Patents

Literature

73results about How to "Reduced support structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

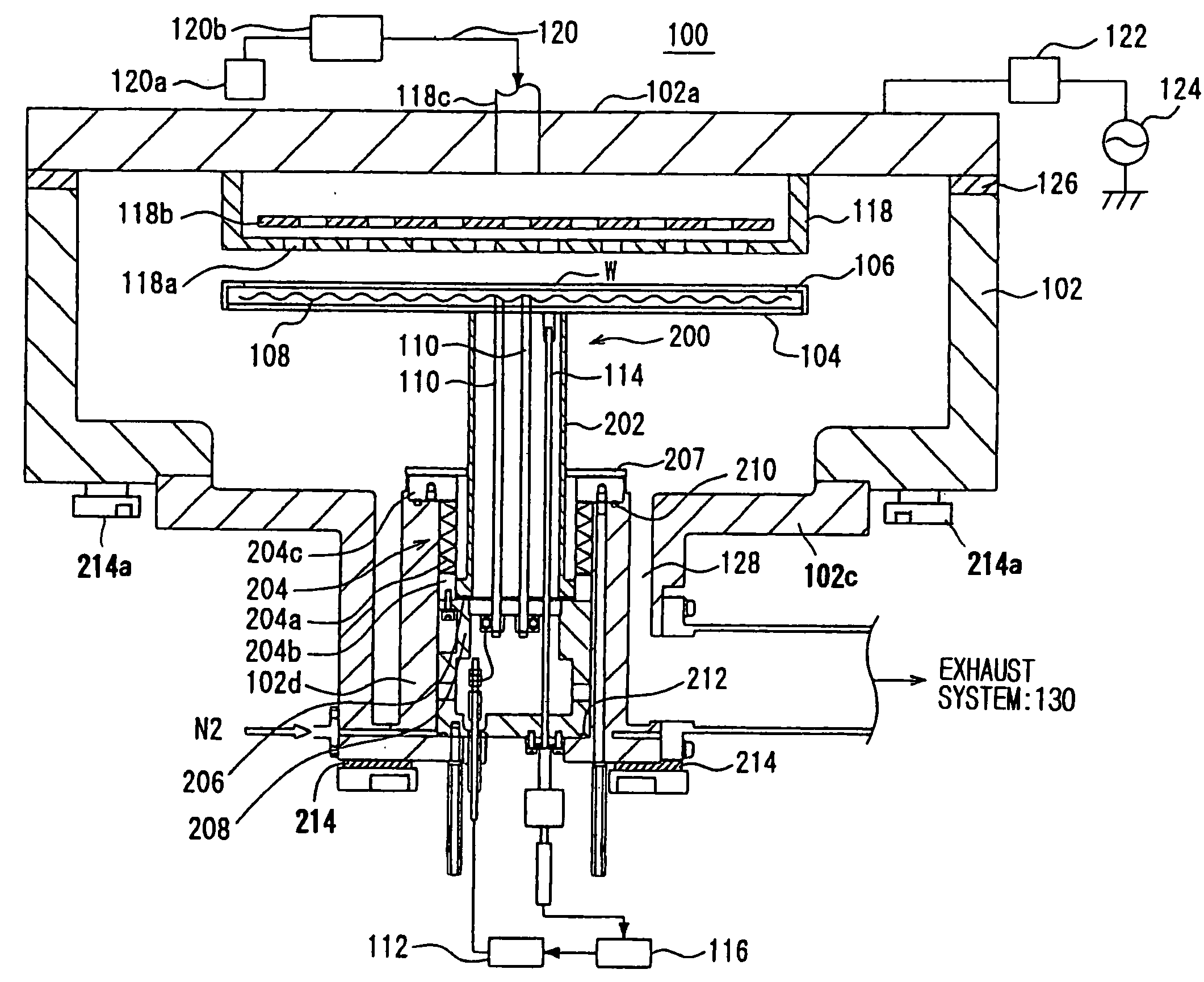

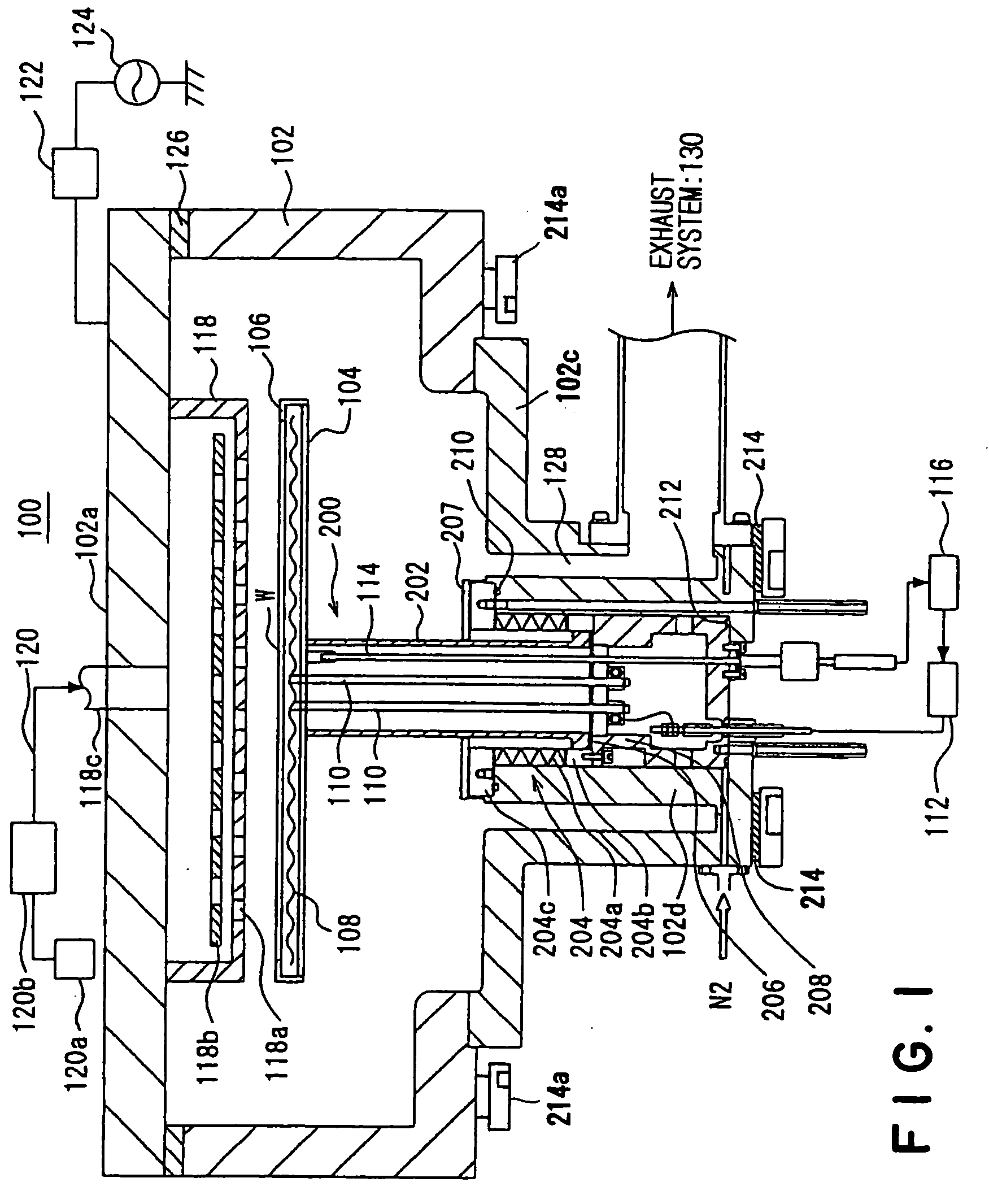

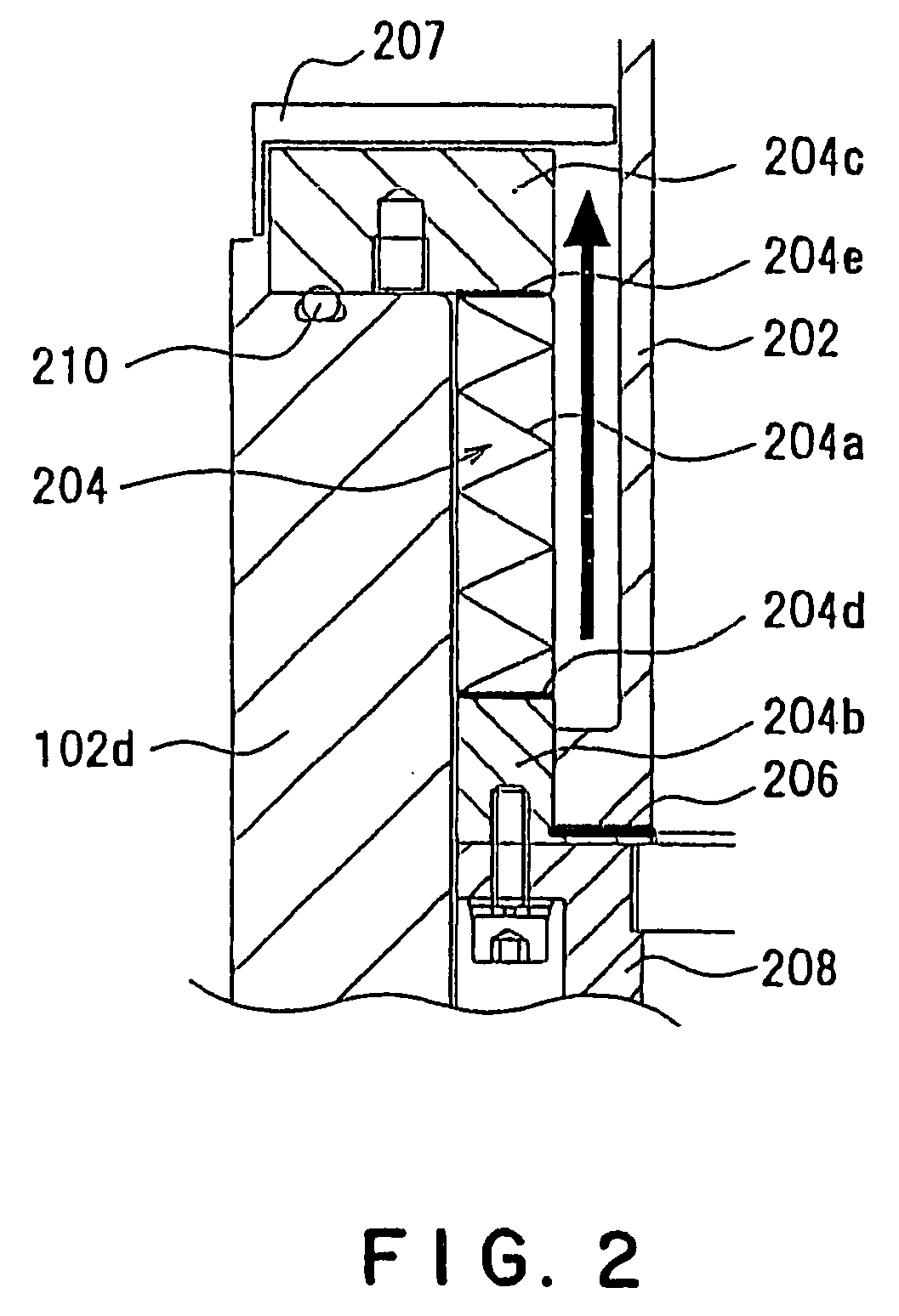

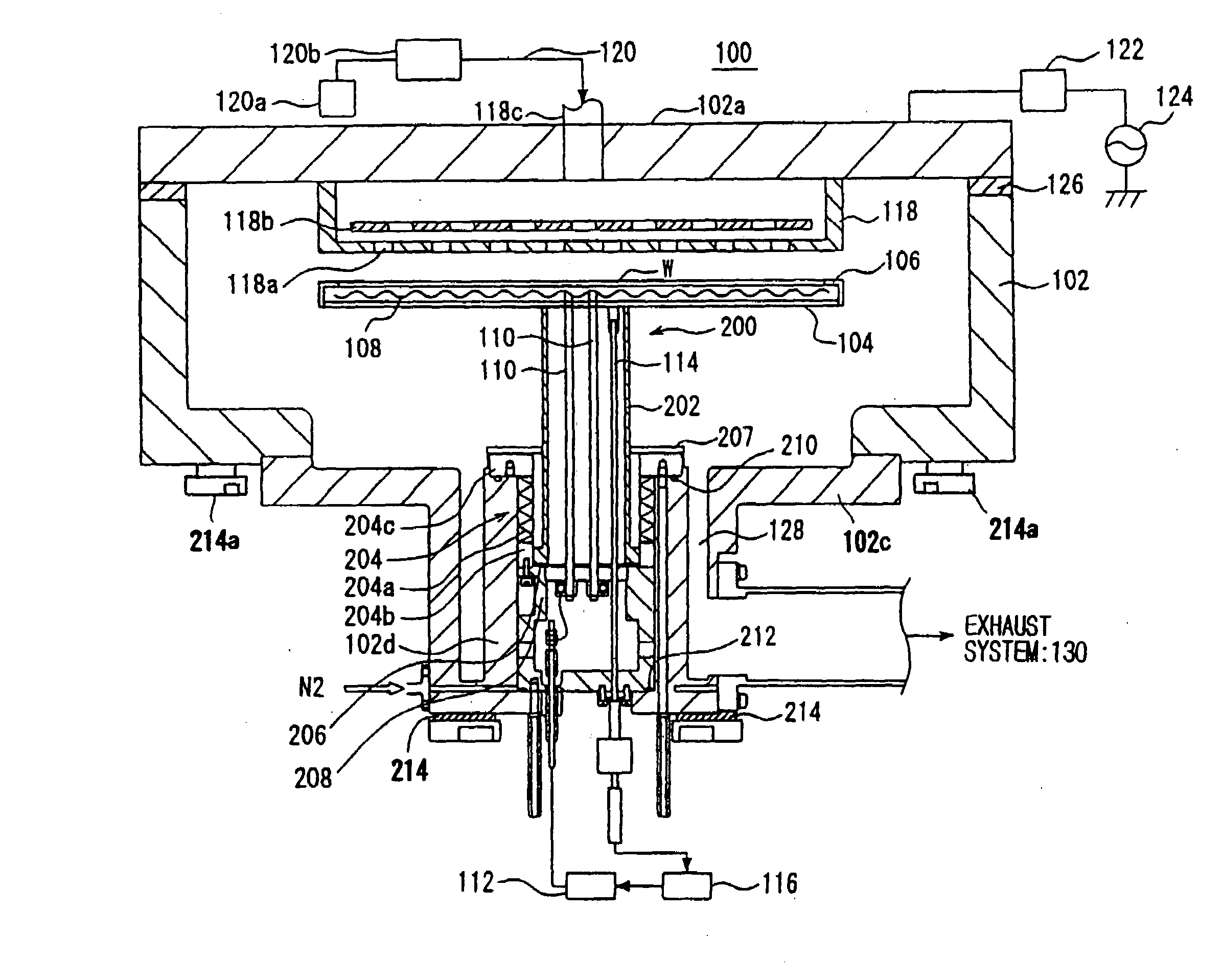

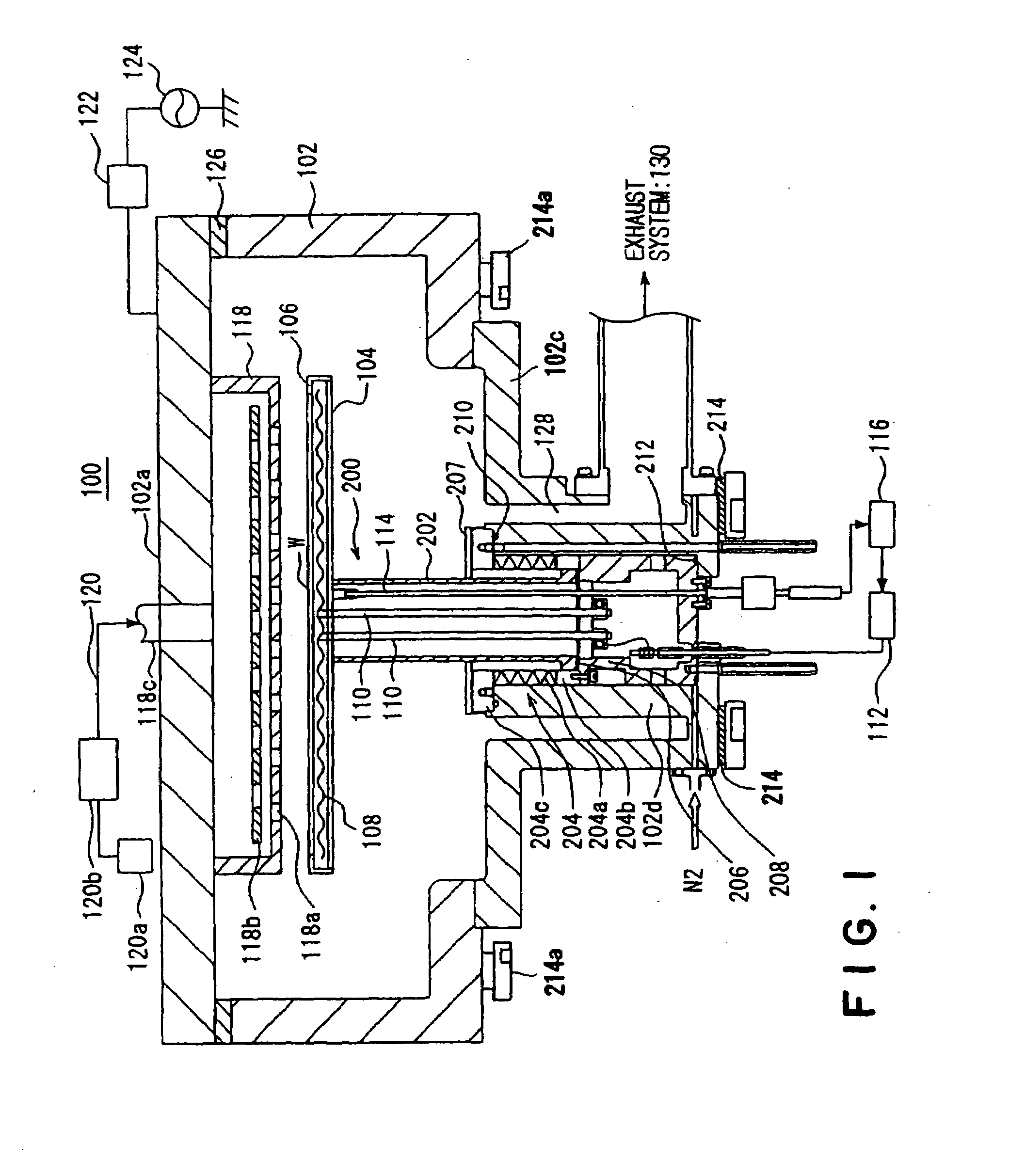

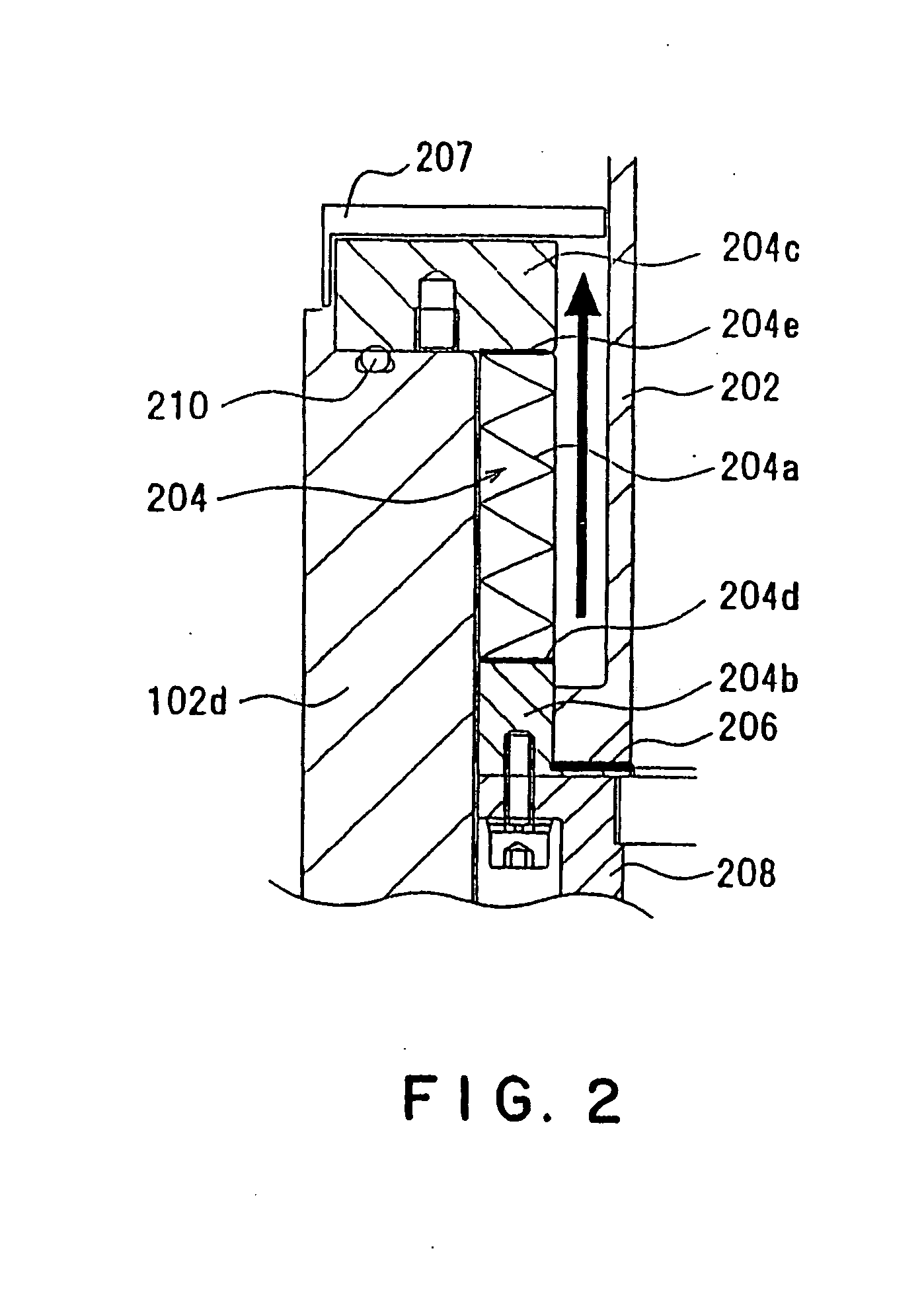

Substrate heating device and method of purging the device

InactiveUS20040149227A1Reduced support structureLower the volumeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringMechanical engineering

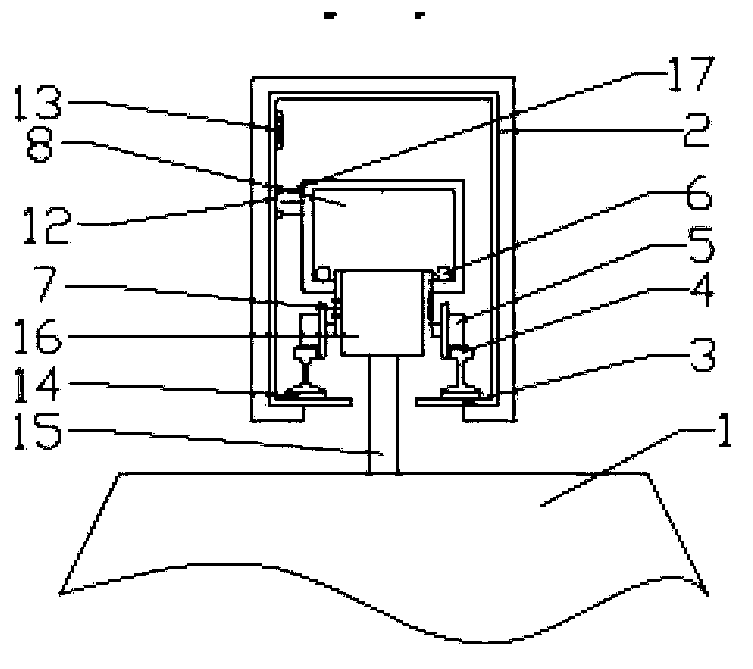

A substrate heating apparatus of the present invention, which heats a substrate mounted on a mount table 104 having heating means 108, in a processing vessel 102, includes a supporting part 202 made from a first material to support the mount table, a sealing part 204 made from a second material different from the first material in heat conductivity to seal the supporting part and the processing vessel and a joint part 206 for joining the supporting part and the sealing part in an airtight manner. With the constitution, by selecting the first material and the second material of different heat conductivities properly, it is possible to reduce a heat gradient between the top of the mount table and the bottom of the mount table. As a result, it is possible to shorten a supporting structure for the mount table, in length.

