Patents

Literature

286results about How to "Package structure is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

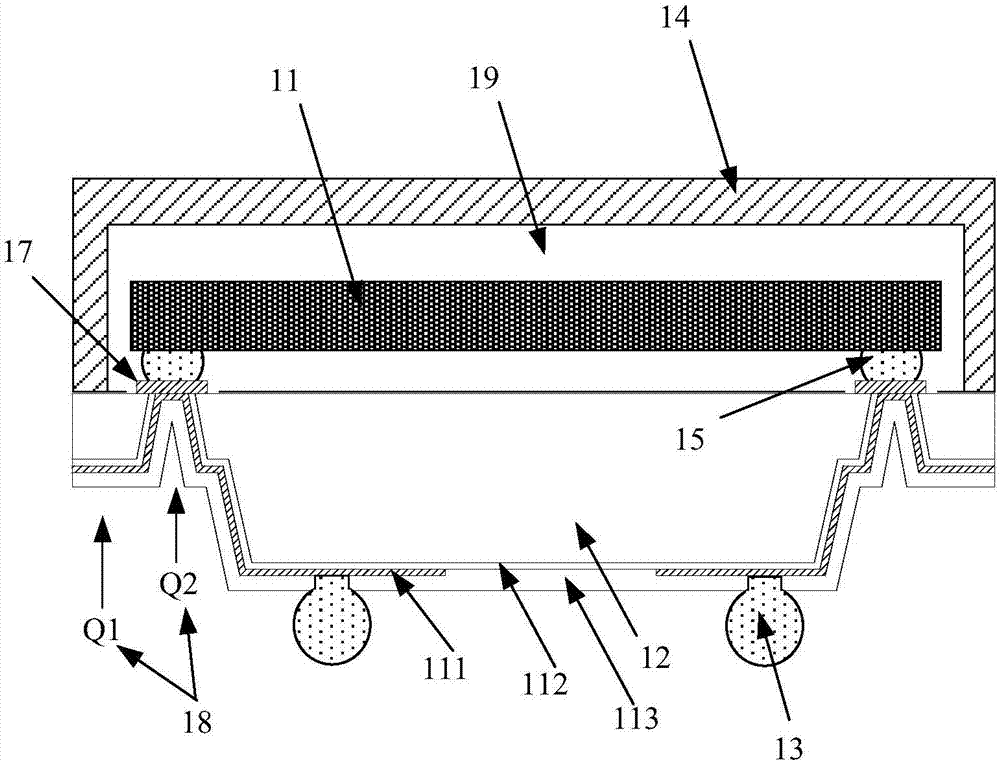

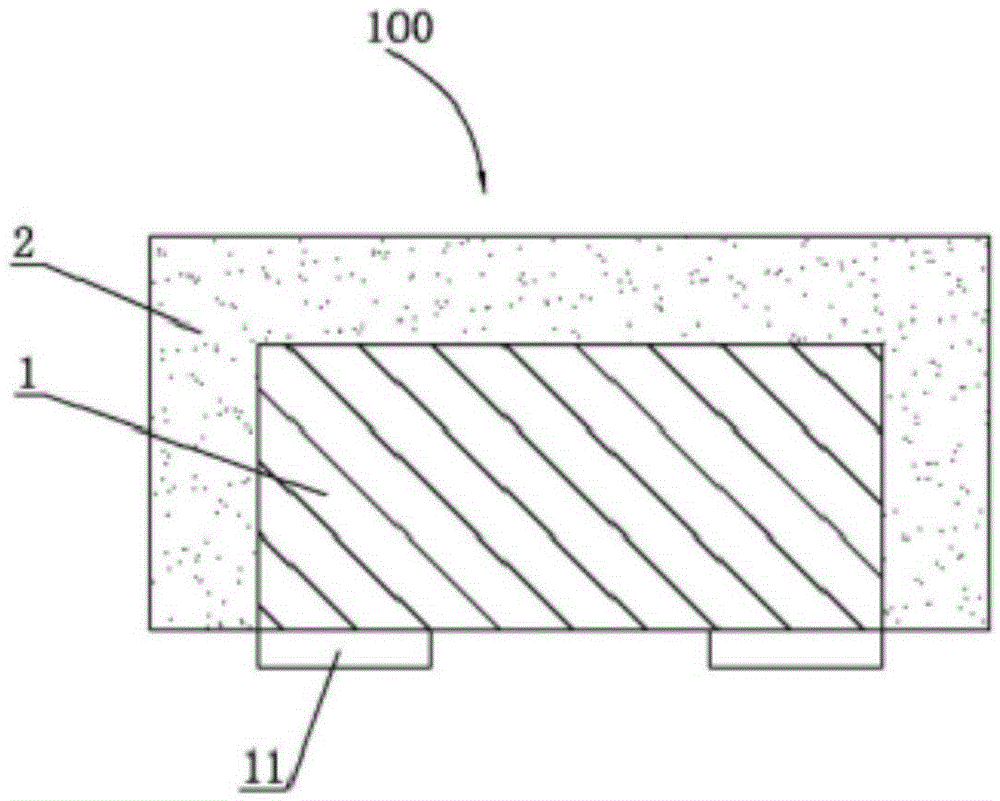

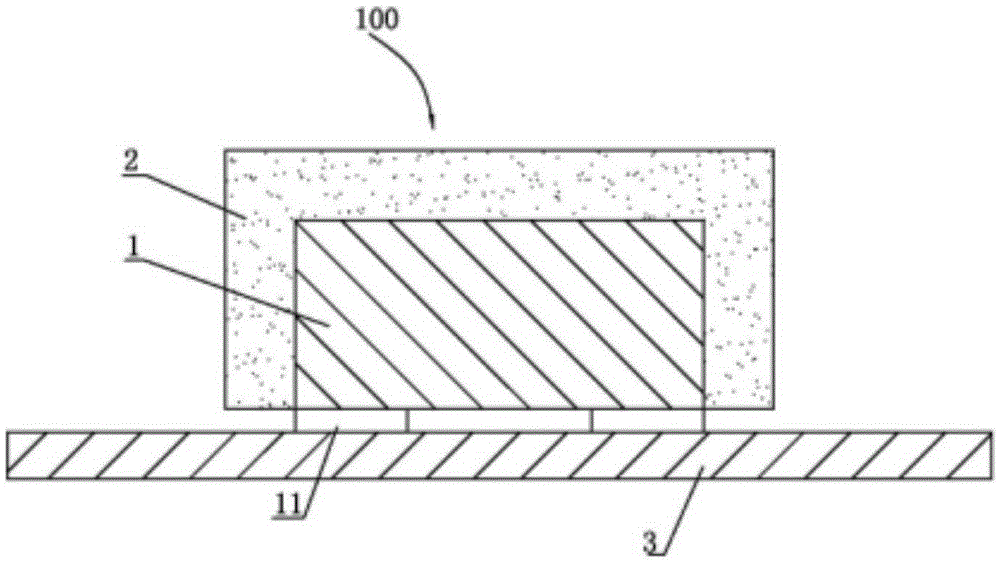

Packaging structure and packaging method for fingerprint recognition chip

InactiveCN104051367AReduce manufacturing costPackage structure is simpleSemiconductor/solid-state device detailsSolid-state devicesEngineeringFingerprint

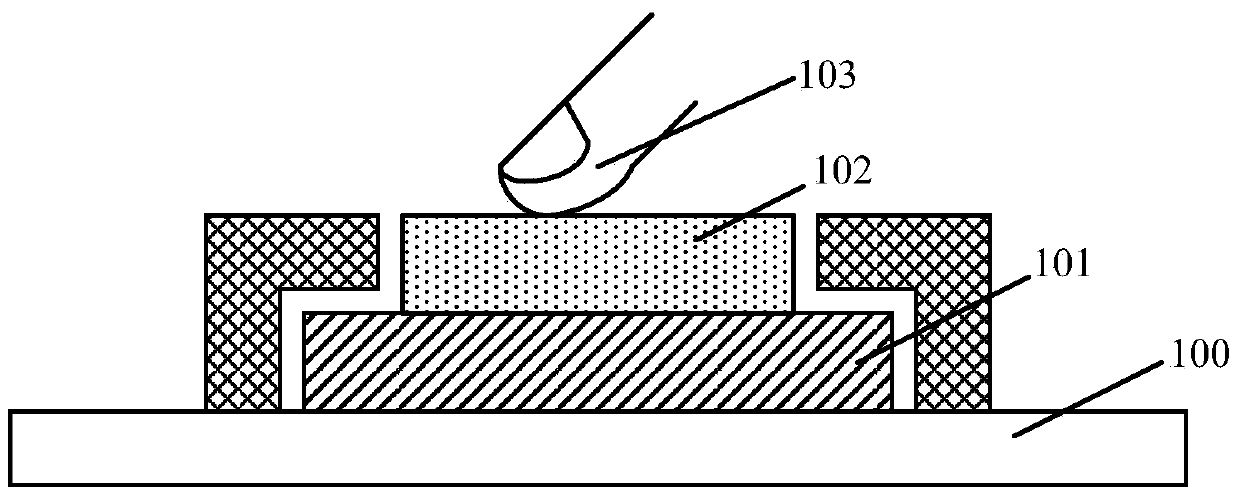

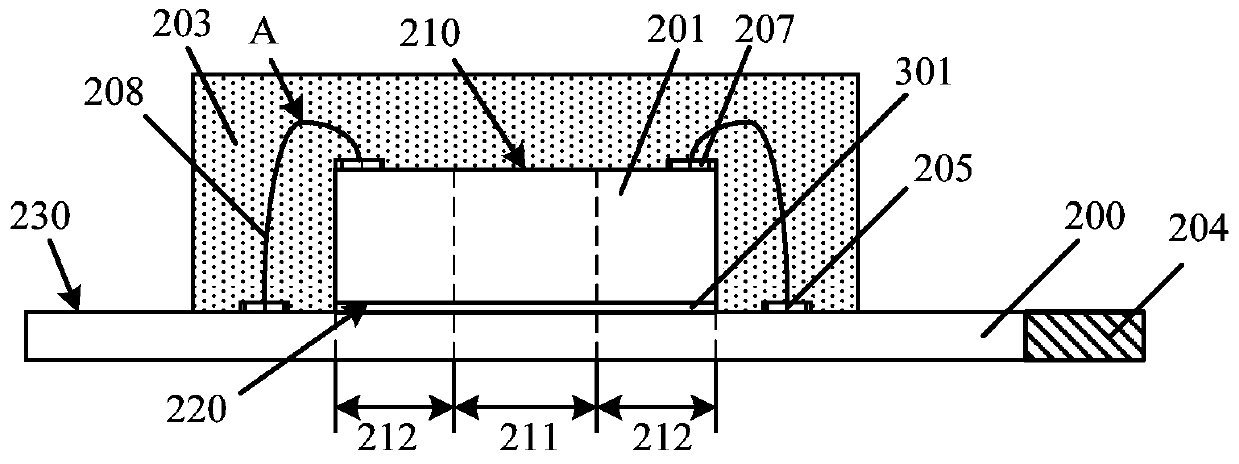

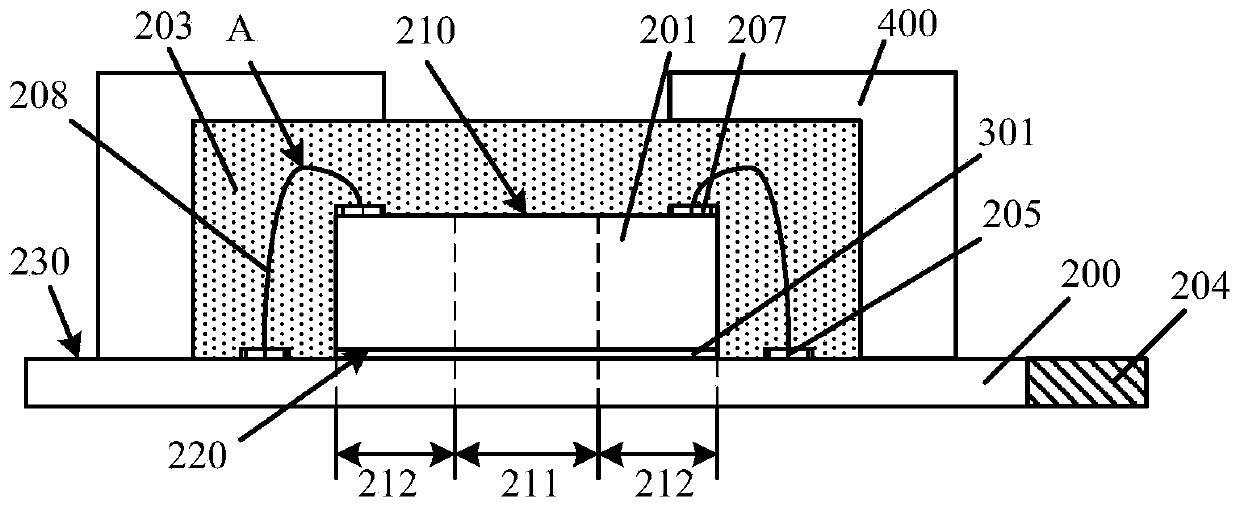

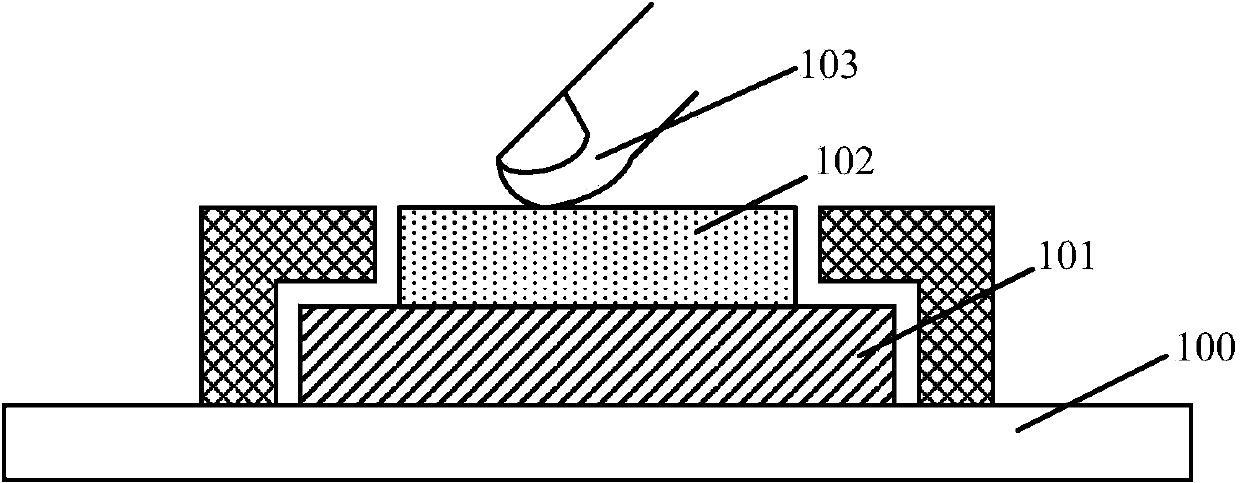

The invention discloses a packaging structure and a packaging method for a fingerprint recognition chip. The packaging structure comprises a substrate, a sensing chip, a plurality of wires and a plastic package layer. The substrate is provided with a first surface, and the first surface of the substrate is provided with a first welding pad layer. The sensing chip is located on the first surface of the substrate and provided with a first surface and a second surface, the second surface of the sensing chip is located on the first surface of the substrate, the first surface of the sensing chip is provided with a sensing area and a peripheral area, and the surface of the portion, in the peripheral area, of the sensing chip is provided with a second welding pad layer. The two ends of the wires are electrically connected with the first welding pad layer and the second welding pad layer respectively, the wires have top points with the maximum distance to the surface of the substrate, and a first distance is reserved between the top points and the first surface of the sensing chip. The plastic package layer is located on the surface of the substrate and the surface of the sensing chip and surrounds the wires and the sensing chip, and a second distance is reserved between the surface of the plastic package layer and the first surface of the sensing chip and is larger than the first distance. According to the packaging structure, the requirement for the sensitivity of the sensing chip is lowered, and application is wider.

Owner:CHINA WAFER LEVEL CSP

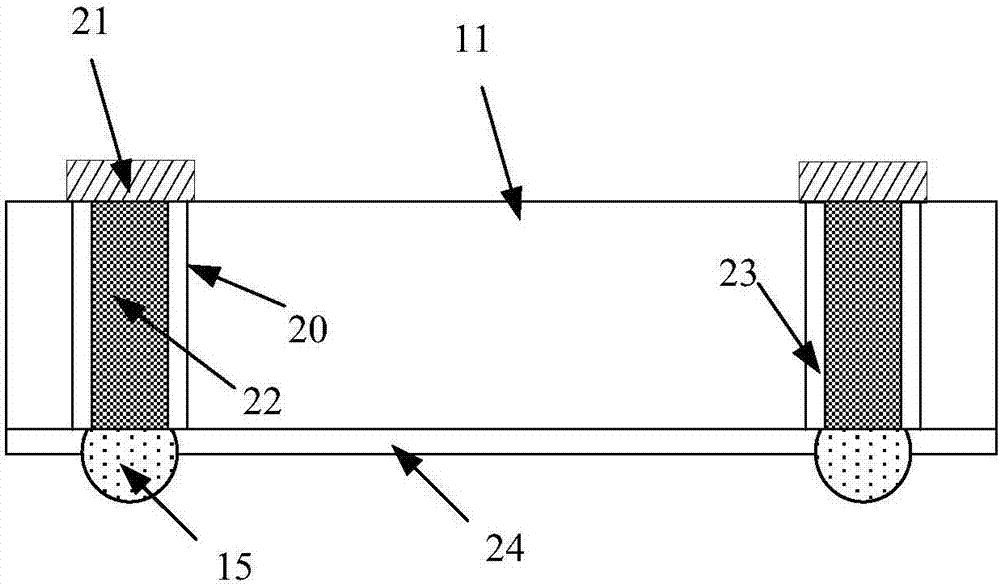

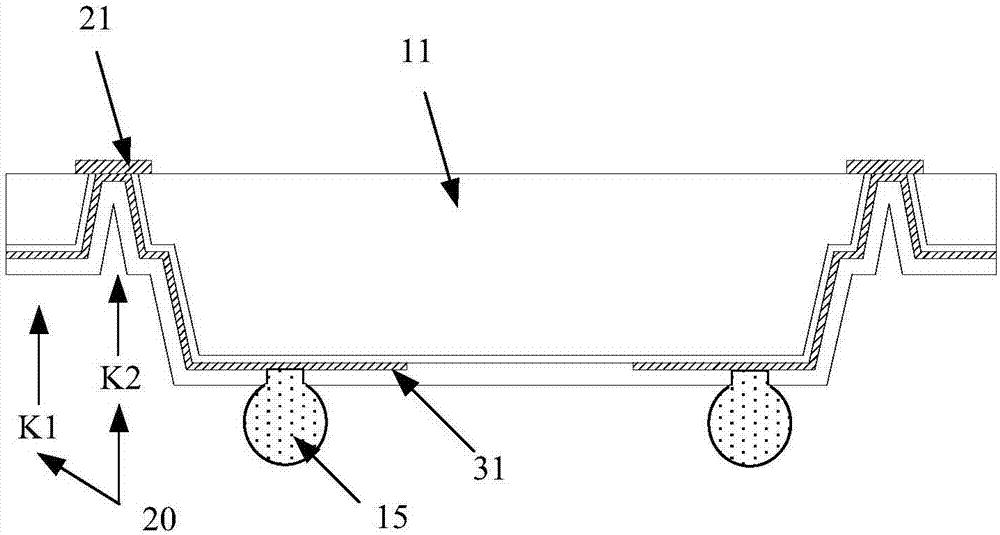

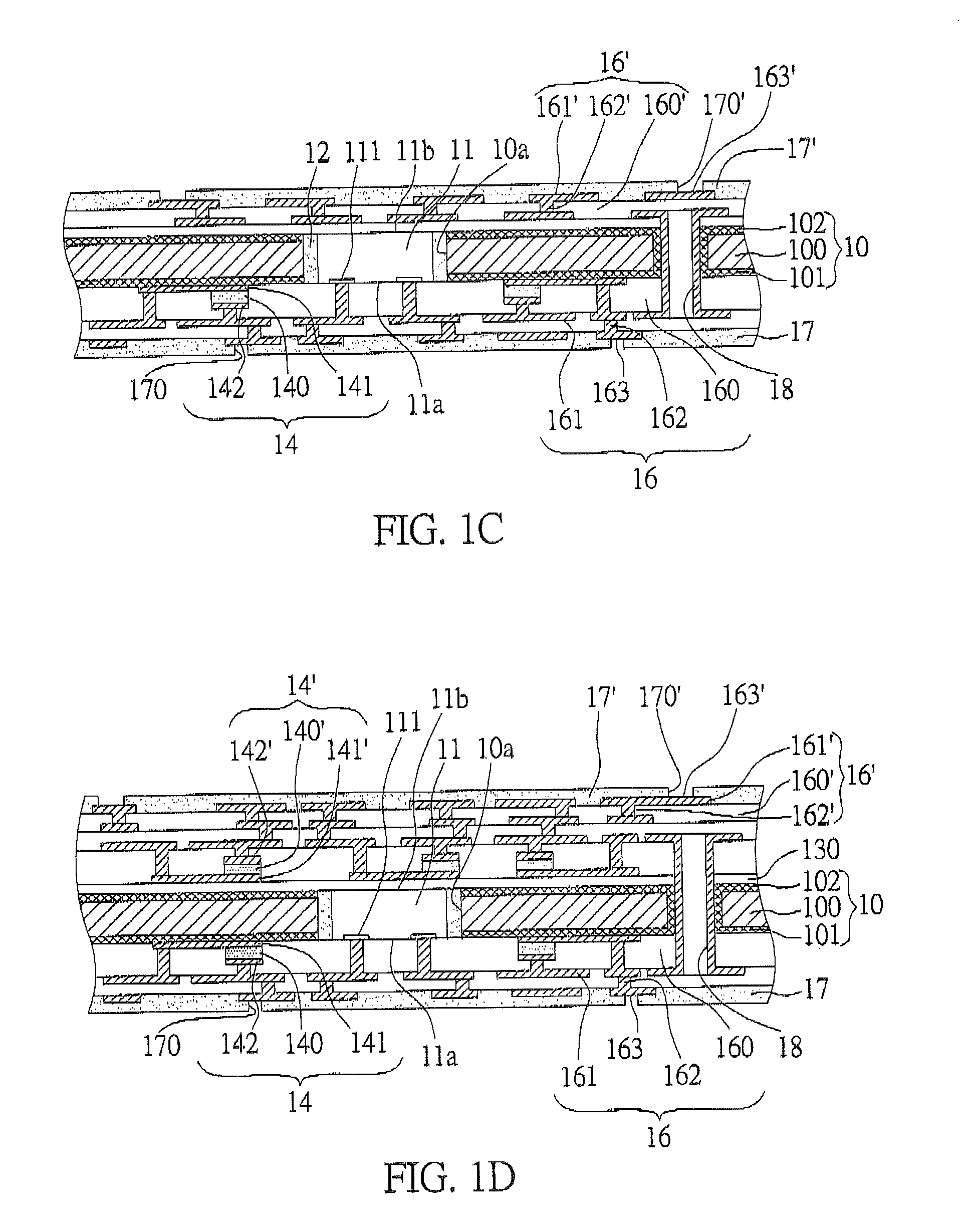

Wafer-level fingerprint recognition chip packaging structure and method

InactiveCN104201115ASimplify the packaging processReduce damageMeasurement apparatus componentsSemiconductor/solid-state device detailsFingerprintComputer science

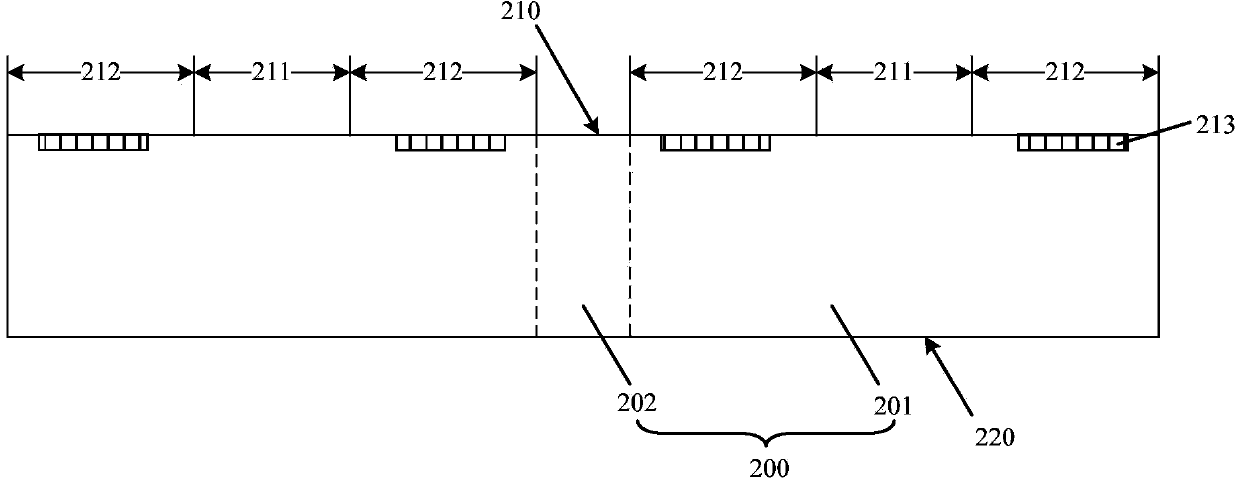

Disclosed is a wafer-level fingerprint recognition chip packaging structure and method. The method includes: providing a substrate which comprises a plurality of induction chip areas and is provided with a first surface and a second surface opposite to the first surface, wherein a first surface of each induction chip area comprises an induction area; forming a covering layer on the first surface of the substrate; forming a plug structure in each induction chip area of the substrate, wherein one end of each plug structure is electrically connected with the corresponding induction area, and the other end of each plug structure is exposed out of the second surface of the substrate. By the forming method, the packaging process of a fingerprint recognition chip can be simplified, the requirement on sensitivity of the induction chip is lowered, and the packaging method is wider in application.

Owner:CHINA WAFER LEVEL CSP

Semiconductor device and method of manufacturing the same

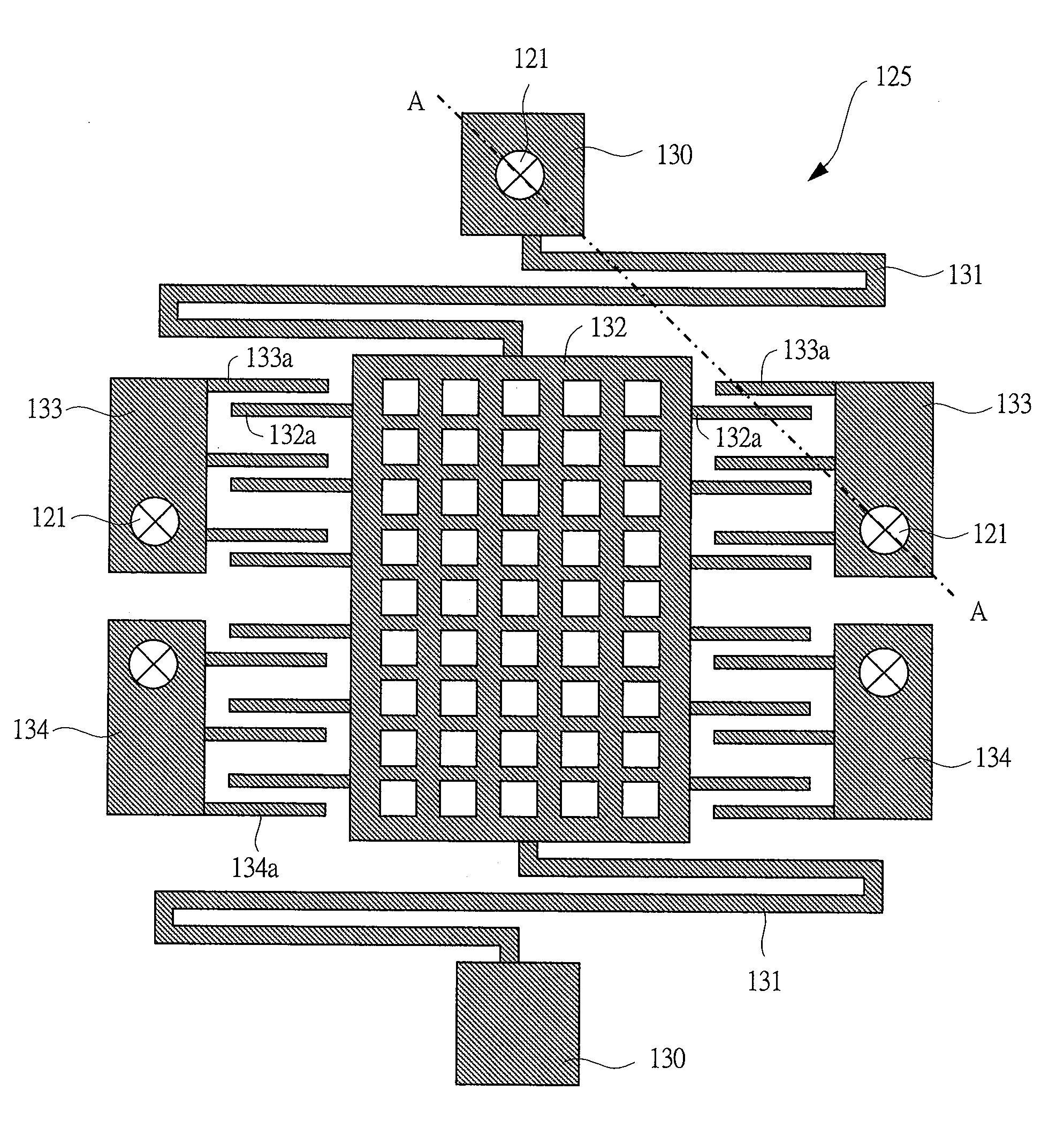

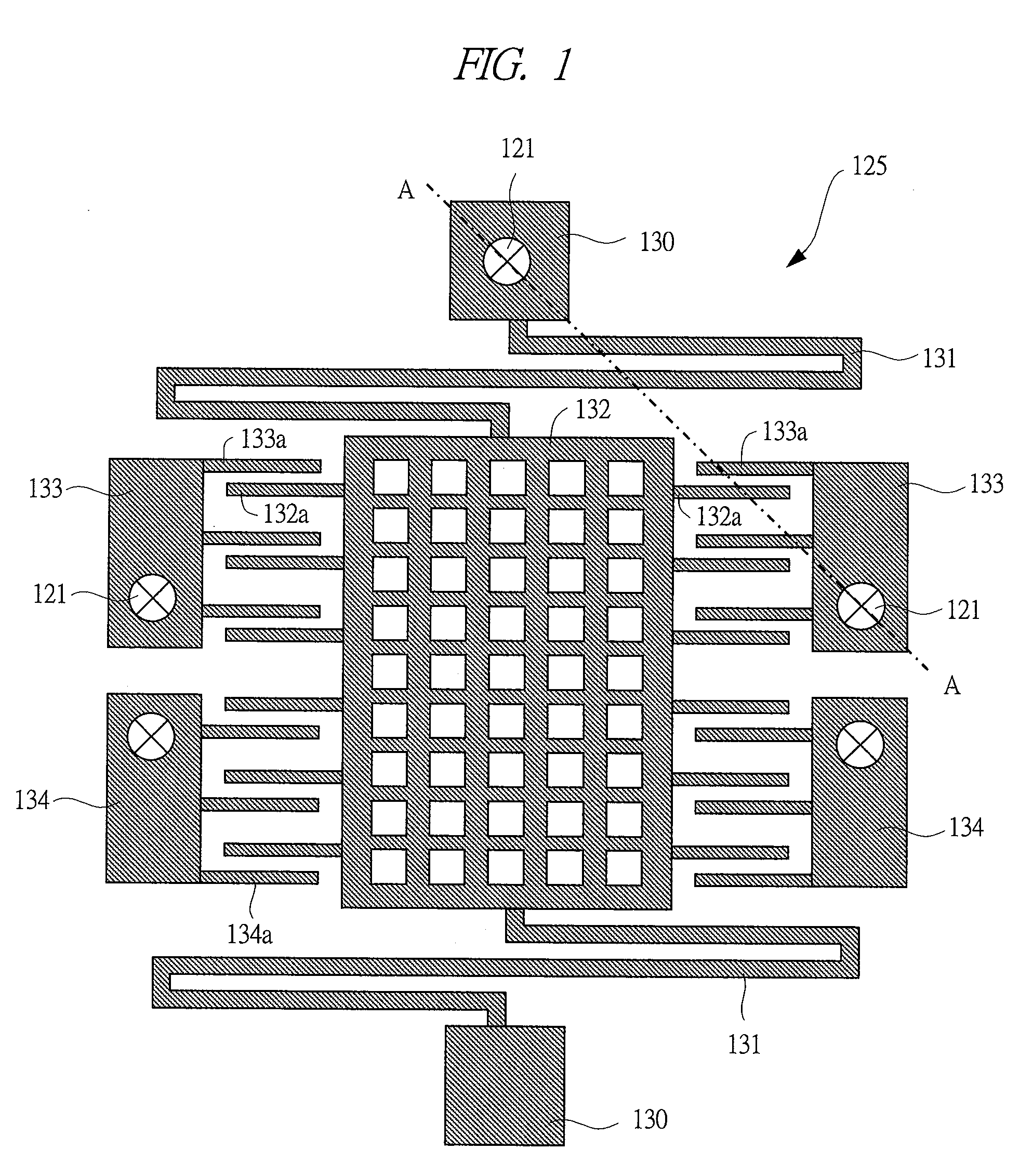

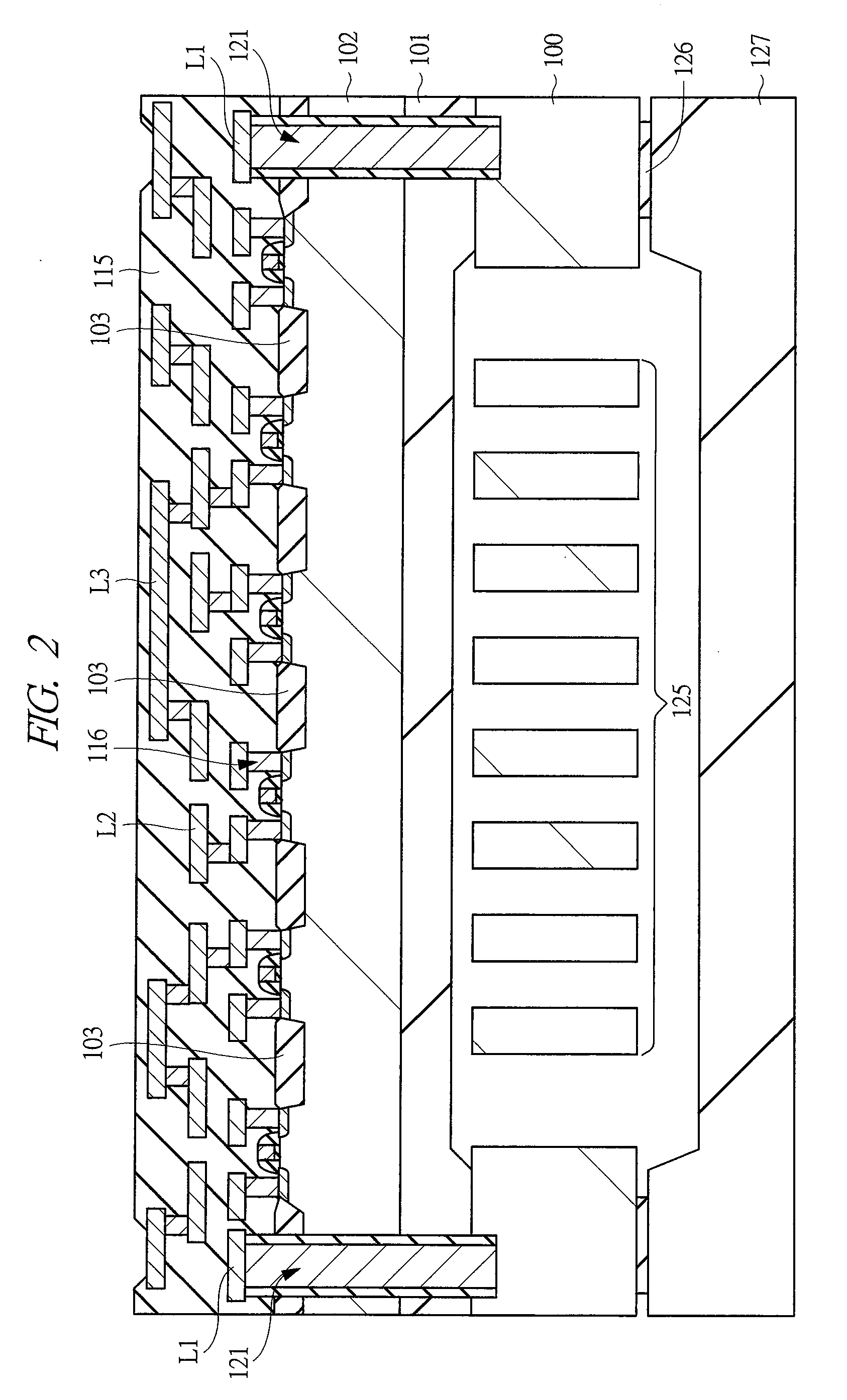

ActiveUS20090134459A1Reduce thicknessPackage structure is simpleTransistorSemiconductor/solid-state device detailsPhysicsAngular rate sensor

As well as achieving both downsizing and thickness reduction and sensitivity improvement of a semiconductor device that has: a MEMS sensor formed by bulk micromachining technique such as an acceleration sensor and an angular rate sensor; and an LSI circuit, a packaging structure of the semiconductor device having the MEMS sensor and the LSI circuit can be simplified. An integrated circuit having MISFETs and wirings is formed on a silicon layer of an SOI substrate, and the MEMS sensor containing a structure inside is formed by processing a substrate layer of the SOI substrate. In other words, by using both surfaces of the SOI substrate, the integrated circuit and the MEMS sensor are mounted on one SOI substrate. The integrated circuit and the MEMS sensor are electrically connected to each other by a through-electrode provided in the SOI substrate.

