Method for preparing paper making antibacterial agents by using oil-tea camellia shells as carriers

A technology of Camellia oleifera husk and antibacterial agent, which is applied to paper and other directions, can solve the problems of low retention rate and poor stability, and achieve the effect of easy operation, low cost and high retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

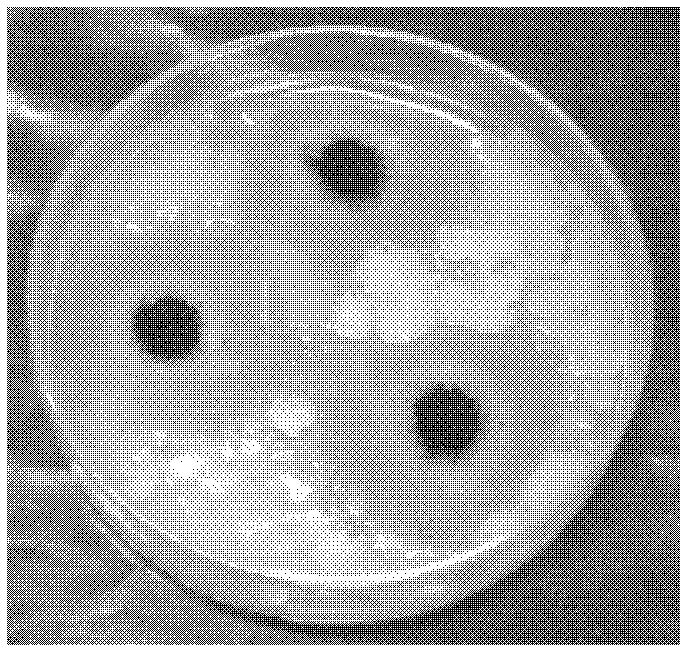

[0022] Add 10 kilograms of oil-tea camellia husk particles crushed to a particle size range of 800um into 30 kilograms of glutaraldehyde aqueous solution with a mass concentration of 3%, stir and add 40 kilograms of concentrated hydrochloric acid, and stir for 4 h at 60℃; add 1 Kg of silver nitrate solids, stir to completely dissolve and continue to stir for 6 hours; filter, wash the filter residue with distilled water until the filtrate is neutral, add the filter residue to 5 kg of sodium borohydride with a mass concentration of 3% at 60℃ Stir the reaction for 2 h; filter, wash the filter residue with distilled water until the filtrate is neutral, and dry the filter residue at 60°C to a constant weight to obtain the camellia husk-based papermaking antibacterial agent.

[0023] The oil-tea husk-based papermaking antibacterial agent prepared in this example was tested for the diameter of the inhibition zone of different strains. The results showed that the diameter of the inhibitio...

