Patents

Literature

190results about How to "Achieve ultra-thin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

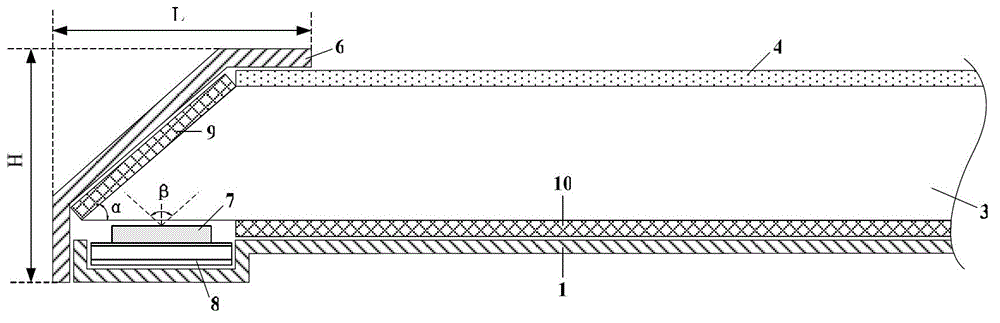

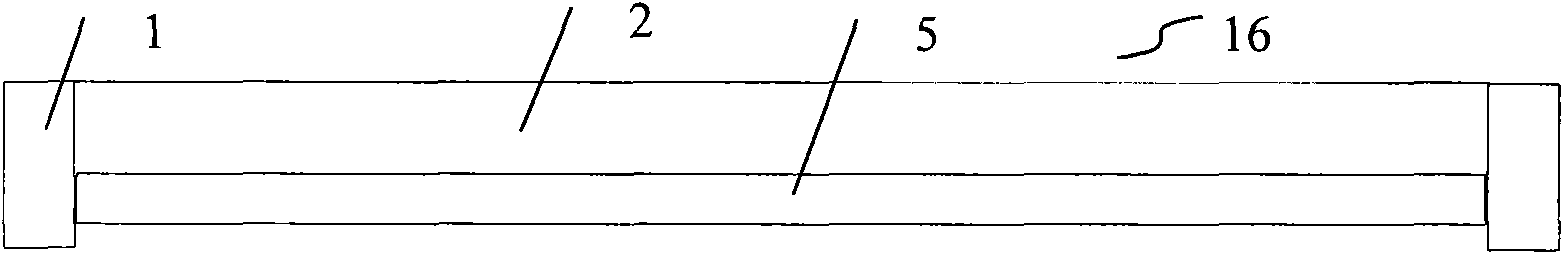

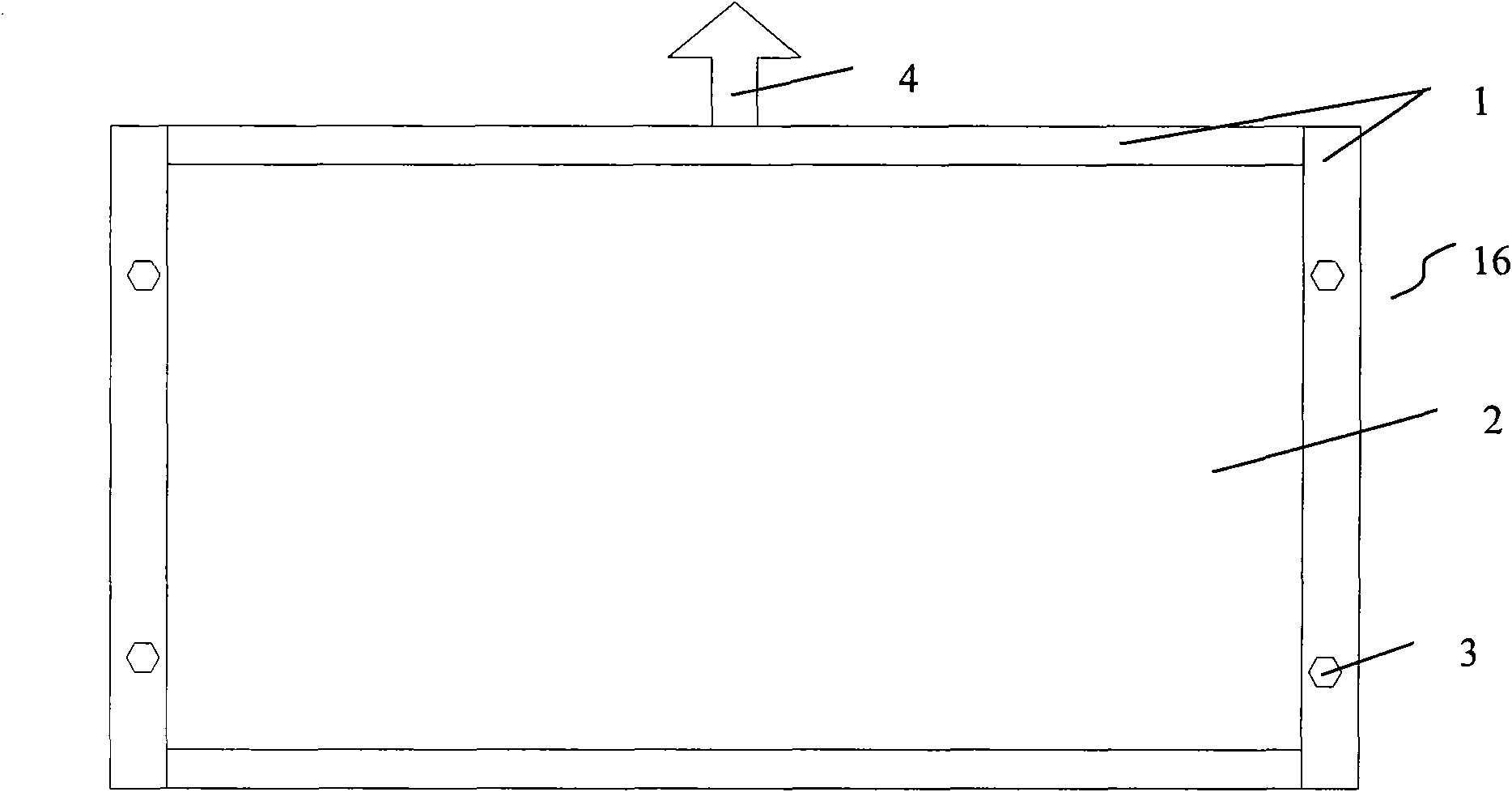

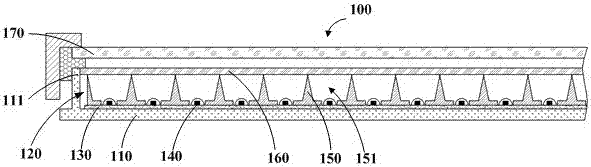

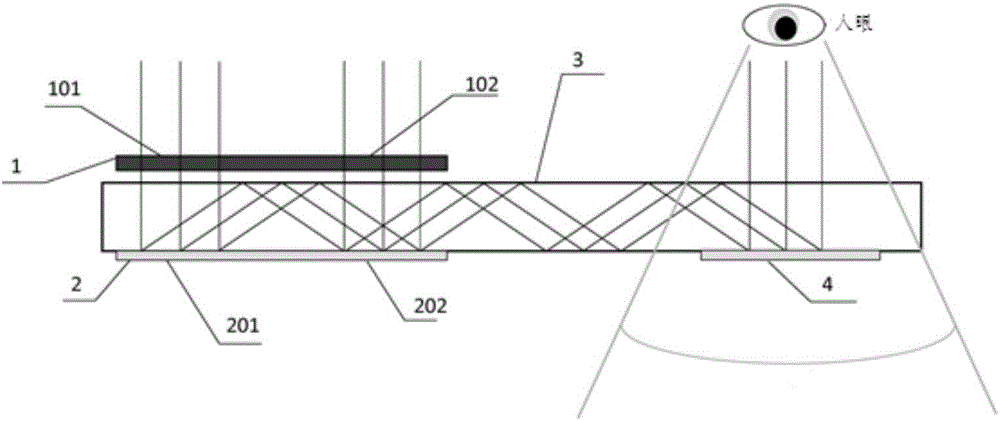

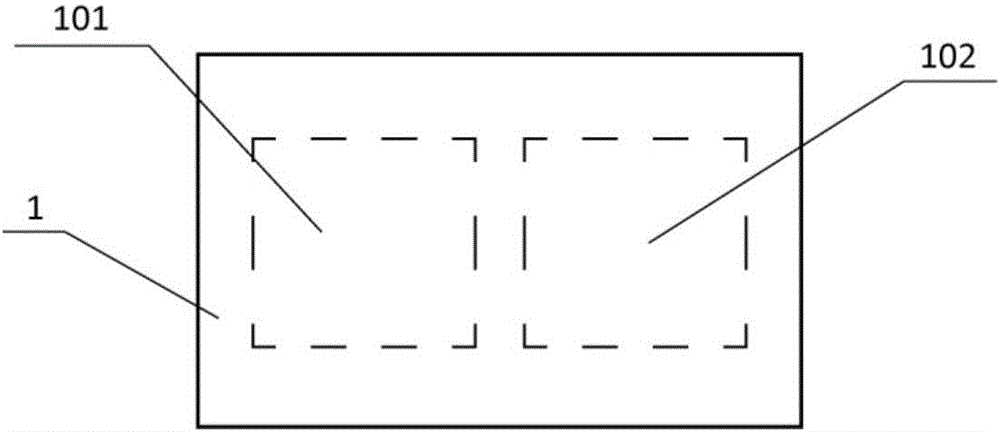

Backlight module and display device

ActiveCN102980105AImprove luminous performanceReduce in quantityLighting device detailsOptical light guidesLight guideDisplay device

The invention provides a backlight module which comprises a light source, a light guide plate and reflective sheets, wherein the reflective sheets comprise a first reflective sheet and a second reflective sheet; the first reflective sheet is arranged on the lateral surface of the light guide plate; the second reflective sheet is arranged at the bottom of the light guide plate; the light source is arranged below the first reflective sheet; the first reflective sheet is used for reflecting light emitted by the light source into the light guide plate; and after being scattered by the light guide plate and reflected by the second reflective sheet, the light is emitted out from the top of the light guide plate. Correspondingly, the invention provides a display device which comprises the backlight module. The backlight module provided by the invention has the advantages of thinning, increase of an effective lighting area, shape diversification and the like.

Owner:BOE TECH GRP CO LTD +1

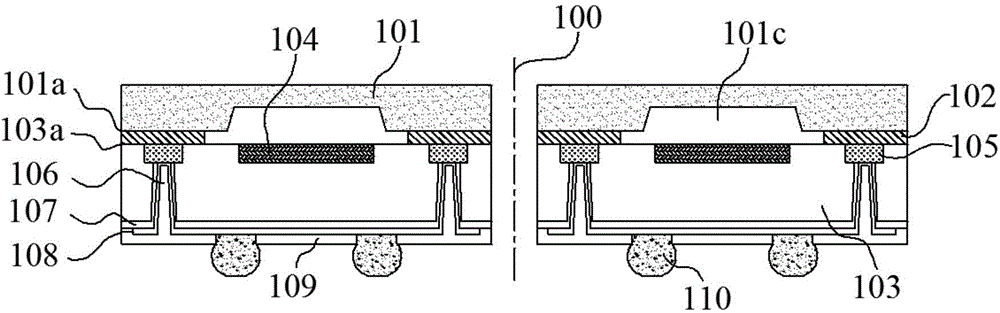

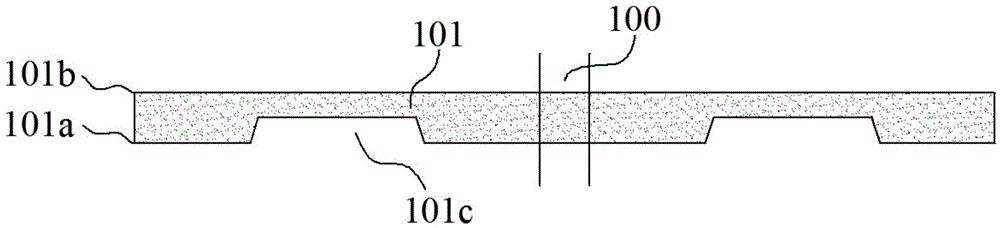

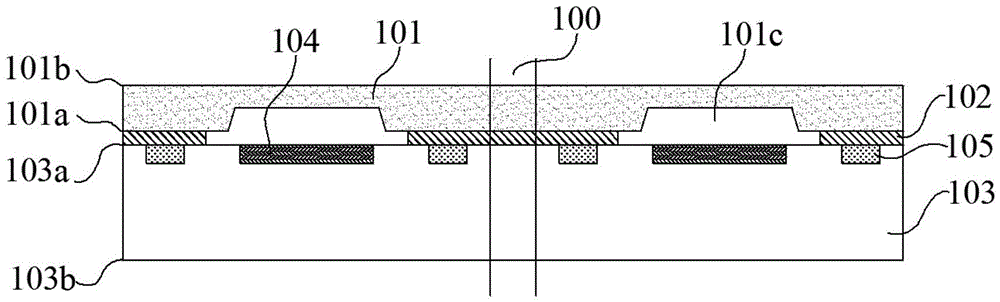

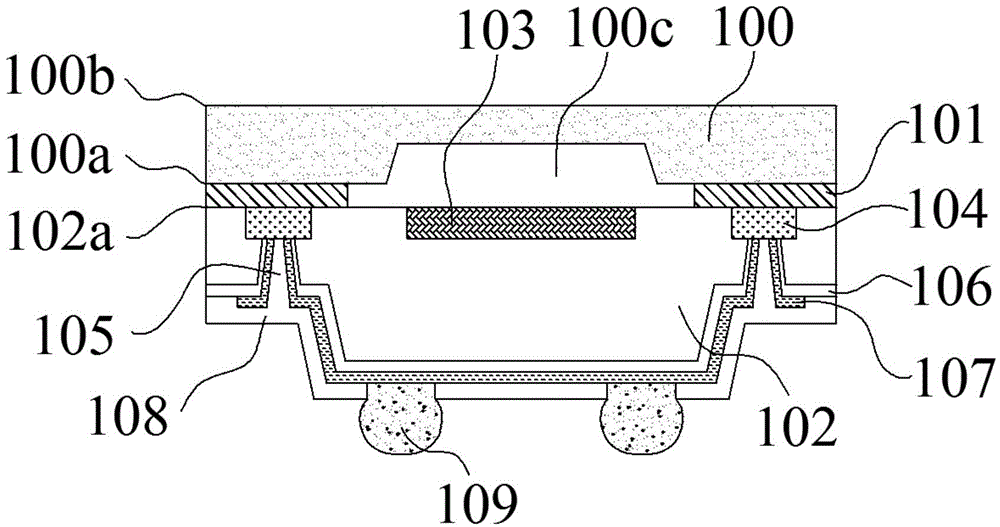

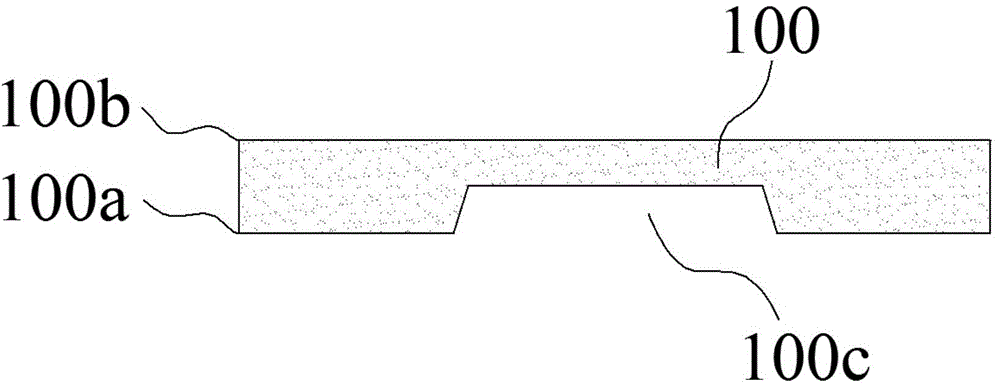

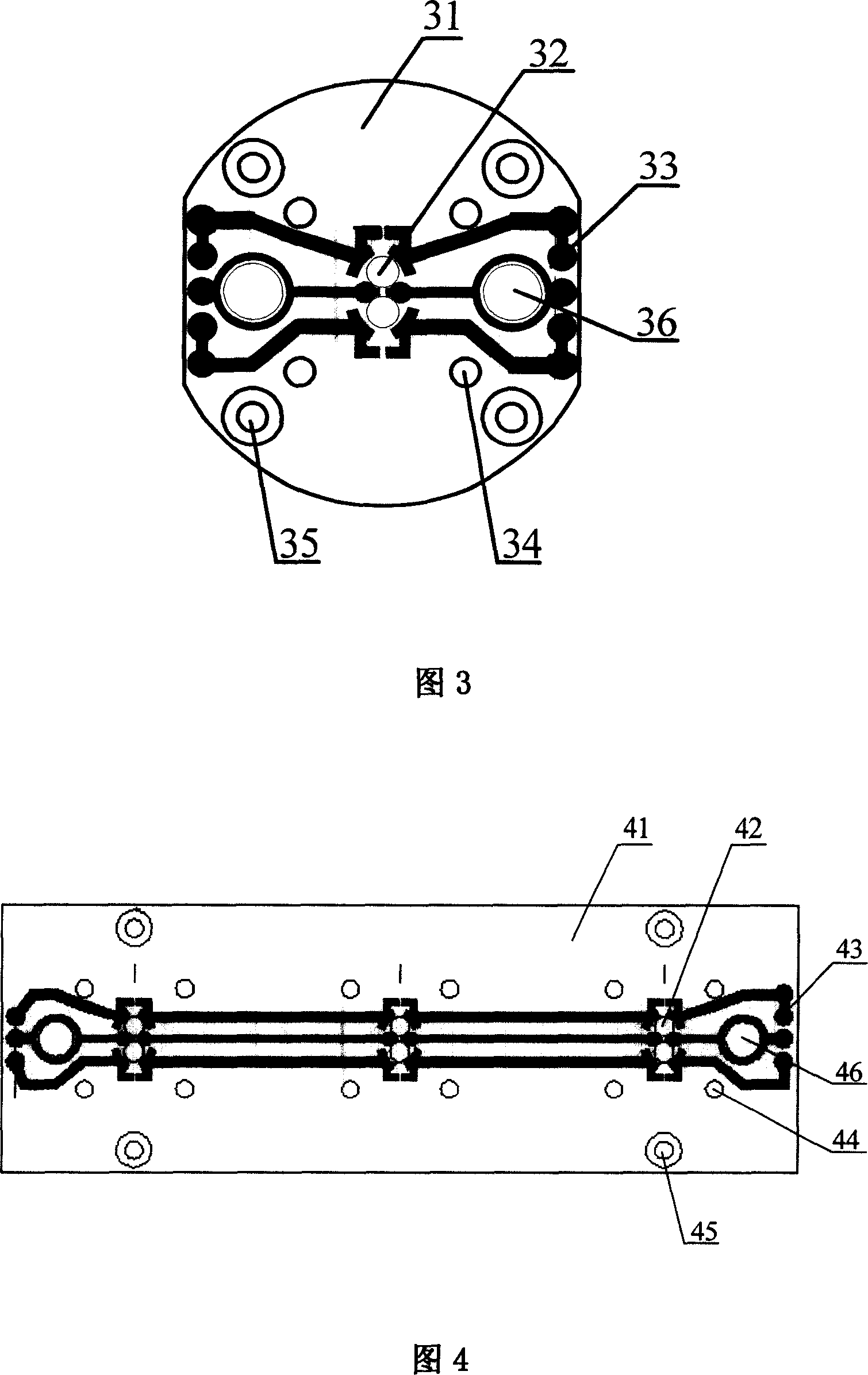

Semiconductor packaging method of wafer level silicon-based through hole

InactiveCN104392958AImprove yieldReduce stress levelsSolid-state devicesSemiconductor/solid-state device manufacturingStress levelSolder ball

The invention discloses a semiconductor packaging method of wafer level silicon-based through hole, belonging to the field of semiconductor packaging. The packaging method substantially comprises the following steps: 1, making a cavity structure on a cover plate; 2, bonding the front surface of the cover plate with the front surface of a wafer through a bonding machine; 3, grinding the rear surface of the wafer by a grinder, and implementing a stress plasma etching on the rear surface of the wafer; 4, removing all silicon belonging to a scribe line region starting from the rear surface of the wafer; 5, etching the rear surface of the wafer in order to form silicon through holes, and exposing a bonding pad; 6, making passivation layers, metal layers and solder mask layers sequentially in the rear surface of the wafer and the silicon through holes, so as to compose a redistributed circuit layer, thereby conducting the solder pad to a designated solder ball position on the rear surface of the wafer; 7, making solder balls and cutting along the scribe line. By the implementation of the semiconductor packaging method of wafer level silicon-based through hole, the yield rate of wafer cutting technique is increased, the stress level in package structure is reduced, and the boundary dimension of the package structure is decreased.