Owner:HITACHI LTD

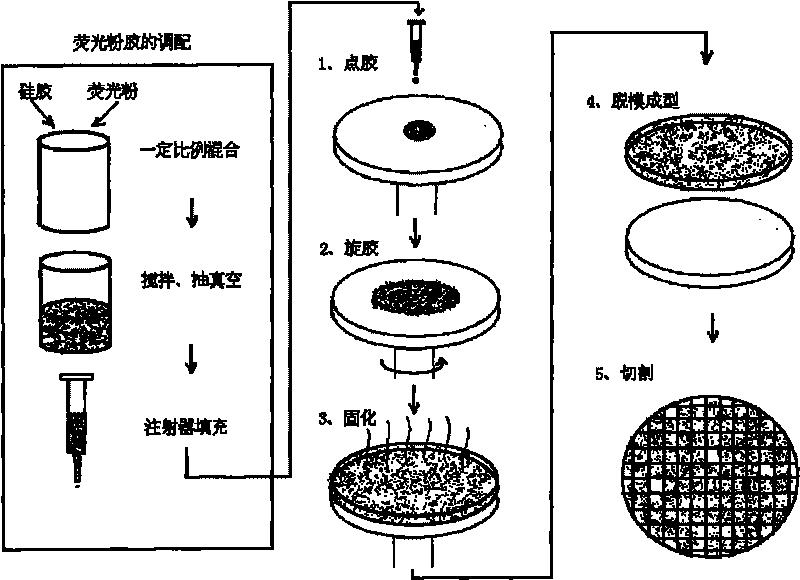

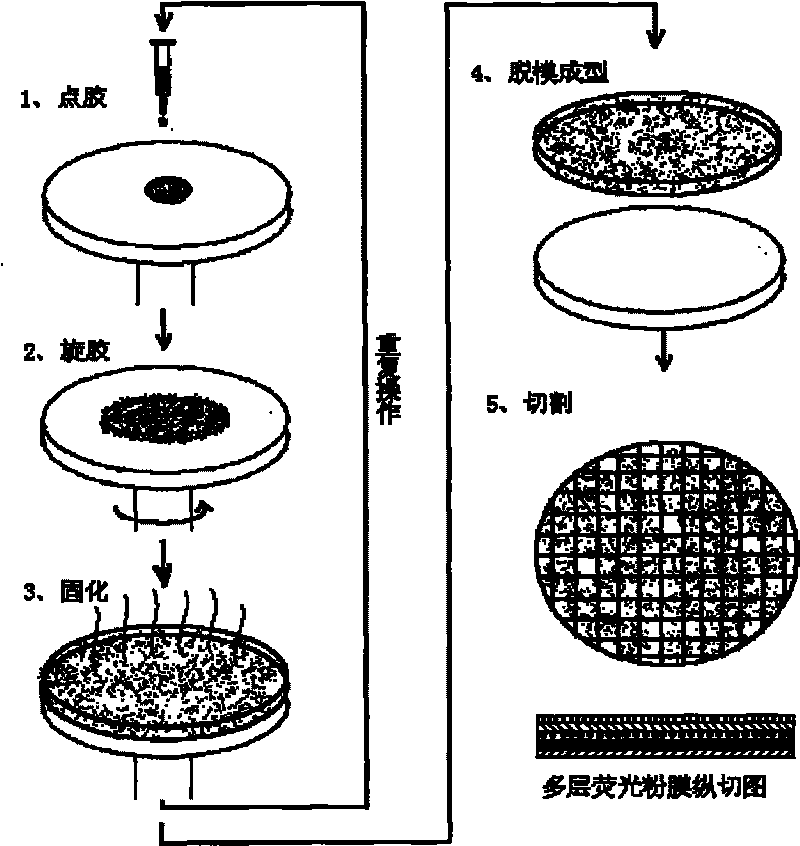

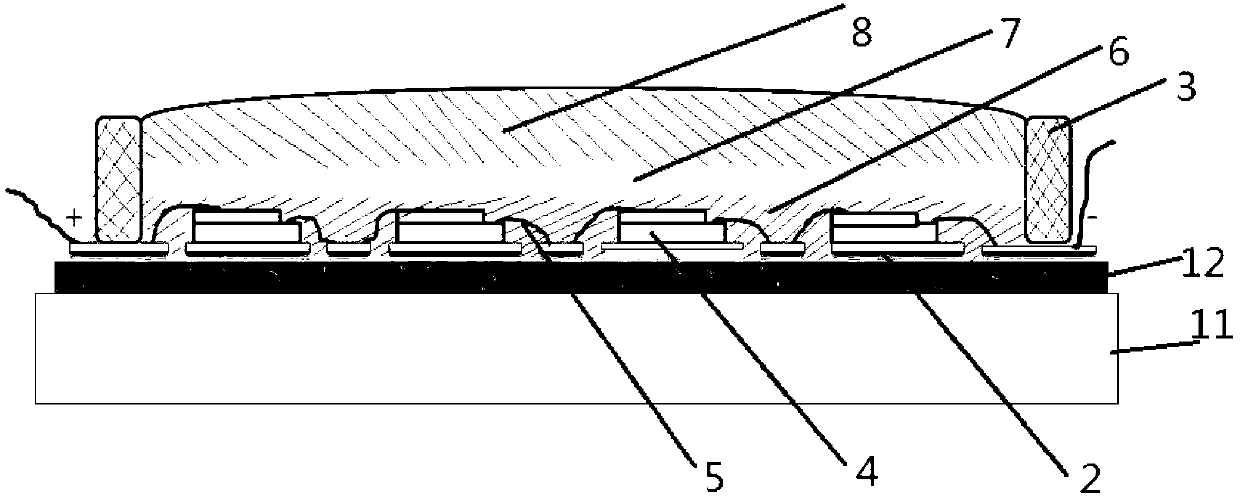

Phosphor powder film making method and obtained phosphor powder film encapsulating method

InactiveCN101699638AStable jobEasy to prepareSolid-state devicesSemiconductor/solid-state device manufacturingPhosphorWhite light

The invention discloses a phosphor powder film making method and obtained phosphor powder film encapsulating method. The invention is characterized in that a method spinning phosphor powder glue is adopted to independently make phosphor powder film in encapsulating process, then the phosphor powder film is covered on an LED chip coated with heat insulating material, and finally the heat insulating material is cured to complete white-light LED phosphor powder coating. The quantity of LED chip is one or more than one. The invention is simple in technology and low in making cost, can accurately control the thickness of phosphor powder film, greatly improves light color consistency of LED product, is applicable to large scale industrialized production and adopts heat insulating encapsulating manner to solve heat dissipation problem of LED and reduce lumens depreciation, so that light color is more stable.

Owner:SUN YAT SEN UNIV

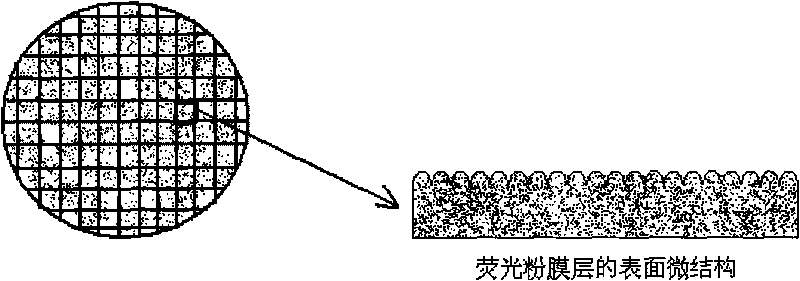

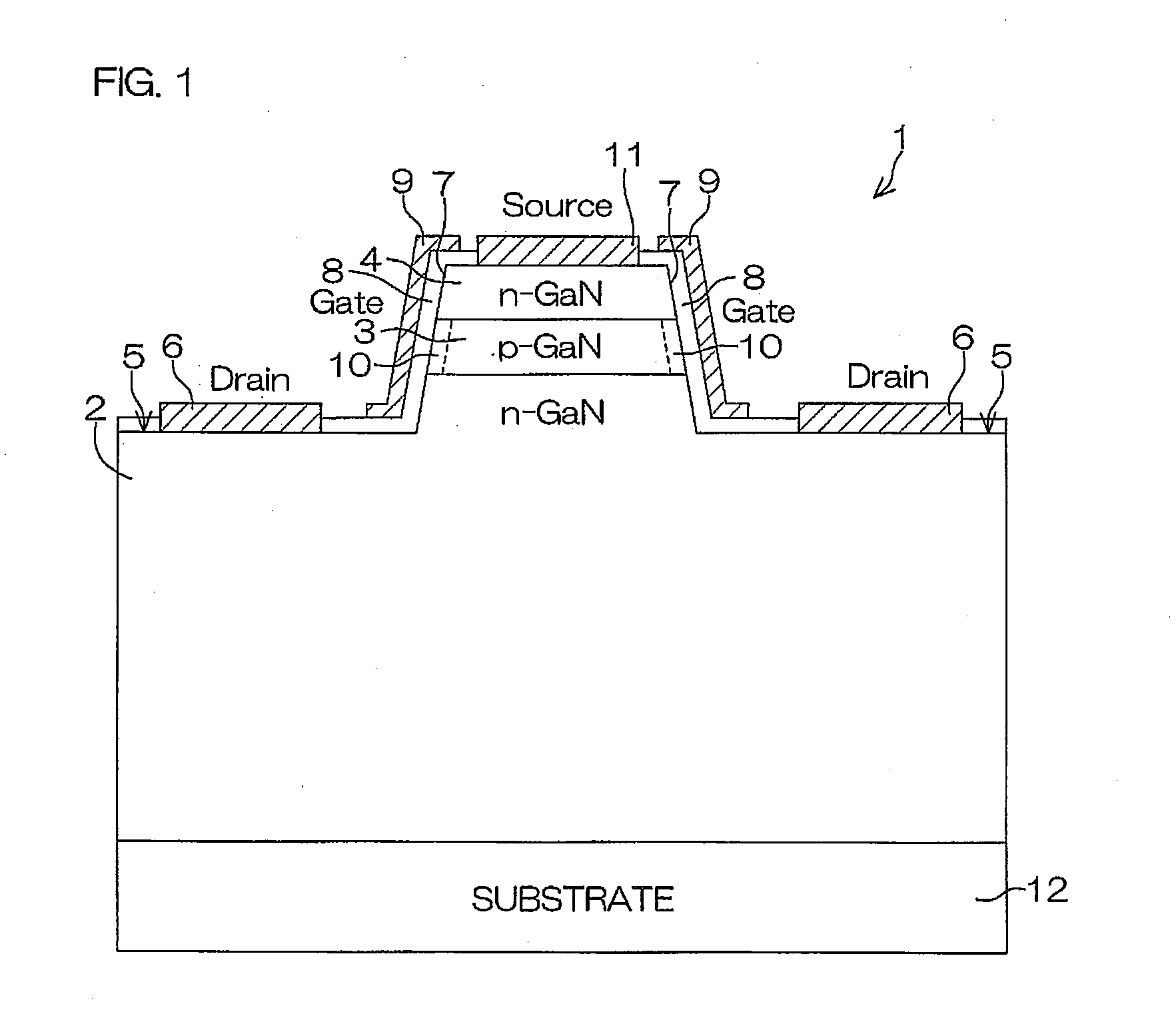

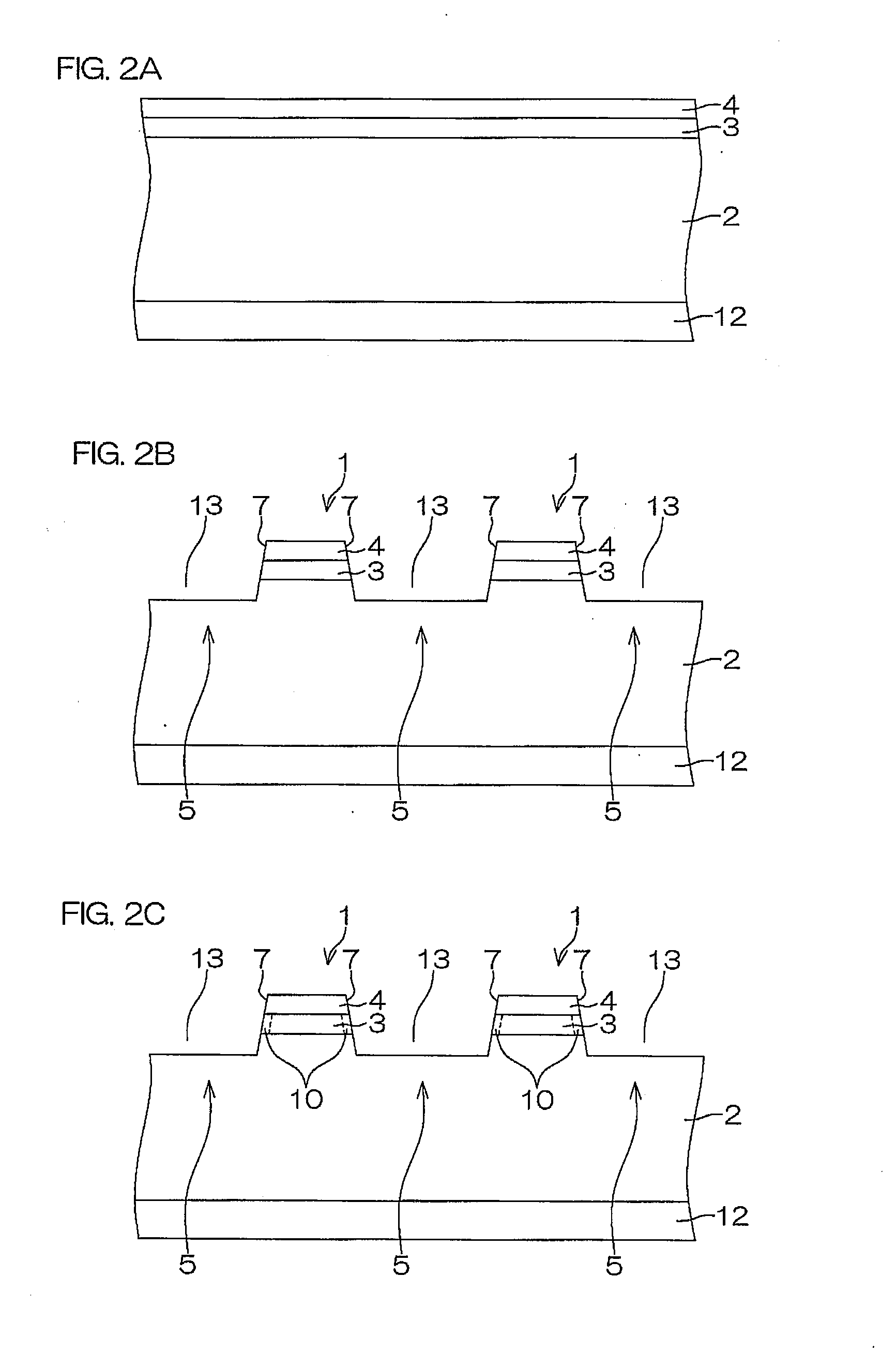

Nitride semiconductor device, nitride semiconductor package, and method for manufacturing nitride semiconductor device

InactiveUS20100078688A1Improve withstand voltage characteristicsLower gate voltageTransistorSemiconductor/solid-state device detailsSemiconductor packageImpurity

A nitride semiconductor device of the present invention includes: a nitride semiconductor laminated structure including an n-type first layer, a second layer that is laminated on the first layer and contains a p-type impurity, and an n-type third layer laminated on the second layer, each layer of the nitride semiconductor laminated structure being made of a Group III nitride semiconductor, and having a wall surface extending from the first, second, to third layers; a fourth layer that is formed on the wall surface in the second layer and that has a different conductive characteristic from that of the second layer; a gate insulating film formed to contact the fourth layer; and a gate electrode formed as facing the fourth layer with the gate insulating film being sandwiched between the gate electrode and the fourth layer.

