Patents

Literature

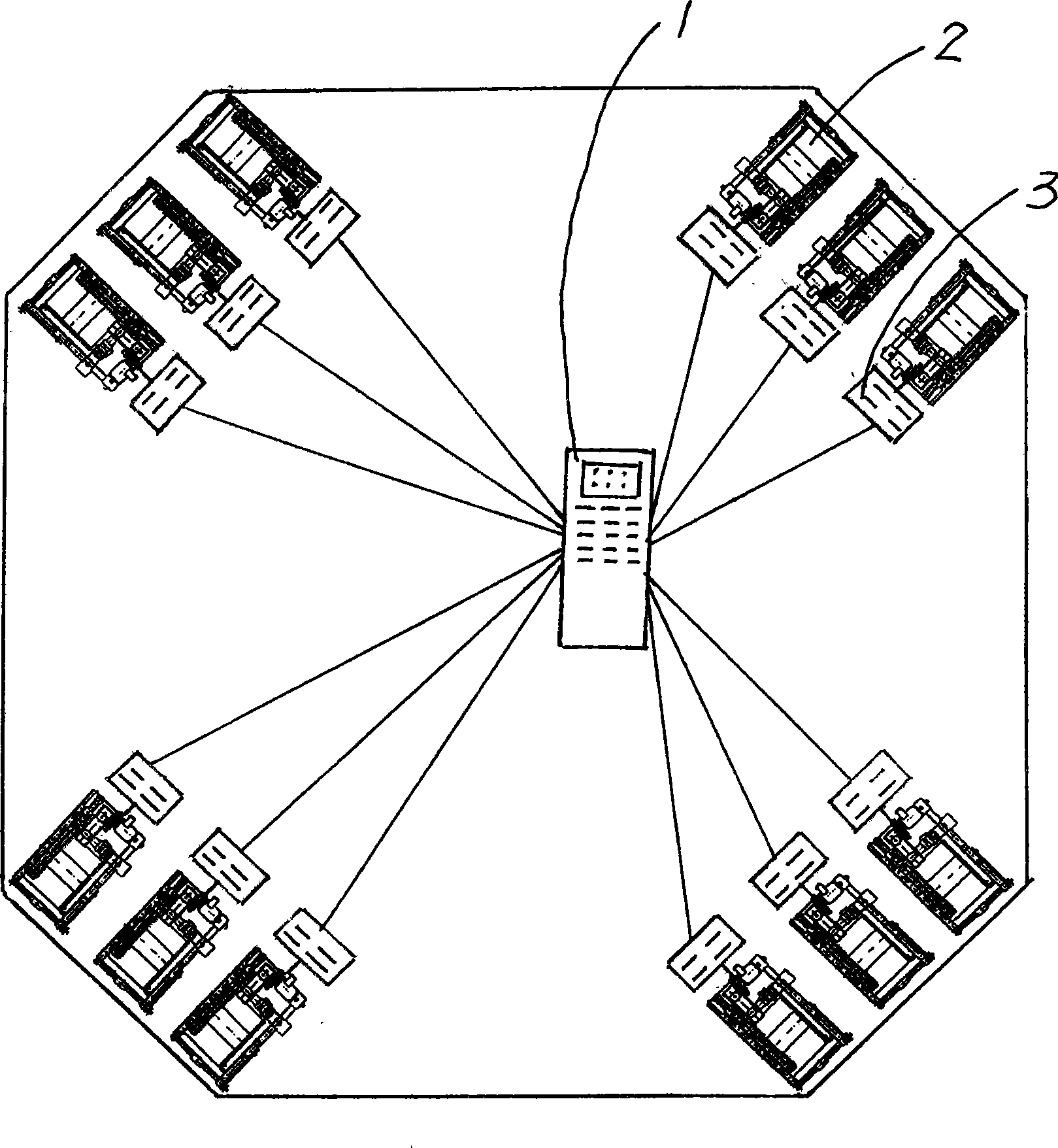

284results about How to "Timely cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of vitamin A microcapsules

InactiveCN102198116AFree from destructionWon't breakHydroxy compound active ingredientsMetabolism disorderAntioxidantDissolution

The invention relates to a preparation method of more stable vitamin A microcapsules, comprising the following steps of: firstly, preparing a vitamin A oil solution containing an antioxidant from vitamin A and the antioxidant in the absence of oxygen, adding chitosan and stirring evenly, after stirring fully, filtering and removing the chitosan to obtain the vitamin A oil solution; adding octenyl succinic acid modified starch to purified water deaerated by a thermal spray deaerator, heating for dissolution; mixing the prepared octenyl succinic acid modified starch solution and the vitamin A oil solution in a certain proportion, emulsifying quickly by an on-line emulsifying machine, and instantly cooling by a cooler; and performing hot air spray drying on the emulsion to obtain stable vitamin A microcapsules. The storage life of the product prepared in the invention reaches two years.

Owner:何德海

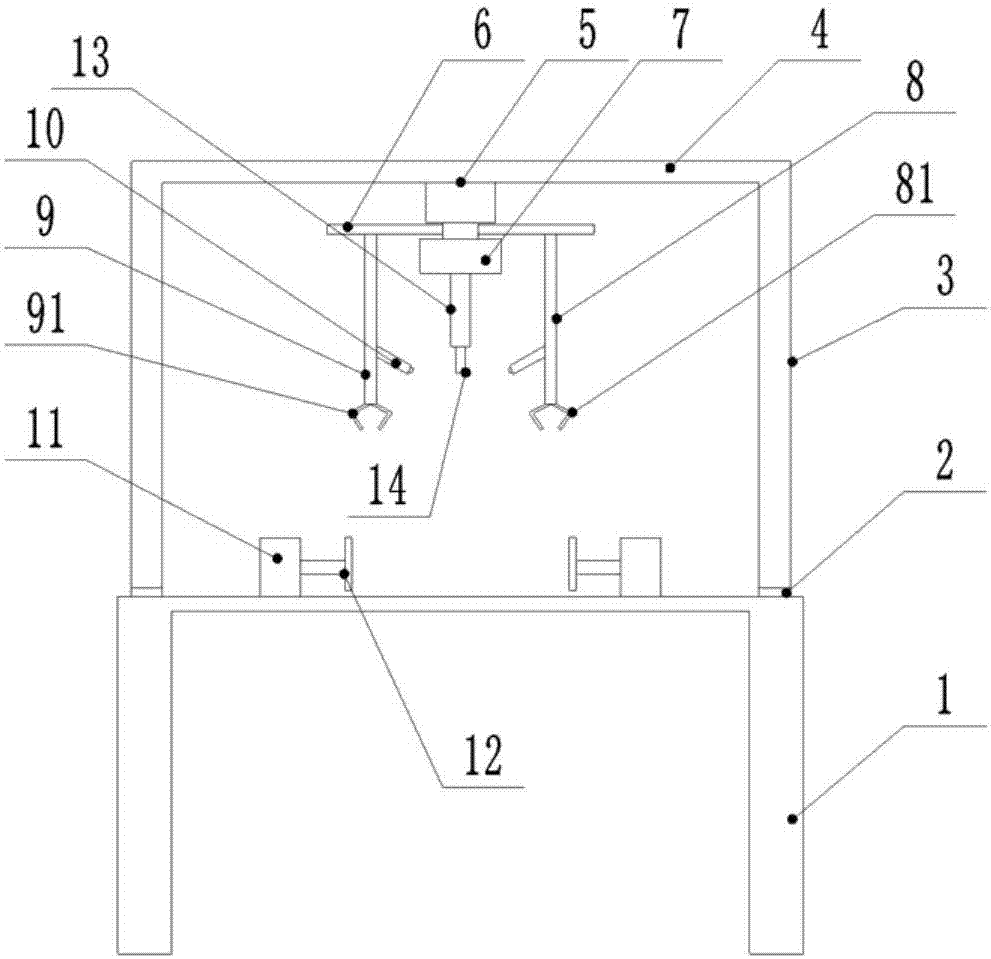

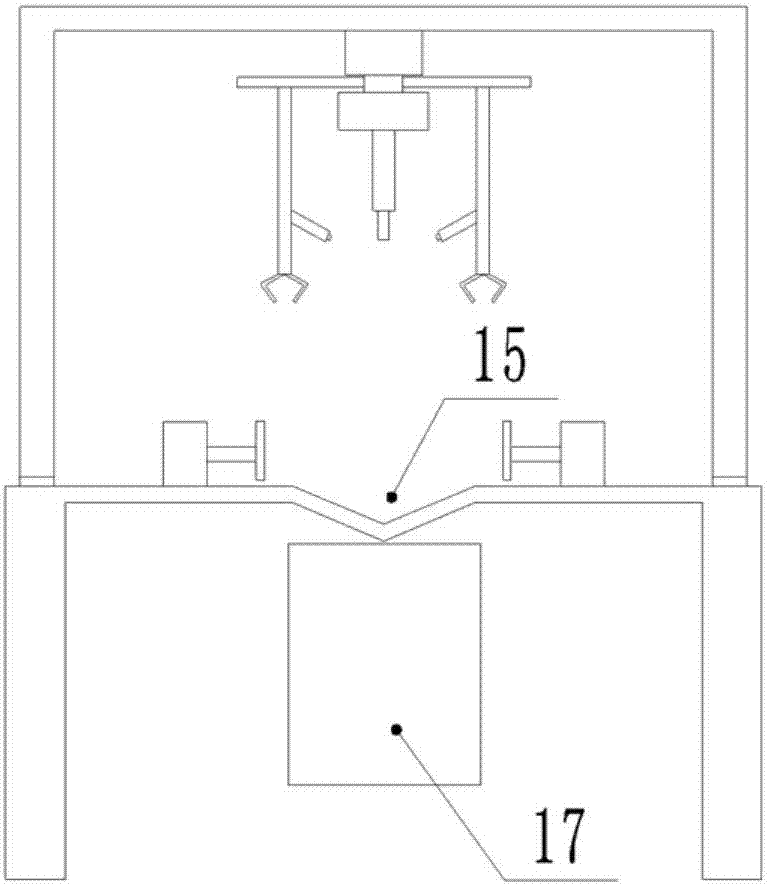

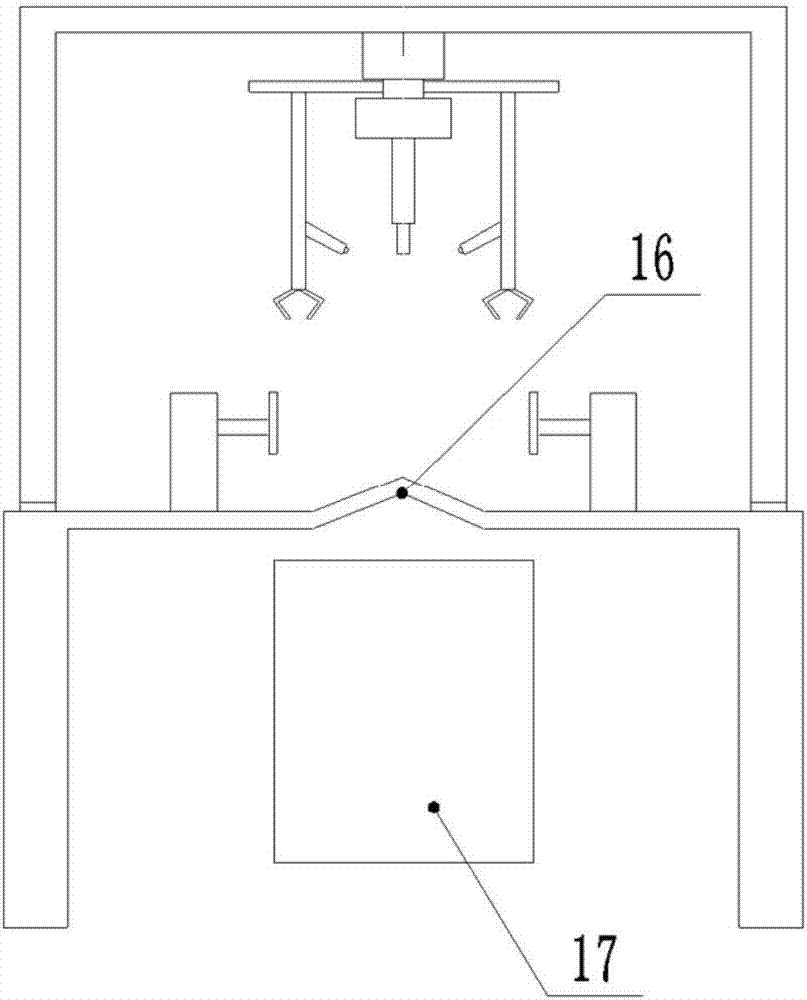

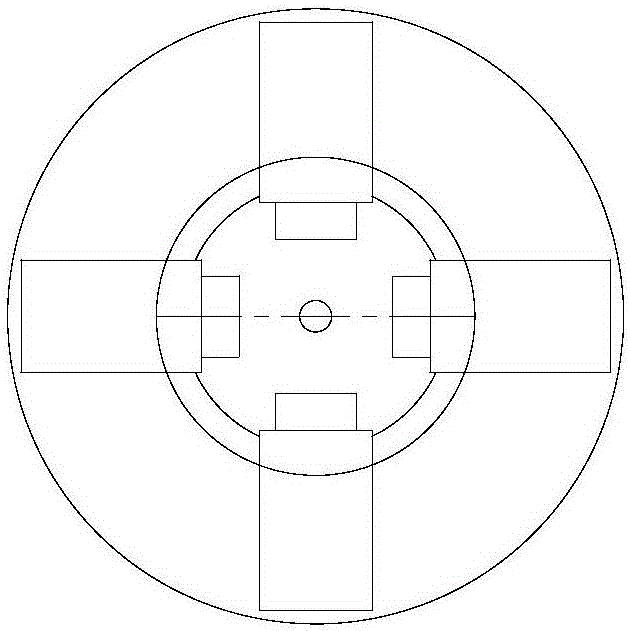

Machine part drilling device

InactiveCN107999805AEasy to clamp and fixEasy to rinseWork clamping meansMetal working apparatusMachine partsBiochemical engineering

The invention belongs to the technical field of drilling equipment, and particularly discloses a machine part drilling device. The device comprises a rack, a guide rail is arranged on the rack, a supporting frame is arranged on the guide rail in a sliding connection manner, a cross beam connected with a telescopic device is arranged on the supporting frame, a motor is arranged on the telescopic device, a drill bit is arranged at the output end of the motor, and the device is characterized in that a transverse rod is arranged on the telescopic device, a first supporting rod and a second supporting rod are arranged on the transverse rod, and are hinged with a first clamp and a second clamp correspondingly, two opposite air cylinders are arranged in the middle of the rack, a clamping plate isarranged on piston rods of the air cylinders, and a first spraying head and a second spraying head connected with a water pipe are arranged in the middle of the first supporting rod and the middle ofthe second supporting rod. The device is mainly used for machine part drilling, and the problem that after drilling, sweeps easily remain in holes is solved.

Owner:宁波德深机械设备有限公司

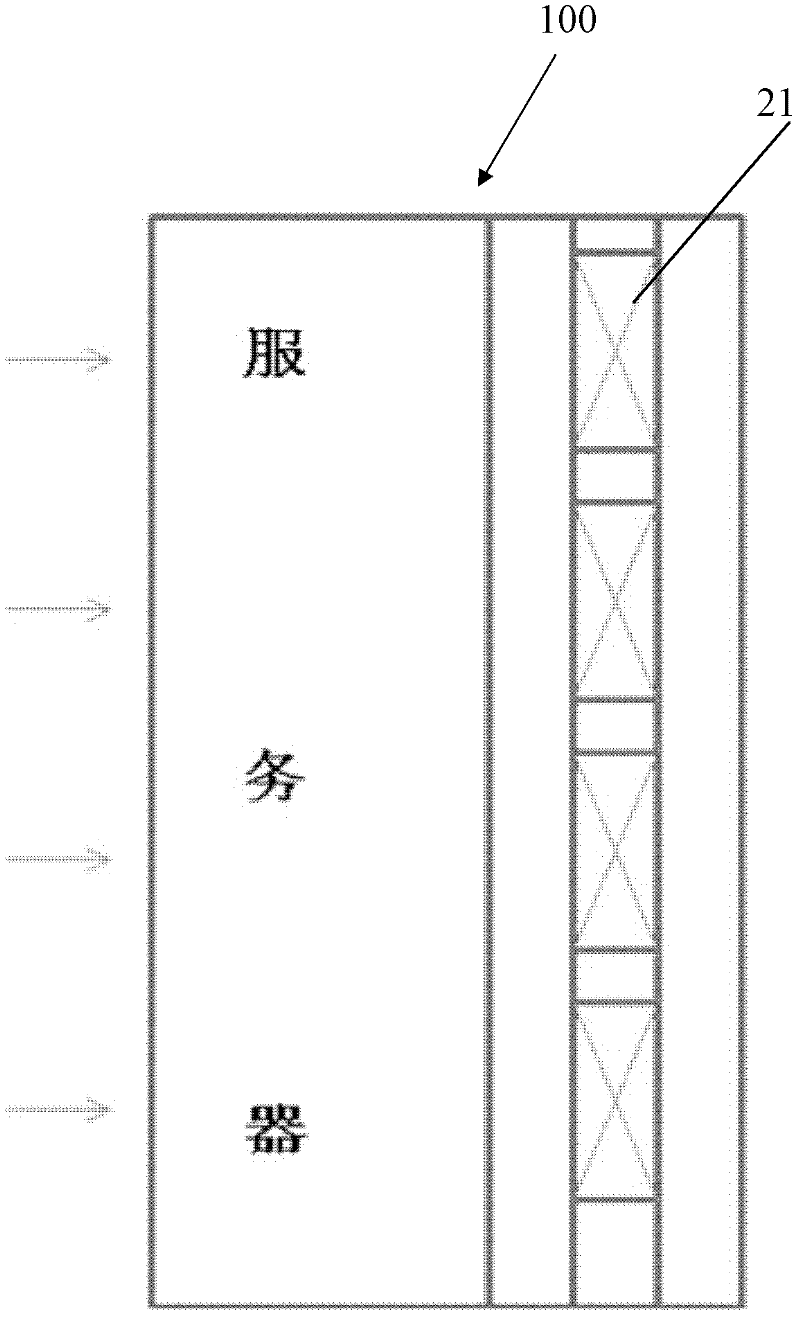

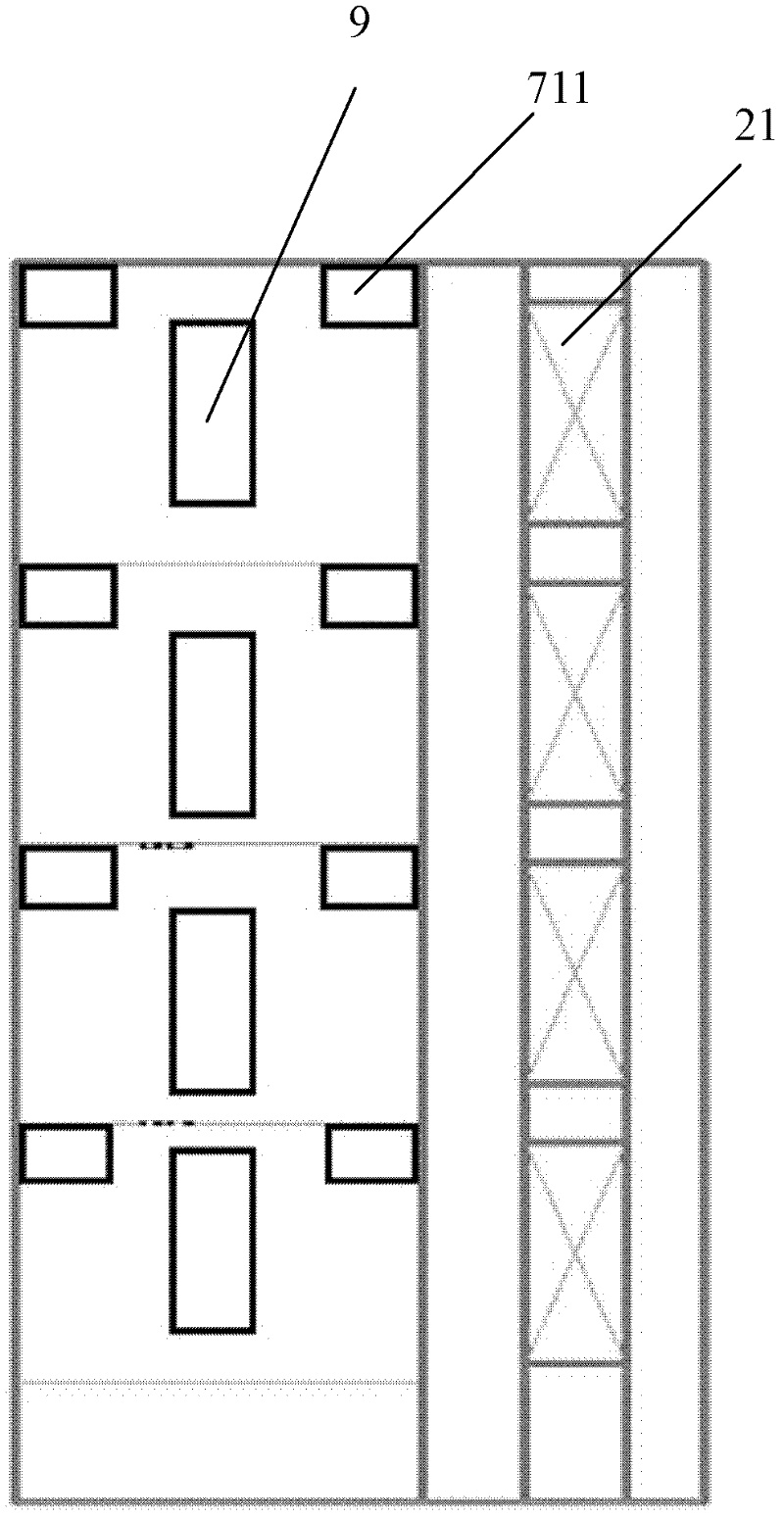

Heat dissipation device for cabinet and method for heat dissipation of cabinet

ActiveCN102340977AHigh densityTimely coolingDigital data processing detailsCooling/ventilation/heating modificationsHeat managementHeat flow

The invention provides a heat dissipation device and a heat dissipation method for a cabinet. Heating parts are arranged in the cabinet. The heat dissipation device comprises a cooling fan wall and control system and a heat dissipation air duct, wherein the cooling fan wall and control system comprises a fan wall which is arranged at the back of the cabinet and is provided with groups of fans, and the heat dissipation air duct is arranged in the cabinet and is communicated with the fan wall. By adopting the heat dissipation device and the heat dissipation method provided by the invention, heat generated by a server in the cabinet can be dissipated in time, and the heat exchange efficiency and the exchanged heat flow rate of a clustered system are improved; by dividing the heat dissipation air duct into a plurality of areas which are isolated from each other, the structure of the air duct can be optimized and the balanced cooling of the cabinet is realized; and by arranging a heat management and health monitoring system, an optimal heat dissipation effect can be reached. Besides, the heat dissipation effect of the server cabinet can be ensured to satisfy the requirements of high efficiency and high density. Moreover, the energy loss of all equipment in the cabinet can be reduced and the maintenance and use costs are reduced.

