Patents

Literature

803 results about "Supersaturation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Supersaturation is a solution that contains more of the dissolved material than could be dissolved by the solvent under normal circumstances. It can also refer to a vapor of a compound that has a higher (partial) pressure than the vapor pressure of that compound.

Traffic control method and system based on intersection group

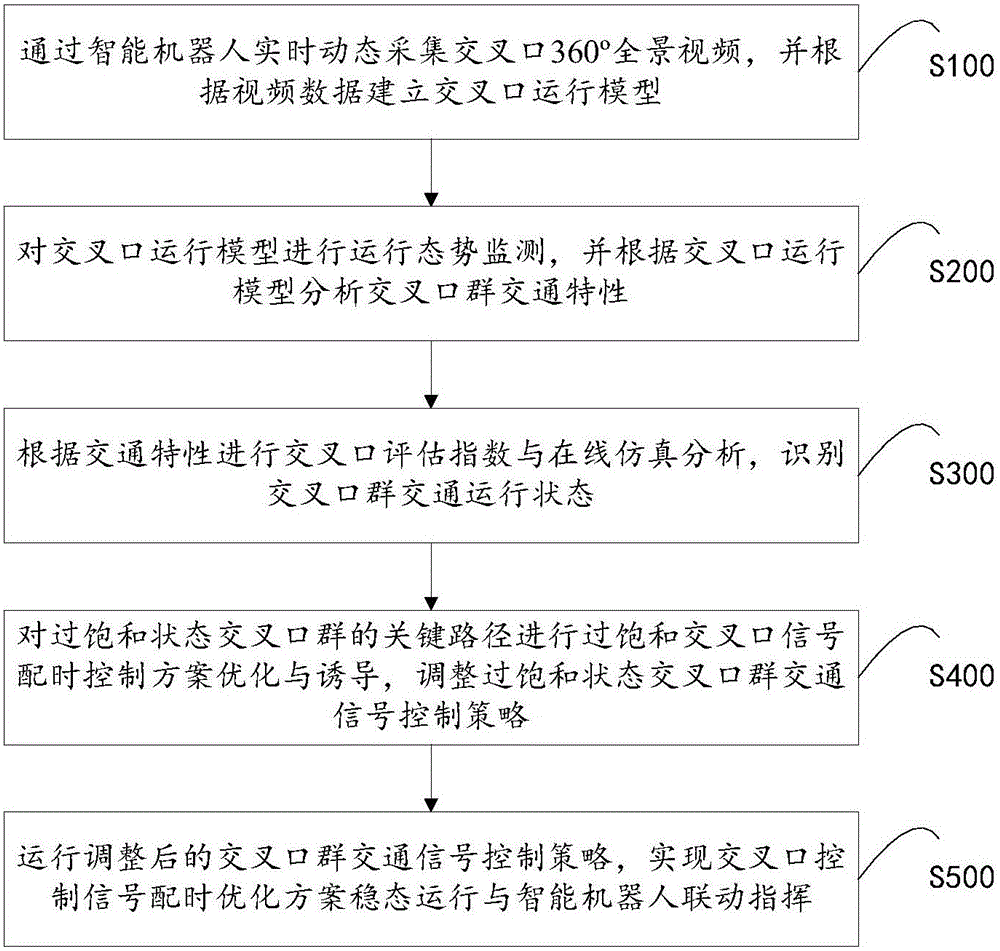

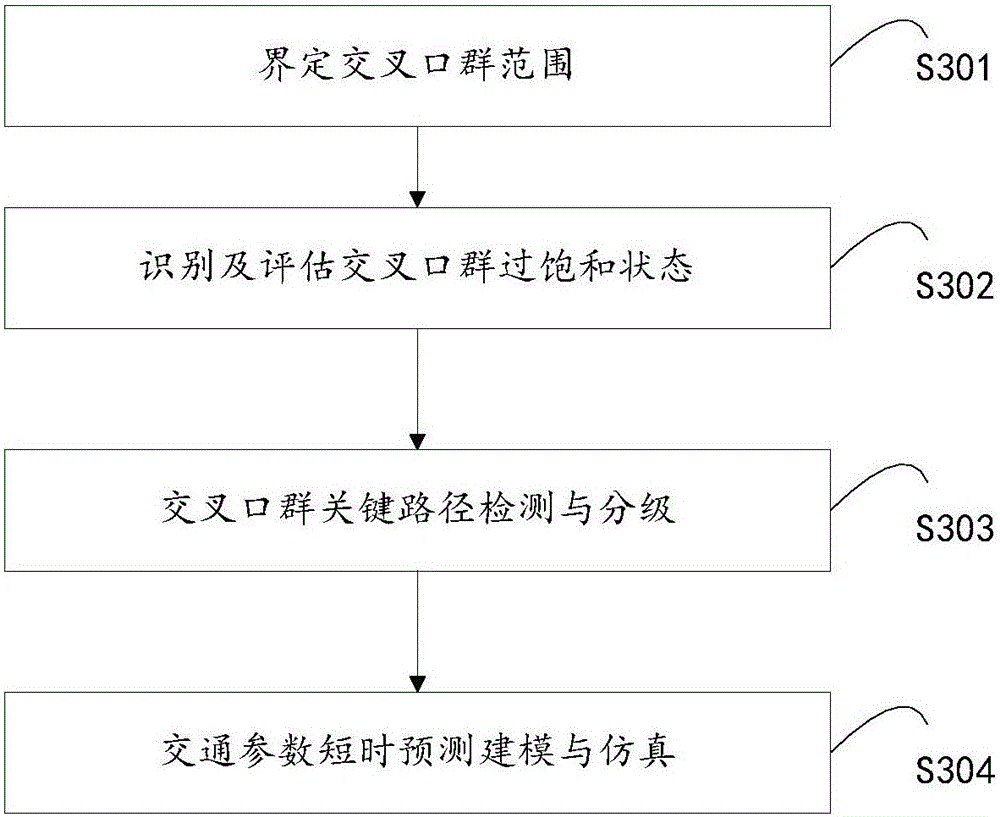

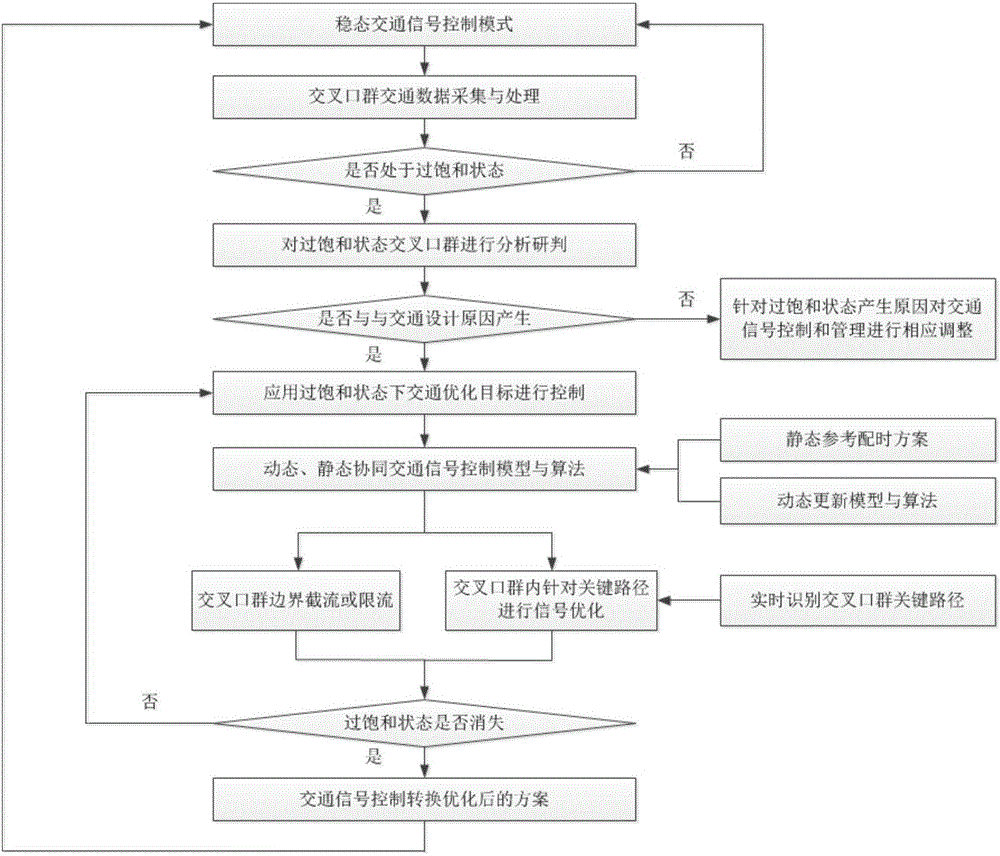

InactiveCN105809958AEase traffic congestionSolve overeatingControlling traffic signalsDetection of traffic movementTraffic characteristicControl signal

The invention relates to a traffic control method and system based on an intersection group.The method comprises the steps that 1, 360-degree panoramic video of intersections is dynamically collected in real time through an intelligent robot, an intersection operation model is established according to video data, and traffic characteristics of the intersection group are analyzed according to the intersection operation model; 2, intersection index evaluation and online simulation analysis are conducted according to the traffic characteristics, and the traffic operation state of the intersection group is identified; 3, supersaturation state intersection signal timing control scheme optimization is conducted on critical paths of a supersaturation state intersection group, and a supersaturation state intersection group traffic signal control strategy is adjusted; 4, the adjusted intersection group traffic signal control strategy is operated, and steady-state operation of an intersection control signal timing optimization scheme and linkage command of the intelligent robot are achieved.By means of the traffic control method and system based on the intersection group, traffic efficiency and service level of intersection single point control can be improved, and therefore the operation efficiency of an urban traffic system is greatly improved, and urban traffic jams are relieved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

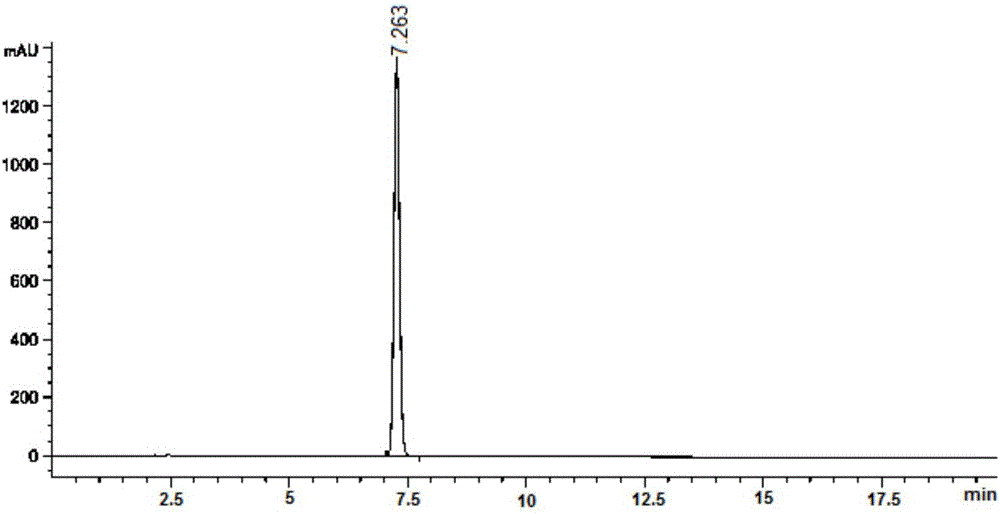

Method for extracting cannabidiol from industrial hemp floral leaves

InactiveCN106278828AHigh purityReduce the impactOrganic chemistryOrganic compound preparationAlcoholSolvent

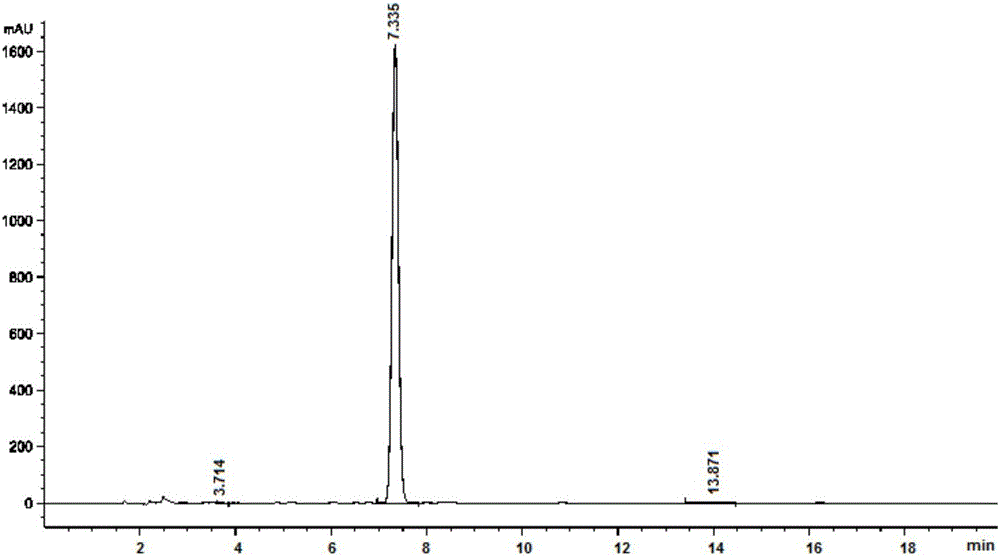

The invention discloses a method for extracting cannabidiol from industrial hemp floral leaves. The method comprises the following steps: grinding and drying floral leaves of industrial hemp, thereby obtaining medicinal powder; extracting the medicinal powder by adopting 30-100v% of ethanol, thereby obtaining extracting solution; concentrating the extracting solution to obtain extract; performing water precipitation on the extract, removing the impurities, thereby obtaining water precipitation solution; centrifuging the water precipitation solution, adding 10-100v% of ethanol into the obtained precipitate, dissolving to obtain an alcoholic solution of the precipitate; performing column chromatography on the alcoholic solution of the precipitate; concentrating the eluent obtained by eluting after column chromatography, adding ethanol to perform supersaturation dissolving, thereby obtaining a crystal; adding the crystal into purified water or ethanol for washing, thereby obtaining a primary product; uniformly mixing the primary product by using the purified water, drying, thereby obtaining the cannabidiol. According to the method disclosed by the invention, the highly safe ethanol serves as a solvent, so that the purity of the cannabidiol in the finished product is improved, a psychotoxic component, namely tetrahydrocannabinol, is removed, the product safety is improved, and the method is suitable for industrial production.