Owner:ROHM CO LTD

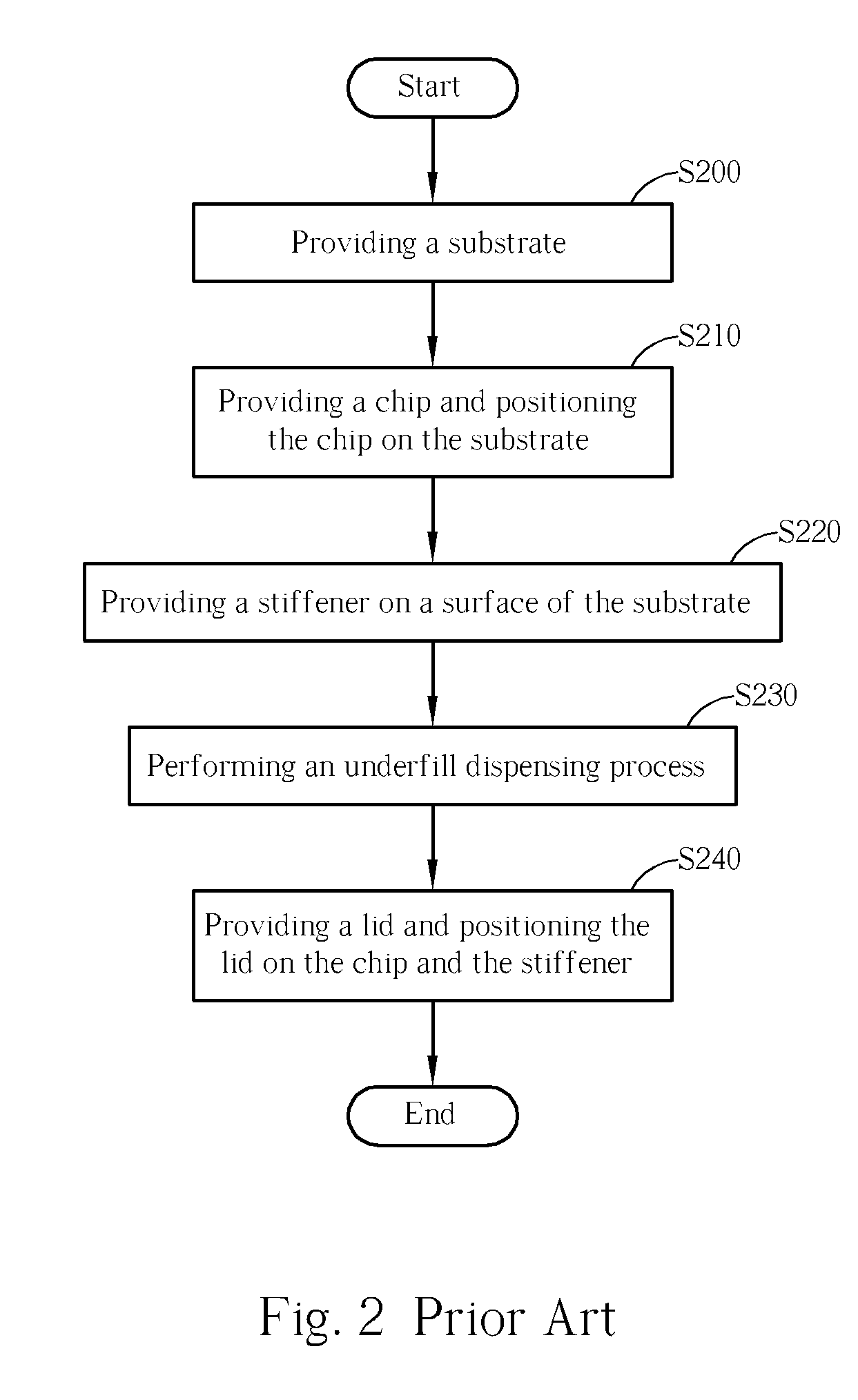

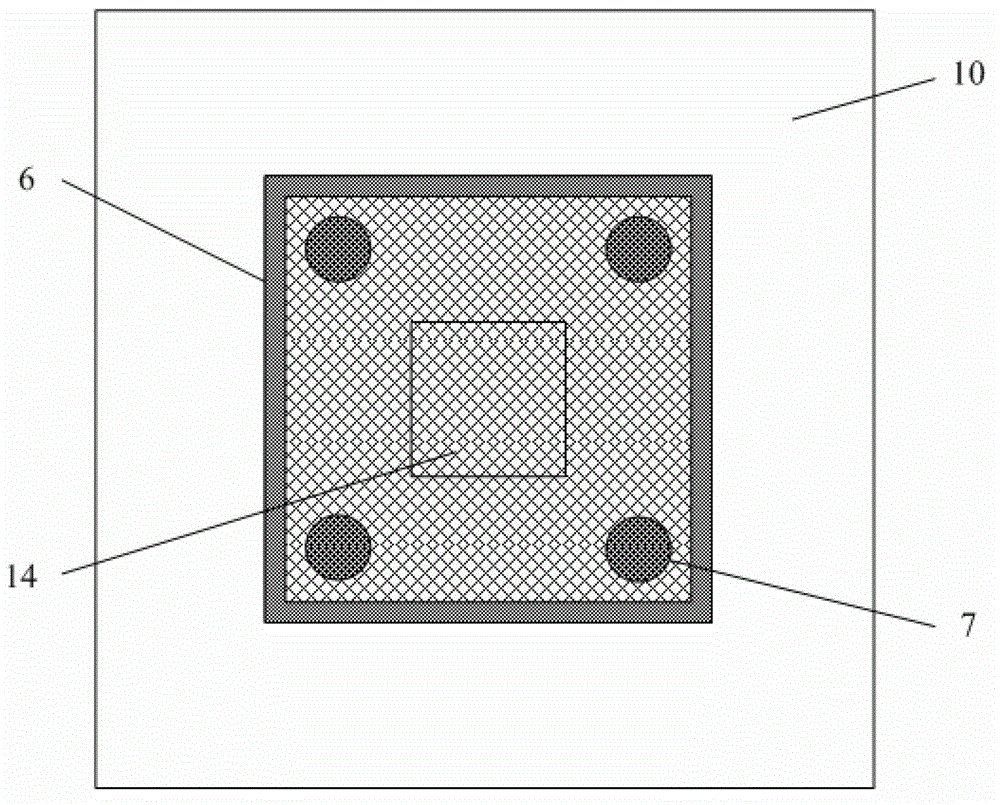

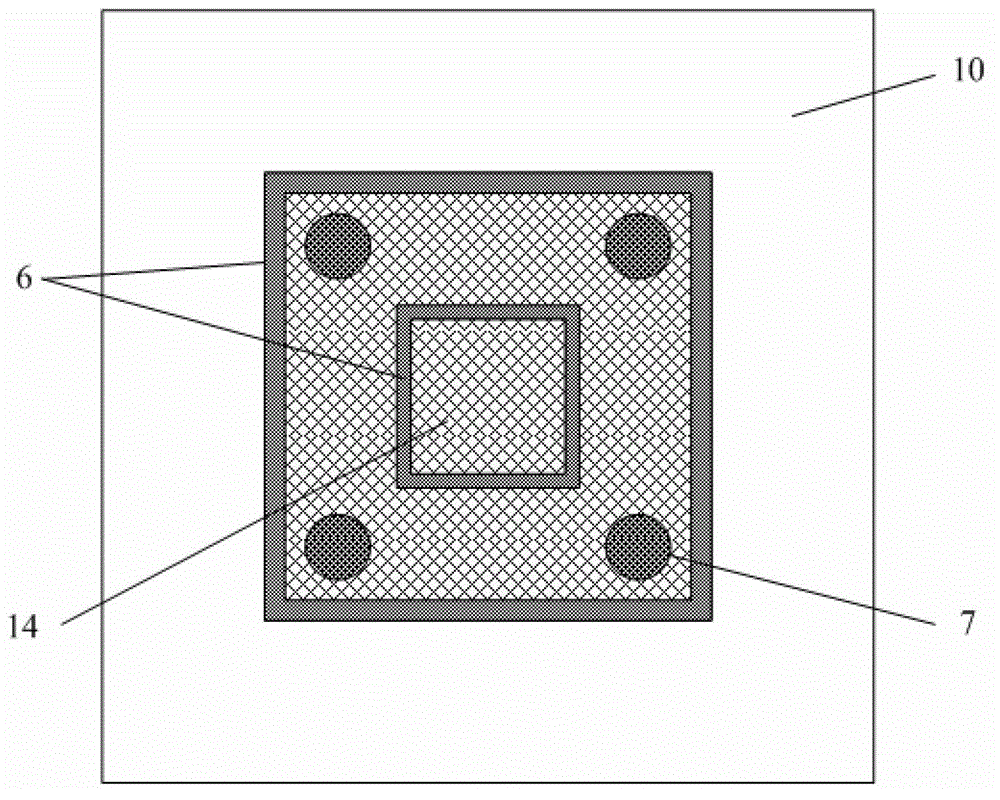

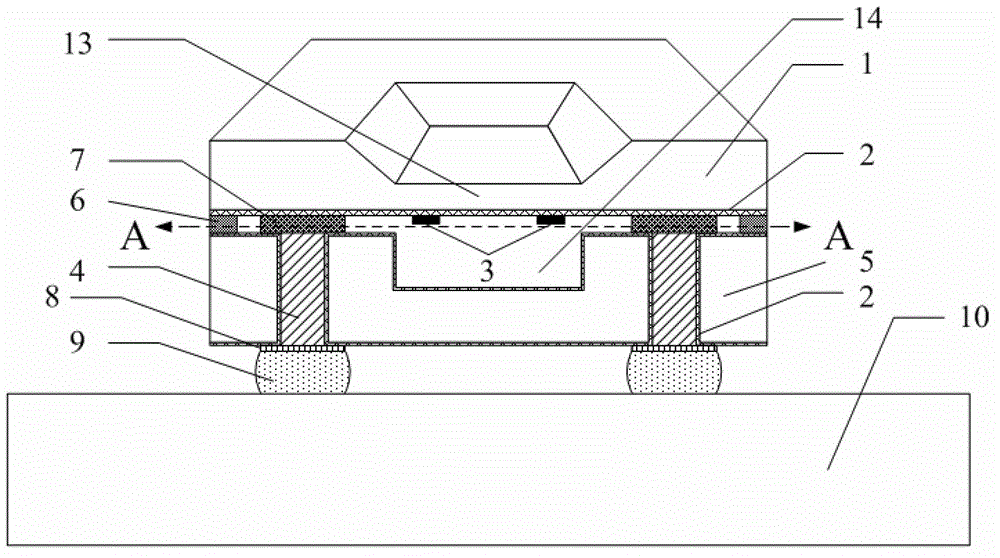

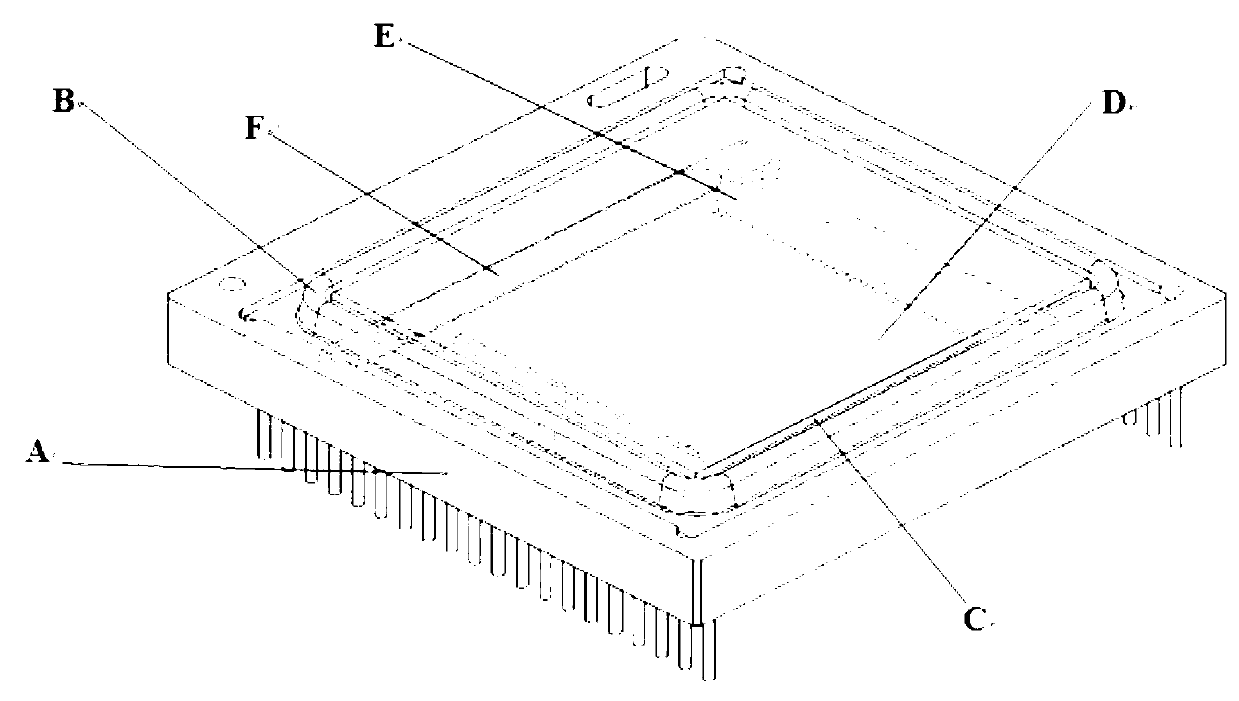

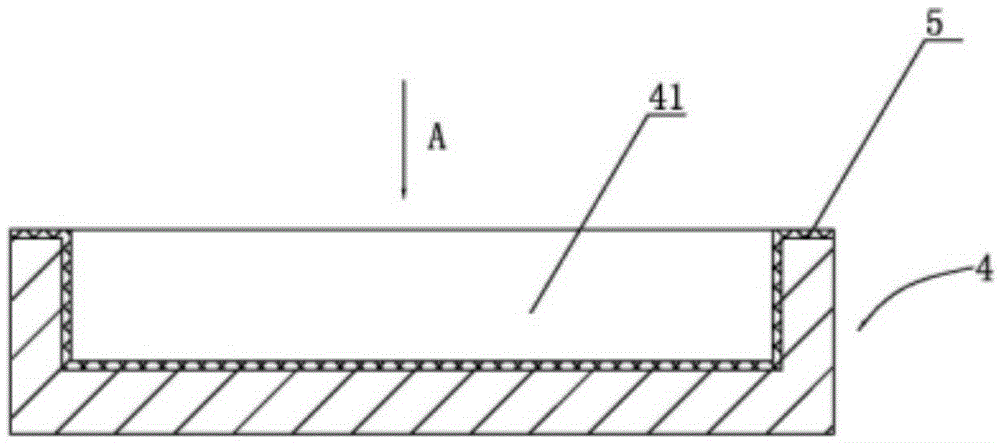

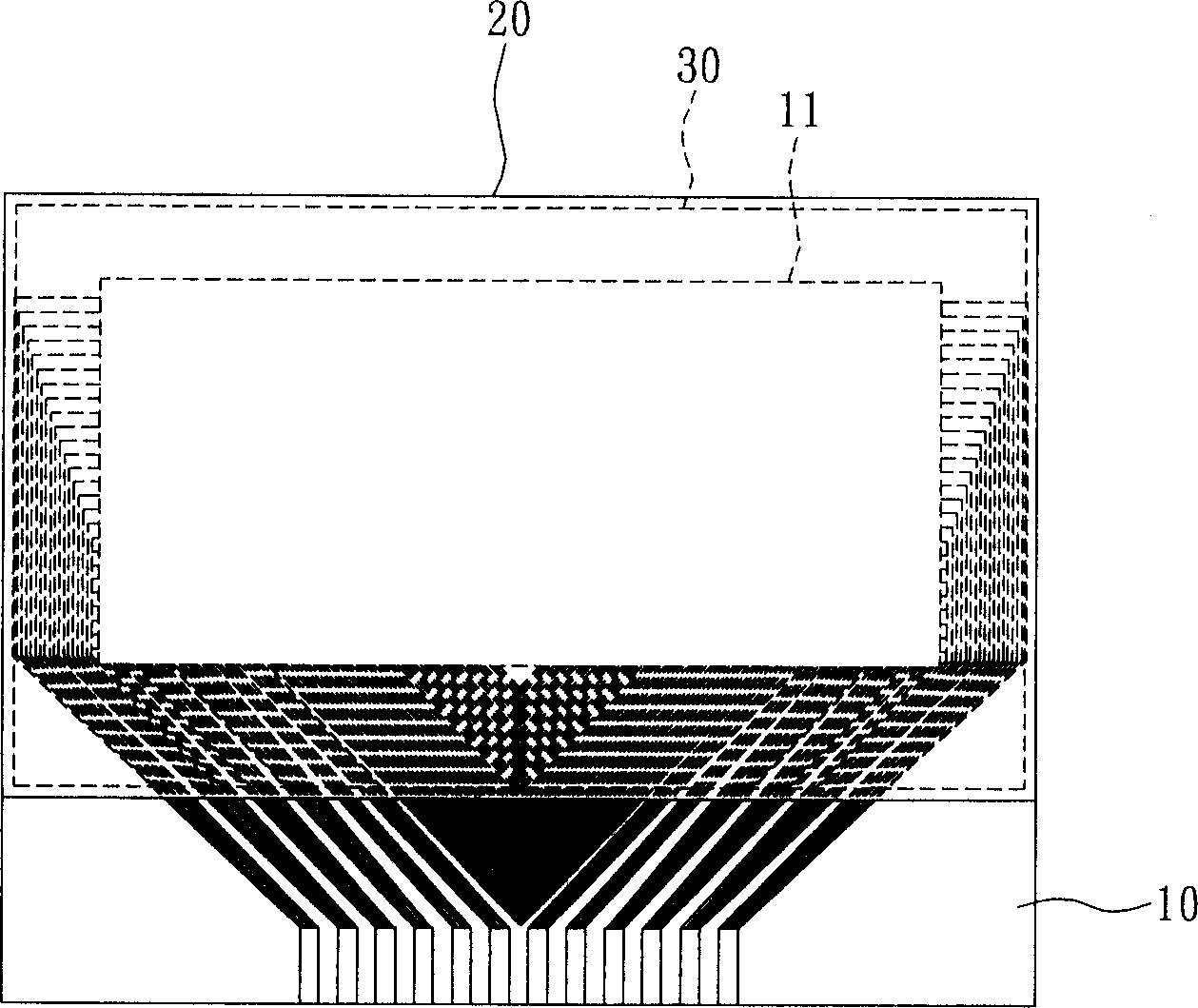

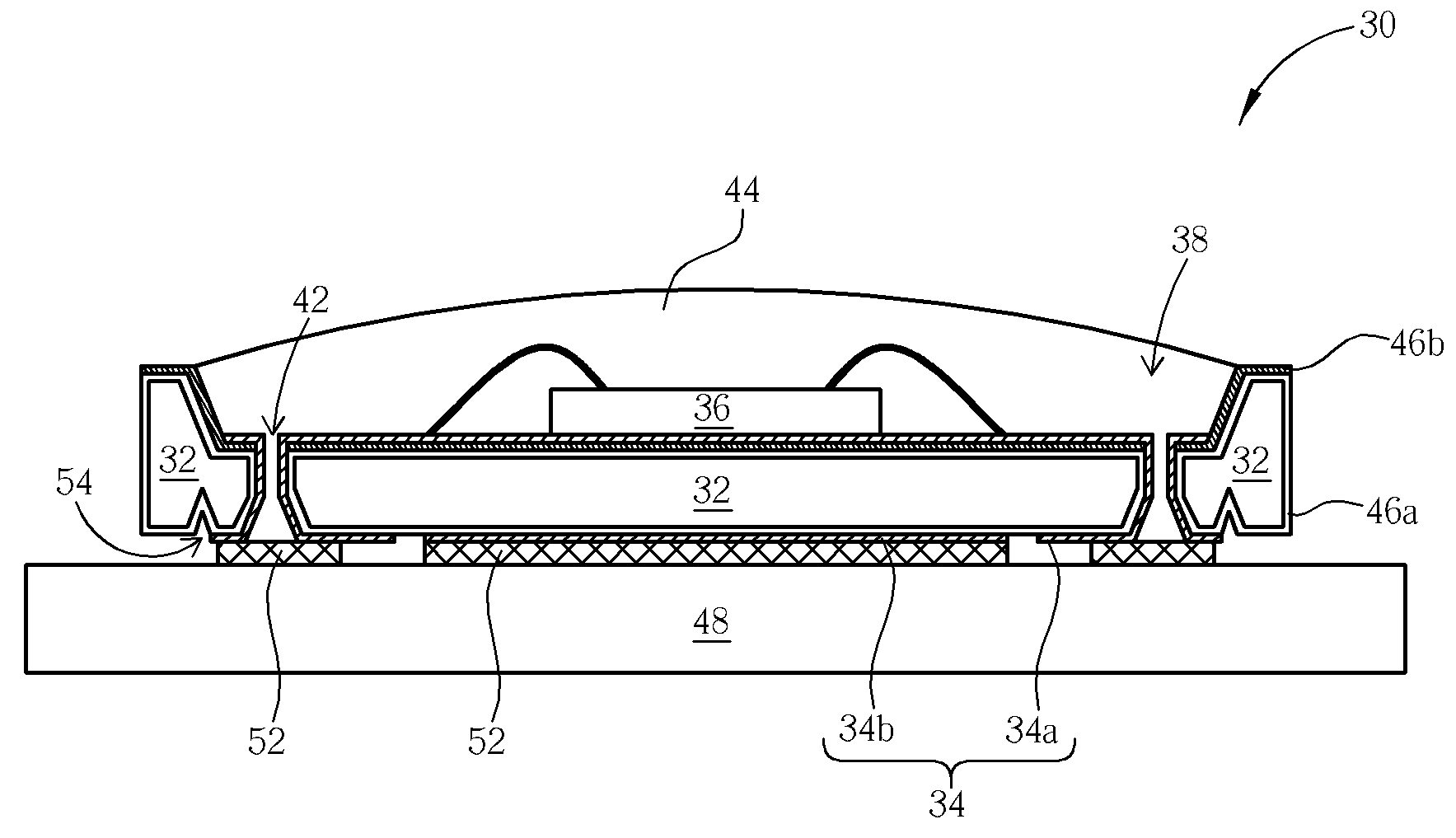

Flip-chip package structure with stiffener

ActiveUS20080001308A1Good coplanarityPackage structure is simpleSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

A flip-chip package structure with stiffener includes a substrate, a first stiffener positioned on a surface of the substrate, a chip having a plurality of bumps adopted to electrically connect the substrate and the chip, and a second stiffener positioned on the surface of the substrate and connected with the first stiffener. The first stiffener is positioned outside of the second stiffener.

Owner:ADVANCED SEMICON ENG INC

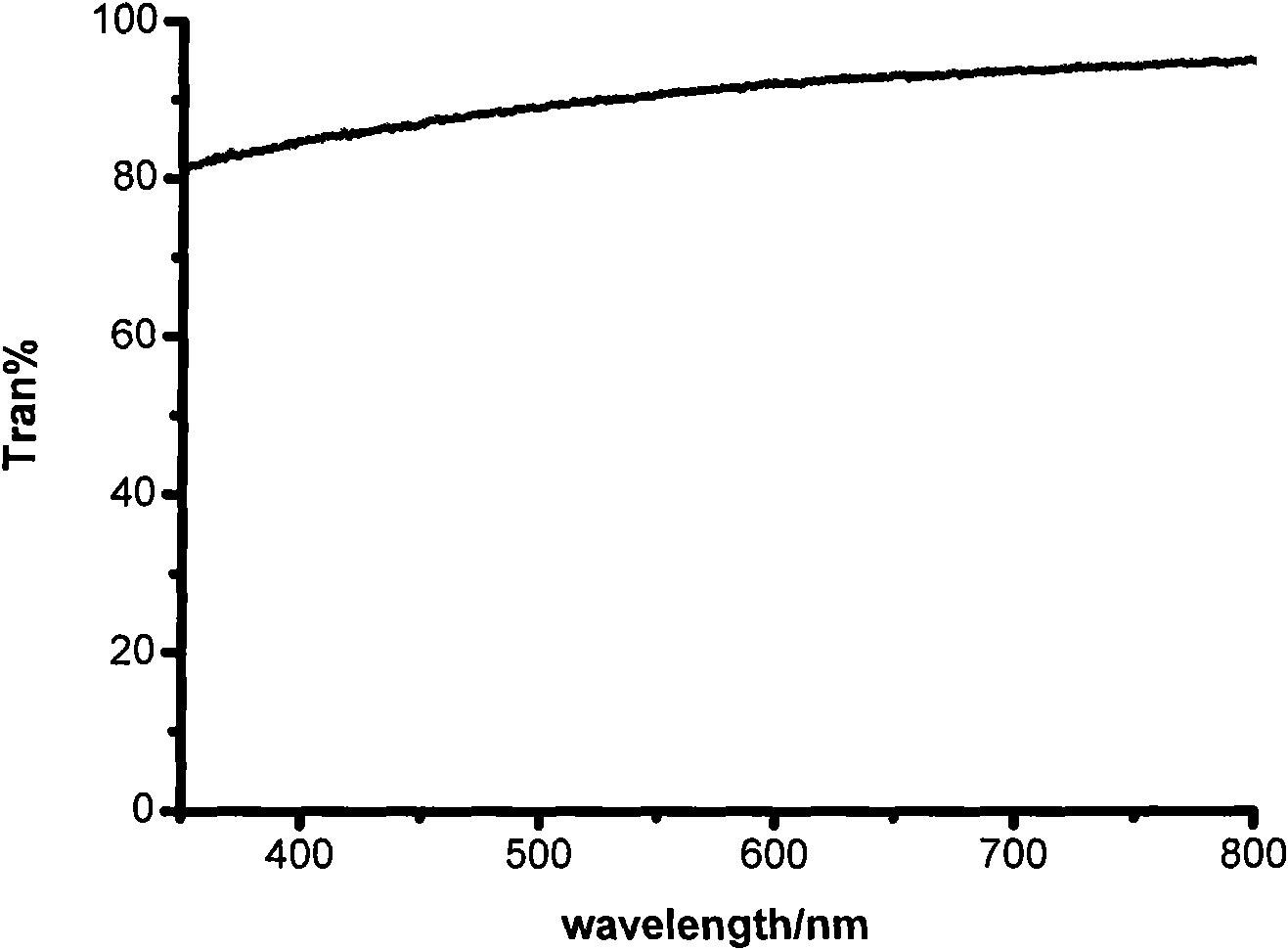

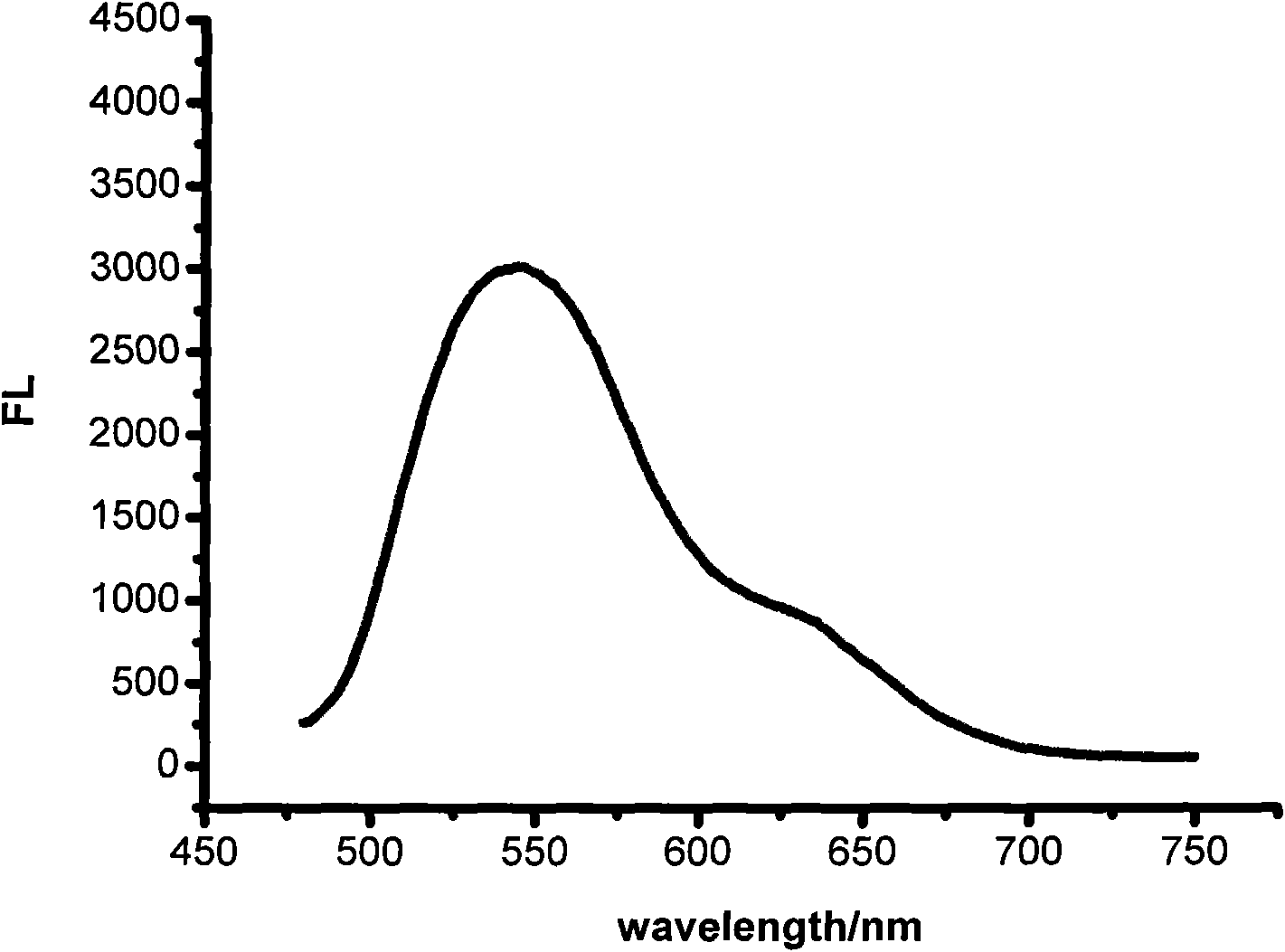

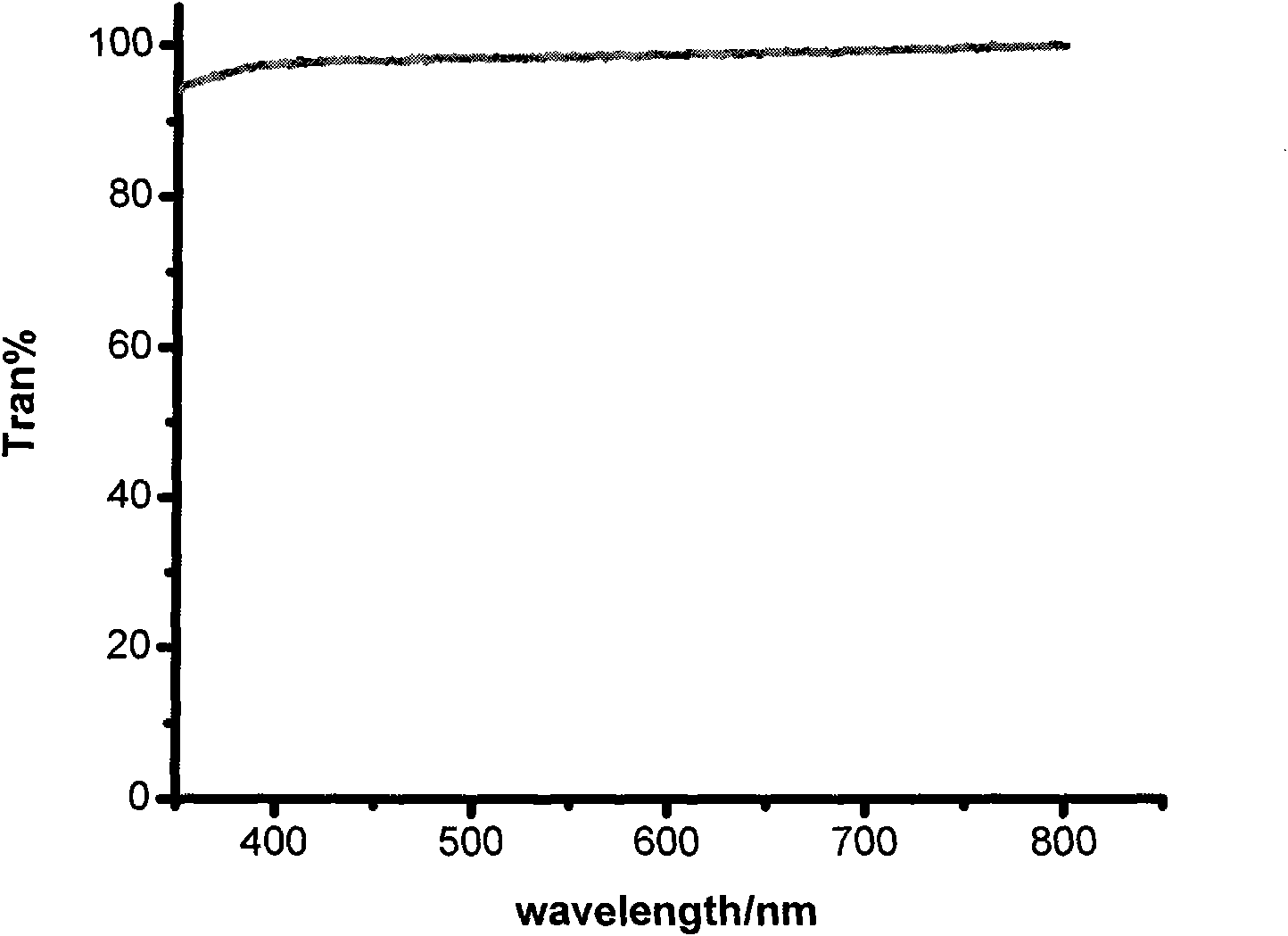

Quantum dot luminescence transparent casting glue composite material

InactiveCN101580628AEasy to prepareEasy to operateOther chemical processesLuminescent compositionsSurface modificationQuantum dot

The invention discloses a quantum dot luminescence transparent casting glue composite material. The material is characterized in that 0.1-5wt% of a quantum dot nano material is doped into transparent high molecular casting glue for preparation to obtain the quantum dot luminescence transparent casting glue composite material. The preparation includes preparation of quantum dot luminescence material, surface modification of quantum dot luminescence material and synthesis of casting glue composite material. Compared with the prior art, the invention has the advantages of simple preparation method, convenient operation and low cost, is applicable to industrialized production of a light emitting diode, optimizes encapsulation structure and well improves luminous efficiency and color rendering of the LED, thus filling the gap of semiconductor lighting technology.

Owner:EAST CHINA NORMAL UNIVERSITY +1

White light LED packaging structure and packaging method thereof

InactiveCN101661987AReduce lossesImprove light extraction efficiencySemiconductor/solid-state device detailsSolid-state devicesFluorescenceWhite light

The invention discloses a white light LED packaging structure comprising a bracket and a plurality of LED chips arranged on the bracket, wherein a heat-insulation transparent material layer is coatedon the LED chips, a fluorescent powder layer is also coated on the heat-insulation transparent material layer, and a light outlet face of the heat-insulation transparent material layer and the fluorescent powder layer directly form a lens structure, or a lens structure is arranged on the fluorescent powder layer. The number of the LED chip is multiple, the heat-insulation transparent material layer and the fluorescent powder layer are sequentially and independently coated on each LED chip, or the heat-insulation transparent material layer and the fluorescent powder layer are integrally coatedon each LED chip. The invention has low manufacturing cost, improves the problem of heat radiation of a high-power white light LED, reduces light attenuation and enables the light color to be more stable.

Owner:SUN YAT SEN UNIV

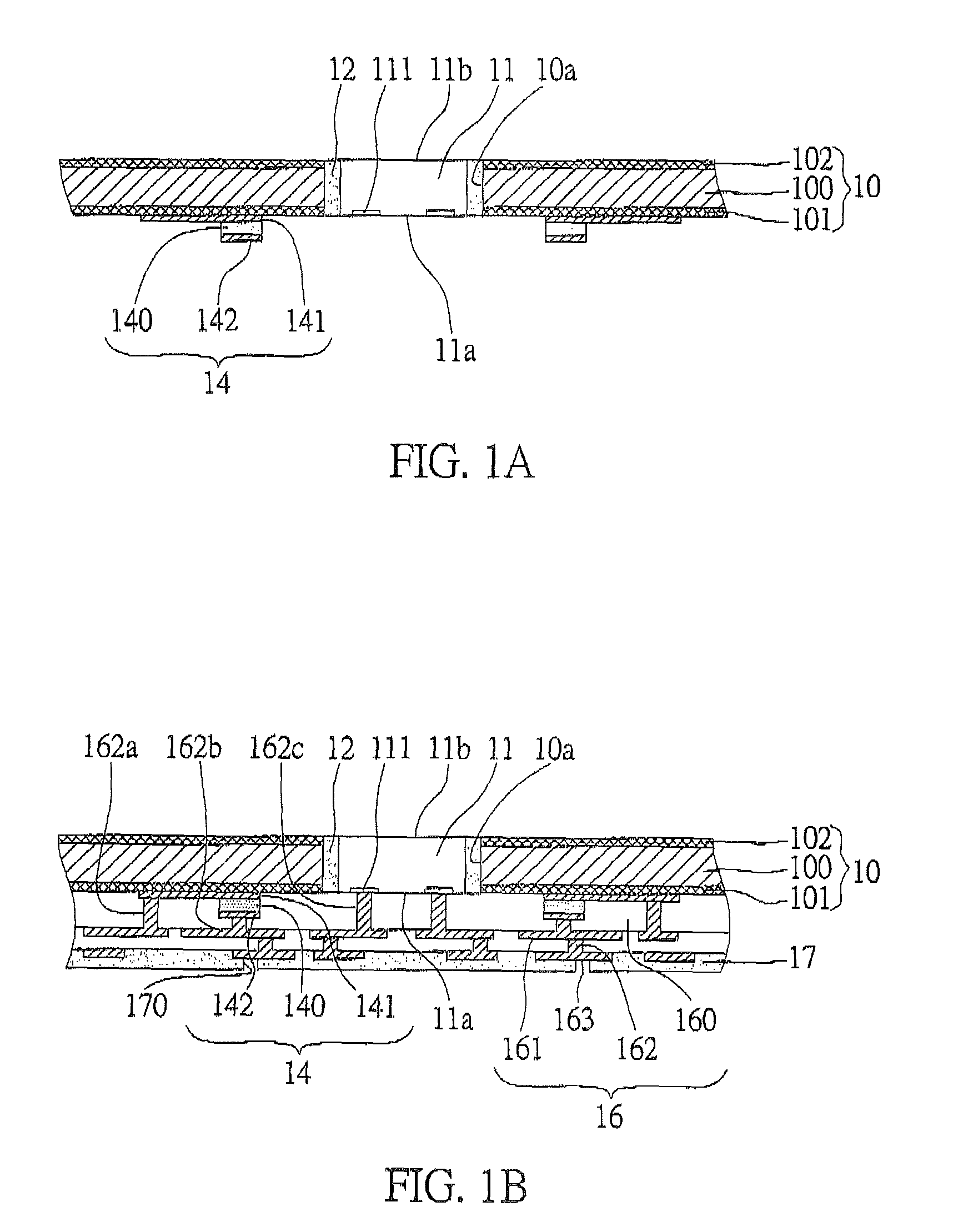

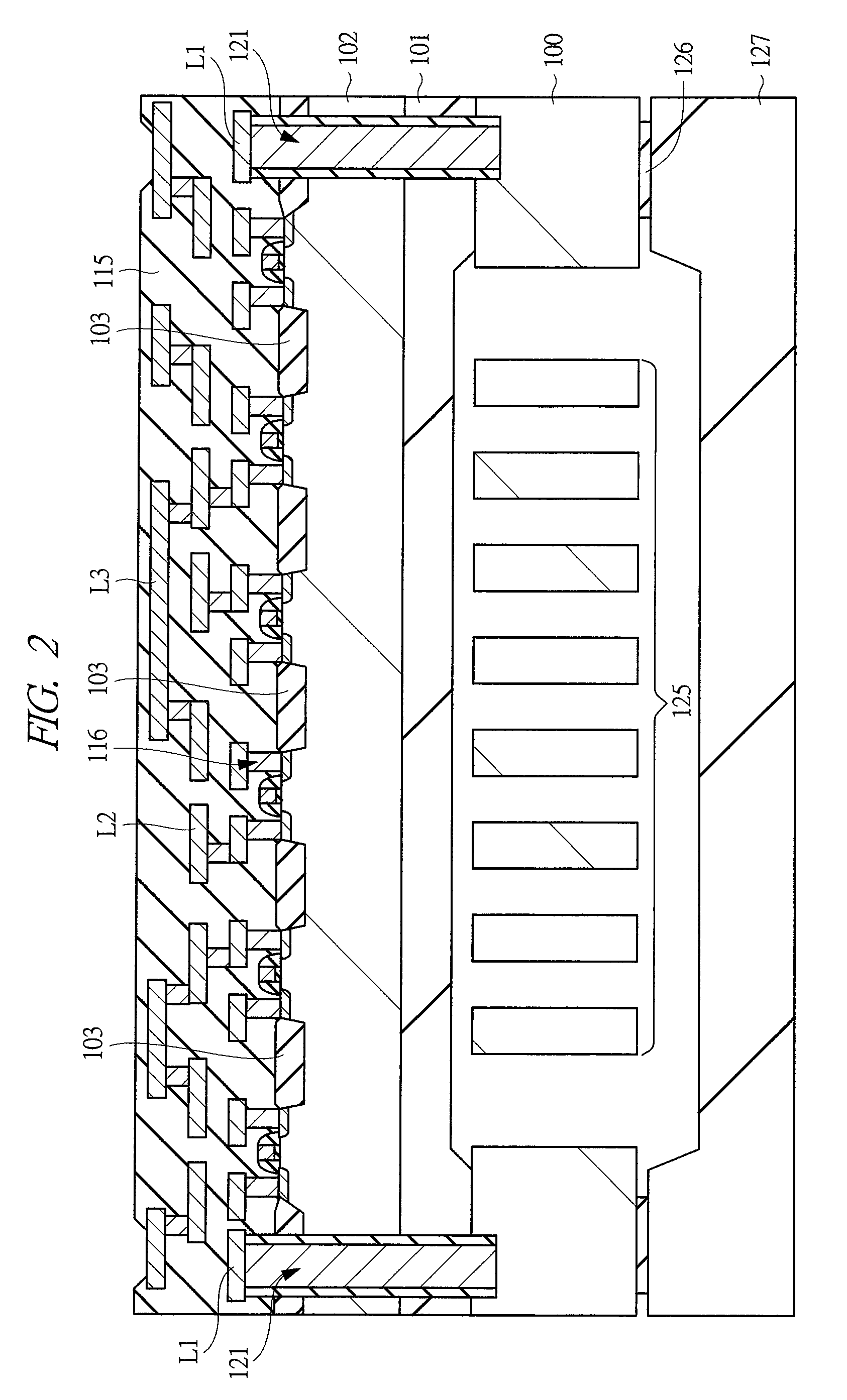

Circuit board structure having electronic components integrated therein

ActiveUS7969745B2Improve structural rigidityReduce the possibilitySemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductor chipElectronic component

The present invention provides a circuit board having electronic components integrated therein, including a carrier board having an metallic oxide layer formed on each two surfaces of a metal layer, and having at least one through cavity; at least a semiconductor chip hold in the opening; at least a capacitor disposed on one surface of the carrier board, wherein the surface with the capacitor disposed thereon is at the same side with the active surface of the semiconductor chip. The capacitor is constituted of a first electrode plate disposed on partial surface of one side of the carrier board, a high dielectric material layer disposed on the surface of the first electrode plate, and a second electrode plate, paralleling and corresponding to the first electrode plate, disposed on the surface of the high dielectric material. The metal layer and the oxidation layer of the carrier board can enhance rigidity as well as tenacity and also integrate semiconductor chips and capacitors in the circuit board structure.

Owner:UNIMICRON TECH CORP

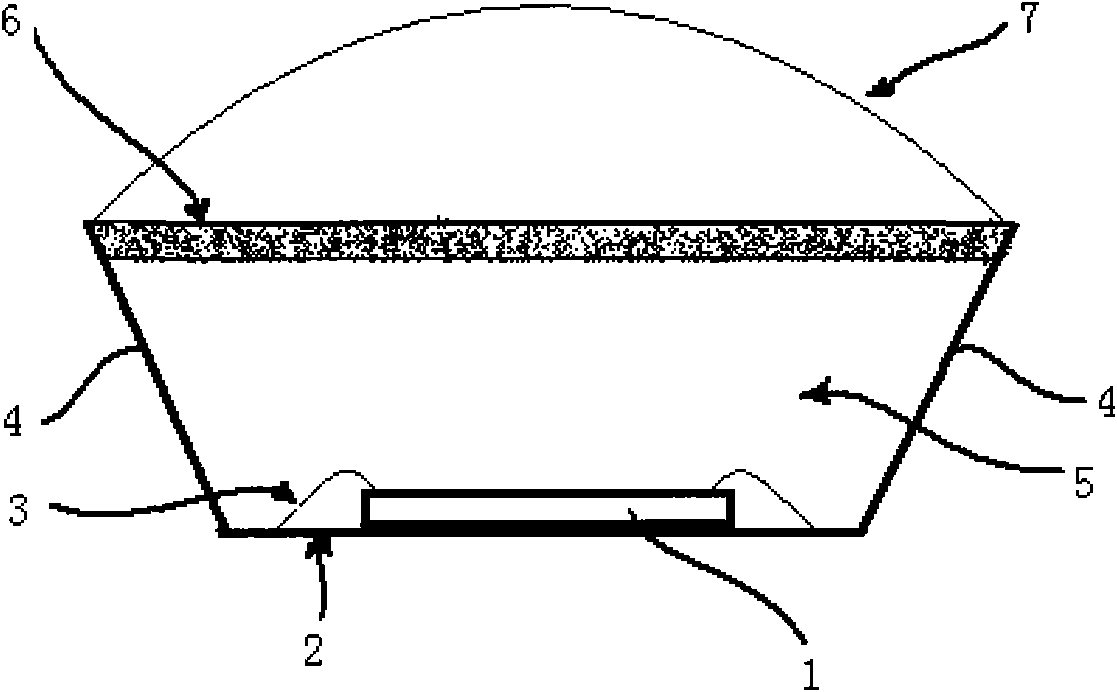

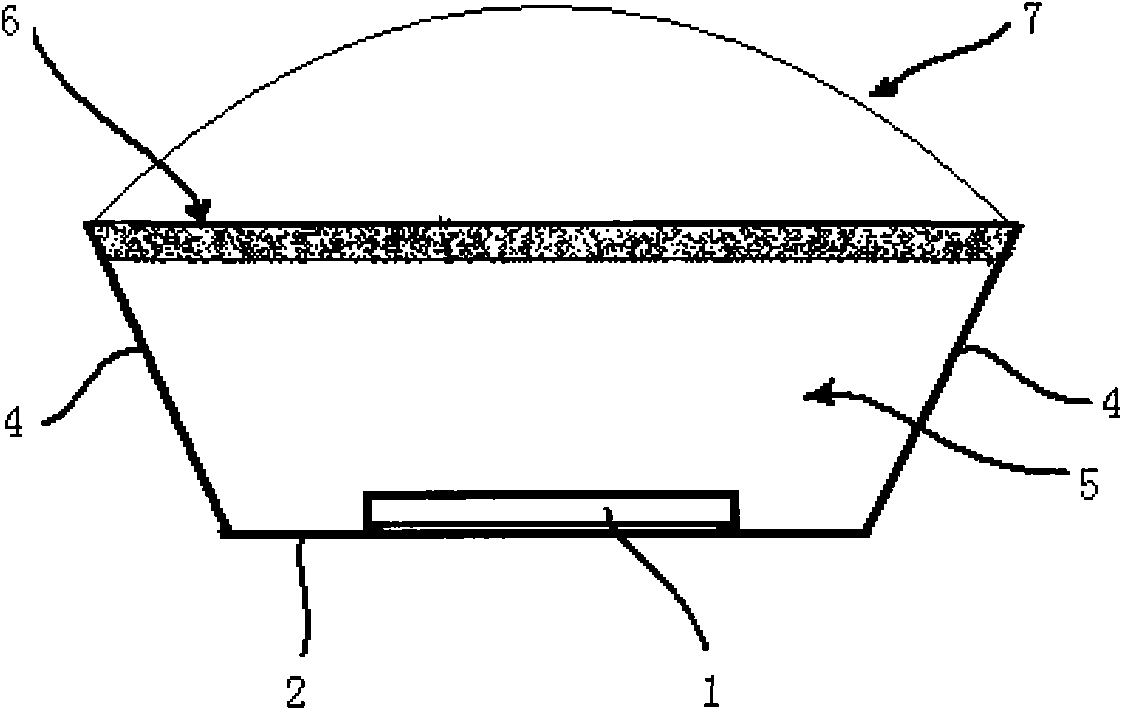

LED packaging structure and packaging method thereof

InactiveCN101937962APackage structure is simpleHigh yieldSolid-state devicesSemiconductor devicesEngineeringColloid

The invention relates to an LED packaging structure and a packaging method thereof. The LED packaging structure comprises a base plate, LED chips, one or more convex walls and a colloid lens molded under the restriction of the convex walls, wherein the convex walls are arranged on the base plate; at least one LED chip is arranged on the base plate in an area encircled by the convex walls; the area encircled by the convex walls is internally provided with the colloid lens for packaging the LED chip; and the colloid lens is formed by placing liquid colloid in the area restricted by the convex walls, utilizing the surface tension of the liquid to form a required colloid shape and carrying out solidification shaping. Compared with the prior art, the LED packaging structure of the invention is simple and reasonable, and the production process is simple and the cost is lower.