Owner:中科腾龙信息技术有限公司

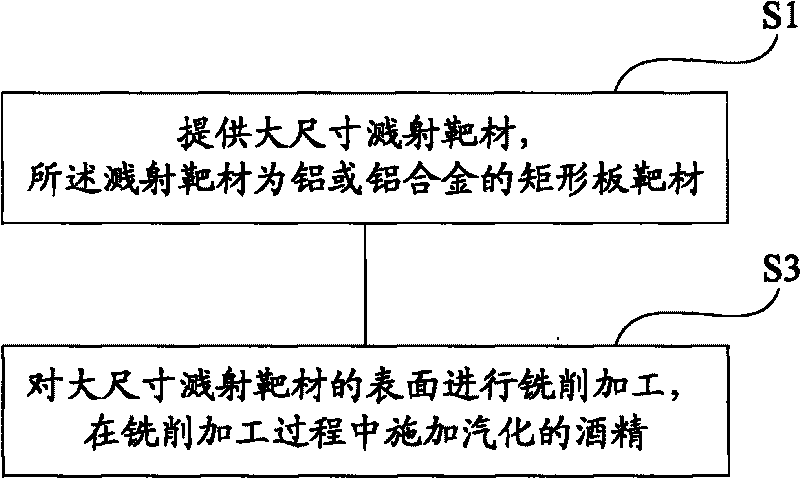

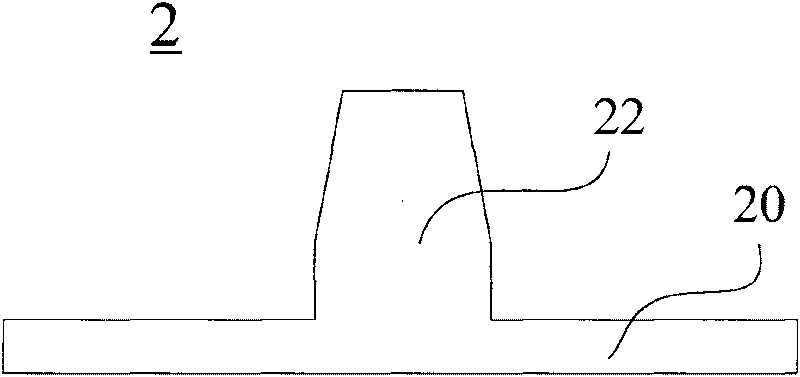

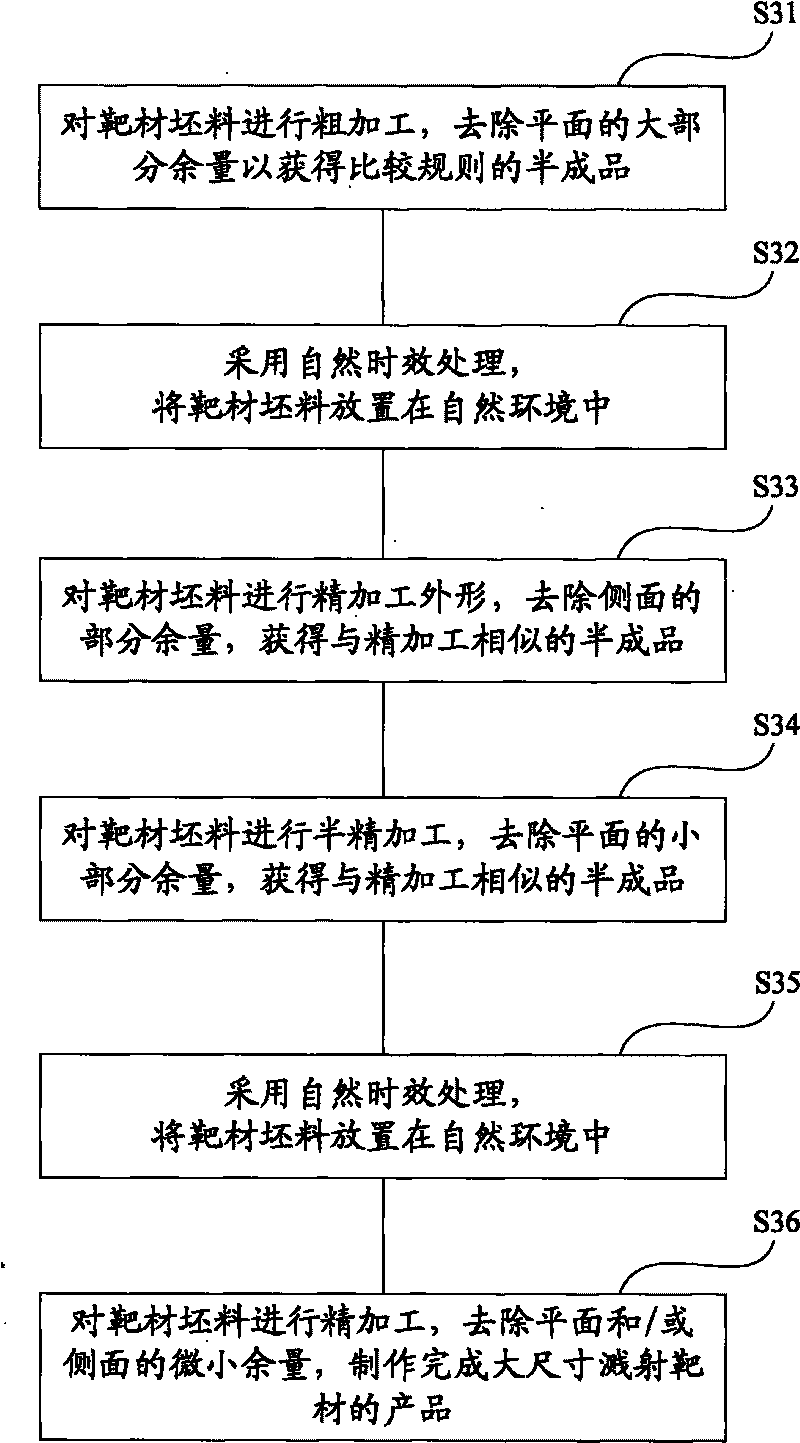

Surface processing method of large-size sputtering target material

ActiveCN101704124ATimely coolingImprove cooling effectMilling equipment detailsMaintainance and safety accessoriesSputteringGas phase

The invention provides a surface processing method of a large-size sputtering target material. The method comprises the following steps of: providing a large-size sputtering target material which is made of aluminum or aluminum alloy; milling the surface of the sputtering target material; and adopting vaporized alcohol to cool in the process of milling. Compared with the prior art, by adopting the vaporized alcohol to cool, the method ensures that gas phase and liquid phase fluids formed after the vaporization of the alcohol can have good cooling and lubricating effects so as to improve the surface evenness and finish of the sputtering target material in the process of milling.

Owner:广东江丰电子材料有限公司

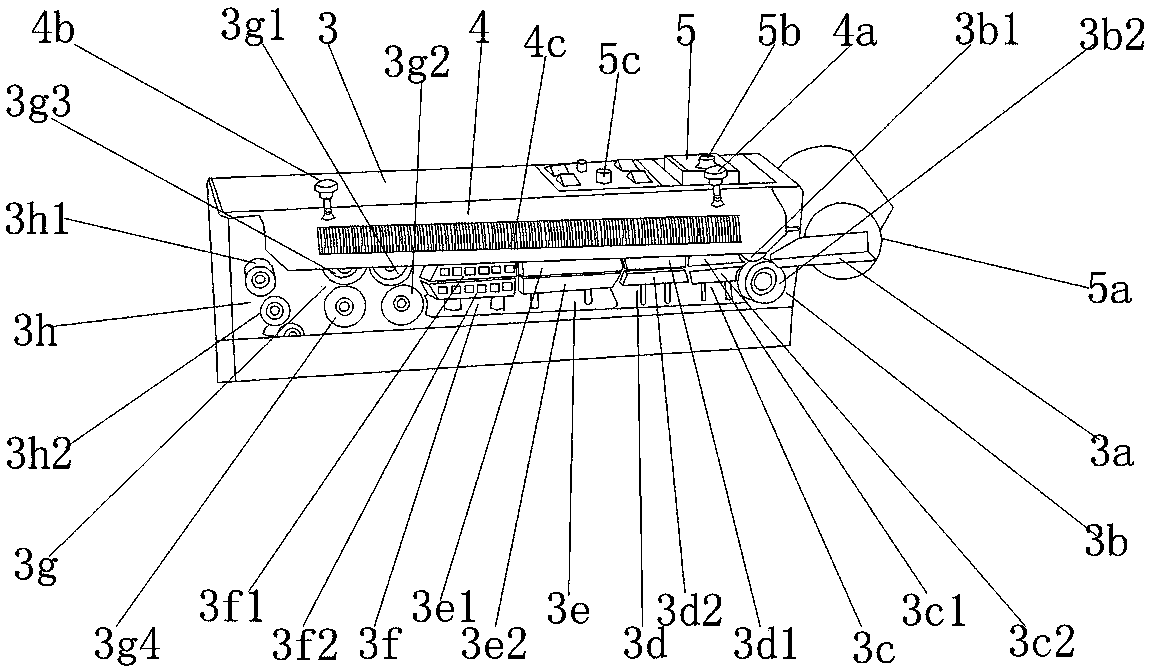

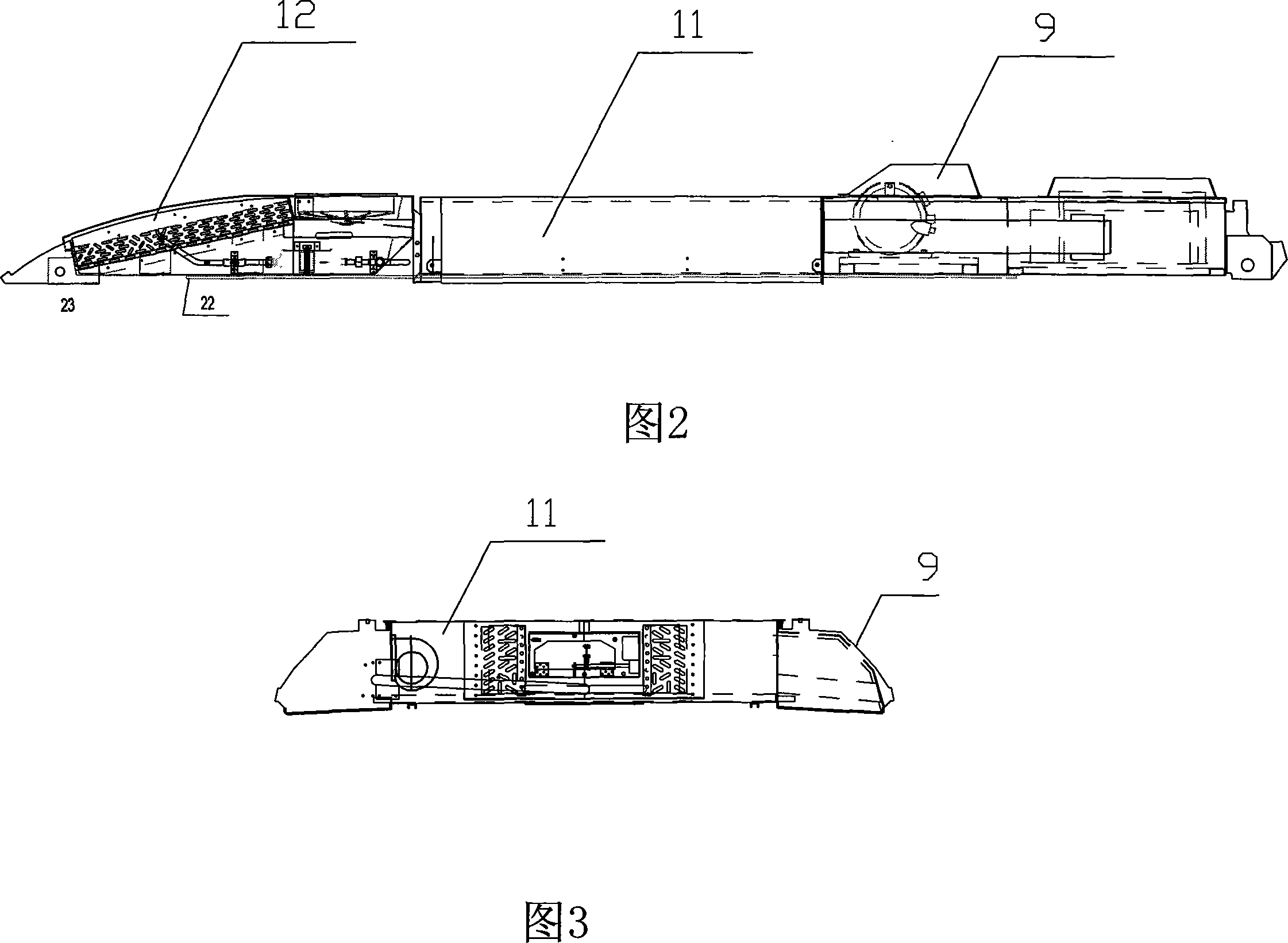

Narrow gap and deep groove welding head

The invention discloses a narrow gap and deep groove welding head. The welding head comprises a hollow tabular welding head shell main body which is thin and long and is suitable for stretching into a narrow and deep groove gap for welding; the welding head is further provided with double gas protection systems, wherein the position of a secondary gas protection system is adjustable so that the surface of a melting pool can be fully protected and the welding quality is ensured; a protected gas lens is connected outside the air outlets of the double gas protection systems so that protected gas can be stably and evenly sprayed out, the surface of the melting pool is fully protected, and the welding quality is increased; a compulsory water cooling system is arranged, then a tungsten electrode fixing device is compulsorily water-cooled, and cooling water circularly flows so that a tungsten electrode can be fully cooled.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

Method for synchronously removing shell and peel of Chinese chestnut through microwaves

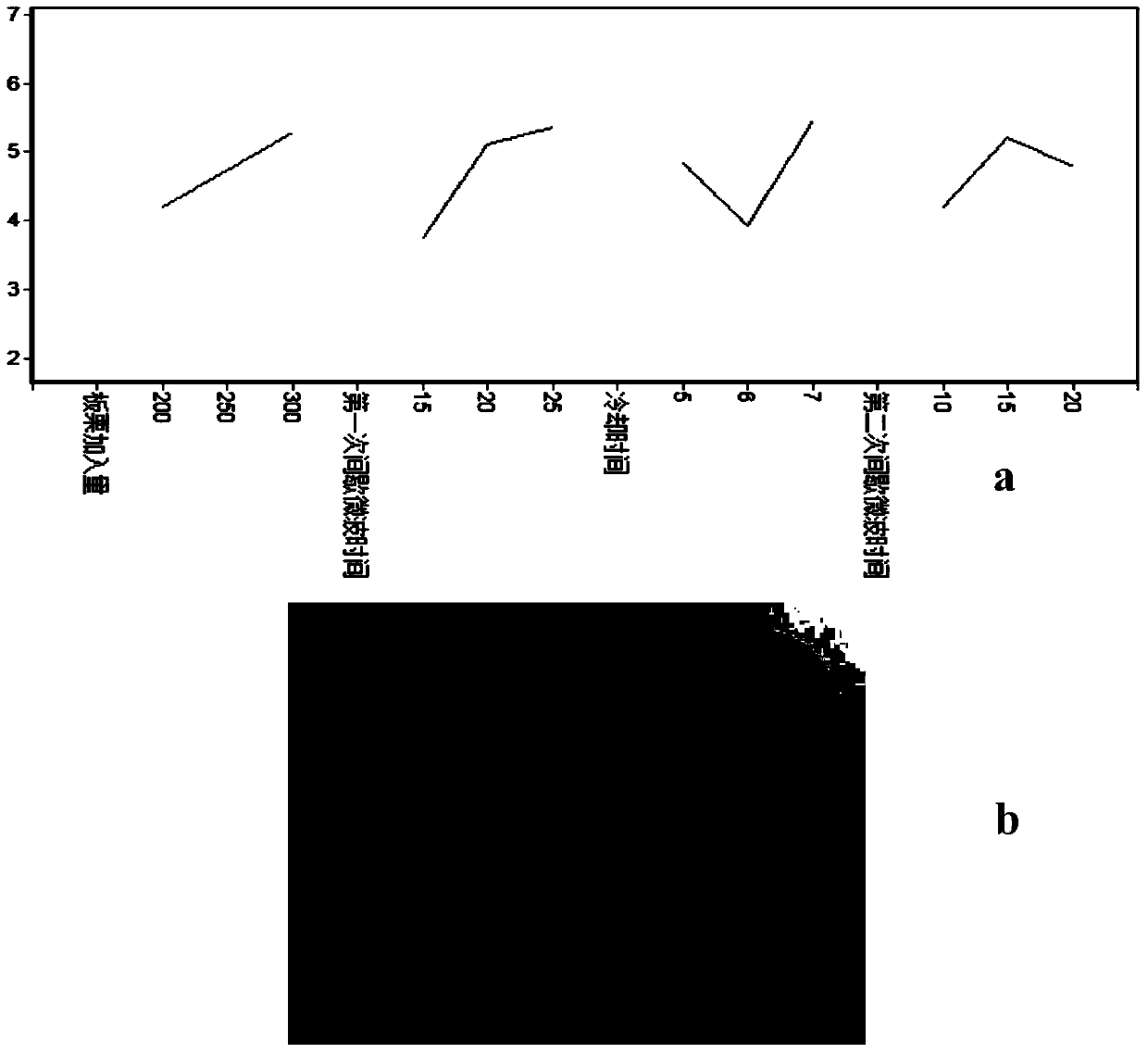

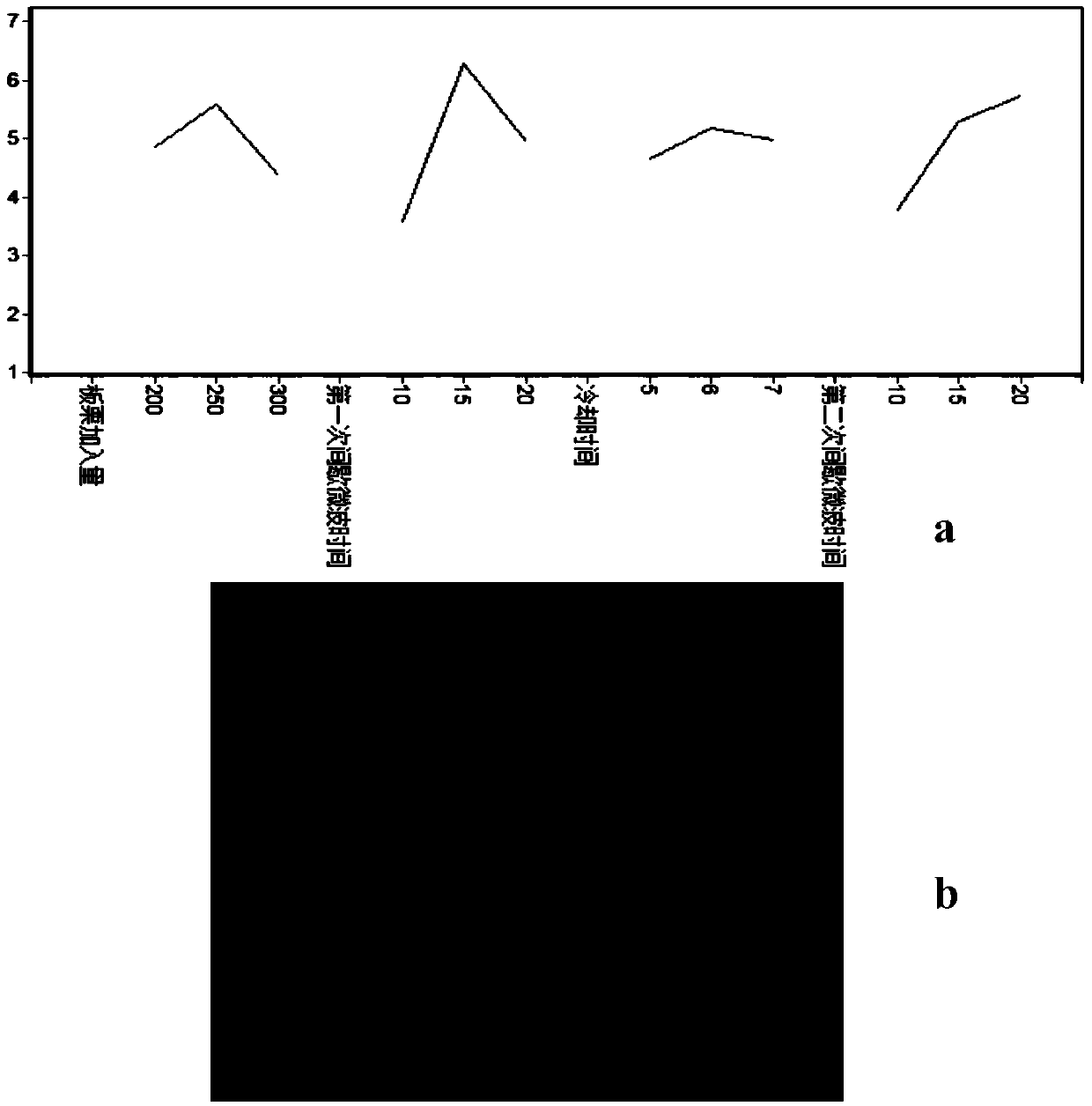

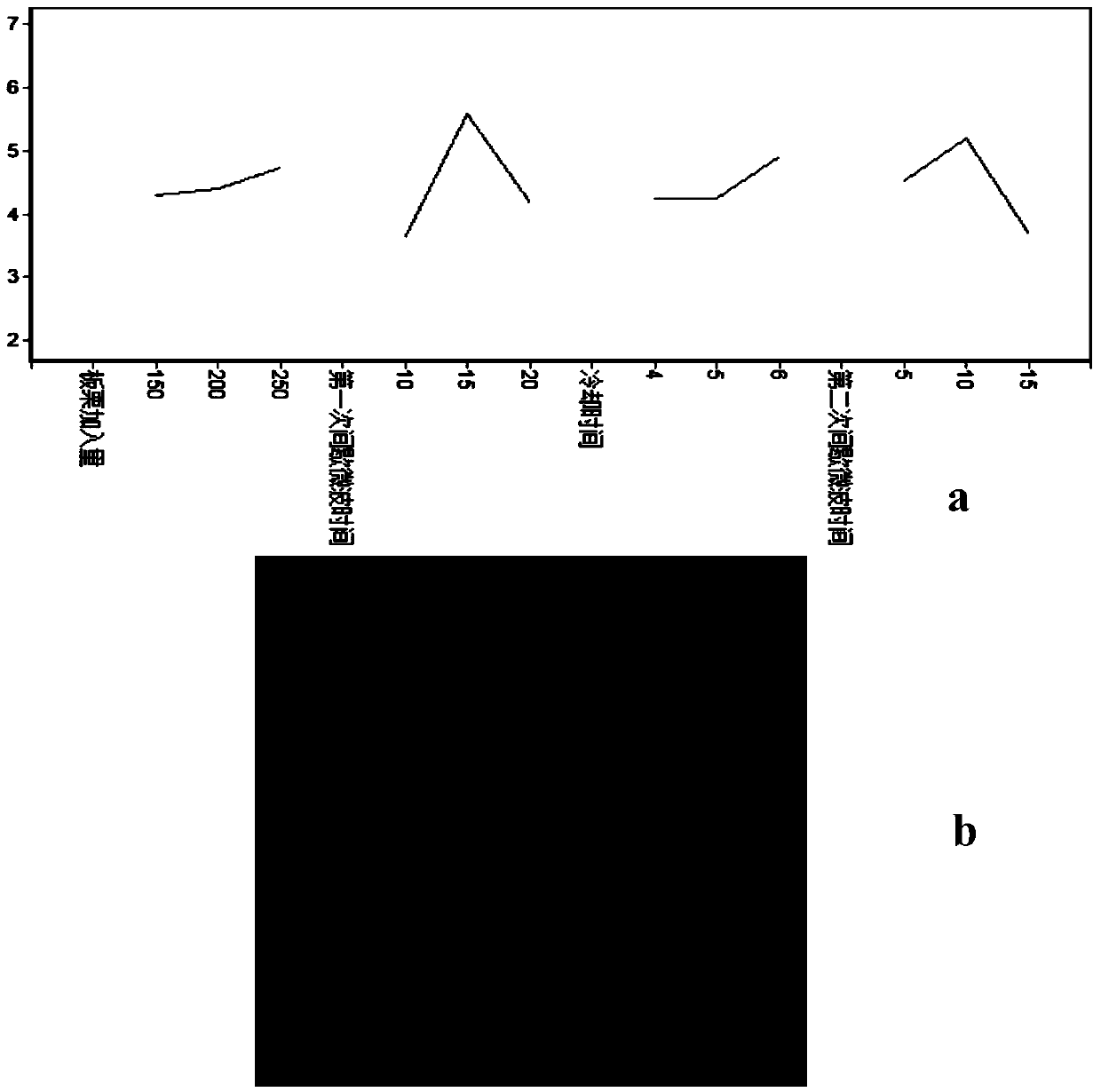

The invention discloses a method for synchronously removing the shell and peel of a Chinese chestnut through microwaves. The method comprises the following steps: the shell of the Chinese chestnut is cut, the Chinese chestnut is subjected to microwave processing for the first time, the Chinese chestnut is cooled after the microwave processing for the first time, then, the Chinese chestnut is subjected to microwave processing for the second time, the shell and the peel of the Chinese chestnut are removed after the microwave processing for the second time, and therefore the kernel of the Chinese chestnut is obtained. According to the method for synchronously removing the shell and peel of the Chinese chestnut through the microwaves, the microwaves are used for instantaneous intermittent heating with a high power, as a result, the kernel of the Chinese chestnut shrinks due to dehydration and is separated from the shell and the peel, and the phenomenon that the kernel of the Chinese chestnut is cooked and exploded due to an excessively quick temperature rise in the one-time heating process can be well avoided; meanwhile, the hot Chinese chestnut is cooled for a short time, as a result, water in the shell of the Chinese chestnut is evaporated, brittleness is further improved, and original color and luster, a special flavor and nutrition of the kernel of the Chinese chestnut are guaranteed to the maximum.