Owner:YUNNAN HANSU BIO TECH CO LTD

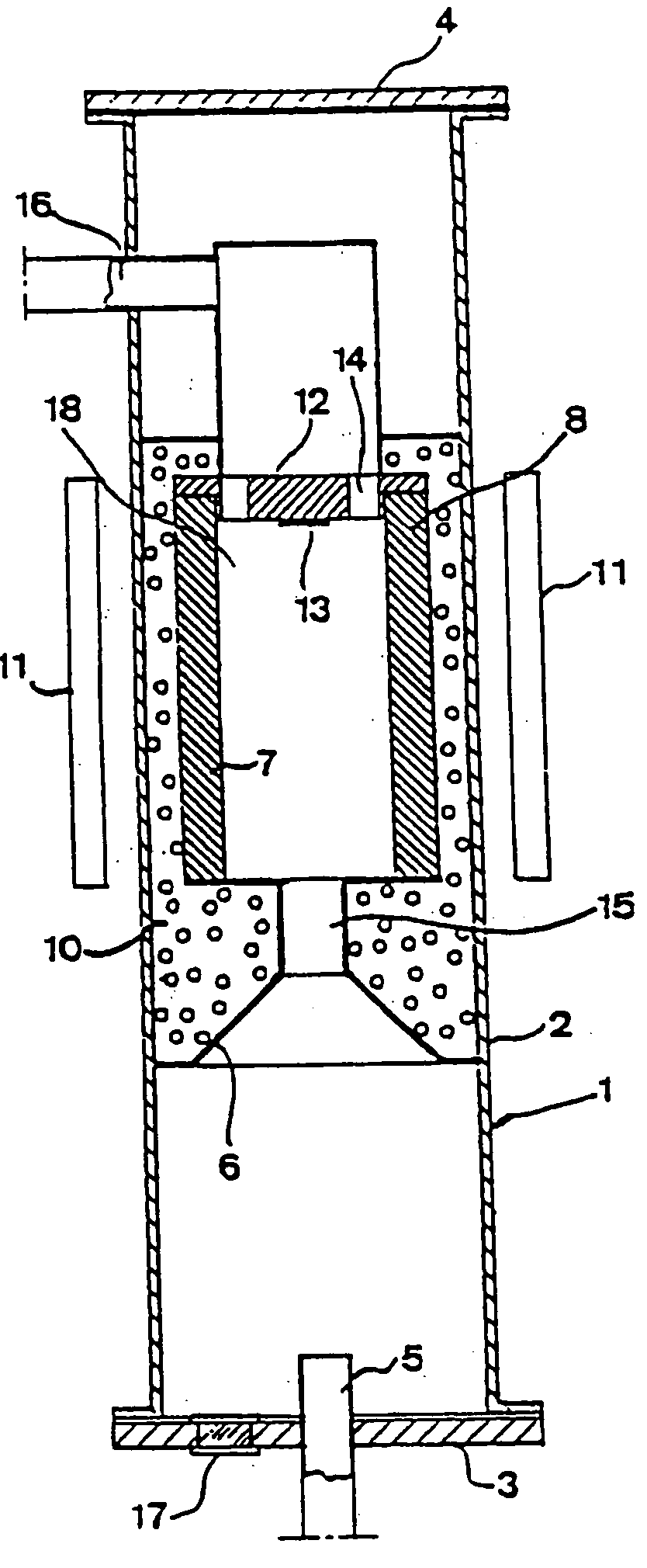

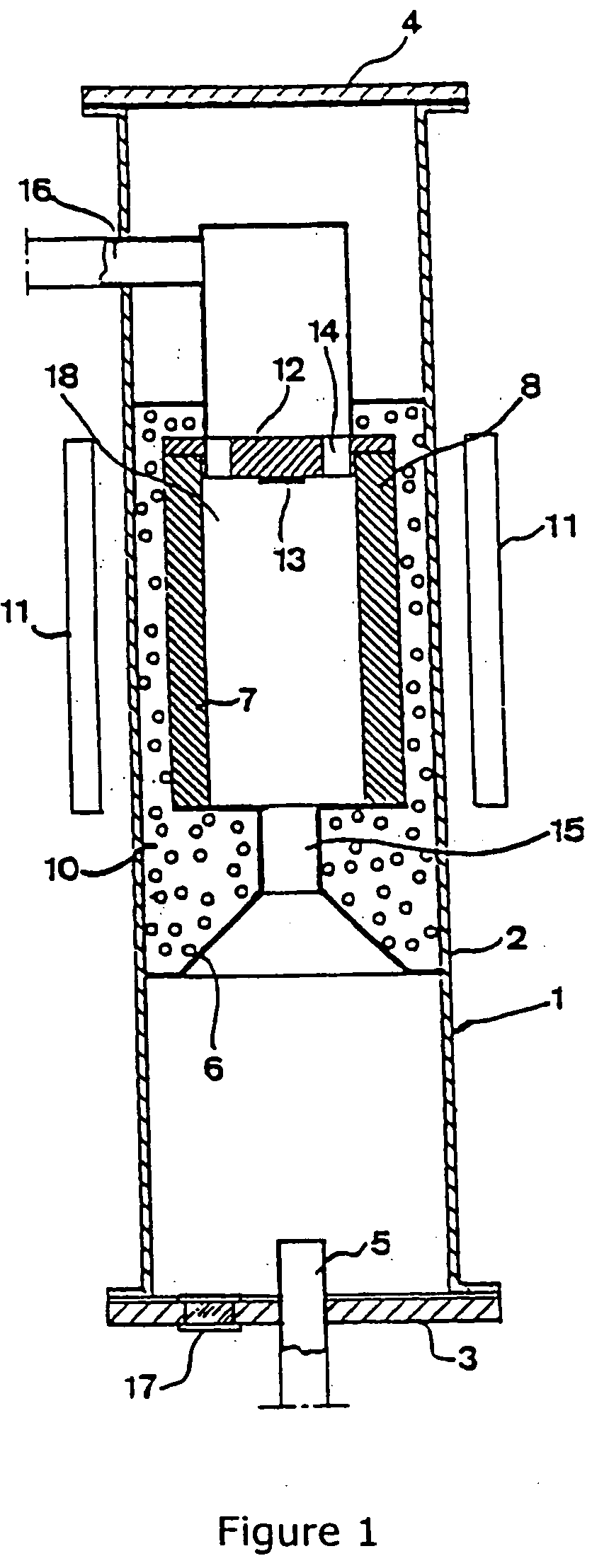

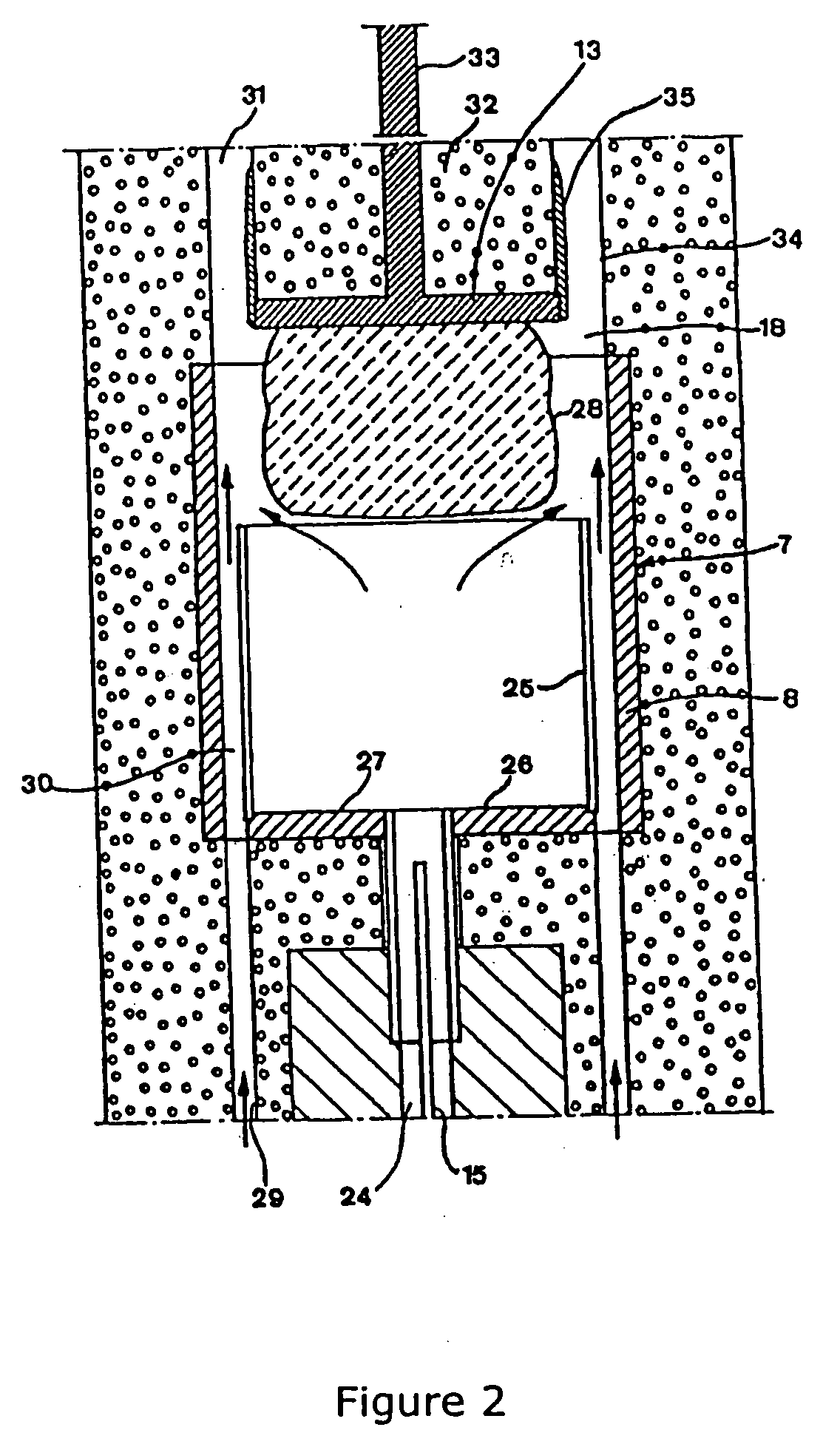

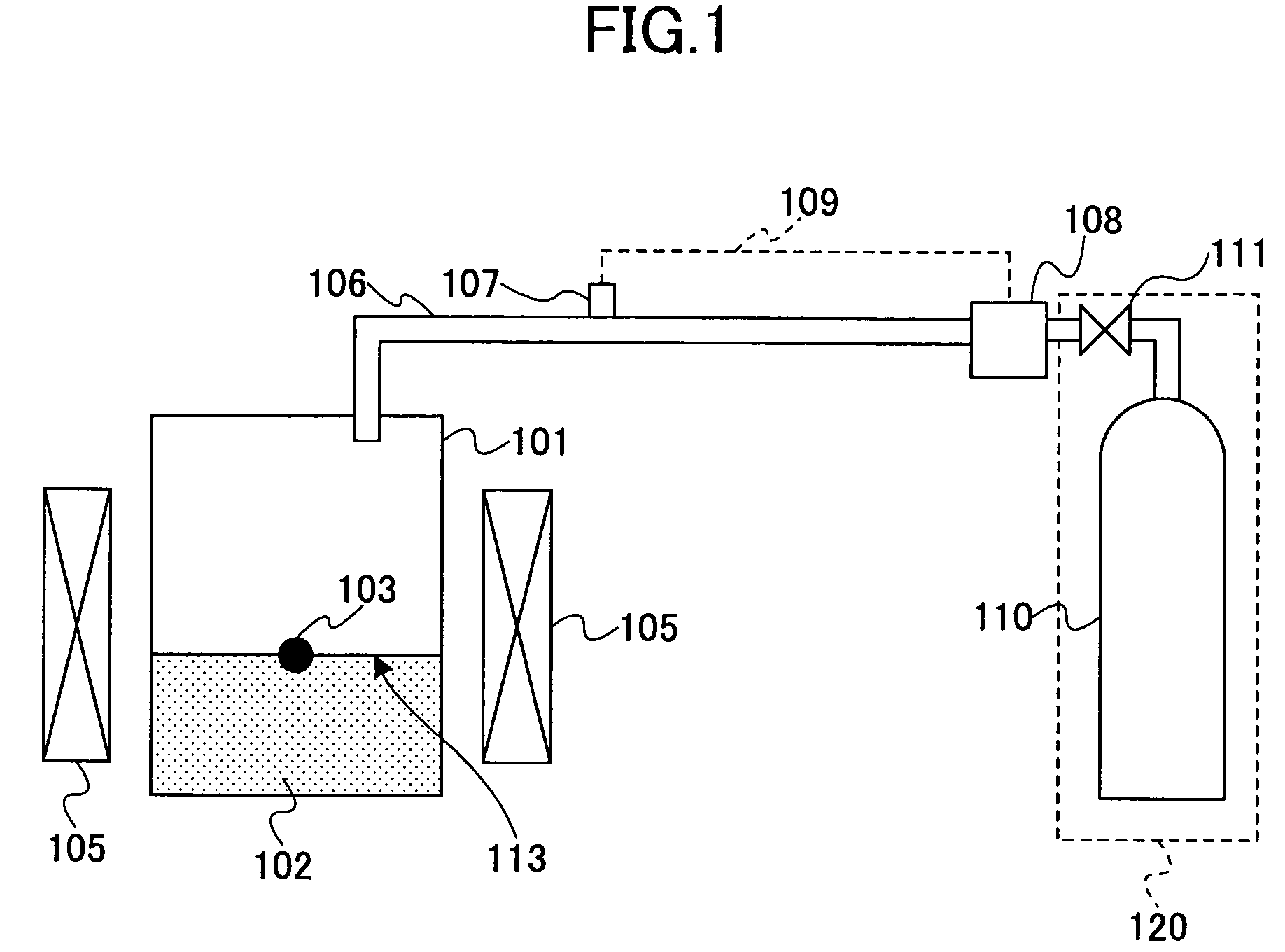

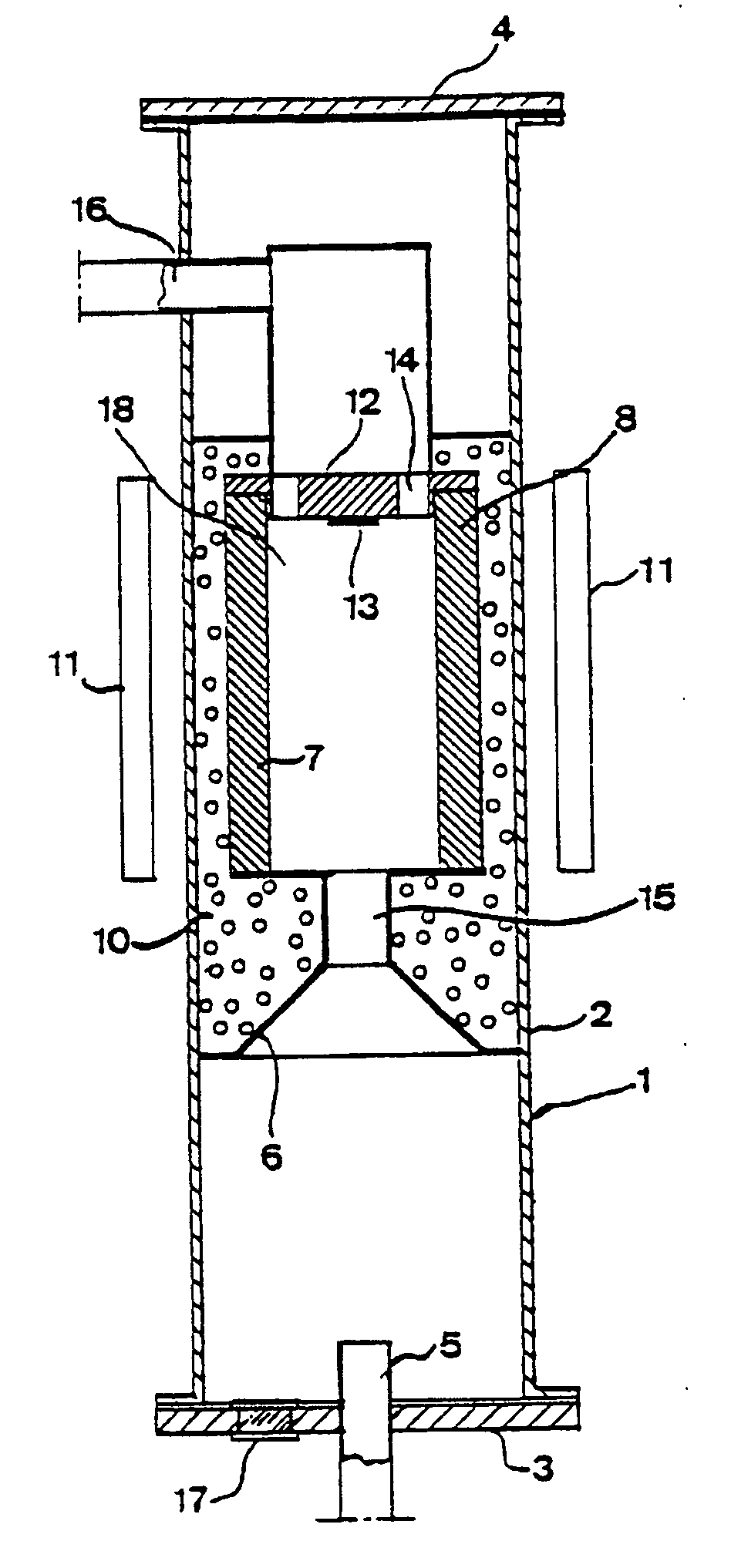

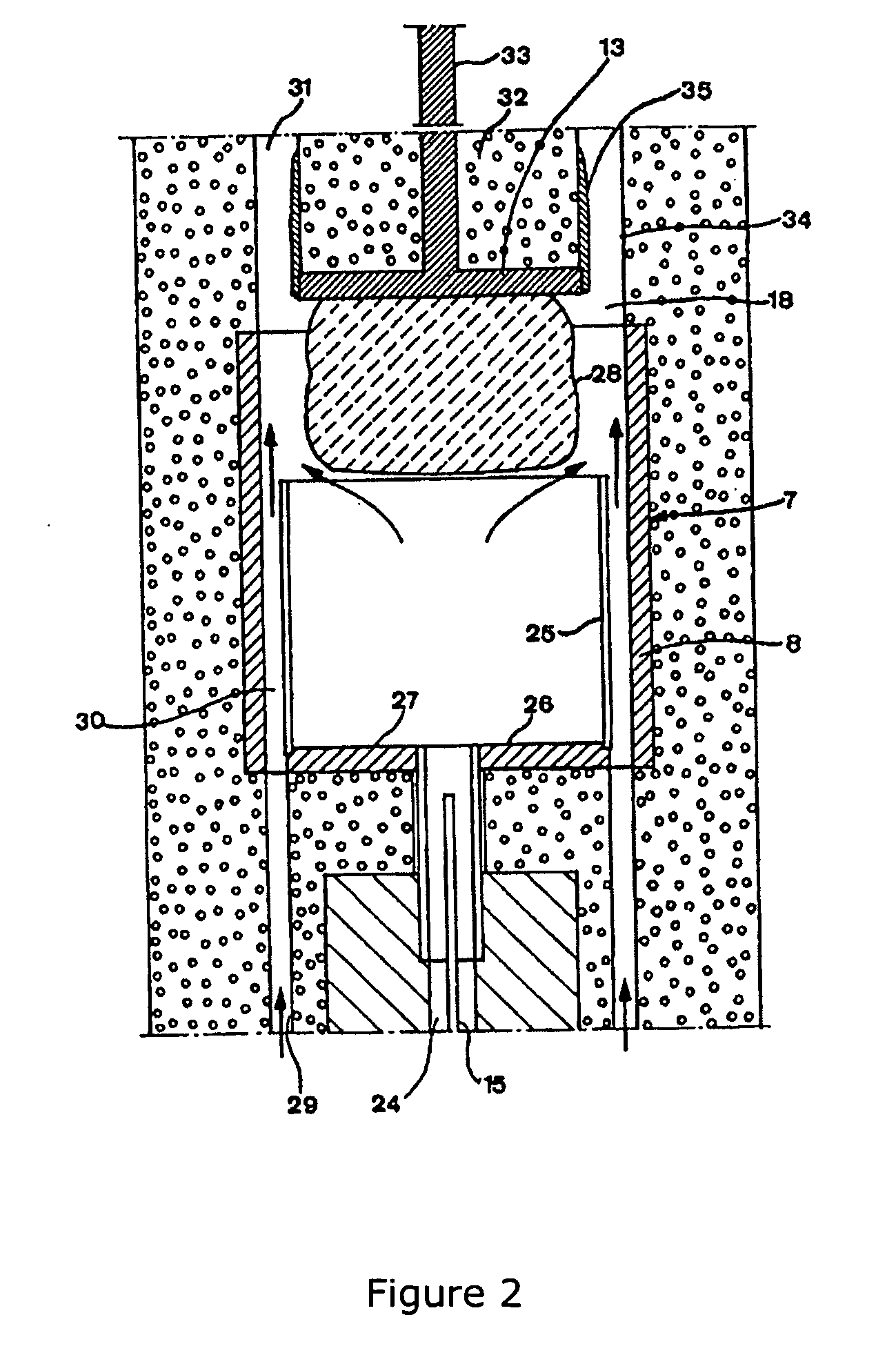

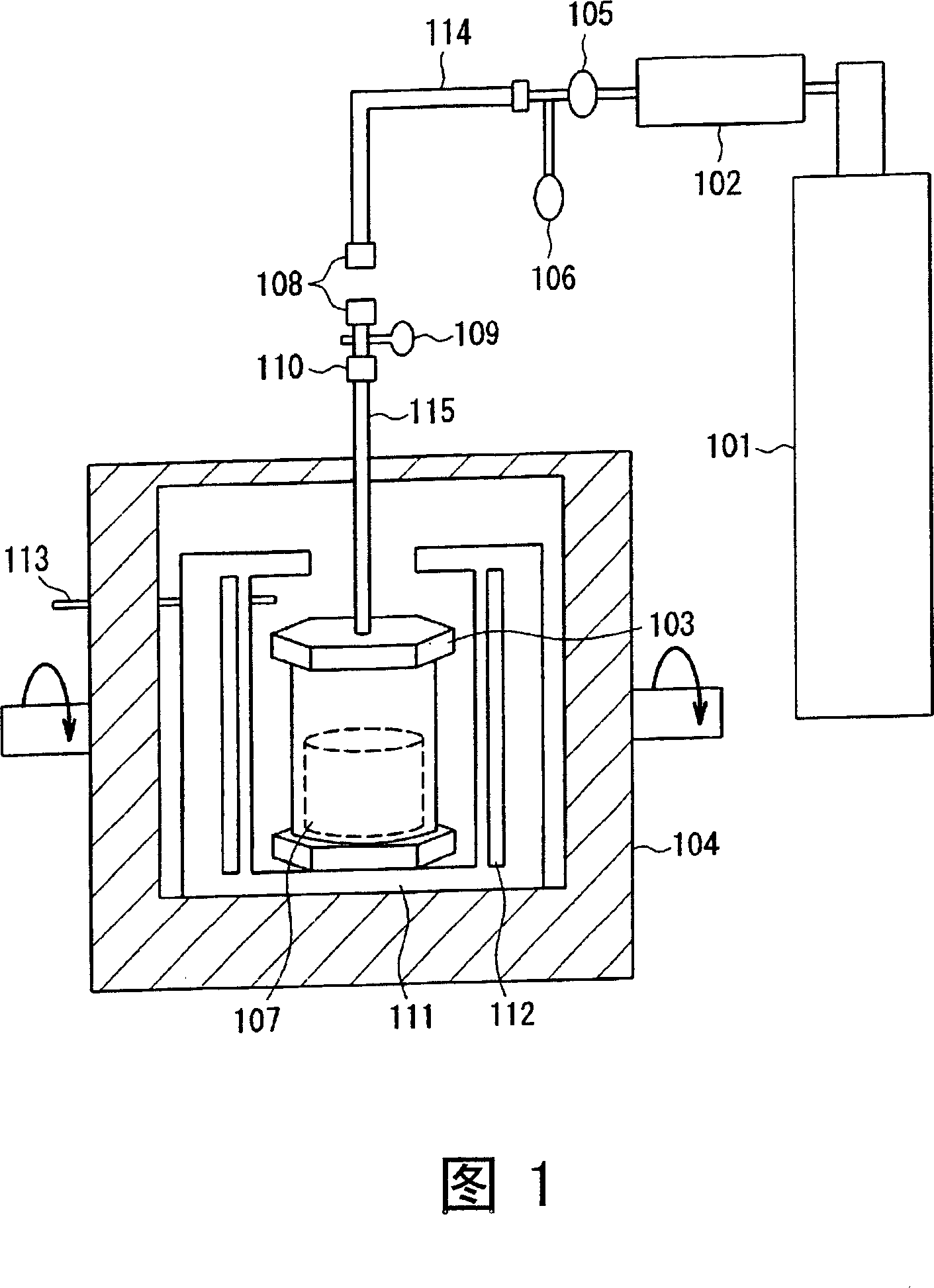

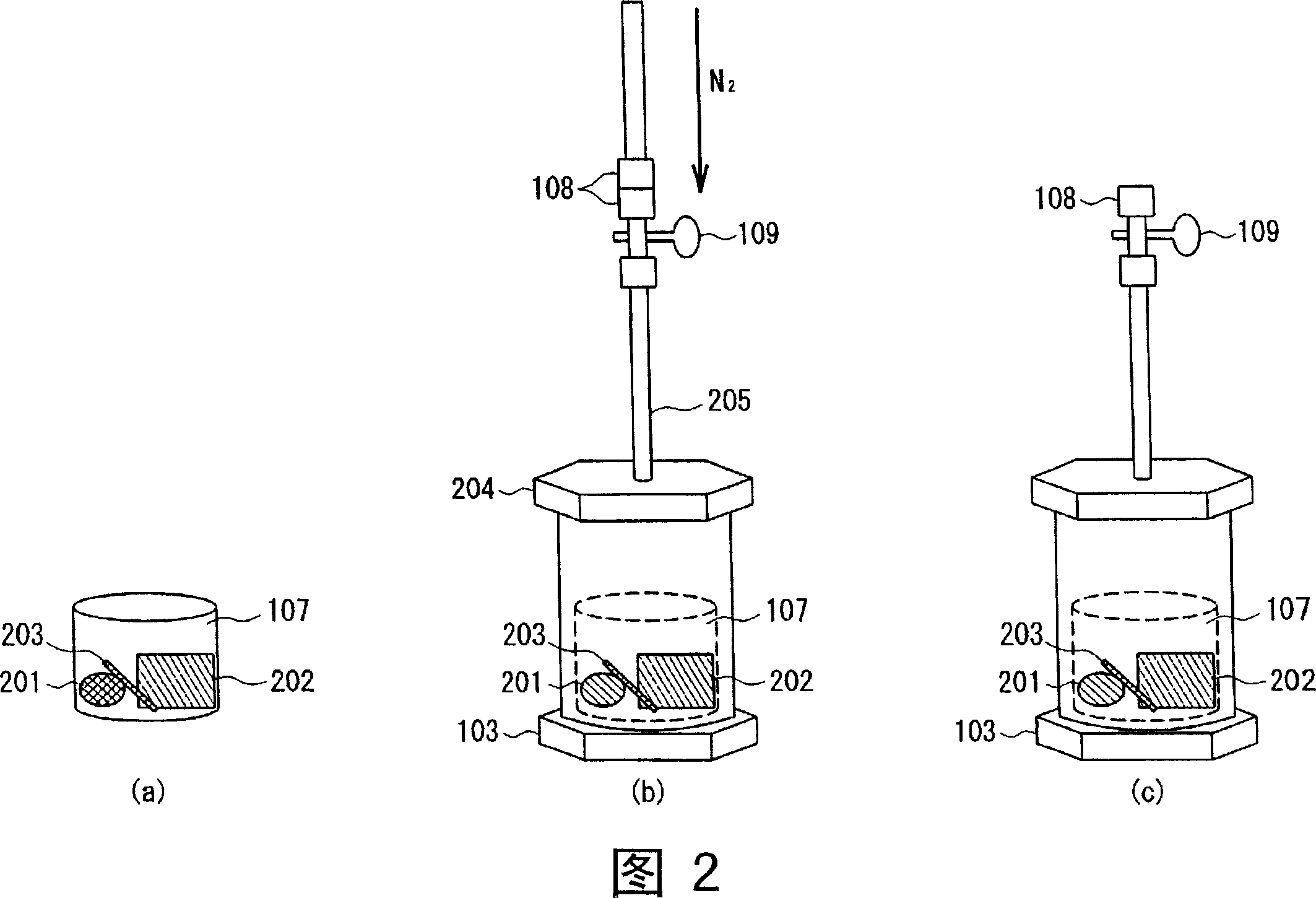

Device and method for producing single crystals by vapor deposition

ActiveUS20050000406A1Down and eliminate formationPreventing structural defect generationFrom gel statePolycrystalline material growthGas phaseSingle crystal

A method and a device to grow from the vapor phase, a single crystal of either SiC, a group III-nitride, or alloys thereof, at a growth rate and for a period of time sufficient to produce a crystal of preferably several centimeters length. The diameter of the growing crystal may be controlled. To prevent the formation of undesirable polycrystalline deposits on surfaces in the downstream vicinity of the single crystal growth area, the local supersaturation of at least one component of the material grown is lowered by introducing a separate gas flow comprising at least one halogen element or a combination of said halogen and hydrogen species.

Owner:NORSTEL

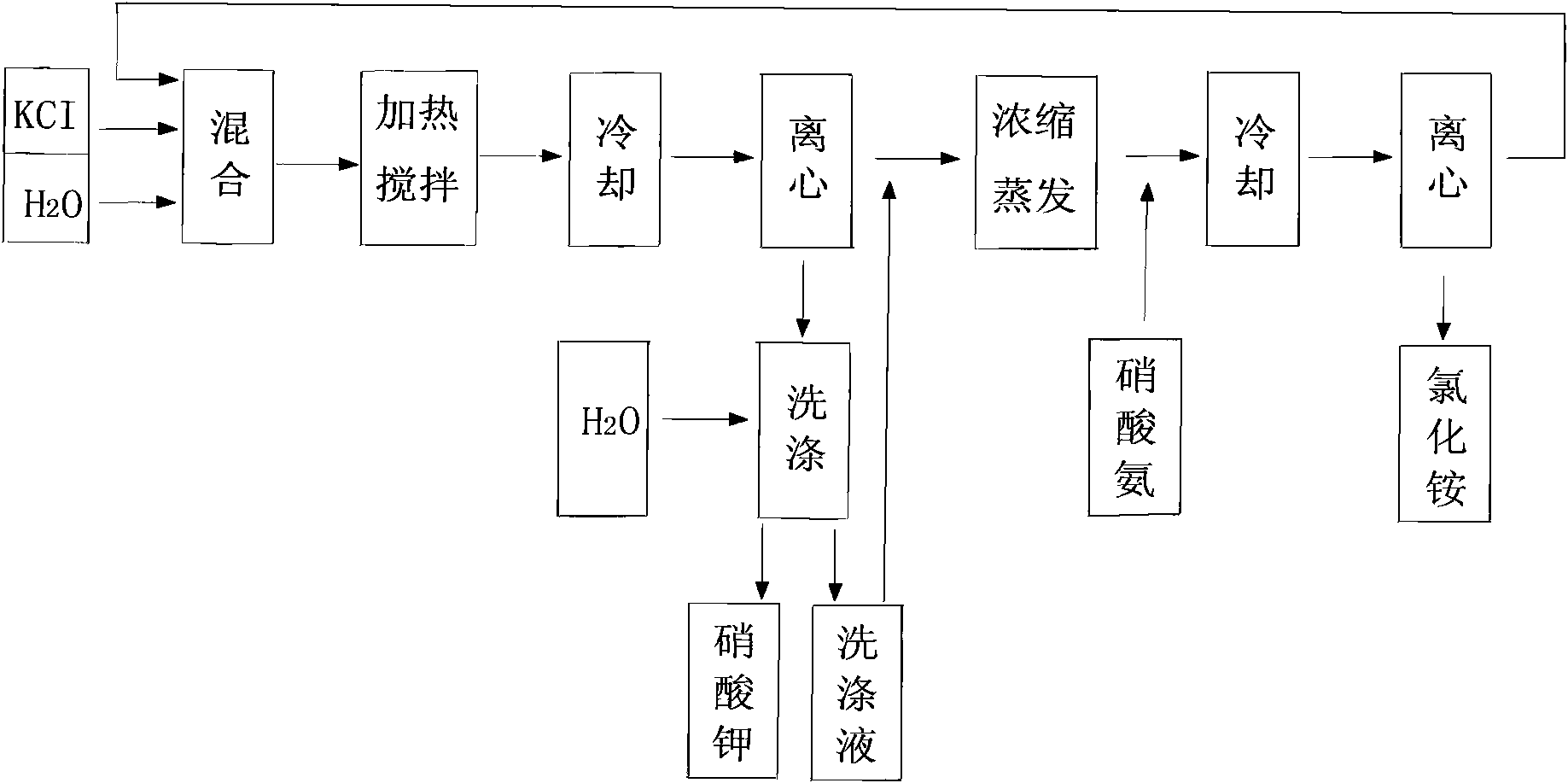

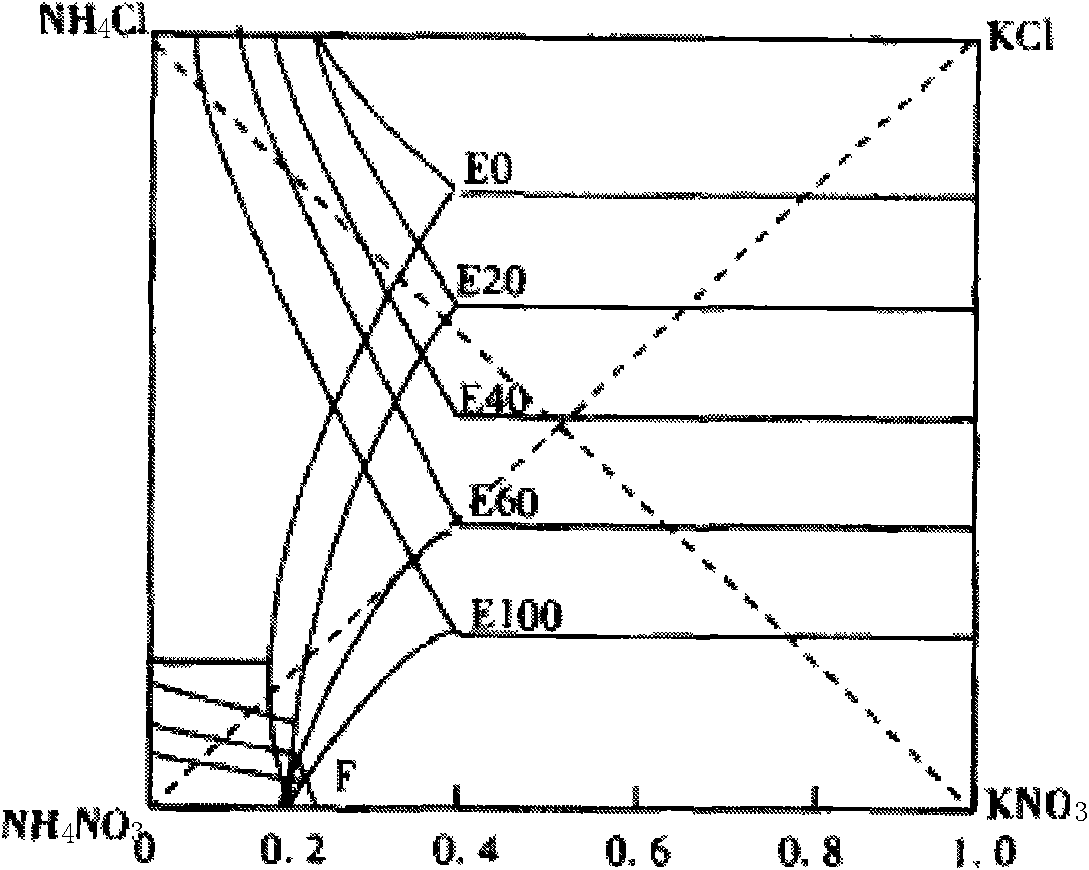

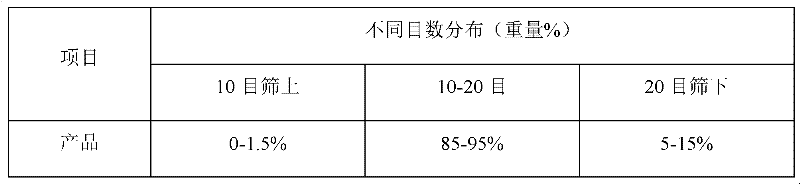

Method for preparing potassium nitrate and ammonium chloride employing double decomposition reaction

InactiveCN101628723ACreate pollutionRealize the concentrated evaporation processAlkali metal nitrate preparationAmmonium halidesDecompositionIon exchange

A method for preparing potassium nitrate and ammonium chloride employing double decomposition reaction comprises the following steps: dissolving ammonium nitrate and potassium chloride in water according to a defined ratio at 110 DEG C, continuously adding potassium chloride and water, heating while stirring to ensure that potassium nitrate is in supersaturation state, after stopping heating, cooling the solution in a vacuum cooling crystallizer to 36-40 DEG C to separate potassium nitrate crystal, placing the potassium nitrate crystal in a centrifugal machine with a filter cloth lining to obtain coarse potassium nitrate, then washing the potassium nitrate with cold water, drying to obtain the finished potassium nitrate; in addition, adding ammonium nitrate in mother solution I and cleaning solution to adjust solution concentration so that ammonium chloride can reach supersaturation state, using a vacuum concentration device to perform negative pressure evaporation, separating and precipitating ammonium chloride by centrifuging and obtaining a solid ammonium chloride product, wherein, when dissolving ammonium nitrate and potassium chloride, the ratio of ammonium ion to chlorine ion is 1:2 and when using the centrifugal machine to obtain the coarse potassium nitrate, the separated mother solution is another mother solution I sharing the same saturation point of potassium nitrate and ammonium chloride. The solution of feed liquid circular reaction overcomes the defects of the prior art that the price of potassium nitrate used in reaction is high, the resource of potassium nitrate is in short supply and the cost of devices used in ion-exchange method is high, thus being applicable to the production of potassium nitrate.

