Patents

Literature

82results about How to "Extended wash range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

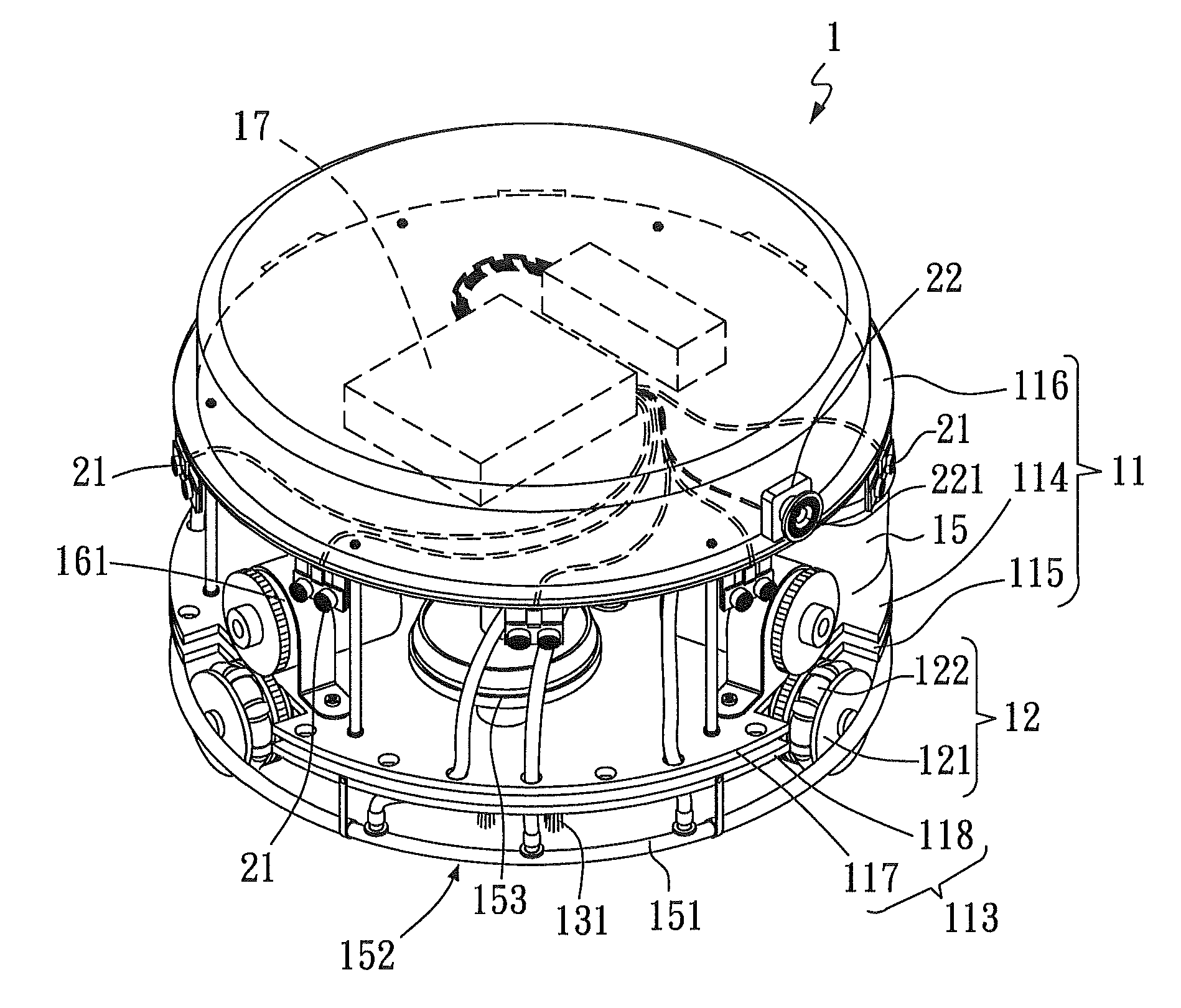

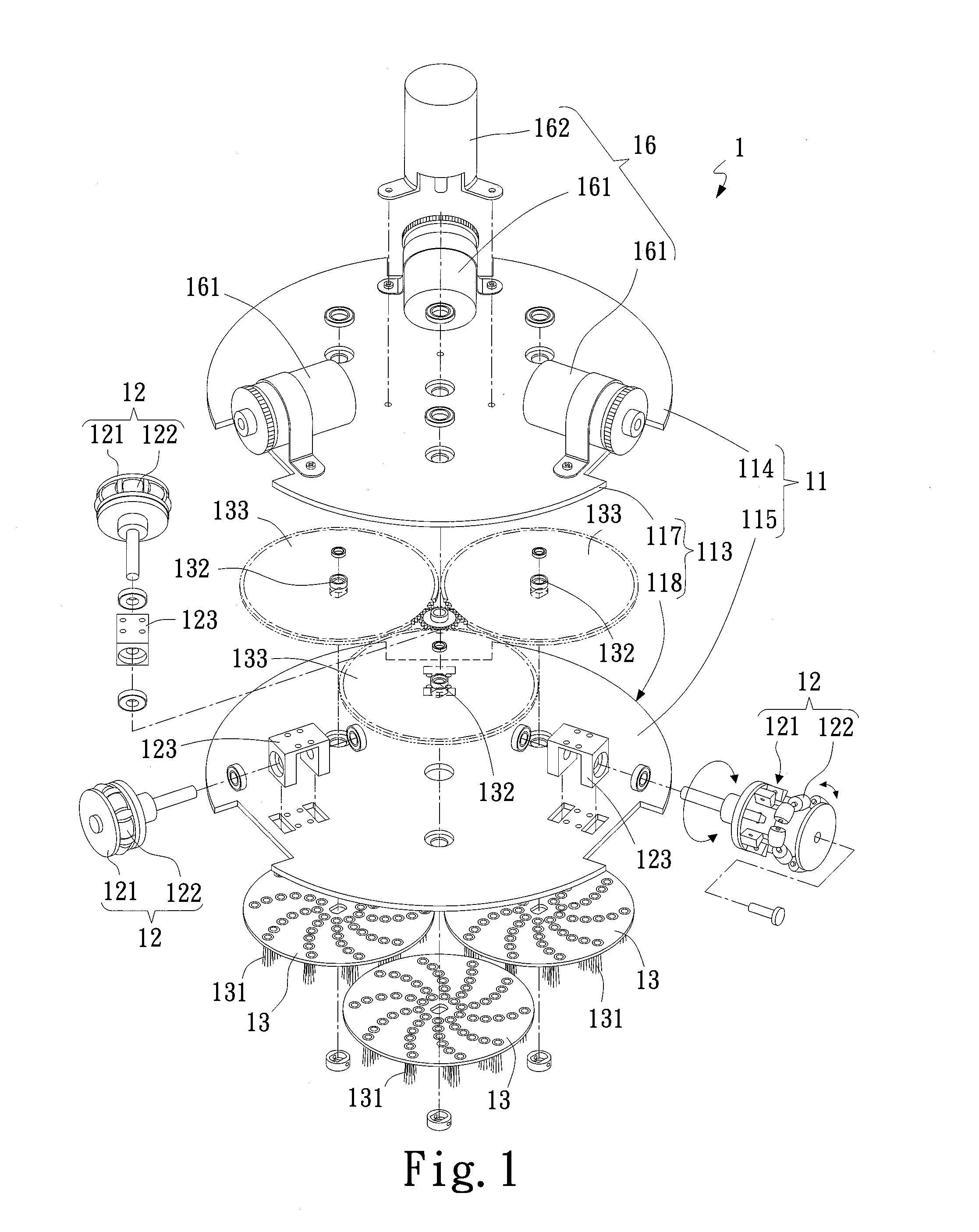

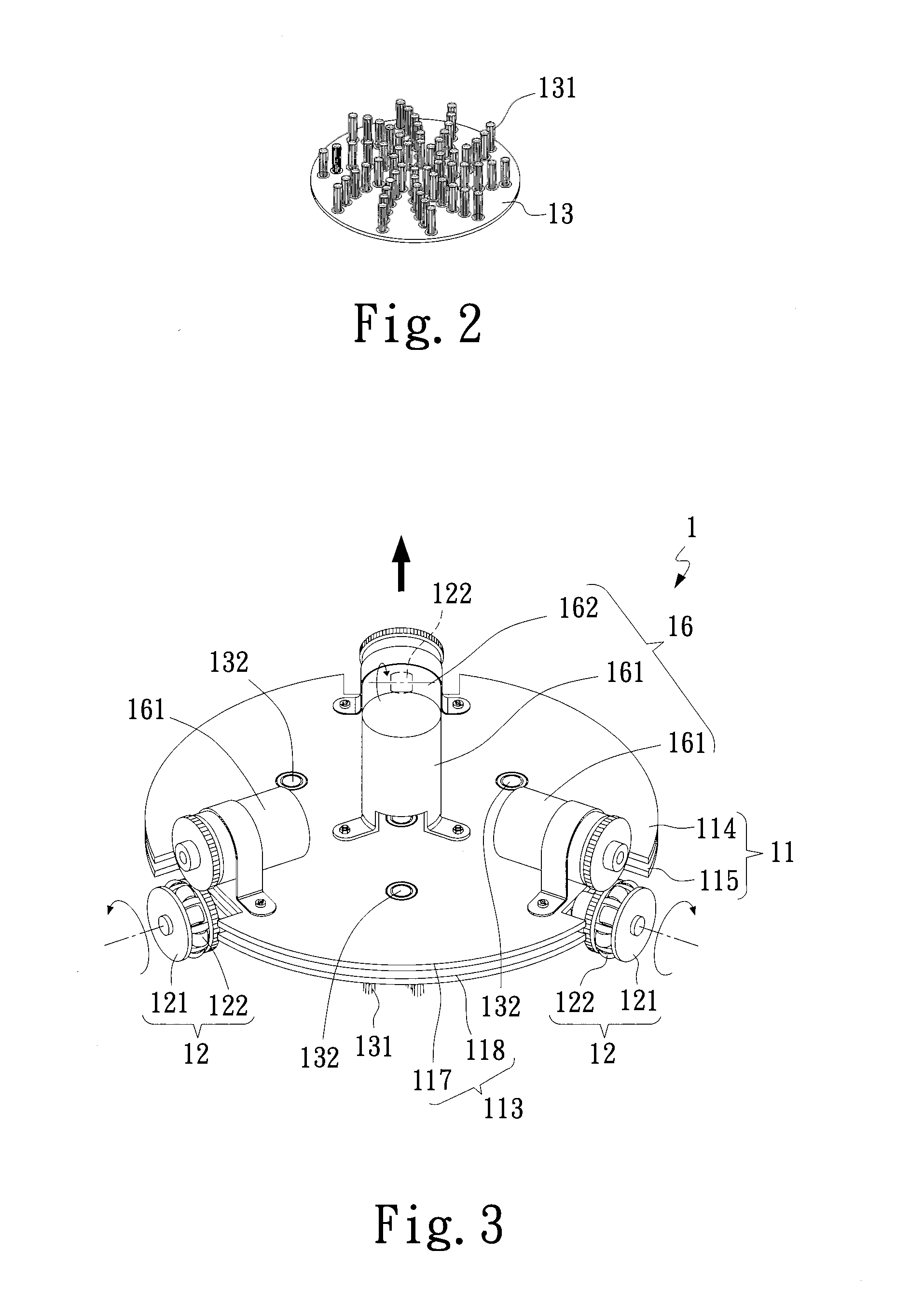

Floor washing robot

InactiveUS8001651B2Easy to cleanSimple structureCarpet cleanersFloor cleanersWater sprayMechanical engineering

A floor washing robot is disclosed. The robot includes: a control unit for controlling a power source to drive at least three omnidirectional wheels and at least one washing disc to rotate to wash a floor; a water spray device for spraying water; and a vacuum device for vacuuming waste water or dirt. The floor washing robot can be moved freely in any direction to improve the cleaning effect.

Owner:NAT TAIPEI UNIV OF TECH

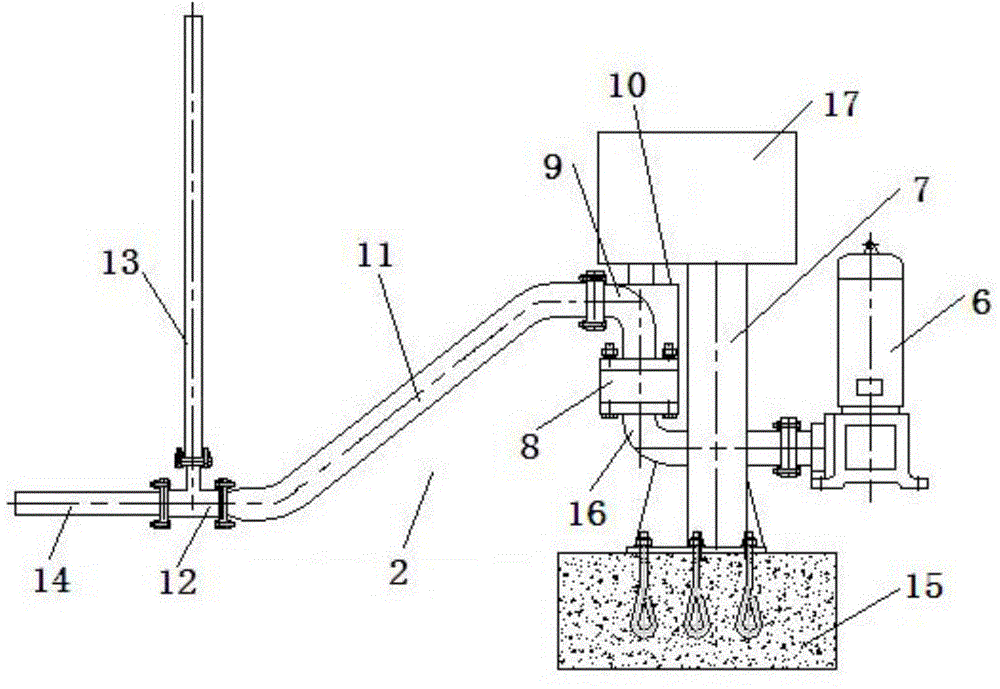

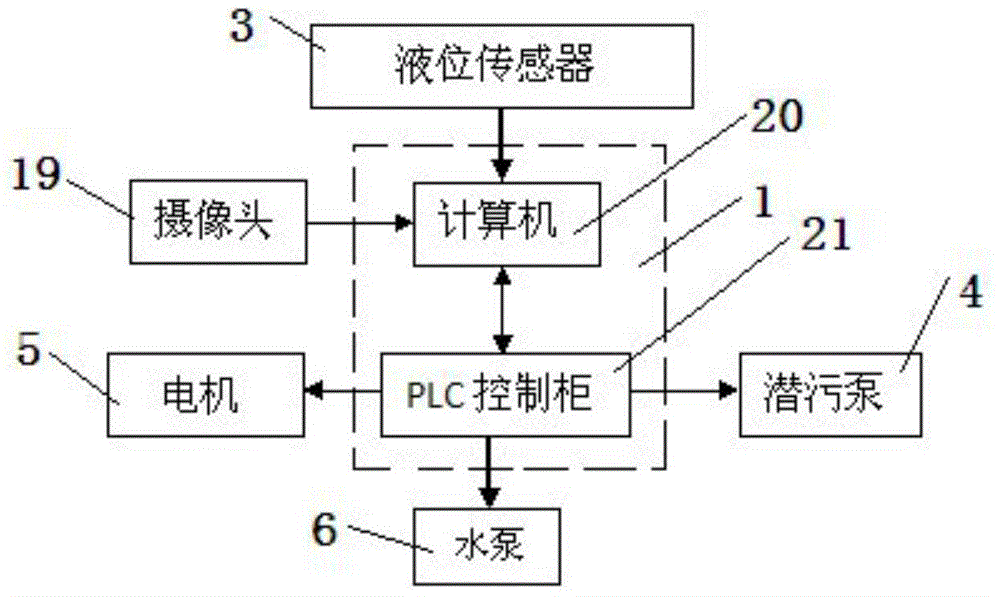

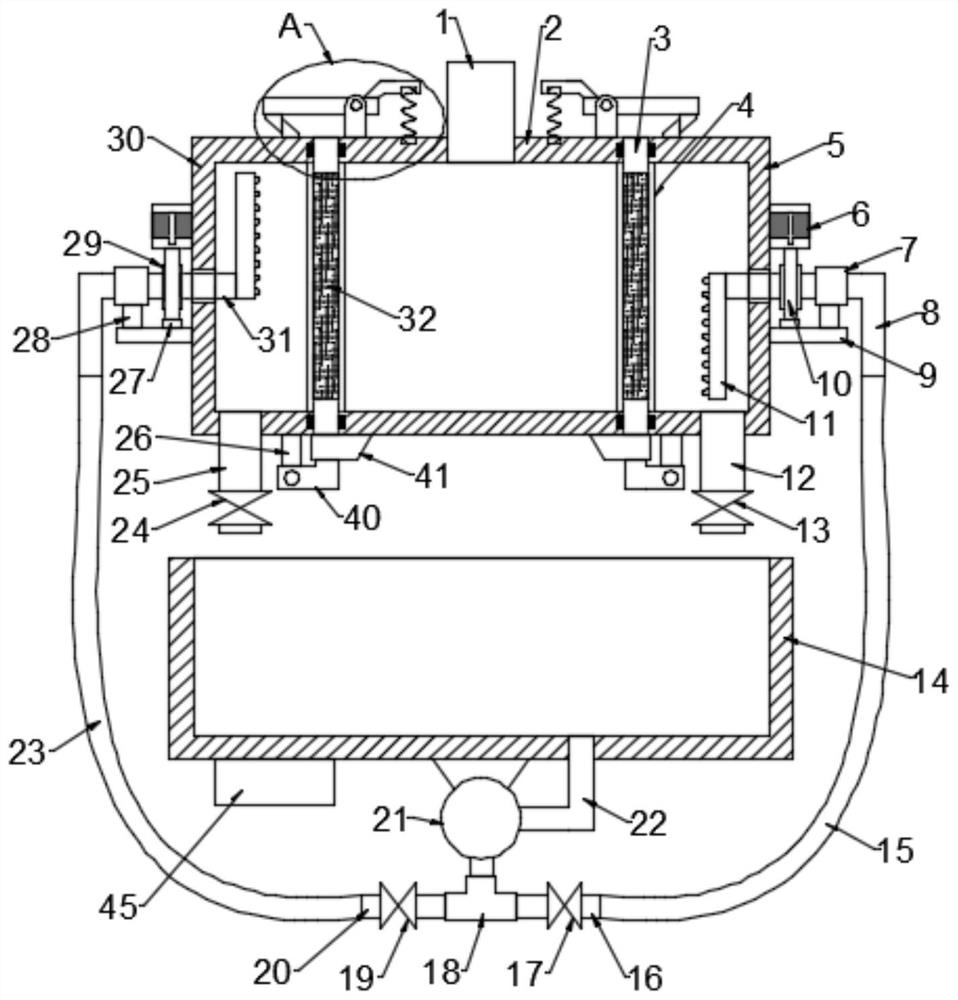

Intelligent water drawing jet flushing device and control method thereof

InactiveCN104912146AAvoid cloggingExtended wash rangeSewerage structuresSoil-shifting machines/dredgersElectricityAutomatic control

The invention relates to the technical field of water pumps, in particular to an intelligent water drawing jet flushing device for flushing a storage pond and a control method thereof. The intelligent water drawing jet flushing device comprises an automatic control system, a liquid level sensor, a flushing device body and a submersible sewage pump. The flushing device body comprises a water pump, a water outlet pipe assembly and a motor, the water pump is connected with the water outlet pipe assembly through a rotary connector capable of rotating along a horizontal plane, the water outlet pipe assembly is connected with a rotary shaft of the motor, the rotary shaft of the motor and the rotary center of the rotary connector are located on the same vertical line, and the liquid level sensor, the motor, the submersible sewage pump and the water pump are all electrically connected with the automatic control system. After the device is fixed to the bottom of the storage pond, a cleaning device can be automatically turned on and off according to the water level of the storage pond, the whole process does not needed to be manually controlled, rewiring is not needed, and convenience and labor saving are achieved.

