Nondestructive tracking and evaluation method for quality of antenna housing made of composite material

A composite material and evaluation method technology, which is applied in the field of non-destructive tracking and evaluation of the quality of quartz fiber reinforced silica composite radome, to achieve the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

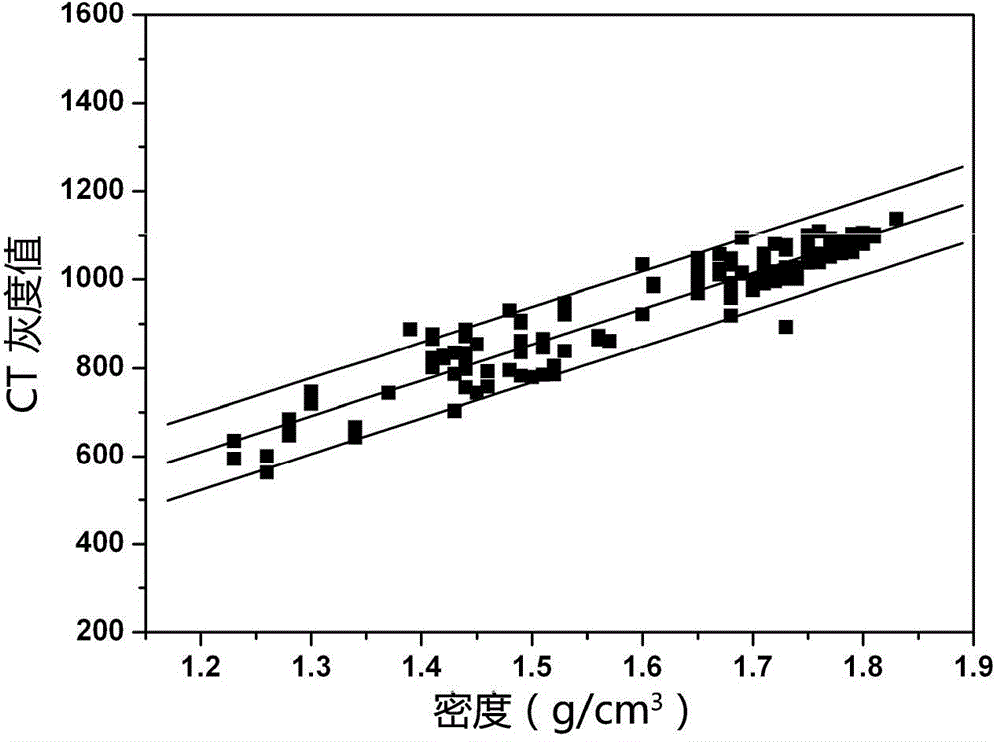

[0052] (1) Preparation of standard samples of quartz fiber reinforced silica composites

[0053] The density of the finished product radome of quartz fiber reinforced silica-based composite material is 1.70~1.90g / cm 3 Within the range, the density of the reinforcement fabric is 0.90~1.20g / cm 3 , in order to determine the numerical relationship between the density of the radome material (including the reinforcement fabric) and the CT gray value, the same preparation process as that of the radome was adopted, and the density distribution was 0.90-1.90g / cm 3 For the standard samples (including reinforcement fabrics) within the scope, the shape of the samples is a cube with a side length of 20mm.

[0054] (2) Determine the test conditions

[0055] Considering the density distribution of the standard sample, after conducting a large number of tests to optimize the test parameters, the test parameters are selected as follows: voltage 120±20KV, current 200±60mA, reconstruction matr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com