Patents

Literature

65results about How to "Increase tangential speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

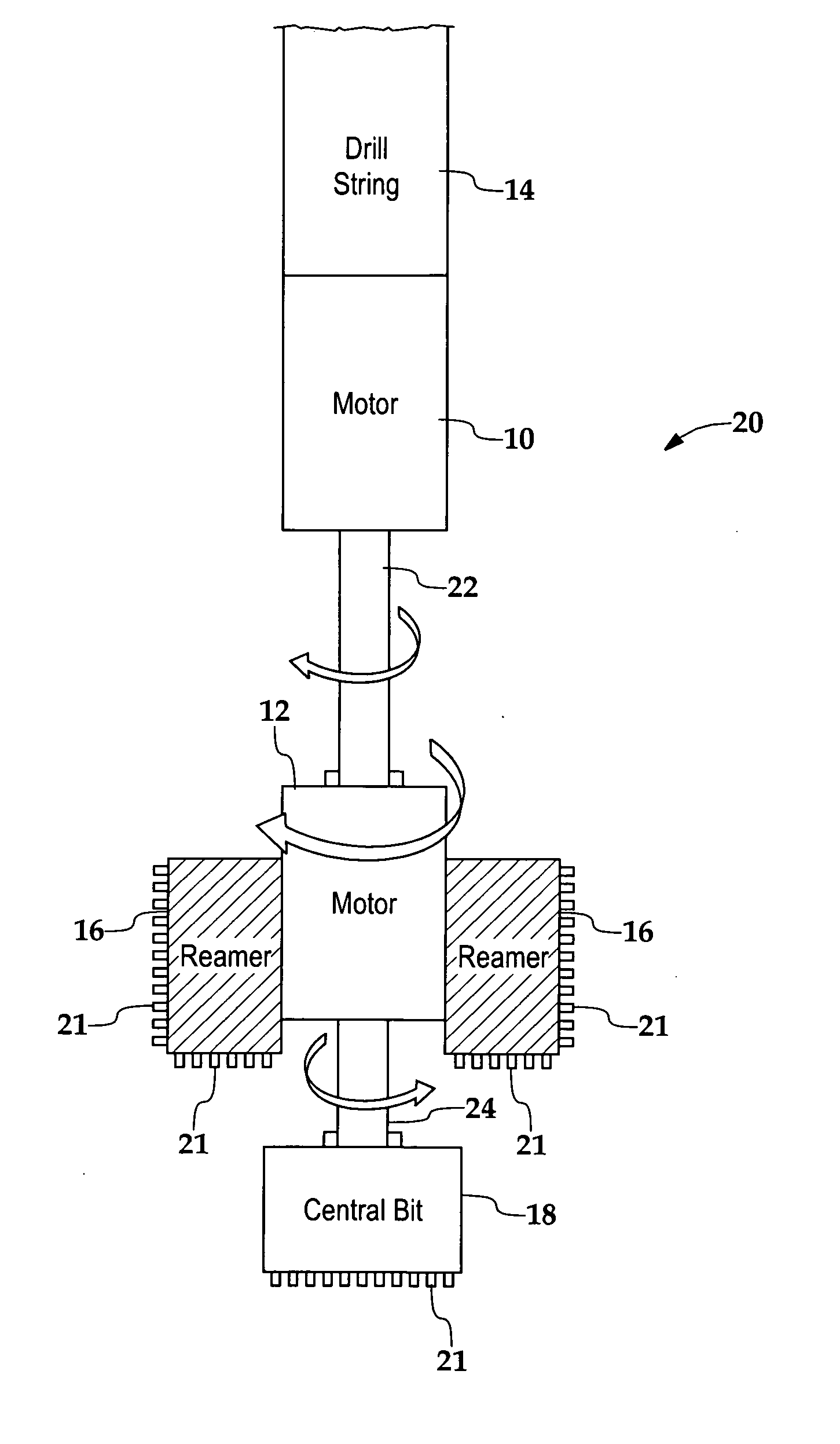

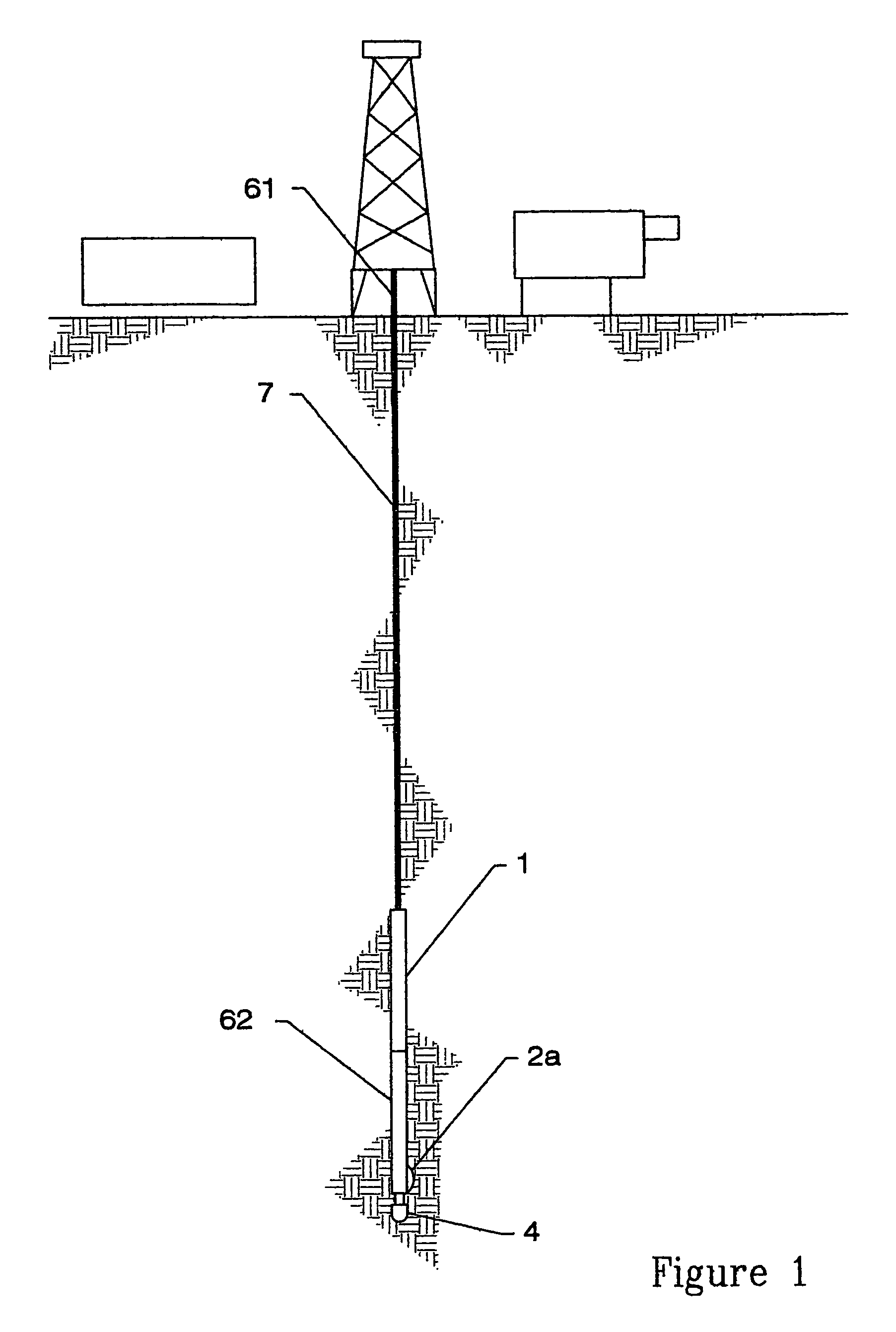

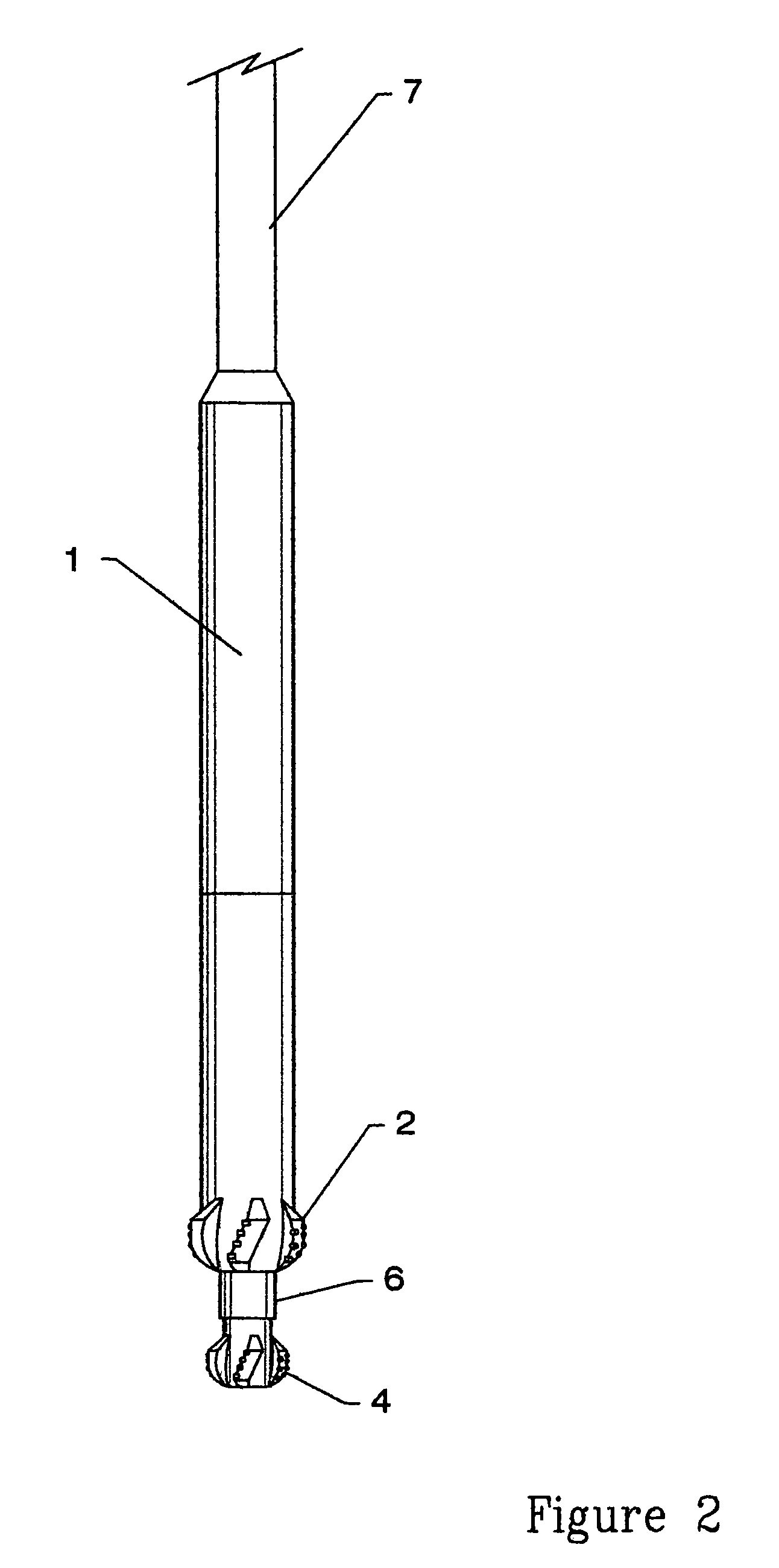

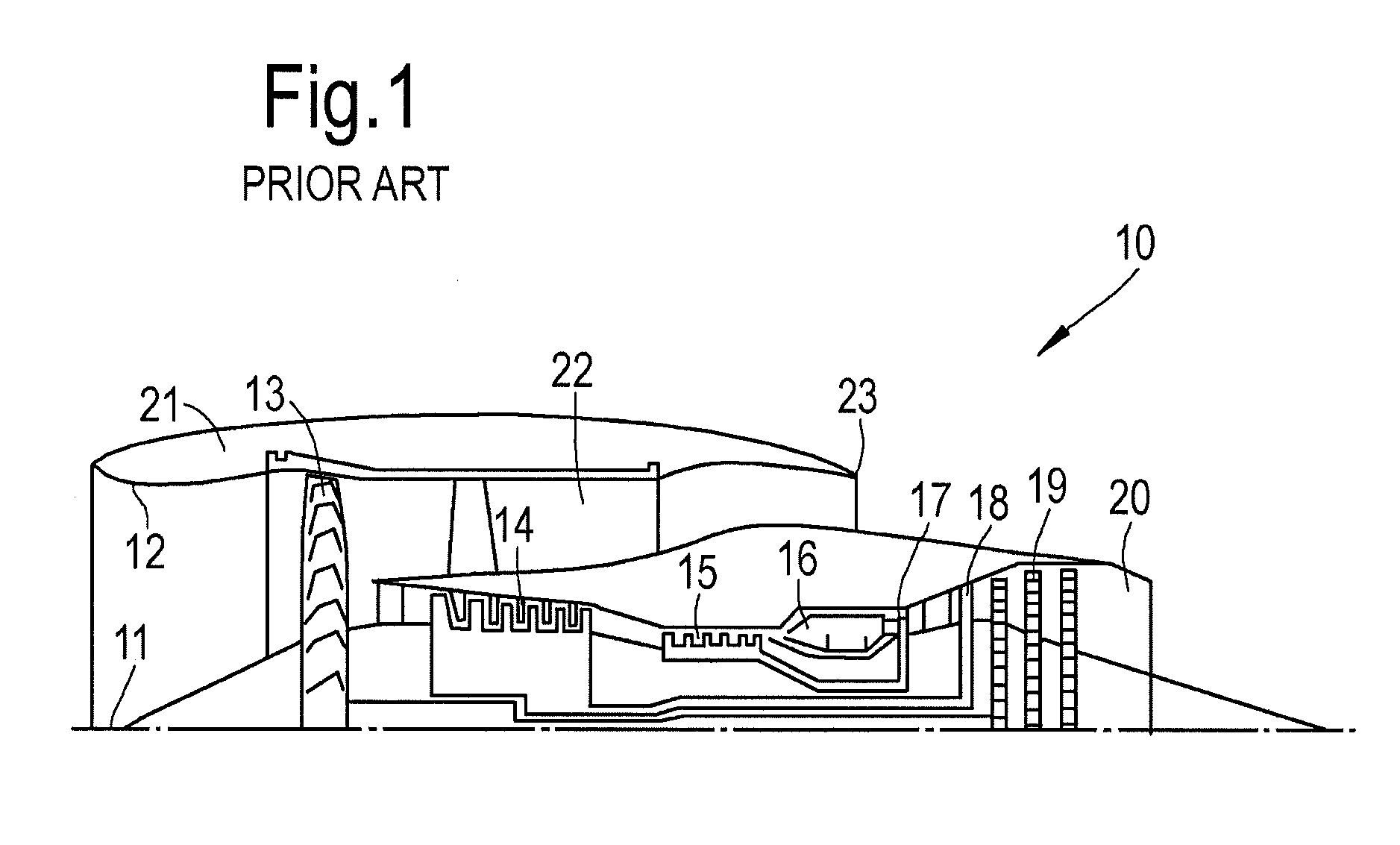

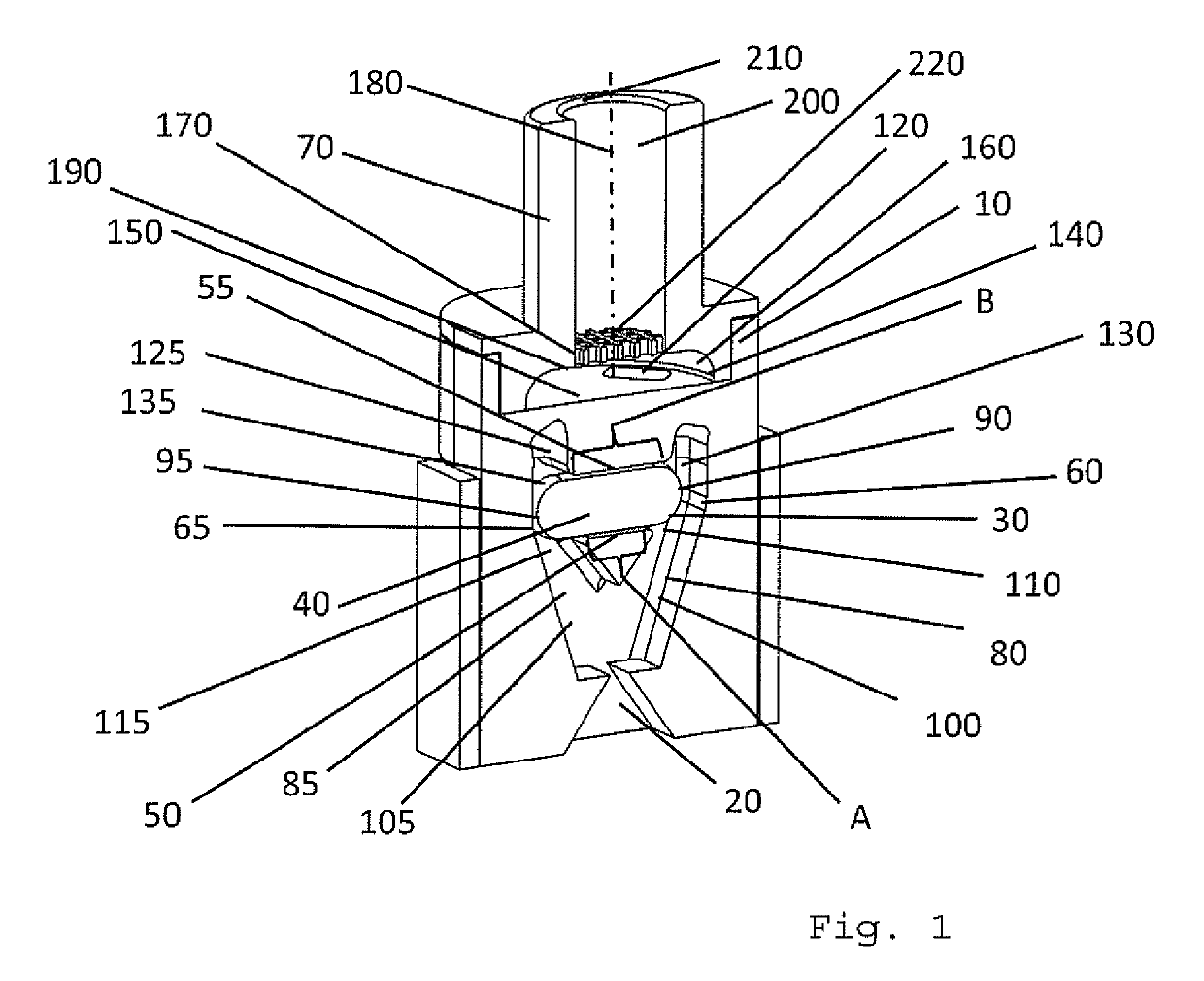

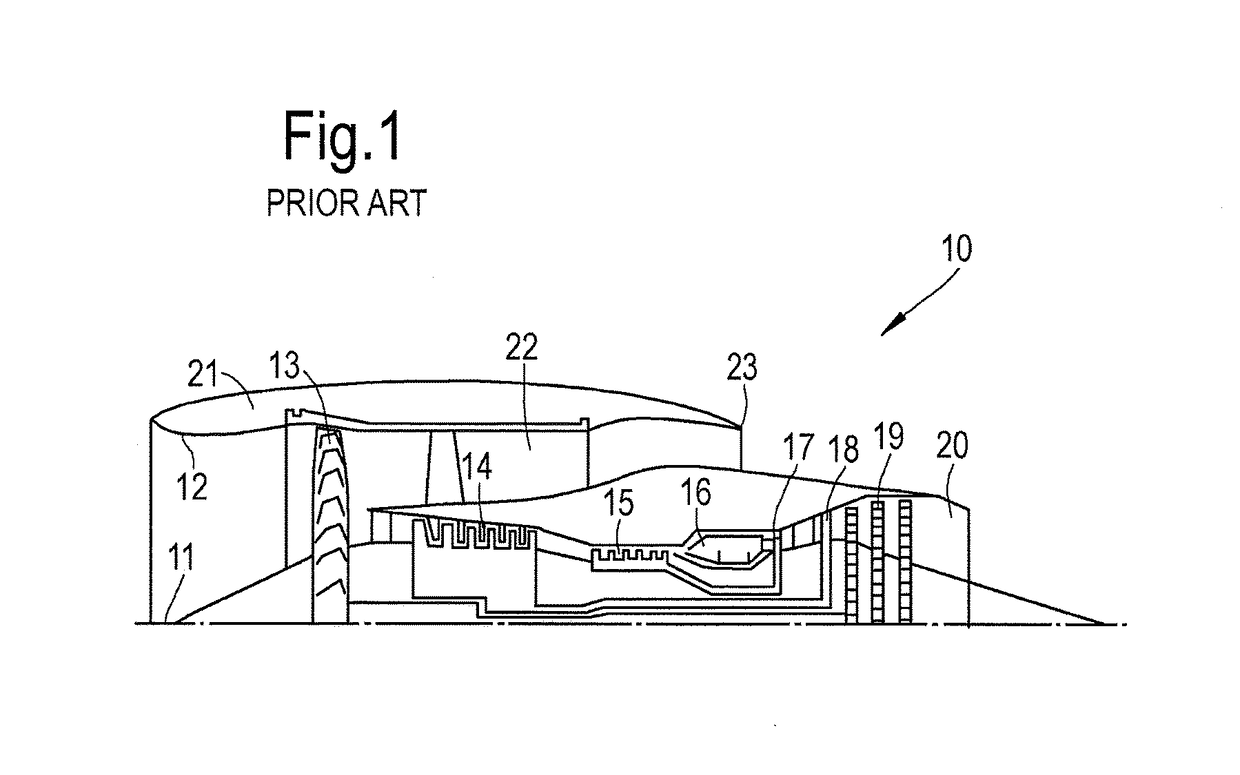

Earth boring tool

InactiveUS20060237234A1Without adversely affecting cutter performance and drilling rateAvoid excessive wearDrill bitsBorehole drivesReamerDrill bit

An earth boring tool includes two coaxially-aligned, positive displacement motors. One motor turns a pilot bit and the other turns a reamer concentric with the pilot bit. The central bit bores the center of the hole and the reamer enlarges it. The central bit is rotated relatively faster, while rotation of the larger diameter reamer is relatively slow. The tool can thus be used to bore larger diameter holes without slowing drilling rates or adversely affecting performance of the cutter elements due to higher tangential velocities.

