Patents

Literature

86results about How to "Less process equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

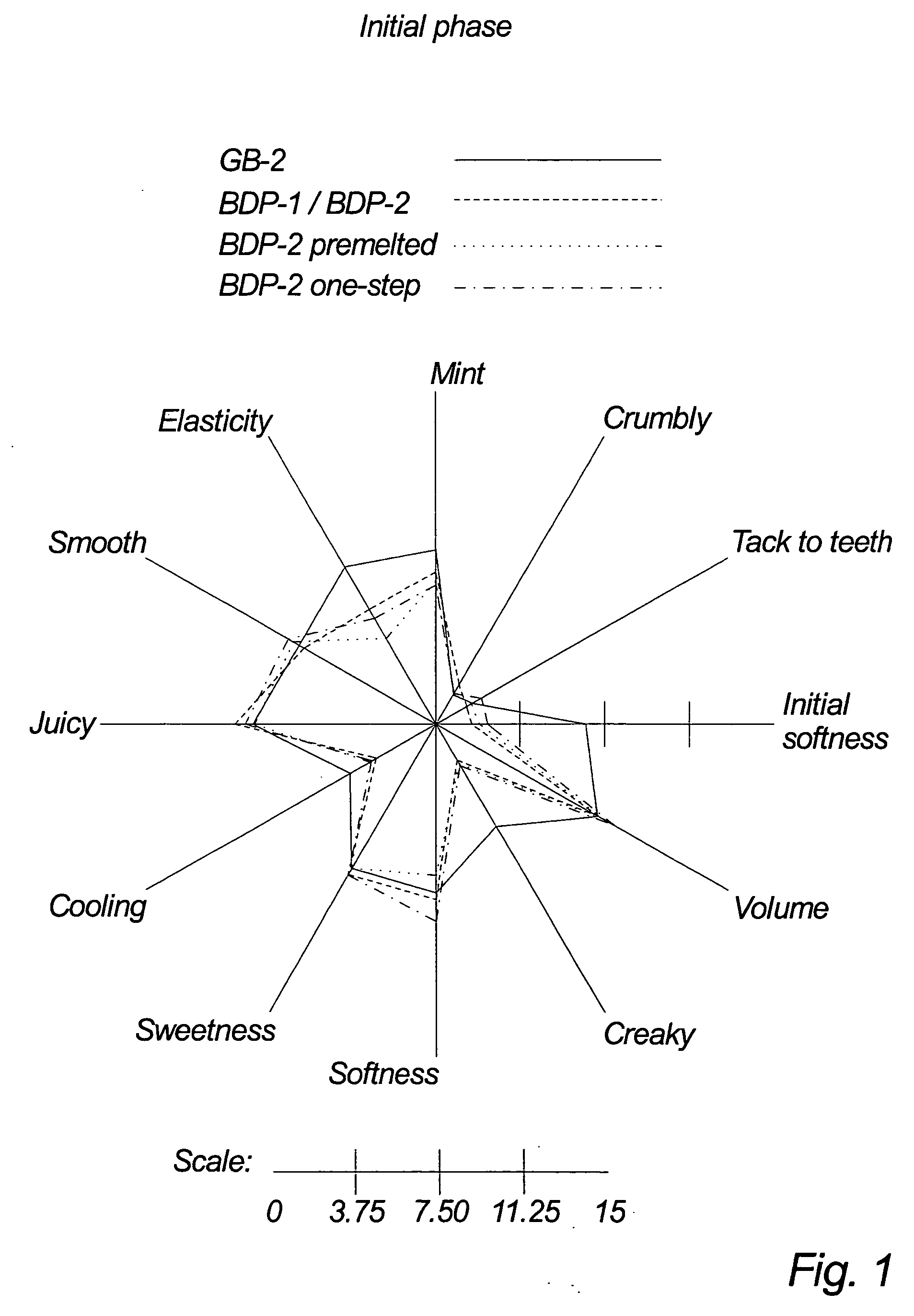

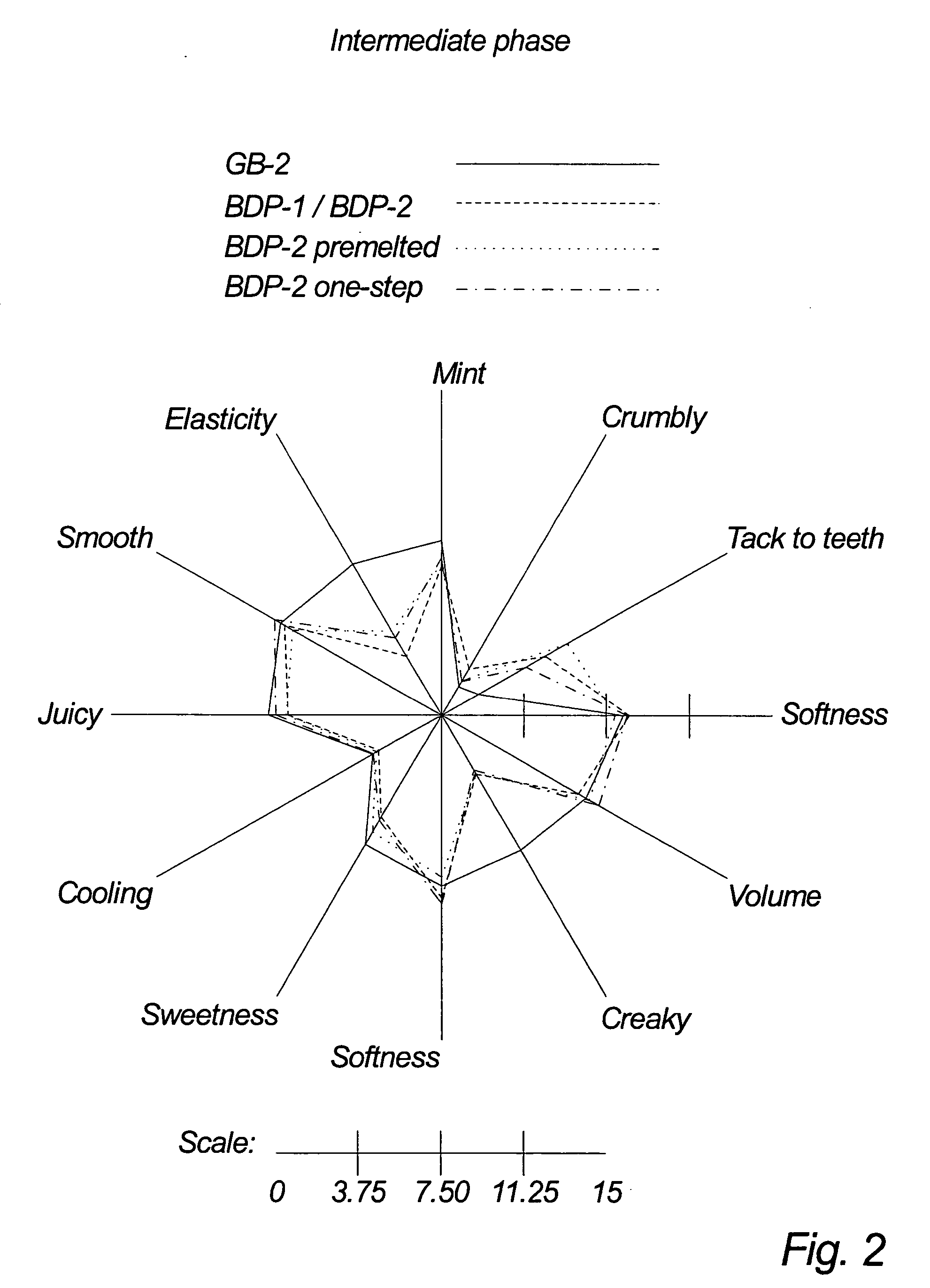

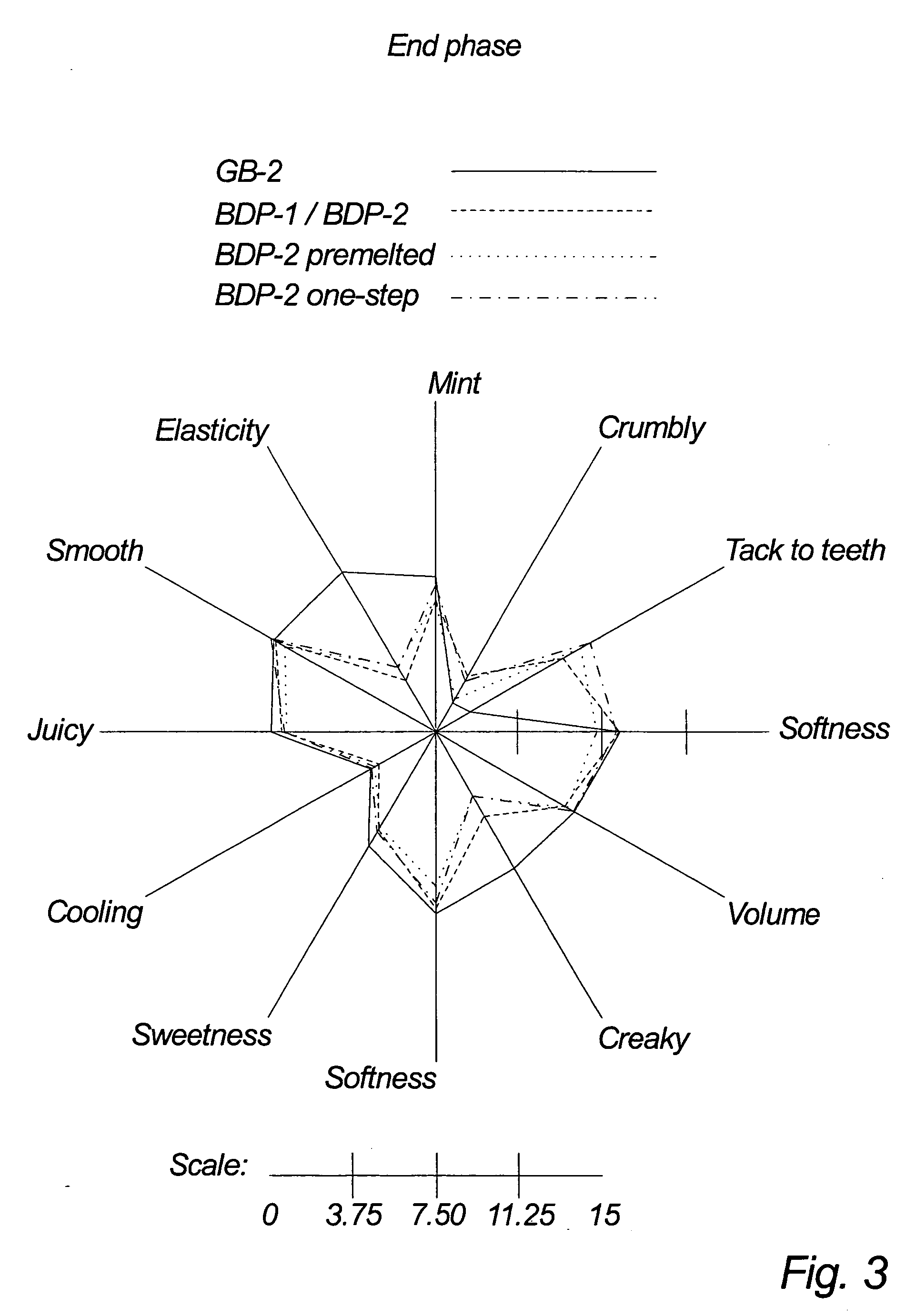

One-step process for preparing chewing gum

InactiveUS20040115305A1More cost-effectivelyLess process equipmentOrganic active ingredientsNervous disorderPolyesterPolymer science

A process for preparing a chewing gum wherein all of the gum base components and all of the chewing gum additives are charged, in any appropriate order, into a mixing apparatus and the apparatus operated at atmospheric pressure to obtain the chewing gum, subject to the limitation that the gum base does not contain a vinyl polyester as the sole polymer. In certain embodiments, the gum base comprises at least one environmentally or biodegradable polymer such as a polyester, a polycarbonates, a polyester amide, a polypeptide and a protein.