Owner:ZHEJIANG UNIV

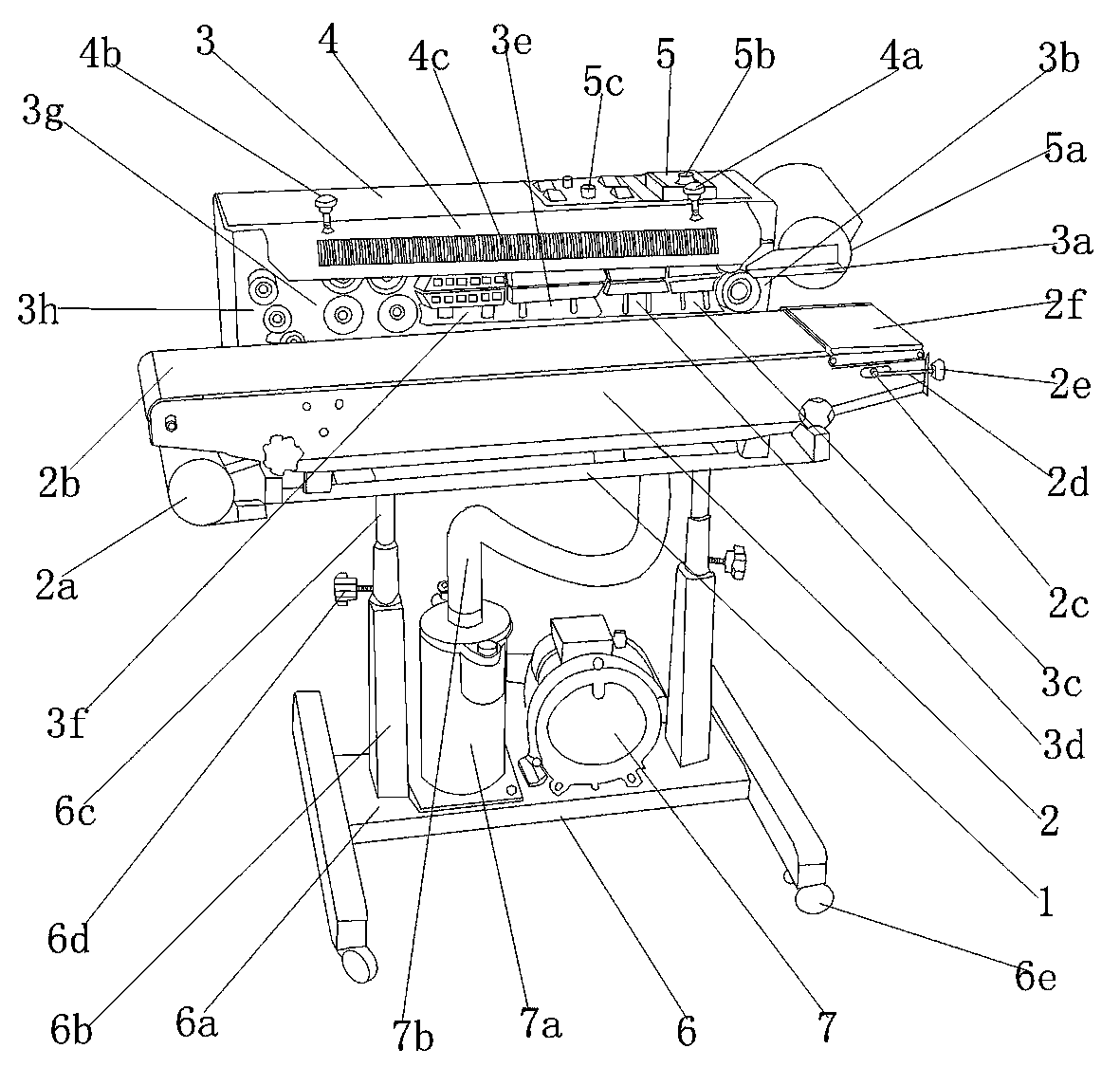

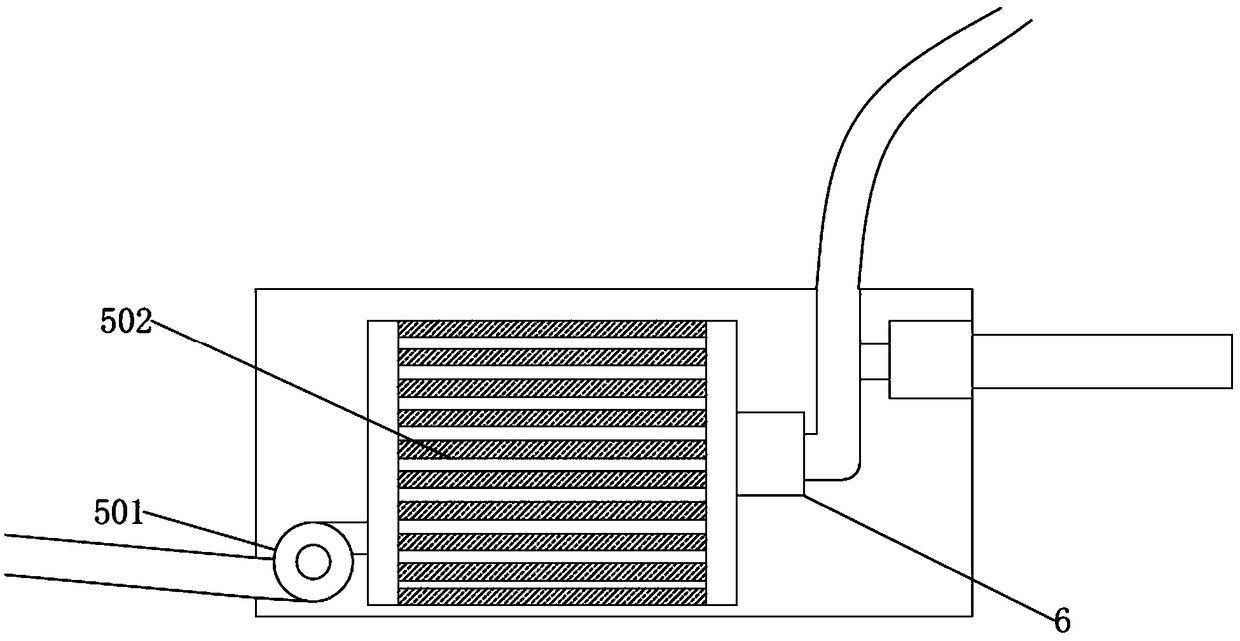

Air-blowing based cooling type sealing machine structure

InactiveCN104071392AGood molding effectAdjustable up and down positionWrapper twisting/gatheringAir compressionEngineering

The invention provides an air-blowing based cooling type sealing machine structure. The air-blowing based cooling type sealing machine structure comprises a housing seat; a feeding strip is arranged on the right end part of the housing seat; a transition wheel mechanism, a pre-pressing strip mechanism, a thermal forming mechanism, a cooling strip mechanism, a cooling strip mechanism, a compressing wheel mechanism and a discharging wheel mechanism are arranged in parallel at a working station of a first strip and fixedly mounted in the middle part of the housing seat from right to left in sequence; a belt seat and a conveyor are arranged at the front side of the housing seat; a position adjusting seat is arranged at the lower part of the belt seat; an air compressing pump is mounted in the position adjusting seat; an air storing tank is arranged at the left side of the air compressing pump; an air supply pipe that supplies air to the cooling strip mechanism is connected to the air storing tank. The air-blowing based cooling type sealing machine structure is reasonable in design, simple in structure and convenient to use; a pocket opening is automatically conveyed and processed; the upper and lower positions of the conveying belt can be adjusted; cooling can be performed timely; the advantages of tight, firm and regular sealing and good forming effect are brought.

Owner:ZHEJIANG MINXIN ECO TECH

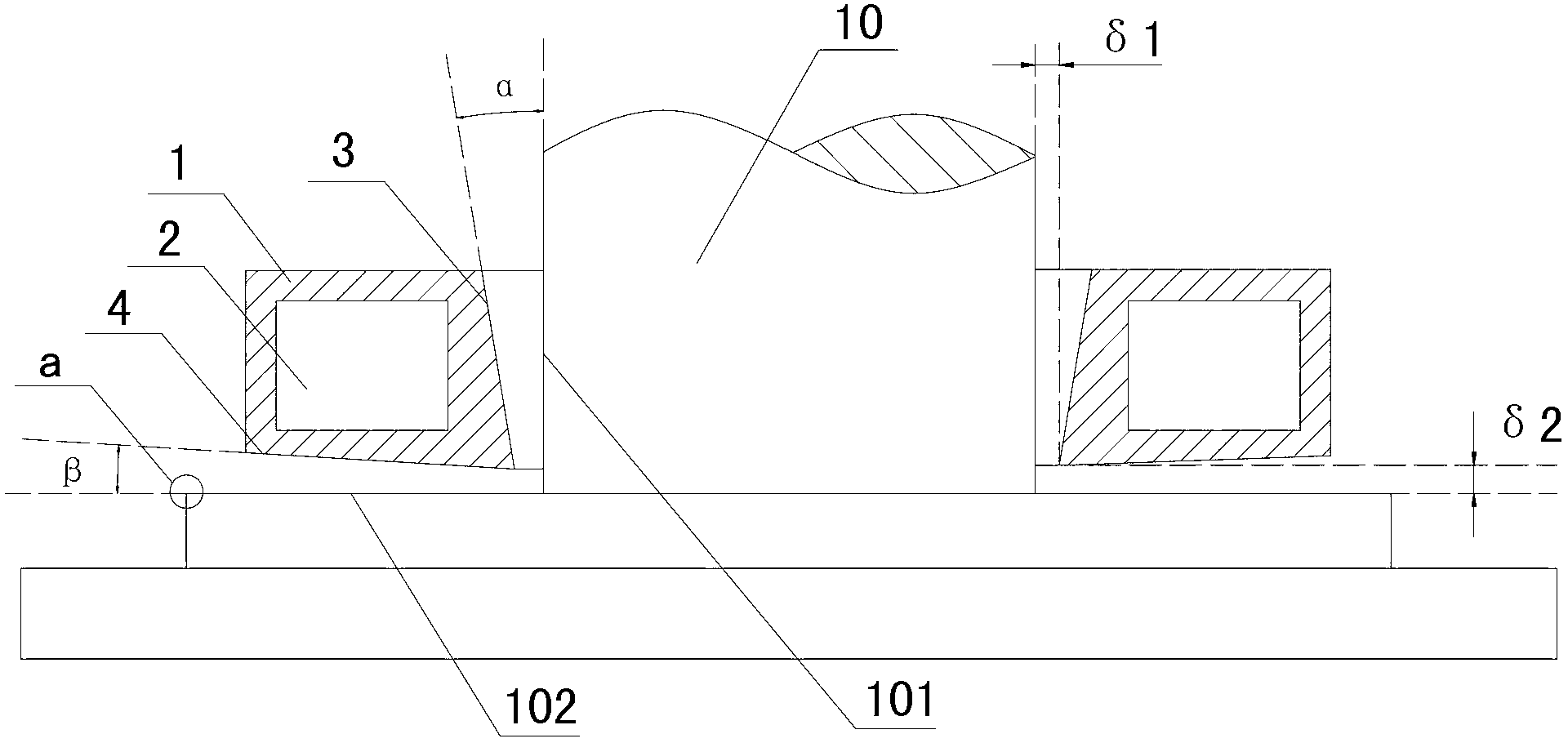

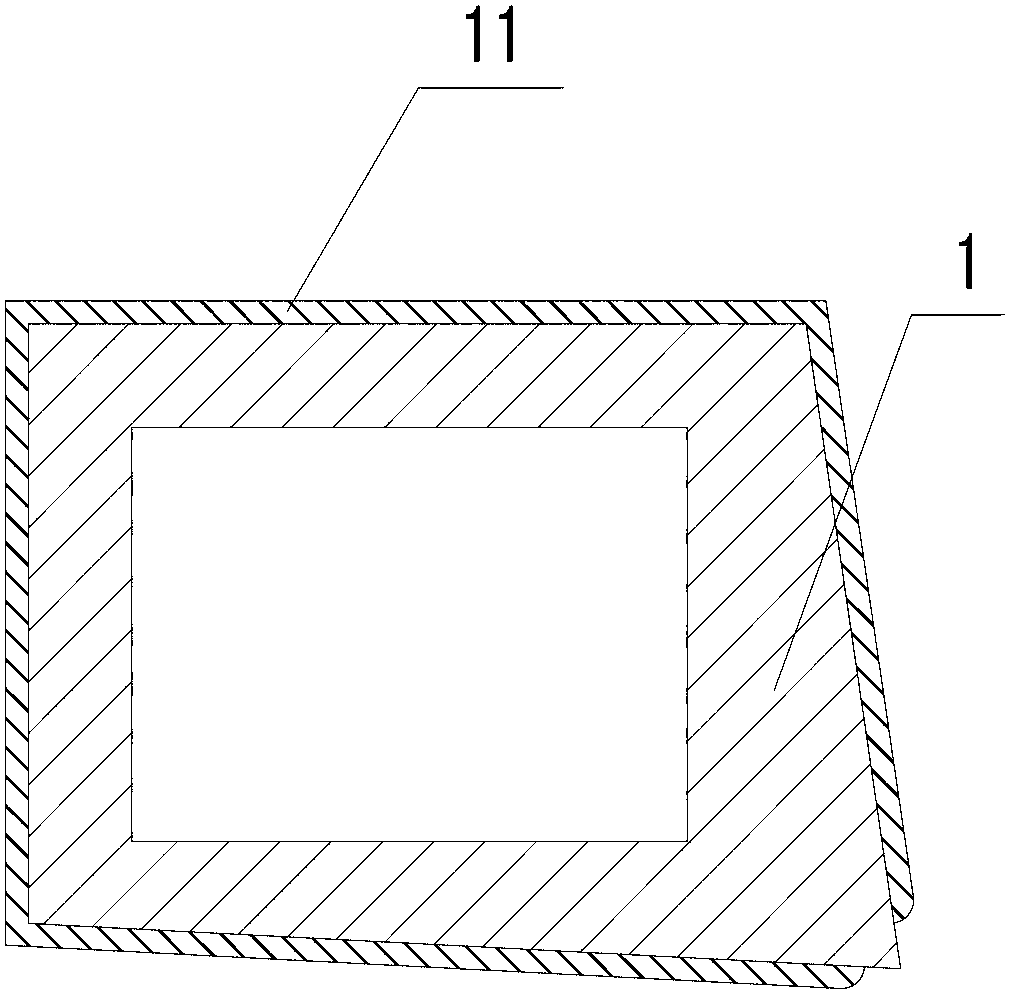

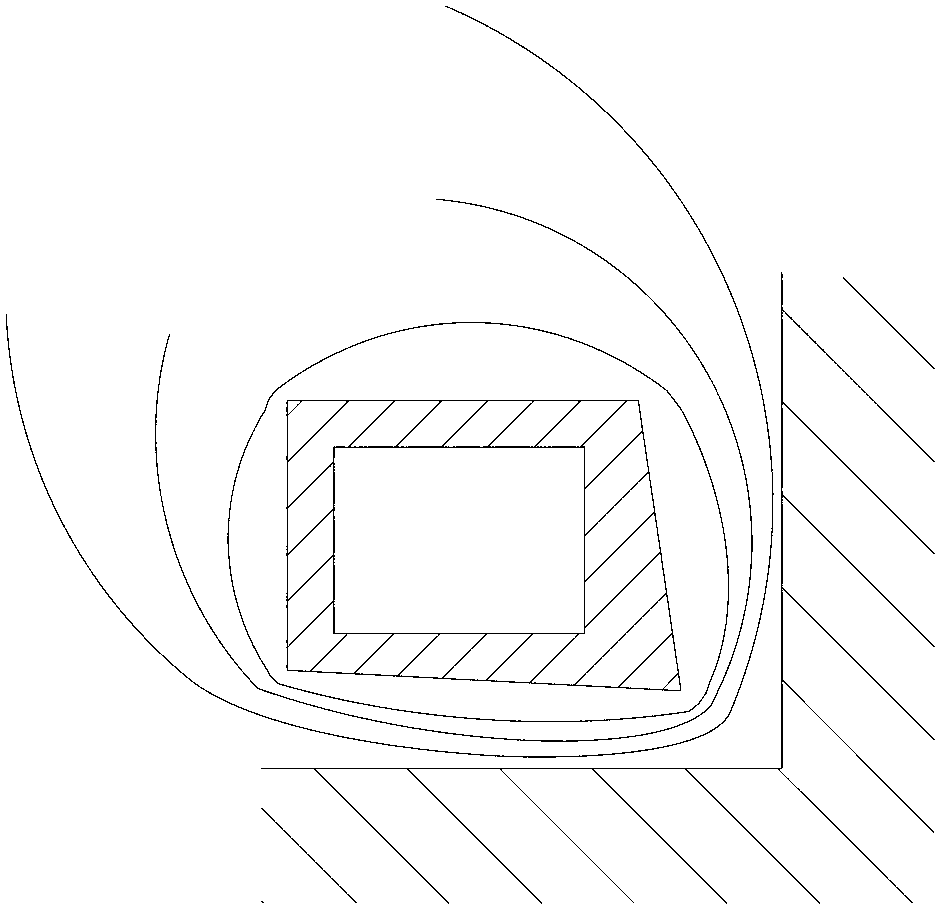

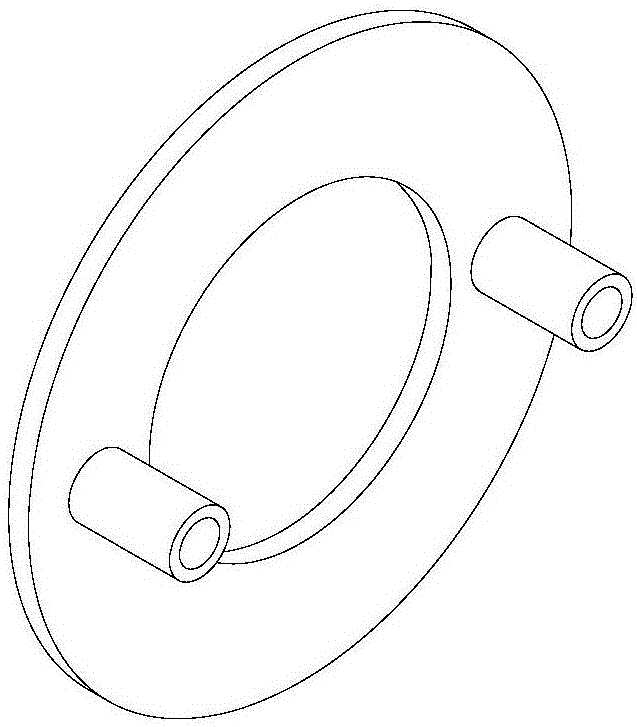

Quenching inductor for shaft parts and quenching method

InactiveCN103173595AMitigating the proximity effectImproved power loss and electrical efficiency performanceFurnace typesIncreasing energy efficiencyQuenchingThin walled

The invention discloses a quenching inductor for shaft parts and a quenching method, which are designed for solving the problem of poor quenching effect of shaft necks of existing shaft parts. The quenching inductor for the shaft parts is a ring-shaped body, wherein the inner surface of the quenching inductor is a conical surface, and the bottom surface of the quenching inductor is an inclined surface. A self-cooling water channel and a quenching liquid channel of the inductor are formed in a cavity. Magnet conduction layers are formed on the outer surface, the inner surface, the top surface and the bottom surface of the quenching inductor. A quenching system for the shaft parts comprises the shaft parts and the quenching inductor for the shaft parts. According to the quenching method, an included angle is formed between the inner surface and the cylindrical surface of the inductor, and an included angle is formed between the bottom surface and the lower end face of the inductor. The quenching inductor and system for the shaft parts are reasonable in structure, convenient to use and low in manufacture cost, and are suitable for the shaft parts including hollow shaft parts and thin-walled tubes. The quenching method is simple in procedure and has low requirements on hardware such as a device.

Owner:CHINA NORTH IND NEW TECH PROMOTION INST +1

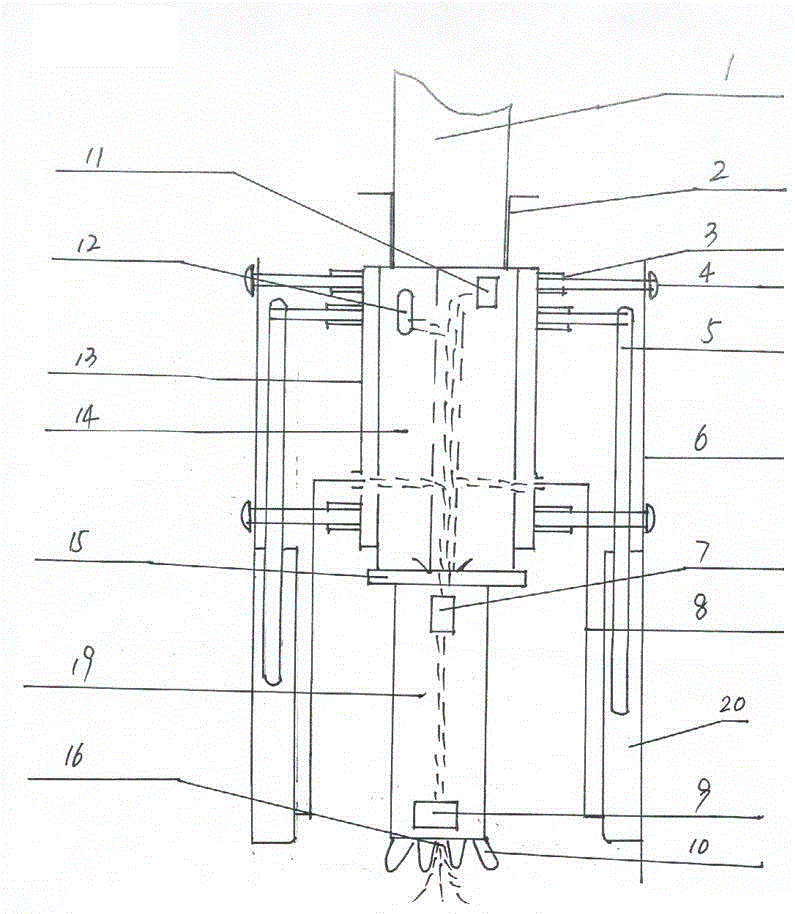

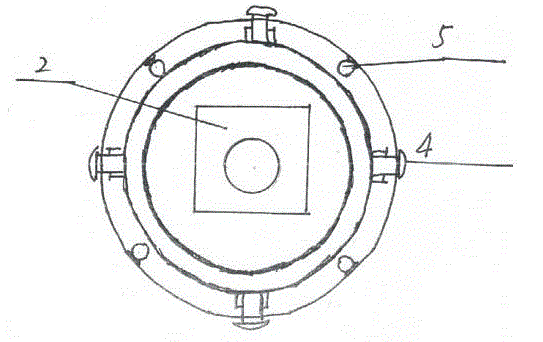

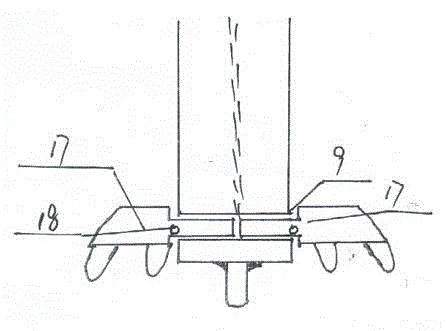

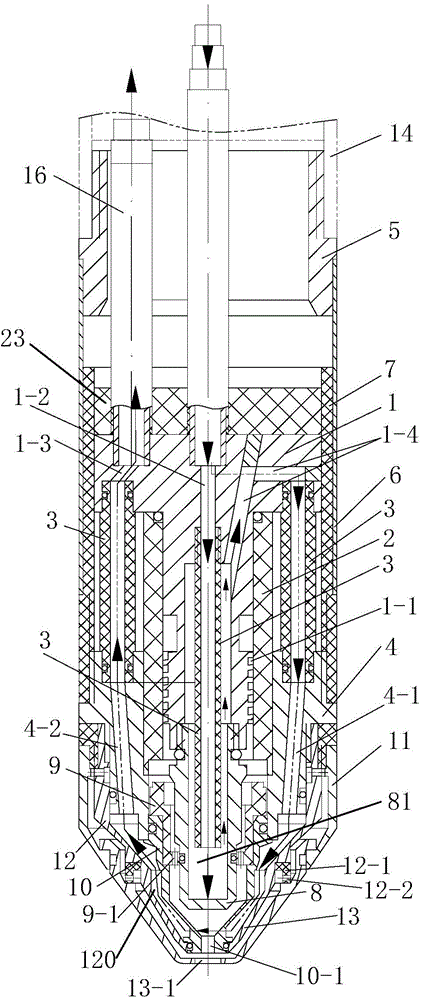

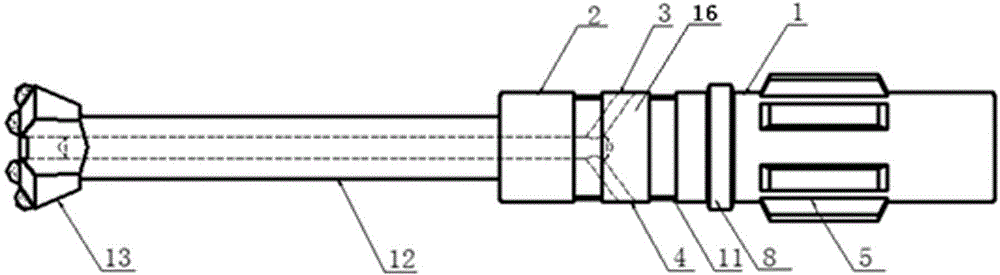

Hole bottom water injection variable-pick multifunctional rock piercing drill of rotary digging pile machine

InactiveCN103982135AIncrease the pressure valueSolve the strength problemDrilling machines and methodsPipingPiston

The invention relates to a rock piercing drill of a rotary digging pile machine, in particular to a hole bottom water injection variable-pick multifunctional rock-piercing drill of the rotary digging pile machine, mainly aiming at solving the problems that the strength of a drill pick is decreased after the drill pick of the existing rock piercing drill of the rotary digging pile machine is heated, the consumption of the drill pick is great, oil and water supply pipelines are frequently twisted on a telescopic drill rod and accidents are caused consequently. The hole bottom water injection variable-pick multifunctional rock-piercing drill of the rotary digging pile machine is characterized in that the lower end of a drill rod socket is fixedly arranged on a rotary water tank core body, the lower end of the rotary water tank core body is connected with a drill rod, a rotary water tank jacket is arranged on the outer circumference of the rotary water tank core body, a water inlet joint, a water pipe and an air exhaust and water overflow valve are arranged on the outer wall of the rotary water tank jacket, an anti-rotating casing is arranged on the outer circumference of the rotary water tank jacket, a water injector is arranged on the inner side of the lower end of the anti-rotating casing, a water injection piston of the water injector is connected onto the rotary water tank jacket, a center hole which is communicated with the rotary water tank core body is formed in the drill rod, one end of a high-pressure water pipe is connected onto the water injector, the other end of the high-pressure water pipe is connected into the water injection hole in the rotary water tank jacket and a check valve is arranged in the drill rod. The hole bottom water injection variable-pick multifunctional rock-piercing drill of the rotary digging pile machine has the advantages that the temperature of the drill pick can be kept normal, the wear is reduced, the structure is safe and reliable and the installation and the maintenance are facilitated.

