Patents

Literature

1029 results about "Surface-mount technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface-mount technology (SMT) is a method for producing electronic circuits in which the components are mounted or placed directly onto the surface of printed circuit boards (PCBs). An electronic device so made is called a surface-mount device (SMD). In industry, it has largely replaced the through-hole technology construction method of fitting components with wire leads into holes in the circuit board. Both technologies can be used on the same board, with the through-hole technology used for components not suitable for surface mounting such as large transformers and heat-sinked power semiconductors.

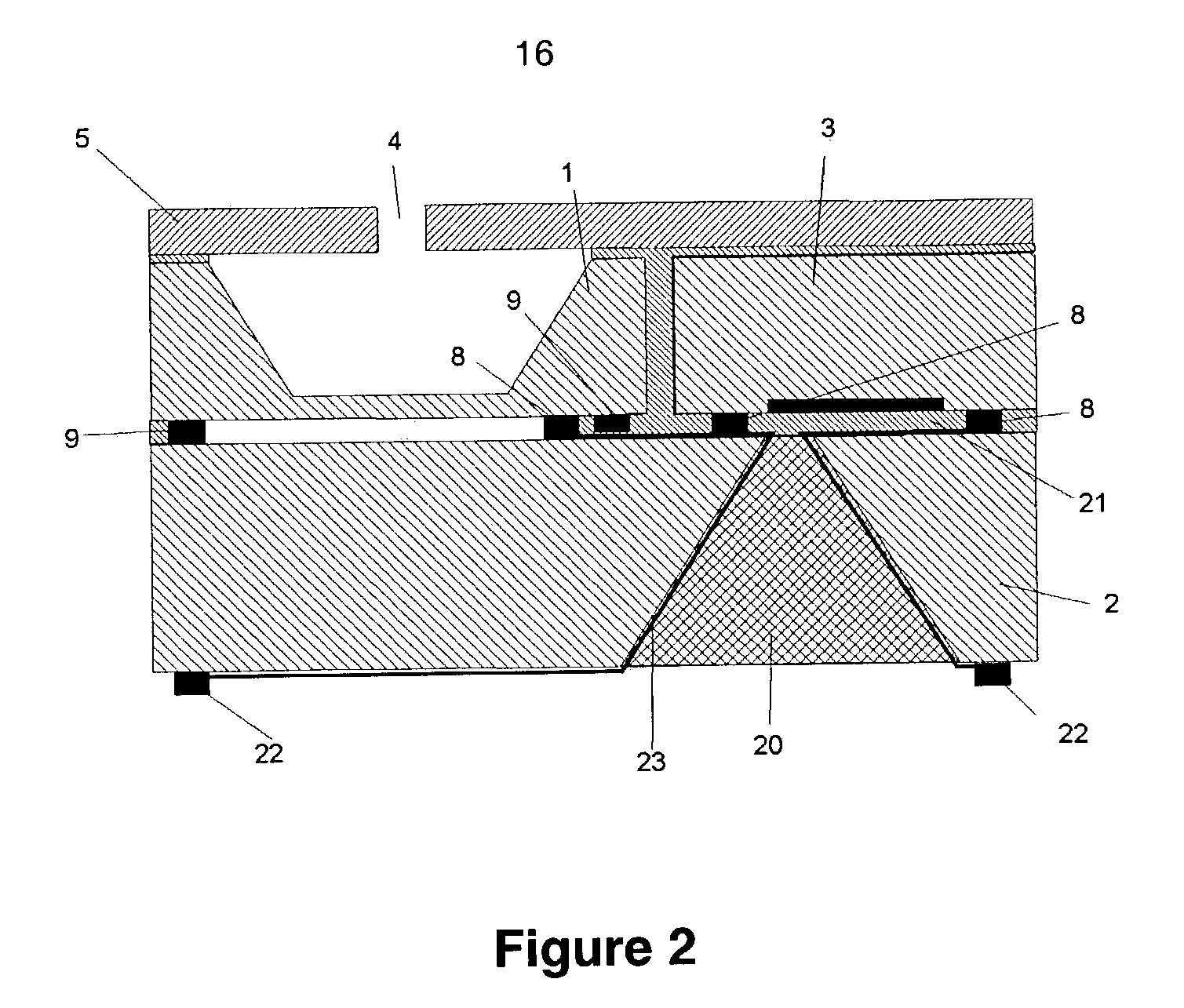

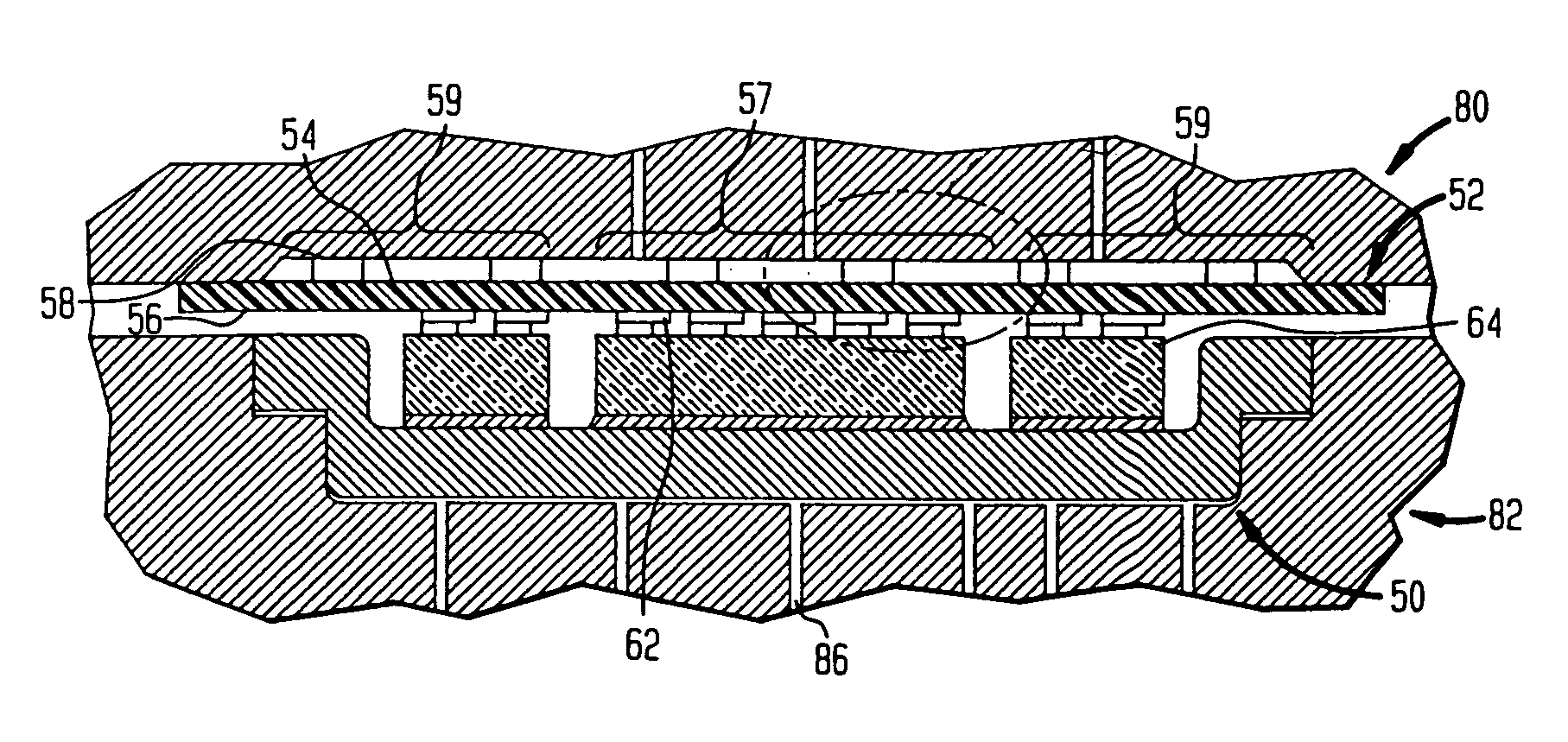

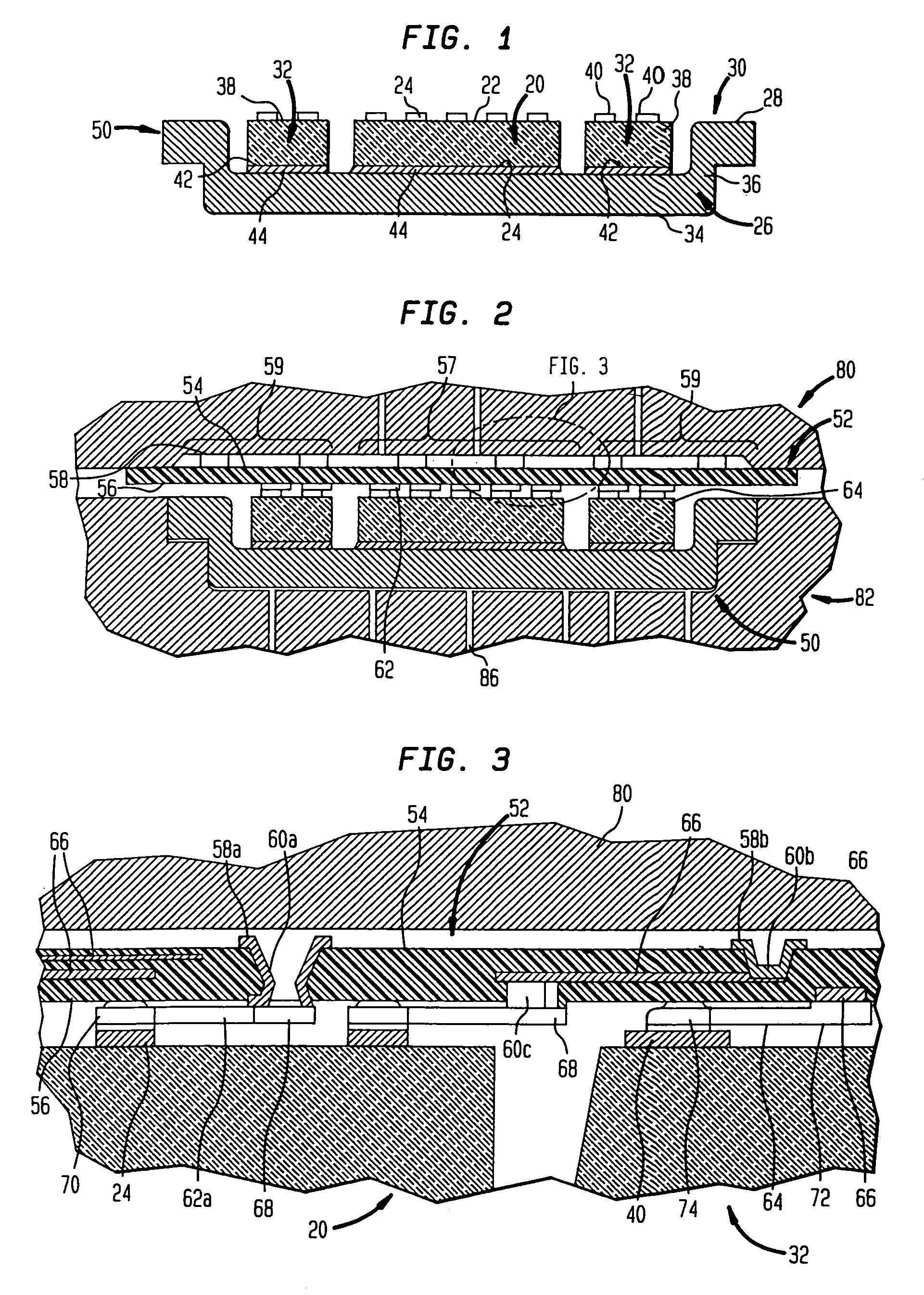

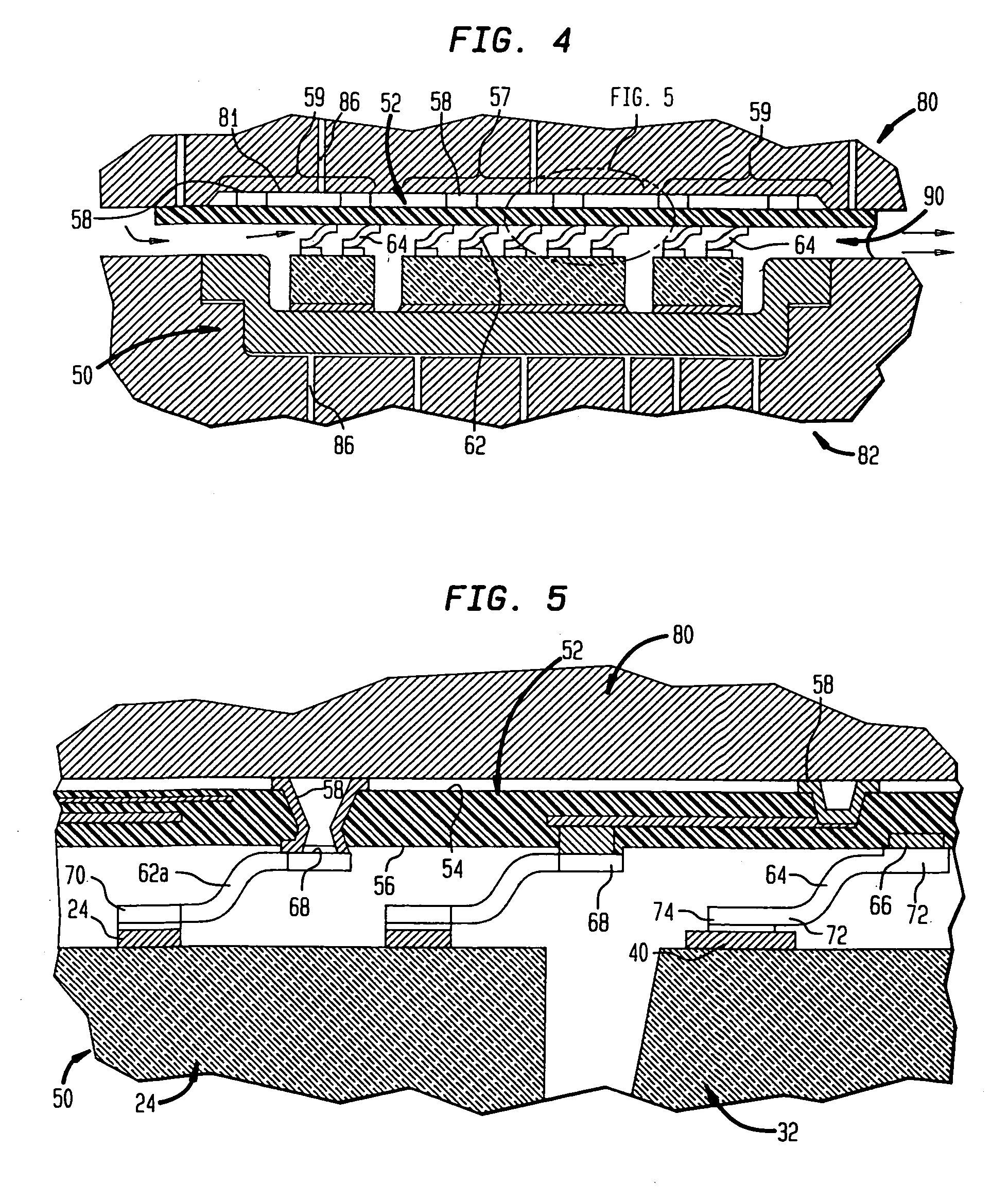

High density integrated circuit packaging with chip stacking and via interconnections

InactiveUS6236115B1Reduced connection exposureLarge capacitySemiconductor/solid-state device detailsSolid-state devicesEngineeringThermal expansion

