Patents

Literature

55results about How to "Improve driving rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

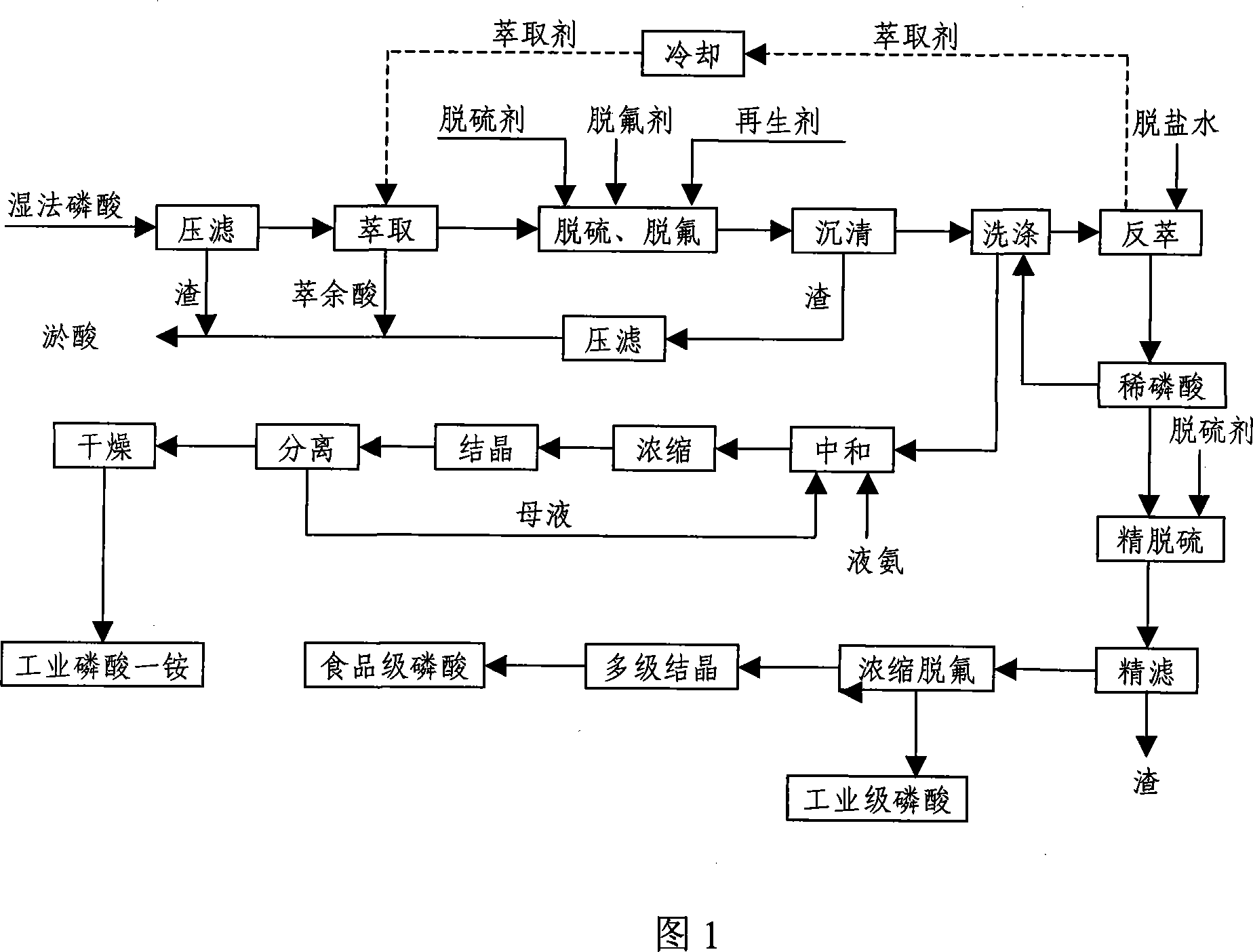

Method for producing technical grade ribose phosphate, food grade ribose phosphate and industry ammonium diacid phosphate using wet-process ribose phosphate

The invention discloses a method of using wet phosphoric acid to prepare industrial grade phosphoric acid, food grade phosphoric acid and industrial ammonium diacid phosphate, which is characterized in using wet phosphoric acid as the material, and preparing industrial grade phosphoric acid and food grade phosphoric acid respectively by using a series of compound purifying technologies such as chemical sedimentation and extracting by organic solvent and concentration and recrystallization and other technologies; meanwhile, the invention uses a part of purified diluted phosphoric acid to prepare industrial ammonium diacid phosphate. The invention has the advantages of reasonable cascade utilization of the wet phosphoric acid, high additional value of phosphorus, and further exploitation of the lower industrial and food grades phosphate.

Owner:中化重庆涪陵化工有限公司

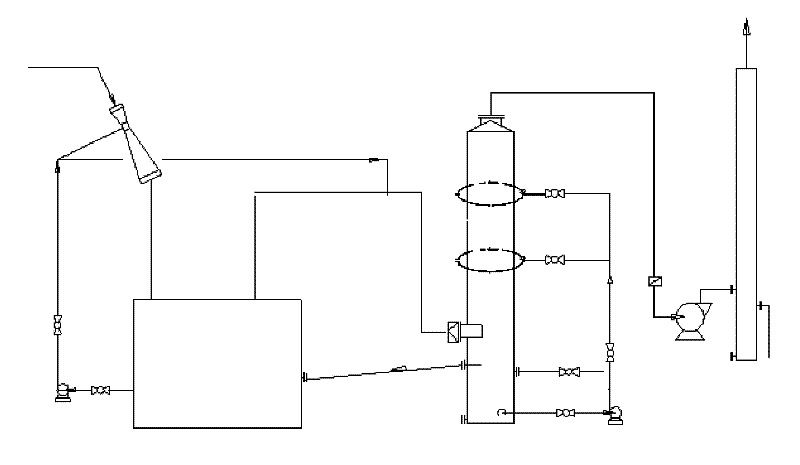

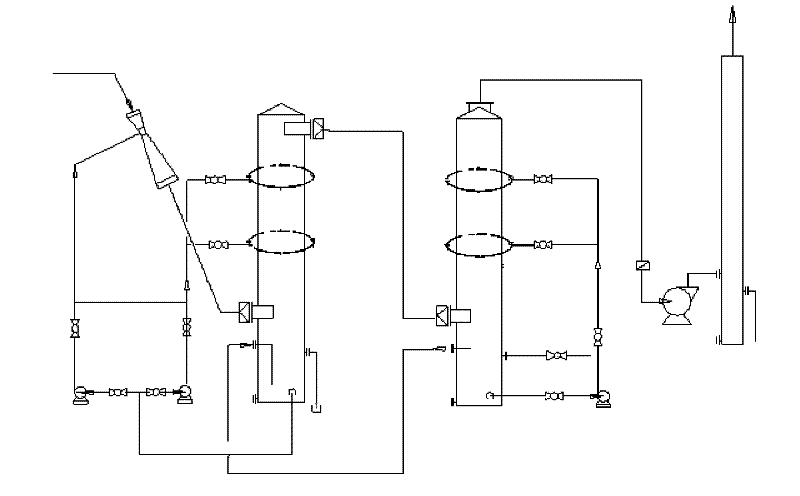

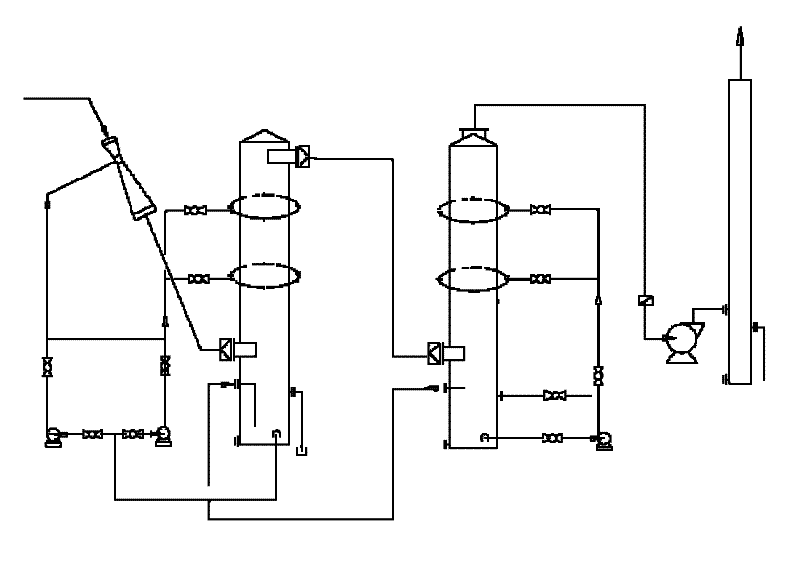

Phosphoric acid production tail gas recovery method

InactiveCN102258929AIncrease flow rateThe beneficial effect of increasing the first-level scrubber is: 1) reduce the flow rateDispersed particle separationPhosphoric acidRecovery methodPhosphoric acid

The invention relates to a method for recovering tail gas from phosphoric acid production. The process flow is as follows: the fluorine-containing gas enters the Venturi scrubber through the tail gas duct, and performs first-stage downstream spray washing with the washing liquid from the first washing pump, and the washed gas enters the first washing tower and the first washing tower. The washing liquid sent by the washing pump is subjected to the first-stage countercurrent two-layer spray washing again, and the gas after washing enters the second washing tower and the washing liquid sent by the second washing pump is subjected to the second-stage countercurrent two-layer spray washing. After being pumped by the tail gas fan, it enters the defoaming tower for defoaming, and finally discharges into the atmosphere through the chimney; the process water for washing first enters the second washing tower and is preheated and sprayed by the second washing pump, and then overflows from the second washing tower into The first washing tower is sent to the Venturi scrubber and the spraying device of the first washing tower by the first washing pump for spray washing and absorption. The beneficial effects of the present invention are: 1) reduce the gas flow rate, increase the washing and absorption efficiency; 2) preheat the washing liquid through the second washing tower, accelerate the formation of H2SiF6, and further strengthen the washing and absorption effect; 3) reduce the adhesion of the fan impeller, Reduce fan failures and corrosion of related equipment; 4) Strengthen the stability of operating indicators and increase the operating rate.

Owner:WUHAN ZHONGDONG PHOSPHATE TECH

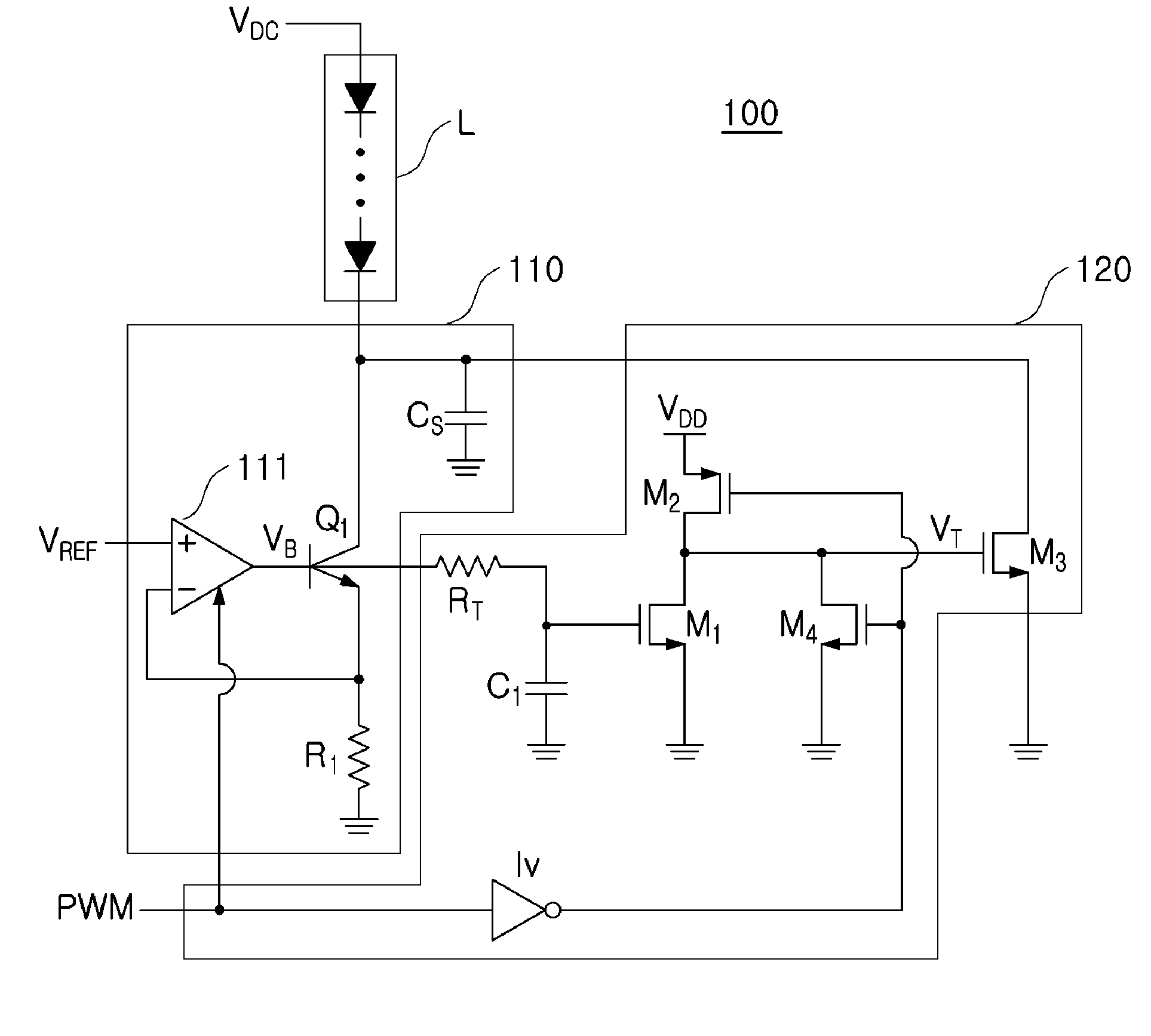

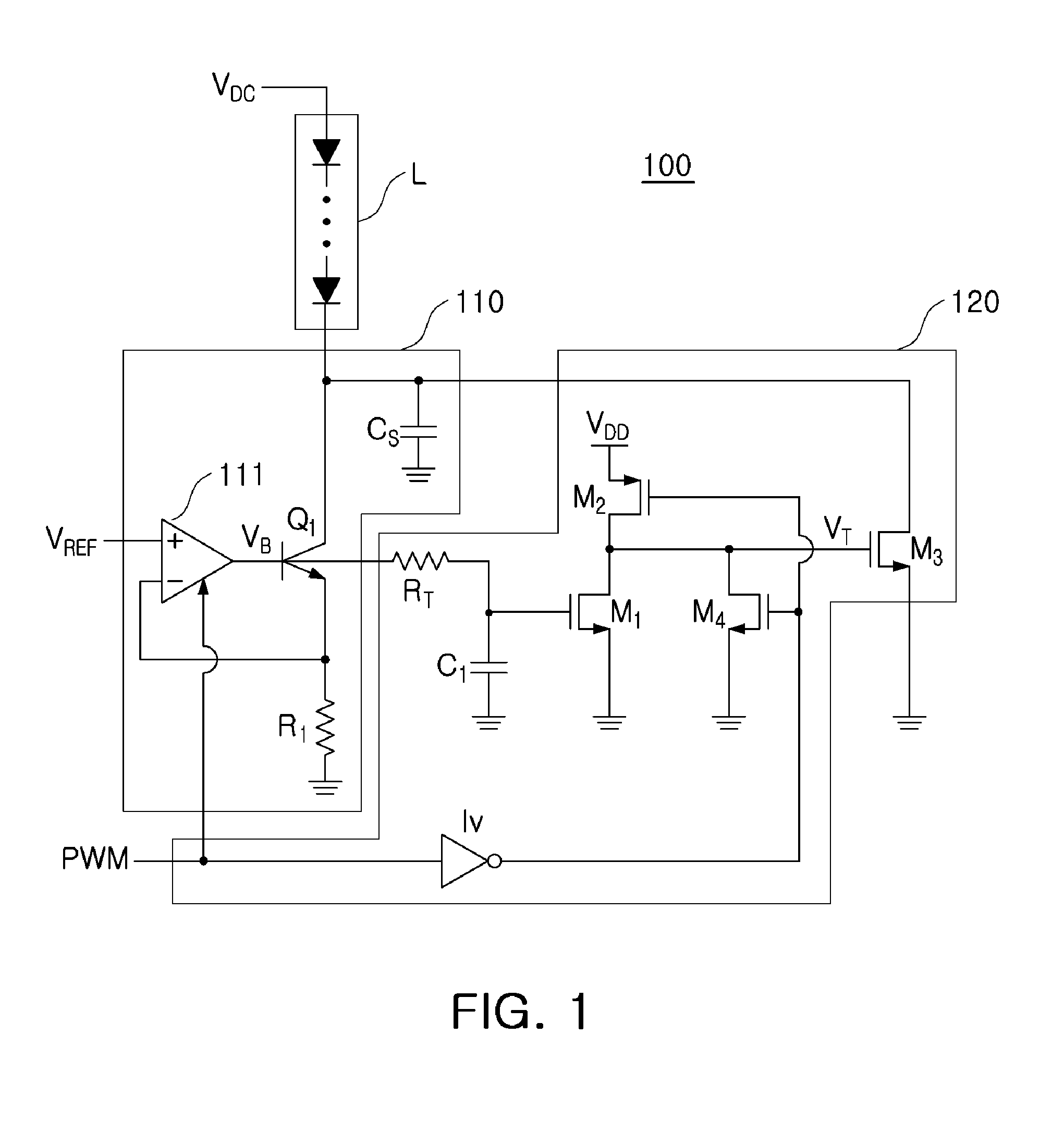

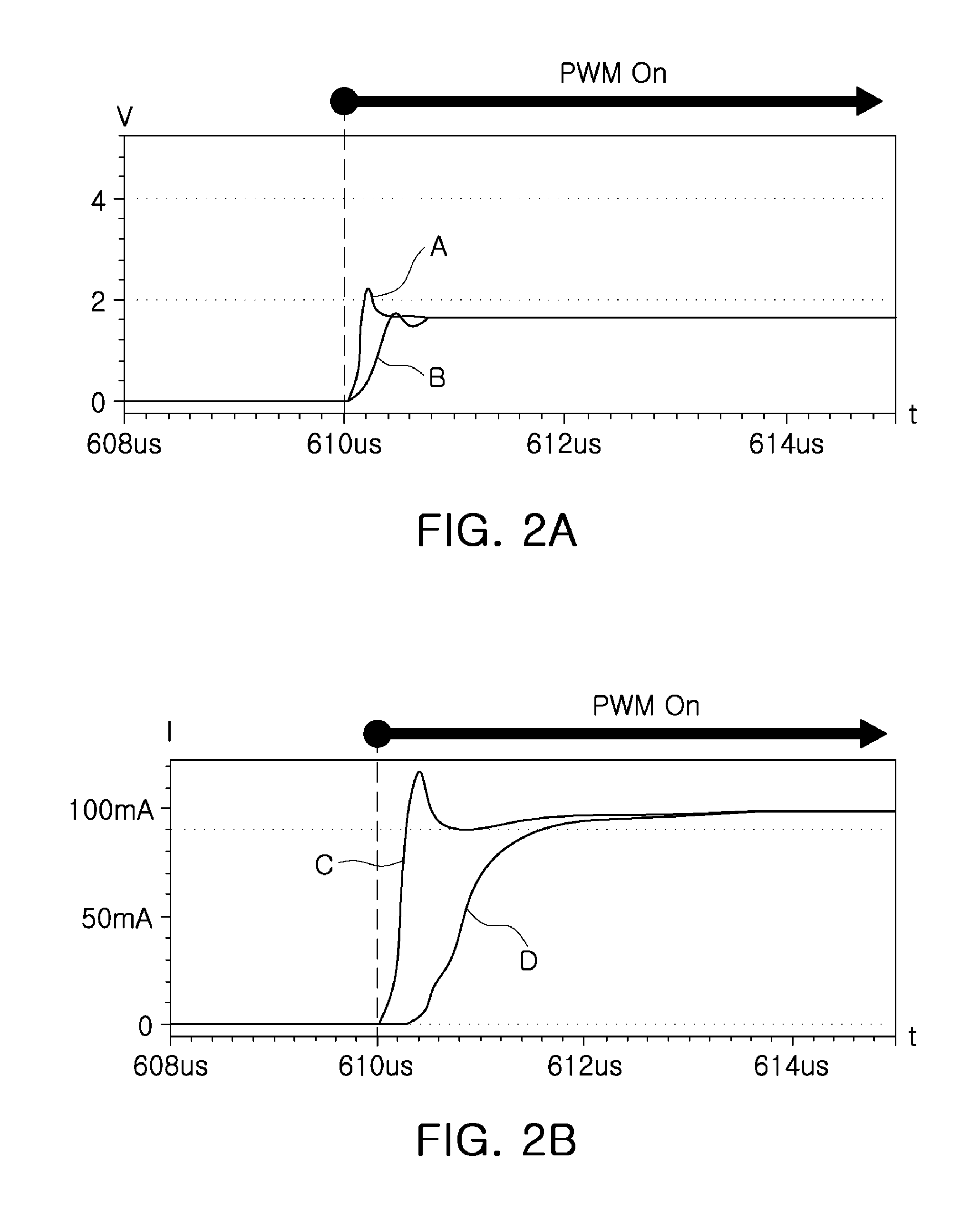

Light emitting diode driving device and method thereof

InactiveUS20130033191A1Improve driving rateElectrical apparatusElectroluminescent light sourcesEngineeringLight-emitting diode

There are provided a light emitting diode (LED) driving device allowing for an increase in an LED driving rate by discharging a charge stored in a capacitor during a certain period of time and a method thereof. The LED driving device includes: a driving unit detecting a current, as a voltage, the current flowing across an LED unit having at least one LED, controlling the current flowing across the LED unit according to a comparison result between the detected voltage and a reference voltage having a pre-set voltage level, and having a capacitor stabilizing an operation of the LED unit when the LED unit is driven; and a discharging unit discharging a charge stored in the capacitor during a pre-set discharge time when the LED unit is initially driven.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD +1

