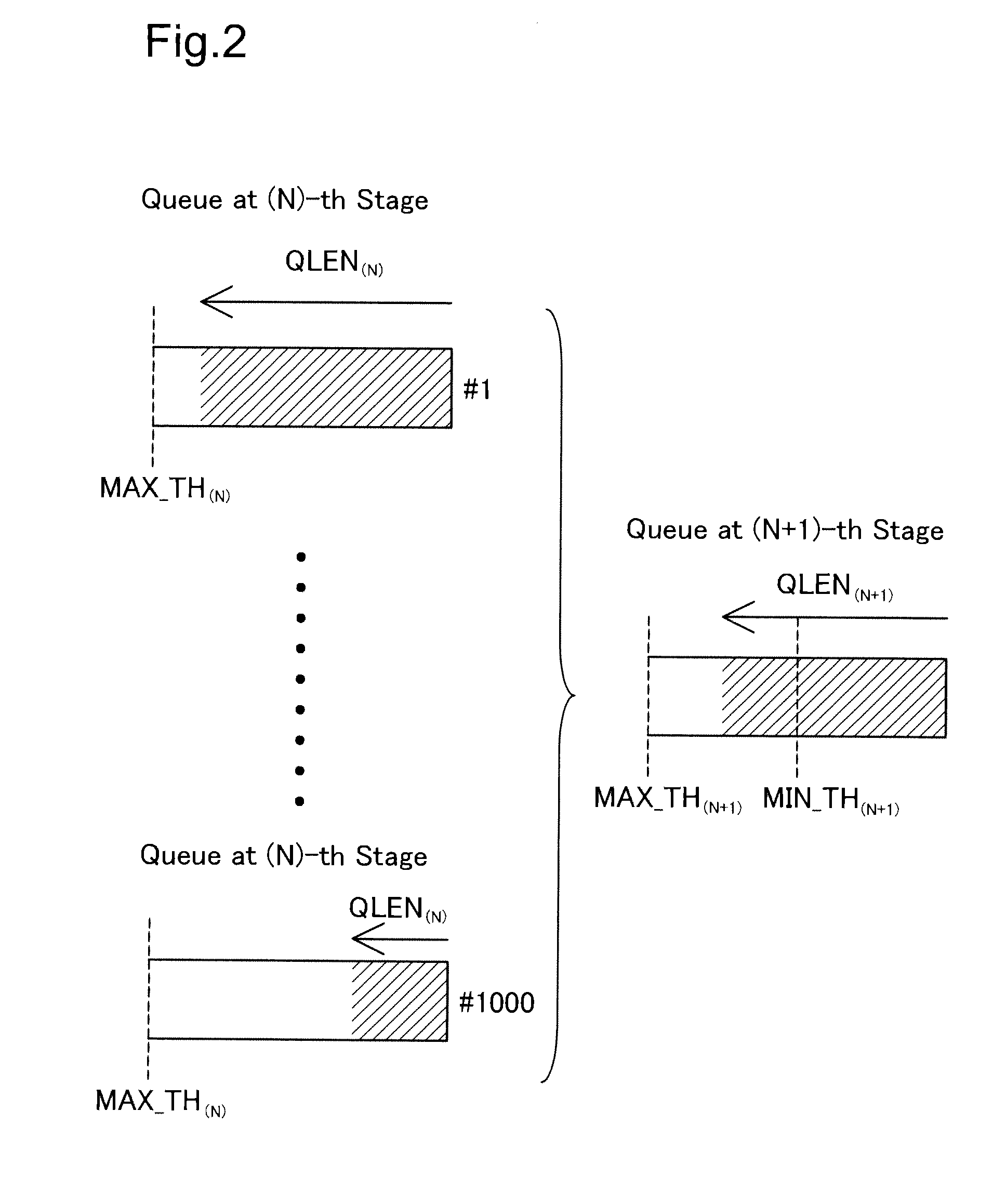

Packet relay apparatus and method of relaying packet

InactiveUS20110176554A1Control deteriorationData switching by path configurationNetwork packetMultilevel queue

The packet relay apparatus is provided. The packet relay apparatus includes a receiver that receives a packet; and a determiner that determines to drop the received packet without storing the received packet into a queue among the multi-stage queue. The determiner determines to drop the received packet at a latter stage, based on former-stage queue information representing a state of a queue at any former stage which the received packet belongs to and latter-stage queue information representing a state of a queue at the latter stage which the received packet belongs to.

