Patents

Literature

79 results about "Limited structures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Providing question and answers with deferred type evaluation using text with limited structure

InactiveUS20120078902A1Digital data information retrievalDigital data processing detailsEntity typePattern matching

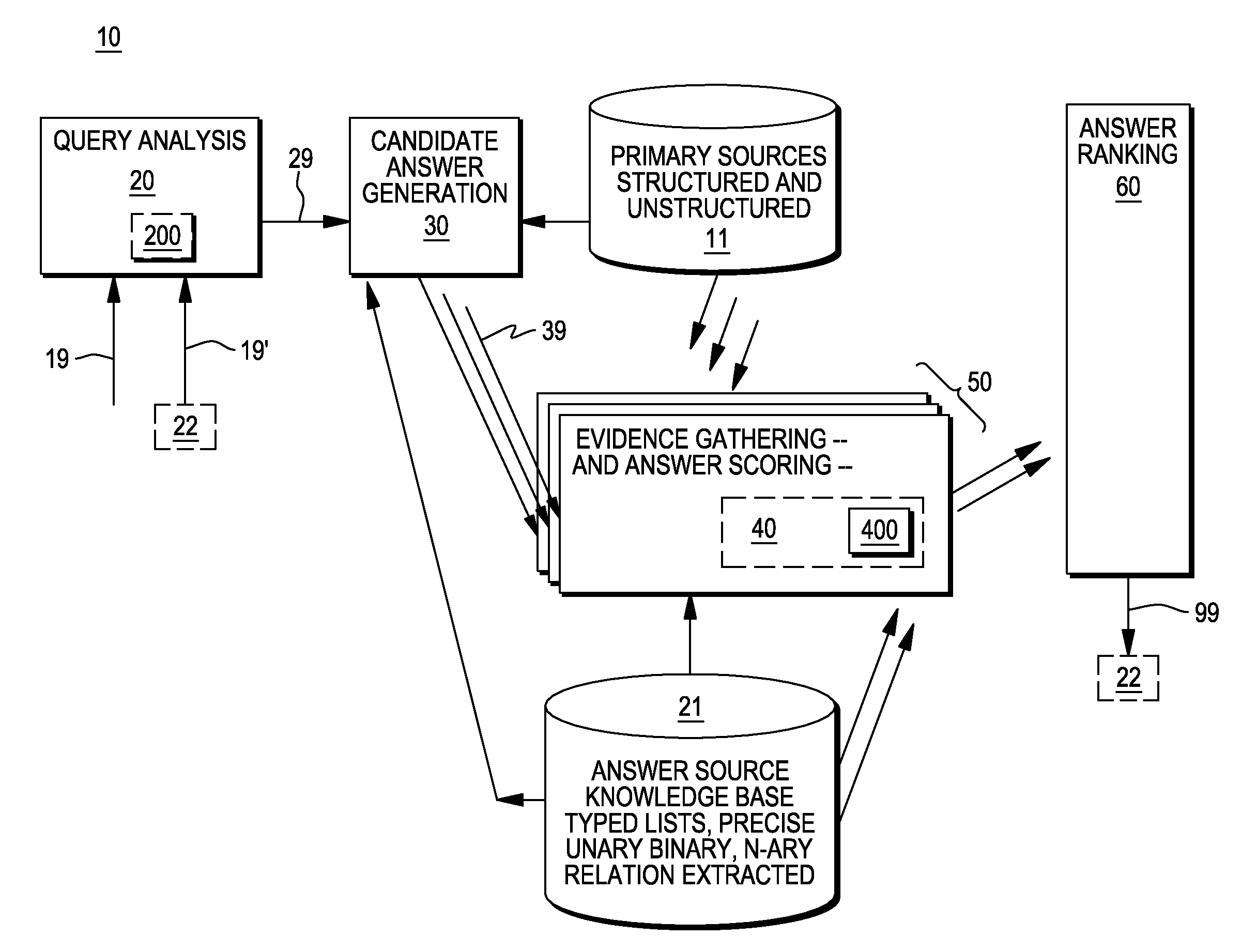

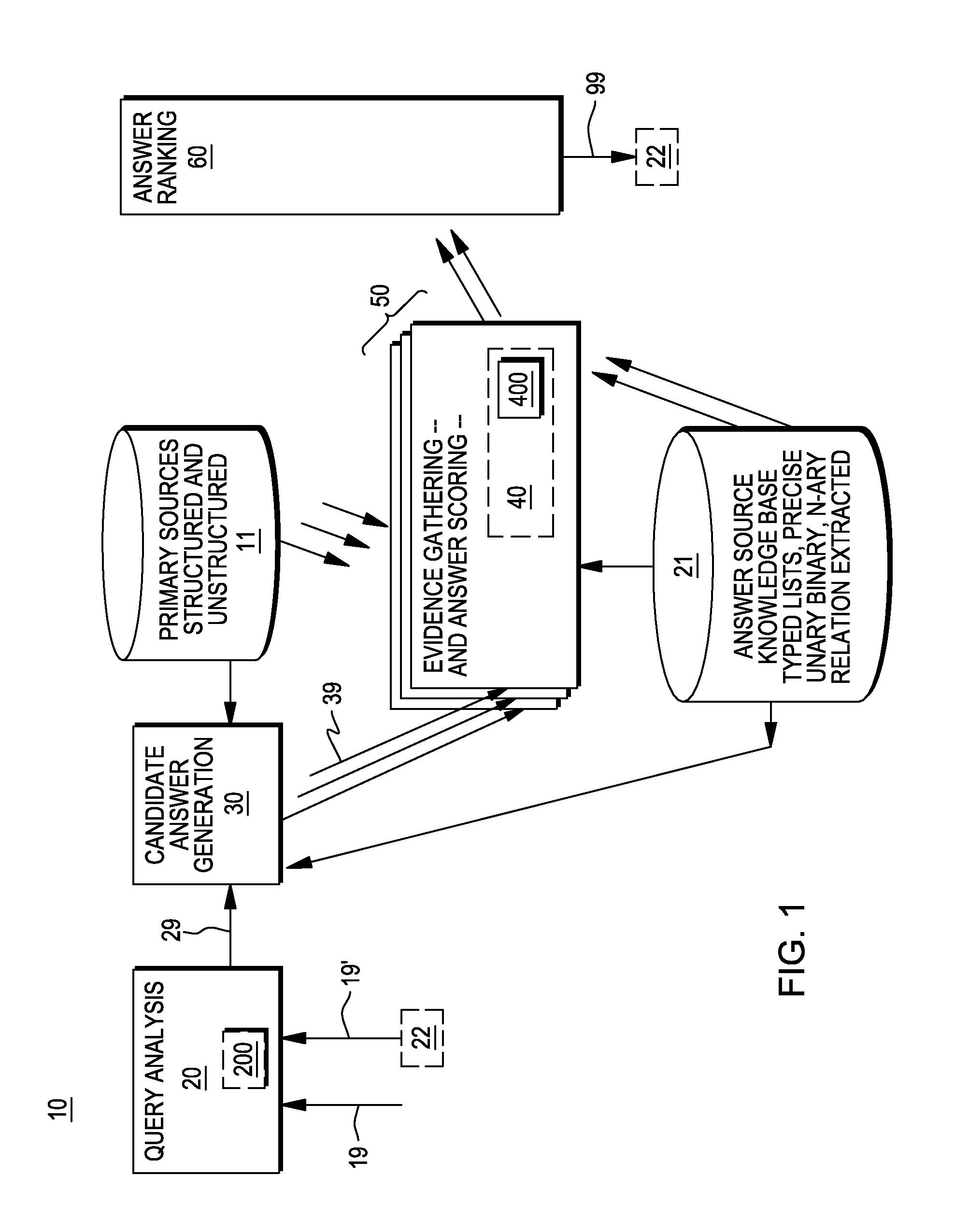

A system, method and computer program product for conducting questions and answers with deferred type evaluation based on any corpus of data. The method includes processing a query including waiting until a “Type” (i.e. a descriptor) is determined AND a candidate answer is provided. Then, a search is conducted to look (search) for evidence that the candidate answer has the required Lexical Answer Type (e.g., as determined by a matching function that can leverage a parser, a semantic interpreter and / or a simple pattern matcher). Prior to or during candidate answer evaluation, a process is provided for extracting and storing collections of entity-type pairs from semi-structured text documents. During QA processing and candidate answer scoring, a process is implemented to match the query LAT against the lexical type of each provided candidate answer and generate a score judging a degree of match.

Owner:IBM CORP

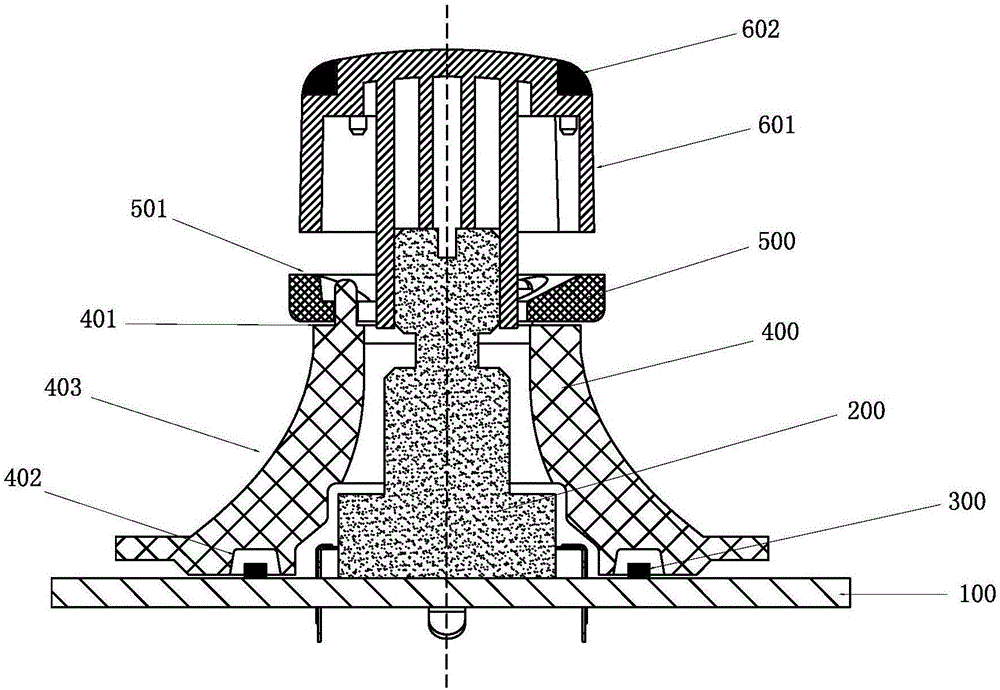

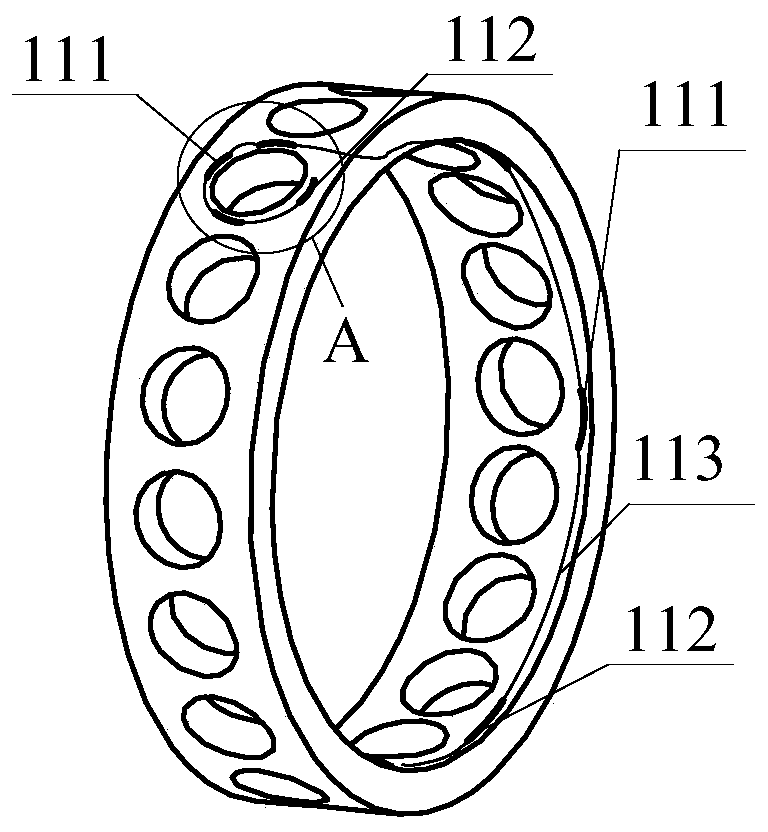

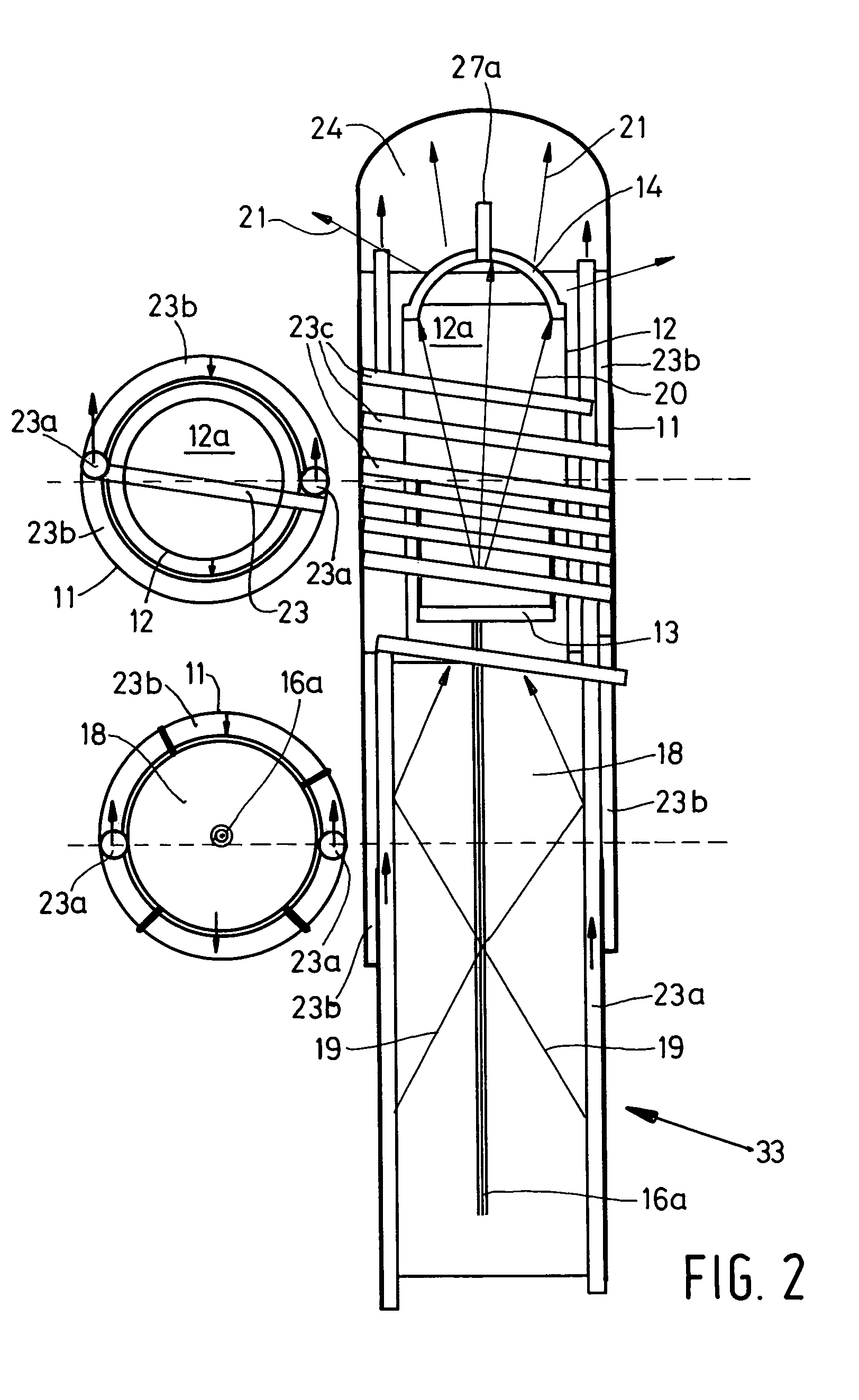

Knob light guide ring structure and light control method thereof

ActiveCN106764683ASatisfy light transmittanceMeet uniformityMechanical apparatusLight guides detailsLight guideOptoelectronics

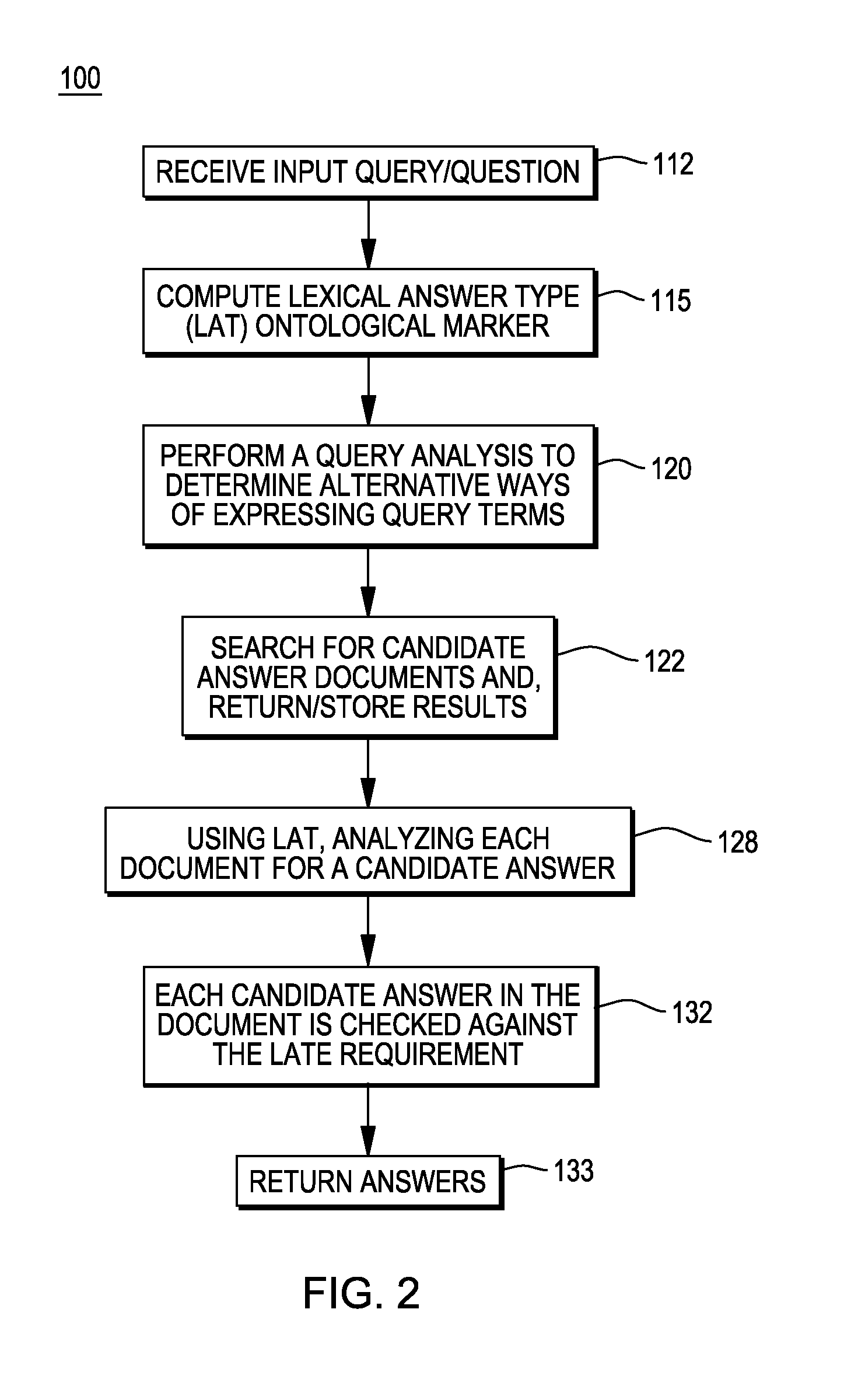

The invention relates to a knob light guide ring structure and a light control method thereof. With a specific structure of upper and lower light guide parts, light is firstly directed to go into the lower guide part from a firstlight-entering surface, and then led out from a first light-exiting surface after undergoing multiple refraction and diffuse reflection by a structure of a first outer refraction and reflection surface and a first inner refraction and reflection surface; the light goes into the upper light guide part from a second light-entering surface, and then led out from a second light-exiting surface after undergoing multiple refraction and diffuse reflection by a structure of a second outer refraction and reflection surface and a second inner refraction and reflection surface in the upper light guide part; thus, a uniform final display effect may be achieved. The knob light guide ring structure in the invention allows uniform light guide by the outer ring gap of the knob based on a truncated cone-shapedknob light guide ring structure design with two vertical LED light sources in compact and limited structure space; thus, the number of the LED light sources may be reduced on the basis of satisfying the transmission of light and uniformity of the light guide ring, thereby saving the product costs.