Owner:WUHAN SHENGYU DRAINING SYST

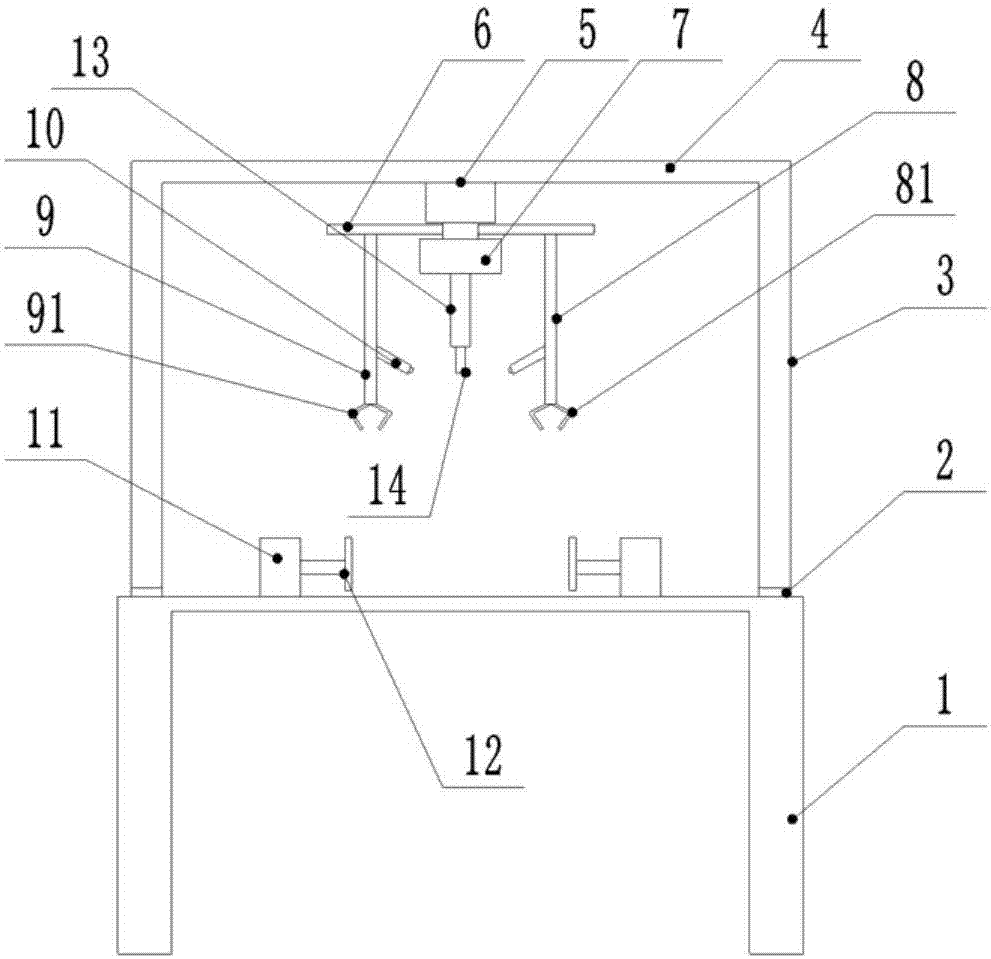

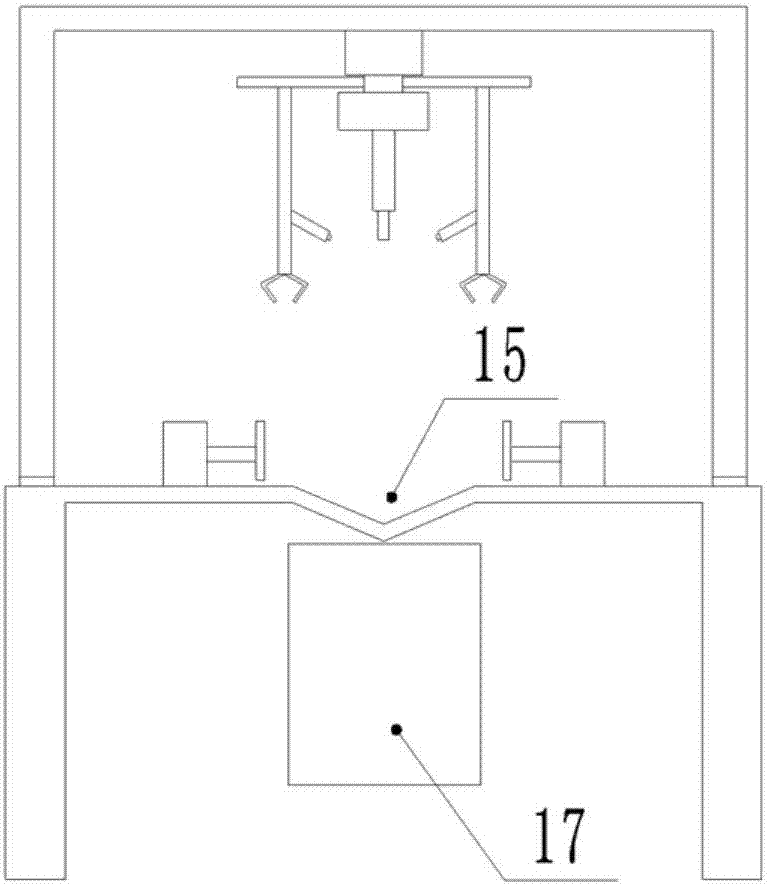

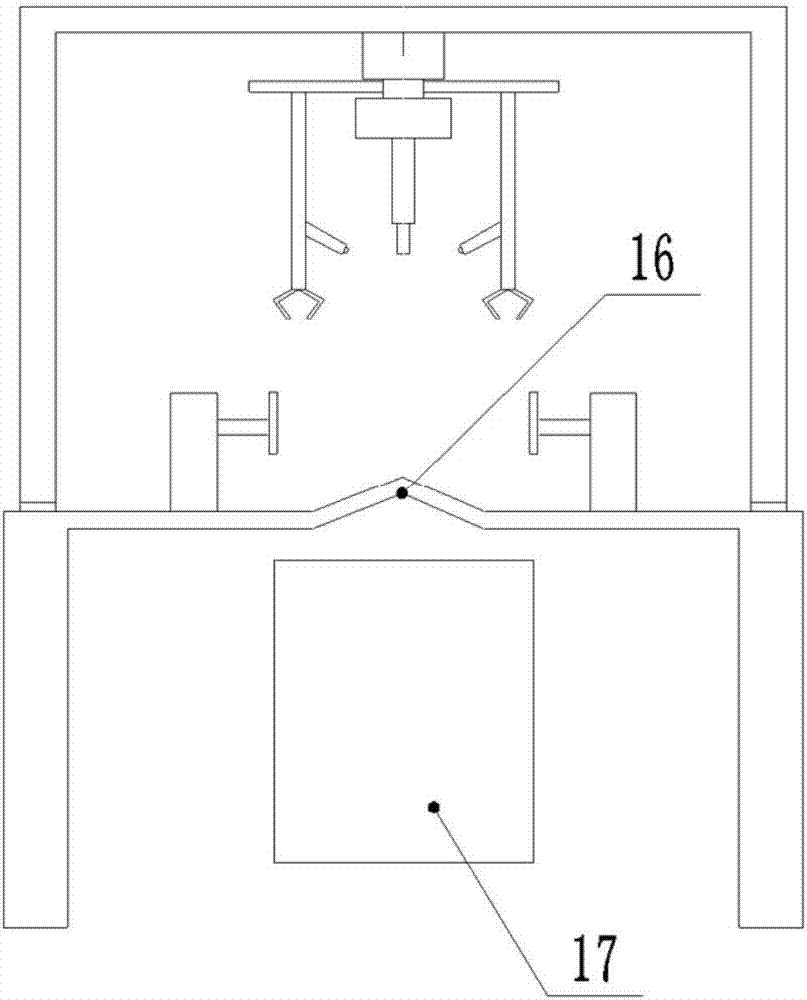

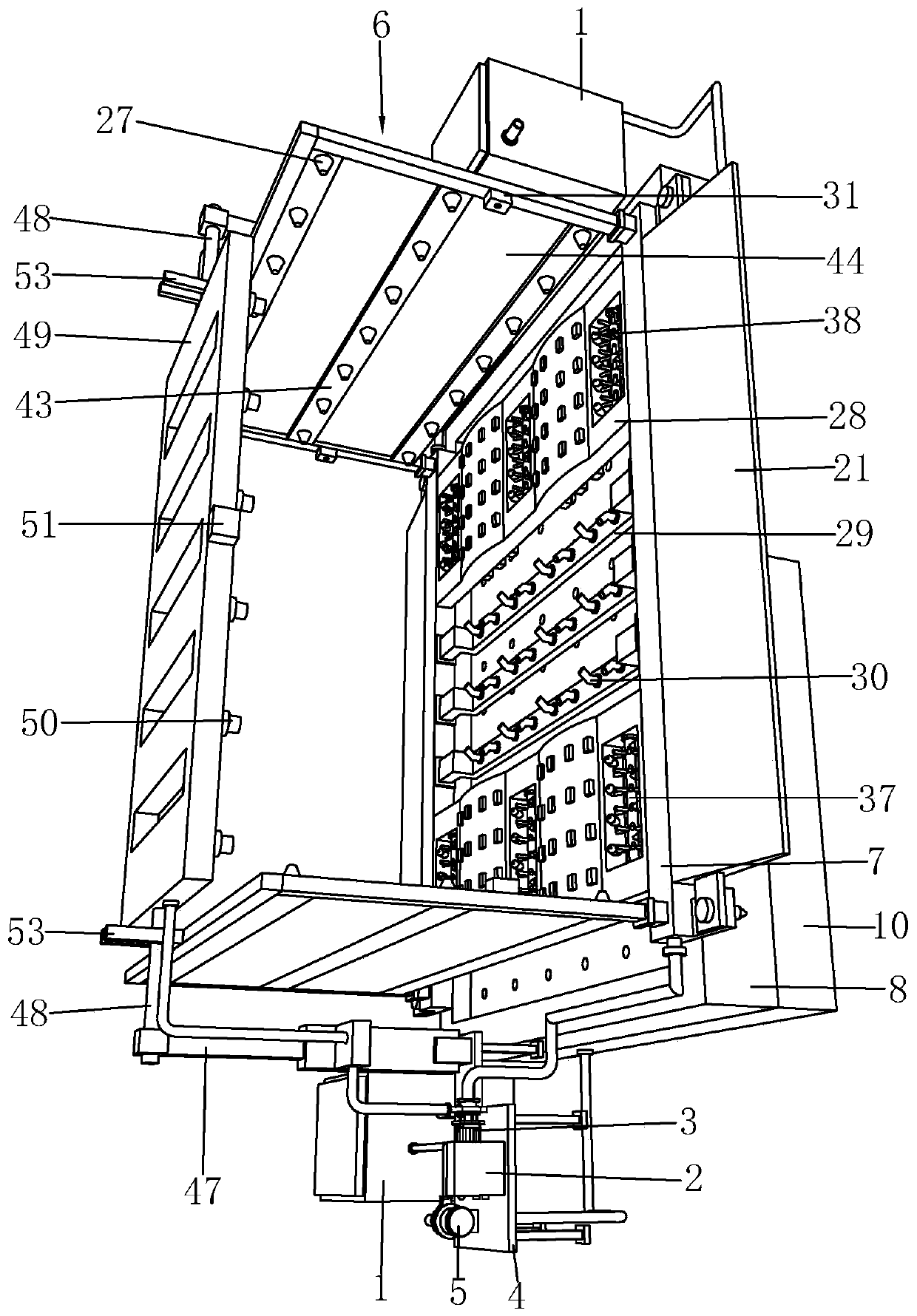

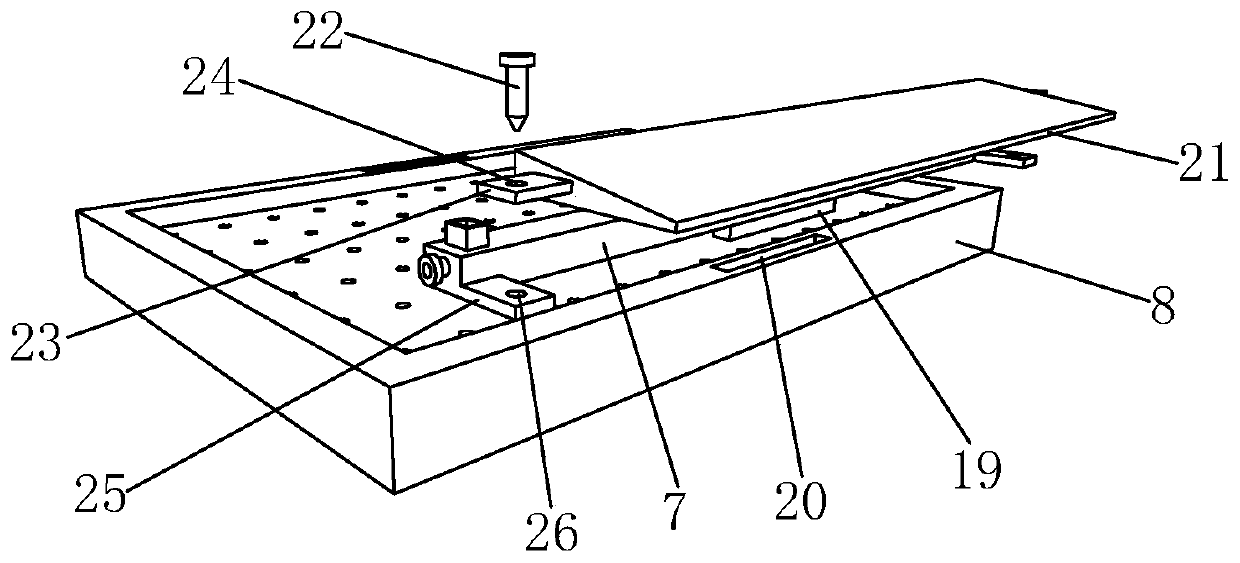

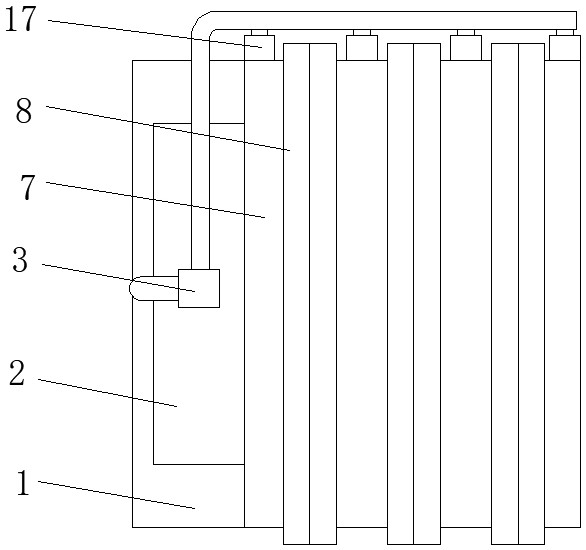

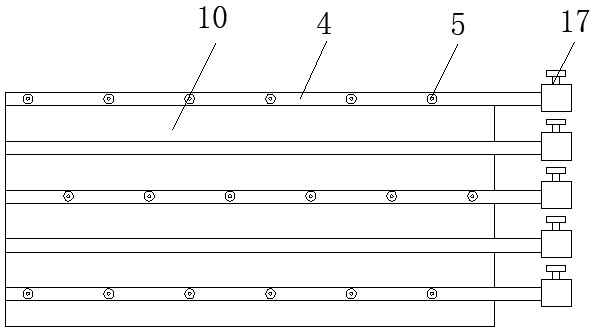

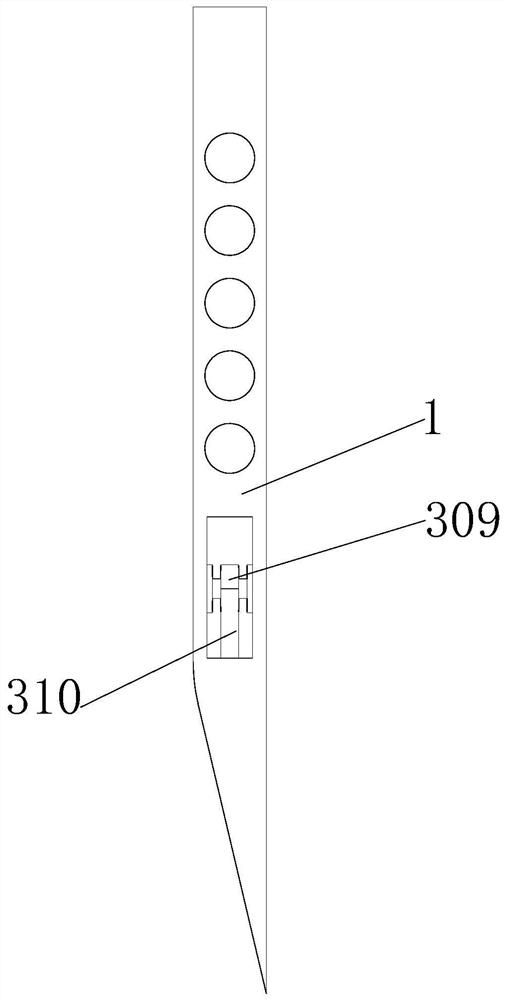

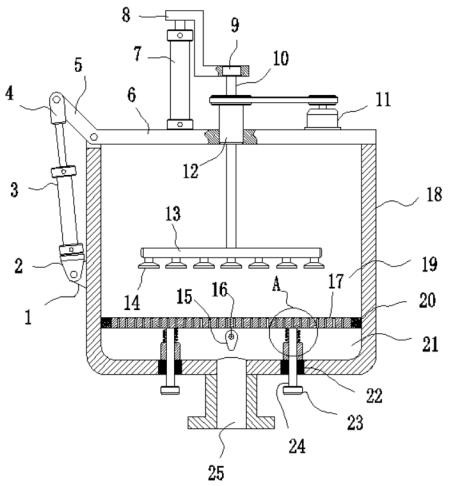

Machine part drilling device

InactiveCN107999805AEasy to clamp and fixEasy to rinseWork clamping meansMetal working apparatusMachine partsBiochemical engineering

The invention belongs to the technical field of drilling equipment, and particularly discloses a machine part drilling device. The device comprises a rack, a guide rail is arranged on the rack, a supporting frame is arranged on the guide rail in a sliding connection manner, a cross beam connected with a telescopic device is arranged on the supporting frame, a motor is arranged on the telescopic device, a drill bit is arranged at the output end of the motor, and the device is characterized in that a transverse rod is arranged on the telescopic device, a first supporting rod and a second supporting rod are arranged on the transverse rod, and are hinged with a first clamp and a second clamp correspondingly, two opposite air cylinders are arranged in the middle of the rack, a clamping plate isarranged on piston rods of the air cylinders, and a first spraying head and a second spraying head connected with a water pipe are arranged in the middle of the first supporting rod and the middle ofthe second supporting rod. The device is mainly used for machine part drilling, and the problem that after drilling, sweeps easily remain in holes is solved.

Owner:宁波德深机械设备有限公司

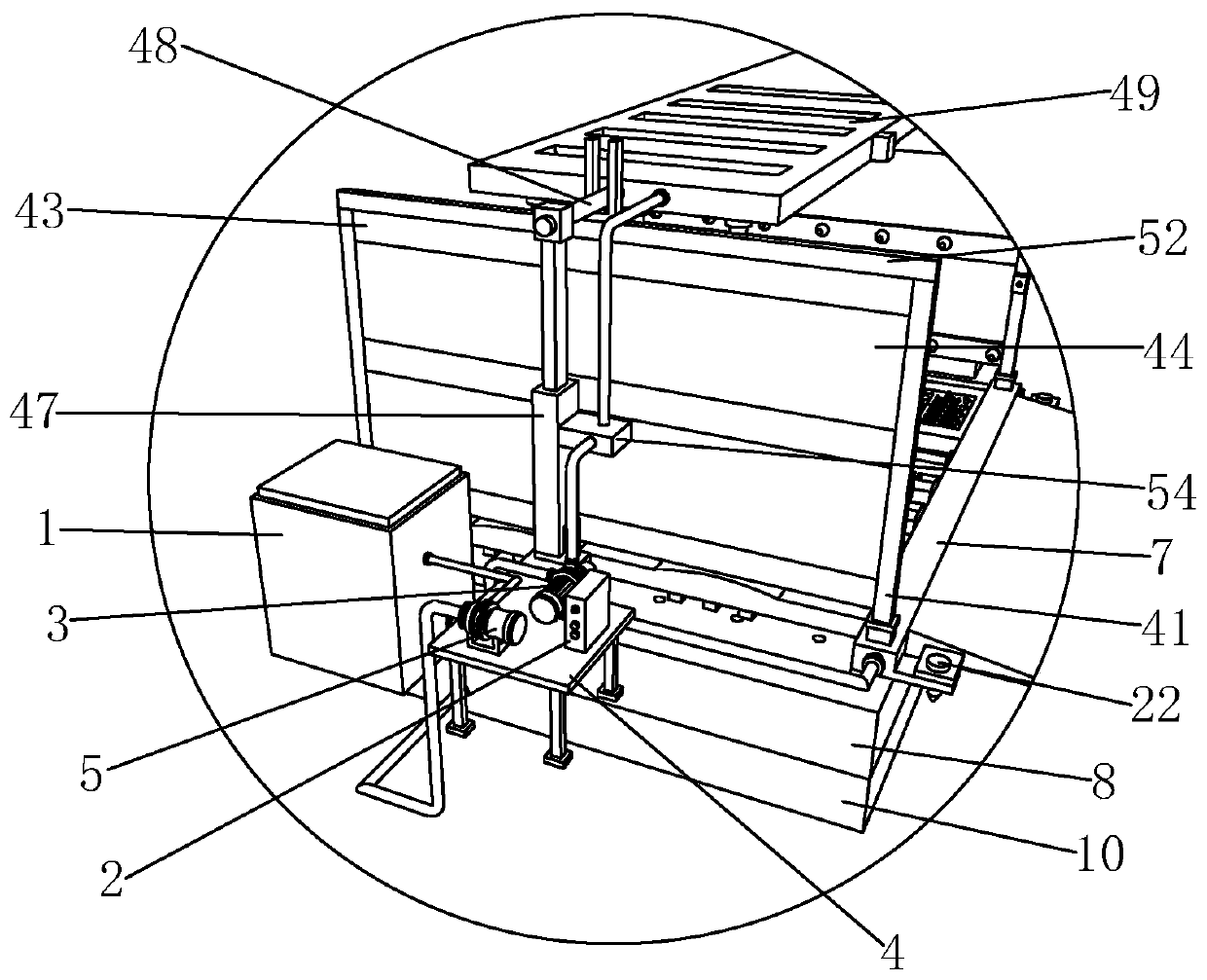

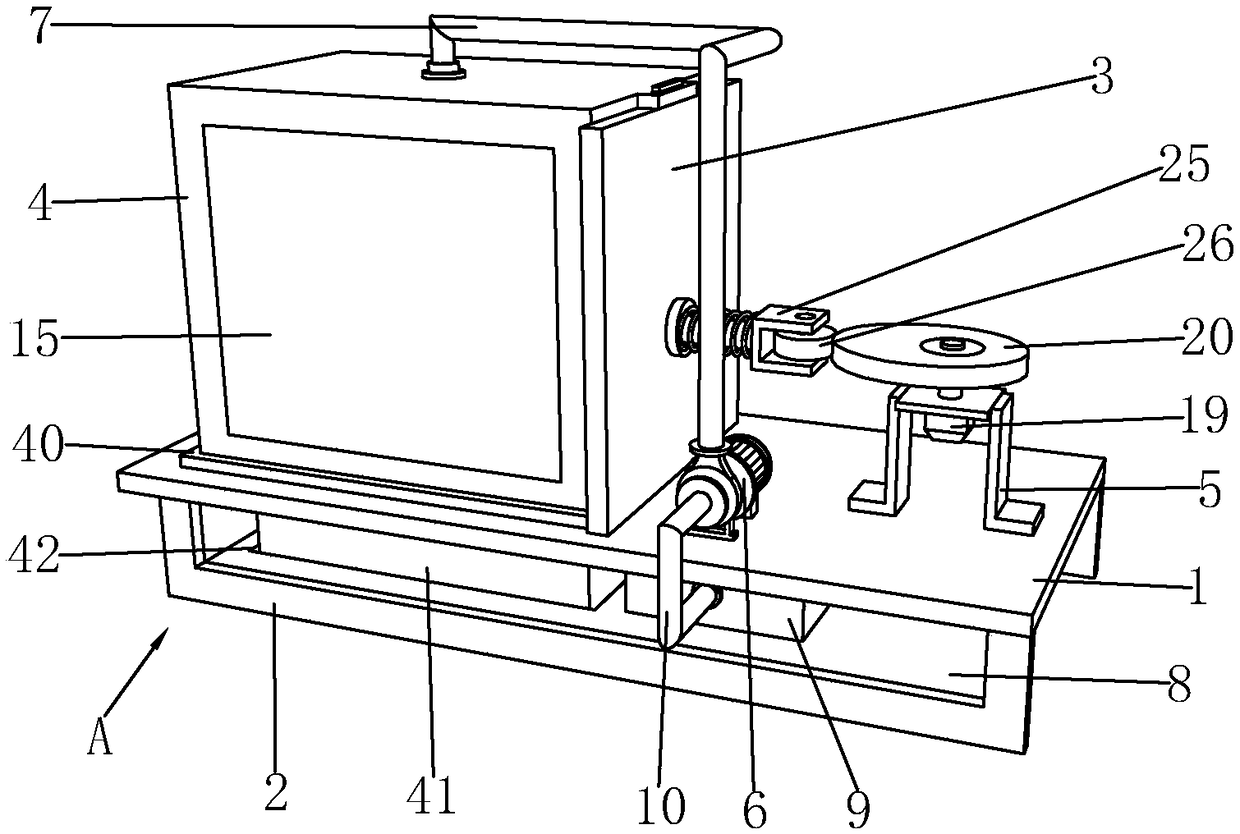

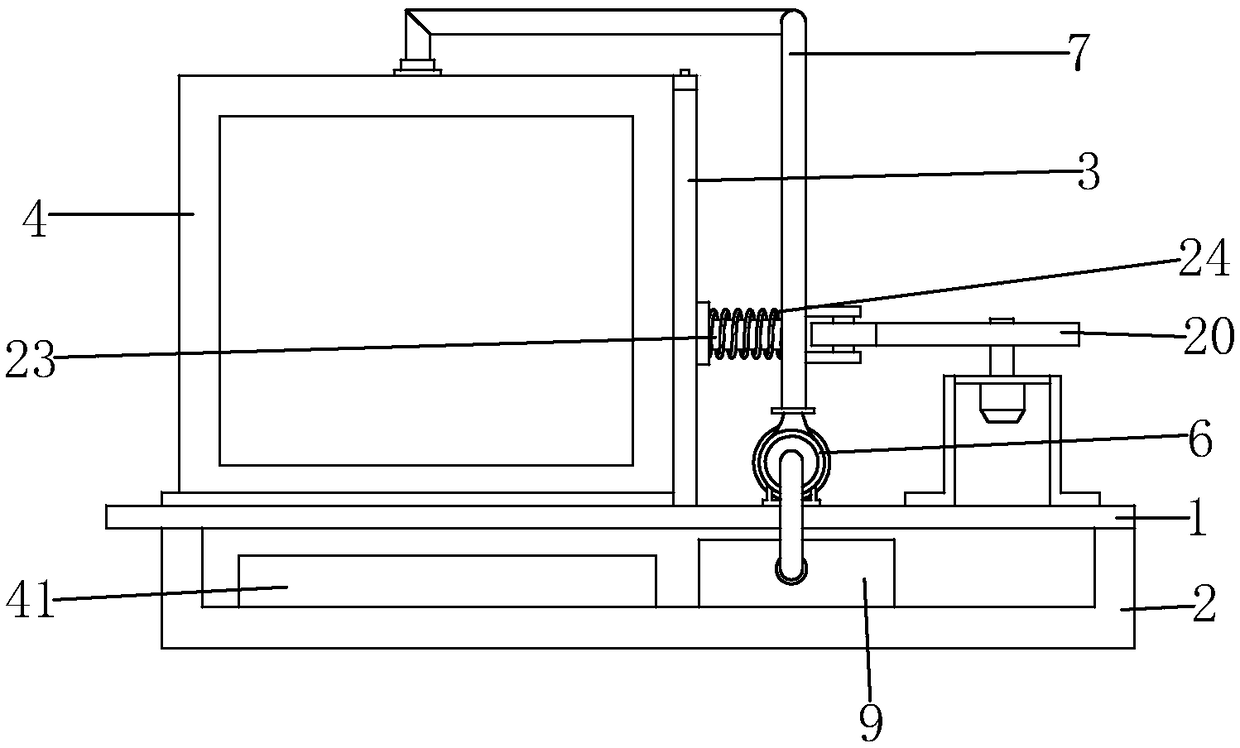

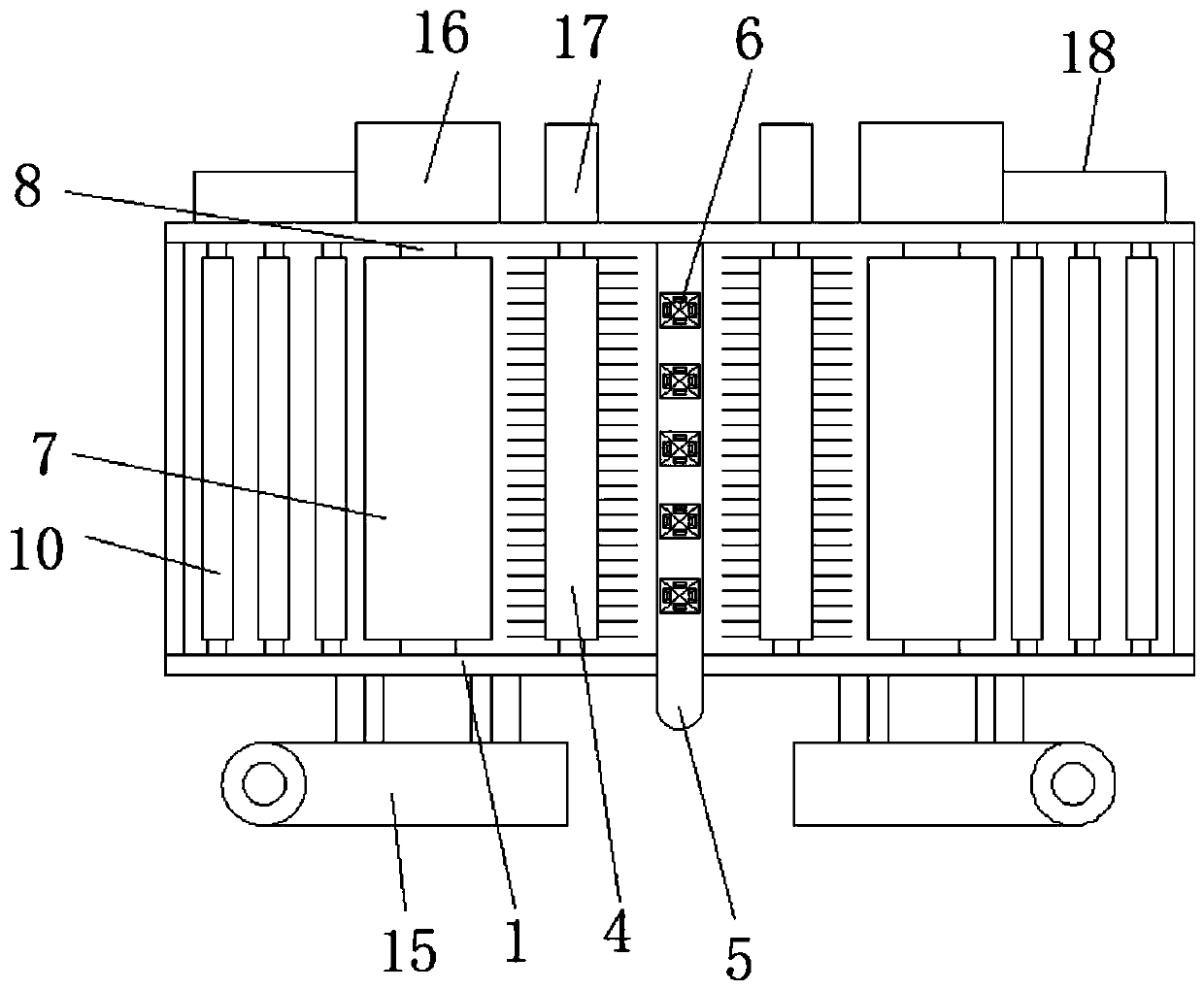

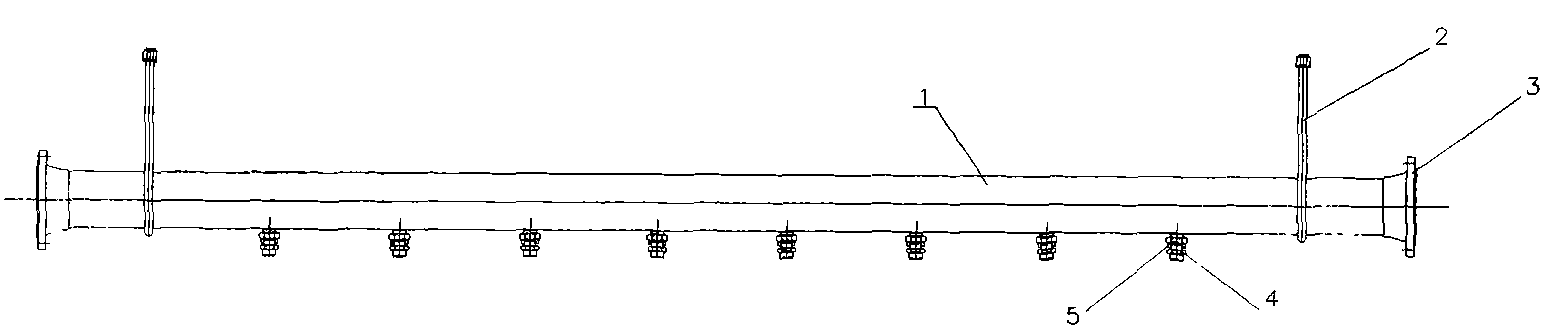

Vehicle cleaning system and method for construction site

InactiveCN110395218APrevent slippingSudden drop in speedTreatment involving filtrationMultistage water/sewage treatmentWater filterWater storage tank

The invention discloses a vehicle cleaning system and method for a construction site. The vehicle cleaning system comprises a water storage tank, a controller, a water delivery pump, a water suction pump, a lateral flushing frame, water distribution pipes, a filtering pool, a sedimentation tank and a water filtering pool, wherein the water suction pump is used for connecting the water storage tankand the water filtering pool, the water delivery pump is connected with one ends of the water distribution pipes, the water distribution pipes are arranged on the filtering pool, the lateral flushingframe is arranged between the water distribution pipes, nozzles are uniformly distributed on the lateral flushing frame, a bearing plate and a U-shaped water spraying pipe are correspondingly arranged between the water distribution pipes, and the U-shaped water spraying pipe is movably connected with a bending nozzle. The cleaning method comprises the following steps of (a) parking cleaning, (b)moving cleaning and c) waste water circulating. The cleaning system is novel in structure, wide in flushing range, high in cleaning efficiency, and good, comprehensive and thorough in cleaning effect,water resources are recycled, the cost is reduced, the cleaning method is orderly conducted by steps, the labor is saved, convenience and rapidity are realized, control is easy, and the cleaning effect and the cleaning quality are ensured.

Owner:浙江永安工程咨询集团有限公司

Tangential injection type whirl flow jet flow grinding drill bit for horizontal well

The invention discloses a tangential injection type whirl flow jet flow grinding drill bit for a horizontal well. The grinding drill bit mainly comprises a PDC drill bit body and is characterized in that a debris discharging groove in the gauge protection portion of the PDC drill bit body is omitted, and the PDC drill bit body is internally and additionally provided with a tangential injection type rotating jet flow sand washing device, a high-concentration turbulence sand pumping device and a jet flow smashing device. According to the tangential injection type rotating jet flow sand washing device, high-speed rotation jet flow is generated through tangential injection type rotating jet flow spray nozzles, a well bottom whirl flow field beneficial to rock debris cleaning is formed, the stress condition of well bottom rock debris is improved, and the well bottom rock debris cleaning efficiency is improved. The high-concentration turbulence sand pumping device pumps and sucks the well bottom fluid based on the principle of a sand pumping pump, the well bottom pressure difference is reduced, unbalance is achieved, and the mechanical drilling speed is increased. The jet flow smashing device effectively smashes the rock debris based on the principle of a jet mill, the rock debris carrying efficiency is improved, the rock debris bed in the horizontal well is eliminated radically, and safe and efficient drilling of the horizontal well is finally achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