Owner:ALAXALA NETWORKS

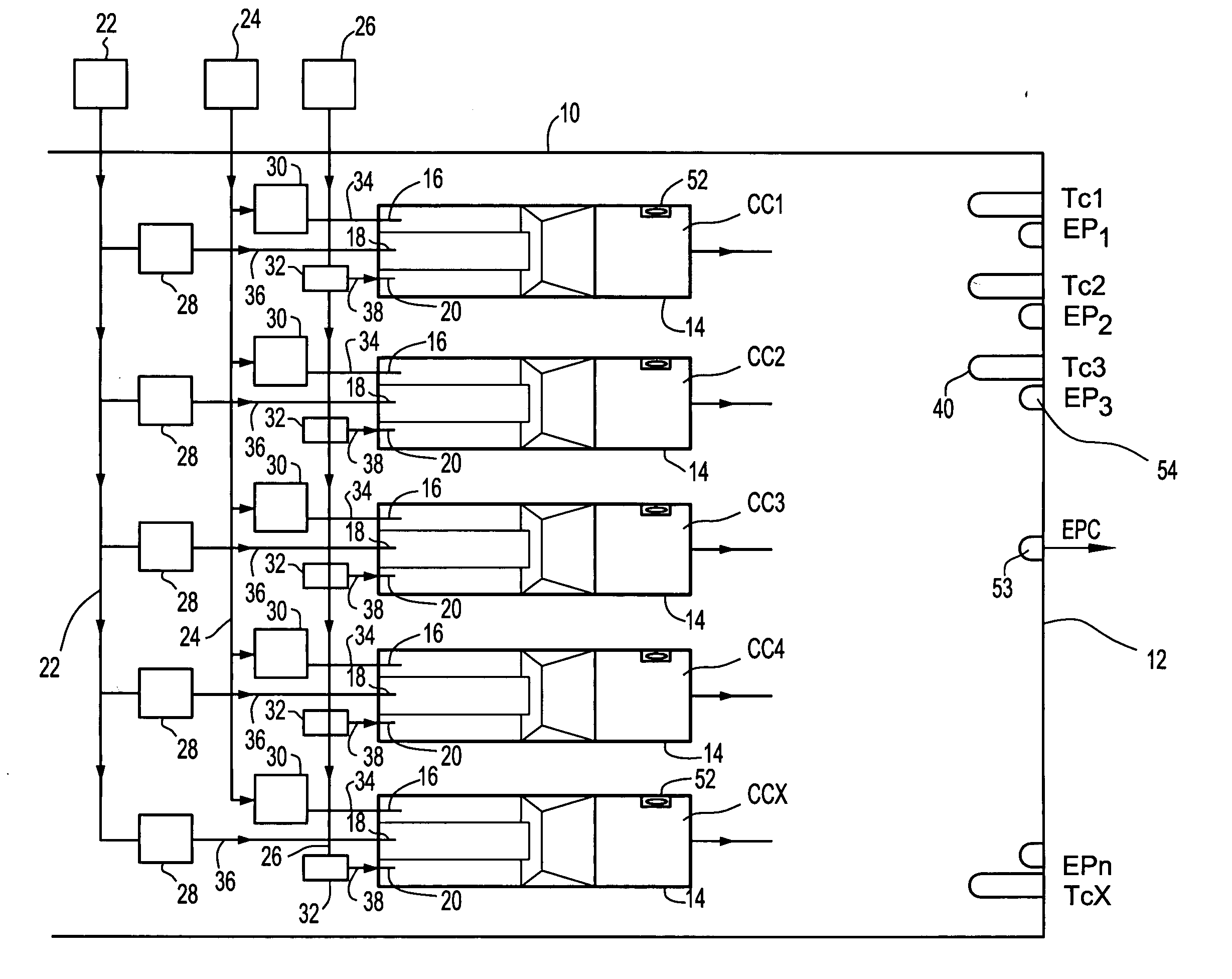

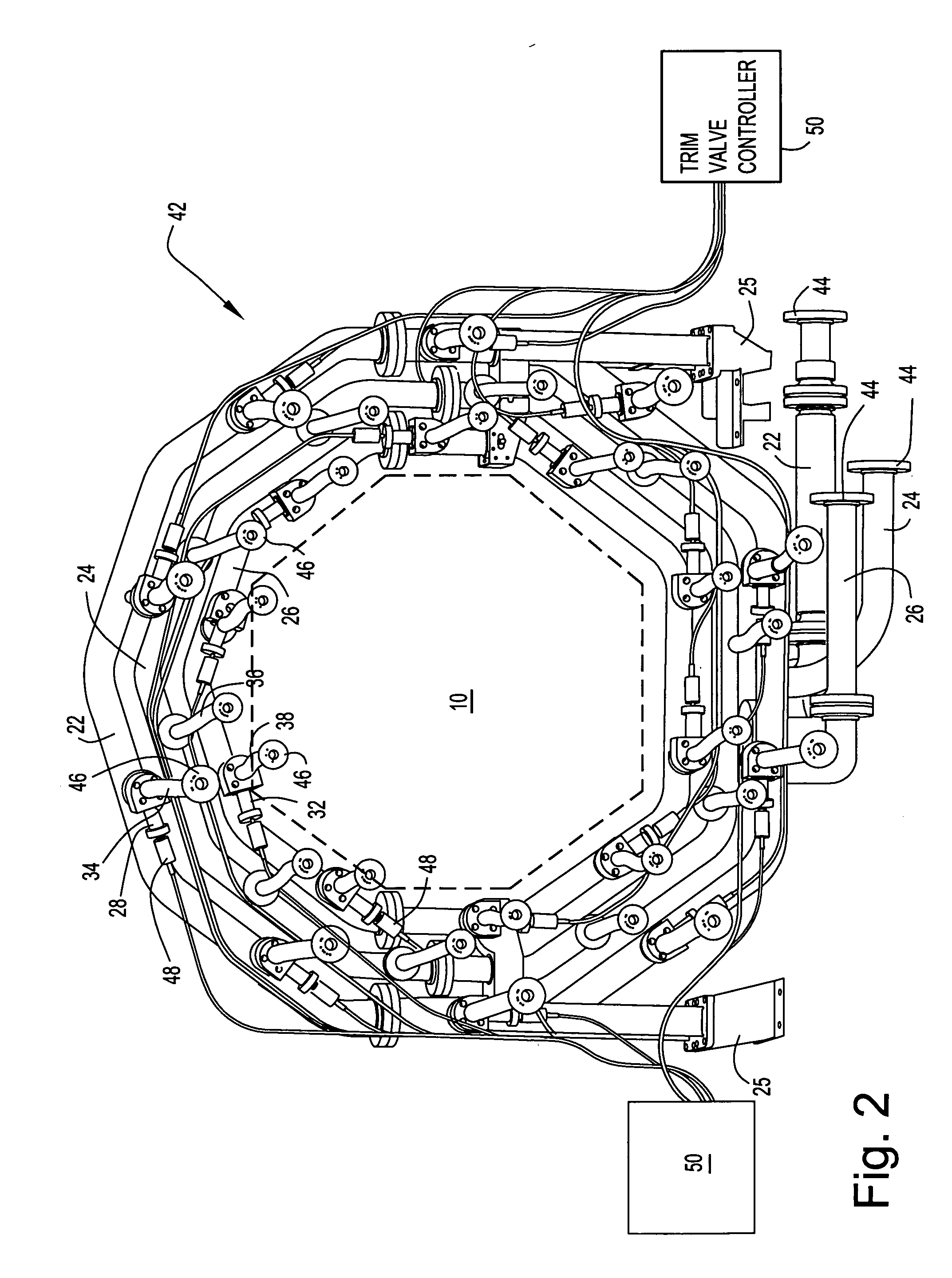

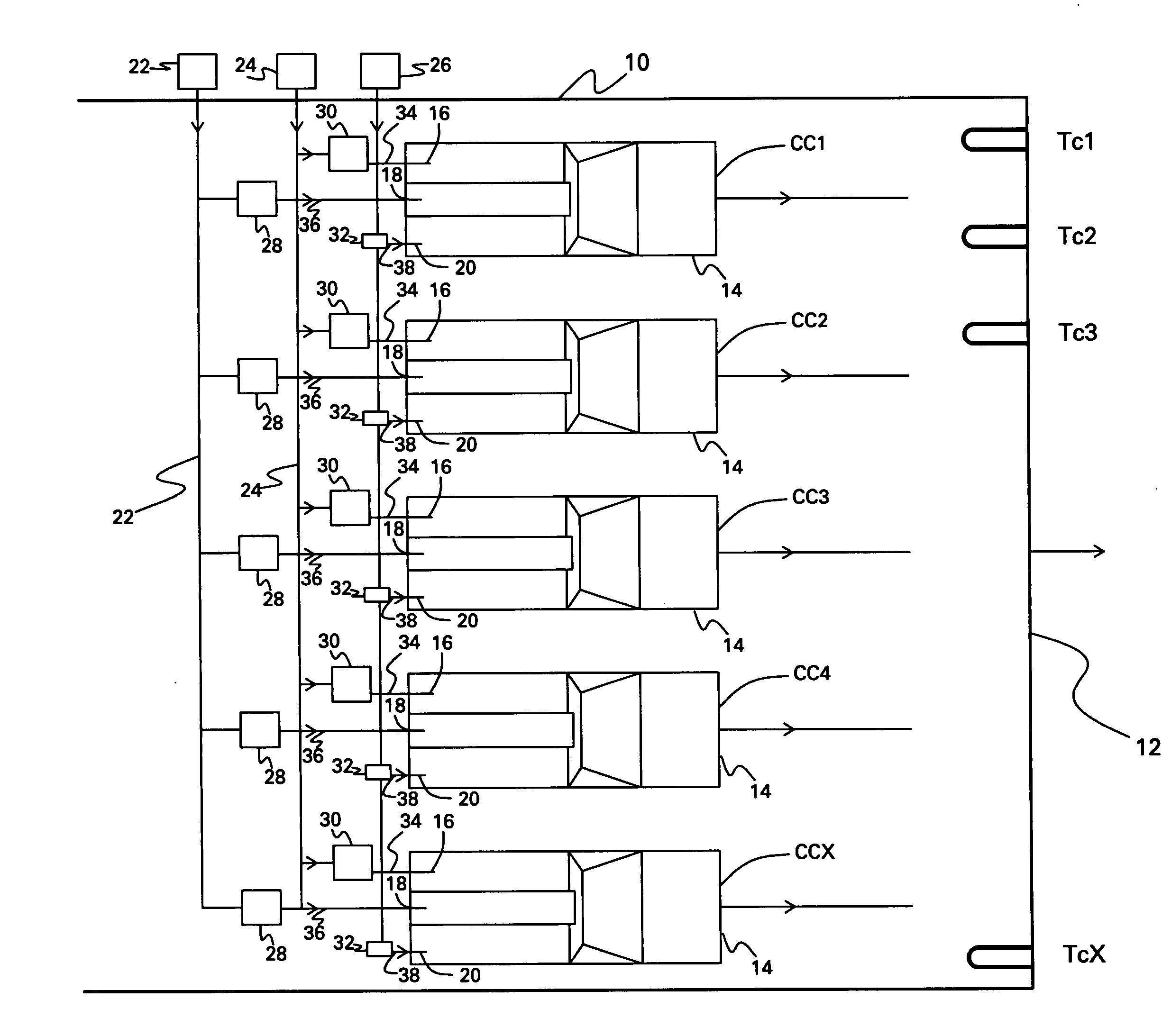

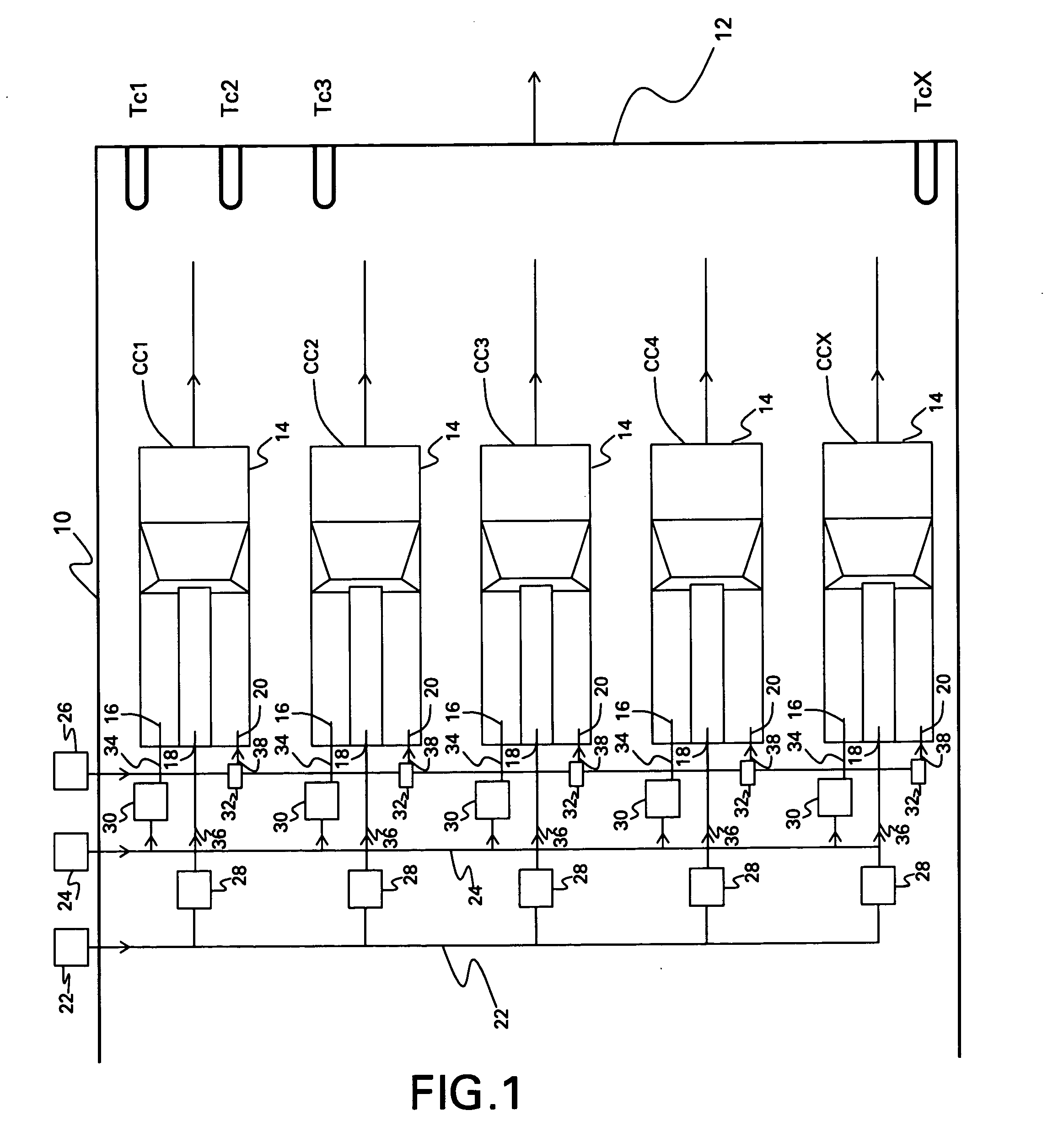

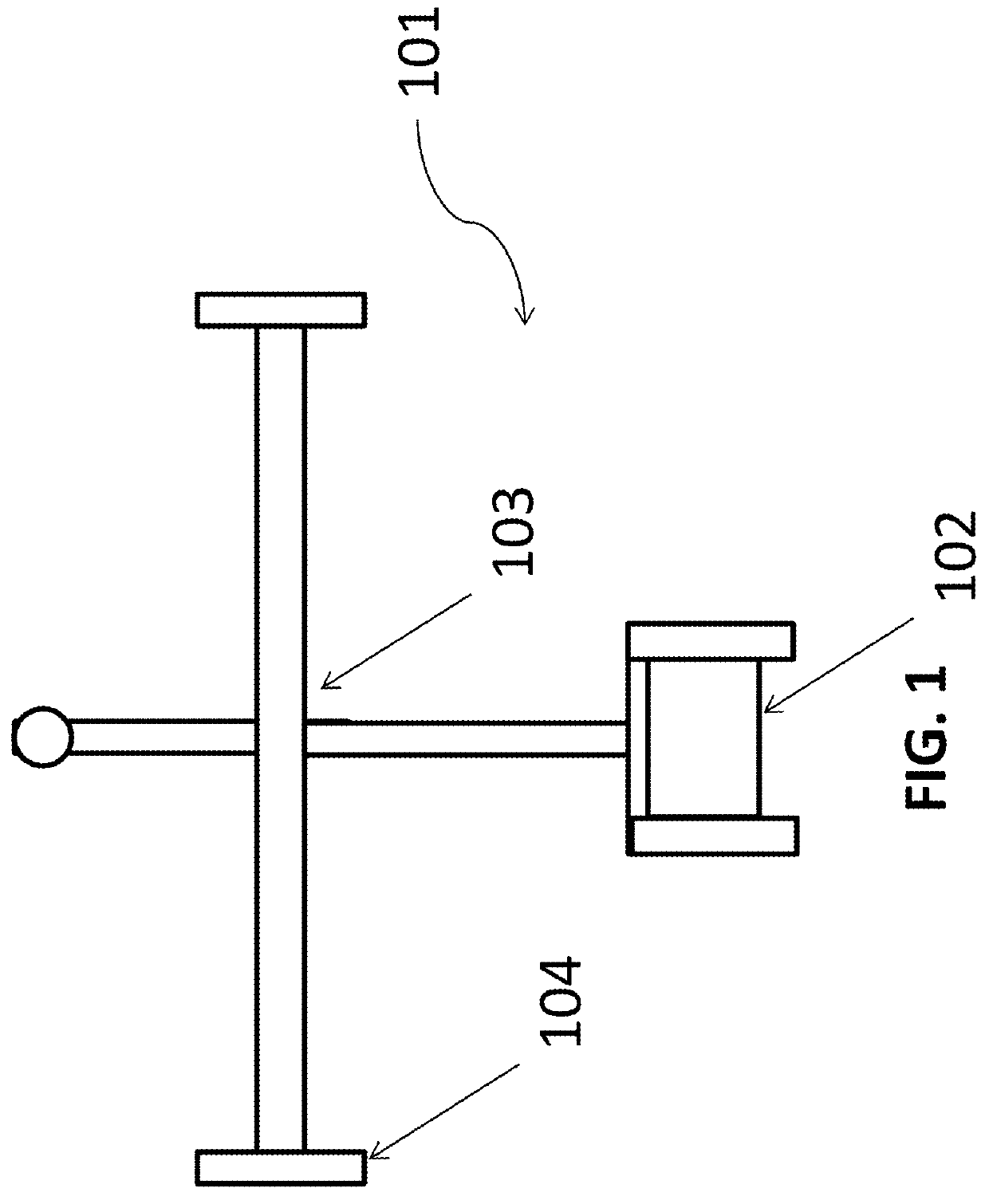

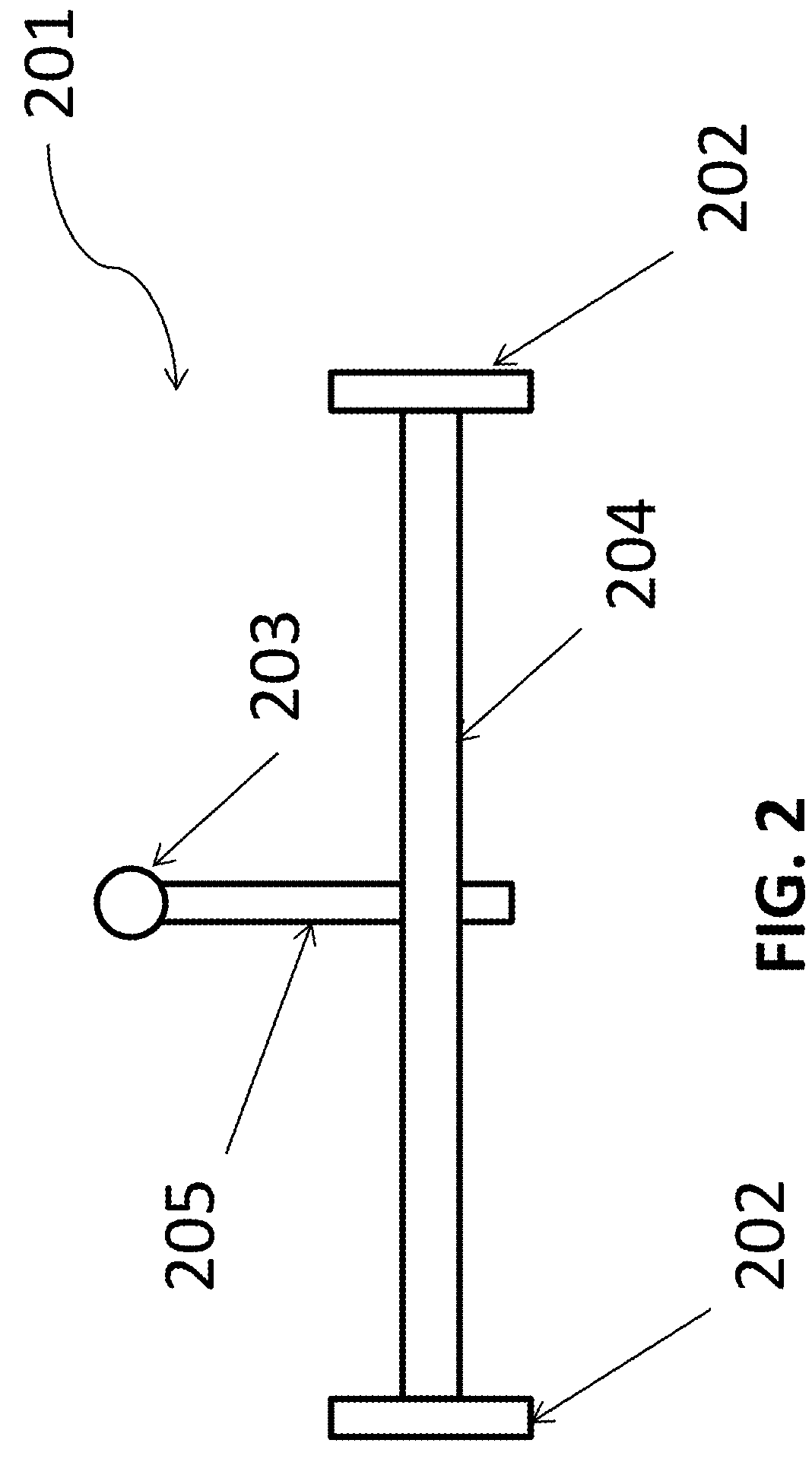

Method and apparatus for actuating fuel trim valves in a gas turbine

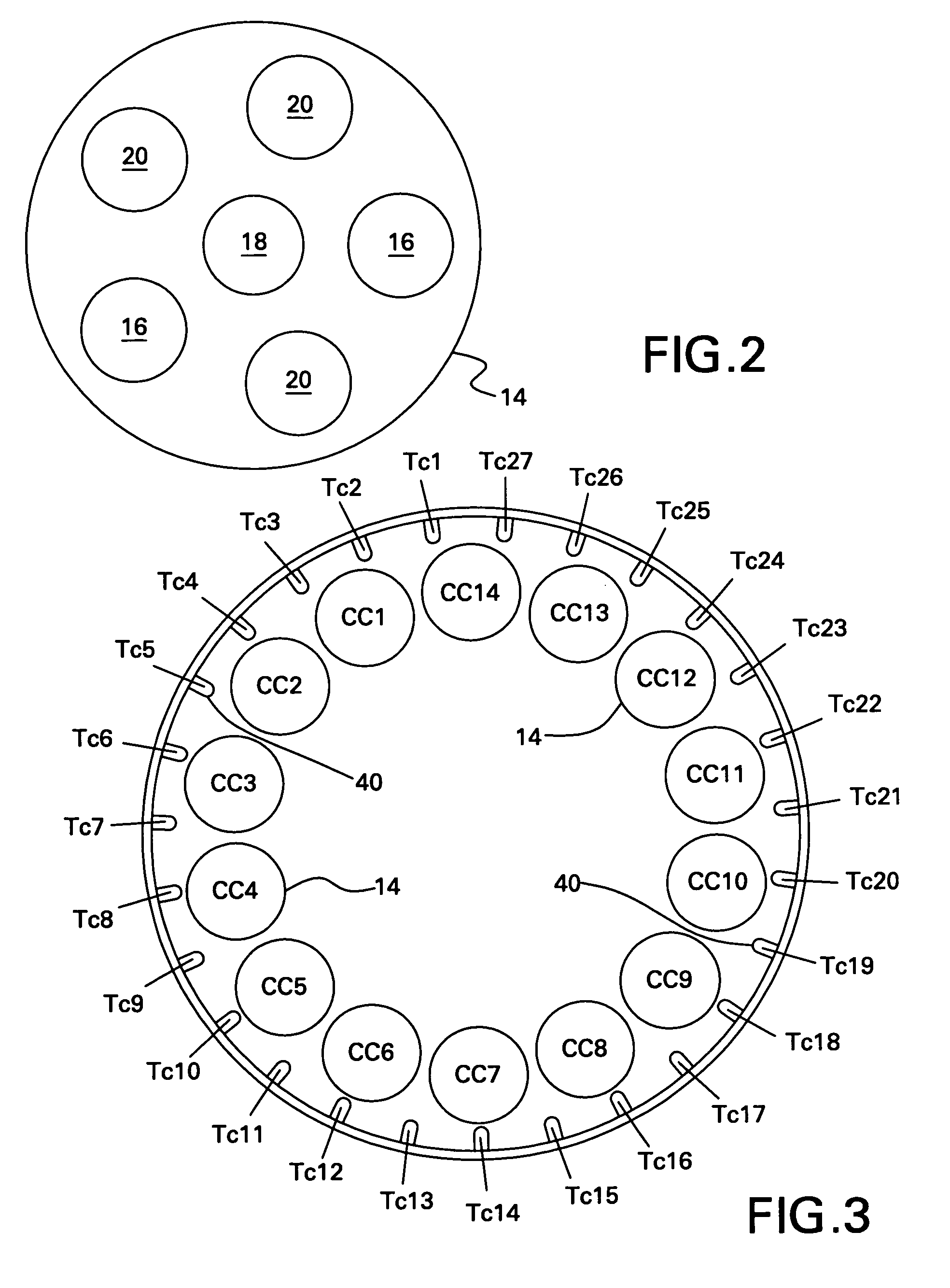

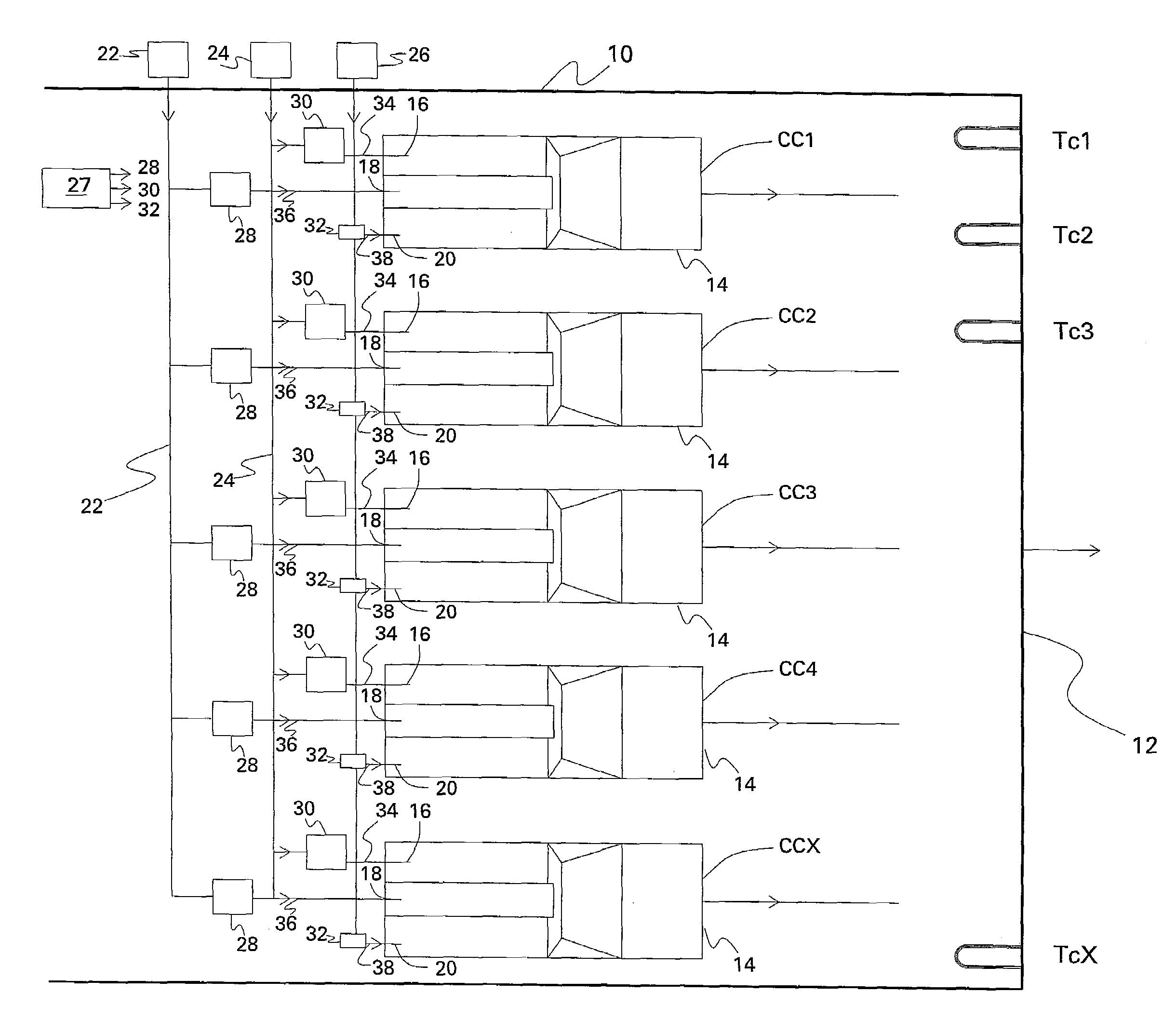

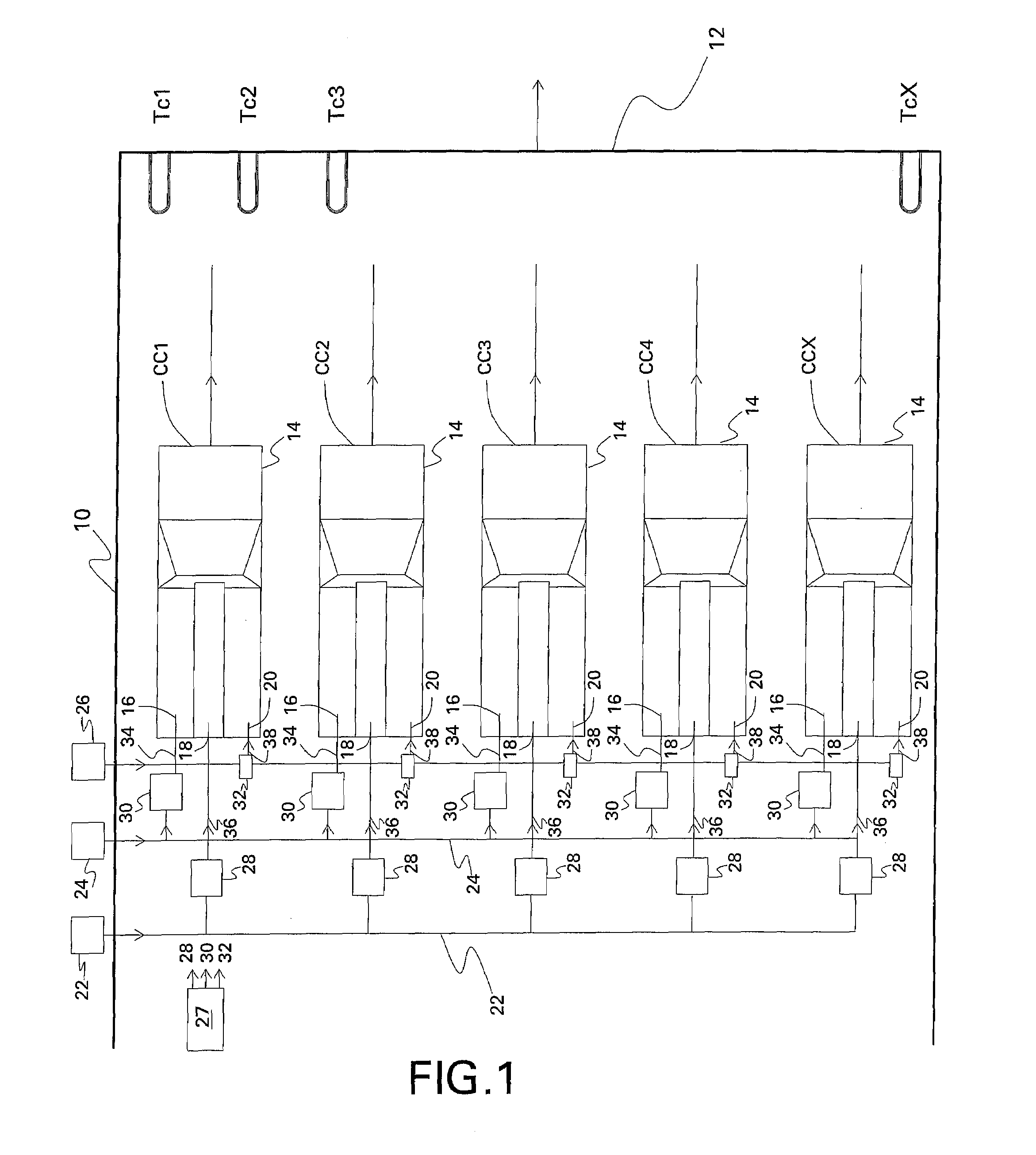

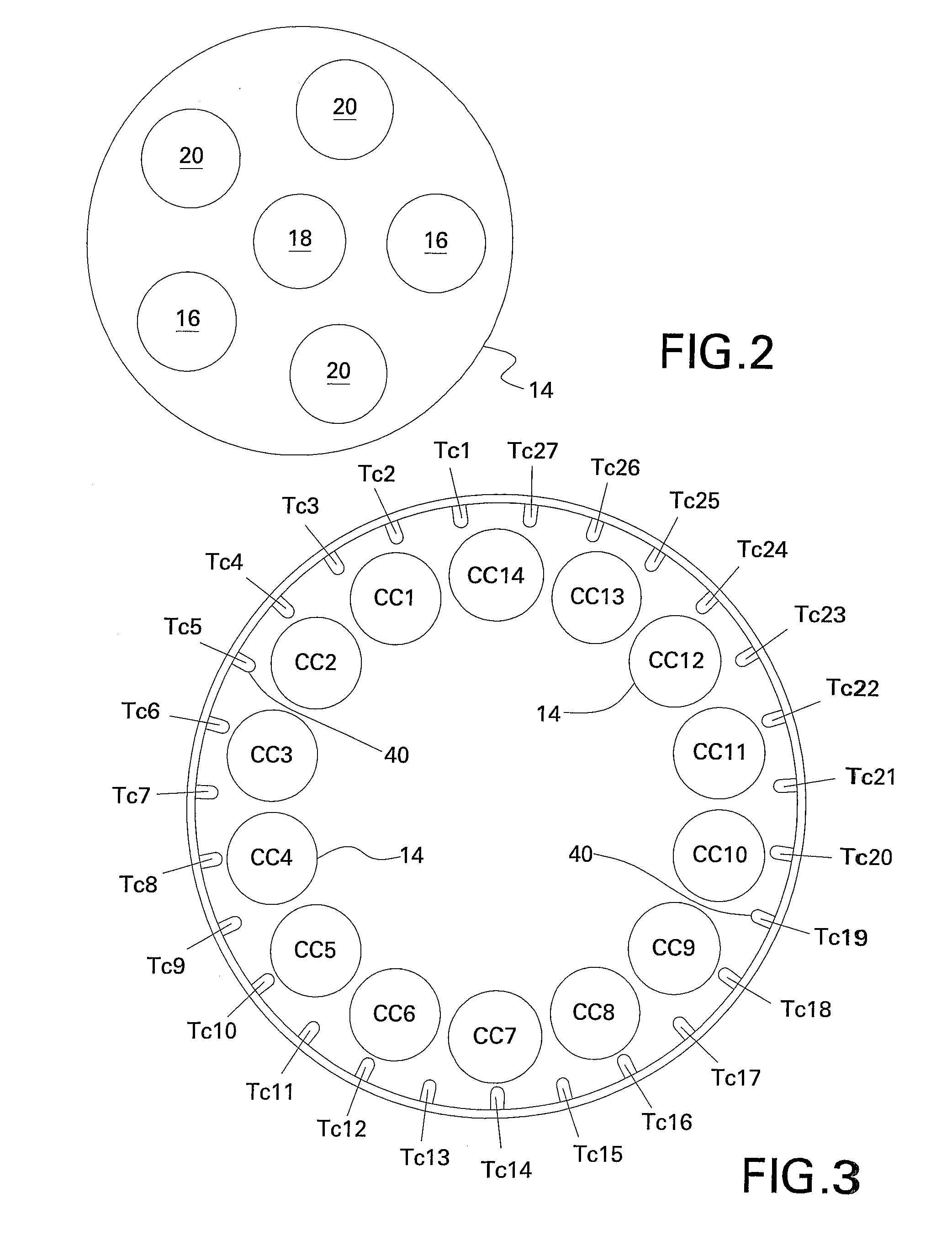

ActiveUS20050097895A1Minimized pressure dropOvercomes shortcomingFuel supply regulationContinuous combustion chamberCombustion chamberNitrous oxide

The gas turbines of the present invention have multiple combustion chambers, and within each chamber are multiple fuel nozzles. Each nozzle has its own fuel control valve to control the fuel flowing to the nozzles. To minimize the pressure drop through the fuel control valves, multiple manifolds are employed. Each manifold supplies at least one fuel nozzle in multiple combustion chambers with fuel. The fuel control valves are mounted on the manifolds such that the weight of the fuel control valves and nozzles are carried by the manifolds, not the multiple combustion chambers. A plurality of thermocouples for measuring exhaust gas from said multiple combustion chambers are employed to sense gas exhaust temperature. In carrying out the methods of the present invention for tuning a gas turbine, it is essential to note that the most efficient gas turbine is one which has the least nitrous oxides, the least amount of unburned hydrocarbons, and the least amount of carbon monoxide for a specified energy output. In order to tune the gas turbine to accomplish these objectives, it is desirable that each combustion chamber in the gas turbine be well balanced relative to the remaining combustion chambers. It is an aim of the present invention to tune each of the multiple combustion chambers such that no specific combustion chamber is rich or lean, and all are operating within about 1% of the remaining combustion chambers.

Owner:GENERAL ELECTRIC CO

Method and apparatus for actuating fuel trim valves in a gas turbine

ActiveUS7188465B2Control deteriorationOvercomes shortcomingFuel supply regulationContinuous combustion chamberCombustion chamberNitrous oxide

The gas turbines of the present invention have multiple combustion chambers, and within each chamber are multiple fuel nozzles. Each nozzle has its own fuel control valve to control the fuel flowing to the nozzles. To minimize the pressure drop through the fuel control valves, multiple manifolds are employed. Each manifold supplies at least one fuel nozzle in multiple combustion chambers with fuel. The fuel control valves are mounted on the manifolds such that the weight of the fuel control valves and nozzles are carried by the manifolds, not the multiple combustion chambers. A plurality of thermocouples for measuring exhaust gas from said multiple combustion chambers are employed to sense gas exhaust temperature. In carrying out the methods of the present invention for tuning a gas turbine, it is essential to note that the most efficient gas turbine is one which has the least nitrous oxides, the least amount of unburned hydrocarbons, and the least amount of carbon monoxide for a specified energy output. In order to tune the gas turbine to accomplish these objectives, it is desirable that each combustion chamber in the gas turbine be well balanced relative to the remaining combustion chambers. It is an aim of the present invention to tune each of the multiple combustion chambers such that no specific combustion chamber is rich or lean, and all are operating within about 1% of the remaining combustion chambers.

Owner:GENERAL ELECTRIC CO

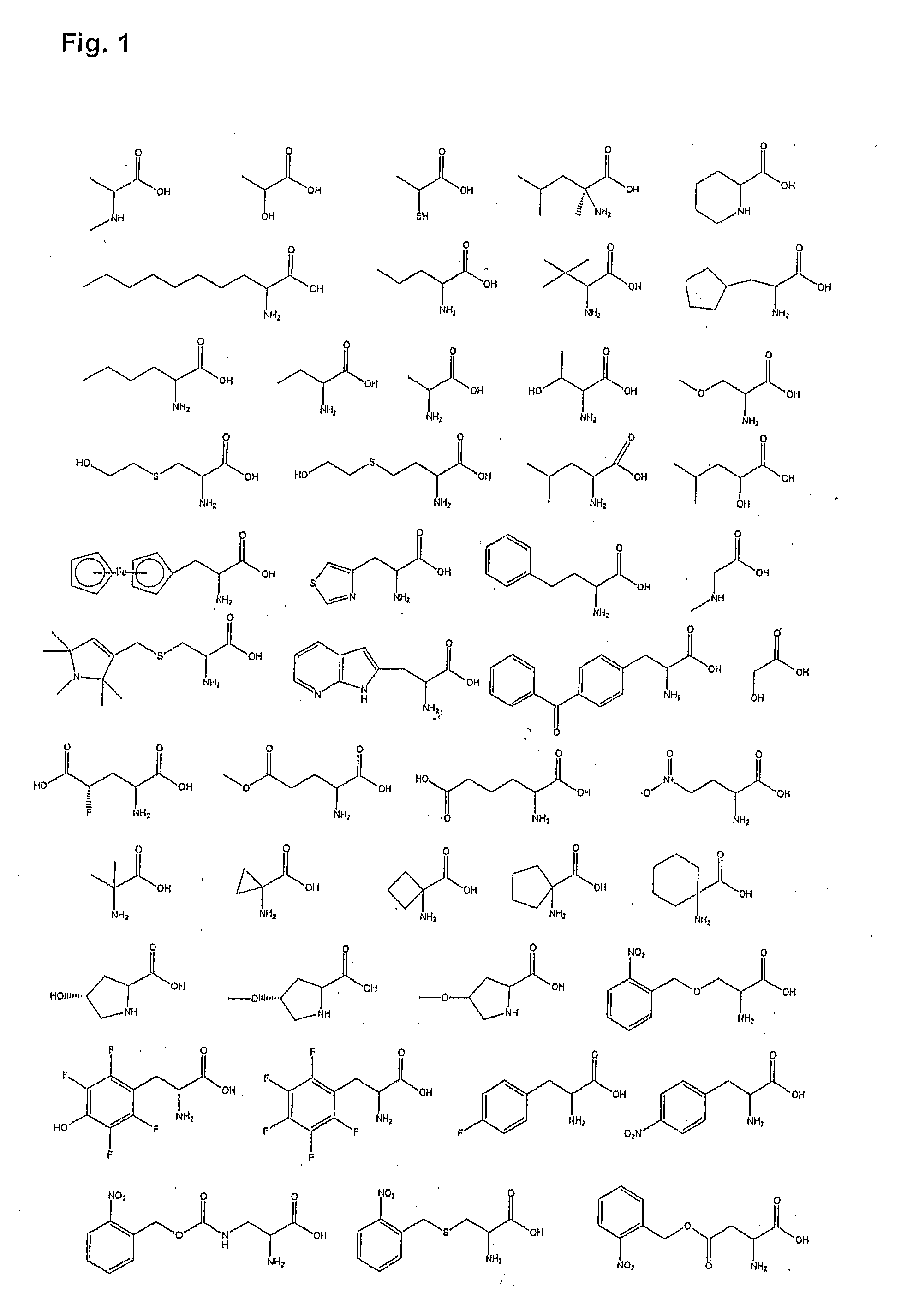

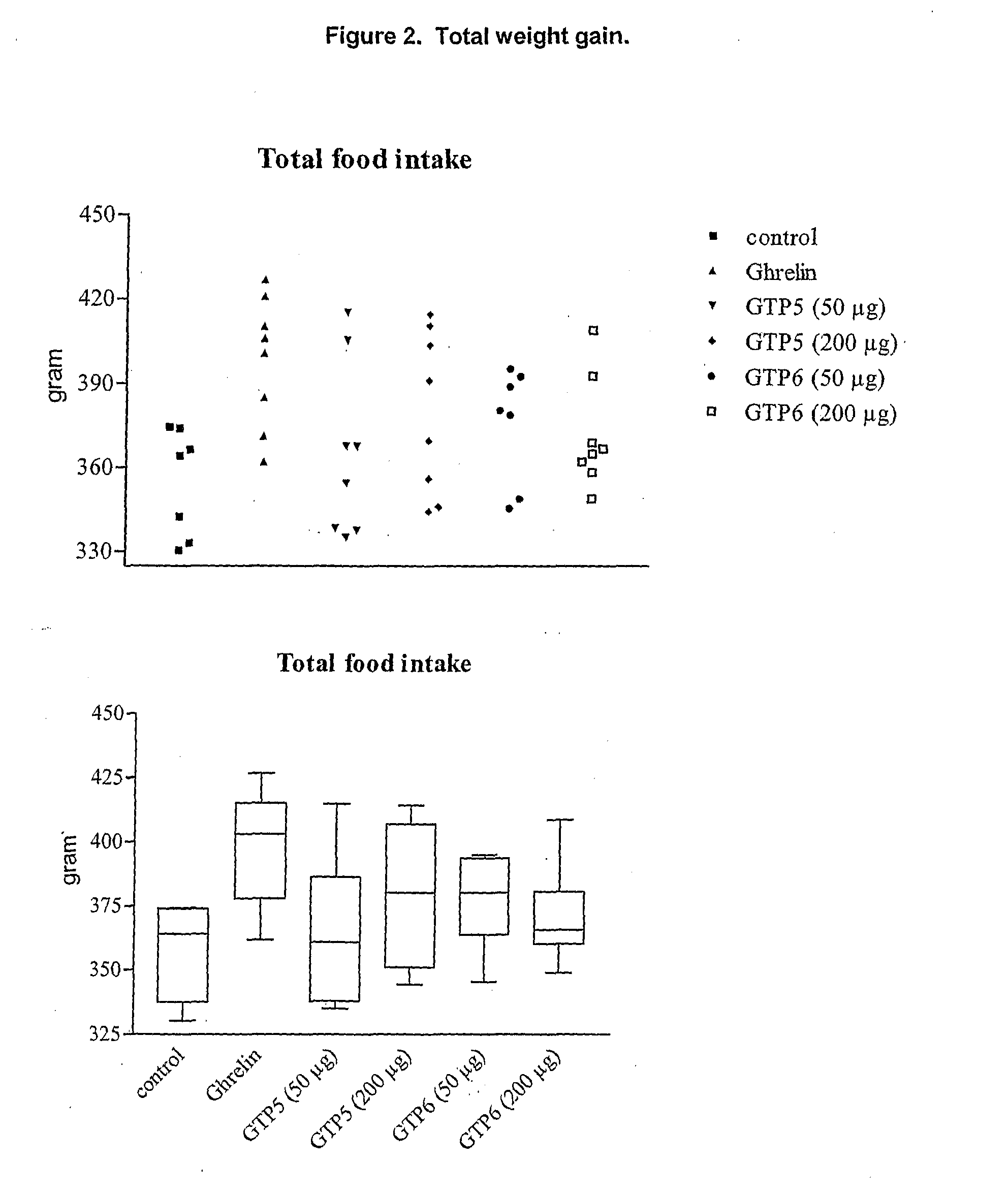

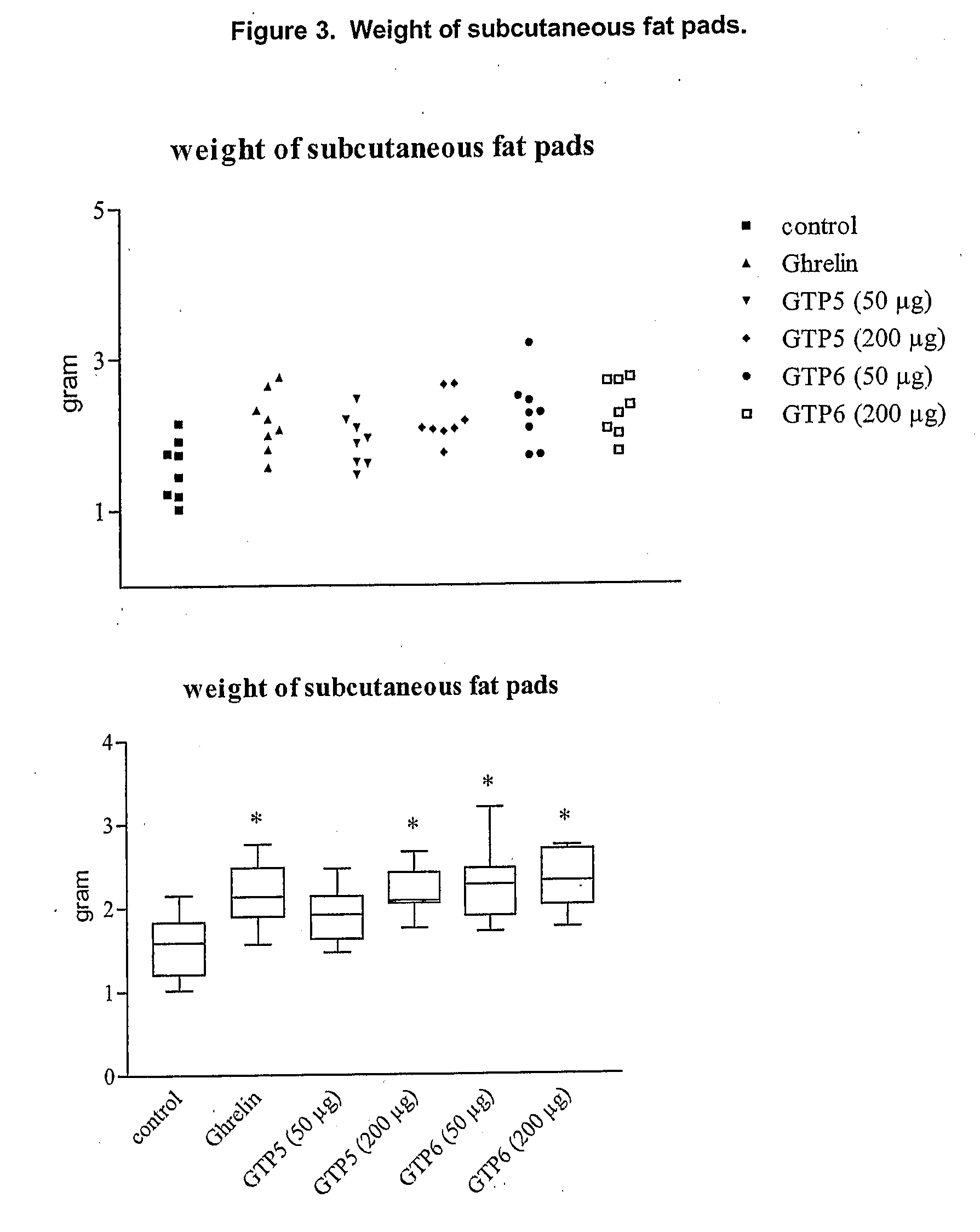

Growth Hormone Secretagogue Receptor 1A Ligands

InactiveUS20080300180A1Good curative effectImprove the anchorage of the GHS-R1A ligandDipeptide ingredientsMetabolism disorderGrowth hormoneGH Receptor

The present invention relates to new growth hormone secretagogue receptor 1A (GHS-R 1A) ligands, and pharmaceutical compositions comprising any of the new GHS-R1 A ligands. The ligands are suitable for a wide range of applications, and thus the present invention also relates to use of the GHS-R1 A ligands according to the present invention in the manufacture of a medicament for the treatment of an individual in need thereof. In another aspect, the present invention relates to a method of treatment of an individual in need thereof, comprising administering to said individual one or more of the GHS-R1A ligands disclosed herein, such as e.g. for treatment of cancer cachexia.