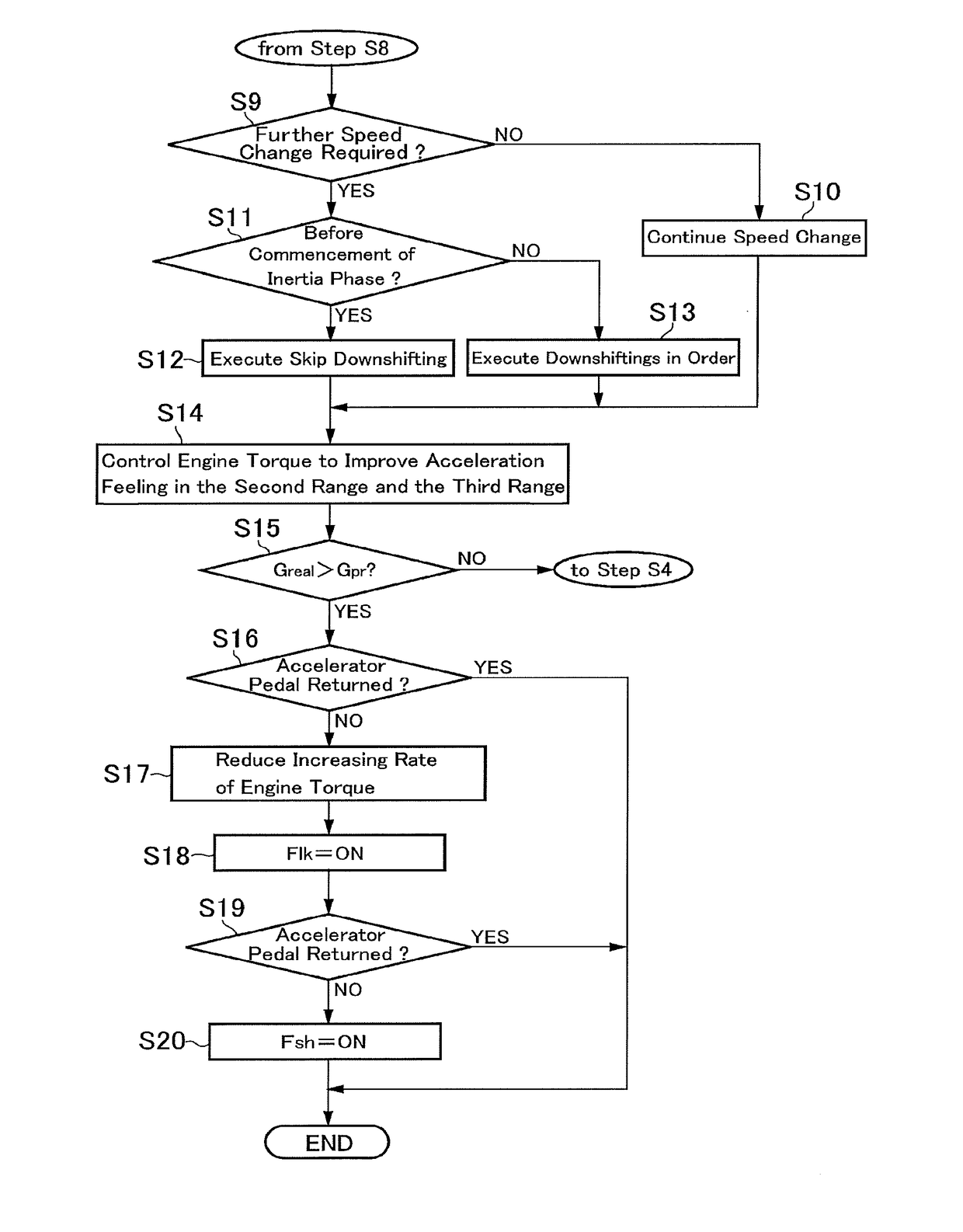

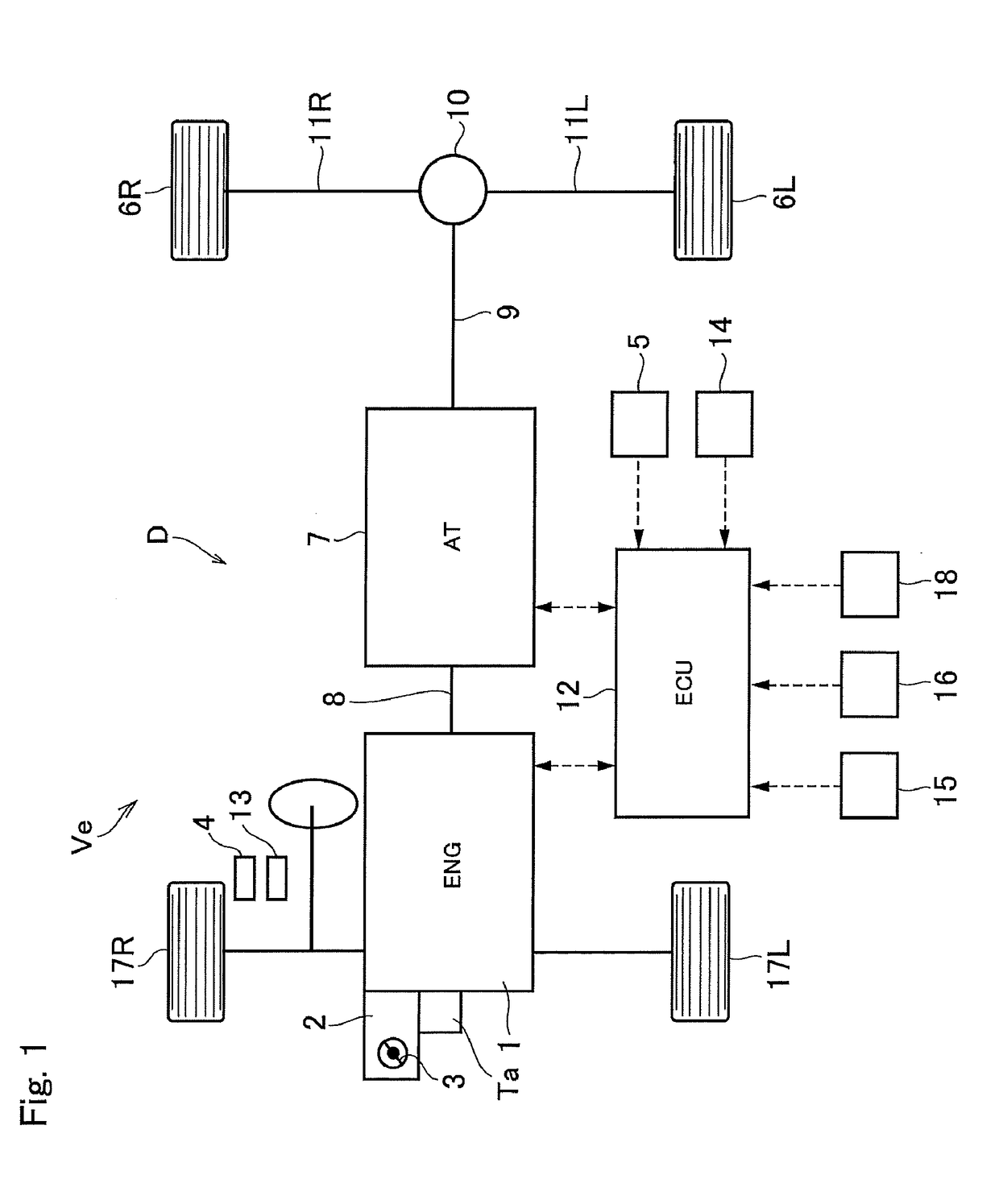

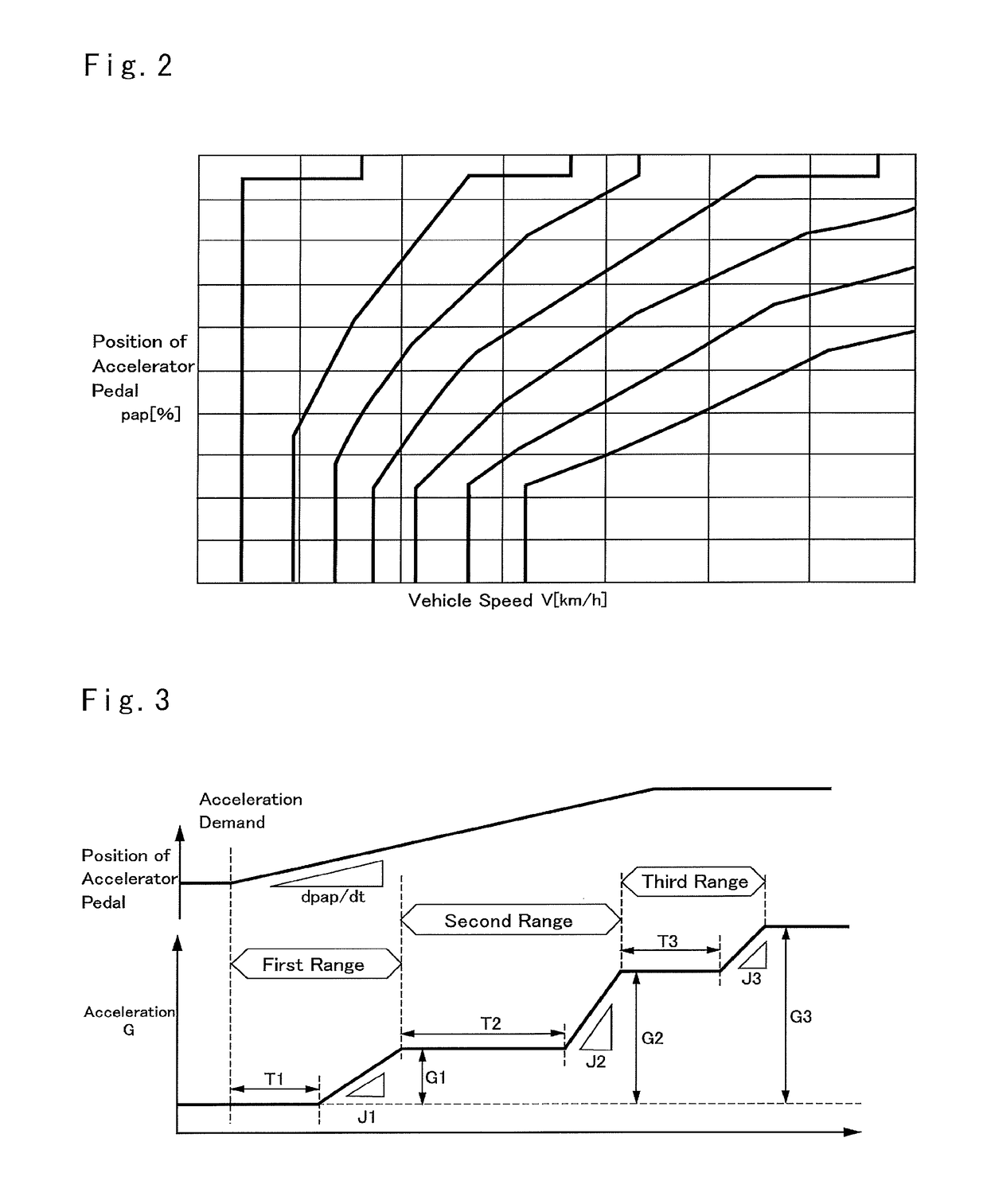

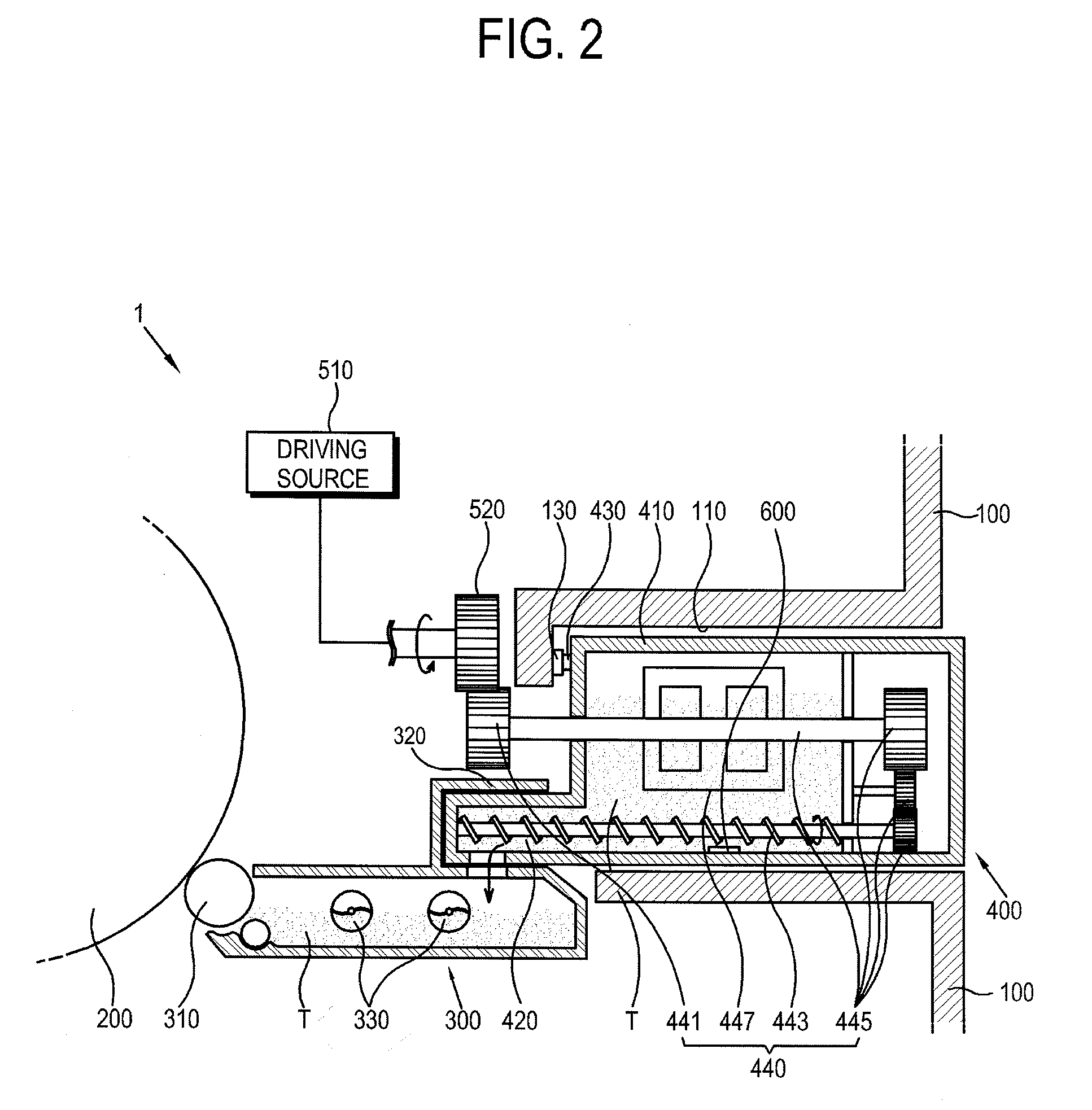

Driving force control system for vehicle

ActiveUS20180297600A1Feel goodImprove driving rateElectrical controlInternal combustion piston enginesControl systemControl theory

A driving force control system for a vehicle configured to control a driving force based on the accelerating operation by the driver. The vehicle comprises a drive unit including a prime mover and a transmission, an accelerator device; and a controller. The controller is configured to: calculate an operating amount of the accelerator device; calculate an operating speed of the accelerator device; calculate a target jerk; and control an output torque of the drive unit based on the target jerk, when the operating amount is smaller than a predetermined amount, and the operating speed is slower than a predetermined speed.

Owner:TOYOTA JIDOSHA KK

Image forming apparatus and controlling method of the same

Owner:HEWLETT PACKARD DEV CO LP

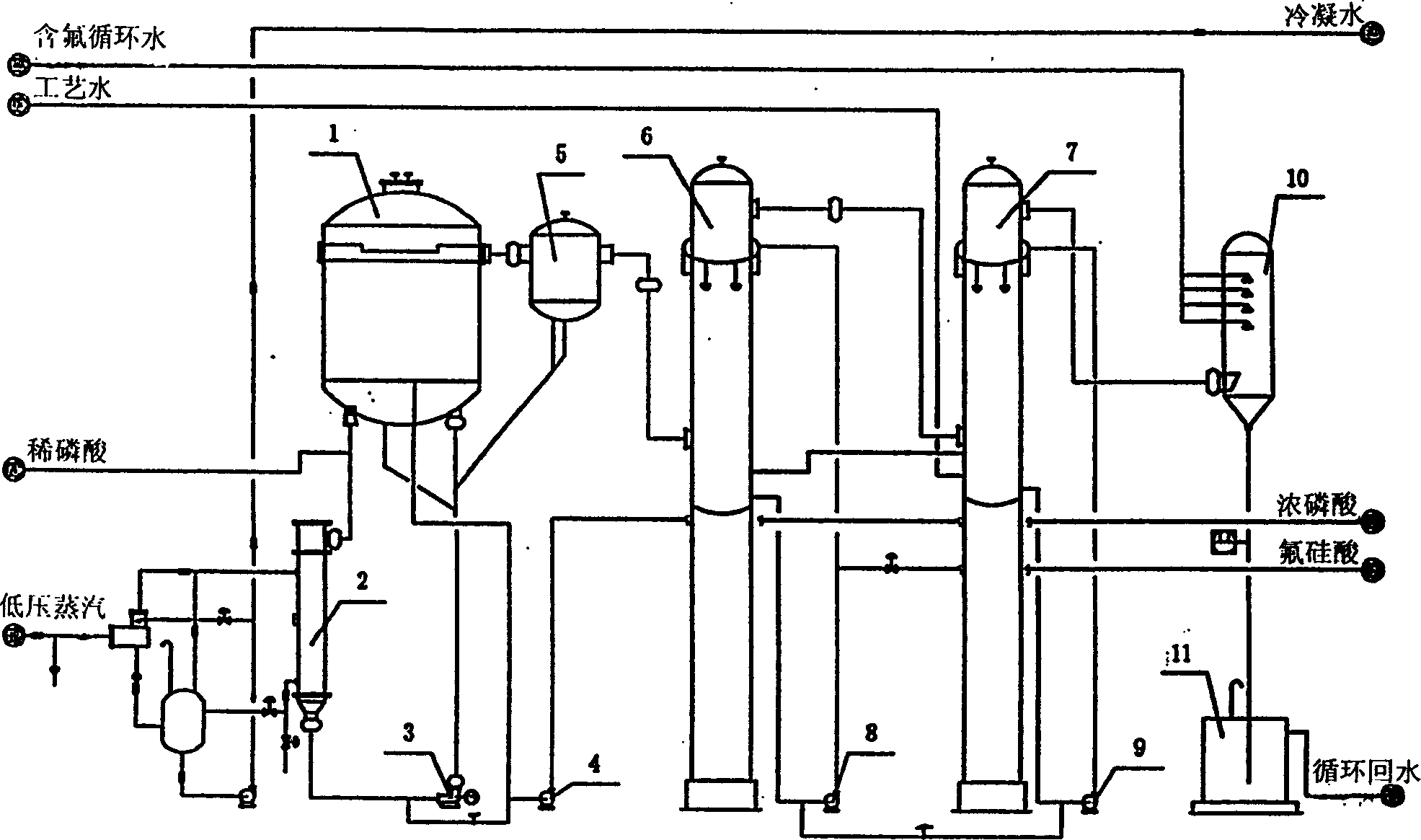

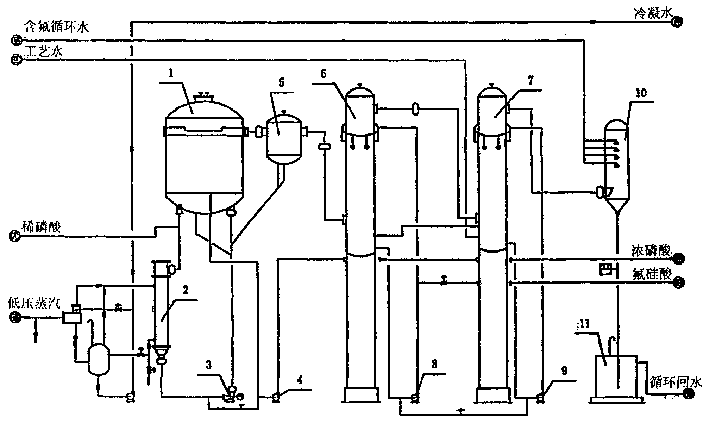

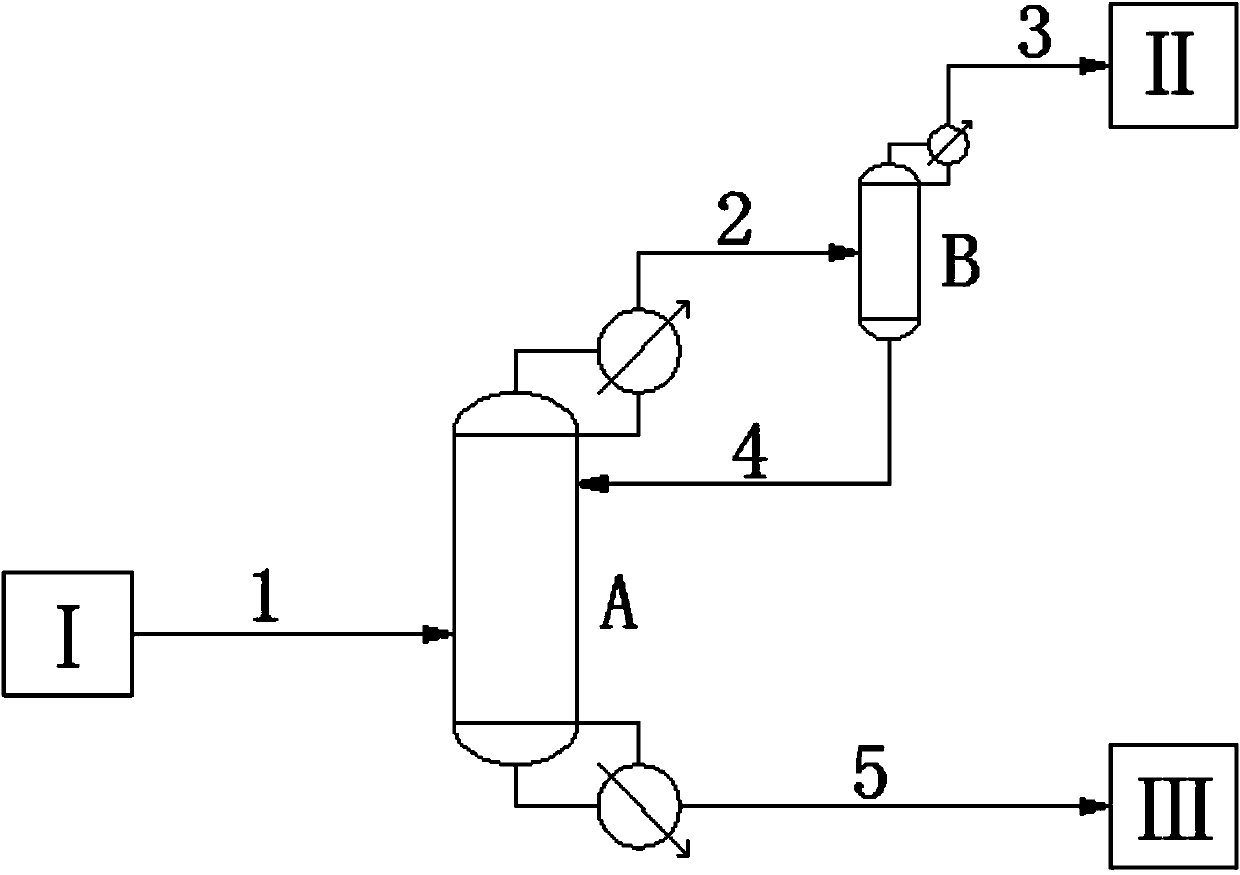

Method and equipment for producing phosphoric acid by adopting steam heating forced circulation concentration wet process

InactiveCN1205116CLess process equipmentCompact layoutSilicon halogen compoundsPhosphorus compoundsGas phasePhosphoric acid

The invention discloses a method and equipment for concentrating wet-process phosphoric acid by steam heating and forced circulation. Phosphoric acid is heated and concentrated in a circulation loop formed by a flash chamber, a graphite heat exchanger and an axial flow circulation pump. Dilute phosphoric acid is condensed from graphite The outlet pipe of the heat exchanger is added to the circulation loop, and the evaporated steam passes through the demister to remove the entrained acid foam, and then sprays and washes the fluoride in the gas phase through the two-stage fluorine absorption tower. The required vacuum degree of the flash chamber Provided by atmospheric condenser. The invention can change wet-process phosphoric acid from 20-25% P 2 o 5 Concentrate to 48-50%P 2 o 5 , and can reduce the P during the enrichment process 2 o 5 Loss, improve the fluorine recovery efficiency of tail gas and the quality of fluosilicic acid.

