Surface-mounted microstrip ferrite circulator

A circulator and ferrite technology, applied in the field of surface mount microstrip ferrite circulators, can solve the problems of increased system integration cost, low manual welding efficiency, unfavorable cost control, etc., so as to improve assembly efficiency and simplify production process , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

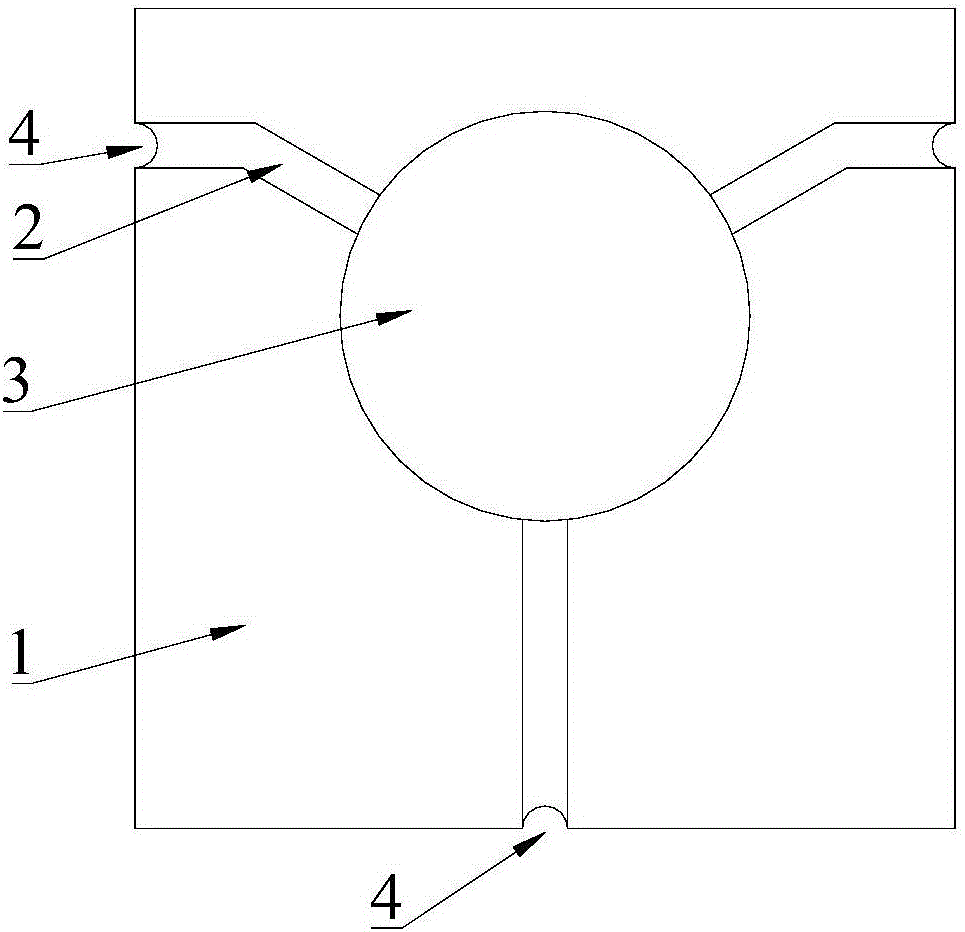

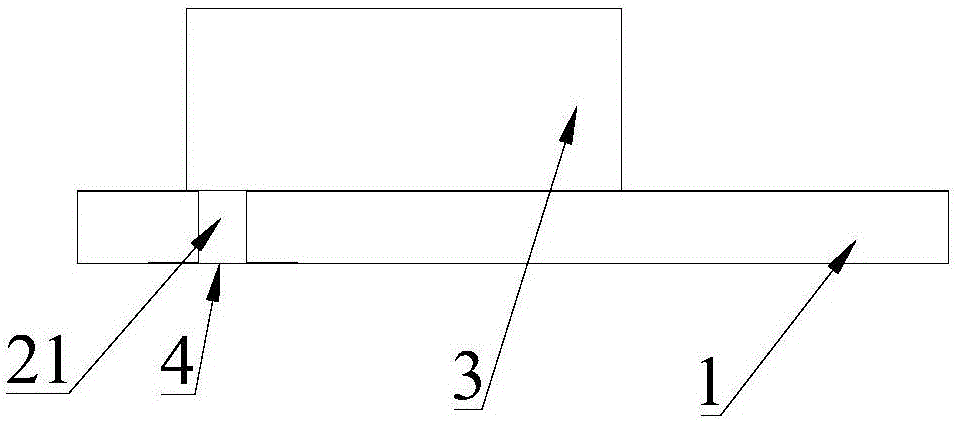

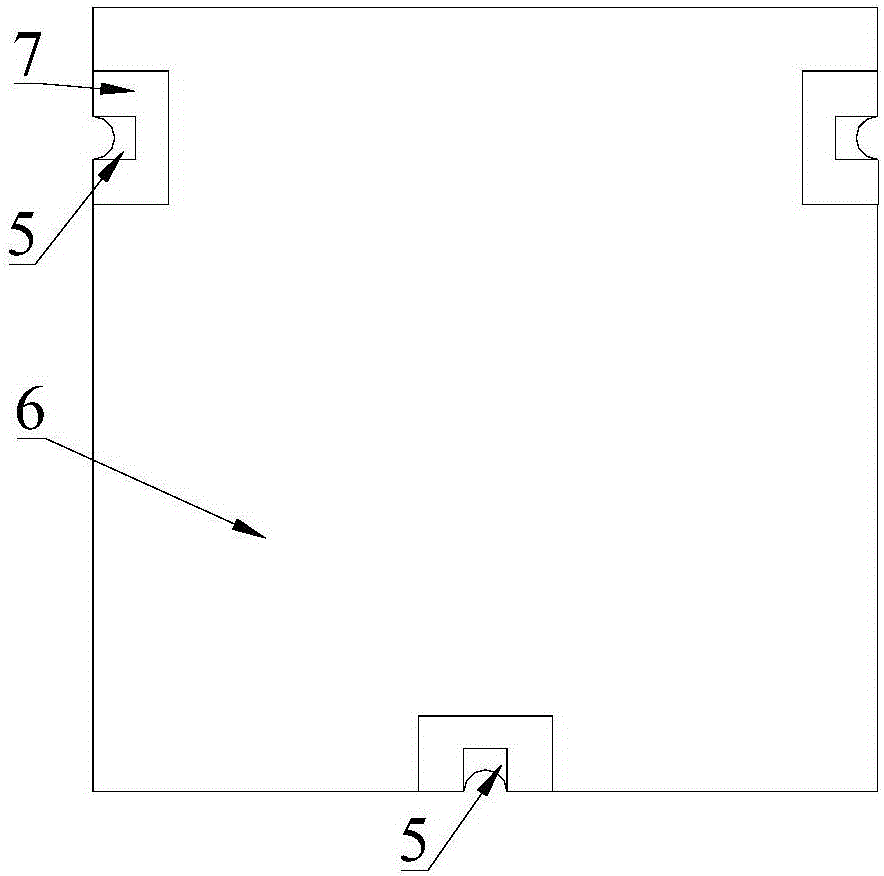

[0040] Please refer to Figure 1 to Figure 4 , Embodiment 1 of the present invention is as follows: figure 1 As shown, a surface-mounted microstrip ferrite circulator includes a spun ferrite substrate 1, a microstrip circuit 2 arranged on the upper surface of the spun ferrite substrate 1, and a microstrip circuit 2 arranged on the microstrip circuit 2. permanent magnet 3, the rotatable ferrite substrate 1 is provided with a notch 4 that runs through the upper and lower surfaces (in other embodiments, it can be set as a through hole), please combine figure 2 and image 3 , the pins 21 of the microstrip circuit 2 extend to the lower surface of the spun ferrite substrate 1 through the gap 4 and form a patch area 5 on the lower surface of the spun ferrite substrate 1, the spun ferrite substrate 1 The bottom surface of the ferrite substrate 1 is also provided with a grounding area 6 , and an isolation zone 7 is provided between the grounding area 6 and the patch area 5 . Specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com