Owner:GUMLINK AS

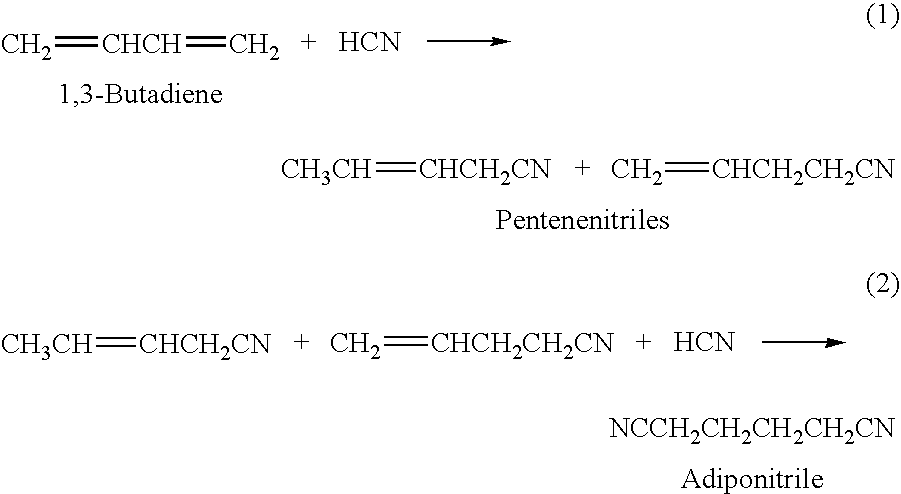

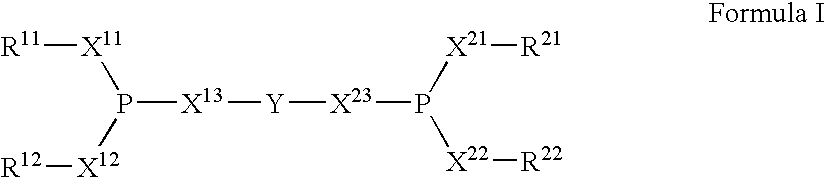

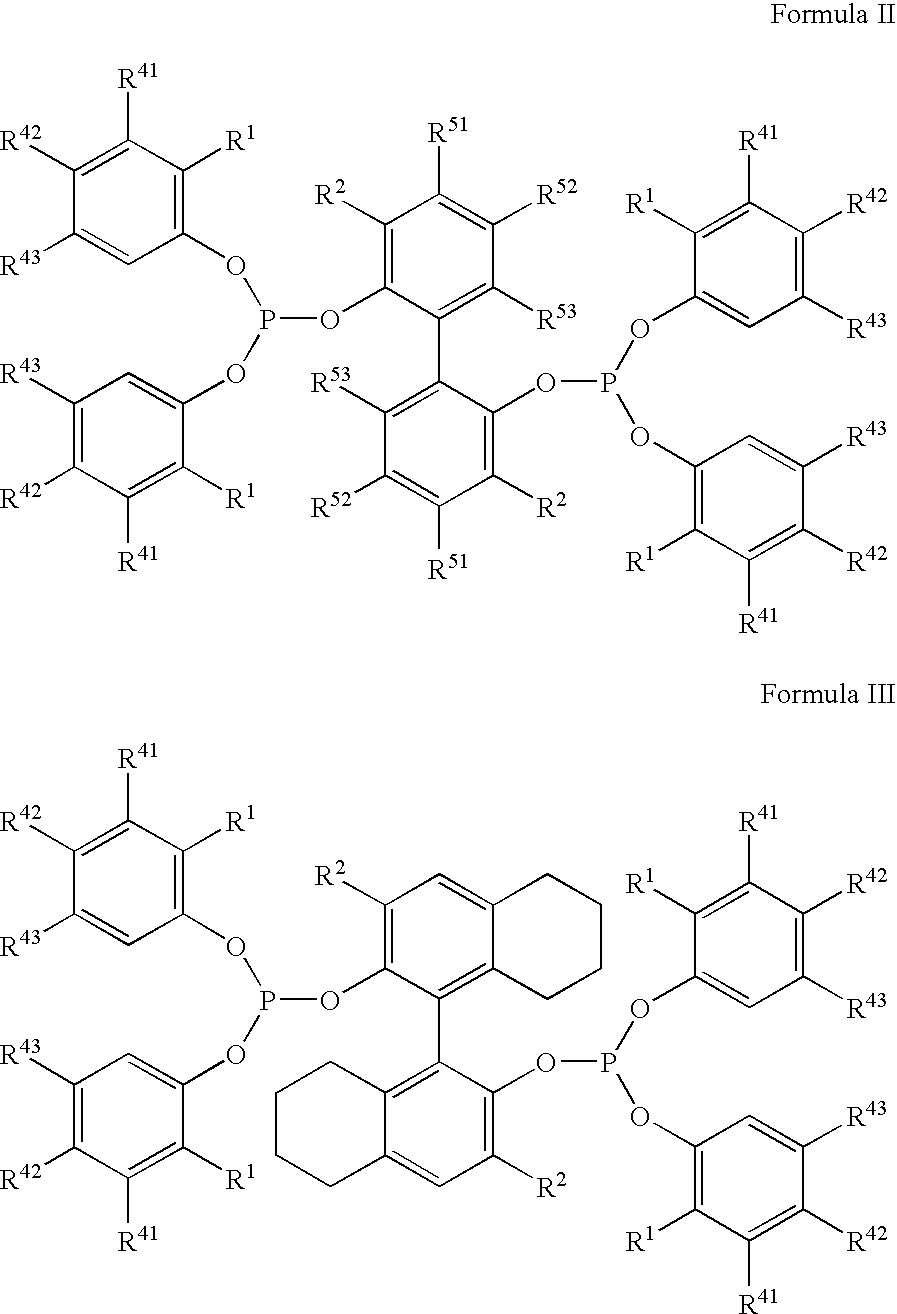

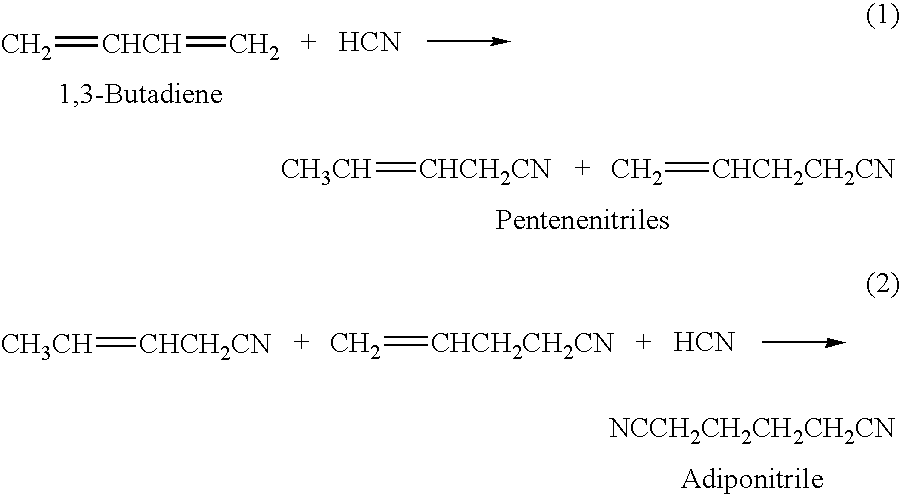

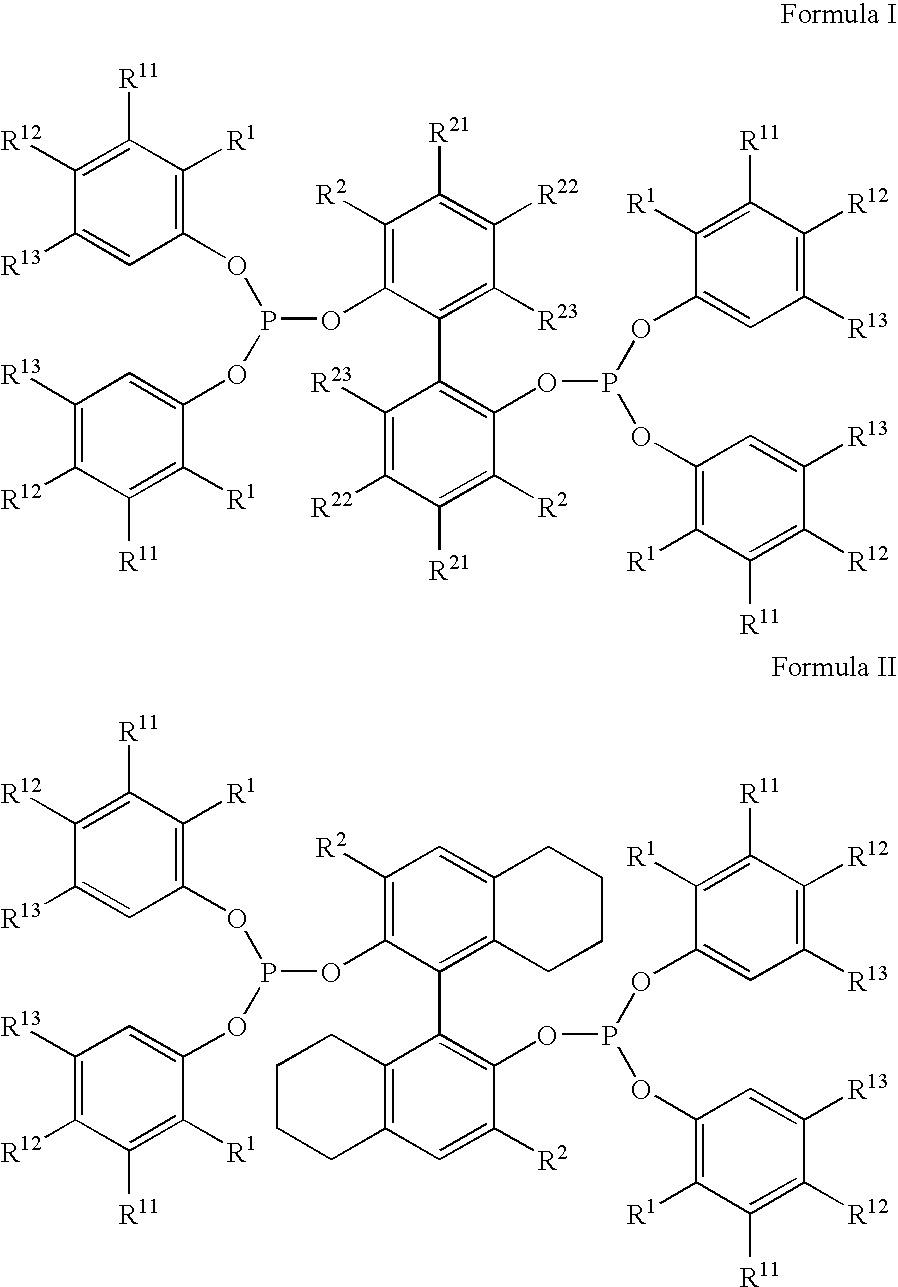

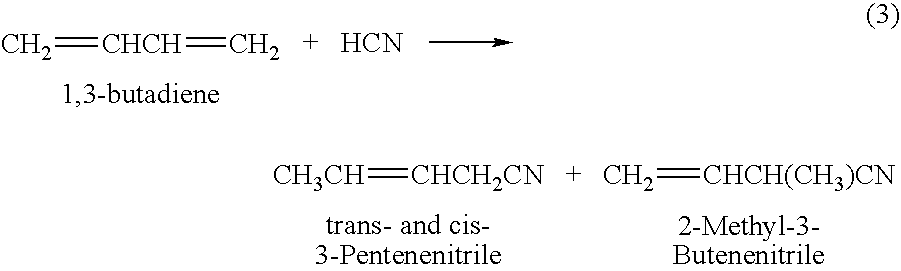

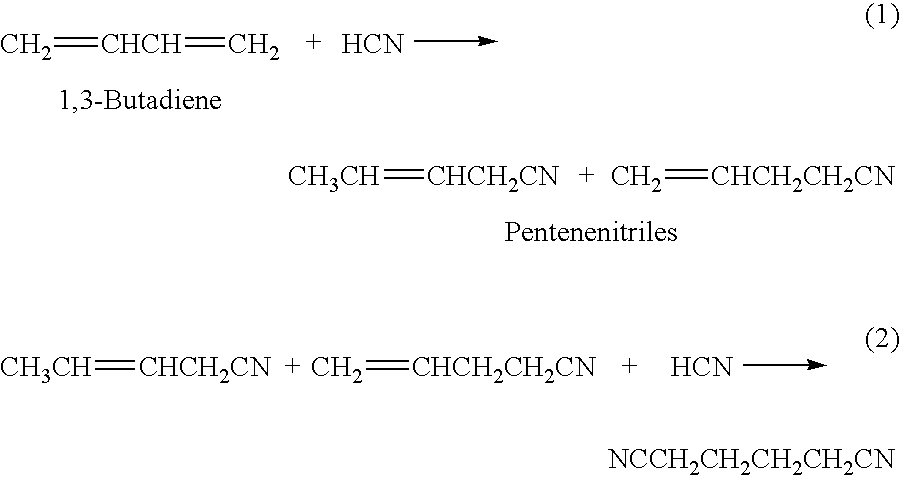

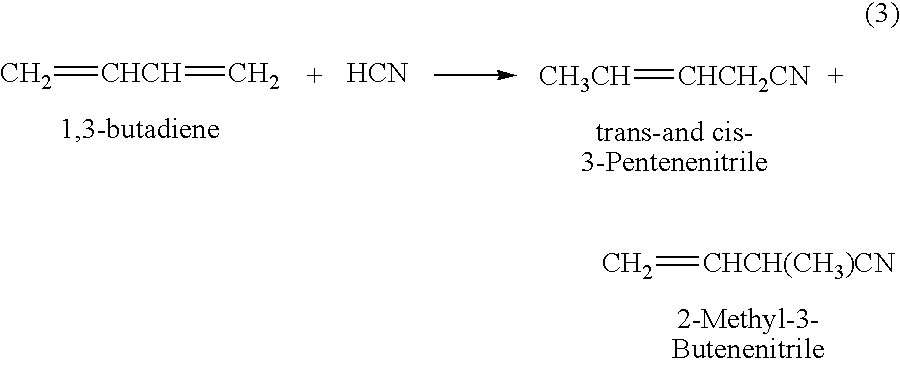

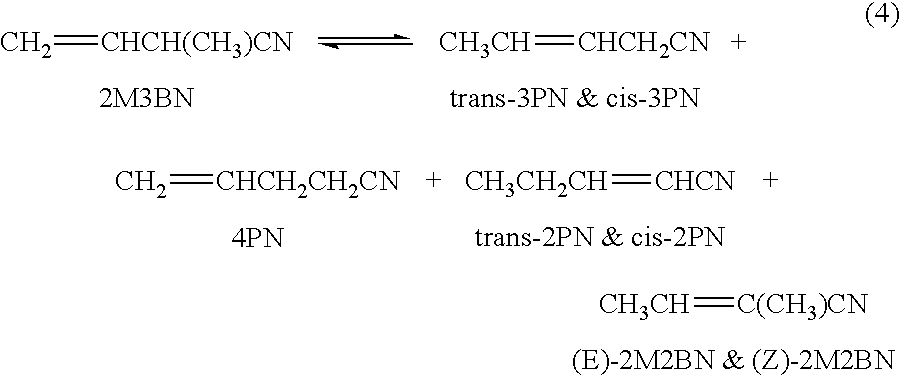

Hydrocyanation process with reduced yield losses

ActiveUS20080015381A1Investment exemptionSelective and efficient and stableOrganic compound preparationPreparation by hydrogen cyanide additionNitriteHydrogen

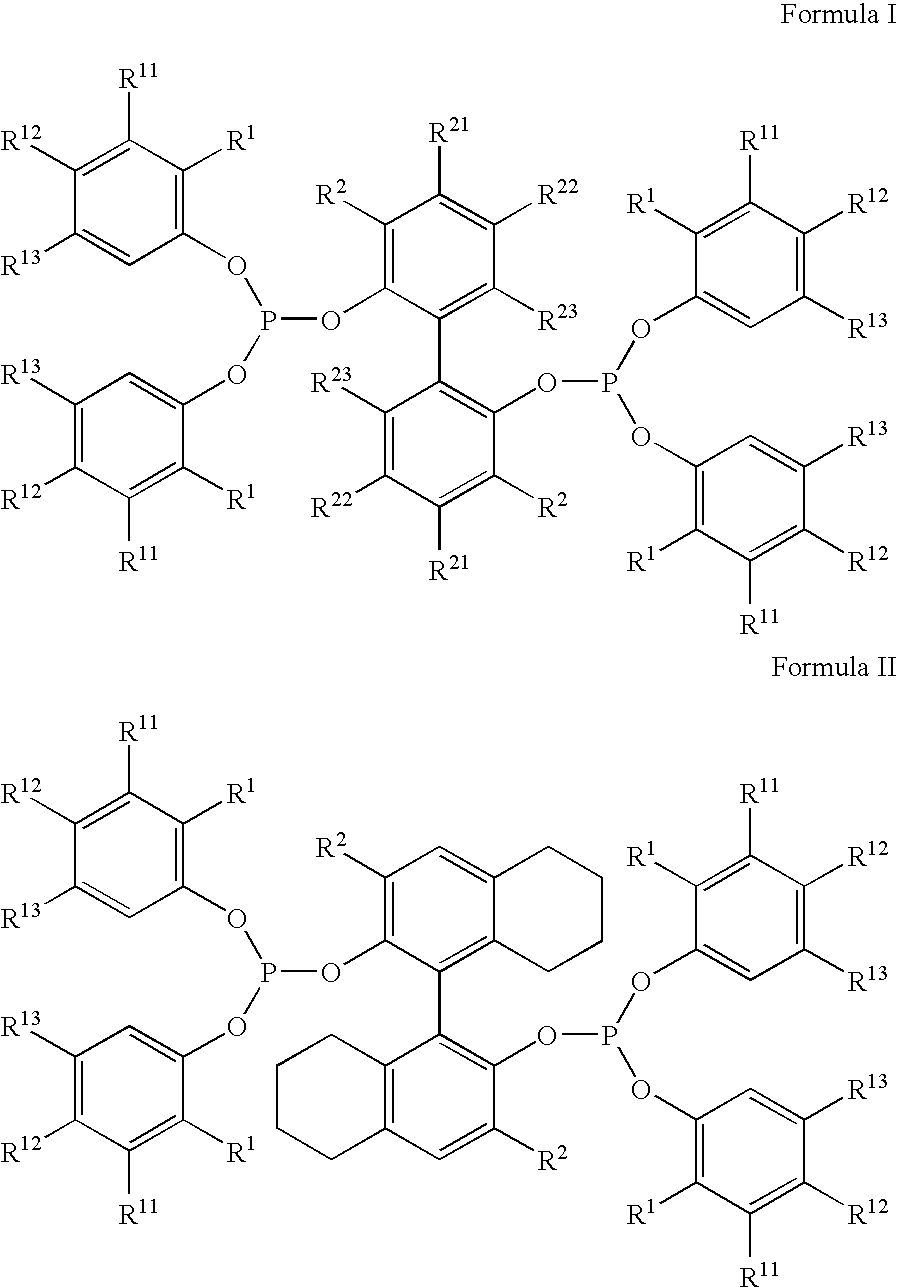

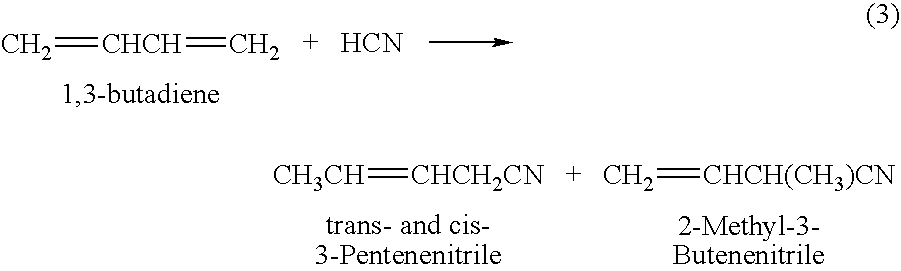

The invention provides a hydrocyanation process for the production of adiponitrile and other dinitriles having six carbon atoms, the process comprising:a) forming a reaction mixture in the presence of at least one Lewis acid, said reaction mixture comprising ethylenically unsaturated nitrites having five carbon atoms, hydrogen cyanide, and a catalyst precursor composition, by continuously feeding ethylenically unsaturated nitrites, hydrogen cyanide, and a catalyst precursor composition;b) controlling X and Z, wherein X is the overall feed molar ratio of 2-pentenenitriles to all unsaturated nitriles and Z is the overall feed molar ratio of hydrogen cyanide to all unsaturated nitrites, by selecting a value for X in the range from about 0.001 to about 0.5, and a value for Z in the range from about 0.5 / 1 to about 0.99 / 1, such that the value of quotient Q, whereinQ=X[(moles3PN+4PNinthefeed)(molesallunsaturatednitrilesinthefeed)]-Zis in the range from about 0.2 to about 10, wherein 3PN is 3-pentenenitriles and 4PN is 4-pentenenitrile; andc) withdrawing a reaction product mixture comprising adiponitrile;wherein the ratio of the concentration of 2-pentenenitriles to the concentration of 3-pentenenitriles in the reaction mixture is from about 0.2 / 1 to about 10 / 1;wherein the catalyst precursor composition comprises a zero-valent nickel and at least one bidentate phosphite ligand; andwherein the bidentate phosphite ligand is selected from a member of the group represented by Formulas I and 11 as described herein.

Owner:INV NYLON CHEM AMERICAS LLC

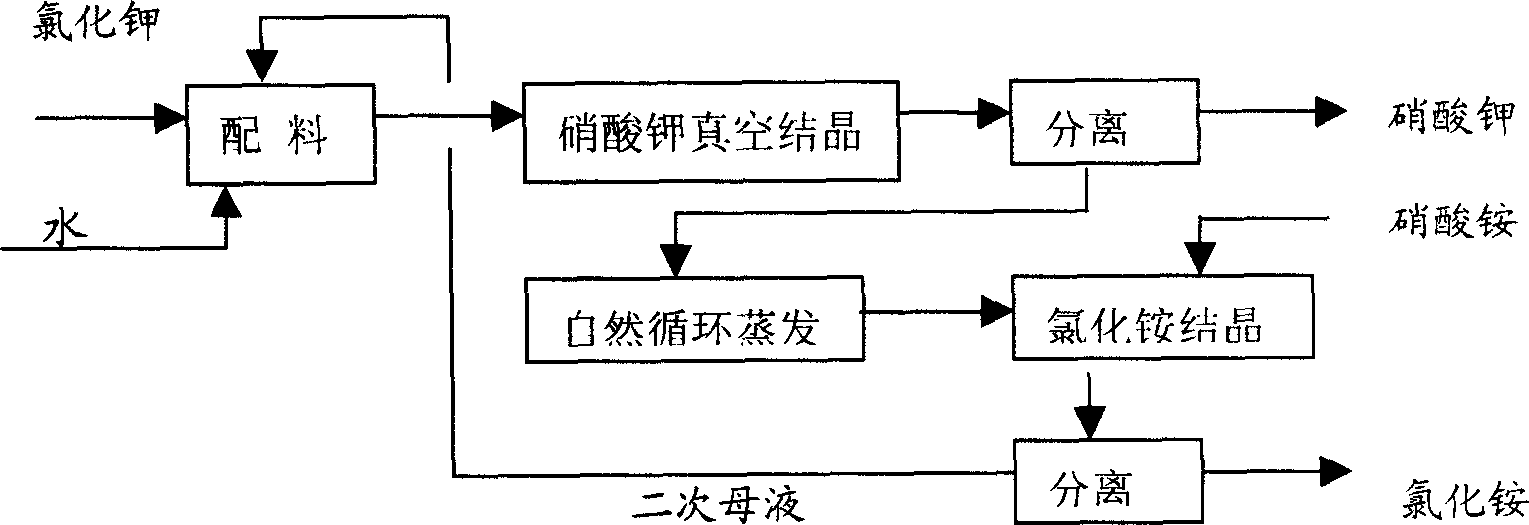

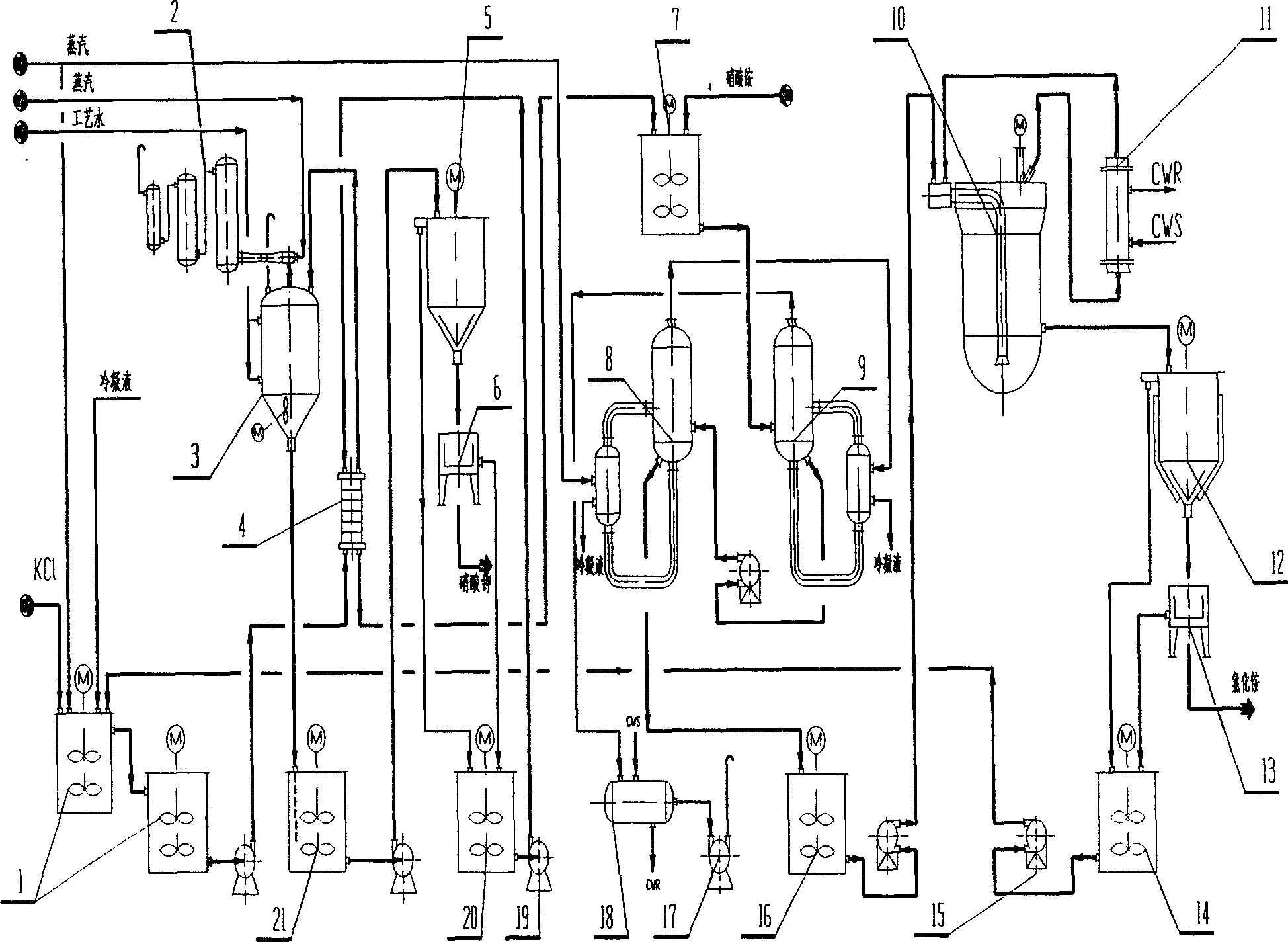

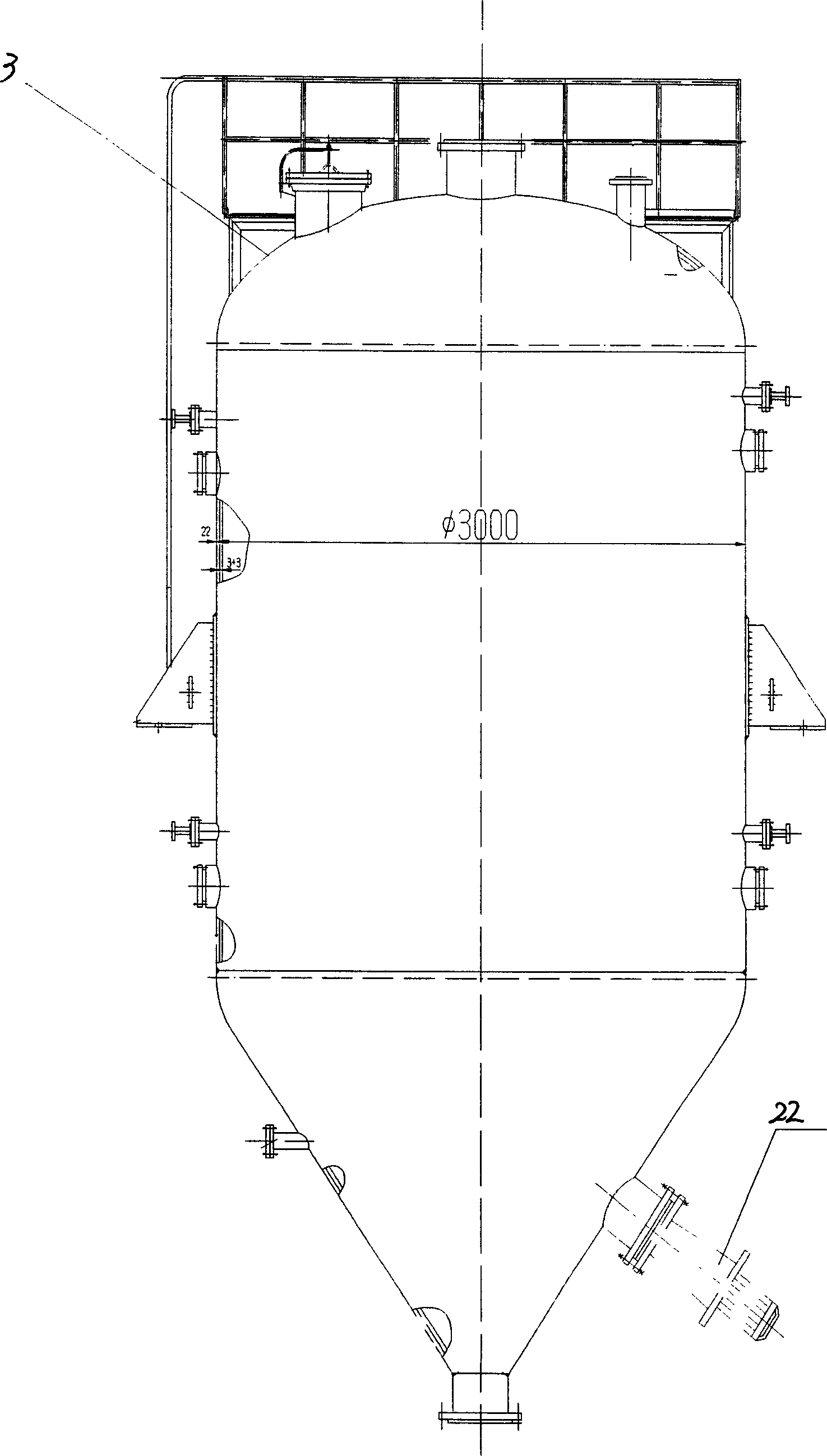

Process for preparing potassium nitrate by double decomposition method

ActiveCN1827526ALess process equipmentEasy to manufactureAlkali metal nitrate preparationCyclic processAmmonium nitrate