Owner:APT ELECTRONICS

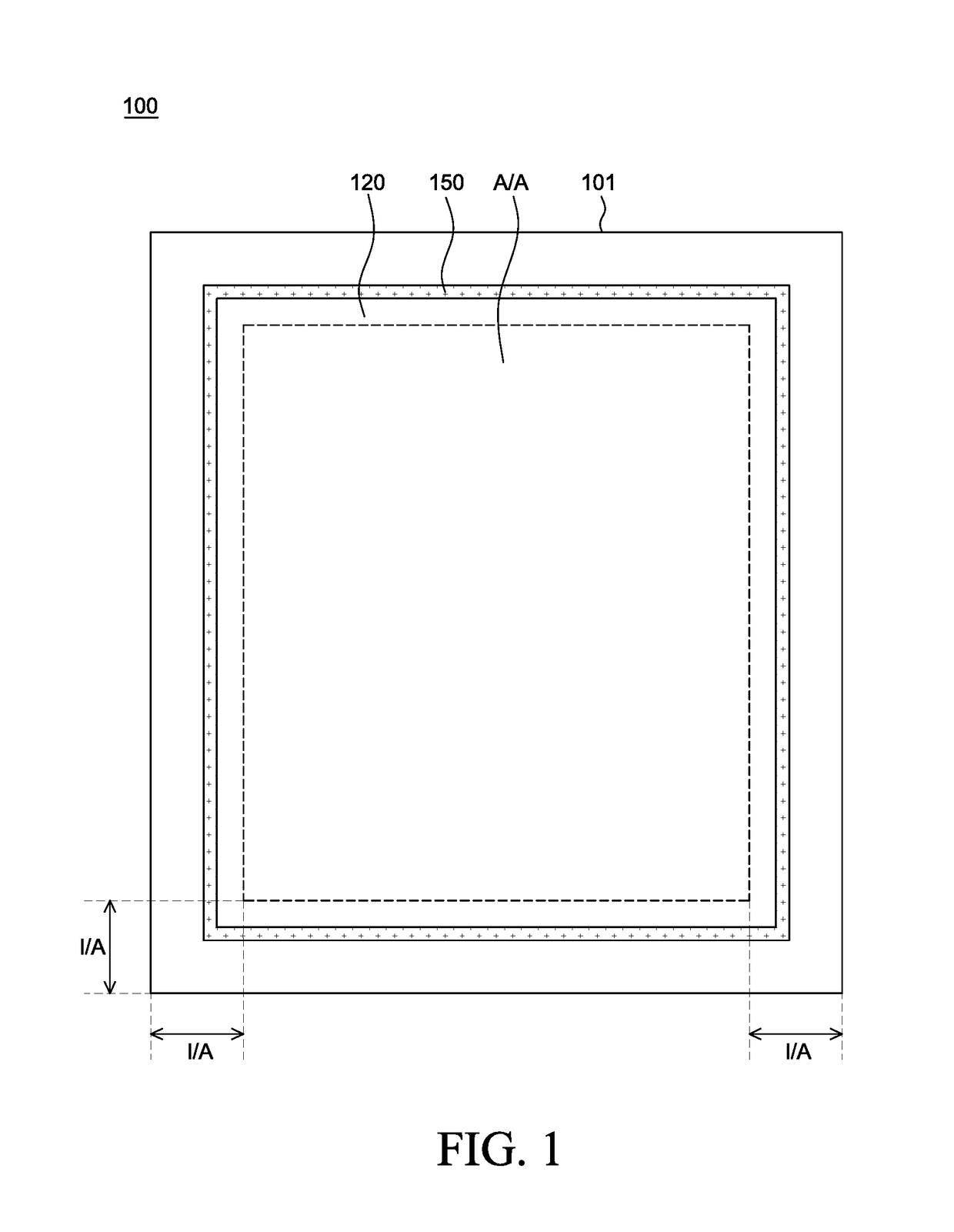

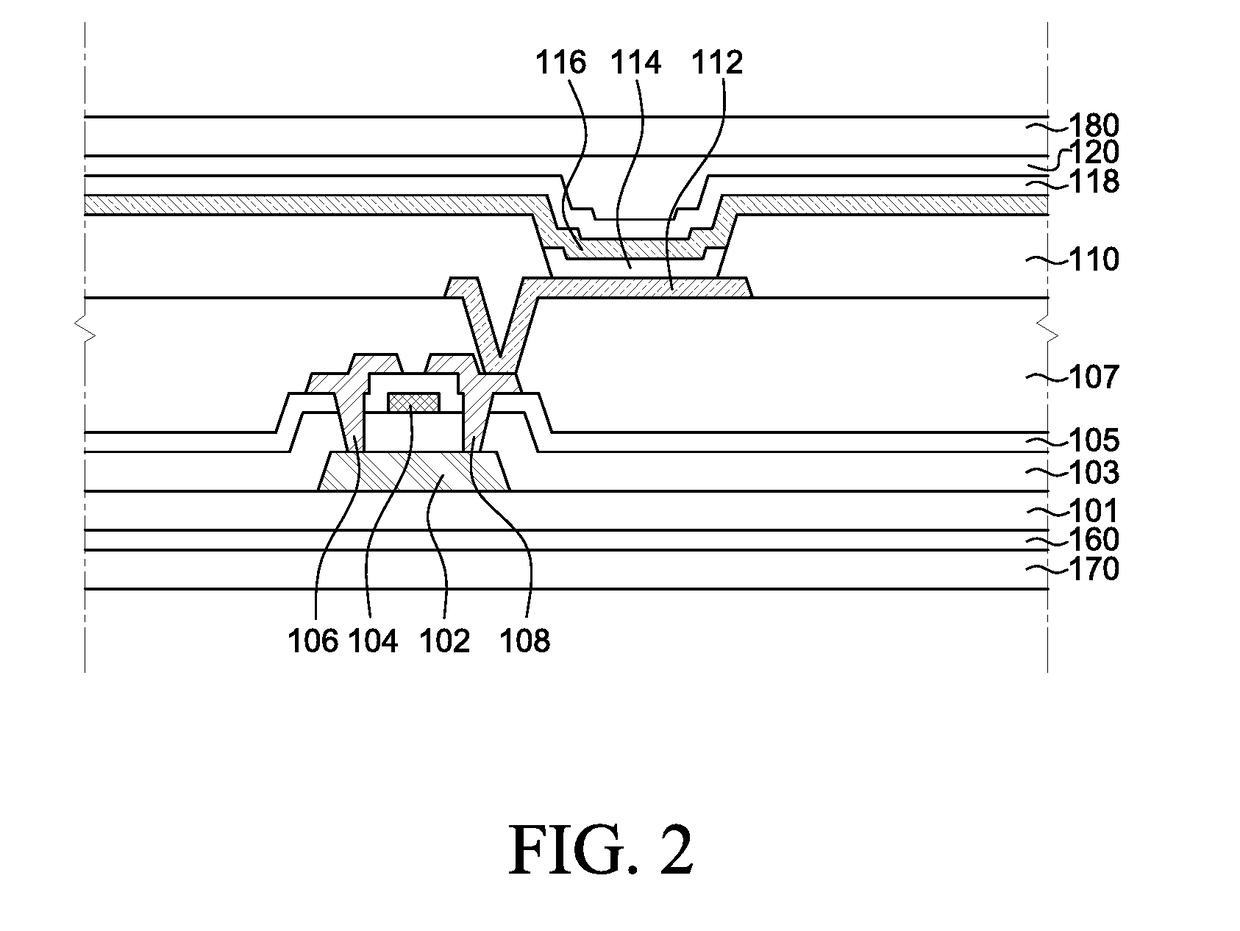

Organic Light-Emitting Display Device

ActiveUS20170155086A1Slow changeCharacteristic changeSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

Disclosed herein is an organic light-emitting display (OLED) device. The OLED device includes a pixel drive circuit and an organic light-emitting element on an array substrate, a passivation layer covering the pixel drive circuit and the organic light-emitting element so as to block permeation of moisture, and an adhesive layer on the passivation layer. The passivation layer is an inorganic thin film including an organosilicon compound.

Owner:LG DISPLAY CO LTD

Pressure sensor encapsulation structure containing silicon through holes

InactiveCN102749167APackage structure is simpleReduce package sizeSolid-state devicesFluid pressure measurementMembrane technologyAir tightness

The invention provides a pressure sensor encapsulation structure containing silicon through holes, which uses a silicon base to substitute a traditional boron-phosphorosilicate glass base, and adopts a flip chip bonding technology and a bonding technology (such as CuSn bonding, AuSn eutectic bonding, Cu-Cu bonding and Au-Au bonding) to realize the airtight vacuum encapsulation of pressure sensors; a monocycle or bi-cycle bonding metal ring is adopted for encapsulation, and plays the role of reducing the bonding stress on the encapsulation of the pressure sensors with different piezoresistance strip distribution under the condition of ensuring the measurement sensitivity; and conductive columns are adopted for replacing metal wires to be used as signal lead wires, so the mutual connection reliability is increased. Compared with encapsulation structures of the silicon glass electrostatic bonding technology, the metal wire bonding technology, the metal isolating membrane technology and the airtight cavity silicone oil filling technology which are adopted traditionally, the pressure sensor encapsulation structure cancelled silicone oil filling and the metal isolating membrane, contributes to the improvement in the pressure sensor sensitivity, can also be used for dynamic pressure detection, and has the advantages of small size and high integration level.

Owner:PEKING UNIV

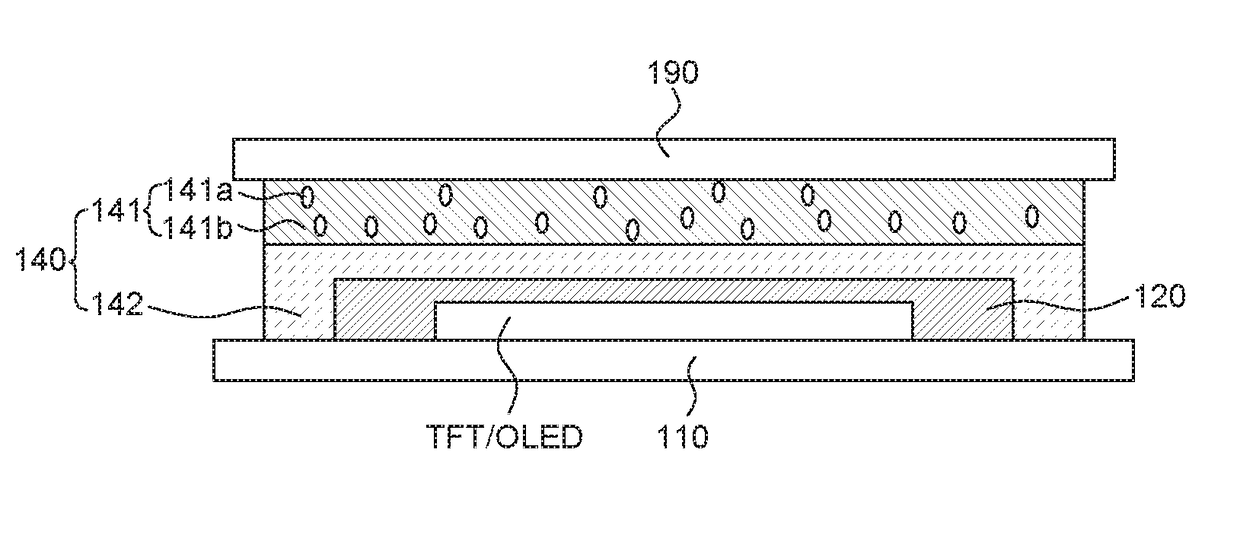

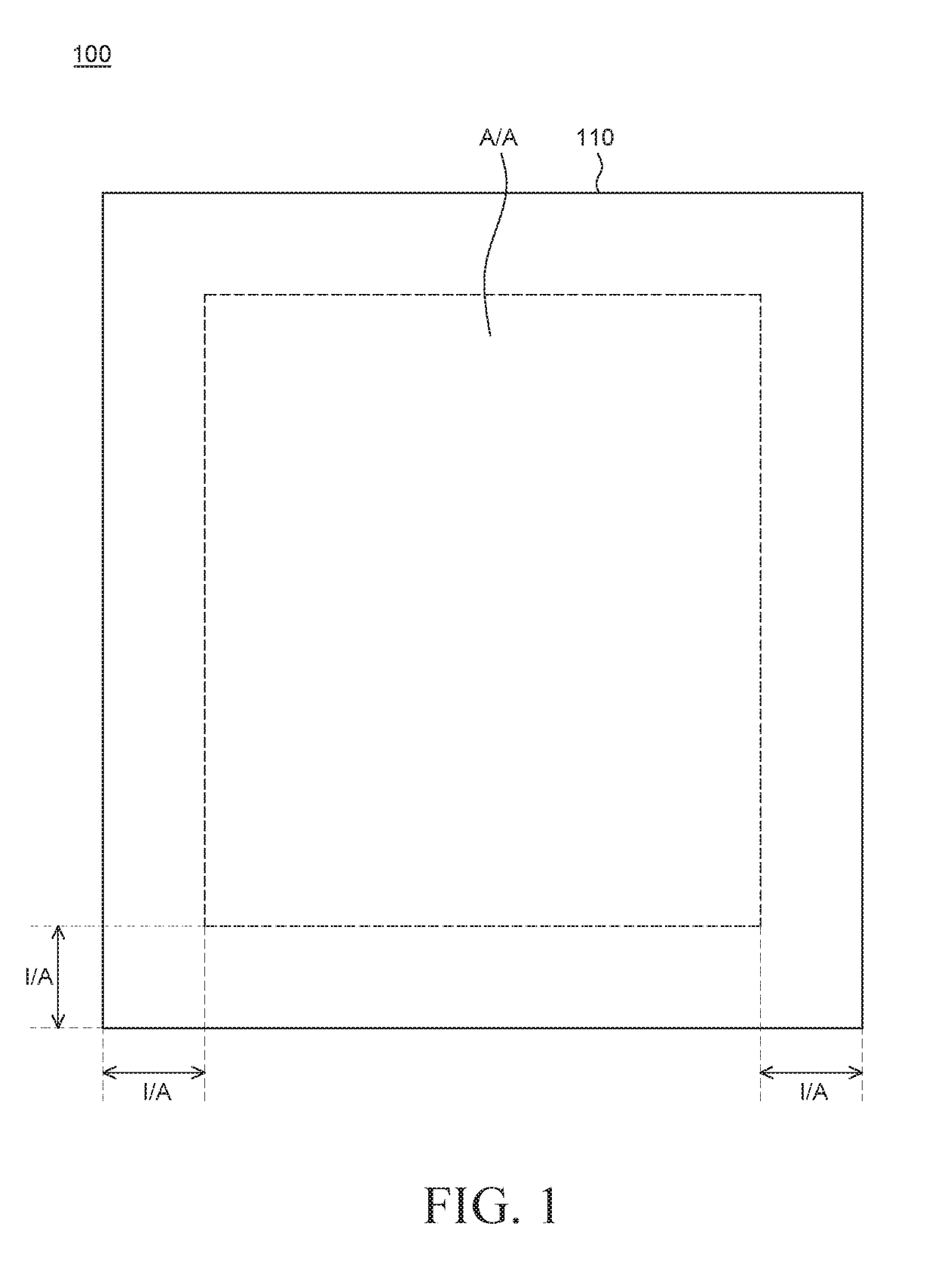

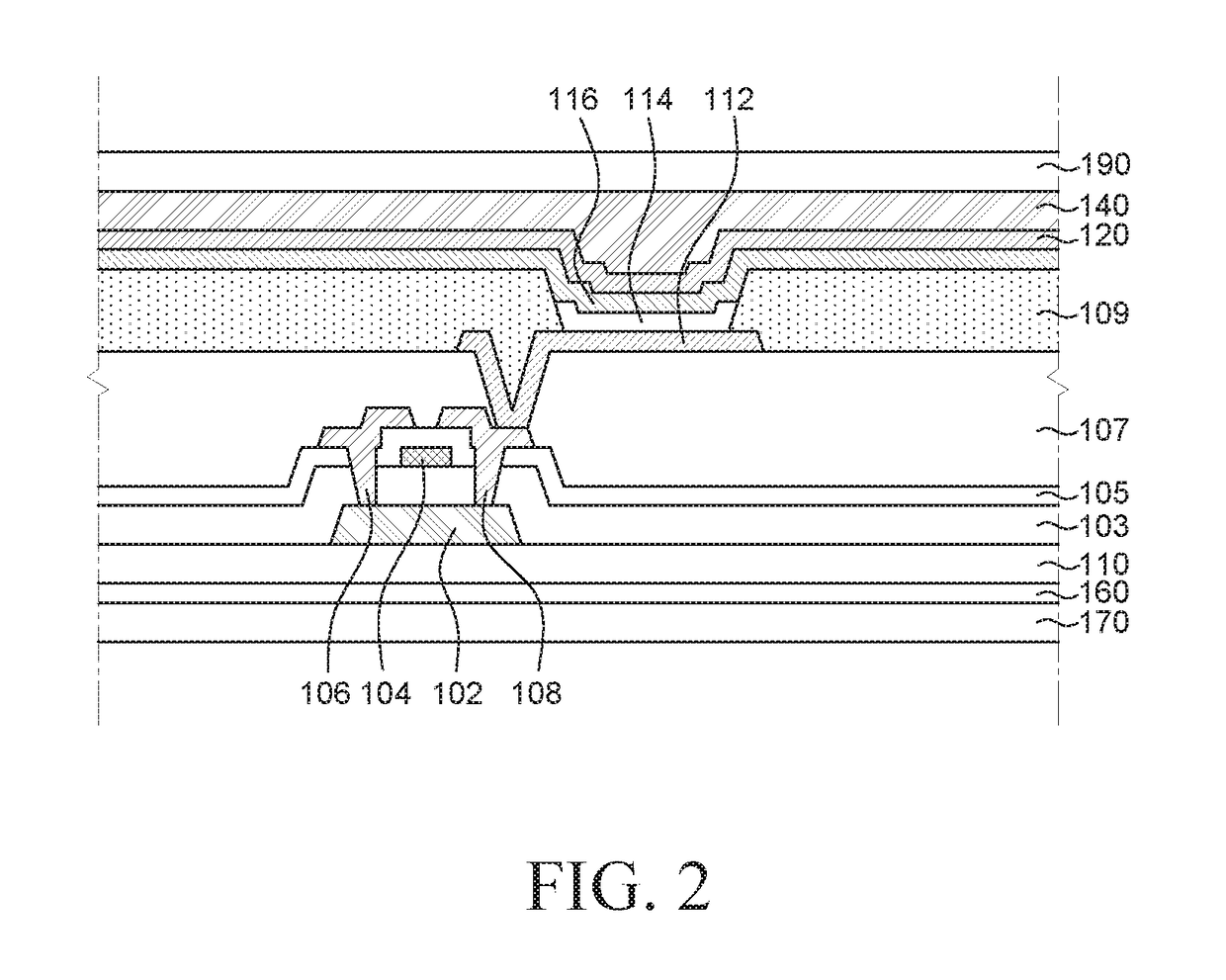

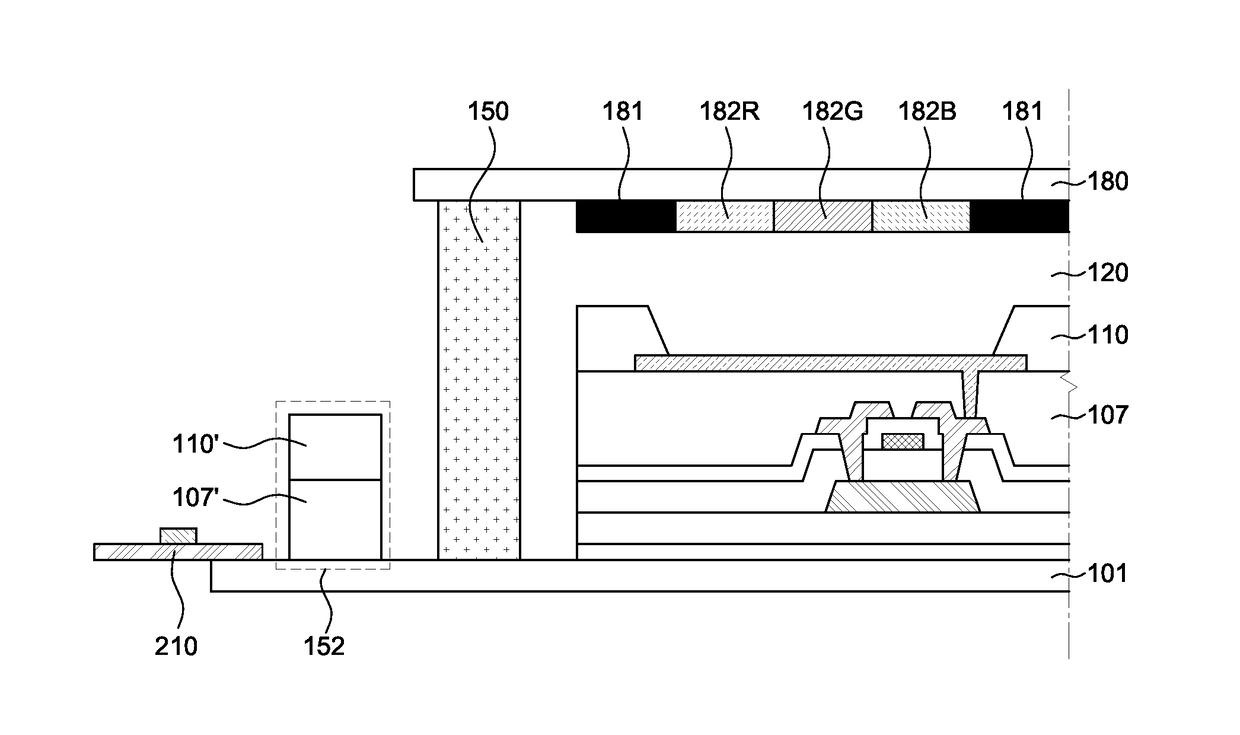

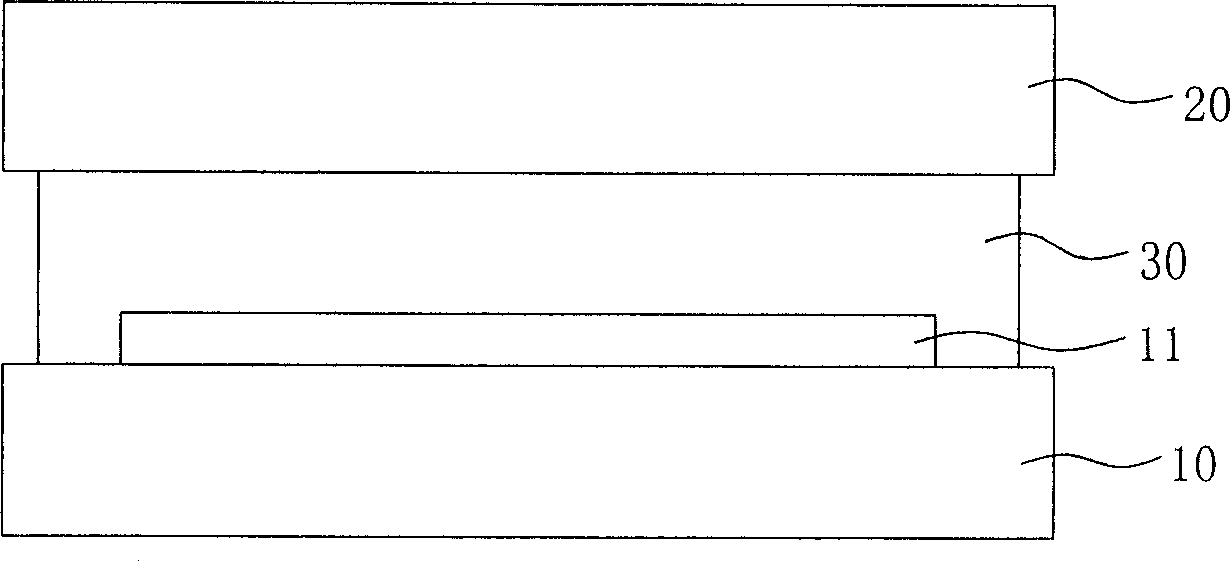

Organic light-emitting display device

ActiveUS20170170247A1Avoid structureImprove moisture proof performanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

Described herein is an organic light-emitting display (OLED) device, comprising: a first substrate comprising an array of pixels; a second substrate facing the first substrate and comprising a color layer corresponding to each pixel in the array of pixels, and comprising a black matrix separating each pixel in the array of pixels from one another; a filler layer between the first substrate and the second substrate; a side encapsulation structure between the first substrate and the second substrate along side edges thereof, wherein the side encapsulation layer is around the filler layer; and a first support on an outer portion of the side encapsulation structure on the first substrate.

Owner:LG DISPLAY CO LTD

White light LED (Light Emitting Diode) packaged on composite ceramic substrate and preparation method thereof

InactiveCN102683570APackage structure is simpleReduce thermal resistanceSolid-state devicesSemiconductor devicesComposite ceramicHeat resistance

The invention belongs to the technical field of an LED (Light Emitting Diode) light source and specifically relates to a white light LED (Light Emitting Diode) packaged on a composite ceramic substrate. The white light LED provided by the invention comprises a radiating substrate, an LED chip, a gold wire cord, fluorescent powder and silica gel, wherein the composite ceramic substrate is served as the radiating substrate. The composite ceramic substrate is prepared by sintering nanocrystalline high-heat-conduction ceramic material added into nanometer substrate ceramics, namely, is composed of 60-95% of molar nanometer substrate ceramics and 5-40% of molar nanometer added ceramics, and the ceramic metallization is performed on the surface. According to the invention, a nanocrystalline network is formed by adding the nanocrystalline high-heat-conduction ceramic material into the ceramic substrate material, so that a heat-conduction path of a high-heat-conduction network is realized and the heat resistance of the white light LED packaged on the ceramic material is reduced. The white light LED provided by the invention has the advantages of simple packaged structure, small heat resistance, high efficiency, excellent light attenuation resisting capacity, low cost and suitability for the manufacturing of the low-cost, high-efficiency and high-power white light LED.

Owner:FUDAN UNIV

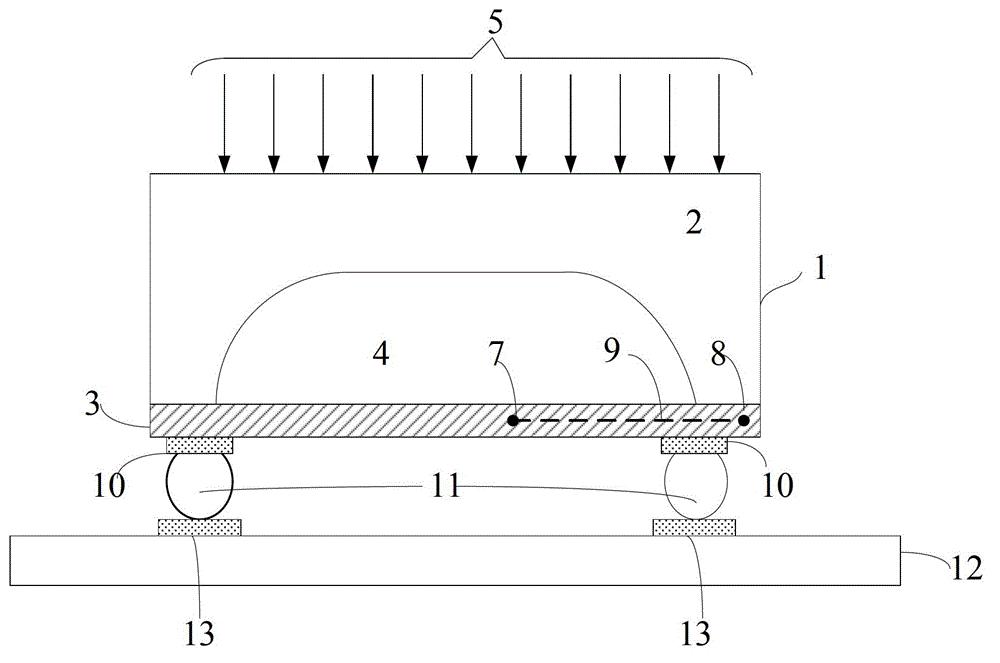

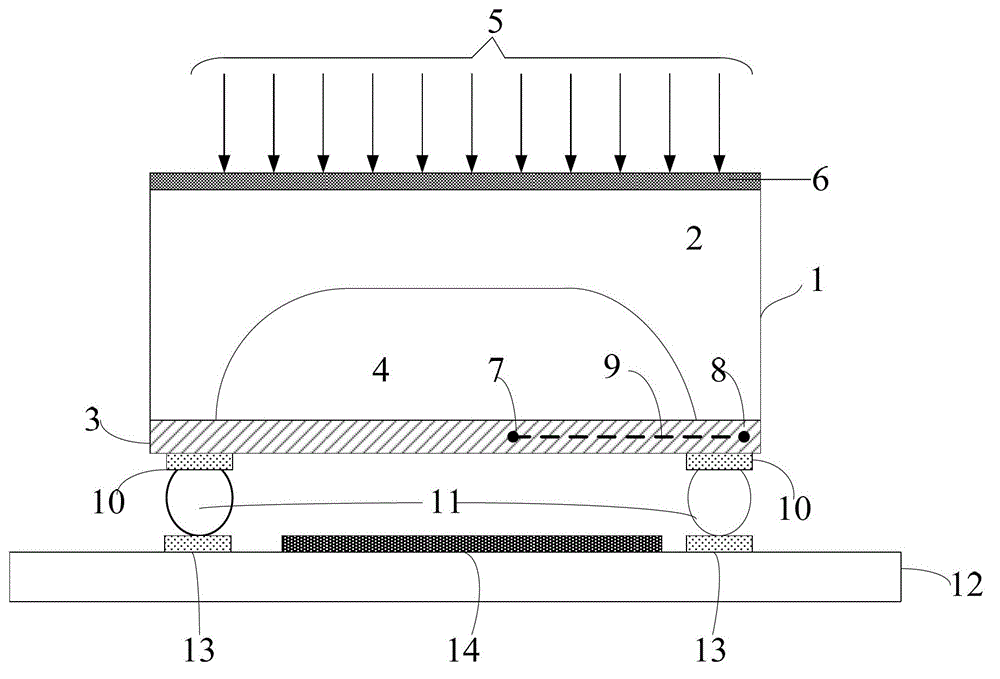

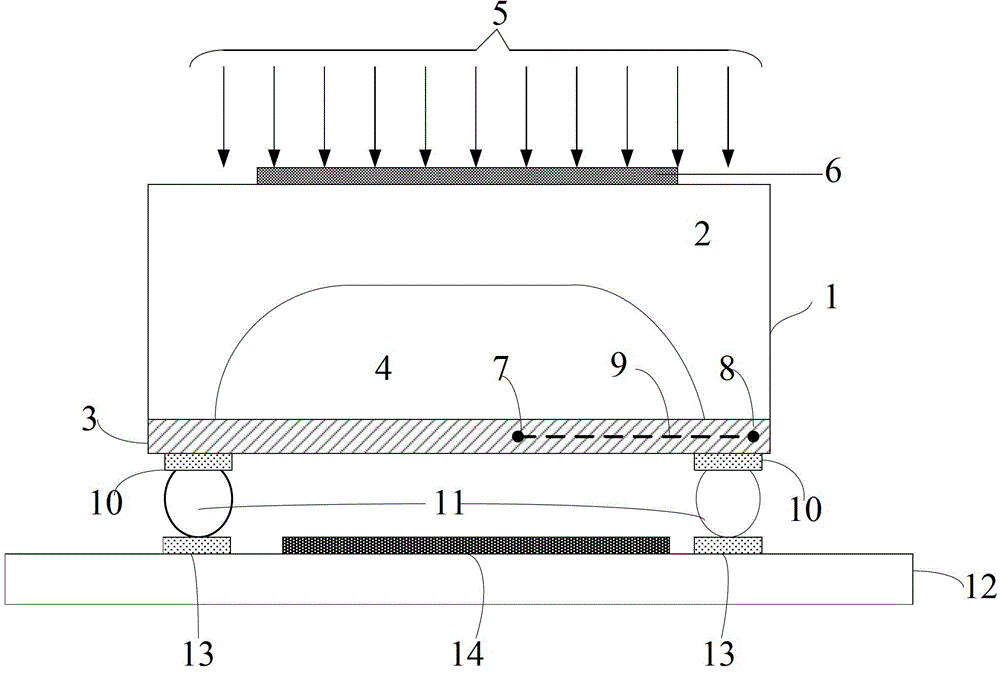

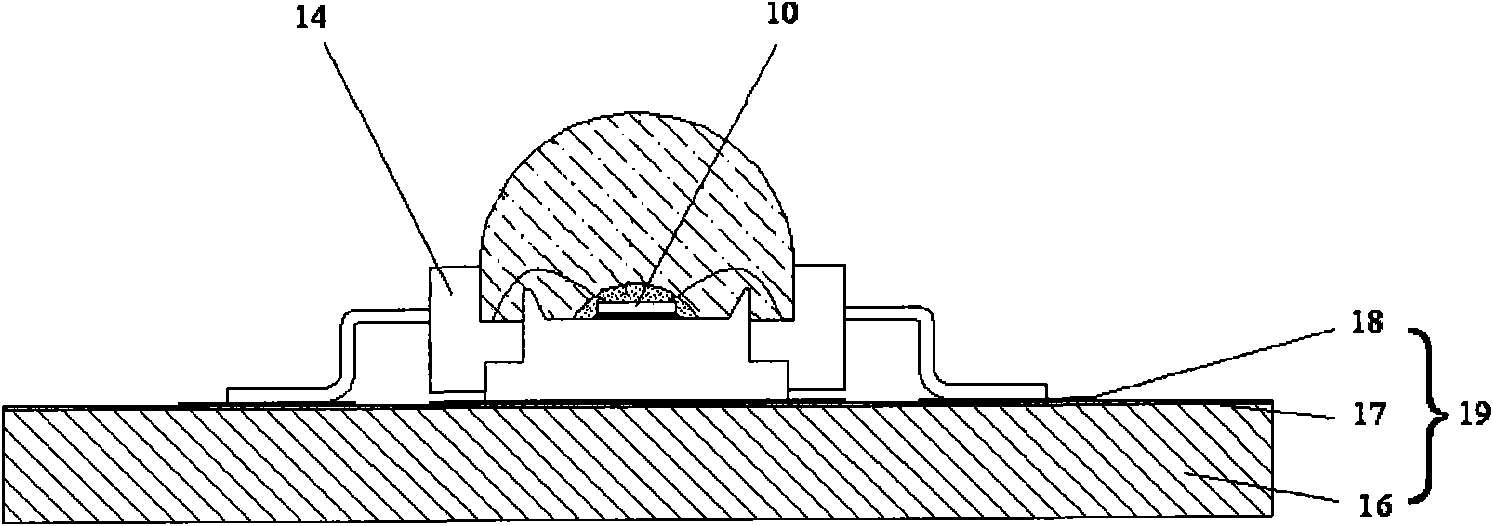

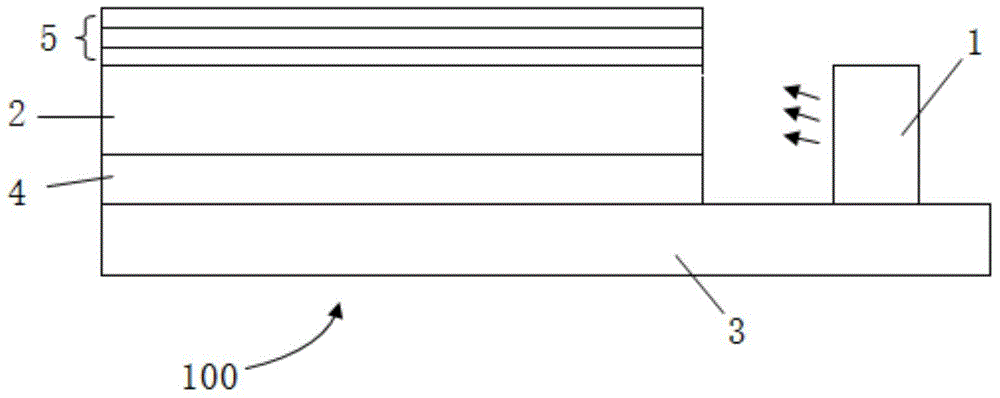

Wafer-level packaging structure for improving response rate of thermopile infrared detector

ActiveCN103148947AIncrease profitPackage structure is simpleSolid-state devicesFluid speed measurementThermopileResponsivity

The invention provides a wafer-level packaging structure for improving a response rate of a thermopile infrared detector. The wafer-level packaging structure comprises an infrared detector and a bearing base plate for bearing the infrared detector; the infrared detector comprises a silicon substrate, a floating film, a cavity structure and a thermopile structure, wherein the cavity structure is formed in the silicon substrate; the thermopile structure is formed in the floating film; one end of the thermopile structure is a hot end; the other end of the thermopile is a cold end; a lead-wire electrode is led out on the floating film; a welding flux convex point is formed on the lead-wire electrode; and the infrared detector is buckled and stacked on the bearing base plate in an inverted manner. The wafer-level packaging structure is improved as follows: an infrared antireflection film is grown on the back surface of the silicon substrate of the infrared detector, and an infrared reflective film is arranged on the surface of the bearing plate directly opposite to the floating film below the cavity structure. The wafer-level packaging structure is further improved as follows: the infrared antireflection film is a graphical infrared antireflection film which is covered on the back surface of the silicon substrate except a corresponding area of the back surface of the silicon substrate above the cold end. The wafer-level packaging structure is used for improving the response rate of the infrared detector.

