Patents

Literature

262results about How to "Simplify the production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

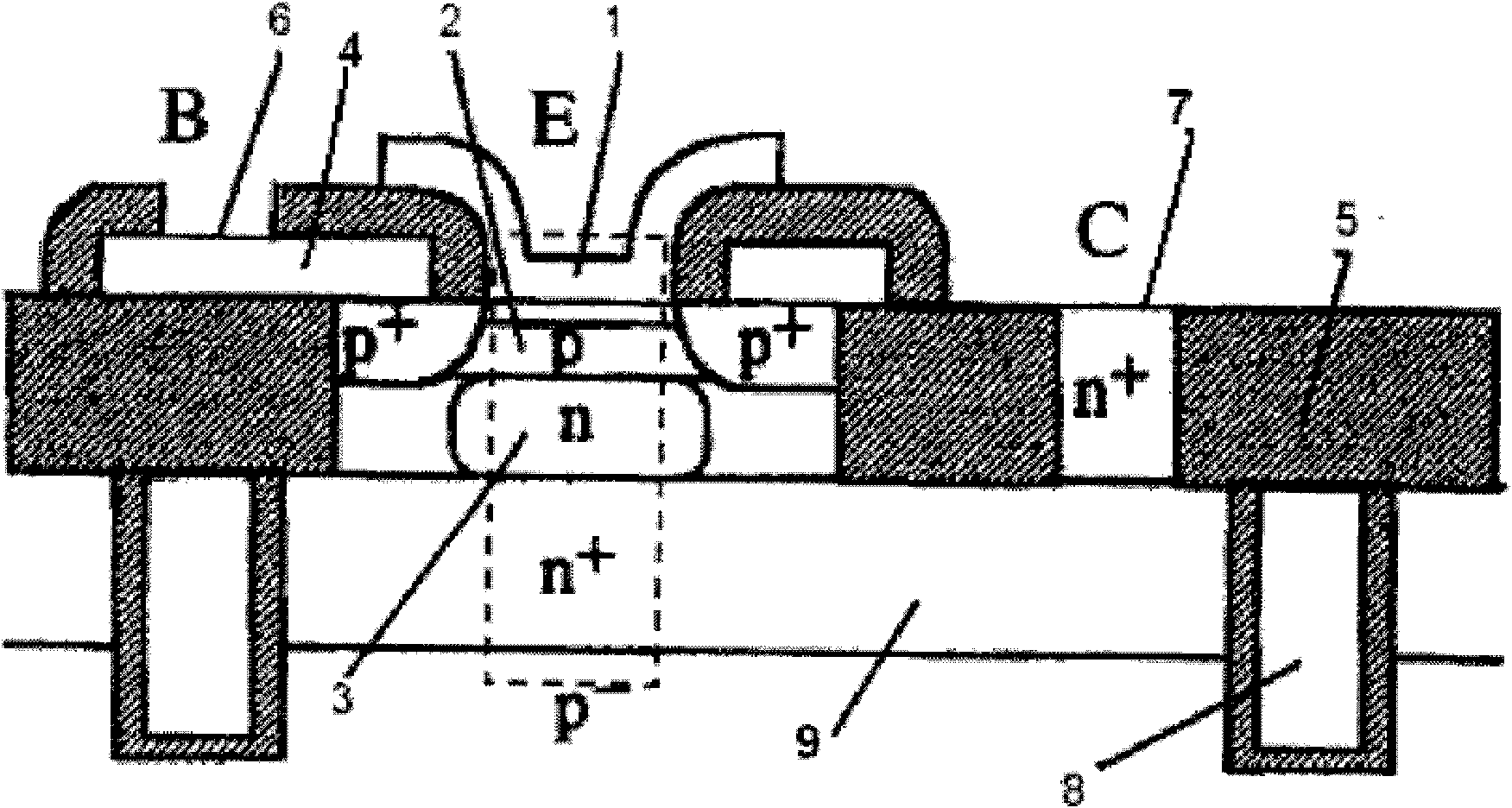

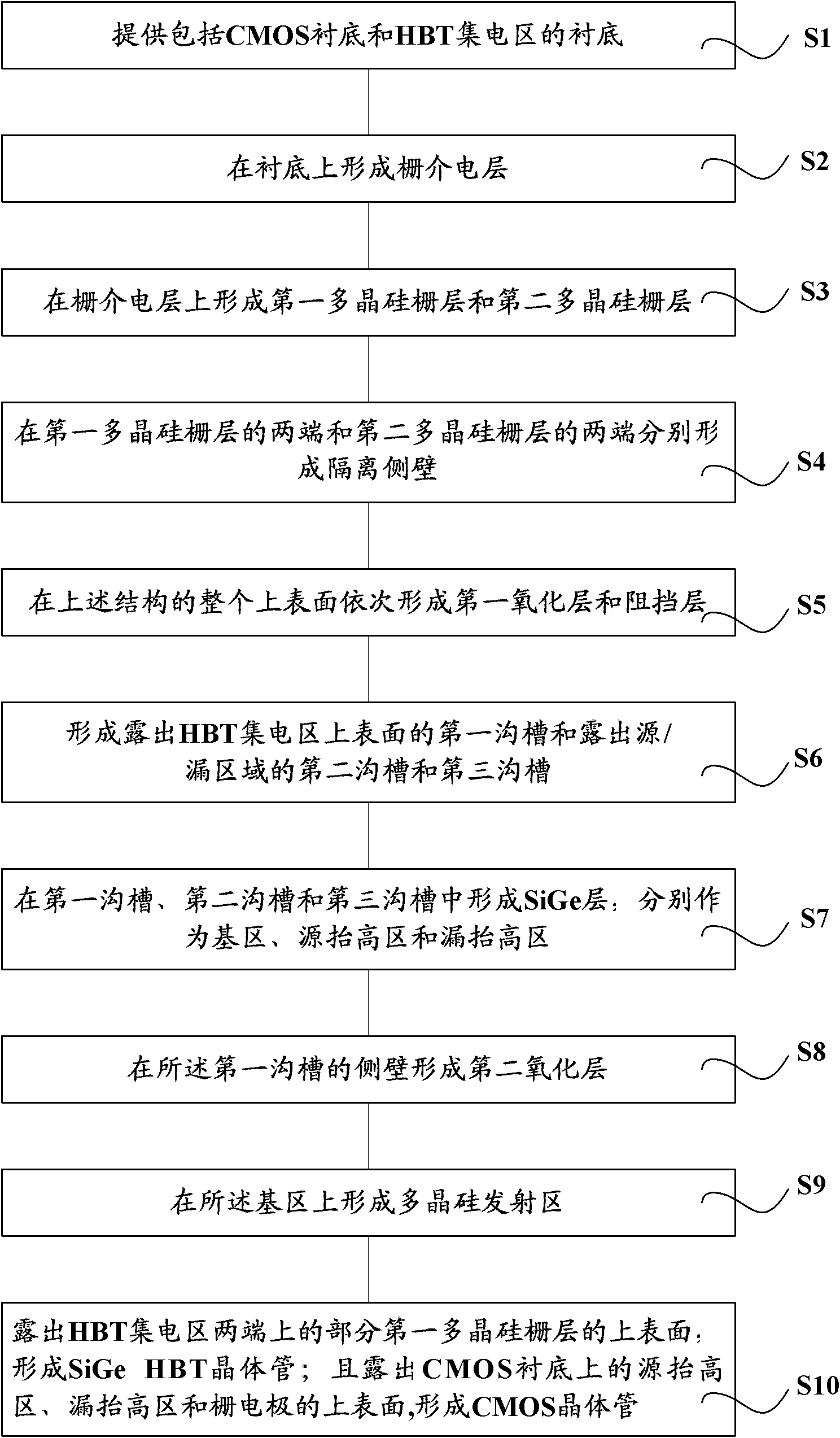

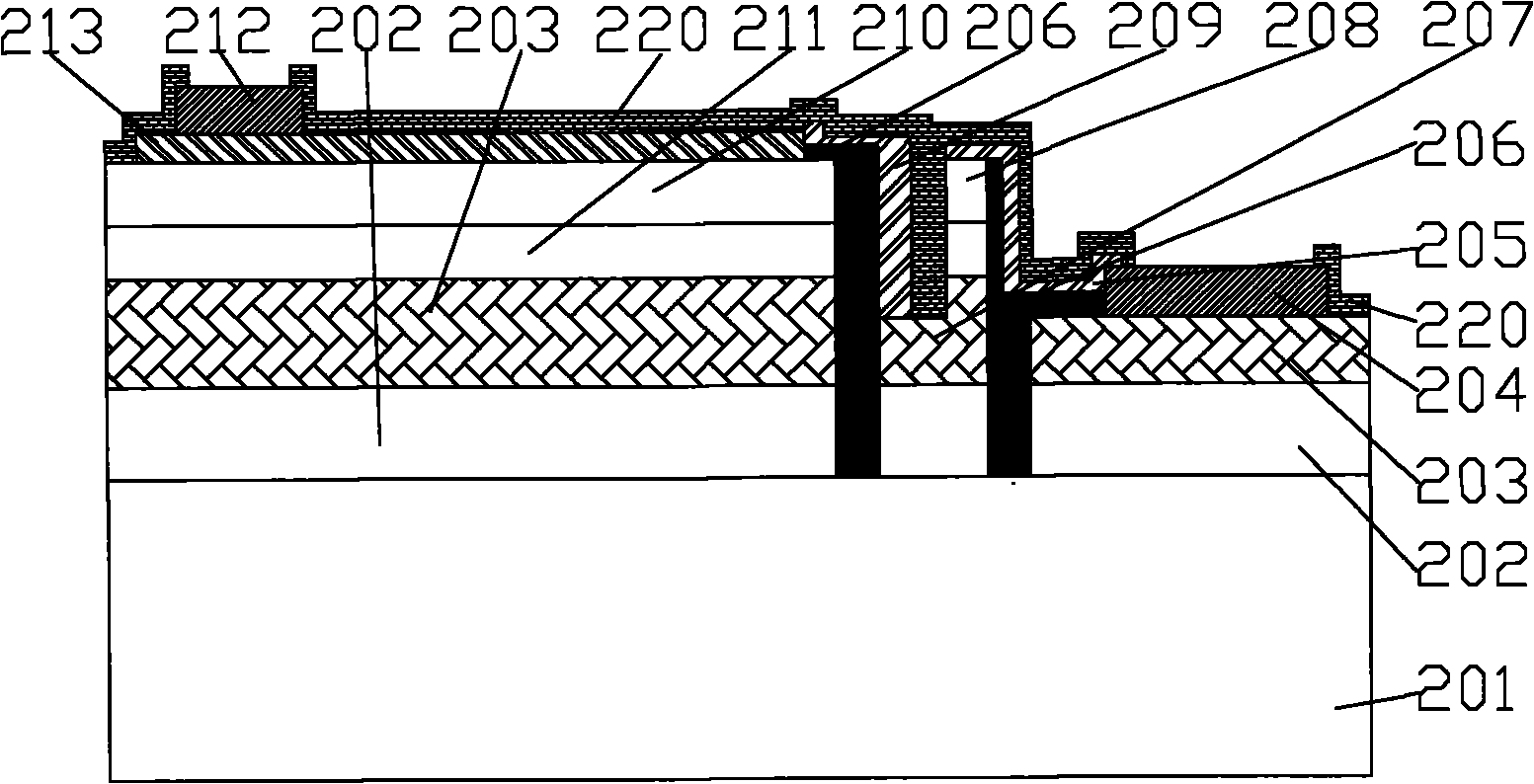

Method for manufacturing semiconductor device and method for manufacturing SiGe HBT (Heterojunction Bipolar Transistor)

ActiveCN102184898ASimplify the production processReduce manufacturing costSemiconductor/solid-state device manufacturingOxide semiconductorCMOS

The invention relates to a method for manufacturing a semiconductor device and a method for manufacturing an SiGe HBT (Heterojunction Bipolar Transistor), wherein the method for manufacturing the SiGe HBT comprises the steps of: offering a substrate comprising an HBT collector region; sequentially forming a gate dielectric layer, a polysilicon gate layer, an oxide layer and a barrier layer on the HBT collector region; removing partial barrier layer as well as the oxide layer, the polysilicon gate layer and the gate dielectric layer under the partial barrier layer on the HBT collector region so as to form a groove where the upper surface of the HBT collector region is exposed; forming an SiGe layer in the groove to serve as a base region; forming a polysilicon emitter region on the base region; and removing the partial barrier layer and the oxide layer under the partial barrier layer on two ends of the HBT collector region till the upper surface of partial polysilicon gate layer on the two ends of the HBT collector region is exposed and preserving the barrier layer surrounding the polysilicon emitter region and the oxide layer under the barrier layer. In the invention, the manufacturing processes of the two kinds of transistors are compatible and the cost is saved; the source / drain region of a CMOS (Complementary Metal Oxide Semiconductors) transistor is raised; and therefore, the self alignment of the base region and the emitter region of the SiGe HBT is realized.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Coating agent for slow release fertilizer

InactiveCN1528717ASimplify the production processEasy to operateFertilizer mixturesFertilizerChemistry

The invention relates to an enveloping agent applied to sustained release fertilizer, using chitosan 1-10wt%, amylum 30-40wt%, vinol 45-55wt%, cross-linking agent 2-10wt%, glycerol 6-8wt%, tween 1-3wt% and NH4Cl 0.5-1.5wt% as main raw materials, reacting for 1-2 hours at pH value of 2-5 and at 85-95 deg.C to make it. Its preparation is simple and its raw material source is wide and it has no environmental pollutions.

Owner:EAST CHINA UNIV OF SCI & TECH

Environmental protection type laser transfer composite aluminium foil paper and its preparation technology

InactiveCN1724811AGood printabilityMeet environmental protection requirementsNon-fibrous pulp additionPaper coatingSolventMaterials science

The invention relates an environmental protection laser transferred composite aluminum foil paper and the preparing technique, mainly solving the problems of the environment pollution and complicated technique caused by separant coating and laser layer protection coating of the existing commonly used solvent laser transferred composite aluminum foil paper. Its mixing proportion (by weight) of the raw materials is: water soluble amino resin 1-20 (or water soluble polyurethane resin 1-30, or water soluble alcohol acid resin 1-30, or water soluble acrylate resin 1-40, or cellulose resin 1-20), assistant 1-10, pigment 0-10, auxiliary solvent 1-30, and water 30-80, or their arbitrary combination, through synthesizing and wet-dispersing to mix into a water laser transfer coating, coating the transfer coating on a carrier thin film, drying, cross-linking curing, laser-mould pressing, and aluminizing to obtain the laser composite aluminum foil paper. It has the characters of improving environmental protection performance, simplifying producing process, saving energy sources, reducing production cost, stable production quality, etc.

Owner:张学毅

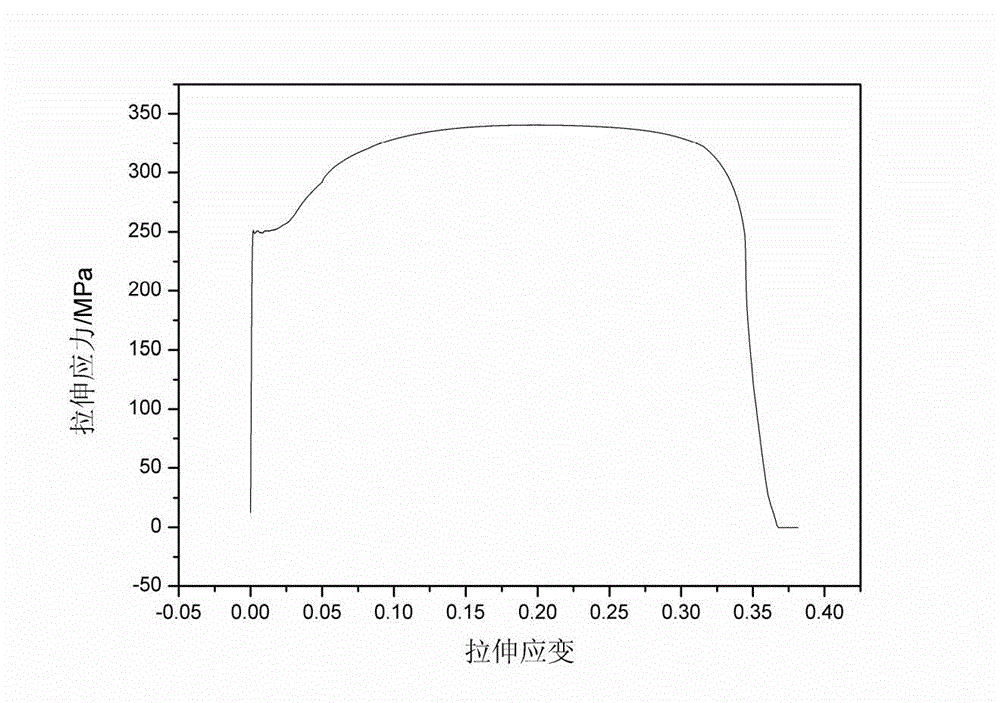

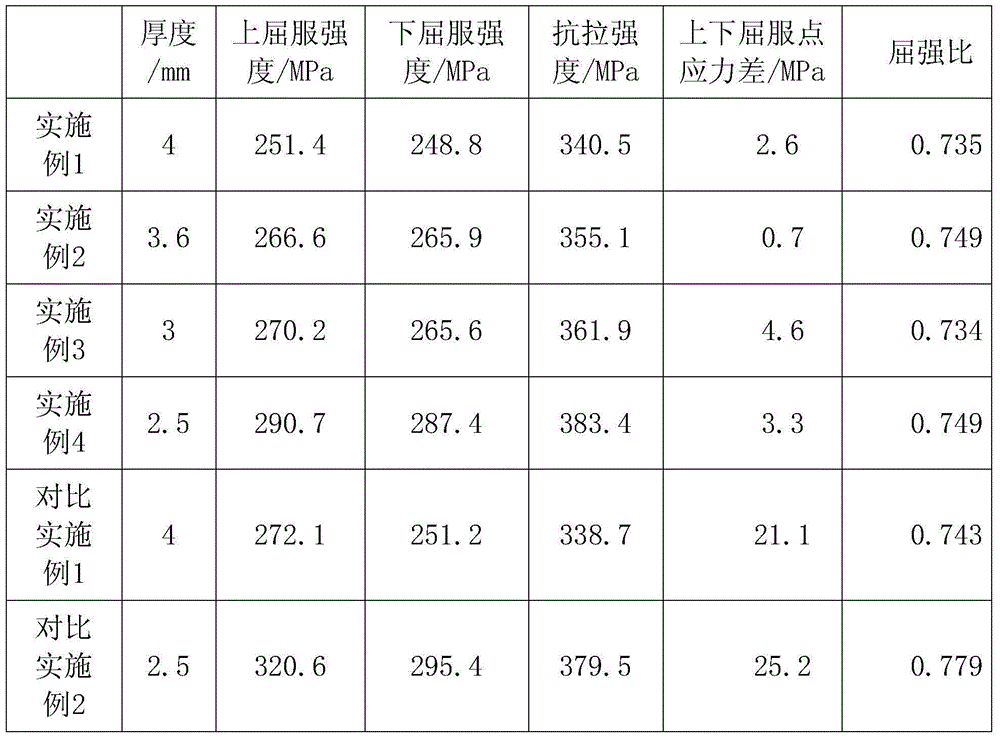

Hot-rolled pickled plate and production method thereof

The invention discloses a hot-rolled pickled plate and a production method thereof. According to the hot-rolled pickled plate, based on a common low carbon steel component system, by reasonably adding microalloy elements B and Ti and combining insulation of a coilbox before finish rolling and relaxation and cooling after finish rolling, the effects of controlling structures and a precipitated phase as well as reducing KESHI gas mass in the low carbon steel are achieved, so that the stress difference of upper and lower yield points of a hot rolled strip is reduced to below 5MPa and the defect of surface cross breaks of the hot rolled strip in a pickling, uncoiling and straightening process is eliminated. Not only is the defect of surface cross breaks of the hot rolled strip solved, but also the conventional production process of eliminating cross breaks by temper rolling is further avoided, thereby shortening the time and lowering the cost for actual production of a steel mill. The production method is an economical and effective production method of the hot-rolled pickled plate. The hot-rolled pickled plate disclosed by the invention can be widely applied to industries of household appliances, automobiles and hardware mechanical and electrical products.