Owner:EAST CHINA ENG SCI & TECH

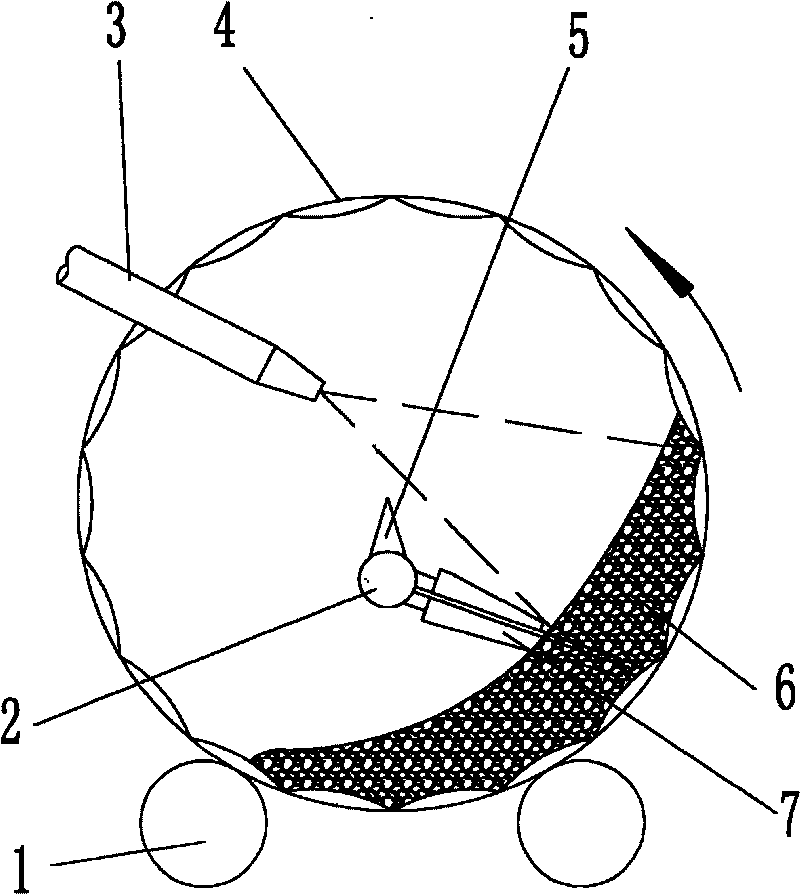

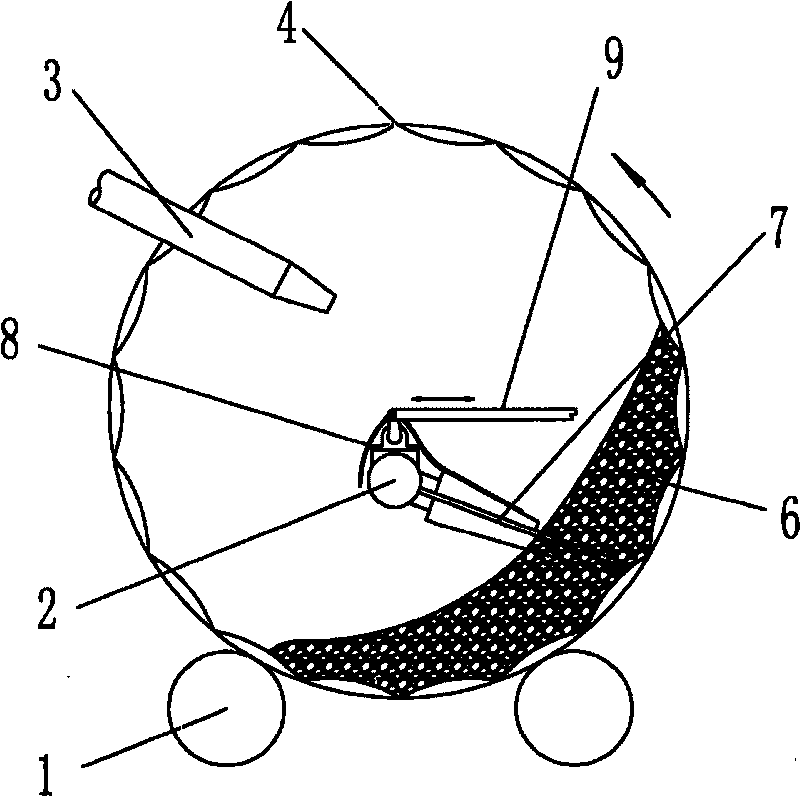

Granulator capable of preventing central tubular beam from scaling

ActiveCN101723744AGood anti-scarring effectExtension of timeFertiliser formsFertilizer mixturesEngineeringDistributor

The invention relates to a granulator capable of preventing central tubular beam from scaling, which comprises a kiln body, a central tubular beam and an ammonia distributor, wherein the central tubular beam is provided with a material bonding-preventing device consisting of a flexible baffle plate and a bracket; the flexible baffle plate is fixed above the central tubular beam by the bracket; and the flexible baffle plate is made in a size big enough to cover the upper part and the two sides of the central tubular beam. When accumulated in a certain weight, the materials falling onto the flexible baffle plate will fall off with the deformation of the baffle plate, the scaling-preventing effect is desirable, the machine-stop cleaning time is prolonged greatly, the normal and stable operation of production is ensured, and the production cost is reduced.

Owner:ANHUI LIUGUO CHEM CO LTD

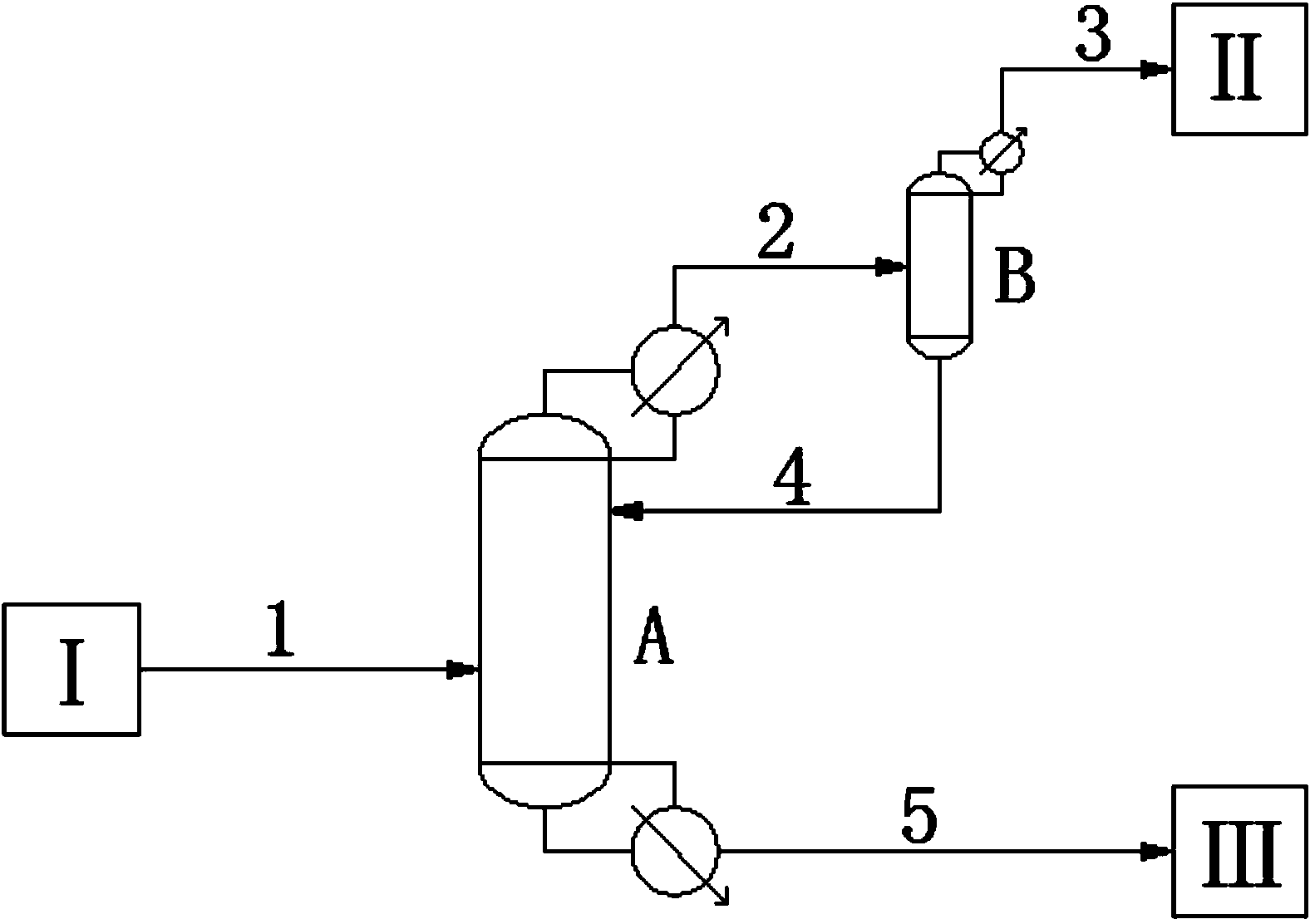

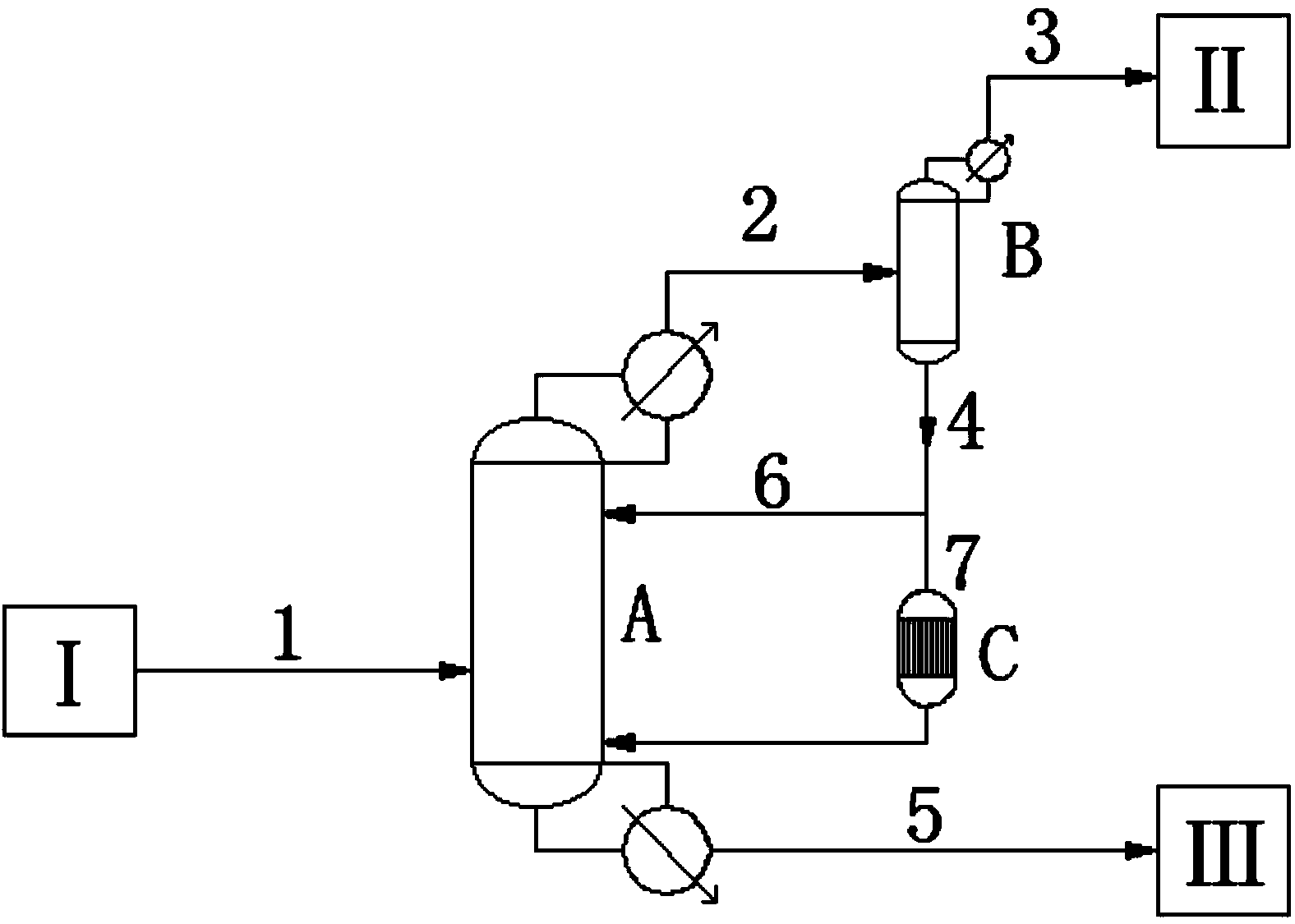

Dehydration method during production process of toluene diisocynate

ActiveCN103724229AEfficient removalReduce corrosionOrganic compound preparationPreparation from carbamatesPhosgeneCarbamoyl chloride

The invention belongs to the field of toluene diisocynate production technology and relates to a dehydration method during the production process of toluene diisocynate. Toluenediamine and phosgene have cold light gasification reaction to obtain a mixture flow of carbamyl chloride, amidogen hydrochloride and hydrogen chloride; the mixture flow flows into a phosgenation reaction tower; carbamyl chloride and amidogen hydrochloride react to produce toluene diisocynate and the by-product hydrogen chloride; at the bottom of a hydrogen chloride rectifying tower, the mixture flow of amidogen and hydrogen chloride is divided into two parts, most of the mixture flow returns to the top of the phosgenation reaction tower and serves as the backflow, and the rest of the mixture flow enters into a drain sump containing activated carbon as the catalyst; water and phosgene in the mixture flow react to produce hydrogen chloride and carbon dioxide to remove water in the mixture flow under the function of the activated carbon catalyst; the dehydrated mixture flow enters into the bottom of the phosgenation reaction tower for further rectification and is discharged from the bottom of the phosgenation reaction tower for next step. The dehydration technology is simple and environmentally friendly, the cost is low, and the dehydration effect is excellent.