Owner:BEIJING UNIV OF TECH

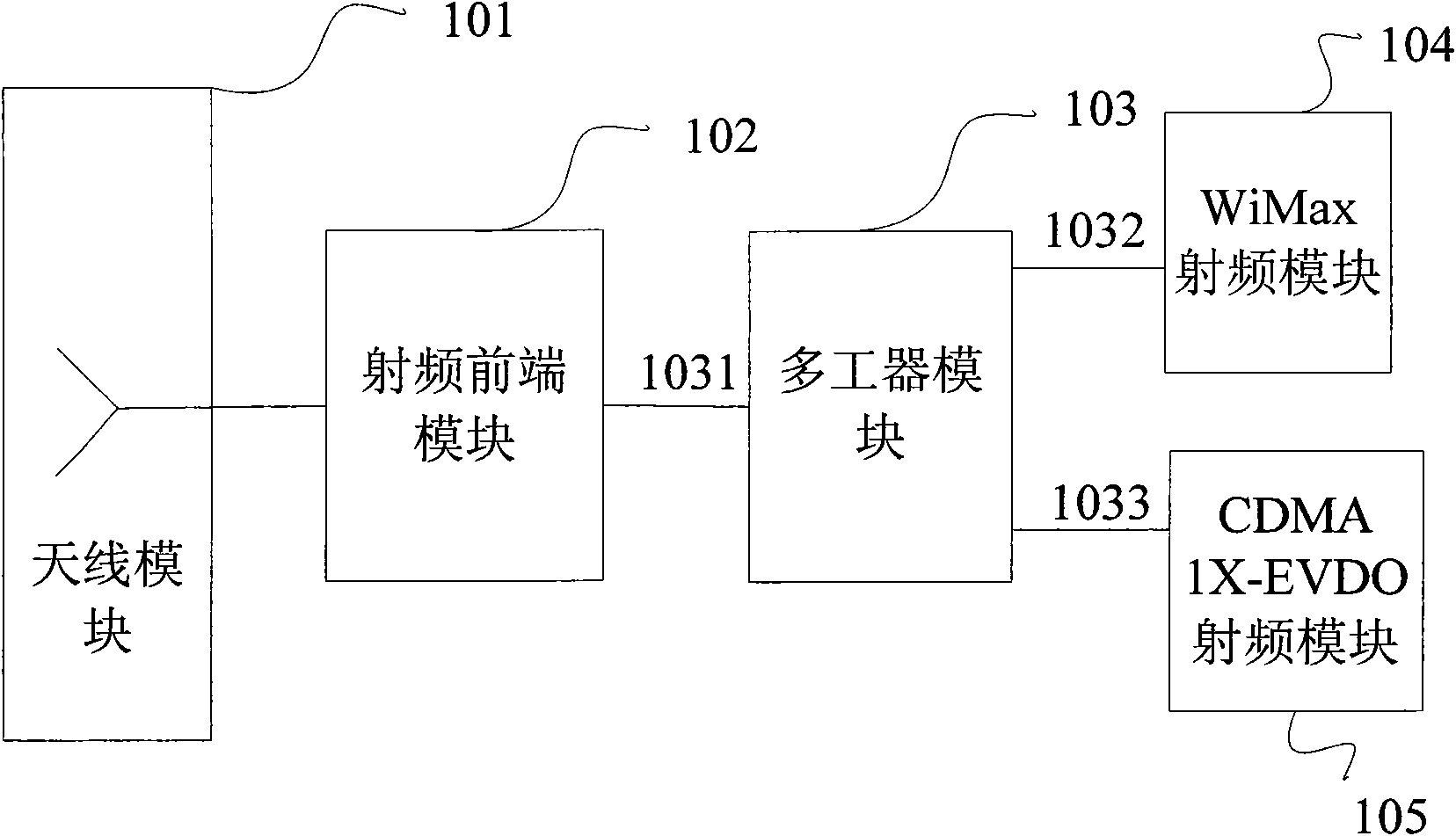

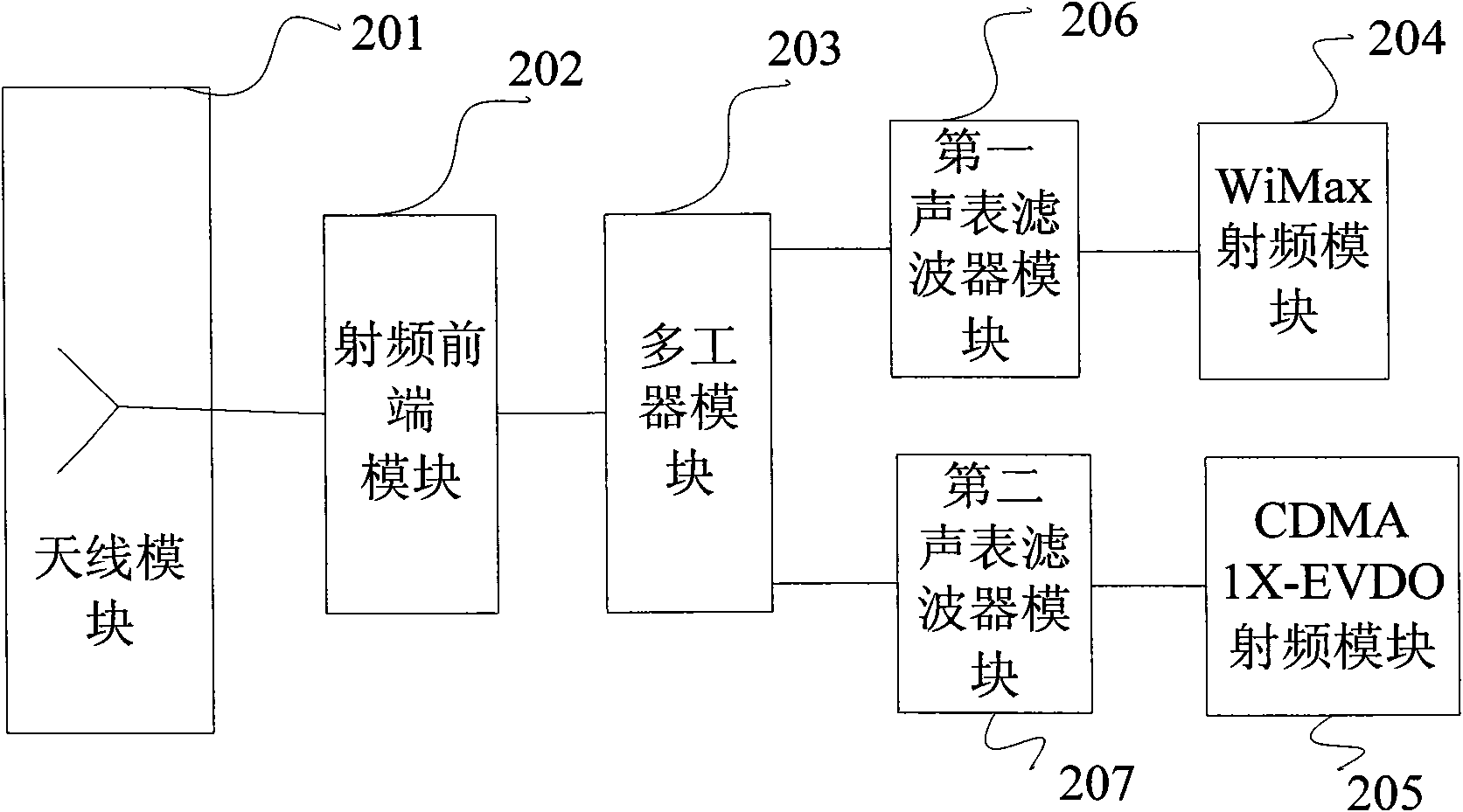

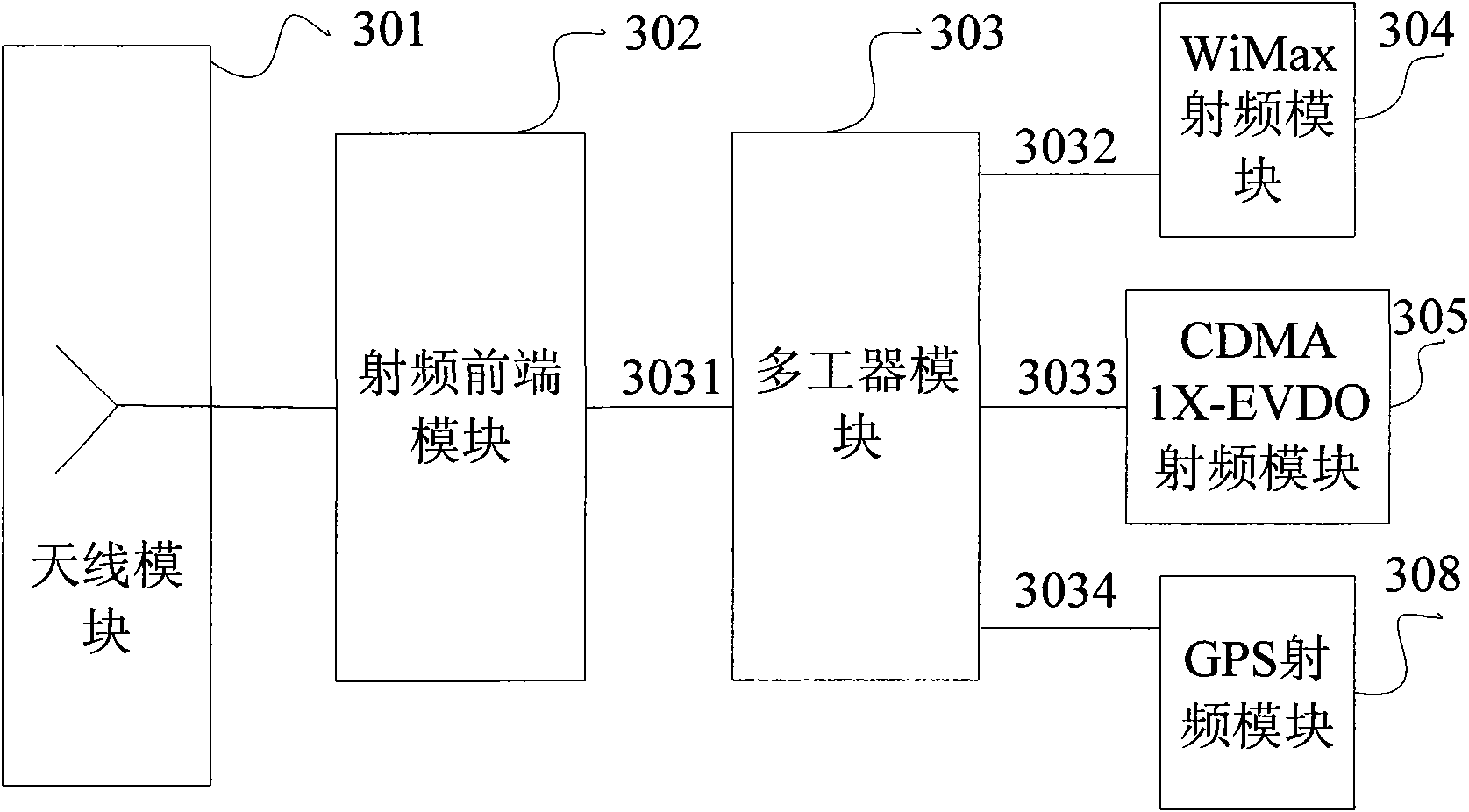

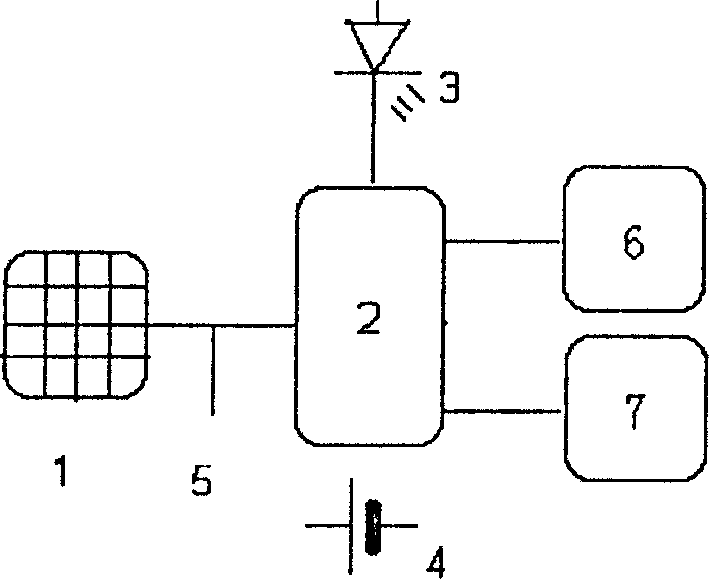

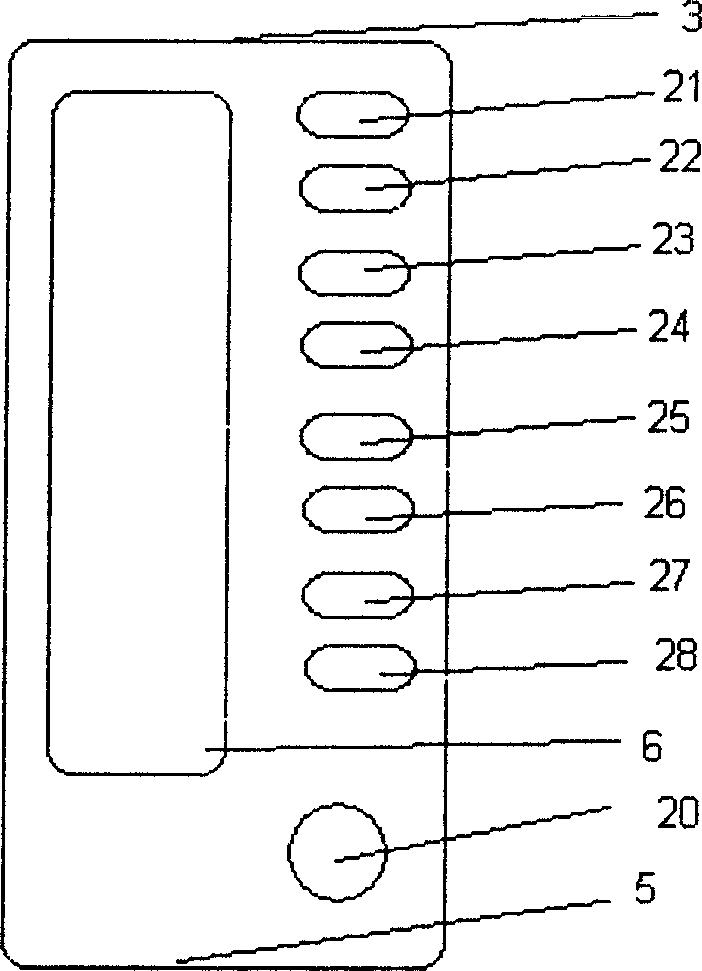

Radio-frequency front-end transceiver and multi-mode mobile terminal

InactiveCN101557237AMiniaturizationAchieve ultra-thinTransmissionWireless communicationTransceiverMultiplexer

The invention discloses a radio-frequency front-end transceiver which comprises an antenna module, radio-frequency modules in various modes and a multiplexer module, wherein the multiplexer module is used for separating signals received by the antenna module to obtain frequency-band signals in various modes and transmitting the frequency-band signals in various modes to the corresponding radio-frequency modules in various modes; or the multiplexer module is used for receiving the frequency-band signals sent by the radio-frequency modules in various modes and transmitting the frequency-band signals to the antenna module. The invention also discloses a multi-mode mobile terminal. By adopting the radio-frequency front-end transceiver and the multi-mode mobile terminal, only one antenna is used, thus occupying less space, avoiding mutual interference of signals between two or more antennas, and having good radio-frequency performance.

Owner:ZTE CORP

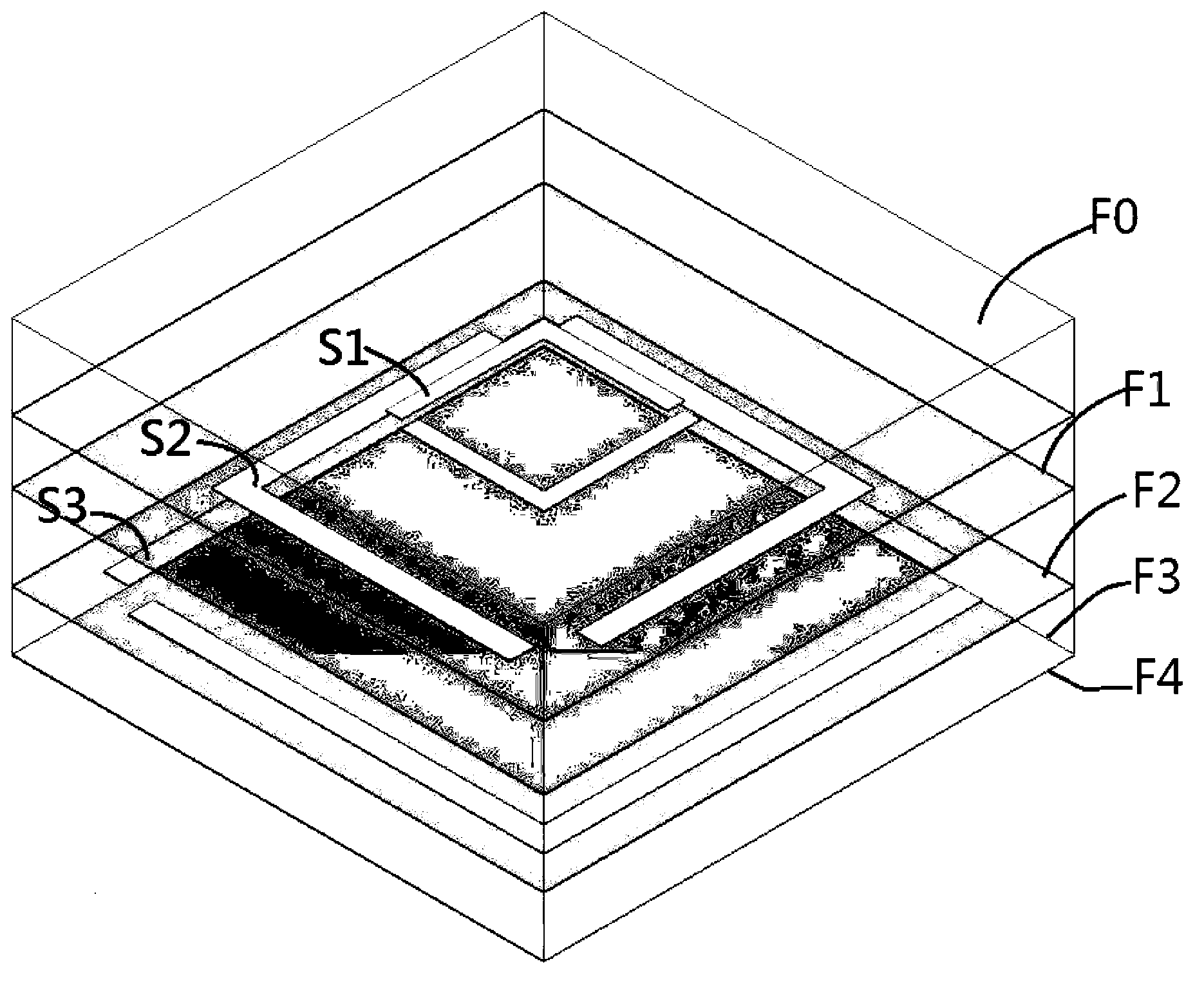

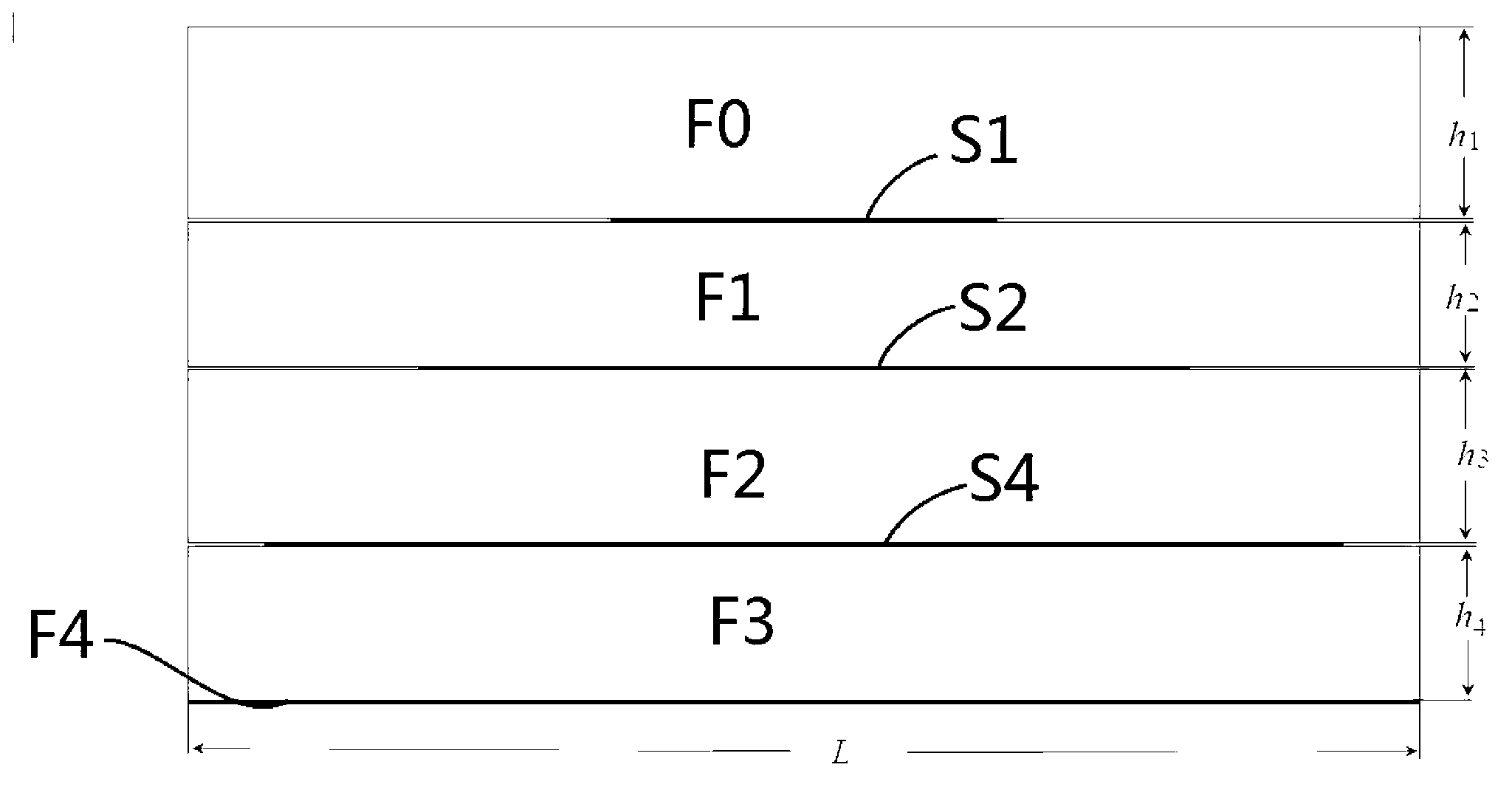

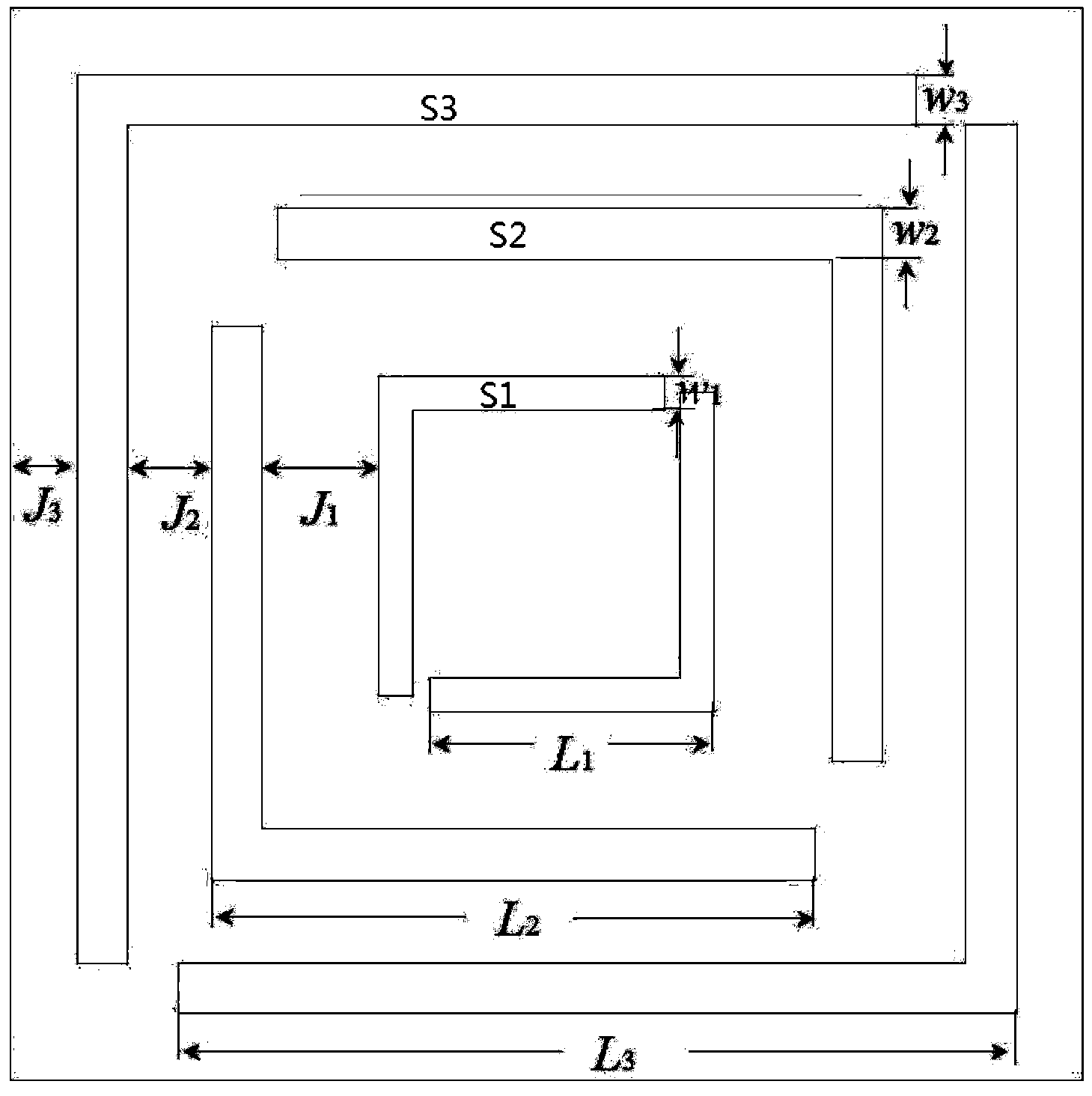

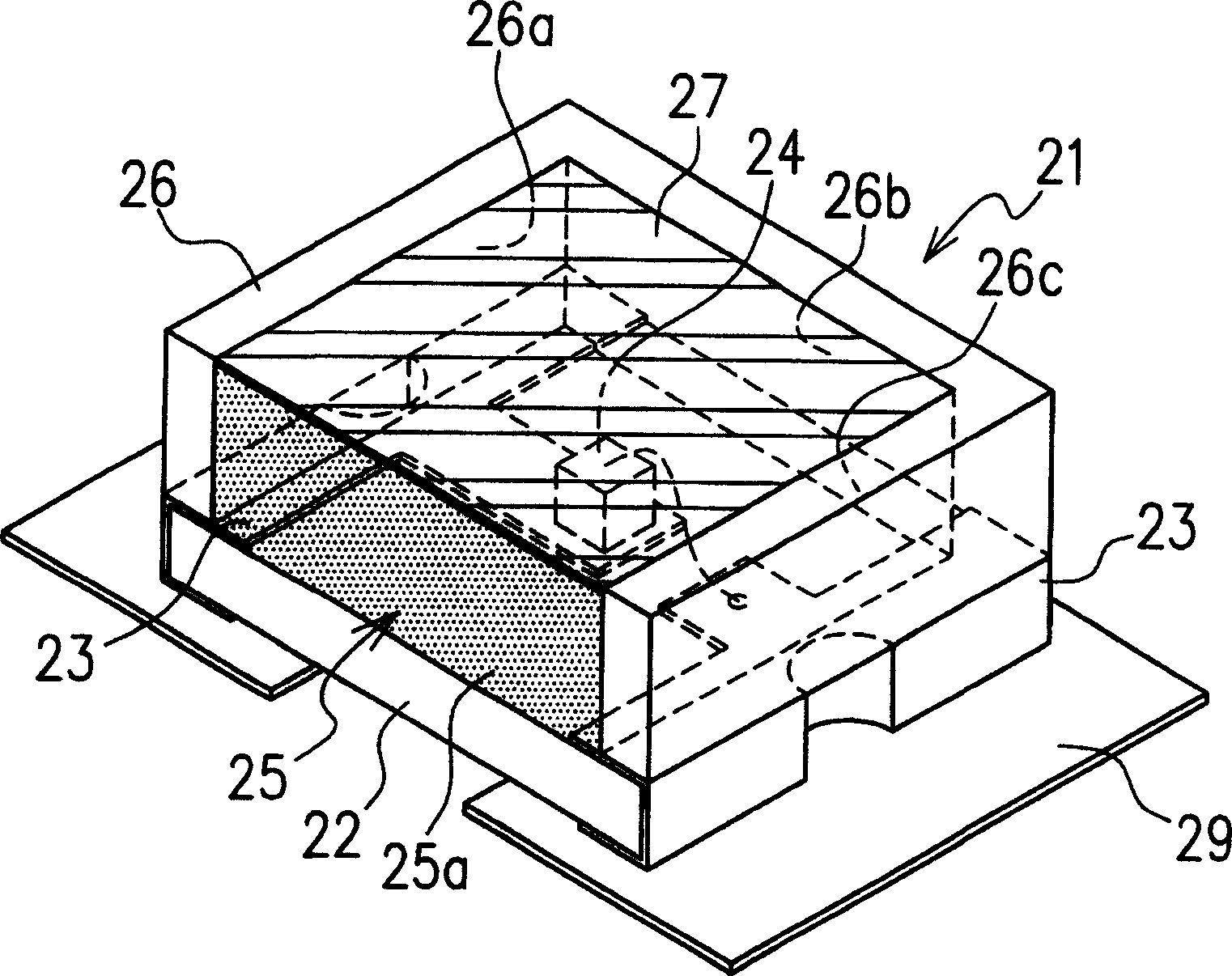

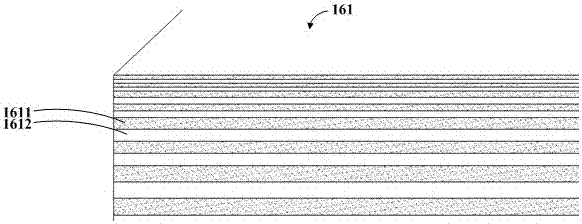

Super-thin broadband wave-absorbing metamaterial

The invention discloses super-thin broadband wave-absorbing metamaterial. The super-thin broadband wave-absorbing metamaterial comprises at least two layers of dielectric slabs which are laminated together. In the laminated dielectric slabs, a matching layer covers the upper surface of the dielectric slab at the top layer, a metal floor layer covers the lower surface of the dielectric slab at the bottom layer, and a non-closed annular metal layer further covers the upper surface of the dielectric slab at each layer. The non-closed annular metal layers located on the different dielectric slabs are same in shapes and mutually different in terms of sizes. The non-closed annular metal layers are distributed according to the pyramid structure, wherein the non-closed annular metal layer with the largest size is located on the dielectric slab at the bottom layer. According to the wave-absorbing metamaterial, due to the fact that electromagnetic parameters of each layer of structure are changed, phase positions of a reflected wave and a refracted wave are changed. Therefore, a final reflected wave and an incident wave are counteracted, so that the same effect that electromagnetic waves are absorbed by the metamaterial is achieved. Due to the fact that a metamaterial structure composed of the three dielectric slabs, three metal rings and the metal floor is adopted, the broadband wave-absorbing metamaterial is super-thin.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