Owner:ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD

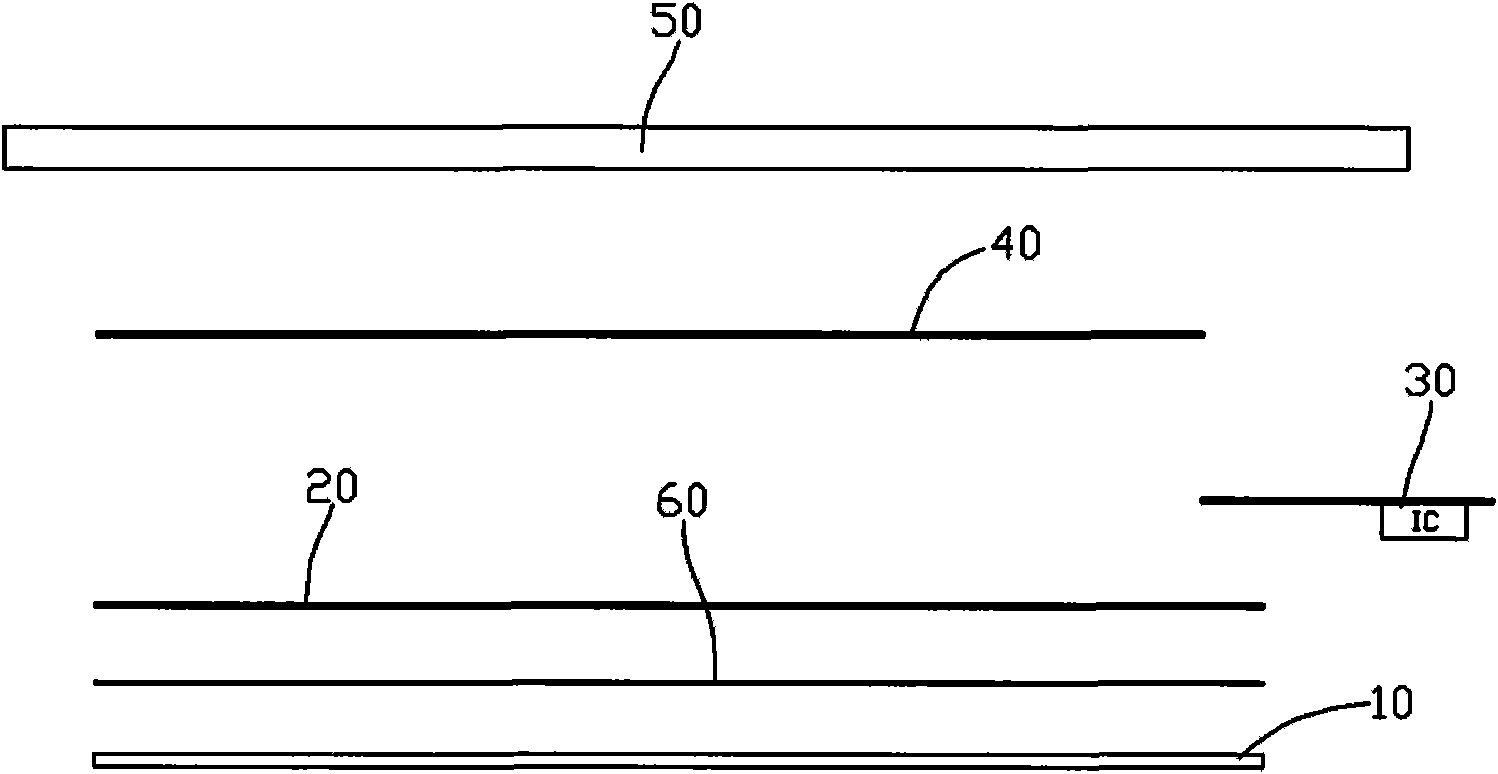

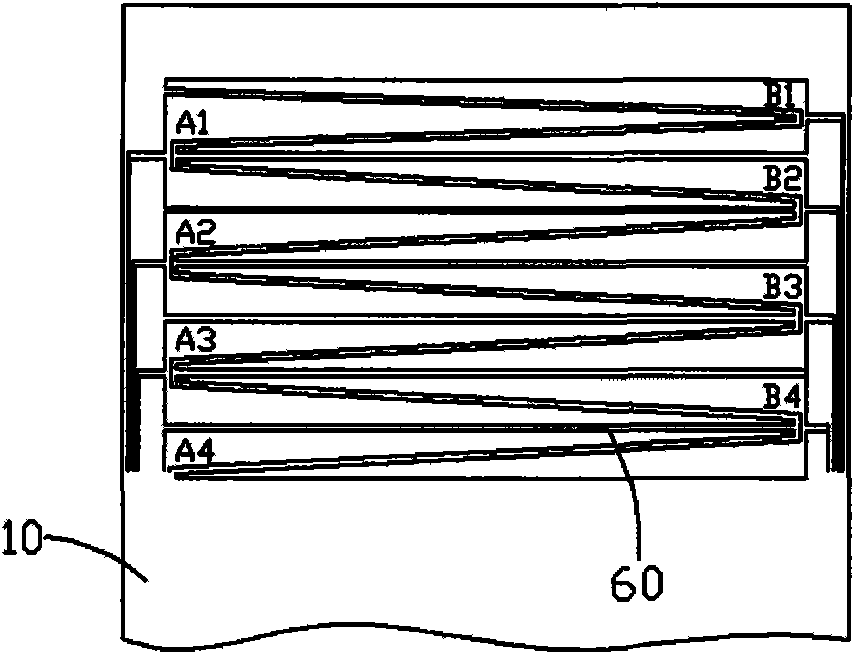

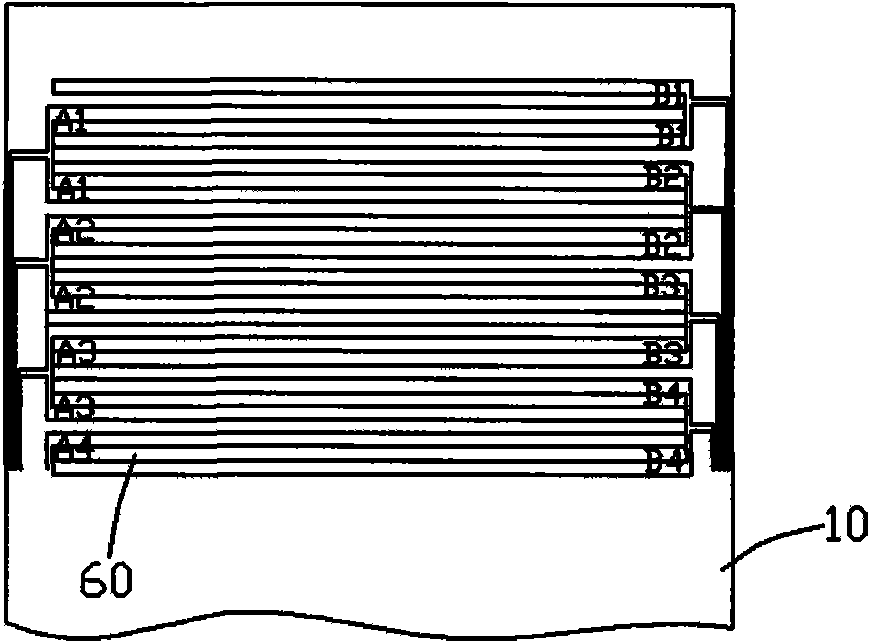

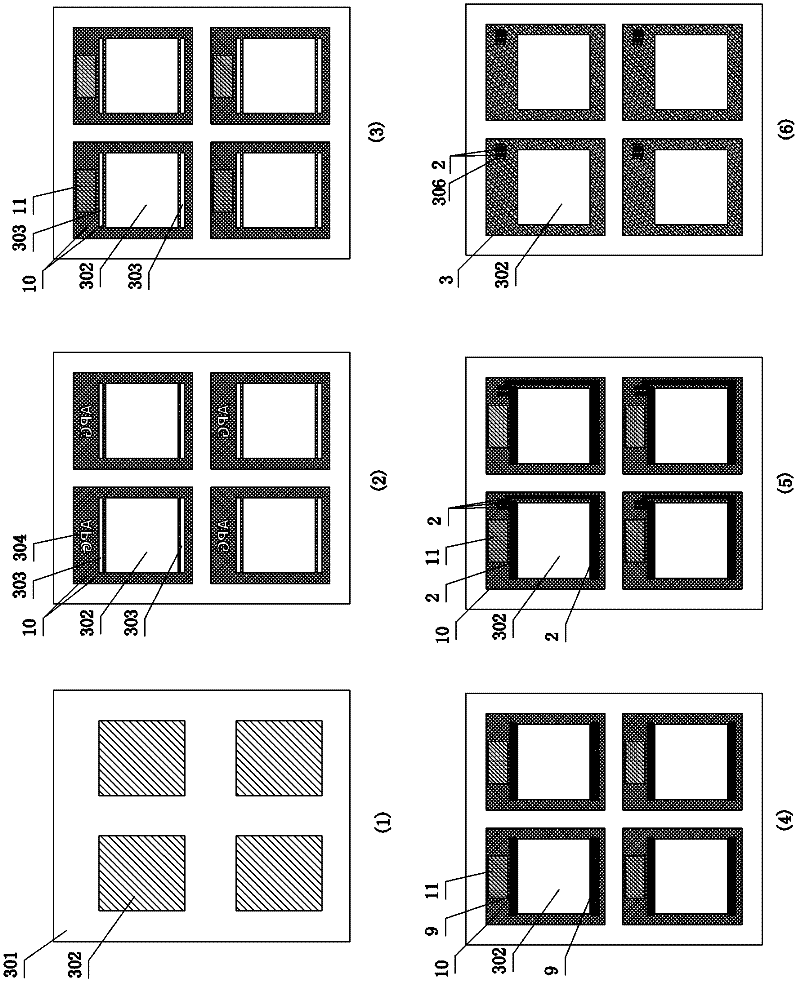

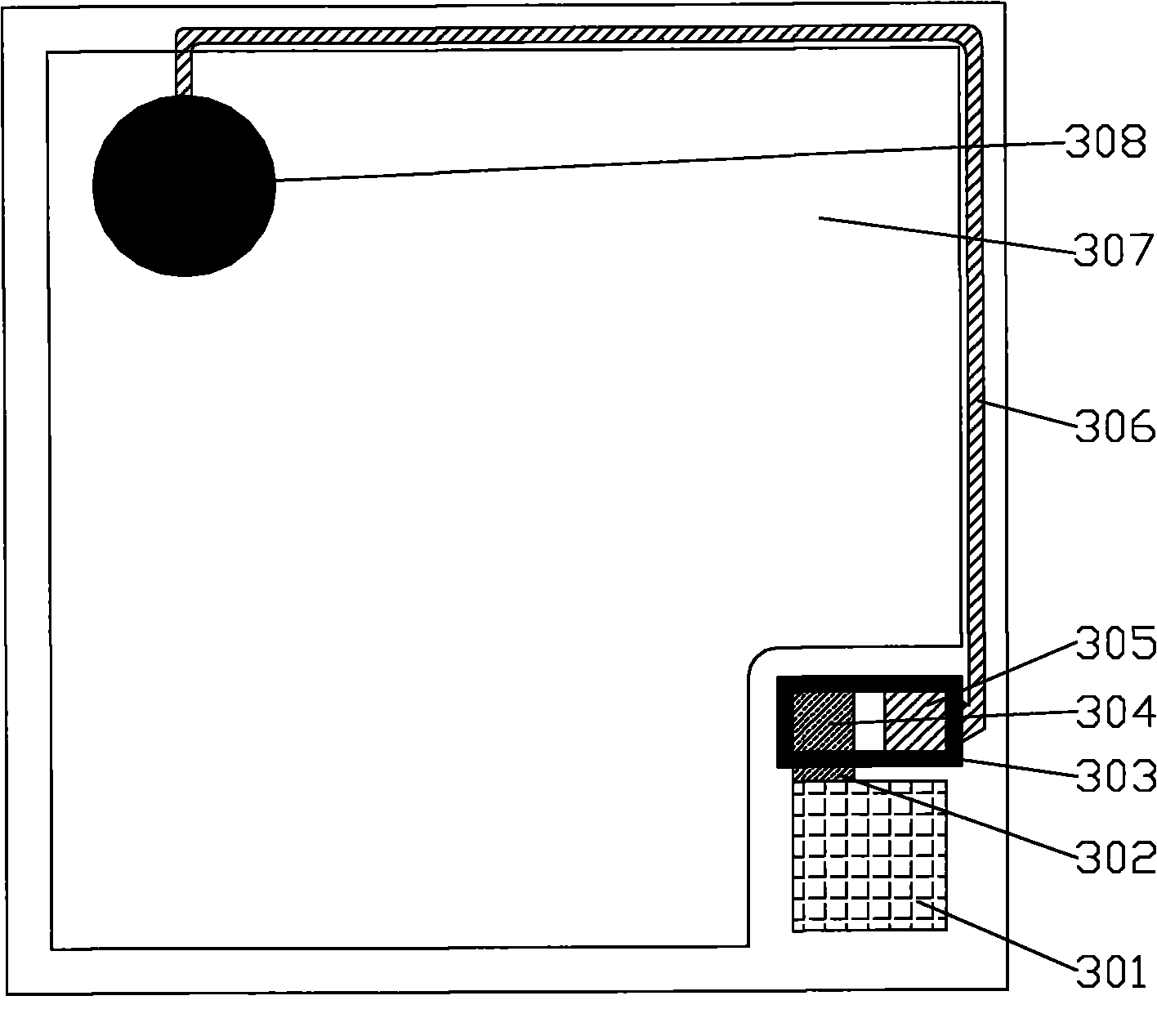

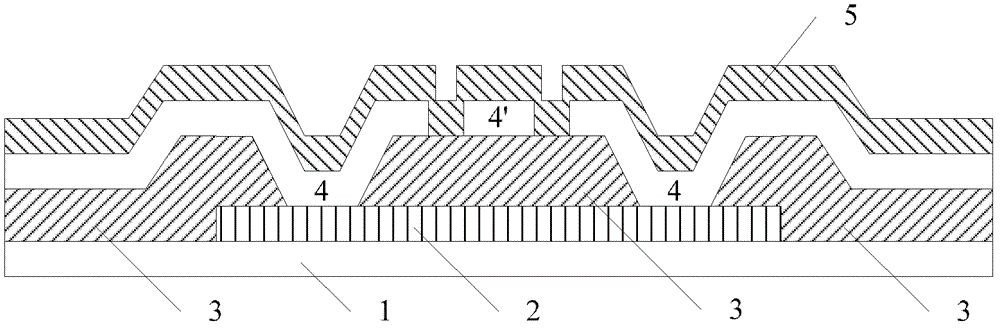

One-dimensional contact point positioning method of capacitive touch screen/board and capacitive touch screen/board

InactiveCN101561738AReduce material consumptionSimplify the production processInput/output processes for data processingFinger touchMaterial consumption

The invention discloses a one-dimensional contact point positioning method of a capacitive touch screen / board and the capacitive touch screen / board. The one-dimensional contact point positioning method of the capacitive touch screen / board comprises the following steps: a single-layer ITO circuit is arranged on a base material, and each ITO line of the ITO circuit has determinate capacitance value and forms a figure with alternate crossing arrangement but no electrical connection; and when a finger touches the screen / board, a touch-control IC firstly determines the position of a touch point at the direction of Y axis according to whether the capacitance value of a plurality of ITO lines touched by the finger changes and then determines the position of the touch point at the direction of X axis according to the ratio of the capacitance value of each line to the total capacitance value of the ITO lines determined when the finger touches the screen / board. In the invention, the capacitive touch screen / board is changed from the traditional double-layer ITO circuit positioning into the single-layer ITO circuit positioning, thus not only greatly reducing material consumption, but also simplifying production process and reducing production cost simultaneously, and being beneficial to the large-scale promotion and application of the capacitive touch screen / board.

Owner:SUPER PIONEER

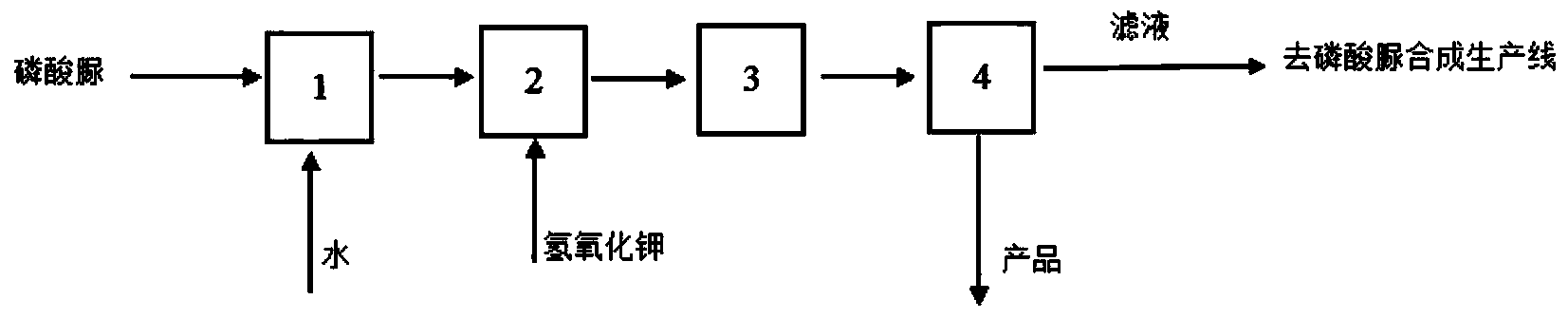

Production method of dipotassium phosphate

InactiveCN104003362ASimplify the production processReduce energy and water consumptionPhosphorus compoundsPotassium hydroxideHeavy metals

The invention relates to the technical field of chemical engineering and particularly relates to a production method of dipotassium phosphate. The method comprises the following step: carrying out a reaction on urea phosphate and potassium hydroxide in a stirring manner for 20 to 70 minutes by controlling a reaction temperature within 50 DEG C to 90 DEG C and controlling a pH (Potential Of Hydrogen) value at a final point of the reaction within 8 to 9.5 so as to prepare the dipotassium phosphate product. The produced dipotassium phosphate product completely conforms to the standard of food-grade dipotassium phosphate by controlling the whole process conditions, i.e., the content of the dipotassium phosphate is between 98.15% and 98.31%, the pH (10g / L of solution) is between 8.9 and 9.2, the content of water insoluble matters is between 0.11% and 0.17%, the content of fluorides is between 8.04mg / kg and 9.13mg / kg, the content of arsenic is between 2.03mg / kg and 2.71mg / kg, the content of heavy metal is between 8.9mg / kg and 9.4mg / kg as well as the loss on drying is between 1.64% and 1.82% according to physical and chemical indexes in a manner of sampling analysis.