Owner:湖南丹化农资有限公司

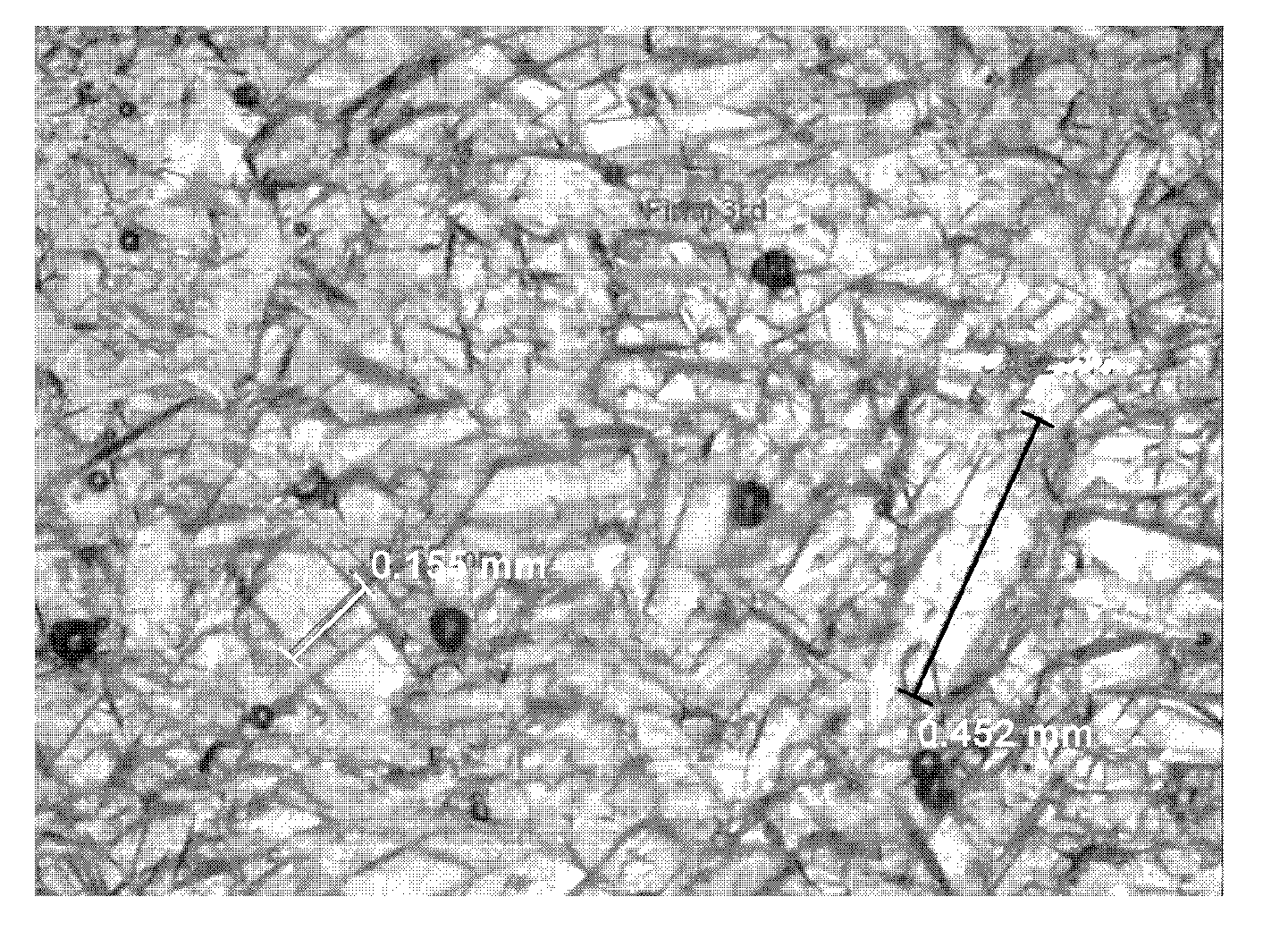

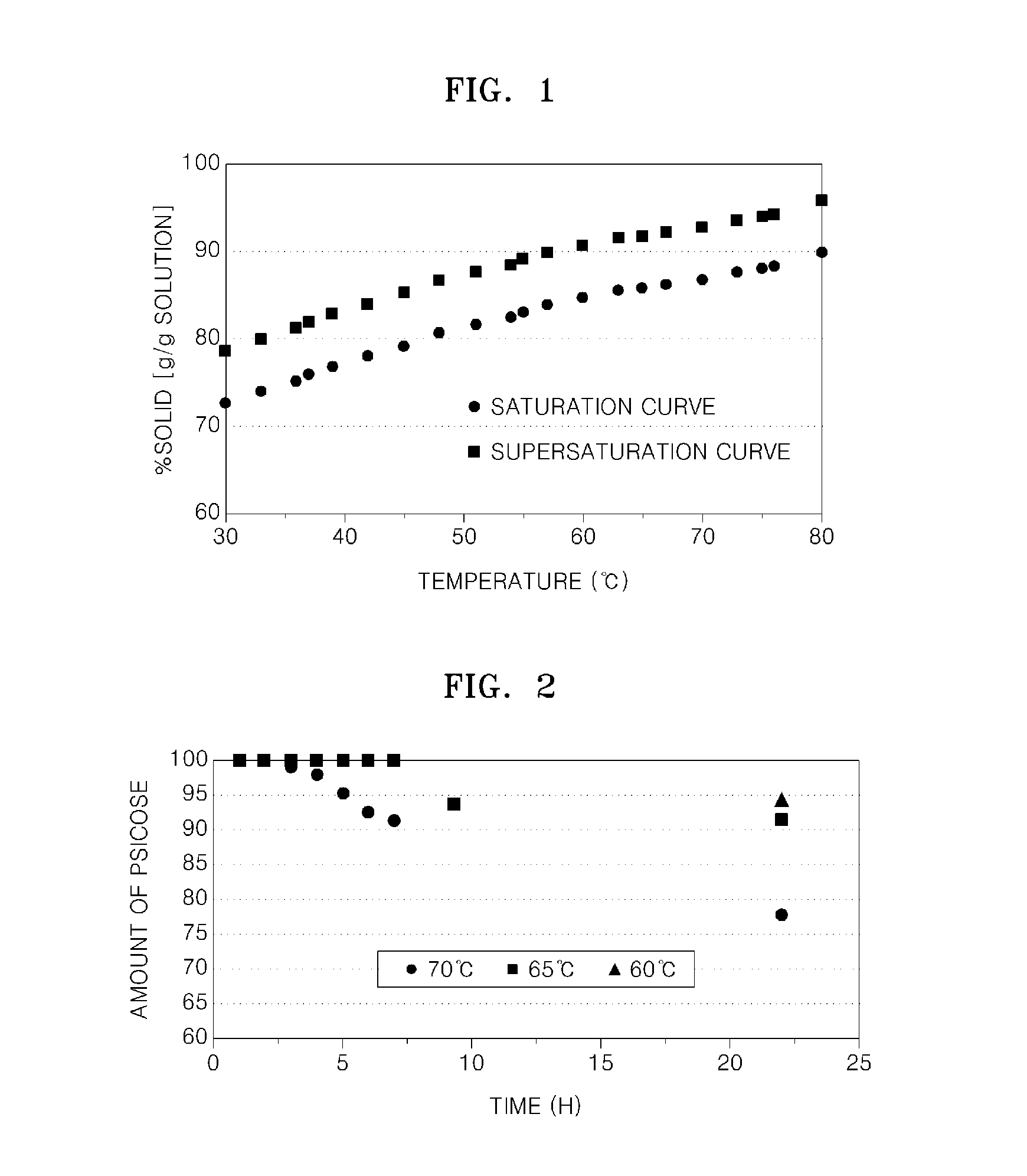

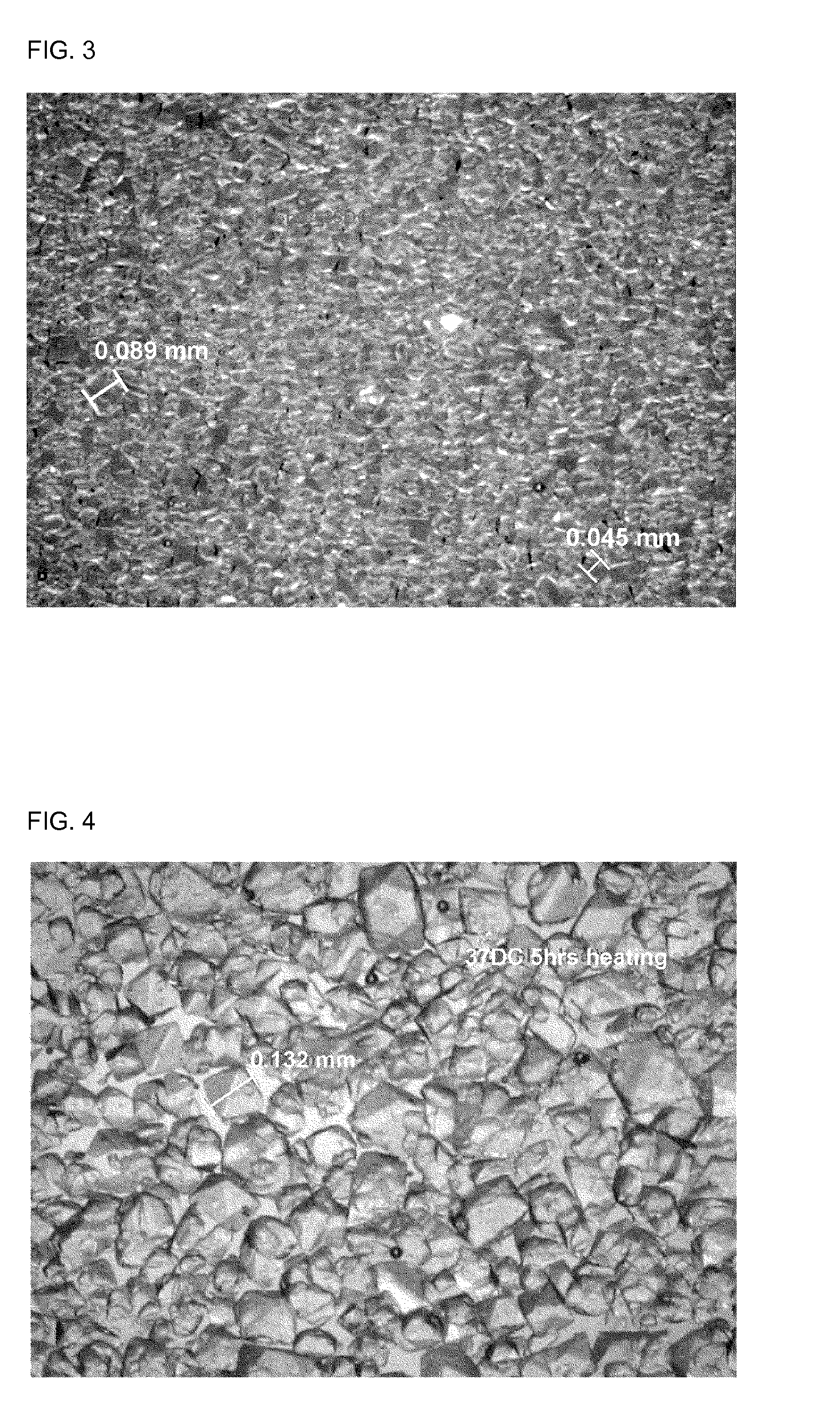

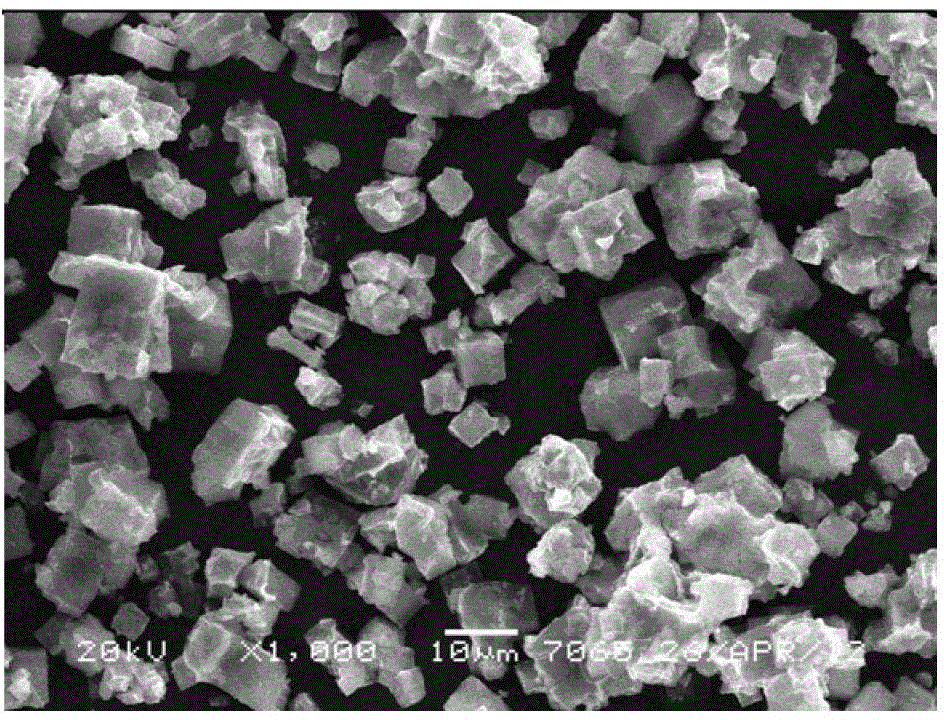

Method of producing d-psicose crystals

ActiveUS20110237790A1Present inventionSugar derivativesSugar derivatives preparationSupersaturationCrystal

The present invention relates to a method of producing D-psicose crystals from a D-psicose solution by using supersaturation.

Owner:CJ CHEILJEDANG CORP

Pharmaceutical composition containing water soluble drug

InactiveUS20050129778A1Reduces solubility of drugReduce solubilityNervous disorderPharmaceutical containersDrugs solutionWater soluble

The present invention is directed to a process of preparing beads coated with a water soluble drug for incorporation into a pharmaceutical composition comprising: (a) preparing a supersaturated drug solution containing a desired amount of drug, which is completely saturated at a first temperature but which is supersaturated at a second temperature which is below the first temperature; and (b) coating inert beads with the drug solution, said drug solution being maintained at or below the first temperature but above the second temperature, and said beads maintained at a second temperature, wherein the second temperature is less than the first temperature and wherein the solution containing the drug is supersaturated at the second temperature, as well as to the pharmaceutical compositions containing same.

Owner:NOSTRUM PHARMA INC

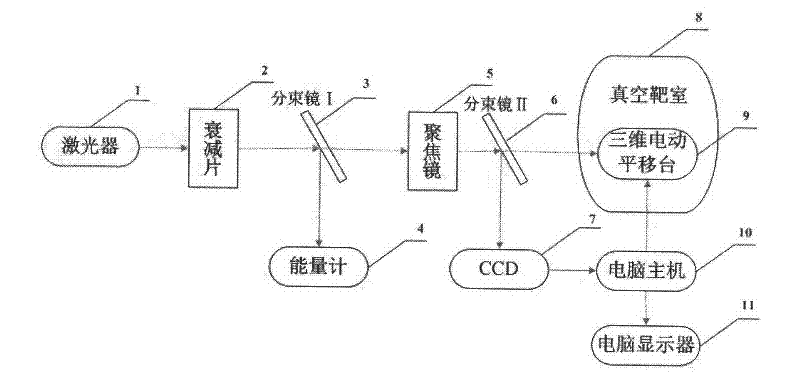

Preparation device for preparing functional micro-nano materials on silicon surfaces based on femtosecond laser and method

InactiveCN102500923AReduce heat damageEasy to processDecorative surface effectsChemical vapor deposition coatingField emission deviceSolar cell

The invention provides a preparation device for preparing functional micro-nano materials on silicon surfaces based on femtosecond laser and a method. When the device is used for preparation, scanning speed reaches 4mm / s, and is increased by 20 times as compared with scanning speed when micro-nano materials are prepared in a traditional method. Simultaneously, supersaturation doping of the silicon material surface and preparation of micro-nano structures of the surfaces are realized during preparation, prepared micro-nano materials can absorb 90% of light with wavelength ranging from 200nm to 2500nm, and silicon materials without scanning traces on surfaces can be obtained. The preparation device and the method are exquisite in design and easy to control, and the prepared materials can be applied to solar cells, detectors, field emission devices and the like in the photoelectric industry.

Owner:CHANGCHUN UNIV OF SCI & TECH

Efficient preparation method for nanostructure oxide dispersion strengthening steel

The invention aims at providing an efficient preparation method for nanostructure oxide dispersion strengthening steel, which adopts an atomization method for direct preparation(for one step) of powder solid solution alloy containing supersaturation solid solution of Y and Ti, so that conventional process for long-time mechanical alloying ball-milling between mother alloy(free of Y and Ti) atomization powder process as well as atomized powder and Y2O3 and Ti is replaced, and necessary microstructure is provided for forming high density nanostructure rich Y-Ti-O precipitated phase in follow-up process. According to the method, the preparation process is simplified, and bad microstructures such as non-nanostructure precipitated phase and the like and degradation of material property caused by long-time ball milling in existing process can be controlled or prevented, the obdurability and radiation resistance and helium fragility resistance of the material can be improved, so that the operation requirement of key structure material of core parts on advanced nuclear reactor is satisfied.

Owner:NORTHEASTERN UNIV

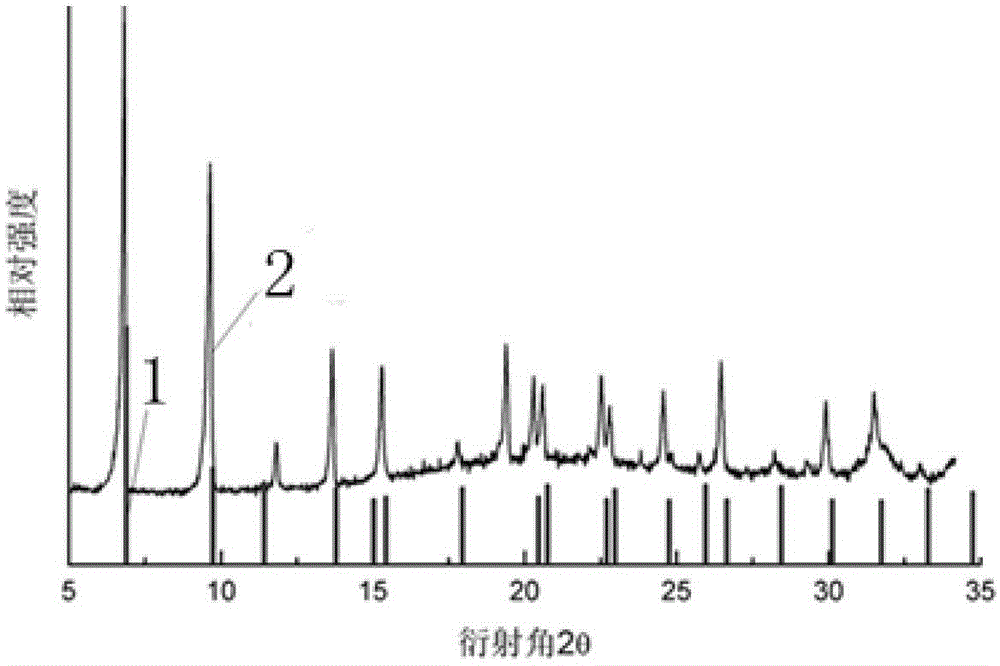

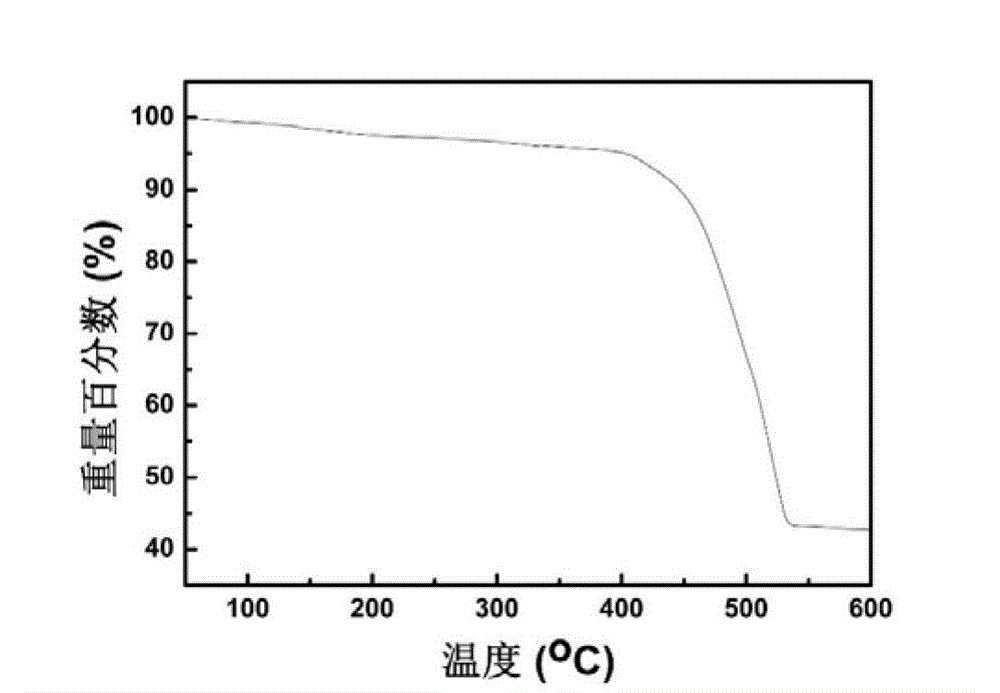

Method for preparing MOF-5

InactiveCN103333182AReduce consumptionImprove thermal stabilityZinc organic compoundsMetal frameworkThermal stability

The invention discloses a method for preparing MOF-5 and belongs to the technical field of preparation of metal framework materials. Zinc sources and terephthalic acid are dissolved in solvents separately. One solution is heated, and the other solution is added into the heated solution dropwise to prepare MOF-5 by a solvothermal method. The method not only utilizes existing devices, but also controls the degree of supersaturation of reaction solutions at a low level without consuming more solvents to prepare MOF-5 with good granule consistency, high specific surface area and good thermostability. The method reduces consumption of solvents, and has loose facility requests and simple operations, and MOF-5 can be prepared economically and effectively.

Owner:CENT SOUTH UNIV

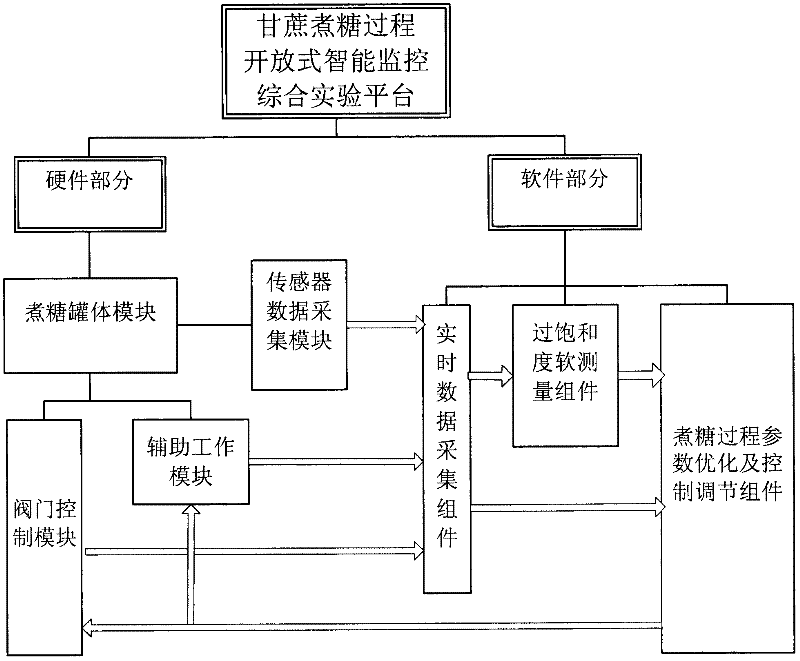

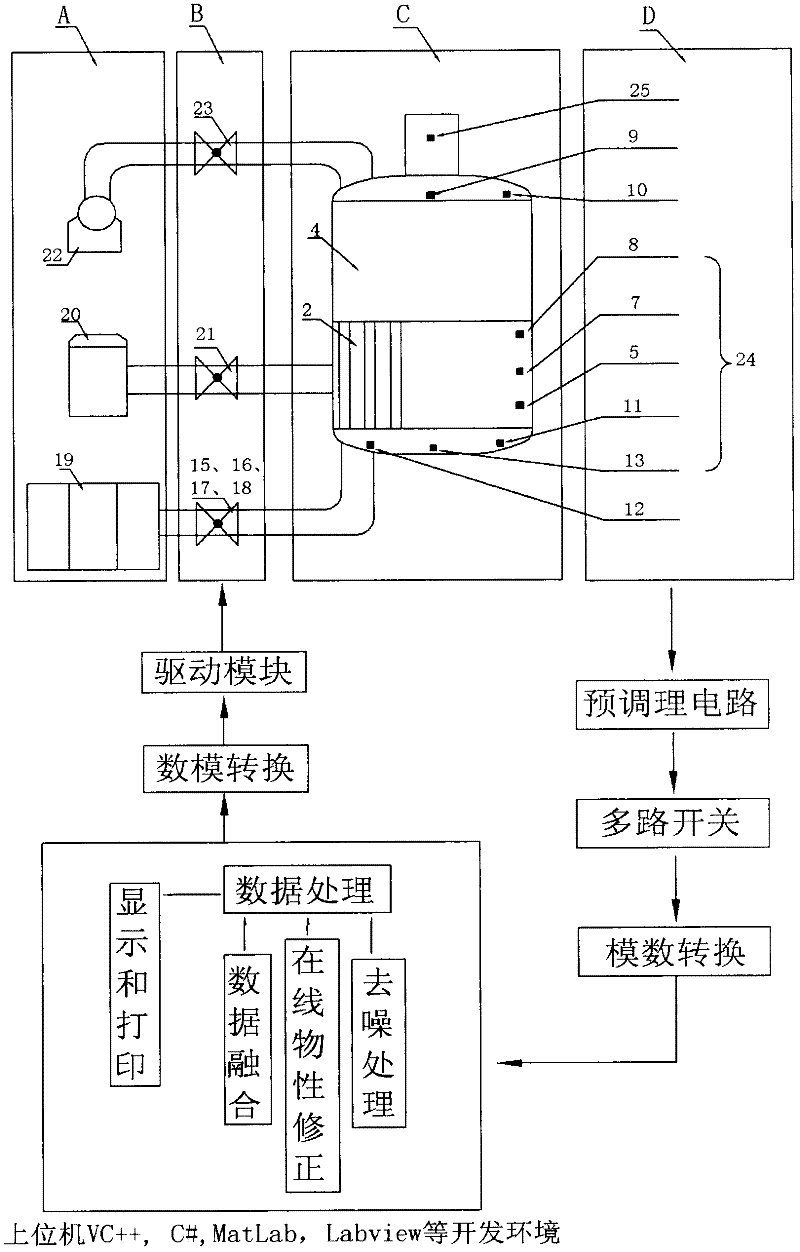

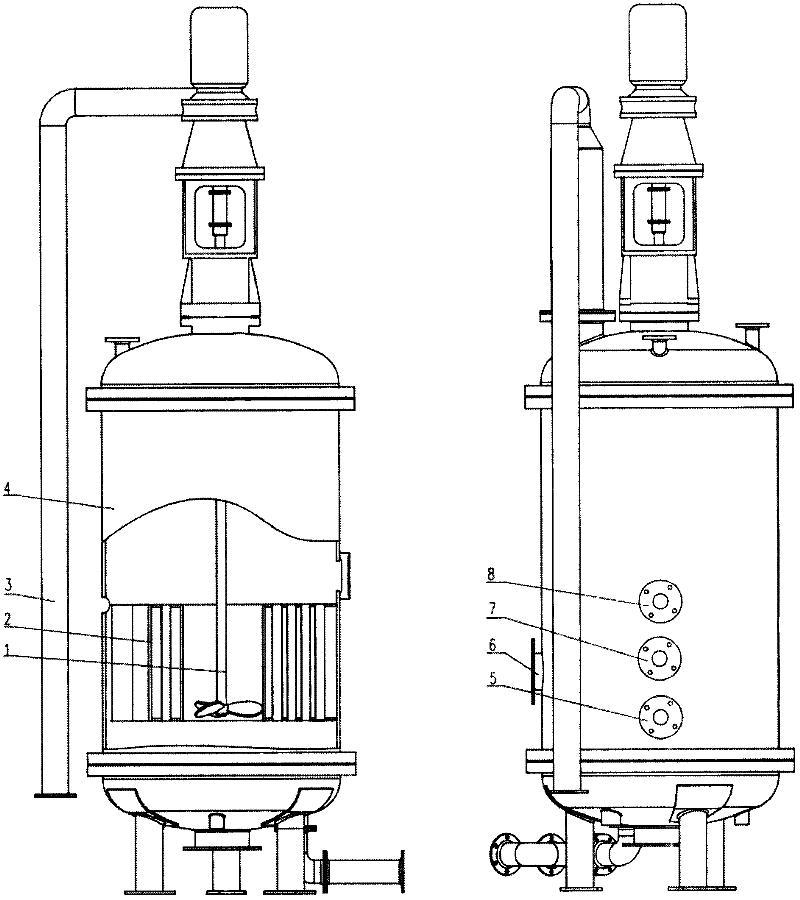

Open type intelligent monitoring comprehensive experiment platform in sugarcane sugar boiling process

ActiveCN102505048AReduce volumeLess materialSugar juice boiling/evaporationTotal factory controlArea networkReal-time data

The invention relates to an open type intelligent monitoring comprehensive experiment platform in the sugarcane sugar boiling process. The open type intelligent monitoring comprehensive experiment platform consists of a hardware part and a software part, wherein the hardware part comprises a sugar boiling tank body module, an auxiliary work module, a sensor data collecting module and a valve control module, the software part comprises a real-time data collecting assembly, a supersaturation degree soft measuring assembly and a sugar boiling process dynamic parameter optimizing and control regulation assembly, and the hardware part and the software part are connected with each other through a Mod bus and a controller area network (CAN) bus. The platform is used for scientific research, various kinds of monitoring method optimizing research are developed under various actual work conditions in the sugar boiling process, and the practical monitoring technology is provided in the actual sugar boiling process. The experiment platform can also be used as a comprehensive experiment teaching platform for students specialized in measuring control and sugar making, and relative comprehensive and design research teaching method research is developed.