Owner:DENNIS TOOL

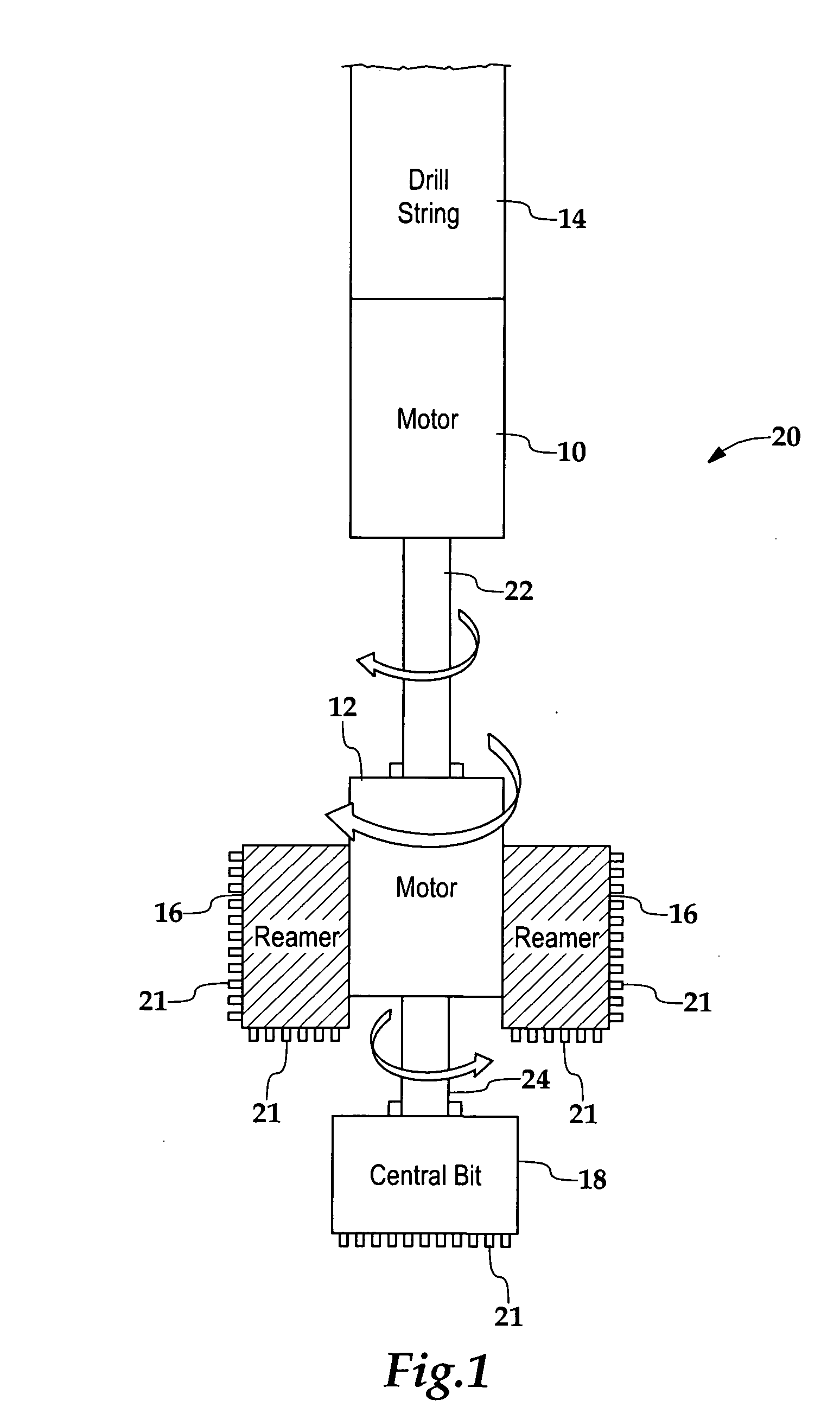

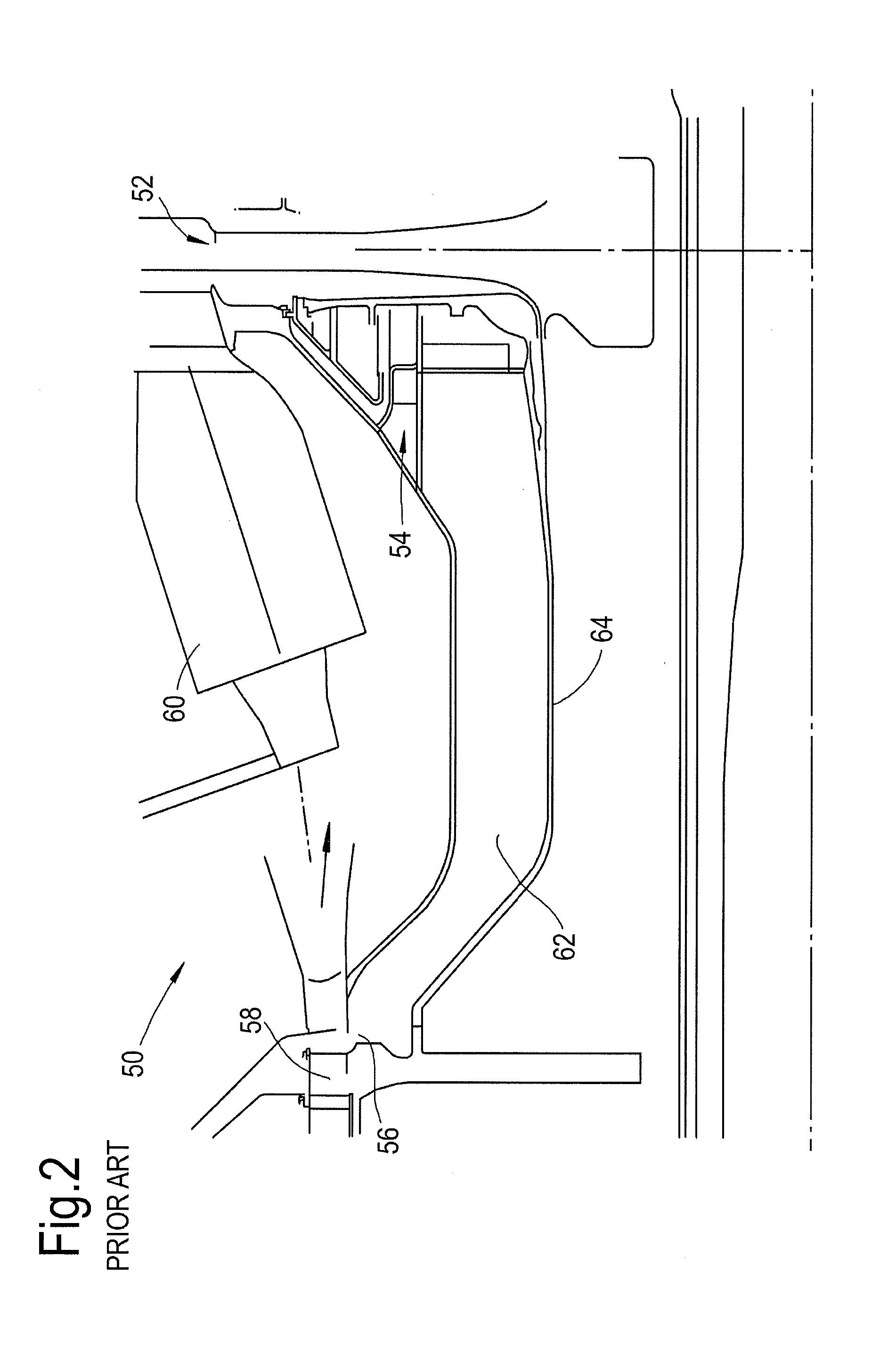

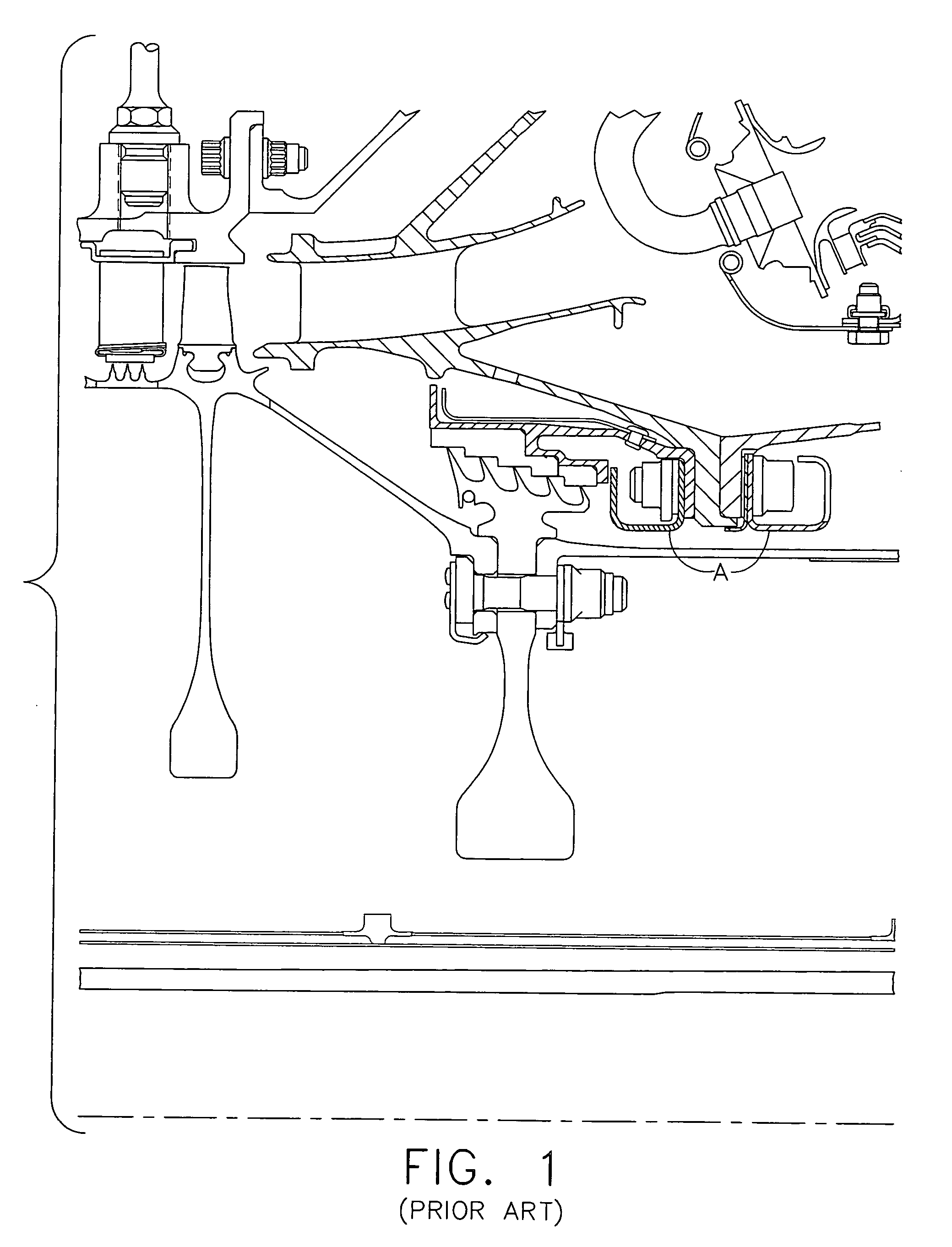

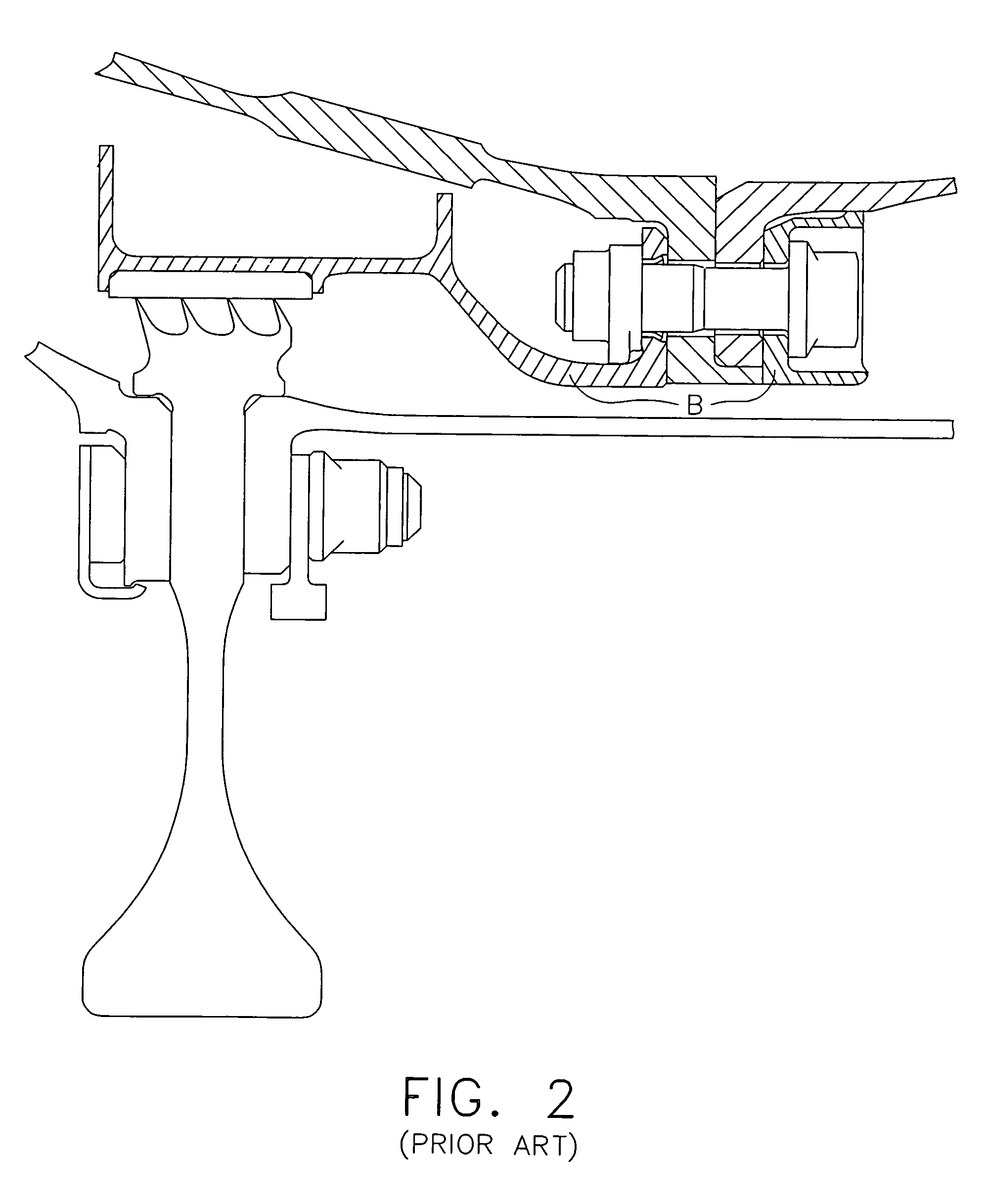

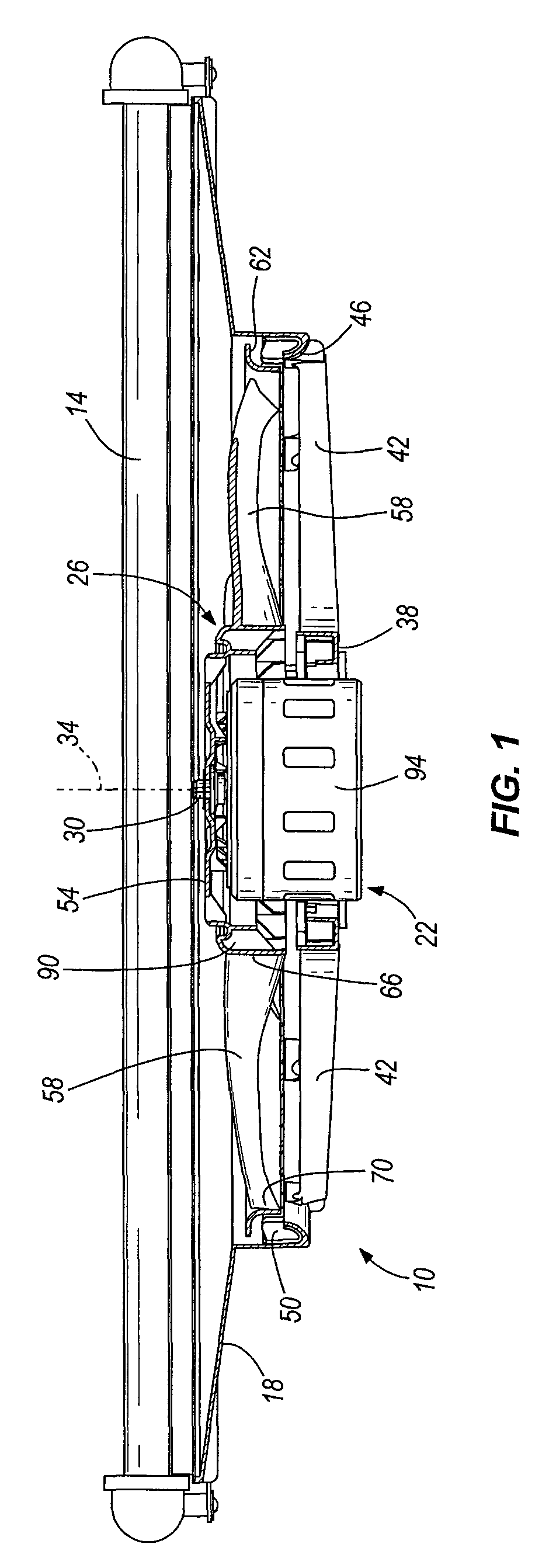

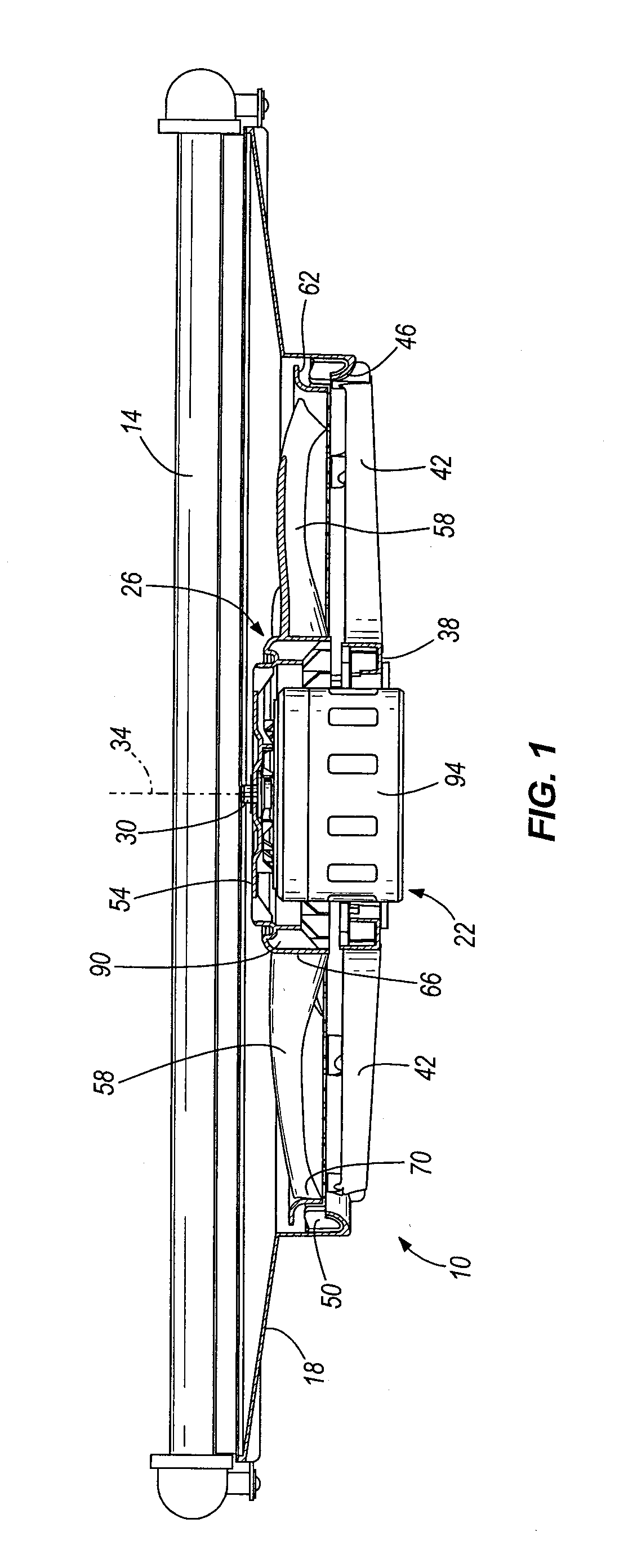

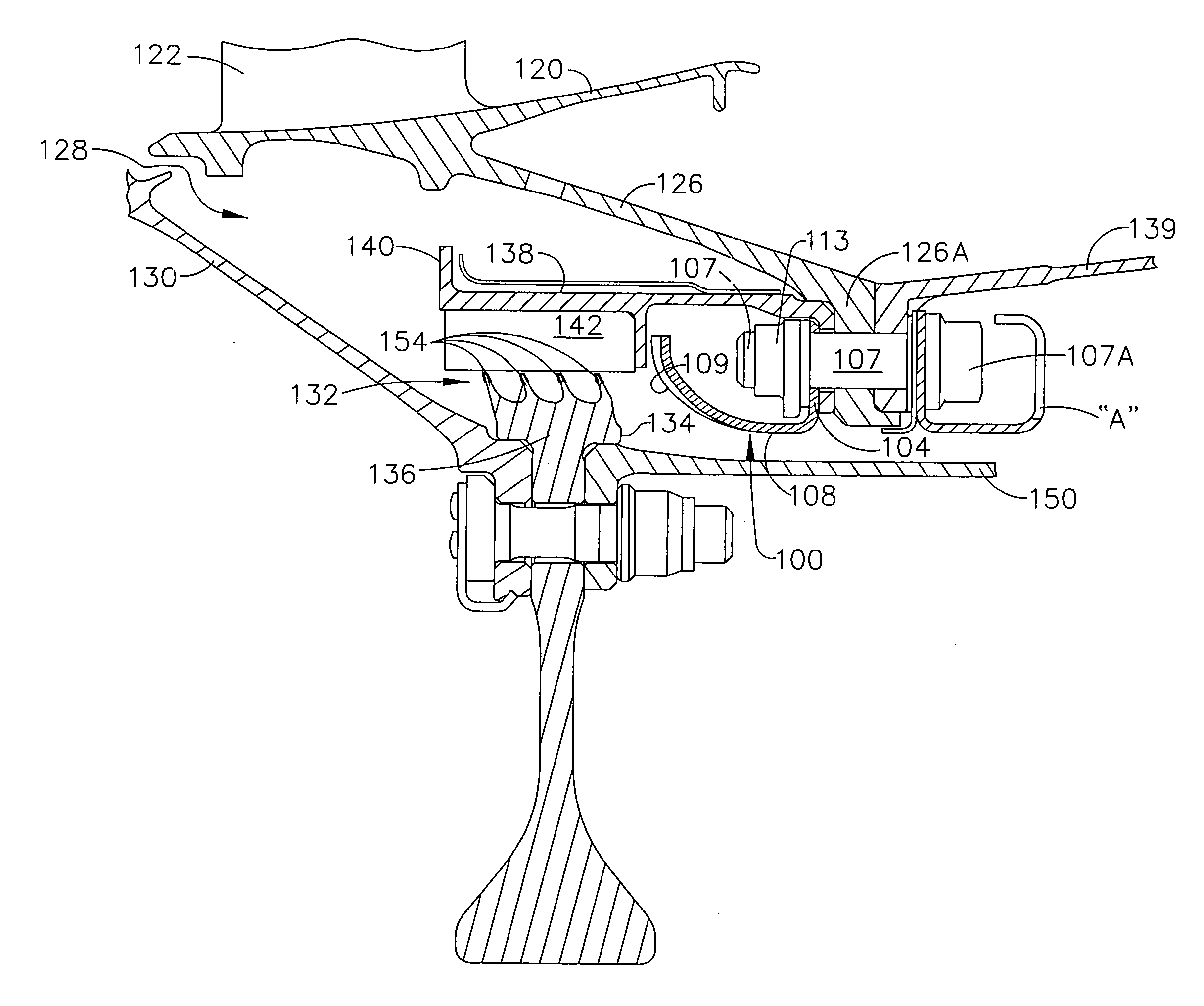

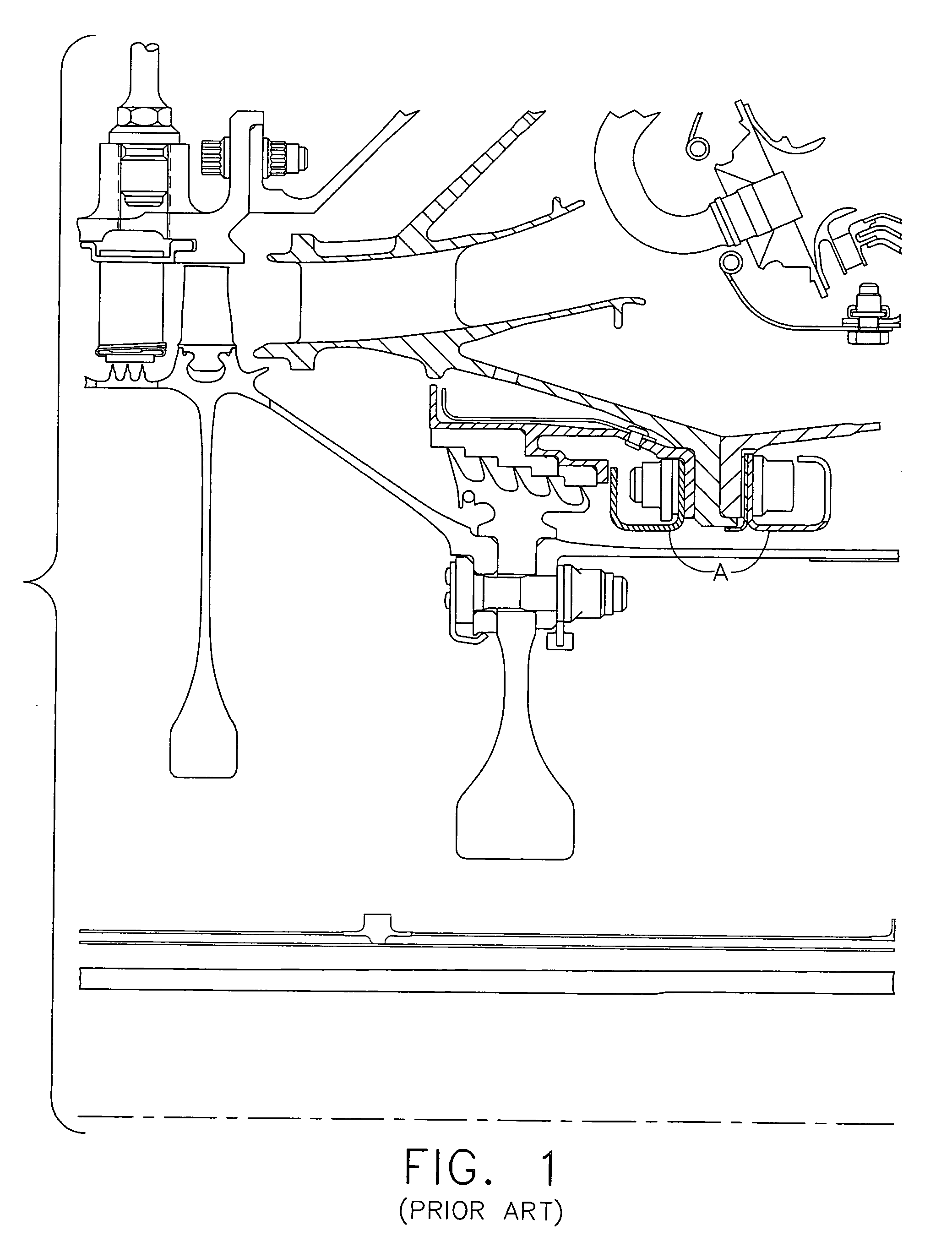

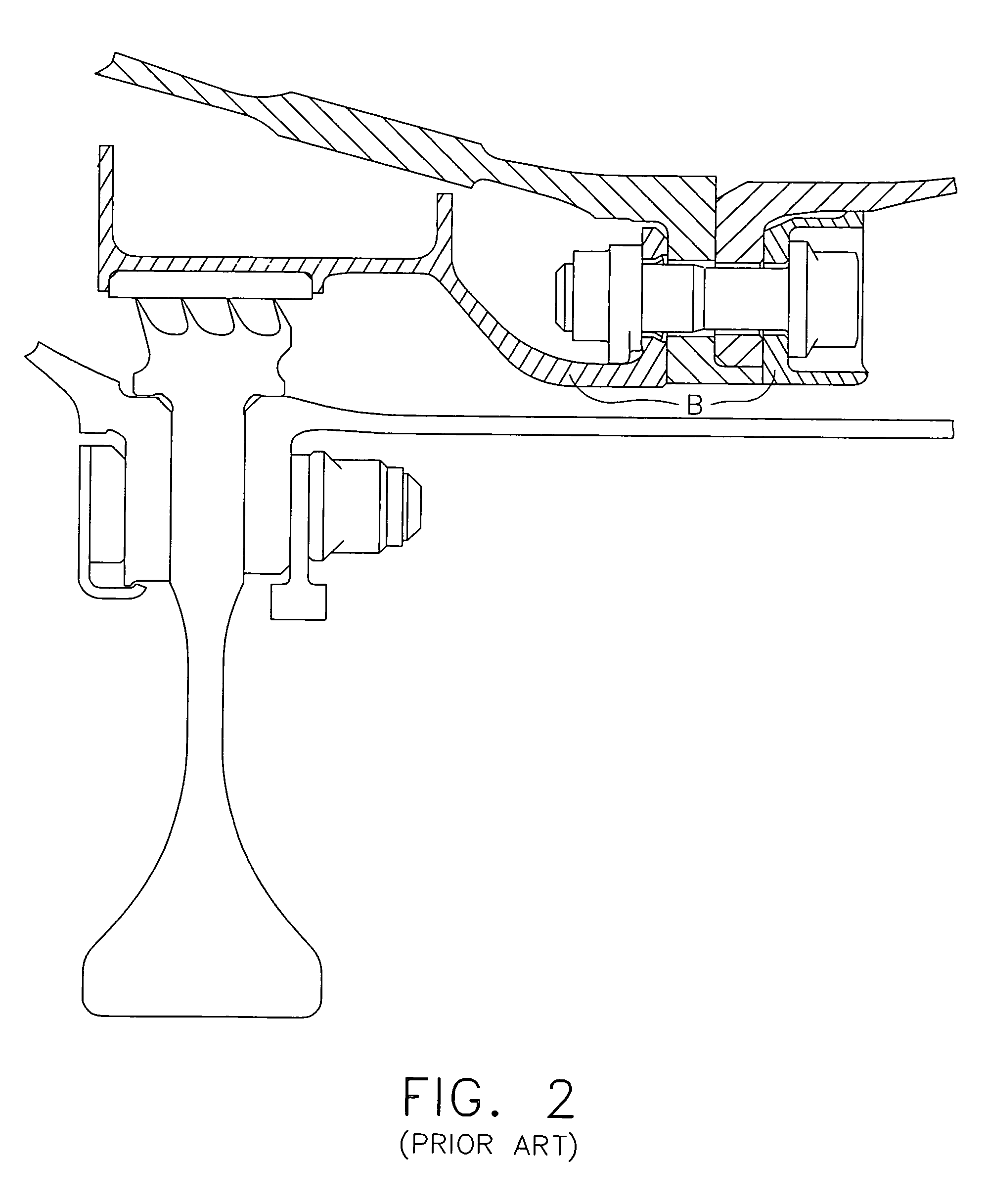

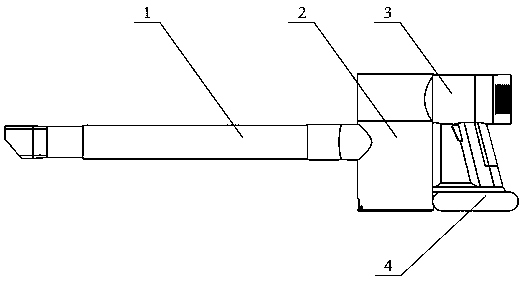

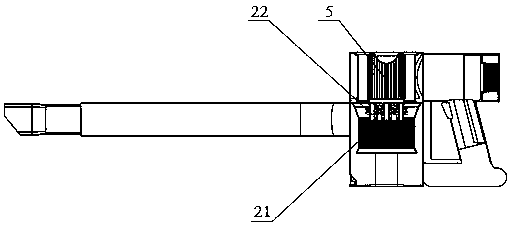

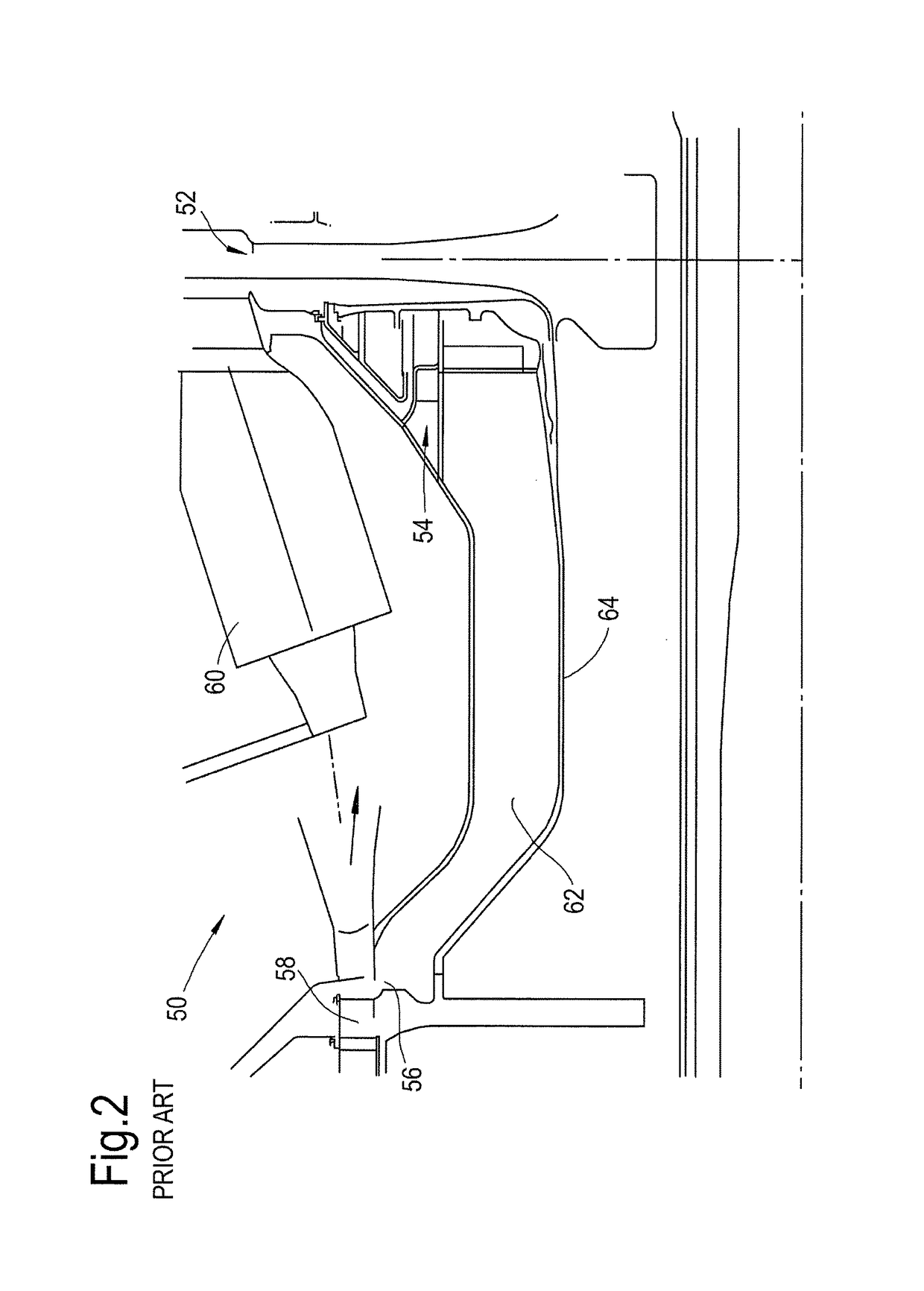

Downhole pilot bit and reamer with maximized mud motor dimensions

InactiveUS7562725B1Large outside diameterIncrease tangential speedDrill bitsDrilling rodsReamerMud motor

A drilling unit containing a combined pilot bit and reamer. The drilling unit includes a housing containing a mud motor and a pilot bit extending from its distal end. A reamer is mounted to the housing. The mud motor turns the pilot bit while the reamer is turned either by the mud motor or as the drill string is rotated from the surface. The well bore is drilled and reamed in one pass.By positioning the reamer between the pilot bit and the mud motor, the mud motor must only pass through the larger reamer bore rather than the smaller pilot hole. This will allow larger mud motors to be used than would otherwise be possible.In one embodiment, the pilot bit is offset relative to the center of the end of the drill housing, providing increased tangential speed at the point of impact between the pilot bit and formation.