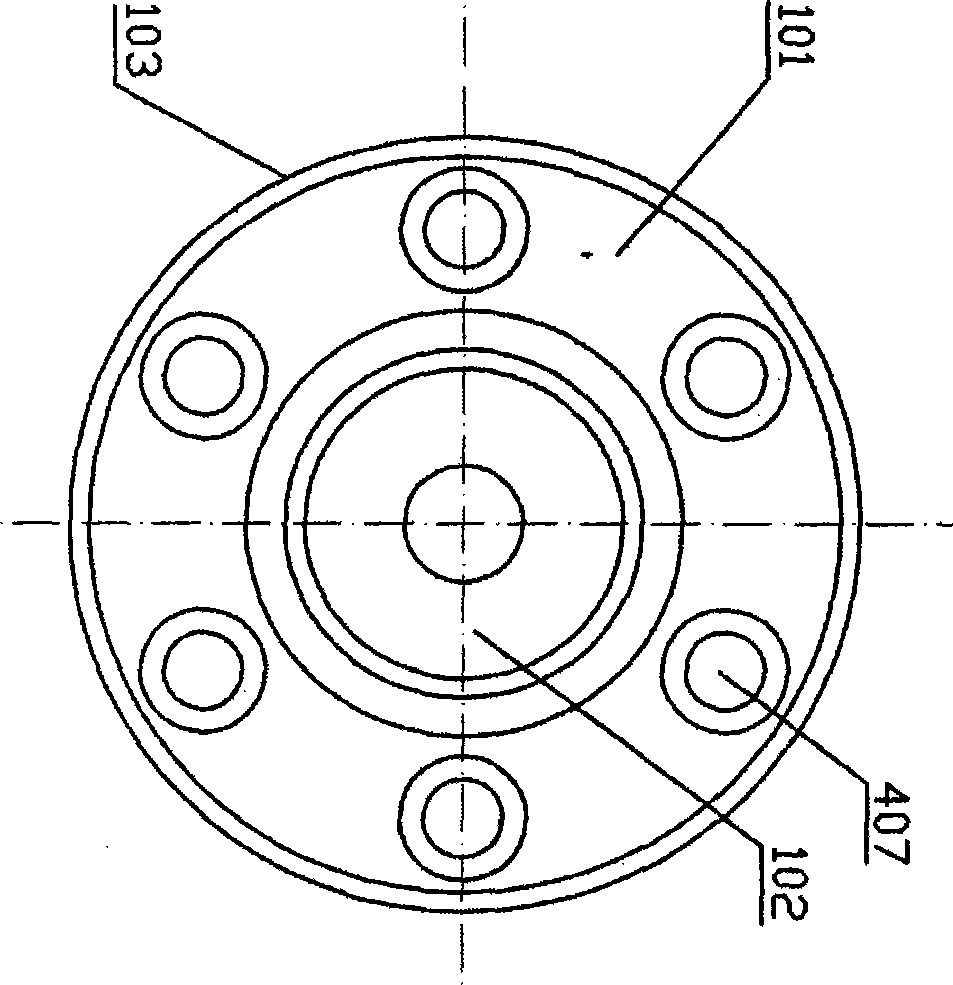

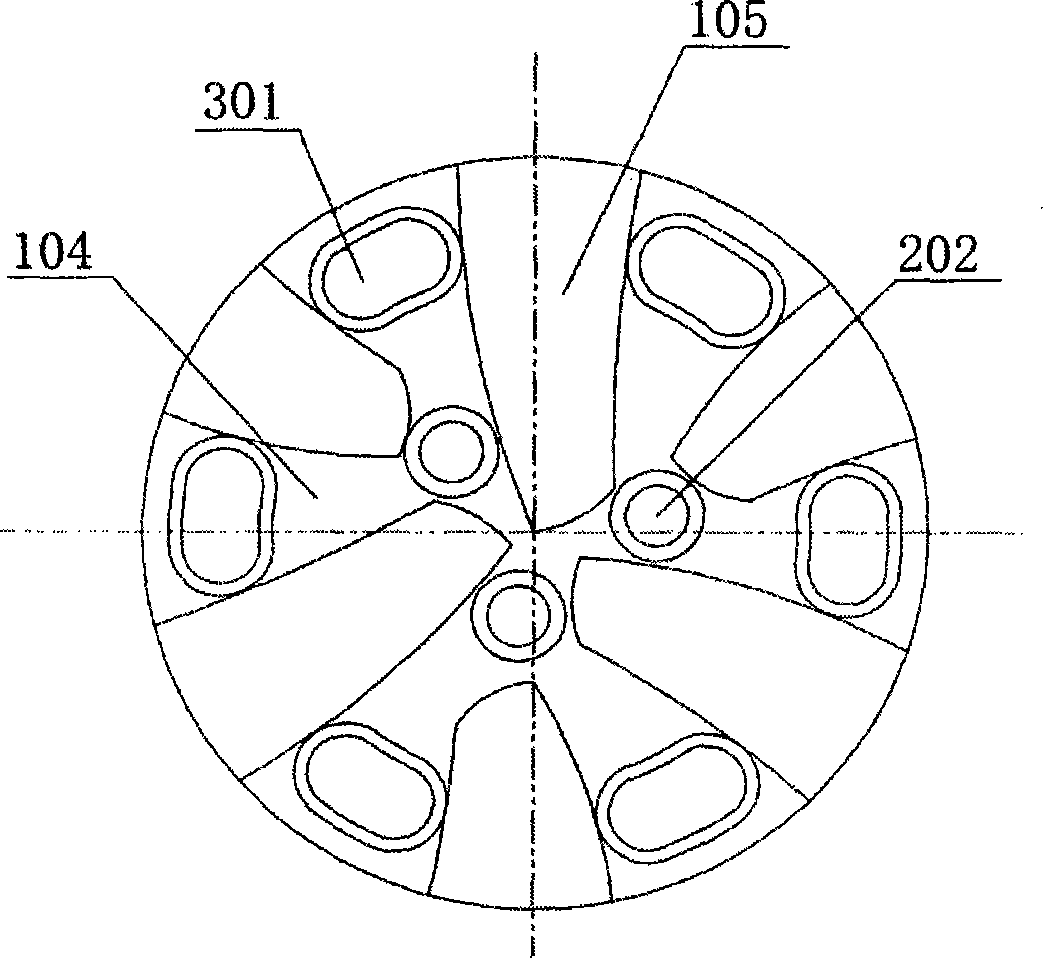

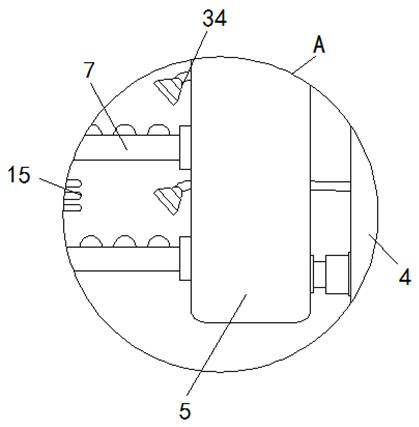

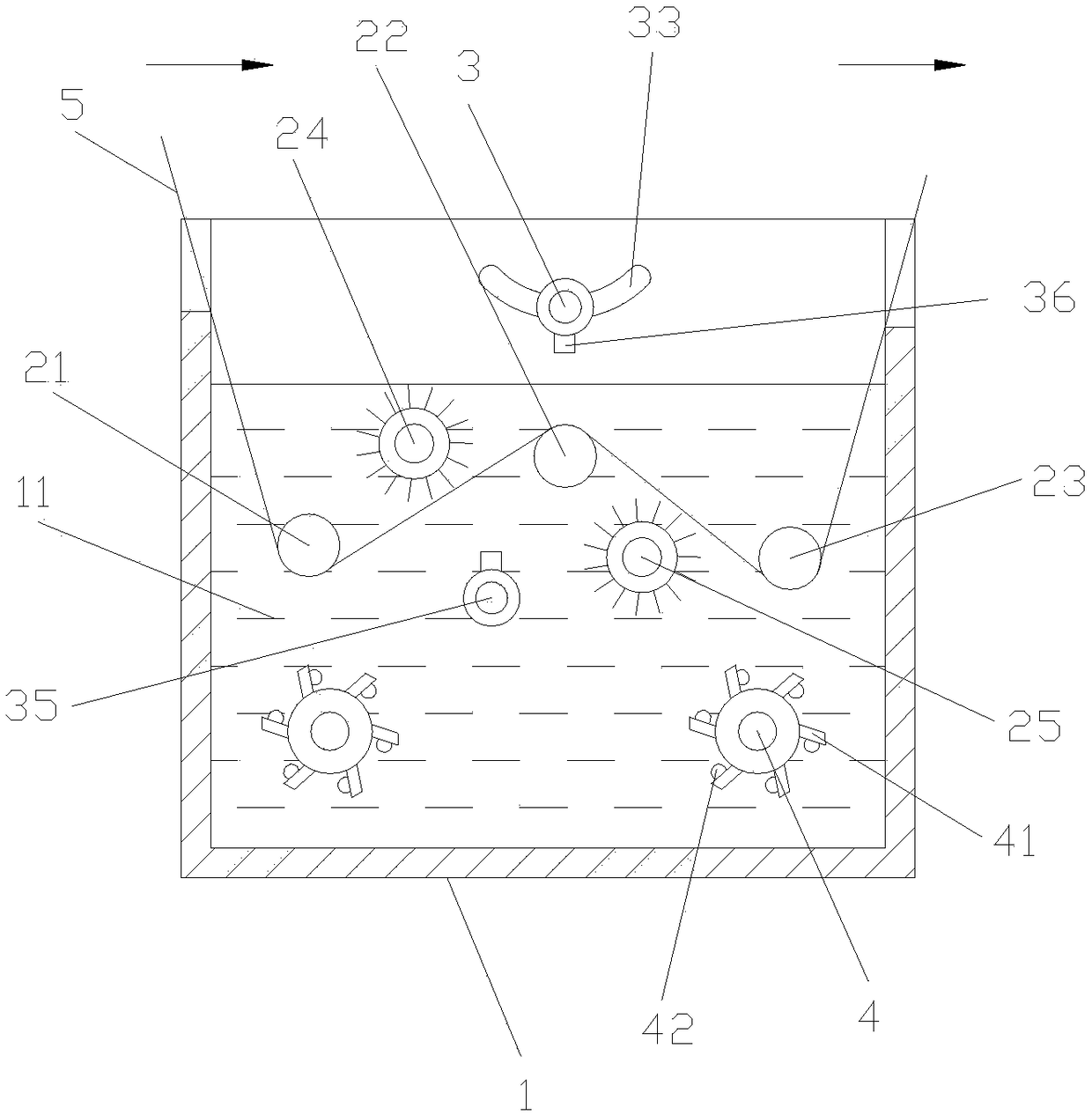

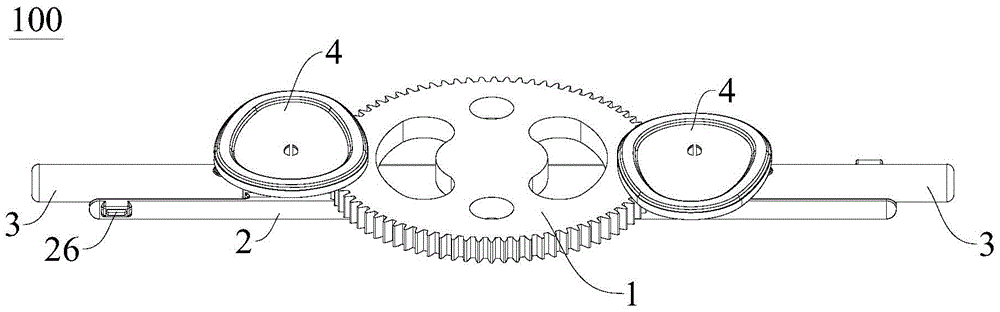

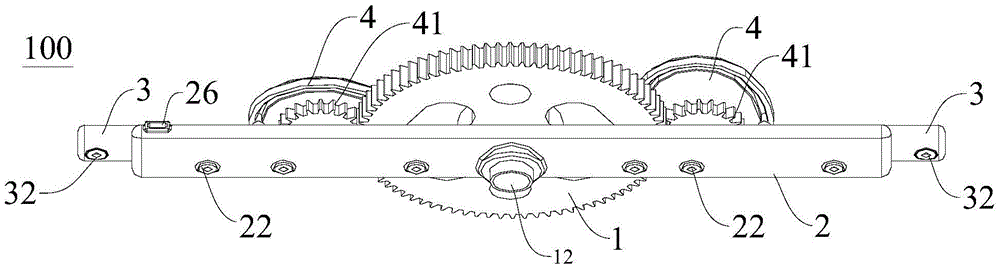

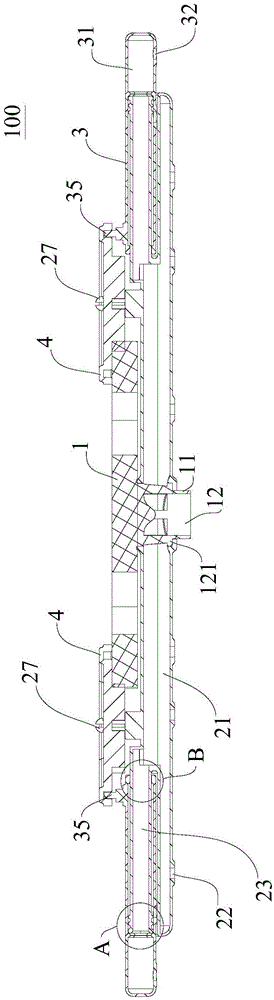

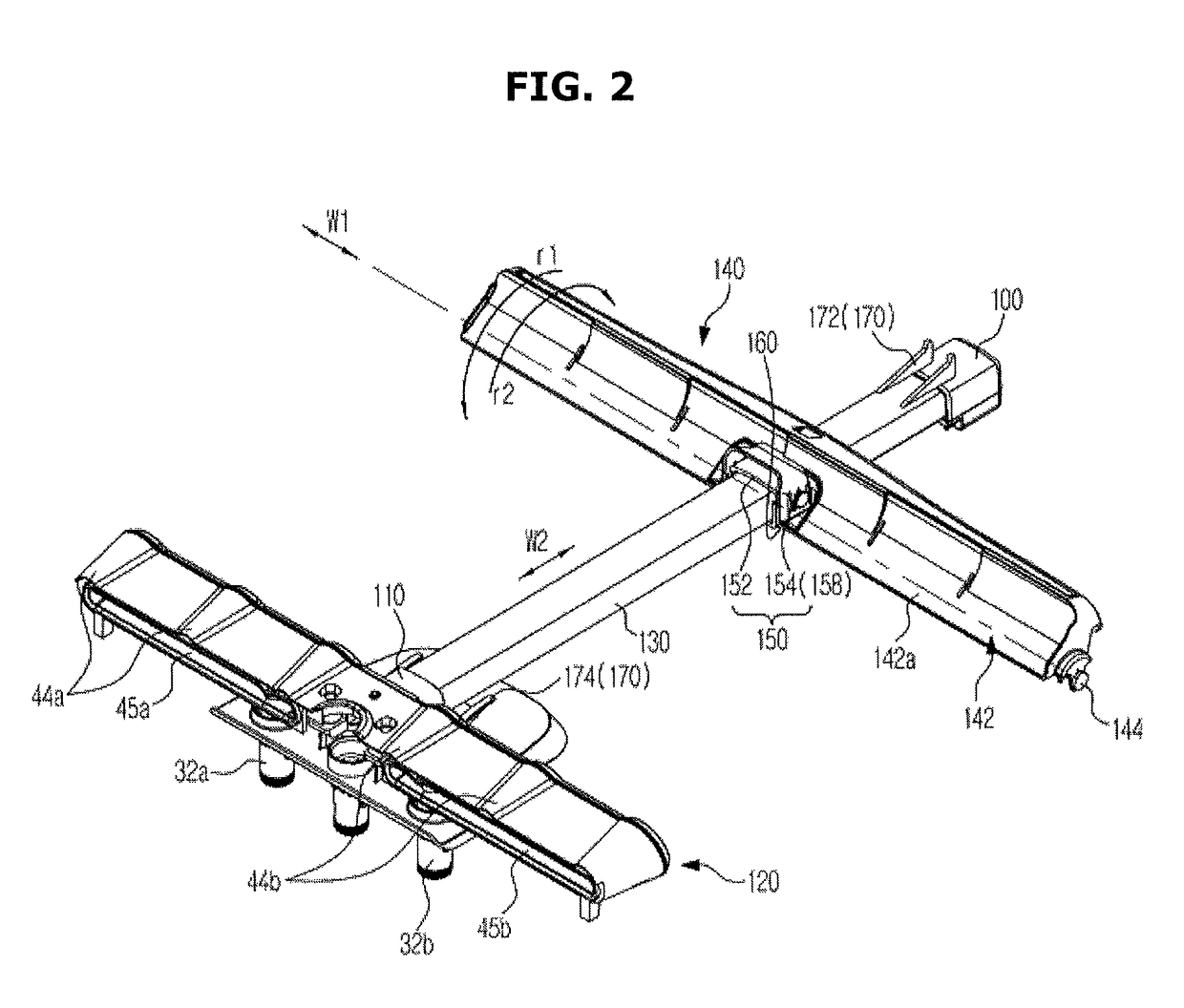

Gushing arm assembly for bowl washing machine and bowl washing machine with gushing arm assembly

ActiveCN105286752AIncreased wash areaEasy to cleanTableware washing/rinsing machine detailsEngineeringMechanical engineering

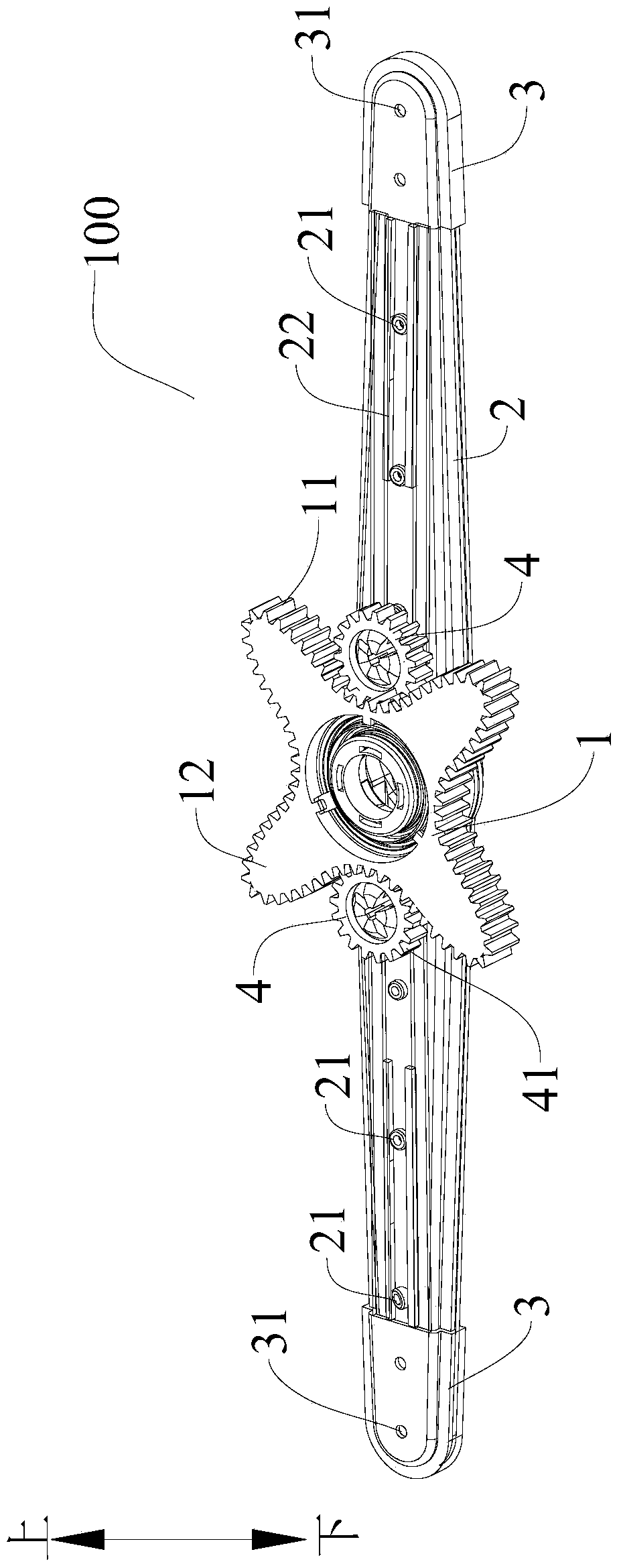

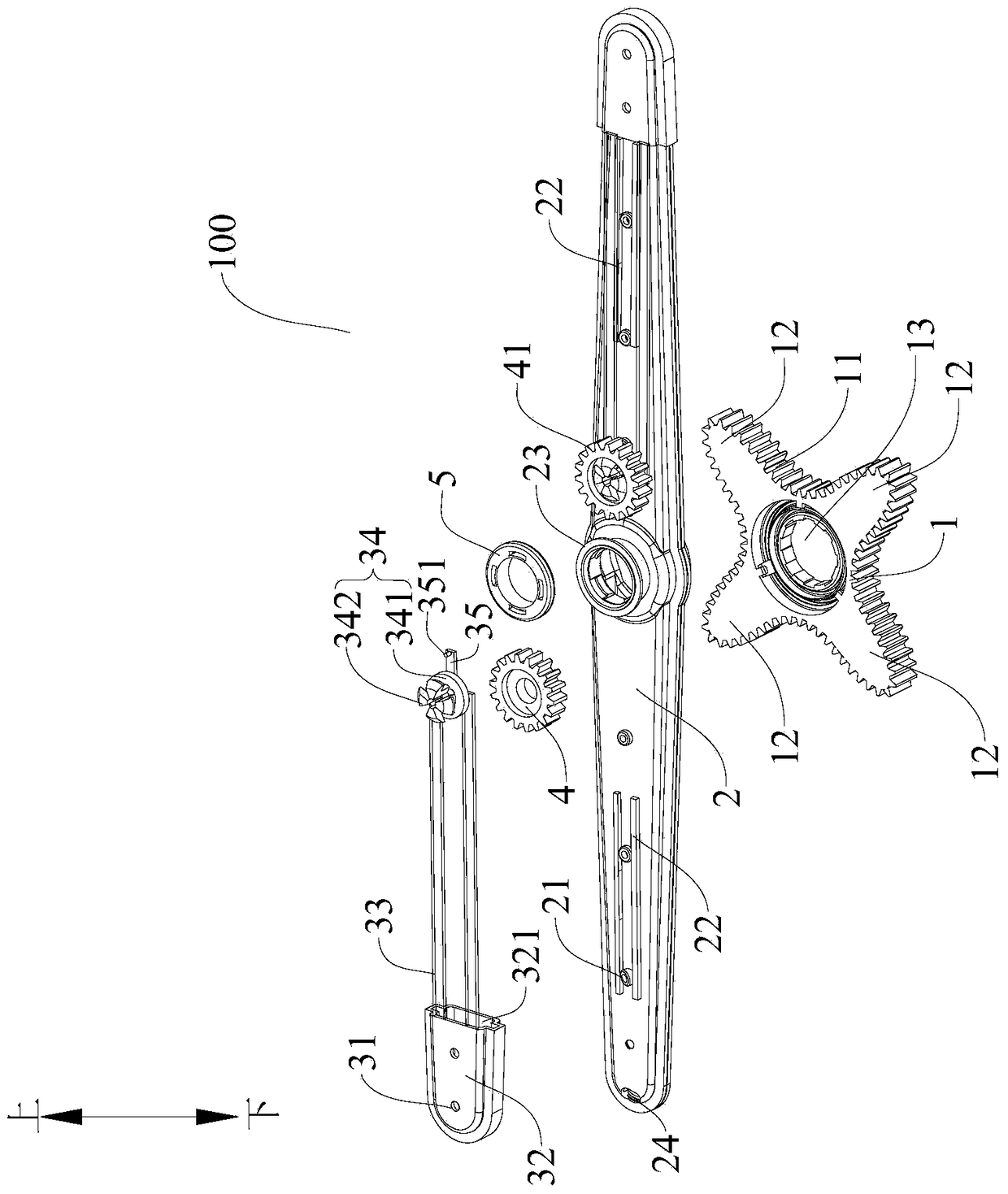

The invention discloses a gushing arm assembly for a bowl washing machine and a bowl washing machine with the gushing arm assembly. The gushing arm assembly comprises a fixed gear, a main gushing arm, at least one movable gushing arm and a transmission gear, wherein the fixed gear is a non-round gear; the main gushing arm is arranged on the fixed gear around the axial line of the fixed gear in a rotatable manner; a first spraying opening is formed in the main gushing arm; the movable gushing arms are movably arranged on the main gushing arm in the directions close to and far away from the axial line of the fixed gear; a second spraying opening is formed in each movable gushing arm; and the transmission gear is connected with the movable gushing arms in a rotatable manner, is meshed with the fixed gear, and is used for driving the movable gushing arms to move during rotation of the main gushing arm. According to the gushing arm assembly for the bowl washing machine, telescopic moving traces of the movable gushing arms can be formed under the meshing transmission of the transmission gear and the fixed gear, so that the flushing area of the gushing arm assembly is enlarged, and the cleaning effect is enhanced.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

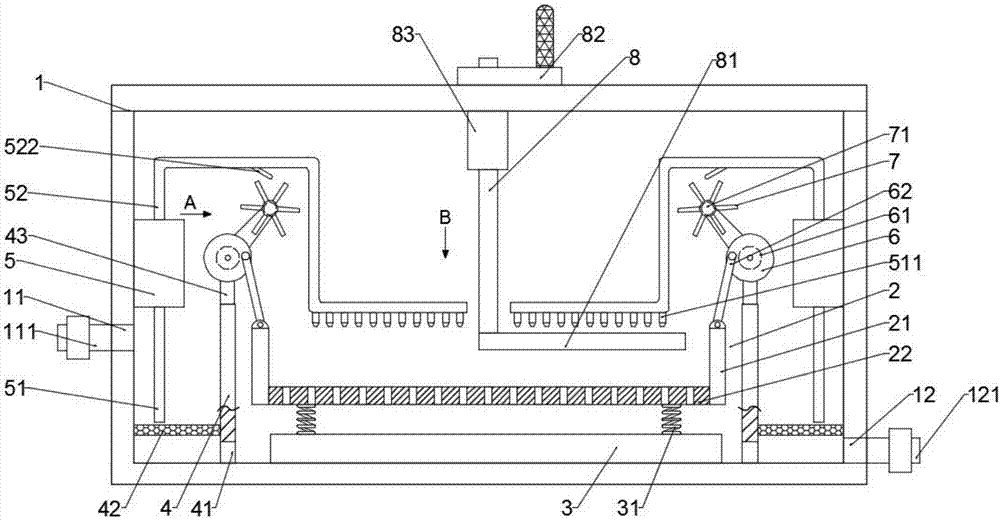

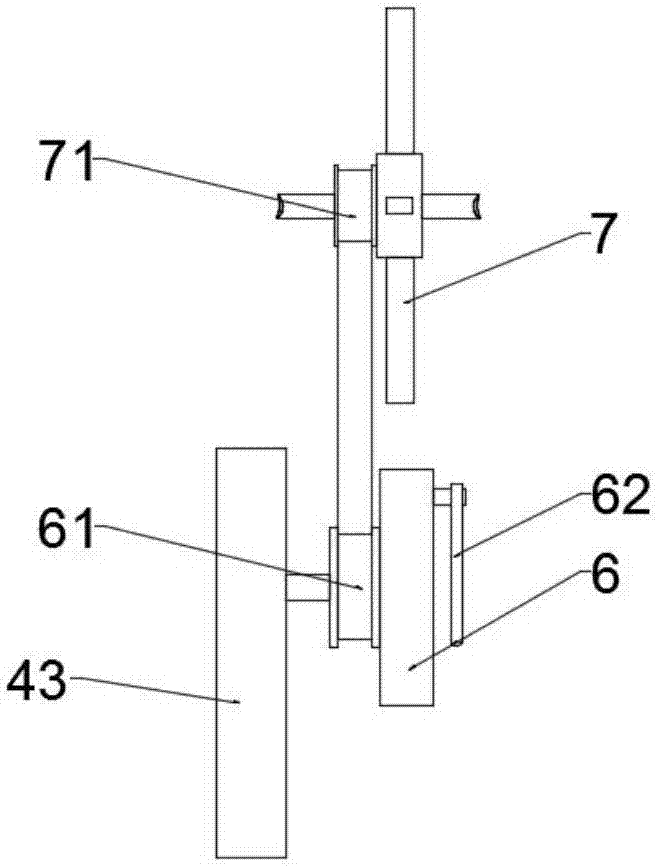

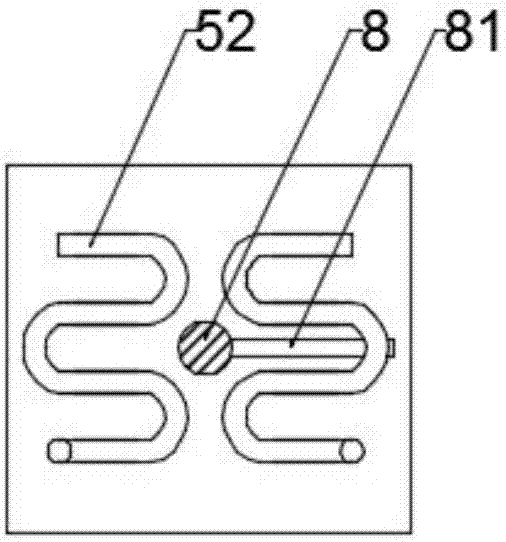

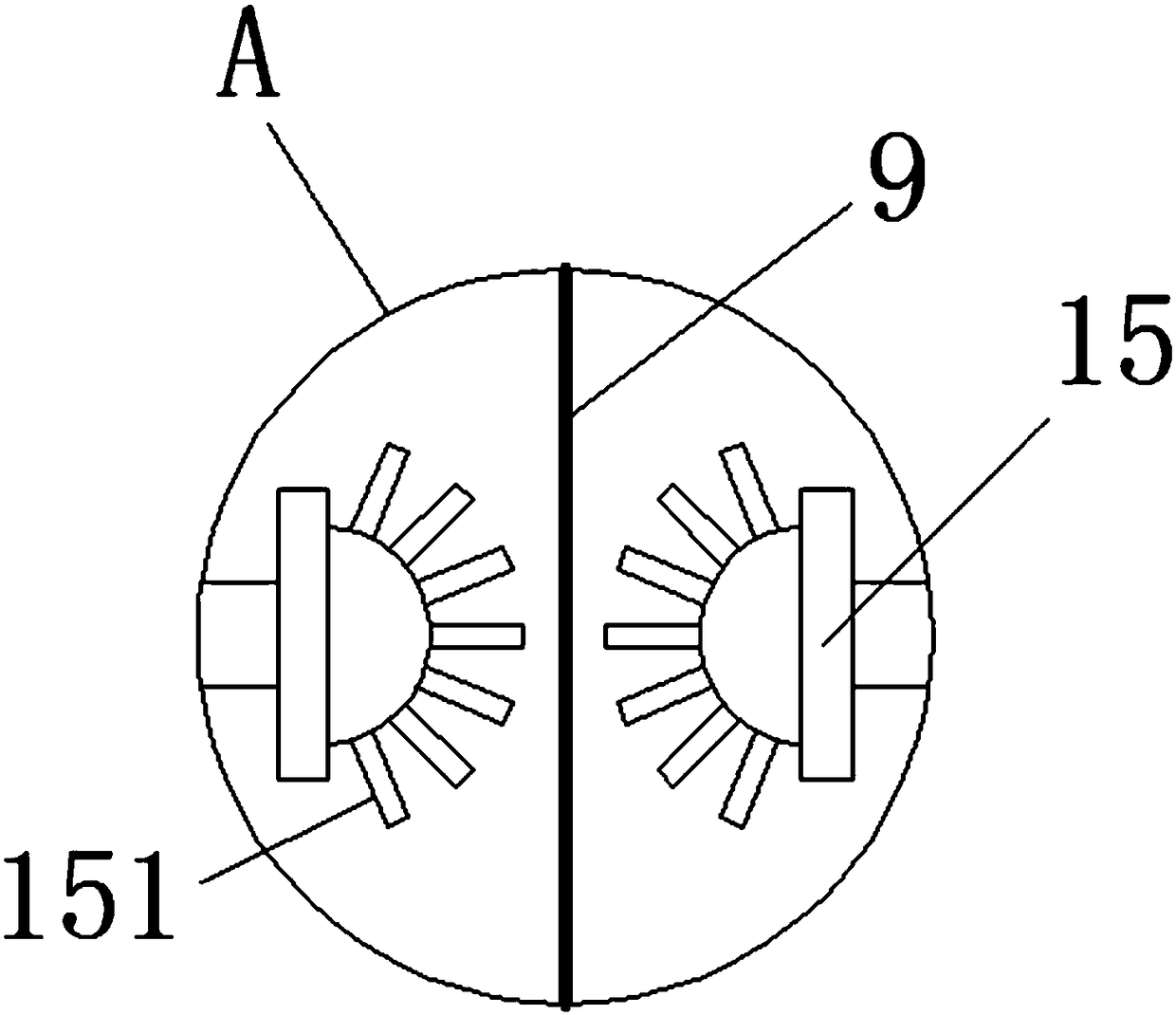

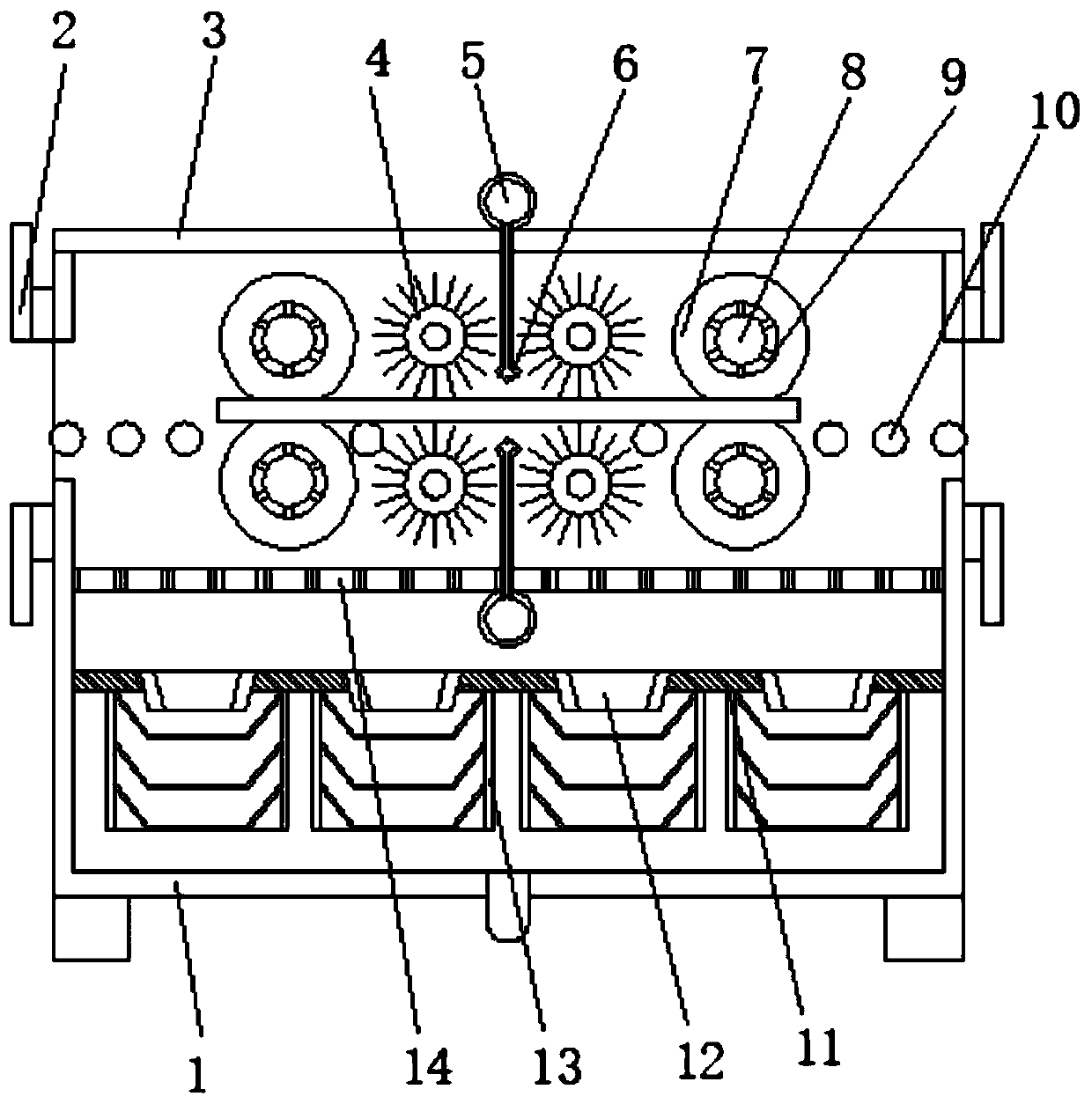

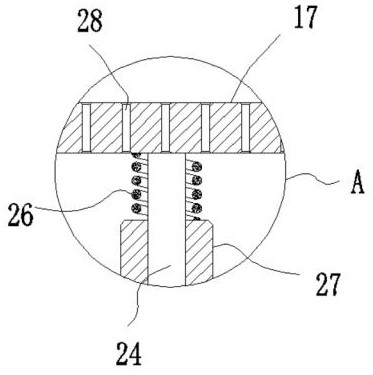

Laboratory sand-stone cleaning device

InactiveCN107309204AThe serpentine outlet pipes above the cleaning frame expand the flushing evenlyAvoid flushing effectsCleaning using liquidsImpellerCircular disc

The invention discloses a sandstone cleaning device for laboratory, which comprises a frame body, a cleaning frame and a water pump; The two sides of the cleaning frame are symmetrically provided with a vertical plate with a return port, and a filter screen is fixed between the inner cavity side wall of the frame and the vertical plate; two water pumps are symmetrically installed on the left and right side walls of the inner cavity of the frame. , the water pump is connected to the suction pipe and the outlet pipe, the suction pipe extends downward to the top of the filter screen, and the outlet pipe extends to the top of the cleaning frame; the upper part of the inner cavity of the frame is symmetrically equipped with impellers, and the position corresponding to the impeller on the outlet pipe is connected to a diagonal The nozzle and the inclined nozzle are facing the blades of the impeller; a disk is arranged above the vertical plate, the impeller drives the disk to rotate, and the disk is connected to the side plate through a connecting rod. The sand and gravel cleaning device of the present invention can recycle water resources, save energy and protect the environment, and has good washing effect at the same time, and is worthy of popularization and use.