Owner:GUANGXI UNIV

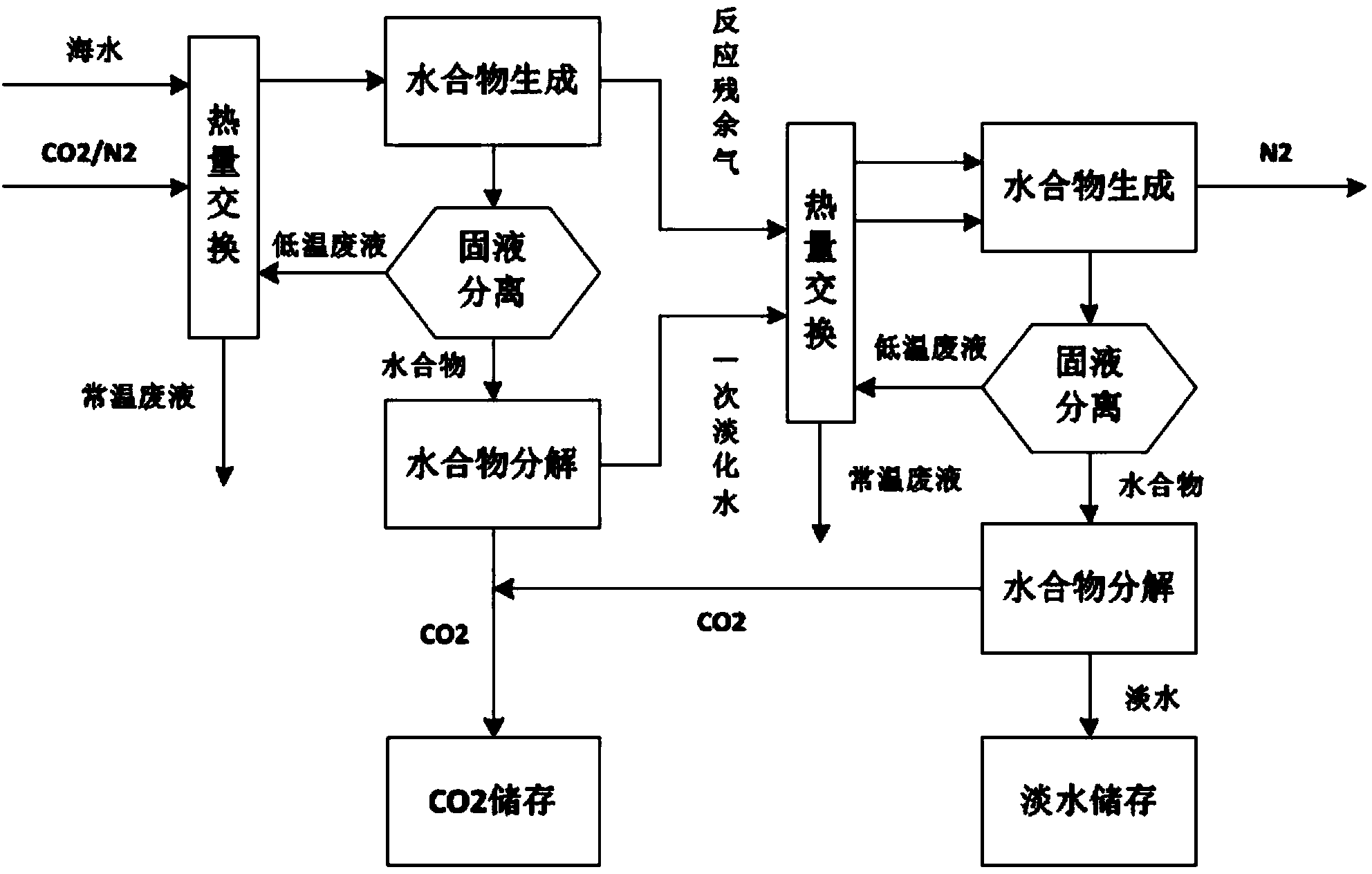

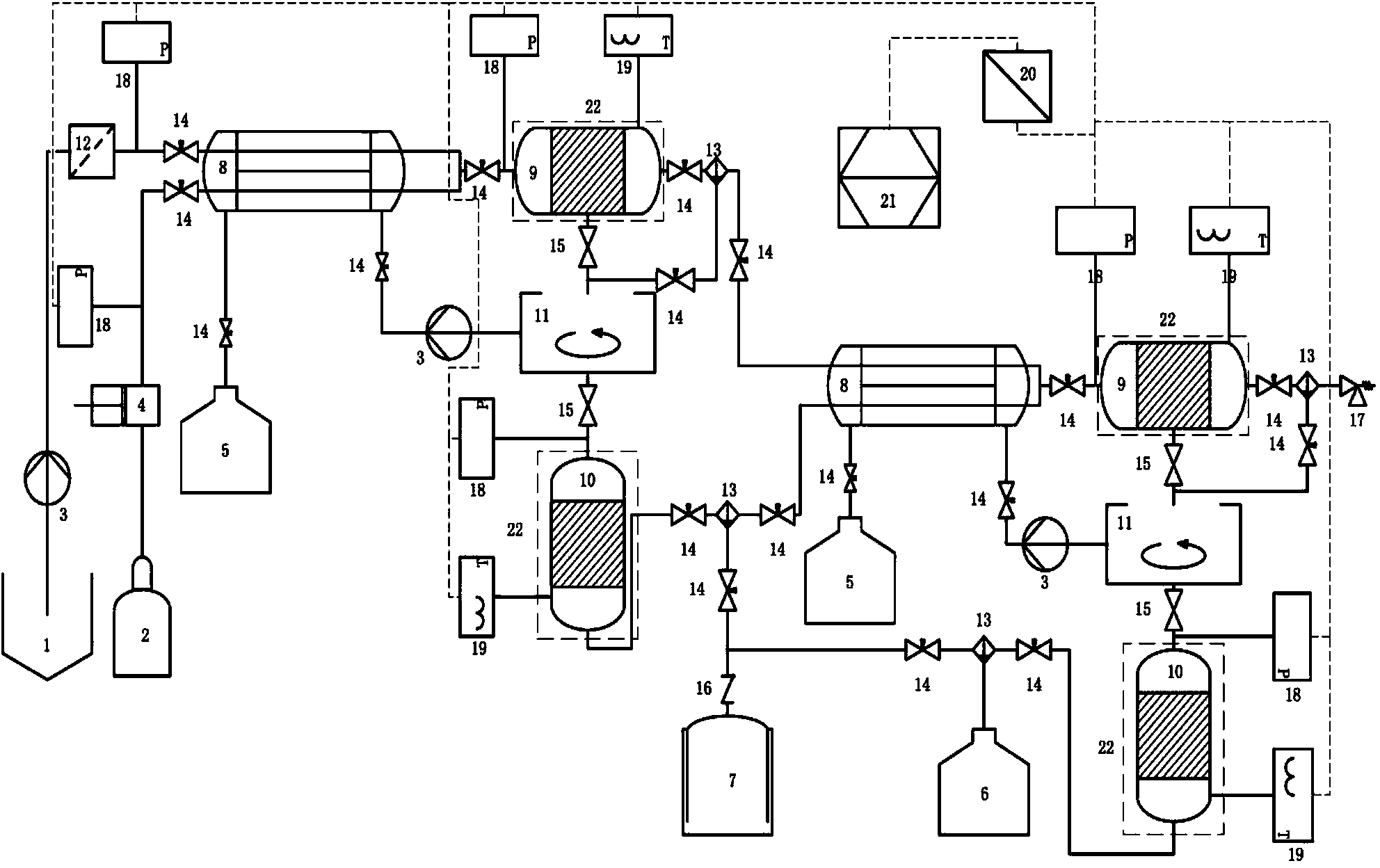

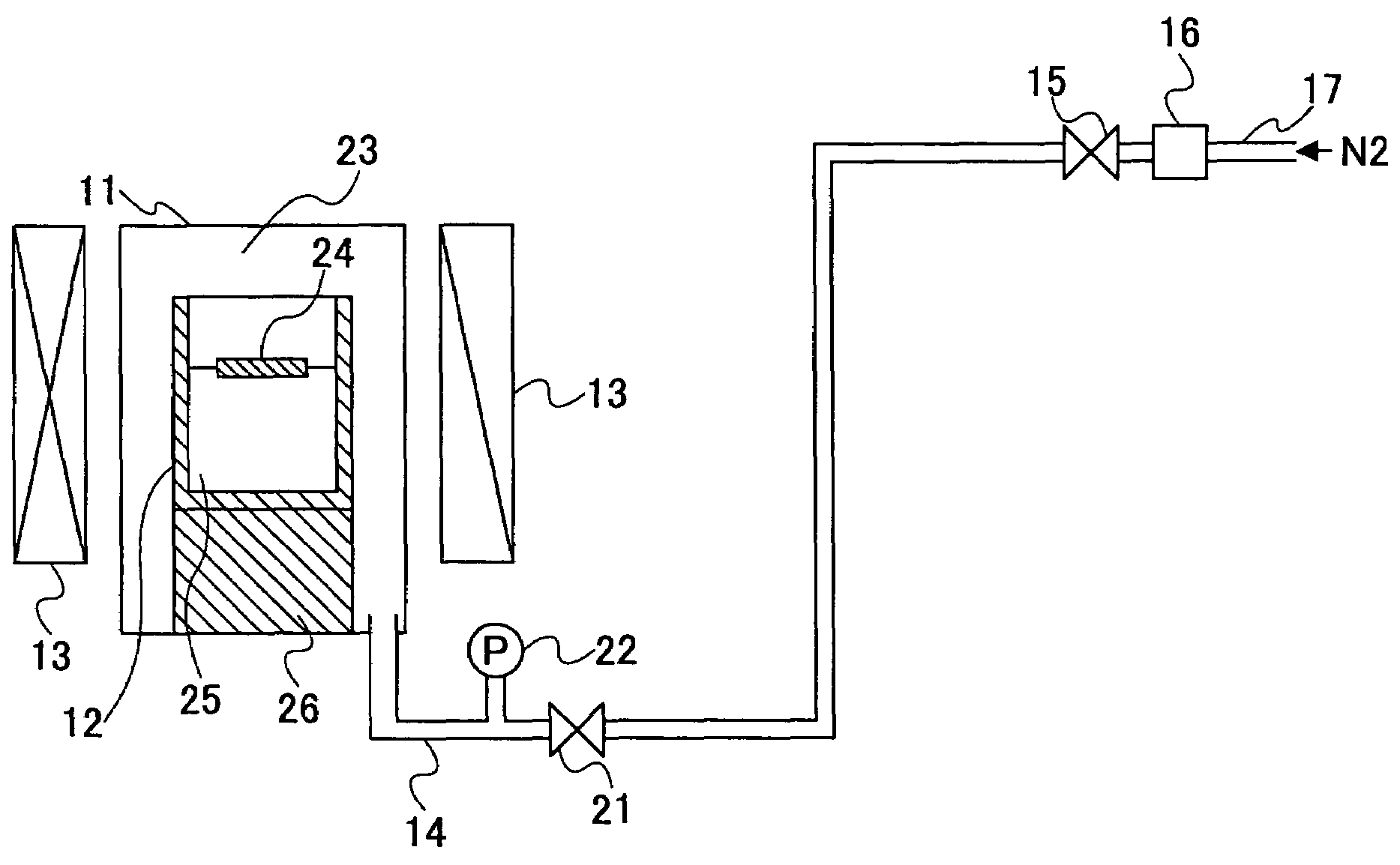

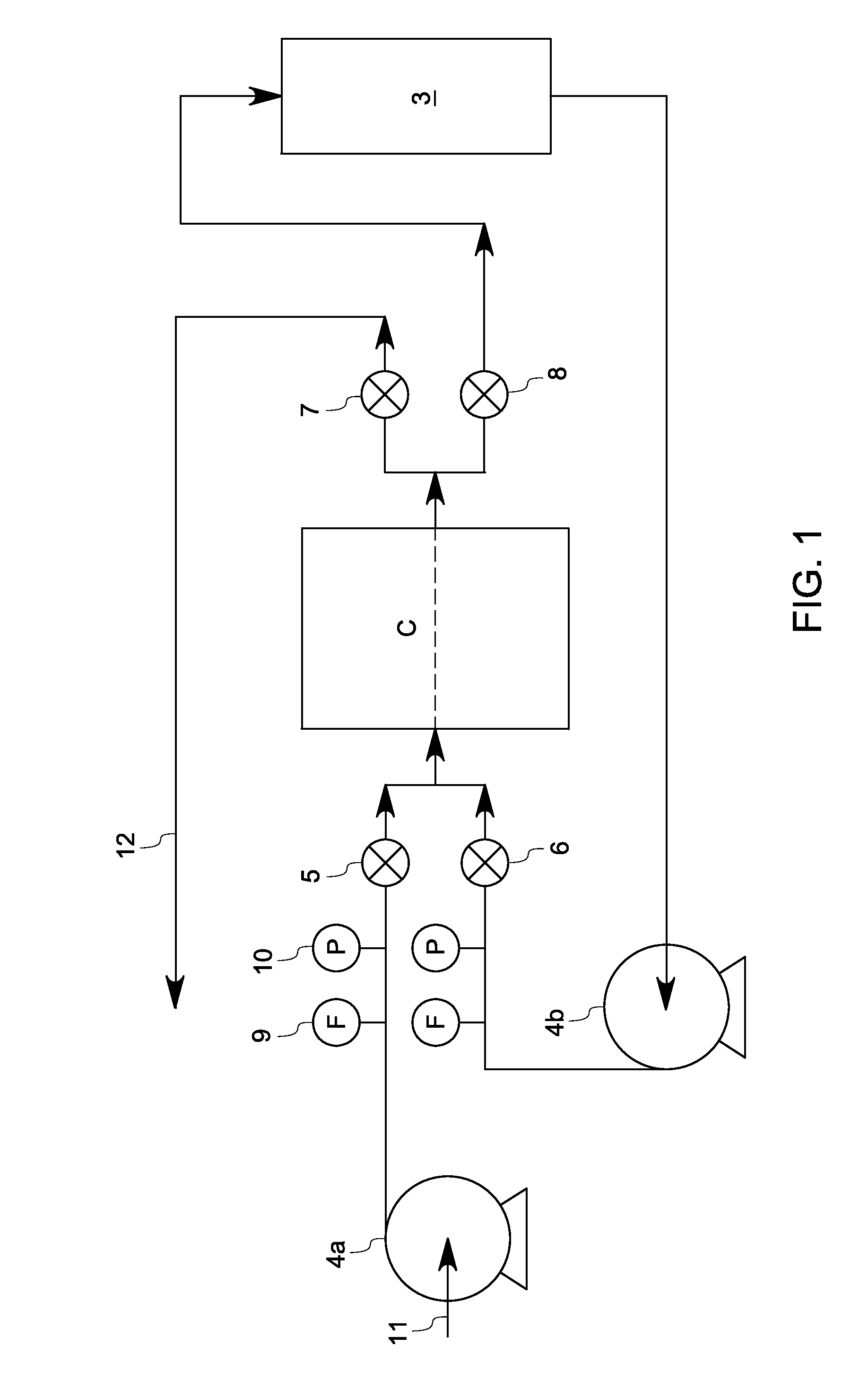

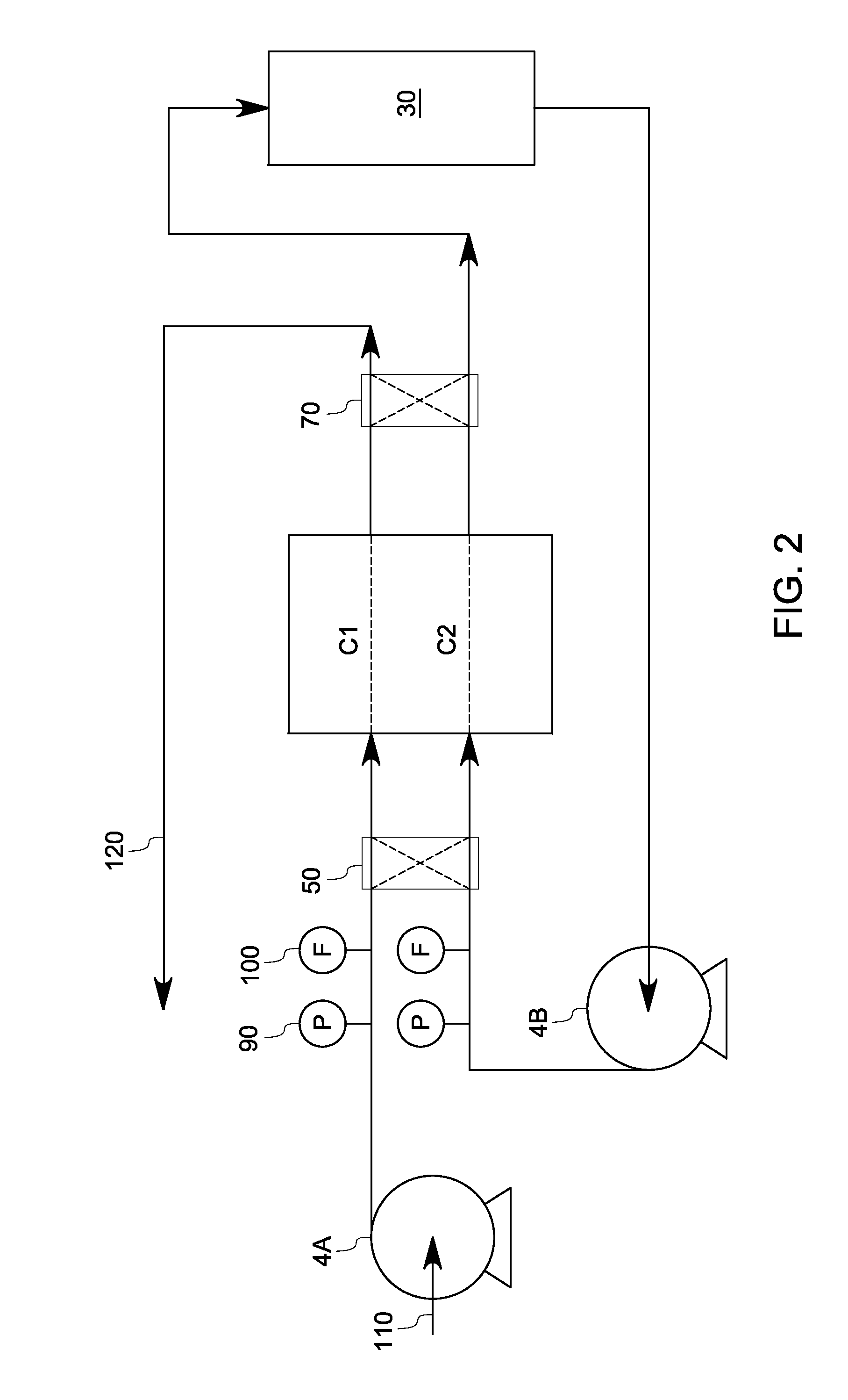

Carbon dioxide capturing and seawater desalting co-production device and method based on hydrate method

The invention provides a carbon dioxide capturing and seawater desalting co-production device and method based on a hydrate method, belonging to the technical field of hydrate application. The carbon dioxide capturing and seawater desalting co-production device comprises a gas-water conveying part, a hydrate generation and decomposition control part and a product storing and discharging part. The hydrate generation and decomposition control part comprises a front-grade structure and a rear-grade structure; a hydrate generation condition is gas supersaturation. A first-grade hydrate generates residual gas and decomposed water to be used as second-grade raw materials; after two grades of treatment, fresh water is obtained and stored; N2 is discharged to atmosphere by a gas exhausting safety valve; carbon dioxide is introduced into a gas tank to be stored. The carbon dioxide capturing and seawater desalting co-production device is applicable to the co-production of carbon dioxide capturing and seawater desalting of a fossil fuel power station in a coastal region, so as to meet the requirements of the carbon dioxide capturing of a smoke CO2 / N2 power station; a heat exchanger is used for pre-cooling so that the cold loss is reduced and the energy utilization rate is improved; the reaction speed is increased by high-speed agitation in a hydrate generation process; emissions comprise the N2 and concentrated seawater and have no pollution to the environment.

Owner:DALIAN UNIV OF TECH

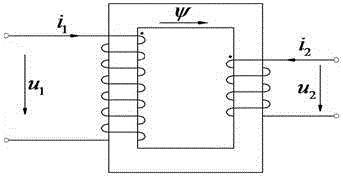

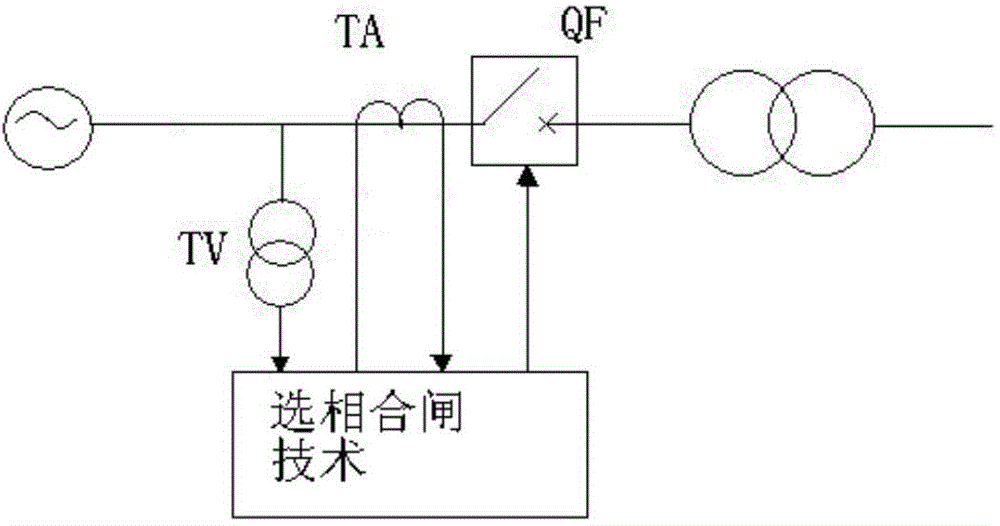

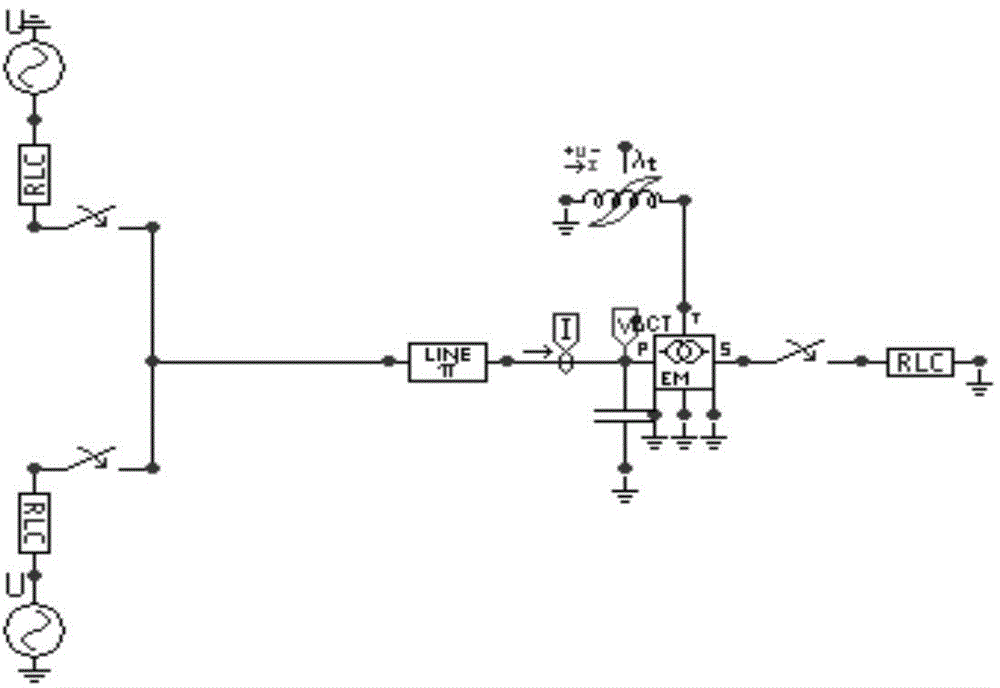

Method for restraining no-load closing magnetizing inrush current of transformer

ActiveCN103986385AThe method of obtaining is simple and effectiveSuppresses inrush currentConversion without intermediate conversion to dcPower factorEngineering

The invention provides a method for restraining no-load closing magnetizing inrush current of a transformer. A power-factor angle of the transformer at the opening moment is measured and used as a basis for selecting the optimal closing phase angle, and mechanical properties of a disconnector are considered to determine the optimal target phase angle and to carry out no-load closing operation on the transformer. According to the method for restraining the no-load closing magnetizing inrush current of the transformer, an arc quenching property of the disconnector is considered, the voltage phase angle at the opening moment is determined according to the power-factor angle so that residual magnetism can be estimated, and key parameters are acquired in a simple, convenient and effective way; meanwhile, the method is combined with the controlled switching technology, the optimal target phase angle is selected to conduct switching on the transformer, supersaturation of an iron core of the transformer is prevented, and the magnetizing inrush current is restrained fundamentally.

