Patents

Literature

308results about "Alkali metal nitrate preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process and equipment for nitrogen oxide waste conversion to fertilizer

The present invention describes a process for converting vapor streams from sources containing at least one nitrogen-containing oxidizing agent therein to a liquid fertilizer composition comprising the steps of: a) directing a vapor stream containing at least one nitrogen-containing oxidizing agent to a first contact zone, b) contacting said vapor stream with water to form nitrogen oxide(s) from said at least one nitrogen-containing oxidizing agent, c) directing said acid(s) as a second stream to a second contact zone, d) exposing said second stream to hydrogen peroxide which is present within said second contact zone in a relative amount of at least 0.1% by weight of said second stream within said second contact zone to convert at least some of any nitrogen oxide species or ions other than in the nitrate form present within said second stream to nitrate ion, e) sampling said stream within said second contact zone to determine the relative amount of hydrogen peroxide within said second contact zone, f) adding hydrogen peroxide to said second contact zone when a level of hydrogen peroxide less than 0.1 % by weight in said second stream is determined by said sampling, g) adding a solution comprising potassium hydroxide to said second stream to maintain a pH between 6.0 and 11.0 within said second stream within said second contact zone to form a solution of potassium nitrate, and h) removing said solution of potassium nitrate from said second contact zone.

Owner:NAT AERONAUTICS & SPACE ADMINISTATION U S GOVERNMENT AS REPRESENTED BY THE ADMINISTATOR

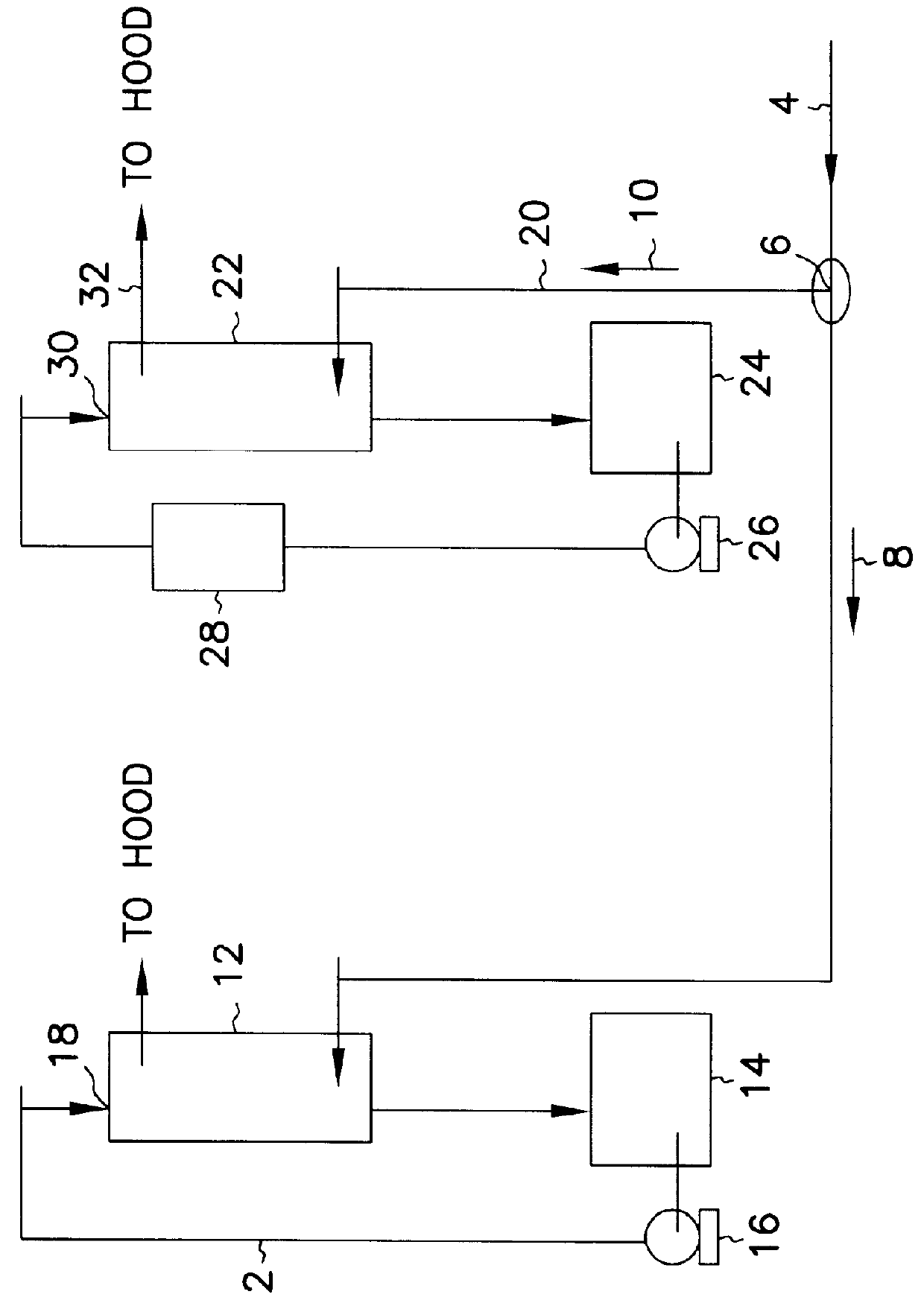

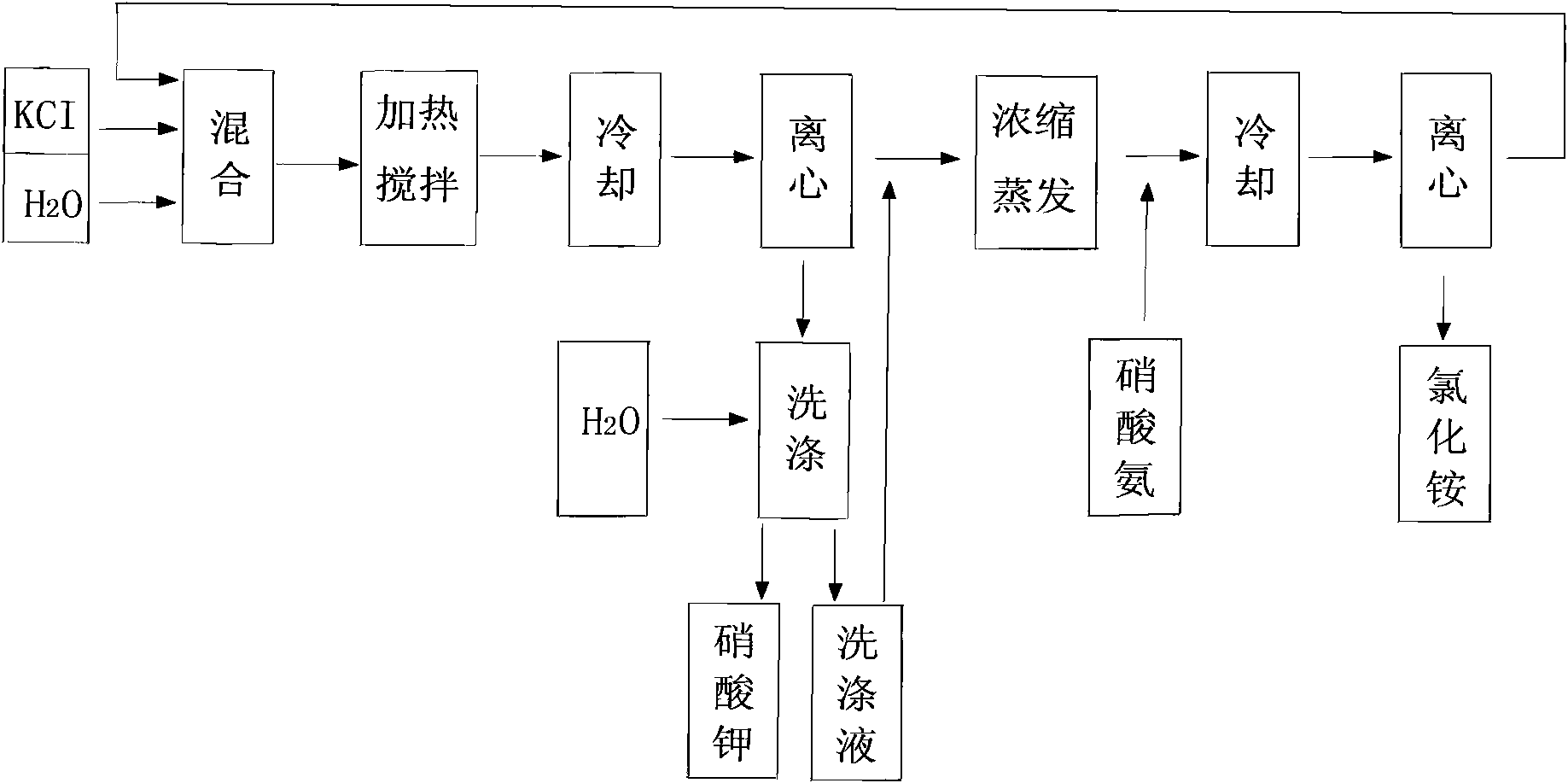

Method for preparing potassium nitrate and ammonium chloride employing double decomposition reaction

InactiveCN101628723ACreate pollutionRealize the concentrated evaporation processAlkali metal nitrate preparationAmmonium halidesDecompositionIon exchange

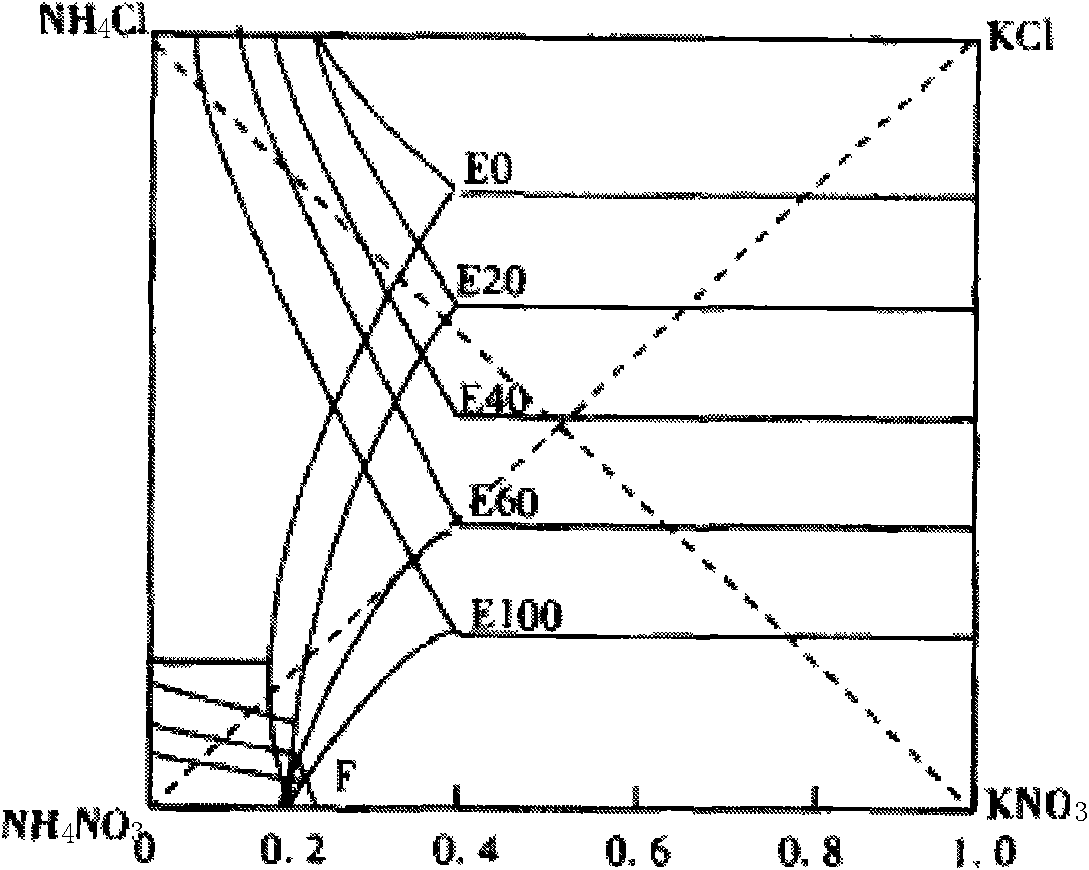

A method for preparing potassium nitrate and ammonium chloride employing double decomposition reaction comprises the following steps: dissolving ammonium nitrate and potassium chloride in water according to a defined ratio at 110 DEG C, continuously adding potassium chloride and water, heating while stirring to ensure that potassium nitrate is in supersaturation state, after stopping heating, cooling the solution in a vacuum cooling crystallizer to 36-40 DEG C to separate potassium nitrate crystal, placing the potassium nitrate crystal in a centrifugal machine with a filter cloth lining to obtain coarse potassium nitrate, then washing the potassium nitrate with cold water, drying to obtain the finished potassium nitrate; in addition, adding ammonium nitrate in mother solution I and cleaning solution to adjust solution concentration so that ammonium chloride can reach supersaturation state, using a vacuum concentration device to perform negative pressure evaporation, separating and precipitating ammonium chloride by centrifuging and obtaining a solid ammonium chloride product, wherein, when dissolving ammonium nitrate and potassium chloride, the ratio of ammonium ion to chlorine ion is 1:2 and when using the centrifugal machine to obtain the coarse potassium nitrate, the separated mother solution is another mother solution I sharing the same saturation point of potassium nitrate and ammonium chloride. The solution of feed liquid circular reaction overcomes the defects of the prior art that the price of potassium nitrate used in reaction is high, the resource of potassium nitrate is in short supply and the cost of devices used in ion-exchange method is high, thus being applicable to the production of potassium nitrate.

Owner:湖南丹化农资有限公司

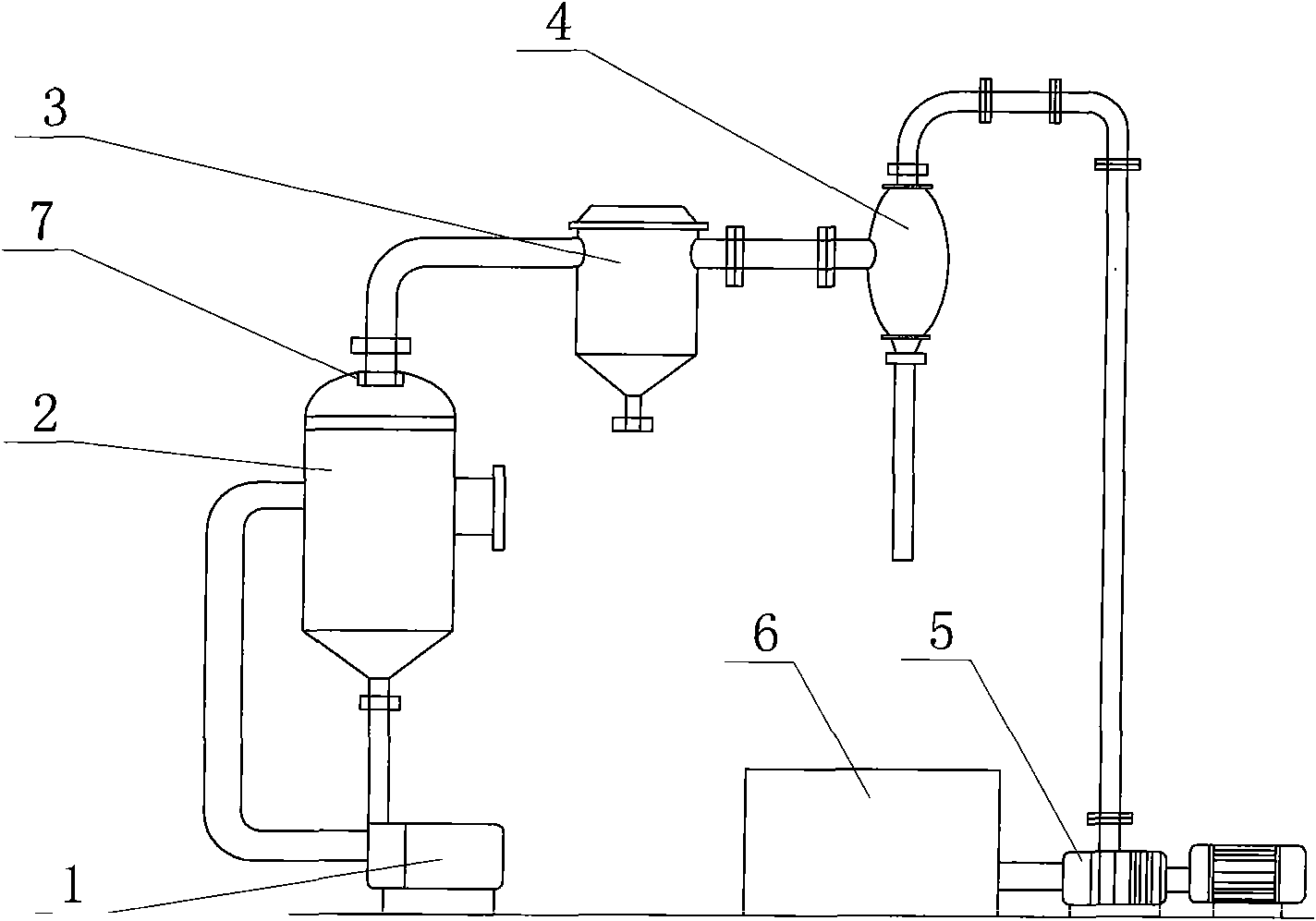

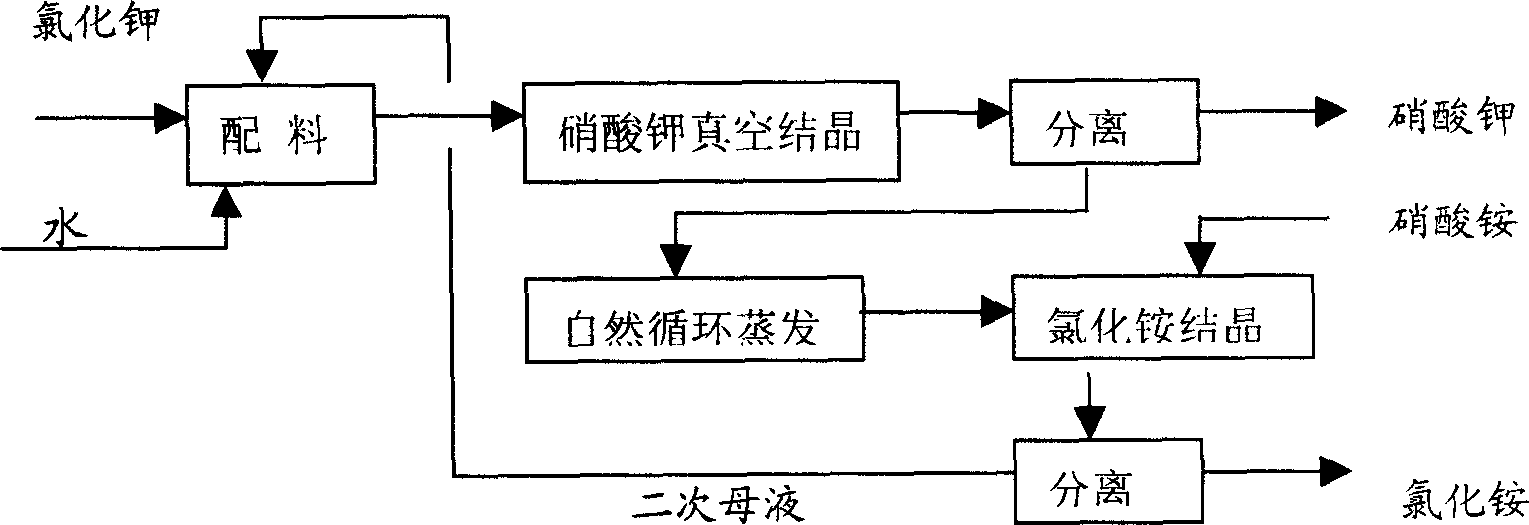

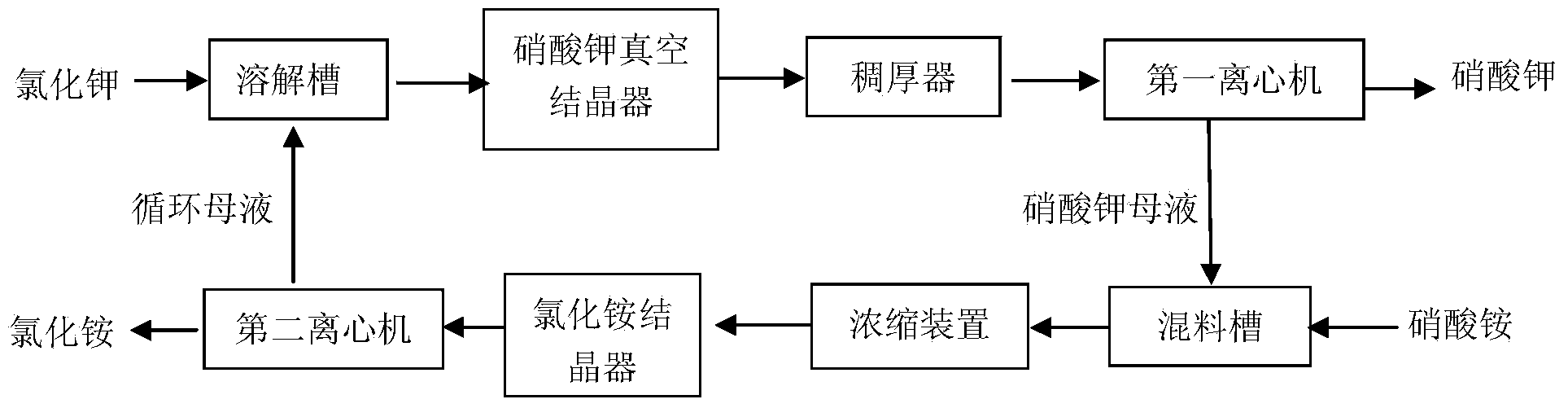

Process for preparing potassium nitrate by double decomposition method

ActiveCN1827526ALess process equipmentEasy to manufactureAlkali metal nitrate preparationCyclic processAmmonium nitrate