Owner:FORYOU GENERAL ELECTRONICS

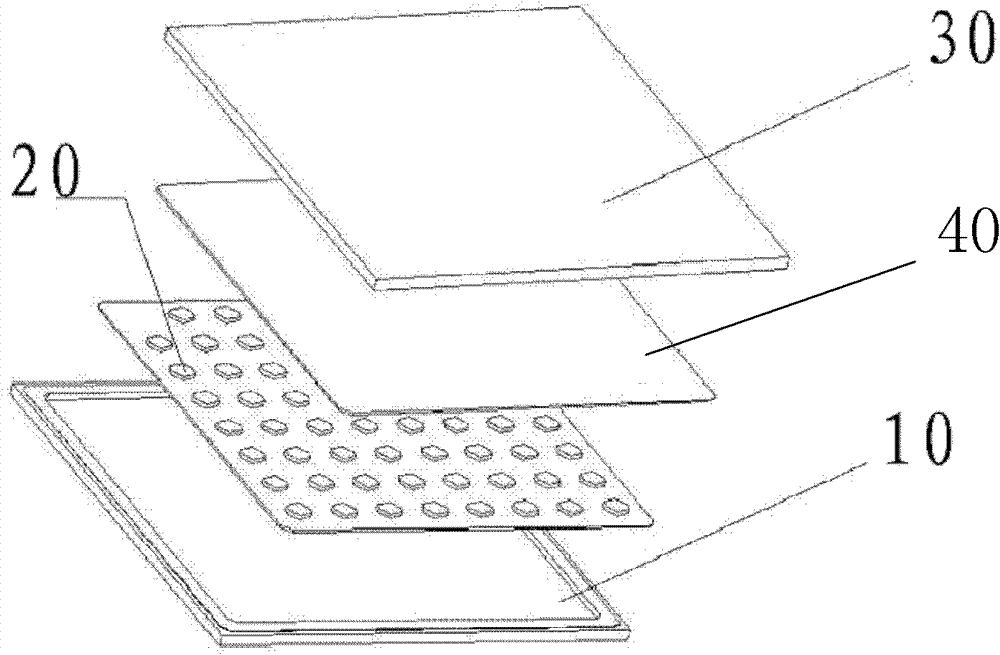

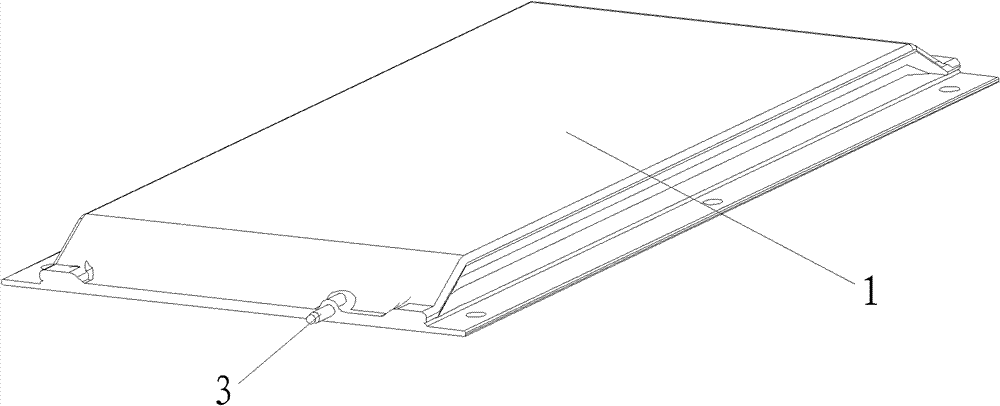

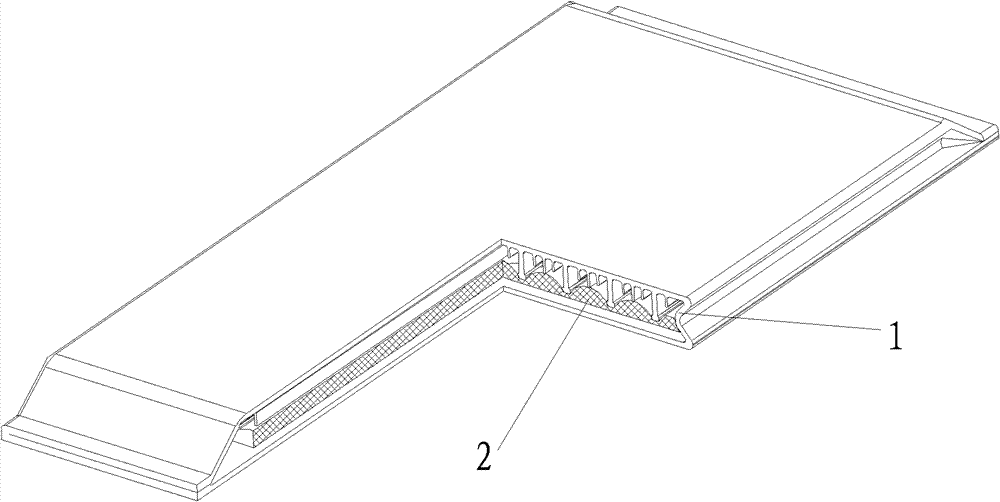

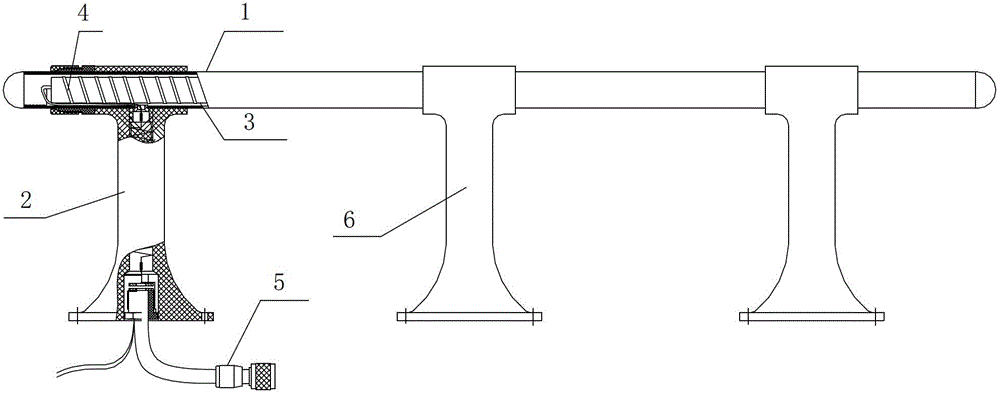

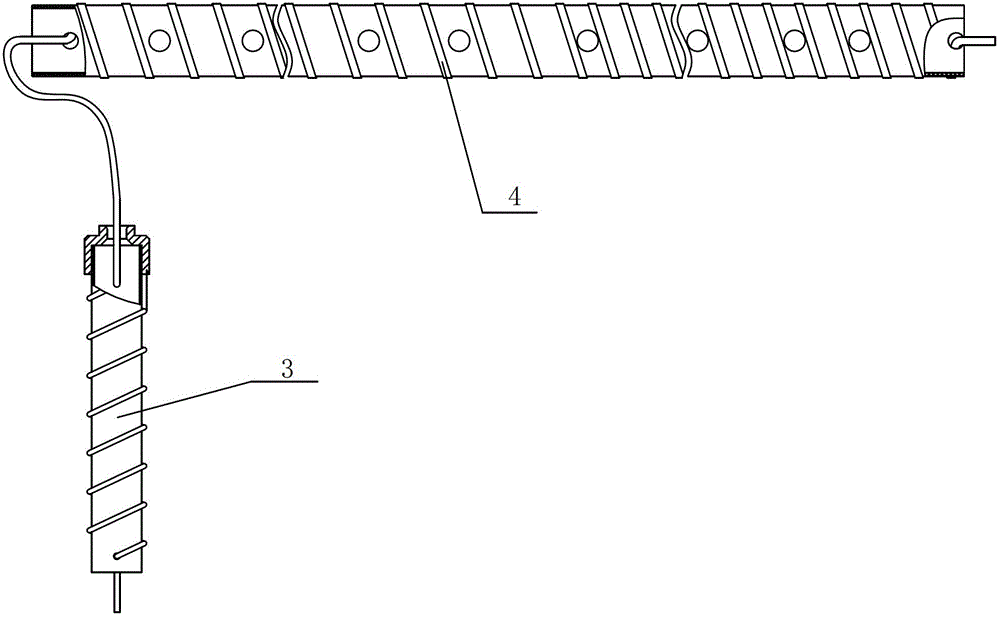

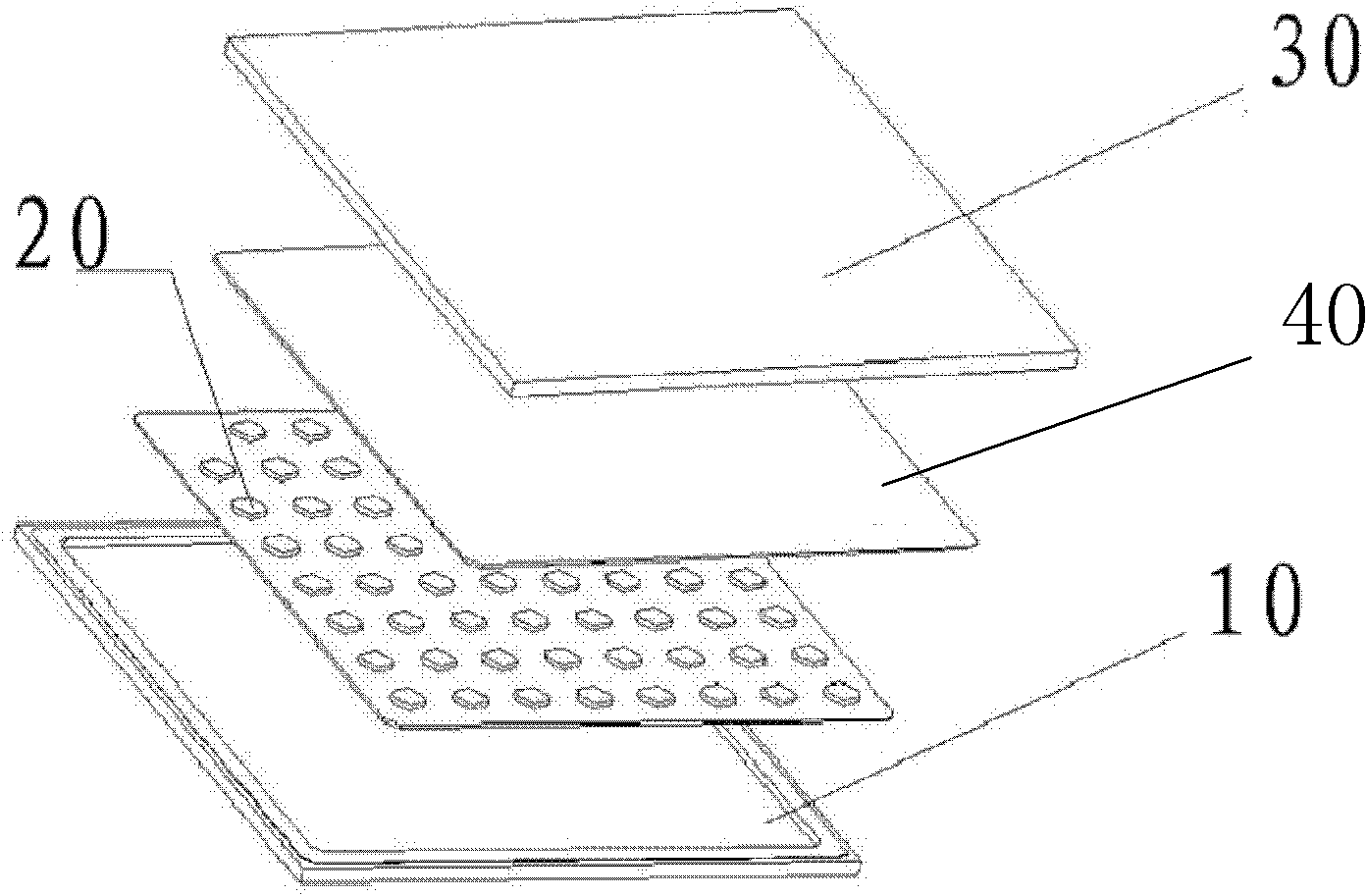

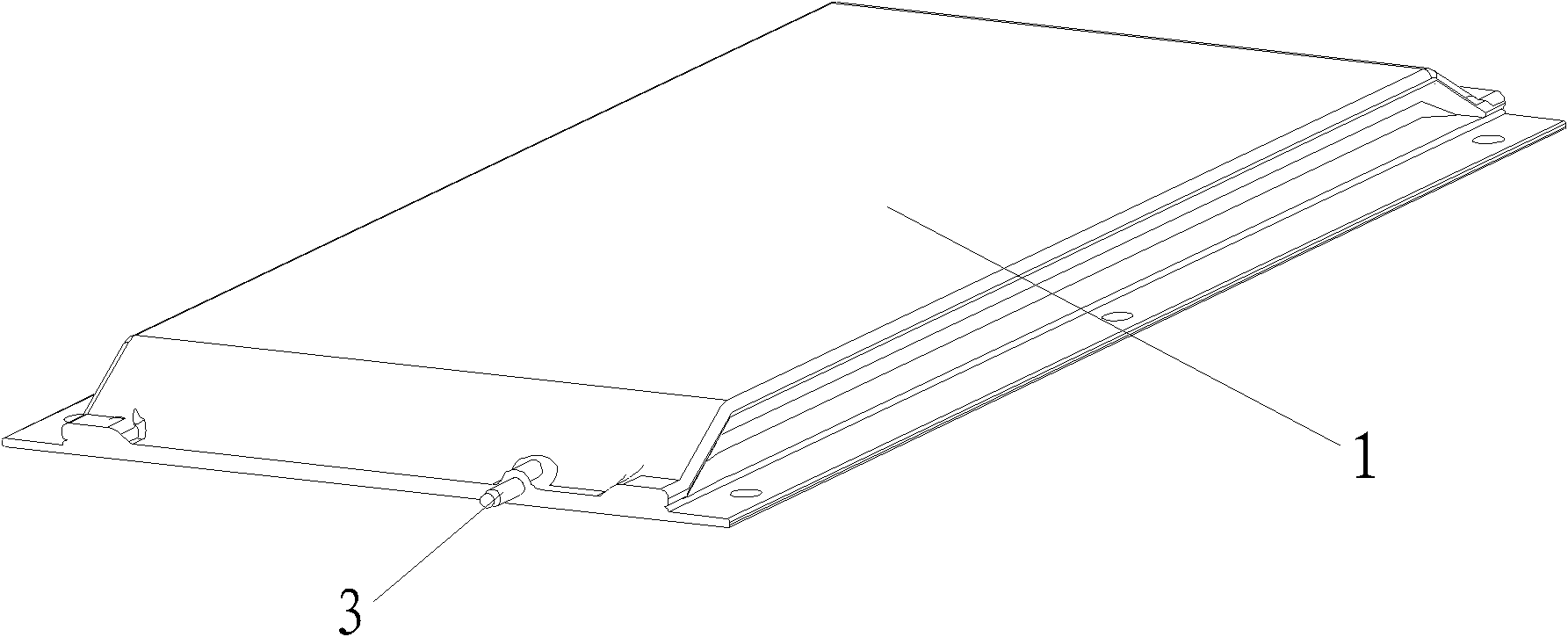

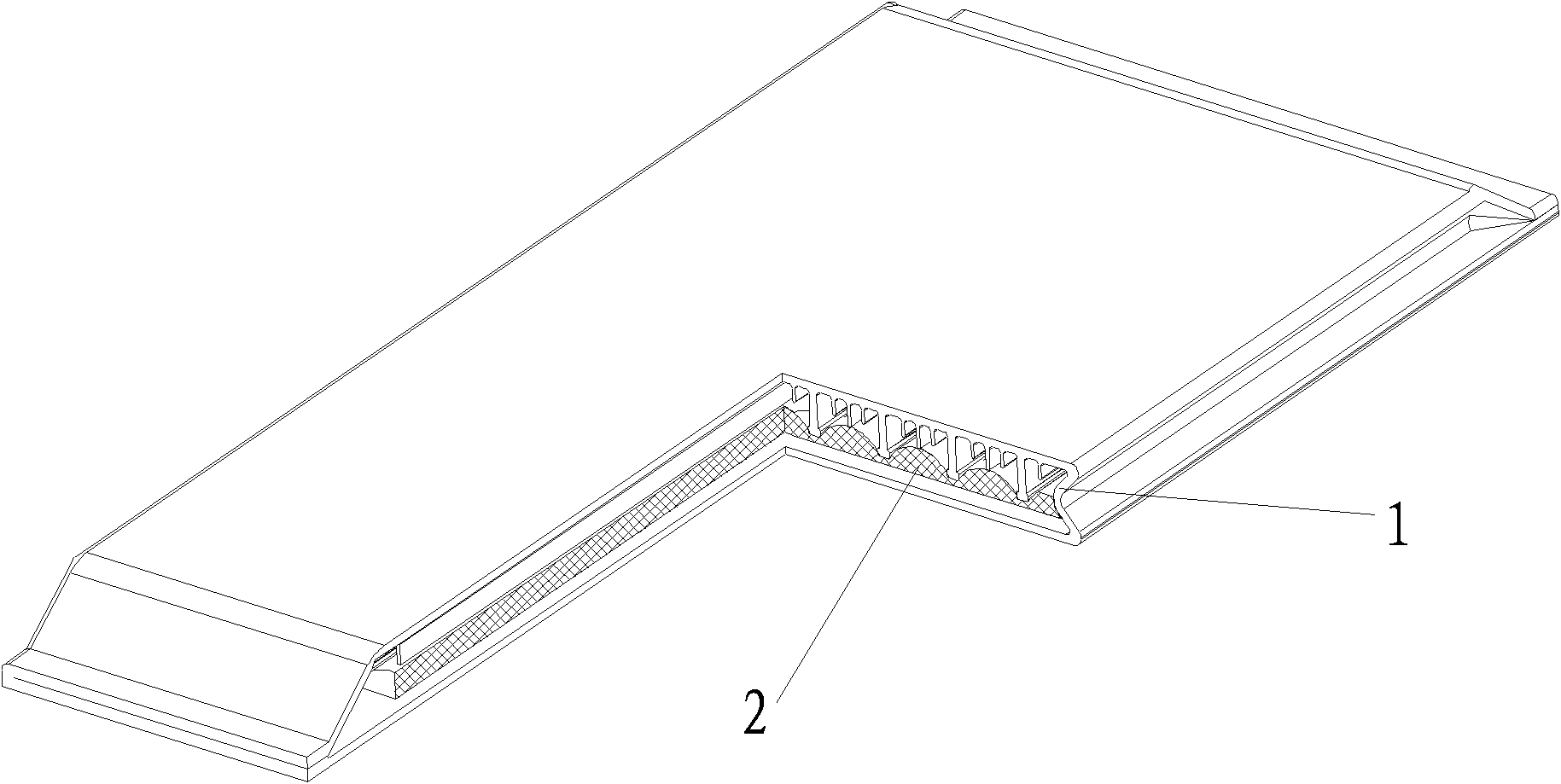

Flat plate vapor chamber and manufacturing method thereof

InactiveCN102778157AArbitrary increase in structure sizeEasy to set upSemiconductor/solid-state device detailsSolid-state devicesEngineeringLimited structures

The invention relates to a flat plate vapor chamber and a manufacturing method thereof. The flat plate vapor chamber comprises a packaging chamber, a porous capillary wick, a working medium and a vacuumizing and work medium filling interface, wherein the porous capillary wire and the working medium are positioned inside the packaging chamber; one end of the vacuumizing and work medium filling interface is communicated with the inside of the packaging chamber; and the other end of the vacuumizing and work medium filling interface is positioned outside the packaging chamber and is sealed. The manufacturing method of the flat plate vapor chamber comprises the following steps of: forming the packaging chamber by extruding or casing; forming the porous capillary wick by sintering or knitting; inserting the porous capillary wick into the packaging chamber; placing one end of the vacuumizing and work medium filling interface in the packaging chamber; extruding the packaging chamber by using a cold press die; moving away the cold press die; welding and sealing a front-rear end closing surface of the packaging chamber; vacuumizing the packaging chamber and filling a working medium; and pinching off the vacuumizing and work medium filling interface and welding and sealing the vacuumizing and work medium filling interface. According to the flat plate vapor chamber disclosed by the invention, the defects of limited structure, high manufacturing cost, low reliability, limited heat-radiating capability and the like in a traditional vapor chamber are fully overcome.

Owner:北京芯铠电子散热技术有限责任公司

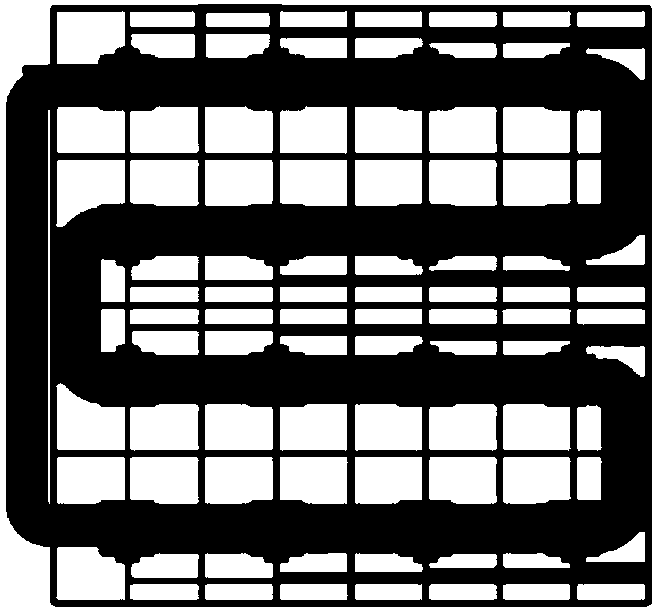

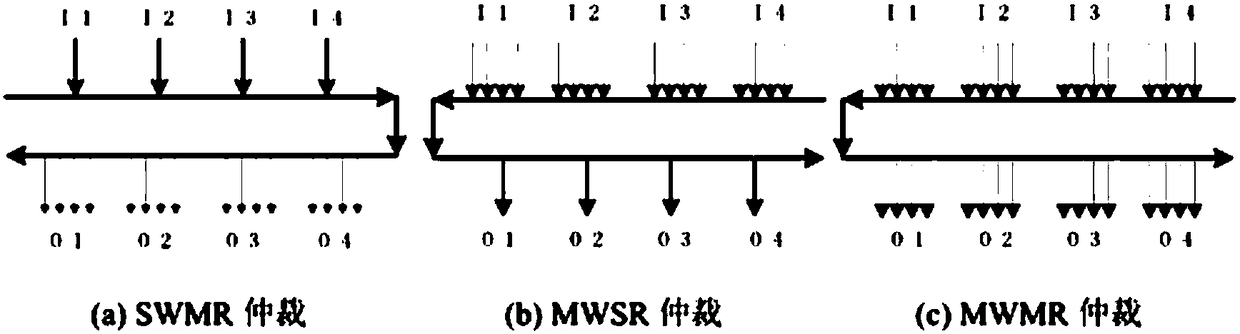

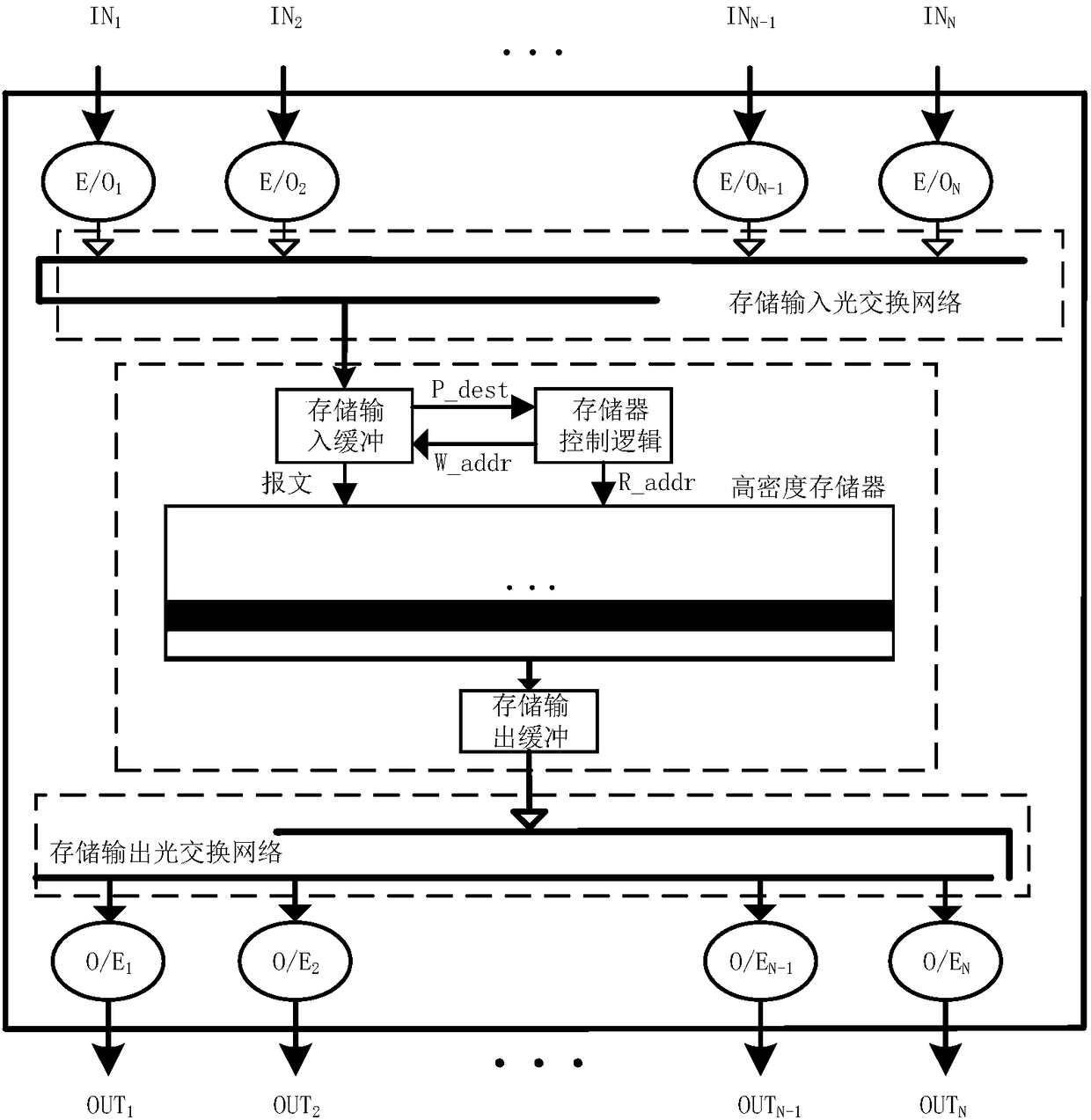

Multi-die higher-order photonic switching structure based on high-density memory

ActiveCN108111930ASolve Bandwidth BottlenecksImprove orderMultiplex system selection arrangementsHigh densityExchange network

The invention provides a multi-die higher-order photonic switching structure based on a high-density memory in order to solve the problem of limited structure of a switching chip due to the bandwidthbottleneck of the memory of the conventional photonic switching structure. The structure is formed by mutual connection of K completely same photonic switching dies based on the high-density memoriesthrough an inter-chip interconnection network and includes N input / output ports, and each photonic switching die comprises N / K input ports, N / K electro-optical conversion modules, N / K separators, a storage input photonic switching network, an optical waveguide, a storage input buffer, a memory control logic, an inter-chip interconnection input output agent module, an inter-chip input buffer, an alternative selector, the high-density memory, a storage output buffer, a storage output photonic switching network, N / K photoelectric conversion modules, and N / K output ports, wherein K, N and k are all integers, 1<=k<=K, and K<=N. According to the structure, the complexity of the switching structure and the cost of optical devices are substantially reduced, and the order of the switching structureis further extended.

Owner:NAT UNIV OF DEFENSE TECH

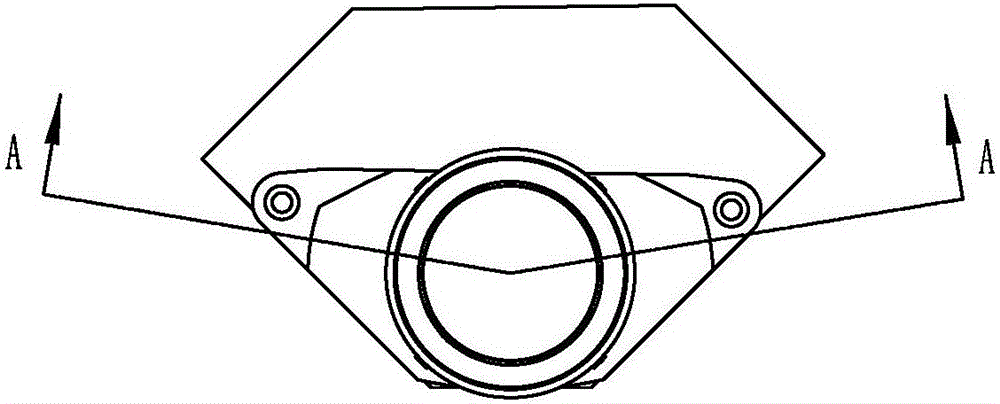

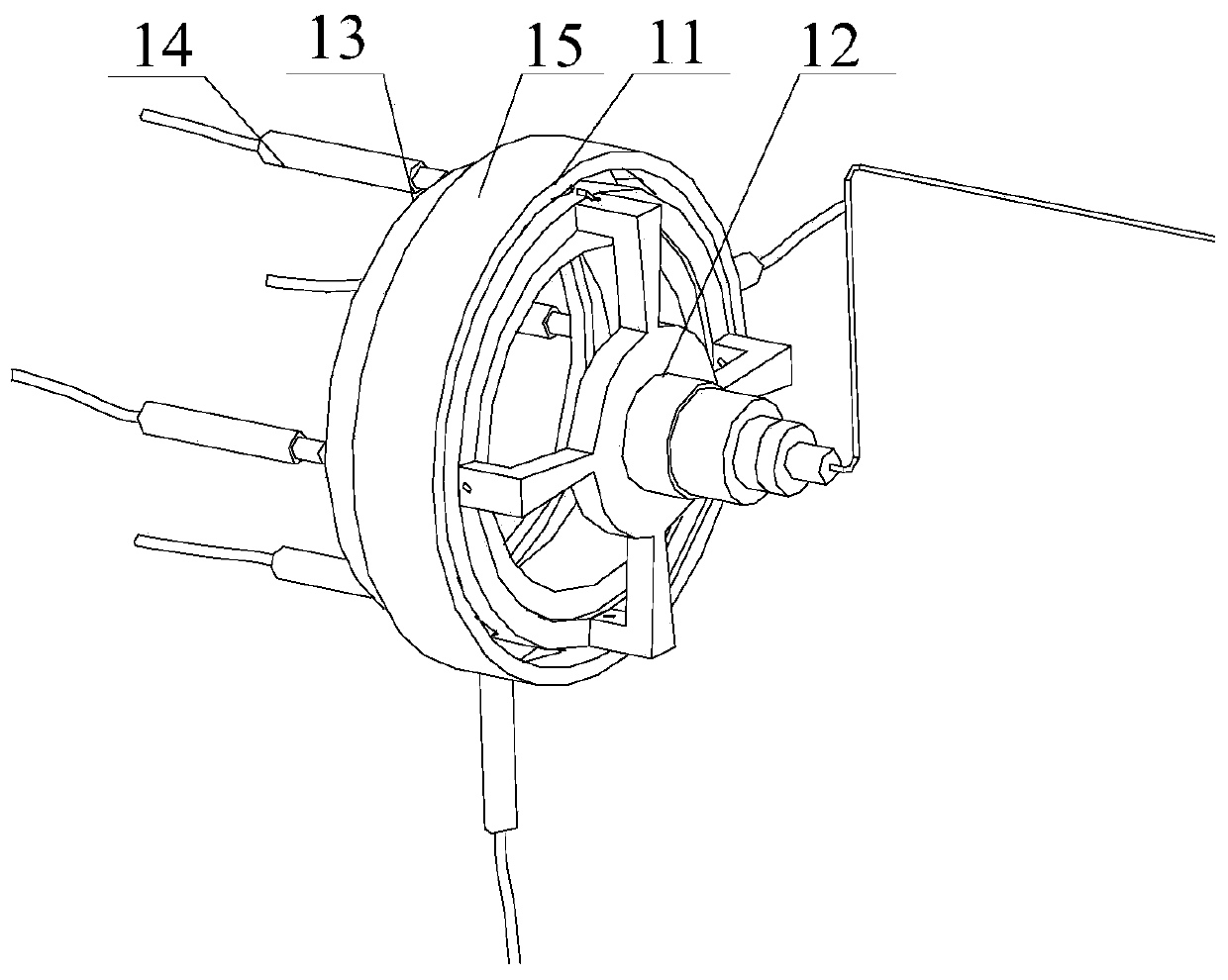

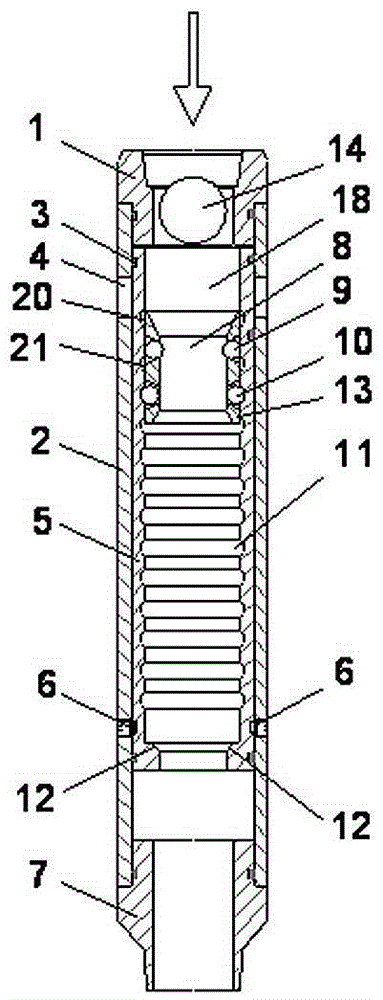

Engine magneto-rheological hydraulic mount method based on circumferential and radial flowing mode

InactiveCN104074919AIncrease the lengthLarge adjustment rangeSpringsJet propulsion mountingEngineeringAlloy

The invention discloses an engine magneto-rheological hydraulic mount method based on a circumferential and radial flowing mode. By means of the combination of a circumferential damping passageway and a radial damping passageway, the length of the damping passageways is increased in the limited structural size; the longer the damping passageways are, the larger the output damping force becomes; due to the fact that the amplitude of an engine is small, the maximum damping force can be increased by increasing the length of the damping passageways, and the adjustable range of the damping force can be widened; the width of the radial damping passageway is determined by the size of an insertion pin, and the width of the radial damping passageway can be changed by changing the size of the insertion pin; a liquid injection hole and an exhaust hole are formed in the middle of a reinforcing block, and therefore exhaust is more smooth in the liquid injection process, and liquid injection can be more convenient; a shell is made of magnetism isolation aluminum alloy material, and therefore magnetic flux leakage is weakened for a magnetic circuit when the engine works.