Owner:XI AN JIAOTONG UNIV +2

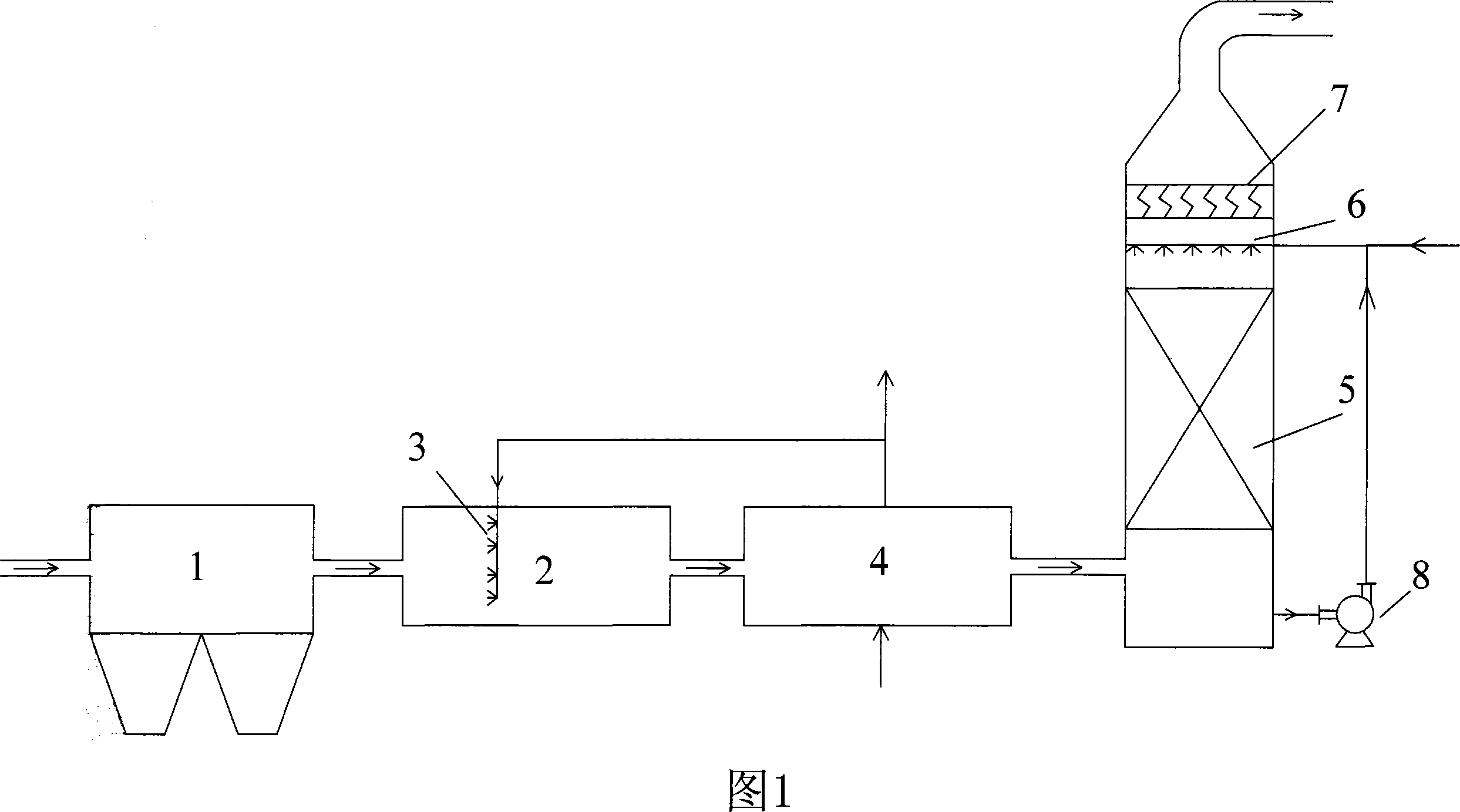

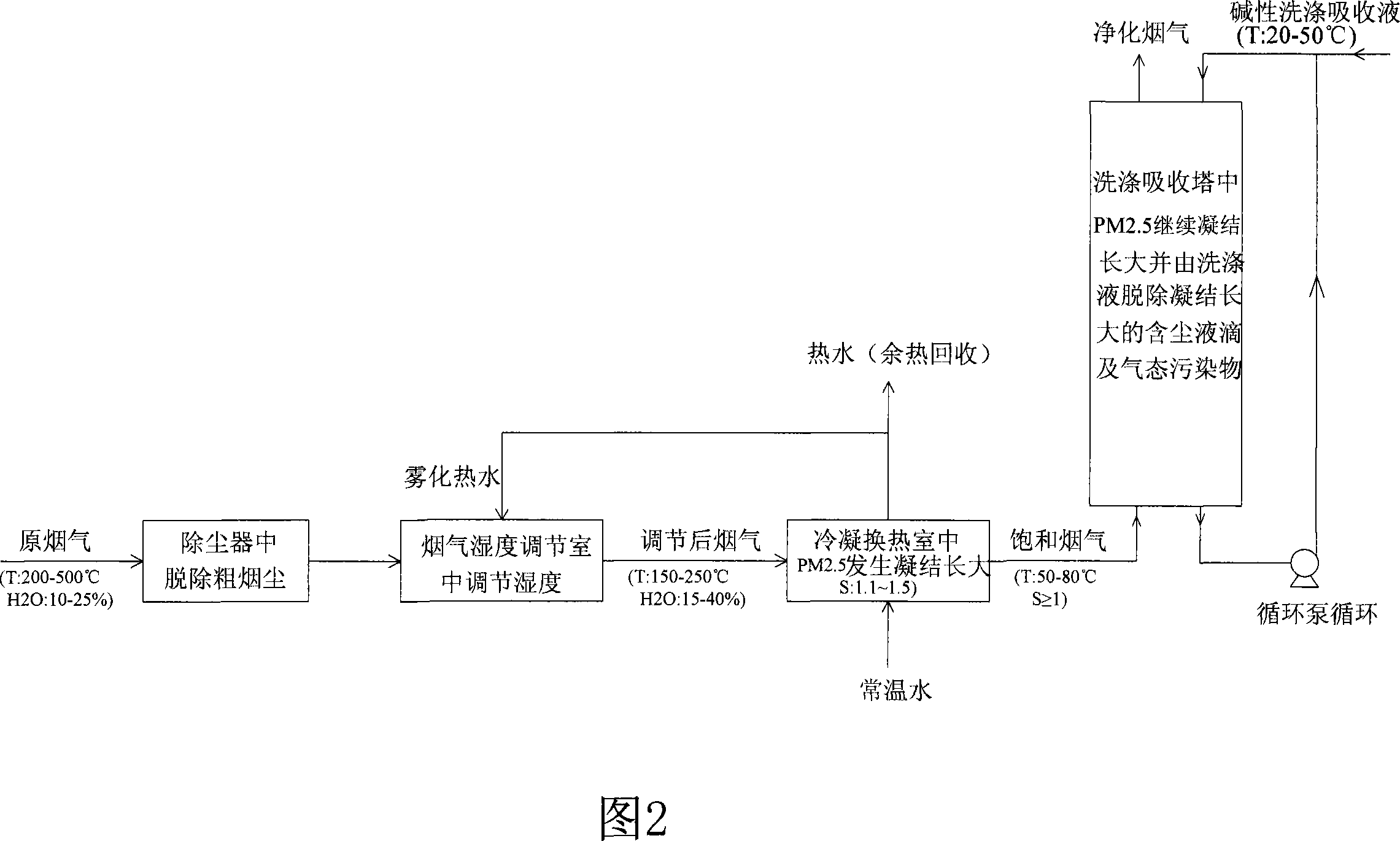

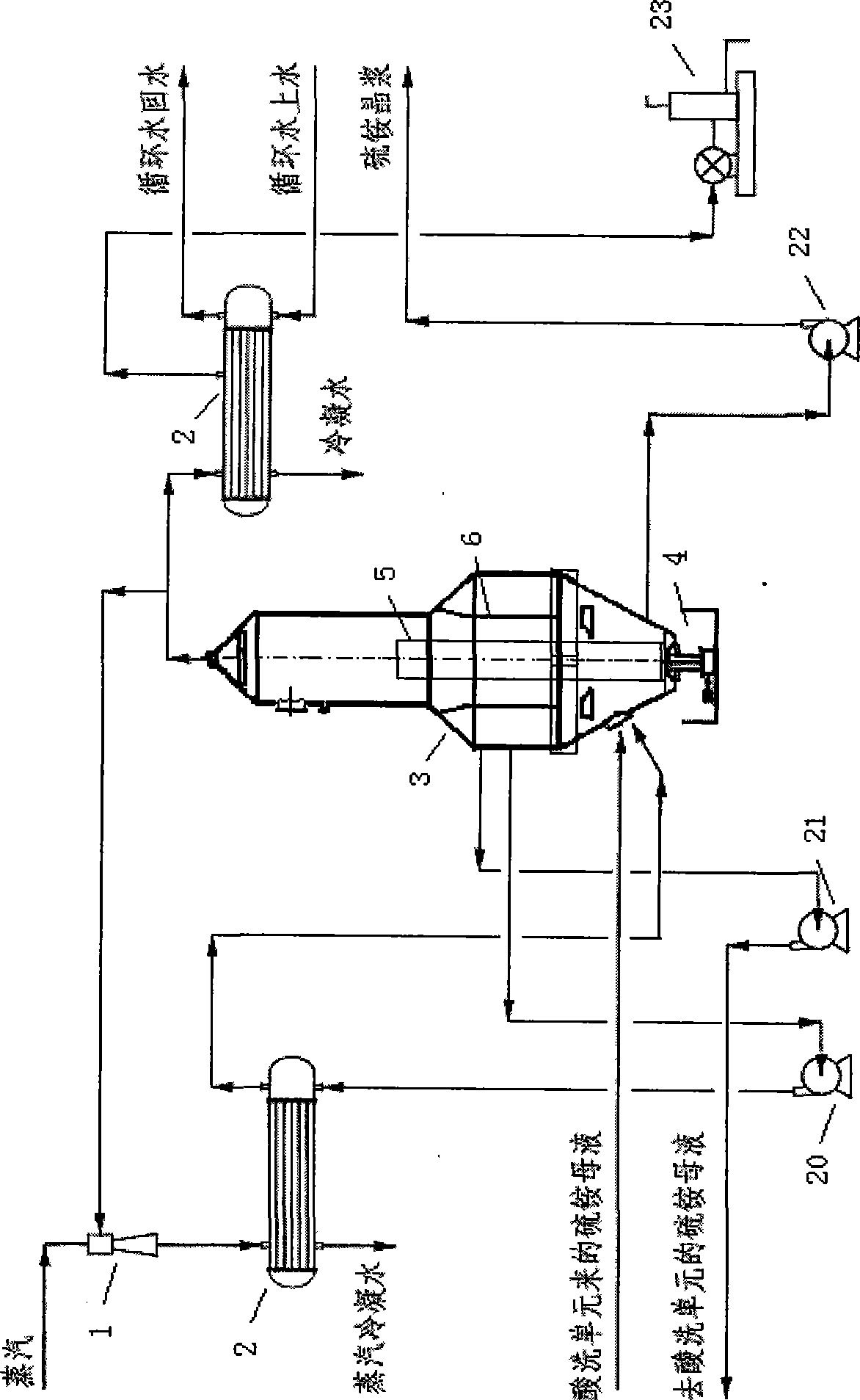

Method of removing PM2.5 and gaseous pollutant using steam phase transition and device thereof

InactiveCN101224367ALarge granularityQuality improvementAuxillary pretreatmentUsing liquid separation agentSteam condensationPollution

The invention relates to a method and a device which adopt steam phase changing to cooperatively remove PM2.5 and gas pollutions from a high temperature and high humidity flue gas. The invention comprises a dust catcher, a flue gas humidity regulating chamber, a condensing heat exchanger and a washing absorption tower. The method is that the flue gas enters the flue gas humidity regulating chamber after coarse dust removing in the dust catcher, and atomized hot water is sprayed to regulate the humidity of the flue gas; after humidity regulation, the flue gas is induced into the condensing heat exchanger to reach supersaturation, and the supersaturation steam takes the PM2.5 as condensing core to generate phase changing, thus increasing the granularity of the PM2.5; then the steam enters the washing absorption tower, and in the tower, the flue gas reversely contact a middle-lower temperature alkalescent washing-adsorbing liquid to be further subject to the phase changing of the steam taking PM2.5 as condensing core, and the alkalescent washing-adsorbing is adopted for removing the growing dust-drop and gas pollutions. Taking the characteristics of the high temperature and high humidity flue gas into account, the invention adopts the steam phase changing theory to lead the PM2.5 to be condensed and to grow so as not only to cooperatively remove PM2.5 and gas pollution, but to recycle the gasifying potential heat released by steam condensing and the sensible heat caused by temperature reduction of the flue gas.

Owner:SOUTHEAST UNIV

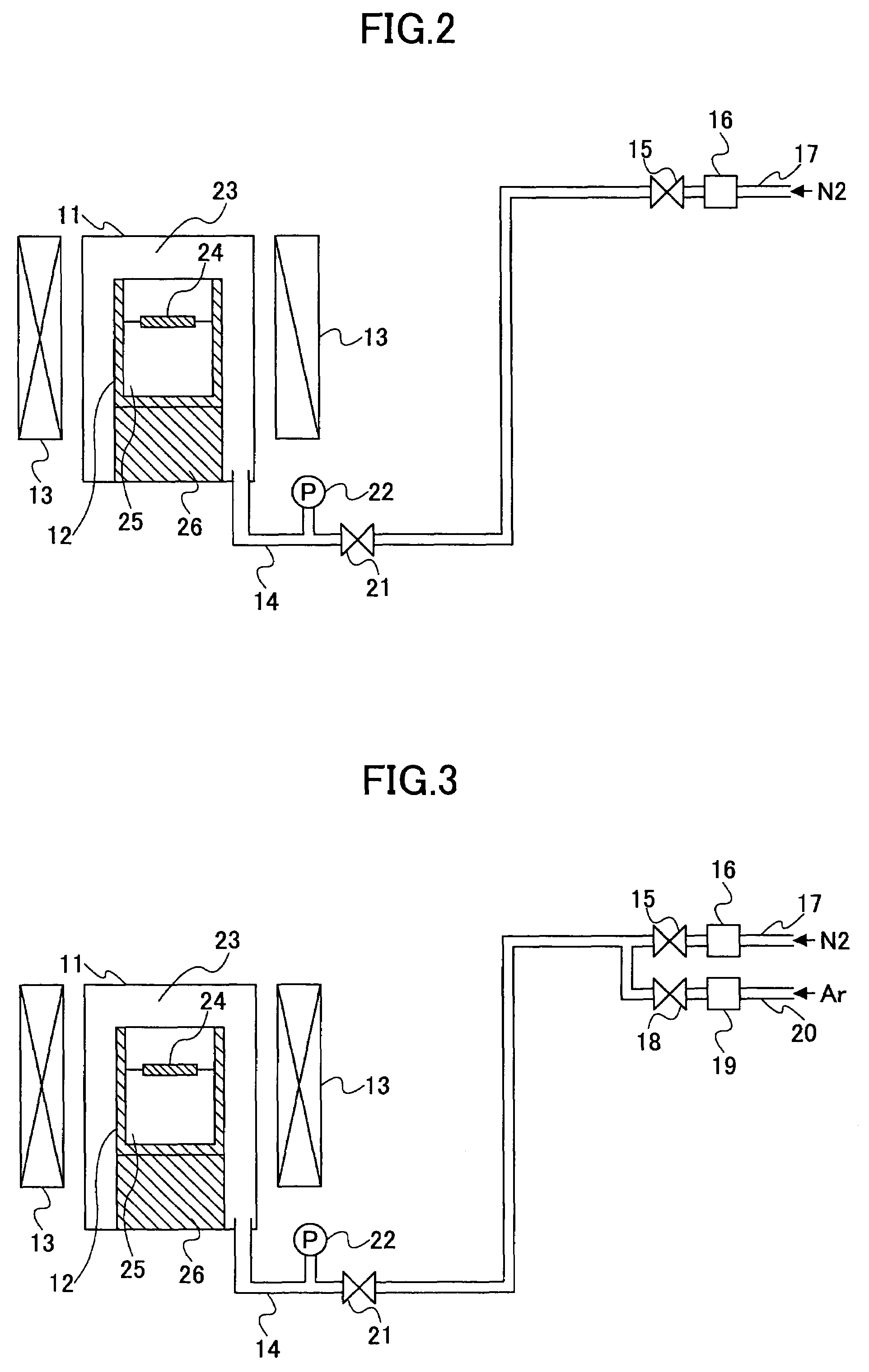

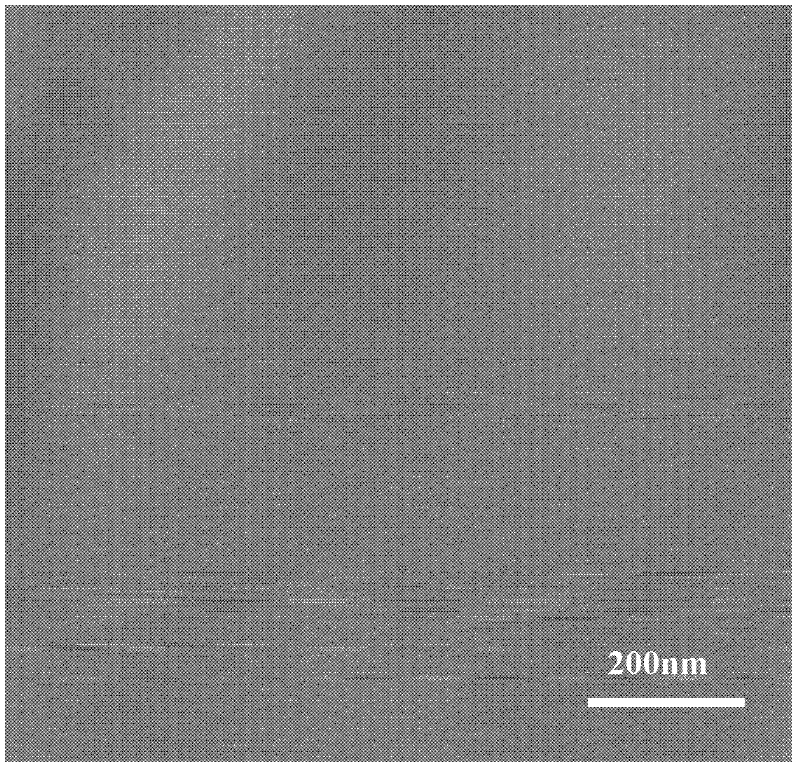

Group III nitride crystal, crystal growth process and crystal growth apparatus of group III nitride

ActiveUS7220311B2Increase nitrogen concentrationDepletion problemPolycrystalline material growthSemiconductor/solid-state device manufacturingNitrogenSupersaturation

A crystal growth method of a group III nitride includes the steps of forming a melt mixture of an alkali metal and a group III element in a reaction vessel, and growing a crystal of a group III nitride formed of the group III element and nitrogen from the melt mixture in the reaction vessel, wherein the step of growing the crystal of the group III nitride is conducted while controlling an increase rate of degree of supersaturation of a group III nitride component in the melt mixture in a surface region of the melt mixture.

Owner:SUMITOMO CHEM CO LTD

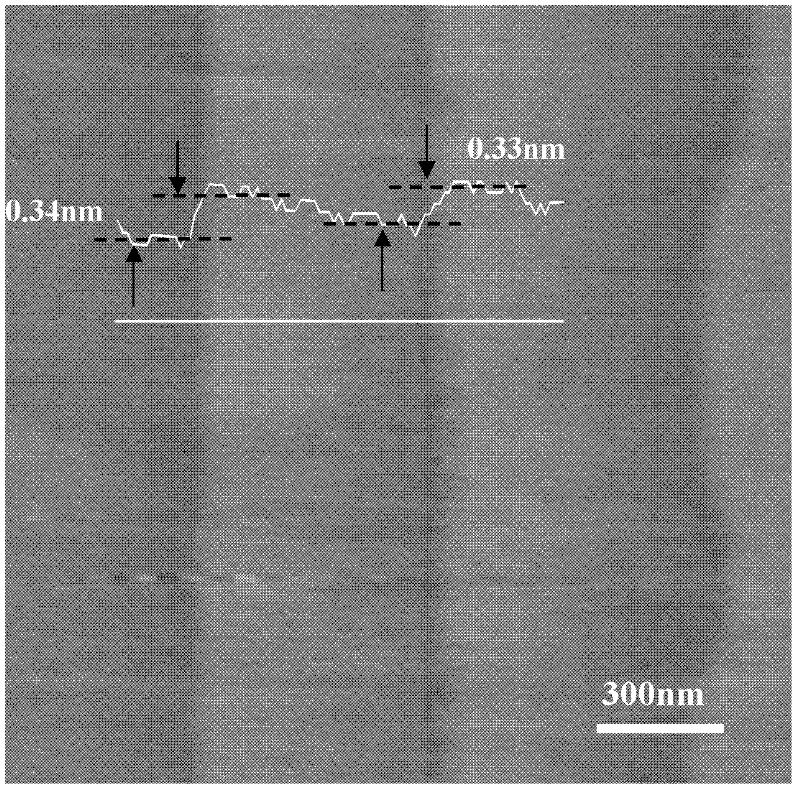

Method for preparing graphene nanoribbon on insulating substrate

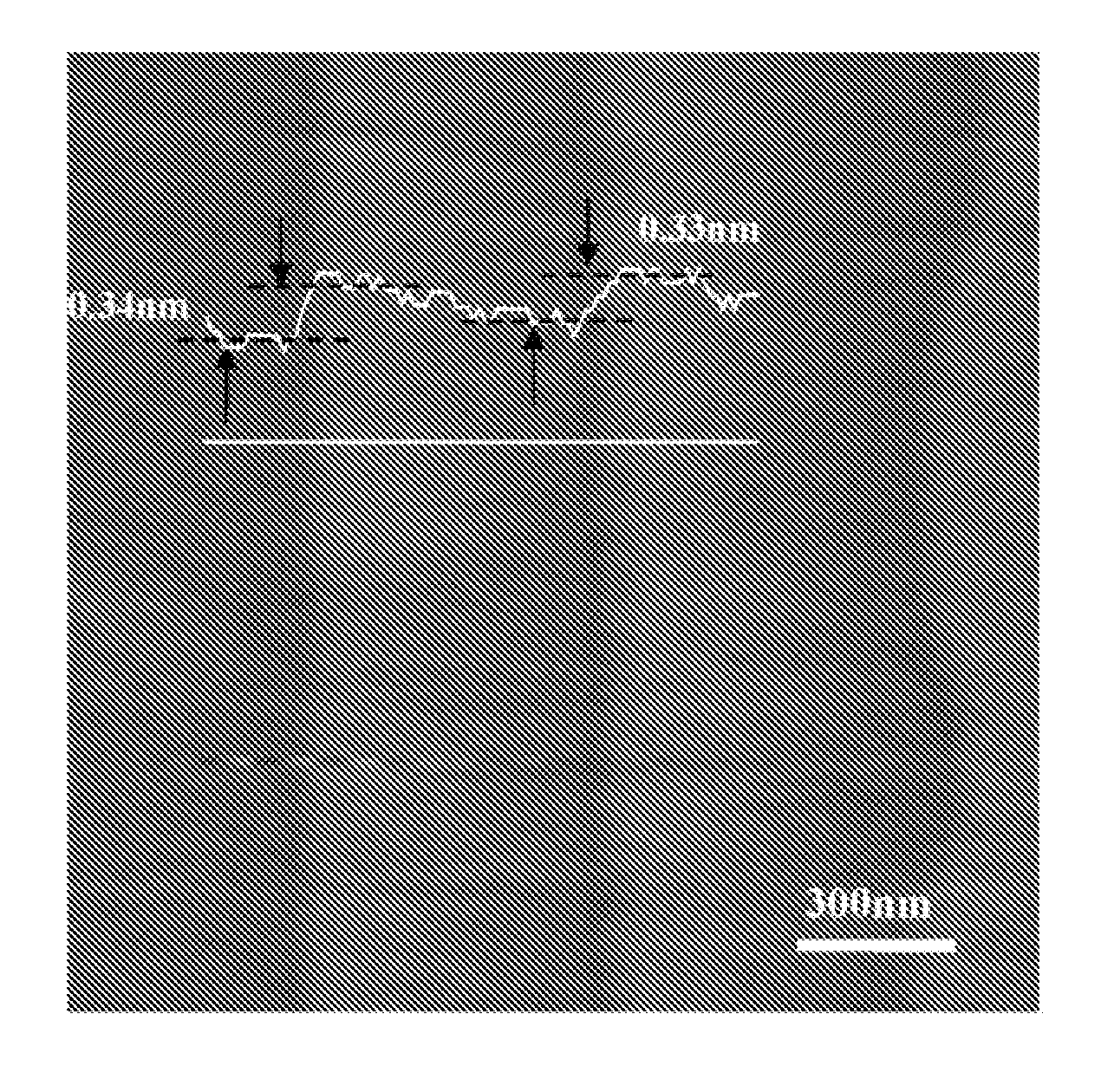

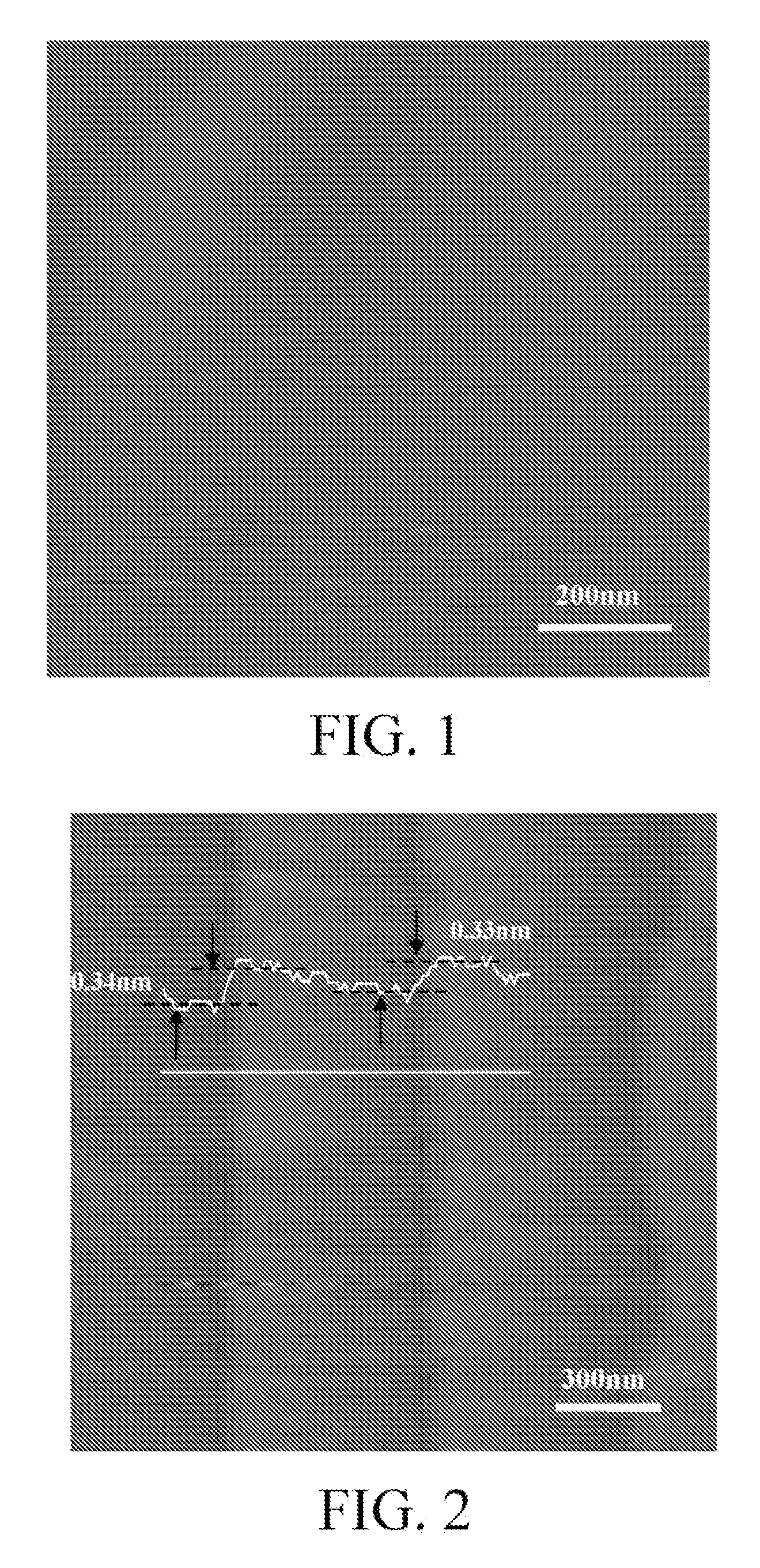

ActiveCN102392225AGrow up toAvoid diversionMaterial nanotechnologyGrapheneGraphene nanoribbonsNucleation