Owner:北京中科微知识产权服务有限公司

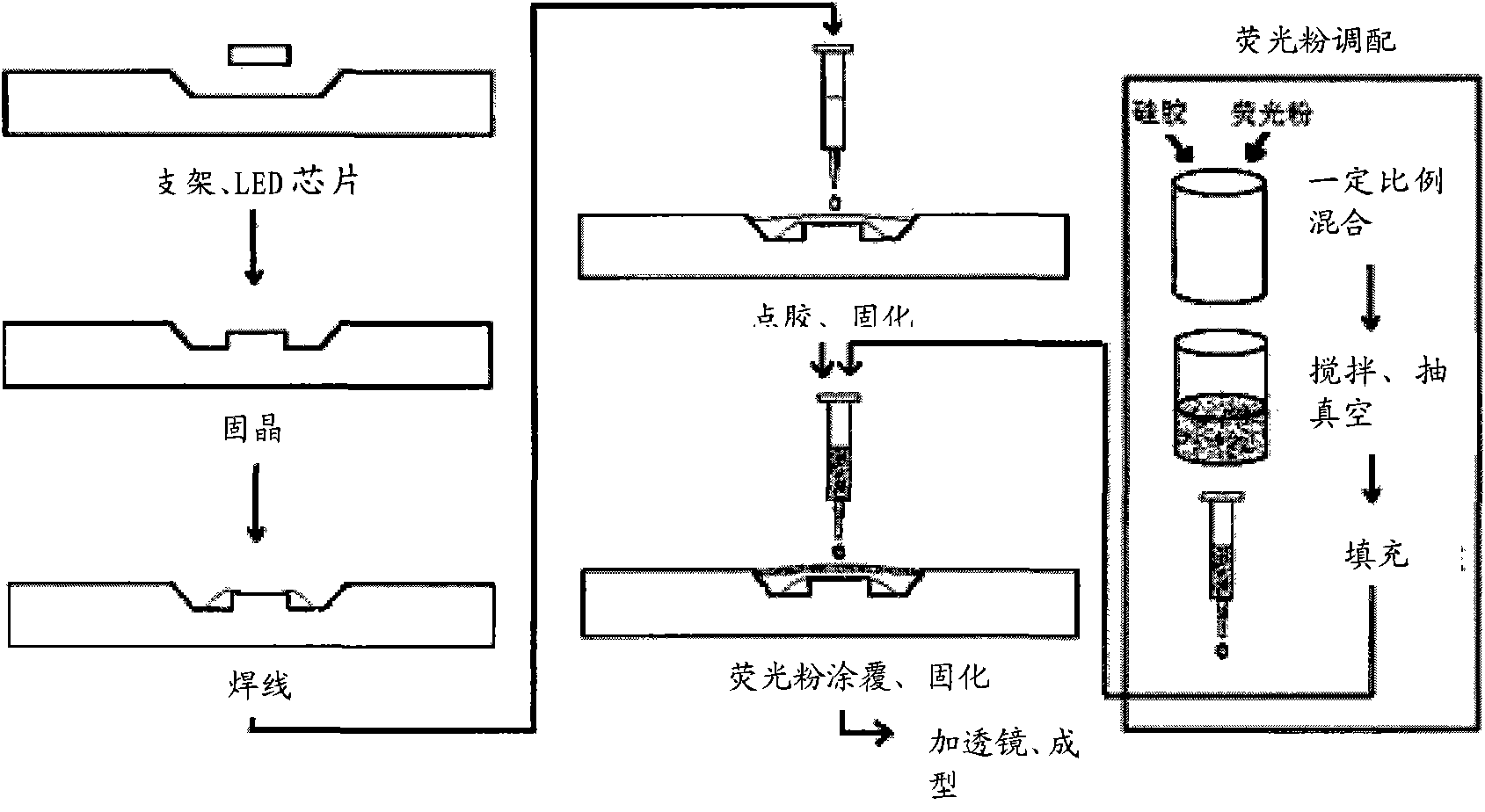

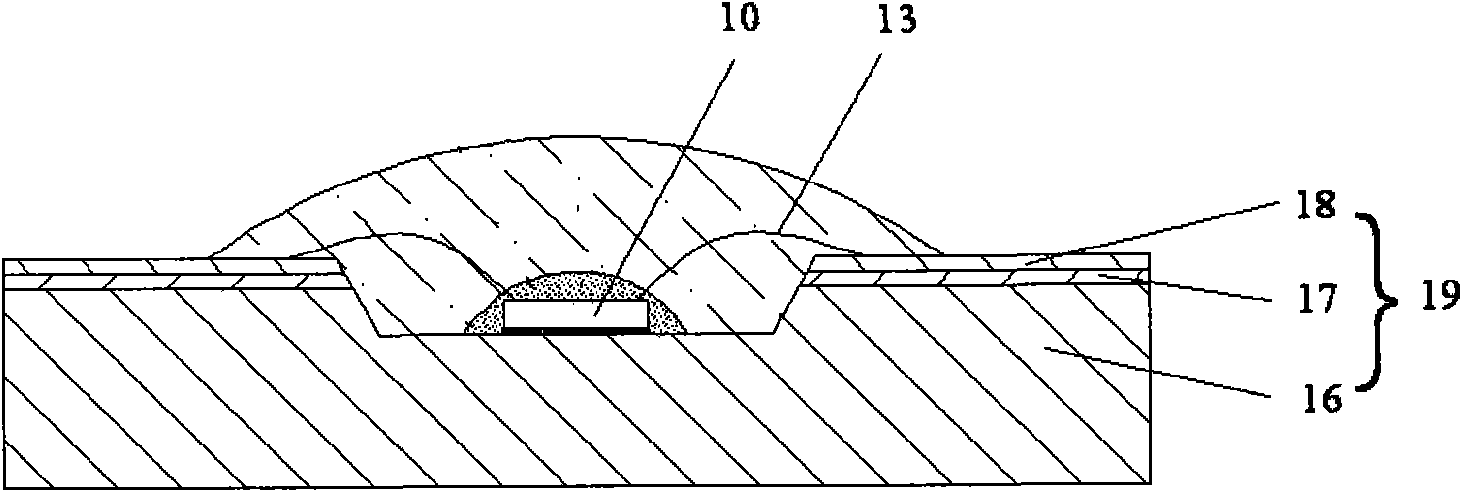

Encapsulating method and encapsulating module for LED chip

InactiveCN101677116APackage structure is simpleGood heat dissipationSemiconductor/solid-state device detailsSolid-state devicesCopper coatingPhosphor

The invention discloses an encapsulating method and an encapsulating module for an LED chip, solving the problems of heat dissipation and cost of LED encapsulation application. The technical scheme ofthe invention is that the method comprises the following steps: opening at least one through hole on a first insulating layer of a FR4 base material; filling the through hole through electroplating high-thermal conductive metal to form a metal column; electroplating or laminating a metal copper layer to be closely connected with the metal column to form a heat diffusing surface; pressing a secondinsulating layer on the metal copper layer, and forming a groove at the part of plating the metal column; coating copper cabling on the second insulating layer by electrical interconnection to form acopper coating layer; constantly laminating a third insulating layer on the copper coating layer, and increasing depth of the groove, and forming a groove with an inclined angle; coating a reflectionlayer on the surface of the groove; arranging a gap on a fourth insulating layer on the uppermost layer of the FR4 base material; encapsulating the LED chip on the metal plated position in the groove, binding the LED chip to the copper coating layer through gold threads, and coating phosphor powder on the LED chip; and injecting silica gel on the LED chip to form a lens. The method is applicablein the filed of LED chip encapsulation.

Owner:上海科学院 +1

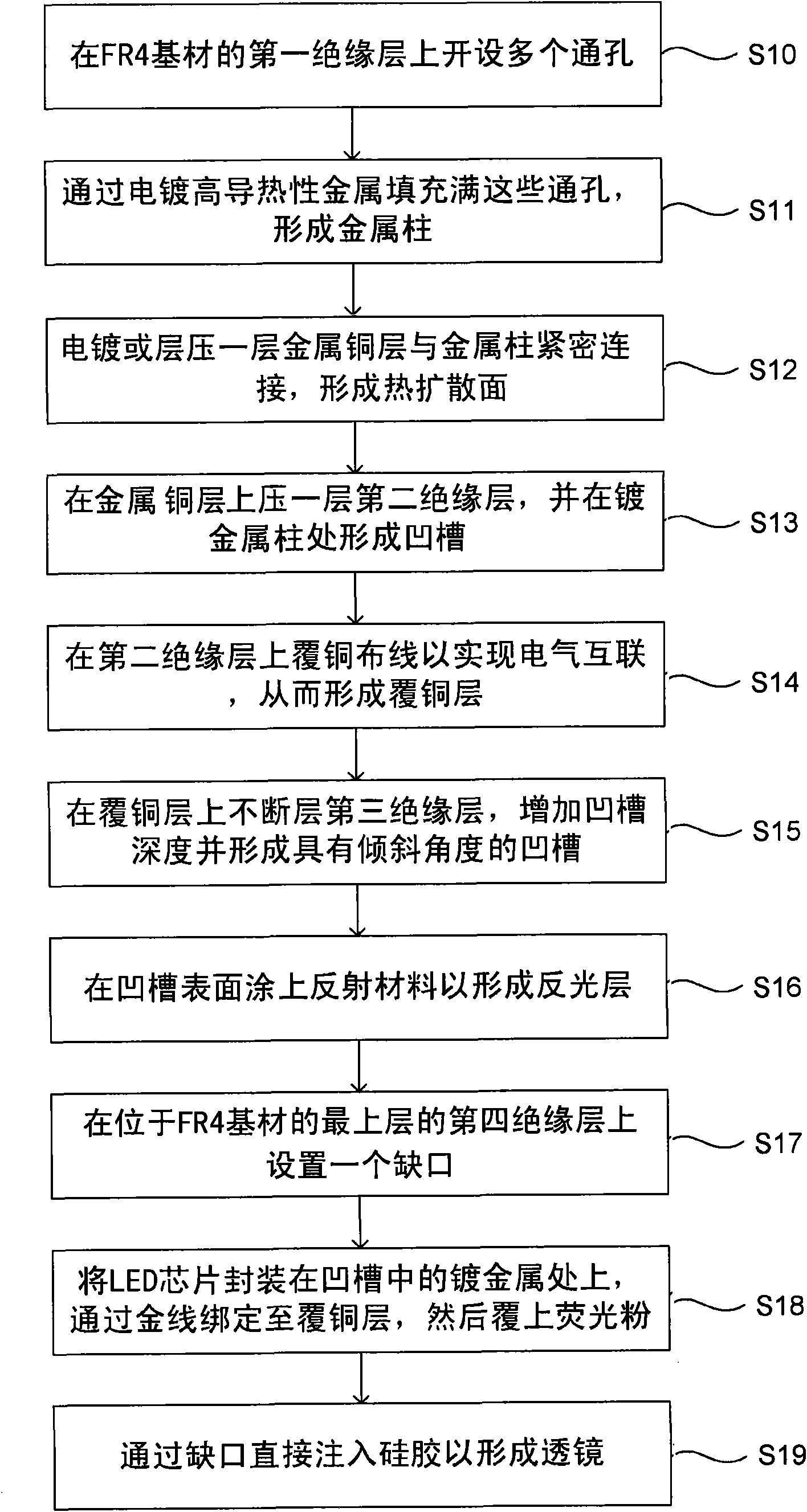

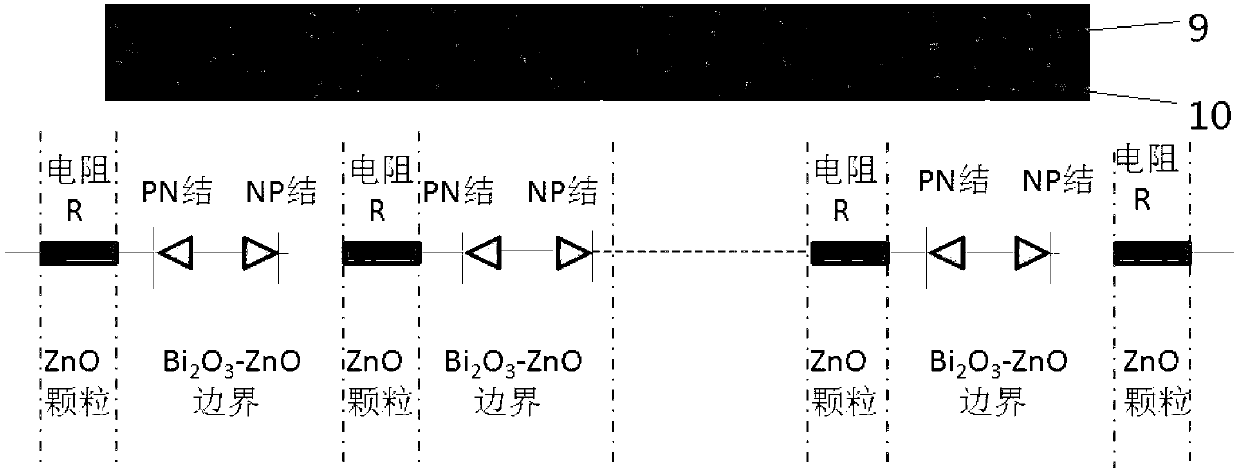

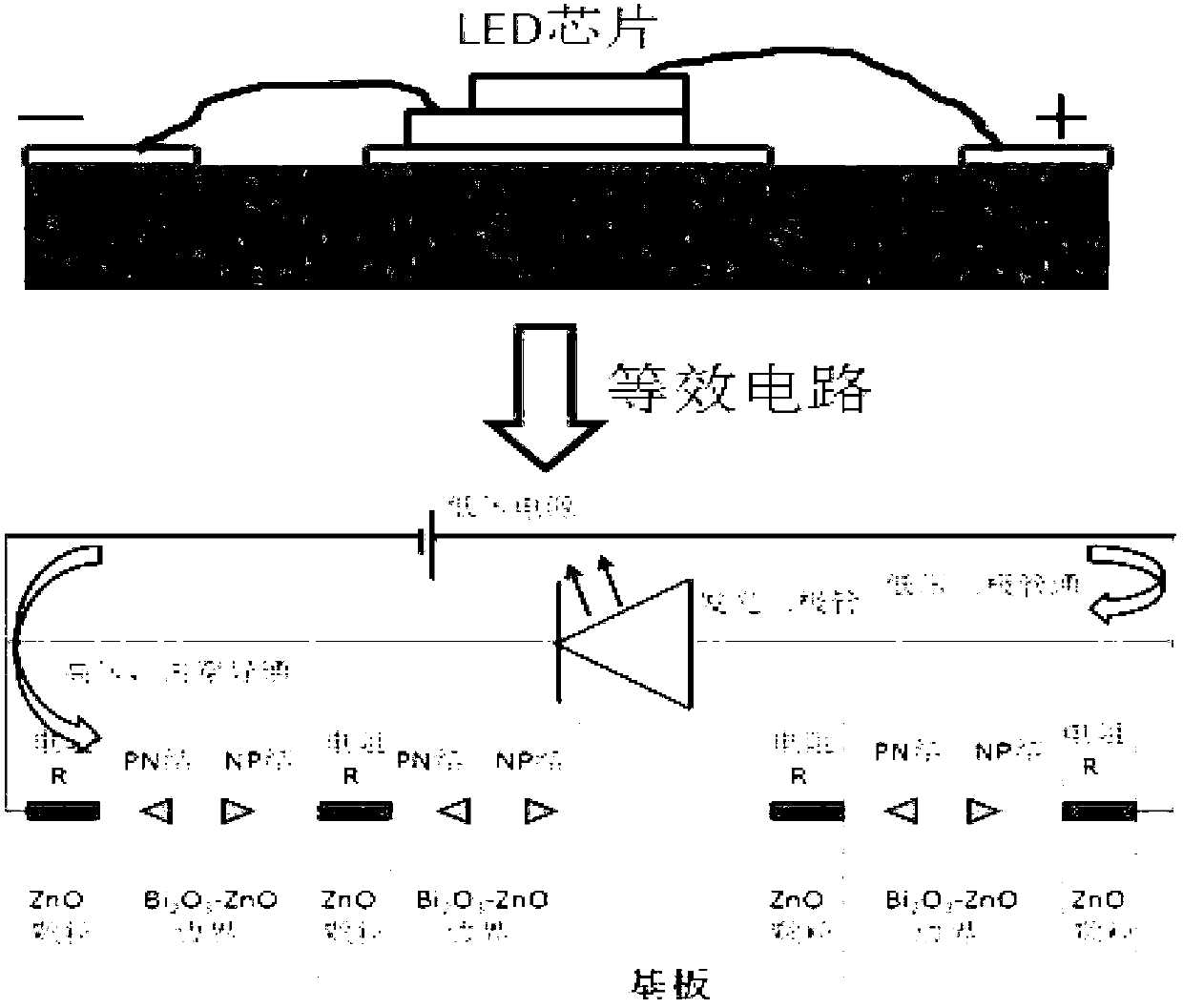

LED (light emitting diode) packaged based on zinc oxide-bismuth oxide composite ceramic substrate and preparation method thereof

ActiveCN103050608APackage structure is simpleReduce thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesHigh resistanceComposite ceramic

The invention belongs to the technical field of LED (light emitting diode) light sources, in particular to an LED packaged on a ZnO-based voltage-sensitive composite ceramic substrate. The LED comprises a radiating substrate, electrostatic protection material, an LED chip, a gold wire connection line, fluorescent powder and silica gel, wherein the radiating substrate adopts a ZnO pressure-sensitive composite ceramic substrate and the like; the ZnO pressure-sensitive composite ceramic is prepared by adding second phase nanometer high thermal conductivity ceramic materials such as Bi2O3 in matrix ceramic and sintering the mixture. In the invention, the high thermal conductivity ceramic material is adopted to add into ZnO ceramic matrix material, so as to form a network, realize a high thermal conductivity network heat conduction route, and reduce the LED thermal resistance of the ceramic material packaging; and a plurality of similar zener didoes which are in positive and negative series connections are formed, so as to realize high resistance and electrostatic function. The LED manufactured by the invention is simple in packaging structure, small in thermal resistance, high efficient, good in resistance to light fade, low in cost, strong in antistatic capability, and is suitable for being used for manufacturing low cost, high efficiency and high power LEDs.