Owner:GUIYANG KAILIN FERTILIZER CO LTD +1

Process for processing two-sided and multilayer circuit board

ActiveCN103491710AReduce the number of turnsSimplify the production processMultilayer circuit manufactureElectroless platingProcess engineering

The invention discloses a process for processing a two-sided and multilayer circuit board. The process includes the steps that the link that an organic electrical membrane is plated is utilized to replace pretreatment and electroless plating copper links in the process of processing a traditional circuit board, and the process of plating the organic electrical membrane is utilized to produce the circuit board. Compared with a traditional process, plate rotating links are reduced, consumption of copper, tin and other metal is saved, the production process is effectively simplified, and production cost is reduced. In addition, in the production process, formaldehyde, strong nitric acid and other hazardous substances are not used, therefore, environment friendliness is achieved, and damage to the body of operators is reduced in the process of processing the two-sided and multilayer circuit board.

Owner:莆田市龙腾电子科技有限公司

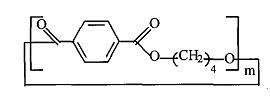

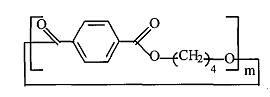

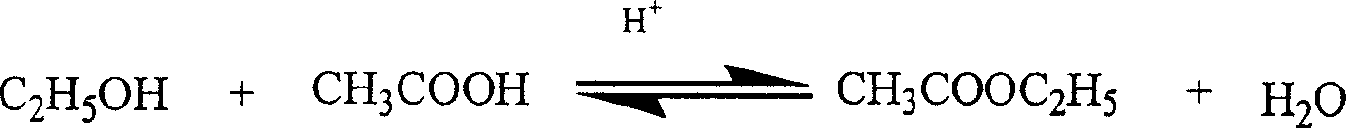

Resin membrane melt impregnation forming method of fiber reinforced PBT composite material

ActiveCN102555234ASimplify the production processReduce manufacturing costPolymer chemistryPolyethylene terephthalate

The invention discloses a resin membrane melt impregnation forming method of a fiber reinforced polyethylene terephthalate (PBT) composite material, comprising the following steps: 1) processing to form a cyclic butylenes terephthalate(CBT) resin membrane with the thickness of 15-700 mu m; 2) successively placing a demolding cloth, the CBT resin membrane, a fiber reinforced material and a demolding cloth on a mold; 3) heating up the assembly obtained by the step 2) to 180-225 DEG C under vacuum and preserving the heat for 5 min-6 h to melt the CBT resin in the CBT resin membrane and completely impregnate the fiber reinforced material, simultaneously polymerizing the CBT resin into PBT with high molecular weight, cooling, and then demolding. According to the invention, the forming method has no need to prepare a prepreg, the forming process can be realized at the temperature which is lower than the PBT melting temperature, the process is simple and easy to operate, the efficiency is high, and large members can be formed. The invention is beneficial for popularization and application.

Owner:中材科技(邯郸)风电叶片有限公司

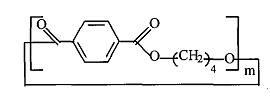

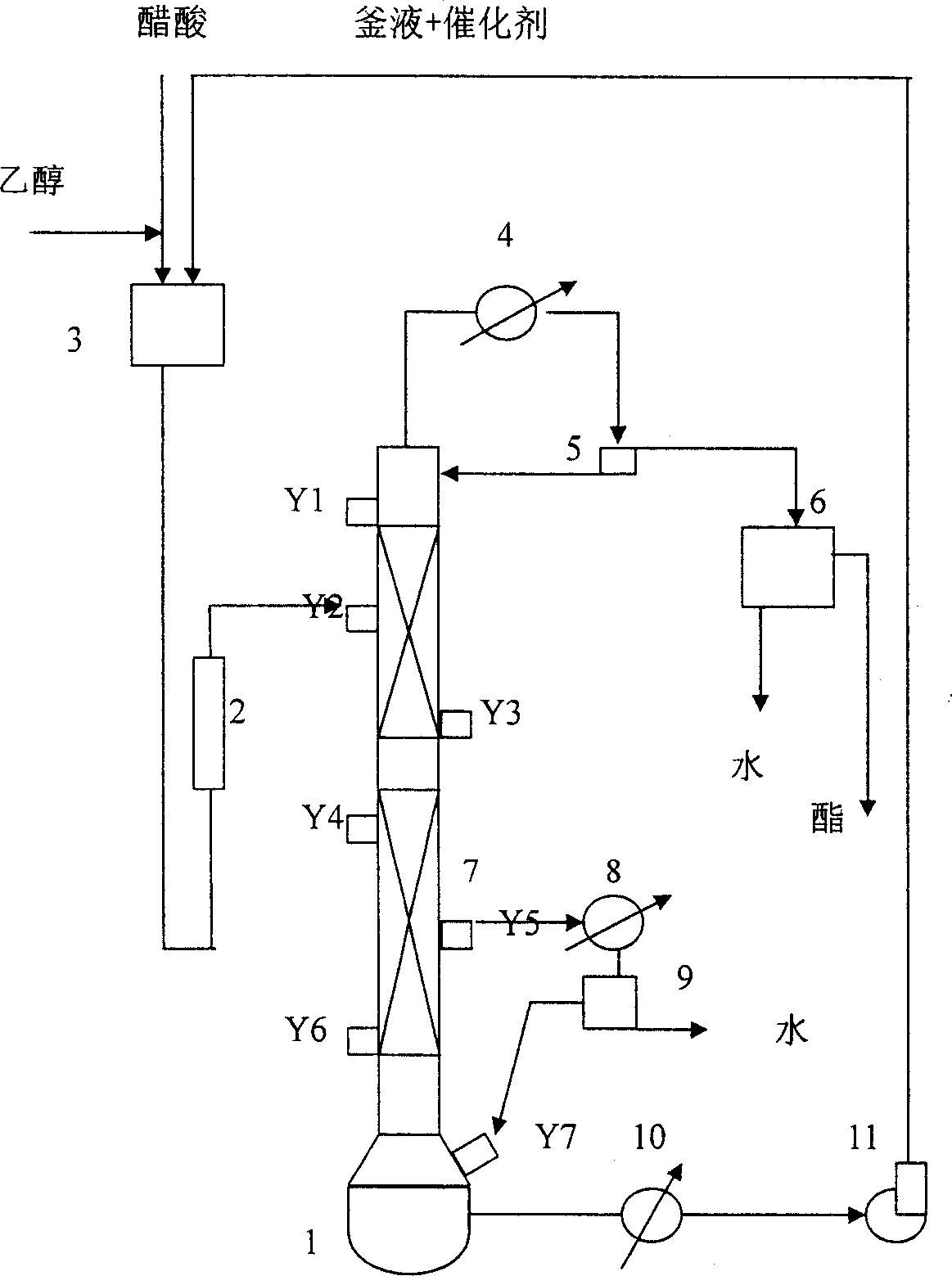

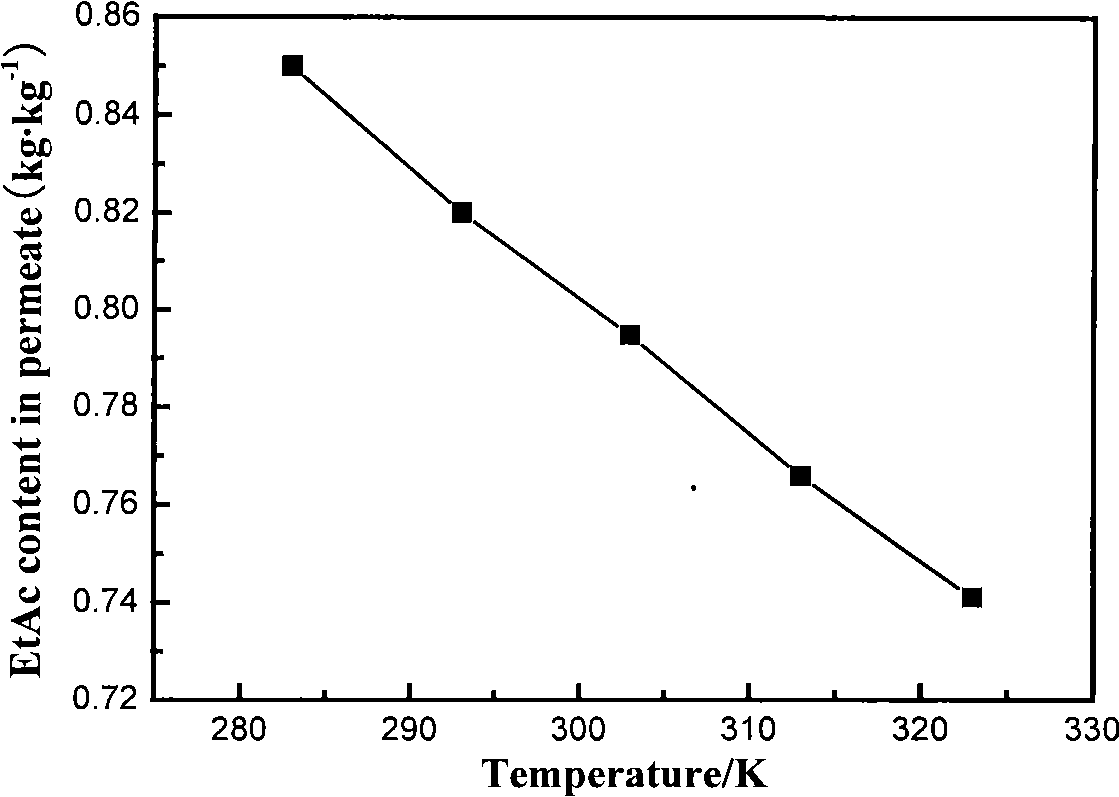

Method and apparatus for continuously preparing ethyl acetate by single tower

InactiveCN1616399ASimplify the production processIncrease conversion rate per passOrganic compound preparationCarboxylic acid esters preparationEthyl esterChemistry

The single tower ethyl acetate preparing process includes boiling the mixed liquid in certain acid / alcohol ratio and with strong acid catalyst and water carrying agent inside tower; opening condensating water for full reflux operation and stable top temperature after the vapor reaches to tower top; regulating acid / alcohol ratio to 1 and feeding strong acid catalyst from the top; regulating certain reflux ratio with the reflux ratio regulator, taking coarse ester product from the top and maintaining the top temperature unchanged; discharging gas material from the bottom, condensating in condensator, separating water in phase separator and refluxing organic phase with rich water carrying agent to the tower. The present invention has ester content in coarse ester product over 94 %, high conversion rate, low power consumption and low production cost.

Owner:GUANGXI UNIV FOR NATITIES

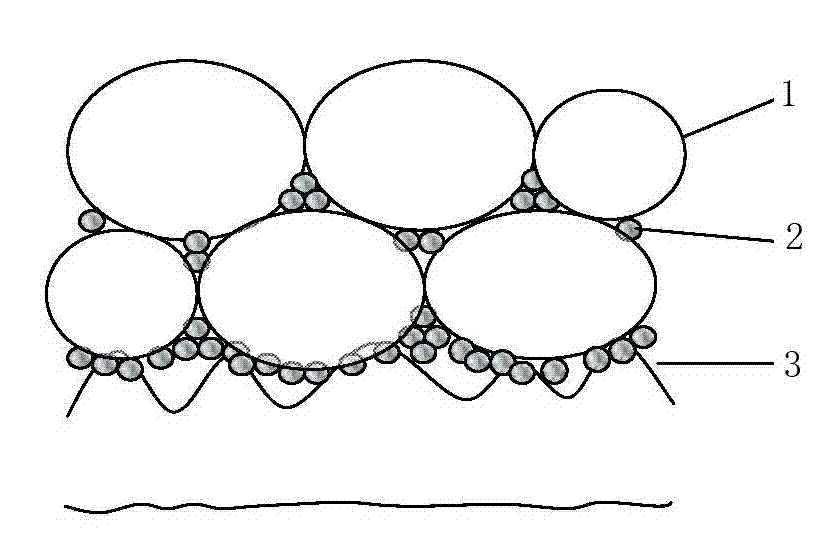

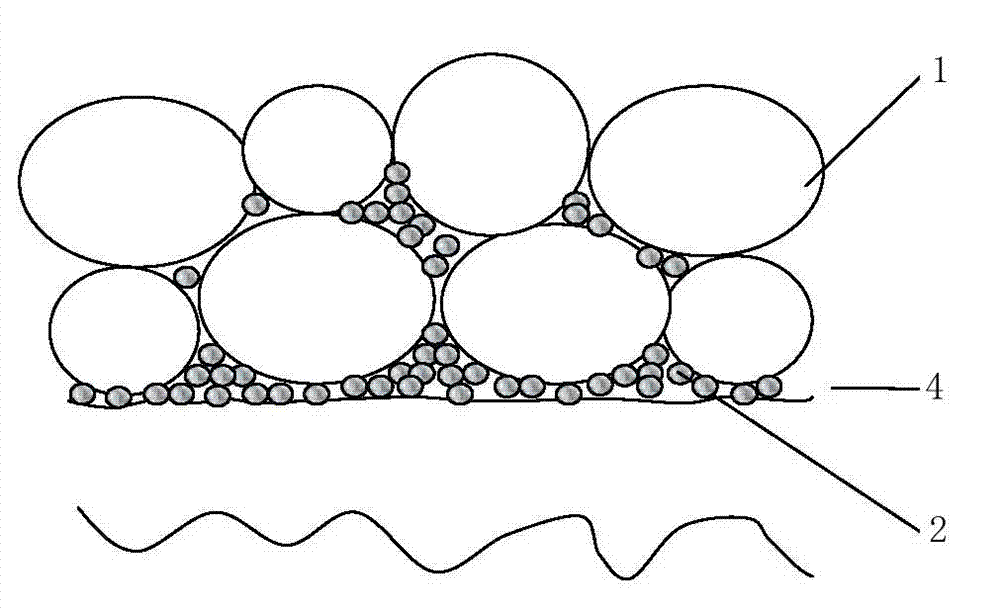

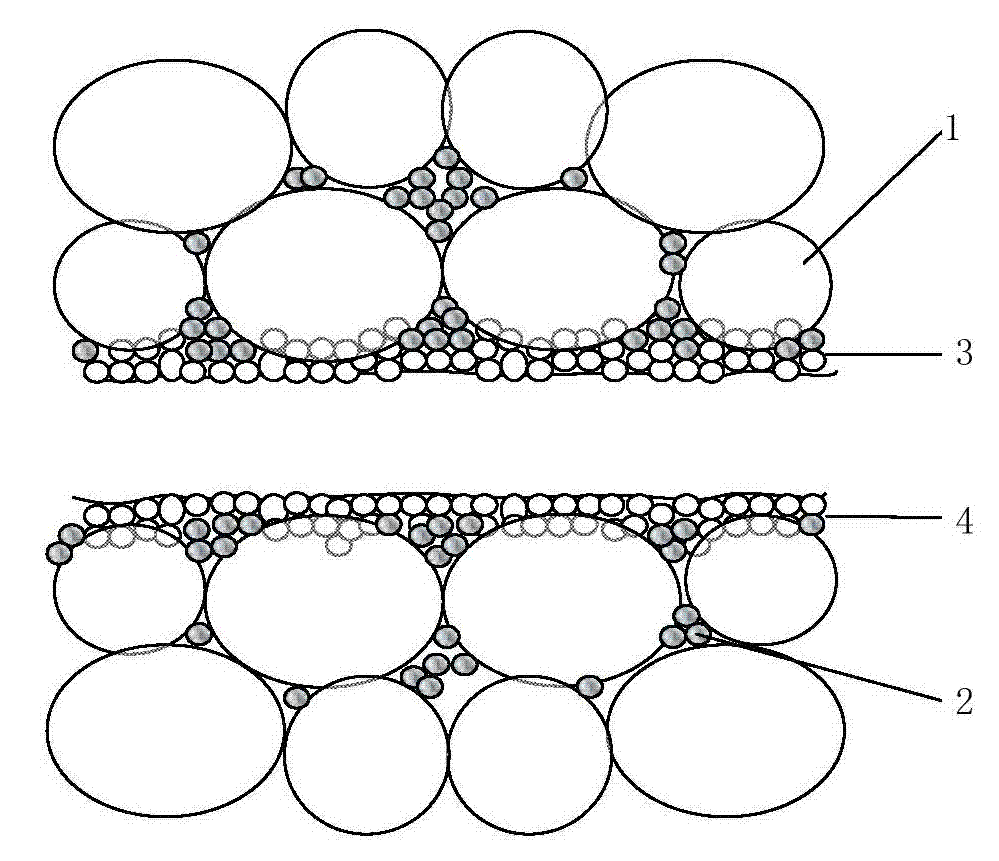

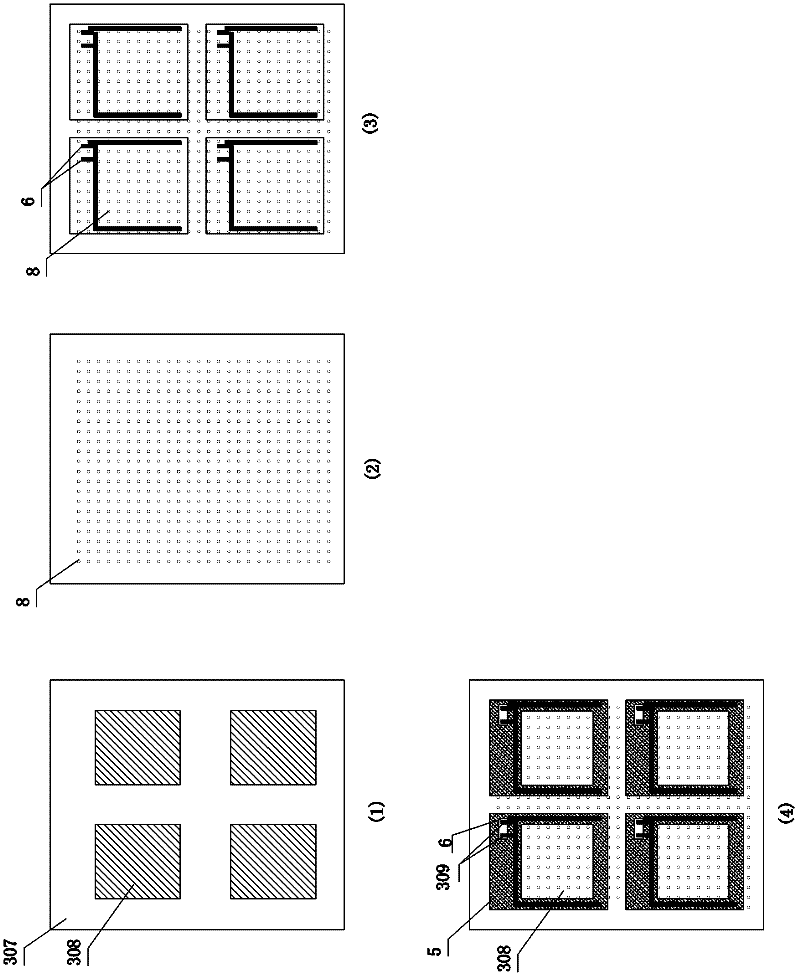

Copper foil production conjoint machine and high-bonding strength copper foil technology for lithium ion battery

ActiveCN103160867AImprove production yieldSimplify the production processElectroforming processesCopper foilElectrical battery

The invention discloses a copper foil production conjoint machine and a high-bonding strength copper foil technology for a lithium ion battery. The copper foil production conjoint machine comprises a foil production machine and a post-treatment machine. The post-treatment machine is connected to the back of the foil production machine. A straight-line distance between a treatment tank copper foil input roller of the post-treatment machine and a copper foil stripping roller of the foil production machine is less than or equal to 3m. A rough treatment anode plate and a curing treatment anode plate are arranged along two surfaces of copper foil in a pre-treatment tank of the post-treatment machine. A post-treatment process comprises carrying out double-surface rough treatment, curing treatment, passivation treatment and washing treatment on copper foil which is fed by the foil production machine and has double-surface roughness vales of Rz less than 1.7 micrometers and Ra less than 0.25 micrometers. Through utilization of a copper sulphate solution as a roughing solution and a curing solution, the production flow is simplified; the control process is simple and can be operated simply; and a yield is improved. The copper sulphate solution does not contain an arsenic compound, reduces pollutant discharge, is conducive to environmental protection, and has obvious economic and social benefits.

