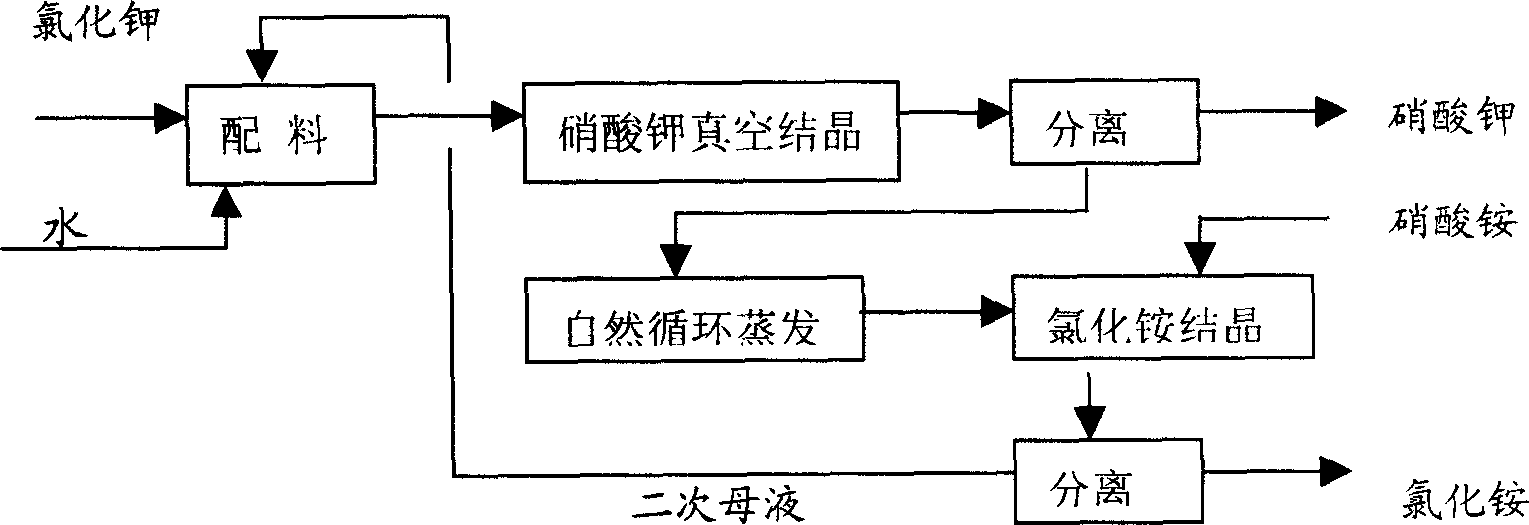

Process for preparing potassium nitrate by double decomposition method

A double decomposition method and potassium nitrate technology, applied in the preparation of alkali metal nitrate, etc., can solve the problems that the end point temperature of the feed liquid cannot reach the expected target, increase labor intensity and consumption of raw materials, and the ratio of raw materials and water addition is difficult to control, etc. , to achieve the effect of being conducive to growing up, easy to filter, eliminating the problem of wall scarring, and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below by example the content of the present invention is given in further detail.