Owner:TOKYO ELECTRON LTD

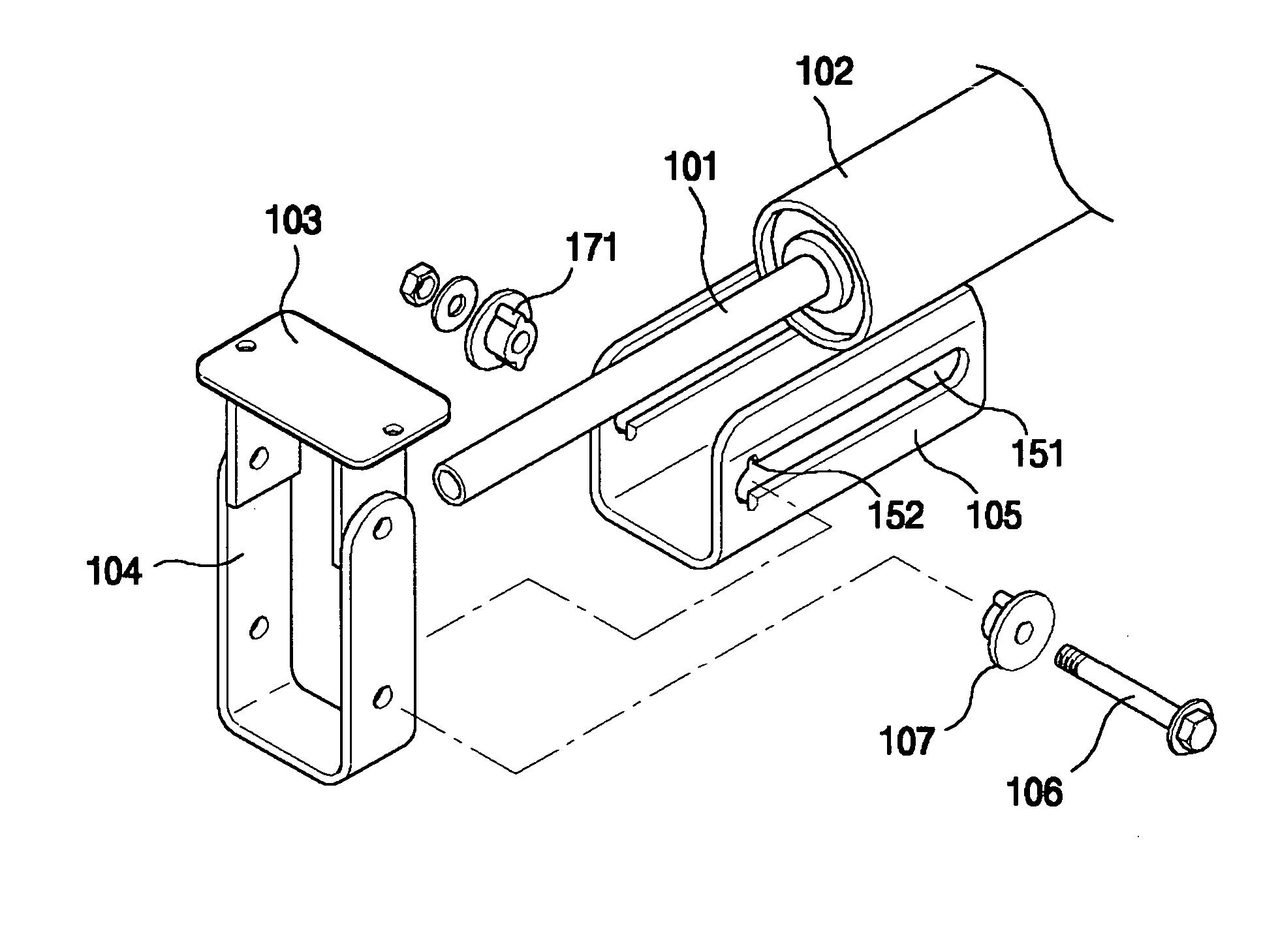

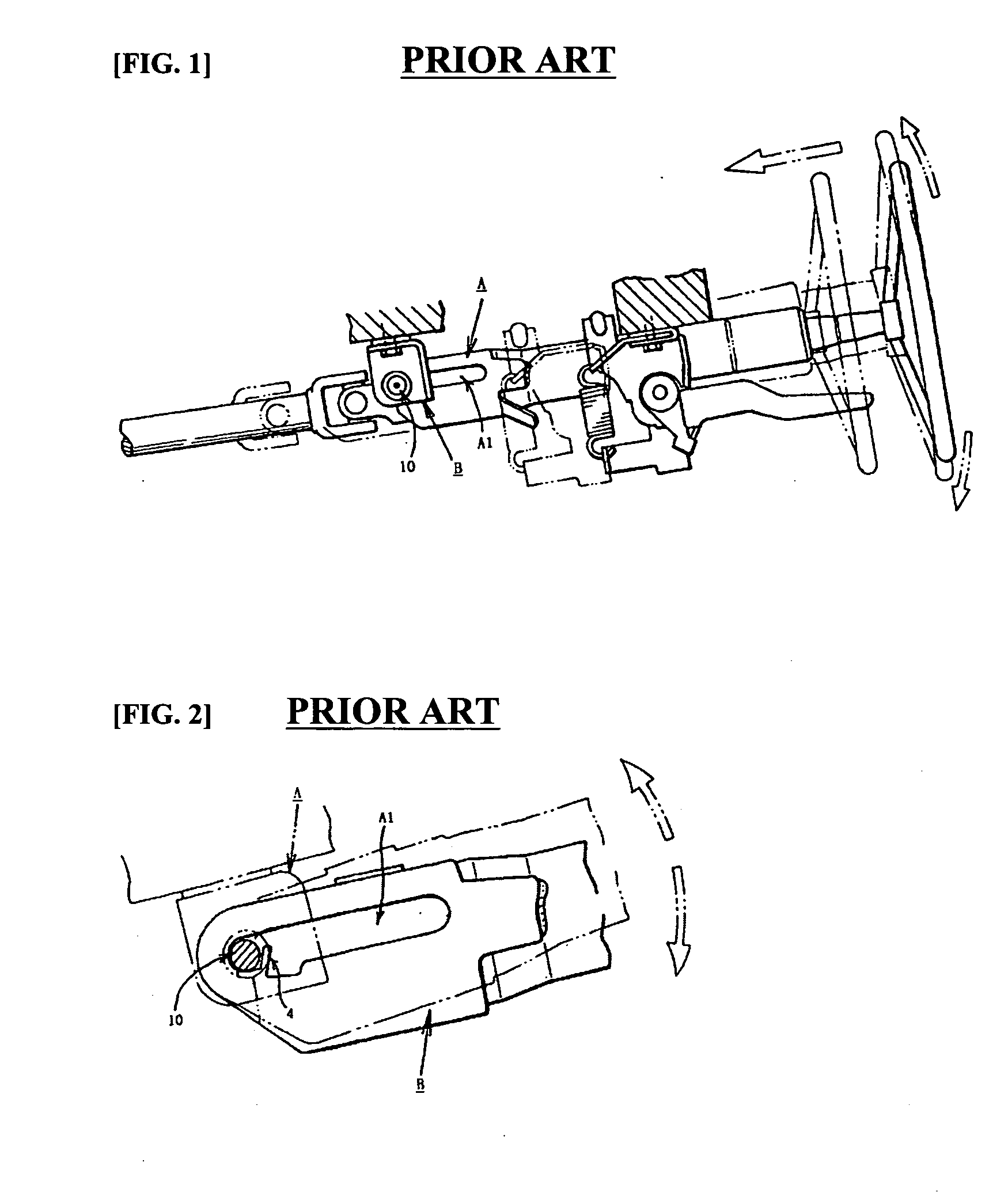

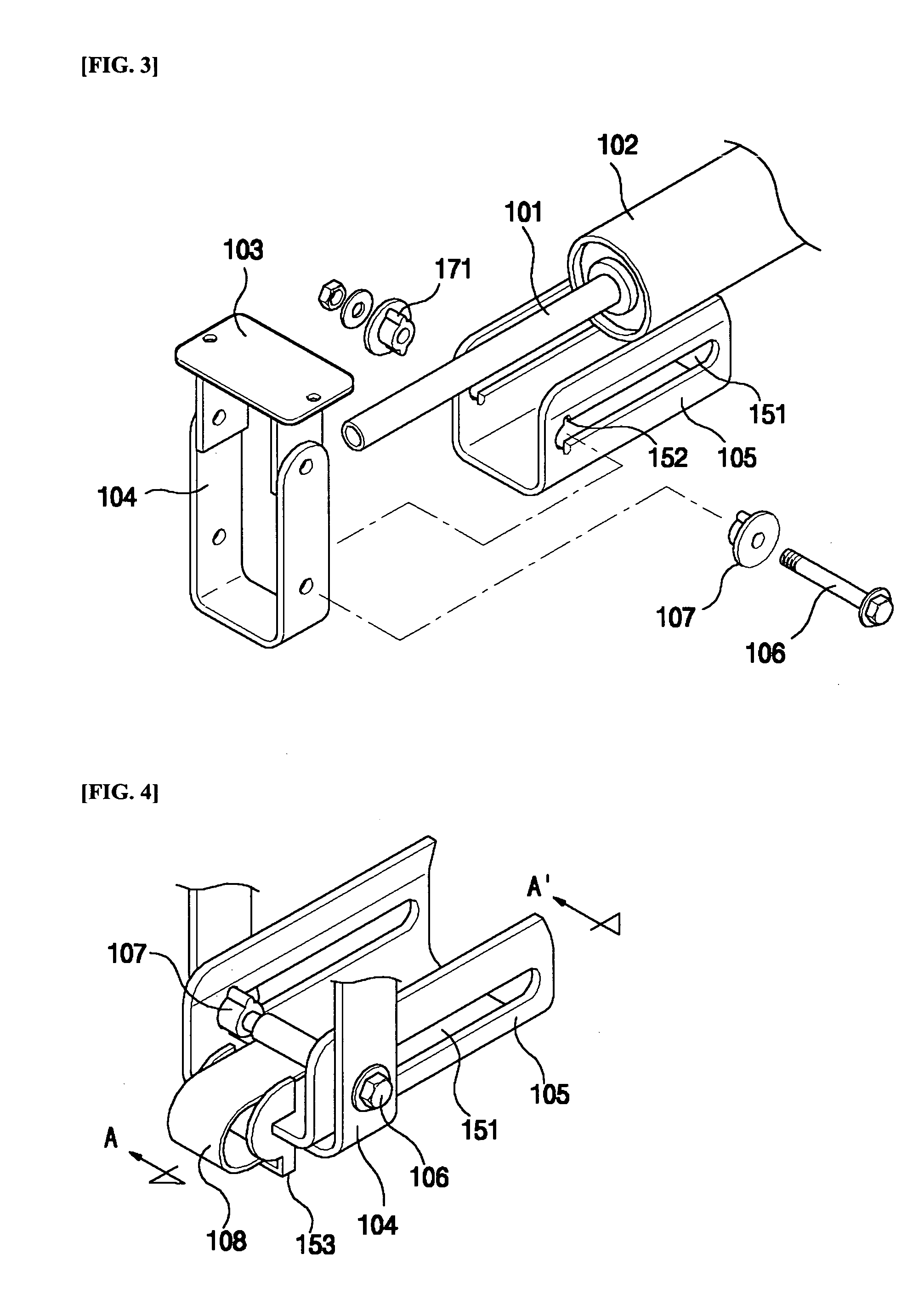

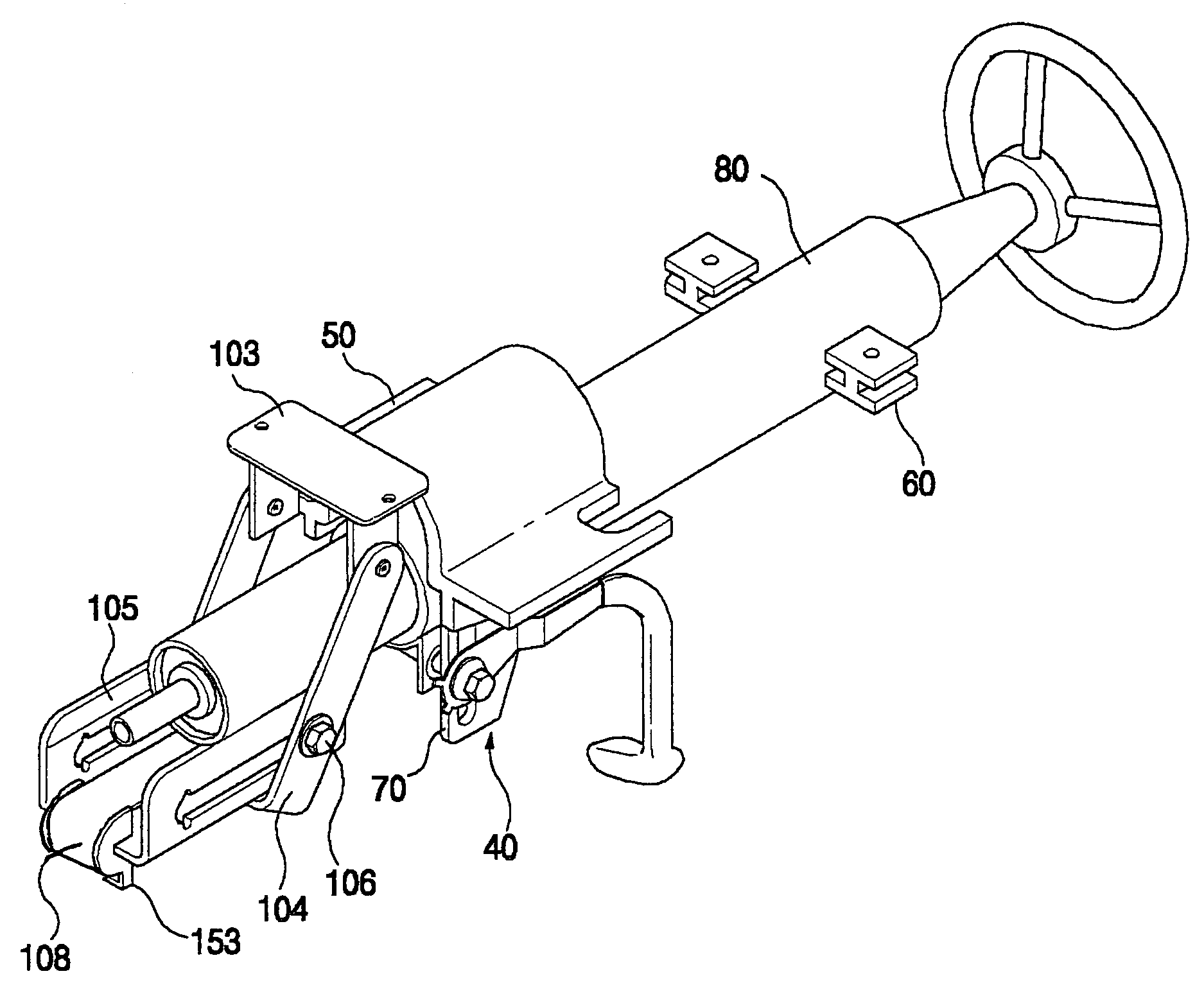

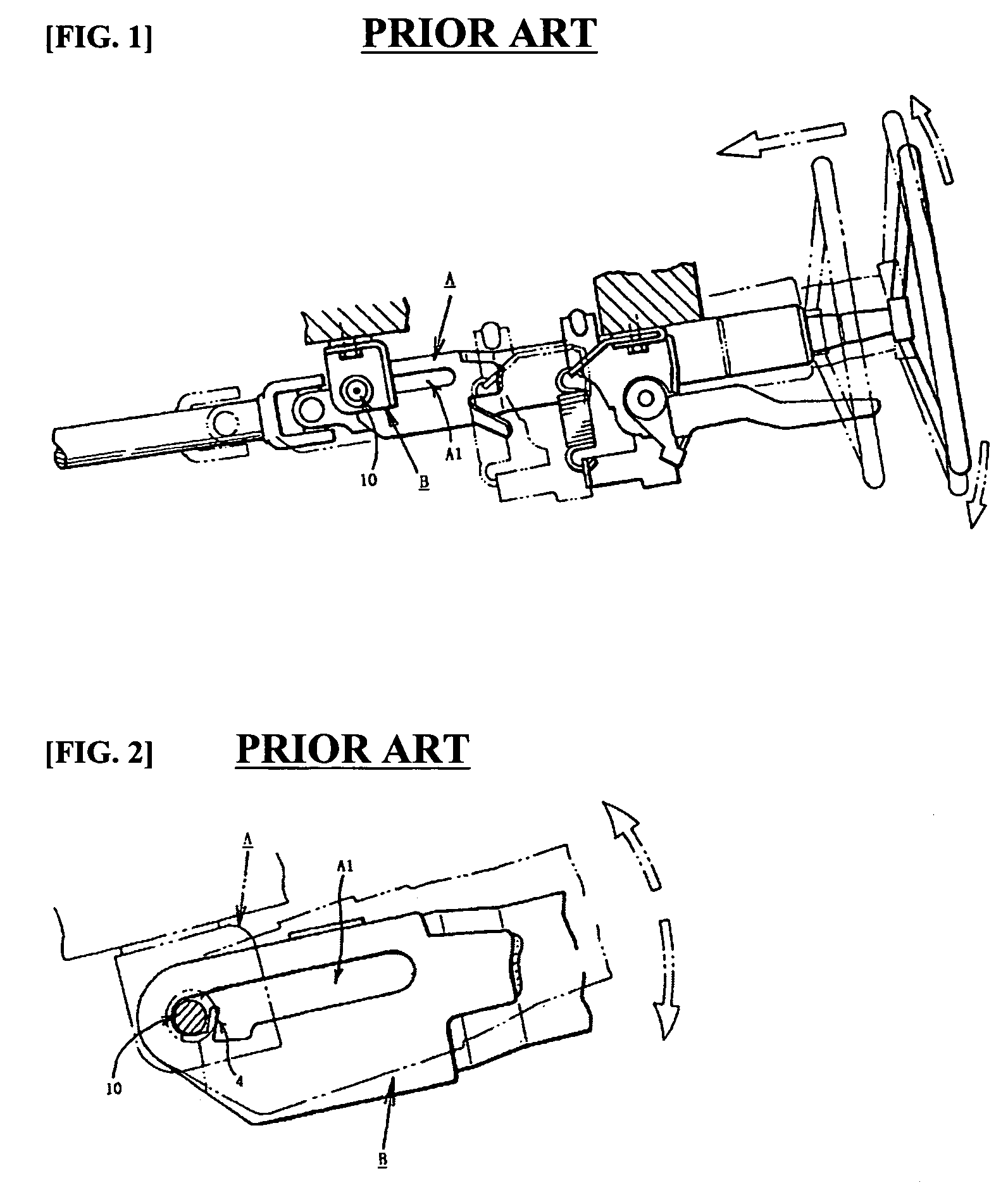

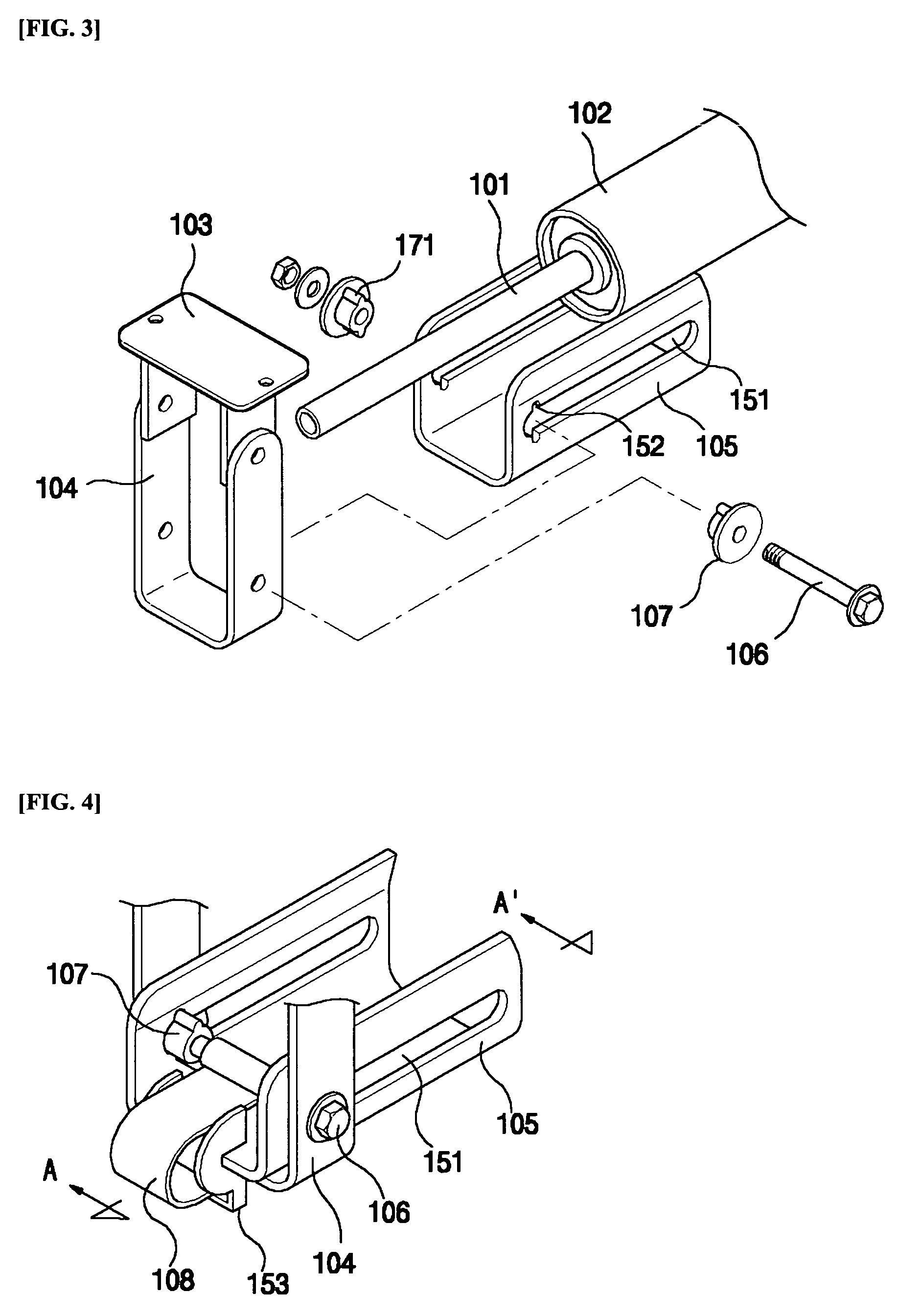

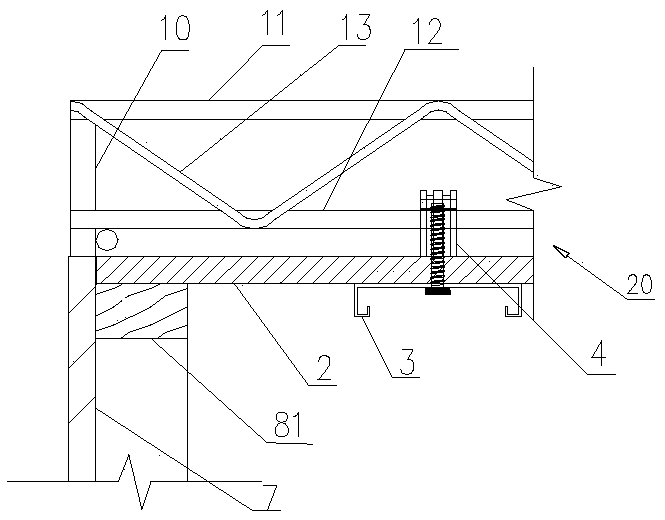

Shock absorbing steering column of low tilt type

InactiveUS20050052014A1Simple processAvoid interferencePedestrian/occupant safety arrangementSteering columnsSteering wheelSteering column

A vehicular steering column of a low tilt type is supported to a body at upper and lower portions thereof to be tilted in whole about a hinge joint located on the lower portion, and more particularly to a shock absorbing steering column is designed to allow a steering column to slide forward when a vehicle driver gets a secondary shock against a steering wheel due to a vehicular collision, thereby absorbing a shock. In particular, the steering column is constructed in such a manner that, in order to absorb a shock in case of the vehicular collision, shock absorbing means is provided to a lower supporting structure of the steering column, and thus an initial shock imposed on the driver can be greatly decreased.