The invention provides a method for growing a graphene nanoribbon on an insulating substrate of a cleavage surface with atomic scale smoothness, belonging to the field of low-dimensional materials and novel materials. The method comprises the following steps of: firstly, splitting the insulating substrate to obtain a cleavage surface with atomic scale smoothness, and preparing a monoatomic layer step; and secondly, directly growing the graphene nanoribbon by using the insulating substrate with the regular monoatomic layer step. With the adoption of the characteristics of different nucleation powers of the graphene on the atomic step and the smooth cleavage surface, the graphene is ensured to grow into the graphene nanoribbon with adjustable size only along step edges through regulating conditions, such as temperature, pressure intensity, active carbon atom supersaturation degree and the like. The method for preparing the graphene nanoribbon on the insulating substrate is mainly applied to the field of novel graphene photoelectric devices.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

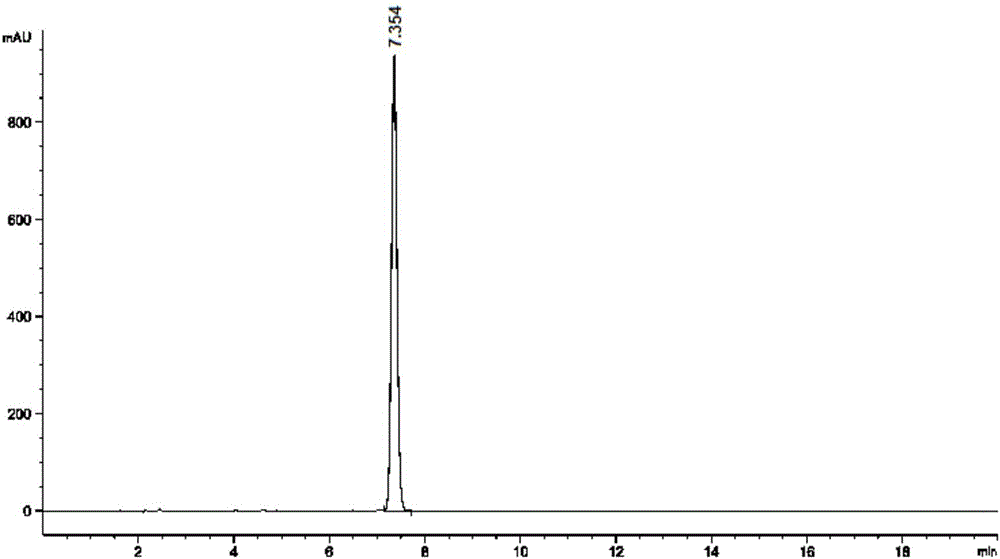

Method for preparing pneumocandin B0

The invention discloses a method for preparing pneumocandin B0. The method comprises the following steps of: a) centrifuging the fermentation liquid of echinocandin B0, taking mycelium, leaching the echinocandin B0 in the mycelium with a first solvent and filtering and removing the mycelium; b) distilling the solvent in the first solvent leaching solution of echinocandin B0 to dryness, soaking with a second solvent and then filtering and removing the insoluble substances; c) distilling the second solvent soak solution of echinocandin B0 to dryness and then dissolving in the first solvent, andcollecting effluent liquid through overly acidic alumina column; d) distilling the collected solution of echinocandin B0 to dryness and then dissolving in the first solvent, utilizing adsorbent resin,performing eluting with the first solvent and then collecting the part with higher purity; e) distilling the collected solution of echinocandin B0 to dryness and then dissolving in the first solvent,utilizing inverse resin, performing eluting with the first solvent and collecting the part with higher purity; and f) distilling the collected solution of echinocandin B0 to dryness and then dissolving in the first solvent, adding in a small amount of water by dripping to achieve the purpose of separation by crystallization after supersaturation, and then preparing the echinocandin B0. The methodfor preparing the echinocandin B0 not only can well remove the pigment, but also leads the purity of the echinocandin B0 to be improved by more than 96 percent.

Owner:SHANGHAI INST OF PHARMA IND

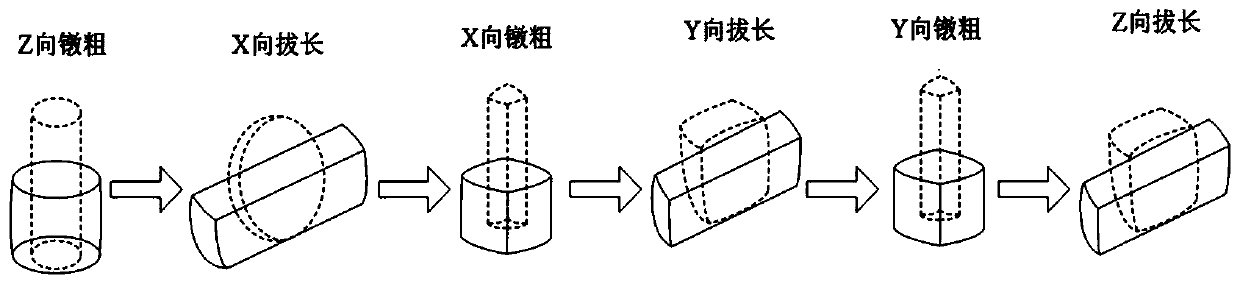

Three-directional near-isotropy high-performance aluminum alloy cylindrical forge piece manufacturing process

InactiveCN109759783AThree-way performance is nearly identicalImprove solubilityQuenchingHeat treated

The invention provides a three-directional near-isotropy high-performance aluminum alloy cylindrical forge piece manufacturing process. The manufacturing process specifically comprises the following steps of raw material size design, cast ingot quality detection, heating before ingot casting, multi-directional forging, return to a furnace for heating, Z-direction upsetting and punching, return toa furnace for heating, core shaft drawing out, return to a furnace for heating, saddle forging, machining, heating before rolling, ring rolling, solution treatment, aging treatment and quality detection. According to the manufacturing process, an aluminum alloy cylindrical forge piece is subjected to nearly equal deformation in three directions, so that the three-direction performance of a productis nearly isotropic; a thick residual crystalline phase in cast-state structure is fully crushed so as to provide structure preparation for second phase uniform dispersion distribution in the heat treatment process; a second phase in the structure is fully dissolved, the degree of supersaturation is improved, the material potential is excavated to the maximum extent, and the performance limit ofa material is exerted; and the small reduction rate is adopted, the quenching water temperature is increased, the stress in the product manufacturing process is reduced, so that the residual stress ofthe forge piece is controlled within a certain range.

Owner:天津航天长征技术装备有限公司

Device and method to producing single crystals by vapour deposition

InactiveUS20080149020A1Down and eliminate formationInhibition of defect generationAfter-treatment apparatusPolycrystalline material growthHalogenHydrogen

A method and a device to grow from the vapor phase, a single crystal of either SiC, a group III-nitride, or alloys thereof, at a growth rate and for a period of time sufficient to produce a crystal of preferably several centimeters length. The diameter of the growing crystal may be controlled. To prevent the formation of undesirable polycrystalline deposits on surfaces in the downstream vicinity of the single crystal growth area, the local supersaturation of at least one component of the material grown is lowered by introducing a separate gas flow comprising at least one halogen element or a combination of said halogen and hydrogen species.

Owner:NORSTEL +1

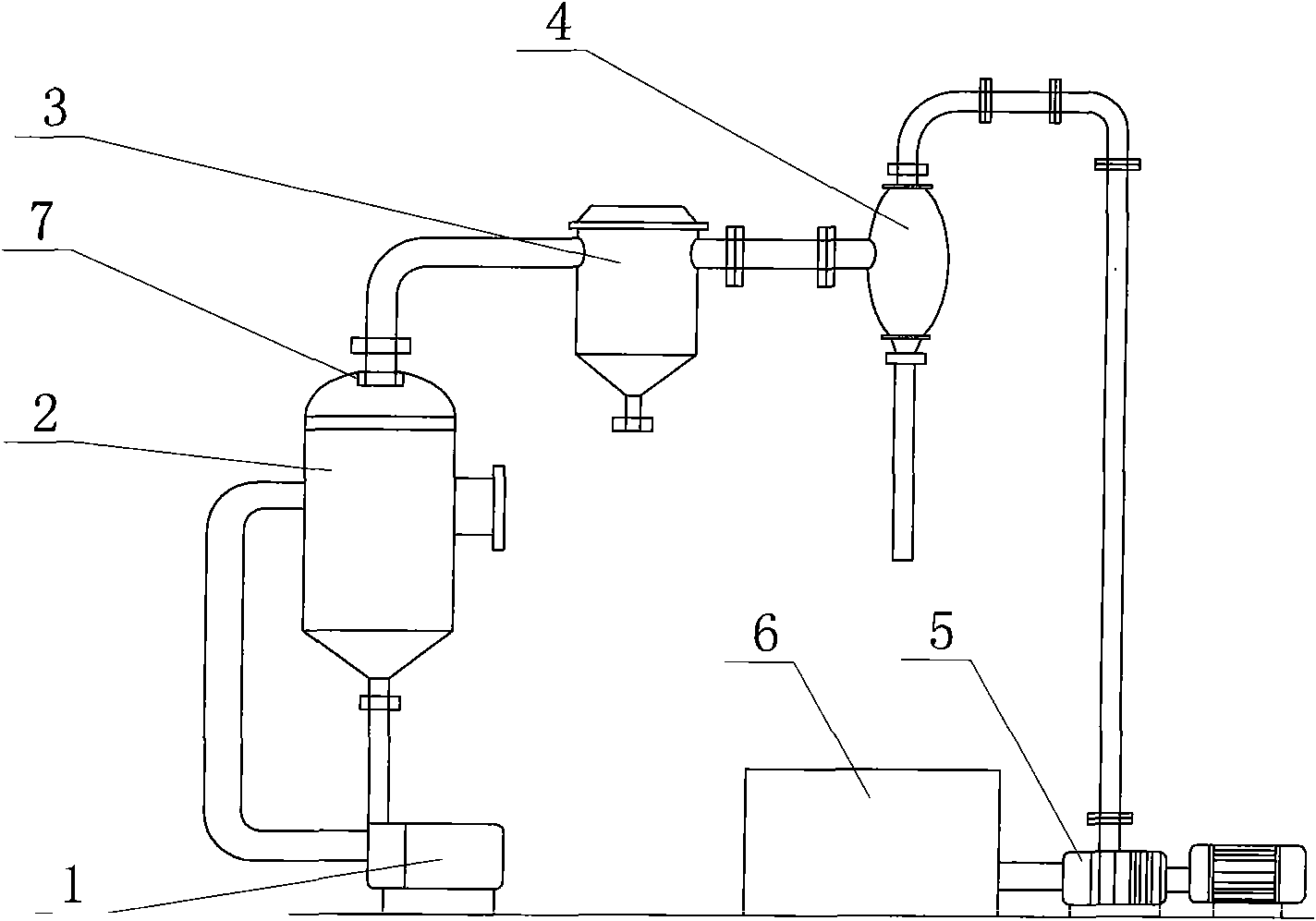

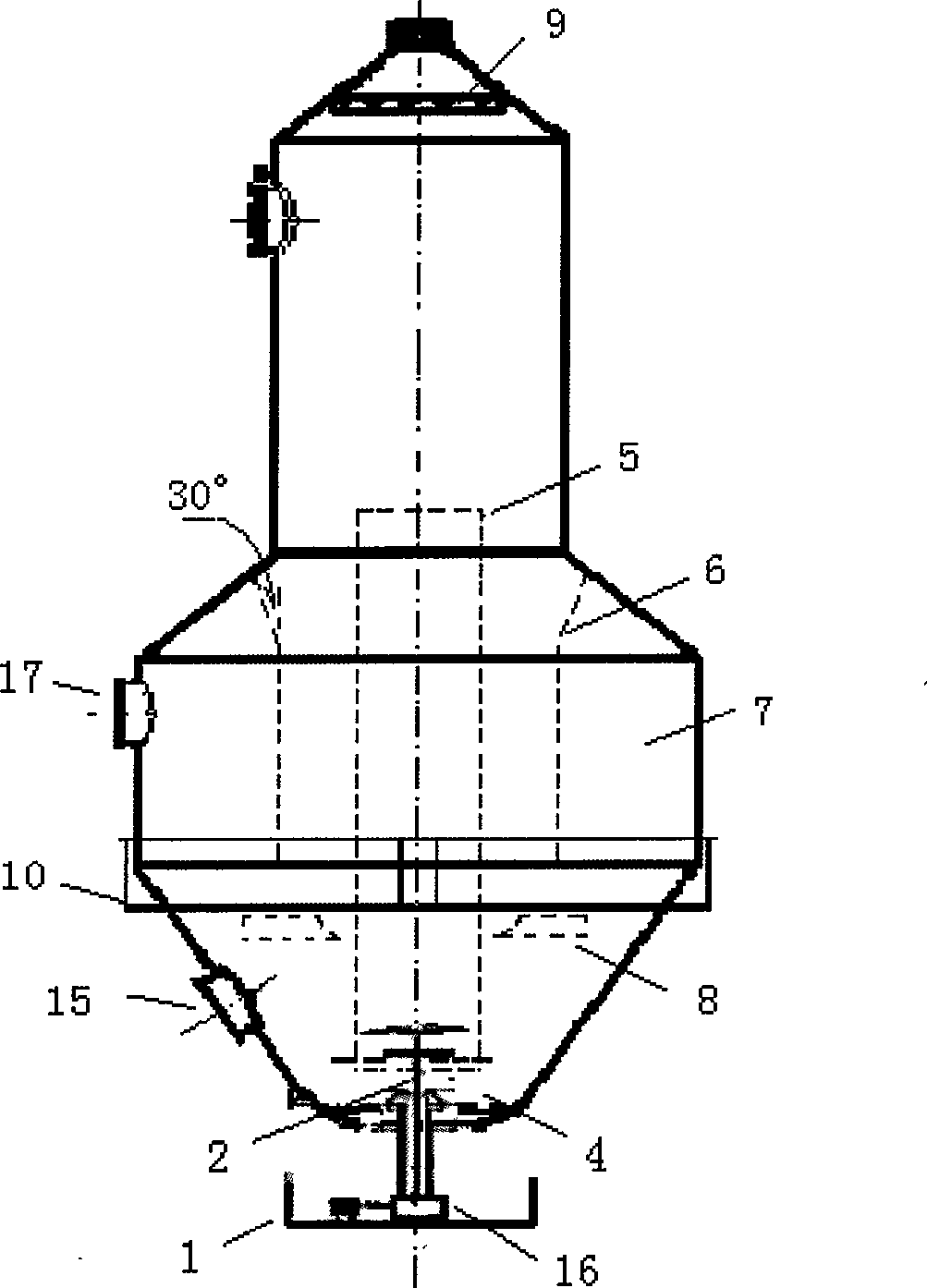

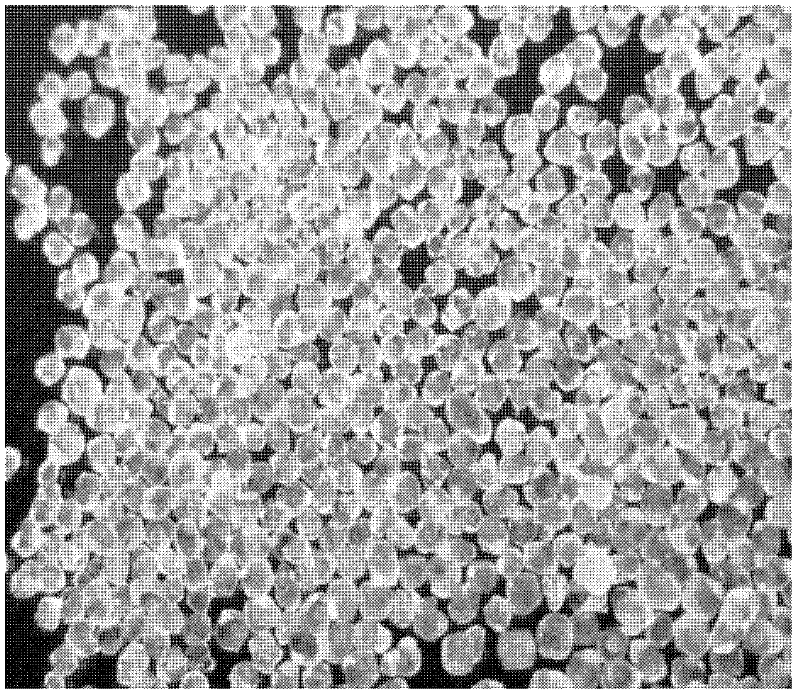

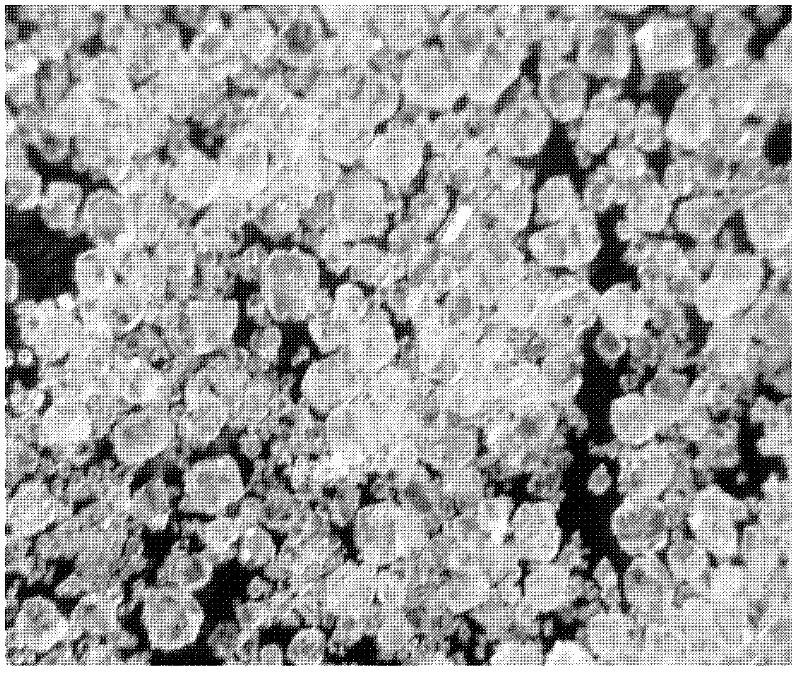

Production process and crystallization device for large-particle ammonium sulfate

ActiveCN101531382AReduced circulation of mother liquorReduce energy consumptionAmmonium sulfatesGranularitySupersaturation

The invention relates to a production process and a crystallization device for large-particle ammonium sulfate. 30-50 percent unsaturated ammonium sulfate solution from an acid-cleaning unit enters a crystallizer and then is evaporated in vacuum at an operation temperature of between 40 and 70 DEG C so as to evaporate moisture and obtain ammonium sulfate crystals; during crystallization, ammonium sulfate mother solution is subjected to heat exchange in an outer circulation channel, and excessive fine crystals are eliminated; and the circulating mother solution entering the outer circulation channel is heated by use of part of low-pressure steam from the crystallizer, so that energy consumption is reduced by 20 to 40 percent. The crystallization device adopts an optimized flow-guiding crystallizer (DTB), and a blender perpendicularly stretches into a flow-guiding cylinder from the bottom of the crystallizer. Because the production process effectively controls the supersaturation degree of the ammonium sulfate mother solution inside the crystallizer, large-particle ammonium sulfate crystals can be obtained, and the quality of ammonium sulfate is improved. The crystallizer is not easy to form crystal scabs inside, has reasonable structure and high production capability, can ensure the production of the crystal products with narrow particle-size range, and can meet the requirements of users on different particle size of the crystal products.

Owner:天津天达联合工程技术有限公司

Method for preparing carbon coated phosphates positive pole material by super critical fluid

InactiveCN101388454ASimple preparation processEasy to operateElectrode manufacturing processesPhosphateHigh pressure

The invention discloses a process for preparing carbon-coated phosphate cathode material of a lithium ion battery through utilizing supercritical fluid, which comprises placing to-be-coated phosphate anode active material in a high-pressure stirred tank reactor, pumping supercritical fluid which dissolves with polymer solution into the reactor through a high-pressure pump, fully stirring under the condition of preset temperature and pressure to fully moisten the polymer solution and anode active substances, then fast spraying the mixed paste of supercritical fluid and active substances in an expansion separating chamber through nozzles, thereby making polymer solutes reach highly super-saturation state in a shorter time and grow on the surface of coated substances to form an even coating layer, and then conducting with high-temperature treatment under the non-oxidizing atmosphere to split off organic polymer material to form an even carbon-coated layer on the surface of the phosphate anode material.

