Patents

Literature

286 results about "Benzocyclobutene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Benzocyclobutene (BCB) is a benzene ring fused to a cyclobutane ring. It has chemical formula C₈H₈. BCB is frequently used to create photosensitive polymers. BCB-based polymer dielectrics may be spun on or applied to various substrates for use in Micro Electro-Mechanical Systems (MEMS) and microelectronics processing. Applications include wafer bonding, optical interconnects, low-κ dielectrics, or even intracortical neural implants.

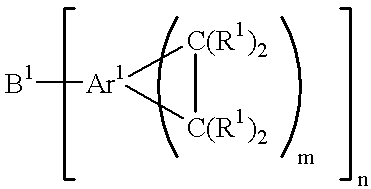

Acid functional polymers based on benzocyclobutene

InactiveUS6361926B1Improve adhesionExcellent of constantDiazo compound compositionsPhotosensitive materials for photomechanical apparatusImage resolutionSolvent

The invention is a curable cyclobutarene based polymer comprising acid functional pendant groups. The cured polymer displays excellent qualities of toughness, adhesion, dielectric constant, and low stress. The preferred system is soluble in an aqueous base and can be used to generate patterned films with excellent resolution without the need to handle organic developer solvents.

Owner:THE DOW CHEM CO

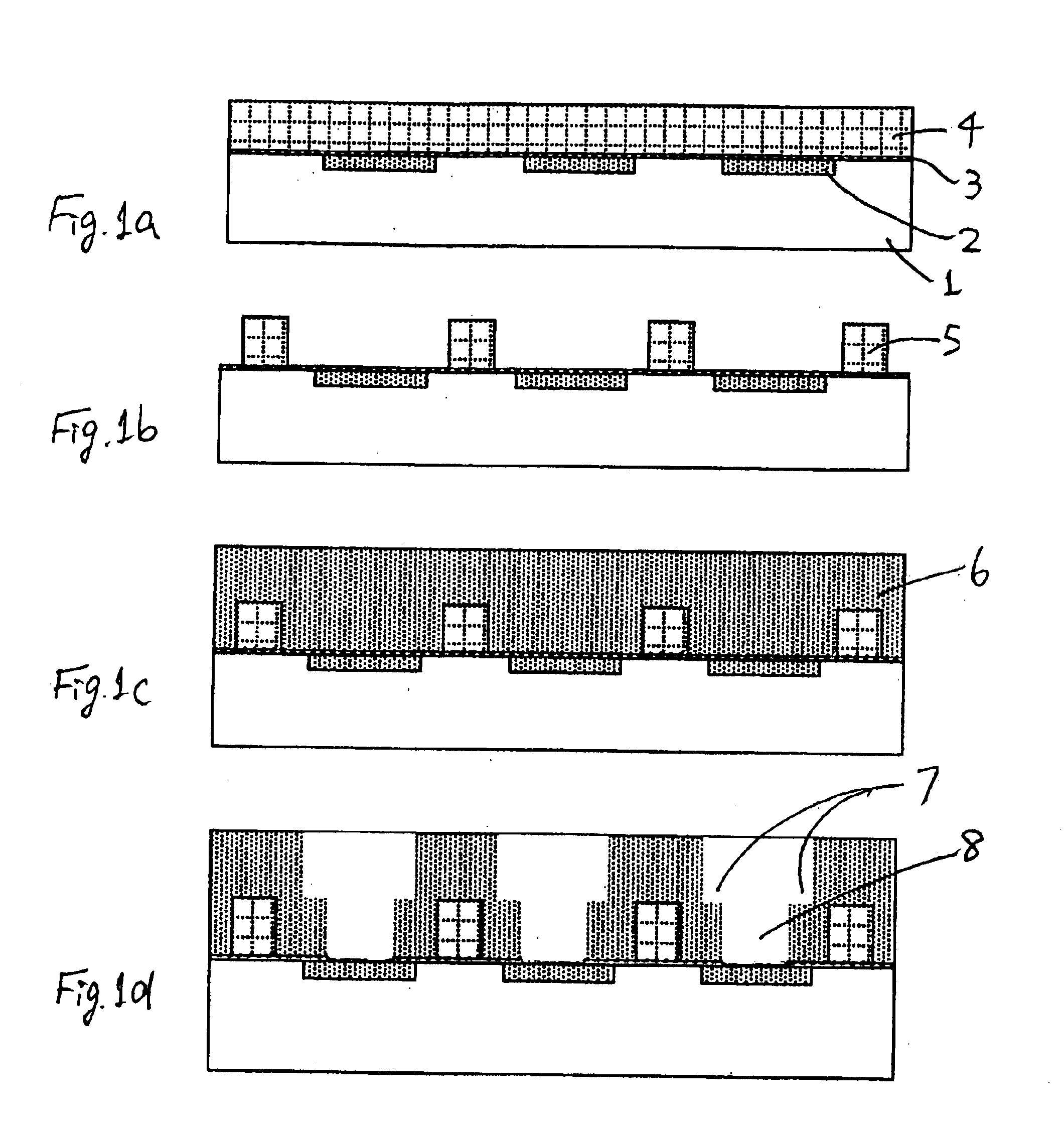

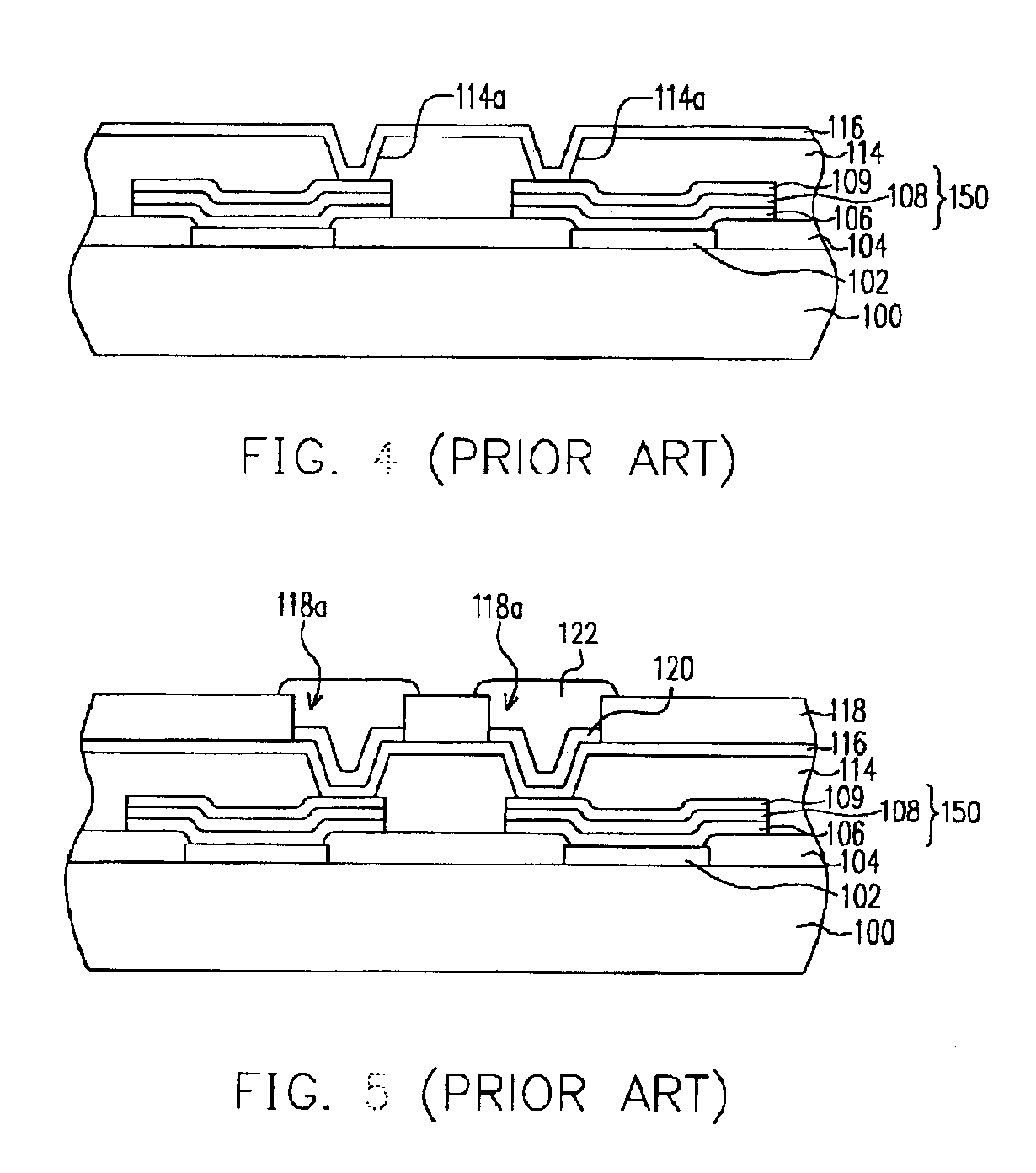

Method for manufacturing semiconductor device having porous structure with air-gaps

ActiveUS6949456B2Effectively and easily be obtainedImprove mechanical propertiesSemiconductor/solid-state device detailsSolid-state devicesCopperDielectric layer

Owner:ASM JAPAN

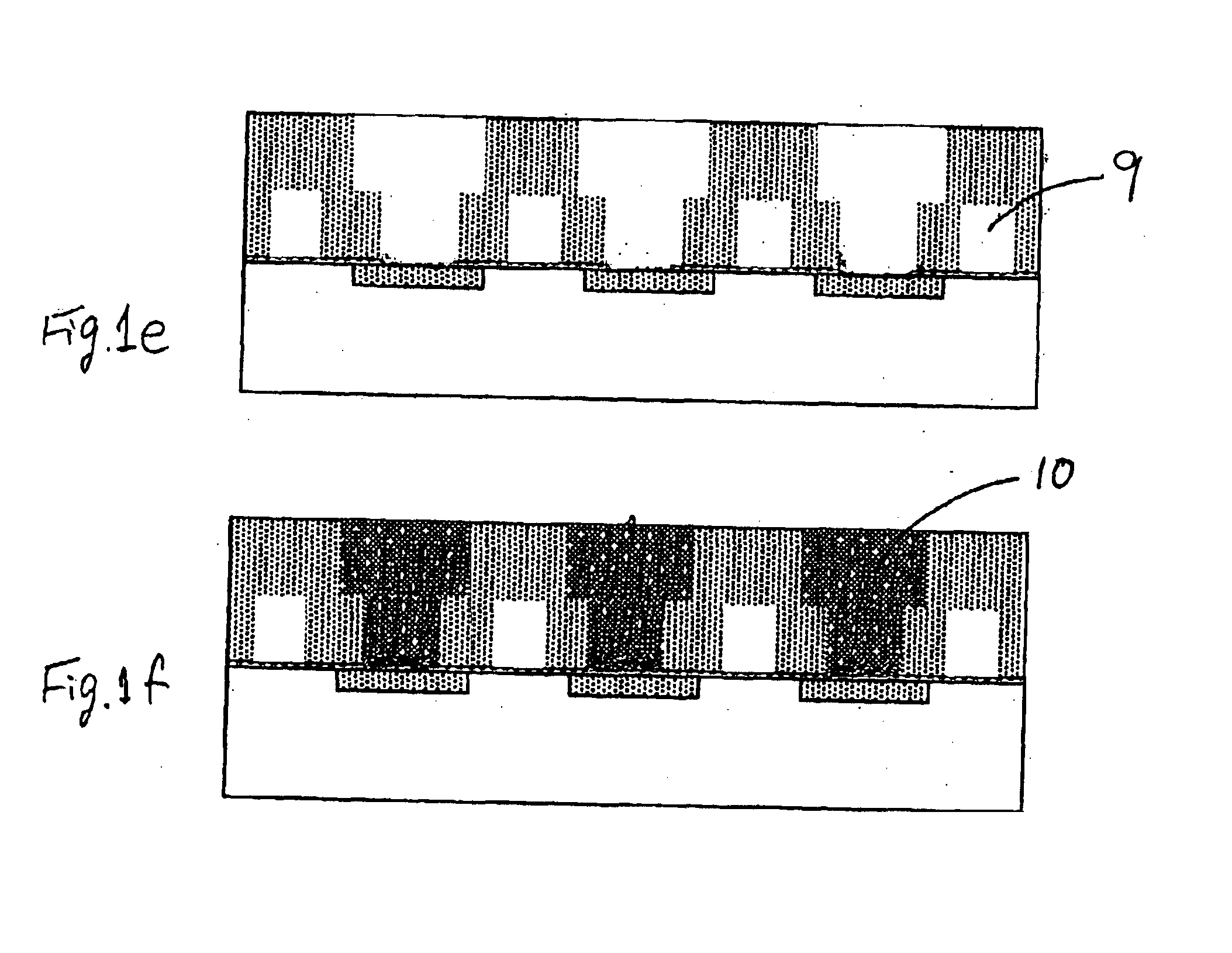

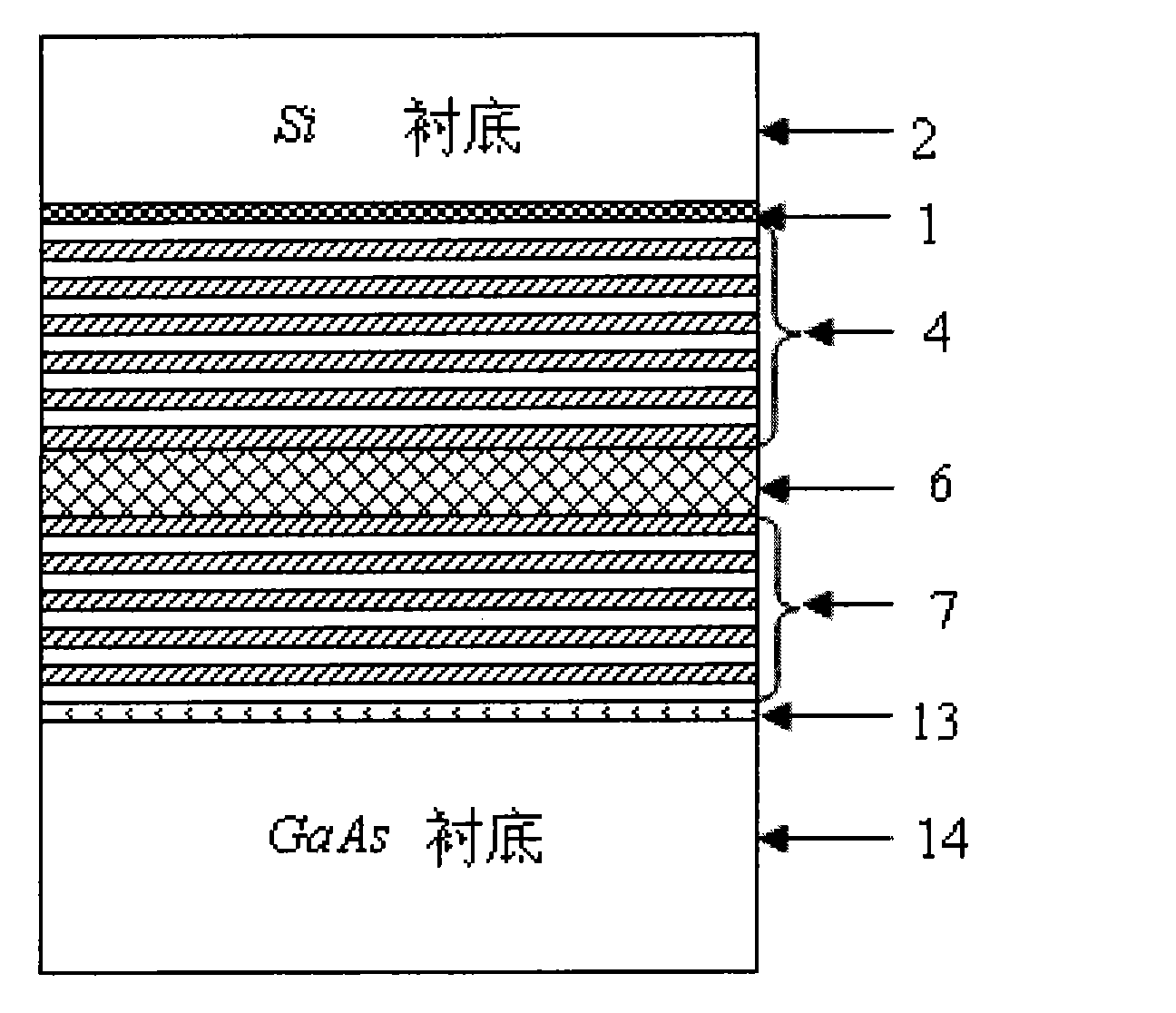

Single-mode high-power vertical cavity surface emitting laser and manufacturing method thereof

ActiveCN101667715AIncrease output powerImprove thermal propertiesLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserElectron

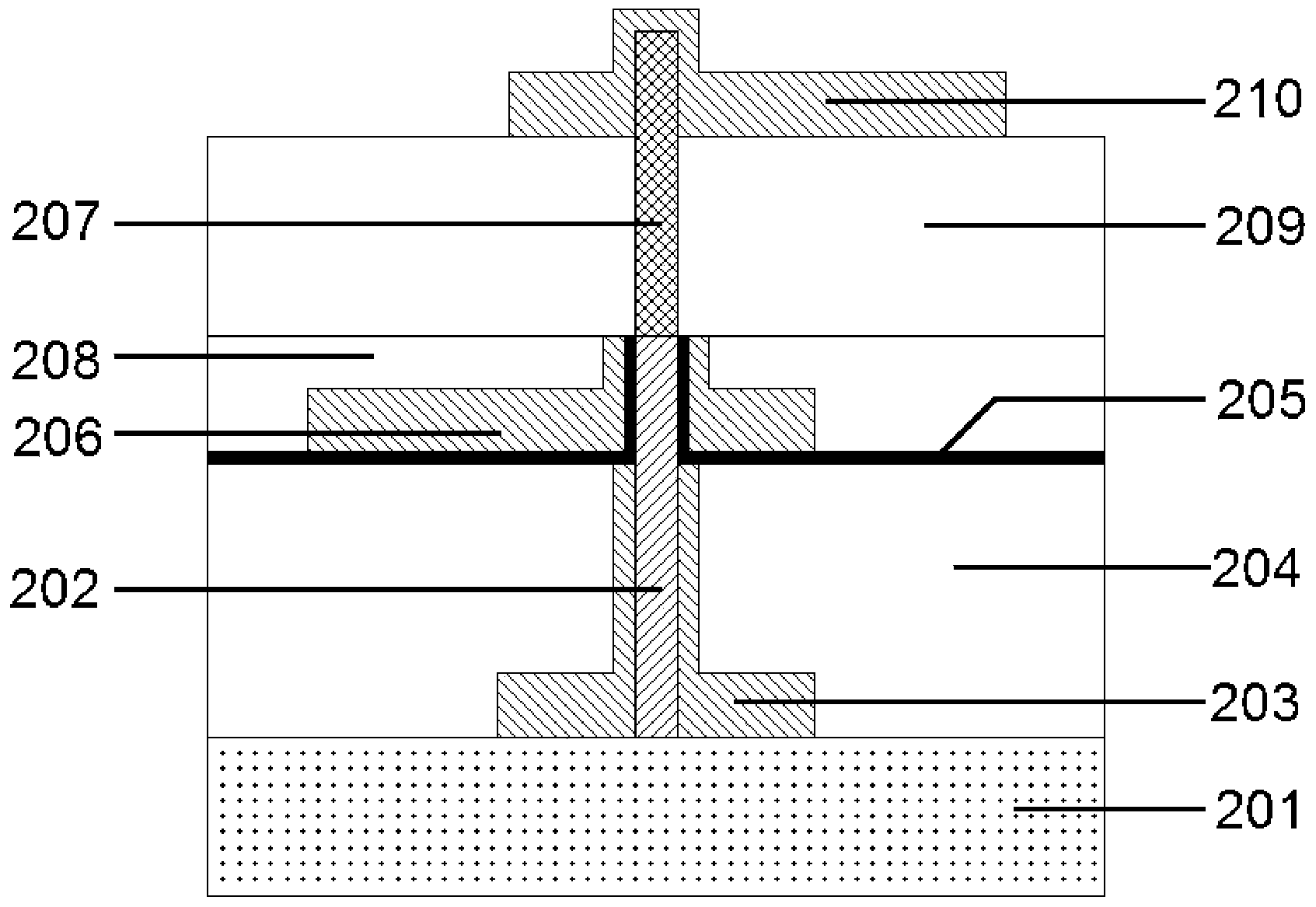

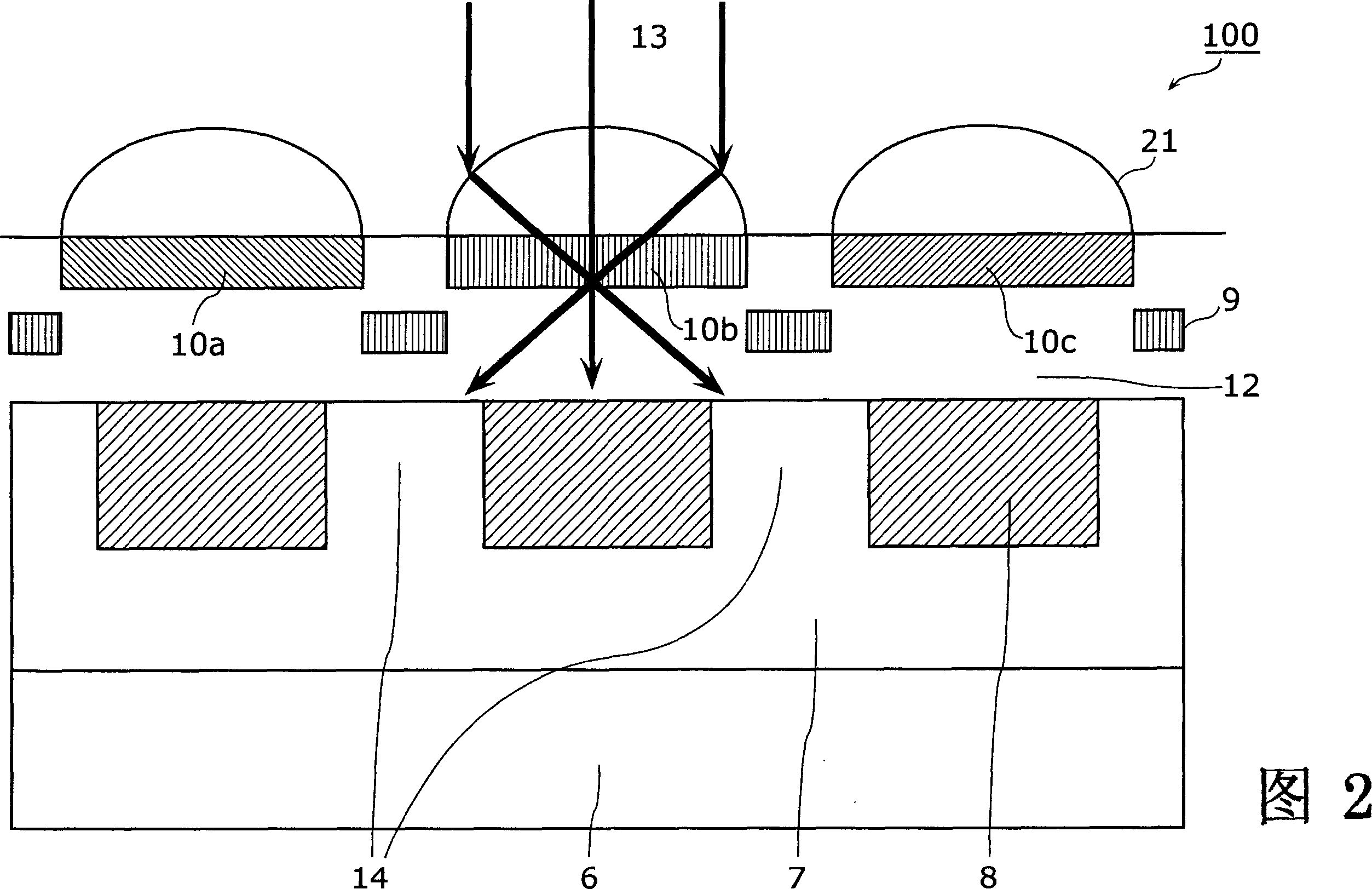

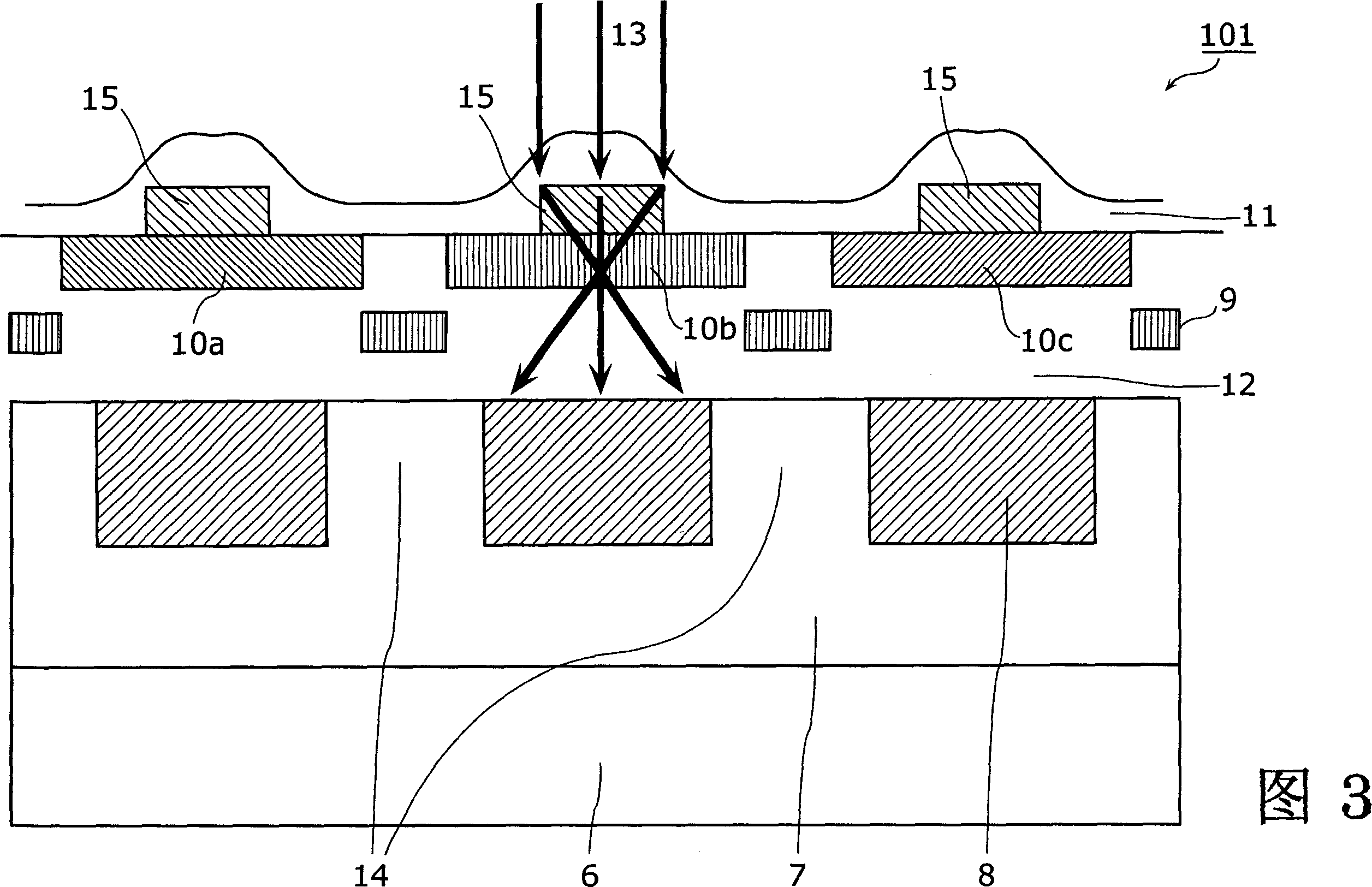

The invention relates to a single-mode high-power vertical cavity surface emitting laser (VCSEL), which belongs to the field of semiconductor photoelectronics. The laser is characterized by comprisinga P-type electrode (1), a P-type Si substrate (2), a metal bonding layer (3), a P-type distributed Bragg reflector (DBR) (4), an oxide limiting layer (5), an active area (6), an N-type DBR (7), a SiO2 mask (8), polymide or benzocyclobutene (BCB) (9), an N electrode (10), a photonic crystal (11) and a light-exiting window (12). The introduction of the photonic crystal into the vertical cavity surface emitting laser with the structure can enlarge an oxidation aperture and improve the single-mode output power; and at the same time, the transfer of the conventional VCSEL epitaxial wafer to the Sisubstrate by adopting bonding technology and the adoption of a design of exiting light at the bottom are convenient for narrowing the distance between a VCSEL epitaxial wafer active area and the Si substrate, improving the thermal characteristics of devices and further improving the single-mode output power.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