Owner:HYUNDAI MOBIS CO LTD

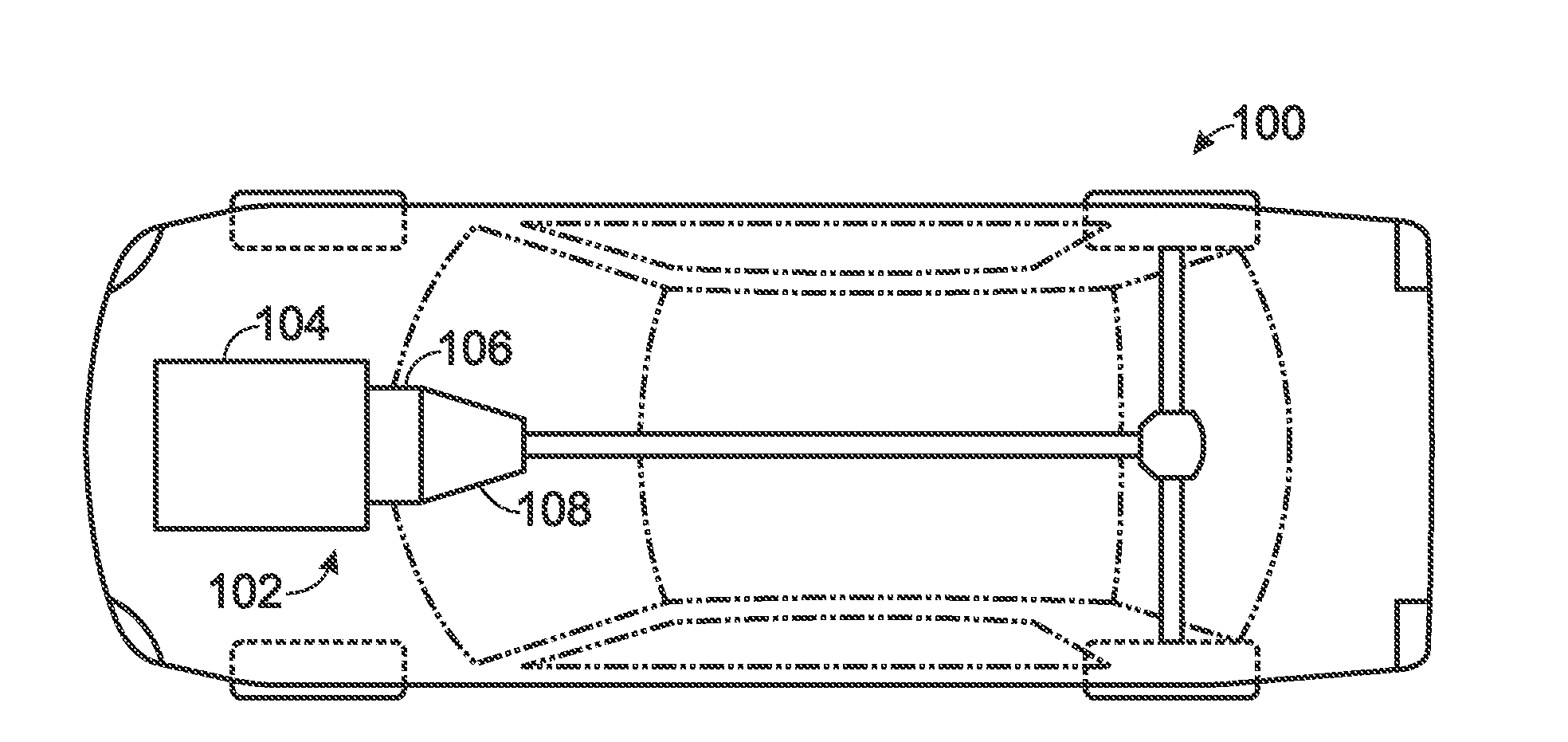

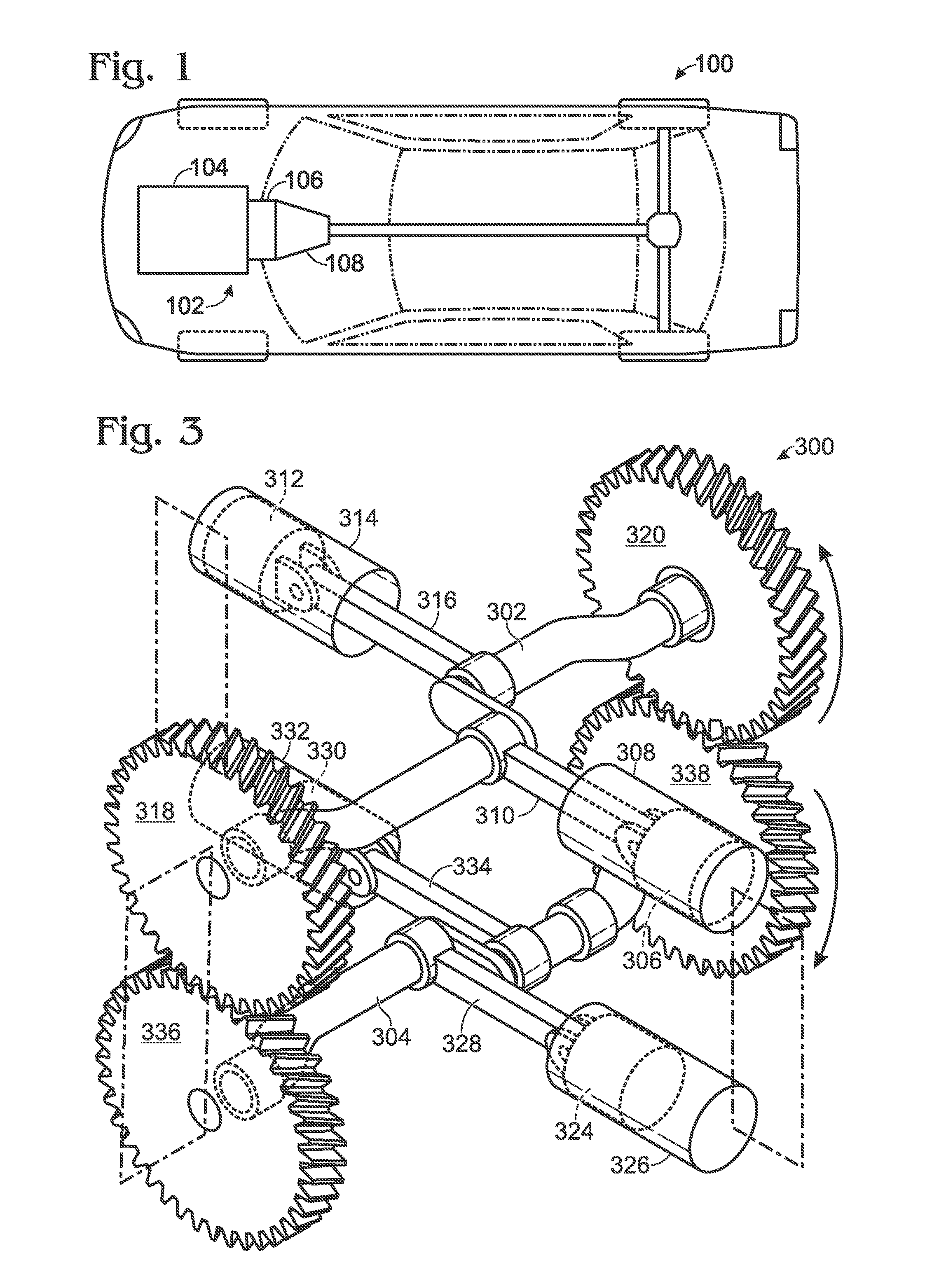

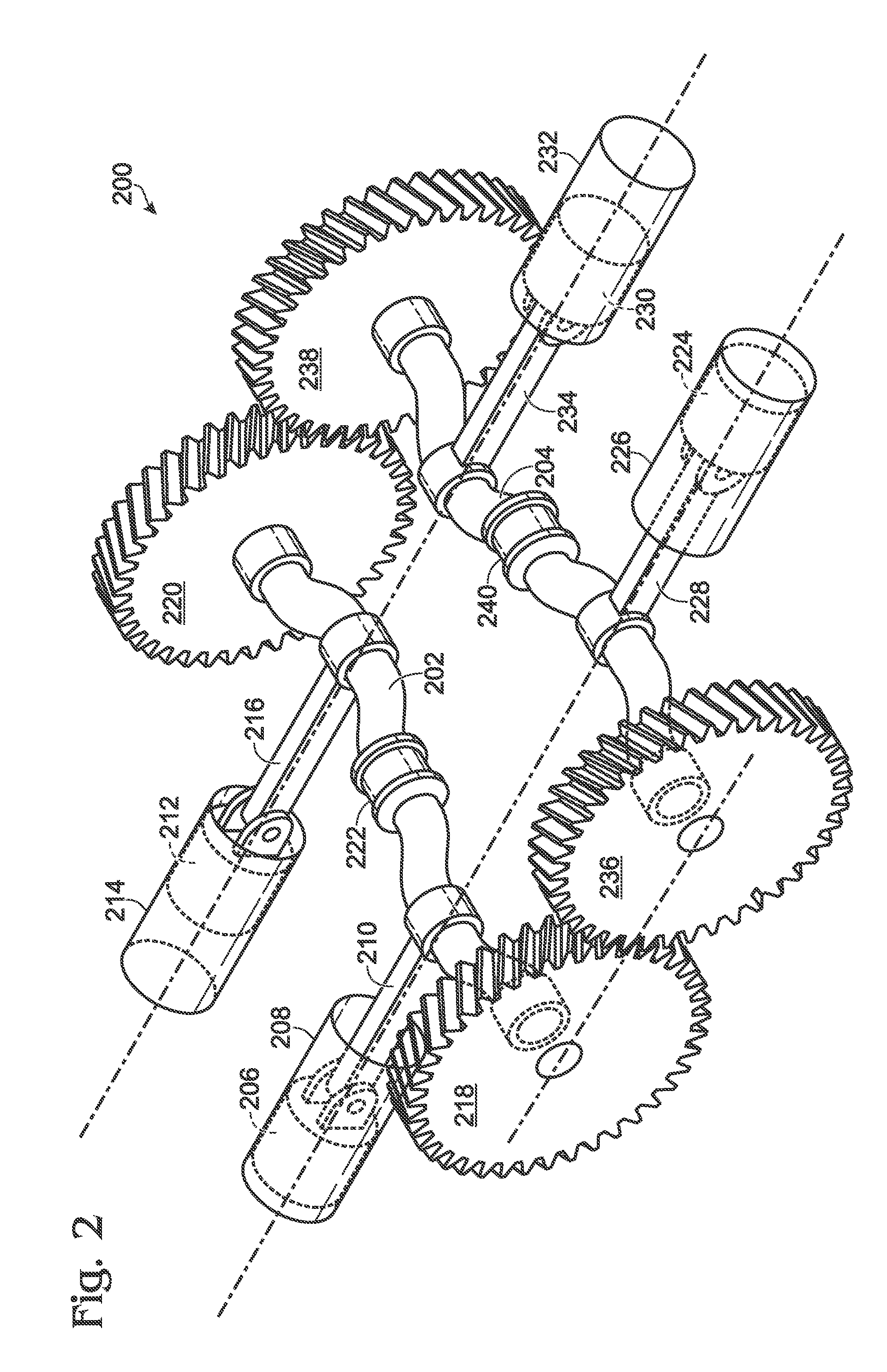

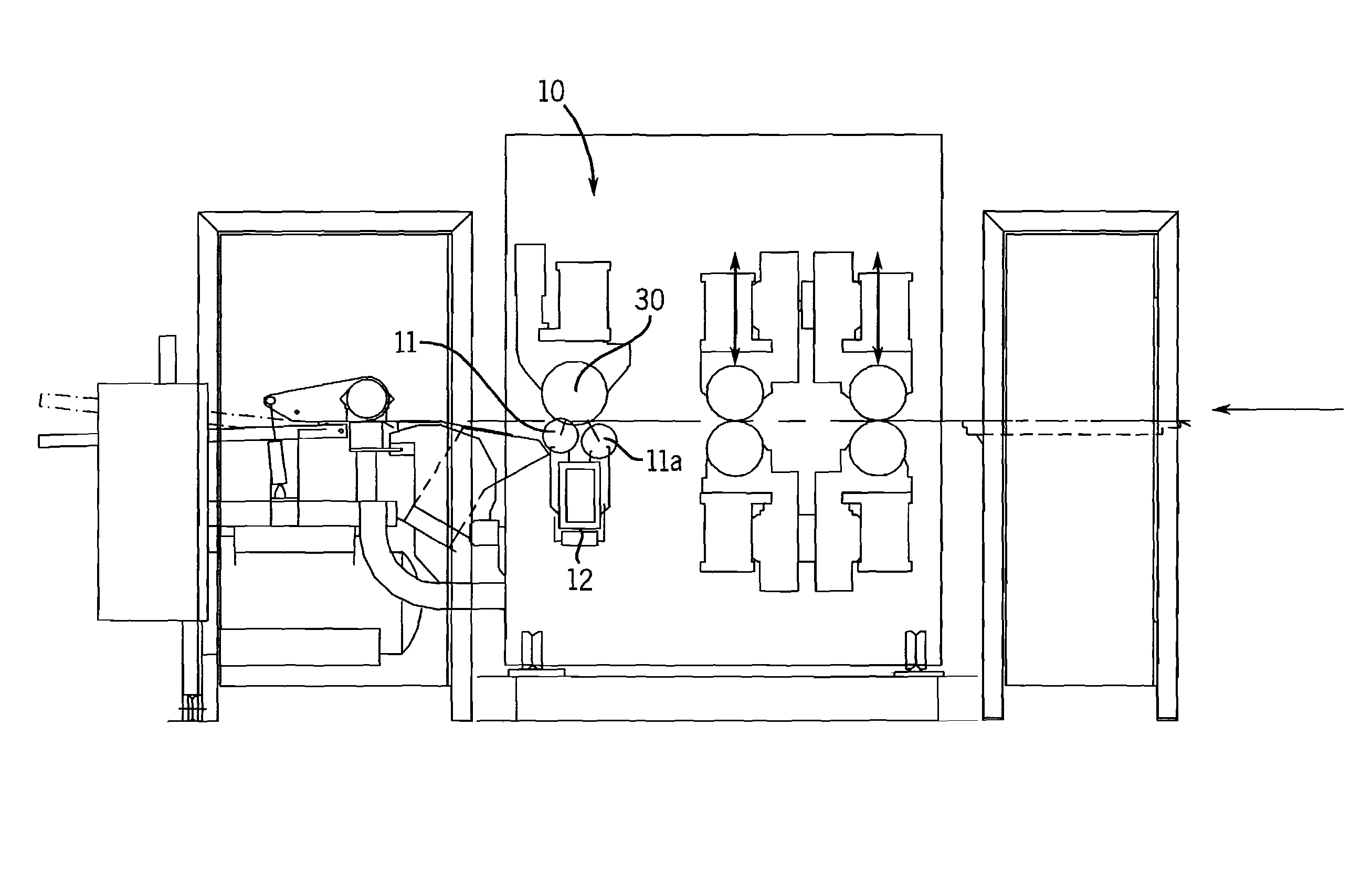

Dual crankshaft engine

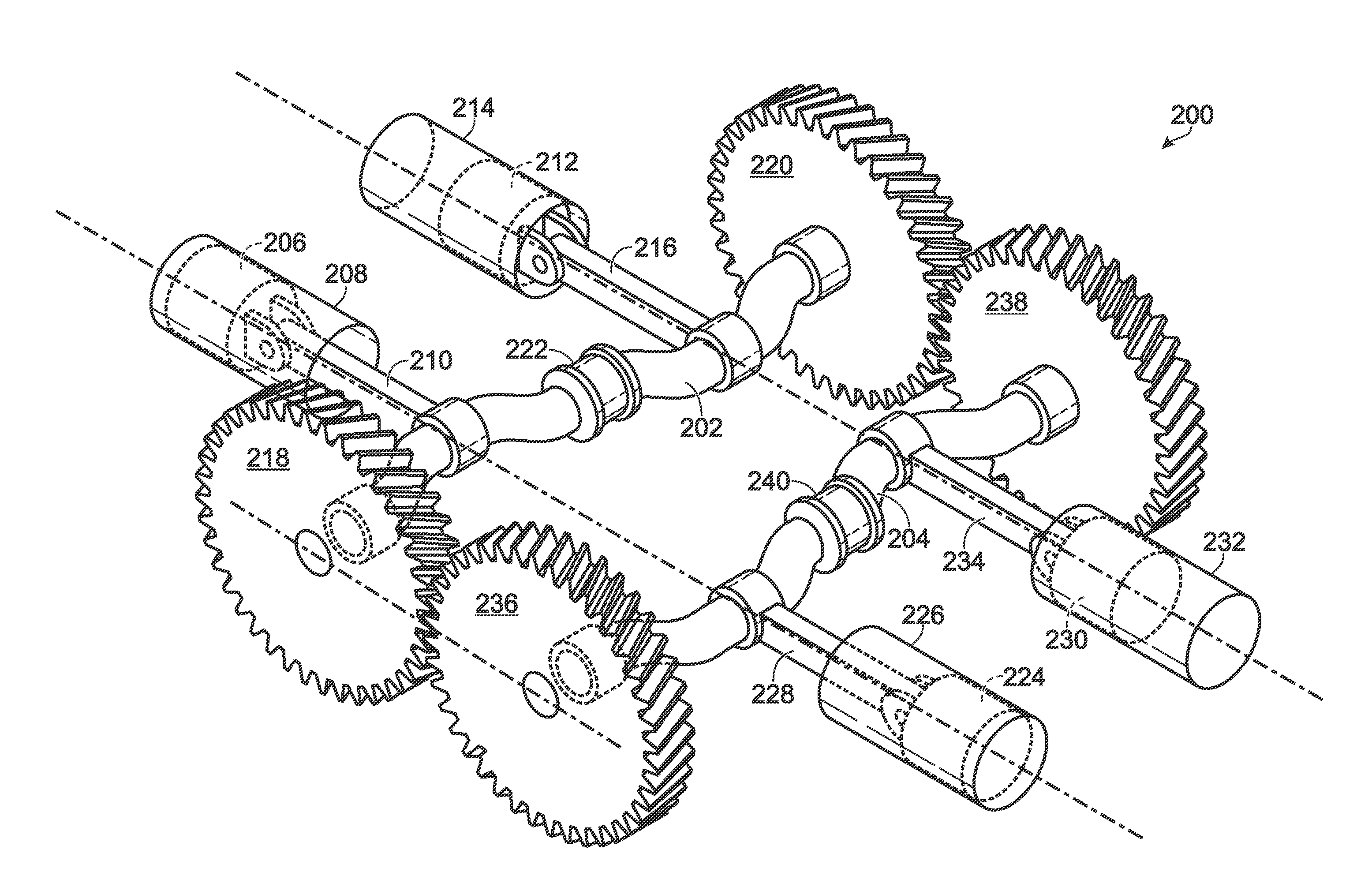

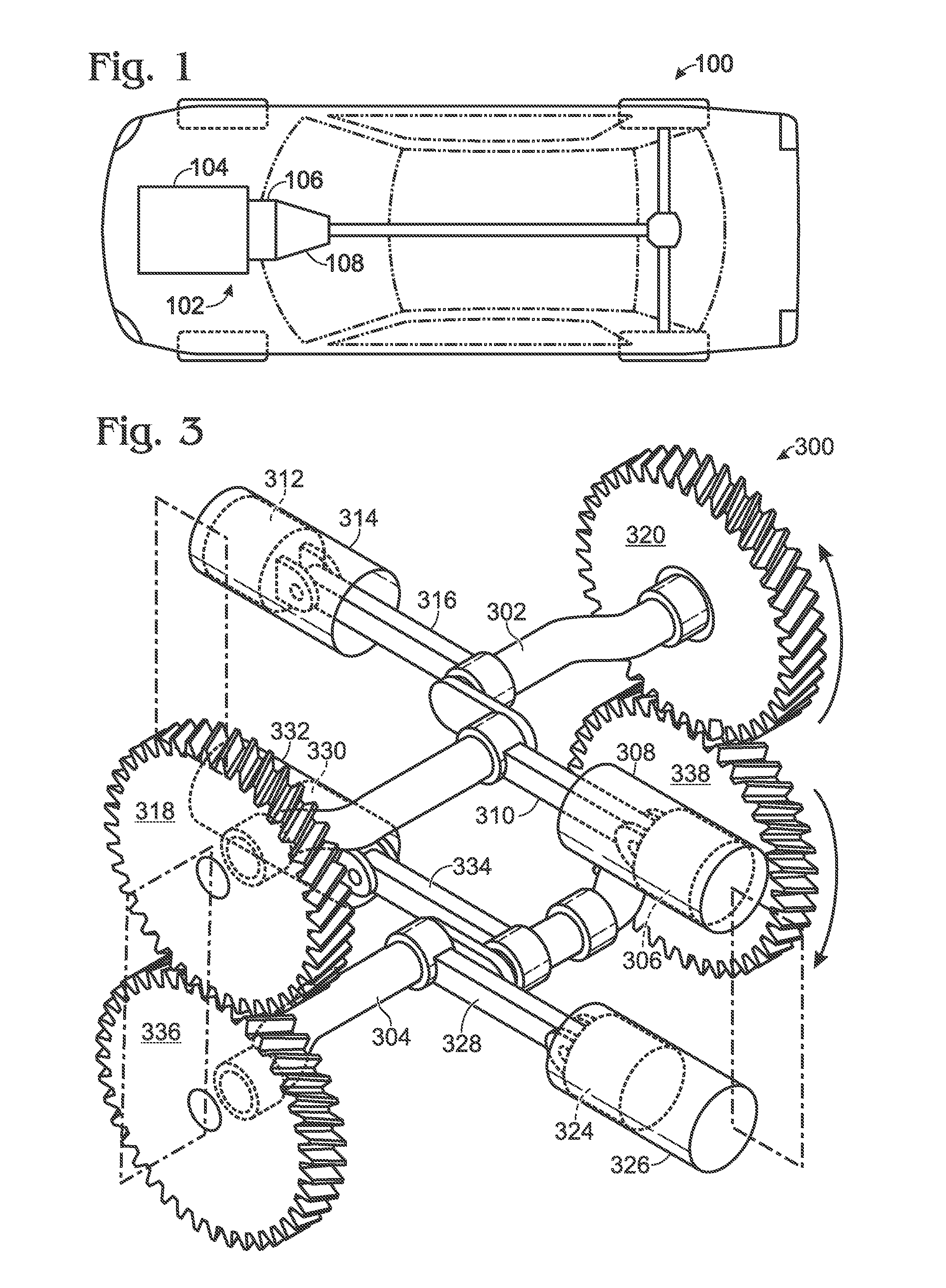

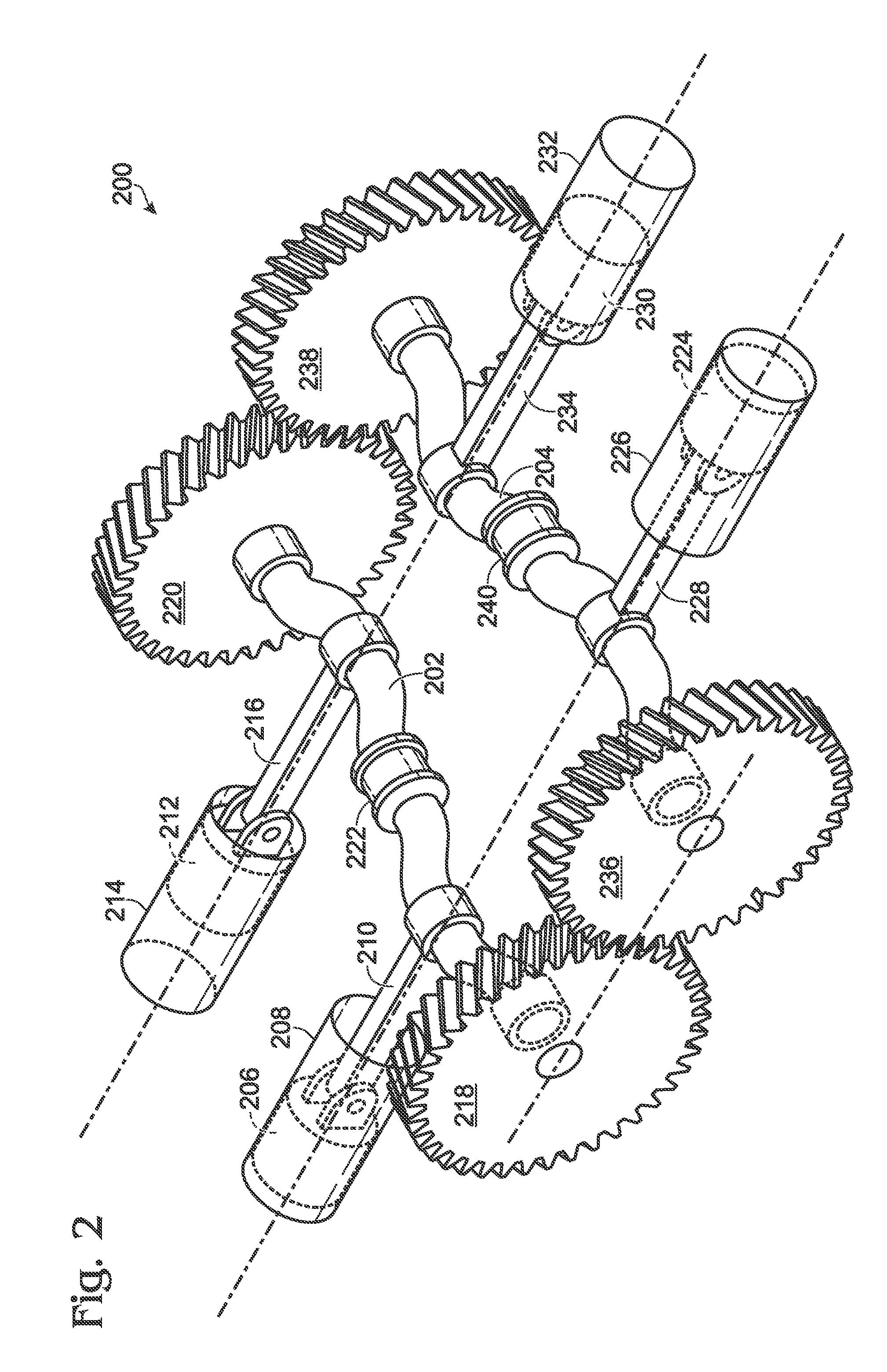

InactiveUS20130239930A1Reduced support structureReduce noiseInertia force compensationCombustion enginesReciprocating motionEngineering

A dual-crankshaft engine is presented. In one embodiment, the engine includes a first crankshaft and a second crankshaft. The second crankshaft is coupled with the first crankshaft such that the first crankshaft and the second crankshaft are horizontally coplanar. The engine further includes a first piston that is operable to reciprocate in a first horizontal cylinder via coupling with the first crankshaft, and a second piston that is operable to reciprocate in a second horizontal cylinder via coupling with the second crankshaft. The second horizontal cylinder is horizontally collinear with and opposing the first horizontal cylinder.

Owner:FORD GLOBAL TECH LLC

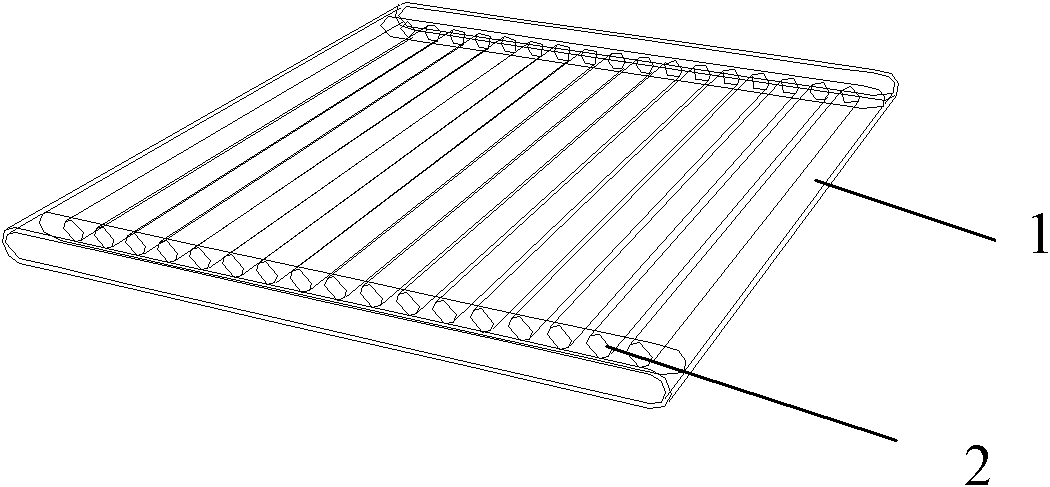

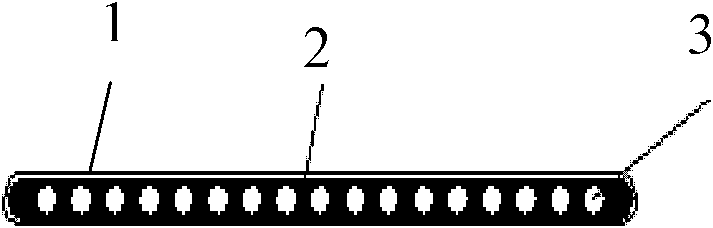

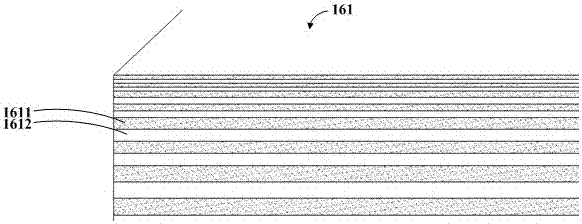

Sintered flat plate heat pipe and manufacturing method thereof

InactiveCN101839663AReduced support structureAvoid Tube Expansion ProblemsIndirect heat exchangersMetal powderHeat pipe

The invention relates to a sintered flat plate heat pipe. The sintered flat plate heat pipe comprises a metal shell and a porous capillary structure arranged inside the metal shell, wherein the metal shell is a sealed flat shell, and the porous capillary structure is connected with two inner walls of the sealed flat shell. The sintered flat plate heat pipe can save a support structure in the prior art so as to avoid the problems of pipe expansion and steam flow disturbance caused by the support structure. The invention also relates to a manufacturing method for the sintered flat plate heat pipe. The manufacturing method comprises the following steps of: A, cutting a hollow metal pipe with predetermined size and two open ends; B, beating the hollow metal pipe to form a flat shape; C, inserting a central bar into the metal pipe and filling metal powder into the flat metal shell; D, molding the filled metal powder into the porous capillary structure with sintering; and E, extracting the central bar, pressing and sealing the two ends of the metal pipe, and the like. The heat pipe obtained by the manufacturing method does not need to be welded with the support structure so as to avoid the problems of pipe expansion and steam flow disturbance caused by the support structure.

Owner:锘威科技(深圳)有限公司

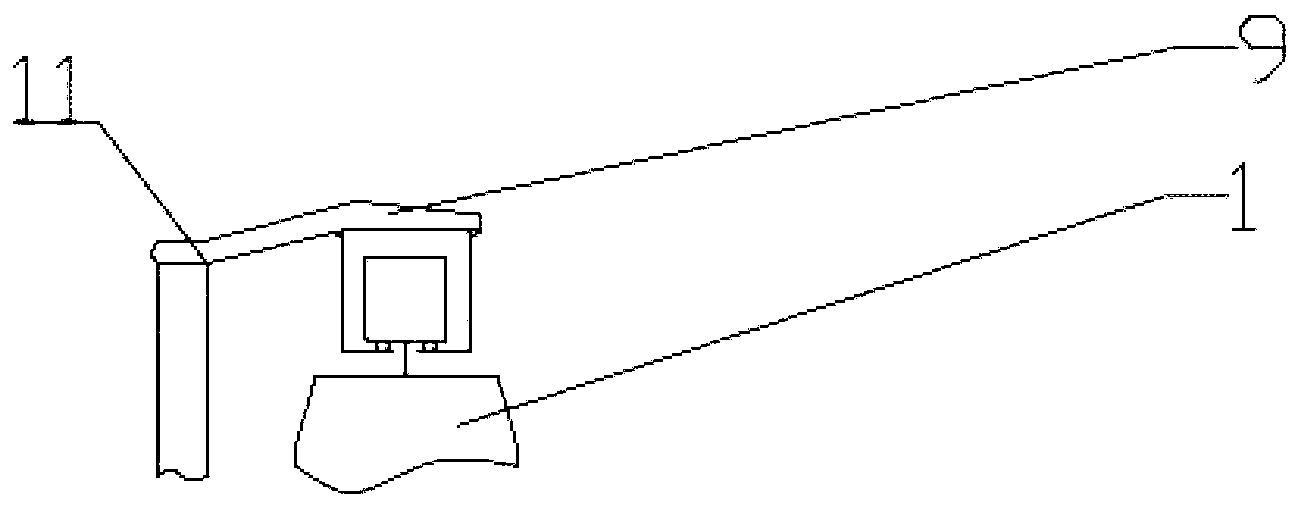

Improved air rail transit system for passenger transport

InactiveCN103010219AReduced support structureReduce the amount of underground foundationElevated railway with suspended vehicleBogieEngineering

The invention is an improved air rail transit system for passenger transport. The system adopts the structure that L-shaped and Y-shaped supporting arms are arranged along lines to support a guide rail beam at the lower part, a bogie trolley travels in a guide rail, a passenger carriage is positioned below a track, two steel rails are arranged on the upper surface of a track beam in an air track beam box body, and the bogie trolley travels to and fro on the steel rails in the track beam. The invention can effectively reduce fractional resistance, lower energy consumption, and improve comfortable level of passengers; and since the bogie trolley employing steel wheels travels on the steel rails, upper and lower guiding wheels are not needed to be arranged on the bogie trolley, thereby simplifying the mechanism of the bogie trolley and reducing the maintenance workload.

Owner:HENAN ZHONGGONG CRANE GRP

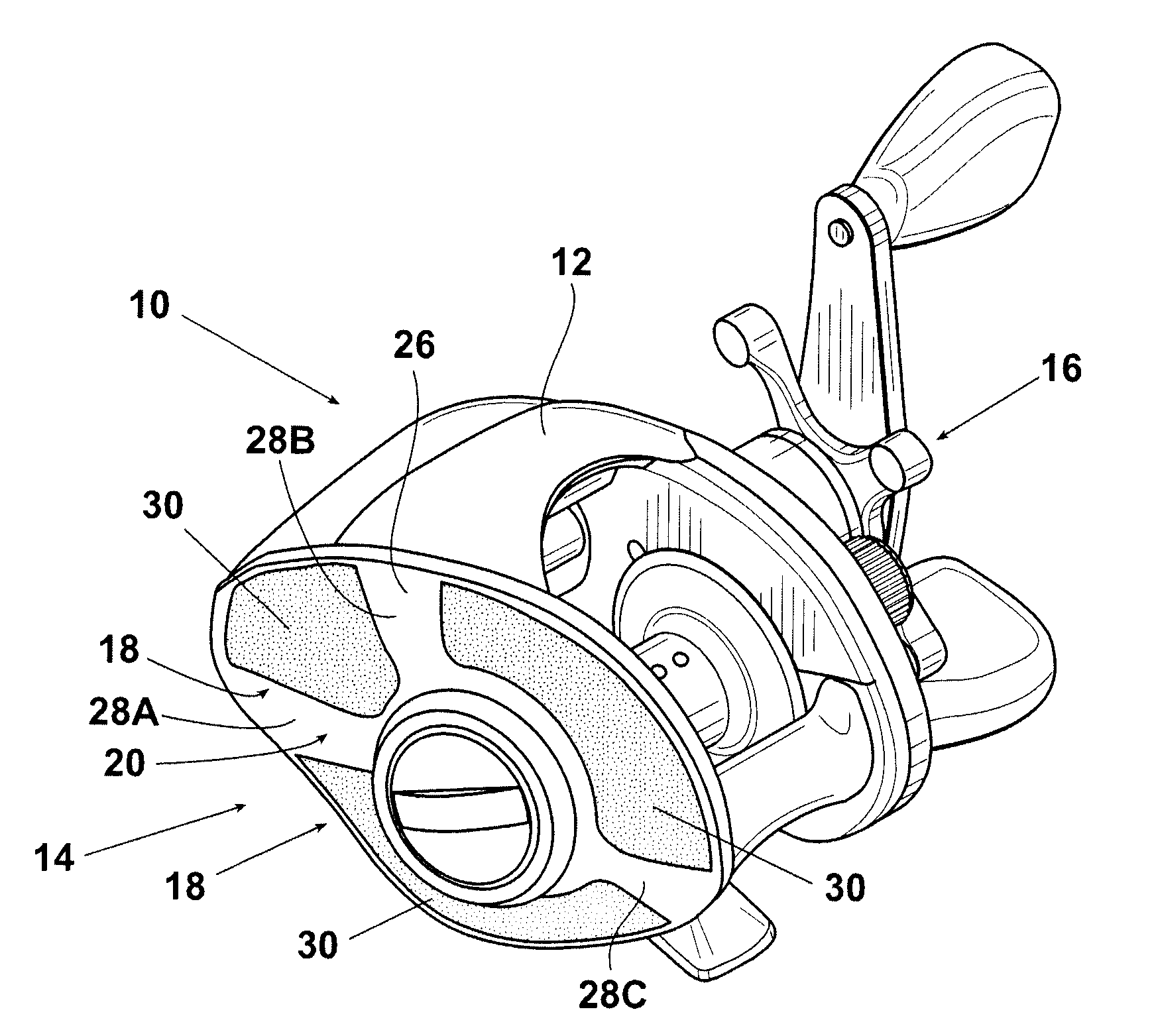

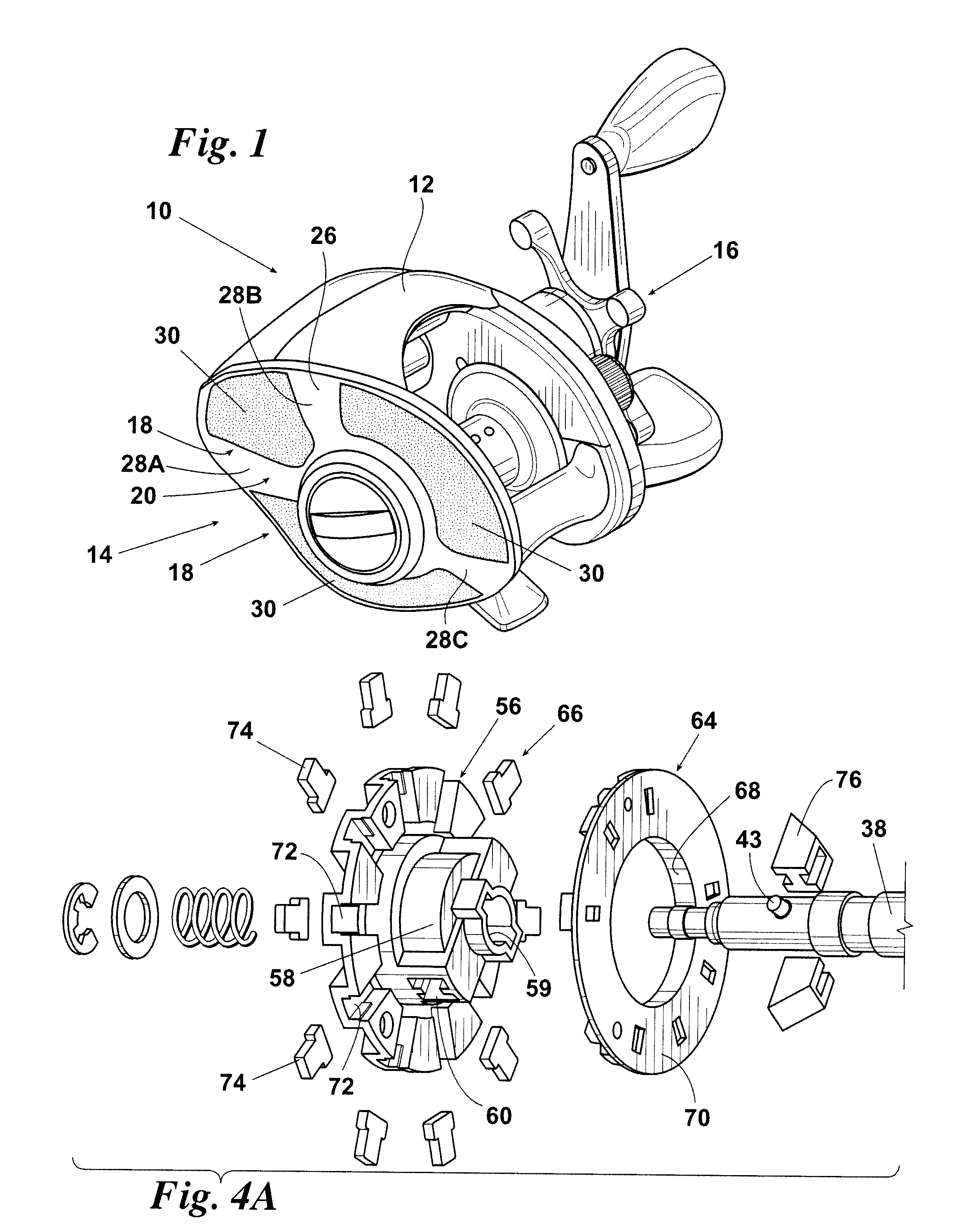

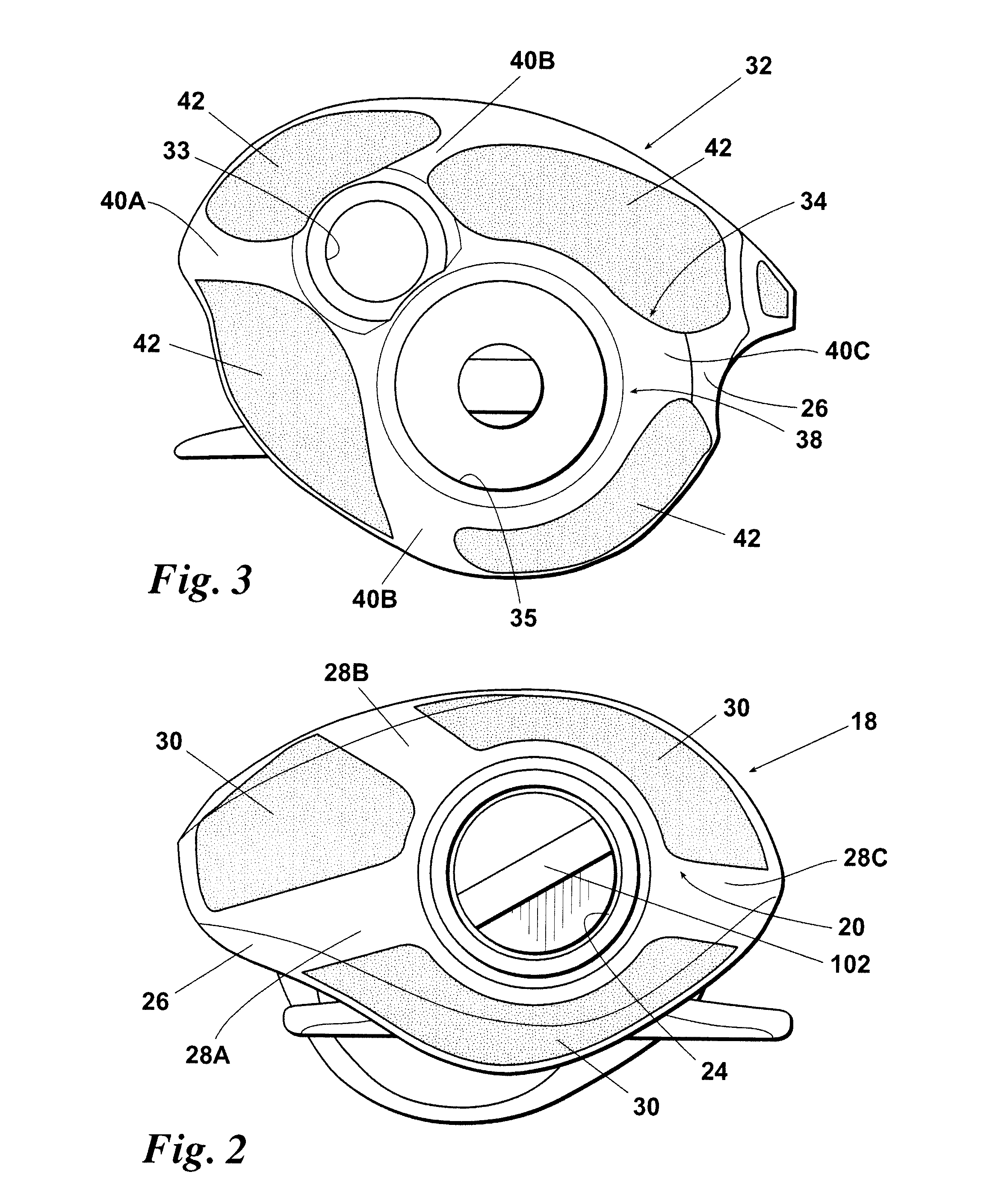

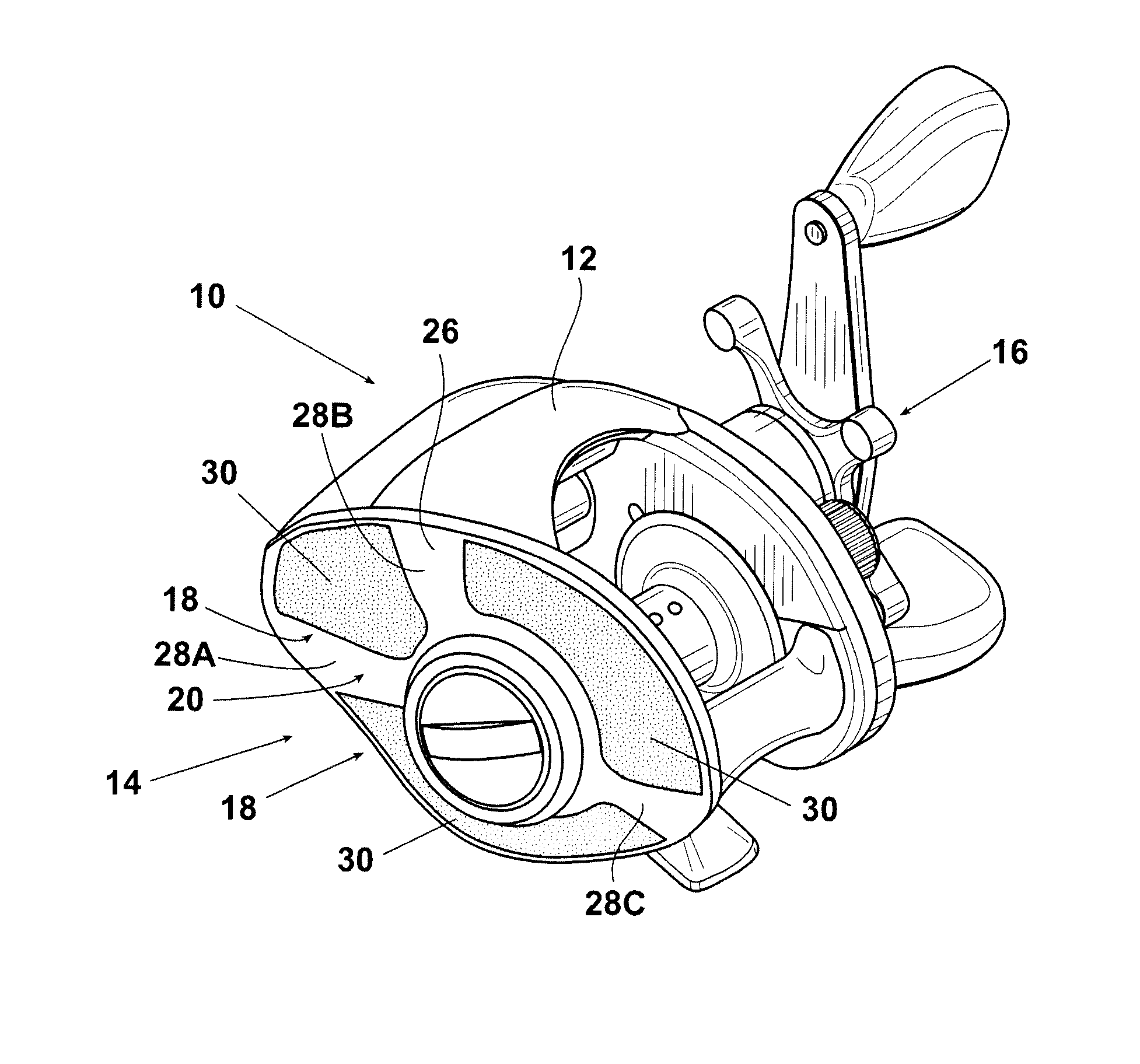

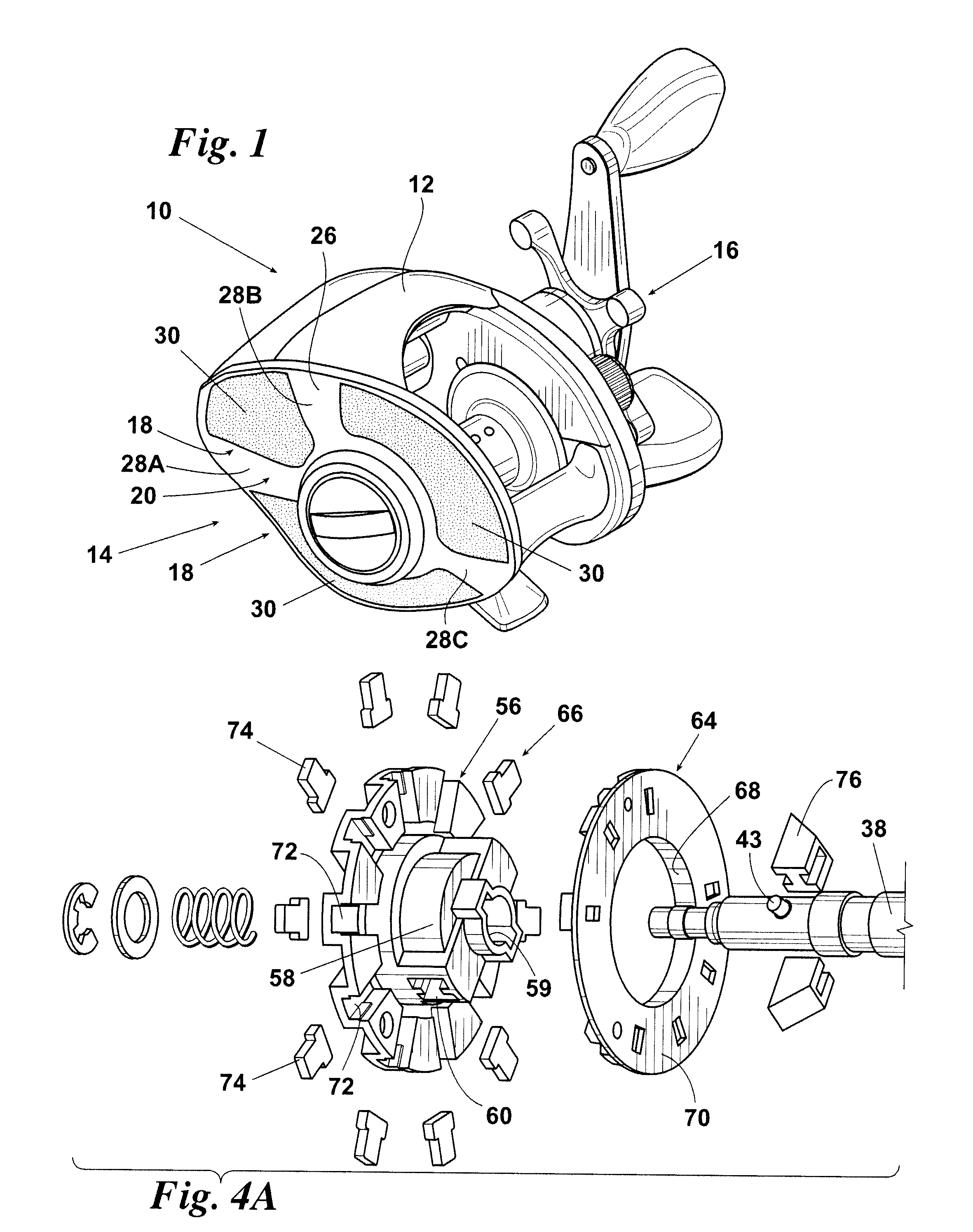

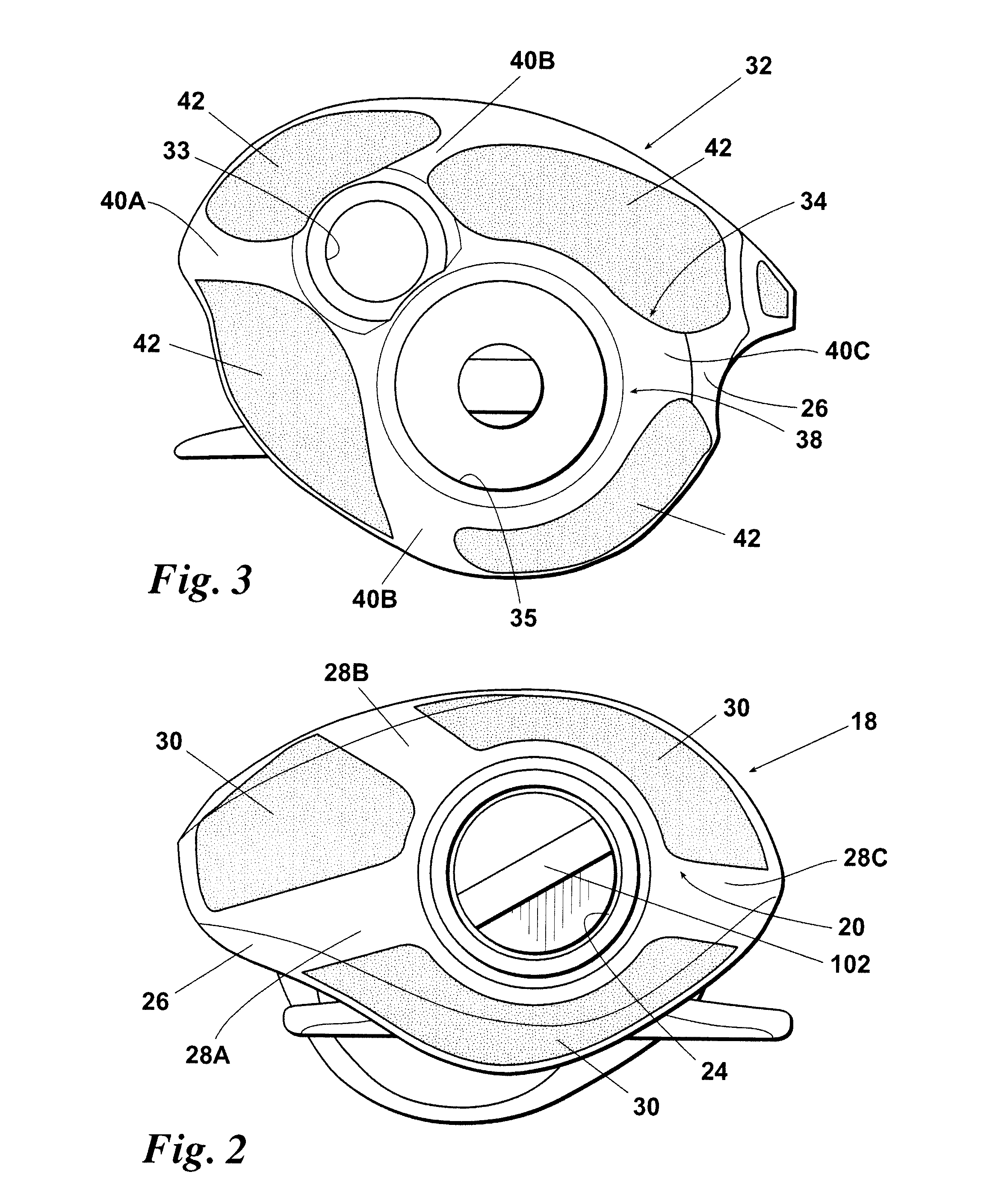

Skeletalized reel side plate

A fishing reel has a frame. A first cover assembly is affixed to a first side of the frame. A second cover assembly is affixed to a second side of the frame. At least one of the first cover assembly and the second cover assembly define at least one opening for receiving a panel member. The cover assemblies define supporting structure that is preferably made of a metal. The panel member defines non-supporting structure that is preferably made up of non-metallic structure such as plastic polymer and carbon fiber. The panel member may be transparent and is preferably replaceable to allow a user to customize the appearance of the reel.