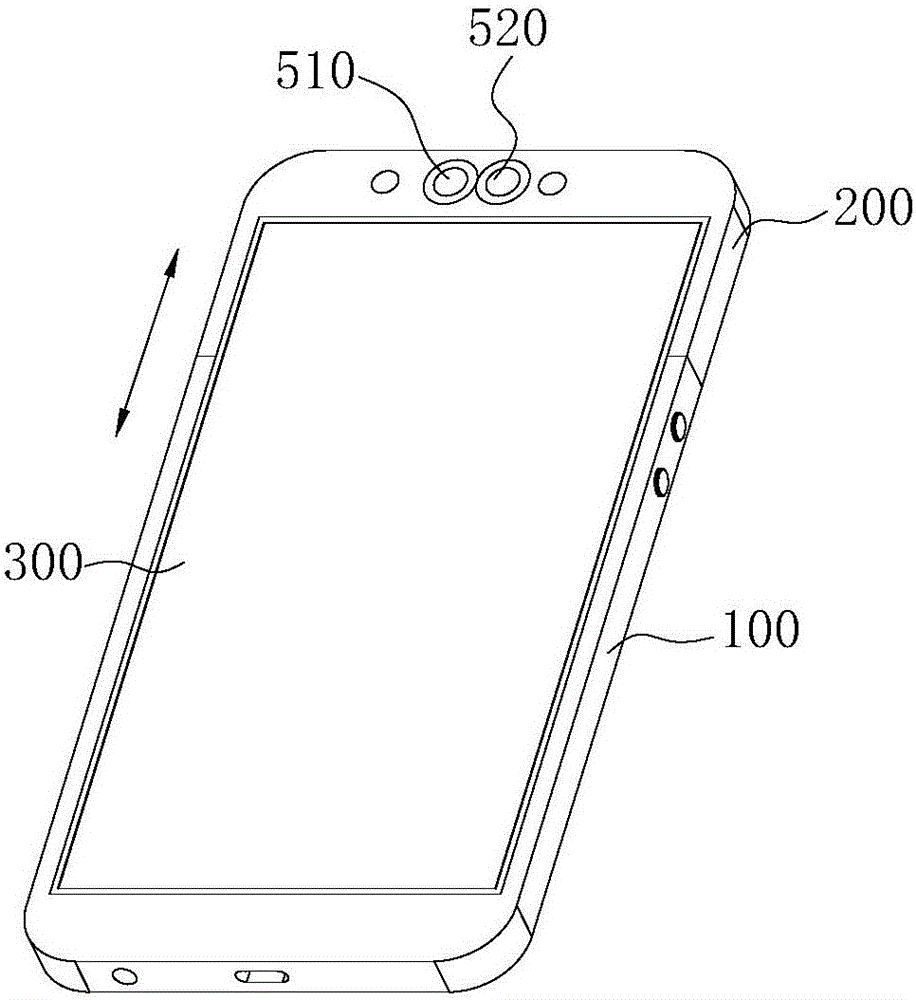

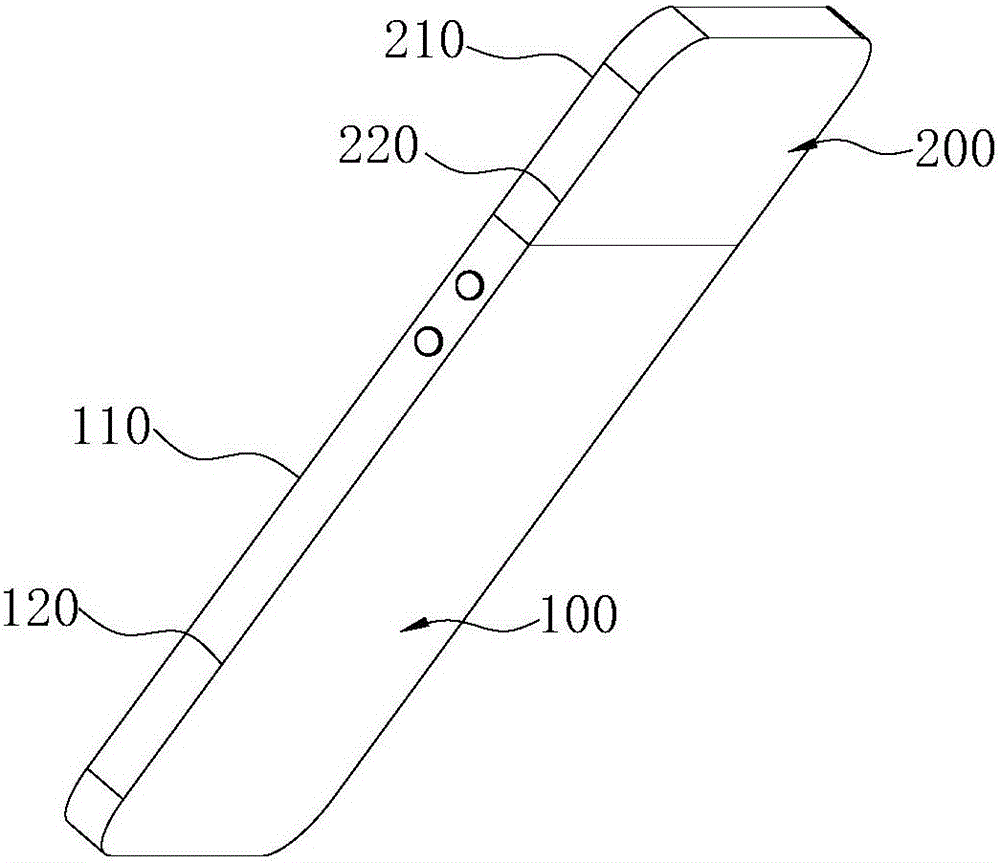

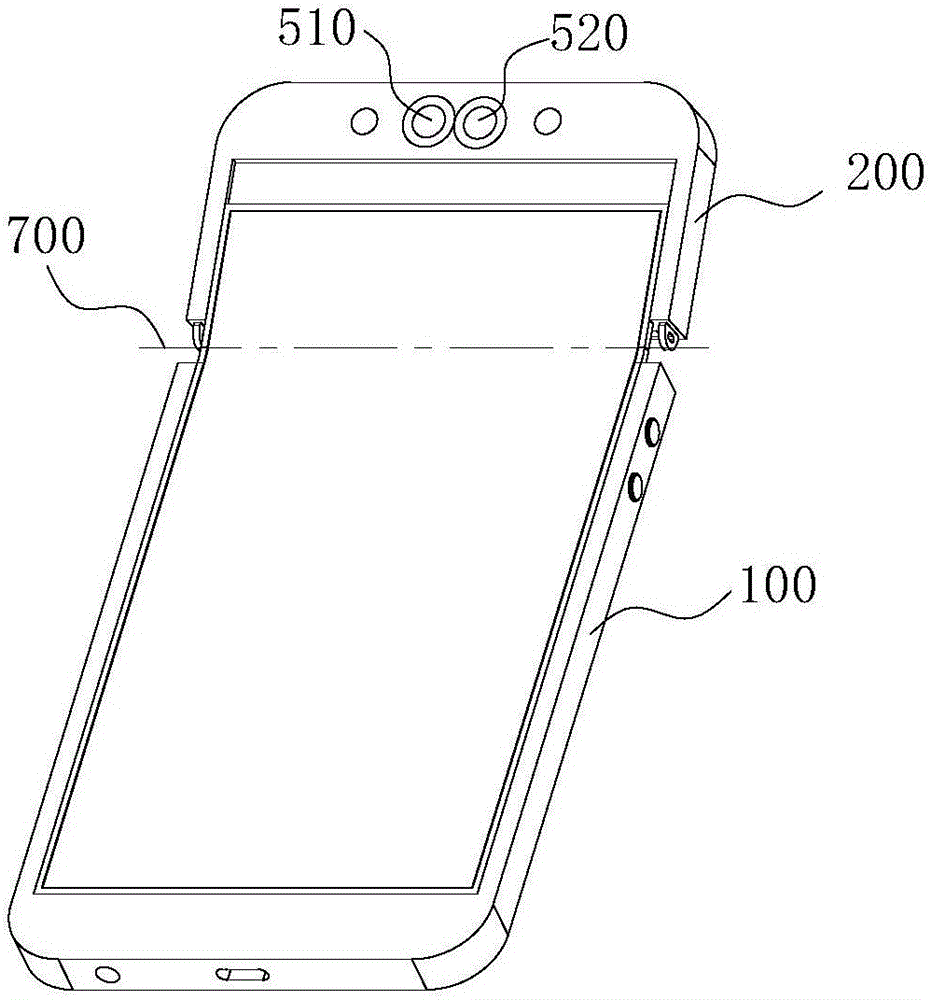

Flexible screen mobile terminal

InactiveCN104994192AAvoid stretchingAvoid compressionTelevision system detailsColor television detailsCamera moduleRelative motion

The invention discloses a flexible screen mobile terminal. The flexible screen mobile terminal comprises a terminal main body which has a first main body surface for mounting a flexible screen and a second main body surface opposite to the first main body surface; a terminal accessory body which is arranged at one end of the terminal main body and has a first accessory body surface for mounting the flexible screen and a second accessory body surface opposite to the first accessory body surface; the flexible screen which is synchronously overlapped on the first main body surface and the first accessory body surface and is at least movably connected with one of the terminal main body and the terminal accessory body; and at least two camera modules which are arranged on the terminal accessory body and are synchronously positioned on the first accessory body surface or the second accessory body surface, wherein the terminal main body is connected with the terminal accessory body in a relative movement way; and the terminal main body and the terminal accessory body can rotate relatively about an axis which is parallel to a plane on which the flexible screen is positioned. The flexible screen movable terminal has the advantages of simple structure, long service life and small thickness.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

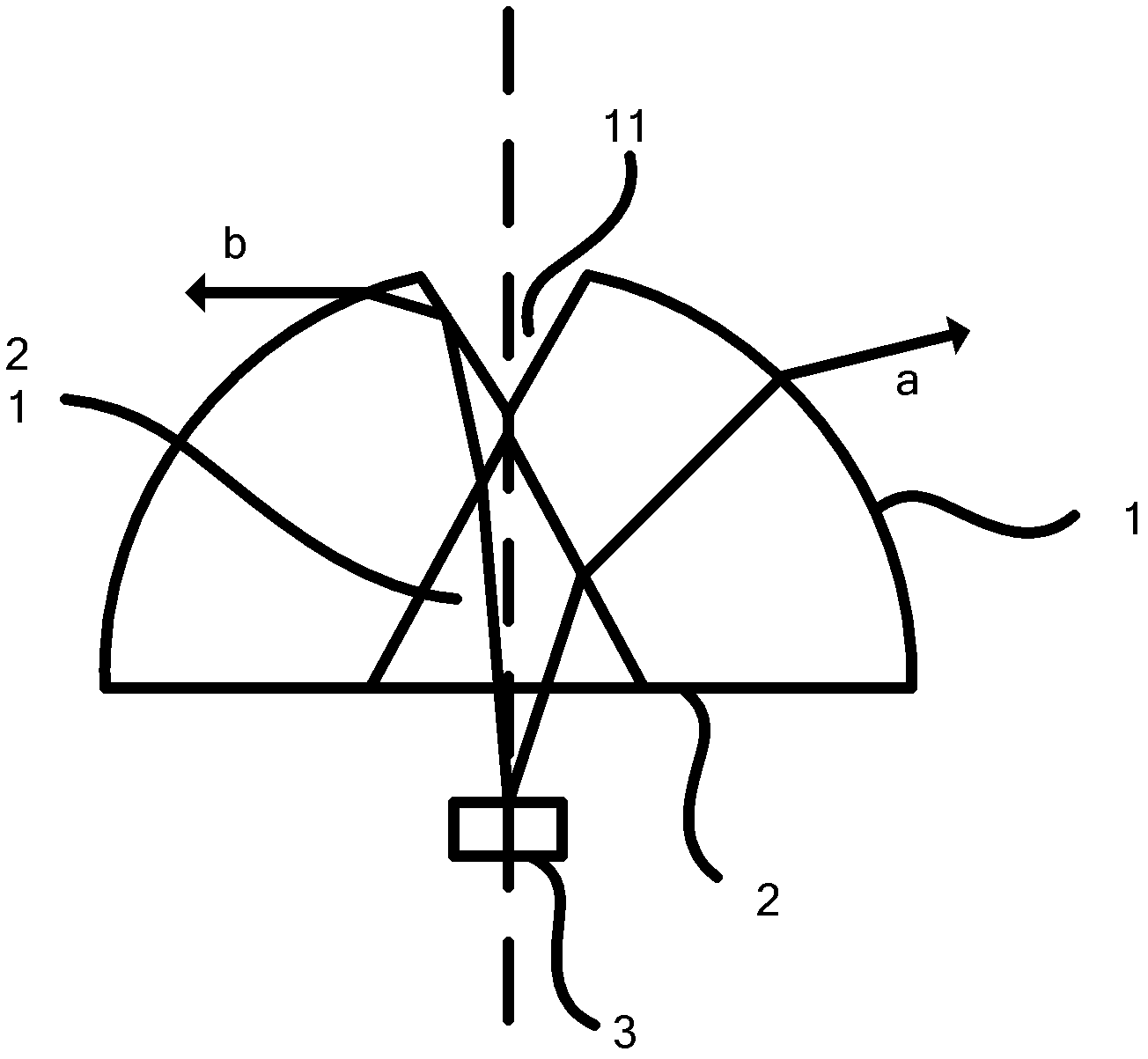

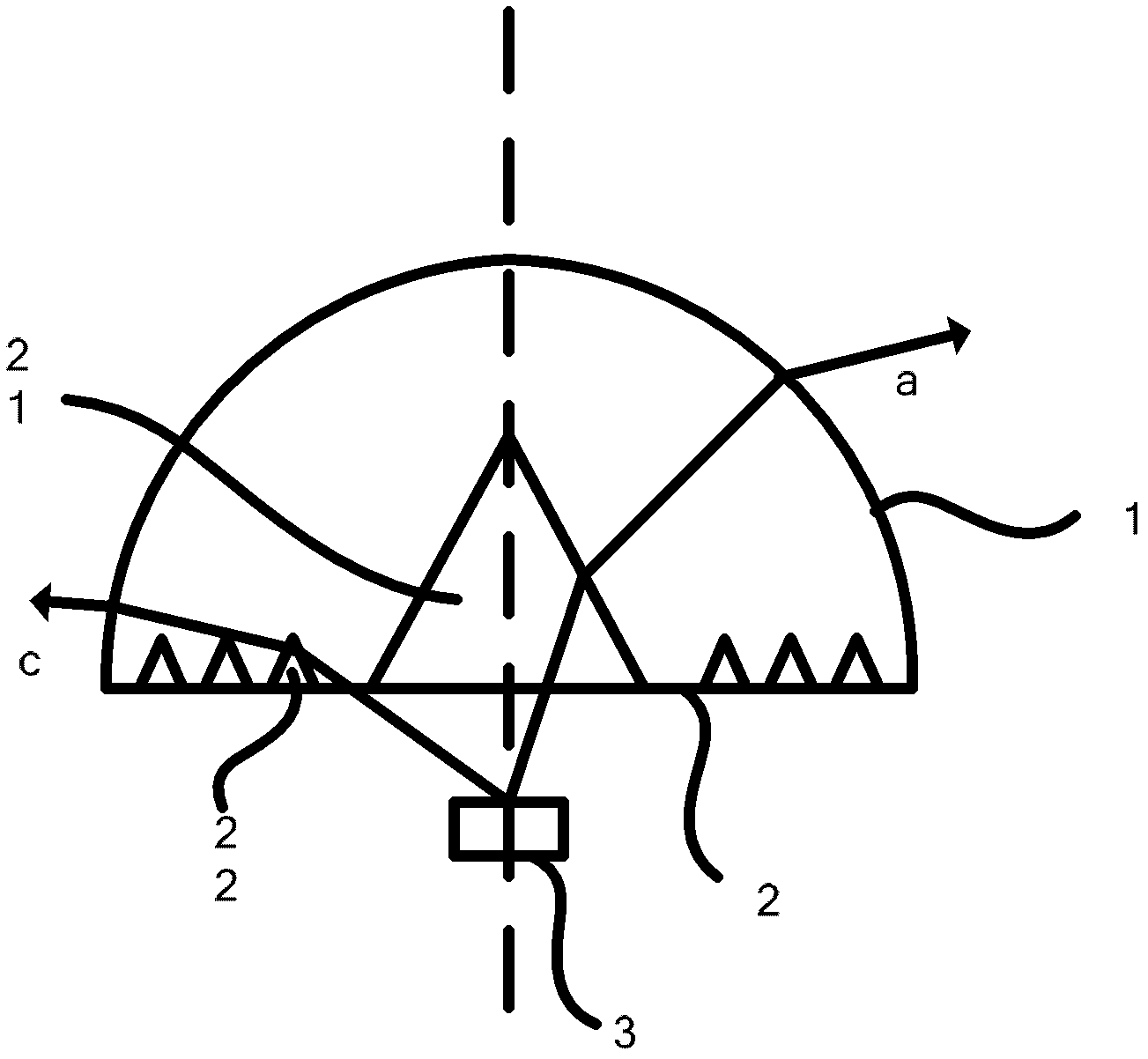

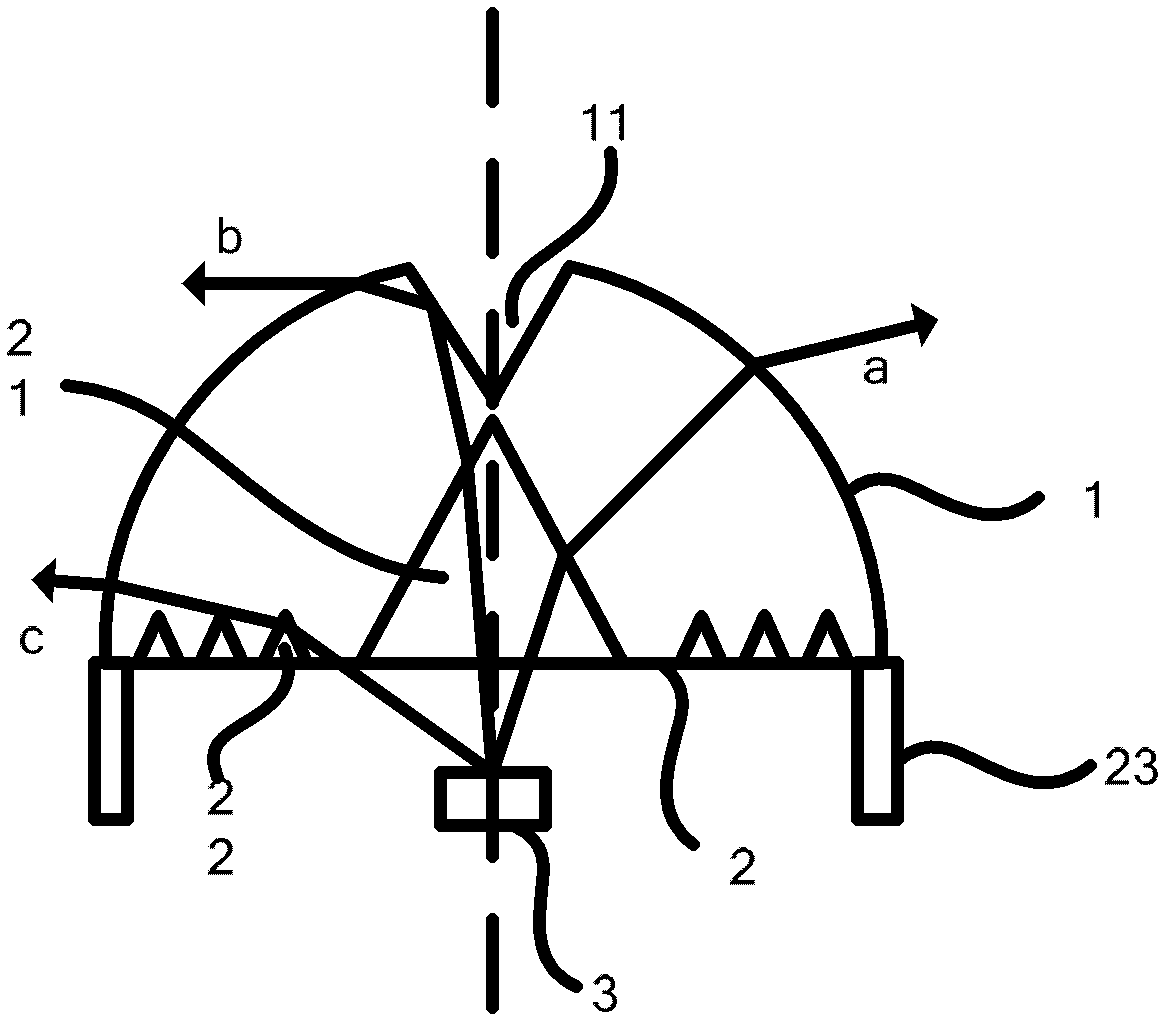

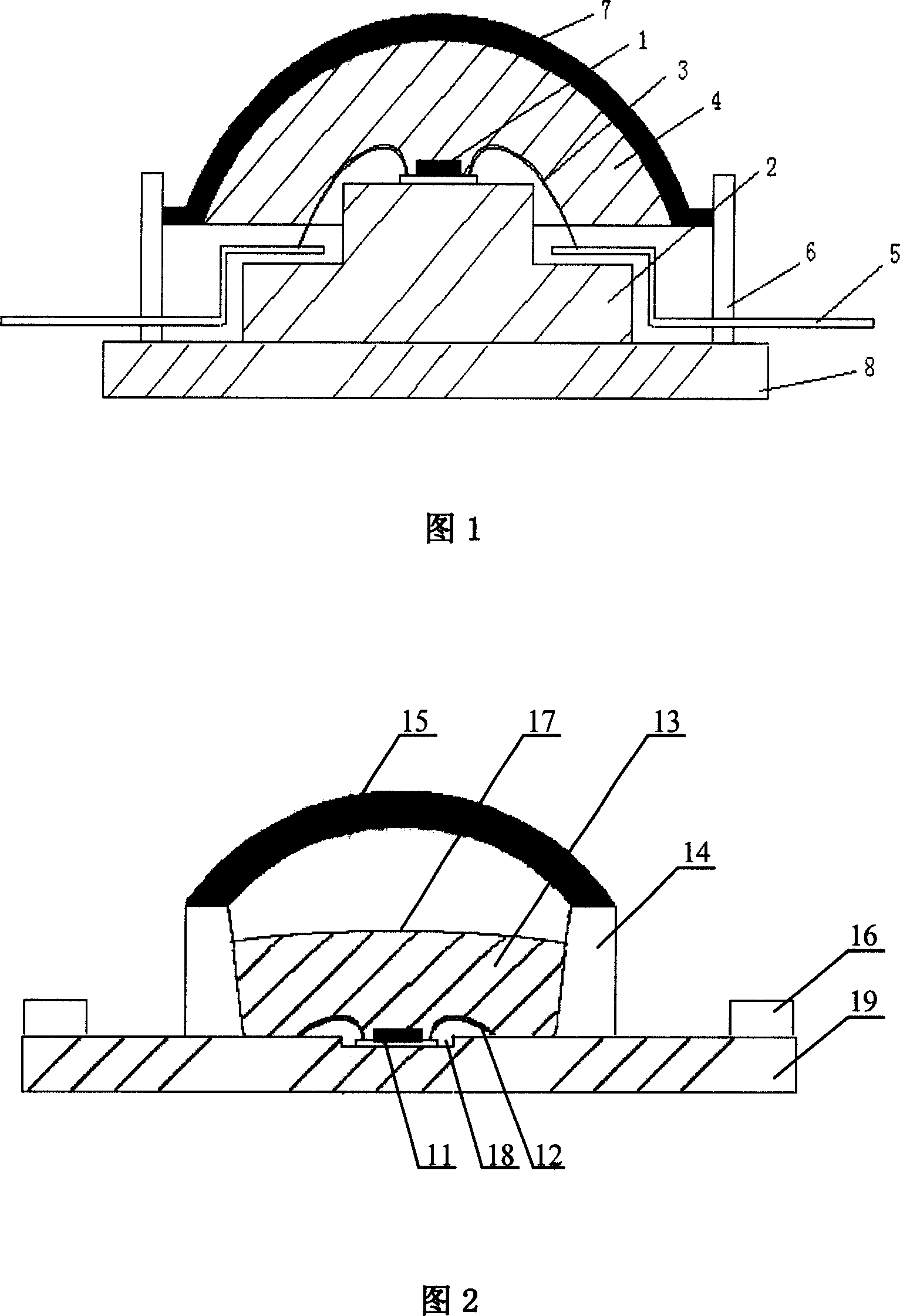

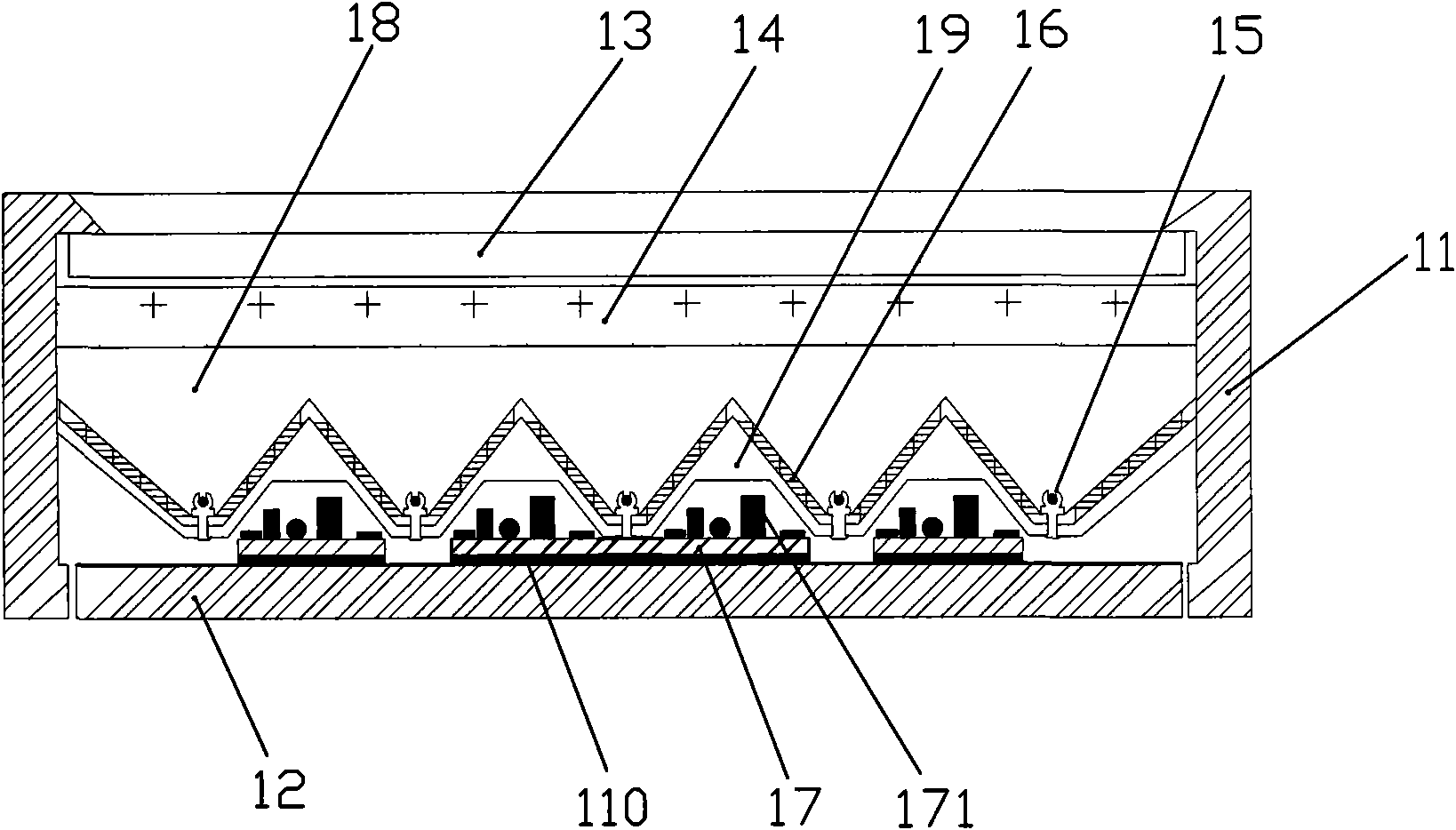

Lens, LED (light emitting diode) light source device and LED (light emitting diode) backlight module

