Patents

Literature

354 results about "Picric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Picric acid is an organic compound with the formula (O₂N)₃C₆H₂OH. Its IUPAC name is 2,4,6-trinitrophenol (TNP). The name "picric" comes from the Greek πικρός (pikros), meaning "bitter", reflecting its bitter taste. It is one of the most acidic phenols. Like other highly nitrated organic compounds, picric acid is an explosive, hence its primary use. It has also been used in medicine (antiseptic, burn treatments) and dyes.

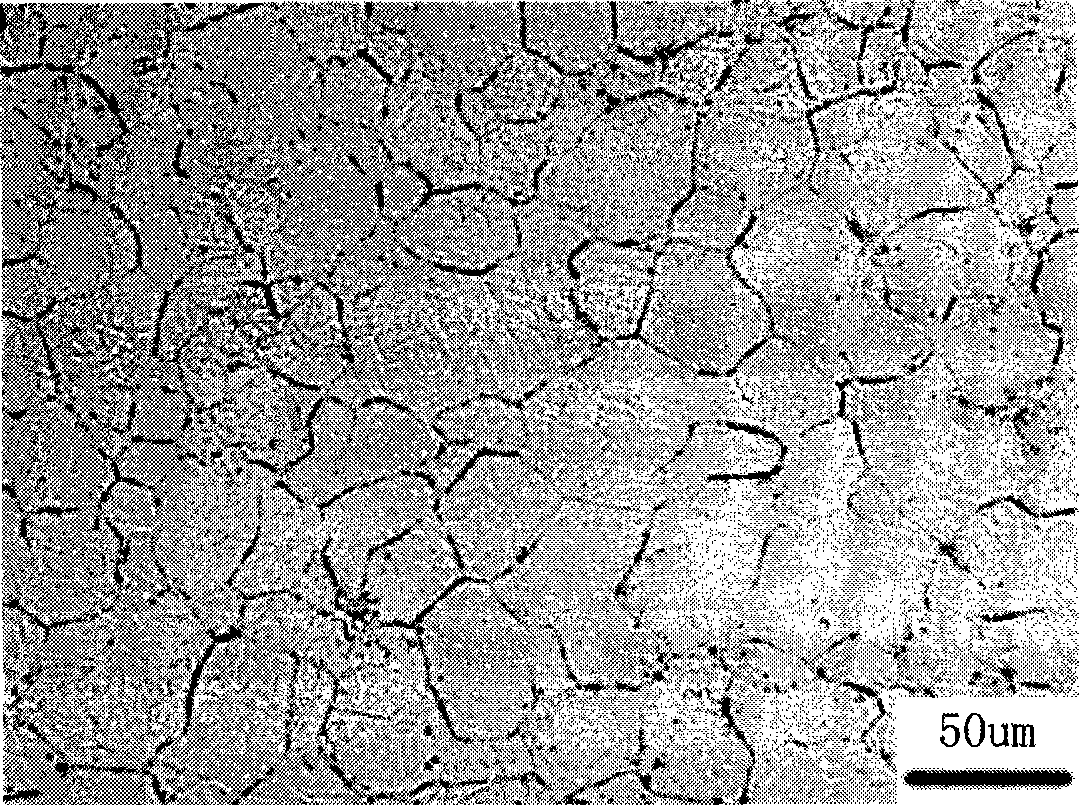

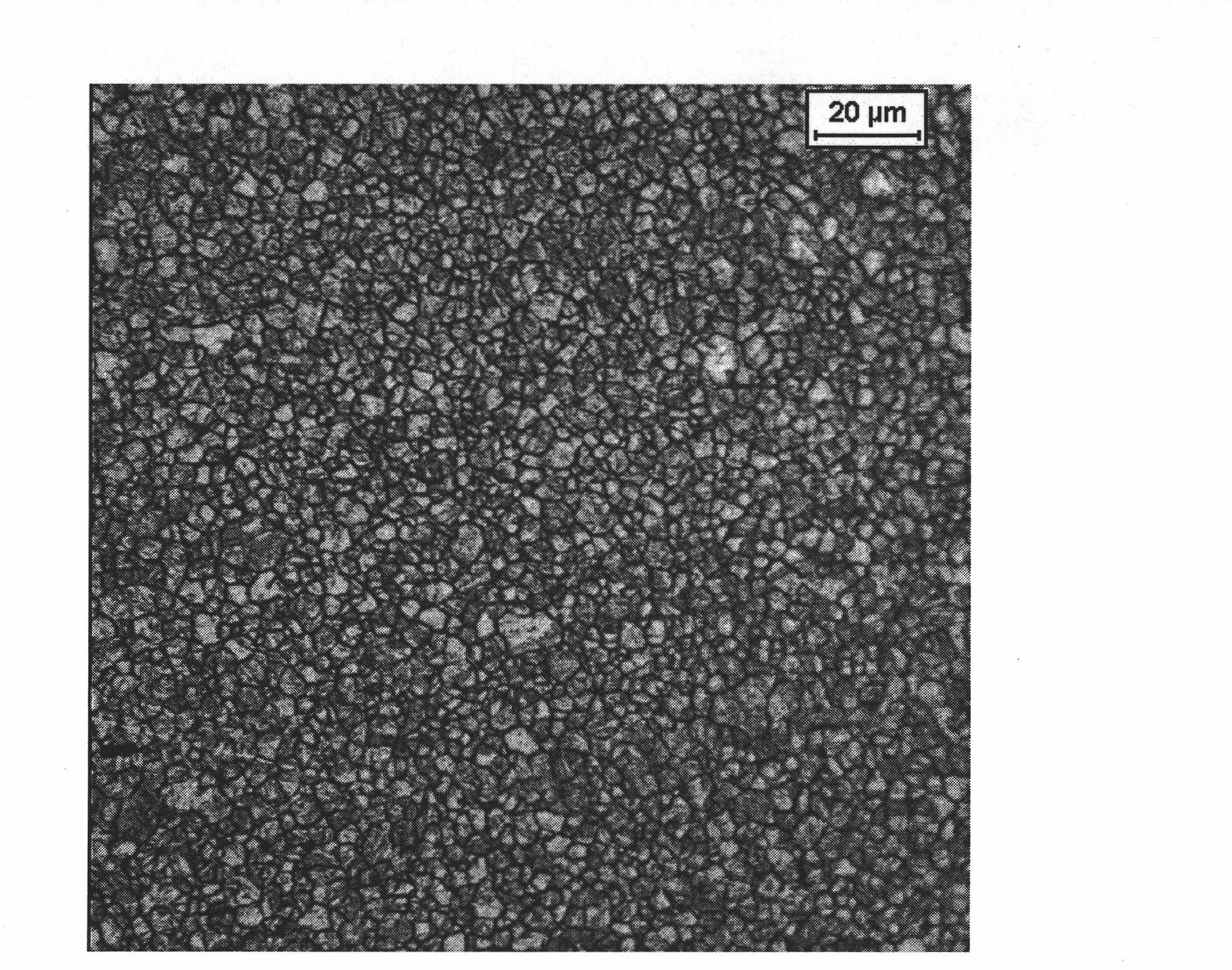

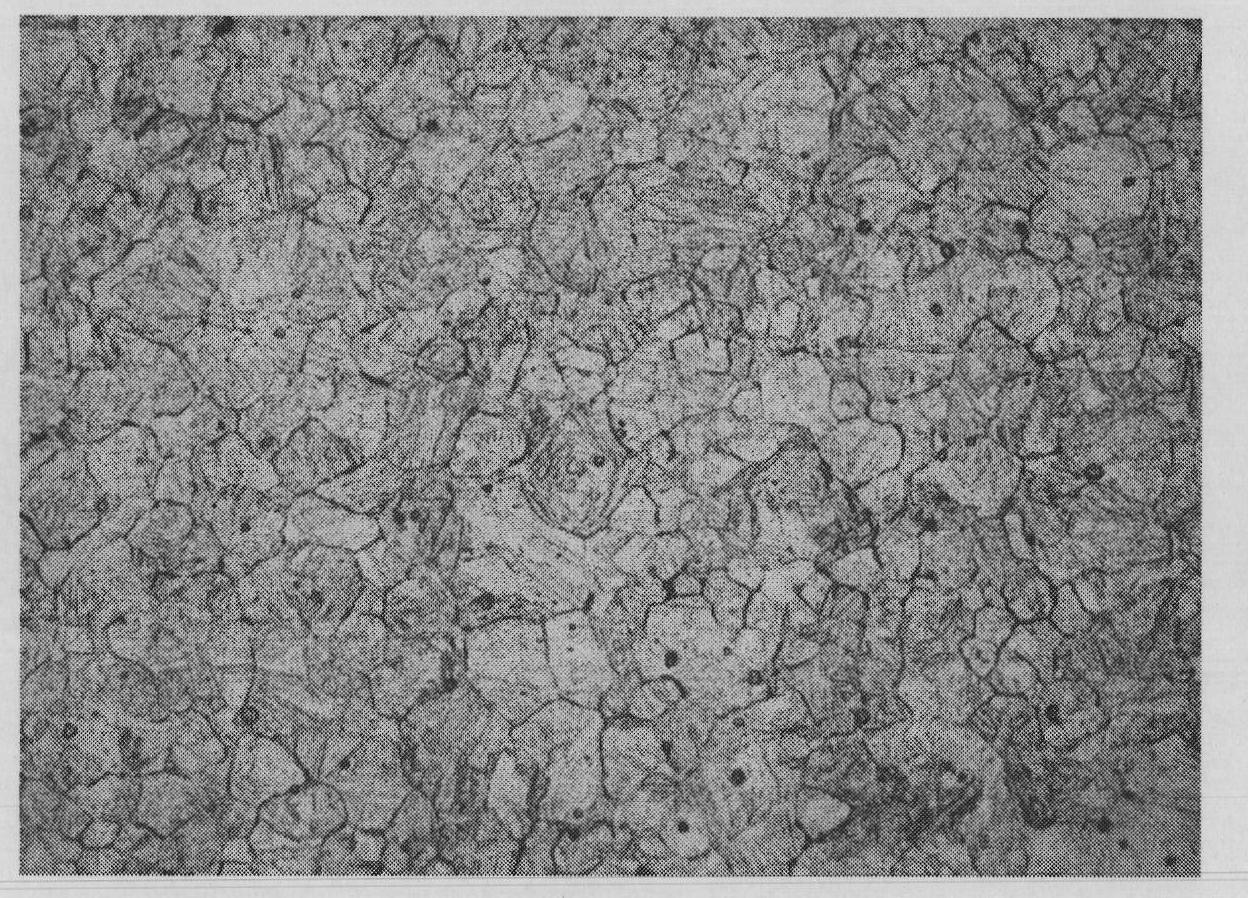

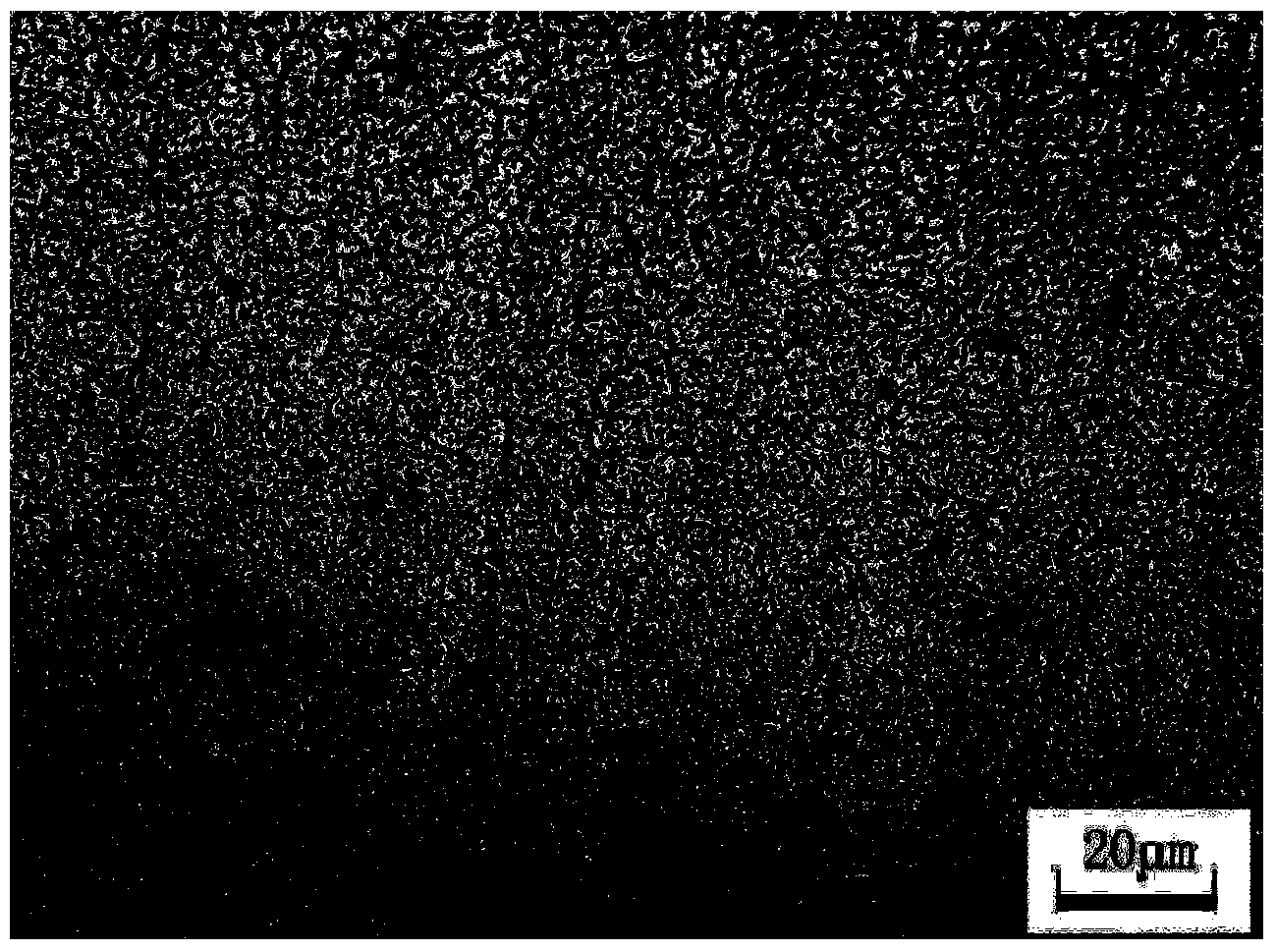

Method for displaying high-strength vessel slab original austenite crystal grain

ActiveCN101368889ADeep corrosionImprove solubilitySurface/boundary effectPreparing sample for investigationMaterials scienceDodecylbenzenesulfonic acid