The invention provides a metathesis method for preparation of potassium nitrate. After raw potassium chloride, ammonium nitrate and craft water finish their preparation at a certain ratio, they are input into vacuum cooling crystallizer. Then potassium nitrate is separated by crystallization and grows up. The crystallized liquid thickens by the thickening apparatus and continuously separates potassium nitrate as aim products by centrifugal machine. After the separated mother liquid exchanges heat with the reacting liquid, it is input into natural circulation evaporator to concentrate, adopting backward feed and dual effect concentration with constant pressure in the first chamber and negative pressure in the second chamber. Through cooling crystallization, thickening by the thickening apparatus, the concentrated liquid continuously separates ammonium chloride as by-products. The gained secondary mother liquid returns to preparation groove. Repeating this cyclic process, we could sequentially get solid potassium nitrate and ammonium chloride.The invention has improved production stability and product quality a lot and reduced raw material consumption and energy consumption, with simple and serial flow process. The invention has realized the mass production.

Owner:EAST CHINA ENG SCI & TECH

Hydrocyanation process with reduced yield losses

ActiveUS20080015382A1Investment exemptionSelective and efficient and stableOrganic compound preparationPreparation by hydrogen cyanide additionHydrogenPhosphite ester

The invention provides a hydrocyanation process for the production of adiponitrile and other dinitriles having six carbon atoms, the process comprising:a) forming a reaction mixture in the presence of at least one Lewis acid, said reaction mixture comprising ethylenically unsaturated nitriles having five carbon atoms, hydrogen cyanide, and a catalyst precursor composition, by continuously feeding ethylenically unsaturated nitriles, hydrogen cyanide, and a catalyst precursor composition;b) controlling X and Z, wherein X is the overall feed molar ratio of 2-pentenenitriles to all unsaturated nitriles and Z is the overall feed molar ratio of hydrogen cyanide to all unsaturated nitriles, by selecting a value for X in the range from about 0.001 to about 0.5, and a value for Z in the range from about 0.5 / 1 to about 0.99 / 1, such that the value of quotient Q, whereinQ=X[(moles3PN+4PNinthefeed) / (molesallunsaturatednitrilesinthefeed)]-Zis in the range from about 0.2 to about 10, wherein 3PN is 3-pentenenitriles and 4PN is 4-pentenenitrile; andc) withdrawing a reaction product mixture comprising adiponitrile;wherein the ratio of the concentration of 2-pentenenitriles to the concentration of 3-pentenenitriles in the reaction mixture is from about 0.2 / 1 to about 10 / 1;wherein the catalyst precursor composition comprises a zero-valent nickel and at least one multidentate phosphorus-containing ligand;wherein the multidentate phosphorus-containing ligand is selected from the group consisting of a phosphite, a phosphonite, a phosphinite, a phosphine, and a mixed phosphorus-containing ligand or a combination of such members; andwherein the multidentate phosphorus-containing ligand gives acceptable results according to at least one protocol of the 2-Pentenenitrile Hydrocyanation Test Method.

Owner:INV NYLON CHEM AMERICAS LLC

Preparation method of cellulose adsorbent

The fiber absorbent is made by weighing the fiber, acroleic acid, acrylamide and epoxy propyl-trimethyl ammonium chloride, alkalizing the fiber with NaOH solution to neutral to get alkalized fiber, neutralizing the acroleic acid integral to get the alkaline solution to add acrylamide, adding alkalized fiber then twisting it evenly, heating and weighing free polymer reaction introducer, solving into proper water, adding to the reaction system, triggering graft copolymerization, cleaning the product with NaOH solution then watering it till Ph is 5-7, and drying it to get the fiber absorbent. It is rich in resource and cheap in price.

Owner:JIANGSU QIANGLIN BIO ENERGY

Hydrocyanation process with reduced yield losses

ActiveUS7659422B2Investment exemptionSelective and efficient and stableOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenHydrogen cyanide

A hydrocyanation process produces adiponitrile and other dinitriles having six carbon atoms. The process involves forming a reaction mixture in the presence of at least one Lewis acid. The reaction mixture includes ethylenically unsaturated nitriles having five carbon atoms, hydrogen cyanide, and a catalyst precursor composition. The reaction mixture is continuously fed while controlling the overall feed molar ratio of 2-pentenenitriles to all unsaturated nitriles and the overall feed molar ratio of hydrogen cyanide to all unsaturated nitriles. In the reaction product mixture, including adiponitrile, the ratio of the concentration of 2-pentenenitriles to the concentration of 3-pentenenitriles is from about 0.2 / 1 to about 10 / 1. Included in the catalyst precursor composition is a zero-valent nickel and at least one bidentate phosphite ligand.

Owner:INV NYLON CHEM AMERICAS LLC

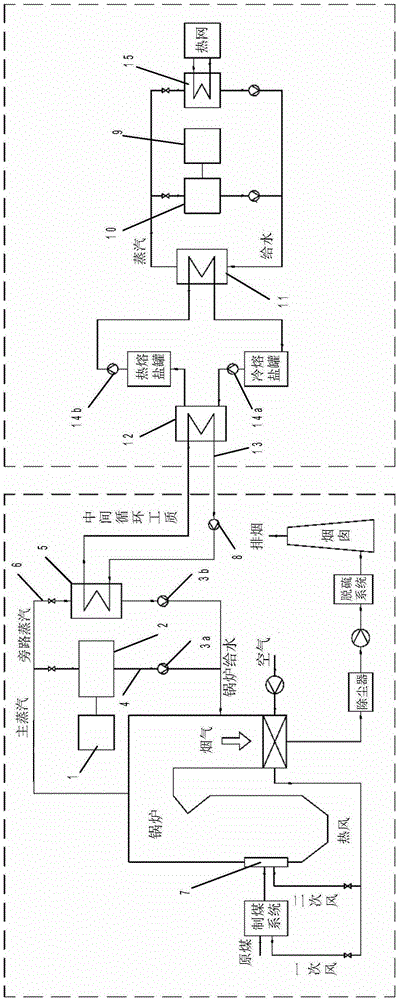

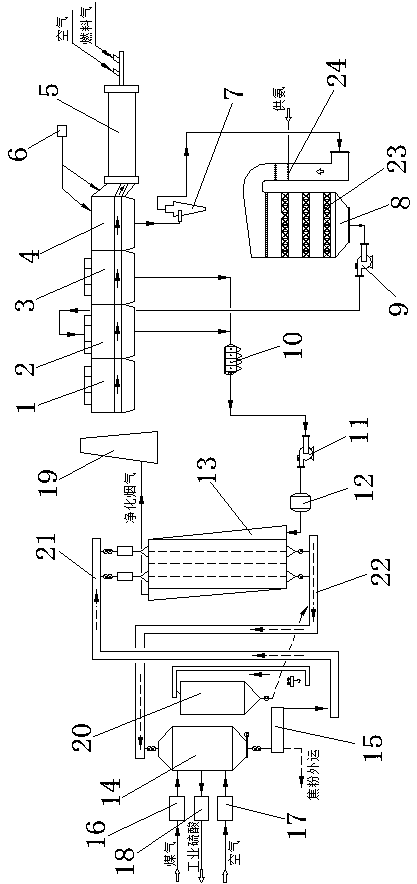

Thermal power generation system and method with fused salt energy storage, power supply and heat supply functions

InactiveCN105351018AThe system process is simpleLess process equipmentHeat storage plantsSteam engine plantsThermal energyThermal energy storage

The invention discloses a thermal power generation system and method with fused salt energy storage, power supply and heat supply functions. By arranging a bypass steam pipeline, a high-pressure condenser and a molten salt heater, excess steam heat energy generated by the load change of a power grid can be stored though molten salt. When the peak load of the power grid is reached, a molten salt energy storage power generation subsystem can participate in peak regulation of power supply of the power grid. In this way, the problems of peak regulation of the power grid, low utilization rate of power equipment and the like are solved, it is guaranteed that the power generation efficiency of the power generation system is equal to that of an existing thermal power generating unit, and the thermal power generation system and method have the outstanding advantages that energy storage and variable-load power supply are achieved, and high-efficiency power generation is guaranteed.

Owner:SHANGHAI YUANMENG ELECTRIC POWER ENERGY TECH CONSULTING CENT

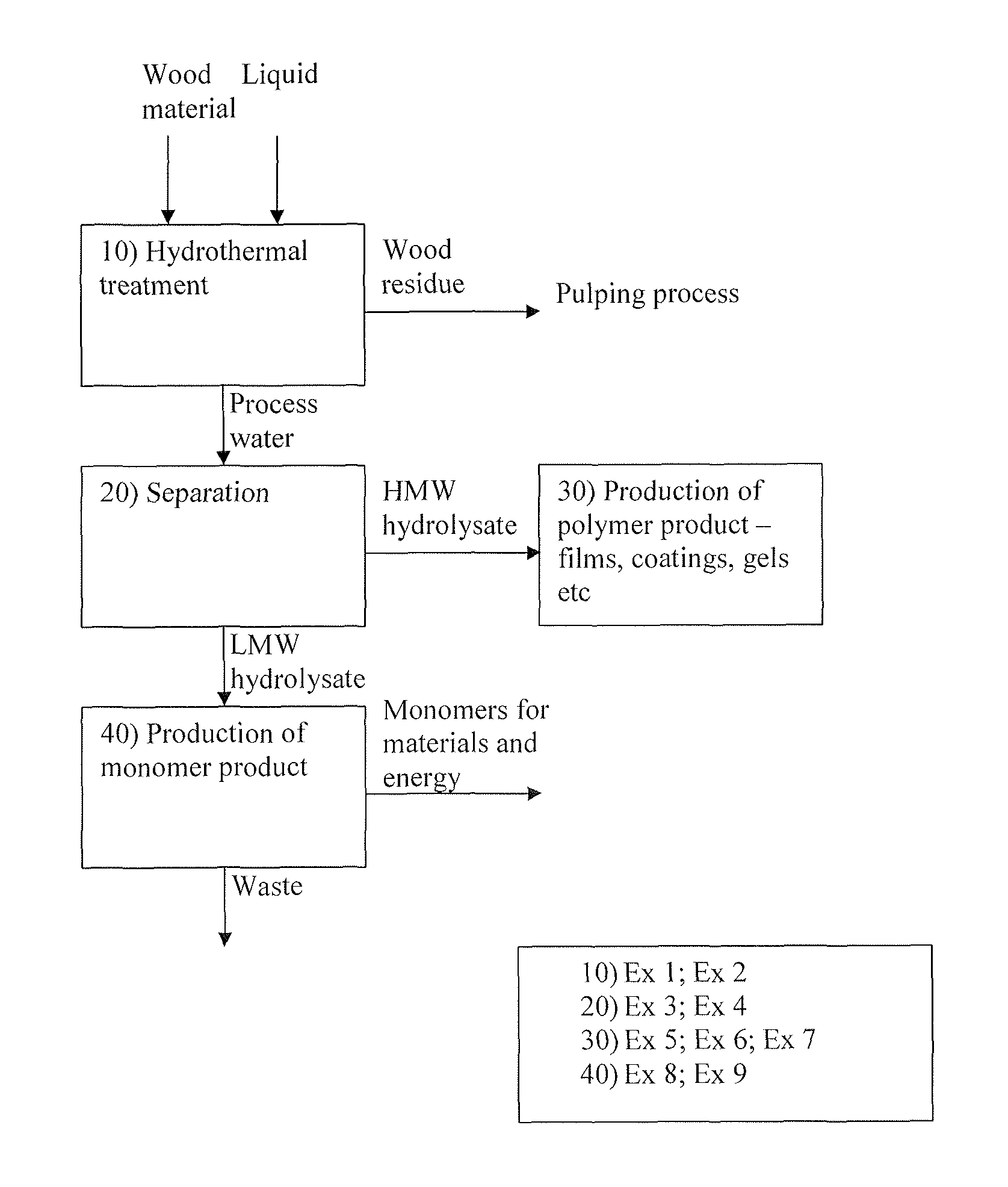

Utilization of a wood hydrolysate

InactiveUS20110028672A1Cost efficientIncrease valuePretreatment with water/steamCellulose material pulpingHydrolysateThermal treatment

The present invention relates to a method for utilizing a wood hydrolysate obtained from a hydrothermal treatment of a wood material method comprises the steps of providing a wood material, treating the wood material by means of an aqueous hydrothermal treatment so that a wood hydrolysate and a wood residue is formed. The wood hydrolysate comprises oligo- and polysaccharides as the main component of dry matter. The method further comprises the steps of; separating the wood hydrolysate into at least a first and a second fraction and using at least one of the at least first and second fractions for production of an intermediate or end product. Such end product may be e.g. a film, coating, package or a gel. The present invention also relates to a polymer product such as a film, a coating or a gel and its applications. The present invention provides for biodegradable and renewable polymer products and a method which utilizes and extracts a very high product value from a process.

Owner:INNVENTIA

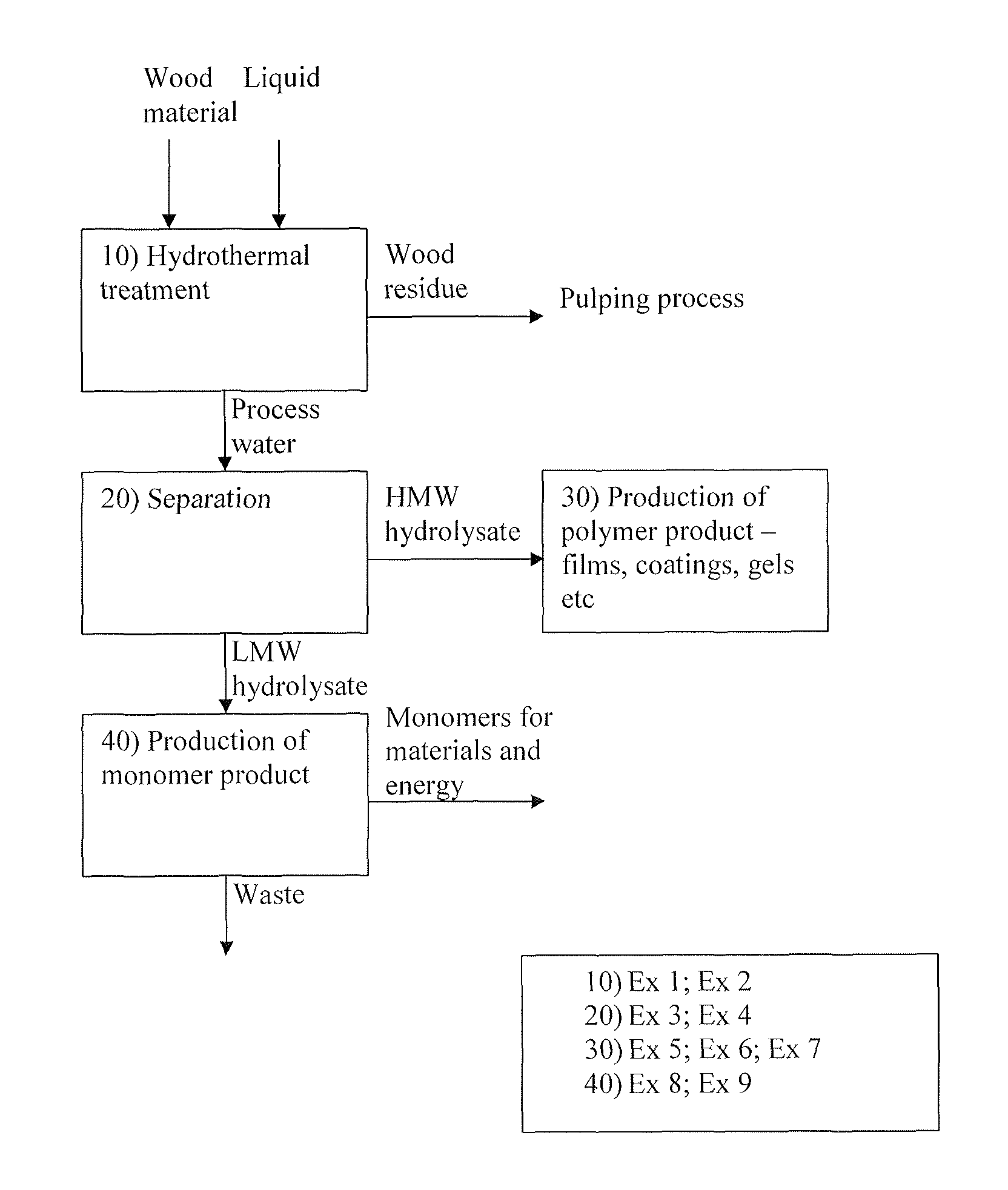

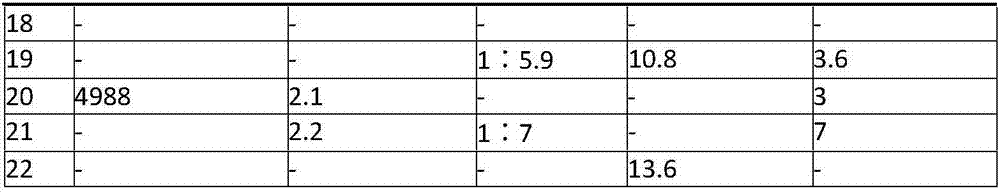

U-shaped support punching blanking bending composite die

InactiveCN104525749AIncrease productivityLess process equipmentShaping toolsPerforating toolsEngineeringEconomic benefits

The invention discloses a U-shaped support punching blanking bending composite die. Blanking, bending and punching of a U-shaped support are completed through one die, production efficiency is high, used process devices are few, economic benefit is high, and the problem that an existing U-shaped support needs a blanking die, a bending die and a punching die and low production efficiency, large process device number and low economic benefit are caused is solved.