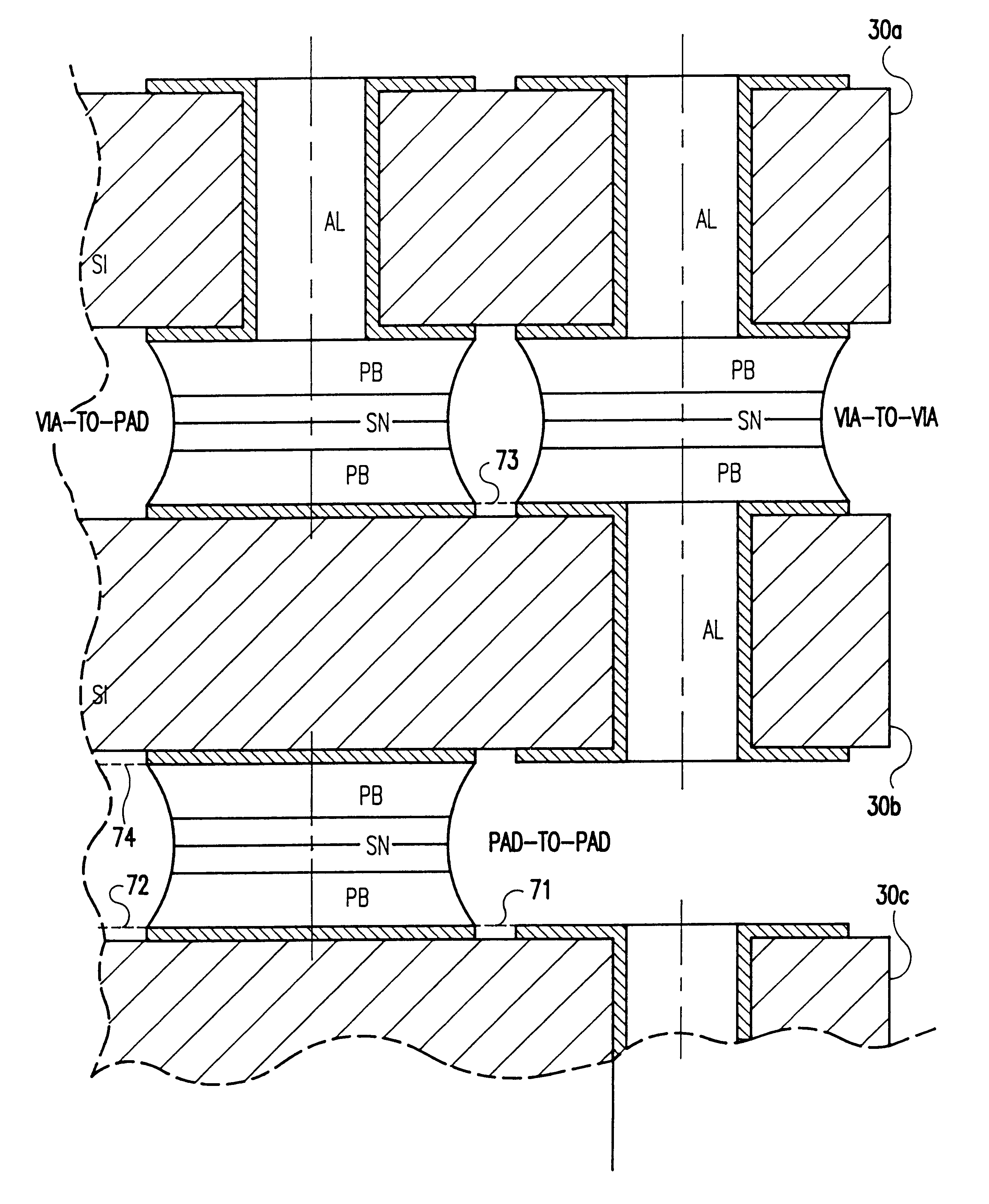

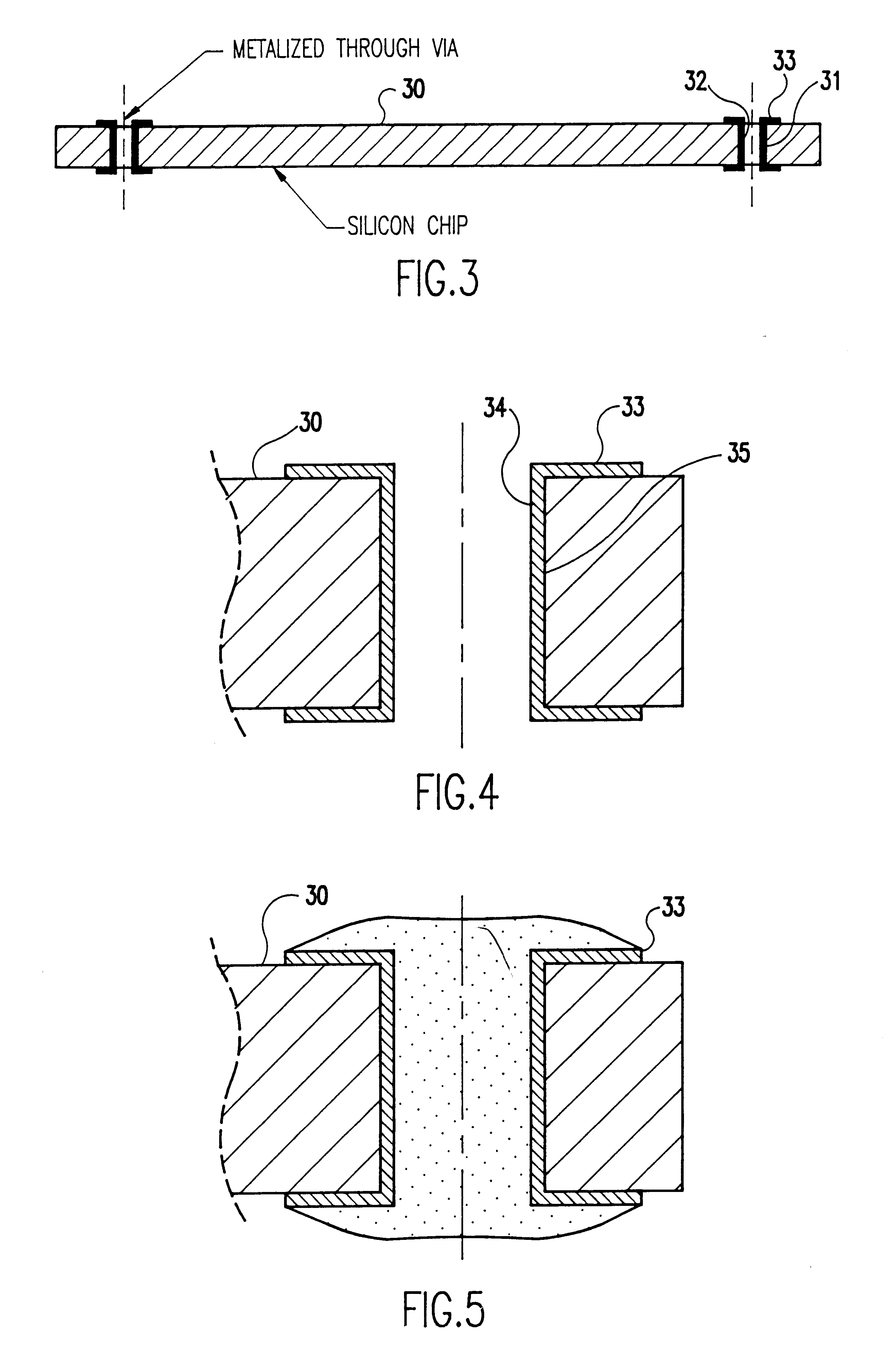

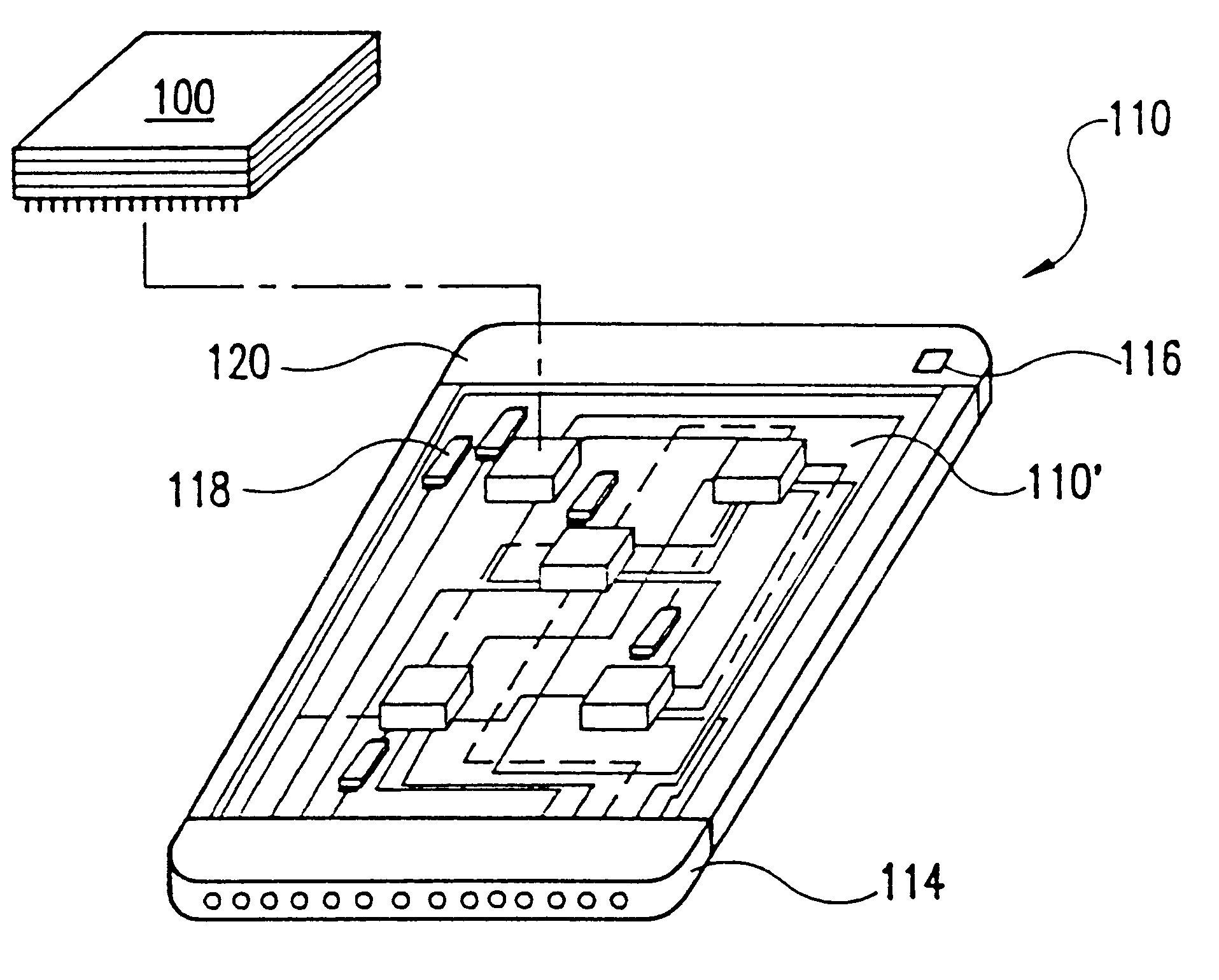

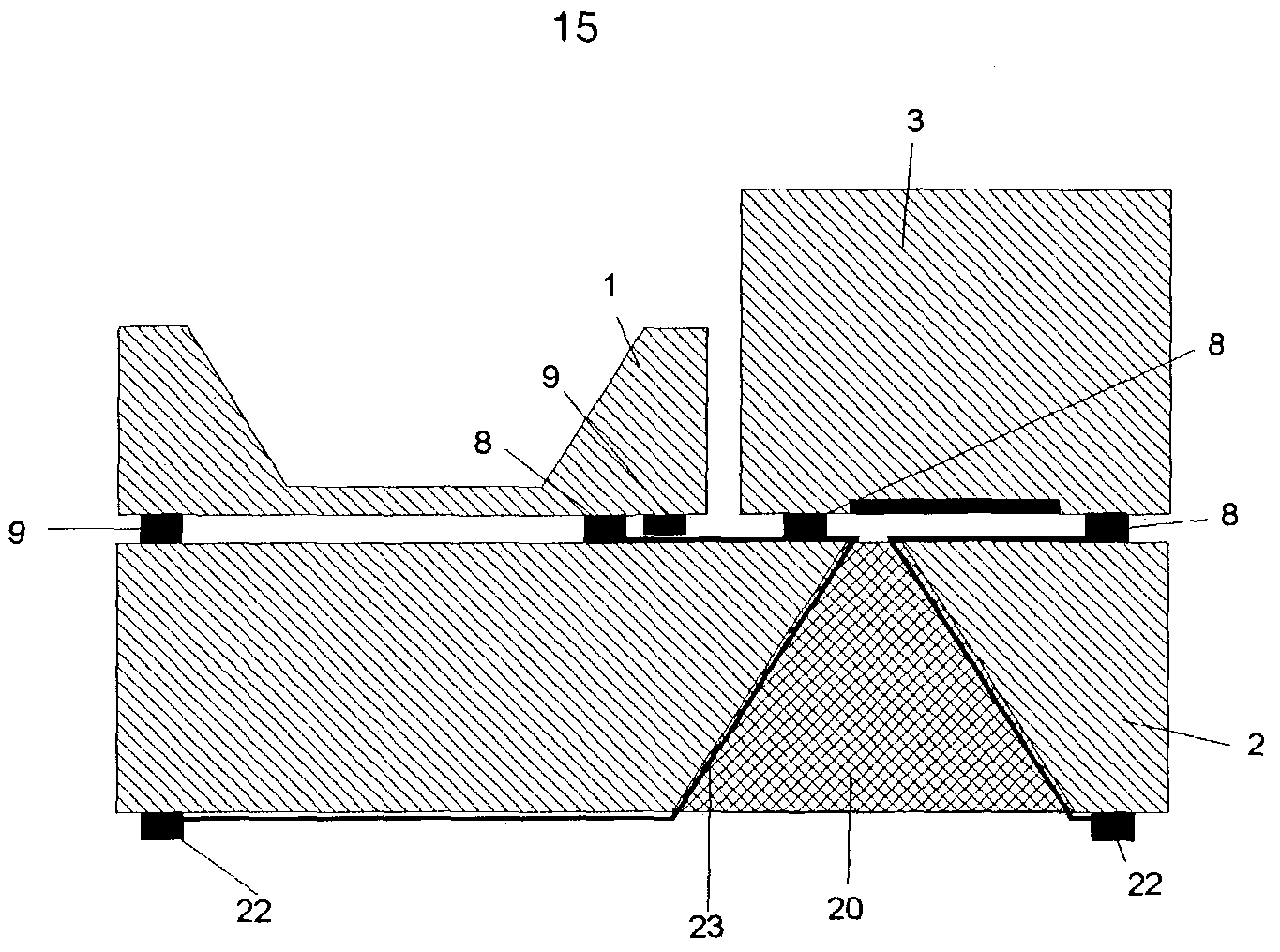

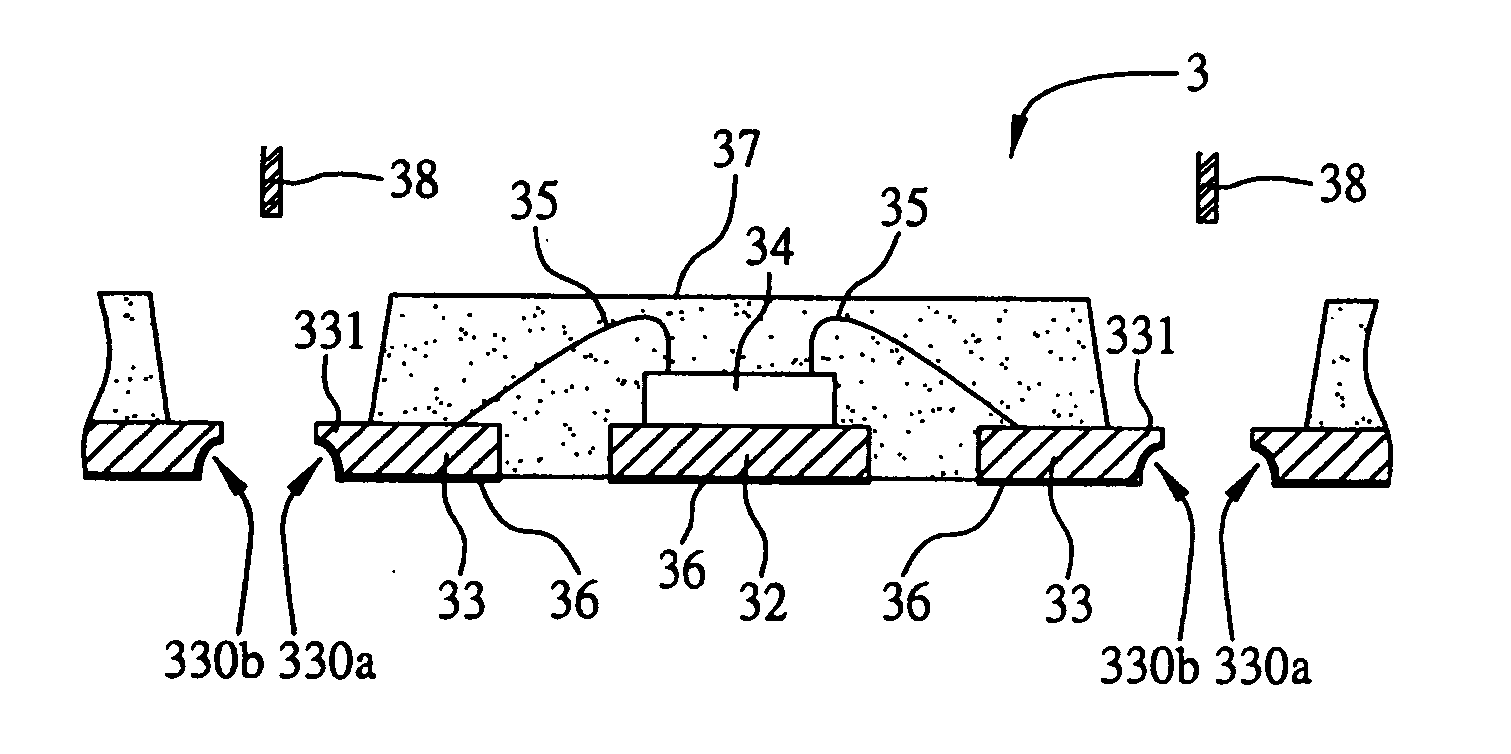

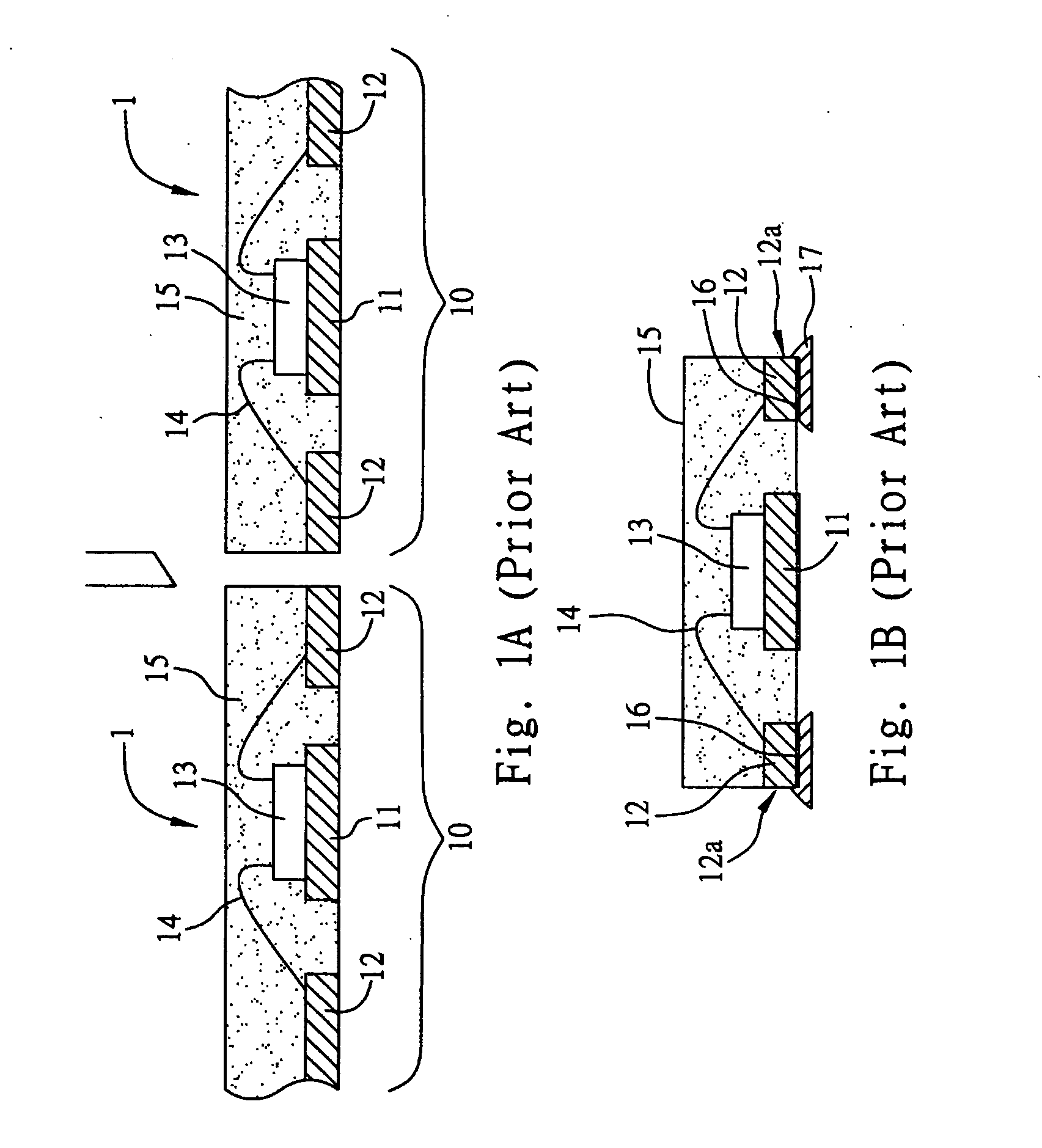

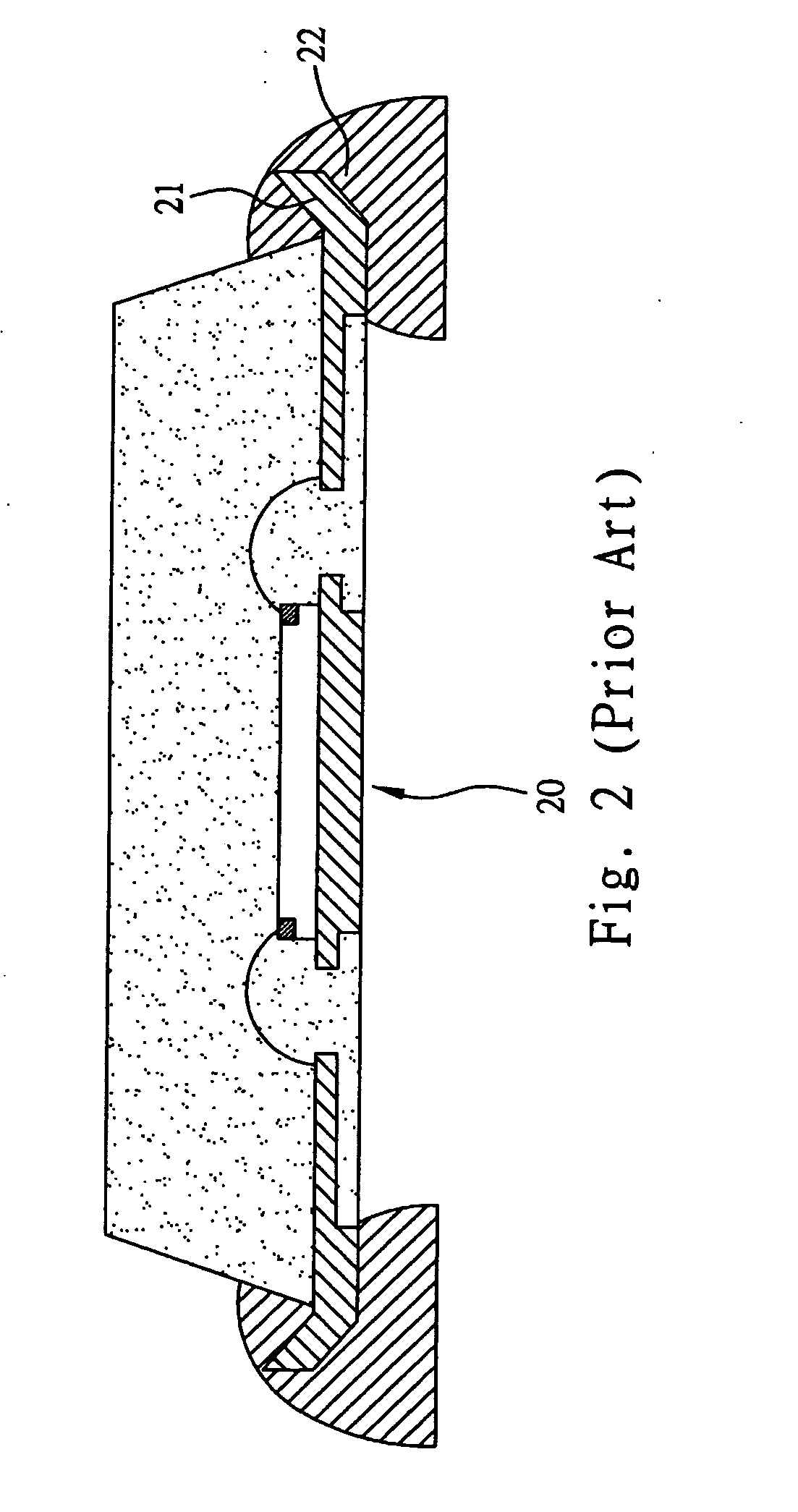

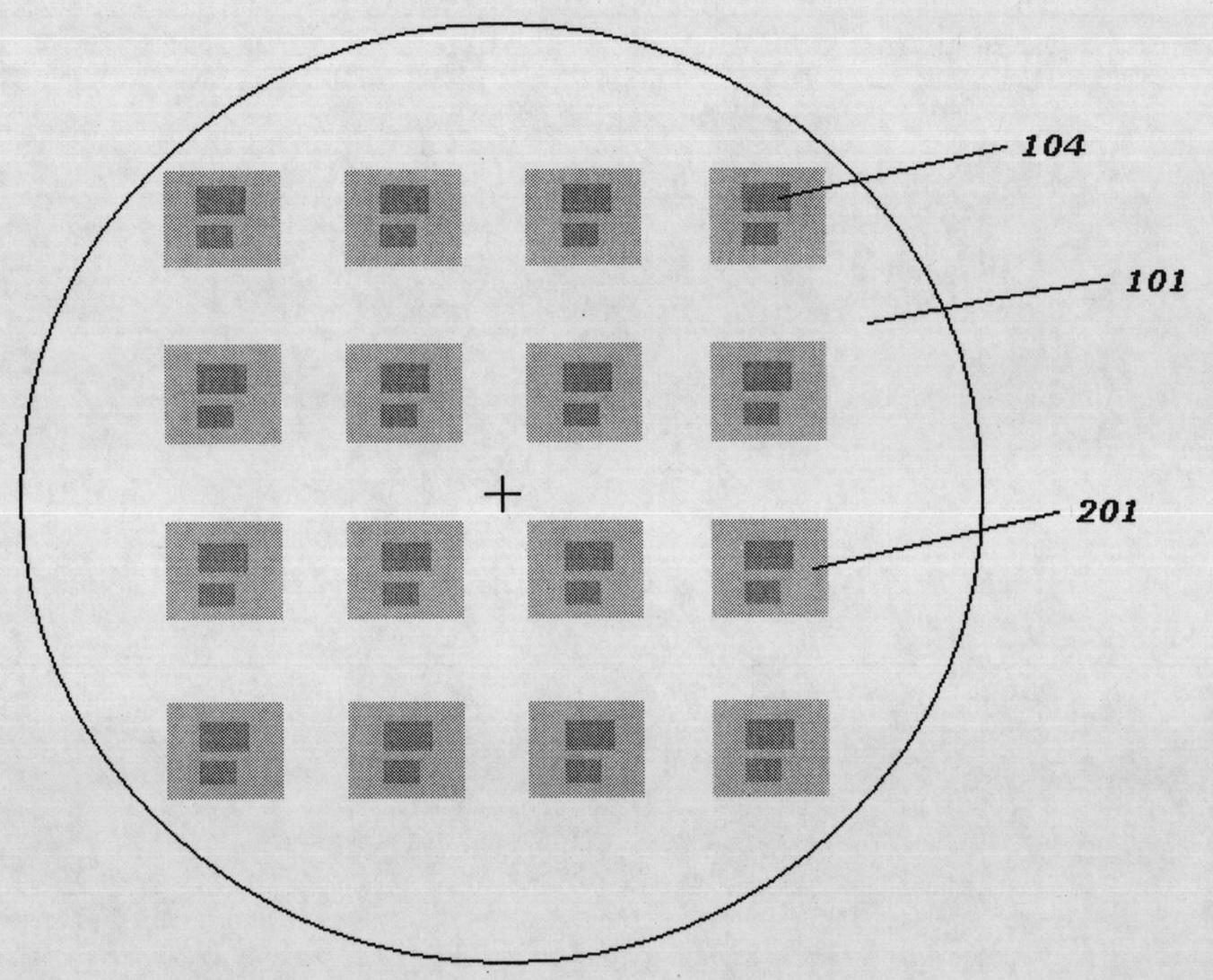

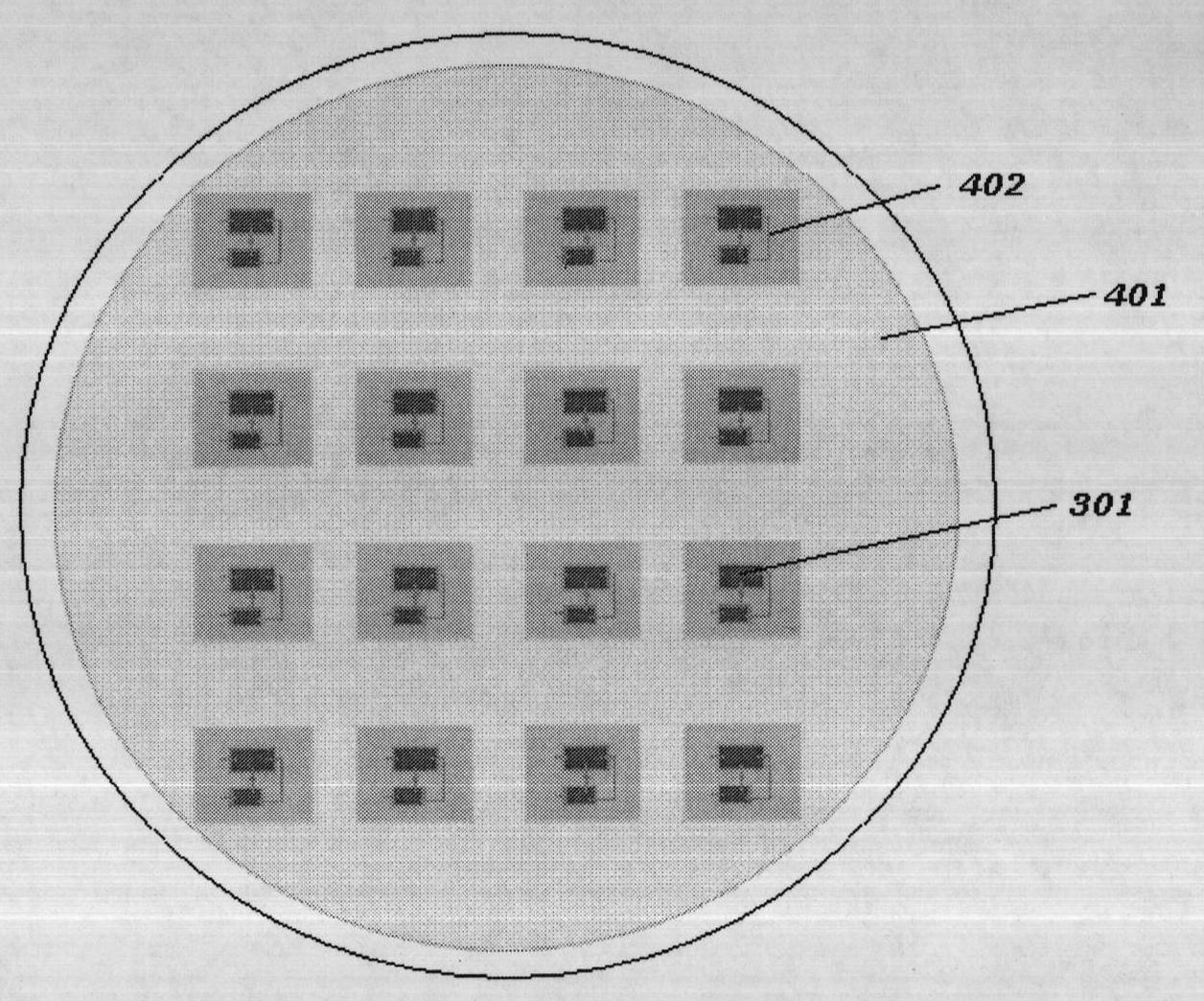

Chip stacks with decreased conductor length and improved noise immunity are formed by laser drilling of individual chips, such as memory chips, preferably near but within the periphery thereof, and forming conductors therethrough, preferably by metallization or filling with conductive paste which may be stabilized by transient liquid phase (TLP) processes and preferably with or during metallization of conductive pads, possibly including connector patterns on both sides of at least some of the chips in the stack. At least some of the chips in the stack then have electrical and mechanical connections made therebetween, preferably with electroplated solder preforms consistent with TLP processes. The connections may be contained by a layer of resilient material surrounding the connections and which may be formed in-situ. High density circuit packages thus obtained may be mounted on a carrier by surface mount techniques or separable connectors such as a plug and socket arrangement. The carrier may be of the same material as the chip stacks to match coefficients of thermal expansion. High-density circuit packages may also be in the form of removable memory modules in generally planar or prism shaped form similar to a pen or as a thermal conduction module.

Owner:INT BUSINESS MASCH CORP

High density integrated circuit packaging with chip stacking and via interconnections

InactiveUS6187678B1Reduced connection exposureLarge capacitySemiconductor/solid-state device detailsSolid-state devicesThermal expansionPrism

Chip stacks with decreased conductor length and improved noise immunity are formed by laser drilling of individual chips, such as memory chips, preferably near but within the periphery thereof, and forming conductors therethrough, preferably by metallization or filling with conductive paste which may be stabilized by transient liquid phase (TLP) processes and preferably with or during metallization of conductive pads, possibly including connector patterns on both sides of at least some of the chips in the stack. At least some of the chips in the stack then have electrical and mechanical connections made therebetween, preferably with electroplated solder preforms consistent with TLP processes. The connections may be contained by a layer of resilient material surrounding the connections and which may be formed in-situ. High density circuit packages thus obtained may be mounted on a carrier by surface mount techniques or separable connectors such as a plug and socket arrangement. The carrier may be of the same material as the chip stacks to match coefficients of thermal expansion. High-density circuit packages may also be in the form of removable memory modules in generally planar or prism shaped form similar to a pen or as a thermal conduction module.

Owner:IBM CORP

Surface mountable transducer system

InactiveUS7221767B2Established economically and reliablySuitable for mass productionSemiconductor electrostatic transducersElectrostatic transducer microphonesSurface mountingElectrical connection

The present invention relates to a surface mountable acoustic transducer system, comprising one or more transducers, a processing circuit electrically connected to the one or more transducers, and contact points arranged on an exterior surface part of the transducer system. The contact points are adapted to establish electrical connections between the transducer system and an external substrate, the contact points further being adapted to facilitate mounting of the transducer system on the external substrate by conventional surface mounting techniques.

Owner:BALLY TECHNOLOGIES +1

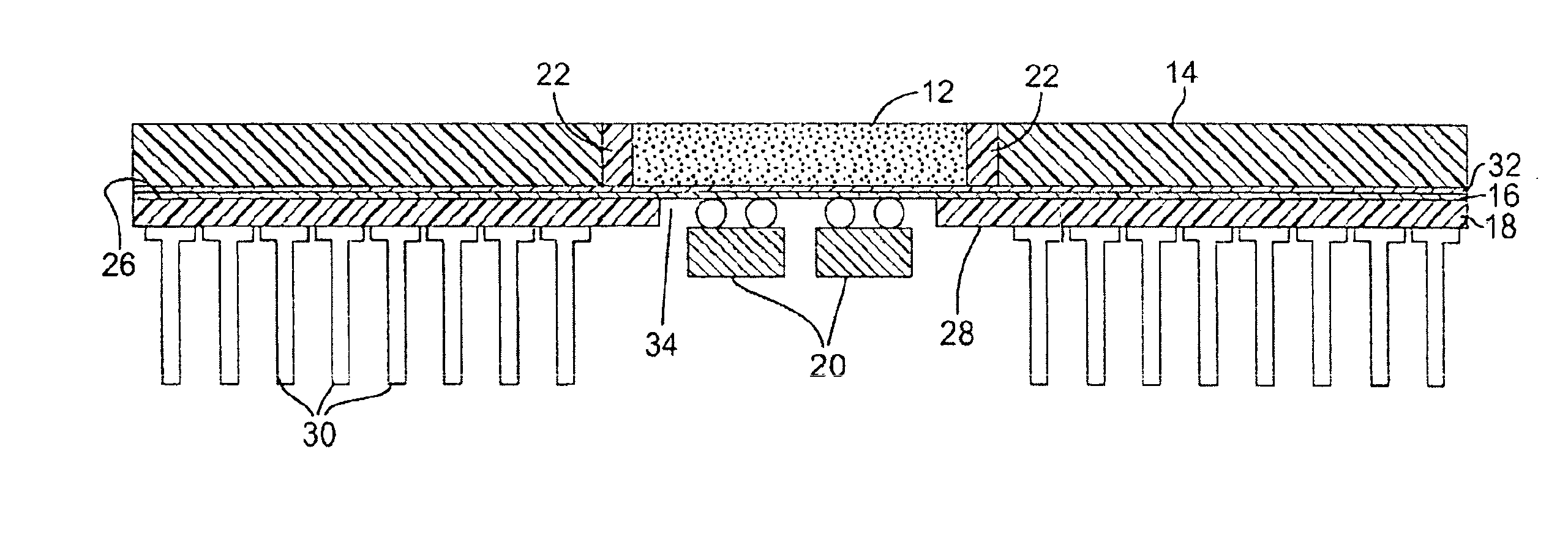

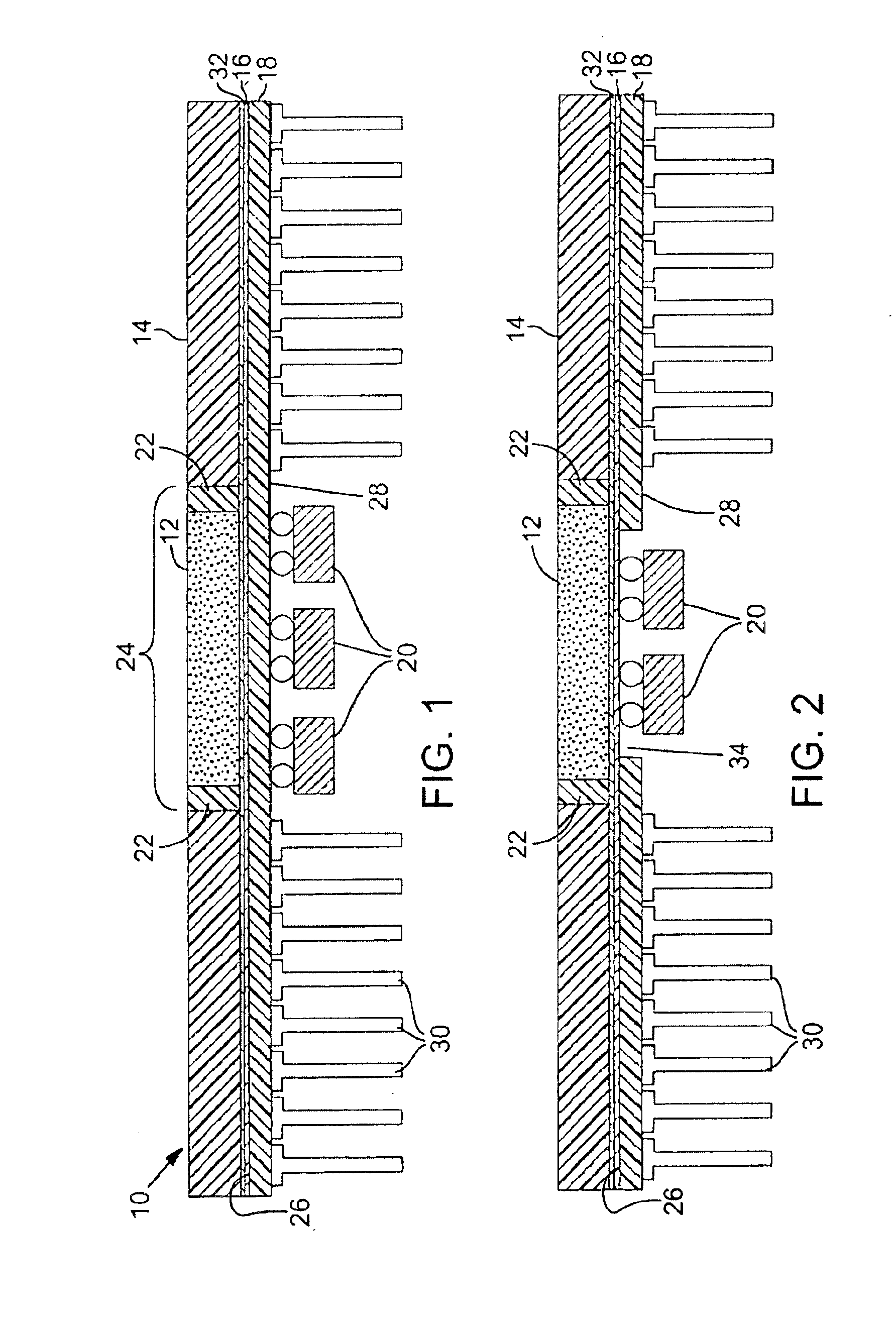

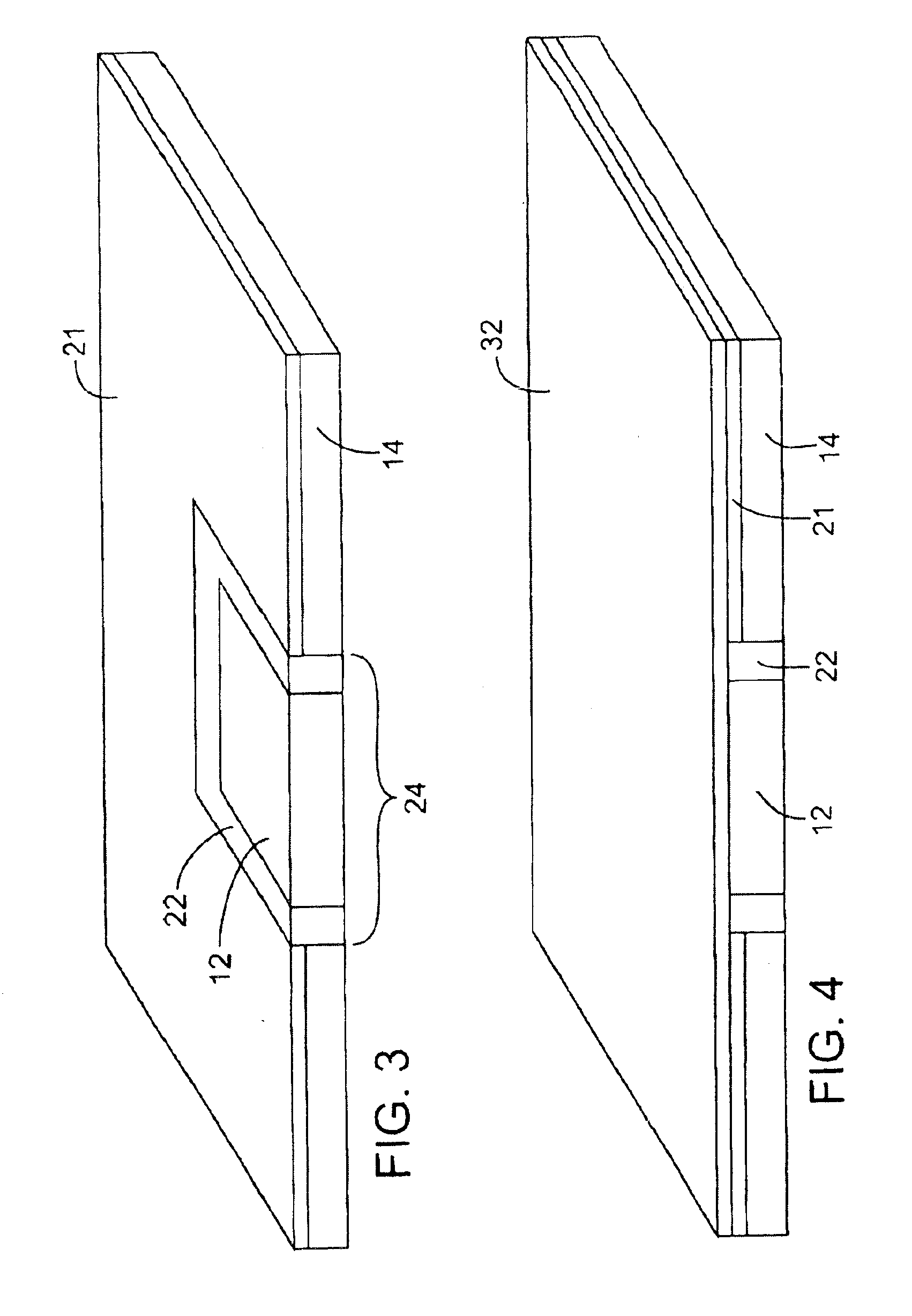

High performance, low cost microelectronic circuit package with interposer

InactiveUS6888240B2Semiconductor/solid-state device detailsSolid-state devicesPin grid arrayInterposer

A low cost technique for packaging microelectronic circuit chips fixes a die within an opening in a package core. At least one metallic build up layer is then formed on the die / core assembly and a grid array interposer unit is laminated to the build up layer. The grid array interposer unit can then be mounted within an external circuit using any of a plurality of mounting technologies (e.g., ball grid array (BGA), land grid array (LGA), pin grid array (PGA), surface mount technology (SMT), and / or others). In one embodiment, a single build up layer is formed on the die / core assembly before lamination of the interposer.

Owner:INTEL CORP

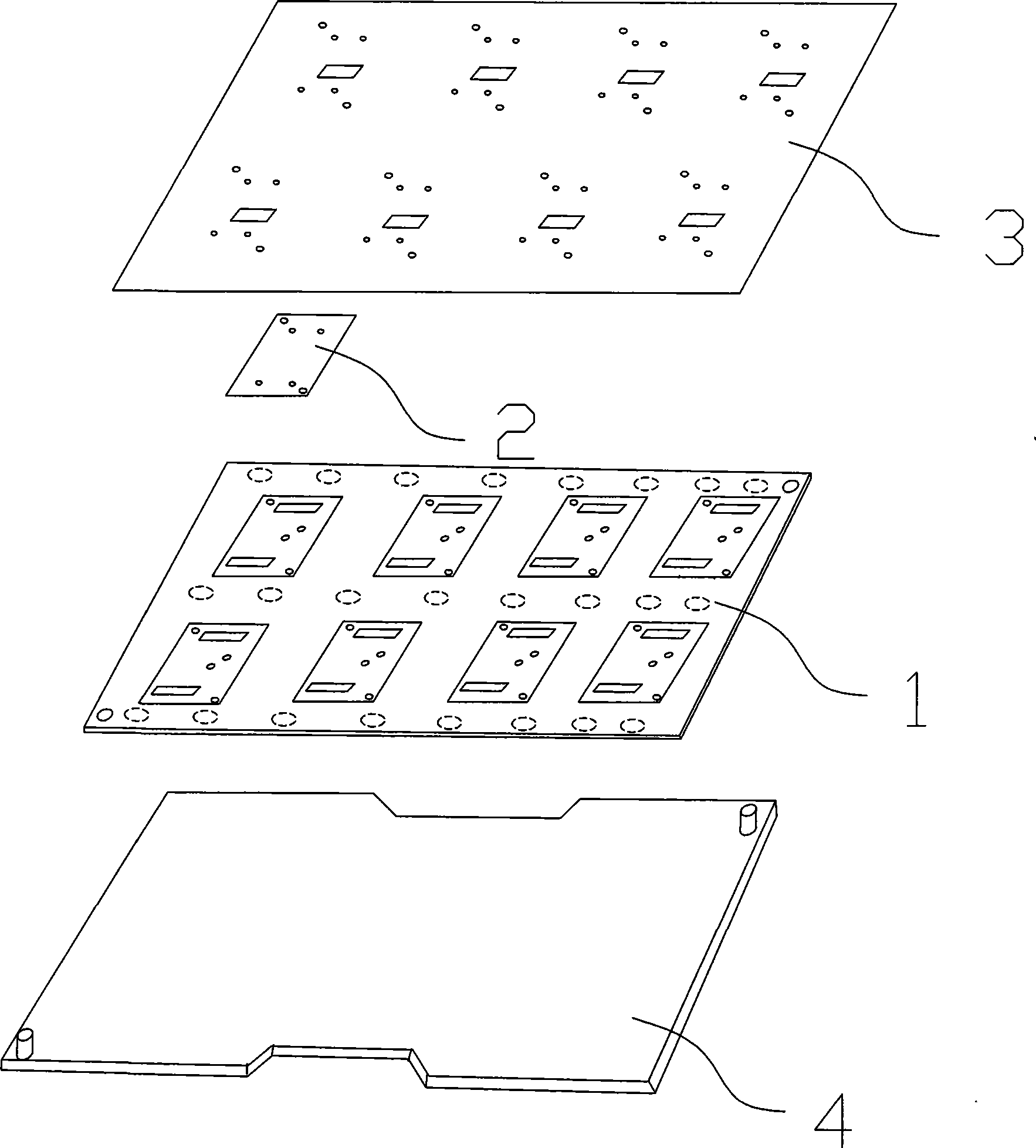

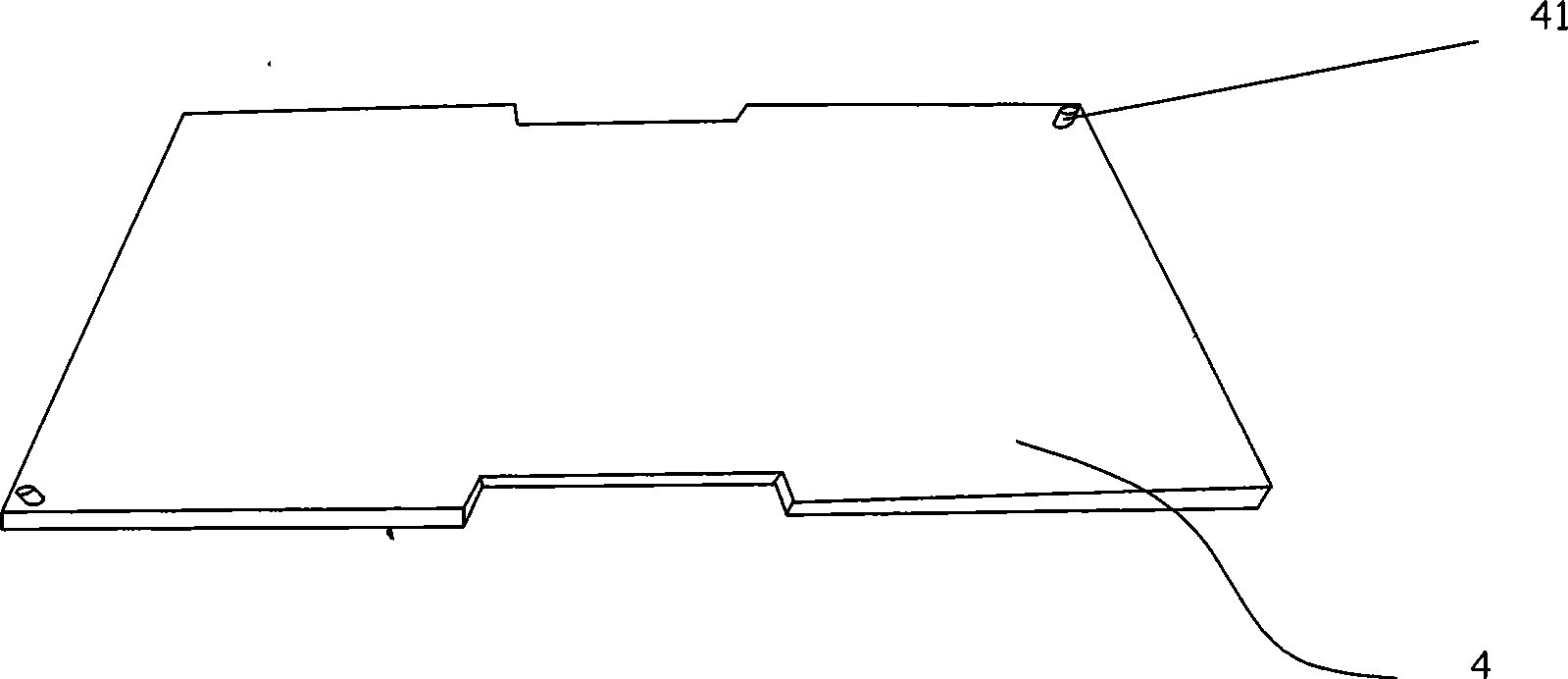

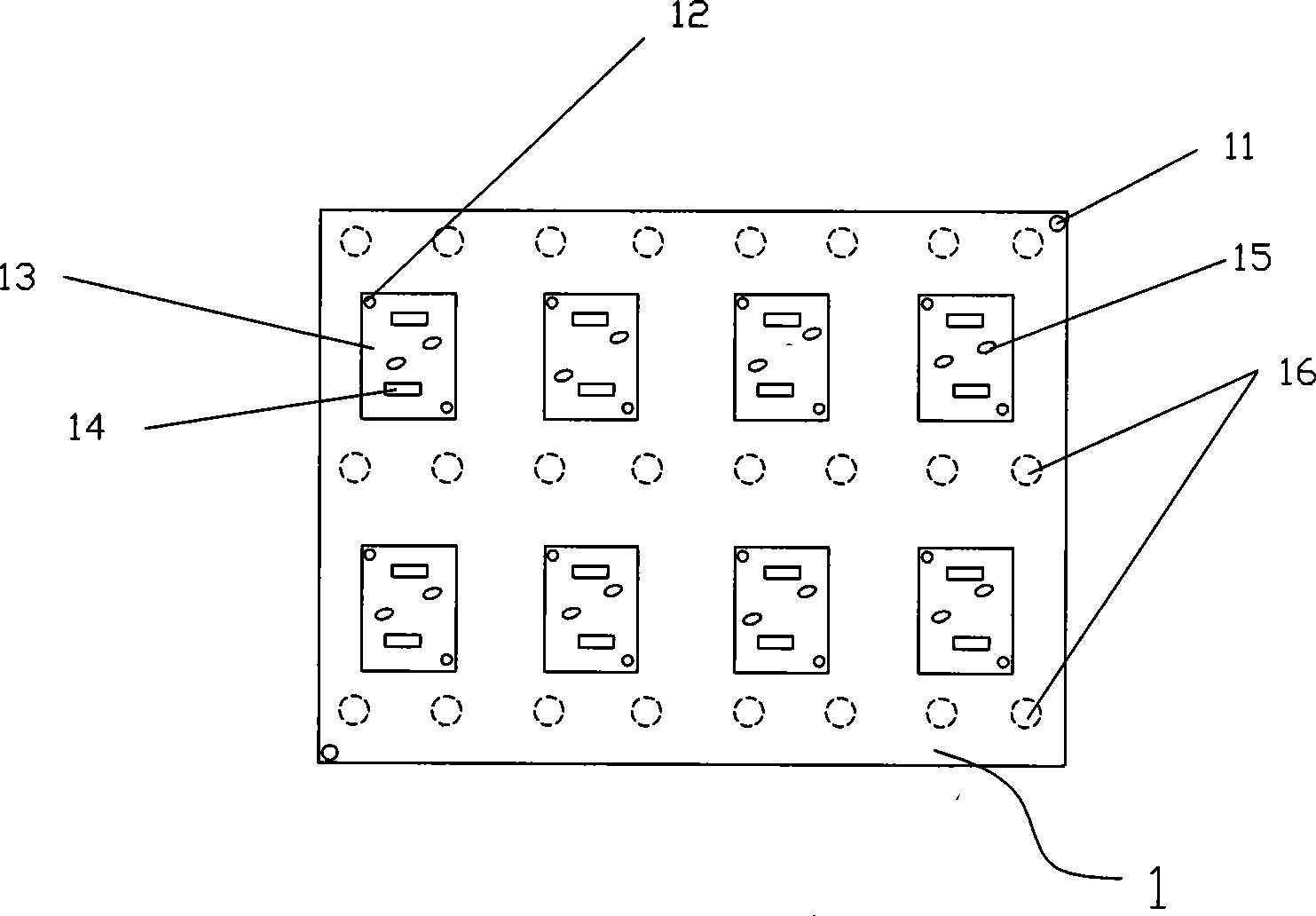

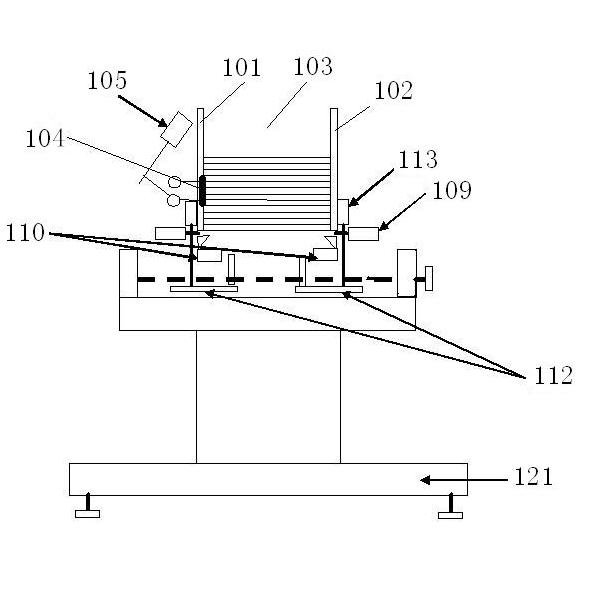

Surface mounting process for flexible circuit board and used magnetic tool and steel mesh

ActiveCN101384136AExtended service lifeLow costPrinted circuit assemblingManufacturing technologyFlexible circuits

The invention relates to the manufacturing technology of printed wiring board, in particular to a flexible printed circuit (FPC) surface mount technology (SMT) as well as a magnetic tool and a steel mesh which are used for the FPCSMT. The magnetic tool comprises a buckle cover board and a magnetic carrying tray, wherein the magnetic carrying tray is a magnetic baseplate, the buckle cover board is a metal sheet which can be attracted by the magnetic baseplate, and the buckle cover board is provided with a slotted hole used for the solder paste printing and the surface mounting of a FPC. The invention is characterized in that the buckle cover board is a steel sheet which can be attracted by the magnetic baseplate, the step layer which is the same as the buckle cover board in shape is etched on the magnetic carrying tray, the depth of the step layer is the same as the thickness of the steel sheet; before the circuit board printing, the magnetic carrying tray is fixed on a positioning base, and then the FPC and the buckle cover board are arranged on the magnetic carrying tray; after the accurate positioning, the FPC and the magnetic tool are taken down the positioning base to conduct the solder paste printing process, the surface mounting process and the reflow soldering process.