Owner:CHONGQING UNIV

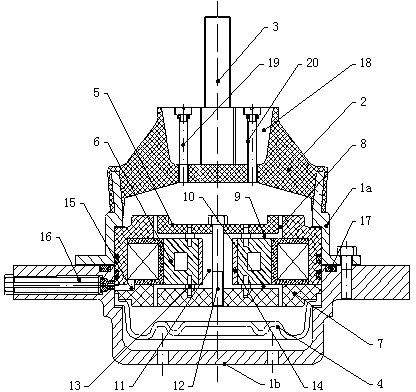

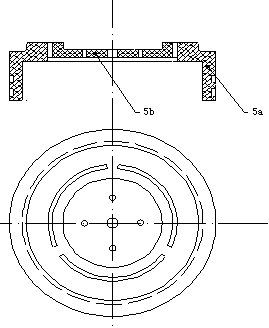

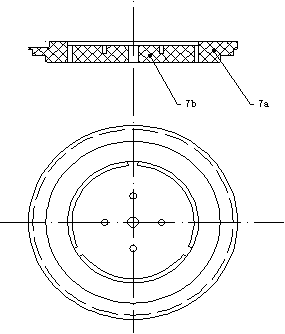

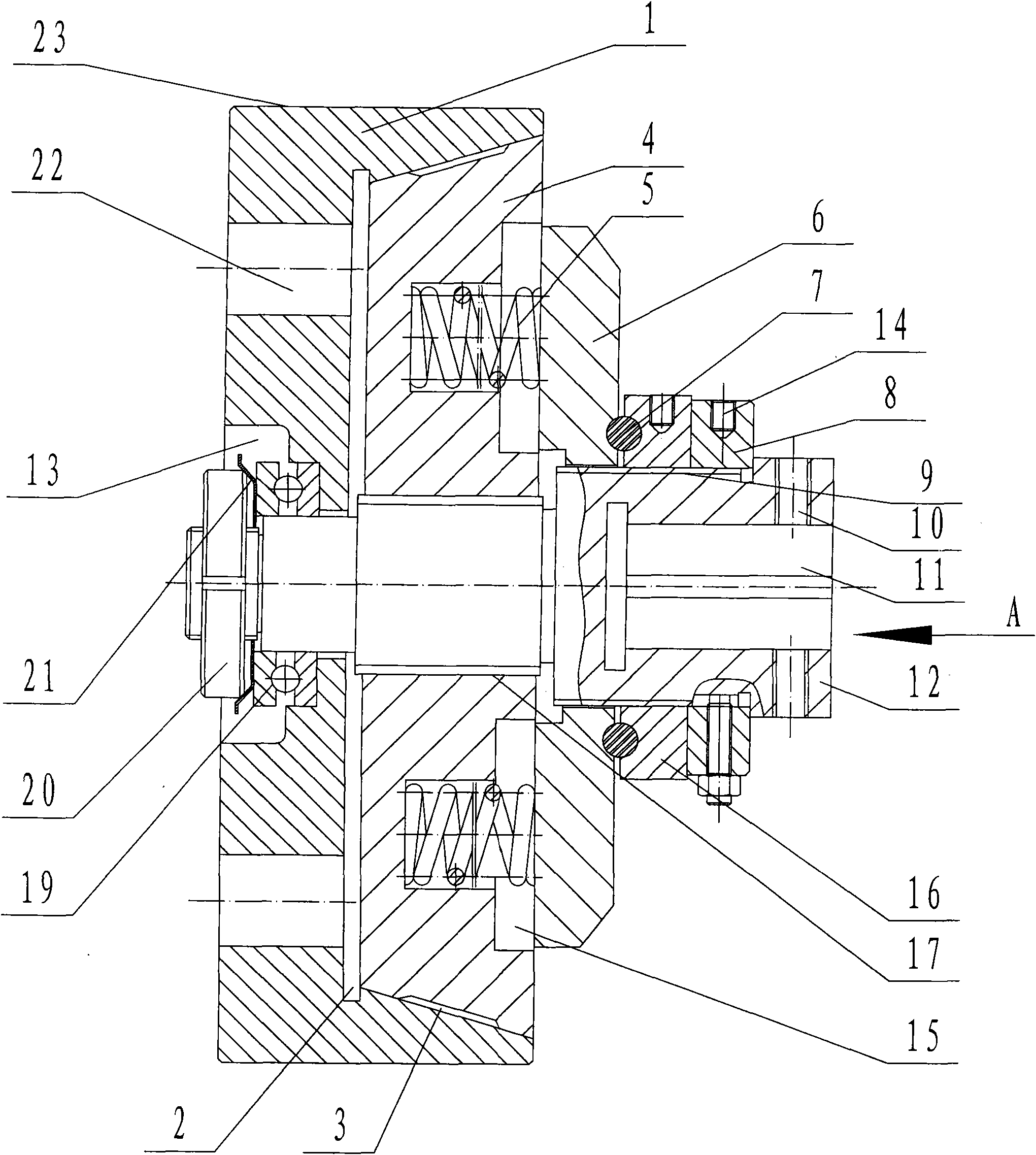

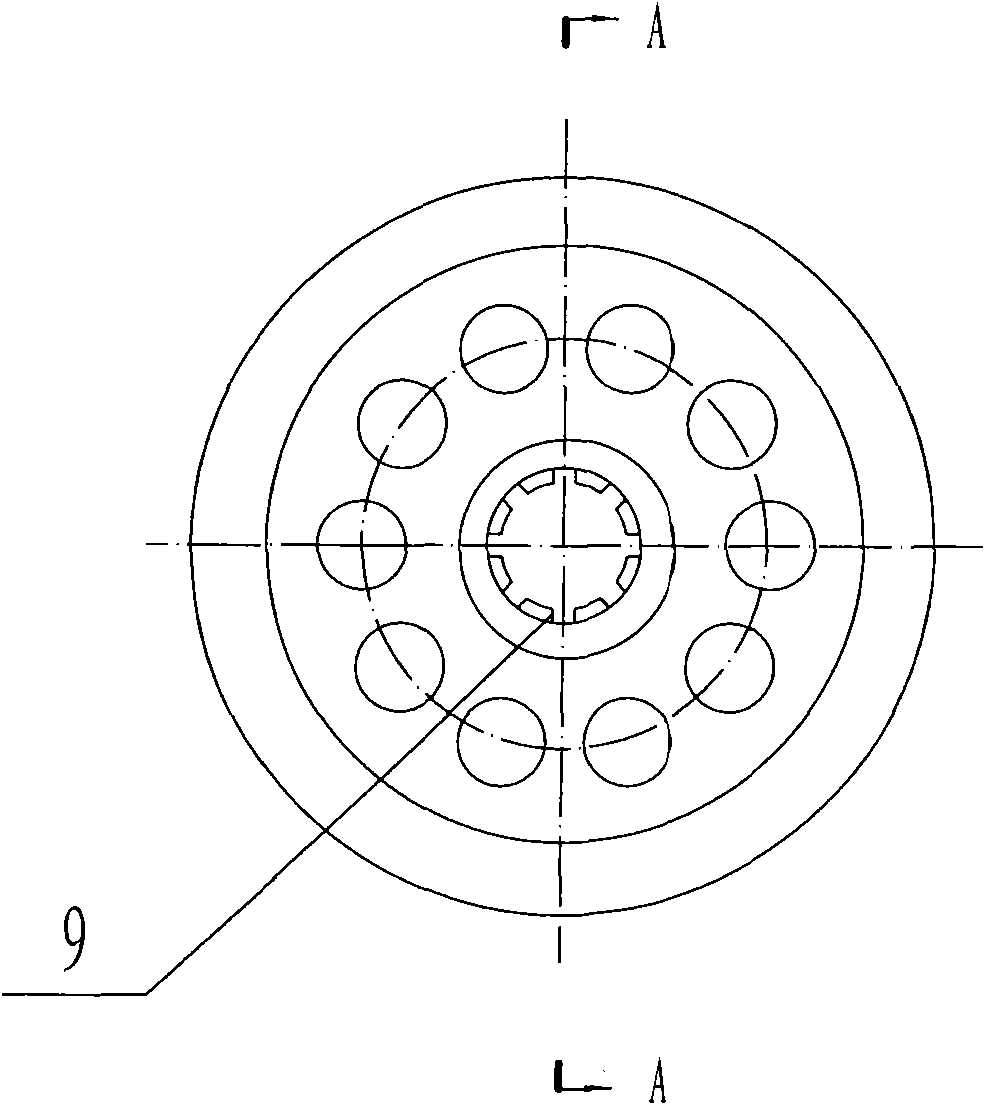

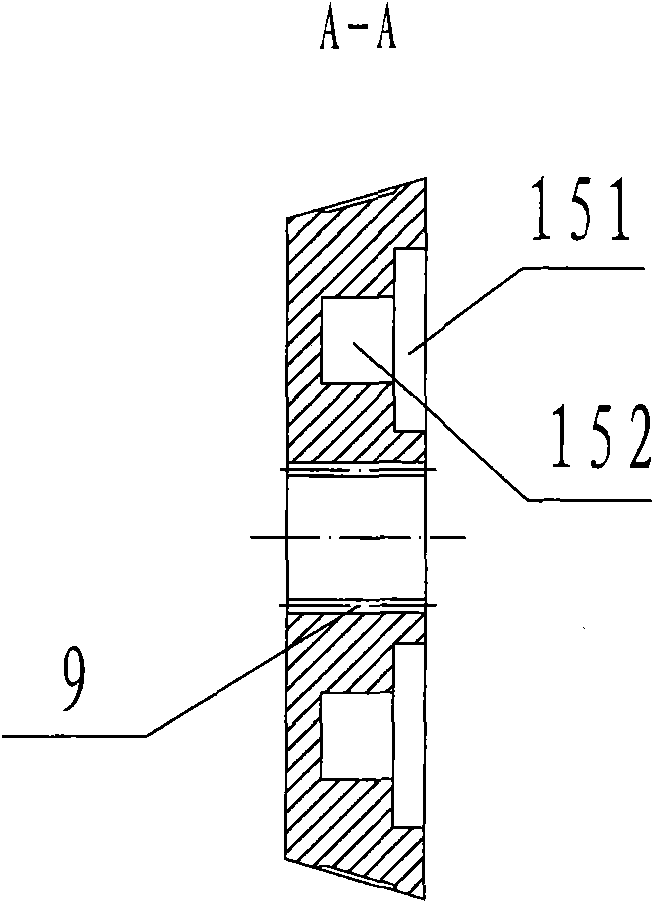

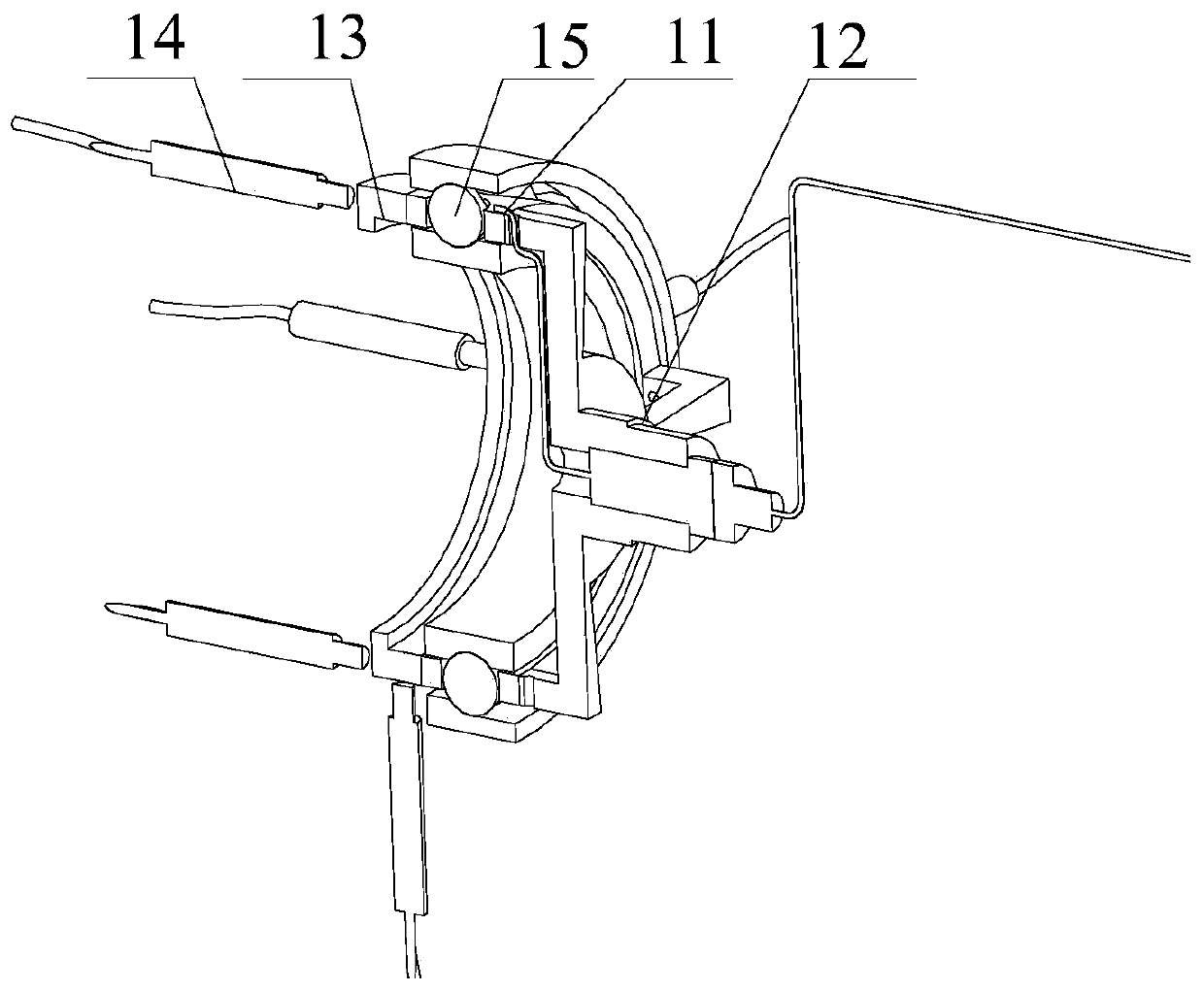

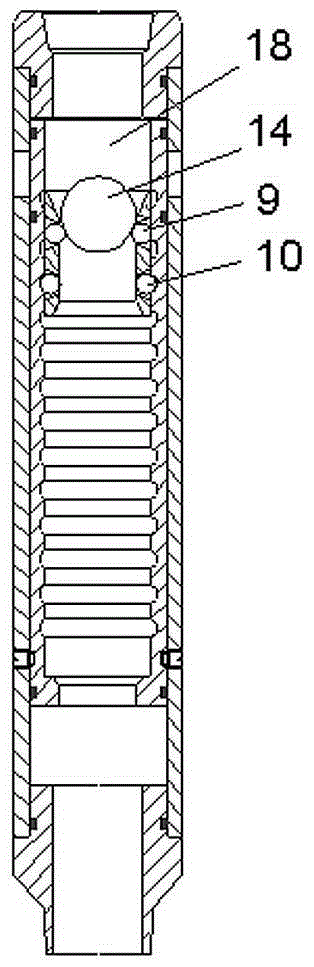

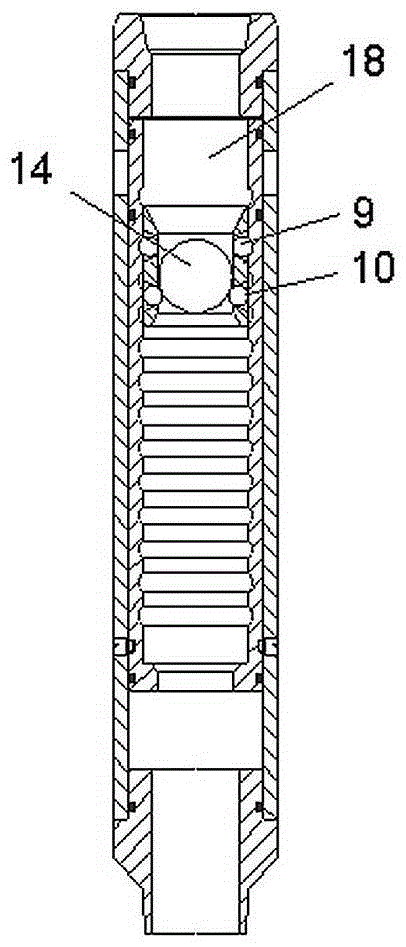

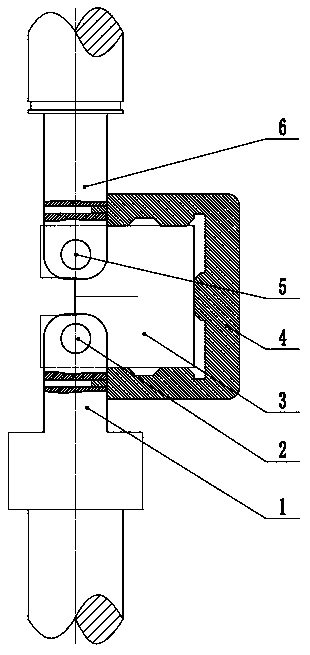

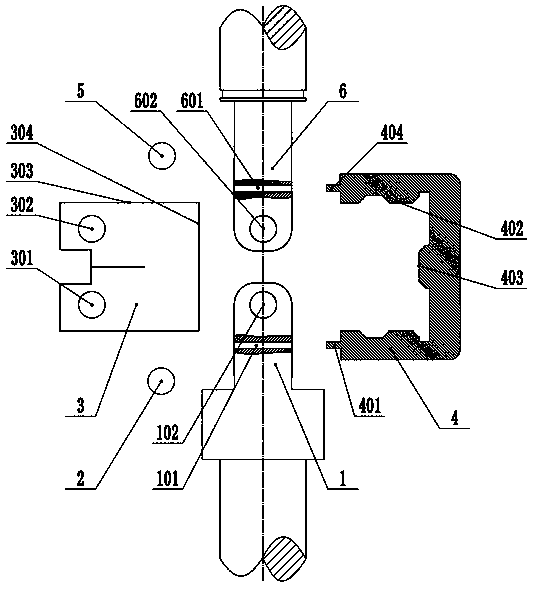

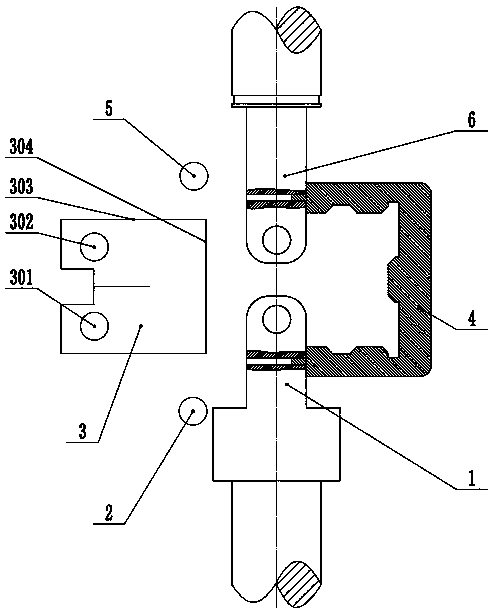

Torque-limited structure

The invention relates to a torque-limited structure, which comprises an external cup (1) with an internal conical face and an internal cup (4) which is matched with the external cup (1) and provided with an external conical face, wherein one end of the internal cup (4) is provided with a spring groove (15) with an annular structure; a spring (5) is positioned in the spring groove (15); a pressure plate ring (6) is positioned on the outer side of the inside of the spring groove (15); and an internal central spindle (12) passes through the centers of the external cup (1), the internal cup (4) and the pressure plate ring (6). The torque-limited structure can be combined with various conventional couplers to form various overload protection modes with torque limitation and is widely applied to various kinds of mechanical equipment.

Owner:WUHAN ZHENGTONG TRANSMISSION TECH

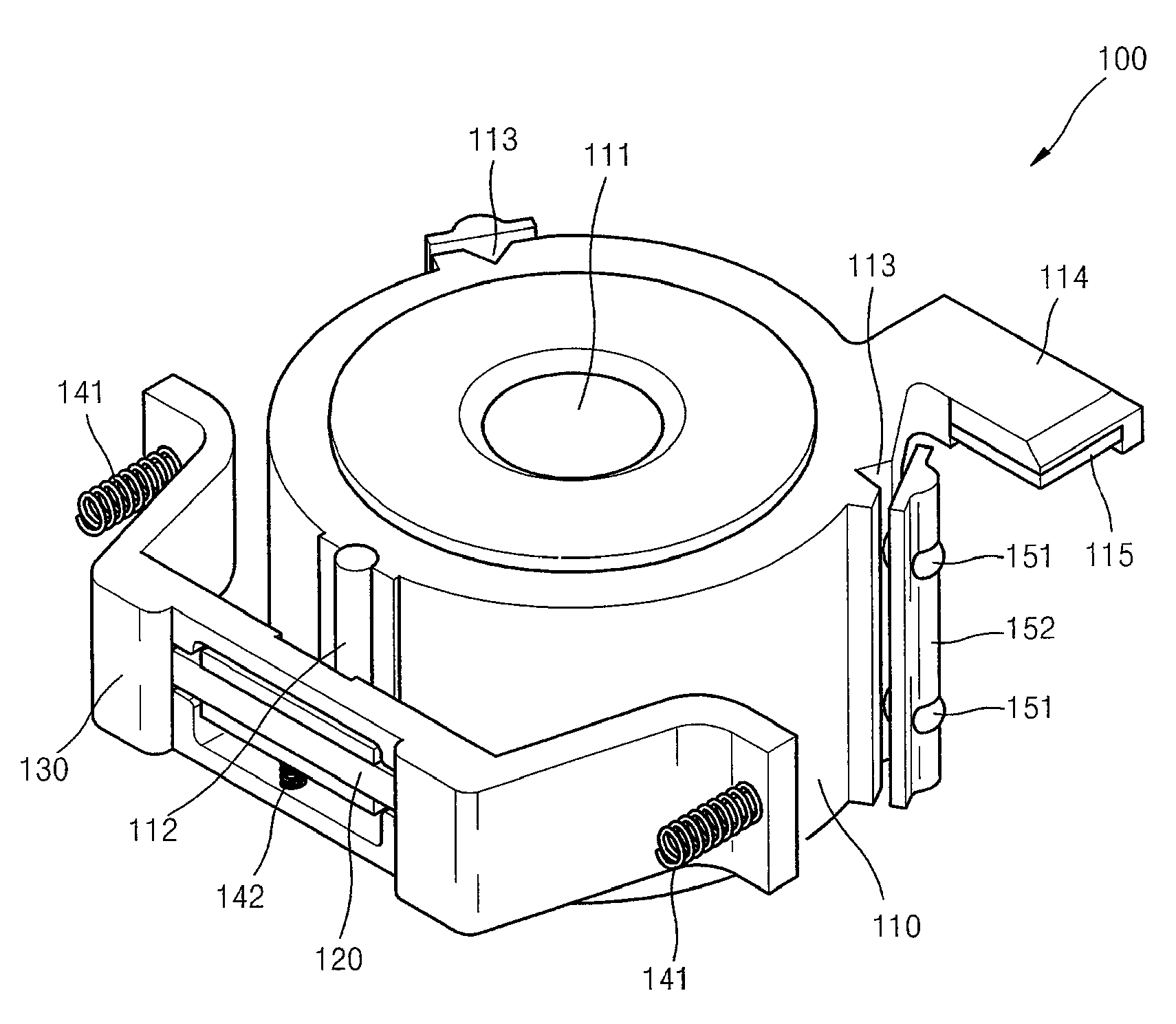

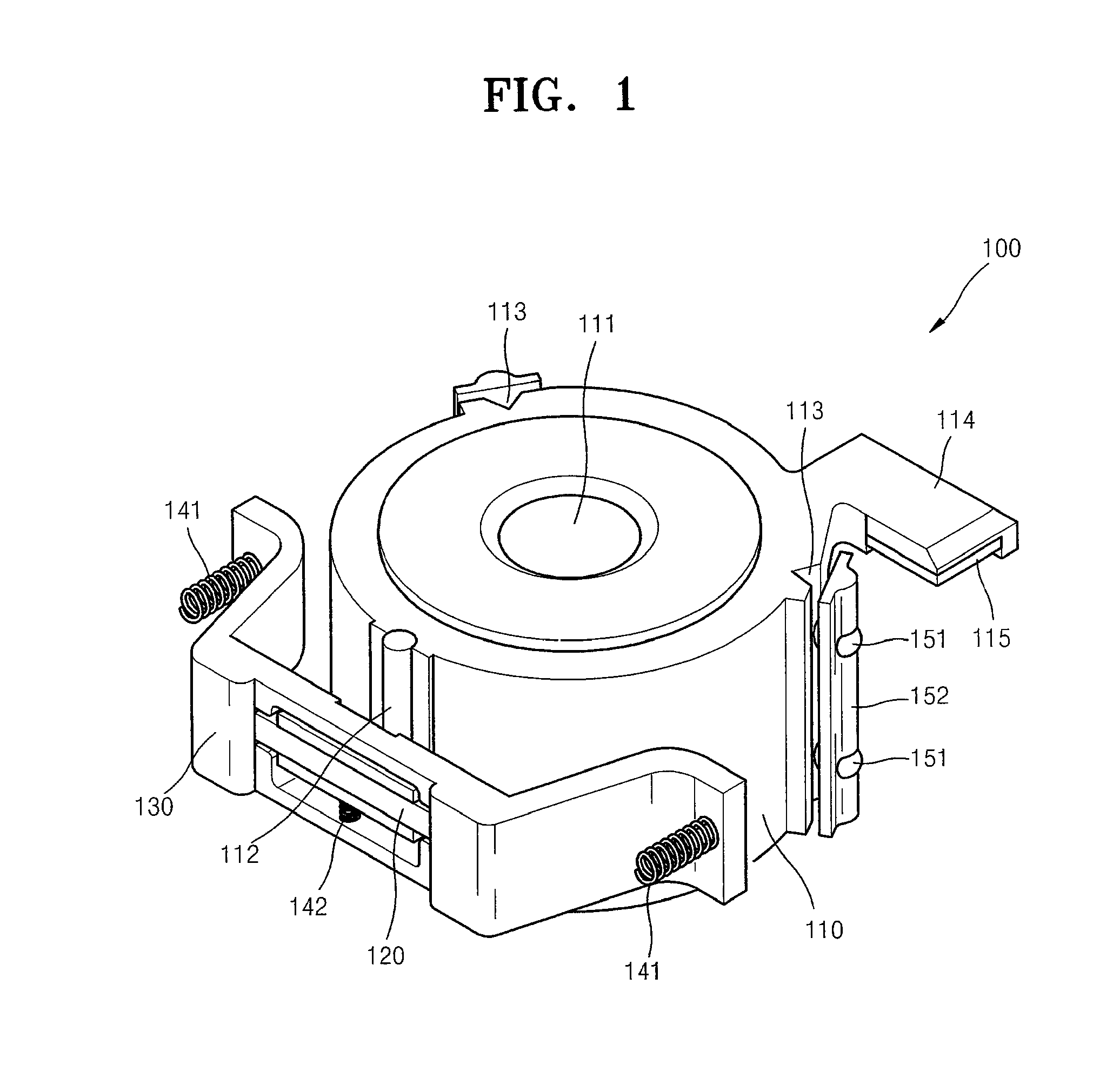

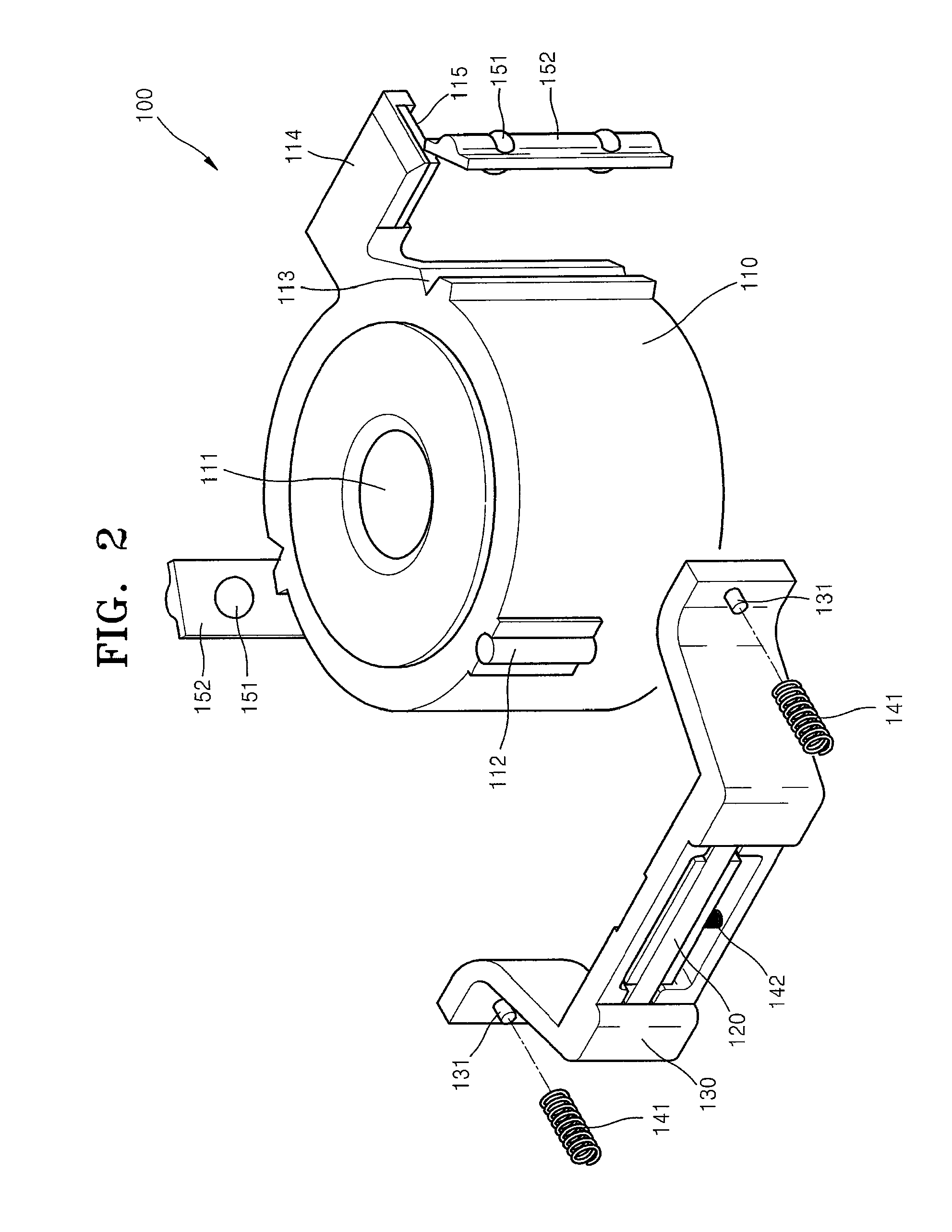

Lens driving unit and camera module comprising the same

ActiveUS8049971B2Piezoelectric/electrostriction/magnetostriction machinesMountingsLinear motionCamera lens

Provided are a lens driving unit that generates a precise linear motion in a spatially limited structure by using a bending vibration piezoelectric motor having a new structure, and a camera module comprising the lens driving unit. The lens driving unit includes: a lens carrier supporting a lens and comprising a guide axis exposed at least partially to the outside and extending in a direction substantially perpendicular to the lens; and a piezoelectric driving unit having a center portion contacting the guide axis according to a bending motion of a piezoelectric element and moving the lens carrier in a direction in which the guide axis extends.