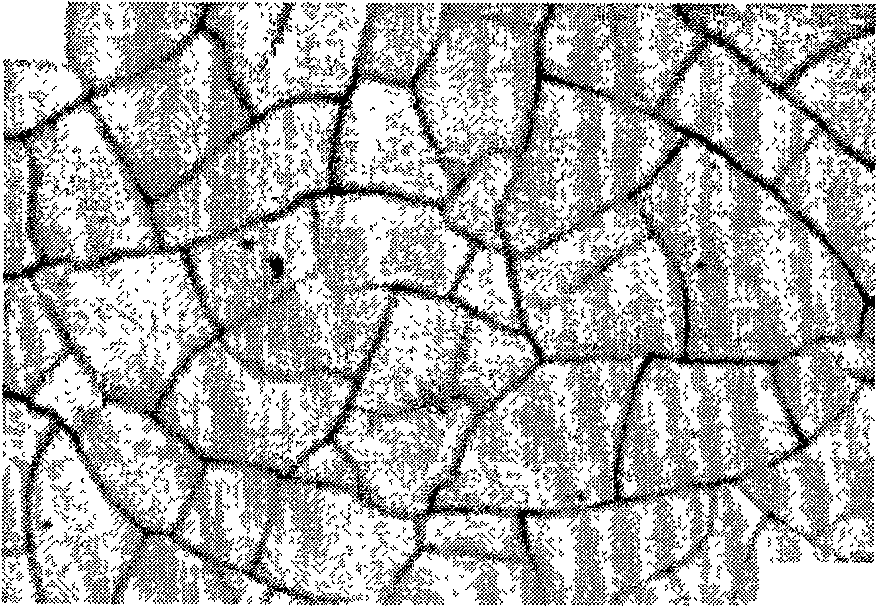

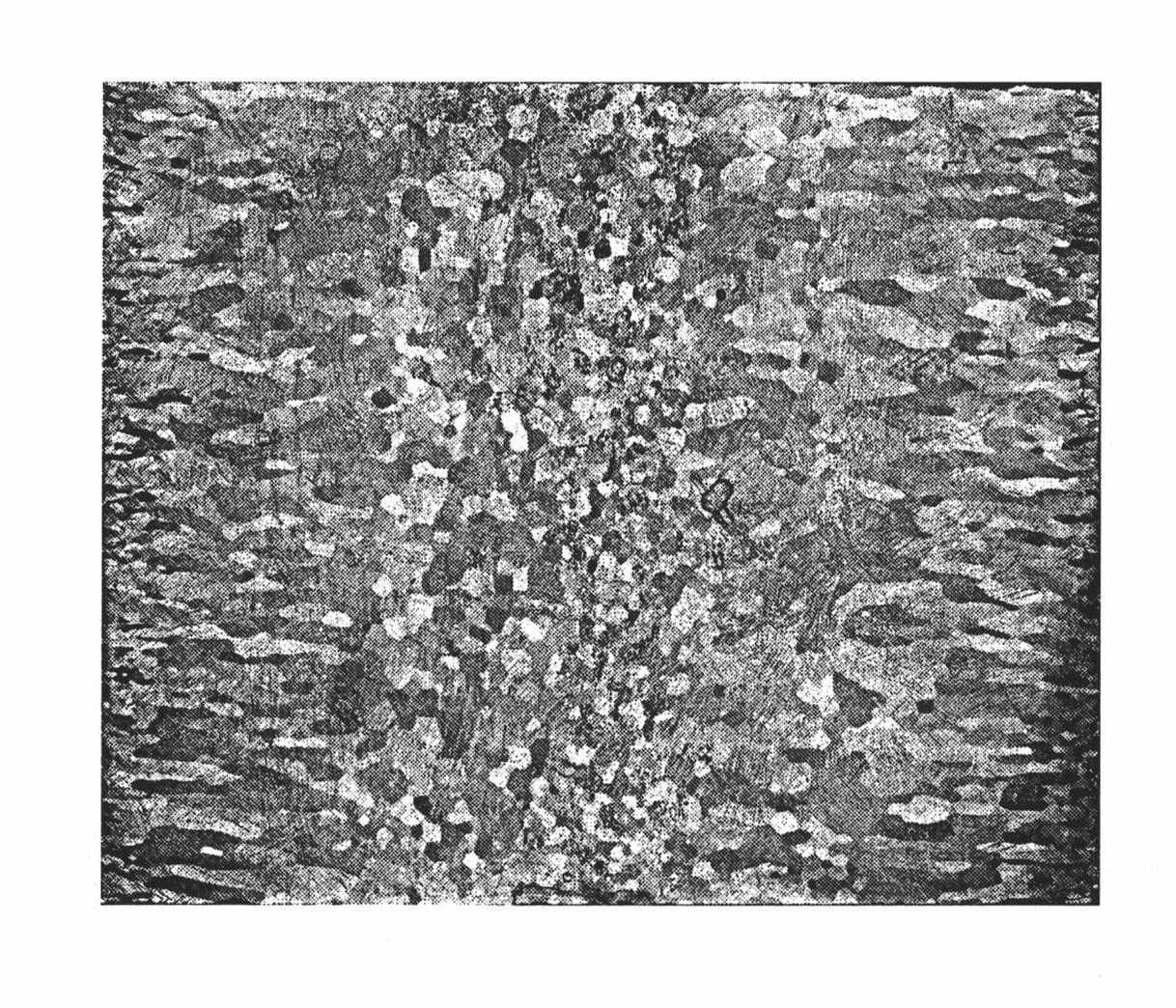

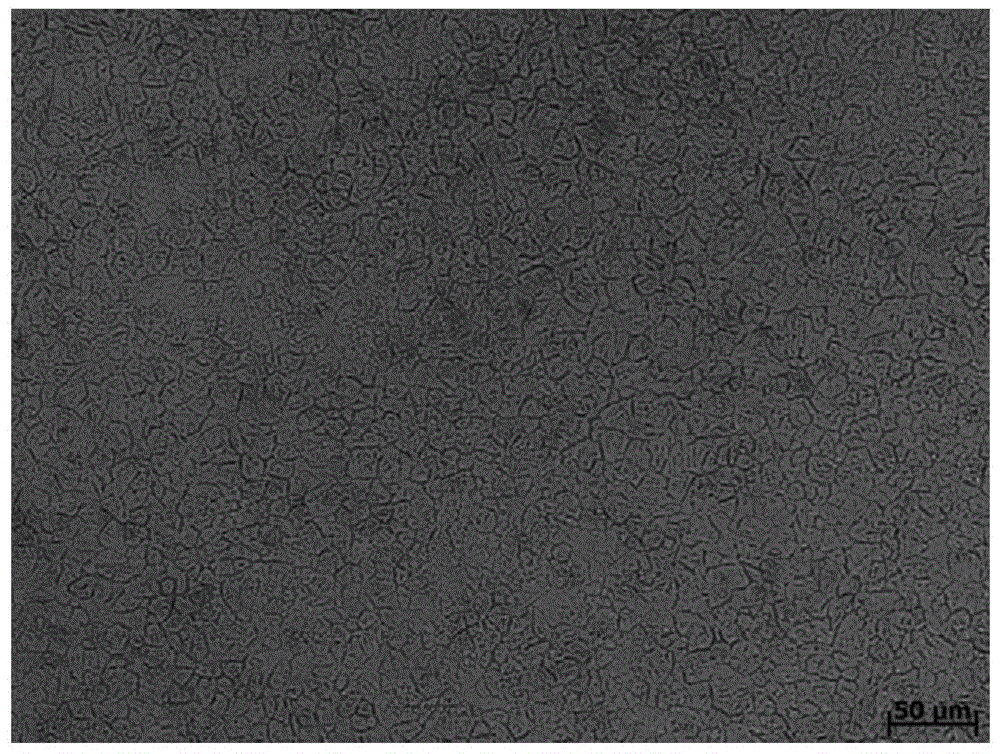

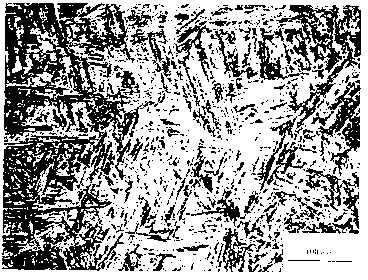

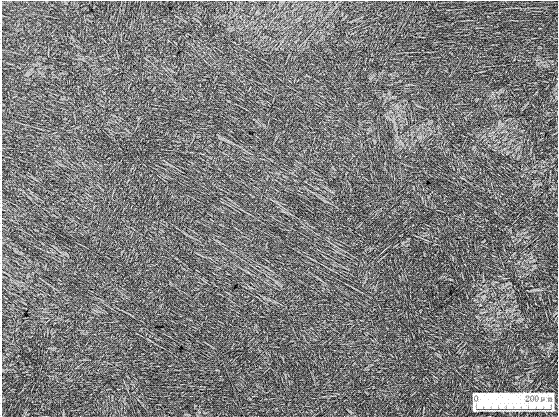

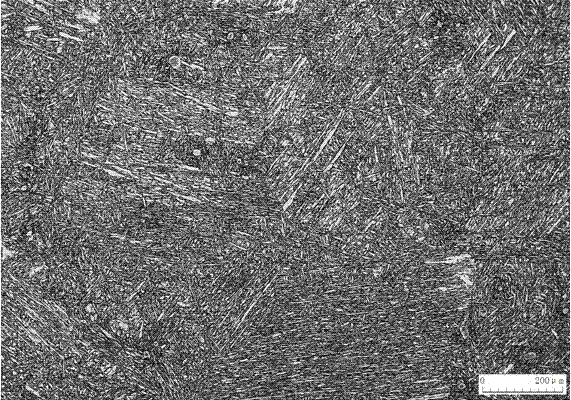

The invention relates to a display method used for preparing high-intensity ship plate metallographic samples and the original austenite grains, belonging to the technical field of metallographic sample preparation. The invention has the following technological steps: coarse grinding, fine grinding, polishing and corrosion; the polished specimen is put in the etching solution at 70-80 DEG C; the formula of the etching solution comprises 100ml of distilled water, 5-7g of picric acid, 0.5-1.5ml of hydrochloric acid, 3-5g of SDBS, 5-15g of Seagull paste shampoo and 0.3-1ml of hydrogen peroxide; after being etched for 1-2 minutes, the surface of the specimen is dimmed, and the specimen is taken out, cleaned with alcohol and then dried; and the relatively clear original austenite structure can be observed under a microscope. The invention has the advantages of solving the problem of different display of the high-intensity ship plate austenite grains and clearly displaying the austenite structure; besides, the invention is easy and simple to implement.

Owner:NANTONG WANBAO IND

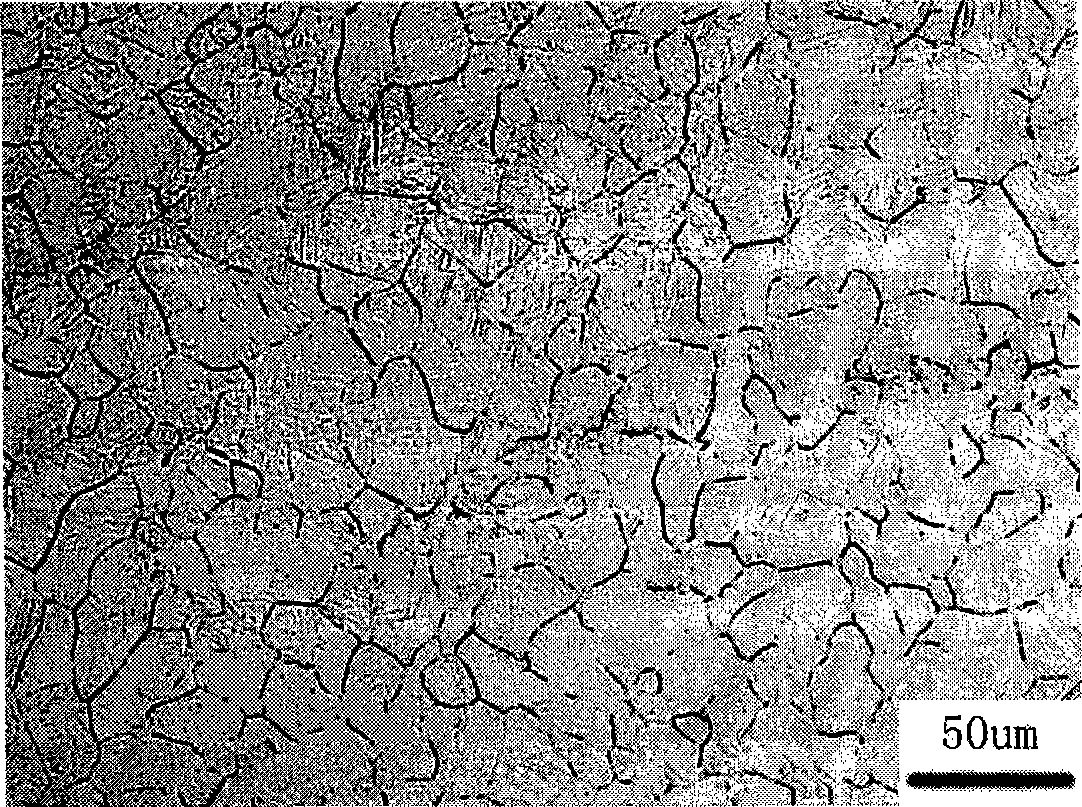

Metallographic etched process for displaying G Cr15 original austenite grain border

InactiveCN101187606AShorten the timeGood reproducibilitySurface/boundary effectPreparing sample for investigationAlcoholMetallography

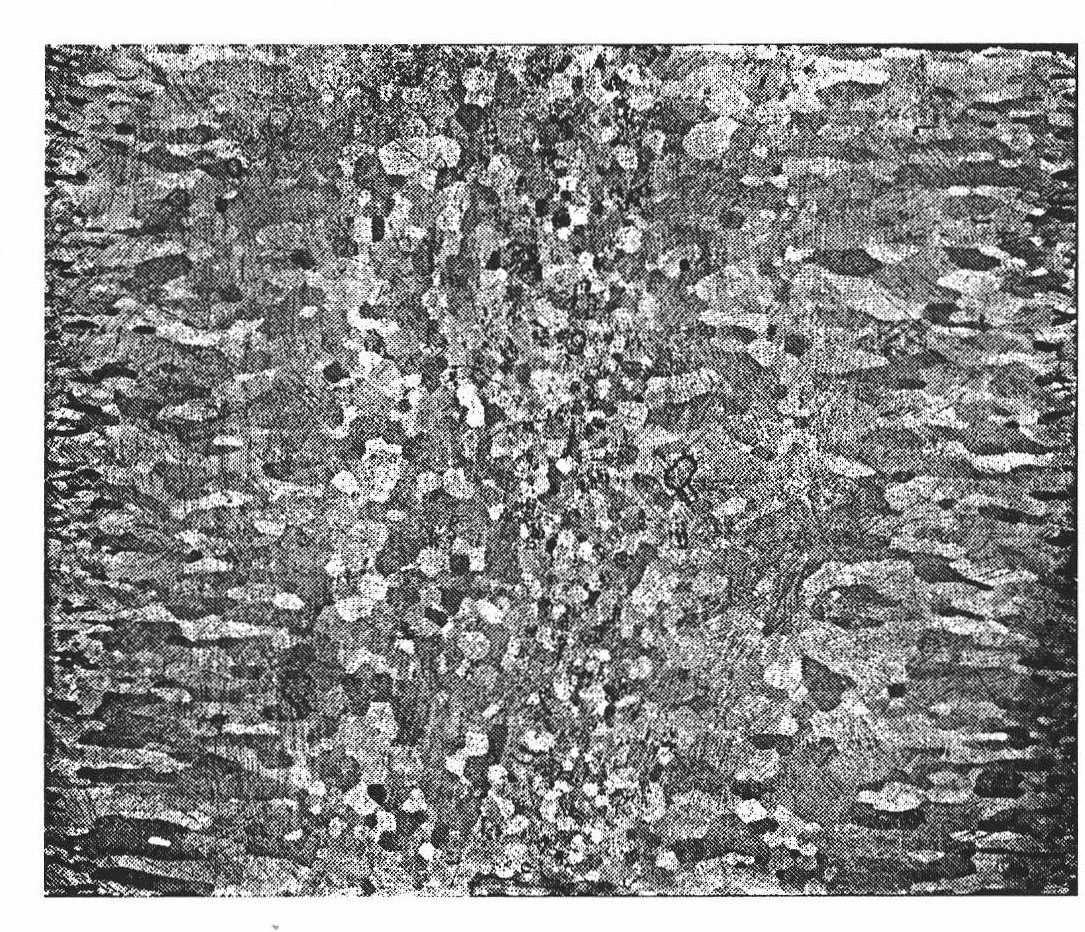

A metallographic corrosion method for displaying a GCr15 original austenitic grain boundary comprises adding picric acid 5g into distilled water100ml and mixing continuously, then adding sodium dodecyl benzene sulfonate 5ml 50% and mixing, finally adding ferric chloride 2g, and using after placing for 24 hours. A sample is grinded roughly, grinded finely, polished, cleared, dried, immersed into caustic erodent for 2-5 minutes according to normal method under a quenching tempering condition until etched surface is changed into silver grey, cleaned up through flowing water, cleaned with alcohol 95%, and dried. If the sample is over-corroded, polishing paste W0.5-1.0 or metallographic polishing egent0.5-1.0 is added on silk polishing cloth, the sample is polished slightly with hands, then cleaned with alcohol 95%, and dried. According to practical condition, grain granularity measurement can adopt methods of picture contrast, grid, intercept, quantitative metallography, and the like, to assess according to relevant standards.

Owner:LUOYANG BEARING SCI & TECH CO LTD

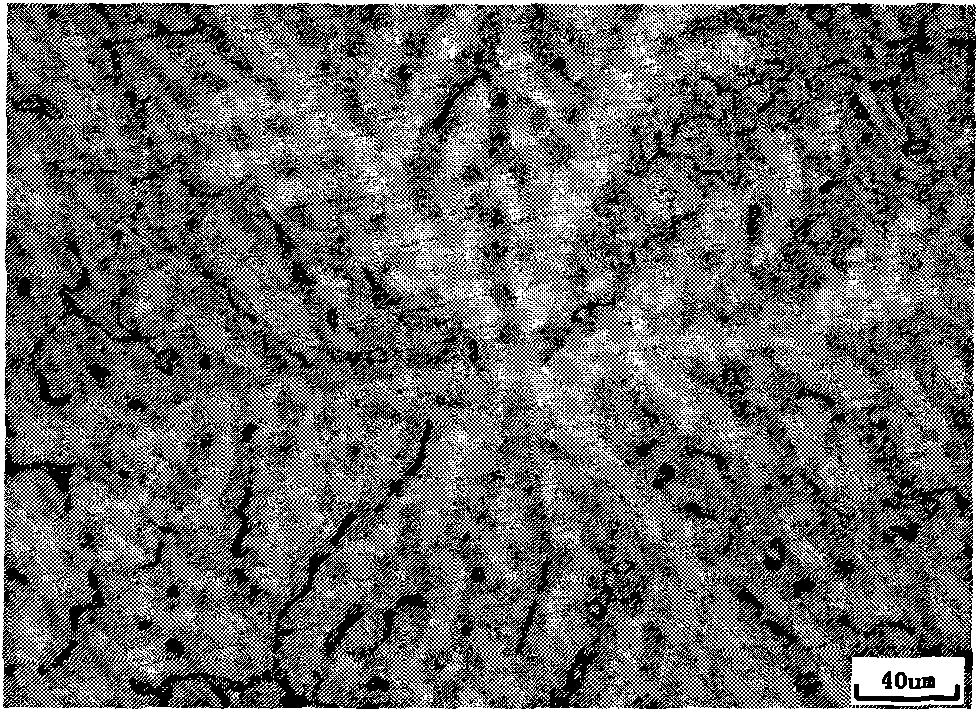

Corrosion agent of high-steel-level pipeline steel metallographic structure and display method

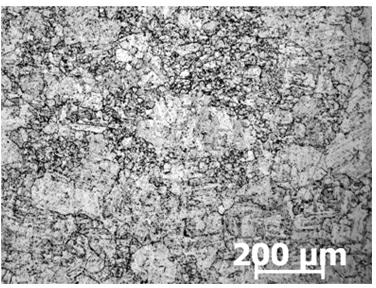

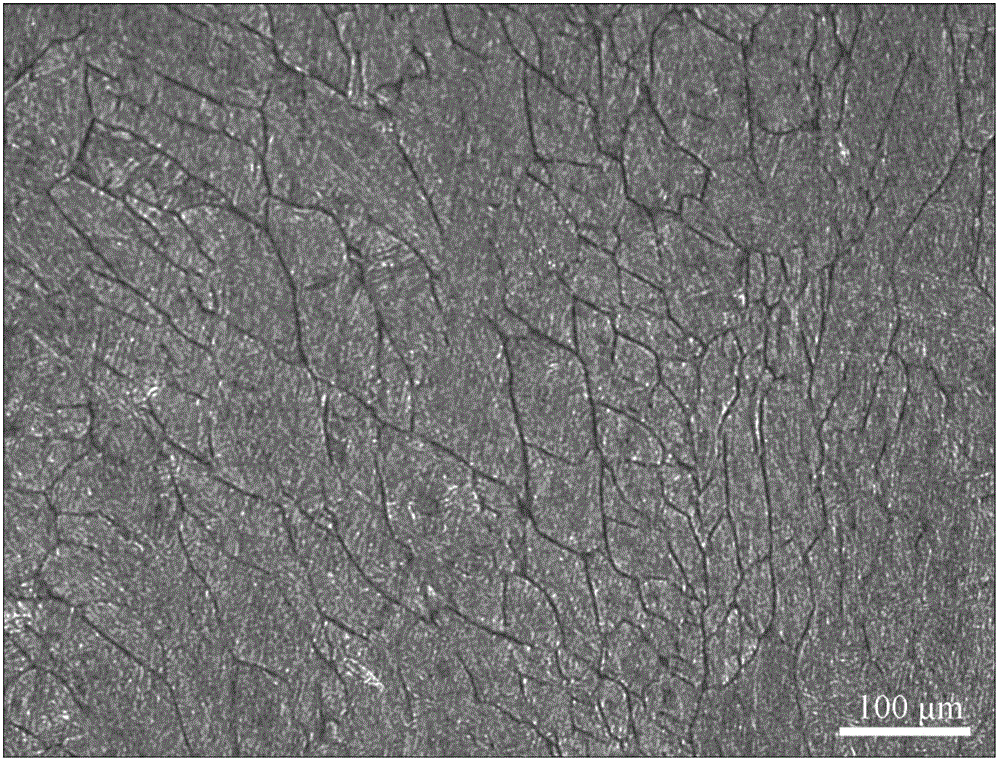

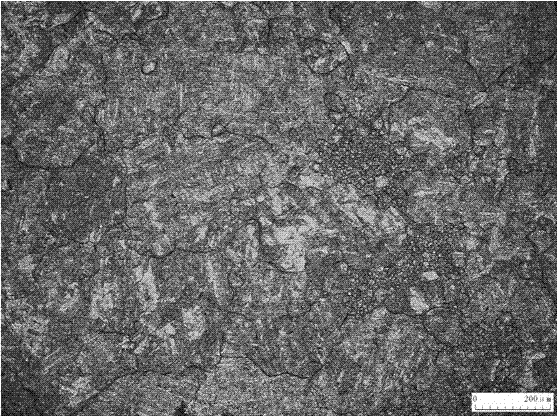

ActiveCN101995349ADirect analysisDirect comparisonPreparing sample for investigationAlcoholGrain boundary

The invention provides a corrosion agent of a high-steel-level pipeline steel metallographic structure and a display method. The corrosion agent consists of 1 to 10g of analysis pure picric acid with the purity higher than or equal to 99.8 percent, 100ml of deionized water, 0.1 to 2ml of 10 percent diluted hydrochloric acid and 5 to 25ml of liquid detergent. The display method comprises the following steps of: 1. preparation of the corrosion agent: adding and dissolving 1 to 10g of the analytically pure picric acid into 100ml of the deionized water, uniformly stirring, then dripping 5 to 25mlof the liquid detergent, adding 0.1 to 2ml of the diluted hydrochloric acid, and uniformly stirring; 2. specimen processing: carrying out corrosion for 0.5 to 5 seconds in nitric acid alcohol solution after the specimen polishing, carrying out flowing flushing by clean water, and repeating the operation for 2 to 5 times in such a way; and 3. specimen corrosion: heating the corrosion agent to 50 to 100 DEG C, maintaining the constant temperature at the same time of soaking the specimen into the corrosion agent for 60 to 600 seconds, and continuously wiping the surface of the specimen by cotton. When the invention is adopted, not only various ferritic structures but also the original austenitic grain boundaries can be displayed on the high-steel-level pipeline steel metallographic structure.