Owner:QINGDAO UNIV OF SCI & TECH +1

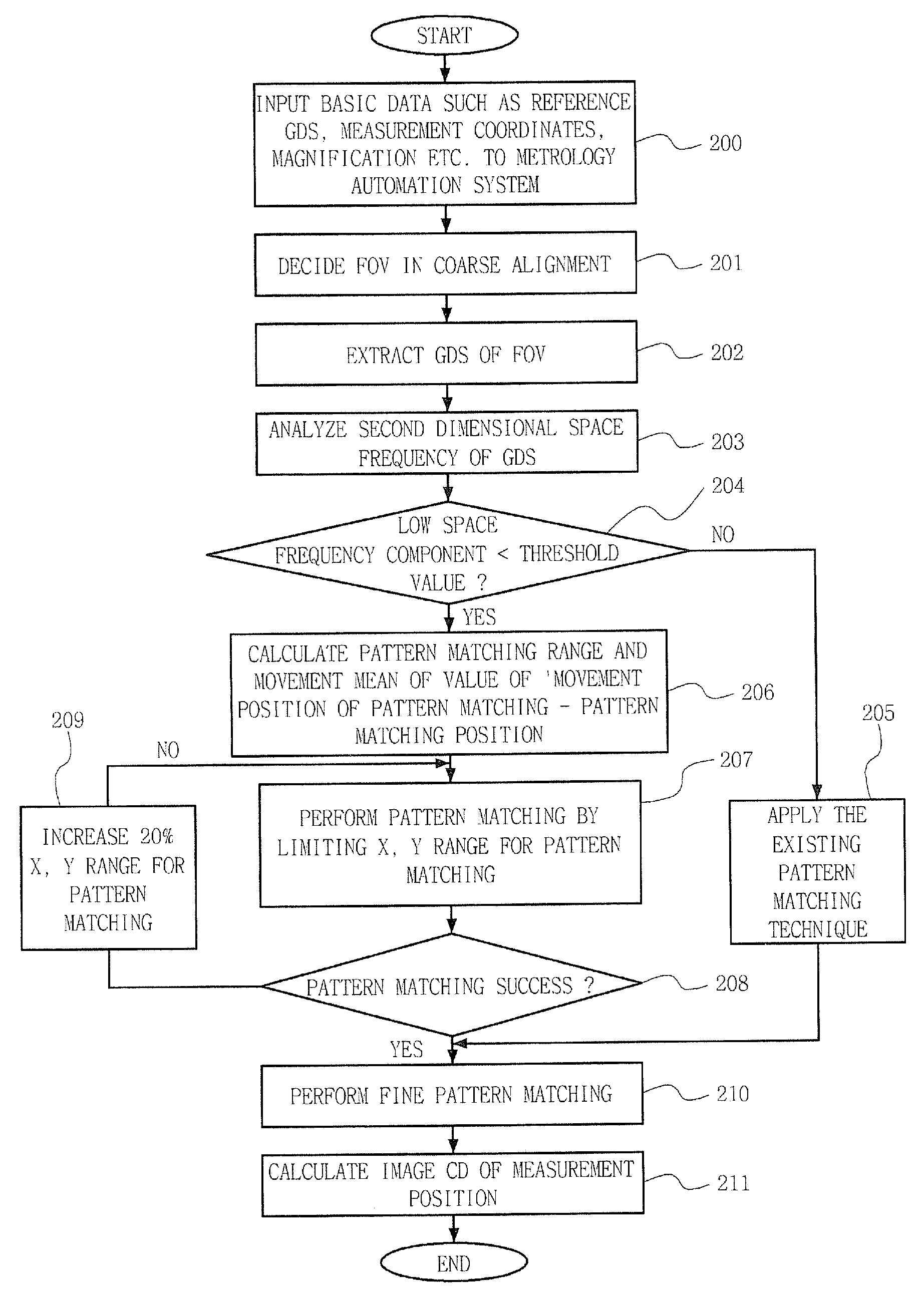

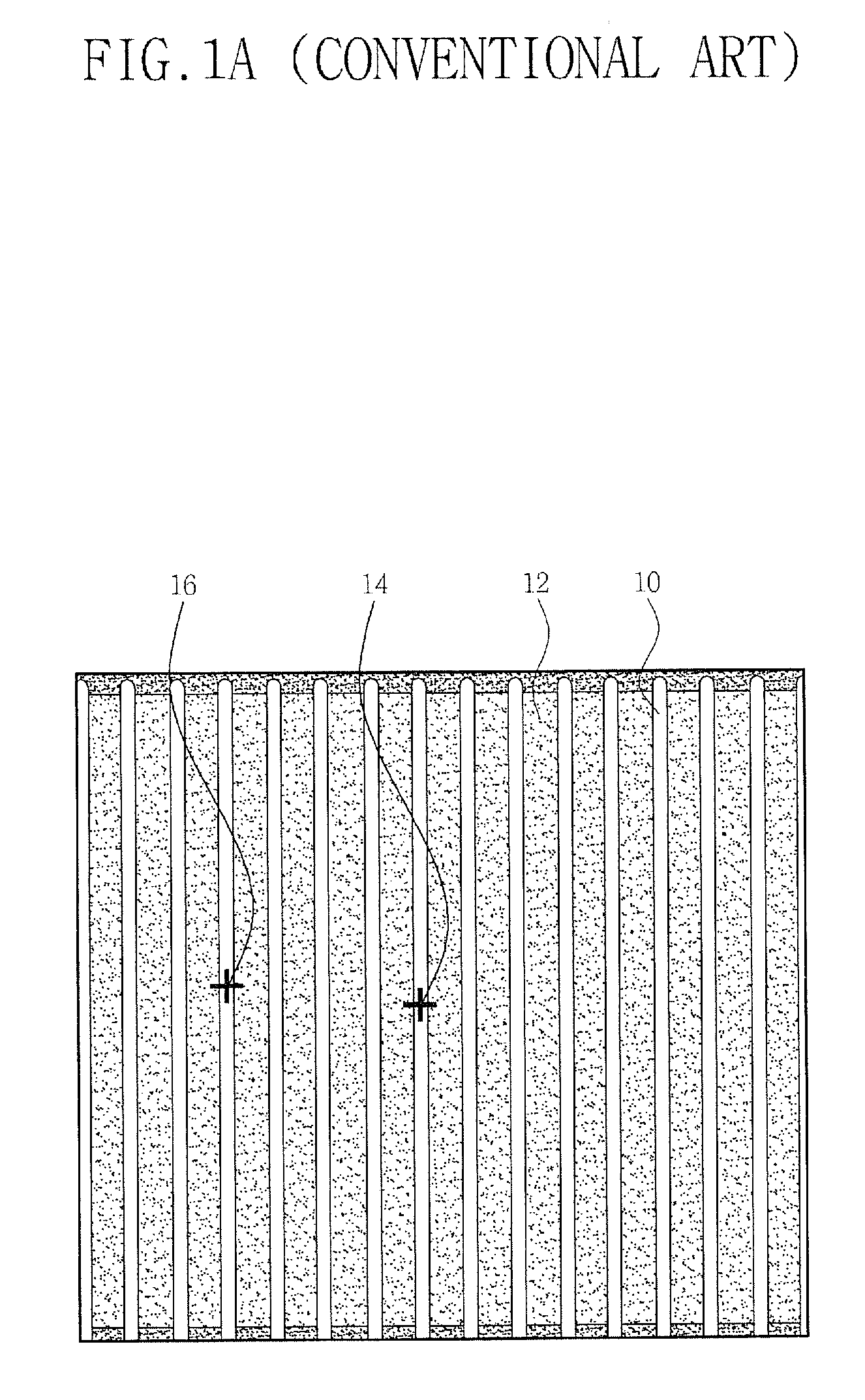

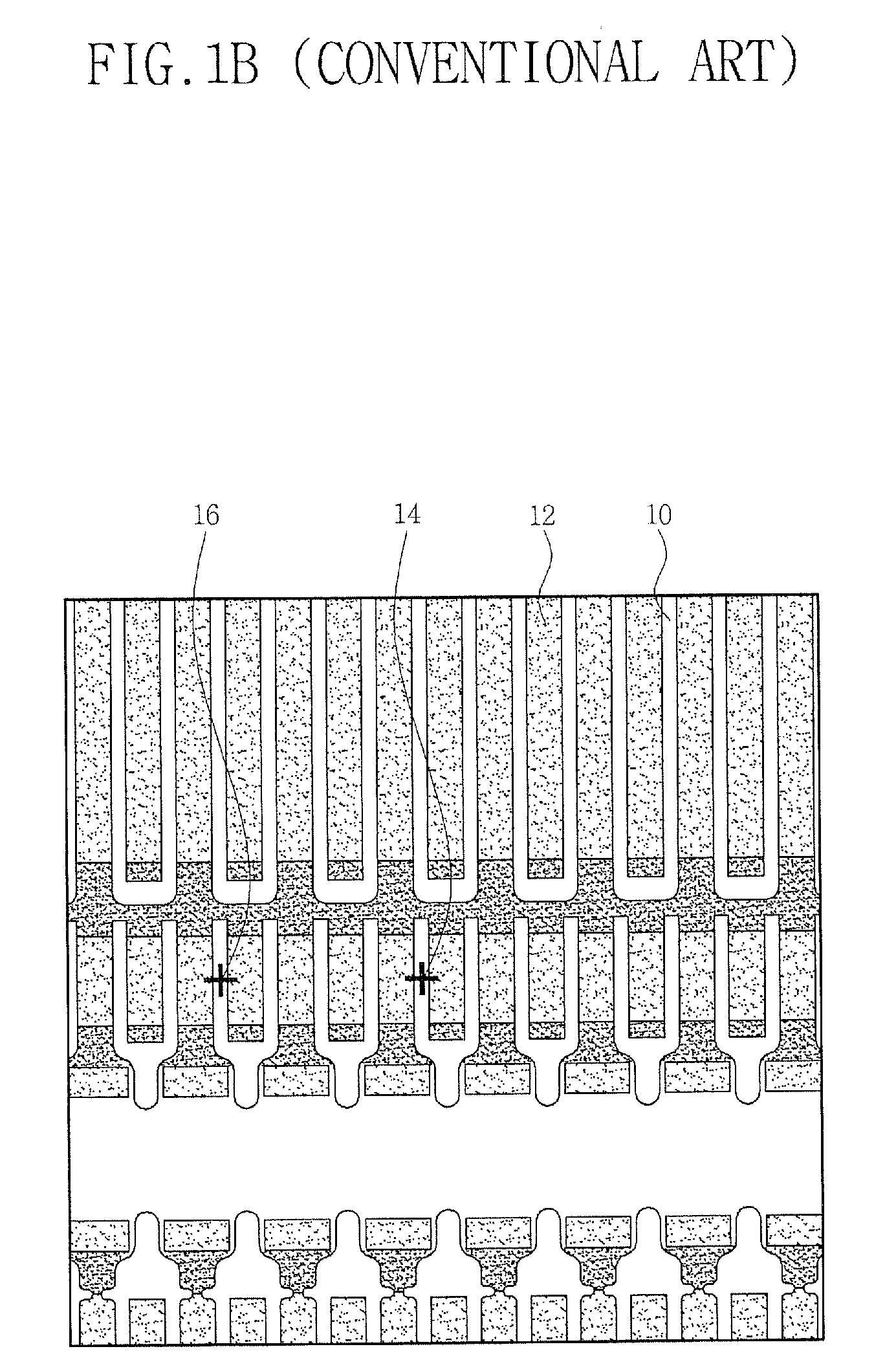

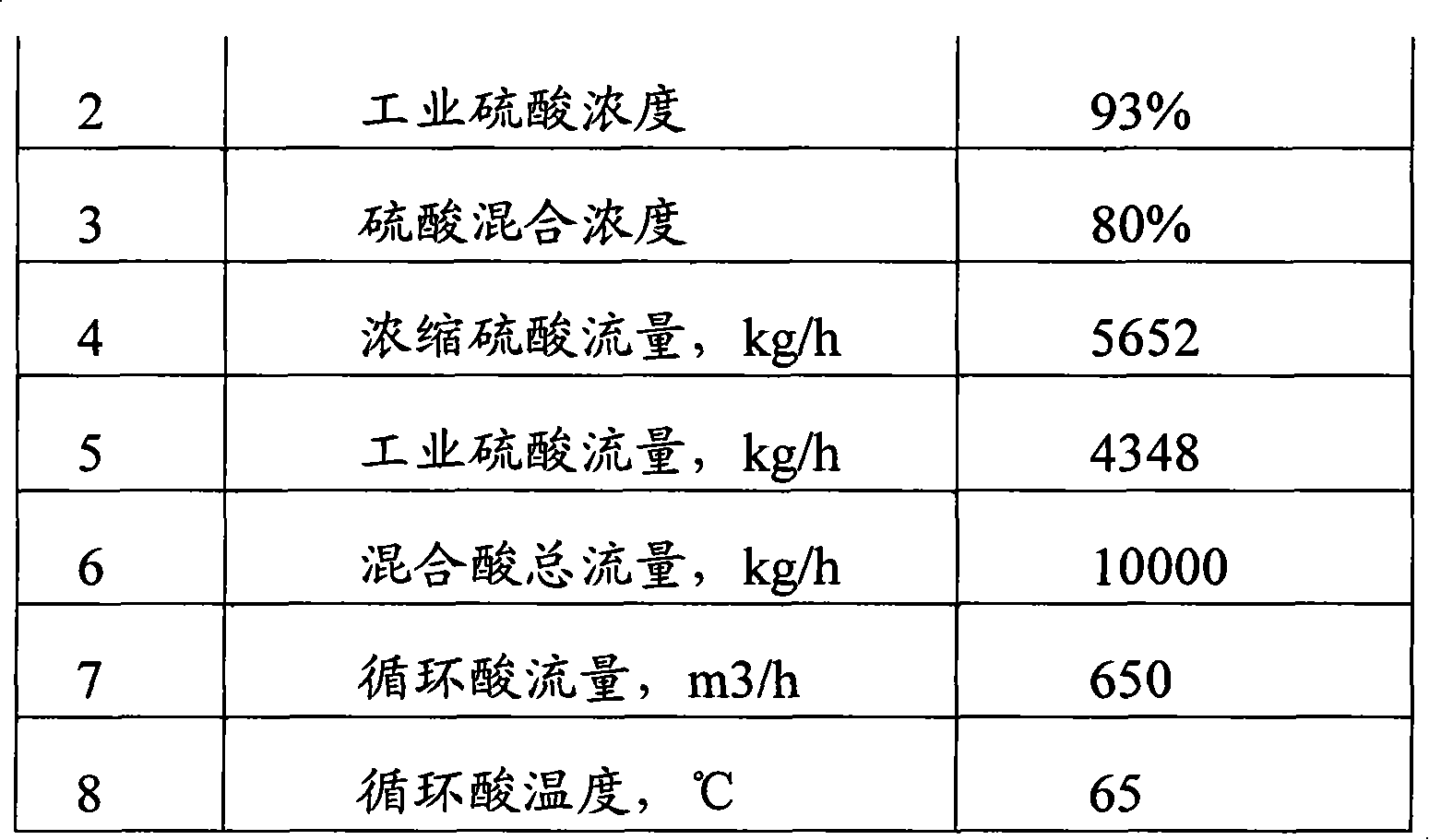

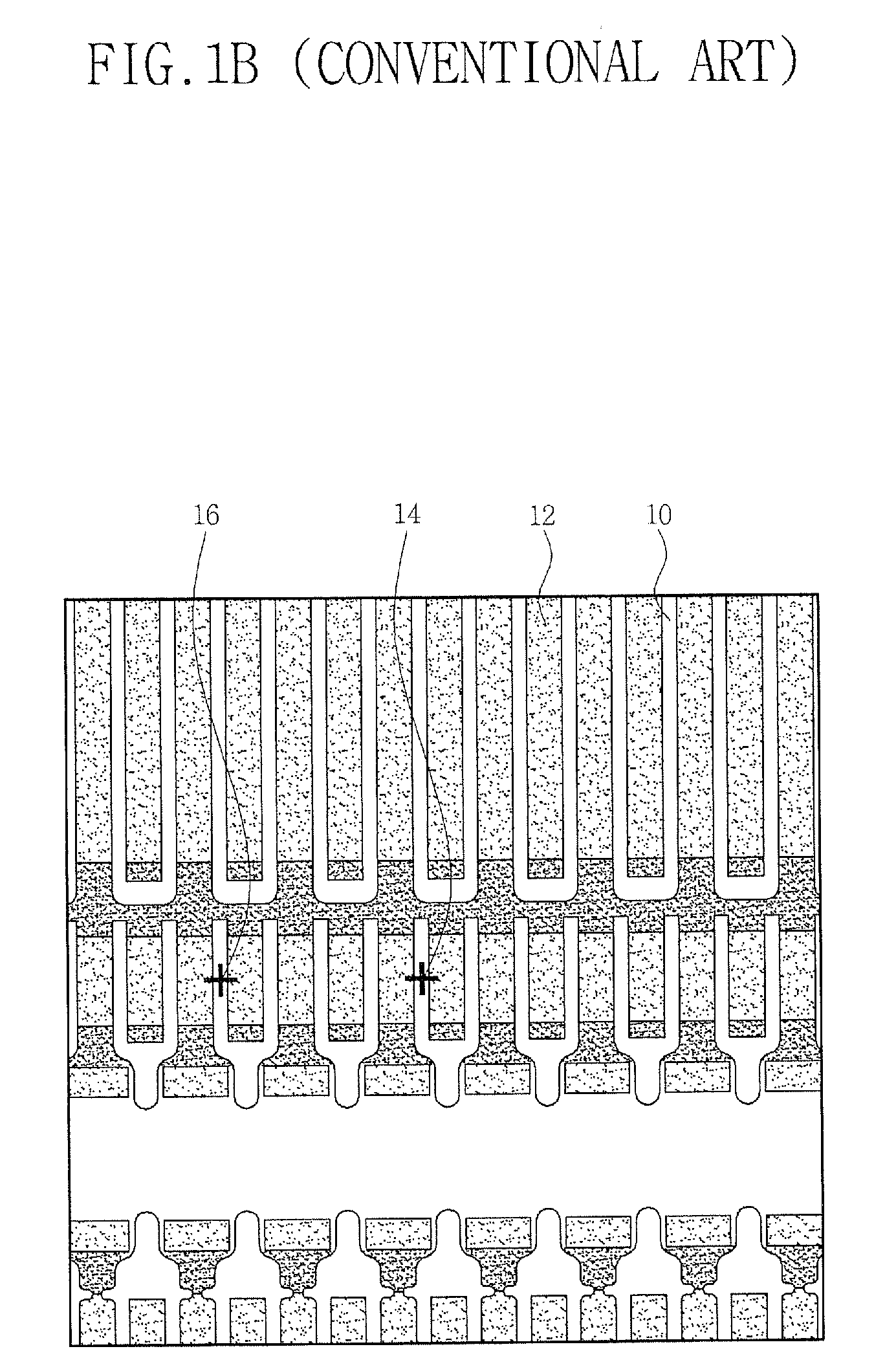

Pattern matching method in manufacturing semiconductor memory devices

ActiveUS20090103799A1Increase rangeImprove match rateCharacter and pattern recognitionOriginals for photomechanical treatmentPattern recognitionGraphics

A pattern matching method for use in manufacturing a semiconductor memory device increases a pattern matching rate between a GDS image and an SEM image. The pattern matching method includes extracting a scanning electron microscope (SEM) image and a graphic data system (GDS) image to perform a pattern matching; performing a two-dimensional furrier transform (FFT) for the extracted GDS image and analyzing a low spatial frequency; deciding whether or not a pattern is a repeated pattern or non-repeated pattern by using the analyzed low spatial frequency; and limiting an X / Y range for a pattern matching when the decision result is for the repeated pattern, and then performing the pattern matching between the SEM image and the GDS image.

Owner:SAMSUNG ELECTRONICS CO LTD

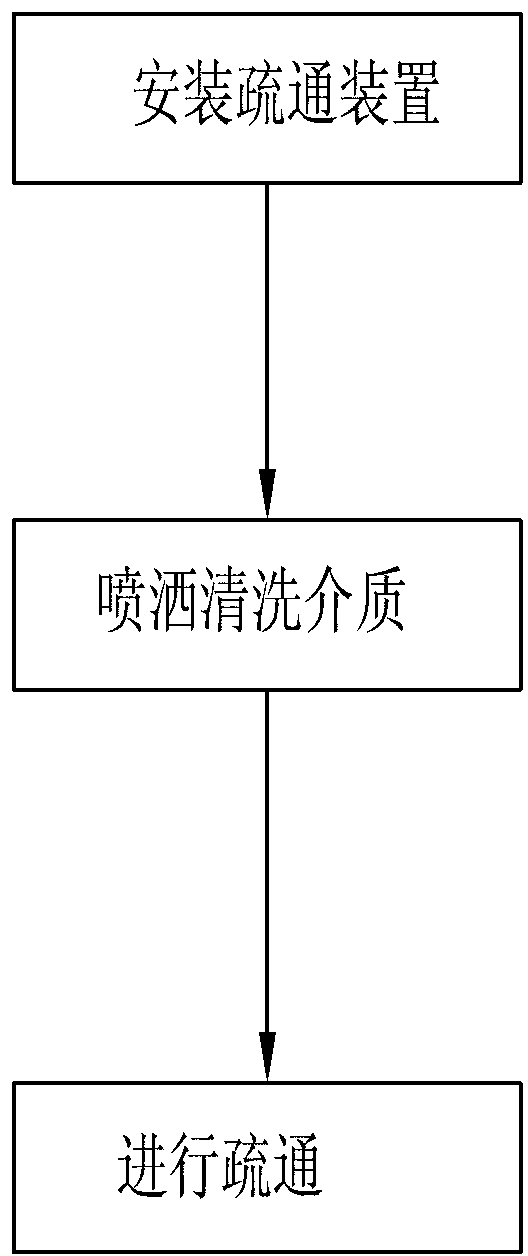

Ammonium phosphate slurry pipeline compound dredging method

ActiveCN103128082AEasy to push and pullReasonable designHollow article cleaningSlurry pipelineMechanical engineering

The invention discloses an ammonium phosphate slurry pipeline compound dredge method which includes a first step of installing a dredging device, wherein a flange mounting seat is arranged on an opening of the tail end of a pipeline for producing ammonium phosphate slurries, a flange plate is fixed on the flange mounting seat, and the dredging device is supported on the flange plate, a second step of spraying cleaning media, wherein a portion, located inside the pipeline, of the dredging device can carry out spraying of the cleaning media on the inner wall of the pipeline, and the cleaning media soaked with the dissolving slurries can dissolve scale layers on the inner wall of the pipeline, and a third step of carrying out dredging, pushing a dredging rod in the process of spraying the cleaning media, and enabling a cleaning disc to move to clean the inner wall of the pipeline. Through the method, the pipeline does not need to be dismantled, and workers can carry out on-line dredging on the clogged pipeline, so the ammonium phosphate slurry pipeline compound dredge method can greatly reduce labor intensity of the maintenance workers, improves working efficiency, reduces safety risks in the operation process of the maintenance workers, shortens down time, and improves on-stream rate.

Owner:中化重庆涪陵化工有限公司

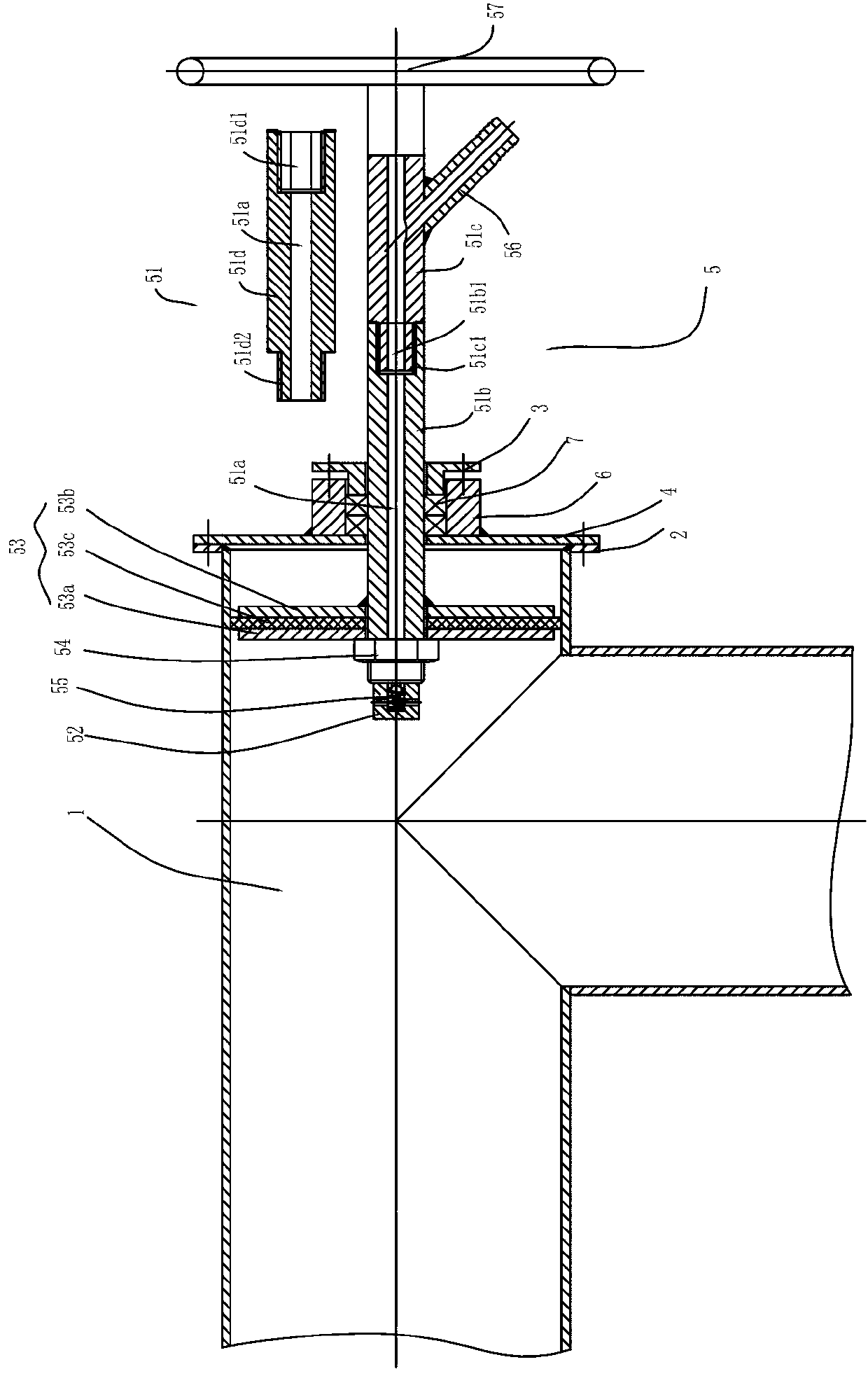

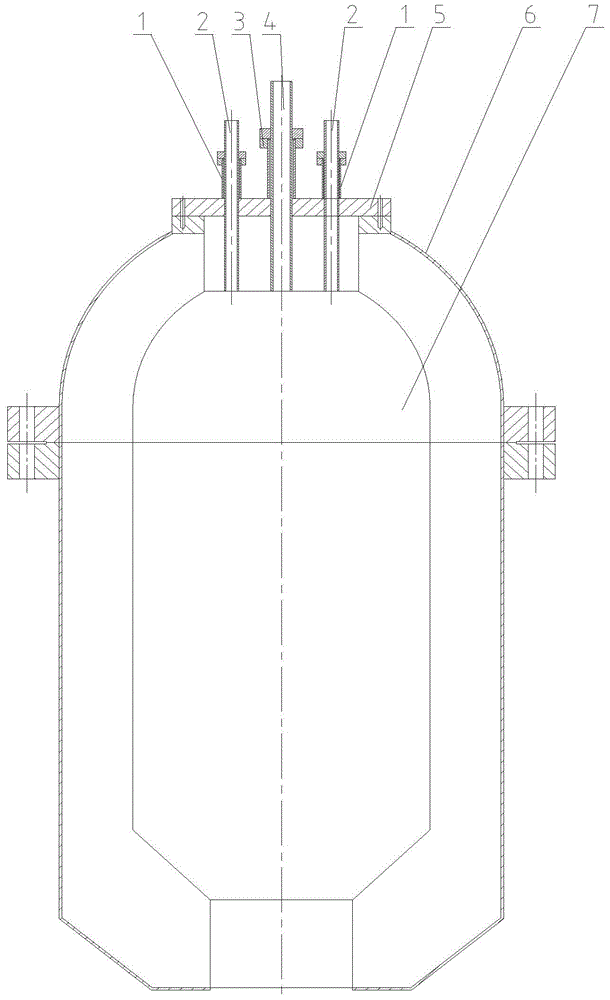

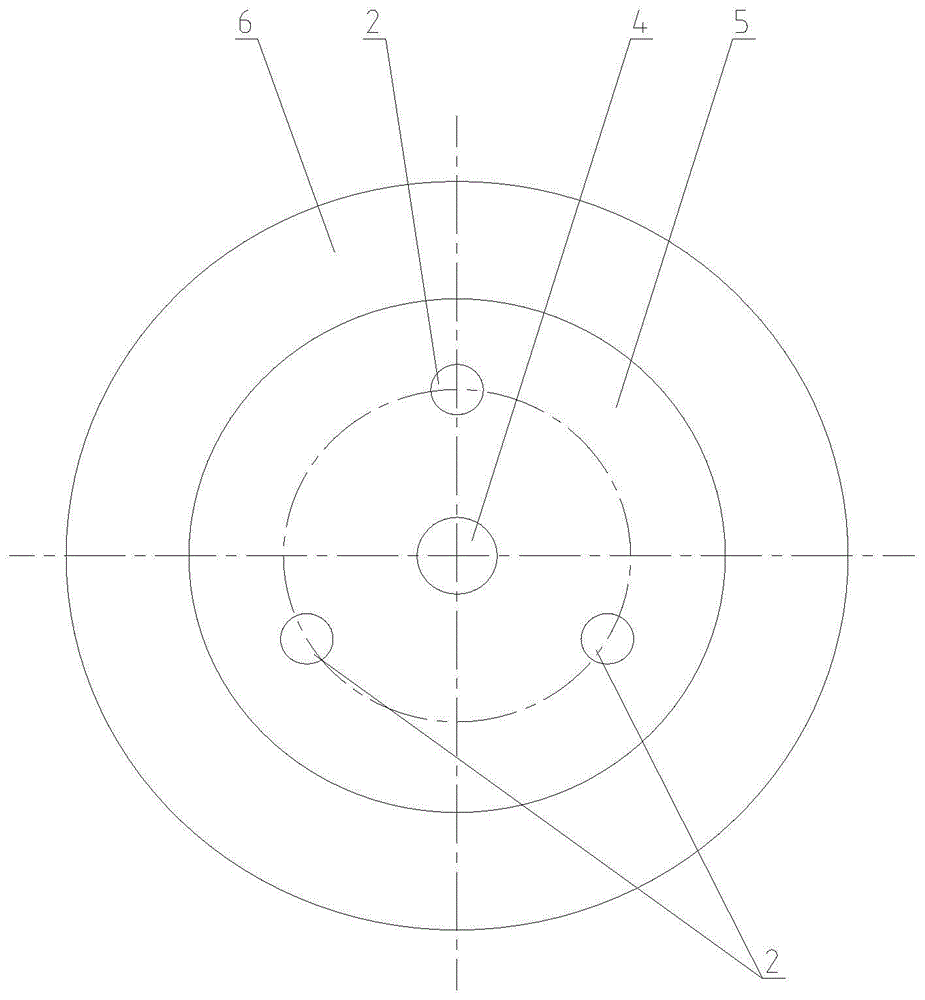

Overhead type multi-nozzle coal-water slurry gasifier

InactiveCN105694978AEasy to operateAvoid problems that increase carbon content and affect conversionGasification processes detailsGasification apparatus detailsCoal waterSocial benefits

The invention discloses an overhead type multi-nozzle coal-water slurry gasifier. The overhead type multi-nozzle coal-water slurry gasifier comprises a coal-water slurry gasification furnace, a furnace hearth, a cover flange, an ignition work-starting burner nozzle and a plurality of coal-water slurry process burner nozzles, wherein the furnace hearth is nested in the coal-water slurry gasification furnace and forms a combustion chamber for coal-water slurry and oxygen gas; the cover flange covers the coal-water slurry gasification furnace; the ignition work-starting burner nozzle is arranged on the cover flange, and the coal-water slurry process burner nozzles surround the ignition work-starting burner nozzle. The number of the coal-water slurry process burner nozzles is increased, so that the power-on rate and operating flexibility of a gasification system can be effectively improved, and the operation and maintenance costs of the coal-water slurry gasification system are further reduced. The overhead type multi-nozzle coal-water slurry gasifier meets the needs of coal-water slurry gasifiers on large-scale development and has very great economic and social benefits.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