Owner:HANWHA TECHWIN CO LTD

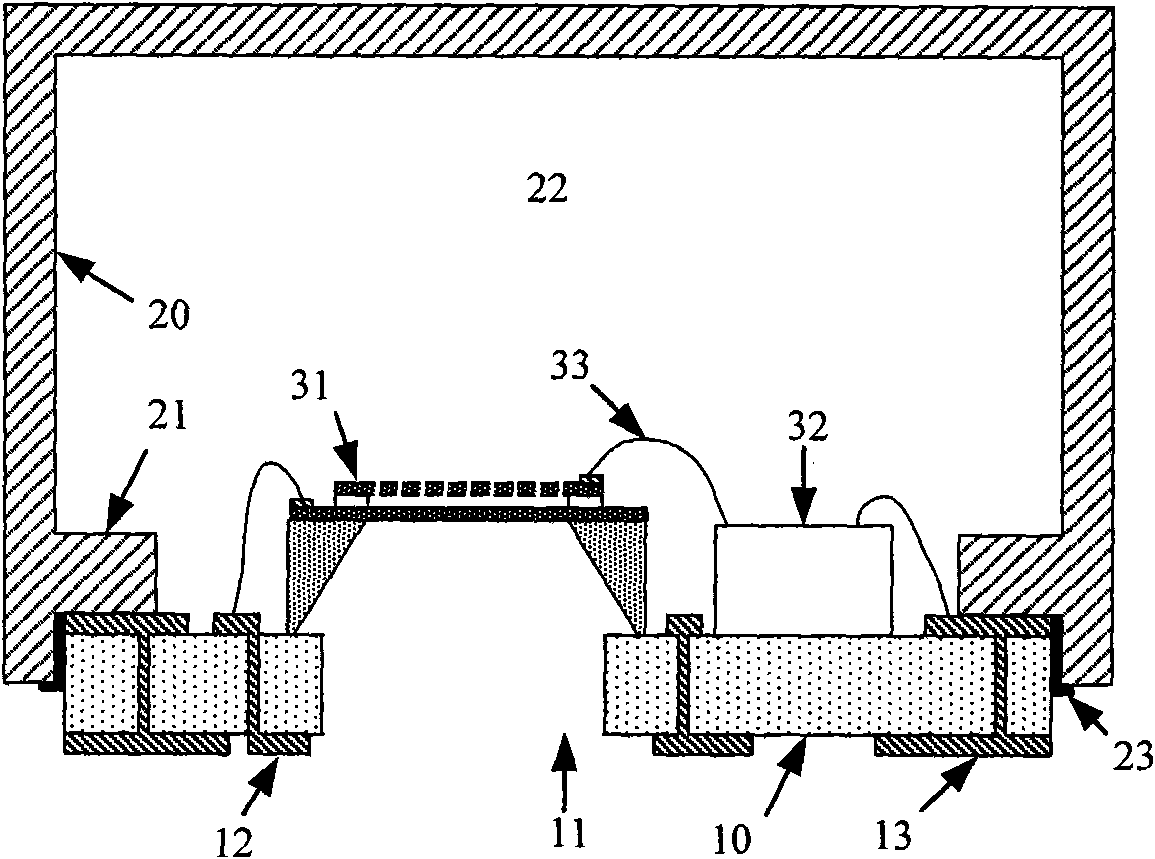

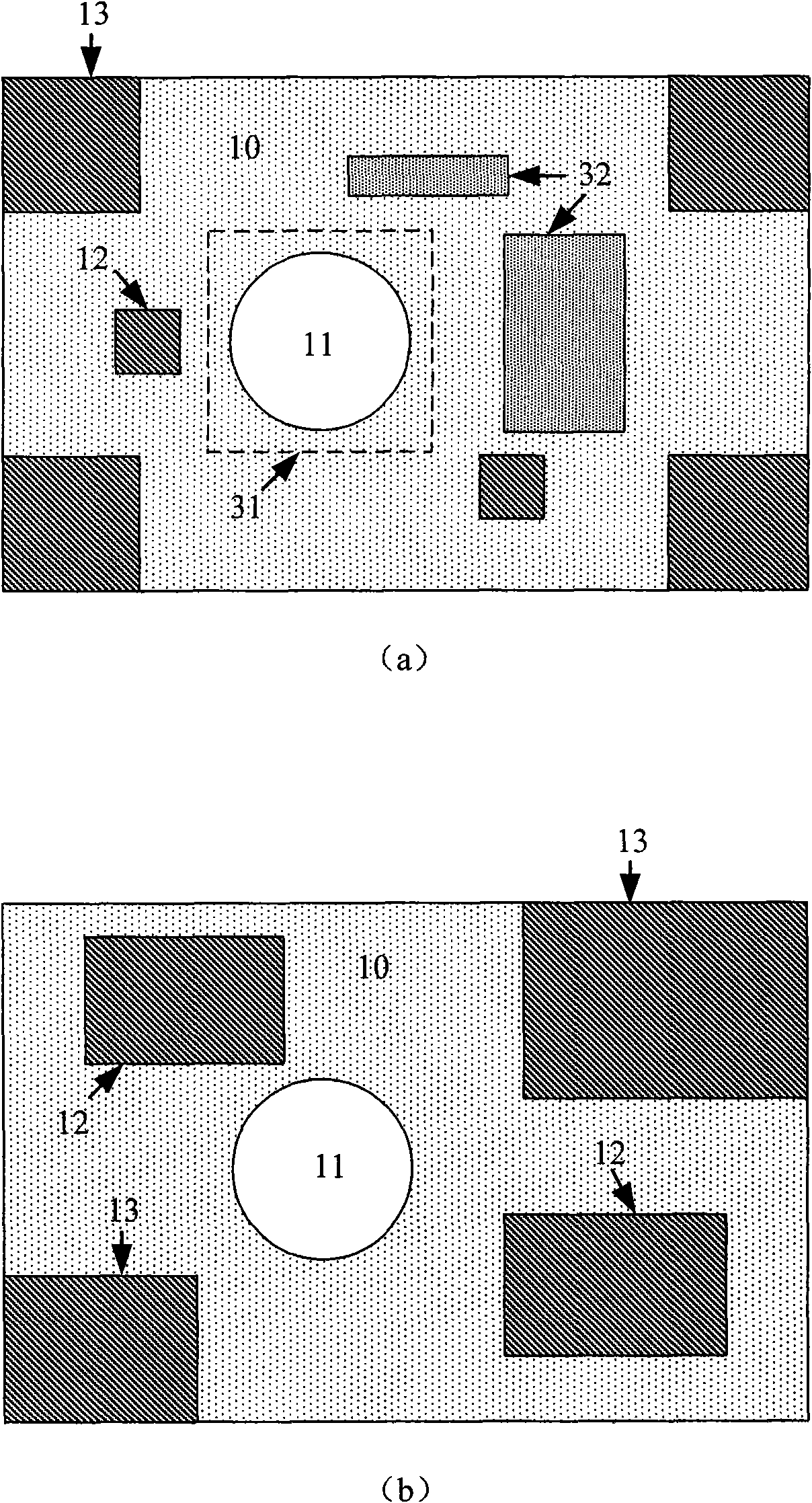

Packaging structure for microphone with embedded substrate

InactiveCN101651916AReduce package sizeLow costSolid-state devicesElectrostatic transducer microphonesLimited structuresHeight difference

The invention relates to a packaging structure for a microphone with an embedded substrate, comprising a metal top cover, a substrate, a microphone chip, a circuit chip and a passive element. The upper surface of the substrate is used for carrying and fixing the microphone chip, the circuit chip and the passive element; grounding electrodes communicated electrically are arranged on the upper and lower surfaces of the substrate and used for being connected with the metal top cover to ground; an acoustic cavity of the microphone is formed hermetically between the inner surface of the metal top cover and the substrate. A limit structure is arranged on the metal top cover. The plane limited by the limit structure is higher than and parallel to the plane on which the bottom edge of the metal top cover is located, the plane is used for embedding the substrate to the metal top cover horizontally in a direction where the chip carrying surface faces upwards, the embedding depth thereof is adjusted via a height difference of the bottom edge of the limited structure and the bottom edge of the metal top cover, and the height difference is not greater than thickness of the substrate. The invention has a simple structure and high space utilization rate.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Optical measurement instrument and measurement method using the same

InactiveCN106840127ARealize self-regulationReduce labor intensityReference line/planes/sectorsBeam expanderMeasuring instrument

The invention relates to an instrument for optical measurement and its measurement method. The measuring instrument includes a laser pointing beam expander, a host, a support and a base. There is a laser pointing beam expander and a longitudinal translation mechanism of the host, and a laser pointing beam expander, a host lifting adjustment mechanism and a horizontal rotation positioning mechanism are arranged between the support and the base; the laser pointing beam expander and the host longitudinal translation mechanism include a micrometer, The laser pointing beam expander and the host horizontal rotation positioning mechanism include a horizontal rotating plate, a rotating rod, a limit block and a horizontal support plate, a support structure and a limit structure, and the laser pointing beam expander and the host lifting adjustment mechanism include a lifting adjustment column I and Ⅱ; The measurement method includes the laser pointing beam expander and the preparatory steps of adjusting the height, longitudinal position and horizontal direction of the host. The invention integrates flexibility, convenience and practicability, thereby reducing labor intensity of workers and improving construction efficiency.

Owner:王玉振

Mechanical drive two-way self-locking device

InactiveCN106081971ASelf-lockingRealize rotation self-lockingWinding mechanismsDrive shaftEngineering

The invention discloses a mechanical drive two-way self-locking device, which comprises a support bracket body, a drive shaft, a ratchet wheel and a pawl arranged on the support bracket body. The drive shaft is connected with the support bracket body through a seat cover; the ratchet wheel is movably connected with the drive shaft; and a limited structure and a friction assembly are arranged on the drive shaft. The friction assembly comprises operation threaded sleeves, compression nuts and friction damping parts. The mechanical drive two-way self-locking device provided by the invention adopts a ratchet wheel-friction self-locking structure, so that not only can the favorable anticlockwise self-locking be ensured, but also the clockwise rotation self-locking can be realized, the anticlockwise rotation operation can be applied under the state of anticlockwise self-locking, the rotation at any direction and the self-locking and unlocking at any position can be realized only through the operation control of an operation mechanism, special unlocking operation is not needed, and the operation is random, convenient and fast.

Owner:HENAN POLYTECHNIC INST

Nondestructive tracking and evaluation method for quality of antenna housing made of composite material

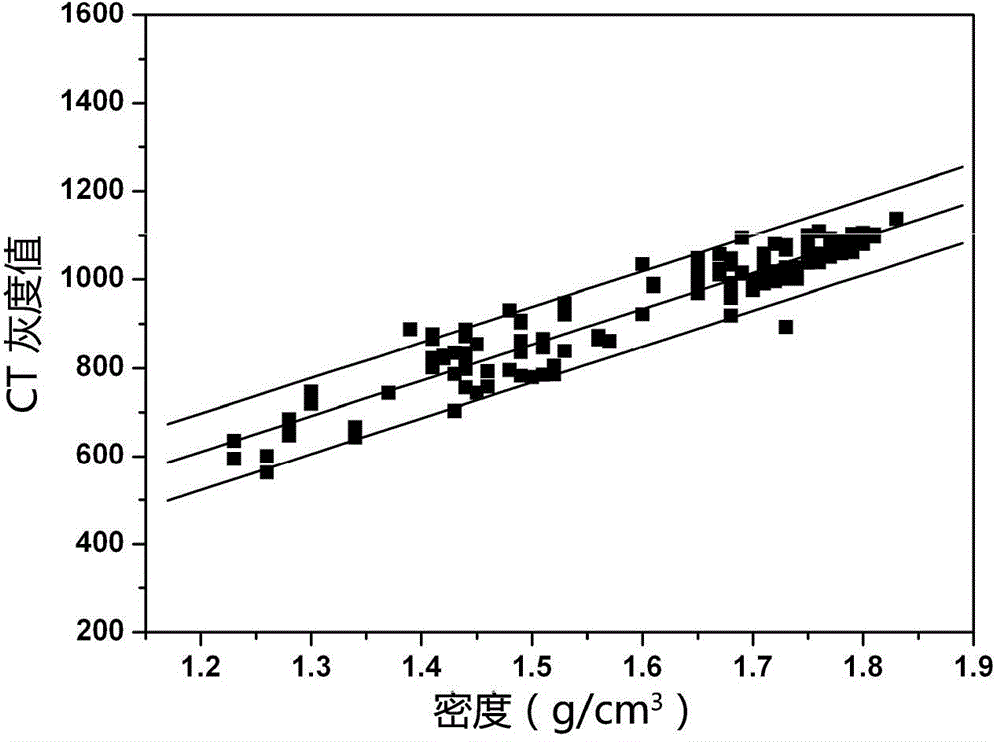

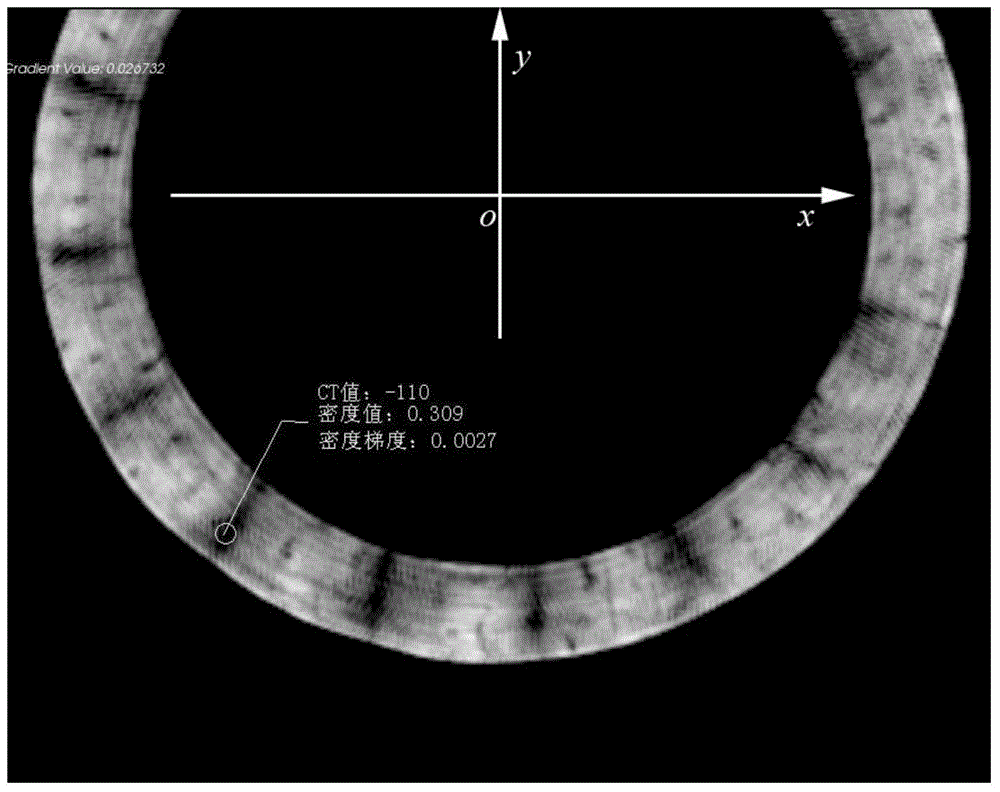

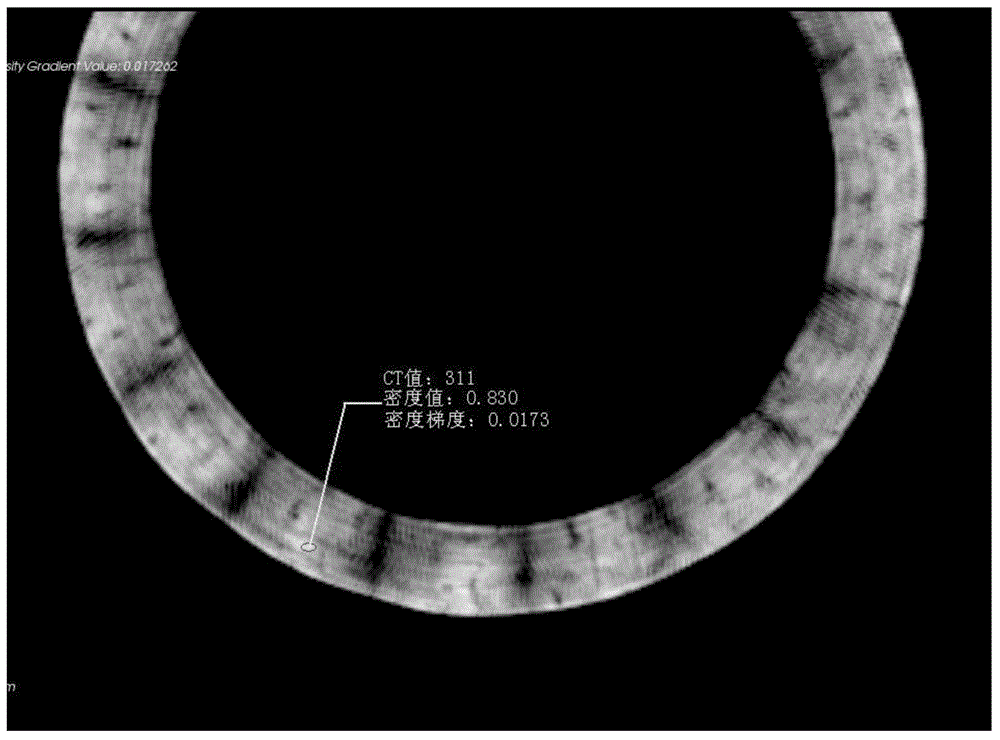

ActiveCN104316546AAccurate quantitative analysisQualitatively accurateMaterial analysis by transmitting radiationDensity distributionQuality control

The invention relates to a nondestructive tracking and evaluation method for the quality of an antenna housing made of a composite material. In the method, a CT analysis technology is taken as the basis, a function relationship between the density of a quartz fiber reinforced silicon-dioxide-based composite material limited structure unit series and a CT gray value is established, the density distribution and the defect location of the antenna housing can be represented by utilizing the CT test result of the antenna housing in practical detection, and the accurate quantitative analysis can be carried out on defects such as holes in antenna housing components, local serious low-density areas, and density gradient caused by uneven density of fabrics and a compound technology. The method has the great engineering significance for carrying out accurate locating, nature-determining and analyzing on quality defects insides the components of the large-size antenna housing, and provides the important means for on-line nondestructive testing and quality control of the antenna housing.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

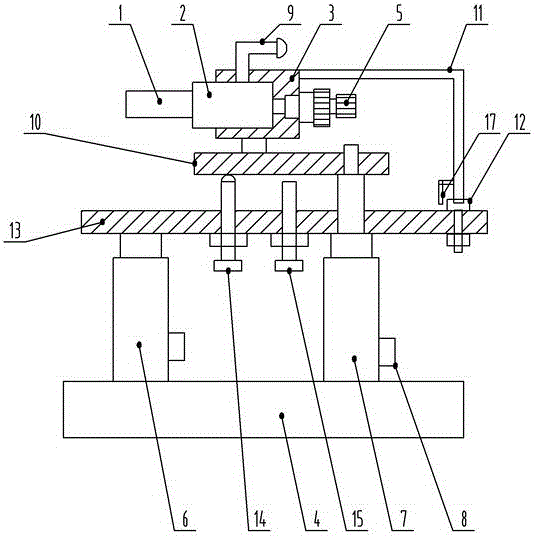

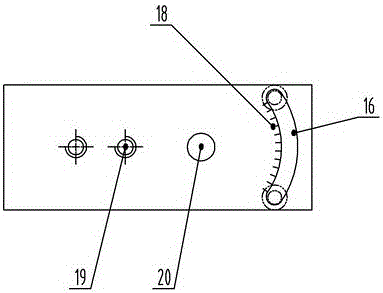

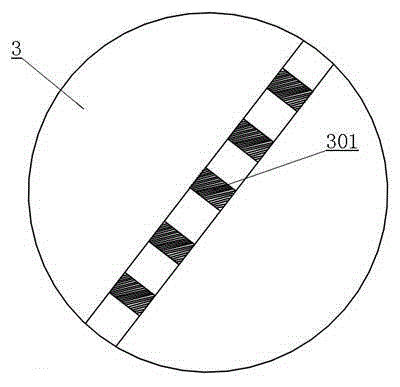

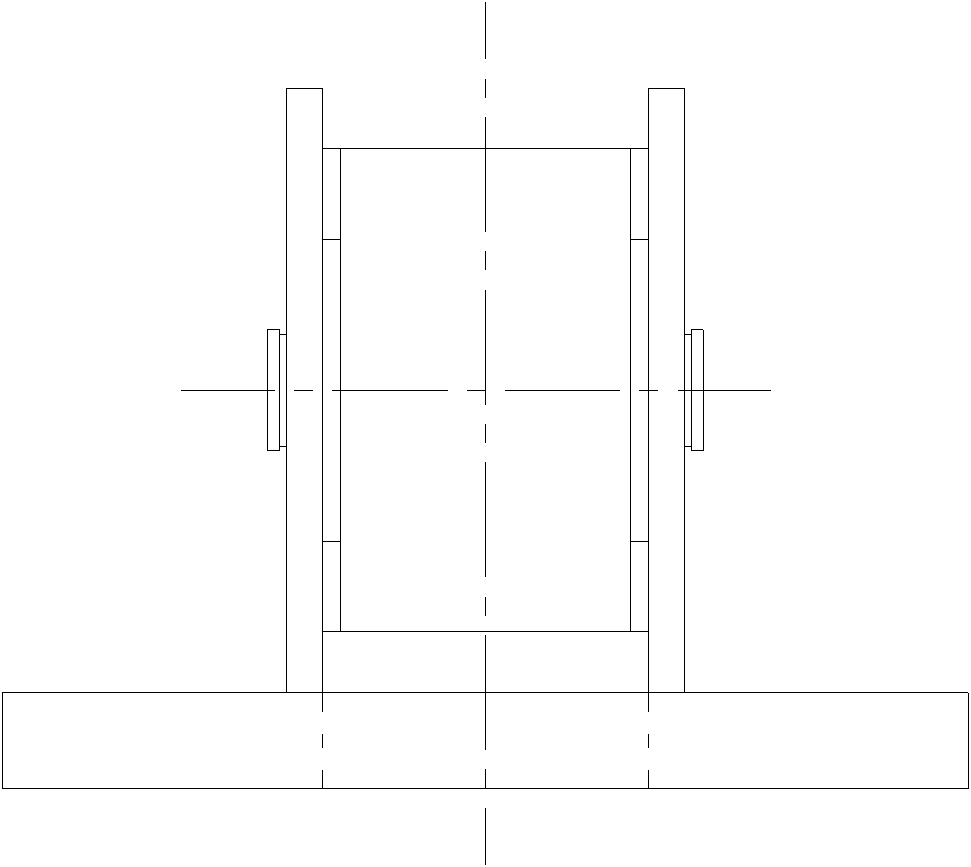

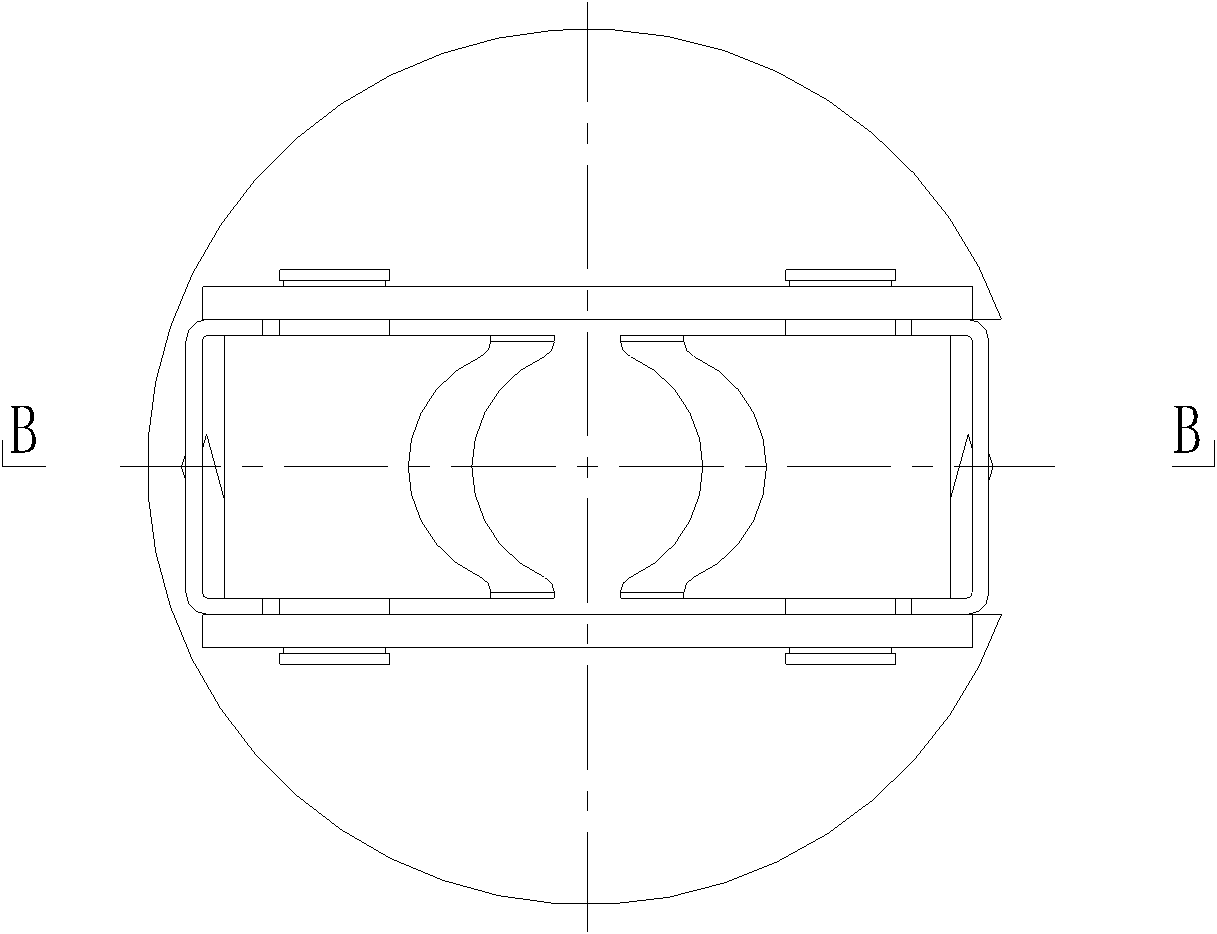

Multi-physical field dynamic parameter test device for rolling bearing cage

ActiveCN109781408ALittle additional impactMore than one line highMachine bearings testingGratingPhysical field

The invention belongs to the technical field of rolling bearing test, and particularly relates to a multi-physical field dynamic parameter test device for a rolling bearing cage. The device comprisesa rolling bearing cage dynamic parameter test device, a sensor test system, a driving device, a radial loading device, an axial loading device and a bearing box, and the experimental test of the rolling bearing cage under a certain complex load and a rotation speed can be realized. The rolling bearing cage dynamic parameter test device comprises a fiber grating sensor, a fiber grating signal transmission device, a test and compensation ring, an eddy current sensor, and a to-be-tested bearing. Multi-test point distributed synchronous test of strain and temperature of the rolling bearing cage under the condition of limited structure space can be realized, and the device is used for studying the relationship among multiple degrees of freedom, multi-point strain and temperature; by adopting the fiber grating sensor, one-line multi-point, high-sensitivity and small-size advantages are achieved; and by adopting a smooth ring and a special transmission bracket, sensor signal transmission is realized, and the impact on the cage test result can be reduced.