Owner:GASTROTECH PHARMA AS

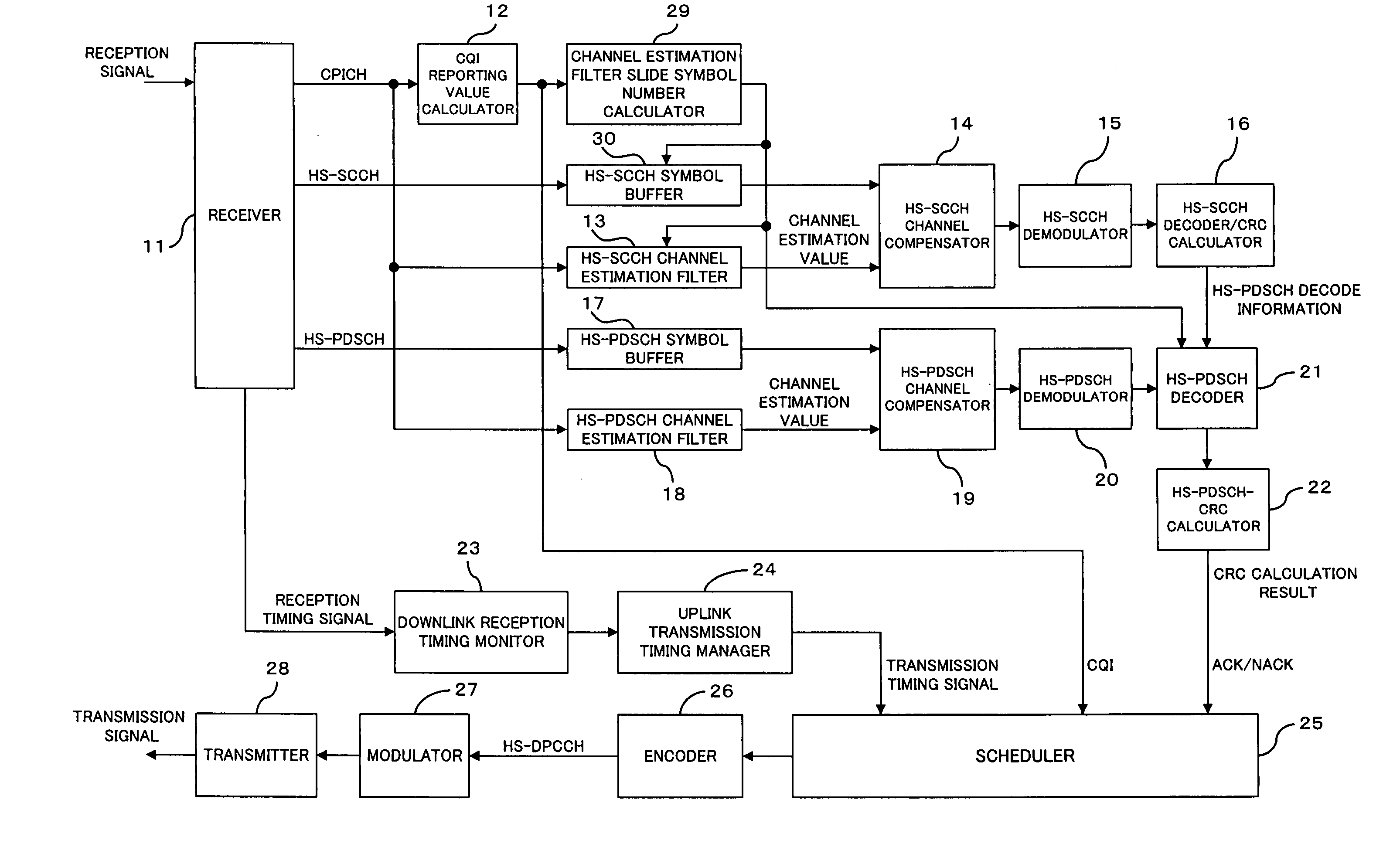

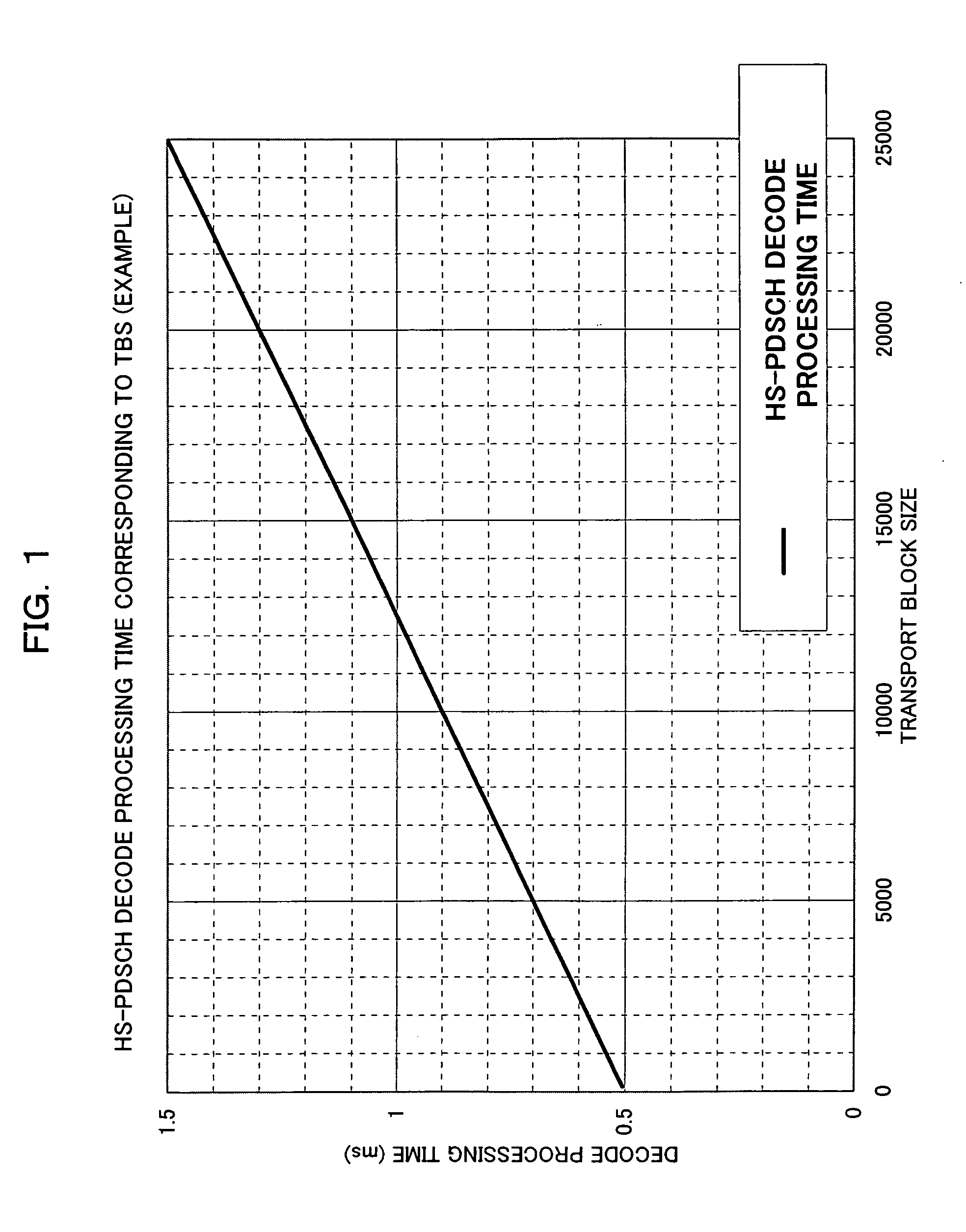

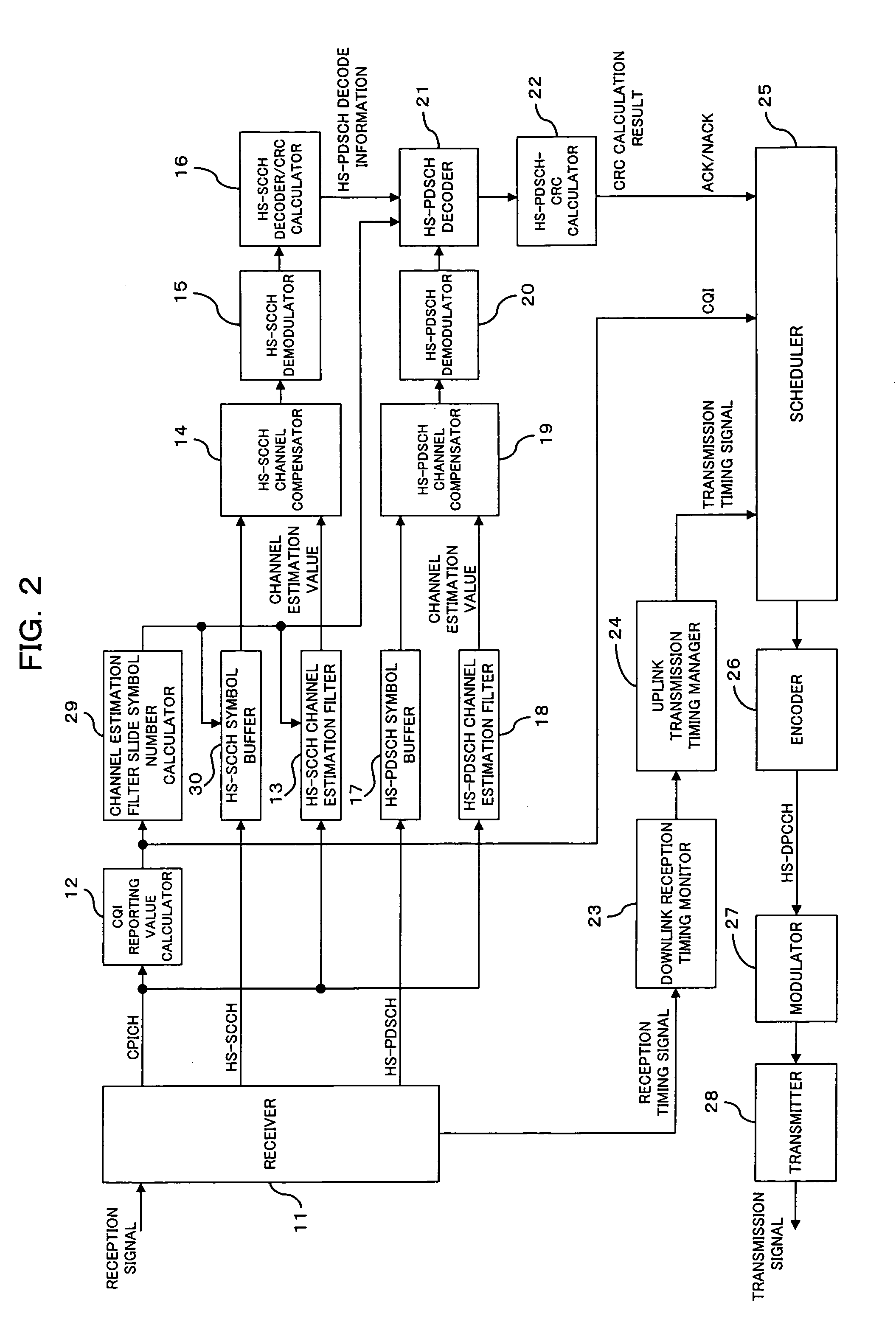

Mobile terminal apparatus and channel compensation method of the same

InactiveUS20070147289A1Improve throughputControl deteriorationNetwork traffic/resource managementData switching by path configurationTerminal equipmentControl channel

A mobile terminal includes a channel estimation processor to obtain the channel estimation value of a first channel reception signal in use of a plurality of known signals received from a base station within a channel estimation period; a channel compensation processor to perform a compensation process of the first channel reception signal in use of the channel estimation value; and a controller to control the channel estimation period so as to use a known signal which is received after the reception of the first channel reception signal for channel compensation. With this, throughput in downlink communication can be improved by controlling the deterioration of HS-SCCH reception quality itself without any particular transmission power control with the base station even under an environment such as high speed fading.

Owner:FUJITSU LTD

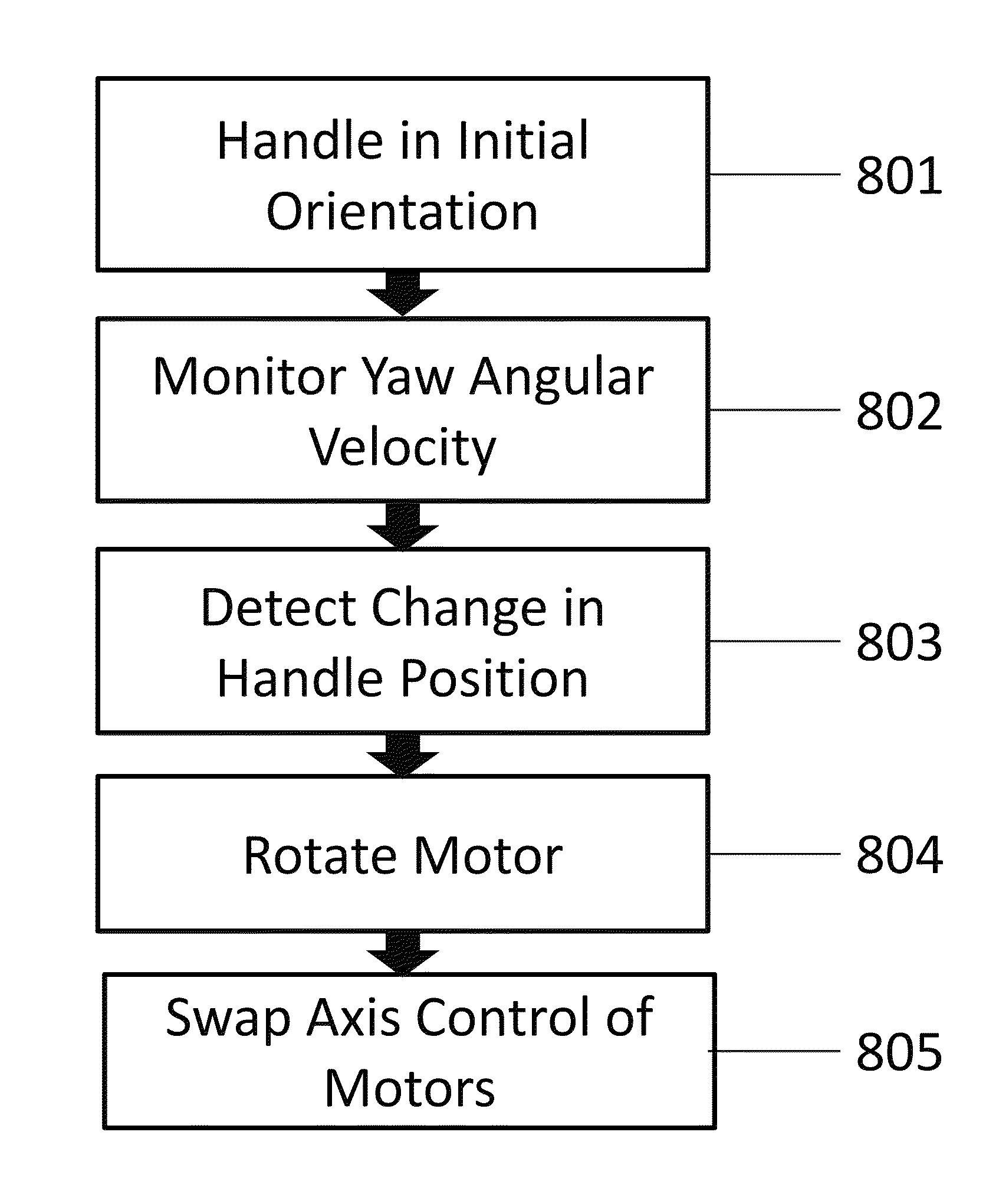

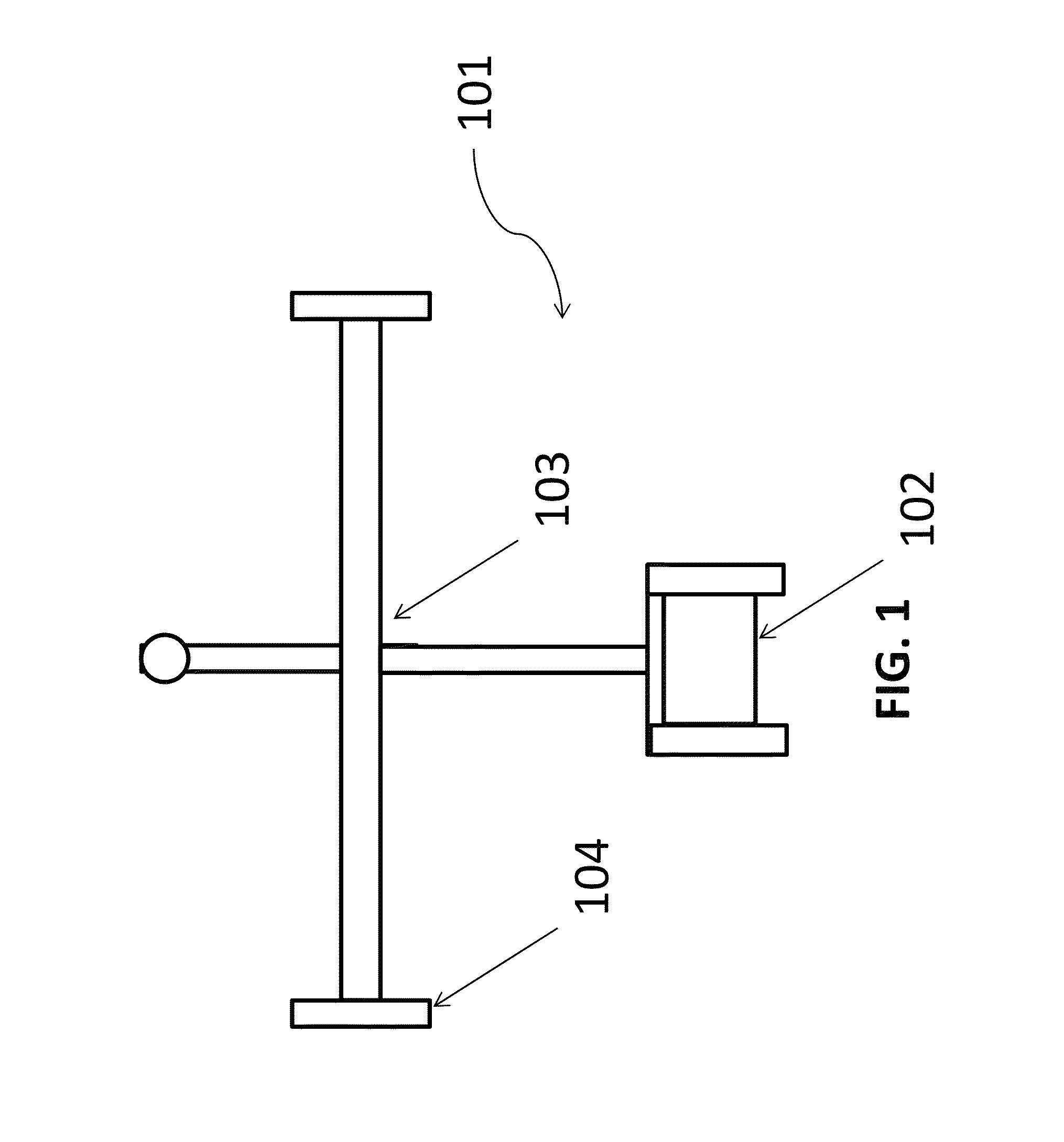

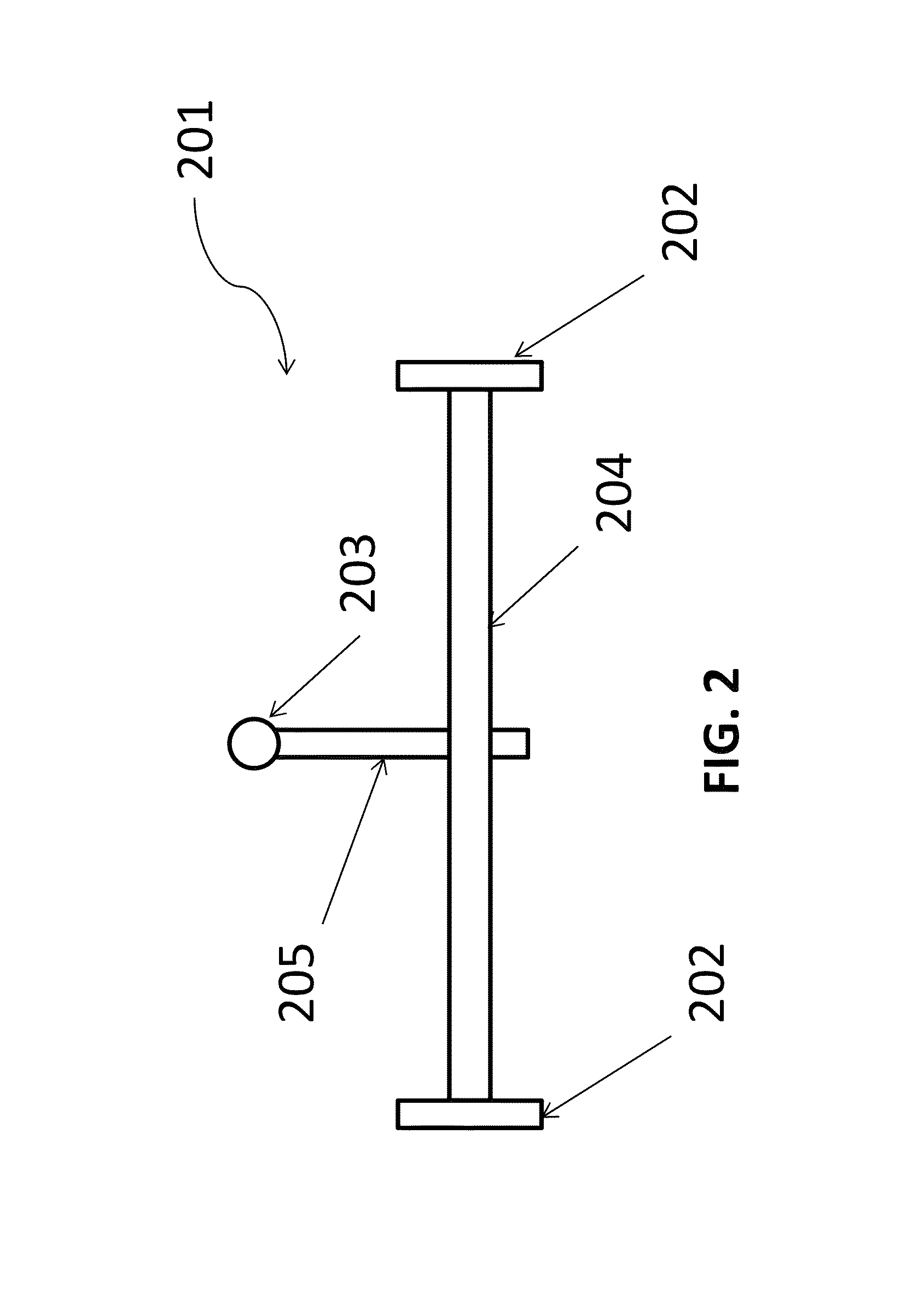

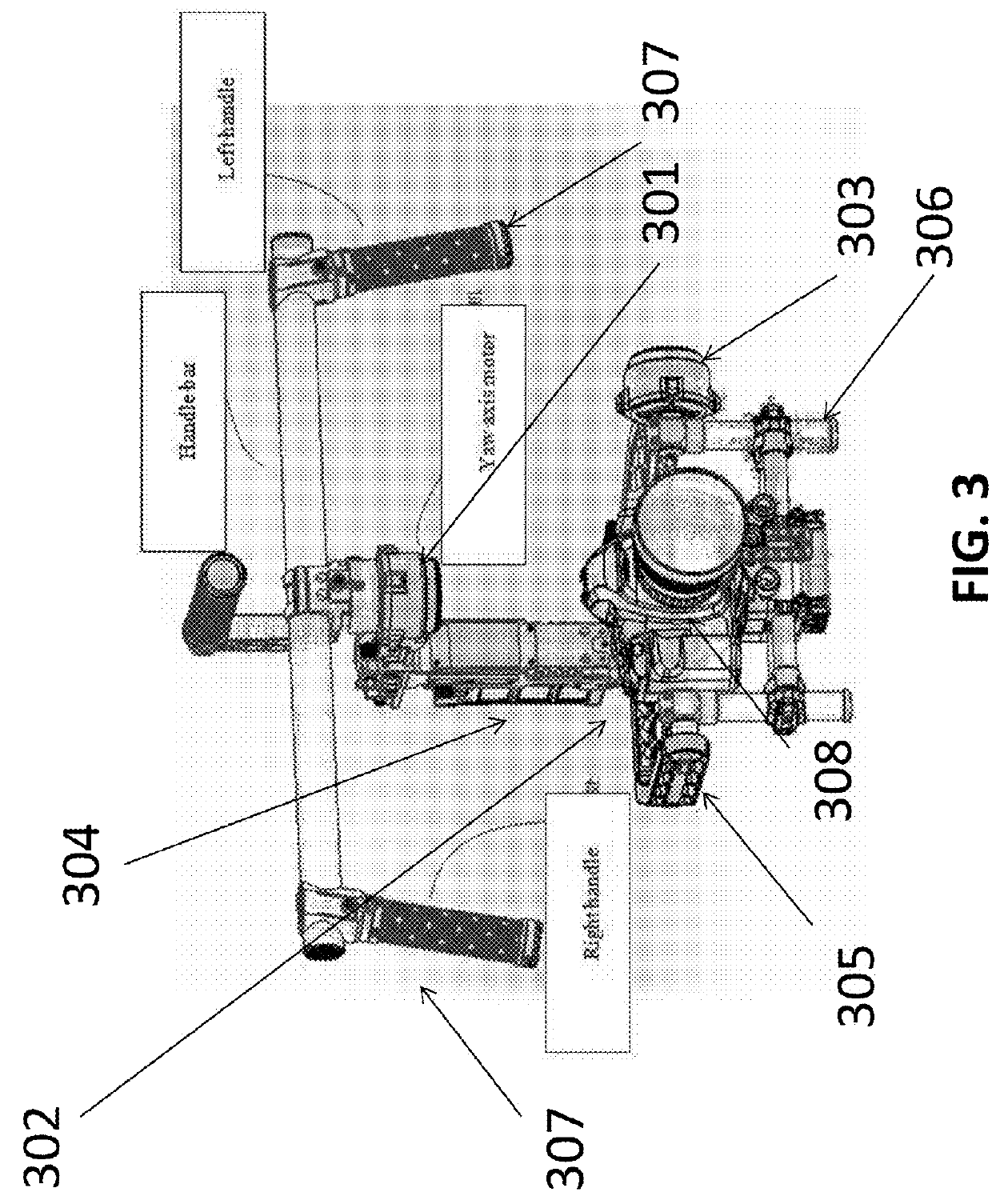

Systems and methods for payload stabilization

ActiveUS20160033077A1Stabilize payloadAvoiding gimbal lockAircraft componentsTravelling carriersGimbal lockPayload