Owner:东莞市贞观盛智控科技有限公司

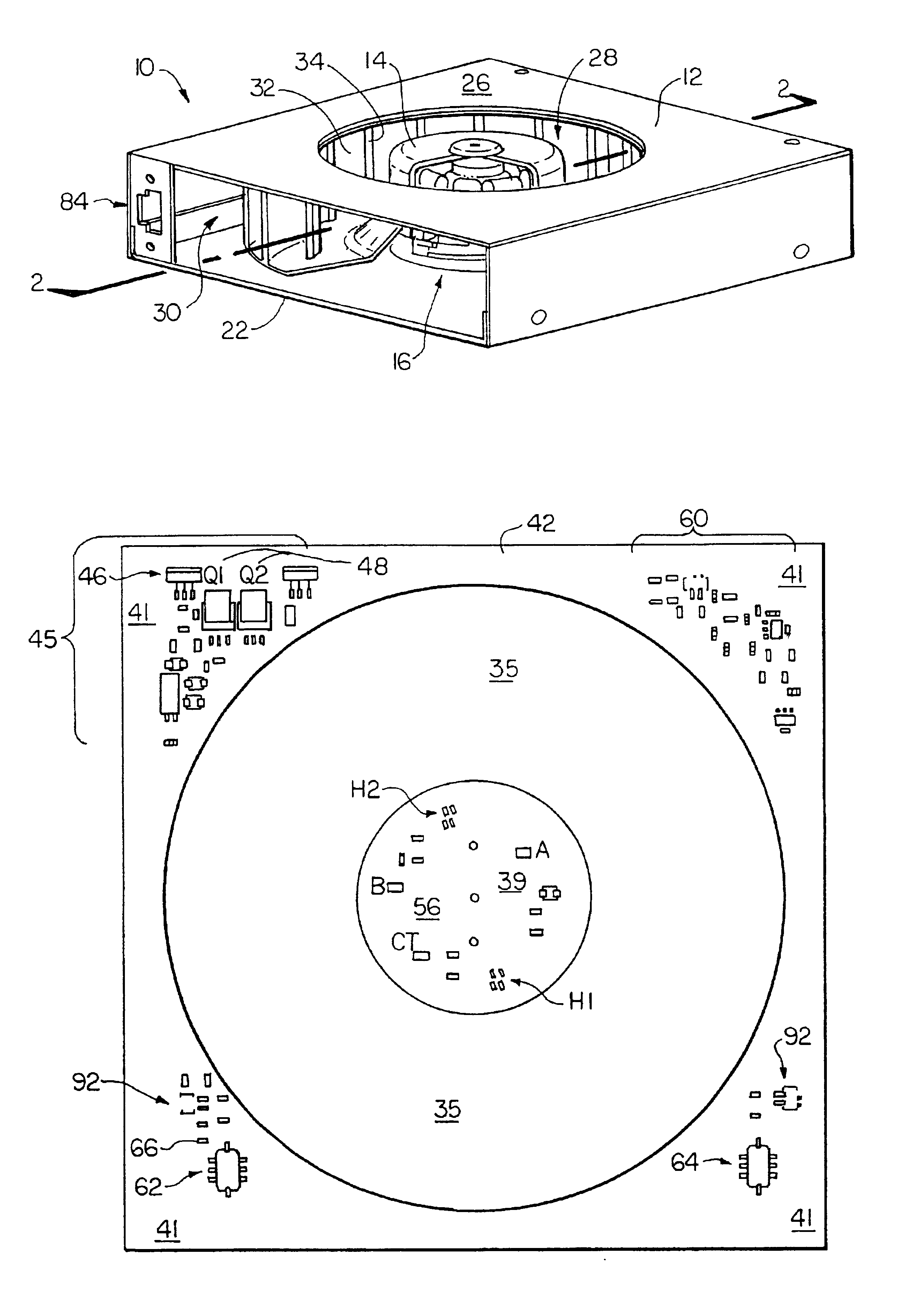

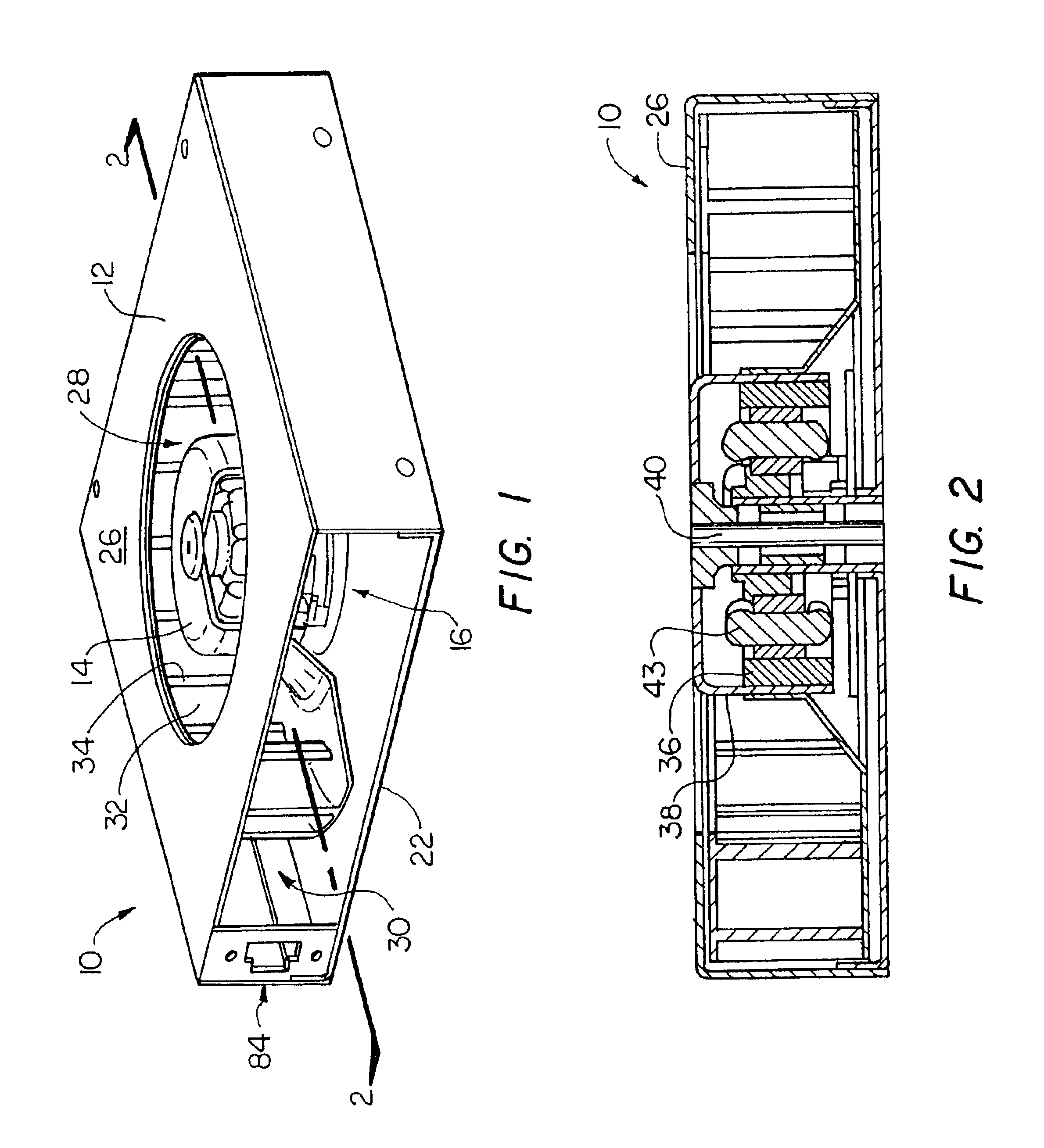

Low profile motor

InactiveUS6841957B2Monitor performanceAC motor controlSynchronous motors startersSurface mountingElectronic component

A flat pack blower utilizes surface mounting techniques for mounting the blower electronics on a thin laminated circuit board to reduce the blower profile. To that end, the blower includes a stator, and a rotor rotatably coupled to the stator. The stator includes a coil, a pole coupled with the coil, and a laminated circuit board having blower control circuitry and pads for electrically connecting the blower control circuitry to the coil. Use of surface mounting techniques on the laminated circuit board thus eliminates the discrete electronic components and the wires connecting such components.

Owner:MOTION HLDG

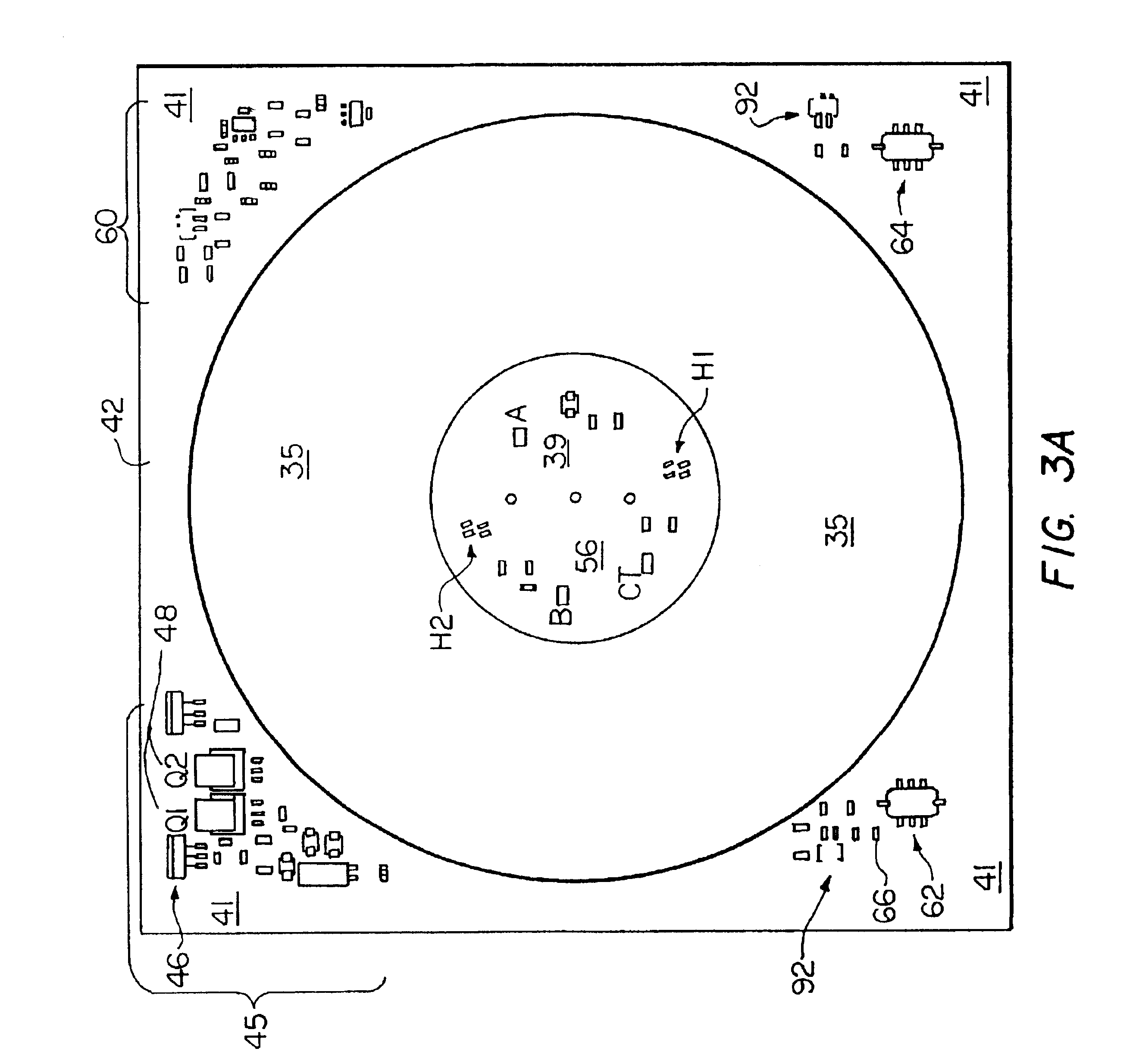

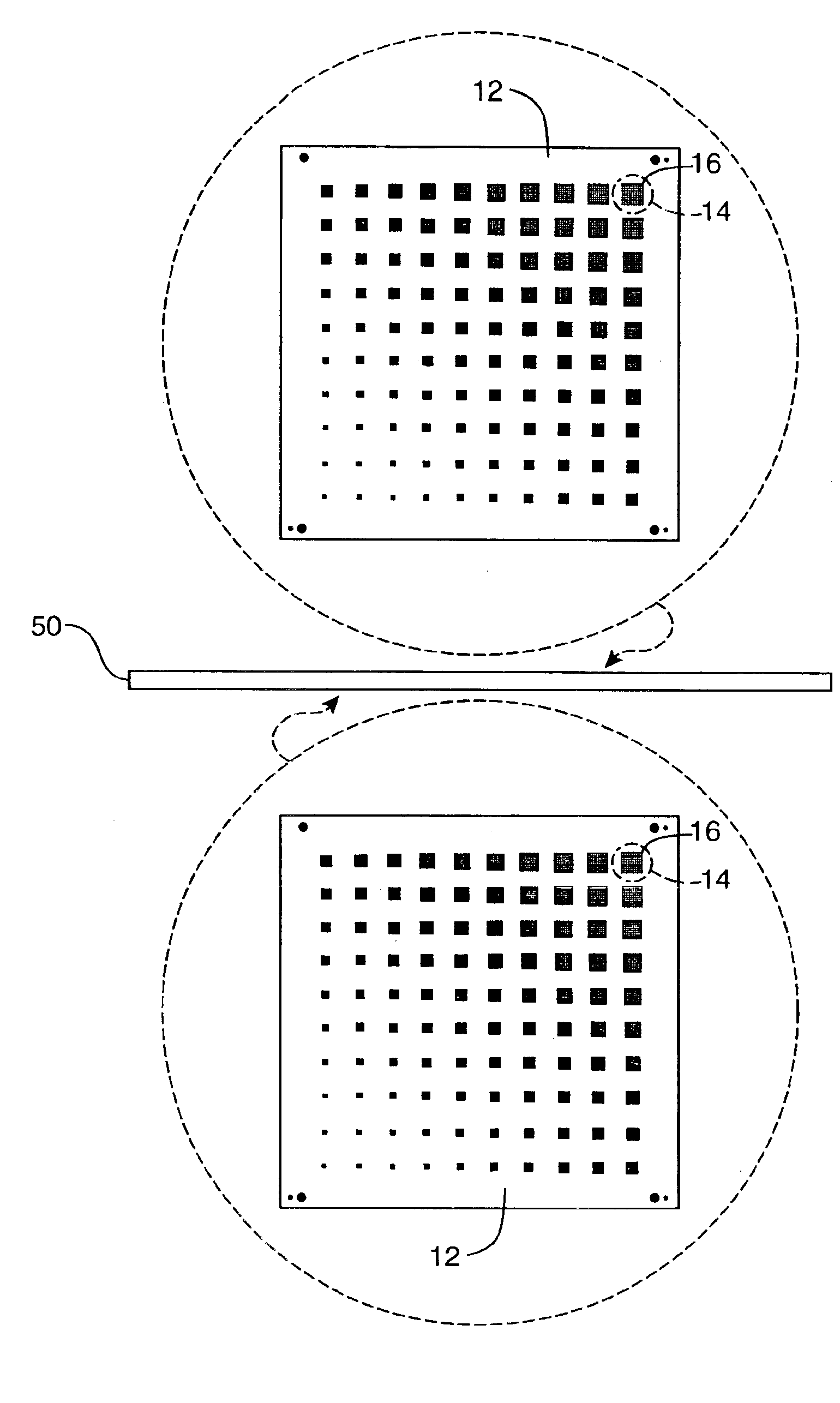

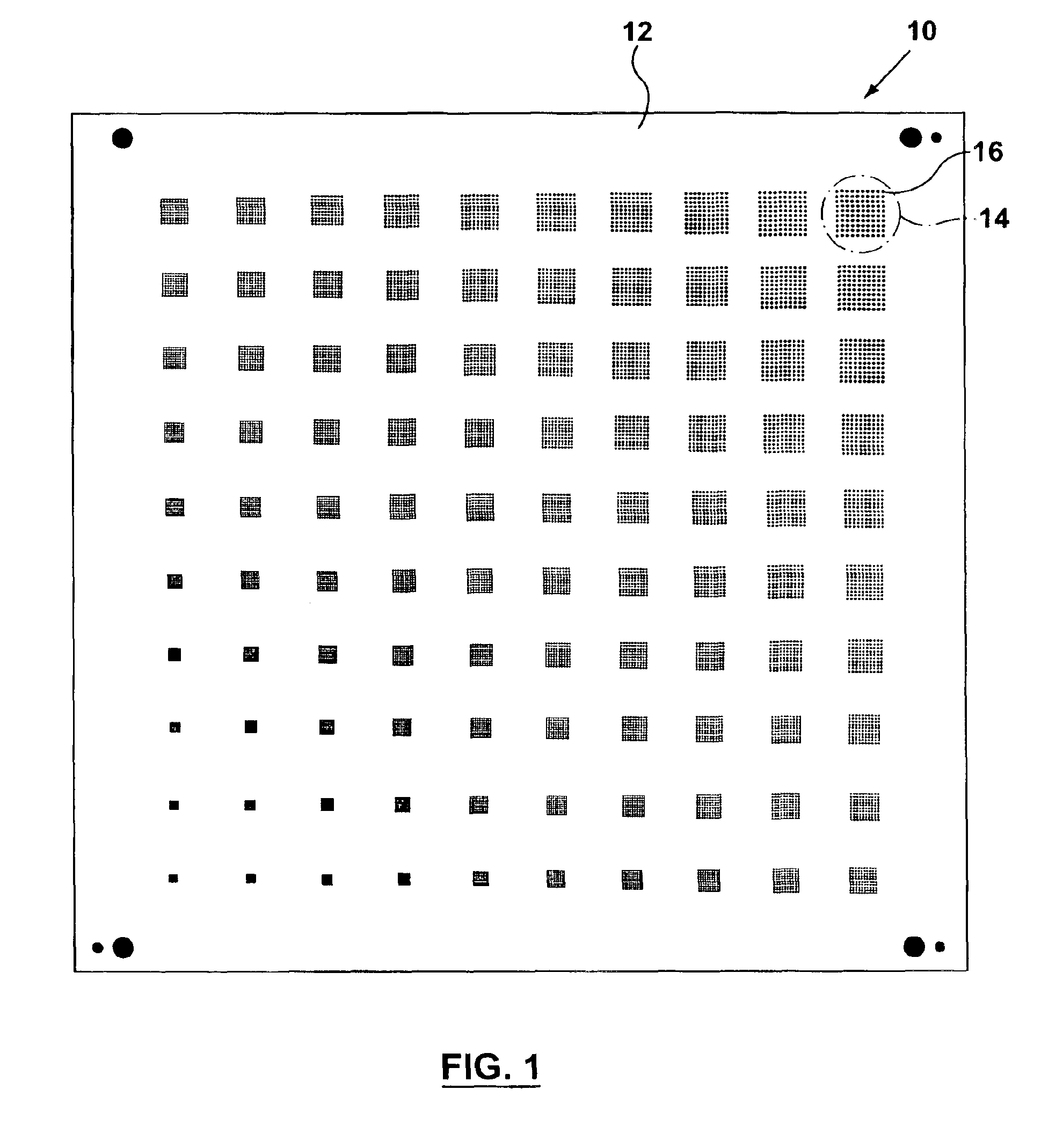

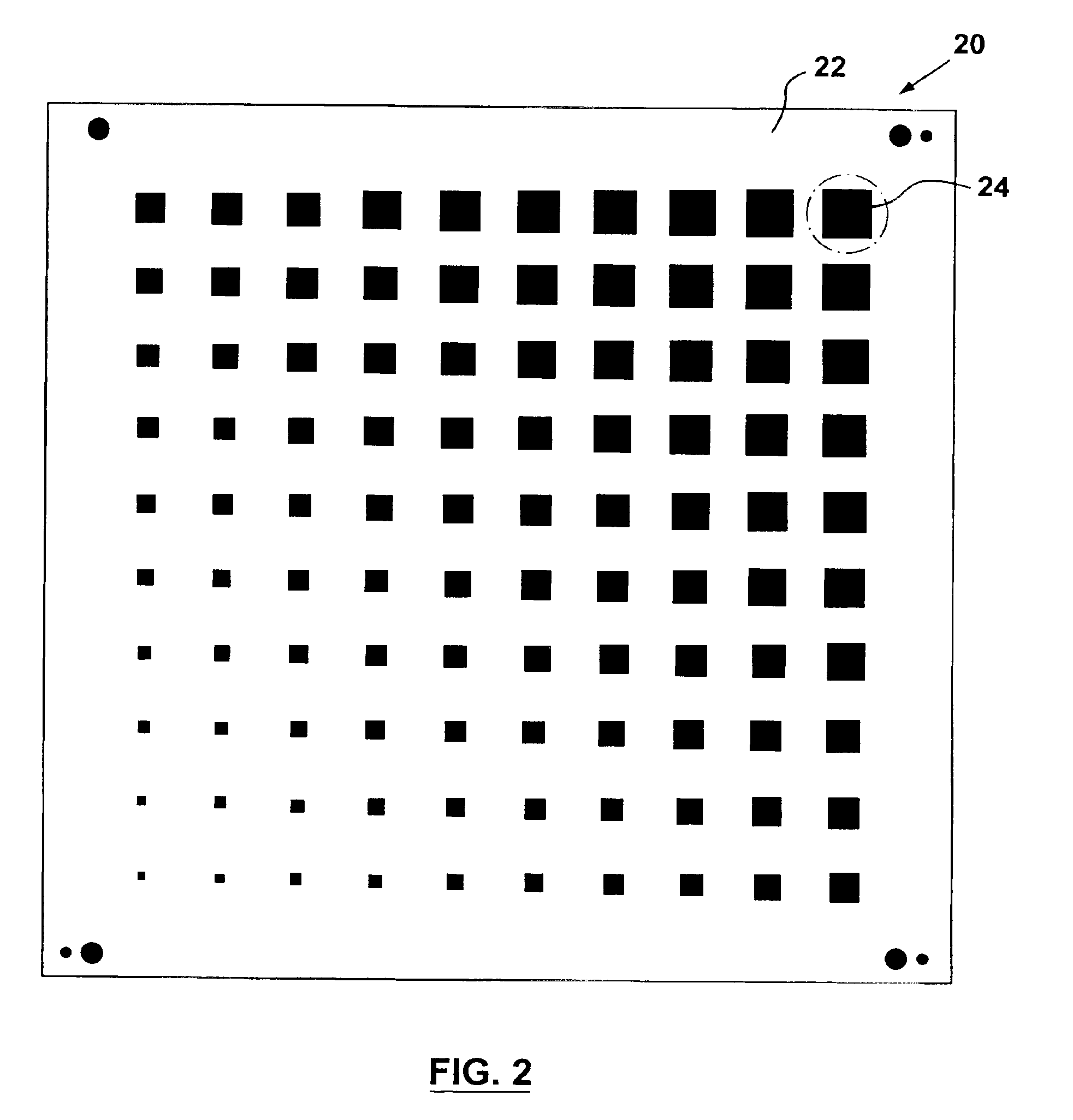

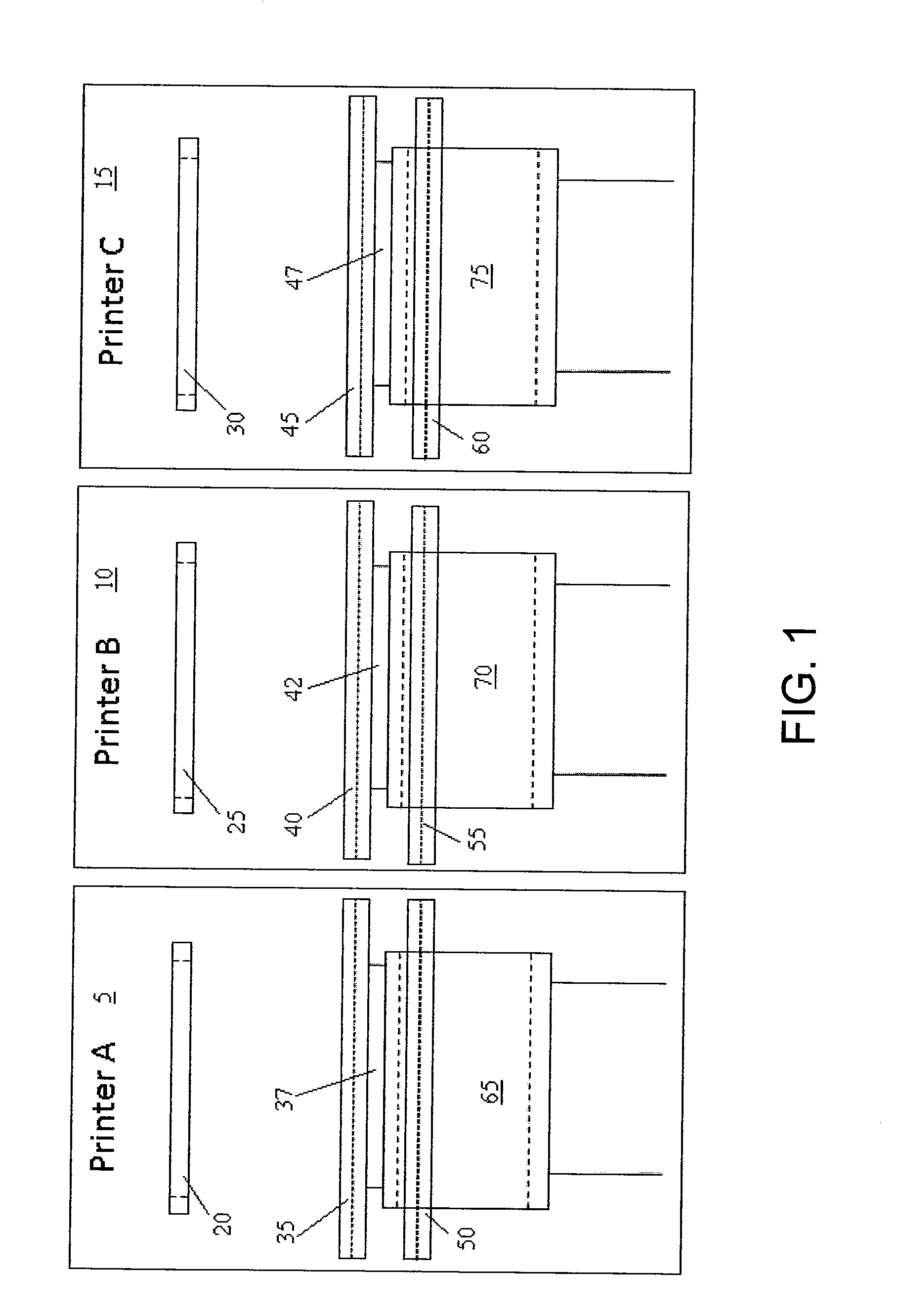

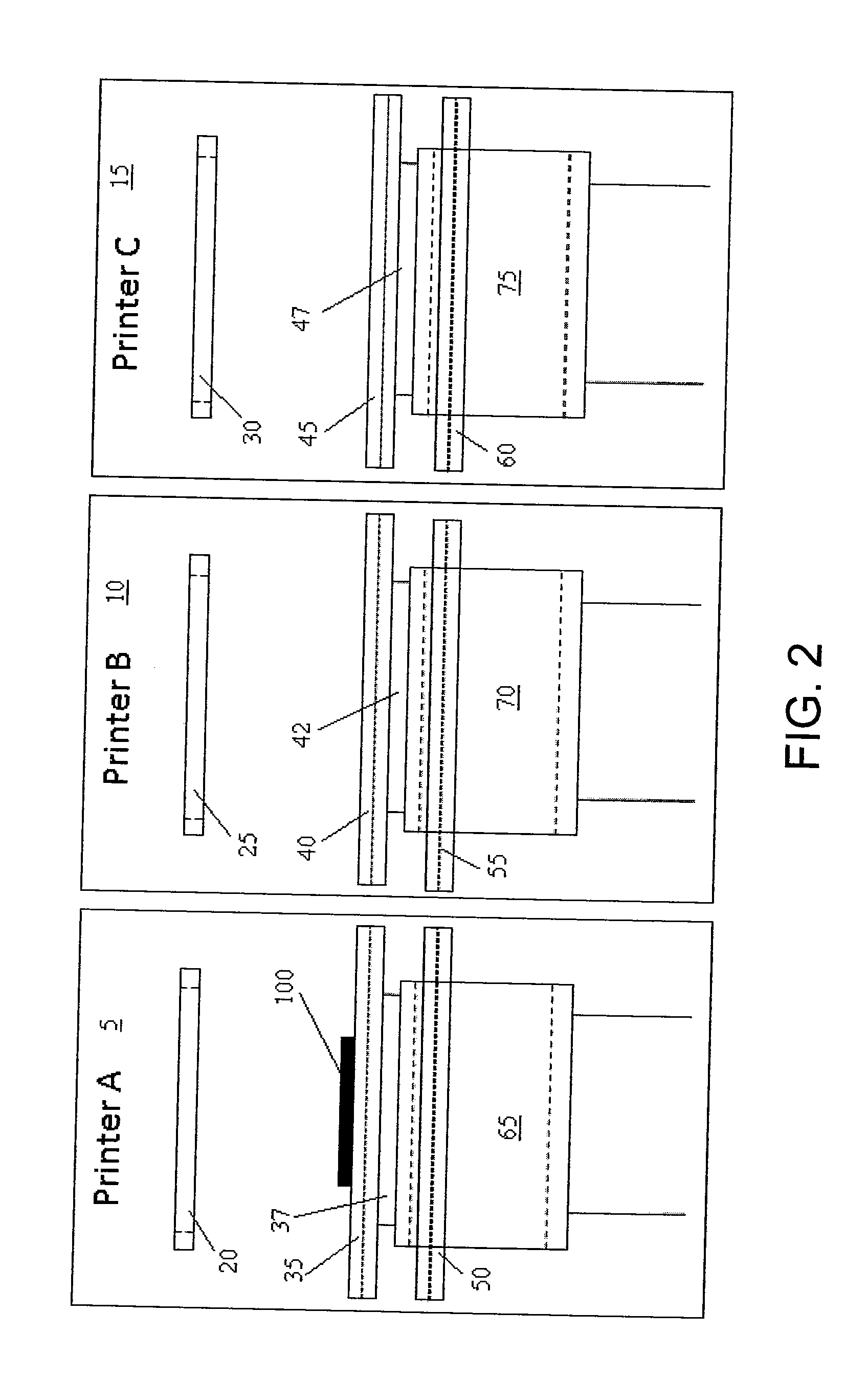

Surface mount technology evaluation board having varied board pad characteristics

ActiveUS6888360B1Final product manufacturePrinted circuit aspectsEngineeringSurface-mount technology

This invention provides an evaluation board for evaluating one or more aspects of a surface mount technology system. In one aspect, the evaluation board has a substrate with at least one surface. A plurality of board pad patterns, each including a plurality of board pads, is formed on the surface. The different board pad patterns may have different shaped, sized and spaced board pads, allowing the characteristics of a surface mount technology to be tested on some or all of the board pad patterns at the same time and under uniform conditions. In another aspect, the surface may have a plurality of area-filled board pads similarly allowing a surface mount technology to be tested on the various area-filled board pads.

Owner:MALIKIE INNOVATIONS LTD

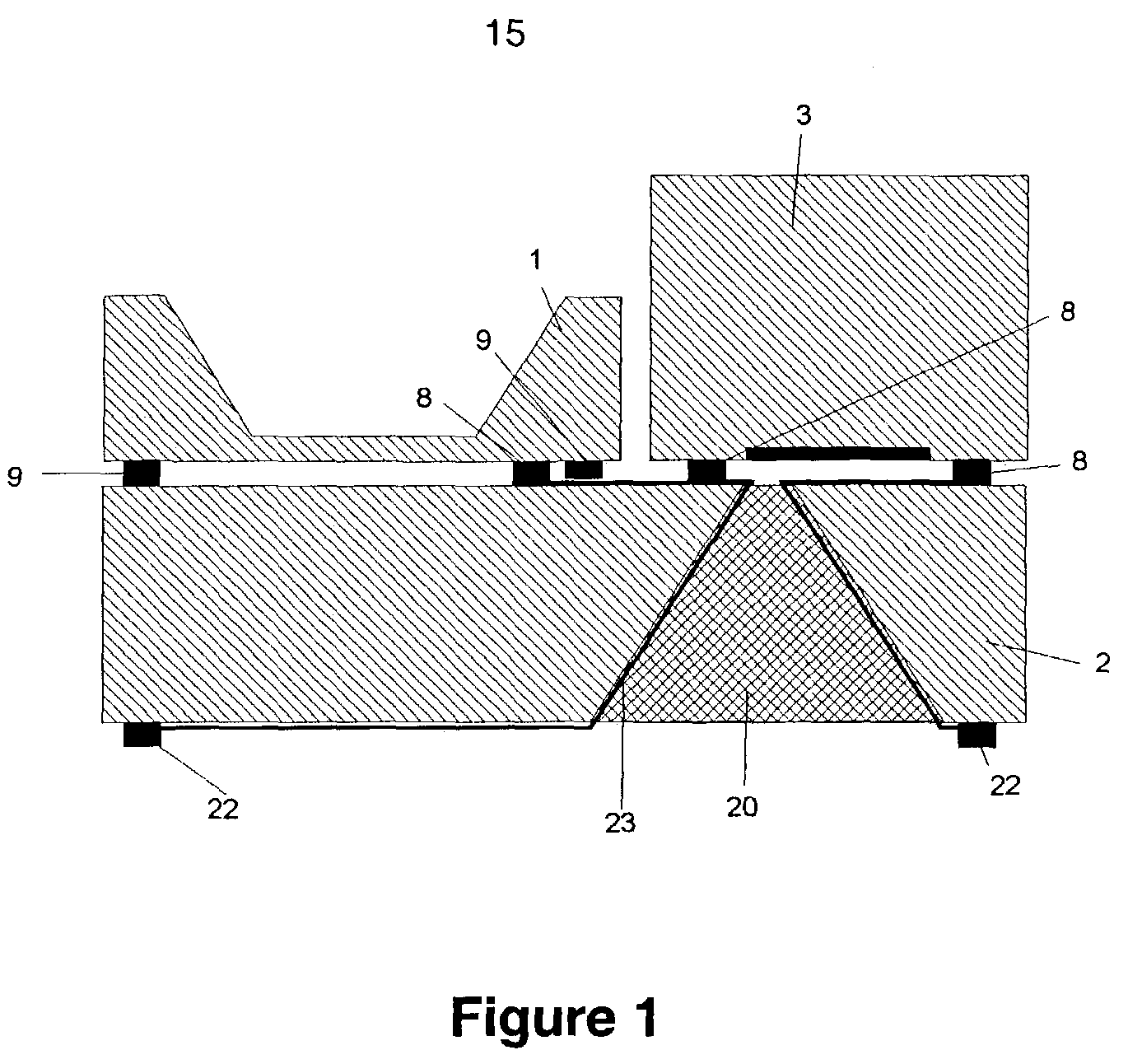

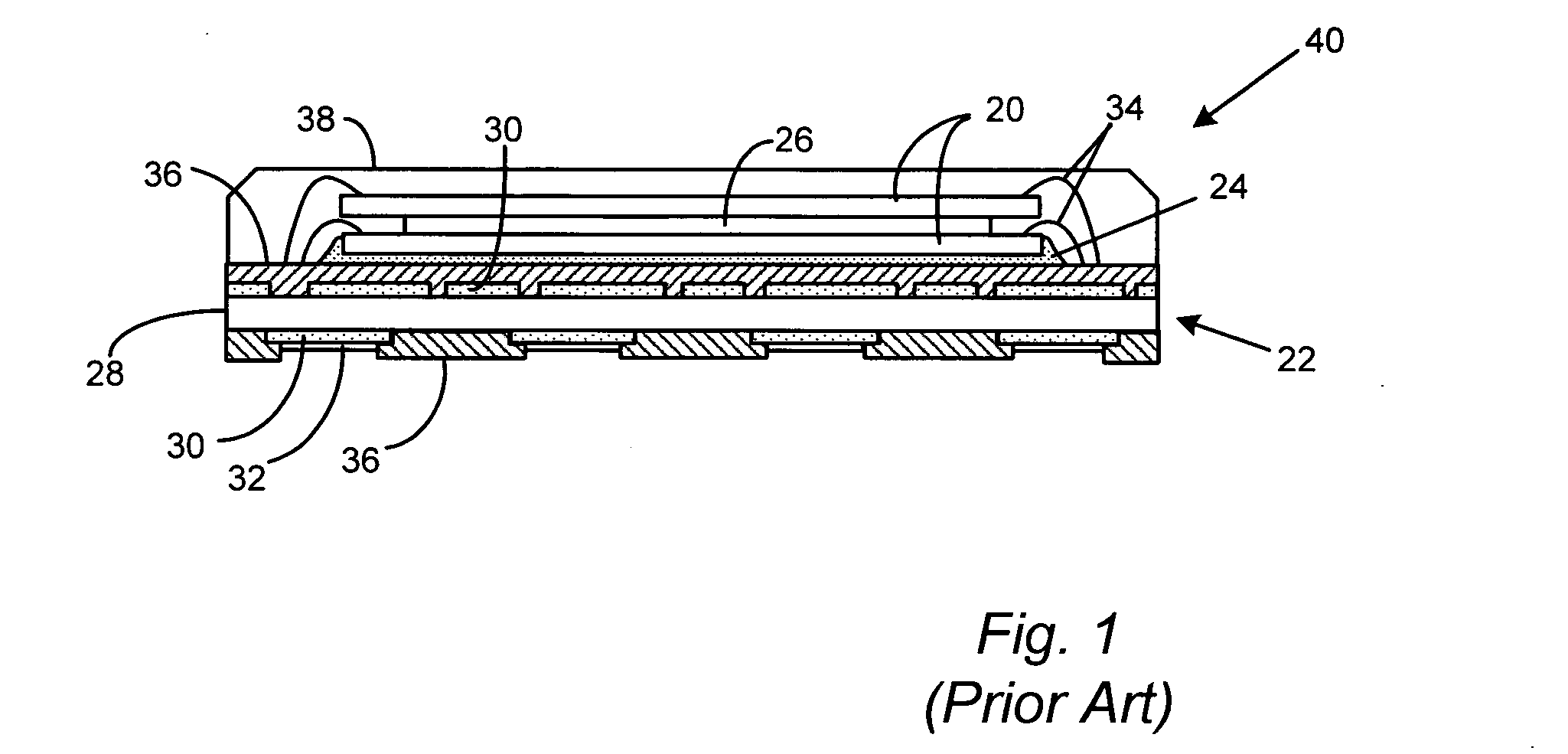

Semiconductor package with heat sink

InactiveUS7166914B2Improve distributionEasy to assemblePrinted circuit assemblingSemiconductor/solid-state device detailsDielectricSurface mounting

A packaged semiconductor chip including the chip, and a package element such as a heat sink is made by connecting flexible leads between contacts on the chip and terminals on a dielectric element such as a sheet or plate and moving the sheet or plate away from the chip, and injecting a liquid material to form a compliant layer filling the space between the package element and the dielectric element, and surrounding the leads. The dielectric element and package element extend outwardly beyond the edges of the chip, and physically protect the chip. The assembly may be handled and mounted by conventional surface mounting techniques. The assembly may include additional circuit elements such as capacitors used in conjunction with the chip.