Owner:李俊

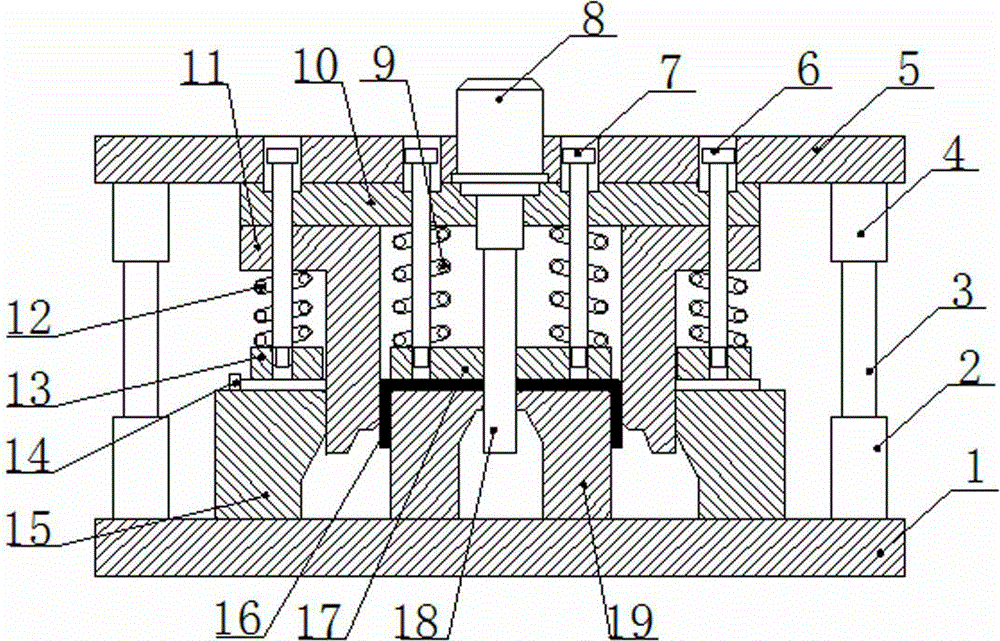

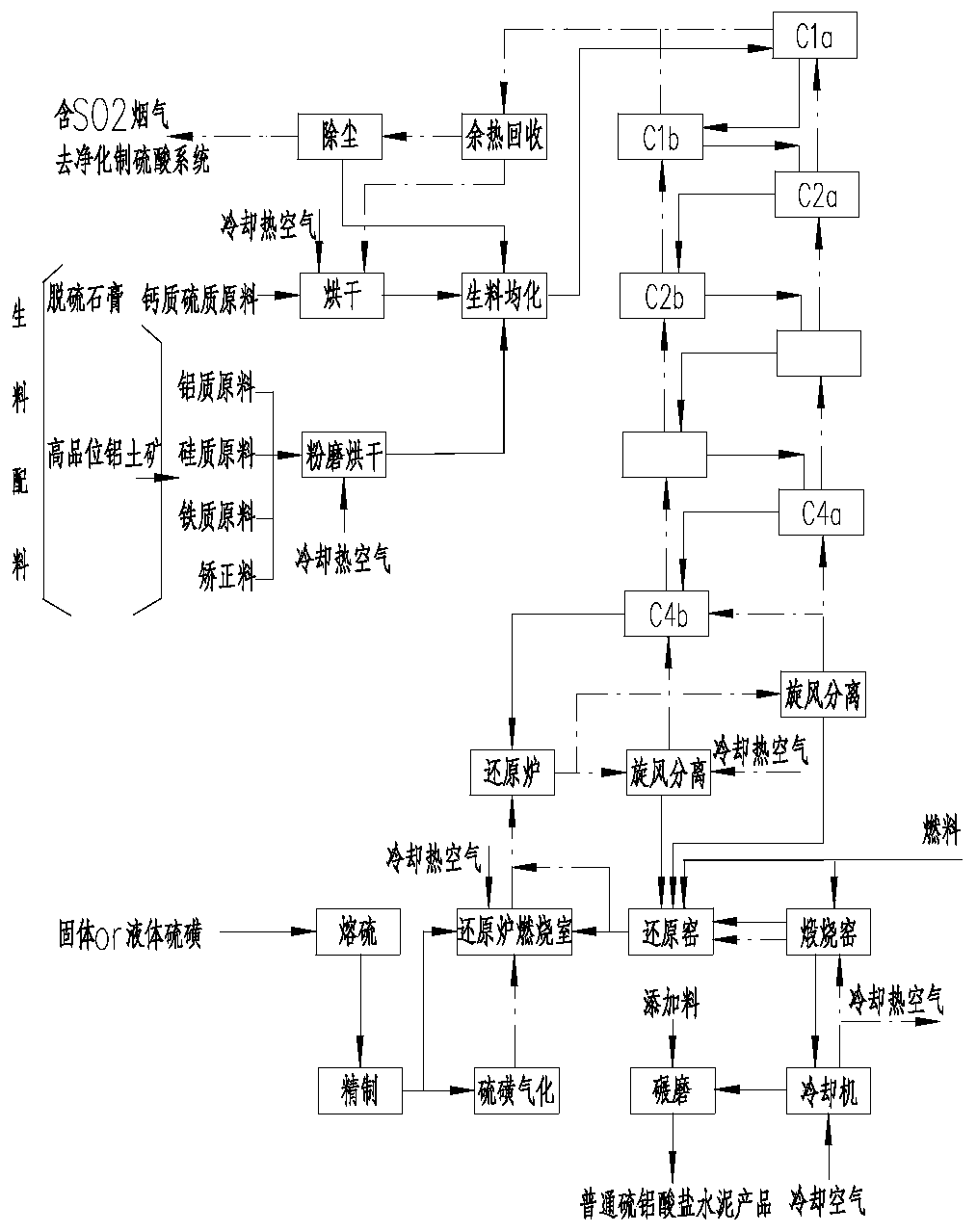

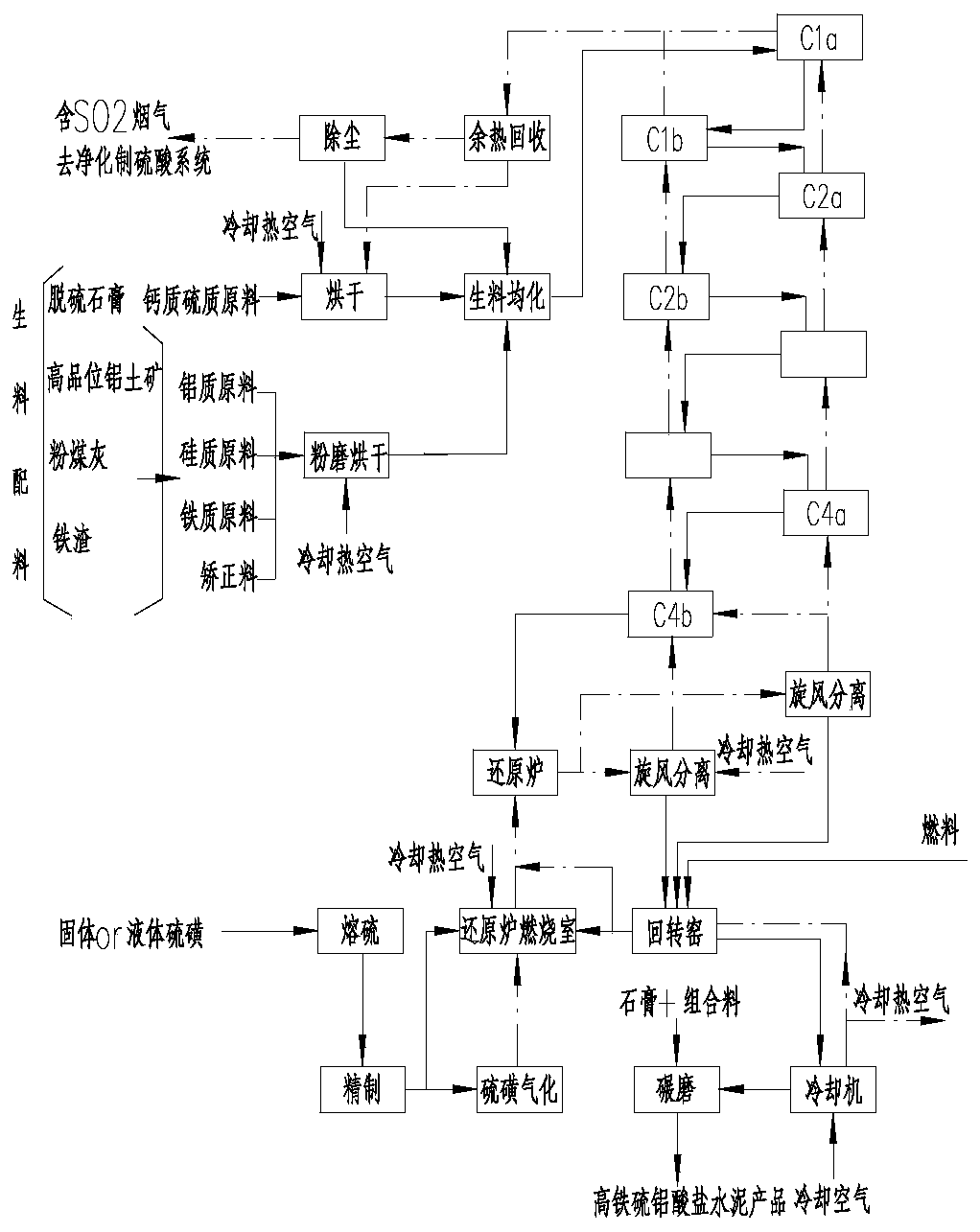

Method for preparing sulphoaluminate cement and coproducing sulfuric acid by reducing gypsum with sulfur gas

ActiveCN111559879AImprove decomposition rateFast and efficient decomposition reactionSulfur compoundsEnergy inputGypsumAluminate

The invention relates to a method for preparing sulphoaluminate cement and coproducing sulfuric acid by reducing gypsum with sulfur gas. The method comprises the following steps: A, preparing gaseoussulfur; B, burdening: preparing dehydrated gypsum, bauxite, a siliceous correction material and an iron correction material into a raw material with uniform components; C, preheating and pre-reducing:preheating the raw material, feeding the preheated raw material into a reduction furnace, performing reduction reaction on the preheated raw material and the gaseous sulfur, performing gas-solid separation, feeding flue gas into a multistage suspension preheating system, and feeding the pre-reduced raw material into a rotary kiln; D, carrying out deep reduction and clinker sintering: performing adeep reduction reaction on the reduced raw material in the rotary kiln, and then performing high-temperature sintering to form sulphoaluminate cement clinker; and E, cooling the clinker, recycling heat, purifying to prepare sulfuric acid, adding gypsum and a combined material into the cement clinker, and processing to obtain sulphoaluminate cement products with different performance requirements.Compared with the prior art, the method has the following advantages: a large amount of industrial waste residues such as industrial gypsum can be consumed, limestone and natural gypsum resources canbe saved, and meanwhile, high-quality sulphoaluminate cement and industrial sulfuric acid products can be obtained.

Owner:上海三夫工程技术有限公司 +1

Crop fertilizer applicable to saline-alkali soil and preparation method of crop fertilizer

InactiveCN102603429AWith ion exchangeHas a complexing effectFertilizer mixturesProcess equipmentAlkali soil

The invention discloses a crop fertilizer applicable to saline-alkali soil. The crop fertilizer comprises humic acid, active carbon, azophoska, gypsum, borax and zinc sulfate, wherein the humic acid has ion exchange and complexing effects, excessive hydrochloride and sulfate of the saline-alkali soil can be reduced, the adsorption effect of the active carbon also has fertilizer keeping and water retention effects, and the added azophoska, the borax and the zinc sulfate form a comprehensive nutritive crop fertilizer; and the added gypsum per se forms a saline-alkali soil modifying agent, so the crop fertilizer is integrally synthesized to become a saline-alkali soil crop fertilizer. According to the preparation method of the crop fertilizer disclosed by the invention, crop fertilizer finished products are formed through mixing, particle forming, drying and cooling, the process is simple, the related process equipment is little, the production efficiency is favorably improved, and in addition, the investment cost is reduced.

Owner:孙玉珂

Ion exchange fiber and its preparation method and use

InactiveCN1438074AEasy to makeRaw materials are easy to getAmphoteric ion-exchangersOrganic electrolyte cellsFiberSynthesis methods

The present invention relates to an ion-exchange fibre, its synthesis method and application. Said alkaline ion-exchange fibre adsorbent is acrylonitrile-methyl methacrylate-itaconate tripolymer containing amino functional group, can remote the acidic matter, transition metal ion and heavy metal ion from non-aqueous solution or non-aqueous solvent. Said invention is simple in preparation of product, and the adsorption volume of adsorbing acidic impurity from non-water is high, and its adsorption speed is high, its chemical property is stable. In the purification of lithium electrolyte by using said product the condition for removing impurity is moderate, at the same time of removing acidic impurity, the impurity into also can be removed.

Owner:FUDAN UNIV

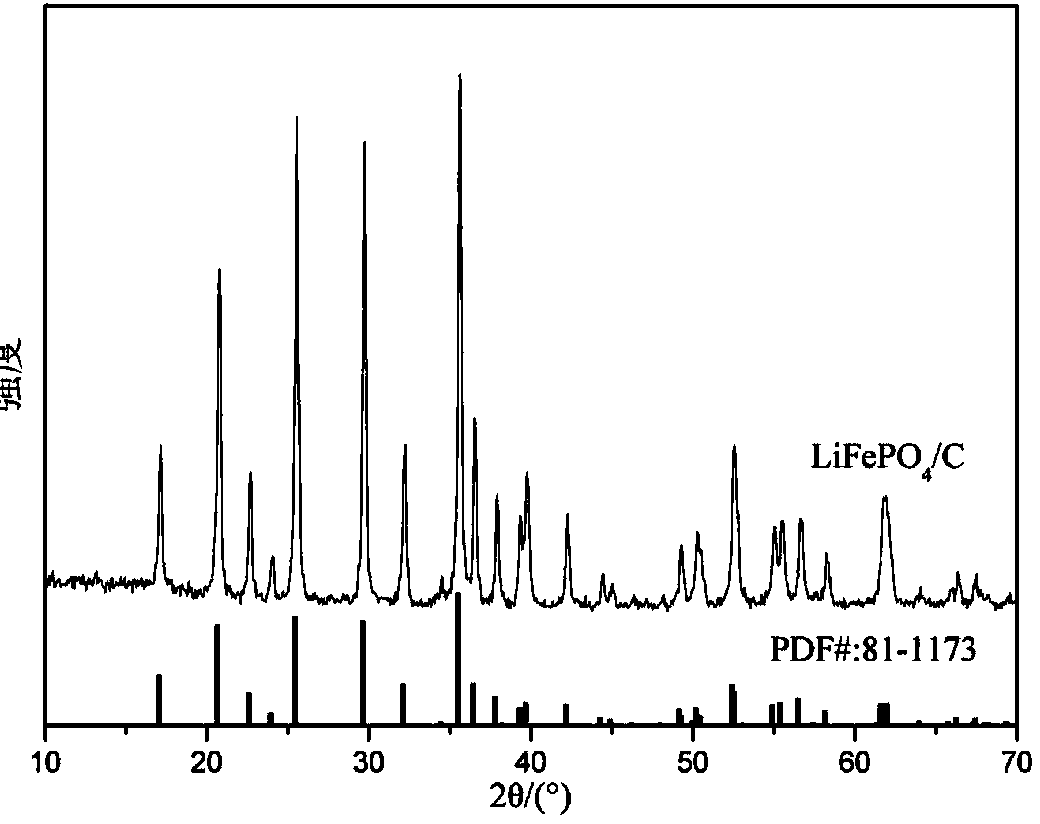

Preparation method of lithium ion phosphate/carbon composite material for high-rate-capability lithium ion battery

InactiveCN103427079ASmall particlesUniform particle size distributionCell electrodesCarbon compositesHigh rate

The invention discloses a preparation method of a lithium ion phosphate / carbon composite material for a high-rate-capability lithium ion battery. The preparation method comprises the following steps: analyzing the iron content and the phosphorus content of a precursor ferrous phosphate powder; adding into mixed slurry of a lithium source, a ferrous phosphate precursor and a phosphorus source according to the molar ratio of Li:Fe:P=(1.02-1):(0.98-1):1, adding a proper amount of a liquid phase reducing agent and a conductive additive, performing reflux reaction at the boiling point temperature of the reducing agent, distilling under reduced pressure and recovering a reducing solvent to obtain a lithium ion phosphate precursor; and calcining under the protection of inert gas to obtain a LiFePO4 / C composite anode material. Compared with other methods, the preparation method has the advantages of simple flow, short reaction time, simple process equipment, fine synthesis product particles, uniform particle size distribution, good high-rate electrochemical performance and excellent circulating stability, and besides, the discharging specific capacity is up to 100 mAh / g at 10 C,. The synthesis reaction process does not need a high-pressure container and only needs short high-temperature calcining time, so the reducing solvent is easy to recover, energy consumption is greatly reduced; the industrial popularization is facilitated.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS

Grate-kiln SNCR/SCR (selective non-catalytic reduction/selective catalytic reduction) denitration and active coke desulfurization combined system and grate-kiln SNCR/SCR denitration and active coke desulfurization combined process

PendingCN109794146AReduce escapeImprove denitrification efficiencyDispersed particle separationMixed gasToxic industrial waste

The invention belongs to the technical field of industrial waste gas control, and relates to a grate-kiln SNCR / SCR (selective non-catalytic reduction / selective catalytic reduction) denitration and active coke desulfurization combined system. A denitration reductant injector of an SNCR system is communicated with one side, close to a rotary kiln, of a preheating section II; the preheating section II is communicated with an SCR system, and the SCR system is communicated with a drying section II; the drying section II and a preheating section I are communicated with an active coke desulfurizationand adsorption tower. The invention also provides a grate-kiln SNCR / SCR denitration and active coke desulfurization combined process. Flue gases of the rotary kiln enter the preheating section II, and the SNCR system sprays ammonia water into the flue gas inlet side of the preheating section II for denitration; the flue gases enter the SCR system for denitration, and then enter the drying sectionII to be mixed with the flue gases of the drying section I; the mixed gases enter the active coke desulfurization and adsorption tower for desulfurization after passing through an electric dust remover, a main exhaust fan and a flue gas heat exchanger. The grate-kiln SNCR / SCR denitration and active coke desulfurization combined system and the grate-kiln SNCR / SCR denitration and active coke desulfurization combined process have the advantages of improved denitration efficiency, reduced cost, high desulfurization and dust removal efficiency, and capability of meeting ultra-clean requirements.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