Embodiment 2

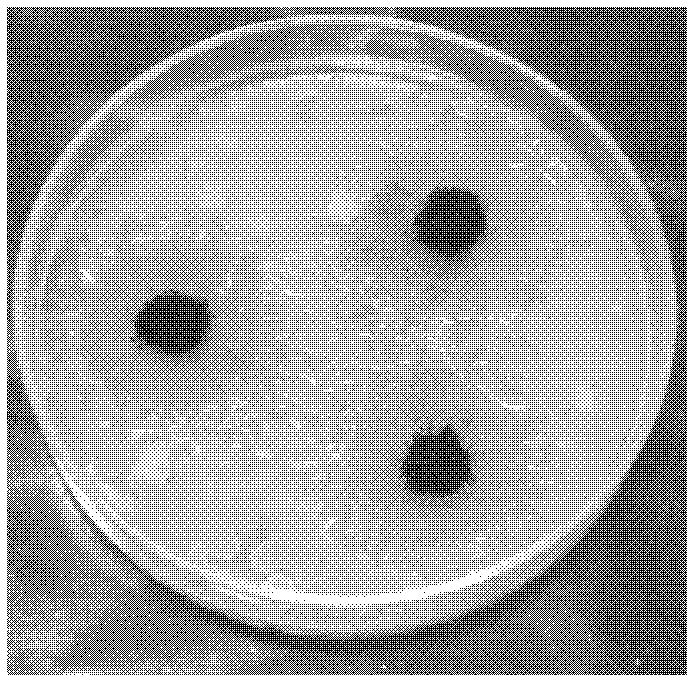

[0025] Add 10 kg of camellia oleifera husk particles crushed to a particle size range of 500um into 25 kg of glutaraldehyde aqueous solution with a mass concentration of 3%, stir and add 350 kg of concentrated hydrochloric acid, and stir for 4 h at 60℃; add 1.5 Kg of copper sulfate pentahydrate, stir to completely dissolve and continue to stir for 8 hours; filter, wash the filter residue with distilled water until the filtrate is neutral, add the filter residue to 5 kg of sodium hydroxide aqueous solution with a mass concentration of 3%. Stir and react for 1.5 h at 70°C; filter, wash the filter residue with distilled water until the filtrate is neutral, and dry the filter residue at 70°C to a constant weight to obtain the camellia husk-based paper-making antibacterial agent.

[0026] The oil-tea husk-based papermaking antibacterial agent prepared in this example was tested for the diameter of the inhibition zone of different strains. The results showed that the diameter of the inh...

Embodiment 3

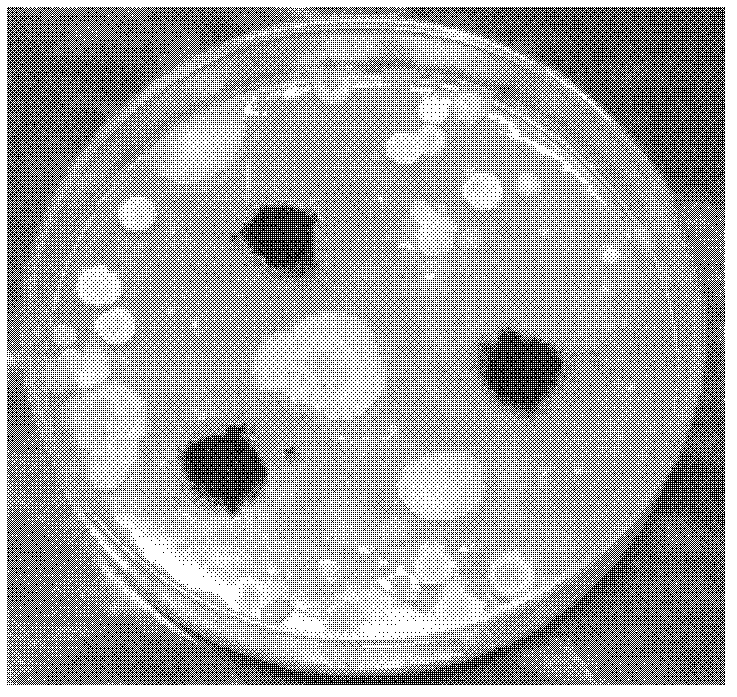

[0028] Add 10 kg of camellia oleifera husk particles crushed to a particle size range of 1000 μm into 28 kg of glutaraldehyde aqueous solution with a mass concentration of 3%, stir and add 400 kg of concentrated hydrochloric acid, and stir for 4 h at 60°C; Add 3.5 kg of zinc chloride solid, stir to completely dissolve and continue stirring for 6 hours; filter, wash the filter residue with distilled water until the filtrate is neutral, add the filter residue to 5 kg of sodium hydroxide with a mass concentration of 3%. Stir the reaction at 65°C for 2.5h; filter, wash the filter residue with distilled water until the filtrate is neutral, and dry the filter residue at 70°C to a constant weight to obtain the camellia husk-based paper-making antibacterial agent.

[0029] The oil-tea husk-based papermaking antibacterial agent prepared in this example was tested on the diameter of the inhibition zone of different strains. The results showed that the diameter of the inhibition zone of Esch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com