Owner:BROUSSARD EDWIN J +1

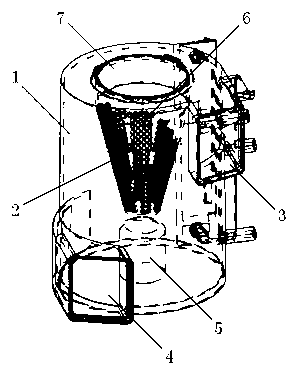

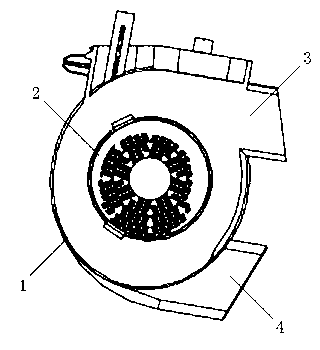

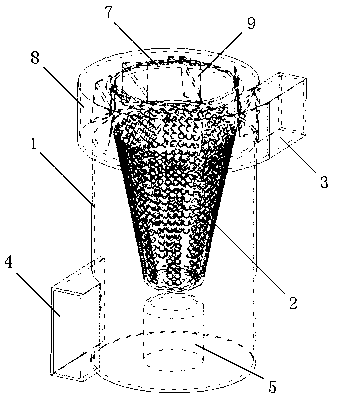

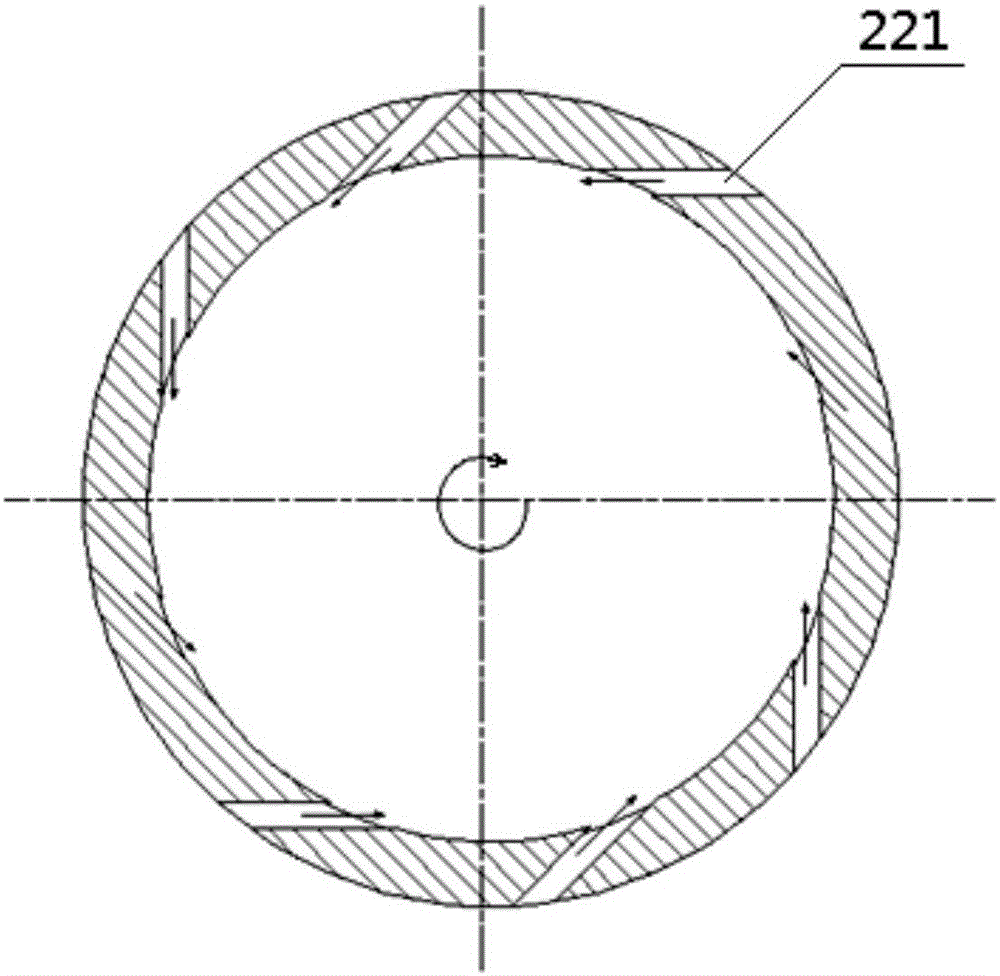

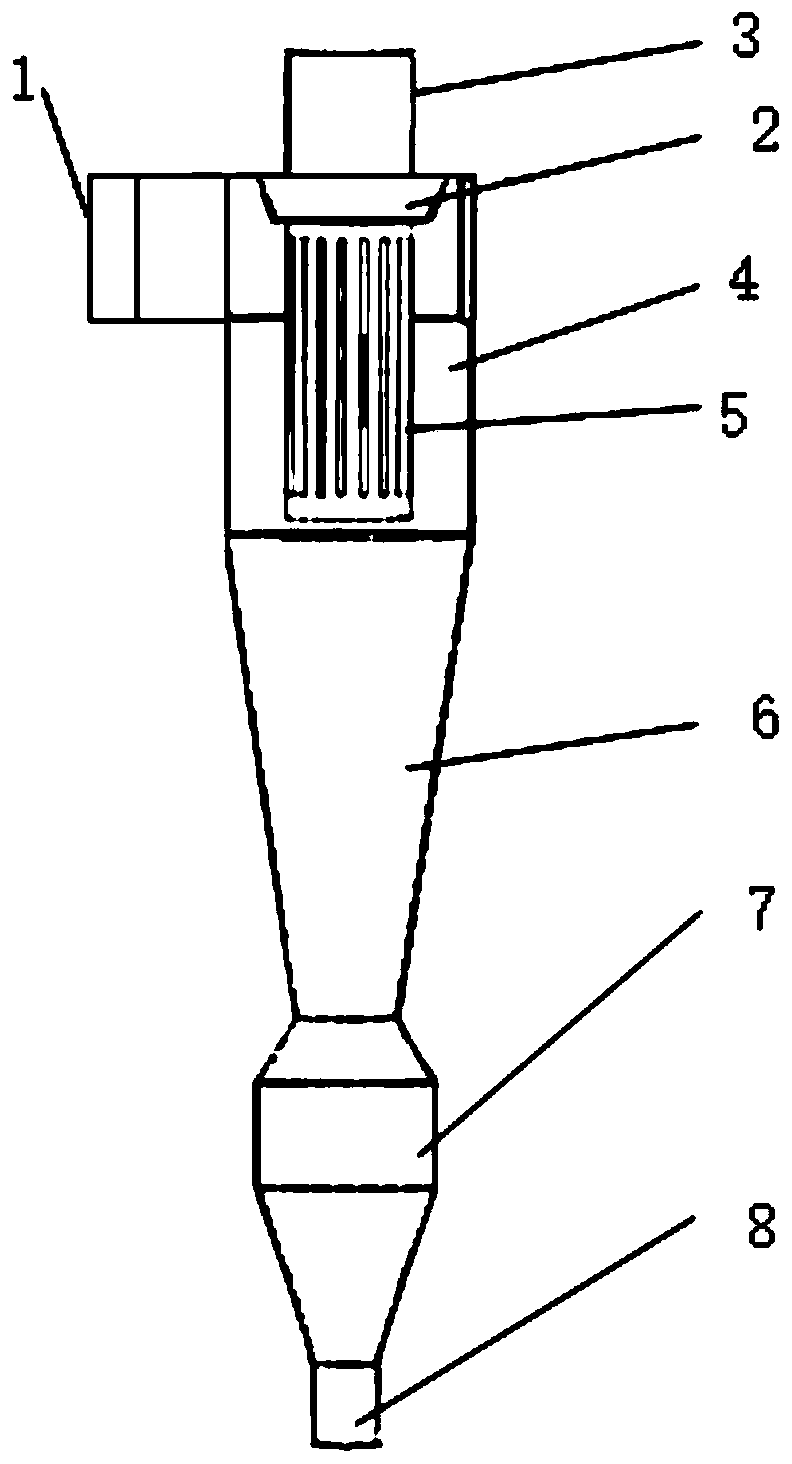

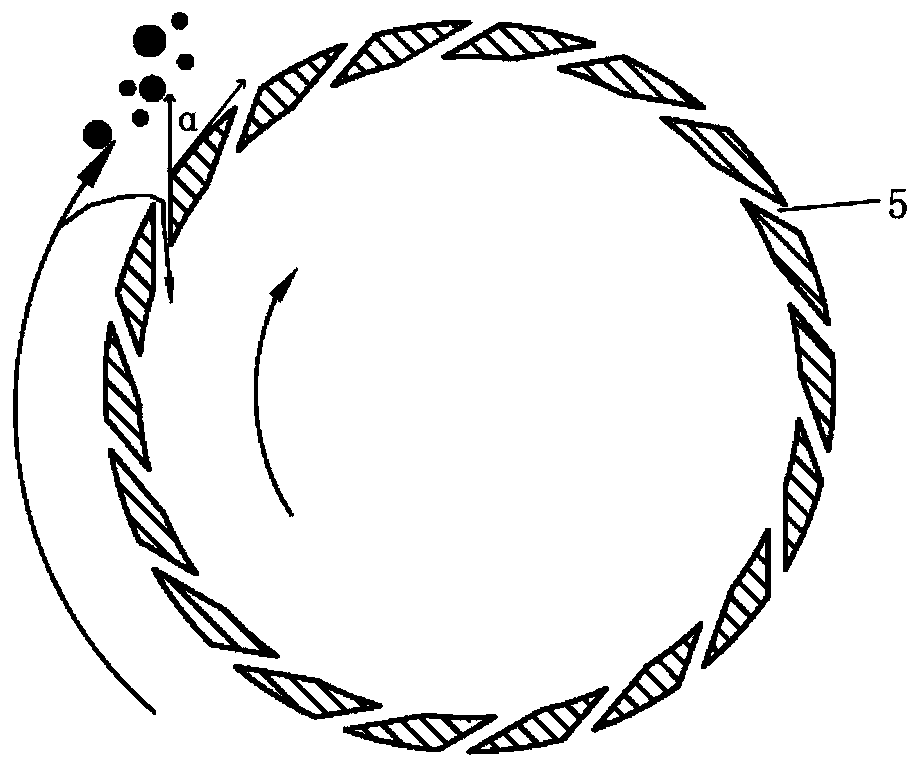

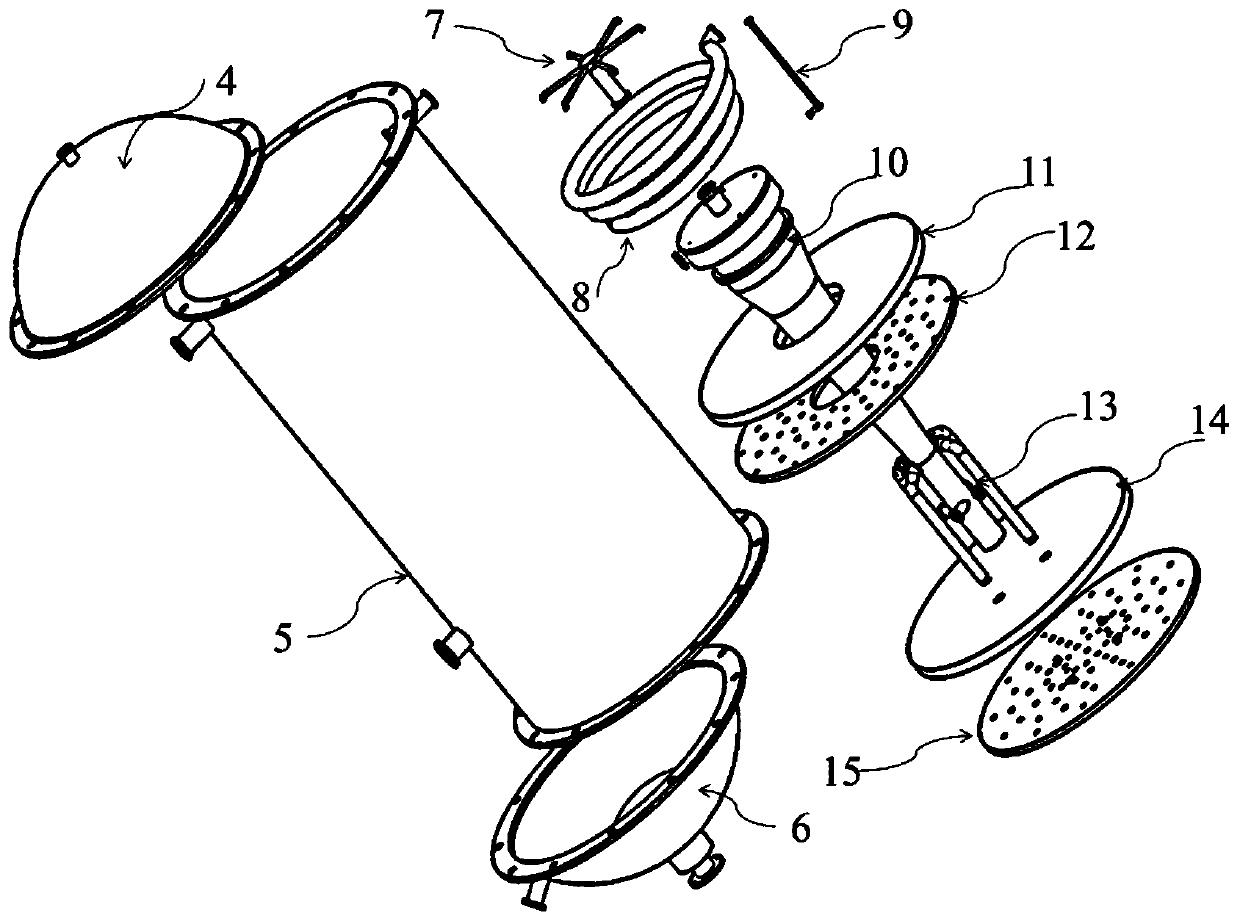

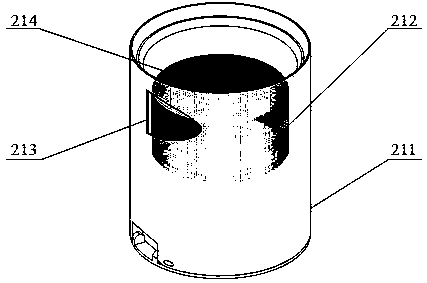

Efficient cyclone separation device for dust remover

InactiveCN103181741AReduce energy lossGreat suctionSuction filtersCycloneElectrical and Electronics engineering

The invention discloses an efficient cyclone separation device for a dust remover, which comprises a barrel body and a filter arranged inside the barrel body, wherein an air inlet communicated with the inside of the barrel is formed on one side of the upper end of the barrel body in tangential direction of the outer wall; the cross section of the outer wall of an air intake way at the upper end of the barrel body, communicated with the air inlet, is helical; and a plurality of air intake guide vanes are evenly arranged inside the air intake way in the circular direction. According to the efficient cyclone separation device for the dust remover, the cross sectional area is gradually reduced from the air inlet to the inside to facilitate the increasement of the tangential speed of the airflow inside the air intake way along with the reduction of the cross sectional area, so as to increase the separation efficiency of an outer eddy side; the air intake guide vanes are arranged inside the air intake way and evenly distributed in the circular direction to facilitate the conversion of the axial speed of the airflow to the tangential speed, reduce the loss of energy of axial downwards speed of an inner eddy and improve the suction power of the dust remover; and therefore, the efficient cyclone separation device for dust remover has the advantages of high efficiency and less power loss and can effectively improve the suction power of a dust remover motor.

Owner:NANJING LG PANDA APPLIANCES

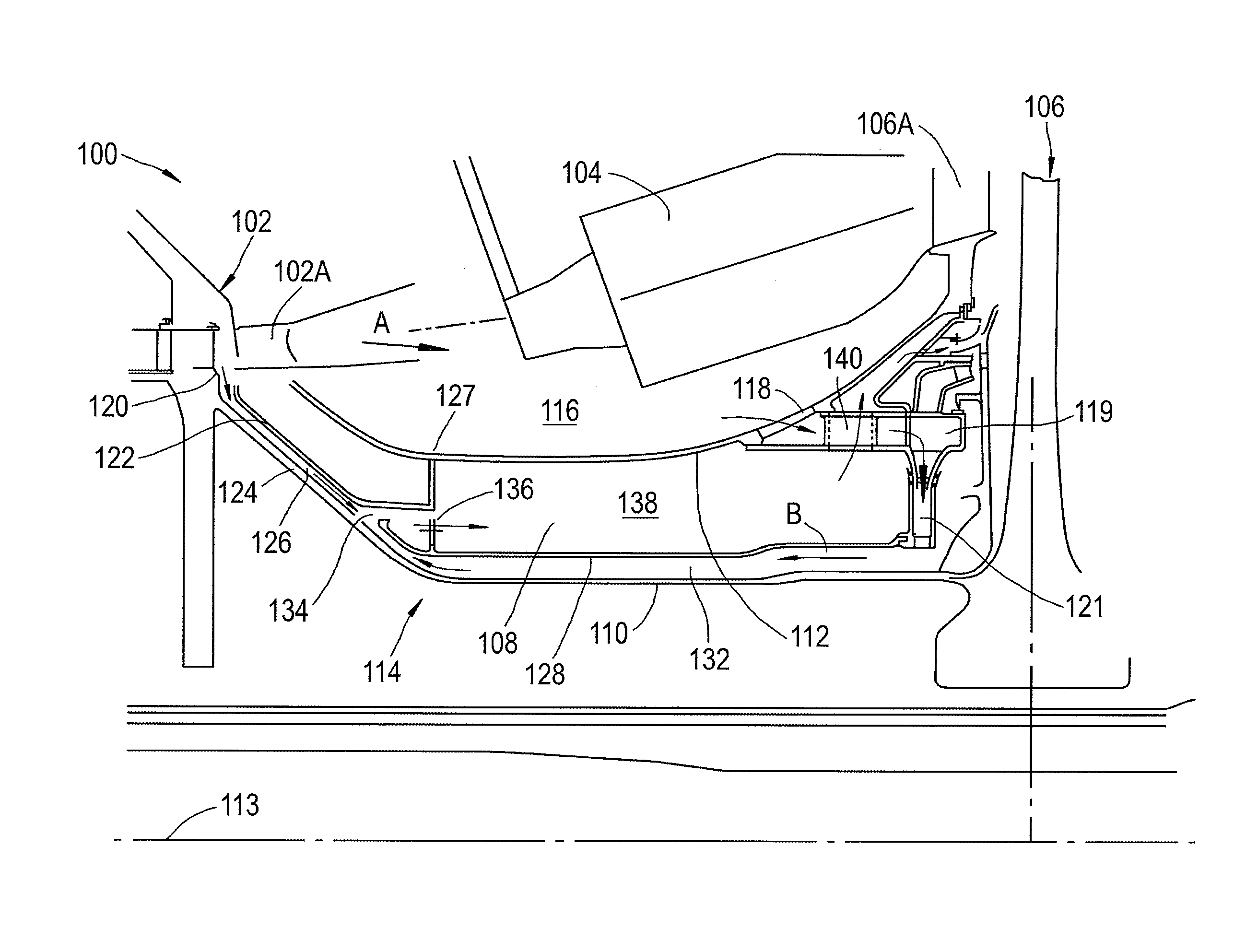

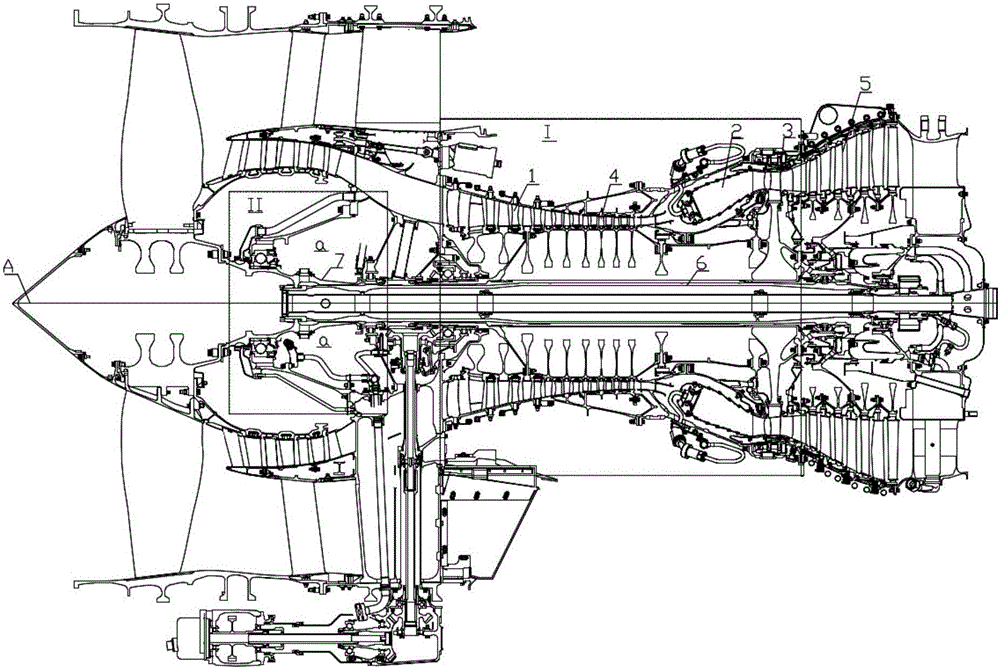

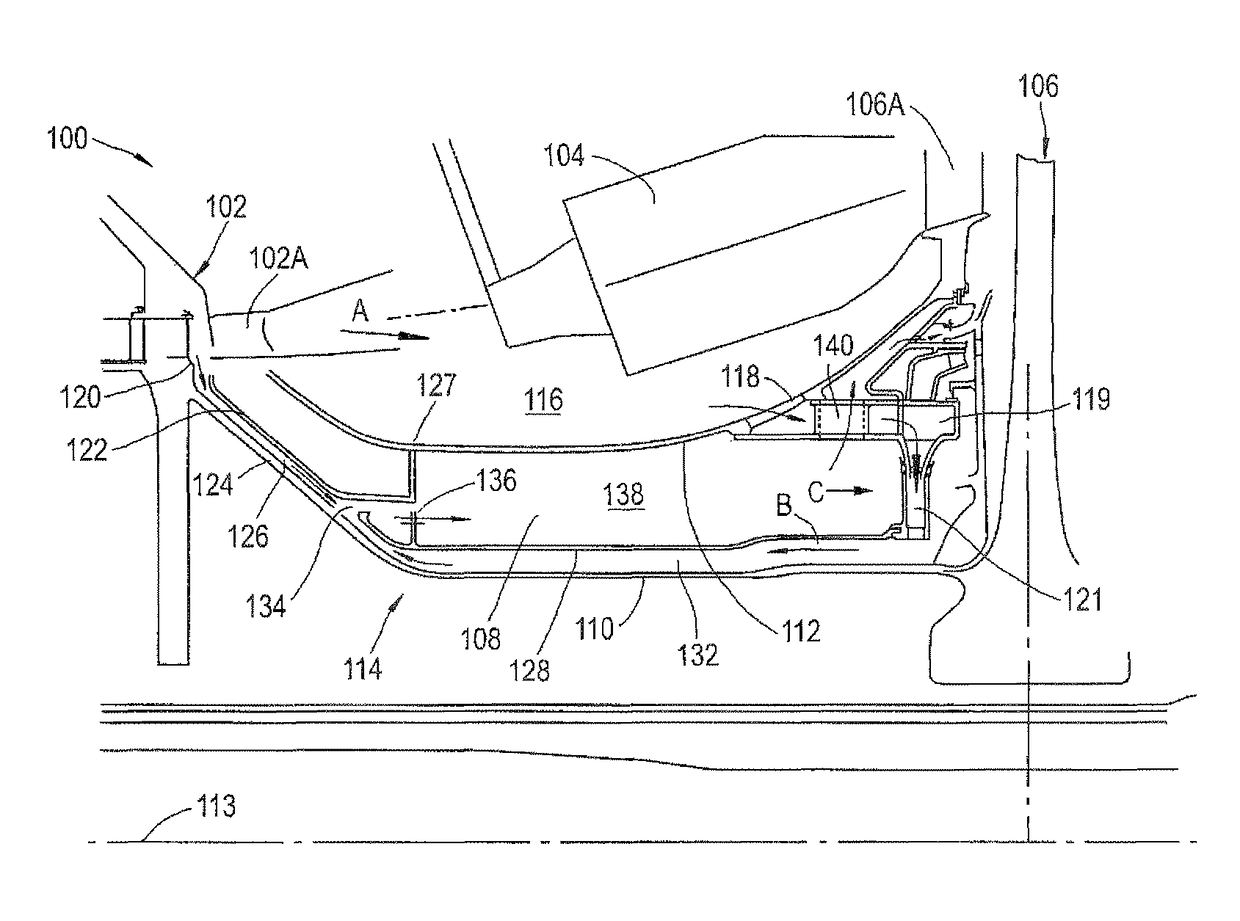

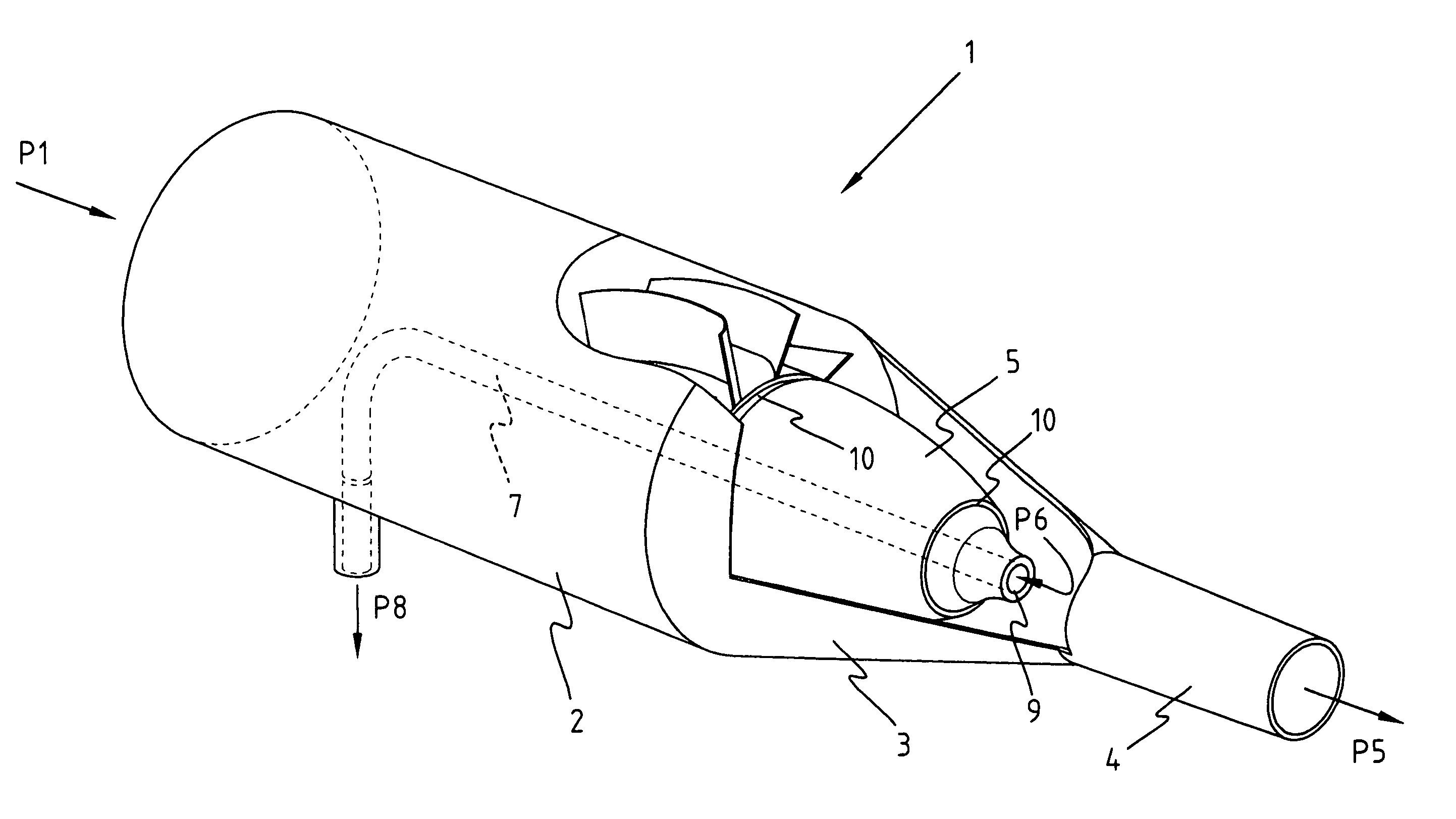

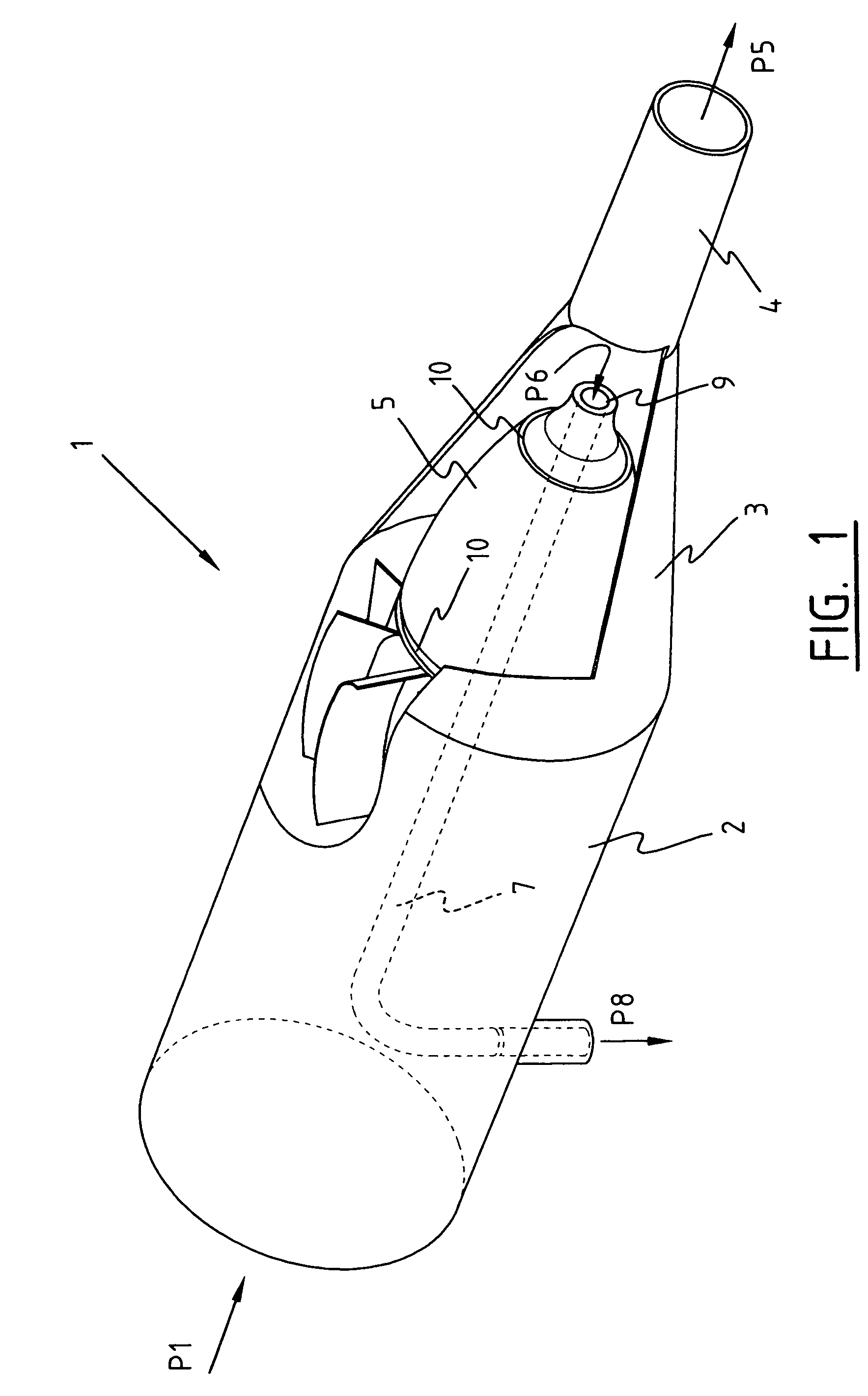

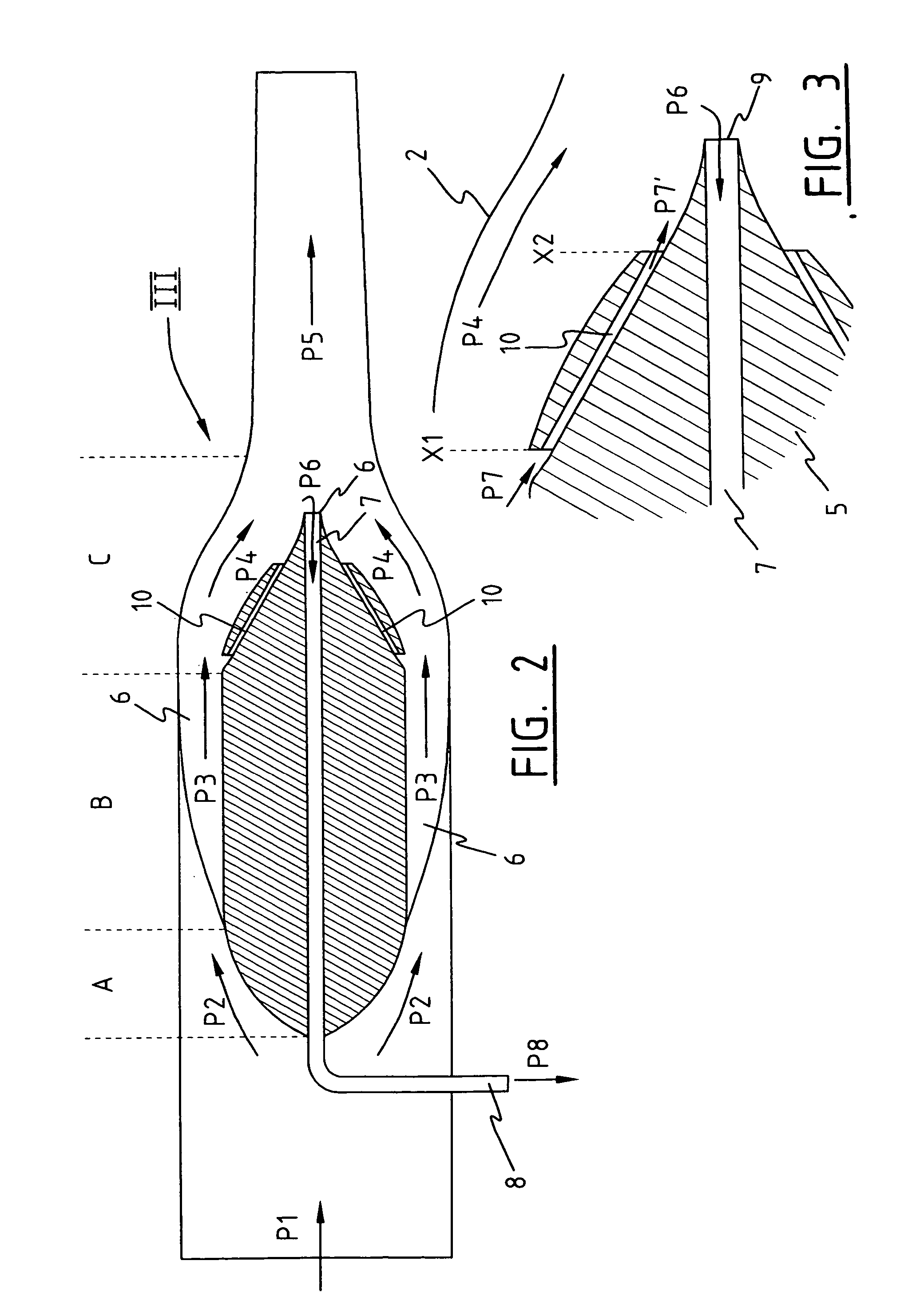

Axial flow machine cooling system

ActiveUS20150047359A1Reduce heat loadIncrease tangential speedEngine fuctionsTurbine/propulsion engine coolingCombustorTurbine

This invention concerns a system for cooling components in a gas turbine engine, the gas turbine engine including a compressor for driving a primary gas flow to a combustor and a turbine arranged to be driven by combustion gases from the combustor, wherein the system includes: an annular cooling flow passage arranged for fluid communication between the compressor and the turbine, the flow passage having a first inlet arranged to receive gas from the primary gas flow downstream of compressor, and a second inlet located upstream of the first inlet, wherein the annular cooling flow passage has at least one internal wall for guiding airflow from the first inlet towards the airflow from the second inlet, the airflow from the first and second inlets coalesce within the annular flow passage prior to passing along the passage in a direction from the compressor to the turbine.

