Method for displaying P91 and P92 steel original austenite grain boundaries

A technology of austenite grain boundary and display method, applied in the field of physical and chemical inspection, can solve problems such as no exposure problem, large human factors and measurement errors, measurement accuracy and precision failing to meet inspection requirements, etc. degree, cost, pollution-free, and the effect of improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

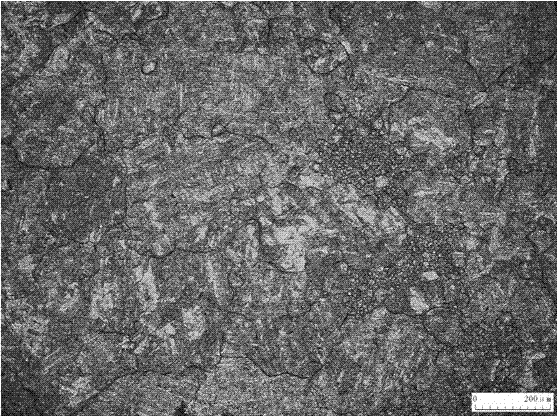

[0039] A method for displaying prior austenite grain boundaries of P91 and P92 steels, comprising the following steps in sequence:

[0040] 1) Chemical heat corrosion: add 4 grams of sodium dodecylbenzenesulfonate to 100ml of supersaturated picric acid aqueous solution, and heat and stir until sodium dodecylbenzenesulfonate is completely dissolved in the saturated solution of picric acid, then add 2ml of hydrogen peroxide, prepared as a chemical corrosion solution. Immerse the polished sample in the chemical corrosion solution first, and care should be taken to keep the polished surface of the sample out of contact with the container. It is best to make the polished surface of the sample face up. After heating and boiling for 3 minutes, take out the sample and wash it with clean water. hot air drying;

[0041] 2) Electrolytic etching: use 10% by volume sulfuric acid aqueous solution as the electrolytic etching solution, immerse the chemically etched sample in an electrolytic ...

Embodiment 2

[0044] Example 2: The mode of operation of this embodiment is the same as that of Embodiment 1, the difference is that:

[0045] A method for displaying prior austenite grain boundaries of P91 and P92 steels, comprising the following steps in sequence:

[0046] 1) Chemical thermal corrosion: Dissolve 2 grams of sodium tridecylbenzenesulfinate completely in 100 ml of supersaturated picric acid aqueous solution, and then add 3 ml of hydrogen peroxide to prepare a chemical corrosion solution. Immerse the polished sample in the chemical corrosion solution, heat, boil and etch for 2 minutes, then take out the sample to clean and dry;

[0047] 2) Electrolytic etching: use 15% sulfuric acid aqueous solution as the electrolytic etching solution to electrolytically etch the sample after chemical thermal etching; electrolytic specification: voltage 25V, time 90S;

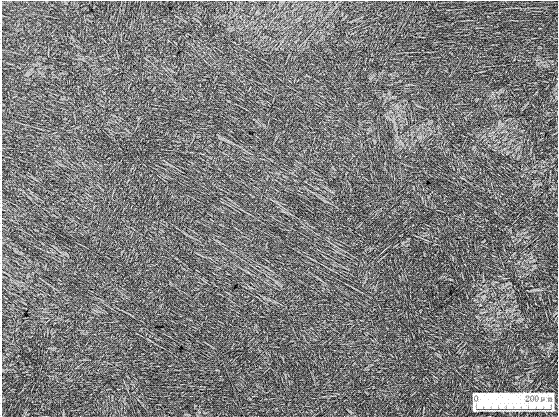

[0048] 3) Microscopic observation: through the dark field illumination of the microscope, the original austenite grain bou...

Embodiment 3

[0050] Example 3: The mode of operation of this embodiment is the same as that of Embodiment 1, the difference is that:

[0051] A method for displaying prior austenite grain boundaries of P91 and P92 steels, comprising the following steps in sequence:

[0052] 1) Chemical thermal corrosion: Dissolve 5 grams of sodium dodecylbenzenesulfonate completely in 120 ml of supersaturated picric acid aqueous solution, and then add 4 ml of hydrogen peroxide to prepare a chemical corrosion solution. Immerse the polished sample in the chemical corrosion solution, heat, boil and etch for 5 minutes, then take out the sample to clean and dry;

[0053] 2) Electrolytic etching: use 10% by volume sulfuric acid aqueous solution as the electrolytic etching solution, and electrolytically etch the sample after chemical thermal etching; electrolytic specification: voltage 15V, time 80S;

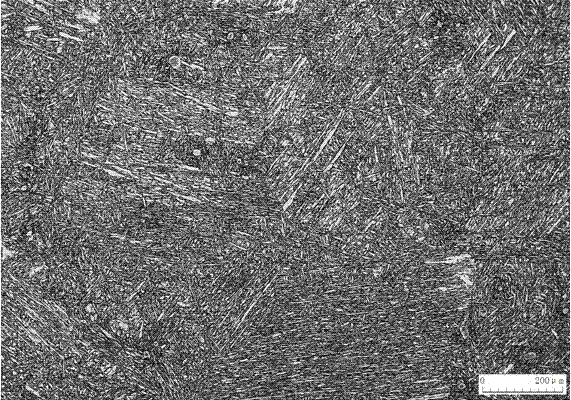

[0054] 3) Microscopic observation: through the dark field illumination of the microscope, the original austen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com