Owner:ANGANG STEEL CO LTD

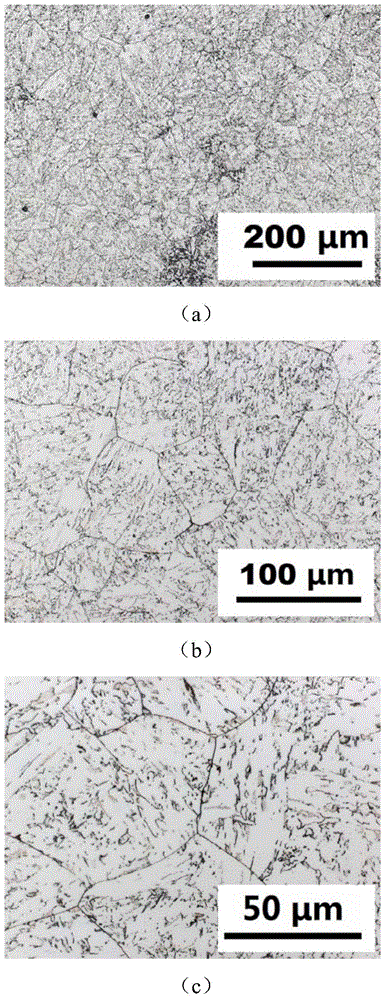

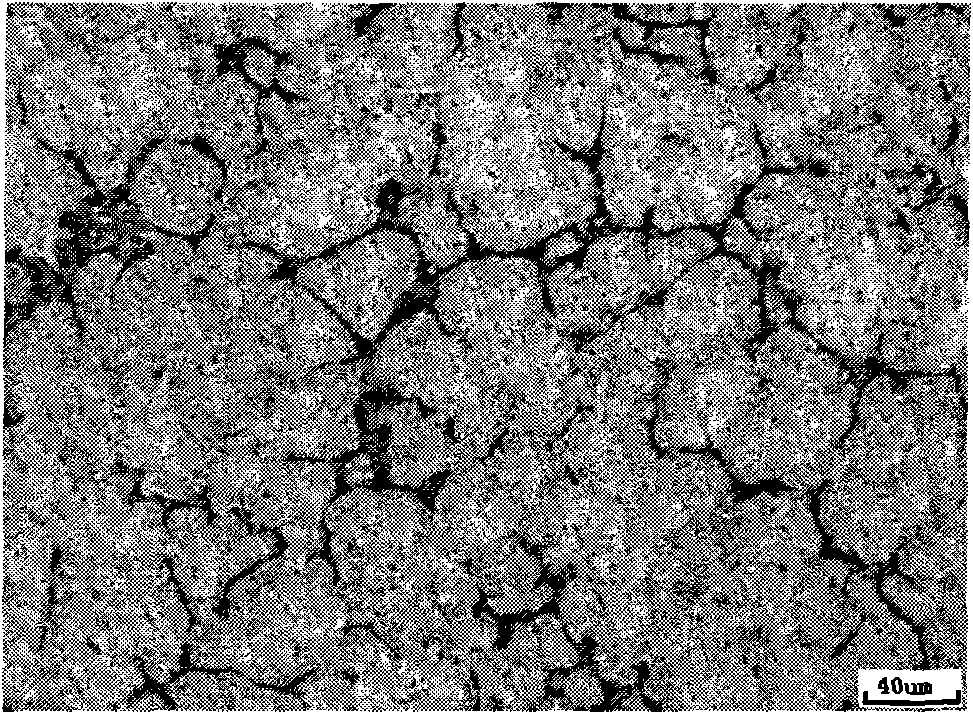

Metallographic corrosion method for clearly displaying original austenite grain boundary of NiCrMoV type rotor steel

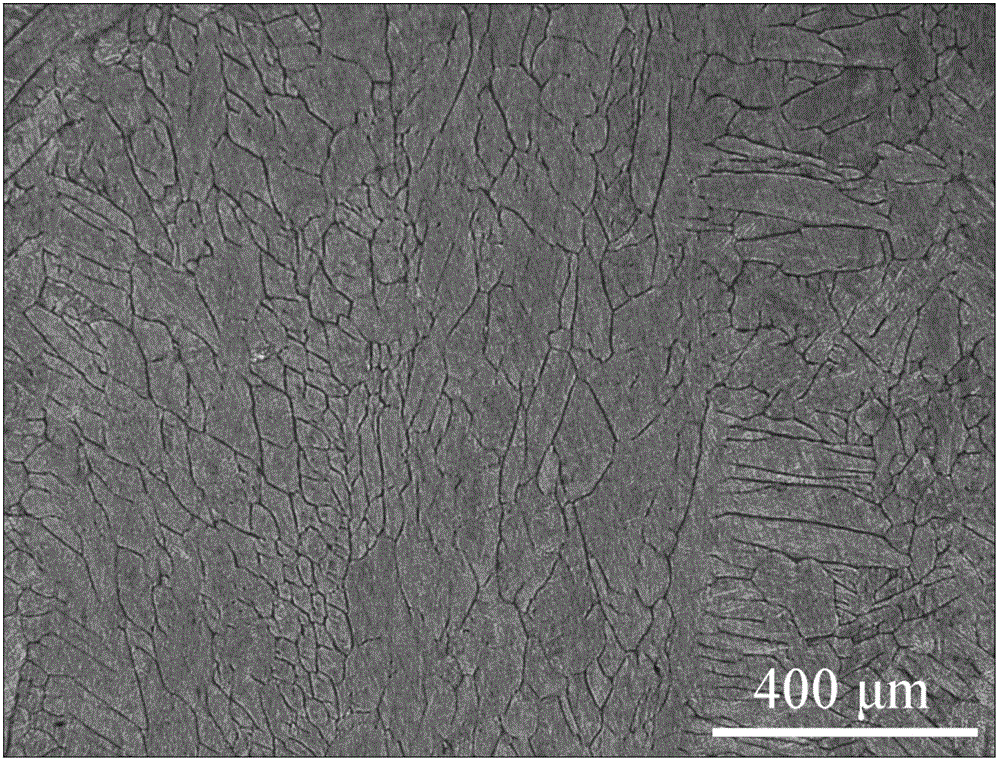

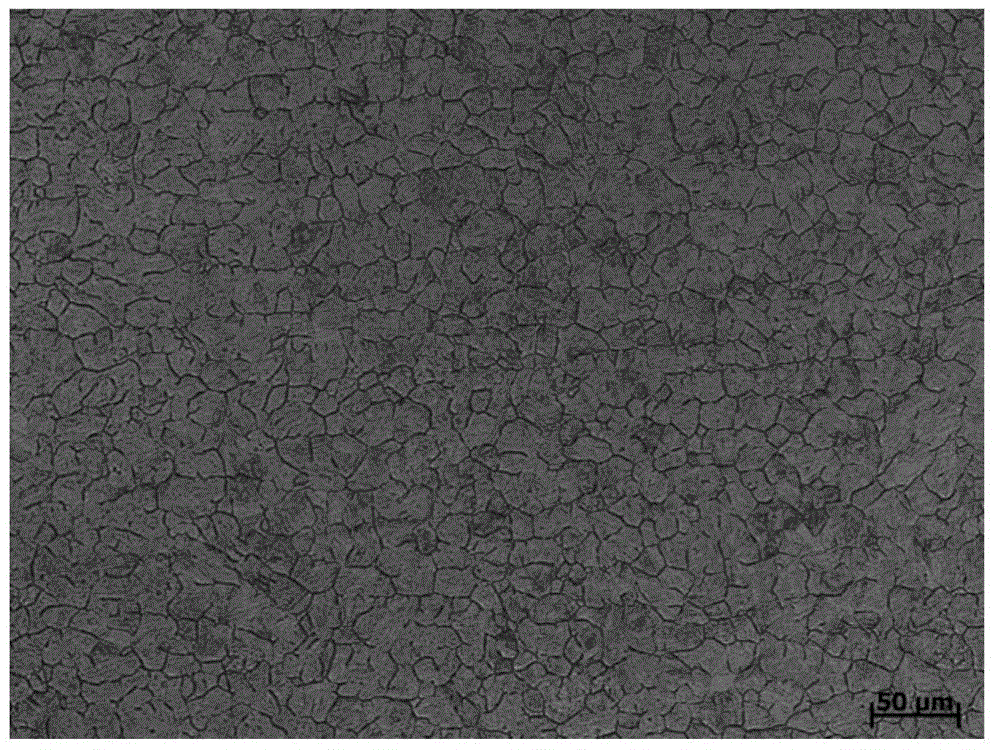

The invention relates to a metallographic corrosion method for clearly displaying the original austenite grain boundary of a NiCrMoV type rotor steel, and belongs to the field of metallographic sample preparation. The method comprises the steps of: coarse grinding, fine grinding, polishing and corroding; putting a polished sample into a corrosive liquid of 75 DEG C, wherein the formula of the corrosive liquid comprises 200ml of distilled water, 5g of picric acid, 2ml of 5% diluted hydrochloric acid and 4g of sodium dodecyl benzene sulfonate; etching for 2minutes, taking the sample out, cleaning the sample with flowing water, cleaning the sample with alcohol and drying; and observing the clear original austenite grain boundary through an optical microscope. The method has the advantages that a difficult displaying problem of the original austenite grains of the NiCrMoV type rotor steel is solved, the original austenite grain boundary can be very clearly displayed, and the method is simple and practicable.

Owner:SHANGHAI UNIV +1

Corrosive agent for displaying 9% Cr steel original austenite grain boundary and application thereof

ActiveCN102517586AEasy grain size ratingGood effectPreparing sample for investigationAustenite grainDodecylsulfonic acid

The invention discloses a corrosive agent for displaying 9% Cr steel original austenite grain boundary and an application thereof. The corrosive agent is prepared by fully mixing the following components of: 60-80ml of H2O, 4-8ml of 36 wt% HCl, 2-4g of FeCl3, 0.2-0.5g of picric acid, and 1.0-2.0g of sodium dodecanesulphonate. The corrosive agent provided by the invention can be used as a reagent for 9% Cr steel grain boundary to clearly display the original austenite grain boundary of large crystal grain, large and small mixed crystal grain and small crystal grain of a sample. Under 100 times, it is easy to carry out grain size rating and the effect is good.

Owner:SHANGHAI BOILER WORKS

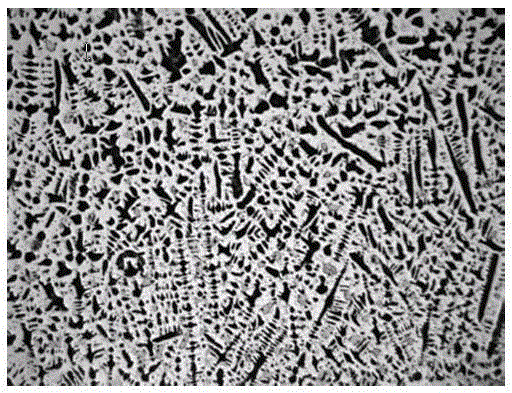

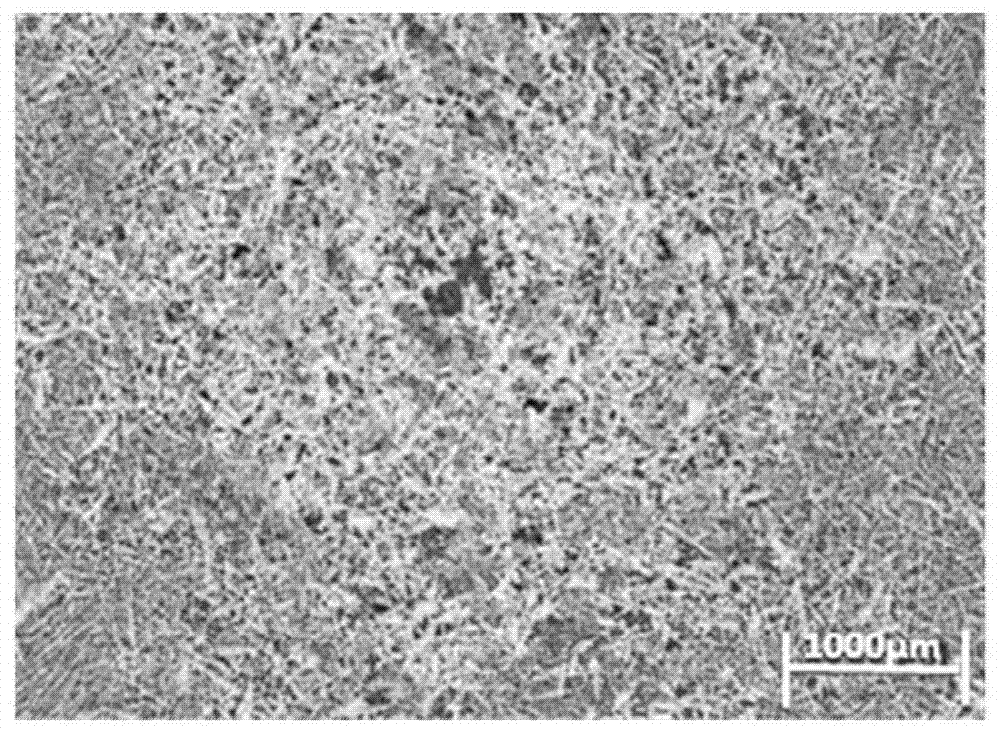

Corrosive capable of displaying ultra low carbon steel solidification arborescent structure and preparation method thereof

ActiveCN102023112ASimplify the manufacturing processReduced finish requirementsPreparing sample for investigationTin(II) chlorideMaterials science

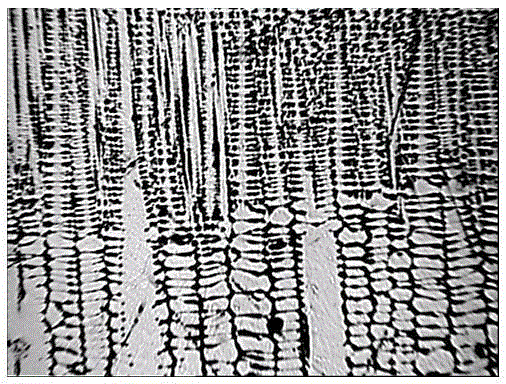

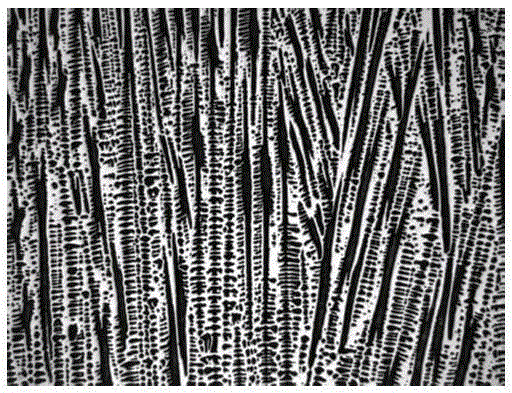

The invention discloses a corrosive capable of displaying an ultra low carbon solidification arborescent structure and a preparation method thereof. The corrosive is prepared from the following components: picric acid, stannous chloride, copper chloride, hydrochloric acid, surfactant, absolute ethyl alcohol and distilled water. The preparation method is as follows: taking a specified amount of the distilled water, and equally dividing the distilled water into two parts; mixing and putting solid medicament into a glass container according to fixed quantity, and adding one part of the distilledwater into the solid mixed medicament to dissolve the medicament; adding a specified amount of the absolute ethyl alcohol into another part of spare distilled water; adding a hydrochloric acid solution into the absolute ethyl alcohol solution; mixing the ethyl alcohol and the hydrochloric acid solution which are poured into an aqueous solution containing the solid medicament; fully stirring; and finally adding the surfactant to finish preparing. By utilizing the reagent provided by the invention, the solidified arborescent structure forms of ultra low C, S, P continuous casting steel billets can be displayed clearly, a finish requirement on sample surface is lowered, the sample preparation working procedure is simplified and the larbour intensity of operators is lowered.

Owner:ANGANG STEEL CO LTD

Etching agent for rapidly displaying ultrafine austenite grains and thermal erosion method thereof

InactiveCN102400146AQuick and clear displayAccurately measure grain sizePreparing sample for investigationAlcoholAustenite grain

The invention discloses an etching agent for rapidly displaying ultrafine austenite grains and a thermal erosion method thereof. The etching agent comprises a saturated aqueous solution of picric acid, a saturated aqueous solution of CuCl2, HF acid and xylene, wherein, the volume ratio of the ingredients is 100-200:1-1.5:0.5-1.5:1-2. The thermal erosion method comprises the following steps: grinding and polishing a sample, then immersing the section in a 60-70 DEG C etching liquid for carrying out thermal erosion with the erosion time of 5-15 s, and then cleaning the section through wiping with anhydrous alcohol, and drying. According to the invention, the rapid and clear display of ultrafine-grained austenite can be realized by using a formula of a few reagents and reasonable assembly, and the invention provides reliable conditions for accurately measuring the grain size of ultrafine-grained austenite.