Owner:SZ DJI OSMO TECH CO LTD

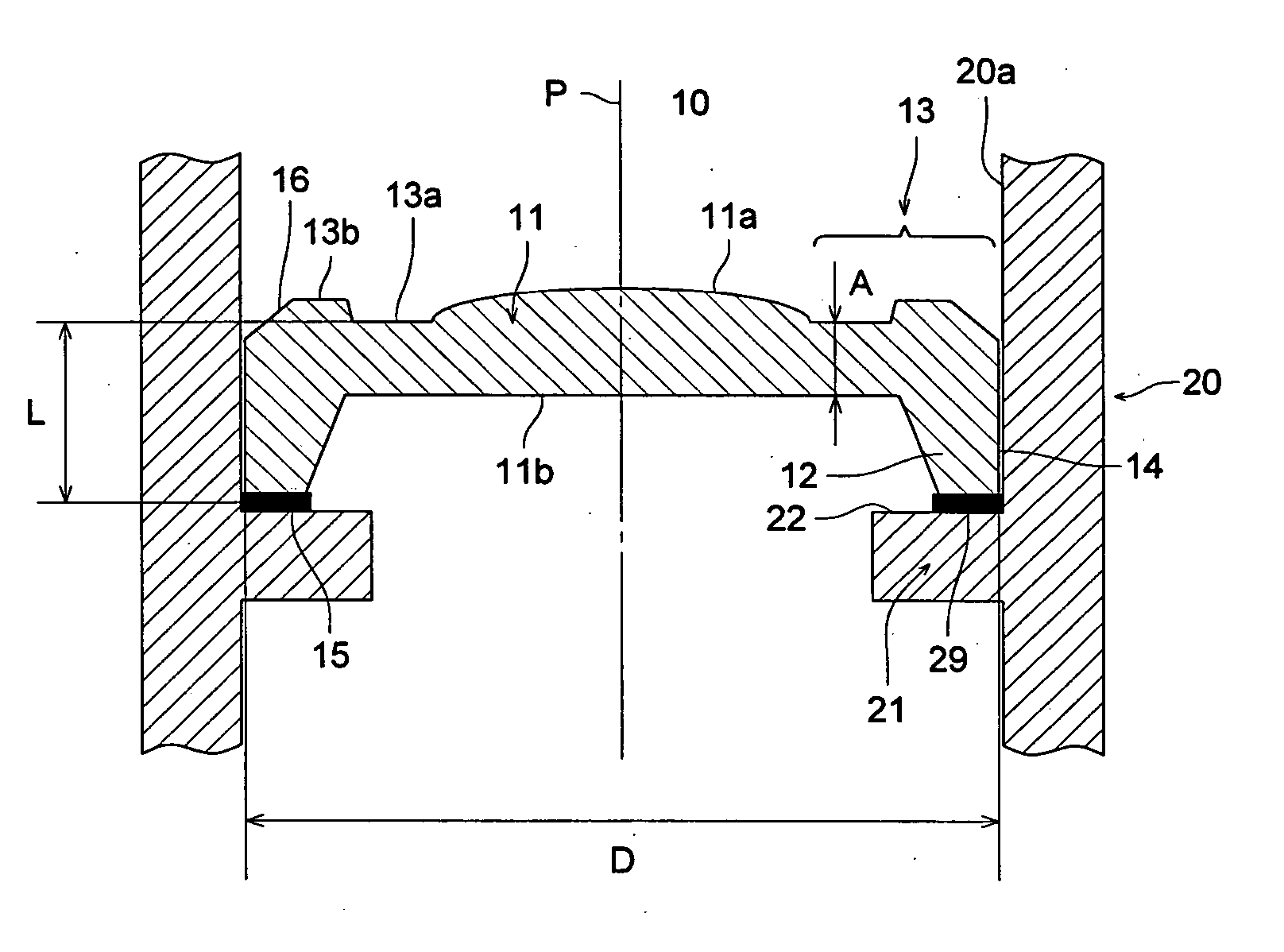

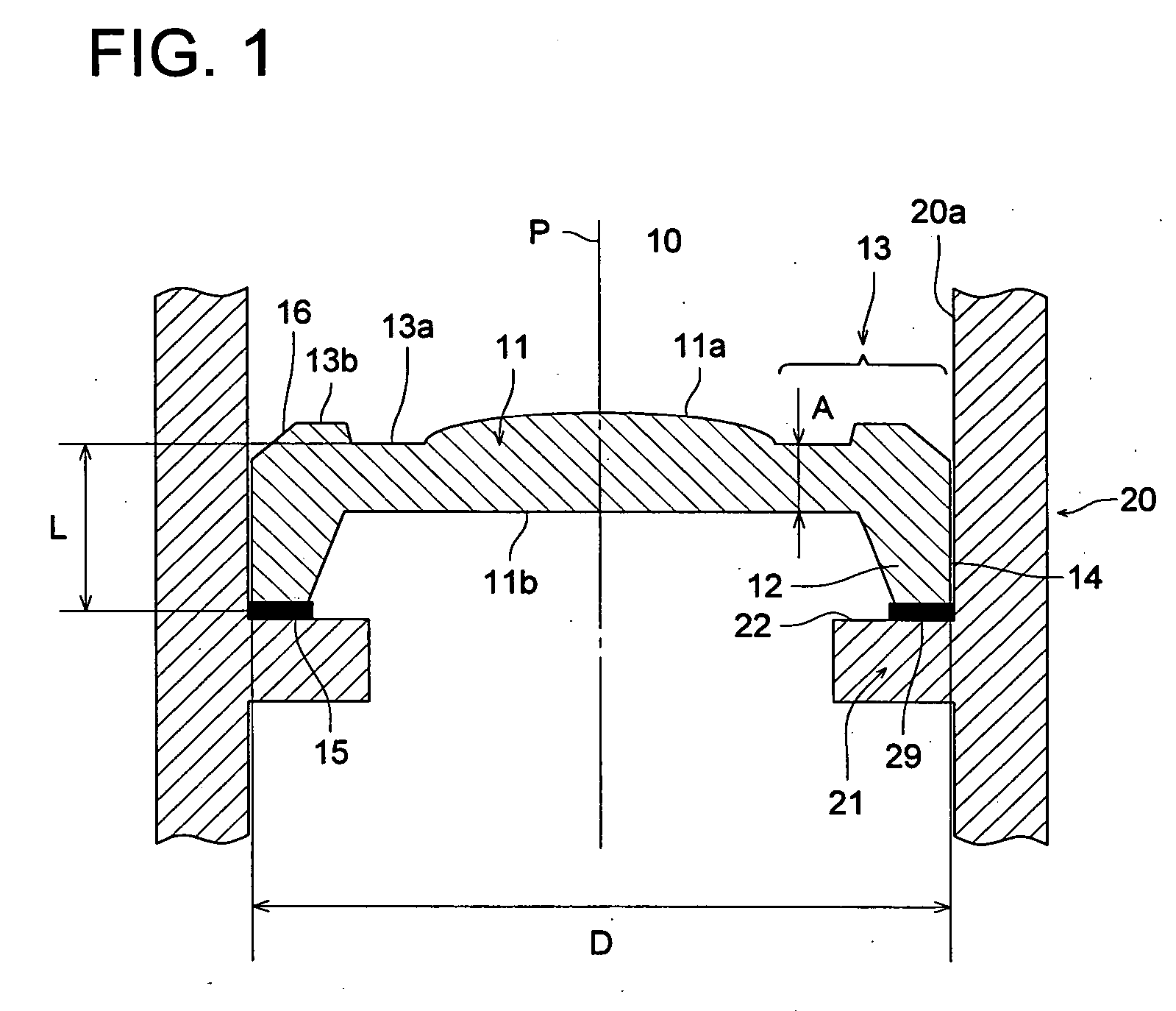

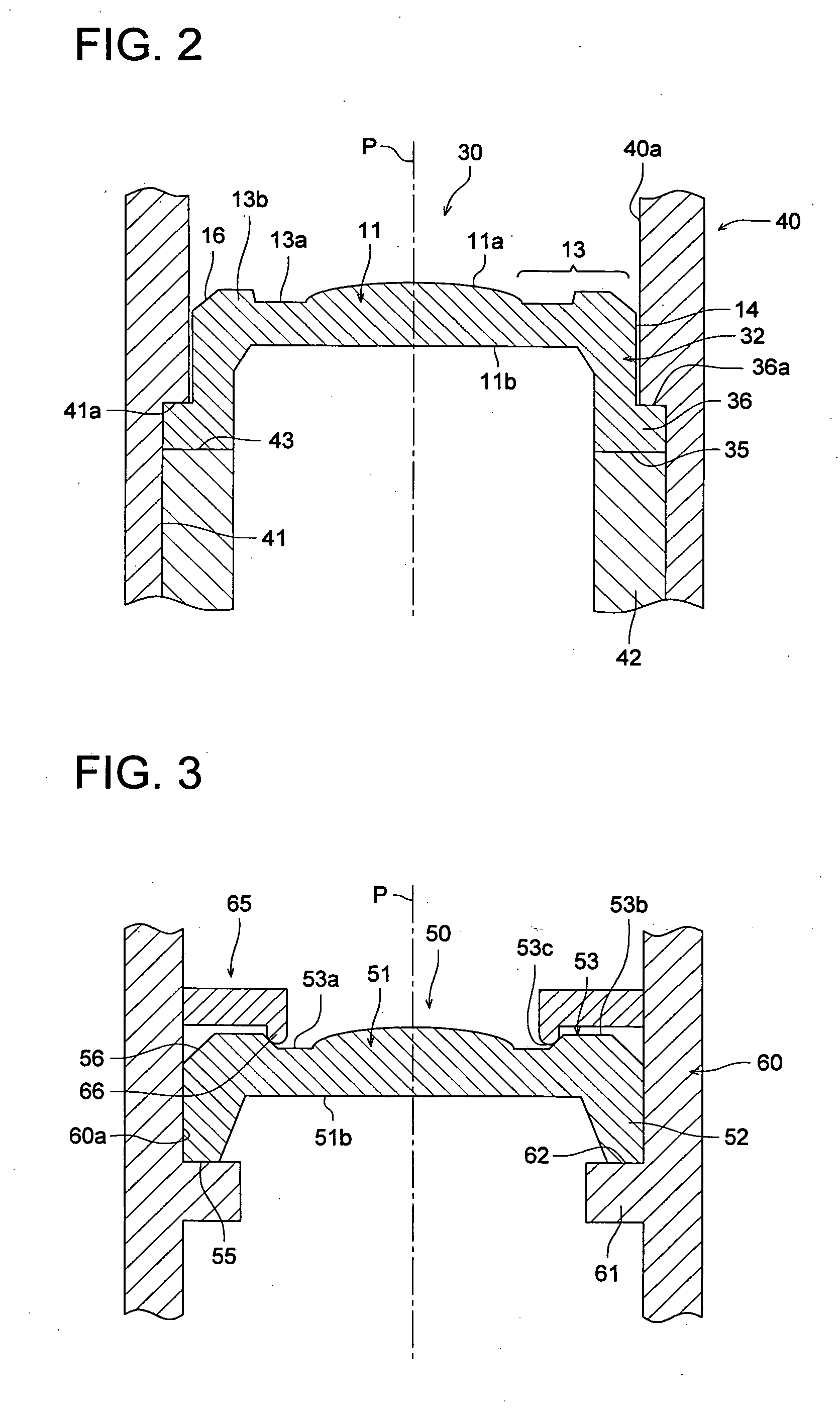

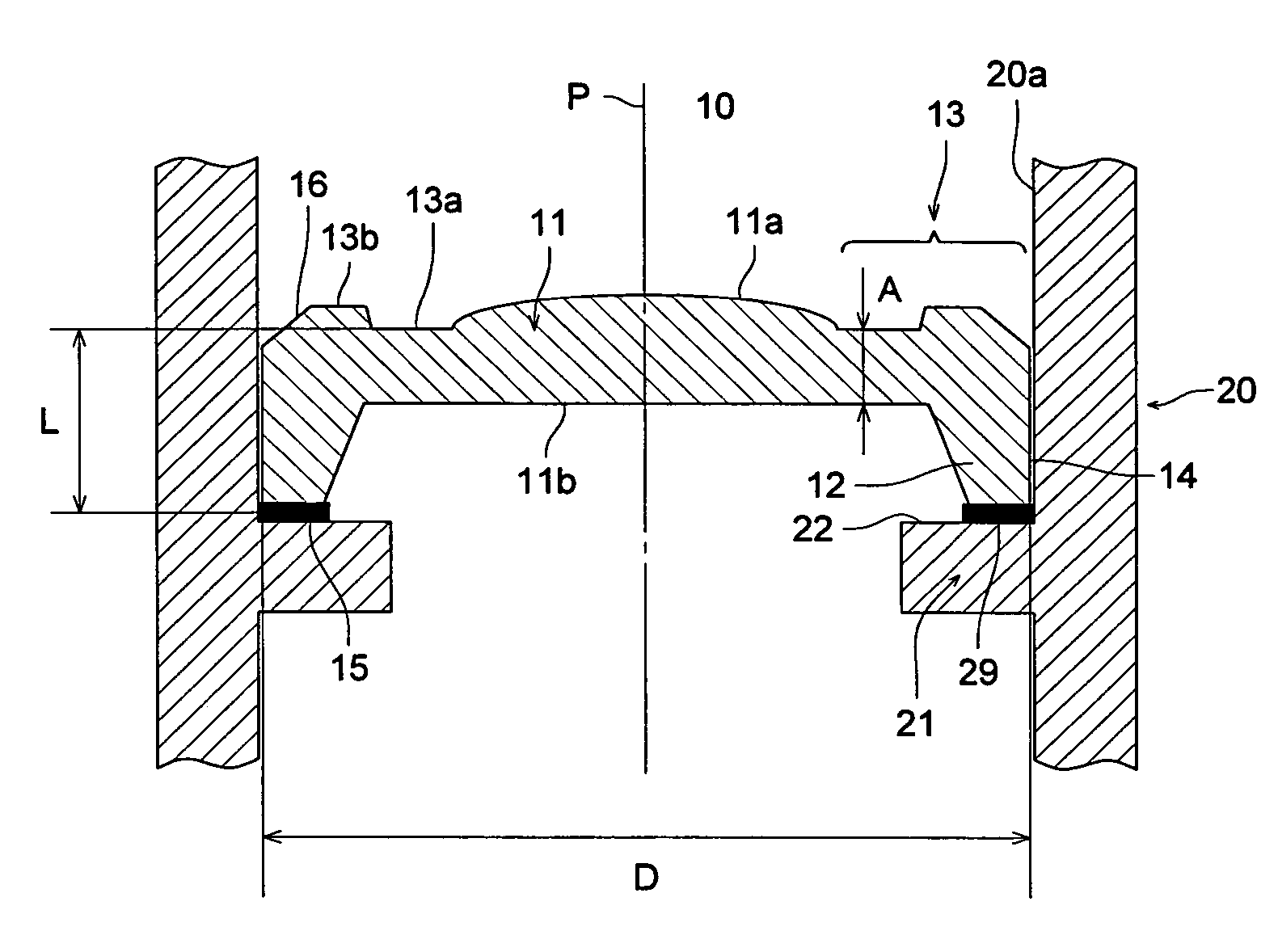

Optical element holding structure, optical element lens-barrel and optical communication module

InactiveUS20060114579A1Prevent movementControl deteriorationMountingsOptical light guidesOptical axisEngineering

An optical element holding structure, having: an optical element including an optical section having optical function, an outer peripheral portion which is positioned at the outer peripheral side of the optical section and a mounting portion which protrudes from the outer peripheral portion in a direction substantially parallel to the optical axis; and a lens barrel holding the optical element inside.

Owner:KONICA MINOLTA INC

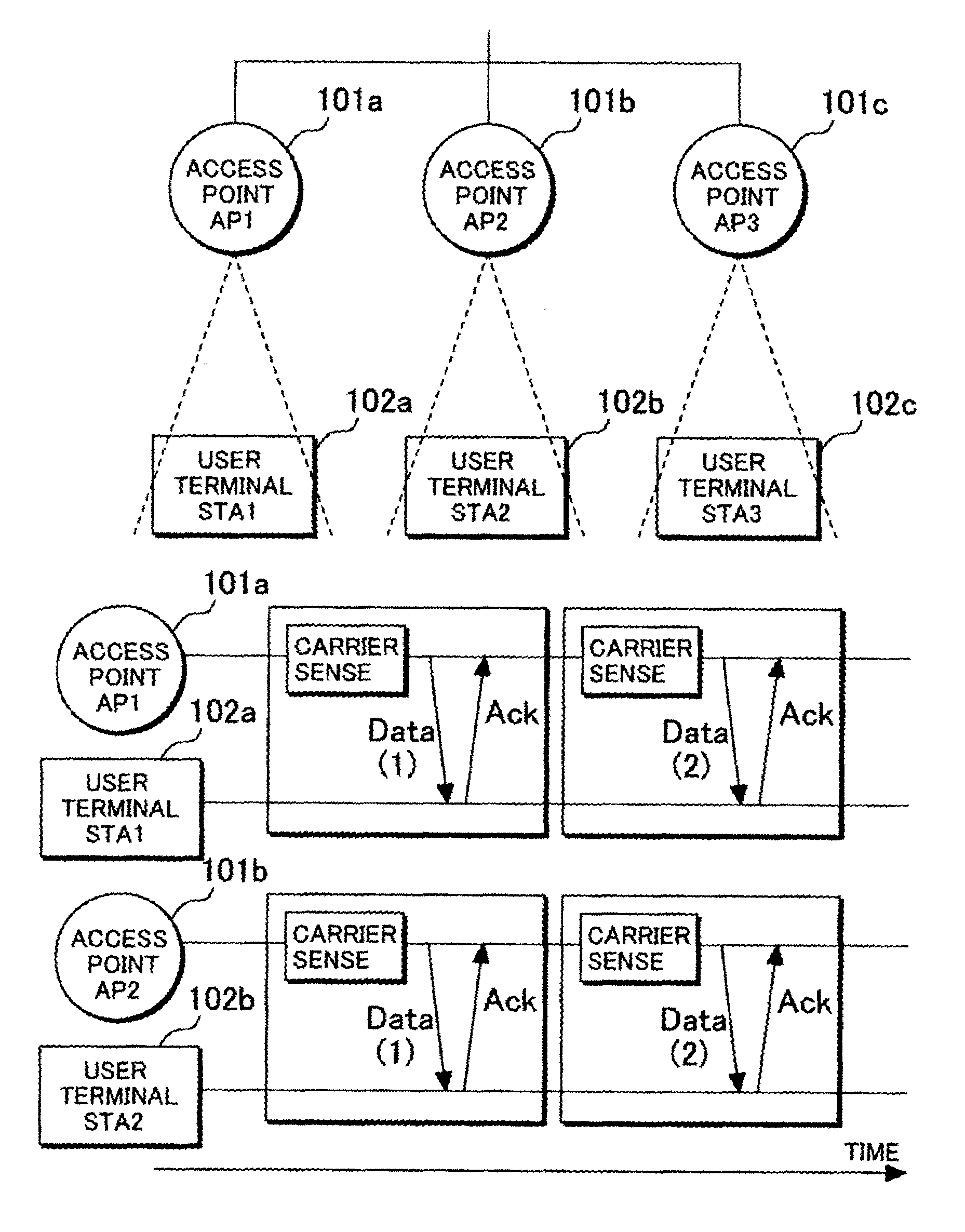

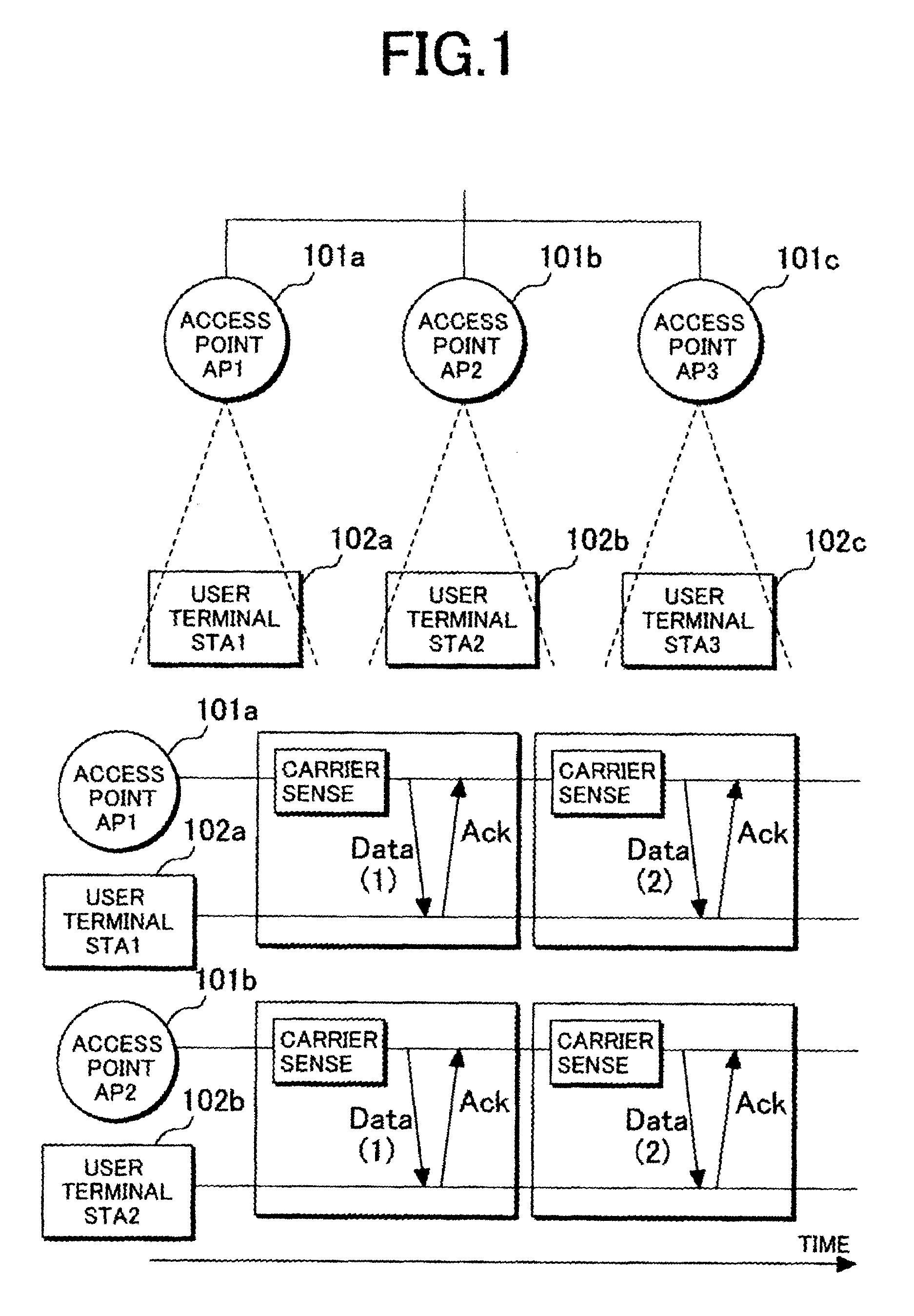

Radio-communication control method and equipment

InactiveUS7092732B2Improve throughputImprove user throughputPower managementSite diversityCommunications systemNetwork packet

A signal pair interference power ratio of the received signal at a user terminal is obtained and this ratio is then compared with the signal pair interference power ratio required for correct demodulation. Accordingly, the user terminals can be classified into those in the non-interference domain and those in the interference domain. A plurality of access points make the simultaneous communications to the user terminals in the non-interference domain and also make the communications on the time-division basis to the user terminals in the interference domain. Thereby, it is now possible to solve the problem, in the communication system in which the total throughput of the system can be improved through simultaneous transmissions from a plurality of access points with the wireless access system to connect the user terminals to the wired network via the access points, that the throughput of the user terminal which cannot demodulate correctly the desired signal if the data packets collide with each other is more deteriorated than the user terminal which can correctly demodulate the desired signal because the desired signal pair interference power ratio is large even when the data packets collide with each other.

Owner:HITACHI LTD

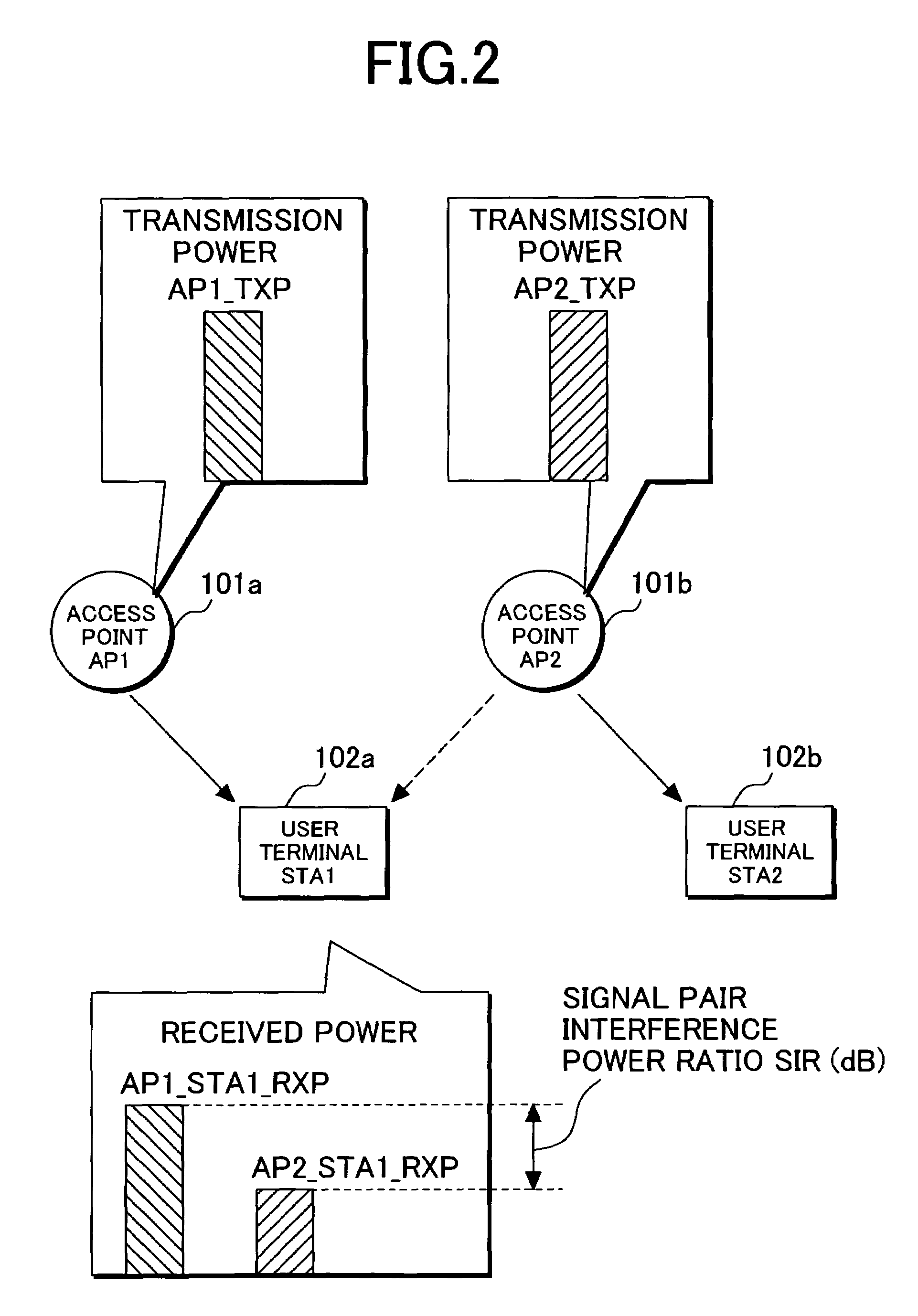

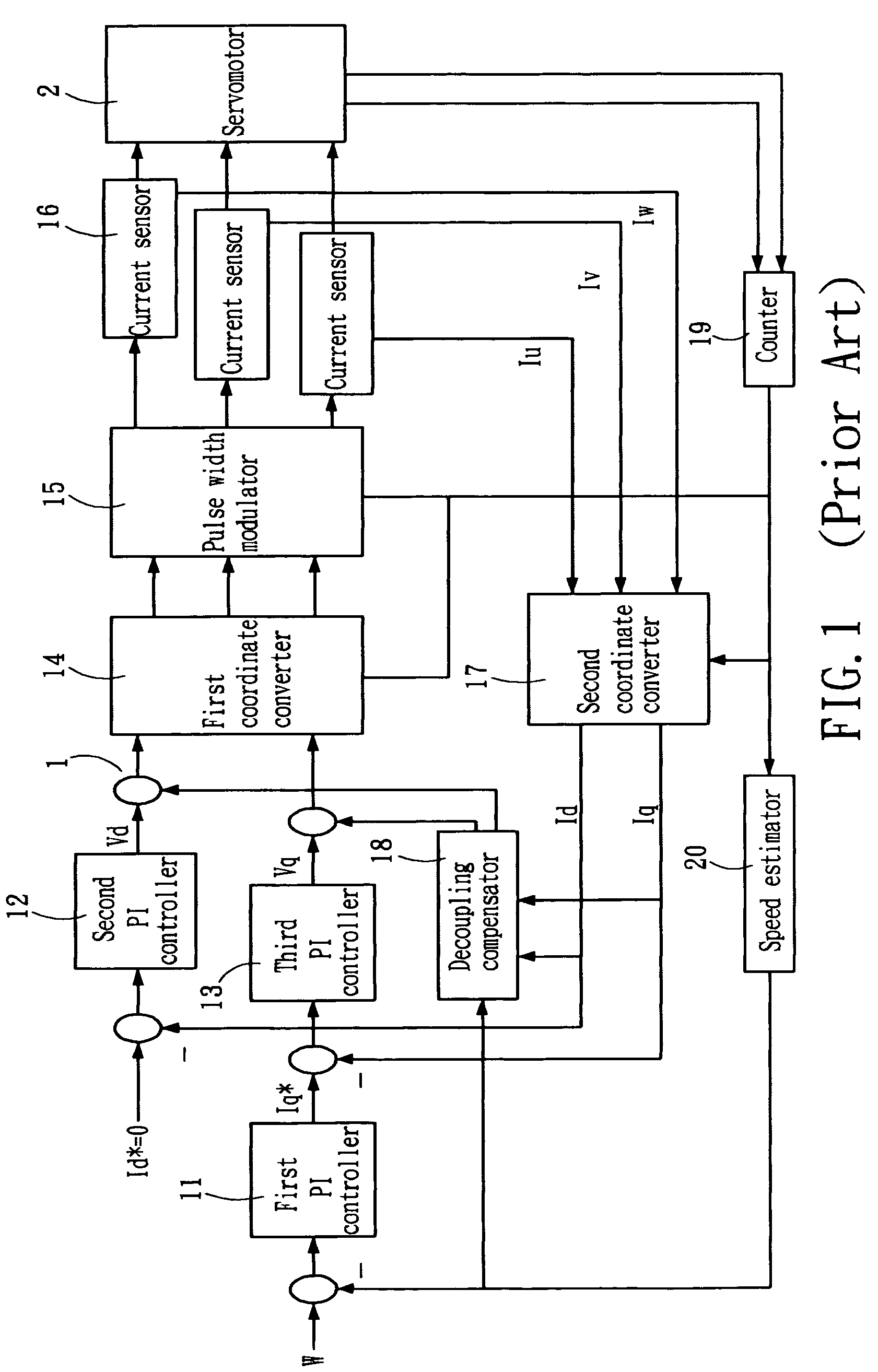

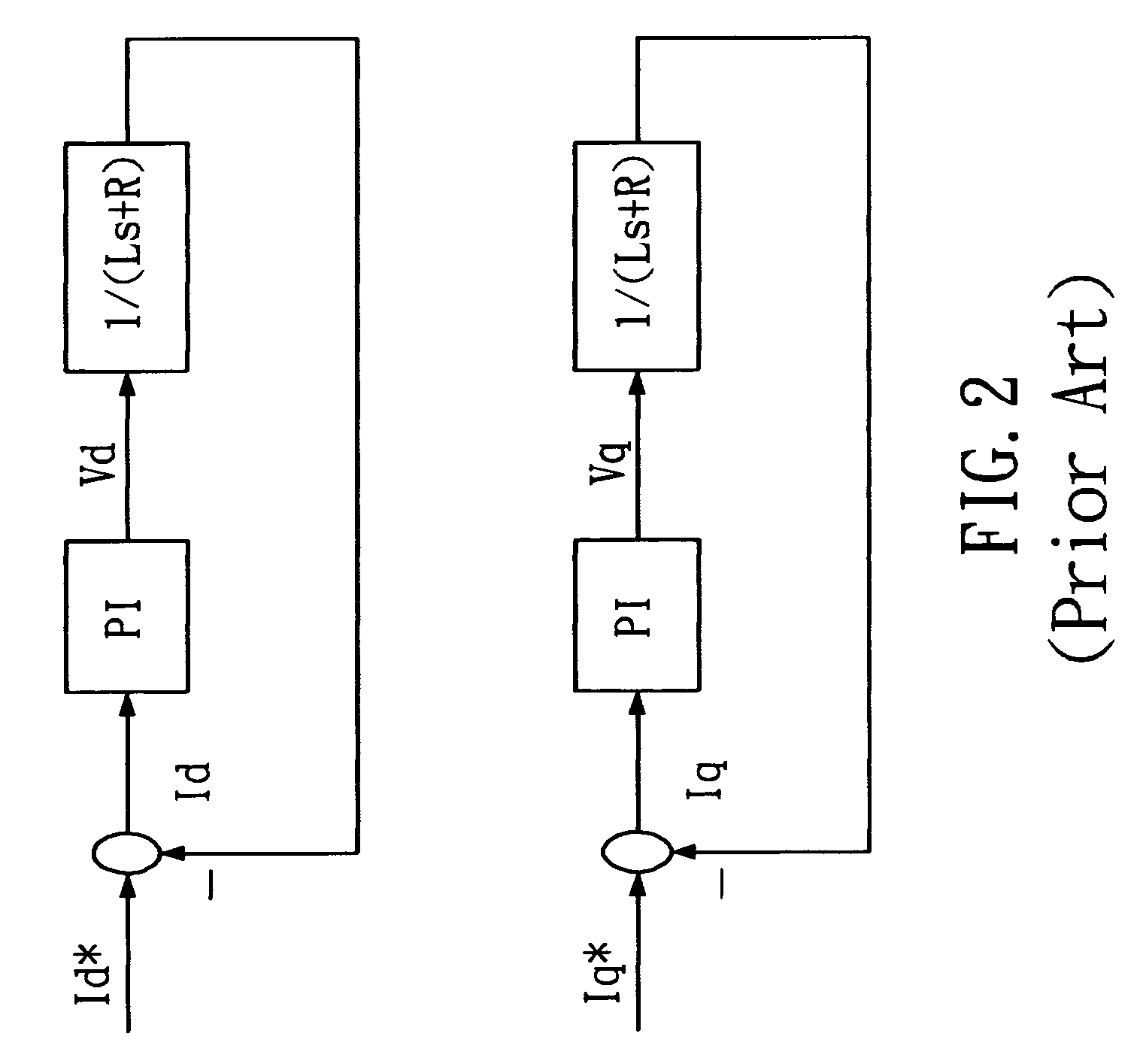

AC servo drive without current sensor

InactiveUS7187152B1Control deteriorationDeterioration of costAC motor controlSynchronous motors startersPwm controllerVIT signals

An AC servo drive without current sensor includes a PI (proportional integration) controller, at least two first-order controllers (polar point and zero point), a decoupling compensator, a coordinate converter, a pulse width modulator, a counter and a speed estimator. The AC servo drive is connected with a servomotor to form an AC servo module. The servomotor comprises an encoder receiving a current command signal from the servo module to function as input current command signal or the d, q axes PI controller and the decoupling compensator. The voltage command signal generated by the d, q axes PI controller and the signal generated by the decoupling compensator form a control signal and input to the coordinate converter. The signal output from the coordinate converter is processed by PWM controller to control the servomotor. Therefore, the deterioration of servo motor control caused by temperature drift and cost can be solved.

Owner:DELTA ELECTRONICS INC

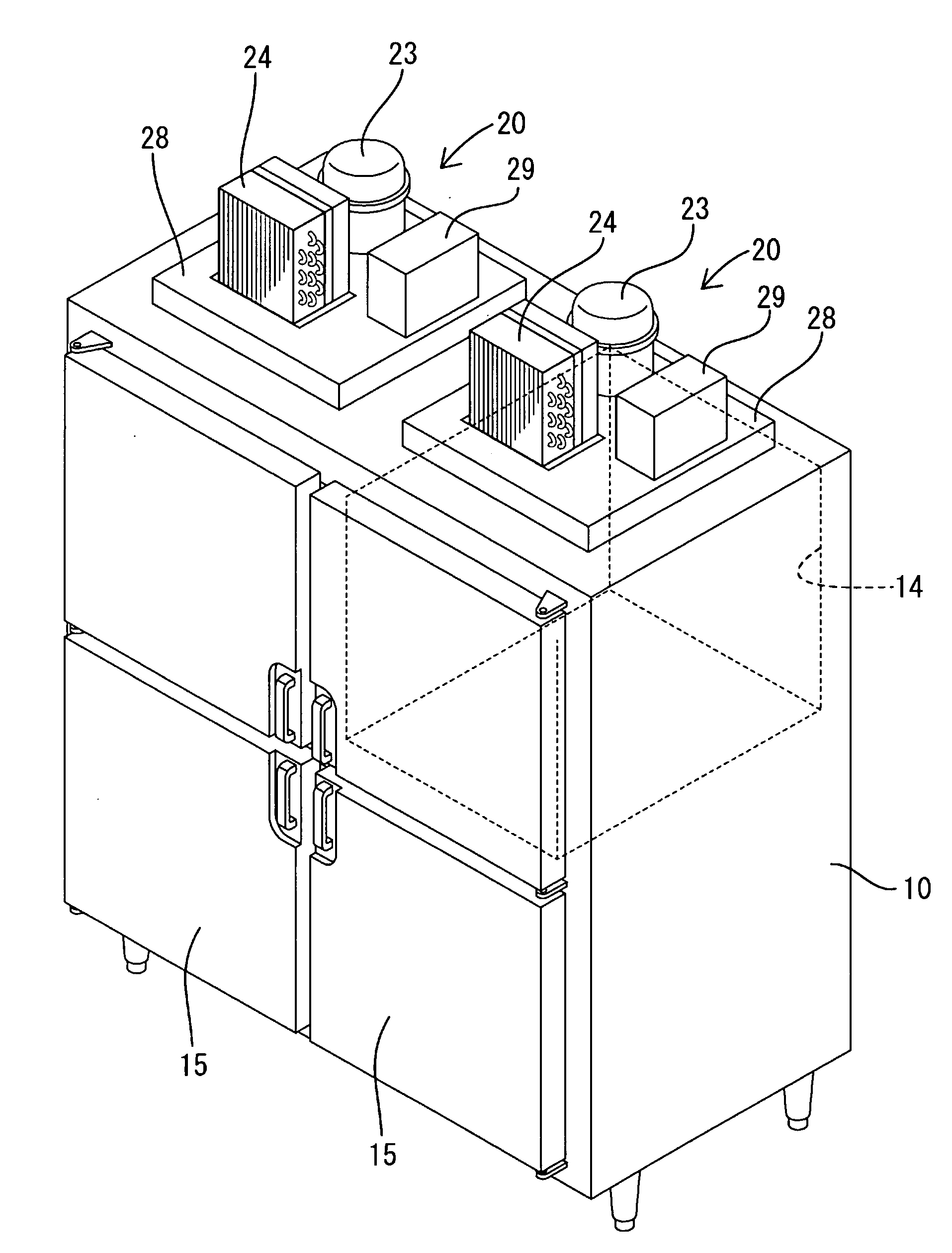

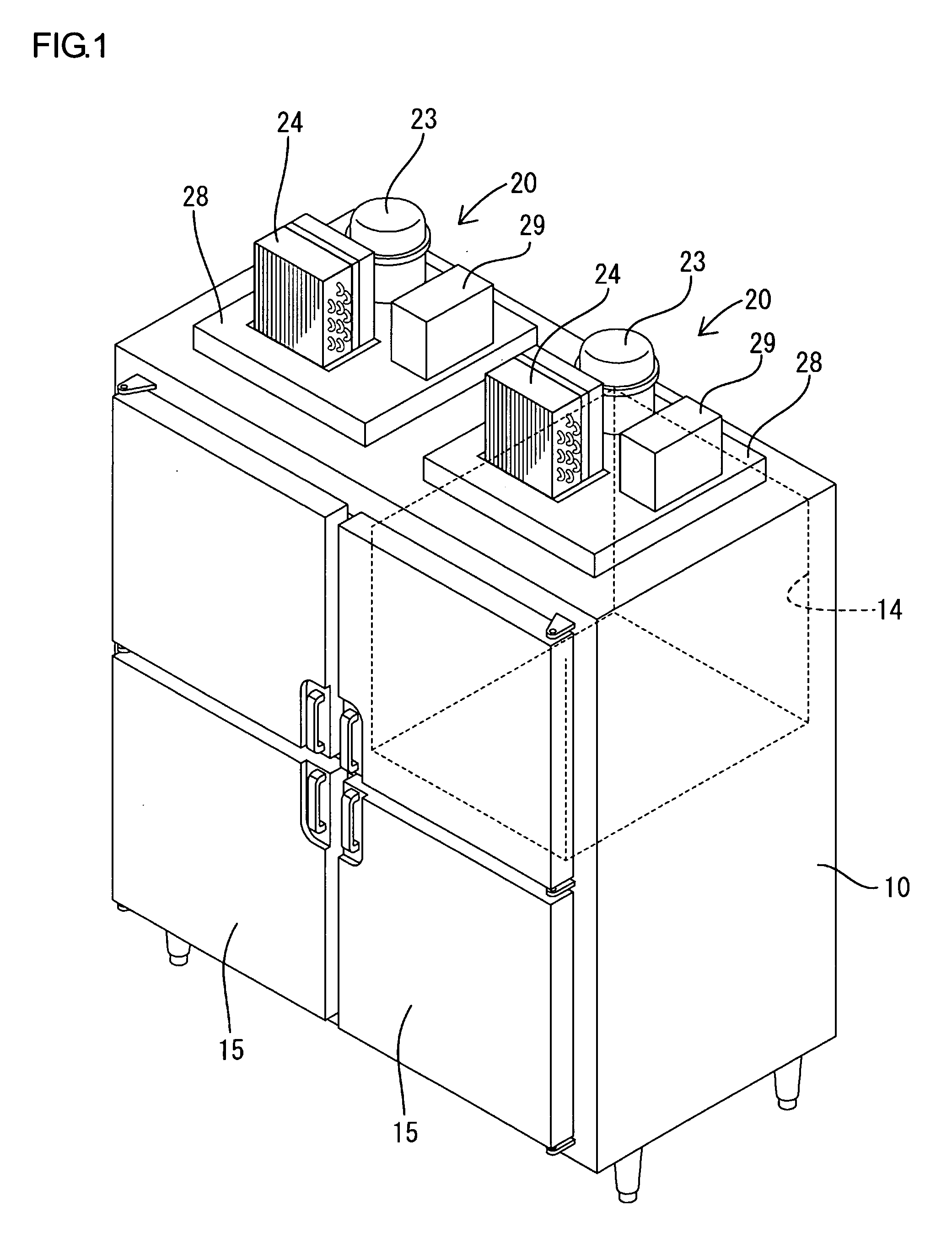

Cooling Storage Cabinet and Method of Operating the Same

InactiveUS20090105884A1Control deteriorationEasily realizedSampled-variable control systemsComputer controlCool storageOperational approach

A cooling device is provided with an inverter compressor. Set speeds of the inverter compressor can be switched to six stages from a first speed to a sixth speed. The relationship between each of the set speeds of the rotational speed is set so that the stages adjacent to each other have gradually larger differences in rotational speed as the rotational speed becomes higher. With this, independently from the level of the rotational speed, a degree of increase in cooling performance between each of the stages can be equalized. In a case of performing a control to increase or decrease the rotational speed of the inverter compressor stage by stage depending whether an actual temperature drop rate is larger or smaller than a target temperature drop rate, the change amounts in cooling performance that can be substantially equalized, and too high or too low cooling performance does not result, i.e. fluctuation in cooling performance can be minimized. Thus, control to drop the internal temperature in accordance with a predetermined cooling characteristic can be stably performed.