Owner:ROLLS ROYCE PLC

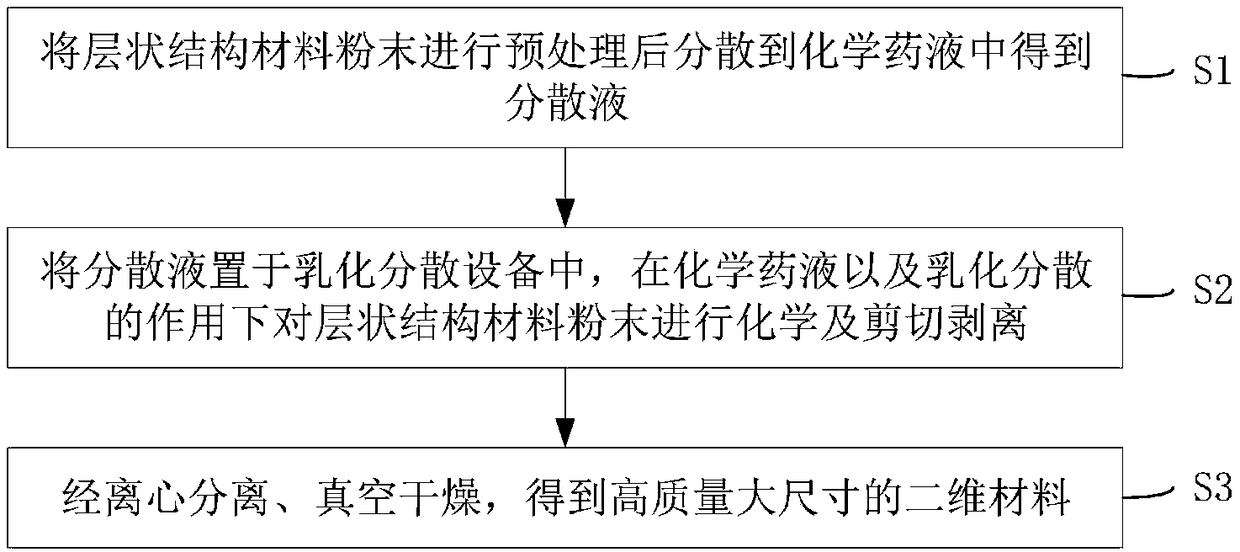

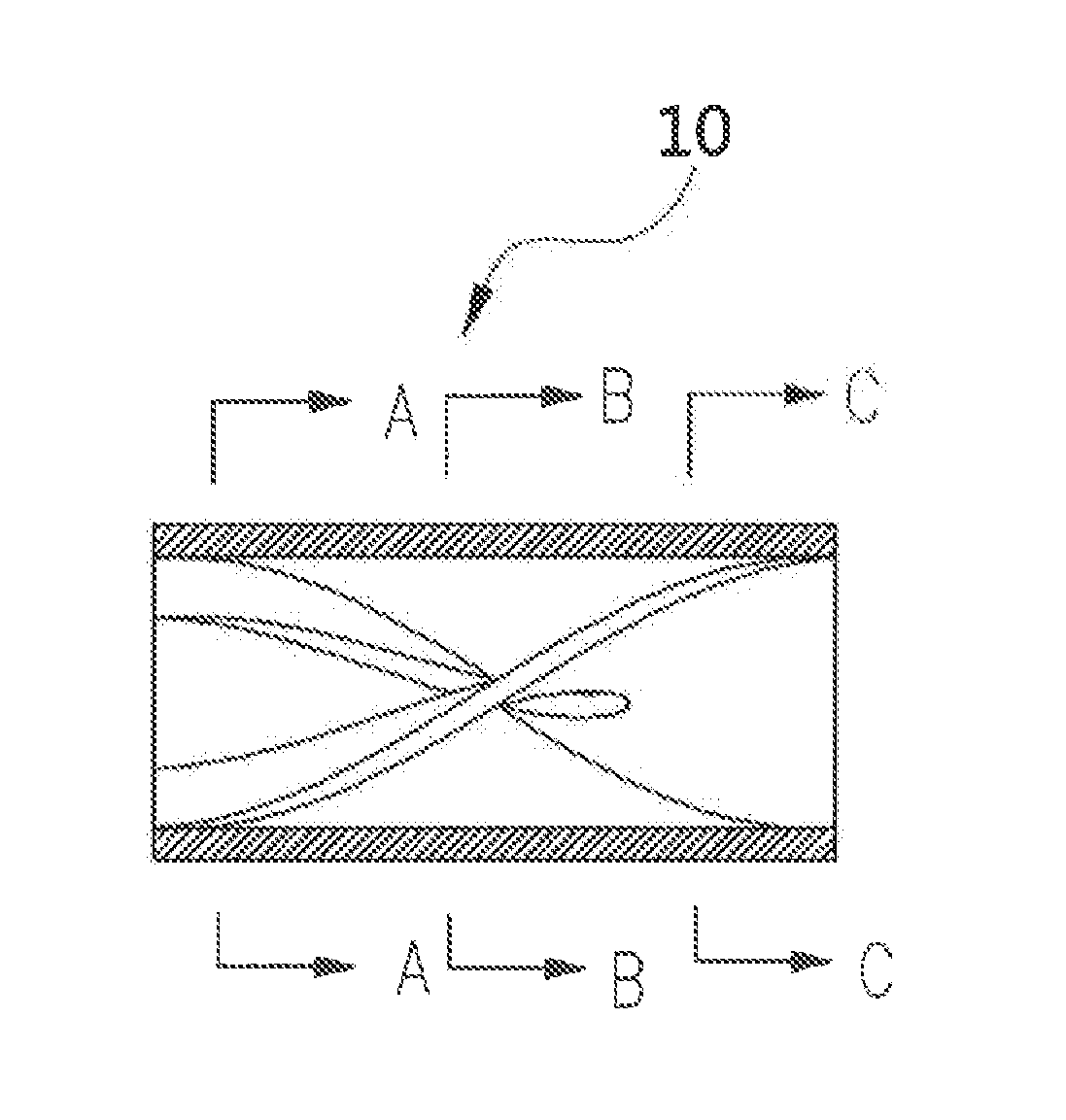

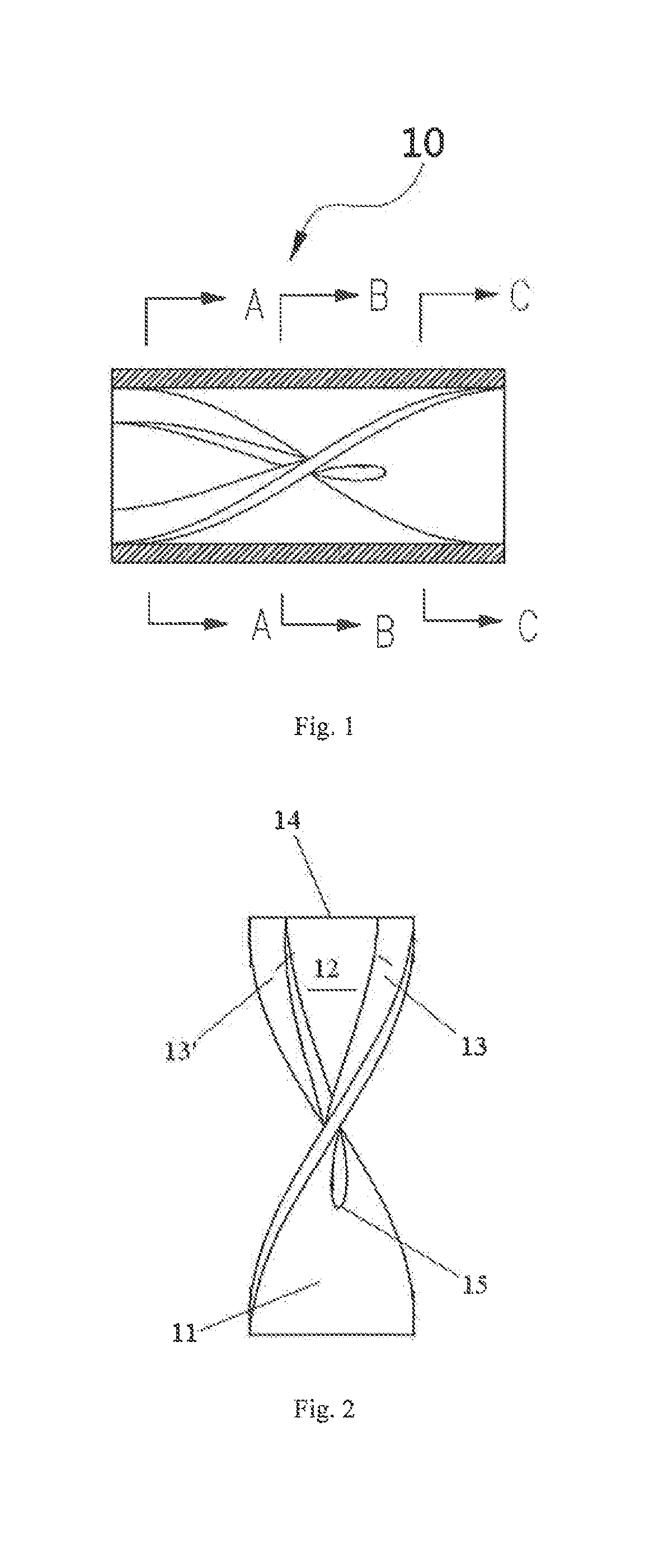

High-quality and large-size two-dimensional material and preparation method thereof

ActiveCN108793140AIncrease tangential speedImprove stripping efficiencyNitrogen compoundsTitanium carbidePre treatmentLarge size

The invention discloses a high-quality and large-size two-dimensional material and a preparation method thereof. The preparation method of the high-quality and large-size two-dimensional material comprises the following steps: S1, after pre-treating lamellar structure material powder, dispersing in chemical drug liquid, so as to obtain a dispersion solution; S2, putting the dispersion solution into emulsifying and dispersing equipment, and carrying out chemical and shearing peeling on the lamellar structure material powder under the action of the chemical drug liquid and emulsification and dispersion; S3, carrying out centrifugal separation and vacuum drying to obtain the high-quality and large-size two-dimensional material. The high-quality and large-size two-dimensional material and thepreparation method thereof, provided by the invention, have the advantages of simplicity and rapidness, high peeling efficiency and capability of realizing continuous scale production.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

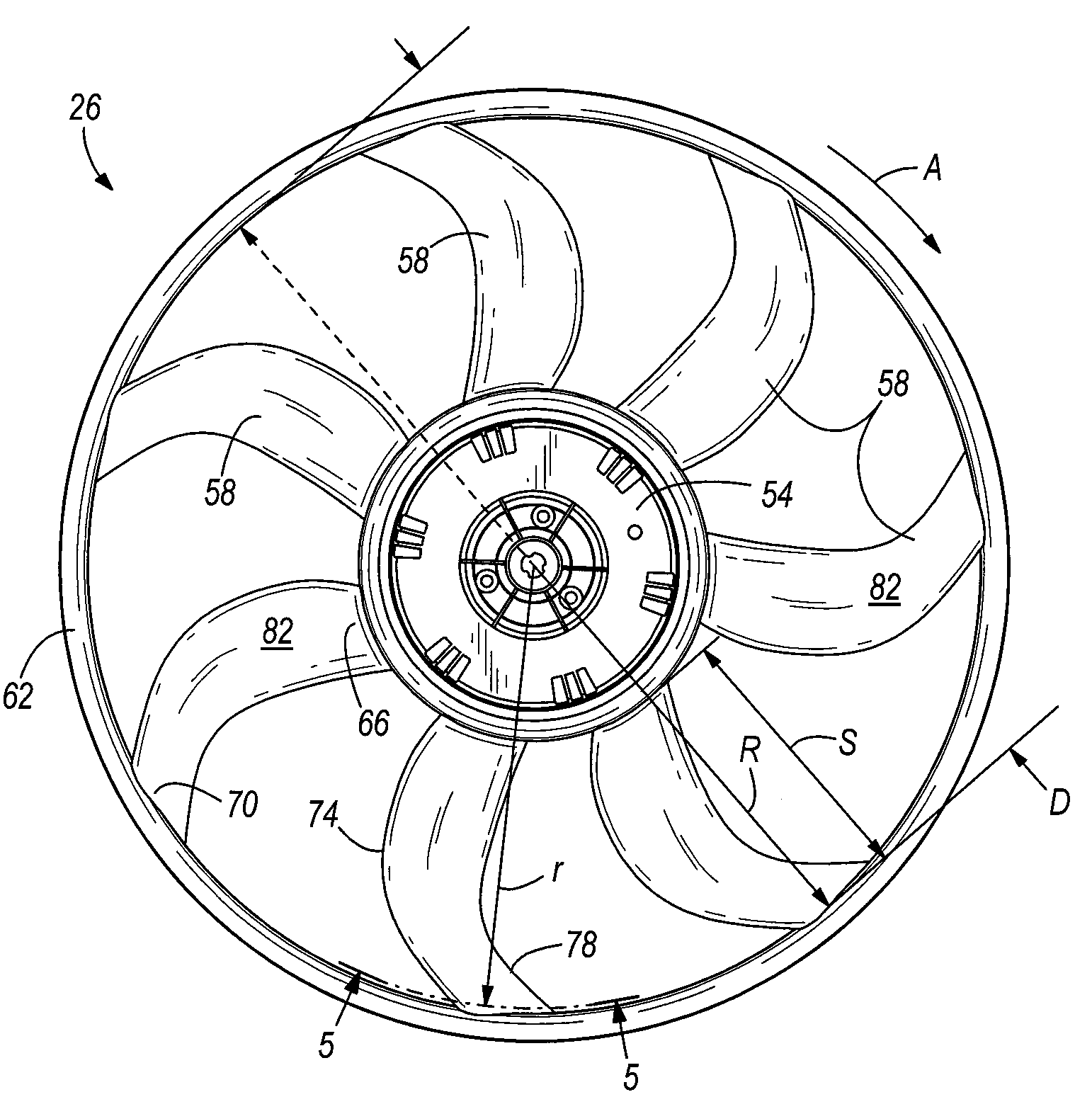

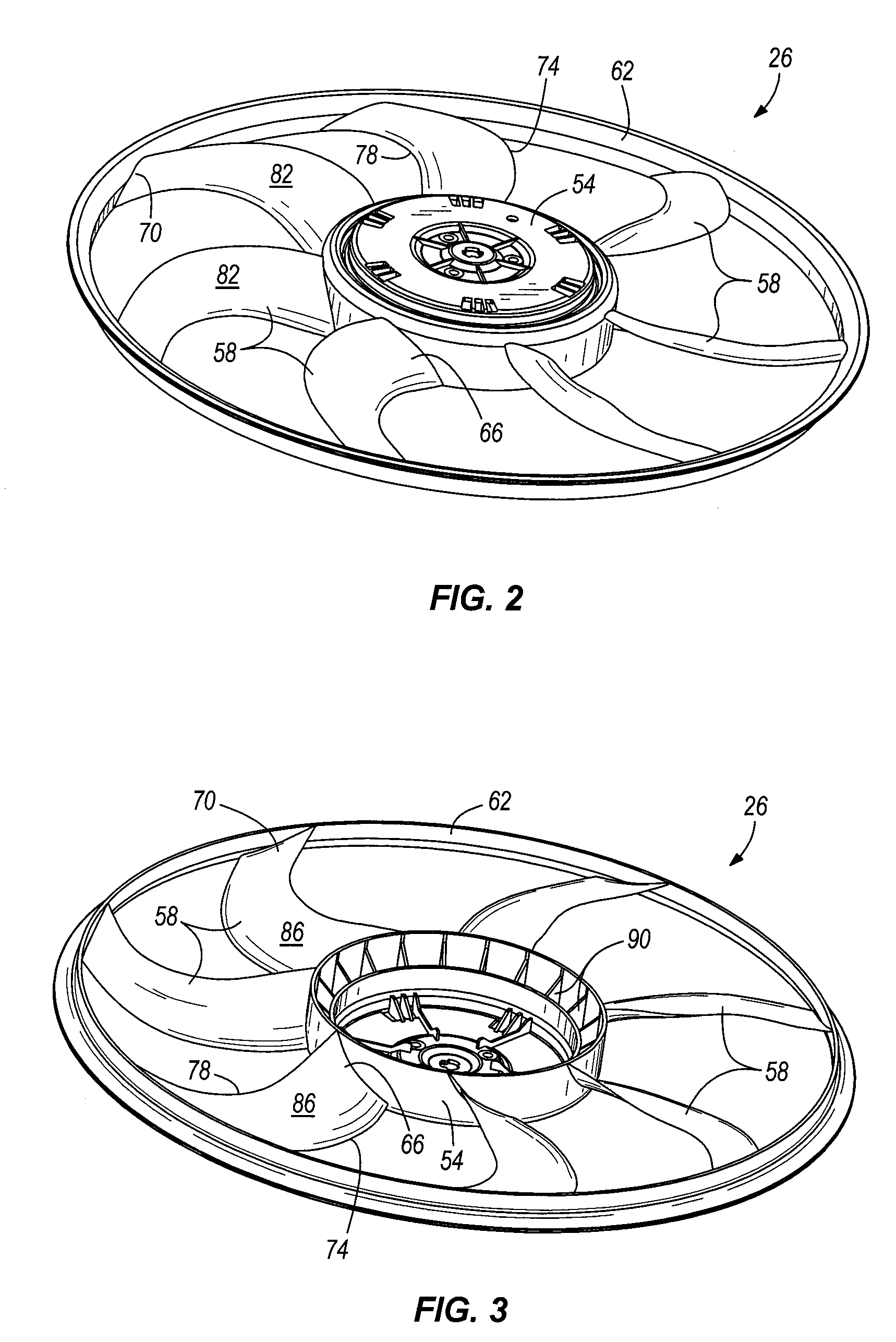

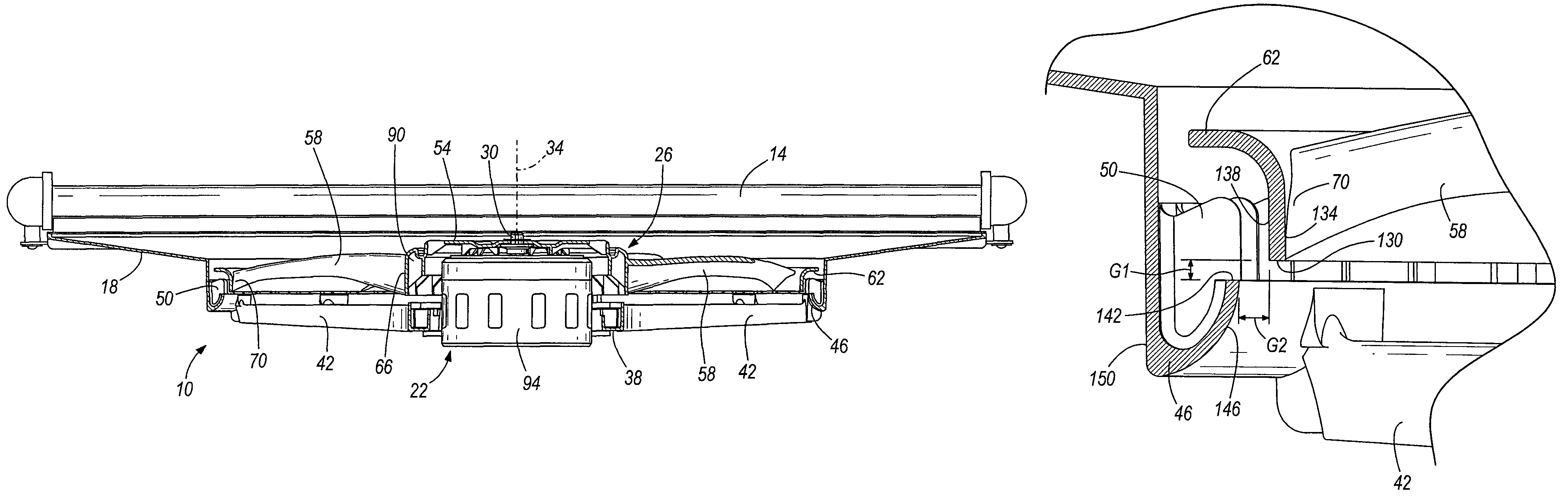

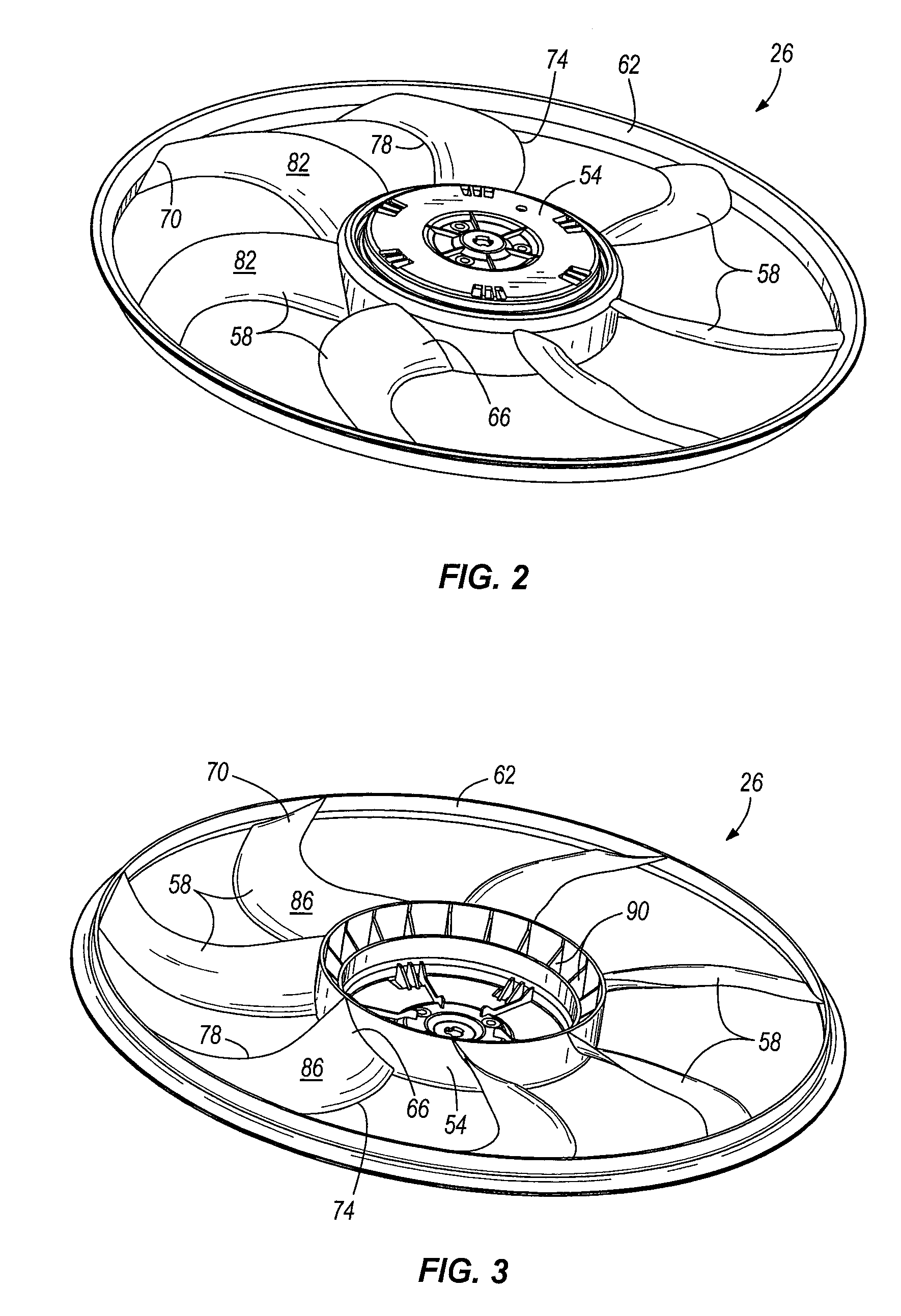

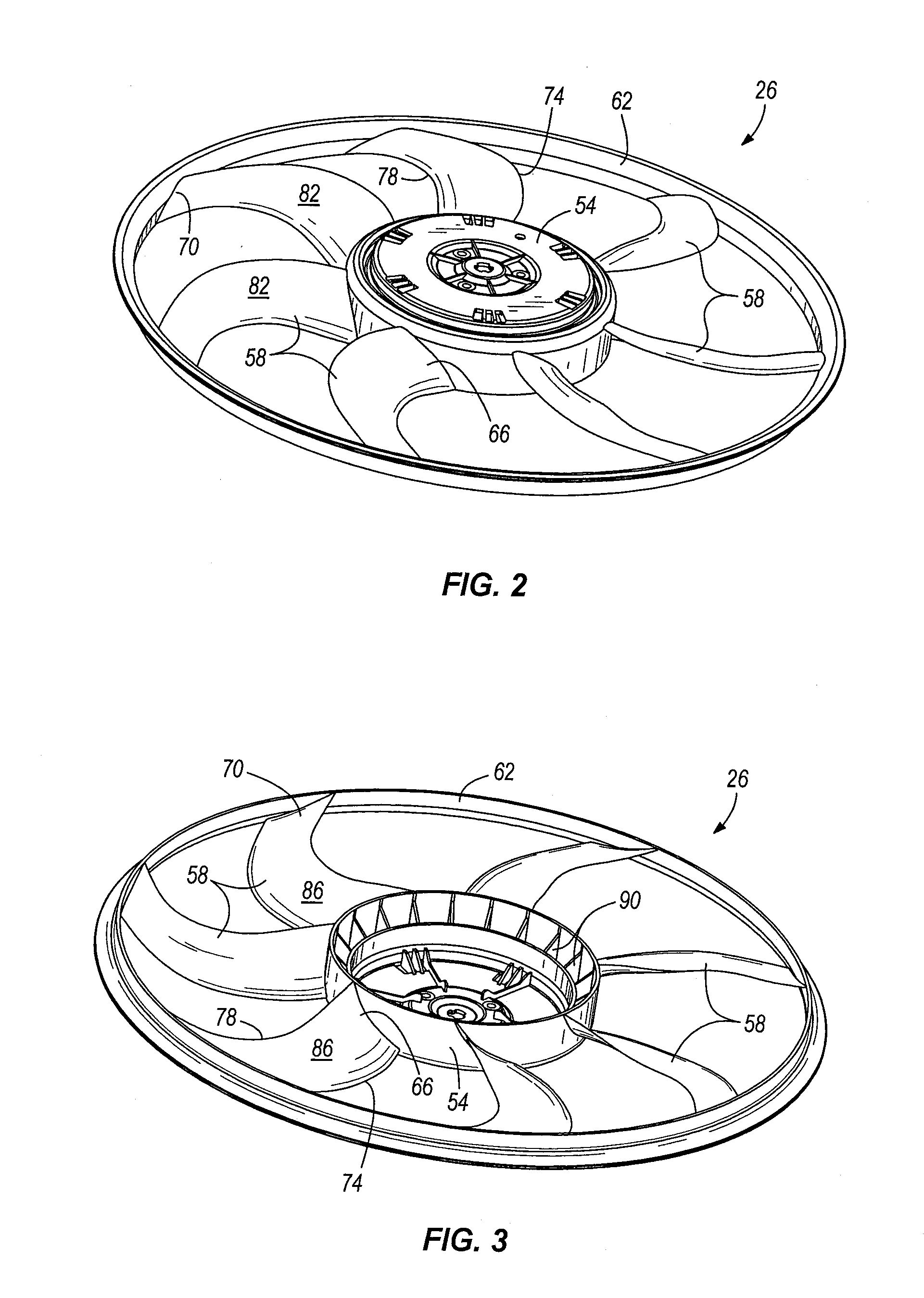

Axial fan assembly

ActiveUS20070280829A1Improve efficiencyReduce noisePropellersRotary propellersLeading edgeSkew angle

The present invention provides an axial fan including a hub adapted for rotation about a central axis and a plurality of blades extending radially outwardly from the hub and arranged about the central axis. Each of the blades includes a root, a tip, a leading edge between the root and the tip, and a trailing edge between the root and the tip. Each of the blades defines a blade radius between the blade tips and the central axis. Each of the blades defines a decreasing skew angle within the outer 20% of the blade radius. The ratio of blade pitch to average blade pitch increases from a lowest value to a highest value within the outer 20% of the blade radius. The highest value is about 30% to about 75% greater than the lowest value.

Owner:ROBERT BOSCH CORP +1

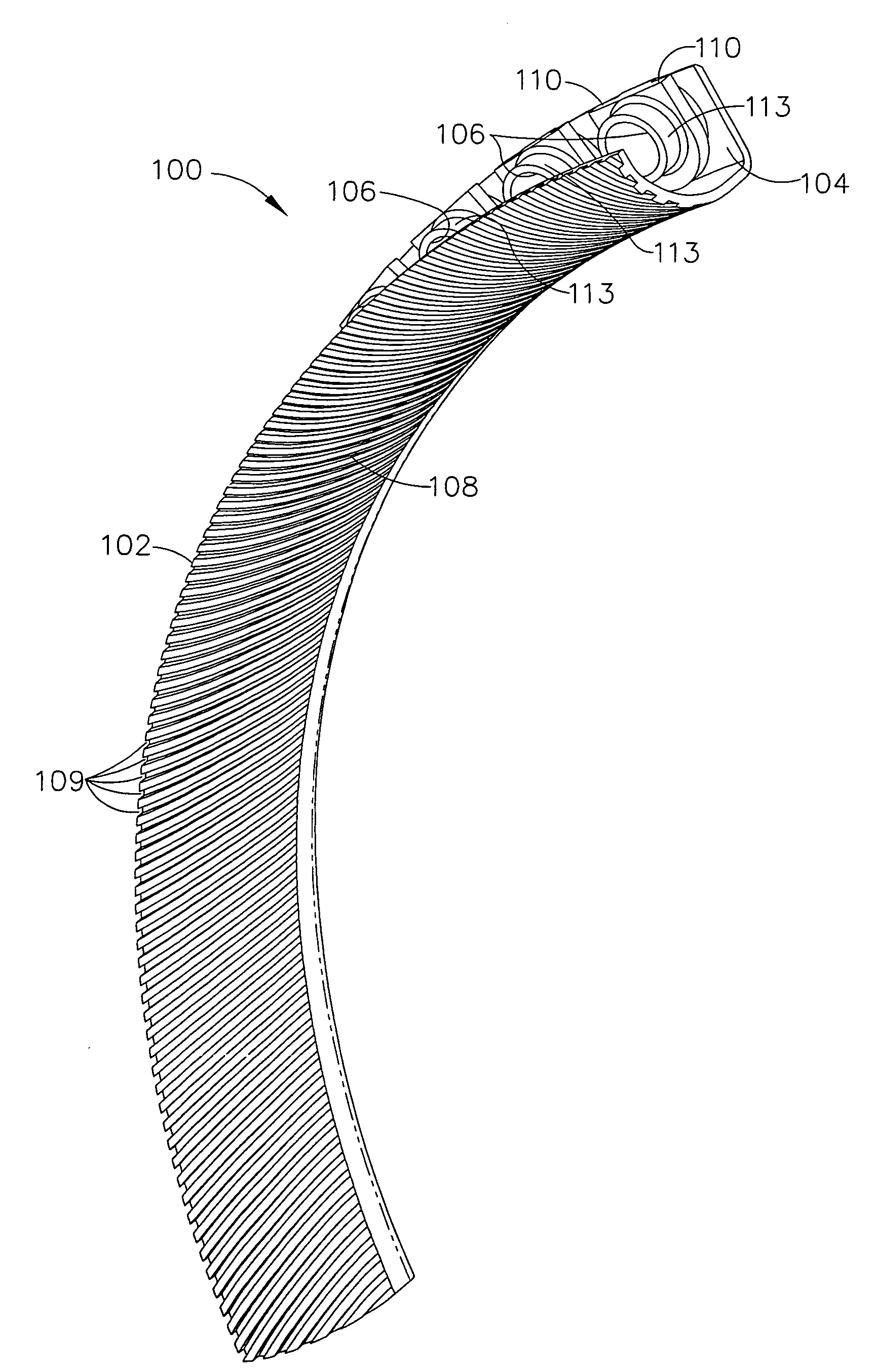

Swirl-enhanced aerodynamic fastener shield for turbomachine

ActiveUS7094020B2Minimize temperature riseInhibition of attachmentEngine sealsPump componentsTurbineEngine mount

A fastener shield for use in a fluid flow path within a gas turbine engine for reducing fluid drag and heating generated by fluid flow over a plurality of circumferentially spaced bolts. The fastener shield has a radially-extending, downstream-facing mounting flange with a plurality of circumferentially spaced bolt holes positioned to receive respective engine mounting bolts therethrough and to attach the mounting flange to elements of the turbine engine. A curved, upstream-facing fastener shield cover is positioned in spaced-apart relation to the mounting flange for at least partially covering and separating an exposed, upstream-facing portion of the bolts from the fluid flow to thereby reduce drag and consequent heating of the bolts. A plurality of closely spaced-apart, spirally-oriented channels are formed in the fastener shield cover for deflecting the fluid flow impinging on the fastener shield cover, thereby increasing the tangential velocity and lowering the relative temperature of the fluid flow.