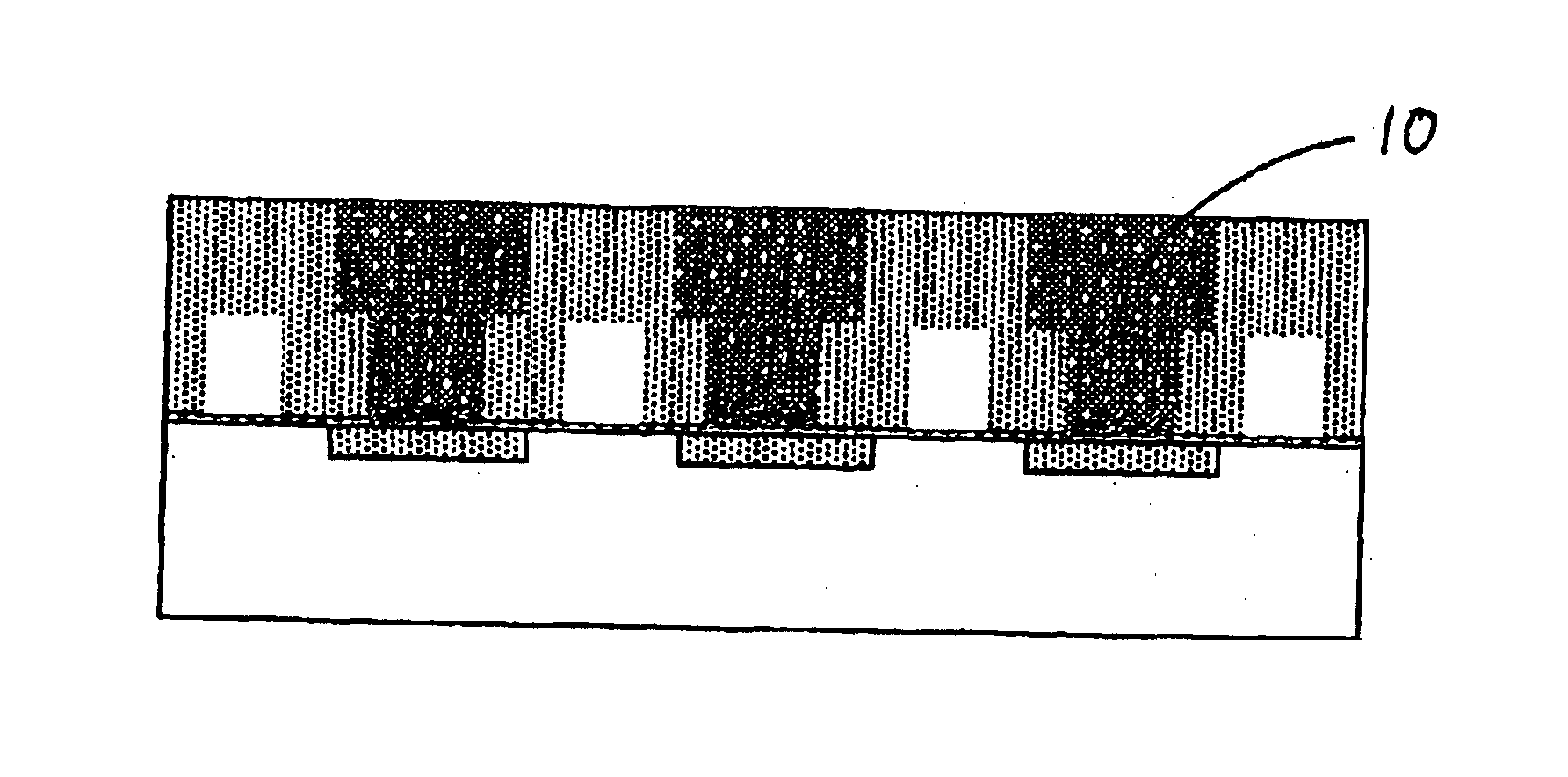

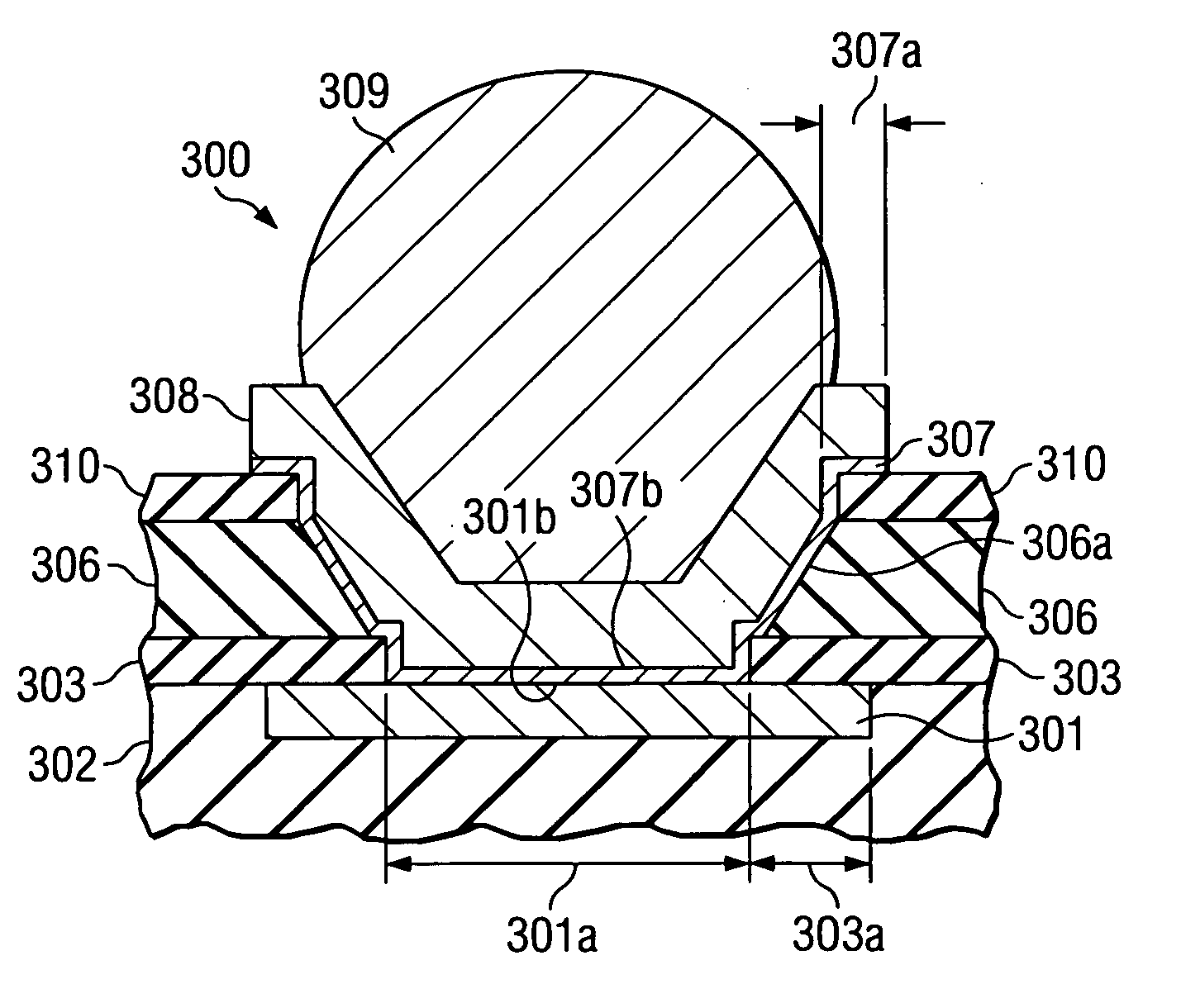

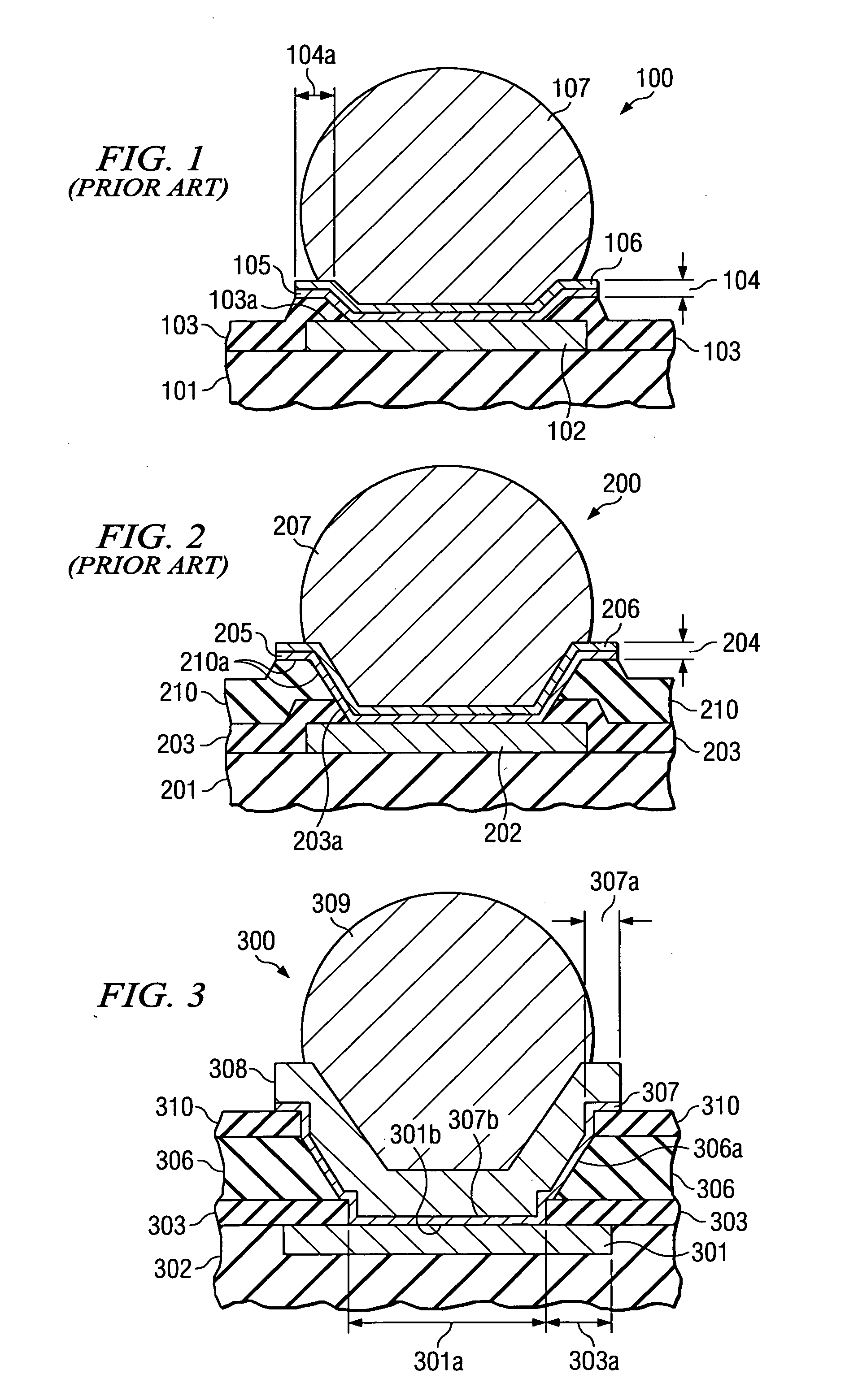

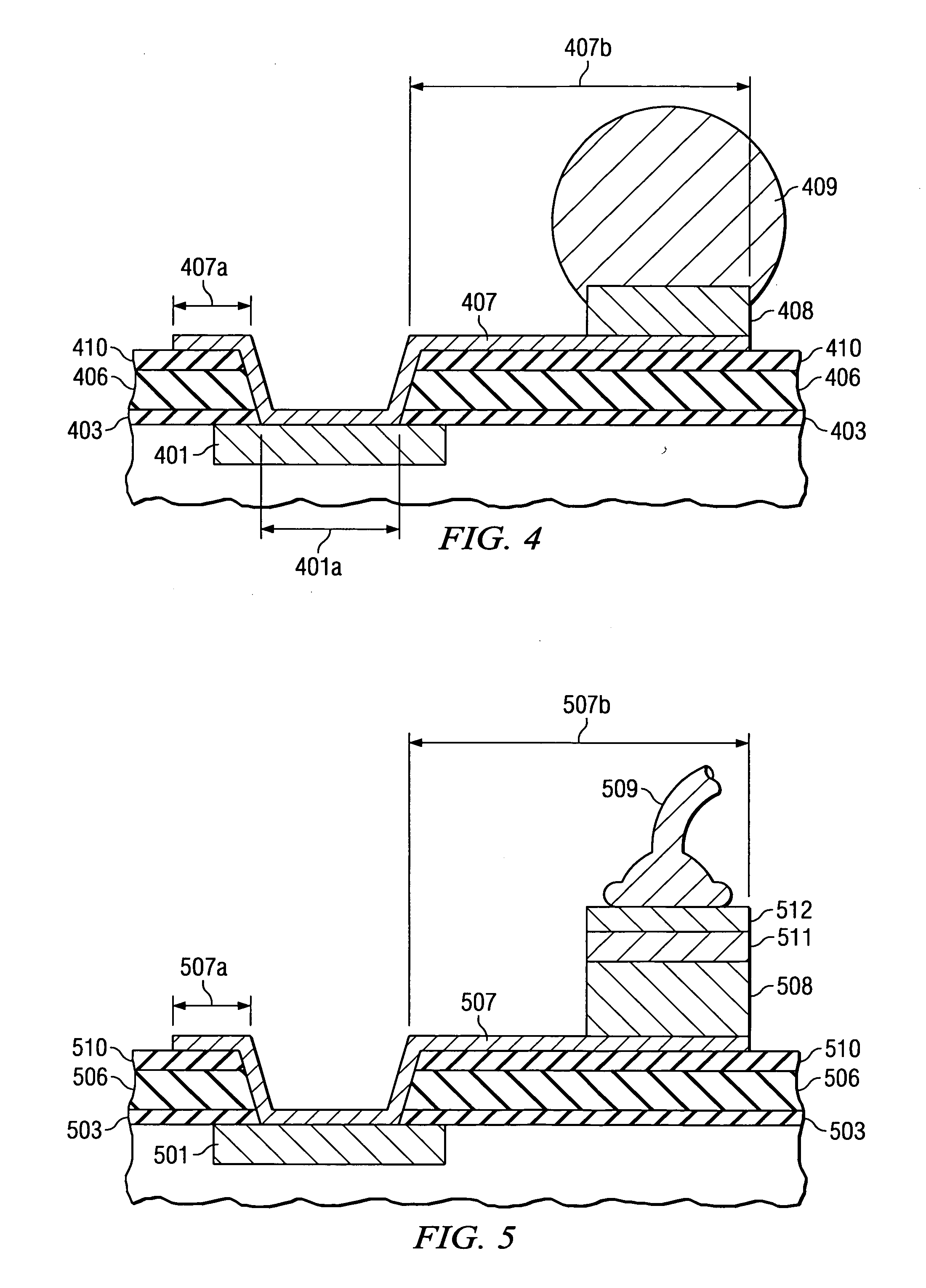

Direct bumping on integrated circuit contacts enabled by metal-to-insulator adhesion

InactiveUS20050082685A1Less crowdedSmall sizeSemiconductor/solid-state device detailsSolid-state devicesContact padDevice material