Owner:ZEBCO HLDG LLC

Shock absorbing steering column of low tilt type

InactiveUS7125047B2Avoid interferenceReduced support structureSteering columnsForward slidingSteering column

A vehicular steering column of a low tilt type is supported to a body at upper and lower portions thereof to be tilted in whole about a hinge joint located on the lower portion, and more particularly to a shock absorbing steering column is designed to allow a steering column to slide forward when a vehicle driver gets a secondary shock against a steering wheel due to a vehicular collision, thereby absorbing a shock. In particular, the steering column is constructed in such a manner that, in order to absorb a shock in case of the vehicular collision, shock absorbing means is provided to a lower supporting structure of the steering column, and thus an initial shock imposed on the driver can be greatly decreased.

Owner:HYUNDAI MOBIS CO LTD

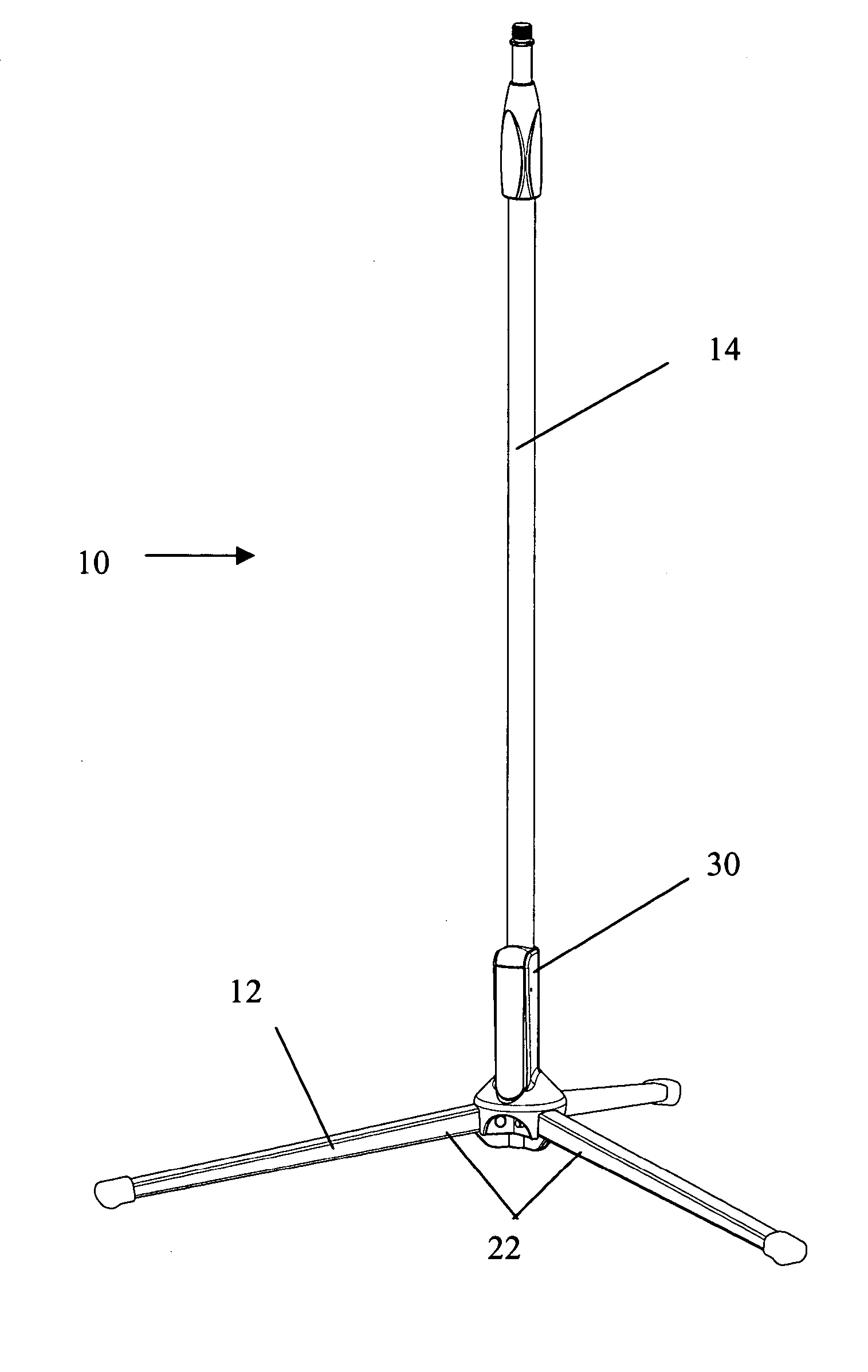

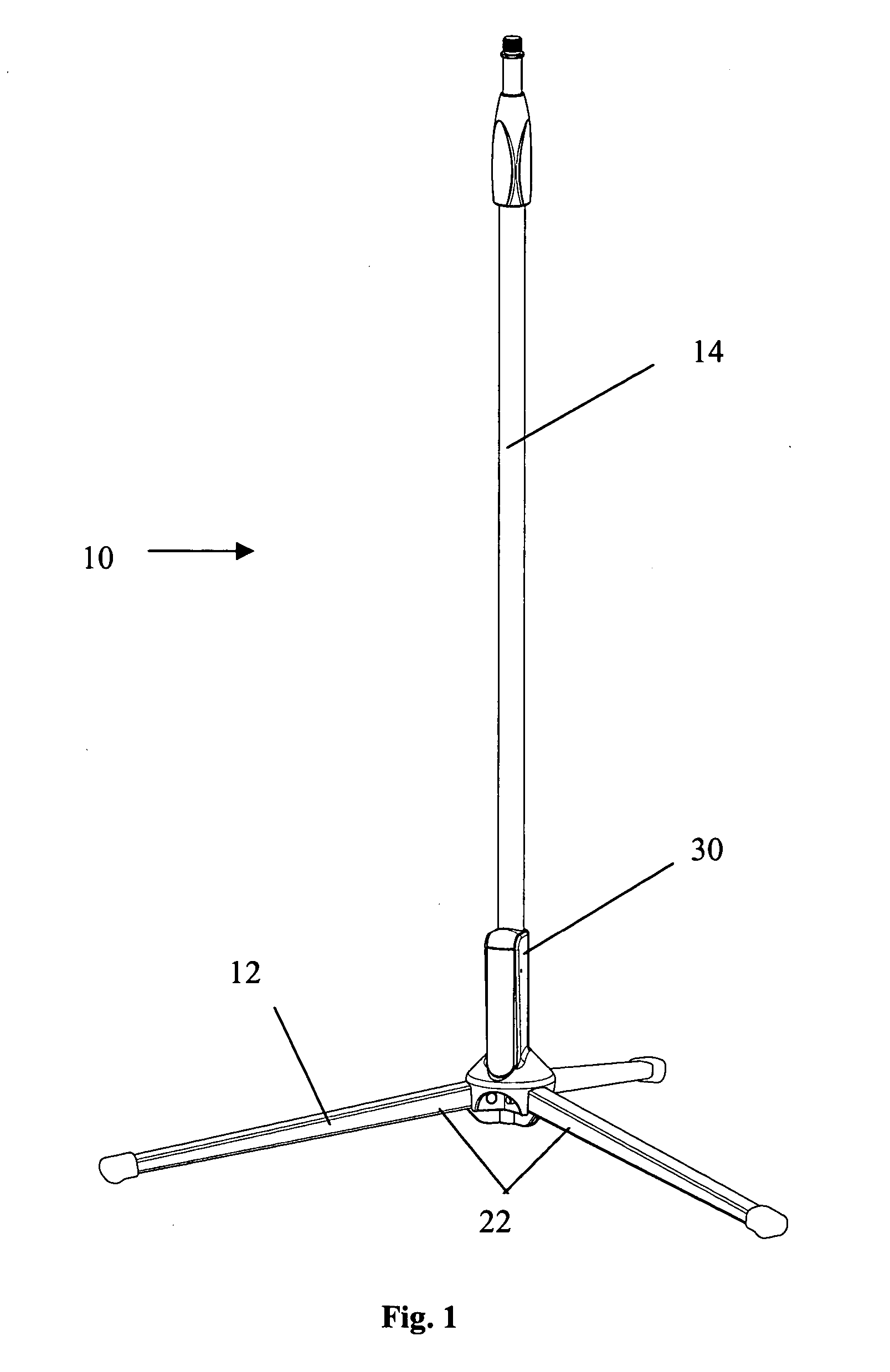

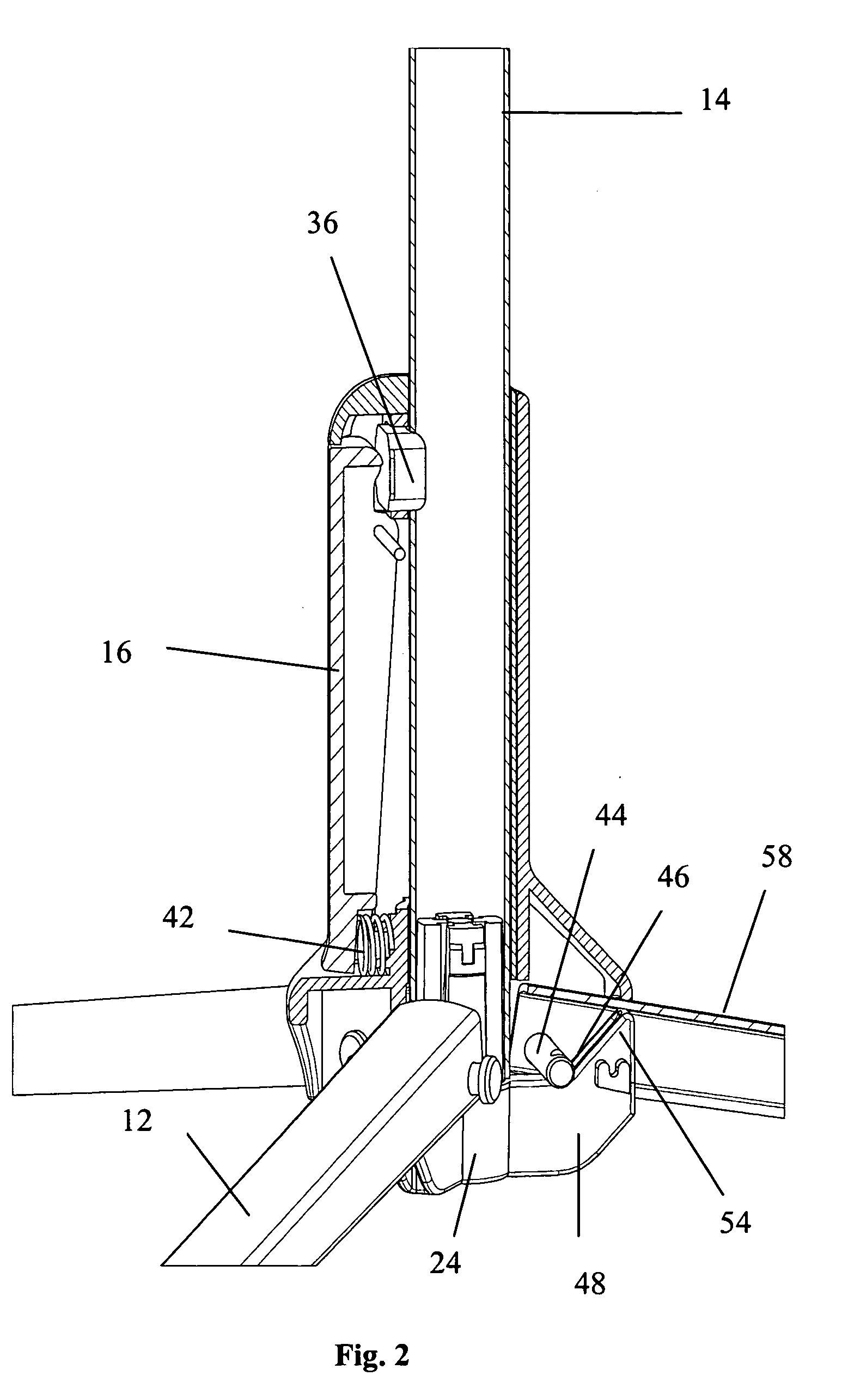

Reducible support structures having off-axis engagement

InactiveUS20050035247A1Different structureLow profileMouthpiece/microphone attachmentsStands/trestlesSupporting systemEngineering

A reducible support system for supporting various items is presented in various embodiments. A reducible support structure, may comprise an operation element which may be attached to an orthogonal element. Limbs, such as a tripod, may be attached to the operation element and a plug element may provide a slide so that the limbs or tripod may open and collapse easily.

Owner:ULTIMATE SUPPORT SYST

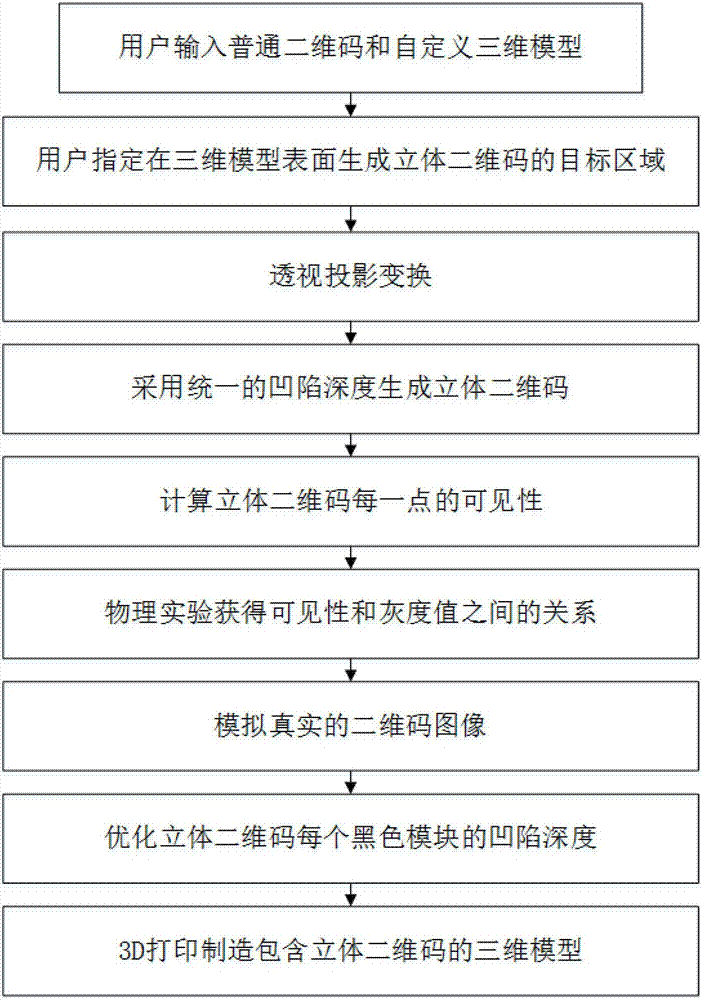

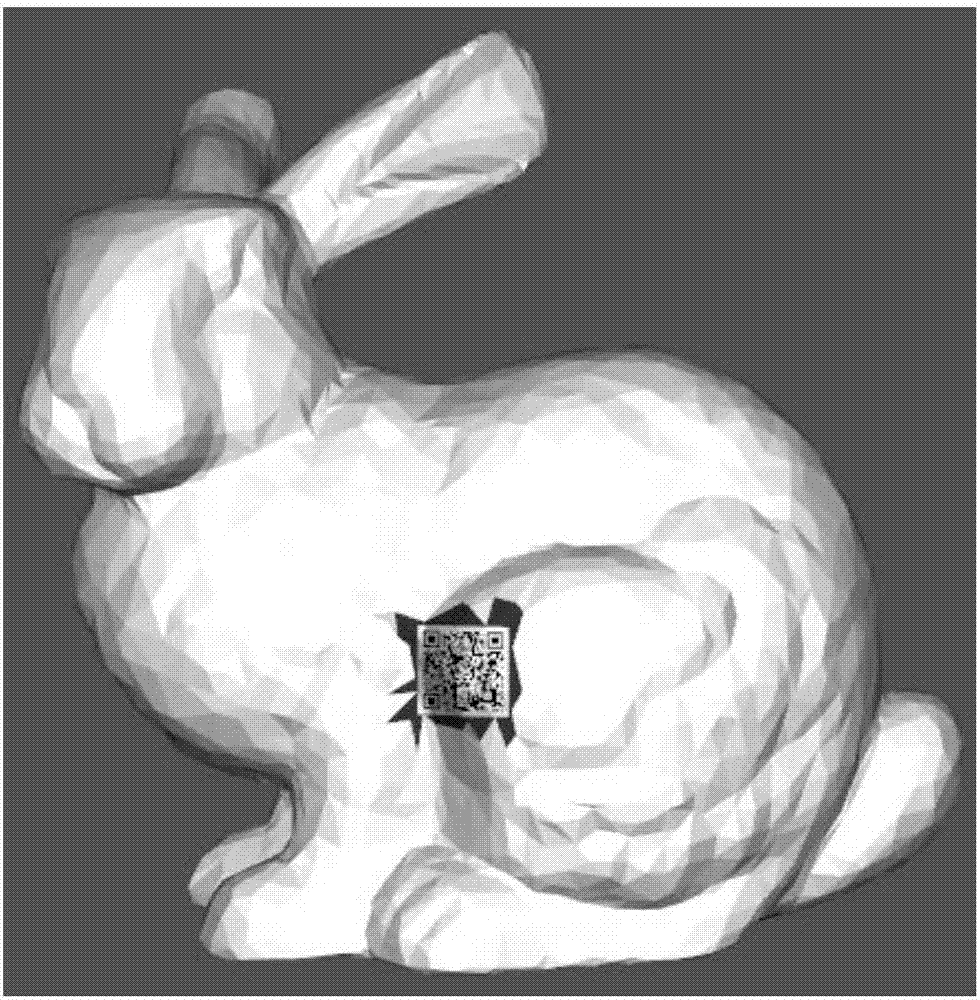

Improved self-defined model three-dimensional two-dimensional code generation method and system facing 3D printing

ActiveCN107145928AIncrease contrastImprove decoding success rateRecord carriers used with machinesCoding blockComputer graphics (images)

The present invention provides an improved self-defined model three-dimensional two-dimensional code generation method and system facing 3D printing. The method comprises: performing meshing and normalization processing of a self-defined model; employing the perspective projection transformation method to map two-dimensional codes to the target area of the self-defined model; performing hollowing operation according to a mapping result, and generating three-dimensional two-dimensional codes with the same hollowing depth at the surface of the self-defined 3D model; simulating a real two-dimensional code image through a physical experiment, and calculating the whole contrast of the three-dimensional two-dimensional codes and the contrast of each black module; optimizing the depth of the three-dimensional two-dimensional code block module according to the simulation result, and generating the three-dimensional two-dimensional codes; inputting the generated 3D model comprising the three-dimensional two-dimensional codes into a 3D printer, employing homogenous materials for printing, and finally outputting a 3D real object with the three-dimensional two-dimensional codes.

Owner:SHANDONG UNIV

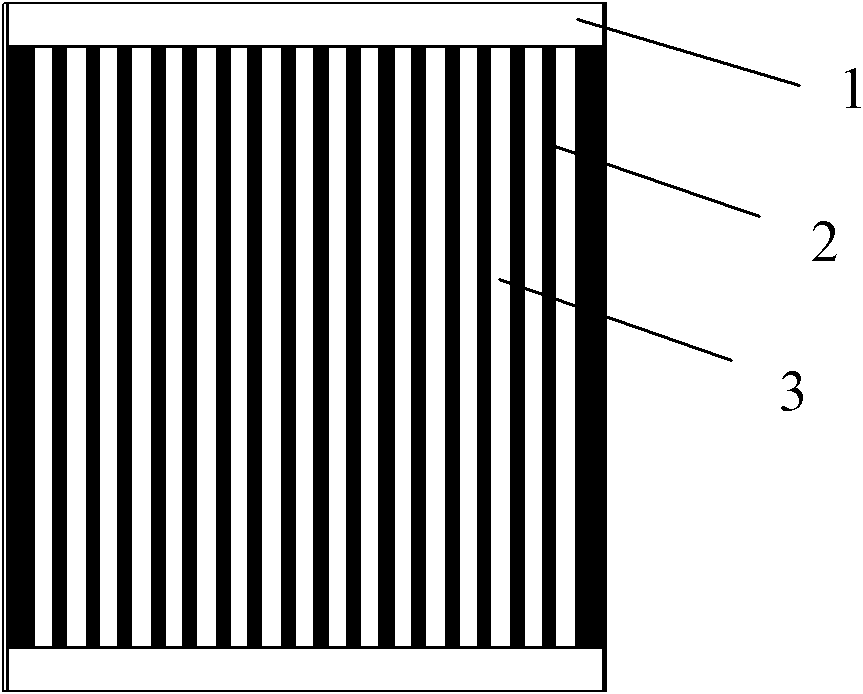

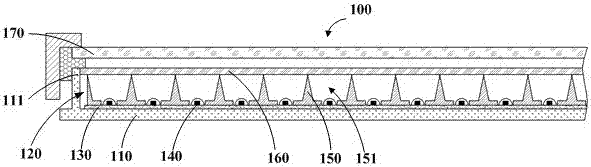

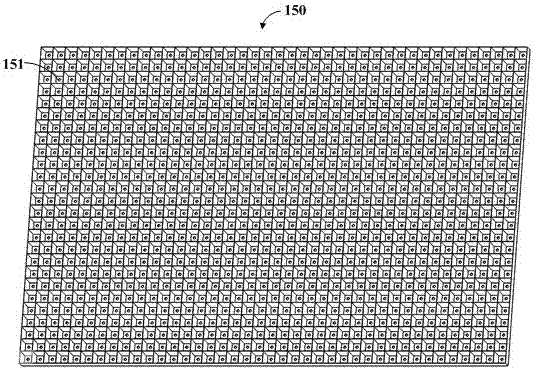

Liquid crystal module and liquid crystal display device

InactiveCN107884976AAchieve ultra-thinReduced support structureNon-linear opticsDiffusionLiquid-crystal display

The invention provides a liquid crystal module and a liquid crystal display device. The liquid crystal module is a direct type liquid crystal module and includes an optical film set and a grid-like optical component. The portion, corresponding to a light emitting unit, of the grid-like optical component is provided with a settling tank, the bottom of the settling tank is provided with an opening in which the light emitting unit can be accommodated, the inner wall of the settling tank is a reflection surface, and the disclosed liquid crystal display device includes a panel and the liquid crystal module. The problems that the light diffusion angle in an ultra-multi-subregion liquid crystal module is large, light overlapping is formed in adjacent subregions, and thus light convergence is notstrong is solved, and meanwhile the liquid crystal module is thinned.