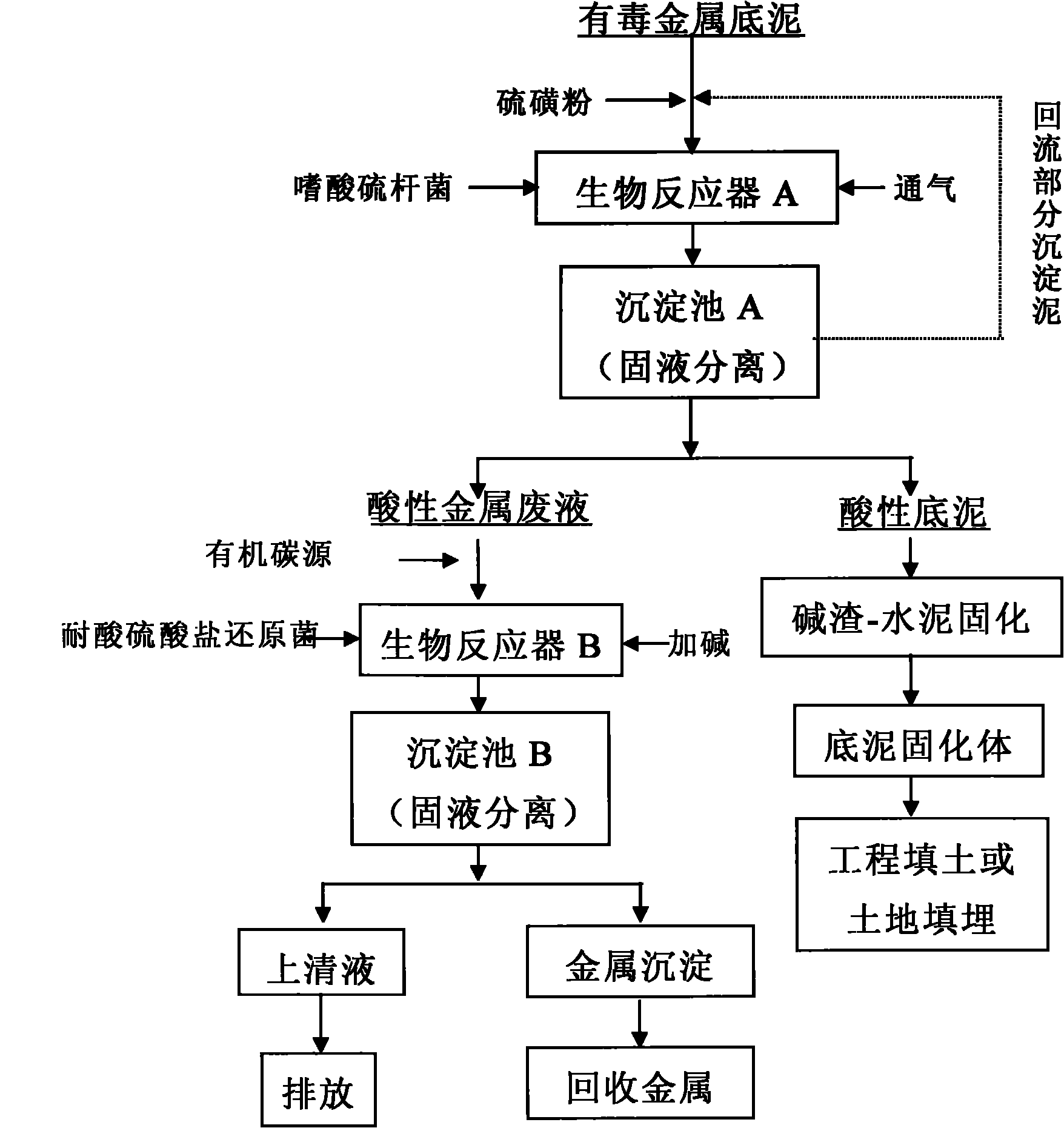

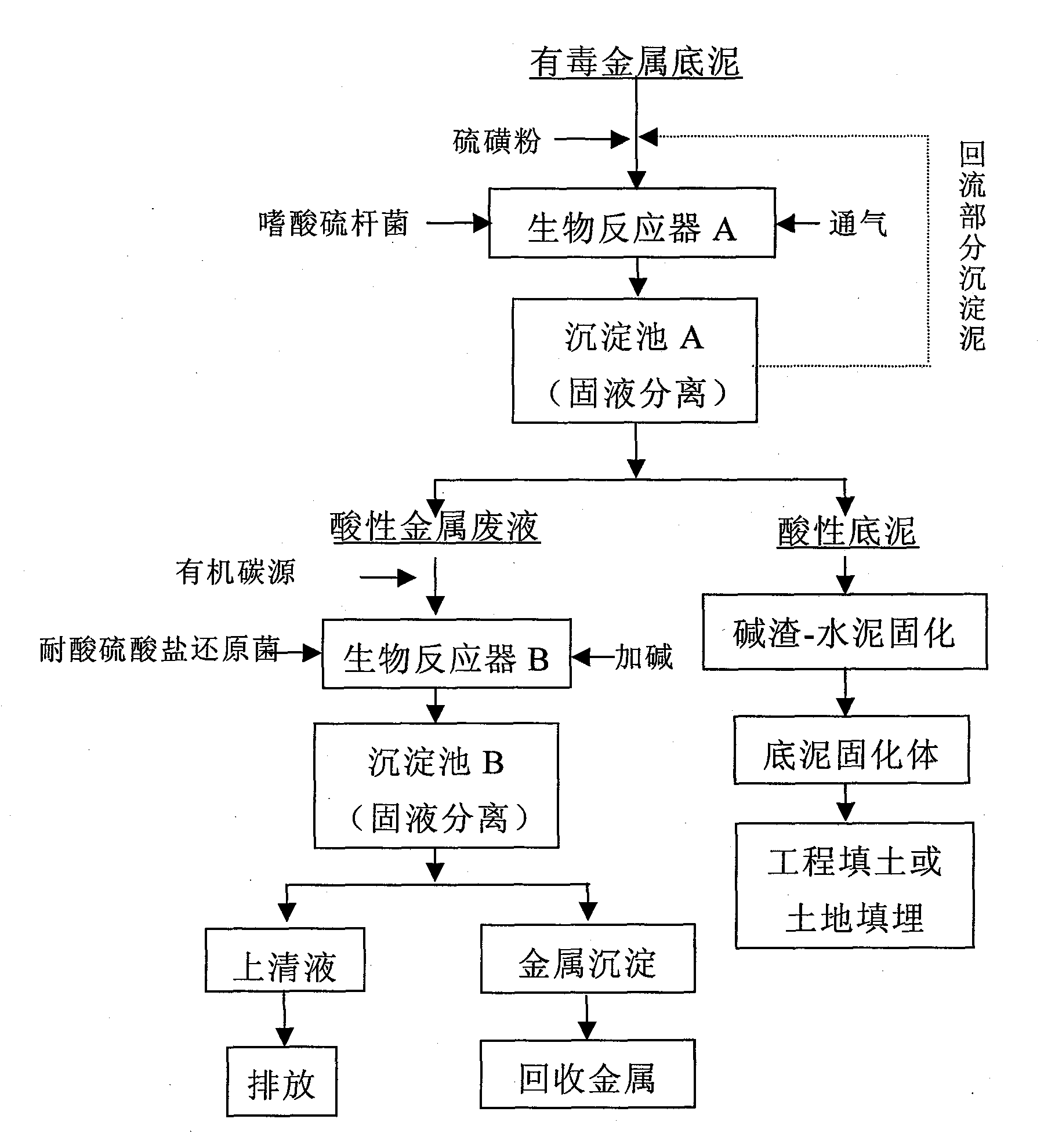

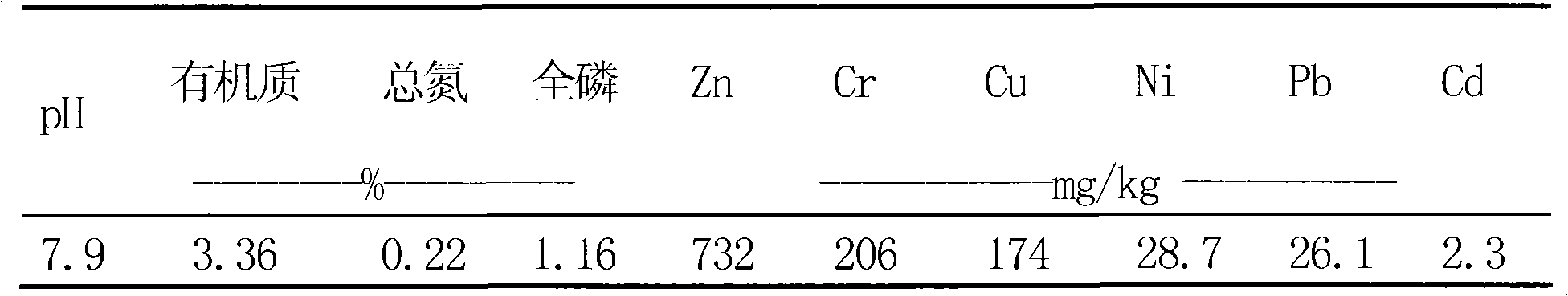

Microorganism detoxification, and solidification and hazard-free treatment method for metal substrate sludge

InactiveCN101898861ARealize closed loopReduce energy consumptionSludge treatment by de-watering/drying/thickeningTreatment with anaerobic digestion processesLiquid wasteSulfate-reducing bacteria

The invention relates to a microorganism detoxification, and solidification and hazard-free treatment method for metal substrate sludge. The method comprises the following steps of: lowering the pH value of the substrate sludge to be 2.5 to 3.0 under the action that sulfuric acid is generated by microbial oxidation of acidithiobacillus spp.; dissolving toxic metal from a solid phase of the substrate sludge into a liquid phase; and performing solid-liquid separation to obtain acid toxic metal waste solution and solid-phase acid substrate sludge which hardly contains toxic metal, and in the liquid-phase part, reacting microbial reduction product H2S of acid-resisting sulfate reducing bacteria with toxic metal ions to obtain metal sulfide deposit to realize standard emission; and performing solidification treatment on the solid-phase part by using caustic sludge as a modifier and using cement as a curing agent to finally finish full detoxification and hazard-free treatment of the toxic metal substrate sludge, wherein the treated substrate sludge meets the requirements of engineering filling and landfill. The method of the invention has the advantages of full detoxification, no secondary pollution, a few process devices, low energy consumption and suitability for industrial operation.

Owner:OCEAN UNIV OF CHINA

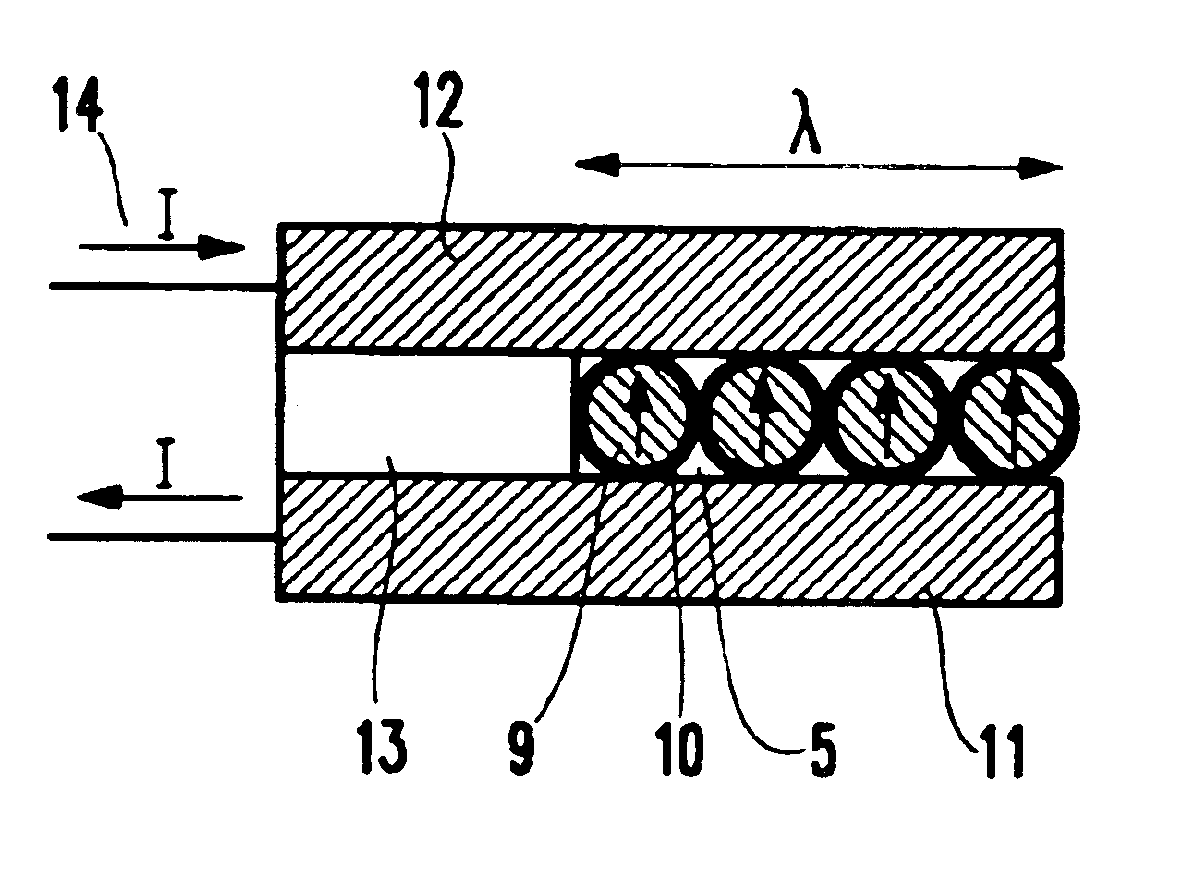

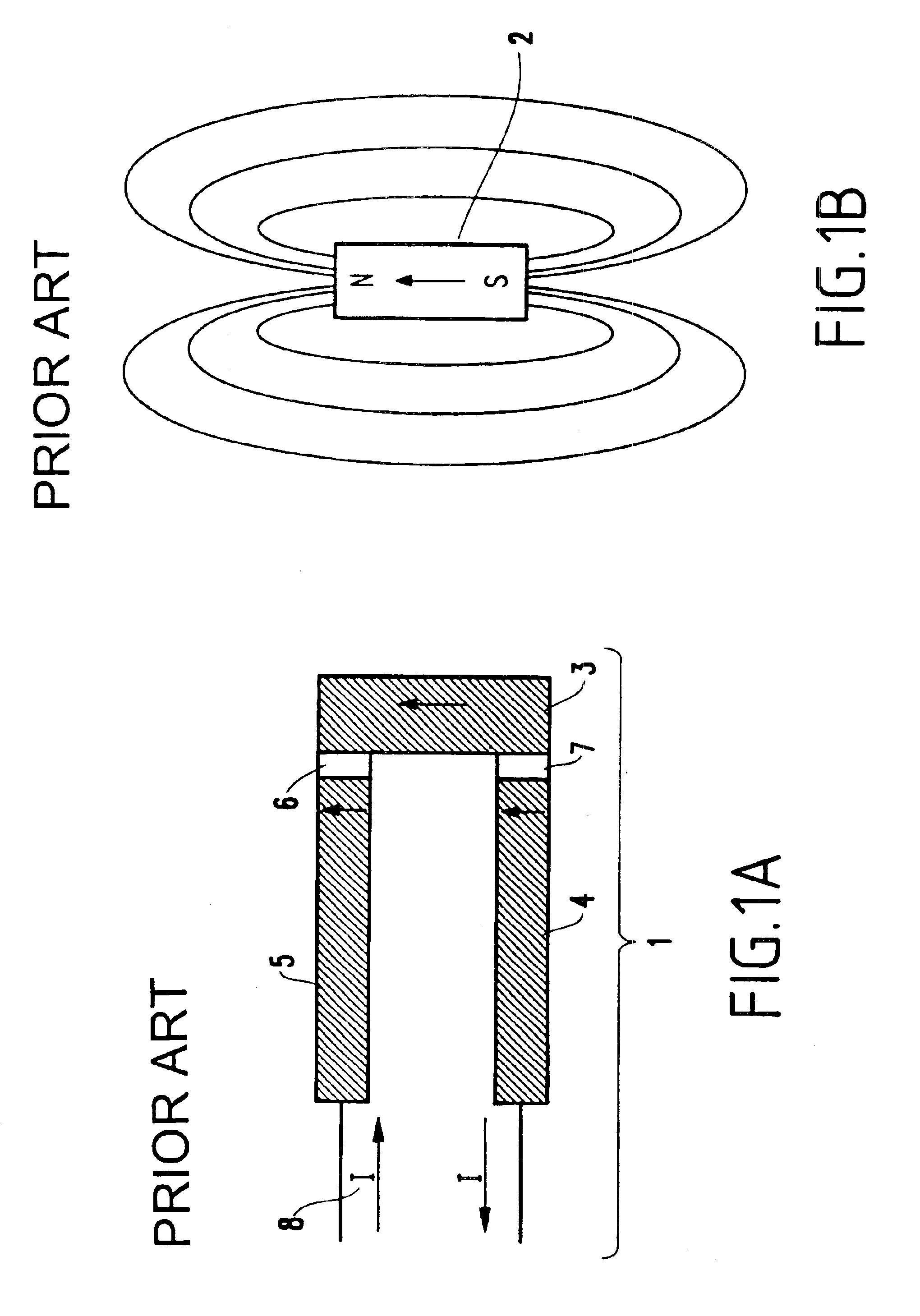

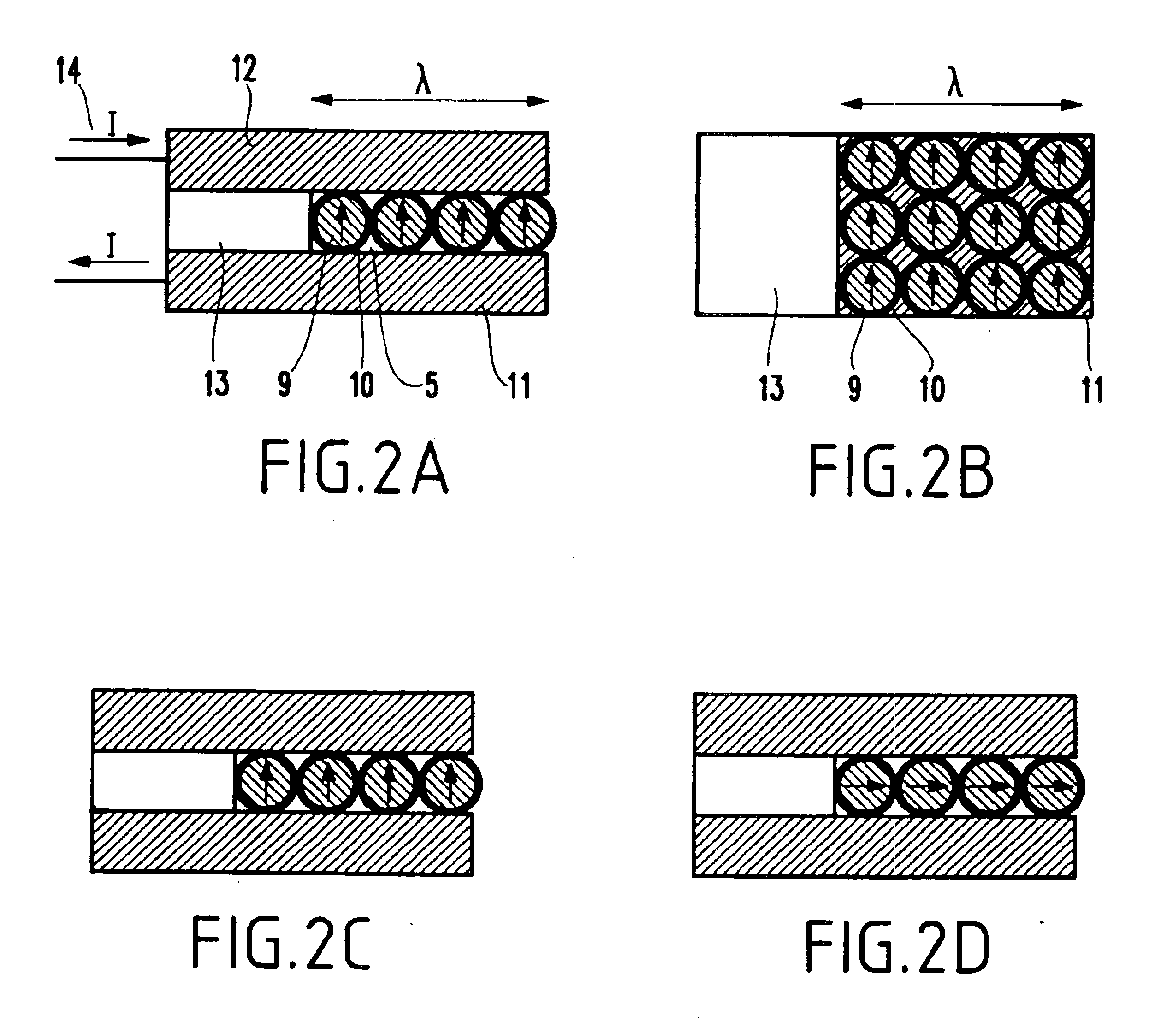

Magnetic-field sensor device

InactiveUS6897650B2Improve spatial resolutionEasy to scaleNanomagnetismLayered productsChemical synthesisMagnetite Nanoparticles

A magnetic-field sensor device comprises at least two electrodes; an insulating layer separating the at least two electrodes; at least one layer of chemically-synthesized magnetic nanoparticles disposed at or above a level with the insulating layer, and disposed between the at least two electrodes; and an organic spacer surrounding each of the chemically-synthesized magnetic nanoparticles. A deviation between diameters of different ones of the nanoparticles is less than 15%. Moreover, the chemically-synthesized magnetic nanoparticles range in size between 2 nm and 20 nm in diameter.