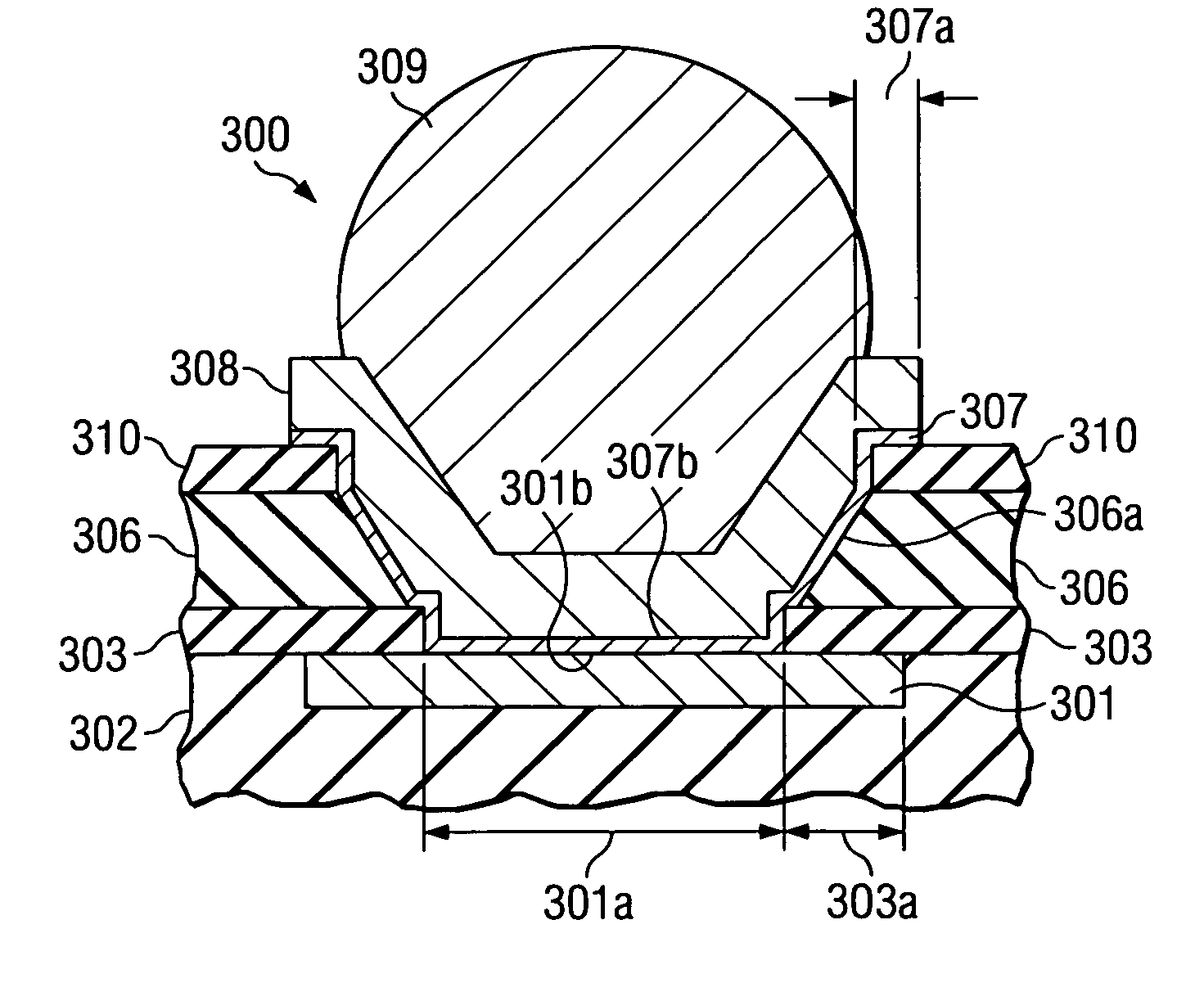

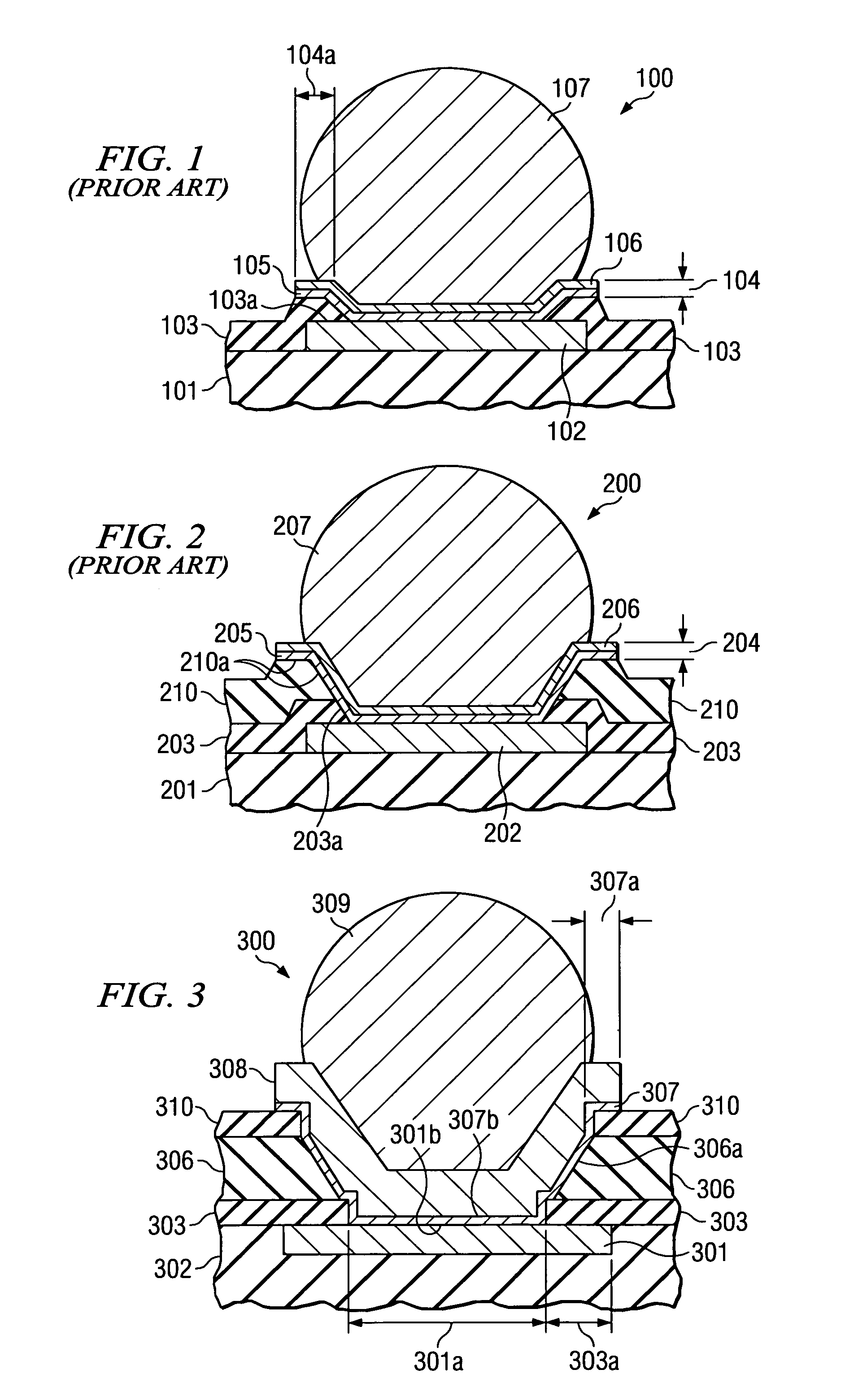

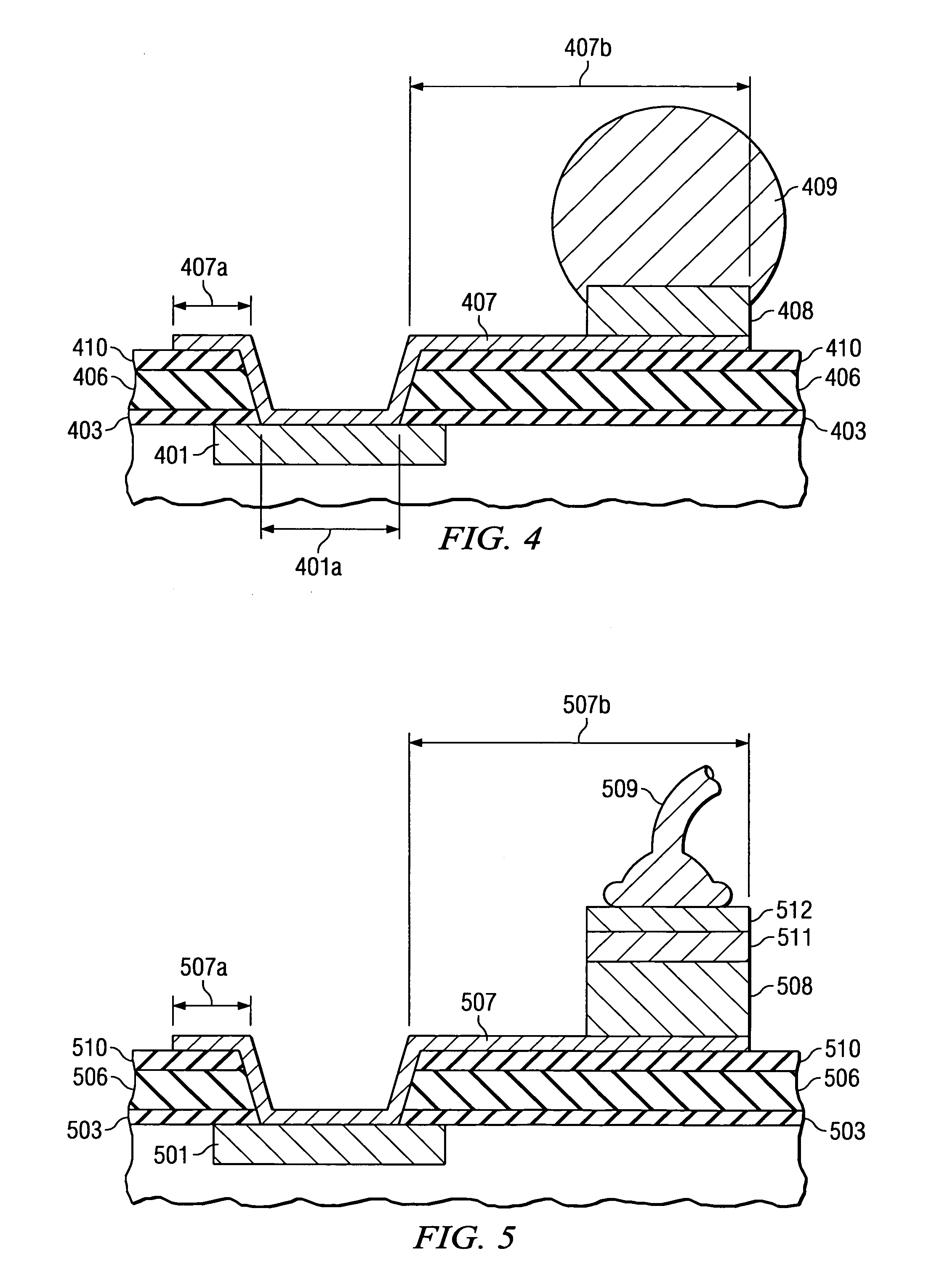

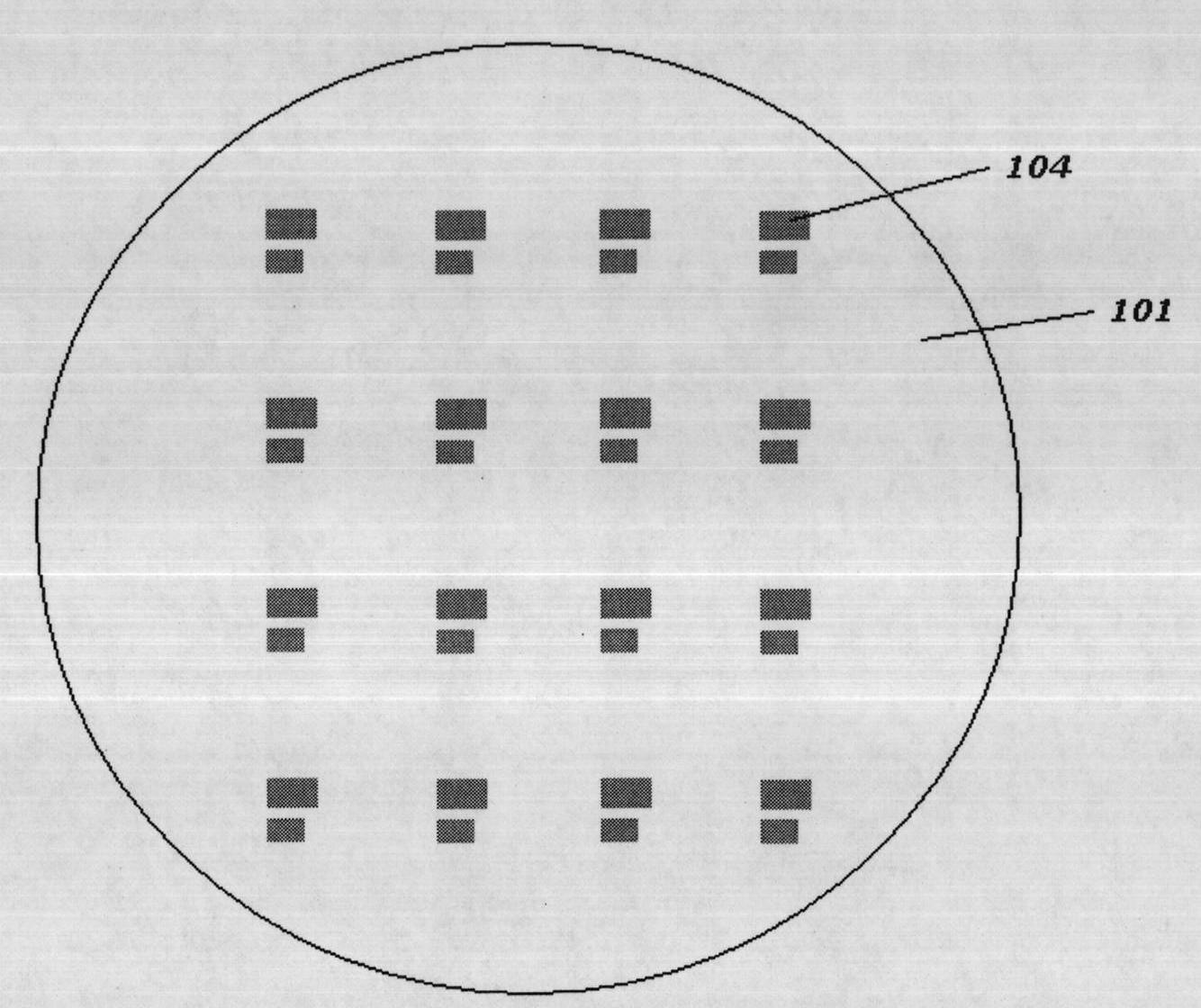

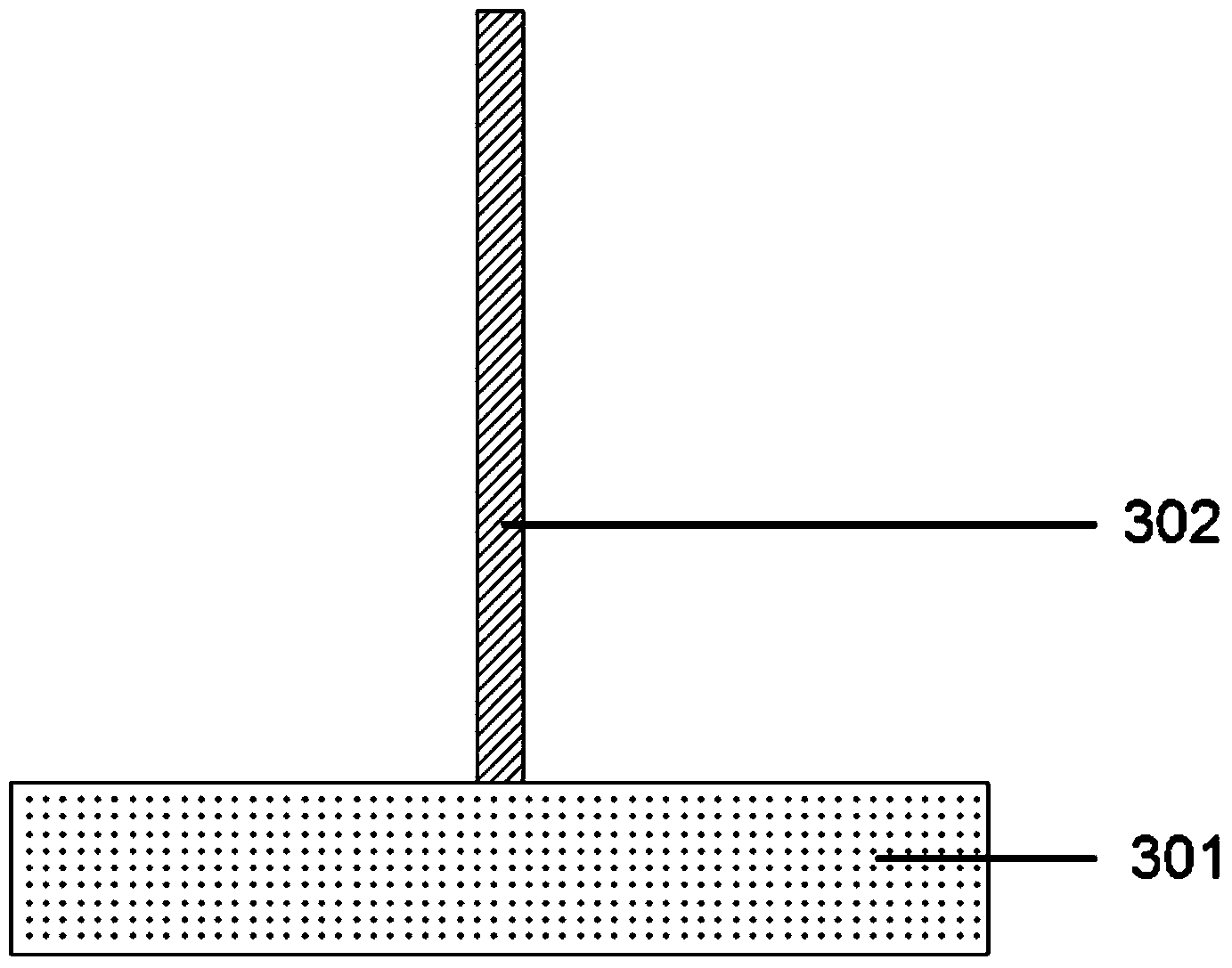

A semiconductor device including a contact pad and circuit metallization on the surface of an integrated circuit (IC) chip comprises a stack of protection layers over the surface of the chip. The stack consists of a first inorganic layer (303, preferably silicon nitride) on the chip surface, followed by a polymer layer (306, preferably benzocyclobutene) on the first inorganic layer (303), and finally an outermost second inorganic layer (310, preferably silicon dioxide) on the polymer layer (303). A window (301a) in the stack of layers exposes the metallization (301) of the IC. A patterned seed metal layer (307, preferably copper) is on the metallization (301) in the window and on the second inorganic layer (310) around the window. A buffer metal layer (308, preferably copper) is positioned on the seed metal layer (307). A metal reflow element (309) is attached to the buffer metal (308).

Owner:TEXAS INSTR INC

Direct bumping on integrated circuit contacts enabled by metal-to-insulator adhesion

InactiveUS7005752B2Less crowdedSmall sizeSemiconductor/solid-state device detailsSolid-state devicesContact padCopper

A semiconductor device including a contact pad and circuit metallization on the surface of an integrated circuit (IC) chip comprises a stack of protection layers over the surface of the chip. The stack consists of a first inorganic layer (303, preferably silicon nitride) on the chip surface, followed by a polymer layer (306, preferably benzocyclobutene) on the first inorganic layer (303), and finally an outermost second inorganic layer (310, preferably silicon dioxide) on the polymer layer (303). A window (301a) in the stack of layers exposes the metallization (301) of the IC. A patterned seed metal layer (307, preferably copper) is on the metallization (301) in the window and on the second inorganic layer (310) around the window. A buffer metal layer (308, preferably copper) is positioned on the seed metal layer (307). A metal reflow element (309) is attached to the buffer metal (308).

Owner:TEXAS INSTR INC

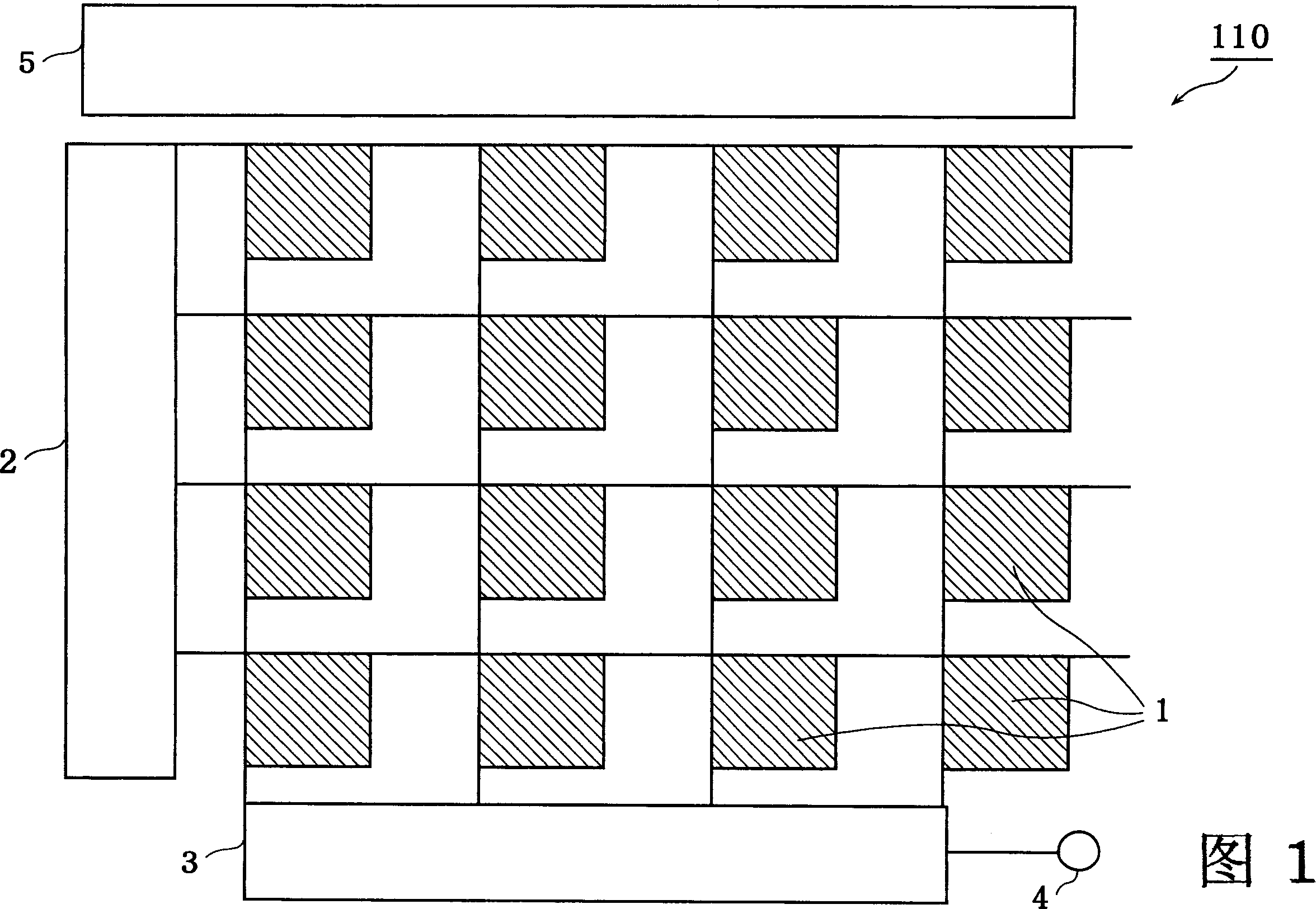

Wafer level MMCM (microwave multichip module) packaging structure using photosensitive BCB (benzocyclobutene) as dielectric layer and method

ActiveCN102110673ASolve the defect of large lossImprove performanceSemiconductor/solid-state device detailsSolid-state devicesAdhesiveSurface-mount technology

The invention relates to a wafer level MMCM (microwave multichip module) packaging structure using photosensitive BCB (benzocyclobutene) as a dielectric layer and a method. The packaging structure is characterized by 1) manufacturing metal ground (GND) shielding layers on a silicon substrate with cavities for embedding; 2) using the photosensitive BCB as the dielectric layers and forming an interconnected through hole structure on the BCB by utilizing photoetching and developing processes; and 3) forming a multi-layer interconnection packaging structure through alternate occurrence of metal layers and the dielectric layers. The method is characterized by eroding or etching the cavities for embedding on the silicon substrate, sputtering a metal seed layer and carrying out electroplating to form the GND, embedding MMIC (monolithic microwave integrated circuit) chips, using conductive adhesives to bond the chips and the substrate, coating the photosensitive BCB and carrying out photoetching and developing to form the interconnected through hole patterns and carrying out curing to realize multi-layer MMCM package. The thickness of the dielectric layers is 20-35mu m. Capacitors, resistors, inductors, power dividers and antenna passive devices can be integrated in the multi-layer interconnection structure or discrete components are integrated through surface mount technology, thus realizing the functionalization of the module.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

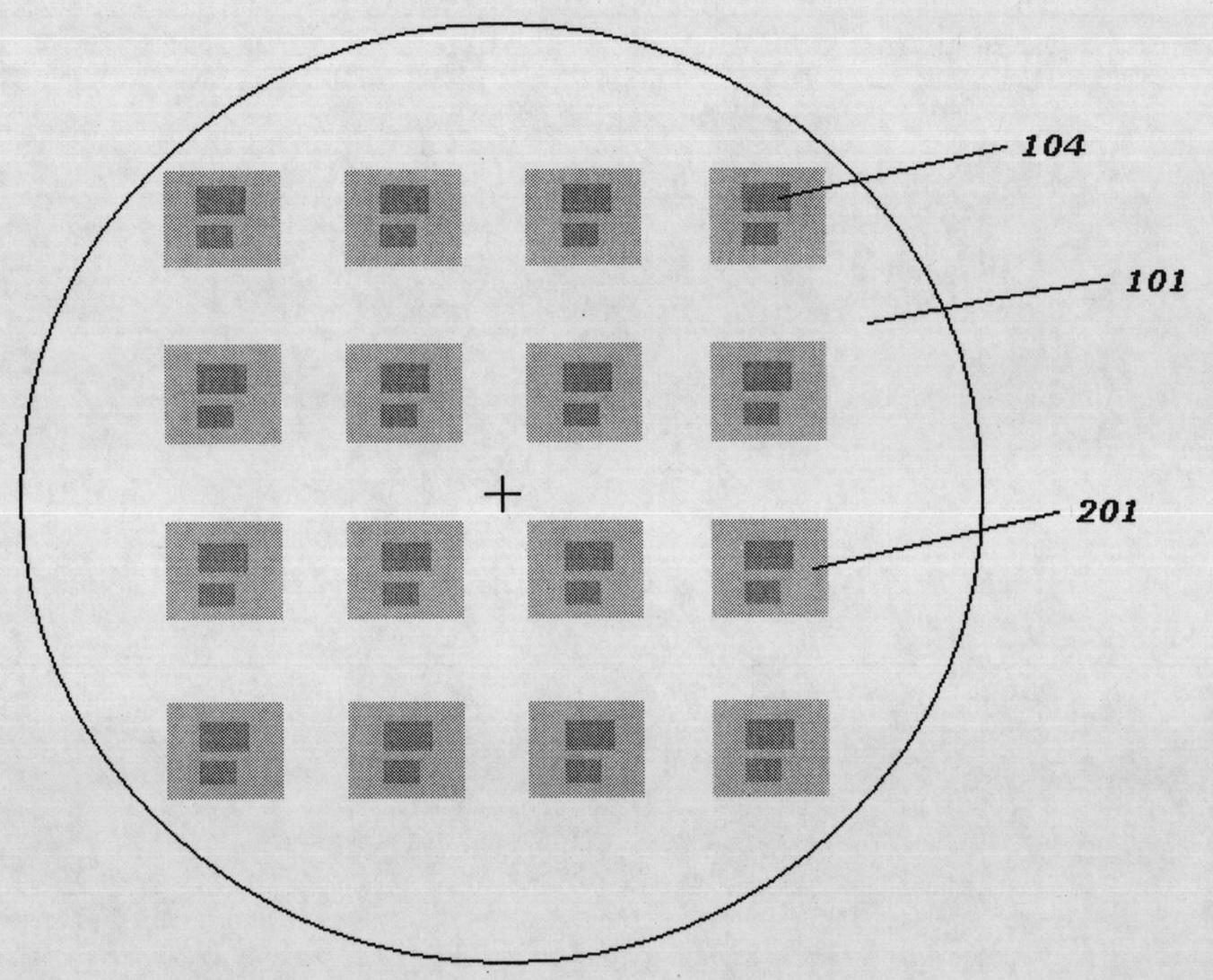

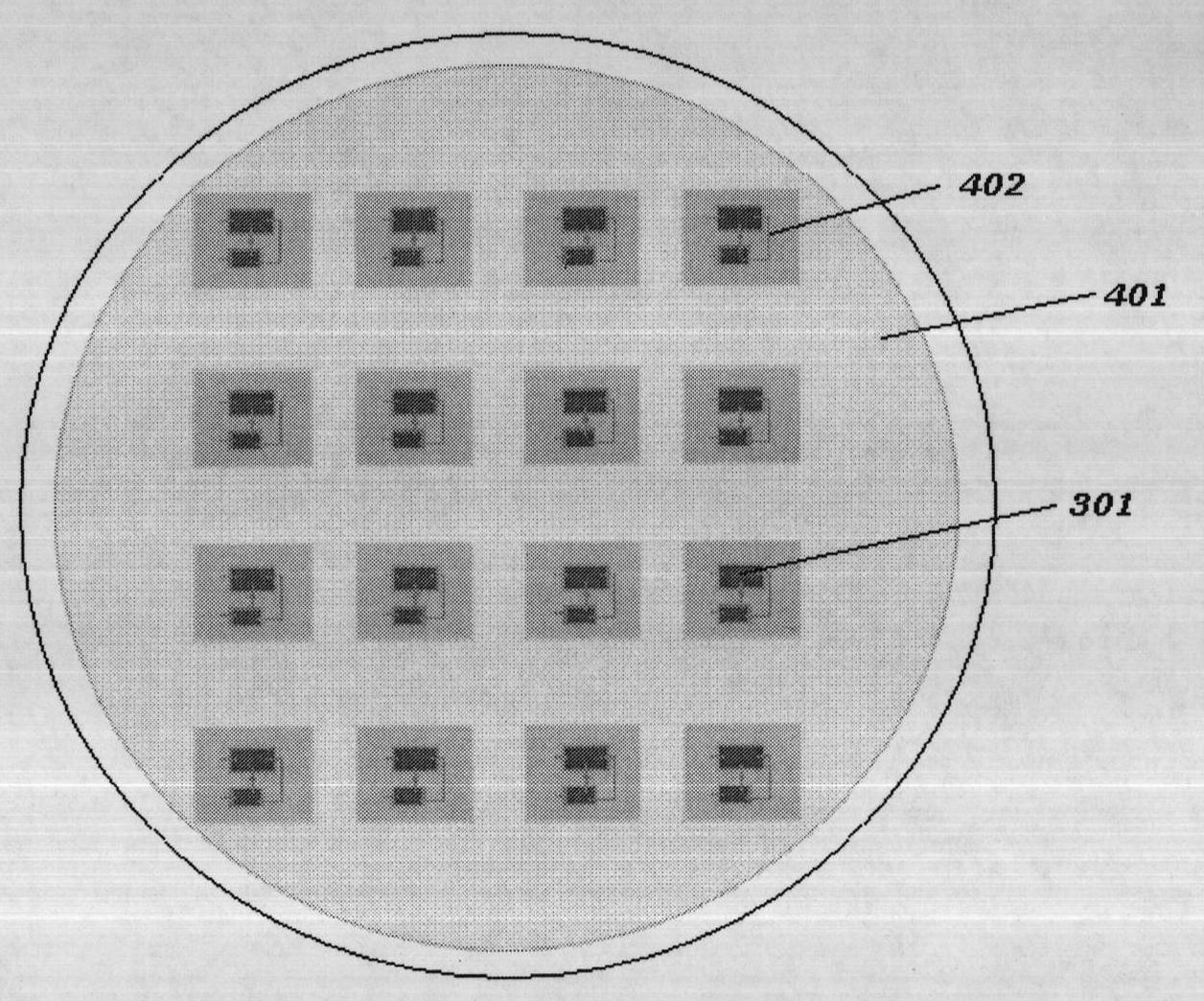

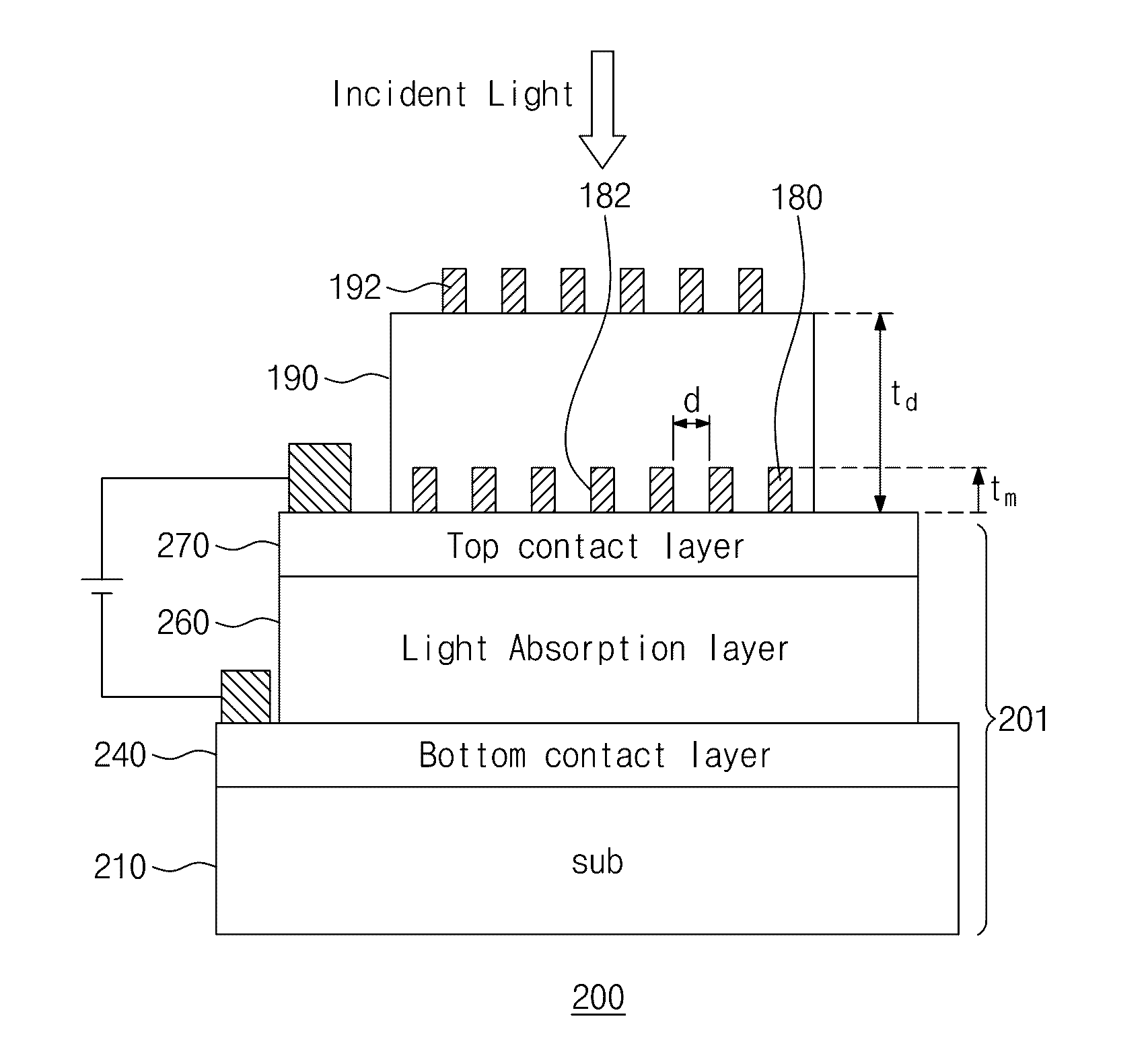

Ir photodetector using metamaterial-based on an antireflection coating to match the impedance between air and sp resonator

InactiveUS20160365463A1Improve quantum efficiencySemiconductor devicesPhotovoltaic energy generationPhotodetectorContact layer

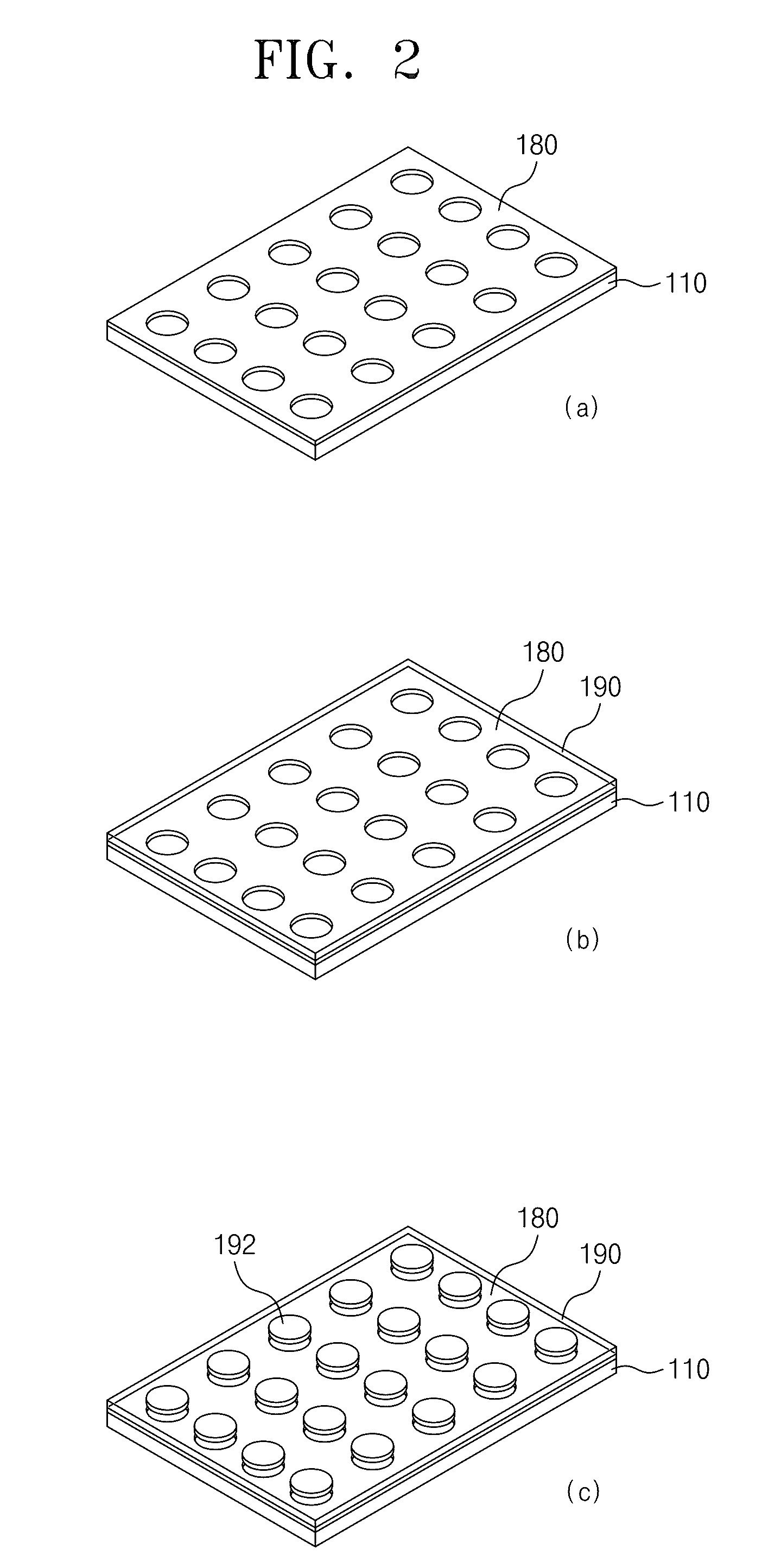

Provided are an infrared photodetector and a method for manufacturing the same. The infrared photodetector includes a bottom contact layer, a light absorption layer stacked on the bottom contact layer, a top contact layer stacked on the light absorption layer, a metal layer stacked on the top contact layer to induce surface plasmon resonance and having a plurality of holes, and a dielectric layer stacked on the metal layer to satisfy an antireflection condition with respect to externally impinging light at a surface plasmon resonance frequency. The dielectric layer is a benzocyclobutene (BCB) layer.

Owner:KOREA RES INST OF STANDARDS & SCI

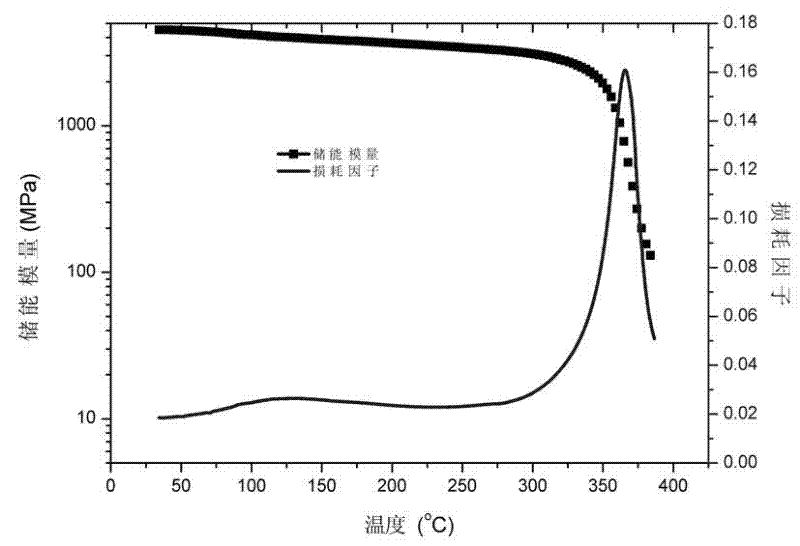

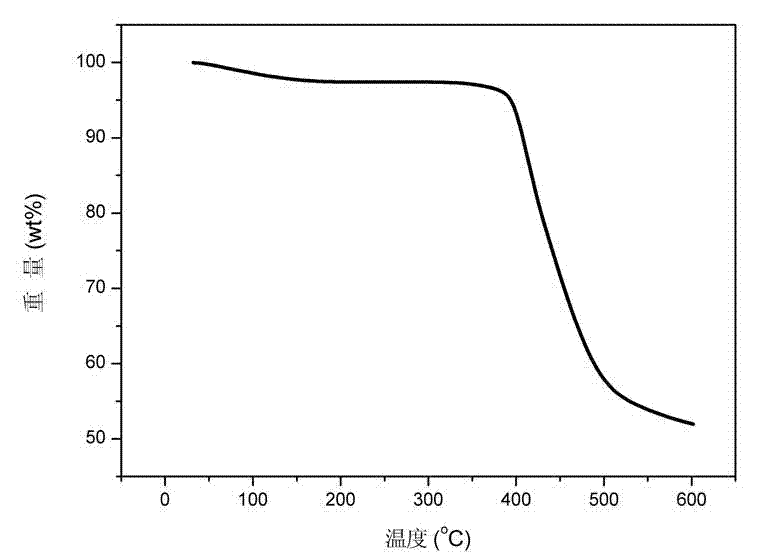

Dielectric composite material comprising benzocyclobutene which contains a filler in order to decrease the coefficient of thermal expansion.