Owner:HISENSE VISUAL TECH CO LTD

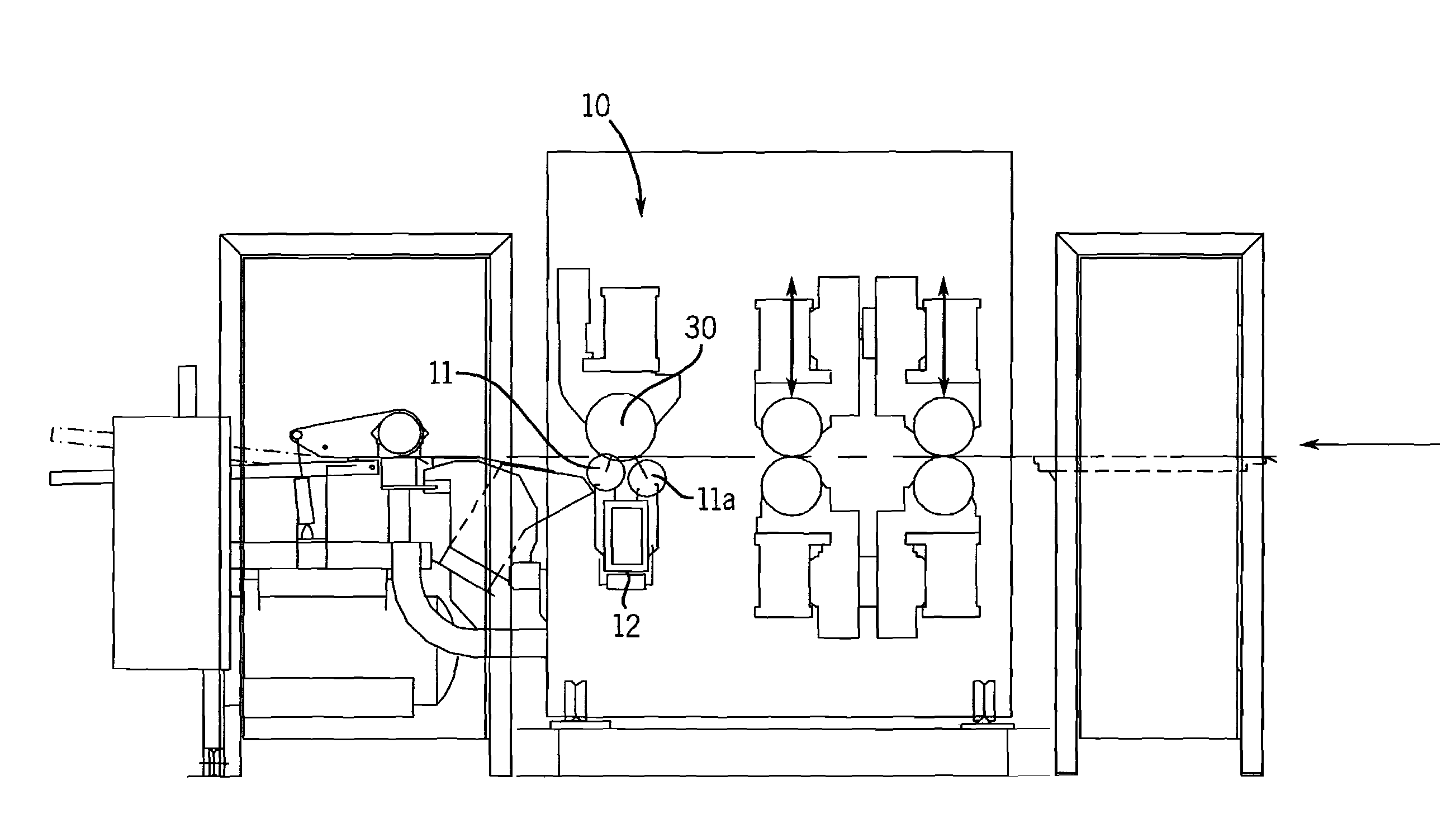

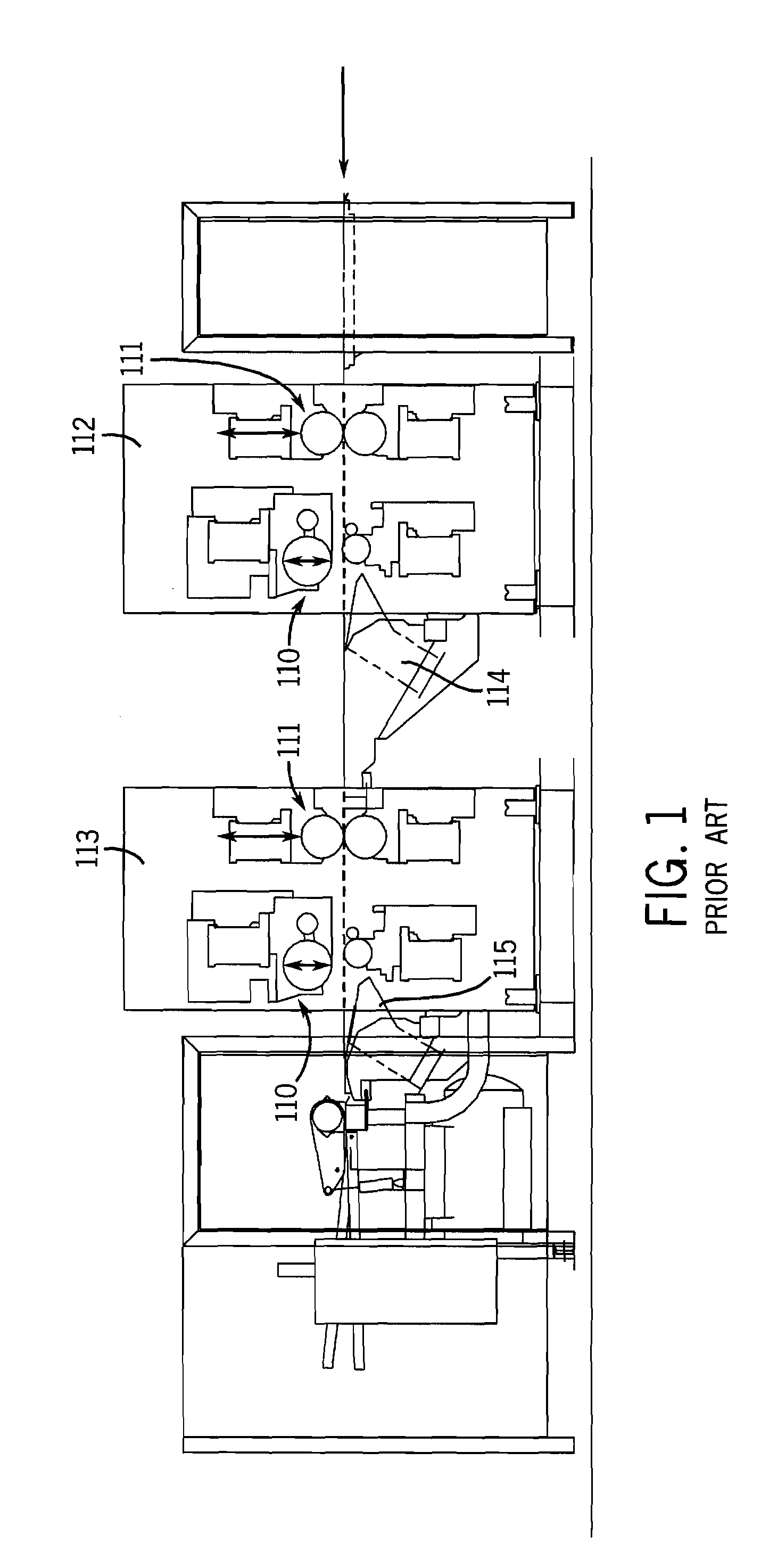

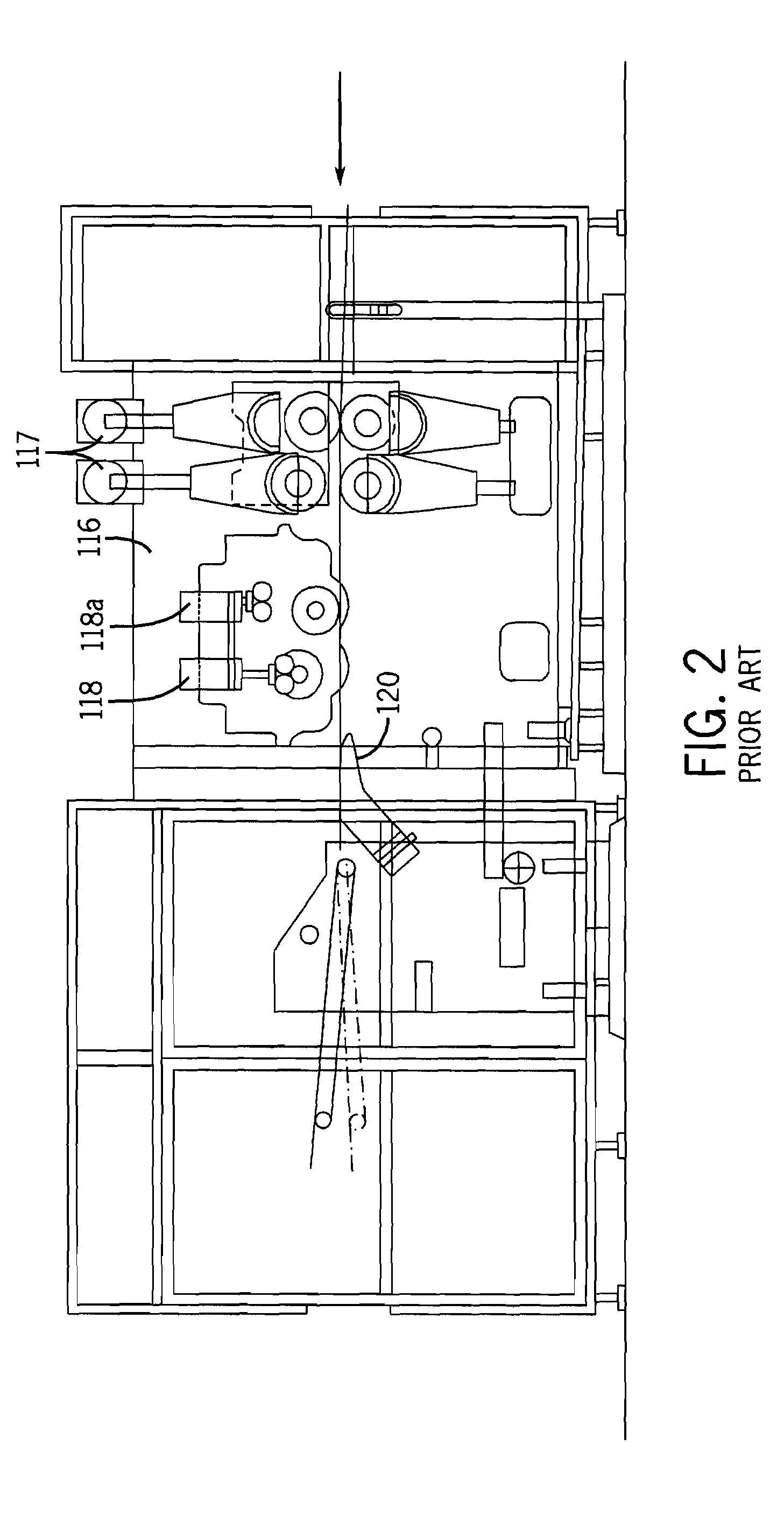

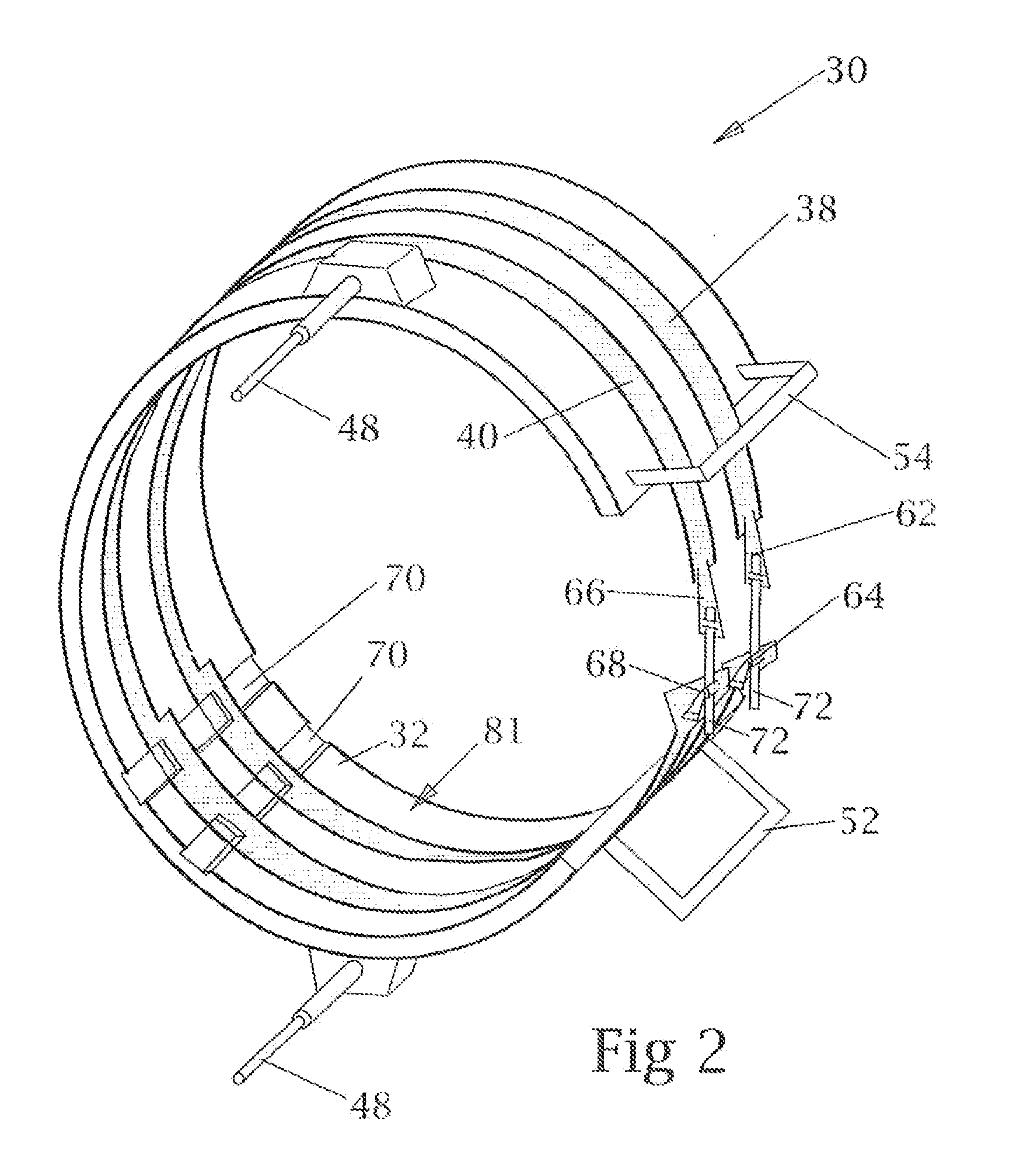

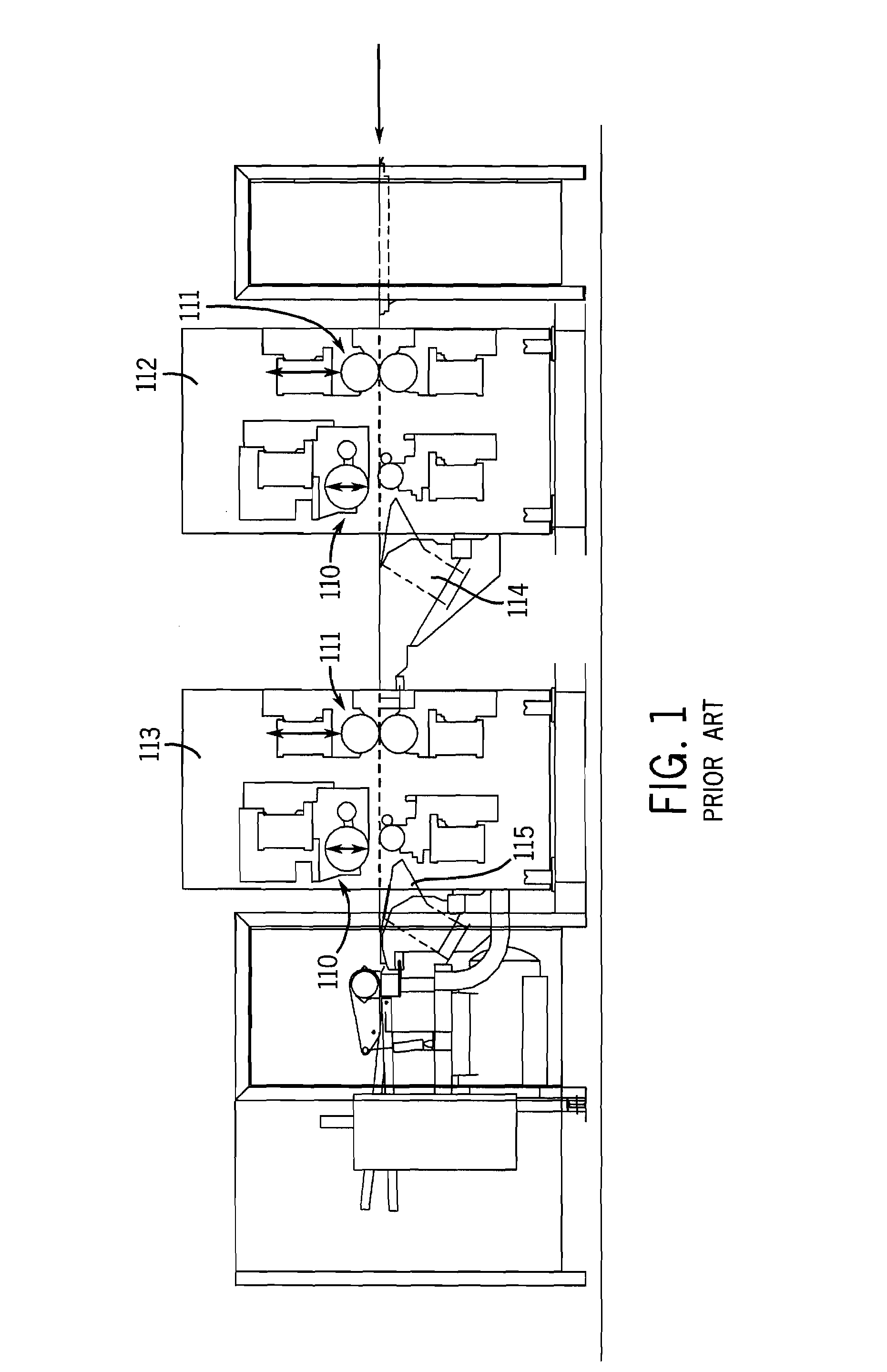

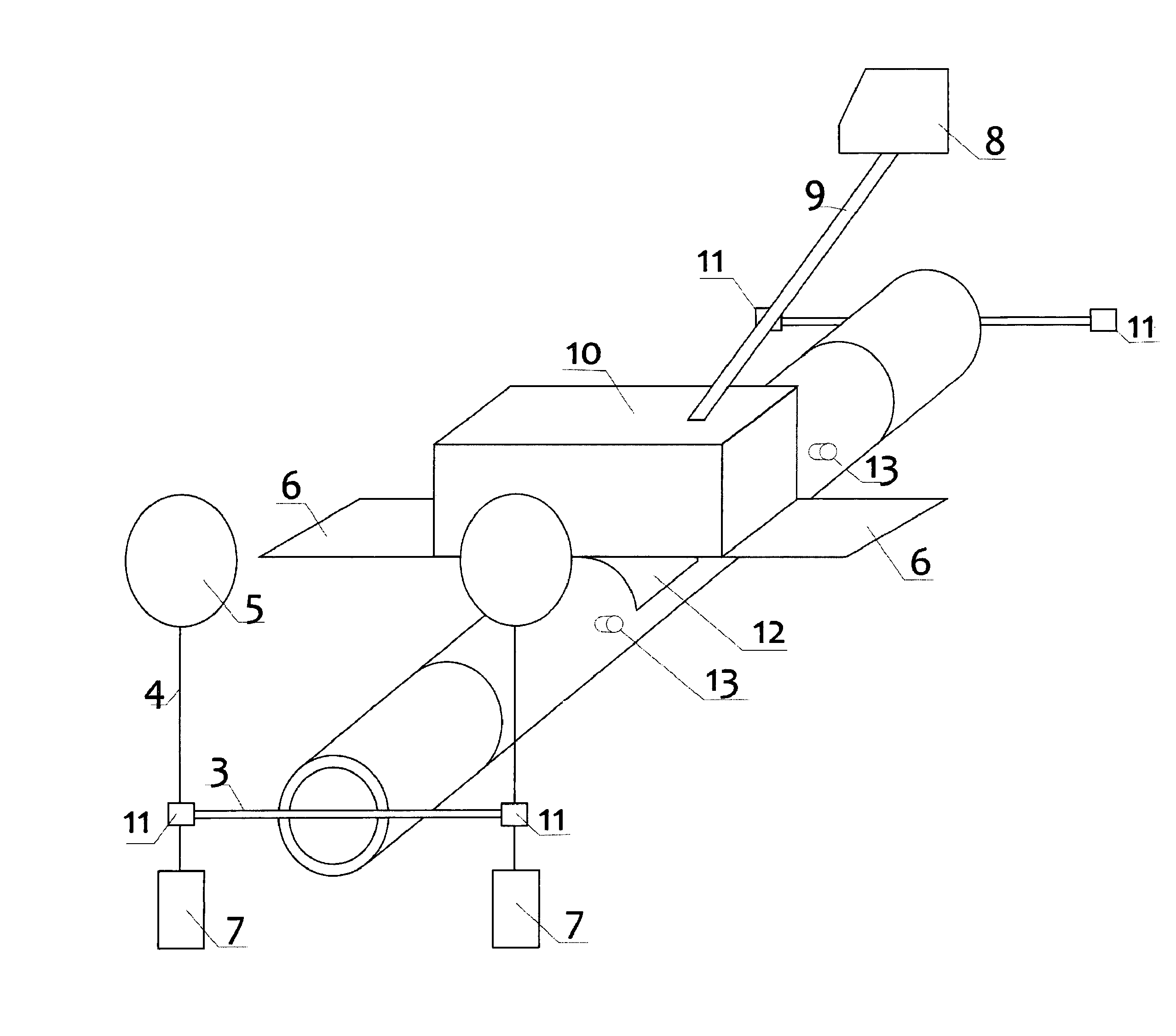

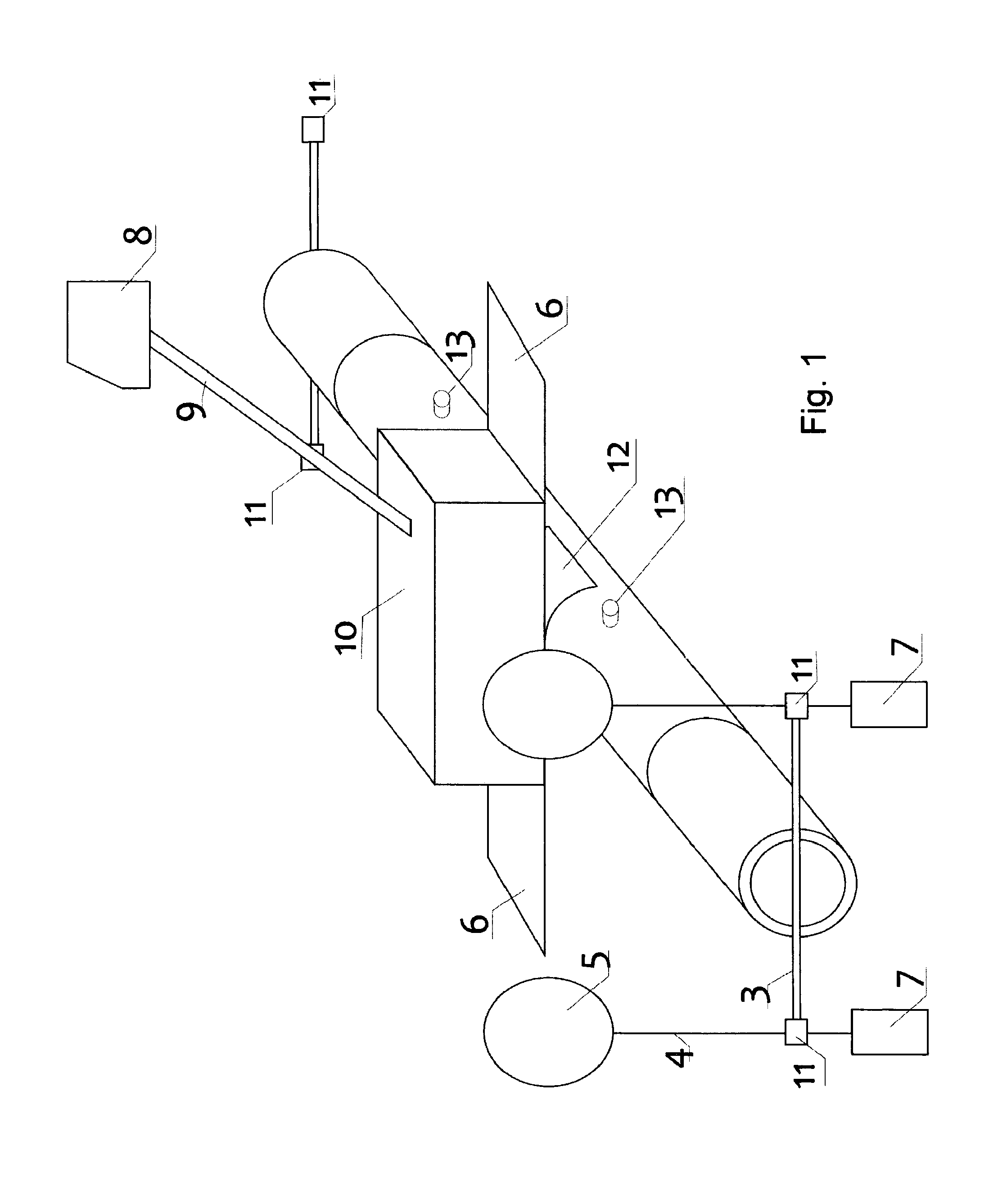

Method and Apparatus for a Rules-Based Utilization of a Minimum-Slit-Head Configuration Plunger Slitter

InactiveUS20100093508A1Length minimizationImprove order change-over reliabilityEnvelopes/bags making machineryMechanical working/deformationOrder schedulingMechanical engineering

A method and apparatus for performing an order change in a corrugator uses a minimum slit head configuration with all slit heads carried on two sides of a single tool support structure. A single robot is operable on the support structure to independently reset the positions of slit heads during a running order to prepare for subsequent order change in a most efficient manner, utilizing order scheduling that eliminates order changes that cannot be formed with the minimum slit head configuration.