Owner:SHANDONG KAIMEIRUI BEARING TECH CO LTD +1

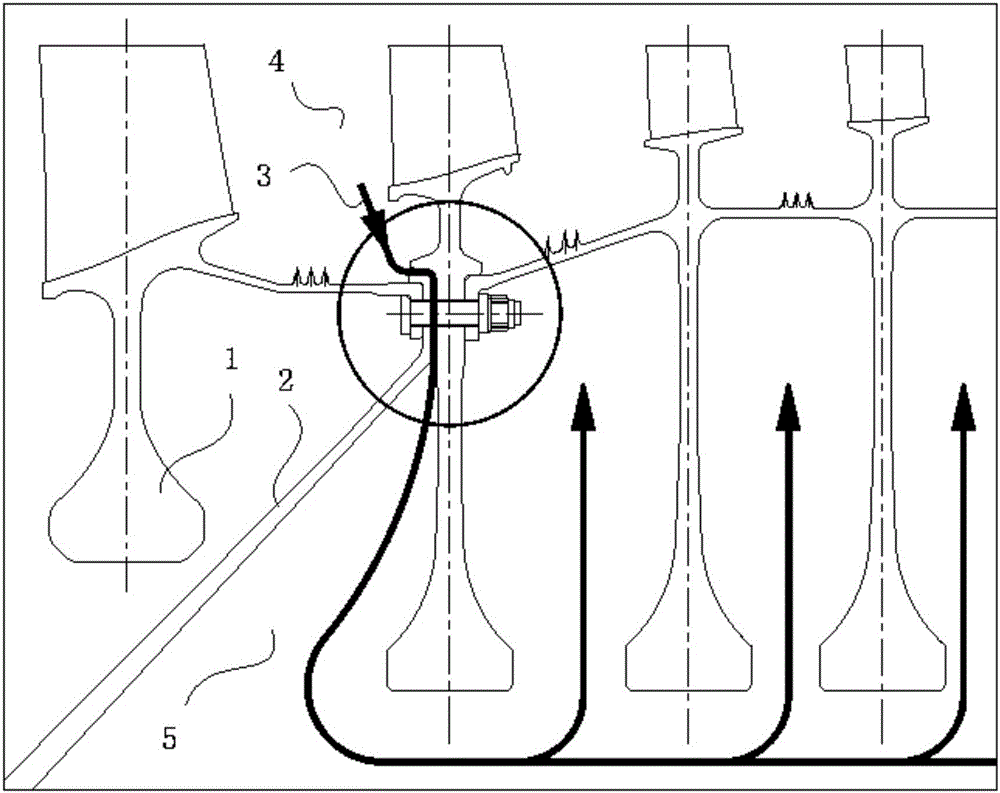

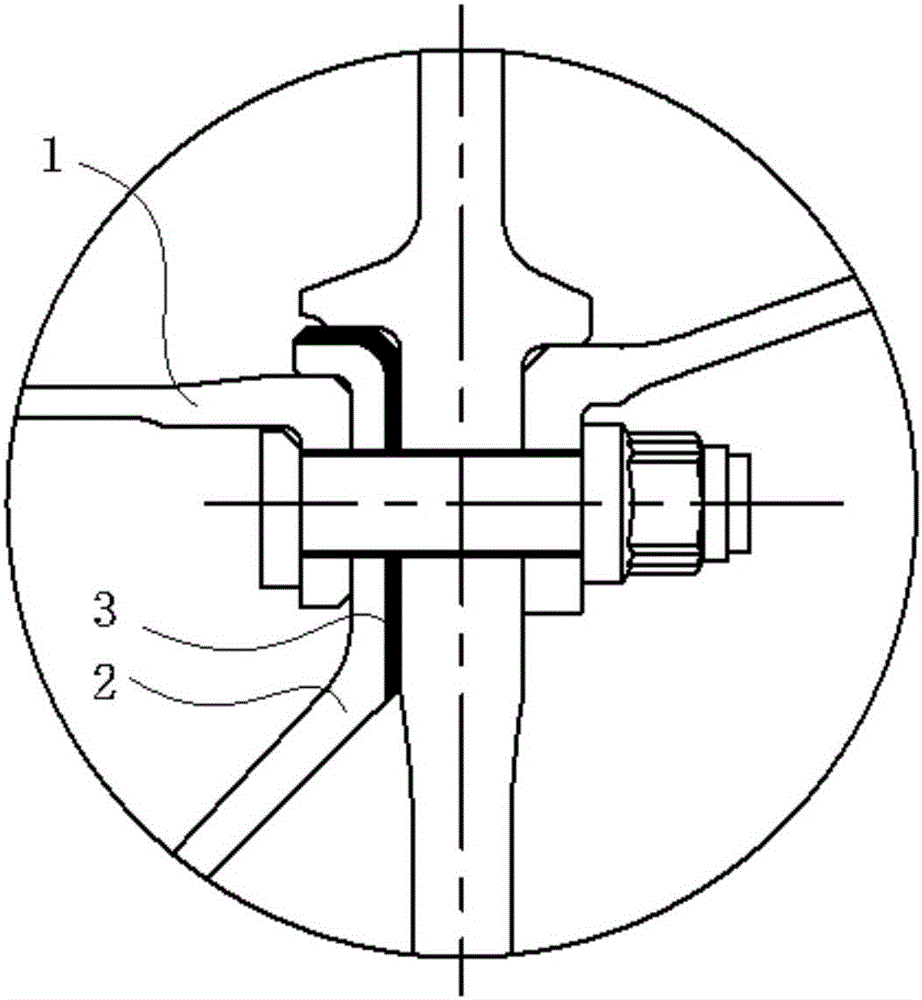

Air entraining structure used for inner rotor cavity of compressor

InactiveCN106194828AReduce additional stressReduce temperature gradientPump componentsPumpsEngineeringLimited structures

The invention relates to an air entraining structure used for an inner rotor cavity of a compressor. Multiple air entraining grooves are formed in the rotor installation edge of the compressor. Air entraining air flow communicates with the rotor inner cavity and an outer rotor cavity through the air entraining grooves. A compressor rotor, the rotor installation edge and a next level of compressor rotor are fixedly connected through a connecting piece. According to the air entraining structure used for the inner rotor cavity of the compressor, the air entraining air flow is entrained into the inner rotor cavity for heating a post level of inner rotor cavity of the compressor, the temperature gradient of a rotor disc is reduced, and therefore rotor additional stress brought by the temperature gradient is reduced; and in a limited structural space, safe and reliable connection of the rotor is not affected, air entraining of the inner rotor cavity is achieved while no extra structural part is arranged, the rotor additional stress, caused by the temperature gradient, on the rotor disc is reduced, the structure is safe, and reliability is high.

Owner:AECC SHENYANG ENGINE RES INST

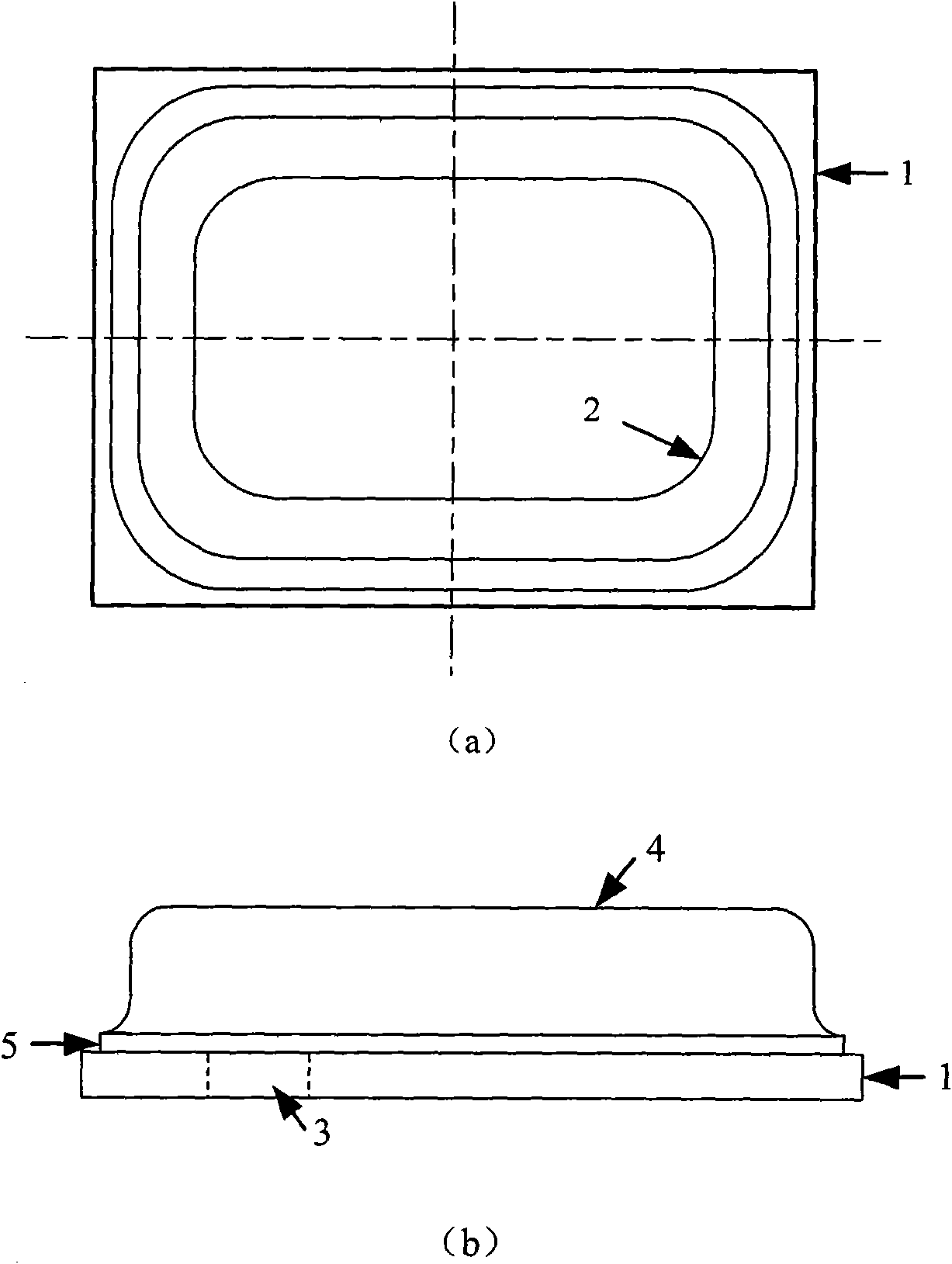

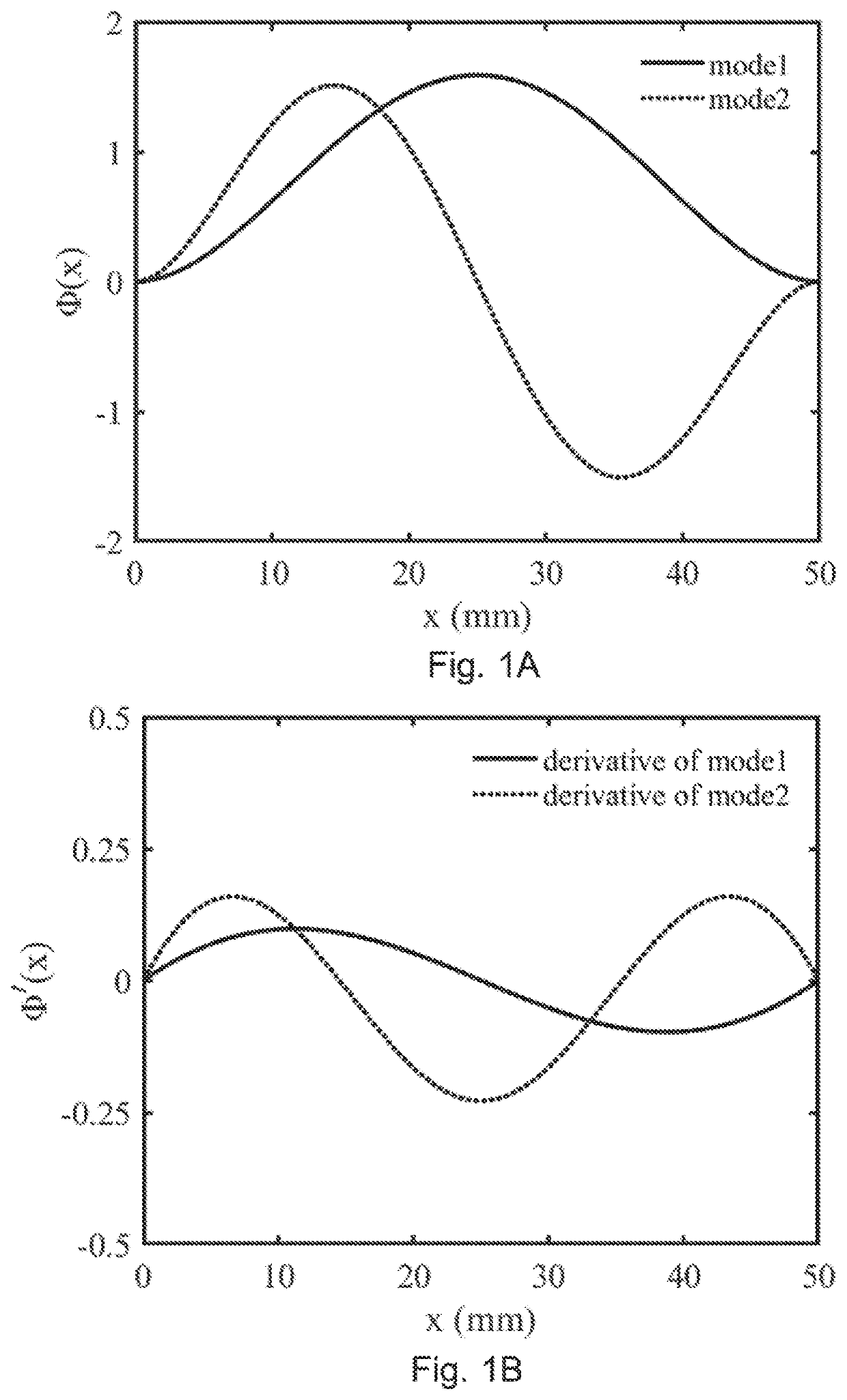

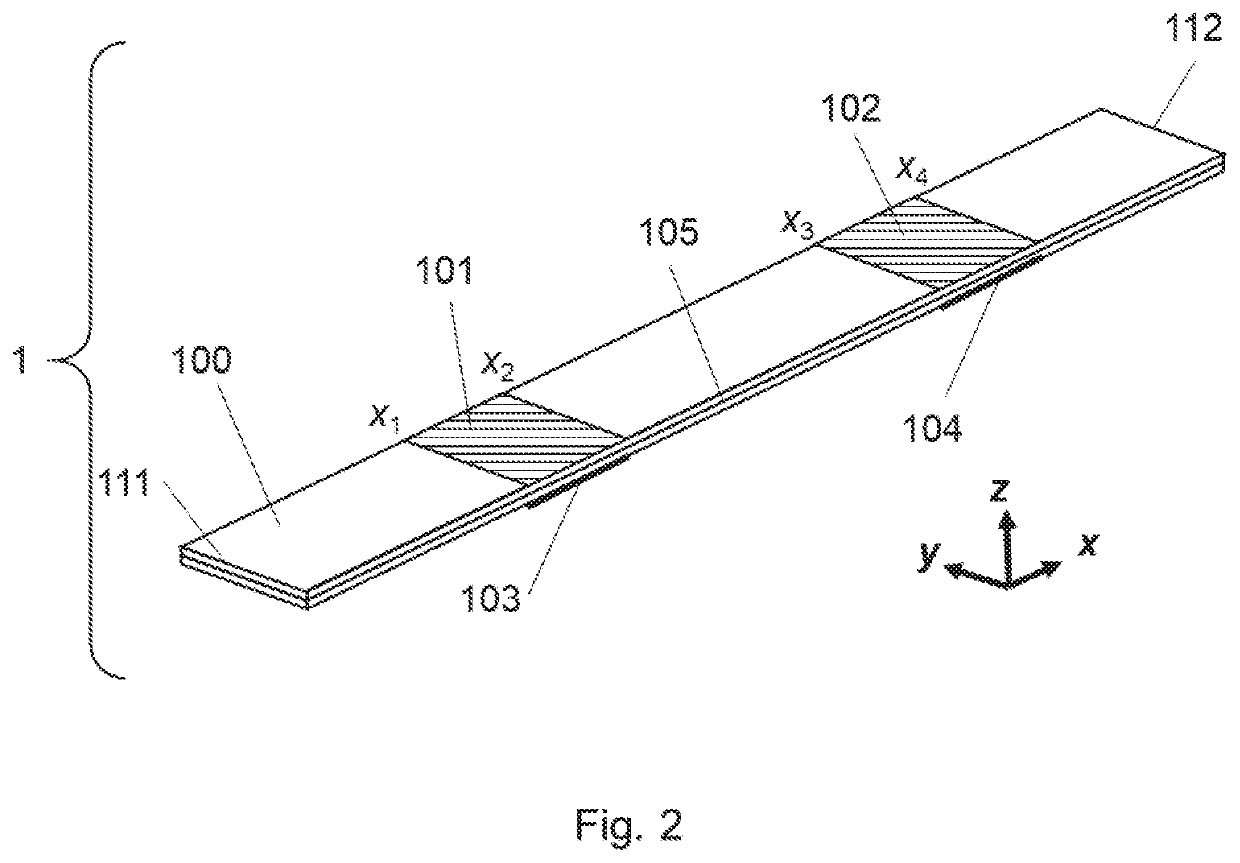

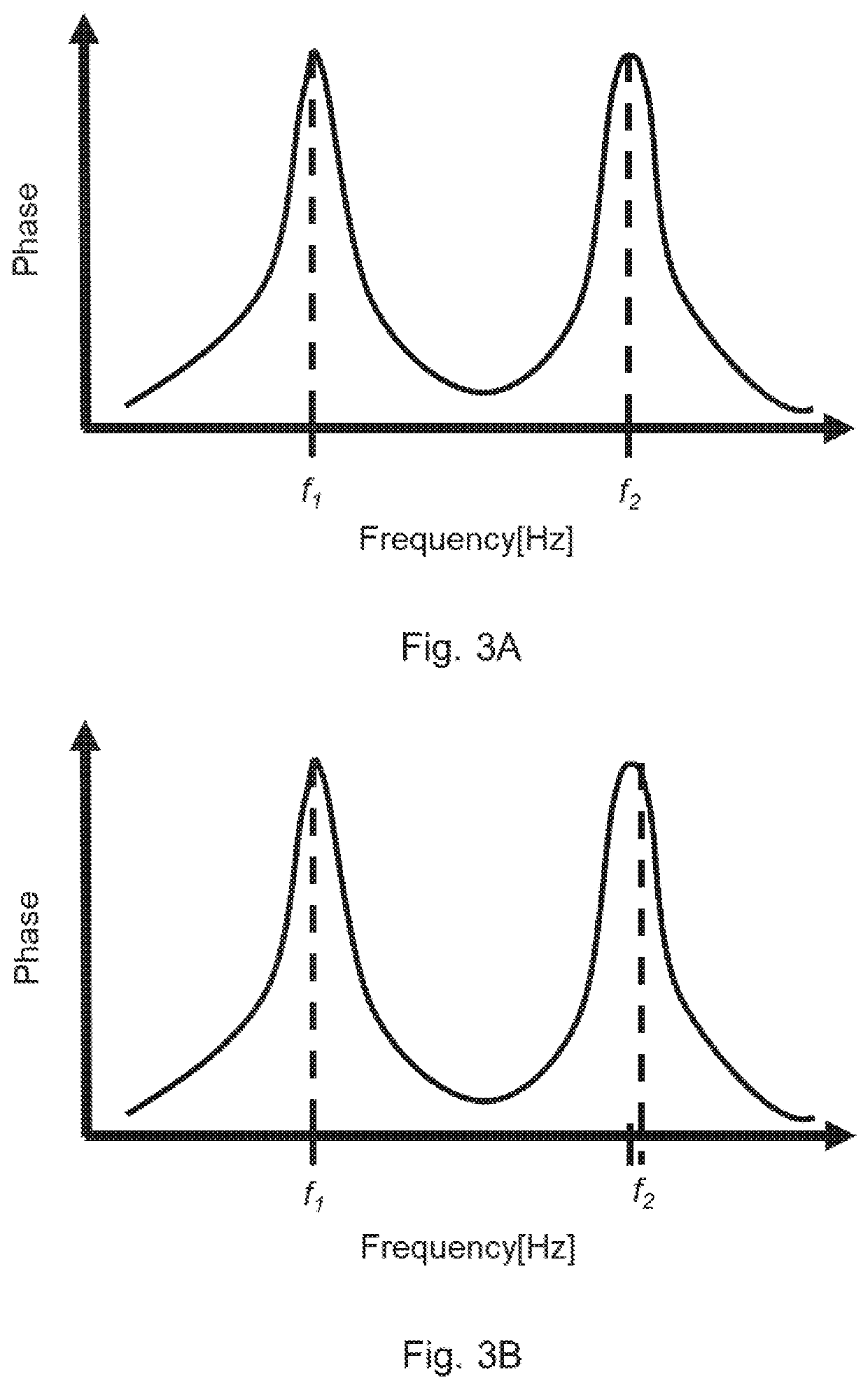

Piezoelectric apparatus for motorization

ActiveUS20190372483A1Piezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesControl signalPhase difference

A piezoelectric motorization system for driving mechanical loads multi-dimensionally by an electronic circuitry is disclosed. The piezoelectric motorization system has a piezoelectric apparatus that is constructed by a mechanically flexible body that has multiple piezoelectric actuators attached its surfaces, where these actuators are controlled by an electronic circuitry. The mechanically flexible body has a finite structure with a sets of boundary conditions to determine its out-of-plane resonant modes. The electronic circuitry inject at least two sets of control signals into different groups of actuators at or near different resonant frequencies. Using these control signals, traveling waves can be generated on the piezoelectric apparatus to move mechanical loads placed on its surface. Or, the traveling waves are used to propel the piezoelectric apparatus for motorization. The moving direction and velocity are controlled and adjusted by amplitude ratio and phase difference among driving frequencies of control signals. The moving direction and velocity also is controlled by the size, shape and locations of piezoelectric actuators on the mechanically flexible body. Different combinations of bending and / or twisting modes are used to generate one-dimensional or two-dimensional movements. Finally, multiple piezoelectric apparatus can be placed on three orthogonal planes of a three-dimensional mass for three-dimensional motorization.

Owner:NAT TAIWAN UNIV

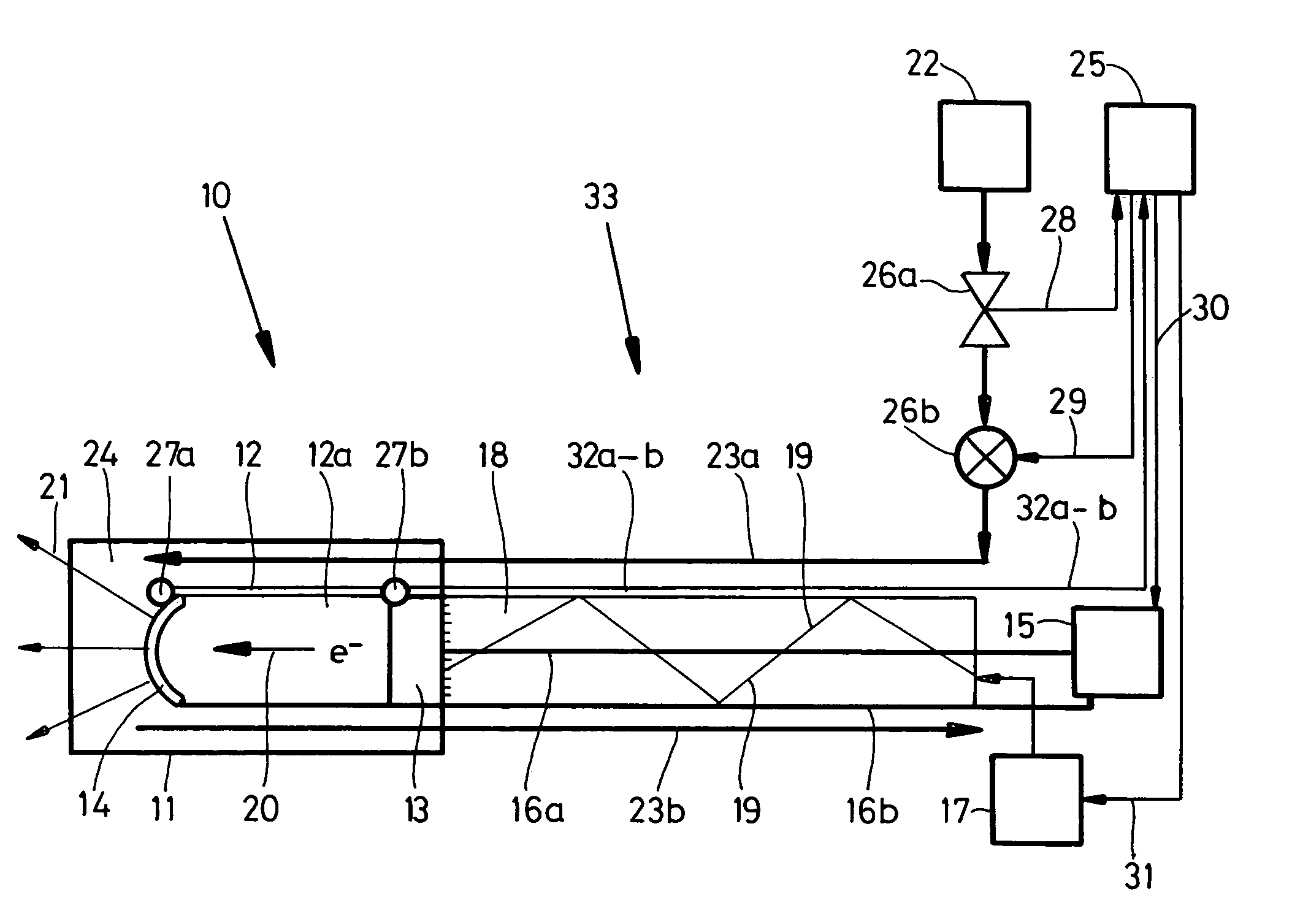

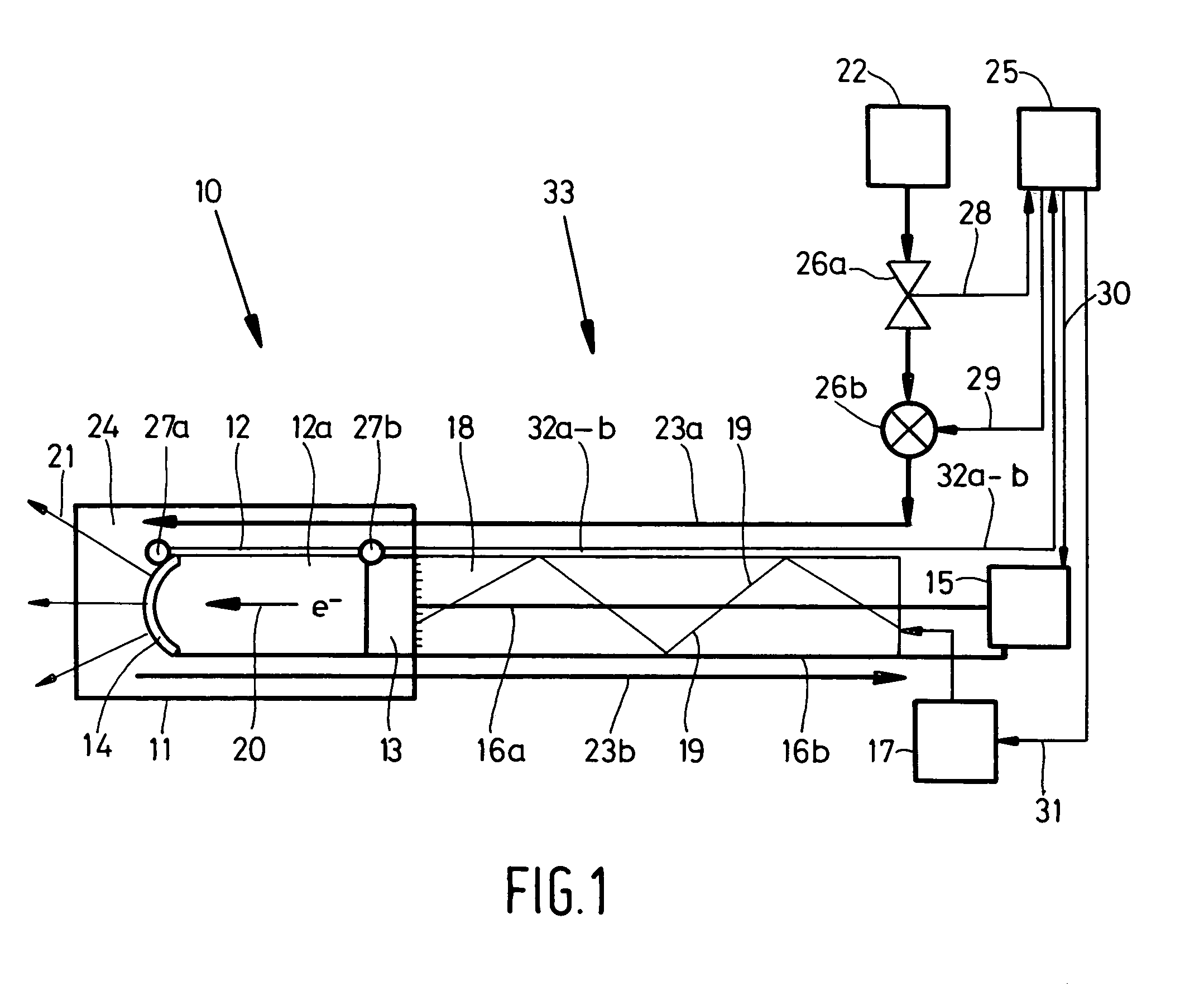

Cryogenic x-ray source device

ActiveUS7027560B2Easy to controlControl DimensionsX-ray tube anode coolingX-ray tube electrodesWorking temperatureX-ray

The invention relates to a miniature X-ray source device connected to a distal end of a guiding wire for insertion towards a desired location within an animal body for effecting radiation therapy, said X-ray source device at least comprising a vacuum tube accommodated in said housing containing a cathode and an anode spaced apart at some distance from each other; electron freeing means for freeing electrons from the cathode; electric field means for applying during use a high-voltage electric field between said cathode and said anode for accelerating said free electrons; said vacuum tube being at least partly transparent to X-ray radiation emitted by said anode, as well as cooling means for cooling at least said anode.It is an object to provide a miniature X-ray source device having further limited constructional dimensions and an improved control of the working temperature of at least the anode and hence the working conditions of the miniature X-ray source device.According to the invention the miniature X-ray source device is hereto characterised in that said cooling means are cryogenic cooling means. More in particular in a specific embodiment of said miniature X-ray source device said cooling means comprise at least one supply passageway for supplying pressurized gas towards said anode and at least one exhaust passageway for exhausting said pressurized gas from said anode, said supply passageway and said exhaust passageway being interconnected by means of an expansion chamber surrounding at least partly said anode.