Owner:高广升

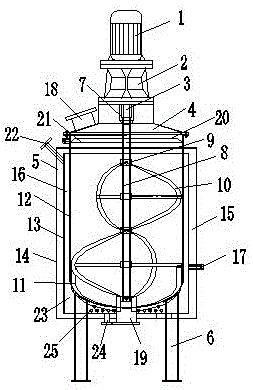

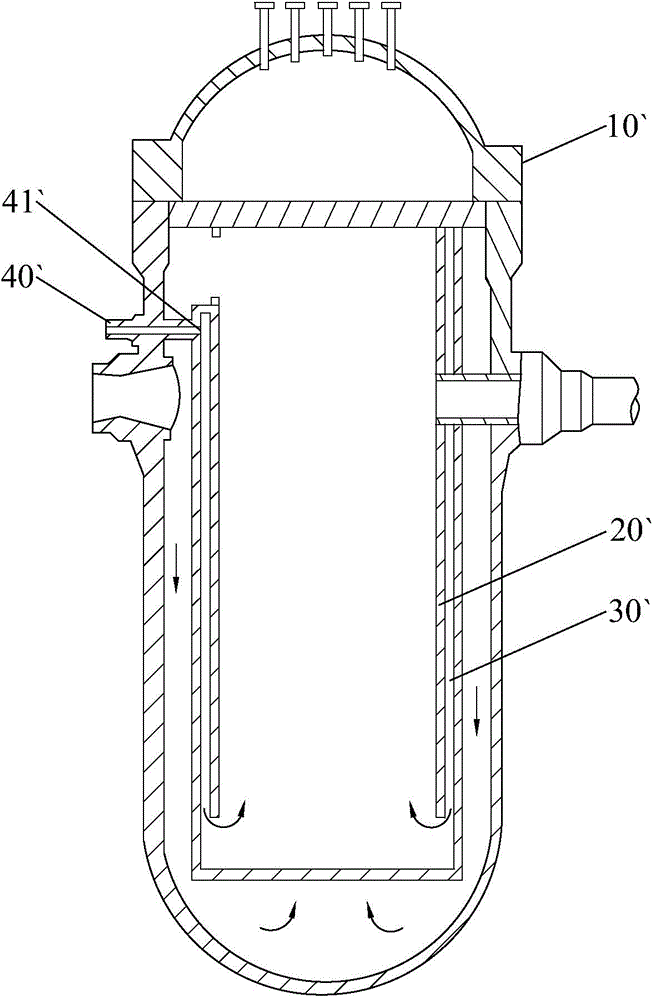

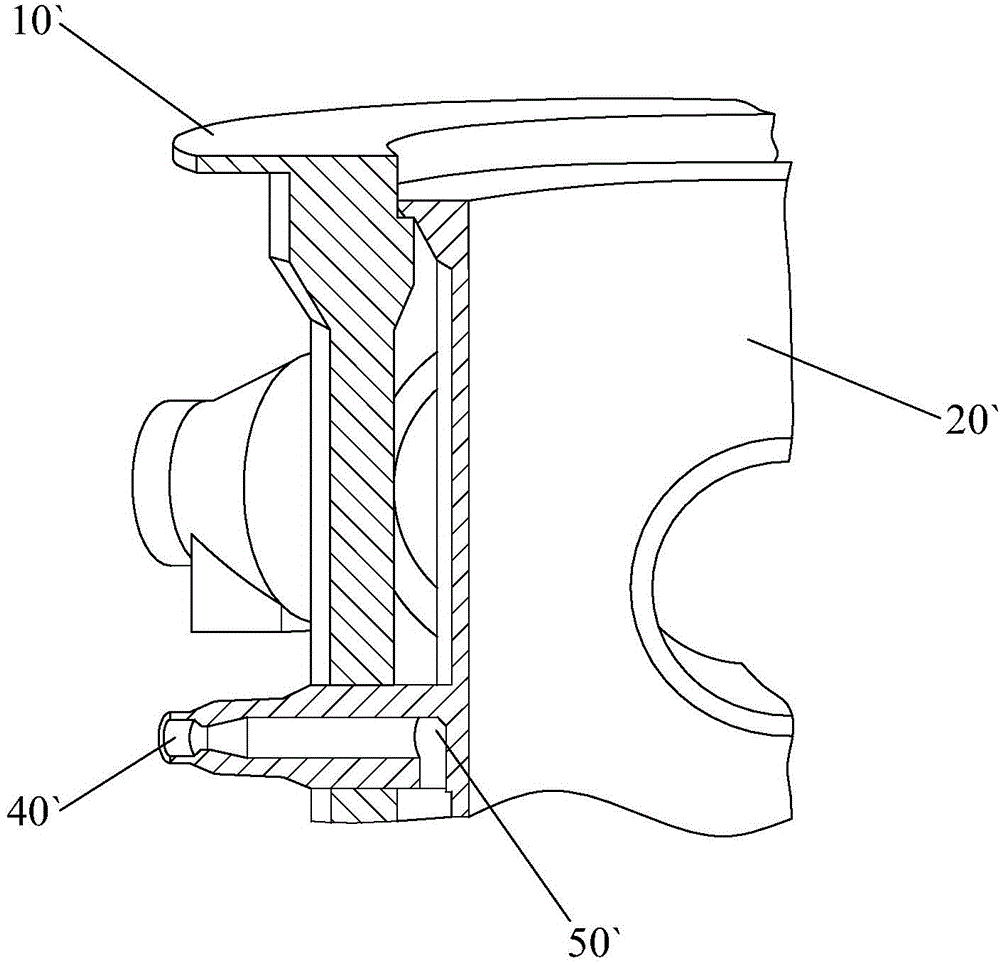

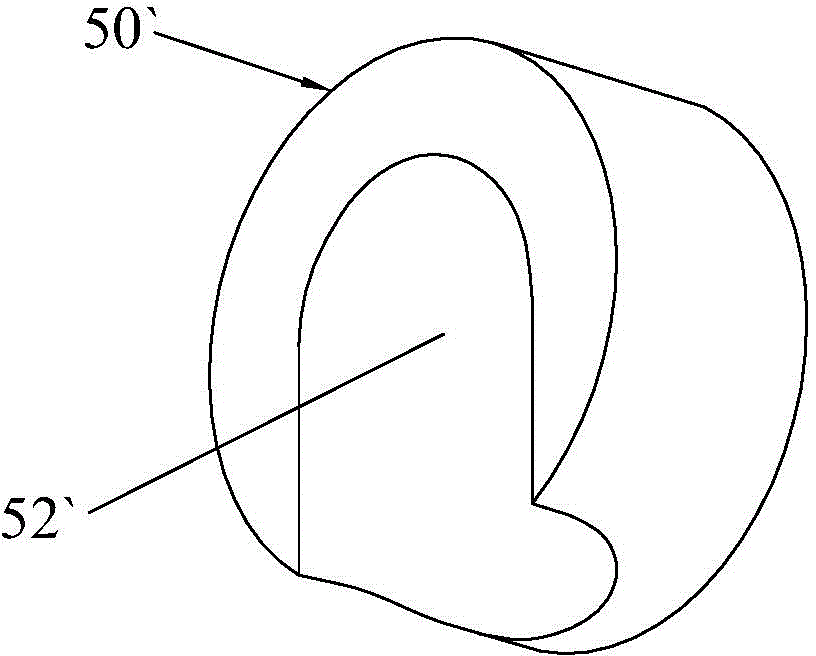

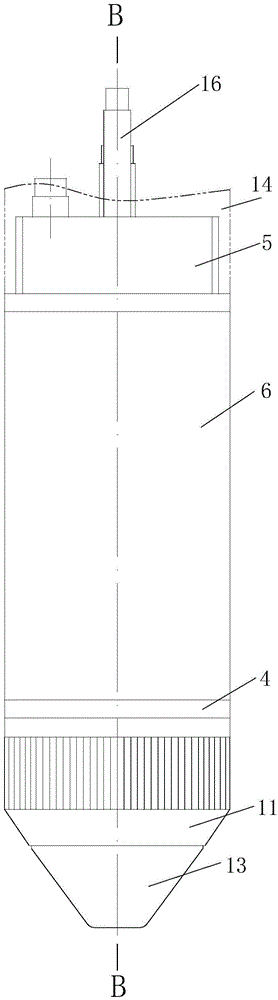

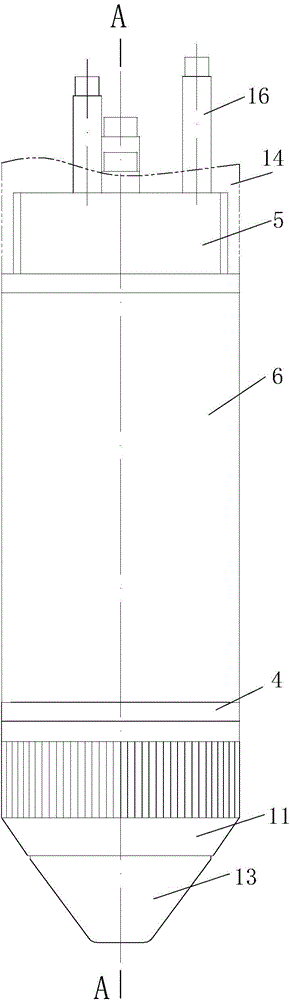

Biological fermentation tank

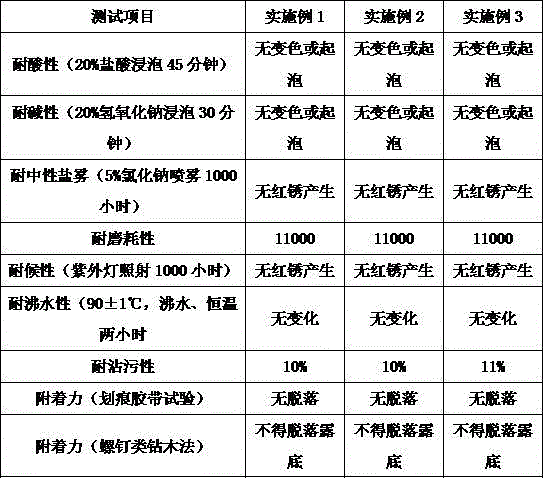

ActiveCN105886388AImprove wear resistanceImprove rust resistanceBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringFermentation

The invention relates to a biological fermentation tank which comprises a motor, a speed reducer, a stirring device, an upper cover, a fermentation bucket and a support. The upper cover is arranged at the upper end of the fermentation bucket and provided with a stirring opening, and the stirring device is arranged in the stirring opening and comprises a stirring shaft and stirring blades arranged on the stirring shaft. The stirring blades comprise the first stirring blade and the second stirring blade, the second stirring blade is arranged at the lower end of the stirring shaft, the first stirring blade is a flood dragon rotary blade, and the second stirring blade is a frame type stirring blade. Coatings are arranged on the outer sides of the stirring blades, the fermentation bucket is provided with an inner barrel body, an outer jacket and a shell in sequence from inside to outside, a heat preservation device is arranged between the outer jacket and the shell, a heating device is arranged between the inner barrel body and the outer jacket, and a sensor is arranged in the heat preservation device. The stirring blades are formed by combining the flood dragon rotary blade and the frame type stirring blade, therefore, reactants can be comprehensively stirred and can be effectively prevented from being pasted to the inner wall of the fermentation bucket, and the reaction rate is increased.

Owner:YANCHENG JIANFENG MACHINERY

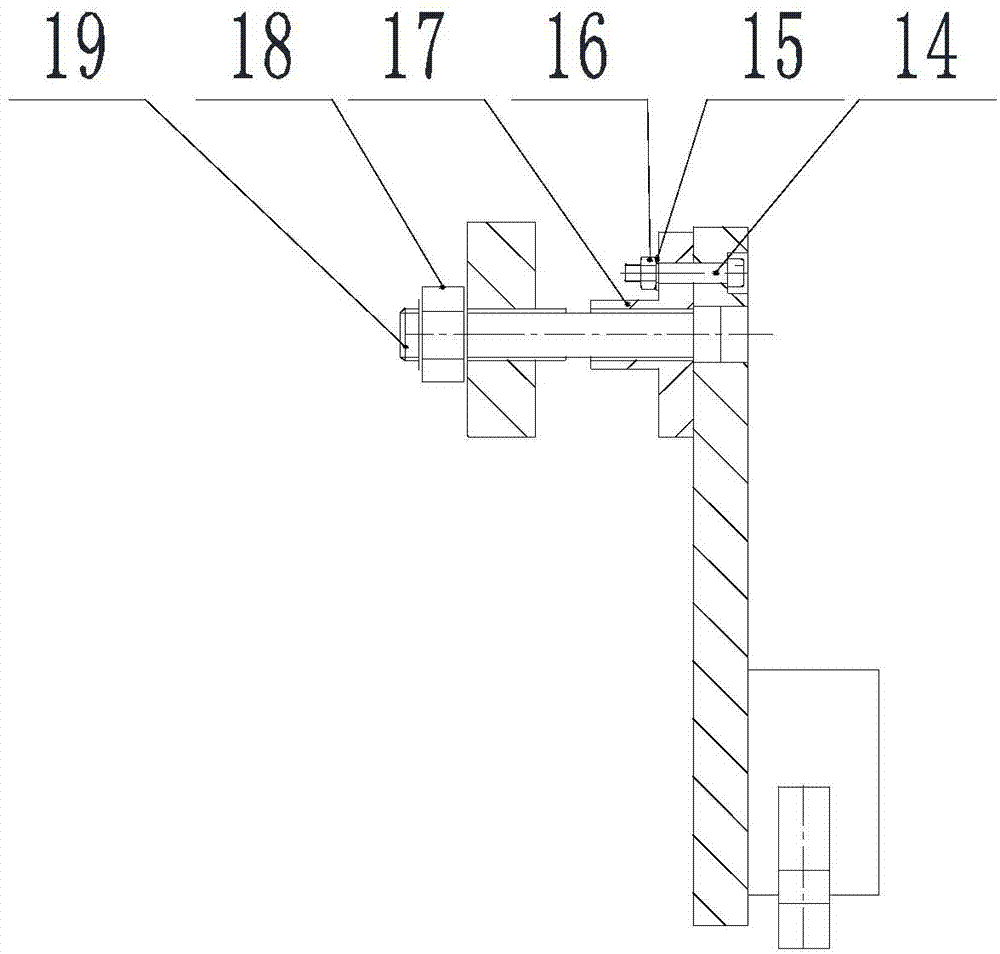

Quick quenching device and method for shaft parts

InactiveCN104775011ATemperature monitoringWon't soften the problemFurnace typesHeat treatment furnacesLaser quenchingLiquid nitrogen cooling

The invention discloses a quick quenching device and method for shaft parts. The quick quenching device for shaft parts is provided with a temperature monitoring device, a laser device, a liquid nitrogen cooling system, a workpiece clamp and a connecting plate assembly, wherein the connecting plate assembly is provided with a manipulator connecting plate, a connecting component and a spray nozzle connecting plate, a laser head is installed on the manipulator connecting plate, and a liquid nitrogen spray nozzle is installed on the spray nozzle connecting plate and is connected with a liquid nitrogen cooling system control valve through an air delivery pipe. The workpiece clamp is arranged under the connecting plate assembly and is provided with a chuck, a tip and a control system for controlling rotation of the chuck, and a workpiece is arranged between the chuck and the tip. The temperature monitoring device is arranged on one side of the connecting plate assembly and is used for monitoring the temperature of a laser quenching zone on the workpiece. By the adoption of the quick quenching device and method for shaft parts, the automation degree of surface laser strengthening of large shafts can be improved, working efficiency can be improved, shaft surface strengthening and near-net shaping can be also achieved, additional machining is not needed basically, and working procedures and cost are saved.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Nuclear reactor direct safety injection system

ActiveCN104658621AInhibit expansionGood drainageNuclear energy generationCooling arrangementNuclear reactor coreNuclear reactor

The invention discloses a nuclear reactor direct safety injection system which is used for directly offering cooling liquid to a pressure container in a nuclear reactor, wherein a hanging basket is arranged inside the pressure container; a nuclear reactor core is arranged inside the hanging basket; an annular cavity is formed between the pressure container and the hanging basket; the safety injection system comprises a safety injection cold source and a direct safety injection tube; the direct safety injection tube has an inlet and an outlet; the inlet is communicated with the safety injection cold source; the direct safety injection tube penetrates into the pressure container and extends into the annular cavity, and the outlet is formed below the nuclear reactor core. Since the direct safety injection tube penetrates into the pressure container and extends into the annular cavity, and the outlet is formed just below the nuclear reactor core, when loss of coolant accident occurs, the cooling liquid can be directly conveyed into the nuclear reactor core by virtue of the direct safety injection tube, so as to cool and boronize the nuclear reactor core timely and effectively, greatly improve the capacity of controlling and relieving accidents and effectively prevent the loss of coolant accident from developing to a hyper design basis accident.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

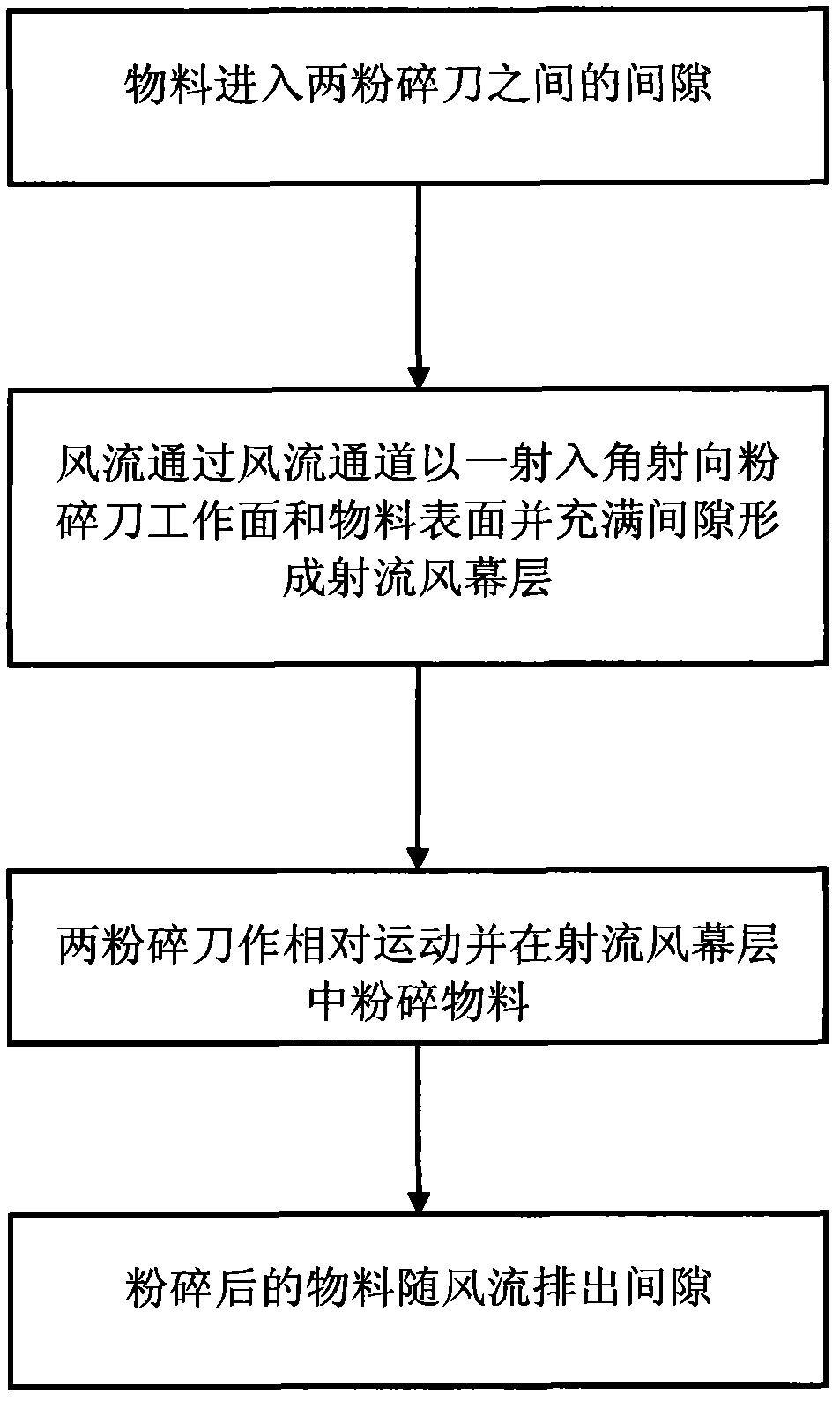

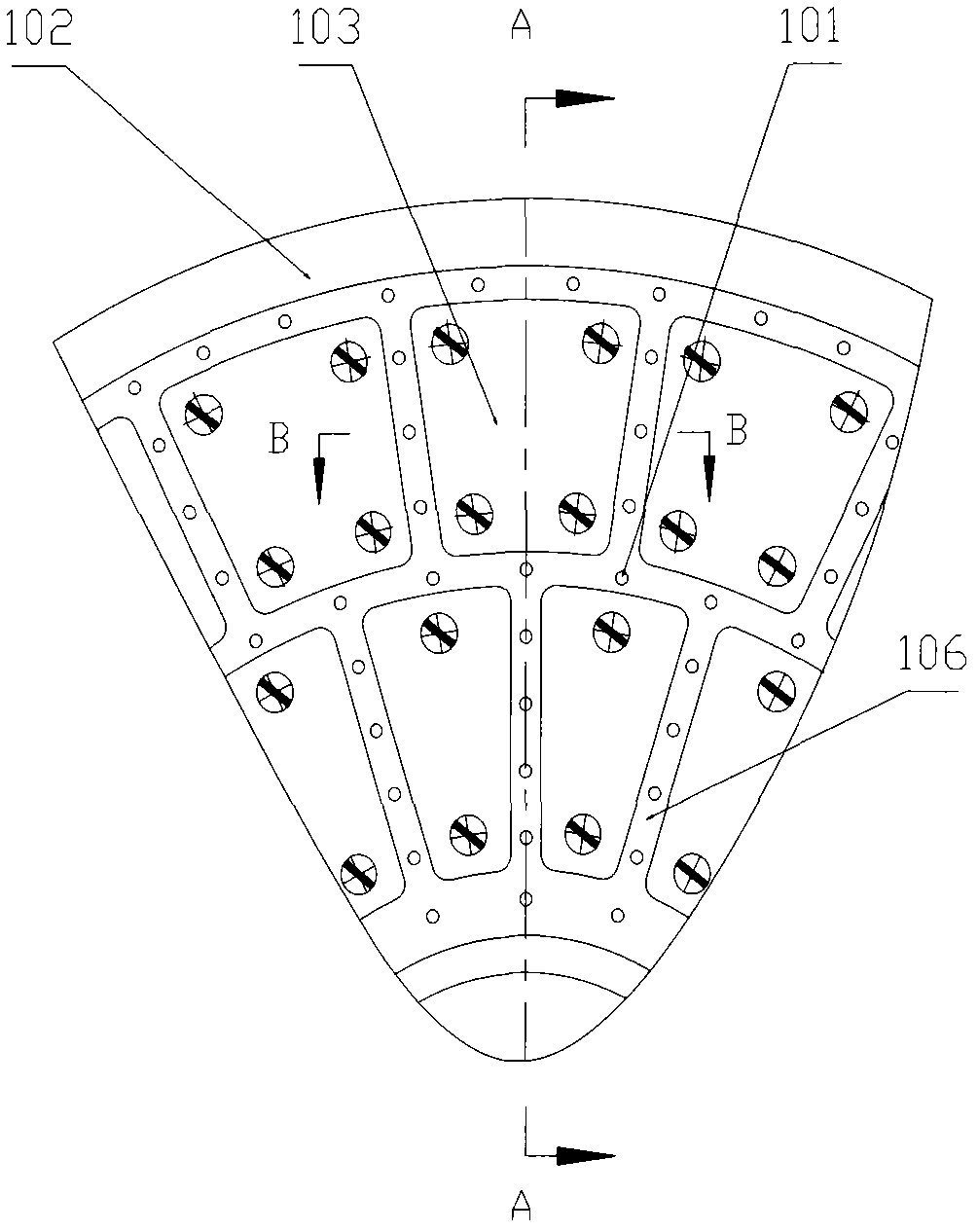

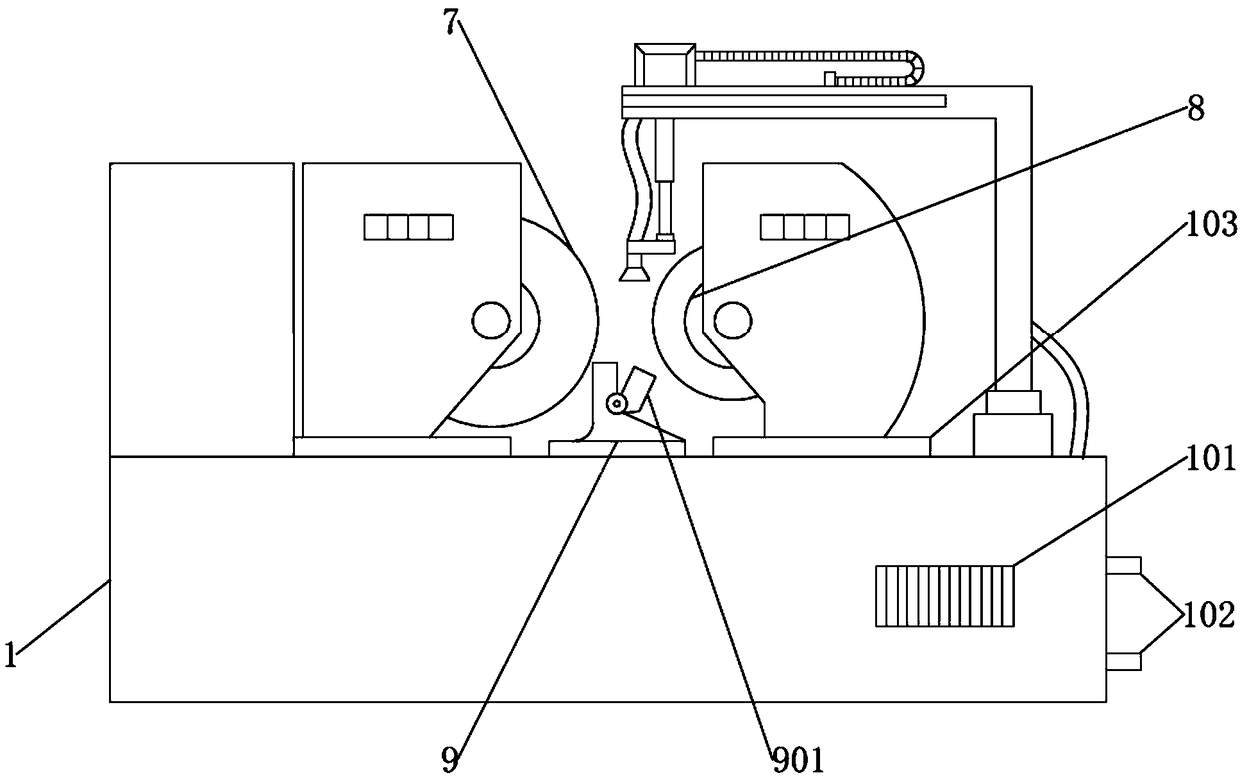

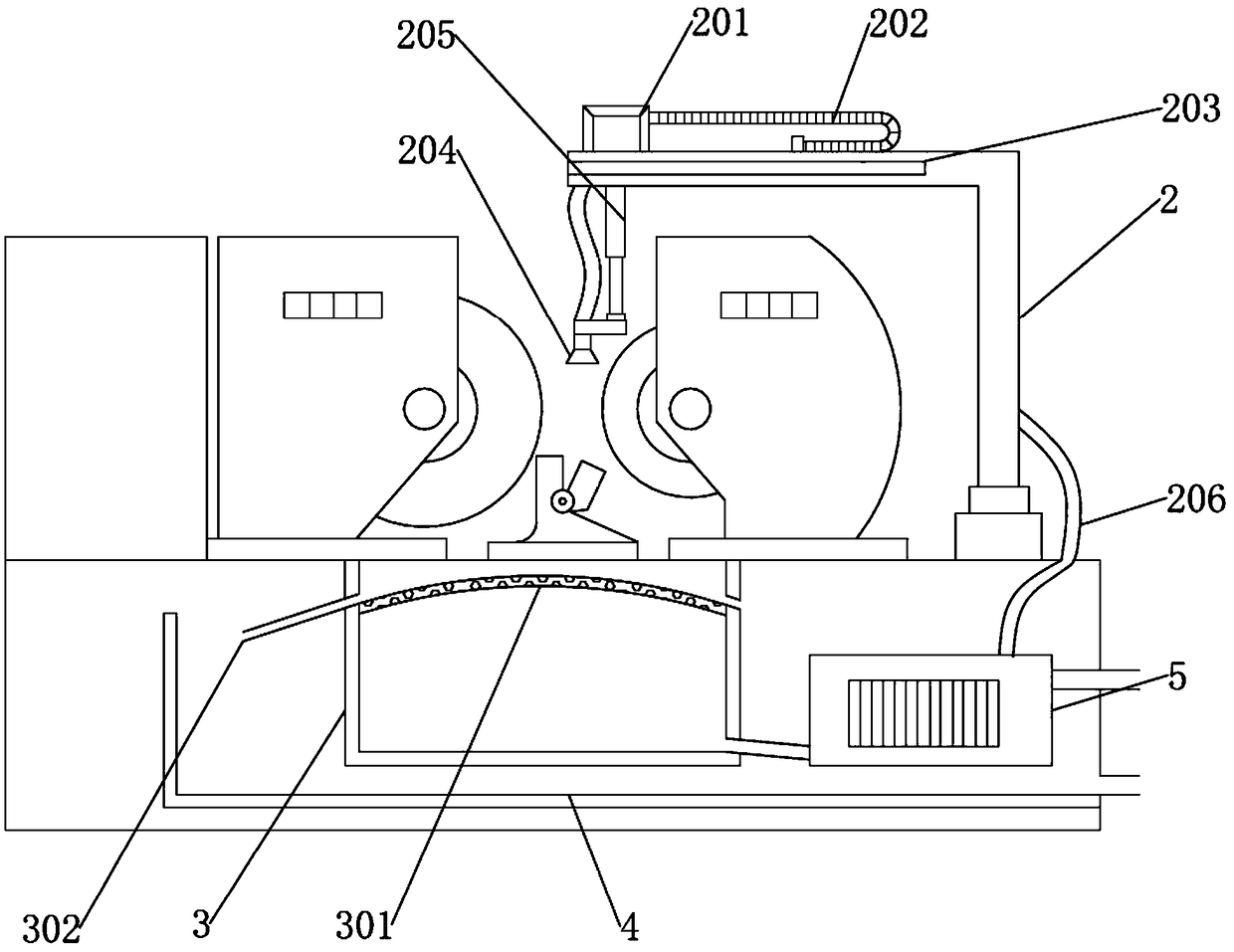

Method and structure for crushing low-temperature materials

ActiveCN102886294AEliminate aggregationReduce surface temperatureGrain treatmentsAngle of incidenceEngineering

A method for crushing low-temperature materials uses a material crushing device which comprises two crushing blades capable of moving relatively and an air flow channel communicated with a gap between the two crushing blades. The method comprises the following steps that: (1) the materials are sent into the gap between the two crushing blades; (2) the air flow passes the air flow channel and goes toward the working face of the crushing blades and the surface of the materials in an angle of incidence, and fills the gaps to form a jet air curtain layer; (3) the two crushing blades move relatively and crush the materials in the jet air curtain layer; and (4) the crushed materials are discharged from the gap with the air flow. By using an air-flow direct cooling way, the method effectively eliminates accumulation of crushing heat and static generated from friction, and prevents occurrence of melting and softening of the materials and degeneration and clustering, thereby meeting crushing requirements of high mesh and fine grain of the low-temperature materials. A structure for crushing low-temperature materials has advantages of large output, low energy consumption and high efficiency, and can be used for crushing the low-temperature materials with relatively low melting temperature, such as rubber, silicone, plastic, protein powder, herbal medicines, etc.