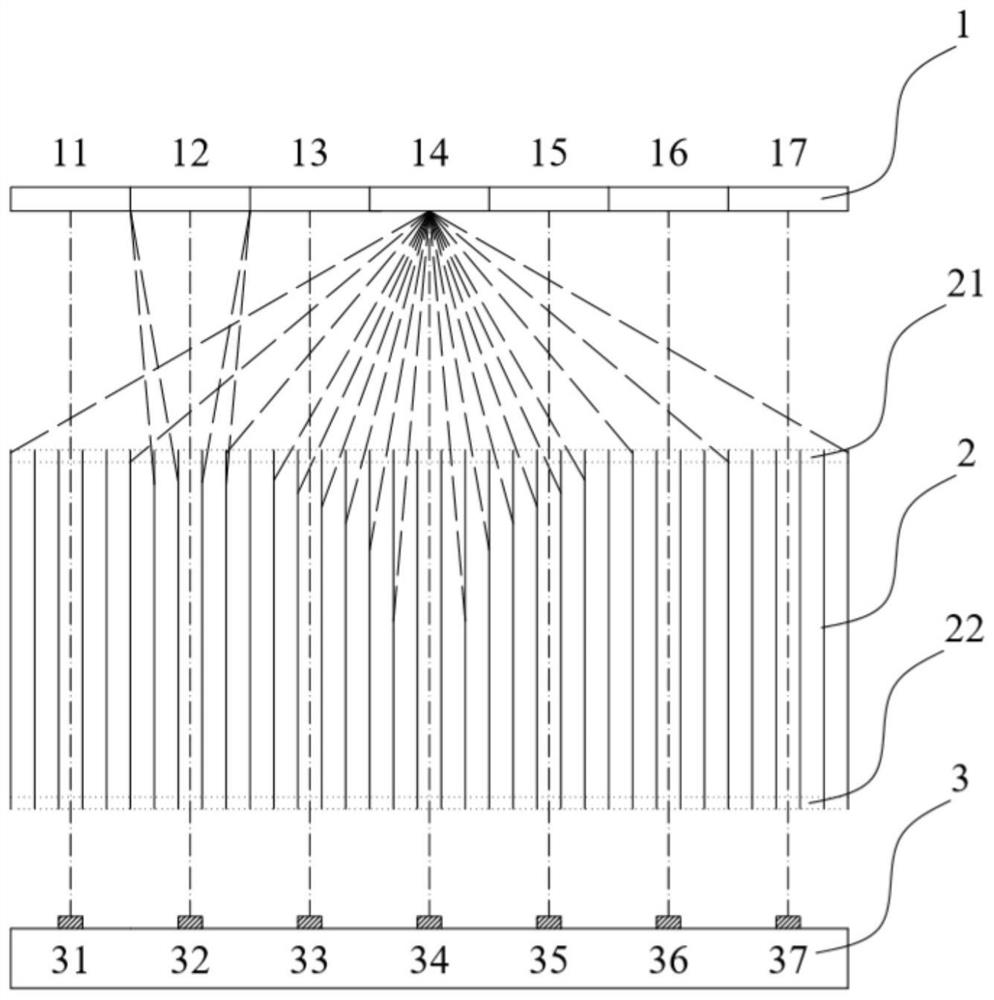

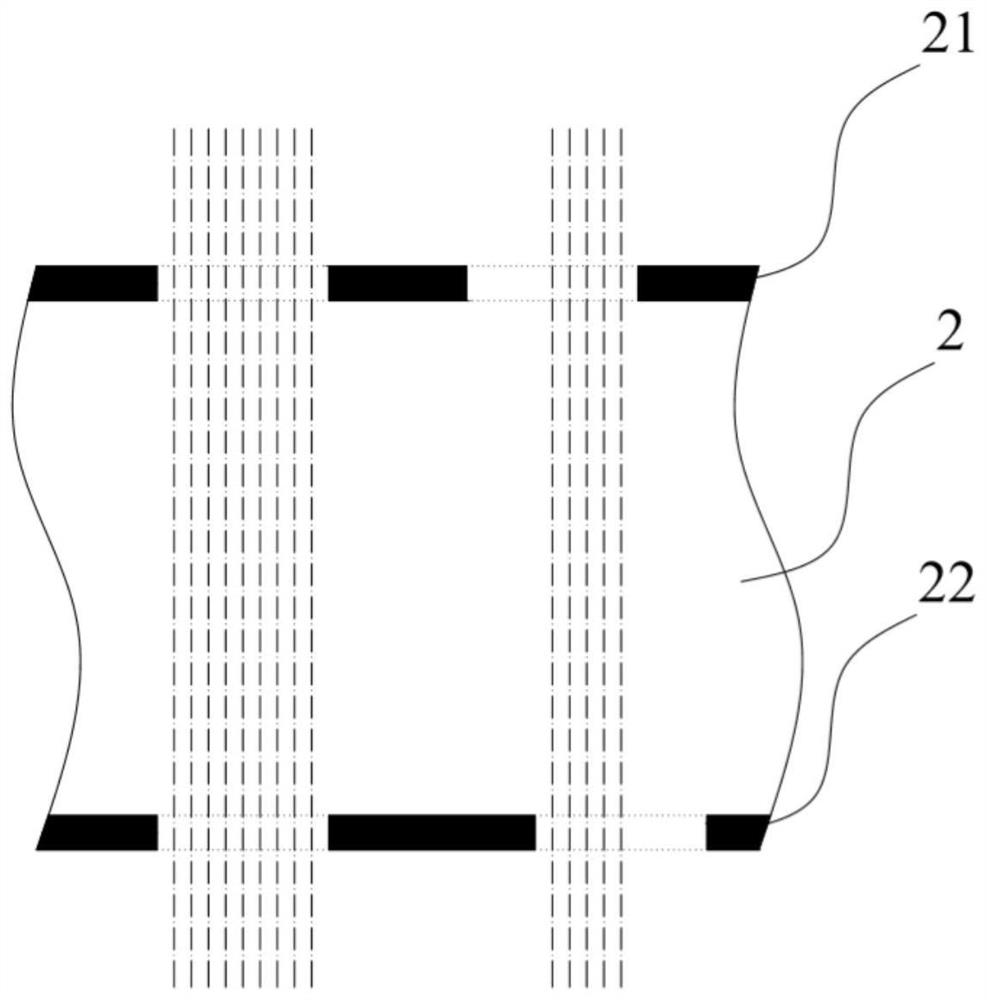

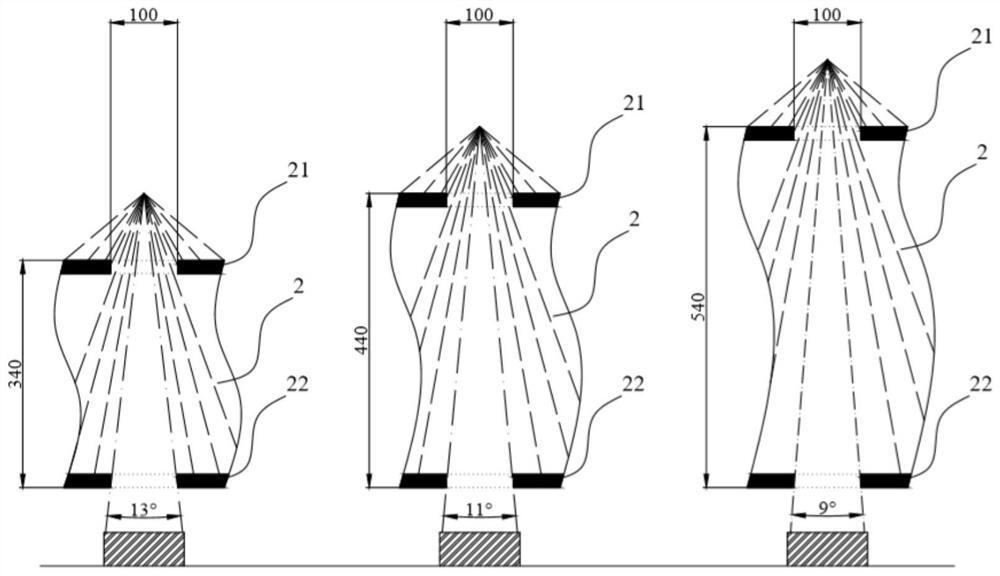

InactiveCN102252267AAchieve ultra-thinEvenly spread lightPoint-like light sourceRefractorsEngineeringLight-emitting diode

The invention provides a lens which can be assembled in an LED (light emitting diode) light source device and is provided with an upper surface and a bottom surface, wherein a first concave part is arranged on the bottom surface, the first concave part is provided with a same central axis with the lens, and the bottom of the first concave part is positioned on the bottom surface. The invention also provides an LED light source device and an LED backlight module. According to the technical scheme of the invention and the secondary optical design of the lens, the light utilization rate is increased, the number of LEDs is reduced, the power dissipation of the LED backlight module is reduced, and the direct type backlight mixing distance is reduced, and a backlight ultrathin design is achieved.

Owner:HISENSE VISUAL TECH CO LTD

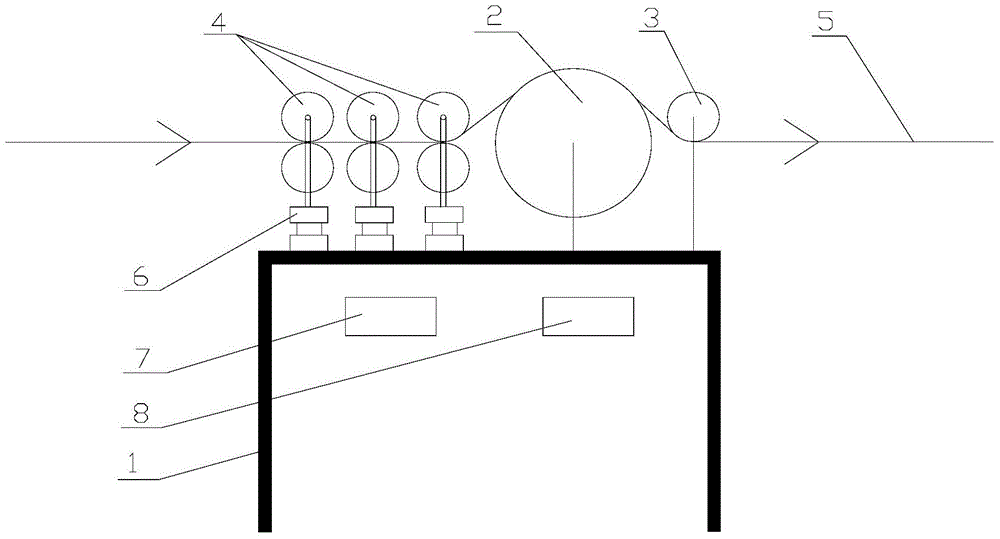

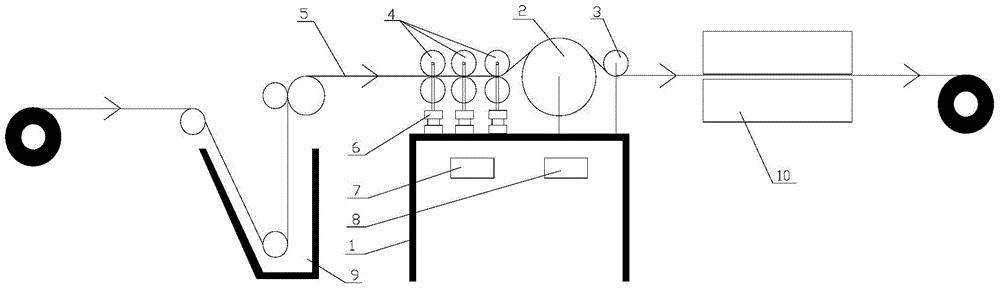

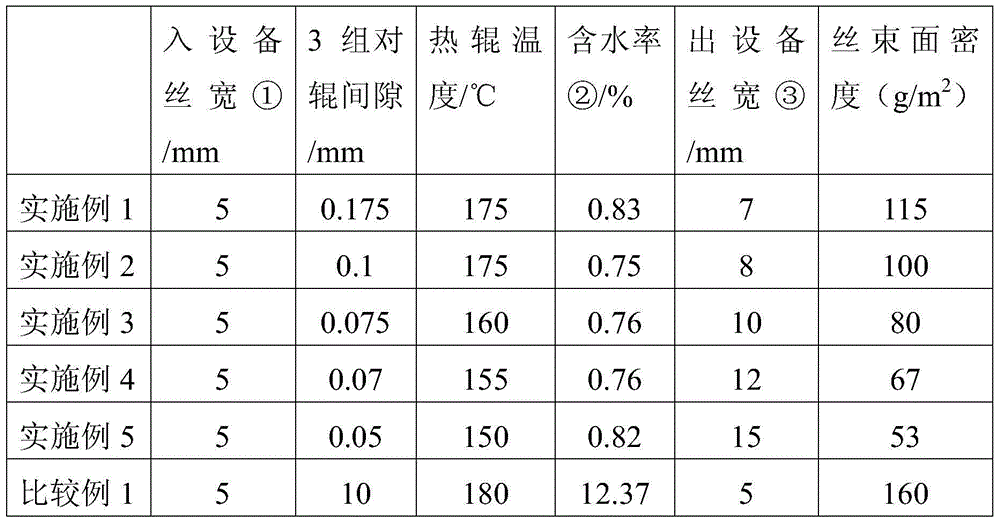

Splitting shaping device and splitting shaping method of ultrathin carbon fiber bundle

ActiveCN104674485AAchieve ultra-thinOnline continuous fastLiquid/gas/vapor removalTextile treatment machine arrangementsCarbon fibersFiber bundle

The invention discloses a splitting shaping device and a splitting shaping method of an ultrathin carbon fiber bundle. The splitting shaping device comprises a plurality of groups of filament spreading double-rollers, a heat roller and a levelness adjusting roller, which are sequentially arranged; each group of filament spreading double-rollers is provided with a hydraulic lifting machine, each hydraulic lifting machine is fixed on a support, two ends of the heat roller are fixedly connected to the support, and two ends of a rotating shaft of the levelness adjusting roller are also fixedly connected to the support; when the carbon fiber bundle is transported, the heat roller is fixed and does not rotate. The splitting and shaping method comprises the steps of enabling the carbon fiber bundle with serous fluid on the surface to sequentially pass through the filament spreading double-rollers, uniformly spreading the carbon fiber bundle under the extruding effect of the filament spreading double-rollers and the lubricating effect of the serous fluid, and pressing and flattening the fluctuated fibers in the carbon fiber bundle; enabling the carbon fiber bundle to pass through the heat roller, enabling the heat roller to be fixed and not to rotate, drying the carbon fiber bundle by virtue of the heat roller, and enabling the carbon fiber bundle to maintain the filament width after he carbon fiber bundle is spread. After the splitting shaping device and the splitting shaping method is applied to the carbon fiber production process, the ultrathin and online continuous and rapid production of the carbon fiber bundle can be realized, and the development of a downstream ultralight ultrathin product can be satisfied.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV +1