Owner:天津斯特兰能源科技有限公司

Method and System for Increasing Recovery and Preventing Precipitation Fouling in Pressure-Driven Membrane Processes

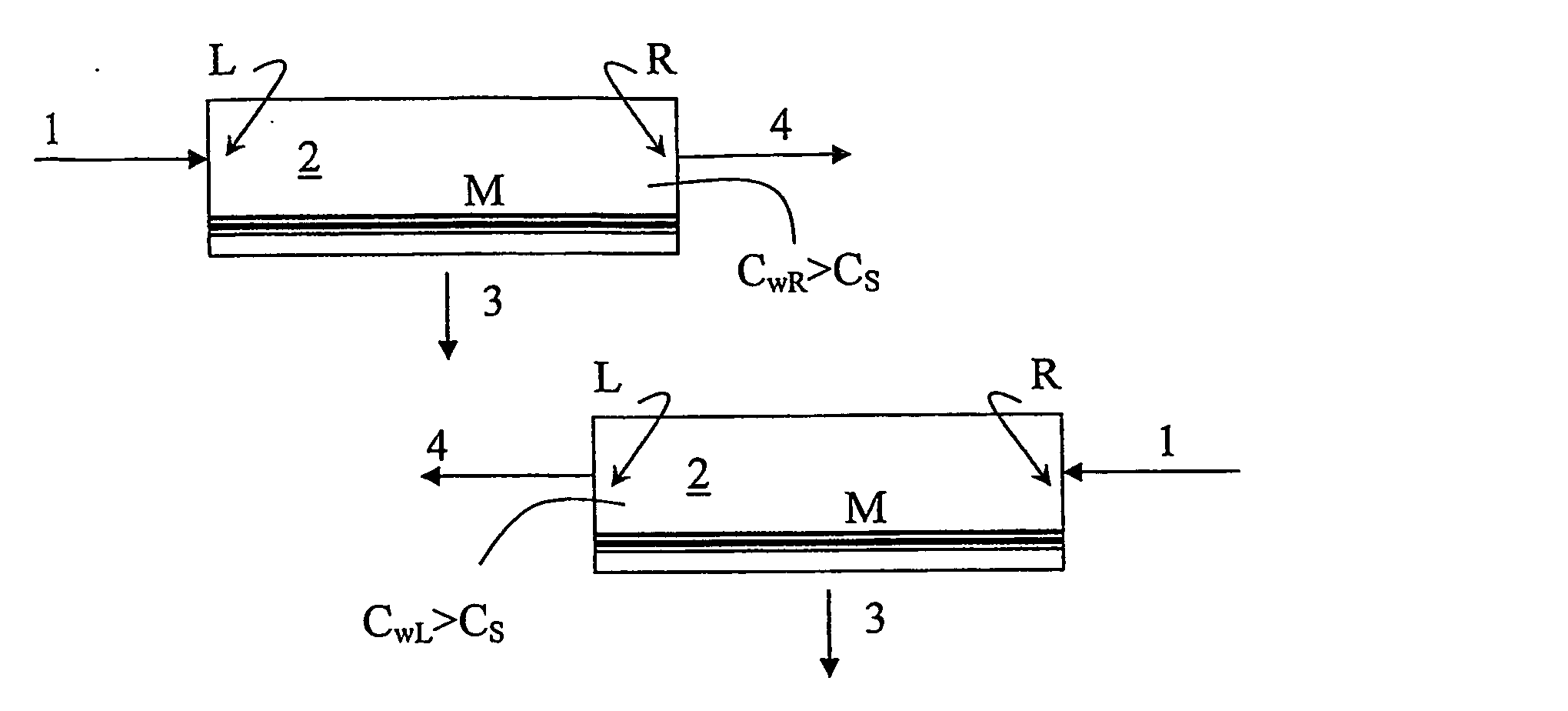

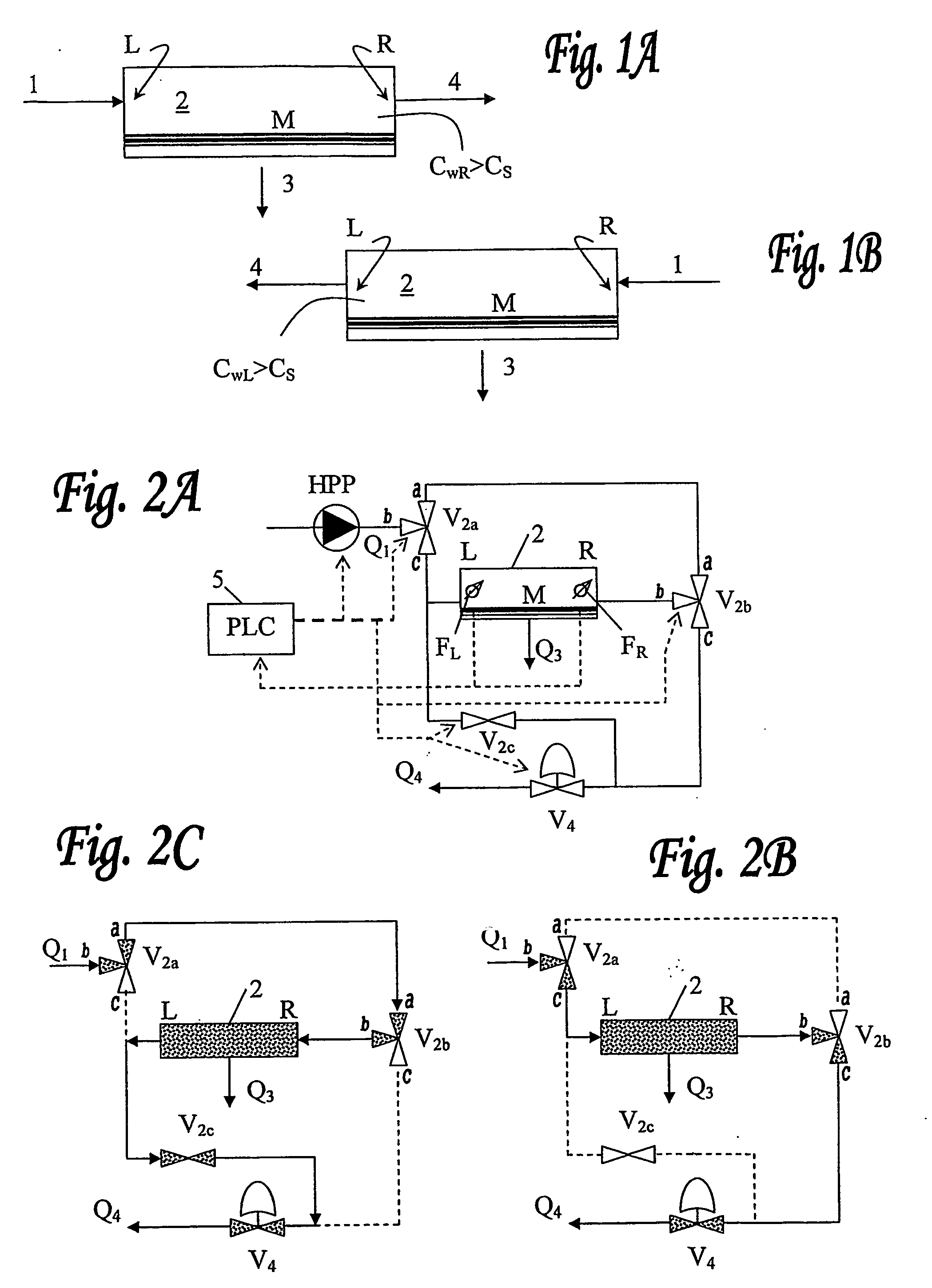

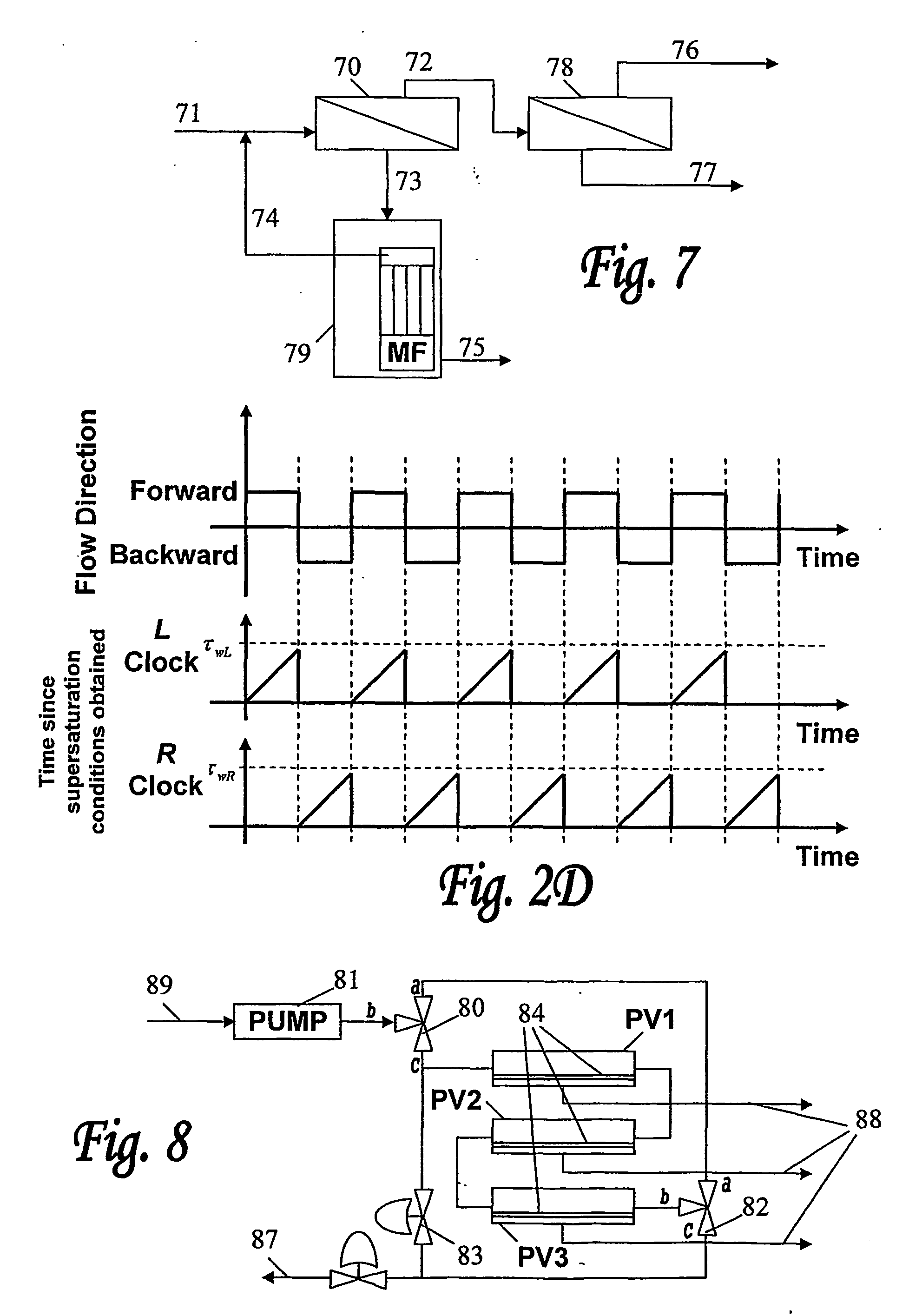

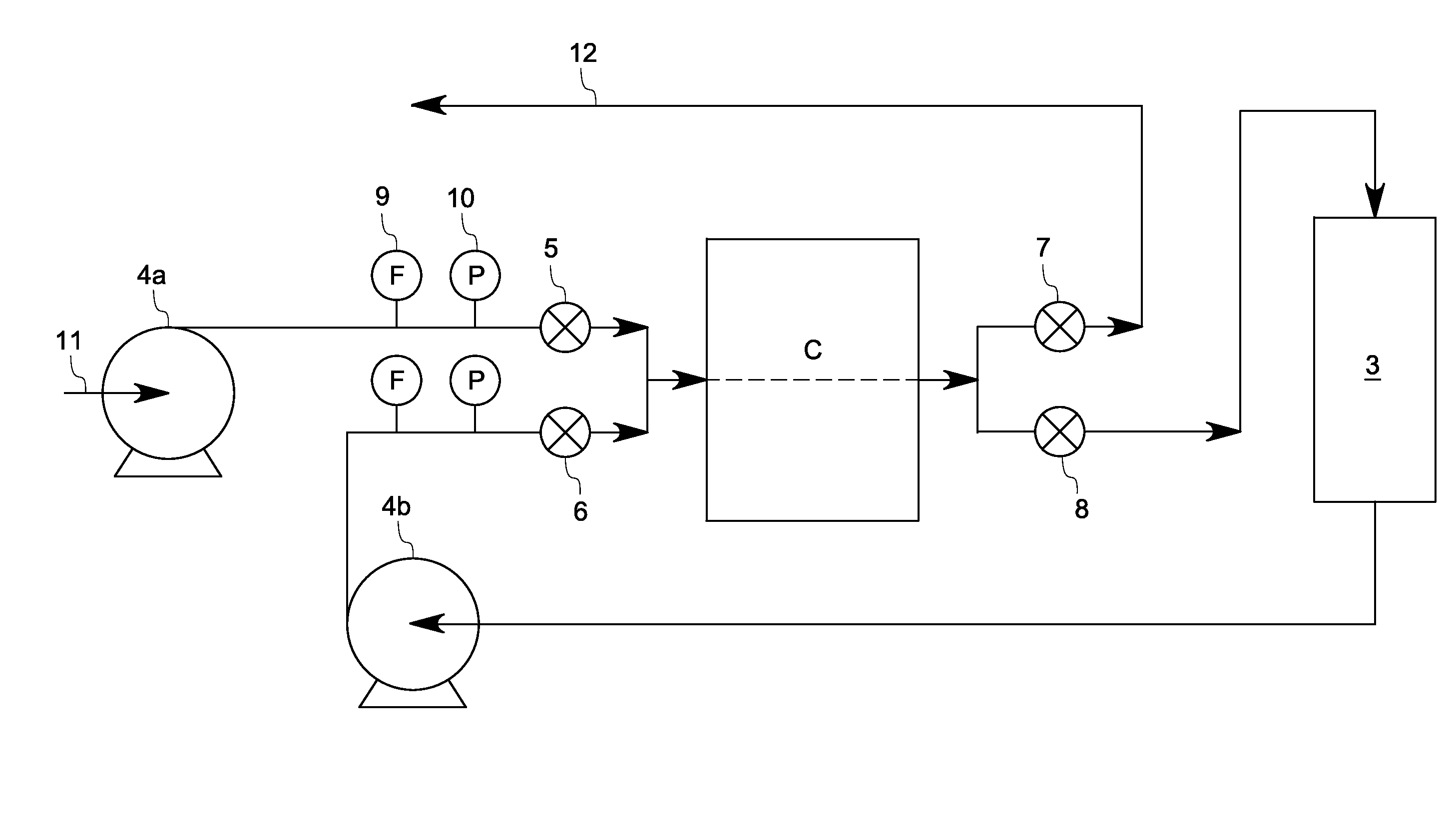

ActiveUS20080230476A1Good estimateShort induction timeSedimentation separationReverse osmosisWater flowSupersaturation

The invention provides a process for purifying water containing soluble species capable of forming one or more sparingly soluble salts or minerals, said process comprising feeding a pressurized water stream into a treatment zone having one or more membranes disposed therein, passing said stream along said membrane(s) to recover a permeate and to withdraw a concentrate therefrom while periodically reversing the direction of the flow of said stream in said treatment zone, wherein the periodicity of the flow reversal is such that said one or more membranes are exposed to supersaturation conditions evolving in said water stream for a period of time which is less then the time required for said supersaturated water stream to precipitate one or more of said sparingly soluble salts and / or minerals therefrom.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

Method for removing ionic species from desalination unit

InactiveUS20100242995A1Increase concentrationMembranesWater treatment parameter controlIonSupersaturation

A method for removing ionic species from a desalination unit, comprises: (a) circulating a wash stream in a closed loop comprising a desalination unit and a precipitation unit, the wash stream flowing at a linear velocity of at least 5 cm / second through the desalination unit, the wash stream becoming more saline after passage through the desalination unit; and (b) removing a portion of calcium sulfate from the wash stream by precipitation in the precipitation unit to obtain a supersaturation degree of calcium sulfate in the wash stream entering the desalination unit in a range of from about 1.0 to about 3.0.

Owner:BL TECH INC

Method for producing anhydrous citric acid crystal

InactiveCN102391103AUniform particle sizeWide particle size distributionCarboxylic compound separation/purificationNucleationSupersaturation

The invention provides a method for producing an anhydrous citric acid crystal. The method comprises the following steps of: concentrating citric acid solution until the degree of supersaturation is between 1.02 and 1.15 at temperature of above 36.6 DEG C, and adding an anhydrous citric acid seed crystal. In the method for producing the anhydrous citric acid crystal, the anhydrous citric acid seed crystal is added within the range of between 1.02 and 1.15 of the degree of supersaturation of the citric acid solution, the content of the anhydrous citric acid crystal in a mixture of the citric acid solution and the anhydrous citric acid crystal in the crystallization process is controlled to be between 20 and 50 weight percent, so that nucleation caused by crystal explosion during the earlier stage of crystallization and nonuniformity of crystal granules due to less crystal nucleus yield in the crystallization process are avoided, the number of the crystal granules is controlled stably and effectively, and thus the production of the anhydrous citric acid crystal is controllable, and the method is easy and convenient to operate. The anhydrous citric acid crystal produced according to the method is uniform in size distribution and attractive in appearance of products.

Owner:COFCO BIOTECHNOLOGY CO LTD

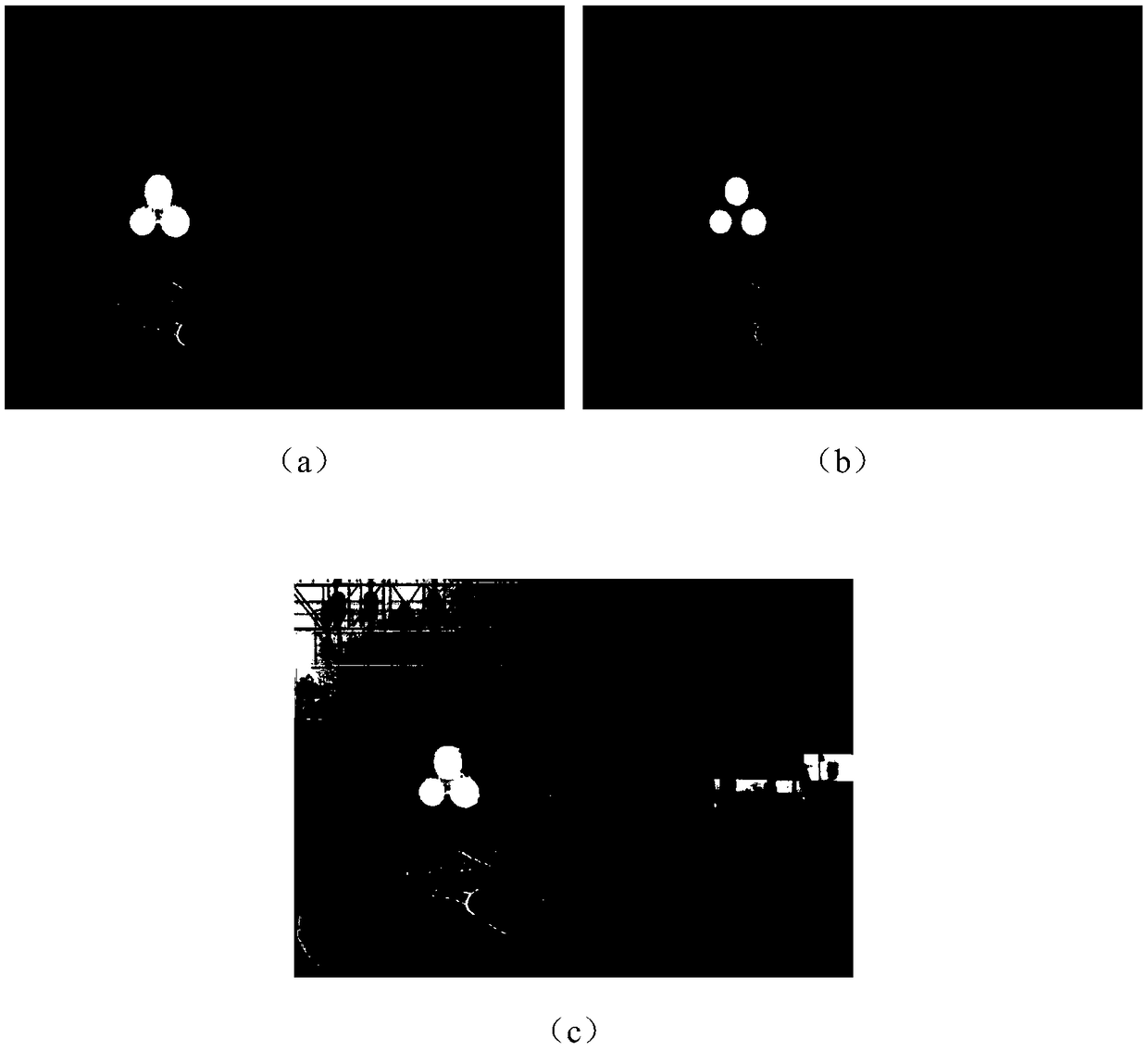

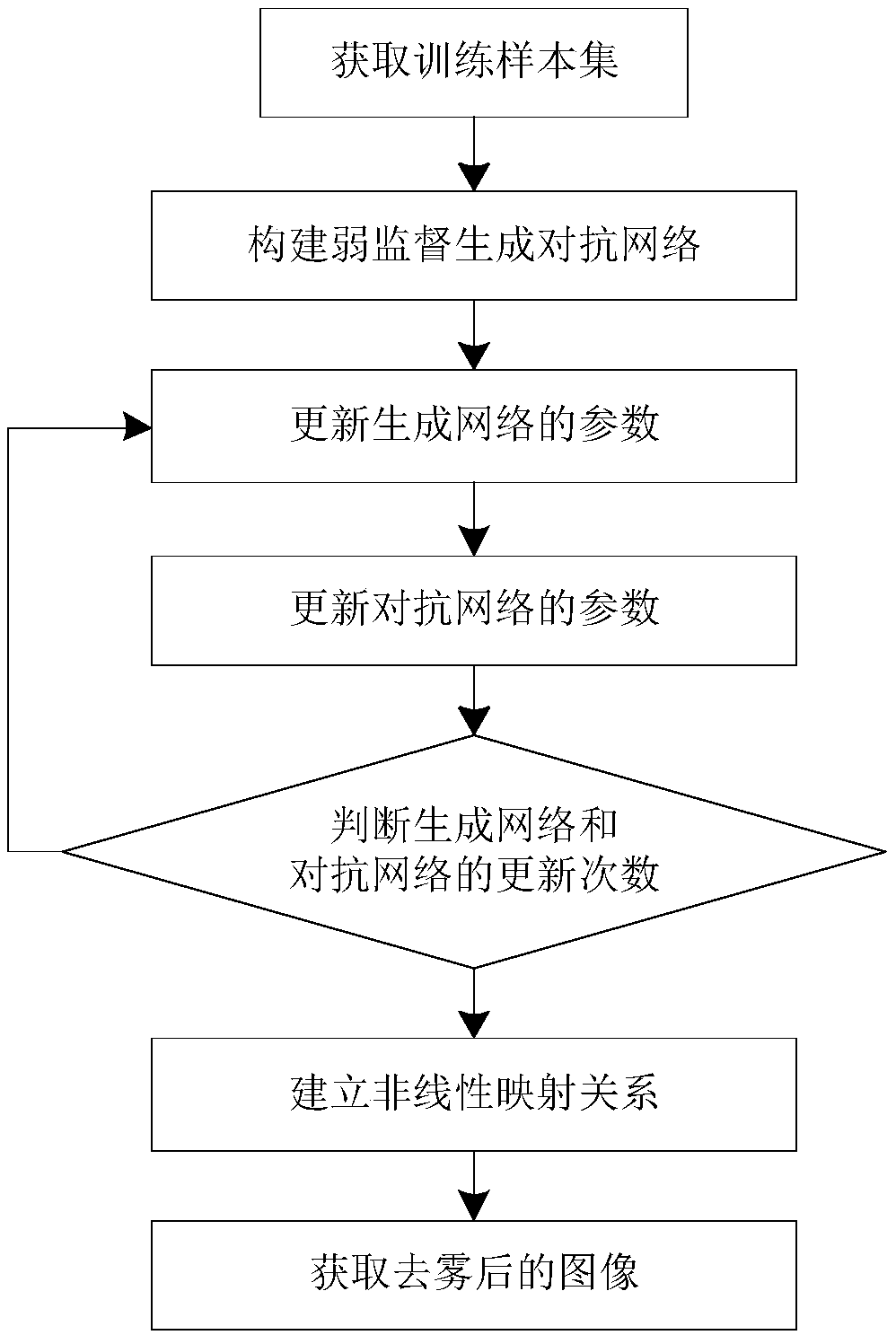

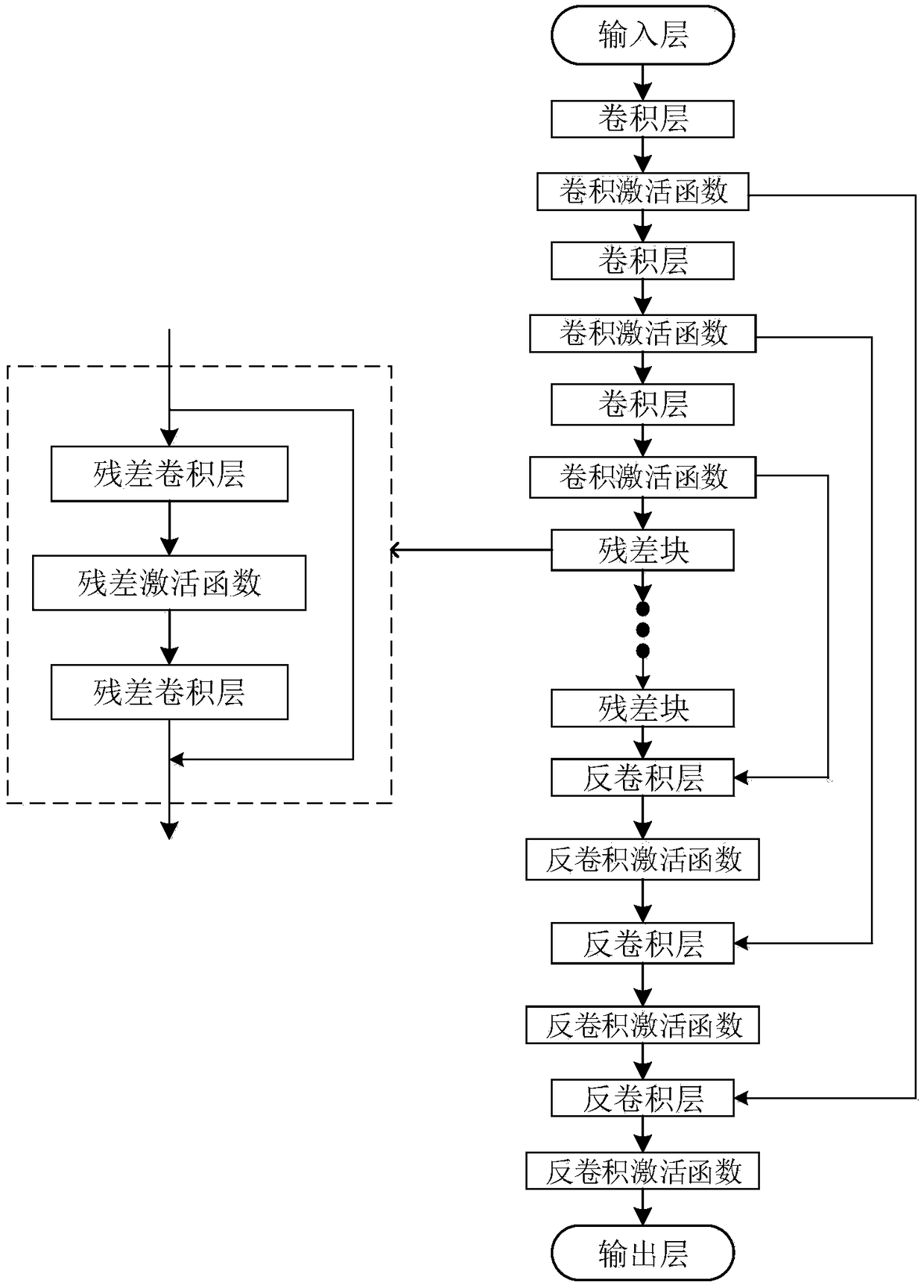

Image defogging method based on weak supervision generation antagonism network

ActiveCN109272455AOvercoming featureOvercome the problem of estimating model parameters in stepsImage enhancementImage analysisInstabilityGenerative adversarial network

The invention discloses an image defogging method based on weak supervision generation antagonism network. The present invention mainly solves the problem of instability of defogging effect of the real foggy day image in the prior art. The implementation scheme is as follows: 1) obtaining a real training set and a composite training set; 2) respectively constructing a generation network and a confrontation network; 3) updating the parameters of the countermeasure network according to the loss function of the countermeasure network; 4) establishing a loss function of the generating network andupdating parameters of the generating network according to the loss function; 5) judging whether the update times of the generation network and the antagonism network reach 100, if so, inputting the real foggy day image into the generation network for defogging, otherwise, returning to step 3). The image after the method of the invention has rich details, improves the brightness, contrast and clarity of the image, reduces the phenomenon of supersaturation and distortion, and can be used in the field of computer vision.