Owner:HOSHIZAKI ELECTRIC CO LTD

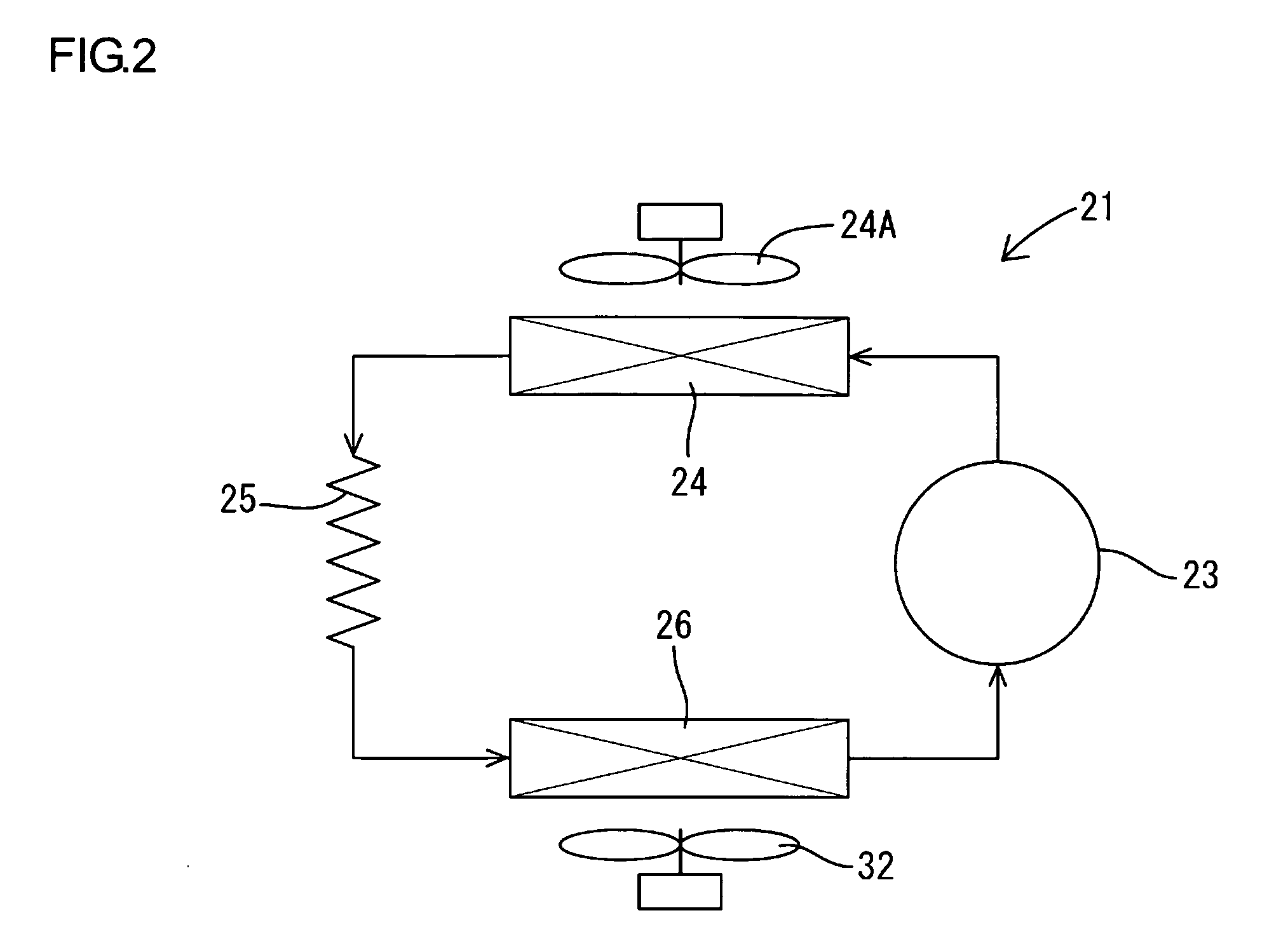

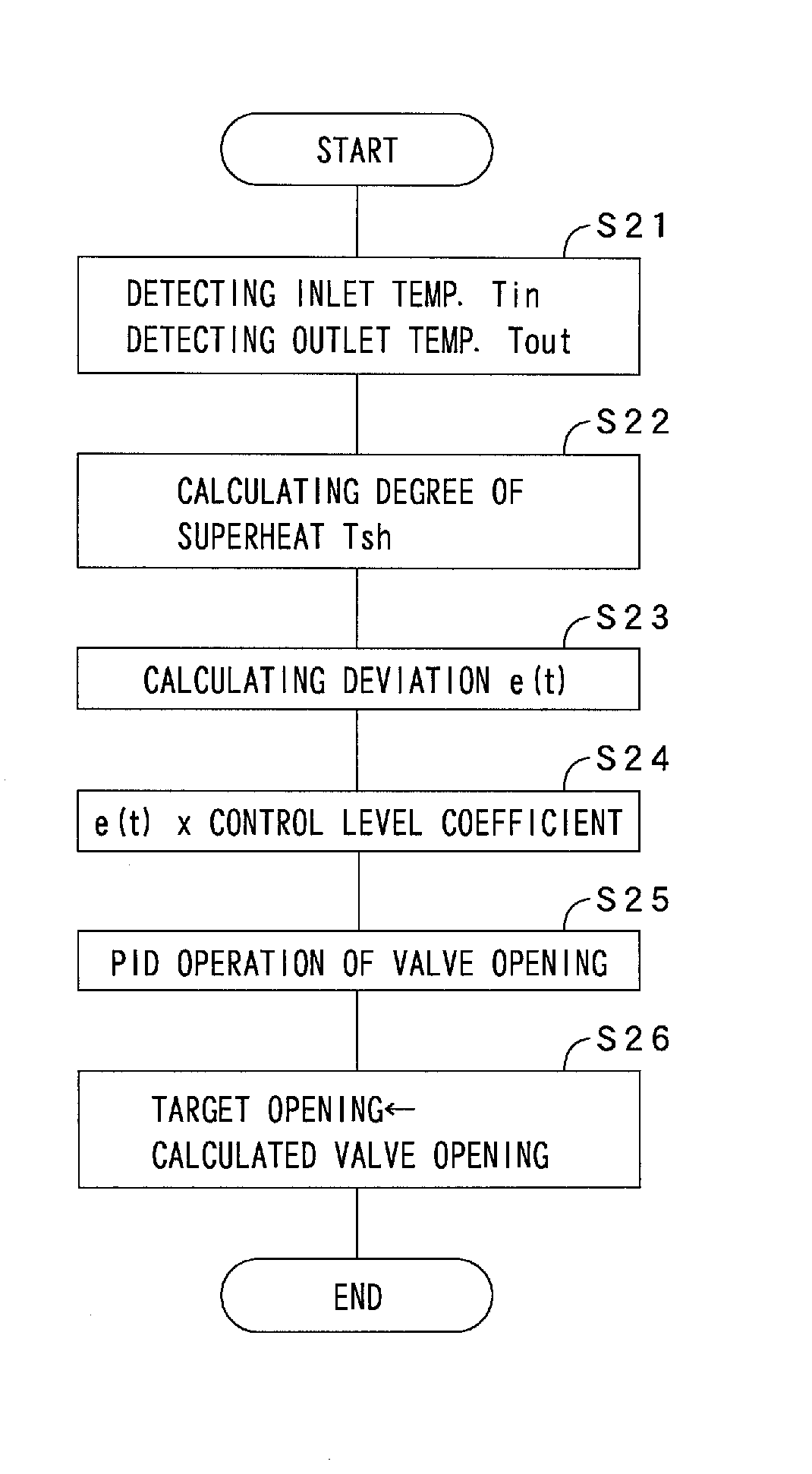

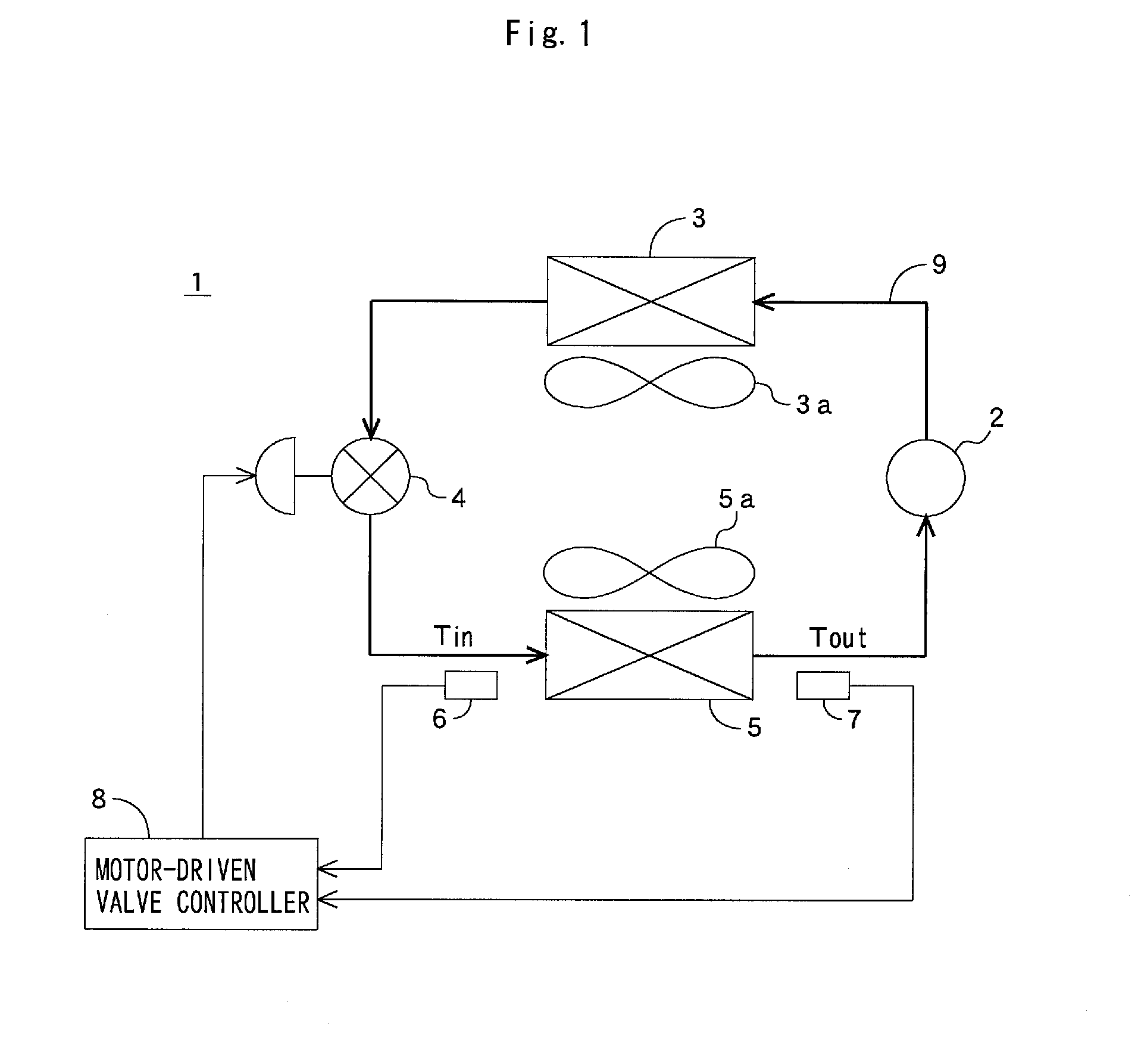

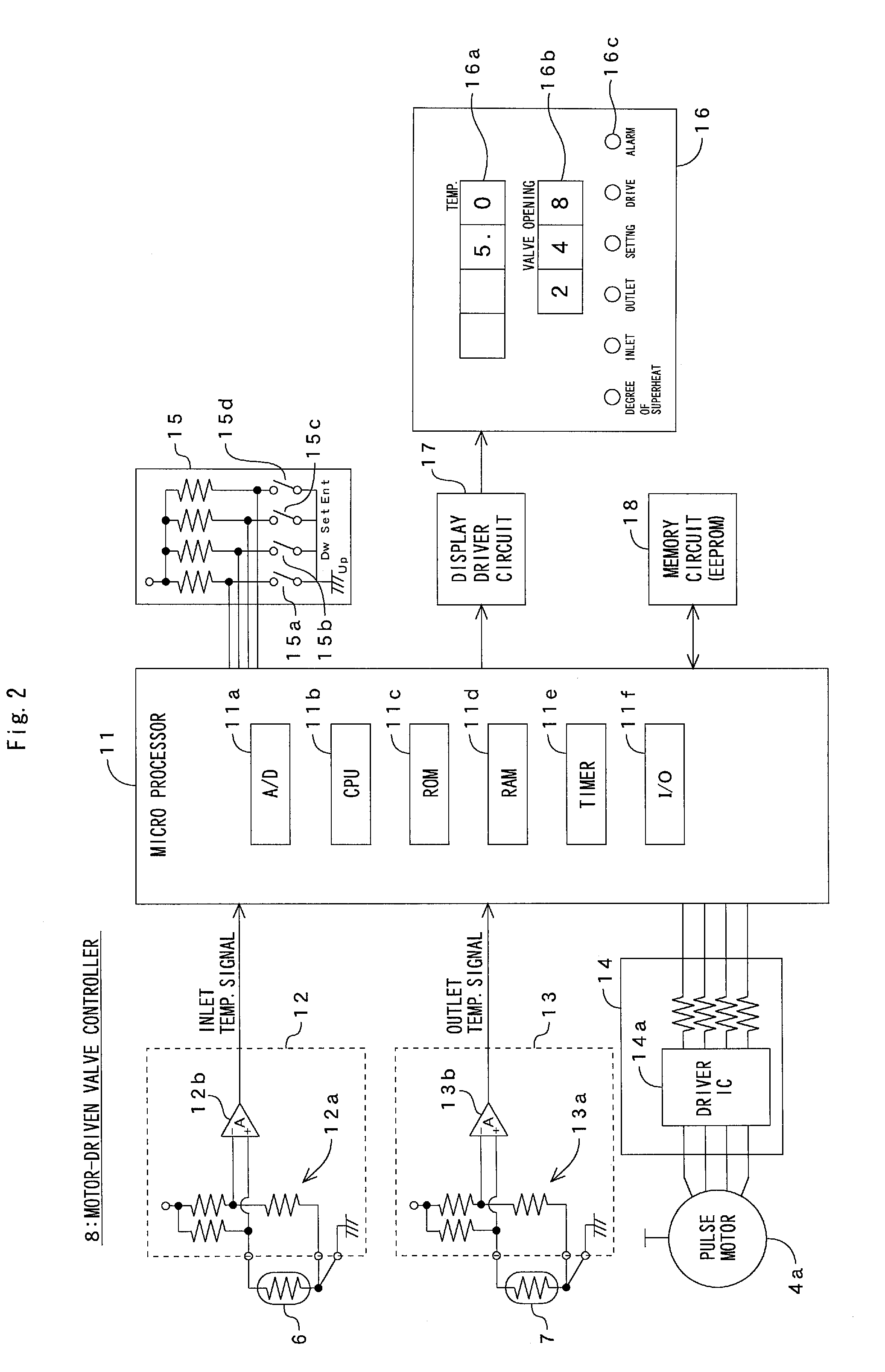

Device and Method for Controlling Valve

InactiveUS20090228153A1Convenient valve controlling methodGuaranteed uptimeMechanical apparatusLevel controlAuto regulationControl valves

To provide a valve controller which is convenient for users in that, even users without abundant experience and expert knowledge can obtain the optimum operation performance for a short period of time; and it can be prevented that control performance is caused to be deteriorated on the contrary in dependence on changing way of each coefficient. A valve controller 8 for controlling valve opening of an expansion valve 4 by calculating the valve opening such that a detected temperature (degree of superheat) Tsh coincides with a target temperature (degree of superheat) TS comprises: automatic tuning means for calculating a deviation e(t) between the detected temperature and the target temperature and for calculating changing amount of the valve opening m(t) by substituting at least the deviation and a set control parameter (PB, Ti, Td) into an arithmetic expression to automatically set the control parameter; and control level adjusting means for adjusting a magnitude of the valve opening calculated with the control parameter set by the automatic tuning means in stages in accordance with a set control level, and so on.

Owner:FUJIKOKI CORP

Optical element holding structure, optical element lens-barrel and optical communication module

InactiveUS7345832B2Prevent movementControl deteriorationMountingsOptical light guidesOptical axisEngineering

Owner:KONICA MINOLTA INC

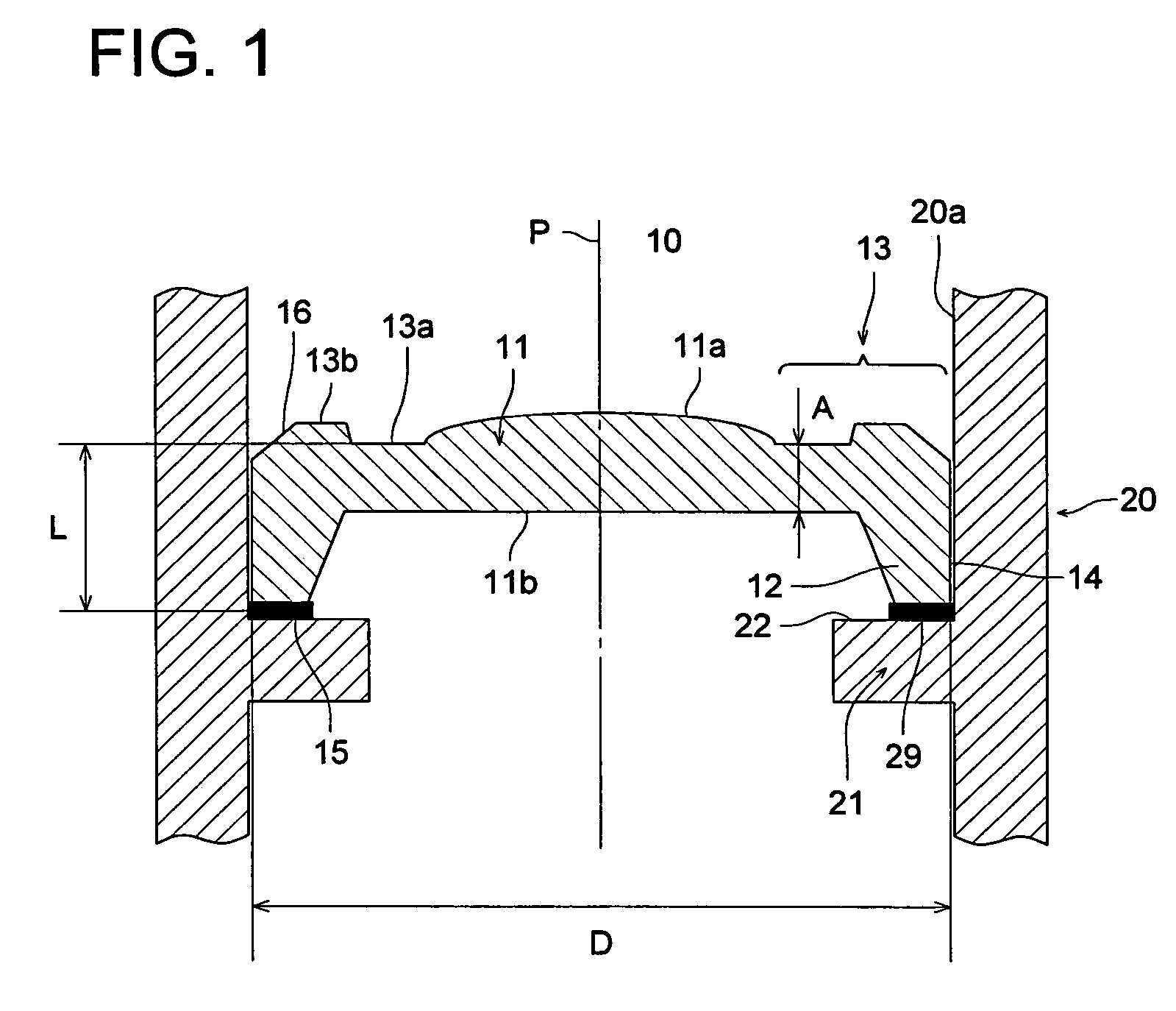

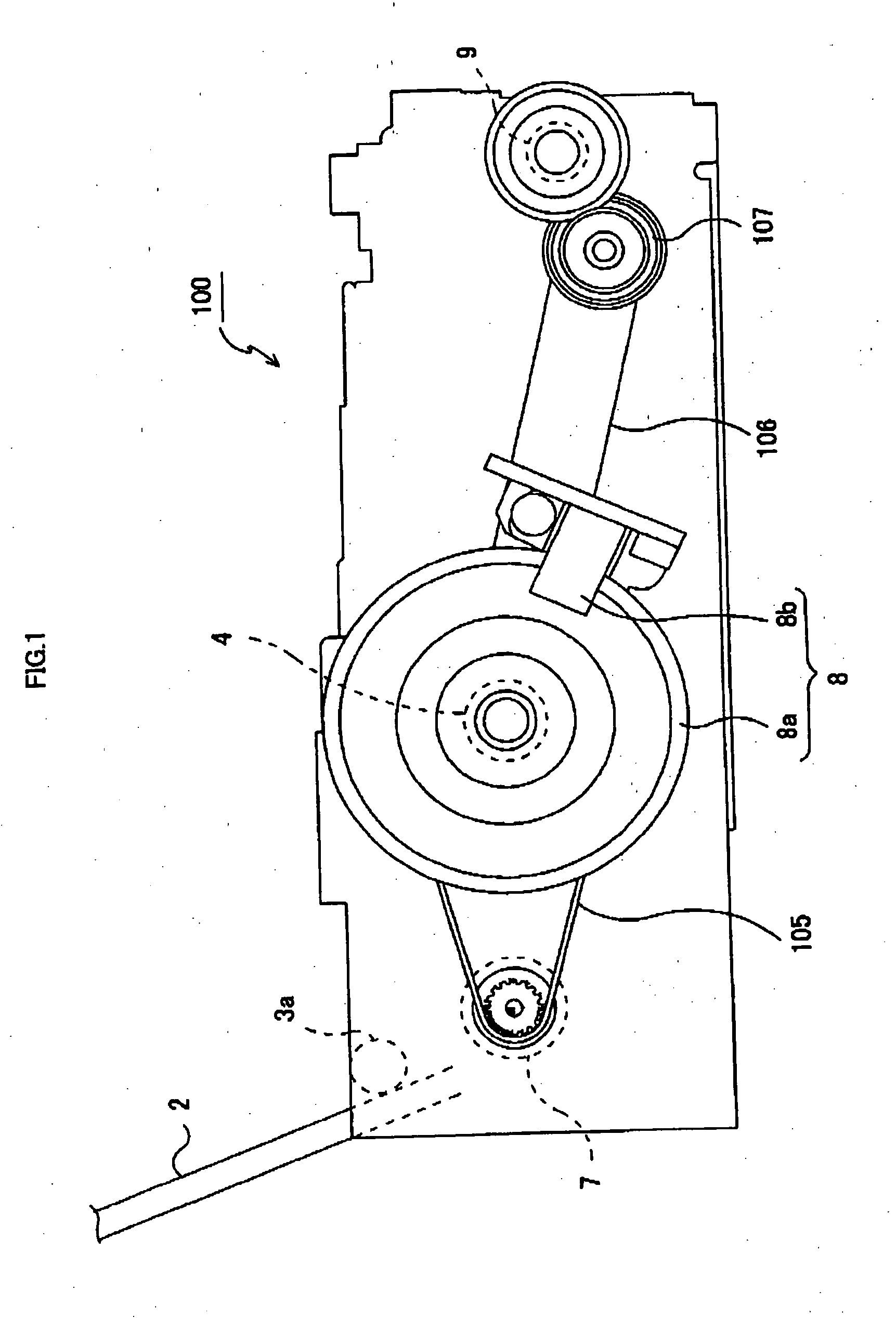

Motor control device

ActiveUS20050151500A1Convenience to workHigh control precisionAC motor angular speed controlNumerical controlEngineeringCalculator

In a motor control device controlling a motor by a state feedback control, high control accuracy is maintained regardless of fluctuations in a motor load so as to improve control performance of the state feedback control. A control signal (manipulation amount) outputted from a feedback calculator for controlling the motor is compared to a manipulation threshold set to a manipulation threshold setting register so as to determine the magnitude of a load amount of the motor. The feedback calculator includes an observer and performs the state feedback control of the motor. When the load amount is in normal level, a normal load observer matrix set in an observer table is selected to configure a normal load observer. When the load amount is increased, a high load observer matrix is selected to configure a high load observer.

Owner:BROTHER KOGYO KK

Motor drive control system and method for controlling the same

ActiveUS8040083B2Control deteriorationAudible noise is generatedAC motor controlDC motor speed/torque controlMotor driveControl system

In a motor drive control system configured to include a converter capable of stepping up the voltage, when the locked state of MG2 operating as an electric motor does not occur (NO in S130), a voltage command value VHref for the converter output voltage is set according to respective required voltages of MG1 operating as an electric generator and MG2 (S140). In contrast, when the locked state of MG2 occurs (YES in S130), the voltage command value VHref is set to a limit voltage Vlmt or less for limiting the voltage step-up by the converter (S150, S180). When the locked state occurs, the converter output voltage is decreased and accordingly the DC voltage switched by the inverter is lowered, so that a switching loss at the switching device forming a part of the inverter is reduced and the temperature increase due to the heat generation can be suppressed.

