Etch tank adopted in process of packaging and manufacturing TSV (Through Silicon Via) wafer and preparation process

A process method and corrosion tank technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of reduced contact area, inability to realize wafer electroplating process, etc., achieve thin thickness, increase yield, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to fully demonstrate the advantages and positive effects of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

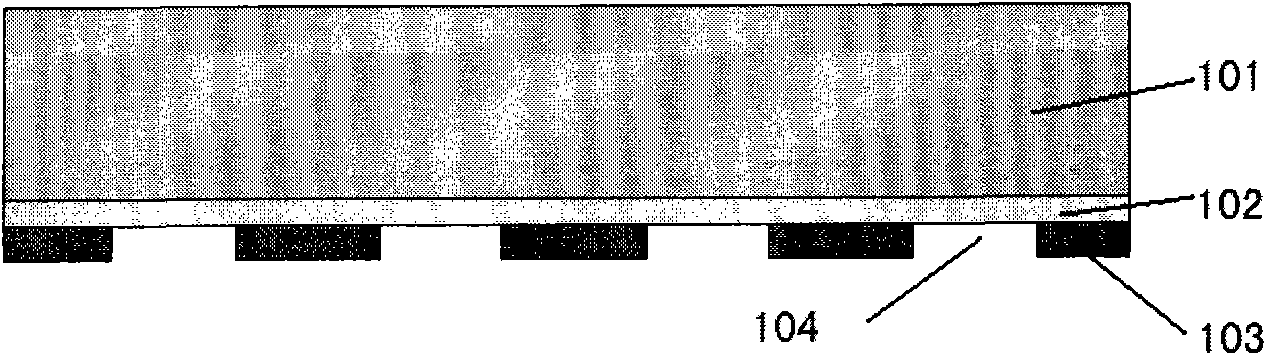

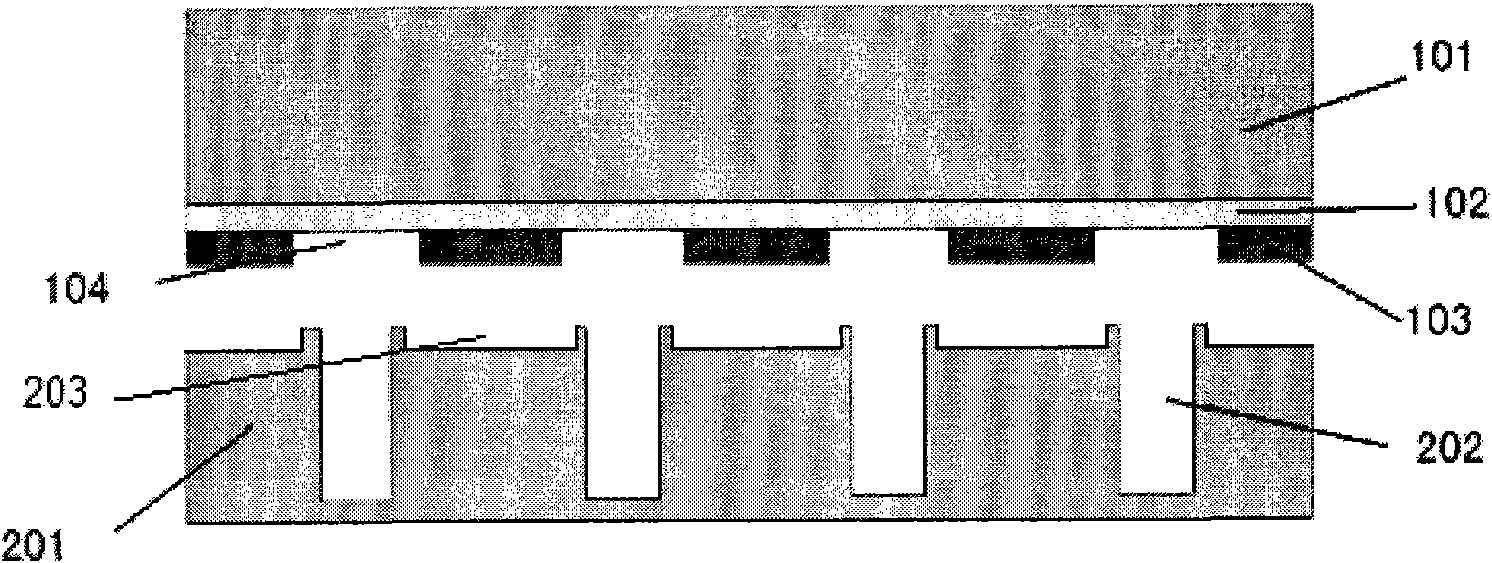

[0016] exist figure 1 In this method, a layer of Au layer 102 with strong oxidation resistance is sputtered on one side of the supporting wafer 