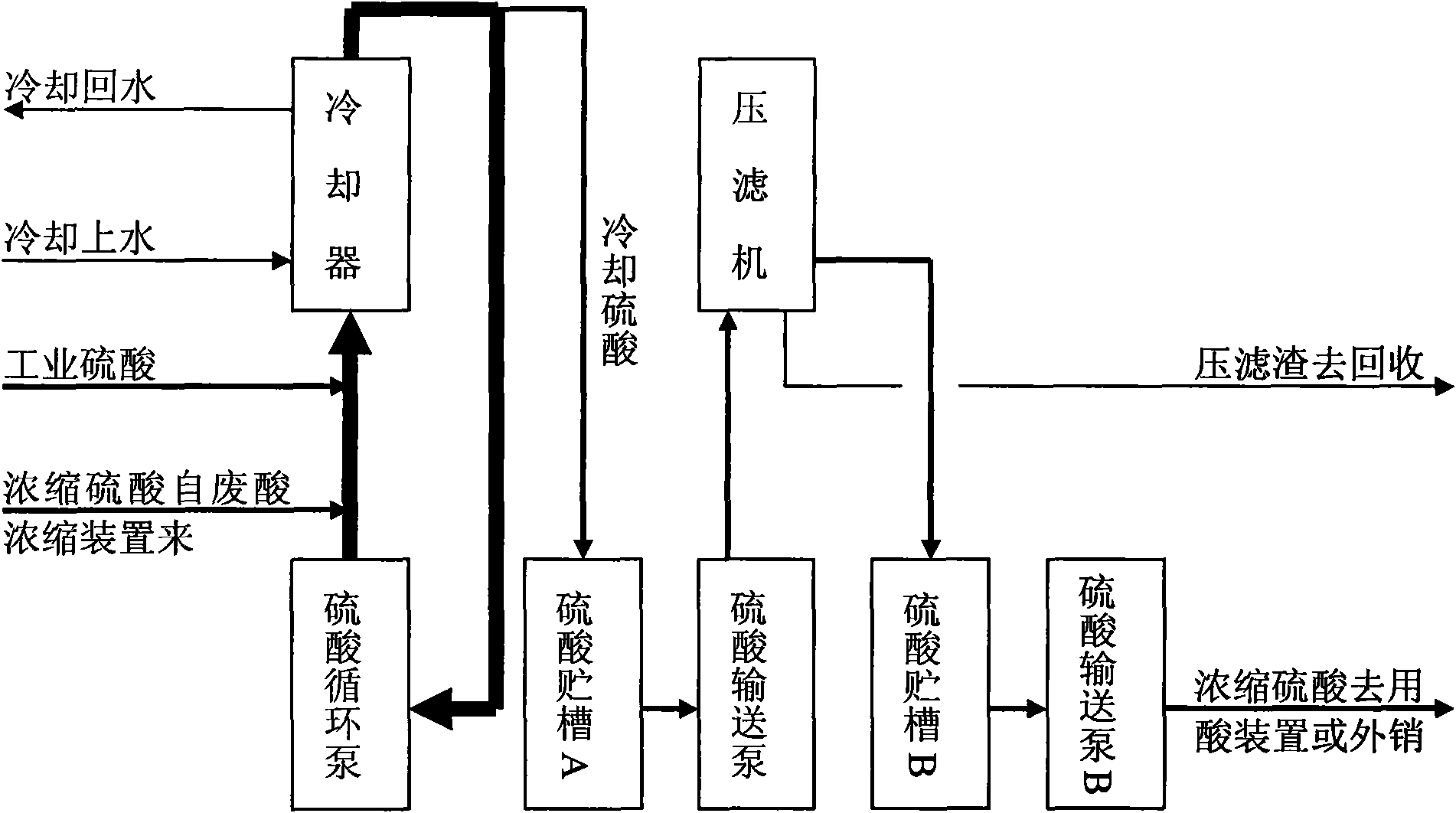

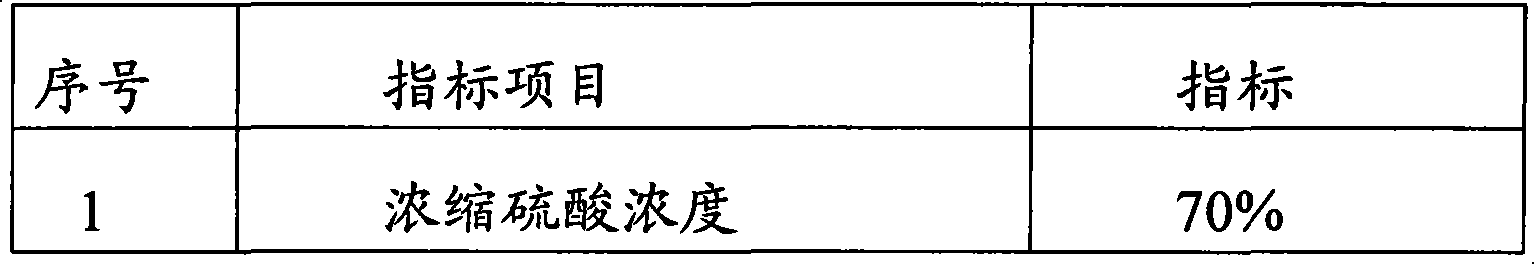

Method for recycling waste product and by-product in sulfuric acid method titanium dioxide production

ActiveCN101618864AEasy to produceLow investment costSulfur-trioxide/sulfuric-acidFiltrationEconomic benefits

The invention relates to a method for recycling the waste product and by-product in sulfuric acid method titanium dioxide production which adopts a forced circulation system which contains a sulfuric acid circulating pump, a cooler and recycle acid pipelines to cool and mix sulfuric acid, and combines the processes of refrigeration, purification and preparation of concentrated sulfuric acid in the sulfuric acid method titanium dioxide production to only one process through filtration, thus greatly simplifying the production process and reducing the production cost and investment. Because the invention adopts big flow forced circulation technology, the temperature of circulating sulfuric acid and the temperature difference are lower so that the demand to the material of the sulfuric acid circulating pump is reduced and the service life is prolonged; besides, the flow velocity on the sulfuric acid side of the cooler in the forced circulation technology is higher so that the scaling forming speed on the sulfuric acid side of the cooler is slower and the operation rate is higher. The invention solves the problems of the sulfuric acid method titanium dioxide production that the flows of refrigeration, purification and preparation of concentrated sulfuric acid are long, the investment is large, the operation rate is low, the production cost and the maintenance cost are high and the like, and the obtained economic benefit is remarkable.

Owner:XIANGYANG LOMON TITANIUM IND CO LTD

Pattern matching method in manufacturing semiconductor memory devices

ActiveUS8229205B2Increase success rateImprove driving rateCharacter and pattern recognitionOriginals for photomechanical treatmentPattern recognitionGraphics

A pattern matching method for use in manufacturing a semiconductor memory device increases a pattern matching rate between a GDS image and an SEM image. The pattern matching method includes extracting a scanning electron microscope (SEM) image and a graphic data system (GDS) image to perform a pattern matching; performing a two-dimensional Fourier transform (FFT) for the extracted GDS image and analyzing a low spatial frequency; deciding whether or not a pattern is a repeated pattern or non-repeated pattern by using the analyzed low spatial frequency; and limiting an X / Y range for a pattern matching when the decision result is for the repeated pattern, and then performing the pattern matching between the SEM image and the GDS image.

Owner:SAMSUNG ELECTRONICS CO LTD

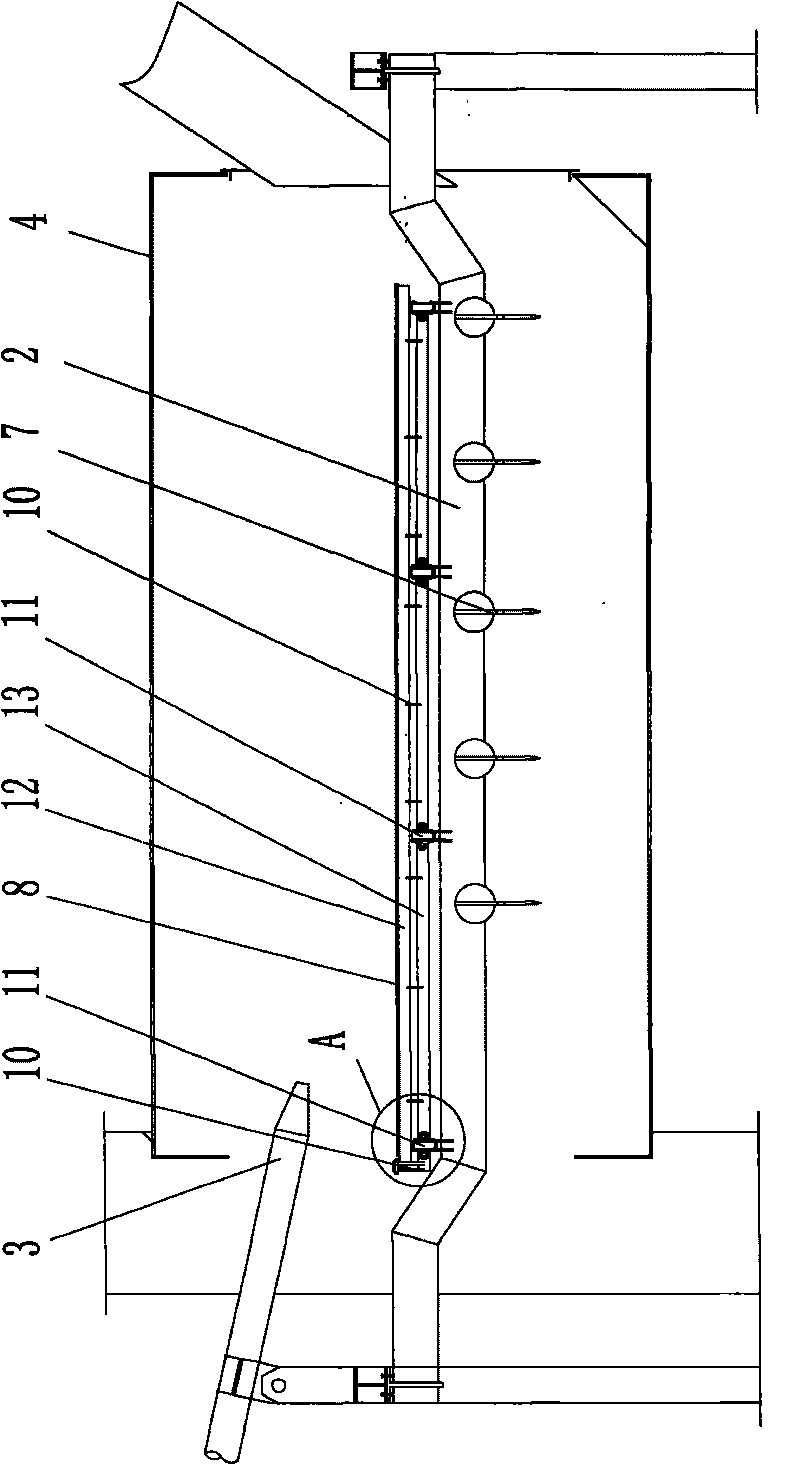

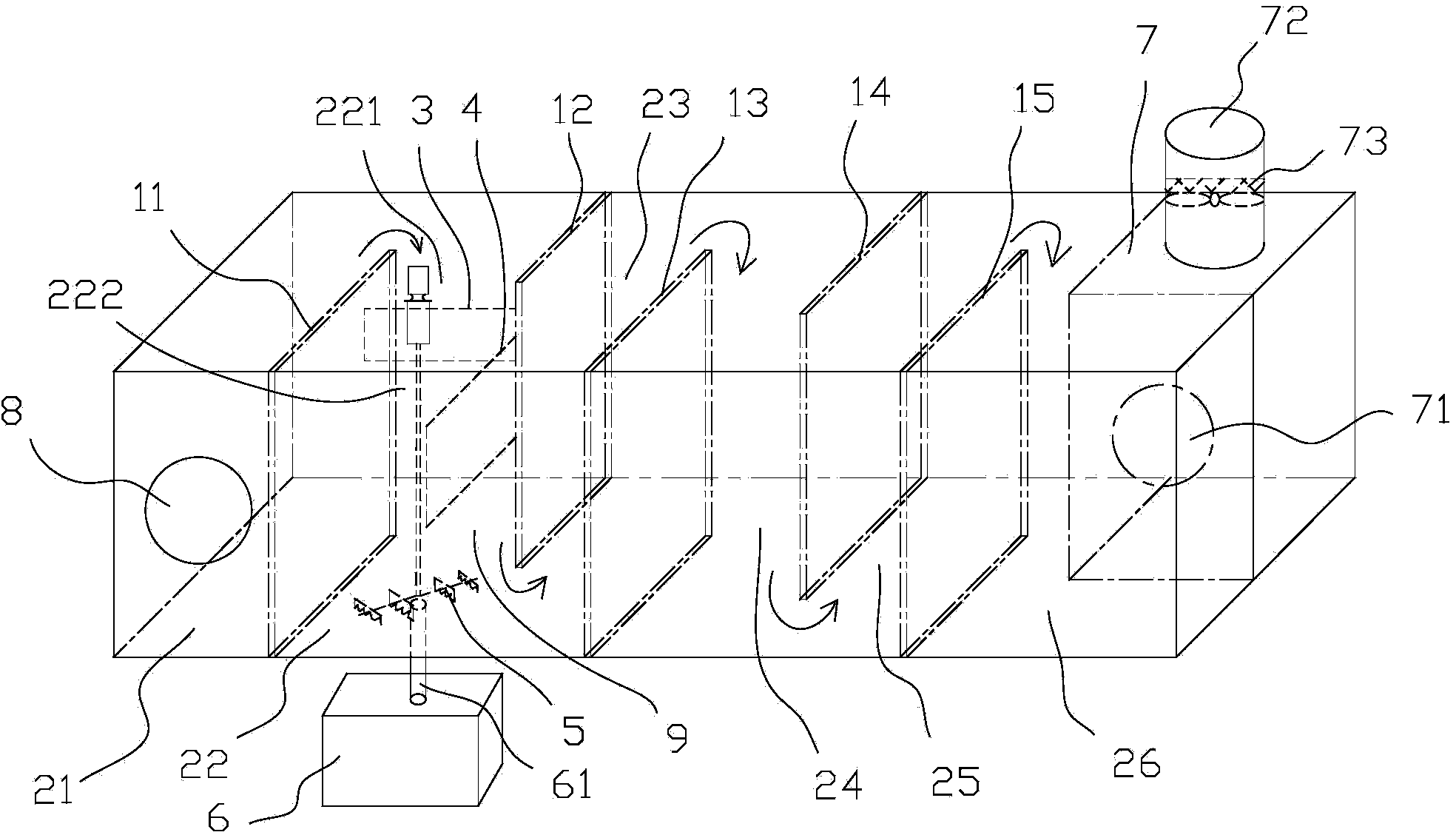

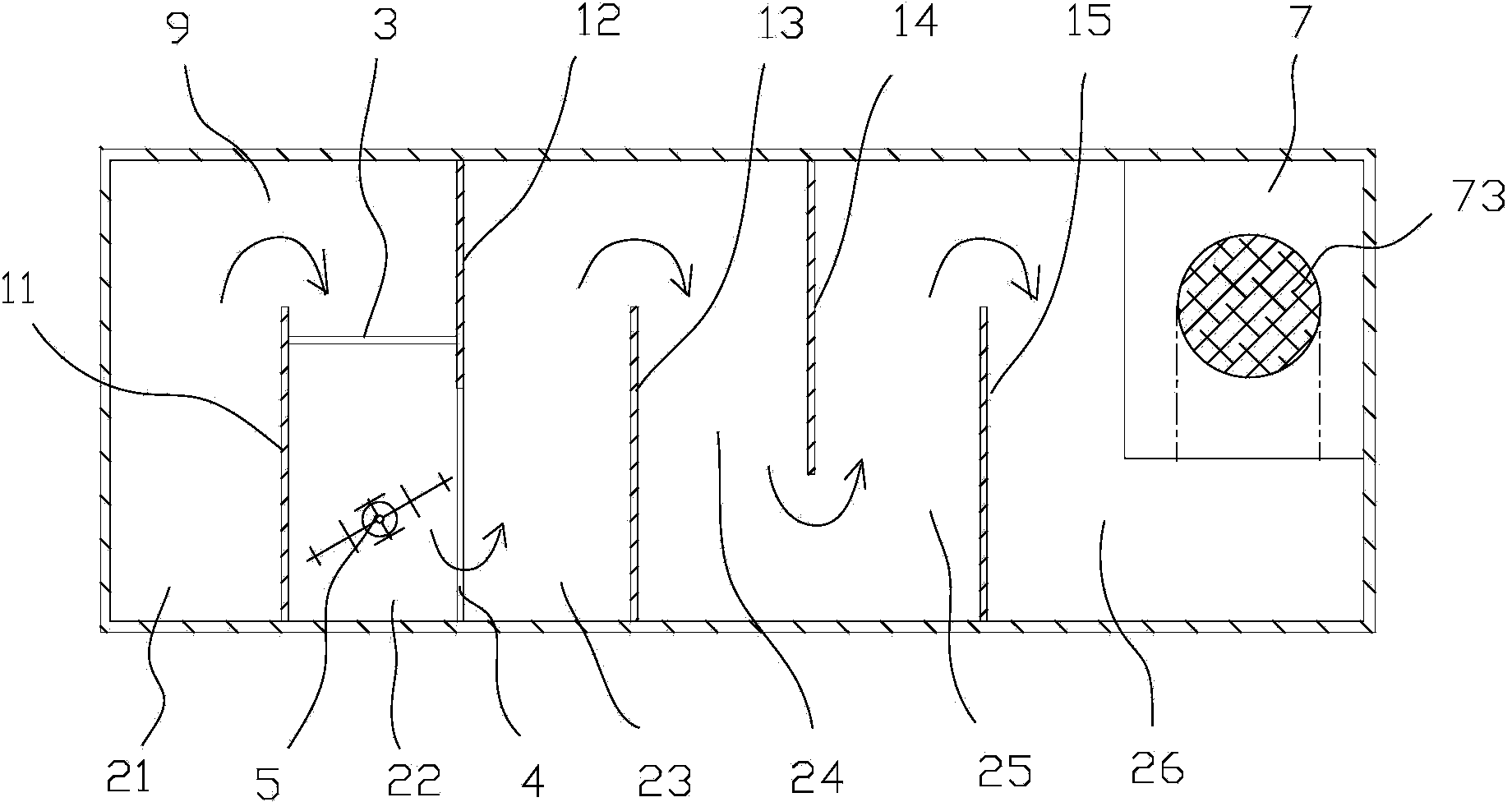

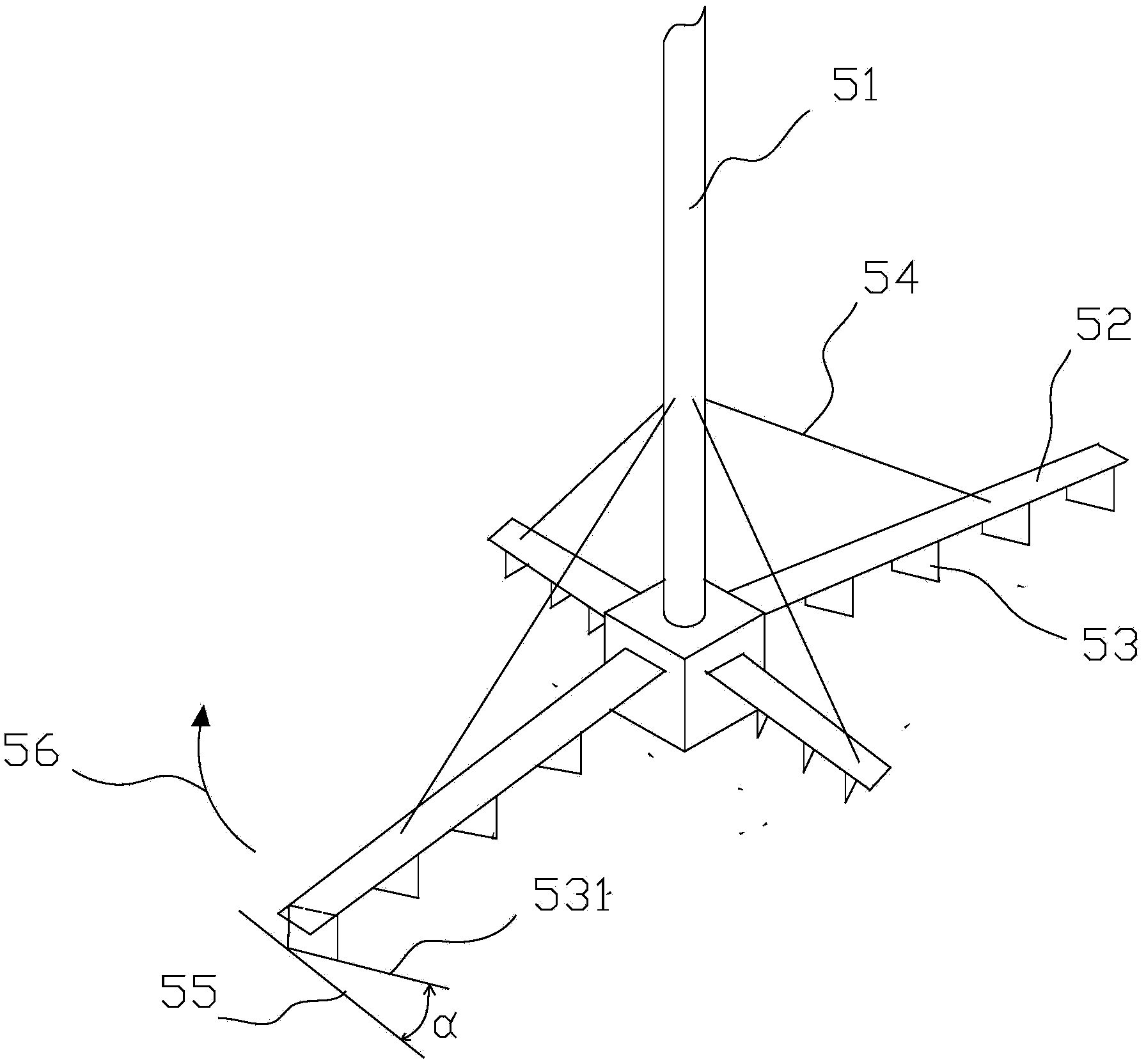

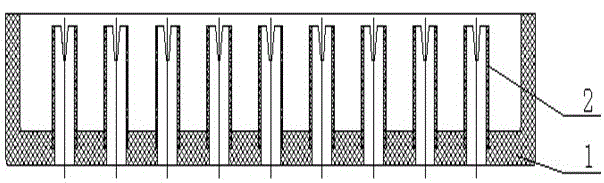

Gravity settling chamber for monoammonium phosphate tail gas dustfall

ActiveCN103657261AAccelerated settlementDrain in timeDispersed particle separationPhosphateGas chamber

The invention relates to a gravity settling chamber for monoammonium phosphate tail gas dustfall. Retaining walls for partitioning the settling chamber into a plurality of gas chambers are arranged in the settling chamber in a longitudinal staggering manner; a gas flow channel leading to the gas chamber adjacent to each retaining wall is formed between one side of each retaining wall and the inner wall of the settling chamber; a longitudinal partition plate is arranged in the gas flow channel between the second retaining wall and the inner wall of the settling chamber and partitions the gas flow channel into an upper part and a lower part; a dust discharging opening is formed in the bottom of the tail end of the second gas chamber and is communicated with a dust gathering chamber arranged below the settling chamber through a pipeline; an electric sweeping device for sweeping dust settling to the bottoms of the gas chambers into the dust discharging opening is arranged in the second gas chamber at the upper end of the dust discharging opening. The longitudinal partition plates and transverse partition plates are arranged in the settling chamber, so that the dustfall effect can be enhanced.