The invention provides a metathesis method for preparation of potassium nitrate. After raw potassium chloride, ammonium nitrate and craft water finish their preparation at a certain ratio, they are input into vacuum cooling crystallizer. Then potassium nitrate is separated by crystallization and grows up. The crystallized liquid thickens by the thickening apparatus and continuously separates potassium nitrate as aim products by centrifugal machine. After the separated mother liquid exchanges heat with the reacting liquid, it is input into natural circulation evaporator to concentrate, adopting backward feed and dual effect concentration with constant pressure in the first chamber and negative pressure in the second chamber. Through cooling crystallization, thickening by the thickening apparatus, the concentrated liquid continuously separates ammonium chloride as by-products. The gained secondary mother liquid returns to preparation groove. Repeating this cyclic process, we could sequentially get solid potassium nitrate and ammonium chloride.The invention has improved production stability and product quality a lot and reduced raw material consumption and energy consumption, with simple and serial flow process. The invention has realized the mass production.

Owner:EAST CHINA ENG SCI & TECH

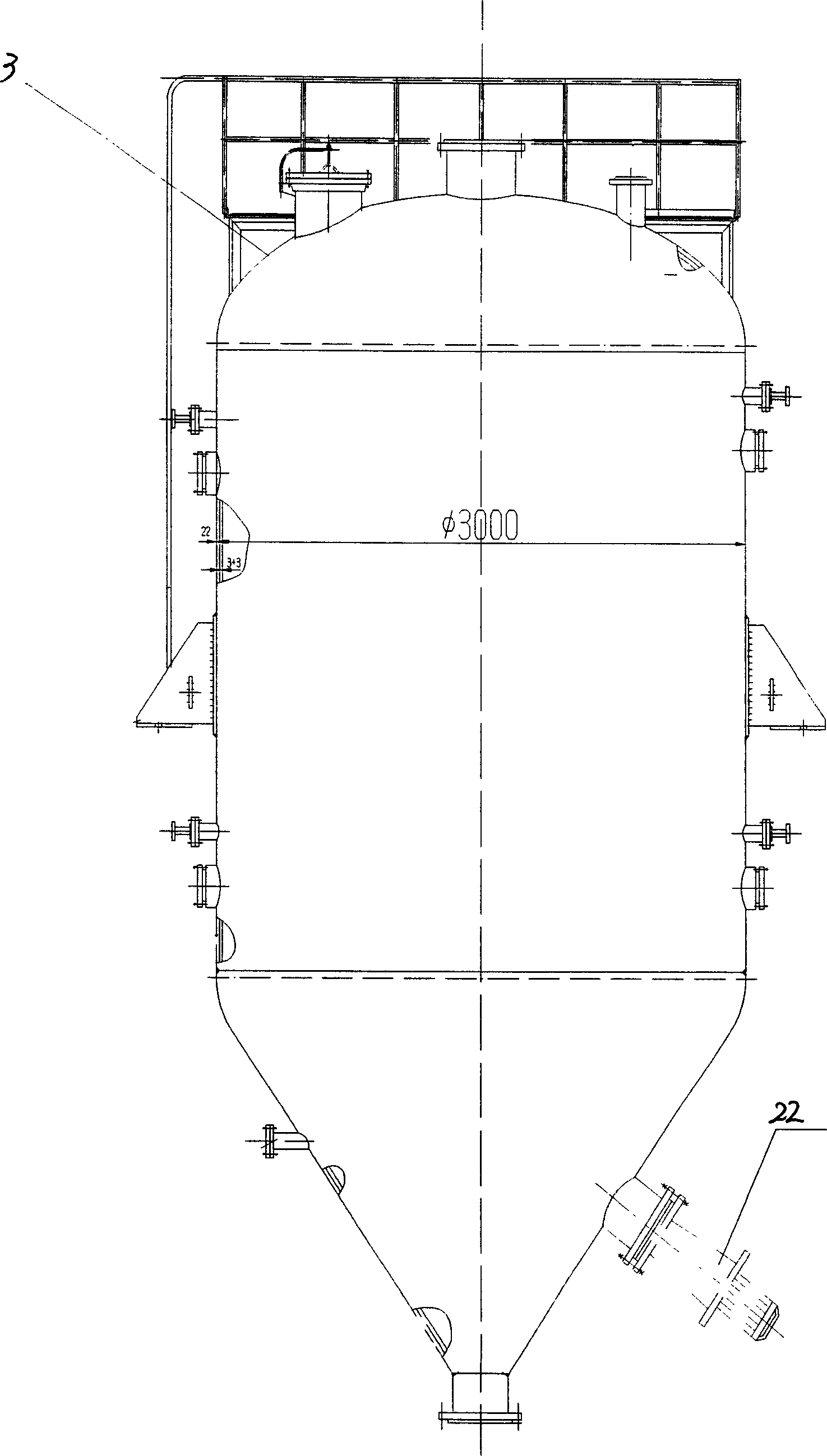

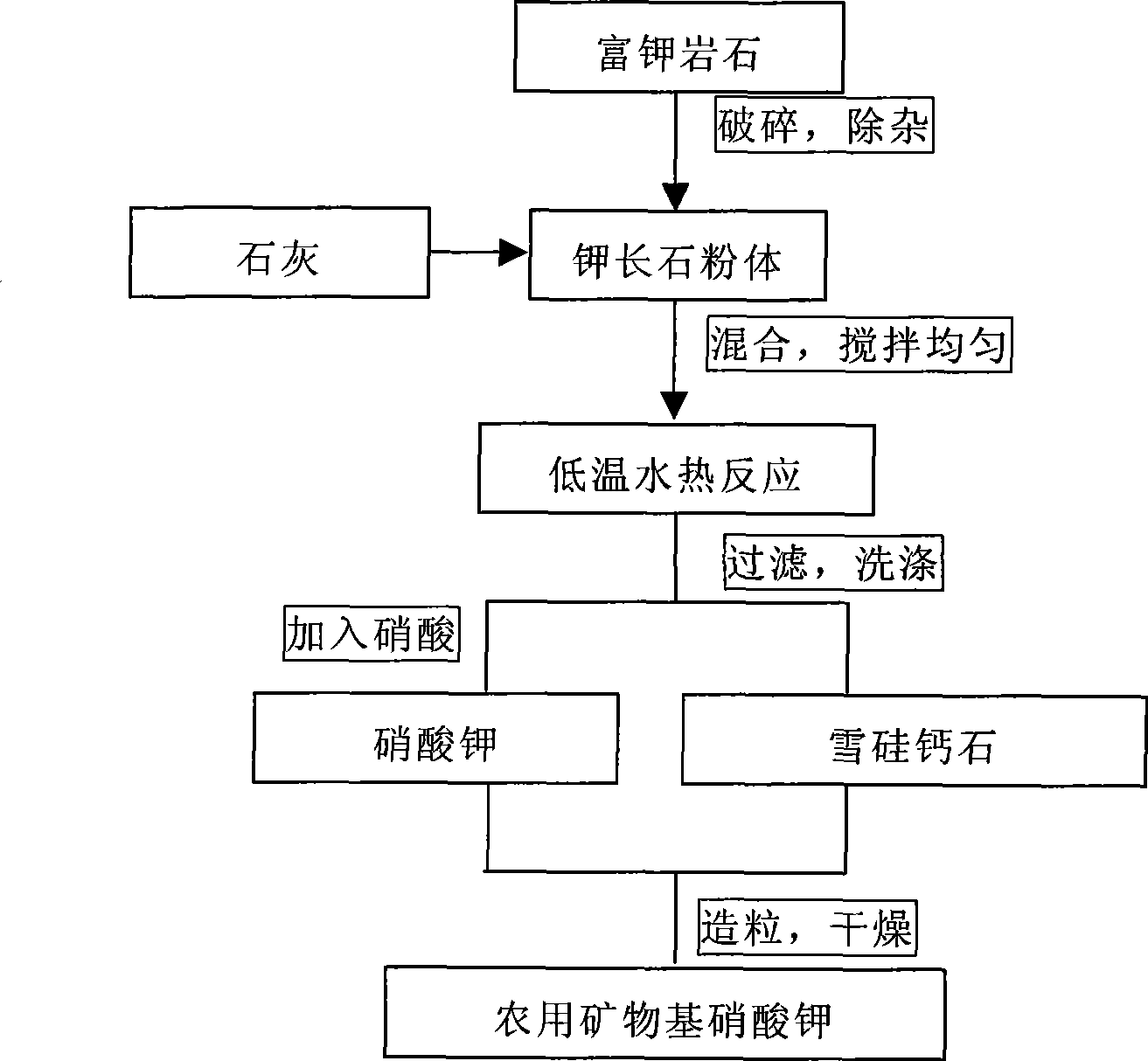

Method for producing agricultural mineral base potassium nitrate by using potassium-rich rock

ActiveCN101450874AObvious adsorption and slow-release effectPlay a sustained release roleAlkali metal nitrate preparationPotassium fertilisersPotassium nitrateMaceral

The invention relates to a method for producing mineral-based potassium nitrate for agricultural use through rocks rich in potassium. The method comprises the following steps: crushing the rocks rich in the potassium, and milling the rocks after mineral dressing and trash extraction to obtain the powder with the main phase of potash feldspar; mixing the potash feldspar powder and lime according to the mass ratio of 1: 0.80-0.85, adding water according to the solid-liquid mass ratio of 1: 15-25, stirring and mixing the materials for reactions in a reaction kettle, carrying out a hydrothermal reaction on the condition of stirring at a temperature of between 180 and 250 DEG C, carrying out the reaction at constant temperature for 5 to 10 hours to obtain KOH solution and tobermorite; and preparing potassium nitrate through the obtained KOH solution, compounding the potassium nitrate with the tobermorite, and adding a binder for granulation and forming so as to obtain the novel mineral-based potassium nitrate for agricultural use. The KNO3 nutrient content can be adjusted in the range of between 22.0 and 58.6 percent.