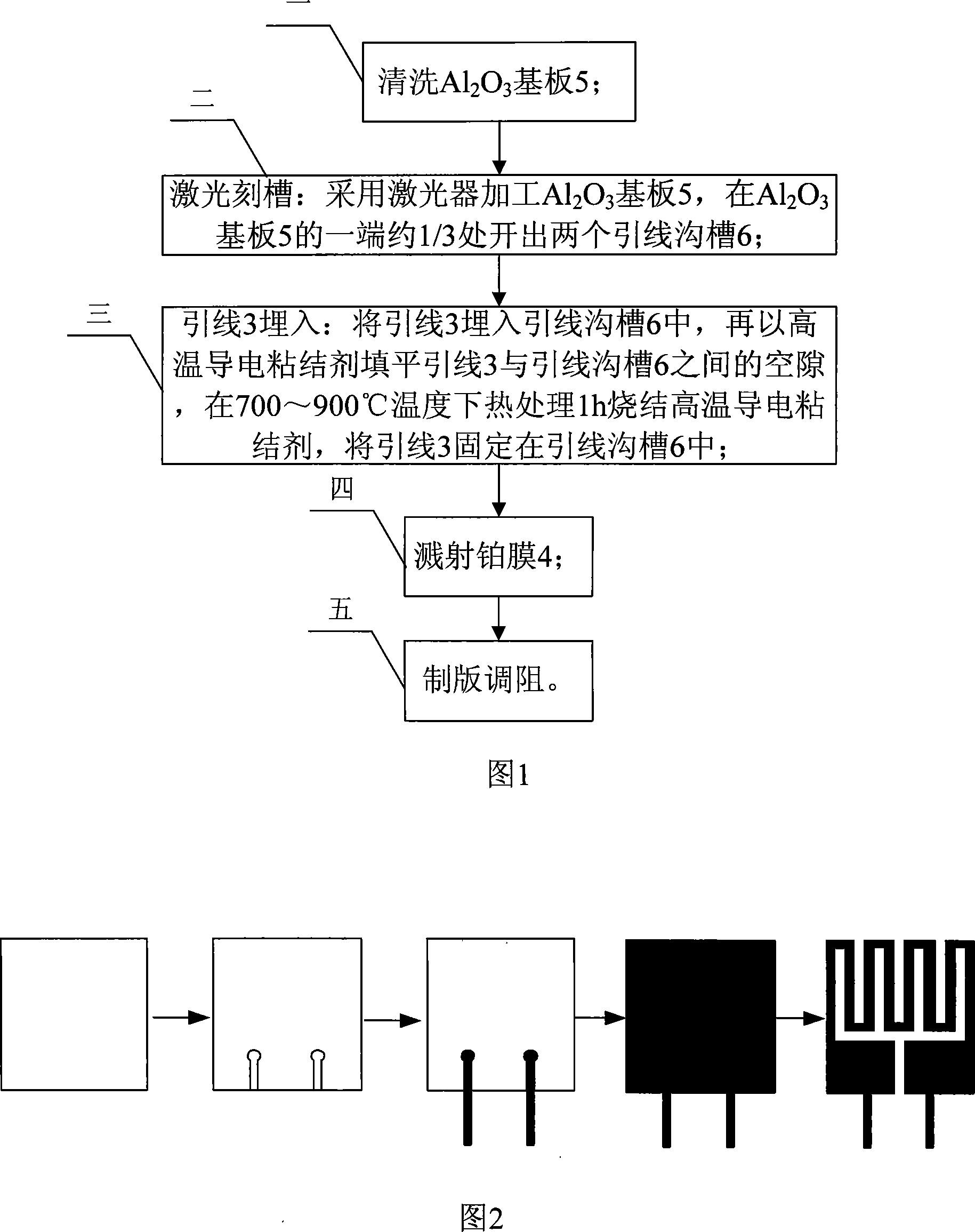

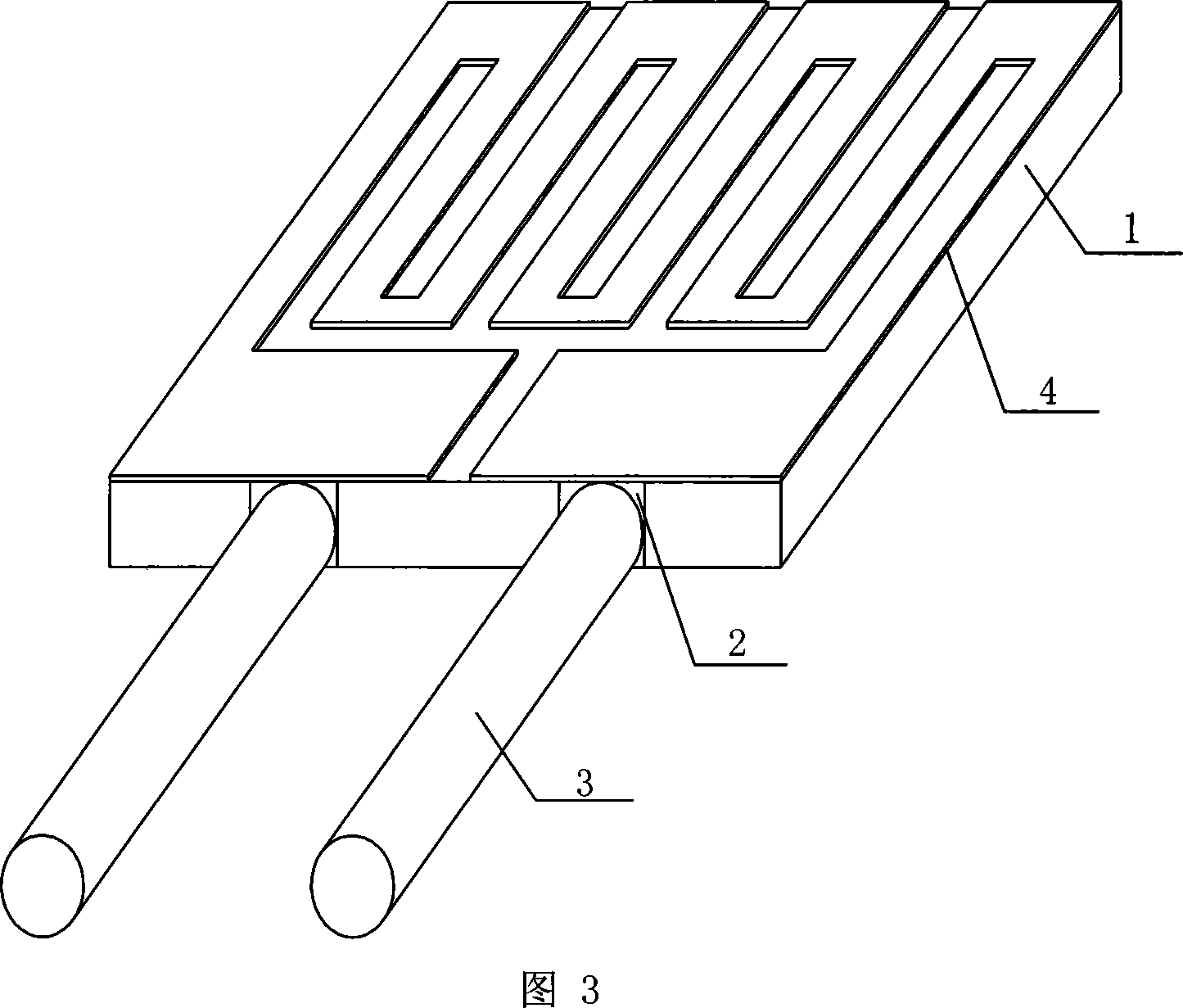

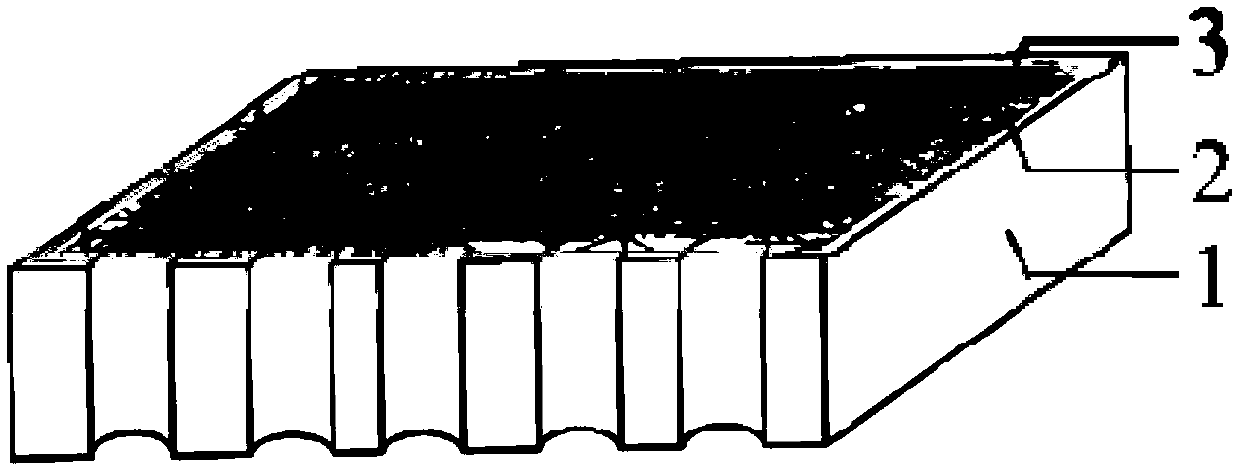

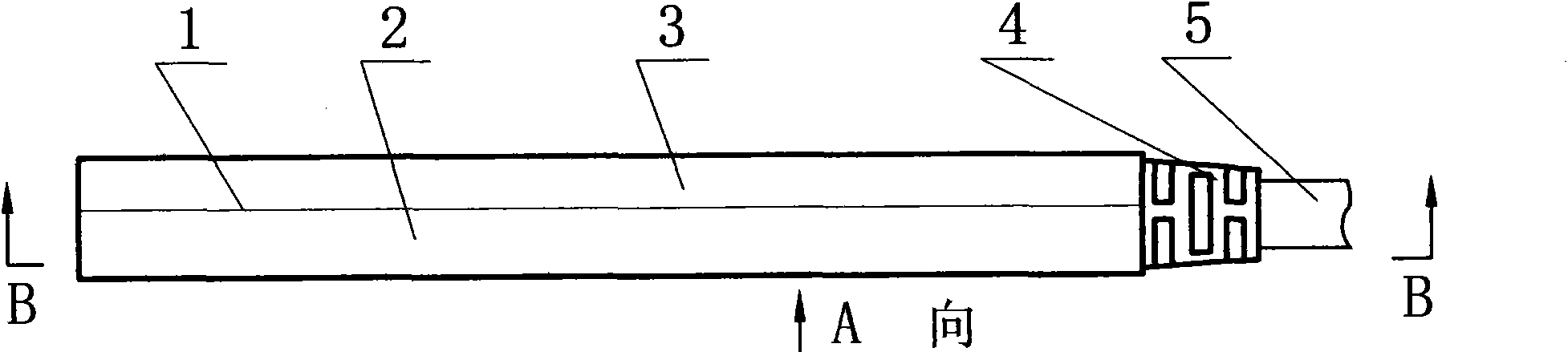

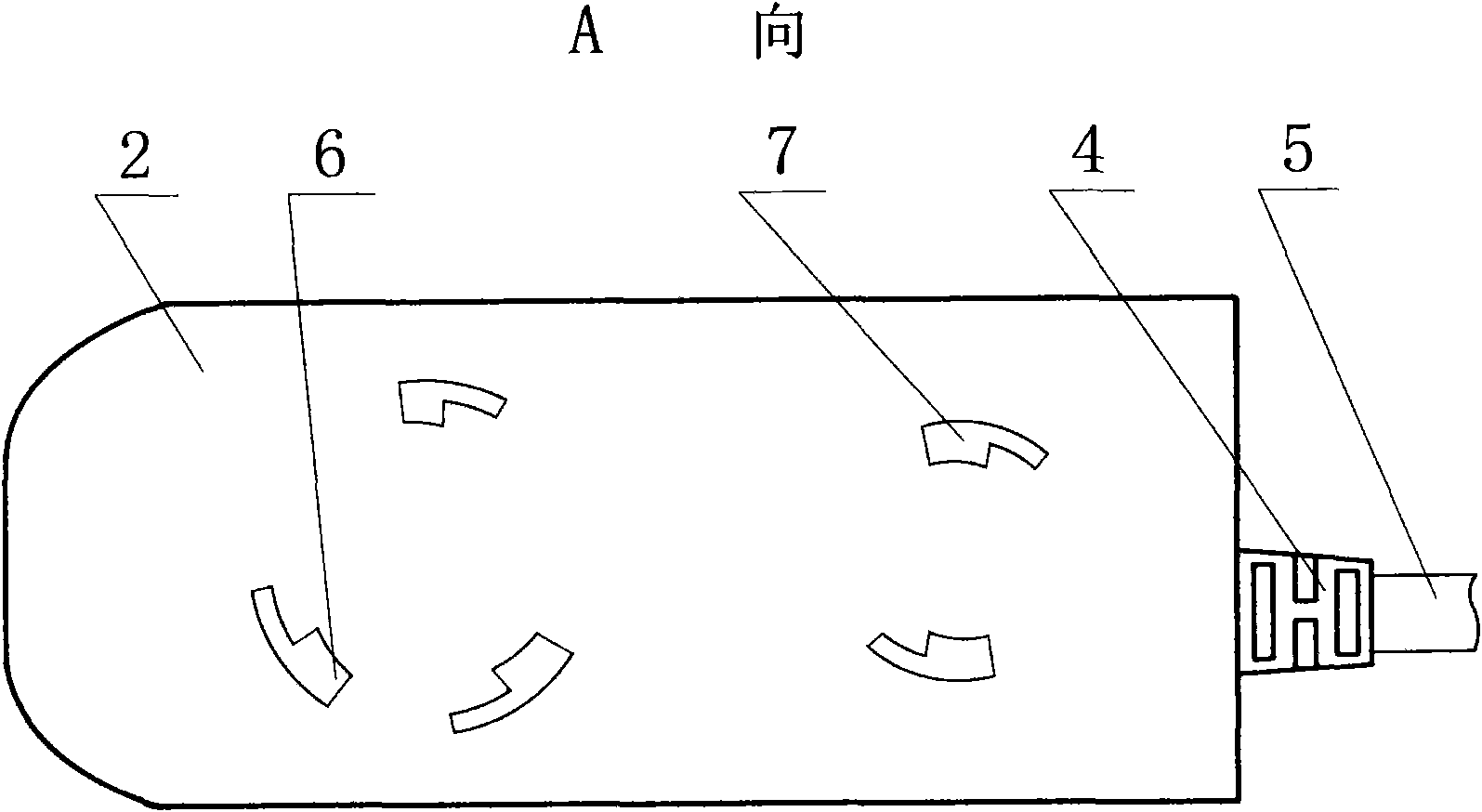

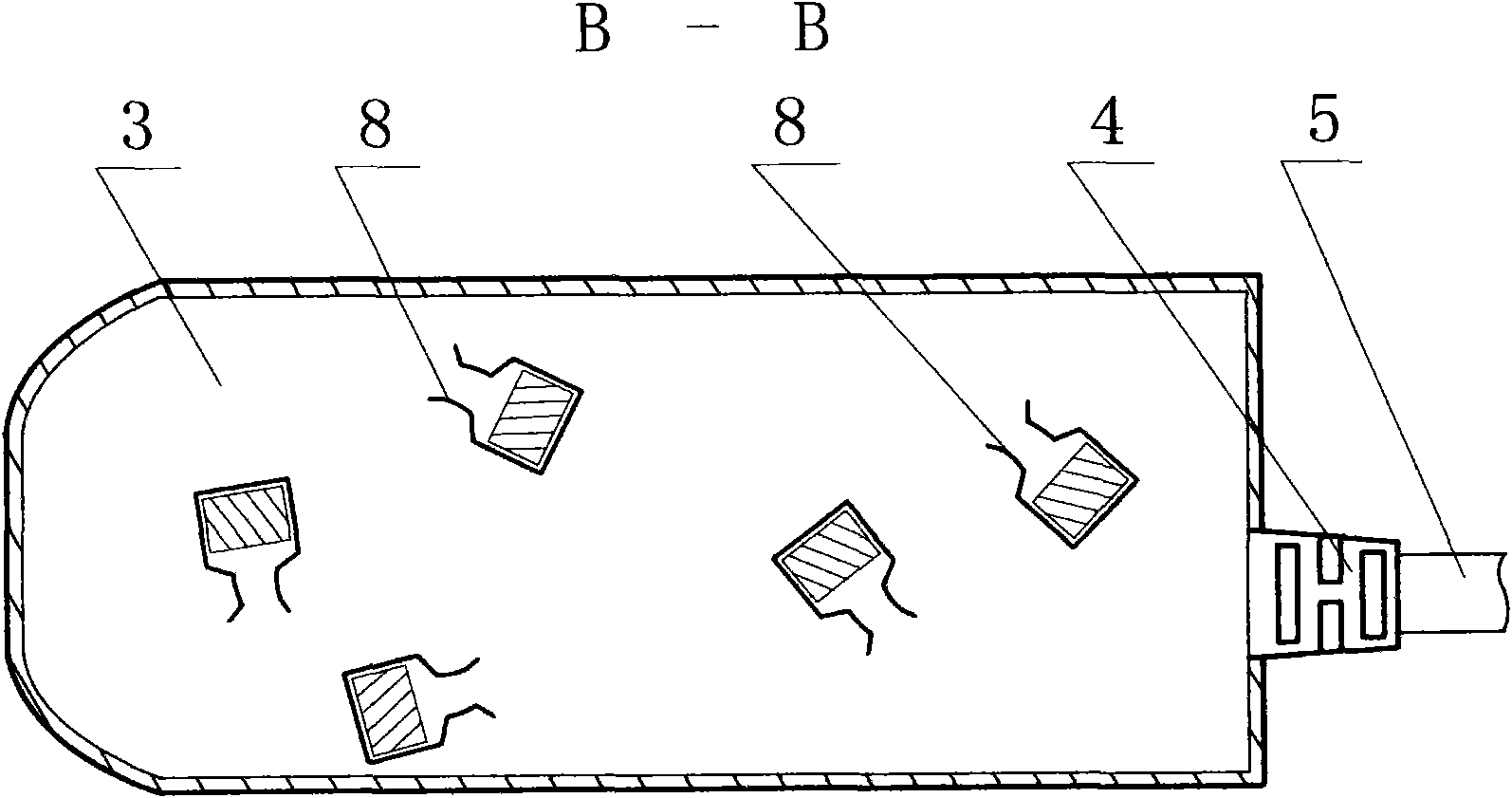

Inserting electrode lead-out method for micro platinum thermal resistance temperature sensor

InactiveCN101021442AAchieve microAchieve ultra-thinThermometers using electric/magnetic elementsUsing electrical meansPlatinumElectrical resistance and conductance

A method leads out electrode of micro-platinum thermo-resistance temperature sensor. In order to meet requirement of ultrathin body, its steps are: (1) Wash Al2O3 base plate<1>. (2) Laser notch: use laser to process <1> and open two electrode grooves <2> at 1 / 3 of its one end. (3) Electrode<3> embedment: embed <3> into <2> and fill slack between them with high-temperature conductive agglomerant. Heat treat the agglomerant under 700-900deg.C for 1h to fix <3> in <2>. (4) Sputter platinum film <4>. (5) Plate-making and resistance adjusting. In this invention, sensitive film surface smooth without tubercle, wiped joint of electrode can not add sensor thickness, which can realize detecting temperature information of micro-parts including slit, slip and micro-space etc. The invention realizes microminiaturization and ultrathin of platinum thermo-resistance temperature sensor. It has merits of simple technology and strong operation.

Owner:HARBIN UNIV OF SCI & TECH

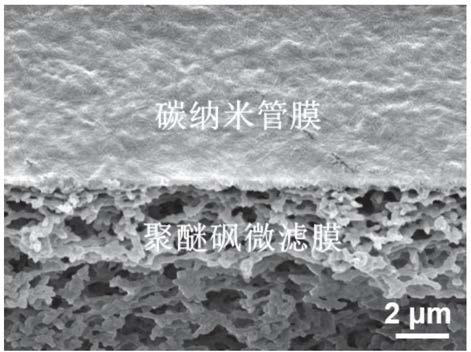

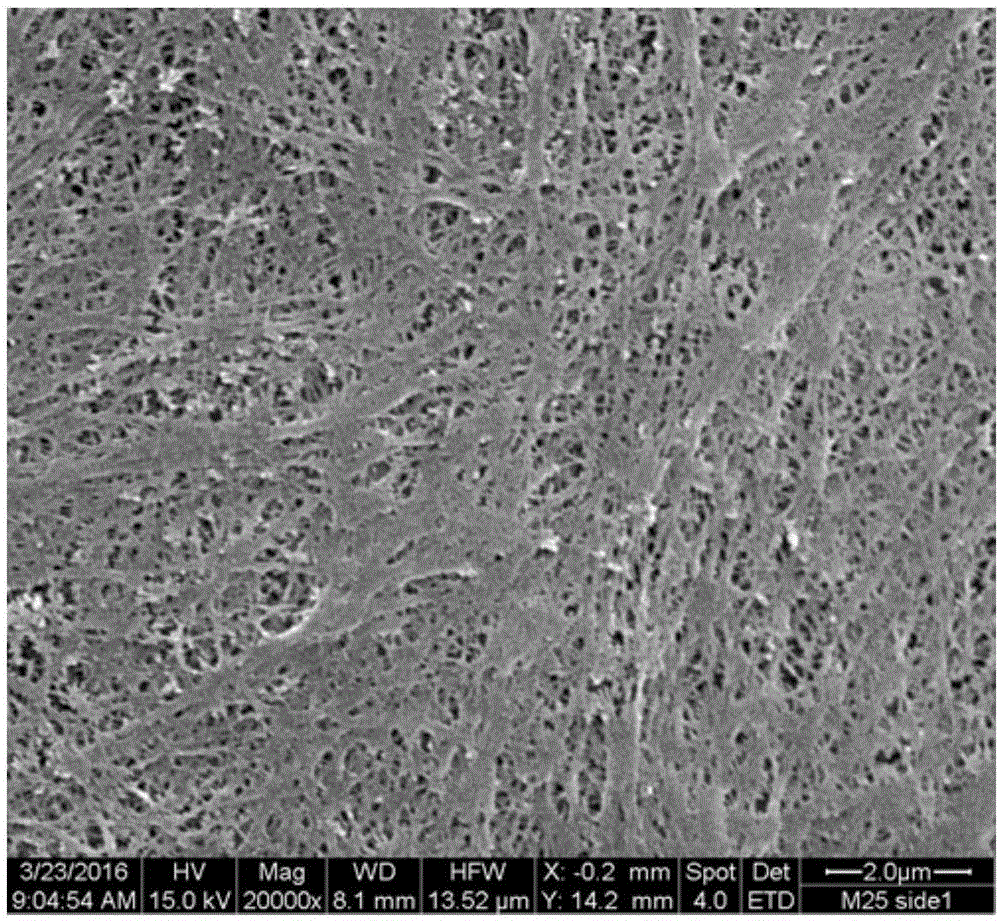

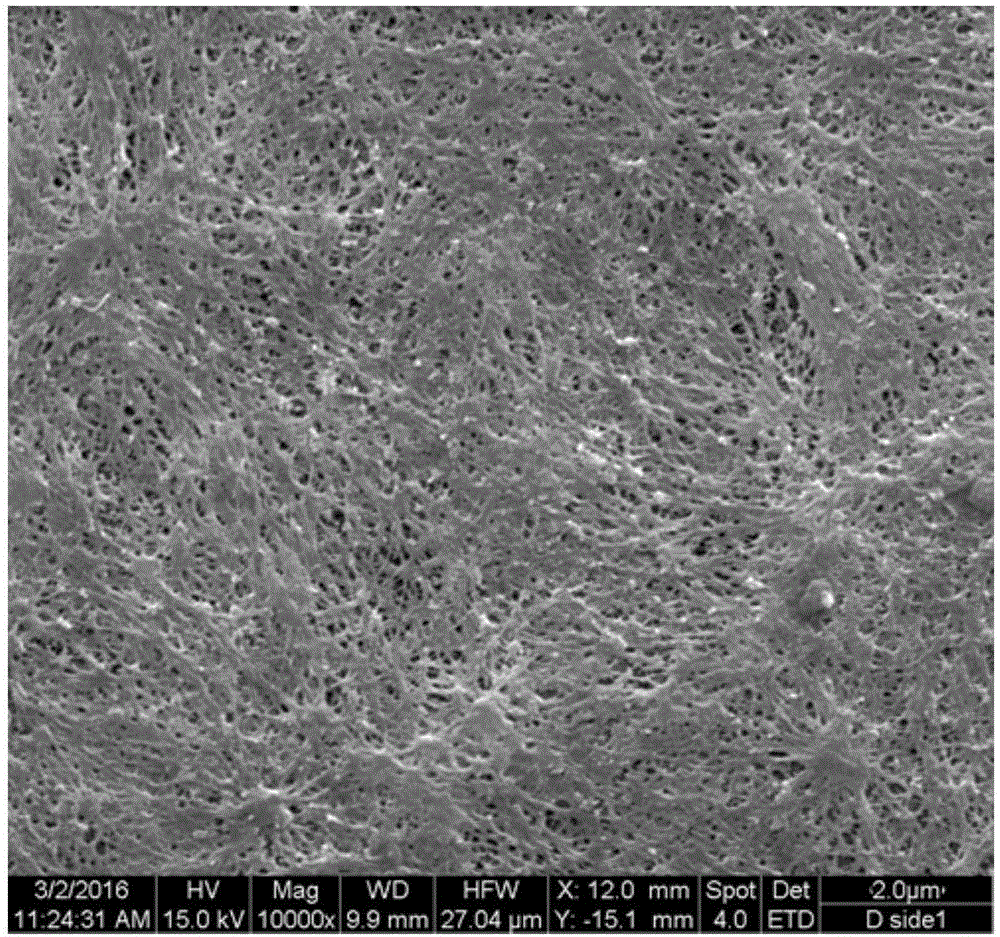

Reverse osmosis membrane, preparation method and application thereof

InactiveCN111214965AHigh porosityAchieve ultra-thinGeneral water supply conservationSeawater treatmentPolymer scienceCarbon nanotube

The invention discloses a reverse osmosis membrane, a preparation method and application thereof. The reverse osmosis membrane comprises a porous filter membrane supporting layer, a carbon nanotube membrane middle layer and a polyamide membrane selection layer which are arranged in sequence. According to the invention, the reverse osmosis membrane is a stable composite membrane integrating a porous filter membrane, a carbon nano tube membrane and a polyamide membrane, wherein the porous filter membrane serves as the substrate loaded by the carbon nano tube membrane and provides good mechanicalstrength, the carbon nano tube membrane has uniformly distributed nano-sized apertures and high porosity, and is used as a support for an interfacial polymerization reaction so as to achieve uniformdistribution of a monomer solution and controllable release of a monomer to prepare an ultrathin and high-quality polyamide membrane, and the polyamide membrane as a performance determination layer has the characteristic of ultra-thinness, and makes the novel reverse osmosis membrane have the flux far higher than that of the traditional reverse osmosis membrane while retaining the high rejection rate. According to the reverse osmosis membrane disclosed by the invention, the carbon nano tube membrane middle layer with uniformly distributed nano-sized apertures and high porosity is introduced for the first time, so that the performance is substantially improved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

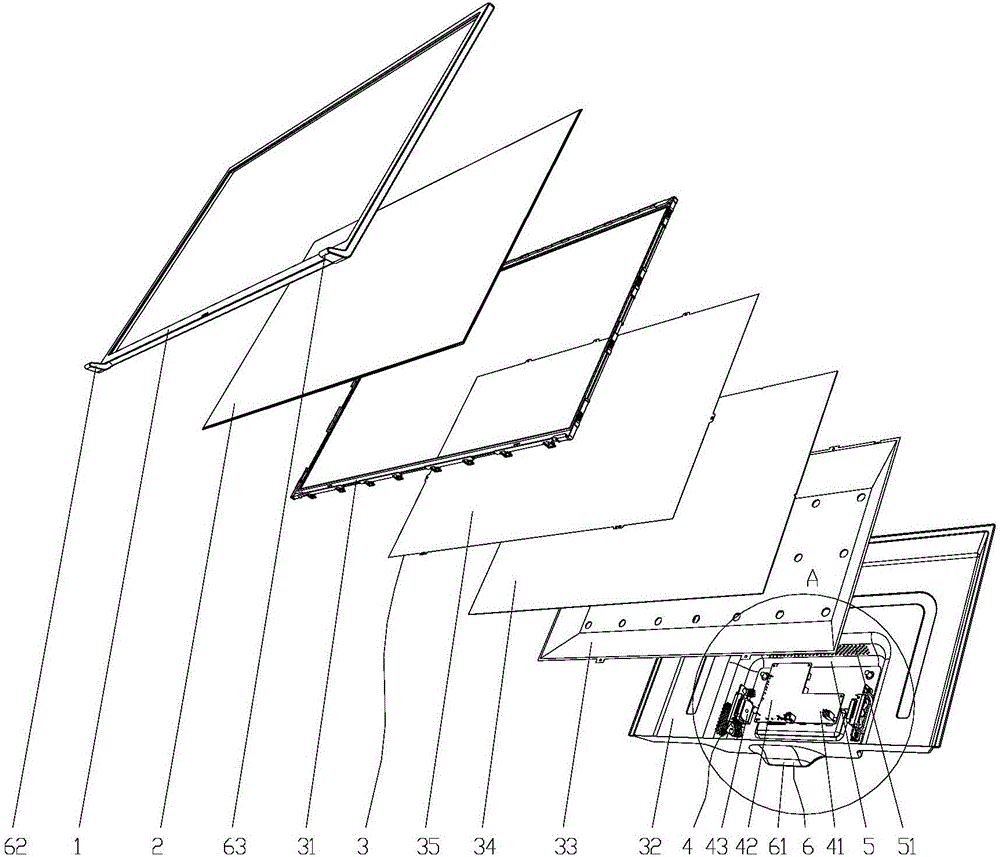

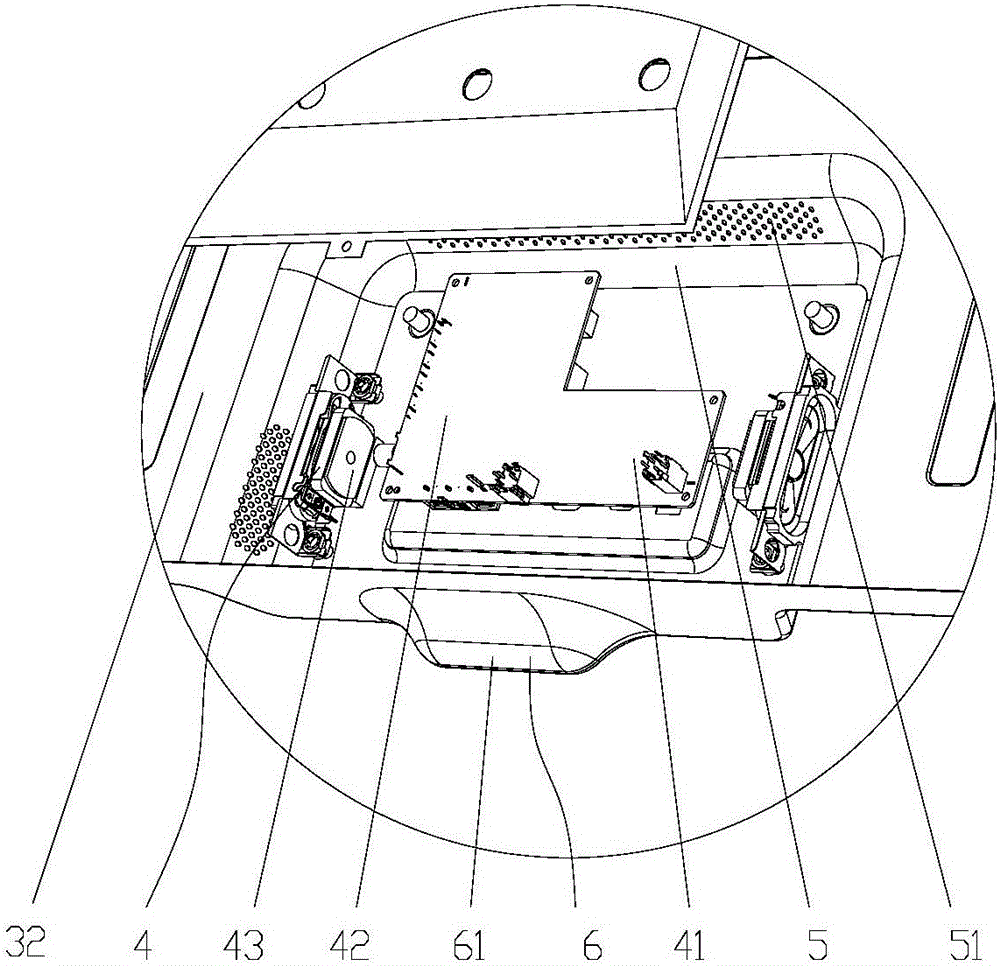

Integrated liquid-crystal display television

ActiveCN106454176AReduce thicknessImprove cooling effectTelevision system detailsColor television detailsEngineeringElectronic component

The present invention relates to an integrated liquid-crystal display television. The television comprises a front frame, a liquid crystal display panel, a backlight module and electronic elements. The backlight module comprises a middle frame and a back board. The middle frame is sheathed in the back board and is firmly connected with the back board so as to form an accommodation cavity. The accommodation cavity is internally provided with a backlight source, a reflective sheet, a diffusion board and an optical diagraph group. The front frame is sheathed at the periphery of the back board and is firmly connected with the back board. The liquid crystal display panel is clamped between the front frame and the middle frame. The electronic elements comprise a power supply board, a movement mainboard and a horn. A bulge is disposed in the inner side of the back board in a protruding manner. The bulge is provided with a plurality of through holes. The electronic elements are disposed in the bulge. A first support foot is integrated at the lower edge of the back board. A second support foot and a third support foot are integrated at the lower edge of the front frame. The first support foot, the second support foot and the third support foot form a base supporting the liquid-crystal display television. The integrated liquid-crystal display television has a simple and elegant structure and a novel appearance, is simple to assemble, has few steps, can be assembled efficiently, is low-cost, and is easy to be ultra-thin.

