Method and equipment for producing phosphoric acid by adopting steam heating forced circulation concentration wet process

A wet-process phosphoric acid, forced circulation technology, applied in chemical instruments and methods, phosphorus compounds, halogenated silicon compounds, etc., can solve the problems of high operation and maintenance costs, low fluorine washing efficiency, large steam consumption, etc., to achieve operation and maintenance. The effect of low cost, high fluorine washing efficiency and less process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Adopt the 60,000 tons / year P of the present invention 2 o 5 Phosphoric acid concentrator

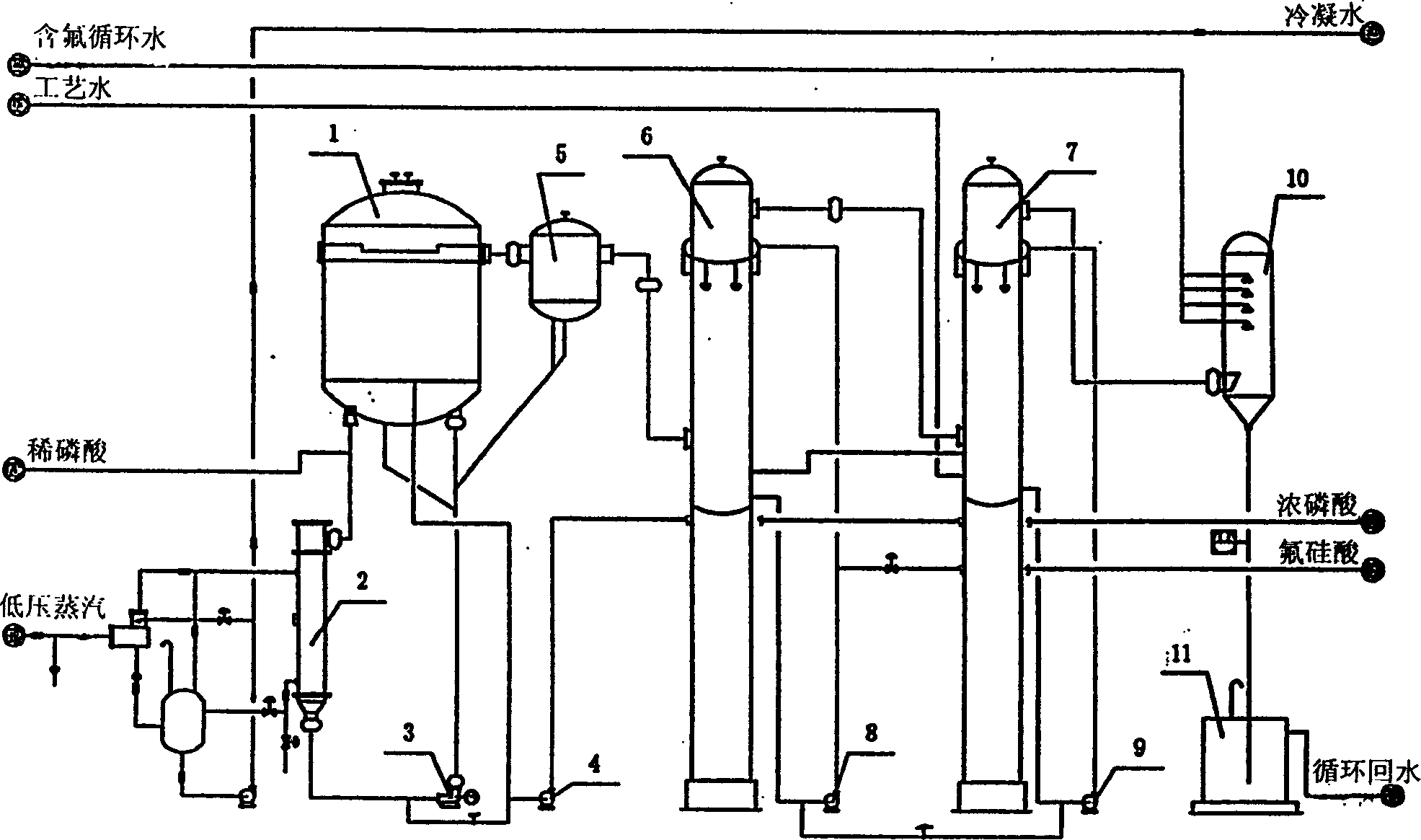

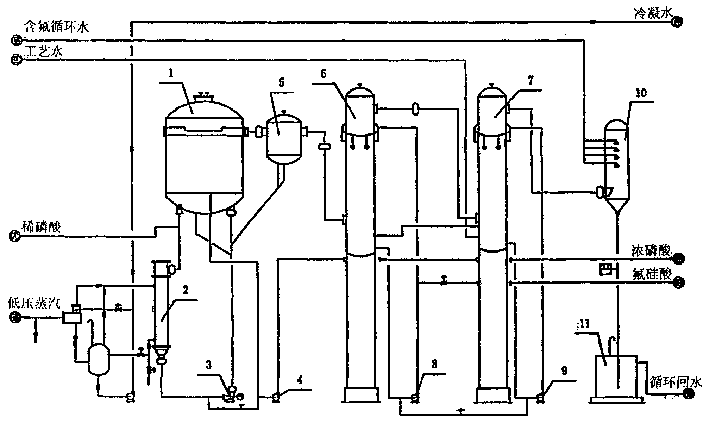

[0026] See attached picture. The equipment for concentrated wet-process phosphoric acid by steam heating and forced circulation includes a circulation loop formed by a flash evaporator 1, a graphite heat exchanger 2 and an axial circulation pump 3. The fluorine absorption tower has first and second fluorine absorption towers 6 and 7, Spray circulation pumps 8 and 9 are installed outside the fluorine absorption towers 6 and 7 respectively. The second fluorine absorption tower 7 communicates with the atmospheric condenser 10 , and the atmospheric condenser 10 communicates with the condensate liquid seal tank 11 .

[0027] 25% P pumped by dilute phosphoric acid 2 o 5 Filter the acid, and add it to the heat exchange area of 315m after metering 2 The outlet pipe of the graphite heat exchanger 2 enters the bottom of the flash evaporator 1 together with the heated circulating aci...

example 2

[0030] Adopt 80,000 tons / year P of the present invention 2 o 5 Phosphoric acid concentrator

[0031] See attached picture. 25% P pumped by dilute phosphoric acid 2 o 5 Filter the acid, and add it to the heat exchange area of 430m after metering 2 The outlet pipe of the shell and tube graphite heat exchanger enters the flash evaporator together with the heated circulating acid for vacuum concentration. The diameter of the flash chamber is φ5800mm, the height is 8358mm, and the effective volume is 160m 3 , after continuous cycle evaporation, dilute phosphoric acid is continuously concentrated, reaching 48%-50% P 2 o 5 , pumped out from the flash evaporator by the concentrated phosphoric acid pump, and sent to the phosphoric acid tank area. Containing HF, SiF escaped from the flasher 4 , water vapor and a small amount of phosphoric acid mist and other gases, the acid mist entrained in the gas is separated by the demister, and enters the fluorine absorption tower for was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com