Owner:SHAANXI DAQIN POTASSIUM CO LTD

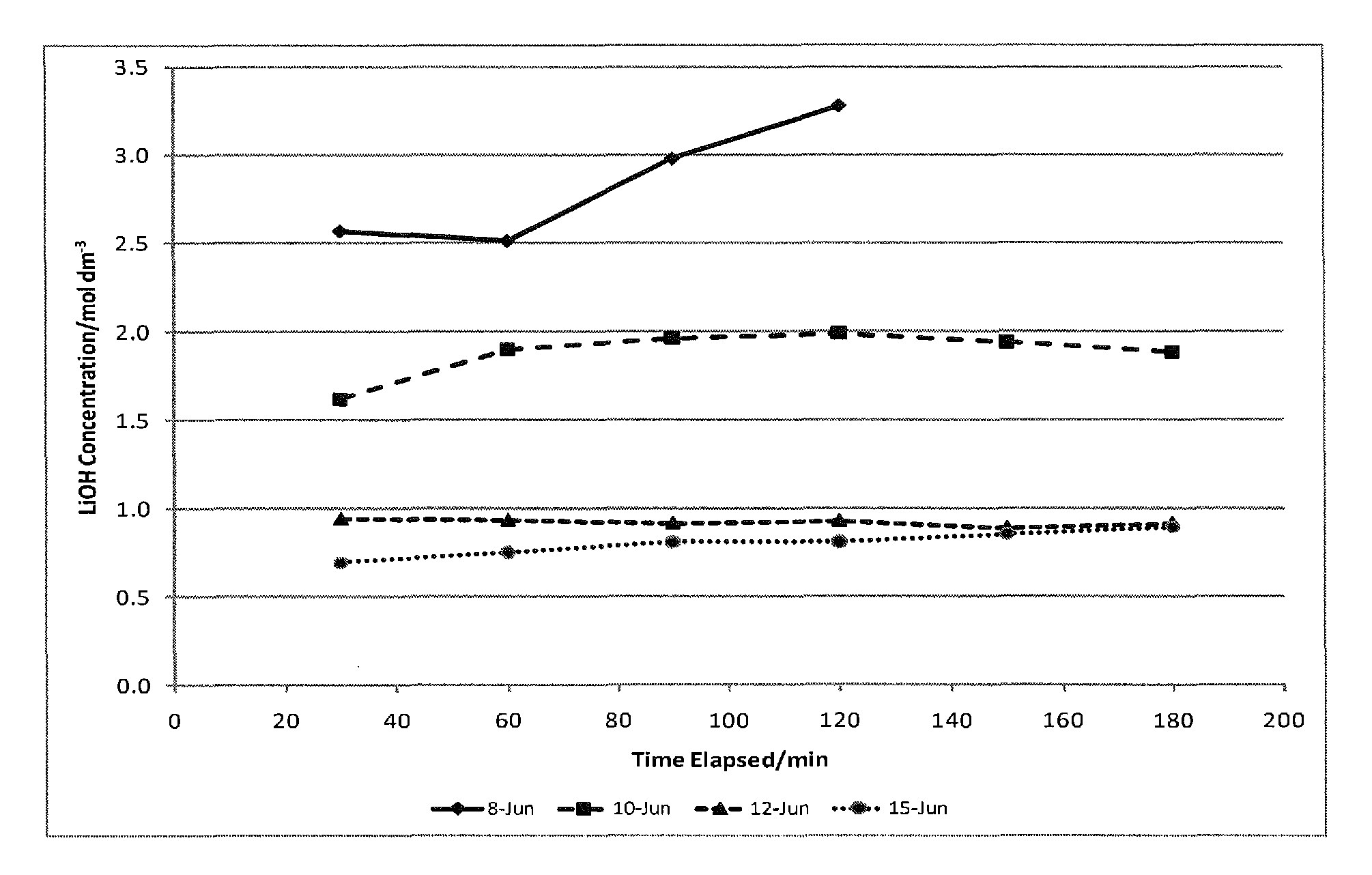

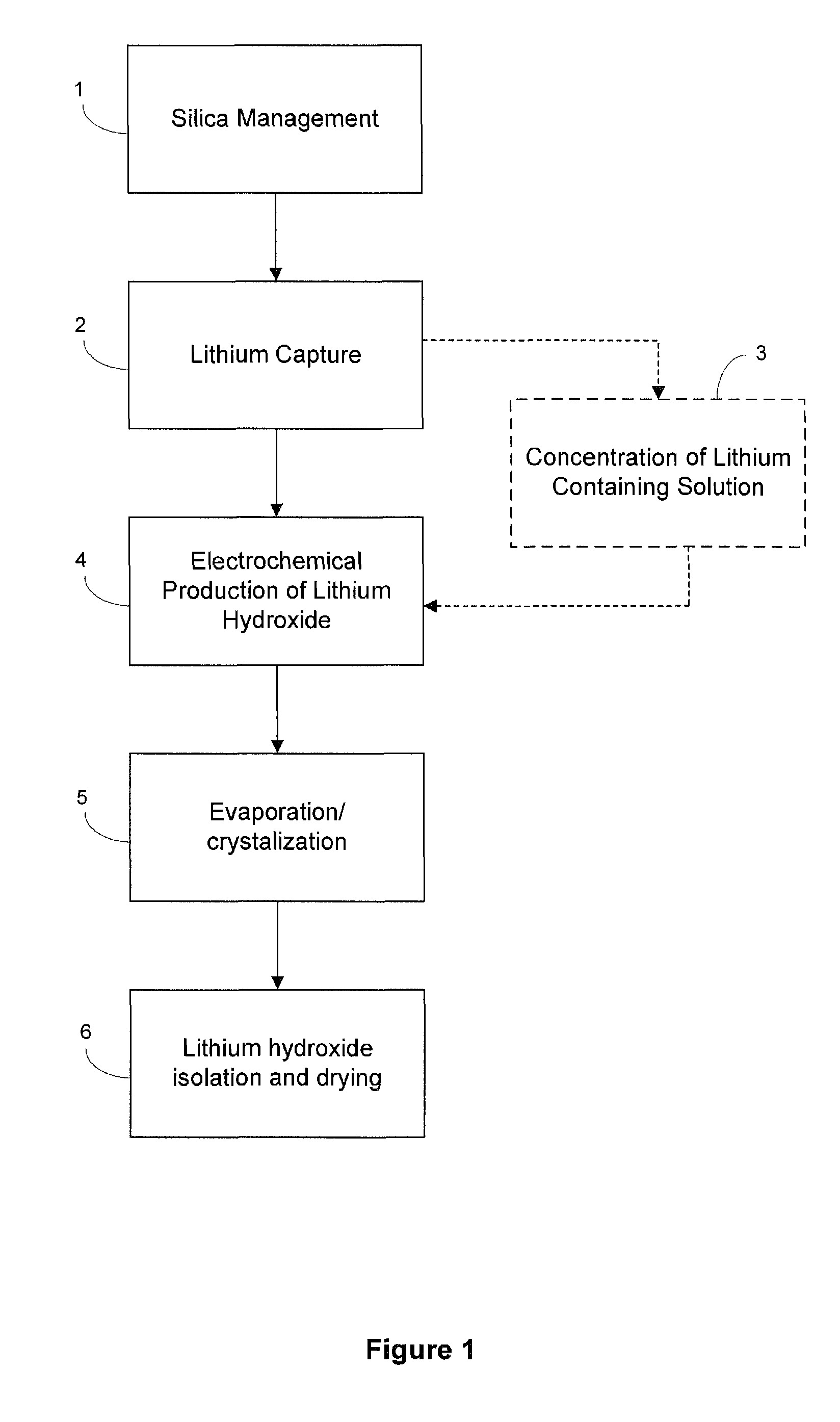

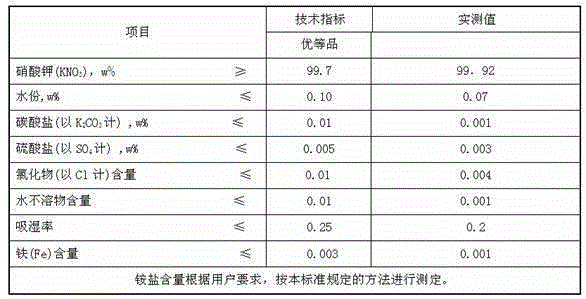

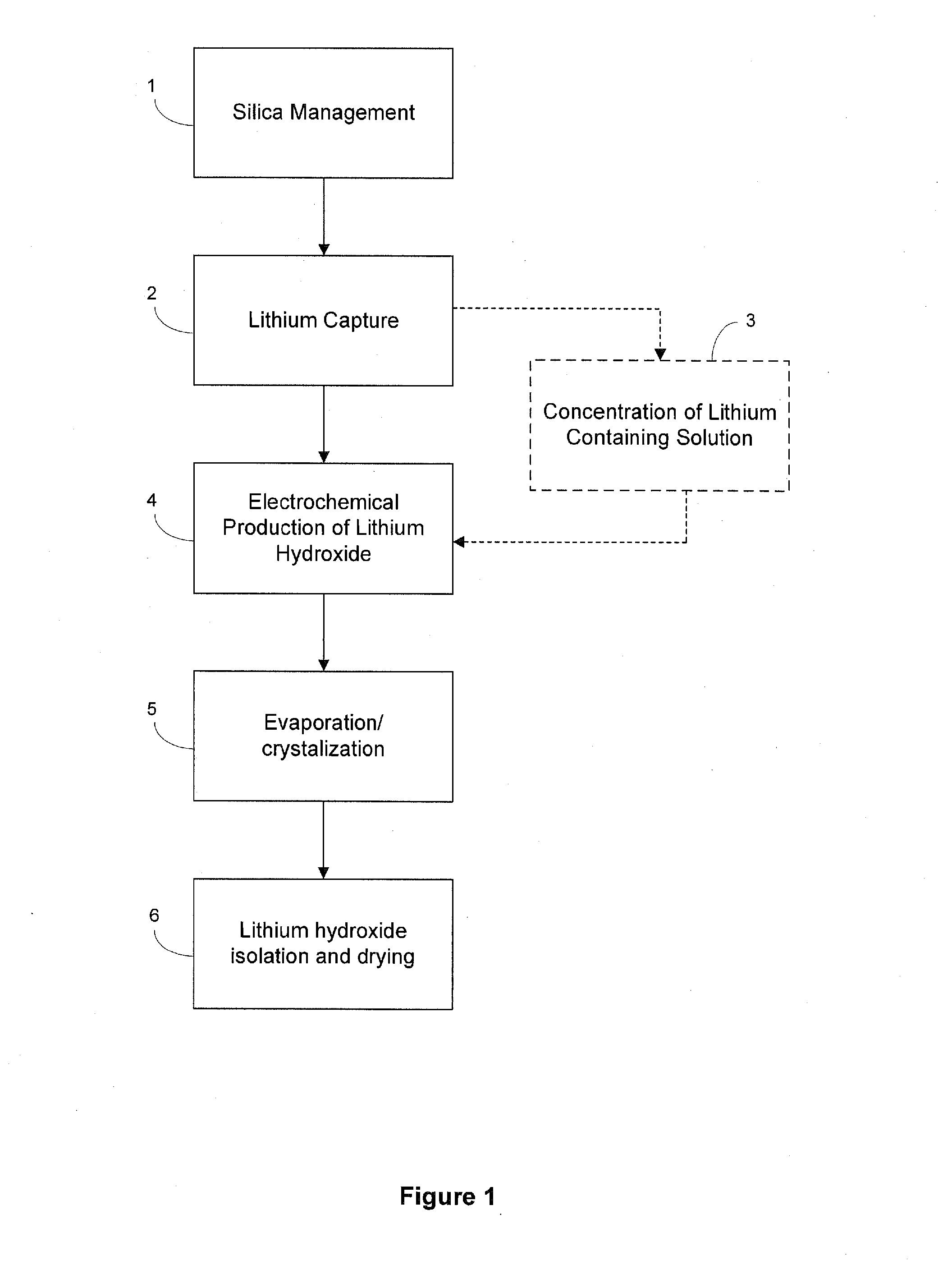

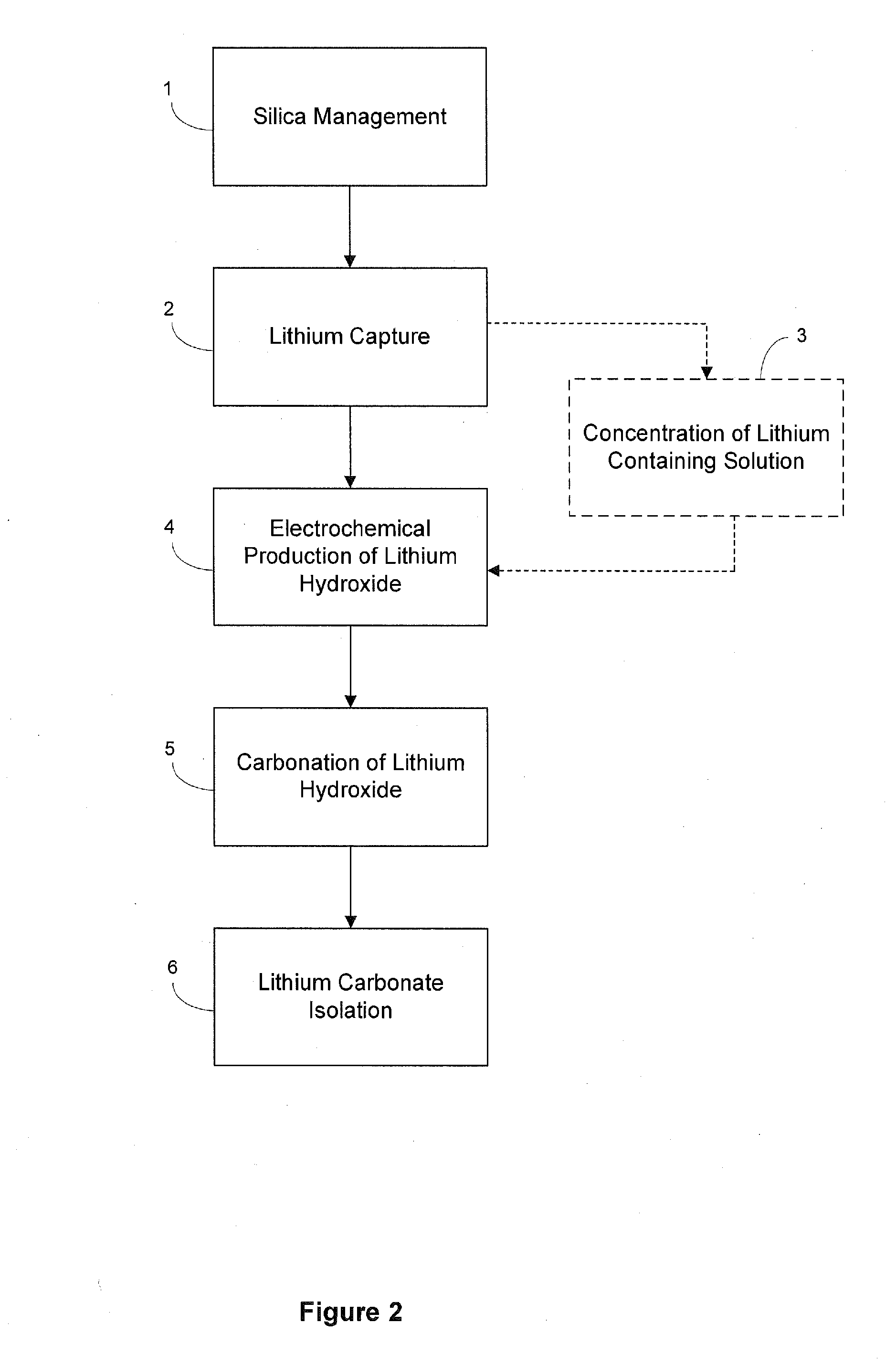

Preparation of lithium carbonate from lithium chloride containing brines

ActiveUS9034294B1Chloride preparationSolid sorbent liquid separationLithium carbonateLithium hydroxide

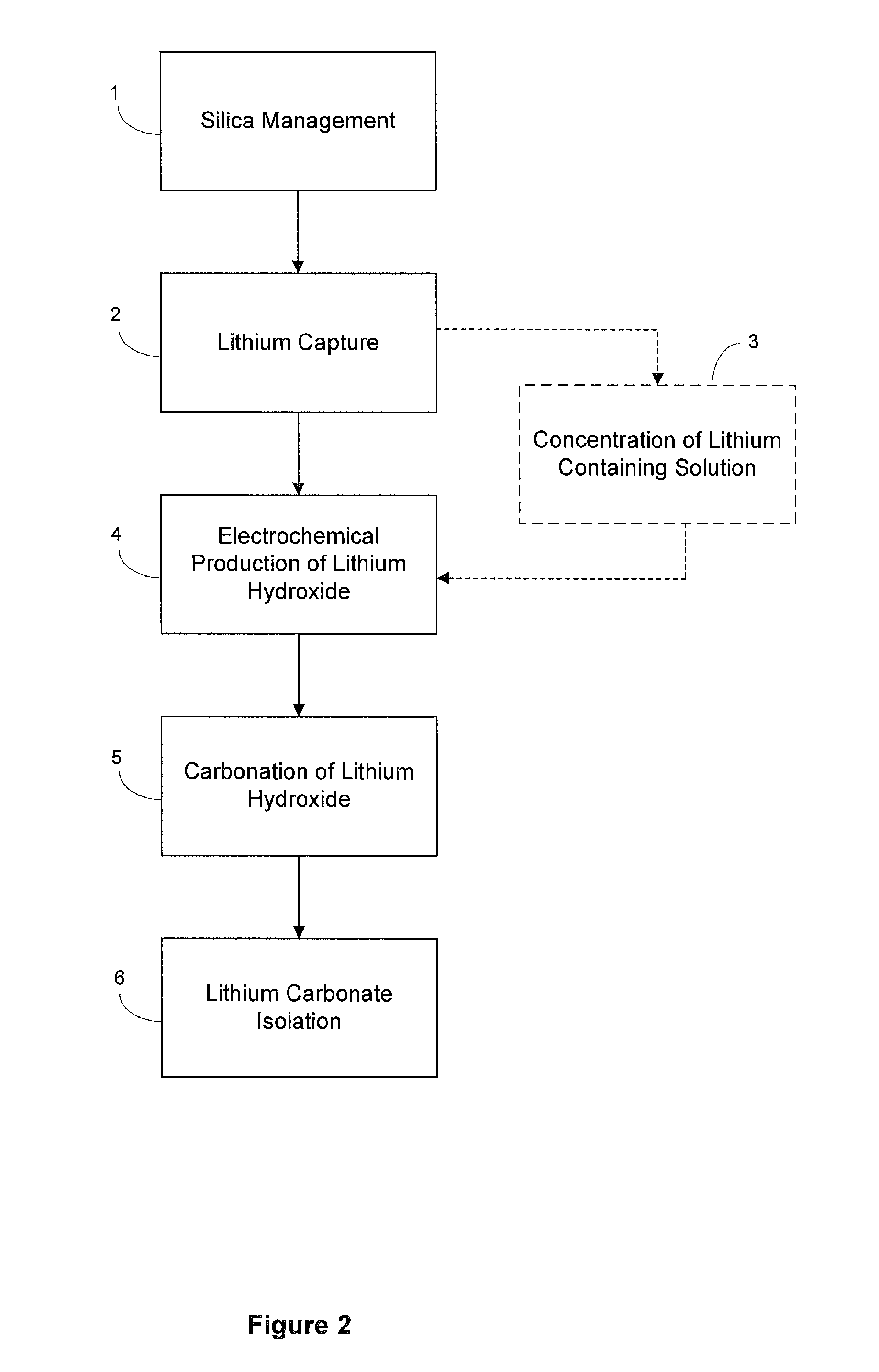

This invention relates to a method for the preparation of lithium carbonate from lithium chloride containing brines. The method can include a silica removal step, capturing lithium chloride, recovering lithium chloride, supplying lithium chloride to an electrochemical cell and producing lithium hydroxide, contacting the lithium hydroxide with carbon dioxide to produce lithium carbonate.

Owner:TERRALITHIUM LLC

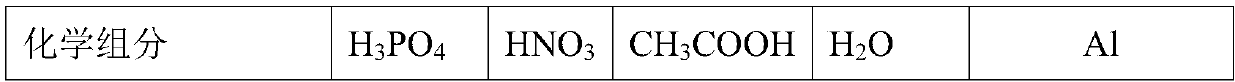

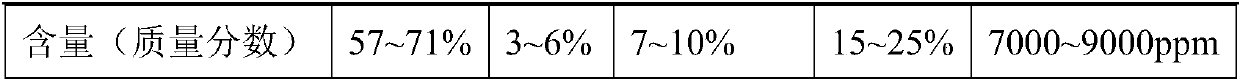

Comprehensive utilization process for waste aluminum etching solution

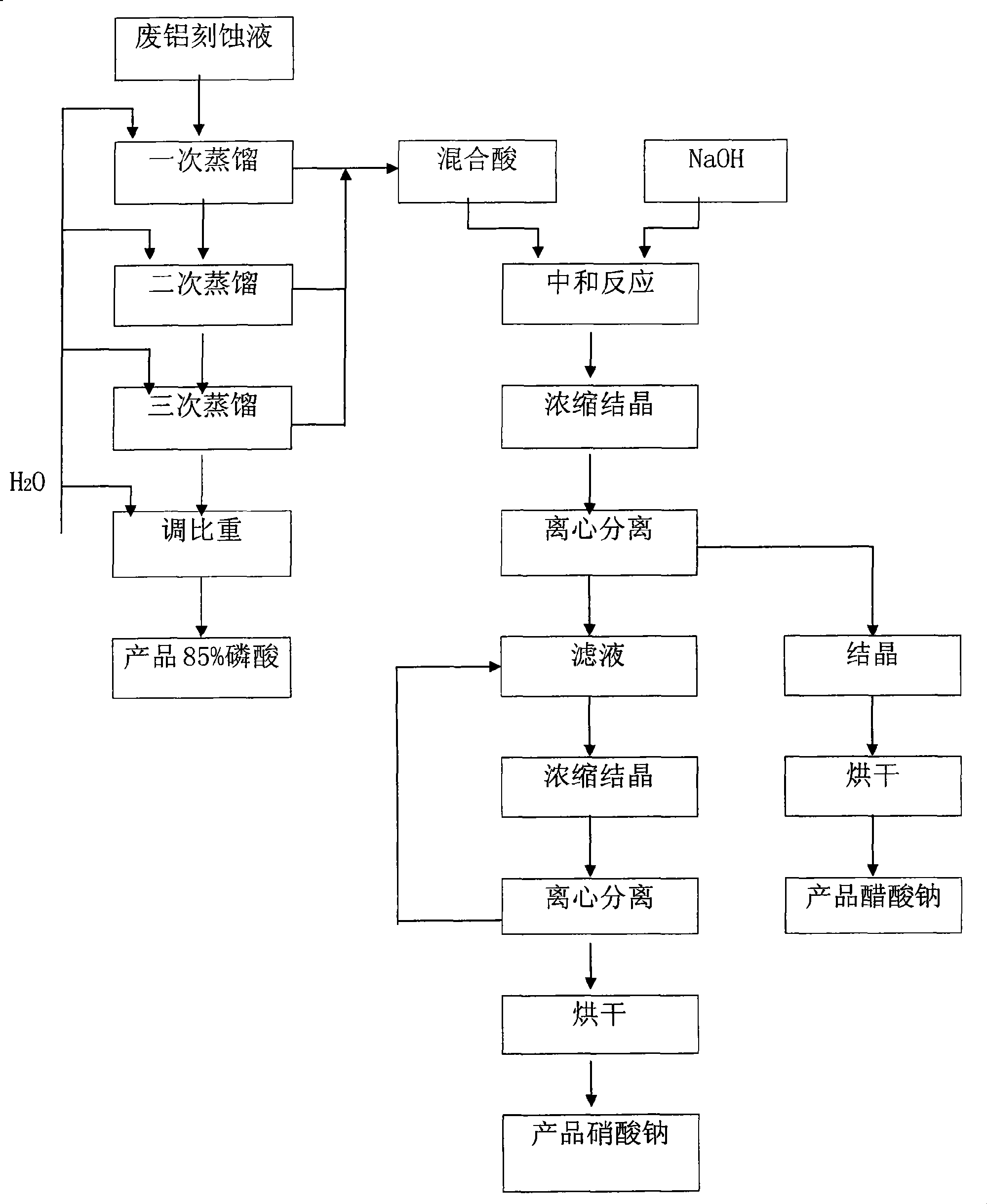

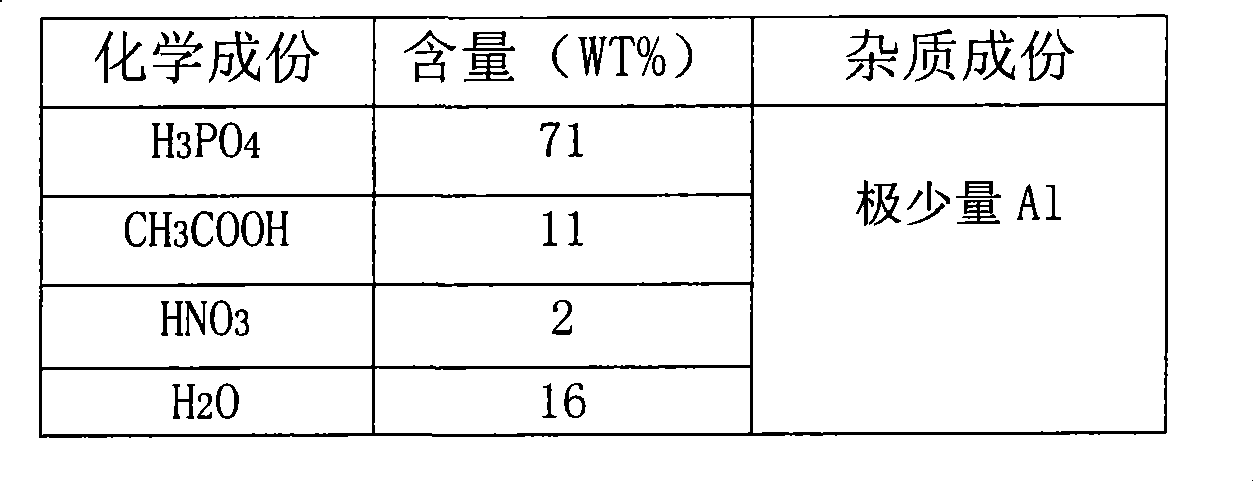

ActiveCN101439849AIncrease production capacityExtend your lifeAlkali metal nitrate preparationCarboxylic acid salt preparationPhosphorous acidSodium acetate

The invention relates to a comprehensive utilization process for a waste aluminum etching solution. The process utilizes the characteristic that the boiling point and the volatility of phosphorous acid are greatly different from those of nitric acid and acetic acid to separate the phosphorous acid from the nitric acid and the acetic acid by adopting a distillation method, then filters the phosphorous acid after the distillation separation to remove mechanical impurities, and then adds distilled water to adjust the specific gravity to obtain 85 percent industrial phosphorous acid; a mixed acid of the nitric acid and the acetic acid obtained by the distillation is placed into a stainless steel reaction kettle, sodium hydroxide is added into the mixed acid to react under the stirring, then a purified reaction liquid is concentrated, crystallized, and separated to obtain a filtrate and crystals; and the crystals are dried to obtain a product, namely sodium acetate, and then the filtrate is concentrated, crystallized, separated, and dried to obtain a product, namely sodium nitrate. The process can recover and utilize a mixed acid waste liquid containing a plurality of acids, and obtain a plurality of novel chemical raw materials from the mixed acid waste liquid.