Owner:卢小平 +1

Centerless grinding machine

InactiveCN108788961AAchieve the effect of reuseGrinding effectRevolution surface grinding machinesGrinding/polishing safety devicesEngineeringWater level

The invention discloses a centerless grinding machine. The centerless grinding machine comprises a grinding machine base, a water collecting water tank, a grinding wheel and a metal chip filtering plate, two grinding wheel adjusting sliding rails are fixedly installed on the upper surface of the grinding machine base, a water cooling system is connected to the upper surface of the grinding machinebase in an inserted mode, a horizontal rod is welded to the top of the water cooling system, and a water level adjusting sliding block is connected to the upper surface of the horizontal rod in a sliding mode; and one side of the water cooling system is connected with a water supply pipe in an inserted mode, and the water collecting water tank is fixedly installed inside the grinding machine base. According to the centerless grinding machine, the metal chip filtering plate is fixedly connected to the center of the inner part of the water collecting water tank, cooling liquid flowing down after grinding through the centerless grinding machine can be filtered through the metal chip filtering plate, scrap iron left by grinding through grinding wheel inside the cooling liquid is filtered, sothat the situation that the scrap iron is sprayed onto the grinding wheel again after passing through the water cooling system, then scratches are left on the surface of a ground workpiece is avoided,and the problem that the interior of the cooling liquid cannot be secondarily utilized due to the residual scrap iron is solved.

Owner:MAANSHAN YASHIDA INTELLIGENT TECH CO LTD

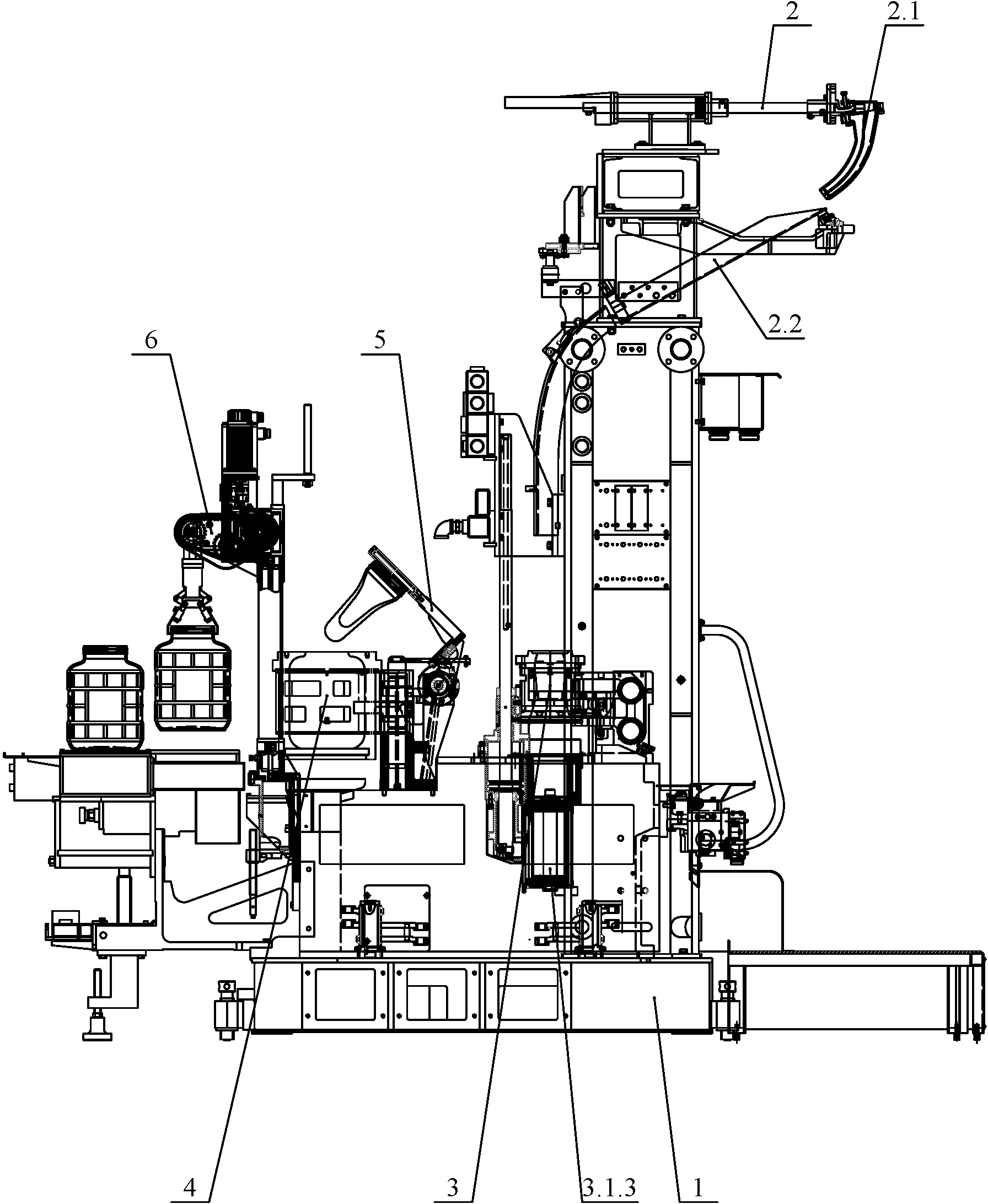

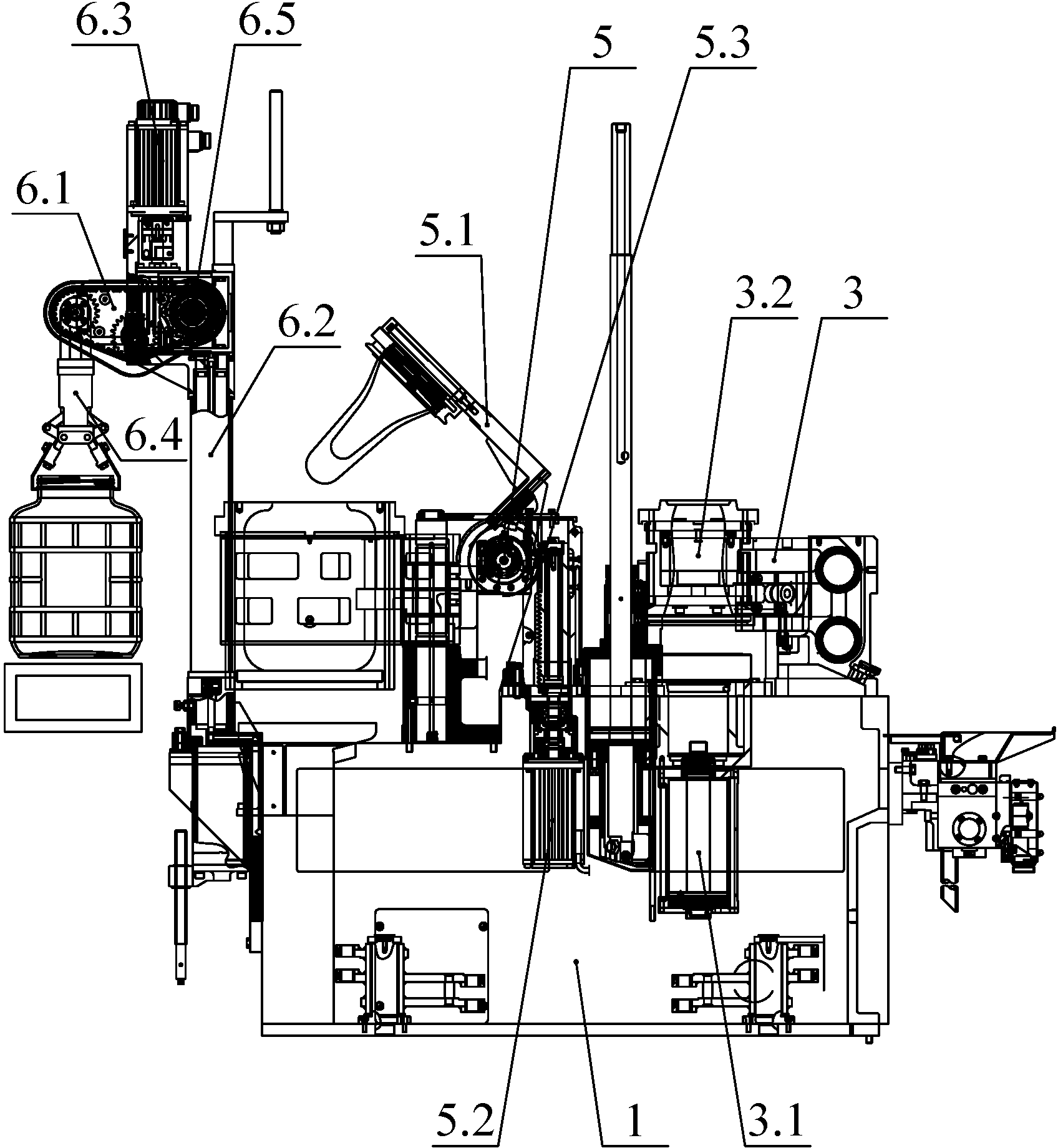

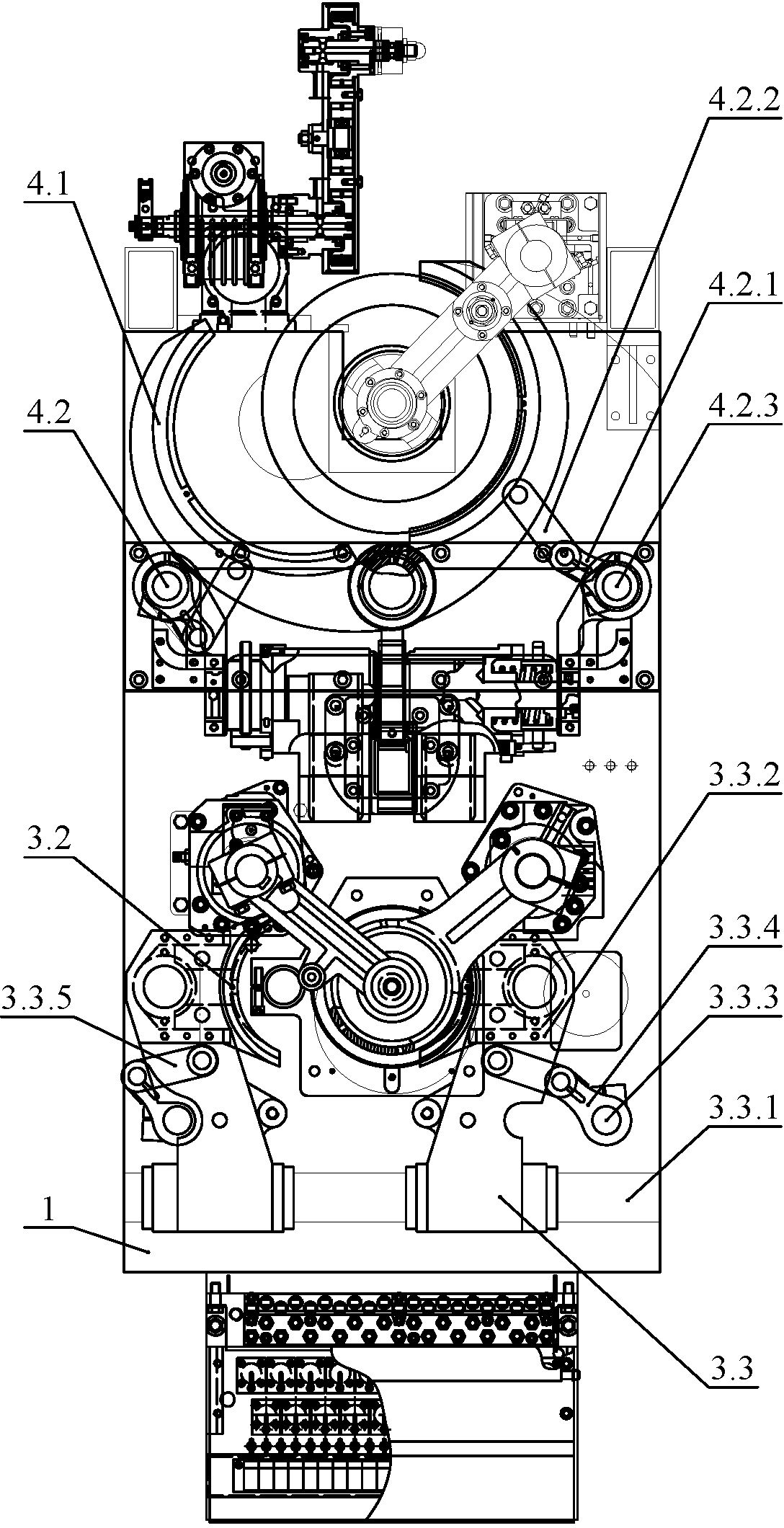

Bottle-making machine and production process for manufacturing extra-large glass bottles

ActiveCN104108856ARealize mechanical automation productionIncrease productionBlowing machine gearingsPress and blow machinesEngineeringBottle

The invention relates to a bottle-making machine and a production process for manufacturing extra-large glass bottles, and belongs to the field of bottle-making machine equipment. The bottle-making machine comprises a rack, and a primary mold forming mechanism, a formed mold forming mechanism and a turnover mechanism which are arranged on the rack, wherein the primary mold forming mechanism comprises a stamping device, a primary mold and a parallel switching mechanism; the stamping device is mounted on the rack; the parallel switching mechanism comprises a horizontal guide shaft mounted on the rack, a clamp arm which sleeves on the horizontal guide shaft, and a first spline shaft, a first rocker arm, a first connecting rod and a first switching cylinder which vertically sleeve at two sides of the rack; one end of the first connecting rod is hinged with the clamp arm while the other end of the first connecting rod is hinged with the first rocker arm; the first rocker arm is connected with the first switching cylinder through the first spline shaft; the primary mold is mounted on the clamp arm. The bottle-making machine has the beneficial effects that the extra-large glass bottles are produced in a manner of automatic mechanized production for replacing manual production, so that the yield of the extra-large glass bottles is increased and the quality of the extra-large glass bottles is improved.

Owner:SHANDONG JIAFENG GLASS MACHINERY

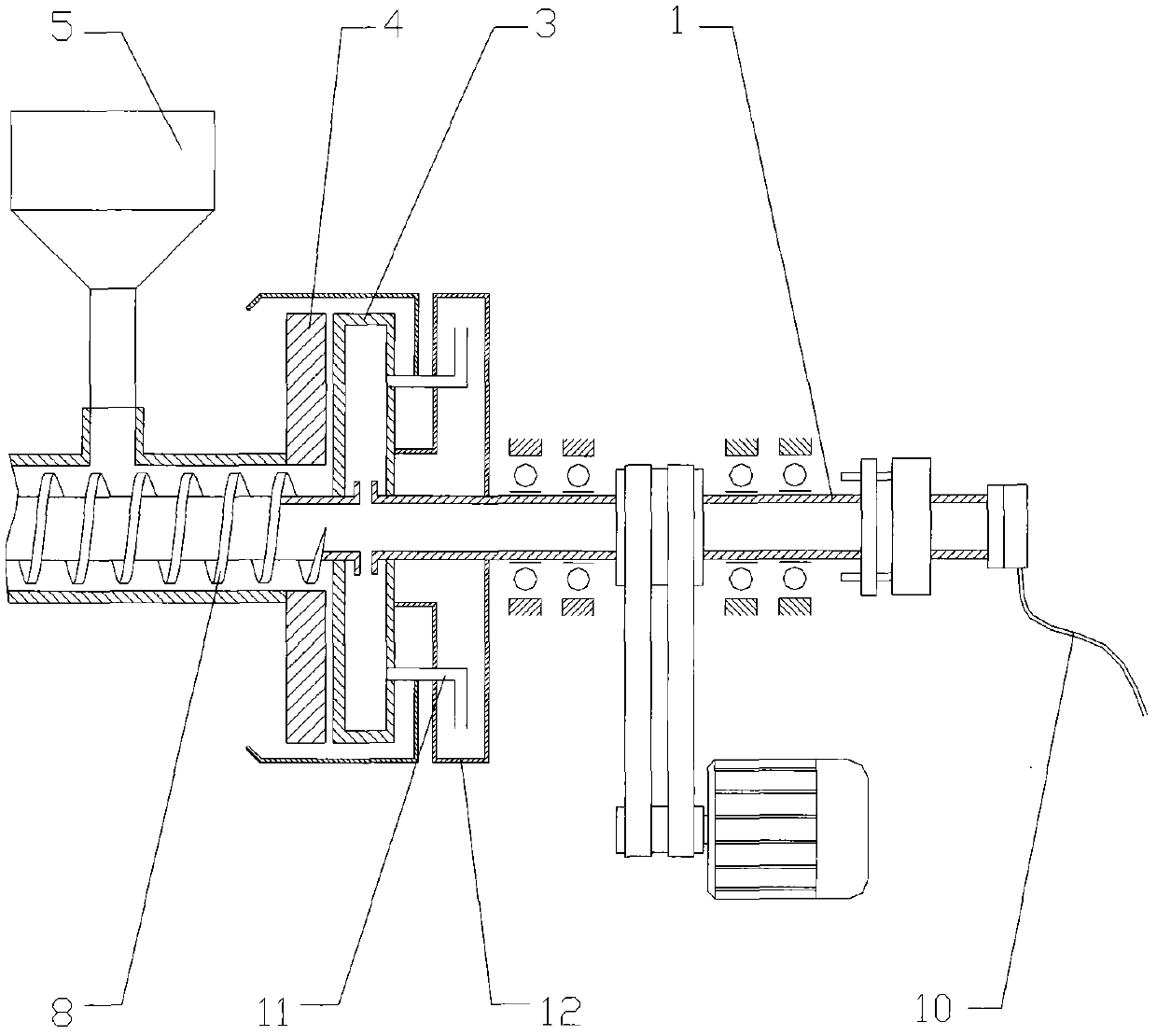

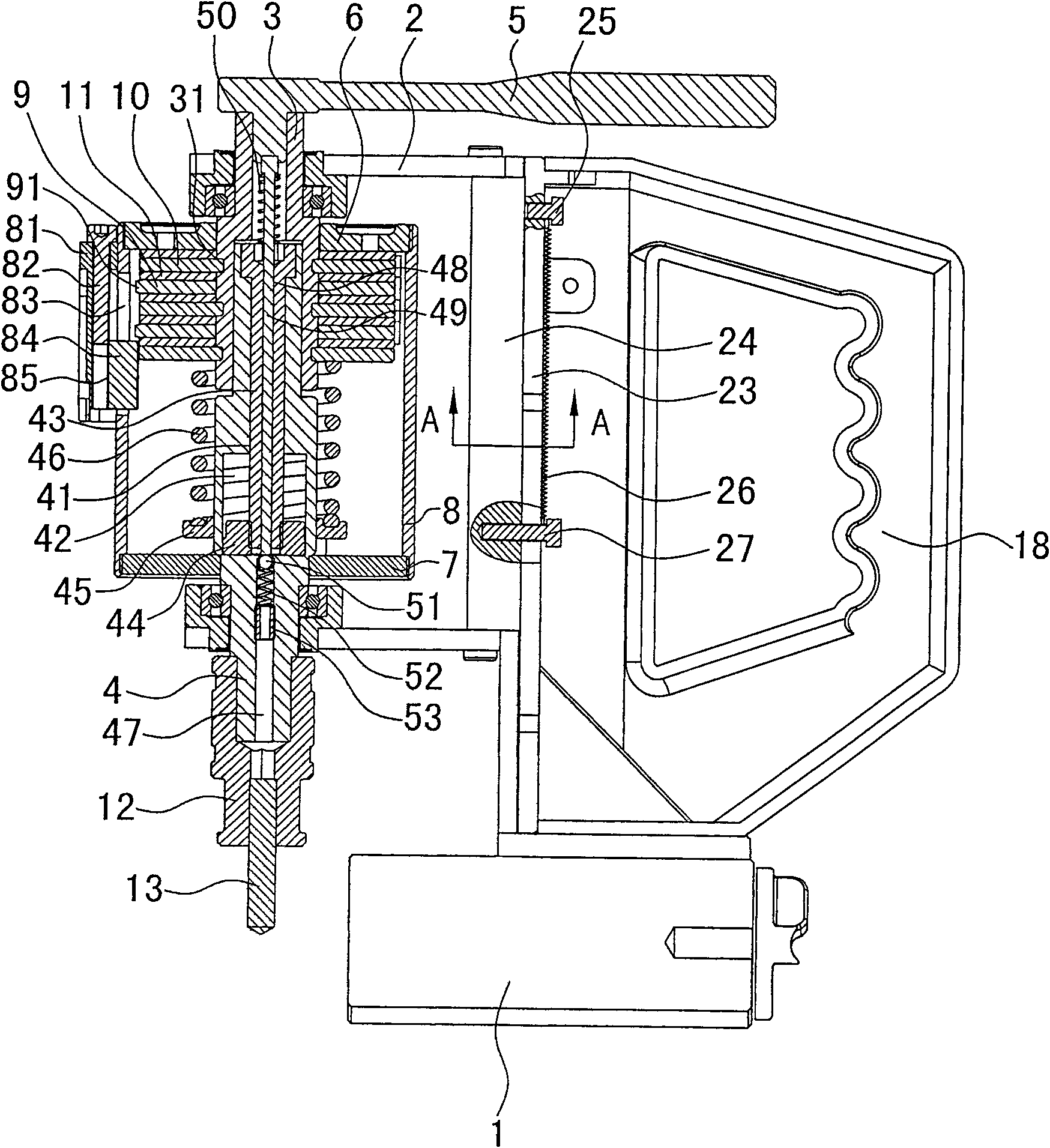

Gear shifting type constant torque tapping mechanism

The invention provides a gear shifting type constant torque tapping mechanism, which comprises a machine frame, wherein the lower part of the machine frame is connected with a base; the inside of themachine frame is provided with a main shaft driven by a handle; the lower part of the main shaft is provided with a drill chuck; and the inside of the drill chuck is provided with a screw tap. The gear shifting type constant torque tapping mechanism is characterized in that: the machine frame comprises a vertical slide plate pair which fixes the main shaft by a pull rod; the main shaft comprises an upper main shaft and a lower main shaft which are movably connected; the handle is connected with the upper main shaft; a shell is arranged between the middle part of the upper main shaft and the middle part of the lower main shaft by an upper cover plate and a lower cover plate; the outside of the upper main shaft is provided with a friction moving plate which is contacted with a friction static plate by a friction connecting plate; the friction static plate drives the shell by a torsional gear shifting lock, the shell drives the lower main shaft, and the drill chuck is connected with the lower main shaft; the lower main shaft is provided with a central hole and an adjusting cavity which are communicated, and the inside of the central hole is provided with an adjusting bolt B of which the lower part is provided with a nut in the adjusting cavity; and a spring support is arranged outside of the lower main shaft and provided with a pre-pressing spring contacted with the friction moving plate.