Owner:FUJIAN QINGJING COPPER FOIL

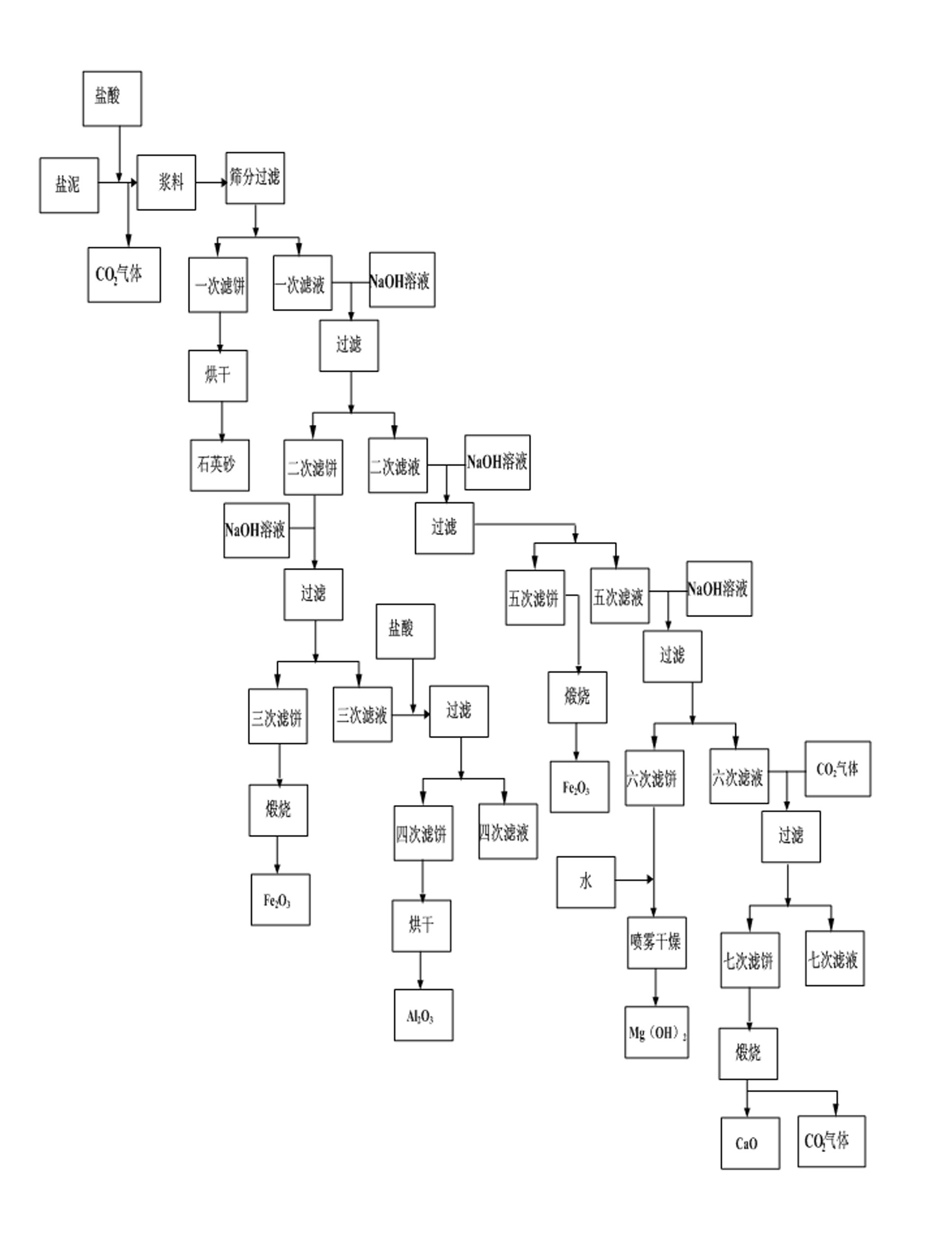

Method for comprehensively utilizing chlor-alkali salt sludge

InactiveCN102040250ASimplify the production processLow equipment requirementsSilicaFerric oxidesProcess engineeringAlkali salt

The invention relates to a method for comprehensively utilizing chlor-alkali salt sludge, which comprises the following steps: mixing and filtering the chlor-alkali salt sludge and water to obtain a first filter cake and first filter liquor; adding alkali liquor to the first filter liquor, and filtering to obtain a second filter cake and second filter liquor; adding the alkali liquor to the second filter cake, and filtering to obtain a third filter cake and third filter liquor; calcining the third filter cake; adding hydrochloric acid to the third filter liquor, and filtering to obtain a fourth filter cake and fourth filter liquor; drying the fourth filter cake; adding the alkali liquor to the second filter liquor, and filtering to obtain a fifth filter cake and fifth filter liquor; calcining the fifth filter cake; adding the alkali liquor to the fifth filter liquor, and filtering to obtain a sixth filter cake and sixth filter liquor; mixing the sixth filter cake and the water into slurry, and carrying out the spray drying on the slurry; introducing CO2 into the sixth filter liquor, and filtering to obtain seventh filter liquor and a seventh filter cake; and calcining the seventh filter cake. The method respectively extracts various materials by adding acid and alkali to the chlor-alkali salt sludge and successively filtering, and has the advantages of simple production process flow, low equipment requirement and no other pollution after the treatment is finished.

Owner:LIAONING TECHNICAL UNIVERSITY

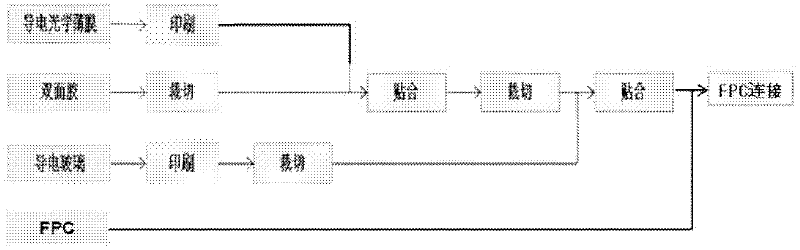

Method for manufacturing resistance-type touch screen and resistance-type touch screen

InactiveCN102520834ASimplify the production processImprove yieldInput/output processes for data processingEngineeringOptical film

The invention provides a method for manufacturing a resistance-type touch screen. The method comprises the following steps of: preparing a conductive optical film; and preparing conductive glass. The invention also provides the resistance-type touch screen which is manufactured by using the method. The resistance-type touch screen consists of the conductive optical film and the conductive glass, wherein the conductive optical film and the conductive glass are bonded by using a double-sided adhesive tape. By adoption of the method provided by the invention, production flow is simplified, yield is improved, and labor time is saved, so that the aim of reducing production cost is fulfilled. The resistance-type touch screen has a two-layer structure and a decoration effect, the conductive optical film serves as an upper electrode, and the conductive glass serves as a lower electrode and a supporting plate. By adoption of the method provided by the invention, the conductive optical film has a conductivity function and the appearance of a decoration part, and can be colorful according to an appearance requirement, so that the conventional decoration parts which are required to be individually arranged are eliminated.

Owner:HANGZHOU AMPHENOL PHOENIX TELECOM PARTS

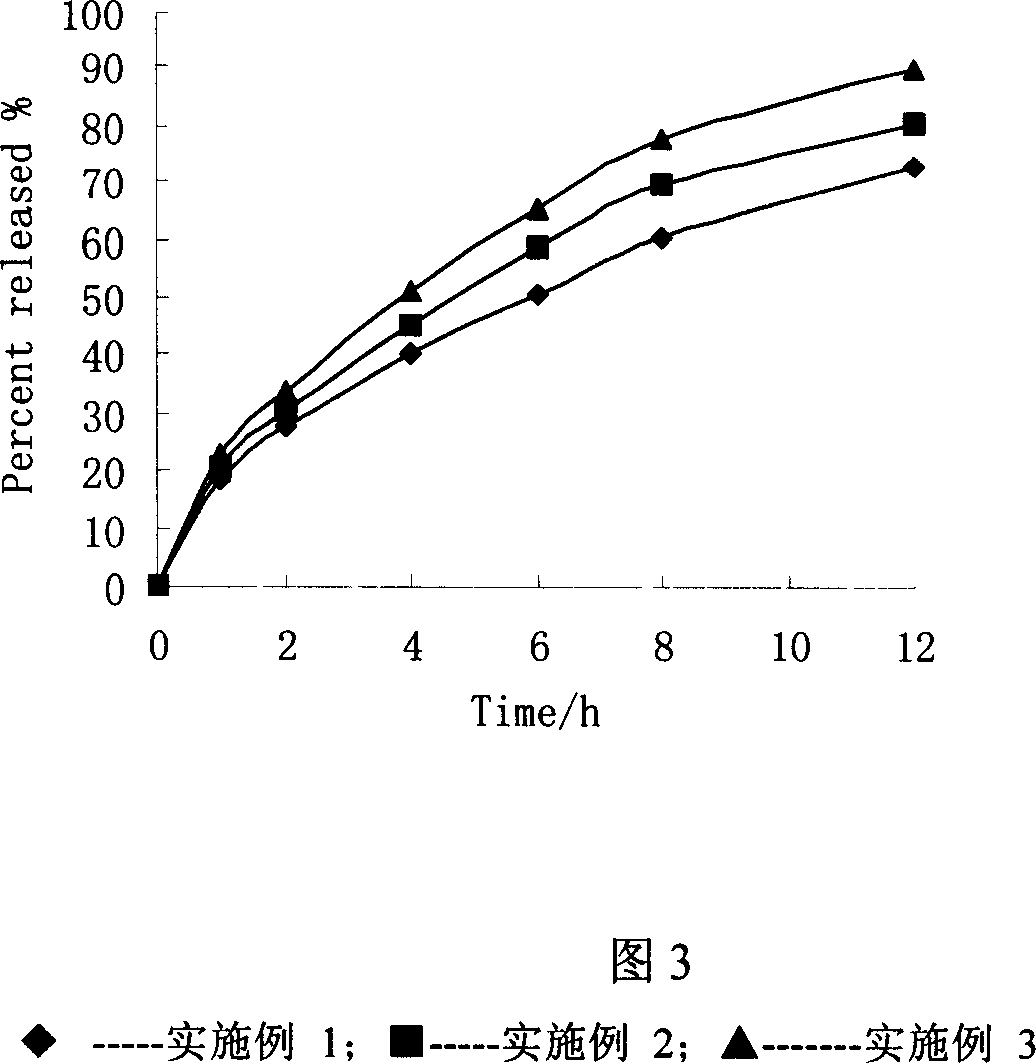

Fenofibrate pellet and method for preparing the same

ActiveCN101134018ASimplify the production processSimple preparation equipmentPowder deliveryOrganic active ingredientsSolventFenofibrate

The present invention relates to a new method for making insoluble medicine fenofibrate be prepared into micropills in liquid phase. Said method includes the following steps: making the fenofibrate and macromolecular material be dissolved in solvent to form medicine-macromolecular material solution; then making insoluble material be uniformly mixed and suspended in the medicine-macromolecular material solution, adding poor solvent, using medicine-macromolecular material solution as inner phase and using poor solvent as outer phase to form metastable emulsion; along with the continuous diffusion of good solvent in emulsion drop the medicine and macromolecular material in said emulsion drop can be simultaneously separated out and precipitated on the internal and external surfaces of diffusion agent, under the bridge-forming action of liquid bridge-forming agent and stirring action the spherical granules can be obtained.

Owner:ANHUI PROV INST OF BIOLOGICAL MEDICINE

Construction garbage concrete brick and production process thereof

InactiveCN101306937ALess types of raw materialsSimplify the production processSolid waste managementWater contentExhaust emission

The invention discloses a construction waste concrete brick and a method for making the same. The concrete brick is prepared by mixing the following raw materials: 15 to 35 portions of construction waste concrete, 50 to 70 portions of construction waste brick dust and 10 to 15 portions of cement. The method for making the brick is as follows: construction wastes are sorted and sieved so as to be mixed and stirred with other raw materials; wet basis water content is controlled between 12 and 16 percent; the mixed materials are formed under a pressure of between 15 and 35 MPa; and a formed brick undergoes natural curing or steam curing. The product meets the requirements of the agricultural industry standards of the people's republic of china, i.e. the 'Concrete Common Brick and Decorative Brick' (NY / T671-2003), and the strength of the product can reach to above MU10. The technology ensures that the total use of construction waste reaches to above 85 percent, and has the advantages of no sintering, low energy consumption and no exhaust emission, etc.; moreover, the technology solves the problems of the prior construction waste wall brick process such as low treatment efficiency of construction waste, more raw materials, high cost of a jelling material and poor market applicability; meanwhile, the technology accords with national energy-saving and emission-reduction policies, and has enormous environmental benefit, economic benefit and social benefit.