Owner:孟庆深

Method for separating lithium carbonate from electrolyte acidic leachate

InactiveCN107935015AEfficient extractionReduce energy consumptionMagnesium fluoridesCalcium/strontium/barium fluoridesEvaporationCarbonate

The invention discloses a method for separating lithium carbonate from electrolyte acidic leachate. The method comprises the following steps of: S1, adding a soluble salt solution to aluminum electrolyte acidic leachate while stirring and heating are performed, monitoring the acidity and the concentration of fluoride ions, and stopping the addition when the pH value is greater than 5 and the concentration of the fluoride ions is less than 0.01 g / L, wherein the soluble salt is one or more selected from MeSO4, MeNO3 and MeCl, and Me is metal which can produce precipitate with F<->; S2, performing filtration on reactants, performing washing and drying on filter residues to obtain a fluoride salt of the metal Me, adding a soluble carbonate solution into the obtained filtrate with stirring andheating, and terminating the reaction when the concentration of lithium ions is less than 0.08 g / L; S3, filter the filtrate, performing washing and drying on the filter cake to obtain lithium carbonate, and performing evaporation, crystallization, washing and drying on the filtrate to obtain inorganic salts. According to the method for separating lithium carbonate from the electrolyte acidic leachate, the reaction process is controlled by controlling the concentration of the fluoride ions and the acidity, so that the lithium ions are separated from other ions, lithium carbonate with high recovery rate is obtained, and meanwhile high-purity fluoride and inorganic salt products are obtained.

Owner:NORTHEASTERN UNIV

Method for preparing potassium nitrate by means of double decomposition

ActiveCN101659431AReduce churnHigh product contentAlkali metal nitrate preparationAmmonium halidesFiltrationDecomposition

The invention discloses a method for preparing potassium nitrate by means of double decomposition. The method comprises the following steps: taking potassium chloride, ammonium nitrate and water solution as raw materials, and controlling the concentrations of Cl<-> and NH4<+> in the reaction solution to be 14-19% and 6-9.6% respectively, wherein the temperature of the reaction solution is 85-95 DEG C; lowering the temperature of a solution obtained from the reaction till a temperature of 0-20 DEG C is realized, crystallizing and precipitating KNO3 semi-finished product, and obtaining a filtrate mother liquor I by means of filtration; flushing KNO3 crystals with water till the Cl<-> concentration is 1-2% and the NH4<+> concentration is 1-3%; and recovering the flushing solution; positioningthe KNO3 crystals in a double decomposition device so that the KNO3 crystals can be fully dissolved, and controlling the solution concentration to be 44-52 Be; lowering the temperature for purpose ofprecipitating the KNO3 crystal, drying the KNO3 crystal till the water content of the KNO3 is less than or equal to 0.1%, and then obtaining the KNO3 finished product. In the method, the double decomposition device is used during the double decomposition reaction process and no stirring device is needed, therefore, the contact reaction of the reaction solution is more complete, and balance, continuous cyclic industrial production, productivity improvement and production cost reduction are realized in the precondition of ensuring 'two highs'.

Owner:江西金利达钾业有限责任公司

Harmlessness and reclamation treatment method of aluminum scrap electrolyte

ActiveCN108677020AEfficient decompositionSolve environmental problemsSulfate/bisulfate preparationAlkali metal nitrate preparationAluminum fluorideElectrolysis

The invention discloses a harmlessness and reclamation treatment method of aluminum scrap electrolyte and belongs to the technical field of inorganic chemistry. The method comprises the main steps that 1, aluminum scraps are electrolyzed and subjected to crushing and screening, and aluminum electrolyte particles are obtained; 2, acid liquor with the concentration of 1 mol / L and an aluminum salt solution with the concentration of 1 mol / L are prepared for standby application; 3, the aluminum electrolyte particles obtained in the step 1 are placed in the acid liquor prepared in the step 2 and leached on the heating and stirring conditions, the PH of the solution is controlled to be smaller than 5, when the fluorinion leaching rate is higher than 94%, leaching is finished, impurities are filtered, and a leaching solution is obtained; 4, the aluminum salt solution prepared in the step 2 is added to the leaching solution in the step 3, the mixture is heated and stirred, Al3+ / Na+ is controlled to be larger than 0.3, when sediment is generated in the solution, the solution is filtered, filter residues and filter liquor are obtained, and the filter residues are washed and dried to obtain alkali type aluminum fluoride products; and 5, the filter liquor in the step 4 is evaporated and crystallized to obtain sodium salt products.

Owner:NORTHEASTERN UNIV

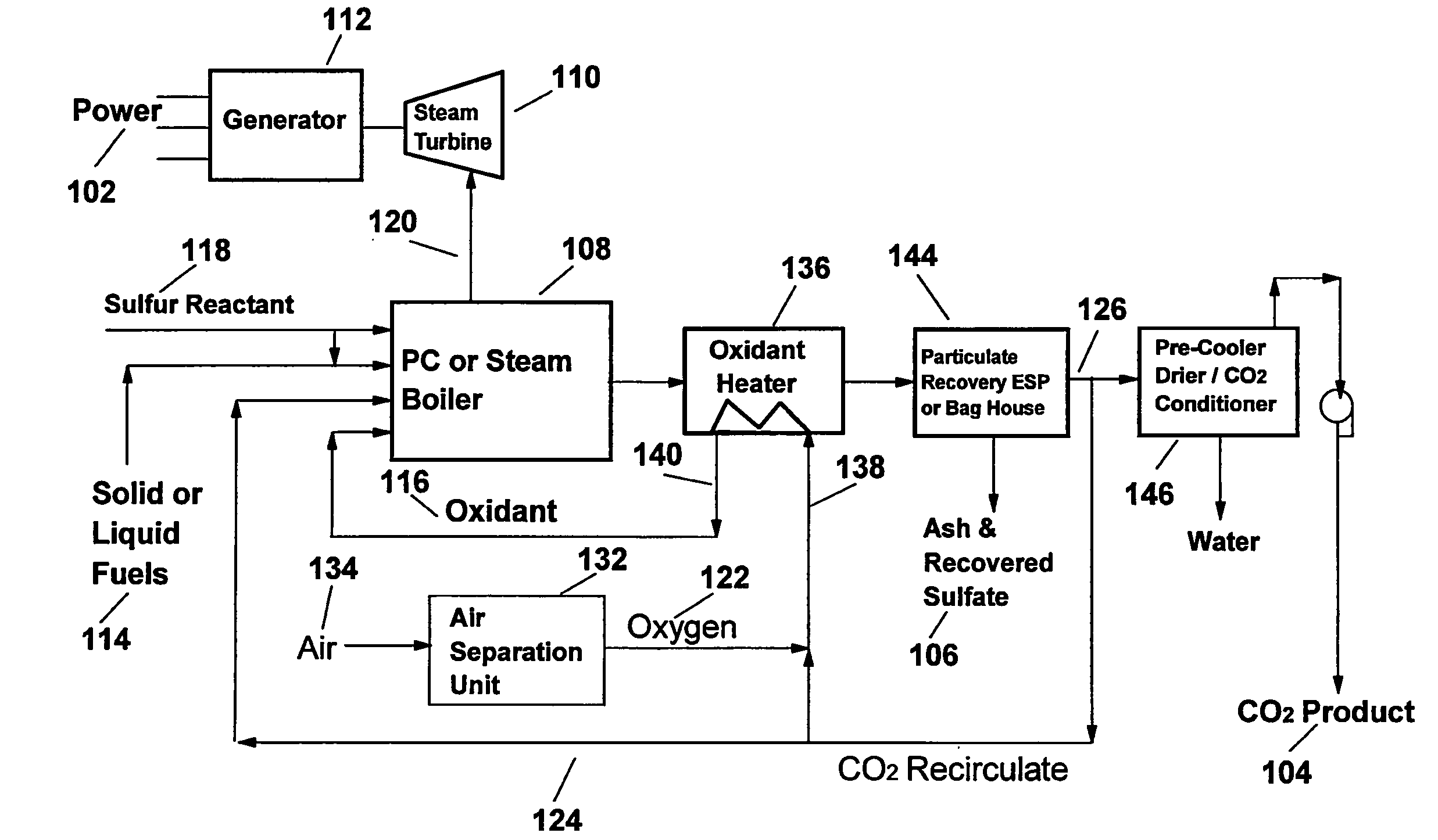

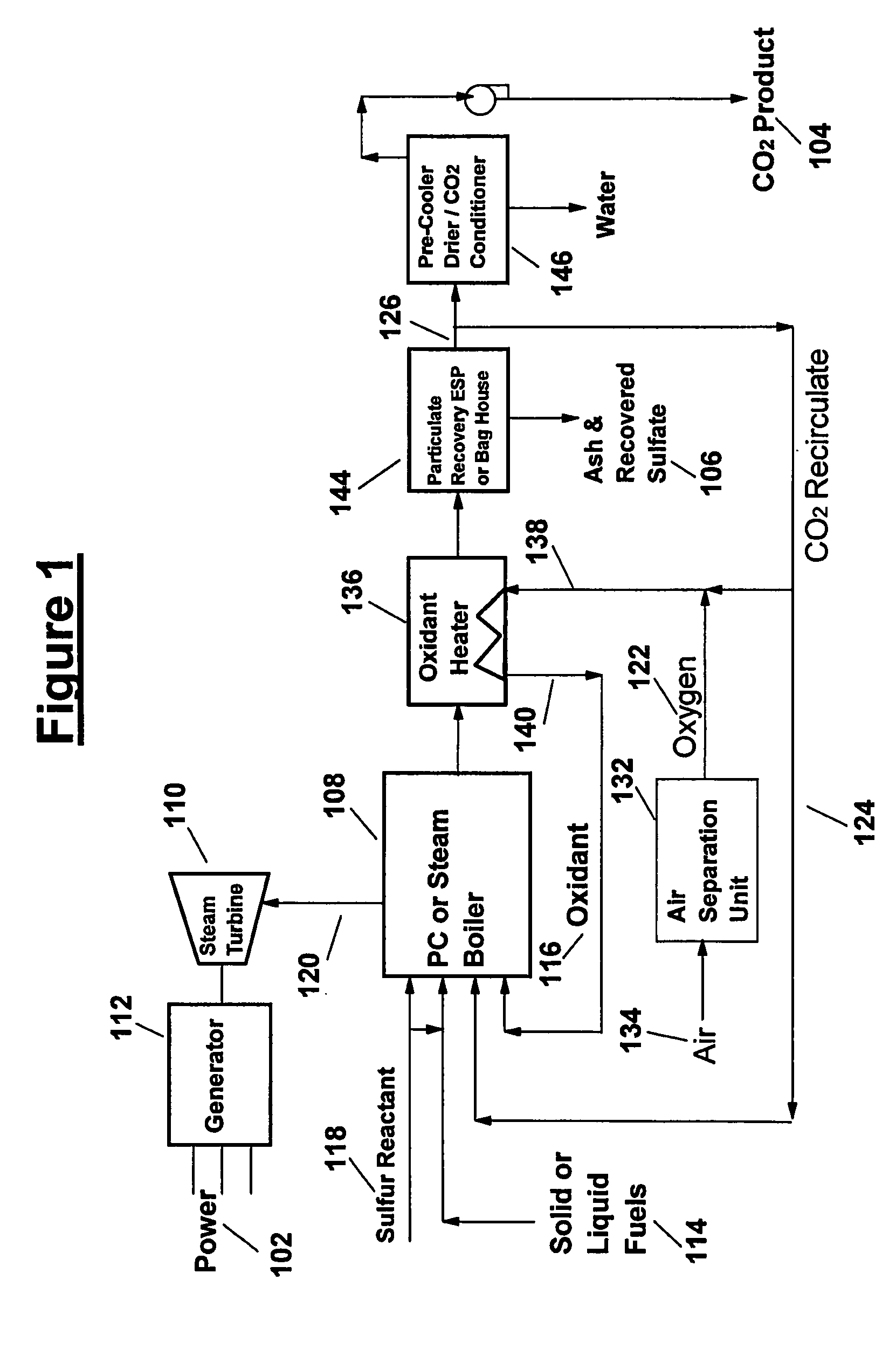

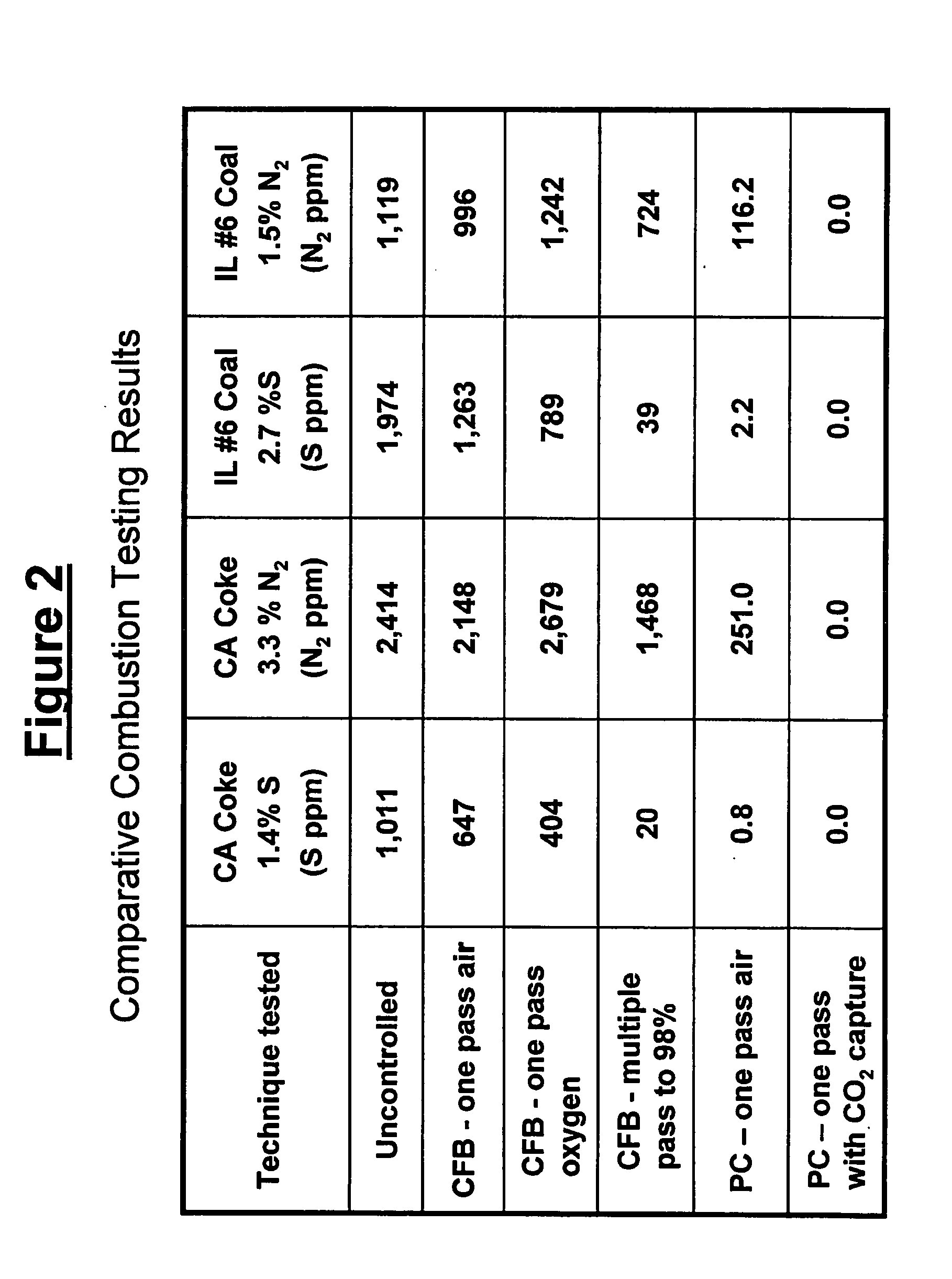

Coal/Coke/Heavy Residual Oil Boiler With Sulfur And Carbon Dioxide Capture And Recovery

A pulverized coal / coke (PC) boiler combusts carbon-based fuel with substantially pure oxygen and a flue gas recirculation stream (containing predominately carbon dioxide) at varied ratios to achieve a desired boiler temperature profile while producing captured sulfur, a high purity captured CO2 and electric power. The boiler includes at least one of (a) a mechanism for admixing a pulverized solid carbon-based fuel with an alkali metal salt and (b) injecting alkali metal salt into the boiler combustion zone containing a pulverized solid carbon-based fuel.