Owner:童淼

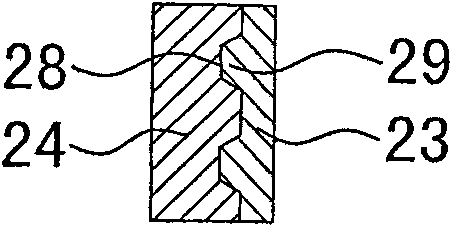

Production process of nylon-6 coarse-denier high-strength yarns

InactiveCN104695033AReduced drawabilityPromote crystallizationArtificial thread manufacturing machinesFilament manufactureBreaking strengthYarn

A production process of nylon-6 coarse-denier high-strength yarns includes slicing, melting, metering, spinning, cooling, oiling, pre-interlacing, drafting and setting, main interlacing, and winding. In the slicing step, nylon-6 slices 2.8 to 3.2 in viscosity are selected. Melting is performed at the temperature of 270 DEG C to 280 DEG C. In the spinning step, pore diameter of a spinneret plate is 0.36mm, pore length is 1.08 mm, and initial pressure of a component is 135 bars to 142 bars. In the oiling step, oil resistant to high temperature, anti-static and high in cohesion is adopted. The nylon-6 slices of specific viscosity are used, the temperature of the melting step is adjusted, and a melt pipe, a spinning component, an oiling device, pre-interlacing and drafting and setting are modified, and the nylon-6 coarse-denier high-strength yarns up to 6.2Cn / dtex in breaking strength are produced.

Owner:QUANZHOU TIANYU CHEM FIBER WEAVING IND

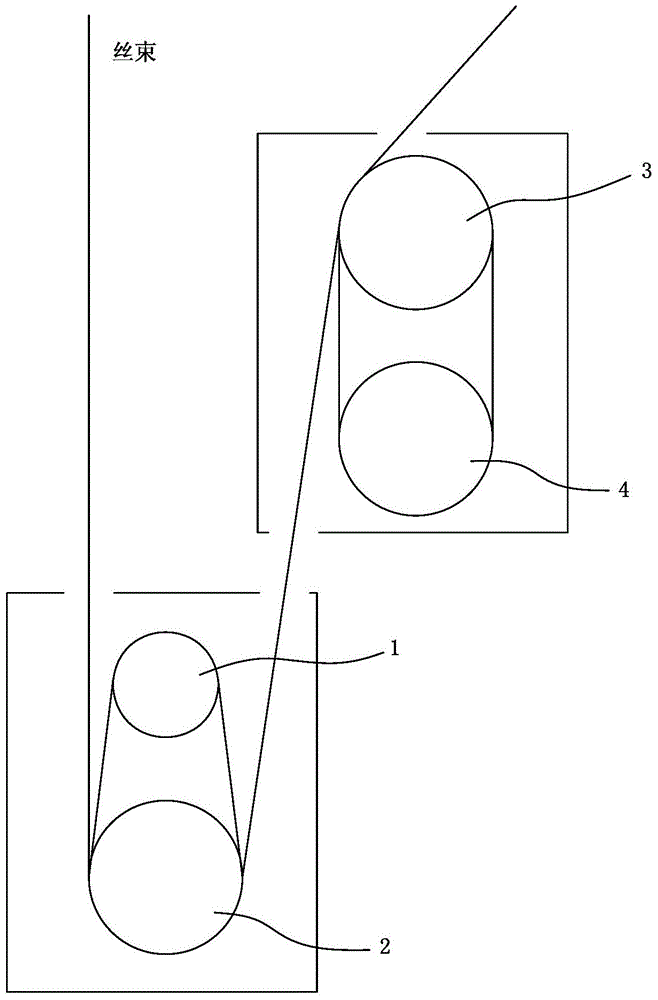

Mooring locating device for sea drill platform

ActiveCN101462581ASmall footprintChange stressAnchoring arrangementsElectrical resistance and conductanceStress conditions

The invention relates to a mooring and positioning device for an offshore drilling platform, which comprises a central controller, at least one mooring and positioning winch and a separating control device, wherein the central controller collectively controls working conditions of each mooring and positioning winch, the separating control device is respectively connected with the central controller and the each mooring and positioning winch, and the mooring and positioning winch is a water-cooled mooring winch with variable frequency resistance. Because a plurality of mooring and positioning winches are used for positioning, and a computer performs central control treatment, a cable of each mooring and positioning winch is in constant tension condition; because the mooring and positioning winch is designed into a multi-braking structural style, the diameter of a brake wheel is reduced, and space occupied by the winch on the platform is reduced; because a water cooled brake is provided, components are cooled in time, and service life of the components is prolonged; and because a wound roll is designed into a structure with a step rope guiding groove, stress condition of the cable is changed during winding, and abrasion of a wire cable is reduced.

Owner:NANTONG LIWEI MACHINERY

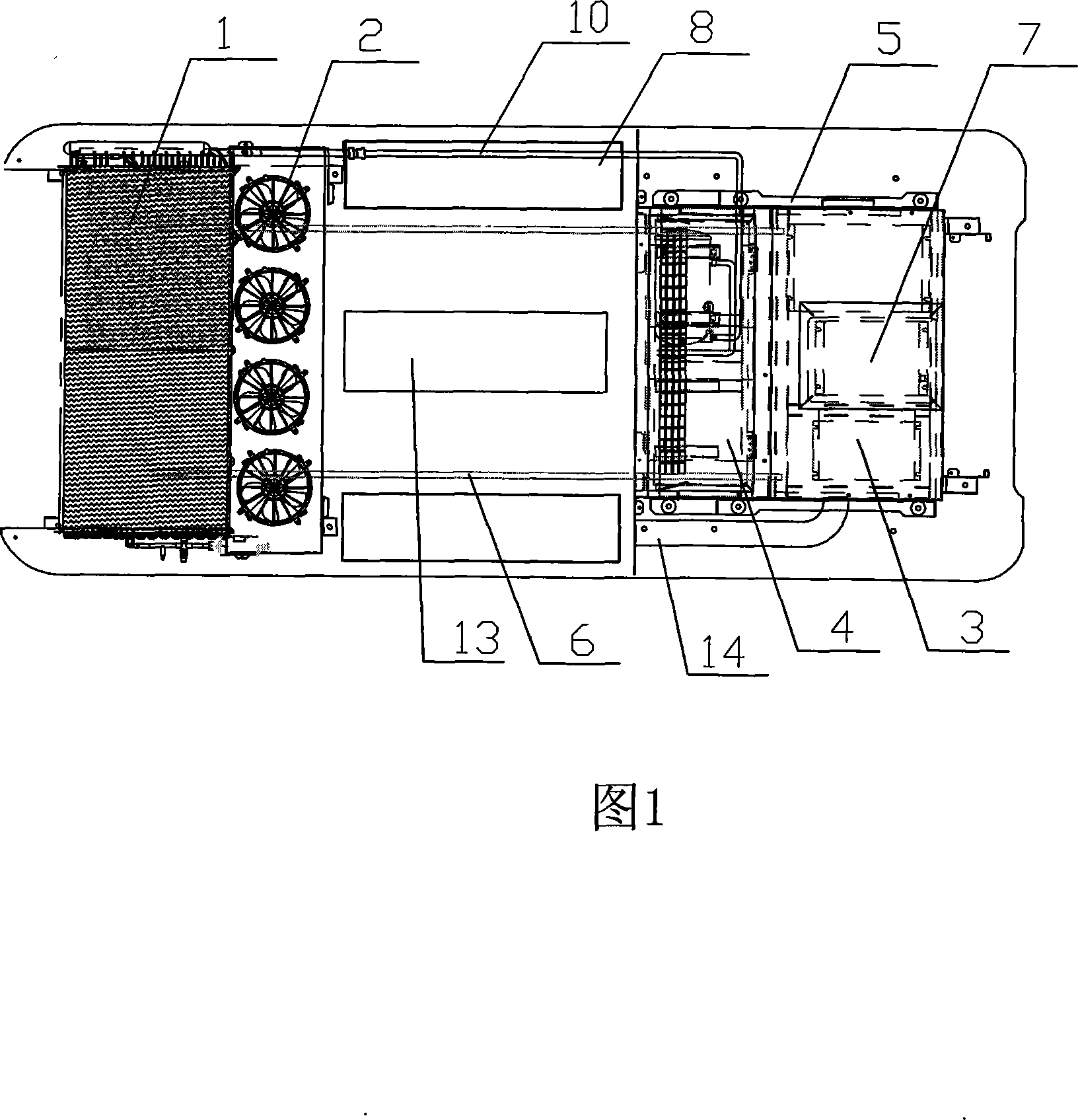

Air conditioner of electric motor coach

ActiveCN101182942AImprove securityTimely coolingAir-treating devicesLighting and heating apparatusAppliance componentEngineering

The invention aims at providing an air conditioner for an electric coach with improvement of reliability of an electric appliance component; a compressor, a power transforming device and an electric appliance control part are provided with a closed metal shell for an electric cabinet with shielding function; a core body of an evaporator and an evaporating blower are provided with a shell of the evaporator outside; a cooling metal pipeline is arranged between the metal shell of the electric cabinet; one interface of the cooling metal pipeline is arranged on the shell of the core body of the evaporator and the other interface is arranged on the metal shell of the electric cabinet; the other end of the metal shell of the electric cabinet is provided with an air outlet with an downward opening.

Owner:GUANGZHOU JINGYI AUTOMOBILE AIR CONDITIONER

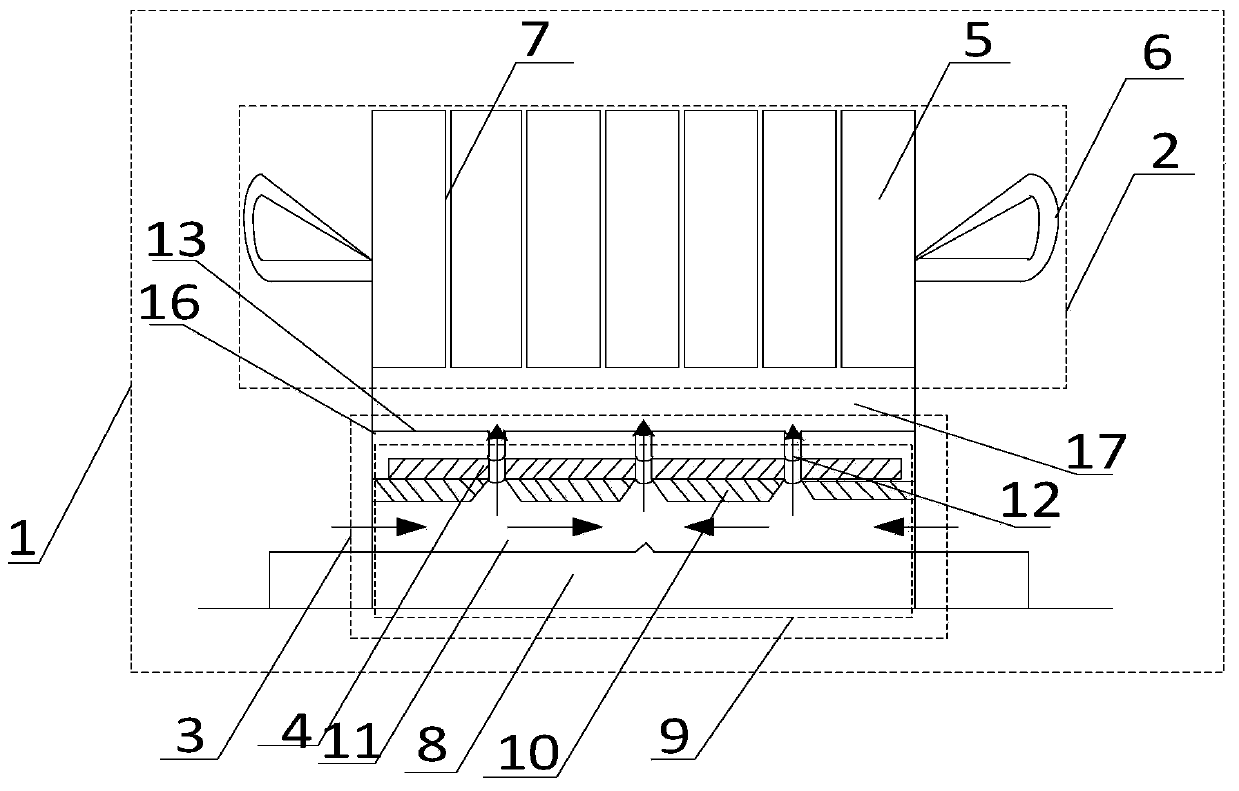

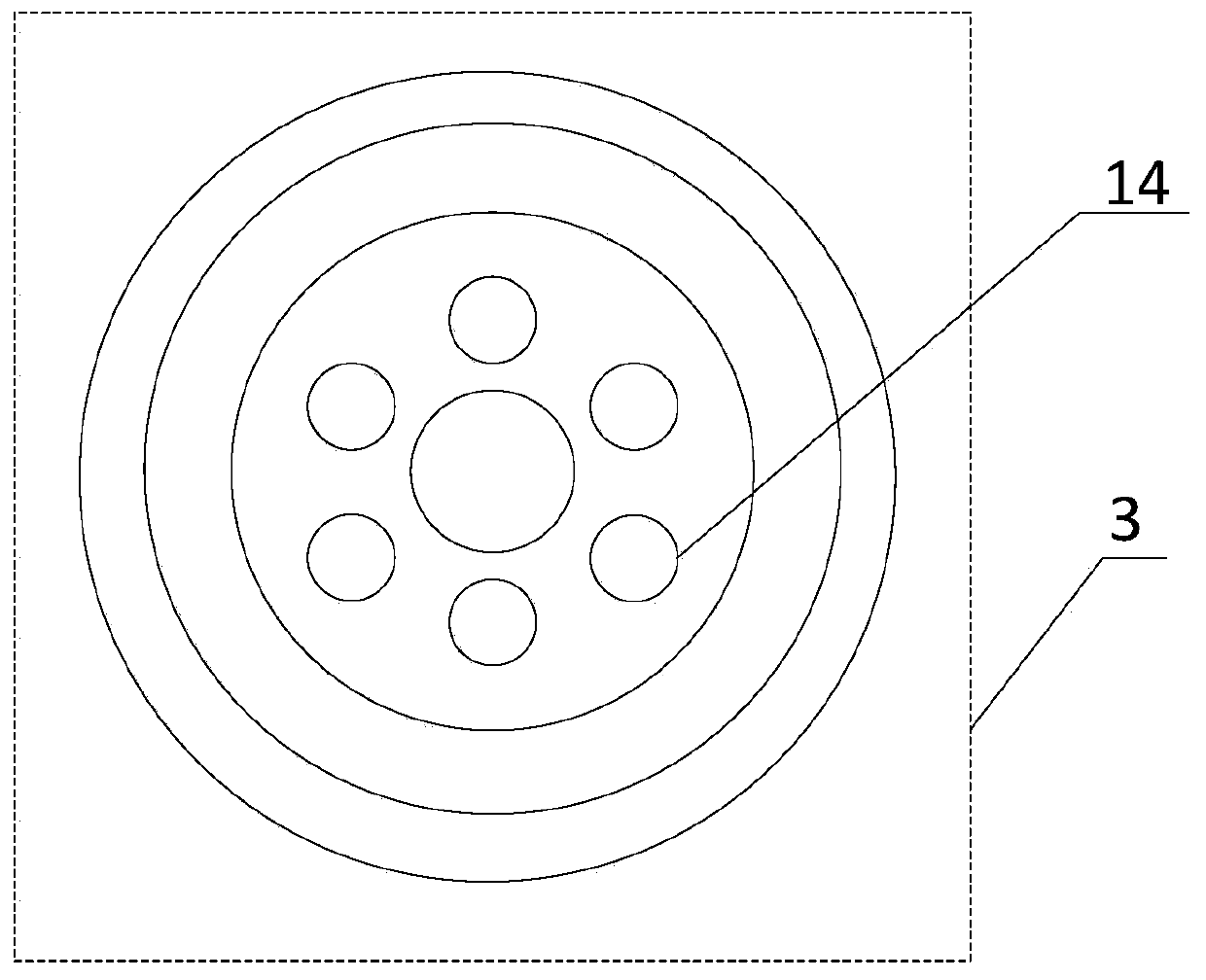

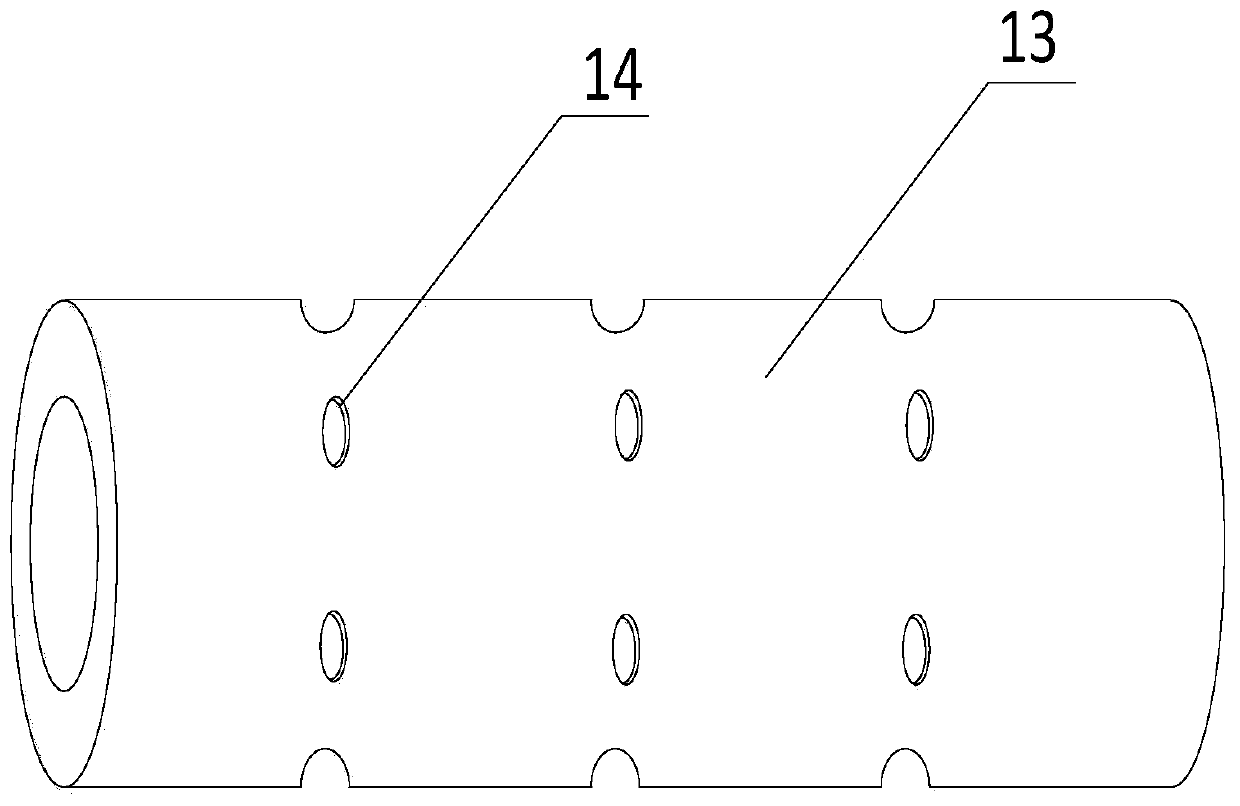

High-speed motor cooling system

PendingCN110474485AEffective coolingReduce lossMagnetic circuit rotating partsMagnetic circuit stationary partsCold airCooling effect

The invention discloses a high-speed motor cooling system. The system comprises a motor, and the motor comprises a stator, a rotor and permanent magnets. The stator comprises stator cores, stator windings and stator core radial ventilating ducts; the stator windings are wound on the stator cores; the stator core radial ventilating ducts are located between the stator cores; the rotor comprises a rotating shaft and a rotor core, the rotating shaft is fixed in the middle of the rotor core, grooves are formed in the surface of the rotor core, and a rotor core axial ventilation hole and rotor ironcore radial ventilation holes which communicate with each other are formed in the rotor core. The permanent magnets are attached to the interiors of the grooves of the rotor core, and the permanent magnets are sleeved with sheaths. According to the invention, the motor is cooled through the ventilating ducts communicating between the stator and the rotor; and the independent cold air supply device and the centrifugal fan are used for cooling the motor and can be used for cooling the motor at the same time, so that the cooling effect of the motor is more obvious.

Owner:NANJING NORMAL UNIVERSITY

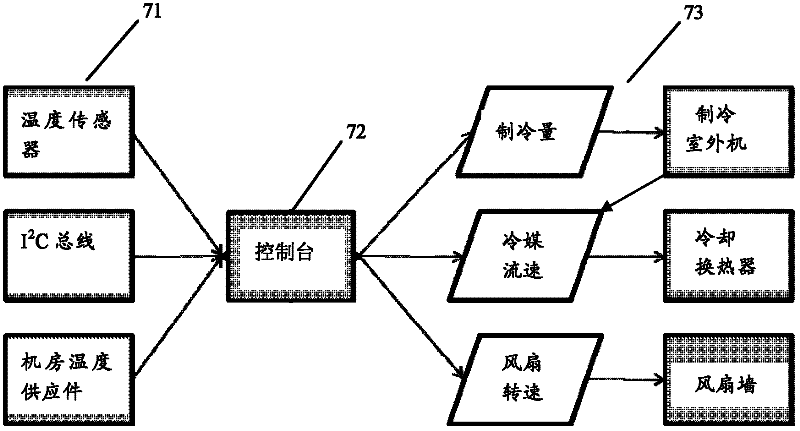

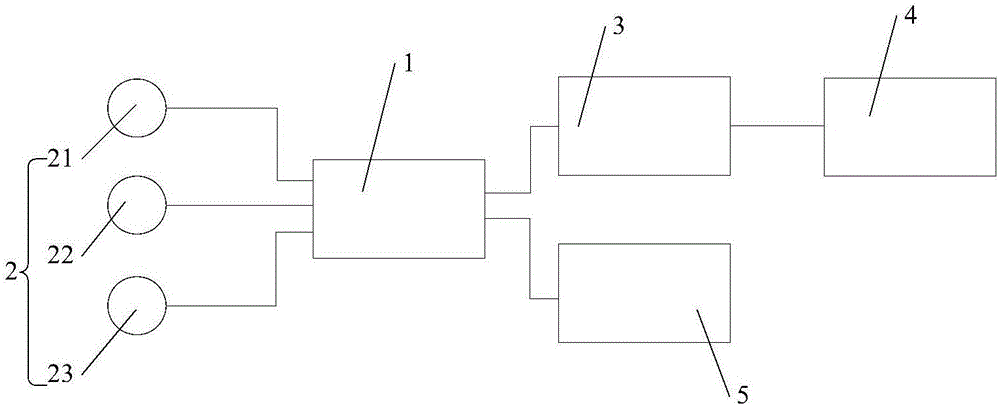

Temperature control device and method, electric cabinet and air-conditioner

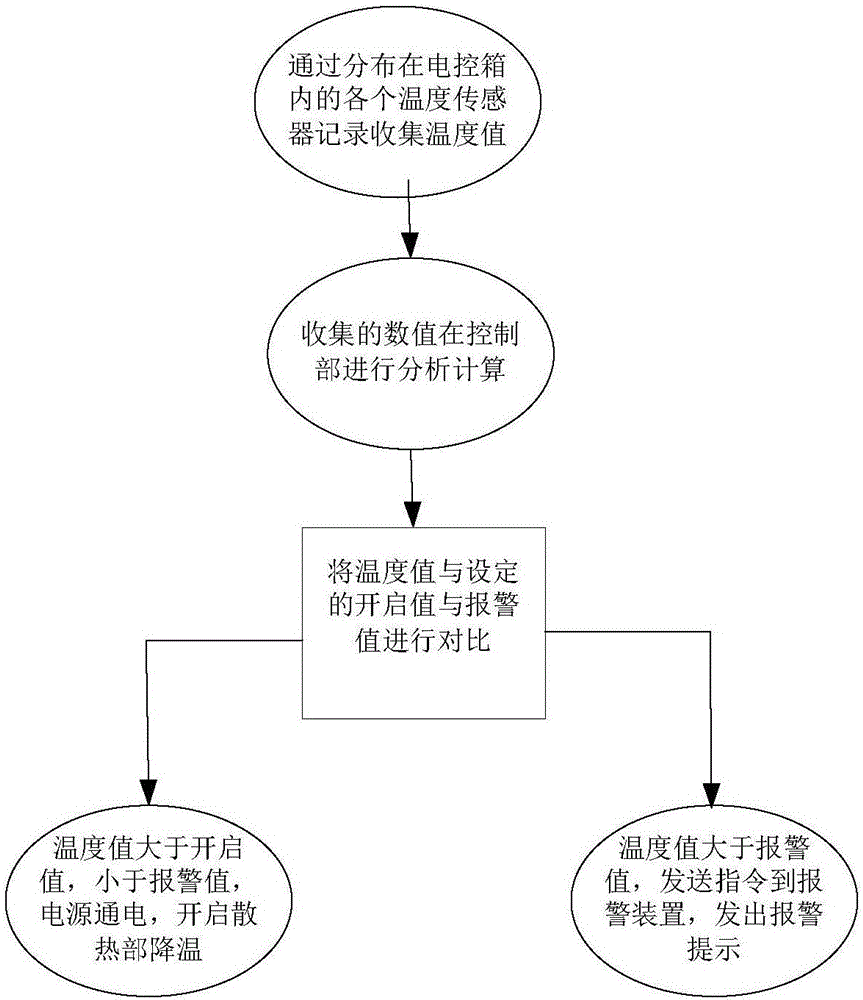

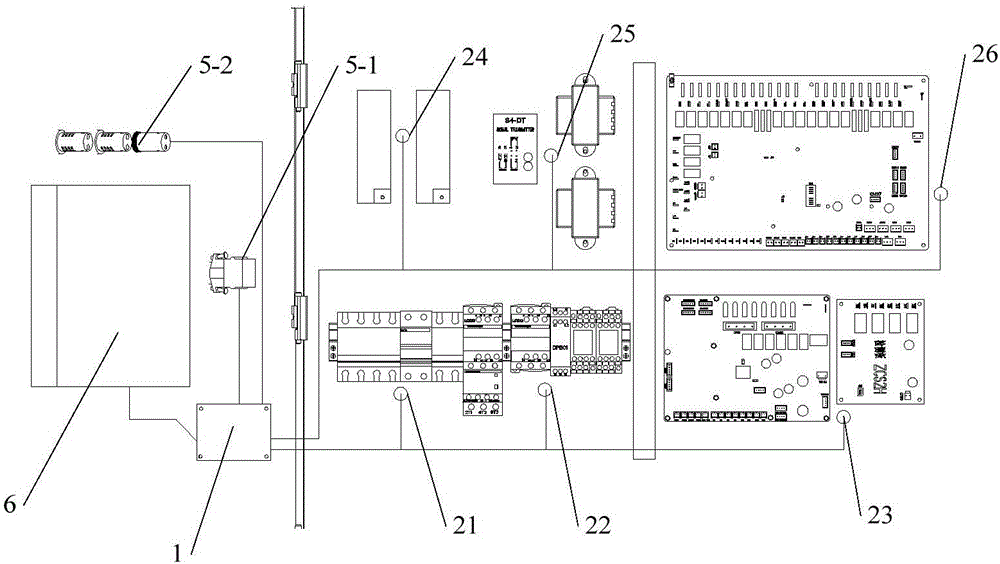

InactiveCN106595007APrecise temperature controlTimely coolingMechanical apparatusSpace heating and ventilation safety systemsTemperature controlEngineering

The invention provides a temperature control device and method, an electric cabinet with the control device and an air-conditioner. The temperature control device comprises a control part and a plurality of temperature sensors, the temperature sensors are arranged at the different positions of a temperature control object so as to detect temperature values at the multiple different positions, the control part is connected with the temperature sensors and enables the detected temperature values at the multiple different positions to be compared with a first temperature preset value, and when the temperature values are larger than or equal to the first temperature preset value, the control part conducts control to do cooling operation and / or alarming treatment on the temperature control target. According to the temperature control device, the multiple temperature sensors conducts multi-point sampling, and therefore accurate temperature control can be carried out at the multiple positions at the same time.