Owner:苏锦忠

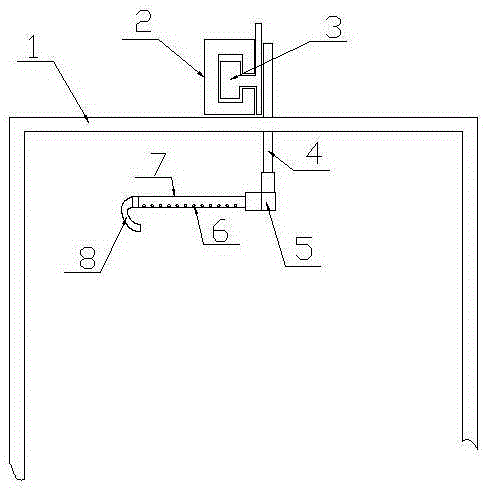

Water circulation flushing type cleaning machine for agricultural product surface processing

InactiveCN112515203AGood removal effectImprove cleanlinessFood treatmentWater useAgricultural science

The invention discloses a water circulation flushing type cleaning machine for agricultural product surface processing. The water circulation flushing type cleaning machine comprises a device body, aservo motor, a circulating water pump, a water storage tank and a filter assembly, wherein the servo motor is fixedly mounted in the middle of the upper end of the device body, a first reciprocating screw rod is mounted at the lower end of the servo motor, an elastic banister brush is installed on the outer side of a carrying plate, the inner end of the elastic banister brush is fixedly installedon the outer side of a conveying belt, the conveying belt is installed on the side of a positioning frame, a belt wheel is installed on the first reciprocating screw rod, and the outer side of the belt wheel is installed at the upper end of a linkage rod. According to the water circulation flushing type cleaning machine for agricultural product surface processing, residual impurities on the brushcan be conveniently removed after agricultural products are cleaned, the overall cleanliness of the cleaning brush is guaranteed, meanwhile, the flushing range of water flow can be widened, and the contact friction force between the agricultural products and the brush can be adjusted during cleaning.

Owner:杨苏琴

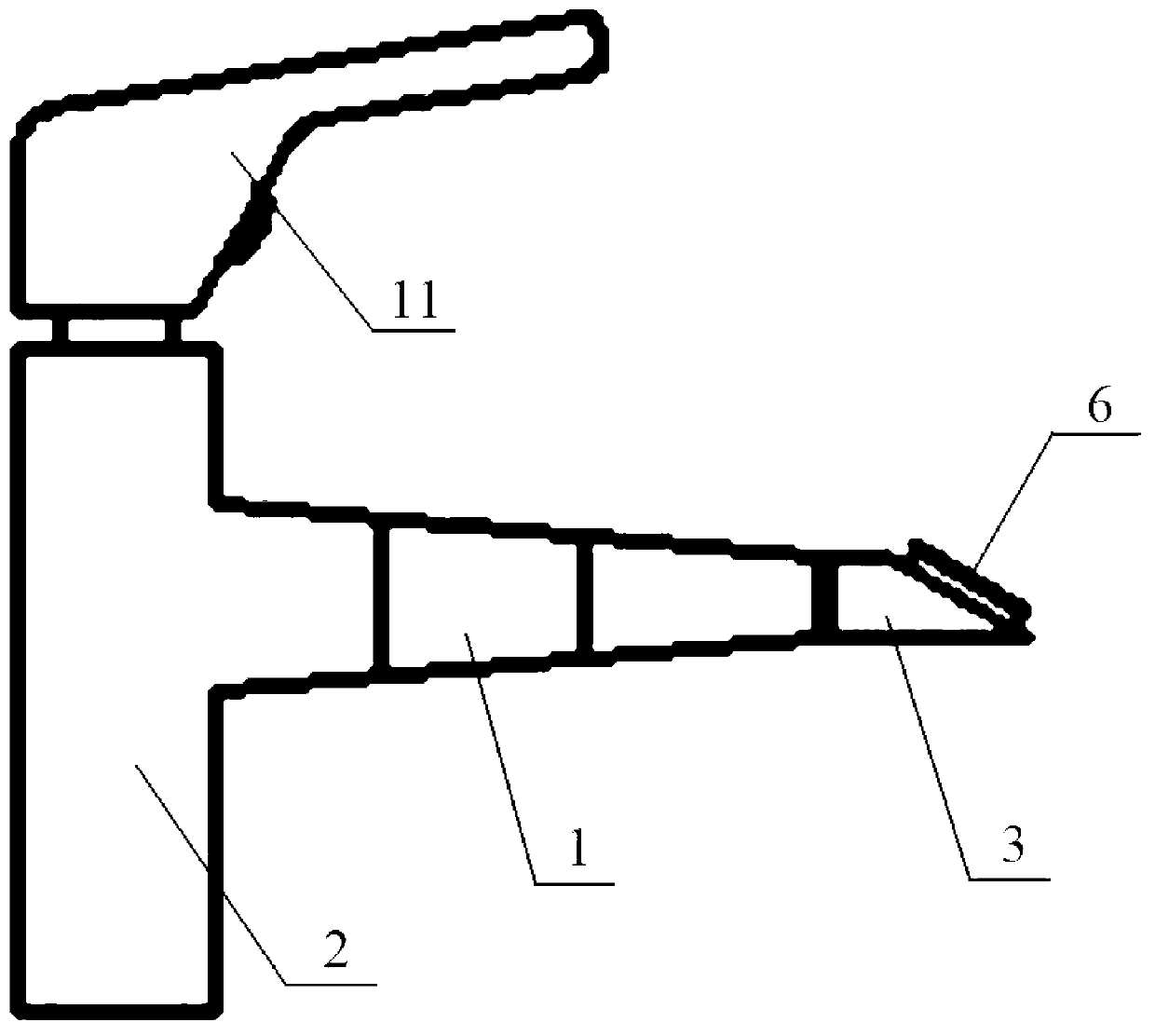

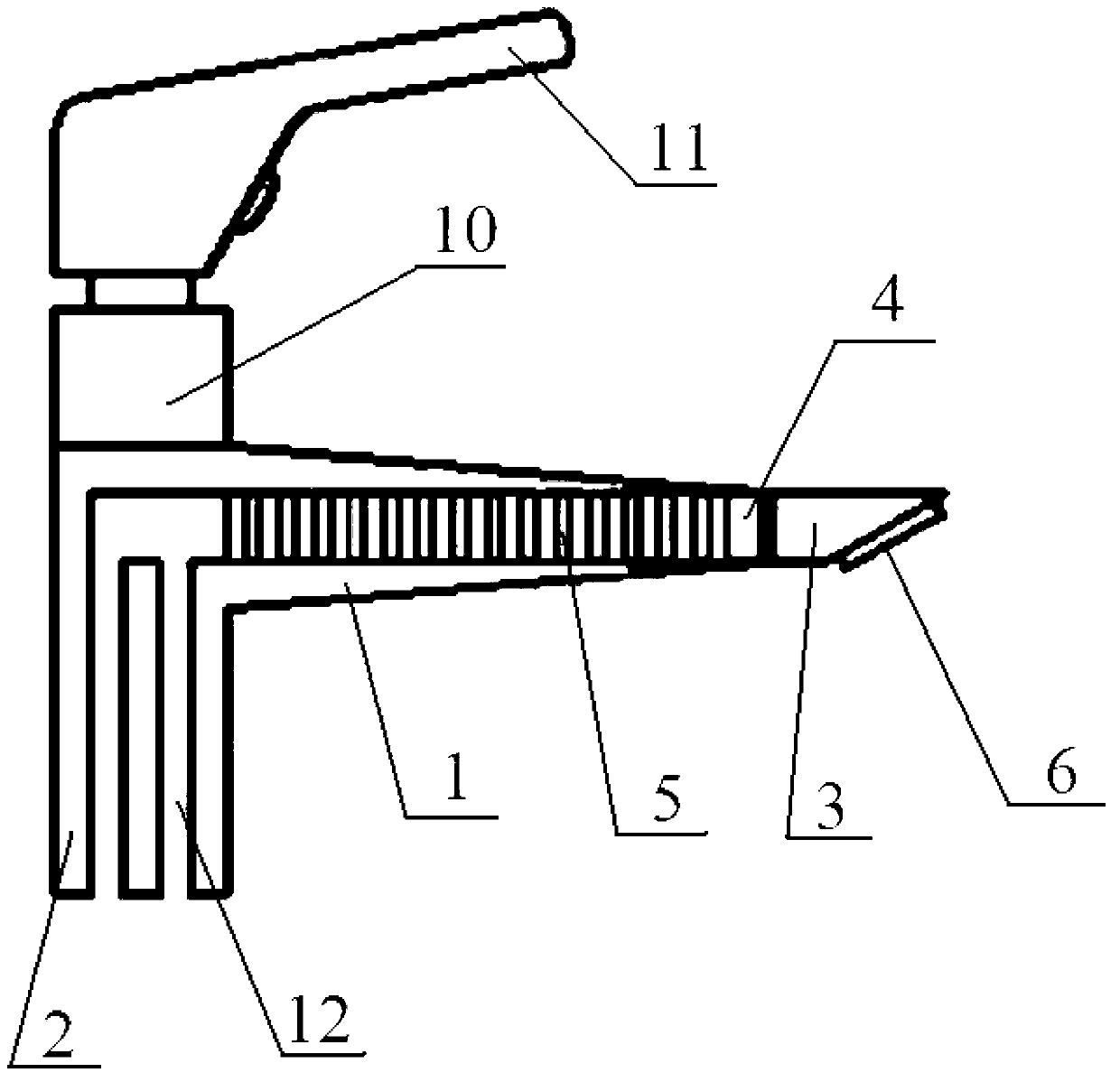

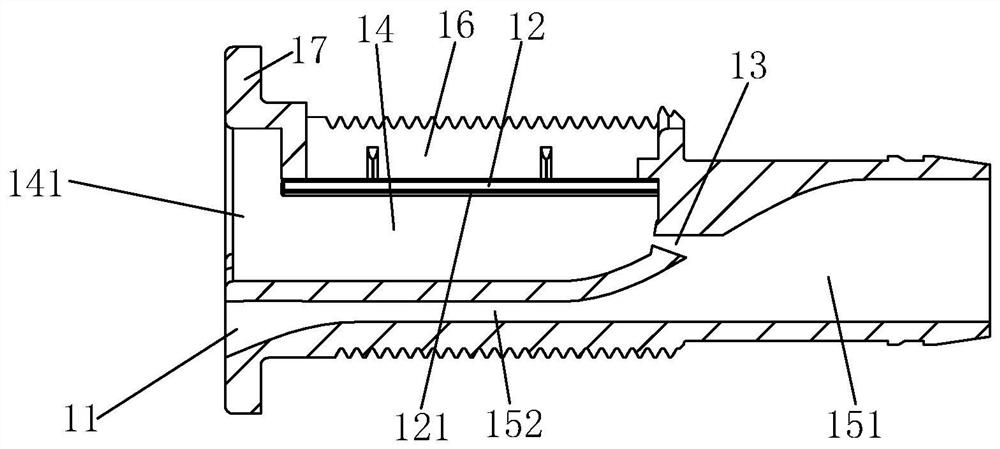

Telescopic faucet

The invention relates to the field of water heating equipment, in particular to a telescopic faucet. The telescopic faucet comprises a plurality of sleeves which are sleeved in sequence; every two adjacent sleeves are in sliding fit; one end of the outermost sleeve is connected with a first water pipe; one end, away from the first water pipe, of the innermost sleeve is connected with a water outlet pipe; a second water pipe is further arranged in the sleeves; a plurality of corrugations are formed on the wall of the second water pipe; one end of the second water pipe is connected with the first water pipe, and the other end thereof is connected with the water outlet pipe; and a water outlet is connected to one end, away from the sleeve, of the water outlet pipe. When using the telescopic faucet, a user can control the overall length of the sleeves according to actual demand; and further, the telescopic faucet has a larger washing range and can cover a larger area of a water tank than existing faucets, thereby being convenient for users to use.

Owner:张兆龙

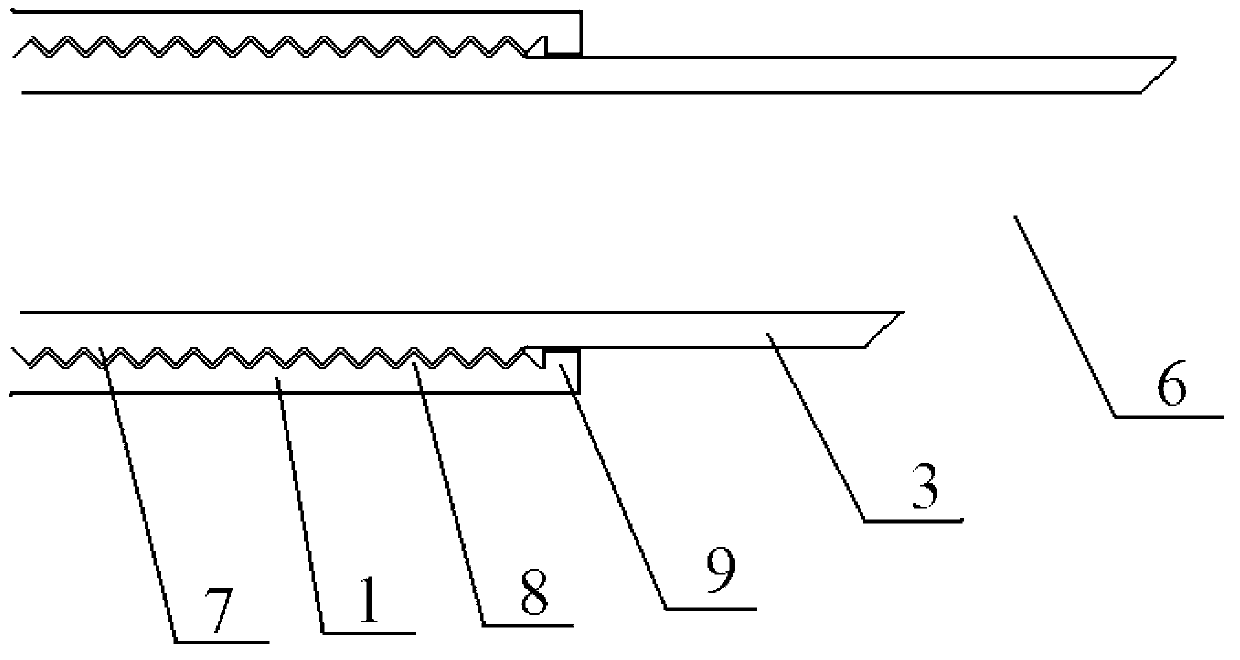

Novel rubber tube wire cleaning device

InactiveCN108057667AExtended wash rangeImprove flushing effectDrying gas arrangementsDrying machines with progressive movementsHydraulic cylinderSteering wheel

The invention discloses a novel rubber tube wire cleaning device which comprises a shell. Partition plates are arranged in an inner cavity of the shell and further divide the inner cavity of the shellinto a washing bin, a drying bin and a roasting bin. The top ends of the two sides of the washing bin are fixedly connected with supports, and the supports are fixedly connected with a fixed shaft. The outer wall of the fixed shaft is movably connected with a spool. A rubber tube wire is wound onto the spool. First hydraulic cylinders are installed at the bottom ends of the two sides of the washing bin, and output shafts of the first hydraulic cylinders are fixedly connected with motor bins. Motors are installed in the corresponding motor bins. Output shafts of the motors are fixedly connected with washing pipes, and the outer walls of the washing pipes are fixedly connected with water inlet pipes. Washing sprayers are arranged at the bottom ends of the corresponding washing pipes. Secondhydraulic cylinders are installed at the bottom ends of the two sides of the drying bin. Output shafts of the second hydraulic cylinders are fixedly connected with a pushing plate, and the two sidesof the pushing plate are fixedly connected with mounting racks. The mounting racks are provided with drying rollers. Steam heaters are installed on the inner walls of the two sides of the roasting bin. A steering wheel is arranged below the shell, and a fixed base is arranged nearby the steering wheel. A take-up reel is installed on the fixed base.

Owner:张家港市华鸿金属制品有限公司

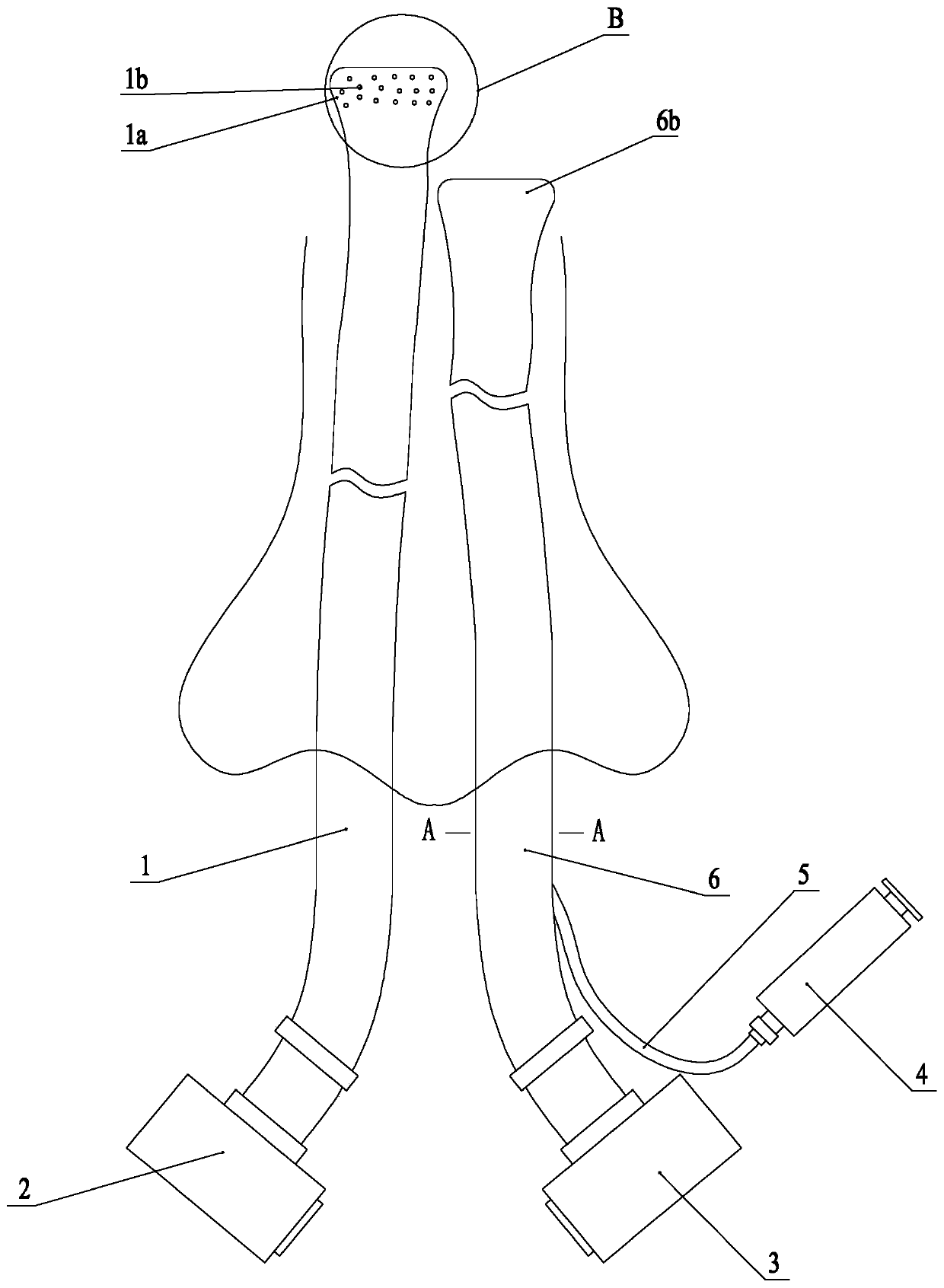

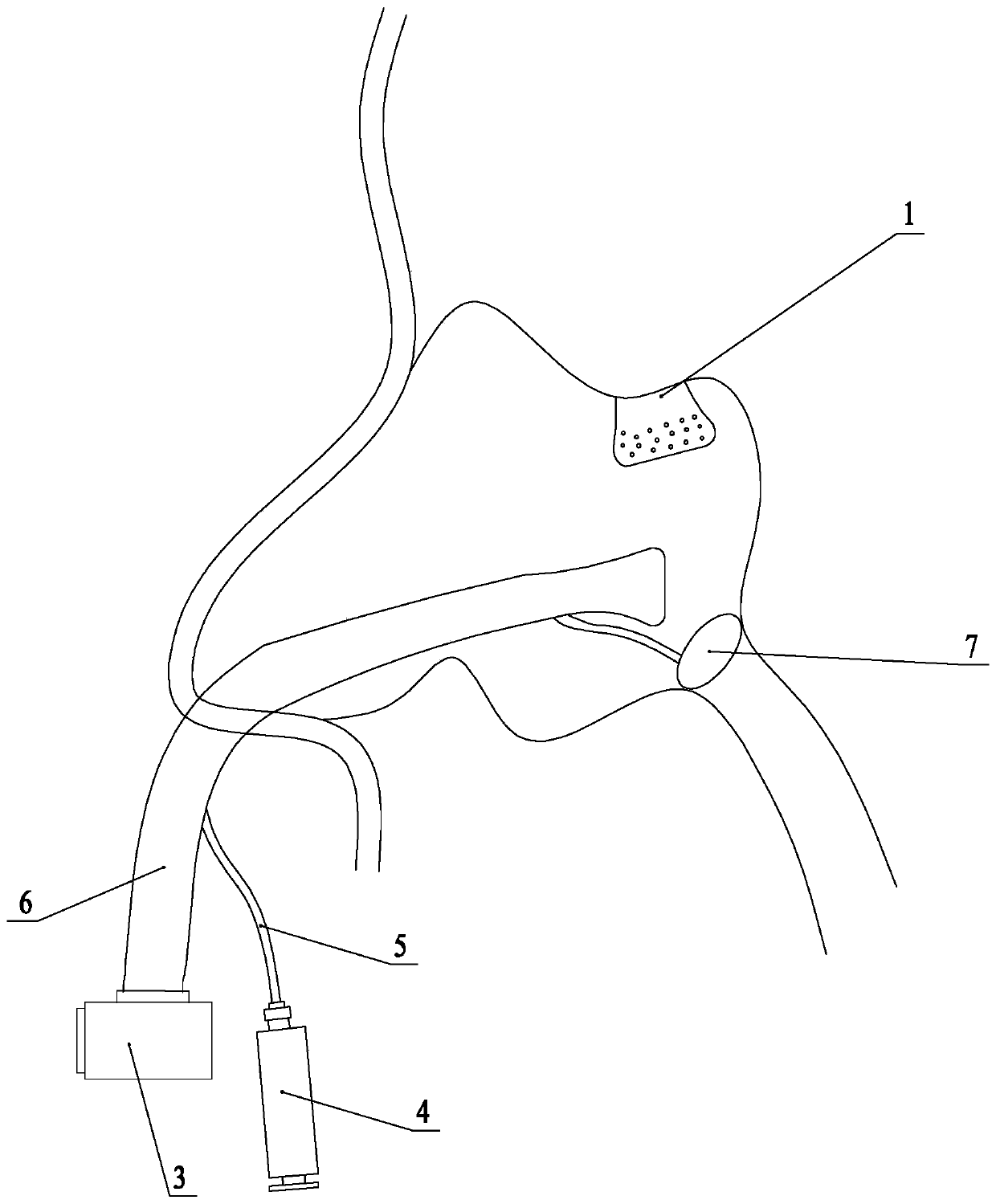

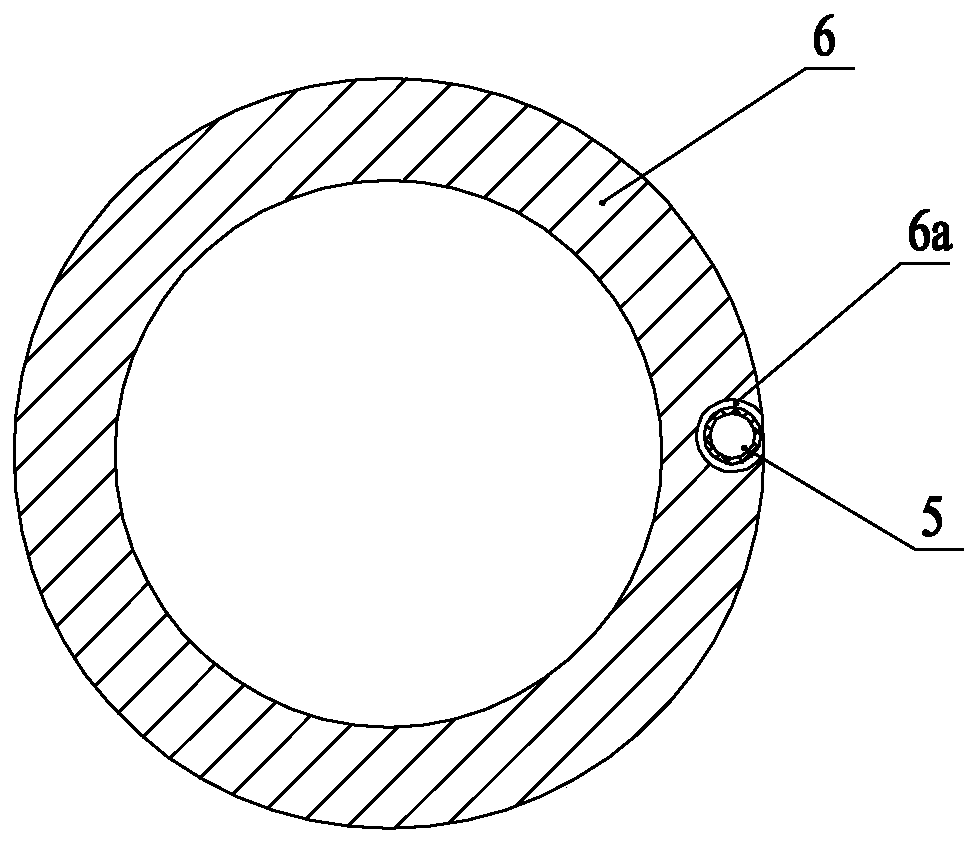

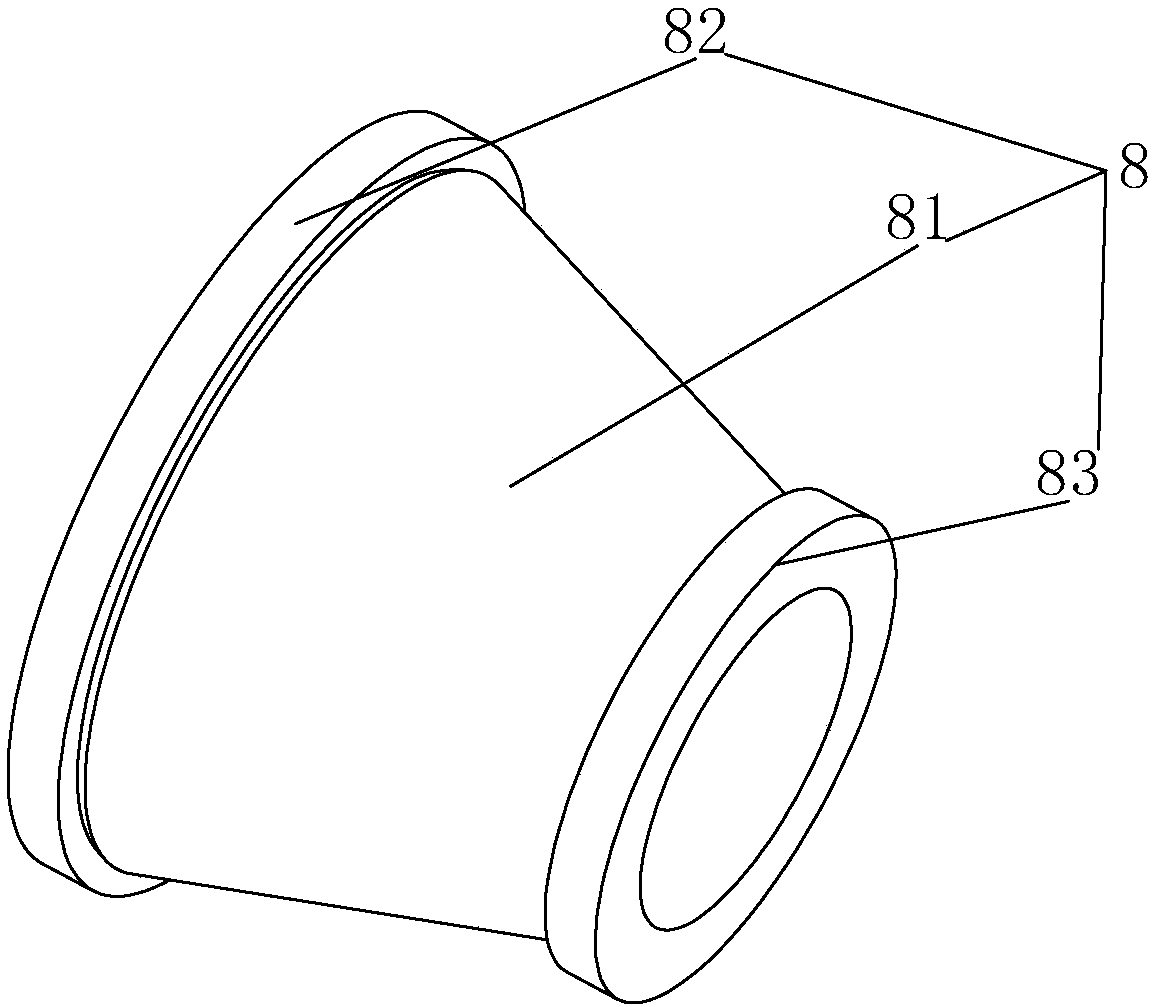

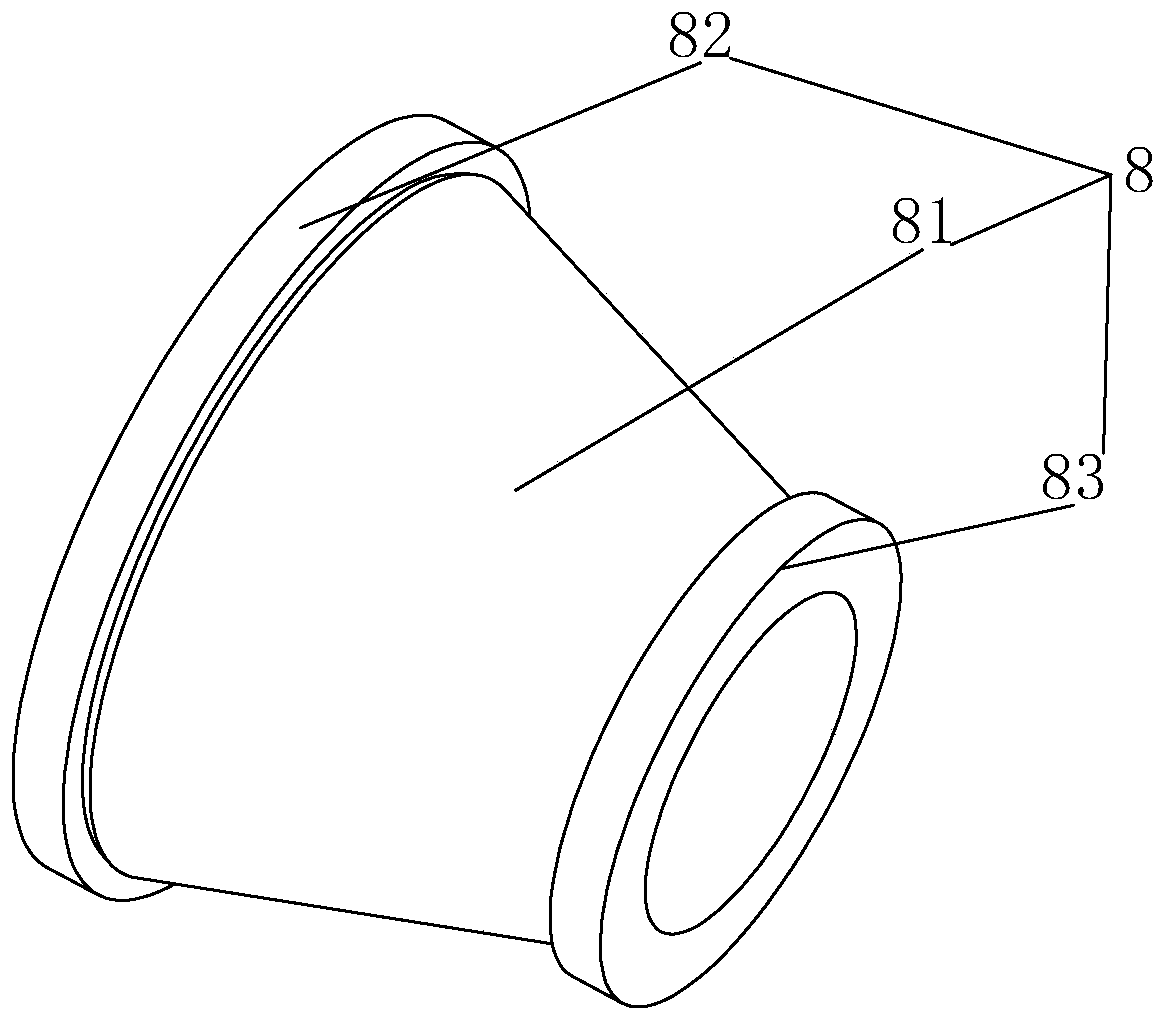

Nasal irrigator

The invention relates to a nasal irrigator. The nasal irrigator comprises a water delivery device, a pumping device and a water blocking device; the water delivery device comprises a water deliveringdevice and a water delivering hose, wherein an outlet end of the water delivering device is connected with the rear end of the water delivering hose, and the front end of the water delivering hose isused for being inserted into the nasal cavity from the nostril at one side; the pumping device comprises a pumper and a pumping hose, wherein an inlet end of the pumper is connected with the rear endof the pumping hose, and the front end of the pumping hose is used for being inserted into the nasal cavity from the nostril at the other side; the water blocking device comprises a water blocker, a water blocking hose and a water blocking ball, wherein an outlet end of the water blocker is connected with the rear end of the water blocking hose, the front end of the water blocking hose is connected with the water blocking ball, a fluid medium is sealed in the water blocker, in the water blocking hose and in the water blocking ball separately, and the fluid medium can be driven to enter the water blocking ball by operating the water blocker, so that the water blocking ball swells to block the communication of the nasal cavity and the oral cavity. According to the nasal irrigator, by adopting the water delivering hose for water delivery, adopting the pumping hose for water extraction, and adopting the water blocking ball for blocking the joint of the nasal cavity and the oral cavity, thenasal cavity can be continuously cleaned, and the use is convenient.