InactiveCN1806329ASemiconductor/solid-state device detailsPrinted circuit aspectsDielectric lossThermal expansion

A dielectric composite material containing a toughened benzocyclobutene resin and at least about 50% by weight of an inorganic filler. Also electronic packages having at least one conductive layer and at least one layer of the dielectric composite material. The dielectric composite material can have a dielectric constant less than about 3.5, and a dielectric loss of less than about 0.004.

Owner:3M INNOVATIVE PROPERTIES CO

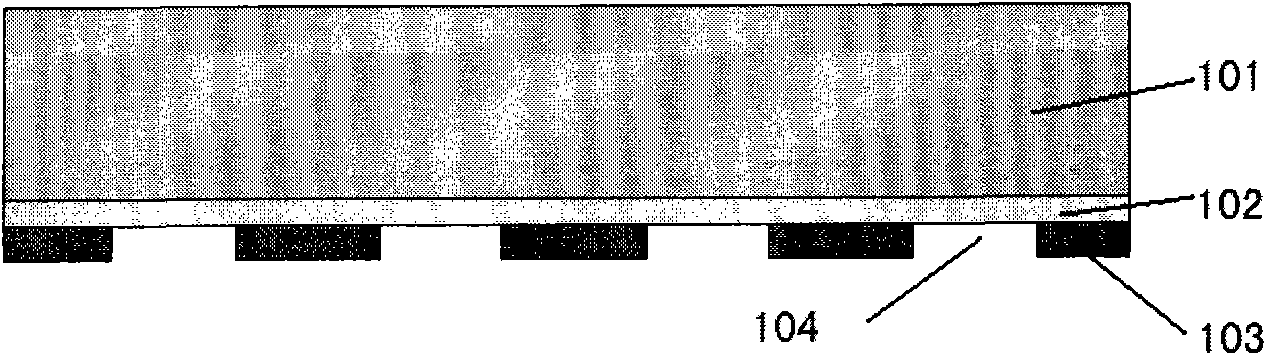

Liner materials and related processes for 3-d integration

ActiveUS20100200989A1Semiconductor/solid-state device detailsSolid-state devicesGas phaseConductive materials

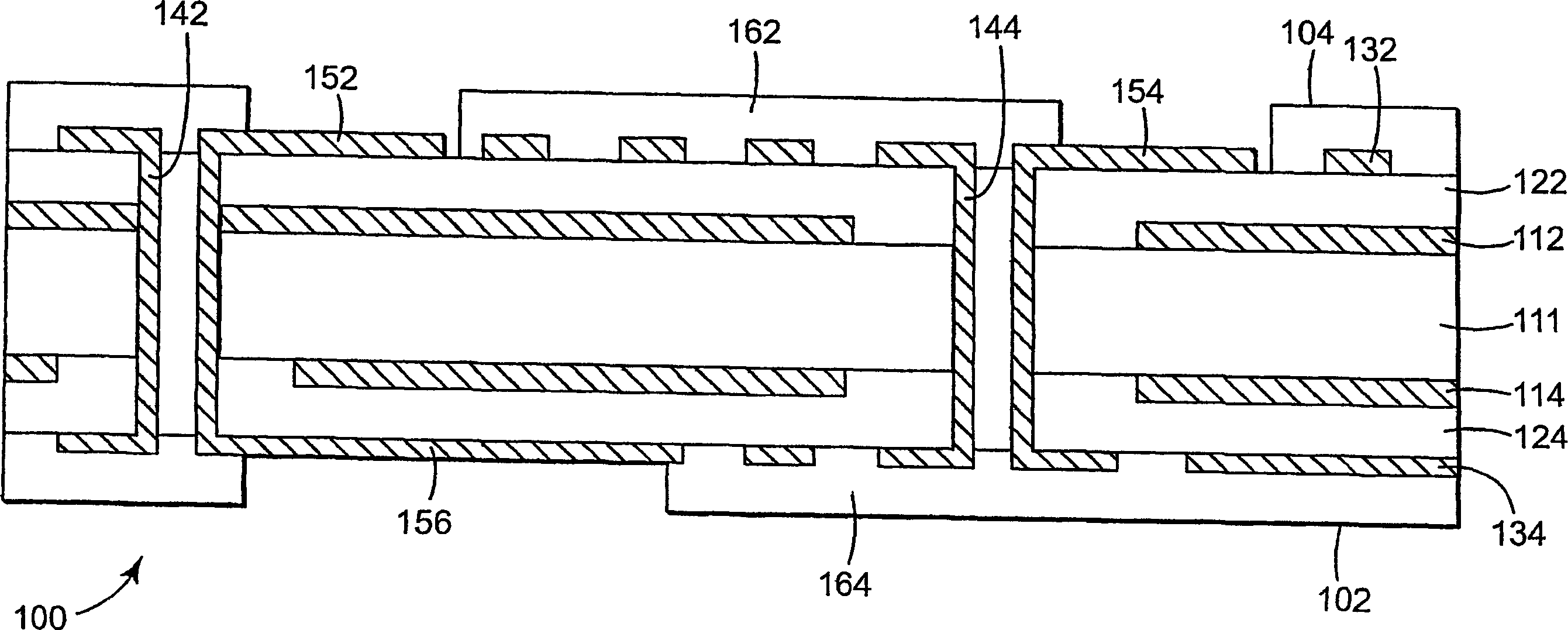

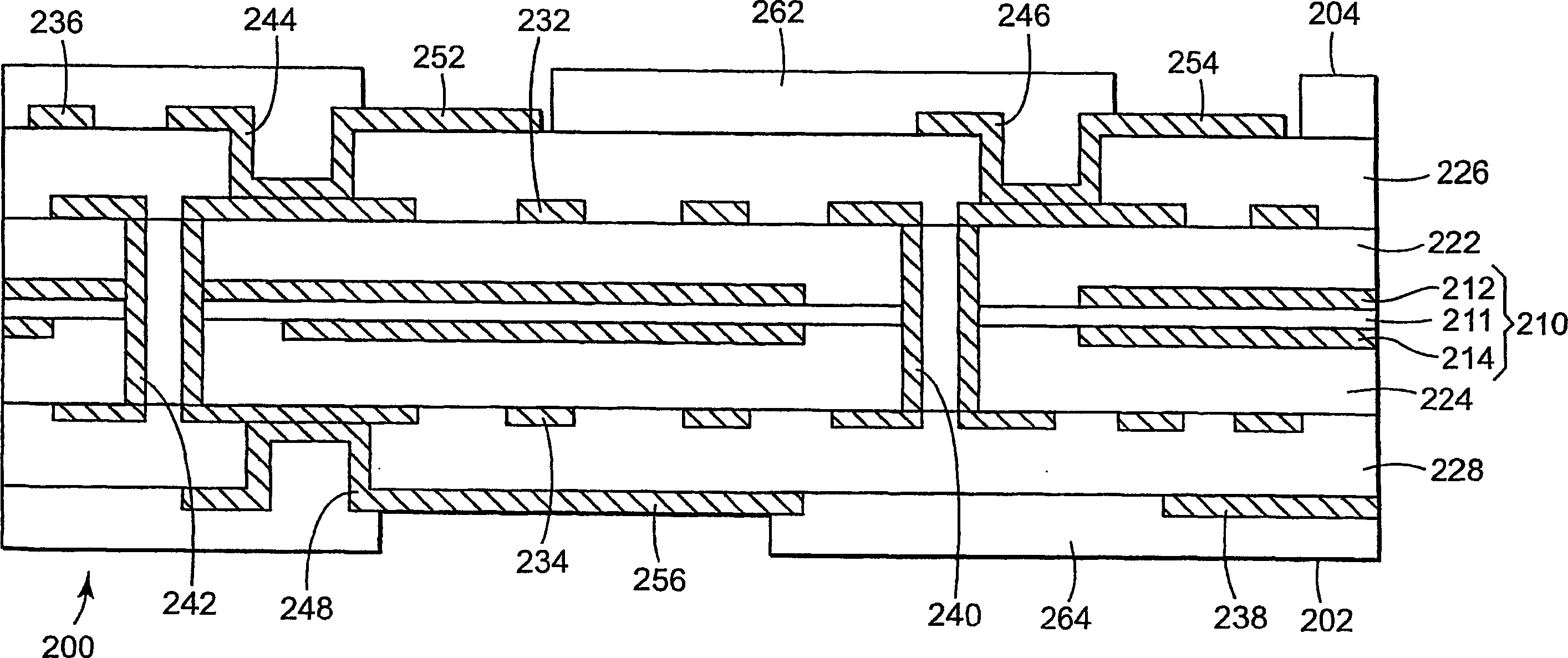

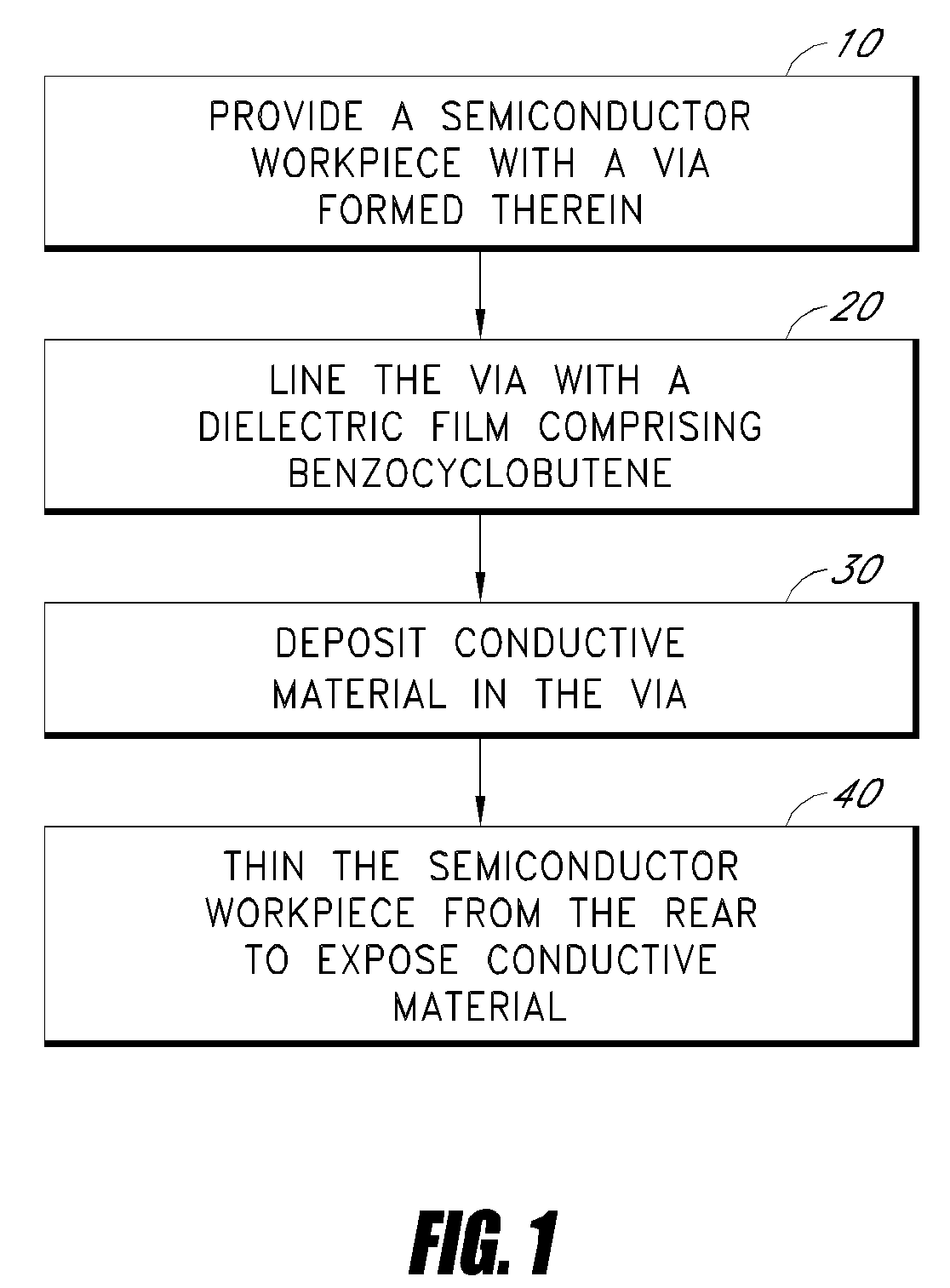

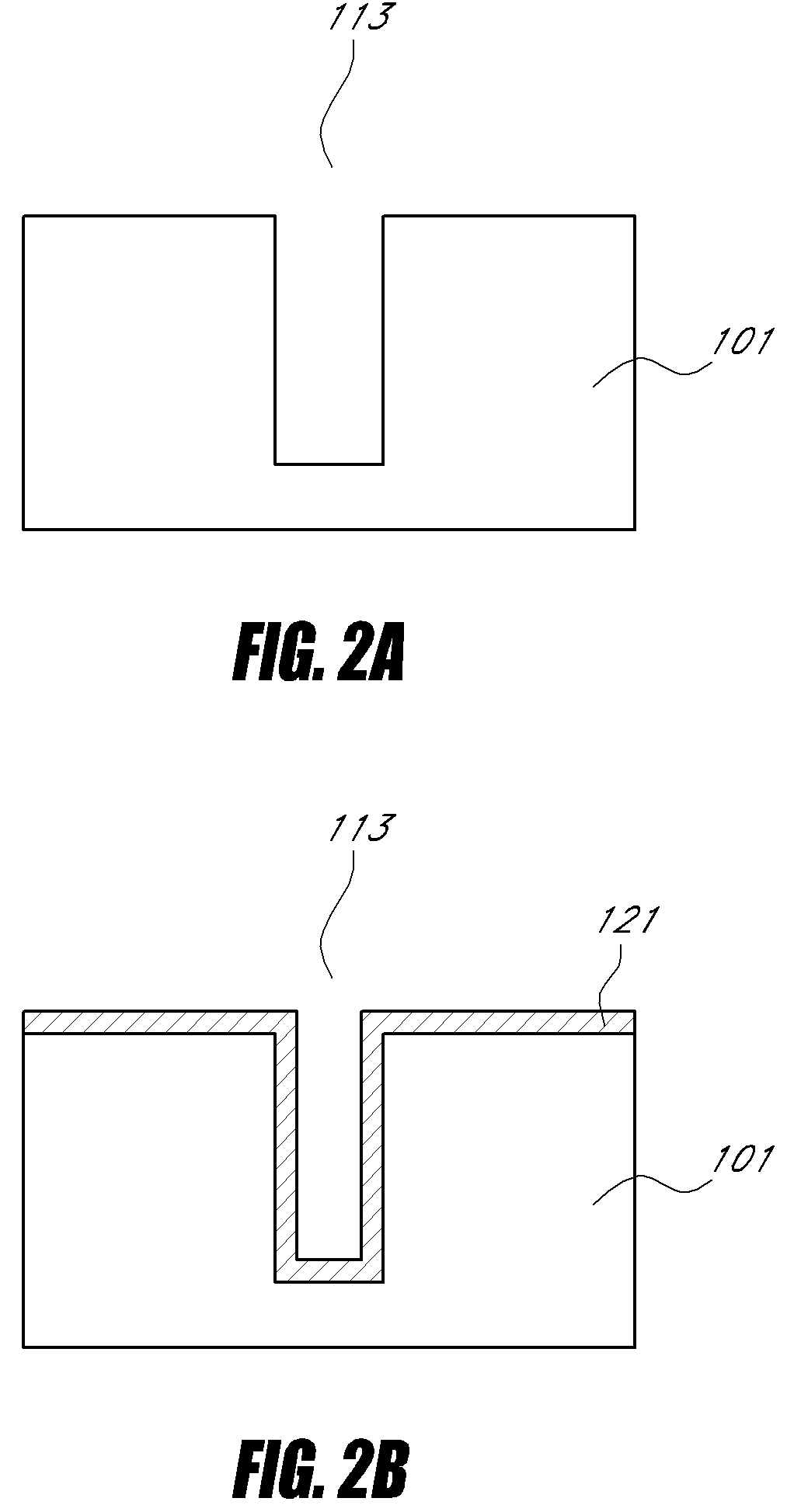

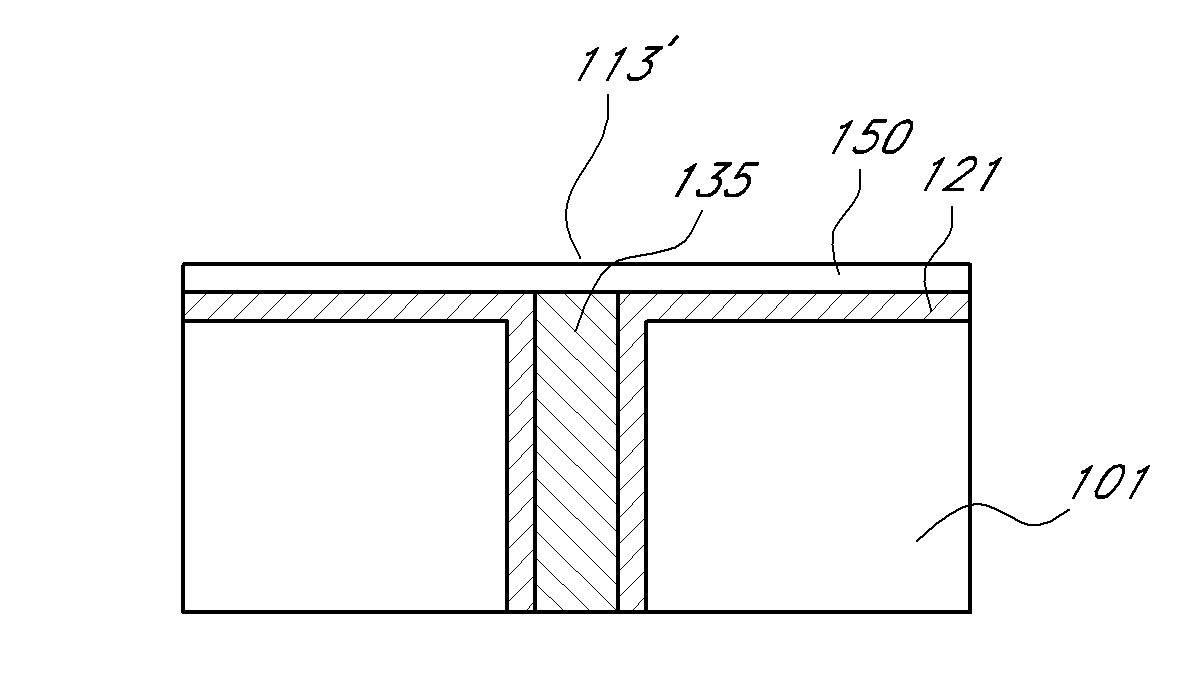

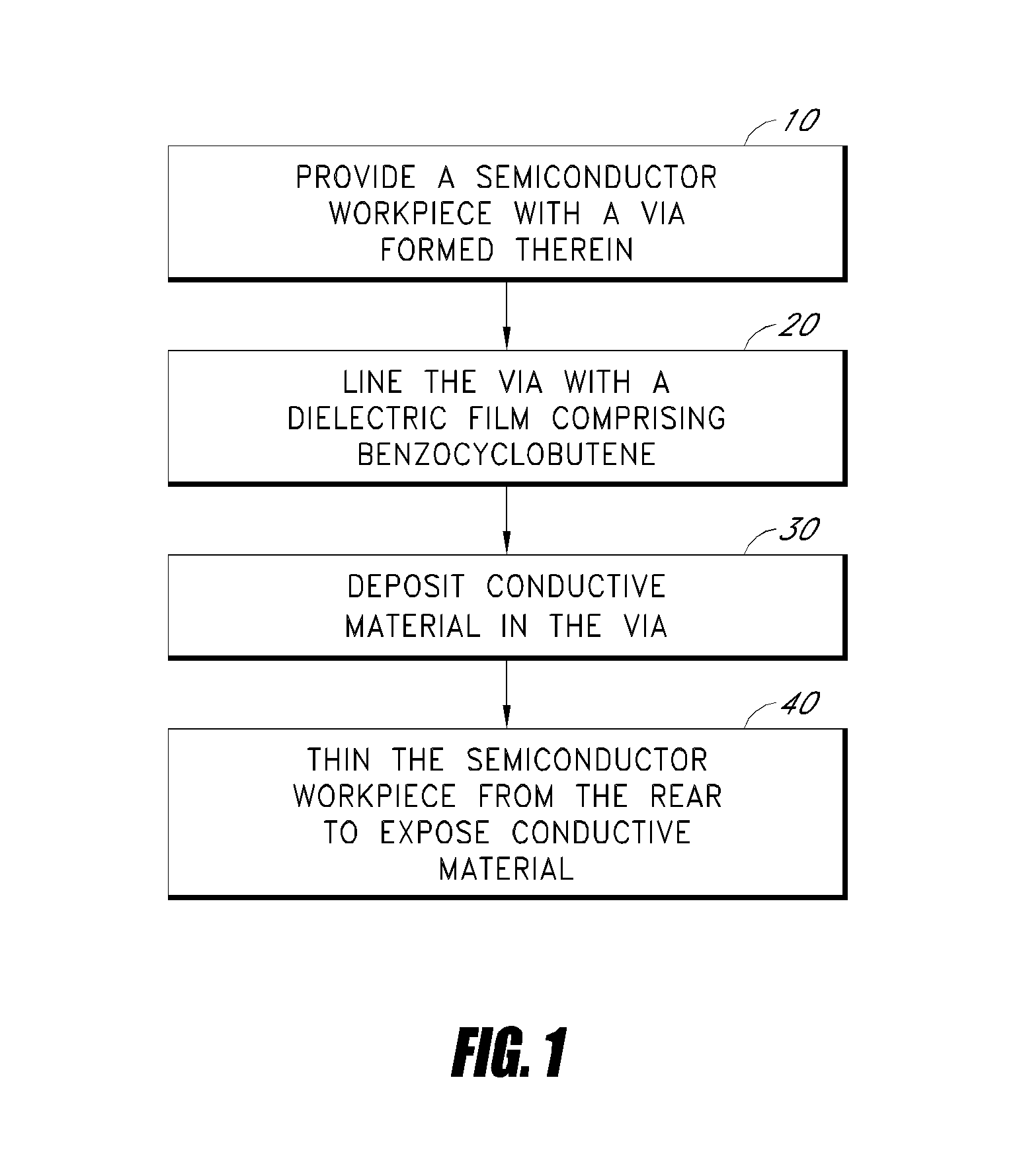

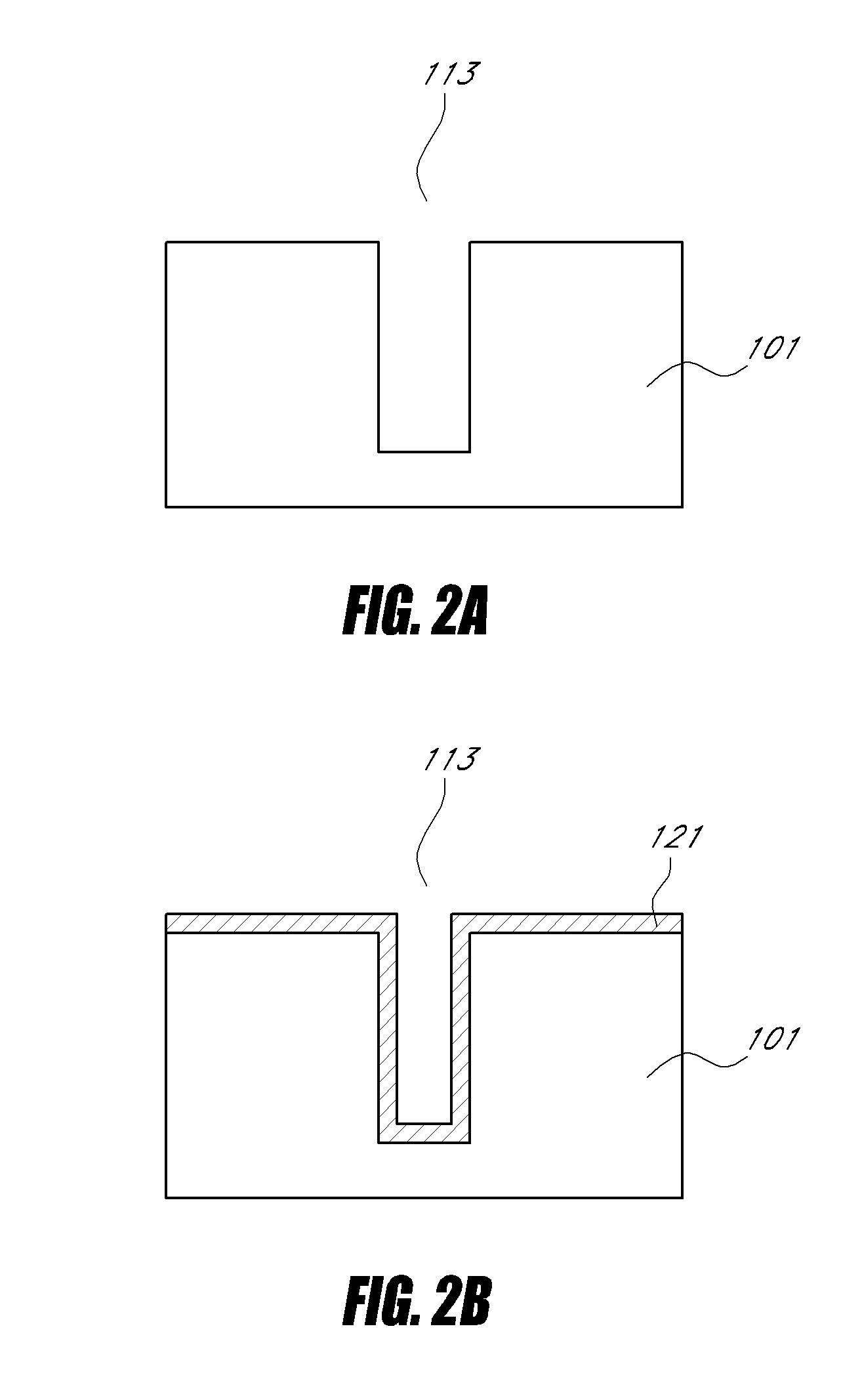

In some embodiments, a low-k dielectric film liner, preferably comprising benzocyclobutene, is deposited on the sidewalls of through-silicon vias used in three-dimensional (3-D) integration of integrated circuits. A semiconductor workpiece having a via is provided. A dielectric film liner, preferably comprising benzocyclobutene, is deposited on the sidewalls of the via by chemical vapor deposition. Following the deposition of the dielectric film liner, conductive material is deposited into the via. The conductive material on the bottom of the via can be exposed by thinning the back of the semiconductor workpiece, thereby forming a through-silicon via. The semiconductor workpiece can form a stack with one or more additional semiconductor workpieces having vias filled with conductive material to form a 3-D integrated circuit. The conductive material electrically interconnects the integrated circuits at different levels of the stack.