Owner:GREE ELECTRIC APPLIANCES INC

Plasma water spray cutting gun

ActiveCN104084683ATimely coolingAchieve coolingWelding/cutting auxillary devicesAuxillary welding devicesInlet channelEngineering

The invention discloses a plasma water spray cutting gun which comprises a cutting gun body. The cutting gun body is provided with a shell, an insulating cylinder, a conductor, an electrode, a distributor and a nozzle, and the insulating cylinder, the conductor, the electrode, the distributor and the nozzle are assembled in the shell. A gap area between the distributor and the electrode serves as an airflow distribution channel, the nozzle is arranged at the bottom of the distributor, an air inlet channel is disposed in the conductor, the nozzle and the periphery of the bottom end of the electrode form an air outlet channel, the bottom end of the nozzle is provided with a plasma flame ejection hole, and the air inlet channel, the airflow distribution channel, the air outlet channel and the plasma flame ejection hole are sequentially communicated to form an airflow channel; a water spray ejecting hole is formed in the portion, opposite to the plasma flame ejection hole, of the bottom of the shell, a water spray generation channel is formed in the cutting gun body, and the water spray ejection hole is communicated with the water spray generation channel. The plasma water spray cutting gun can achieve plasma cutting of parts to be cut, can cool the parts to be cut in a water-cooling mode at the same time, avoids smoke, dust, strong light and harmful gas generated in the cutting process, and improves environmental friendliness during cutting.

Owner:CHANGZHOU WULIAN ELECTRIC WELDING & CUTTING EQUIP

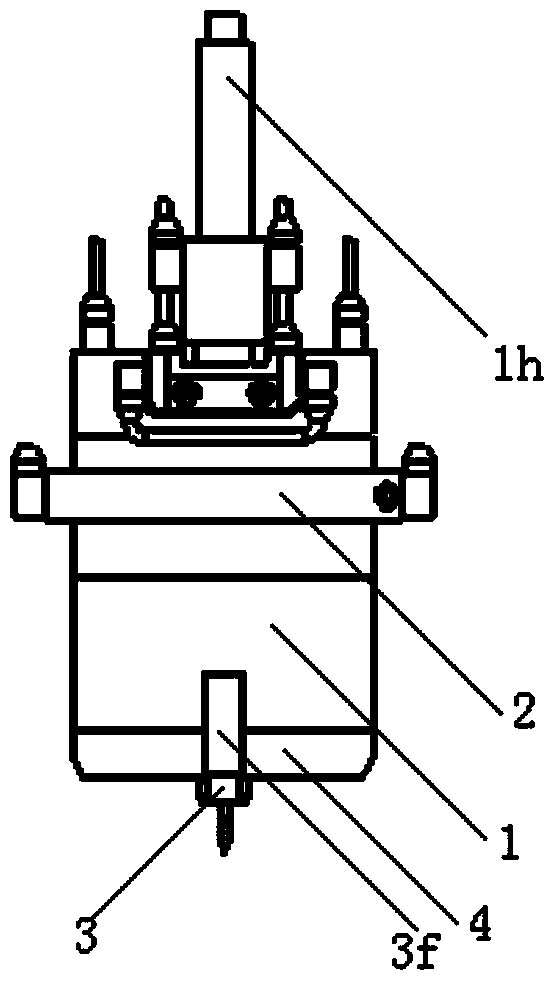

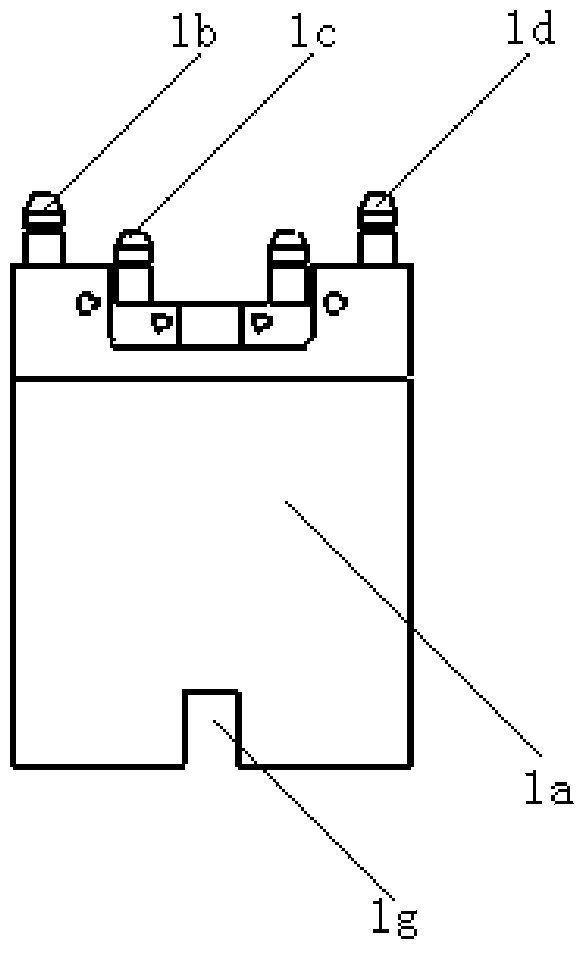

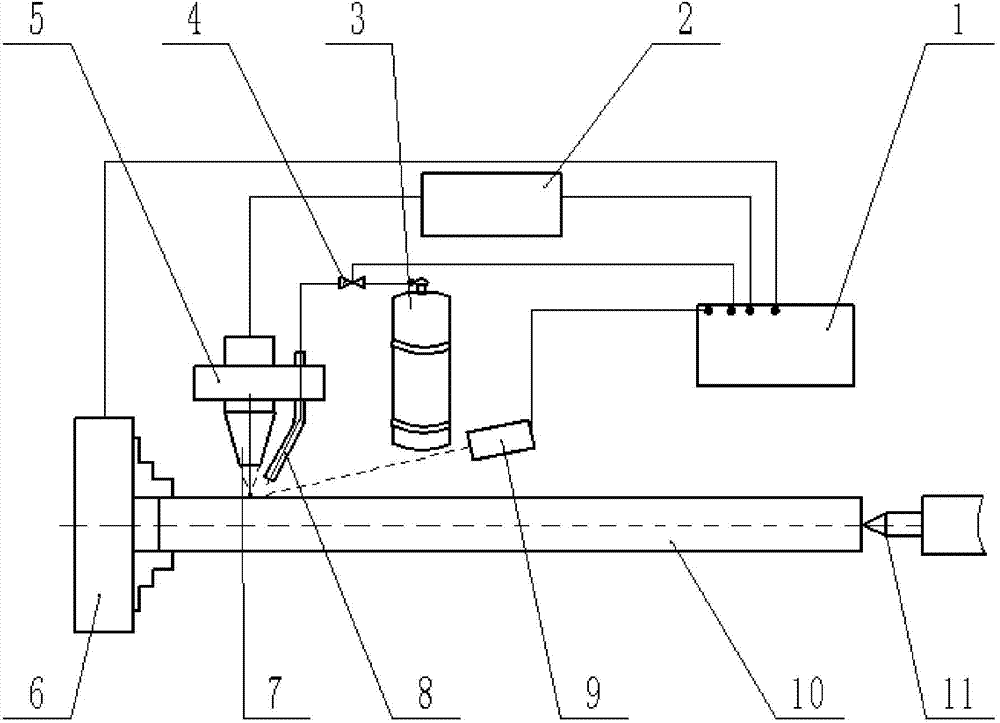

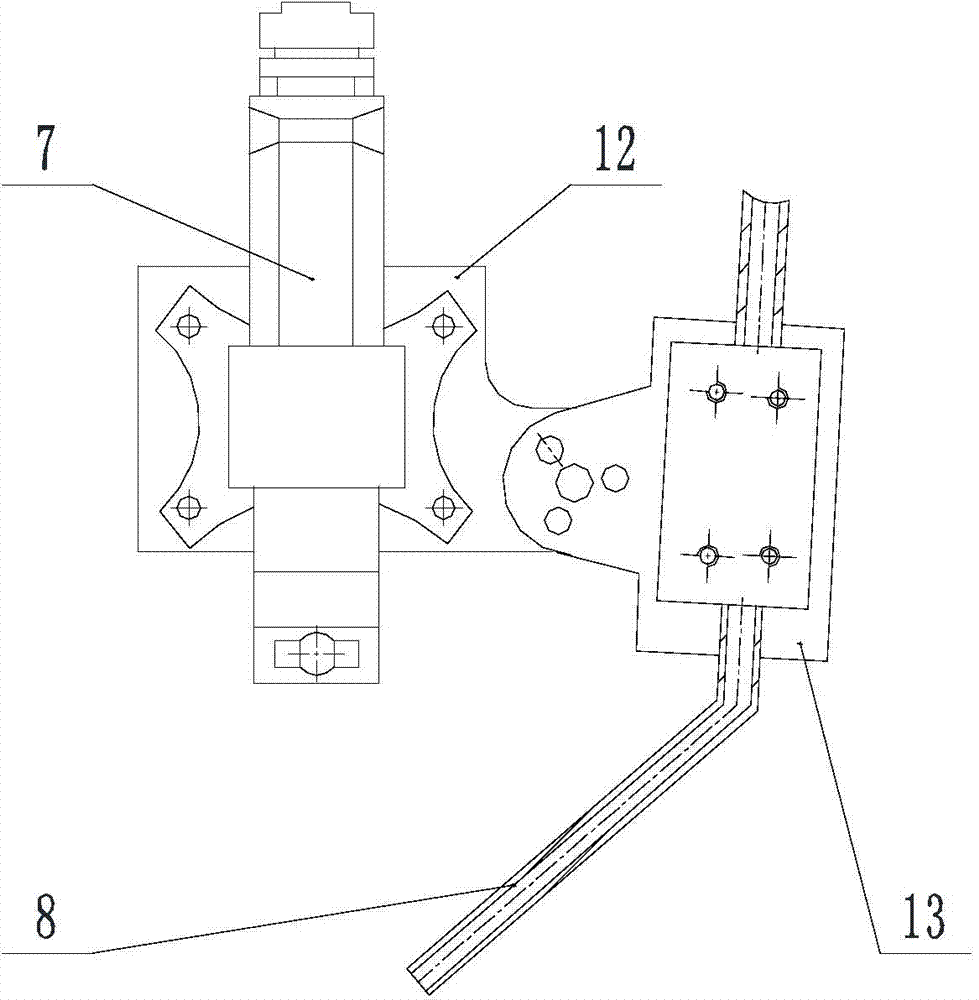

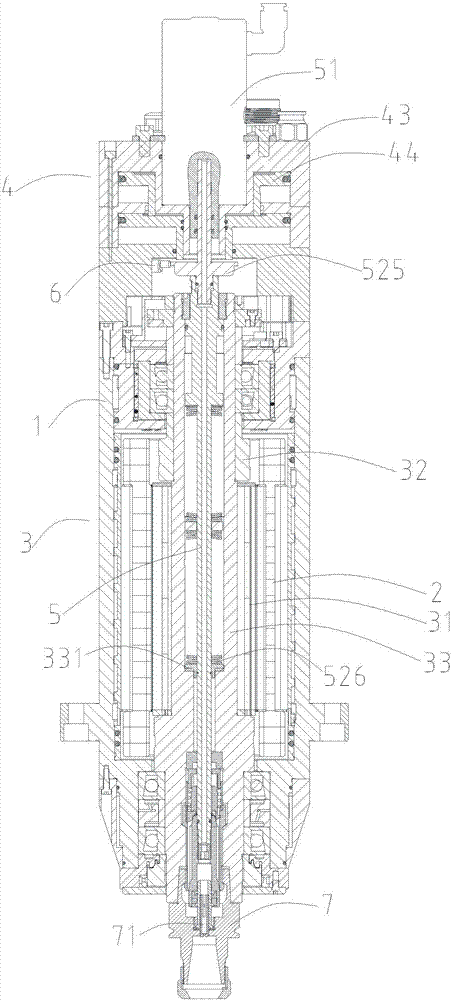

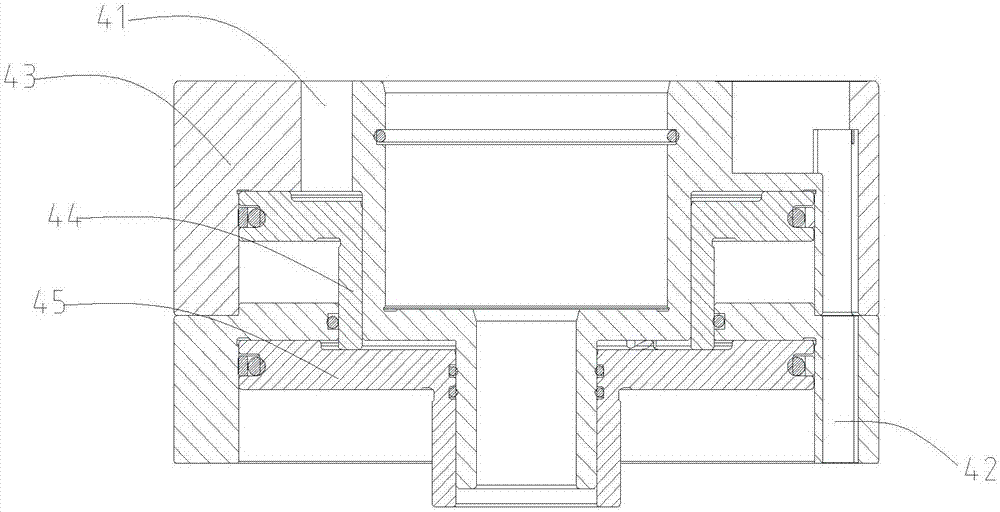

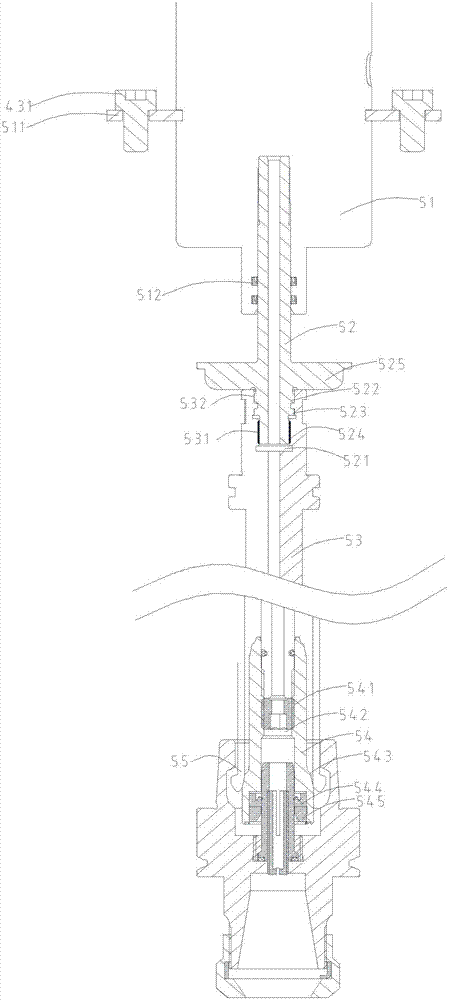

Contact-type central water-discharging permanent magnet synchronous electric spindle

ActiveCN107378004AImprove reliabilityTimely coolingLarge fixed membersMaintainance and safety accessoriesPhysicsPiston

The invention discloses a contact-type central water-discharging permanent magnet synchronous electric spindle. The contact-type central water-discharging permanent magnet synchronous electric spindle comprises a machine body, a stator, a permanent magnet spindle core assembly, an air cylinder assembly and a central water-discharging assembly; the permanent magnet spindle core assembly comprises a permanent magnet rotor, a between-spindle sleeve and a spindle core, the permanent magnet rotor is arranged on the spindle core in a sleeving mode, and the spindle space sleeve is arranged above the permanent magnet rotor; the air cylinder assembly is arranged at the upper end of the machine body and comprises a first air duct, a second air duct, an air cylinder top cover, a first piston and a second piston, the air cylinder top cover, and the first piston and the second piston sequentially abut against from top to bottom in the central axial direction of the electric spindle; the central water-discharging assembly comprises a rotary connector, a connecting rod, a pulling rod, a sliding core and a pulling claw which are sequentially connected from top to bottom, the pulling claw is arranged on the lower end portion of the sliding core in a sleeving mode, the pull claw and the sliding core slide oppositely so that the pull claw can switch under the stretching and retracting states. According to the contact-type central water-discharging permanent magnet synchronous electric spindle, central water discharging is achieved, the cooling problem and the difficult problem of chip removing of tools in the ceramic processing and deep hole processing are solved.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

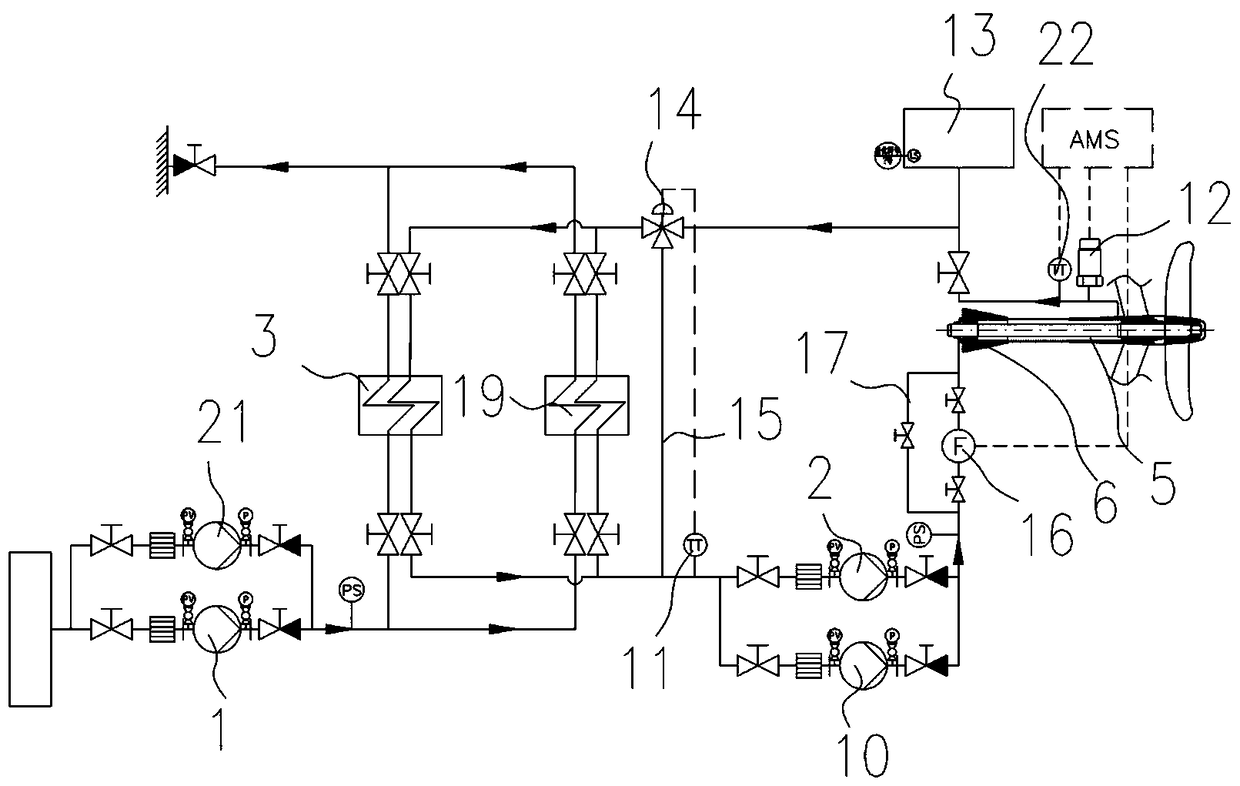

Cooling monitoring device and method for water lubricated bearing of propeller shaft

PendingCN108791796AExtended service lifeReduce maintenance costsPropulsive elementsBearing coolingPropellerChiller

The invention provides a cooling monitoring device and method for a water lubricated bearing of a propeller shaft. The cooling monitoring device includes a seawater cooling pump, a fresh water coolingpump and a plate cooler. A water outlet of the fresh water cooling pump communicates with a cooling channel on the water lubricated bearing in a stern shaft tube cavity through a pipeline, and a water inlet of the fresh water cooling pump communicates with the plate cooler through a pipeline. A water inlet of the seawater cooling pump communicates with the outside through a pipeline, and a wateroutlet of the seawater cooling pump communicates with the plate cooler through a pipeline. The plate cooler further communicates with the outside and the stern shaft tube cavity separately through pipelines, seawater flowing from the seawater cooling pump into the plate cooler is discharged through the pipeline communicating the plate cooler with the outside, and fresh water flowing out from the stern shaft tube cavity flows into the fresh water cooling pump through the pipeline communicating the plate cooler with the fresh water cooling pump. A temperature sensor and a granularity sensor arearranged on the pipeline communicating the stern shaft tube cavity with the plate cooler so as to cool the water lubricated bearing, and the abrasion degree of the water lubricated bearing is monitored in real time.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

Rapidly extinguished battery tank

PendingCN107579180AShort strokeShorten the timeSecondary cellsFire rescueElectrical batteryEngineering

The invention discloses battery tank fire extinguishing technique and discloses a rapidly extinguished battery tank which comprises channels, wherein the channels are formed in a tank wall; an external interface for connecting the channel with a fire extinguishing agent pipeline is formed in the battery tank; internal ejection holes corresponding to battery packs are formed inside the battery tank; the internal ejection holes are communicated with the channels; one or more channels are formed in the tank wall; a plurality of the channels are uniformly formed in the tank wall at intervals. Thechannels are formed in the tank wall of the battery tank, and a fire extinguishing agent can be directly ejected to the battery packs through the channels, so that the distance and the time that the fire extinguishing agent reaches the battery packs are shortened, the temperature can be rapidly reduced, the battery packs can be prevented from contact with the air, a flame retardancy effect is achieved, a rapid fire extinguishing speed is achieved, and a good effect is achieved.

Owner:SICHUAN CAMY NEW ENERGY CO LTD

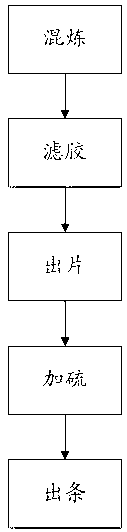

Process for preparing rubber compound of ethylene propylene diene monomer waterproof roll

The invention discloses a process for preparing a rubber compound of an ethylene propylene diene monomer waterproof roll. The process comprises the following steps: compounding, filtering rubber, yielding sheets, sulphurating and yielding strips. With the adoption of the manner, in the process for preparing rubber the compound of the ethylene propylene diene monomer waterproof roll, during sulphurating, an open mill is replaced with an internal mixer for sulphurating and compounding. A film cooling machine is used for guaranteeing timely and rapid cooling of the sulphurated rubber compound firstly in the industry, the quality of a prepared product is stable, linkage operation of the internal mixer, a rubber filter, a sheet-outputting machine and the film cooling machine, the energy consumption is reduced, the labor intensity of workers is reduced, the environmental pollution is reduced, and the production efficiency is improved.

Owner:常熟市三恒建材有限责任公司

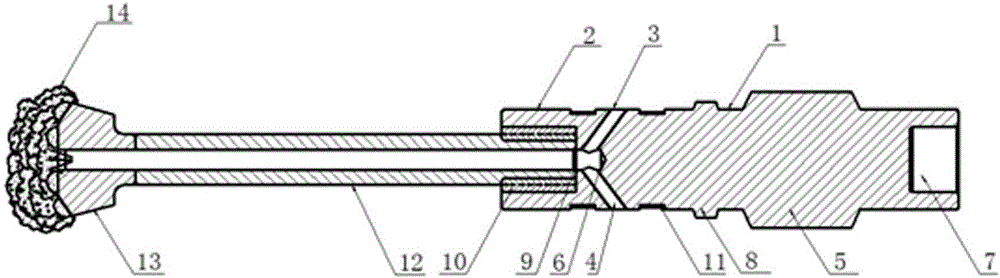

Blast furnace tap hole apparatus

ActiveCN103981314AAvoid breakingReduce assembly partsBlast furnace componentsBlast furnace detailsScrew threadDrill bit

The invention provides a blast furnace tap hole apparatus. The apparatus comprises a drilling rod, a connecting sleeve and a bit shank which are sequentially connected; the drilling rod has a through hole, a drill bit is welded to one end of the drilling rod, the other end of the drilling rod has a threaded connection with the connecting sleeve, a sealing sleeve is arranged between the connecting sleeve and the bit shank, and the connecting sleeve, the sealing sleeve and the bit shank form one body; the sealing sleeve is provided with a wind inlet and a water inlet, and the wind inlet and the water inlet are connected with the through hole respectively; and one end of the bit shank far from the sealing sleeve is provided with a stern notch, the middle portion of the bit shank is provided with a spline, and the spline and the bit shank form one body. The bit shank, the connecting sleeve and the sealing sleeve are designed to form one body, so the assembling part and the connecting portion are reduced, and the fracture of the weak link of a fitting connection is avoided; and the tail end of the bit shank is provided with the impact stern notch, so when an opening machine impacter impacts, an impact tail portion is difficult to impact and damage, and the service life of a connecting mechanism is prolonged.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Magnetic control K-TIG welding gun based on water-cooled permanent magnets

InactiveCN106695086AIncrease energy densityImprove penetrationCooled electrode holdersElectric arcToroidal magnetic fields

The invention belongs to the technical field of K-TIG welding guns and discloses a magnetic control K-TIG welding gun based on water-cooled permanent magnets. The magnetic control K-TIG welding gun mainly comprises a cover body and a holding body connected to the lower portion of the cover body. The cover body and the holding body form a closed space and are fixed to the gun head of the welding gun. The radially and evenly distributed permanent magnets are arranged in the closed space, and water cooling devices are arranged around the permanent magnets. According to the magnetic control K-TIG welding gun, the permanent magnets are used for replacing electromagnets to construct a circular magnetic field to compress K-TIG welding electric arcs, thus the restraining effect and penetrability of the electric arcs can be enhanced; and meanwhile, the water cooling devices are arranged to wrap the permanent magnets so as to achieve the purposes of in-time cooling and demagnetization reduction, thus the stability of the obtained magnetic field is improved, and the electric arcs are restrained and controlled better.