Owner:GENERAL ELECTRIC CO

Axial fan assembly

ActiveUS7762769B2Improve efficiencyReduce noisePropellersRotary propellersEngineeringMechanical engineering

Owner:ROBERT BOSCH CORP +1

Tangential injection type whirl flow jet flow grinding drill bit for horizontal well

The invention discloses a tangential injection type whirl flow jet flow grinding drill bit for a horizontal well. The grinding drill bit mainly comprises a PDC drill bit body and is characterized in that a debris discharging groove in the gauge protection portion of the PDC drill bit body is omitted, and the PDC drill bit body is internally and additionally provided with a tangential injection type rotating jet flow sand washing device, a high-concentration turbulence sand pumping device and a jet flow smashing device. According to the tangential injection type rotating jet flow sand washing device, high-speed rotation jet flow is generated through tangential injection type rotating jet flow spray nozzles, a well bottom whirl flow field beneficial to rock debris cleaning is formed, the stress condition of well bottom rock debris is improved, and the well bottom rock debris cleaning efficiency is improved. The high-concentration turbulence sand pumping device pumps and sucks the well bottom fluid based on the principle of a sand pumping pump, the well bottom pressure difference is reduced, unbalance is achieved, and the mechanical drilling speed is increased. The jet flow smashing device effectively smashes the rock debris based on the principle of a jet mill, the rock debris carrying efficiency is improved, the rock debris bed in the horizontal well is eliminated radically, and safe and efficient drilling of the horizontal well is finally achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

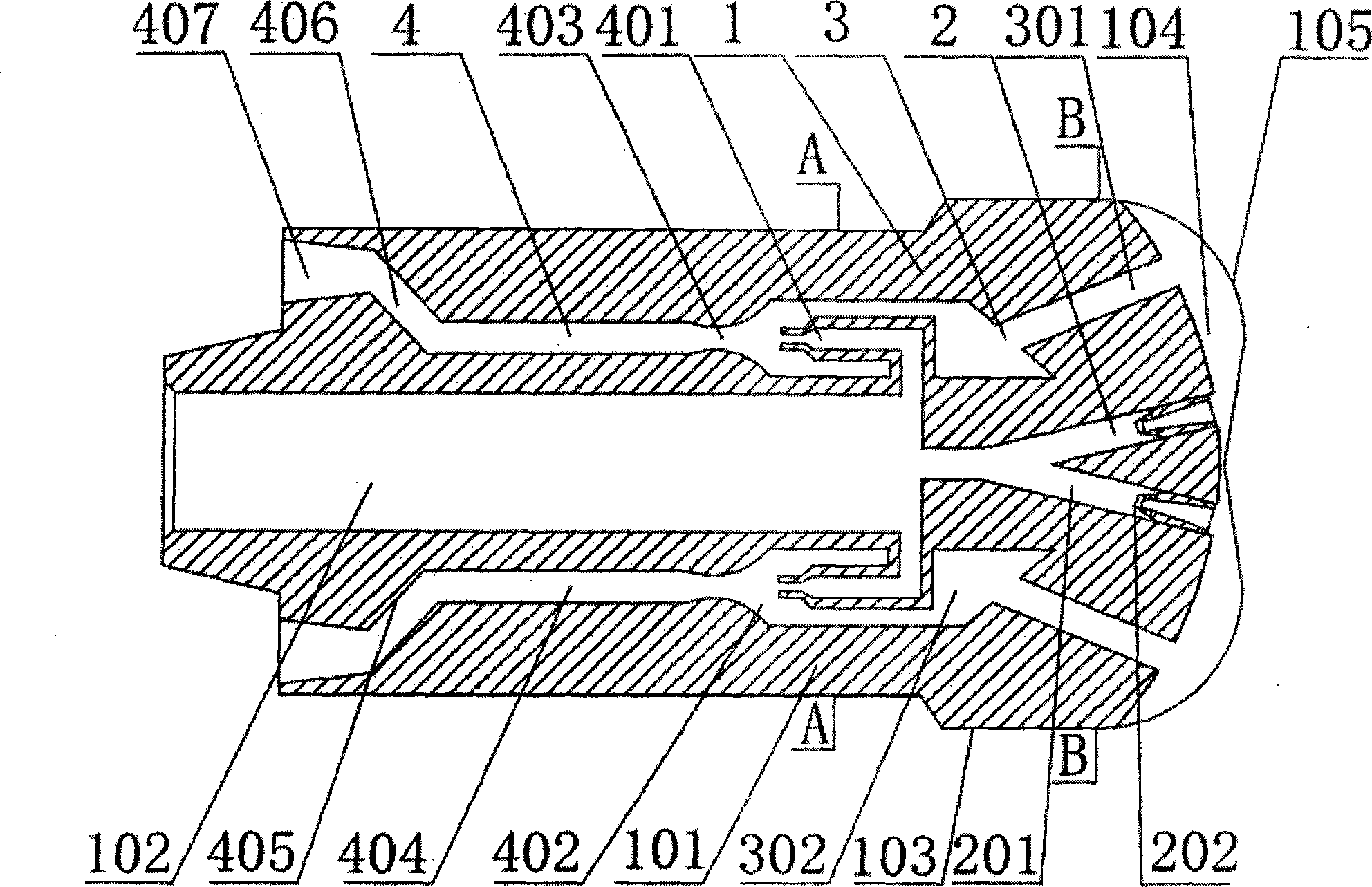

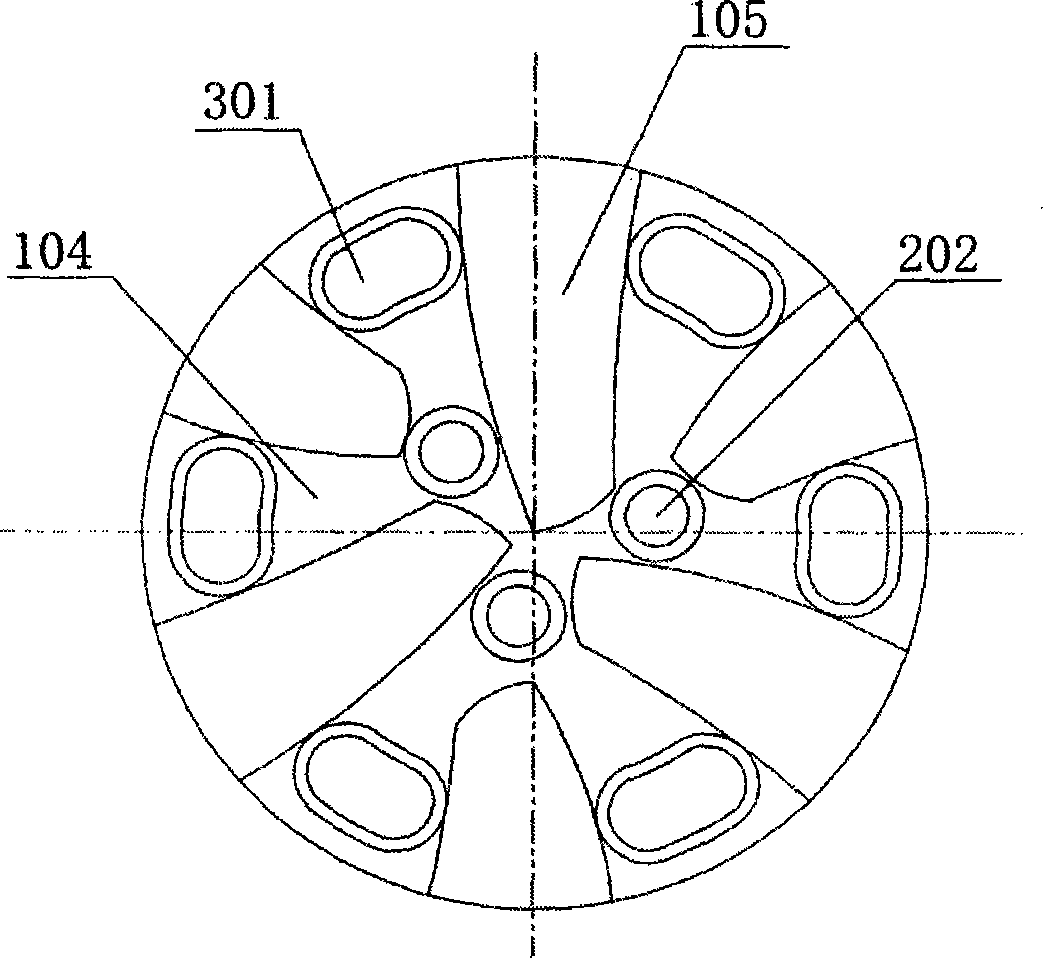

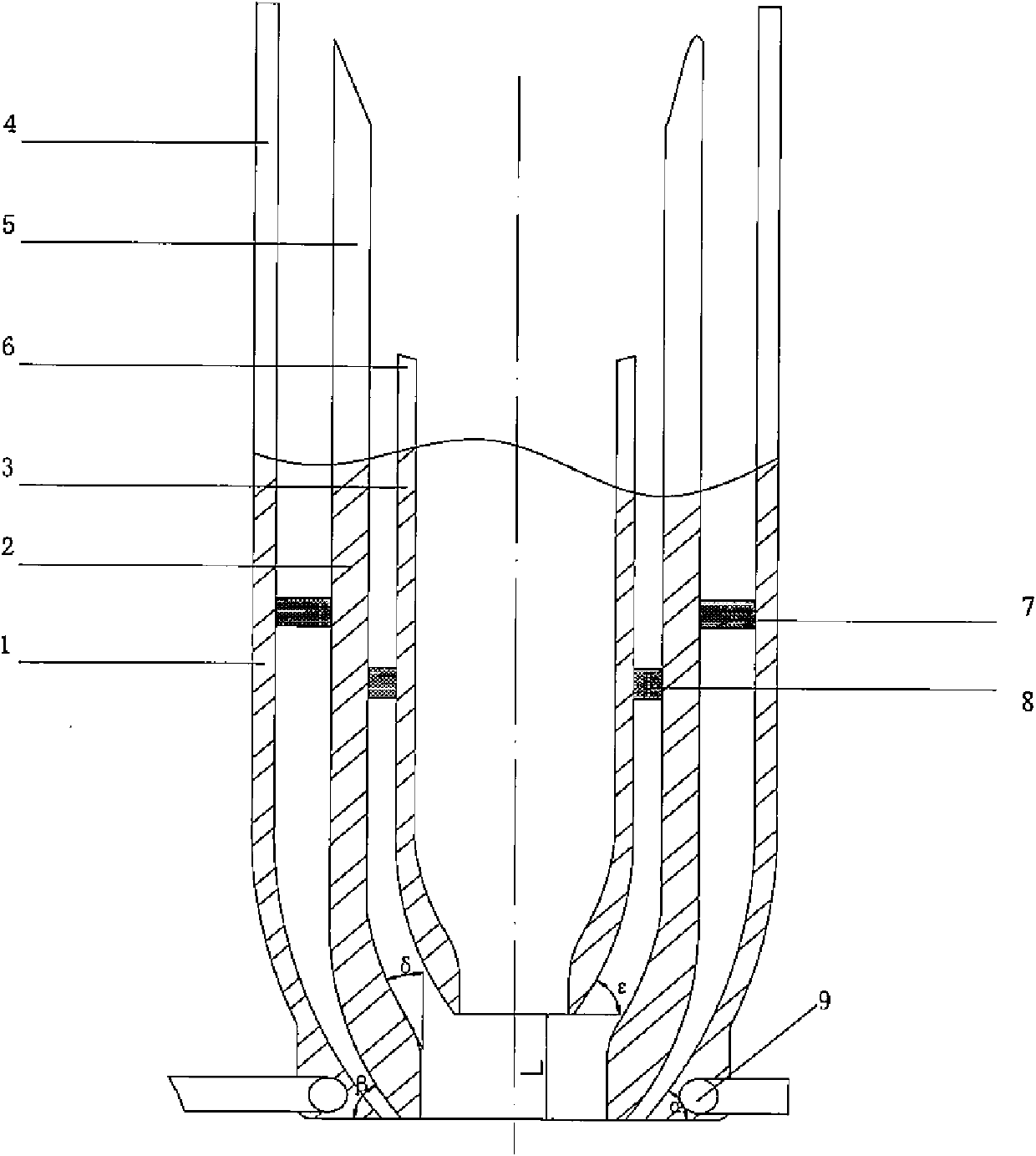

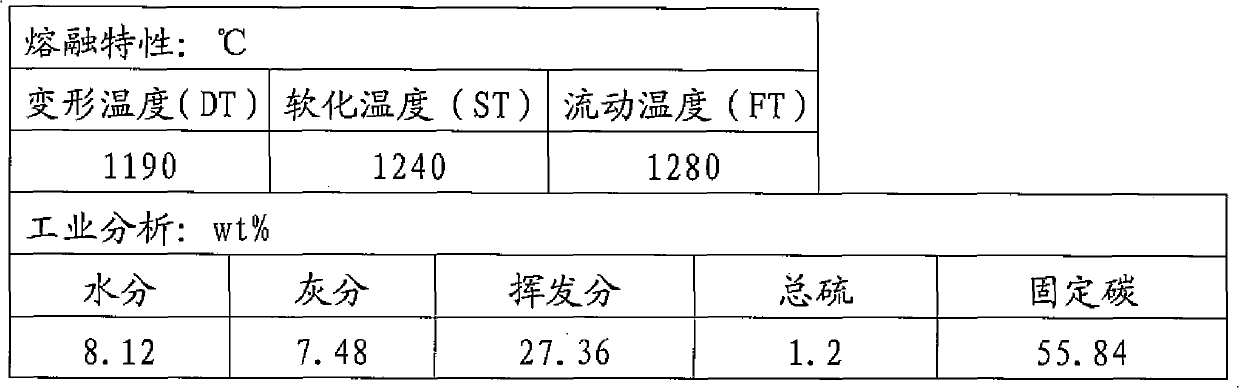

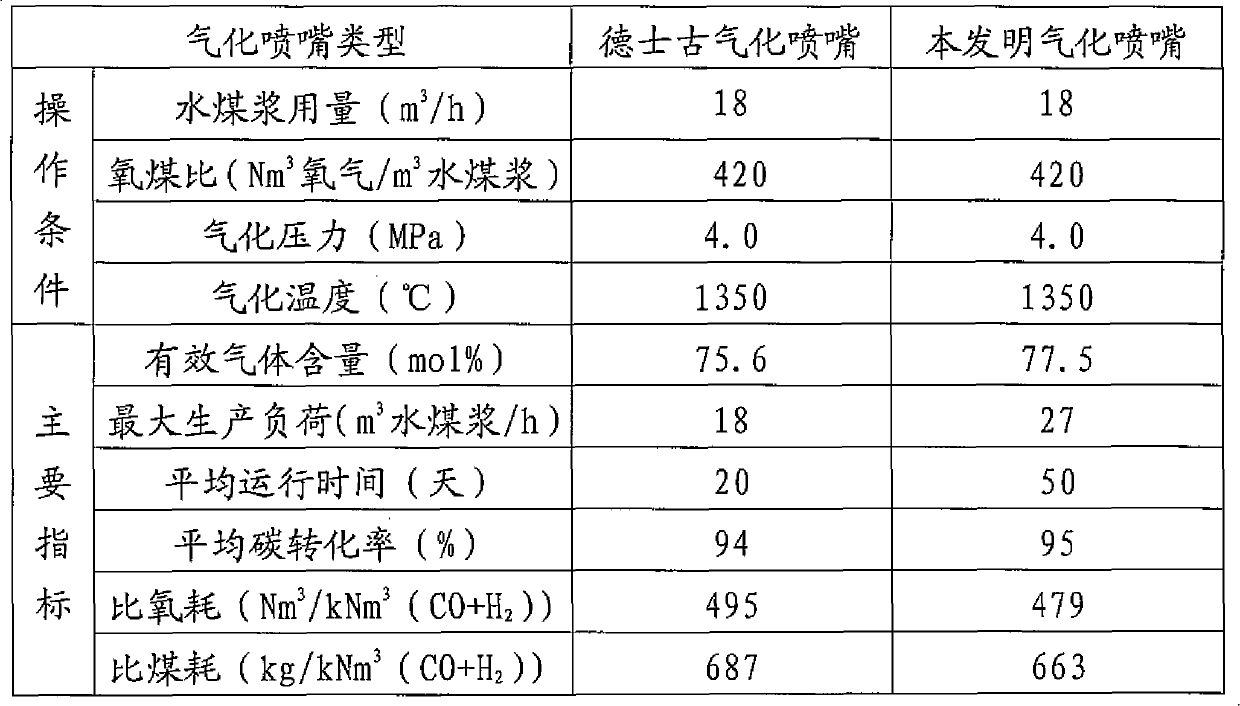

A gasification nozzle

InactiveCN102260533AImprove premix atomization effectWell mixedLiquid spraying apparatusGranular/pulverulent flues gasificationEpoxyCoal water

A gasification nozzle, which comprises a central oxygen nozzle, a coal-water slurry nozzle and an epoxy nozzle that are concentrically arranged from the inside to the outside, wherein the end section of the central oxygen nozzle is relative to the inner diameter of the end section of the coal-water slurry nozzle. The shrinkage is 20mm-100mm; the inclination angle of the epoxy nozzle is 20°-50°; the inclination angle of the outer side of the coal-water slurry nozzle is 30°-70°, and the inclination angle of the inner side is 30°-80°; the center The outside inclination angle of the oxygen nozzle is 30°-70°; a first locator is arranged in the epoxy channel, and a second locator is arranged in the coal-water slurry channel, and the top of the first locator is in the shape of a swirl sheet, so The included angle between the top and the feeding direction of oxygen is 20°-60°. When the gasification nozzle of the invention is used for gasification, the gasification effect of the coal-water slurry is better, the maximum production load of the gasification nozzle is increased, and the service life of the gasification nozzle is longer.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Gasification burner

PendingCN108728168AAdjust operating loadImprove conversion rateGasifier mechanical detailsGasification processes detailsCombustionReaction rate

The invention relates to a gasification burner. The gasification burner comprises a mother burner, N levels of sub-burners are arranged on the inner side of the mother burner, wherein N is an integergreater than or equal to 1, the mother burner and the sub-burners of each level are equipped with independent fuel channels and oxidant channels respectively, and the mother burner and the sub-burnersof each level are arranged to be a coaxial suit structure from the outside to the inside; the inner diameter of the mother burner is larger than the outer diameter of a first level sub-burner, and the inner diameter of the sub-burner of each level is larger than the outer diameter of the sub-burner of a next level; in a limited reaction space and residence time, the sufficient and uniform mixingof a fuel and an oxidant can be ensured, and the combustion reaction rate is accelerated, so that the fuel conversion rate and the gasification performance of a device are improved; in addition, through the adjustment of the load of the mother burner and the sub-burners of each level, the flame shape can be flexibly adjusted without reducing the load of a gasifier, so that the overheating of a gasifier furnace is effectively avoided, and different production load requirements of a project site can be met.

Owner:CHANGZHENG ENG

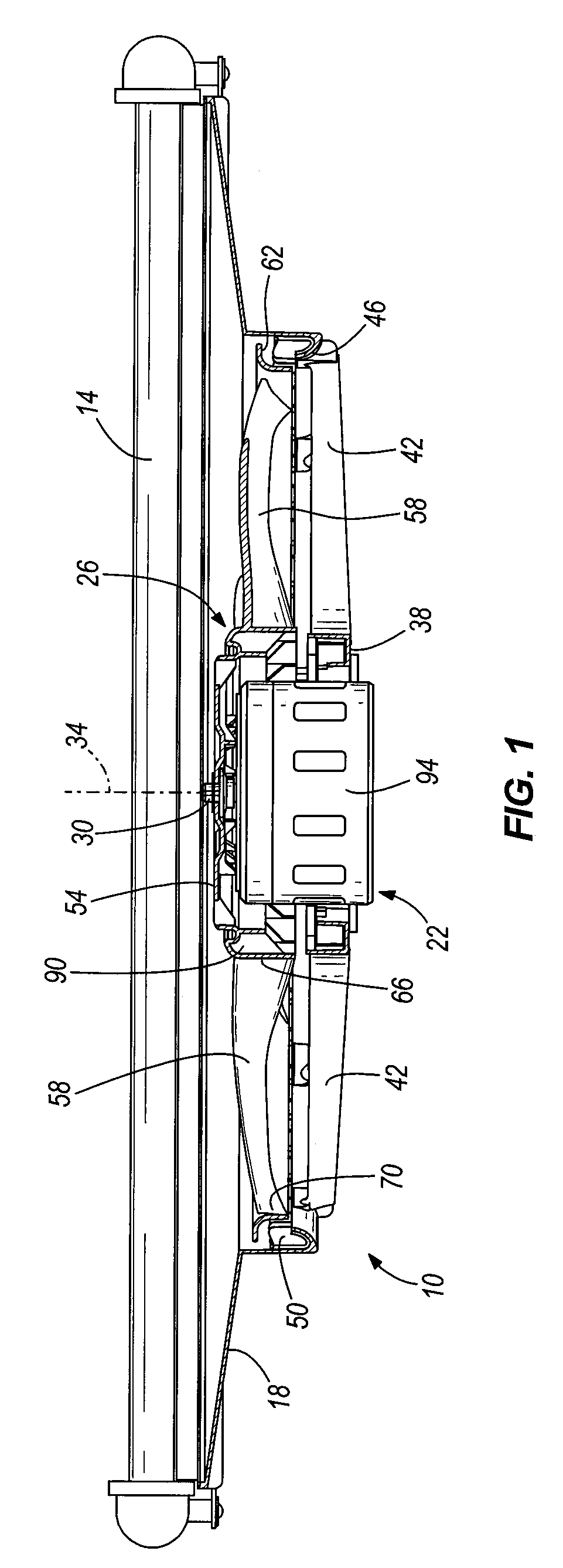

Axial fan assembly

ActiveUS20070280827A1Improve efficiencyReduce noisePropellersPump componentsEngineeringMechanical engineering

The present invention provides an axial fan assembly including a motor having an output shaft rotatable about a central axis and a shroud coupled to the motor. The shroud includes a substantially annular outlet bell centered on the central axis. The axial fan assembly also includes an axial fan having a hub coupled to the output shaft for rotation about the central axis, a plurality of blades extending radially outwardly from the hub and arranged about the central axis, a substantially circular band coupled to the tips of the blades, and a plurality of leakage stators positioned radially outwardly from the band and adjacent the outlet bell.

Owner:ROBERT BOSCH CORP +1

Cyclone oil-gas separator for multi-online system

InactiveCN102767925AEasy to catchIncrease the chance of aggregationRefrigeration componentsVapor–liquid separatorAir conditioning

The invention discloses a cyclone oil-gas separator for a multi-online system. The cyclone oil-gas separator comprises a main cylindrical barrel, a tangential inlet pipe is arranged on the upper side wall of the main barrel, a vertical exhaust pipe is arranged at the top center of the main barrel, the bottom of the exhaust pipe extends into the main barrel, a vertical oil discharging pipe is arranged at the bottom center of the main barrel, the inlet pipe is connected with an exhaust pipe of an air conditioning multi-online system compressor, the vertical exhaust pipe is connected with an inlet of a condenser, the oil discharging pipe is connected with an inlet pipe of a gas-liquid separator, the diameters of the tangential inlet pipe and the vertical exhaust pipe are di and do respectively, the pipe pitch between the tangential inlet pipe and the vertical exhaust pipe is d, d<(di / 2+do / 2), part of fluid led into by the tangential inlet pipe collides with the vertical exhaust pipe, the entered fluid regularly flows around an annular space formed by the vertical exhaust pipe and the main barrel when the fluid flows stably, and oil after being separated is discharged from the cyclone oil-gas separator through the oil discharging pipe. The probability that small oil drops adhere to wall faces and oil drops aggregate is increased by means of inlet gas collision, and accordingly separating efficiency is improved.