Owner:NUCLETRON OPERATIONS

Airborne tubular antenna

ActiveCN102881995ASolve long-distance communication problemsEasy to assemble and disassembleAntenna supports/mountingsRadiating elements structural formsLimited structuresRadio frequency

An airborne tubular antenna comprises an L-shaped spiral radiator. The spiral radiator is positioned in an antenna radiant tube and a hollow support frame which are perpendicular to each other, a spiral line on the spiral radiator is divided into three sections in the antenna radiant tube, each section of thread pitch is different, two neighboring sections of spiral lines are hinged, and the spiral line on the spiral radiator is connected with a tail connector of a radio frequency cable. Since a spiral line technology is introduced in the antenna, by the aid of a spiral line model, within a limited structure size of the antenna, length of an antenna radiator can be increased, and radiation efficiency of short-wave communication can be improved. A partial spiral radiator is mounted in the antenna support frame, so that a radiation pattern of the antenna is close to be omnibearing, and the problem of telecommunication of the antenna is solved effectively according to the principle. The antenna has the advantages of convenience in mounting and dismounting, non-maintenance, high reliability and the like.

Owner:陕西烽火诺信科技有限公司

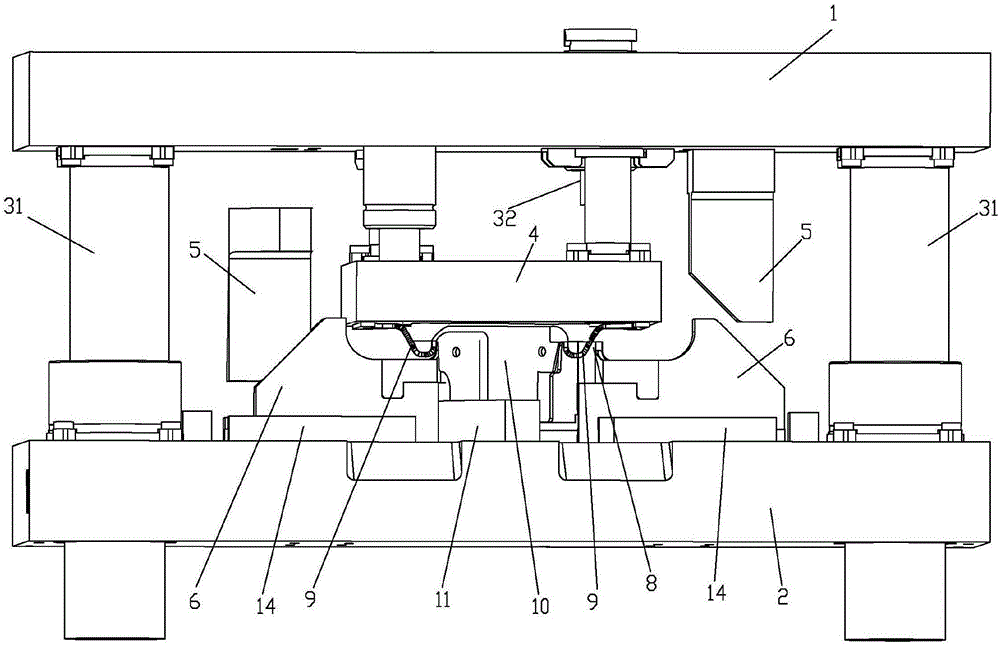

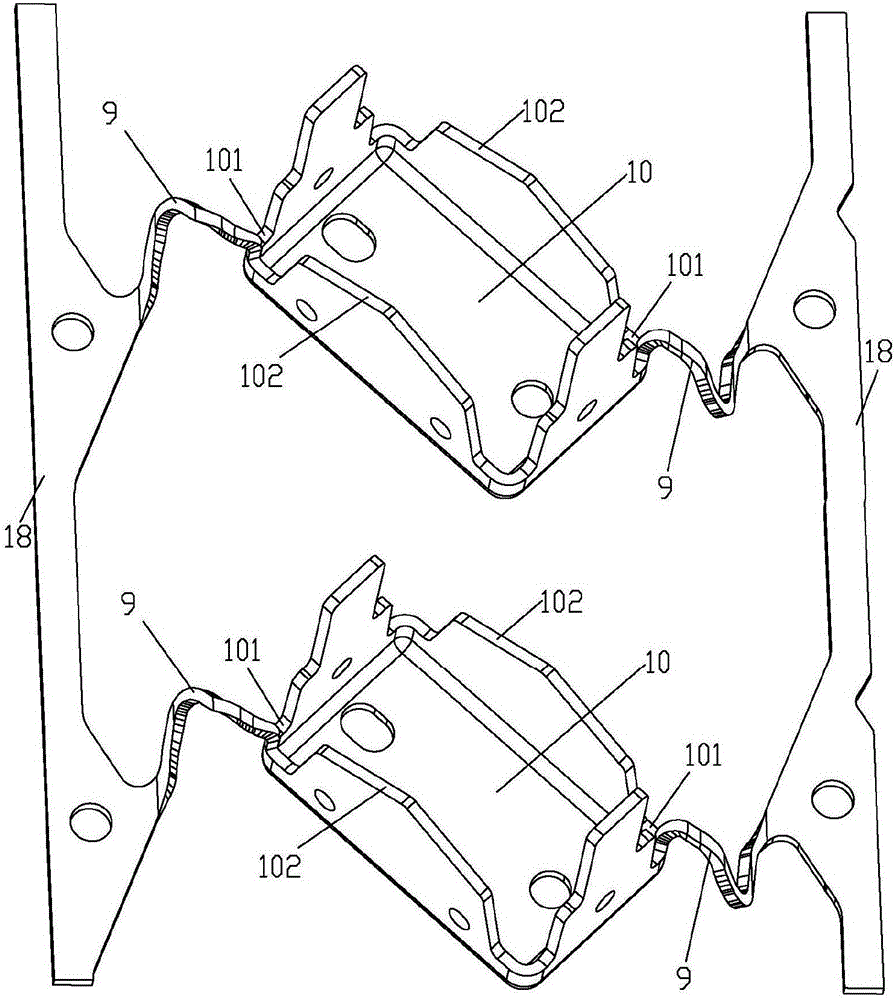

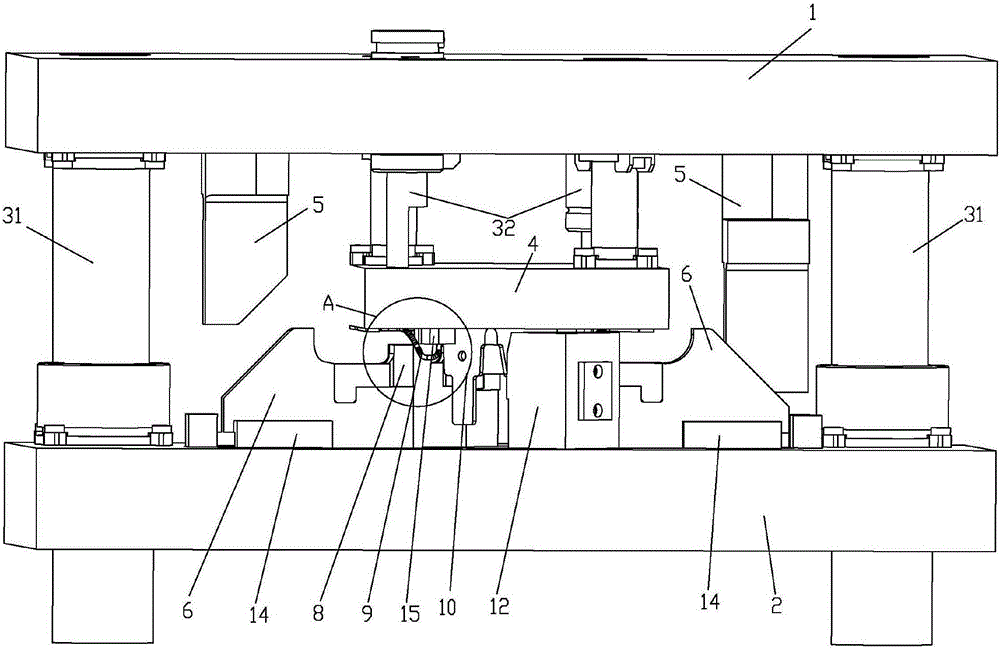

Scrap cutting mechanism

ActiveCN106077231ARealize continuous mold productionMetal-working feeding devicesPositioning devicesFree fallingLimited structures

The invention relates to the technical field of hardware stamping molds, in particular to a scrap cutting mechanism, which comprises an upper mold seat and a lower mold seat. The upper mold seat is connected with a stripper plate with upper mold cutter bits, and is also connected with shovel bases; slide blocks and limited structures are arranged on the lower mold seat; lower mold cutter bits are arranged on the slide blocks; the upper mold cutter bits are provided with notches; and bearing pieces and through holes are also arranged on the lower mold seat. According to the scrap cutting mechanism provided by the invention, when the upper mold seat moves downwards, the stripper plate, the bearing pieces and the notches close to a parts and cooperatively fix the parts in a three-dimensional direction; the upper mold seat continuously moves downwards along with the lower mold seat, and scraps of the parts are cut through the cooperative action of the upper mold cutter bits and the lower mold cutter bits; the upper mold seat stops moving downwards but moves upwards, the stripper plate, the bearing pieces and the notches are far away from the parts, and the parts is fallen into a next work station from one through hole in a free falling way under the action of gravity so as to be processed in the next work process, so that the continuous mold production of the parts is realized.

Owner:TANGXIA BRANCH VISION TOOL & MOLD

Flat plate soaking plate and manufacturing method thereof

InactiveCN102778157BArbitrary increase in structure sizeEasy to set upSemiconductor/solid-state device detailsSolid-state devicesEngineeringLimited structures

The invention relates to a flat plate vapor chamber and a manufacturing method thereof. The flat plate vapor chamber comprises a packaging chamber, a porous capillary wick, a working medium and a vacuumizing and work medium filling interface, wherein the porous capillary wire and the working medium are positioned inside the packaging chamber; one end of the vacuumizing and work medium filling interface is communicated with the inside of the packaging chamber; and the other end of the vacuumizing and work medium filling interface is positioned outside the packaging chamber and is sealed. The manufacturing method of the flat plate vapor chamber comprises the following steps of: forming the packaging chamber by extruding or casing; forming the porous capillary wick by sintering or knitting; inserting the porous capillary wick into the packaging chamber; placing one end of the vacuumizing and work medium filling interface in the packaging chamber; extruding the packaging chamber by using a cold press die; moving away the cold press die; welding and sealing a front-rear end closing surface of the packaging chamber; vacuumizing the packaging chamber and filling a working medium; and pinching off the vacuumizing and work medium filling interface and welding and sealing the vacuumizing and work medium filling interface. According to the flat plate vapor chamber disclosed by the invention, the defects of limited structure, high manufacturing cost, low reliability, limited heat-radiating capability and the like in a traditional vapor chamber are fully overcome.

Owner:北京芯铠电子散热技术有限责任公司

Full Bore Layered Fracturing Sleeves for Oil and Gas Well Operations

ActiveCN103556971BAvoid misuseImprove reliabilityFluid removalWell/borehole valve arrangementsLimited structuresMechanics

The full -diameter layered fracture sliding cover for oil and gas well operation is set up in the form of cooperation with the outer cylinder. There are working tube including the inner tube that can move in the inner direction of the outer cylinder.There is a limited structure that is positioned and limited to the sliding distance of the inner tube. At least one axial end of the outer cylinder has a connector, and a diversion that can be connected with the inner cavity of the workpress of the workpress is set up.In the hole, there is a groove structure with intervals and grooves that can be turned over and can be used to the diameter of the starting ball with the diameter of the diameter.Control the diameter switching structure of the startup ball; the spacing of each adjacent groove on the inner wall of the working tube is non -integer that the distance between the diameter switch structure.The sliding cover of the present invention can achieve unlimited slide jackets. You only need to enter the same size to start the sliding cover step by step, which significantly improves the reliability of construction.The salvage of the tool greatly simplifies the construction process and improves operational efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

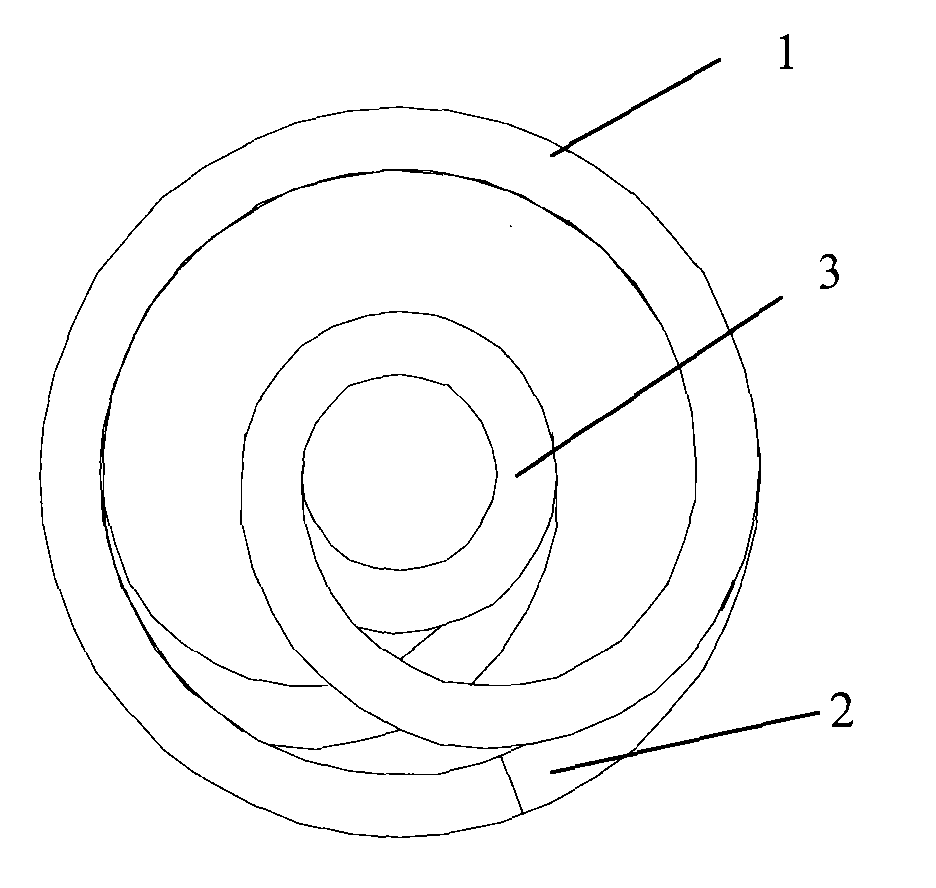

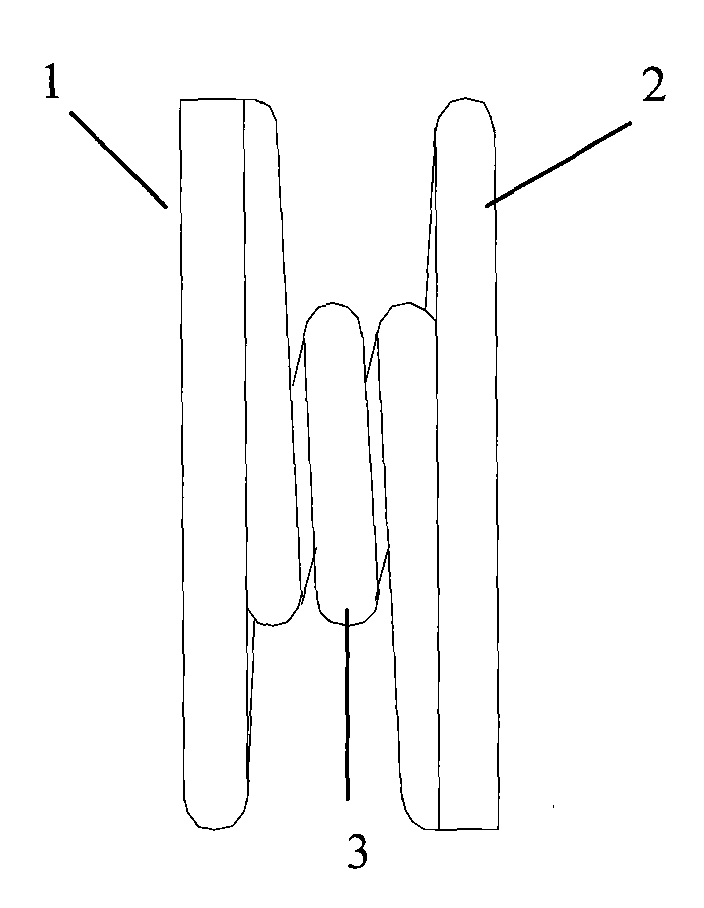

Spring

InactiveCN101598183AWith shock absorptionAvoid deformationWound springsEngineeringLimited structures

The embodiment of the invention discloses a spring, which comprises a first spring outer ring, a second spring outer ring and a spring inner ring which are coiled by using a steel wire, wherein the first spring outer ring and the second spring outer ring are distributed on two sides of the spring inner ring, and the calibers of the first spring outer ring and the second spring outer ring are larger than the caliber of the spring inner ring. The spring with the shape has the characteristics of buffering and difficult deformation. The spring with the shape is equivalent to the combination of two pagoda springs with opposite small ends, thereby greatly reducing the stroke space, and compared with the combination of the two pagoda springs with the opposite small ends, the spring reduces materials and saves the cost. Besides, the spring with the shape has the characteristics of buffering and difficult deformation. The spring is applicable for any mechanical structure requiring tension buffering, in particular to the structures with limited forming spaces. The buffering spring replacing a buffering gum cover in a clutch of a motorcycle can prolong the service life of the clutch and can play a role of buffering.

Owner:CHONGQING TENGHAN IND & TRADE

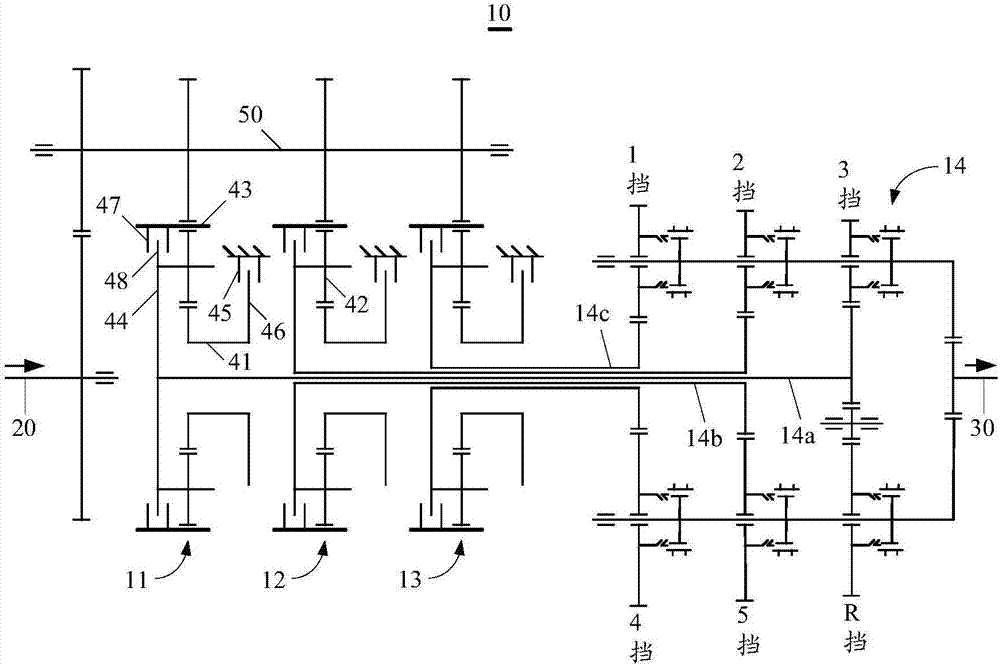

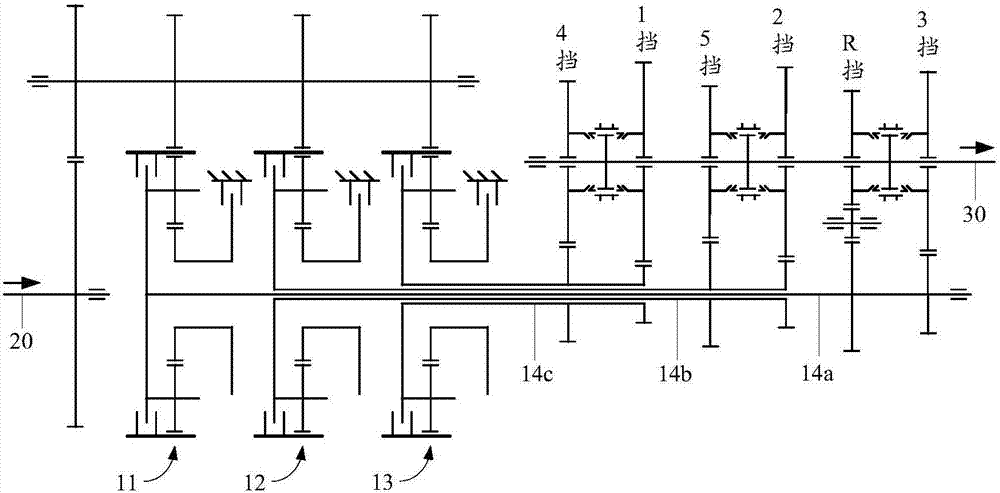

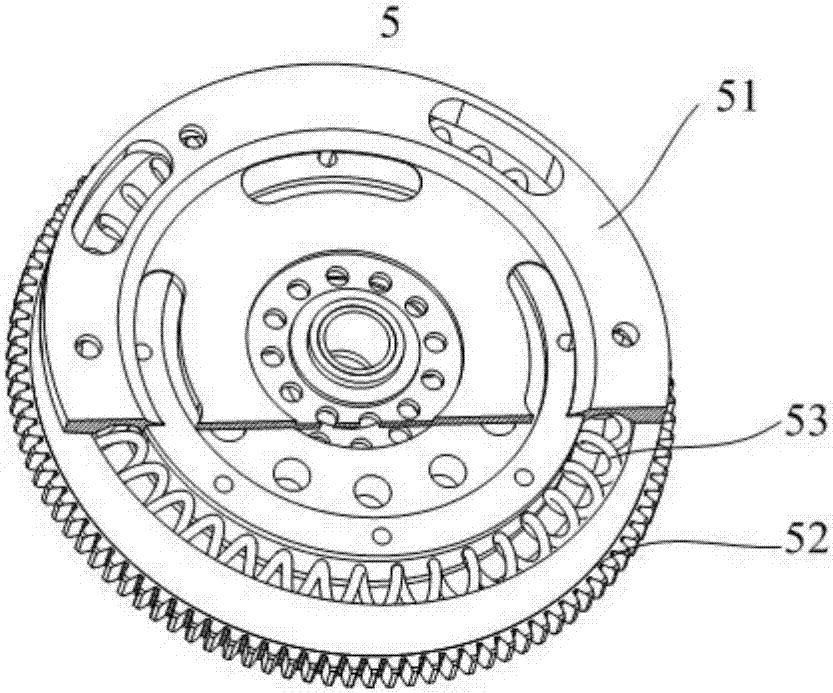

Three-shaft type clutch speed changing device

InactiveCN106907434AIncrease logarithmDoes not increase horizontal sizeGear vibration/noise dampingToothed gearingsEngineeringLimited structures

The invention discloses a three-shaft clutch speed change device, which includes a speed change gear set, three clutch devices, at least one and at most three clutches, the speed change gear set includes a first input shaft, a second input shaft and a third input shaft, the first The second input shaft and the third input shaft are hollow shafts, the first input shaft is passed through the second input shaft which is a hollow shaft, the second input shaft is passed through the third input shaft which is a hollow shaft, and the three clutch devices They are respectively connected between the power output shaft and the first input shaft, the second input shaft and the third input shaft; the three clutches are respectively connected to any two of the power input part, power output part and transmission control part of the three clutch devices. Between them, it is used for selective engagement, so that the power drives the input shaft of the variable speed gear set at a constant speed. The invention can meet the multi-gear requirements of the vehicle on the limited structural size.