Owner:ASM INTERNATIONAL

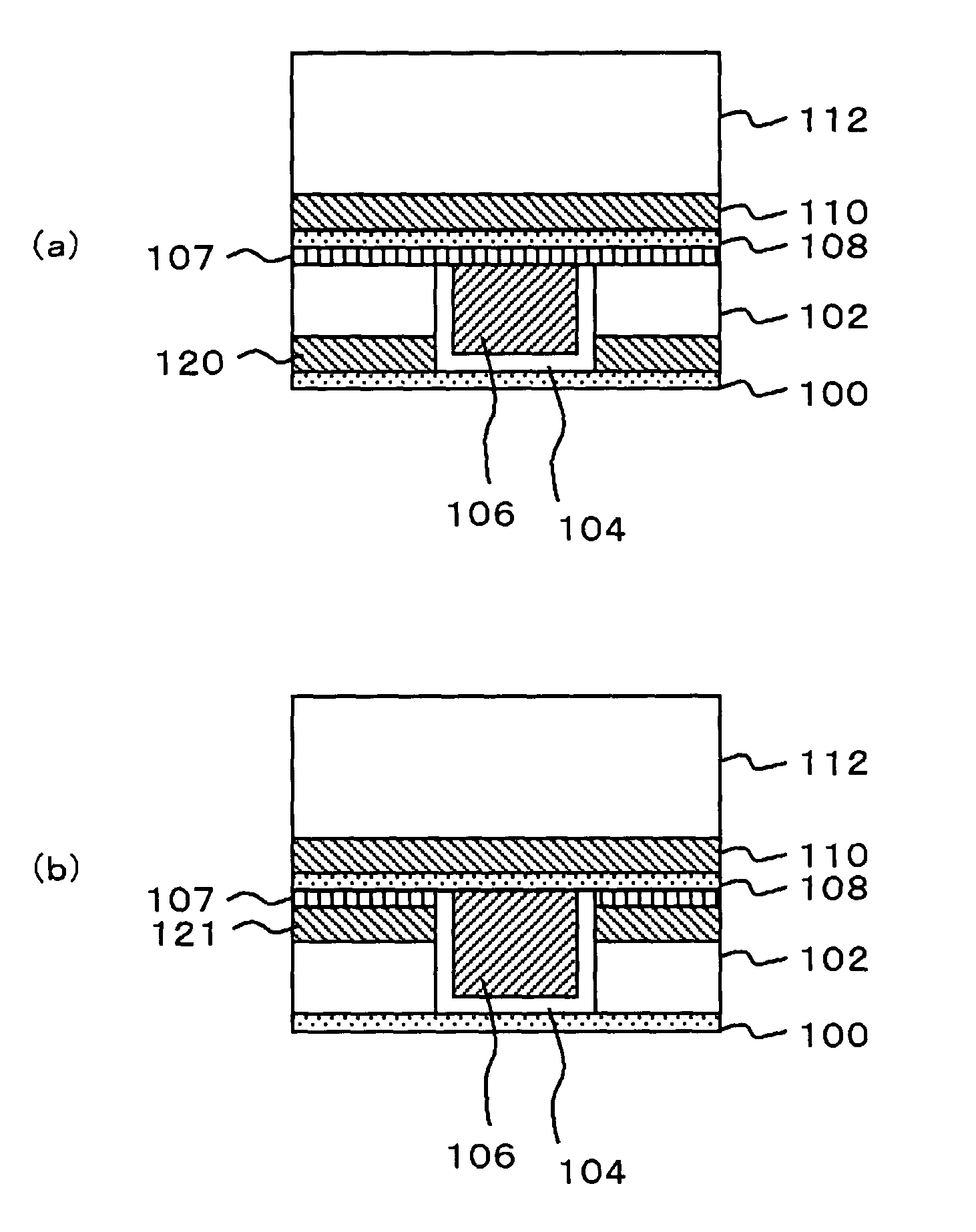

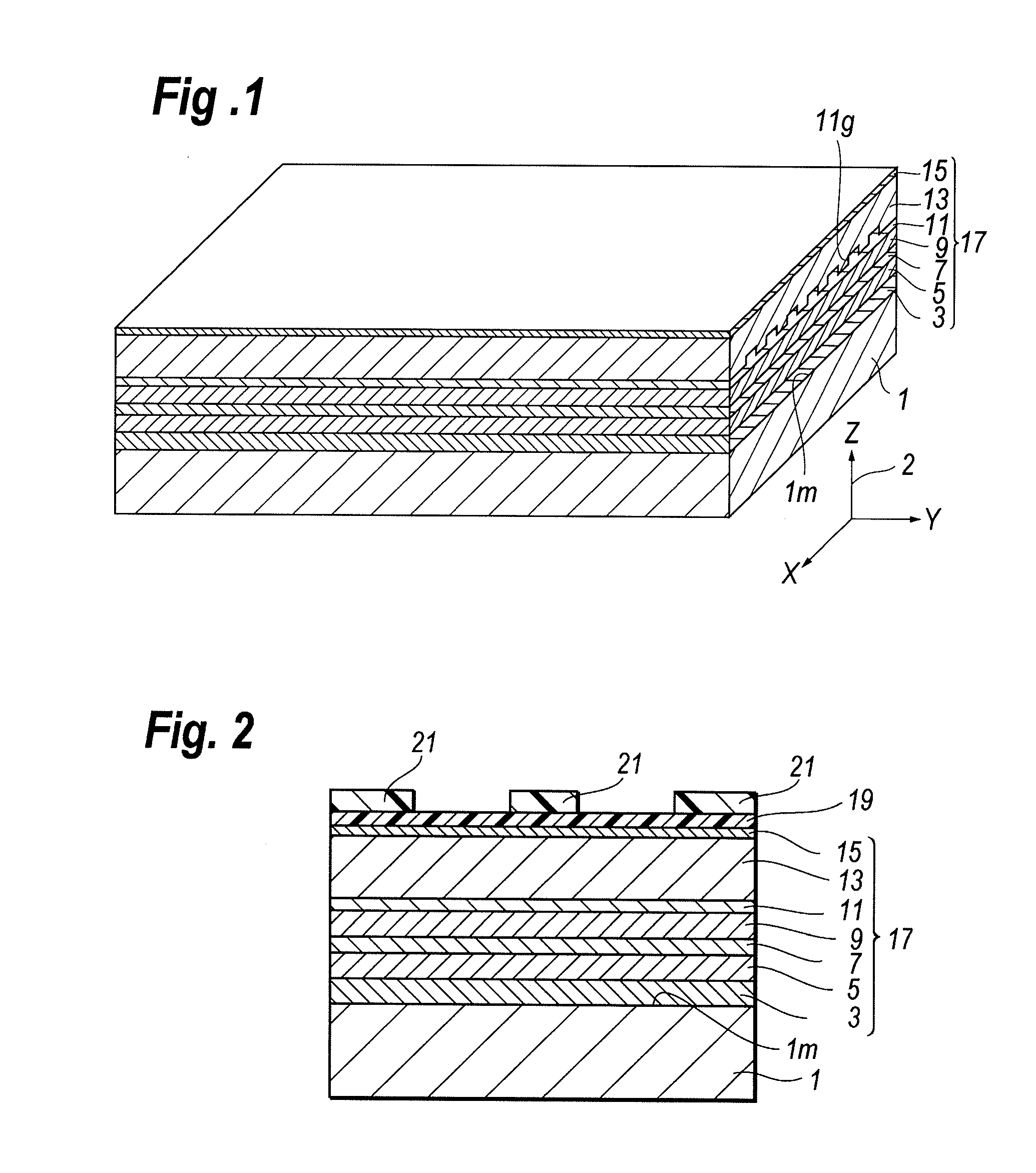

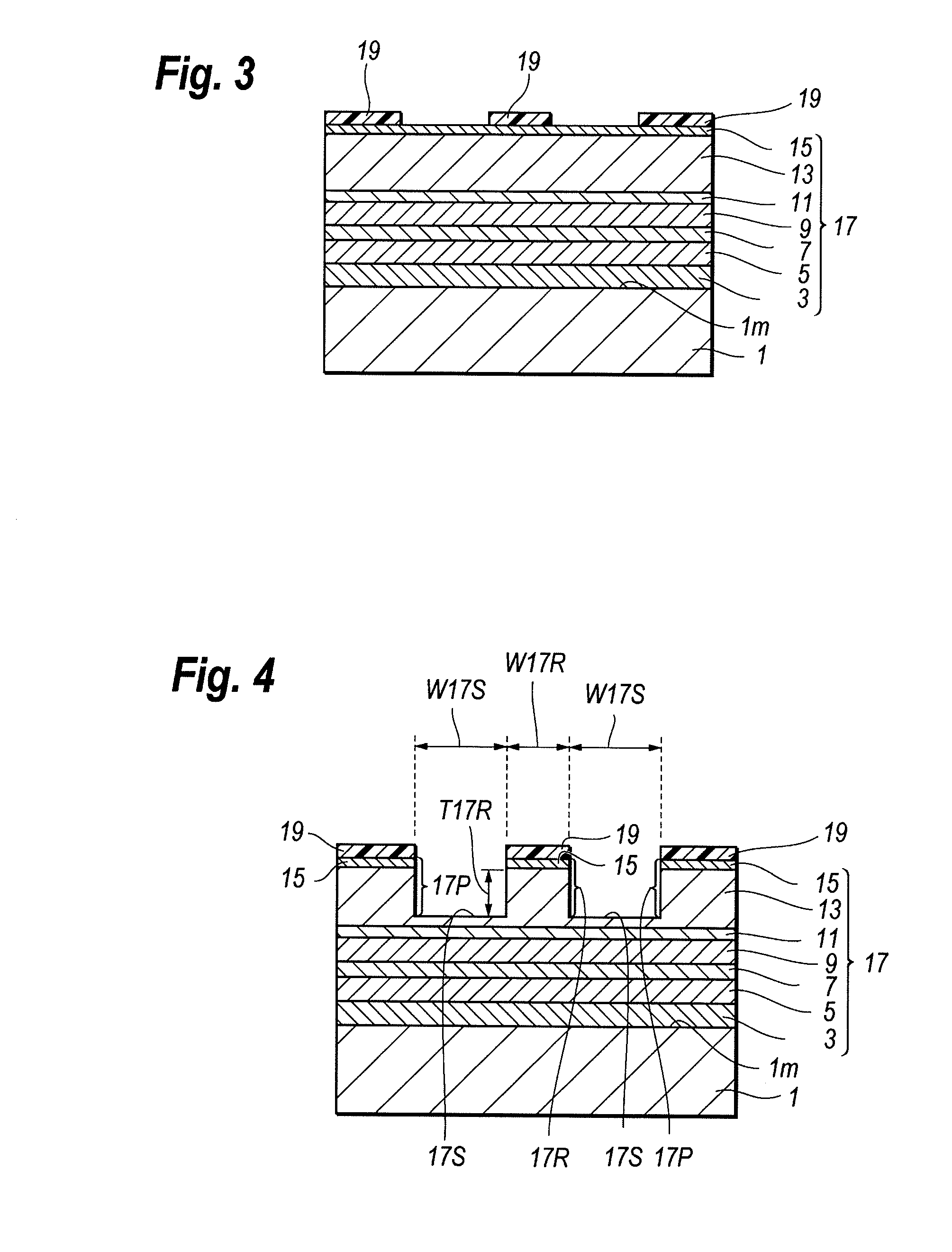

Semiconductor device and manufacturing method thereof

InactiveUS20040041269A1Semiconductor/solid-state device detailsSolid-state devicesCopper interconnectDevice material

Owner:NEC ELECTRONICS CORP

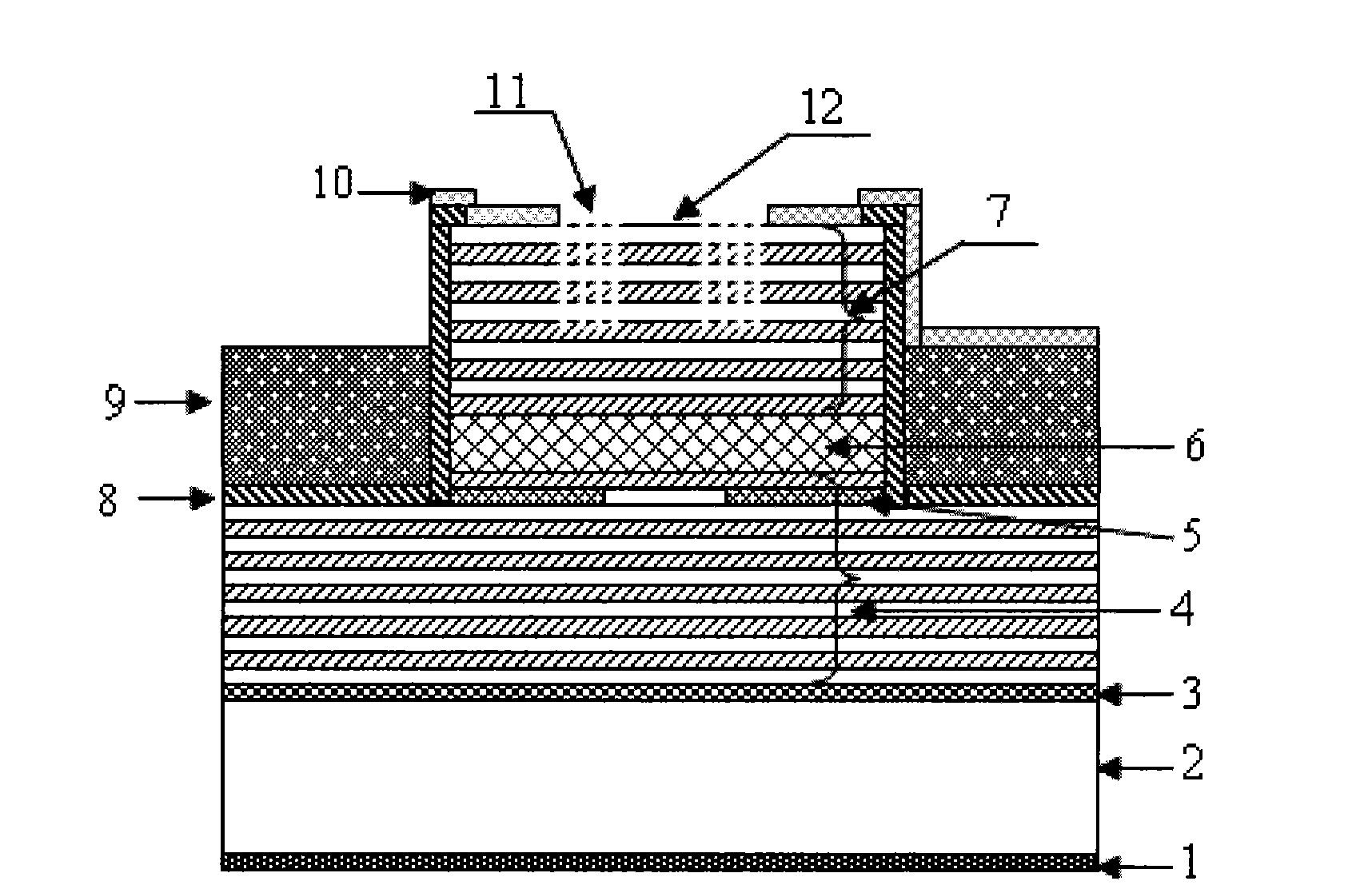

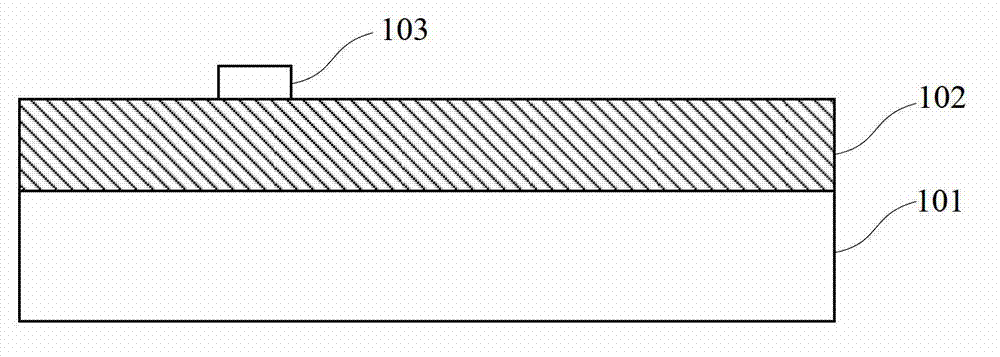

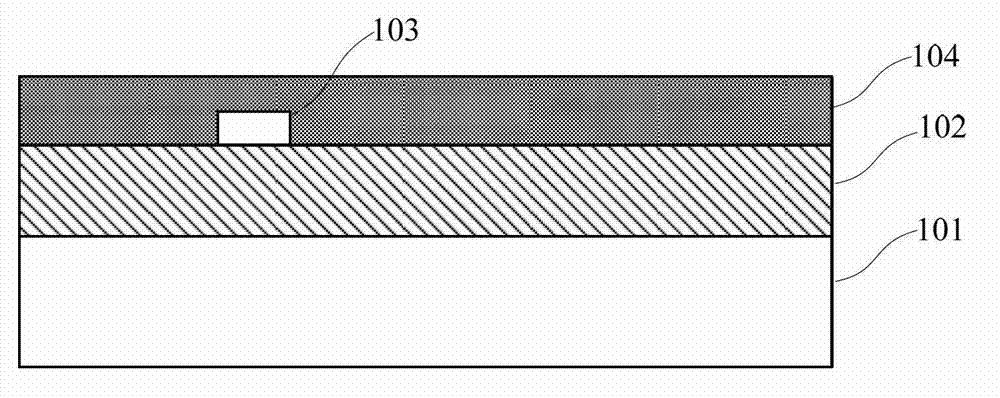

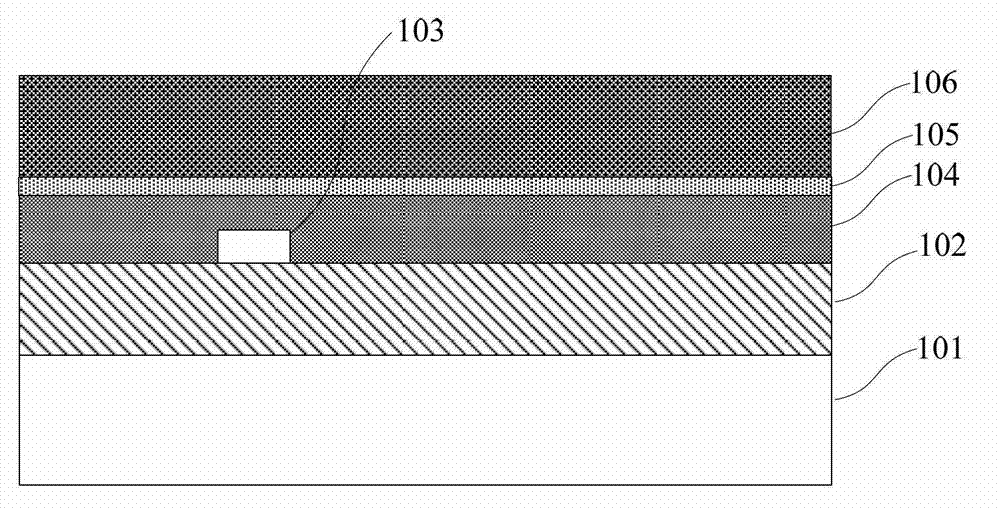

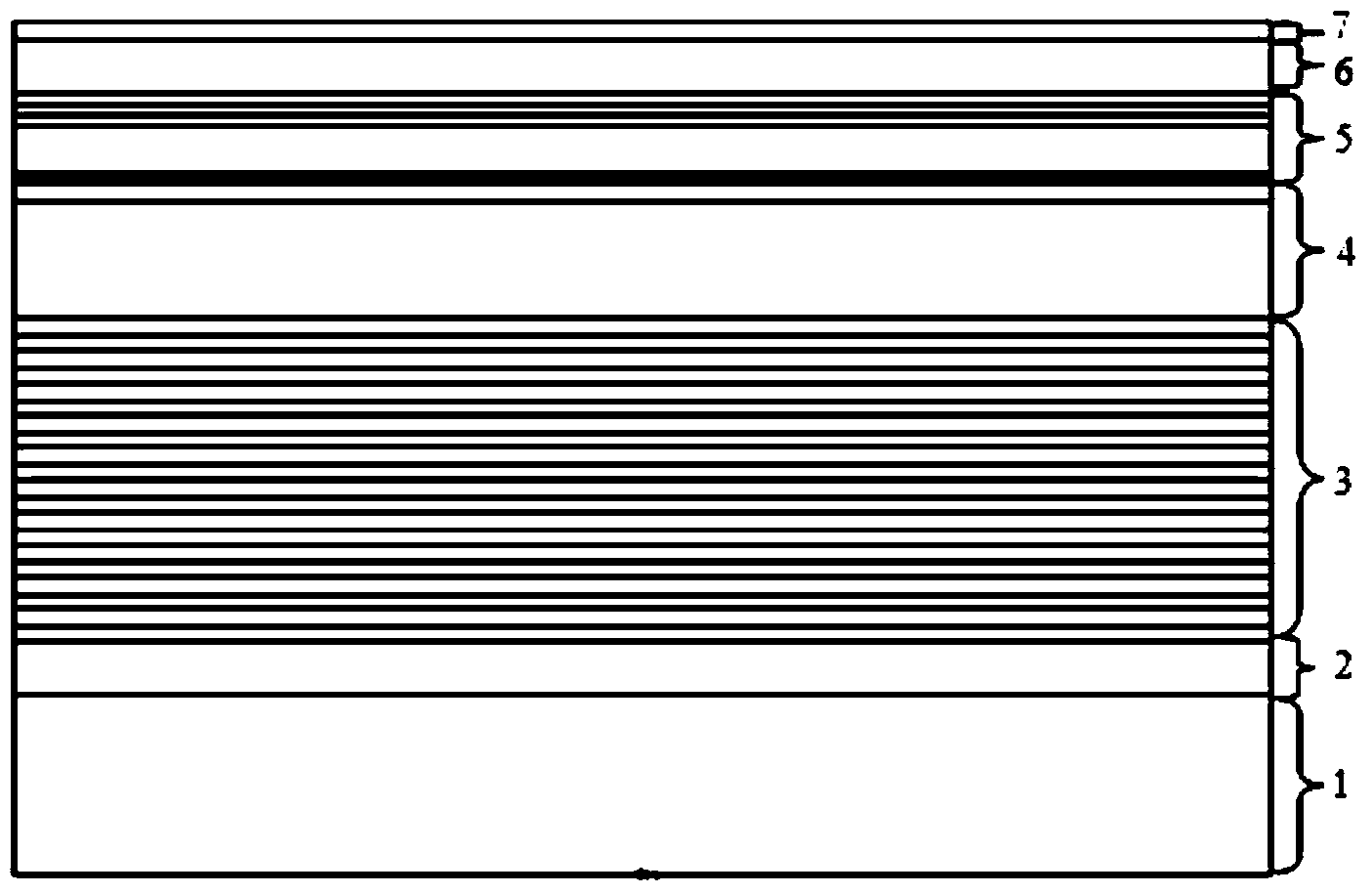

Hybrid integrated laser based on BCB (benzocyclobutene) bonding process and manufacturing method thereof

ActiveCN102904159AAchieve monolithic integrationSmall sizeOptical wave guidanceLaser detailsBonding processContact layer

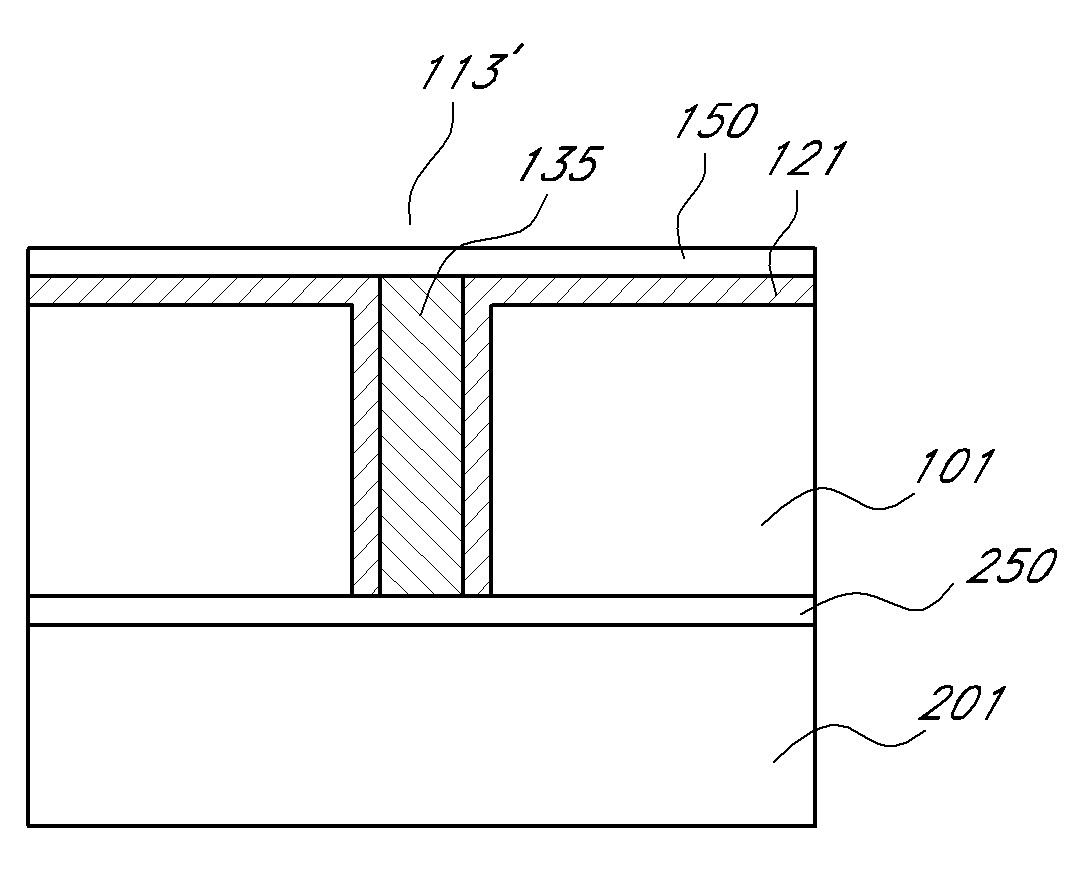

The invention provides a hybrid integrated laser based on BCB (benzocyclobutene) bonding process and a manufacturing method thereof. The hybrid integrated laser comprises an SOI-based optical waveguide chip including a silicon substrate, a buried oxide layer and a silicon waveguide structure, a BCB coating layer, a III-V group laser epitaxial layer, a heat sink through hole and a polycrystalline silicon heat sink filled in the heat sink through hole, wherein the III-V group laser epitaxial layer is provided with a bottom contact layer, an active layer, a tunnel junction and a top contact layer; the heat sink through hole runs through the III-V group laser epitaxial layer, the BCB coating layer and the buried oxide layer, as well as a silicon nitride isolation layer combined with the he surface of the III-V group laser epitaxial layer and provided with electrode through holes and an electrode structure. The hybrid integrated laser based on BCB bonding process and the manufacturing method thereof realize the monolithic integration of the SOI-based optical waveguide chip and the III-V group laser epitaxial layer by adopting the BCB bonding process, and improve the performance of the laser by introducing the polycrystalline silicon heat sink structure. The hybrid integrated laser based on BCB bonding process can be used as a silicon substrate light source device and provides an on-chip light source for a silicon substrate light integrated chip.

Owner:南通新微研究院 +1

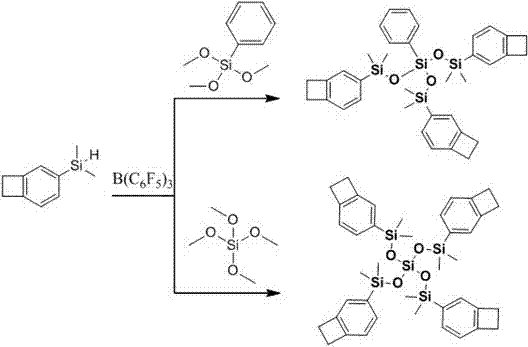

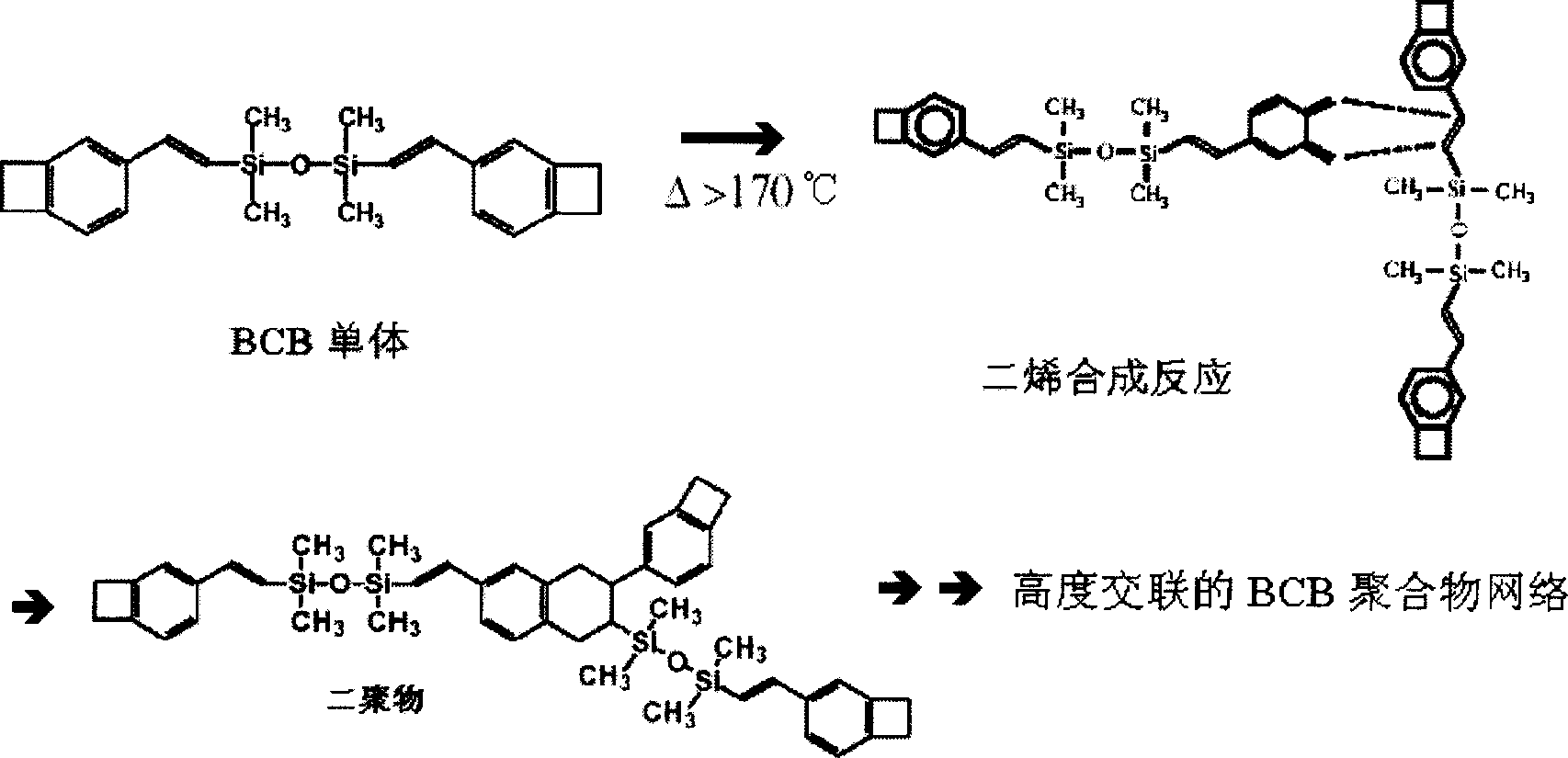

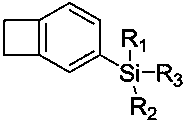

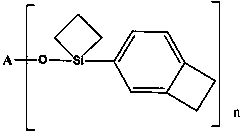

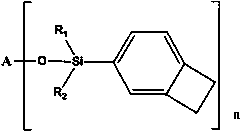

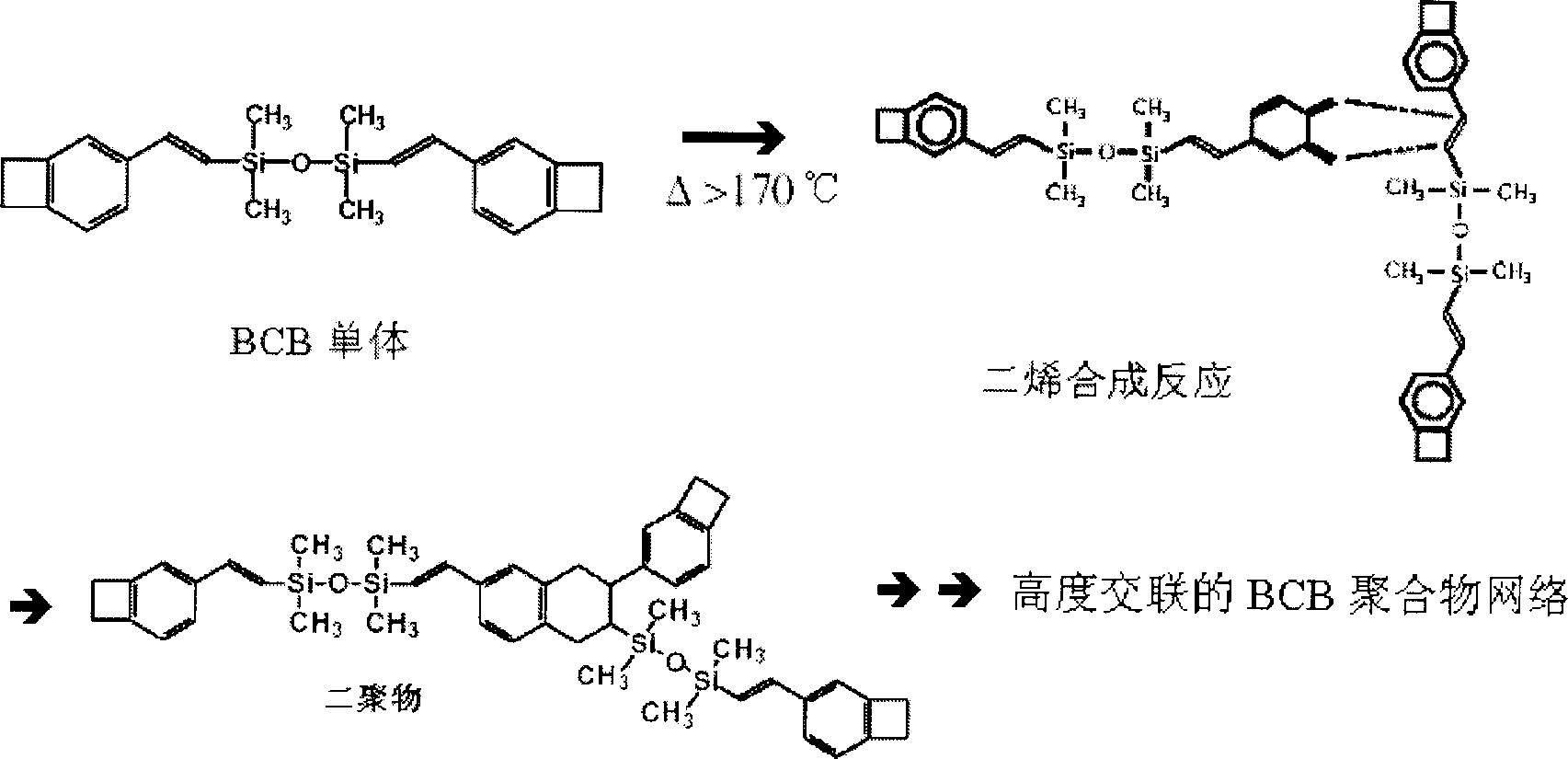

Silicon-containing benzocyclobutene monomers and preparation method thereof

InactiveCN102206229AImprove performanceLow toxicitySilicon organic compoundsLithium chlorideDistillation