Owner:TPV DISPLAY TECH (XIAMEN) CO LTD

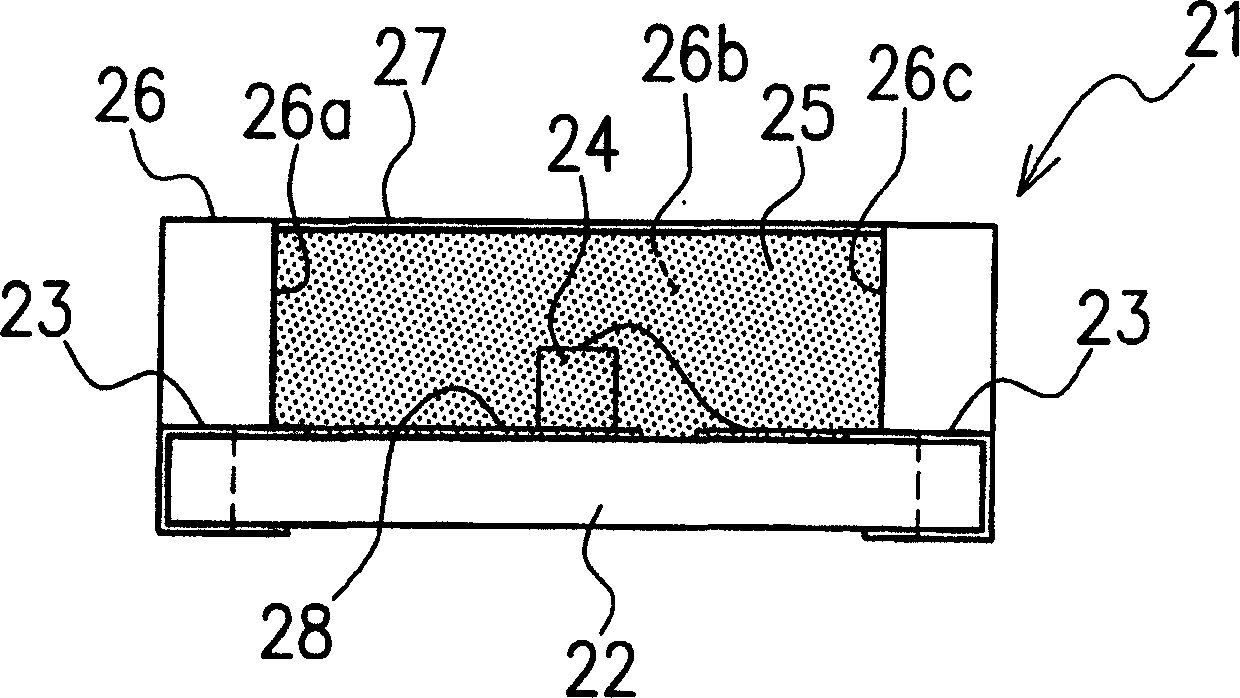

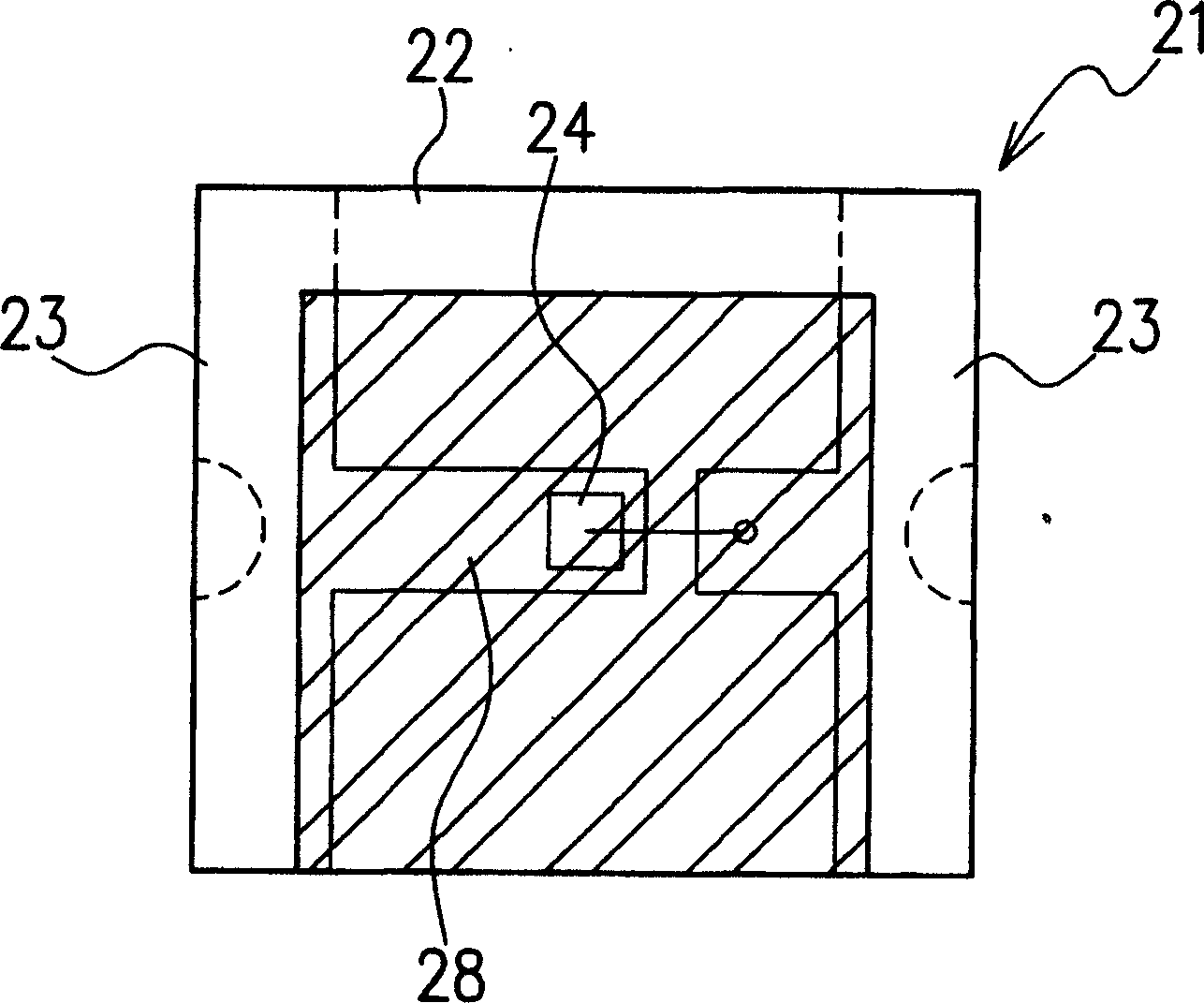

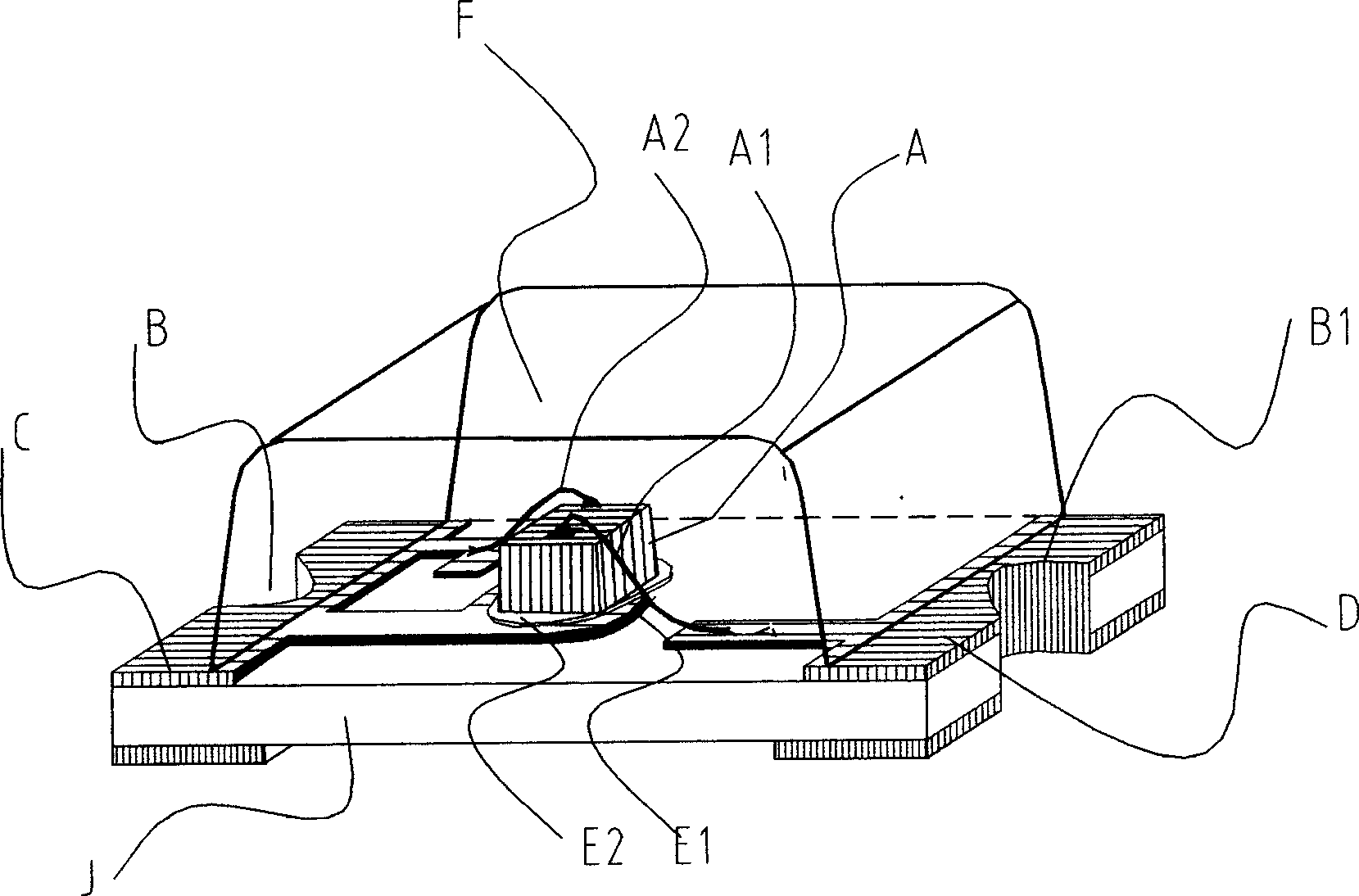

Light emitting diode

InactiveCN1652366AAchieve ultra-thinSolid-state devicesOptical light guidesSurface mountingEngineering

An LED comprises: a chip substrate formed with a die bond pattern and electrode terminals; an LED chip mounted on the chip substrate; a reflective frame arranged on the chip substrate to enclose a circumference of the LED chip and having an opening at a part of its side walls and on an upper surface; reflecting surfaces formed on inner circumferential surfaces of the side walls of the reflective frame; a light transmissive resin body formed in the reflective frame and using the opening in the side wall as a light emission face; and a reflecting film covering an upper surface of the light transmissive resin body exposed on an upper surface side of the reflective frame; wherein light produced by the LED chip is reflected by a reflecting surface of the refractive frame and by the reflecting film and is emitted outward from the light emission face. The side emission type LED of this construction can be reduced in thickness for surface mounting and can illuminate a small-width side surface of a liquid crystal panel with high efficiency.

Owner:CITIZEN ELECTRONICS CO LTD

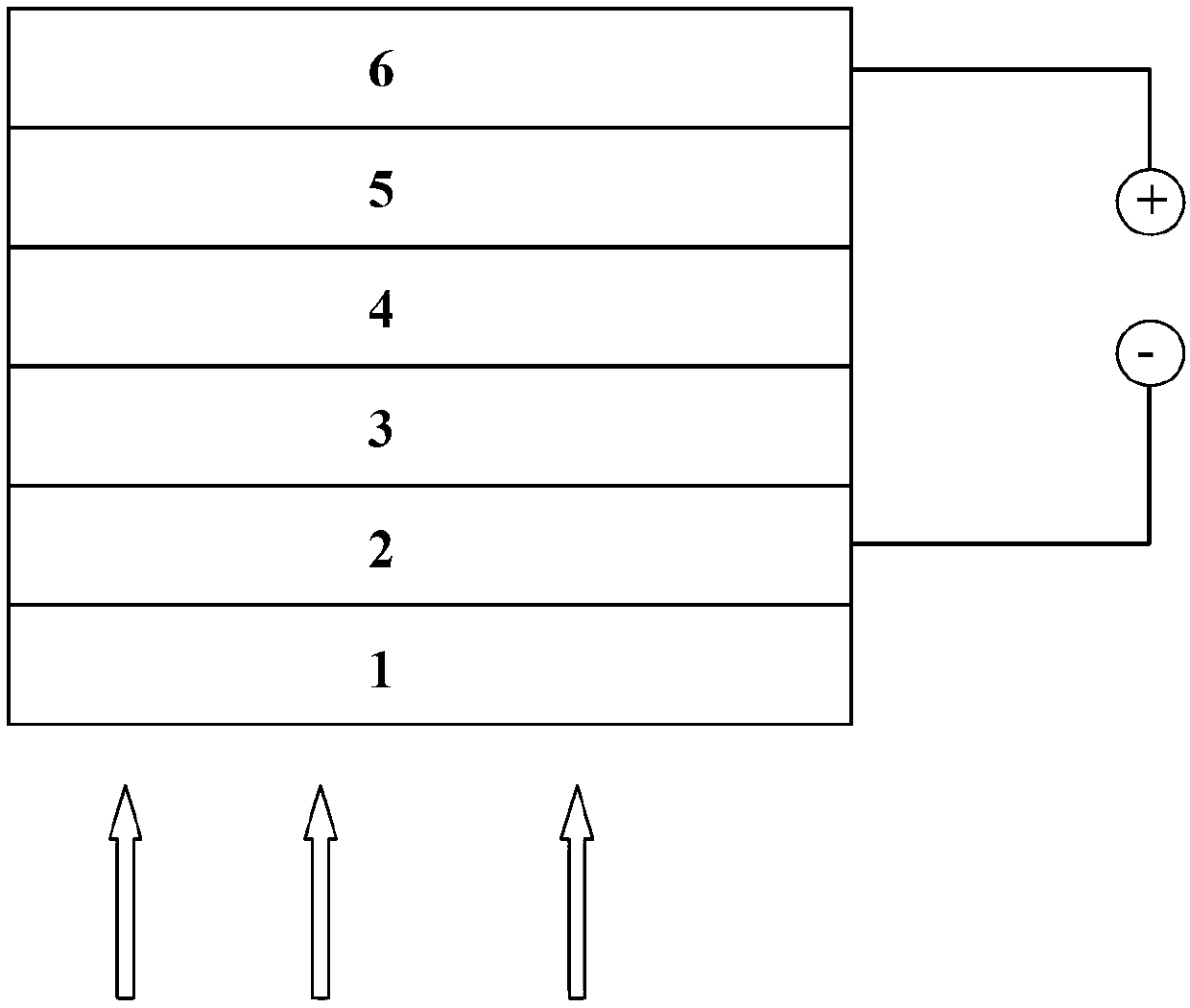

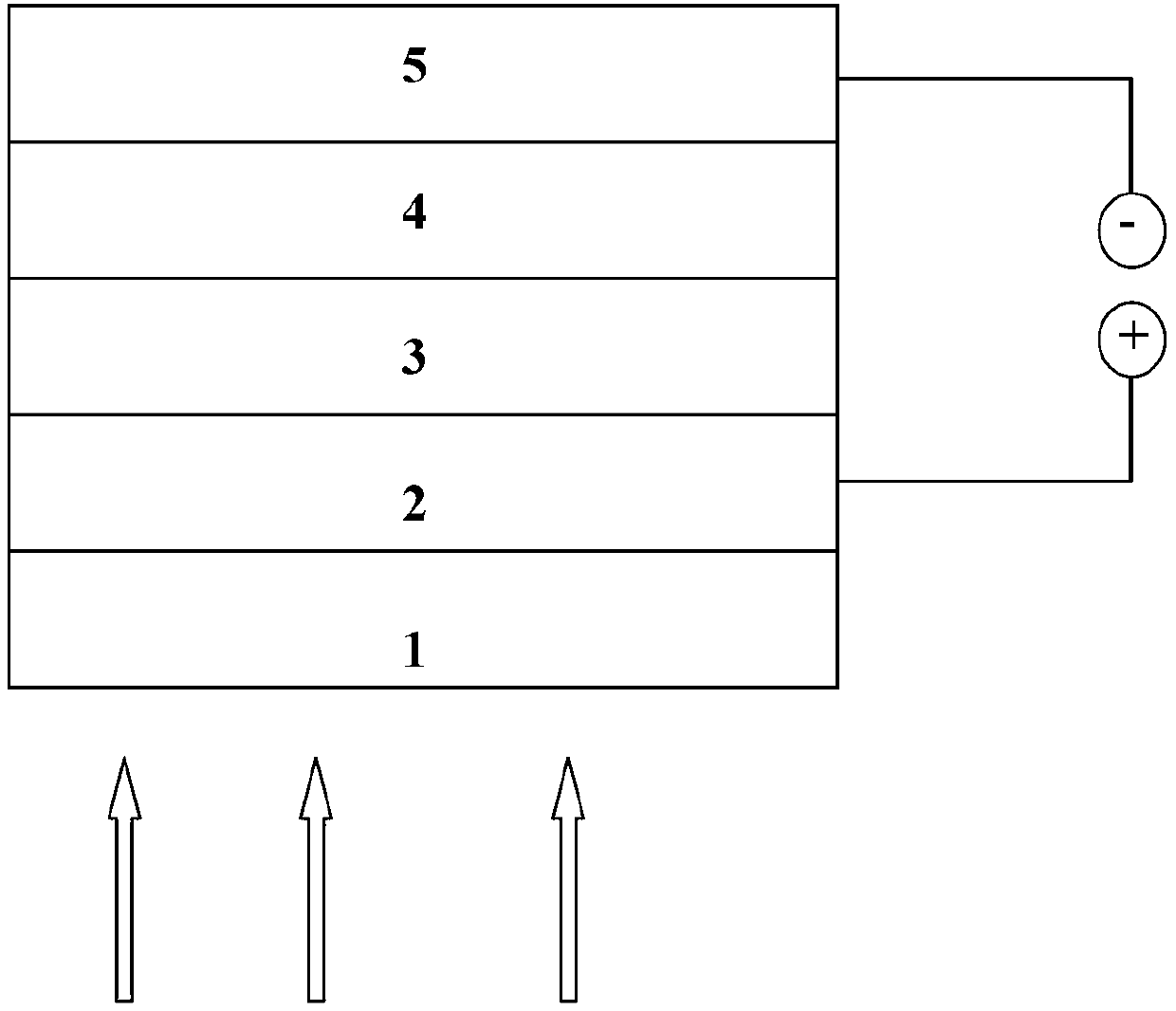

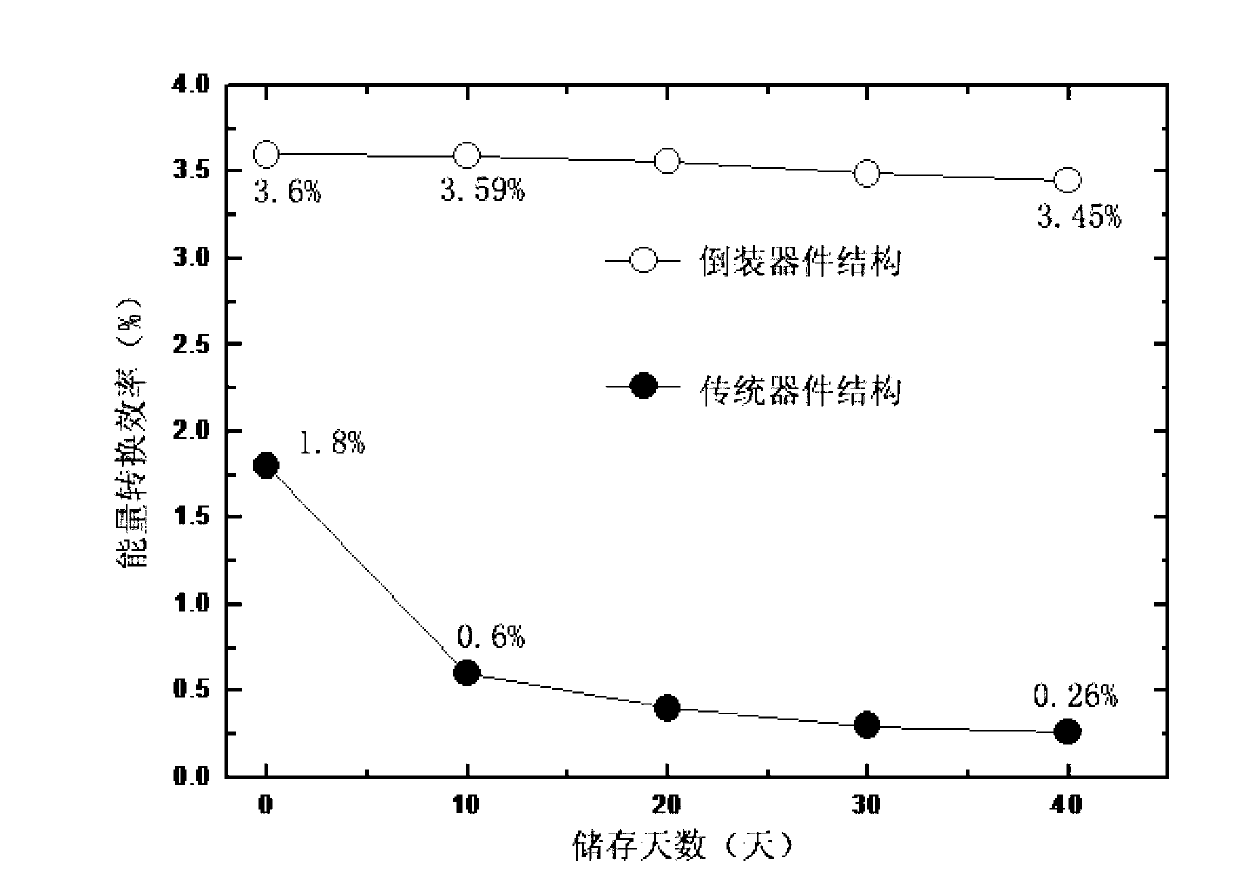

CdTe nanometer crystalline heterojunction solar battery and manufacturing method thereof

ActiveCN103346193AEfficient collectionEasy to separateFinal product manufacturePhotovoltaic energy generationHeterojunctionIndium tin oxide

The invention belongs to the field of photoelectric devices, and discloses a CdTe nanometer crystalline heterojunction solar battery and a manufacturing method of the CdTe nanometer crystalline heterojunction solar battery. The CdTe nanometer crystalline heterojunction solar battery is formed by a glass substrate, a negative electrode, a negative electrode interface layer, a window layer, an optical activity layer and a positive electrode in a sequentially stacked mode. The negative electrode interface layer is a ZnO film or a TiO2 film. The optical activity layer is composed of one or more CdTe nanometer crystalline layers. The negative electrode is at least one of an indium tin oxide conductive film, doped stannic oxide, a metal film and a metal oxide film. The window layer is a CdS film. The positive electrode is made of Ag or Al. A MoO3 oxidation film is arranged between the optical activity layer and the positive electrode. According to the CdTe nanometer crystalline heterojunction solar battery, the solution machining technology is used, the ultra-thin solar battery is achieved, the performance is excellent, and the energy conversion efficiency is as high as 3.73%.

Owner:SOUTH CHINA UNIV OF TECH

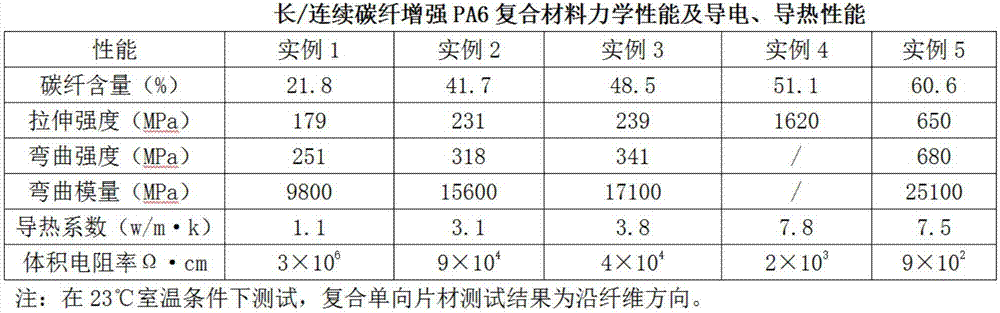

Continuous carbon fiber-reinforced PA6 composite with high strength, high modulus, electrical conductivity and thermal conductivity, and preparation method thereof

InactiveCN106939124AImprove conductivityHigh thermal conductivityHeat-exchange elementsFiberCarbon fibers

The invention relates to a continuous carbon fiber-reinforced PA6 composite with high strength, high modulus, electrical conductivity and thermal conductivity, and a preparation method thereof. The composite comprises, by weight, (1) 100 parts of PA6 resin, (2) 0.2 to 1 part of an anti-oxidant, (3) 0.2 to 1.2 parts of a flow promoter, (4) 2 to 10 parts of a flexibilizer and (5) 1 to 5 parts of a compatilizer. The preparation method comprises the following steps: premixing the above components according to a certain ratio, carrying out melting and mixing via a double / single-screw set and then extruding the obtained mixture into a die head for flow splitting and impregnation so as to prepare the continuous carbon fiber-reinforced PA6 composite with high strength, high modulus, electrical conductivity and thermal conductivity. Compared with conventional staple carbon fiber-reinforced PA6 composites, the continuous carbon fiber-reinforced PA6 composite prepared by using a special impregnation process in the invention has greatly improved mechanical properties since the length retention rate of carbon fibers in a PA6 carrier is high or continuous and has substantially improved electrical conductivity and thermal conductivity due to a continuous network structure, so the application range of the composite is greatly broadened.

Owner:浙江胜钢新材料有限公司

Surface deformation distribution test sensing element

InactiveCN102305587AAchieve ultra-thinStrain sensitiveElectrical/magnetic solid deformation measurementElectrical resistance and conductanceInsulation layer

The invention discloses a surface deformation distribution test sensing element which comprises a flexible sensing thin film, electrodes arranged at the periphery of the flexible sensing thin film uniformly at intervals, lead wires which are connected with the electrodes, an upper flexible insulation layer and a lower flexible insulation layer. Composite materials with strain sensitivity characteristics are utilized to prepare the flexible sensing thin film; and the electrodes and the lead wires are used for outputting specific resistivity information at different positions of the flexible sensing thin film. When in test, the lead wires and a testing instrument are connected; collection test and calculation are carried out by utilizing the electrical impedance imaging technology, the specific resistivity distribution at different positions of the flexible sensing thin film is obtained, and the strain size distribution is obtained through the specific relationship between the strain size of the sensing thin film and the size of the specific resistivity again. The test of two-dimensional deformation field quantity can be realized by the sensing element disclosed by the invention, and the sensing element has the characteristics of simple and ultrathin structure, flexibility, high resolution ratio and precision, great strain range and low cost.

Owner:CHINA UNIV OF MINING & TECH

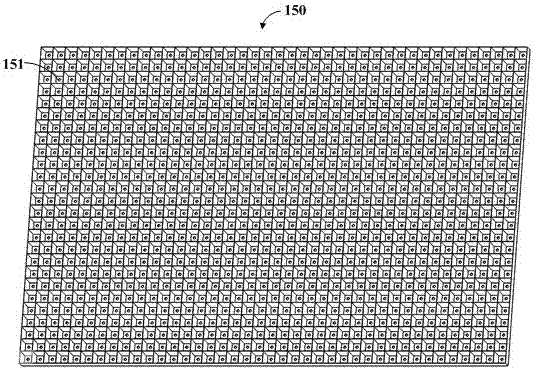

Collimating film and preparation method of collimating film

The invention relates to a collimating film, in particular to a collimating film in the field of image recognition and a preparation method of the collimating film. In order to solve the problem that two layers of collimating diaphragms in a traditional rigid collimating sheet are difficult to align, the invention provides a collimating film and a preparation method of the collimating film. The collimating film sequentially comprises a collimating lens layer, a flexible substrate layer and a collimating hole layer; the collimating lens layer comprises a micro-lens array and a lens layer, and the collimating hole layer comprises a collimating hole array; the distribution of the collimation hole array is completely consistent with that of the micro-lens array; and the micro lens arrays of the collimating lens layer are arranged in order. The collimating film provided by the invention only comprises one collimating hole layer, so that the problem that two collimating diaphragms are difficult to align is solved. The collimating film can collimate and filter diffused light at a single-point pixel of an image to a certain extent to form a normal small-beam optical signal, transmits the normal small-beam optical signal to a corresponding photoelectric sensor, and is particularly suitable for a large-size, ultrathin and even flexible image recognition module.

Owner:NINGBO EXCITON TECH

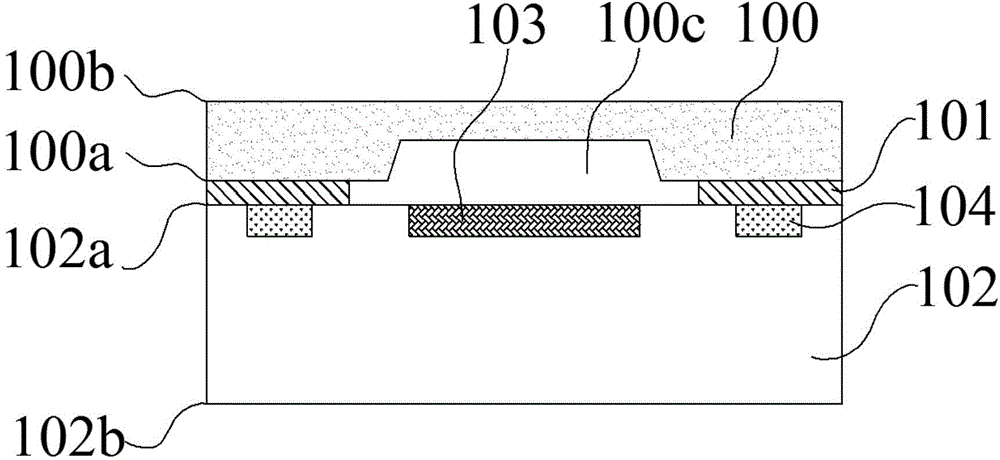

Low-thickness and low-cost chip size package with cavity

InactiveCN104409422AImprove reliabilityReduce thicknessTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesRedistribution layerChip size

The invention discloses a low-thickness and low-cost chip size package with a cavity, and belongs to the field of packaging of semiconductors. The package structure comprises a cover plate, a wafer, a function region, bonding pads, bonding glue, silicon through holes, a redistribution circuit layer and a solder ball, wherein a cavity structure is formed in the front surface of the cover plate; the wafer comprises a wafer front surface and a wafer back surface; the function region and the bonding pads are distributed on the wafer front surface; the bonding pads are distributed on the periphery of the function region and are communicated with one another; the bonding glue is positioned between the cover plate and the wafer; the cover plate and the wafer are bonded together by the bonding glue; the bonding pads are exposed via the silicon through holes, so that the bonding pads are communicated with the a follow-up redistribution layer; the redistribution circuit layer is positioned on the wafer back surface and comprises a passivation layer, a metal layer and a solder layer; the bonding pads are communicated with the solder ball via the redistribution circuit layer; and the solder ball is positioned on the redistribution circuit layer of the wafer back surface. The thickness of the package is reduced, and the stress in the structure is also reduced. Moreover, the yield of a cutting process and the reliability of the package are improved.

