Method for recovering liquid sulfur containing carbon disulfide and hydrogen sulfide

A carbon disulfide and recovery method technology, applied in chemical instruments and methods, sulfur compounds, sulfur preparation/purification, etc., can solve the problems of poor safety, incomplete separation, high investment cost, and achieve good safety and total recovery. The effect of high rate and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The liquid sulfur recovery method containing carbon disulfide and hydrogen sulfide of the present invention, concrete steps are as follows:

[0028] (1) Carbon disulfide and hydrogen sulfide are prepared by natural gas low-pressure method, and the liquid sulfur in the reaction product is captured through a condenser and a sulfur trap, and enters the sulfur receiver, and the gas is removed from the top; the liquid sulfur in the sulfur receiver The components are: 94% liquid sulfur, 4% carbon disulfide, 2.5% hydrogen sulfide, in mass percentage; the temperature of the sulfur receiver is 155°C, and the pressure is 0.4MPa.

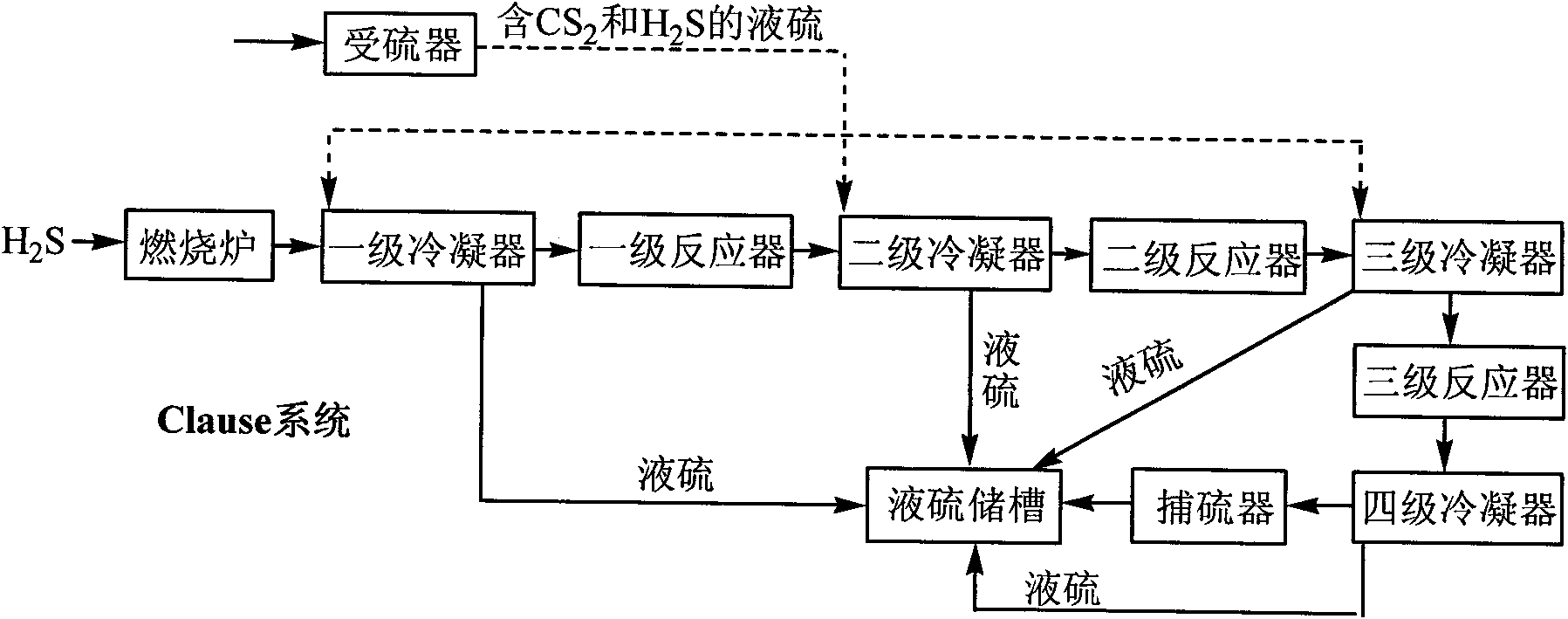

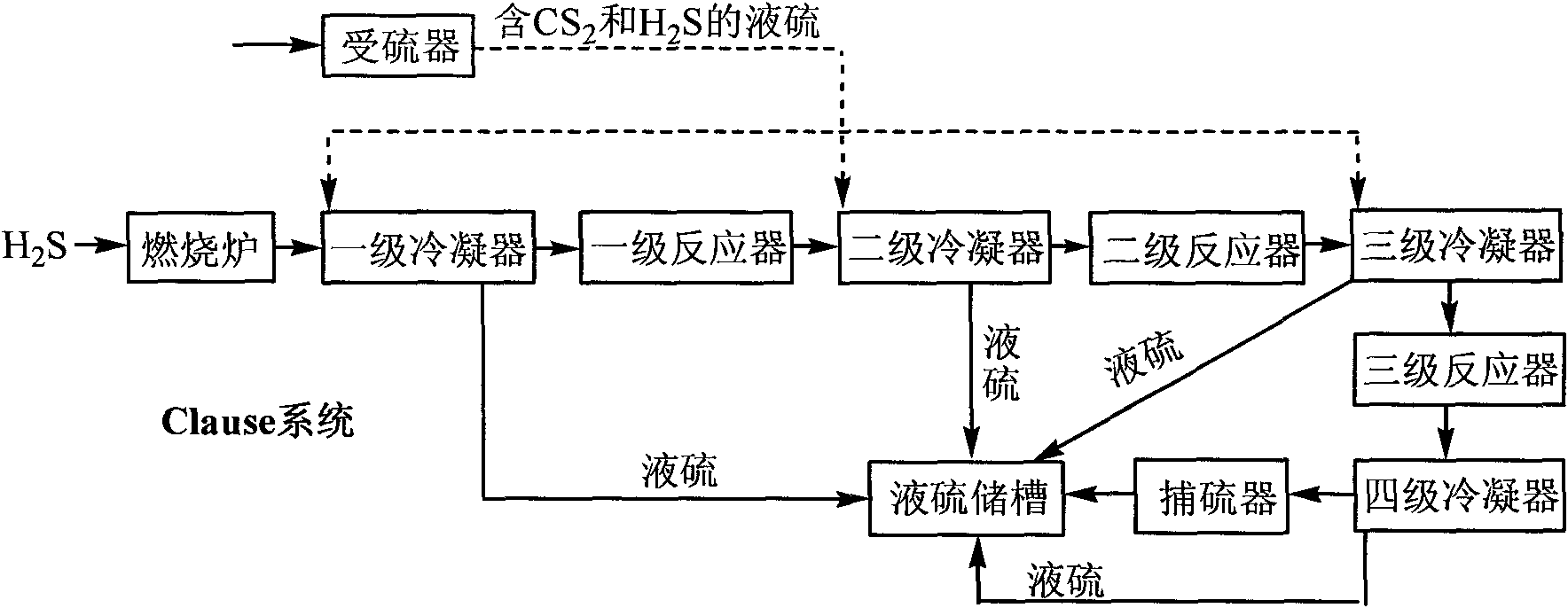

[0029] (2) The liquid sulfur from the above-mentioned sulfur receiver directly enters the three-stage Clause system, such as figure 1 As shown, the liquid sulfur from the above-mentioned sulfur collector first enters the secondary condenser of the Clause system, then enters the subsequent reactor and condenser in turn, and finally the liquid sulfur from...

Embodiment 2

[0032] The liquid sulfur recovery method containing carbon disulfide and hydrogen sulfide of the present invention, concrete steps are as follows:

[0033] (1) Carbon disulfide and hydrogen sulfide are prepared by natural gas low-pressure method, and the liquid sulfur in the reaction product is captured through a condenser and a sulfur trap, and enters the sulfur receiver, and the gas is removed from the top; the liquid sulfur in the sulfur receiver The components are: 95.5% liquid sulfur, 2.8% carbon disulfide, and 1.5% hydrogen sulfide, expressed in mass percent; the temperature of the sulfur receiver is 155°C, and the pressure is 0.45MPa.

[0034] (2) The liquid sulfur from the above-mentioned sulfur receiver directly enters the three-stage Clause system, such as figure 1 As shown, the liquid sulfur from the above-mentioned sulfur collector first enters the secondary condenser of the Clause system, then enters the subsequent reactor and condenser in turn, and finally the li...

Embodiment 3~5

[0038] Carry out by following processing parameter, other are all identical with embodiment 2. The recovery method requires less equipment and effectively reduces the cost. The liquid sulfur recovery method is simple, easy to operate, good in safety and hardly pollutes the environment.

[0039] implement

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com