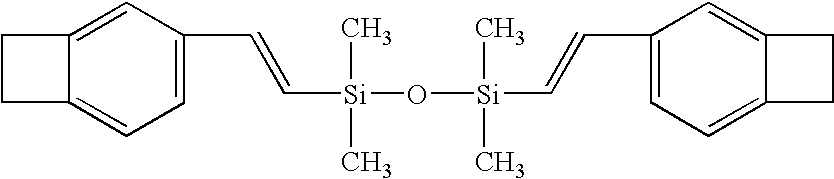

The invention discloses silicon-containing benzocyclobutene monomers, such as dimethyl vinyl benzocyclobuten-1-ylsiloxane, and a preparation method thereof. The preparation method of the compound comprises: adding magnesium, anhydrous lithium chloride and lithium aluminum hydride into a reactor under water-free, anaerobic and nitrogen-protection conditions; dripping the tetrahydrofuran solution of 1-bromobenzocyclobutene with stirring, dripping the tetrahydrofuran solution of methylvinyldichlorosilane after the magnesium is reacted completely, and reacting at -20 to 40 DEG C for 3 to 24 hours; and adding water to terminate reaction, extracting with an organic solvent, drying an organic phase by using an organic salt drying agent, concentrating, and subjecting the concentrated material to reduced-pressure distillation or silica column chromatography to obtain a product. The compound contains reactive vinylsilyl and hydrosilyl reaction groups, and the high polymer material formed by reaction has high comprehensive performance and has great development potential and application prospect in fields of microelectronics, aerospace and national defense.

Owner:SOUTHWEAT UNIV OF SCI & TECH

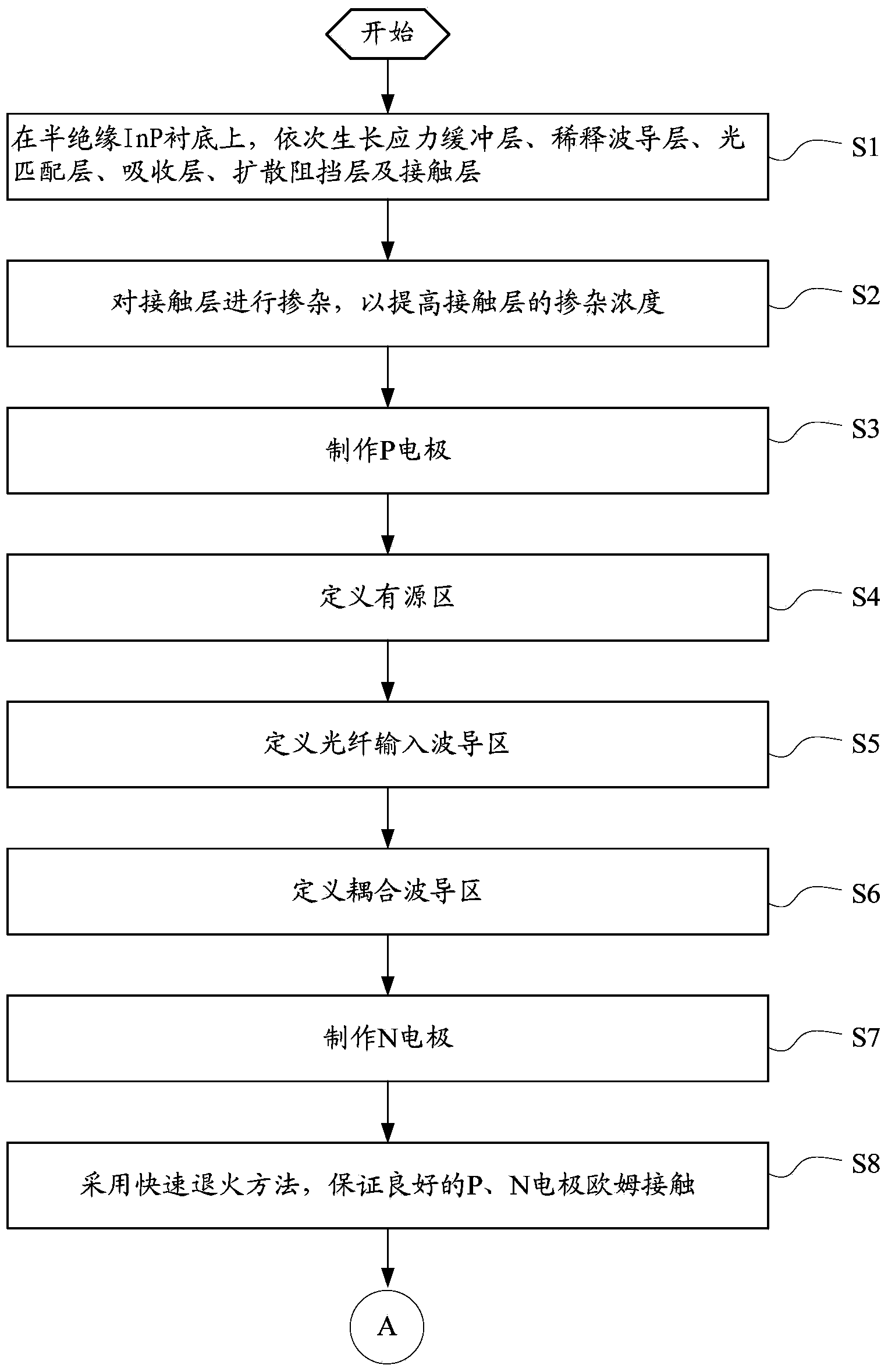

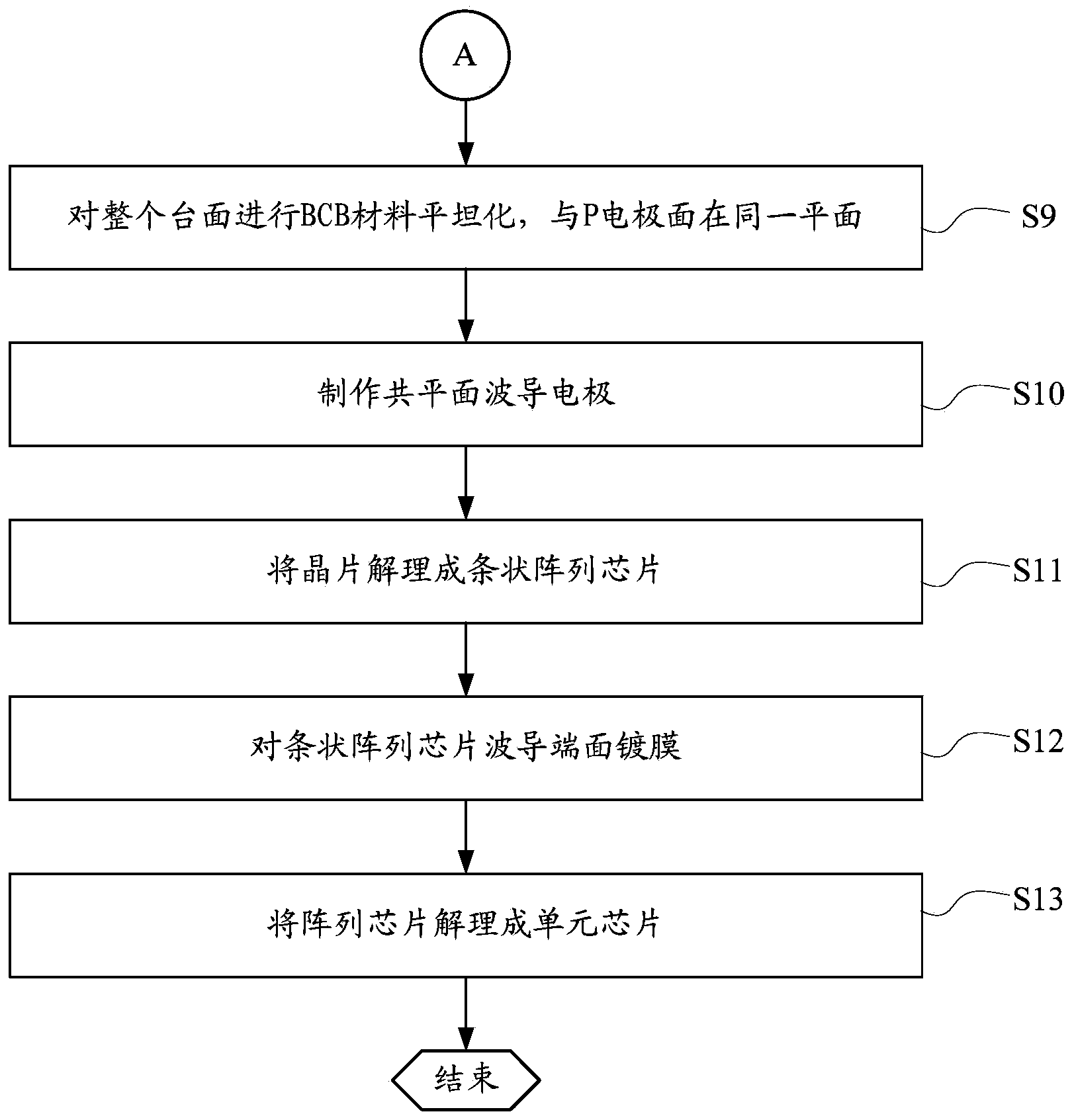

Manufacturing method of evanescent wave coupling high-speed high-power photoelectric detector

ActiveCN103646997AIncrease contactReduce the difficulty of cleavage processFinal product manufactureSemiconductor devicesOhmic contactCoplanar waveguide

The invention comprises a manufacturing method of an evanescent wave coupling high-speed high-power photoelectric detector. The method comprises a, sequentially growing an InP stress buffering layer, ten cycle-alternating InP / InGaAsP diluted waveguide layers, two InGaAsP light matching layers, three InGaAs absorbing layers, an InP diffusion barrier layer and an InGaAs contact layer; b, doping the InGaAs contact layer through a Zn3As2 source; c, fabricating a P electrode; d, defining an active area; e, defining an optical fiber input waveguide area; f, defining a coupling waveguide area; g, fabricating an N electrode; h, guaranteeing good ohmic contact between the P electrode and the N electrode through a rapid annealing method; i, planarizing the whole table board through benzocylobutene materials to the same plane with the P electrode; j, fabricating coplanar waveguide electrodes; k, thinning epitaxial wafers to 110 mu m and cleaving the epitaxial wafers to strip array chips; l, coating film on the waveguide end surfaces of the strip array chips; m, cleaving the array chips into unit chips.

Owner:THE 44TH INST OF CHINA ELECTRONICS TECH GROUP CORP

Method for manufacturing semiconductor laser diode

A method for manufacturing an LD is disclosed. The LD has a striped structure including an optical active region. The striped structure is buried with resin, typically benzo-cyclo-butene (BCB). The method to form an opening in the BCB layer has tri-steps etching of the RIE. First step etches the BCB layer partially by a mixed gas of CF4 and O2, where CF4 has a first partial pressure, second step etches the photo-resist patterned on the top of the BCB layer by a mixed gas of CF4 and O2, where CF4 in this step has the second partial pressure less than the first partial pressure, and third step etches the BCB left in the first step by mixed gas of CF4 and O2, where CF4 in this step has the third partial pressure greater than the second partial pressure.

Owner:SUMITOMO ELECTRIC IND LTD

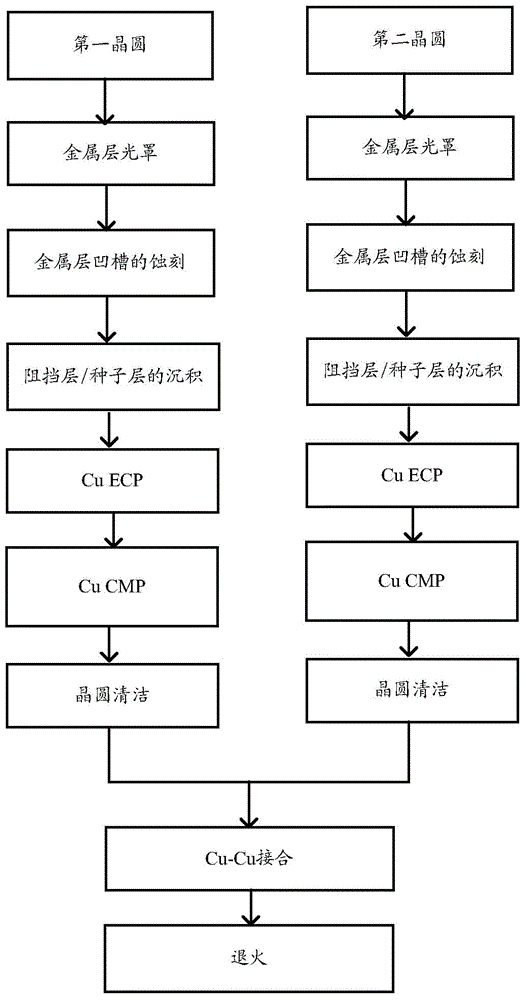

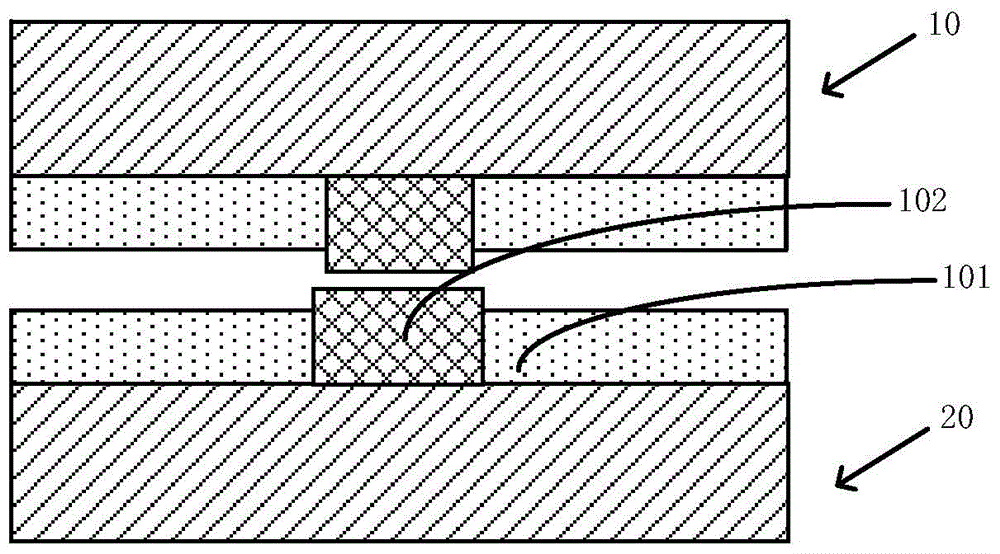

Semiconductor device, preparation method and packaging method thereof

InactiveCN105575930AImprove bonding qualityHigh bonding strengthSemiconductor/solid-state device detailsSolid-state devicesBonding processWeak current

The invention relates to a semiconductor device, a preparation method and a packaging method thereof. The preparation method comprises the steps of S1, providing a substrate on which an interlayer dielectric layer and a binding pad in the interlayer dielectric layer are formed; S2, forming a photosensitive benzocyclobutene material layer on the interlayer dielectric layer and the binding pad, thereby covering the interlayer dielectric layer and the binding pad; and a step S3, patterning the benzocyclobutene material layer for forming an opening and exposing the binding pad. The semiconductor device, the preparation method and the packaging method are advantageous in that 1, a hybrid bonding process is used for performing sealed bonding on a bond pad (such as a Cu pillar), thereby improving bonding strength and improving bonding quality of a wafer; 2, an AD-BCB material with insulativity is used for performing auxiliary bonding, a problem of weak current between Cu pillars can be settled, and electric stability is improved; and 3, hybrid bonding is utilized, thereby greatly improving packaging stability and prolonging service life of a chip.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Liner materials and related processes for 3-D integration

ActiveUS7884016B2Semiconductor/solid-state device detailsSolid-state devicesGas phaseConductive materials

In some embodiments, a low-k dielectric film liner, preferably comprising benzocyclobutene, is deposited on the sidewalls of through-silicon vias used in three-dimensional (3-D) integration of integrated circuits. A semiconductor workpiece having a via is provided. A dielectric film liner, preferably comprising benzocyclobutene, is deposited on the sidewalls of the via by chemical vapor deposition. Following the deposition of the dielectric film liner, conductive material is deposited into the via. The conductive material on the bottom of the via can be exposed by thinning the back of the semiconductor workpiece, thereby forming a through-silicon via. The semiconductor workpiece can form a stack with one or more additional semiconductor workpieces having vias filled with conductive material to form a 3-D integrated circuit. The conductive material electrically interconnects the integrated circuits at different levels of the stack.

Owner:ASM INTERNATIONAL

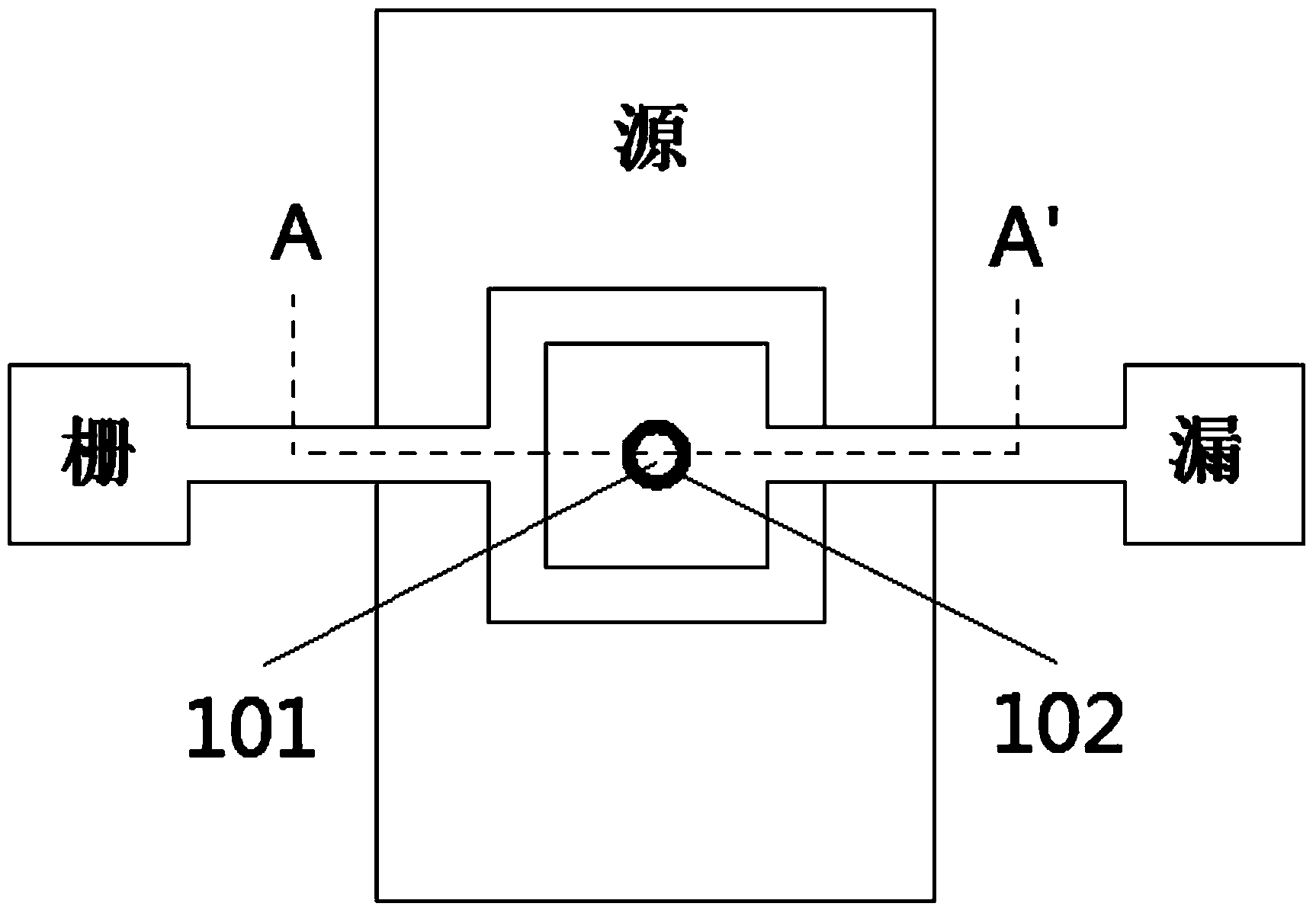

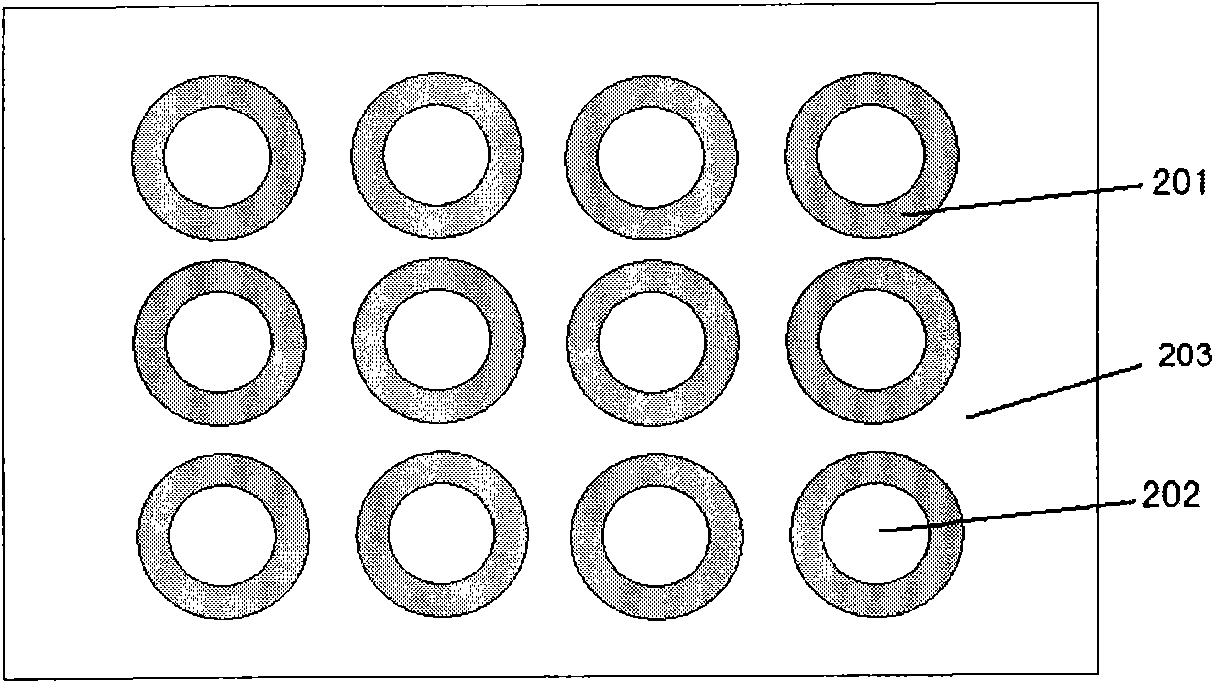

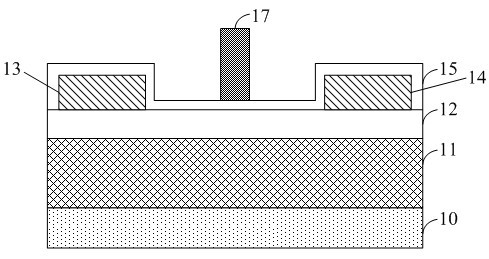

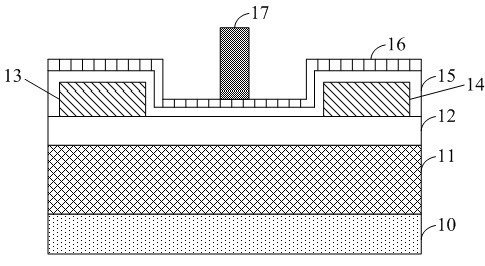

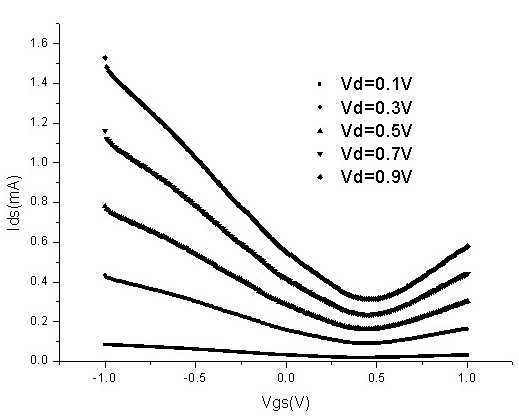

Nanowire based vertical circular grating transistor and preparation method thereof

InactiveCN103531635AReduce parasitic resistanceImprove transconductanceSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical resistance and conductanceGrating

The invention discloses a nanowire based vertical circular grating transistor and a preparation method thereof. According to the structure, a conducting channel material is an intrinsic or low doped nanowire perpendicular to a substrate; a low-resistance nanowire is connected above the intrinsic or low doped nanowire in a gapless manner; the intrinsic or low doped nanowire is surrounded by a source electrode, a gate medium and a gate electrode sequentially from bottom to top; the source electrode and the gate medium as well as the gate medium and the grate electrode are connected in the position of the side wall of the nanowire in a gapless manner; the low-resistance nanowire is surrounded by a drain electrode; and three isolation layers are arranged among the electrodes. The invention further provides the preparation method of the transistor. Both the source electrode and the gate electrode are obtained with the method that firstly, a metal film is plated and then metal above BCB (benzocyclobutene) is eroded by using BCB as a mask; and the low-resistance nanowire is obtained through heavy doping of the intrinsic or low doped nanowire or through metal alloy. According to the short-channel transistor structure and the preparation method, a device with a short channel can be prepared, the parasitic resistance and the parasitic capacitance can be effectively reduced, and the device performance is improved.