Owner:TESSERA INC

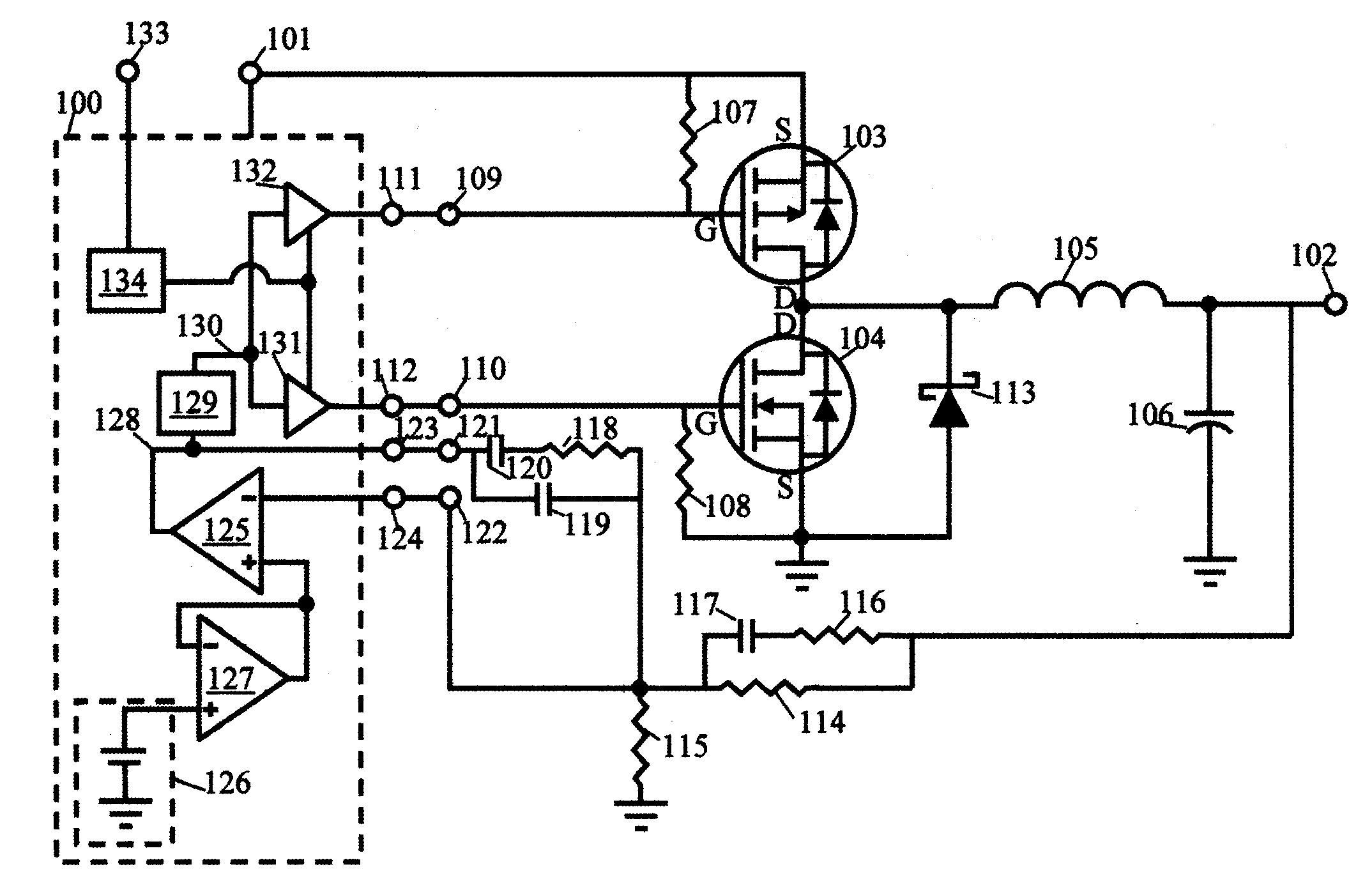

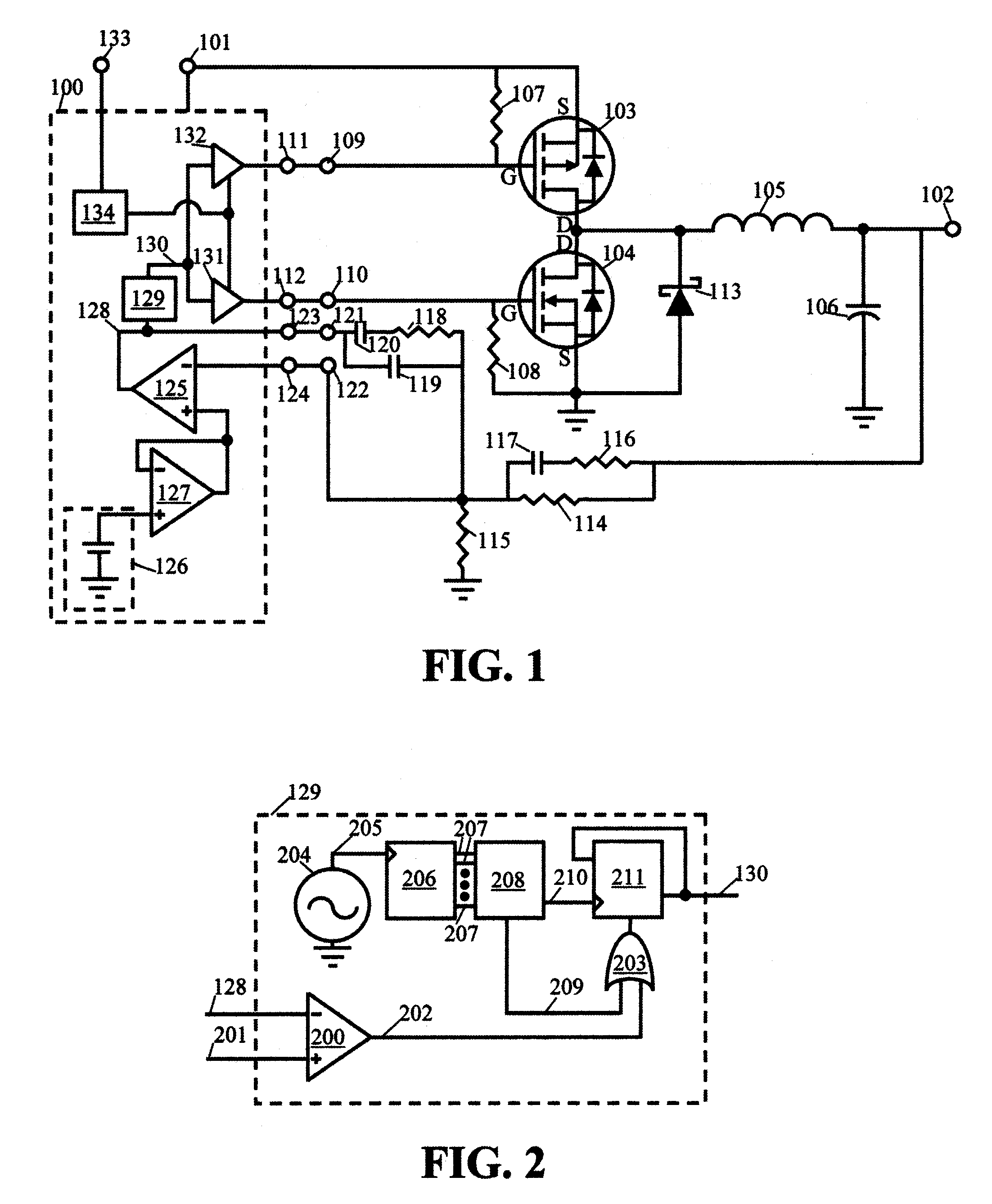

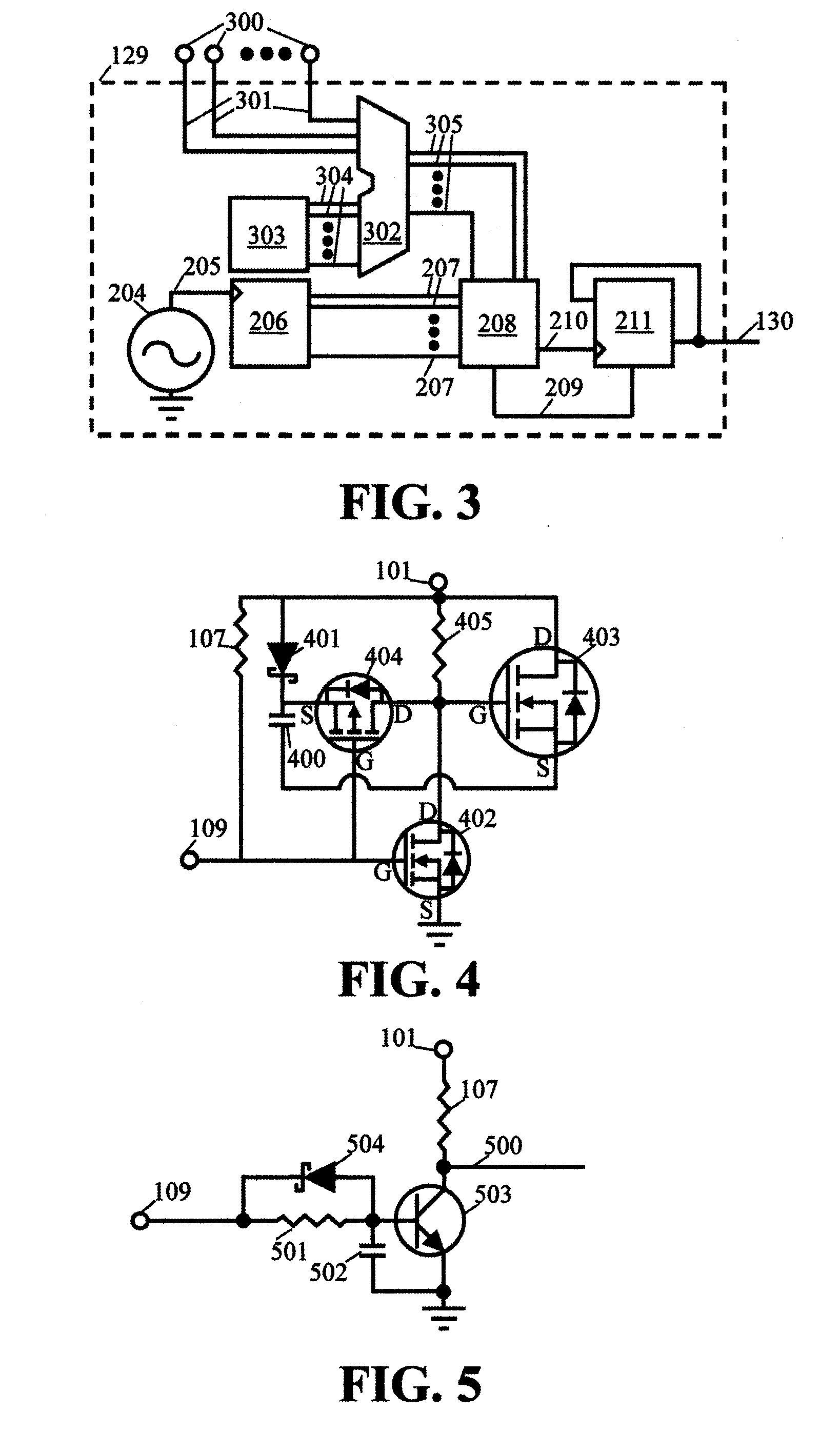

System and method for integrating a digital core with a switch mode power supply

InactiveUS20050024908A1Good power savingMinimal costDigital data processing detailsDc-dc conversionCapacitanceEngineering

A digital core embodied within a semiconductor die is situated within any of a variety of integrated circuit packaging technologies including but not limited to Ball Grid Array or Quad Flat Pack surface mount technology. Said semiconductor die is of the variety that requires plural separate power supply voltage domains such as a digital core supply of differing voltage than the input / output pad ring supply voltage. Within the integrated circuit package including said semiconductor die also exists a high efficiency DC-to-DC voltage converter of type commonly known as a chopper or a switch mode power supply. In the preferred embodiment this switch mode power supply would be of the highest efficiency, a synchronous step-down regulator, thus to enable powering the entire integrated circuit from one supply voltage. The components contained within the integrated circuit package along with the semiconductor die include the majority if not the totality of the components comprising the switch mode power supply, which could include the power switching transistors; an inductor core and windings; the output voltage fixing circuitry; the output capacitor; and the substrate for mounting said components when integrated within a packaging technology that does not already include a substrate such as within the periphery of a lead frame for leaded devices.

Owner:CUFER ASSET LTD LLC

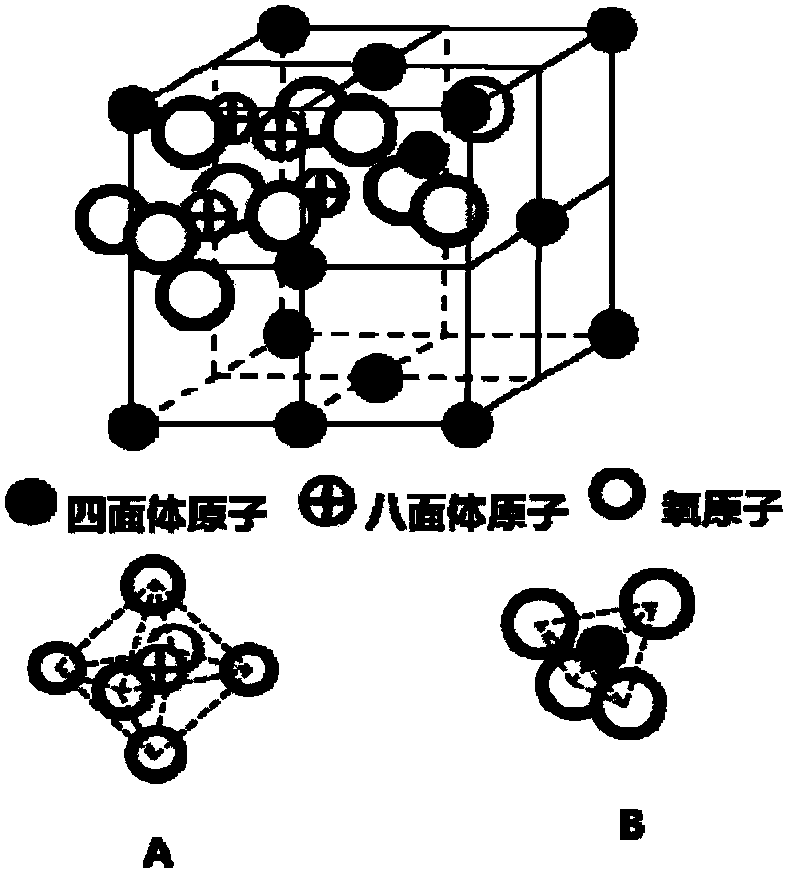

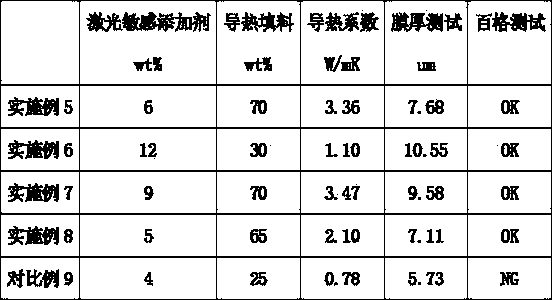

Resin composition having laser direct-structuring function and its preparation method and use

InactiveCN103450675AImprove high temperature resistanceImprove thermal conductivityPoint-like light sourceLighting heating/cooling arrangementsSurface mountingResin matrix

The invention provides a resin composition having a laser direct-structuring function and its preparation method and use. The resin composition comprises 15-60wt% of a resin matrix, 30-70wt% of a heat-conduction filler, 5-12wt% of a laser-sensitive additive and 0-15wt% of other additives. The laser-sensitive additive has a general chemical formula of XY2O4, belongs to an isometric system and has axial length a=b=c and axial angle alpha=beta=gamma=90 degrees, wherein X and Y represent metal elements belonging to an IIIA group, an IB group, an IIB group, a VIB group, a VIIB group and a VIII group of the periodic table of elements. The resin composition has high temperature resistance and good thermal conductivity, realizes optional sedimentation of metals such as Cu, Ni and Au in a laser-scanned area and can be used for surface mounting technology (SMT) products.

Owner:KINGFA SCI & TECH CO LTD +1

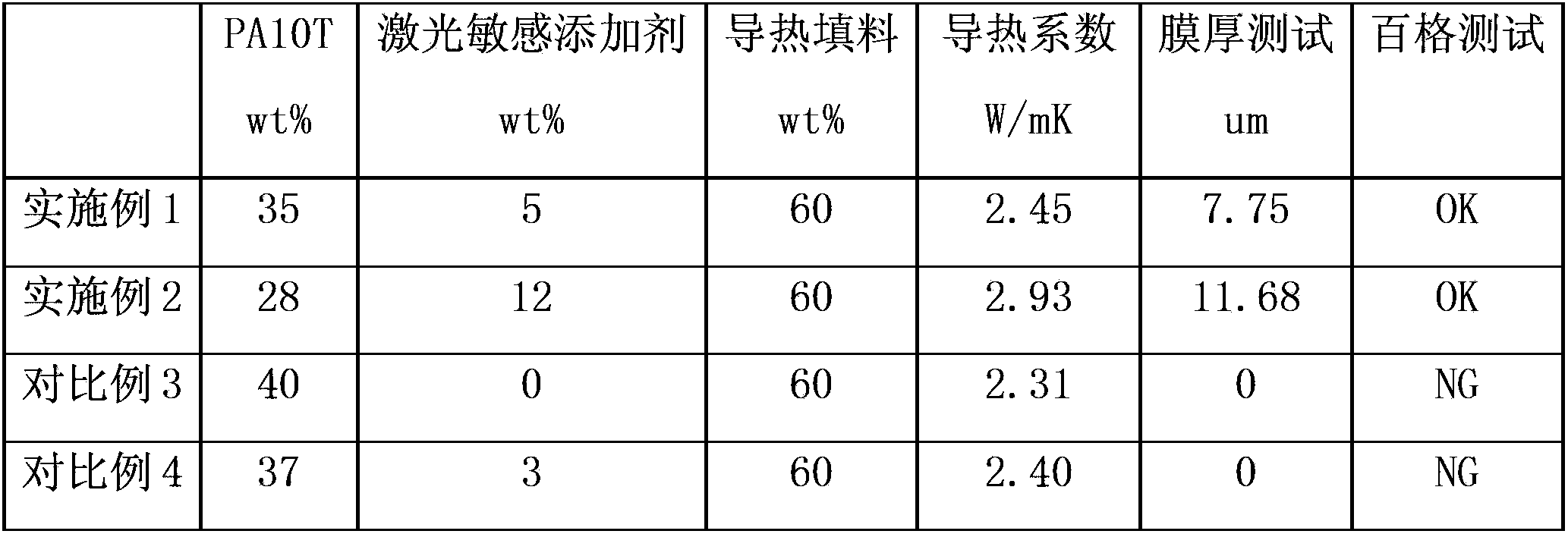

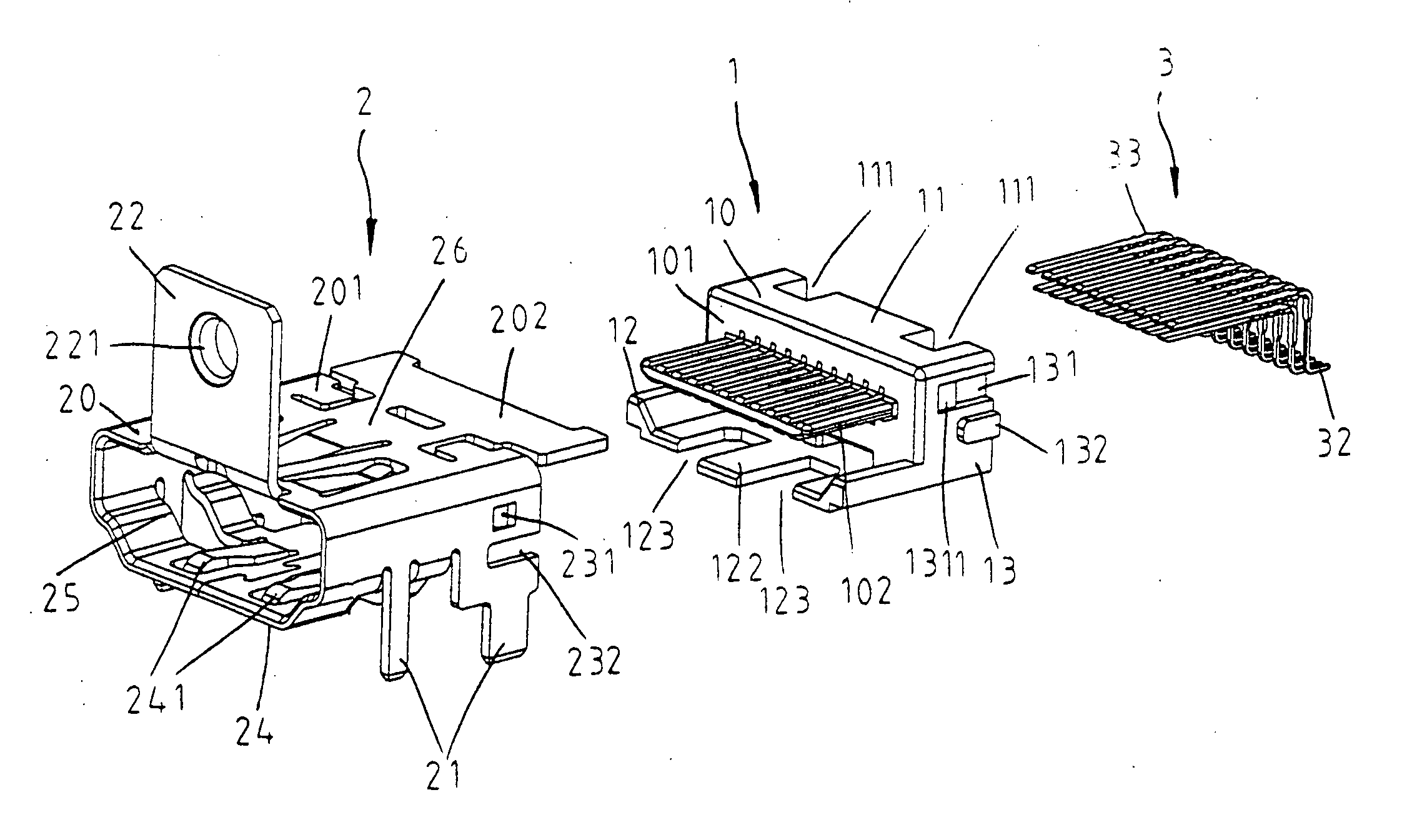

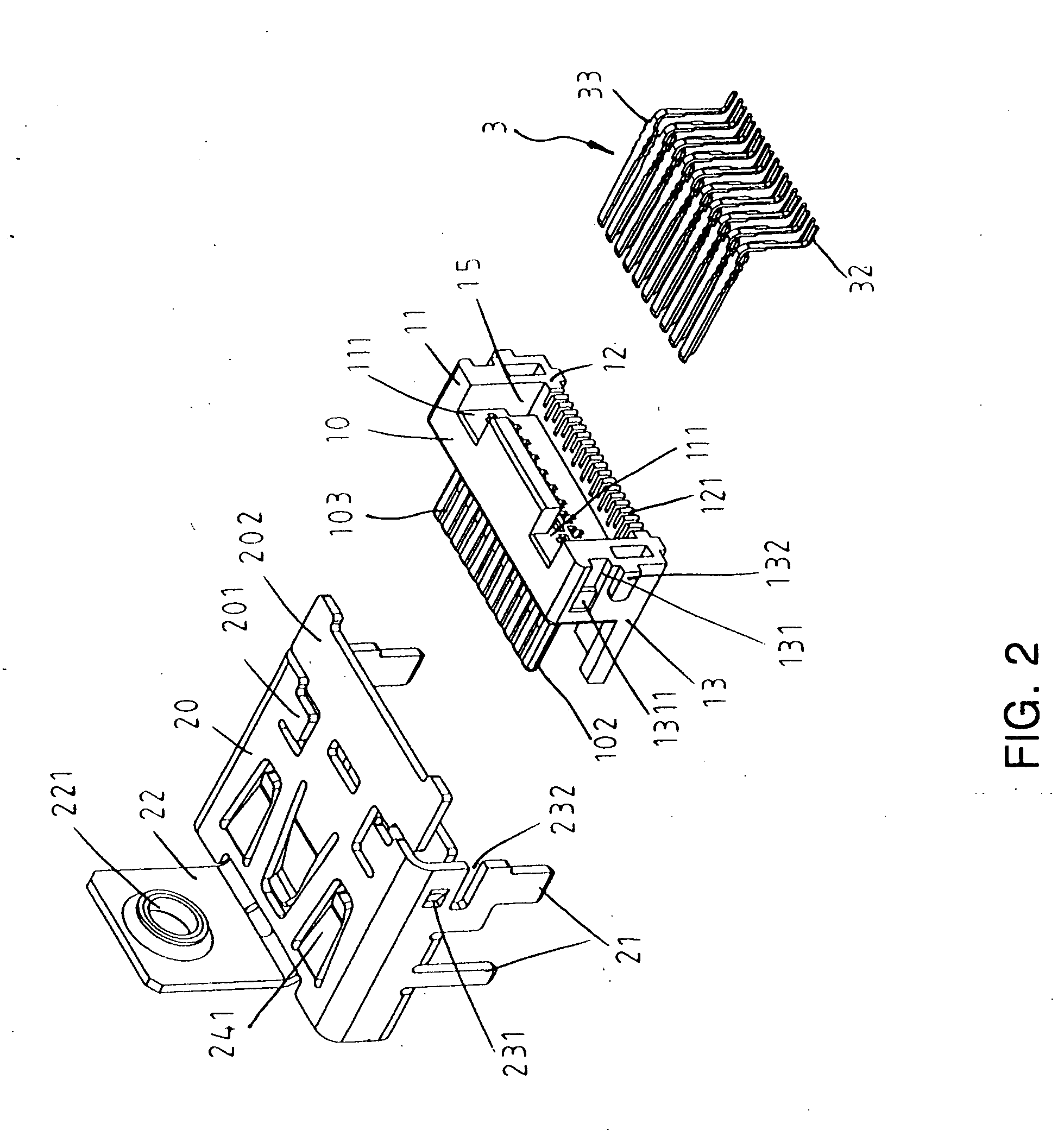

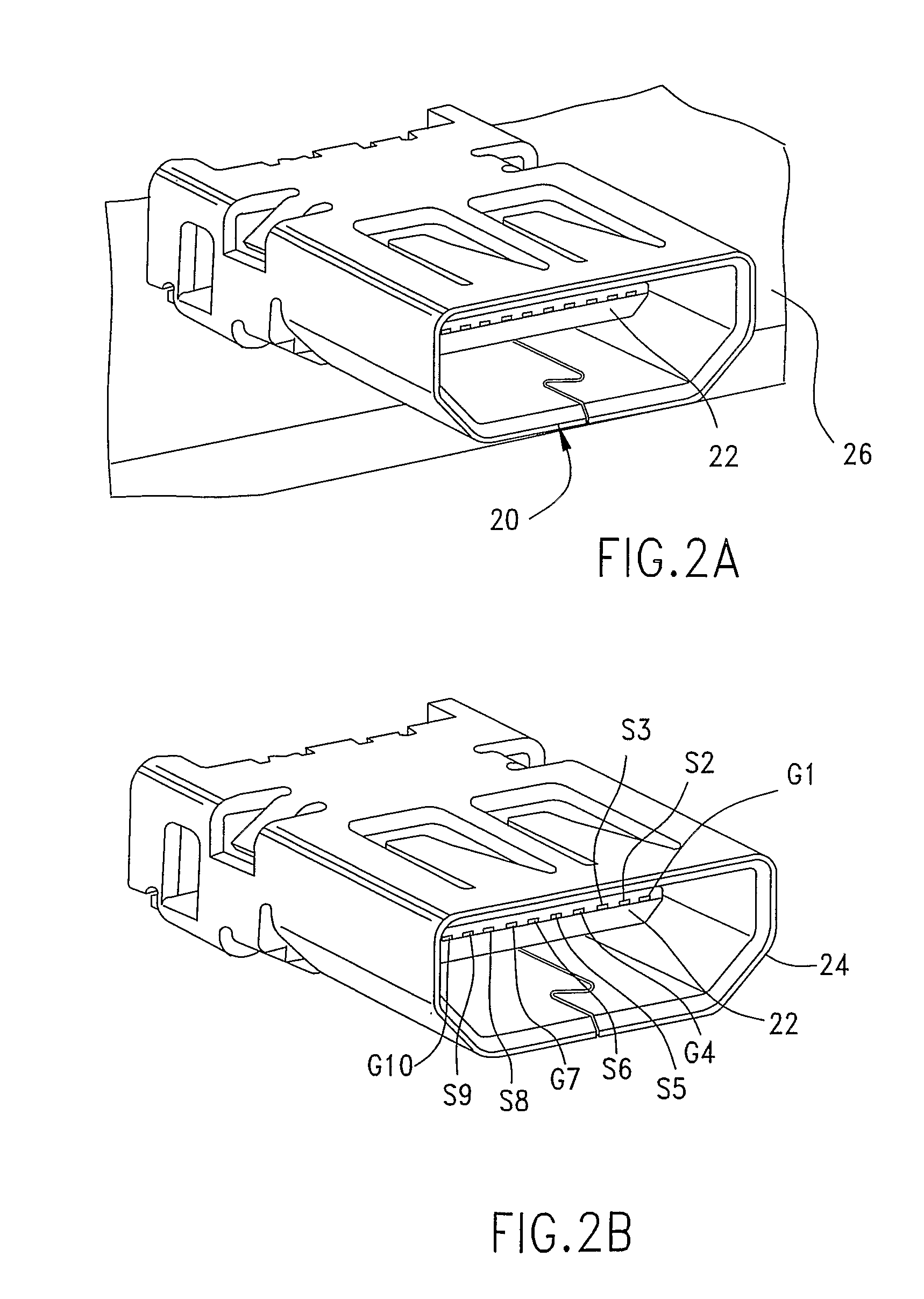

HDMI connector

InactiveUS20050186843A1Quality improvementHigh fidelity video signalTwo-part coupling devicesCoupling protective earth/shielding arrangementsEngineeringFront edge

The present invention provides a high definition multimedia interface (HDMI) connector with various types through combinations of the outer metallic shells and the inner terminal modules of the HDMI connector. The outer metallic shell may exhibit various types including with or without the presence of flange on the front edge of said outer metallic shell and with or without the application of the surface mount technology (SMT) to the solder pins. Therefore, the HDMI of the present invention is applicable to provide different types of connector to fulfill market requirements through the combinations of different types of module.