Owner:HUAZHONG UNIV OF SCI & TECH

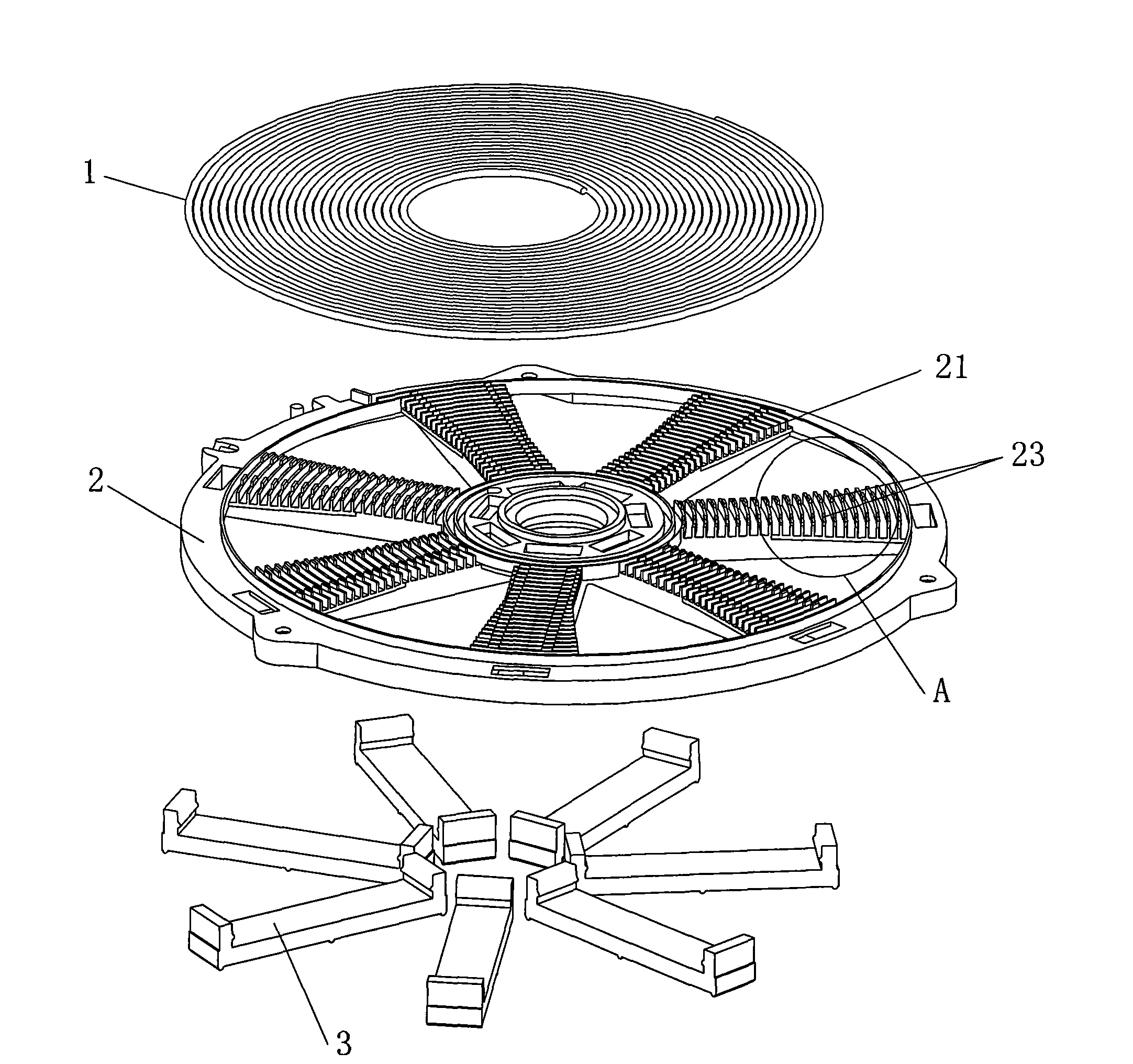

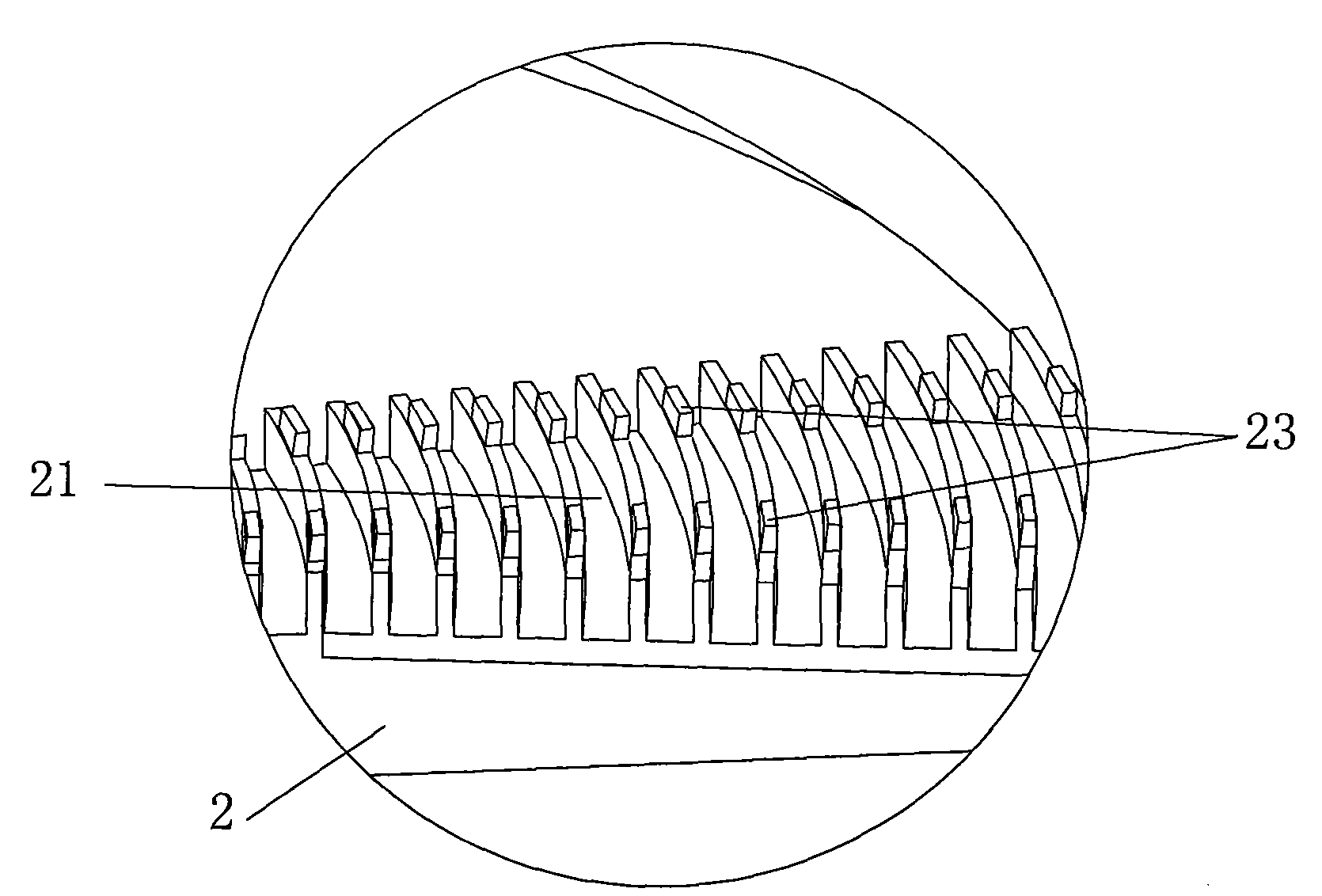

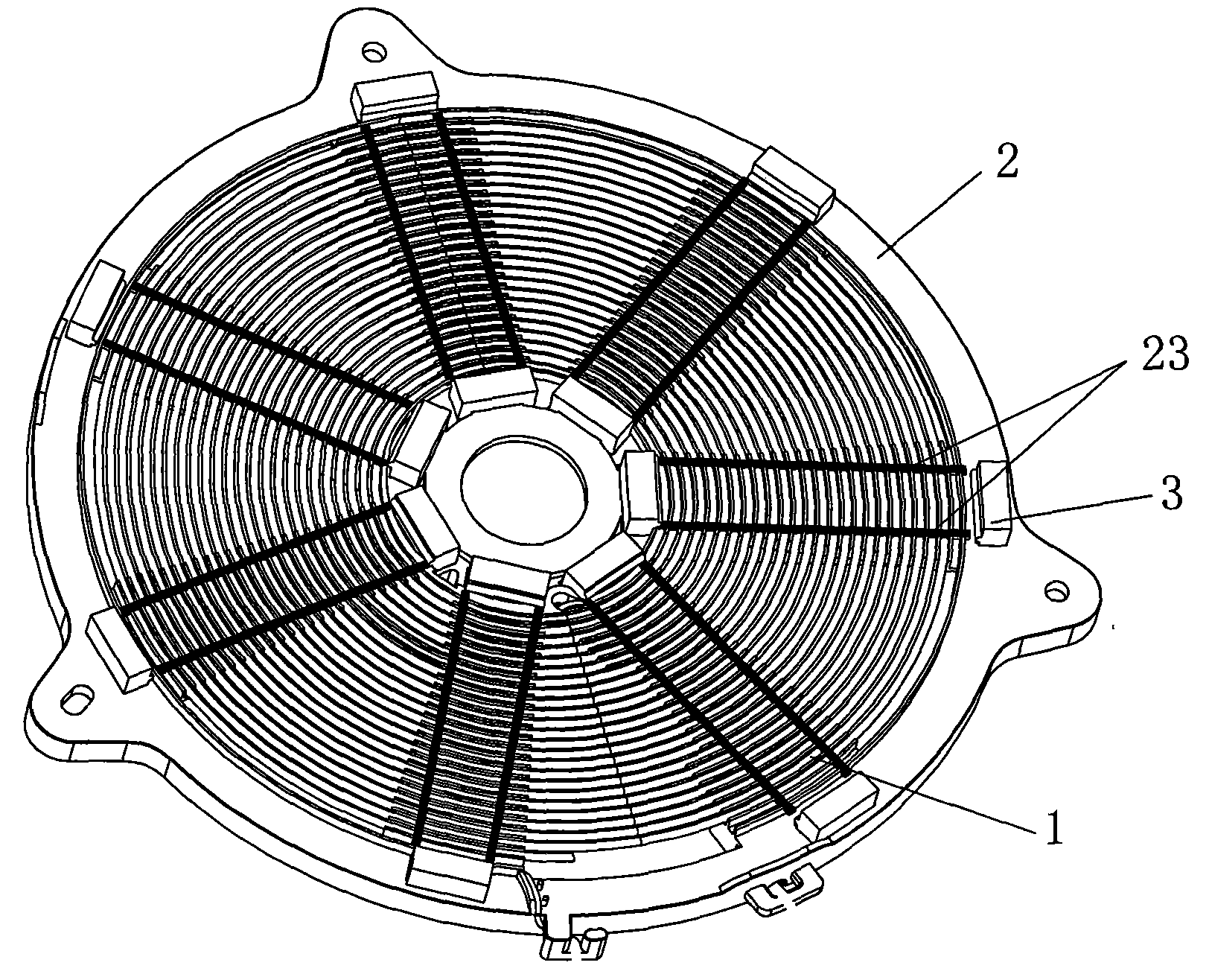

Electromagnetic induction coil panel and manufacturing process thereof

ActiveCN102098819ASimplify the production processKeep cleanDomestic stoves or rangesCoil arrangementsElectromagnetic inductionHot press

The invention discloses an electromagnetic induction coil panel, which comprises a coil winding, a plastic bracket and a plurality of magnetic stripes, wherein the coil winding is wound in a wire casing on the upper surface of the plastic bracket; the plurality of magnetic stripes are arranged in a plurality of accommodation grooves formed on the lower surface of the plastic bracket respectively; and one or more positioning lug bosses are arranged on the two sides of each of the wire casing and the accommodation grooves, and are hot-pressed to embed the coil winding into the wire casing and partially wrap the magnetic stripes. The manufacturing process comprises the following steps of: 1, winding the coil winding in the wire casing on the upper surface of the plastic bracket; 2, clamping the magnetic stripes in the accommodation grooves on the lower surface of the plastic bracket; and 3, simultaneously heating the two surfaces of the plastic bracket to heat, soften and deform the positioning lug bosses on the two sides of each of the wire casing and the accommodation grooves, and pressing the lug bosses to embed the coil winding into the wire casing and integrate the coil winding and the wire casing and partially wrap the magnetic stripes. According to the manufacturing process, a process flow is simplified and working environment is clean and sanitary; and the coil panel has a secure and stable structure.

Owner:MIDEA GRP CO LTD

Liquid crystal display device and assembly method thereof

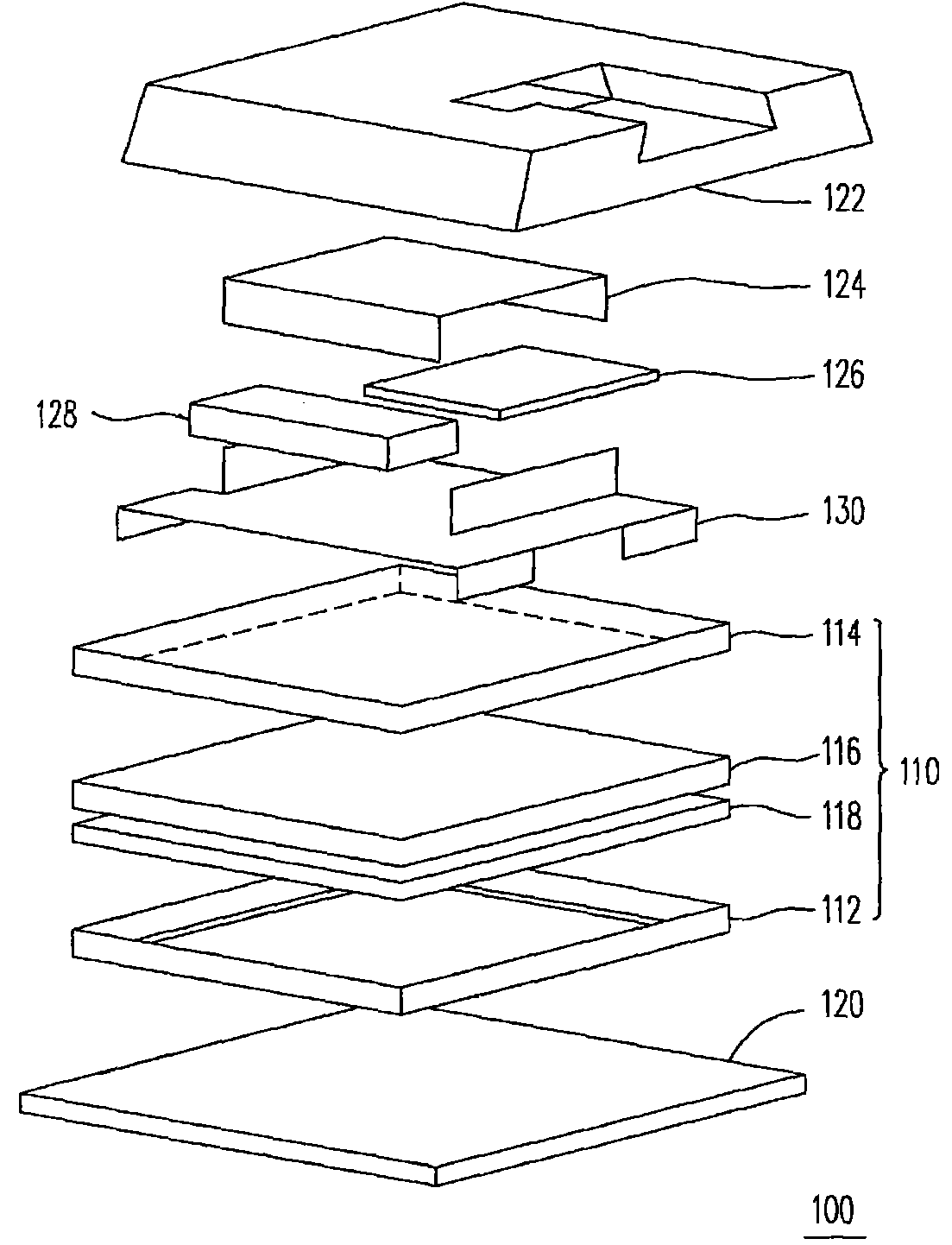

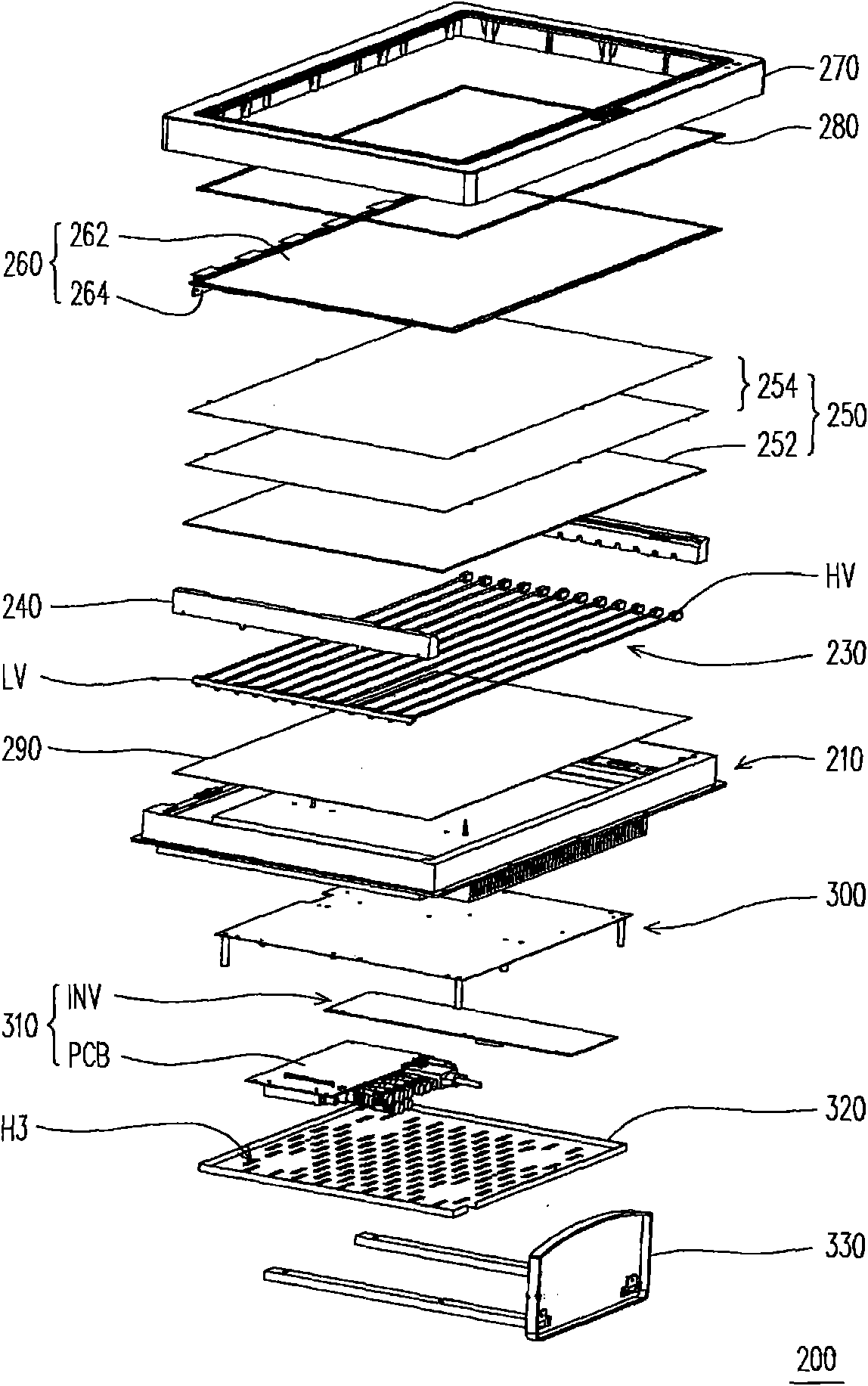

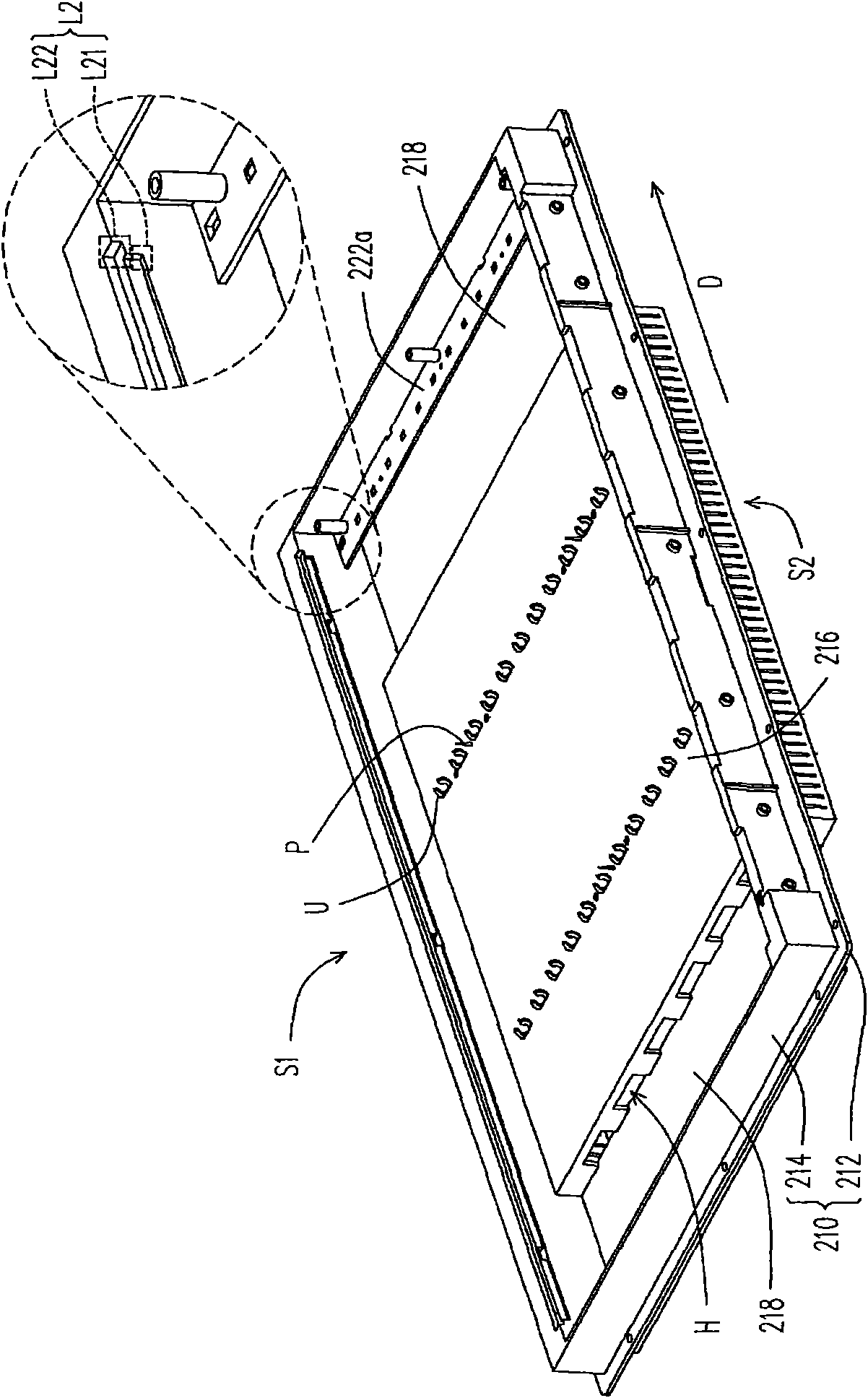

InactiveCN102053394ALower assembly costsSimplify the production processNon-linear opticsIdentification meansLiquid-crystal displayEngineering

The invention discloses a liquid crystal display device and an assembly method thereof. The liquid crystal display device comprises a rear cover, a signal control module, a plurality of line light sources, a pair of loaders, a plurality of optical diaphragms, a display panel and a front frame. The rear cover is provided with a first side and a second side which are opposite. The loaders are arranged on the first side of the rear cover, and the loaders and the rear cover hold the line light sources, wherein each loader is provided with a plurality of openings and a step loading structure. The optical diaphragms and the display panel are sequentially arranged on the step loading structures, and the front frame and the rear cover hold the display panel together. The signal control module is arranged on the second side of the rear cover. When the liquid crystal display device using the integrated rear cover is assembled, the use number of dies can be effectively reduced so as to reduce the cost, simplify the production flow and promote the assembly efficiency.