Owner:DENSO CORP

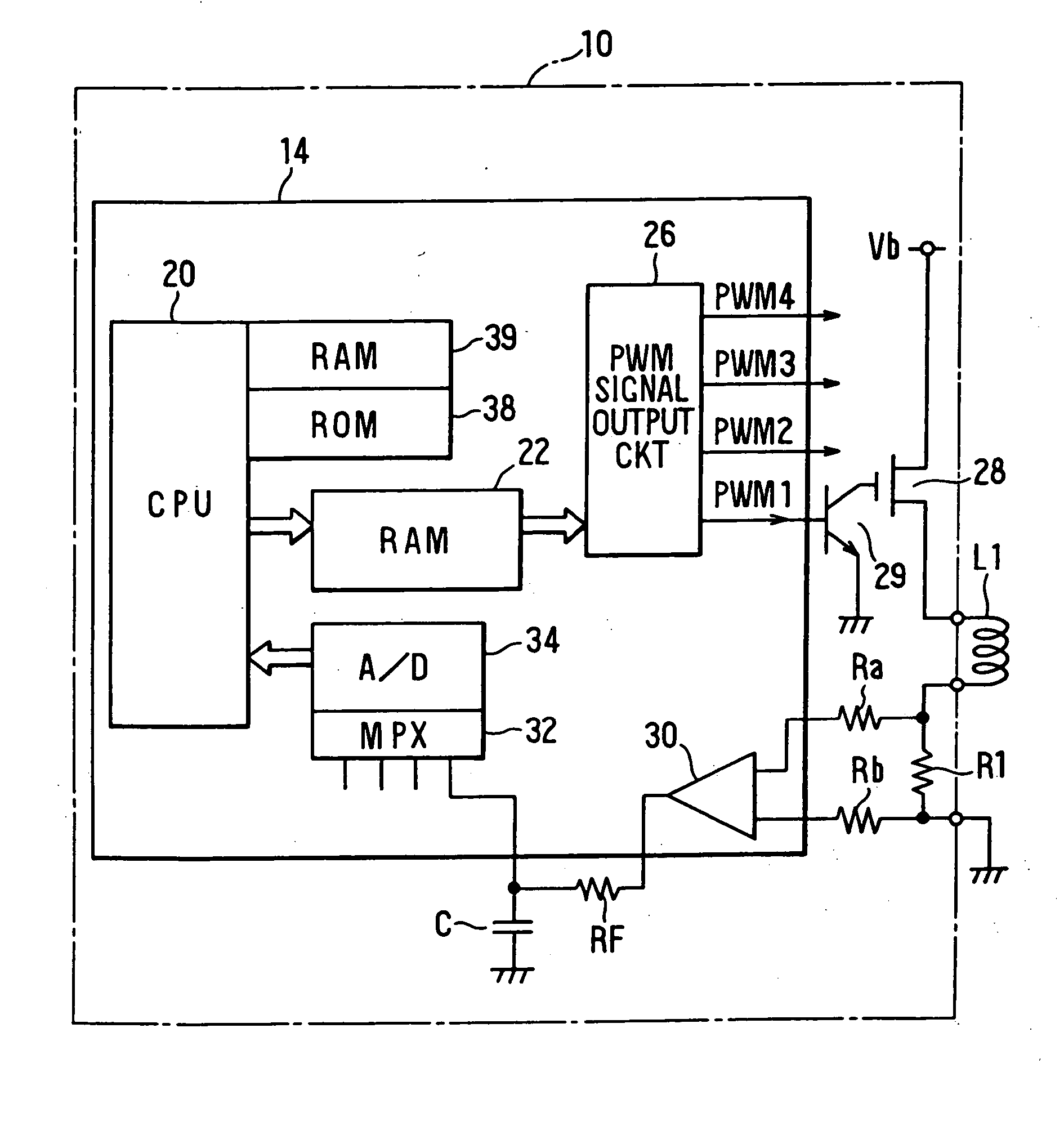

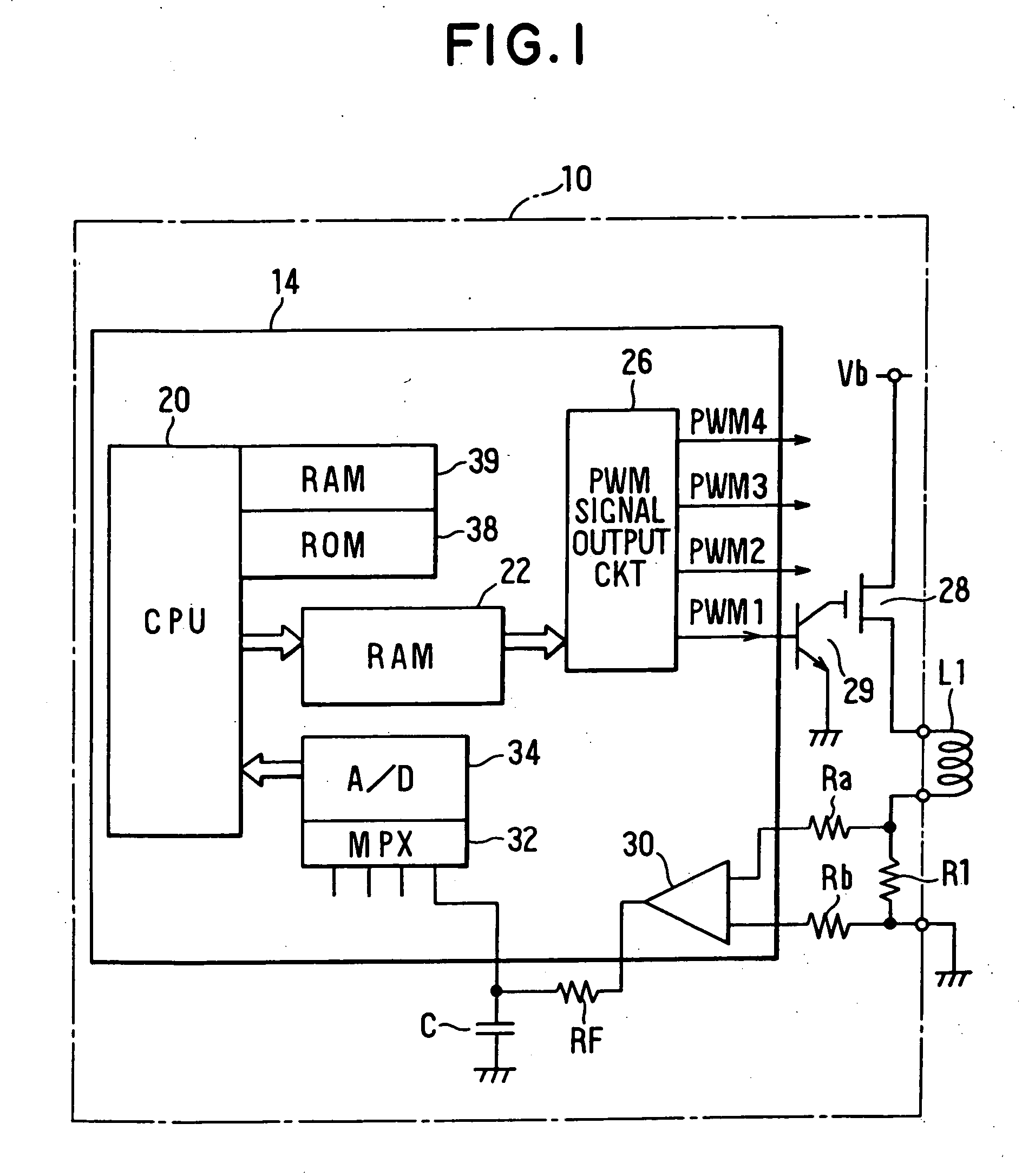

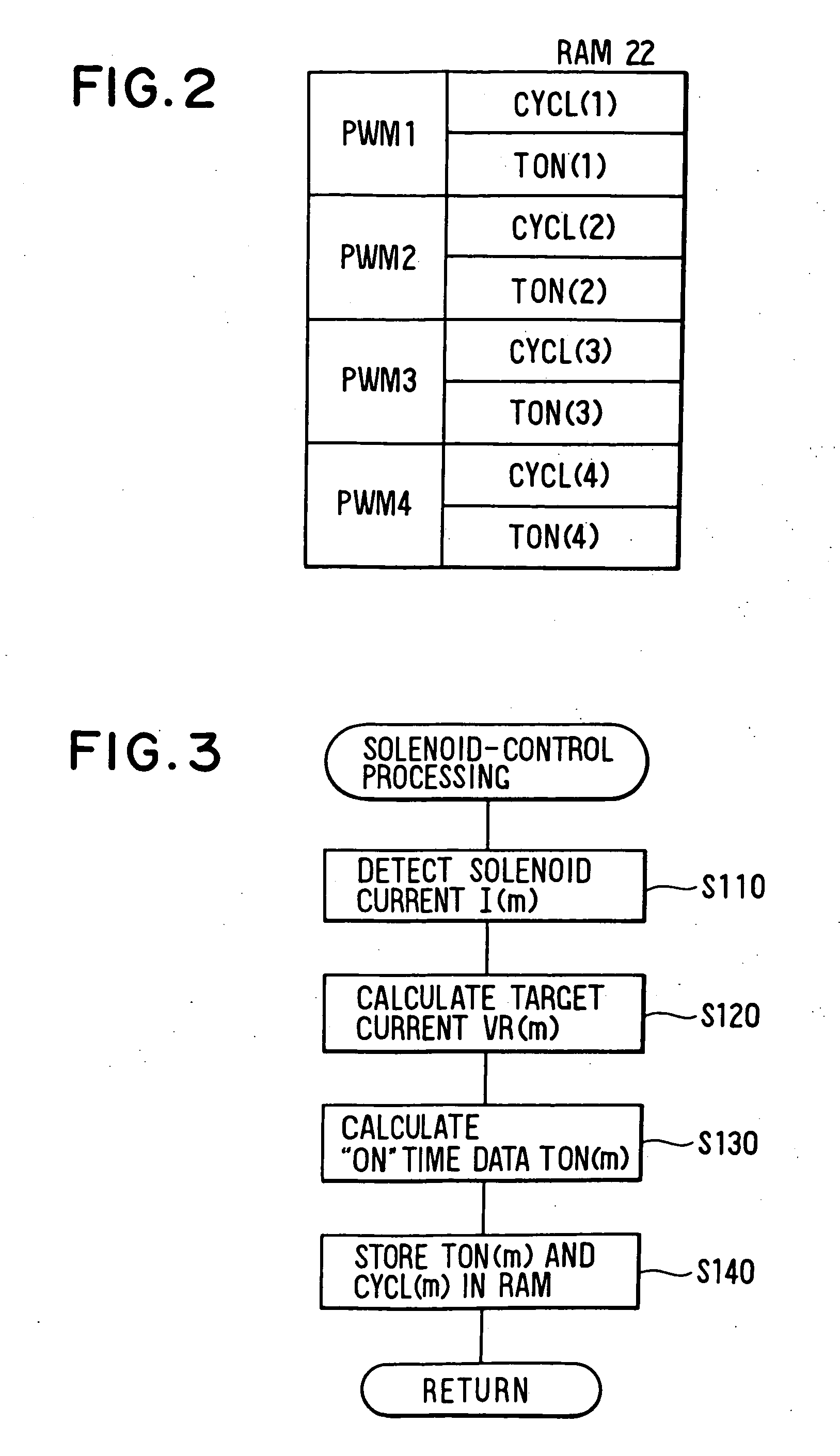

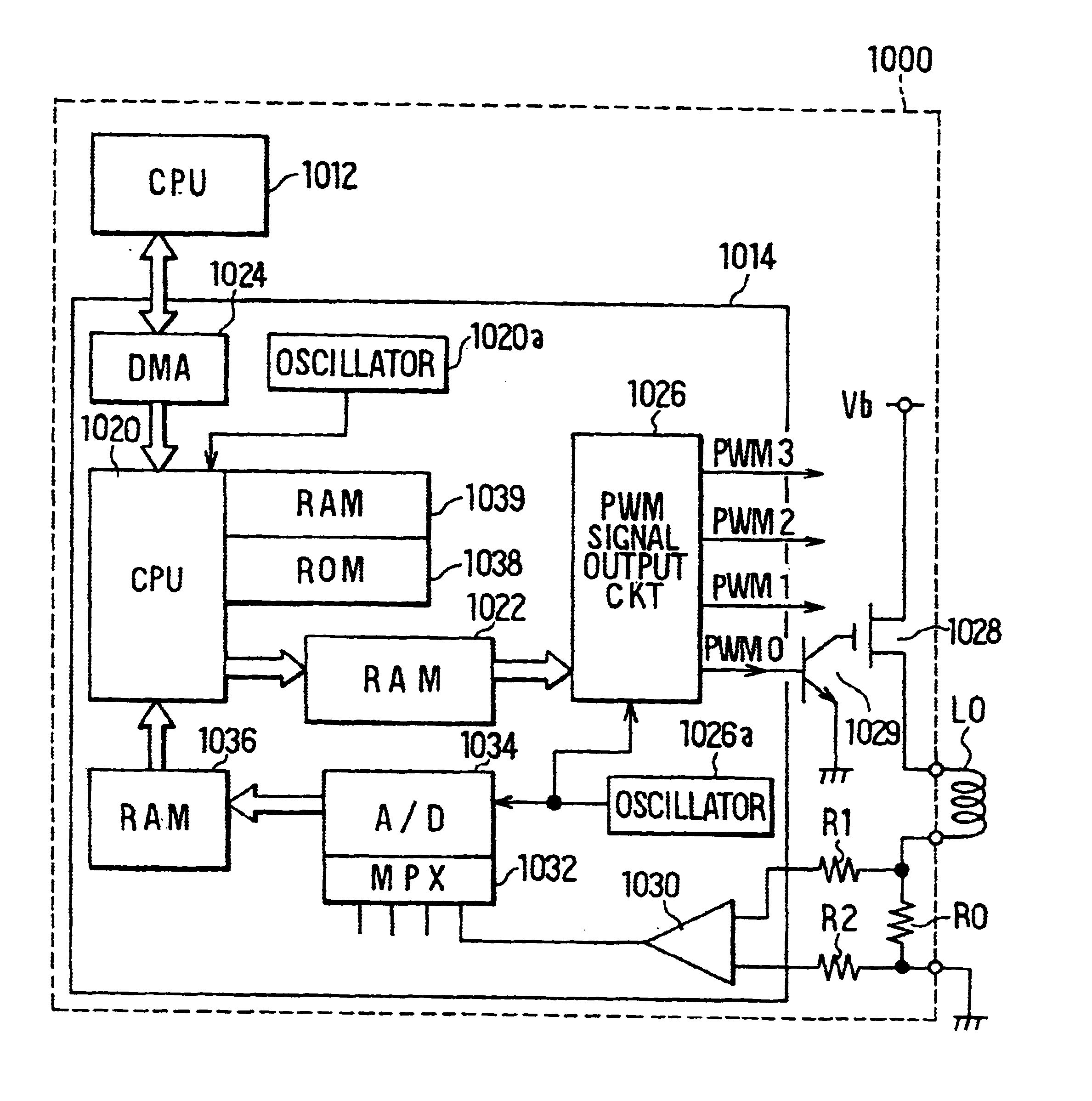

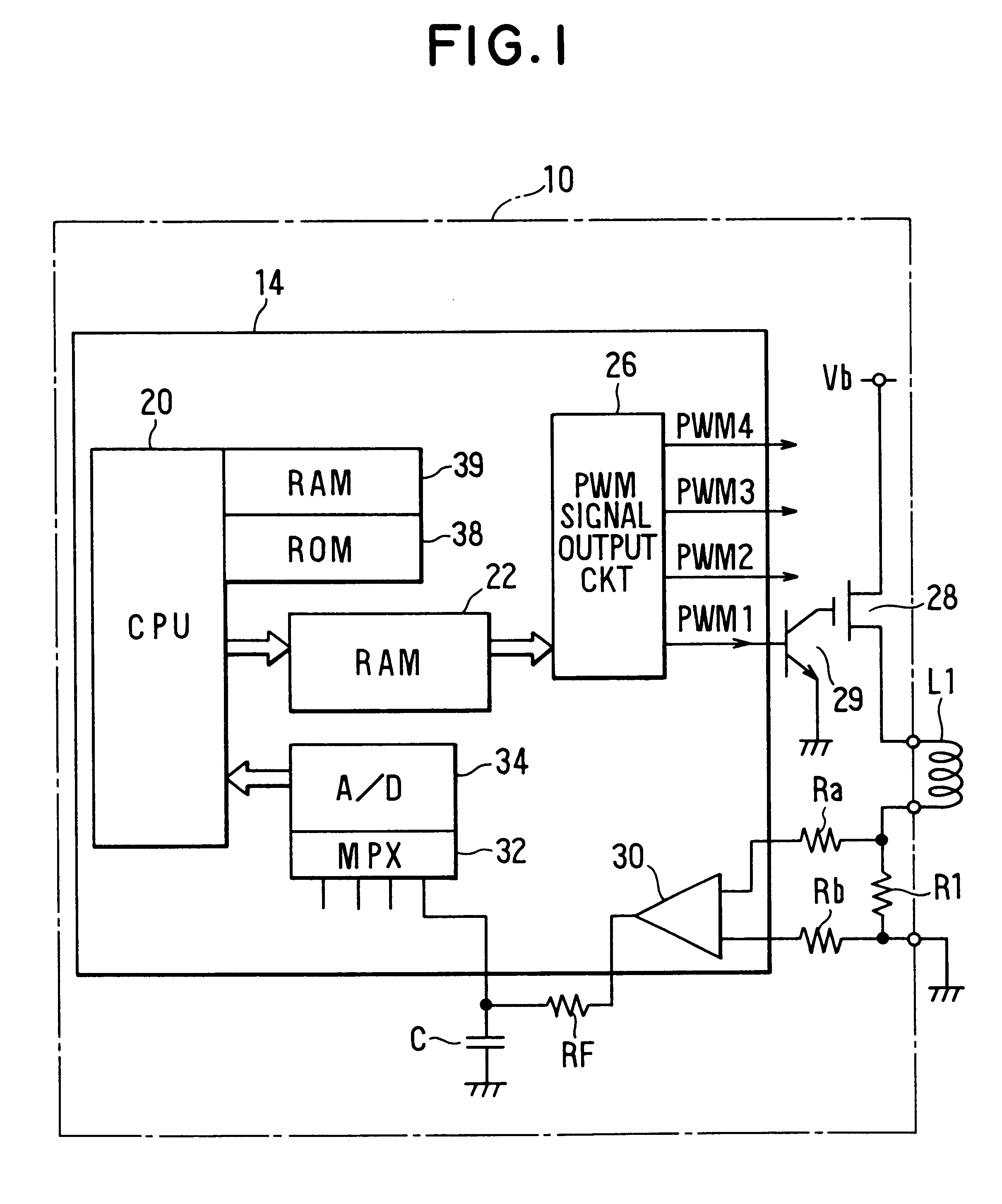

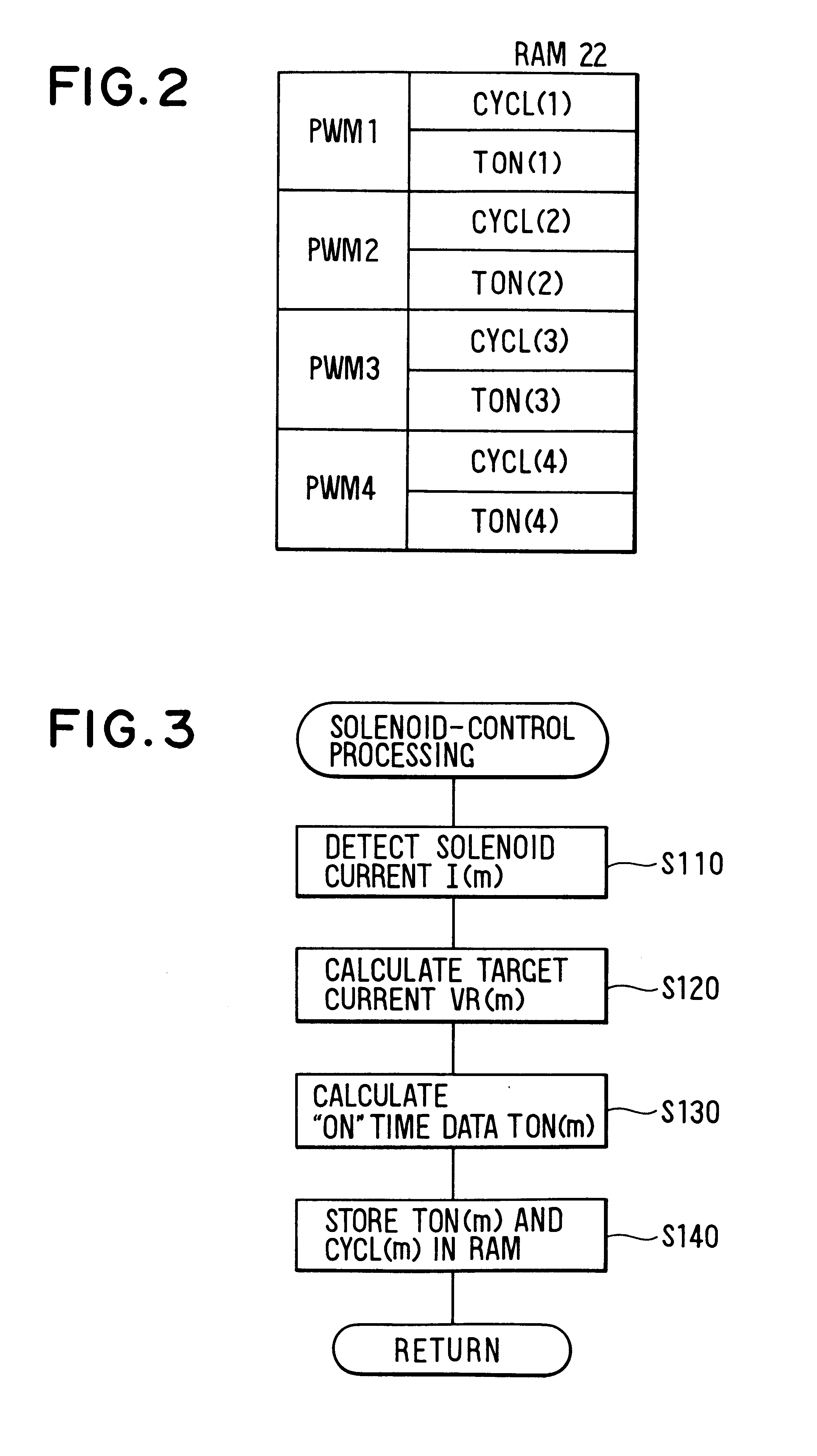

Linear solenoid control apparatus and method having increased responsiveness features

InactiveUS20040109273A1Improve responsivenessControl deteriorationSampled-variable control systemsControllers with pulse-train output signalElectricitySignal response

A control system and method for controlling operation of a group of linear solenoids, which in turn control operation of an electrical load such as a solenoid or actuator, that exhibits increased responsiveness to a change in the target linear solenoid load current. A microcomputer cyclically generates and outputs pulse-width-modulated drive signals based on acquired drive data to establish clock periods. A switch connected between the microcomputer and the target load switchably connects the target load to a power source based on the drive data to selectively drive the target load. A feedback loop between the target load and the microcomputer provides actual target load drive data to the microcomputer, and the microcomputer adjusts the drive signals at a rate of not more than two times per cycle based on the actual drive data to converge the actual drive data to a calculated target load drive value. The present invention also provides an apparatus that prevents a drop in controller current control responsiveness due to signal response delay produced by feedback or the drive system. A converter converts input signals to digital values at a conversion cycle shorter than a cycle of the input signals. A data storage device sequentially stores digital values obtained from the converter, and a processor calculates a mean value to fetch the stored digital values for a cycle time of the input signals, and computes an arithmetic mean of the fetched digital values for target control purposes.

Owner:DENSO CORP

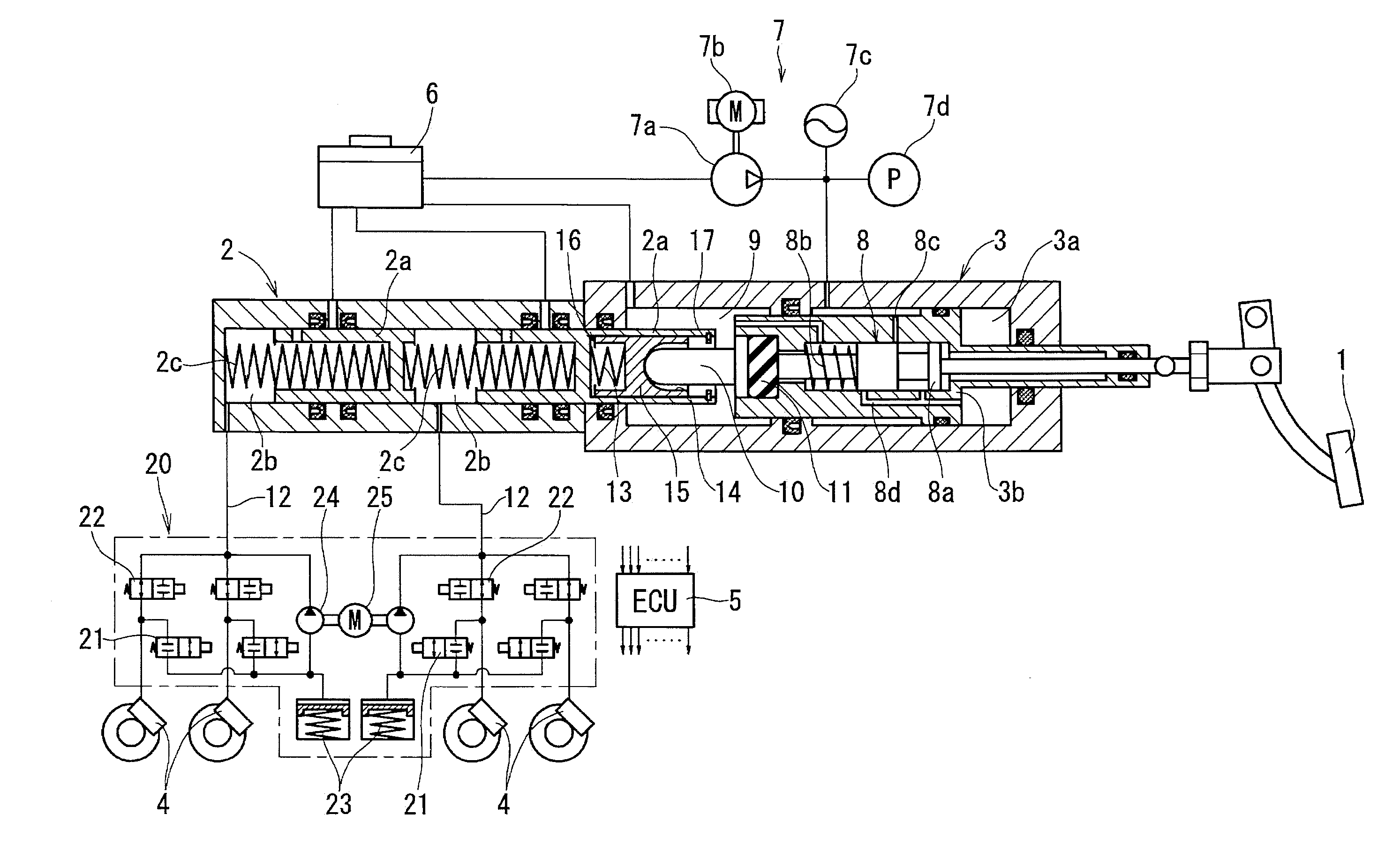

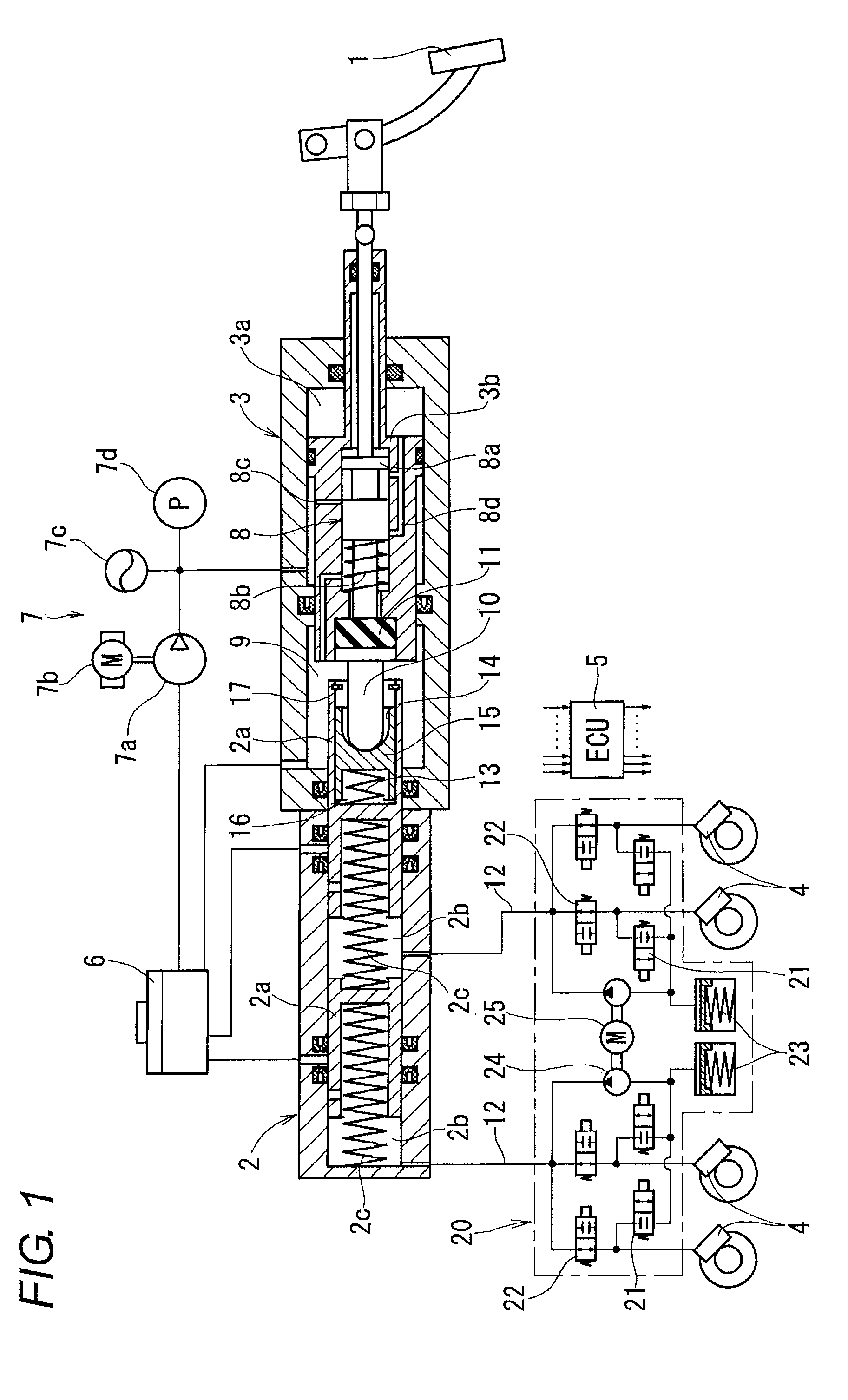

Fluid pressure booster and fluid pressure brake apparatus having the same

InactiveUS20120248861A1Control deteriorationImprove reliabilityBraking action transmissionRotary clutchesSpool valveMaster cylinder

A fluid pressure booster and a fluid pressure brake apparatus having the same are provided. The fluid pressure booster includes an auxiliary fluid pressure source having a pump and a pressure accumulator, a pressure adjusting device which adjusts fluid pressure supplied from the auxiliary fluid pressure source to a value corresponding to an operating amount of a brake operation member by displacement of a spool valve and introduces the same into a boost chamber, a boost piston which receives the fluid pressure introduced into the boost chamber to generate assist force and operates a master piston of a master cylinder by assisted force, and a displacement absorption member which is provided at a position to which thrust force of the master piston is applied, and which is compressed in an axial direction when transfer power between the boost piston and the master piston exceeds a setting value.