Owner:ANGANG STEEL CO LTD

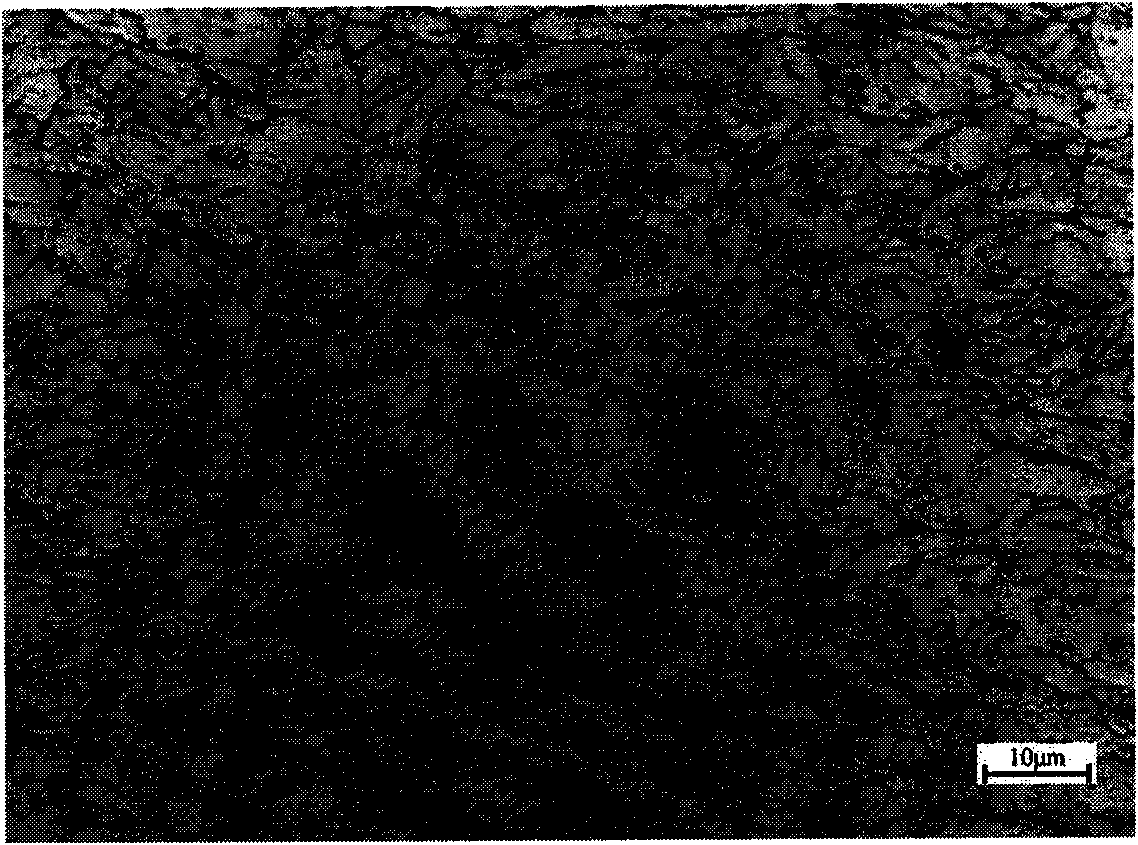

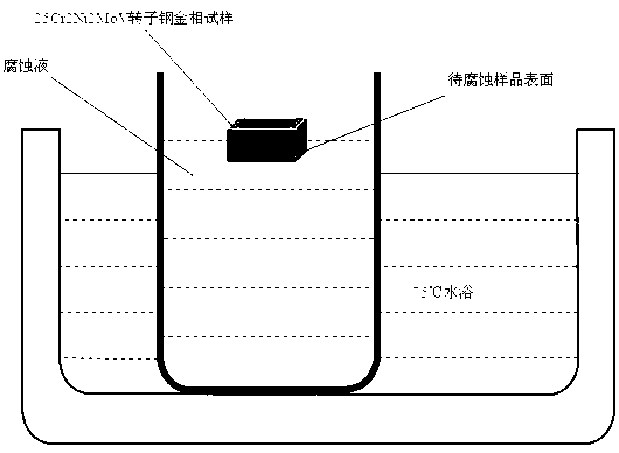

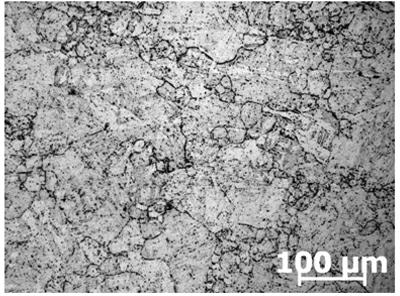

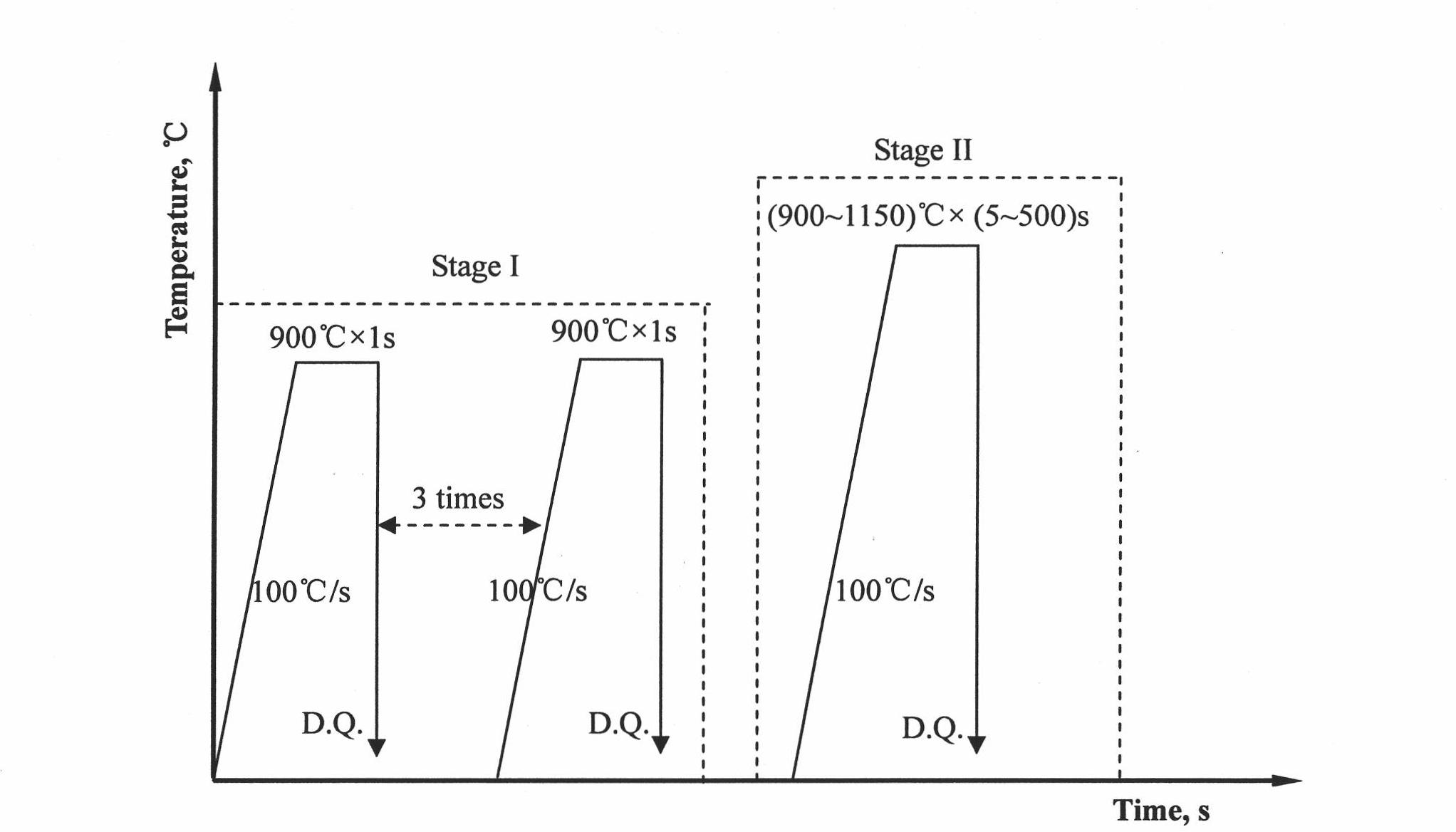

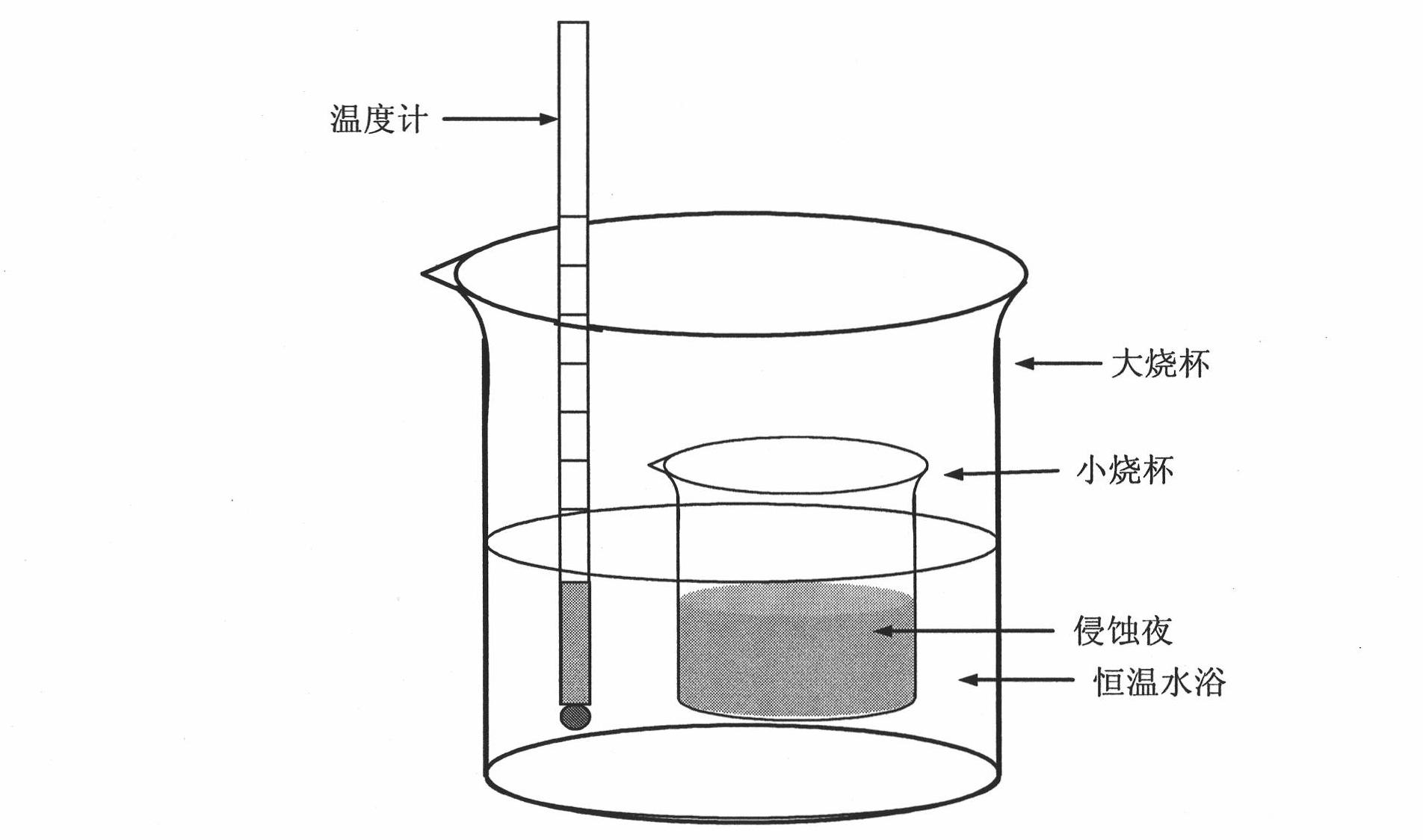

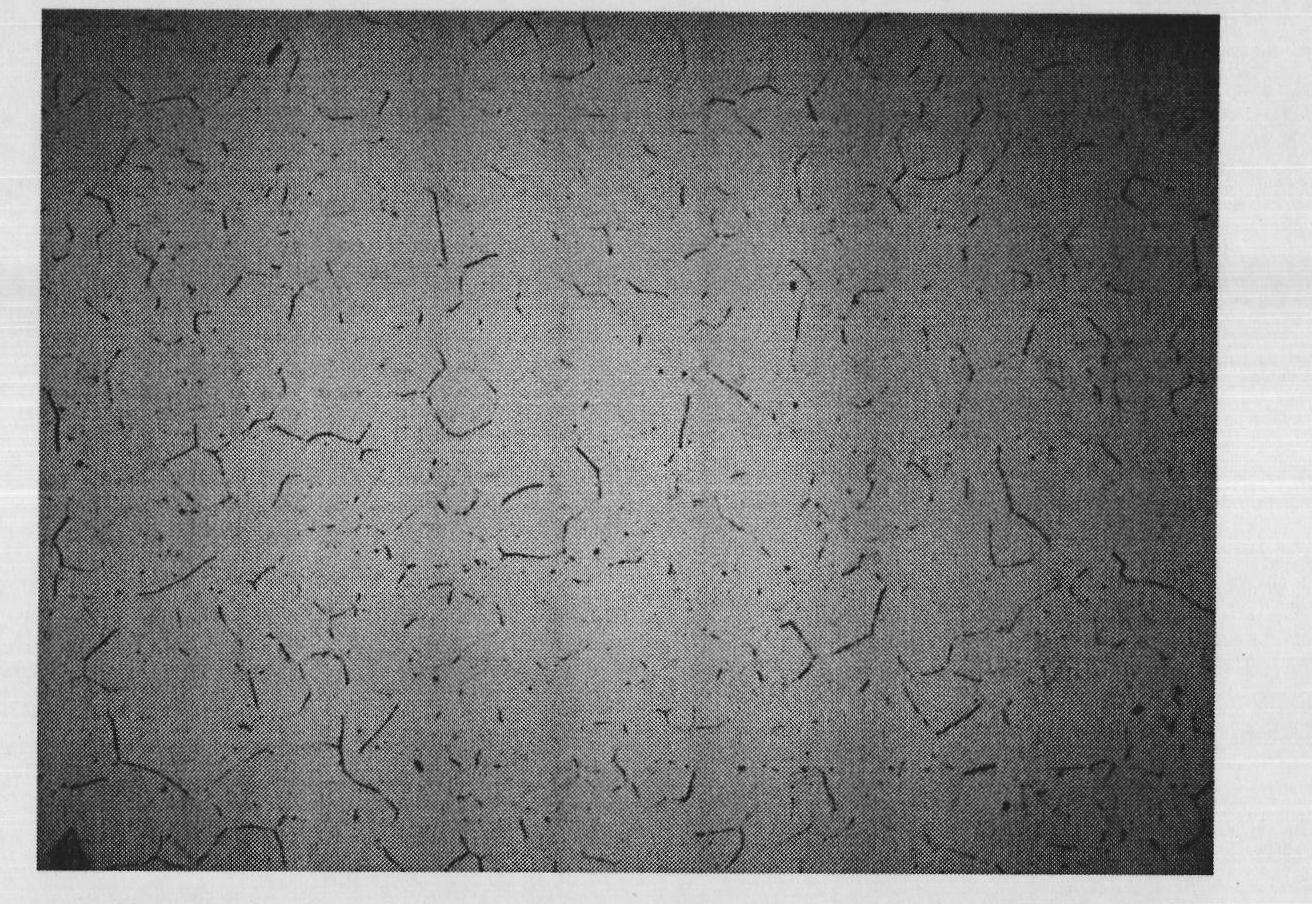

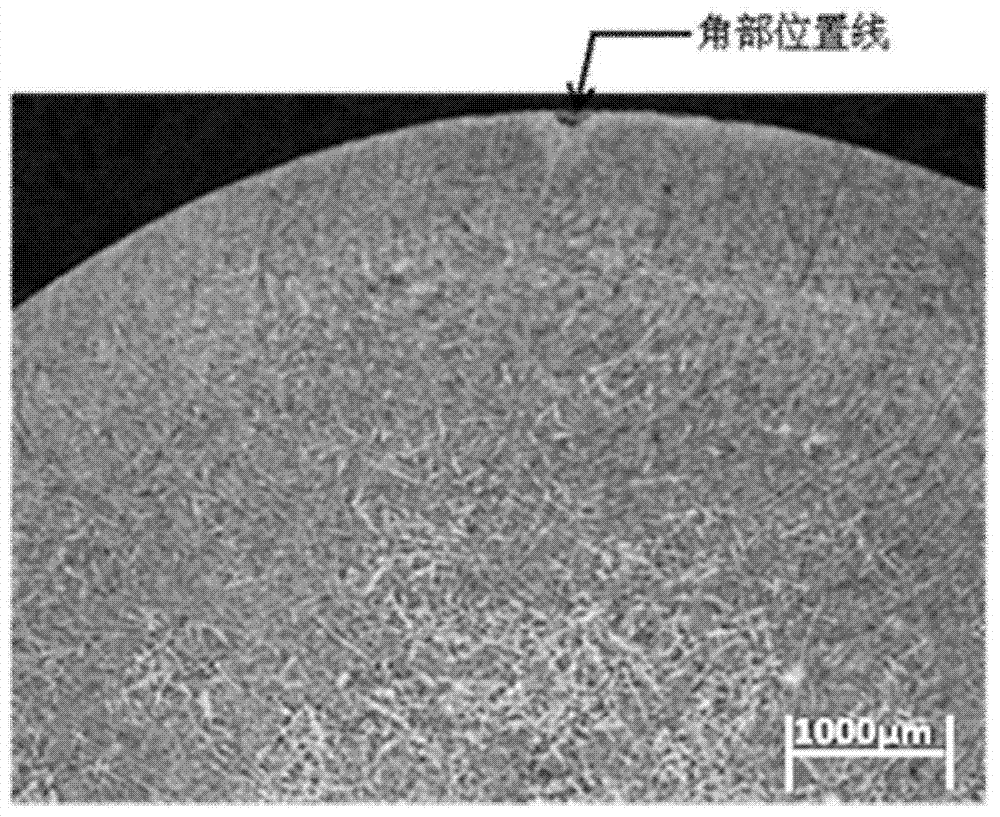

Method for displaying thermal deformation texture of steel used for nuclear power pressure container

ActiveCN102353566AAvoid direct contactPlay an inhibitory rolePreparing sample for investigationWater bathsAustenite grain

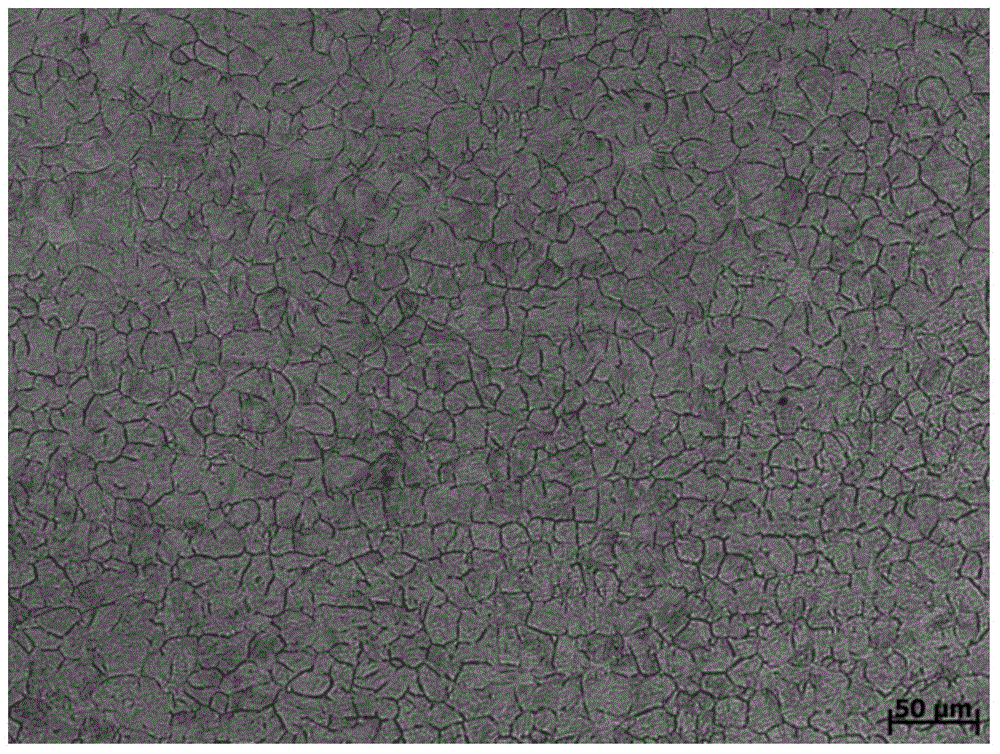

The invention relates to the metallic phase sample preparation and austenite crystal grain display technical field, concretely relates to a method for displaying original austenite crystal grains obtained by performing thermal deformation to a low carbon low alloy steel used for a nuclear power pressure container, and is used for solving the problem for displaying thermal deformation texture austenite crystal grain of SA 508-3 steel used for the nuclear power pressure container. The method of the invention comprises the steps of preparing a thermal deformation sample, grinding and polishing the metallographic sample, chemically etching the sample and mechanically polishing by selectivity. According to the reasonable ratio of a supersaturated picric acid solution to paste shampoo (the weight ratio of the picric acid to paste shampoo is 1:1) and the selection of the water-bath temperature (80-90 DEG C) and corrosion time (3-5 minutes), the original austenite crystal grain of a quenched texture obtained by performing the thermal deformation on SA 508-3 steel at the temperature of 800-1200 DEG C can be clearly displayed, and the method provides an important foundation for researching the recrystallization rule of the steel used for the nuclear power pressure container and optimizing the thermal deformation technology of the steel used for the nuclear power pressure container.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for displaying original austenitic grain boundary of martensitic heat-resistant steel

InactiveCN102721593AErosion speed is fastEasy to operatePreparing sample for investigationEtchingAlcohol

The invention relates to a method for displaying an original austenitic grain boundary of martensitic heat-resistant steel, and belongs to the technical field of metallographic sample preparation. The method comprises the process steps of polishing and etching. A polished sample is put into an etching agent, the etching time is 5 to 10 seconds, and the sample is taken out when copper decorating the surface of the sample is observed, washed cleanly by alcohol and dried by blowing; and the clear original austenitic grain boundary can be observed under a metallographic microscope. According to the formula, the etching agent comprises the following components: 5 to 15 g of copper sulfate pentahydrate, 30 to 50 ml of hydrochloric acid and 50 to 70 ml of deionized water. The method has the advantages that the clear original austenitic grain boundary of the martensitic heat-resistant steel can be etched out at normal temperature while a martensitic structure is not displayed, the method is convenient to operate, and the corrosion rate of austenite is higher than that of picric acid solution.

Owner:UNIV OF SCI & TECH BEIJING

Method for clearly displaying low carbon low alloy steel austenite crystal

InactiveCN101349621AGuaranteed product performancePreparing sample for investigationAustenite grainDistilled water

The invention relates to a method for clearly displaying lower carbon and low alloy steel austenite crystal, which belongs to the technical field of physical detection. The method is used to solve the problem that lower carbon and low alloy steel can not clearly display the austenite crystal thereof. The method comprises a quenching process and a corrosion process, which is characterized in that the proportion of corrosive agent in the process of corroding is that CrO3 8g-10g, NaOH 40g-50g, picric acid 1.6g-2g, epoxyethane 2ml-4ml and distilled water 80ml-100ml. The method adopts specific corrosive agent and is matched with a correct corrosion method, which can clearly display austenite grain boundary. The method fills a gap of low carbon alloy steel austenite grain boundary display technology, which provides an important theoretical basis for a manufacturing enterprise to research the influence of technological parameters to microstructure evolution when the steel is deforming, and plays an important function for producing low carbon alloy steel, reasonably controlling technological parameters and guaranteeing the property of products.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Medium-high carbon steel actual grain size developer and developing method

InactiveCN102103051ANovel ideaImprove performancePreparing sample for investigationMaterial analysis by optical meansHigh carbonMicroscopic observation