Owner:ADVANCED CONNECTEK INC

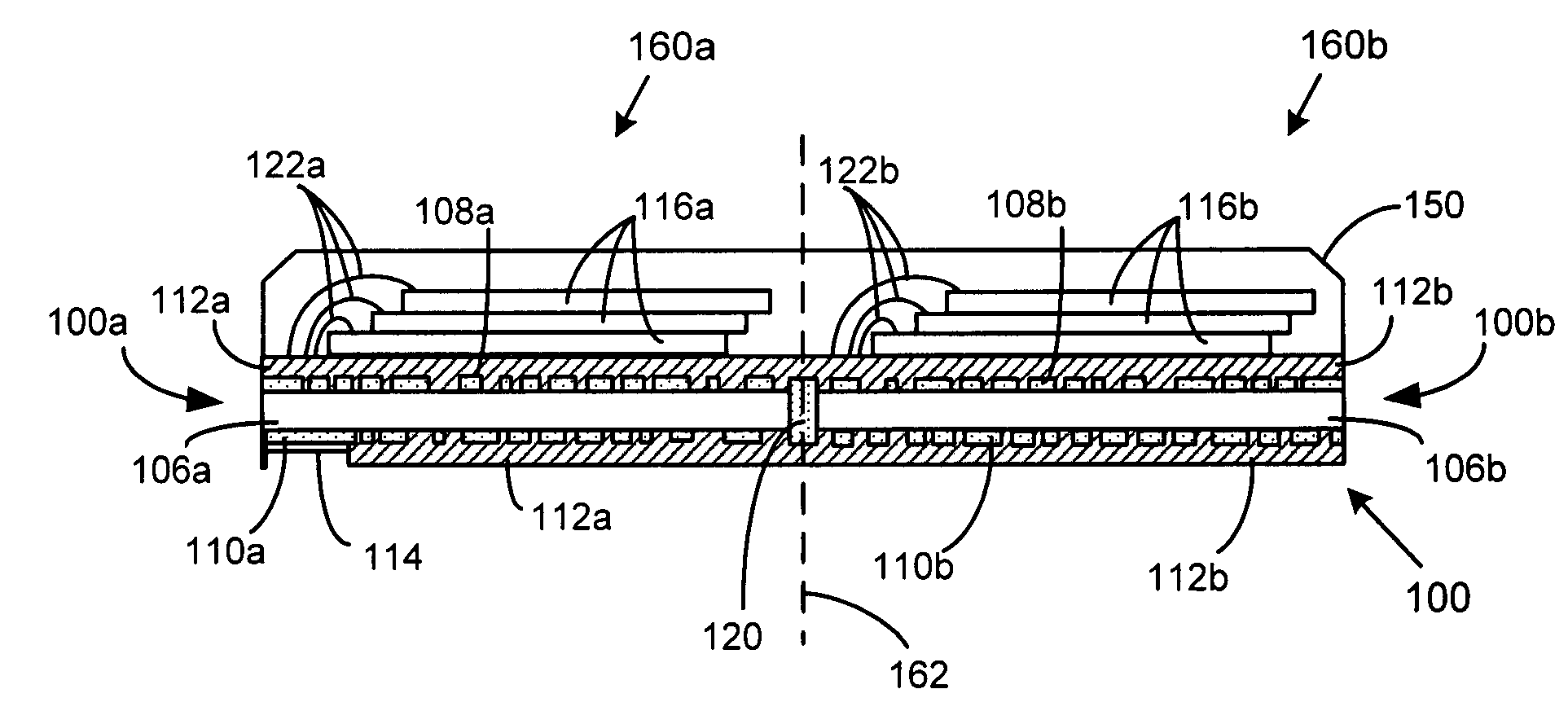

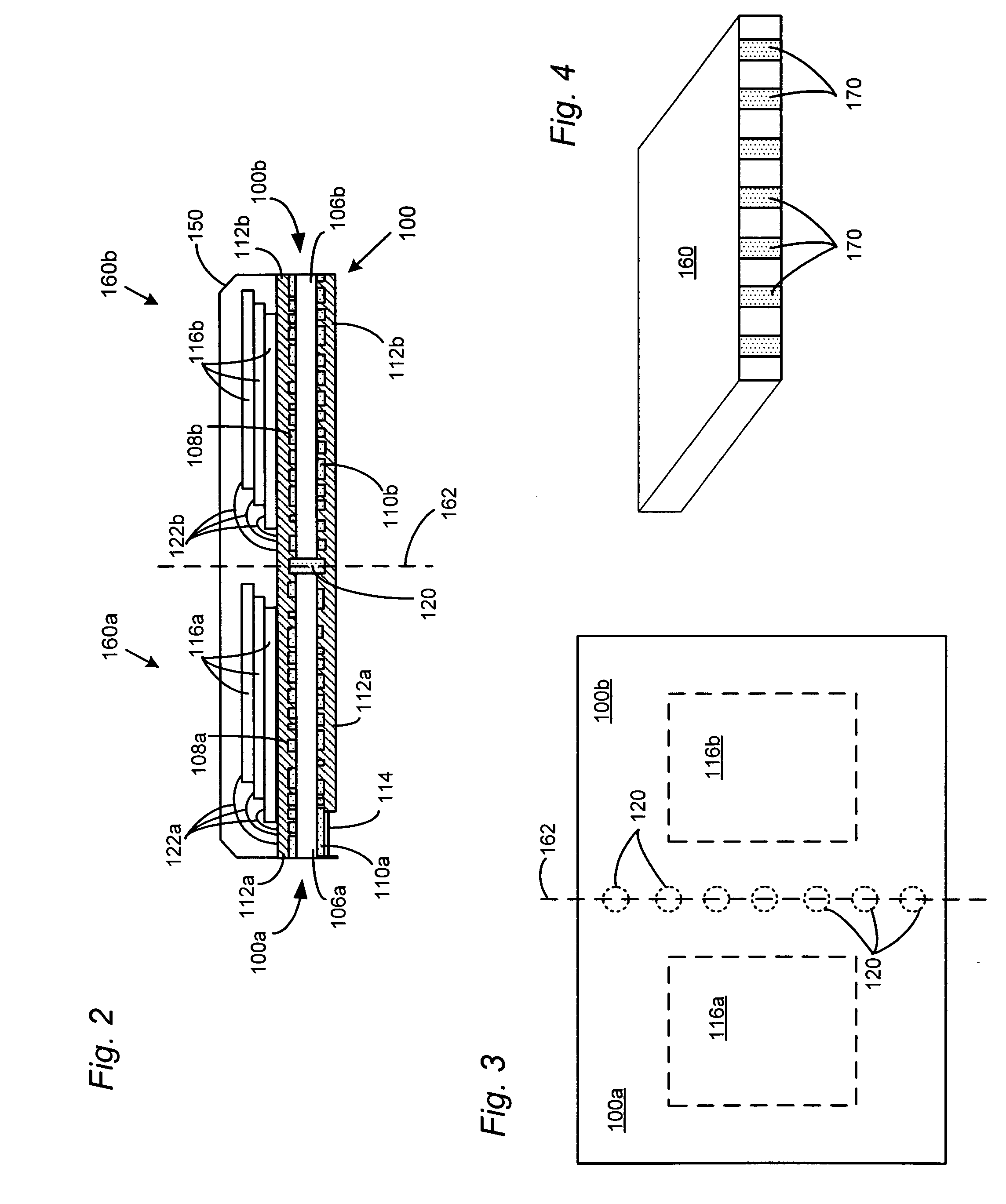

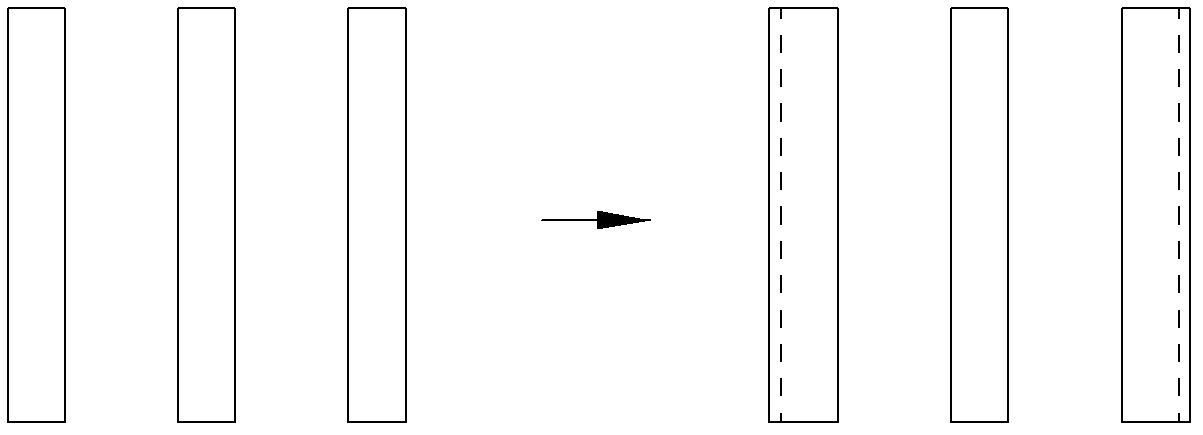

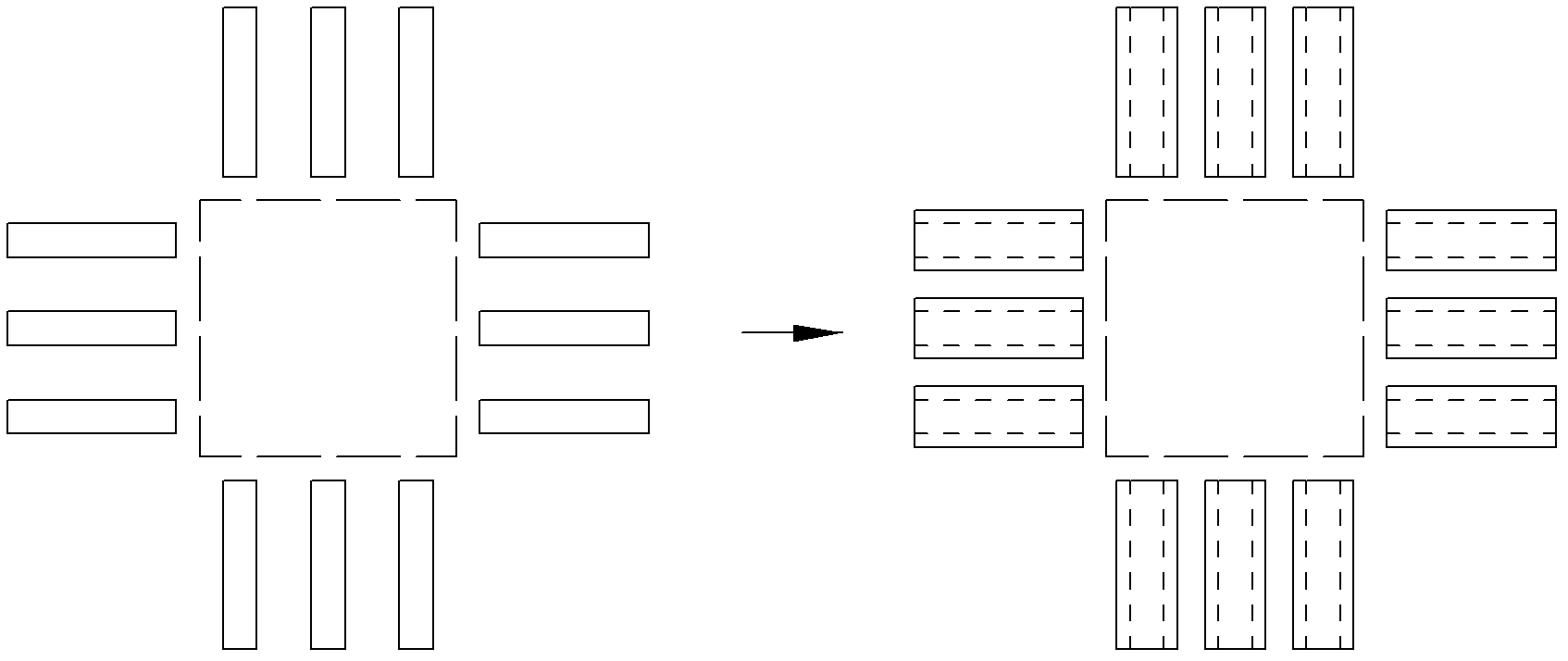

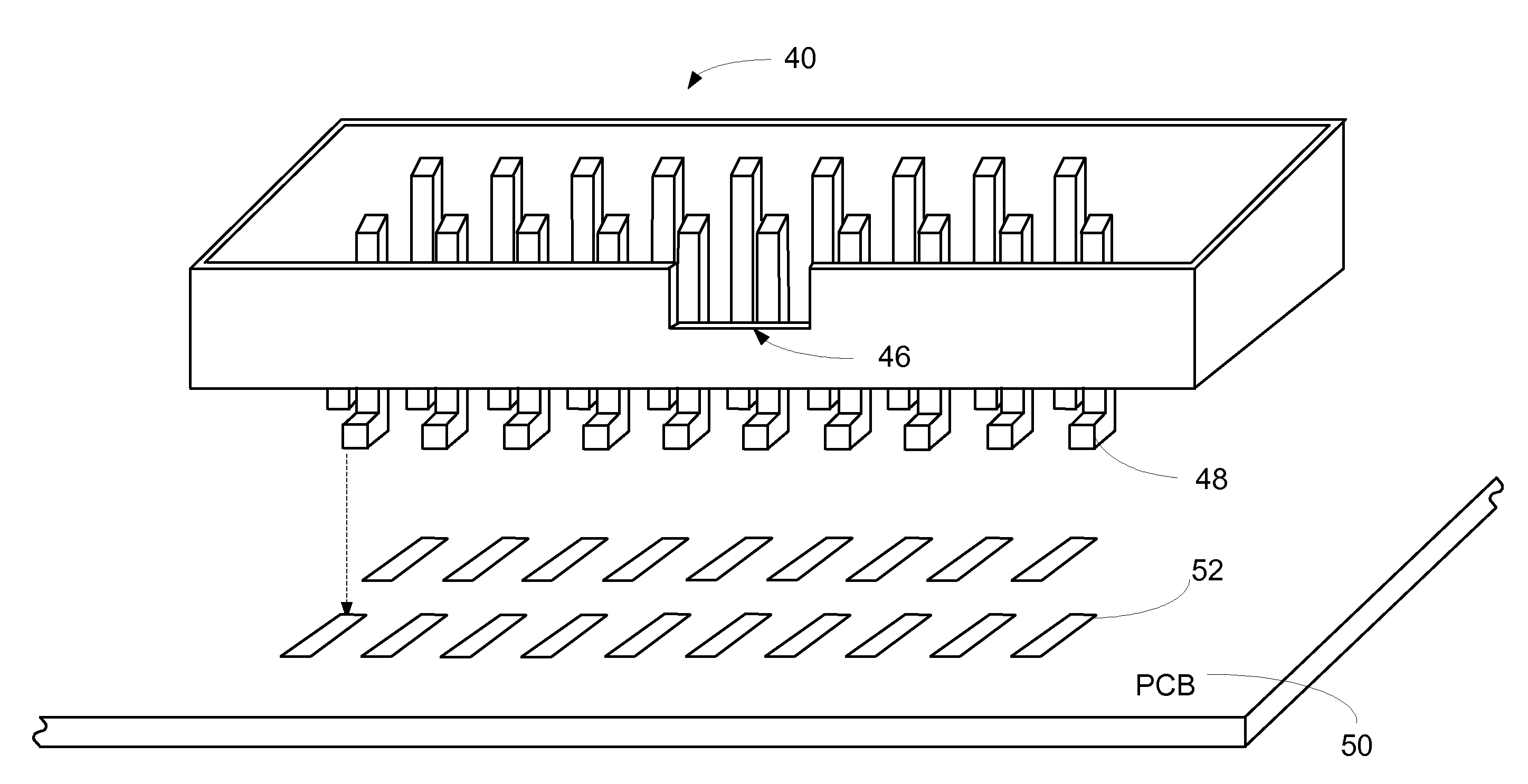

Interconnected IC packages with vertical SMT pads

InactiveUS20070158799A1Semiconductor/solid-state device detailsPrinted circuit aspectsElectrical conductorSurface mounting

An electronic component is disclosed including a plurality of semiconductor packages soldered together in a side-by-side configuration. The packages are batch processed on a substrate panel. The panel includes a plurality of through-holes drilled through the panel and subsequently filled with metal such as copper or gold. These filled through-holes lie along the cut line between adjacent packages so that, upon singulation, the filled through holes are cut and a portion of the filled through-holes are exposed at the side edges of the singulated packages. These exposed portions of the filled through-holes form vertical surface mount technology (SMT) pads. After the semiconductor packages are singulated and the SMT pads are defined in the side edges, SMT is used to solder the SMT pads of a first semiconductor package to the respective SMT pads of a second semiconductor package to structurally and electrically couple the two packages together side-by-side.

Owner:SANDISK TECH LLC

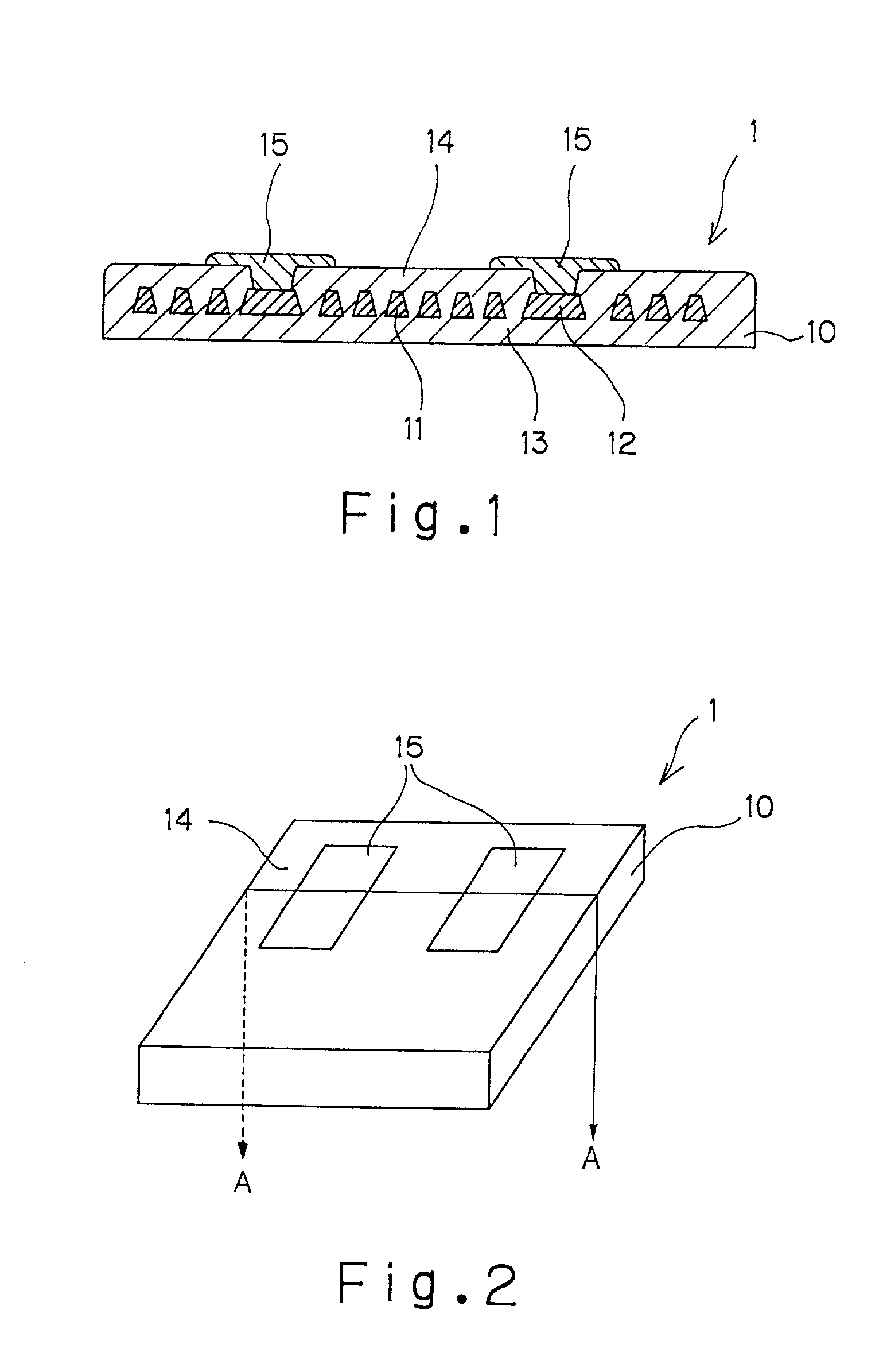

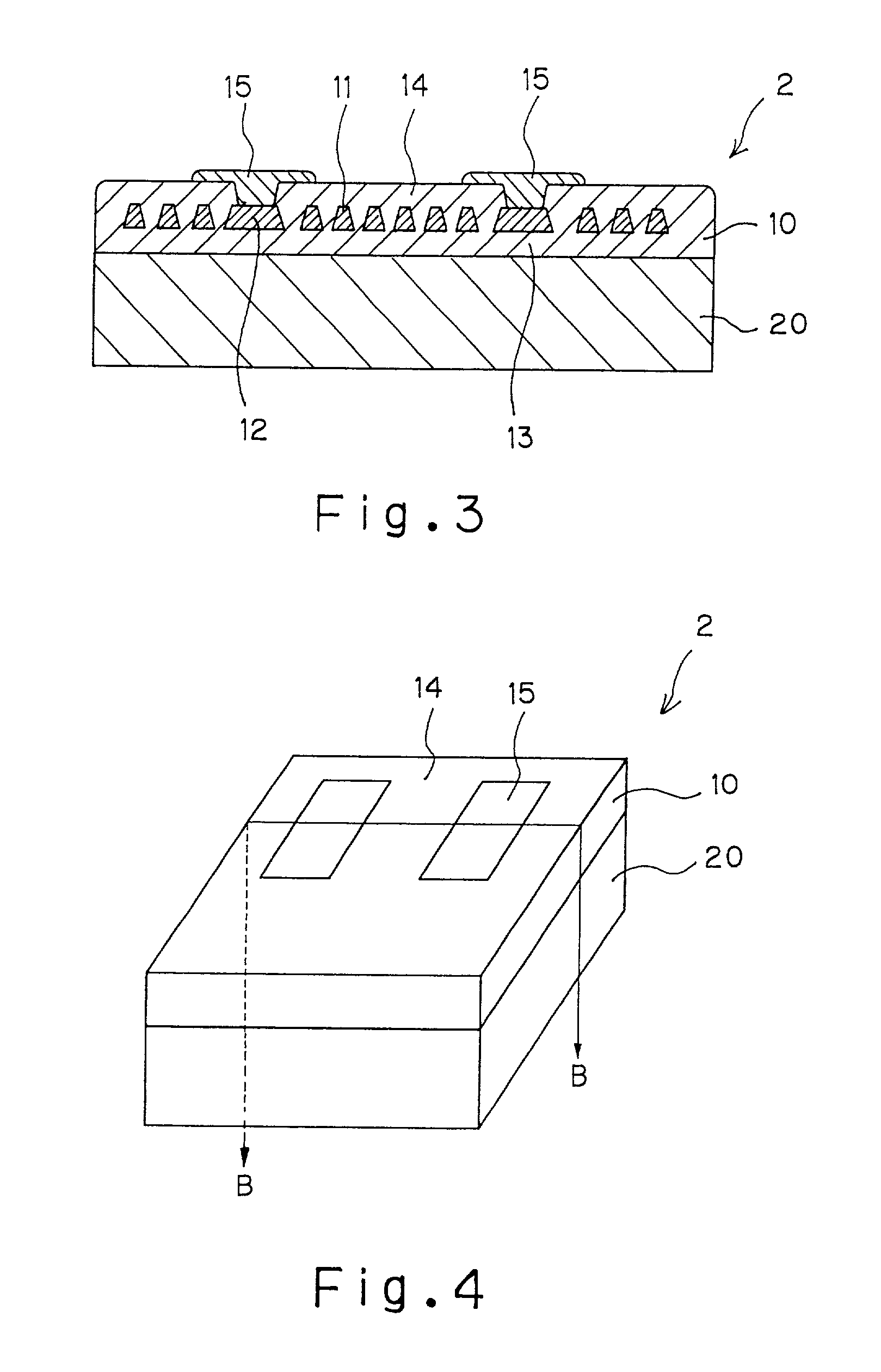

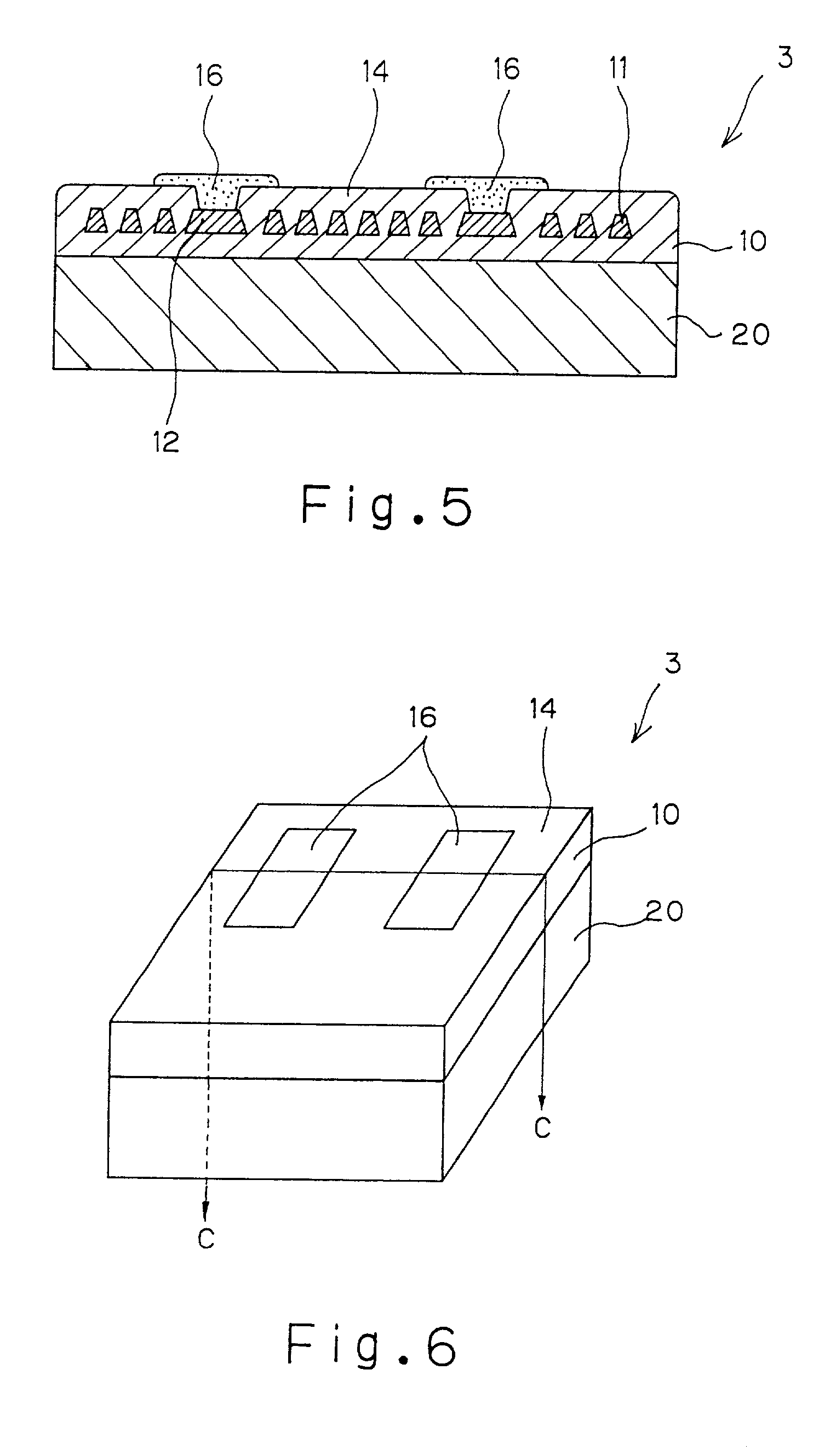

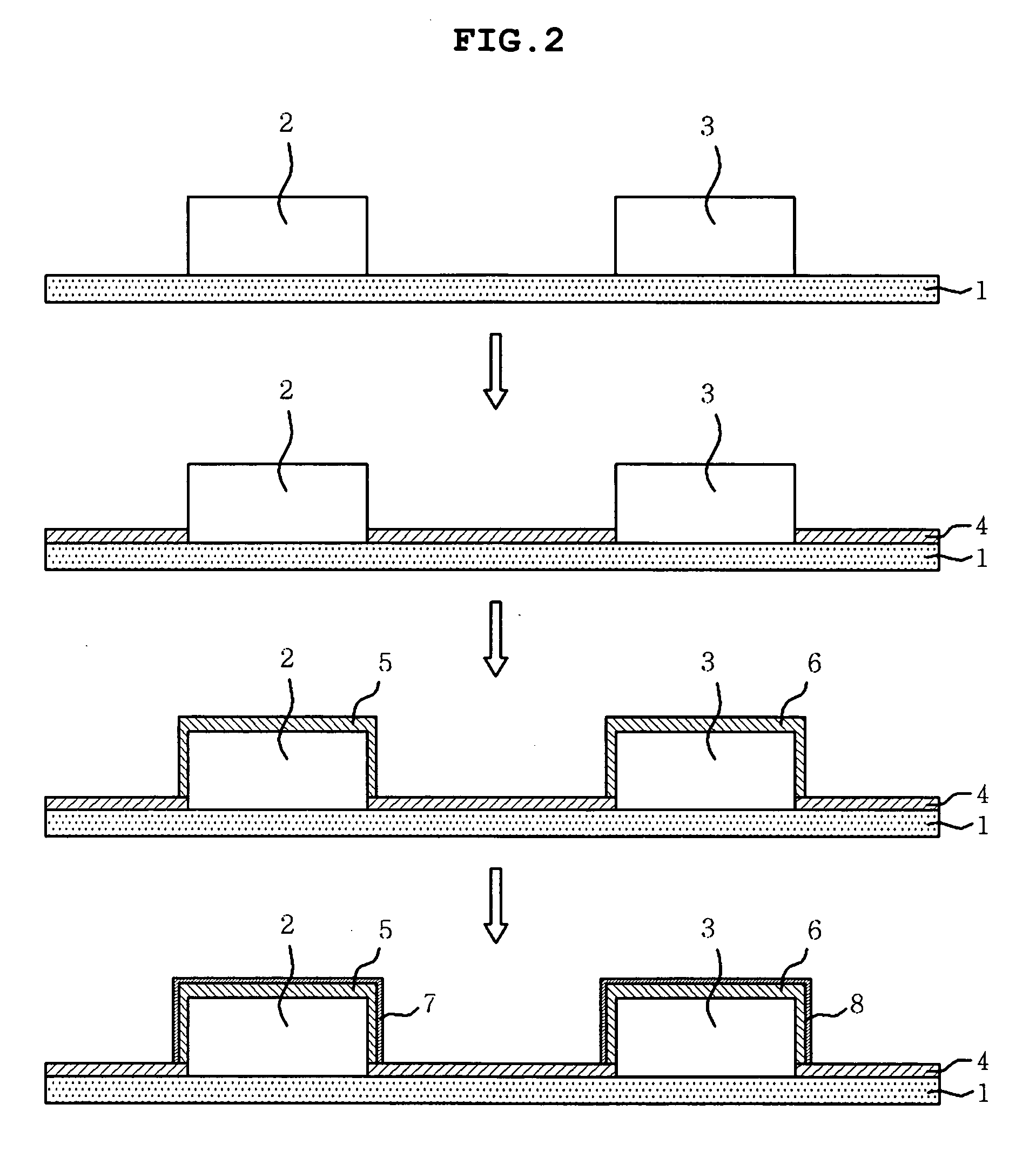

Surface mounting type planar magnetic device and production method thereof

InactiveUS20010024739A1Reduce loss by DC resistance of the coilIncrease the sectionTransformers/inductances coils/windings/connectionsRecord information storageSurface mountingEngineering

This invention provides a surface mounting type planar magnetic device comprised of upper ferrite magnetic film, lower ferrite magnetic film and a planar coil interposed therebetween. For applying surface mount technology, an opening is formed in the upper ferrite magnetic film above a coil terminal portion and then, an external electrode conductive with the coil terminal portion through the opening is formed on the upper ferrite magnetic film. Further, this surface mounting type planar magnetic device is of a thin structure and can be mounted on the surface of a printed board. Its power loss is small, its inductance is large, its frequency characteristic is excellent, the disparity of the characteristic is small and its reliability is excellent.

Owner:KK TOSHIBA +1

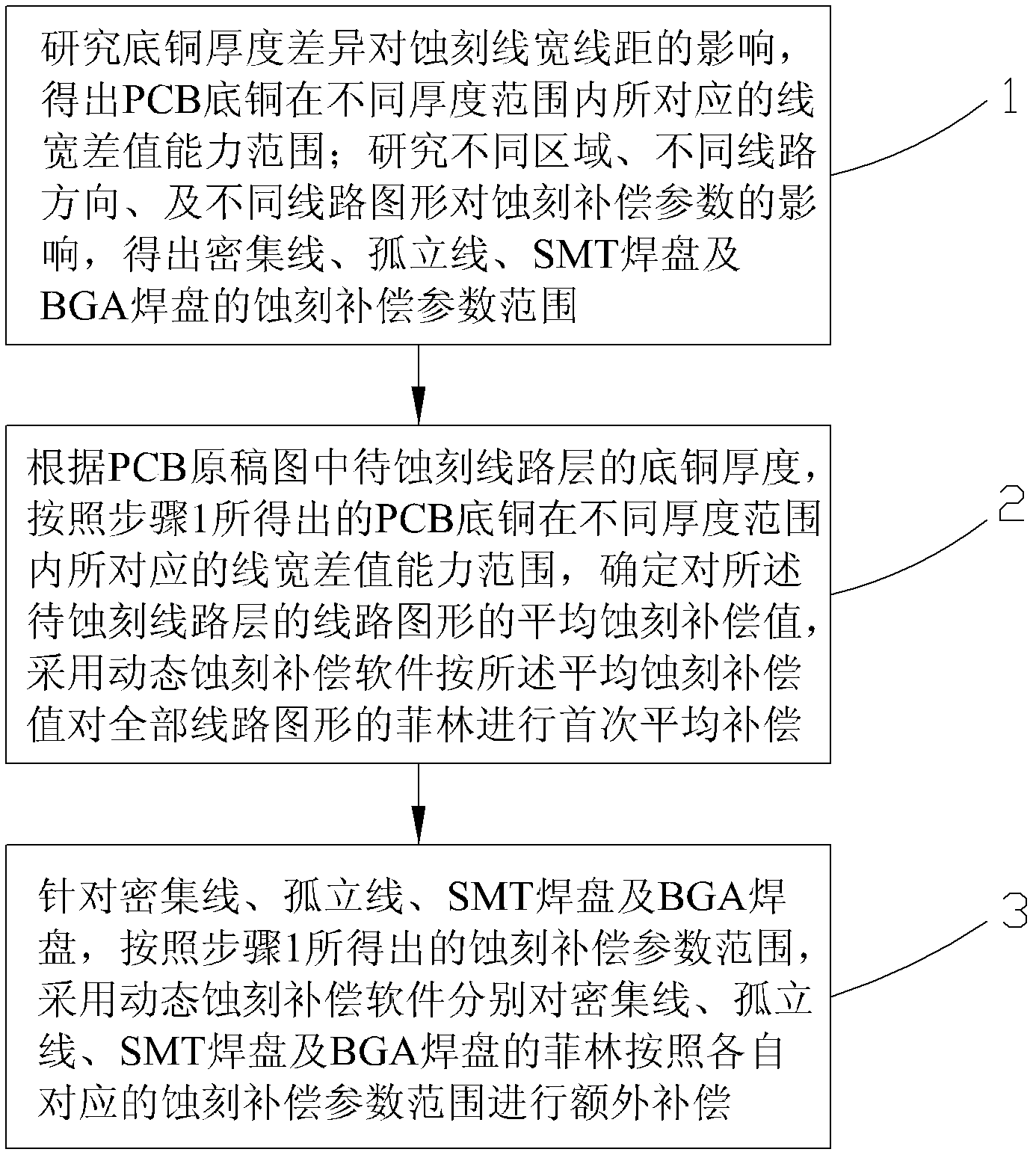

Method for improving graphic precision of substractive process printed circuit board (PCB) by adopting dynamic etching compensation method

InactiveCN102573309AImprove production efficiencyAvoid multiple revisionsConductive material chemical/electrolytical removalGraphicsLine width

The invention relates to a method for improving the graphic accuracy of a substractive process printed circuit board (PCB) by adopting a dynamic etching compensation method. The method comprises the following steps of: step 1: studying the influence of thickness differences of base copper over etching line width and line distance so as to obtain the line width difference value ability ranges corresponding to the PCB base copper in different thickness ranges, and studying the influence of different areas, different line directions and different line graphs over etching compensation parameters so as to obtain etching compensation parameter ranges of compact lines, isolated lines, surface-mount technology (SMT) bonding pads and ball grid array (BGA) bonding pads; step 2: determining an average etching compensation value according to step 1 in accordance with the base copper thickness in an original draft of the PCB so as to firstly and averagely compensate films of all line graphs; and step 3: additionally compensating films of the compact lines, the isolated lines, the SMT bonding pads and the BGA bonding pads by adopting dynamic etching compensation software. By adopting the method disclosed by the invention, the influence of the base copper thickness, the etching uniformity and the like over the line width of the areas such as the compact lines, the isolated lines, the SMT bonding pads and the BGA bonding pads can be eliminated.