Owner:GLOBALFOUNDRIES U S INC

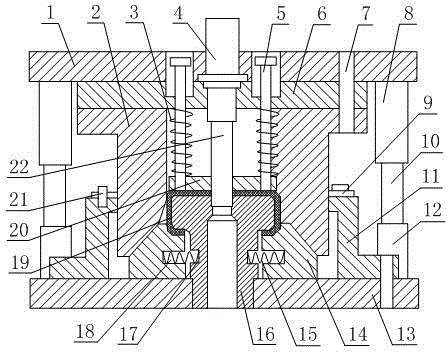

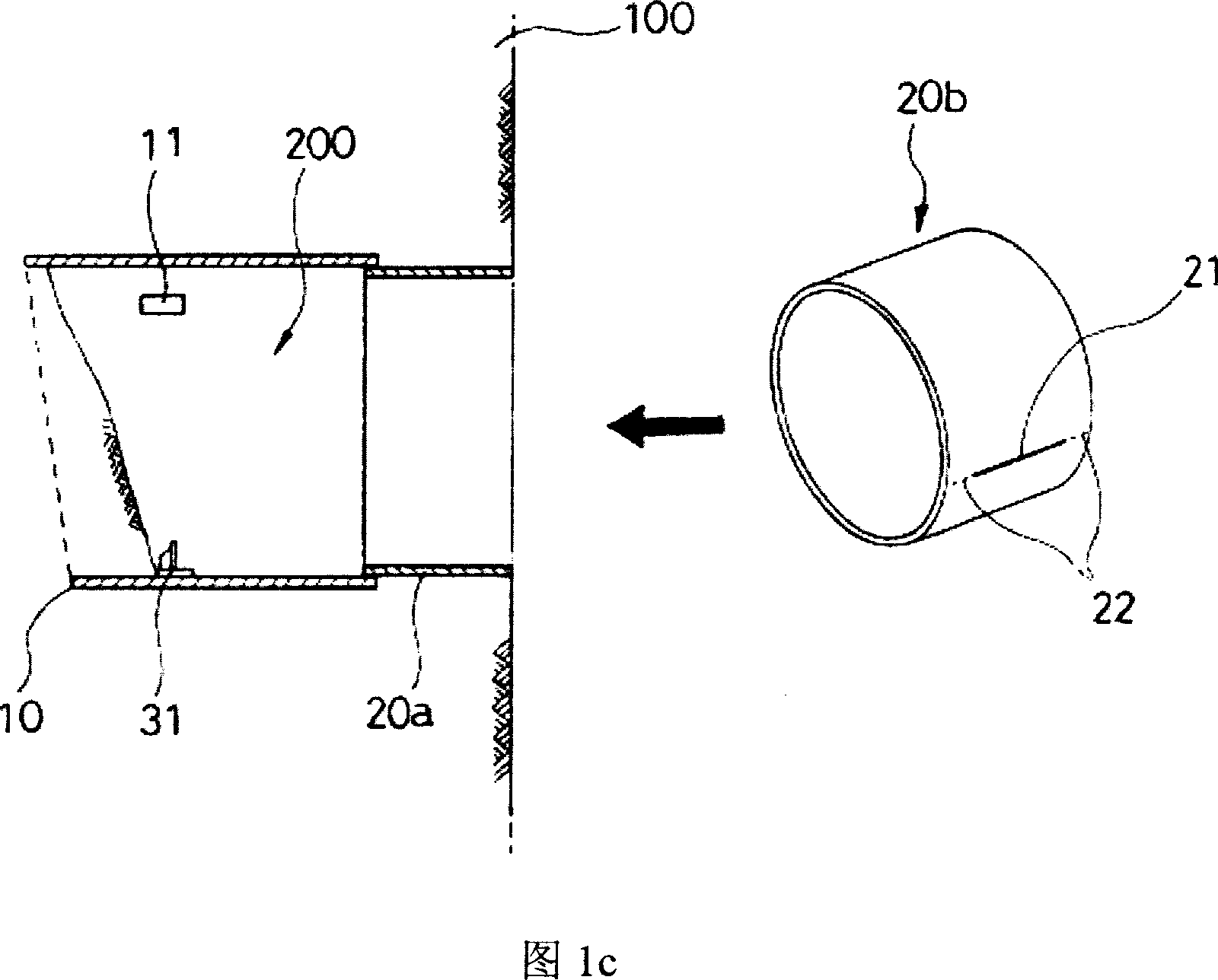

Composite stamping die for supporting seat

The invention discloses a composite stamping die for a supporting seat. A mounting plate is arranged between an upper die base and a lower die base and fixed to the upper die base, and a female die is arranged between the mounting plate and the lower die base and fixed to the lower die base; a side plate is arranged on the female die, and a locating pin is arranged in the side plate and connected with the side plate and the female die at the same time; a fixed wedge plate is arranged between the mounting plate and the lower die base, a movable wedge plate makes contact with the lower die base, and cavities communicated with each other are formed in the fixed wedge plate and the movable wedge plate respectively; a forming male die is arranged in the lower die base and the fixed wedge plate, and second springs are arranged between the forming male die and the movable wedge plate; a material pressing plate is arranged in one cavity, pull rods are arranged in the material pressing plate and arranged on the upper die base, and each pull rod is sleeved with a first spring; a die shank is arranged in the upper die base, and a punching male die is fixed to the die shank and arranged in the forming male die. One set of die is adopted for the stamping die to complete blanking, forming and punching of the supporting seat, and production efficiency is high.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

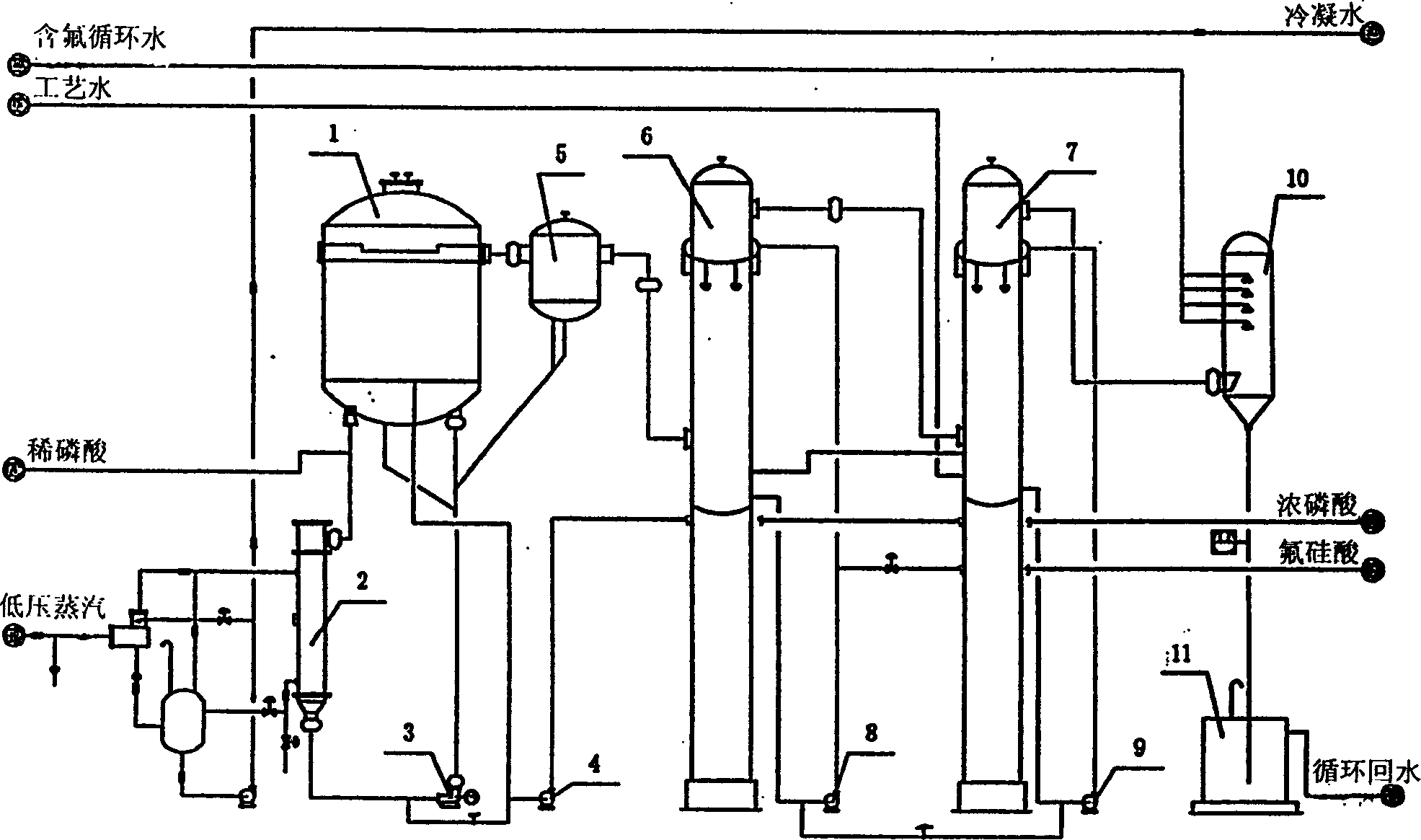

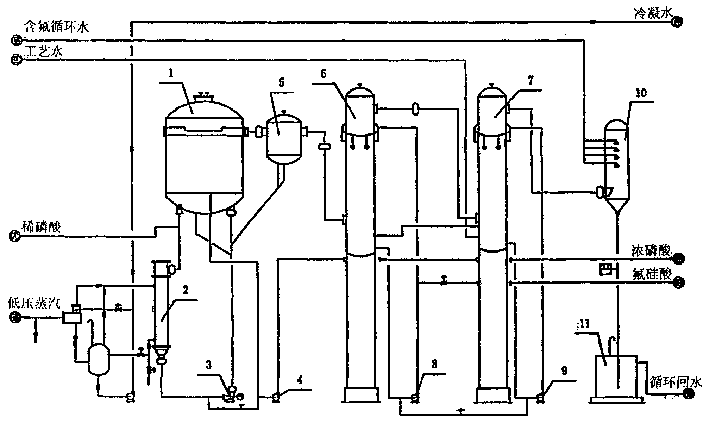

Method and equipment for producing phosphoric acid by adopting steam heating forced circulation concentration wet process

InactiveCN1205116CLess process equipmentCompact layoutSilicon halogen compoundsPhosphorus compoundsGas phasePhosphoric acid

The invention discloses a method and equipment for concentrating wet-process phosphoric acid by steam heating and forced circulation. Phosphoric acid is heated and concentrated in a circulation loop formed by a flash chamber, a graphite heat exchanger and an axial flow circulation pump. Dilute phosphoric acid is condensed from graphite The outlet pipe of the heat exchanger is added to the circulation loop, and the evaporated steam passes through the demister to remove the entrained acid foam, and then sprays and washes the fluoride in the gas phase through the two-stage fluorine absorption tower. The required vacuum degree of the flash chamber Provided by atmospheric condenser. The invention can change wet-process phosphoric acid from 20-25% P 2 o 5 Concentrate to 48-50%P 2 o 5 , and can reduce the P during the enrichment process 2 o 5 Loss, improve the fluorine recovery efficiency of tail gas and the quality of fluosilicic acid.

Owner:EAST CHINA ENG SCI & TECH

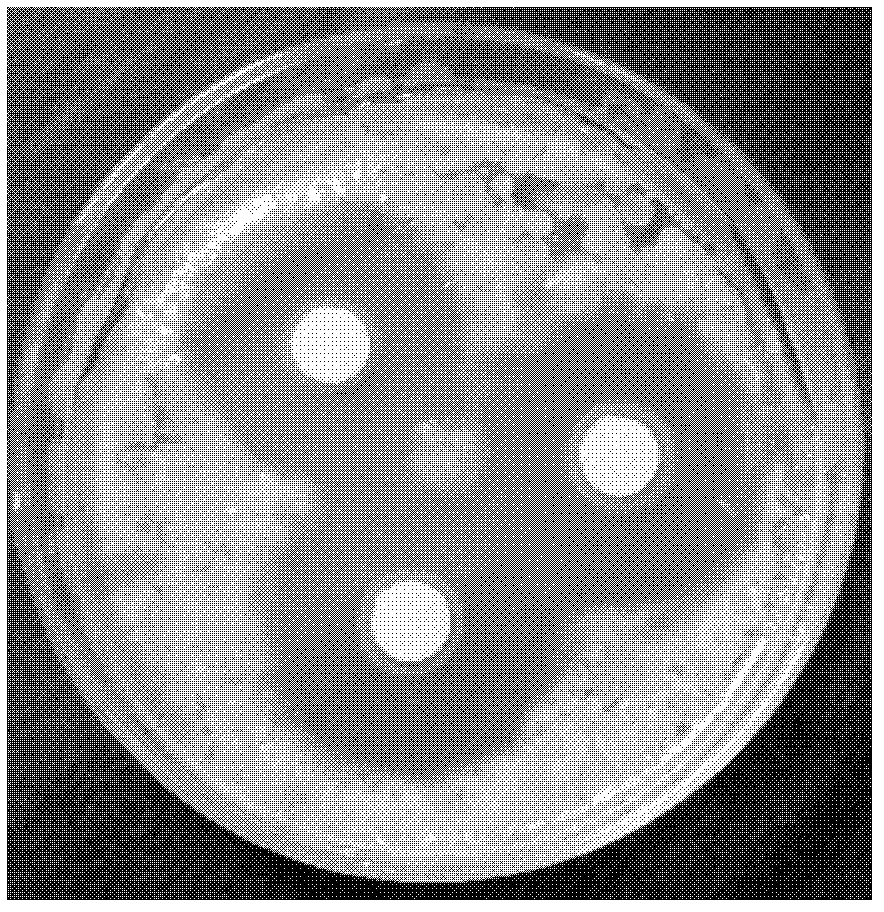

Method for preparing tea saponin/copper compound antibacterial agent

The invention discloses a method for preparing a tea saponin / copper compound antibacterial agent, and the preparing steps include:adding natural product tea saponin and copper ions by mass ratio of (0.1-2) : 1 with stirring, keeping stirring for 2 hours to 6 hours, drying by a spray drier and then obtaining the tea saponin / copper compound antibacterial agent. The purity of the tea saponin is above 70%. The copper ions are a mixture prepared from one or more than two of solid copper sulfate, cupric nitrate and copper chloride in an arbitrary proportion. The compound antibacterial agent has an excellent broad-spectrum antibacterial property and obvious inhibiting effect for various pathogenic bacteria such as Escherichia coil, staphylococcus aureus and the like. Compared with the bacteriostatic activity of using tea saponin or a metal new antibacterial agent alone, the bacteriostatic activity of the compound antibacterial agent is remarkably enhanced, and the compound antibacterial agent is widely used in the fields of daily chemicals, textile and food and the like, and has a good harmony and a high security with the environment. According to the method for preparing the tea saponin / copper compound antibacterial agent, the antibacterial agent has the advantages of simple technology, low cost, easiness in industrialization and stable quality and the like.

Owner:FUJIAN SHENGHUA AGRI SCI & TECH DEV

Overlapped natural gas liquified system in mixed refrigerant cycling expansion machine

InactiveCN102878779ANo compression cycleFlexible configurationSolidificationLiquefactionModular designProcess engineering

The invention relates to the field of natural gas liquified systems in refrigeration and at low temperature, and in particular relates to an overlapped natural gas liquified system in a mixed refrigerant cycling expansion machine. The overlapped natural gas liquified system in the mixed refrigerant cycling expansion machine comprises a compressor module, a precooling module, a condensation module and a liquified module; multi-element mixed medias are adopted as refrigerants, MRC (mixed refrigerant cycling) and expansion machine refrigeration cycling are internally overlapped; the system runs reliably; the energy consumption is low; the load match is flexible, and the single line production energy is high; the liquified flow is simplified; the structure is compact; and the modular design is easy to adopt flexibly in various occasions.

Owner:SUN YAT SEN UNIV

Psidium guajava fruit wine and process for preparing same

InactiveCN102952658AStrong fragranceDelicate and mellow tasteAlcoholic beverage preparationBiotechnologyFruit wine

The invention discloses a psidium guajava fruit wine, comprising the following raw materials by weight: 40-60 parts of psidium guajava raw juice and 40-60 parts of sugarcane juice. A process for preparing the psidium guajava fruit wine comprises the following steps of: S1, preparing the psidium guajava raw juice; S2, preparing the sugarcane juice; and S3, brewing. The psidium guajava fruit wine has the beneficial effects of being rich in fragrance, pure and sweet, mellow and fine in taste, lasting in remaining taste, clear and transparent in vinosity, lustrous in color, rich in various nutritional ingredients beneficial for the human body, capable of clearing away heat and toxic materials and preventing enteritis and diarrhea, free of additives, good in stability, and capable of being stored for a long time and more sufficiently utilizing the psidium guajava resources, prolonging the storage period of psidium guajava and improving the utilization rate of the resources; and the preparation process requires little process equipment, and is low in cost, short in time and capable of remaining the quality and nutritional ingredients of psidium guajava.

Owner:梅普农

Hydrocyanation process with reduced yield losses

ActiveUS7709674B2Yield lossInvestment exemptionOrganic compound preparationPreparation by hydrogen cyanide additionPhosphonitePhosphine

A hydrocyanation process produces adiponitrile and other dinitriles having six carbon atoms. The process involves forming a reaction mixture in the presence of at least one Lewis acid. The reaction mixture includes ethylenically unsaturated nitrites having five carbon atoms, hydrogen cyanide, and a catalyst precursor compositions. The reaction mixture is continuously fed while controlling the overall feed molar ratio of 2-pentenenitriles to all unsaturated nitriles and the overall feed molar ratio of hydrogen cyanide to all unsaturated nitrites. In the reaction product mixture, including adiponitrile, the ratio of the concentration of 2-pentenenitriles to the concentration of 3-pentenenitriles from about 0.2 / 1 to about 10 / 1. Included in the catalyst precursor composition is a zero-valent nickel and at least one multidentate phosphorus-containing ligand. The multidentate phosphorus-containing ligand may be a phosphite, a phosphonite, a phosphinite, a phosphine, and a mixed phosphorus-containing ligand or a combination of such members.