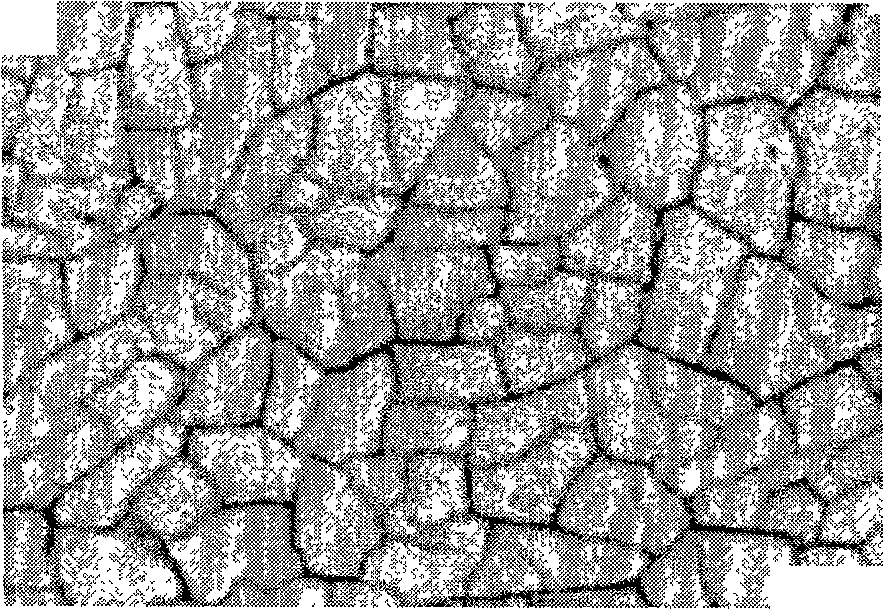

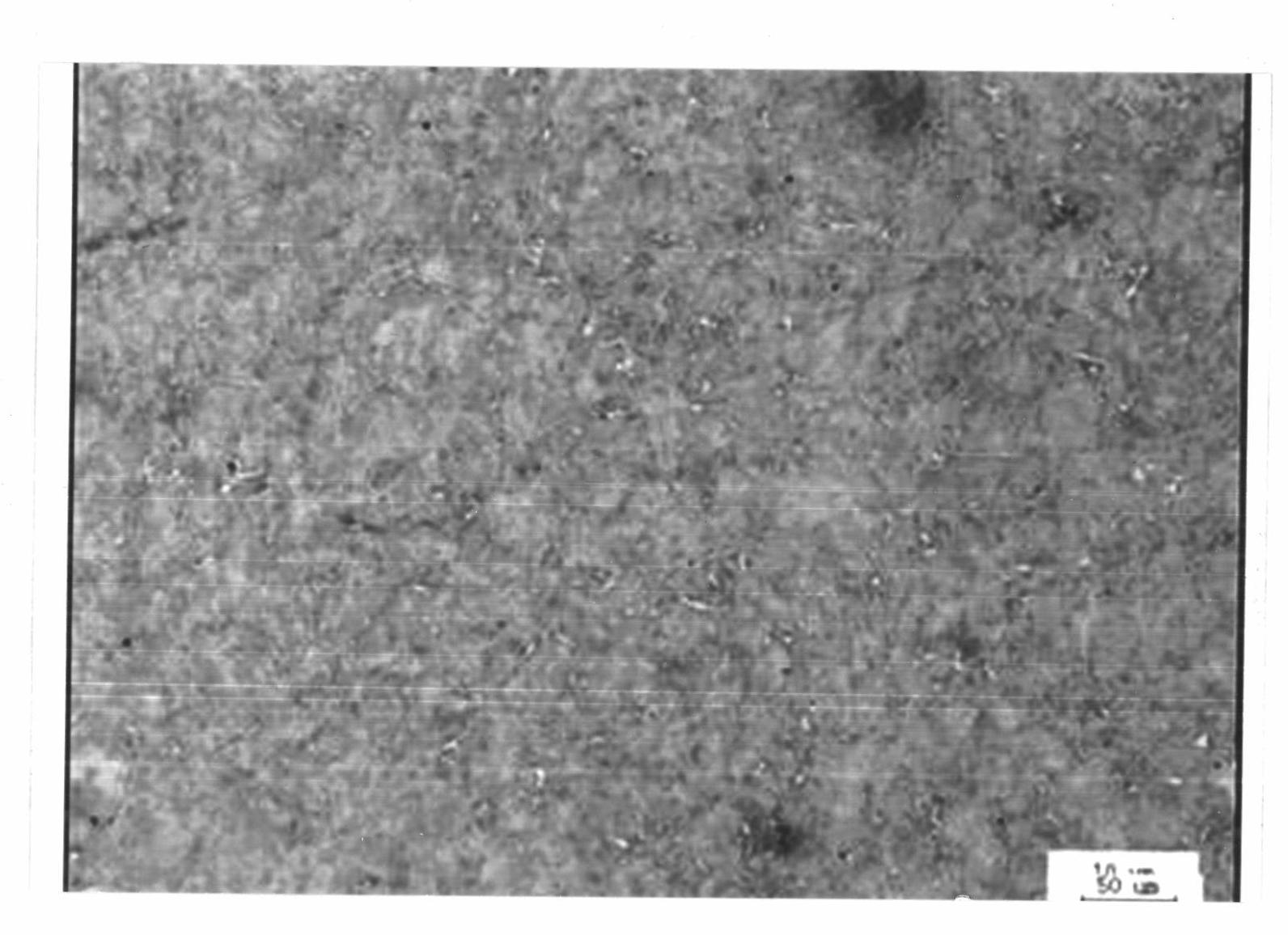

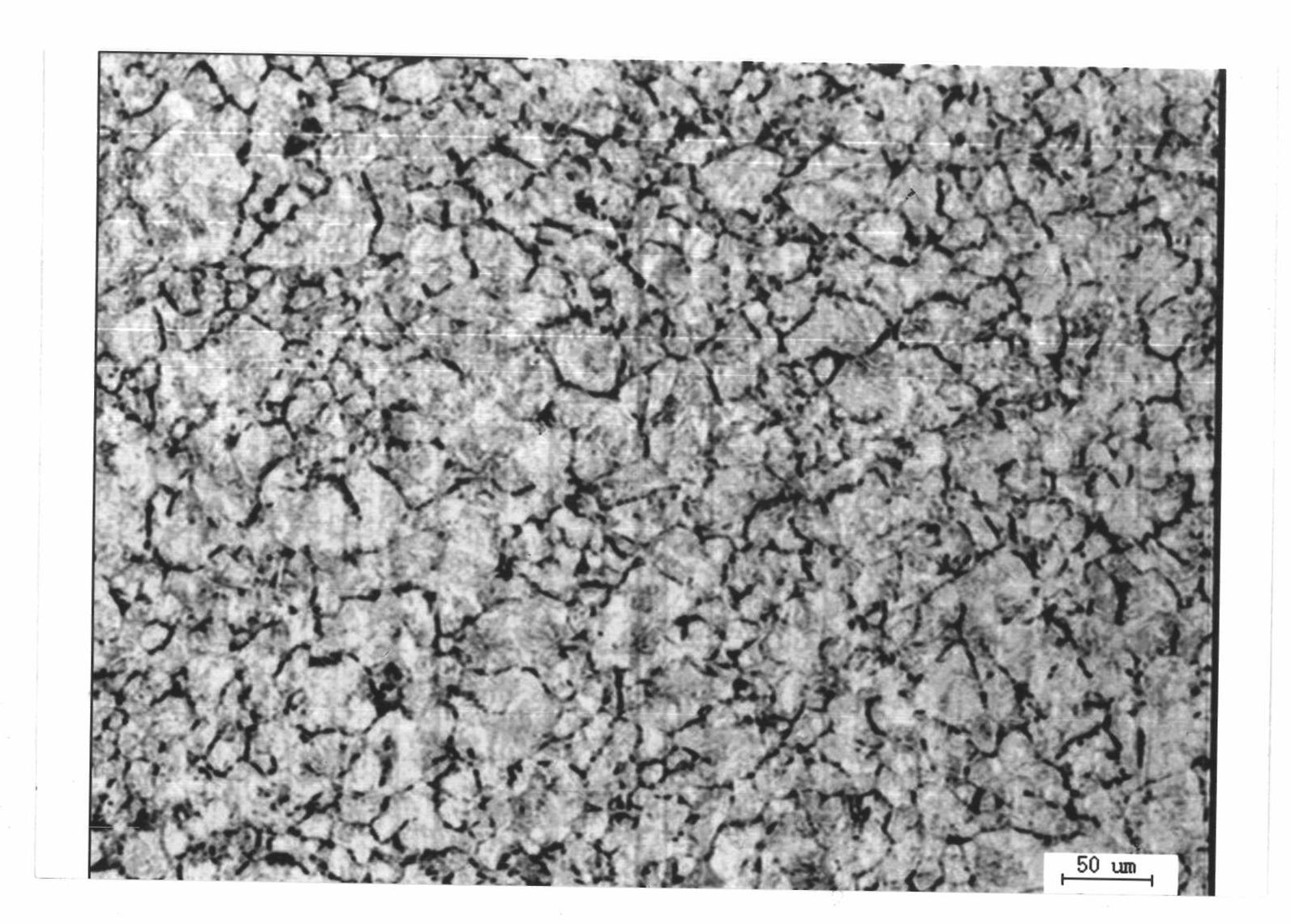

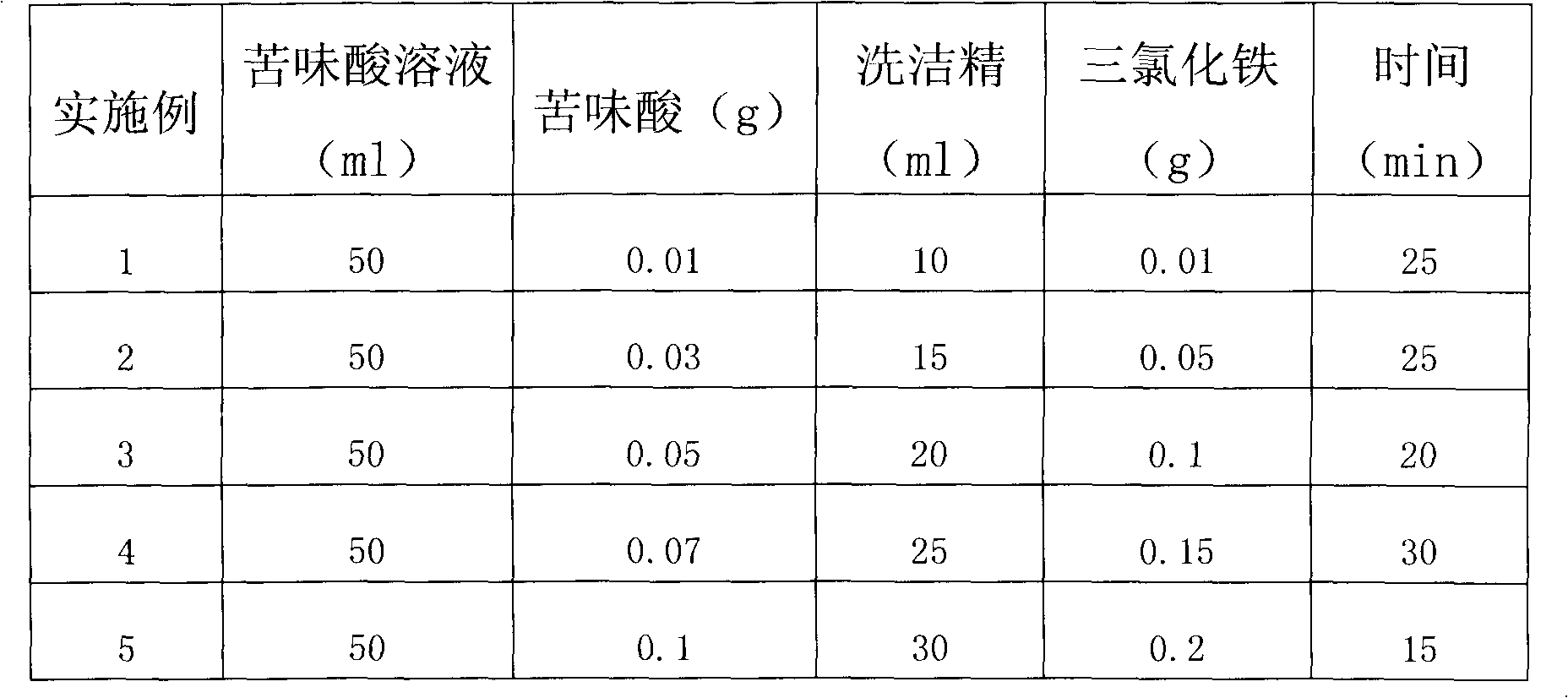

The invention discloses a medium-high-carbon steel actual grain size developer, belonging to a reagent and a method used for microexamination of the metallographic structure of iron and steel materials, and particularly relates to a medium-high carbon steel metallographic structure micro detection reagent and a detection method. The developer is composed of the following components in terms of solution volume (ml) and mass (g): 50ml of saturated picric acid solution, 0.01-0.1g of picric acid, 10-30ml cleanser essence and 0.01-0.2g of ferric trichloride. The method comprises the following steps of sample preparation, developer preparation, sample dyeing, microscopic observation and electronic image acquisition. The medium-high carbon steel actual grain size developer provided by the invention has the advantages of novel component conception, stable solution performance, good repeatability, simple and reliable operational process and complete grain boundary display; the medium-high carbon steel actual grain size can be clearly recognized, and is ranked; and the display and detection of the actual grain size of the steel product are ranked, thus providing advantageous conditions for product safe application and product research and development, and obtaining remarkable economic benefits and social benefits.

Owner:MAANSHAN IRON & STEEL CO LTD

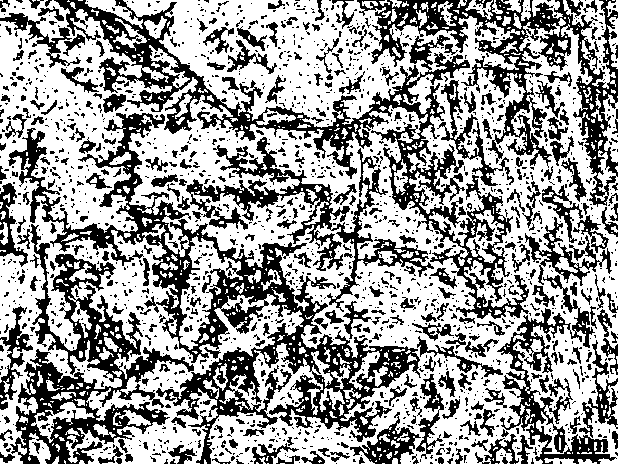

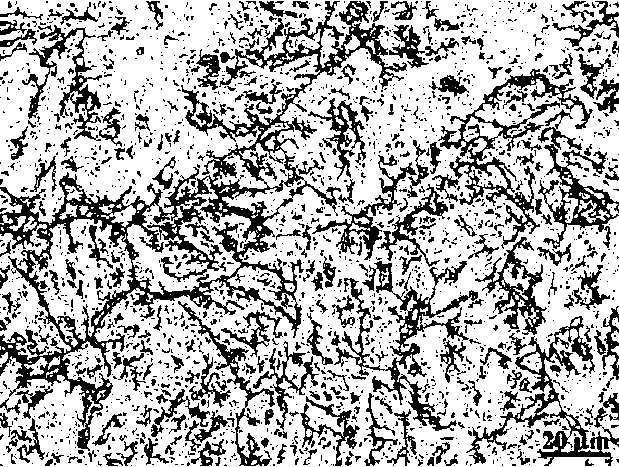

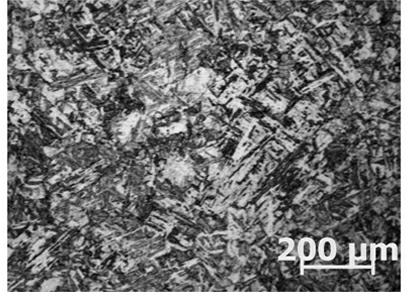

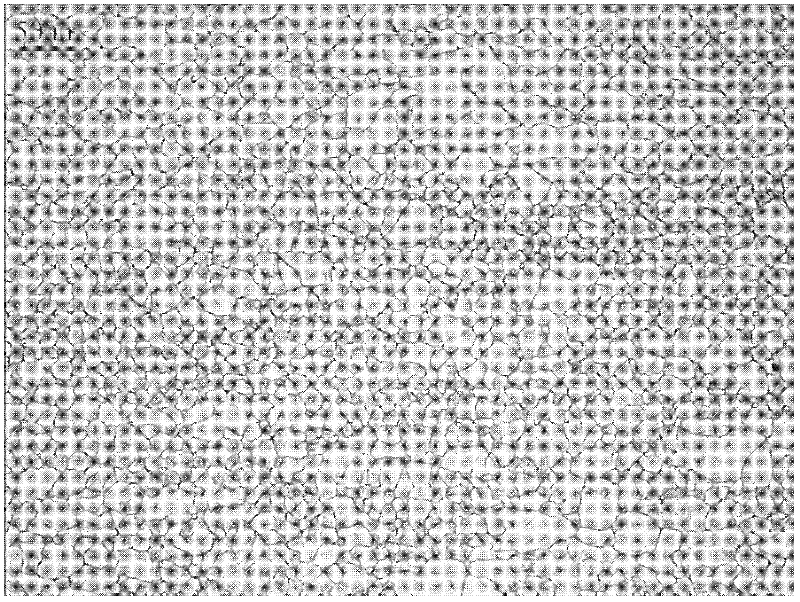

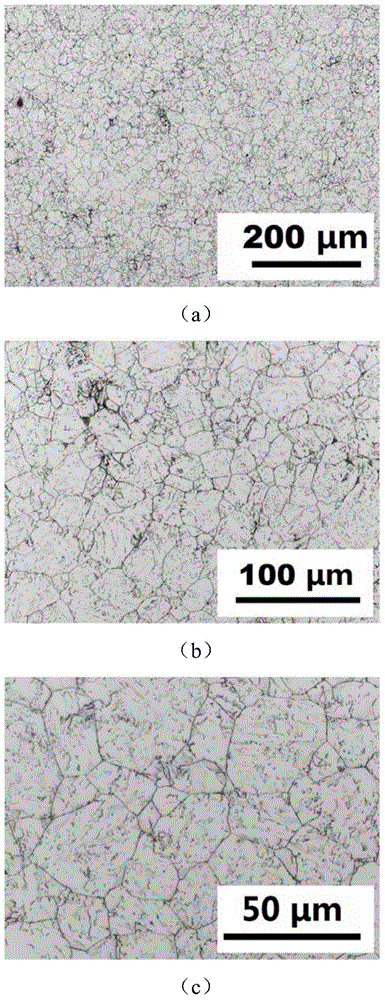

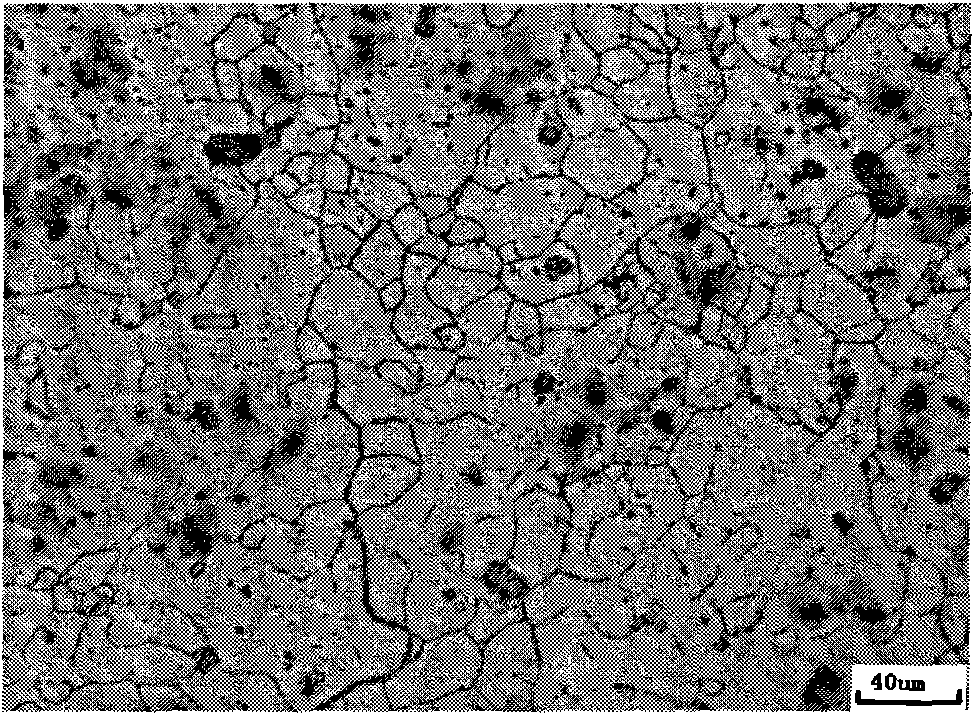

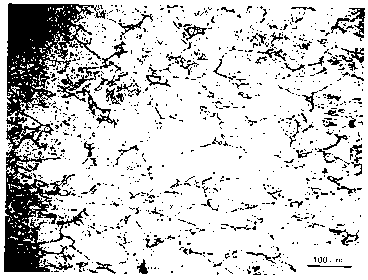

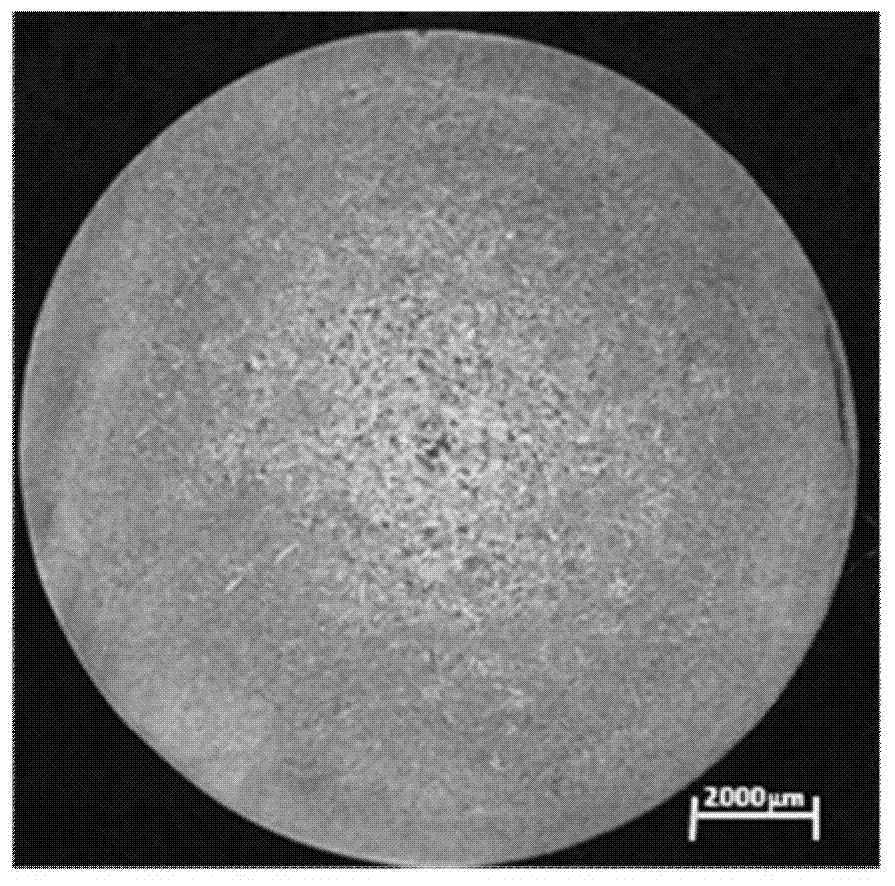

Method for testing autstenitic grain size of steel bainite structure for nuclear pressure vessel

InactiveCN104458511ALow efficiencyPreparing sample for investigationParticle size analysisReactor pressure vesselNuclear power

The invention relates to a method for testing autstenitic grain size of a steel bainite structure for a nuclear pressure vessel. The method comprises the steps of preparing, grinding and polishing a metallographic phase sample, carrying out chemical etching on a sample and carrying out statistics on the grain size. According to the method, the rational proportions of picric acid, dodecylbenzene sulfonic acid and an additive as well as the etching time are selected, so that the original autstenitic grain size of the low-carbon and low-alloy steel SA508 Gr.3 steel bainite structure for nuclear power can be clearly displayed. After the method is adopted, the problem that the original autstenitic grain boundary is difficult to display in the actual production process of a forge piece of the nuclear pressure vessel can be solved; compared with the traditional method which is used for judging the autstenitic grain size by experience, the method has the advantage that the displayed autstenitic grain boundary is clear and complete; after the method is used for picture processing and statistics, the tested autstenitic grain size is more accurate and the repeatability is good.