Owner:PLASMA POWER PROD

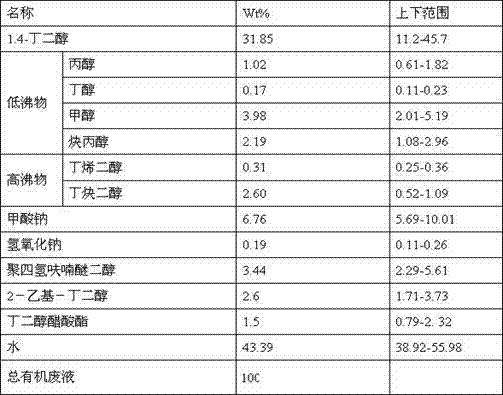

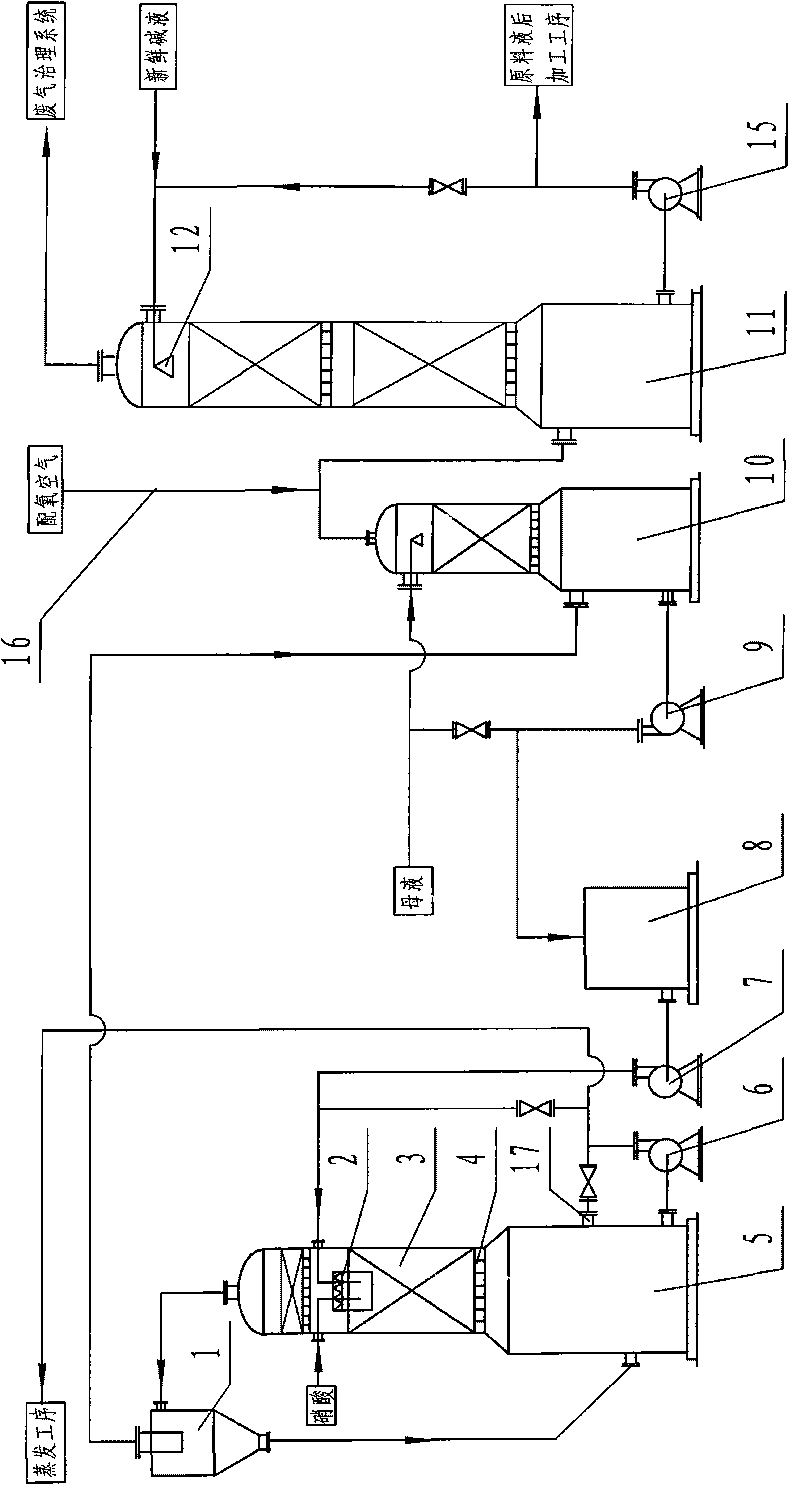

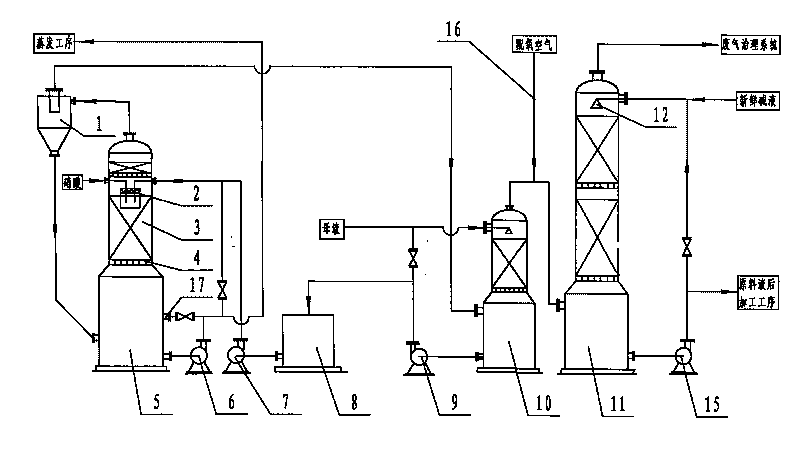

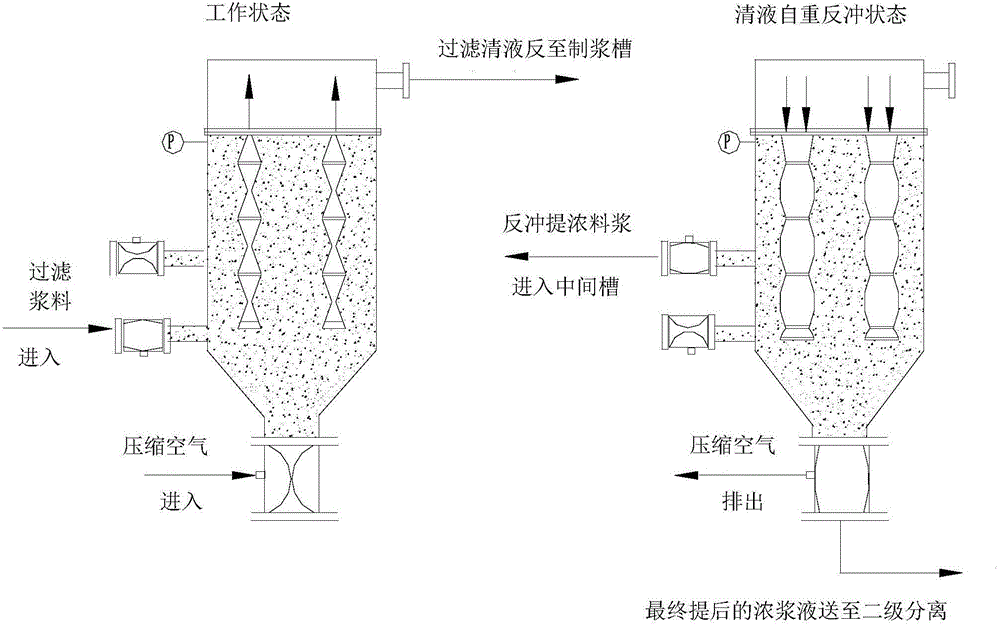

Method for innocently treating organic waste liquid generated in BDO production

ActiveCN105439820AHigh yieldReduce pollutionOrganic compound preparationPlastic recycling1,4-ButanediolAdditional values

The invention discloses a method for innocently treating an organic waste liquid generated in BDO production. According to the method, an organic waste liquid generated in BDO production is treated to obtain high-purity 1,4-butanediol (BDO), high-boiling residues, low-boiling residues, sodium nitrate and polyether polyol products, and innocent, recycling and zero emission treatment of the organic waste liquid generated in BDO production can be realized. The whole method is simple in process, easily controllable in condition and high in finished product yield, and all prepared products have high purity, little equipment investment, low production cost and energy consumption conservation. The method is applied to recycling treatment of organic waste liquid generated in BDO industrial production process to prepare products (industrial raw materials) which can be utilized in industrial production, meanwhile, innocent treatment and zero emission of pollutants can be realized. The method has extremely economic meaning and social meaning in the aspects of increasing production additional values, reducing environmental pollution and the like.

Owner:迪邦(泸州)化工有限公司

Methods of making cesium salts and other alkali metal salts

A method of making a cesium salt is described and involves reacting a cesium sulfate containing solution with lime to form 1) a solution containing at least cesium hydroxide and 2) a residue comprising calcium sulfate. The method further involves removing the residue from the solution and converting the cesium hydroxide that is present in the solution to at least one type of cesium salt. The present invention further relates to uses of the cesium salt as well as methods of making cesium hydroxide using lime. Also, methods of making alkali metal salts and alkali metal hydroxides are also described.

Owner:CABOT SPECIALTY FLUIDS

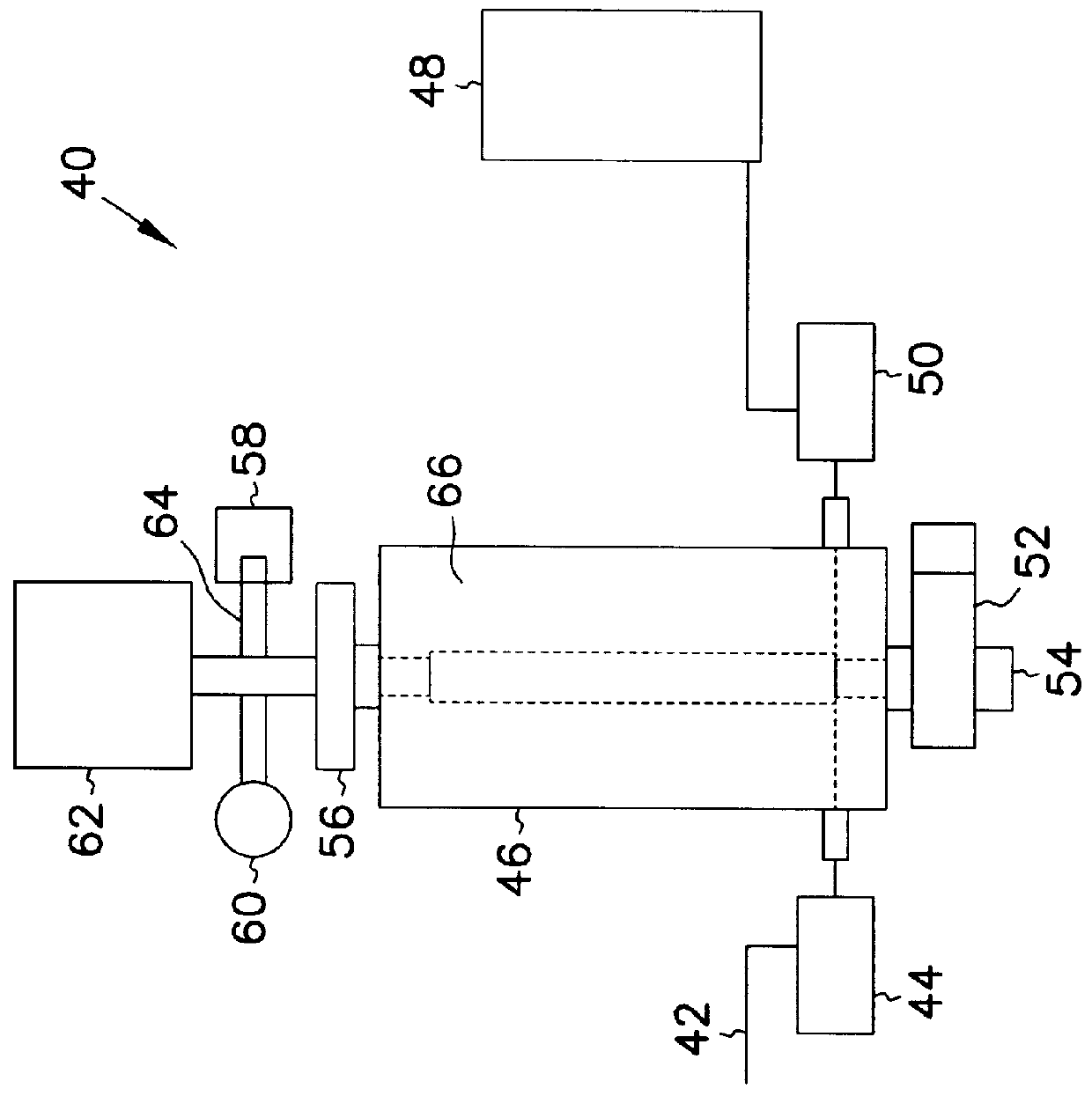

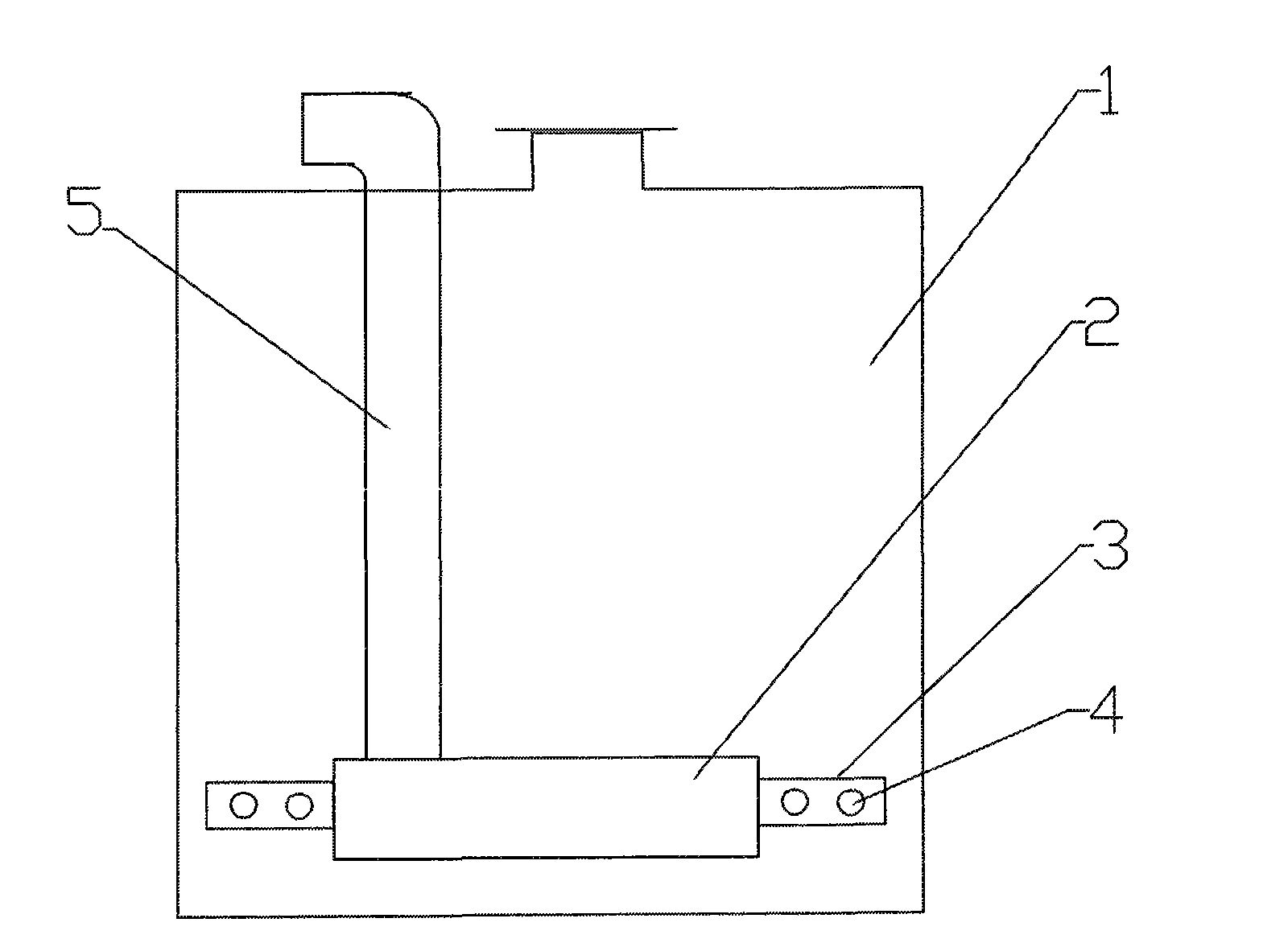

Stirring-free method and device for producing sodium nitrate through continuous conversion

InactiveCN101696024AReduce entryReduce acid mistAlkali metal nitrate preparationOxygenEnergy expenditure

The invention provides a stirring-free method and a stirring-free device for producing sodium nitrate through continuous conversion. The device mainly comprises an ammoxidation-prepared oxynitride system, a soda ash solution preparing system and a sodium nitrite mother solution conversion system, wherein the sodium nitrite mother solution conversion system mainly comprises a converter tower, a pre-converter tower, an absorption tower, a motor solution storage tank and matched pumps and pipelines. Nitric acid and the mother solution undergo conversion reaction in the converter tower; conversion solution reflows and back washes the bottom of the converter tower; gas of the converter tower is separated by a gas-liquid separator and enters the pre-converter tower; and converted gas and oxygen-mixed air are mixed quantitatively and then the mixture enters the absorption tower for absorption to prepare feed solution. The method and the device have the advantages that: the production of the sodium nitrate can be continuously performed; the reflowing and backwashing of the conversion solution replaces air stirring; in the converted gas absorbing process, the converted gas is added with the oxygen-mixed air in a ratio, the process operation is optimized, and loads of the adsorption tower and subsequent processing procedure are lightened; the production capacity is improved; energy consumption is reduced; NOx emission is decreased; and the method and the device are favorable for environmental protection.

Owner:SHIJIAZHUANG FENGSHAN CHEM

Method for preparing sodium nitrate with soda niter

ActiveCN101343072ABlocked mobilityGuaranteed liquidityEnergy inputAlkali metal nitrate preparationEvaporationNiter

The invention provides a method for using nitratine to produce sodium nitrate, which is characterized in that the method comprises the steps of: crushing a piece of nitratine raw ore, and sieving the raw ore to obtain nitratine ore and nitratine ore powder; adding water into the nitratine ore powder, and agitating and leaching the powder and then gaining a clear liquid by sedimentation and clarification; positioning the nitratine ore in a leaching pond, feeding a mother liquor for cold separation and / or a washing liquid, starting up a circulating pump to circulate the leaching solution, and leaching the ore under normal temperature; inputting the leaching solution to a solar pond after the leaching; heating the leaching solution to a temperature between 30 DEG C and 80 DEG C by utilizing the stored energy in the solar pond, and extracting high-temperature concentrated solution from the bottom of the solar pond after evaporation concentration; and separating out NaNO3 through crystallization by cooling. The method is applied to low grade nitratine resources, and locations of resources are areas short of water seriously and rich in solar energy resources, and the method has advantages of energy and water saving and easy realization.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Vacuum crystallization technique for producing potassium nitrate from potassium chloride by sodium nitrate

InactiveCN101143731AWide variety of sourcesImprovement ingredientsAlkali metal nitrate preparationCelsius DegreeFiltration

A vacuum crystallization process uses the sodium nitrate to transform the potassium chloride for the production of the potassium nitrate. The process comprises the following steps: (1) a first time low temperature mother liquid is prepared according to a corresponding phase diagram; (2) the sodium nitrate and the potassium chloride are added by proportion; and the constant temperature conversion is processed at 75-90 Celsius system; (3) the slurry is precipitated at 75-90 Celsius system until the solid percentage reaches 30%-45%, the crystallized high temperature salt is separated through centrifugation and the clear liquid enters into a vacuum crystallizer after filtration; (4) the high temperature salt is washed and the washing liquid is directly sent into the vacuum crystallizer; (5) the cold separation temperature of the vacuum crystallizer is controlled at 25-40 Celsius system, and the potassium nitrate crystal is precipitated; (6) the slurry is pumped into a slurry elevated slot after vacuum crystallization, the slurry is introduced into a centrifuge for the centrifugal separation to obtain the primary product of potassium nitrate; (7) the primary product of potassium nitrate is washed, re-dried and packaged. The invention has a convenient proportion, a mild isolation and transformation condition and a short production process, which can save more than 18% water and more than 20% energy. The operation of the invention is simple, and the process is easy to realize the continuous production and automatization. The invention also has a low production cost and good economic benefits.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