Owner:INNOLUX CORP

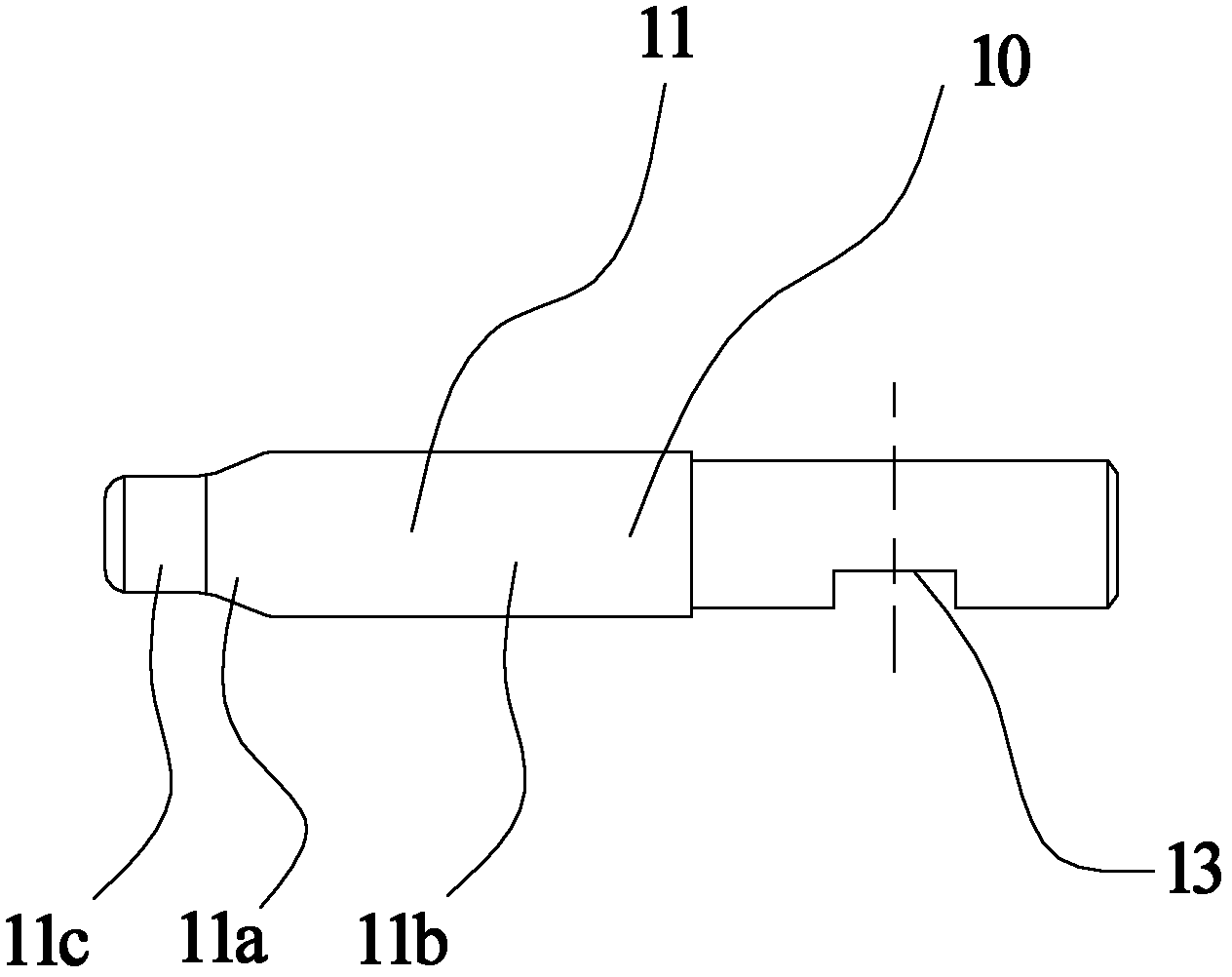

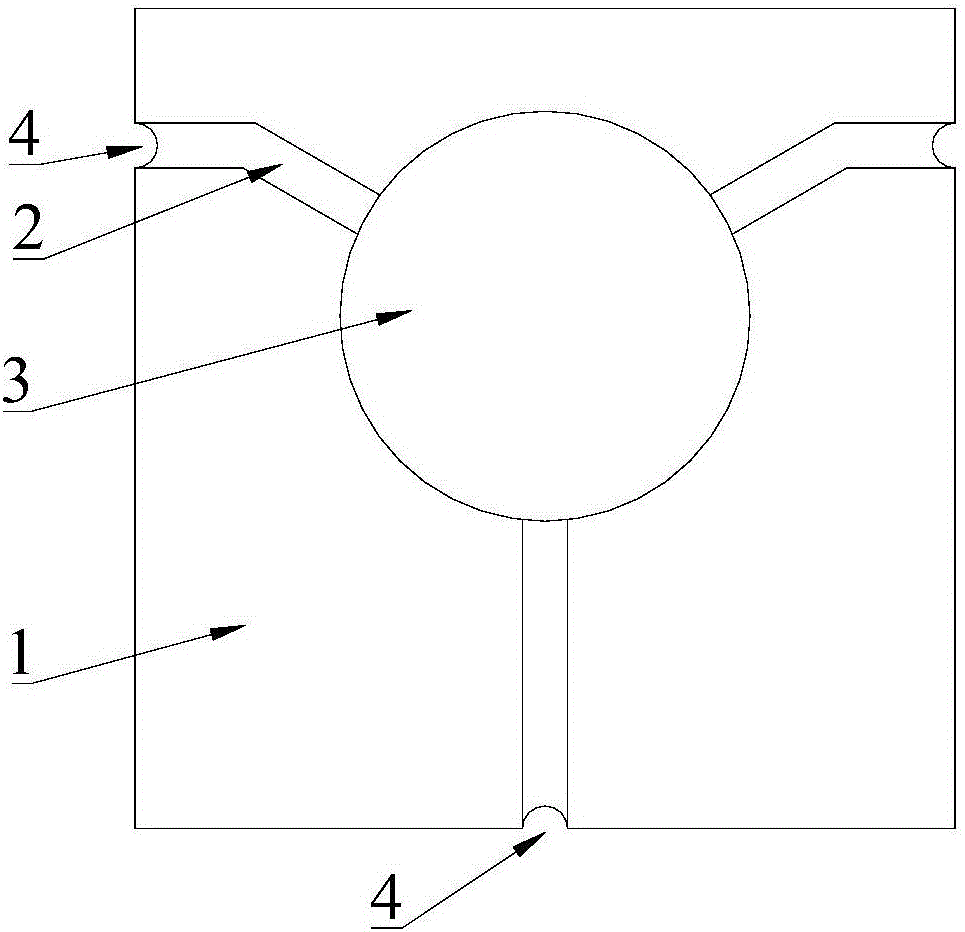

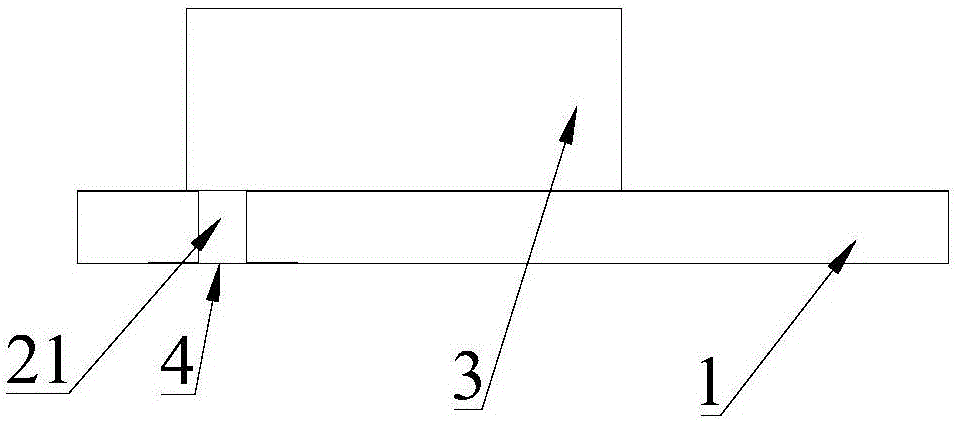

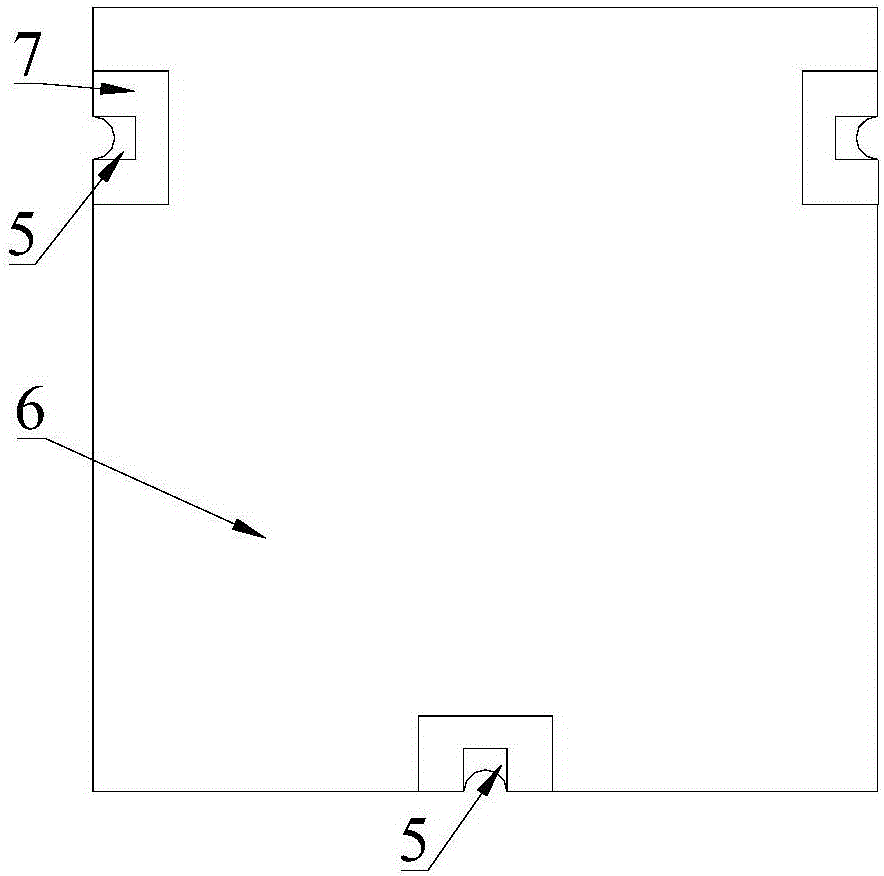

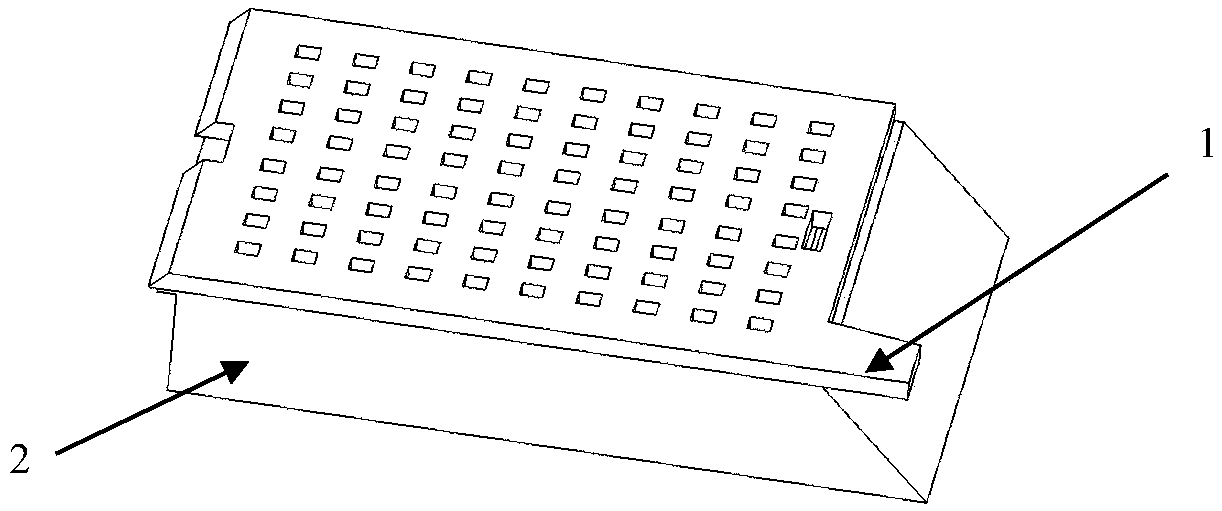

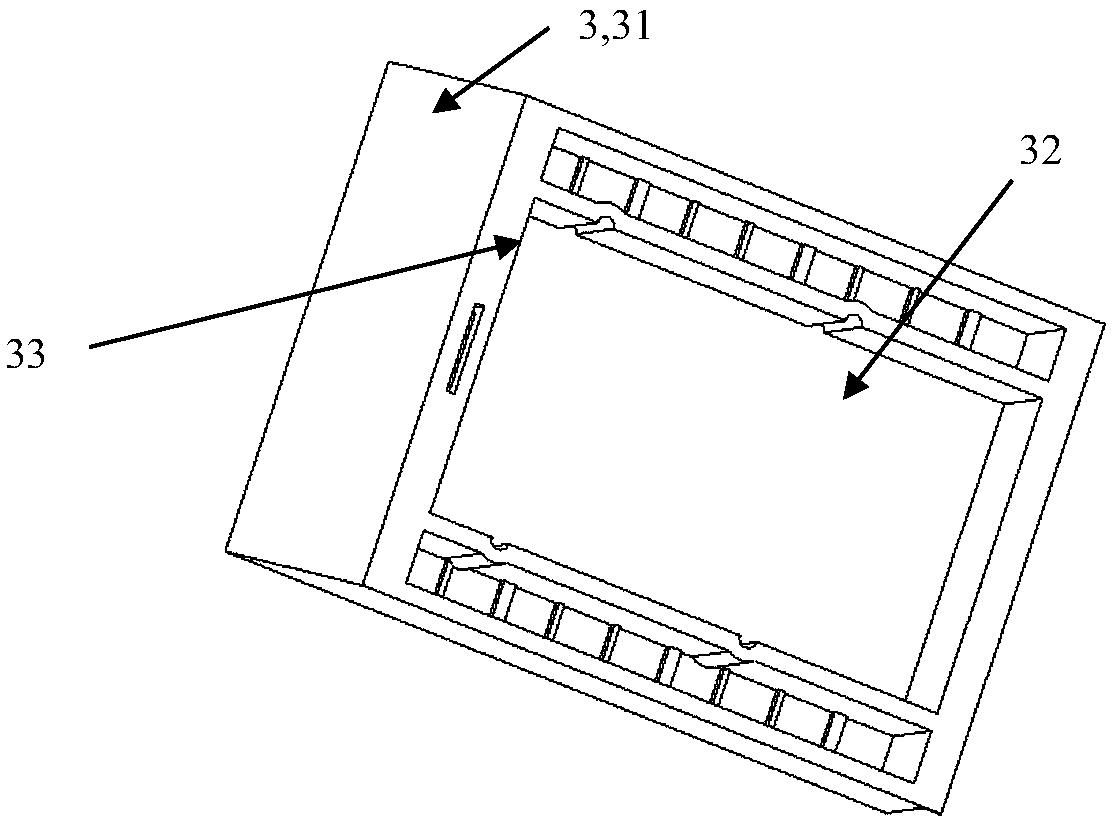

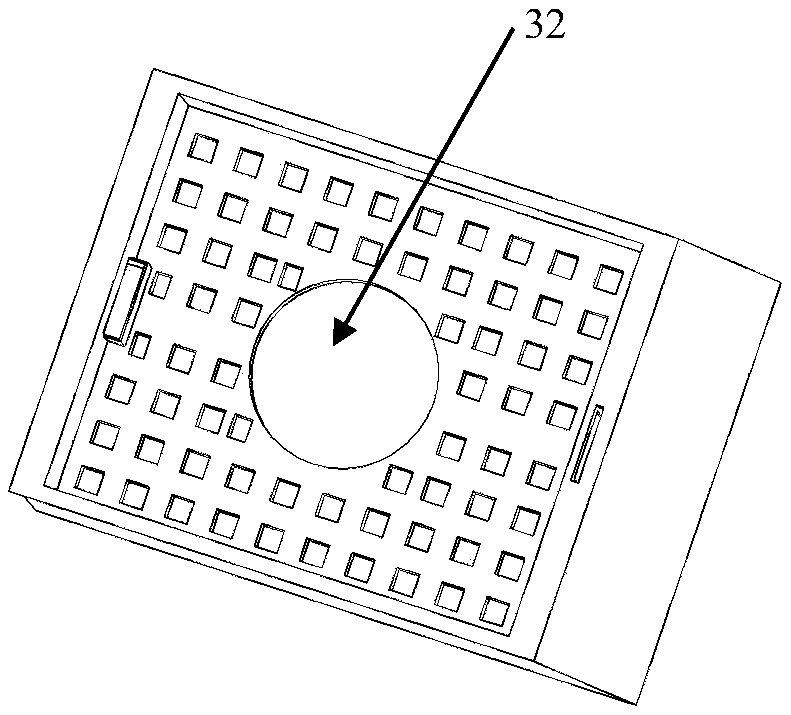

Punching head

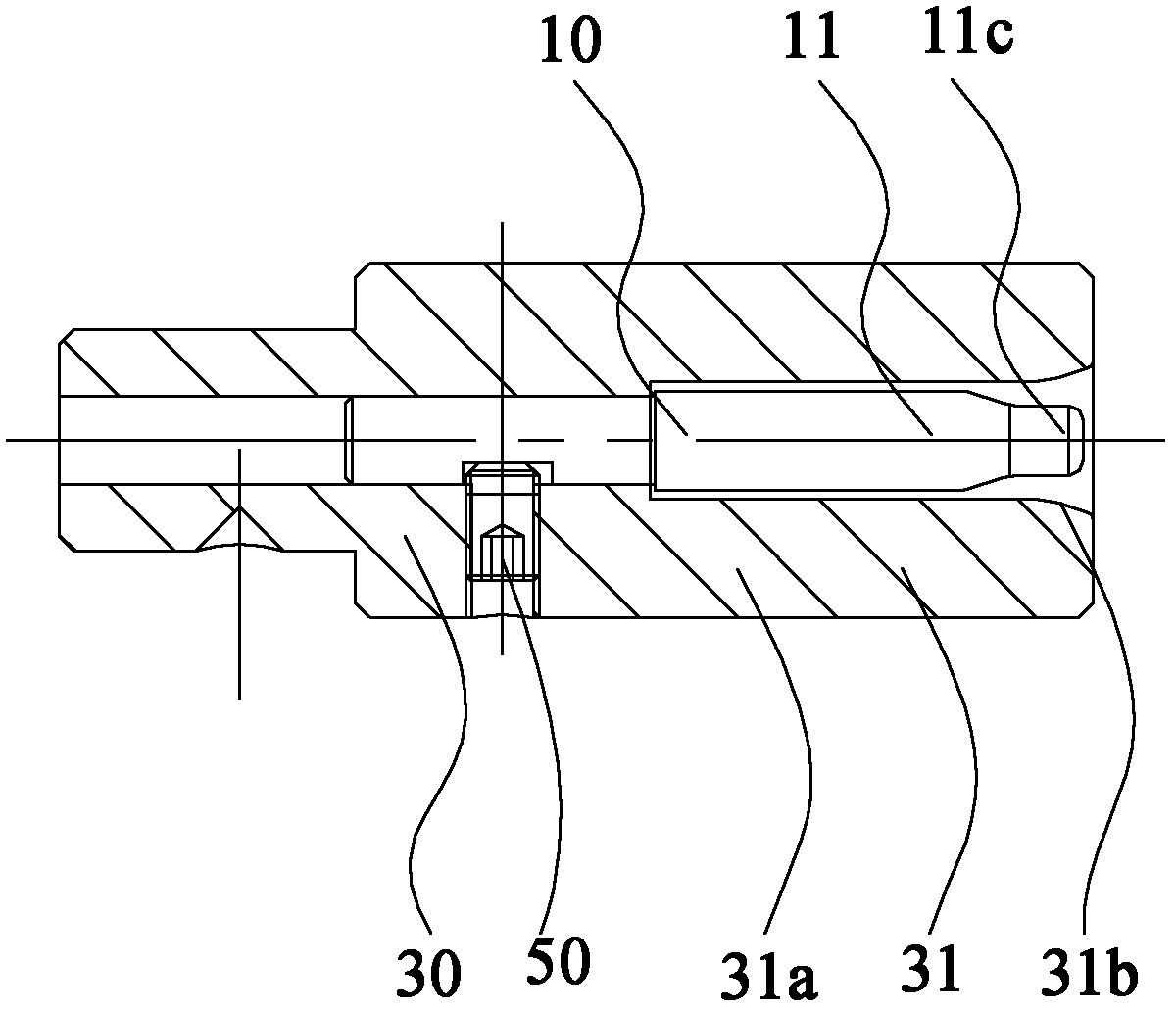

ActiveCN102962333AGuaranteed inner diameterSimplify the production processShaping toolsEngineeringPunching