Owner:SHANGHAI JIAO TONG UNIV

Method for displaying original austenite grains of pipeline steel with strength grade of X70 and above

InactiveCN101788419ADisplay clear displayFix display issuesPreparing sample for investigationLine tubingAustenite grain

The invention discloses a method for displaying original austenite grains of pipeline steel with strength grade of X70 and above, and belongs to the technical field of metallographic structure observation. The method comprises the following steps: firstly, performing heat treatment and quenching on a sample at the temperature of 950 DEG C to obtain a single austenite structure; secondly, grinding and polishing the obtained austenite structure; and thirdly, corroding the ground and polished austenite structure in etching solution, wherein the etching solution is mixed liquor of supersaturated picric acid, Eagle high-efficiency detergent and 2 percent nitric acid, so that the austenite structure can be showed and can be clearly observed under a microscope. The method for displaying the original austenite grains of the pipeline steel with the strength grade of X70 and above solves the display problem of the original austenite grains of the pipeline steel with high-strength grade. The method has the advantages of capability of clearly displaying the original austenite grains of the pipeline steel with the strength grade of X70 and above, economic and safe etchant formula and simple test process operation.

Owner:BEIJING LONGSHINE OIL TUBULAR TECH

High aluminum zinc alloy etching agent and use method thereof

InactiveCN101880881AClear grain boundariesEasy to distinguishPreparing sample for investigationPicric acidCorrosion

The invention relates to a high aluminum zinc alloy etching agent, which can be used for preparing the metallurgical sample of cast and solution treated high aluminum zinc alloy, and is especially suitable for the high aluminum zinc alloy modified by adding zirconium, rare earth and the like. The etching agent comprises hydrochloric acid, nitric acid, glacial acetic acid, picric acid, anhydrous ethanol and water. The corrosion method of the metallic phase of high aluminum zinc alloy using the etching agent is as follows: (1) corrosion, the high aluminum zinc alloy sample after grinding and polishing treatment is immersed in the etching agent at a temperature of 15-30 DEG C, is corroded for 3-15 seconds under the swing condition and taken out; (2) cleaning, the high aluminum zinc alloy sample taken out of the etching agent is immersed in the anhydrous ethanol, and is taken out after ultrasonic cleaning; and (3) drying, the cleaned high aluminum zinc alloy sample is dried by cold wind at room temperature. The metallurgical etching agent of the invention is adopted, so that the metallurgical structure grain boundary is clear, and a second phase is easy to distinguish; and the etching agent has the advantages of short corrosion time of the sample, simple preparation process of the etching agent and the like.

Owner:SOUTHWEST UNIVERSITY

Freeze-etching agent of ultra-low-carbon steel casting billet macrograph grain structure, and preparation method thereof

ActiveCN102401759ALow S.P contentEasy to distinguishPreparing sample for investigationFreeze EtchingGlass vessel

The invention discloses a freeze-etching agent of ultra-low-carbon steel casting billet macrograph grain structure, and a preparation method thereof. The freeze-etching agent is prepared from materials of: 30 to 50g of ferric chloride, 0.5 to 1.2g of stannous chloride, 2 to 3 parts of trinitrophenol, 10 to 20ml of sodium alkyl phenyl sulfonate, 200 to 500ml of absolute alcohol, and 600 to 1000ml of hydrochloric acid. Solid agents of the formulation are mixed and placed into a glass vessel according to the ratio; 1500 to 2000ml of distilled water is divided into two parts; one part is added to the solid mixed agents, and the other part is preserved for later use; absolute alcohol is added to the preserved part of distilled water; hydrochloric acid is added to the alcohol solution; sodium alkyl phenyl sulfonate is added to the aqueous solution containing agents such as ferric chloride, and the mixture is uniformly stirred; the alcohol + hydrochloric acid solution is then added to the aqueous solution containing the agents such as ferric chloride; the solution is sufficiently stirred, such that the freeze-etching agent is prepared. With the freeze-etching agent, the form of the ultra-low-carbon continuous casting steel billet macrograph grain structure can be clearly shown. The freeze-etching agent provided by the invention has advantages of high detection speed, low pollution, and convenient operation. Also, the freeze-etching agent is energy-saving.

Owner:ANGANG STEEL CO LTD

Erosion agent capable of displaying solidified dendritic structure of Fe-36 Ni invar alloy and erosion method of erosion agent

ActiveCN105386057AModerate erosion timeSimplify operating proceduresPreparing sample for investigationInvar alloyAlcohol

Disclosed are an erosion agent capable of displaying the solidified dendritic structure of a Fe-36 Ni invar alloy and an erosion method of the erosion agent. The erosion agent includes 1 g-2 g of picric acid, 0.5 g-1 g of anhydrous cupric chloride, 50 ml-60 ml of absolute ethyl alcohol, 0.5 ml-1 ml of hydrochloric acid and 1 g-2 g of sodium dodecylbenzene sulfonate. The erosion method of the erosion agent includes the steps that the prepared erosion agent is heated to the temperature of 50 DEG C-60 DEG C, a processed sample with the downward polishing face is suspended in the heated erosion agent to be eroded for 20 s-30 s, the eroded surface is wiped with ethyl alcohol firstly after erosion is completed, and then the sample is slightly polished at the one fourth radius position of a polishing machine for 4 s-6 s so that a copper film generated on the eroded surface can be removed. According to the method, the operating procedure is simple, the erosion effect is good, and the solidified dendritic structure of an invar alloy can be observed quickly and clearly, so that the solidification condition corresponding to continuous casting is obtained, and technical bases are provided for optimizing the continuous casting process technologies.

Owner:山西高义钢铁有限公司

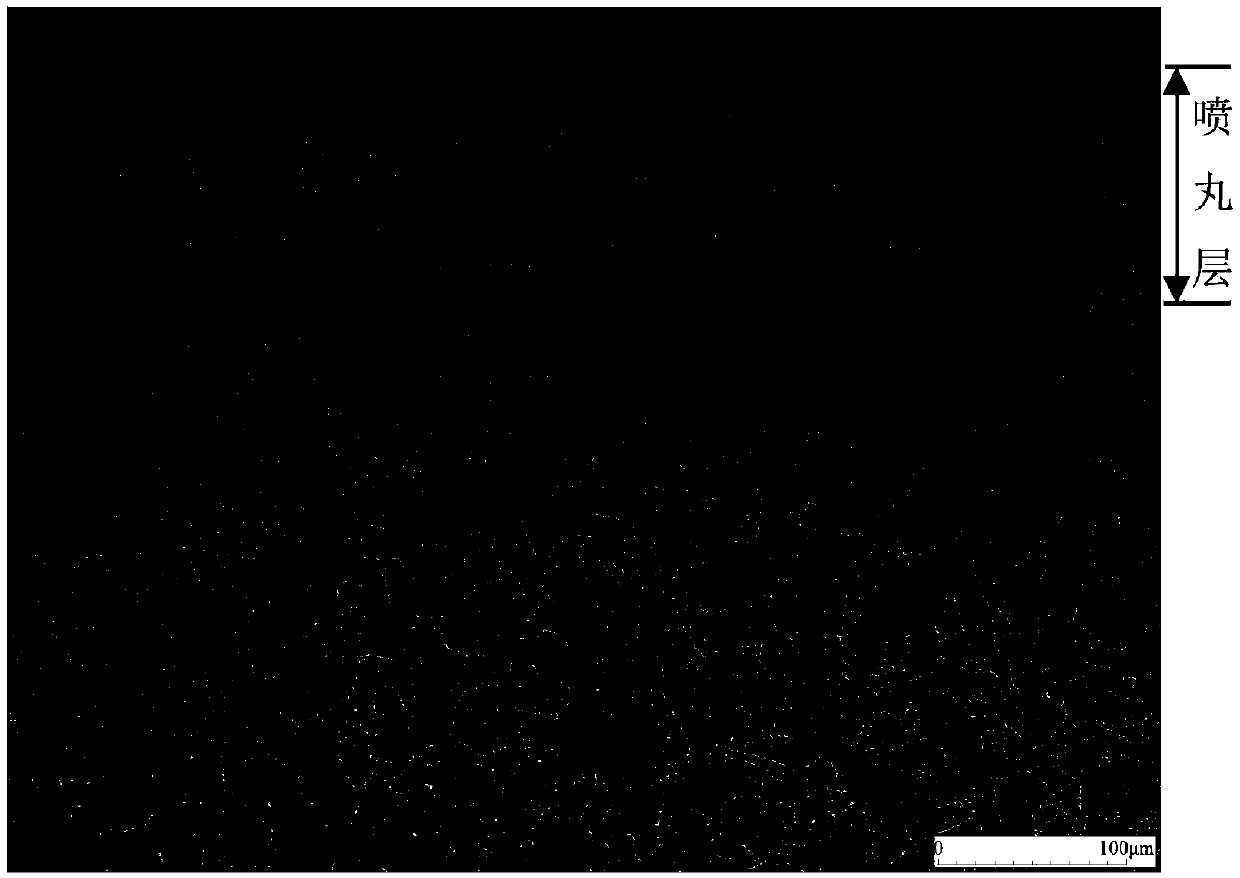

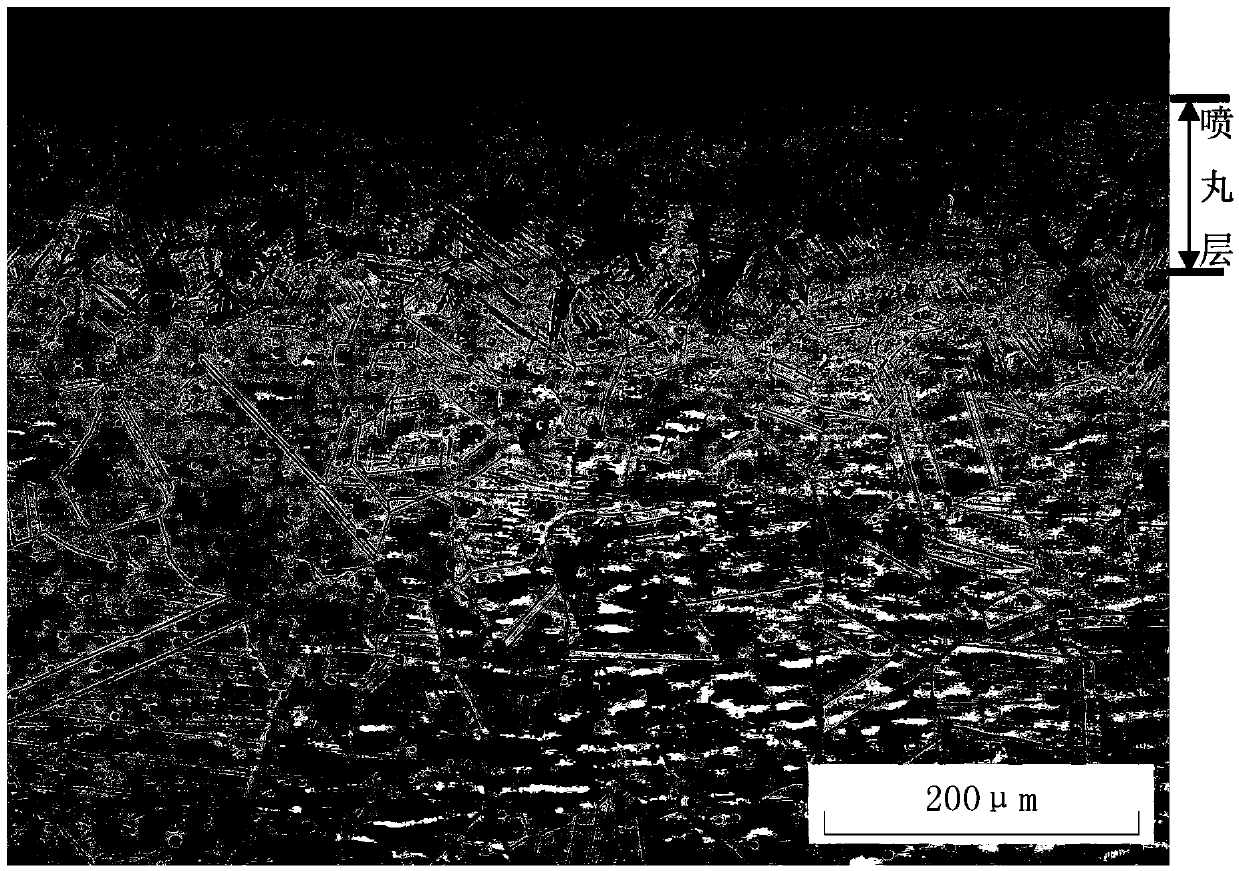

Corrosive agent for detecting shot-blasted layer on austenitic stainless steel surface and using method of corrosive agent

ActiveCN105372246AEasy to measureConducive to accurate determinationPreparing sample for investigationMaterial analysis by optical meansChemical reactionGlycerol

The invention provides a corrosive agent for detecting a shot-blasted layer on an austenitic stainless steel surface and a using method of the corrosive agent. The corrosive agent is prepared from, by volume, 25-31% of hydrochloric acid, 26-28% of glycerol, 12-16% of nitric acid and 25-35% of a picric acid ethanol solution. By means of the advantages that a metallographic phase is rapidly, visually, easily and conveniently displayed, the chemical corrosive agent which is easy and convenient to use and applicable to daily inspection is developed, and the corrosive agent intensively corrodes the region of a shot-blasted hardened layer on the inner surface and does not intensively corrode a base body which does not deform. By means of the advantages of a chemical reaction, the appearance of the region of the shot-blasted hardened layer of inner stainless steel surface can be clearly and completely displayed under illumination of perpendicular light of a microscope, the stainless shot-blasted layer is deep measured conveniently and accurately, and the good practical value for control over the shot-blasted quality inside austenitic stainless steel for a super-(super)-critical boiler is achieved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Display method of F/M heat resistant steel welded joint heat affected zone original austenite grain boundary

ActiveCN105300774ADisplay clearAchieve normal displayPreparing sample for investigationTesting metalsHeat-affected zoneEtching

The invention discloses a display method of an F / M heat resistant steel welded joint heat affected zone original austenite grain boundary, and belongs to the technical field of preparation of metallographic samples. The F / M heat resistant steel is 9-12% Cr ferrite martensite heat resistant steel. The original austenite grain boundary can be observed through a microscope after a polished sample is subjected to chemical thermal etching by virtue of a chemical hot corrosion liquid (supersaturated picric acid-Seagull brand shampoo-hydrochloric acid). According to the display method, the operation is convenient, the repeatability is high, the stability is good, the original austenite grain boundary can be clearly and completely displayed, and reference is provided for analyzing the grain evolution in a heat affected zone after weld thermal cycle.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

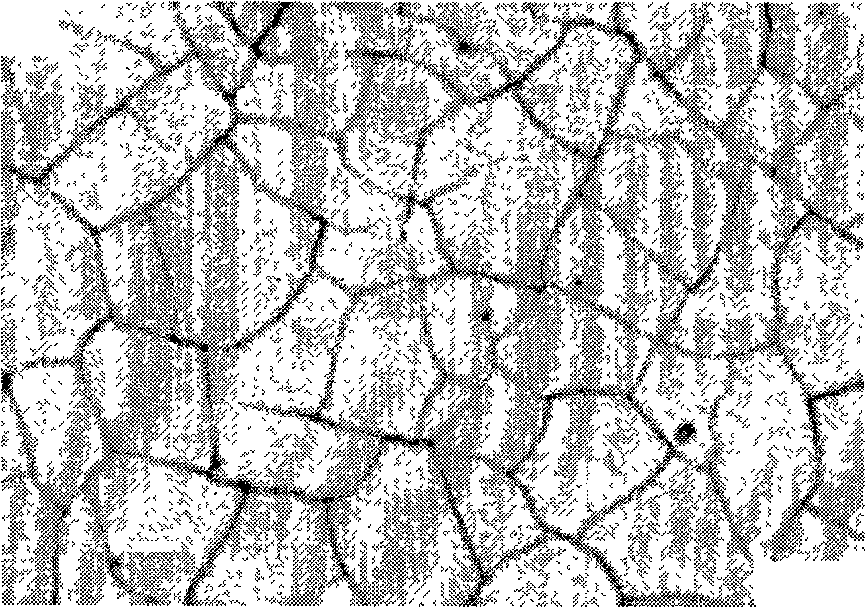

Method for displaying austenite grain boundary of low-carbon micro-alloy steel

InactiveCN102507292AQuality improvementSolving the difficult problem of obtaining austenite grainsPreparing sample for investigationManufacturing enterprisesStain

The invention provides a method for displaying an austenite grain boundary of low-carbon micro-alloy steel, which belongs to the technical field of physical testing and is used for solving the problem that the low-carbon micro-alloy steel cannot clearly display austenite crystalline grains of the low-carbon micro-alloy steel. The method is characterized in that according to the reagent ratio, corrodent comprises 70-100mL of distilled water, 1-2g of seagull-brand shampoo paste, 1.8-2.5g of picric acid, 0.1-lml of dimethylbenzene with concentration larger than 60%, 0.1-lml of hydrochloric acid with concentration larger than 70%, 0.1-lml of hydrofluoric acid with concentration larger than 70% and 0.1-1g of copper chloride. The polishing-grinding surface of a test sample is guaranteed to be free of any deflects of scratches, pocks, pits, stains and the like during preparation of the test sample. By utilizing specific corrodent to be matched with an appropriate corrosion method, the method can clearly display the austenite grain boundary, provides a significant theoretical basis for researches carried out by manufacturing enterprises on influences of technological parameters on microstructure evolution in the deformation process of the steel, and can play important role on reasonably controlling the process parameters and guaranteeing product performance when the low-carbon micro-alloy steel is produced.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Original crystalline grain displaying agent of high-alloy and low-carbon martensite steel and displaying method

ActiveCN103018141AThe matching ratio is novelEasy to operatePreparing sample for investigationParticle size analysisAlcoholTest sample

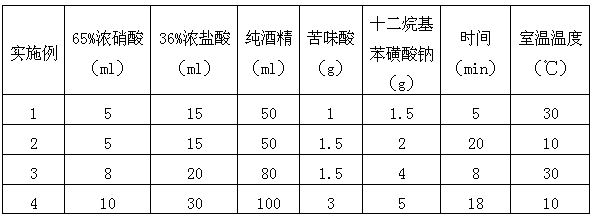

The invention relates to an original crystalline grain displaying agent of high-alloy and low-carbon martensite steel and a displaying method. The displaying agent is formed by the following components according to solvent volume (ml) and mass (g): 5-10 ml of concentrated nitric acid, 10-30 ml of concentrated hydrochloric acid, 50-100 ml of alcohol, 0.5-4 g of picric acid and 1.0-6.0 g of sodium dodecyl benzene sulfonate. The displaying method is carried out by the steps of preparing a test sample, configuring the displaying agent, corroding the test sample, organizing and observing, and collecting an image. The original crystalline grain displaying agent of high-alloy and low-carbon martensite steel and the displaying method have the advantages of novel concept, simplicity in operation, complete crystal boundary display effect, capability of clearly recognizing a grain size, and convenience for accurately measuring the original grain size and grain fineness number, and provide good conditions for formulating and optimizing a steel product production process.

Owner:安徽华驰动能科技有限公司

Method for staining medical tissue slice

The invention provides a medical tissue section staining method which comprises the following steps that: olefin is sliced into sheets, dewaxed and hydrated; sliced sheets are put into solution of picric acid, formaldehyde and glacial acetic acid after being heated, taken out and washed by running water; the sliced sheets are put into a 5 percent sodium thiosulfate solution to soak and washed by distilled water; the sliced sheets are put into an alcian blue solution to soak and washed by the running water; the sliced sheets are put into a preheated alkaline ethanol solution to soak and washed by the running water; under the lighttight condition, the sliced sheets are put into a haematoxylin working solution and washed by the running water and the distilled water; the sliced sheets are put into a saffron / acid fuchsine working solution and washed by the distilled water; the sliced sheets are put into a phosphotungstic acid solution to soaked, then transferred to the glacial acetic acid to soak and washed by the distilled water; the sliced sheets are dehydrated by ethanol; the sliced sheets are put into an ethanol saffron solution to soak, then dehydrated by the ethanol and sealed. The medical tissue section staining method has low cost and vivid staining, shortens the time for a staining flow and also increases the application range.