Owner:XI AN JIAOTONG UNIV

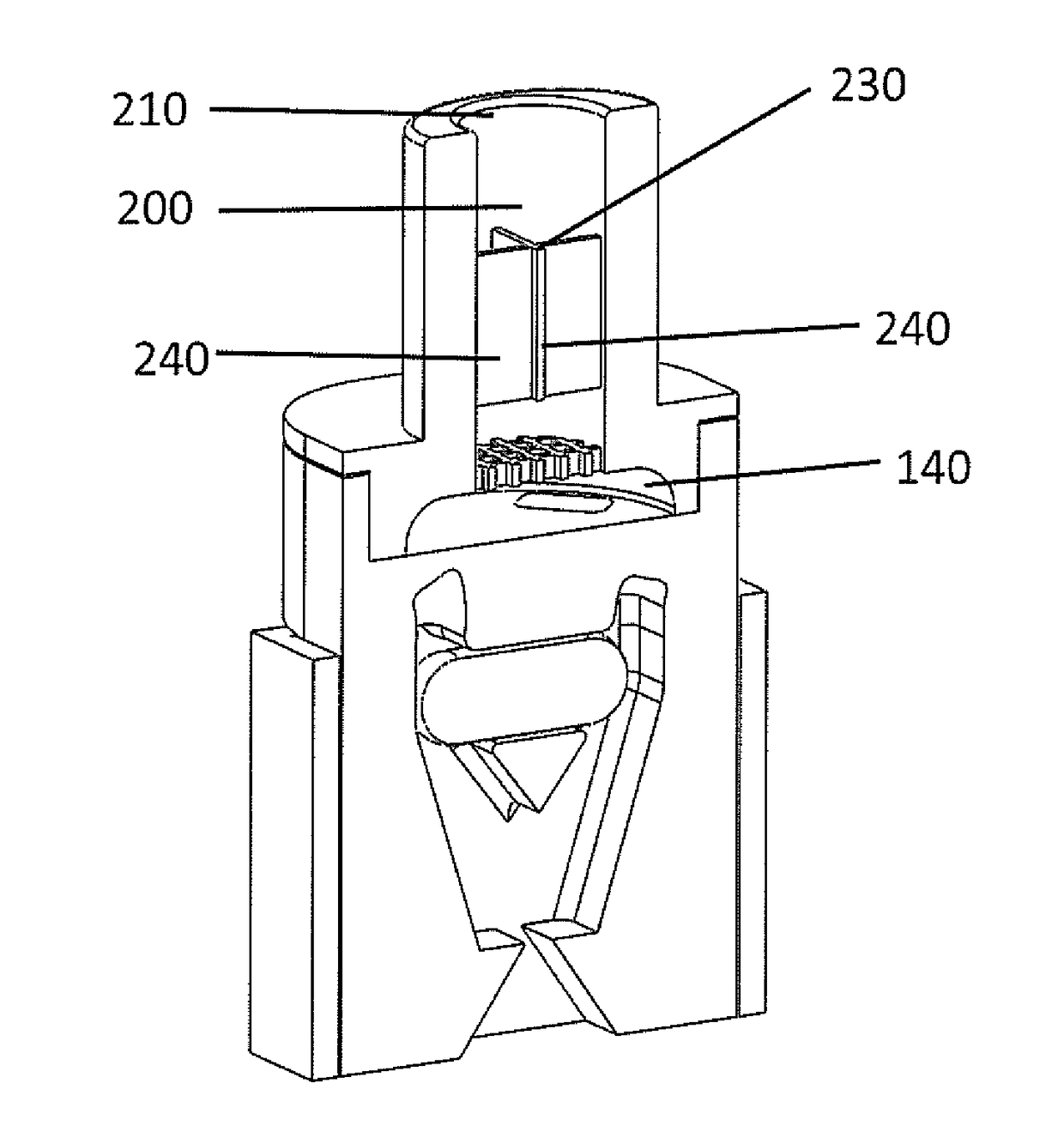

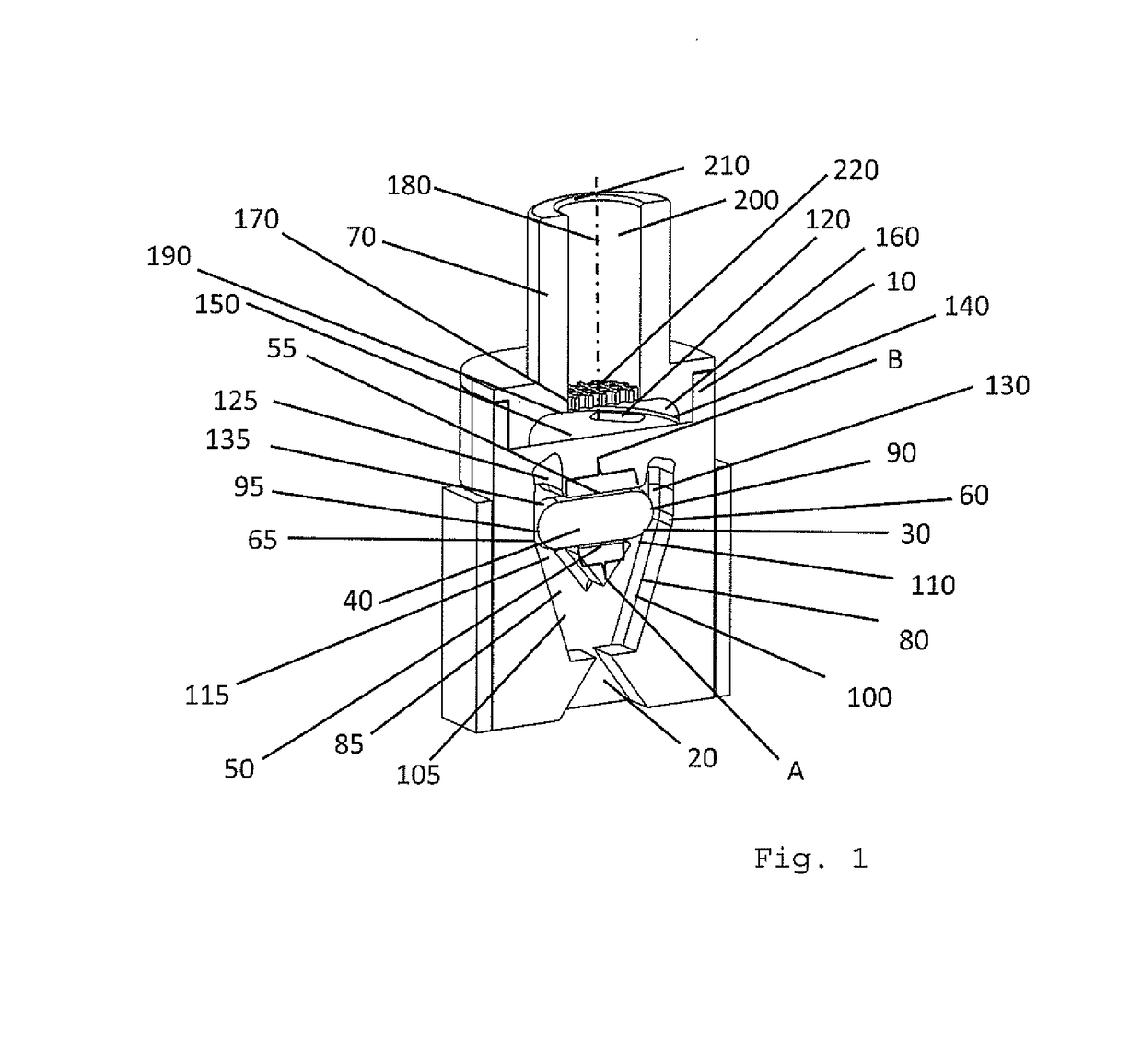

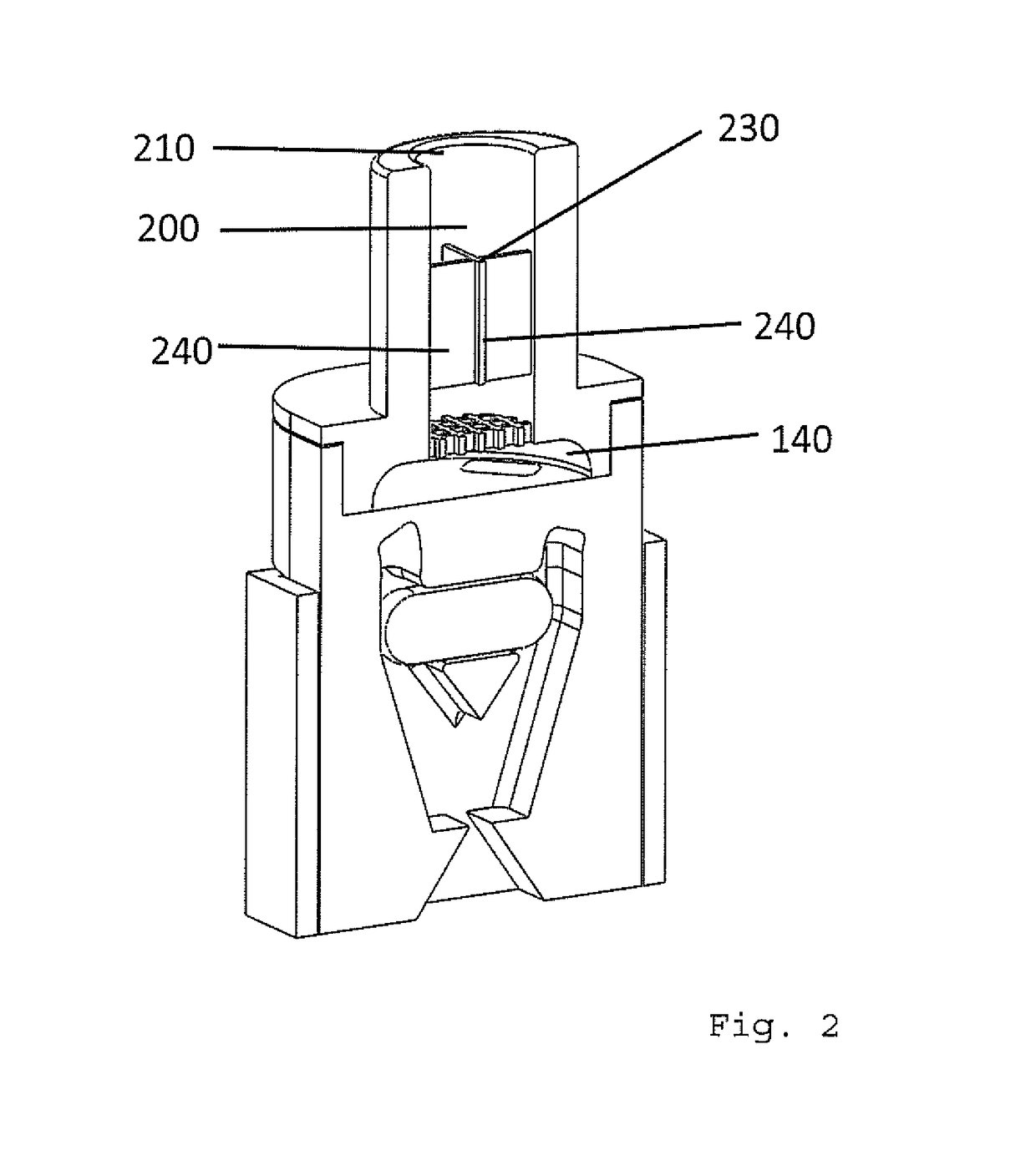

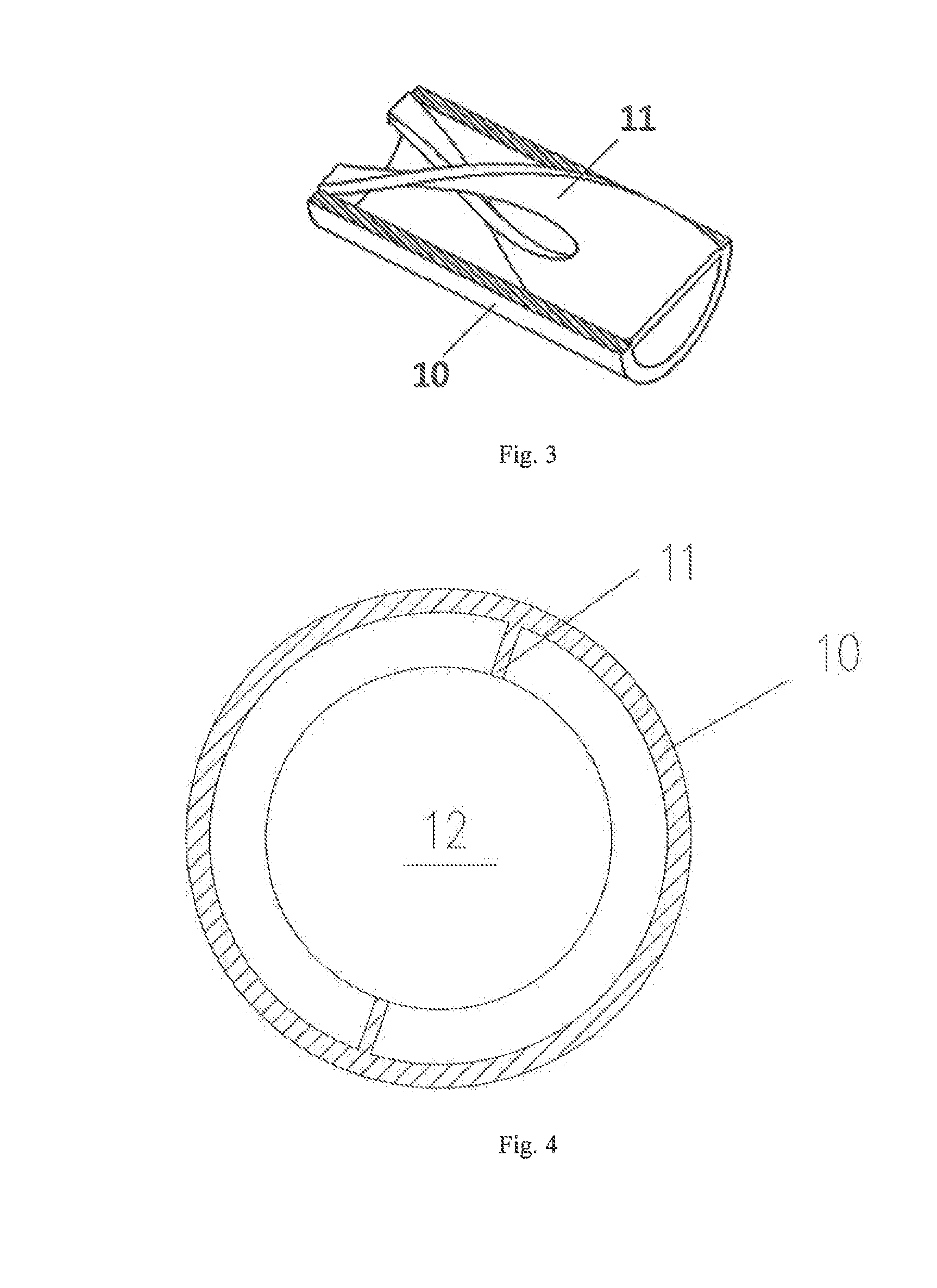

Dry powder inhaler

ActiveUS20170333646A1Reduce swirlSmooth transitionMedical devicesMedical atomisersAirflowBiomedical engineering

The present invention relates to an inhaler device for delivering a dose of medicament in dry powder form from a container to a patient in need thereof. The inhaler comprises a swirl chamber in which particles of the medicament entrained in an airflow swirl upon inhalation thereby breaking up the agglomerates into finest dispersed powder.

Owner:PRESSPART MFG

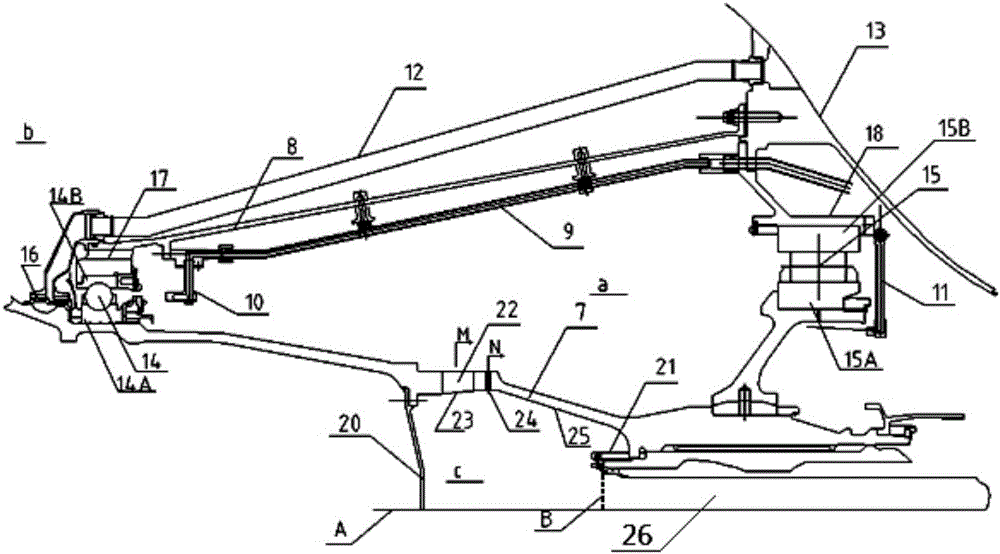

Oil-gas separation device and gas turbine engine

ActiveCN107435590AEasy to separateImprove separation efficiencyFlash degasificationRefining by centrifugal forceEngineeringTurbine

The invention relates to an oil-gas separation device and a gas turbine engine. The oil-gas separation device comprises a cavity structure provided with a separation cavity. The wall face of the separation cavity is provided with an inlet, a first outlet and a second outlet. The inlet comprises multiple tangential channels. The multiple tangential channels enable oil-gas mixture to enter the separation cavity in the tangential direction. The first outlet is arranged in the radial direction of the separation cavity, the second outlet is arranged in the axial direction of the separation cavity, the separation cavity is rotated to achieve oil-gas separation for the oil-gas mixture, oil obtained after separation flows out through the first outlet, and gas obtained through separation flows out through the second outlet. In the embodiment of the oil-gas separation device and the gas turbine engine, the oil-gas mixture entering the separation cavity has the large tangential speed and small or almost zero radial speed and axial speed, standing time of vortical motion of the oil-gas mixture in the separation cavity can be longer, and the oil-gas separation efficiency can be better improved.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

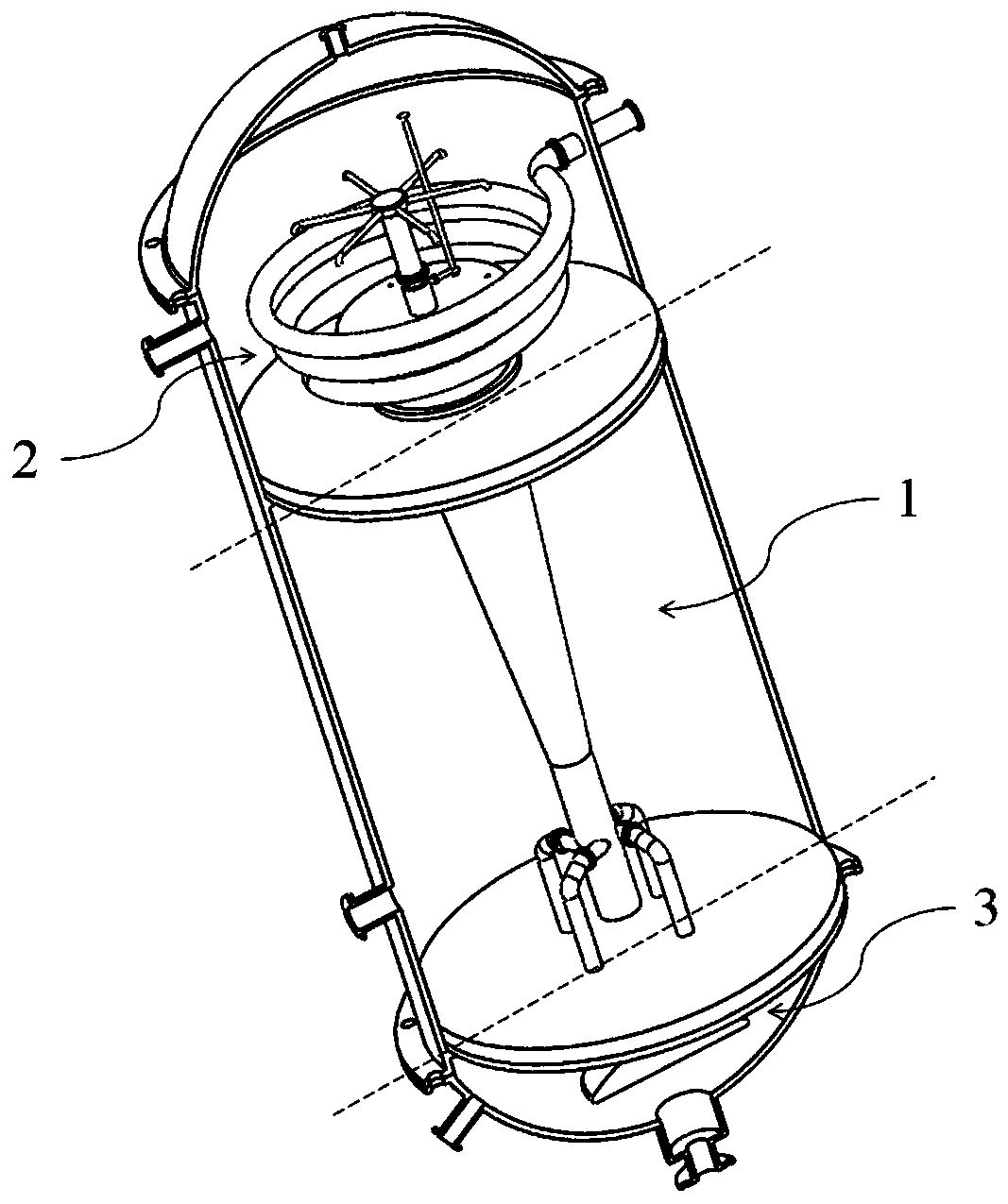

Cyclone separator and separation system suppressing coking on outer wall of riser

PendingCN110215765AReduce cokingReduce spreadDispersed particle separationEngineeringMechanical engineering

A cyclone separator and a separation system suppressing coking on an outer wall of a riser are disclosed. The cyclone separator includes a cylinder body the upper end of which is provided with a feeding portion, and the top of which is provided with a top plate; a riser at least partially disposed in the cylinder body, with one end of the riser in the cylinder body being provided with a gas inlet;a convex ring which fixedly sleeves the riser, which protrudes radially along the riser, which is disposed below the top plate, which is disposed in an annular space formed by the inner wall of the cylinder body and the outer wall of the riser, and which is at least partially aligned with the feeding portion in the radial direction; and a communication portion on the wall of the riser, wherein the communication portion communicates the inside and outside of the riser, and is on the upstream of the gas inlet and downstream of the convex ring. The cyclone separator and the separation system caneffectively reduce pressure drop and energy consumption, and destroy a low-speed boundary layer of the outer wall of the riser while not reducing the separation efficiency, thus preventing coking andparticle deposition, and ensuring long-period operation of equipment. The cyclone separator and the separation system are simple in structure and easy to implement.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

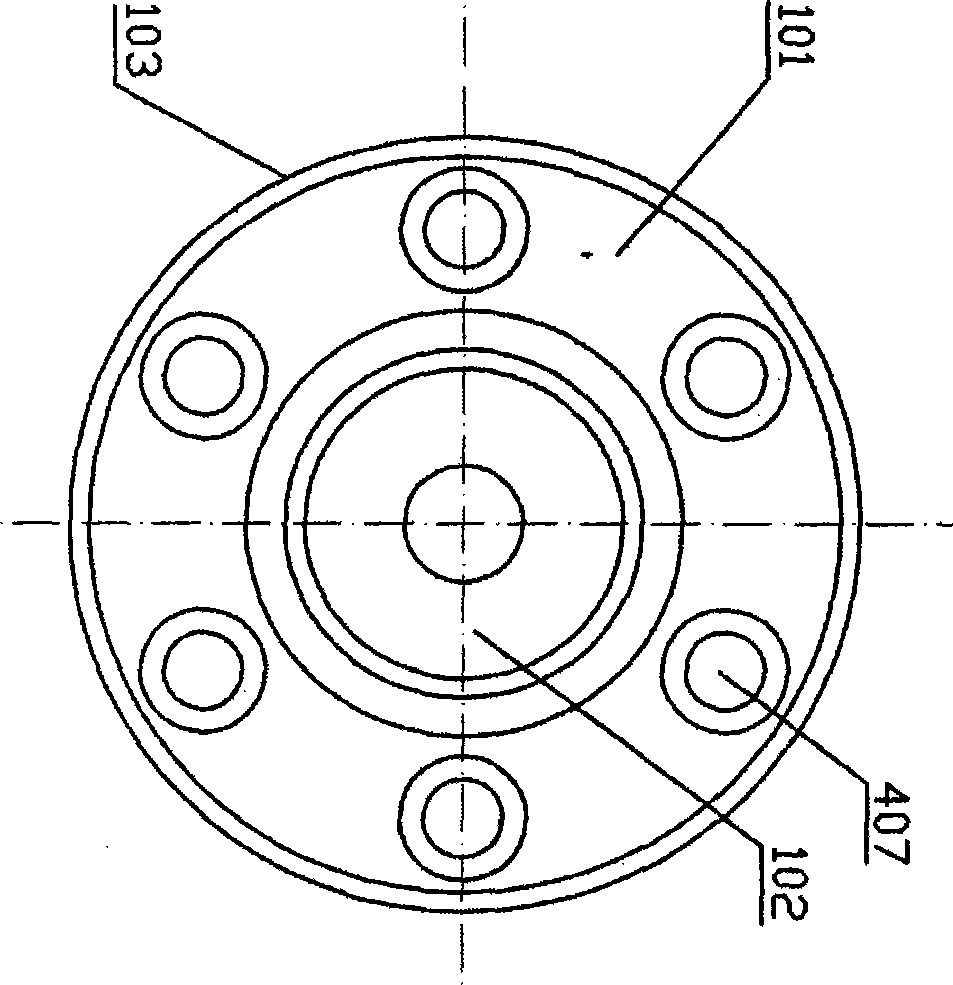

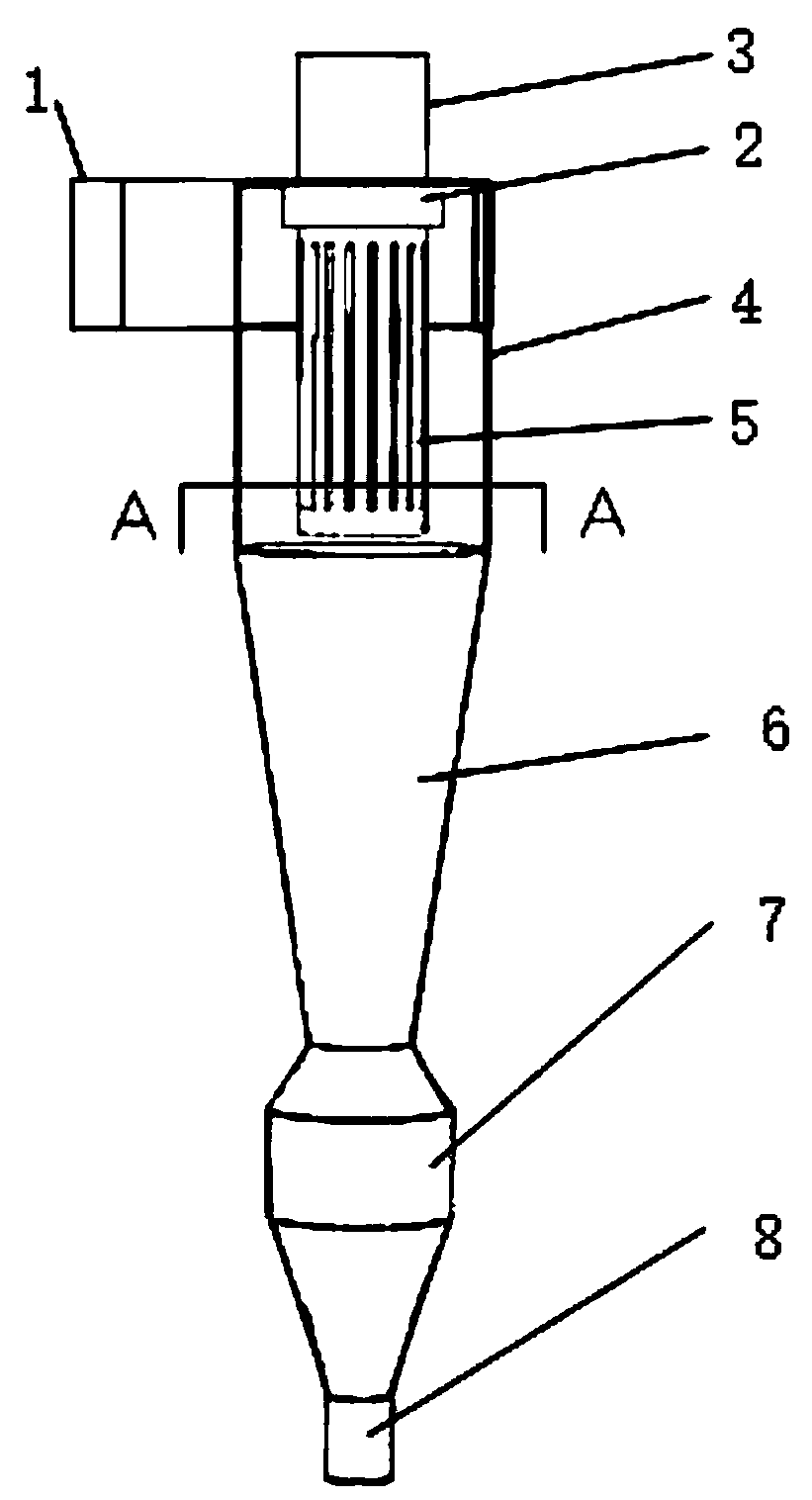

Nozzle for increasing carbon conversion rate of pulverized coal entrained-bed gasifier

InactiveCN103937554AIncrease tangential speedHigh effective gas contentCombined combustion mitigationGranular/pulverulent flues gasificationCycloneEngineering

The invention relates to a nozzle for increasing carbon conversion rate of a pulverized coal entrained-bed gasifier. The nozzle comprises outer water-cooled sleeves, an inner water-cooled sleeves, outer ring spray heads and inner ring spray heads which are coaxial from the outside and inside, wherein a cooling water leading-out channel is arranged between the outer water-cooled sleeves and the inner water-cooled sleeves, a cooling water introduction channel is arranged between the inner water-cooled sleeves and the outer ring spray heads, an outer ring channel is arranged between the outer ring spray heads and the inner ring spray heads, the inner ring spray heads form an inner ring channel, a front end water-cooled chamber is arranged at an outlet of the cooling water leading-out channel and an outlet of the outer ring channel is provided with a plurality of cyclones symmetrically. According the invention, the flow field in the gasifier is changed by designing the gasifier nozzle to enhance the mixing of pulverized coal and air flow, thereby prolonging the residence time of the particles and ultimately improving the carbon conversion rate in pulverized coal.