Owner:JIANGSU CANCER HOSPITAL

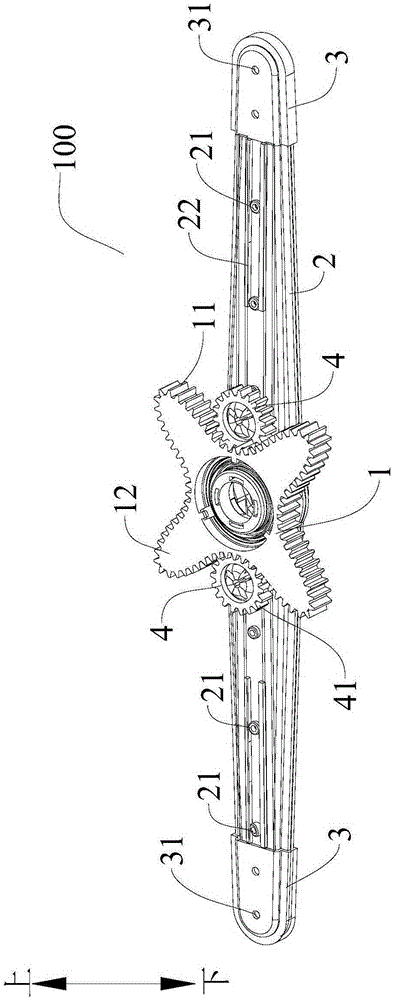

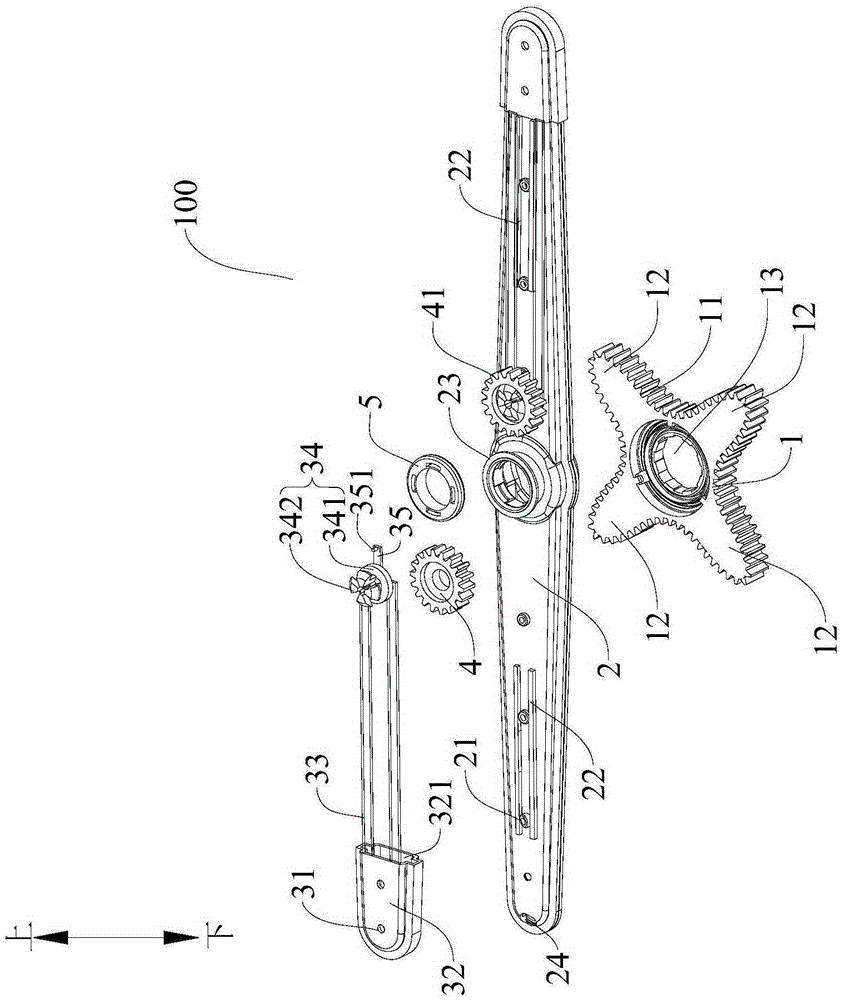

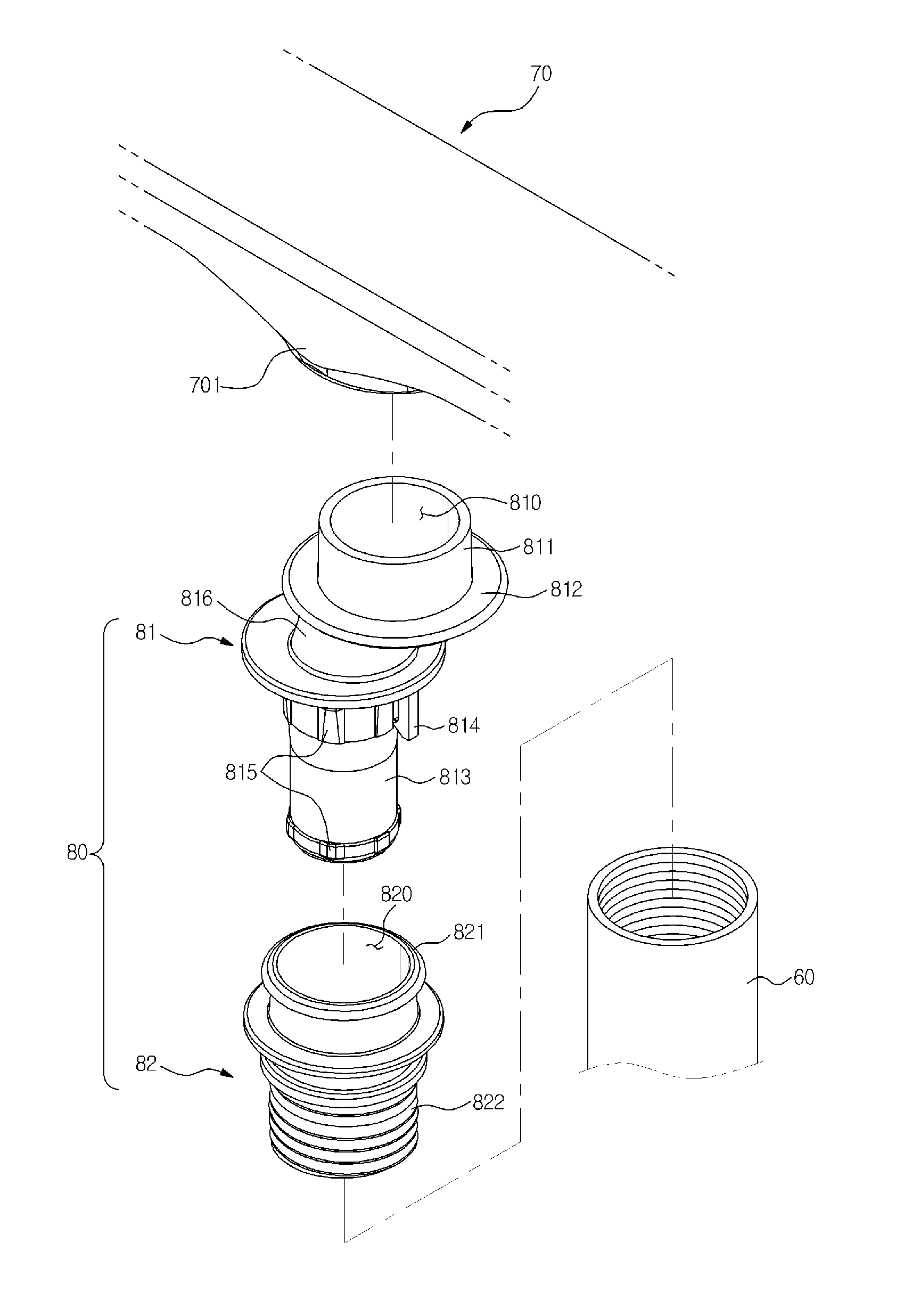

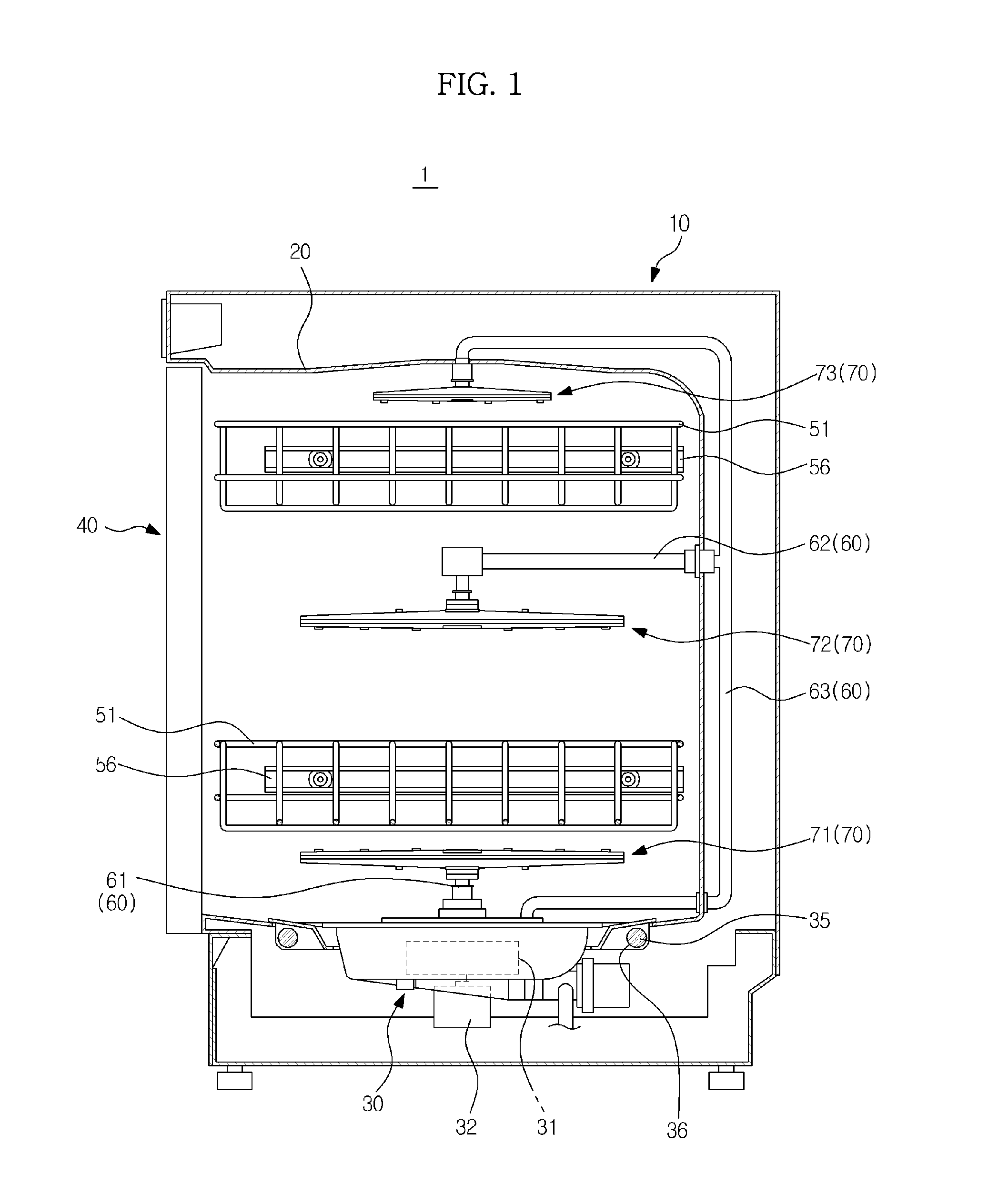

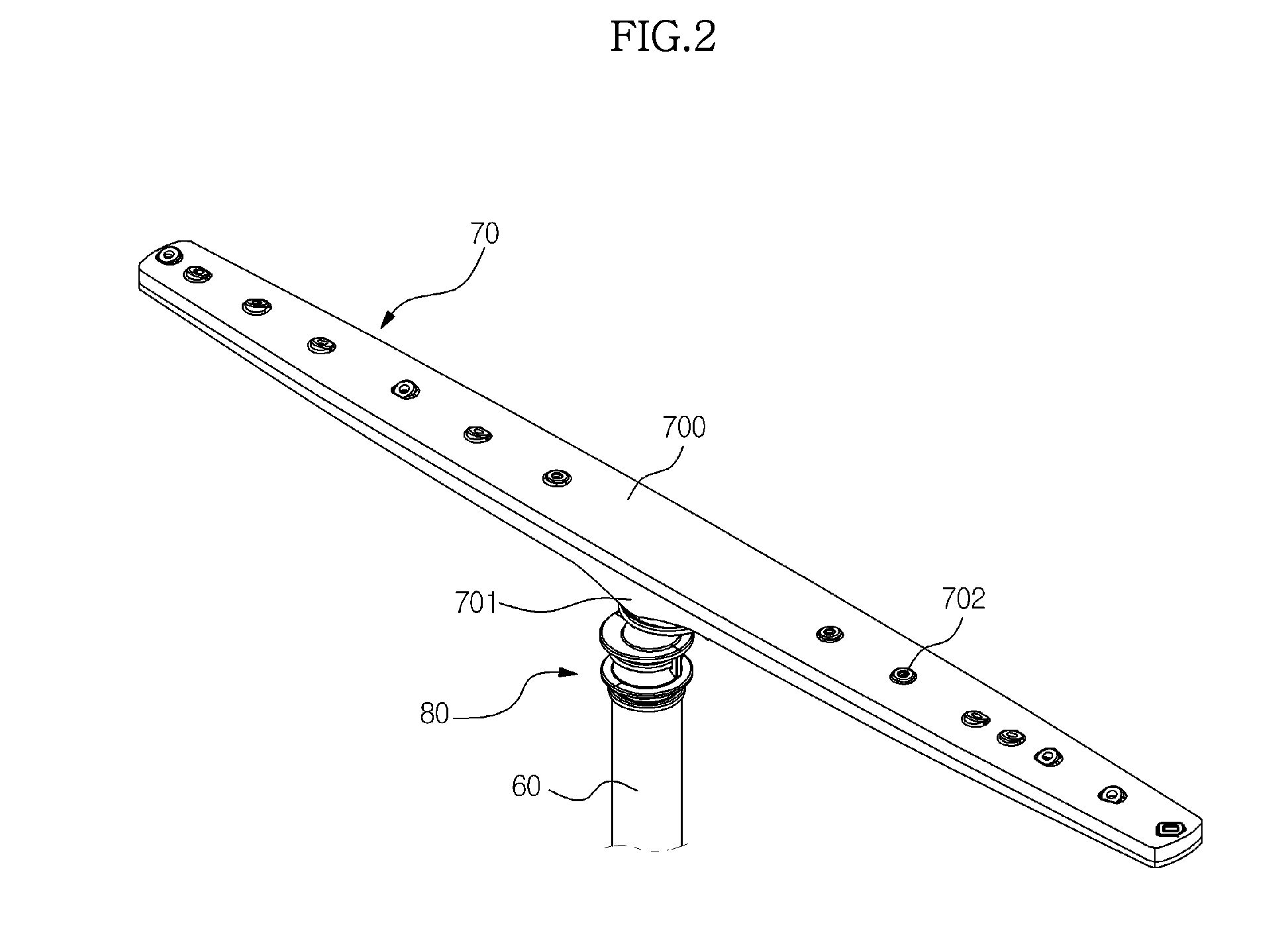

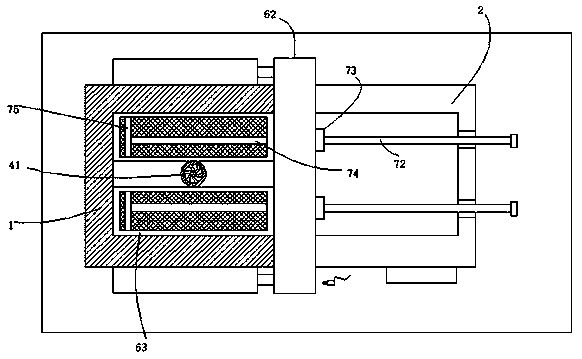

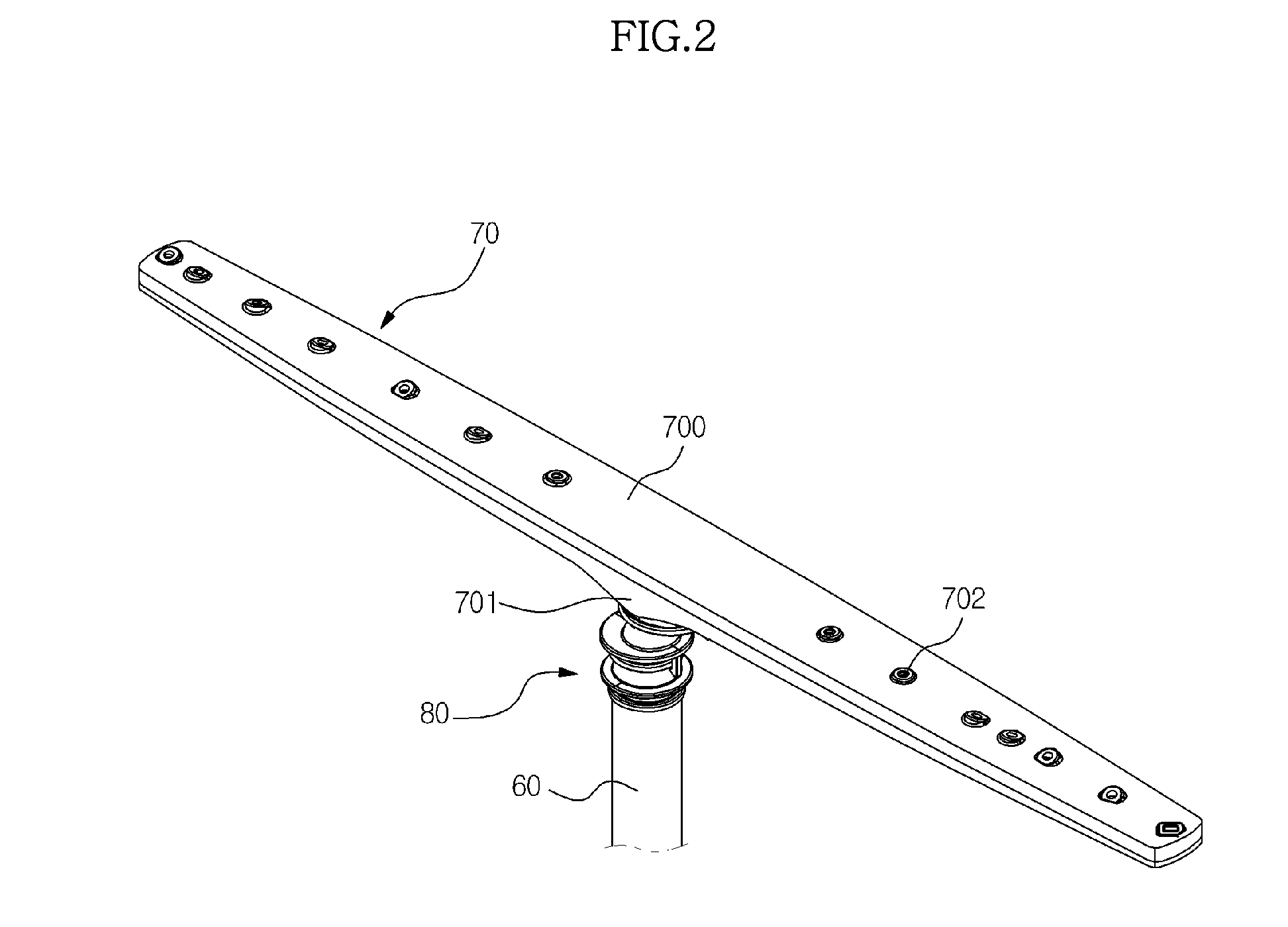

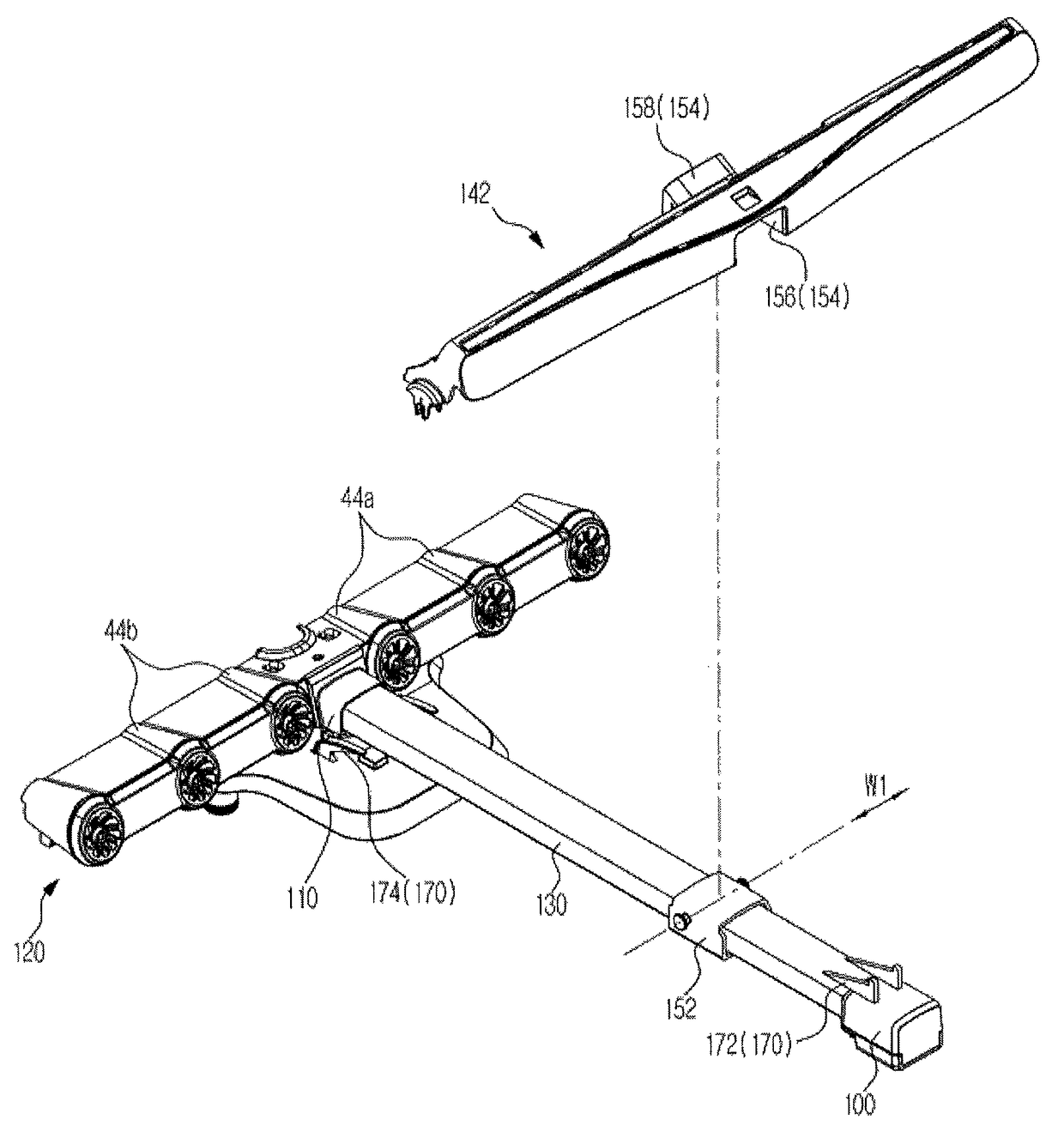

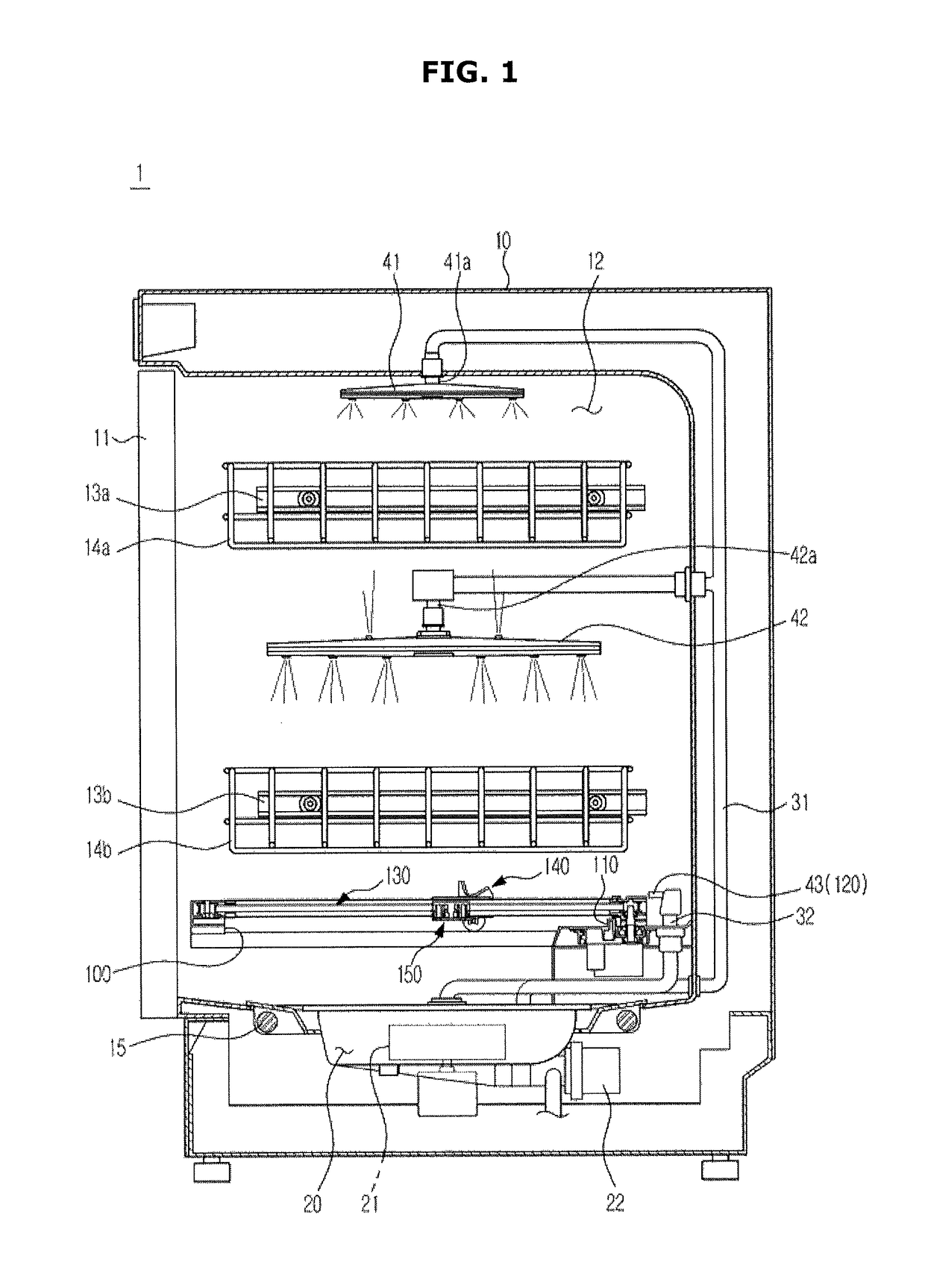

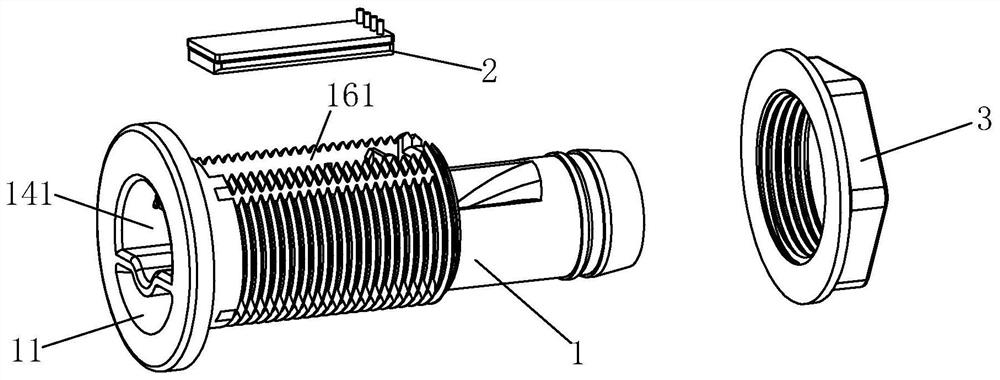

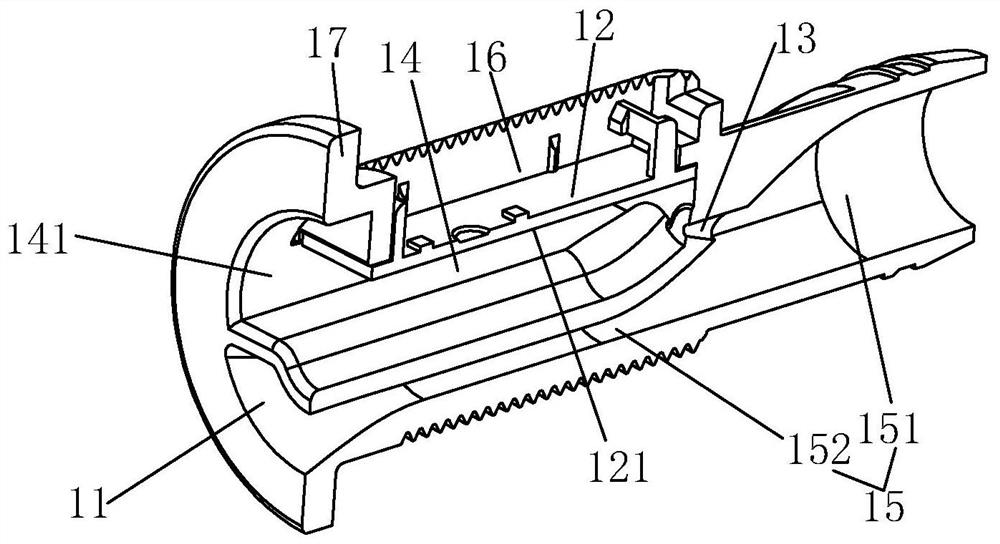

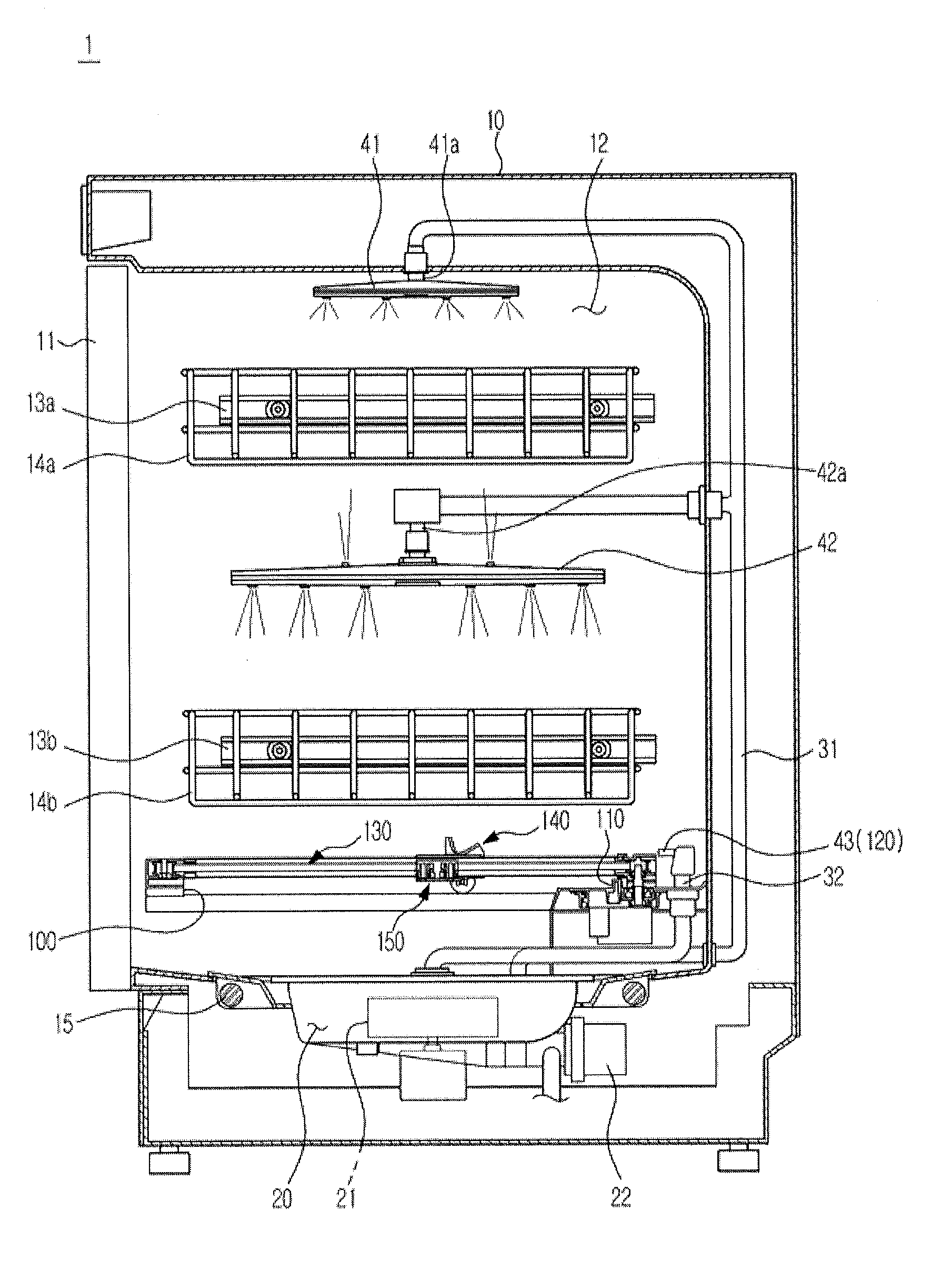

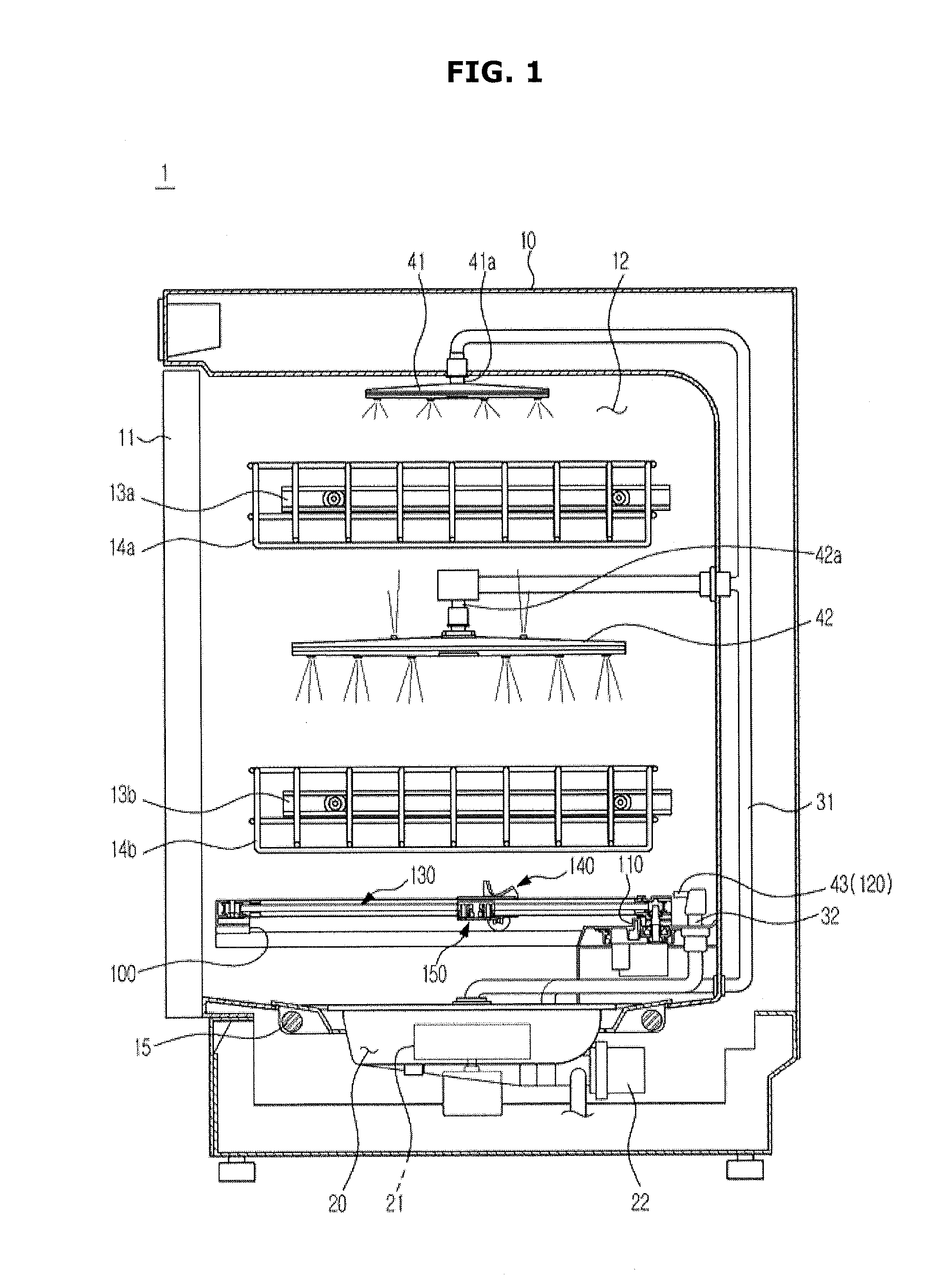

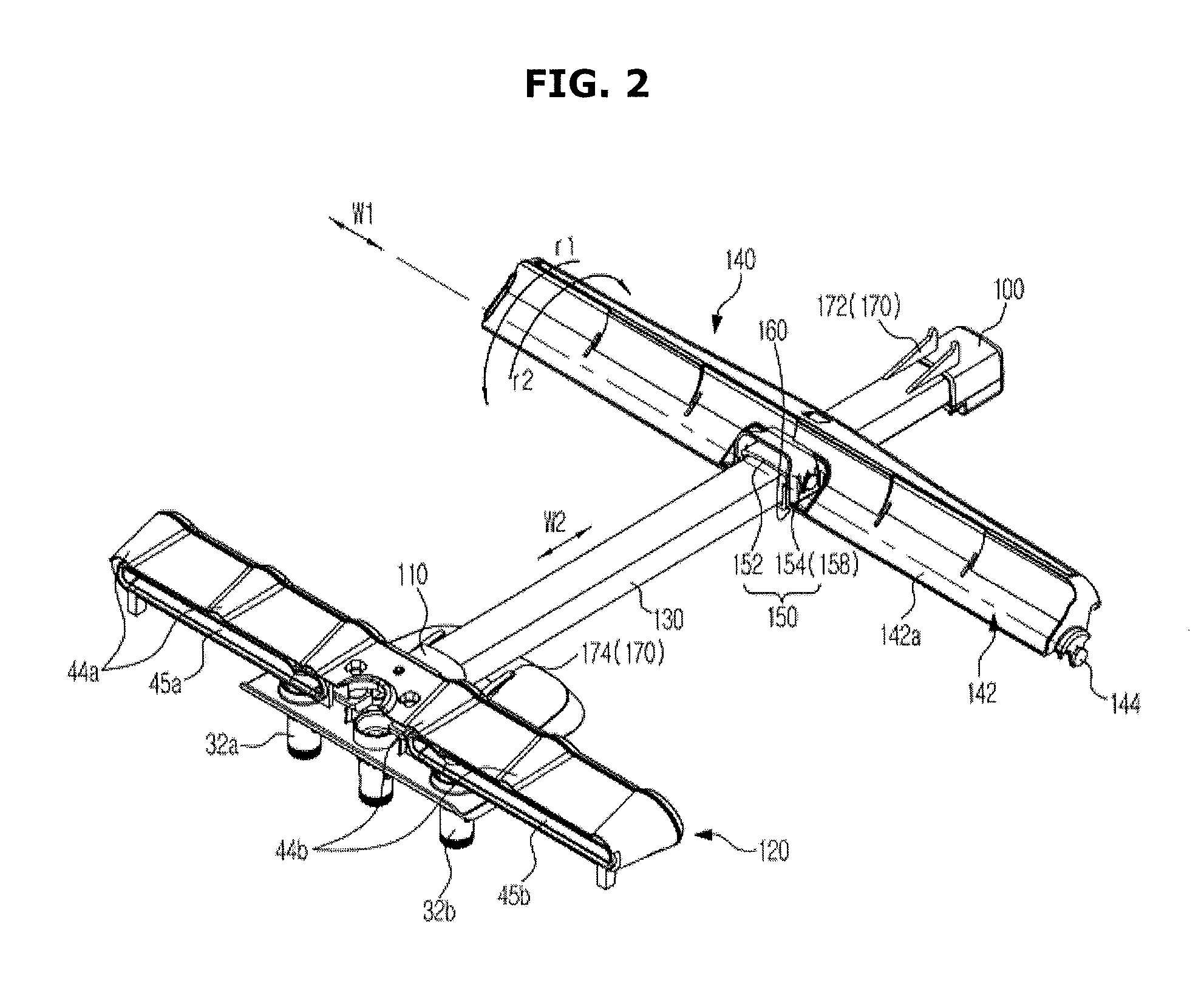

Nozzle assembly for dishwasher and dishwasher having the same

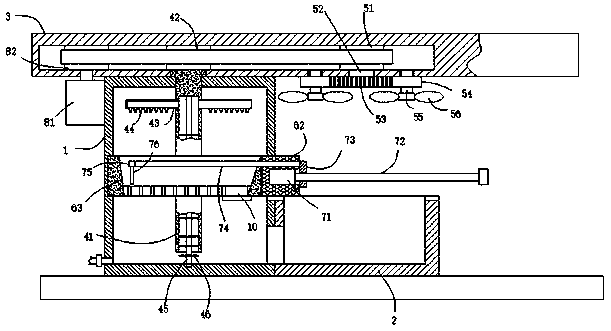

ActiveUS9462927B2Extended wash rangeEvenly spraying wash waterTableware washing/rinsing machine detailsCarpet cleanersWash waterEngineering

Disclosed herein are a nozzle assembly for a dishwasher capable of evenly spraying wash water in a wash tub and a dishwasher having the same. The dishwasher includes a sump to pump wash water, a supply pipe to which the wash water from the sump is supplied, and a nozzle assembly connected to the supply pipe. The nozzle assembly includes a lower rotor arm connected to the supply pipe, an upper rotor arm having a portion rotatably received in the lower rotor arm and having a first rotation center of an upper end thereof and a second rotation center of a lower end thereof positioned eccentrically from the first rotation center, and a nozzle rotatably connected to the upper rotor arm.

Owner:SAMSUNG ELECTRONICS CO LTD

Cotton woven fabric cleaning device

InactiveCN109162043AReduce cleaning dead angleExtended wash rangeMechanical cleaningPressure cleaningBiochemical engineeringCotton material

The invention discloses a cotton woven fabric cleaning device comprising a cleaning tank containing cleaning liquid. A first guiding roller, a second guiding roller and a third guiding roller are arranged successively in the cleaning tank. A first roller brush in contact with the top surface of cotton woven fabric is arranged between the first guiding roller and the second guiding roller; and a second roller brush in contact with the bottom surface of the cotton woven fabric is arranged between the second guiding roller and the third guiding roller. Besides, a first flushing pipe is also arranged in the cleaning tank; and a rotating motor is arranged at the outer side of the cleaning tank. A first arc-shaped groove using the rotating shaft center of the rotating motor as the circle centeris formed in one side of the cleaning tank and is ranged above the cleaning tank; a second arc-shaped groove corresponding to the first arc-shaped groove is formed in the other side of the cleaning tank; one end of the first flushing pipe passes through the first arc-shaped groove and is connected with the rotating shaft of the rotating motor by a connecting rod; and the other end of the first flushing pipe passes through the second arc-shaped groove and is connected with a limiting block. The cotton woven fabric cleaning device has characteristics of high cleaning efficiency and good cleaningeffect.

Owner:湖州南浔维意纺织有限公司

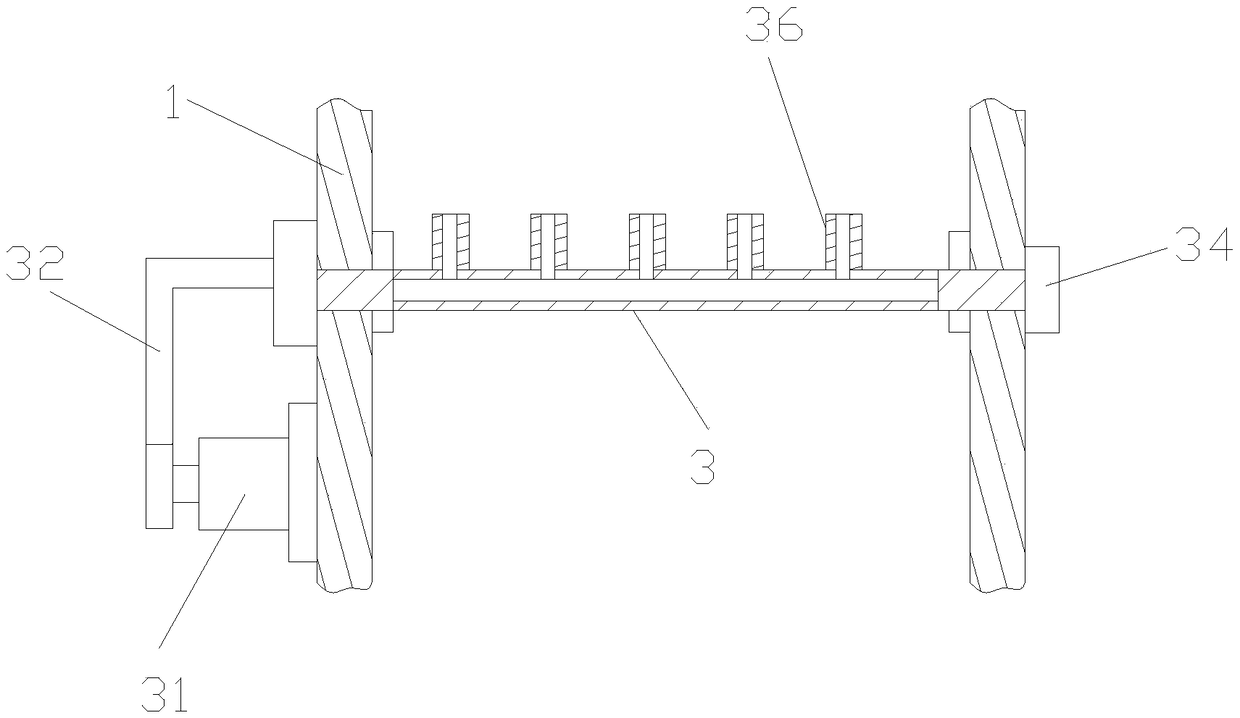

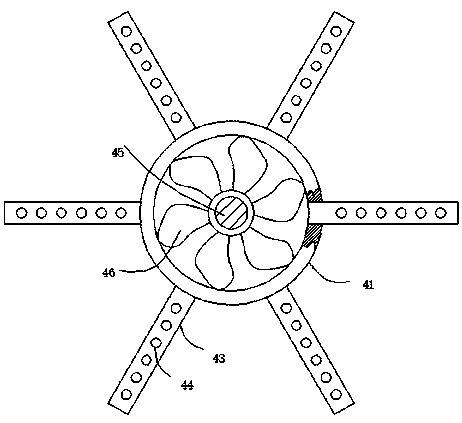

Spray arm assembly for dishwasher and dishwasher having same

ActiveCN105286752BIncreased wash areaEasy to cleanTableware washing/rinsing machine detailsMechanical engineeringNon-circular gear

The invention discloses a gushing arm assembly for a bowl washing machine and a bowl washing machine with the gushing arm assembly. The gushing arm assembly comprises a fixed gear, a main gushing arm, at least one movable gushing arm and a transmission gear, wherein the fixed gear is a non-round gear; the main gushing arm is arranged on the fixed gear around the axial line of the fixed gear in a rotatable manner; a first spraying opening is formed in the main gushing arm; the movable gushing arms are movably arranged on the main gushing arm in the directions close to and far away from the axial line of the fixed gear; a second spraying opening is formed in each movable gushing arm; and the transmission gear is connected with the movable gushing arms in a rotatable manner, is meshed with the fixed gear, and is used for driving the movable gushing arms to move during rotation of the main gushing arm. According to the gushing arm assembly for the bowl washing machine, telescopic moving traces of the movable gushing arms can be formed under the meshing transmission of the transmission gear and the fixed gear, so that the flushing area of the gushing arm assembly is enlarged, and the cleaning effect is enhanced.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