Owner:ANHUI LIUGUO CHEM CO LTD

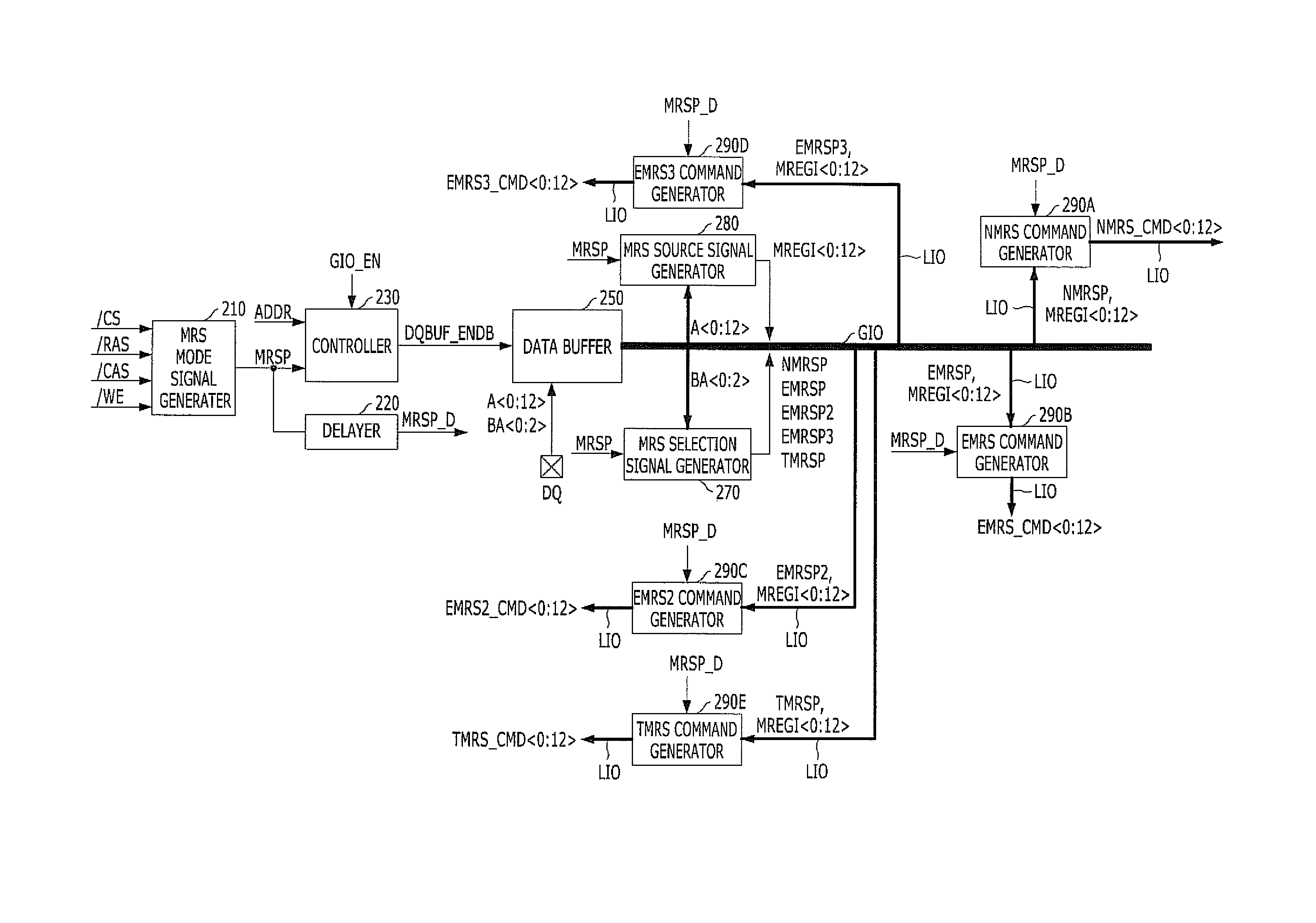

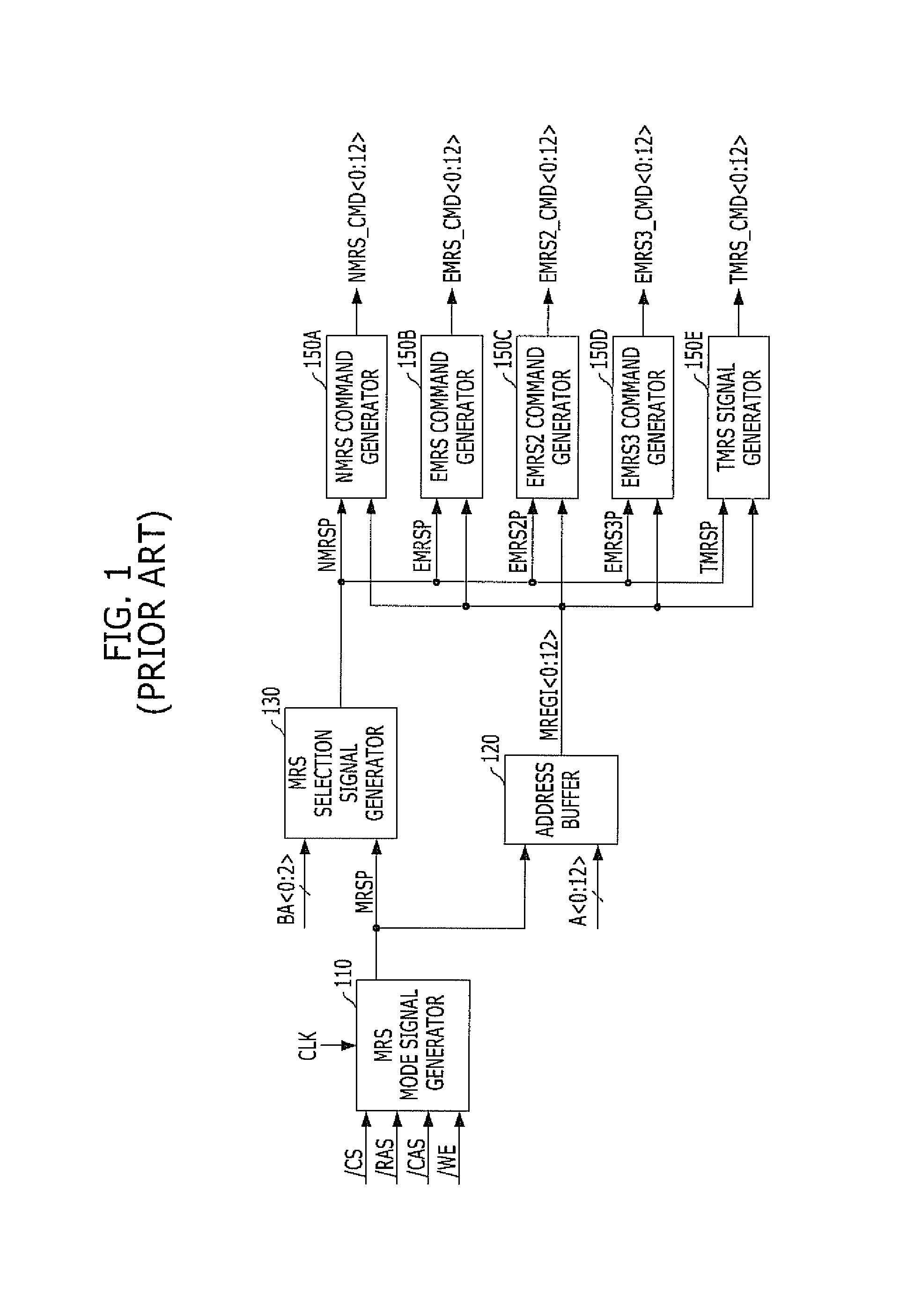

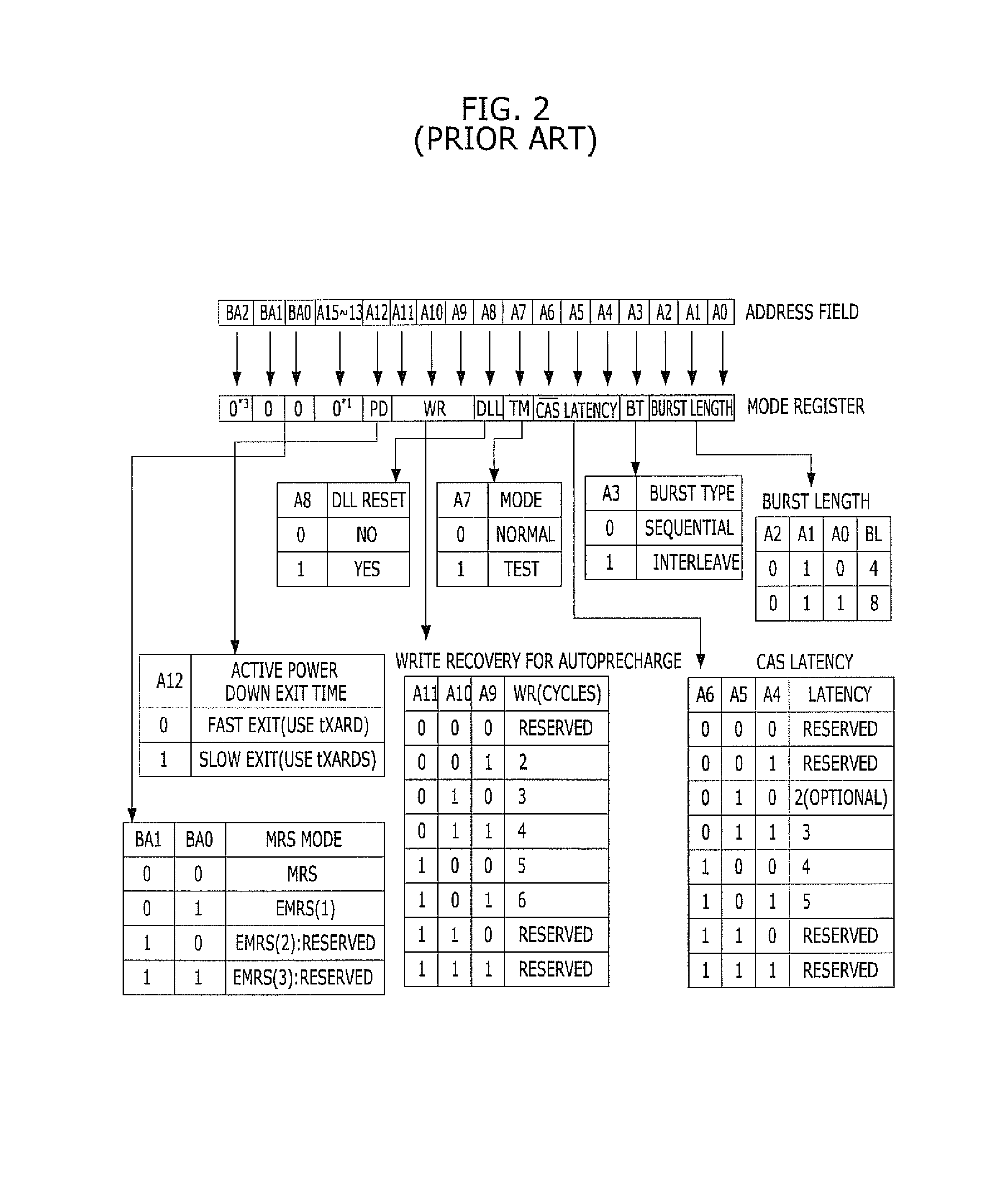

Semiconductor memory device including mode register set and method for operating the same

A semiconductor memory device and method for operating the same includes a controller configured to generate a data buffer control signal in a mode register set (MRS) mode, a data buffer configured to buffer and output a plurality of MRS codes inputted through a data pad in response to the data buffer control signal, and a plurality of MRS command generators configured to receive the MRS codes outputted from the data buffer through a data line and generate a plurality of MRS commands based on the received MRS codes.

Owner:SK HYNIX INC

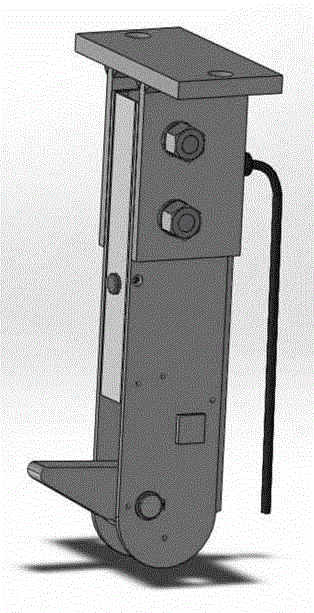

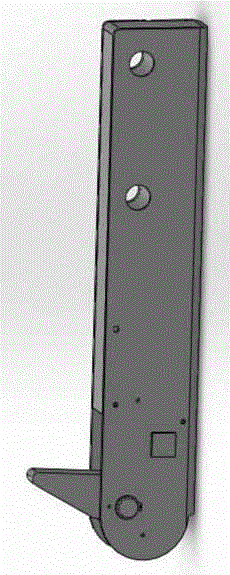

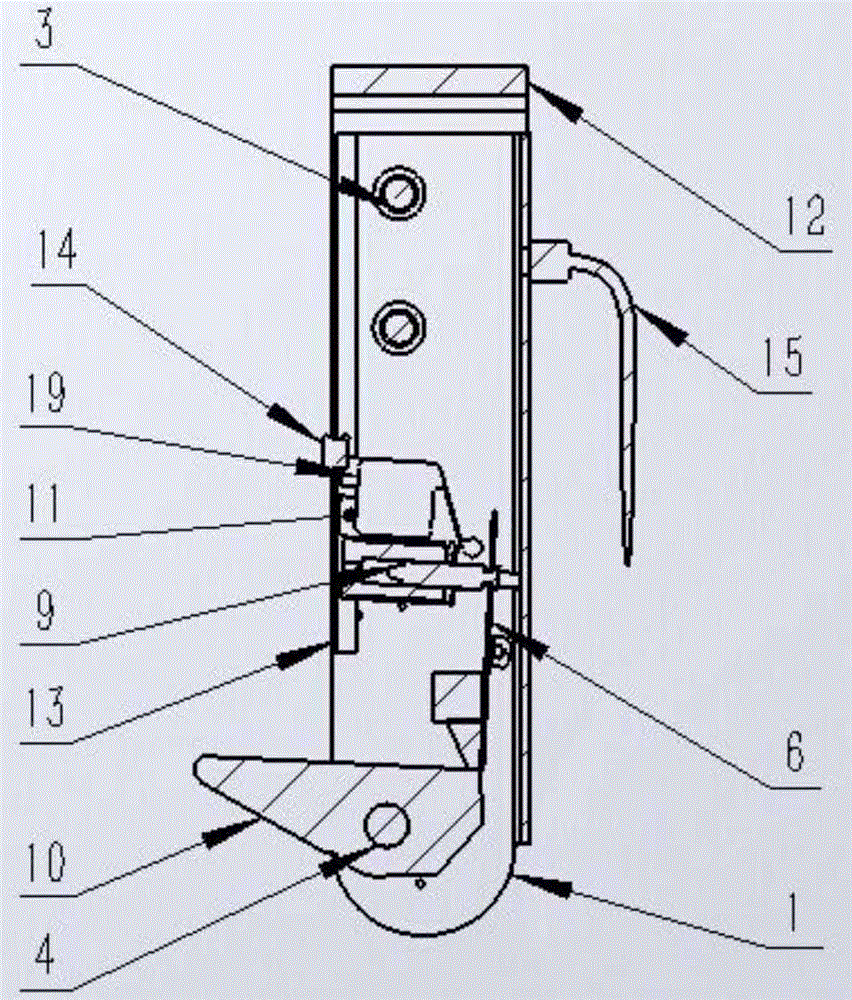

Direct-current low-voltage 24V safe and energy-saving anti-dropping device for parking equipment

The invention discloses a direct-current low-voltage 24V safe and energy-saving anti-dropping device for parking equipment. The device mainly consists of a device loading and fixing structure, a power supply and signal feedback circuit, an electric energy and mechanical energy conversion structure, and an operation state LED (light-emitting diode) display lamp. In a using process of the device, a safety grab (in a power-off state) extends out, so that a car carrying board can be firmly grabbed during sudden failure to achieve safety protection effect; the device adopts a direct-current low-voltage 24V safety power supply to supply power, so that damages, during electric leakage, to a human body, equipment and the like can be avoided; the operation state LED display lamp is additionally arranged to display a device operation state in real time, so that a failure position can be conveniently found and maintenance is convenient. The direct-current low-voltage 24V safe and energy-saving anti-dropping device has the advantages of being energy-saving, environmentally-friendly, safe and reliable, compact in structure, simple to mount, and the like, is suitable for various forms of lifting and transverse-moving mechanical type stereo garages, and is used as a safety protection device of other mechanisms which possibly have dropping faults.

Owner:储华群 +3

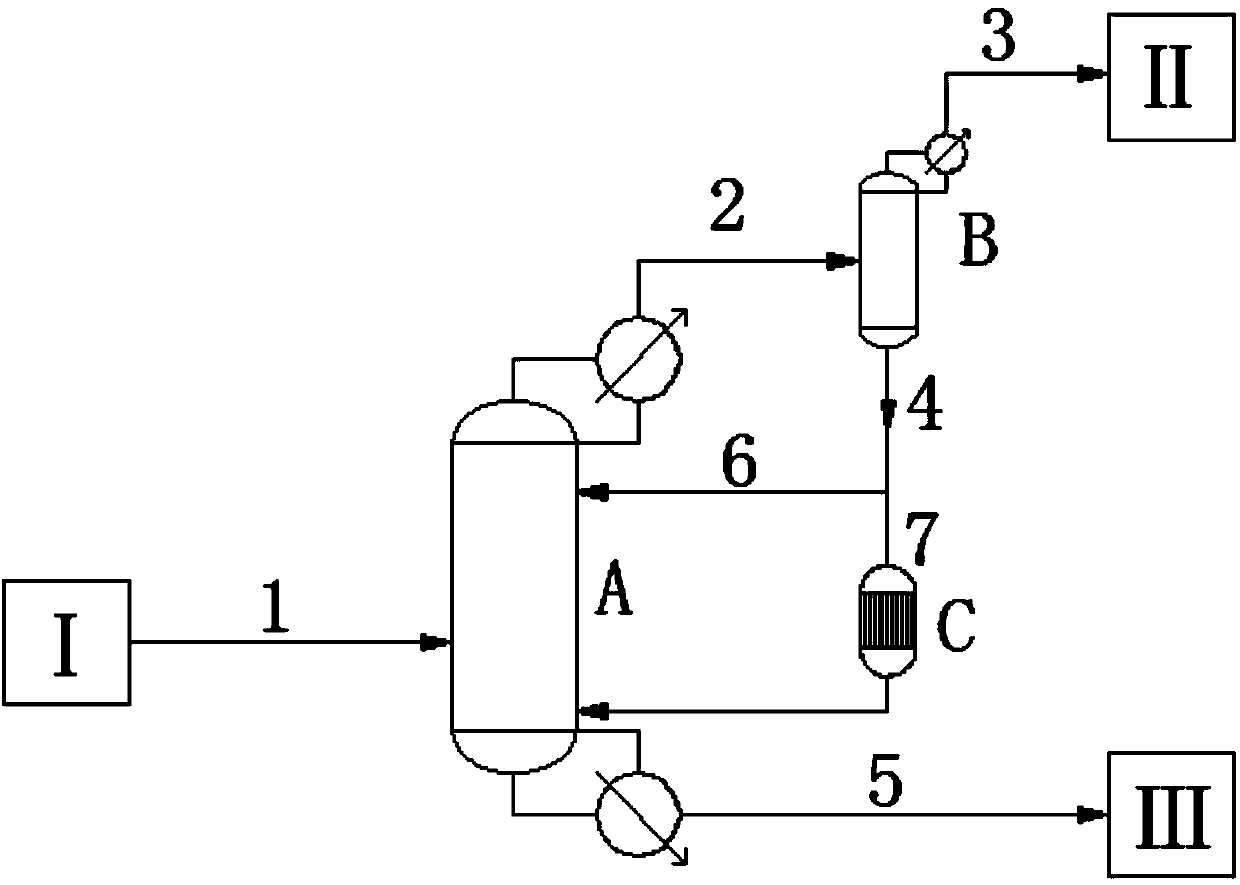

Method for delaying deposition of sieve plate of extraction column

This invention discloses a method for delaying deposition of sieve plate of extraction column, including following steps: applying a condensing liquid generated by the heat exchange of low pressure steam of a phosphoric acid concentration production system, the temperature of the condensing liquid being in the range of 100 to 120 degrees centigrade; applying an extracting agent that will be added into the extraction column to a heat exchanger so as to make it execute the heat exchange with the condensing liquid in the heat exchanger and to improve the extracting agent temperature; sending the extracting agent having higher temperature into the extraction column to realize the extraction to the iodine in the phosphoric acid; controlling the temperature of the extracting agent via adjusting the condensing liquid quantity in the heat exchanger, controlling the temperature difference of the acid temperature before entering and after existing from the column in the range of 5 to 20 degrees centigrade. This invention can reduce the deposition of the sieve plate of the extraction column, improve the system driving rate, thereby improving the running efficiency of the system and realizing the production cost.

Owner:WENGFU (GRP) CO LTD

Method and device for regulating nutrients of diammonium phosphate

InactiveCN103553758AHigh nitrogen contentReduce nitrogen contentFertilizer mixturesO-Phosphoric AcidDiammonium phosphate

The invention discloses a method for regulating nutrients of diammonium phosphate. The method comprises the steps of pumping sulfuric acid into a tubular reactor through a sulfuric acid pump, enabling the sulfuric acid to be mixed with phosphoric acid and ammonia for reacting, and spraying a reaction product on a granulating material through a reverse nozzle of the same pipe for coating and granulating to obtain the diammonium phosphate, wherein the diammonium phosphate contains the following components in percentage by mass: 46% of phosphorus and over 18% of nitrogen. By using the method, the nitrogen content of a diammonium phosphate product can be effectively increased, and the phosphorus content of the diammonium phosphate product can be reduced; the corrosion of a cleaning system to equipment can also be relieved, so that the production cost is greatly reduced; the method is very suitable for diammonium phosphate production enterprises.

