Production method of dipotassium phosphate

A technology of dipotassium hydrogen phosphate and its production method, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of no economic effect and environmental protection value, large energy consumption, serious pollution, etc., and achieve optimal economy Benefits and environmental protection value, reduction of water consumption and energy consumption, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

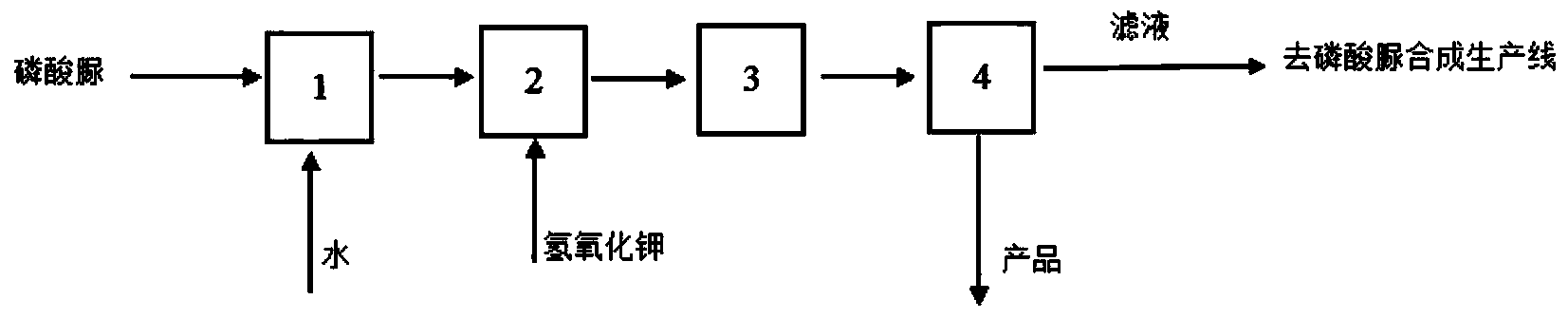

[0054] A production method of dipotassium hydrogen phosphate, specifically comprising the following steps:

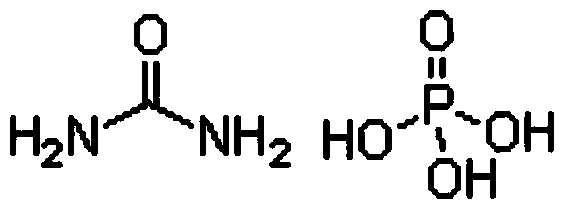

[0055] (1) Preparation of urea phosphate solution: put urea phosphate solid in a dissolving tank, add a certain amount of water into the dissolving tank, stir at a constant speed of 30r / min to obtain a urea phosphate solution, and heat to 45°C;

[0056] (2) Synthesis by adding potassium hydroxide: transport the heated urea phosphate solution to the reaction tank with a delivery pump, and transfer the metered potassium hydroxide solid to Add it into the reaction tank, stir at a stirring speed of 50 r / min at the same time, control the reaction temperature at 50°C, react for 20 minutes, and control the pH value at the end point to 8.2 to obtain dipotassium hydrogen phosphate slurry;

[0057] (3) Centrifugal separation of cooling crystallization: transport the dipotassium hydrogen phosphate slurry to the crystallizer with a delivery pump to cool down to 40°C, cool and cryst...

Embodiment 2

[0060] A production method of dipotassium hydrogen phosphate, specifically comprising the following steps:

[0061] (1) Preparation of urea phosphate solution: put urea phosphate solid in a dissolving tank, add a certain amount of water into the dissolving tank, stir evenly at 30 r / min to obtain a urea phosphate solution, and heat up to 45°C;

[0062] (2) Synthesis by adding potassium hydroxide: transport the urea phosphate solution to the reaction tank with a delivery pump, and add the metered potassium hydroxide solid into the reaction tank according to the molar ratio of urea phosphate and potassium hydroxide as 1:2.05 , while stirring at a stirring speed of 60r / min, and controlling the reaction temperature at 90°C, reacting for 70min, and controlling the end point pH value to 9.5 to obtain dipotassium hydrogen phosphate slurry;

[0063] (3) Cooling crystallization and centrifugation: transport the dipotassium hydrogen phosphate slurry to the crystallizer with a transport p...

Embodiment 3

[0066] A production method of dipotassium hydrogen phosphate, specifically comprising the following steps:

[0067] (1) preparation of potassium hydroxide solution: potassium hydroxide solid is placed in dissolving tank, a certain amount of water is added into dissolving tank, adopts 30r / min to stir evenly, obtains potassium hydroxide solution;

[0068] (2) Synthesis by adding urea phosphate: the potassium hydroxide solution is transported to the reaction tank by a delivery pump, and the metered urea phosphate solid is added to react with it according to the ratio of 1:2 in the molar ratio of urea phosphate and potassium hydroxide, At the same time, stir at a speed of 55 r / min, and control the reaction temperature at 70°C, react for 50 minutes, and control the pH value at the end point to 8.5 to obtain dipotassium hydrogen phosphate slurry;

[0069] (3) Cooling crystallization and centrifugation: transport the dipotassium hydrogen phosphate slurry to the crystallizer with a de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com