Owner:TIANJIN UNIV

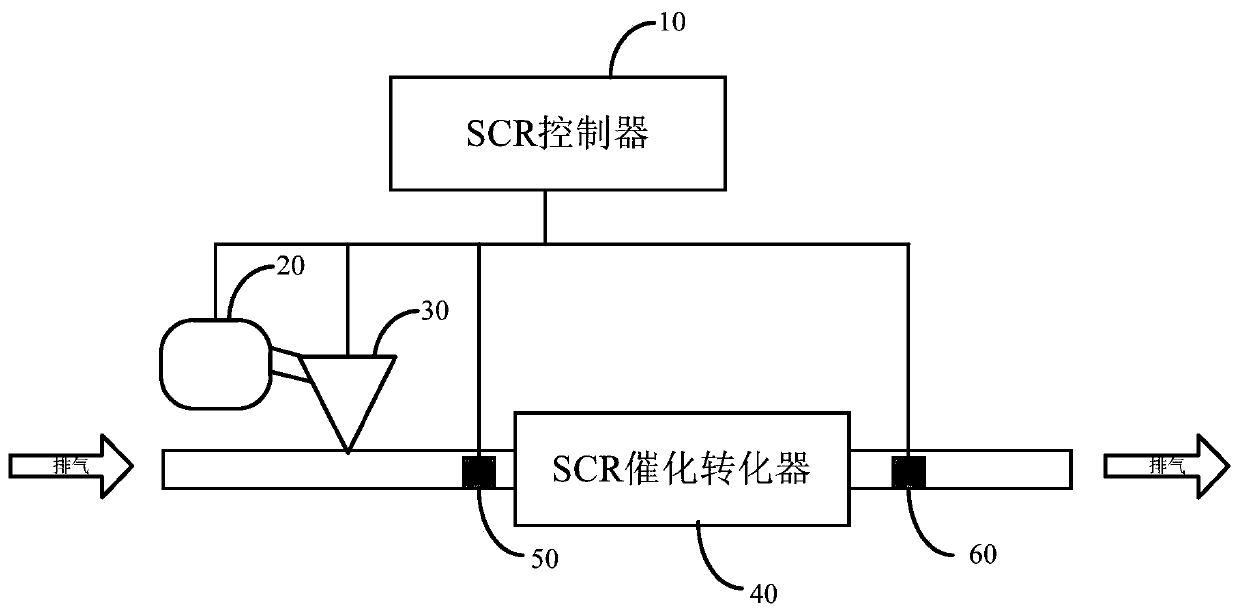

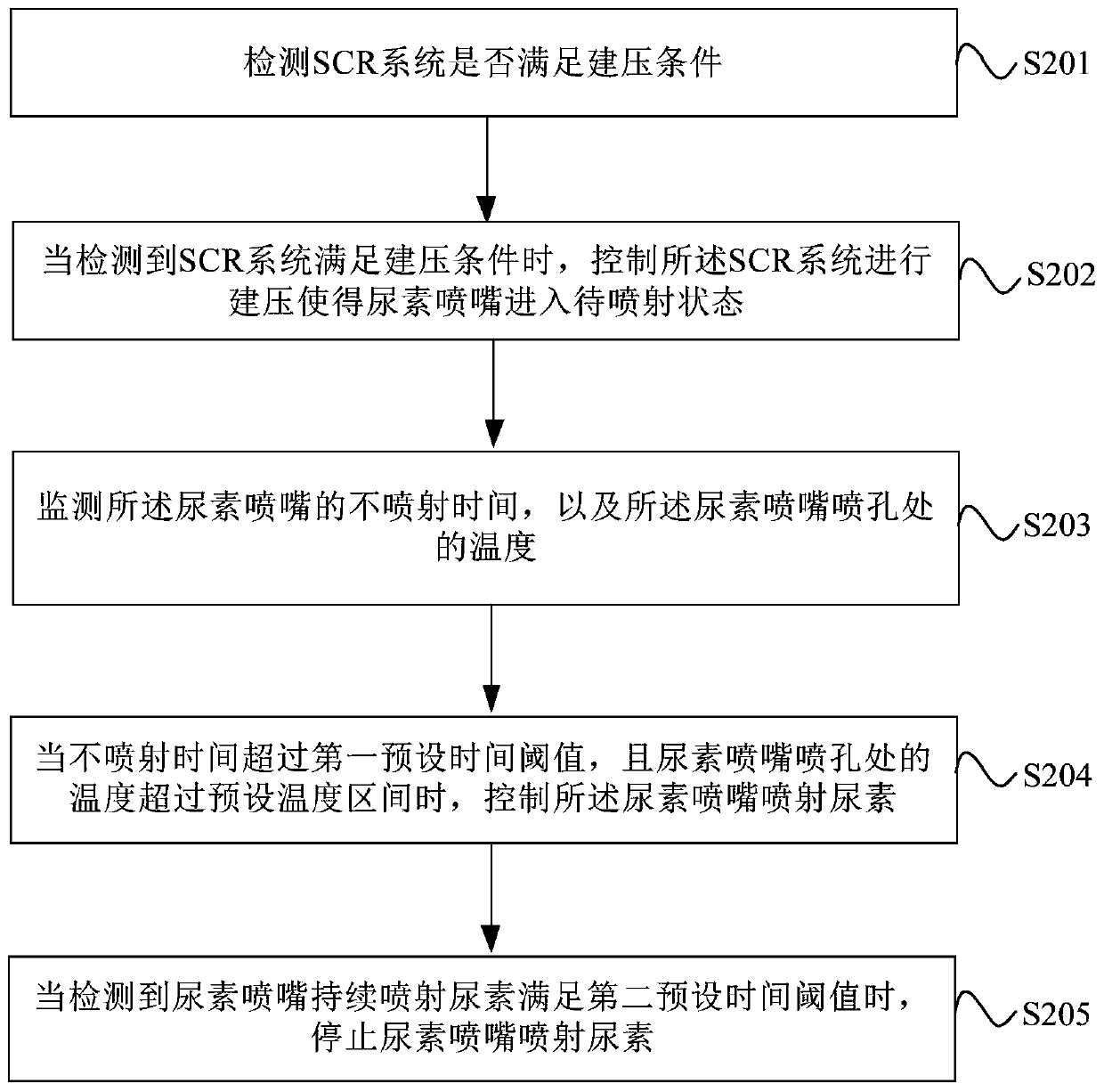

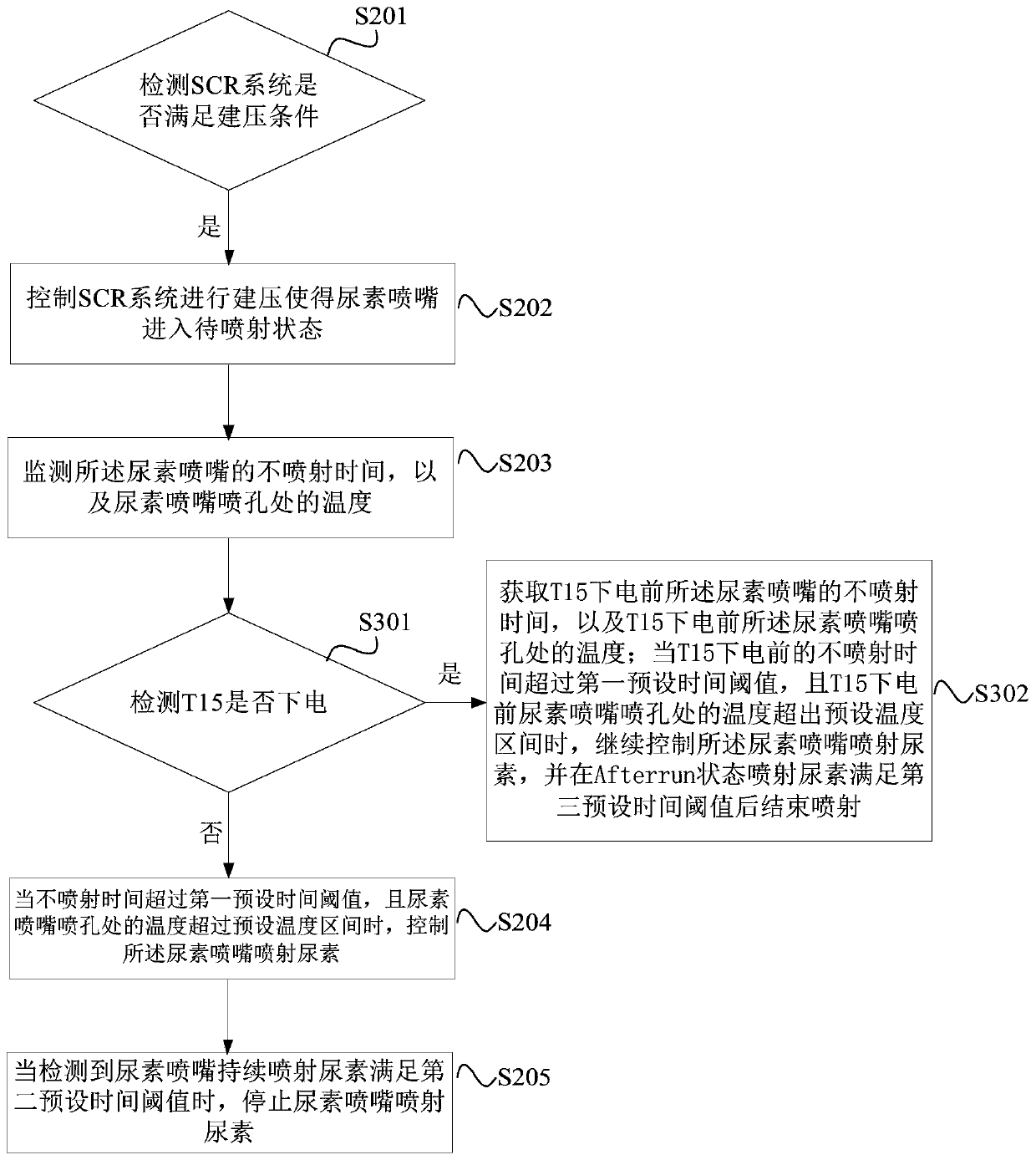

Urea nozzle cooling protection control method and device

ActiveCN110630363ATimely coolingExtended service lifeInternal combustion piston enginesExhaust apparatusEngineeringWait state

The embodiment of the invention provides a urea nozzle cooling protection control method and device. The method comprises the following steps that whether a SCR system satisfies a voltage buildup condition or mote is detected; when the SCR system is detected to satisfy the voltage buildup condition, the SCR system is controlled to perform voltage buildup so as to enable a urea nozzle to enter a spraying waiting state; the non-spraying time of the urea nozzle and the temperature at a spraying hole of the urea nozzle are monitored, wherein the temperature is collected by an SCR upstream temperature sensor; when the non-spraying time exceeds a first preset time threshold and the temperature of the spraying hole of the urea nozzle exceeds a preset temperature interval, the urea nozzle is controlled to spraying urea; and when the urea continuous spraying time of the urea nozzle is detected to meet a second preset time threshold, the urea nozzle is stopped from urea spraying. According to the embodiment, the urea nozzle can be cooled in time after the urea nozzle is not operated for a long time in a high-temperature environment, the situation that the nozzle is damaged when urea solutionis not sprayed for a long time in a high-temperature environment is avoided, and the service life of the urea nozzle is prolonged.

Owner:WEICHAI POWER CO LTD

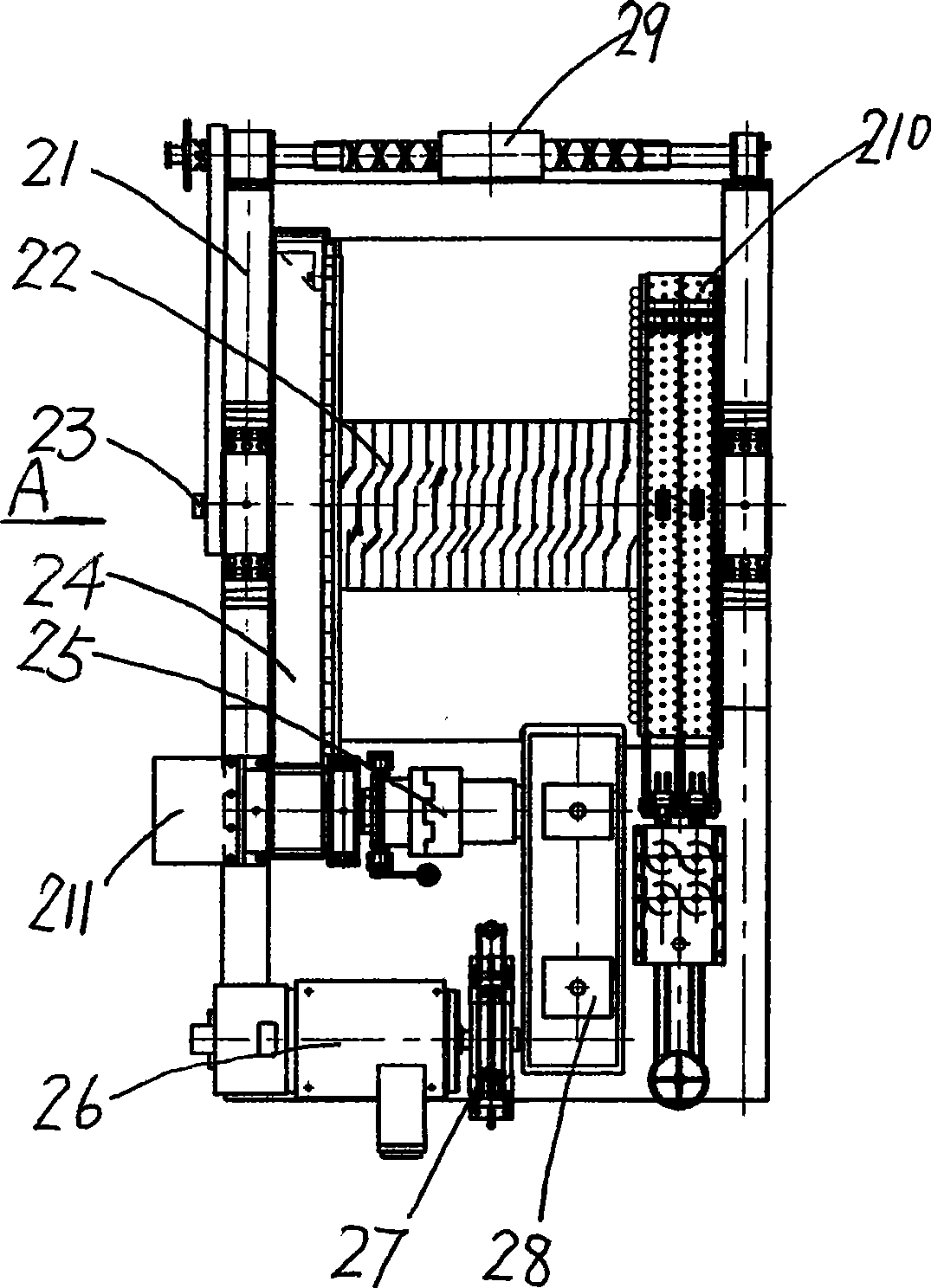

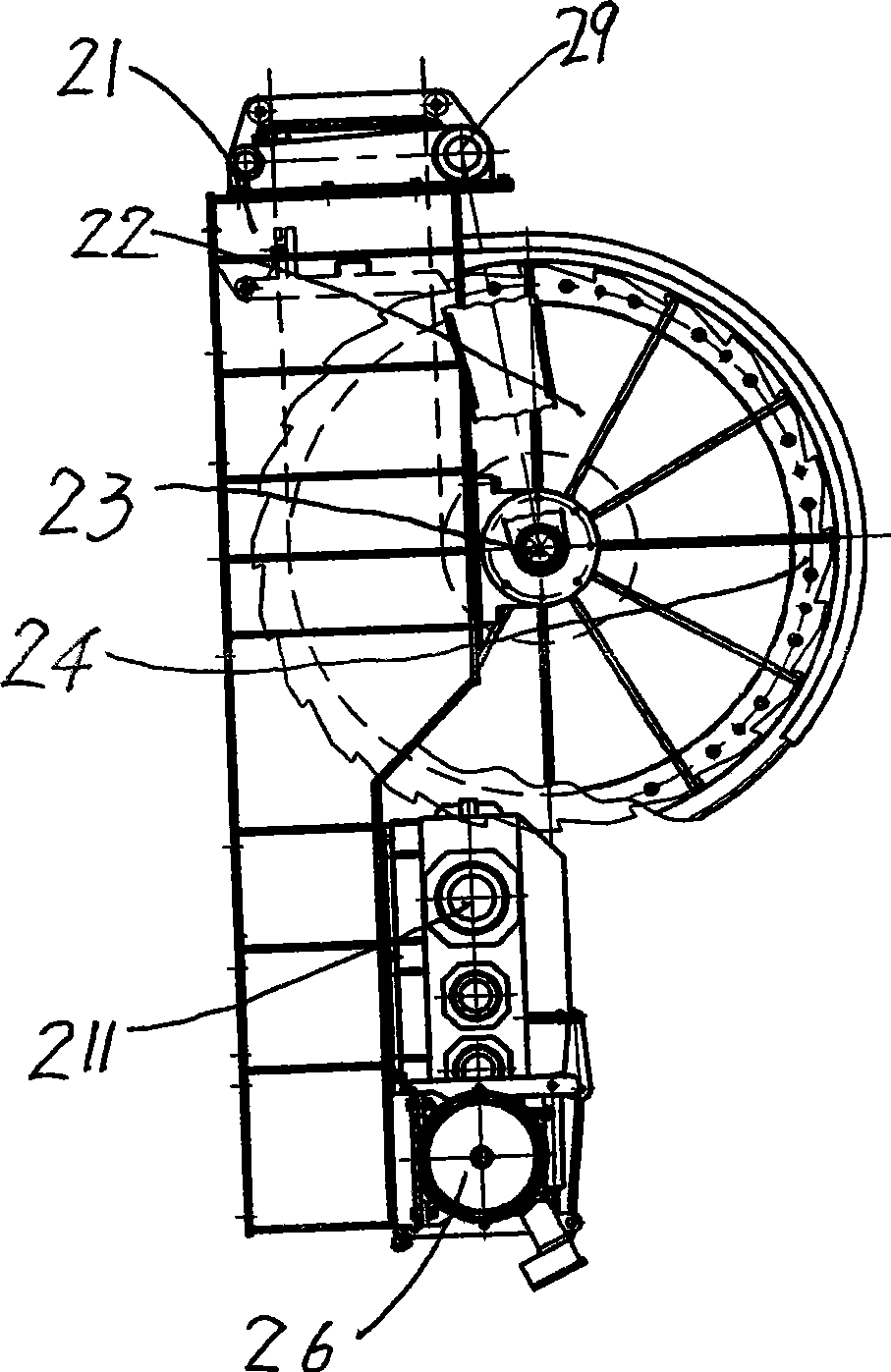

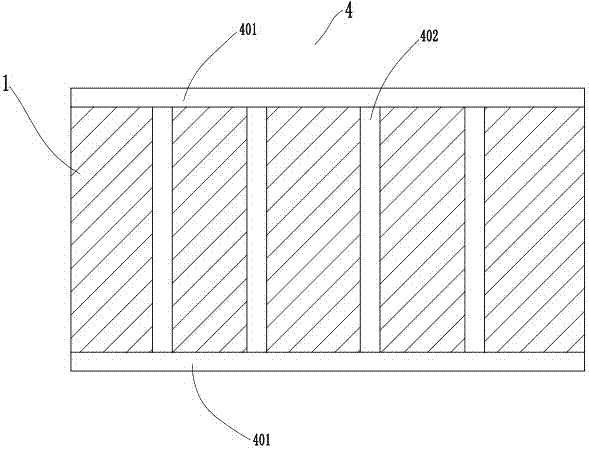

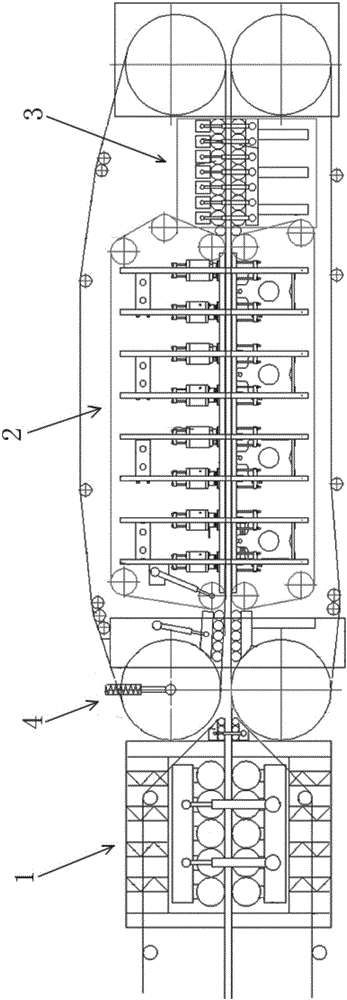

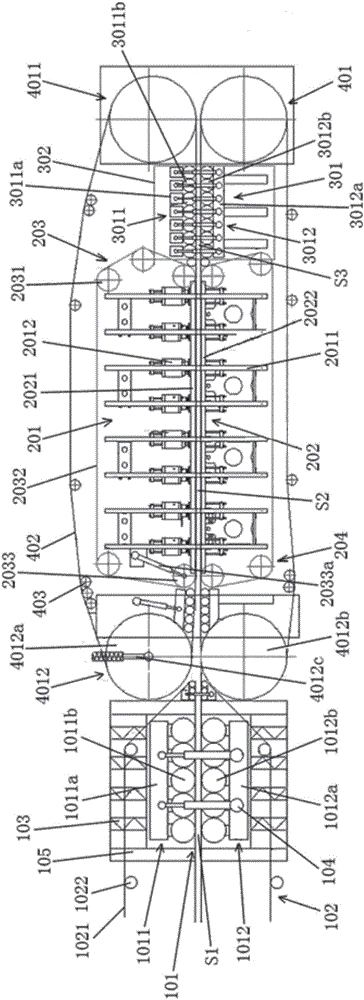

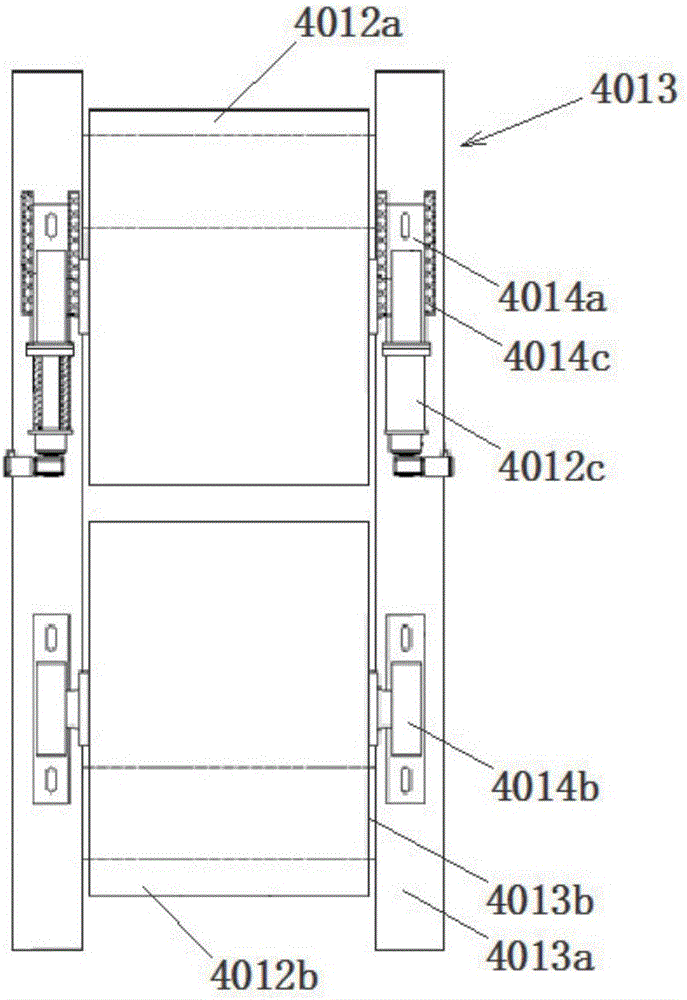

A continuous type press

PendingCN106607971ARealize continuous productionIncrease production capacityPlywood pressesVeneer pressesThermal isolationEngineering

The invention provides a continuous type press comprising a pre-heating and pressurizing unit, a heating and pressurizing unit, a cooling and pressurizing unit and a steel belt conveying unit used for connecting the heating and pressurizing unit and the cooling and pressurizing unit in series. The pre-heating and pressurizing unit comprises a first roller group mechanism used for providing pressure and a heating device used for providing non-contact heating, as well as a conveying device which is arranged between the first roller group mechanism, cooperates with the first roller group mechanism and is used for conveying mechanisms. The cooling and pressurizing unit comprises a second roller group mechanism used for providing pressure and a thermal isolation device used for maintaining the internal temperature of the cooling and pressurizing unit. The continuous type press has the advantages of low energy consumption, low cost, long service life, short production cycle, high plywood production efficiency and high forming quality.

Owner:CHINA FOMA GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com