Owner:WENGFU (GRP) CO LTD

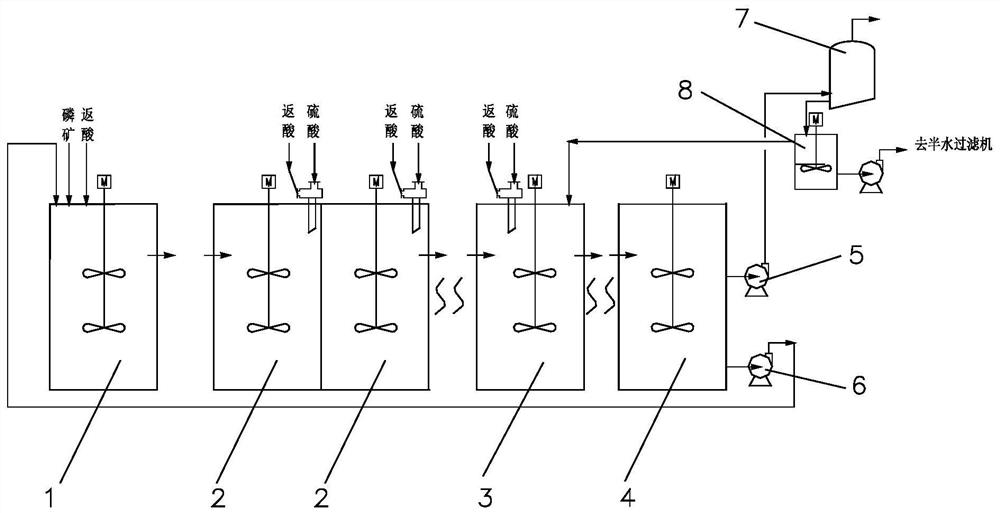

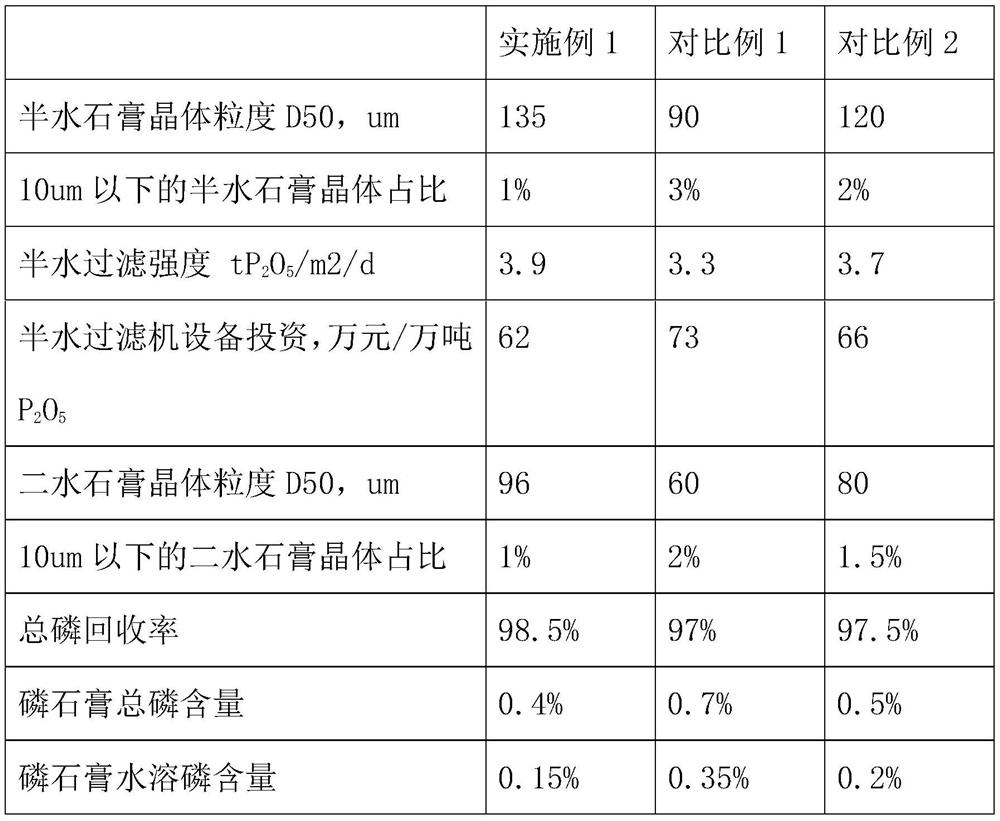

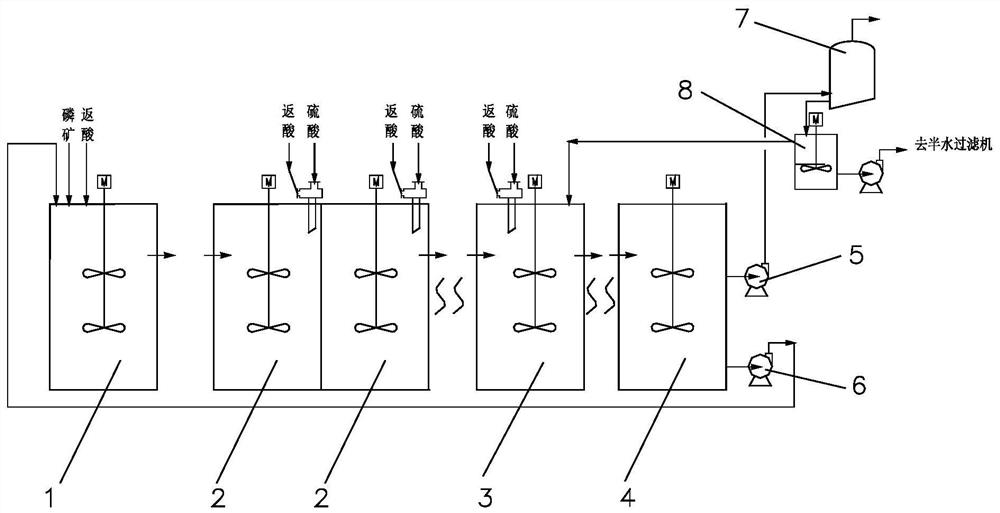

Method for controlling coarse crystallization of semi-hydrated gypsum

ActiveCN113185160AStable growthUniform particle sizeCalcium/strontium/barium sulfatesPhosphorus compoundsSulfatePhysical chemistry

The invention discloses a method for controlling coarse crystallization of semi-hydrated gypsum, which comprises the steps of 1, firstly feeding phosphorite into a premixing area, mixing with returned acid, and quickly decomposing; 2, feeding the slurry discharged from the premixing area into a dissolving area, and fully dissolving the slurry in the presence of returned acid and sulfuric acid to avoid generating a compact calcium sulfate wrapping film; 3, feeding the reaction slurry discharged from the dissolving area into a crystallization area, and crystallizing and growing in the presence of concentrated sulfuric acid; and 4, feeding the reaction slurry out of the crystallization region into a curing region, and further growing the semi-hydrated gypsum crystals. The method is simple, easy to control, high in yield and capable of effectively obtaining coarse and large semi-hydrated gypsum crystals with good uniformity.

Owner:WUHUAN ENG

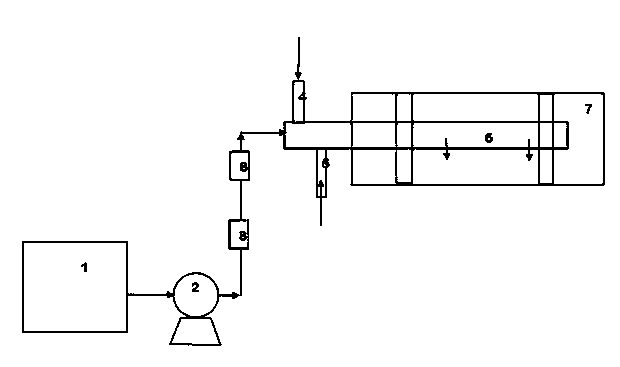

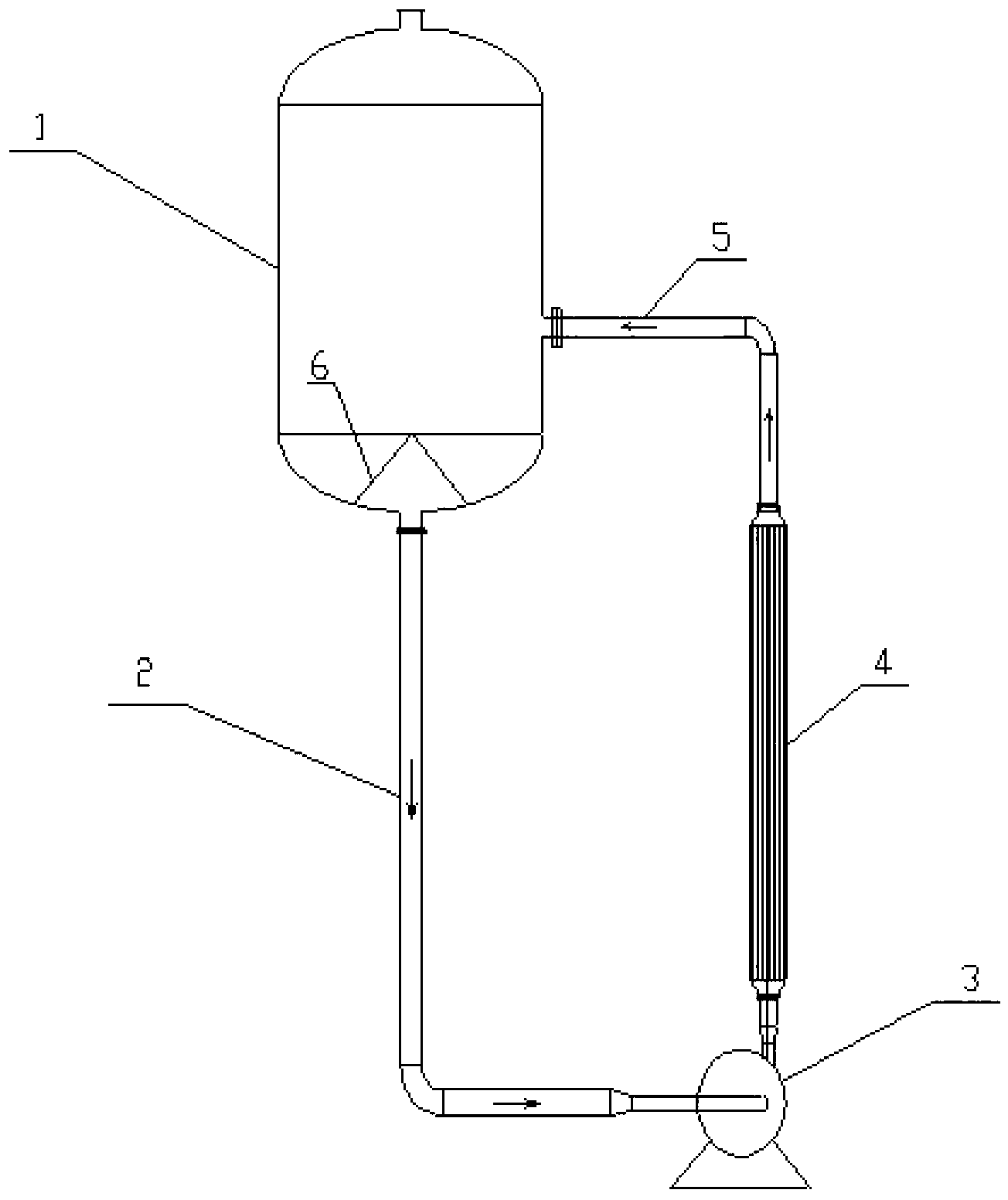

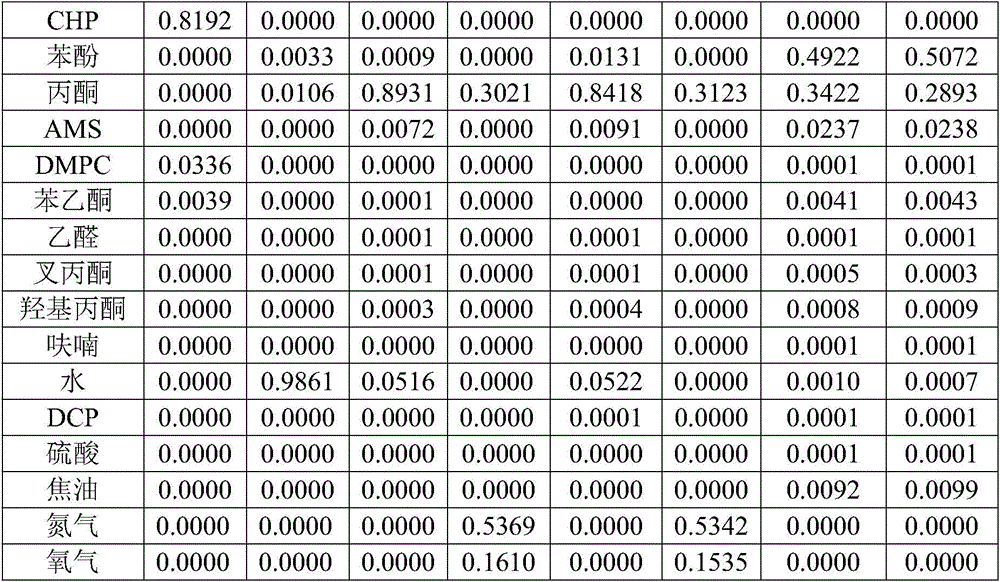

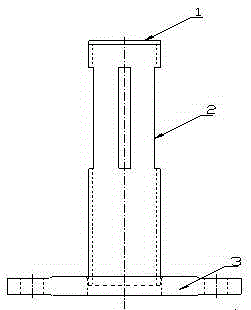

Ammonium phosphate flash evaporation chamber improved structure

The invention discloses an ammonium phosphate flash evaporation chamber improved structure which comprises a flash evaporation chamber (1), a feed pipeline (2), a slurry circulating pump (3), a slurry heater (4) and a discharge pipeline (5). The part, close to a pipe opening on the bottom, in the flash evaporation chamber is provided with a cross-shaped sheath (6). Therefore, compared with the prior art, the ammonium phosphate flash evaporation chamber improved structure is low in cost, simple, and easy to process; the slurry circulating pump maintains the stable feeding velocity through the effect of the cross-shaped sheath, the slurry turbulent flow phenomenon is prevented, and further, the possibility of bonding slurry into blocks is reduced; meanwhile, slurry, which is bonded into blocks, can be prevented from entering the feed pipeline, so that the blocking possibility of the slurry heater is reduced, the driving rate is improved, and further, the production cost is lowered while the production efficiency is improved.

Owner:江苏绿陵润发化工有限公司

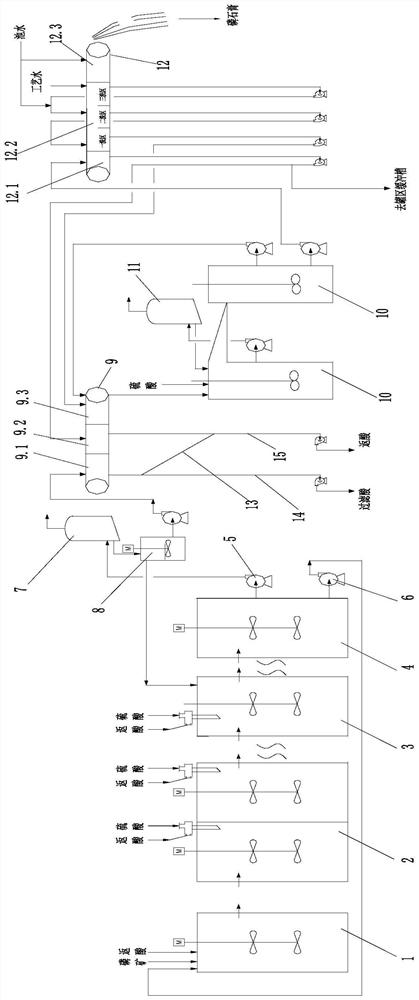

High-yield hydrated crystalline phase reconstruction wet-process phosphoric acid production technology

ActiveCN113173566AImprove overall recoveryAvoid acid accumulationPhosphorus compoundsHydration reactionO-Phosphoric Acid

The invention discloses a high-yield hydrated crystalline phase reconstruction wet-process phosphoric acid production technology. The technology comprises a semi-hydrated reaction filtration process and a dihydrate reaction filtration process, and the semi-hydrated reaction filtration process comprises the steps of premixing, dissolving, crystallizing, curing and semi-hydrated filtration; and the dihydrate reaction filtration process comprises a conversion step and a dihydrate filtering step. According to the invention, through gradient control of the relationship between the sulfate ion concentration and the CaO concentration in different stages of the semi-hydrated reaction, the crystal size is increased, the crystal is kept stable, and the semi-hydrated gypsum crystal with uniform particle size is obtained; by changing the circulation path of the slurry, the reaction retention time is prolonged, and the growth of semi-hydrated gypsum crystals in a relatively stable environment is ensured; coarse, uniform and stable dihydrate gypsum crystals are obtained by controlling the degree of supersaturation of a dihydrate reaction, the filtering performance is good, the content of water-soluble phosphorus in the dihydrate gypsum is reduced, and the filtering yield is improved; and by reasonably utilizing the filtrate and the flushing water, the wastewater discharge is reduced, and the total yield of P2O5 is increased.

Owner:WUHUAN ENG

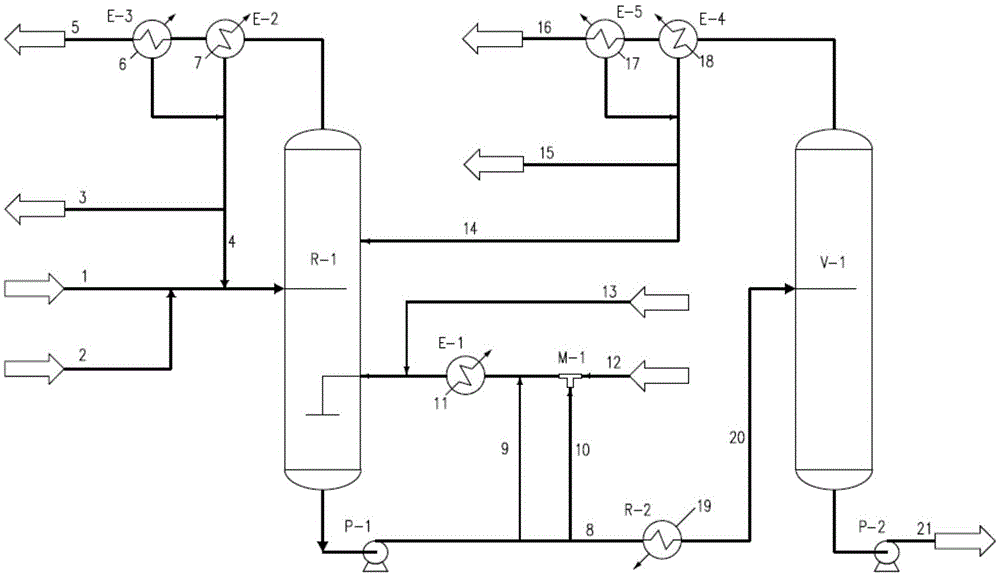

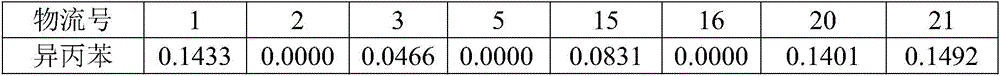

Method of raising decomposition yield of cumyl hydroperoxide

ActiveCN105669367AReduce energy consumptionReduce generationOxygen-containing compound preparationOrganic compound preparationReaction temperaturePhenol

The invention relates to a method for raising the decomposition yield of cumyl hydroperoxide of a phenol-acetone unit.The method includes the steps that 1, first-level decomposition liquid is recycled to a decomposer through a special distributor after being cooled; 2, a concentrated sulfuric acid catalyst is added into a decomposition liquid recycling system from two different points; 3, the concentration of sulfuric acid in the decomposer is lowered; 4, standing time of decomposition liquid in the decomposer is increased, and the reaction temperature of the decomposer is lowered; 5, standing time of the decomposition liquid in a second-level composer is increased; 6, the reaction temperature of second-level decomposition is increased; 7, flash evaporation is conducted on materials discharged through second-level decomposition to recycle energy, total or part of flash evaporation condensate liquid is recycled to the decomposer, and the remaining part is sent to a crude acetone tower on the downstream of the phenol-acetone unit; 8, part of decomposer steam condensate liquid is sent to a fine acetone tower on the downstream of the phenol-acetone unit or fed into a feeding tank.The method mainly solves the problems that by means of an existing phenol acetone production technology, the decomposition yield is low, a great number of tar by-products are generated, and a distilled fed material is high in salt content.

Owner:张殿豪

Simple tubular filter

InactiveCN105268236AEnsure personal safetyStable controlStationary filtering element filtersBiochemical engineeringFlange

A simple tubular filter comprises a baffle, a filter tube and a flange. The baffle is fixedly connected with the filter tube, and the filter tube is in threaded connection with the flange. The simple tubular filter is applicable to the field of wet-process smelting for treatment of various materials and can greatly decrease the time required by dredging of a blocked position and downtime, ensure production continuity, stabilize control of technical indexes, improve the product quality and reduce the working intensity of workers.

Owner:JINCHUAN GROUP LIMITED

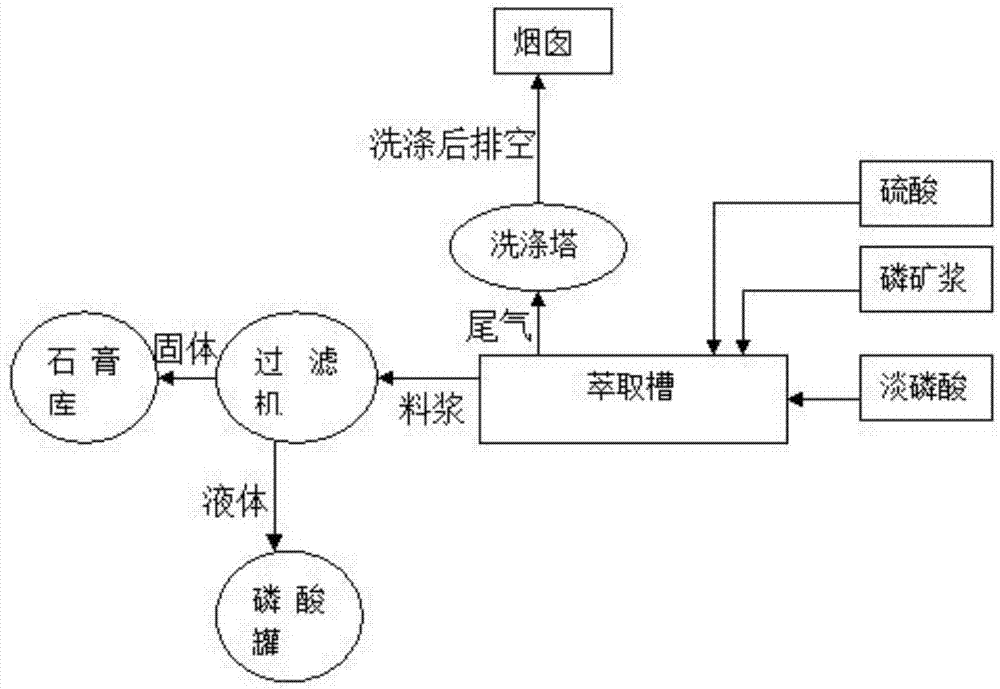

Rapid heating extraction method of extraction tank

ActiveCN103496684AReduce manufacturing costFast heating and thickening timePhosphorus compoundsFiltrationPhosphoric acid

The invention discloses a rapid heating extraction method of an extraction tank. The method comprises the steps: (1) after the extraction tank is cleared, complementing dilute phosphoric acid to a 1.5m position in the extraction tank; (2) starting stirring fans and tail gas fans in all regions, and keeping the extraction tank at micro-negative pressure; (3) respectively adding sulfuric acid and phosphoric ore pulp into the extraction tank at the speeds of 3m<3> / h and 5m<3> / h, heating and thickening, wherein the dilute phosphoric acid or sewage is complemented again into the heating process so that the liquid level of the extraction tank and the proportion of the extracted phosphoric acid are controlled; (4) when the extraction temperature is up to 60 DEG C, adjusting the negative pressure value of each tail gas fan, gradually increasing the adding amounts of the sulfuric acid and the phosphoric ore pulp, and shortening the heating and thickening times of the extraction tank; and (5) when the liquid level and all indexes of the extraction tank meet a filtrations condition, filtering and washing, collecting solids into a gypsum stockpile, collecting liquid into a phosphoric acid tank, and exhausting tail gas after the tail gas is washed and emptied by using a washing tower. The rapid heating extraction method has the advantages that the heating and thickening times are saved, reducing the production costs of enterprises is reduced, extraction reaction effect is good and the like.