Owner:INV NYLON CHEM AMERICAS LLC

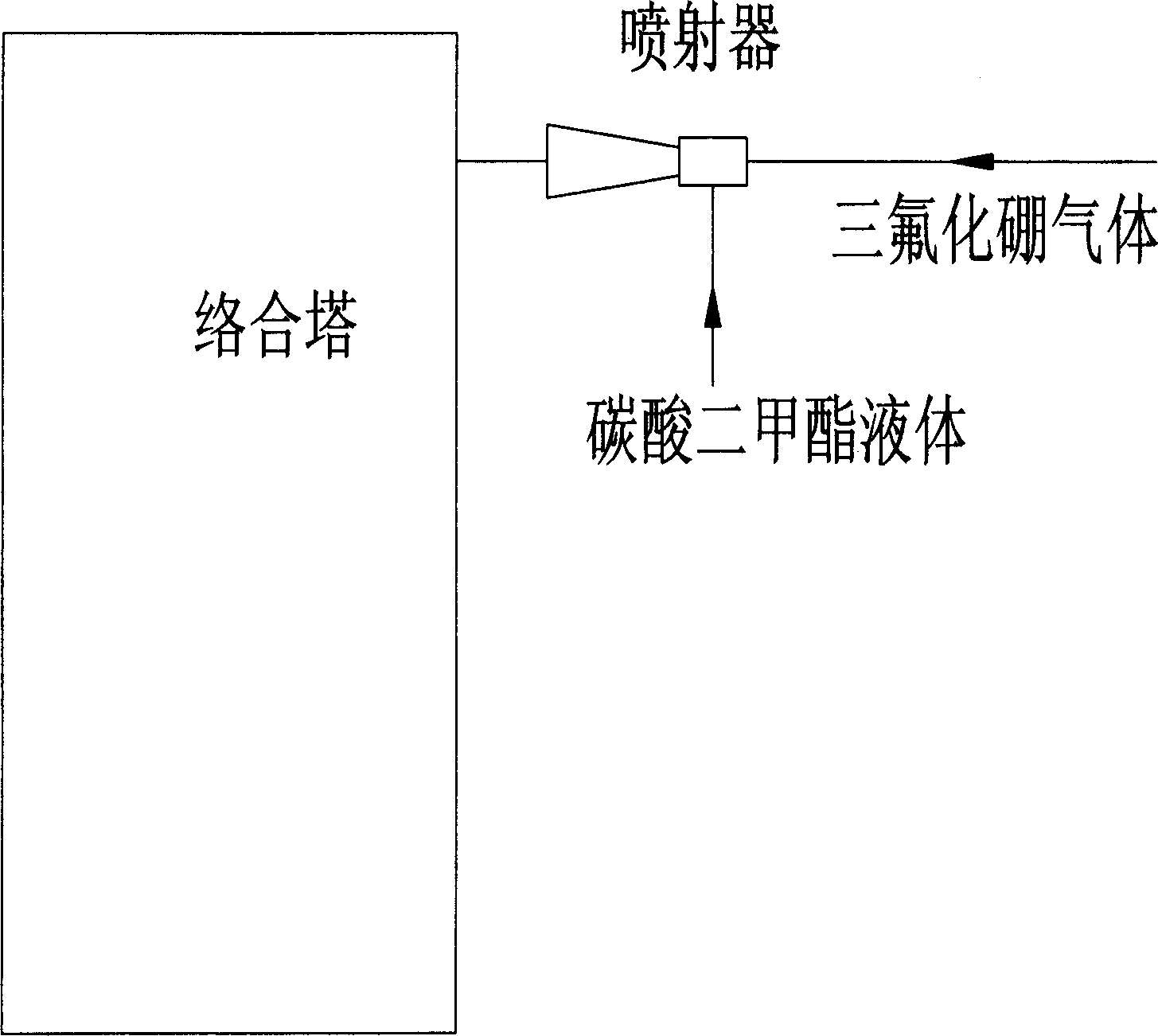

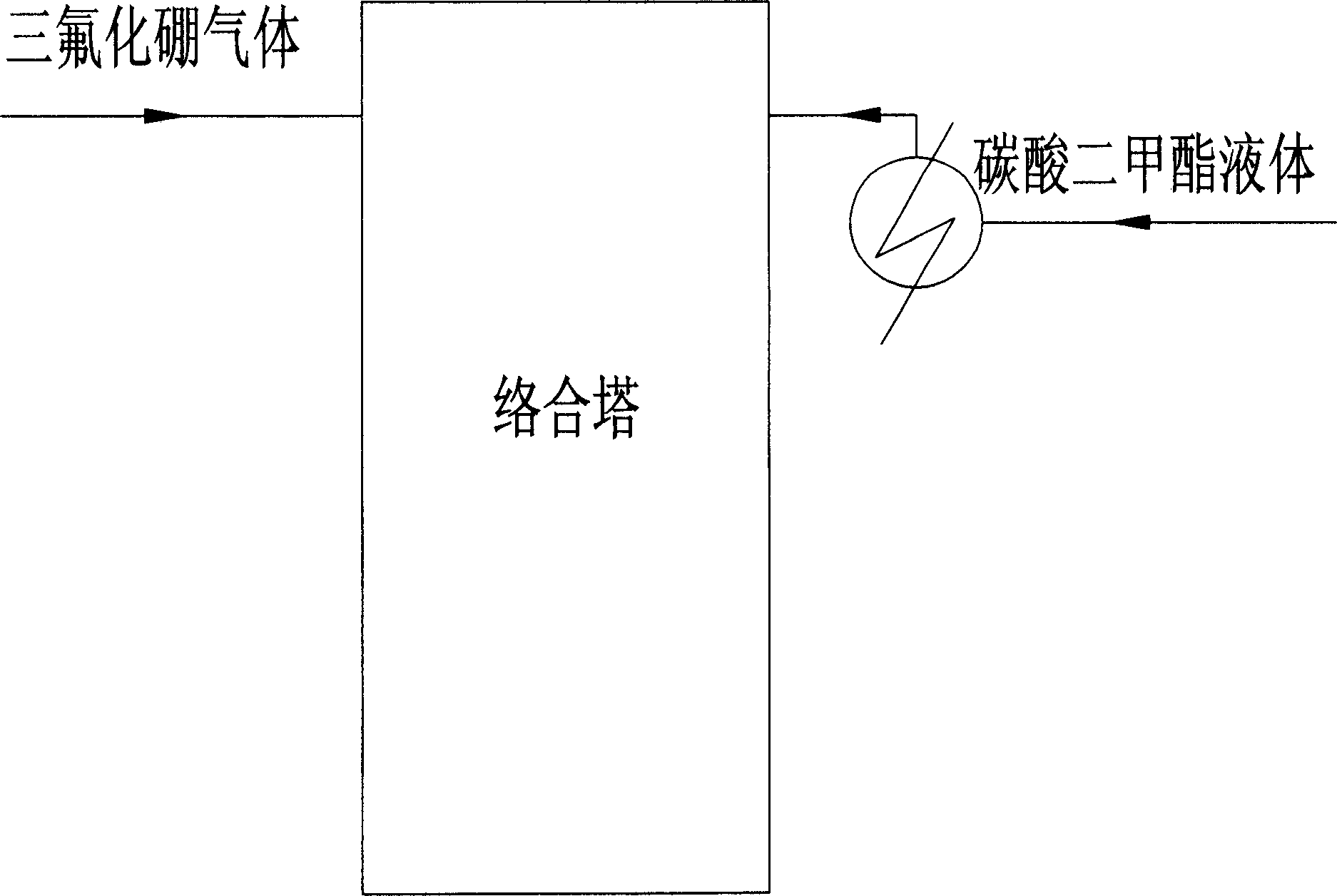

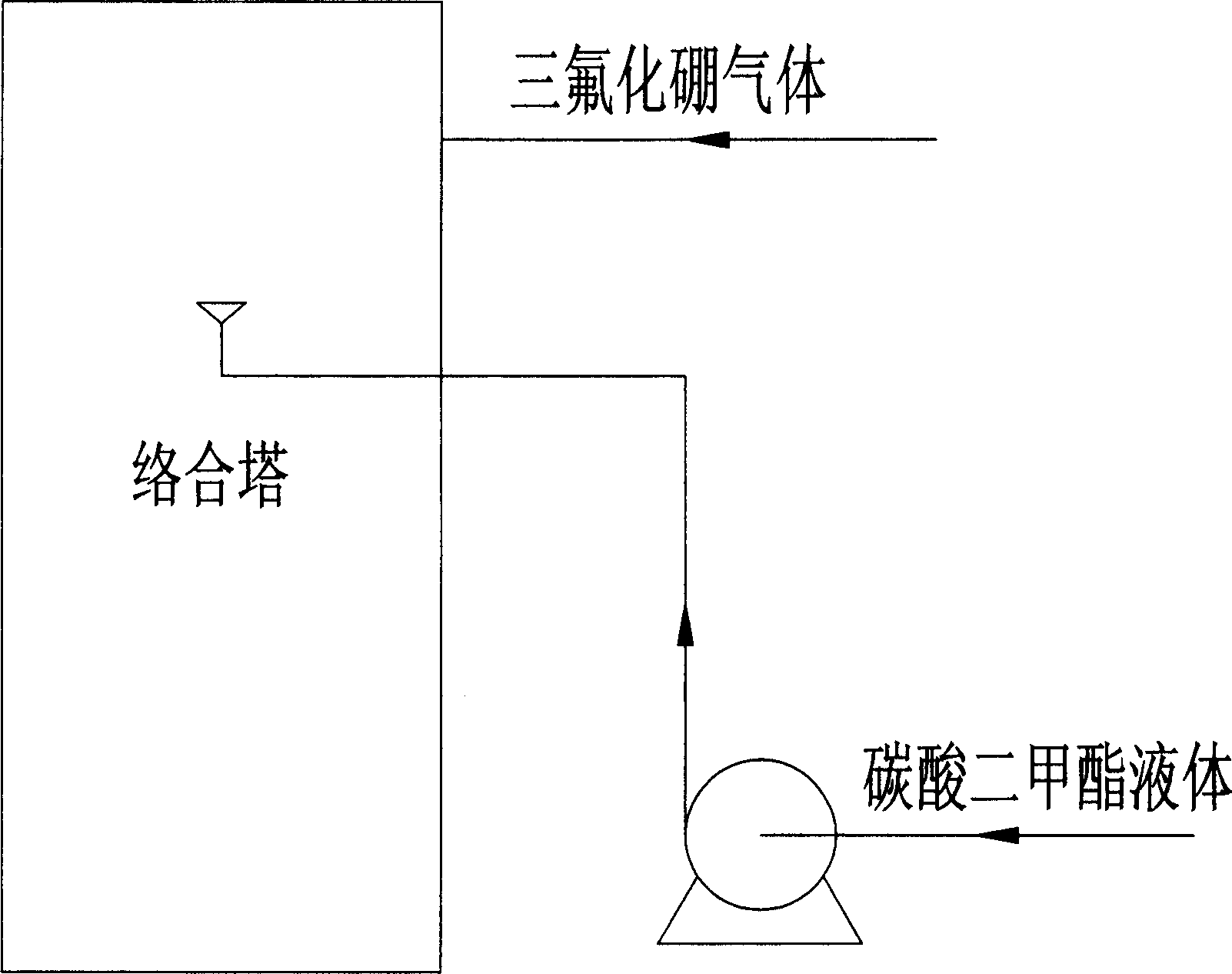

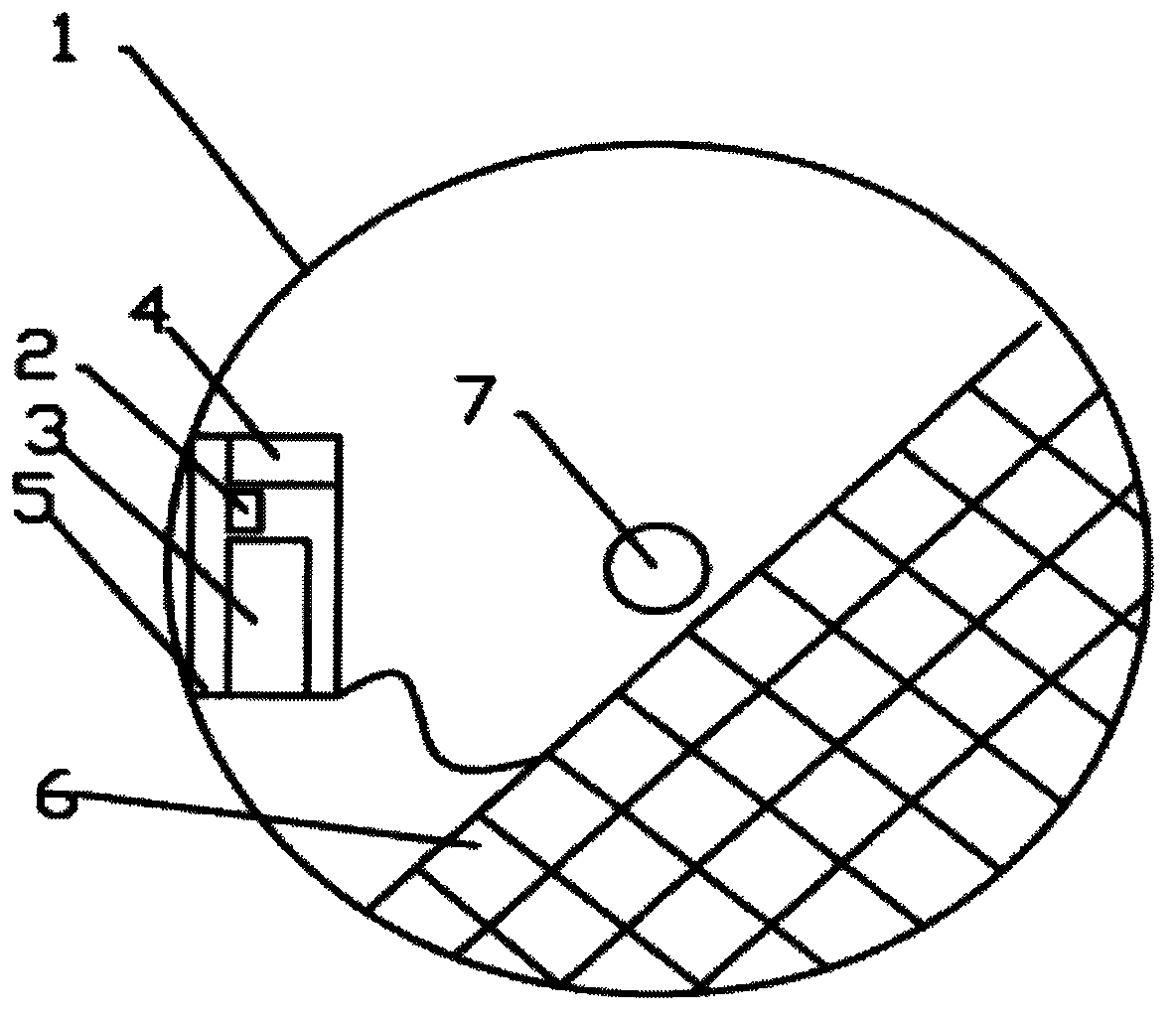

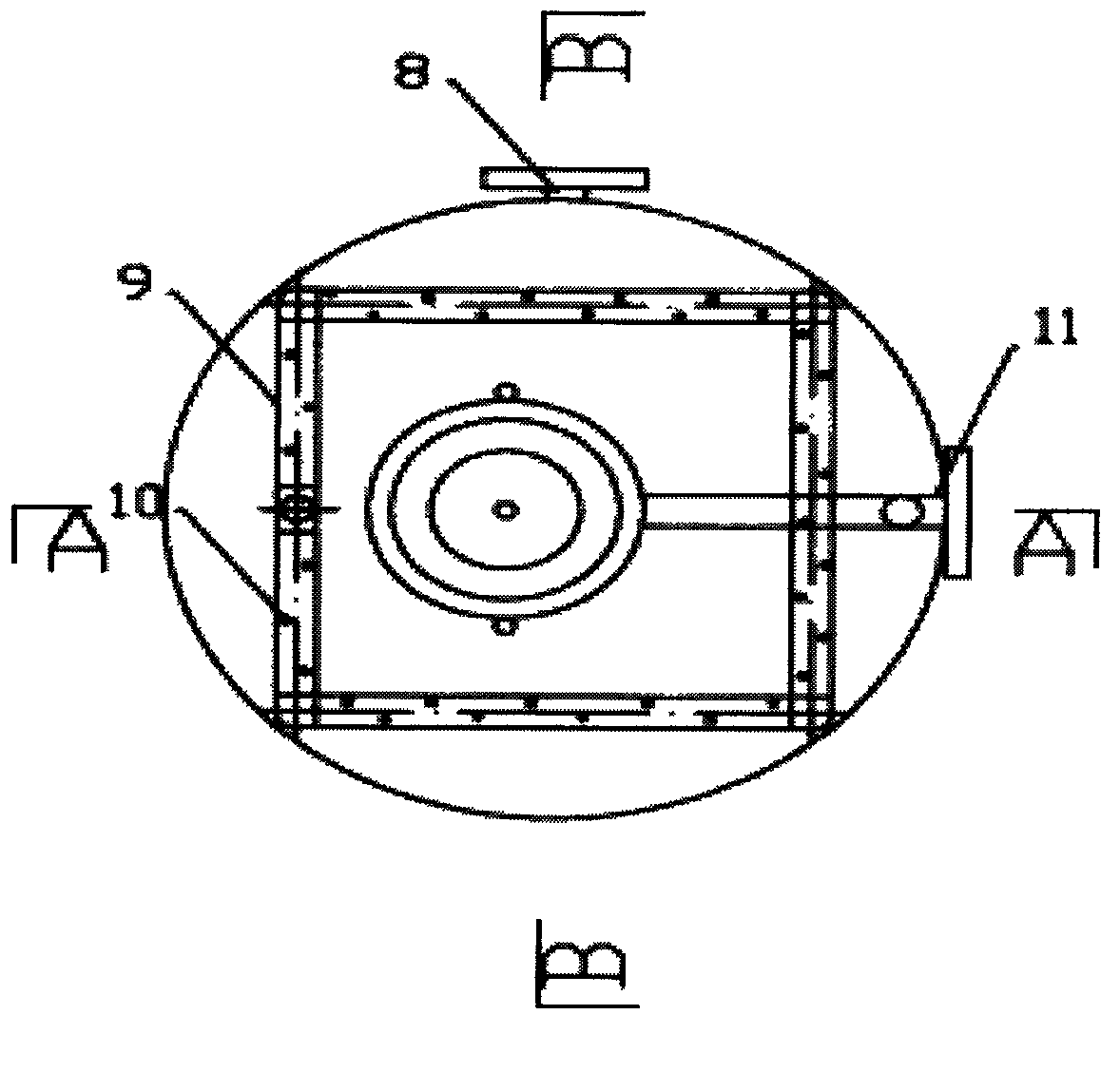

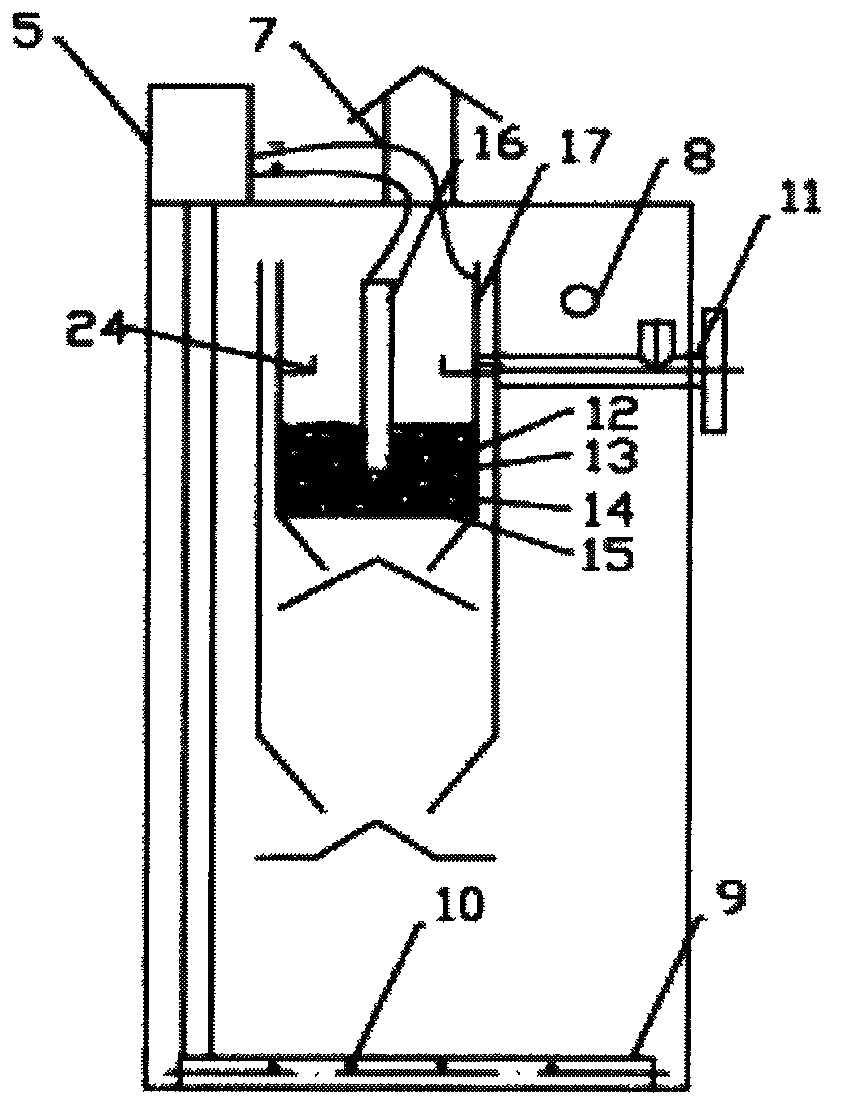

Complexing method of boron trifluoride methylcarbonate complex

InactiveCN1876660ASimple production methodLess process equipmentGroup 3/13 element organic compoundsProcess equipmentMethyl carbonate

The invention relates the complexing method of boron trifluoride dimethyl carbonate complex compound. The method comprises the following steps: transferring the liquid dimethyl carbonate to gas or spray pattern, adding the dimethyl carbonate and boron trifluoride in the rate of 1: 0.5-1: 1.5 to complex reactor, controlling the temperature below 90Deg.C, carrying out complex reaction, and getting the product. The invention simplifies the preparing method. The invention has the advantages of easy operation and good quality.

Owner:哈尔滨广渠经贸有限公司

Integrated life sewage nitrogen and phosphorus removal apparatus

InactiveCN102795744AImprove processing efficiencyReduce redundant process equipmentTreatment with aerobic and anaerobic processesEnergy based wastewater treatmentSludgeTransformer

The invention discloses an integrated life sewage nitrogen and phosphorus removal apparatus, which can be widely used for nitrogen and phosphorus removal treatment of the life sewage, and comprises a cylindrical pool body and a mud-water separation device. A water inlet and a water outlet are provided on the sidewall of the pool body. A through-hole aerated tube is arranged on the bottom of the pool body. The mud-water separation device is fixed in the pool body by a metal support, and is divided into to two grades, and a physical phosphorus removal area and an electrochemistry nitrogen removal area are arranged in a two grades mud-water seperator. A cover plate is provided with the pool body, an air exhaust opening is provided on the cover plate, and an electrical cabinet is provided, an air pump, a time switch and a current stabilization transformer are arranged in the electrical cabinet, and the electrical cabinet is connected to a solar energy power device. By aiming the characteristics of life sewage, the apparatus has the advantages of compact structure and simple management, the integrated design is capable of substantially reducing the land occupation, no sludge backflow system is provided, the cost of investment and operation is low, thereby the integrated life sewage nitrogen and phosphorus removal apparatus is a bioelectrochemical sewage treatment device with the characteristics of no power consumption and economical and practical effects.