Owner:HUANENG CLEAN ENERGY RES INST

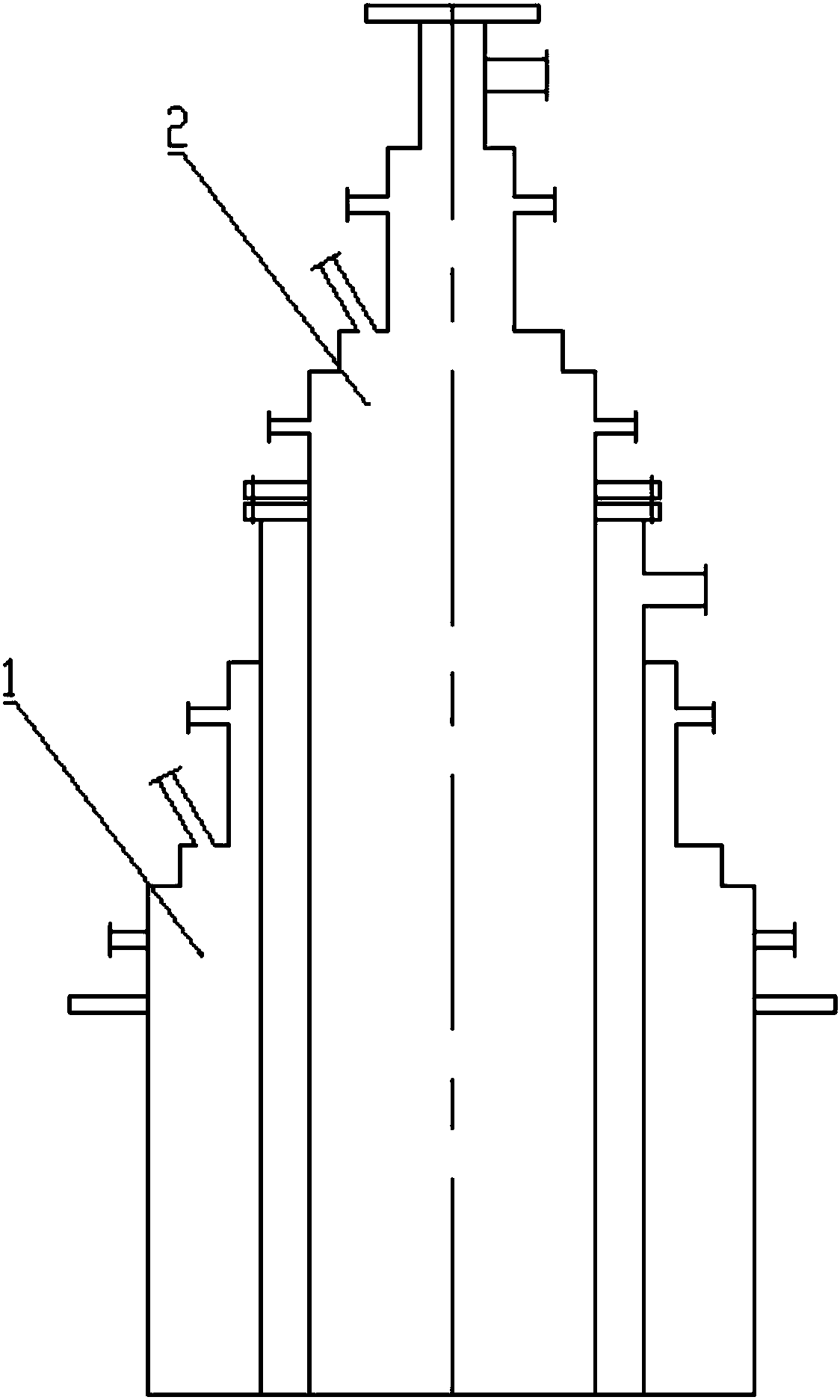

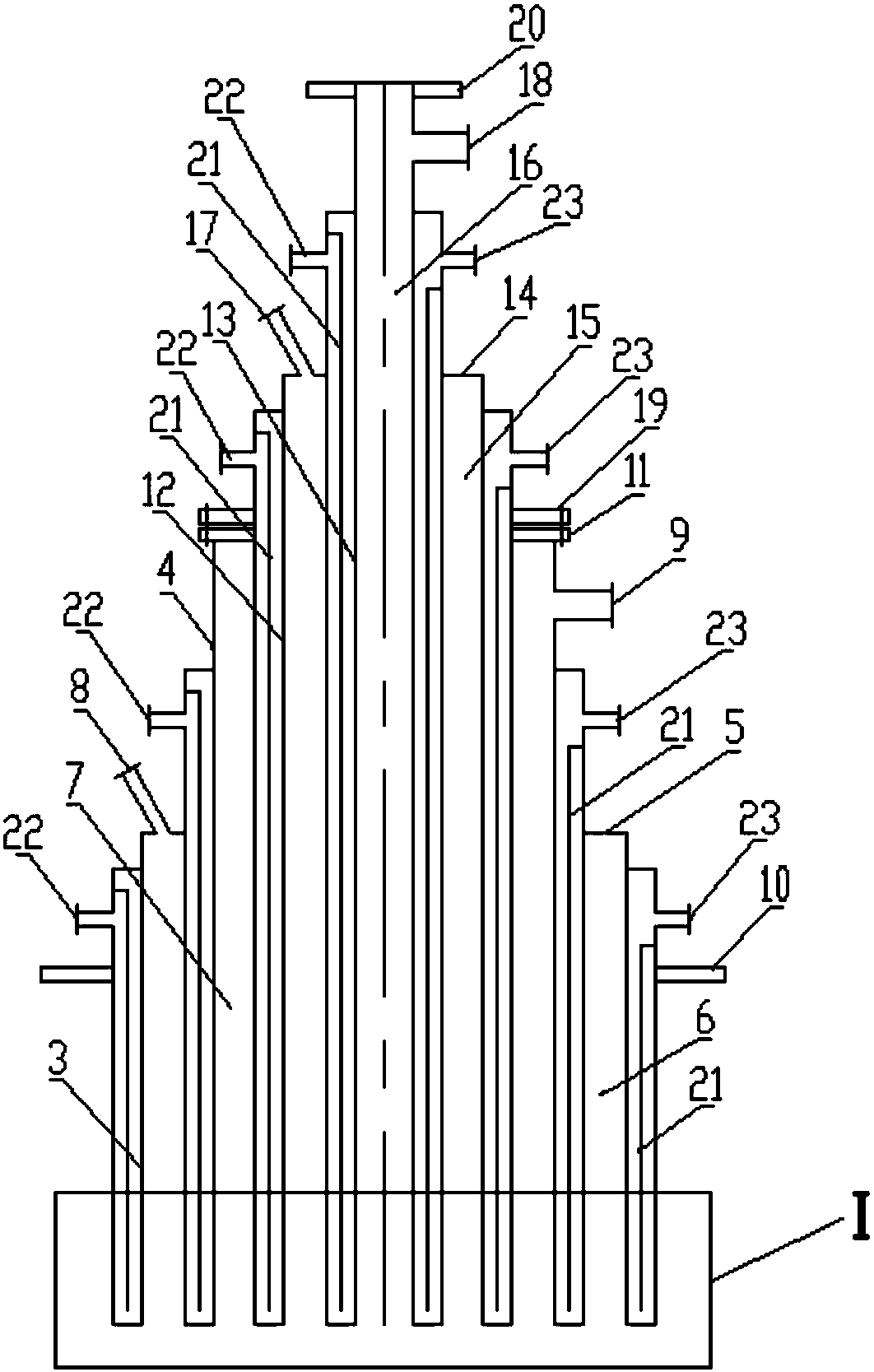

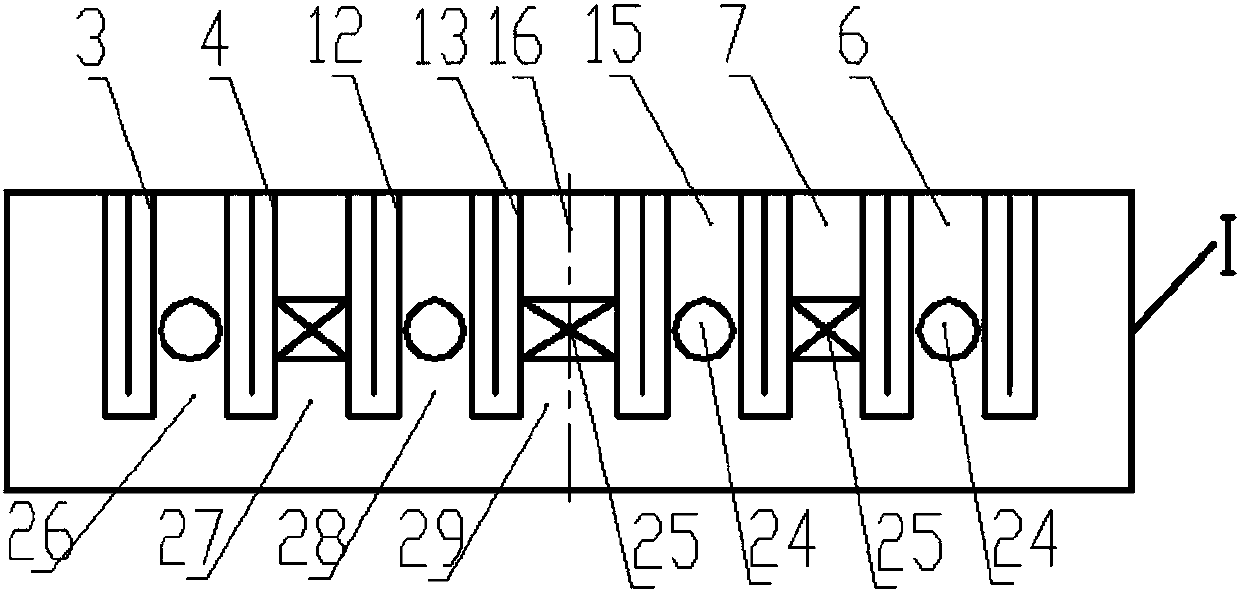

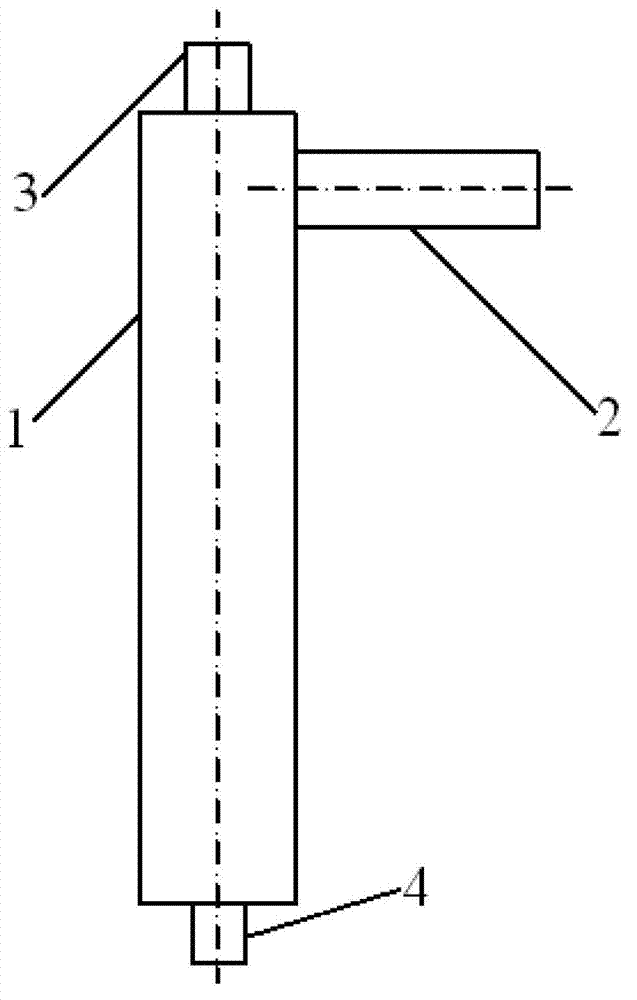

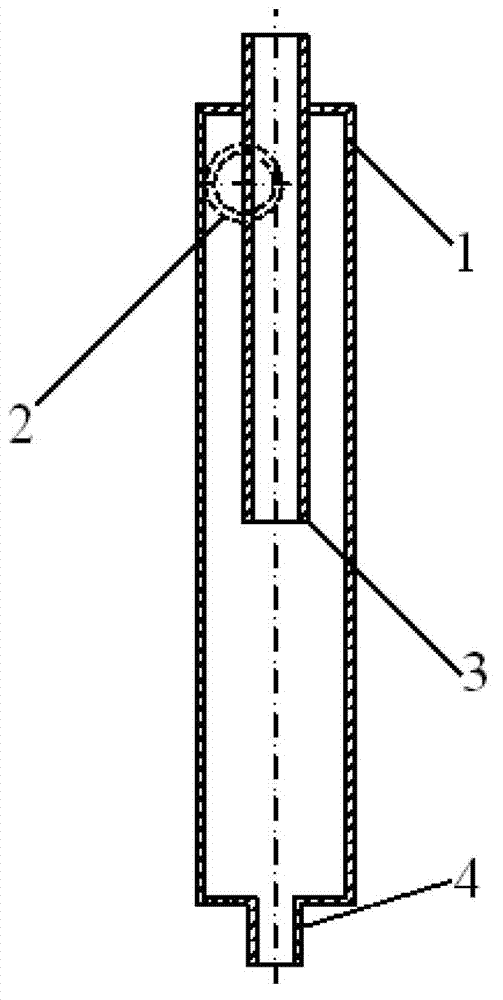

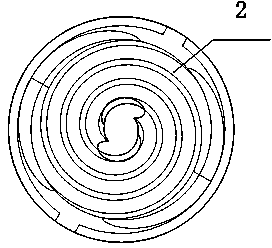

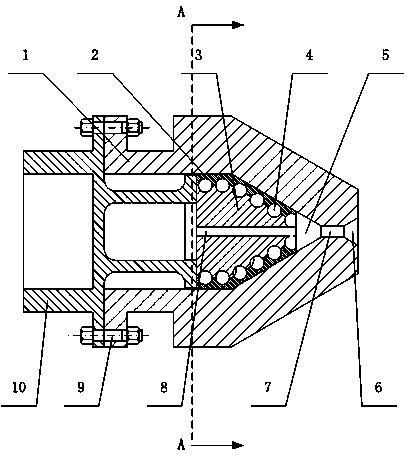

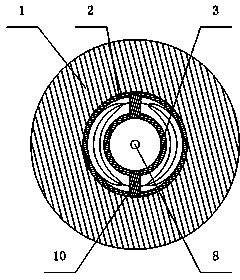

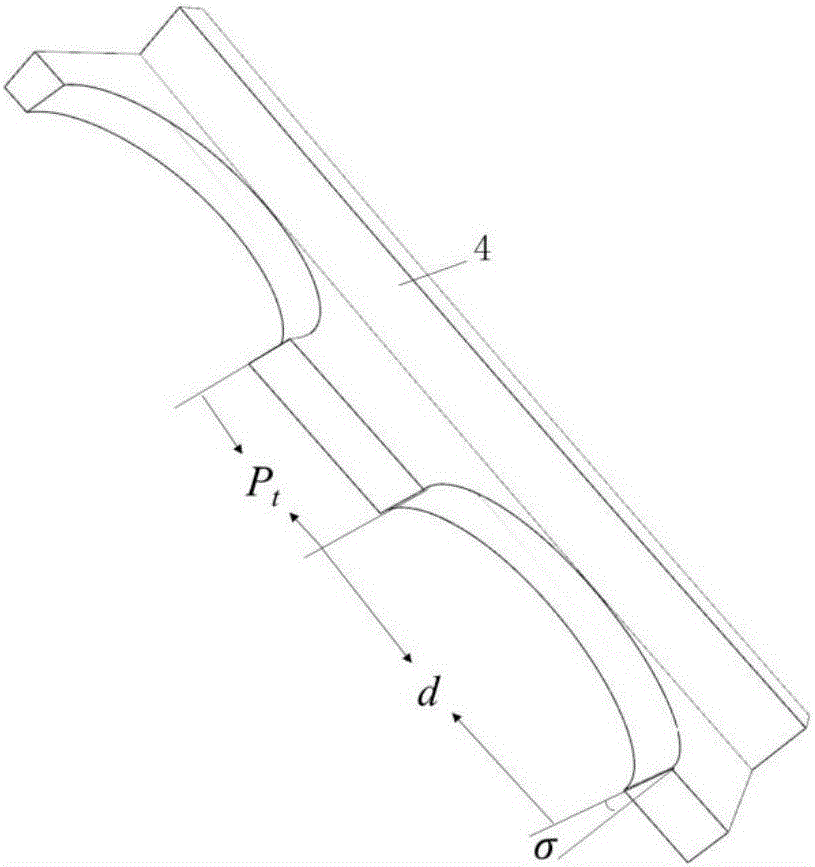

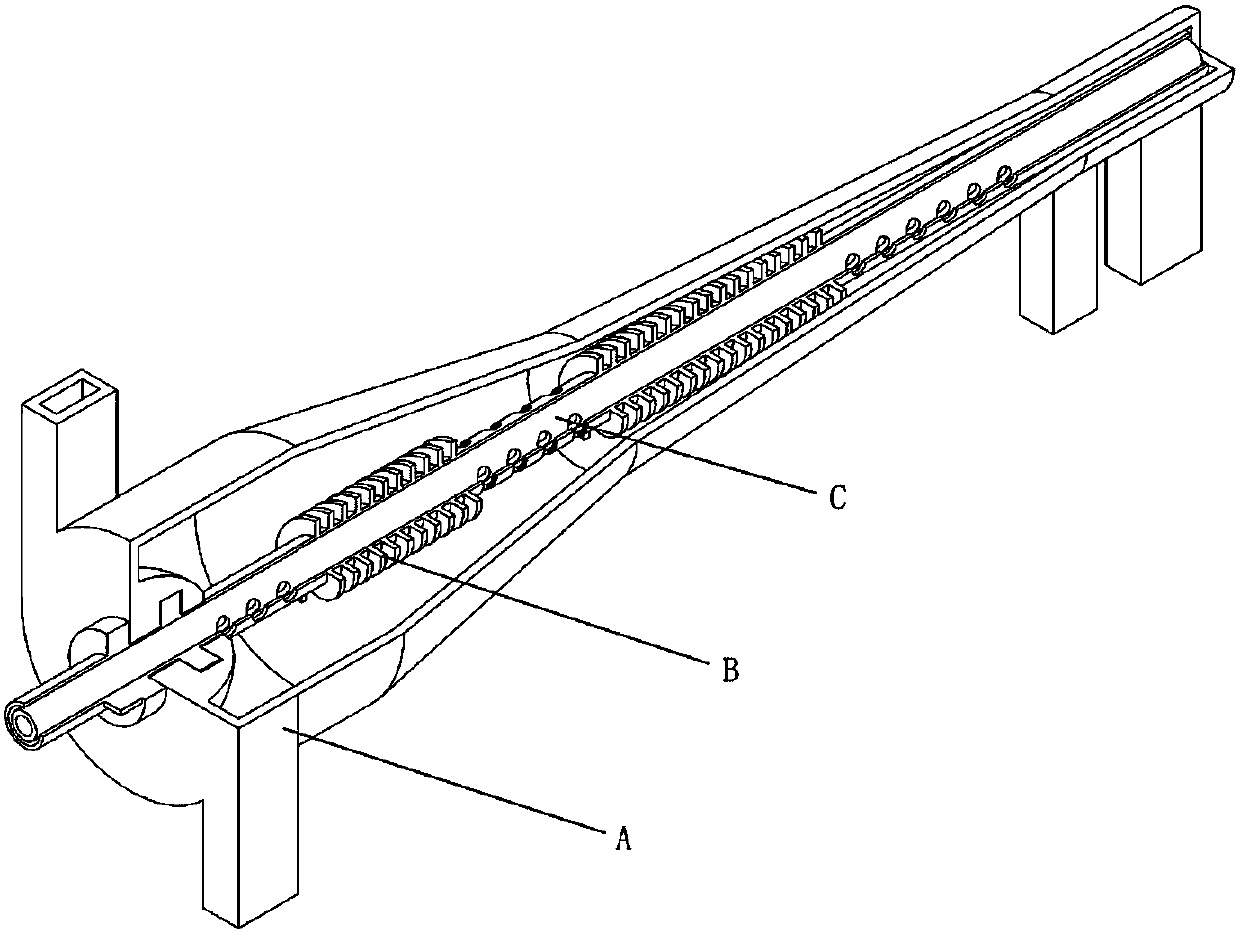

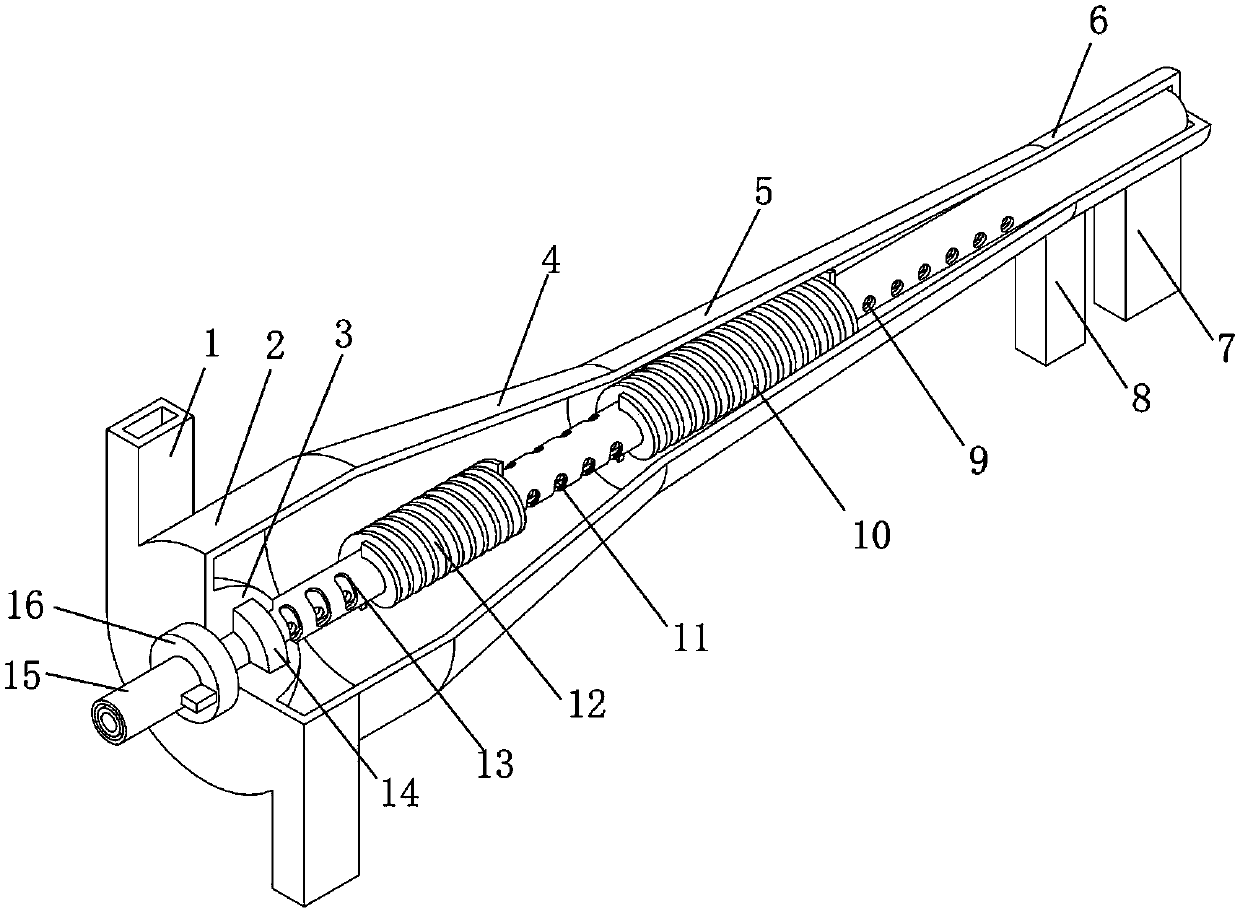

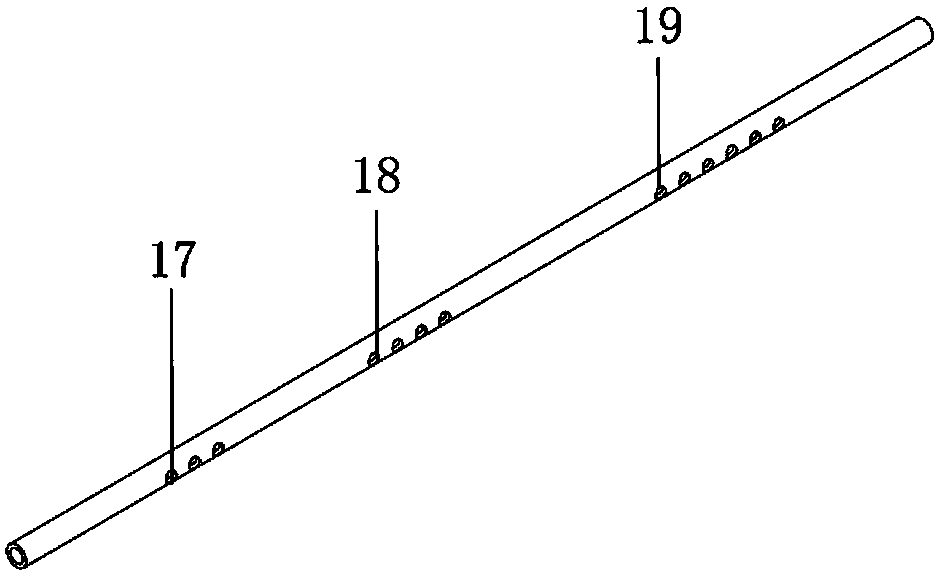

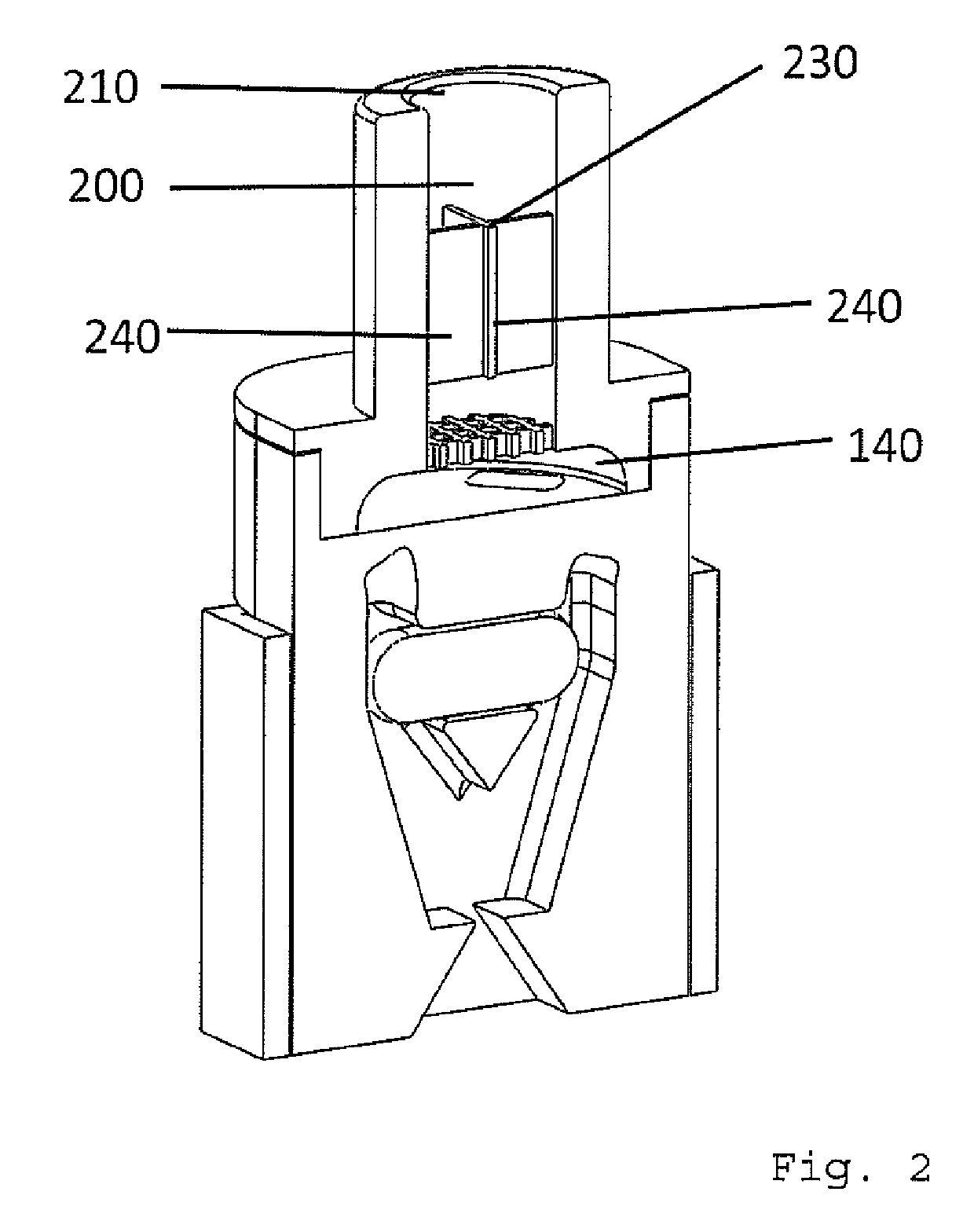

Direct-through double-helix convergent type water pressure atomizing spray nozzle

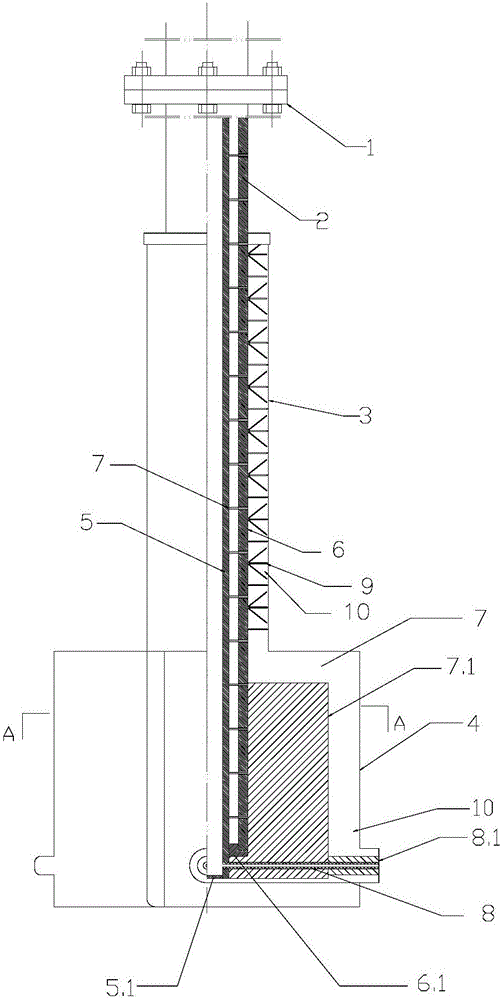

The invention discloses a direct-through double-helix convergent type water pressure atomizing spray nozzle. The direct-through double-helix convergent type water pressure atomizing spray nozzle comprises a spray nozzle body (1), wherein an inner spiral pushing rod (3) and an outer spiral pushing rod (2) are arranged in the spray nozzle body (1); a spray nozzle ejector rod (10) is further connected with a water inlet of the spray nozzle body (1); the inner spiral pushing rod (3) and the outer spiral pushing rod (2) are coaxially and fixedly connected with each other; a spiral groove in the outer surface of the inner spiral pushing rod (3) is matched with a spiral groove in the inner surface of the outer spiral pushing rod (2) to form a complete round-mouth spiral convergent water path (4); the outer surface of the outer spiral pushing rod (2) is in seamless fitting with the inner surface of the spray nozzle body (1); the bottom surface of the cone part of the outer spiral pushing rod (2) and the bottom surface of the cone part of the inner surface of the spray nozzle body (1) are on the same plane. The direct-through double-helix convergent type water pressure atomizing spray nozzle disclosed by the invention has the advantages of being small in size, light in weight, simple in structure and simple to install. Water at the outlet flows quickly and has very high tangential speed, so that an atomizing range and atomizing capacity are easy to increase. The direct-through double-helix convergent type water pressure atomizing spray nozzle disclosed by the invention can be applicable to a fire extinguishing apparatus carried in front of a water-pressure self-servo snakelike fire-extinguishing and disaster-relief robot.

Owner:WUHAN UNIV OF SCI & TECH

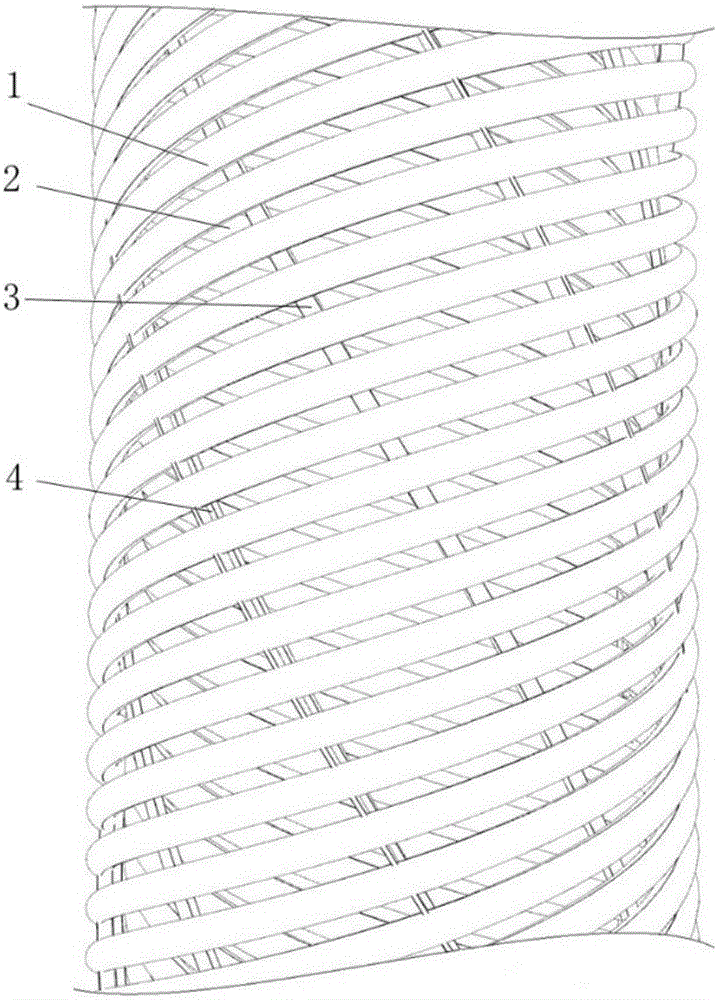

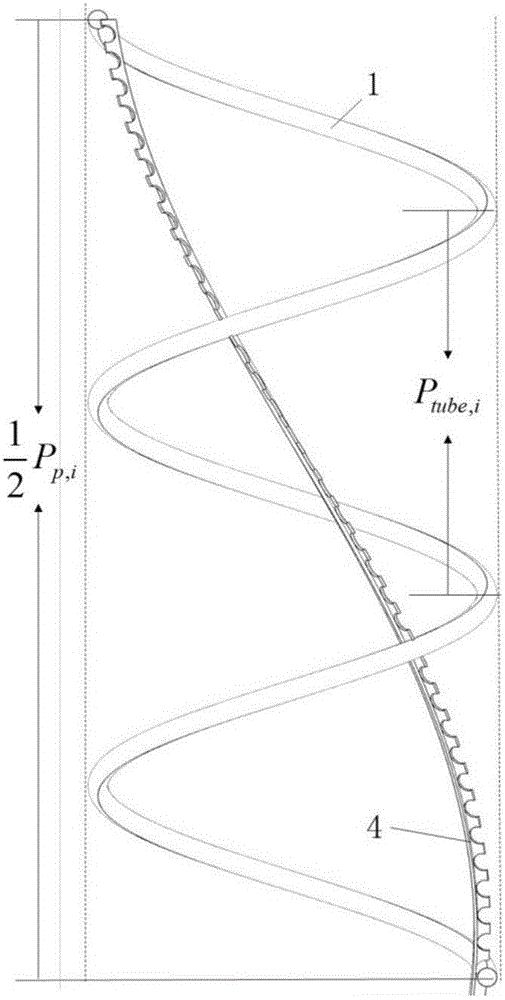

Spiral filler strip type winding pipe heat exchanger

ActiveCN105928392AAvoid vibrationImprove structural strengthStationary tubular conduit assembliesHeat transfer modificationEngineeringConductor Coil

A spiral filler strip type winding pipe heat exchanger comprises spiral flat filler strips and spiral special-shaped filler strips. Flow channels formed between layers of heat exchange tubes and flow channels formed between the spiral filler strips should be perpendicular to the layer of heat exchange tubes in the mounting process. According to the mounting mode of the spiral winding pipe heat exchanger, as for the ith layer, after the winding pitch and the inclination angle of locating slots of the ith layer of spiral flat filler strips and the winding pitch and the inclination angle of locating slots of the ith layer of spiral special-shaped filler strips are calculated, the number of required spiral flat filler strips of the ith layer and the number of required spiral special-shaped filler strips of the ith layer are selected; one faces of the spiral flat filler strips of the ith layer are attached to the upper surface of heat exchange tubes of the (i-1)th layer and are evenly distributed and mounted in the circumferential direction; after completion of mounting, the ith layer of heat exchange tubes are mounted in a reverse spiral mode, and mounting is carried out repeatedly in this way until the outermost layer is mounted. The spiral filler strip type winding pipe heat exchanger is good in heat transfer performance and small in resistance drop.