Owner:ADVICS CO LTD

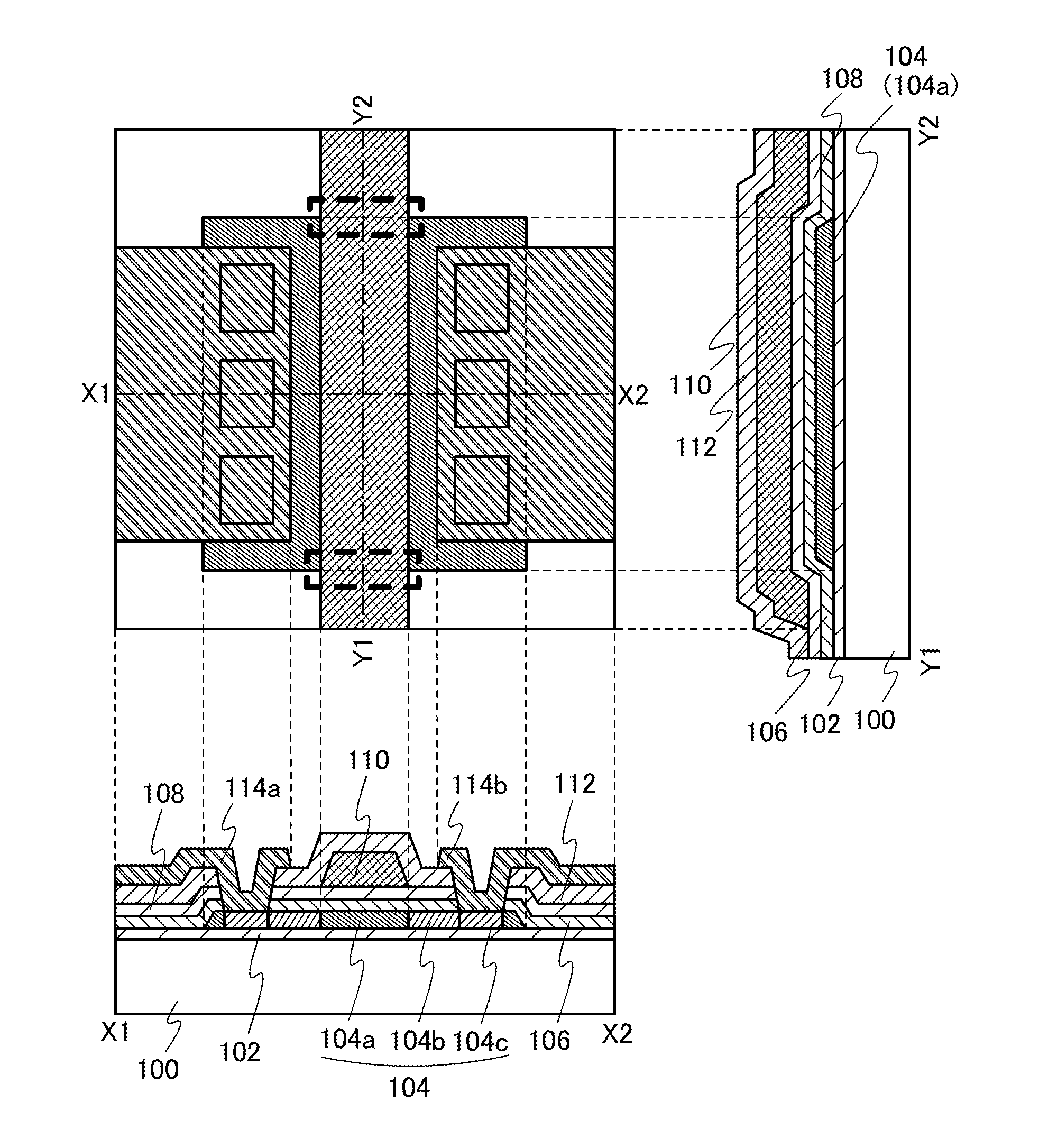

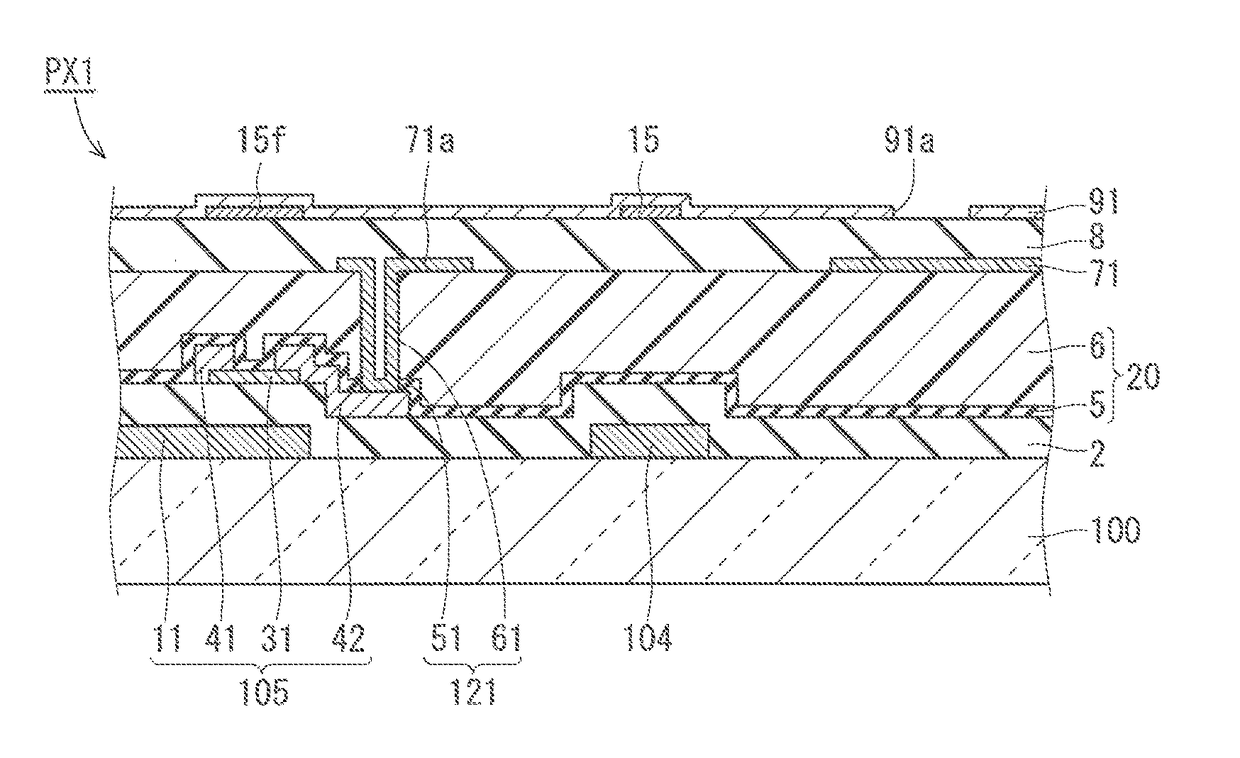

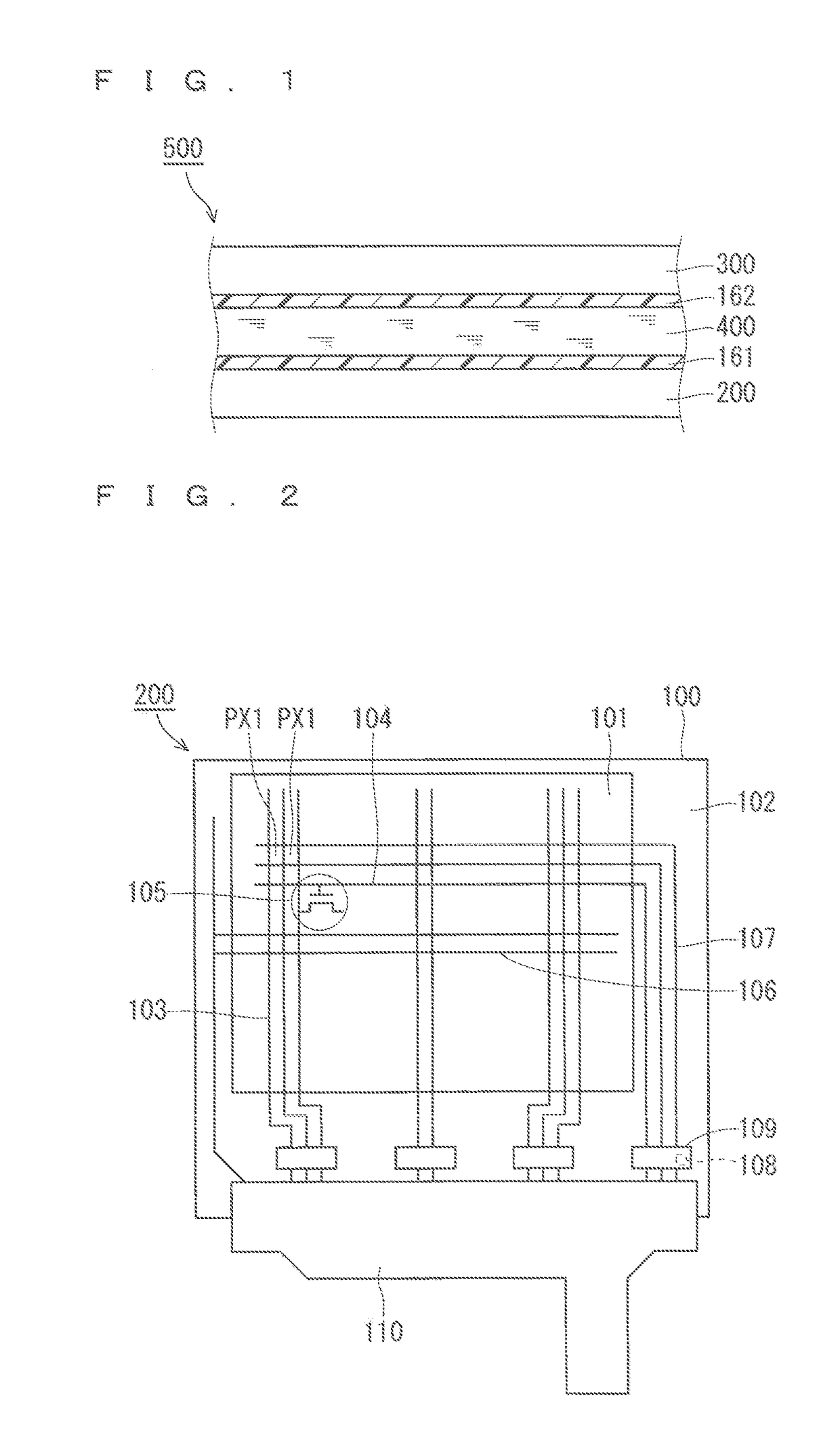

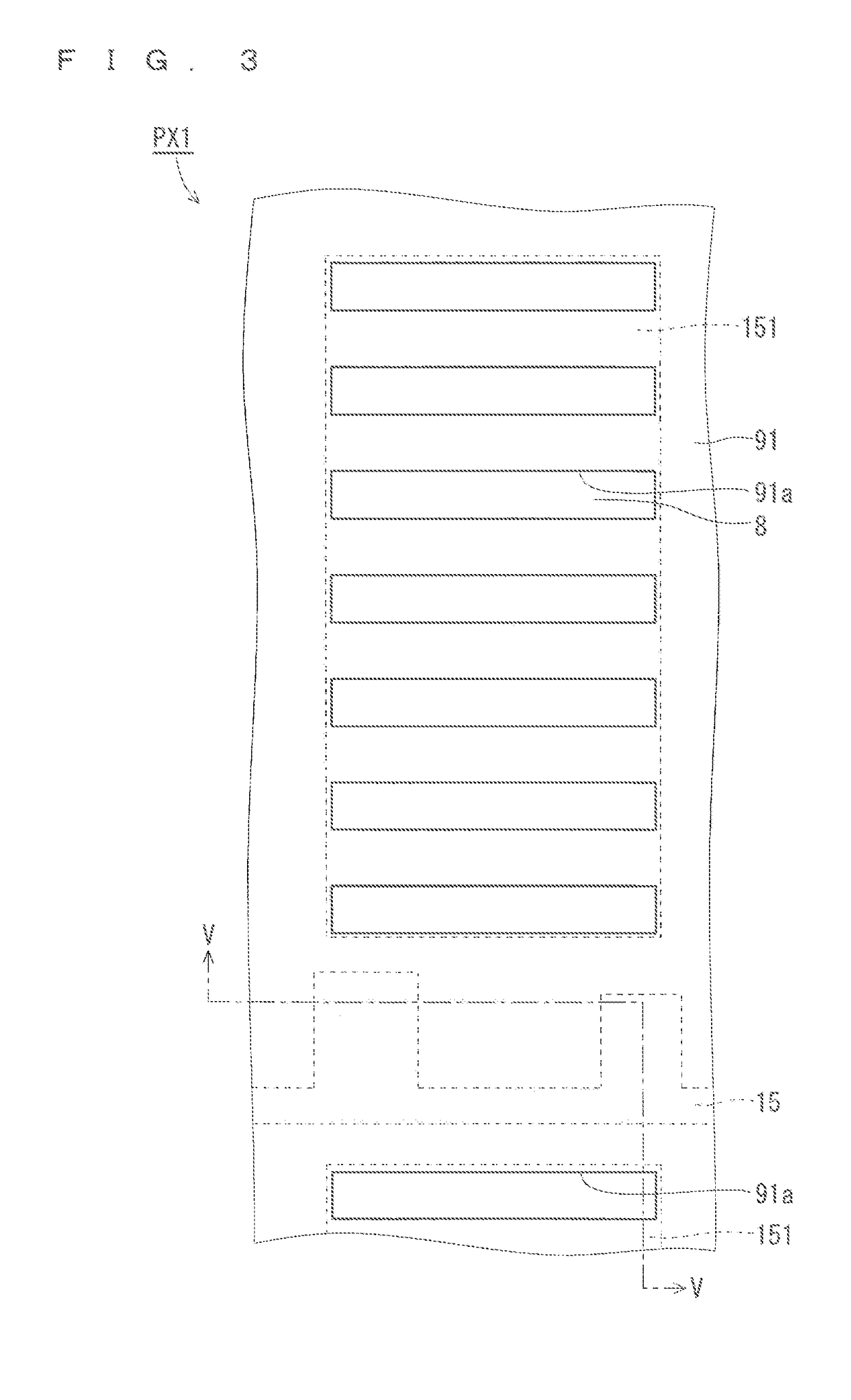

Thin-film transistor substrate and liquid crystal display

ActiveUS20170329176A1InhibitionAperture ratioTransistorSolid-state devicesLiquid-crystal displayEngineering

A channel layer is formed of an oxide semiconductor. A first insulating film is provided on the channel layer, a source line, and a drain electrode, and includes a drain contact hole which reaches the drain electrode. A pixel electrode is provided on the first insulating film, includes a connection conductive layer which is connected to the drain electrode by the drain contact hole, and is formed of a transparent conductive material. The pixel electrode is covered with a second insulating film. A common electrode is provided on the second insulating film, includes an opening which faces the pixel electrode in a thickness direction, and is formed of a transparent conductive material. A metal layer, in conjunction with a part of the common electrode, forms a laminated structure, and includes a light-shield part which overlaps the channel layer at least partially in plan view.

Owner:TRIVALE TECH

Linear solenoid control apparatus and method having increased responsiveness features

InactiveUS6687555B1Improve responsivenessControl deteriorationSampled-variable control systemsElectric signal transmission systemsEngineeringActuator

A control system and method for controlling operation of a group of linear solenoids, which in turn control operation of an electrical load such as a solenoid or actuator, that exhibits increased responsiveness to a change in the target linear solenoid load current. A microcomputer cyclically generates and outputs pulse-width-modulated drive signals based on acquired drive data to establish clock periods. A switch connected between the microcomputer and the target load switchably connects the target load to a power source based on the drive data to selectively drive the target load. A feedback loop between the target load and the microcomputer provides actual target load drive data to the microcomputer, and the microcomputer adjusts the drive signals at a rate of not more than two times per cycle based on the actual drive data to converge the actual drive data to a calculated target load drive value. The present invention also provides an apparatus that prevents a drop in controller current control responsiveness due to signal response delay produced by feedback or the drive system. A converter converts input signals to digital values at a conversion cycle shorter than a cycle of the input signals. A data storage device sequentially stores digital values obtained from the converter, and a processor calculates a mean value to fetch the stored digital values for a cycle time of the input signals, and computes an arithmetic mean of the fetched digital values for target control purposes.

Owner:DENSO CORP

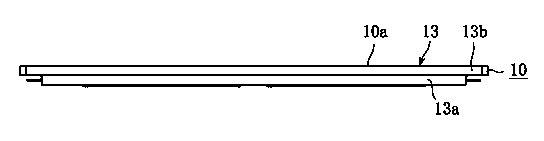

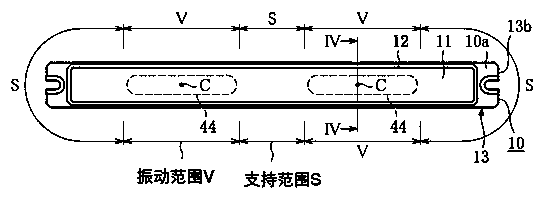

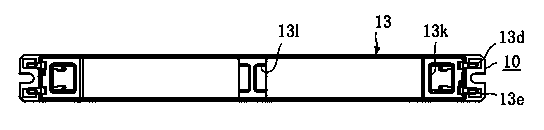

Flat horn

ActiveCN103618979AUnbalanced controlAchieve ultra-thinPlane diaphragmsFrequency/directions obtaining arrangementsVibrating membraneSound wave

The invention relates to a flat horn including a supporting framework. The flat horn is characterized in that at least one sounding unit is disposed along the axial direction of the supporting framework; each the sounding unit is composed of a plane vibrating membrane emitting sound waves through vibration, a frame body mounted along the periphery of the plane vibrating membrane, and a drive device driving the plane vibrating membrane according to a sound signal; and two side edges of an open groove disposed in the supporting framework respectively have a non-contact space, each the non-contact space is a corner cut disposed in the bottom, along an outside edge, of the open groove disposed in the supporting framework, and the frame body mounted along the periphery of the plane vibrating membrane is adhered to the open groove disposed in the supporting framework. The flat horn has good output frequency characteristic, can achieve an ultrathin structure in condition of large input power, and the sound propagation has the directional property of being forward.

Owner:谭菊花

Polysaccharide biomedical colloidal fluid and preparation method

InactiveCN105106292AHigh activityImprove the blocking effectOrganic active ingredientsAntisepticsSide effectPhosphoric acid

The invention discloses polysaccharide biomedical colloid. The colloidal fluid is prepared from, by weight, 0.5-10% of sodium carboxymethyl cellulose, 0.5-1.5% of sodium chloride, 0.5-1.5% of carbomer, 0.08-0.7% of sodium hyaluronate, 0.01-0.05% of phytate, 0.02-0.1% of sodium alginate, 0.1-0.3% of glycerol, 0.15-0.45% of chitobiose, 0.15-0.35% of polyhexamethylene guanidine, 0.01-0.2% of liquorices extract and the balance water used for injection. By means of formula optimization, the polysaccharide biomedical colloid is free of toxic and side effects, has great clinical application value, is short in healing time and high in healing rate, forms a wound surface wet environment, can directly restrain scar forming when used for cell repairing, and can form a wound surface protection film, block injuries caused by bacteria to wound surfaces, and restrain the adsorption process, the multiplication process, the copying process and other processes of bacteria on wound surfaces.

Owner:任汉学

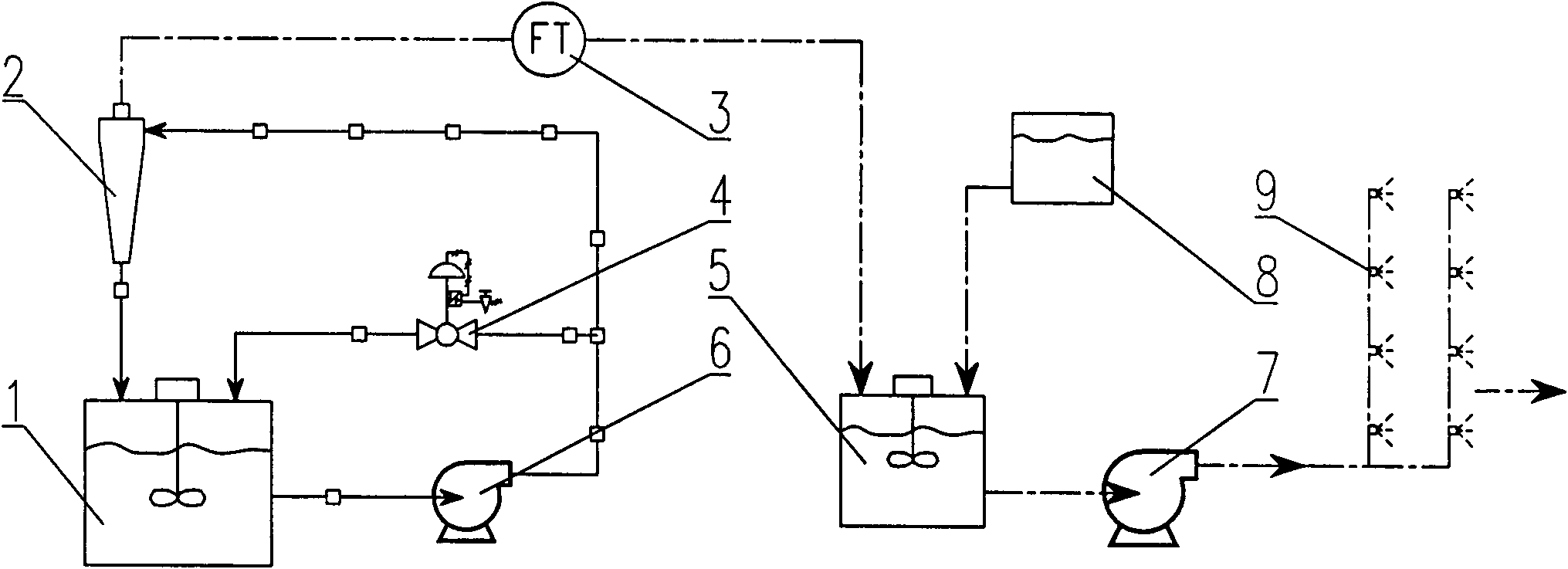

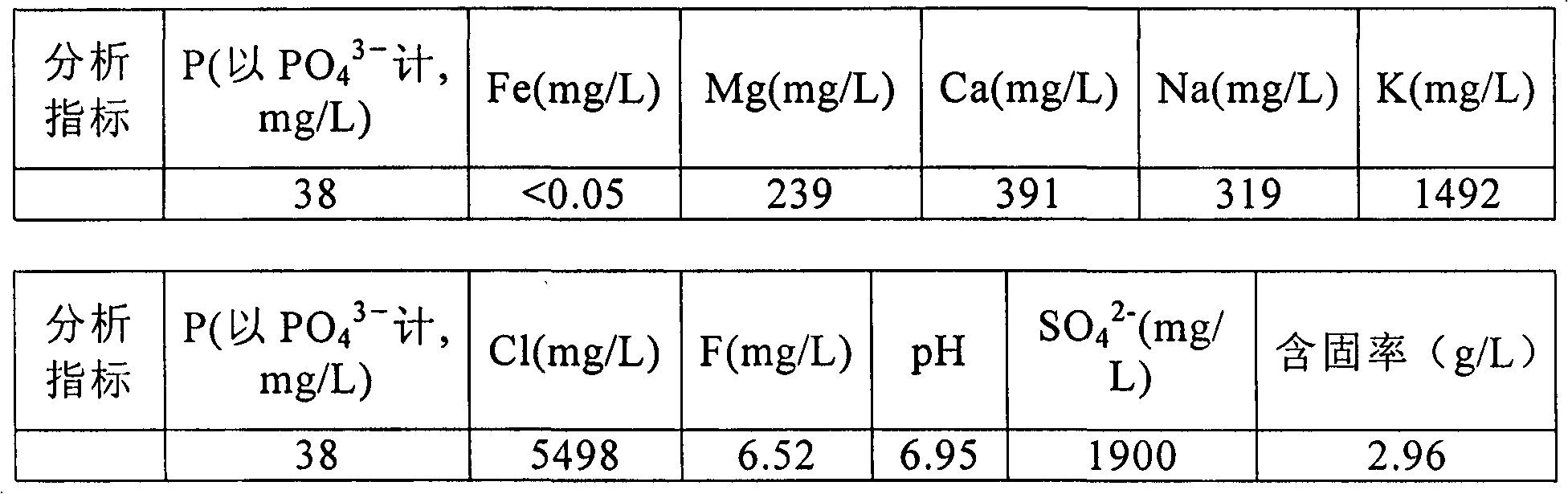

Sintering flue gas desulfurization wastewater treatment system and method for sintering finished ores

InactiveCN101653696AMeet the amount of calcium chloride sprayedMeet needsDispersed particle separationWater treatment systemSpray nozzle

The invention relates to sintering flue gas desulfurization wastewater treatment system and method for sintering finished ores. A wastewater whirlcone, an adjusting valve and a wastewater whirlcone feeding pump are respectively connected with a recovered water tank, and the wastewater whirlcone feeding pump is connected with the wastewater whirlcone and the adjusting valve. The other end of the wastewater whirlcone is connected to a wastewater tank, and a flowmeter is connected between the wastewater whirlcone and the wastewater tank. The wastewater tank is connected with a CaCl2 water solution tank and a wastewater pump, and the wastewater pump is connected to a nozzle through a pipeline. The treatment method is realized as follows: recovered water in the recovered water tank of a sweetener is transmitted to the wastewater whirlcone through the wastewater whirlcone feeding pump, one part of the recovered water in the wastewater whirlcone is returned to the recovered water tank, and the other part of the recovered water enters in the wastewater tank through the flowmeter to become wastewater, and the opening of the adjusting valve is adjusted so as to control the desulfurated wastewater. By adopting the system and the method, the invention realizes recycle of sintering flue gas desulfurization wastewater, energy saving and emission reduction, investment saving and running costreduction.

Owner:BAOSTEEL ENG & TECH GRP

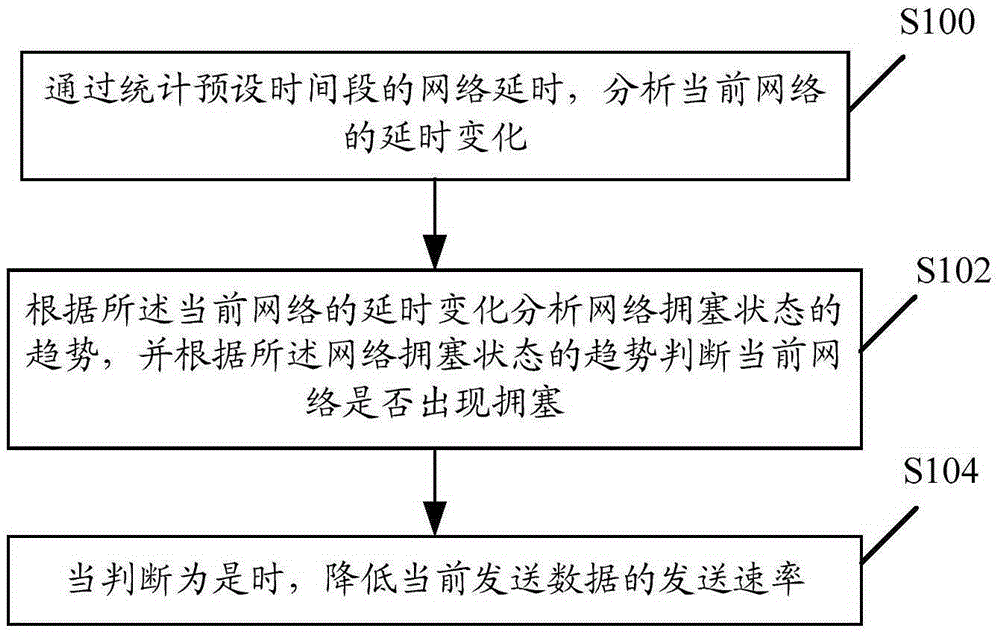

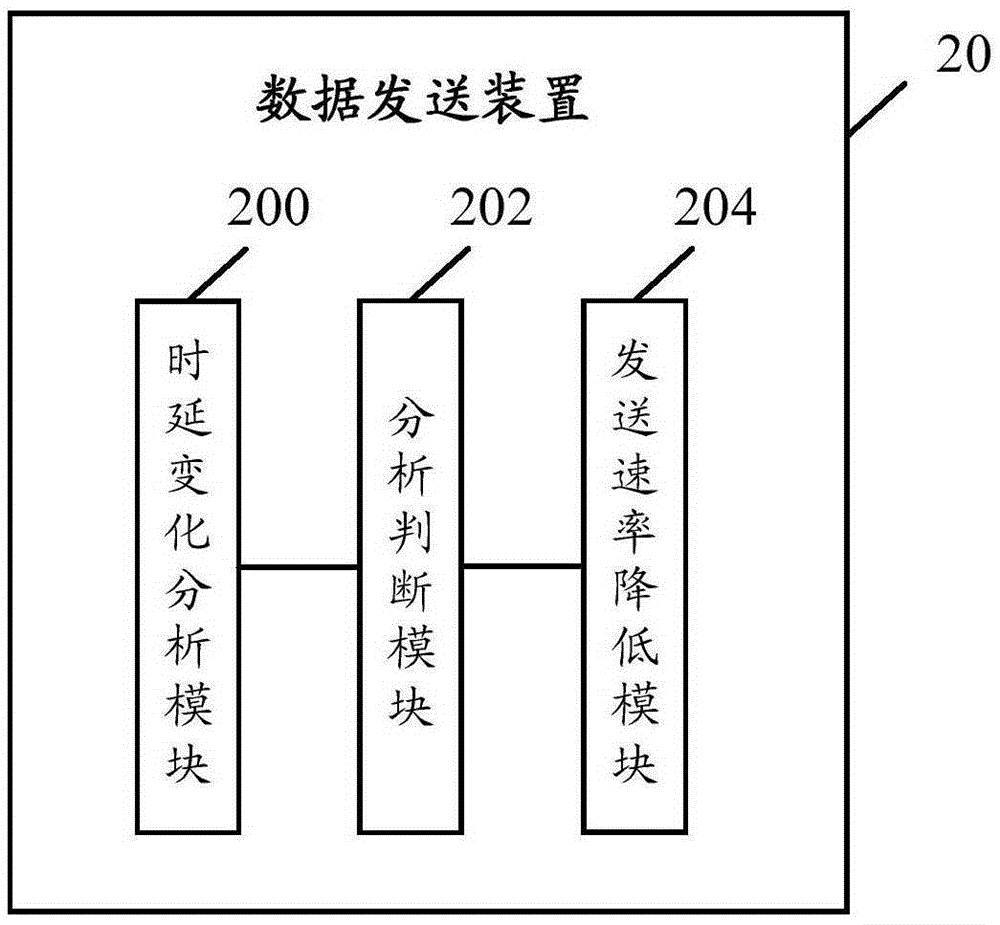

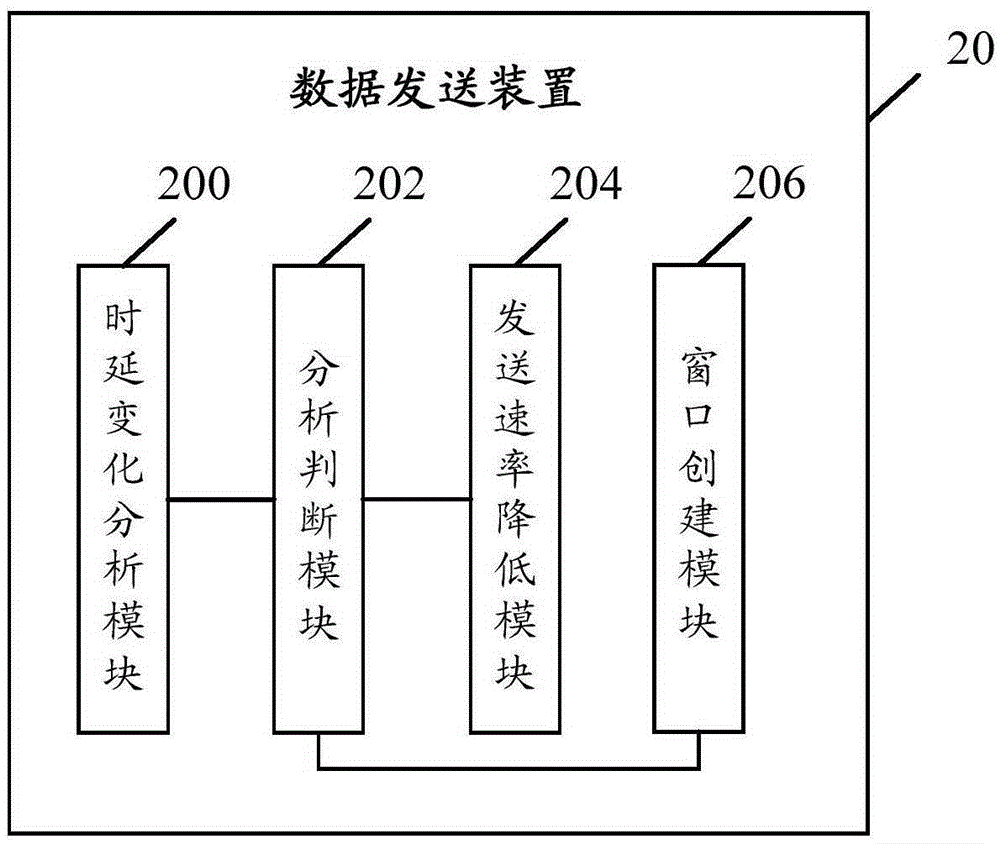

Data sending method and data sending device

ActiveCN105407411AControl deteriorationTroubleshoot technical issues with transmission qualitySelective content distributionVideo transmissionTime segment

Embodiments of the invention disclose a data sending method. The method comprises the following steps of through calculating network time delay of a preset time segment, analyzing time-delay changes of a current network; according to the time-delay changes of the current network, analyzing a network congestion state trend; according to the network congestion state trend, determining whether the current network is in a congestion state; when the current network is in the congestion state, reducing a sending rate of current sending data. The invention also discloses a correlation device. By using the method and the device, the sending rate can be adjusted in advance, and a technical problem that video transmission quality is severely influenced because congestion network recovery time is long in a low bandwidth network in the prior art is solved. In addition, through creating a sending window used for limiting an instantaneous sending rate, a network deterioration degree during a detection process can be further controlled; jamming and pause frequencies of video playing are greatly reduced and real-time and fluent performance of the video playing are guaranteed.