Owner:杭州净洋环保科技有限公司

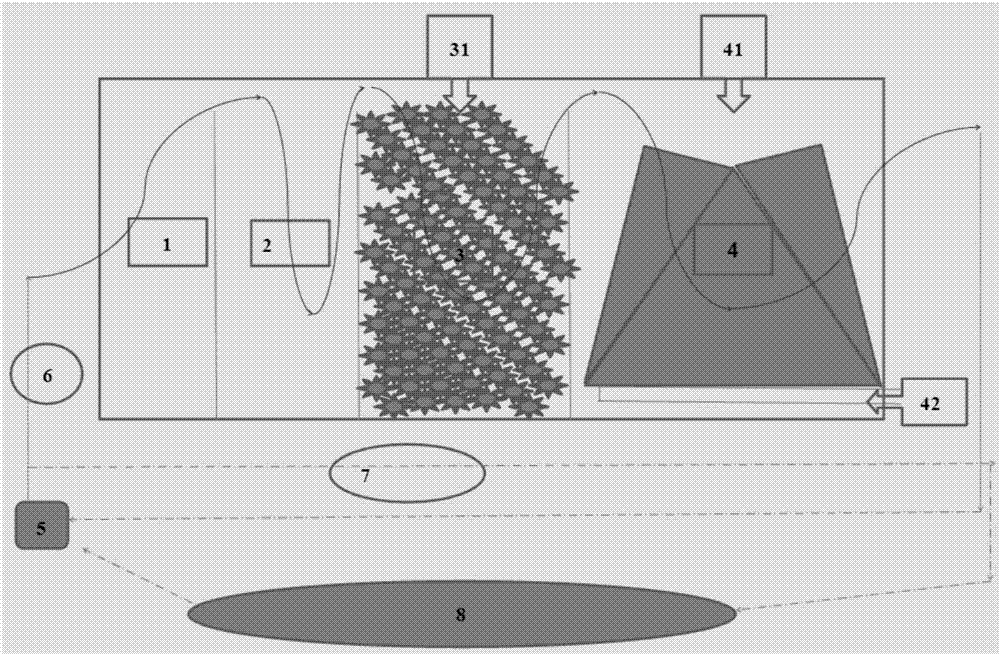

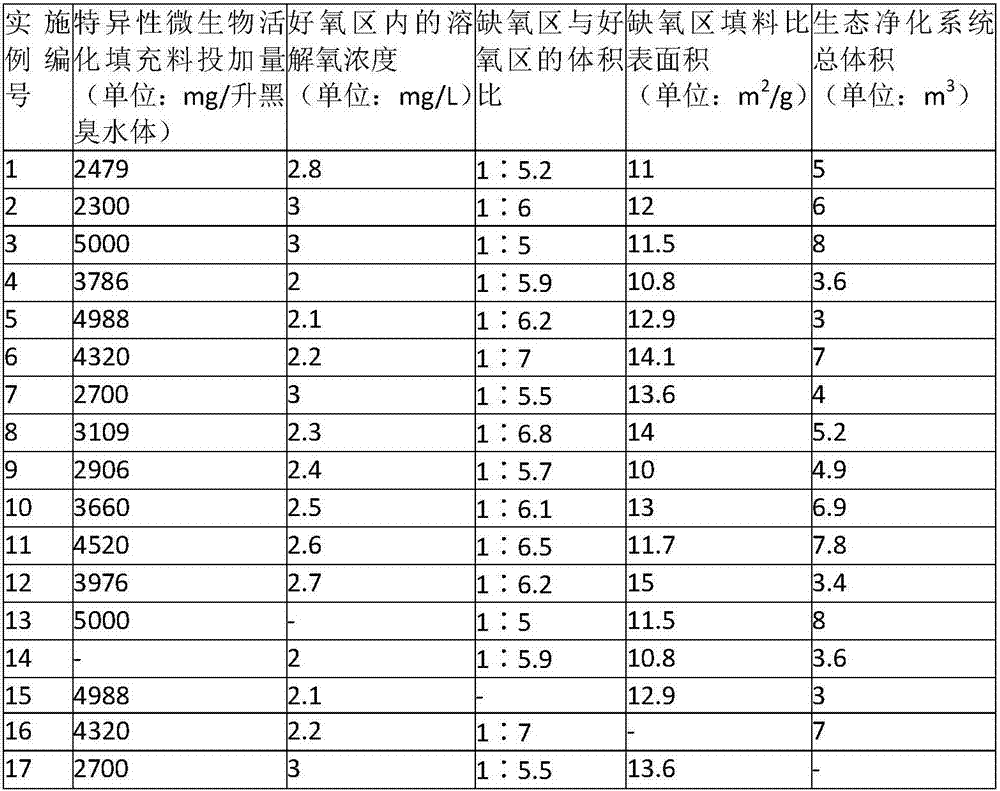

Specific microorganism activating filler for treating black and odorous water bodies

InactiveCN107098481ARealize self-cleaning abilityFree up room to growBacteriaSpecific water treatment objectivesSelf purificationNitrifying bacteria

The invention provides a specific microorganism activating filler for treating black and odorous water bodies and belongs to the technical field of water treatment. The filler is prepared from the following raw materials in parts by weight: 3-5 parts of a microorganism inducer, 40-80 parts of an attachment carrier, 0-10 parts of an organic macromolecule polymer, 0-4 parts of an inorganic flocculate and 1-30 parts of an oxidization decoloring agent, wherein the microorganism inducer comprises nitrobacteria and / or denitrifying bacteria and a culture medium matter for the growth of the nitrobacteria and / or the denitrifying bacteria. The filler provided by the invention has the advantages that traditional water body purification is broken through; indigenous microorganisms of the water bodies are activated mainly and the water bodies per se serve as cultivating and breeding bases, so that the growth space of the microorganisms is greatly released, the effective biomass and the functionality of the microorganisms are increased, the microbial ecosystem of the water bodies is recombined, improved and optimized and the self-purification capacity of the water bodies is realized eventually.

Owner:中林山水(北京)生态科技有限公司

Method for preparation of biological adsorbent with canna edulis ker slags

The invention relates to a method for preparation of a biological adsorbent with canna edulis ker slags, comprising the steps of: washing and air-drying or drying the canna edulis ker slags from which canna edulis ker starch is extracted, pulverizing the slags, and sieving the pulverized powder through a 20-mesh sieve; modifying the canna edulis ker slag powder in an acid solution at a concentration of 0.02-2M, with the powder and the acid in a mass ratio of 1:2-20 and a soaking time of 1-8 hours; washing the powder into neutrality and drying at a temperature of 30-120 DEG C, pulverizing the dried canna edulis ker slag powder and sieving it through a 200-mesh sieve, thus obtaining the product of biological adsorbent. The adsorption capacity of the biological adsorbent of canna edulis ker slags to basic dyes can reach 120-385mg / g, and the adsorption capacity to metal ions reaches 50-248mg / g. The preparation method of the invention is characterized by easily available raw material, simple, economical and environmentally friendly preparation process, as well as capability to make waste profitable. And the adsorbent prepared by the method can purify water resources, thus realizing the sustainable development of ecological resources.

Owner:FUJIAN NORMAL UNIV

Composite stamping die

The invention discloses a composite stamping die which comprises an upper die base, a lower die base, a die handle and a convex punching die. The die handle is arranged in the middle of the upper die base, the convex punching die is arranged in the middle of the lower die base, the die handle is fixedly connected with the convex punching die, an installing plate is arranged under the upper die base, a pull rod is arranged in the installing plate, springs are arranged at two ends of the pull rod, a convex forming die, a spring and a movable tapered wedge are sequentially arranged on the outer side of the convex punching die, the convex forming die is connected with the movable tapered wedge through the spring, the movable tapered wedge is provided with a fixed tapered wedge and is matched with the fixed tapered wedge, a guide column and a guide sleeve are arranged at two ends of the lower die base, and the lower die base is connected with the upper die base through the guide column and the guide sleeve. The composite stamping die can achieve continuous implementation of blanking, forming and punching, production efficiency is high, and production cost is reduced.

Owner:WUHU JINLONG MOLD FORGING

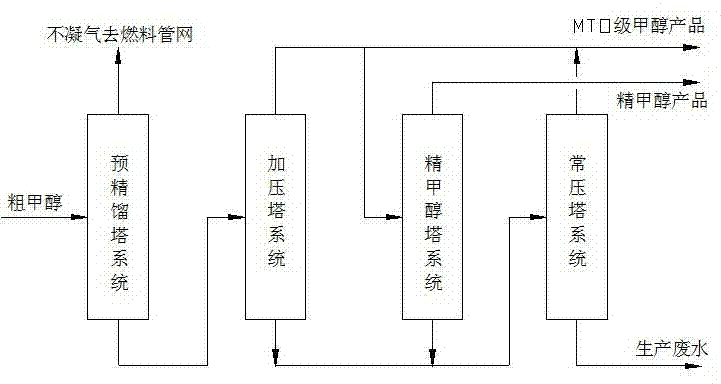

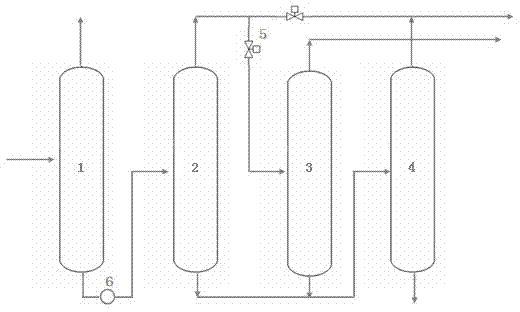

Method for obtaining fine methanol products by using methanol to olefins (MTO) methanol products

ActiveCN103539634AEasy to convertLess process equipmentOrganic compound preparationHydroxy compound preparationProcess engineeringMethanol

The invention discloses a method for obtaining fine methanol products by using methanol to olefins (MTO) methanol products. The key is as follows: a fine methanol rectifying tower is added in a three-tower distillation process of producing MTO-grade methanol products, so as to obtain the fine methanol products and meet the requirements of downstream products on the fine methanol. The method comprises the following concrete steps: separating out a part of MTO-grade methanol products from the top of an MTO methanol pressure tower; and feeding to the fine methanol rectifying tower, thereby obtaining the fine methanol products from the top of the fine methanol rectifying tower in a rectifying manner and returning the tower bottom liquid of the fine methanol rectifying tower back to an MTO methanol atmospheric tower. The fine methanol products are obtained under the condition that a few of equipment are added by the steps, and production of the original MOT-grade methanol products is not affected, so that the target of saving investments is achieved.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

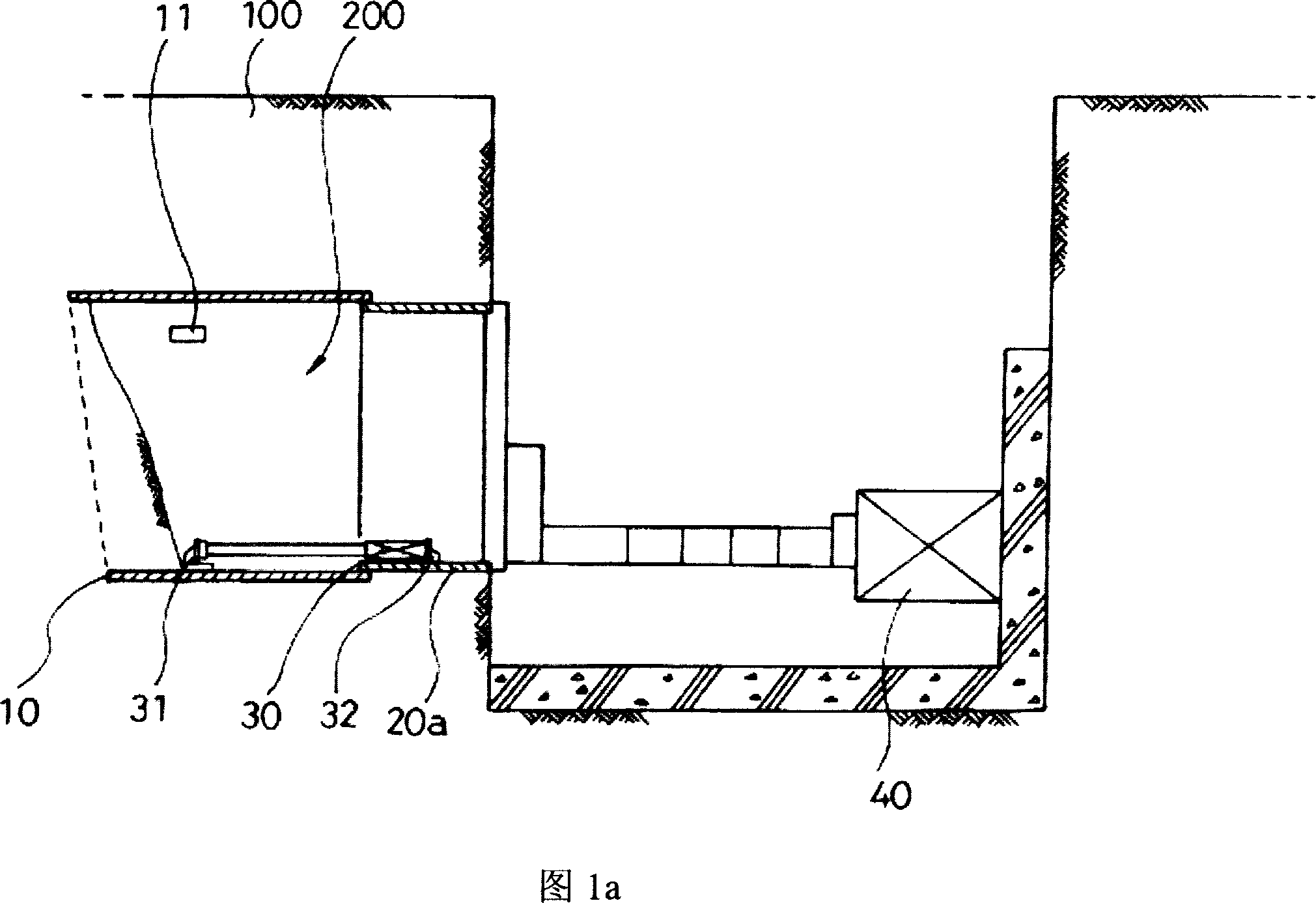

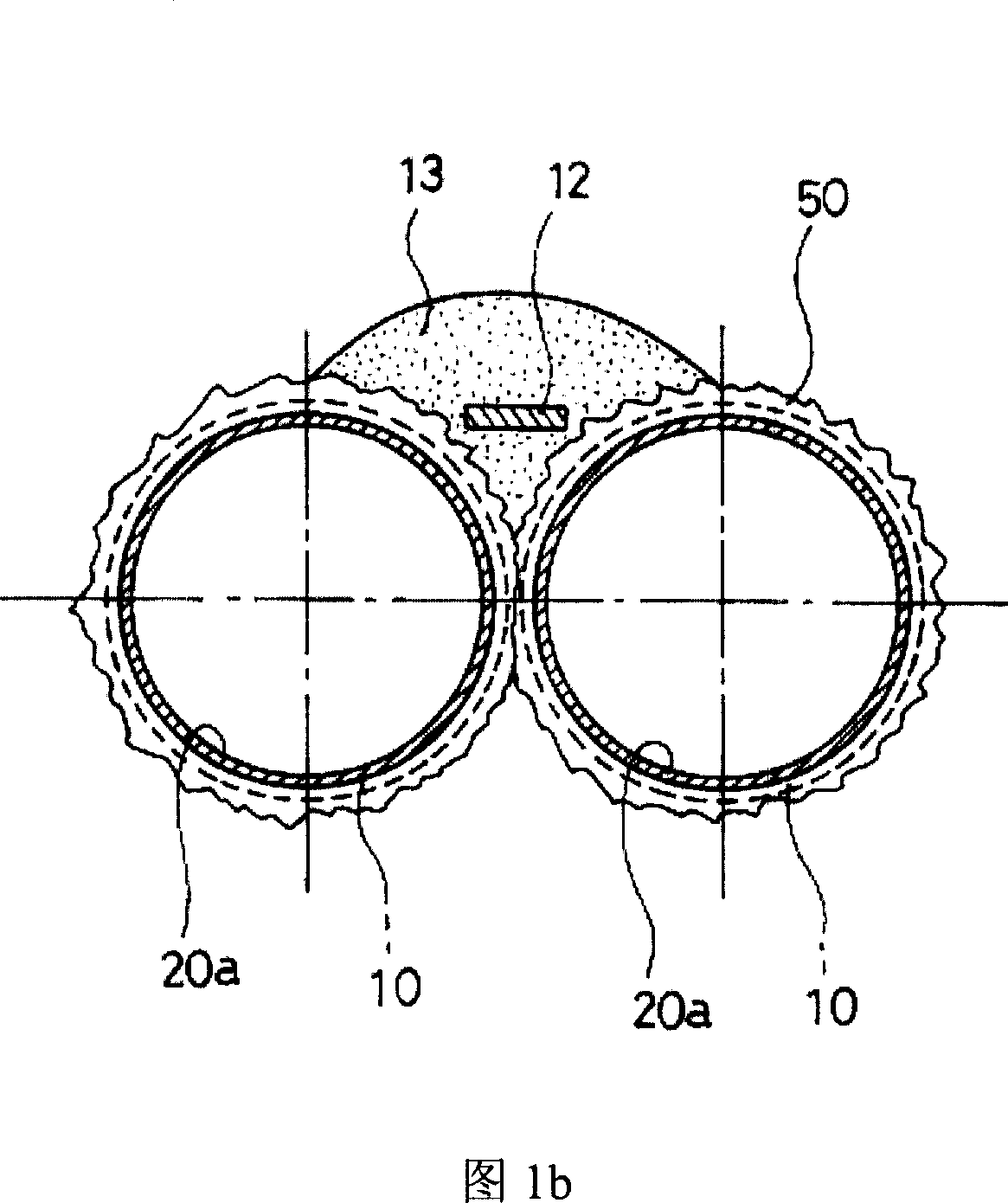

Main duct construction method laid down tunnel structure article

InactiveCN101092878AEasy to laySpeed up layingUnderground chambersTunnel liningLandslideBuilding construction

The invention discloses a main pipe construction method for establishing the tunnel formation, comprising following steps: pushing down a leading pipe and an initial main pipe underground; preventing landslide; conveying the next main pipe whose outer diameter is far smaller than the initial pipe to the inside of the main pipe setting space; expanding the diameter of the next main pipe to make it the same as the diameter of the initial main pipe; connecting the next main pipe after expansion treatment with the front end of the initial main pipe; repeating the connection operation of the next main pipe for establishing the tunnel formation. The technique scheme is able to construct in a direct or curve way, swift, safe and simple.

Owner:NTS ENC

Method for preparing paper making antibacterial agents by using oil-tea camellia shells as carriers

InactiveCN102587210AEfficient use ofEmission reductionPaper/cardboardCamellia oleiferaProcess equipment

The invention relates to a method for preparing paper making antibacterial agents by using oil-tea camellia shells as carriers. The method is characterized in that 10 weight parts of oil-tea camellia shells particles are added into 25 to 30 weight parts of glutaraldehyde water solution, 350 to 400 weight parts of concentrated hydrochloric acid is added in a stirring way, and the reaction lasts 4 hours at 60 to 75 DEG C; 0.5 to 5 weight parts of sliver, zinc or copper metal compound solid is added, and the materials are continuously stirred for 4 to 12 hours after the dissolution; filtering, washing slag filtering are carried out until the materials to neutral, 5 weight parts of alkali liquor or reducing agents are added into the filter slag, and the materials are stirred at 40 to 80 DEG C for reaction for 0.5 to 3 hours; after the filtering is filtered slag and washed to the neutral state, and the filter slag is dried at 40 to 80 DEG C to obtain oil-tea camellia shell base paper making antibacterial agents. The antibacterial agents have the advantages that the oil-tea camellia shells are used as preparation raw materials, the resources are wide, the price is low, and the waste discharge is reduced; the preparation process is simple, the cost is lower, and high remaining rate is realized in pulp; and the preparation conditions are mild and can be easily controlled, the process equipment is less, and the operation is easy.

Owner:FUJIAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com