101 with a thickness of about 100-200 nm. The role of this metal layer is to provide a seed layer for TSV electroplating Cu. Then a layer of BCB 103 is coated on the metal layer 102, and the thickness of the BCB is about 2-4 μm. The BCB is shaped by photolithography, so that the BCB that will be bonded to the TSV position 104 is removed.

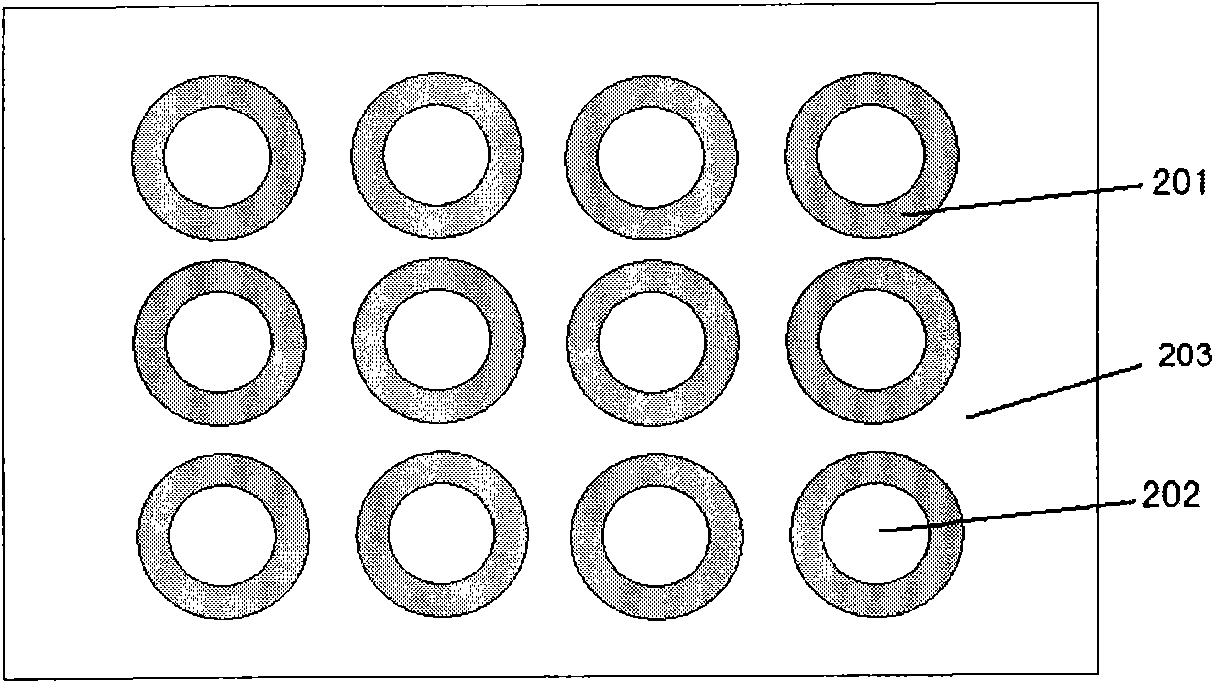

[0017] exist figure 2 Among them, using photoresist as a mask, DRIE is used to etch the etching groove 203 on the front side of the TSV wafer 201, the groove wall has a vertical feature, the depth of the etching groove is 2-3 μm, and the surface area is 1.2-1.3 times that of the BCB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com