Owner:泰州市华强照明器材有限公司

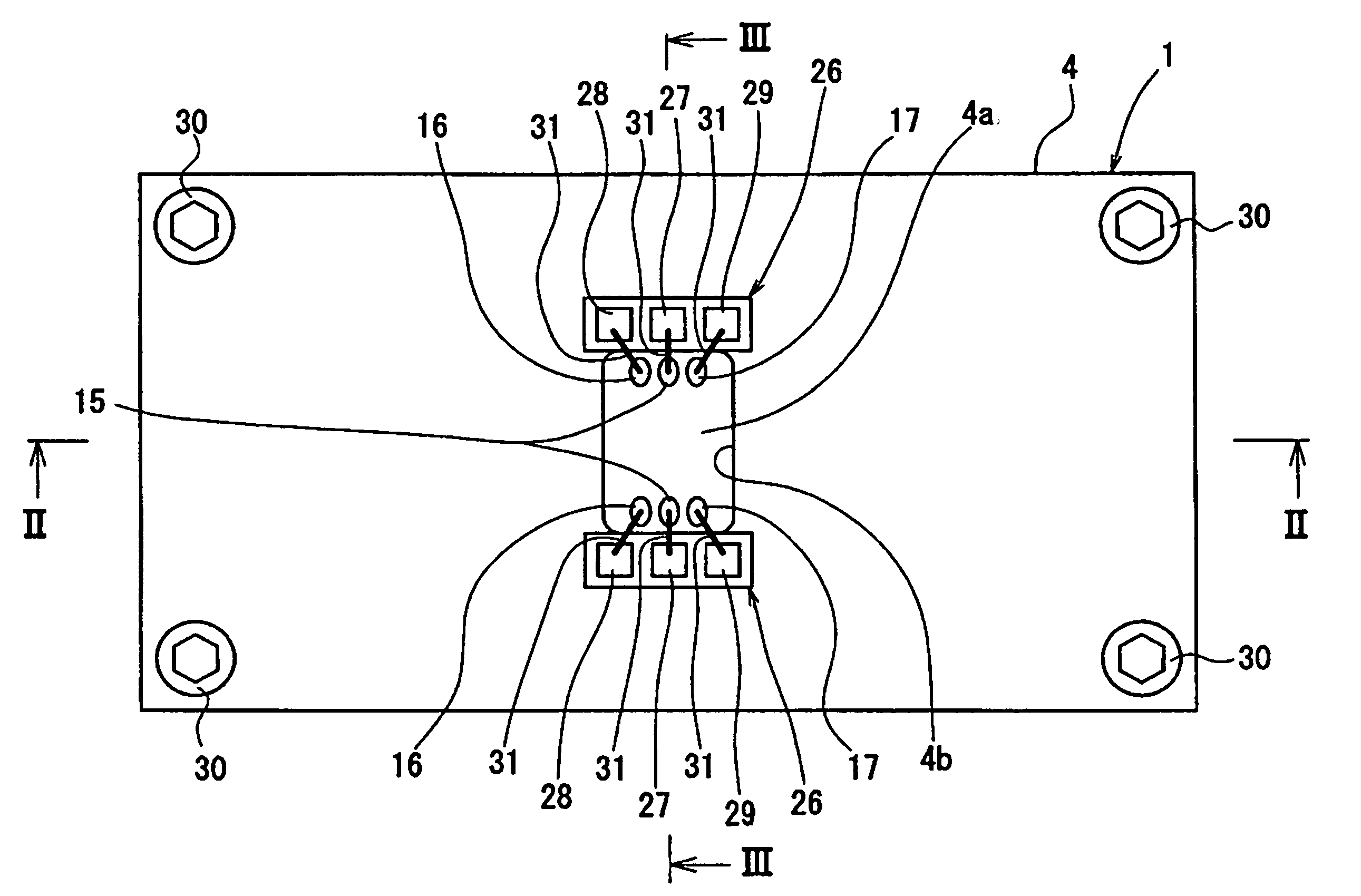

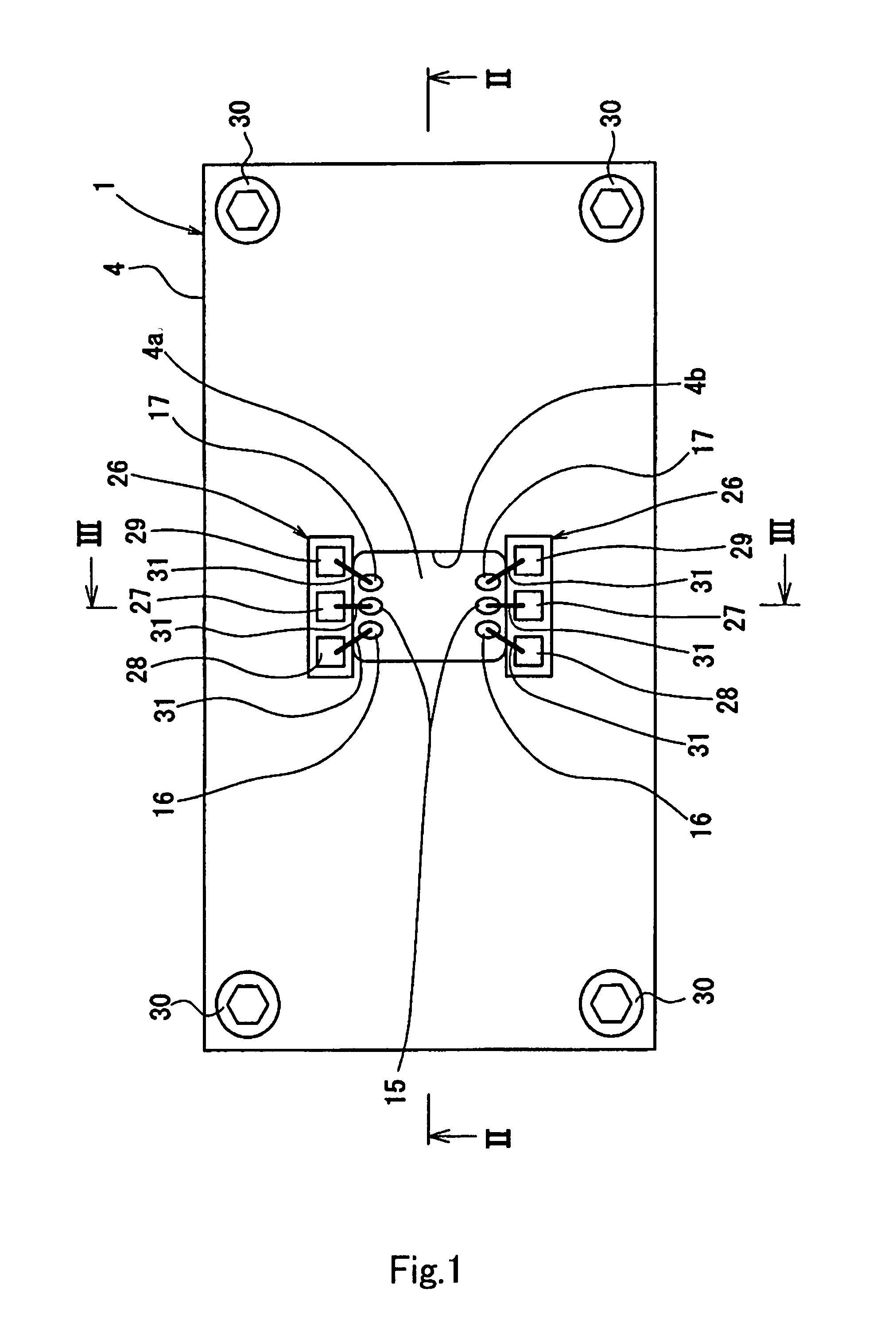

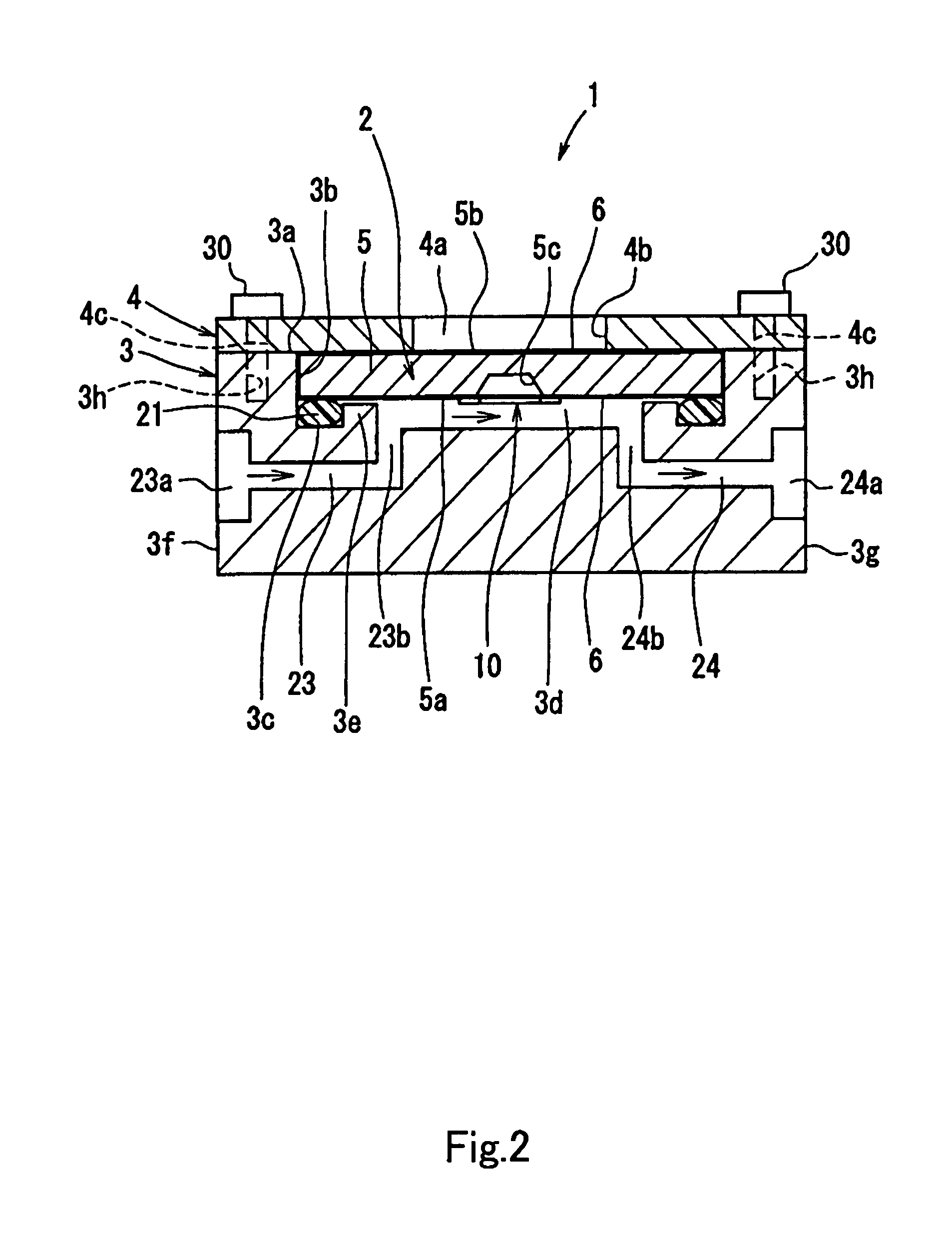

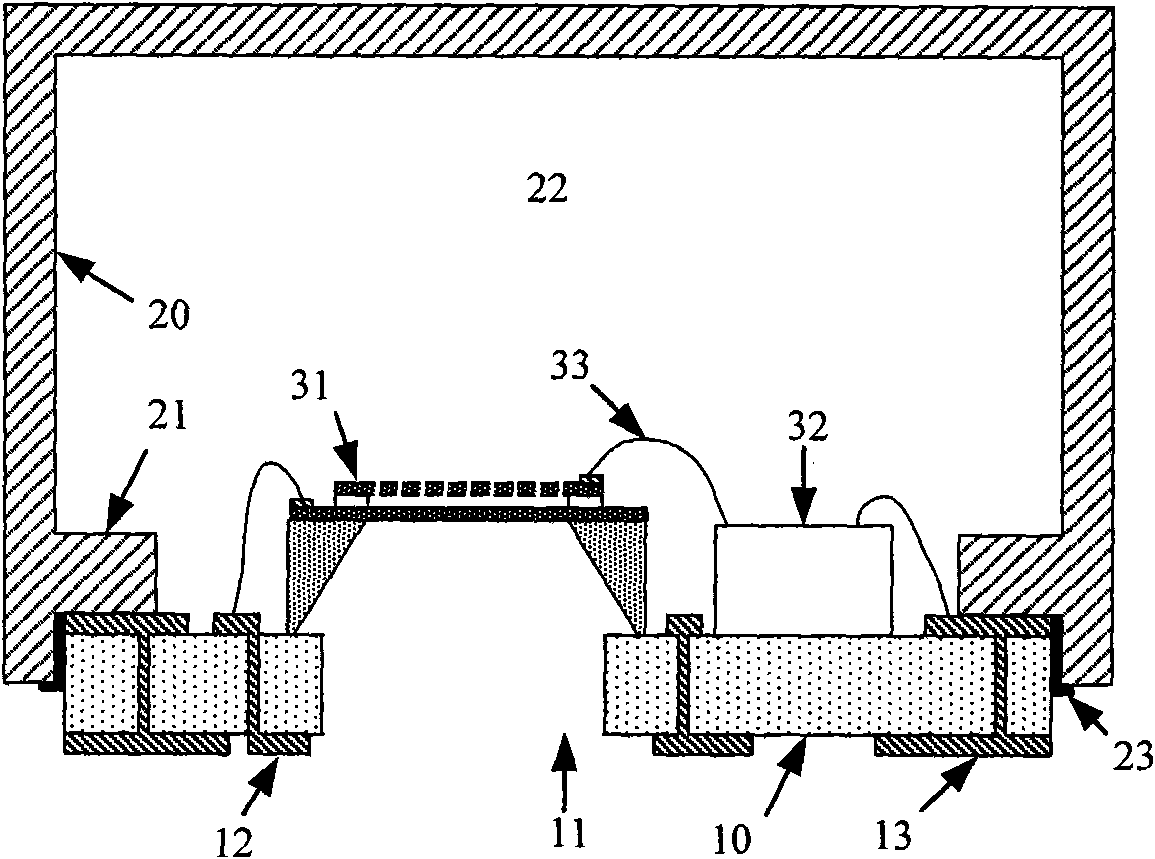

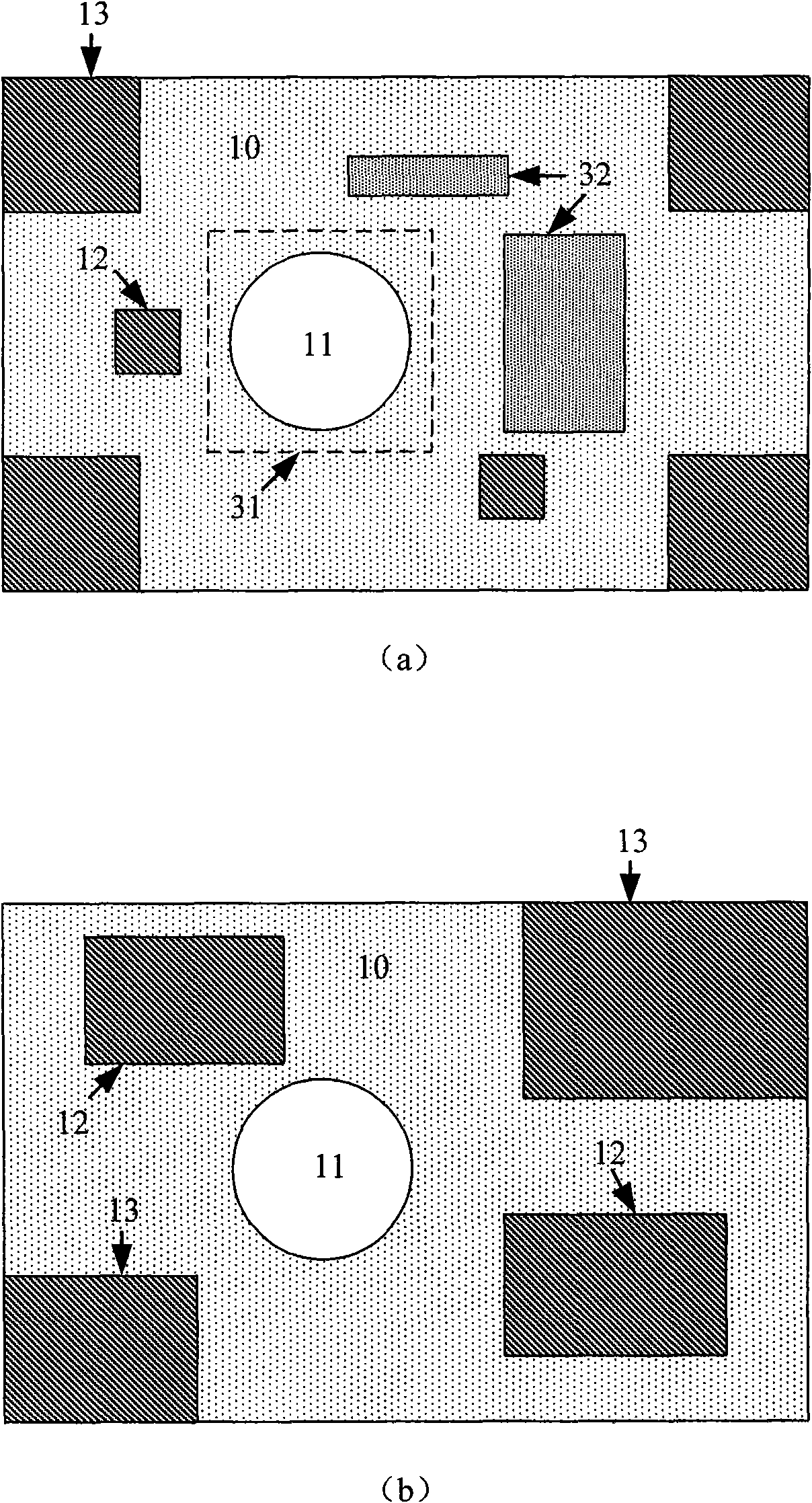

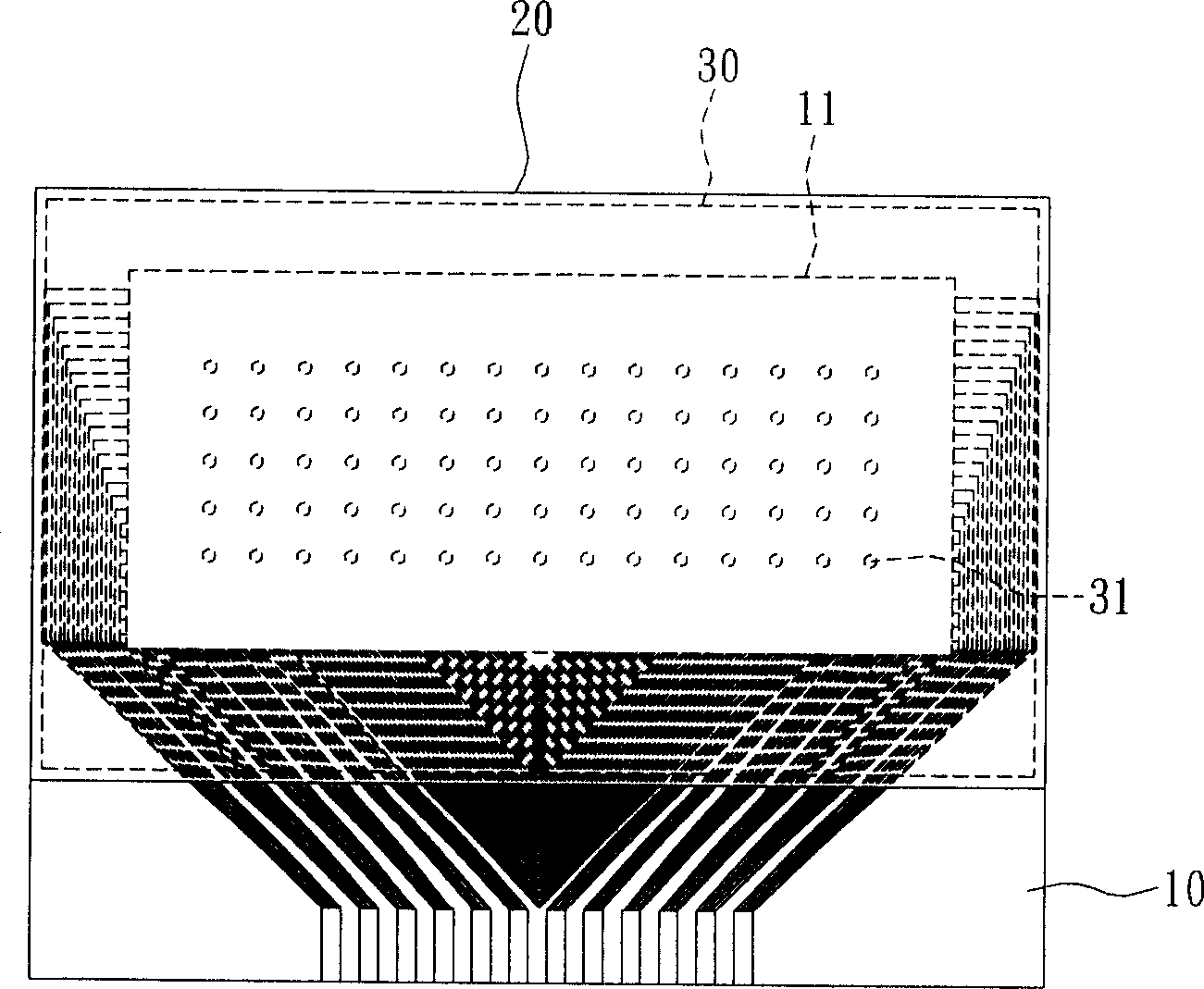

Package structure of sensor and flow sensor having the same

InactiveUS7383726B2Improve stabilityReduce the differenceVolume/mass flow by thermal effectsDevice formEngineering

The package structure may includes: a sensor chip having a detecting device formed on a front surface of a substrate; through electrodes that are arranged at predetermined positions of the substrate around the detecting device, electrically insulated at circumferences thereof, pierce the substrate from the front surface to a rear surface, are connected with lead patterns of the detecting device on the front surface side, and connected with signal fetching means for the outside on the rear surface side; a flow path body on which the sensor chip is mounted and which has a flow path (a conduction path) for a fluid being formed on a surface facing the detecting device and sealing means.

Owner:YAMATAKE HONEYWELL CO LTD

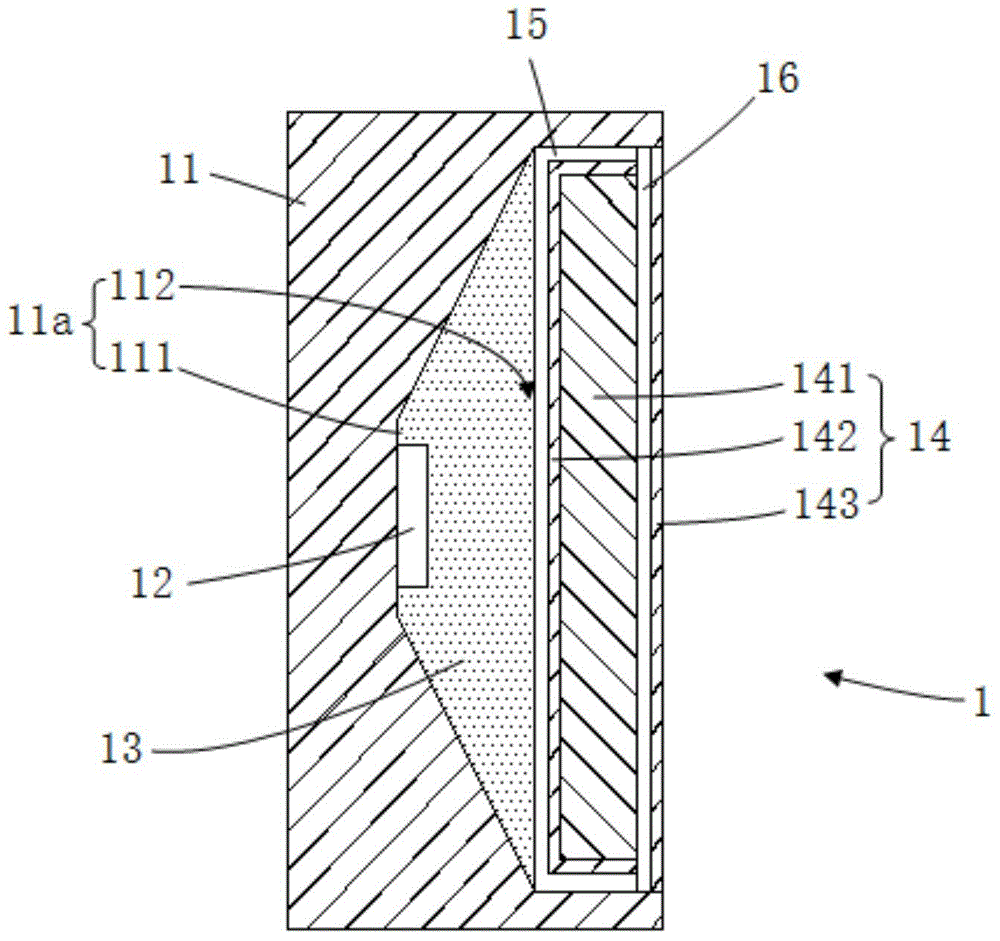

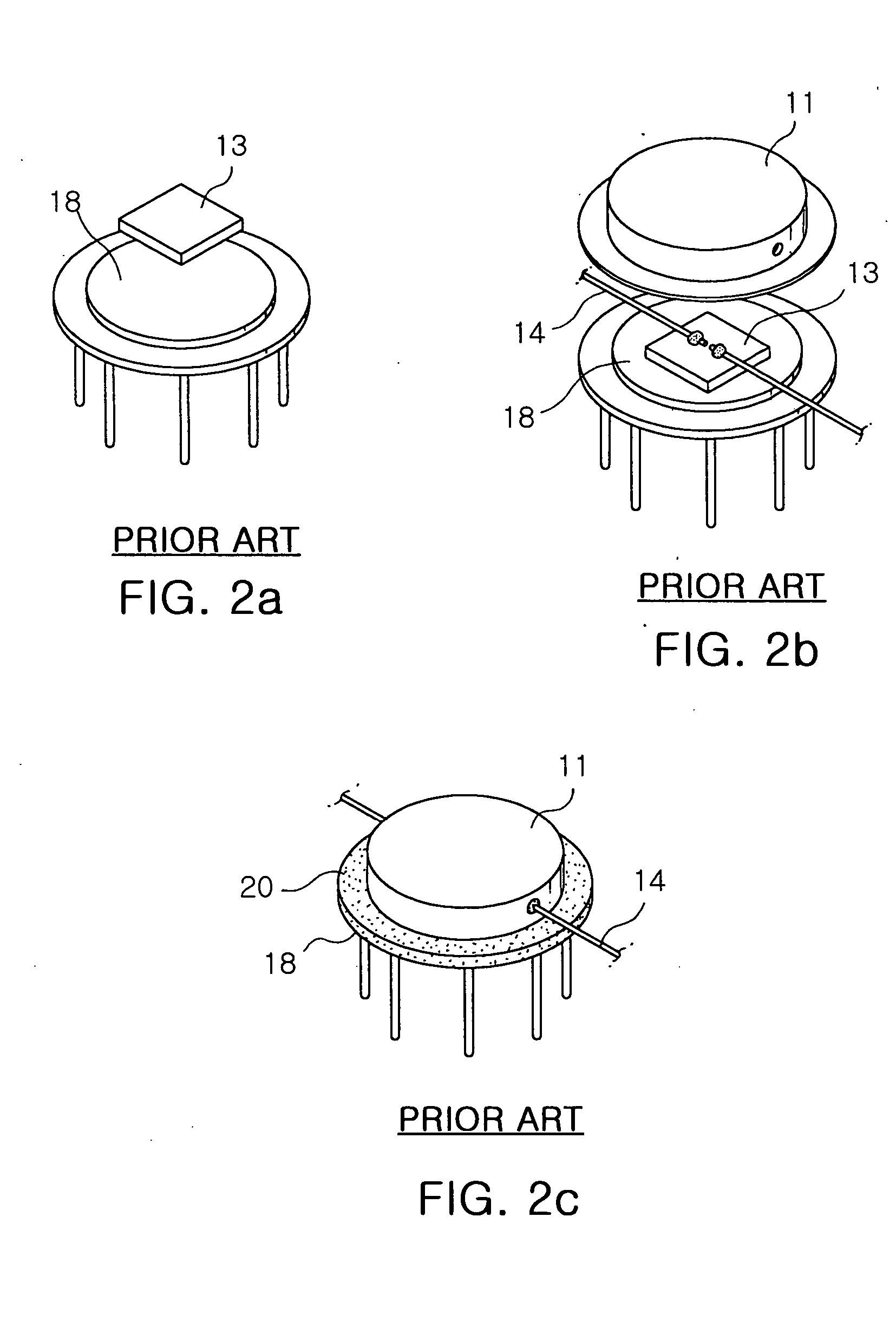

Infrared focal plane array detector

InactiveCN102997999AReduce volumeReduce packaging costsRadiation pyrometryFocal plane detectorSemiconductor

The invention relates to the field of semiconductor photoelectrons, in particular to an infrared focal plane array detector which comprises an encapsulation casing, an infrared optical window and a buffering ring. The encapsulation casing, the infrared optical window and the buffering ring form a closed vacuum cavity. The buffering ring is positioned between the encapsulation casing and the infrared optical window. An electrical activation getter and an infrared focal plane detector chip are arranged in the vacuum cavity. The encapsulation casing comprises a bottom surface, wherein the infrared focal plane detector chip is arranged on the bottom surface. A welding plate is arranged on the side of the bottom surface, a metal pin is arranged outside the bottom surface, the welding plate is electrically communicated with the metal pin, and the electrical activation getter is electrically communicated with the metal pin. A metal welding plate is arranged on the infrared focal plane detector chip and connected with the welding plate through a metal wire. The encapsulation structure of the infrared focal plane array detector is simplified, the size of the infrared focal plane array detector is reduced, and the encapsulation cost of the infrared focal plane array detector is reduced.

Owner:YANTAI RAYTRON TECH

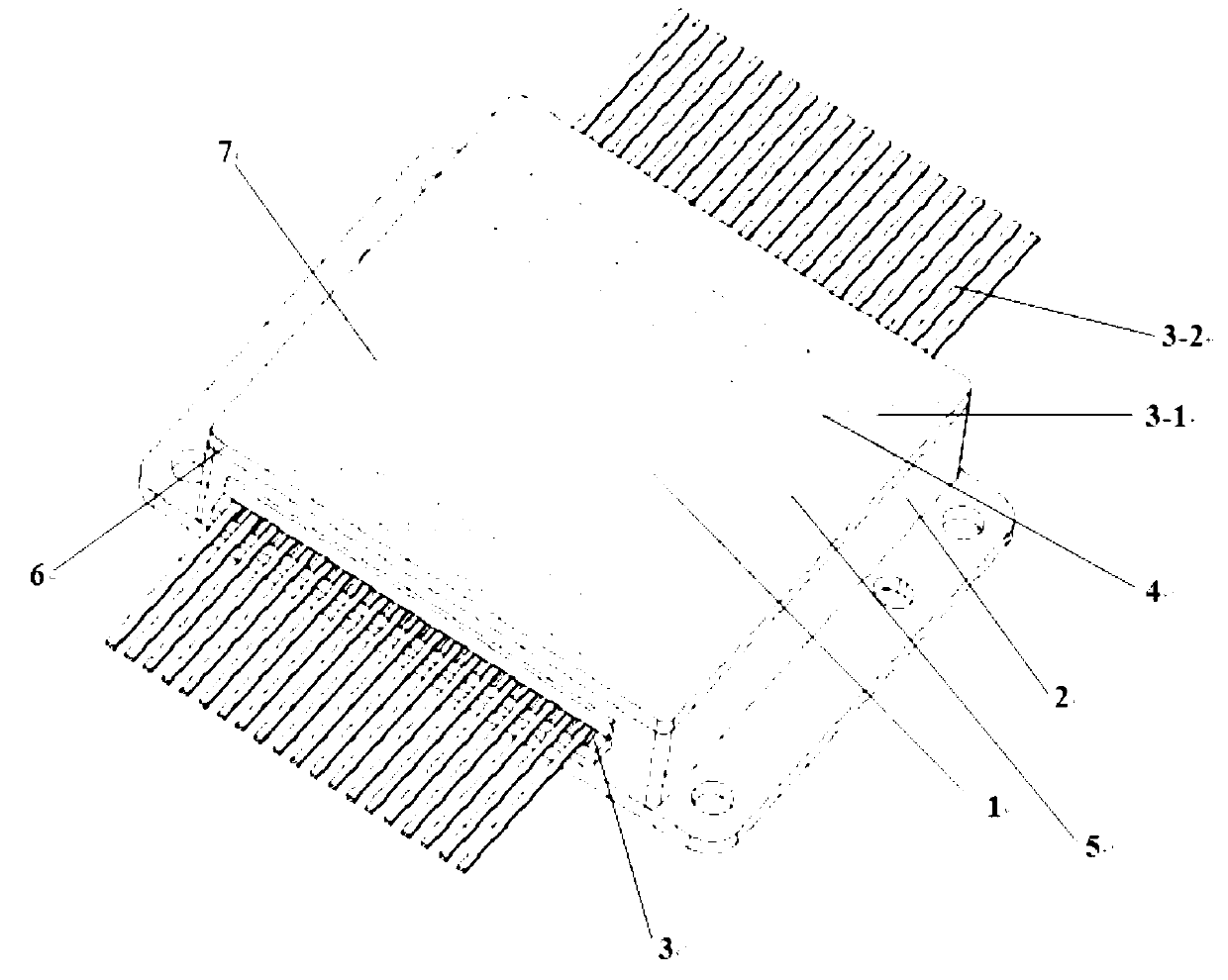

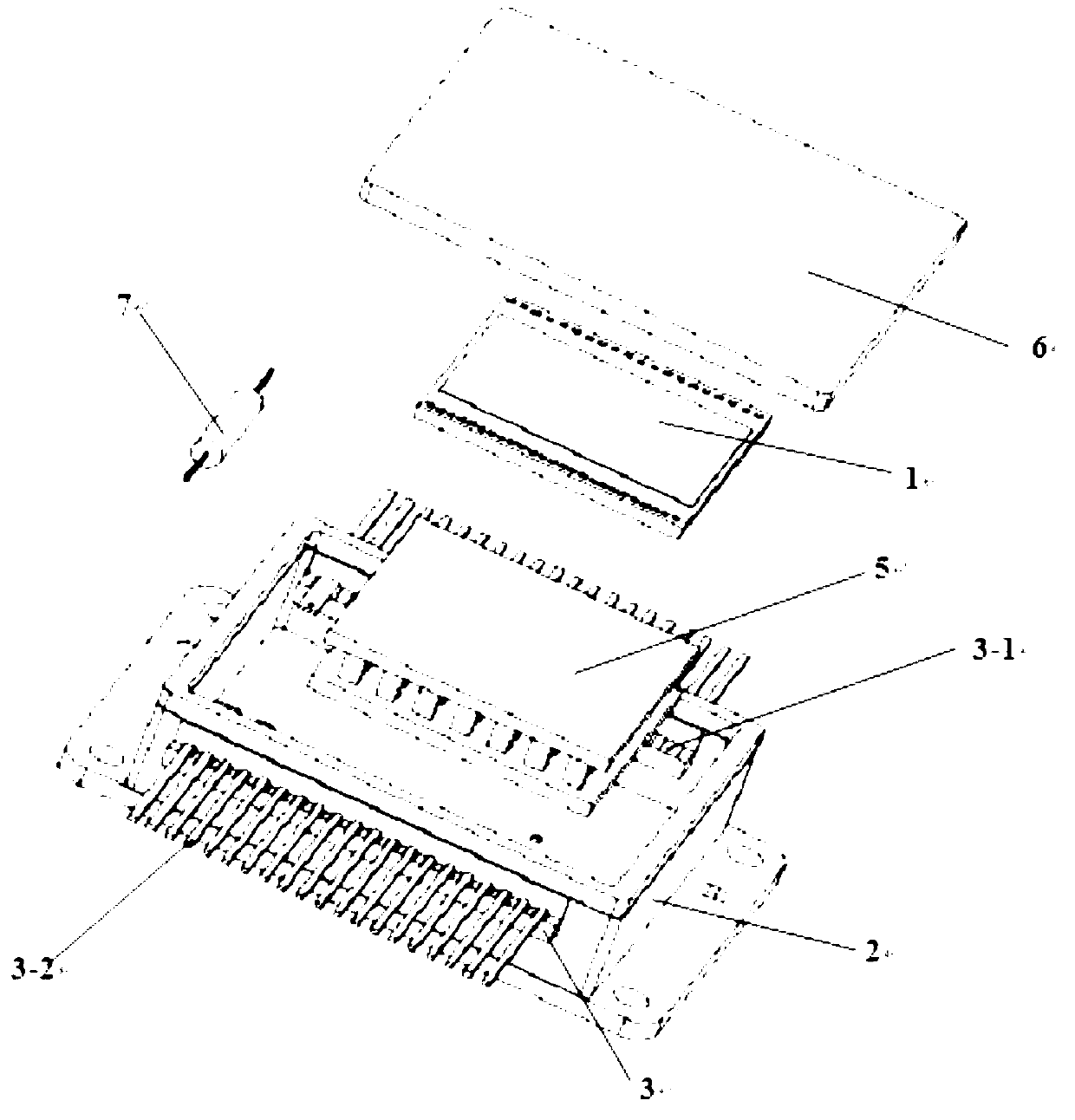

Encapsulating structure of MEMS chip and ASIC and encapsulating method

PendingCN107176586APackage structure is simpleReduce manufacturing costTelevision system detailsImpedence networksComputer hardwareHemt circuits

The invention discloses an encapsulating structure and an encapsulating structure of integrally encapsulating an MEMS chip and an ASIC chip. The encapsulating structure comprises the MEMS chip which is provided with opposite front face and back face and the ASIC chip which is provided with opposite front face and back face; the front face of the ASIC chip and the back face of the MEMS chip are attached and fixed, and the ASIC chip is electrically connected to the MEMS chip; a first welding bump is formed in one side, deviated from the MEMS chip, of the ASIC chip, and the first welding bump is connected to an external circuit; the encapsulating structure also comprises a cover plate which is provided with an accommodating cavity. The cover plate is arranged on the ASIC chip, the MEMS chip is located in the accommodating cavity, and the cover plate is hermetically connected to the ASIC chip. The encapsulating structure of the MEMS chip and the ASIC chip provided by the technical scheme is simple and low in manufacturing cost.