Waste plastic rinsing system

The invention belongs to the field of plastic recycling, and particularly discloses a waste plastic rinsing system. The system aims to solve the problem that an existing rinsing device has low recycling efficiency with the following solutions. The waste plastic rinsing system includes a rinsing box, a water-containing box, a mounting box and a rinsing mechanism, wherein the water -containing box is fixedly arranged at one side of the rinsing box, the mounting box is fixedly arranged at the top of the water-containing box, the rinsing box communicates with the water-containing box, one side, close to the water-containing box, of the rinsing box is provided with an opening, the front of the water-containing box is fixedly provided with a controlling platform, and the rinsing mechanism includes a flushing assembly, a drying assembly, a driving assembly, and a loading assembly. The waste plastic rinsing system has the advantages that the system not only has good rinsing effect, but also the materials can quickly be dried after being rinsed, the continuity of the drying and rinsing process is good, the transfer processing time is greatly shortened, the recycling efficiency is improved,and the two processes can be driven to finish with only a second motor, so that less driving devices are needed to be installed to a certain extent and the cost is reduced.

Owner:安徽中环绿科再生科技有限公司

Nozzle assembly for dishwasher and dishwasher having the same

ActiveUS20140069472A1Extended wash rangeEvenly spraying wash waterTableware washing/rinsing machine detailsCarpet cleanersWash waterEngineering

Disclosed herein are a nozzle assembly for a dishwasher capable of evenly spraying wash water in a wash tub and a dishwasher having the same. The dishwasher includes a sump to pump wash water, a supply pipe to which the wash water from the sump is supplied, and a nozzle assembly connected to the supply pipe. The nozzle assembly includes a lower rotor arm connected to the supply pipe, an upper rotor arm having a portion rotatably received in the lower rotor arm and having a first rotation center of an upper end thereof and a second rotation center of a lower end thereof positioned eccentrically from the first rotation center, and a nozzle rotatably connected to the upper rotor arm.

Owner:SAMSUNG ELECTRONICS CO LTD

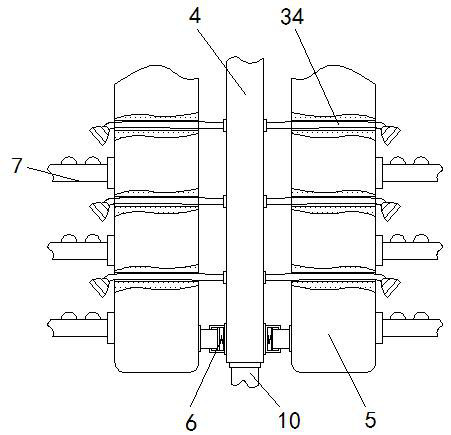

Spraying arm assembly for dish-washing machine and dish-washing machine with spraying arm assembly

InactiveCN105595942AExtended wash rangeImprove washing effectTableware washing/rinsing machine detailsCleaning equipmentEngineeringCam

The invention discloses a spraying arm assembly for a dish-washing machine and the dish-washing machine with the spraying arm assembly. The spraying arm assembly for the dish-washing machine comprises a fixed gear, a main spraying arm, movable spraying arms and cams, wherein the main spraying arm can be rotationally arranged on the fixed gear; a first cavity is limited in the main spraying arm, and first water spraying openings communicated with the first cavity are formed in the main spraying arm; the movable spraying arms are arranged on the main spraying arm in a sliding manner in the direction that the main spraying arm is close to and away from the rotating central shaft of the main spraying arm; second cavities communicated with the first cavity are limited in the movable spraying arms; second water spraying openings are formed in the movable spraying arms; the cams are rotationally arranged on the main spraying arm; the movable spraying arms are connected with the cams, so that the movable spraying arms can be pushed to move when the cams rotate; transmission gears fixed to the cams at the corresponding positions are arranged on the cams; the transmission gears are meshed with the fixed gear, and are used for driving the cams to rotate when the main spraying arm rotates. According to the spraying arm assembly for the dish-washing machine, the washing area is large, and the cleaning effect is good.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD +1