Owner:PEKING UNIV

Redistribution process

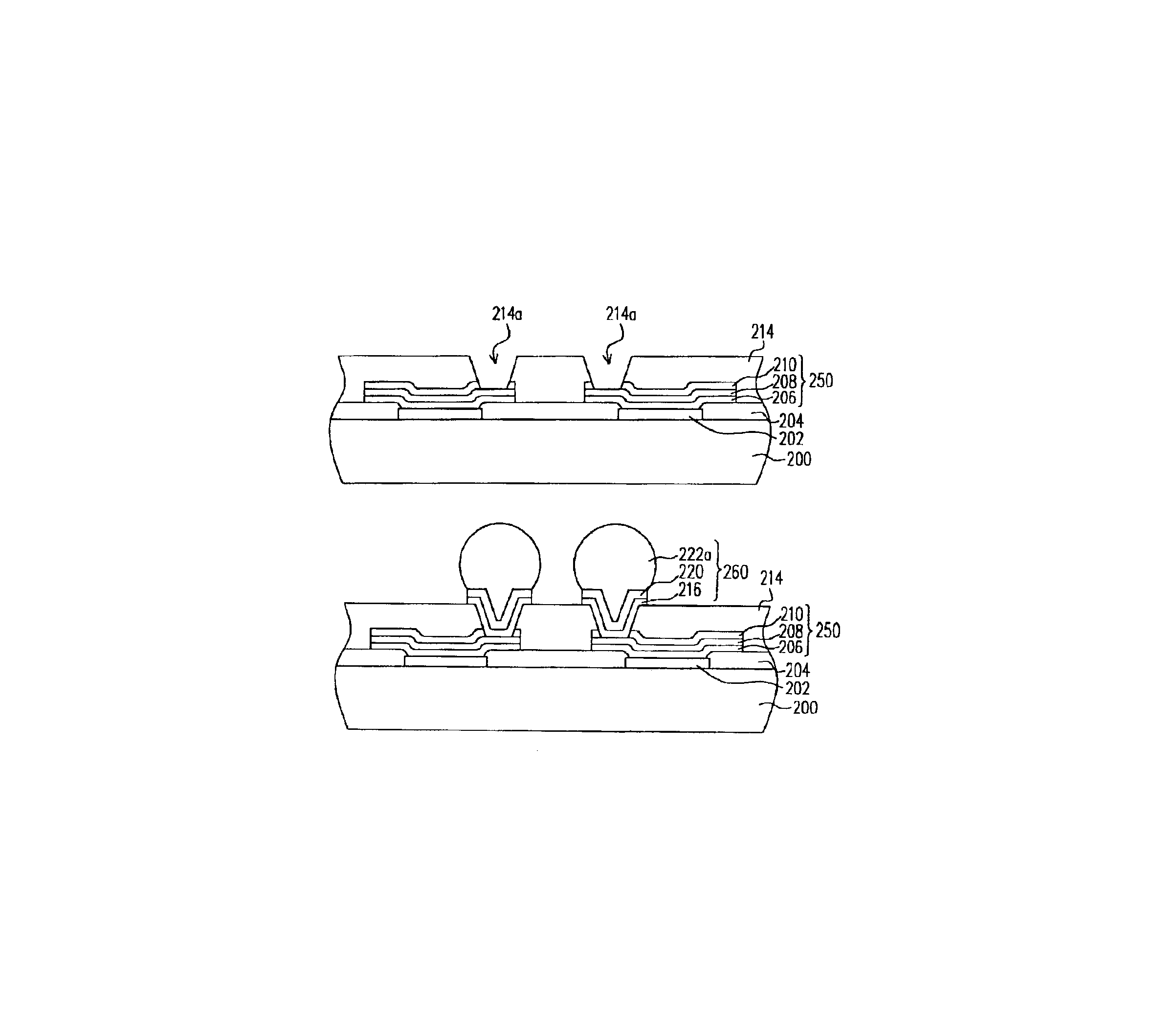

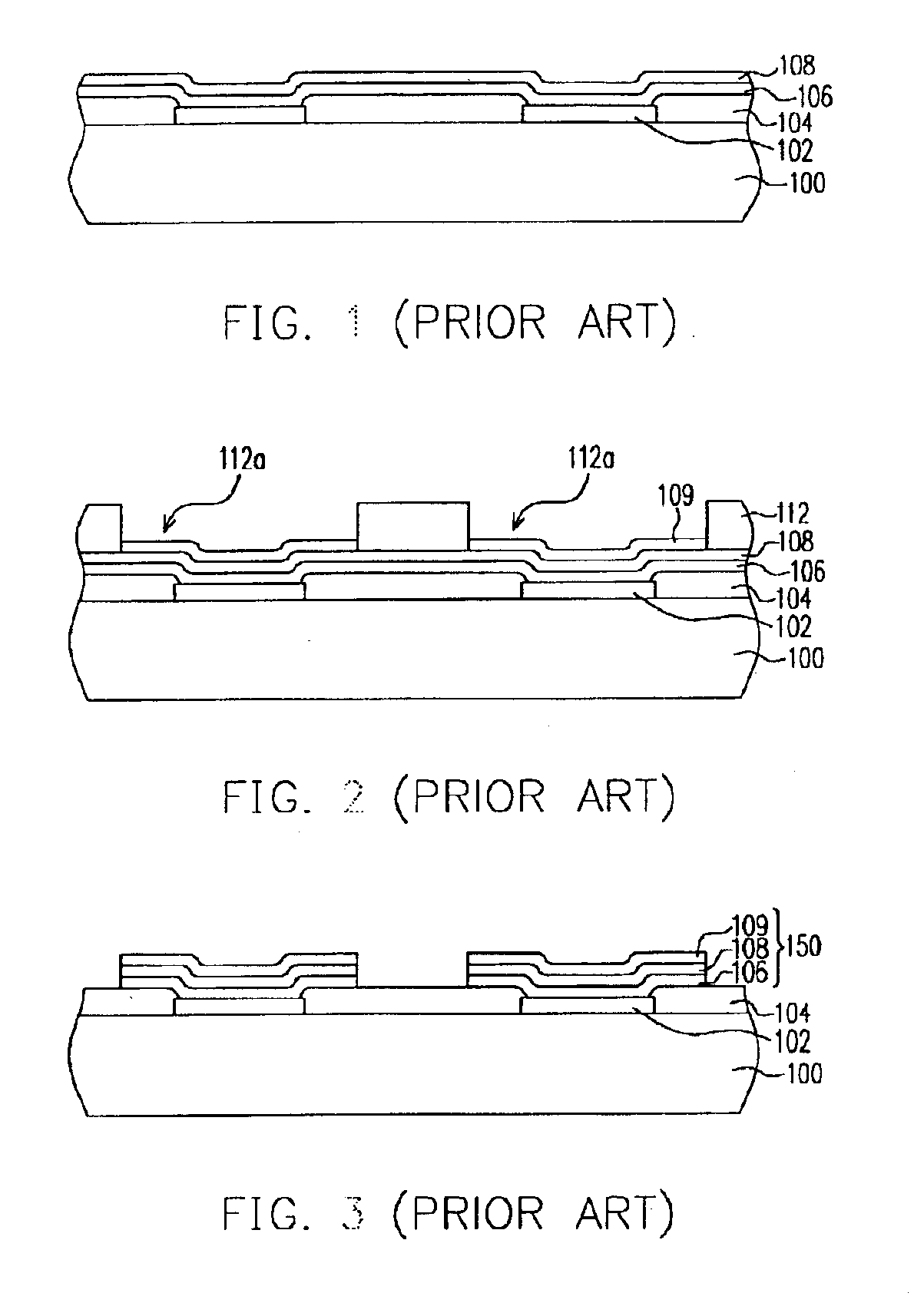

InactiveUS6867122B2Maintain productionPrevent peelingSolid-state devicesPhotomechanical apparatusTitaniumCopper

A redistribution process is described. A wafer is provided, wherein a first titanium layer, a first copper layer and a second titanium are sequentially formed over the surface of the wafer. The second titanium layer, the first copper layer and the first titanium layer are then defined to form a patterned trace layer. A patterned benzocyclobutene layer is then formed to expose the second titanium layer. The exposed second titanium layer is further removed to expose the first copper layer. Thereafter, a plurality of contacts is formed over the patterned benzocyclobutene layer and to connect with the first copper layer. Further, the wafer comprises a plurality of bonding pads, wherein each bonding pad is connected with each contact through the patterned trace layer.

Owner:ADVANCED SEMICON ENG INC

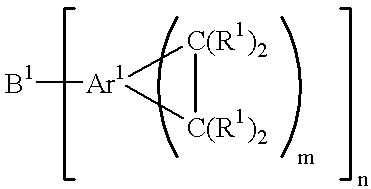

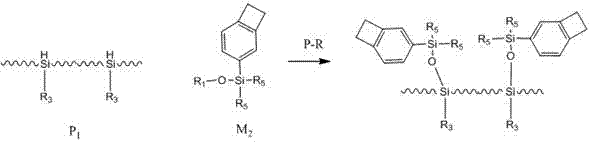

Benzocyclobutene functional organic silicone resin and preparation method thereof

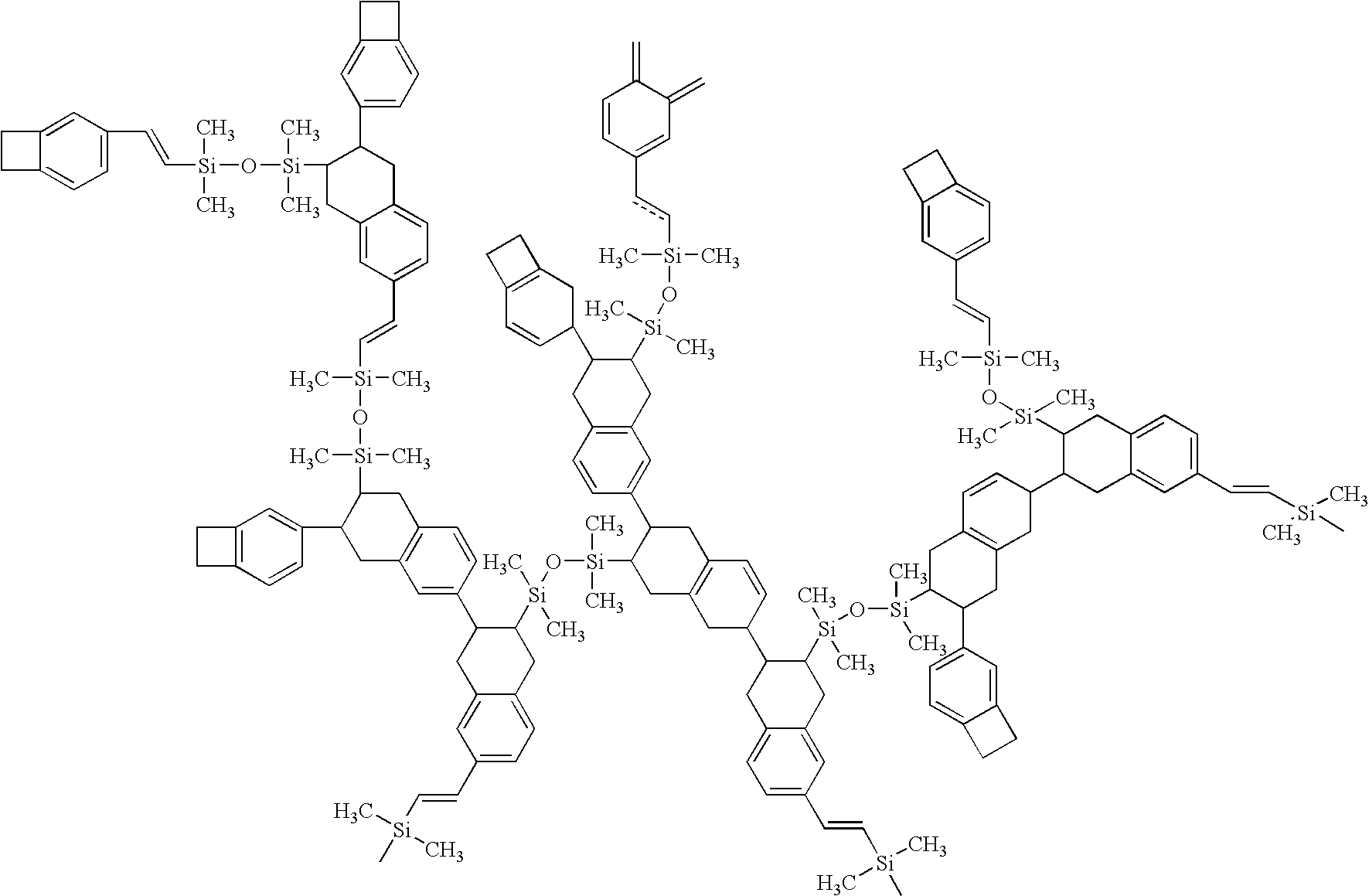

The invention belongs to the technical field of high-performance resin, and particularly relates to a preparation method of benzocyclobutene functional organic silicone resin. Benzocyclobutene functional organic silicone raw materials-a compound containing silicon-hydrogen bonds and an organic silicone compound containing siloxy (at least one compound is functionalized by benzocyclobutene) are used to prepare an organic silicone polymer containing a BCB functional group by virtue of P-R condensation polymerization. By adopting different structures of silicon-hydrogen compounds and siloxane, the preparation of benzocyclobutene functional organic silicone resin of different topological structures can be realized. The organic silicone resin prepared by the invention can be cured to prepare alow-dielectric high-temperature-resistant film by spin coating and heating or to prepare a polymer composite material, and the organic silicone resin is widely applied to the fields of electron encapsulation, integrated circuits and the like.

Owner:FUDAN UNIV

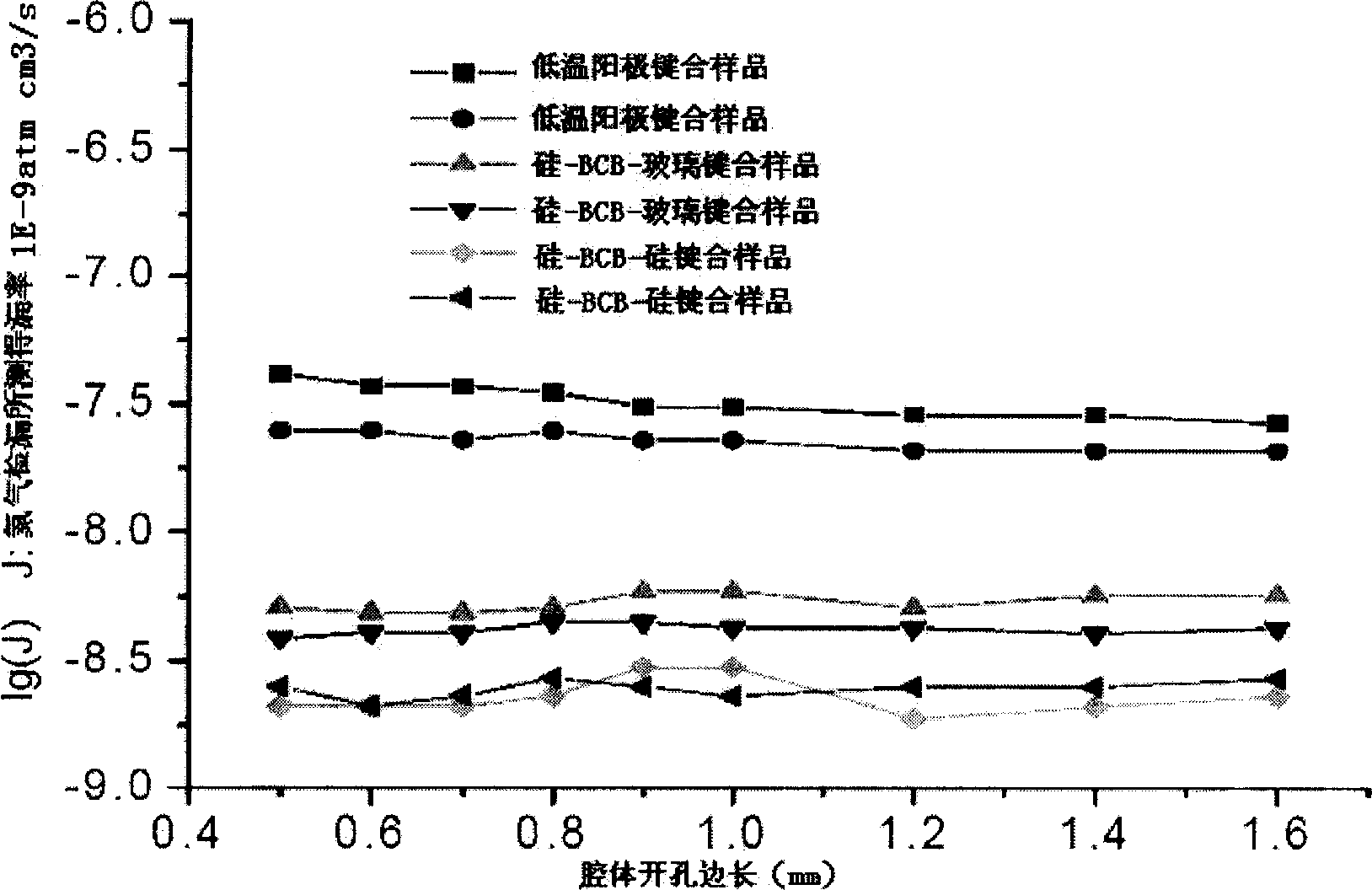

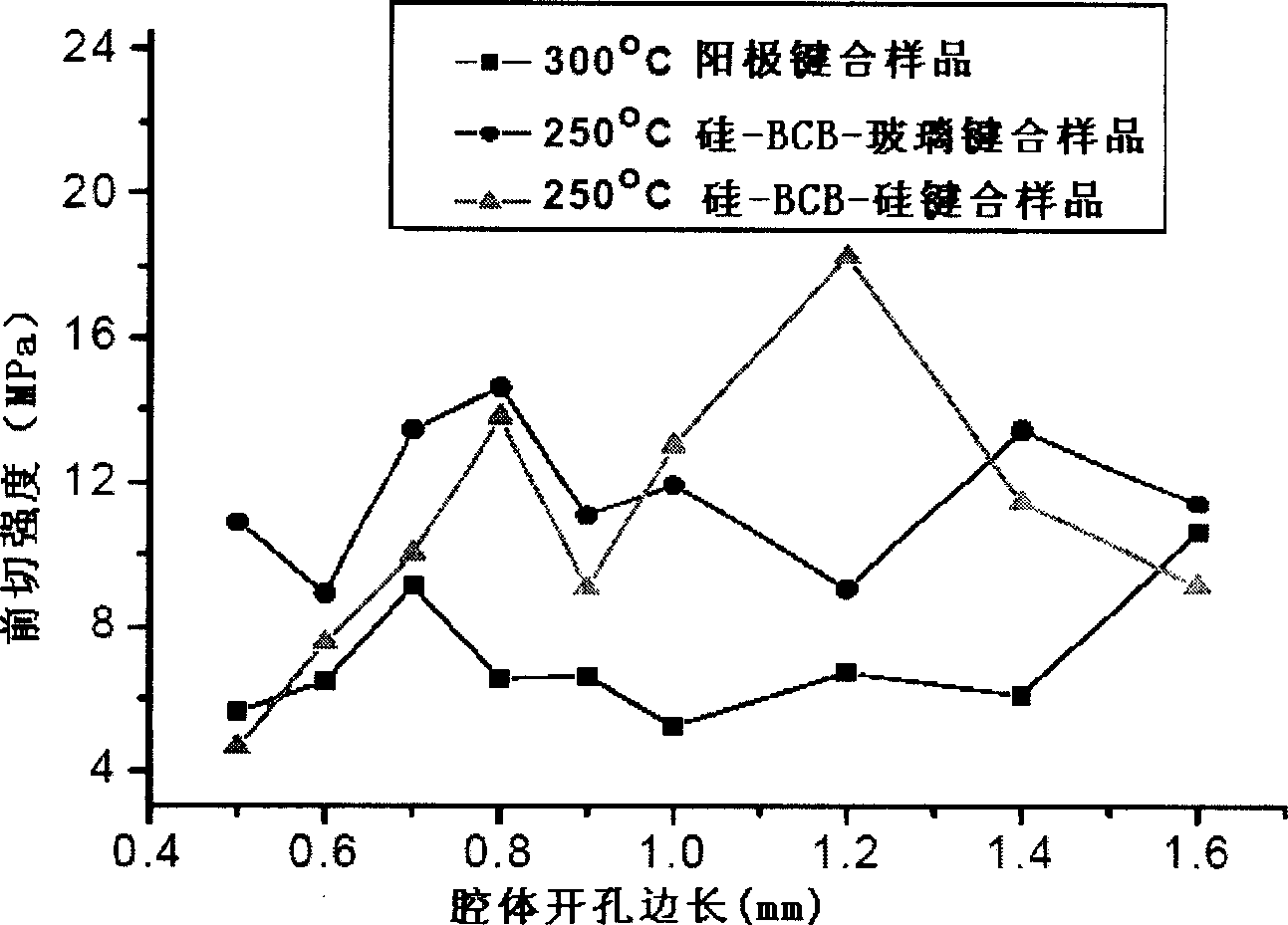

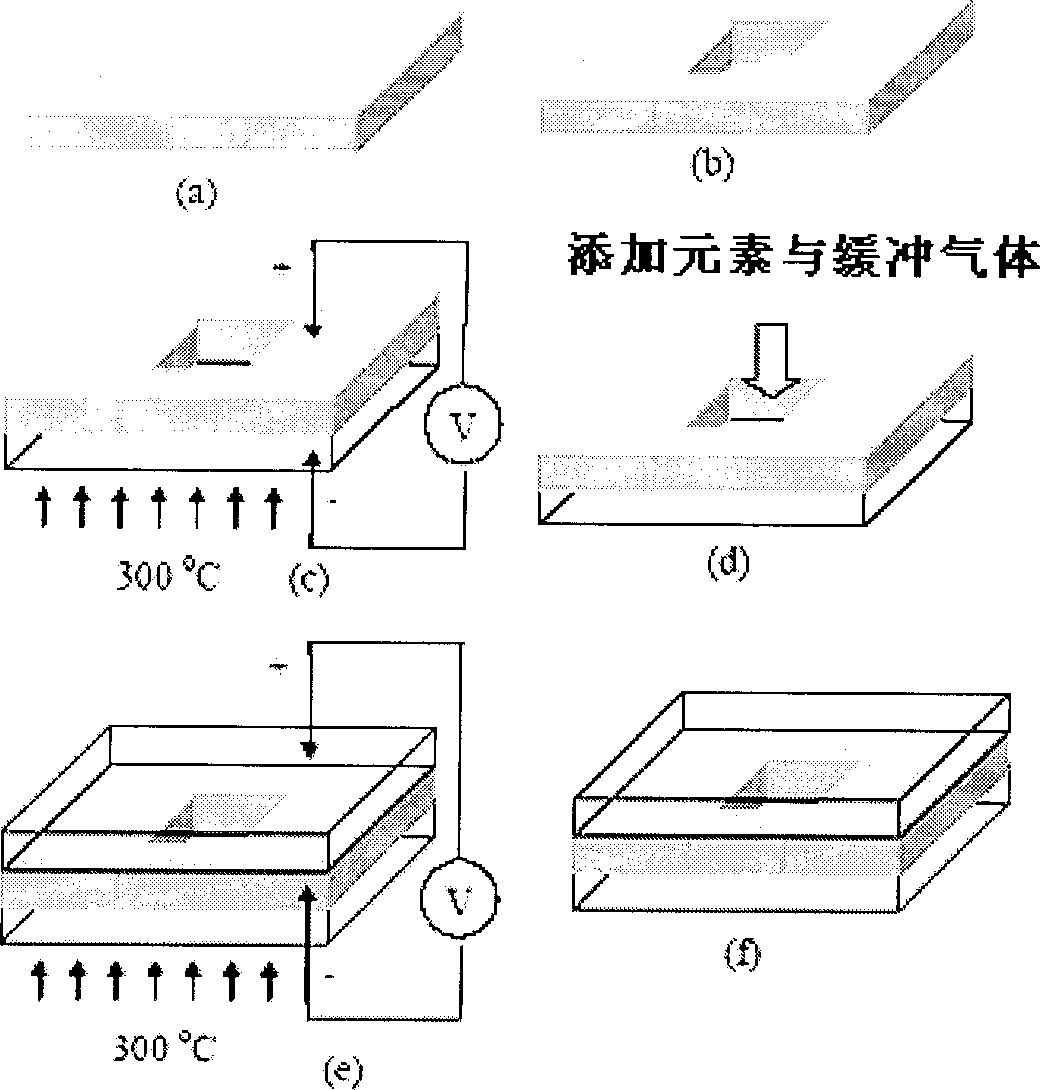

Low temperature airtightness packaging method for wafer level micro machinery device and photoelectric device

InactiveCN1821052ALow costShrinkage ignoredPrecision positioning equipmentDecorative surface effectsSemiconductor materialsEngineering

The low temperature airtight packaging method for wafer level micro mechanical device and photoelectric device features that semiconductor material or glass through wet etching or dry etching is airtight bonded at pressure of (1-3)í‡10<-5> Pa and vacuum degree of 10< -3 > Pa by using benzocyclobutene (BCB). The BCB bonded micro mechanical device and photoelectric device may reach air tightness of (2.1í½5.9)í‡10< -4 > Pa cu cm / s He and shear strength over 4.65 MPa. The packaging method of the present invention is suitable for MEMS device, micro acceleration meter, micro gyro, micro heat radiation instrument, etc. and can raise the performance of the packaged device obviously.

Owner:QST CORP

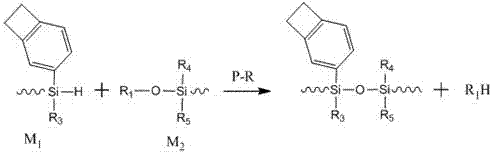

Functionalized organosilicon compound containing benzocyclobutene, and preparation method thereof

The invention belongs to the technical field of polymer materials, and concretely relates to a functionalized organosilicon compound containing benzocyclobutene, and a preparation method thereof. The functionalized organosilicon compound containing the benzocyclobutene is prepared through reacting an organosilicone precursor containing the benzocyclobutene and a substrate containing hydroxyl under an alkaline condition, and can be subjected to reduced pressure distillation or column chromatography purification. The functionalized organosilicon compound containing the benzocyclobutene can be used for polymerization reaction, and can be pre-polymerized in a sym-trimethylbenzene solvent at the temperature of 150 to 180 DEG C to obtain a prepolymer with a certain molecular weight, and a thin film is prepared through further spin-coating and post curing; a nitrine type photosensitizer can be added in a monomer prepolymer containing double bonds so as to be used for preparing a photoresist, which can be applied in the fields of electronic packaging and integrated circuits.