Owner:DONGGUAN SHENGYI ELECTRONICS

Method for plating printed circuit board and printed circuit board manufactured therefrom

InactiveUS20070104929A1Reduce thicknessDecreasing solderabilitySemiconductor/solid-state device detailsSolid-state devicesElectroless nickelCrazing

Disclosed herein are a method for plating a printed circuit board and the printed circuit board manufactured therefrom. In the method, a bare soldering or wire bonding portion of a copper (Cu)- or copper alloy layer, is plated with palladium (Pd) or a palladium alloy, and then gold (Au) or a gold alloy is deposited over the palladium or palladium alloy plated layer by an electroless substitution plating process based on ionization tendency. Having superior hardness, ductility and corrosion resistance, palladium is suitable for use between a connector and a substrate and meets requirements for the printed circuit board even when applied to a low thickness, greatly reducing the process time. Accordingly, the problem of black pad, which frequently occur on electroless nickel and electroless gold finish upon surface mount technology, can be perfectly solved. Particularly, fatal bending cracks can be prevented from occurring in the rigid-flexible or flexible printed circuit boards.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD +1

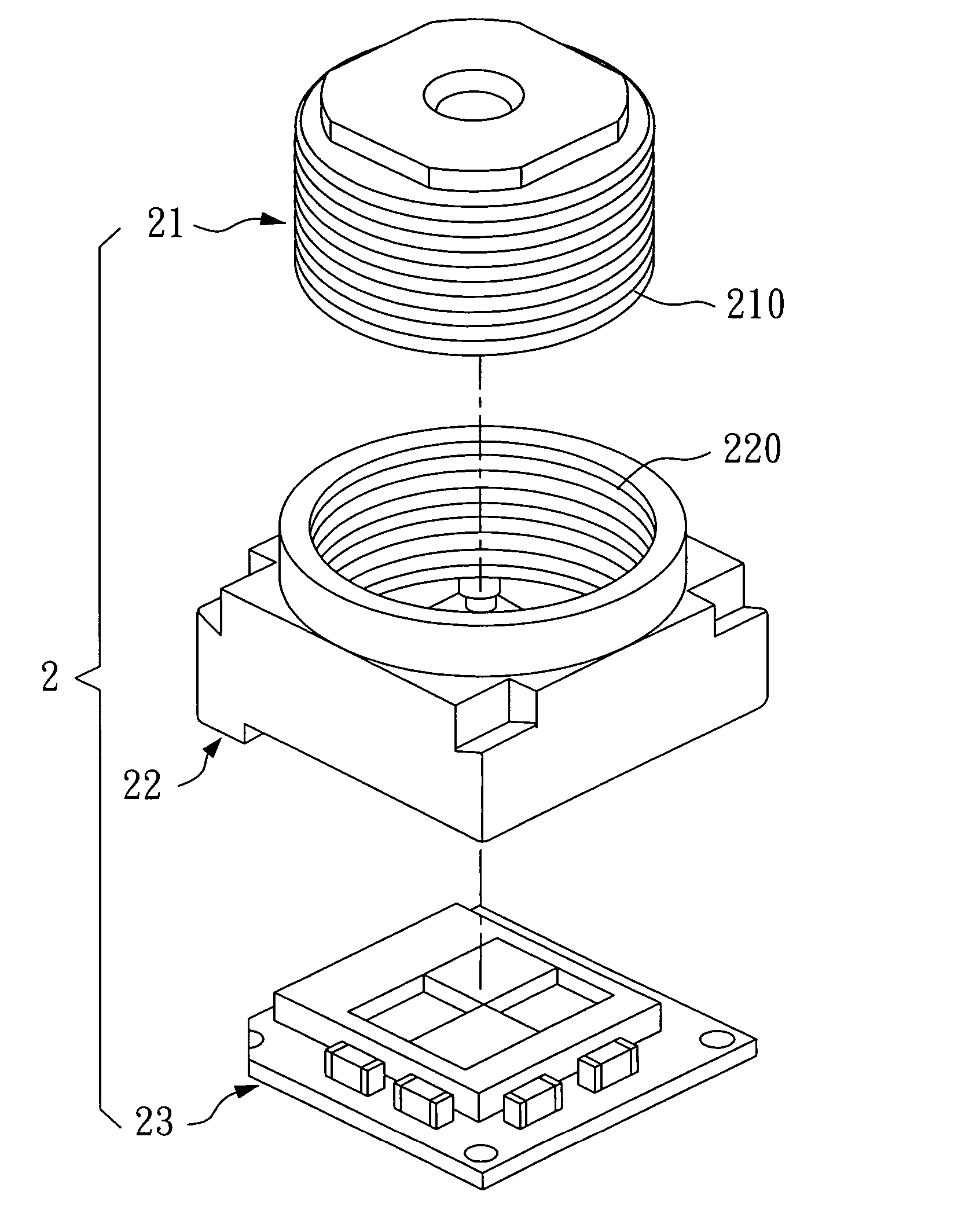

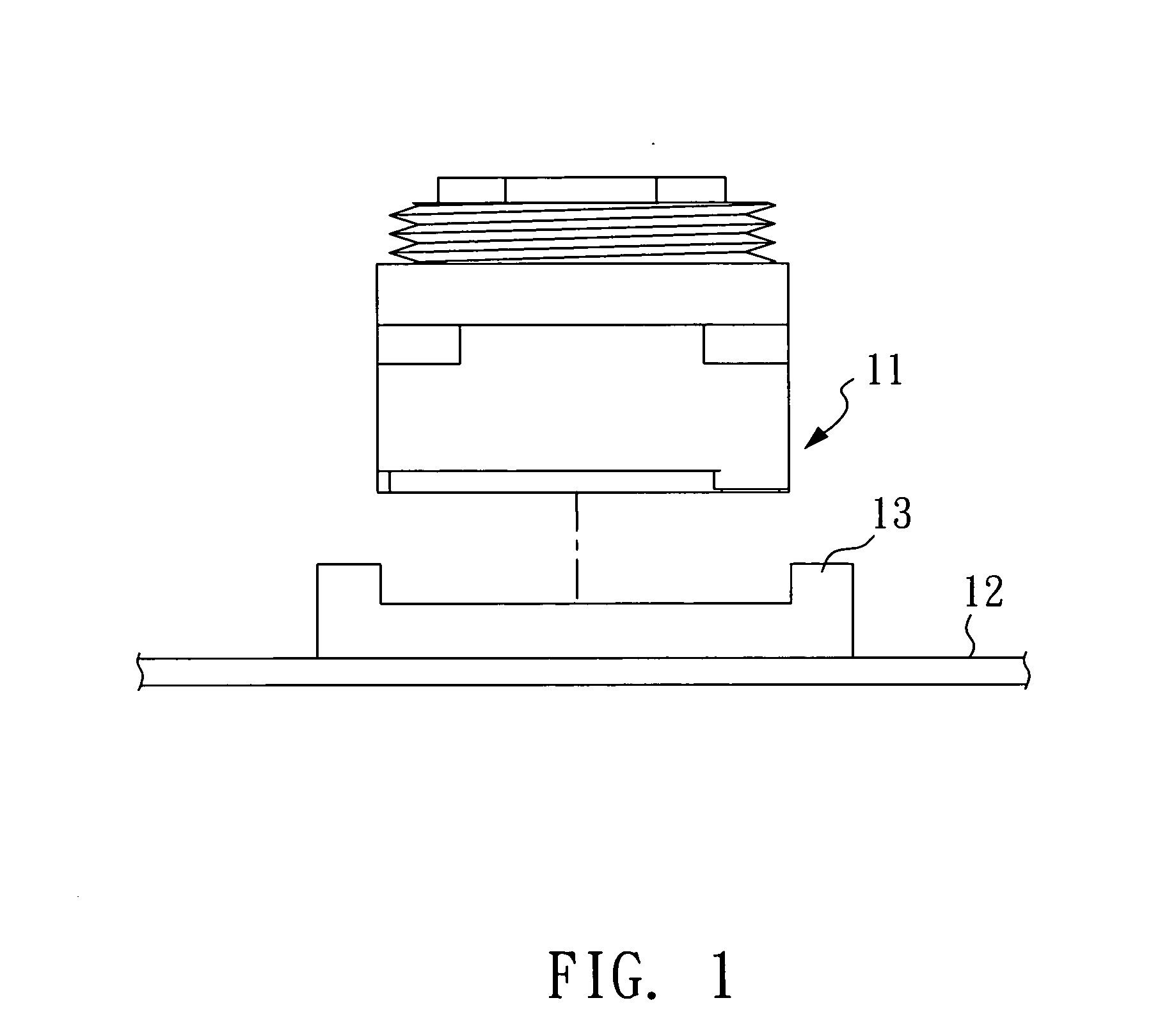

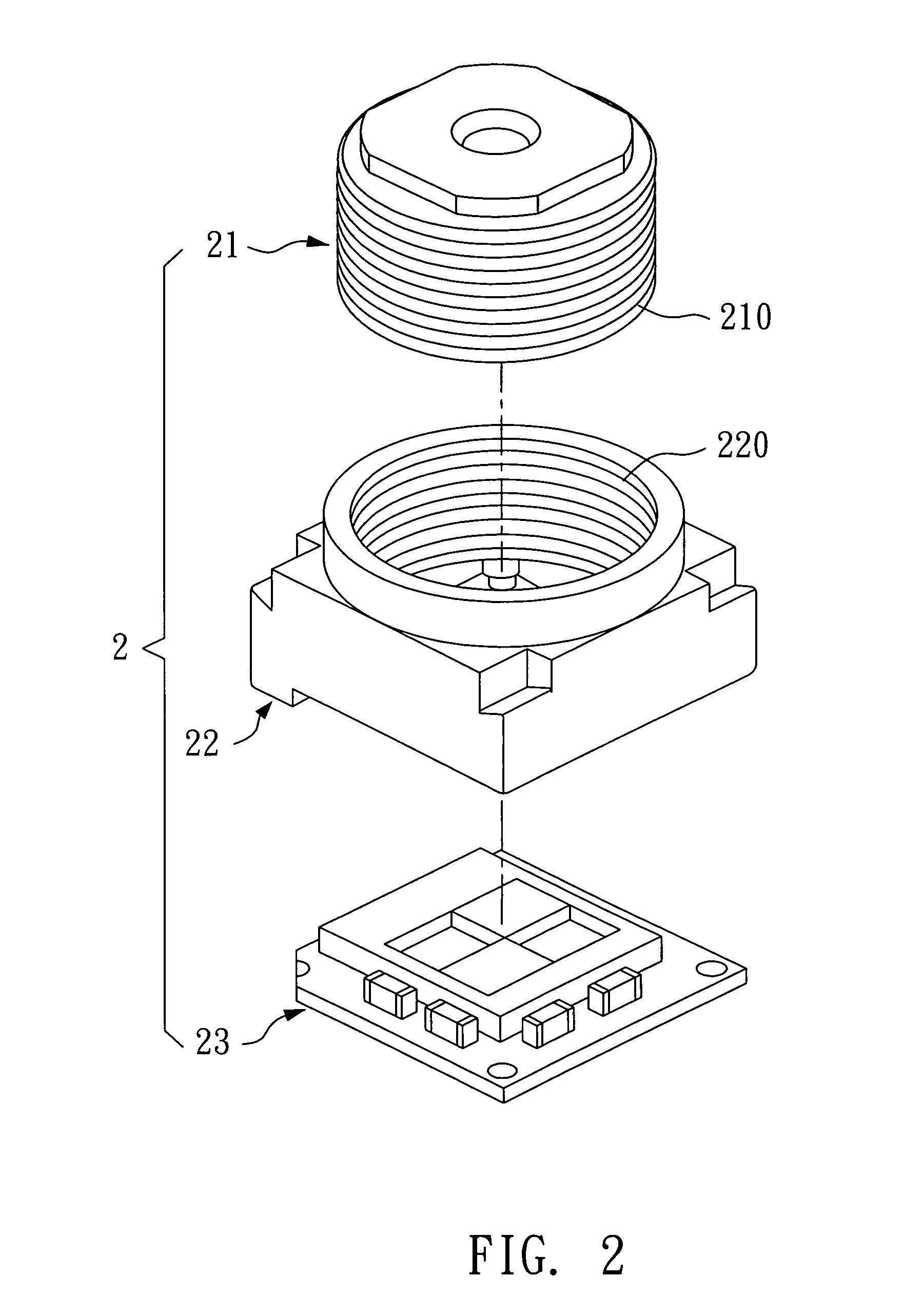

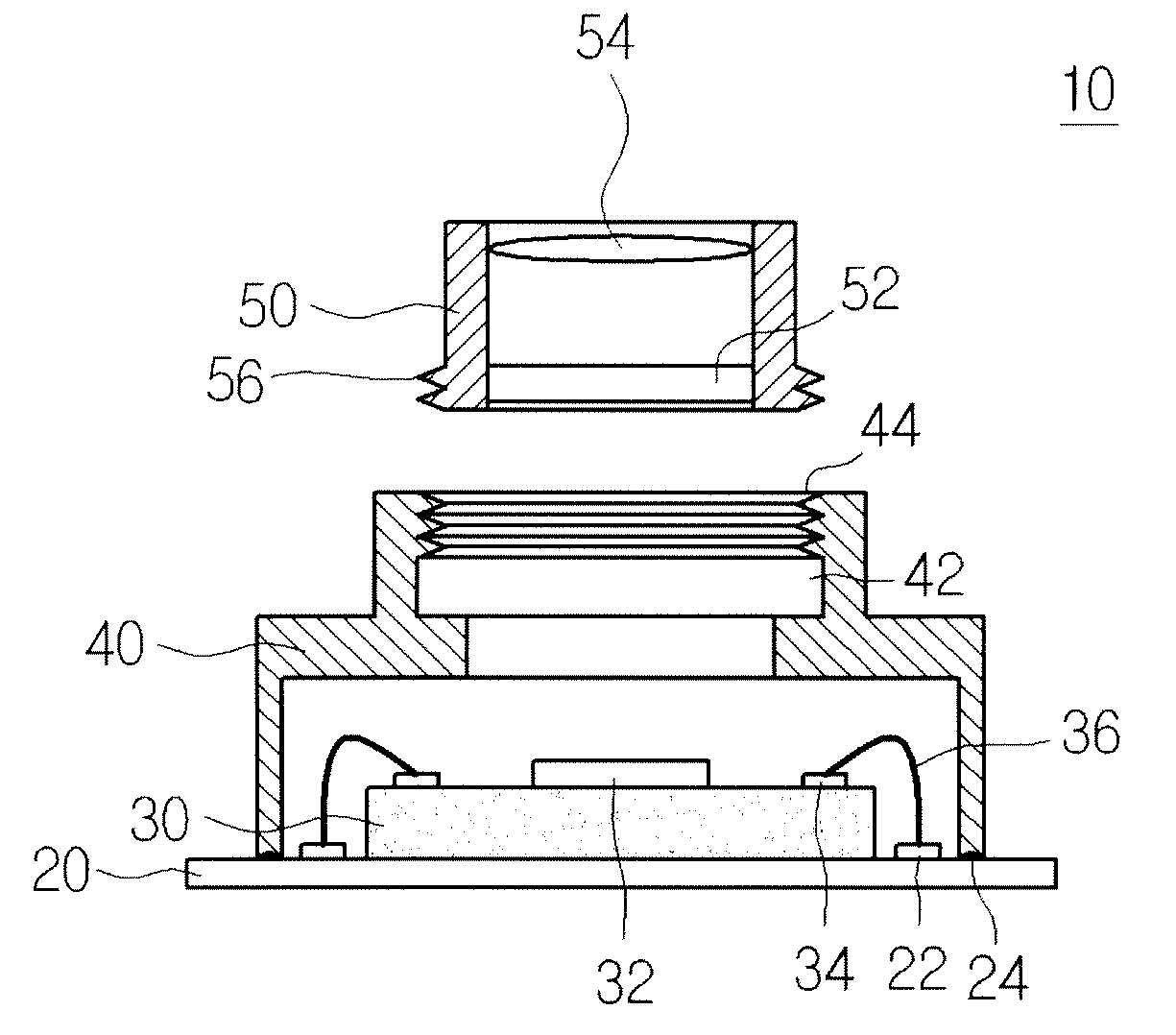

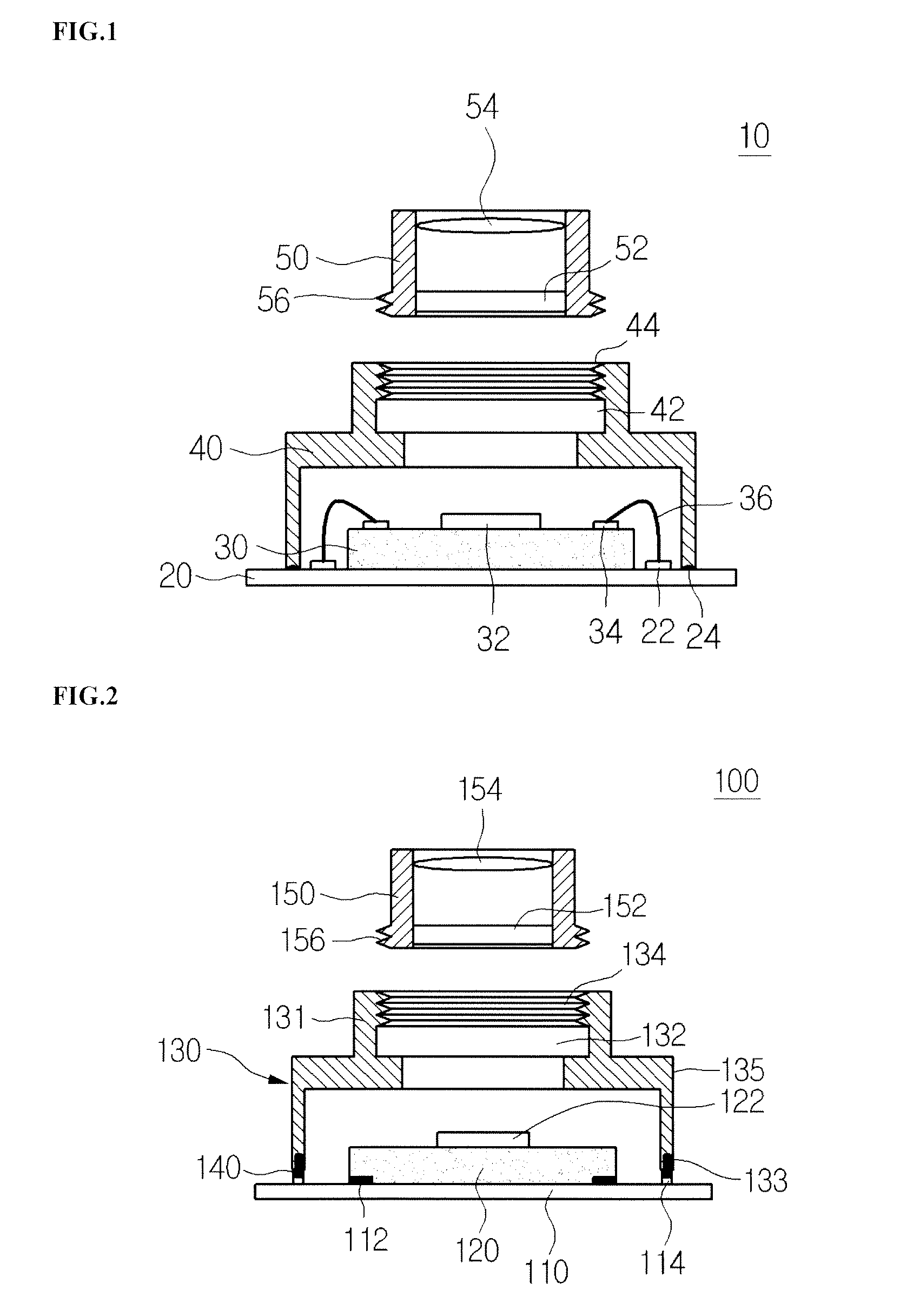

Camera module and the manufacturing process thereof

InactiveUS20060197862A1High materialTelevision system detailsColor television detailsManufacturing technologySurface mounting

This invention provides a camera module and a manufacturing process thereof. The camera module is compatible with surface mount technology (SMT) machines for bonding onto a main board. The camera module comprises a lens, a lens holder, and an image sensor device. The lens and the lens holder are connected to each other, and the image sensor device is located under the lens holder. The lens is formed from a heatproof material for enduring the high-temperature process of an SMT soldering machine. The lens holder is also formed from a heatproof material for enduring the high-temperatures process of the SMT soldering machine. The camera module can thus be a surface mount device (SMD) to be bonded by SMT machines onto the main board of a system.

Owner:PREMIER IMAGE TECH

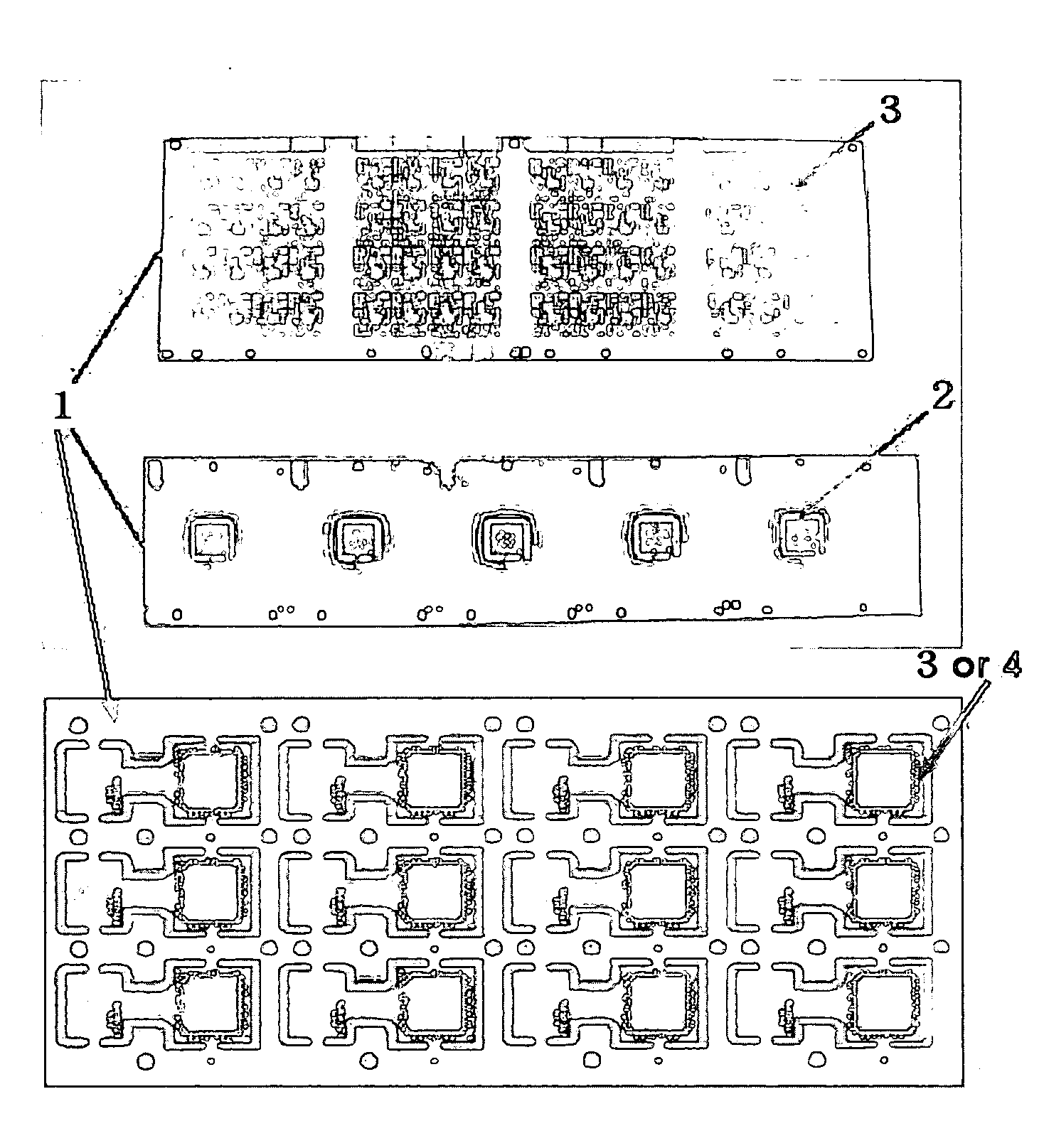

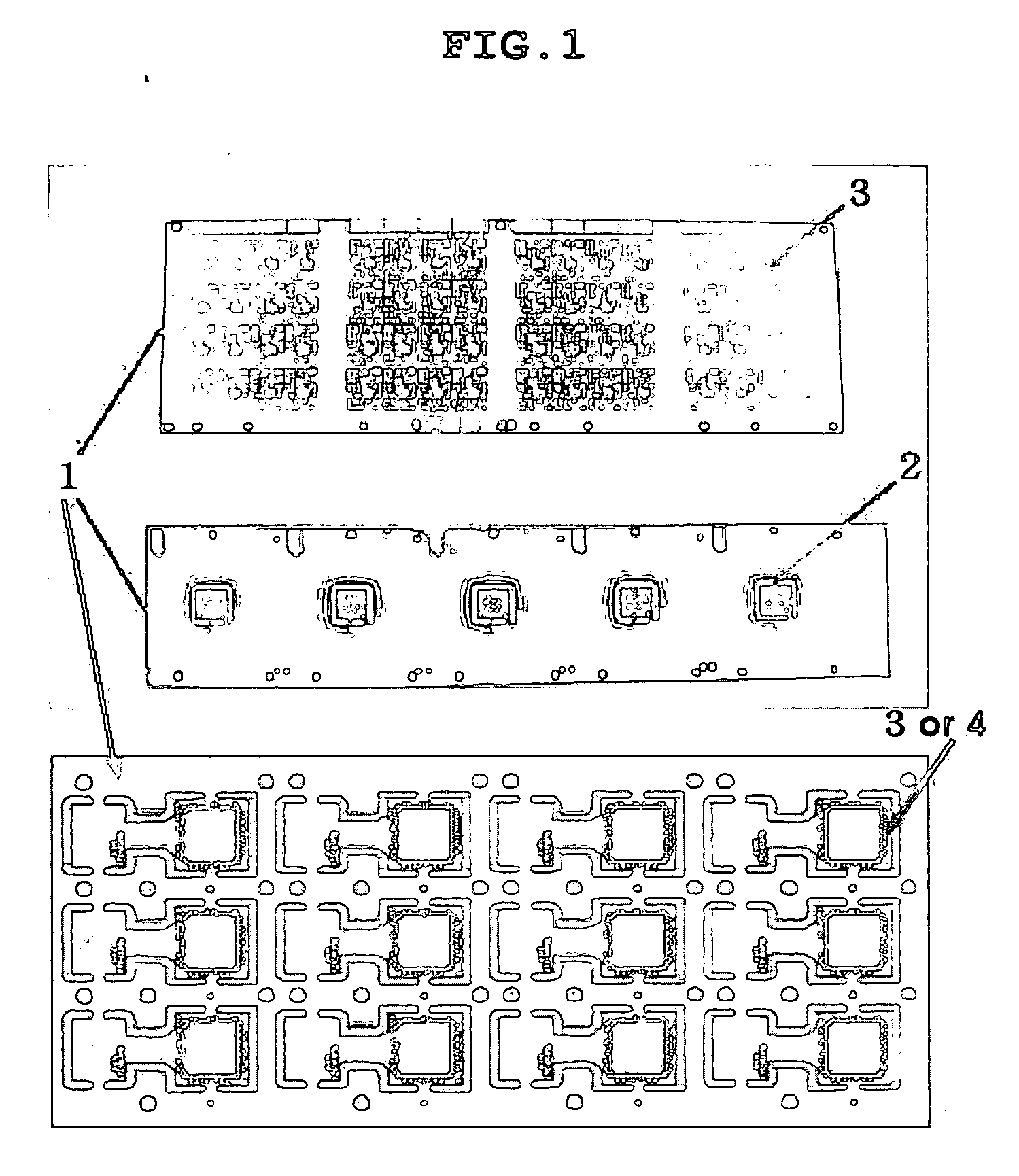

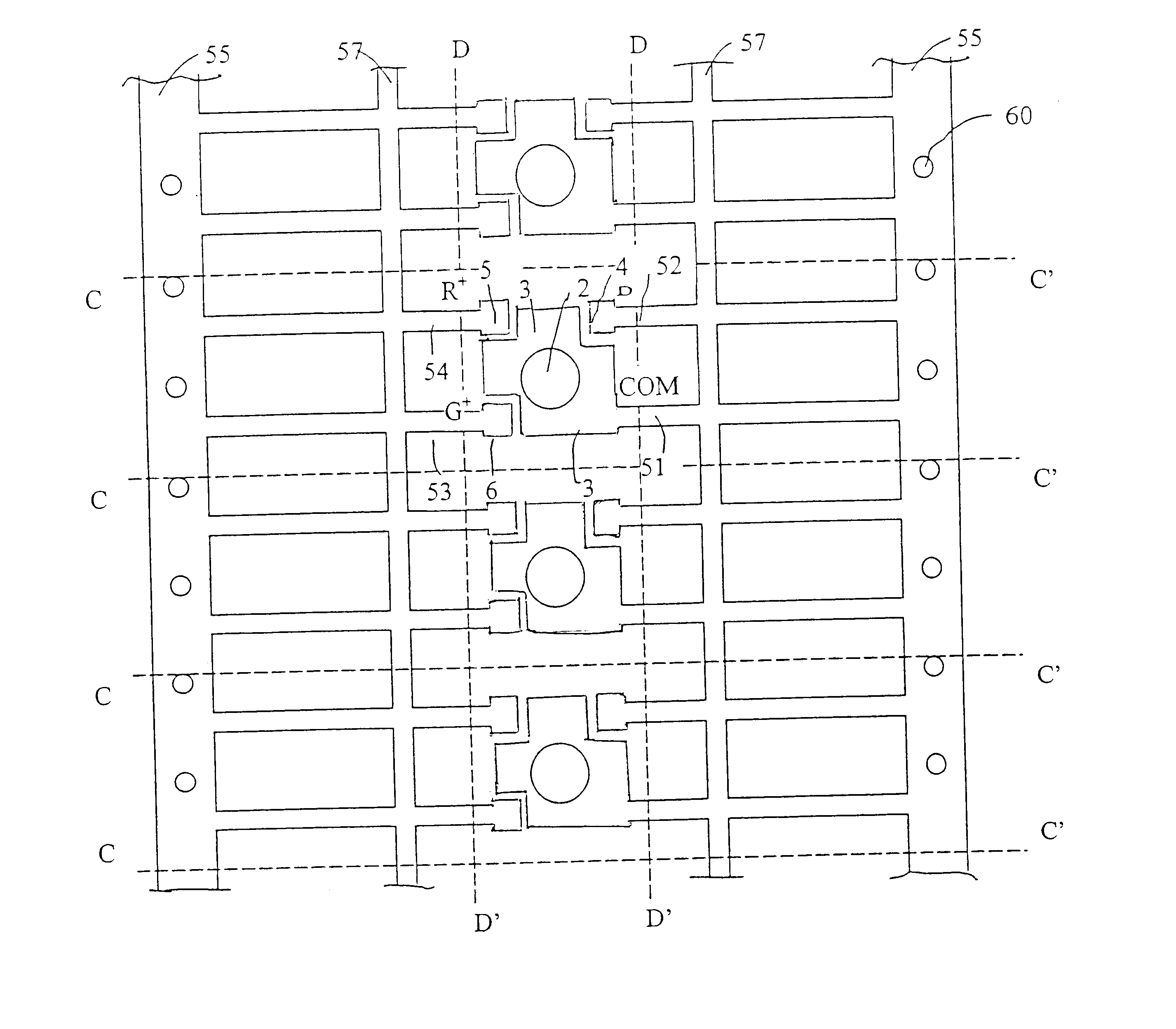

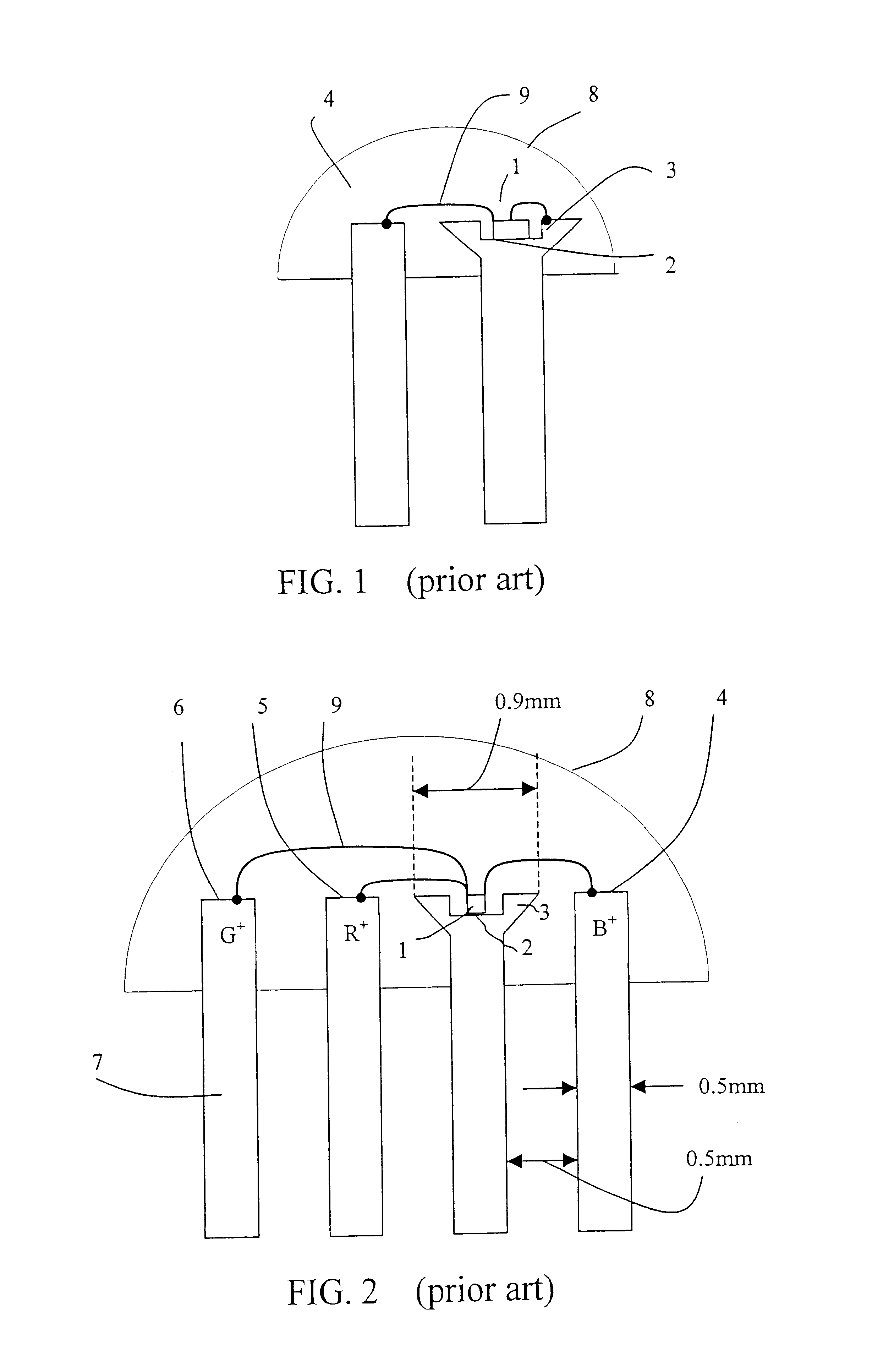

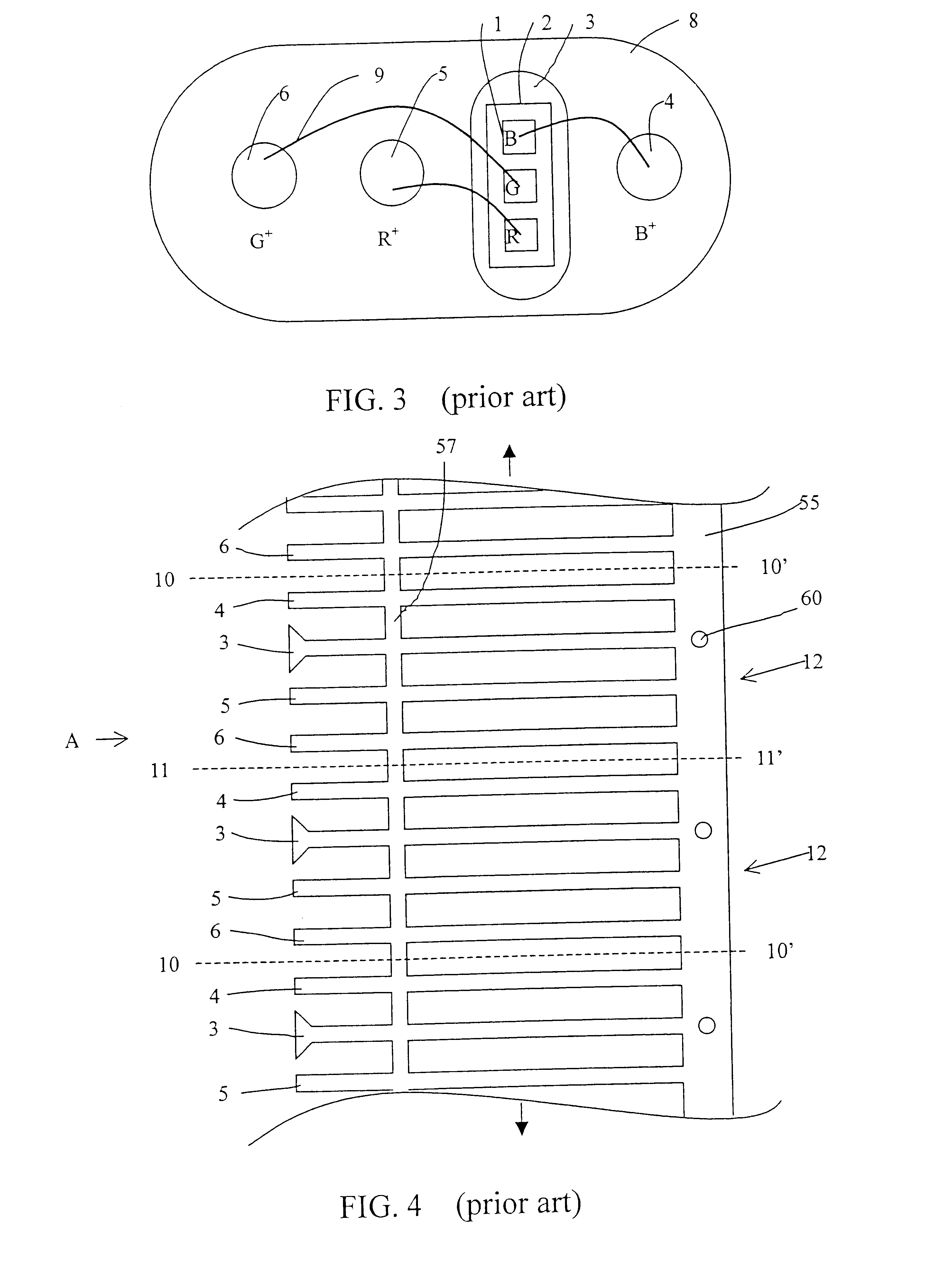

Package socket and package legs structure for led and manufacturing of the same

InactiveUS6621223B1Reduce widthReduce areaSemiconductor/solid-state device detailsSolid-state devicesEpoxyLead bonding

The present invention discloses a structure of package socket and package legs for three-primary-color LED and the manufacturing method of this structure. One of the leg forms a die bonding seat and a common negative bonding pad, the other three legs form positive bonding pads. Said negative and positive bonding pads are arranged in the four corners of a square, with two legs stretch to the right, the other two legs stretch to the left. Then punch by a punch machine with a tooling to form an array of the structures, or by electrode plating or by etching to form the array. The four legs are then bending 90° to one side near the bonding pads such that it can stand alone. After die bond and wire bond has performed, the LED is sealed by transparent epoxy molding, and then cut to single structures, or the structure is cut to single structures before the LED is sealed by transparent epoxy. The other structure is by further bending the four legs near the end of the legs to satisfy surface mount technology (SMT).

Owner:HEN CHANG HSIU

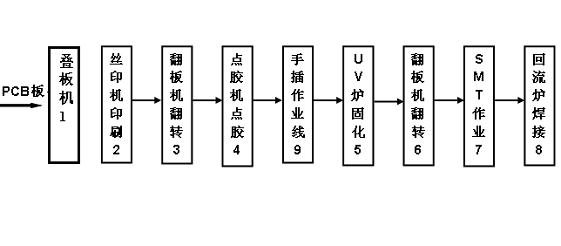

PCB (Printed Circuit Board) production line combining manual in process processing and paster processing

ActiveCN101977484AShorten production timeReduce turnoverPrinted circuit assemblingElectrical componentsProduction lineUV curing

The invention discloses a PCB (Printed Circuit Board) production line combining a manual in process processing and paster processing, which is characterized by comprising a board feeding machine (1), a screen printing machine (2), as well as a first board overturning machine (3), an adhesive dispenser (4), a UV curing oven (5), a second board overturning machine (6), SMT (Surface Mounting Technology) equipment (7) and a reflow soldering heating curing oven (8). The first board overturning machine (3) is responsible for overturning a PCB subjected to low-temperature solder past printing of the screen printing machine (2) and then dispensing an adhesive, and after adhesive dispensing, a UV adhesive with a large long-pin device is cured under UV irradiation; after the PCB is overturned by the second board overturning machine, the step of paster production begins; and finally, PCB heating curing is finished in the reflow soldering heating curing oven (8). The invention combines SMT operation and manual in process operation together to realize a double-faced reflow soldering technology, solves the defects of traditional wave-soldering technology, and saves energy since reflow soldering is performed only twice and elements are heated twice.