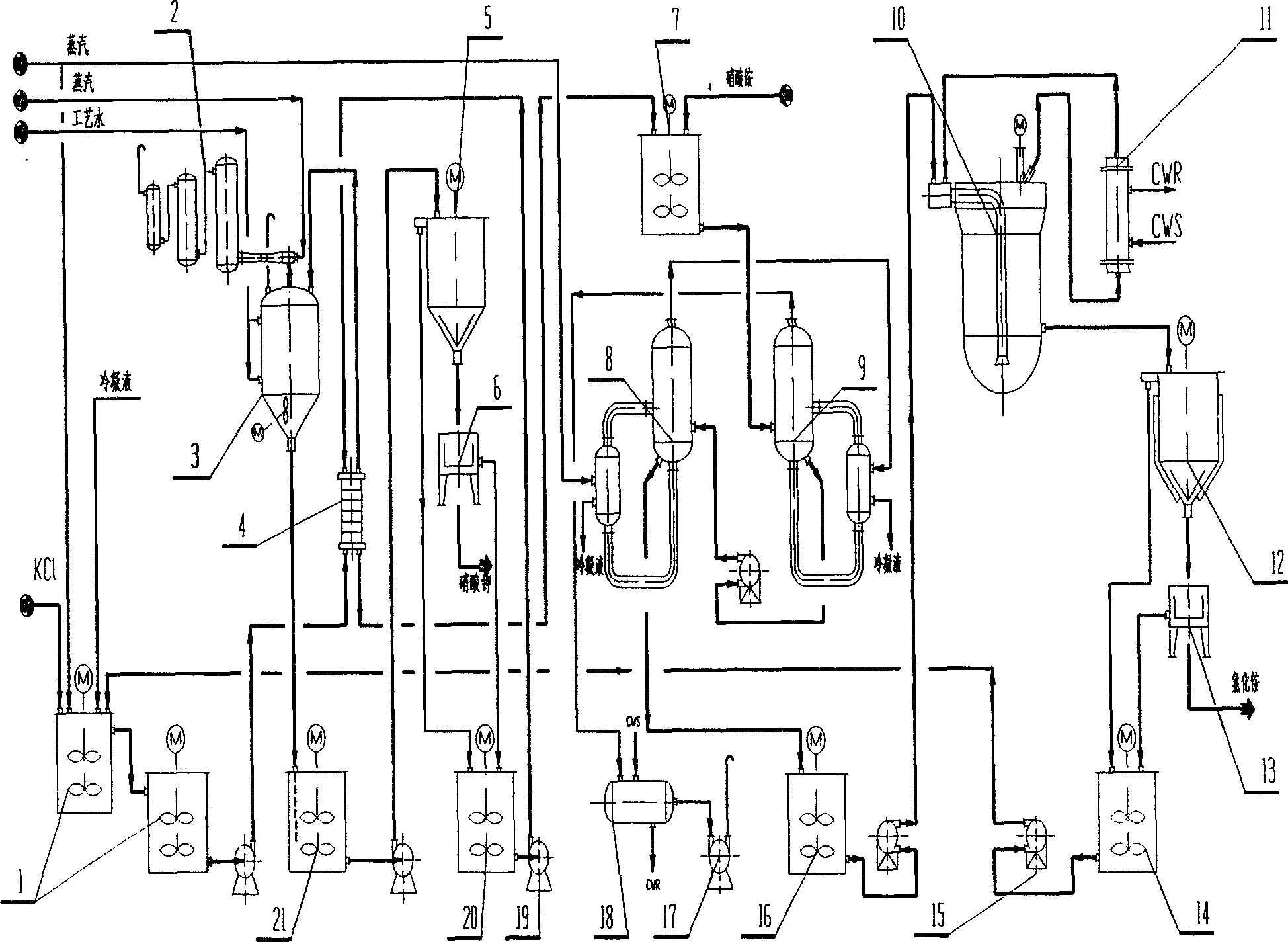

[0055] Adopt the process description of 10kt / a potassium nitrate production plant of the present invention