The invention provides a punching head, which comprises an expanding mold core (10) and a reducing jacket (30), wherein the first end of the expanding mold core (10) is an expanding end (11) and the second end of the expanding mold core (10) is a connecting end; and the expanding mold core (10) is installed in the inner hole of the reducing jacket (30), the first end of the reducing jacket (30) is a reducing end (31), and a gap is kept between the reducing end (31) and the expanding end (11). The punching head has the advantages of high production accuracy, simple production process and high efficiency.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Method for preparing resistant starch by simultaneously adopting crosslinking and heat moisture treatment

InactiveCN102190737AGood product qualitySimplify the production processFood preparationFunctional foodChemistry

The invention discloses a method for preparing resistant starch by simultaneously adopting crosslinking and heat moisture treatment, which comprises the following steps of: regulating the pH value of 30 to 45 weight percent starch milk at the temperature of between 25 and 50DEG C to be 10.5-12.5, adding sodium trimetaphosphate / sodium tripolyphosphate in an amount which is 0.2 to 12 percent based on the weight of the dry basis of starch, keeping for 30 to 240 minutes, drying until the weight percent of water is 15-45 percent, and performing heat moisture reaction at the temperature of between 100 and 140DEG C for 1 to 72 hours in a heat moisture reactor; and washing, drying, crushing and sieving to obtain a product. In the method, starch is taken as a raw material, the content of resistant starch is greatly improved by a physiochemical means, a process of preparing the resistant starch is simplified, the efficiency is effectively improved, waste liquor and pollution are avoided in the production process, and the energy consumption is reduced. The prepared resistant starch can serve as a functional food material and biochemical medicine carrier.

Owner:SOUTH CHINA UNIV OF TECH

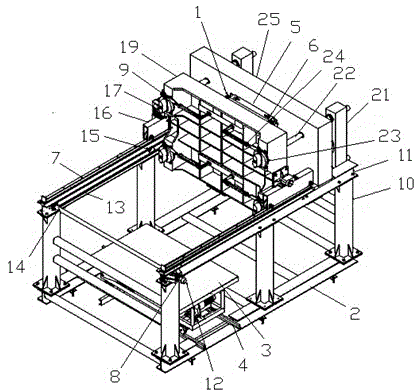

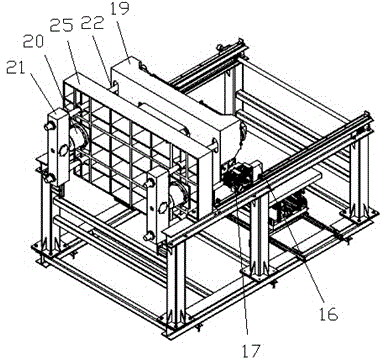

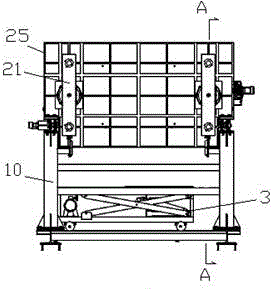

High-pressure automatic forming device for producing large-scaled washing basin

ActiveCN104786346ASimplify the production processIncrease productivityDischarging arrangementAuxillary shaping apparatusWork in processEngineering

The invention provides a high-pressure automatic forming device for producing a large-scaled washing basin, belongs to the technical field of sanitary ceramic production devices, and is used for automatic producing of the large-scaled washing basin. According to the technical scheme, a clamping mechanism is fixed to one end of a forming machine framework, an outer shape of a mold is arranged on a mold fixing plate of the clamping mechanism, and an inner shape is arranged on a mold pushing plate of a mold opening and compounding mechanism. The mold pushing plate of the mold opening and compounding mechanism can carry out reciprocation movement along mold opening and compounding rails of the forming machine framework, the processes of forming and demolding can be automatically completed. An automatic transferring machine is arranged below the forming machine framework, and the blank taking process can be automatically completed. According to the high-pressure automatic forming device for producing the large-scaled washing basin, the production procedures are simplified, the production efficiency is greatly improved, the labor intensity of workers is lowered, the damage rate of semi-finished products is lowered, the production occupation area is saved, and the energy consumption is lowered. The traditional independent production of the large-scaled washing basin is changed into the modern automatic continuous production, and the very important significance is provided for the production development and benefit improving.

Owner:HUIDA SANITARY WARE

Production method of pipeline steel plate with excellent impact toughness

ActiveCN103014497AImprove impact toughnessSimplify the production processTemperature control deviceSteel platesSmelting process

The invention discloses a production method of a pipeline steel plate with excellent impact toughness. The pipeline steel plate comprises the following components in percentage by weight: 0.02-0.07% of C, 0.10-0.40% of Si 1.00-1.80% of Mn, not more than 0.015% of P, not more than 0.0050% of S, 0.030-0.060% of Nb, 0.006-0.020% of Ti, not more than 0.30% of Ni, 0.012-0.050% of Al, and the balance of Fe and impurities. According to the invention, by means of composition control of extremely low content of S and low contents of P, O, N and H, the smelting process of calcium treatment and combination with a pouring process under dynamic soft reduction, processes of precise rolling and precise cooling control are adopted to improve the toughness of the steel plate, so that the center macroscopic and microscopic segregation grades of a cast blank are reduced effectively, ferrites with more tough tissues are obtained, the impact toughness performance of the steel plate is improved, and in addition, the production method is simple in production process and lower in cost.

Owner:NANJING IRON & STEEL CO LTD

Antistatic gallium nitride based luminescent device and manufacturing method thereof

InactiveCN101916769ASimplify the production processImprove product yieldSolid-state devicesSemiconductor/solid-state device manufacturingMultiple quantumGallium nitride

The invention discloses an antistatic light-emitting diode device structure and a manufacturing method thereof. The method comprises the following steps: growing a buffer layer, an N-shaped gallium nitride layer, a luminescent layer multiple quantum well (MQW) structure and a P-shaped gallium nitride layer on a sapphire substrate in sequence; etching an epitaxial layer between a light-emitting diode and a protection diode on the substrate; manufacturing the P electrode and the N electrode of the light-emitting diode; respectively connecting the P electrode and N electrode of the light-emitting diode with the N electrode and P electrode of the protection diode; and integrating the protection diode and the light-emitting diode in a light-emitting diode device on the basis of not changing the existing gallium nitride base epitaxial structure, thus improving antistatic capacity of products, reducing parallel protected diodes in packaging subsequent products, reducing working procedures, and lowering product cost.

Owner:HC SEMITEK CORP

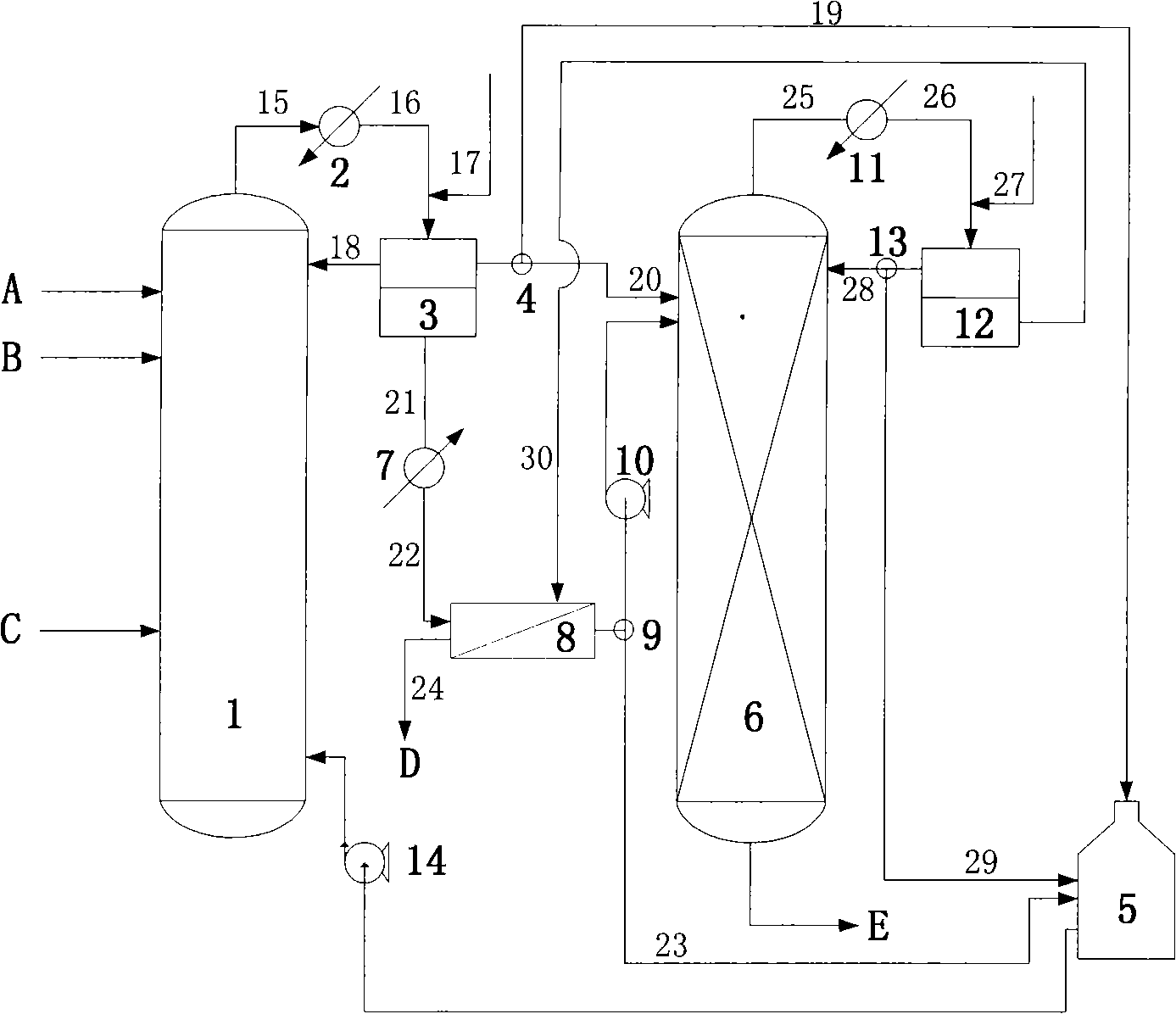

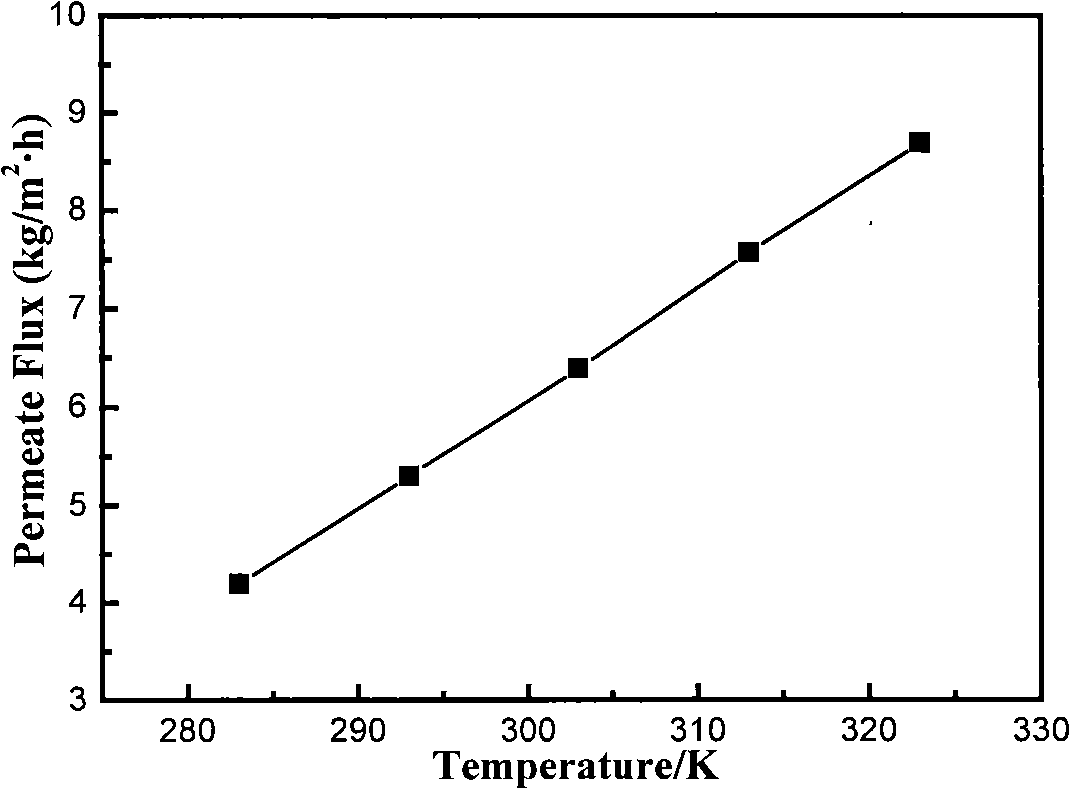

Production process of ethyl acetate

ActiveCN101289389AAvoid wastingSimplify the production processOrganic compound preparationCarboxylic acid esters preparationEthyl esterEthyl acetate

The invention relates to a producing technology of ethyl acetate, the concrete steps of which are as follows: the acetic acid, concentrated sulphuric acid and ethanol of the reacting crude materials are transferred to a rectifying tower; the vapor distilled from the top of which enters into a sedimentation pond by a condenser after being condensed; an organic phase at the upper layer of the sedimentation pond is transferred to a treating column for refining; the water phase at the lower layer is transferred to a permeation vaporization film component by a heater after being heated to concentrate ethyl acetate with a low mass fraction; the material solution in the low stream of the film component is transferred to the treating column by a pump and the material solution which is degreased is discharged directly; the finished product of the ethyl acetate is obtained from the caldron of the treating column. The producing technology of the ethyl acetate brings the permeation vaporization technique into the producing process, recycles and concentrates the ethyl acetate with low mass fraction in the water solution to achieve the aim of simplifying the producing process, saving the investment of equipment, improving the purity and recycling of the products and preventing the environment from being polluted.

Owner:NANJING UNIV OF TECH

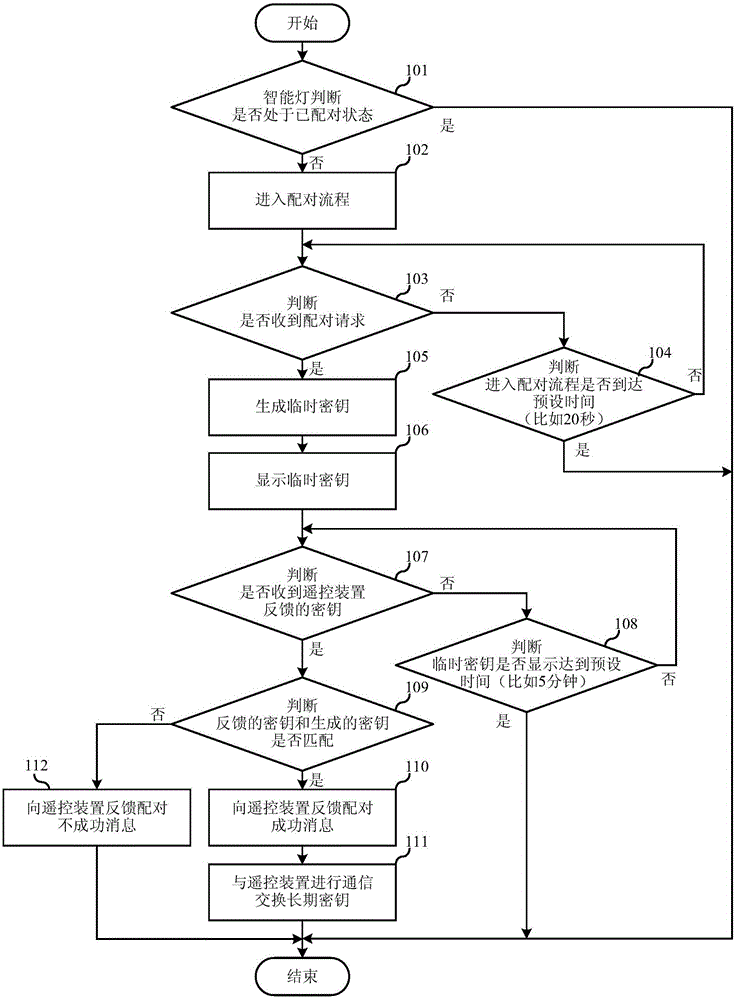

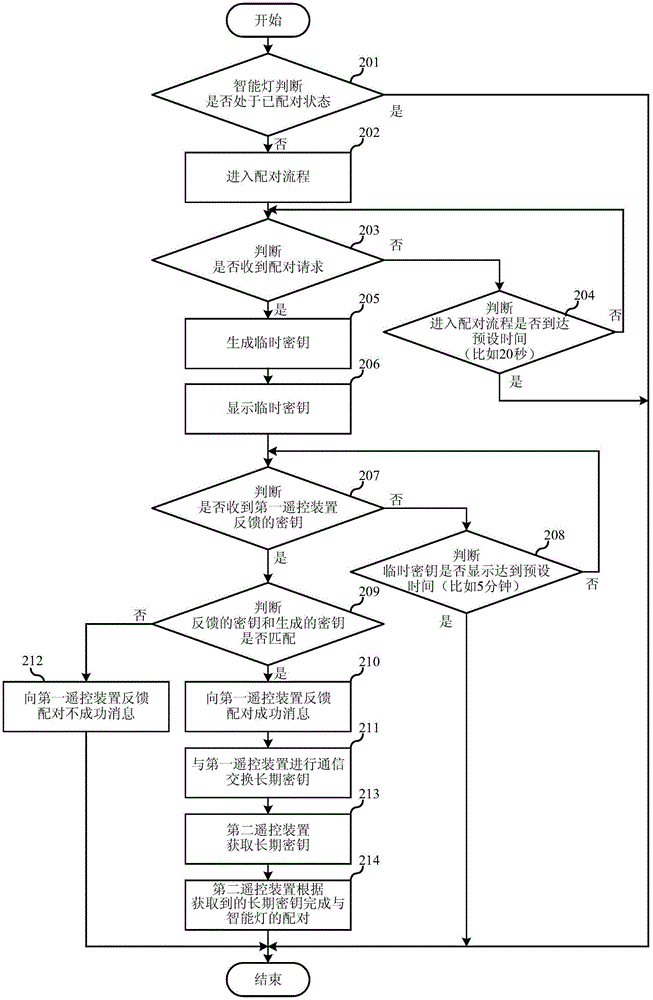

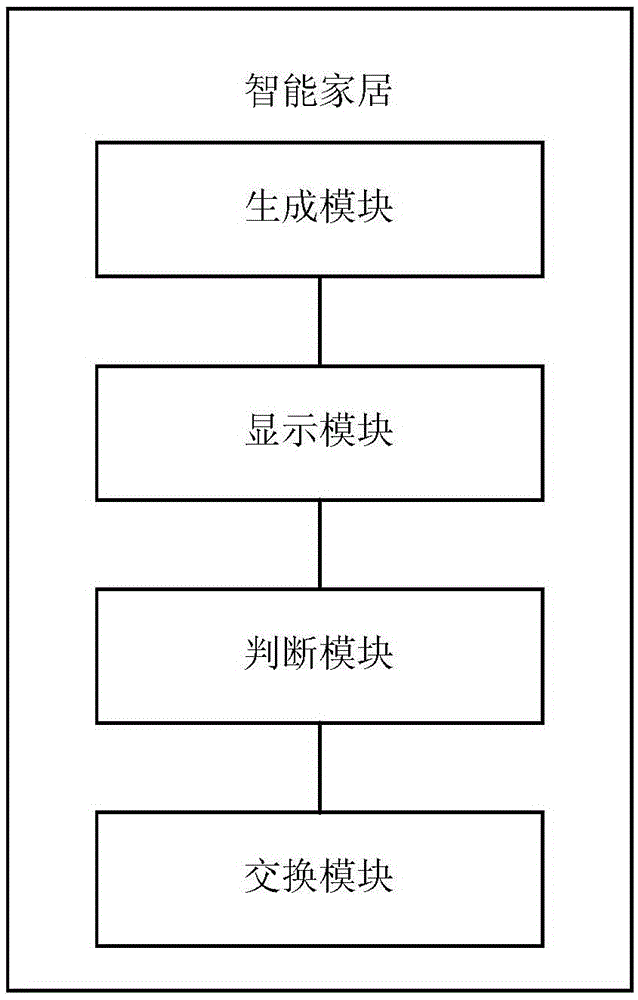

Intelligent equipment, as well as remote control system and remote control pairing method of intelligent equipment