Owner:NANJING PANDA ELECTRONICS MFG

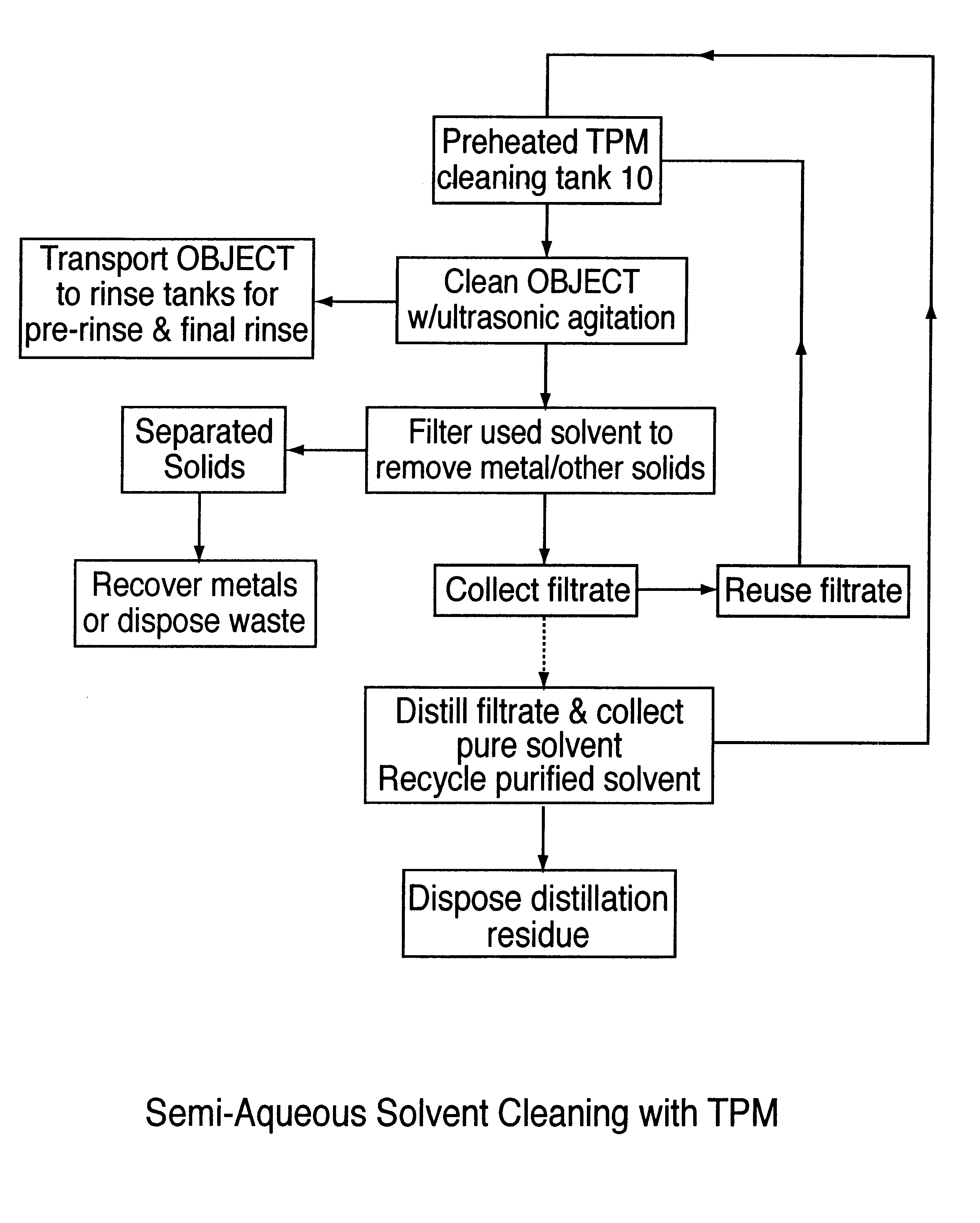

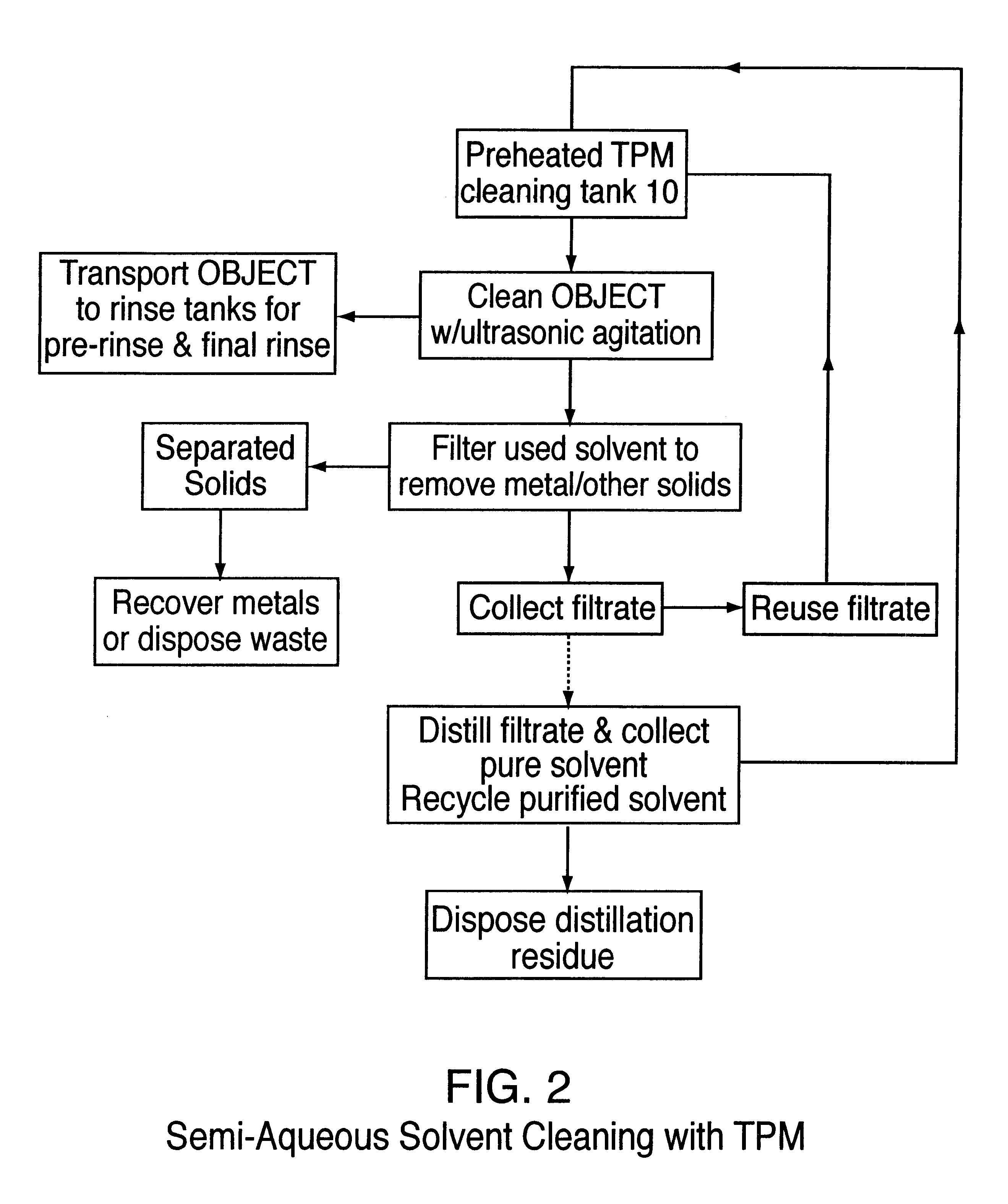

Semi-aqueous solvent cleaning of paste processing residue from substrates

A process of cleaning of objects that relate to semiconductor fabrication processes, such as, for example, conductive paste screening in the production of multilayer ceramic substrates and composite solder paste by stencil printing in electronic circuit assembly. Specifically, the process removes a metal / polymer composite paste from screening masks and associated paste making and processing equipment used in printing conductive metal pattern onto ceramic green sheet in the fabrication of semiconductor packaging substrates. The process also cleans solder paste residue from stencil printing equipment used in electronic module assembly surface mount technology for SMT discretes, solder column attachment, and BGA (Ball Grid Array) attachment on ceramic chip carrier or for screening solder paste onto printed circuit board. More particularly, paste residue is cleaned from metal, ceramic, and plastic substrates by a non-alkaline semi-aqueous cleaning method employing high boiling propylene glycol alkyl ether or mixtures of propylene glycol alkyl ether and propylene glycol solvents.

Owner:INT BUSINESS MASCH CORP

Solder pastes comprising nonresinous fluxes

InactiveUS20090152331A1Minimize formation of residueOther chemical processesSolid-state devicesOn boardElectrical connection

According to the invention, a resin-free solder paste made from a metal powder, particularly soft solder and a gel, is prepared, wherein the gel according to the invention leaves no residue on the metal surface during the remelting of the metal powder. The gel according to the invention is based on a mixture that is stable during storage and that comprises carboxylic acid(s), amine(s), and solvent(s). Important uses are the application of soft solder pastes on power-modules, die-attach, chip-on-board, SiP (System-in-Package), for wafer-bumping, particularly on UBM's (Under-Bump-Metallization), and SMT (Surface Mounted Technology), particularly coated circuits. With the use of resin-free soft solder pastes according to the invention, cleaning is eliminated before a protective coating process after the soldering of an electrical connection, and the formation of pores in solder bumps deposited on UBM's is reduced to less than 20 vol. %.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

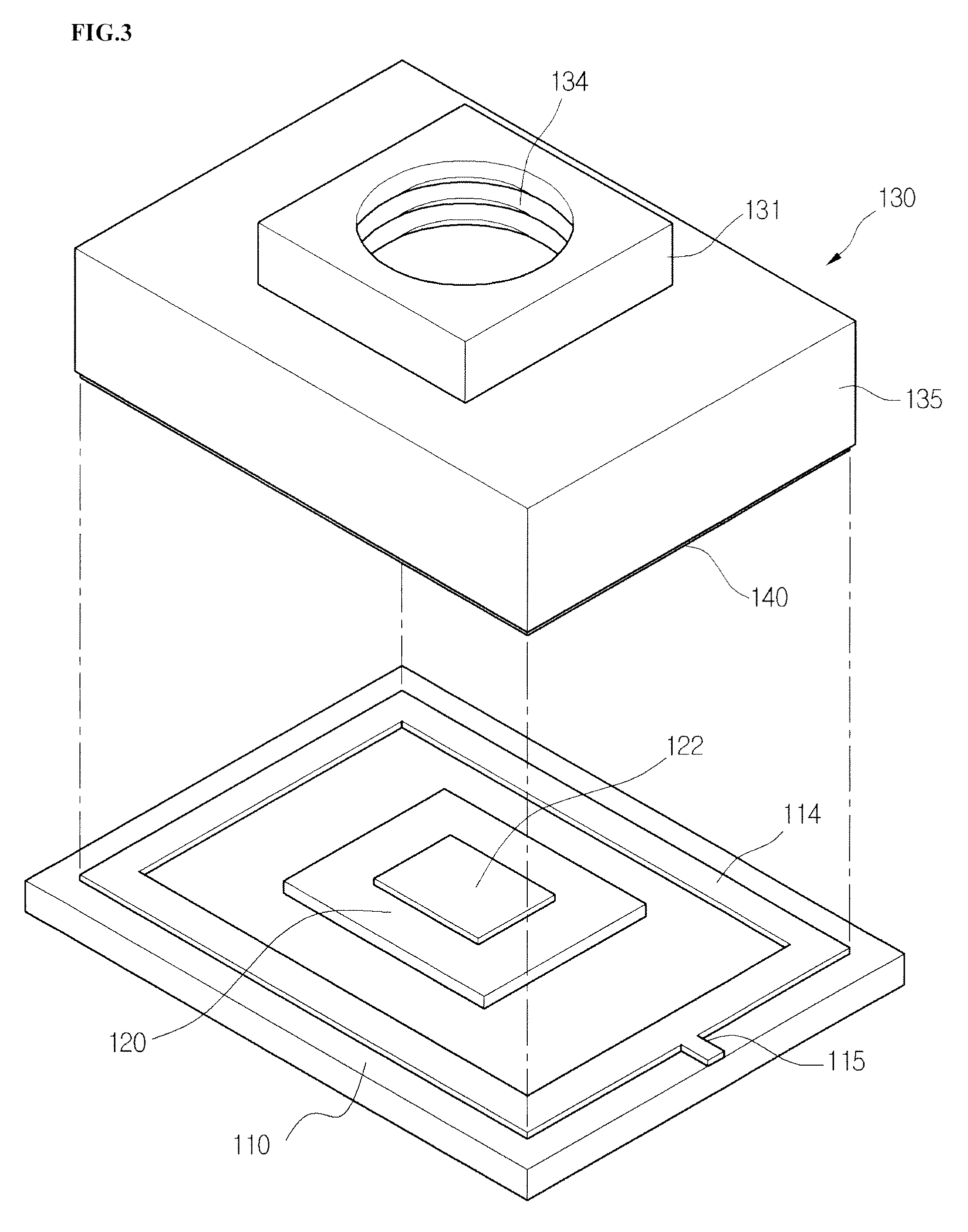

Camera Module and Method of Manufacturing The same

ActiveUS20070212061A1Improving assembleability and productivityAvoid leaningTelevision system detailsWheelchairs/patient conveyanceCamera moduleSurface-mount technology

Camera module embodiments and methods of manufacturing camera modules are provided. A camera module can include a housing and a printed circuit board having an image sensor. The housing can be mounted to the printed circuit board using a surface mount technology. In a method of manufacturing the camera module, the image sensor and the housing can be mounted to the printed circuit board, and a lens and a filter can be coupled to an upper portion of the housing.

Owner:LG INNOTEK CO LTD

Soft surface mount technology compatible EMI gasket

InactiveUS7129421B2Pipe supportsElectrically conductive connectionsElectromagnetic interferenceConductive materials

An Electromagnetic Interference (EMI) gasket formed of a hollow, conductive material which is mechanically fastened to a metal support layer. The assembly can be installed using standard high speed SMT pick and place equipment.

Owner:WL GORE & ASSOC INC

Surface-mount-enhanced lead frame and method for fabricating semiconductor package with the same

InactiveUS20040238923A1Printed circuit assemblingFinal product manufactureSurface mountingSemiconductor chip

A surface-mount-enhanced lead frame and a method for fabricating a semiconductor package with the lead frame are proposed, wherein a dam bar structure between any two neighboring lead frames of a lead frame module plate is formed with an indentation and at least a solder metal layer is applied on the bottom surface of the lead frame and the indentation. A singulation process is performed along the indentation to separate the lead frame module plate mounted with semiconductor chips and package body into a plurality of packages. Therefore, the indentation and the solder metal layer applied thereon can provide solder paste improved wettability and increased solder surface, while the semiconductor package with the lead frame is mounted on an external device via a surface-mount-technology, so as to prevent problems of signal transmission owing to separation of solder joint from solder open.

Owner:SILICONWARE PRECISION IND CO LTD

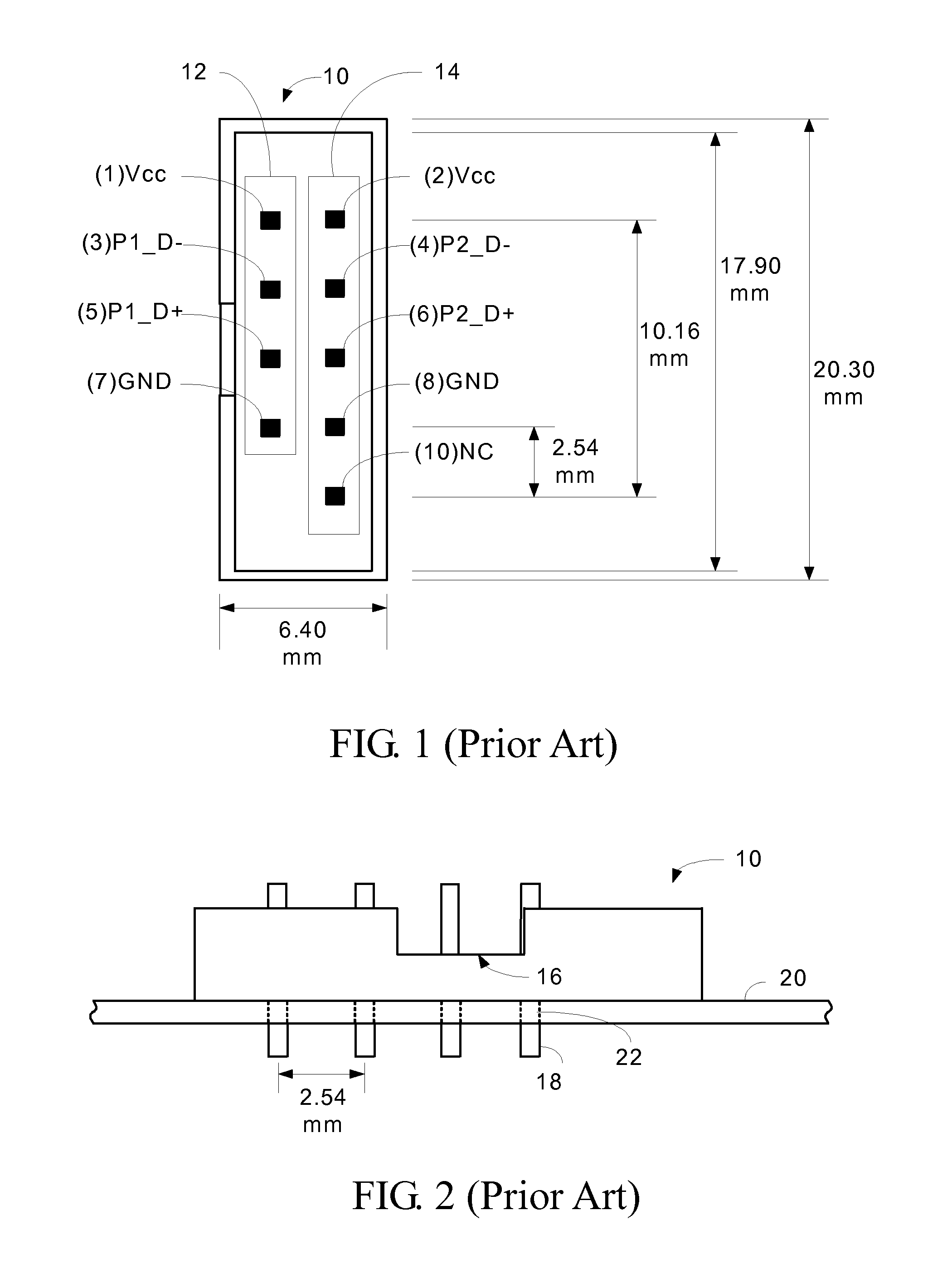

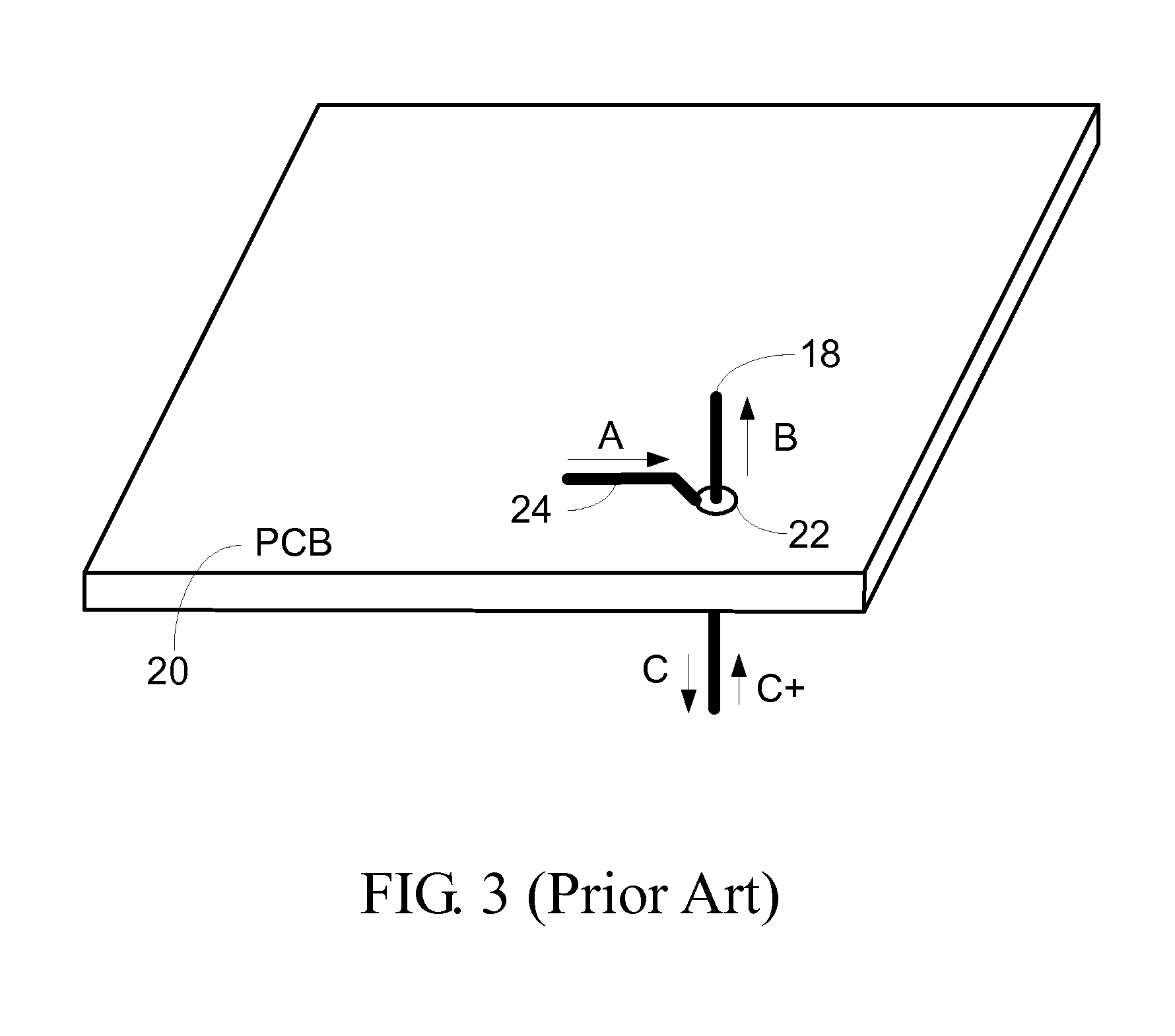

Motherboard with universal series bus connector

InactiveUS20120033369A1Avoid Impedance DiscontinuitiesAvoid signalingDigital data processing detailsCoupling device detailsContact padEngineering

A motherboard including a bus connector and a printed circuit board (PCB) is provided. The bus connector includes a plurality of pins, and each of the pins further includes a first end and a second end. The PCB includes a plurality of contact pads. The second ends of the pins are electrically connected to the contact pads of the PCB via a surface mounted technology (SMT), respectively.

Owner:ASUSTEK COMPUTER INC

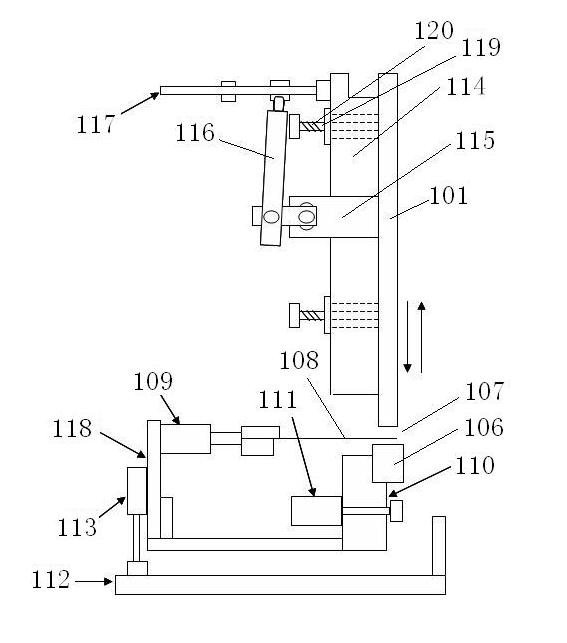

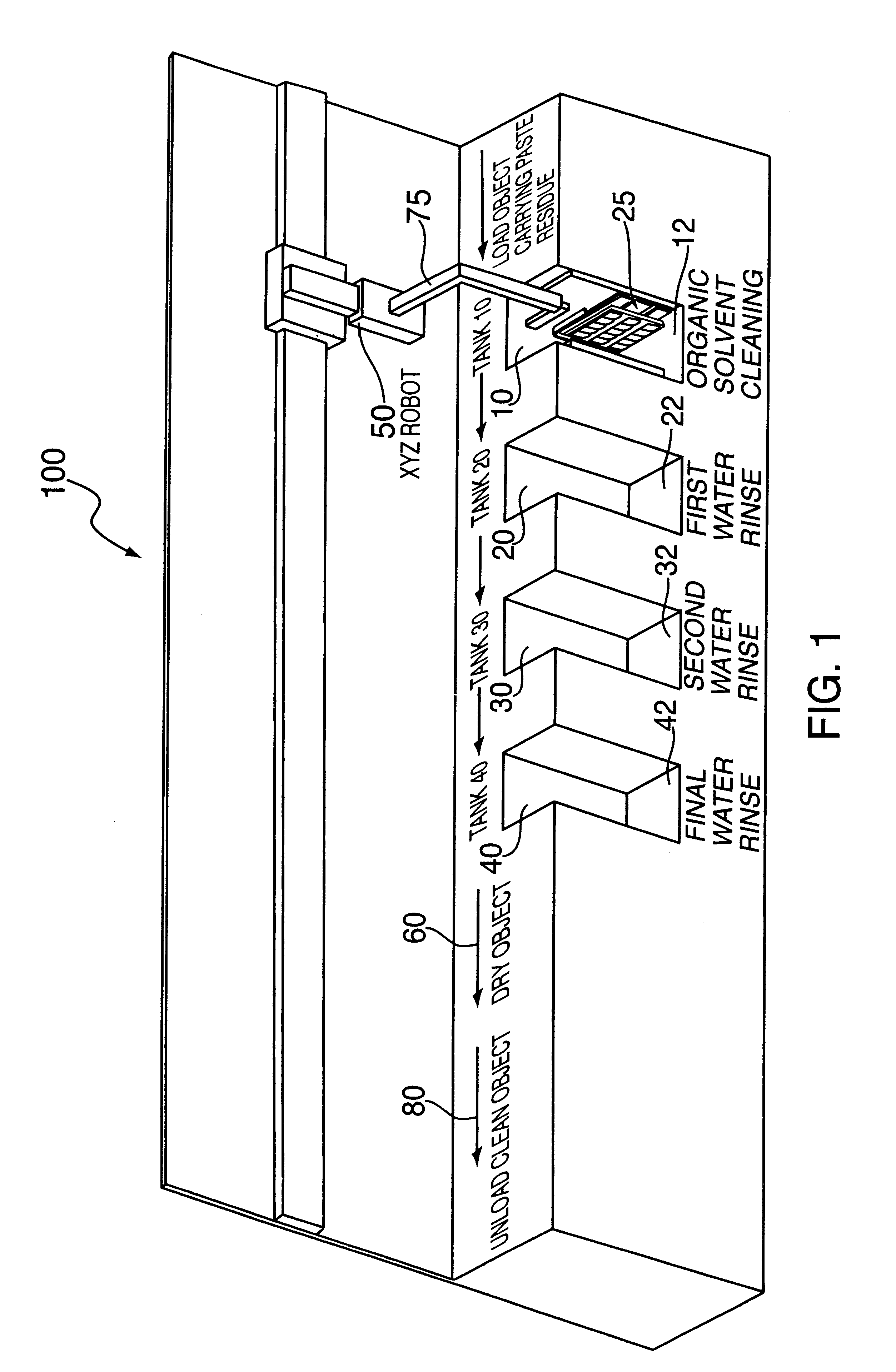

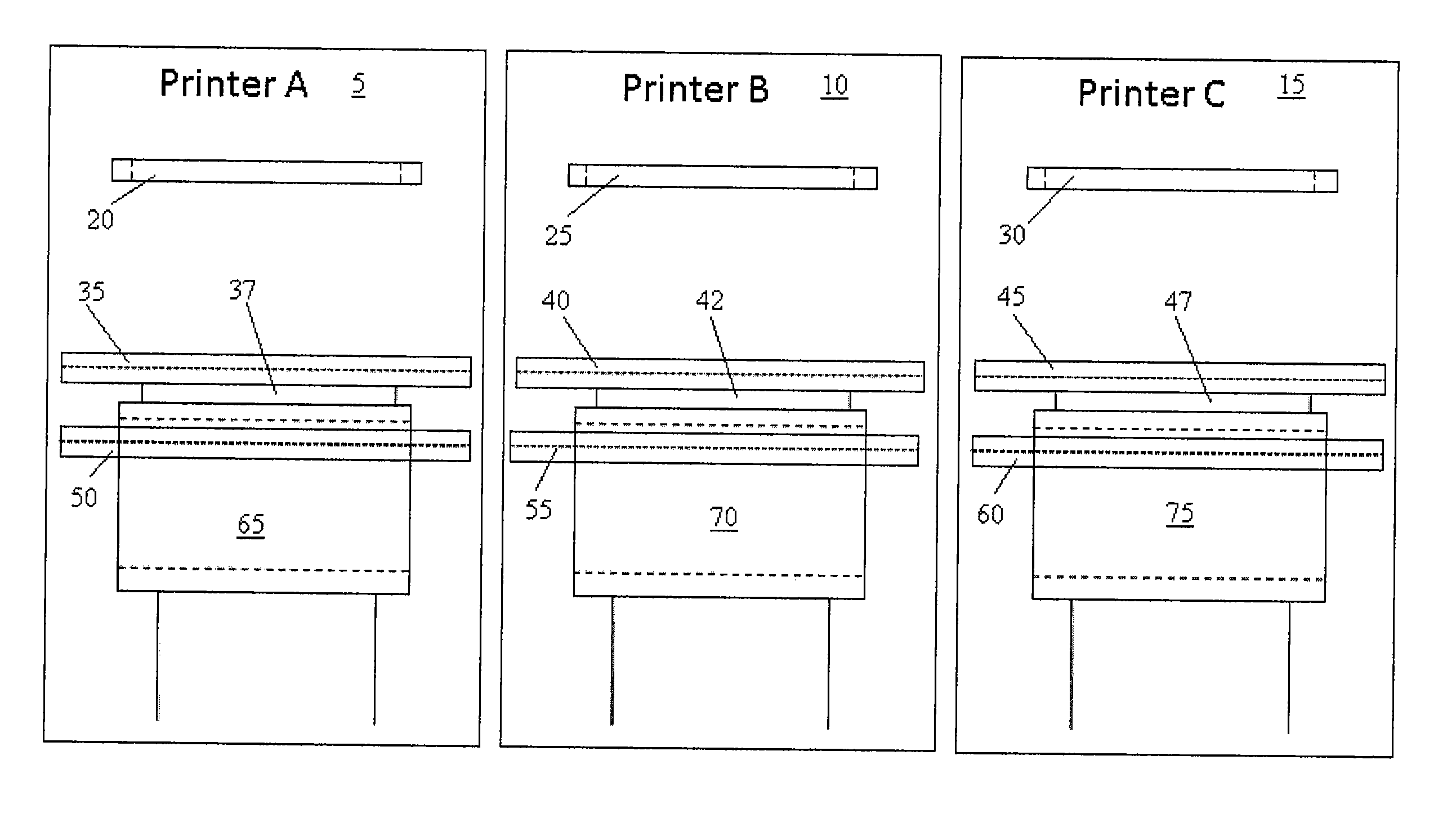

Vertically separated pass through conveyor system and method in surface mount technology process equipment

InactiveUS20100122633A1Printed circuit assemblingLiquid surface applicatorsProcess equipmentTransport system

Disclosed herein is an apparatus for depositing viscous material on an electronic substrate. The apparatus comprises a frame, an assembly material applicator coupled to the frame and configured to apply assembly material to the electronic substrate, a substrate support assembly, coupled to the frame, configured to support and secure the electronic substrate in a material application position, and a transport system, coupled to the frame, to shuttle electronic substrates to and from the substrate support assembly, the transport system including an upper track and a lower track disposed below the upper track.