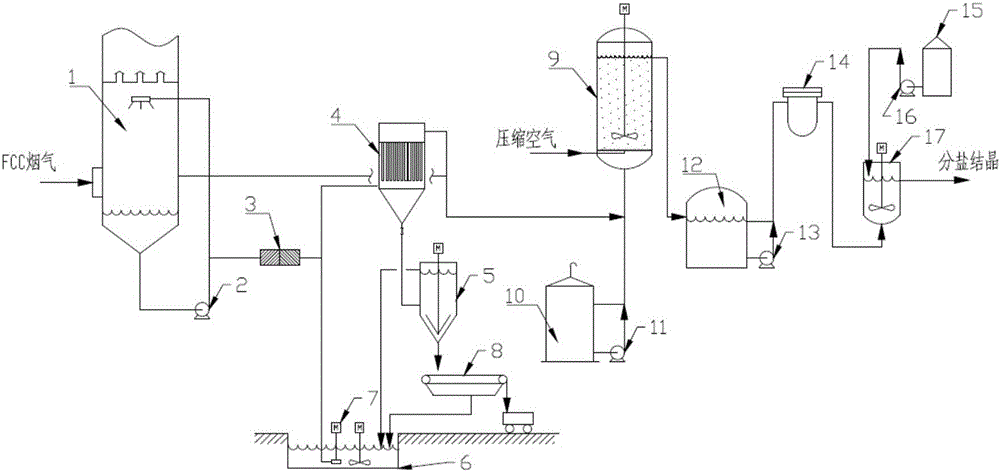

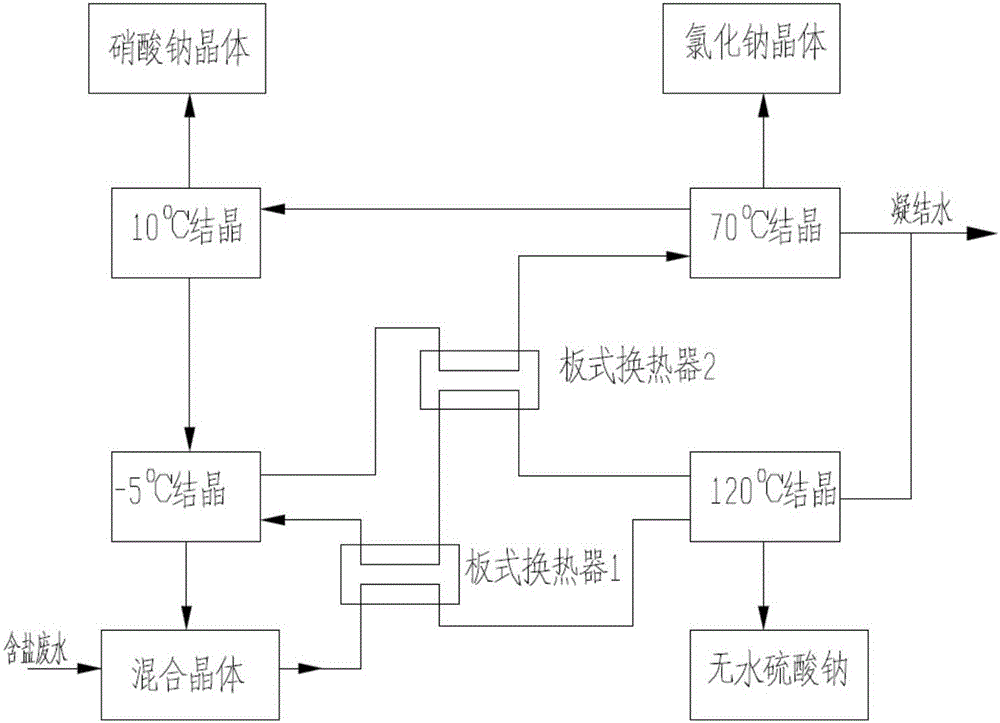

Treatment method of catalytic cracking flue gas desulfurization wastewater

InactiveCN106007148ASolve the emission problemSolve the problem of mixed salt hazardous wasteTreatment involving filtrationSulfate/bisulfate preparationChemical oxygen demandHigh energy

The invention provides a treatment method of catalytic cracking flue gas desulfurization wastewater. The treatment method comprises the following steps: fully utilizing waste heat of high-temperature flue gas, concentrating circulation slurry in a washing tower, and controlling the concentration of the circulation slurry, thus ensuring normal operating of a desulfurization system; meanwhile, carrying out pretreatment (flocculating, filtering, removing calcium and magnesium ions, reducing COD (Chemical Oxygen Demand) through oxidization and the like) on concentrated discharged wastewater, enabling the wastewater to meet the feeding requirements of a concentration system, and then carrying out evaporation and crystallization (multi-effect evaporation or MVR (Mechanical Vapor Recompression)), thus realizing zero emission of salt-containing wastewater and recycling of inorganic salt. According to the technology, a sodium alkaline flue gas desulfurization technology and an inorganic salt evaporative crystallization recovery technology are organically integrated, the problems of membrane pollution and membrane scaling during a membrane concentration process, large investment, high energy consumption and the like are avoided, the emission problem of salt-containing wastewater in an alkaline washing technology is completely solved, and zero emission is really realized; meanwhile, separated crystallization is carried out on inorganic sodium salt products, the recycled products are used as products, the problems of mixed salt and hazard waste are solved, and secondary pollution is removed.

Owner:SINOPEC ENG GRP CO LTD

Methods of making cesium salts and other alkali metal salts

A method of making a cesium salt is described and involves reacting a cesium sulfate containing solution with lime to form 1) a solution containing at least cesium hydroxide and 2) a residue comprising calcium sulfate. The method further involves removing the residue from the solution and converting the cesium hydroxide that is present in the solution to at least one type of cesium salt. The present invention further relates to uses of the cesium salt as well as methods of making cesium hydroxide using lime. Also, methods of making alkali metal salts and alkali metal hydroxides are also described.

Owner:CABOT SPECIALTY FLUIDS

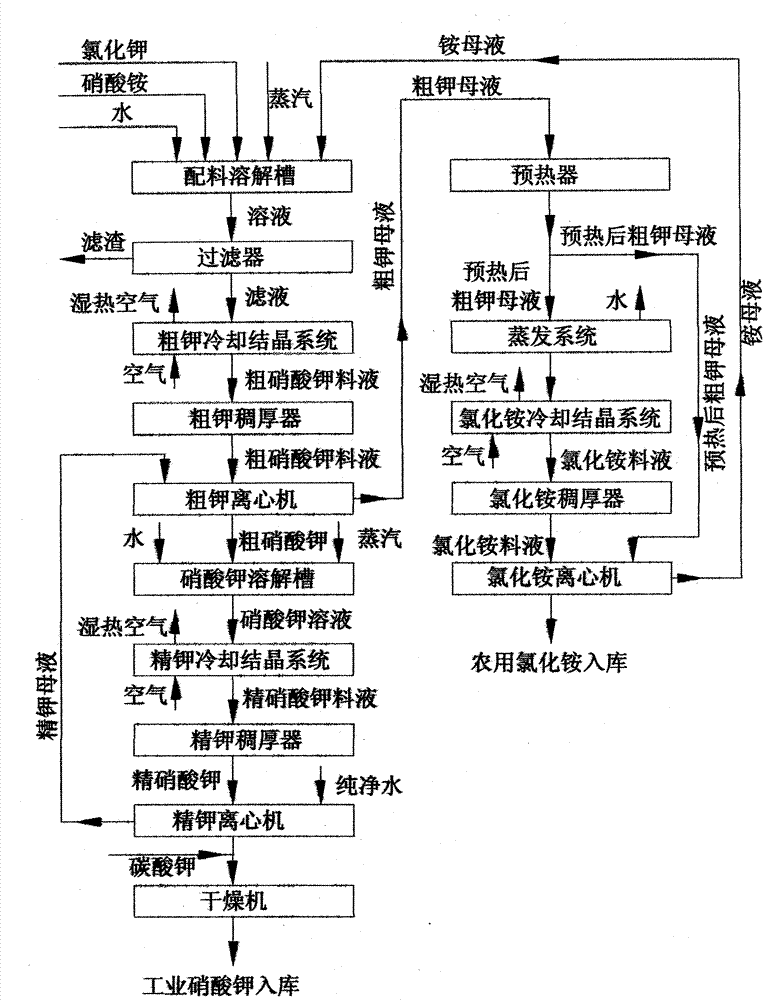

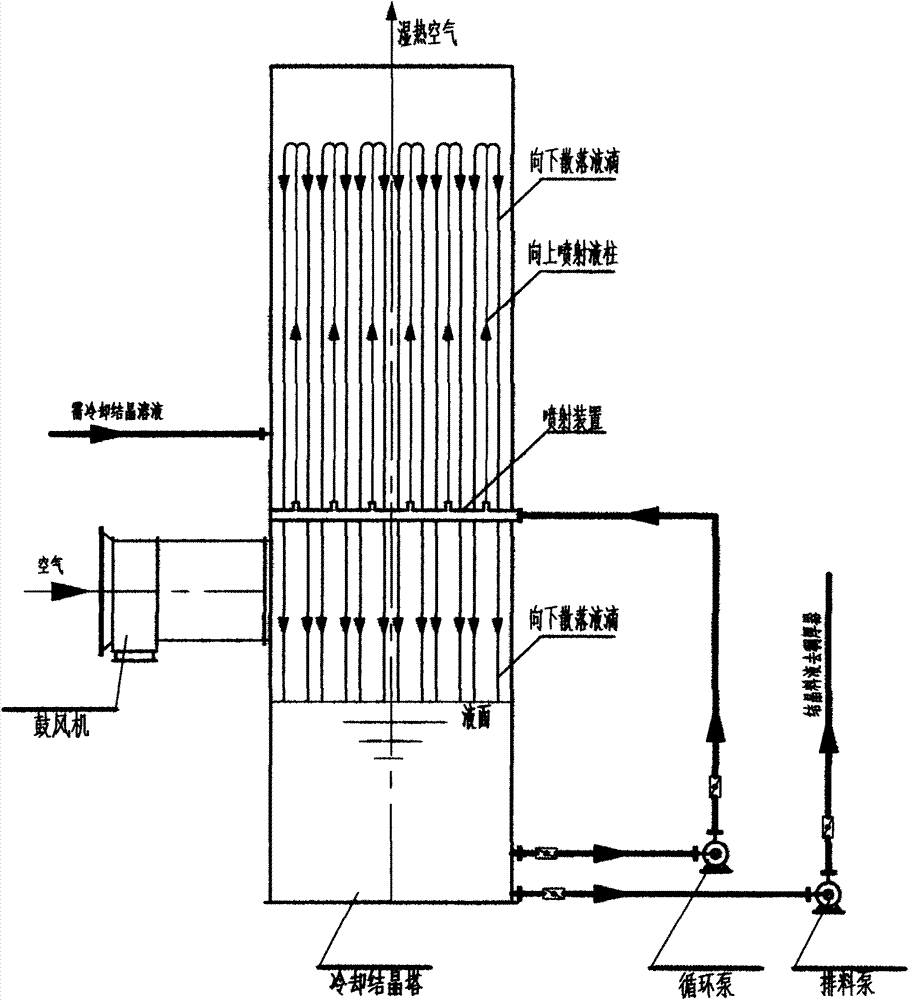

Potassium nitrate production process by double decomposition-air cooling crystallization method

InactiveCN104118891AImprove washing effectDecreased potassium levelsAlkali metal nitrate preparationDecompositionAmmonium nitrate

A potassium nitrate production process by a double decomposition-air cooling crystallization method is disclosed. Ammonium nitrate and potassium chloride are adopted as raw materials. A double decomposition reaction is adopted to produce the potassium nitrate and ammonium chloride. In a process of producing the potassium nitrate and the ammonium chloride, an air cooling crystallization process is adopted, air is adopted as a cooling medium and is directly mixed with and in contact with a solution and convective heat transfer and diffusion heat transfer occur, thus achieving cooling crystallization of the potassium nitrate and the ammonium chloride. The potassium nitrate production process has characteristics of high raw material utilization rate, significant energy conservation and consumption reduction, good potassium nitrate product quality and good ammonium chloride product quality, and achieves large-scale continuous production.

Owner:YUEYANG SYLVITE SCI INST

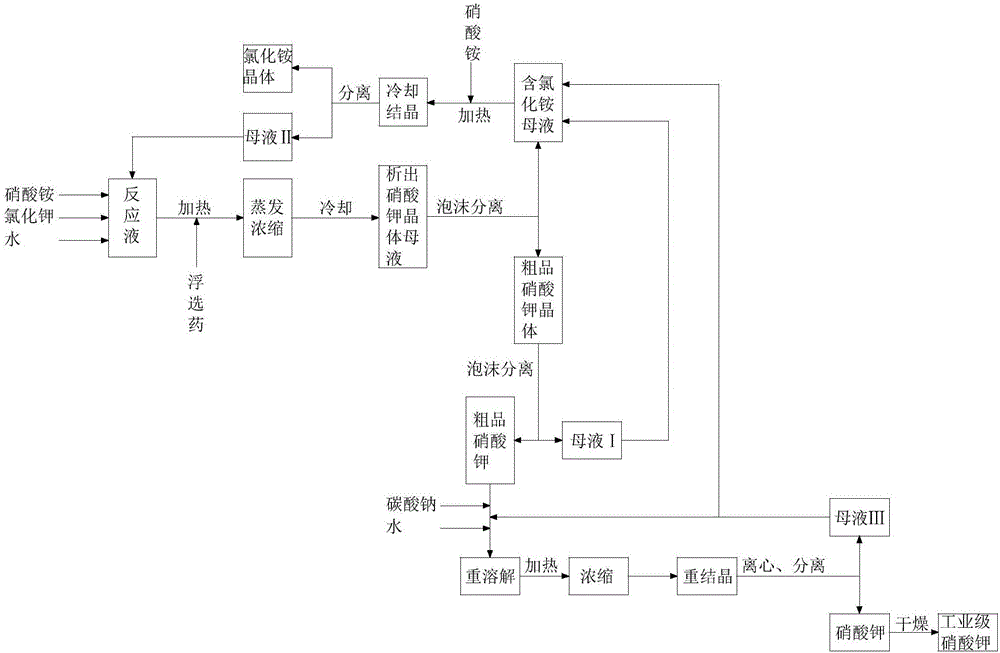

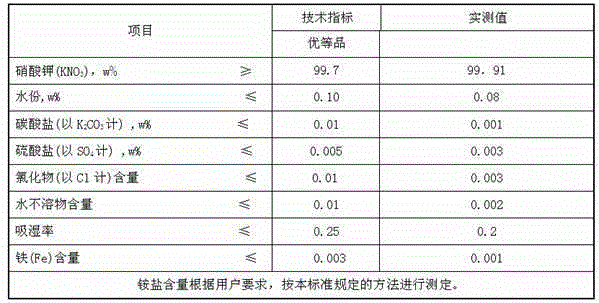

Potassium chloride and ammonium nitrate double decomposition and circulation method for producing high quality potassium nitrate

ActiveCN105060317AHigh quality contentSimple separation processAlkali metal nitrate preparationWater useSeparation technology

The invention discloses a potassium chloride and ammonium nitrate double decomposition and circulation method for producing high quality potassium nitrate. According to the method, potassium chloride and ammonium nitrate are taken as the raw materials, and the method comprises steps of raw material preparation, potassium nitrate crystallization, foam floatation and separation, potassium nitrate refinement, and ammonium chloride crystallization. The method is developed on the basis of conventional potassium nitrate production technology by improving part of the technology; wherein in the foam flotation and separation technology, in the presence of a floatation reagent (C12-C20 higher straight-chain aliphatic amine) and in a certain pH value range, the ammonium chloride and coarse potassium nitrate can be separated through foam entrainment; in the potassium nitrate refinement, the refined potassium mother liquid in the previous circulation is used to wash the coarse potassium nitrate, and then potassium nitrate is purified by sodium carbonate. In one aspect, the conventional potassium nitrate production technology is optimized, the potassium nitrate quality is improved, and the impurity content of the potassium nitrate product is greatly reduced. In the other aspect, the water using amount is reduced, the labor intensity is also reduced, and the production cost is saved. The industrial grade KNO3 mass content is not less than 99.7%, the content of Cl<-> is not more than 0.01%, and the content of NH4<+> is not more than 0.03%. the method has a wide application value and can generate prominent social benefit and economic benefit.

Owner:湖南丹化农资有限公司

Technology for producing highly pure potassium nitrate through reaction of sodium nitrate and potassium chloride

ActiveCN105236452AImprove product qualityReduce energy consumptionAlkali metal nitrate preparationPotassium nitrateChloride potassium

A technology for producing highly pure potassium nitrate through a reaction of sodium nitrate and potassium chloride comprises the following steps: 1, adding clear water or a mother liquor into a reactor, dosing raw materials potassium chloride and sodium nitrate according to a molar ratio of 1:0.9-1.5, and carrying out a metathesis reaction at 70-150DEG C under normal pressure or an elevated pressure for 0.5-5h; 2, carrying out solid-liquid separation; 3, carrying out solid-liquid separation; 4, crystallizing; 5, dissolving crude potassium nitrate in water at 50-120DEG C to obtain a potassium nitrate solution; 6, filtering the potassium nitrate solution obtained in step 5 through a filtering device, or adding a flocculating agent to clarify the potassium nitrate solution; 7, re-crystallizing; and 8, washing purified potassium nitrate, centrifuging, and drying to obtain potassium nitrate. The technology has the advantages of realization of continuous or intermittent production, stable and reliable quality of the above product, and low energy consumption. The product meets superior product requirements, and the main content of potassium nitrate reaches 99.9% or above.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Preparation Of Lithium Carbonate From Lithium Chloride Containing Brines

ActiveUS20150259215A1Photography auxillary processesChloride preparationLithium chlorideLithium hydroxide

This invention relates to a method for the preparation of lithium carbonate from lithium chloride containing brines. The method can include a silica removal step, capturing lithium chloride, recovering lithium chloride, supplying lithium chloride to an electrochemical cell and producing lithium hydroxide, contacting the lithium hydroxide with carbon dioxide to produce lithium carbonate.

Owner:TERRALITHIUM LLC

Method for preparing potassium nitrate and ammonia chloride by double decomposition

This invention relates to a method for preparing KNO3 and NH4Cl taking KCl and NH4NO3 as the raw materials and applying a de-analyzing method, in which, in the mixed solution of KNO3 mother solution and NH4NO3, evaporation of water and crystallization of NH4Cl are finished in the process of evaporation and crystallization, the mixed solution is evaporated in a continuous evaporator under 100-120deg.C and evaporation pressure of 540-935mmHg.

Owner:四川米高化肥有限公司

Hierarchically recycling method of waste aluminum etching liquid

PendingCN110482572AConstant distillation temperatureReduce risk of component breakdownPreparation from carboxylic acid saltsAlkali metal nitrate preparationSodium acetateAcetic acid

The invention discloses a method for hierarchically recycling phosphoric acid, acetic acid and nitric acid from an aluminum scrap etching solution, which comprises the following steps of volatilizingthe acetic acid and nitric acid in the aluminum etching solution by reduced pressure distillation, and recycling by condensation; adding an additive into the residual phosphoric acid solution, crystallizing, washing, dissolving and the like to obtain the high-purity phosphoric acid; adding the sodium acetate into the collected distillate containing the acetic acid and nitric acid, and distilling to collect the acetic acid; and carrying out vacuum concentration, crystallization, filtration and drying on the acetic acid distilled liquid to obtain a sodium nitrate finished product. The reusable high-purity phosphoric acid is obtained by methods of distillation, concentration, recrystallization and the like, the acetic acid is recycled, and the nitric acid is converted into the available sodium nitrate, so that the useful components in the aluminum etching solution are reasonably and effectively utilized, and the resource waste and the environmental pollution are avoided. The method is high in recycling rate and high in operability, can meet the large-scale production, realizes the resource cyclic utilization to the maximum extent, and avoids the direct emission of the aluminum etchingsolution.