Owner:龚小娥

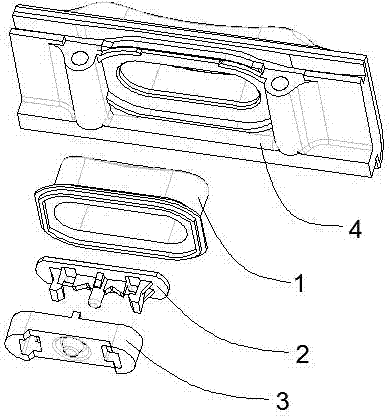

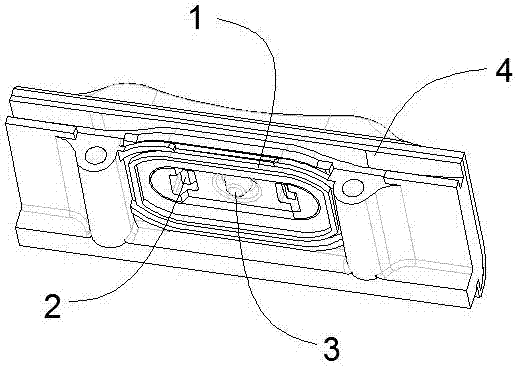

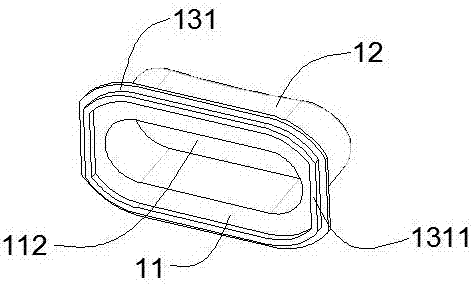

Waterproof side key structure and waterproof mobile phone with structure

ActiveCN107887210AImprove waterproof reliabilityImprove reliabilityElectric switchesThree levelKey pressing

The invention relates to a waterproof side key structure which comprises a key body formed by an elastic material, a key support made of a hard material, an elastic member and a shell. The key body, the key support and the elastic member are assembled on the shell, the key body is pressed, pressing force can be transmitted to the elastic member through the key support, and thus the switch-on of aside key is triggered. At the same time, three levels of waterproof protection are set in the assembly structures of the key body and the shell, a technical scheme of converting a large key stroke into a small keystroke is proposed, and a novel technical idea of the realization of multiple levels of waterproof protection of side keys in a limited structure space at the same time to effectively improving waterproof reliability is proposed.

Owner:POWER IDEA TECH (SHENZHEN) CO LTD

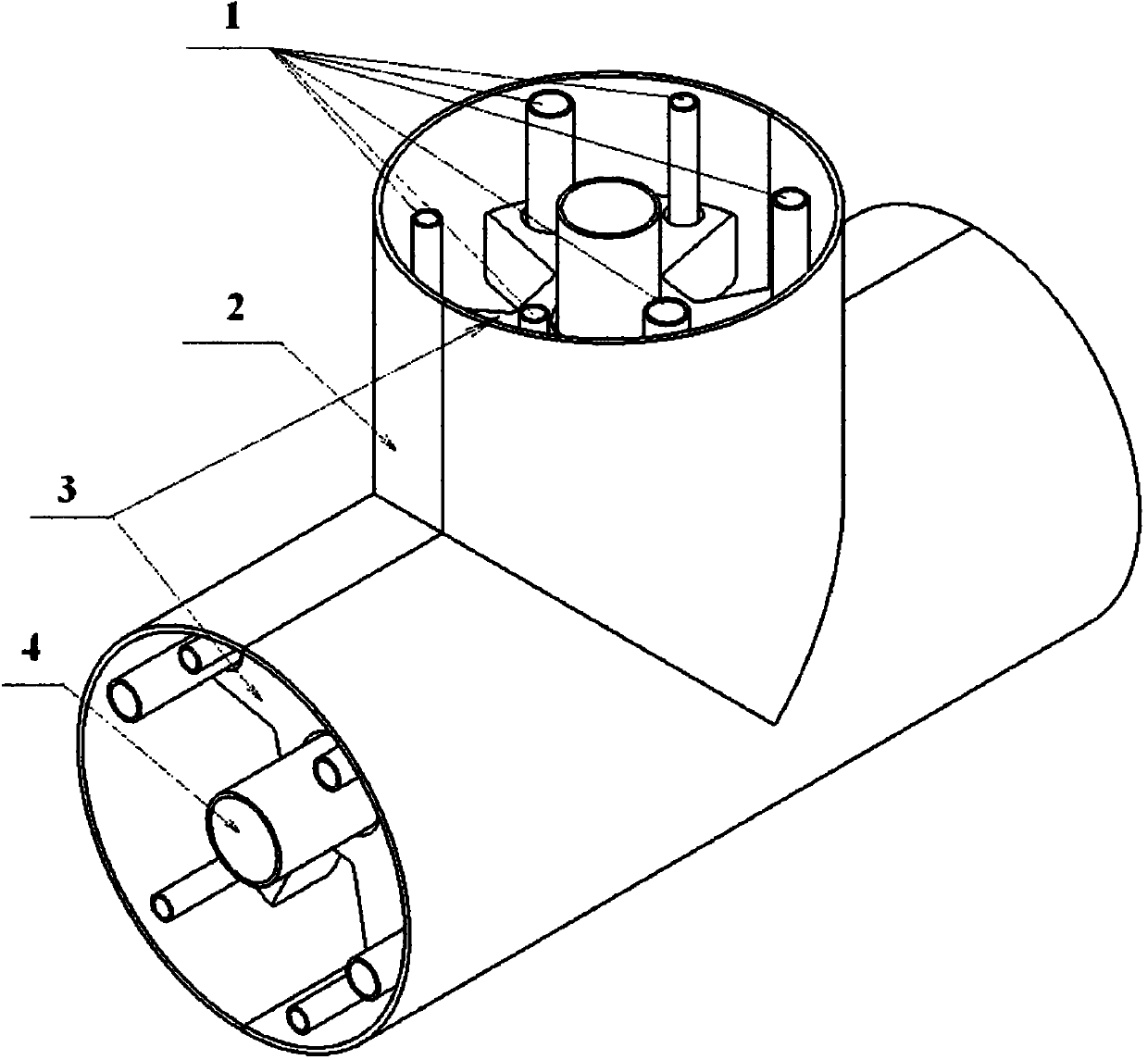

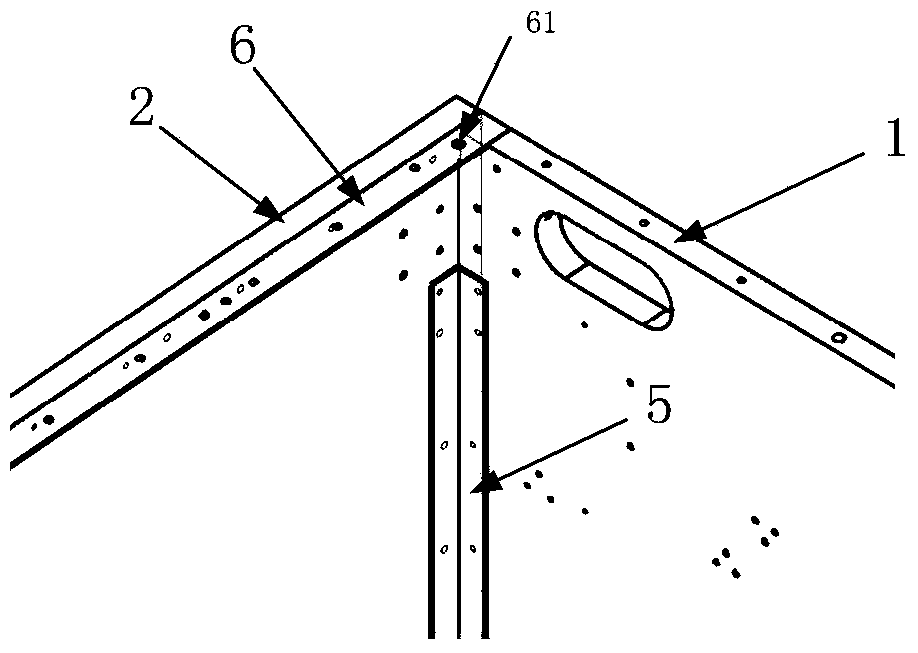

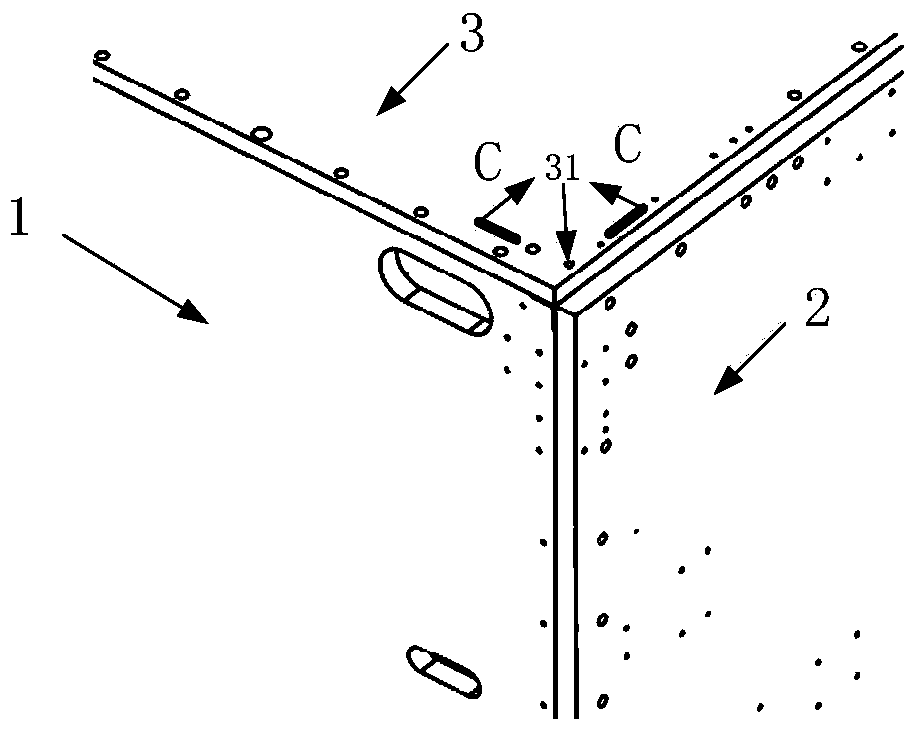

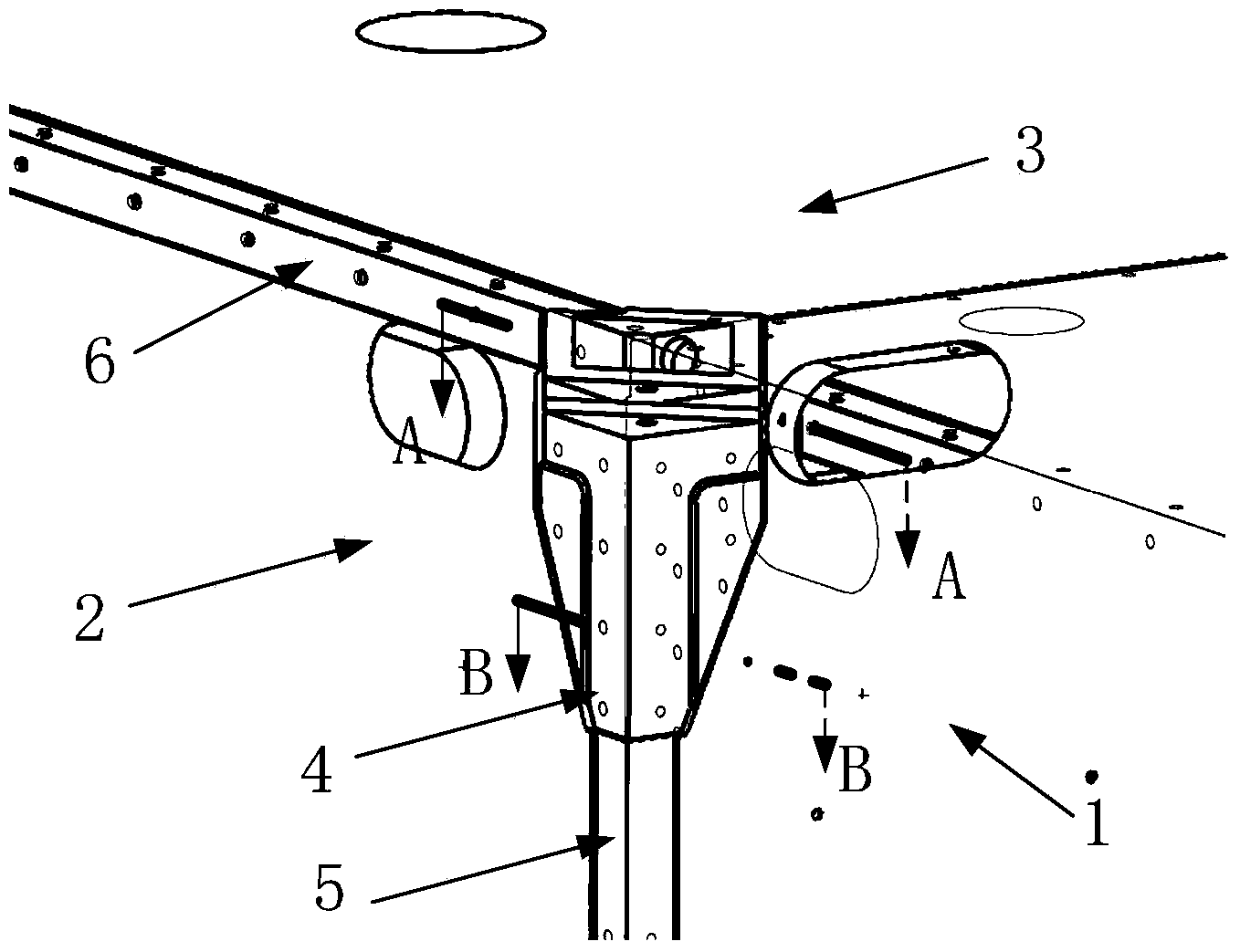

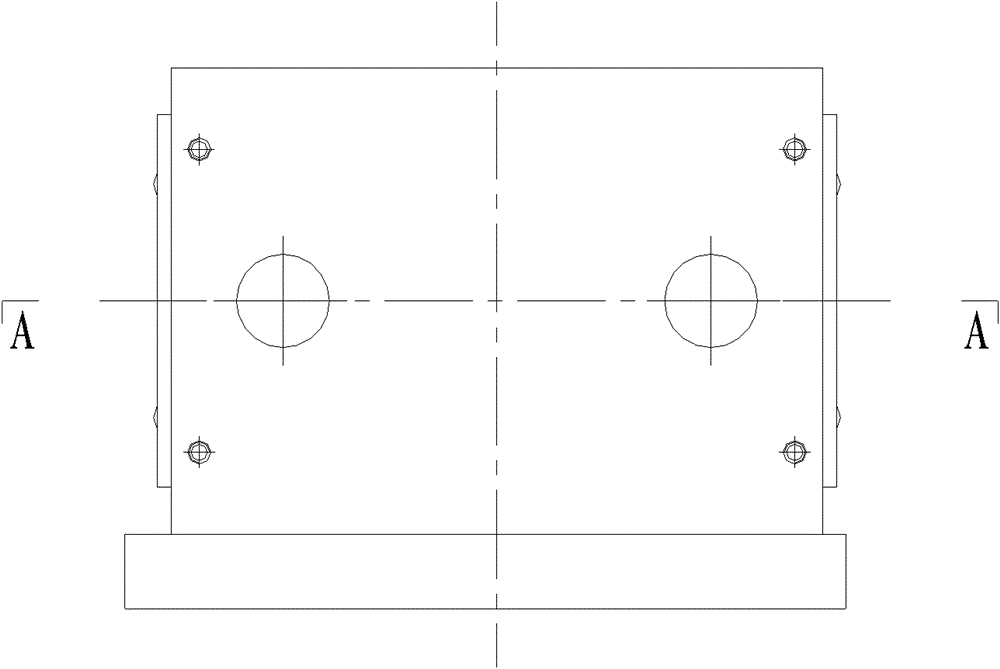

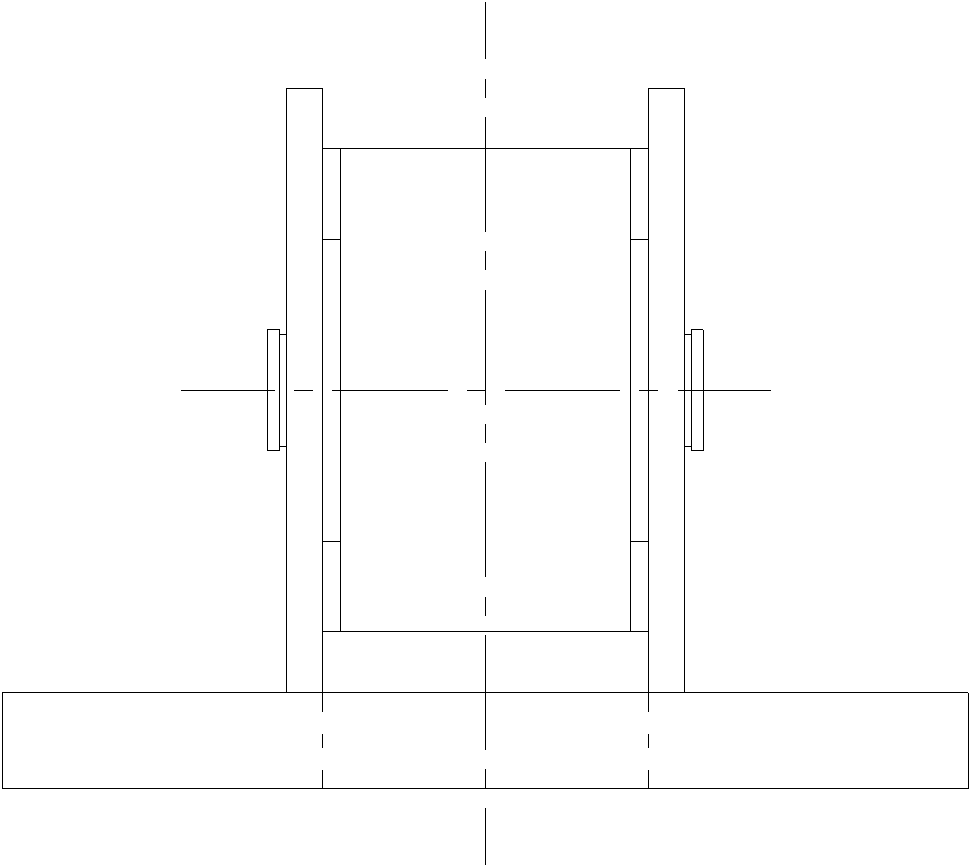

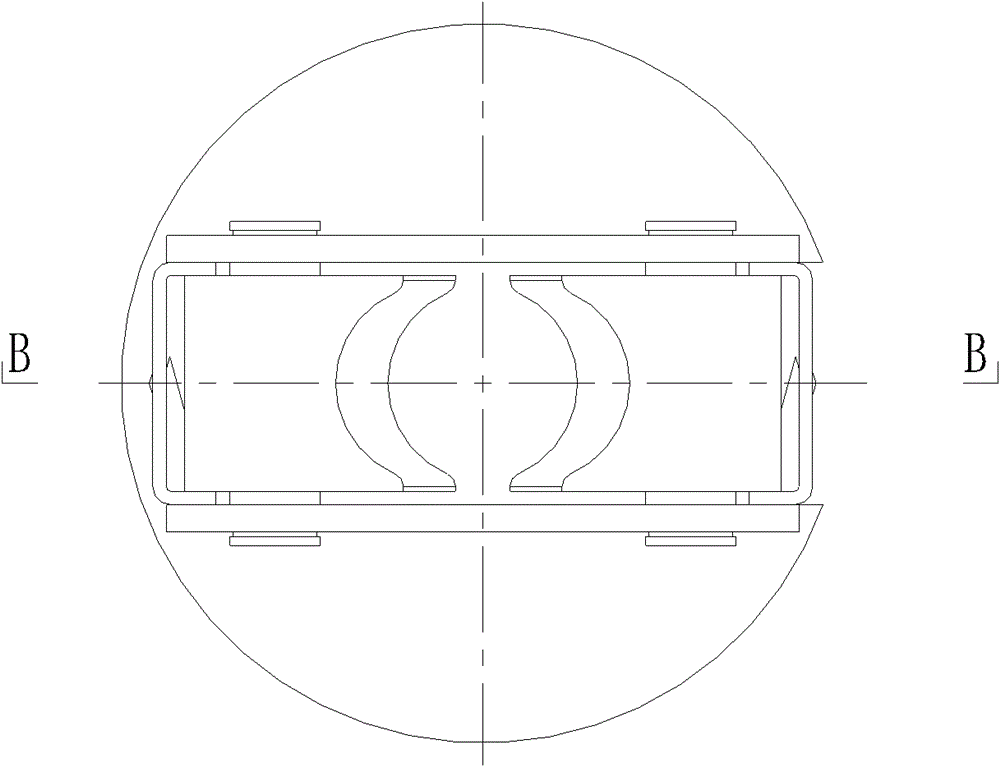

Composite multi-pipeline tee joint structure assembly

ActiveCN102444759AReduce volumeHigh strengthPipe elementsLimited structuresUltimate tensile strength

The invention belongs to a pipeline structure assembly, in particular relates to a tee joint structure assembly with multiple gas-transportation and composite pipeline structures. The tee joint structure assembly comprises a containing pipeline, wherein an air supplying pipeline, an emptying pipeline and an internal support structure are arranged in the containing pipeline, each air supplying pipeline and the emptying pipeline independently realize the tee joint, and each air supplying pipeline and the emptying pipeline are sheathed on the internal support structure. The pipeline structure assembly has the advantages that: the problem that branches of multiple pipelines in horizontal and vertical directions are interfered by reasonable internal pipeline arrangement, a pipeline structure is simplified in a limited structure space, unnecessary bend pipe design is avoided, welding and maintaining operation is convenient, and the volume of the whole assembly is reduced. By adopting the internal support structure designed specially, the structure position of the pipeline arrangement can be effectively controlled and the pipeline assembly intensity is also improved.

Owner:SOUTHWESTERN INST OF PHYSICS

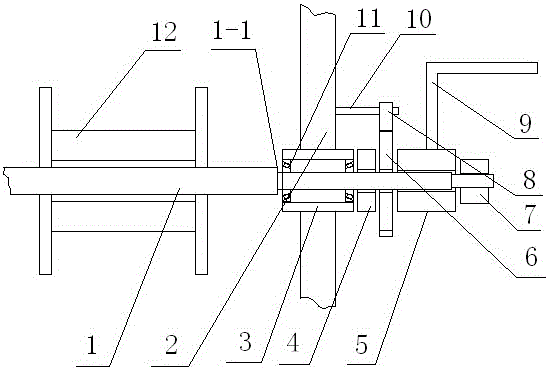

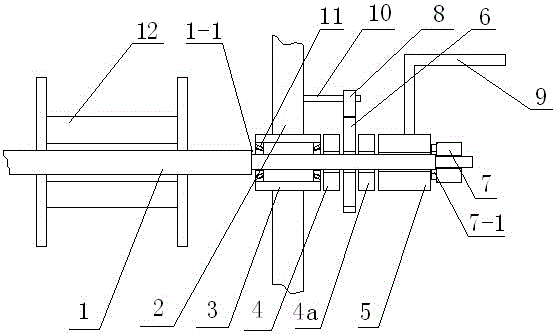

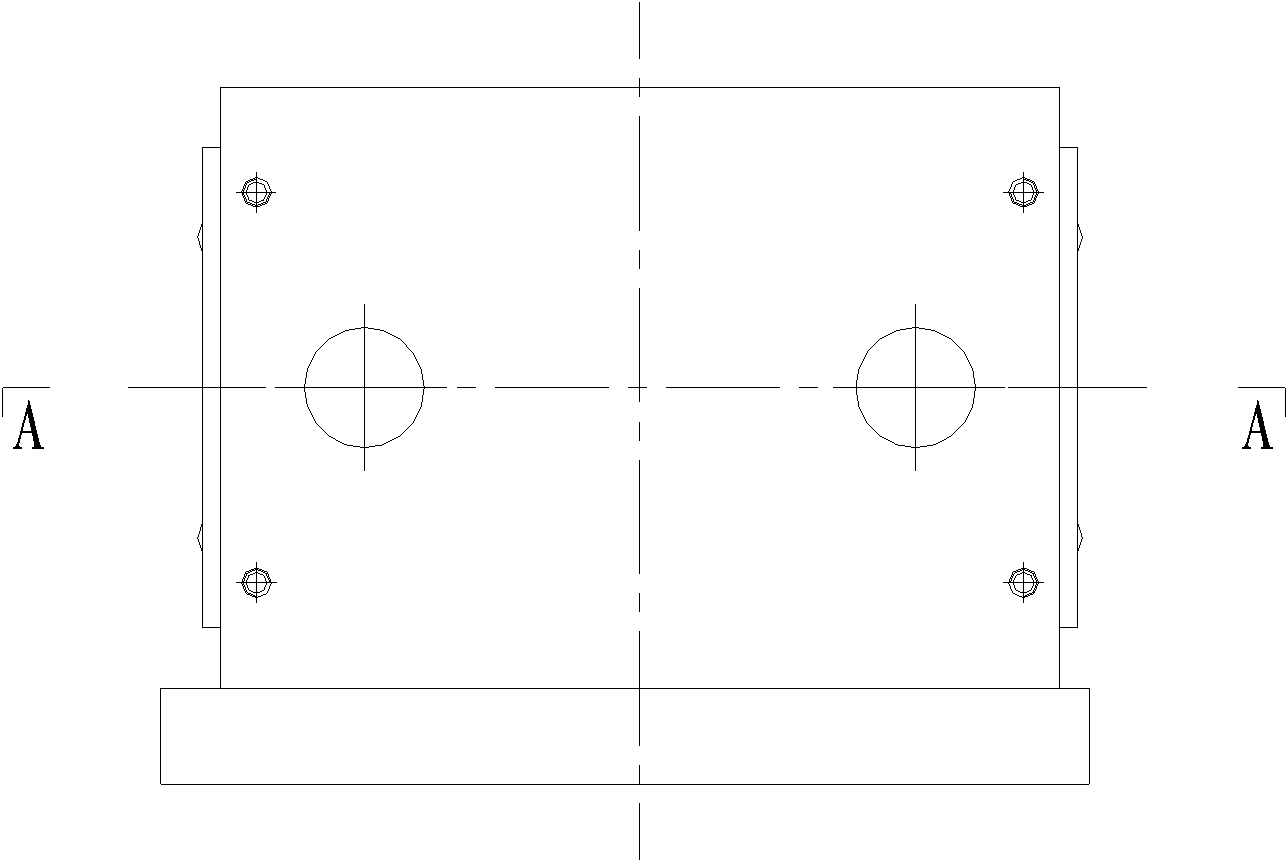

Cone penetration measuring instrument

InactiveCN107328693AGuaranteed accuracyEasy to adjustFlow propertiesMeasuring instrumentLimited structures