InactiveCN105070004ASimplify the production processLow costTransmission systemsIntelligent equipmentRemote control

The invention relates to the field of intelligent equipment, and discloses the intelligent equipment, as well as a remote control system and a remote control pairing method of the intelligent equipment. The remote control pairing method comprises the following steps: A, after the intelligent equipment receives a pairing request, generating and displaying a random key I; B, after the intelligent equipment receives a key II matched with the random key I generated in the step A, exchanging the received key II with the long-term key of a remote control device sending the key II, so as to fulfill remote control pairing, and the intelligent equipment and the remote control system are in a paired state. The intelligent equipment, the remote control system and the remote control pairing method have the advantages that the procedures of the production process of the intelligent equipment can be simplified; the cost can be reduced; the key losing possibility is low; the security can be improved.

Owner:TELINK SEMICON SHANGHAI

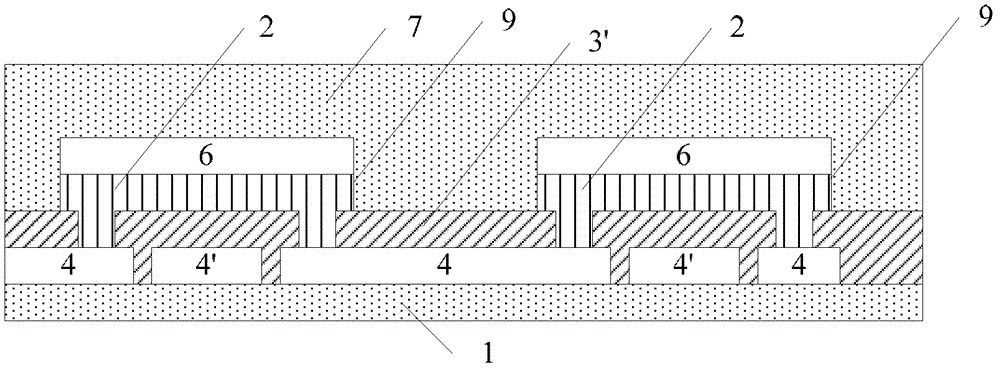

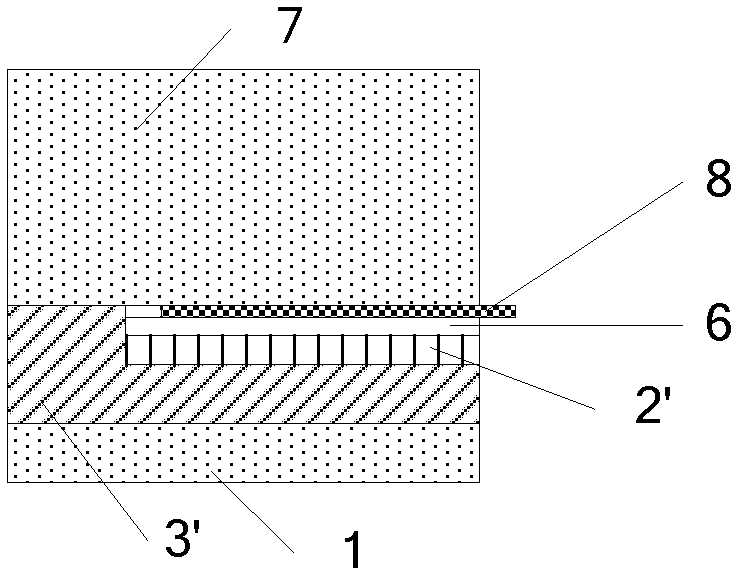

Touch sensor and manufacturing method thereof, and touch panel liquid crystal display

ActiveCN102722276ASimplify the production processLow production costStatic indicating devicesNon-linear opticsTouch panelLiquid-crystal display

The invention discloses a touch sensor and a manufacturing method thereof, and a touch screen liquid crystal display. The touch sensor comprises: a substrate, a touch inductive layer in the first direction, a touch inductive layer in the second direction that perpendicular to the first direction, insulating layers and a metal bridge. The characteristics of the touch sensor lie in that, the touch inductive layer in the first direction and the touch inductive layer in the second direction are positioned on the surface of the substrate, and the touch inductive layer in the first direction is disconnected; the insulating layers are positioned on the substrate, and surfaces of the touch inductive layer in the first direction and the touch inductive layer in the second direction; the metal bridge is connected with the touch inductive layer in the first direction, and positioned on the surface of the insulating layer. According to the invention, the touch sensor can be produced by carrying out three composition technologies on three mask plates. Accordingly, production process of the touch sensor is simplified, and production cost is lowered.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

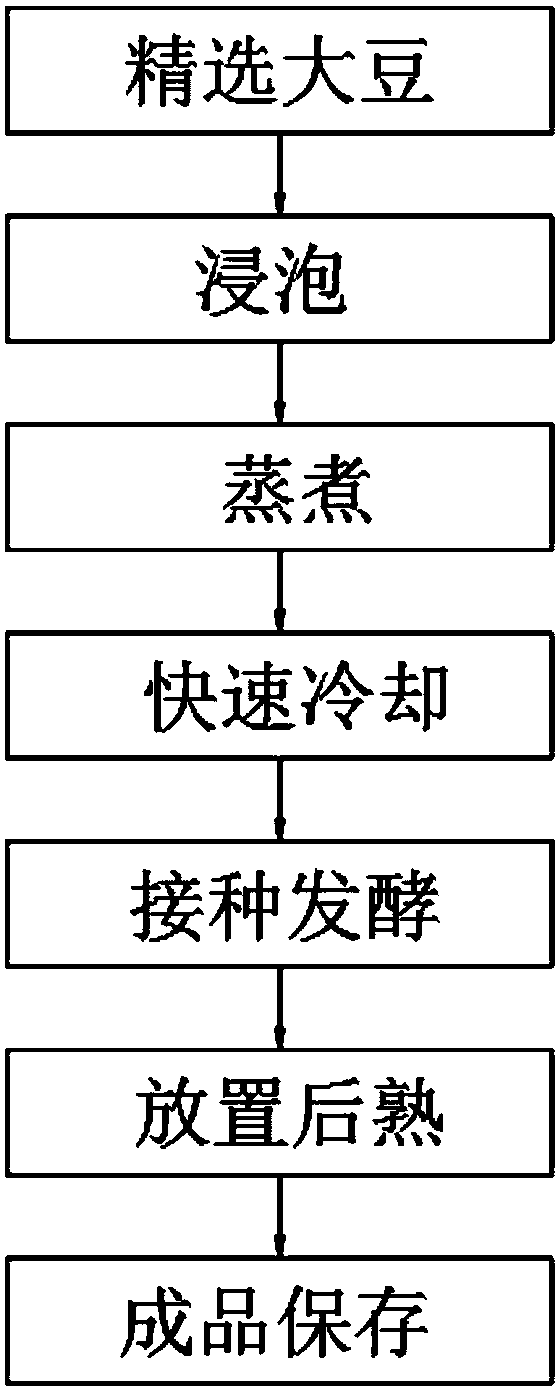

Preparation process of fermentation of non-ammonia-smell natto

InactiveCN108029972ASimplify the production processIncrease productivityBacteriaLactobacillusLactobacillus acidophilusBacillus natto

The invention discloses a preparation process of fermentation of non-ammonia-smell natto, which includes the steps of: 1) fine selection of soya beans; 2) soaking; 3) steaming; 4) quick cooling; 5) inoculation and fermentation; 6) standing post-maturation and storage of finish product. In the step 3), the soya beans are steamed without necessity of high temperature, so that loss on amino acids andsaccharides due to Maillard reaction is prevented and color deepening of the finish product is avoided. Generally, the steaming operation is carried out under 0.08-0.1 MPa for 30-40 min, and if the soya beans are crushed, the time only lasts for 7-8 min. The method simplifies the production route of the natto and improves production efficiency of enterprises, thus effectively improving convenience. Meanwhile, in the method, bacillus natto-lactobacillus acidophilus fusant strain is used instead of the bacillus natto strain, so that on the basis of maintaining the natto kinase activity to be not changed basically, content of amino acid nitrogen in the natto is increased. The natto is free of pungent ammonia smell, has a gentle mouth feel and reduced irritation, and has no difference from traditional natto in wire drawing.

Owner:SHANXI AGRI UNIV

Radix tetrastigme micro powder and preparation method and application thereof

ActiveCN102908464ASimplify the production processImprove efficacyAntineoplastic agentsFood preparationTissue fiberDewatering

The invention relates to a radix tetrastigme extracting preparation method, in particular to radix tetrastigme micro powder and a preparation method and application thereof. The preparation method of the radix tetrastigme micro powder includes the steps: 1) cleaning, by weight, 60%-90% of radix tetrastigme leaves, 8%-35% of aerial stems and 0.5%-5% of radix tetrastigme flowers by clear water prior to centrifugal dewatering; 2) adding filtered and disinfected clear water accounting for 5%-20% of the total weight of the raw materials, grinding, crushing, passing through 150-200 meshes, and centrifugally removing tissue fibers in slurry; 3) performing solution spray drying for the centrifuged radix tetrastigme slurry, and performing atomization drying at the temperature of 90-95 DEG C so that radix tetrastigme powder is obtained; and 4) performing vacuum packaging for the radix tetrastigme powder for standby. The radix tetrastigme extracting preparation method has the advantages of simple technological production process, high pharmaceutical effect and high effective component retention.

Owner:浙江仲兴生物医药科技有限公司

Immune colloidal gold reagent for detecting sulfamethazine and preparation method thereof

InactiveCN1547016ALow priceSimplify the production processAntibody ingredientsBiological testingChemistryAntibody

The invention is a kind of immune colloidal gold reagent for measuring the sulfamethazole and the manufacturing method. The reagent includes a sample cushion, a colloidal gold combination cushion, aeotic acid cellulose film, a suction cushion and a PVC back lining, one end of the PVC back lining is adhered with sample cushion, colloidal gold combination cushion in order, the middle part is adhered with aeotic acid cellulose film, the other end is adhered with a suction cushion. The character lies in: the colloidal gold combination cushion is enclosed with a kind of sulfamethazole resisting specificity single clone antibody-colloidal gold label, the aeotic acid cellulose film is enclosed by sulfamethazole-BSA couplings and sheep (rabbit) antiplague IgG. The reagent has a strong specificity, high sensitivity, quick and simple, cheap, and convenient.

Owner:博顿生物检验技术(杭州)有限公司

Surface-mounted microstrip ferrite circulator

InactiveCN106410343AImprove assembly efficiencySimplify the production processWaveguide type devicesMicrostrip circuitsMagnet

The invention discloses a surface-mounted microstrip ferrite circulator, which comprises a gyromagnetic ferrite substrate, a microstrip circuit arranged at the upper surface of the gyromagnetic ferrite substrate and a permanent magnet arranged on the microstrip circuit, and is characterized in that the gyromagnetic ferrite substrate is provided with through holes or openings penetrating through the upper and lower surfaces, pins of the microstrip circuit extend to the lower surface of the gyromagnetic ferrite substrate through the through holes or the openings and form a chip mounting area at the lower surface of the gyromagnetic ferrite substrate, the lower surface of the gyromagnetic ferrite substrate is further provided with a grounding area, and an isolation strip is arranged between the grounding area and the chip mounting area. According to the invention, the through holes or the openings are set so as to enable the microstrip circuit to extend from the upper surface of the gyromagnetic ferrite surface to the lower surface of the gyromagnetic ferrite surface, and the pins of the microstrip circuit are enabled to be located at the same horizontal plane with the grounding area, so that the microstrip ferrite circulator is enabled to be assembled with a PCB (Printed Circuit board) by using an SMT (Surface Mount Technology).

Owner:HUAYANG TECH DEV

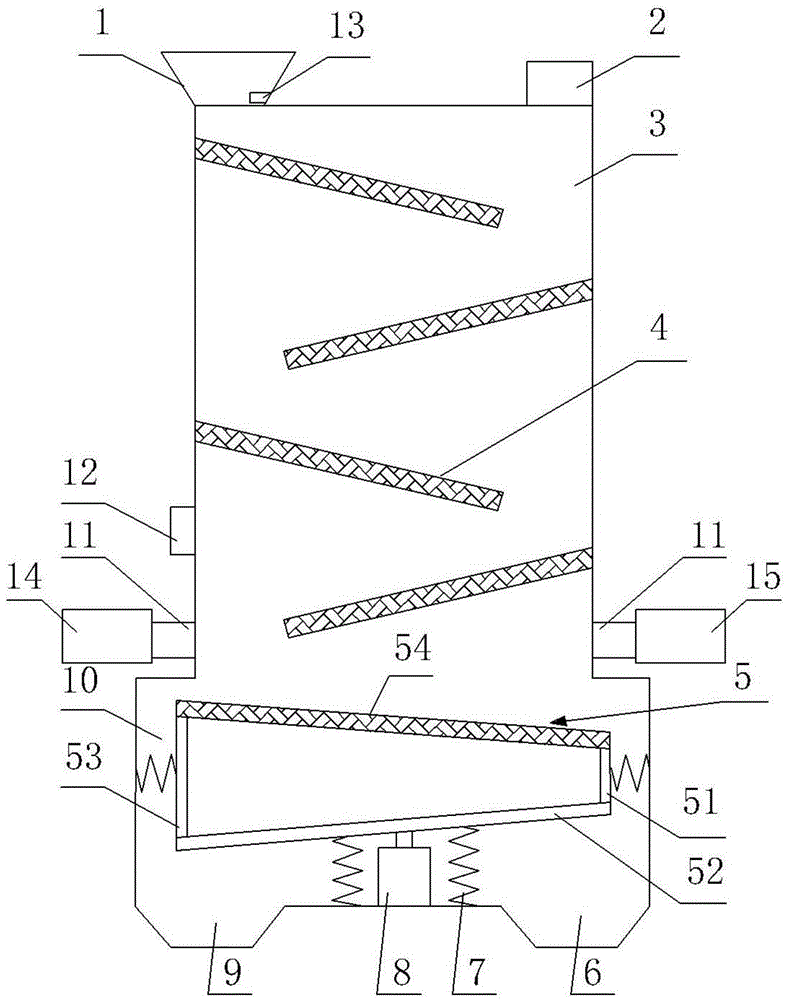

Automatic sand drying machine

InactiveCN104864694AReduce equipment costsSimplify the production processSievingScreeningAir heaterMoisture sensor

The invention provides an automatic sand drying machine which comprises a drying chamber and a screening chamber. An air outlet and a sand inlet with a humidity sensor are arranged at the top of the drying chamber, a microcontroller and two opposite air inlets are formed in the side wall of the lower portion of the drying chamber, one air inlet is connected with a first air heater, the other air inlet is connected with a second air heater, the microcontroller is electrically connected with the humidity sensor, the first air heater and the second air heater, and ventilating dense screens inclined downwards are arranged on two opposite side walls in the drying chamber in a staggered mode. A coarse sand outlet and a fine sand outlet are arranged at the bottom of the screening chamber, a screen body and a vibration motor are arranged in the screening chamber, the screen body comprises a screen mesh and a flow guide plate, the screen mesh is obliquely arranged on the upper layer, the flow guide plate is located on the lower layer oppositely to the inclination direction of the screen mesh, and the vibration motor is connected with the flow guide plate. Drying equipment and screening equipment are arranged to a whole, sand can be automatically dried and screened after being added to the machine, equipment cost is lowered, and the production procedure is simplified.

Owner:CHENGDU GUANGMAI TECH

Multifunctional integrated tissue embedding box

InactiveCN109443897ASimplify the production processReduce chance of confusionPreparing sample for investigationTissue EmbeddingFastener

The invention discloses a multifunctional integrated tissue embedding box and belongs to the technical field of medical apparatus and instruments. The multifunctional integrated tissue embedding box comprises an embedding frame body and an extruding fastener, wherein the embedding frame body is provided with an extruding frame at the bottom; the extruding fastener is in sliding fit or interferencefit connection with an inner side surface of the extruding frame of the embedding frame body through a side surface; a right-angle or forked tail slide rail is arranged on the surface of the extruding frame of the embedding box; the extruding fastener is adopted for extruding and fixing a to-be-treated sample, so as to effectively prevent the sample from skewing and dumping during the treatment processes of dehydration, waxing, and the like; and a flange I of the side surface of the extruding fastener can be in fitting connection or interference fitting with a groove in the extruding frame, so as to select a proper fixing position. According to the multifunctional integrated dehydration embedding box, in spite of size, samples, including puncturing tissues, are positioned in the embeddingbox and are directly embedded after conventional dehydration without taking out. The multifunctional integrated tissue embedding box has the advantages that tiny tissues can not be lost; capsule walltissues do not fall or tilt; large and medium tissue blocks do not displace; no error occurs; and errors can be avoided.

Owner:沈阳安真医疗器械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com