Owner:BEIJING UNIV OF TECH

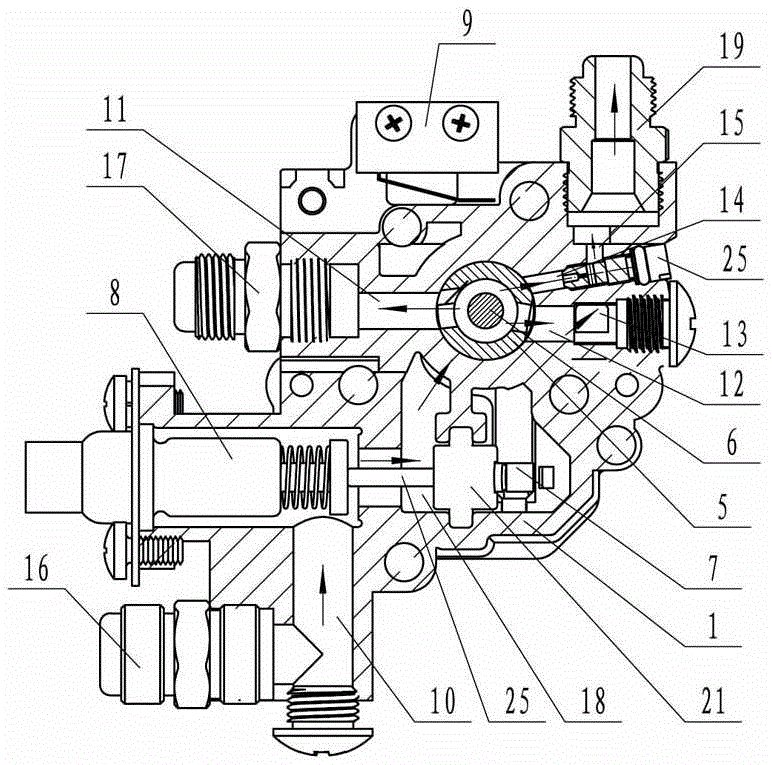

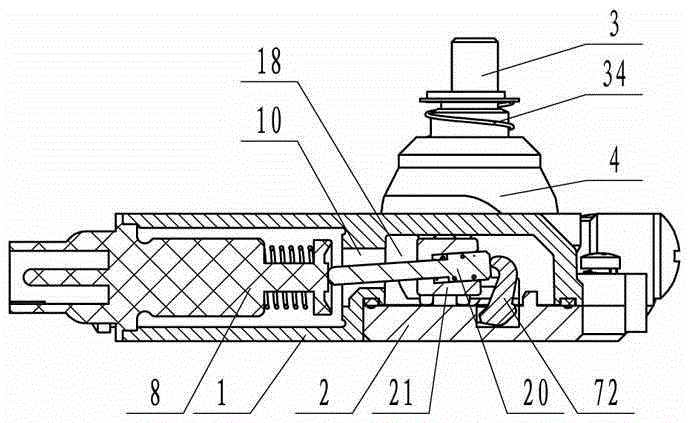

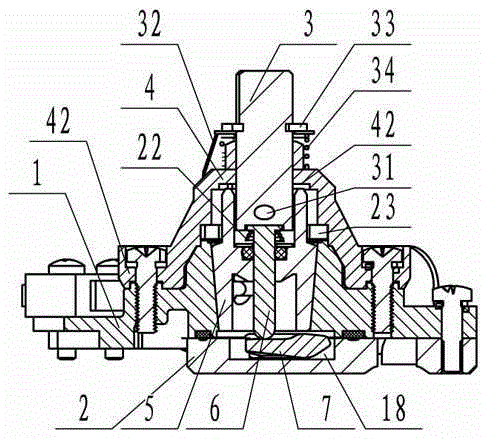

Ultrathin fuel gas plug valve

ActiveCN105402429AReduce thicknessReasonable airway distributionPlug valvesDomestic stoves or rangesPlug valveEngineering

The invention discloses an ultrathin fuel gas plug valve. The ultrathin fuel gas plug valve comprises a valve seat, a valve bottom cover, a valve rod, an upper cover, a valve core, a gas inlet channel and a gas outlet channel. The gas inlet channel and the gas outlet channel are located on the same horizontal plane, and a gas inlet connector connected to the gas inlet channel and a gas outlet connector connected to the gas outlet channel are located on the same horizontal plane as well. The thickness of the valve seat is the sum of the outer diameter of the gas inlet channel and the necessary structural wall thickness. According to the ultrathin fuel gas plug valve, the thickness of the valve seat is reduced to the maximum degree. The ultrathin fuel gas plug valve can be applied to fuel gas stoves and is especially suitable for ultrathin fuel gas stoves.

Owner:HUNAN XUNDA JI TUAN YOU XIAN GONG SI

Lithium battery composite membrane and preparation method thereof

InactiveCN106299220AAchieve lightweightHigh densityMaterial nanotechnologyCell component detailsHigh energyThermal stability

The invention discloses a lithium battery composite membrane which is formed by coating a porous base membrane with nano sol and then drying the sol. The lithium battery composite membrane has the following performances: the surface density is 10.04-12.70g / m<2>, the thickness is 15.3-16.6 microns, and the gas permeability is 140-696s / 100cc. If the discharged membrane is put into an oven, the temperature is set to be 105 DEG C or 130 DEG C and the set temperature is kept for one hour, the thermal shrinkage rate is 2.5-3.5 105 DEG C / TD, 2.5-3.0 105 DEG C / MD and 3.3-10 130 DEG C / TD, and 3.5-8.5 130 DEG C / MD. The composite membrane consists of the porous base membrane and an inorganic material high-temperature coating coated between the surface and holes of the base membrane, has good thermal stability, good quality and less thickness increase, can be used for preparing high-energy density lithium batteries and also has the characteristics of simple preparation process, low cost and the like.

Owner:SHANGHAI SHUANGAO ENERGY TECH

Rotary contact socket and plug

InactiveCN102655289AReduce space occupationIncrease contact surfaceCoupling contact membersTwo-part coupling devicesElectrical and Electronics engineeringElectrode

The invention relates to rotary contact socket and plug. A three-pole jack slide and a two-pole jack slide are arranged on a socket front housing, each jack slide comprises a jack and a narrow slide which are communicated, a horizontal electrode clamping spring is fixed in the front shell, and a rear cover is fixed on the front shell to form a housing. A three-pole cascade insert, a three-pole power lead jacket and a three-pole power lead are fixed on a three-pole plug; and a two-pole cascade insert, a two-pole power lead jacket and a two-pole power lead are fixed on the plug II. According to the rotary contact socket and plug, under the condition of reaching the rated load of the traditional socket and plug, the ultrathin structure is realized; after the pug is inserted into the socket, the plug is locked with the socket, the plug can not be vertically pulled out, no shaking exists between the socket and the plug, so that the socket and the plug can keep better contact for a long time; and the rotary contact socket and plug are safe in use and convenient for operation.

Owner:侯永昌

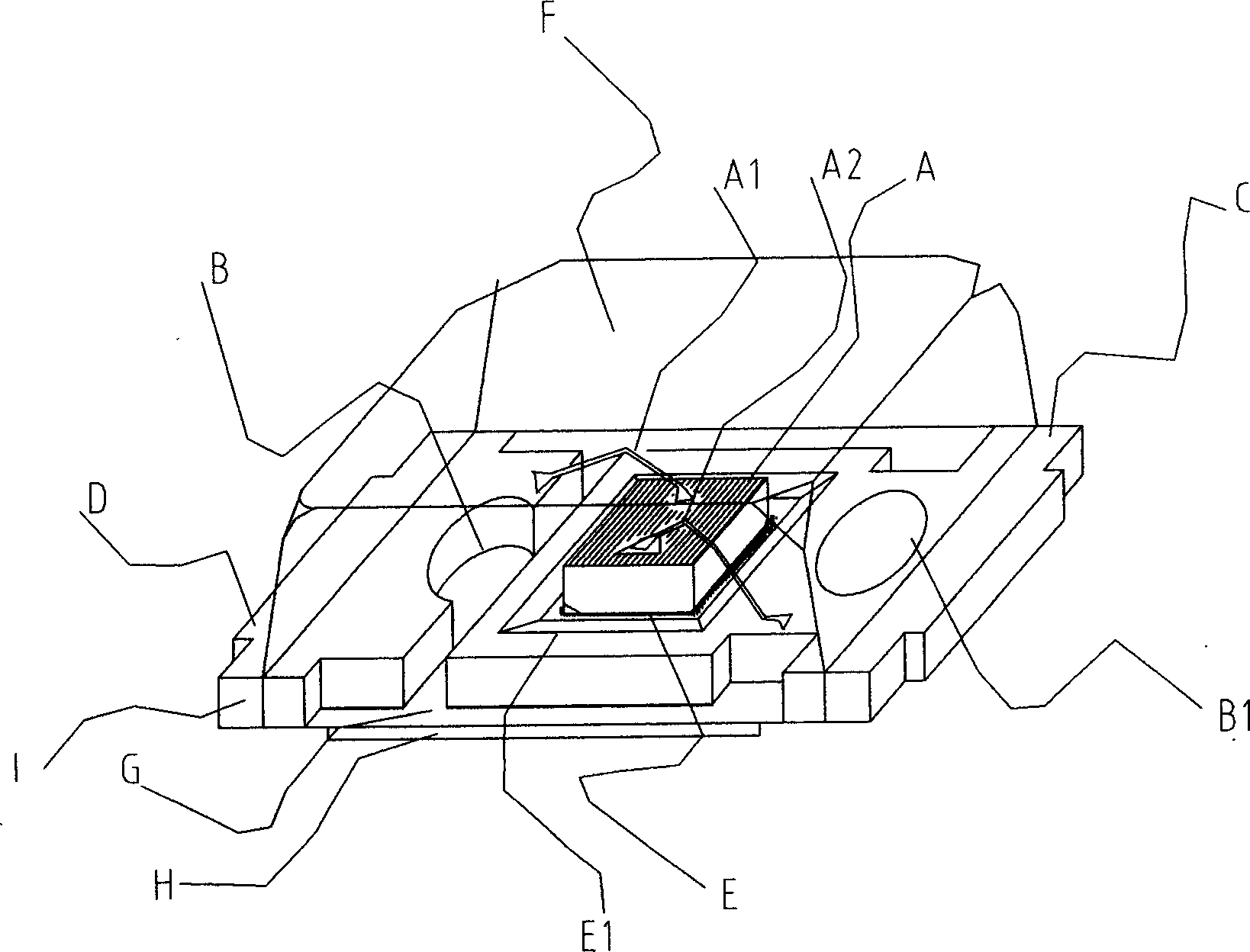

High-brightness ultrathin light semiconductor device

InactiveCN1489224AIncrease brightnessAvoid short circuit (Short) phenomenonSolid-state devicesSemiconductor devicesHigh reflectivityThermal shock

LED chip (A) (InGan / GaN) is glued on Die PAD CUP of lead frame by using insulated transparent chip adhesive (E) (UV Cure). Light beam in inverse direction emitted by LED passing through insulated transparent epoxy resin adhesive is reflected back by Die PAD CUP with high reflectivity Ag being coated. Thus, much light-beam is in the direction wanted so as to obtain microminiature LED with higher brightness. Moreover, the invention also reduces stress caused by thermal shock.

Owner:陈洪花

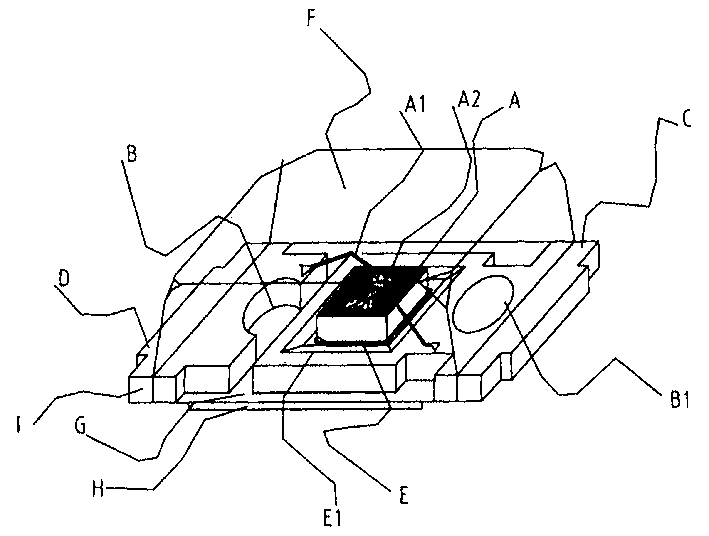

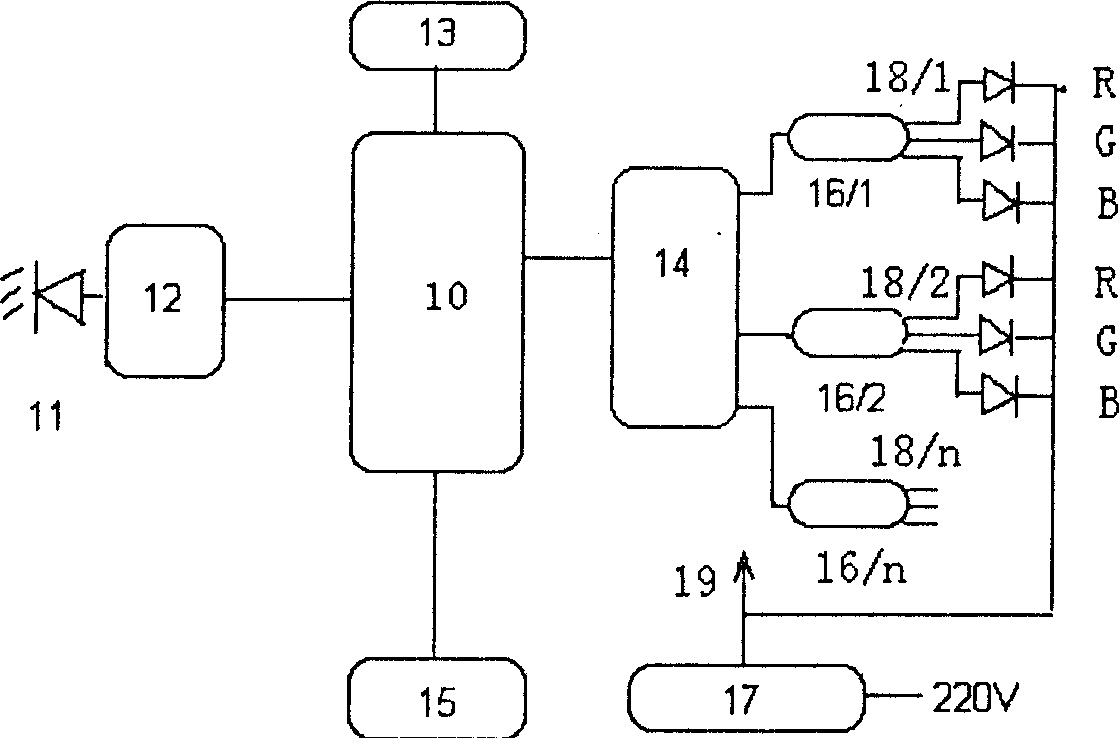

High power LED two-dimension light source

InactiveCN101097973AReduce volumeSimplify the manufacturing processSemiconductor devicesSilver plateEffect light

The invention provides a high-power LED two-dimension light source, wherein an aluminum-base printed circuit board is directly welded or adhered with a high-power LED chip, the chip welded area is processed with a bowl-shape concave which circumference is furnished and plated with silver to form a light reflective area, the chip is arranged with a light reflective bowl with silver plated at inner surface to be fixed on the aluminum-base circuit board, a chip light outlet is packed with silicon-type transparent resin, in curvature shape, the light reflective bowl is covered with a lens unit, arranged with an electric connecting structure. The invention can be used to produce mono product or multiple beamed product, with standard distance connecting port, surface light source with low cost and high integration, better heat radiation, and uniform lighting effect, which can be used as general semi-conductor lighting source of variable lamps.

Owner:NANJING HANDSON SCI & TECH CORP

Remote control method of LED decorative illuminating light

InactiveCN1909008ARealize digital controlReduce volumeNon-electrical signal transmission systemsElectric light circuit arrangementInfraredControl manner

The related control method for LED used as decorative lighting lamp comprises: applying IR technology to remote control the LED, using MCU or ASIC to code or random control signal, arranging an external analog electric signal input interface and pre-set remote control coding data memory, using embedded-MPU to receive signal and generate digital PWC signal to control RGB current of every LED. This invention is benefit to build individual dynamic lighting atmosphere.

Owner:NANJING HANDSON SCI & TECH CORP

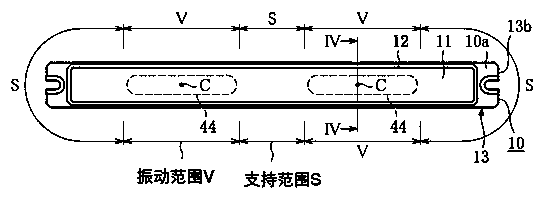

Flat horn

ActiveCN103618979AUnbalanced controlAchieve ultra-thinPlane diaphragmsFrequency/directions obtaining arrangementsVibrating membraneSound wave

The invention relates to a flat horn including a supporting framework. The flat horn is characterized in that at least one sounding unit is disposed along the axial direction of the supporting framework; each the sounding unit is composed of a plane vibrating membrane emitting sound waves through vibration, a frame body mounted along the periphery of the plane vibrating membrane, and a drive device driving the plane vibrating membrane according to a sound signal; and two side edges of an open groove disposed in the supporting framework respectively have a non-contact space, each the non-contact space is a corner cut disposed in the bottom, along an outside edge, of the open groove disposed in the supporting framework, and the frame body mounted along the periphery of the plane vibrating membrane is adhered to the open groove disposed in the supporting framework. The flat horn has good output frequency characteristic, can achieve an ultrathin structure in condition of large input power, and the sound propagation has the directional property of being forward.

Owner:谭菊花

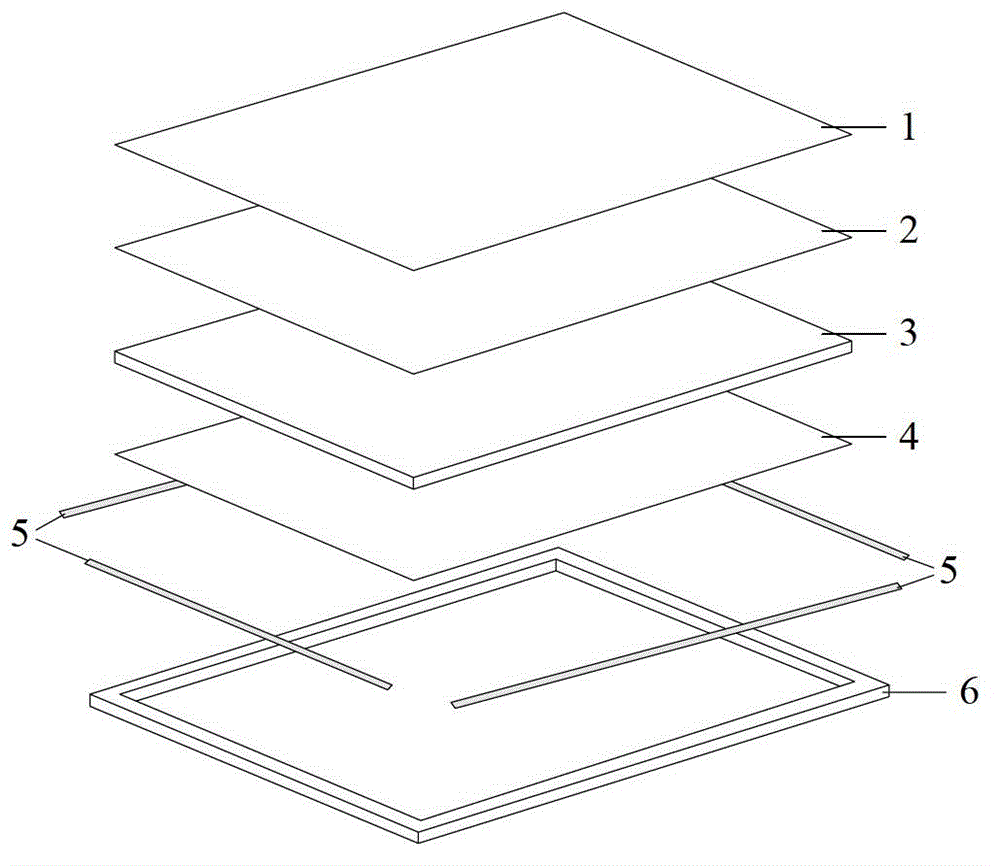

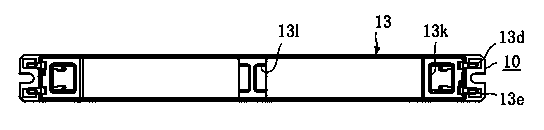

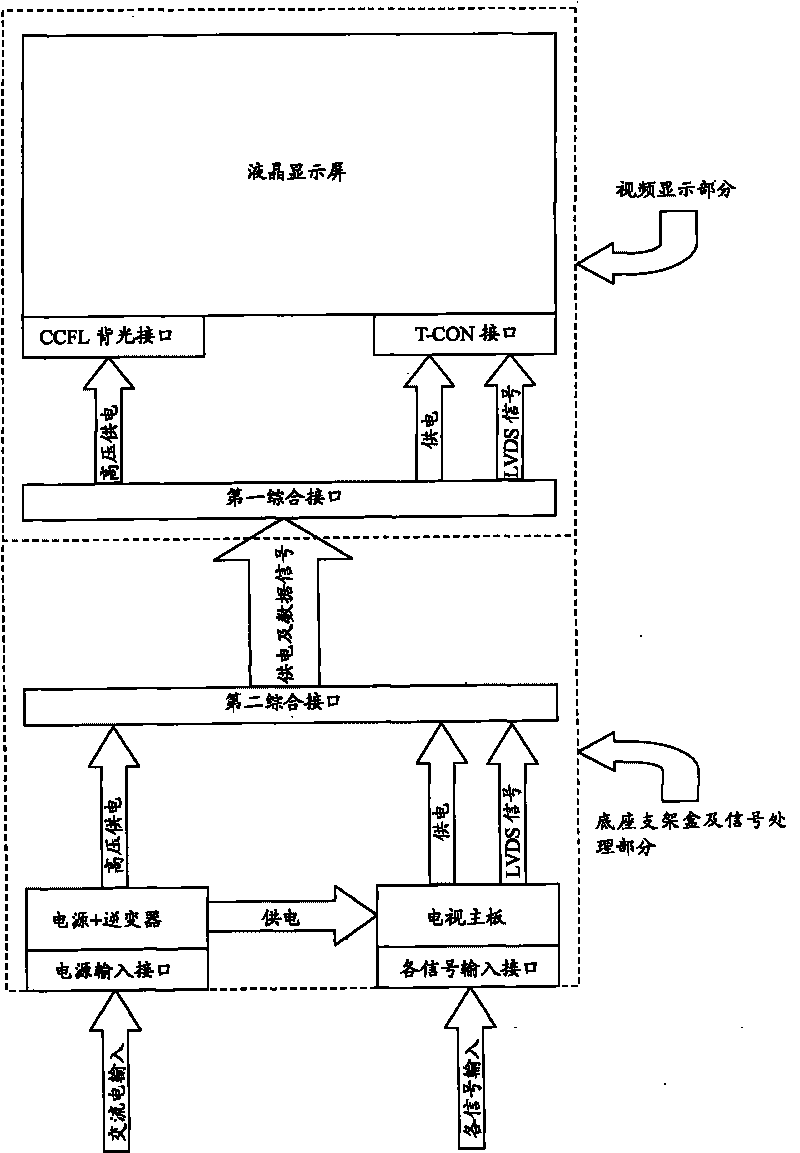

Split liquid crystal television and realizing method thereof

ActiveCN102055926AEasy maintenanceEasy to replaceTelevision system detailsStatic indicating devicesSignal processing circuitsLCD television

The invention discloses a split liquid crystal television and a realizing method thereof. The split liquid crystal television comprises a liquid crystal module, a backlight module and a television signal box, which are split, wherein the liquid crystal module comprises a liquid crystal CELL and a supporting glass back plate, which are tightly pressed against and matched in shape with each other; an outer frame I is arranged on the edges of the liquid crystal cell and the supporting glass back plate; the backlight module comprises a square outer frame II, and a protective layer, an optical film, a diffusion plate, a lamp tube and a back plate are arranged in turn in the outer frame II along the opening direction of the outer frame II; and the television signal box comprises a television circuit, a power supply, and a lamp driving and TCON signal processing circuit. The liquid crystal television can be made ultrathin by accommodating a backlight module and a television signal box in an indoor wall body or a television cabinet; more importantly, the backlight module can be used alone for lighting, and the liquid crystal cell and the backlight module are partially separated, so the maintenance and replacement of the lamp tube of the backlight module are as simple as the replacement of a fluorescent lamp tube at home.