Owner:SHANDONG UNIV

Two-part aqueous metal protection treatment

InactiveUS6902766B1Avoids and reduces blister formationOvercome disadvantagesAdhesive processes with surface pretreatmentAbrasion apparatusOrganic filmElastomer

A two-part metal protection composition includes: an aqueous metal treatment conversion coating component that includes an admixture of an acid and a coating forming component; and an aqueous protective coating component that is applied over metal treated with the aqueous metal treatment conversion coating component and includes an admixture of a blister suppressing agent and an organic film forming protective component. The aqueous metal treatment conversion coating component may contain an accelerator, such as hydroxylamine. In a preferred embodiment, the blister suppressing agent is an organic oxidizing agent that includes one or more of nitroguanidine; aromatic nitrosulfonates, Naphthol Yellow S; and picric acid (trinitrophenol). A method for treating a metallic surface includes: (a) applying an aqueous metal treatment conversion coating component described above; and (b) applying an aqueous protective coating component, described above, to the surface that has at least been partially treated with the aqueous metal treatment conversion coating component. A method for bonding an elastomeric substrate surface to a metallic substrate surface includes: (a) applying an aqueous metal treatment conversion coating component, described above, to the surface; (b) applying an aqueous coating or primer composition, described above, to the surface that has at least been partially treated with the aqueous metal treatment conversion coating component; and (c) applying an adhesive overcoat to effect bonding of the metallic substrate to the elastomeric substrate.

Owner:LORD CORP

Method for displaying P91 and P92 steel original austenite grain boundaries

ActiveCN102590050ABig contrastEasy to compare ratingsPreparing sample for investigationParticle size analysisElectrolysisAustenite grain

The invention discloses a method for displaying P91 and P92 steel original austenite grain boundaries, which belongs to the field of physical and chemical inspection. A sample which is well ground and polished is subjected to a corrosion method which combines supersaturated picric acid-sodium dodecyl benzene sulfonate (or sodium tridecyl benzene sulfinic acid)-hydrogen peroxide thermal etching and sulfuric acid electrolytic pickling, through utilizing microscope dark-ground illumination or bright-ground illumination of the light polished sample, the P91 and P92 steel original austenite grain boundaries can be displayed. The method disclosed by the invention is safe to operate, low in cost and pollution-free; and by the method, the P91 and P92 steel original austenite grain boundaries can be clearly and completely displayed, the grain size grades of P91 and P92 steel are accurately evaluated, and a basis is provided for material quality control.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

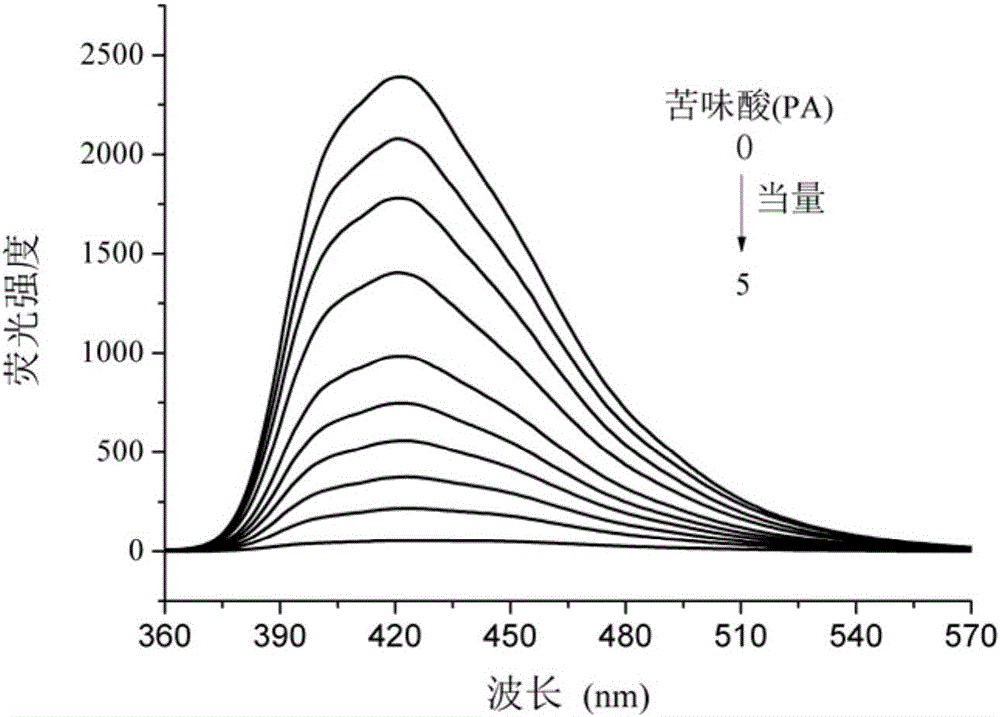

Benzimidazolyl chemical sensor used for fluorescence quenching detection of nitroaromatic explosives, and preparation method of benzimidazolyl chemical sensor

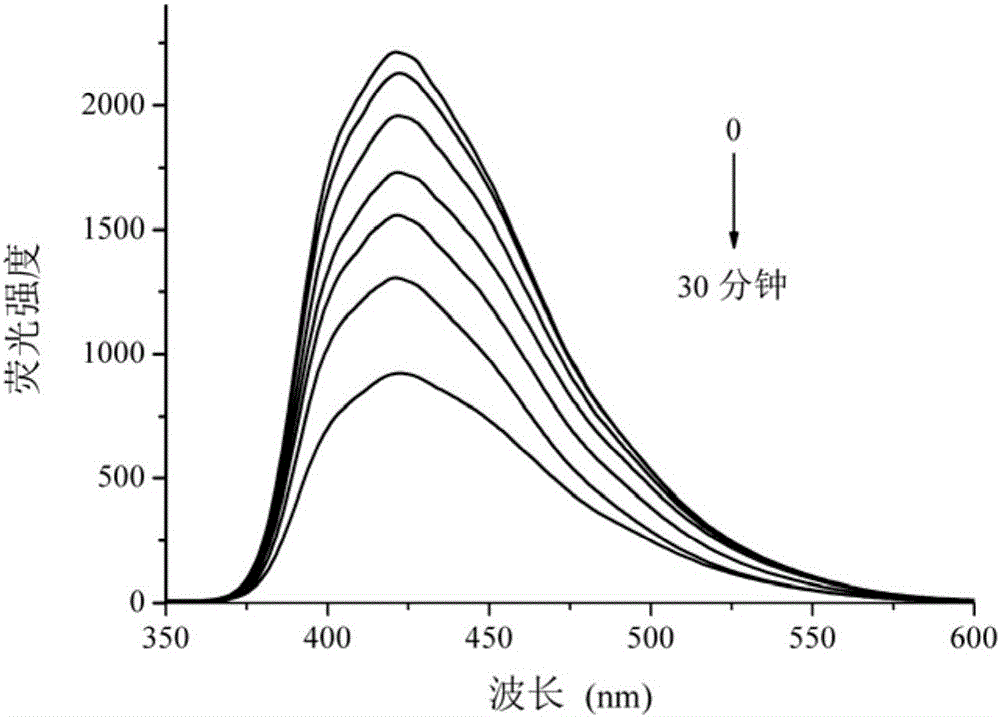

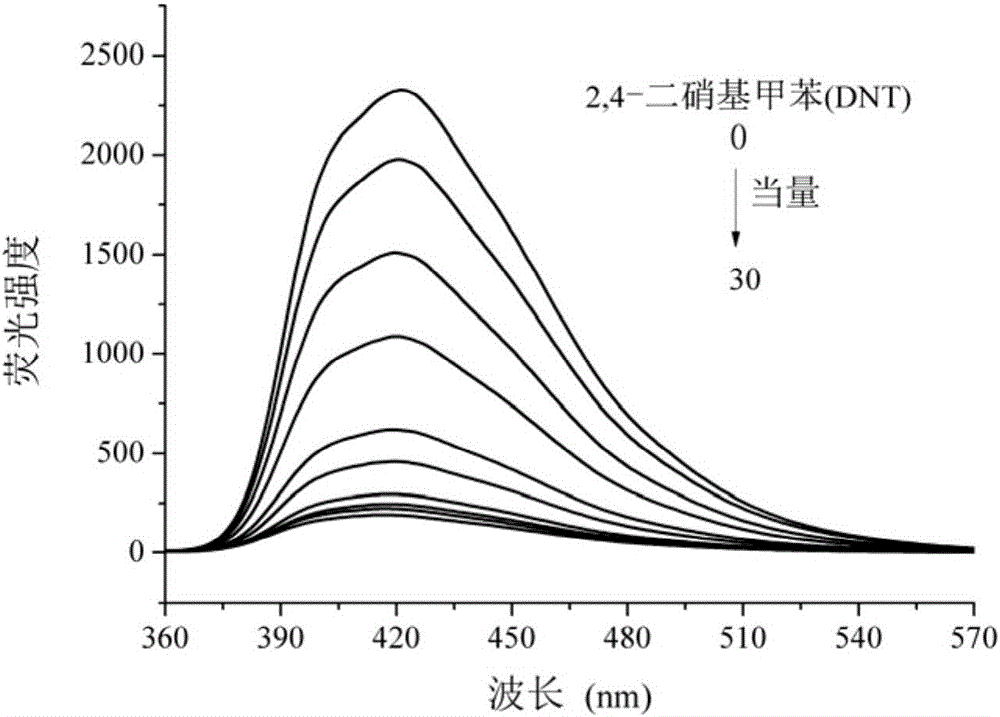

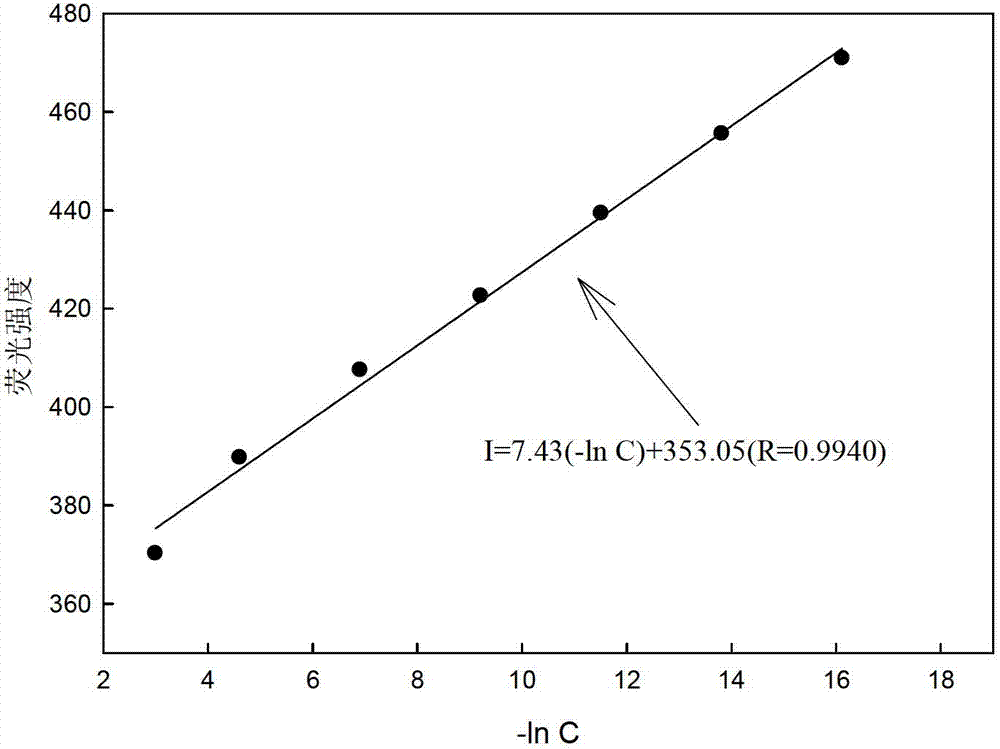

InactiveCN106008358AEasy temperature controlSimple processOrganic chemistryFluorescence/phosphorescenceHalohydrocarbonNitroaromatic explosives

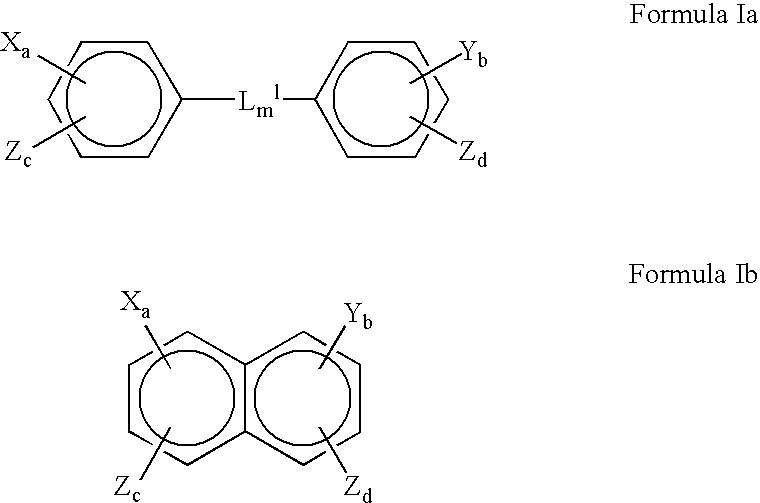

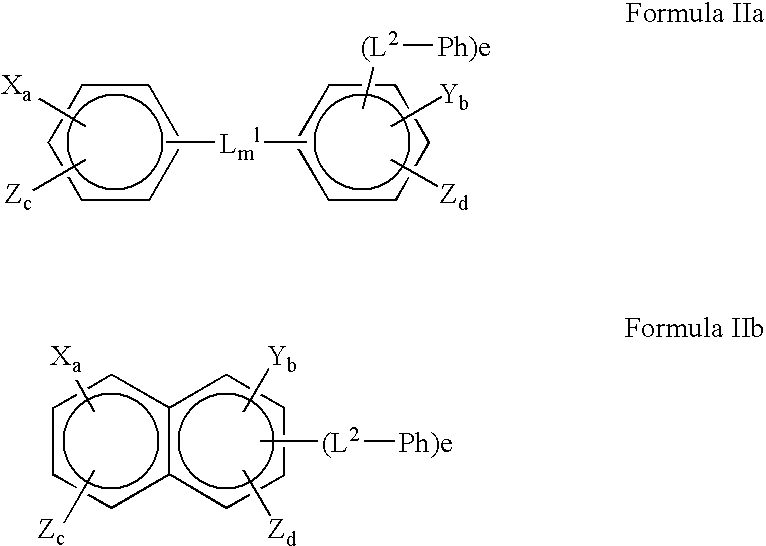

The invention relates to a benzimidazole-based chemical sensor for fluorescence quenching detection of nitroaromatic explosives and a preparation method thereof. Using bis(benzimidazole)naphthalene and halogenated hydrocarbons as raw materials, mainly through simple and easy N ‑Alkylation substitution reaction to prepare a benzimidazole-based fluorescent chemical sensor with high selectivity and high sensitivity to detect explosive NAC, which mainly detects PA. The prepared benzimidazole-based fluorescent chemical sensor can visually detect PA in solution and in solid state by using fluorescence quenching under ultraviolet light, and can realize the detection of gaseous PA. The present invention proposes for the first time the structure and synthesis method of a novel bis(benzimidazole)naphthalene chemical sensor based on fluorescence quenching detection of nitroaromatic compounds. The sensor provides highly selective and sensitive detection of explosive nitroaromatic compounds, especially picric acid, in multiple ways.

Owner:SOUTH CHINA NORMAL UNIVERSITY

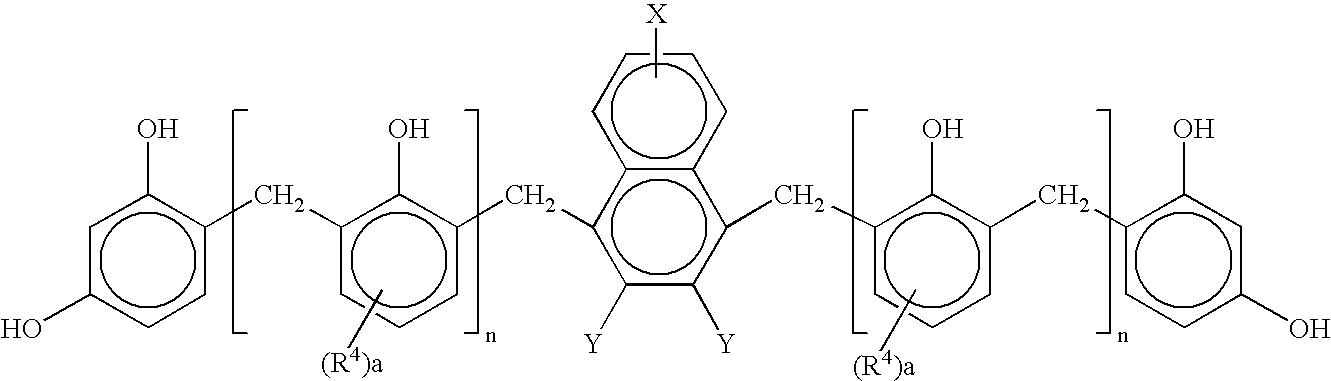

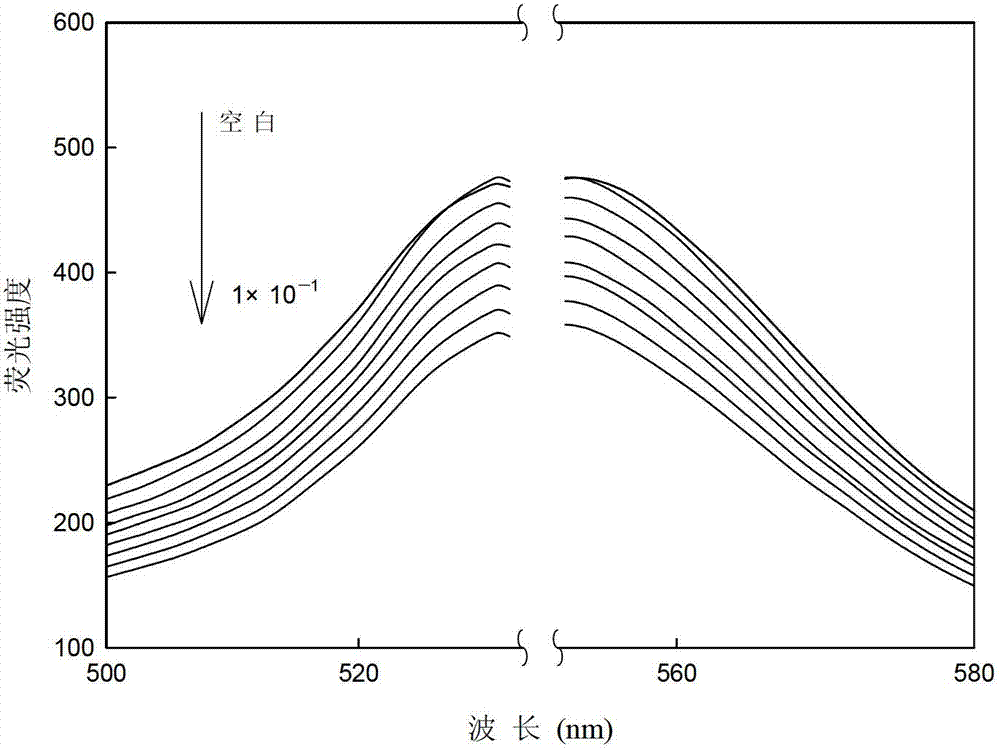

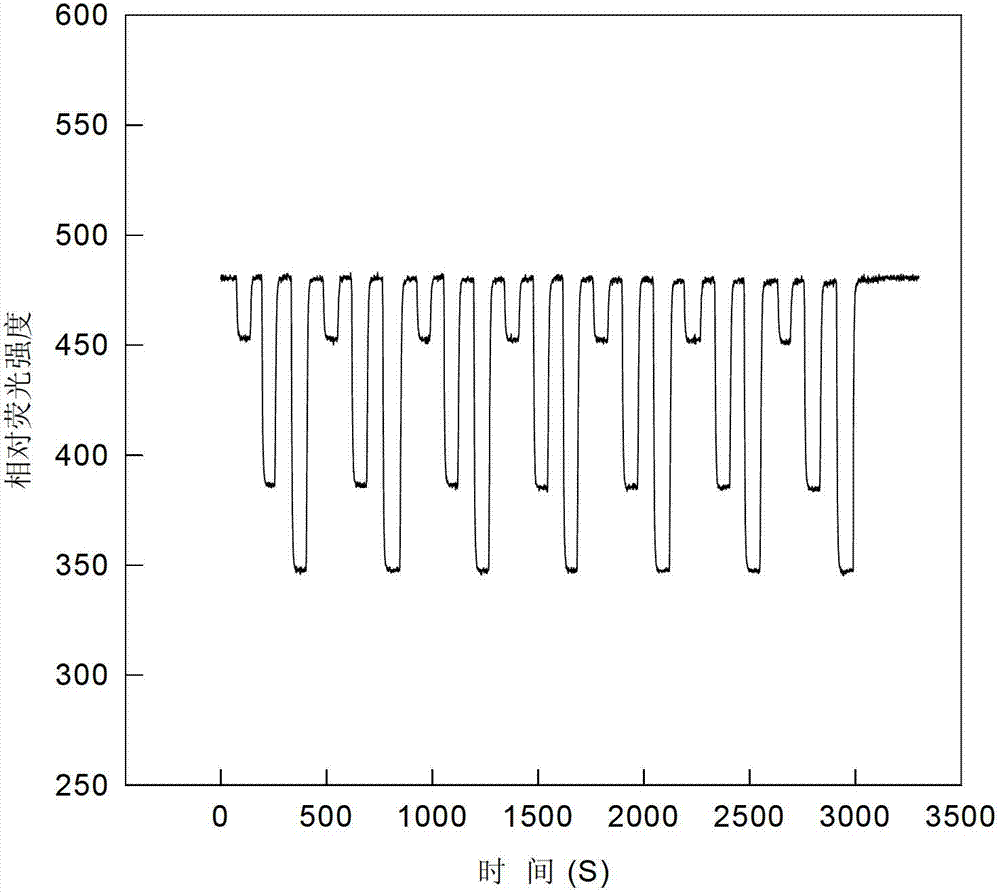

Fluorescent sensor for measuring picric acid content and preparation method thereof

InactiveCN102830098AEasy to synthesizeStop lossFluorescence/phosphorescenceCross-linkN dimethylformamide

The invention discloses a fluorescent sensor for measuring the picric acid content. A fluorescent carrier in a film substrate monomer is an allyl four iodine fluorescein. 15mg of fluorescent carrier allyl four iodine fluorescein is dissolved in 0.2ml of N, N-dimethylformamide for sufficient dissolution, 200mg of acrylamide, 0.4ml of hydroxyethyl methylacrylate, 0.15ml of cross-linking agent triethoxy trimethyl acrylate and 0.2ml of triethanolamine are added, finally 0.25ml of 1-oxhydryl cyclohexyl phenyl ketone is added for even mixing; and a solution is removed to drop on a Teflon plate, a quartz slide subjected to silanization is covered on the Teflon plate, an ultraviolet lamp is used for irradiating for 20 minutes, and drying is carried out at a room temperature. The sensor has the advantages of simple preparation, good stability, short response time, good reproducibility and the like, and can continuously and timely measure the picric acid content on line.