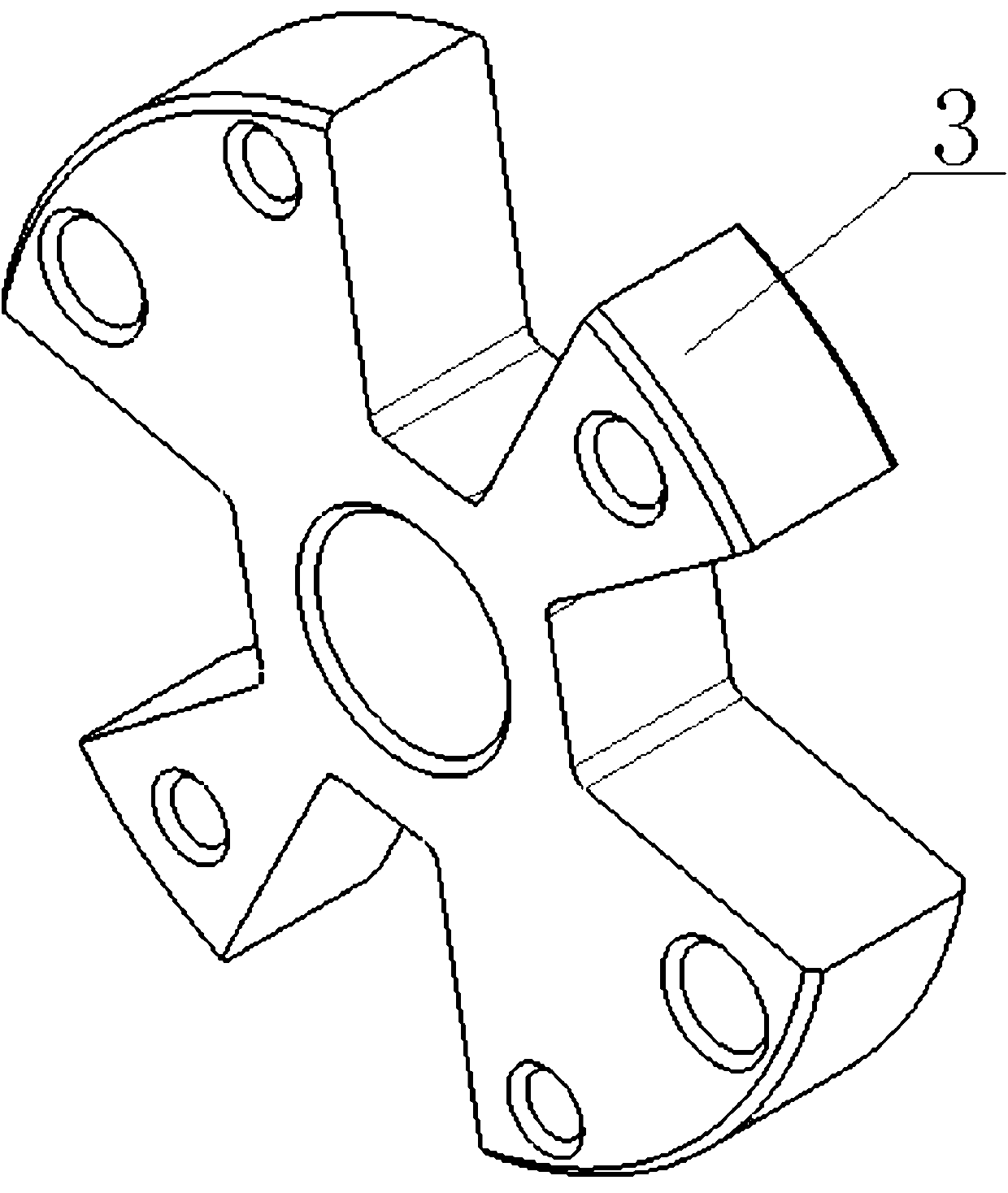

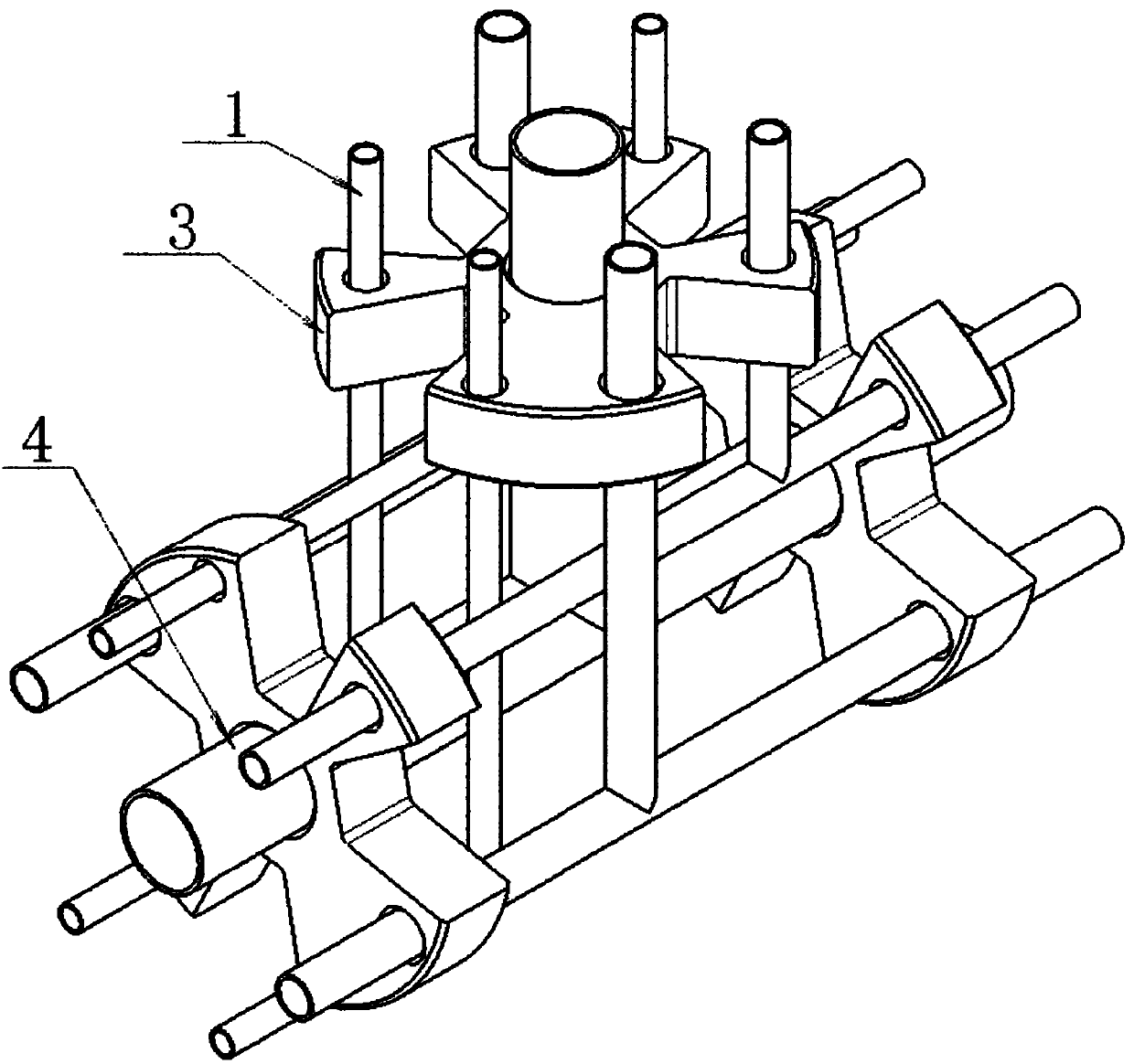

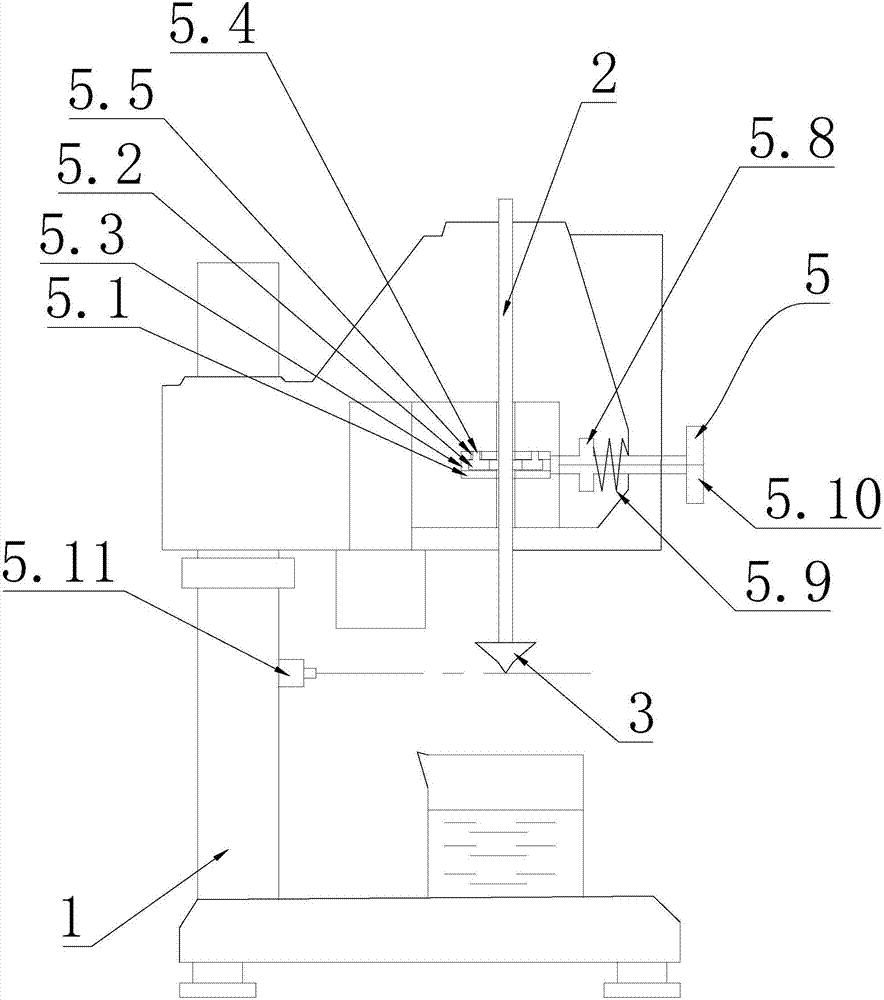

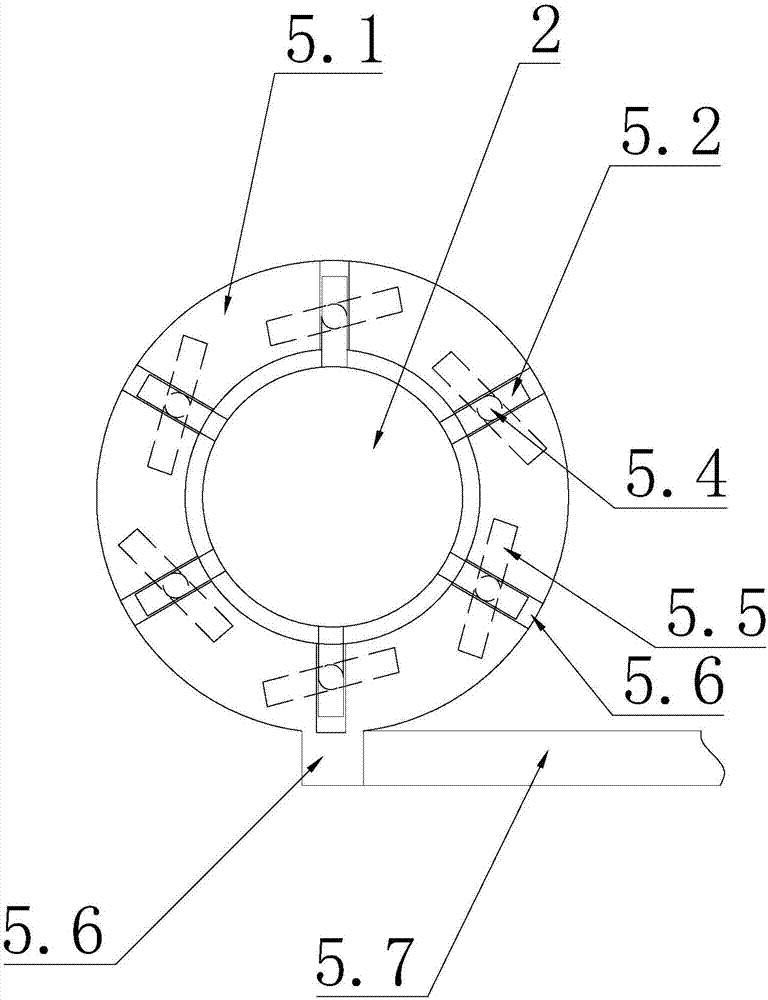

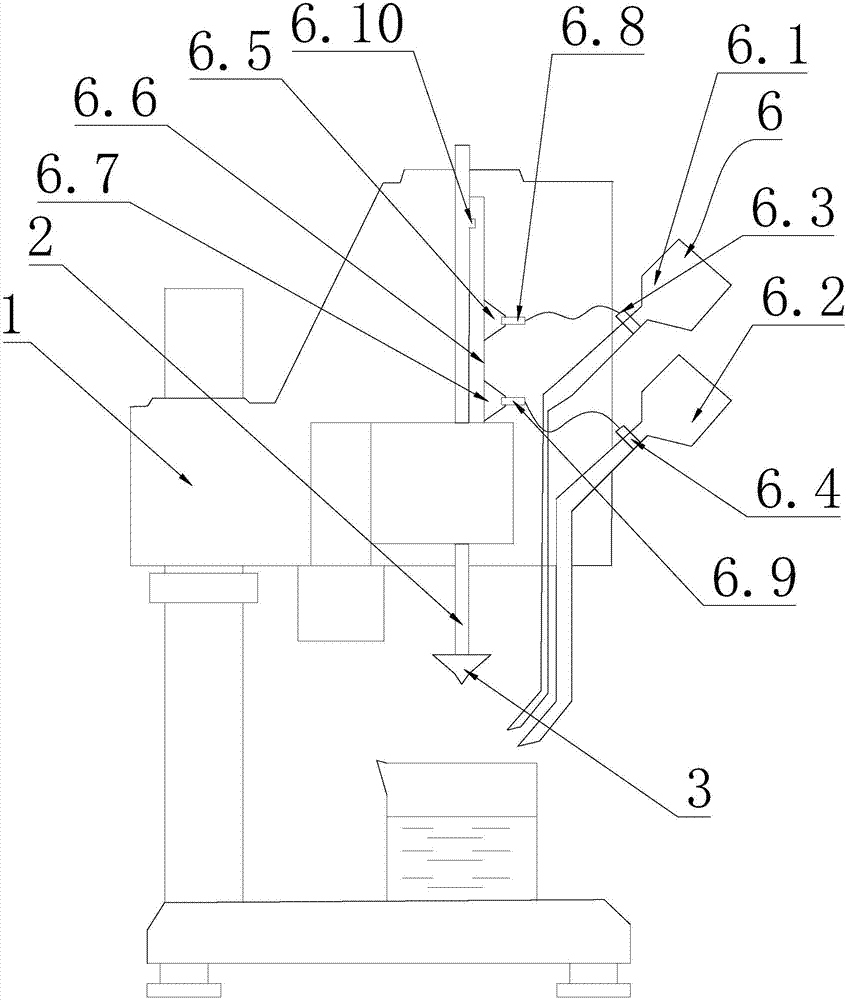

The invention discloses a cone penetration measuring instrument. The cone penetration measuring instrument comprises a rack body (1), wherein a test needle (2) is arranged on the rack body (1); a test cone head (3) is arranged at the lower end of the test needle (2); a guide hole (4) for allowing the test needle (2) to vertically drop into a test material is arranged in the rack body (1); the cone penetration measuring instrument is equipped with a limited structure (5) for allowing the test needle (2) to relieve limiting in the peripheral direction; the limited structure (5) comprises a limiting disc (5.1) which is arranged in the rack (1) and sleeves in the peripheral direction of the test needle (2); and a plurality of limited posts (5.2) which abut against the peripheral wall of the test needle are arranged in the peripheral direction in the limited disc (5.1) at intervals. The invention provides the cone penetration measuring instrument which relieves the limiting in the peripheral direction, so that the test needle drops, is not liable to tilt or is not liable to colloid with the guide hole, and speed, dropping into the test material, of the test cone head is consistent.

Owner:王文乐

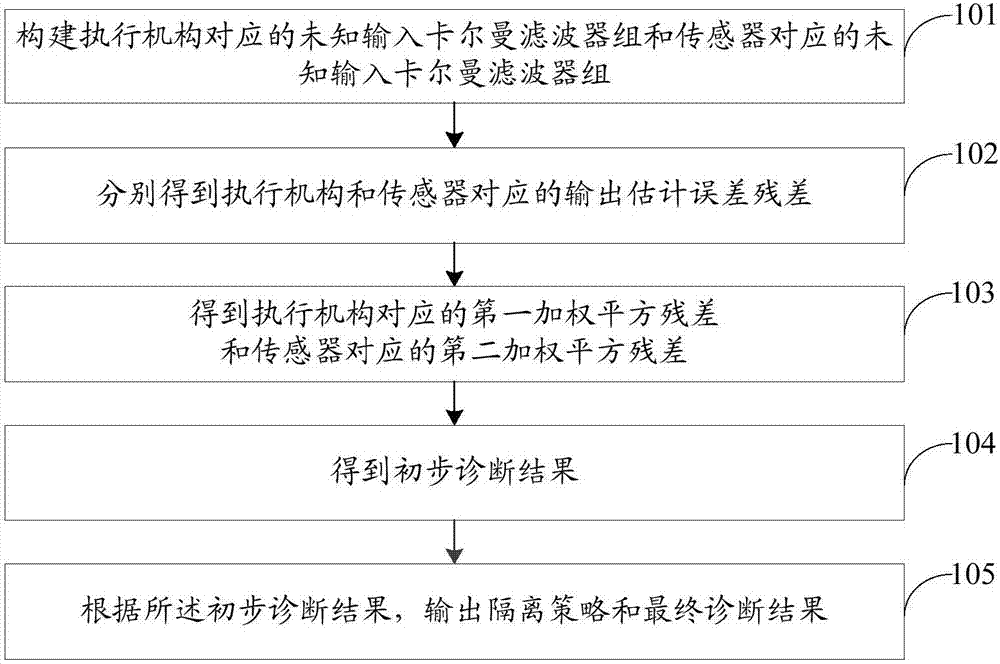

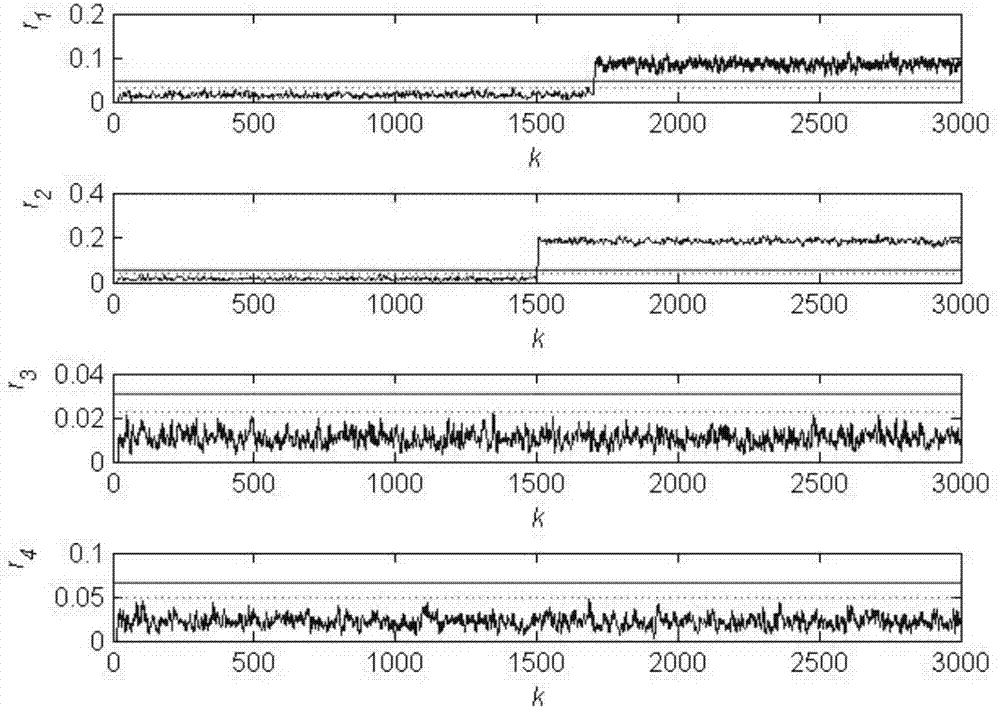

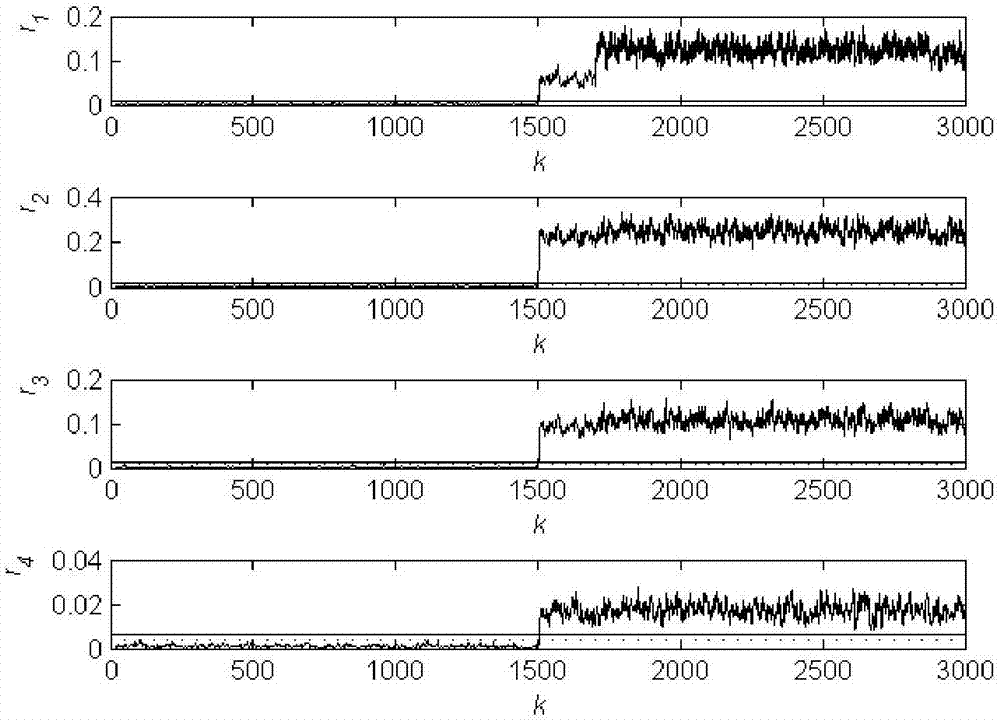

Multi-fault diagnosis and optimization method of control system

ActiveCN107544459AImprove accuracyAvoiding the inadequacy of only considering single-fault casesElectric testing/monitoringEngineeringActuator

The invention discloses a multi-fault diagnosis and optimization method of a control system. The method comprises a step of constructing unknown input Kalman filter groups corresponding to actuators and sensors according to a discrete state space model, a step of obtaining output estimation error residuals corresponding to the actuators and the sensors according to an optimal state estimator X<^><C>(i,k) of a Kalman filter corresponding to an ith actuator in a kth step and an optimal state estimator X<^><O>(i,k) of a Kalman filter corresponding to an ith sensor in a kth step, a step of carrying out weighted quadratic sum processing on the output estimation error residuals and obtaining corresponding weighted squares residuals, a step of obtaining a preliminary diagnosis result according toa comparison result of the weighted squares residuals and a mechanism detection threshold, and a step of outputting an isolation strategy and a final diagnosis result according to the preliminary diagnosis result. According to the method, the Kalman filter groups with limited structures are used to carry out control system multi-fault isolation and optimization, a global optimal solution of stateperception can be obtained, and the accuracy of a fault diagnosis result of the control system is improved.

Owner:BEIJING INST OF CONTROL ENG

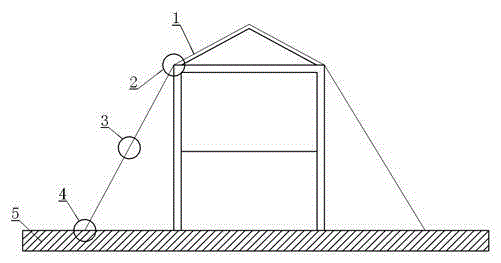

Windproof reinforcing structure used for temporary board houses on soil

ActiveCN105201223ACan't solve the problem of not being well reinforcedReasonable structureBuilding repairsTraffic signalsEngineeringLimited structures

The invention relates to a windproof reinforcing structure used for temporary board houses, and in particular relates to a windproof reinforcing structure used for temporary board houses on soil. The reinforcing structure comprises a board house connecting device, a lacing wire rope and a ground anchoring device, wherein the lacing wire rope is connected with a first wire rope connection ring of the board house connecting device, and the board house connecting device is fixed on the roof in a threaded connection manner; the lacing wire rope is connected with a second wire rope connection ring of the ground anchoring device; the ground anchoring device comprises a supporting column, a clamping part and a supporting plate and is integrally buried in the soil. By adopting the windproof reinforcing structure, the windproof reinforcing requirement of the temporary board houses built on the soil can be met, and the windproof reinforcing structure has the advantages of reasonable and limited structure, significant windproof reinforcing effect, and convenience in mounting and demounting.

Owner:ZHEJIANG QIAOXING CONSTR GRP

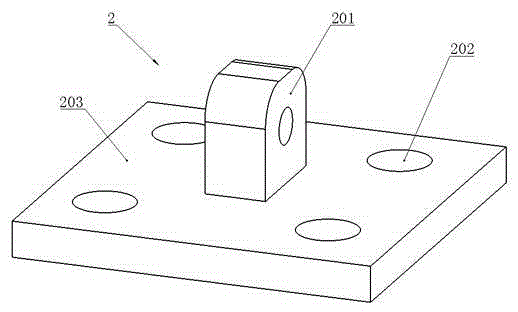

Steel cable guide mechanism and building curtain wall fixing device consisting of steel cable guide mechanism

The invention discloses a steel cable guide mechanism and a building curtain wall fixing device consisting of the steel cable guide mechanism. The steel cable guide mechanism comprises a fixed seat with open slots, and guide wheels which are arranged in the open slots, wherein the guide wheels are rotatably connected with the fixed seat and the number of the guide wheels is one or two. The building curtain wall fixing device comprises a steel cable with two ends which are fixedly arranged on a structural member main body, and the steel cable guide mechanism which is used for positioning the steel cable, wherein the steel cable guide mechanism is fixedly arranged on the structural member main body. The steel cable guide mechanism provided by the invention is used for a vertical steel cable. When external force is applied to the vertical steel cable, pressure is applied to the guide wheel on any side and the vertical steel cable moves up and down, the guide wheel can rotate; and when the external force disappears, the guide wheel rebounds to the original position. Therefore, the friction of the steel cable at a bearing point becomes rolling friction; if sector-shaped wheels are used, the contact area between the steel cable and the guide wheels can be increased within a limited structural space and the stress state of the steel cable can be improved; and since the guide wheels are made of a material such as aluminum, copper or engineering plastic which is softer than the material of the steel cable, the wear of the steel cable can be reduced as much as possible.

Owner:SHENZHEN SANXIN FACADE ENG

Suspension centre joint

InactiveCN104340846AStrong and reliable connectionFirmly connectedCosmonautic vehiclesSystems for re-entry to earthLimited structuresMechanical engineering

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Steel cable guide mechanism and building curtain wall fixing device consisting of steel cable guide mechanism

The invention discloses a steel cable guide mechanism and a building curtain wall fixing device consisting of the steel cable guide mechanism. The steel cable guide mechanism comprises a fixed seat with open slots, and guide wheels which are arranged in the open slots, wherein the guide wheels are rotatably connected with the fixed seat and the number of the guide wheels is one or two. The building curtain wall fixing device comprises a steel cable with two ends which are fixedly arranged on a structural member main body, and the steel cable guide mechanism which is used for positioning the steel cable, wherein the steel cable guide mechanism is fixedly arranged on the structural member main body. The steel cable guide mechanism provided by the invention is used for a vertical steel cable. When external force is applied to the vertical steel cable, pressure is applied to the guide wheel on any side and the vertical steel cable moves up and down, the guide wheel can rotate; and when the external force disappears, the guide wheel rebounds to the original position. Therefore, the friction of the steel cable at a bearing point becomes rolling friction; if sector-shaped wheels are used, the contact area between the steel cable and the guide wheels can be increased within a limited structural space and the stress state of the steel cable can be improved; and since the guide wheels are made of a material such as aluminum, copper or engineering plastic which is softer than the material of the steel cable, the wear of the steel cable can be reduced as much as possible.

Owner:SHENZHEN SANXIN FACADE ENG

Fixture for security and fast installation of CT sample

PendingCN110631902AEasy to installSafe installationMaterial strength using tensile/compressive forcesMating connectionEngineering

The invention discloses a fixture for security and fast installation of a CT sample. The fixture for security and fast installation of the CT sample includes a chuck assembly and a U-shaped fixture; the chuck assembly includes two chucks and two pins that are cooperated and connected; the two chucks are separately connected to the base and top chuck of a universal testing machine; each chuck is provided with two through holes; the ends of the two sides of the U-shaped fixture extend outward to form protrusions, and the size of each protrusion matches the through hole; the two protrusions of the U-shaped fixture are inserted into the through holes corresponding to the two chucks; the U-shaped fixture is provided with an inner cavity for accommodating the CT sample; and the CT sample is provided with a mounting hole for mounting a pin. According to the invention, the U-shaped fixture is first installed and fixed on the chuck assembly by using a fixture with a limited structure; and thenthe CT sample is put into the fixture and fixed with the pin; therefore, the operation is faster, more accurate and easier, the safety of the experimental operation is greatly improved, and the injuryof the fingers of an experimenter caused by clamping is avoided; and meanwhile, the fixture for security and fast installation of the CT sample is provided, and the automated experiment on fracture toughness is possible.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com