Owner:CHINA WAFER LEVEL CSP

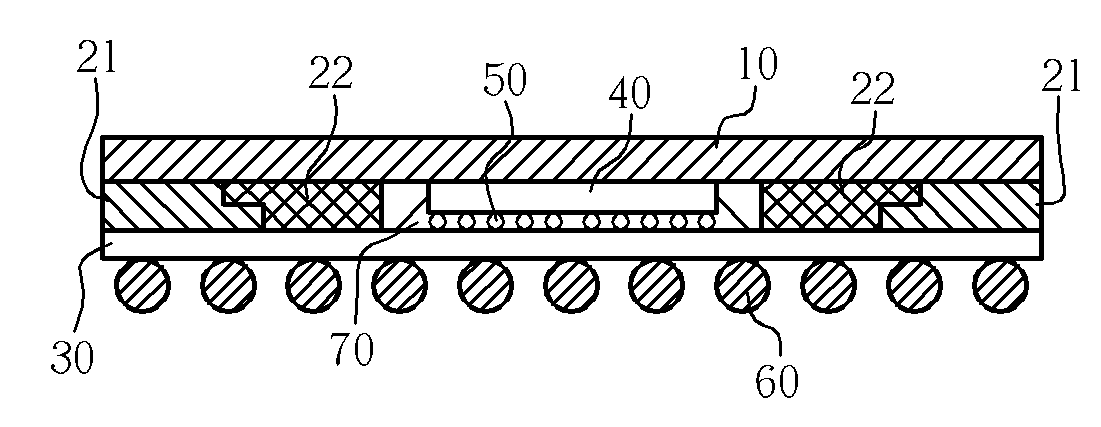

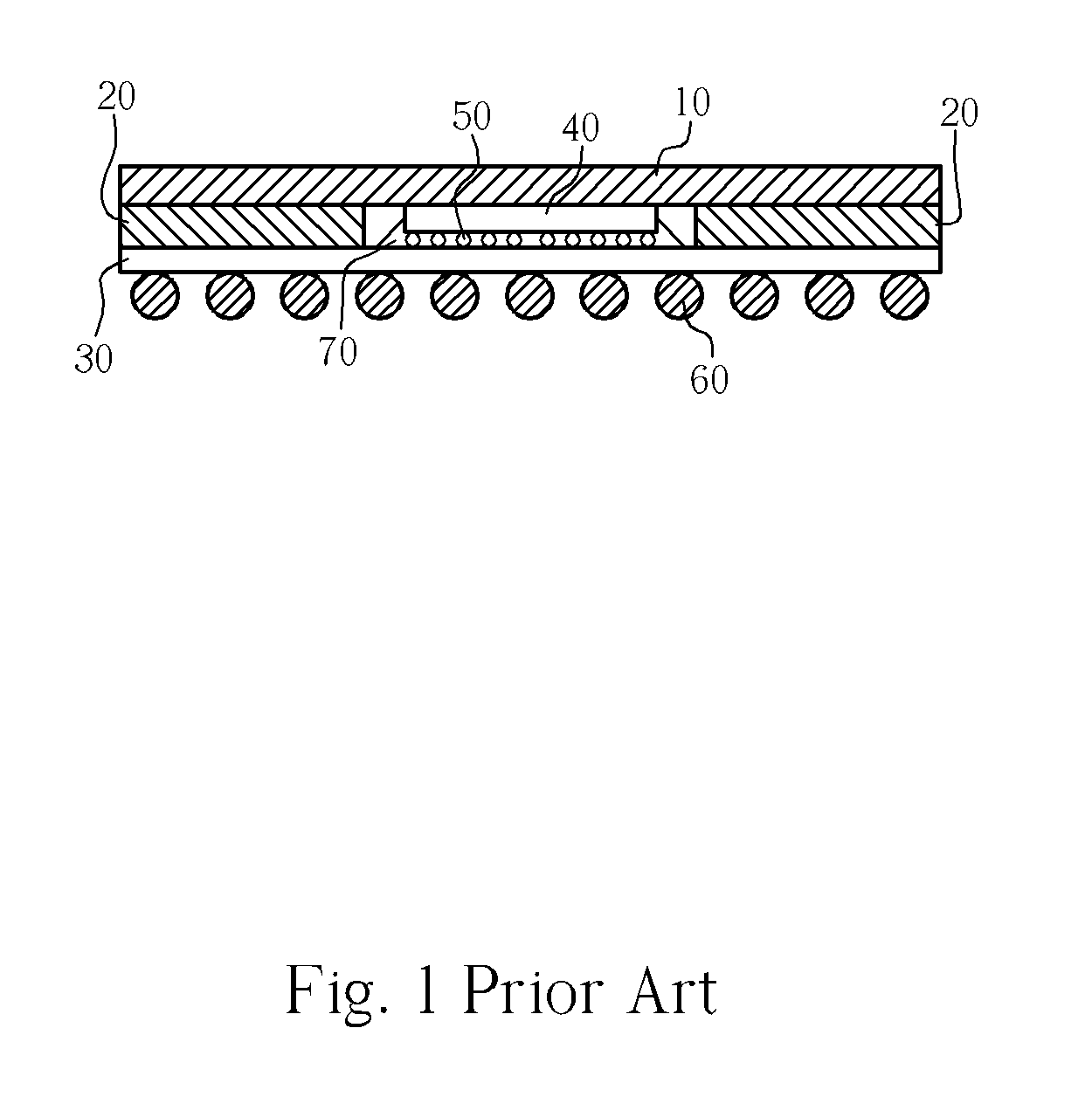

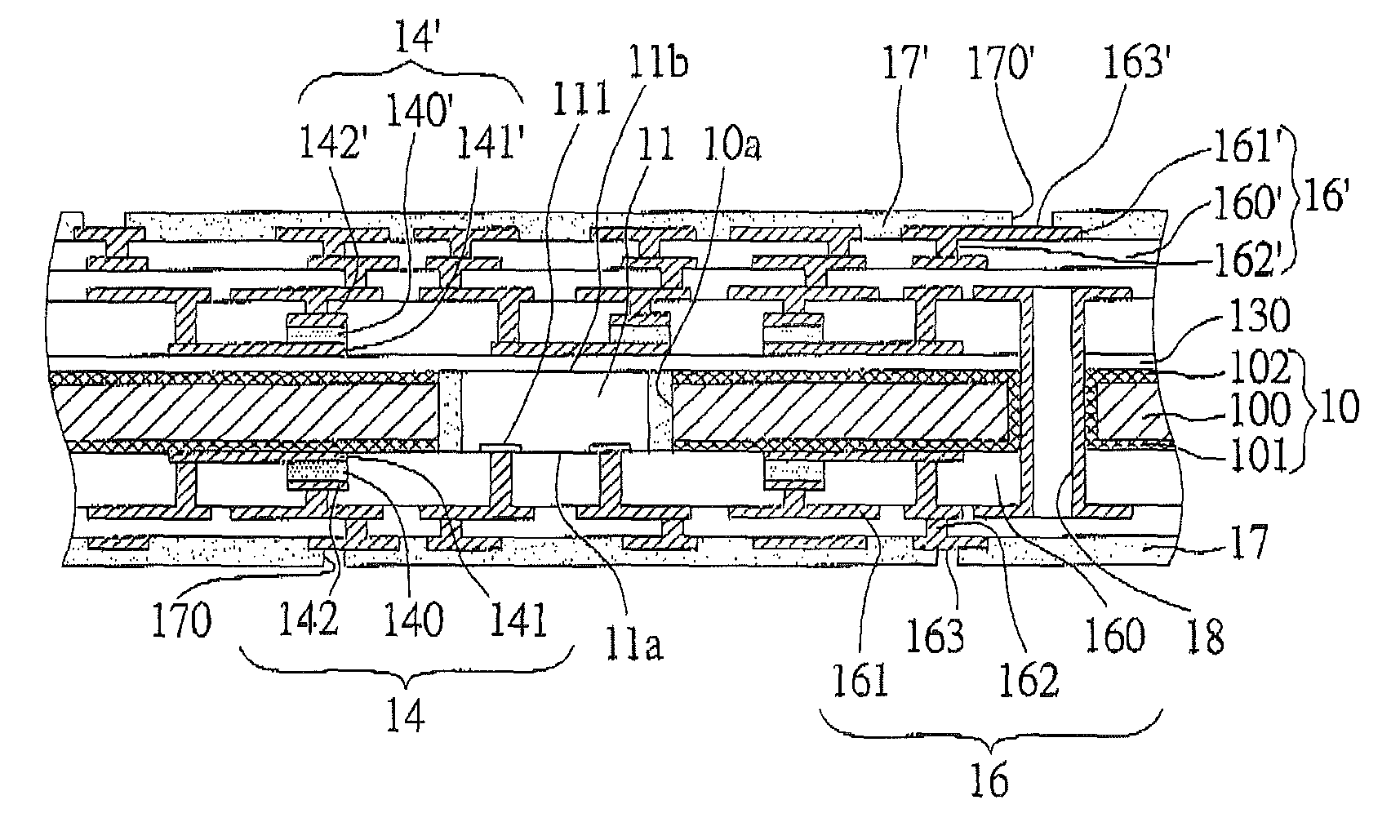

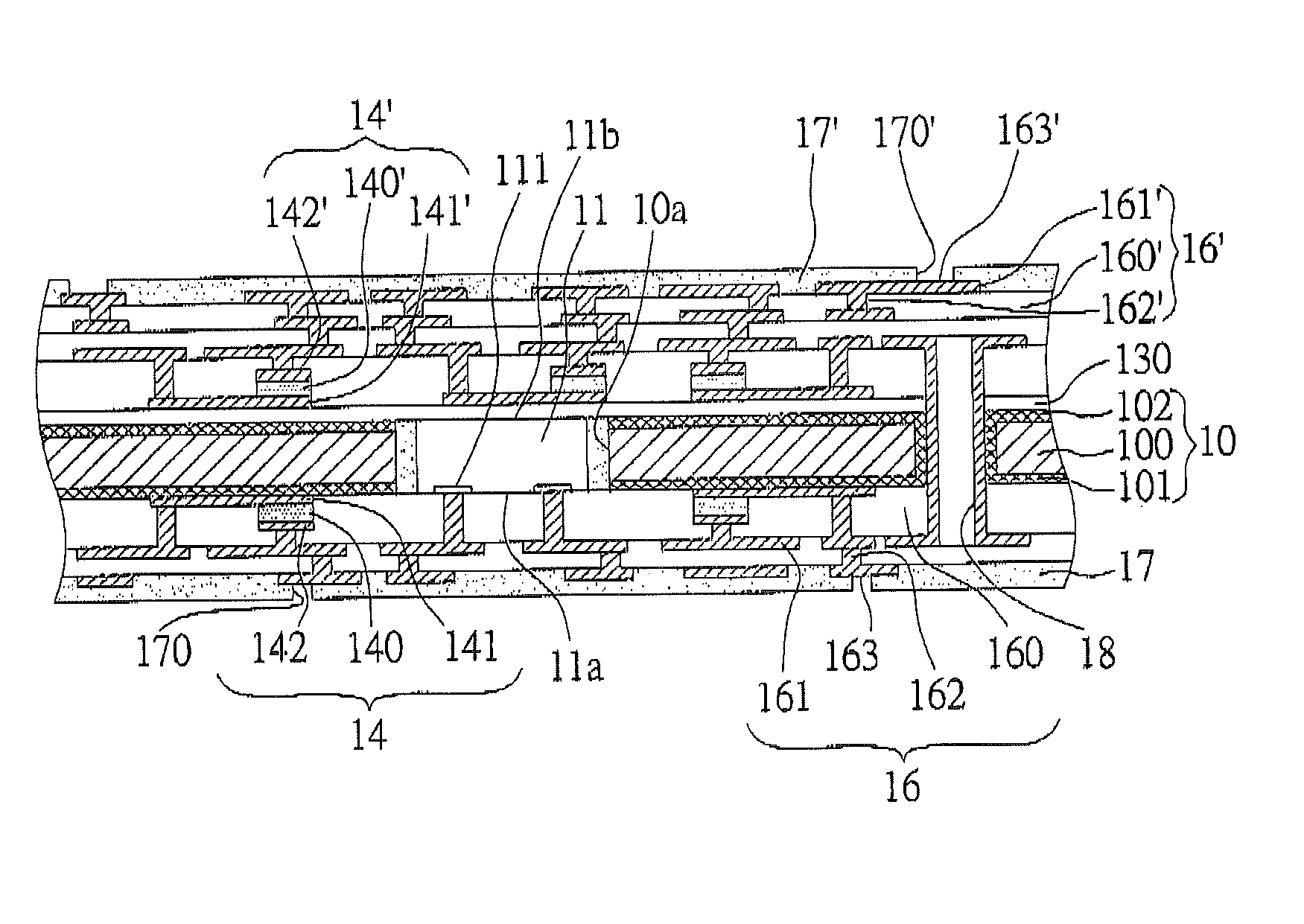

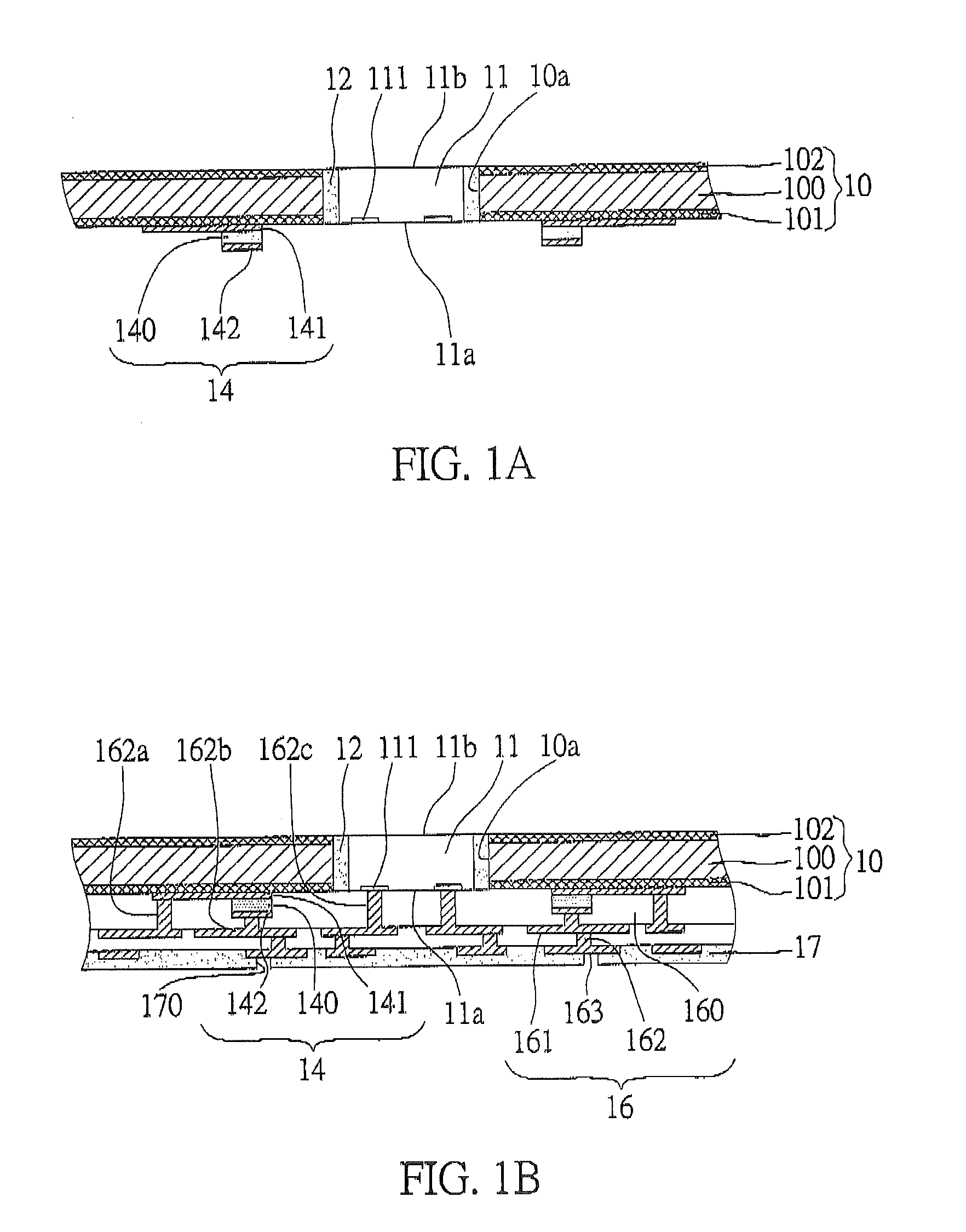

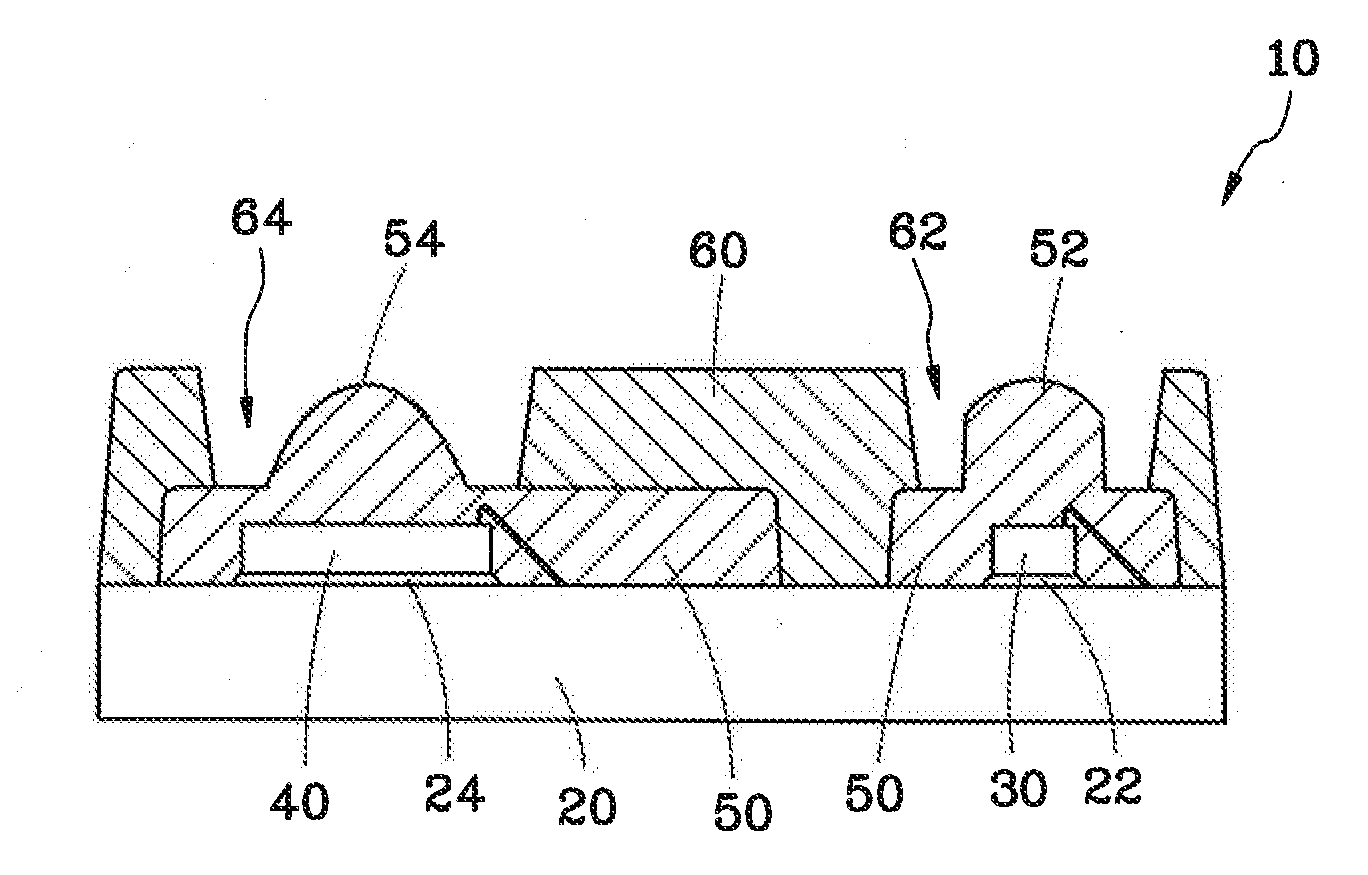

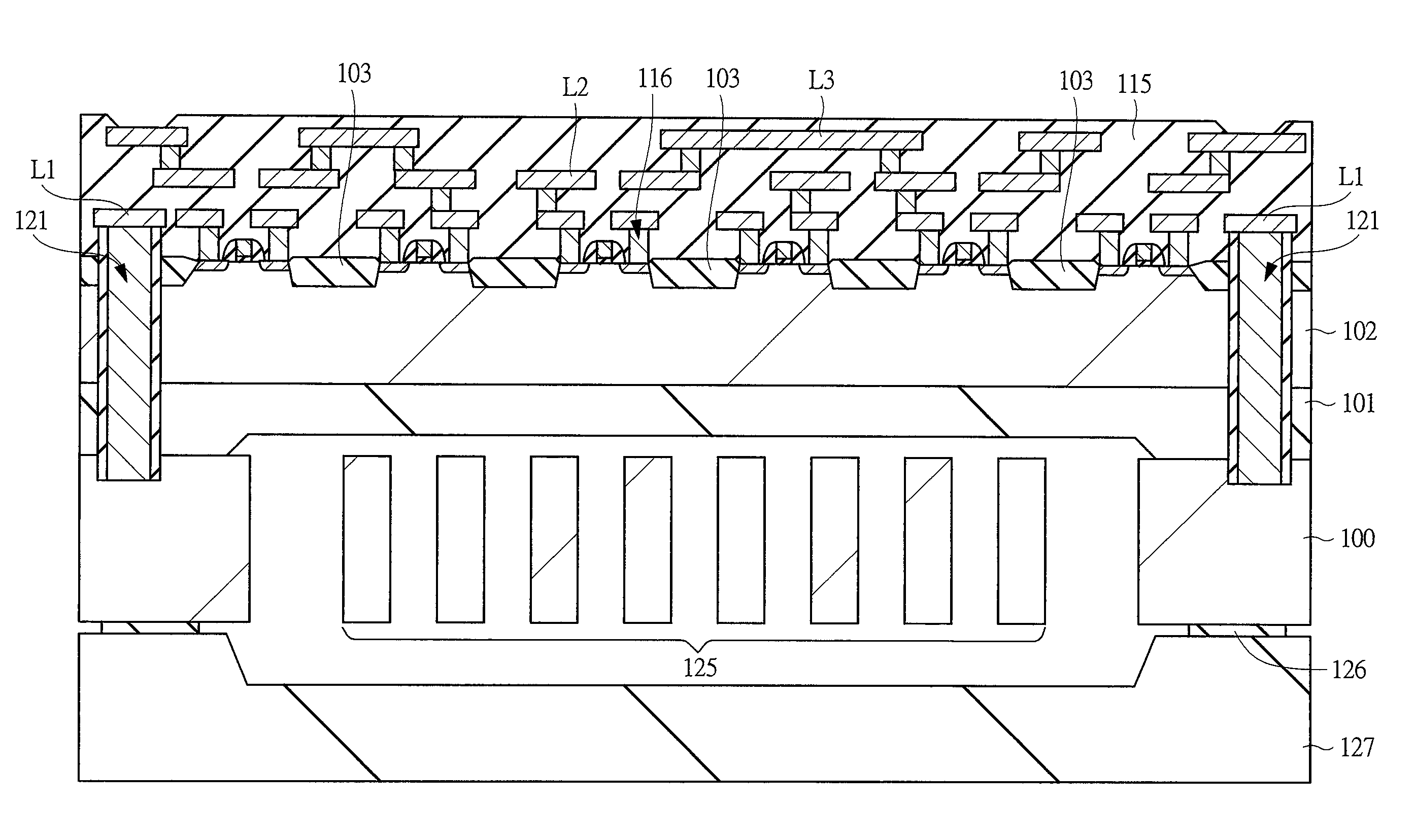

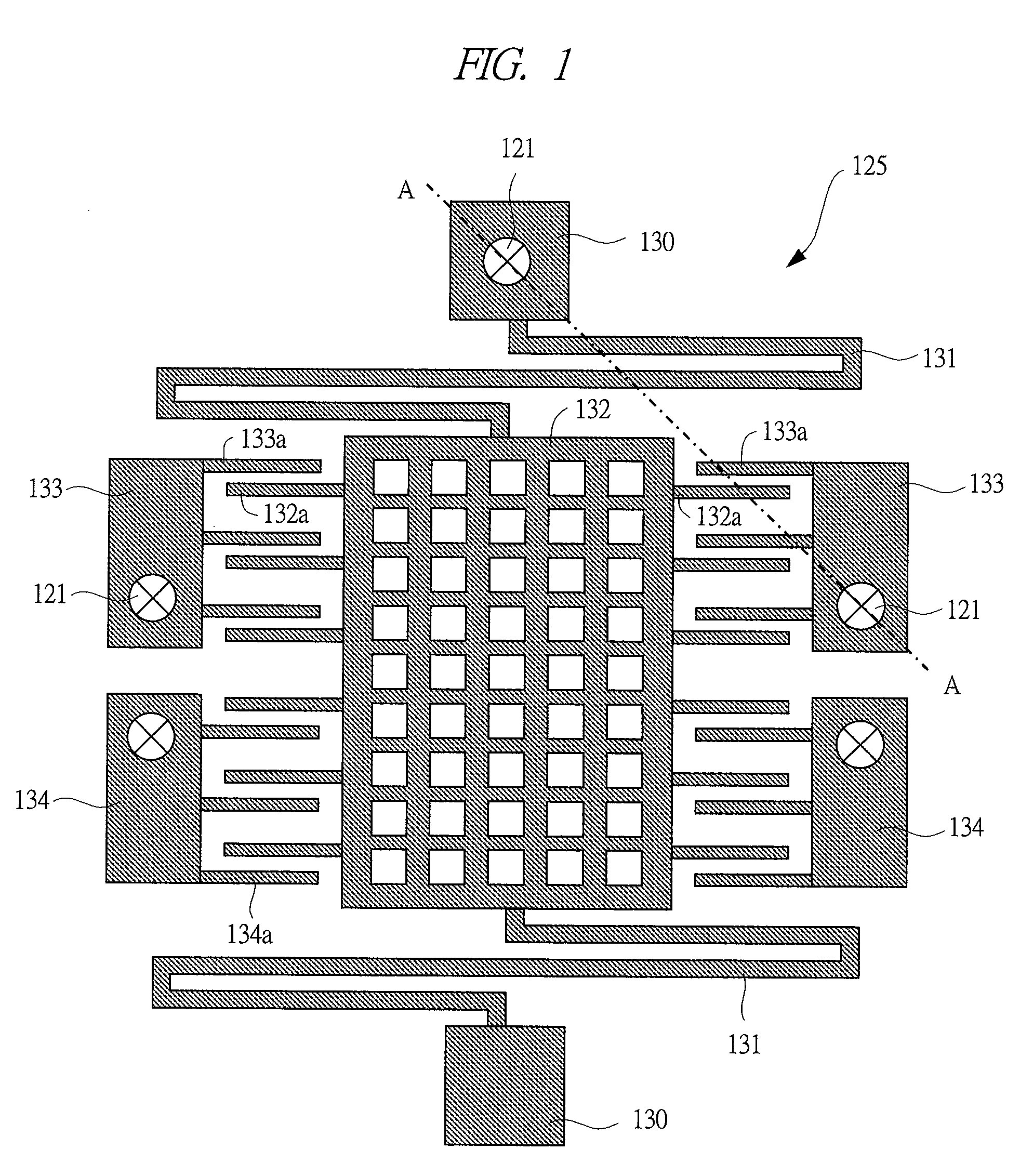

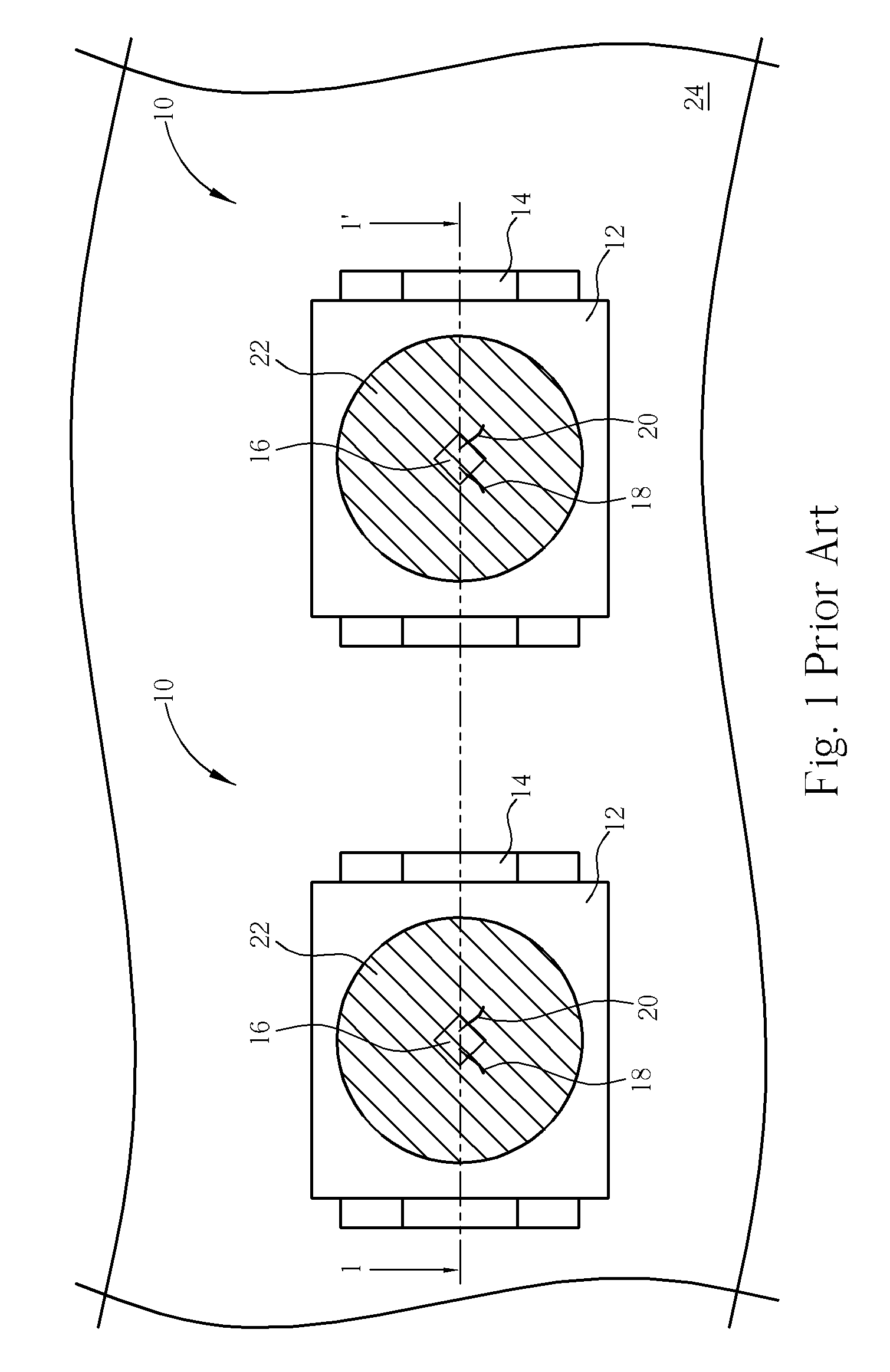

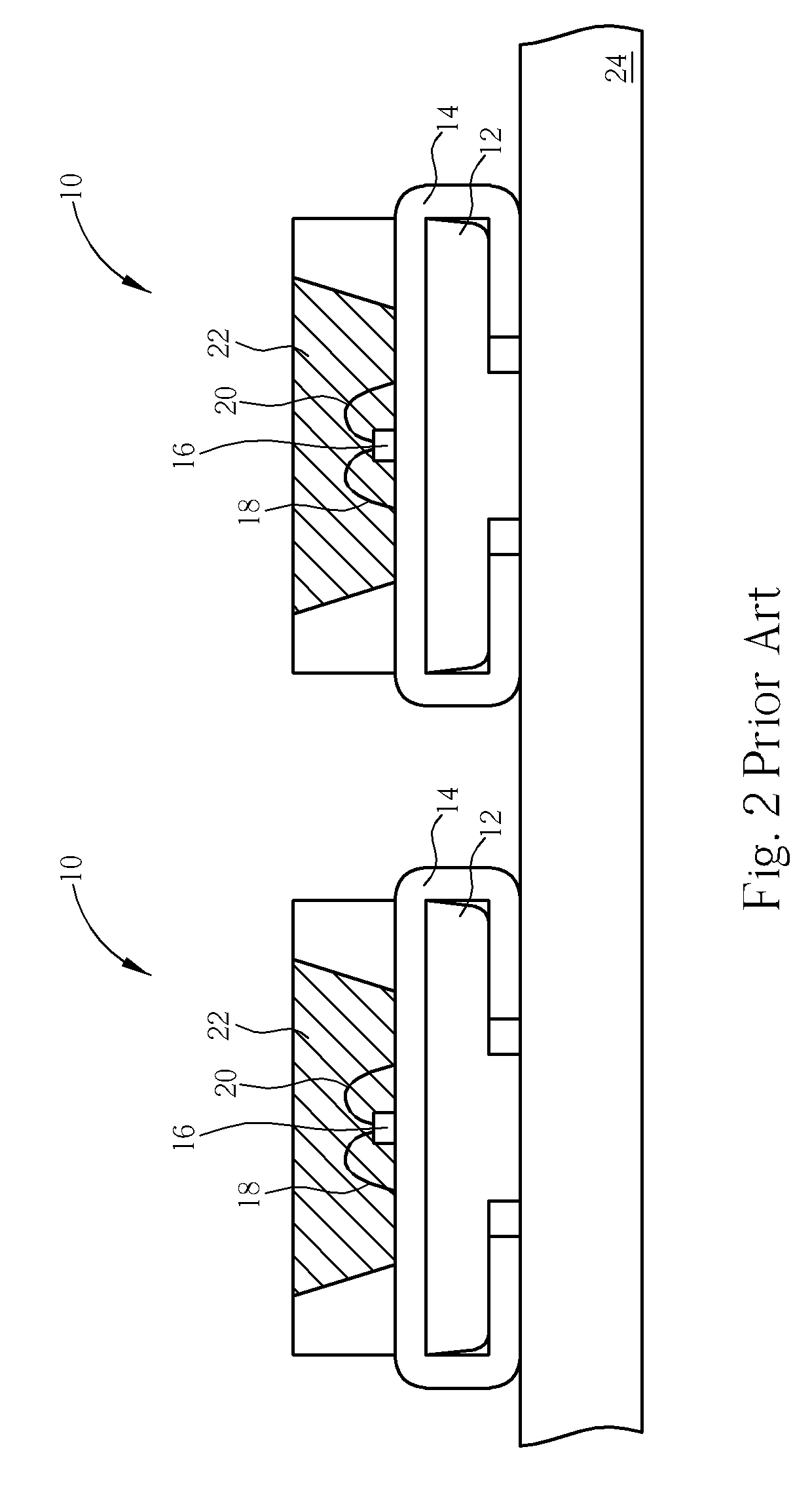

Circuit board structure having electronic components integrated therein

ActiveUS20080165515A1Improve structural rigidityAvoid warpingSemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductor chipEngineering

The present invention provides a circuit board having electronic components integrated therein, including a carrier board having an metallic oxide layer formed on each two surfaces of a metal layer, and having at least one through cavity; at least a semiconductor chip hold in the opening; at least a capacitor disposed on one surface of the carrier board, wherein the surface with the capacitor disposed thereon is at the same side with the active surface of the semiconductor chip. The capacitor is constituted of a first electrode plate disposed on partial surface of one side of the carrier board, a high dielectric material layer disposed on the surface of the first electrode plate, and a second electrode plate, paralleling and corresponding to the first electrode plate, disposed on the surface of the high dielectric material. The metal layer and the oxidation layer of the carrier board can enhance rigidity as well as tenacity and also integrate semiconductor chips and capacitors in the circuit board structure.

Owner:UNIMICRON TECH CORP

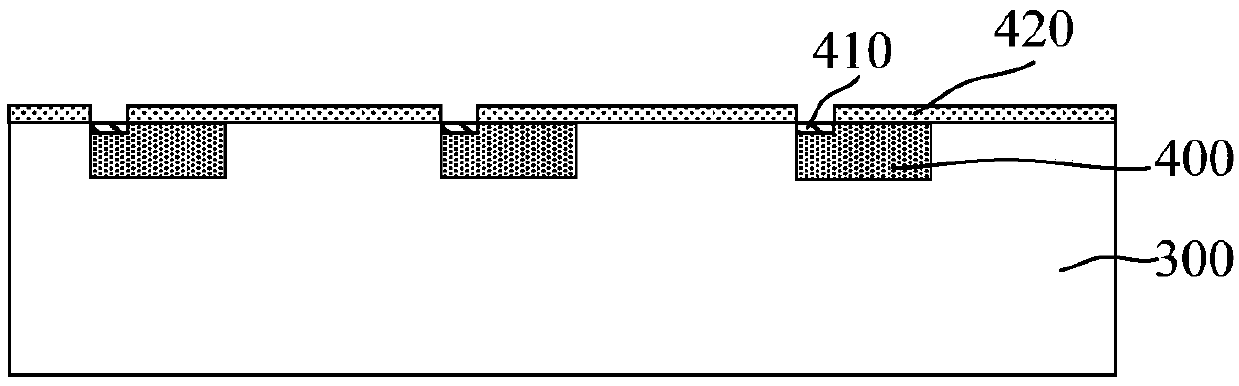

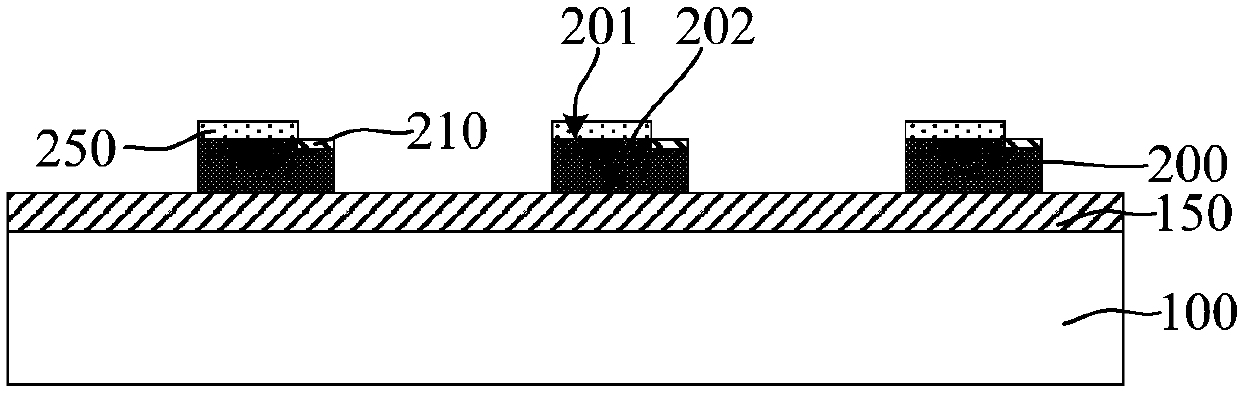

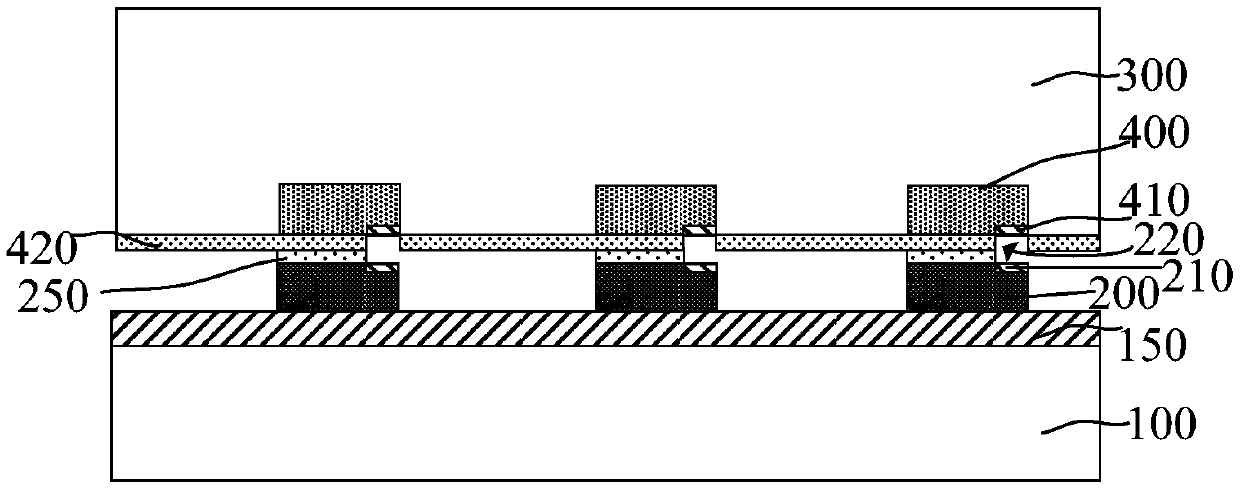

Wafer level packaging method and packaging structure

ActiveCN110875203AAchieve electrical connectionThe packaging method is simpleSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionDielectric layer

The invention provides a wafer level packaging method and a packaging structure. The method comprises the steps: a first wafer is provided, wherein a plurality of first chips are formed in the first wafer, the surface of the first chip is provided with a first electrode, and a first dielectric layer exposing the first electrode is formed on the surface of the first wafer; a plurality of second chips are provided, wherein the surface of the second chip is provided with a second electrode, and a second dielectric layer exposing the second electrode is formed on the second chip; the second dielectric layer and the first dielectric layer are oppositely arranged so that the second chip is enabled to be bonded to the first wafer, wherein the position of the second chip is enabled to correspond to the position of the first chip, and a cavity is formed between the first electrode and the second electrode; a chip interconnection structure for electrically connecting the first electrode and thesecond electrode is formed in the cavity; and a packaging layer covering the second chip is formed. Thus, the packaging process is simplified.