Owner:湖北兴福电子材料股份有限公司

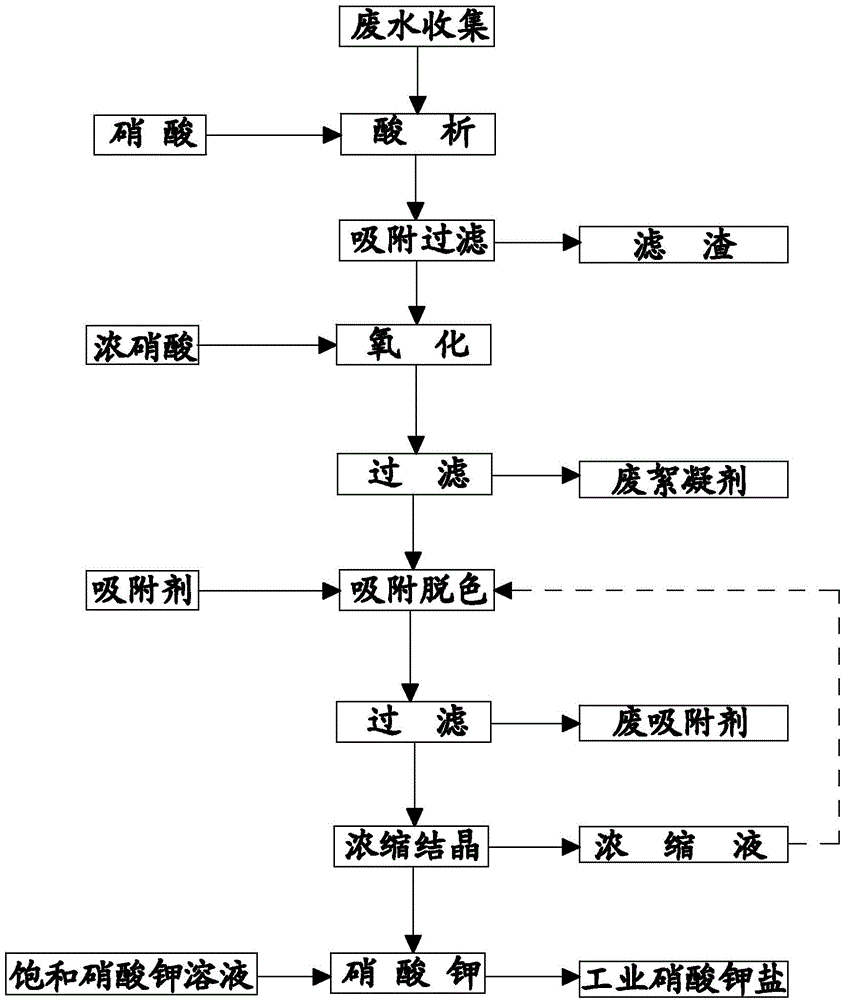

Method for recovering potassium nitrate from anthraquinone dye alkali wastewater

ActiveCN103979705AImprove recycling efficiencyHigh removal rateAlkali metal nitrate preparationMultistage water/sewage treatmentPotassium nitrateSorbent

The invention relates to a method for recovering potassium nitrate from anthraquinone dye alkali wastewater and belongs to the technical field of recovery and recycle of printing and dyeing wastewater. The method comprises the following steps of adding nitric acid into collected alkali wastewater, carrying out primary acidification with stirring for primary acidification time of 0.5-12h, when a solution pH value is in a range of 1-4, adding an adsorbent, a neutral flocculating agent or an acidic flocculating agent into the solution so that a precipitation reaction occurs, filtering the reaction product, adding nitric acid into the solution, carrying out secondary acidification with stirring for secondary acidification time of 0-8h, when a solution pH value is in a range of 3-5h, adding an adsorbent, a neutral flocculating agent or an acidic flocculating agent into the solution so that a precipitation reaction occurs, filtering the reaction product, and carrying out HNO3 oxidation, decoloring, condensation and salt-leaching so that a qualified industrial salt is obtained. The method is used for anthraquinone dye alkali wastewater, can realize recovery of a large amount of potassium nitrate, can remove organic matters in wastewater, can reduce a COD value of the wastewater, and can recover and recycle potassium nitrate.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

Technique for producing sodium nitrate by chilisaltpeter adverse current circulation leaching

ActiveCN101168444AShort processEasy to operateAlkali metal nitrate preparationSingle processLower grade

The invention relates to a process for producing sodium nitrate by using nitratine reverse-flow circulation extraction, which comprises steps as follows: (1) breaking ores into the grains smaller not larger than 5cm, (2) reverse-flow circulation leaching: after 2-6 stages of reverse-flow circulation immerge, the sodium nitrate content of extraction solution is increased from 300-380g / l to 390-500g / l, (3) separating, washing and drying at low temperature that exchanges heat between the extraction solution and low-temperature separation mother liquid, to reduce temperature, mixing and reducing temperature to -10-20DEG C, and keeping temperature for 100-140min, separating solid and liquid, filtering and washing via a saturated sodium nitrate, according to the mass ratio between product and sodium nitrate solution as 6 / 1-5 / 1, then drying to obtain sodium nitrate product, and feeding the separated mother liquid into the step (2), to process next circulation. The invention can save water more than 40%, and save energy more than 25%, while the single-process collecting rate is more than 25% and the total collecting rate of sodium nitrate in ore is more than 95.0%. The product obtained by low-temperature separation contains sodium nitrate more than 92%, and the washed product contains sodium nitrate more than 98%. The invention can use low-grade nitratine mine to produce sodium nitrate.

Owner:TURPAN BRANCH OF SINKIANG NITRATE MINERALS +1

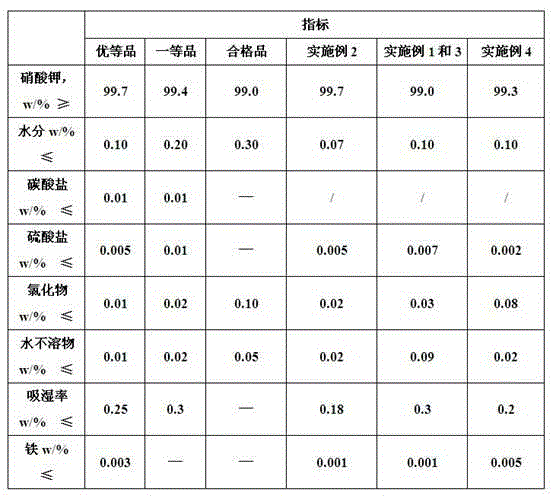

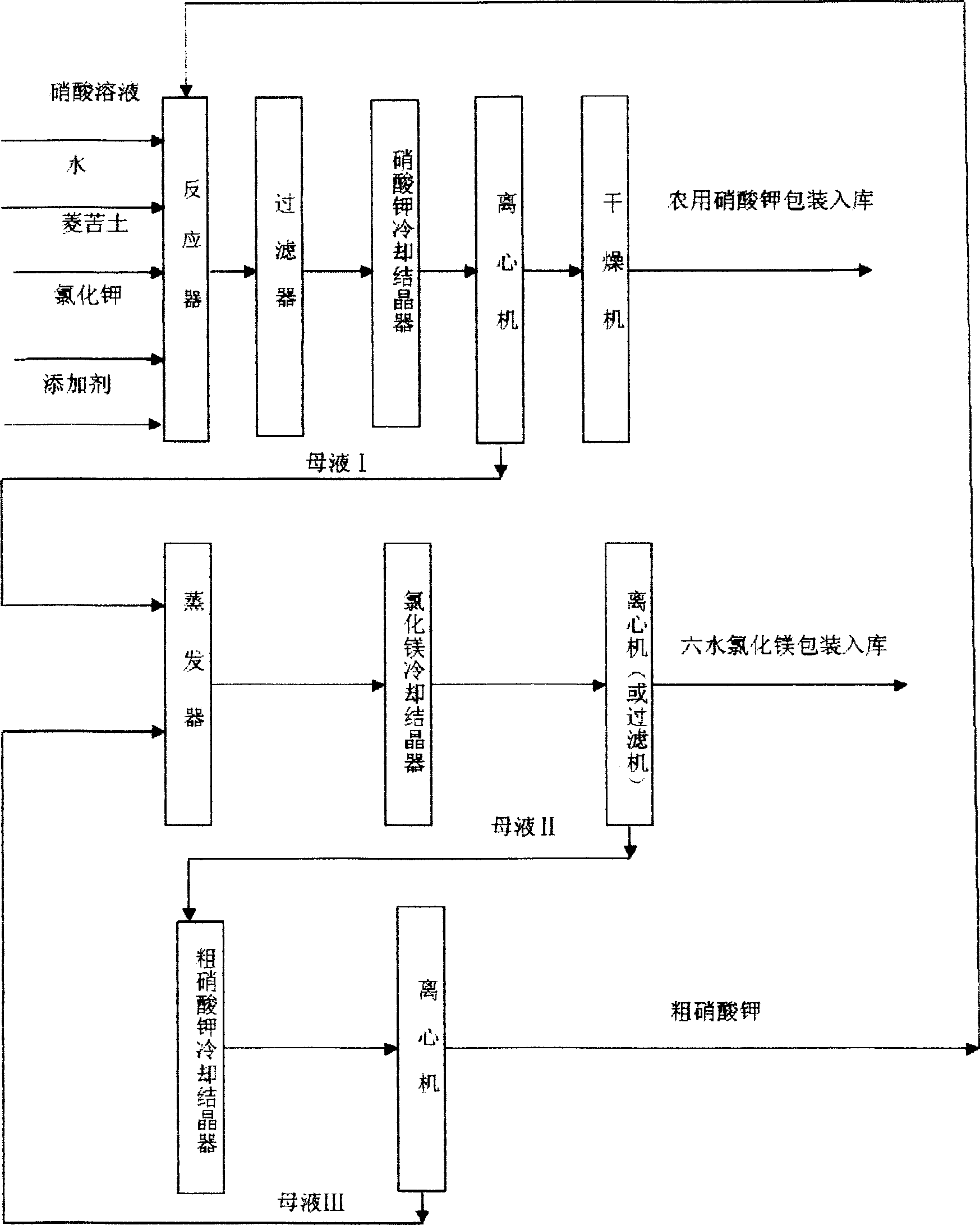

Technological process of preparing potassium nitrate and magnesium chloride

InactiveCN1673083ALow costWide variety of sourcesAlkali metal nitrate preparationMagnesiaMagnesium chloride hexahydrateMother liquor

The technological process of preparing potassium nitrate and magnesium chloride includes the following steps: adding powdered magnesite into nitric acid solution to react, adding potassium chloride for reacting with coarse potassium nitrate, adding additive, maintaining the temperature to deposit, filtering, cooling to crystallize, centrifugally separating and drying to obtain potassium nitrate product for farm use; mixing mother liquor I and mother liquor III, evaporating to concentrate, and cooling to crystallize and separate magnesium chloride hexahydrate crystal; cooling mother liquor II to crystallize, and centrifugally separating to obtain coarse potassium nitrate and mother liquor III. The technological process is simple, low in power consumption, hermetically circulated and without waste produced.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

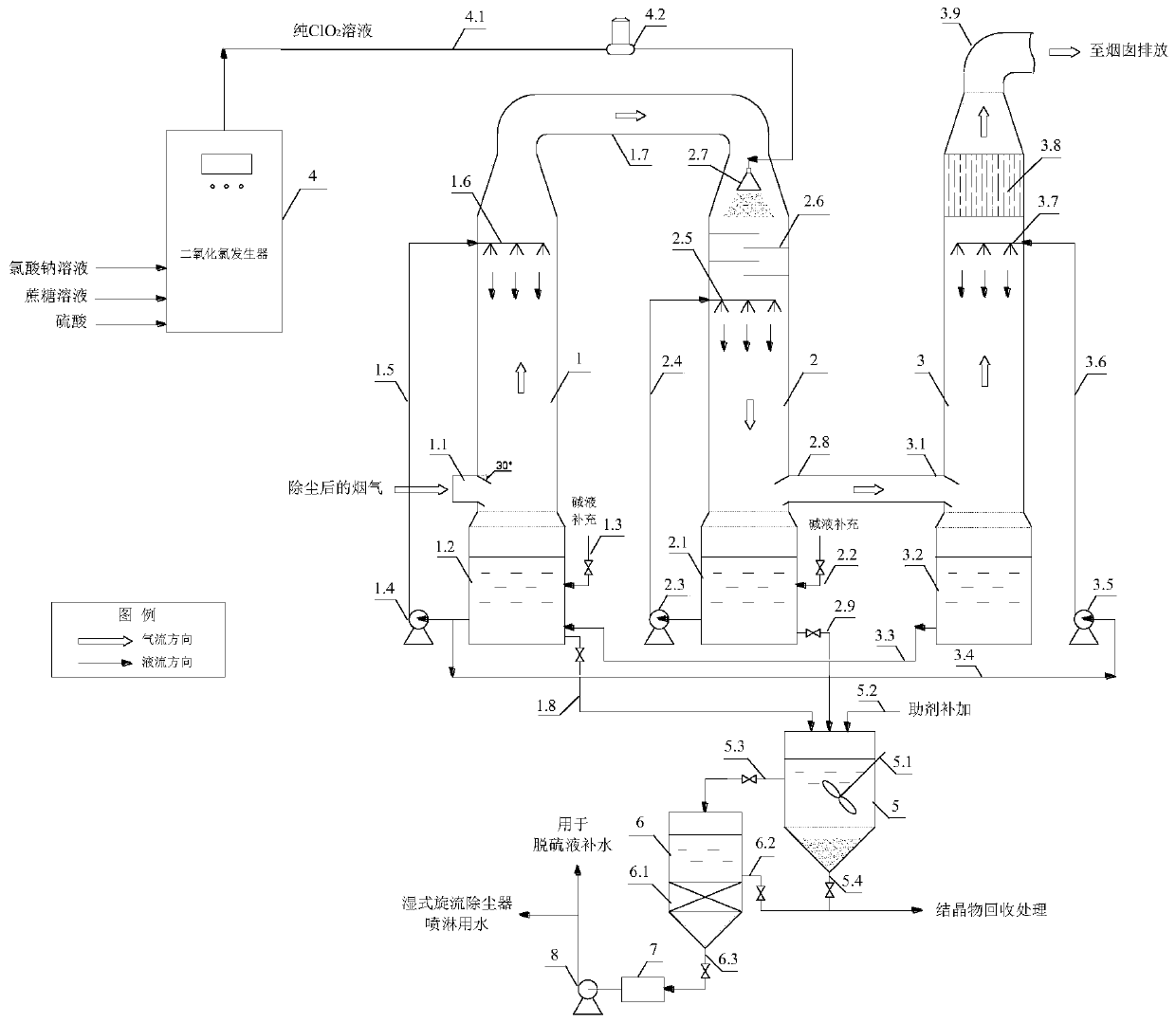

Desulfurization liquid cooperated chlorine dioxide gas-phase oxidation denitration integrated flue gas purification device and process

PendingCN111408250AShorten the lengthReduce energy consumptionGas treatmentDispersed particle separationWater savingChlorine dioxide

The invention provides a desulfurization liquid cooperated chlorine dioxide gas-phase oxidation denitration integrated flue gas purification device and process, a desulfurization tower, an oxidation denitration tower and a secondary purification tower are communicated through a flue, and the flue gas flow direction is in an S-shaped layout. The flue gas subjected to dust removal firstly enters a desulfurizing tower and is desulfurized in an alkali liquor spraying and absorbing manner; the desulfurized flue gas is firstly mixed with ClO2 gas in an oxidation denitration tower to oxidize NO intoNO2, and then denitration is carried out in an alkali liquor spraying absorption mode; and the desulfurized and denitrified flue gas are sprayed and cleaned in the secondary purification tower again by using a desulfurizing solution, residual NOx and SO2 are absorbed in the flue gas, and demisting is performed by using wet electric precipitation to finish final purification. According to the invention, desulfurization, oxidation denitration, secondary purification and waste liquid pretreatment links which are independently arranged and organically combined are utilized to realize effective utilization of desulfurization liquid, ultra-clean treatment of flue gas, recovery of desulfurization and denitration products and reuse of process water, so that the effects of water saving and emissionreduction are achieved while the flue gas is purified.