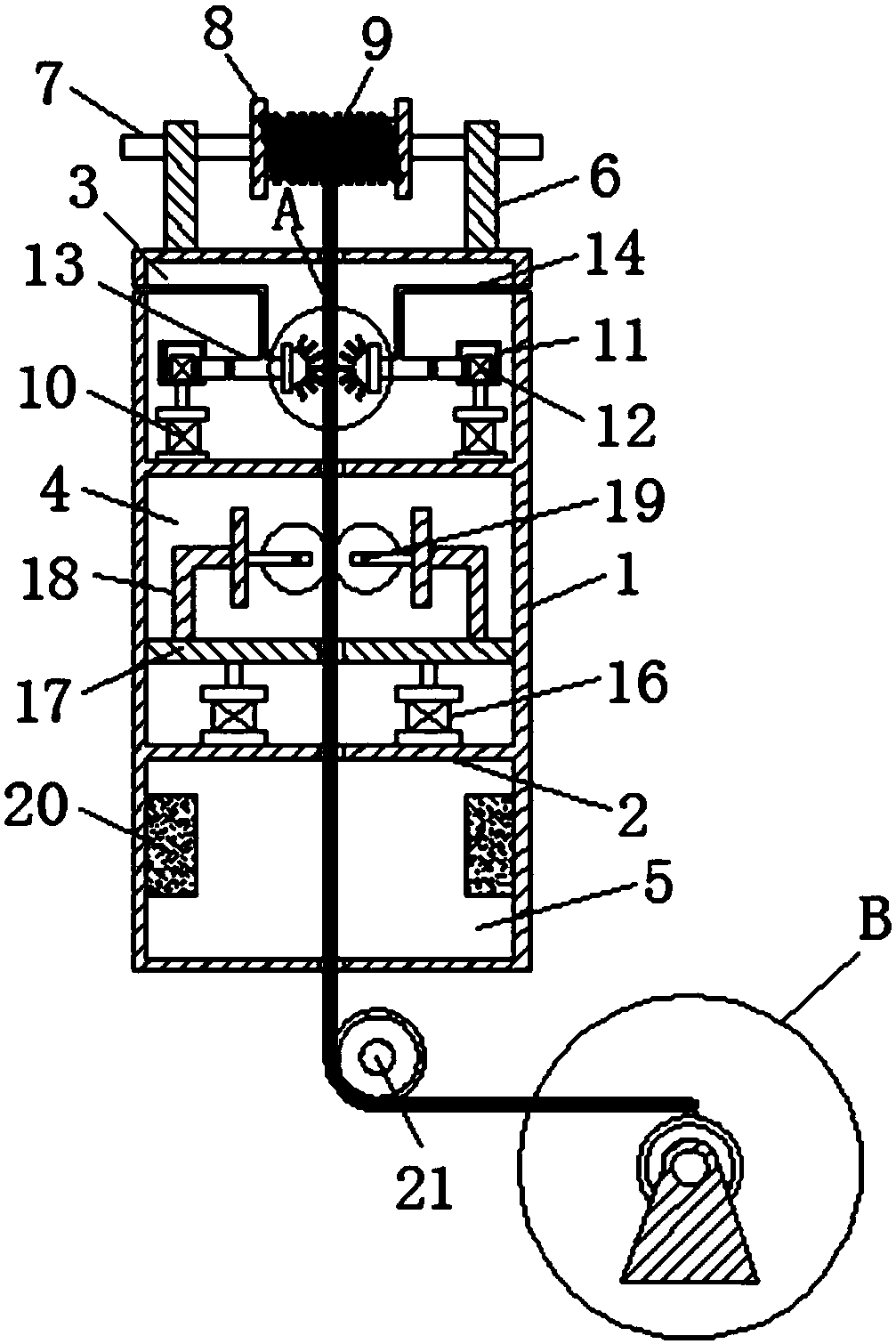

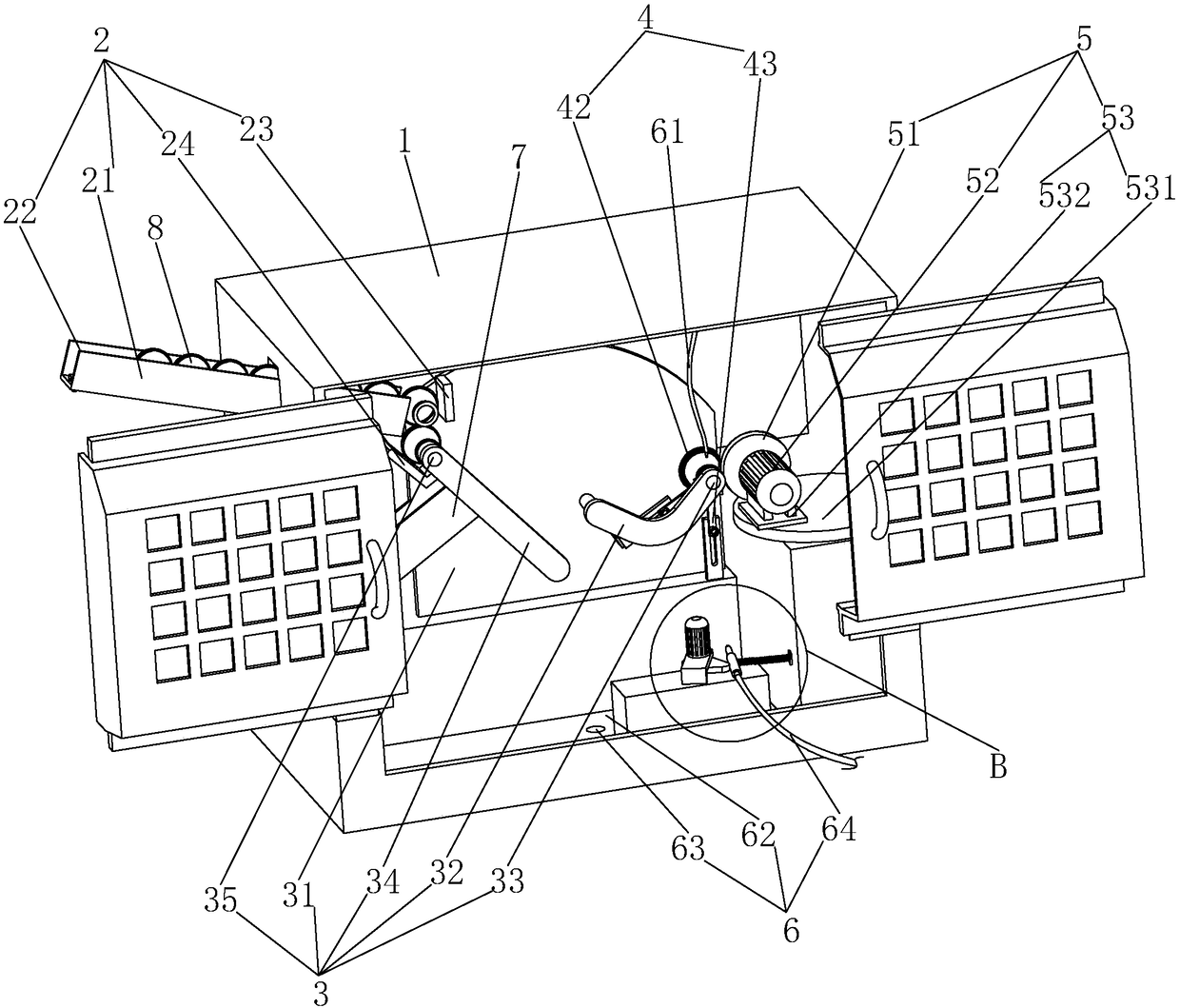

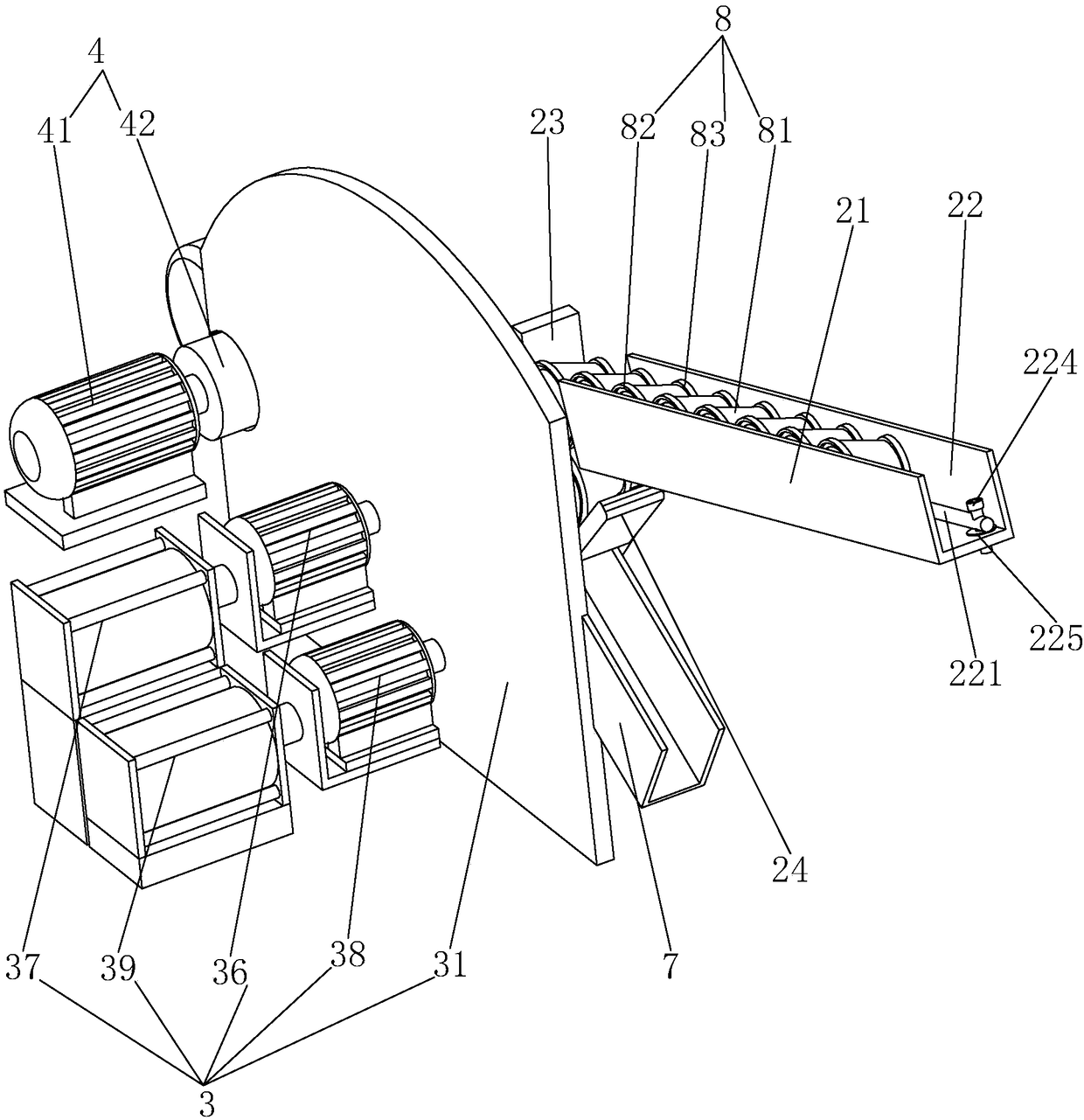

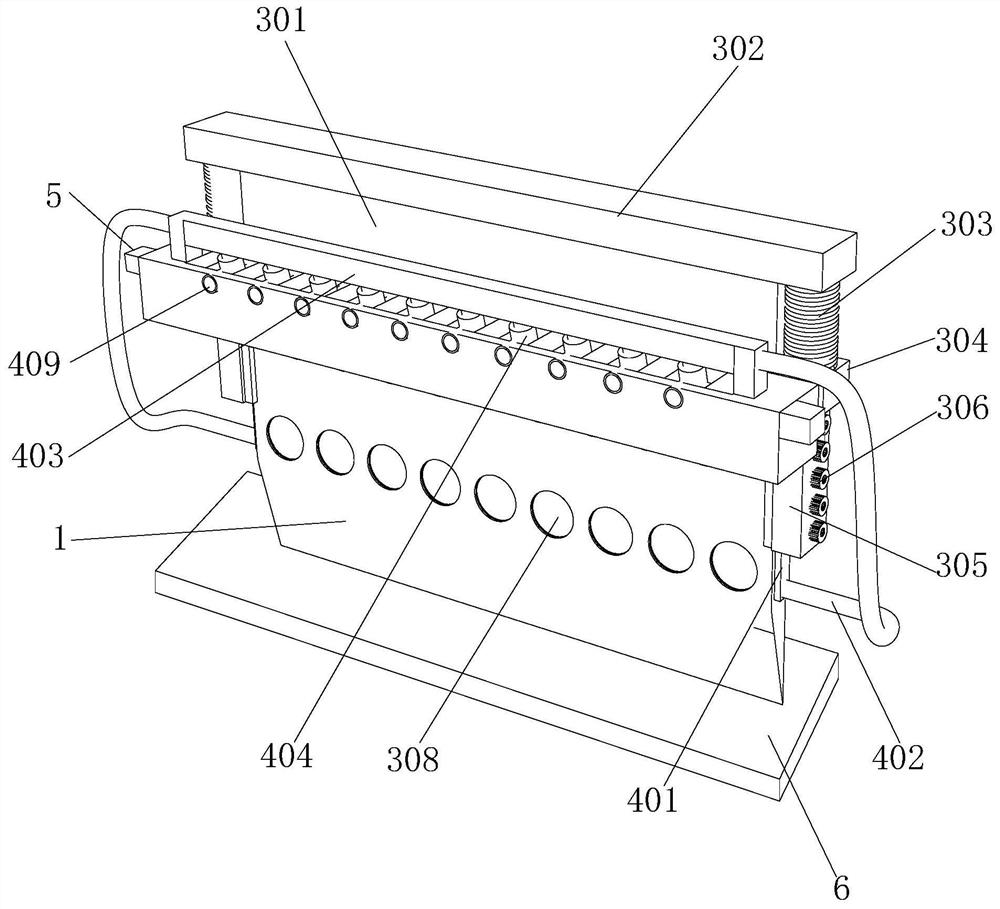

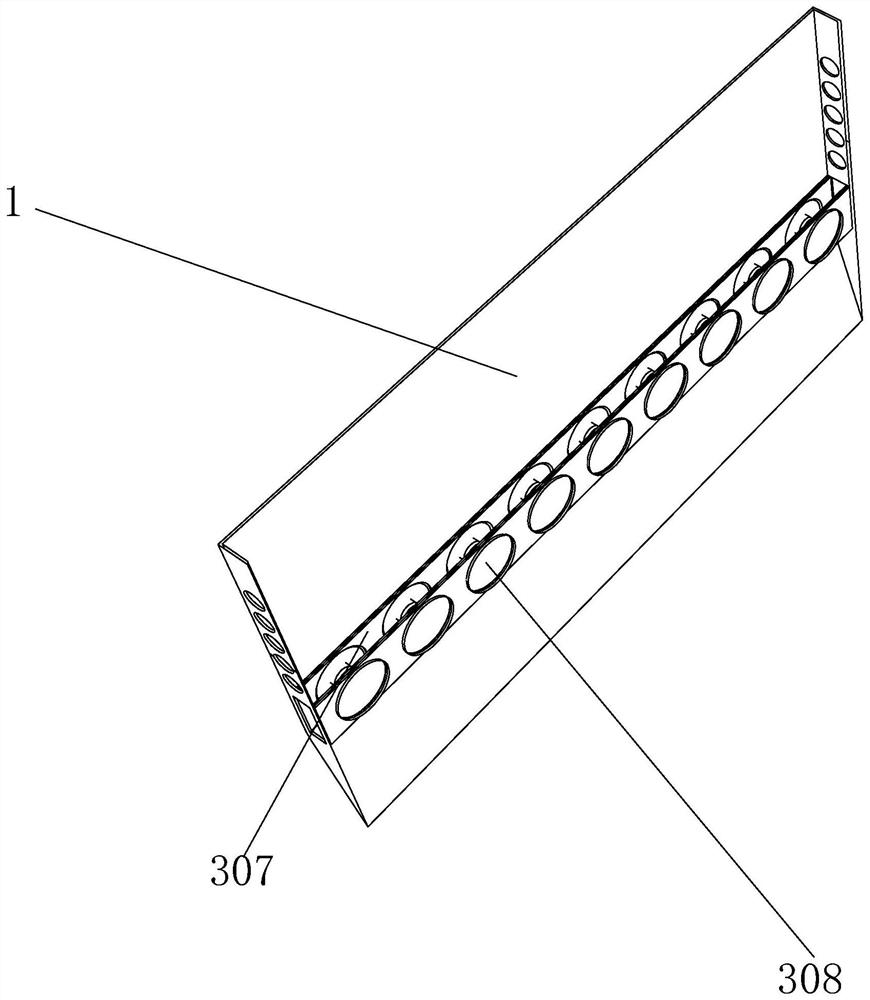

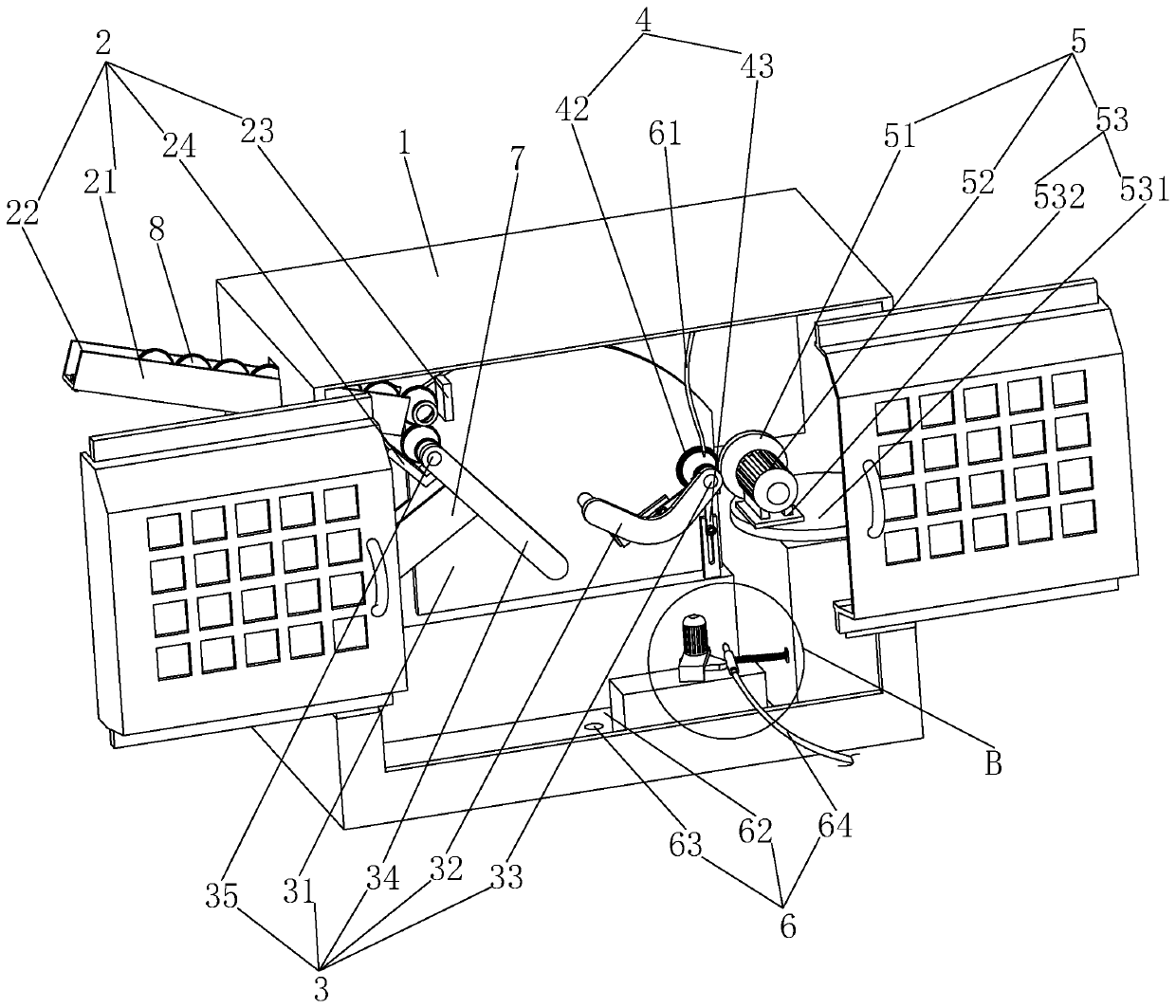

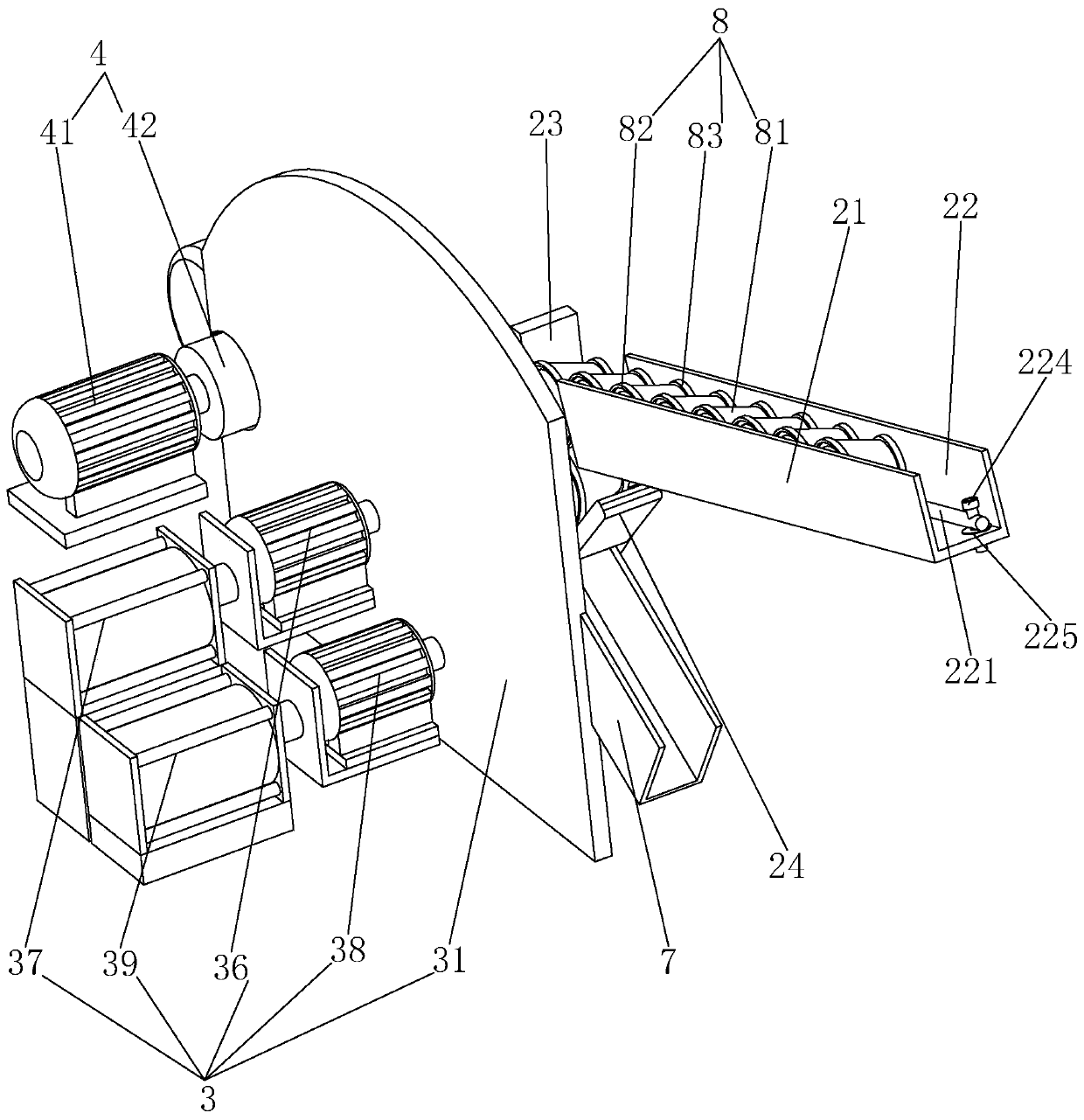

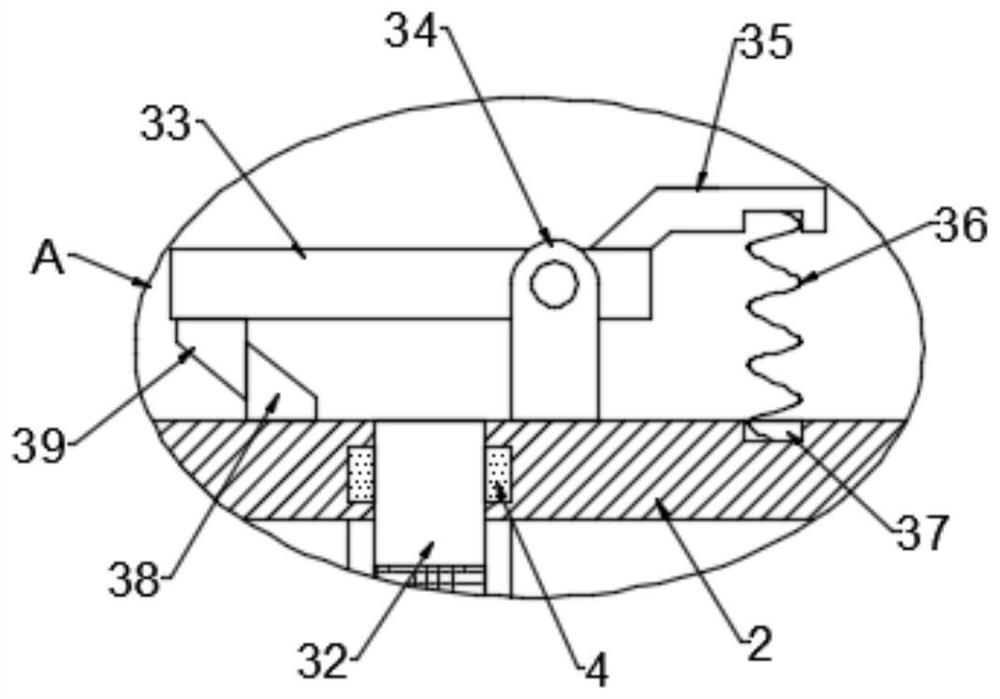

Grinding machine for inner ring of bearing

ActiveCN108326695AReduce adhesionReduce the possibilityGrinding machinesGrinding feedersEngineeringGrinding wheel

The invention relates to the technical field of bearing processing equipment, and discloses a grinding machine for an inner ring of a bearing. The machine comprises a machine body, a feeding mechanism, a charging and discharging mechanism, a workpiece mounting mechanism, a grinding mechanism, and a cleaning mechanism which is arranged on the machine body and used for cleaning waste dust of a grinding wheel, wherein the cleaning mechanism comprises a spraying pipe which is arranged on the machine body and is positioned above the workpiece mounting mechanism, a collecting platform which is arranged at the lower side of the machine body, an unloading port which is formed in the collecting platform, a flushing water pipe which is arranged on the collecting platform, and a driving part which isarranged on the collecting platform and used for driving a nozzle of the flushing water pipe to swing in a reciprocating manner. According to the machine, a workpiece is cooled through the spraying pipe, and meanwhile, the machine body is sprayed by the spraying pipe, so that the possibility that the waste dust of the grinding wheel is attached to the machine body is reduced; the collecting platform is flushed through the flushing water pipe, thus the waste dust, accumulated on the collecting platform, of the grinding wheel is flushed into the unloading port, and finally, the waste dust of the grinding wheel is discharged from one side of the unloading port, and as a result, the fallen waste dust of the grinding wheel can be effectively cleaned.

Owner:GOLDEN HORSE BEARING ZHEJIANG

Silk rinsing device for textile production

InactiveCN111876927AImprove rinsing efficiencyQuality improvementTextile treatment machine arrangementsTextile treatment carriersPolymer scienceWater flow

The invention discloses a silk rinsing device for textile production, and relates to the technical field of textile production. The problem that in the stirring process, impurities at the bottom of apool are prone to being stirred up again, and consequently the silk rinsing efficiency is reduced is solved. The device specifically comprises a base, wherein a box body is fixedly mounted at the topof the base, a box cover is fixedly mounted at the top end of the box body, a filter communicating with the bottom of the box body is fixedly mounted at the top of the base, a conveying pump is fixedly mounted at the outlet end of the filter, and a plurality of rectangular grooves are formed in the top of the box cover. According to the silk rinsing device, blowing branch pipes and multiple flushing spray heads are sprayed to the surfaces of the two sides of a rinsing net box mechanism, silk is rinsed through water flow, and the silk is driven by the water flow to be stirred in the rinsing netbox mechanism in the rinsing process, so that the silk rinsing efficiency is improved; and cleaning liquid circulates from the bottom of the box body, so that impurities can be carried into the filter to be purified, and the silk rinsing quality is improved.

Owner:宣城红妆美人床上用品有限公司

Potato slicing anti-sticking device

InactiveCN112476592AFast pushAvoid stickingMetal working apparatusAgricultural engineeringStructural engineering

The invention provides a potato slicing anti-sticking device, and relates to the technical field of potato processing. The potato slicing anti-sticking device comprises a cutter body, a telescopic device, an anti-sticking mechanism, cleaning mechanisms, supports and a chopping board, the telescopic device is arranged on the cutter body, the anti-sticking mechanism is arranged at the bottom end ofthe telescopic device, and the potato slicing effect is prevented from being affected due to the fact that potato slices are stuck to the cutter body through the anti-sticking mechanism; and the top end of the anti-sticking mechanism is fixedly connected with the top end of the telescopic device. The anti-sticking mechanism is arranged in the cutter body, the cleaning mechanisms are arranged at the two sides of the cutter body, starch remaining on the cutter body is cleaned through the cleaning mechanisms, and the phenomenon that the potato slices are stuck to spherical elastic pieces, and when the spherical elastic pieces shrink, the potato slices are attached to the cutter body in a following manner can be avoided. The cleaning mechanisms are fixedly connected with the two sides of the cutter body, the supports are arranged at the positions, located at the top end of the cutter body, of the two sides of the cleaning mechanisms, the two sides of the cleaning mechanisms are fixedly connected with the supports, the chopping board is arranged at the bottom end of the cutter body, and the problem that the potato slices stuck to the cutter body during potato slicing is solved.

Owner:余吉坤

A bearing inner ring grinding machine

ActiveCN108326695BReduce adhesionReduce the possibilityGrinding machinesGrinding feedersEngineeringGrinding wheel

The invention relates to the technical field of bearing processing equipment, and discloses a grinding machine for an inner ring of a bearing. The machine comprises a machine body, a feeding mechanism, a charging and discharging mechanism, a workpiece mounting mechanism, a grinding mechanism, and a cleaning mechanism which is arranged on the machine body and used for cleaning waste dust of a grinding wheel, wherein the cleaning mechanism comprises a spraying pipe which is arranged on the machine body and is positioned above the workpiece mounting mechanism, a collecting platform which is arranged at the lower side of the machine body, an unloading port which is formed in the collecting platform, a flushing water pipe which is arranged on the collecting platform, and a driving part which isarranged on the collecting platform and used for driving a nozzle of the flushing water pipe to swing in a reciprocating manner. According to the machine, a workpiece is cooled through the spraying pipe, and meanwhile, the machine body is sprayed by the spraying pipe, so that the possibility that the waste dust of the grinding wheel is attached to the machine body is reduced; the collecting platform is flushed through the flushing water pipe, thus the waste dust, accumulated on the collecting platform, of the grinding wheel is flushed into the unloading port, and finally, the waste dust of the grinding wheel is discharged from one side of the unloading port, and as a result, the fallen waste dust of the grinding wheel can be effectively cleaned.

Owner:GOLDEN HORSE BEARING ZHEJIANG

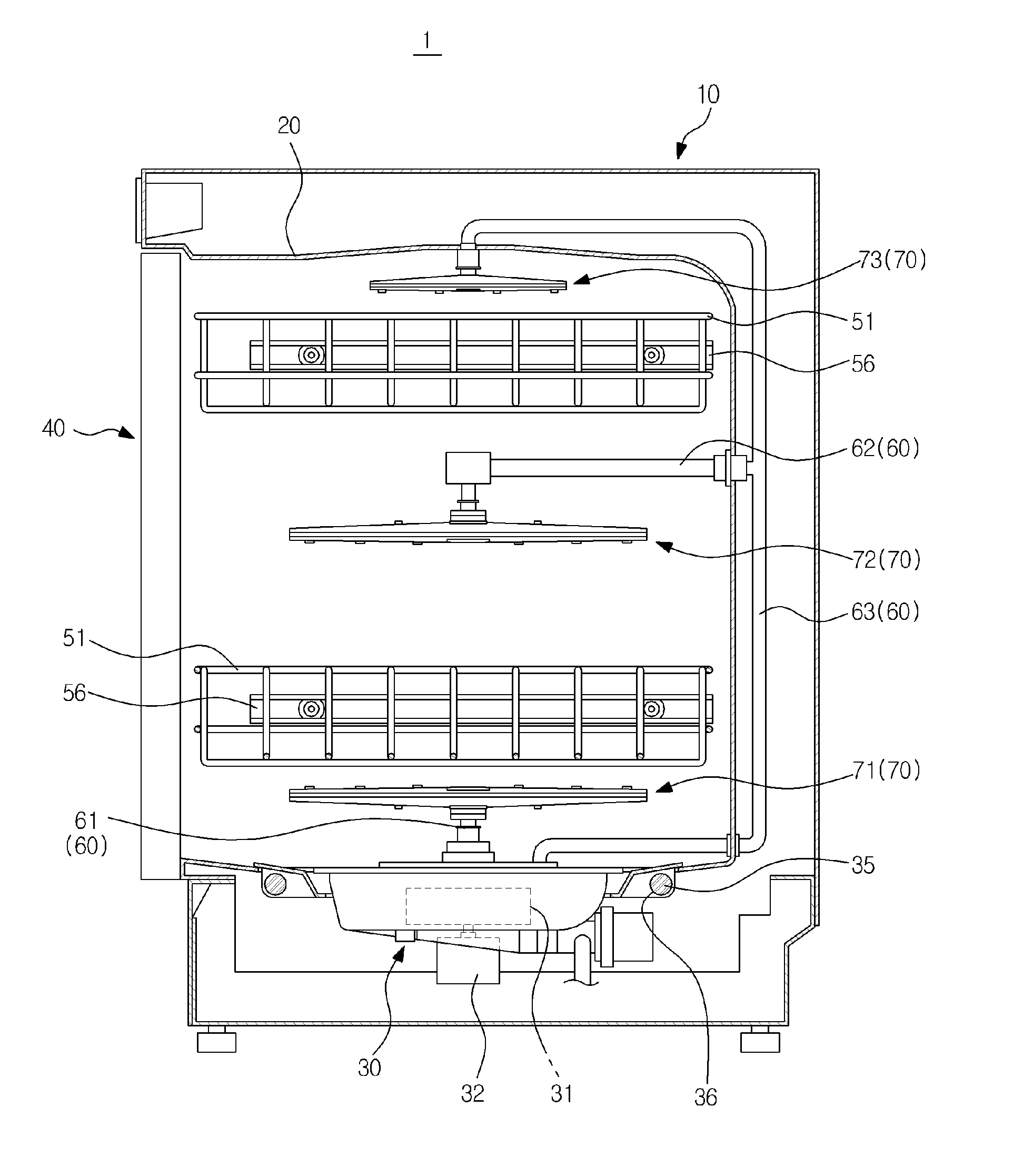

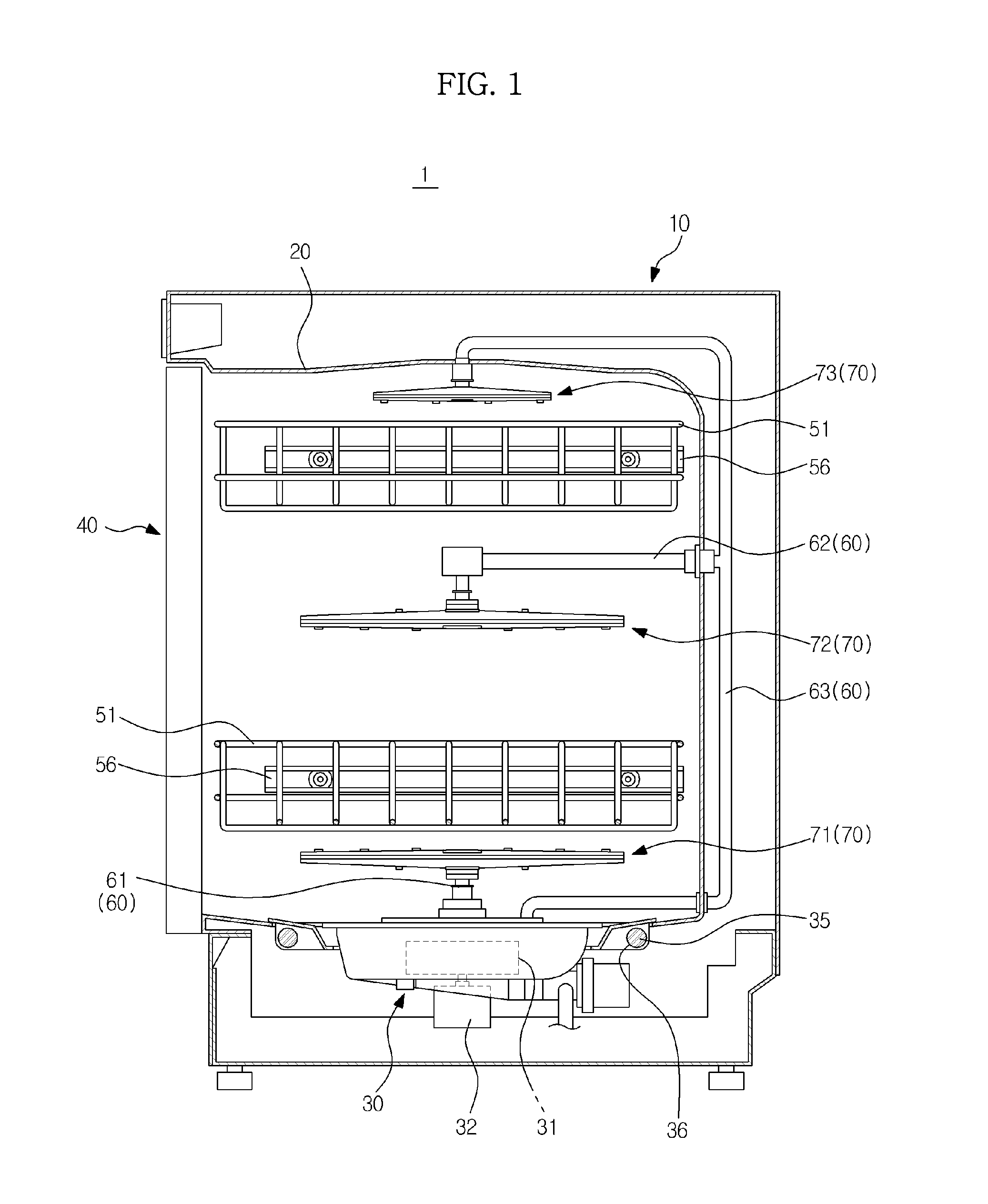

Dishwasher

ActiveUS9706896B2Extended wash rangeSimple structureTableware washing/rinsing machine detailsWash waterNoise minimization

A dishwasher having a spray unit fixed at a washing tub and configured to spray wash water, and a conversion assembly provided as to convert the direction of the wash water being sprayed from the spray unit toward a tableware basket. The conversion assembly includes a vane rotatably provided while disposed as to face with respect to the spray unit such that the direction of the converted wash water is adjusted. Through the structure as such, the spraying range of the wash water is extended, and may be able to minimize noise from the striking of the wash water against an inside wall or door of the dishwasher.