Owner:XI AN JIAOTONG UNIV

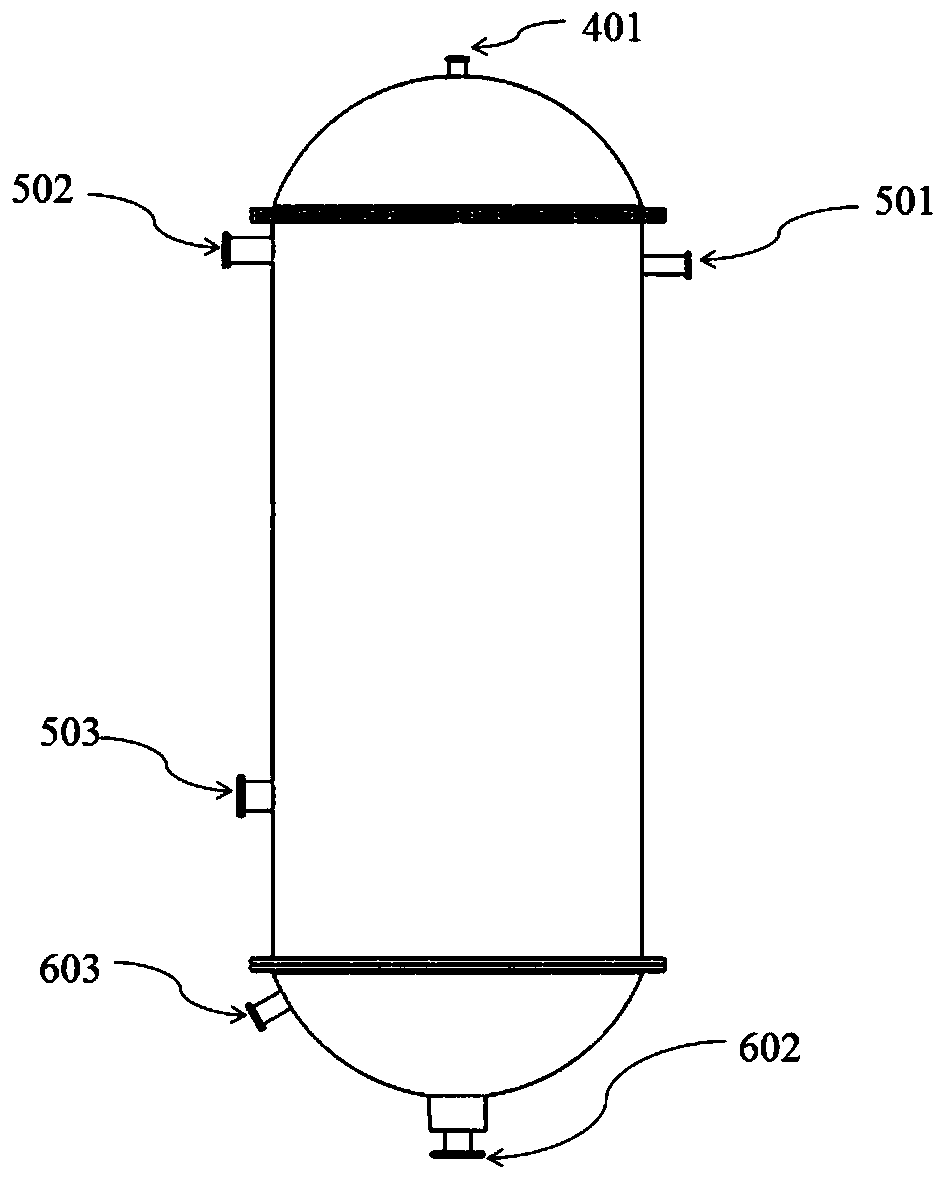

Pulsation swirler with internally arranged screw rod

ActiveCN107824346AEasy to separateReduce radial rangeReversed direction vortexEngineeringVolumetric Mass Density

Provided is a pulsation swirler with an internally arranged screw rod. The main purpose is to provide swirling separation equipment which is high in separation efficiency, small in equipment size andconvenient to operate and maintain. The pulsation swirler is characterized in that the interrupted screw rod is arranged in the center of a cyclone separator, the interrupted screw rod is of a hollowstructure and is composed of spiral sections and open hole sections in an interval distribution manner, and the spiral rotation direction of the spiral sections is opposite to the rotational flow direction after liquid enters the swirler; a backwash round tube is nested in the interrupted screw rod, open hole sections on the backwash round tube correspond to those of the interrupted screw rod, a top end opening of a hollow part of the interrupted screw rod and the backwash round tube is connected with an overflow port of the swirler, the liquid can enter the internal hollow part through the open hole sections of the screw rod and the backwash round tube, moves upwards and is discharged from the swirler through the overflow port. The swirler can effectively solve the technical problems of small density differences of two-phase media, high viscosity of separation media, low separation accuracy and the like.

Owner:NORTHEAST GASOLINEEUM UNIV

Rotary blowing desulphurization spray gun applicable to molten iron jars of various dimensions or various desulfurizing agents

The invention discloses a rotary blowing desulphurization spray gun applicable to molten iron jars of various dimensions or various desulfurizing agents. The rotary blowing desulphurization spray gun comprises a connecting flange, a connecting section spray gun body, a gun body section spray gun body and a spray gun section; a plurality of rotating blades are arranged on a main pipe of the spray gun section and the outer wall of a reinforced pipe; each rotating blade comprises a blade metal core; a plurality of inner insertion type spraying pipes are arranged on the side wall of the bottom of the main pipe symmetrically; each inner insertion type spray pipe penetrates through the corresponding blade metal core; a graphite sleeve is arranged on the outer wall of each inner insertion type spray pipe of the corresponding blade metal core. By means of the spray gun, in the blowing desulfurization process, the ascent time of the desulfurizing agents is prolonged, and the ratio of bubbles which are penetrated through is increased substantially, the mixing time of a molten pool is shortened remarkably, the desulphurization dynamics conditions of a desulphurization reaction are improved remarkably, the undulation of the liquid level of molten iron is reduced, and therefore the spray gun can be used for blowing desulphurization of the various desulfurizing agents and the molten iron jars of various dimensions.

Owner:武汉钢铁有限公司

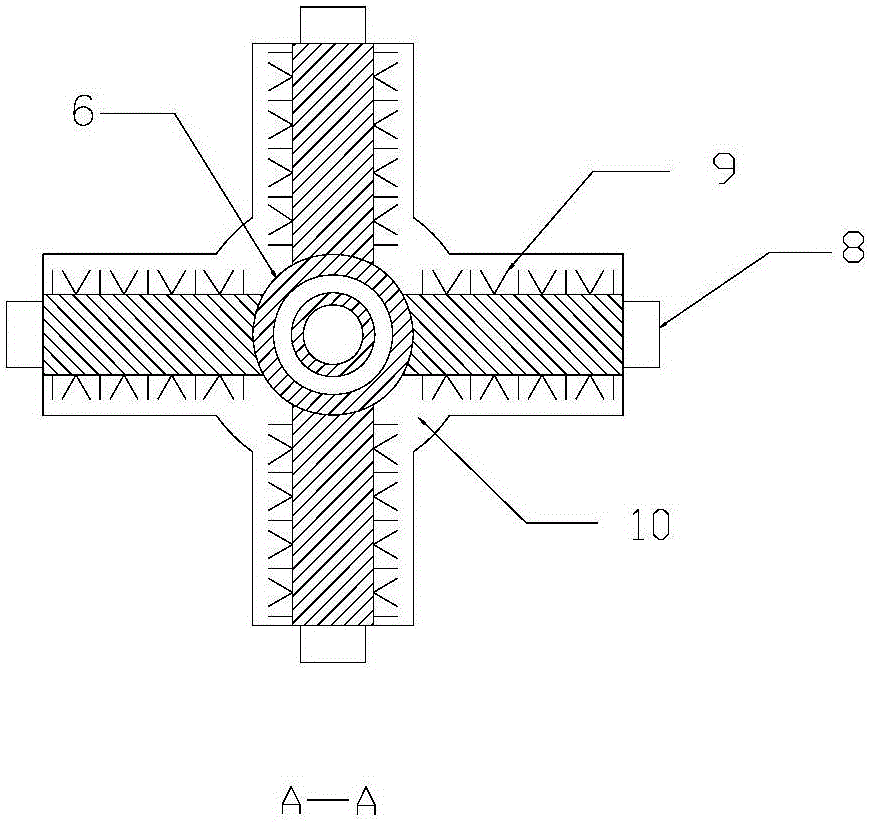

Integrated gas-liquid-solid continuous separation device

InactiveCN111318058AMaintain precision separation performanceSimple processLiquid degasificationCentrifugal force sediment separationPhysical chemistryOil water

The invention discloses an integrated gas-liquid-solid continuous separation device. The device comprises an upper sealing cover, an outer cylinder and a lower sealing cover, and the upper sealing cover, the outer cylinder and the lower sealing cover are connected into a whole through flanges. An upper layer, a middle layer and a lower layer are formed in an inner cavity of the outer cylinder, theupper layer is used for storing oil and gas after primary separation, the middle layer is used for storing oil after secondary separation, the lower layer is used for storing sand and water which arefinally separated, and all the layers are separated through perforated sieve plates and oil absorption felts. Mixed incoming liquid is accelerated to enter a cyclone for primary separation through atangential inlet and a spiral pipe type acceleration flow channel, and then is subjected to secondary separation by oleophylic and hydrophobic oil absorption felts, and continuous separation of a multiphase medium is realized. Multi-stage continuous separation is realized based on the combined action of cyclone separation, settling separation and membrane separation, and high-precision continuousseparation of oil-water-sand-gas four-phase media can be achieved in one device.

Owner:NORTHEAST GASOLINEEUM UNIV

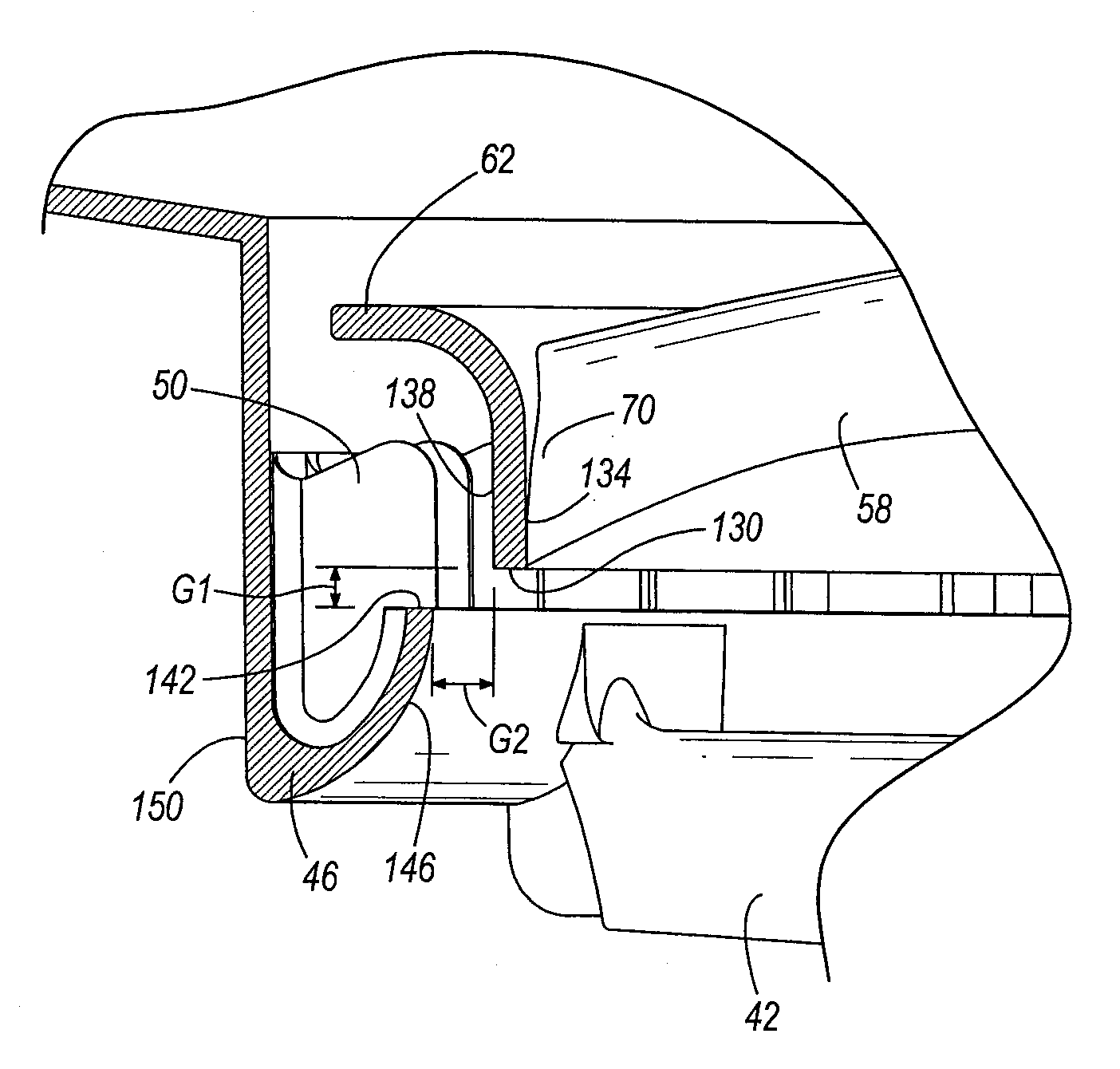

Swirl-enhanced aerodynamic fastener shield for turbomachine

ActiveUS20060056957A1Minimize temperature riseAerodynamic effectEngine sealsPump componentsTurbineEngine mount

A fastener shield for use in a fluid flow path within a gas turbine engine for reducing fluid drag and heating generated by fluid flow over a plurality of circumferentially spaced bolts. The fastener shield has a radially-extending, downstream-facing mounting flange with a plurality of circumferentially spaced bolt holes positioned to receive respective engine mounting bolts therethrough and to attach the mounting flange to elements of the turbine engine. A curved, upstream-facing fastener shield cover is positioned in spaced-apart relation to the mounting flange for at least partially covering and separating an exposed, upstream-facing portion of the bolts from the fluid flow to thereby reduce drag and consequent heating of the bolts. A plurality of closely spaced-apart, spirally-oriented channels are formed in the fastener shield cover for deflecting the fluid flow impinging on the fastener shield cover, thereby increasing the tangential velocity and lowering the relative temperature of the fluid flow.

Owner:GENERAL ELECTRIC CO

Dry powder inhaler

ActiveUS10456535B2Smooth transitionEfficient decompositionMedical devicesMedical atomisersInhalationBiomedical engineering

The present invention relates to an inhaler device for delivering a dose of medicament in dry powder form from a container to a patient in need thereof. The inhaler comprises a swirl chamber in which particles of the medicament entrained in an airflow swirl upon inhalation thereby breaking up the agglomerates into finest dispersed powder.

Owner:PRESSPART MFG

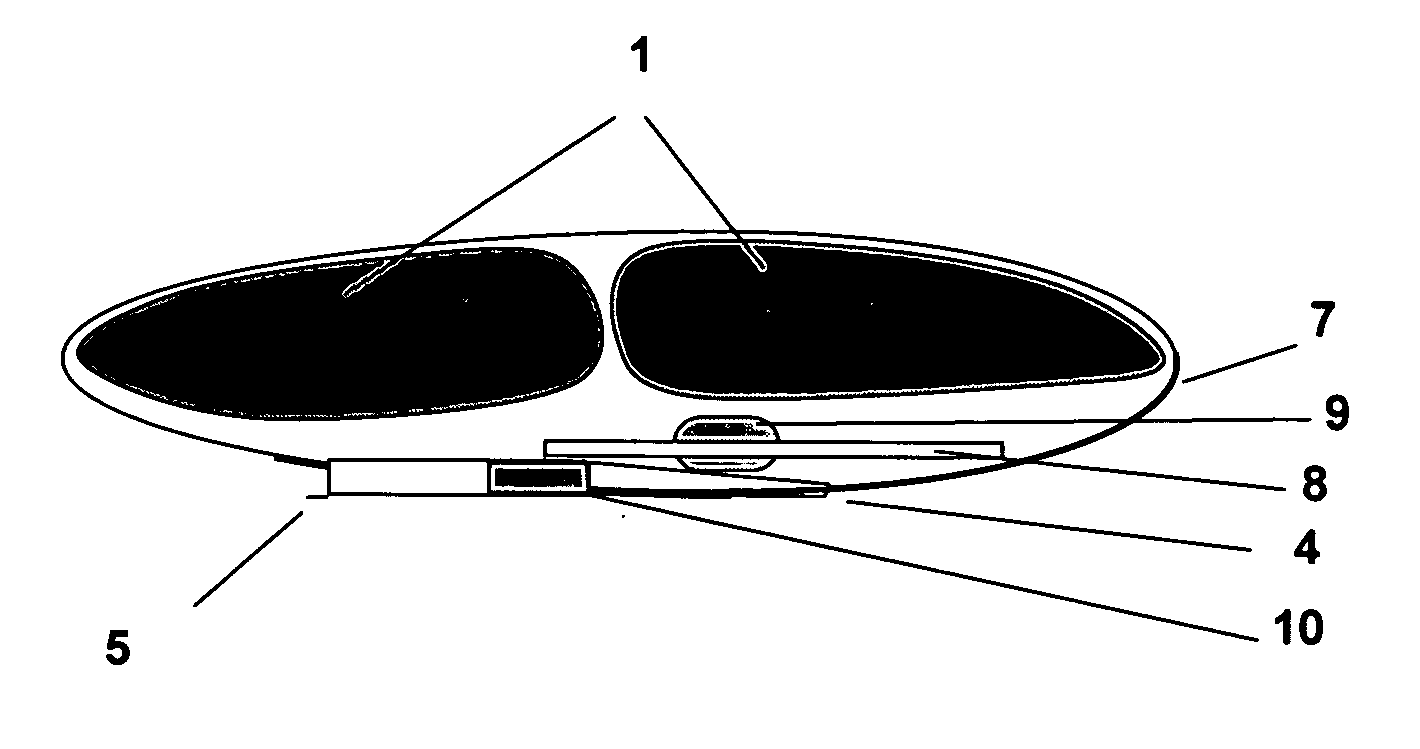

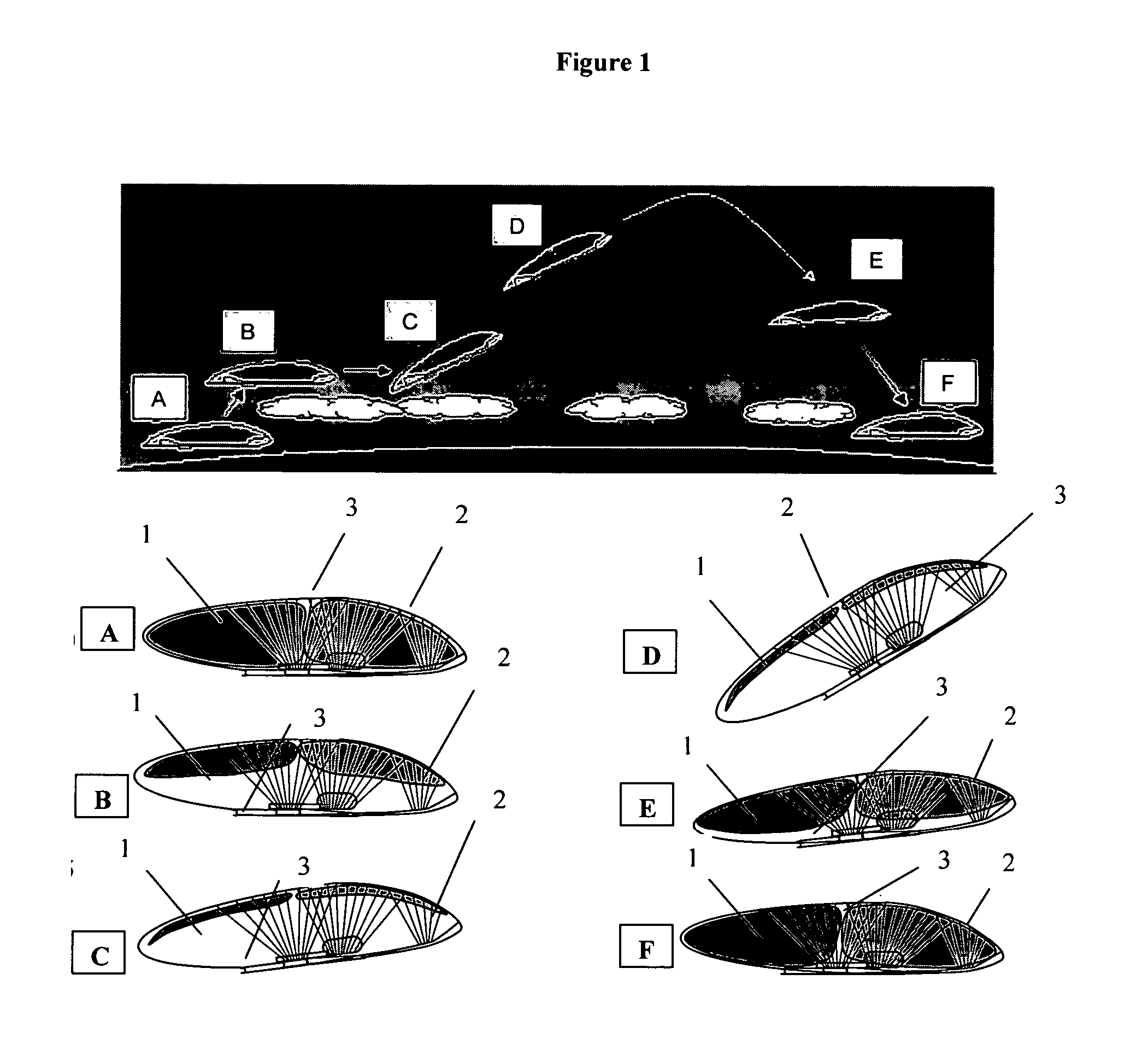

Flight/launch vehicle and method using internally stored air for air-breathing engines

InactiveUS20070205330A1Unlimited scale-up capacityIncreased safety marginLaunch systemsCosmonautic propulsion system apparatusJet aeroplaneMature technology

An airship is disclosed that stores air and uses it in a propulsion system that requires oxygen. This allows the airship to travel above the atmosphere, where oxygen is not available. The airship maximizes known mature technologies such as the buoyancy of a lighter than air balloon and the aerodynamic lift and propulsion of an airplane, until the altitude renders these technologies ineffective. The modified airship uses the stored air to extend transportation operations above natural limits and permit high-speed travel beyond traditional atmospheric speeds. Entering the edge of space at high tangential velocity permits placement of payloads into orbit. Entering the edge of space at low tangential velocity presents opportunities for low energy plane changes in orbital inclination. The modified airship may also alter the aerodynamic shape as desired in flight. The airship takes off, leaves and re-enters the atmosphere and lands without specialized launch facilities or long landing strips. The reusable vehicle provides transportation services from point to point on the earth surface and from the earth to points in space.

Owner:HUBBARD AEROSPACE

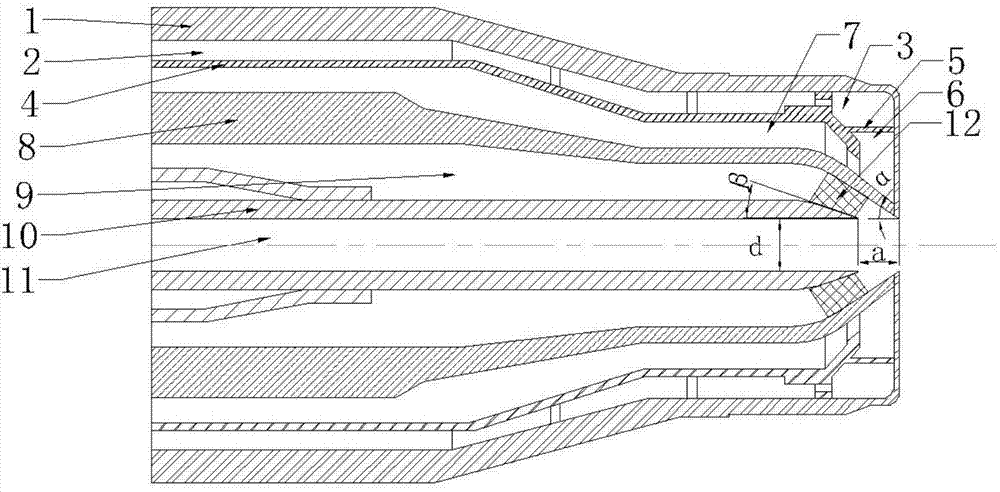

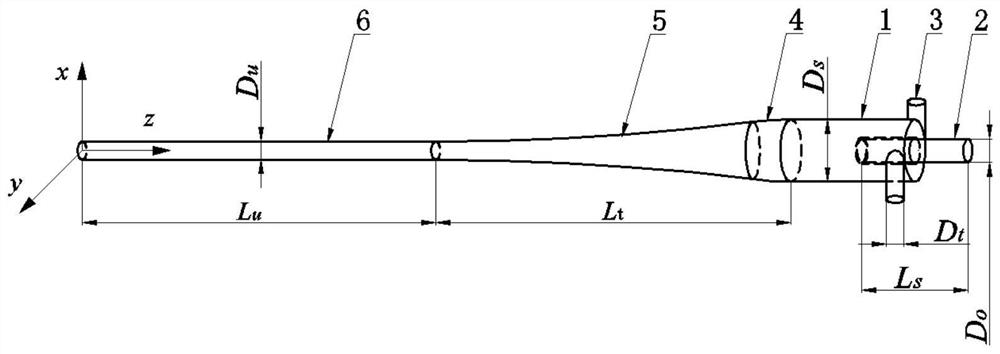

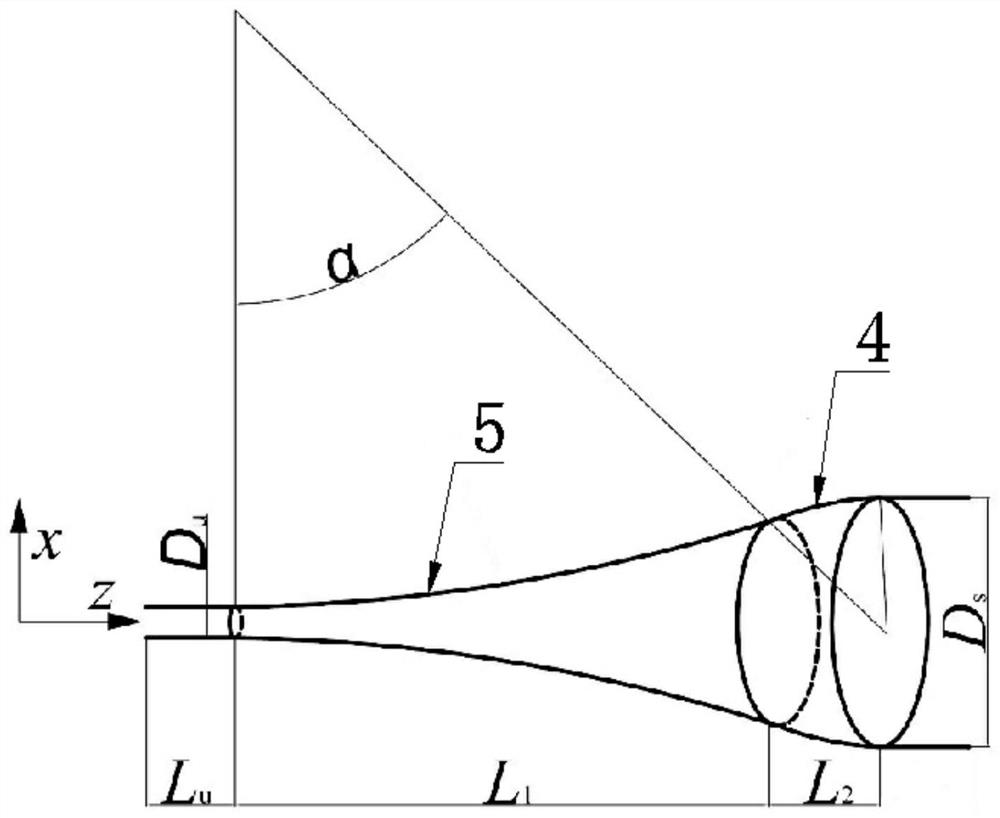

Heat transfer tube and cracking furnace using the same

ActiveUS20150114609A1Increase tangential speedImprove heat transfer performanceThermal non-catalytic crackingFluid dynamicsEngineeringHeat transfer tube

The present disclosure relates to a heat transfer tube and a racking furnace using the heat transfer tube. The heat transfer tube comprises a twisted baffle arranged in an inner wall of the tube, said twisted baffle extending spirally along an axial direction of the heat transfer tube. The twisted baffle is provided with a non-through gap extending along an axial direction of the heat transfer tube from an end to the other end of the twisted baffle. The heat transfer tube and cracking furnace according to the present disclosure have good heat transfer effects and small pressure loss.

Owner:CHINA PETROCHEMICAL CORP +1

Vacuum cleaner utilizing cyclone tube for separation

InactiveCN108324177AEfficient separationEfficient replacementSuction filtersEngineeringCentrifugal force

The invention discloses a vacuum cleaner utilizing a cyclone tube for separation. The cyclone tube in the vacuum cleaner has a blade structure, so that bypassing air is enabled to rotate at a high speed to give a radial speed and a tangential speed to solid pollutants in the air; the solid pollutants are discharged through a dust discharging port of the cyclone tube under action of inertial centrifugal force, so that separation efficiency is improved greatly.

Owner:航宇智创科技(北京)有限公司

Axial flow machine cooling system

ActiveUS9879603B2Increase tangential speedReduce frictional heatEngine fuctionsTurbine/propulsion engine coolingCombustorTurbine

This invention concerns a system for cooling components in a gas turbine engine, the gas turbine engine including a compressor for driving a primary gas flow to a combustor and a turbine arranged to be driven by combustion gases from the combustor, wherein the system includes: an annular cooling flow passage arranged for fluid communication between the compressor and the turbine, the flow passage having a first inlet arranged to receive gas from the primary gas flow downstream of compressor, and a second inlet located upstream of the first inlet, wherein the annular cooling flow passage has at least one internal wall for guiding airflow from the first inlet towards the airflow from the second inlet, the airflow from the first and second inlets coalesce within the annular flow passage prior to passing along the passage in a direction from the compressor to the turbine.

Owner:ROLLS ROYCE PLC

Separating cyclone and method for separating a mixture

InactiveUS7066987B2Improved propertyEasy to separateCombination devicesLiquid degasificationCycloneHigh density

A separating cyclone for at least partially separating a mixture of fluids of different density into a light fraction with a relatively low density and a heavy fraction with a relatively high density, comprising a flow body in a flow space between the flow body and casing around the flow body wherein at least one bypass channel is provided in the distal part of the flow body, via which channels a part of the mixture flowing along the flow body in the flow space can be guided. Also, a method for separating the above stated mixtures.

Owner:FMC TECH CV

Demulsification, dehydration and separation method of emulsion

ActiveCN113182086AReduce turbulence intensityImprove coalescenceReversed direction vortexEmulsionAqueous droplet

The invention relates to a demulsification, dehydration and separation method for emulsion. A hydrocyclone comprises a rotational flow chamber and an underflow pipe, the closed end of the rotational flow chamber is connected with an inlet pipe and an overflow pipe, the inlet pipe is tangent to and communicates with the circumferential inner wall of the rotational flow chamber, the overflow pipe penetrates through the closed end of the rotational flow chamber in an insulated mode to communicate with the interior of the rotational flow chamber, the other end of the rotational flow chamber communicates with the underflow pipe through a smooth transition pipe section, and both the rotational flow chamber and the overflow pipe are conductive. The method comprises the following steps that firstly, the emulsion is pretreated; then the overflow pipe faces upwards and is electrically connected with the positive electrode of a high-voltage pulse power supply, the rotational flow chamber is grounded; and then the pretreated emulsion is continuously input into the rotational flow chamber from the inlet pipe. According to the hydrocyclone used in the demulsification and dehydration method, the smooth transition pipe section is adopted for transition between the rotational flow chamber and the underflow pipe, so that the turbulence intensity in the hydrocyclone is reduced, a flow field is promoted to be stable, under the action of an electric field, coalescence of water drops in the emulsion is facilitated, the particle size is increased, and therefore the separation effect and the separation efficiency are improved.

Owner:CHONGQING TECH & BUSINESS UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com