Owner:NANJING UNIV OF SCI & TECH

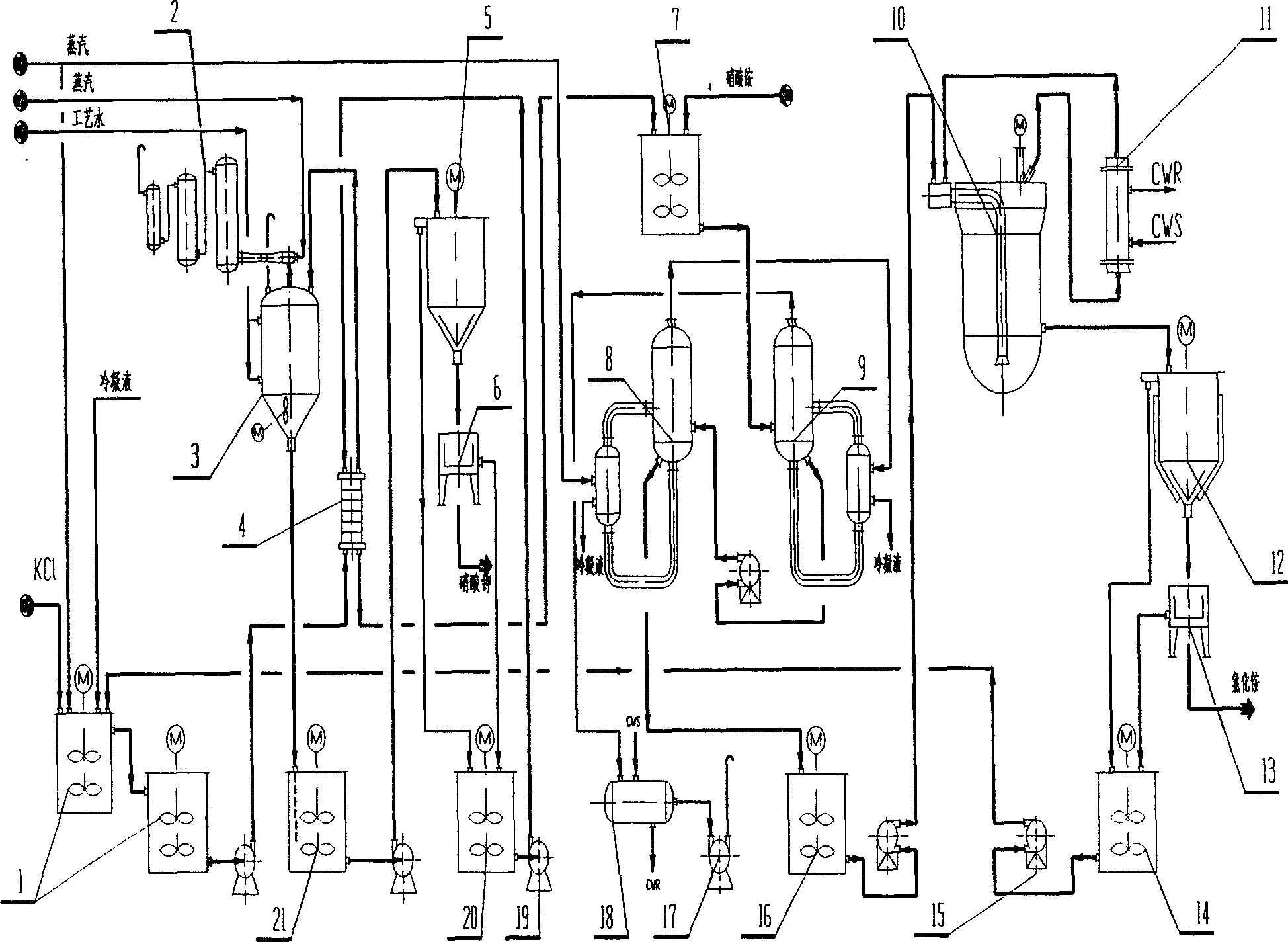

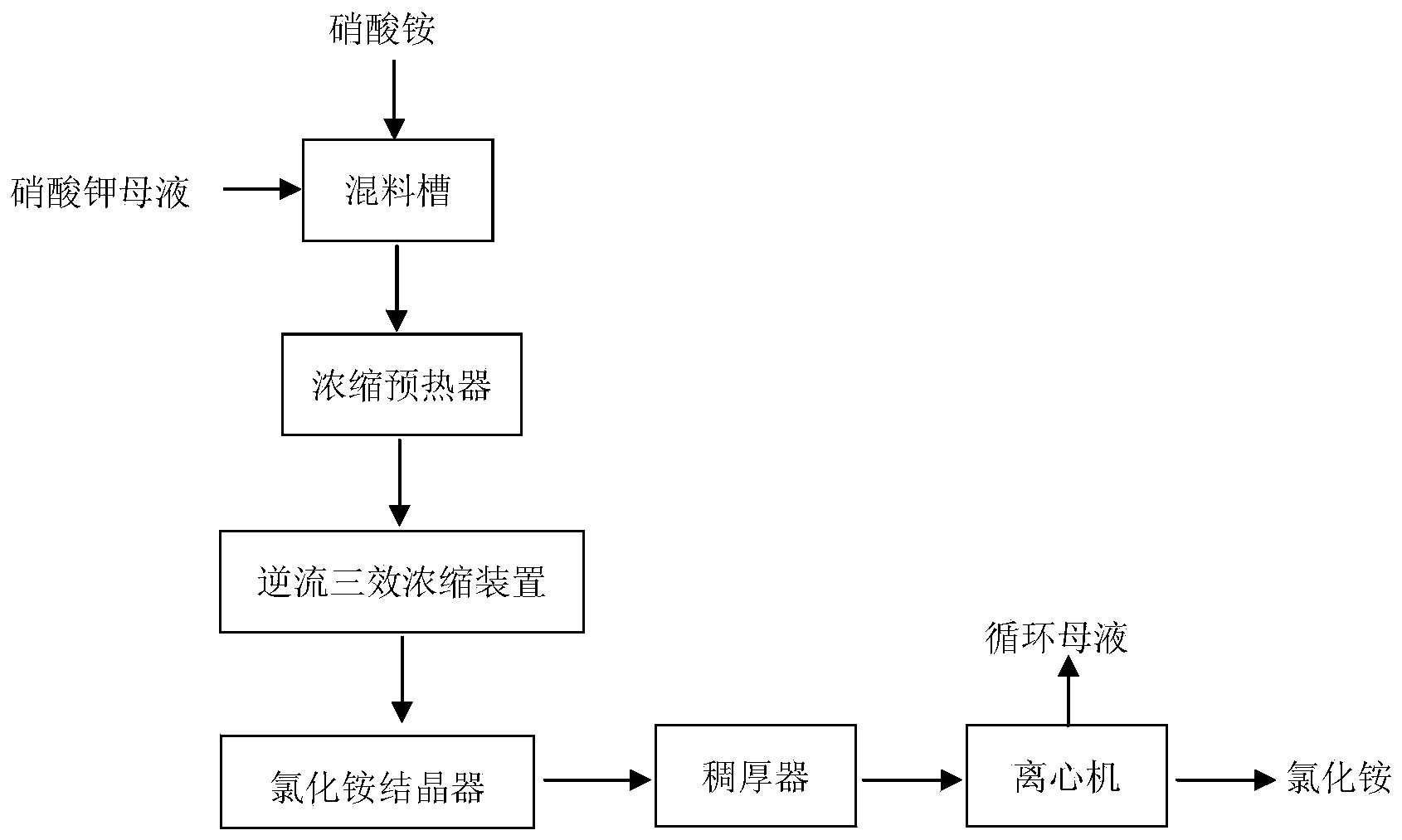

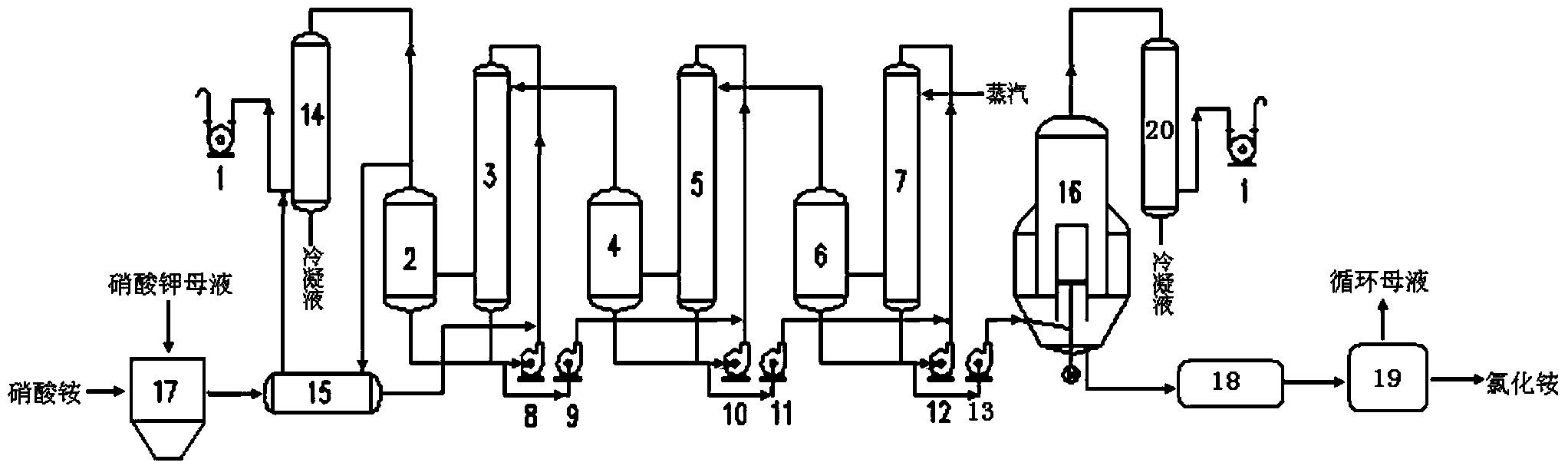

Continuous triple-effect falling-film concentration and vacuum crystallization system and method in potassium nitrate production through double-decomposition method

ActiveCN104261429AAchieve large scaleIncrease production capacityAlkali metal nitrate preparationAmmonium halidesPotassium nitrateAmmonium nitrate

The invention relates to a continuous triple-effect falling-film concentration and vacuum crystallization system and method in potassium nitrate production through a double-decomposition method. The continuous triple-effect falling-film concentration and vacuum crystallization system comprises a mixing tank, a concentration preheater, a backflow triple-effect concentration device, an ammonium chloride crystallizer, a thickener and a centrifuge, which are sequentially connected. The continuous triple-effect falling-film concentration and vacuum crystallization method comprises the following steps: adding potassium nitrate mother liquid and ammonium nitrate into the mixing tank for uniformly mixing, subsequently conveying to the mixture to the concentration preheater for preheating, feeding into the backflow triple-effect concentration device for concentration, feeding into the ammonium chloride crystallizer for crystallization after concentration, further sequentially feeding into the thickener and the centrifuge, separating a solid ammonium chloride product from the centrifuge, and returning the separated solution as a circulating mother liquid to a potassium nitrate production process through the double-decomposition method for circulation. Under the condition that the number of concentration equipment is not increased, the continuous triple-effect falling-film concentration and vacuum crystallization system and method in potassium nitrate production through double-decomposition method, provided by the invention, can achieve large-scale and continuous production, and the production efficiency is improved.

Owner:KINGENTA ECOLOGICAL ENG GRP

Method for preparing potassium nitride from calcium nitride byproduct of nitro phosphate

InactiveCN102502719ASolve processing problemsAlkali metal nitrate preparationHigh concentrationPhosphate

The invention relates to a potassium nitride preparation method, in particular to a method for preparing potassium nitride from a calcium nitride byproduct of nitro phosphate, which belongs to the technical field of production of agricultural potassium nitride fertilizers. The method includes steps of a, firstly, adding water in a dissolving tank, starting to stir and dissolve after industrial potassium chloride or potassium sulfate is poured, preparing the potassium chloride or potassium sulfate into saturated solution and pumping the saturated solution into a potassium nitride reaction tank; b, secondly, metering wet calcium nitride crystals, adding the wet calcium nitride crystals into the potassium nitride reaction tank, mixing and stirring the wet calcium nitride crystals with the solution obtained in the step a to carry out double replacement reaction, and preparing potassium nitride reaction liquid; and c, finally, crystallizing the potassium nitride reaction liquid prepared in the step b, and then separating potassium nitride crystals. The method solves problems of treatment of calcium nitride industrial byproducts of nitro phosphate, simultaneously, produces high-quality high-concentration potassium nitride fertilizers, and cannot produce waste difficult to be treated in a procedure.

Owner:YUNNAN CHEM RES INST +1

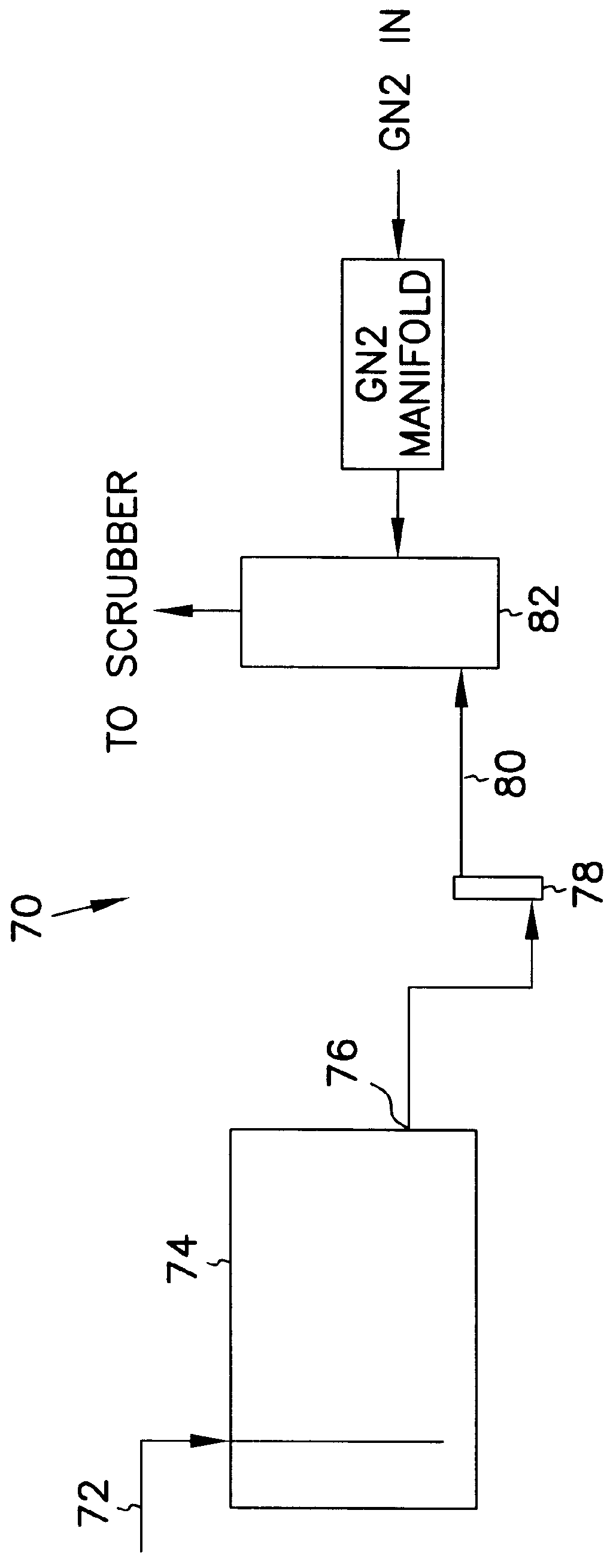

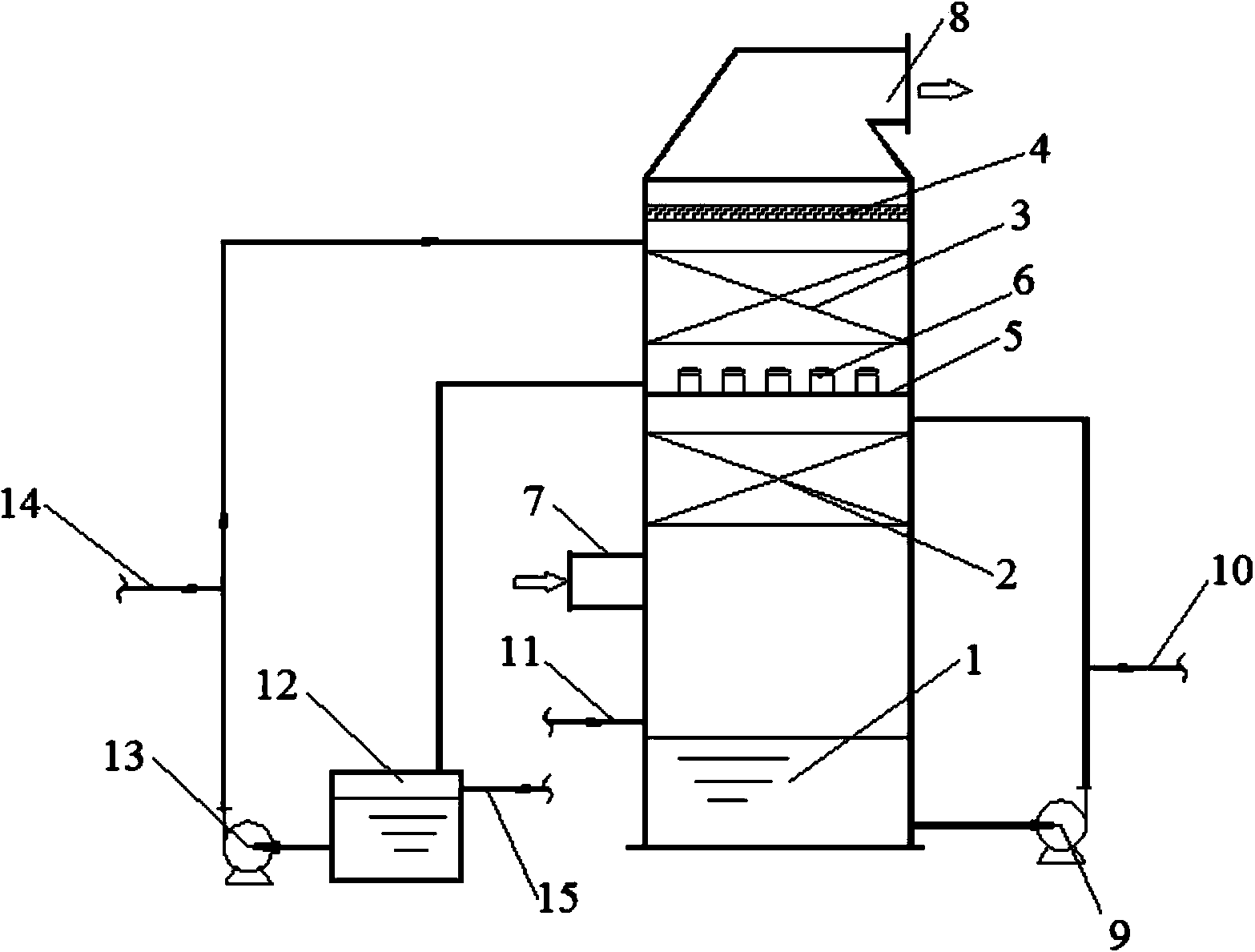

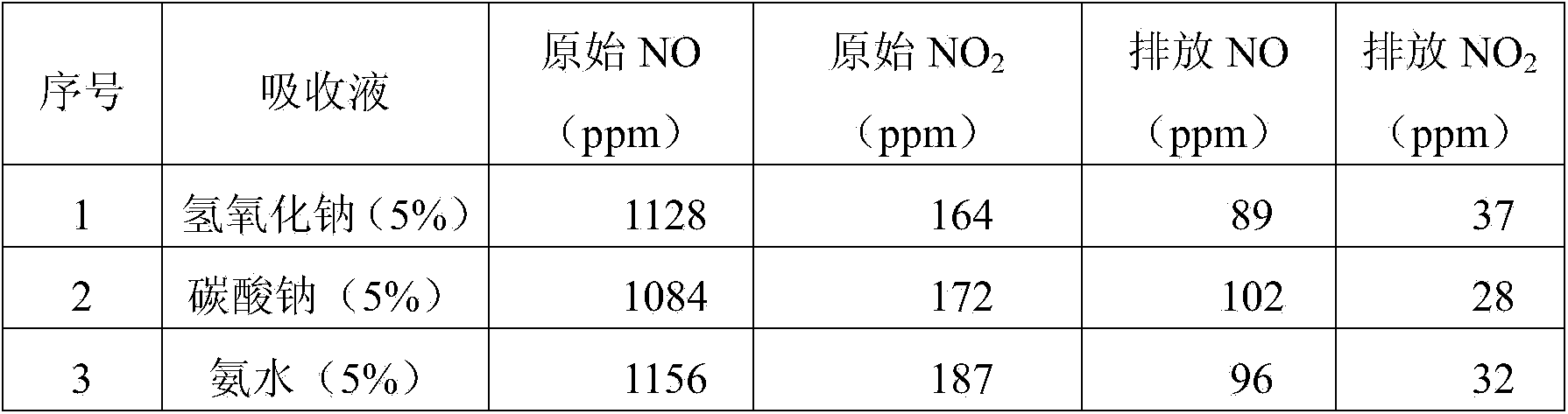

Process and device for treating nitric oxide in tail gas generated in nitric acid and nitrate production

InactiveCN103933848AReduce purchasing costsLow running costDispersed particle separationAlkali metal nitrate preparationNitriteEmission standard

The invention discloses a process and a device for treating nitric oxide in tail gas generated in the nitric acid and nitrate production. The process comprises the following steps: (1) carrying out tempering reaction on the tail gas generated in the the nitric acid and nitrate production by virtue of a 30-68% nitric acid solution, and controlling the volume percentage of NO to NO2 in the tempered tail gas to be 0.95-1.05; and (2) carrying out absorption reaction on the tempered tail gas by virtue of an alkaline absorption liquid, so as to generate nitrate and nitrite. The device comprises an absorption tower which comprises an oxidized-nitric-acid circulating storage tank, a tail gas tempering region, an alkali absorption region and a demisting region from bottom to top, wherein the tail gas tempering region and the alkali absorption region are separated by a tower board, air hoods are uniformly distributed on the tower board, a tail gas inlet is formed in the lower end of the tail gas tempering region, and a tail gas outlet is formed above the demisting region. The process and the device have the advantages that the efficiency is high, the cost is low, the nitric oxide in the tail gas can be recycled, and the tail gas processed by virtue of the process and the device can meet an emission requirement of 'emission standard of pollutants for nitric acid industry'.

Owner:北京中环新锐环保技术有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com