Owner:山东聊城鲁西化工第五化肥有限公司

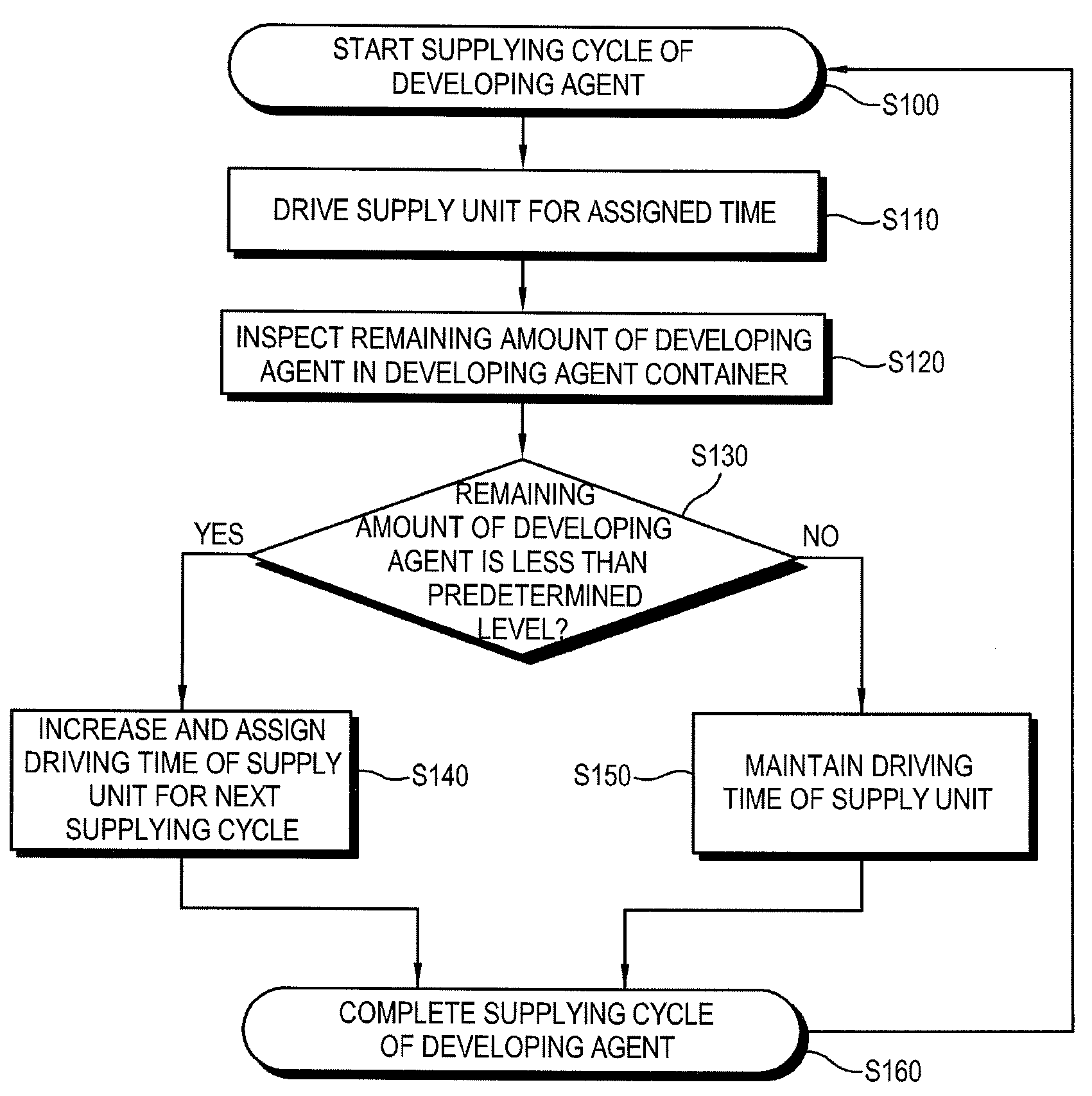

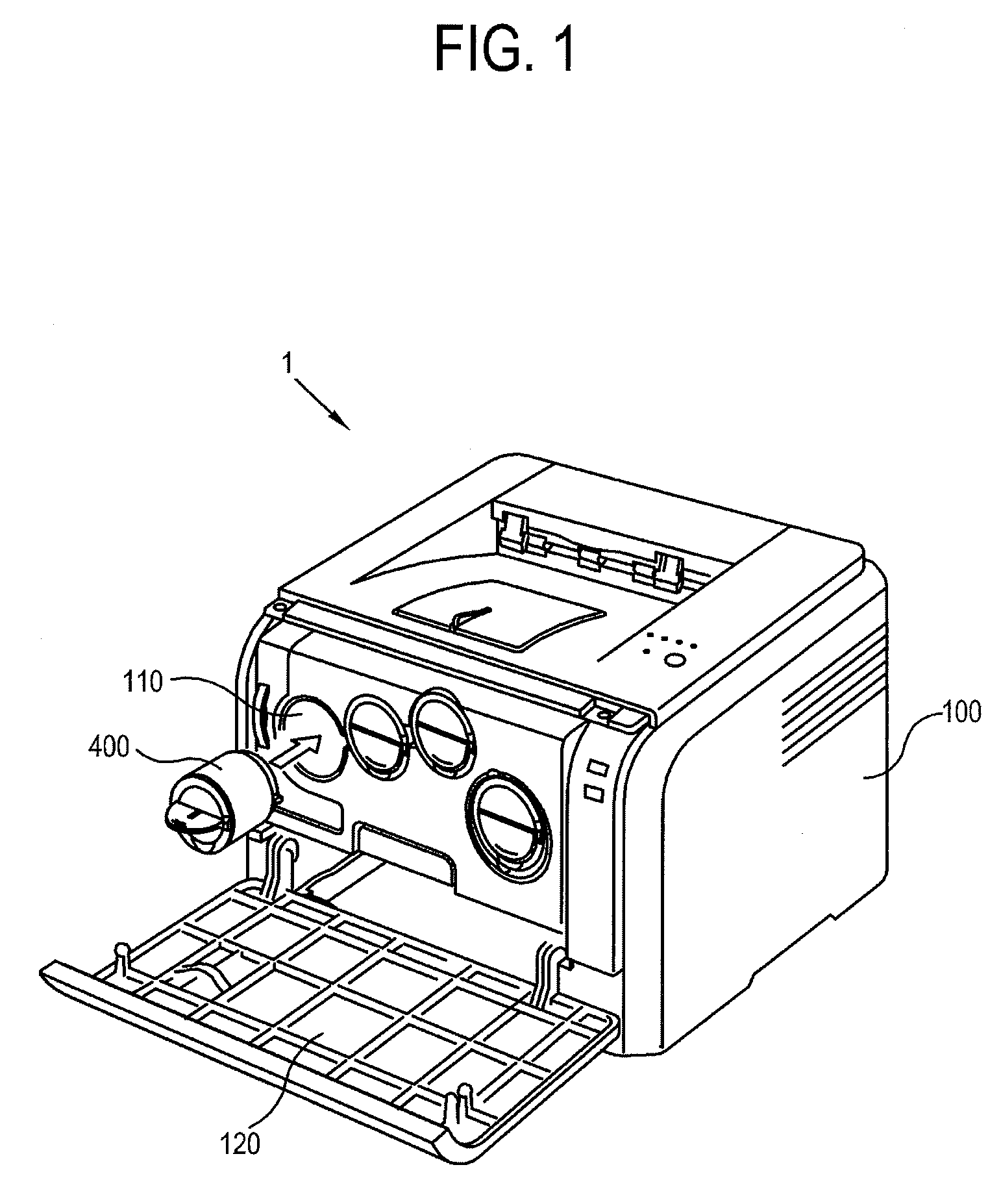

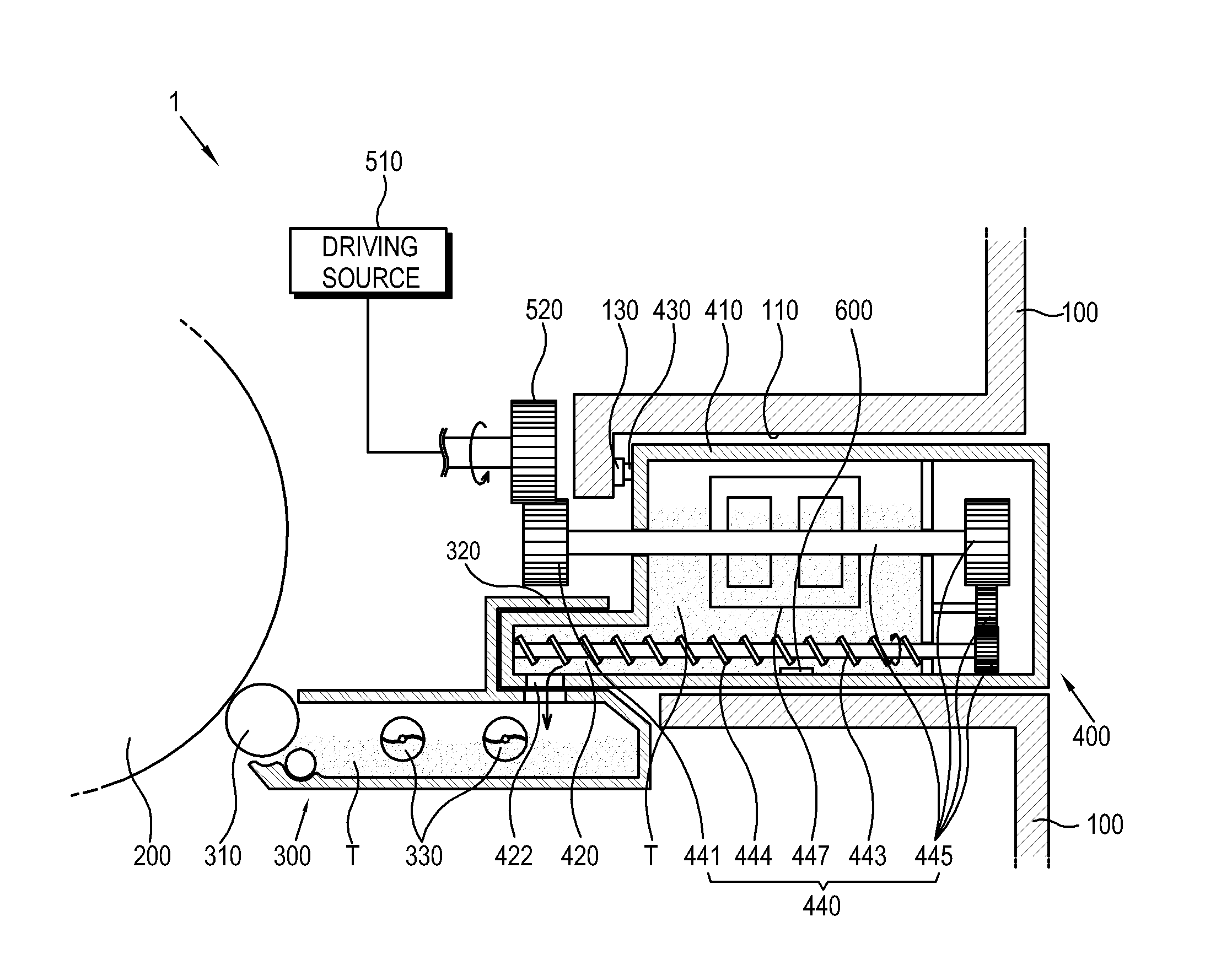

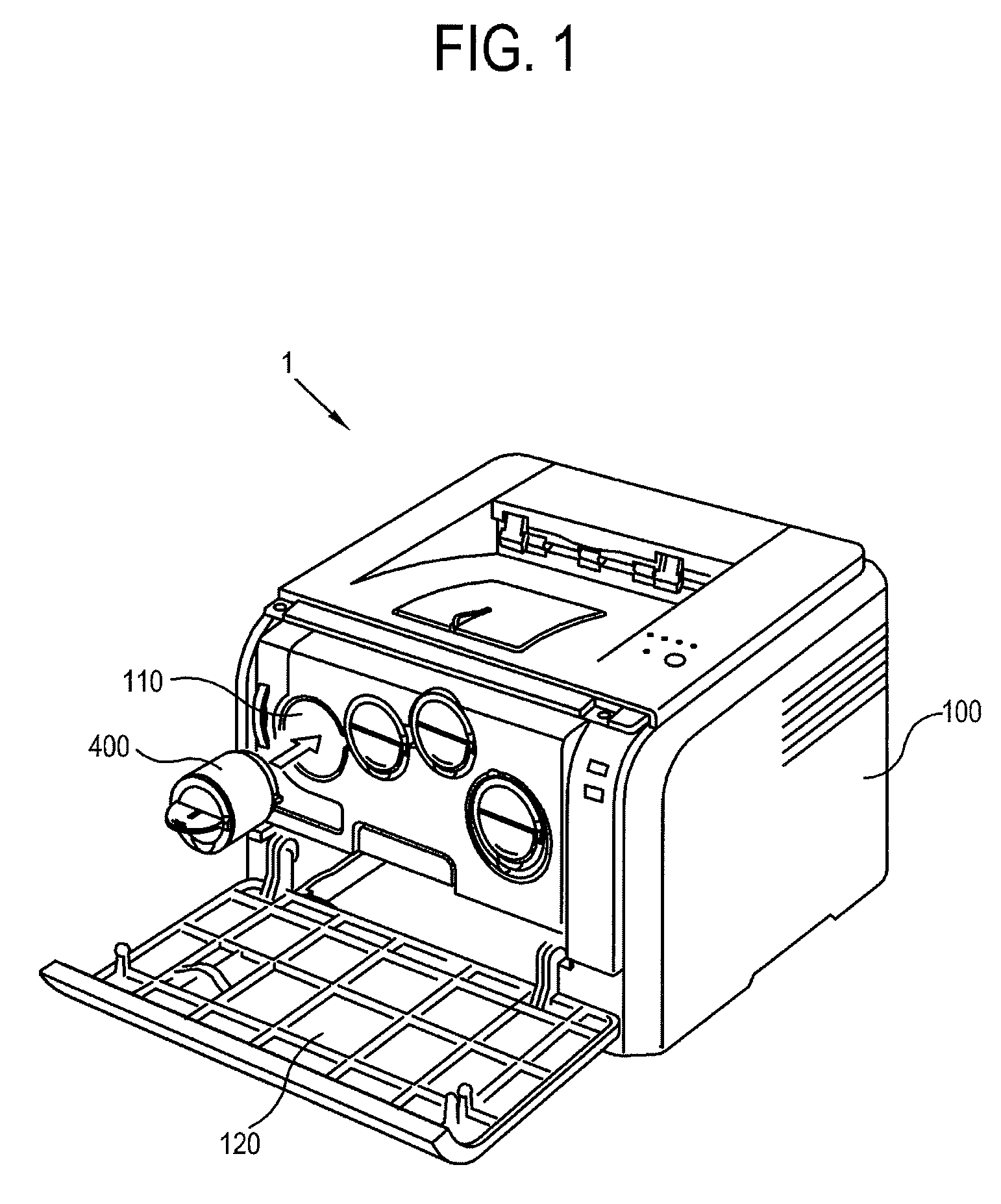

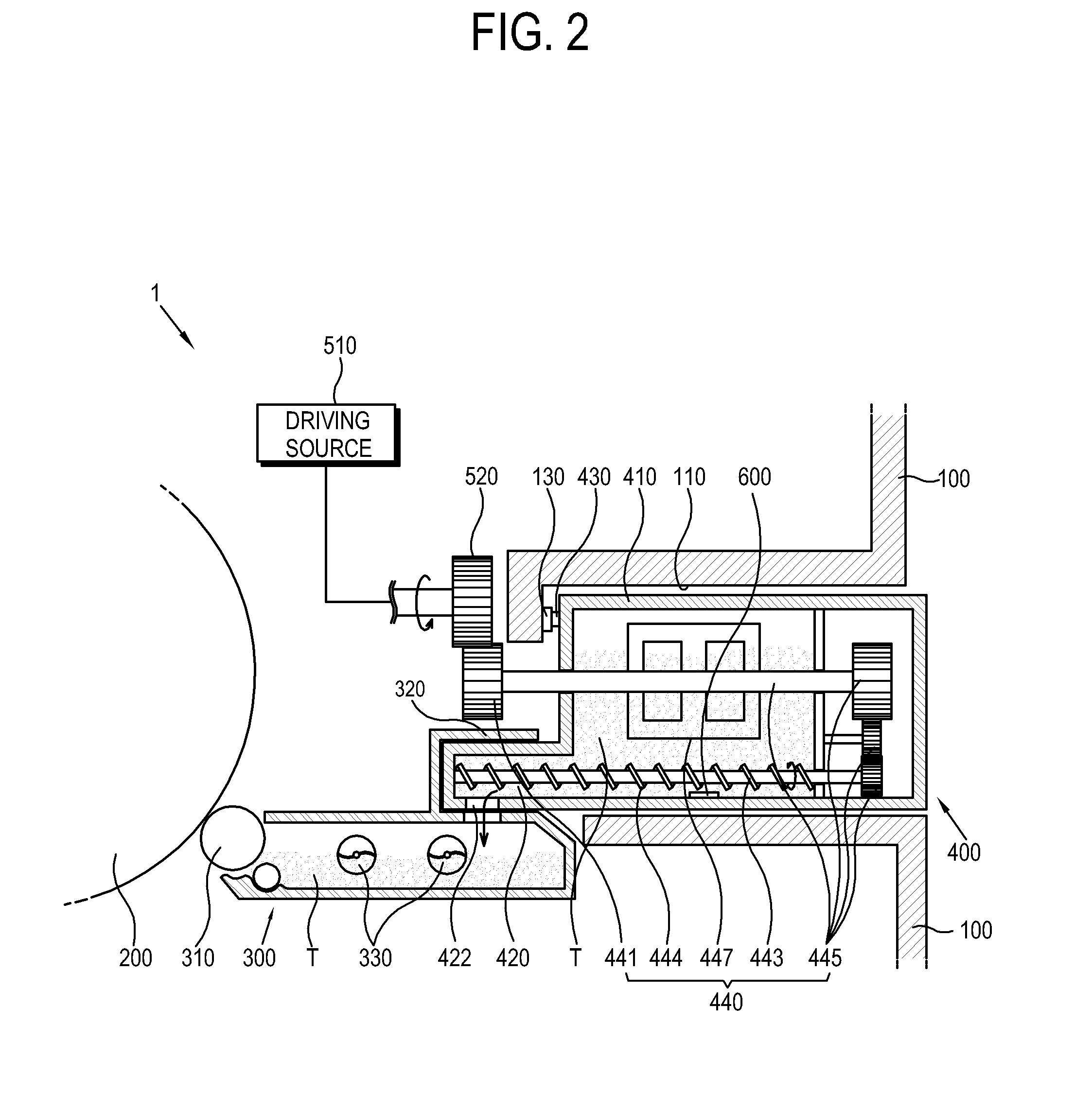

Image forming apparatus to adjust driving rate of a supply unit and controlling method of the same

Owner:HEWLETT PACKARD DEV CO LP

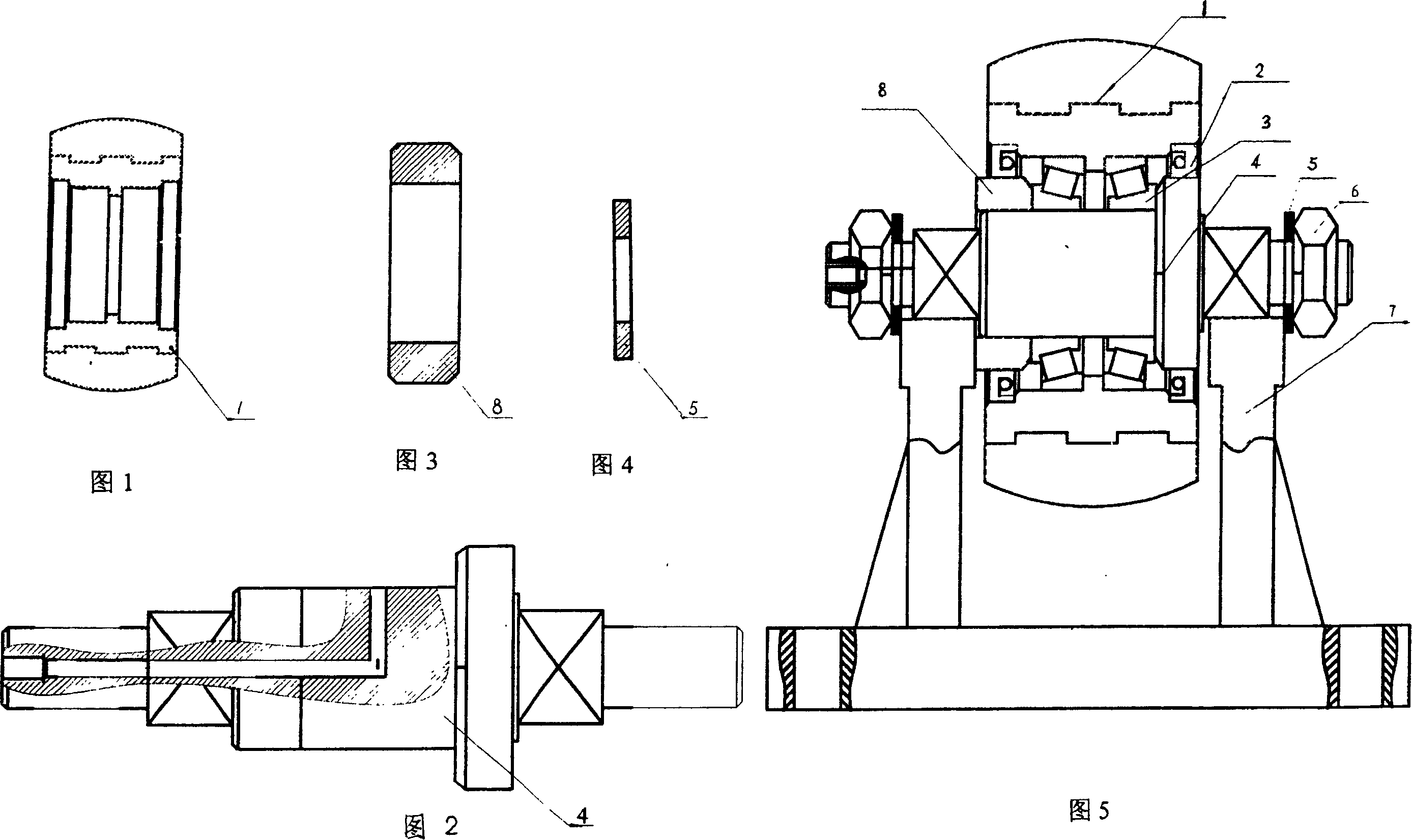

Conveyor idler of revolving-leaf type filter and its installation

ActiveCN100374179CGuaranteed uptimeImprove driving rateMoving filtering element filtersEngineeringPolypropylene

A supporting roller for the tray turning-over filter is composed of internal layer made of carbon steel and external layer made of polypropene. The tenon-mortise structure is between said internal and external layers. Its axle hole has shoulder matched with the shoulder on axle. Its advantages are high running stability and high durability. Its assembling method is also disclosed.

Owner:WENGFU (GRP) CO LTD

Method for delaying deposition of sieve plate of extraction column

Owner:WENGFU (GRP) CO LTD

Dehydration method during production process of toluene diisocynate

ActiveCN103724229BEfficient removalReduce corrosionOrganic compound preparationPreparation from carbamatesPhosgeneCarbamoyl chloride

Owner:QINGDAO UNIV OF SCI & TECH +1

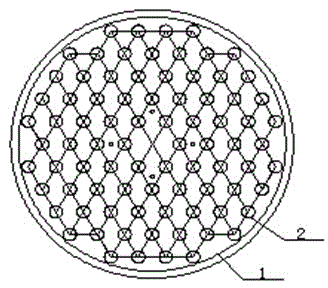

A method for manufacturing a high-temperature and corrosion-resistant graphitic acid distributor

ActiveCN103752141BIncrease stiffnessEasy to separateDispersed particle separationChemical industryPetrochemical

The invention discloses a high-temperature-resistant corrosion-resistant graphitic acid distributor and a manufacturing method thereof. The graphitic acid distributor comprises an acid disc, wherein overflow pipes are uniformly distributed inside the acid disc; both the acid disc and the overflow pipes are made of graphite material. The acid distributor is made of the graphite material, the graphite has high-temperature resistance and corrosion resistance, the influence of temperature on the graphite material is slight, the deformation amount is small, the distribution uniformity of materials in tower equipment in chemical production is guaranteed, and bias of the materials in the tower equipment is reduced. Compared with the conventional acid distributor made of a polytetrafluoroethene material, the graphitic acid distributor manufactured by adopting the manufacturing method has the advantages that the temperature resistance and corrosion resistance are improved by 30 percent, the strength is improved by 5-10 times, the bias is reduced, the production consumption is lowered, the service life is prolonged by two times, the problem that the high-temperature highly corrosive materials are easily biased in the tower equipment is solved, and great contribution is made to the development of fluorine chemical industry and other petrochemical industries.

Owner:龚孝祥

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com