High-yield hydrated crystalline phase reconstruction wet-process phosphoric acid production technology

A wet-process phosphoric acid and production process technology, applied in phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of inaccurate and stable sulfuric acid concentration control, low filtration rate, hindering the decomposition of phosphate rock, etc., to avoid the concentration of phosphoric acid. The effect of accumulating, reducing the amount, and improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

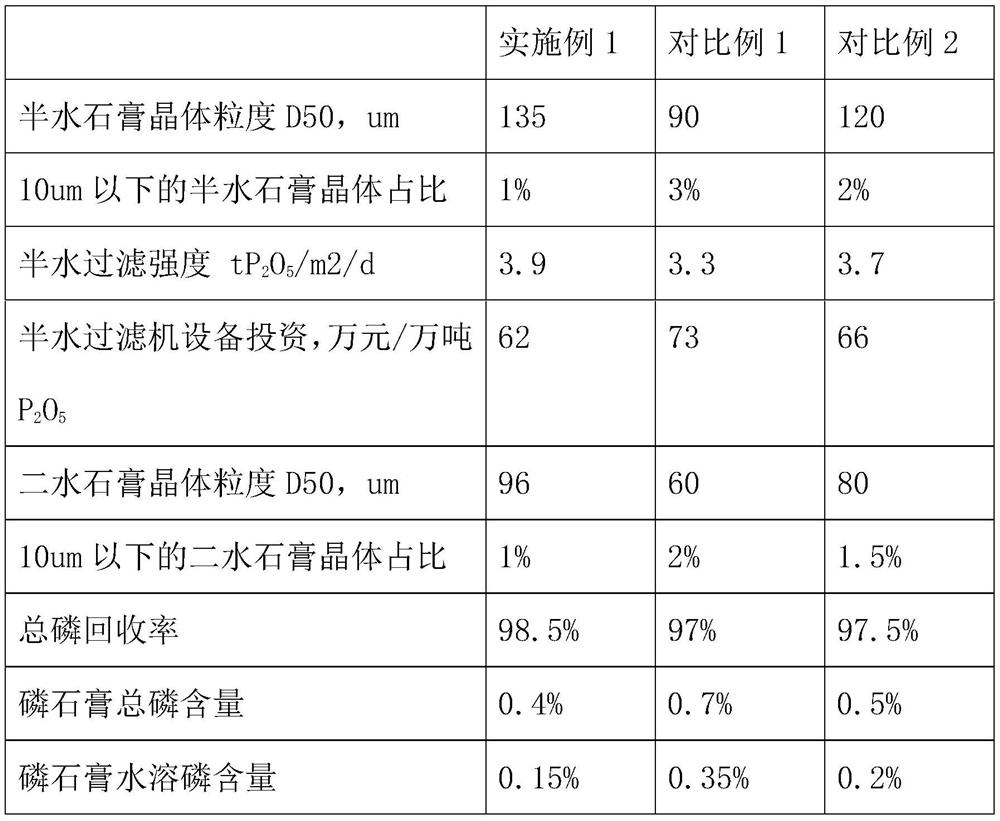

Embodiment 1

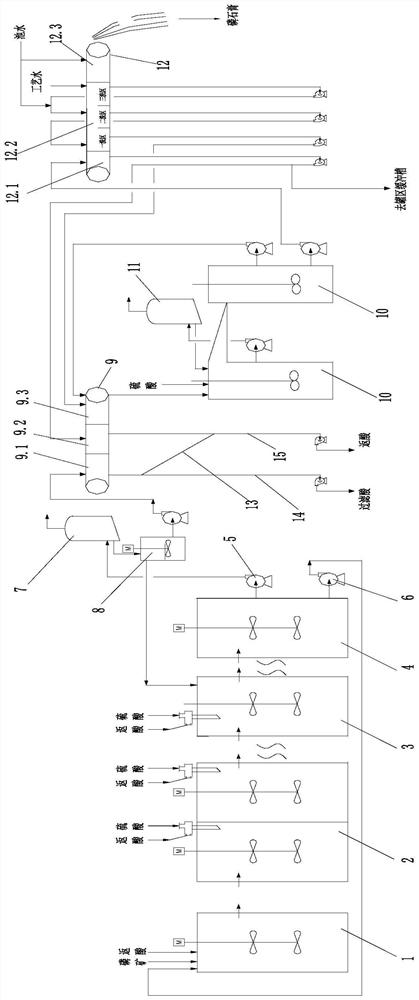

[0039] 1. Semi-water reaction filtration process

[0040] A1) including sending the phosphate rock into the premixing zone 1 first, mixing with back acid, and rapidly decomposing; controlling the sulfate ion concentration in the liquid phase of the premixing zone 1 to be lower than the CaO concentration of 3.6wt% to 4.6wt%, and the temperature is 90 ℃~100℃;

[0041] A2) The slurry from the premixing zone 1 is sent into the dissolving zone 2, fully dissolved in the presence of back acid and sulfuric acid, wherein the sulfate ion concentration in the liquid phase is controlled to be lower than the CaO concentration by 2.7wt% to 3.4wt%. ;

[0042] A3) the reaction slurry that goes out dissolving zone 2 is sent in the crystallization zone 3, crystallization grows up under the presence of the vitriol oil, wherein, the sulfate ion concentration in the control liquid phase is higher than CaO concentration 1.2wt%~6wt%, temperature 90℃~100℃, phosphoric acid concentration is 36wt%~42w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com