Owner:JIANGSU RADIO & TV UNIV

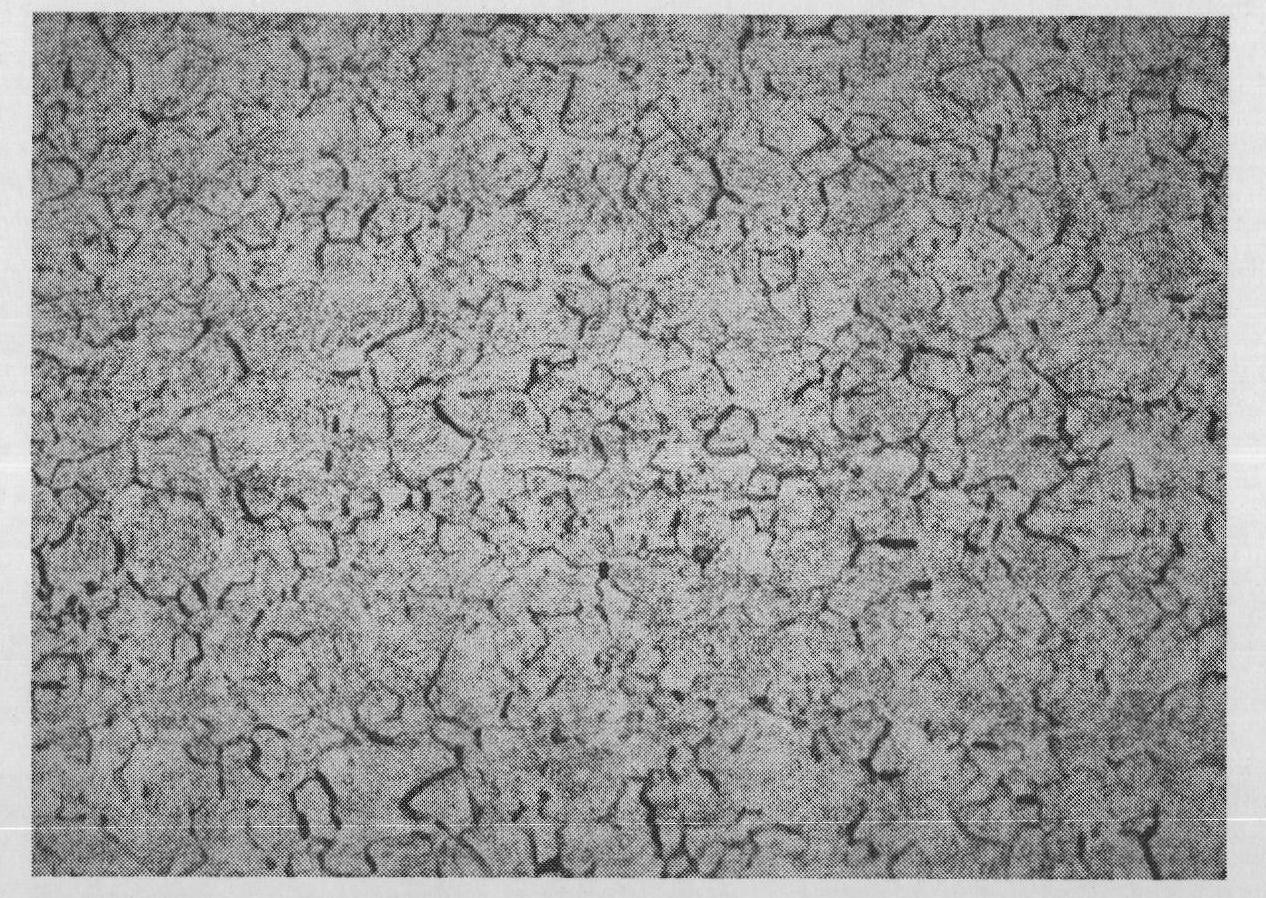

Aggressive agent for displaying solidification genetic dendritic structure in high-carbon steel plate strip and display method

InactiveCN103698191AContinuous Casting Process OptimizationPreparing sample for investigationWater bathsCleansers skin

The invention relates to an aggressive agent for displaying a solidification genetic dendritic structure in a high-carbon steel plate strip and a display method. The aggressive agent comprises the following components: 100ml of distilled water by volume, 5-8g of picric acid by mass and 5-30ml of cleanser essence by mass. The display method comprises the steps of heating and stabilizing the aggressive agent to 60-80 DEG C through a constant-temperature water bath kettle, then putting a prepared sample into the aggressive agent and aggressing for 10-30 seconds, washing the surface of the sample by using ethyl alcohol, and drying, so that the dendritic structure can be observed by using a metallographic microscope. The method has the advantages of being simple to operate and quick to display, and the structure is clear and reliable; through the solidification genetic dendritic structure in the plate strip, a corresponding solidification process condition during continuous casting can be obtained so as to provide technical base for improving plate strip quality and optimizing continuous casting process.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Chemical erosion agent for displaying macrostructure of expansion alloy, and erosion method thereof

InactiveCN105486567ASimple preparation procedureReduced finish requirementsPreparing sample for investigationAqueous alcoholAlloy

The invention relates to a chemical erosion agent for displaying the macrostructure of expansion alloy, and an erosion method thereof, and belongs to the technical field of metallographic examination analysis. The chemical erosion agent comprises 3-4g of picric acid, 90-100ml of anhydrous alcohol, 2-3ml of hydrochloric acid and 2g of sodium dodecylbenzene sulfonate. The erosion method of the erosion agent comprises the following steps: heating the prepared erosion agent to a boiling state, allowing the polished surface of a ground sample to be downward, and suspending the ground sample in the boiling erosion liquid for 3-5min; and cleaning the eroded surface with alcohol after the erosion, and flushing the cleaned sample with clear water. The chemical erosion agent has the characteristics of simple operation process, good erosion effect, and easy control of the erosion time, and can be used to rapidly and accurately observe the microstructure of the expansion in order to provide technical bases for optimizing a continuous casting technology and improve the solidification structure of a continuous cast blank.

Owner:TAIYUAN UNIV OF TECH

Wear-resistant 450 steel austenite grain size detection method

InactiveCN104165828AHigh clarityEasy to observePreparing sample for investigationParticle size analysisAustenite grainTest sample

The invention discloses a wear-resistant 450 steel austenite grain size detection method which comprises the following steps: 1) preparation of a sample; 2) quenching treatment: heating the sample to 800 DEG C-1000 DEG C, carrying out heat preservation for 20-60 minutes, and then quickly quenching the heated sample into water; 3) erosion: fully mixing a saturated picric acid solution and a washing liquid according to a volume ratio of 1:2-4 to obtain an erosion agent; and putting the to-be-tested sample after quenching treatment into the erosion agent, eroding for 3-6 minutes at the temperature of 20-50 DEG C, then taking out, washing cleanly with water, and blow-drying; and 4) grain grading: carrying out metallographic observation on the sample after blow-drying, taking pictures on austenite grains, contrasting with standard atlas by a comparative method, and grading. The saturated picric acid solution and the washing liquid are mixed to obtain the erosion agent, the erosion agent is adopted for eroding the high-strength wear-resistant steel 450, the purpose that only original austenite grain boundaries are clearly displayed and a matrix structure is not displayed is reached, and thus a condition is created for accurate evaluation of the original austenite grain boundaries.

Owner:武钢集团有限公司

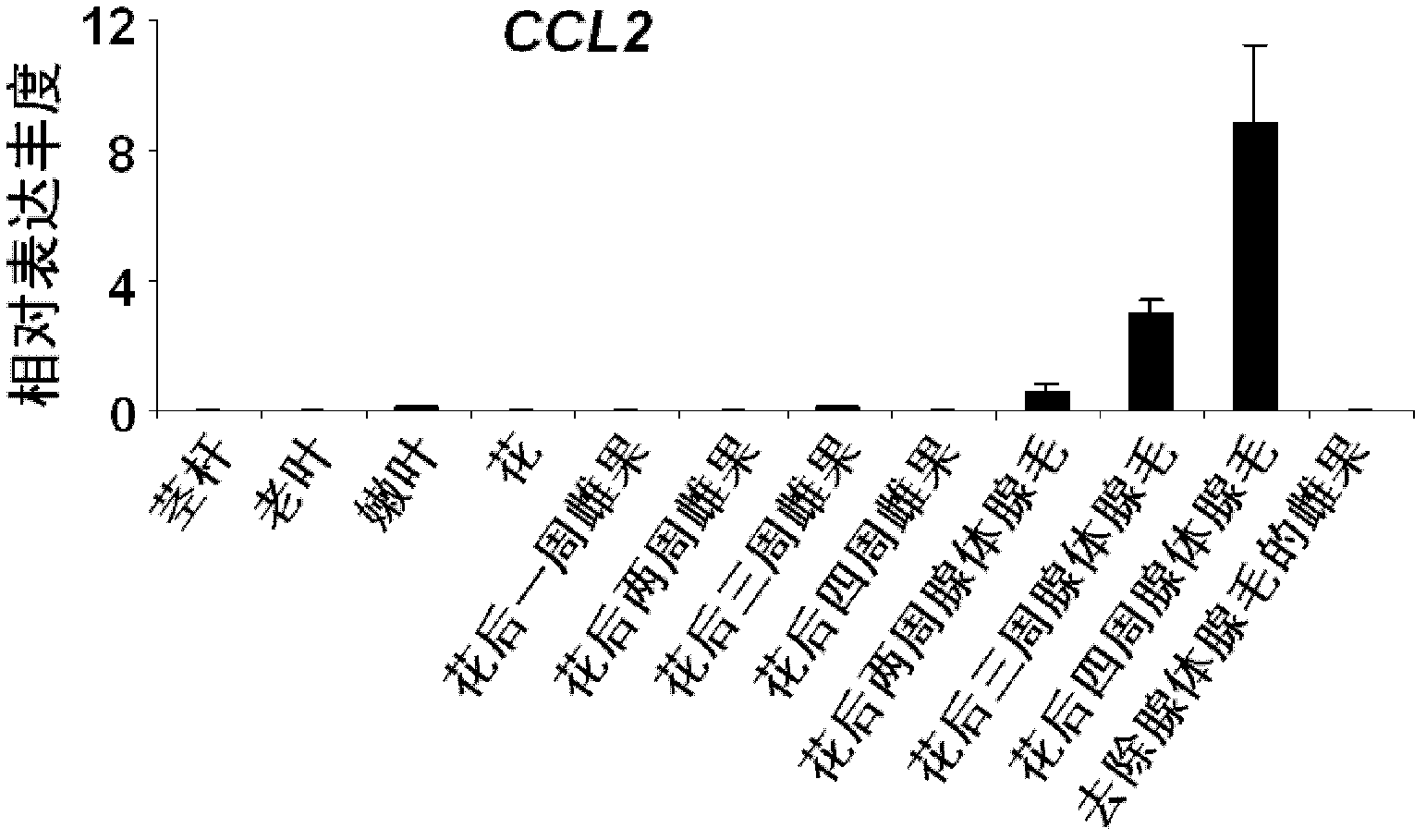

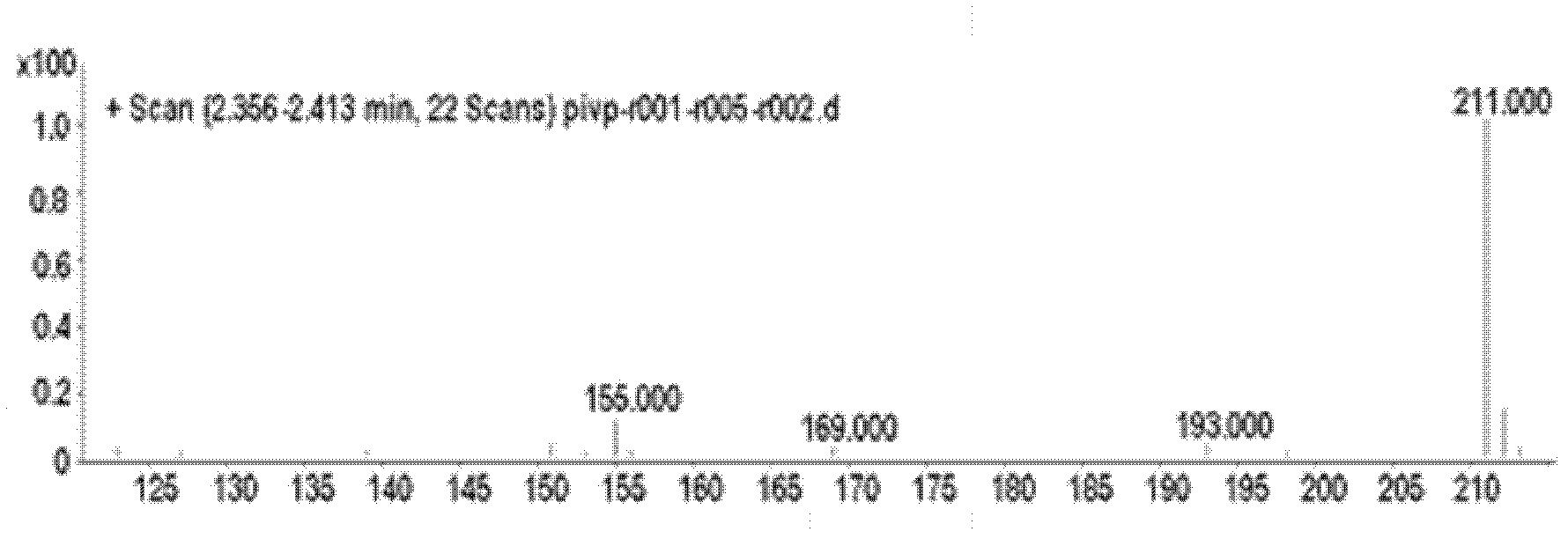

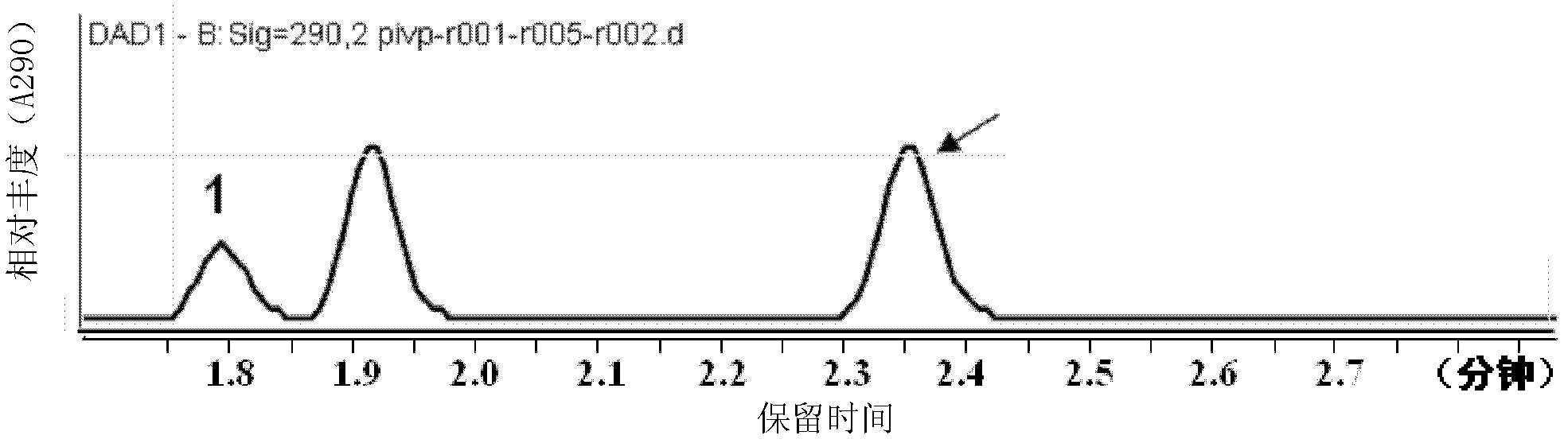

Fatty acid CoA ligase CCL2 of short-side chains of humulus lupulus, and coding gene and application of fatty acid CoA ligase CCL2

The invention discloses fatty acid CoA ligase CCL2 of short-side chains of humulus lupulus, and a coding gene and application of the fatty acid CoA ligase CCL2. The protein, namely, the fatty acid CoA ligase CCL2 provided by the invention is from (Humulus lupulus L.), is named as CCL2 protein, and is the following (a) or (b), wherein (a) is the protein consisting of amino acid sequences shown in sequences 1 of a sequence table 1 shown as the specification; and (b) is the protein which is formed by substitution and / or deficiency and / or addition of one or more amino acid residue of amino acid sequences in the sequence 1, has the function of the fatty acid CoA ligase and is derived from the (a). The CCL2 protein provided by the invention has the action of the CoA ligase, is a necessary key factor for the path of picric acid synthesis, and can generate 2mg / L precursor phlorisovalerophenone (PIVP) for picric acid synthesis by coexpression of CCL2 and VPS (Valerophenone Synthase) genes in yeast. The fatty acid CoA ligase CCL2 disclosed by the invention has wide application prospect in the bear brewing industries and the fields of human health care and the like.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

Corrosive for original austenite grain boundary of superhigh strength alloy structure steel and display method of original austenite grain boundary

The invention belongs to the technical field of metallographic structure observation, and particularly relates to a display method for an original austenite grain boundary of superhigh strength alloy structure D6AE steel. A corrosive for the austenite grain boundary of the superhigh strength alloy structure steel comprises the following components in parts by weight: 4.5 to 5.5 parts of picric acid, 7.5 to 8.5 parts of fatty alcohol-polyoxyethylene ether, 1.8 to 2.8 parts of ammonium cupric chloride, 100 parts of water and 6.6 to 8.1 parts of hydrogen peroxide. By the adoption of the corrosive disclosed by the invention, crystalline grains of original austenite of the superhigh strength alloy structure D6AE steel can be displayed clearly, and thus the problem that the original austenite grain boundary of the D6AE steel is difficult to display is solved.

Owner:成都积微物联集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com