[0056] (1) Process flow

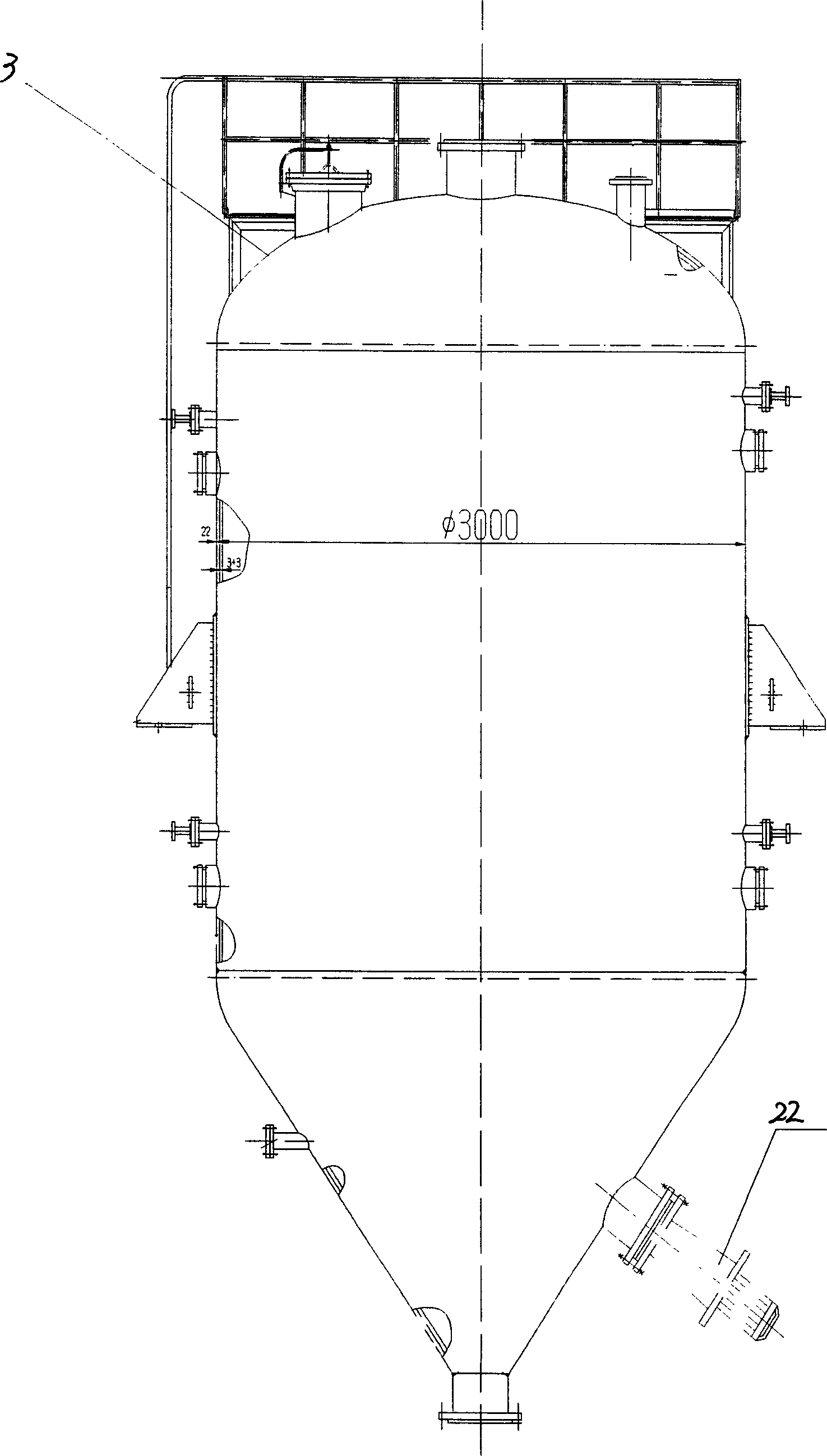

[0057] Add a certain amount of water and secondary mother liquor in the reaction tank, heat to 80 ° C, start stirring, gradually add a certain amount of potassium chloride (containing KCL ≥ 95%) in the tank, control potassium chloride: water: two The weight ratio of the secondary mother liquor is 1: 2.4: 1.85, continue heating to make it all dissolve, and measure the specific gravity of the solution at 95°C to be 32Be, and the batching ends. Then the reaction liquid is pumped to the plate heat exchanger, where KNO is separated from 3 The primary mother liquor after crystallization is subjected to heat exchange. The reaction liquid after heat exchange enters the reaction liquid high level tank. The reaction liquid from the high level tank of the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com