Owner:XIDIAN UNIV

Crystallization method of abamectin Bla

The present invention relates to a crystallization method of abamectin B 1a. Said method includes the following steps: using crystallization solvent n-butanol to stir and dissolve primary crude powder of abamectin B 1a at 75-100deg.C to saturation, filtering while the saturated solution is hot to obtain clear hot-saturated solution; slowly cooling said solution to that when the supersaturation degree is 1-3, adding crystal seeds, constant stirring for 20-60min, its stirring speed is 120-300rpm, and cooling to make crystallization, fitering crystal slurry or centrifugally-separating said crystal slurry, washing crystal and drying so as to obtain the invented abamectin B 1a.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Process for release of biologically active species

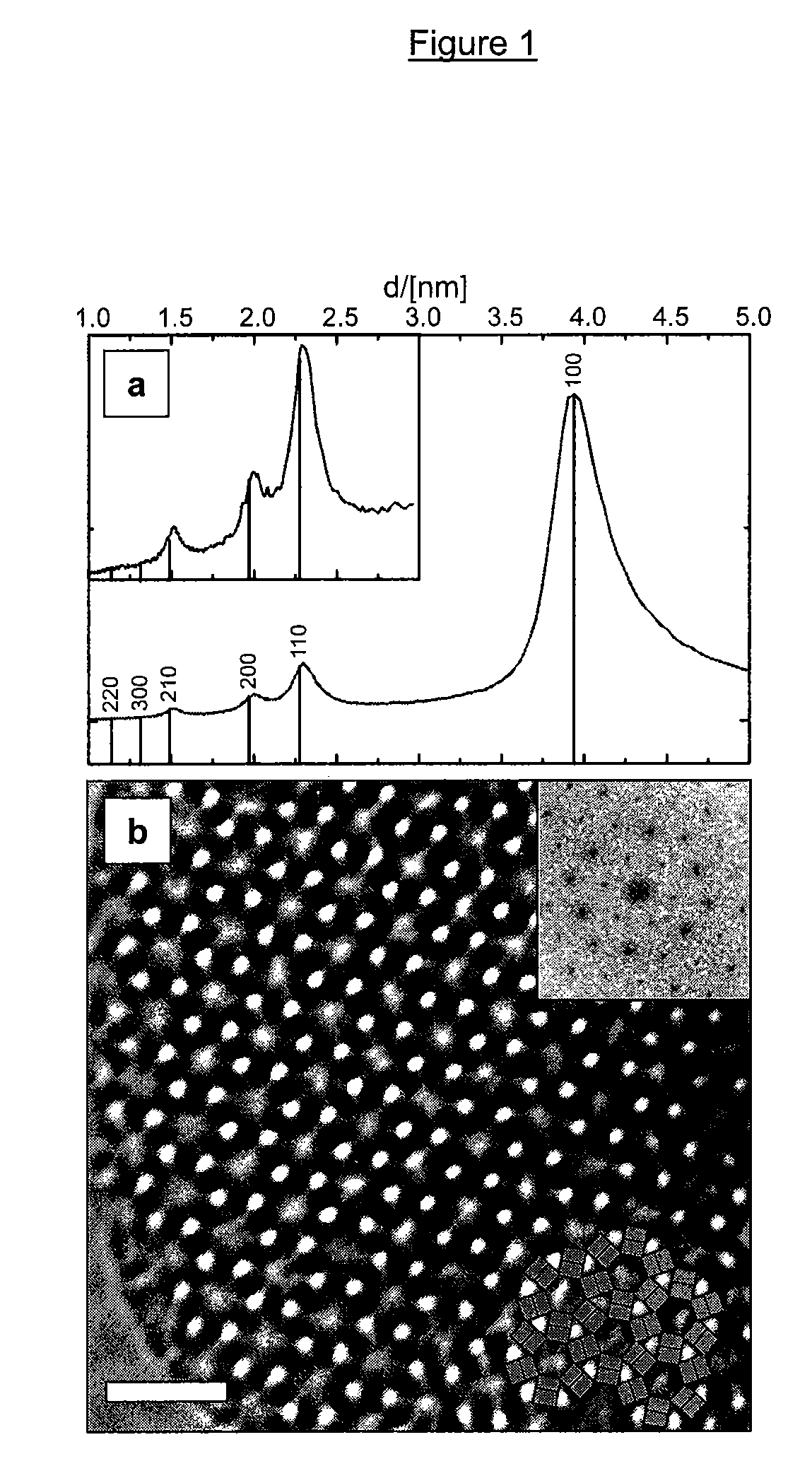

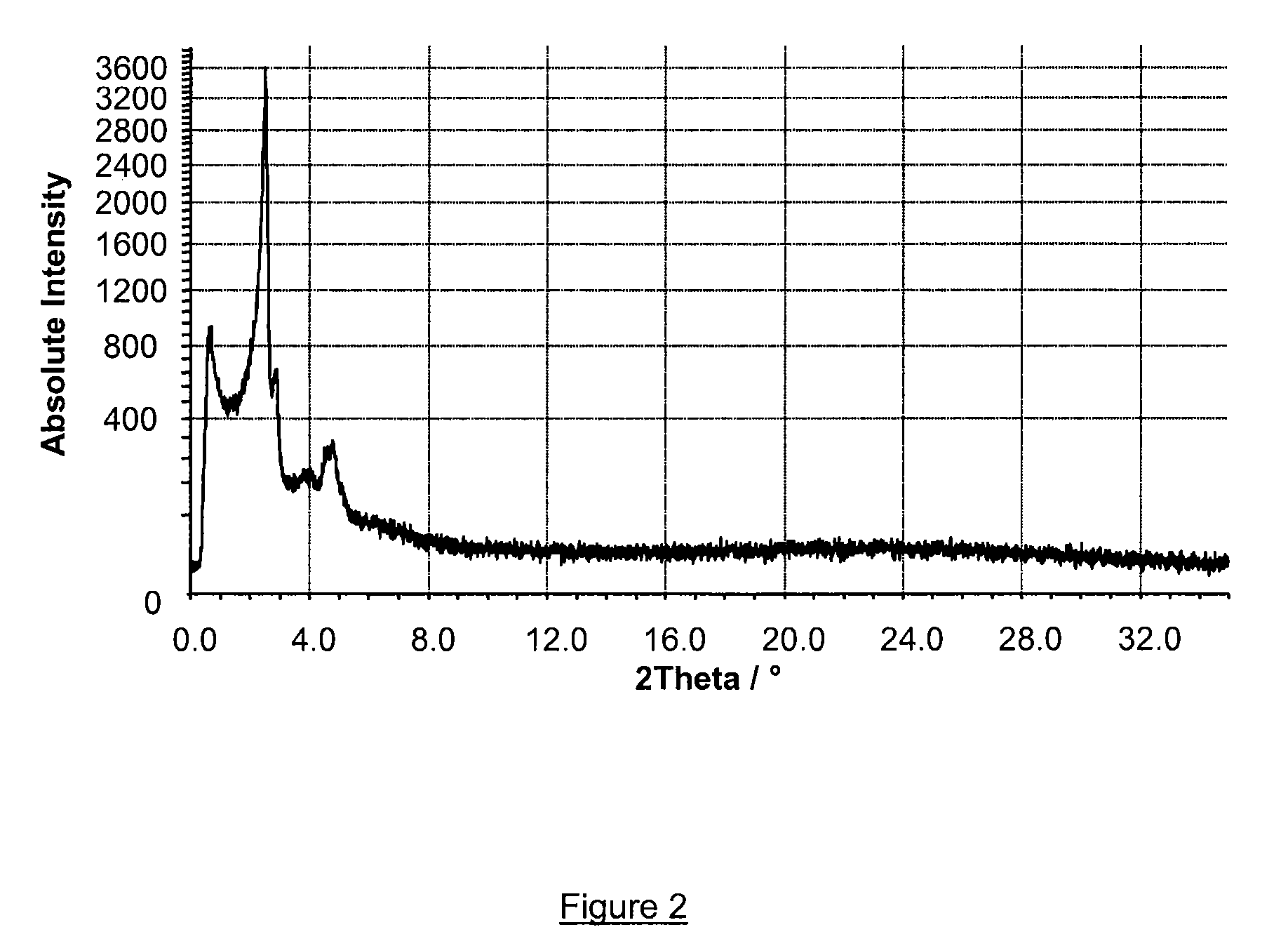

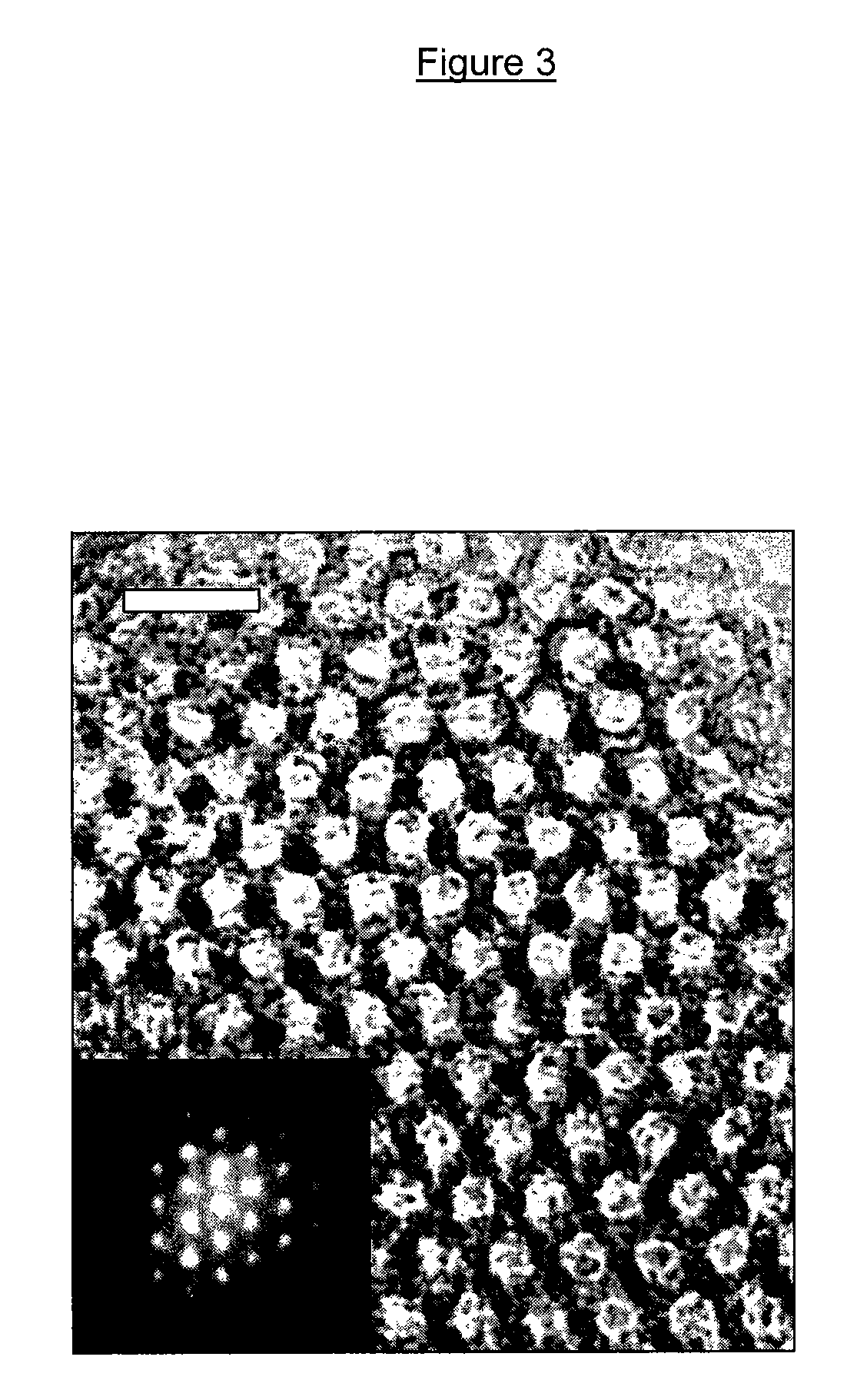

ActiveUS20090192205A1Improve bioavailabilityPromote absorptionCosmetic preparationsBiocidePorosityIn vivo

A process for the release of a biologically active species comprising the steps of:providing a mesoporous oxide-based material having structural order and at least one level of porosity;fixing or immobilizing said biologically active species in said ordered mesoporous oxide; andproviding said ordered mesoporous oxide with said fixed or immobilized biologically active species in vivo thereby realizing intraluminally induced substantially pH-independent supersaturation of said biologically active species resulting in enhanced transepithelial transport; wherein said biologically active species is a poorly soluble therapeutic drug classified as belonging to Class II or Class IV of the Biopharmaceutical Classification System and said ordered mesoporous oxide has a pore size in the range of 4 to 14 nm.

Owner:FORMAC PHARMA

Heat treatment process for scandium-containing Al-Zn-Mg-Cu base squeeze casting aluminum alloy

InactiveCN103866216AAvoid overheatingPrevent excessive solid solution residual crystalline phasesStress concentrationThermal insulation

The invention belongs to the field of aluminum alloy heat treatments, and particularly relates to a heat treatment process for a scandium-containing Al-Zn-Mg-Cu base squeeze casting aluminum alloy. The heat treatment process adopts a three-stage strengthening solid-solution treatment process and a single-stage aging treatment process, wherein the three-stage strengthening solid-solution treatment comprises: carrying out thermal insulation for 24 h at a temperature of 460 DEG C, heating to a temperature of 470 DEG C, carrying out thermal insulation for 8 h, continuously heating to a temperature of 480 DEG C, carrying out thermal insulation for 2 h at a temperature of 480 DEG C, immediately taking, and carrying out water quenching, and then the single-stage aging heat treatment is performed and comprises: carrying out thermal insulation for 24 h at a temperature of 120 DEG C. According to the present invention, the coarse non-equilibrium phase in the alloy can be sufficiently dissolved and homogenized, the supersaturation degree of the solid solution is increased, the stress concentration tendency with the grain boundary eutectic phase is reduced, the matrix structure after aging is fine GP zones distributed in a diffusion manner and an eta<,> phase, the grain boundary is a grain boundary precipitation phase distributed in a discontinuous manner, the ultra high strength ([sigma]s is more than or equal to 500 MPa) is achieved, and the good plasticity (delta is more than or equal to 10%) is provided.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Method for preparing graphene nanoribbon on insulating substrate

ActiveUS20130022813A1Inhibit transferEnsure performanceMaterial nanotechnologyLayered productsActivated carbonGraphene nanoribbons

A method for growing a graphene nanoribbon on an insulating substrate having a cleavage plane with atomic level flatness is provided, and belongs to the field of low-dimensional materials and new materials. The method includes the following steps. Step 1: Cleave an insulating substrate to obtain a cleavage plane with atomic level flatness, and prepare a single atomic layer step. Step 2: Directly grow a graphene nanoribbon on the insulating substrate having regular single atomic steps. In the method, a characteristic that nucleation energy of graphene on the atomic step is different from that on the flat cleavage plane is used, and conditions, such as the temperature, intensity of pressure and supersaturation degree of activated carbon atoms, are adjusted, so that the graphene grows only along a step edge into a graphene nanoribbon of an adjustable size. The method is mainly applied to the field of new-type graphene optoelectronic devices.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

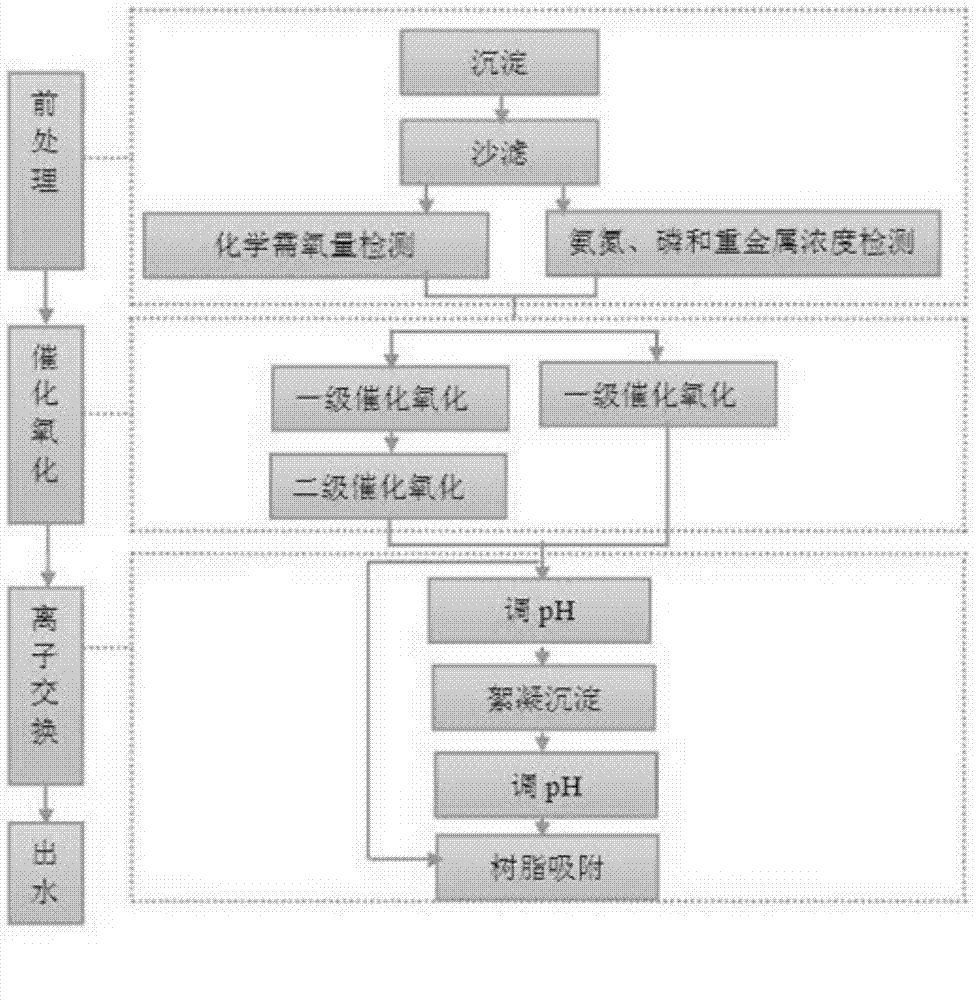

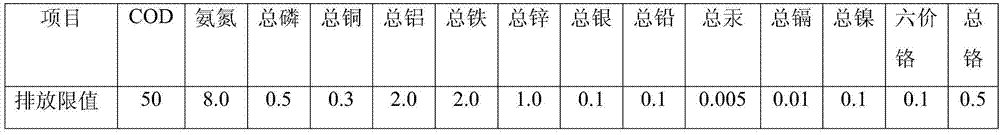

Electroplating comprehensive wastewater treatment process

InactiveCN104512975AExtended service lifeImprove pH requirementsWater treatment compoundsWater contaminantsActivated carbonChemical oxygen demand

The invention discloses an electroplating comprehensive wastewater treatment process, and relates to the technical field of electroplating wastewater treatment. The electroplating comprehensive wastewater treatment process comprises the following steps: step 1, pretreatment of electroplating comprehensive wastewater, comprising (1) precipitating and sand filtering; (2) wastewater composition detection; step 2, classified catalytic oxidation of the electroplating comprehensive wastewater, comprising (1) for the electroplating comprehensive wastewater with a chemical oxygen demand less than 950 mg / L, adopting one-stage heterogeneous Fenton-like reaction as catalytic oxidation; (2) for the electroplating comprehensive wastewater with a chemical oxygen demand more than or equal to 950 mg / L, adopting two-stage heterogeneous Fenton-like reaction as catalytic oxidation; step 3, ion exchange of the electroplating comprehensive wastewater: adopting chelate resin to adsorb corresponding heavy metal ions. The electroplating comprehensive wastewater treatment process disclosed by the invention improves the requirement of the Fenton technology on pH value, enhances the catalytic oxidation effect, prolongs the service life of activated carbon, prolongs the resin supersaturation time, ensures that the effluent meets the standard, reduces the cost, is convenient to operate, and facilitates implementation of large-scale automatic wastewater treatment.

Owner:SHENZHEN LVQIN ENVIRONMENTAL PROTECTION TECH CO LTD

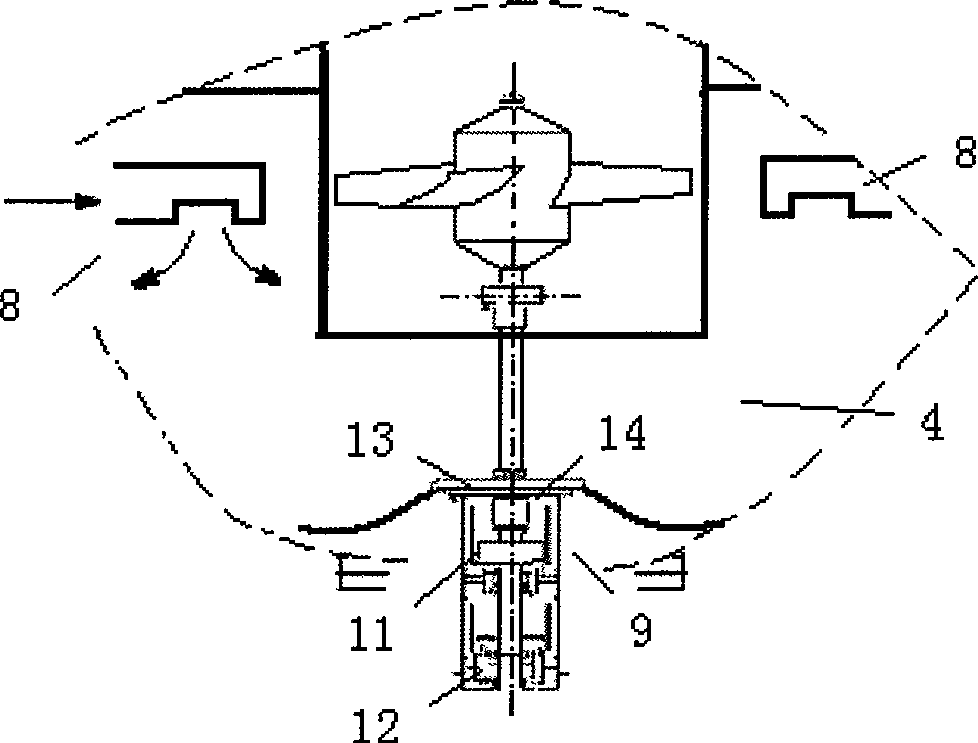

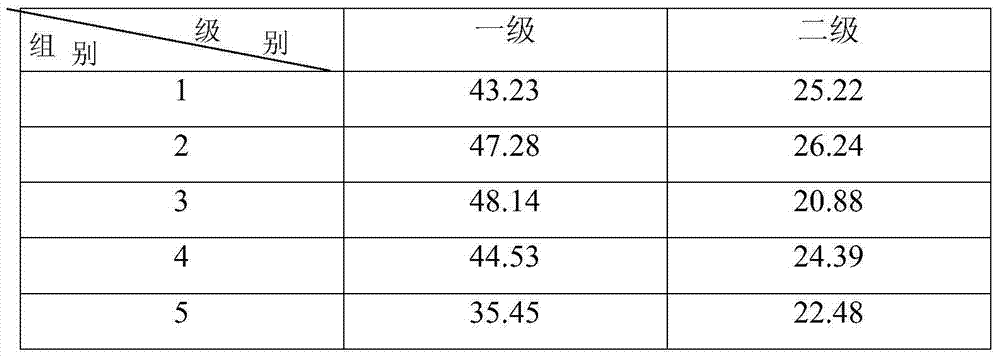

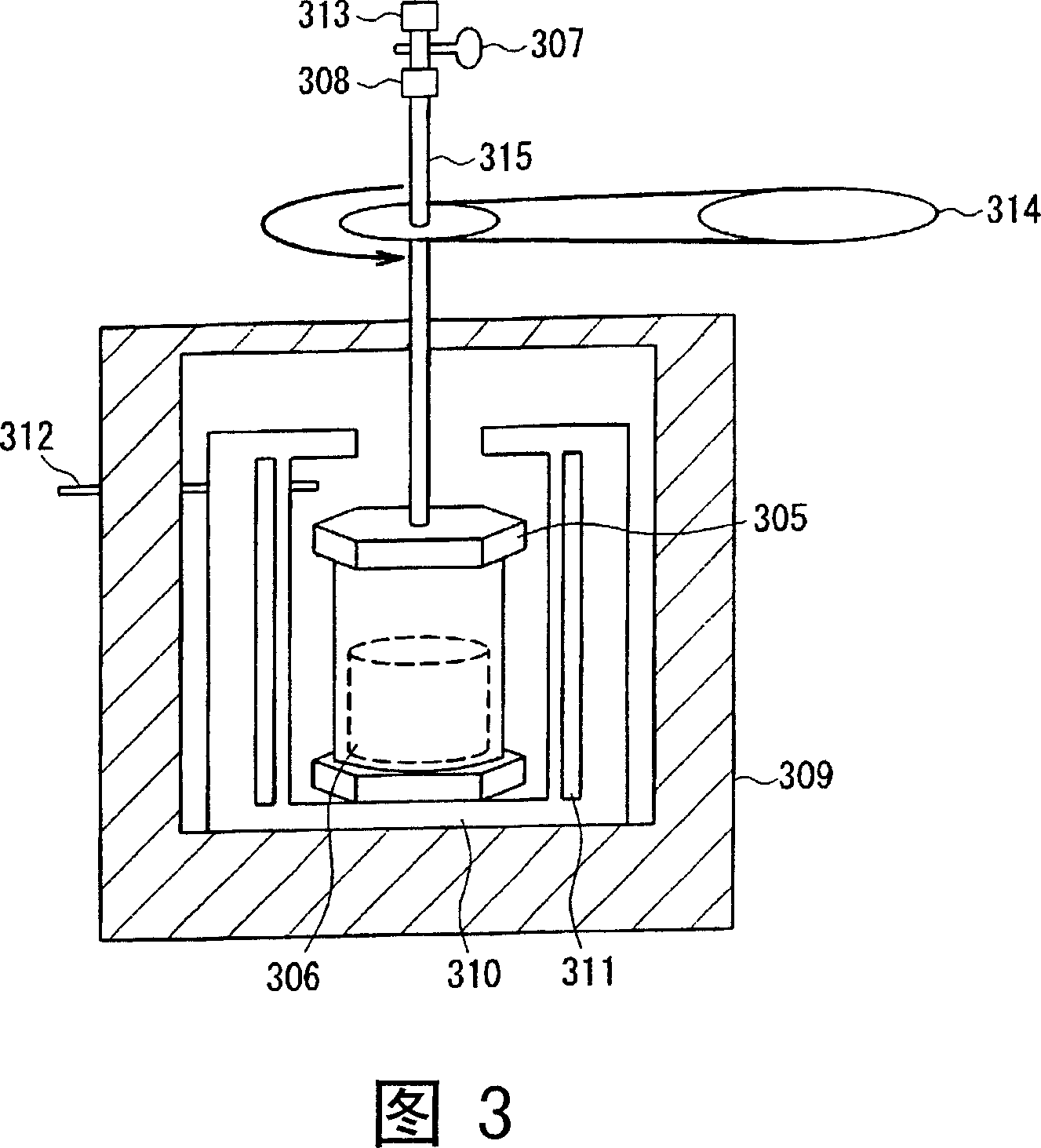

Method of manufacturing compound single crystal and apparatus for manufacturing it

ActiveCN1922345AIncrease growth rateQuality improvementPolycrystalline material growthLiquid-phase epitaxial-layer growthProduct gasSingle crystal

A method for producing a compound single crystal involving reacting a gaseous raw material and a liquid raw material, wherein the compound single crystal is grown with agitation of the liquid raw material in such a manner that a flow is formed in the liquid raw material, from the gas-liquid interface, at which the gas and the liquid contact with each other, to the inside of the liquid raw material; and an apparatus for use in the method. The above agitation allows the easy dissolution of the gaseous raw material into the liquid raw material and the achievement of a supersaturation state in a short time, resulting in the improvement in the grow rate of the compound single crystal, and further allows more uniform dissolution of the gaseous raw material through the formation of the flow from the gas-liquid interface having a high content of the gaseous raw material to the inside of the liquid raw material having a low content of the gaseous raw material, resulting in the inhibition of non-uniform generation of nuclei in the gas-liquid interface, which in turn leads to the improvement in quality of the resultant compound single crystal.

Owner:PANASONIC CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com