Owner:NINGBO SEMICON INT CORP

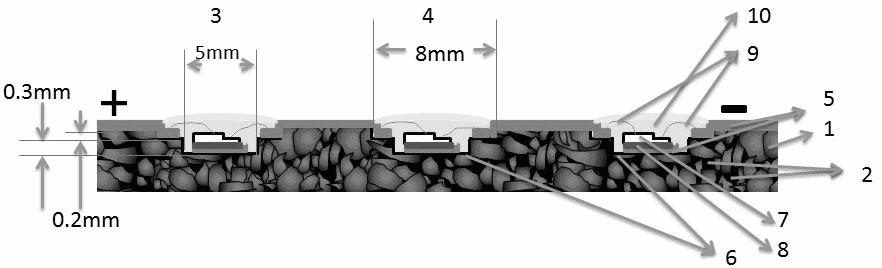

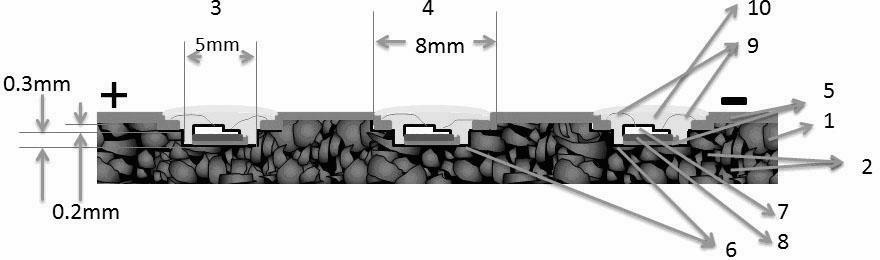

Light source unit, backlight module and a liquid crystal display

ActiveCN104808386APackage structure is simpleReduce light lossNon-linear opticsLiquid-crystal displayQuantum dot

The invention discloses a light source unit, which comprises a supporting framework, a light source for emitting blue light and a quantum dot film assembly, wherein the supporting framework comprises an encapsulation slot provided with a first surface and a light emitting window, the width of the light emitting window is larger than that of the first surface; the light source for emitting blue light is encapsulated on the first surface by a encapsulating material layer; the quantum dot film assembly comprises a quantum dot film, a first protective film connected to a first side face of the quantum dot film, and a second protective film connected to a second side face of the quantum dot film; the quantum dot film assembly is connected onto the encapsulating material layer in the way that the first protective film faces the direction of the light emitting window; the width of the quantum dot film assembly is not less than that of the light emitting window; the quantum dot film assembly is configured to convert the blue light part emitted by the light source to green light and red light. The invention also discloses a backlight module of the light source unit and a liquid crystal display comprising the backlight module.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

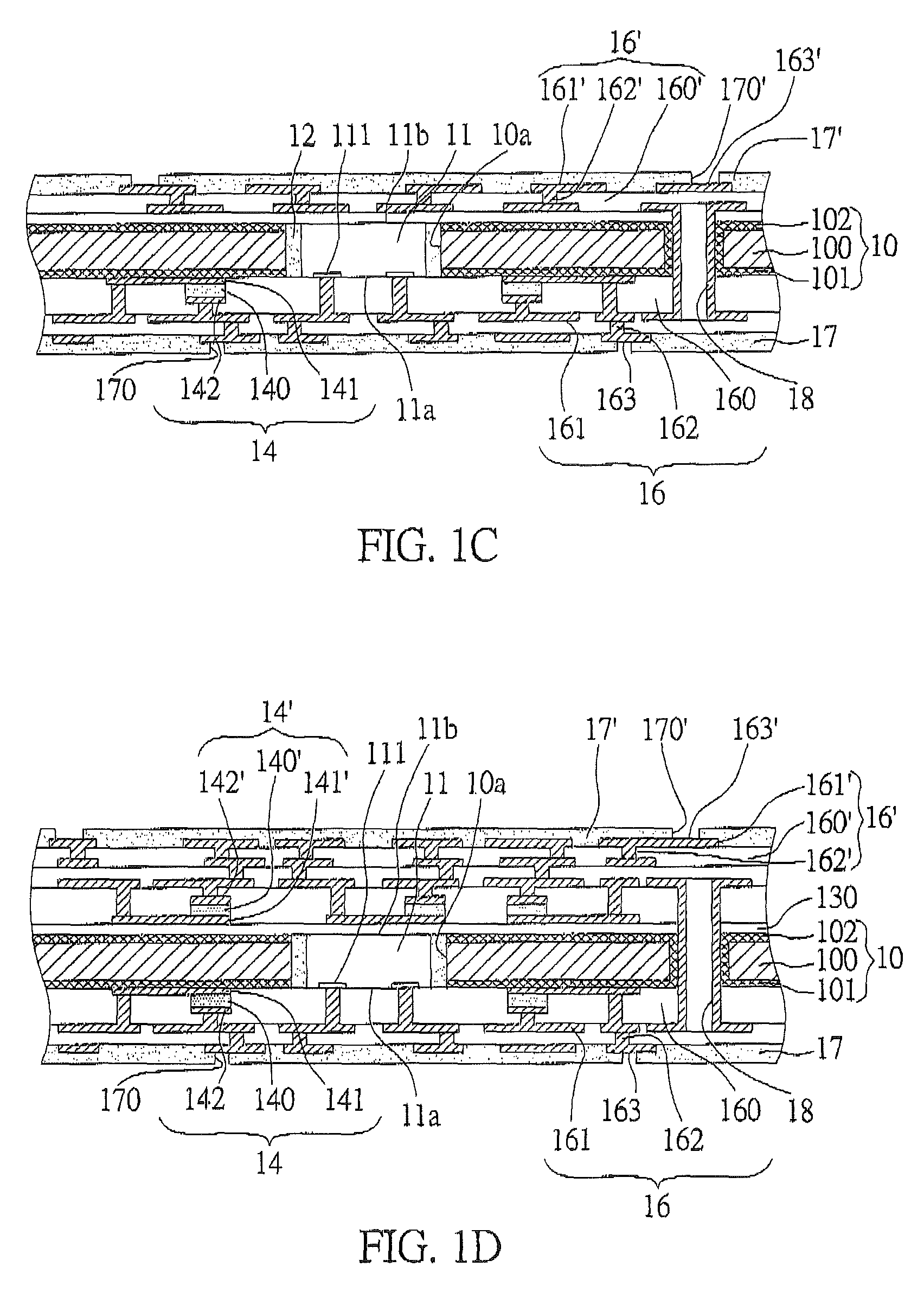

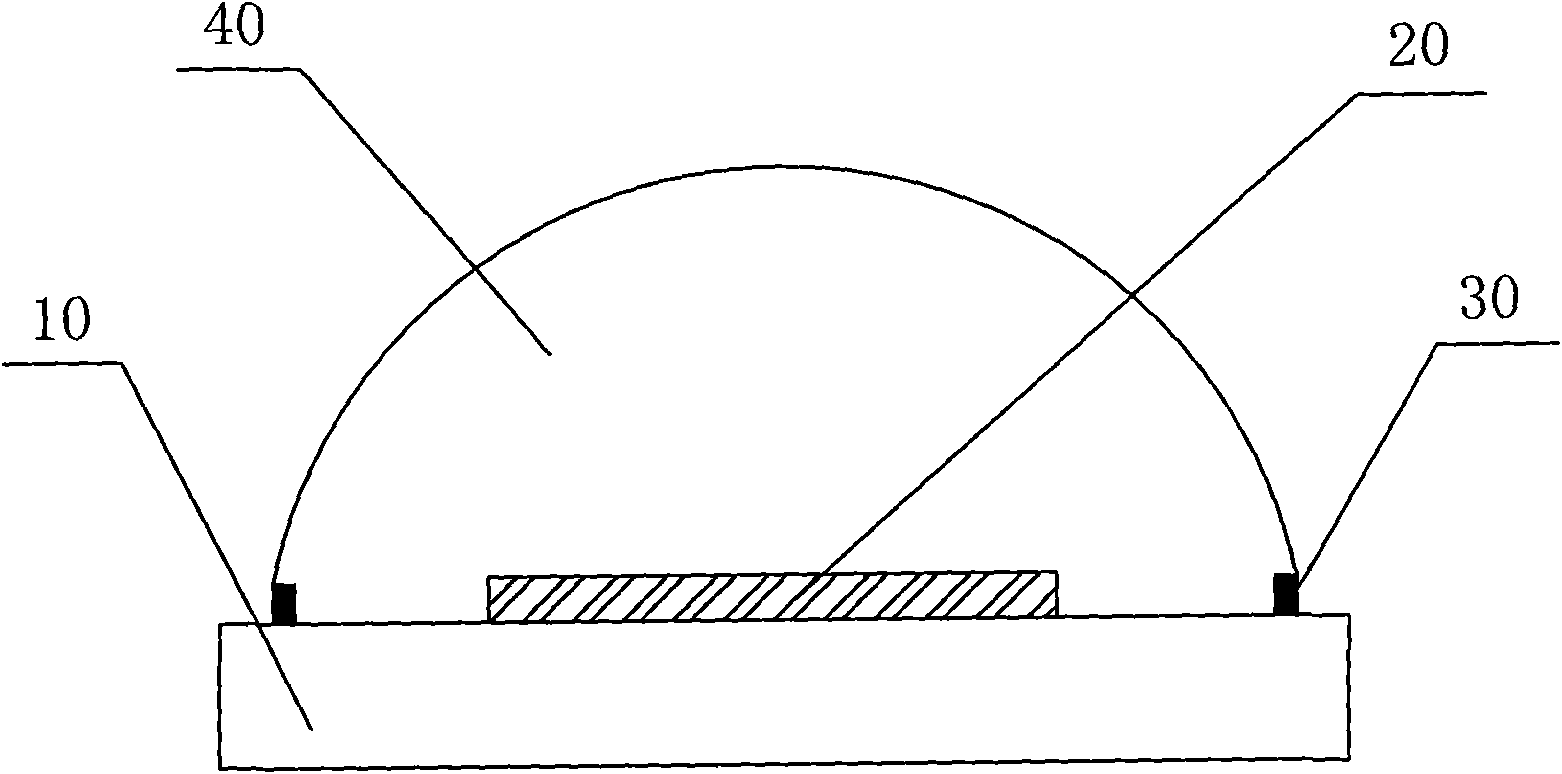

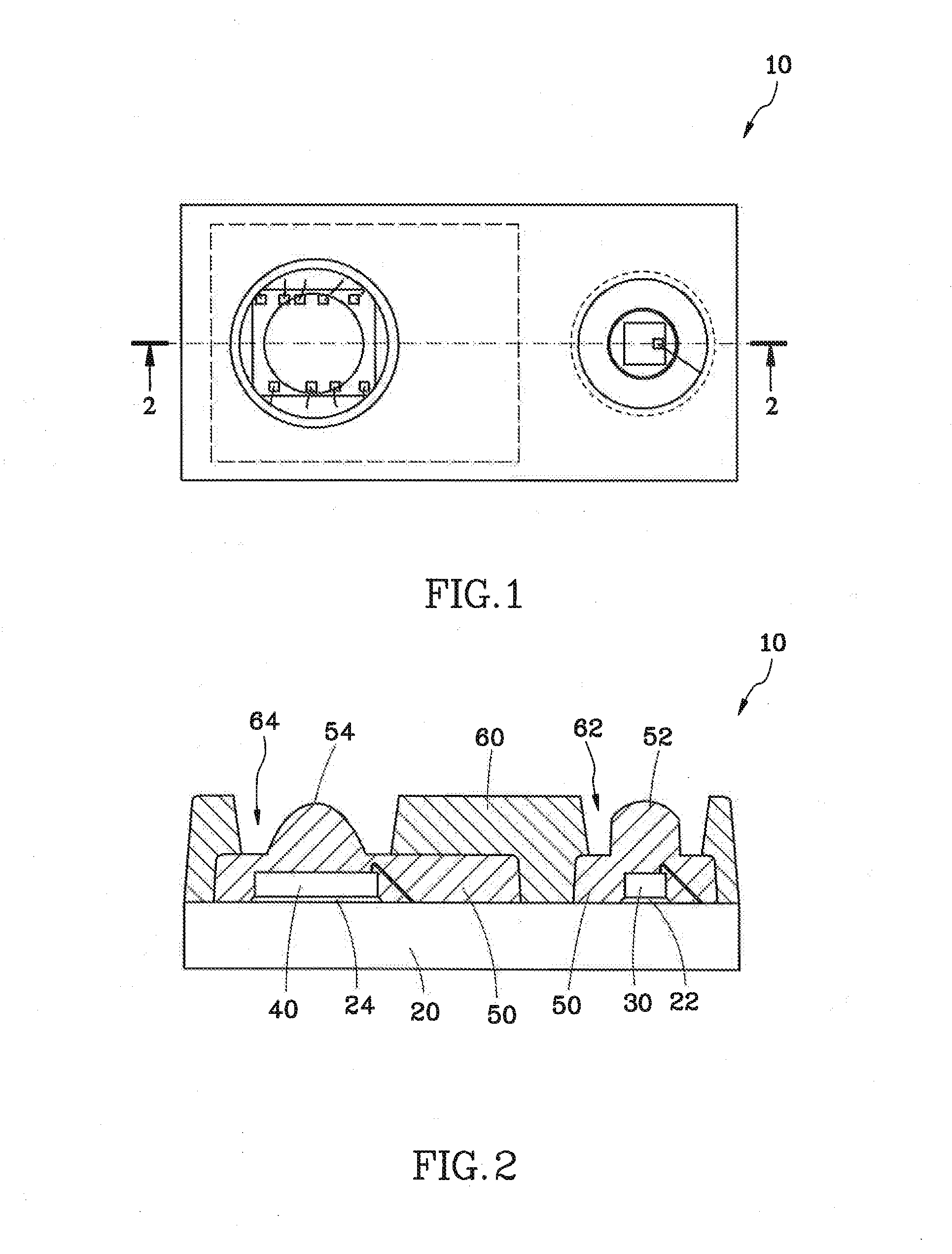

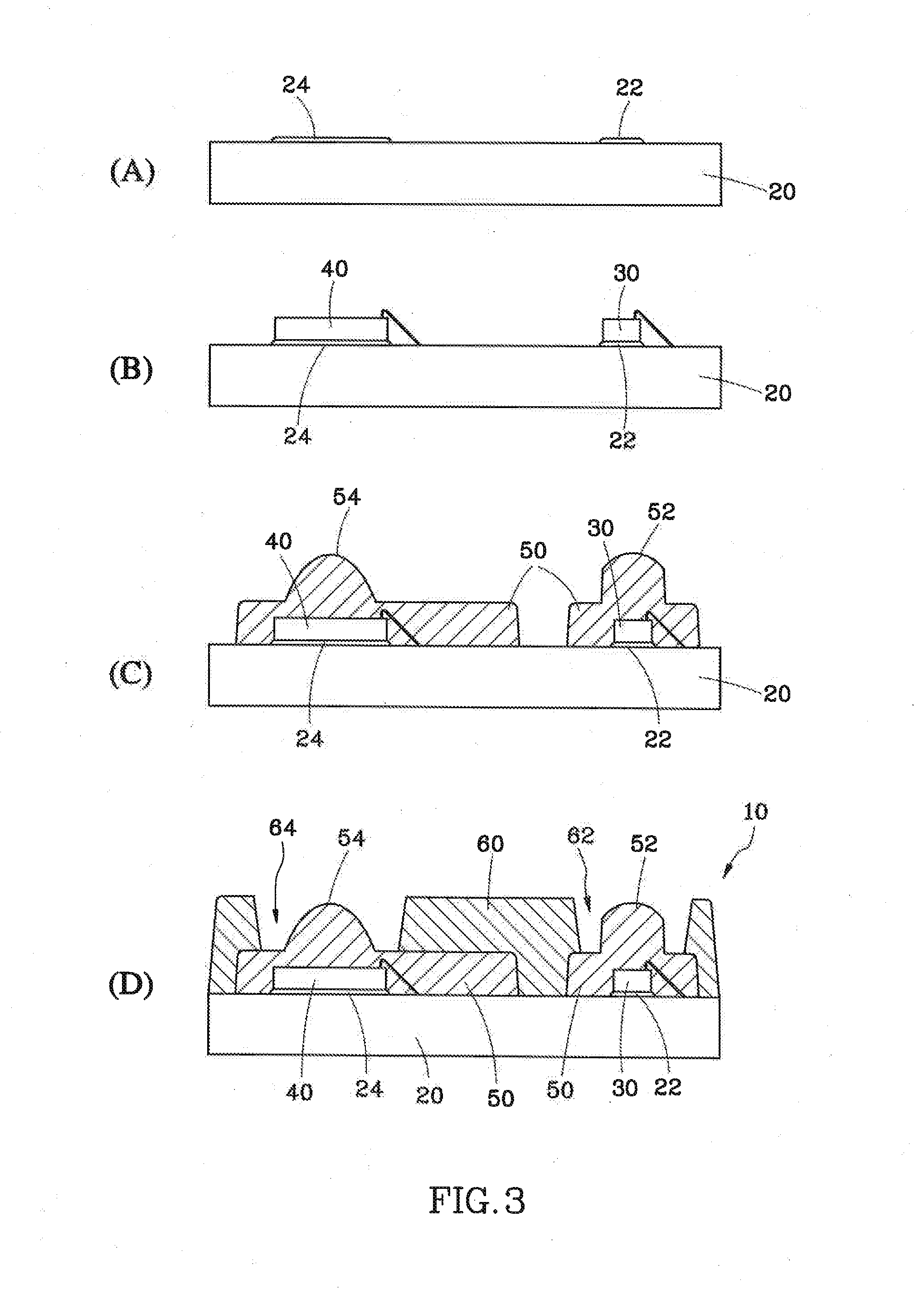

Package structure of an optical module

InactiveUS20150028358A1Improve lighting efficiencyConvenient lightingSolid-state devicesSemiconductor/solid-state device manufacturingOptical ModuleSpherical form

The present invention relates to a package structure of an optical module. The light emitting chip and the light receiving chip are disposed on the light emitting region and the light receiving region of the substrate, respectively. Two encapsulating gels are coated on the light emitting chip and the light receiving chip to form a first and a second hemispherical lens portions thereon, respectively. A cover is affixed on the substrate and each of the encapsulating gels and has a light emitting hole and a light receiving hole, where the first and second lens portions are accommodated, respectively. In this way, the package structure of an optical module of the present invention can be made with the encapsulating gels of different curvatures according to different needs to improve the luminous efficiency of the light emitting chip effectively and to improve the reception efficiency of the light receiving chip.

Owner:LINGSEN PRECISION INDS

Semiconductor device with integrated circuit electrically connected to a MEMS sensor by a through-electrode

InactiveUS7919814B2Package structure is simpleReduce thicknessTransistorSemiconductor/solid-state device detailsAngular rate sensorMiniaturization

Owner:HITACHI LTD

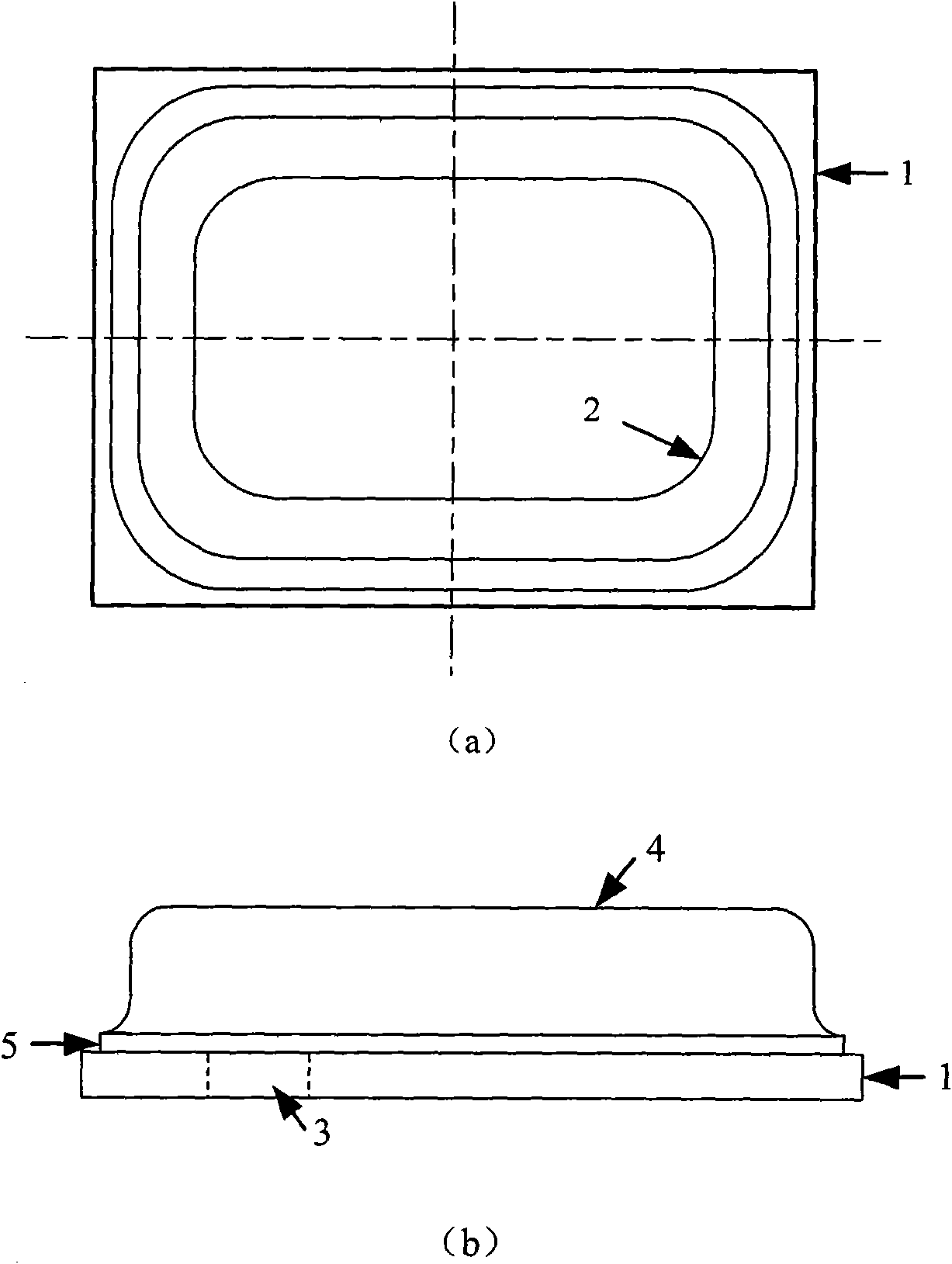

Packaging structure for microphone with embedded substrate

InactiveCN101651916AReduce package sizeLow costSolid-state devicesElectrostatic transducer microphonesLimited structuresHeight difference

The invention relates to a packaging structure for a microphone with an embedded substrate, comprising a metal top cover, a substrate, a microphone chip, a circuit chip and a passive element. The upper surface of the substrate is used for carrying and fixing the microphone chip, the circuit chip and the passive element; grounding electrodes communicated electrically are arranged on the upper and lower surfaces of the substrate and used for being connected with the metal top cover to ground; an acoustic cavity of the microphone is formed hermetically between the inner surface of the metal top cover and the substrate. A limit structure is arranged on the metal top cover. The plane limited by the limit structure is higher than and parallel to the plane on which the bottom edge of the metal top cover is located, the plane is used for embedding the substrate to the metal top cover horizontally in a direction where the chip carrying surface faces upwards, the embedding depth thereof is adjusted via a height difference of the bottom edge of the limited structure and the bottom edge of the metal top cover, and the height difference is not greater than thickness of the substrate. The invention has a simple structure and high space utilization rate.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

LED packaging structure and manufacturing method

ActiveCN105390570ASimple processReduce manufacturing costSemiconductor devicesAdhesiveElectrical connection

The invention discloses an LED packaging structure and a manufacturing method. The manufacturing method comprises the steps of providing an adhesive carrying device and a carrier plate, laying a first isolation film and a second isolation film, injecting adhesive, curing, cutting, and separating. The LED packaging structure comprises a flip chip, the bottom of the flip chip is provided with electrodes, the sides and the top of the flip chip are coated with packaging adhesive, and the lower surface of the packaging adhesive is higher than the lower surfaces of the electrodes. An LED packaging structure with a step between the electrodes and the packaging adhesive can be manufactured by the manufacturing method. The hole rate of connection between the LED packaging structure and a substrate is reduced, the fixing reliability of the LED packaging structure is improved, and the reliability of electrical connection between the LED packaging structure and the substrate is improved.

Owner:HONGLI ZHIHUI GRP CO LTD

Organic electric-excitation luminescent displaying panel package structure

InactiveCN1816232ASimple structurePackage structure is simpleElectrical apparatusElectroluminescent light sourcesPhotoluminescenceUltraviolet

The packaging structure includes following parts: glass base plate, where organic electro photoluminescence display unit is formed on; closing cap as a closing pair of the glass base plate; double-faced adhesion glue film located between the glass base plate and the closing cap. The glue film is non-conducting material with low moisture absorption and high plasticity. The glue film can stick glass base plate and closing cap all sidedly in laminar. After solidified by ultraviolet radiation or heat, glue film can be used or glue film can be used directly without solidification.

Owner:UNIVISION TECHNOLOGY

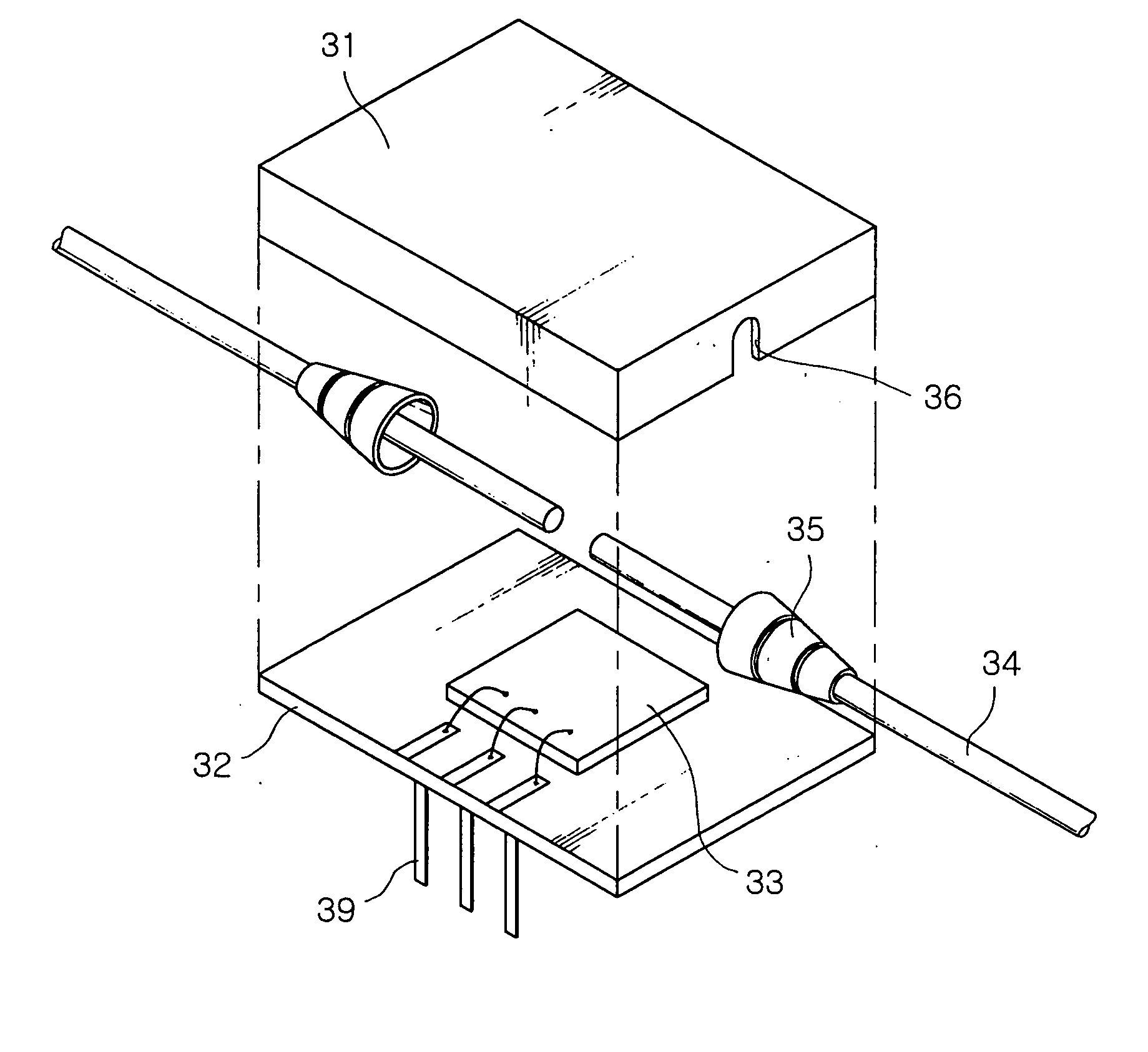

Micro optical communication device package

InactiveUS20050078920A1Package structure is simpleFacilitate communicationTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesInterior spaceEngineering

The present invention relates to a micro optical communication device package. The package of the invention comprises a Micro-Electro-Mechanical System (MEMS) chip for executing an optical communication function. The MEMS chip is mounted on a base. An upper housing having an opened bottom is placed on the base to form an internal space together with the base. The upper housing is sealed with the base to hermetically seal the MEMS chip within the internal space. The MEMS chip is connected an optical fiber, which is extended through the upper housing to form a light path. A boot is fit around the optical fiber and fixed to the upper housing to seal a portion of the upper housing for allowing passage of the optical fiber.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

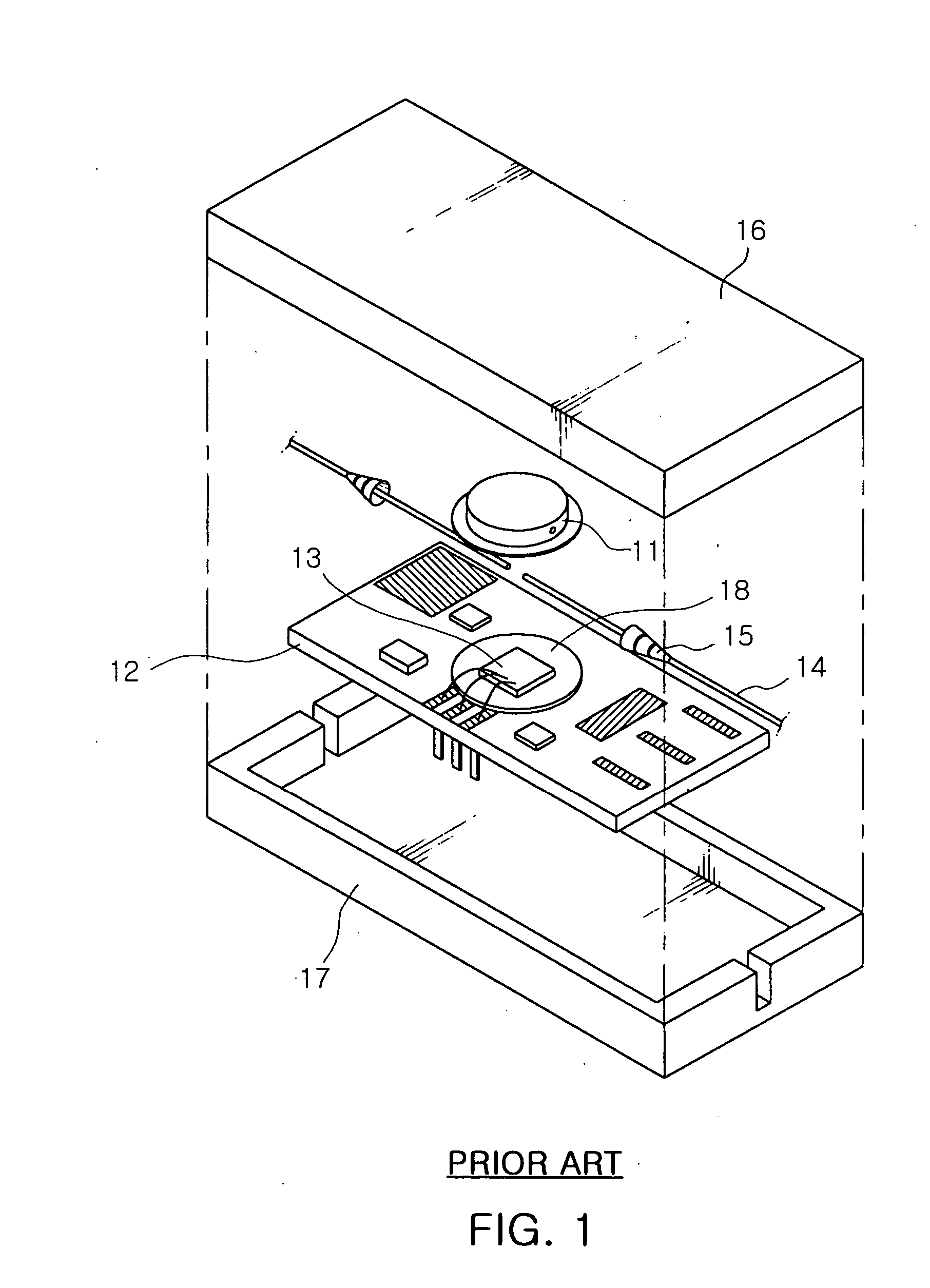

Si-substrate and structure of opto-electronic package having the same

InactiveUS20080017876A1Simplify component complexityIncrease heatSolid-state devicesPrinted circuit manufactureEngineeringOpto electronic

Disclosed herein is a structure of an opto-electronic package having a Si-substrate. Si-substrates are manufactured in batch utilizing micro-electromechanical processes or semiconductor processes, so that these Si-substrates are made with great precision and full of varieties. Based on the material characteristic of the Si-substrate, and the configuration of the components, such as the connecters, opto-electronic devices, depressions, solder bumps, etc., the present invention can improve the optical effect, the heat dissipating effect, and the reliability of the structure of opto-electronic package, and simplifies the complexity of the structure of opto-electronic package.

Owner:TOUCH MICRO SYST TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com