Owner:GUANGZHOU BAIGUOYUAN NETWORK TECH

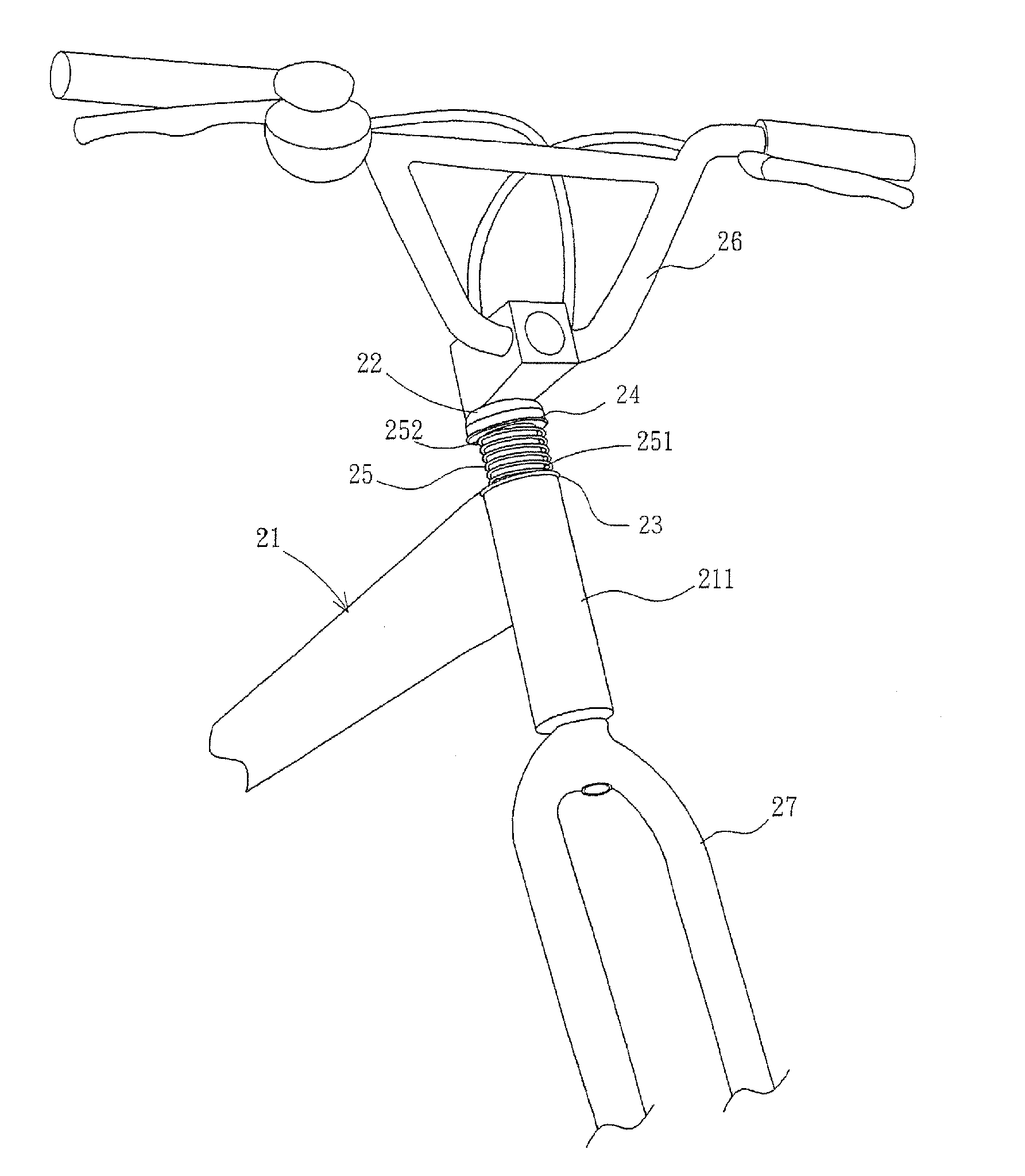

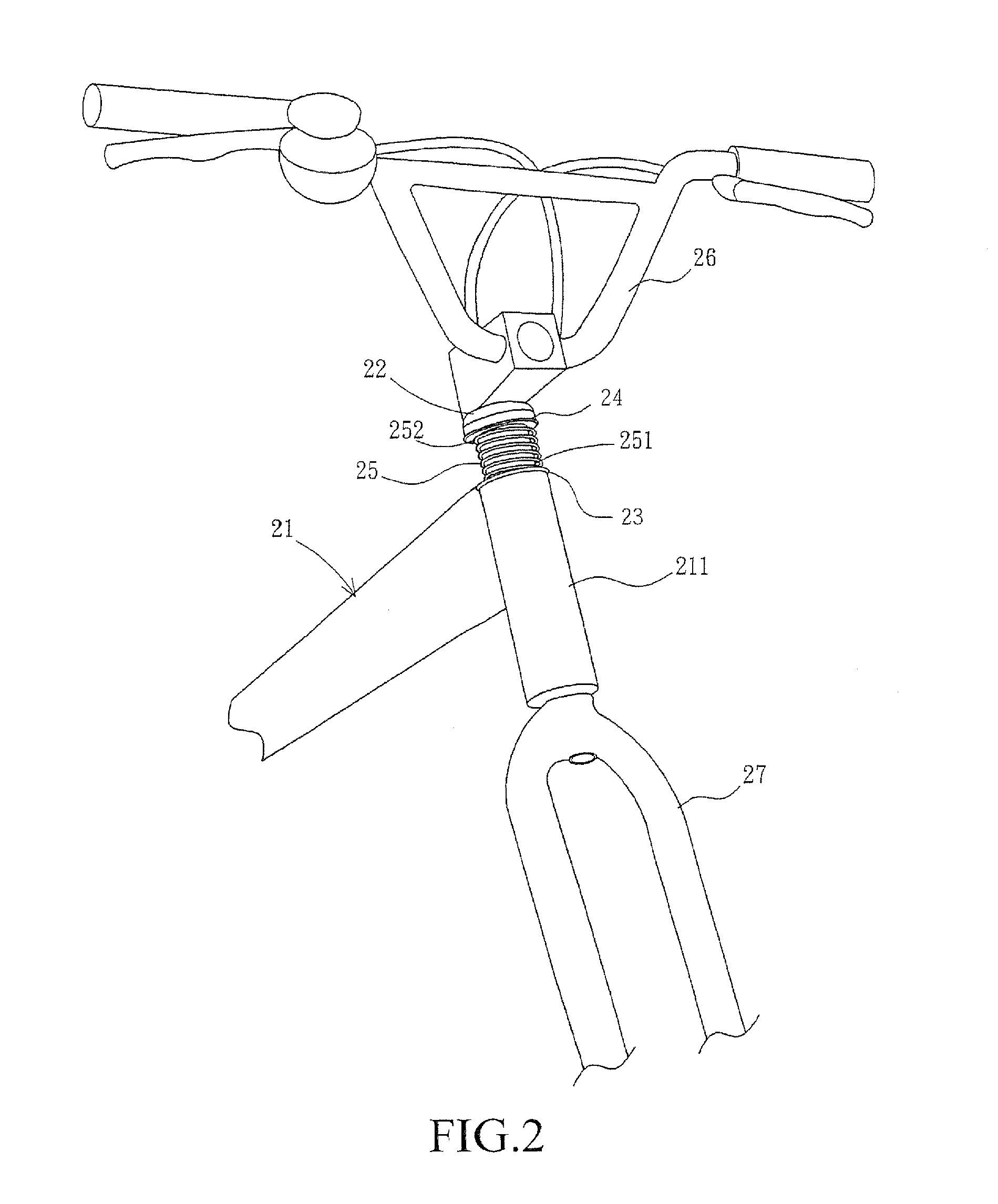

Steering safety mechanism for bicycle

InactiveUS20110133428A1Convenient rotation angleEnhance bicycle safetyFoot-driven leversWheel based transmissionEngineeringFastener

A steering safety mechanism is provided for a bicycle and includes a frame, a steering stem, at least one first fastener, at least one second fastener, and a damping element. The frame includes a head tube portion. An end of the steering stem is received through the head tube portion. The first fastener is attached to the frame, and the second fastener is attached to the steering stem. The damping element has a first end attached to the first fastener and a second end attached to the second fastener.

Owner:ALFA POWER

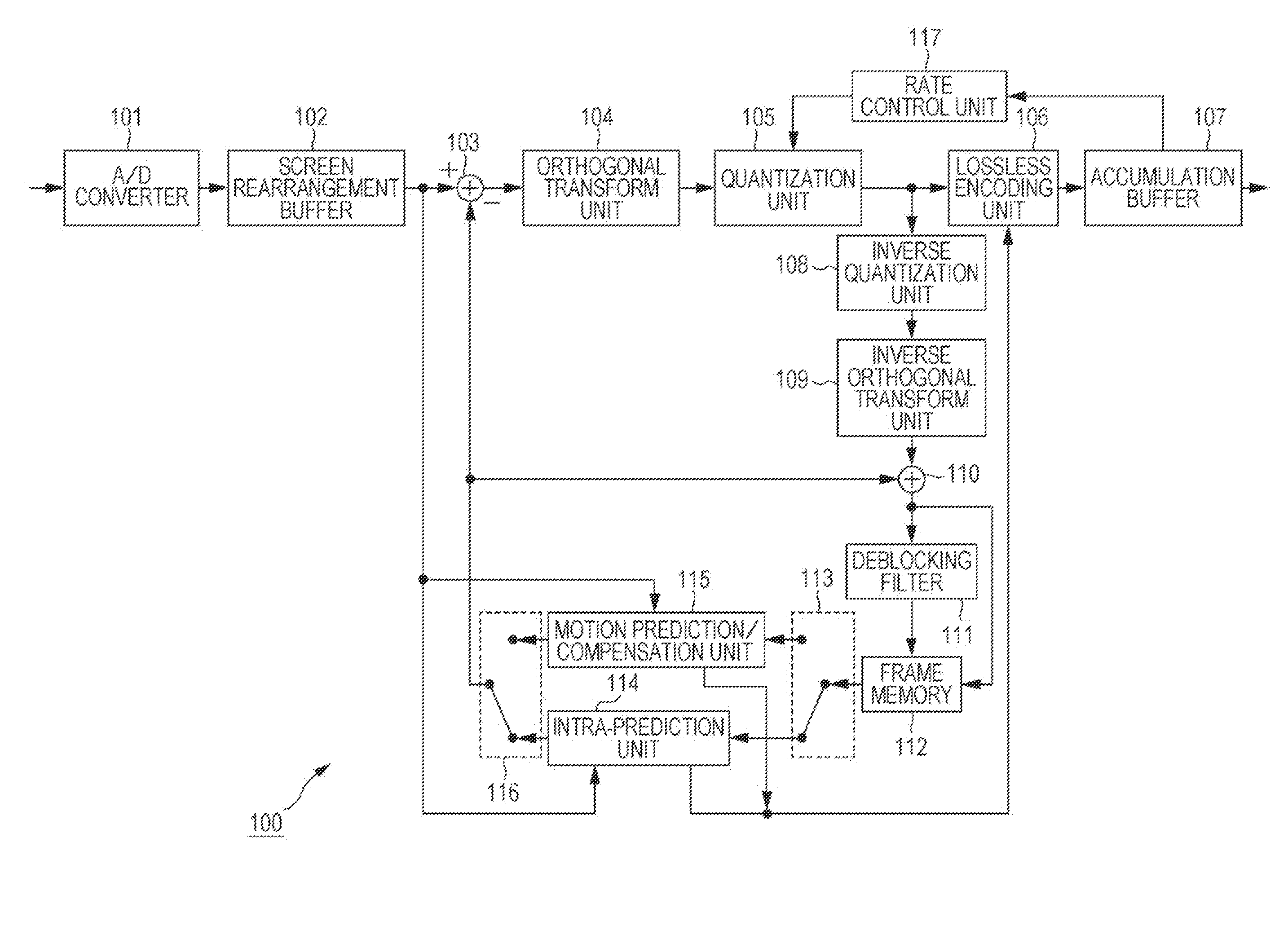

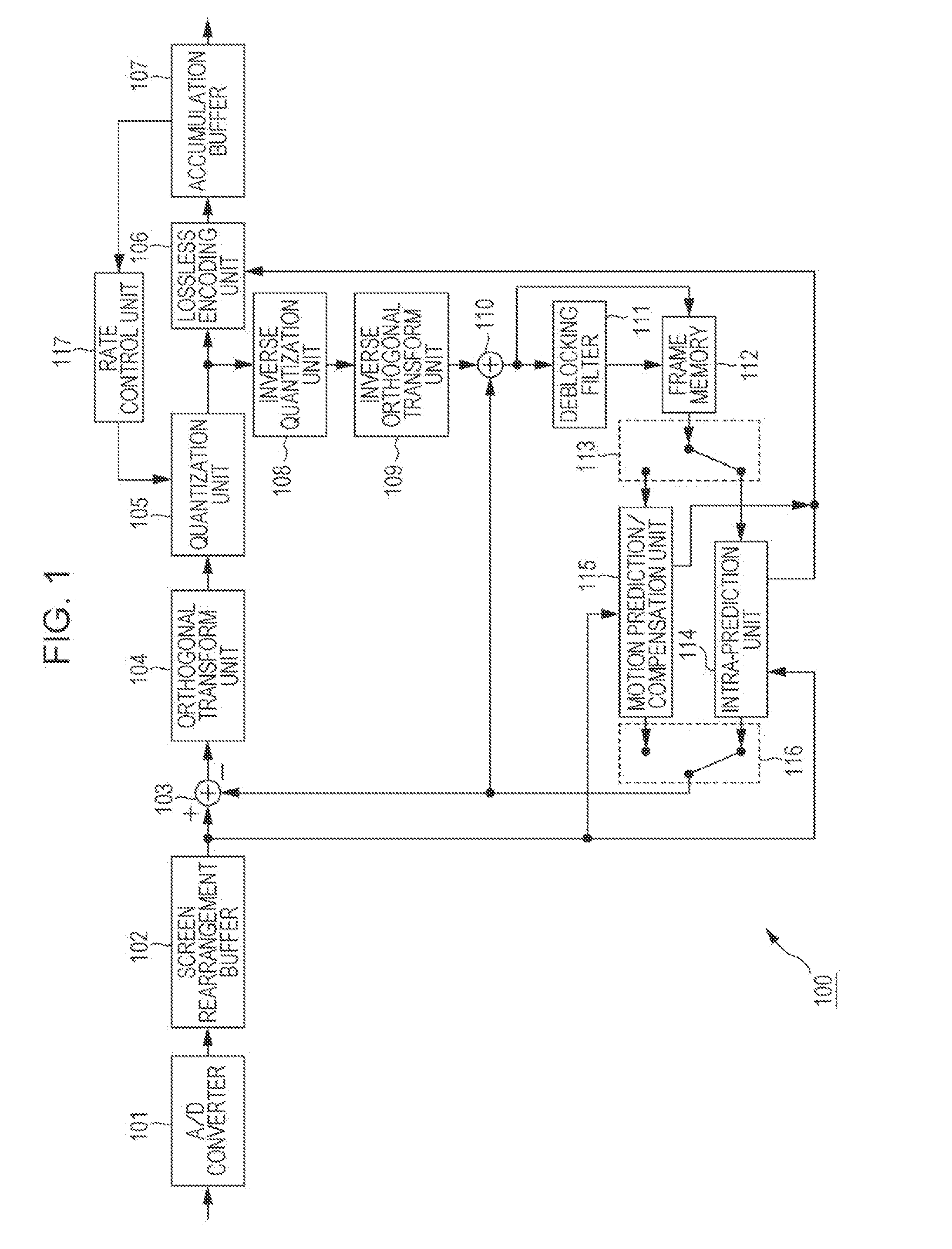

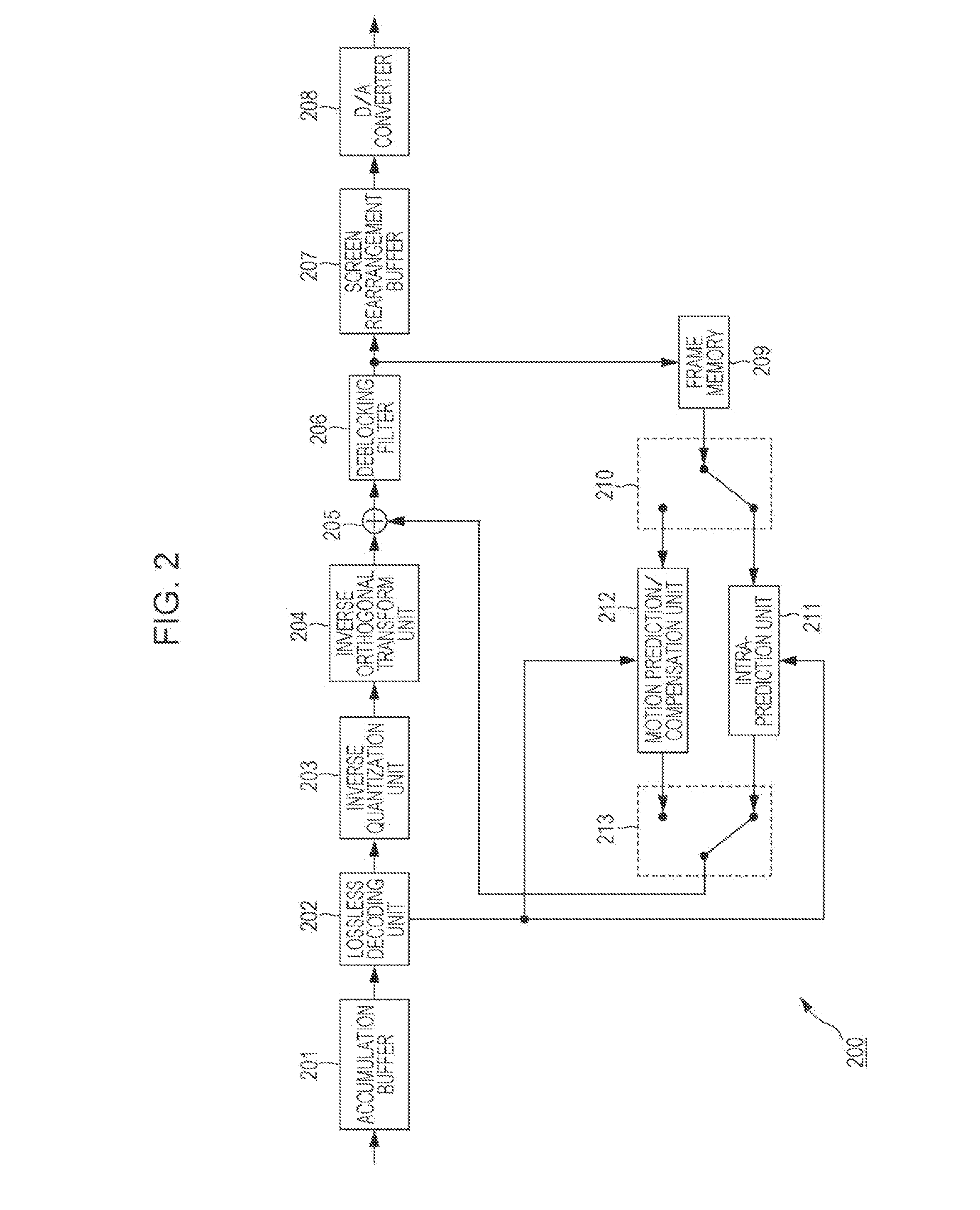

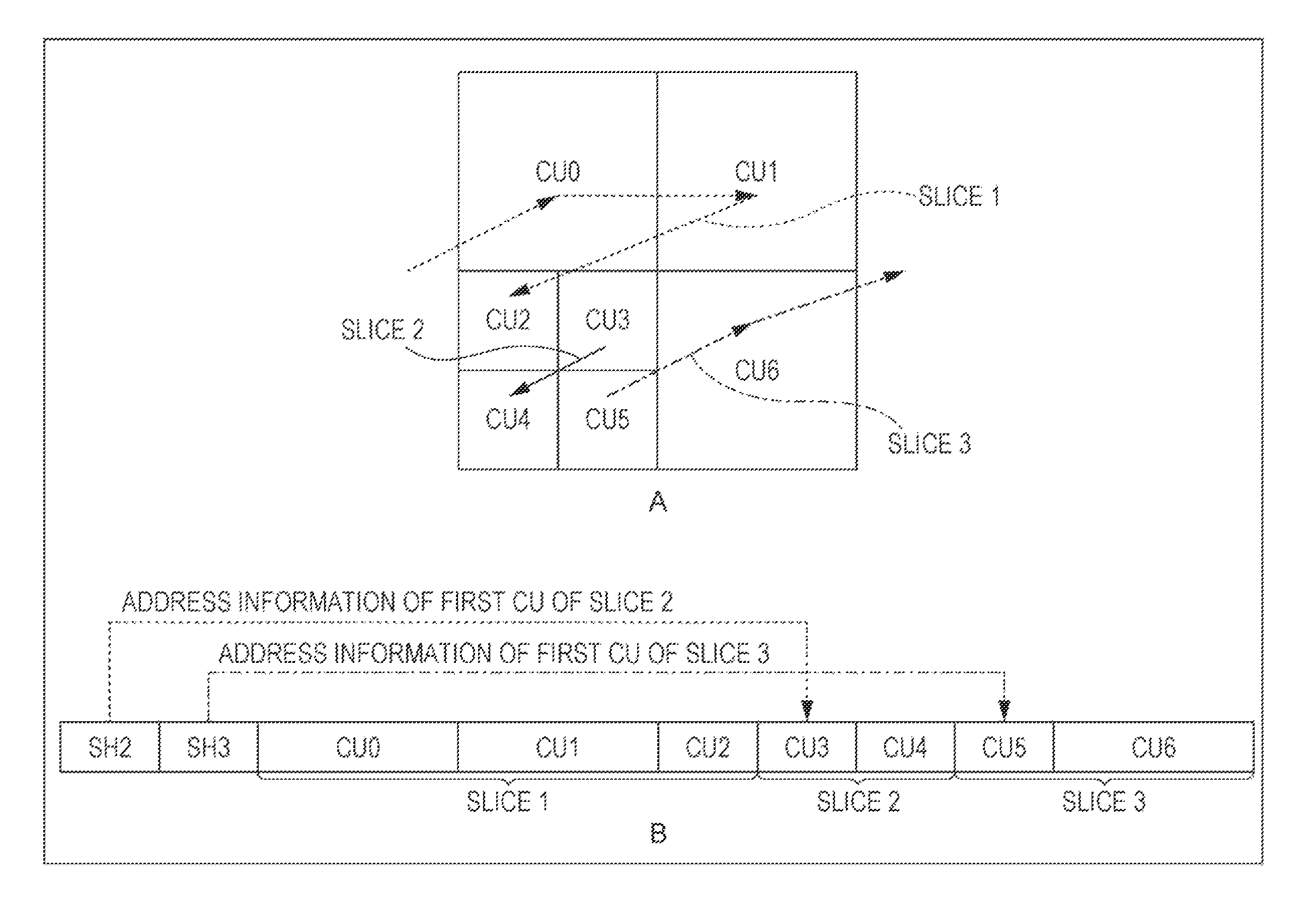

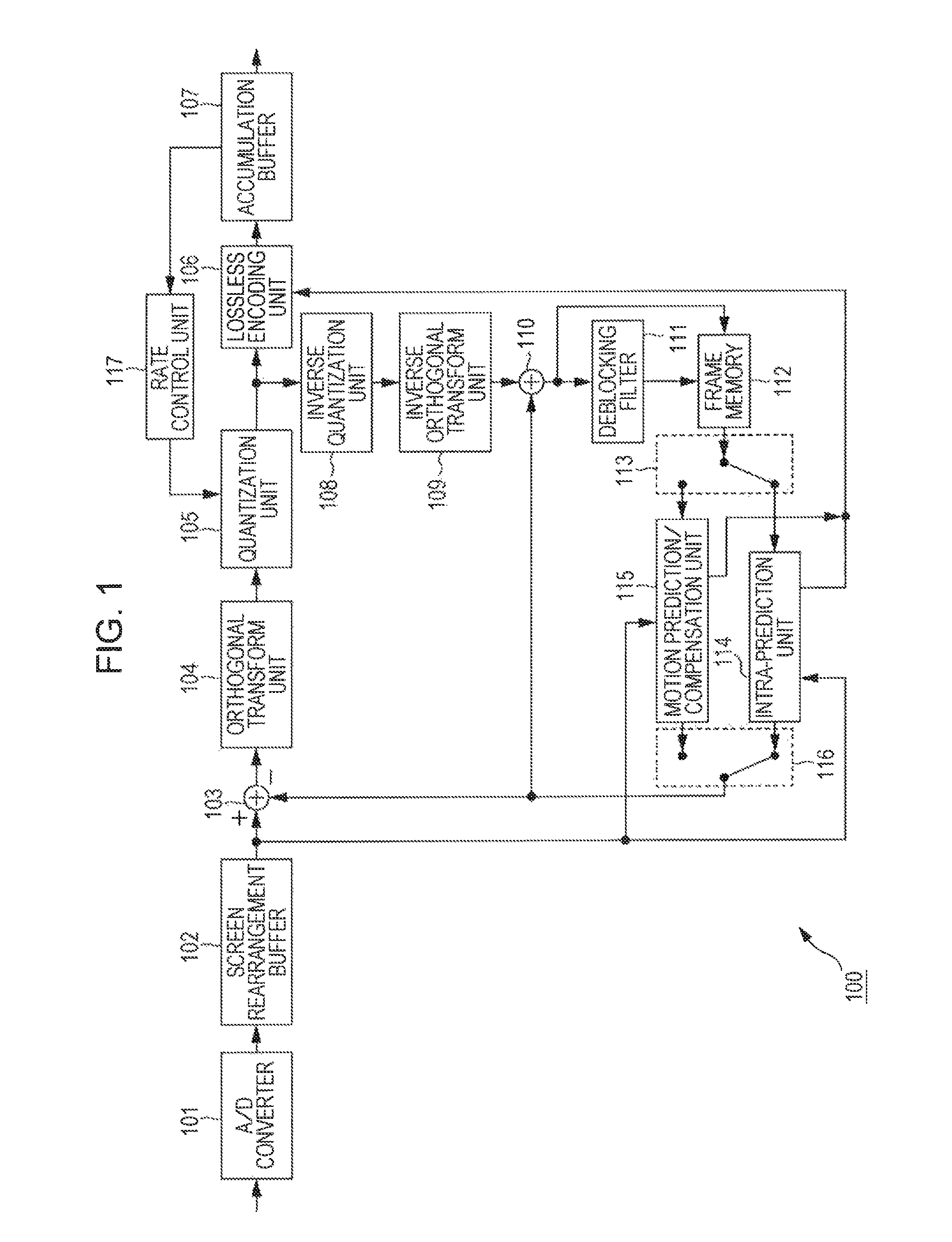

Image processing device and method

InactiveUS20130287309A1Reduce controlDeterioration in convenience is suppressedCharacter and pattern recognitionImage codingImaging processingImaging data

The present technology includes a setting unit that sets the position of a boundary of image data in an upper hierarchy unit to be in a lower hierarchy unit that is lower than the upper hierarchy unit when the image data is encoded in a unit of encoding with a hierarchical structure; an encoding unit that generates encoded data by encoding the image data according to the position of the boundary set by the setting unit; and an addition unit that adds information on the image data in the upper hierarchy unit before encoded data in an intermediate hierarchy unit that includes the boundary set by the setting unit, is lower than the upper hierarchy unit, and is higher than the lower hierarchy unit. The present technology can be applied to, for example, an image processing device.

Owner:SONY CORP

Image processing device and method with hierarchical data structure

InactiveUS9123130B2Control deteriorationReduce controlCharacter and pattern recognitionImage codingImaging processingAlgorithm

The present technology includes a setting unit that sets the position of a boundary of image data in an upper hierarchy unit to be in a lower hierarchy unit that is lower than the upper hierarchy unit when the image data is encoded in a unit of encoding with a hierarchical structure; an encoding unit that generates encoded data by encoding the image data according to the position of the boundary set by the setting unit; and an addition unit that adds information on the image data in the upper hierarchy unit before encoded data in an intermediate hierarchy unit that includes the boundary set by the setting unit, is lower than the upper hierarchy unit, and is higher than the lower hierarchy unit. The present technology can be applied to, for example, an image processing device.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com