Owner:SAMSUNG ELECTRONICS CO LTD

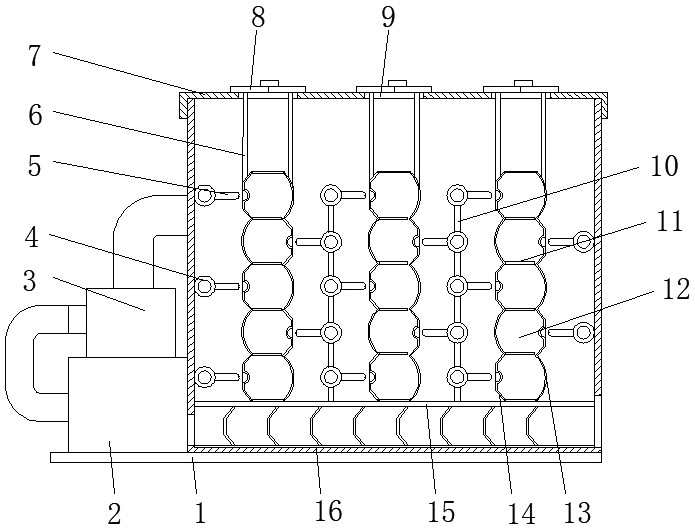

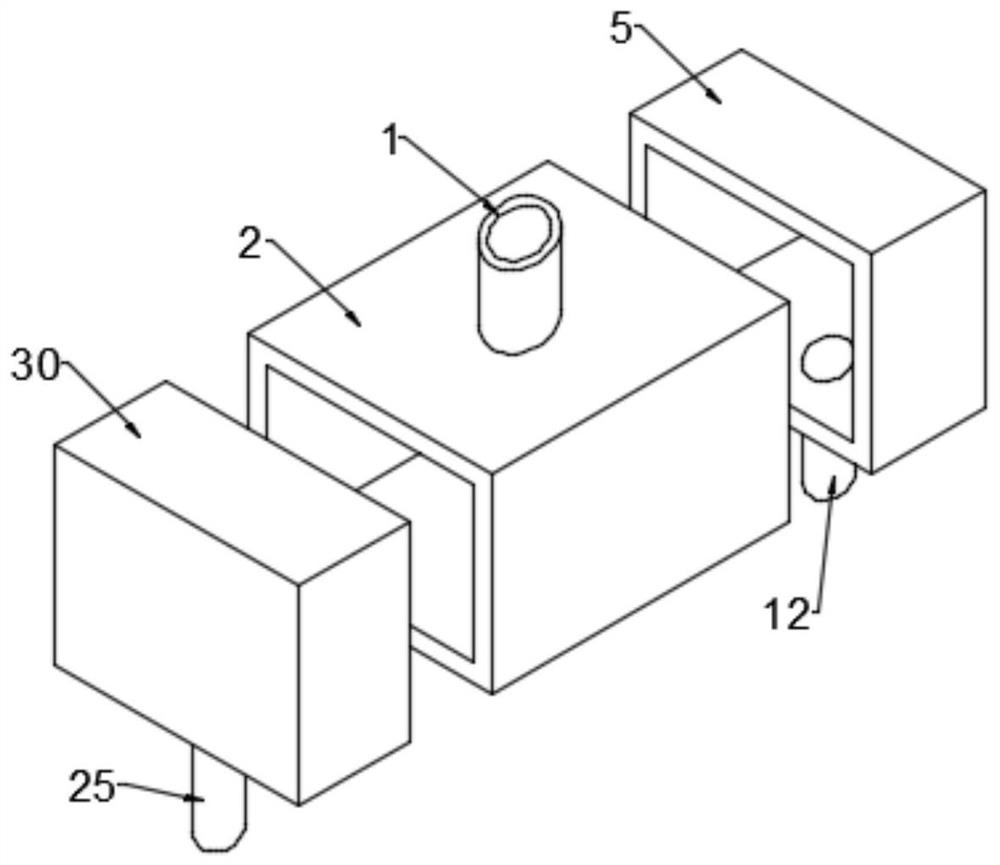

Automatic backwash filtering sewage treatment system based on big data

ActiveCN112121497AExtended wash rangeImprove filtering effectStationary filtering element filtersSewage treatmentWater treatment system

The invention is applicable to the technical field of sewage treatment, and provides an automatic backwash filtering sewage treatment system based on big data. The system comprises a central cylinder,wherein a first side cylinder and a second side cylinder are respectively arranged on two sides of the central cylinder, a first filter plate is arranged between the central cylinder and the first side cylinder, a second filter plate is arranged between the central cylinder and the second side cylinder, the bottom of the first side cylinder is connected with a first water outlet pipe, the bottomof the second side cylinder is connected with a second water outlet pipe, water spraying plates are arranged in the first side cylinder and the second side cylinder, a controller is installed at the bottom of a water receiving tank, and a water conveying assembly is arranged on the water receiving tank. According to the automatic backwash filtering sewage treatment system based on big data, on-offof a first electromagnetic valve, a second electromagnetic valve, a third electromagnetic valve and a fourth electromagnetic valve can be controlled through the controller according to actual conditions, water in the water receiving tank is pumped through the pump and sent to the water spraying plates, backwash is conducted on the first filter plate and the second filter plate, and the filteringefficiency is improved.

Owner:深圳市长菁环保科技有限公司

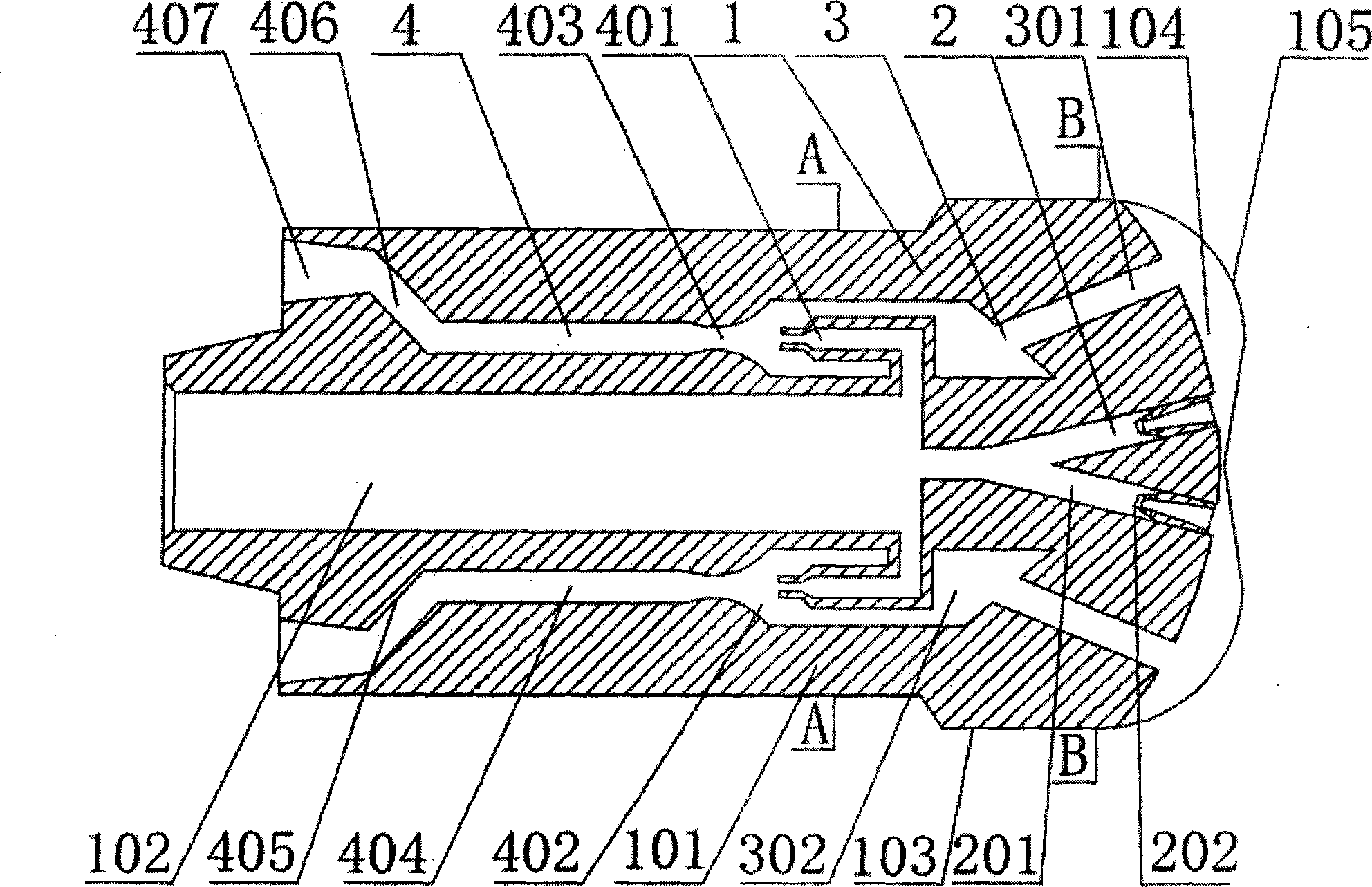

Jet detection nozzle with self-cleaning function and closestool

The invention discloses a jet detection nozzle with a self-cleaning function and a closestool. The jet detection nozzle is mounted at a jet orifice at the bottom of a urinal of the closestool, the jet detection nozzle comprises a nozzle main body and a detection sensor, the nozzle main body is provided with a jet orifice capable of communicating with a water seal of the closestool, and the detection sensor is arranged on the nozzle main body. The nozzle main body is provided with a transparent detection window corresponding to a sensing head of the detection sensor, and one surface, back to the sensing head, of the detection window is a detection surface; and the nozzle main body is further provided with a self-cleaning cleaning hole, and water entering the self-cleaning cleaning hole can clean the detection surface and is discharged into a closestool water seal. According to the invention, dirt can be effectively prevented from remaining on the detection surface of the detection window so that the influence of dirt remaining on the detection surface on the accuracy of detection data of the detection sensor is avoided.

Owner:JOMOO KITCHEN & BATHROOM

Dishwasher

ActiveUS20150182102A1Extended wash rangeSimple structureTableware washing/rinsing machine detailsElectrostatic cleaningWash waterNoise minimization

A dishwasher having a spray unit fixed at a washing tub and configured to spray wash water, and a conversion assembly provided as to convert the direction of the wash water being sprayed from the spray unit toward a tableware basket. The conversion assembly includes a vane rotatably provided while disposed as to face with respect to the spray unit such that the direction of the converted wash water is adjusted. Through the structure as such, the spraying range of the wash water is extended, and may be able to minimize noise from the striking of the wash water against an inside wall or door of the dishwasher.

Owner:SAMSUNG ELECTRONICS CO LTD

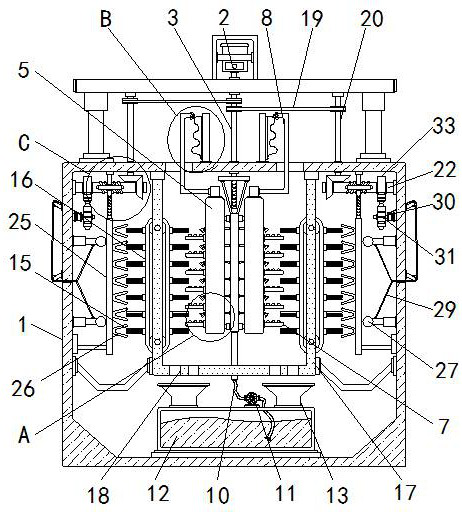

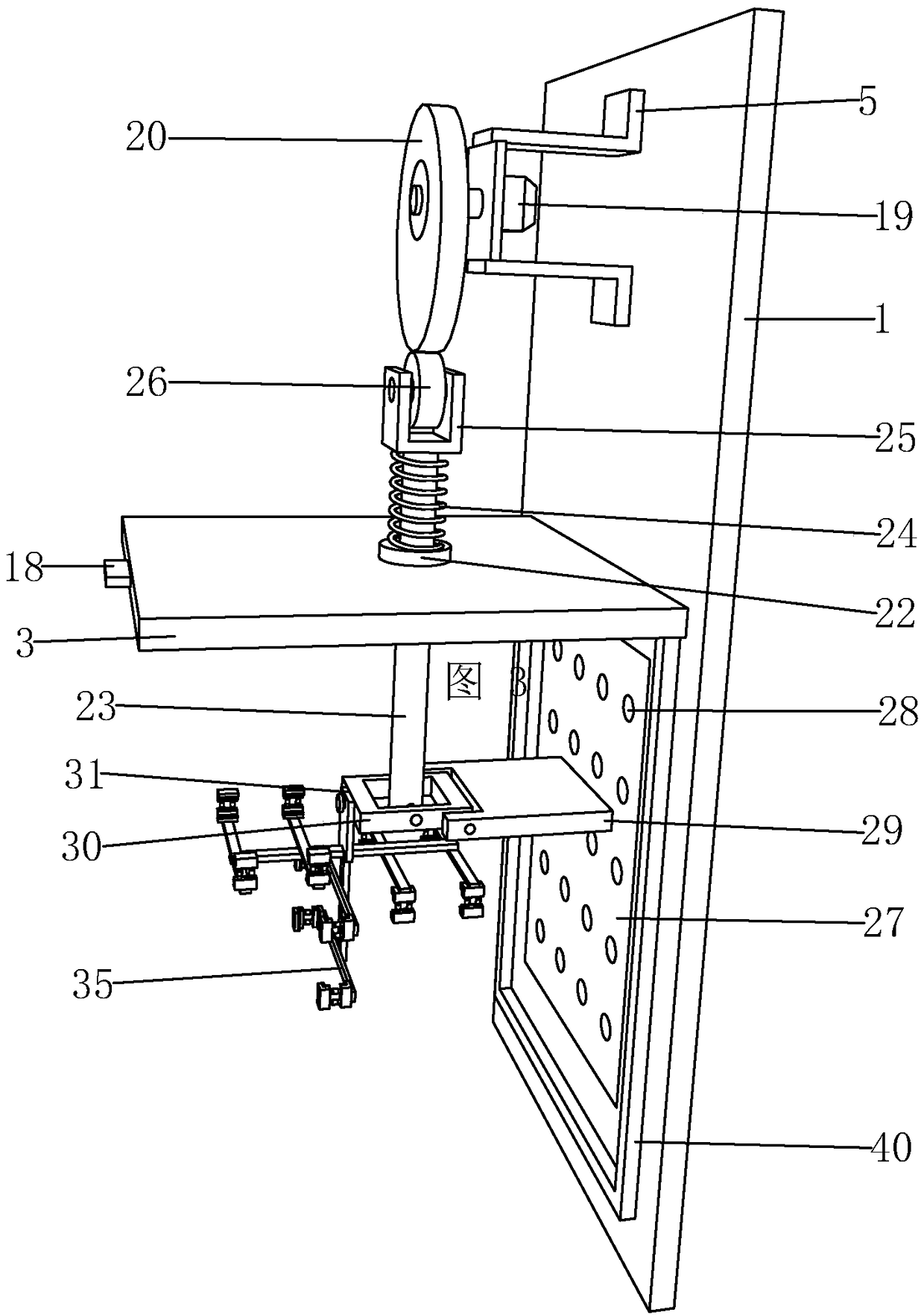

Cleaning device for production of brake pad and cleaning method

ActiveCN109290254AExtended wash rangeImprove washing effectCleaning using liquidsCleaning methodsEngineering

The invention discloses a cleaning device for production of a brake pad and a cleaning method. The cleaning device comprises a supporting flat plate and supporting feet; a backup plate, a cleaning cover, fixing brackets and a liquid pumping pump are arranged on the supporting flat plate, the backup plate is provided with a transmission assembly, and the transmission assembly comprises a supportingblock, a transmission rod, a pressure spring and a U-shaped seat; one end of the transmission rod is arranged on the U-shaped seat, the supporting flat plate is provided with a liquid draining plate,and the liquid draining plate is provided with a mounting base; and the mounting base is movably connected with a swinging plate, and the swinging plate is movably connected with the other end of thetransmission rod. The cleaning method comprises the following steps of (a) mounting of the brake pad, (b) preparation, (c) cleaning, (d) still standing and (e) removing. The cleaning device is novelin structure, flexible in connection, high in cleaning efficiency and good in cleaning effect, and thus the quality of the brake pad is ensured; and the cleaning method is easy to operate and control,segmented cleaning is achieved, the cleaning effect is improved, and the comprehensive and thorough effects are achieved.

Owner:SHAOXING WISDOM AUTO PARTS

Surface treatment device for charging pile accessory production

InactiveCN110918519AImprove filtering effectImprove purification qualityCleaning using toolsCleaning using liquidsWater rinsingSewage

The invention belongs to the technical field of charging pile accessory production, and particularly relates to a surface treatment device for charging pile accessory production. Aiming at the problemthat a supporting metal plate is put into the inner part of a water pool, running water in and out washes the supporting metal plate, then supporting metal plate bails out and is dried, or way of cleaning treatment is carried out by adopting manual wiping, so that the surface treatment efficiency of the supporting metal plate is affected, the following scheme is proposed. The surface treatment device comprises a box body, the top end of the box body is fixedly provided with a box cover, the inner part of the box body is fixedly provided with a supporting mesh plate, and the inner part of thebox body is provided with a conveying mechanism. In the surface treatment device for charging pile accessory production, the rotating speed of a roller brush is faster than the rotating speed of a sponge sleeve, slow cleaning liquid coats on the surface of the metal plate through the sponge sleeve at the front end, after the roller brush is brushed, the sponge sleeve at the rear and a washing mechanism can wash sewage and oil stains out, so that the surface of the charging pile metal plate part is quickly cleaned to remove the oil stains, the adhesion of a plurality of metal plate parts is avoided due to the oil stain when a manipulator grasps the metal plate parts, and the assembling work of the charging pile is convenient.

Owner:株洲瑞尔泰机电科技有限公司

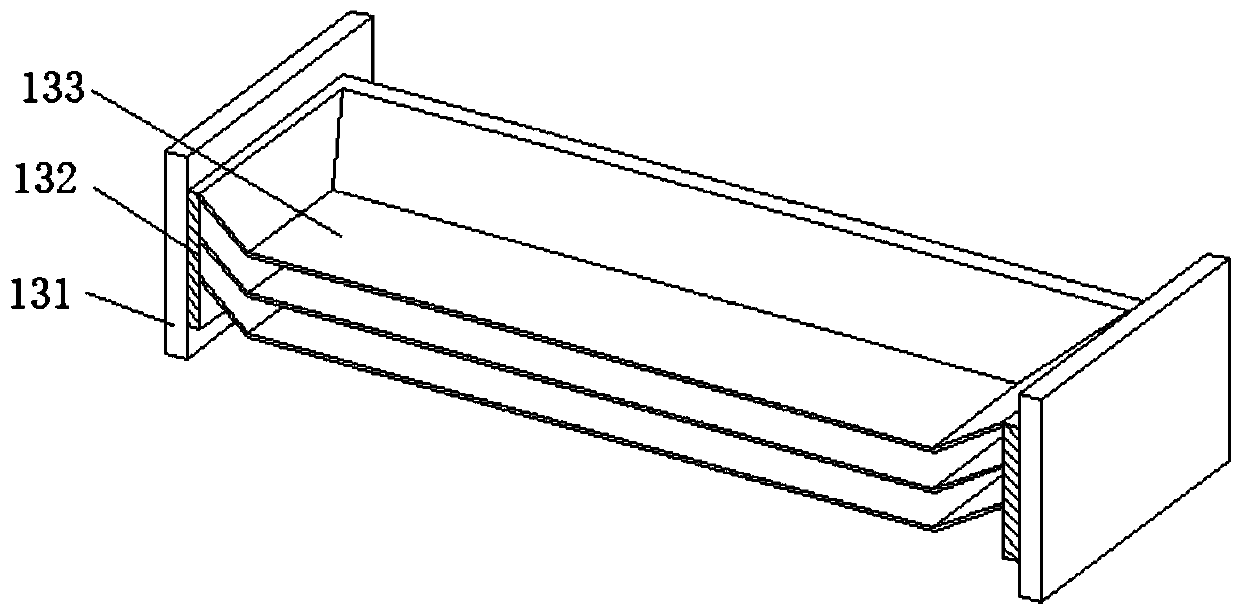

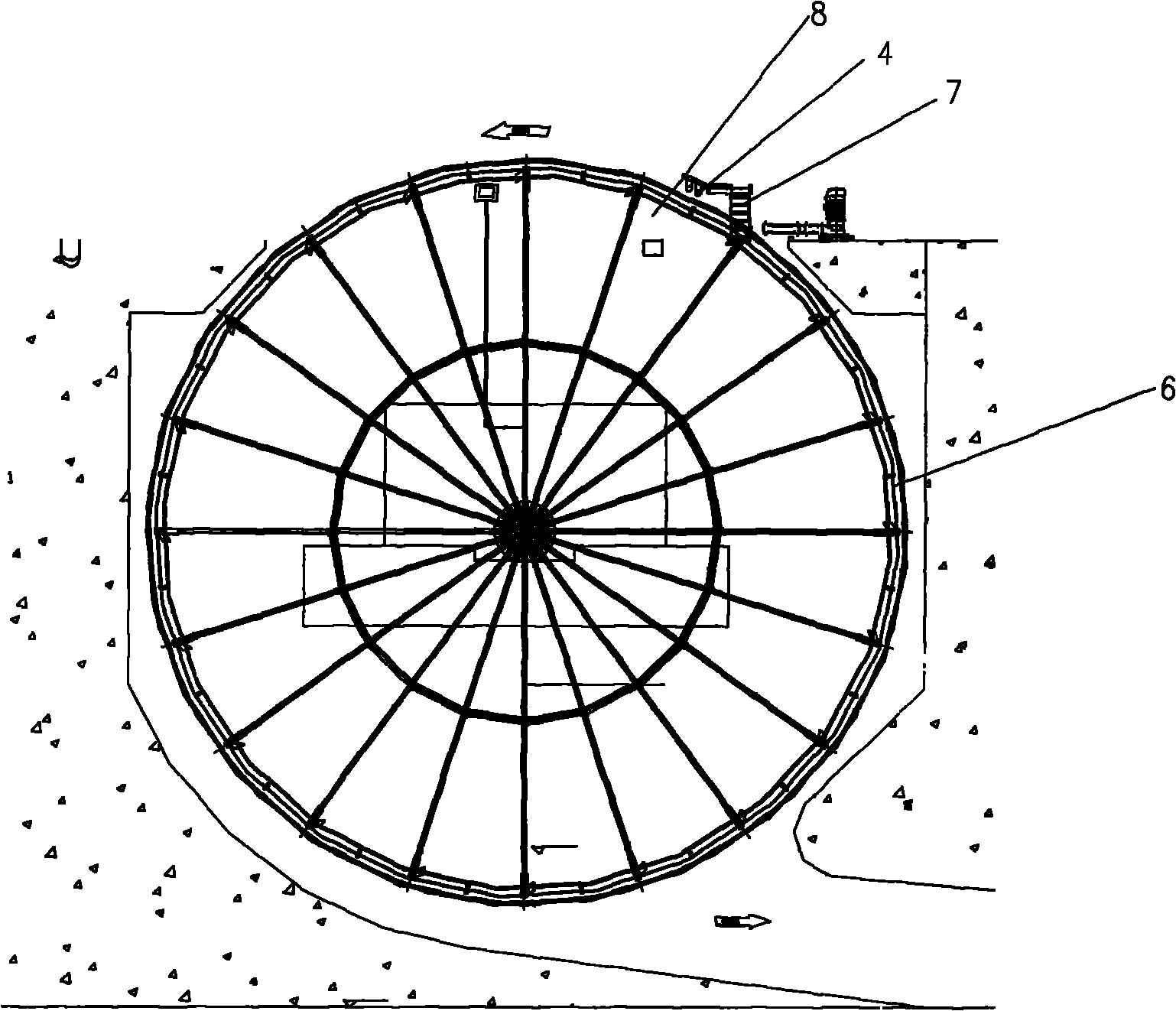

Drum-shaped rotating filter net flushing system of nuclear power plant

InactiveCN101927108AReduce in quantityExtended wash rangeMoving filtering element filtersNuclear powerEngineering

The invention aims to provide a shower nozzle for a flushing system of a drum-shaped rotating filter net of a nuclear power plant, which can effectively solve the problems that flushing dead zones can be formed in a local area which can not be flushed by flushing water or the flushing water pressure is insufficient in the prior art, thus a filter plate can be blocked due to accumulation of sundries in a long time by changing the outlet shape of the shower nozzle, thereby improving the flushing capability.

Owner:JIANGSU GUOQUAN PUMP MFG CO LTD

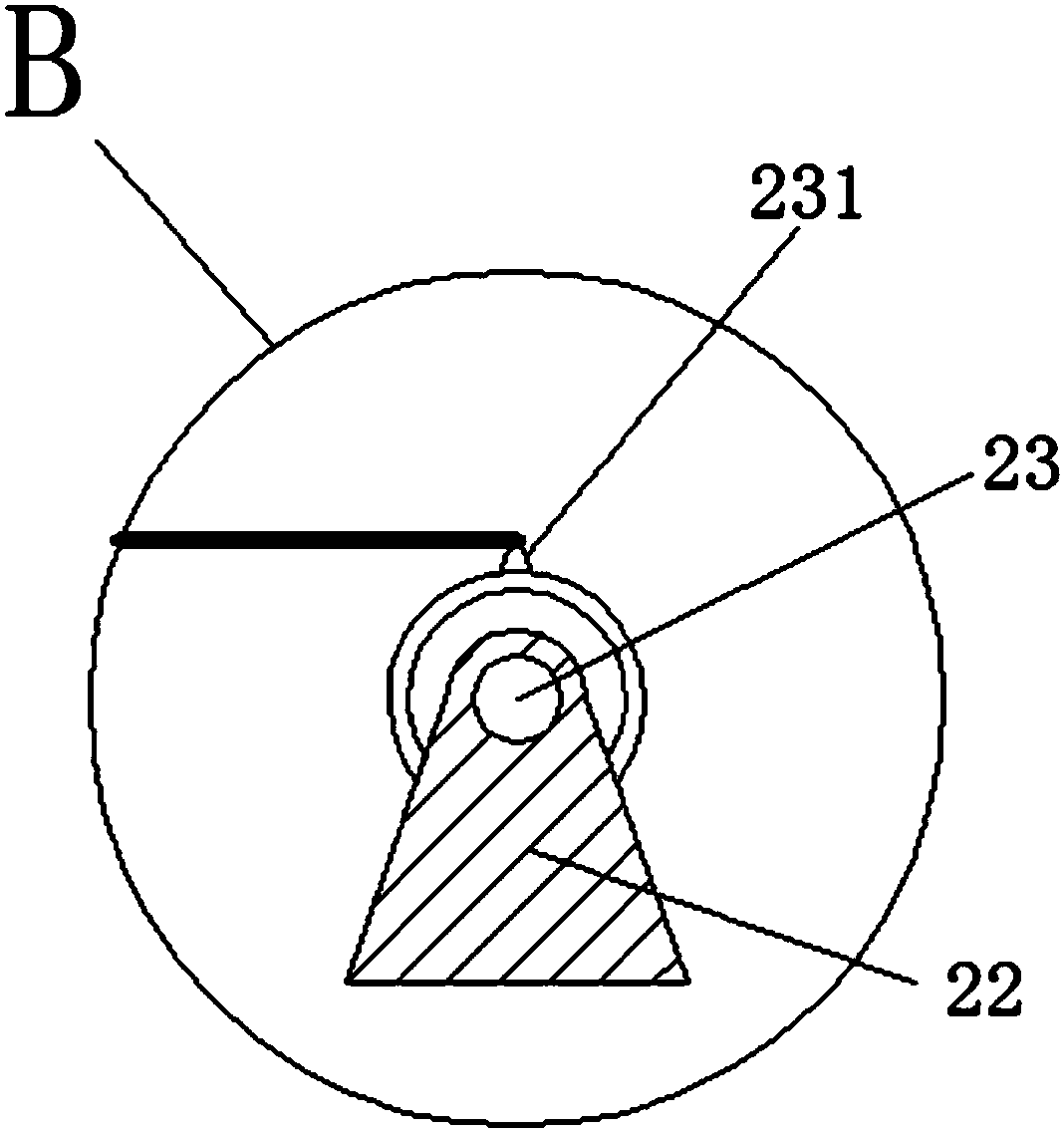

Device for washing cuprous chloride precipitate by using anhydrous ethanol for removing chlorine from zinc sulfate solution

ActiveCN112391543AIncrease flushing powerAvoid affecting the flushing effectHollow article cleaningSulfate zincPhysical chemistry

The invention discloses a device for washing cuprous chloride precipitate by using anhydrous ethanol for removing chlorine from a zinc sulfate solution. The device comprises a chlorine removal bin, abin cover, a turnover driving assembly, a filter plate, a washing cavity, a liquid storage cavity, filter holes, a vertical movement driving assembly, a rotating sleeve, a transmission assembly, a rotating shaft, a communicating pipe and spray heads, wherein the upper end of the rotating shaft penetrates out of the rotating sleeve and is rotationally connected with a rotating joint, and the rotating joint is driven by a lifting assembly to move vertically so as to drive the spray heads to move up and down. The device has the beneficial effects that through the rotation of the rotating shaft, the plurality of spray heads can rotate in the axial direction of the rotating shaft, so that the washing range is increased under the condition that the number of the spray heads is fixed; meanwhile,the lifting assembly is arranged to drive the spray heads to move up and down, so that the washing strength of the spray heads can be improved, and the washing efficiency is further improved; and thevertical movement driving assembly is arranged to drive the filter plate to move vertically, and the vibration of the filter plate is utilized, so that the cuprous chloride precipitate is prevented from being accumulated on the filter plate, and the washing effect is prevented from being influenced.

Owner:衡阳市大宇锌业有限公司

Large diameter quartz tube cleaning method and cleaning machine

ActiveCN103817116BGuaranteed cleaning effectSoak thoroughlyHollow article cleaningHydrofluoric acidAcid washing

The invention provides a large-caliber quartz tube cleaning method, which comprises the following steps that firstly, quartz tubes are placed into an acid washing groove with the hydrofluoric acid concentration being 15 percent to 20 percent to be soaked for 10 to 15 minutes; then, the quartz tubes are placed into an acid washing groove with the hydrofluoric acid concentration being 7 percent to 10 percent to be soaked for 15 to 20 minutes; then, the quartz tubes are placed into a tap water groove to be soaked for 4 to 6 minutes; next, the quartz tubes are placed into a deionized water groove to be soaked for 4 to 6 minutes; the soaked quartz tubes are placed into a cleaning machine to be flushed for 18 to 25 minutes, and the cleaning is completed. The large-caliber quartz tube cleaning method has the advantages that the step-by-step cleaning is carried out on the quartz tubes, so impurities on the quartz tube walls can be thoroughly soaked; through the arrangement of a horizontal slide passage and a slide block, the reciprocating flushing can be realized, and the flushing range is wide; an upper spray head and a lateral spray head are adopted, cleaning dead corners do not exist, and the overall cleaning of the quartz tubes is ensured; a multi-way connecting head is arranged, the cleaning on several groups of quartz tubes in one step can be realized, and the cleaning efficiency is improved; the water consumption of a device is low, the water resources are saved, and good cleaning effects are also obtained.

Owner:江苏宏伟石英科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com