Owner:BARRY WEHMILLER PAPERSYST INC

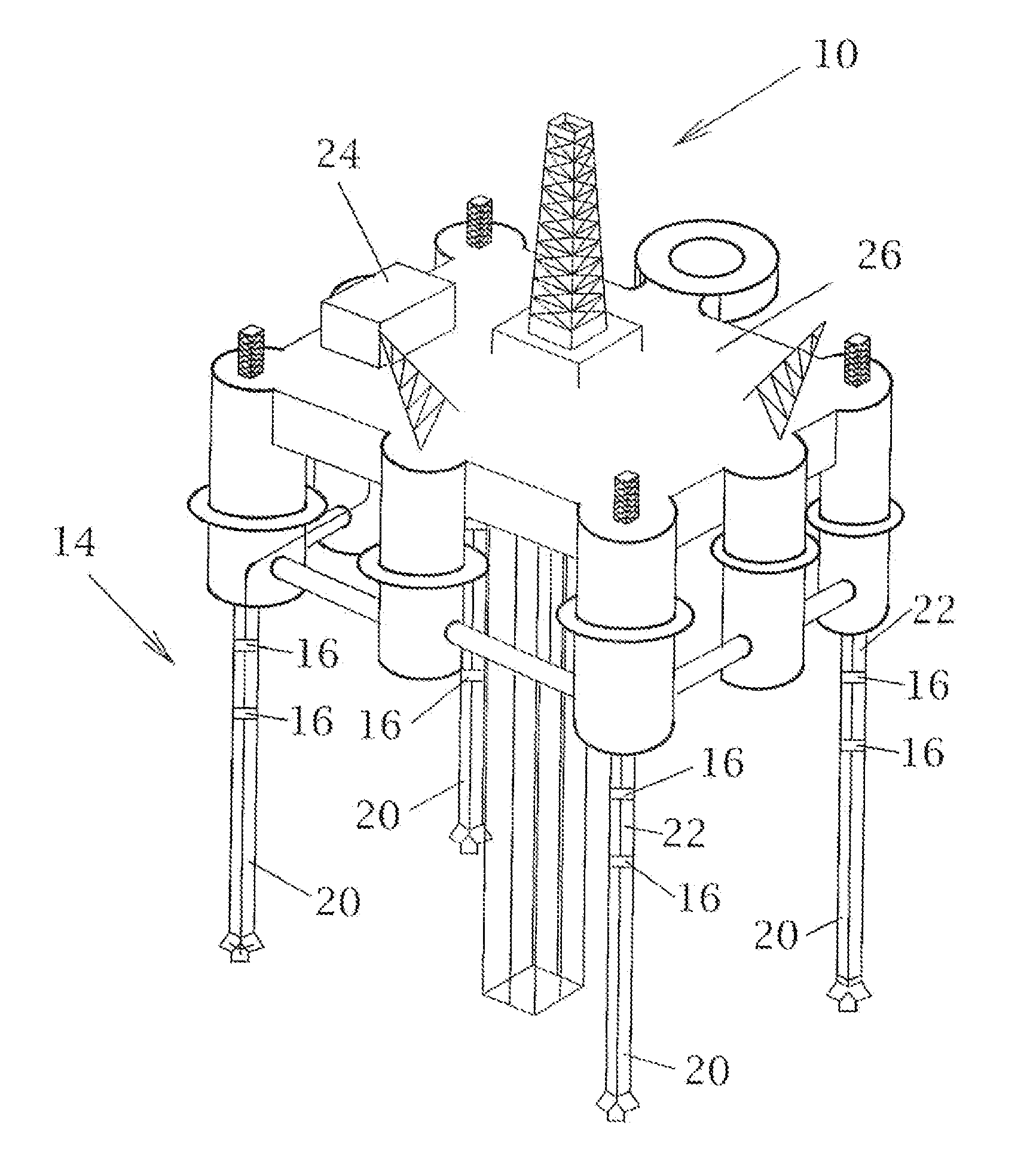

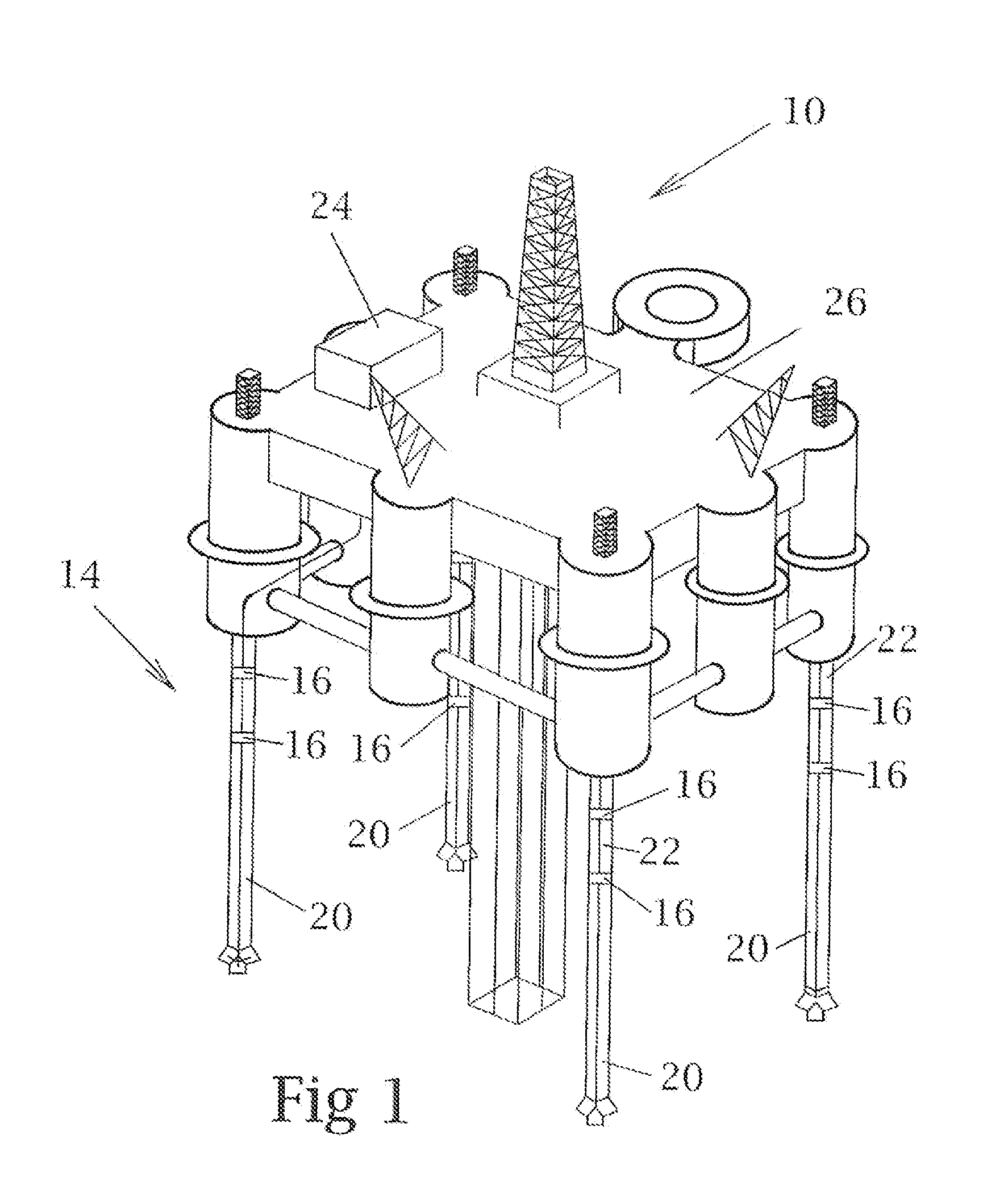

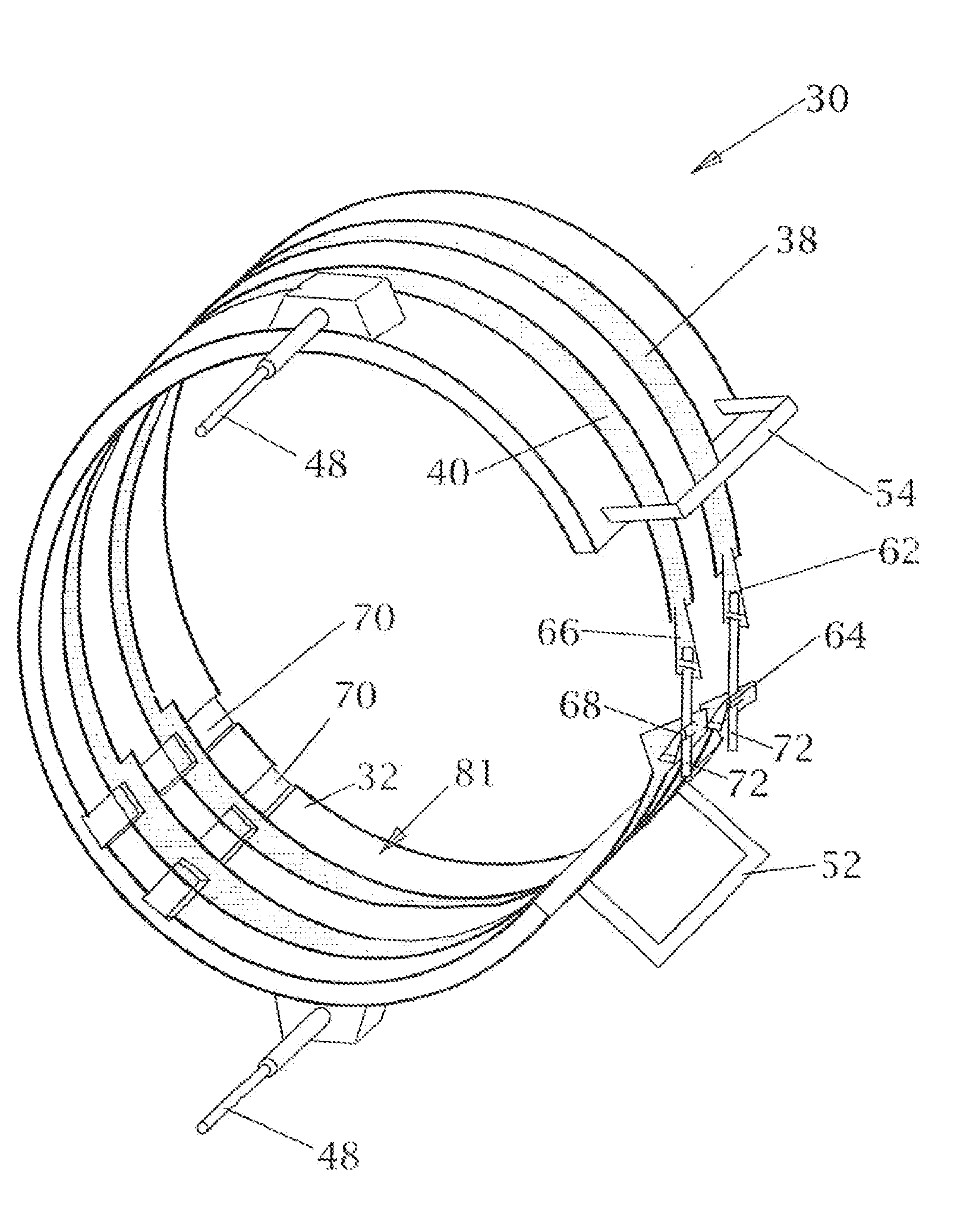

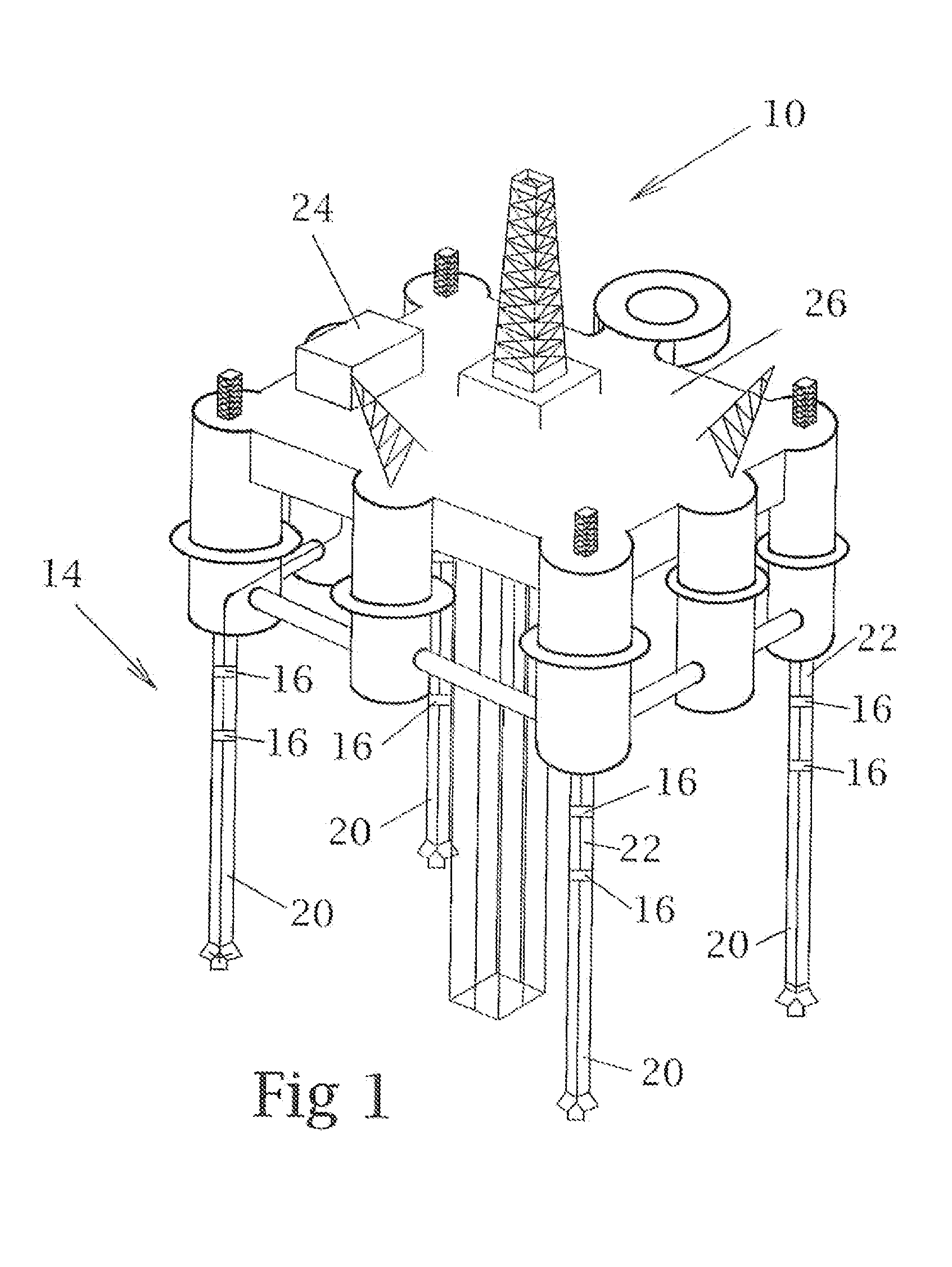

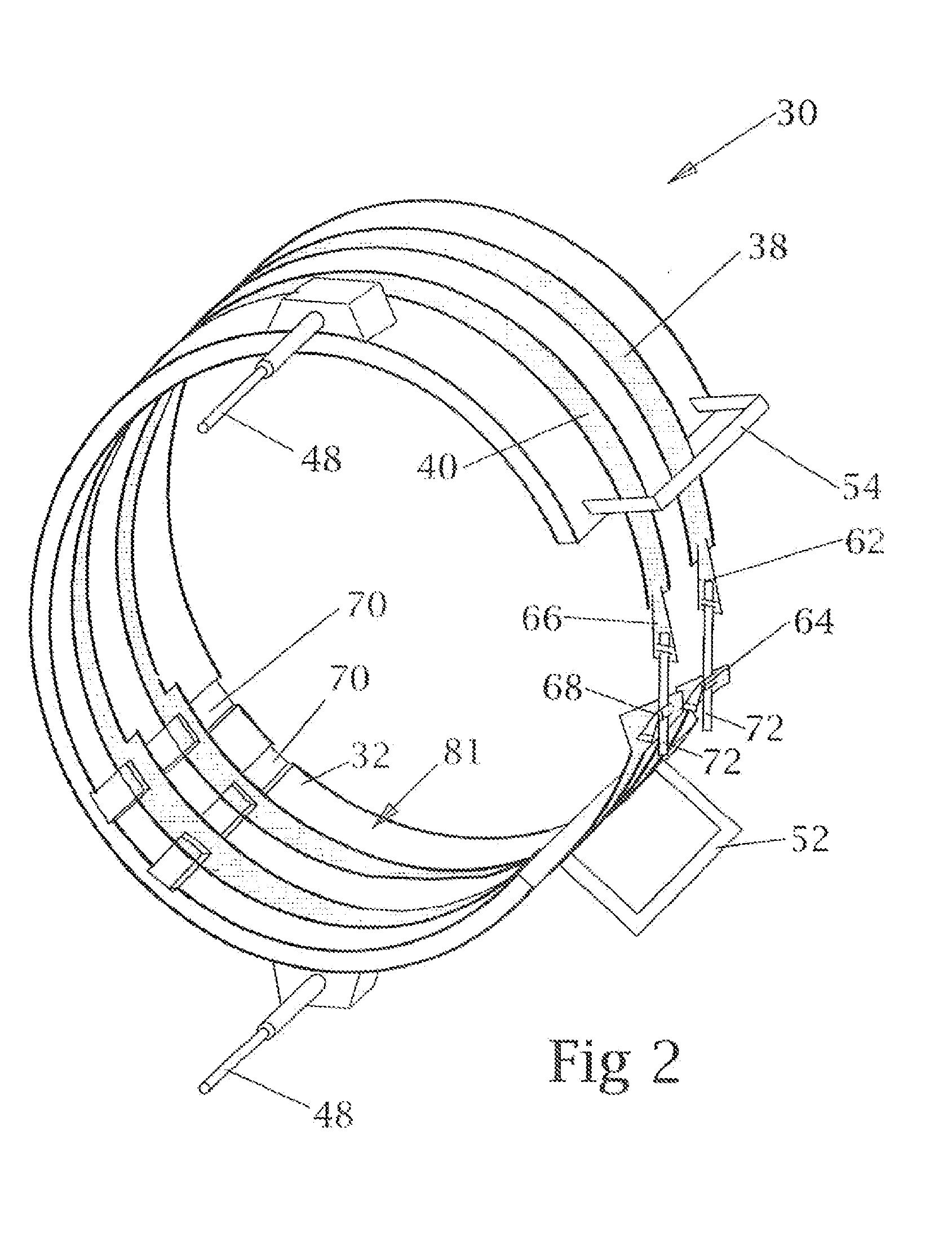

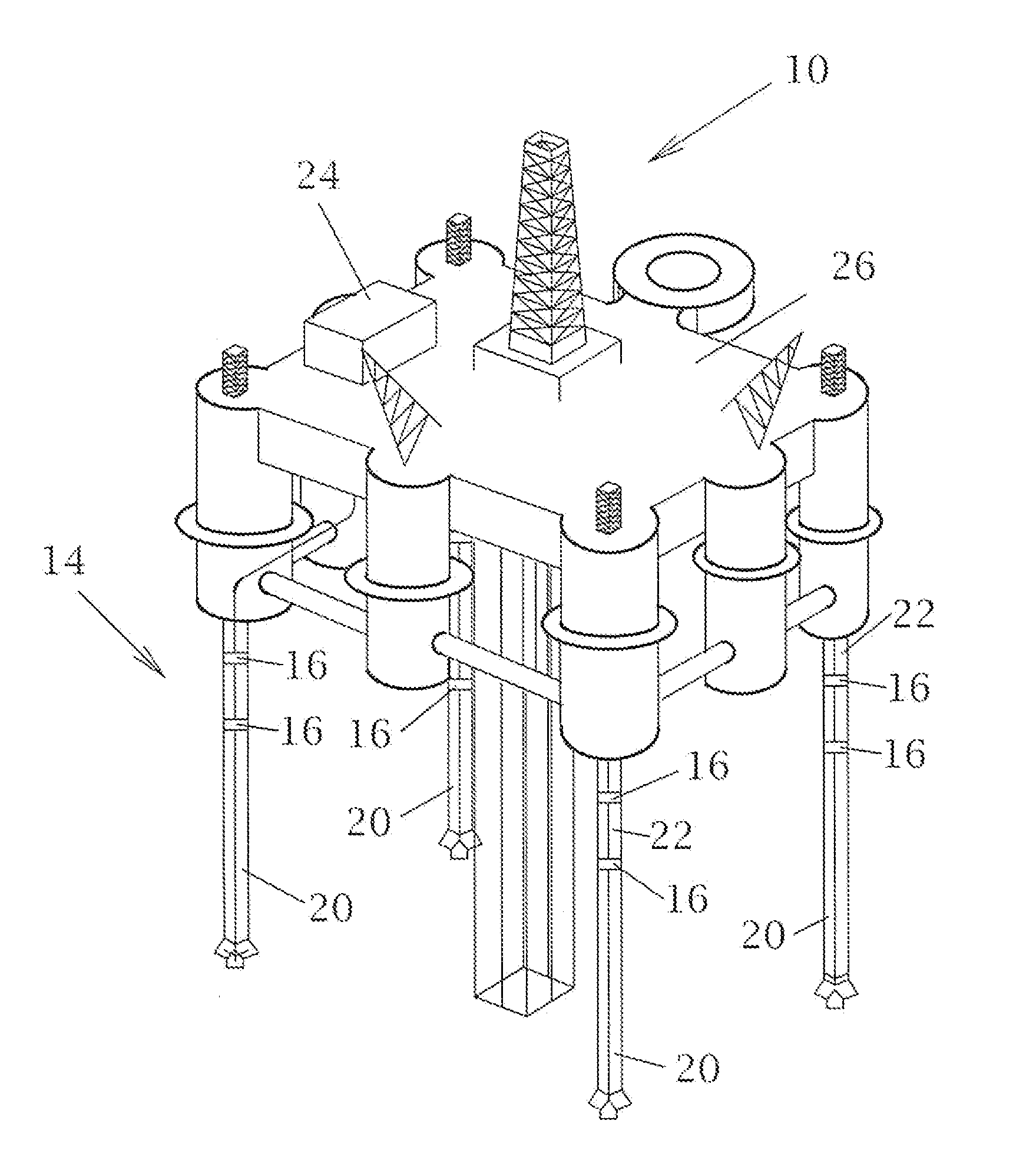

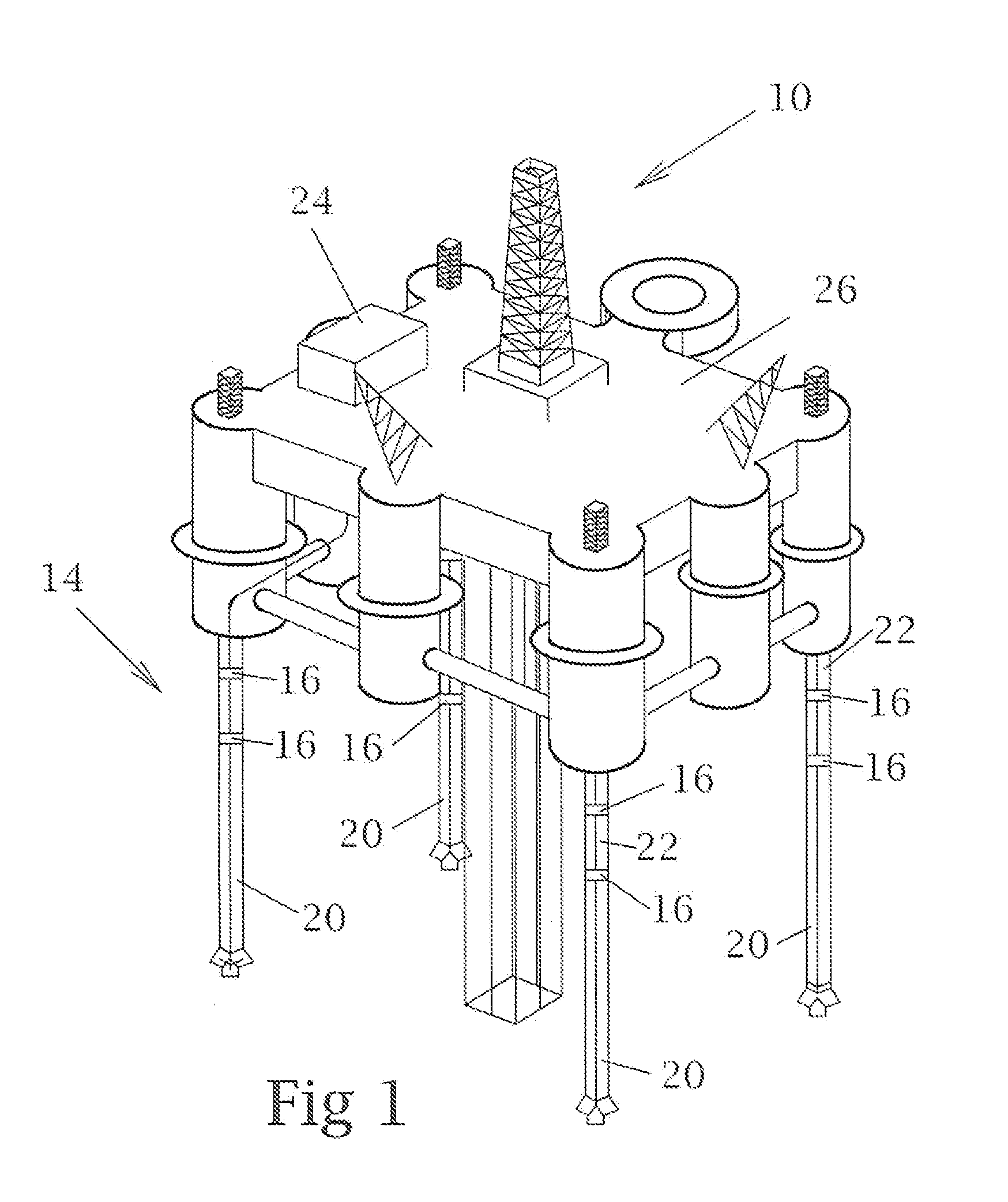

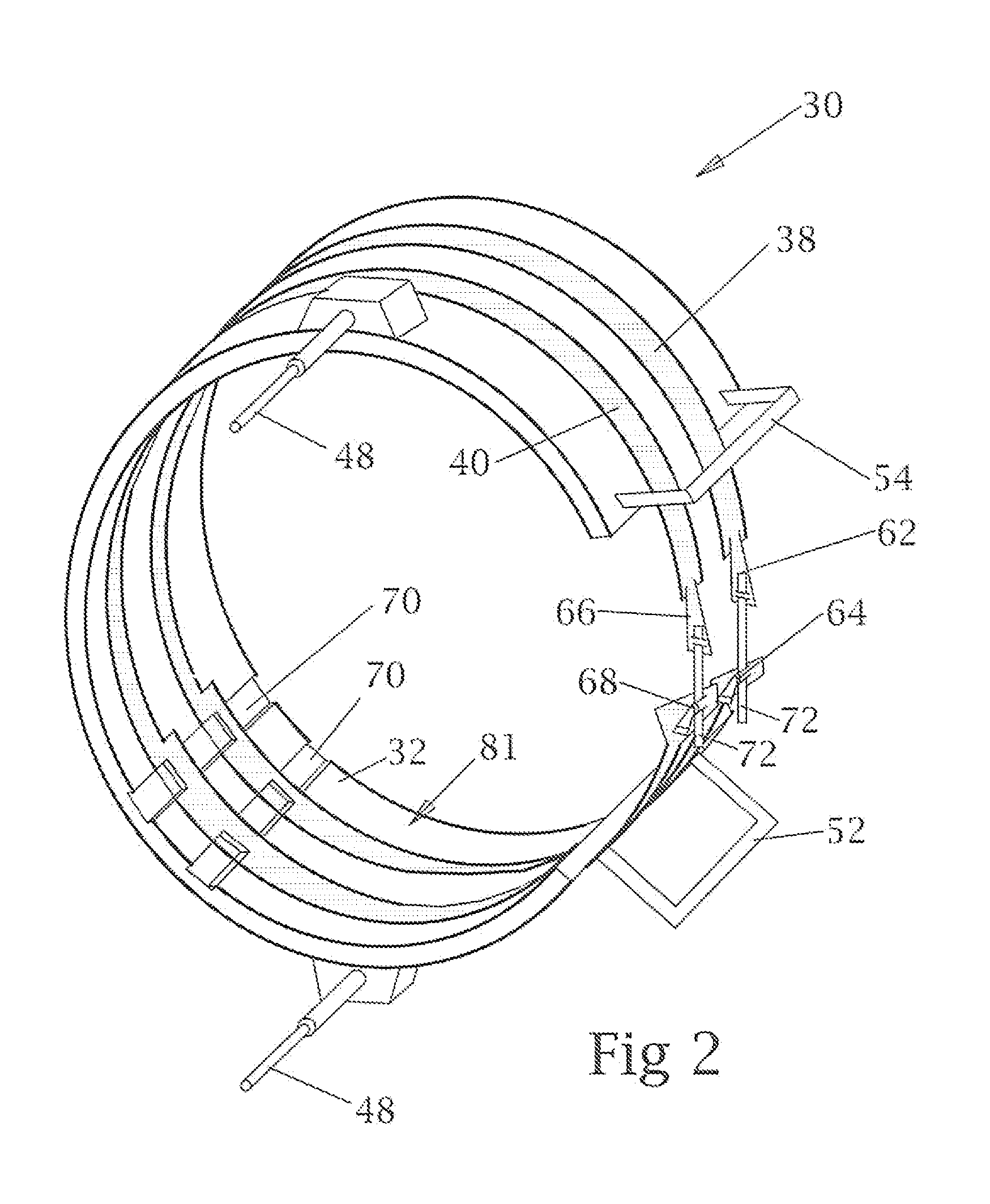

Apparatus and Method for Monitoring the Mechanical Properties of Subsea Longitudinal Vertical Components in Offshore Drilling and Production Applications

InactiveUS20140354974A1Low costStable and reliableWaterborne vesselsForce measurement by measuring optical property variationOcean bottomMarine engineering

An apparatus to monitor the loads and mechanical behavior of subsea longitudinal vertical components of off shore drilling and production platforms (SLVCs) uses sensors attached directly to the tendons by adhesive or by friction mount. The sensors are typically in a sensor ring assembly which is placed around the perimeter of the SLVC. Ruggedized cables carry the sensor reading from the ring assembly to the SLVC working platform and to a control center for monitoring the action and stresses on the tension legs. The system may be deployed on existing SLVCs or may be installed on new construction during initial assembly and installation.

Owner:ASTRO TECH GRP LLC

Method and apparatus for a rules-based utilization of a minimum-slit-head configuration plunger slitter

InactiveUS8267847B2Length minimizationImprove reliabilityEnvelopes/bags making machineryMechanical working/deformationOrder schedulingEngineering

A method and apparatus for performing an order change in a corrugator uses a minimum slit head configuration with all slit heads carried on two sides of a single tool support structure. A single robot is operable on the support structure to independently reset the positions of slit heads during a running order to prepare for subsequent order change in a most efficient manner, utilizing order scheduling that eliminates order changes that cannot be formed with the minimum slit head configuration.

Owner:BARRY WEHMILLER PAPERSYST INC

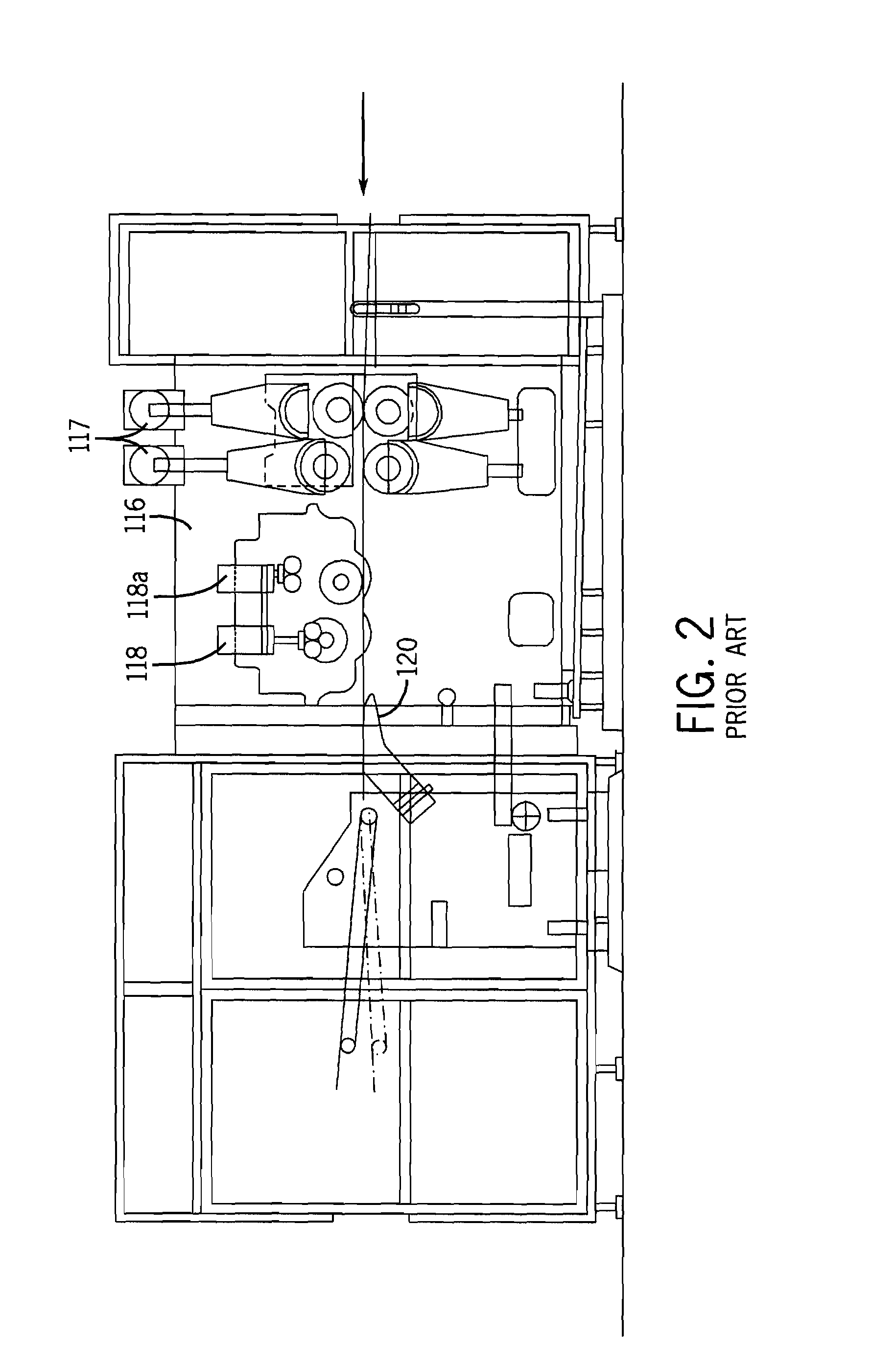

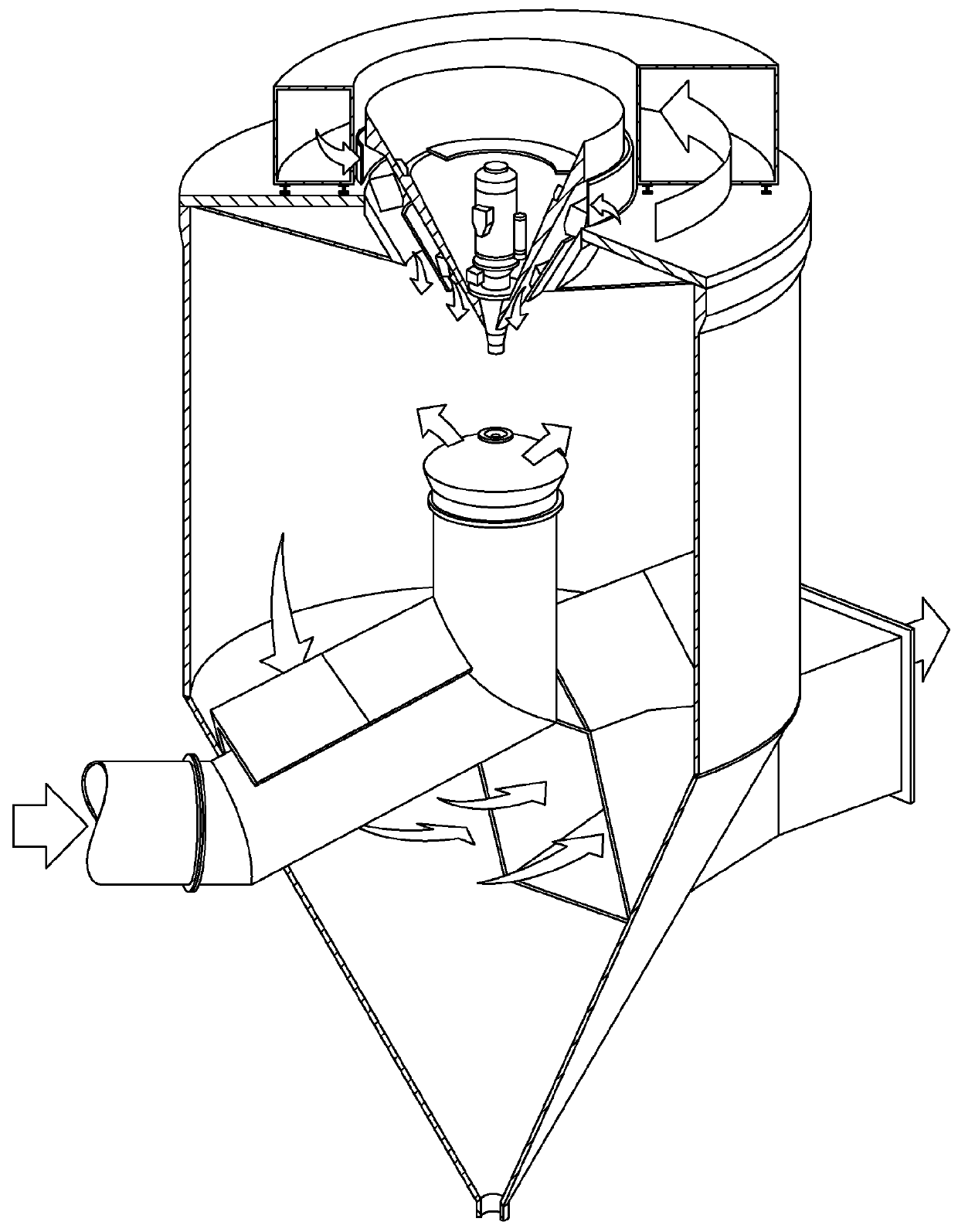

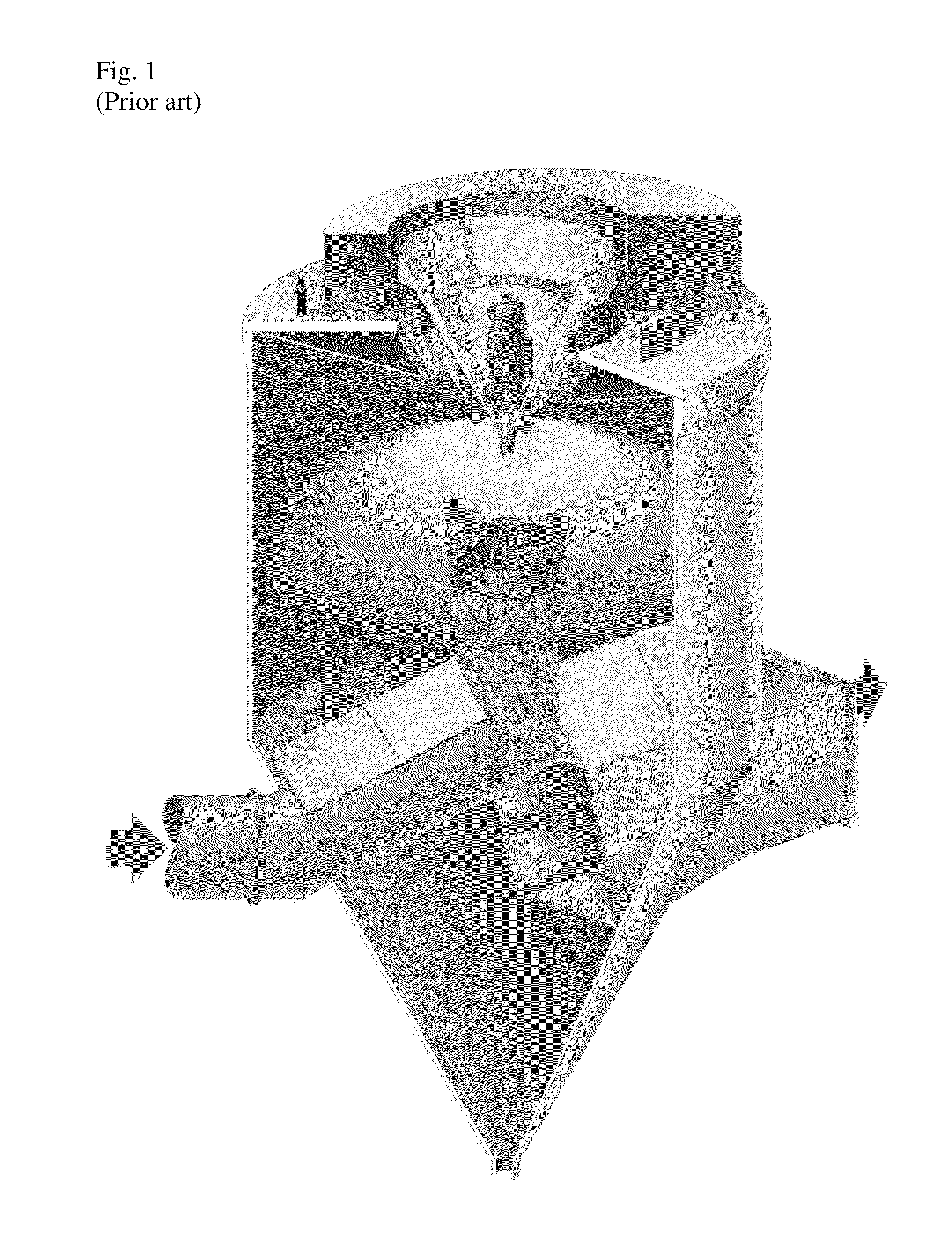

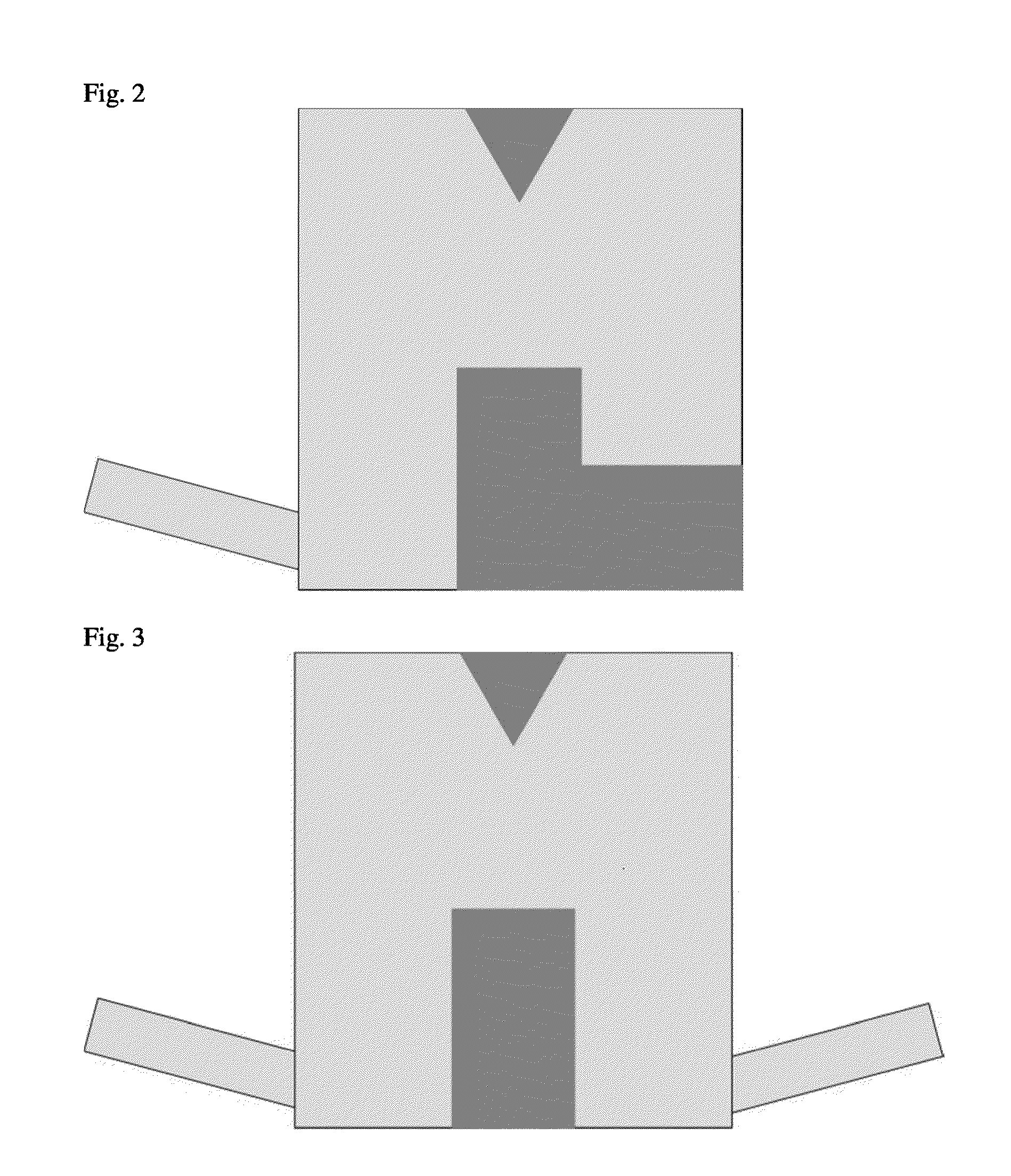

Spray dryer absorption apparatus with flat-bottomed chamber

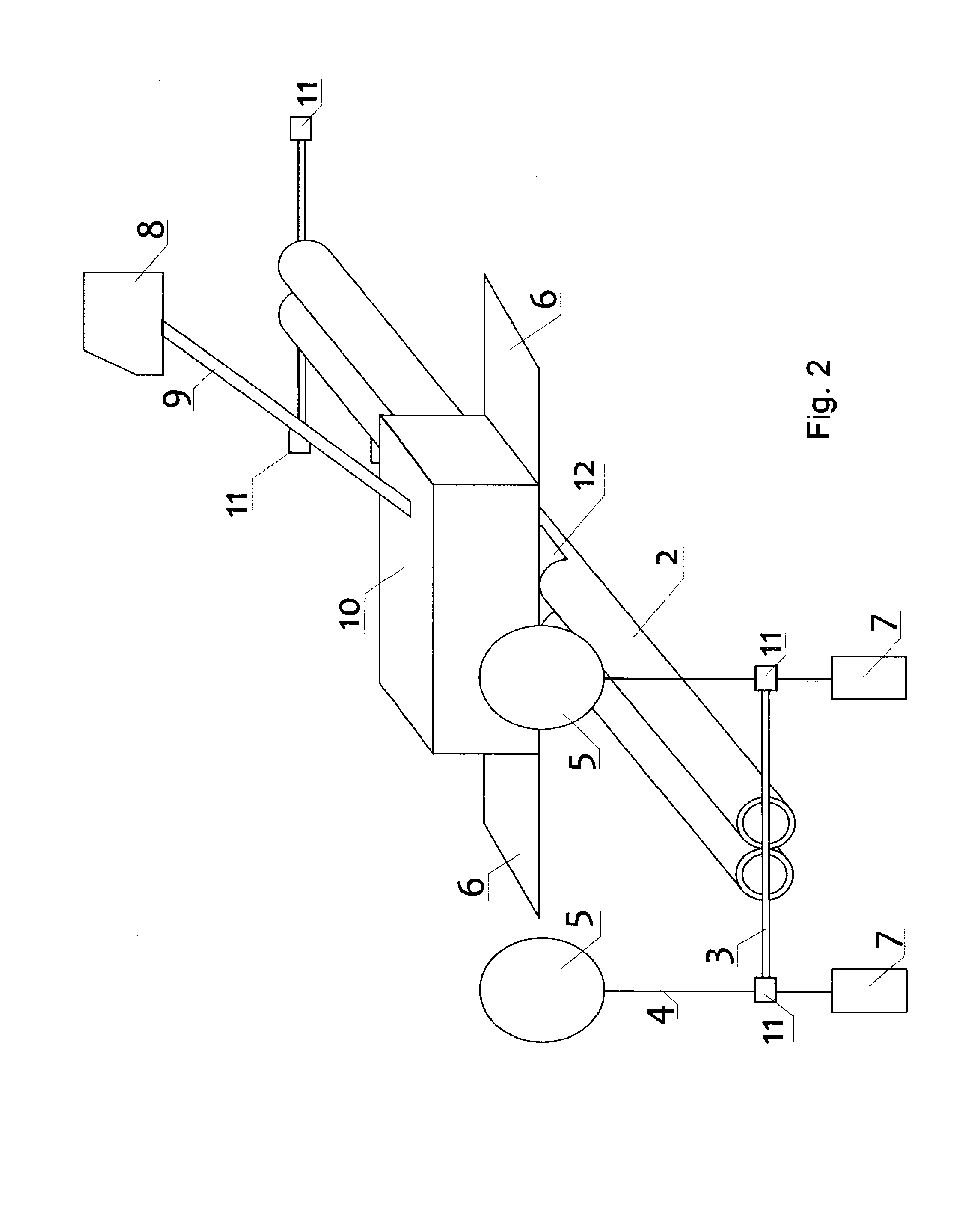

ActiveUS9227157B2Reduced support structureAvoid excessive heightCombination devicesGas treatmentParticulatesChemical reaction

In the application a spray dryer absorption apparatus for treating a stream of flue gas containing acidic components is disclosed. The apparatus comprises a chamber having vertical cylindrical walls, said chamber comprises (i) an inlet for a flue gas stream containing an acidic component, (ii) an atomizer for spraying droplets of an absorbent slurry into said flue gas stream to effect a chemical reaction between the droplets and the acidic component of the flue gas, thereby forming a particulate reaction product, and (iii) an outlet for the treated flue gas and entrained particulate reaction product, wherein the bottom of the chamber having vertical cylindrical walls is substantially horizontal and impervious to gases. The apparatus of the invention has the advantage of a simplified geometry accounting for lower building and maintenance costs.