Owner:FUDAN UNIV

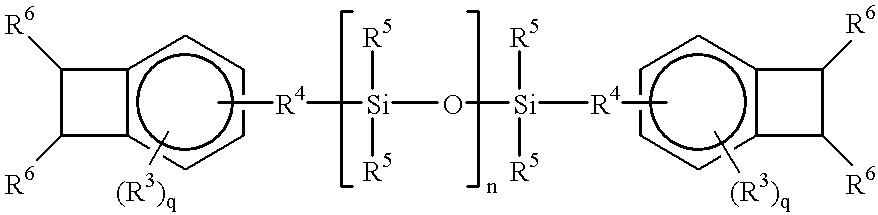

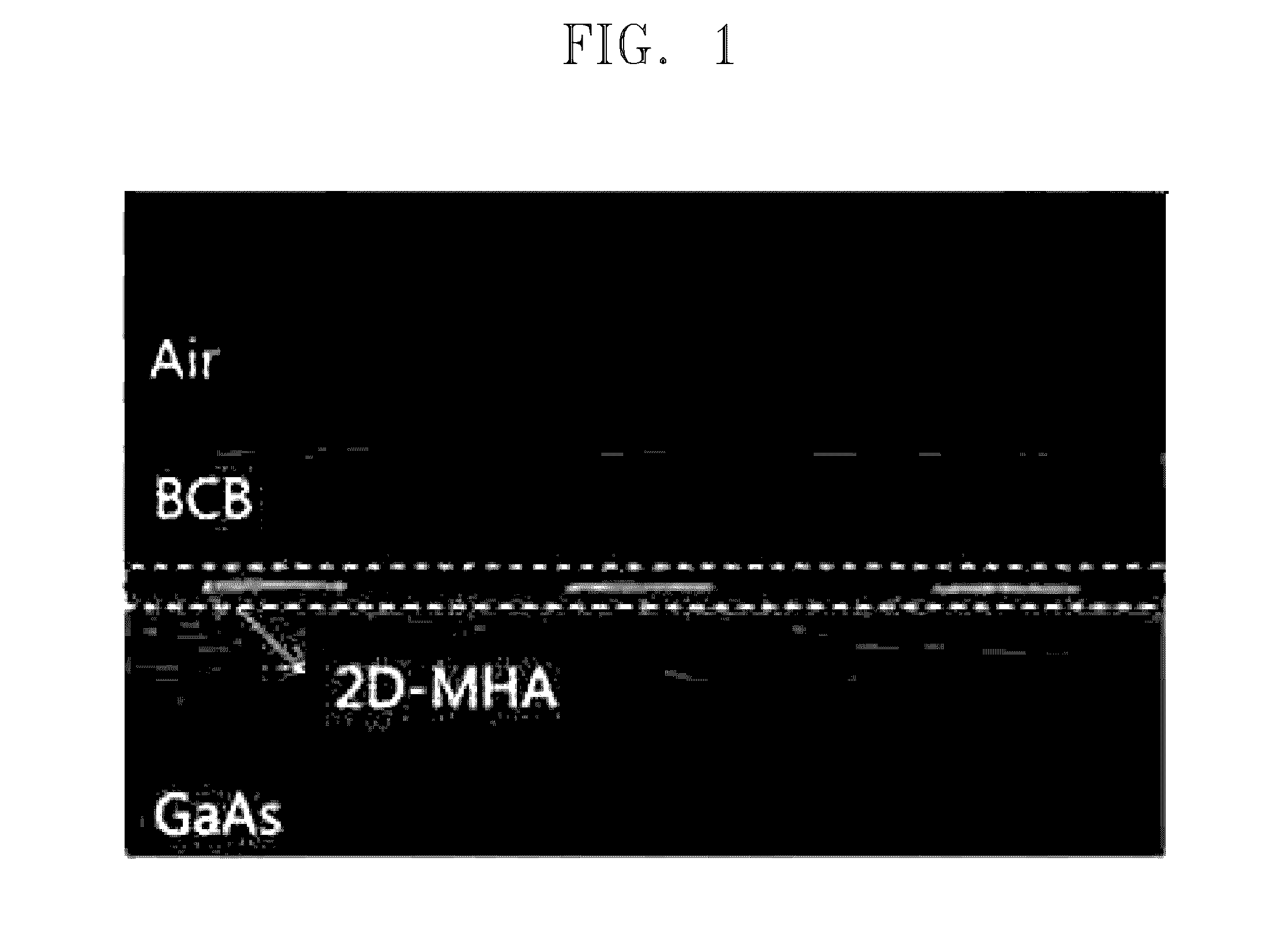

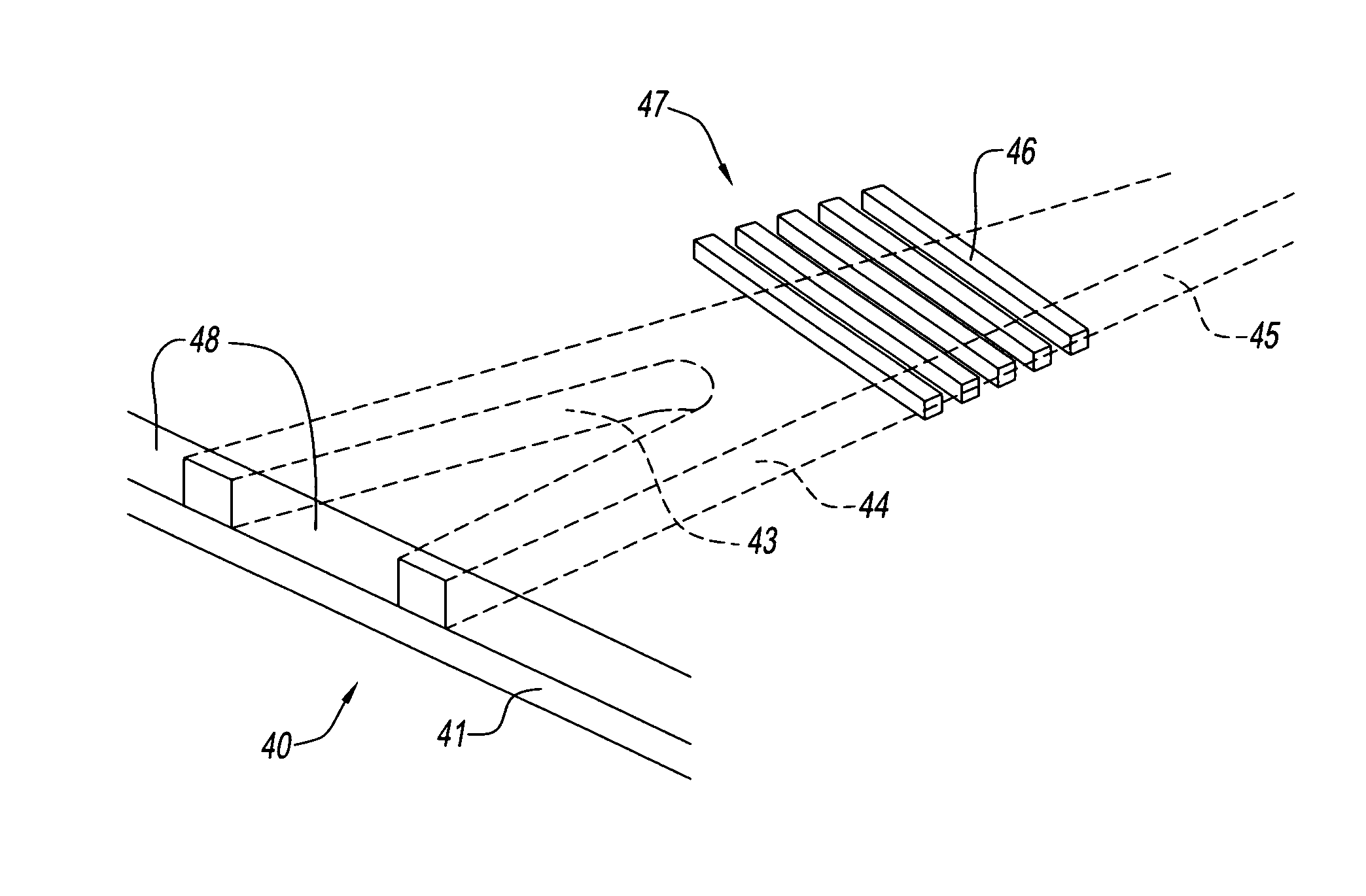

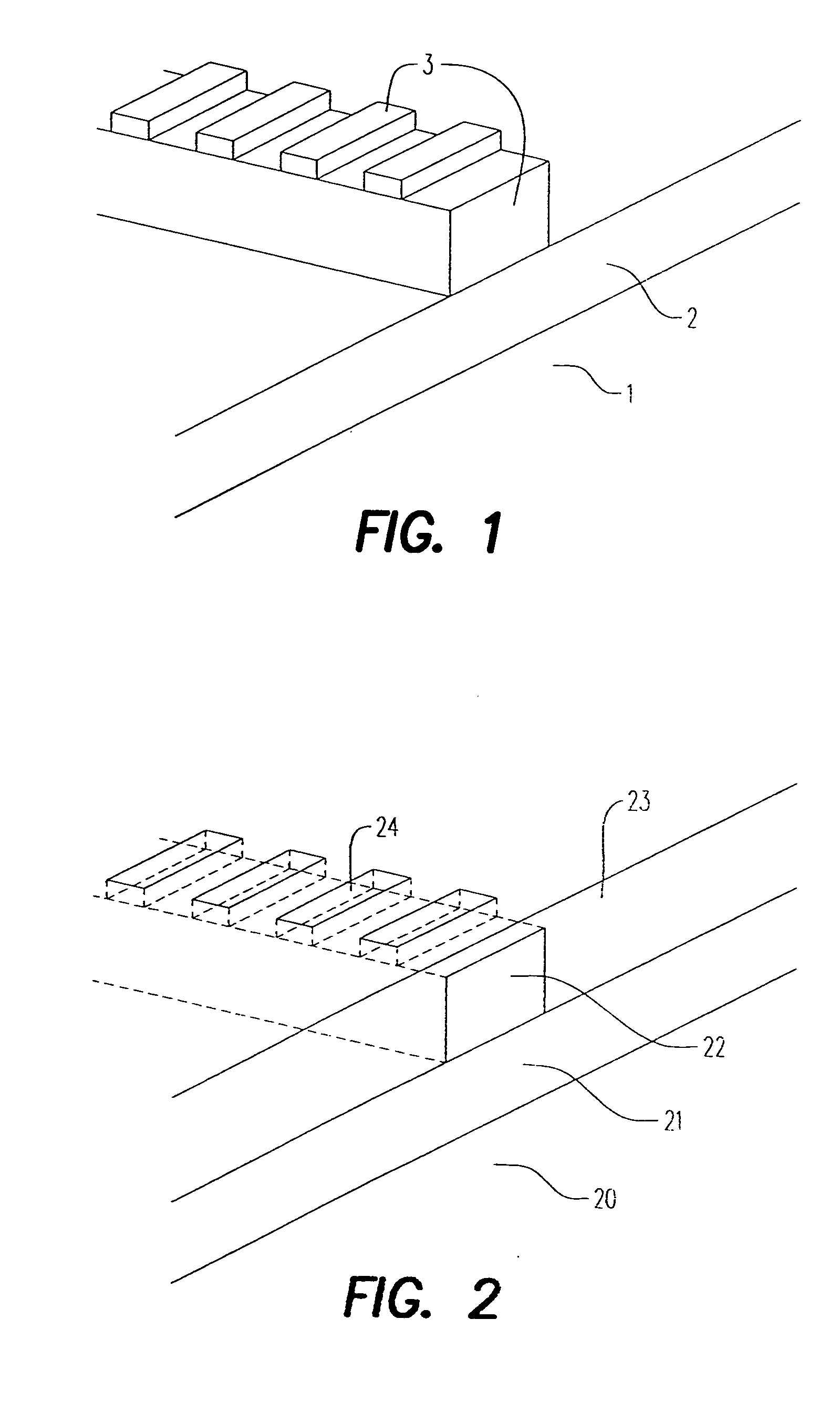

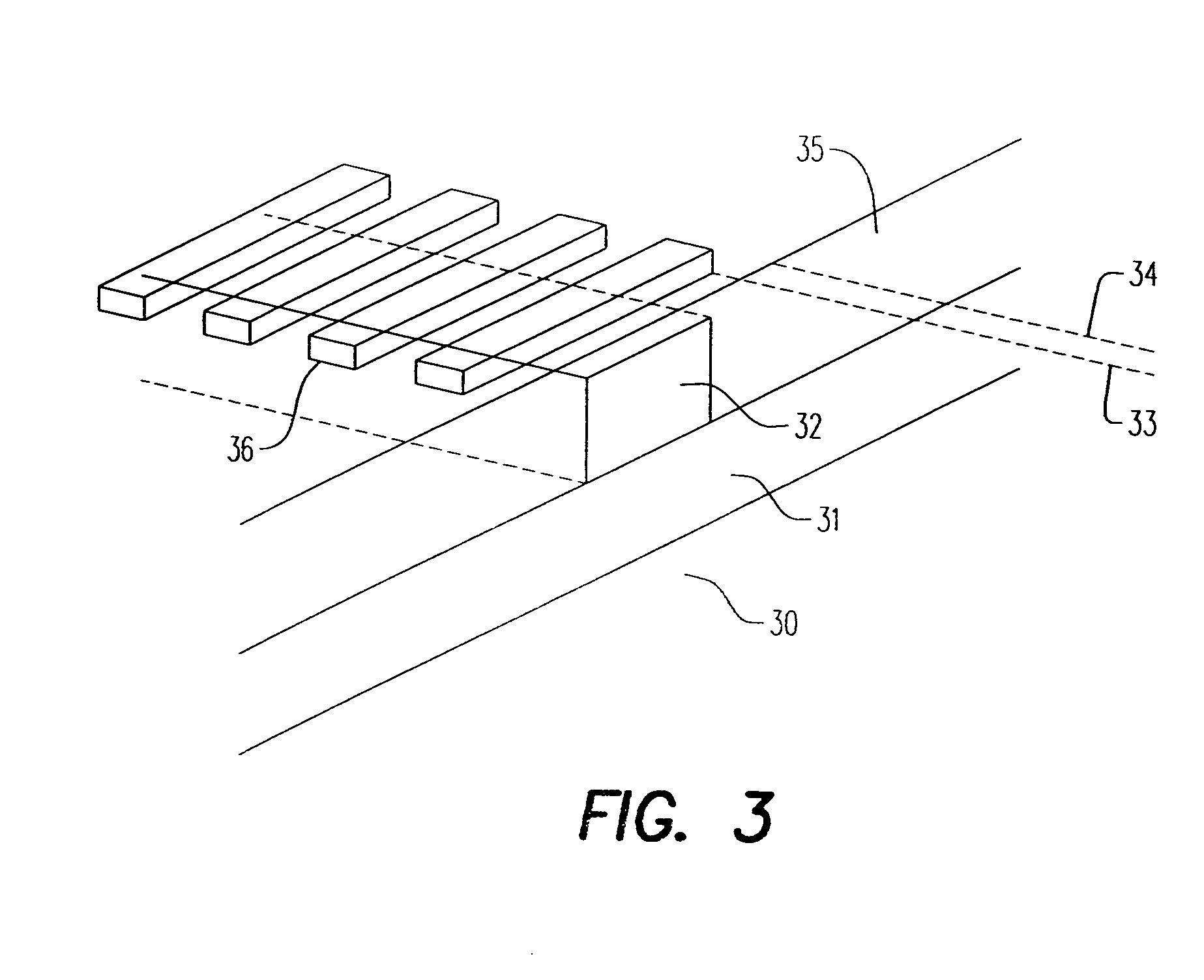

Optical waveguides and grating structures fabricated using polymeric dielectric compositions

Using polymeric dielectric materials (preferably materials derived from bisbenzocyclobutene monomers) and an electron beam lithography process for patterning this material, we have developed a process for fabricating optical waveguides with complex integrated devices such as gratings. Such gratings are not limited to one-dimensional type gratings but can include 2 dimensional gratings such as curved gratings or photonic crystals. Due to the properties of BCB, this process could also be implemented using optical photolithography depending upon the waveguide dimensions desired and the grating dimensions desired. Alternatively, the optical waveguide could be patterned using optical lithography and the grating can be patterned using electron beam lithography. In addition, the general process described below can be applied to the fabrication of complex lightwave circuits containing, for example, multiple optical waveguides, couplers / splitters, grating based filters and even more complex devices and structures.

Owner:PENN STATE RES FOUND

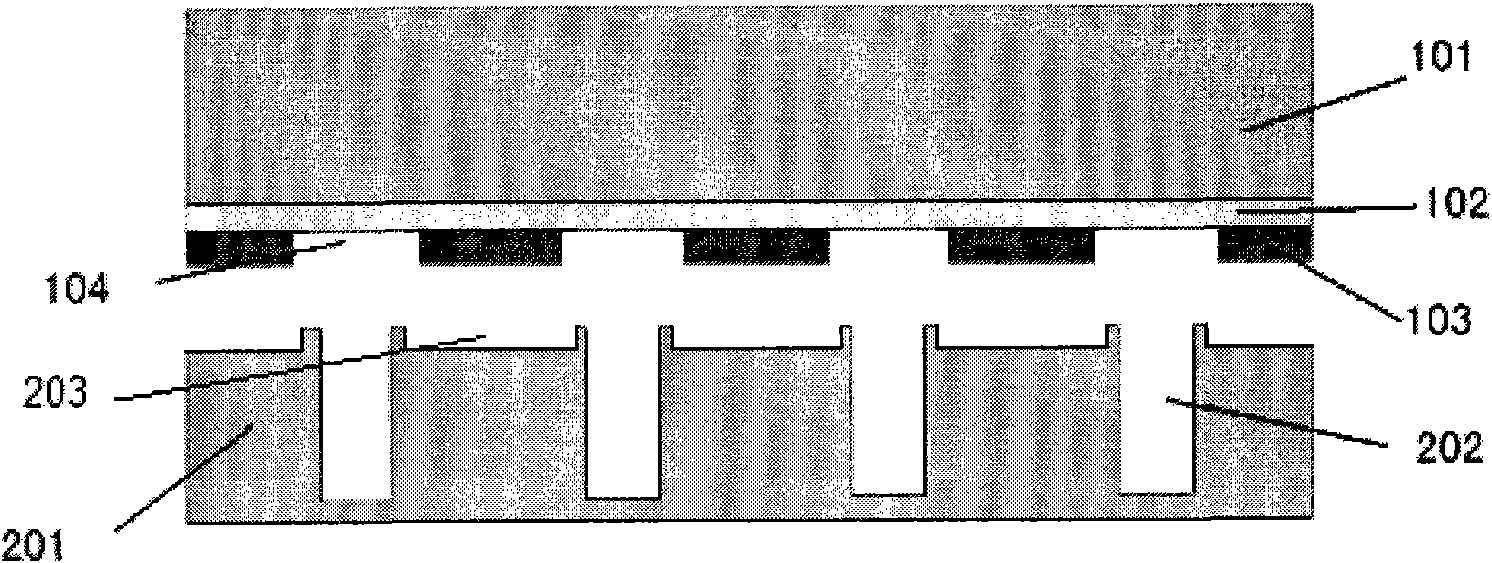

Etch tank adopted in process of packaging and manufacturing TSV (Through Silicon Via) wafer and preparation process

InactiveCN101840856AControl bond sizeThe overall thickness is thinSemiconductor/solid-state device manufacturingSputteringEngineering

The invention relates to an etch tank adopted in the process of packaging and manufacturing a TSV (Through Silicon Via) wafer and a preparation process. The etch tank is characterized in that the wall of the etch tank is vertical, the surface area of the etch tank is 1.2-1.3 times that of BCB (Benzocyclobutene) coated on photoetching, the depth of the vertical tank wall of the etch tank is slightly less than the thickness of the coated BCB, and the BCB is coated on a naked supporting wafer. The etch tank is made of the TSV wafer. The TSV packaging and manufacturing process comprises the following steps of: sputtering a metal layer on the naked supporting wafer, and then etching after coating a layer of BCB; etching the etch tank on the front face of the TSV wafer by using DRIE (Deep Reactive Ion Etching), and then etching a TSV array by using the DRIE, wherein the etch tank corresponds to the BCB photoetched on the supporting wafer; and bonding one face of the supporting wafer with the BCB and the front face of the TSV wafer after being aligned, and blocking the fused BCB in an extension process by using the etch tank. The structure has the function of controlling the bonding size of the BCB.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

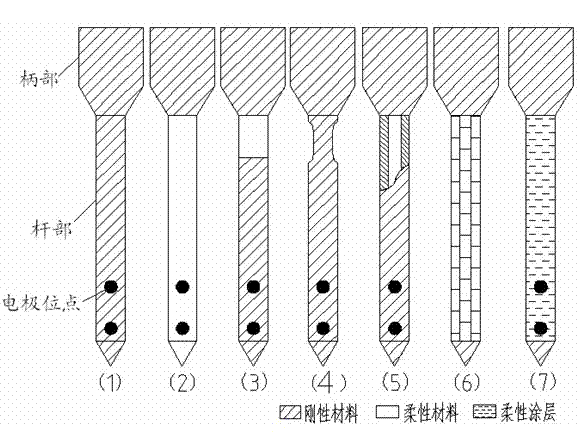

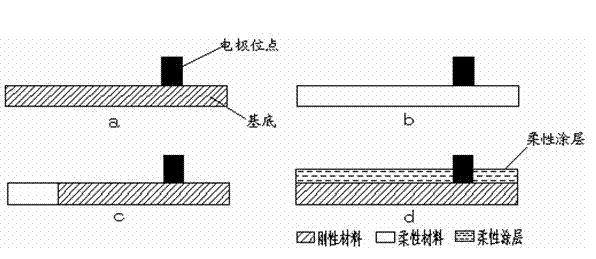

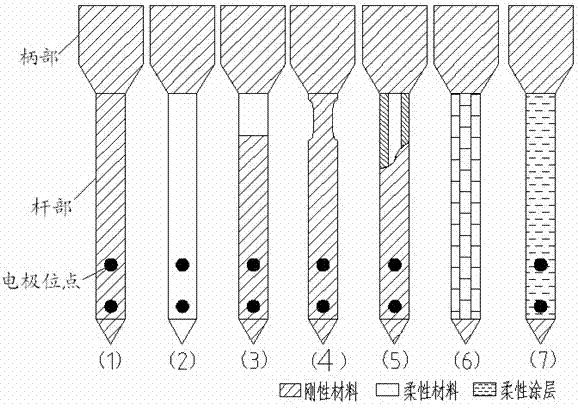

Neural microelectrode with rigid and flexible structures

ActiveCN102499666AImprove flexibilityReduce stiffnessInternal electrodesDiagnostic recording/measuringEngineeringMicroelectrode

The invention relates to a neural microelectrode with rigid and flexible structures. The microelectrode comprises a rigid structure part and a flexible structure part, wherein the geometric structure of the electrode is improved and a flexible material coating is coated on the surface of the electrode; the flexible structure part can completely replace the rigid structure part or penetrates through the rigid structure part or is attached to the rigid structure; the rigid material is silicon or other ceramic materials; the flexible material is polyimide, benzocyclobutene, SU-8, polydimethyl siloxane and poly-p-xylene; the method for improving the geometric shape of the electrode mainly comprises the step of reducing the sectional area of the electrode; a layer of flexible material coating is deposited on the surface of the electrode; and the flexible coating material is conductive hydrogel, mucoprotein and polyethyleneimine. According to the invention, the flexibility of the improved microelectrode is effectively improved, the injury of jiggle to biological tissues is alleviated, which is beneficial to the long-term in-vivo indwelling of the electrode.

Owner:SHANGHAI JIAO TONG UNIV

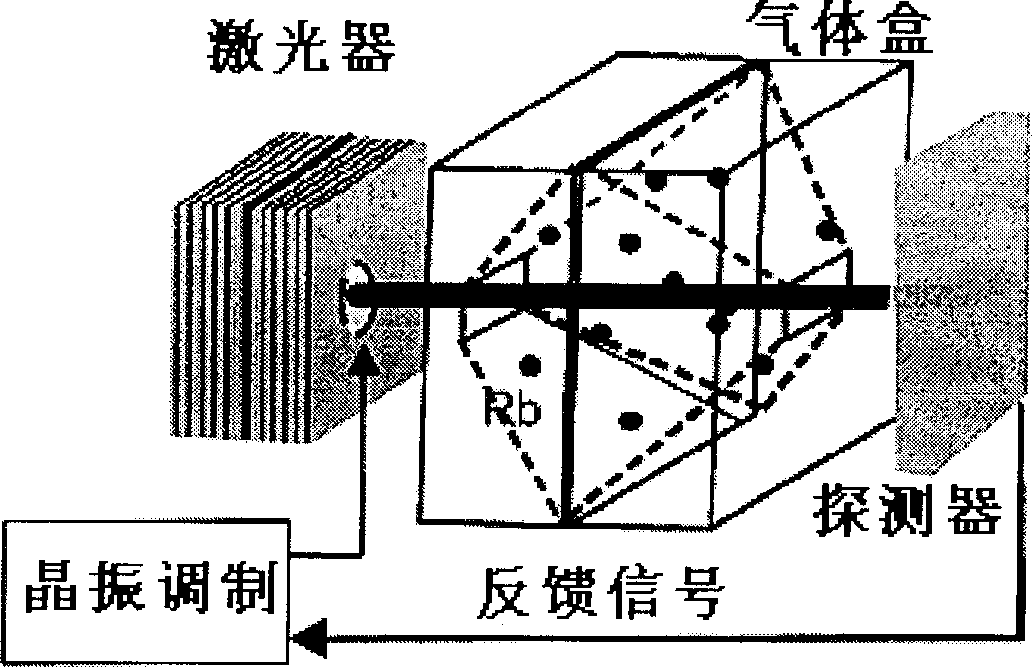

Process for preparing low-temperature wafer-level mini-sized gas container

InactiveCN1827522AMeet packaging requirementsAvoid lostNanostructure manufactureSemiconductor materialsAir tightness

The invention relates to a method for producing low-temperature circle sheet micro gas box, which is characterized in that: the benzocyclobutene is used to process material linkage with humid etching or dry etching technique of semi-conductor in 250Deg. C, to realize the circle sheet air-tightness sealing linkage of chip-level gas box. The invention comprises a atom gas box containing a chip-level atom clock gas box, a high-precision magnetic field sensor gas box, a atom feedback glimmer frequency stabilizer; a atom gas box containing a atom light filter, with glimmer Fabry-Perot chamber. The linked BCB glue is in 0.2ª–m thickness, the air-tightness of sealed He gas can reach 2.1-5.9X10-4Pa cm3 / s, and the linkage strength is higher than 4.65MPa, while the thermal cycle reliability can fully reach the packing standard of micro electric device.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Benzocyclobutene functional groups-contained benzoxazine monomer and synthetic method and use thereof

InactiveCN102391202AImprove flame retardant performanceImprove heat resistanceOrganic chemistryPolymer sciencePtru catalyst

The invention belongs to the technical field of macromolecular materials and particularly relates to a benzocyclobutene functional groups-contained benzoxazine monomer and a synthetic method and a use thereof. According to the synthetic method, amino-contained benzocyclobutene, phenolic compounds and formaldehydes (or paraformaldehydes) are adopted as raw materials, and the target monomer is obtained through synthesizing by adopting a solvent method or a solvent-free method. The benzoxazine monomer has lower viscosity at a certain temperature and can be cured through a method of heating or catalyzing by a catalyst. The obtained resin after curing has excellent thermal stability, mechanical properties, and extremely-low hygroscopicity, and thus, the resin can be used as an electronic packaging material, a high-temperature resisting and flame-retarding material, a high-performance composite material, an aerospace material and the like.

Owner:FUDAN UNIV

Low dielectric constant composite and preparation method thereof

InactiveCN101226786ALow water absorptionSemiconductor/solid-state device manufacturingHydrocarbon from halogen organic compoundsNitrogenOxygen

The invention discloses a composite material with low dielectric constant and a process for preparation. The composite material with low dielectric constant includes benzocyclobutene and hollow inorganic nano-particles or includes benzocyclobutene derivative and hollow inorganic nano-particles. The process for preparation comprises adding benzocyclobutene and hollow inorganic nano-particles in a solvent, or adding benzocyclobutene derivative and hollow inorganic nano-particles to the solvent, mixing evenly to prepare spin coating liquid, forming films on a substrate by employing whirl coating method, positioning the prepared substrate in a tumbler with a stopper, then evacuating, inputting nitrogen, removing oxygen and remaining solvent in the system, keeping the temperature between 70 DEG C and 100 DEG C for 20-80 minutes, then increasing the temperature to 190-350 DEG C and keeping for 40-120 minutes, lowering the temperature and obtaining composite material with low dielectric constant. The prepared composite material has the advantages of low dielectric constant, high heat stability, high chemical stability, simple preparation and the like.

Owner:SOUTH CHINA UNIV OF TECH

Benzocyclobutene substituted annular siloxane monomer as well as preparation method and application of benzocyclobutene substituted cyclic annular siloxane monomer

ActiveCN102093408AImprove thermal stabilityImprove efficiencySilicon organic compoundsSemiconductor/solid-state device detailsPolymer sciencePalladium catalyst

The invention belongs to the technical field of micro-electronic packaging dielectric materials, particularly relates to a benzocyclobutene (BCB) substituted annular siloxane monomer as well as preparation and an application of the BCB substituted annular siloxane monomer. Annular vinyl siloxane and 4-benzocyclobutene are reacted in one step in the presence of a palladium catalyst so as to obtain a target monomer; and the monomer can be directly heated for polymerization forming, or the monomer also can be prepared into an organic solution of prepolymer and then spin film making is carried out on base plate materials such as metal, ceramic, silicon and the like. The preparation and use methods of the BCB substituted annular siloxane monomer are simple and convenient, the resins subjected to heat curing have the advantages of high stability, low dielectric constant, low dielectric loss, low water absorption and good film forming property, can be used as a high property dielectric material, and has wide application prospects in the fields of electronic packaging, system integration and the like.

Owner:FUDAN UNIV

Carbon-based field effect transistor and preparation method thereof

ActiveCN102593169ASimple preparation processLow costSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricCharge carrier mobility

The invention relates to a carbon-based field effect transistor and a preparation method thereof, and belongs to the technical field of nanoelectronics. The carbon-based field effect transistor comprises a semiconductor substrate, an insulating layer, a conductive channel, a source electrode, a drain electrode, a gate dielectric layer and a gate electrode, wherein the insulating layer is arranged on the semiconductor substrate, and the conductive channel is arranged on the insulating layer; the conductive channel is made of a carbon-based material, and the source electrode and the drain electrode are respectively arranged at the two ends of the conductive channel; the gate dielectric layer is covered on the source electrode, the drain electrode, and the conductive channel arranged between the source electrode and the drain electrode, and the gate electrode is positioned above the gate dielectric layer; and the gate dielectric layer comprises a benzocyclobutene organic dielectric layer. According to the carbon-based field effect transistor and the preparation method thereof, the problem that a high-dielectric-constant gate dielectric film directly grows on the conductive chanel formed by a carbon-based material in the atomic layer deposition method, and the benzocyclobuten provides an atomic layer deposition nucleation center without causing a significant decrease in the carrier mobility of the carbon-based material and causing the decline in the device performance.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Solid-state imaging device, method for manufacturing the same, and camera using the same

InactiveCN1910754AImprove light gathering efficiencyHigh sensitivityTelevision system detailsColor television detailsRefractive indexPhotodiode

In order to implement a solid-state imaging device with high photo-sensitivity that includes a light collecting part which can reduce undesired variations during manufacture and which has high light collection efficiency, the solid-state imaging device includes: a photodiode ( 8 ) which converts incident light ( 13 ) into electric charges; a convex lens layer ( 15 ) which is formed above the photodiode ( 8 ) and through which the incident light is transmitted; and a concavo-convex lens layer ( 11 ) which is formed on and around the lens layer ( 15 ) and which collects the incident light and outputs the incident light to the lens layer ( 15 ). A refractive index of the lens layer ( 15 ) is greater than a refractive index of the lens layer ( 11 ). A thickness and a width of the lens layer ( 15 ) are set to achieve a predetermined focal length for light of a predetermined wavelength range. The lens layer (15) is made of one of a BPSG film, a TEOS film, a benzocyclobuthane and polyimide based resin.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com