Owner:深圳康佳控股集团有限公司

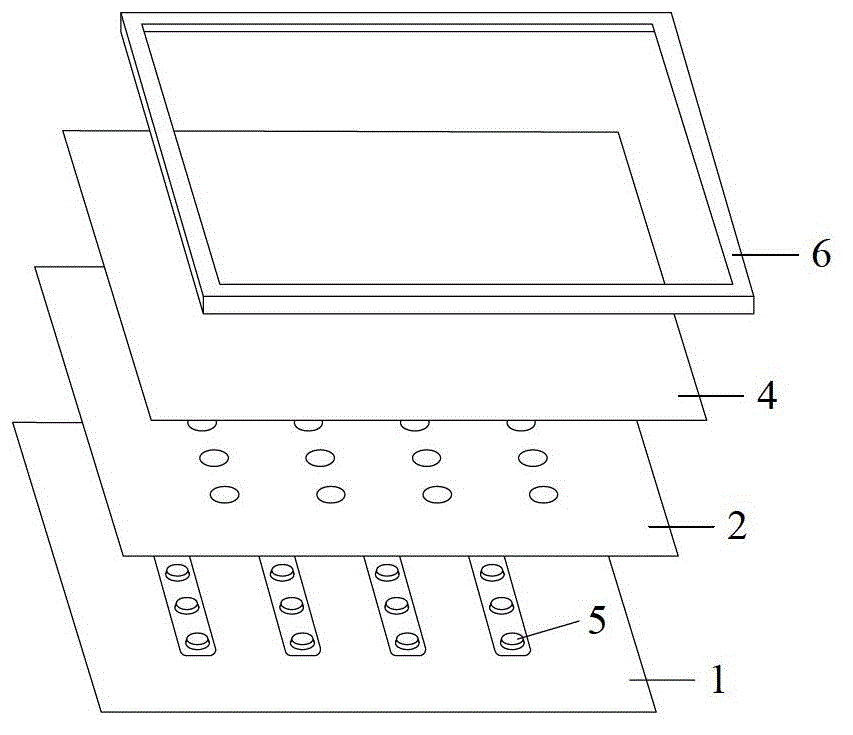

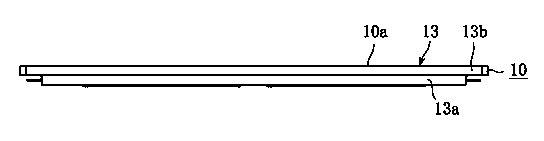

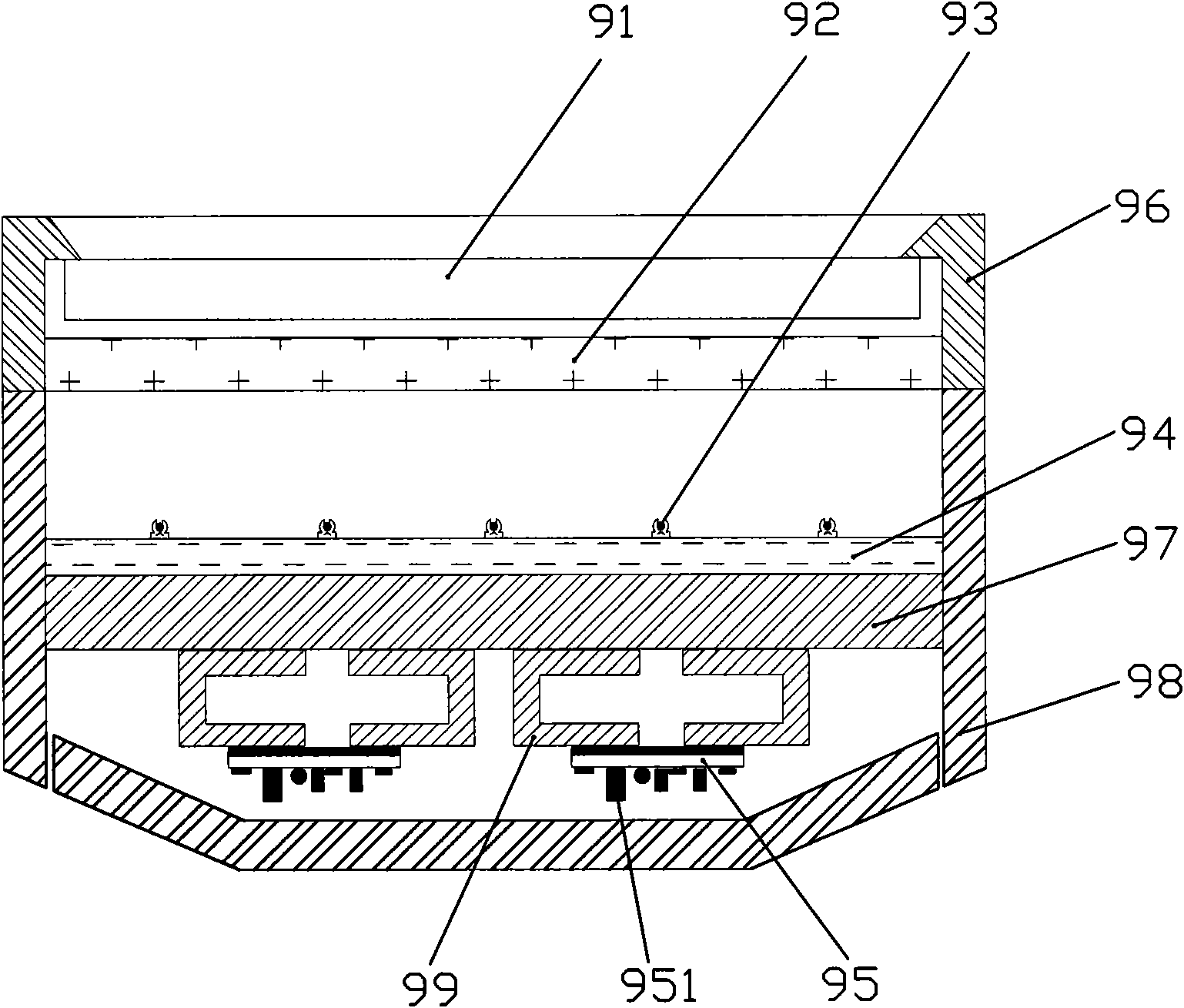

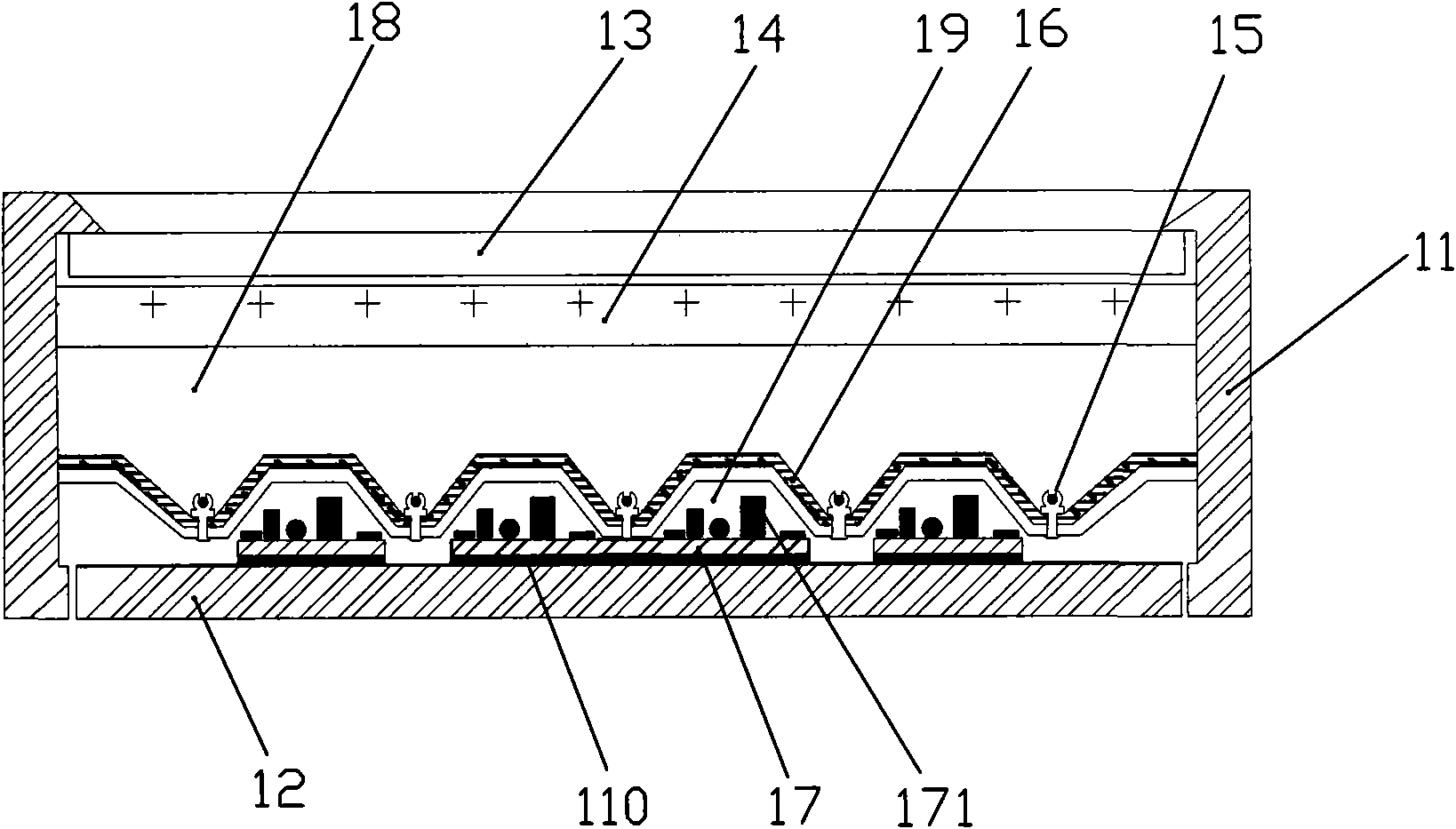

Direct type ultrathin liquid crystal display device

InactiveCN102033339AAchieve ultra-thinReduce thicknessNon-linear opticsDiffusionLiquid-crystal display

The invention is suitable for the display field of a TV, an integrated computer, a display, and the like and provides a direct type ultrathin liquid crystal display device. The direct type ultrathin liquid crystal display device comprises a front cover and a back cover which are matched to form a cavity body; and the cavity body is internally provided with a display screen, a diffusion film, light sources, a reflective film and a PCB (Printed Circuit Board), wherein the PCB is provided with a plurality of electronic elements, and the PCB and circuit elements thereon are arranged between the light sources. Compared with the traditional direct type liquid crystal display device, the PCB and the circuit elements thereon are arranged in a space between the light sources, the concept is skillful, the thickness of the display device is remarkably reduced, and the ultra-thinness of the direct type liquid crystal display device is realized.

Owner:东莞帝光电子科技实业有限公司

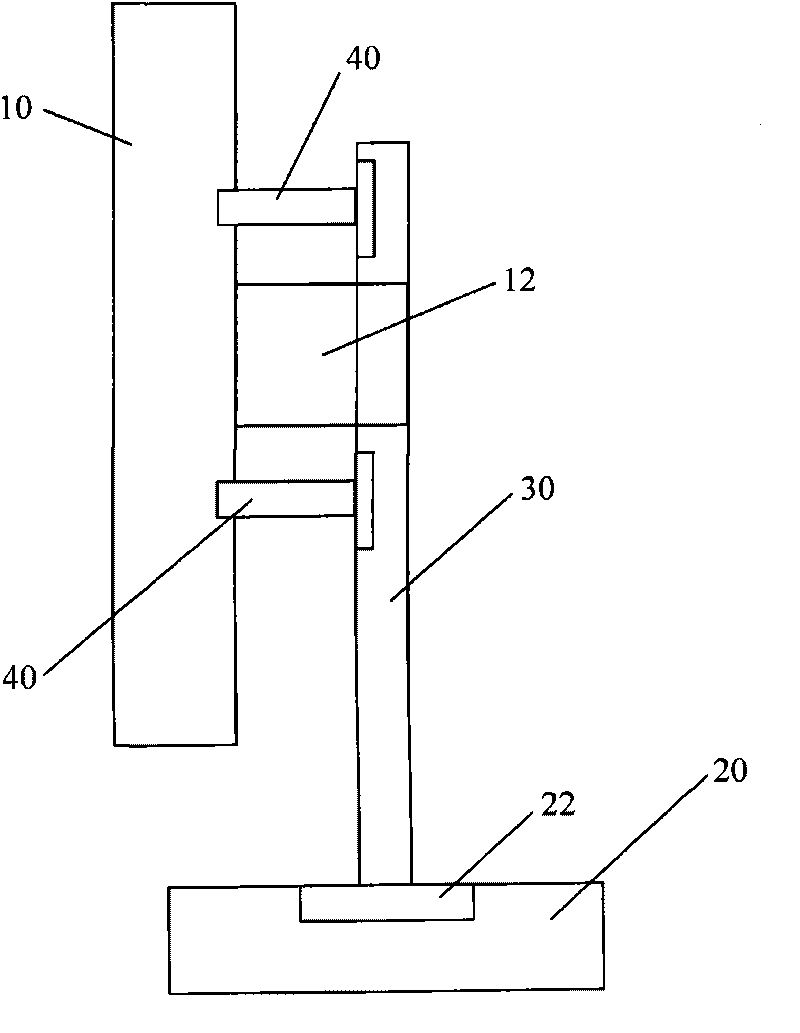

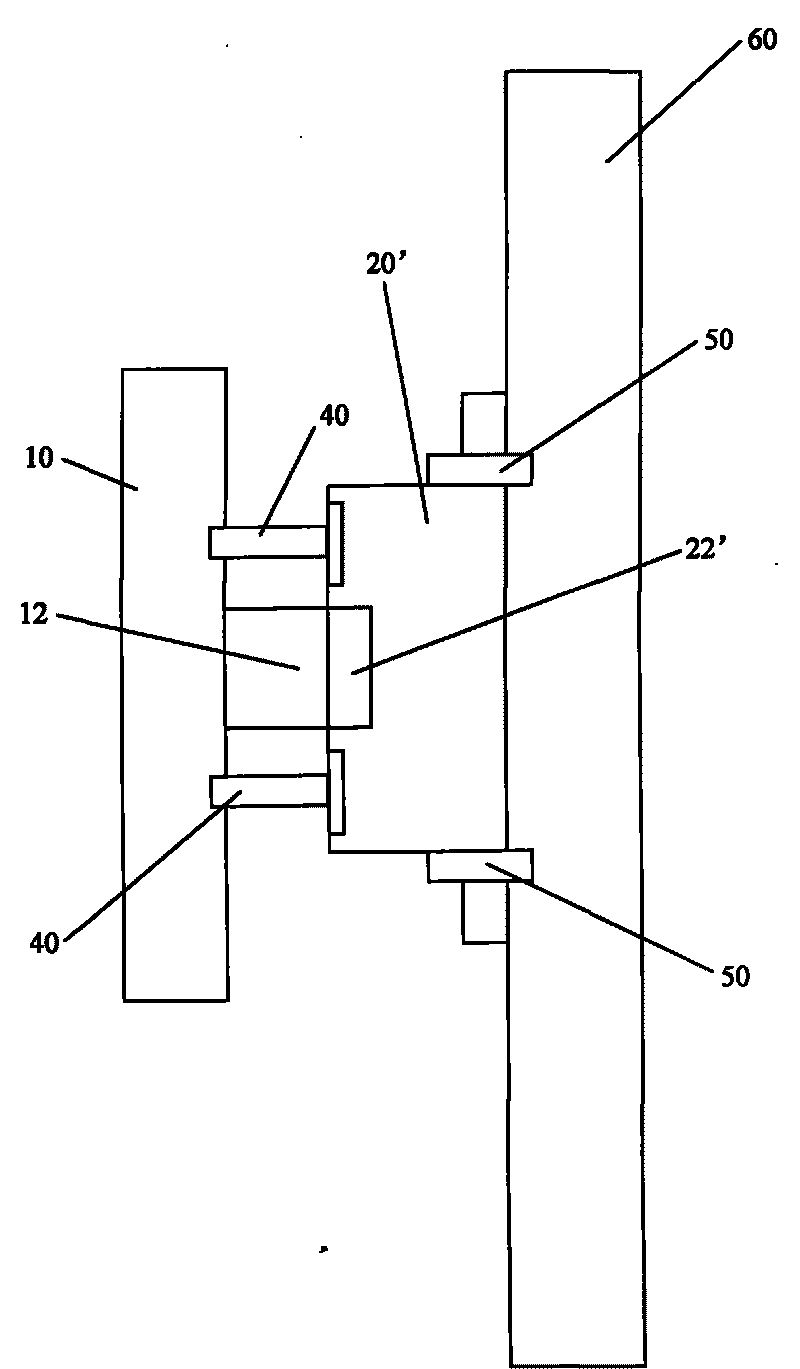

Method for realizing ultra-thin television and device thereof

InactiveCN101753930AAchieve ultra-thinAchieve narrow bordersTelevision system detailsColor television detailsEngineeringSignal processing

The invention relates to a method for realizing an ultra-thinned television and a device thereof. The ultra-thin television device comprises a television body, a base support case and a base support, wherein the base support case is arranged on the television body through the base support; a display screen and a first integrated interface are arranged on the television body, and the first integrated interface is connected with the display screen; a second integrated interface and a power supply, an inverter and a mainboard which are connected with the second integrated interface are arranged in the base support case; the first integrated interface is mutually connected with the second integrated interface; and the power supply, the inverter and the mainboard supply power and transmit data signals to the display screen through the connection of the first integrated interface and the second integrated interface. The television disassembles a video display part and signal processing parts reasonably, utilizes the thickness and space of the base support case reasonably, and transfers the signal process parts such as the power supply, the inverter, the mainboard and the like to the base support case, so that the ultra-thin and narrow border of the television can be realized simultaneously, and the television is convenient to assemble, disassemble and maintain.

Owner:KONKA GROUP

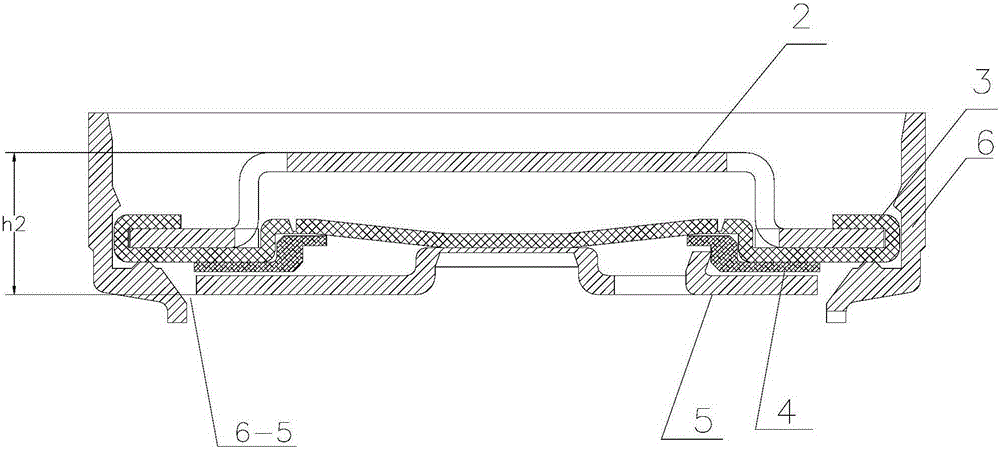

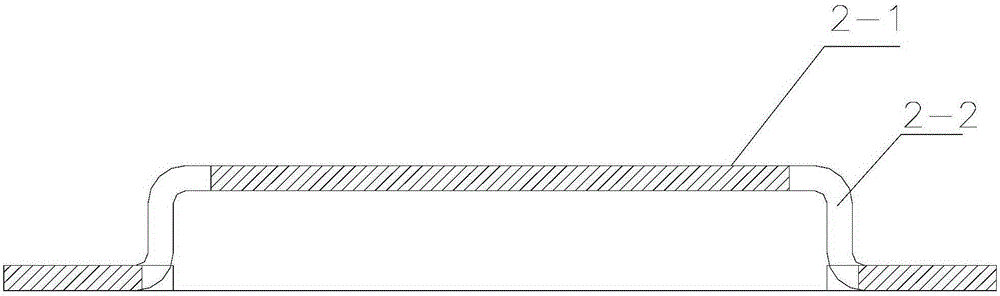

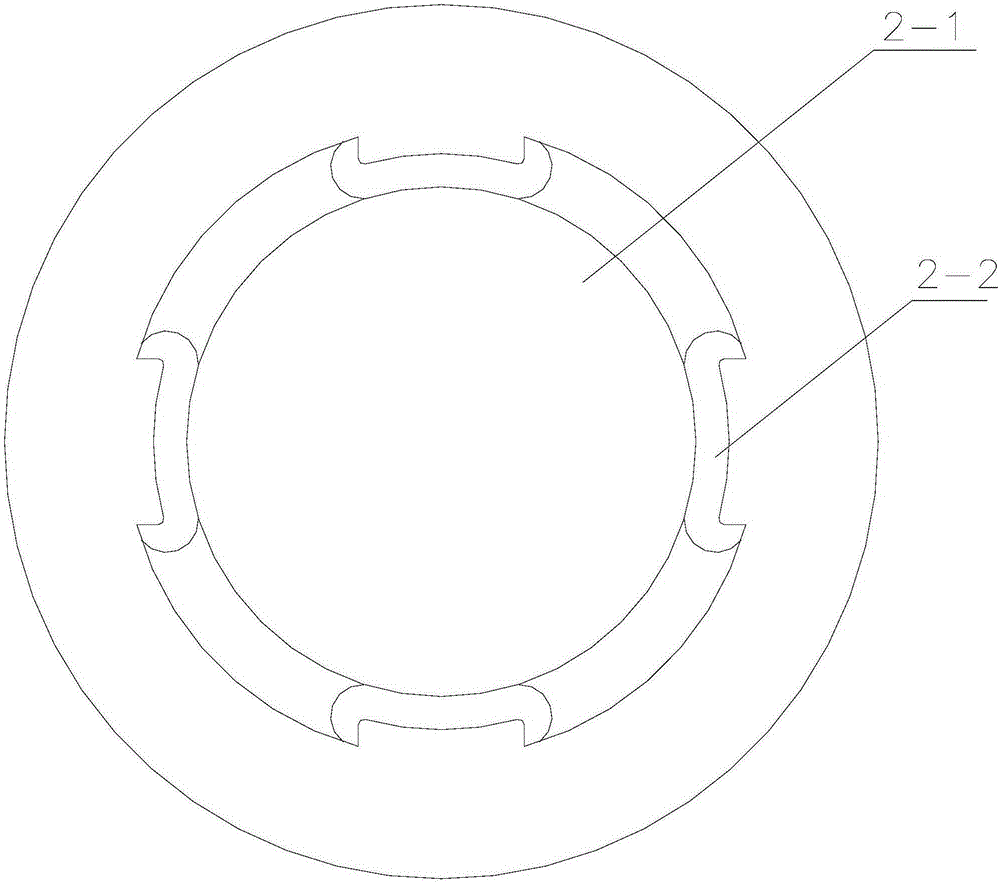

Ultra-thin dynamic combined cap for lithium battery

ActiveCN105226209AIncrease energy densityReduce the overall heightLi-accumulatorsCell sealing materialsEngineeringShock resistance

The invention relates to the technical field of lithium battery assemblies, in particular to an ultra-thin dynamic combined cap for a lithium battery. The ultra-thin dynamic combined cap comprises a top cover, an explosion-proof plate, a spacing ring, a connecting plate and a sealing ring, wherein the explosion-proof plate is arranged below the top cover; the connecting plate is arranged below the explosion-proof plate; a covered edge which is rolled up inwards is arranged on the edge of the explosion-proof plate; the covered edge wraps the edge of the top cover; the explosion-proof plate is fixedly connected with the middle part of the connecting plate; the spacing ring is arranged between the edge of the connecting plate and the explosion-proof plate; and the sealing ring sleeves the outside of the top cover, the explosion-proof plate, the spacing ring and the connecting plate. According to the ultra-thin dynamic combined cap for the lithium battery provided by the invention, the height of the cap can be reduced to below 3mm; the height of an internal space of the battery is increased; the height of a roll core of the lithium battery can be increased by about 1mm; and the energy density of the battery is effectively improved. The structures of the spacing ring, the explosion-proof plate and the connecting plate are changed, so that the target of reducing the overall height of the cap is achieved; ultra-thinning of the cap is achieved; the ultra-thin dynamic combined cap is high in shock resistance and reliable in application; and massive automatic production is facilitated.

Owner:CHANGZHOU WUJIN ZHONGRUI ELECTRONICS

Liquid crystal module and liquid crystal display device

InactiveCN107884976AAchieve ultra-thinReduced support structureNon-linear opticsDiffusionLiquid-crystal display

The invention provides a liquid crystal module and a liquid crystal display device. The liquid crystal module is a direct type liquid crystal module and includes an optical film set and a grid-like optical component. The portion, corresponding to a light emitting unit, of the grid-like optical component is provided with a settling tank, the bottom of the settling tank is provided with an opening in which the light emitting unit can be accommodated, the inner wall of the settling tank is a reflection surface, and the disclosed liquid crystal display device includes a panel and the liquid crystal module. The problems that the light diffusion angle in an ultra-multi-subregion liquid crystal module is large, light overlapping is formed in adjacent subregions, and thus light convergence is notstrong is solved, and meanwhile the liquid crystal module is thinned.

Owner:HISENSE VISUAL TECH CO LTD

Compound vibration amplitude modulation holographic ultrathin waveguide augmented reality display system and method

ActiveCN106773046AReduce difficultyQuality improvementOptical elementsVibration amplitudeComplex amplitude

The invention provides a compound vibration amplitude modulation holographic ultrathin waveguide augmented reality display system and method. The system comprises a light modulator and a first diffractive optical element which are positioned on two sides of a waveguide base and opposite to each other, a second diffractive optical element on the same / opposite side of the first diffractive optical element is arranged at the other end of the waveguide base, two phase images are simultaneously loaded by one light modulator, and compound vibration amplitude waves of an object to be displayed are formed by different modulation of different exposure areas of the first diffractive optical element and transmitted in the waveguide base in a total-internal-reflection mode. According to the compound vibration amplitude modulation holographic ultrathin waveguide augmented reality display system and method, a three-dimensional augmented reality display system is light and thin, and the quality of compound vibration amplitude signals can be effectively improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

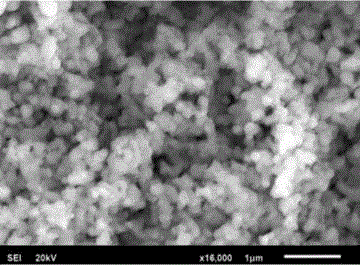

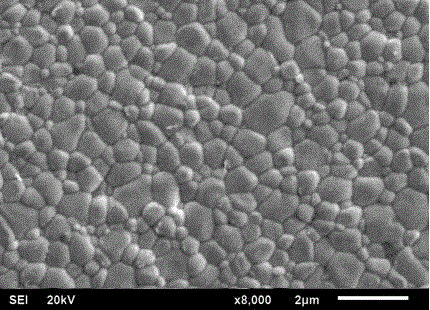

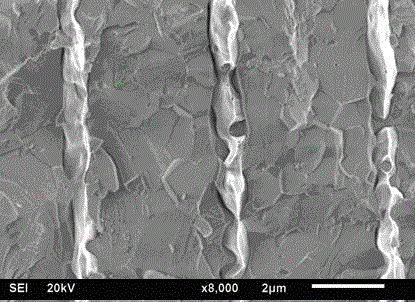

COG dielectric ceramic material for low-temperature sintering thin-media multilayer ceramic capacitor

The invention discloses a low-temperature sintering thin-media nickel electrode dielectric ceramic material. The compositions of the dielectric ceramic material comprise a principal component and additives, wherein the principal component is (Ca1-xSrx)zZryO3, wherein x is more than or equal to 0.2 and less than or equal to 0.4, y is more than or equal to 0.90 and less than or equal to 1.0, and Z is more than or equal to 0.985 and less than or equal to 1.003; the additives are at least two or more compounds of Al2O3, MnCO3, MgO, TiO2, SiO2, BaCO3 and ZnO. The material is in line with COG characteristics of American EIA (Electronic Industries Association) standard, is small in particles, uniform in size distribution, good in dispersibility, and favorable in dielectric property. The material is low in sintering temperature, and uniform and compact in grain sizes when being used for manufacturing a multilayer ceramic capacitor, can realize the thickness of a dielectric layer to be less than 5mum, and is favorable in matching with a nickel internal electrode.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com