Owner:GEA PROCESS ENG

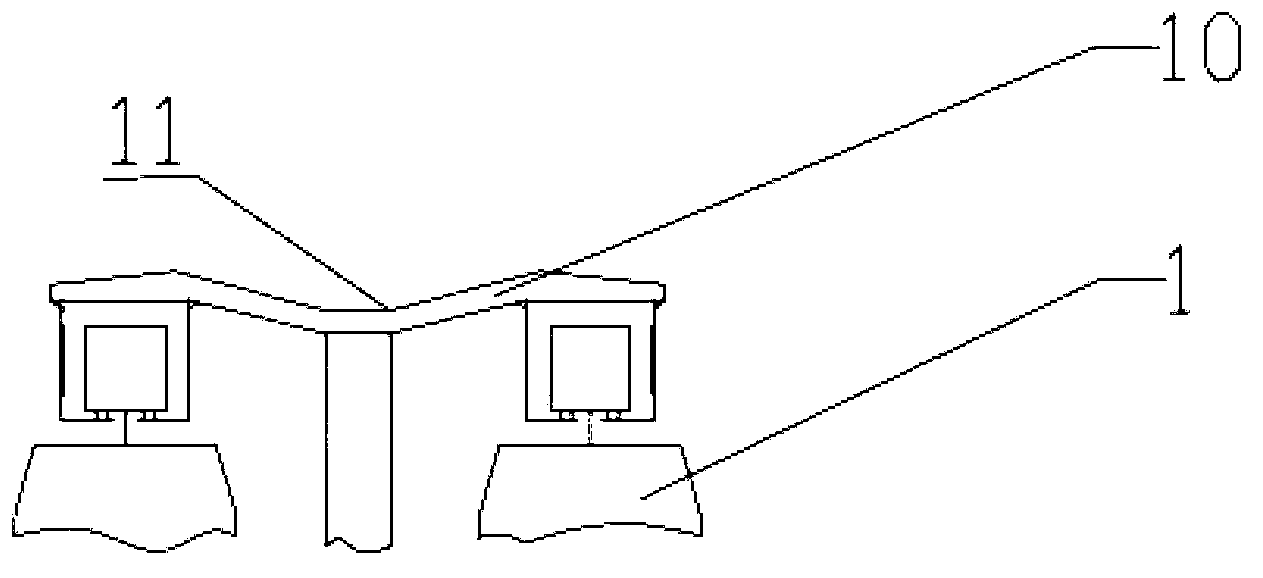

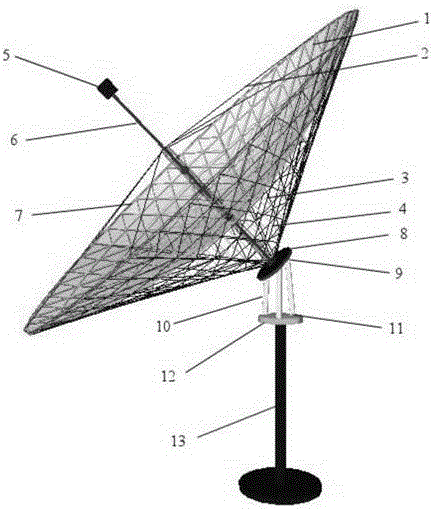

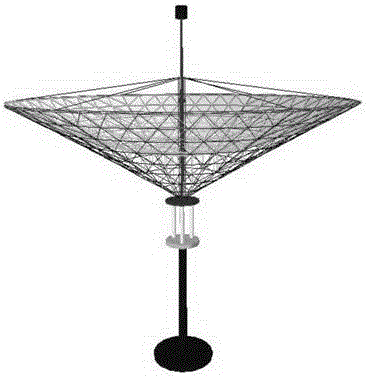

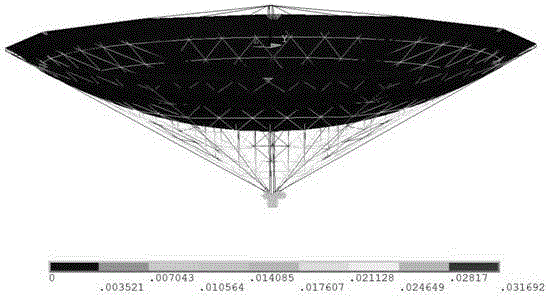

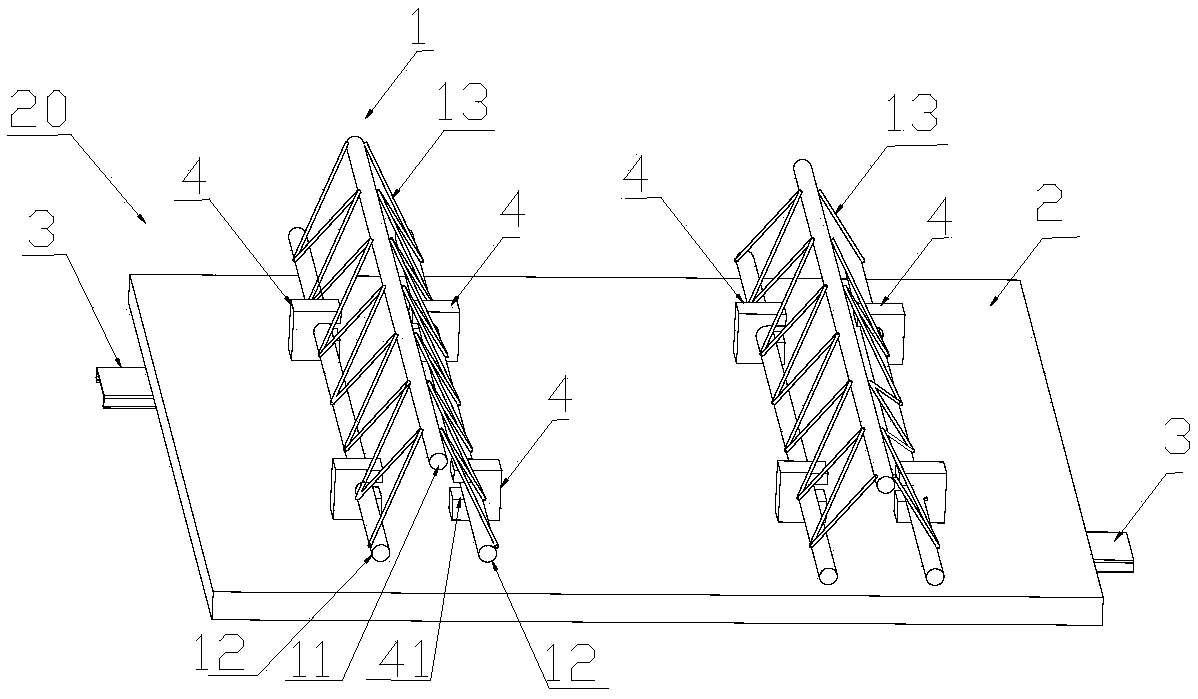

Cylindrical cable net reflection system driven by three telescoping rods

ActiveCN106200684AGuaranteed accuracyGuaranteed Rigidity RequirementsControl without using feedbackAttitude controlCable net

The invention discloses a cylindrical cable net reflection system driven by three telescoping rods, aiming to solve the problems that a reflection system in the prior art is large in intensity and complex in structure. The cylindrical cable net reflection system includes a net surface cable (1), a fastening cable (4), a center column (6), an expandable outer circular ring unit (7), an upper platform (8), the three telescoping rods (10), a lower platform (12), and a support platform (13), a feed source (5) is arranged at the top of the center column, the center column and the outer circular ring are connected through upper and lower support cables (2), an adjusting cable (3) is connected between the net surface cable and the fastening cable to control the deformation of the reflection plane by changing the length, the upper ends of the three telescoping rods are connected with the upper platform through a spherical hinge connection structure (9), the lower end is connected with the lower platform through a revolute pair connection structure (11), and by changing the length of the three telescoping rods, the attitude control of the reflection device is realized. The reflection system is simple in structure, portable and flexible, accurate in attitude control, and can be used for the reflection or convergence of optical and electrical energies.

Owner:XIDIAN UNIV

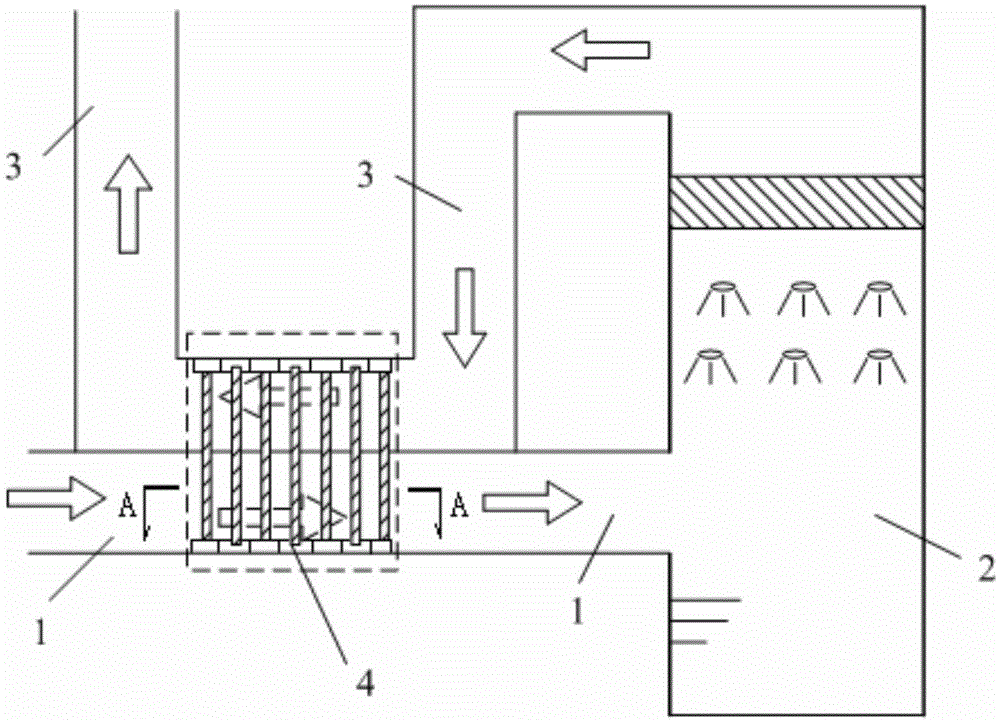

Integrated heat exchange device for wet desulphurization system

ActiveCN105889959AReduce the temperatureIncrease lift heightIndirect heat exchangersWork performanceFlue gas

The invention provides an integrated heat exchange device for a wet desulphurization system. The wet desulphurization system is provided with an inlet flue, an outlet flue and a desulphurization tower. The inlet flue and the outlet flue are provided with a horizontal intersection segment which comprises multiple columns of hot tube bundles. Each column of hot tube bundles comprises a plurality of hot tubes distributed linearly and evenly. The heat absorbing ends of the hot tubes extend into the inlet flue, and the heat release ends of the hot tubes extend into the outlet flue. Each column of hot tube bundles and the adjacent hot tube bundles are distributed in parallel in a staggered mode. Heat of flue gas in a high-temperature segment is used for heating flue gas in a low-temperature segment, an external heat source is not needed, work performance of the system is improved, diffusion of flue gas emission is promoted, and engineering construction investment and occupied area are reduced. Compared with a traditional GGH system and various heat exchange devices replacing the GGH system, the integrated heat exchange device is simple and light in structure, the number of corresponding flue supporting structures can be reduced, overall operation of a heat exchange system is not affected when single hot tubes break down, and stability is high.

Owner:DATANG ENVIRONMENT IND GRP

Substrate heating apparatus and purging method thereof

InactiveUS20080163818A1Reduced support structureLower the volumeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingMechanical engineeringEngineering

A substrate heating apparatus of the present invention, which heats a substrate mounted on a mount table 104 having heating means 108, in a processing vessel 102, includes a supporting part 202 made from a first material to support the mount table, a sealing part 204 made from a second material different from the first material in heat conductivity to seal the supporting part and the processing vessel and a joint part 206 for joining the supporting part and the sealing part in an airtight manner. With the constitution, by selecting the first material and the second material of different heat conductivities properly, it is possible to reduce a heat gradient between the top of the mount table and the bottom of the mount table. As a result, it is possible to shorten a supporting structure for the mount table, in length.

Owner:SAITO TETABUYA +1

Apparatus and Method for Monitoring the Mechanical Properties of Subsea Longitudinal Vertical Components in Offshore Drilling and Production Applications

An apparatus to monitor the loads and mechanical behavior of subsea longitudinal vertical components of off shore drilling and production platforms (SLVCs) uses sensors attached directly to the tendons by adhesive or by friction mount. The sensors are typically in a sensor ring assembly which is placed around the perimeter of the SLVC. Ruggedized cables carry the sensor reading from the ring assembly to the SLVC working platform and to a control center for monitoring the action and stresses on the tension legs. The system may be deployed on existing SLVCs or may be installed on new construction during initial assembly and installation.

Owner:ASTRO TECH GRP LLC

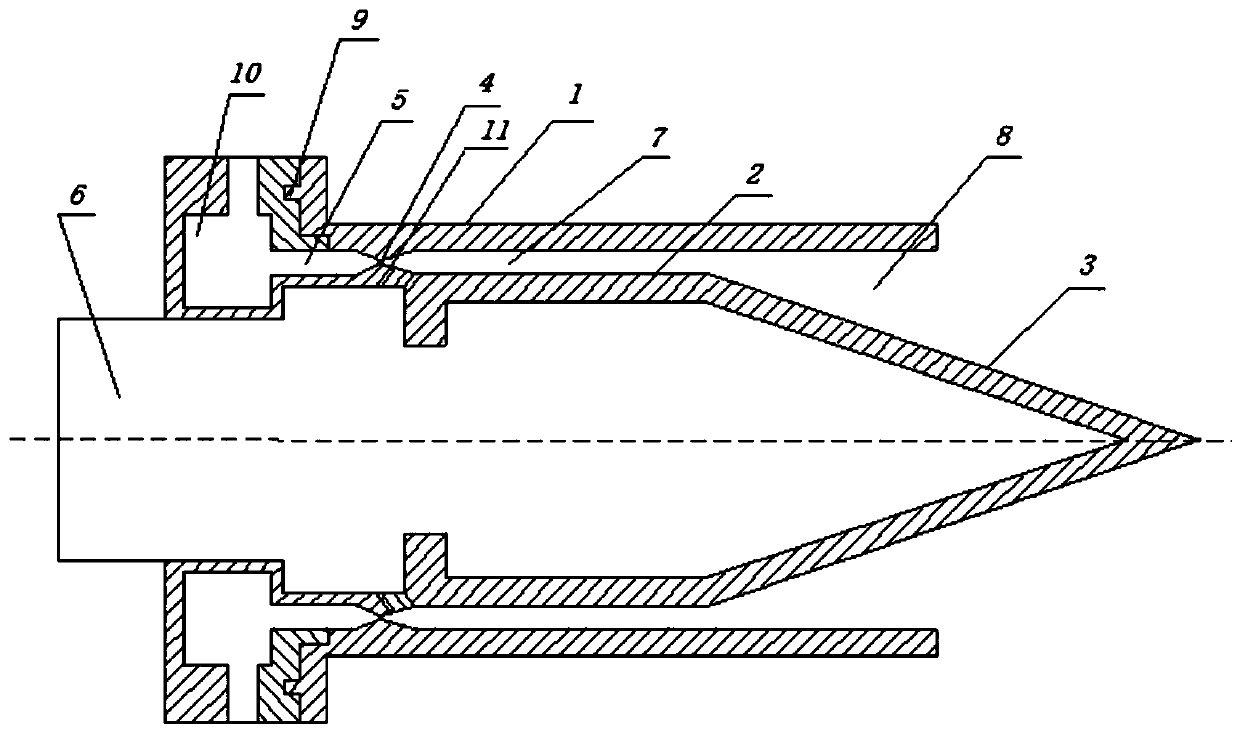

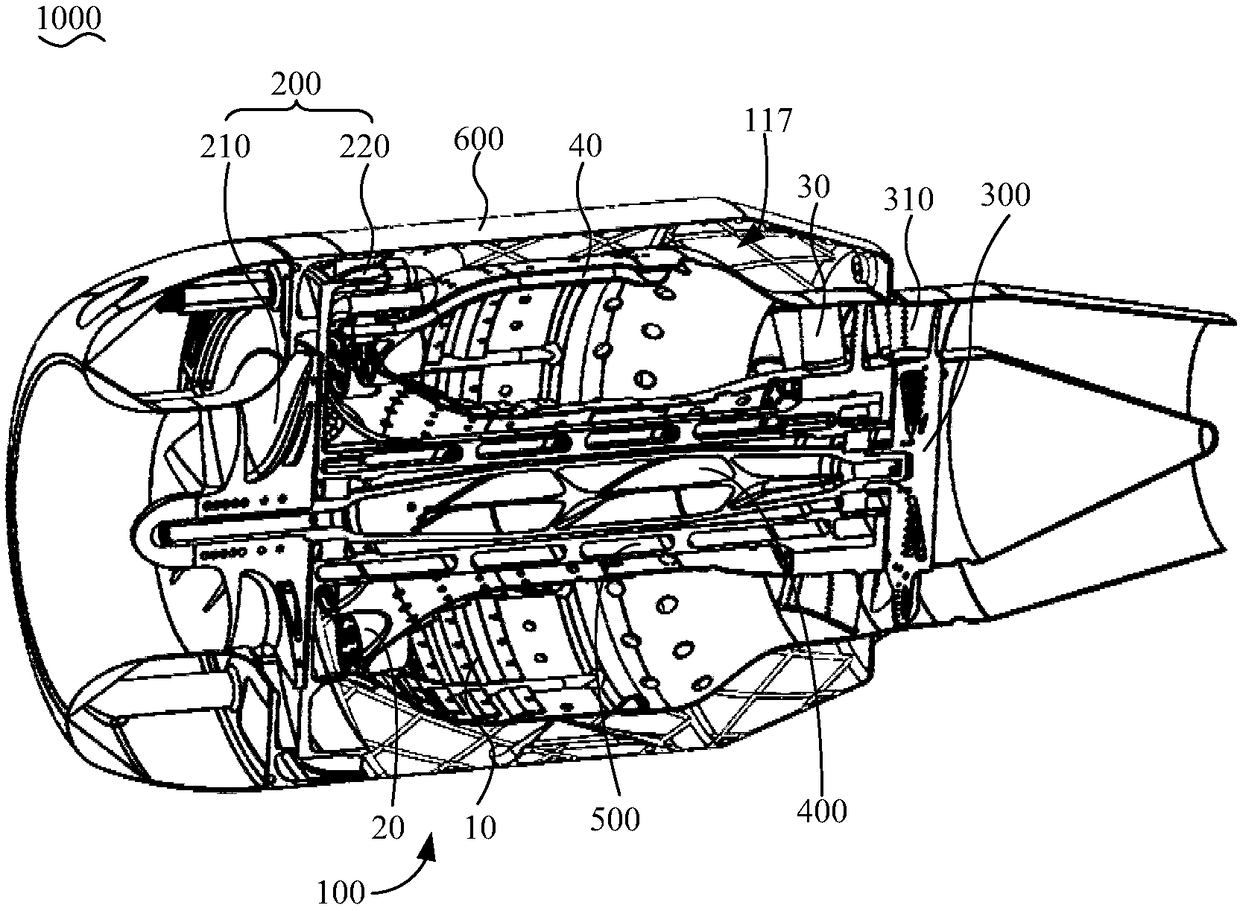

Continuous rotation detonation rocket engine manufactured by additive manufacturing and additive manufacturing method thereof

PendingCN111140399AReduced support structureReduce connection structureAdditive manufacturing apparatusIncreasing energy efficiencyCombustion chamberManufacturing technology

The invention relates to the technical field of aerospace equipment, in particular to a continuous rotation detonation rocket engine manufactured by additive design and manufacturing. The continuous rotation detonation rocket engine comprises an inner cylinder 2 of a rocket engine, a fuel injection unit 4, an oxidant annular cavity 5 and an oxidant gas collection chamber 10, wherein the fuel injection unit 4, the oxidant annular cavity 5 and the oxidant gas collection chamber 10 are connected with the inner cylinder 2 of the rocket engine; the inner cylinder 2, the fuel injection unit 4, the oxidant annular cavity 5 and the oxidant gas collection chamber 10 are integrated into an integral piece by additive manufacturing technology; and the space between a rocket engine casing 1 and the integral piece is a combustion chamber 7, and the rocket engine casing 1 and the integral piece are connected through positioning pins 9. The invention further relates to an additive manufacturing methodfor manufacturing the continuous rotation detonation rocket engine. The continuous rotation detonation rocket engine is integrally manufactured through the additive manufacturing technology, supportand connection structures between various components are reduced, machining is facilitated, and weight reduction and the reduction of the cost and difficulty of machining and maintenance are facilitated.

Owner:TSINGHUA UNIV

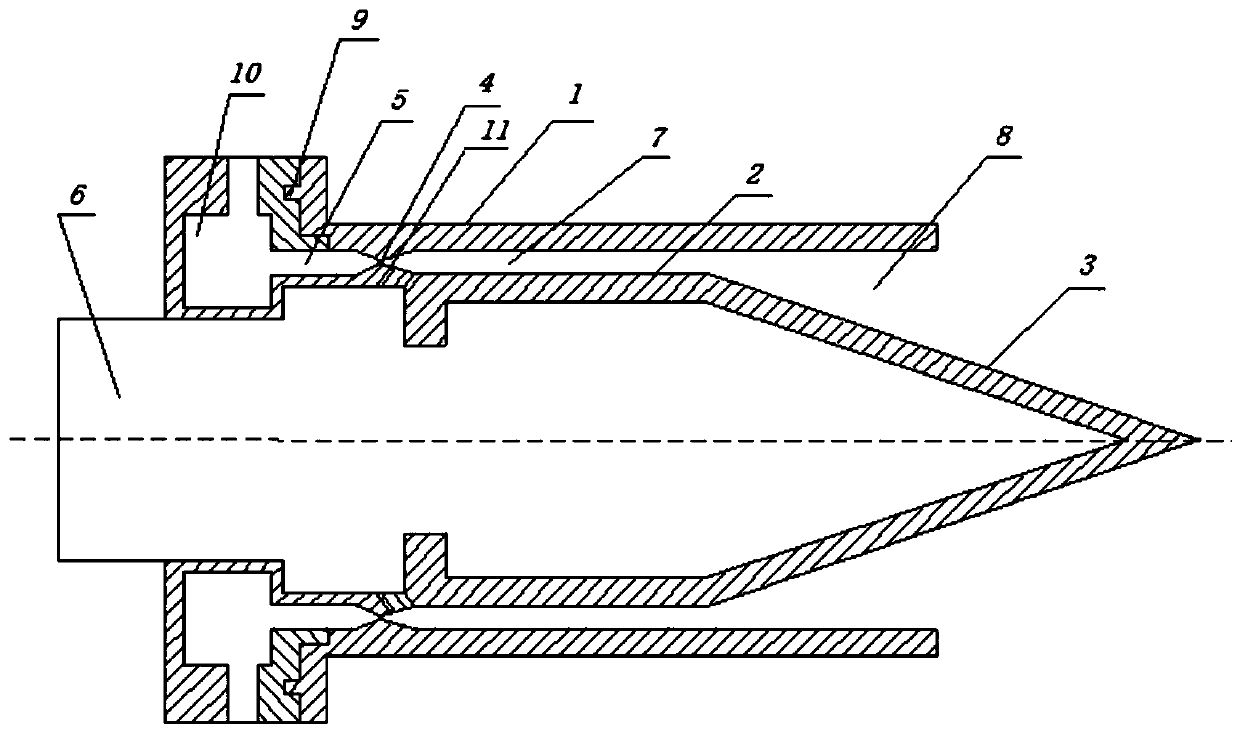

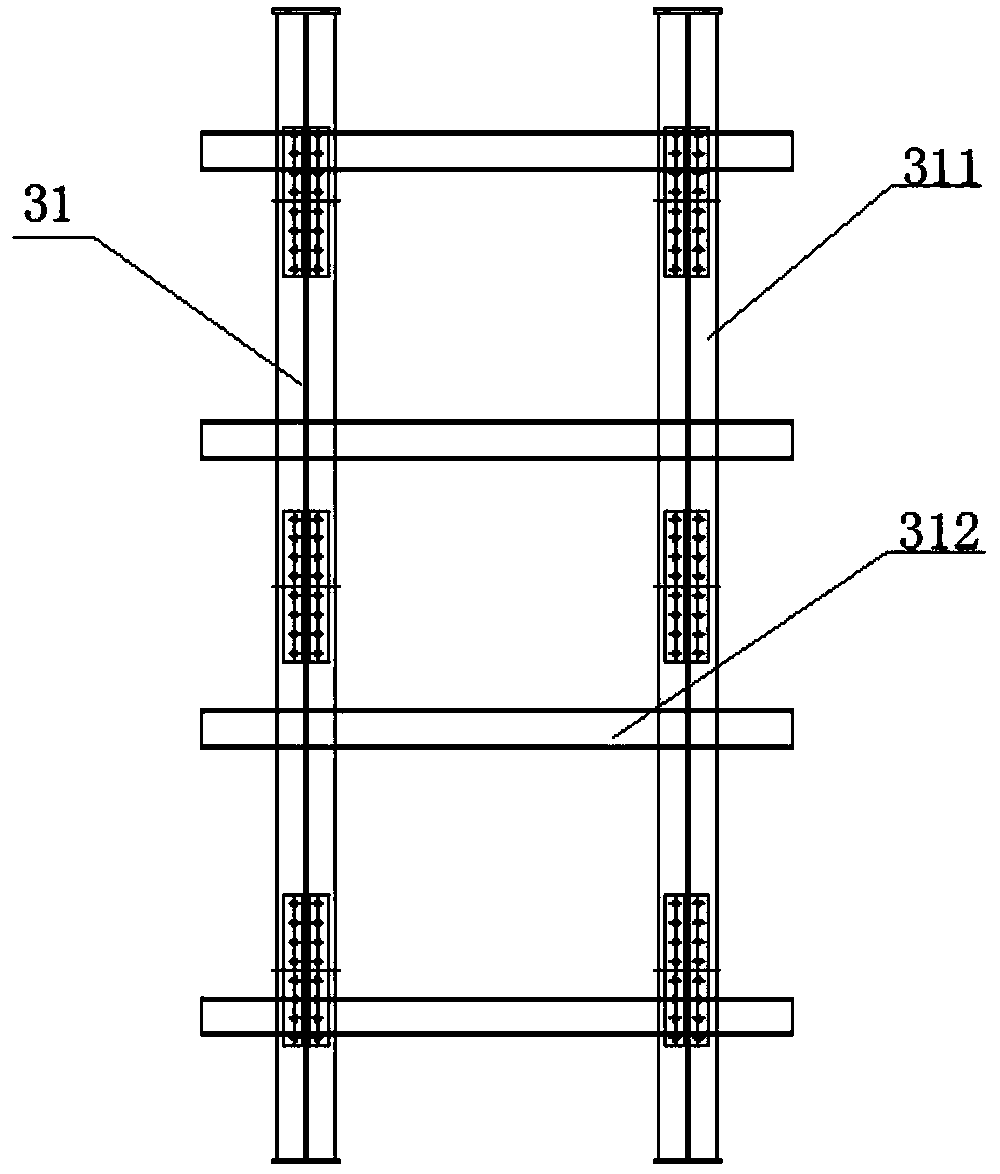

Support joint structure for rebar truss plates and framework formwork

PendingCN109577491AFirmly connectedHigh strengthFloorsForms/shuttering/falseworksArchitectural engineeringRebar

The invention relates to the field of construction of concrete structure buildings, in particular to a support joint structure for rebar truss plates and a framework formwork. The structure comprisesa framework structure and the rebar truss plates located at the two sides of the framework structure, the framework formwork is arranged at the outer side of the framework structure and comprises twoside formwork bodies and a bottom formwork body, a floor support plate is arranged at one side of each side formwork body, and the heights of the upper ends of the side formwork bodies are equal to that of the upper surfaces of the floor support plates; the structure comprises a first supporting part for supporting the end of each rebar truss plate, and a supporting base is arranged at the end ofeach rebar truss and located above the corresponding first supporting part. Through connecting bars, the rebar truss plates at the two sides of the framework structure are connected, and the connecting bars are simple and convenient in connection and easy to operate; meanwhile, floor plates after setting of cast concrete have high connecting strength and bearing capability, through support of thefirst supporting parts, staggering of side portions of the rebar truss plates and side formwork bodies is small, and after forming, the joint parts of the floor plates are level.

Owner:ZHE JIANG ZHONGYI BUILDING MATERIALS TECH CO LTD

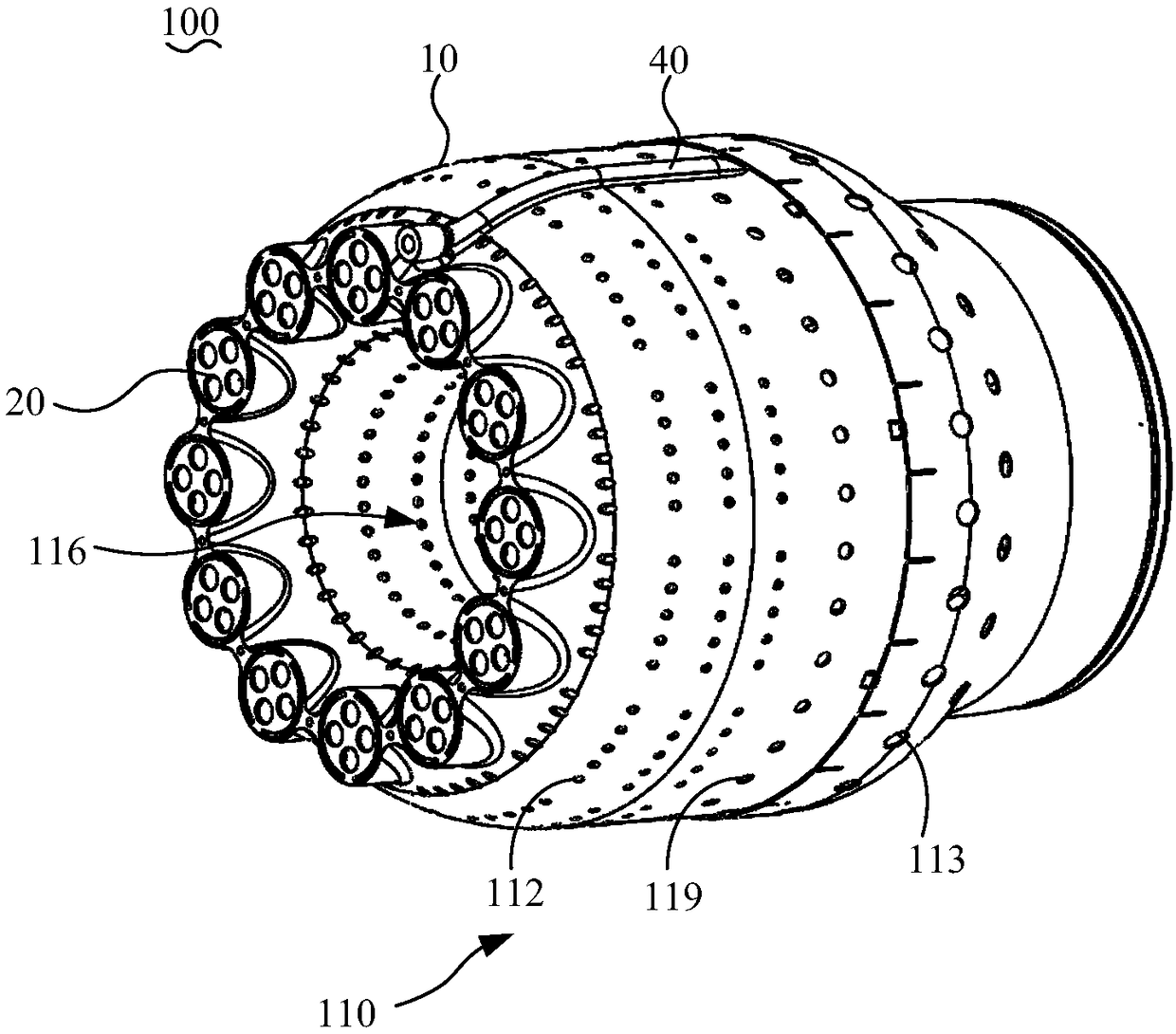

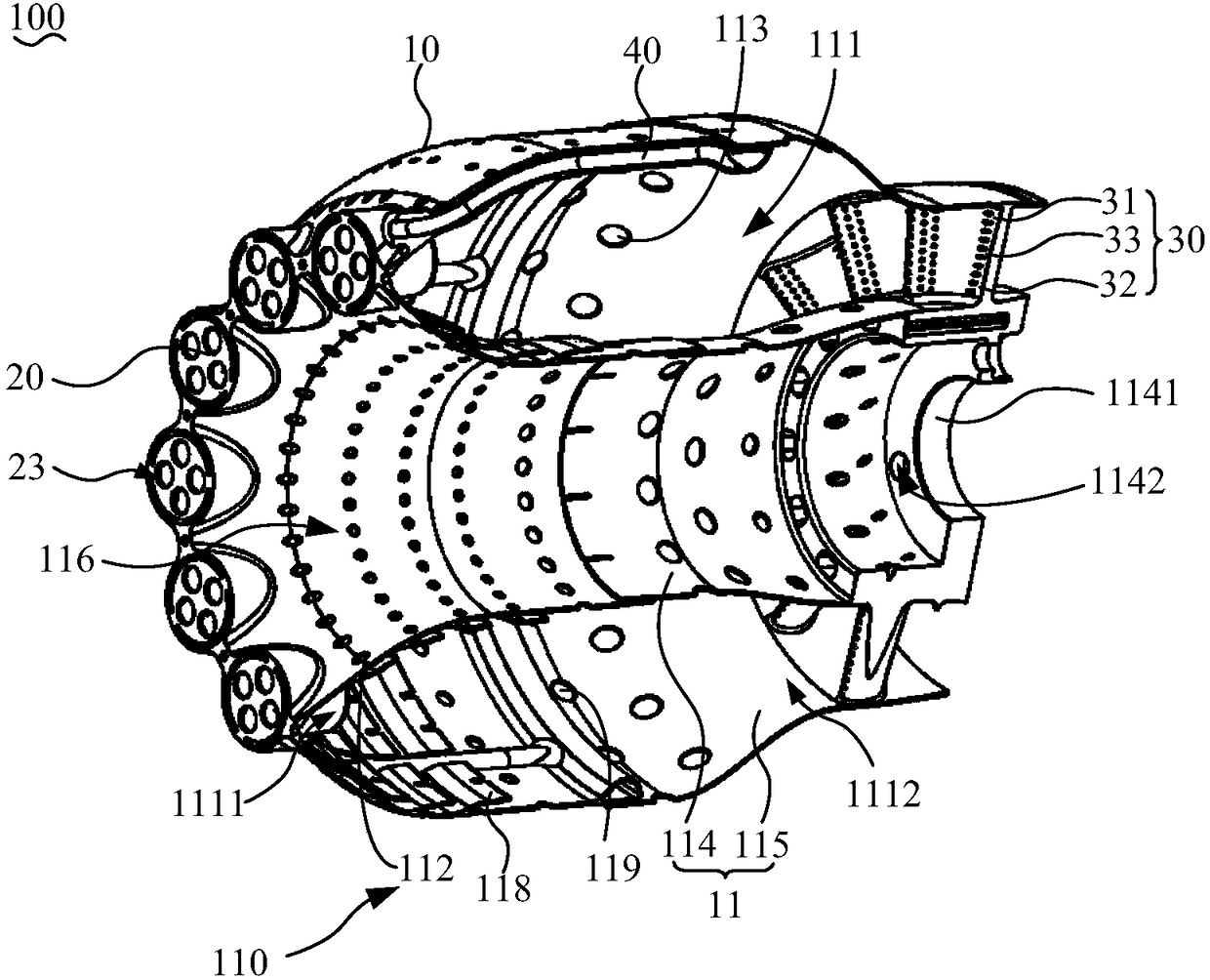

Engine, combustion assembly of engine and integrated designing and manufacturing method for combustion assembly

ActiveCN108592086ASimple structureReduced support structureContinuous combustion chamberCombustion chamberManufacturing technology

The invention discloses an engine, a combustion assembly of the engine and an integrated designing and manufacturing method for the combustion assembly. The combustion assembly comprises a flame tubeand nozzles; the flame tube comprises a main body; a combustion chamber is formed in the main body; through holes are formed in the main body and enable the combustion chamber to communicate with theoutside of the flame tube; the combustion chamber comprises a head part and a tail part which back onto each other; gas enters the flame tube from the head part and the through holes and flows out ofthe flame tube from the tail part; the nozzles are arranged on the head part; and the nozzles and the flame tube are integrally manufactured through an additive manufacturing technology. According tothe engine, the combustion assembly of the engine and the integrated designing and manufacturing method for the combustion assembly, the combustion assembly of the engine is integrally designed and manufactured by utilizing the additive manufacturing technology, the flame tube and the nozzles are fused into a whole, the structure of the combustion assembly can be simplified, supporting and connecting structures among components of the combustion assembly can be reduced, machining can be facilitated, weight reduction can be facilitated, the reliability can be improved, and the machining and maintenance cost can be lowered.