Owner:ILLINOIS TOOL WORKS INC

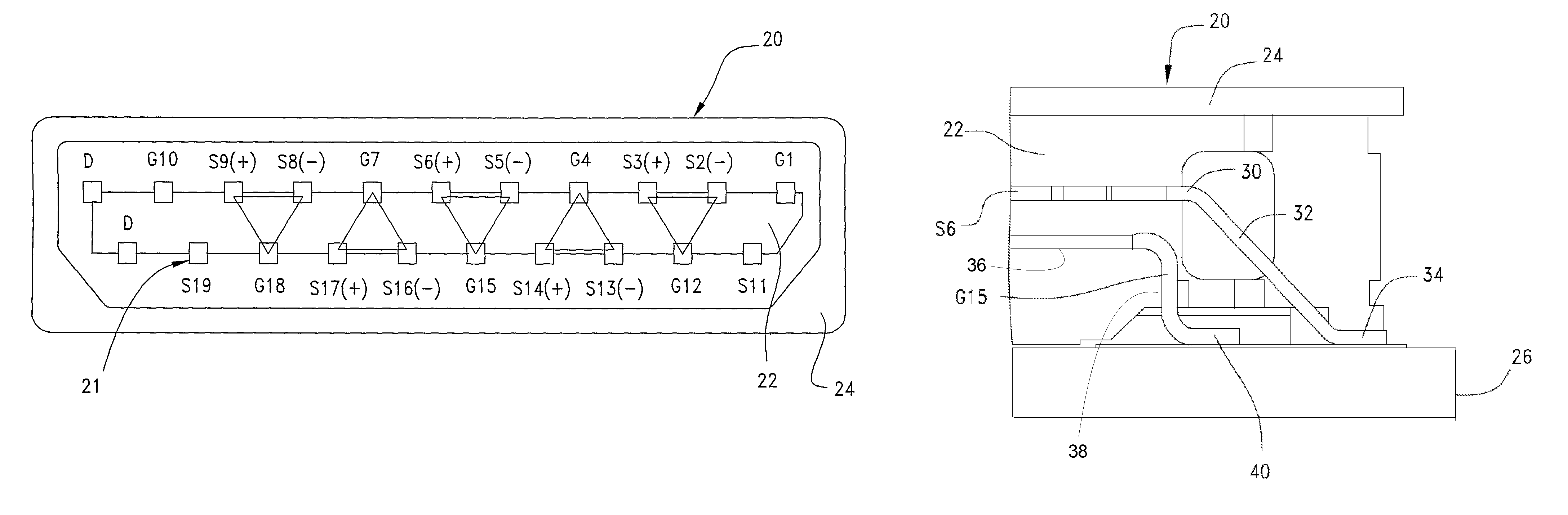

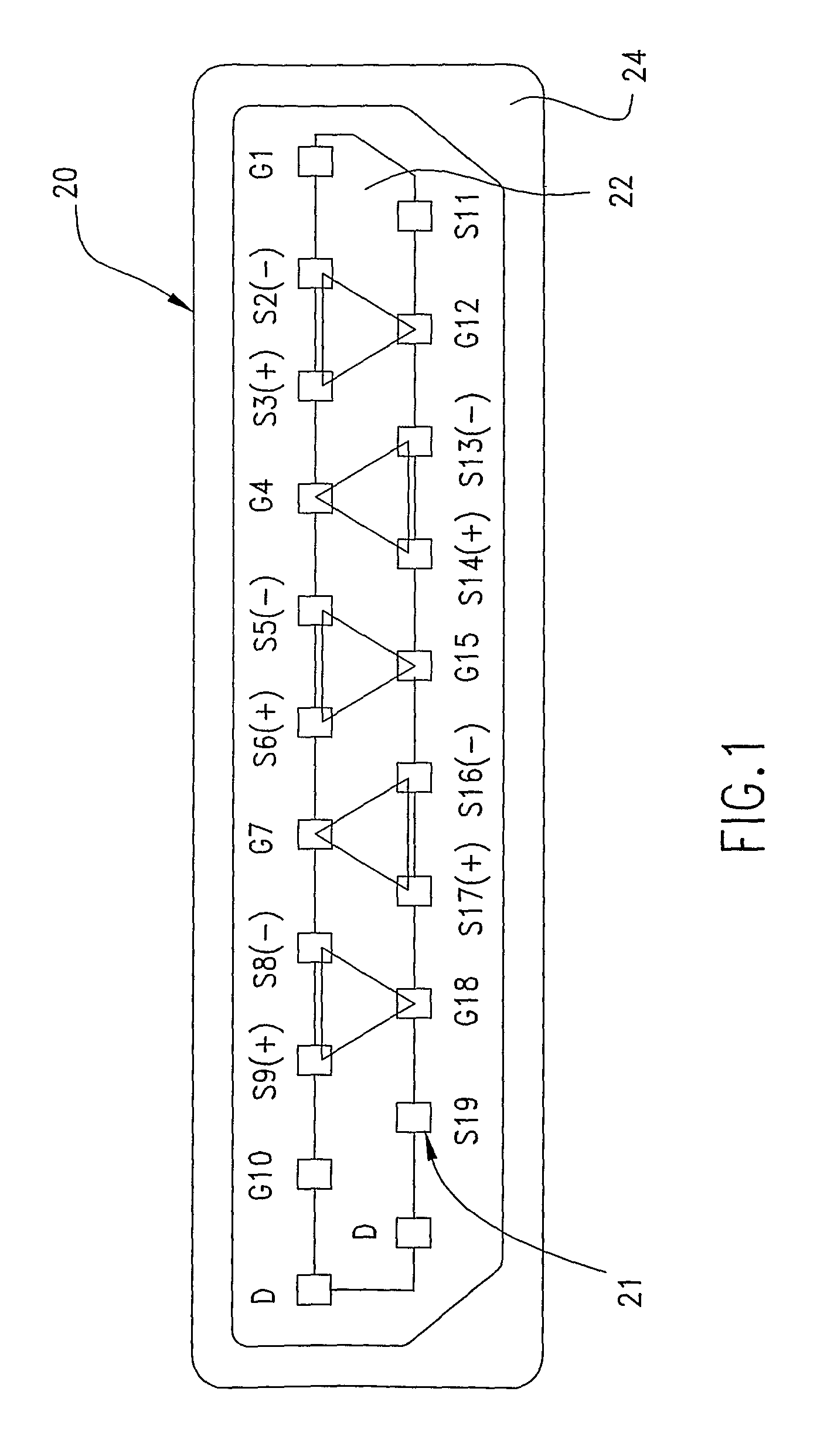

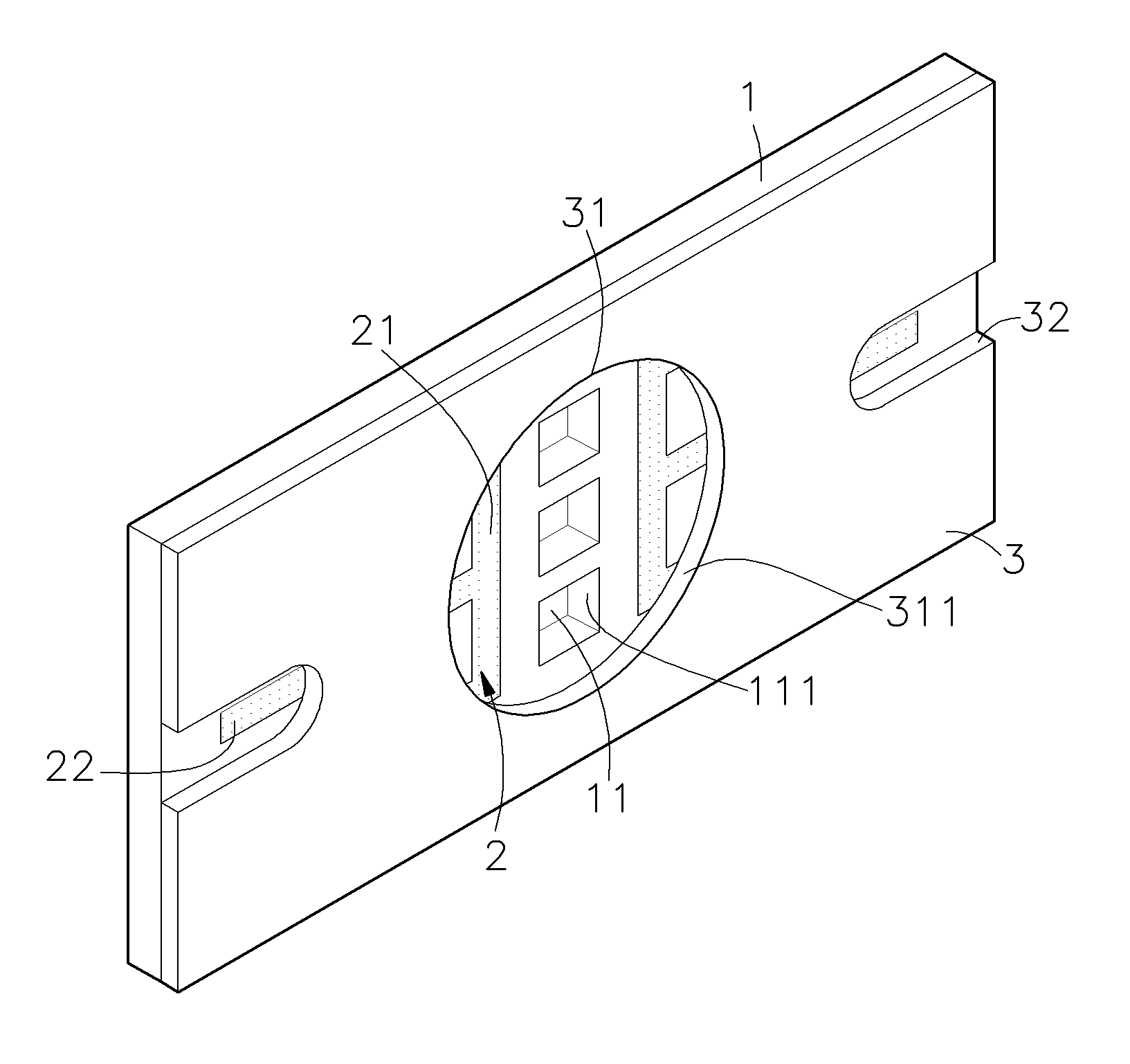

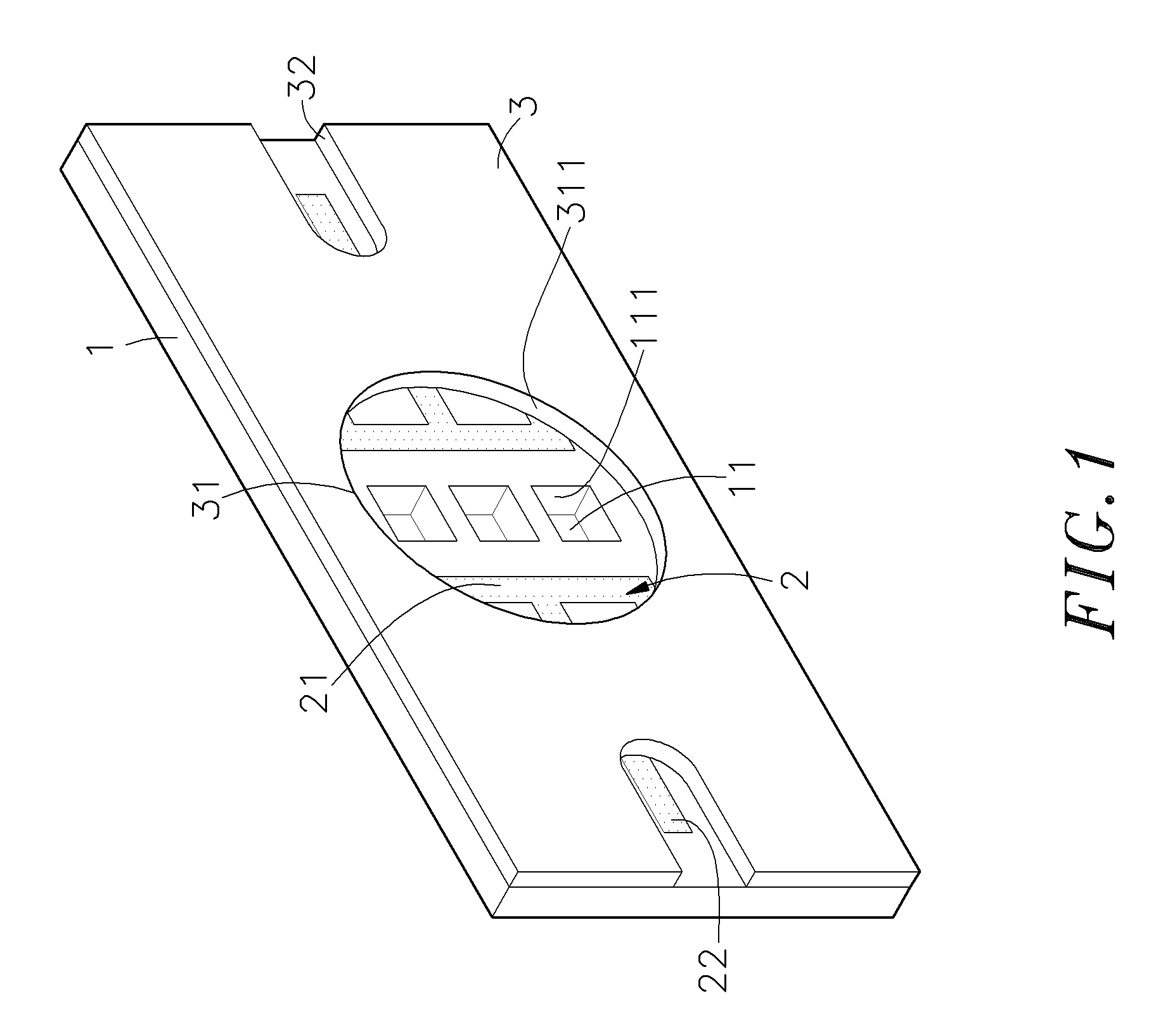

Impedance controlled electrical connector

ActiveUS8506332B2Two-part coupling devicesPrinted circuit manufactureElectrical connectorSurface-mount technology

A board-mountable connector is provided. The connector includes a shield and an insulative housing with a tongue. Terminals are supported by the housing in two rows and the rows extend from a mating interface to a board mounting interface. The terminals may be mounted to the board via surface mount technology in two rows that are at about 0.4 mm pitch. The two rows of terminals are configured in a signal, signal, ground triangular configuration so as to provide a triangular terminal arrangement that extends from the mating interface to the mounting interface.

Owner:MOLEX INC

Packaging struture for high power light emitting diode(LED) chip

InactiveUS20100096642A1Simple manufacturing processEase of mass productionSolid-state devicesSemiconductor devicesEngineeringElectrode Contact

The present invention relates to a packaging structure for high-power light emitting diode (LED) chip, comprising a metal plate, insulators and a cover plate. The metal plate comprises a containing slot and isolating slots formed on the surface by working, and the insulators can be embedded in the isolating slot. After forming a hollow slot and notches on the surface of the cover plate by working, the cover plate is combined with the metal plate and insulators and at the same time, the hollow slot and the notches are corresponding to the containing slot and the isolating slots on the metal plate to form a hollowness state, followed by application of surface treatment to form soldering portions and an anti-soldering layer at the bottom of the metal plate. Then the metal plate is cut on both sides along free ends of the insulators so as to generate electrode contacts with positive and negative electrodes, and the surface mount technology (SMT) can be adopted for assembly of the packaging structure of high-power LED chip so as to simplify manufacturing processes, facilitate mass production and achieve separation of electricity from heat, etc.

Owner:BRILLIANT TECH

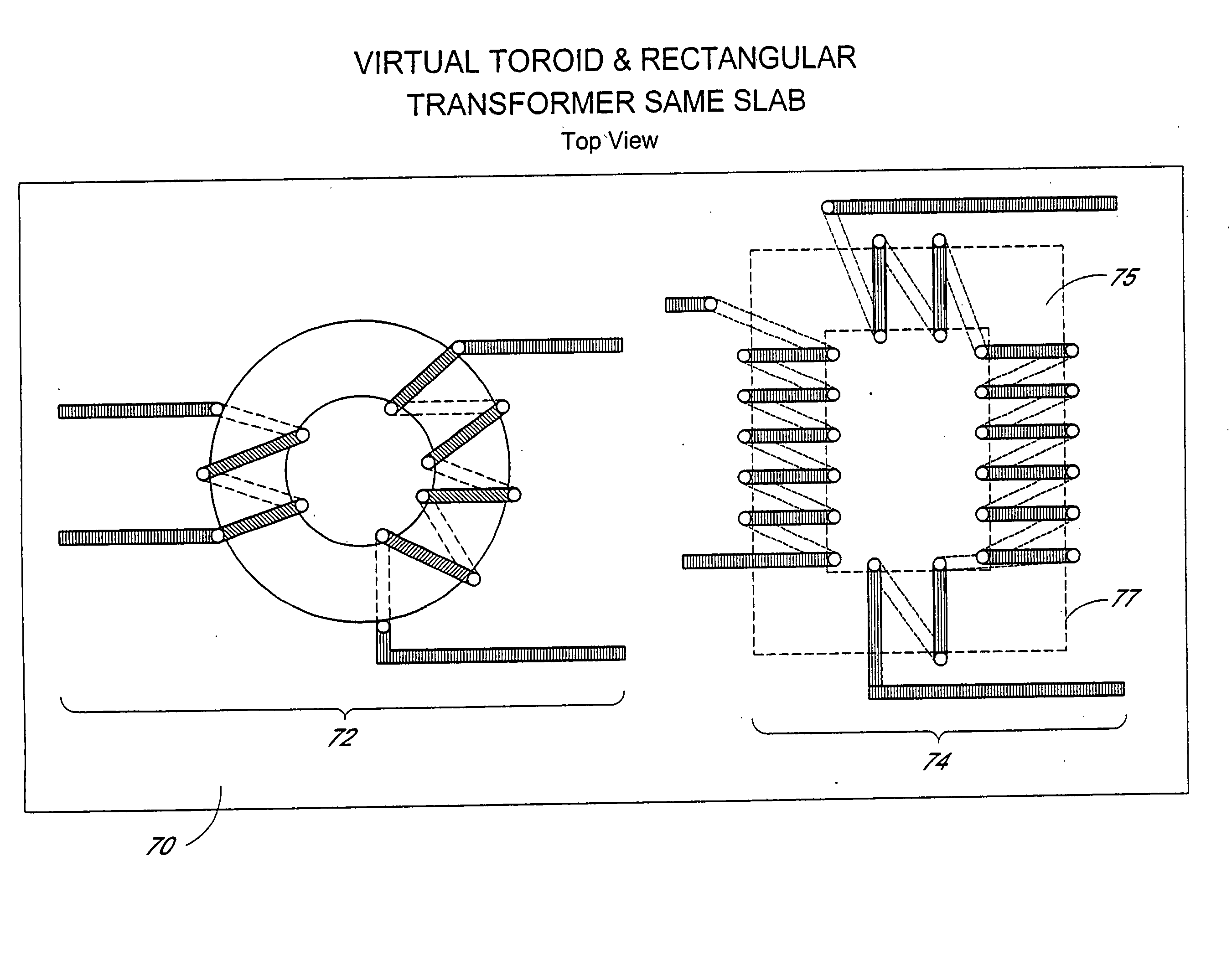

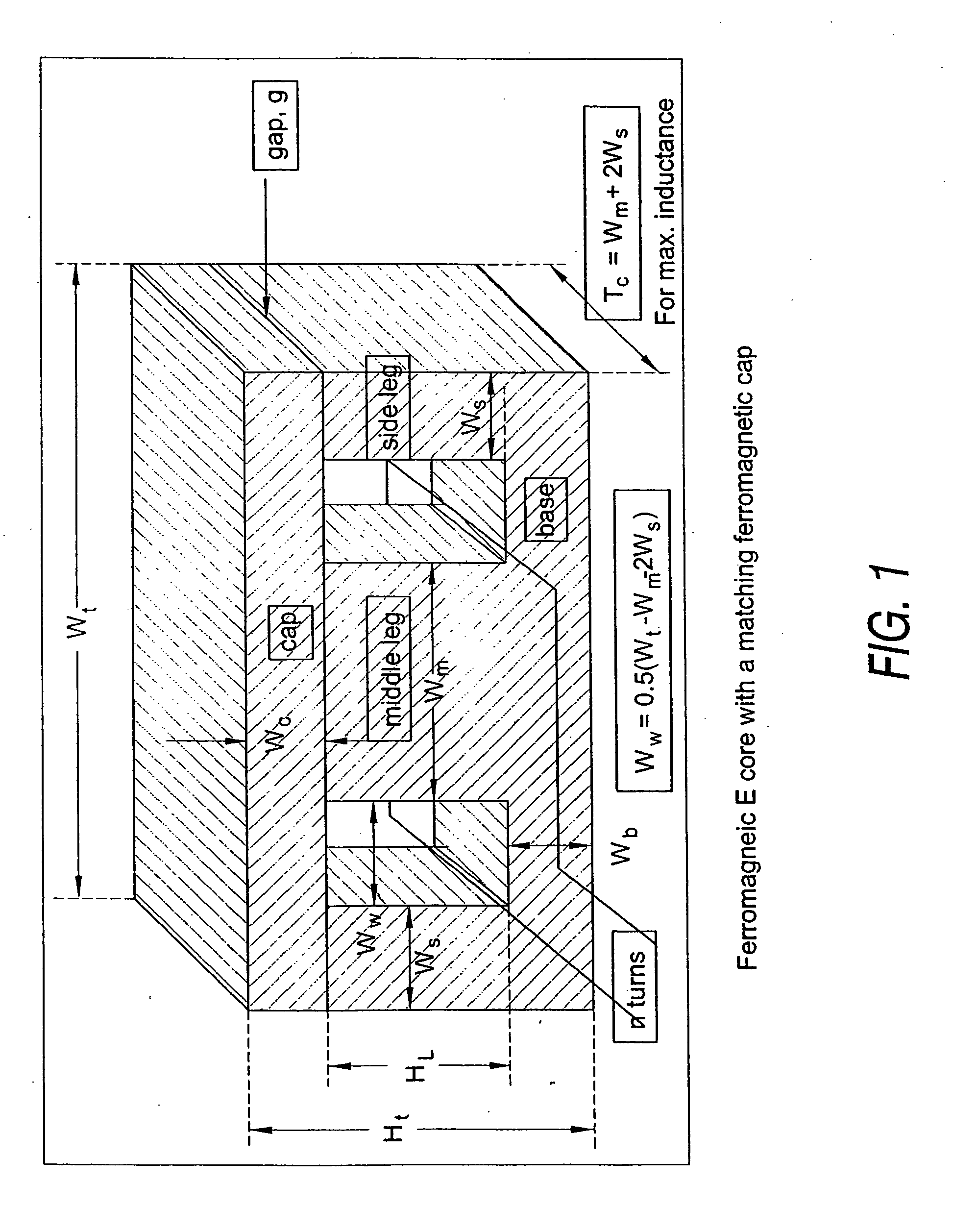

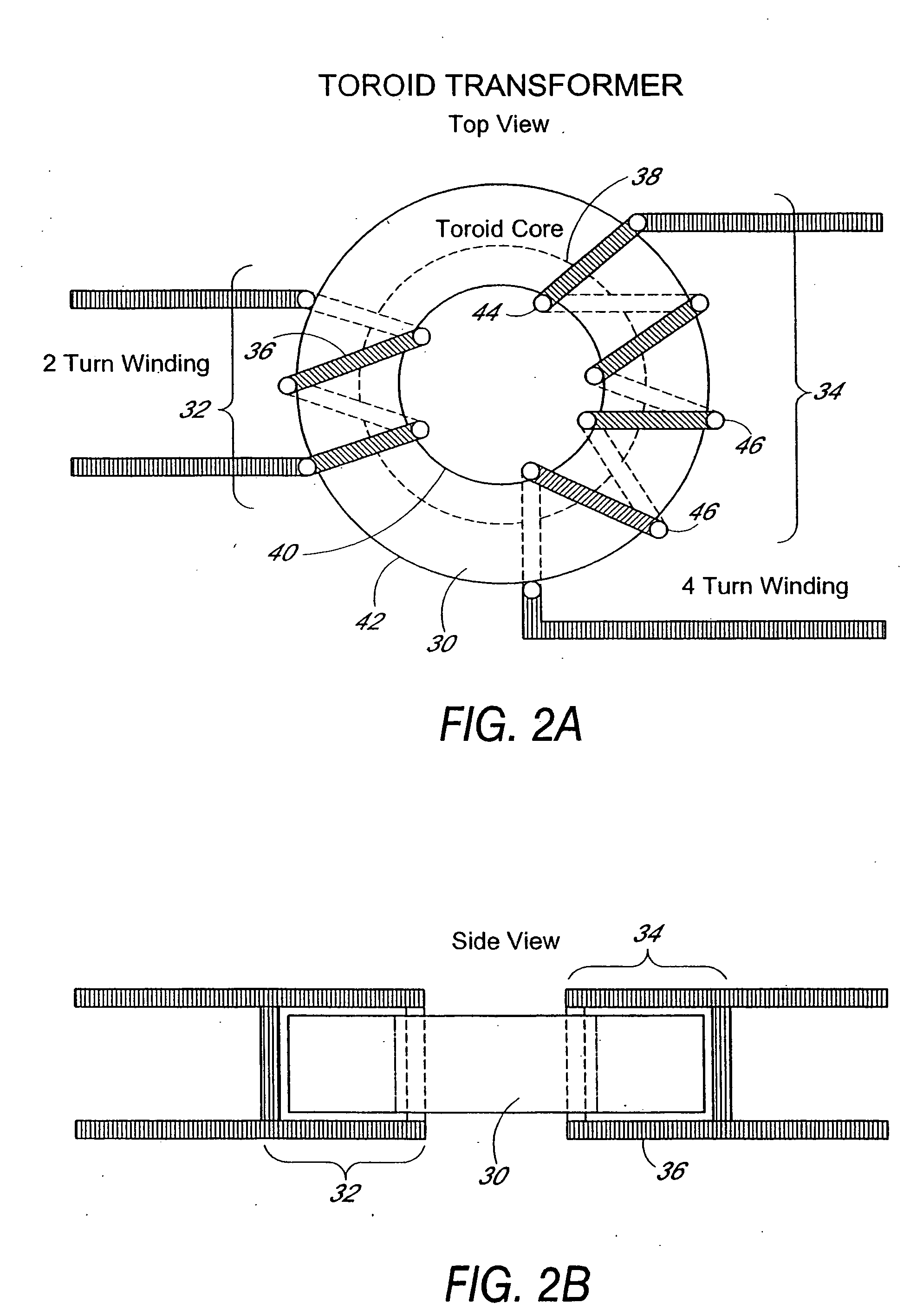

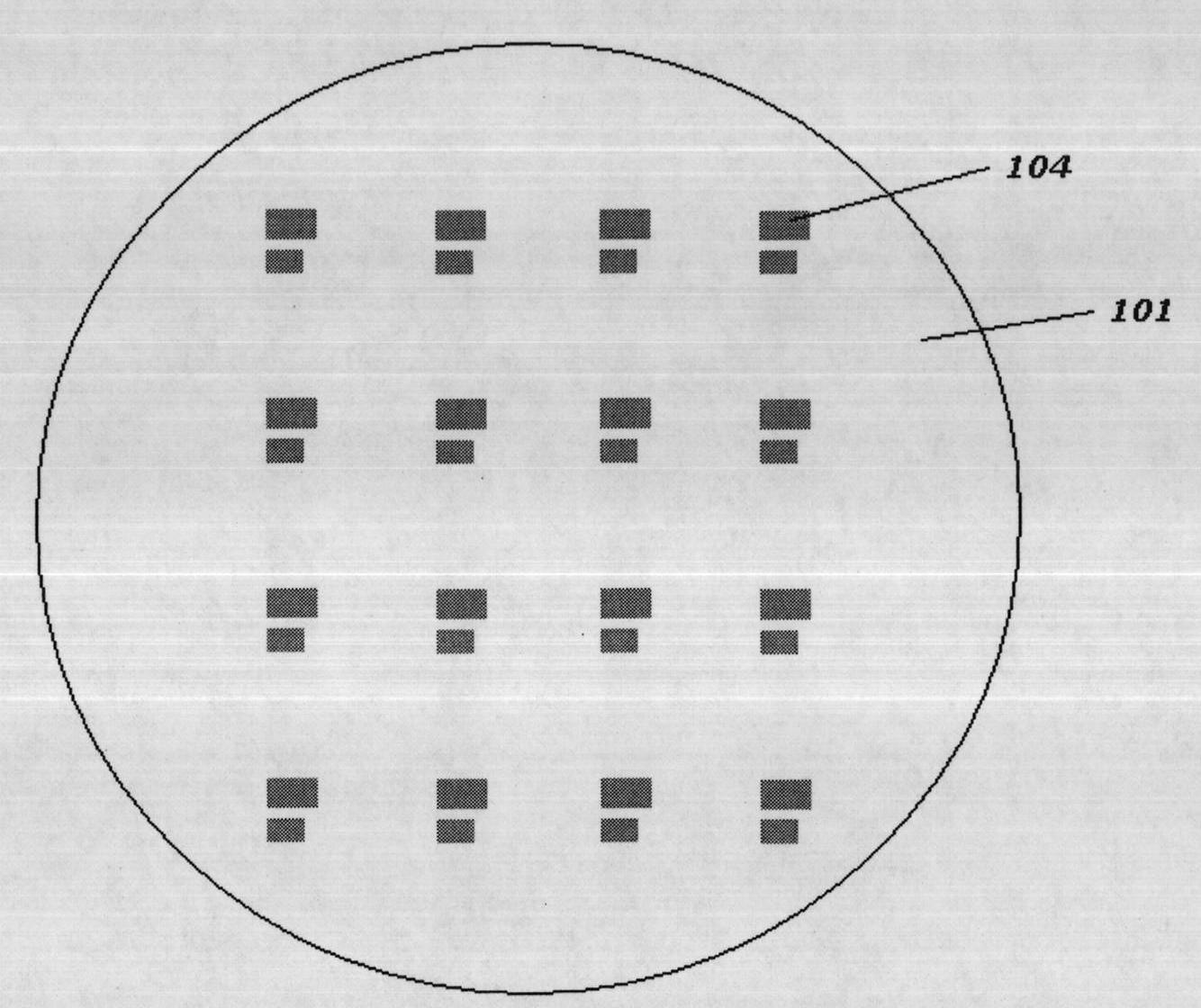

Electronic transformer/inductor devices and methods for making same

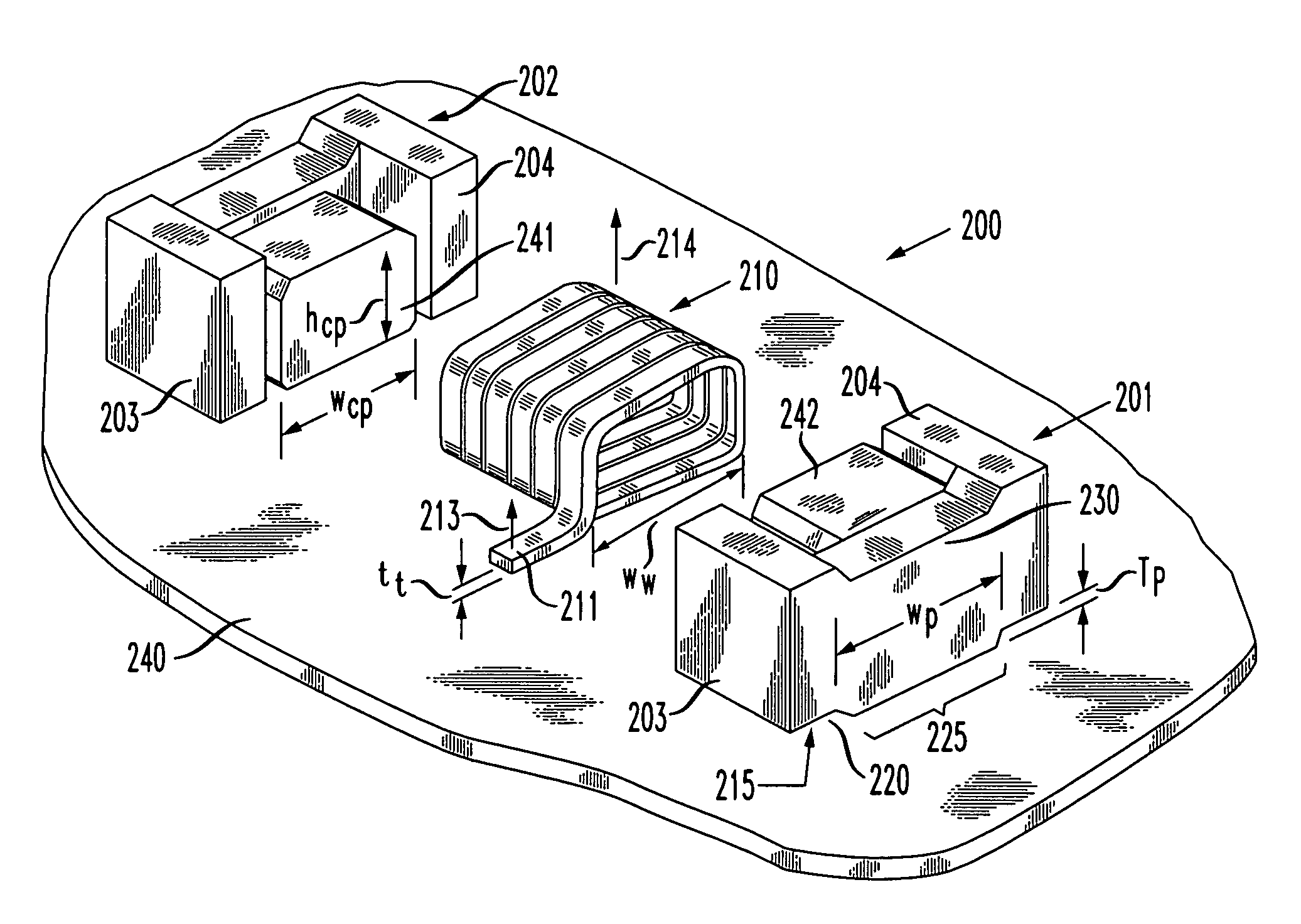

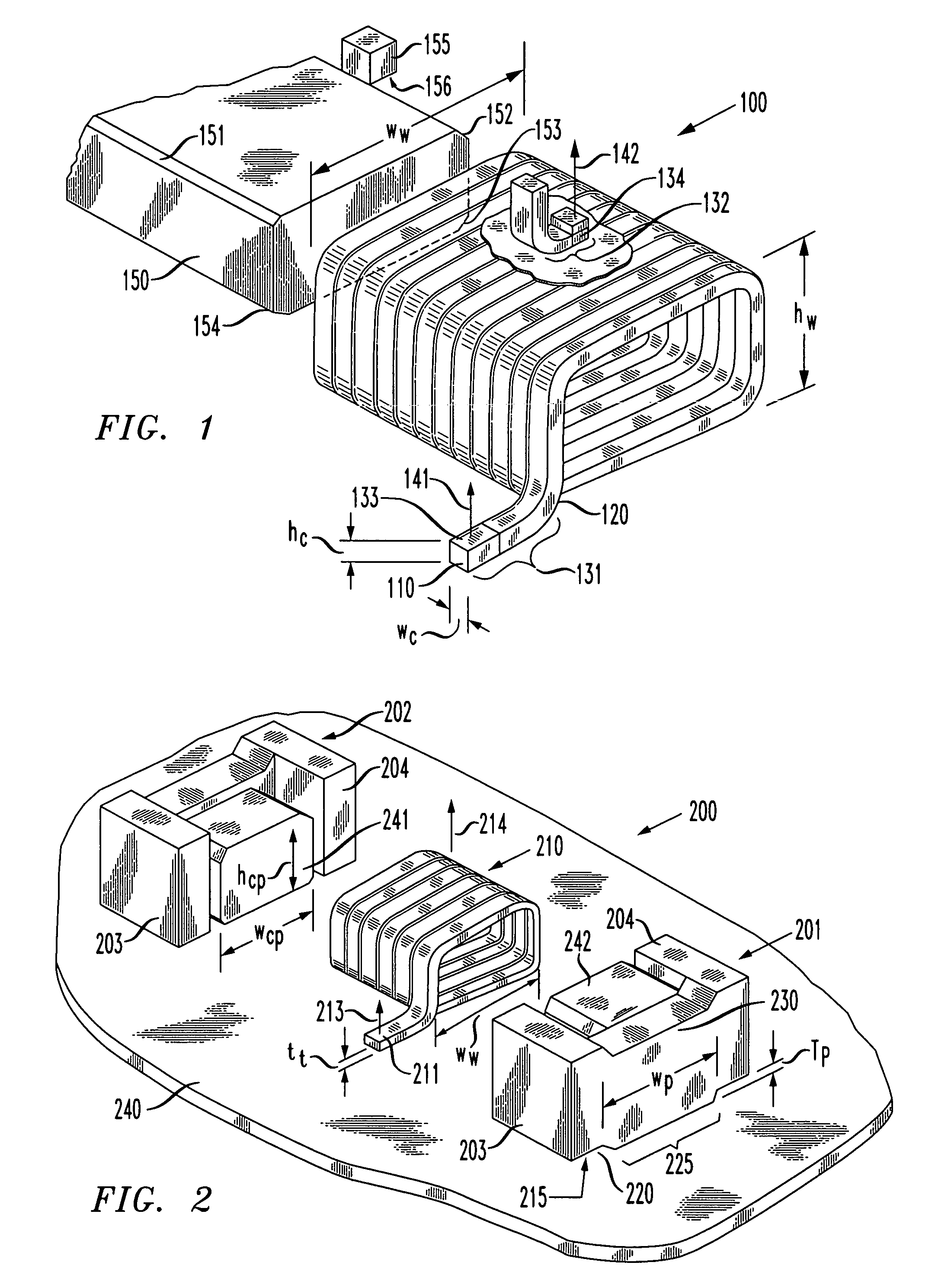

InactiveUS20050093672A1Improve cooling effectSimplifies electrical connectionsTransformers/inductances coils/windings/connectionsPrinted circuit aspectsModem deviceTransformer

The present invention relates to the methods of construction for inductive components of, preferably, ferromagnetic materials such as inductors, chokes, and transformers when used as an integral part of the fabrication of PCB's or FLEX's. In one preferred embodiment, holes are formed through a ferromagnetic substrate and plated with conductive material. The arrangement of these holes, and the subsequent design that ensues, will form the inductive components within the plane of the media in which the device is formed; using the substrate for a magnetic core. By using this approach, the inductive components can be miniaturized to physical sizes compatible with the requirements of modem surface mount technology (SMT) for integrated circuitry (IC). This process also allows these components to be fabricated using mass production techniques, thereby avoiding the need to handle discrete devices during the manufacturing process. In another preferred embodiment, a series of thin, concentric high permeability rings are etched on a substrate to provide high permeability transformers and inductors having minimal eddy current effects.

Owner:HARDING PHILIP A

Wafer level MMCM (microwave multichip module) packaging structure using photosensitive BCB (benzocyclobutene) as dielectric layer and method

ActiveCN102110673ASolve the defect of large lossImprove performanceSemiconductor/solid-state device detailsSolid-state devicesAdhesiveSurface-mount technology

The invention relates to a wafer level MMCM (microwave multichip module) packaging structure using photosensitive BCB (benzocyclobutene) as a dielectric layer and a method. The packaging structure is characterized by 1) manufacturing metal ground (GND) shielding layers on a silicon substrate with cavities for embedding; 2) using the photosensitive BCB as the dielectric layers and forming an interconnected through hole structure on the BCB by utilizing photoetching and developing processes; and 3) forming a multi-layer interconnection packaging structure through alternate occurrence of metal layers and the dielectric layers. The method is characterized by eroding or etching the cavities for embedding on the silicon substrate, sputtering a metal seed layer and carrying out electroplating to form the GND, embedding MMIC (monolithic microwave integrated circuit) chips, using conductive adhesives to bond the chips and the substrate, coating the photosensitive BCB and carrying out photoetching and developing to form the interconnected through hole patterns and carrying out curing to realize multi-layer MMCM package. The thickness of the dielectric layers is 20-35mu m. Capacitors, resistors, inductors, power dividers and antenna passive devices can be integrated in the multi-layer interconnection structure or discrete components are integrated through surface mount technology, thus realizing the functionalization of the module.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

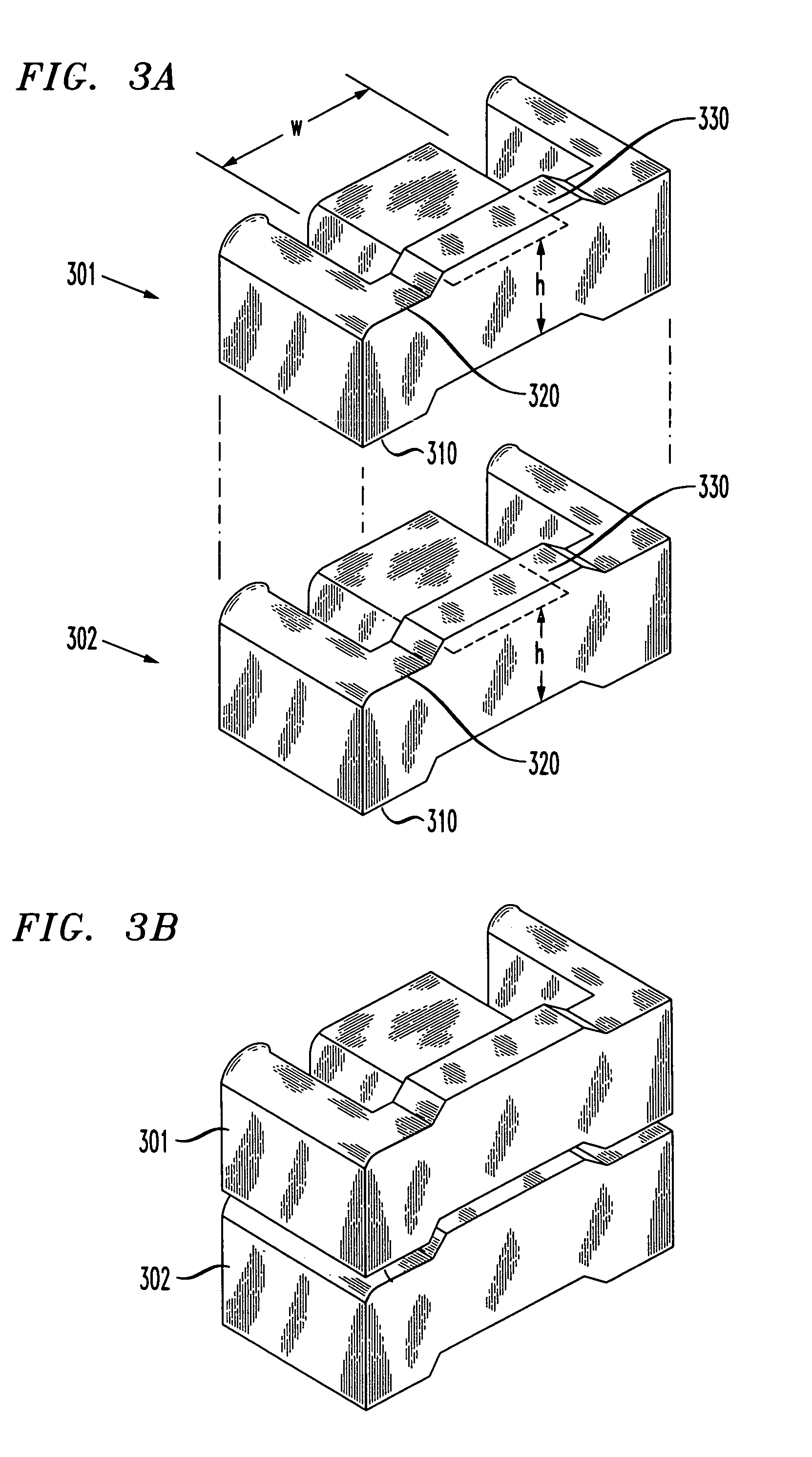

Magnetic device having a springable winding

InactiveUS6927667B1Transformers/inductances coils/windings/connectionsInductance with magnetic coreEngineeringSurface-mount technology

A magnetic device is provided that may be employed with surface mount technology. In an advantageous embodiment, the magnetic device includes a magnetic core having a magnetic core half and a springable winding positioned about at least a portion of the magnetic core half. The springable winding includes a terminus biased against the magnetic core half.

Owner:ABB POWER ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com