Owner:峰特(浙江)新材料有限公司

Apparatus and Method for Measuring Mechanical Properties of Tendons in Tension Leg Platforms

InactiveUS20140354975A1Low costStable and reliableWaterborne vesselsForce measurement by measuring optical property variationAdhesiveMechanical property

An apparatus to monitor the loads and mechanical behavior of tendons for a tension leg platform (TLP) uses sensors attached directly to the tendons by adhesive of by friction mount. The sensors are typically in a sensor ring assembly which is placed around the perimeter of the tension leg. Ruggedized cables carry the sensor reading from the ring assembly to the TLP working platform and to a control center for monitoring the action and stresses on the tension legs. The system may be deployed on existing TLPs or may be installed on new construction before while on land.

Owner:ASTRO TECH GRP LLC

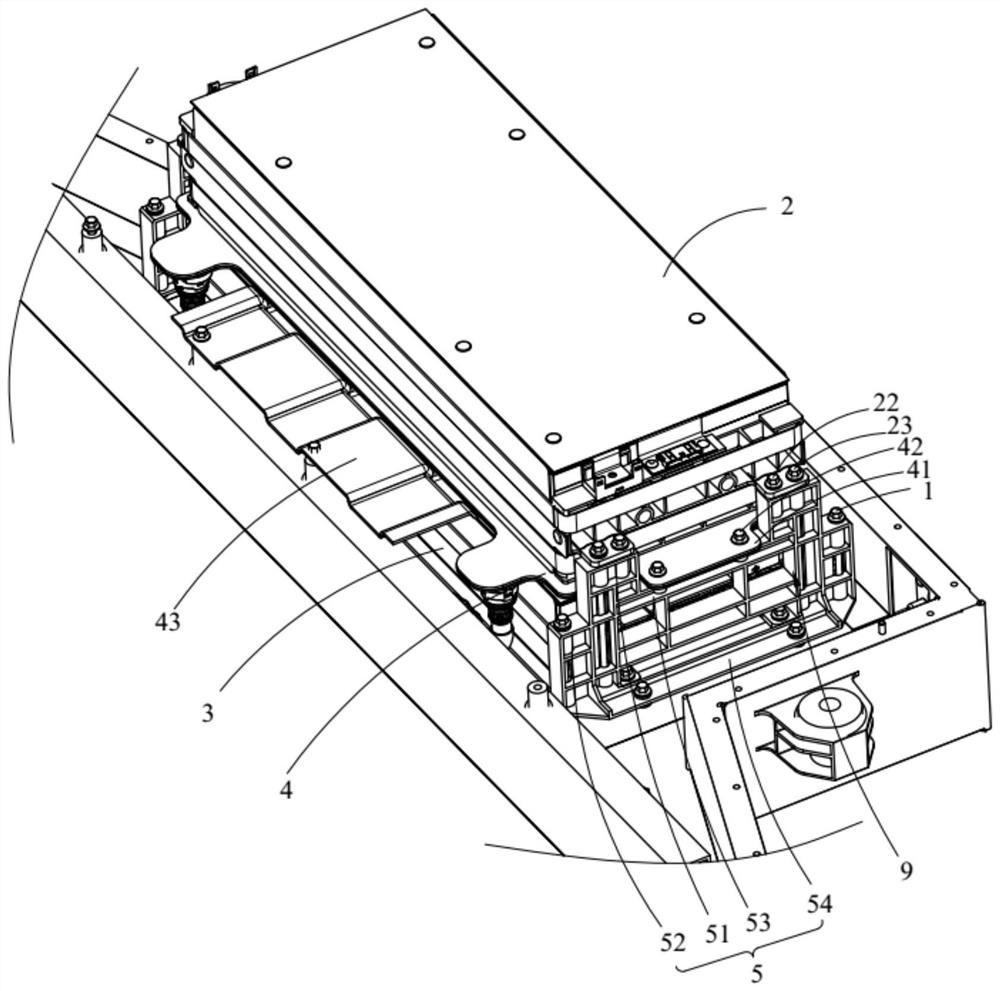

Battery pack and vehicle

ActiveCN112670646AAvoid bloatingImprove securityElectric propulsion mountingPropulsion by batteries/cellsMechanical engineeringBattery cell

The invention belongs to the technical field of vehicles, and discloses a battery pack and a vehicle. The battery pack comprises a battery shell; the battery shell is internally provided with a first battery module, a second battery module, first supports and a supporting rib assembly; the second battery module is arranged below the first battery module and is at least partially overlapped with the projection of the first battery module in the height direction; the first supports are arranged on the two sides of the first battery module in the length direction, and the first supports are connected to the first battery module and the second battery module correspondingly and can abut against the side face of the first battery module and the side face of the second battery module correspondingly; the supporting rib assembly is arranged in the first supports and used for restraining deformation of the first supports. The supporting rib assembly is arranged in the first supports, the strength and rigidity of the first supports are improved, the risk that the first supports deform is reduced, and thus the stability of the whole structure is guaranteed.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

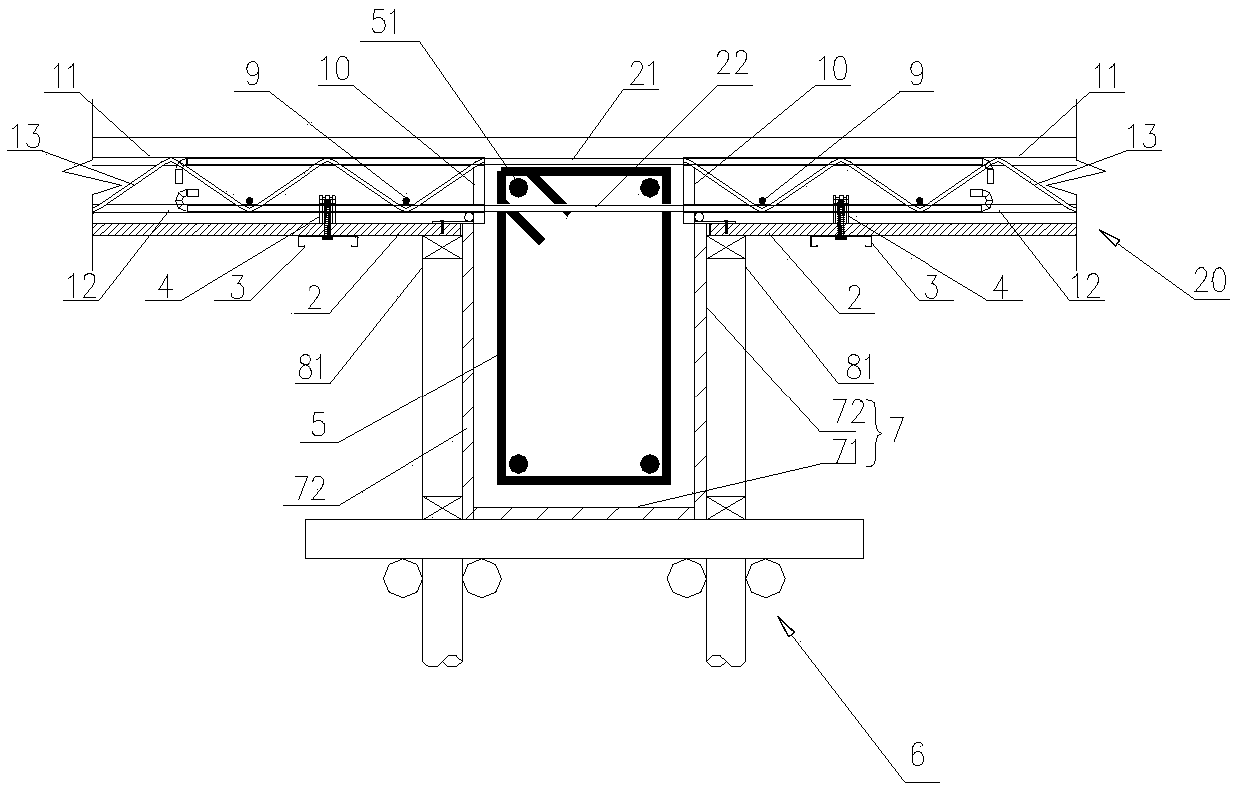

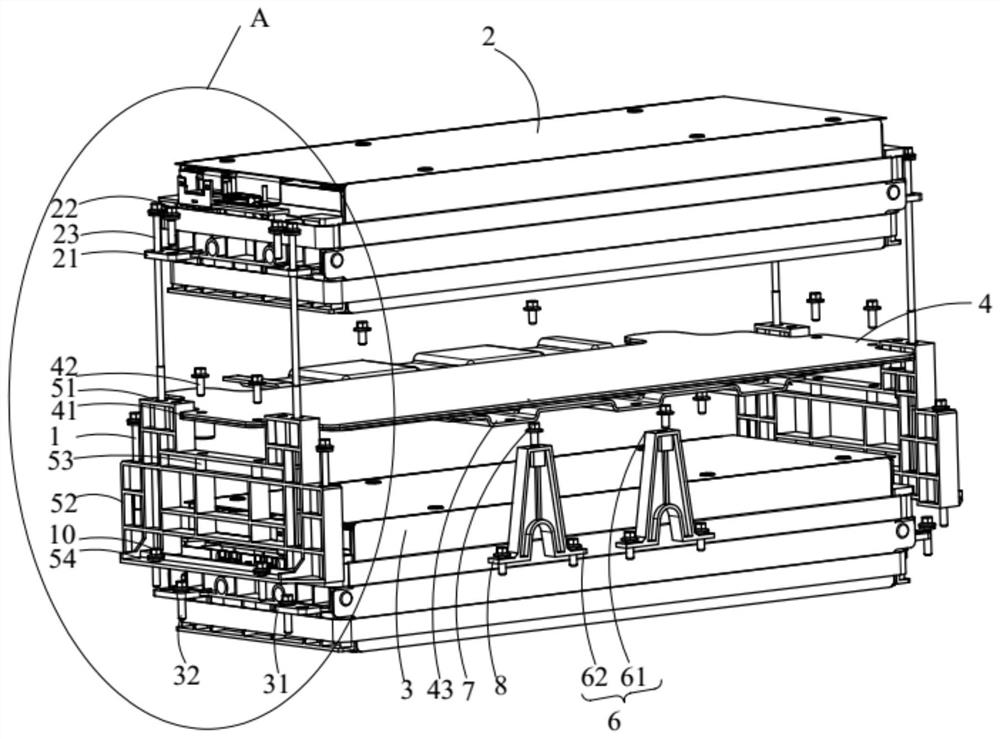

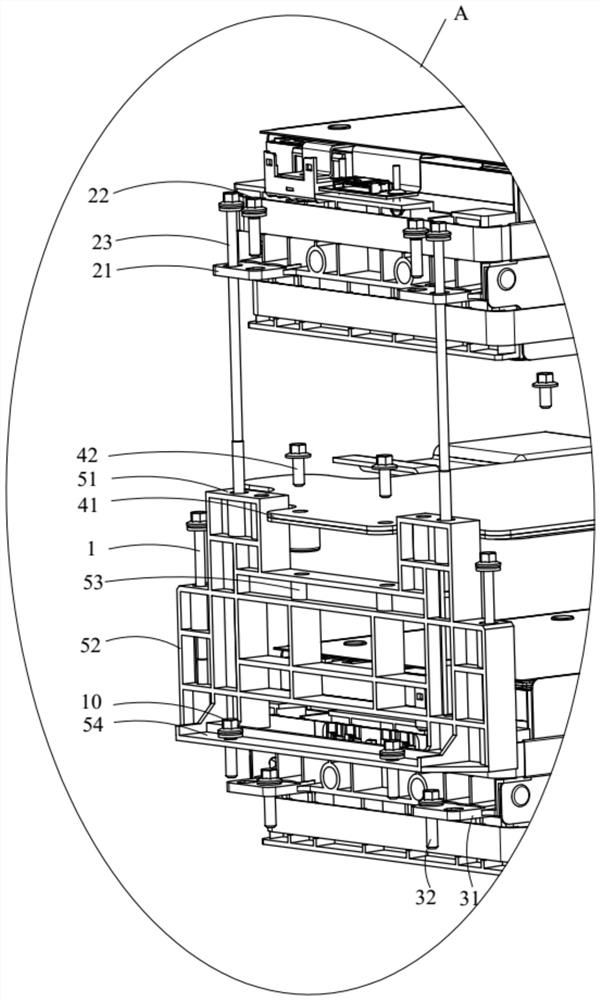

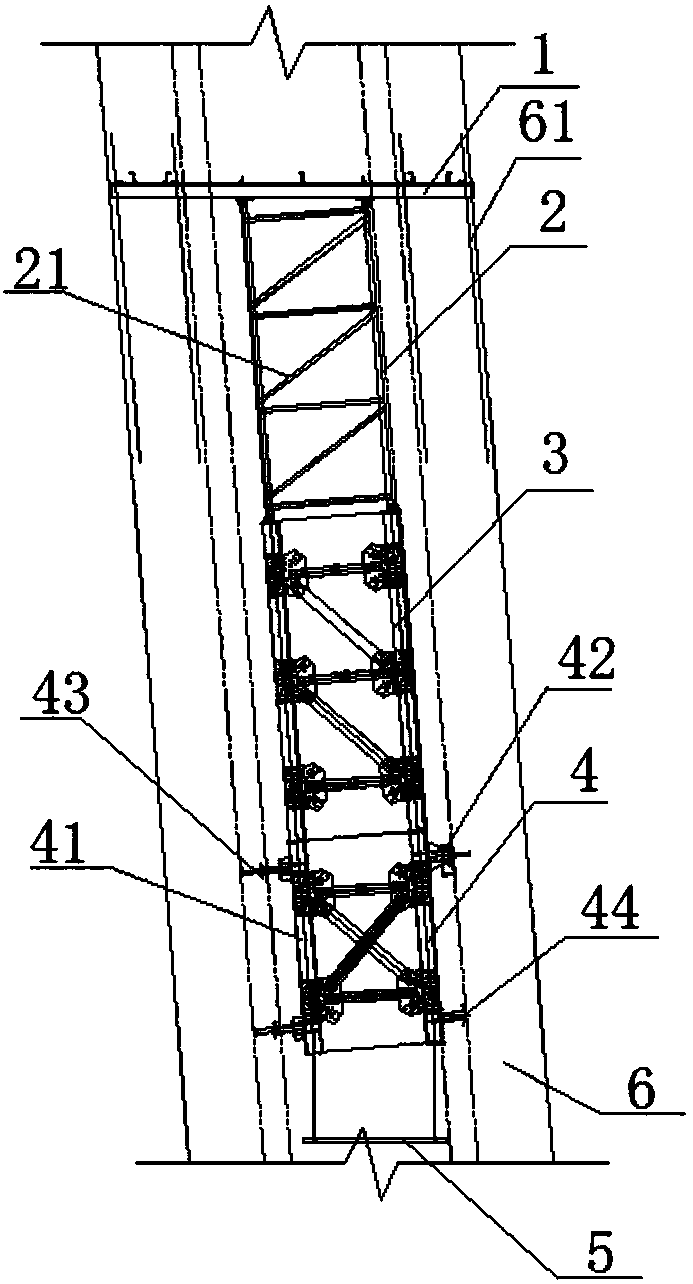

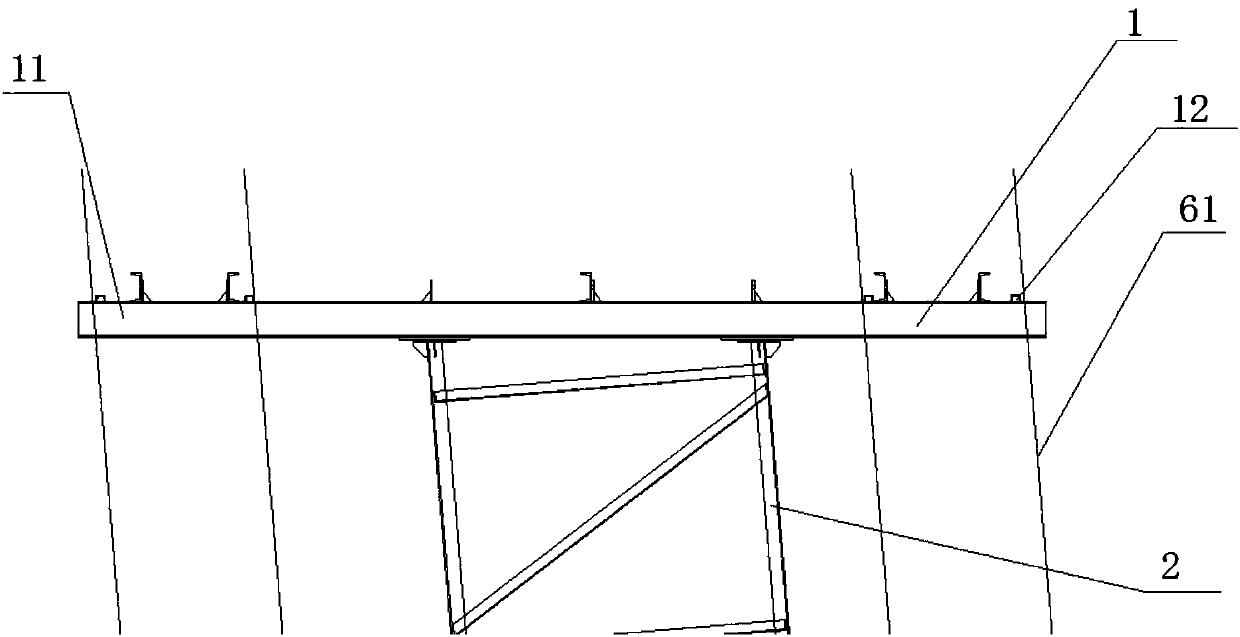

Tower column construction internal climbing frame and tower column construction method adopting same

ActiveCN107700819AReduce construction proceduresShort timeForms/shuttering/falseworksWind energy generationArchitectural engineeringTower

The invention discloses a tower column construction internal climbing frame and a tower column construction method adopting the same, and relates to the technical field of tower column construction. The tower column construction internal climbing frame sequentially comprises a rebar construction platform, a rebar construction frame body, an internal formwork construction upper frame body, an internal formwork construction lower frame body and a lifting platform from top to bottom. With adoption of the tower column construction internal climbing frame, after a main rebar of each section of a tower column is installed, the tower column construction internal climbing frame is lifted through hoisting equipment to the next section of the tower column for construction, the construction process is fewer, and time consuming is less; and meanwhile, the internal formwork construction upper frame body and the internal formwork construction lower frame body provide an operating platform when an internal formwork is installed and serve as internal formwork supports at the same time, so that an internal formwork supporting structure is omitted, the construction efficiency is high, and steel resources are saved.

Owner:中铁大桥局集团第八工程有限公司 +1

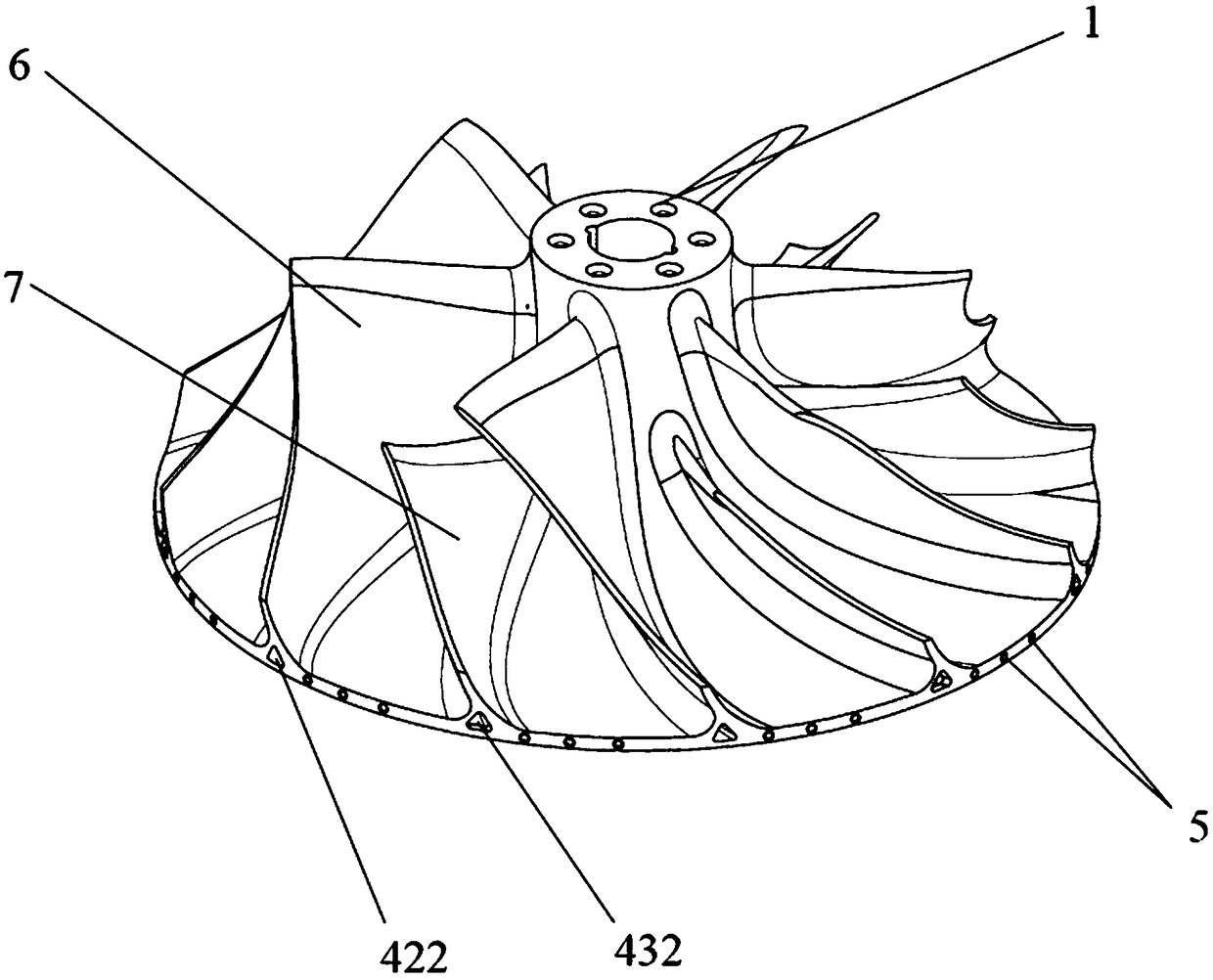

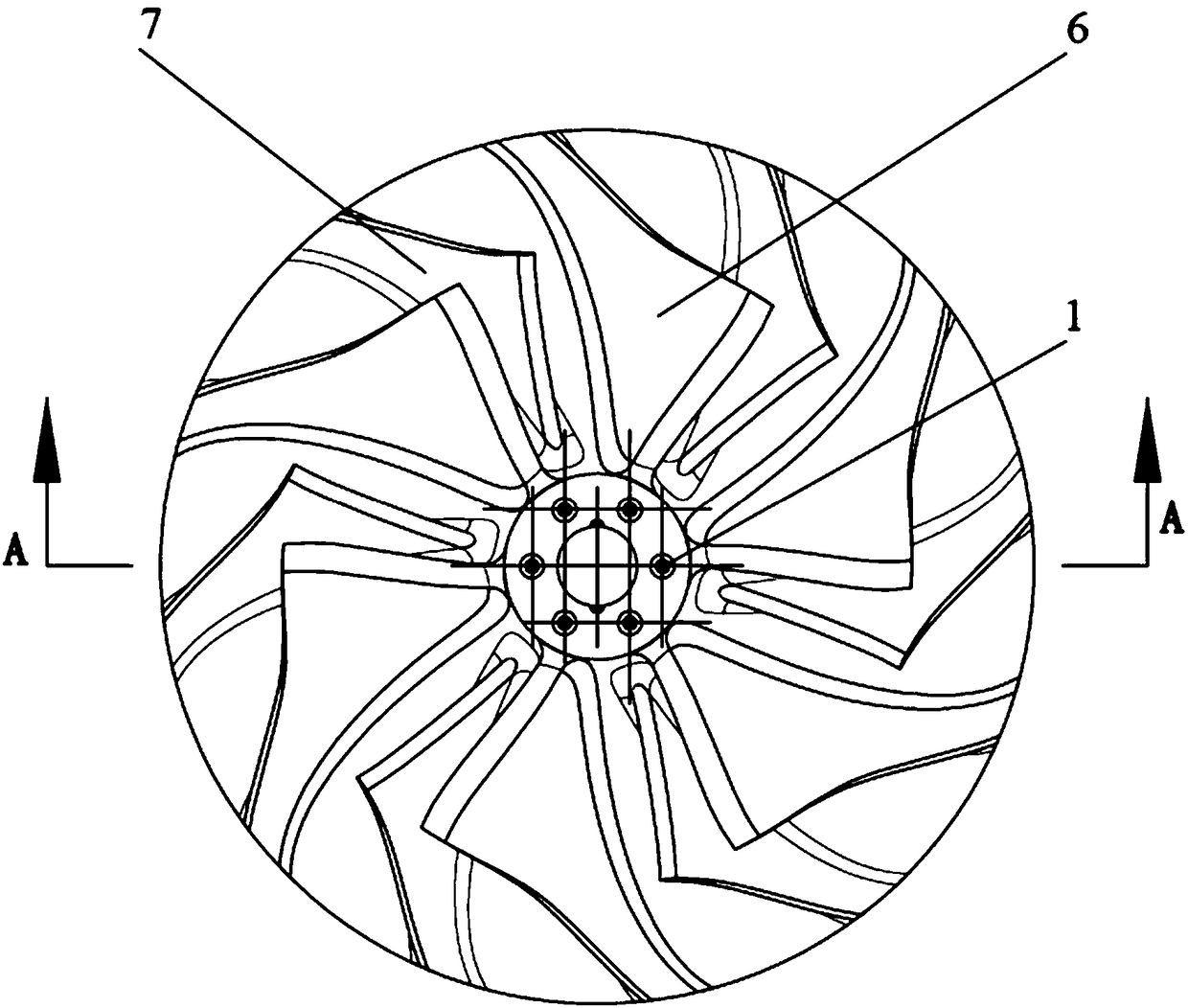

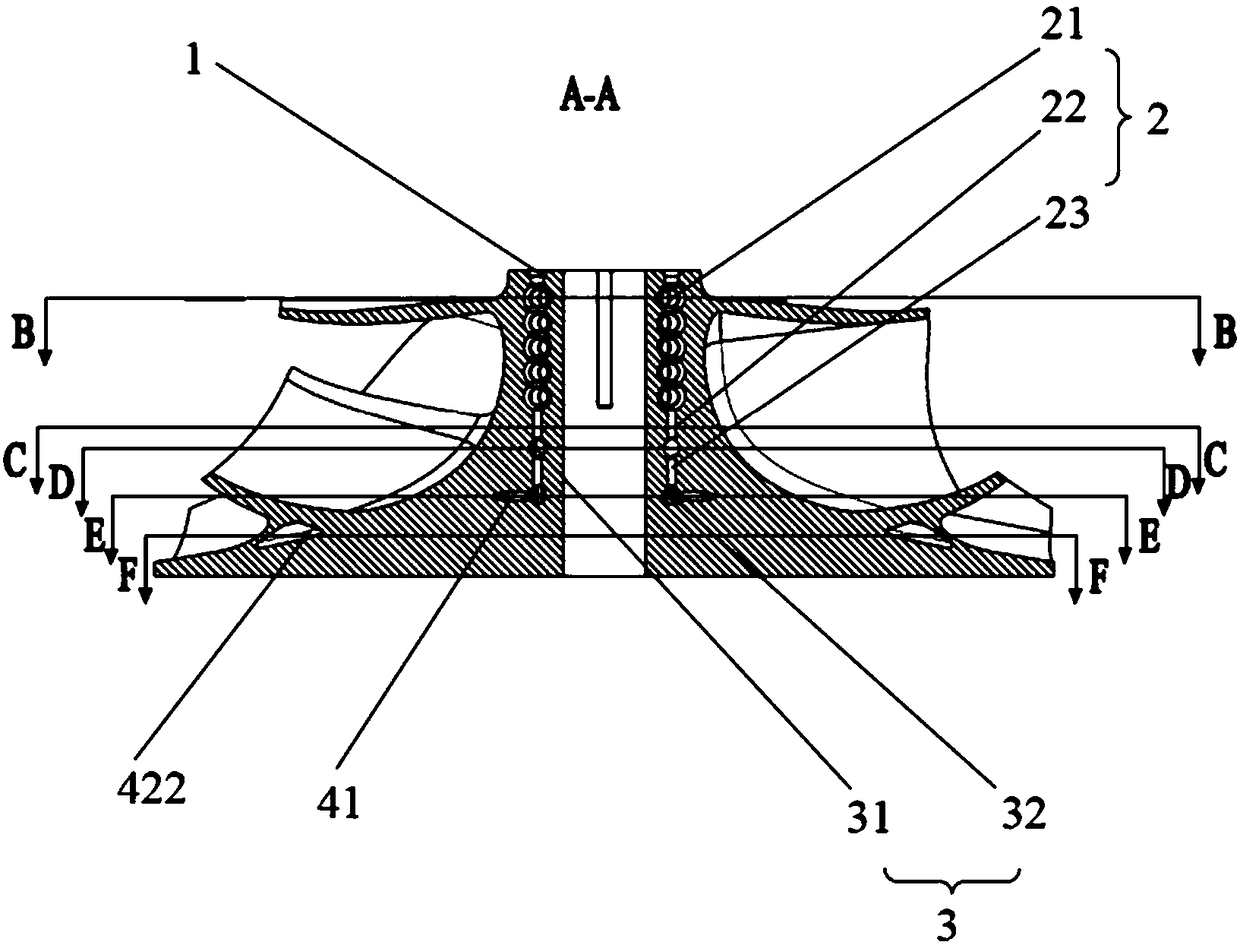

Wheel disc and air compressor comprising same

ActiveCN108412806ASimplify the production processEasy to processPump componentsPumpsAir compressorProduction cycle

The invention belongs to the technical field of aero-engine manufacturing, and discloses a wheel disc and an air compressor comprising the same. The wheel disc comprises a wheel disc body; a pluralityof main vanes and a plurality of sub vanes are arranged on the wheel disc body; the wheel disc body is of an integral structure; the wheel disc body is of a hollow structure; the hollow structure comprises a communication ring component which is arranged along the periphery of the wheel disc body, a main pipeline component which is arranged in the axial direction of the wheel disc body and a subpipeline component which is arranged in the radial direction of the wheel disc body; a plurality of first powder discharging holes are formed in the top end surface of the wheel disc body; a pluralityof second powder discharging holes are formed in the bottom outer side of the wheel disc; and the first powder discharging holes, the main pipeline component, the communication ring component, the sub pipeline component and the second powder discharging holes communicate with one another. The invention further provides the air compressor comprising the wheel disc. The wheel disc body is of the integrated structure, so that production procedures are simplified, and a production cycle is shortened.

Owner:SHENZHEN YIDONG AVIATION TECH CO LTD

Skeletalized reel side plate

A fishing reel has a frame. A first cover assembly is affixed to a first side of the frame. A second cover assembly is affixed to a second side of the frame. At least one of the first cover assembly and the second cover assembly define at least one opening for receiving a panel member. The cover assemblies define supporting structure that is preferably made of a metal. The panel member defines non-supporting structure that is preferably made up of non-metallic structure such as plastic polymer and carbon fiber. The panel member may be transparent and is preferably replaceable to allow a user to customize the appearance of the reel.

Owner:ZEBCO HLDG LLC

Spray dryer absorption apparatus with flat-bottomed chamber

ActiveUS20130302229A1Reduced support structureAvoid excessive heightCombination devicesGas treatmentParticulatesChemical reaction

In the application a spray dryer absorption apparatus for treating a stream of flue gas containing acidic components is disclosed. The apparatus comprises a chamber having vertical cylindrical walls, said chamber comprises (i) an inlet for a flue gas stream containing an acidic component, (ii) an atomizer for spraying droplets of an absorbent slurry into said flue gas stream to effect a chemical reaction between the droplets and the acidic component of the flue gas, thereby forming a particulate reaction product, and (iii) an outlet for the treated flue gas and entrained particulate reaction product, wherein the bottom of the chamber having vertical cylindrical walls is substantially horizontal and impervious to gases. The apparatus of the invention has the advantage of a simplified geometry accounting for lower building and maintenance costs.

Owner:GEA PROCESS ENG

Base Module For A Starting Apparatus Of Boat Competitions

ActiveUS20150209685A1Easy to assembleReduced support structureSlipwaysRace-coursesEngineeringMechanical drive

The invention is a base module for a starting apparatus of sport-purpose flatwater boat competitions, comprising a longitudinal holder arranged crosswise to the direction of motion of the boats, a level adjustment unit, a dynamic stabilizer, and a remote controlled start permitting unit having a mechanical drive unit. According to the invention, the longitudinal holder (2) is made of one or more rigid, hollow pipe or profiled bar.

Owner:POLARITAS GM

Photovoltaic building panel

InactiveCN101654944ALarge concentration spaceLow costRoof covering using slabs/sheetsRoof covering using tiles/slatesEngineeringDistributor

Owner:苏州同济材料科技股份有限公司

Dual crankshaft engine

InactiveUS8960138B2Reduced support structureReduce noiseInertia force compensationReciprocating piston enginesReciprocating motionCrankshaft

A dual-crankshaft engine is presented. In one embodiment, the engine includes a first crankshaft and a second crankshaft. The second crankshaft is coupled with the first crankshaft such that the first crankshaft and the second crankshaft are horizontally coplanar. The engine further includes a first piston that is operable to reciprocate in a first horizontal cylinder via coupling with the first crankshaft, and a second piston that is operable to reciprocate in a second horizontal cylinder via coupling with the second crankshaft. The second horizontal cylinder is horizontally collinear with and opposing the first horizontal cylinder.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com