Method and structure for crushing low-temperature materials

A process method and material technology, applied in the field of process method and equipment structure of low-temperature material crushing, can solve the problems that the temperature of crushed materials cannot be sufficiently reduced, and achieve the effects of avoiding melting and softening, non-agglomerated filterability, and eliminating heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

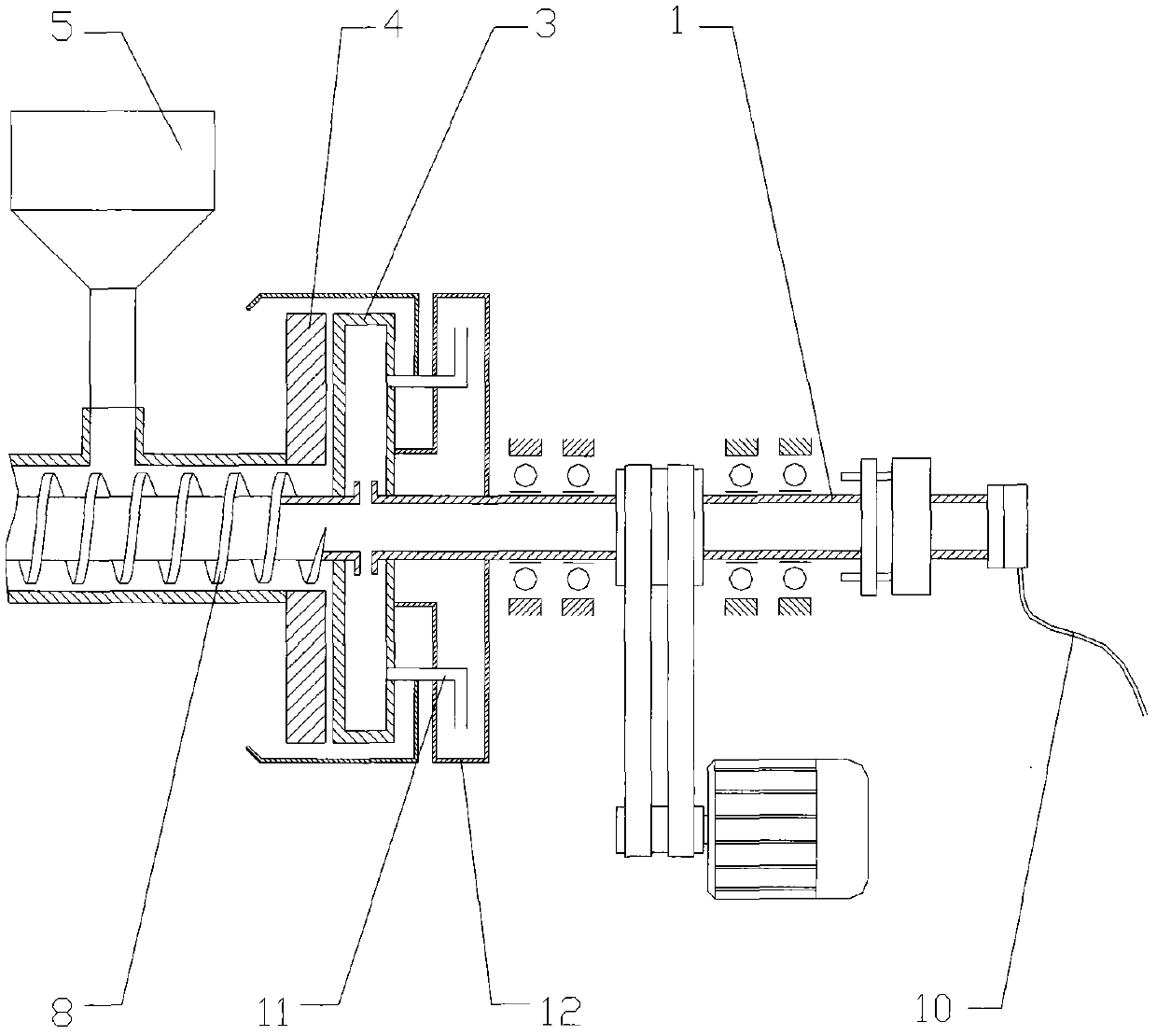

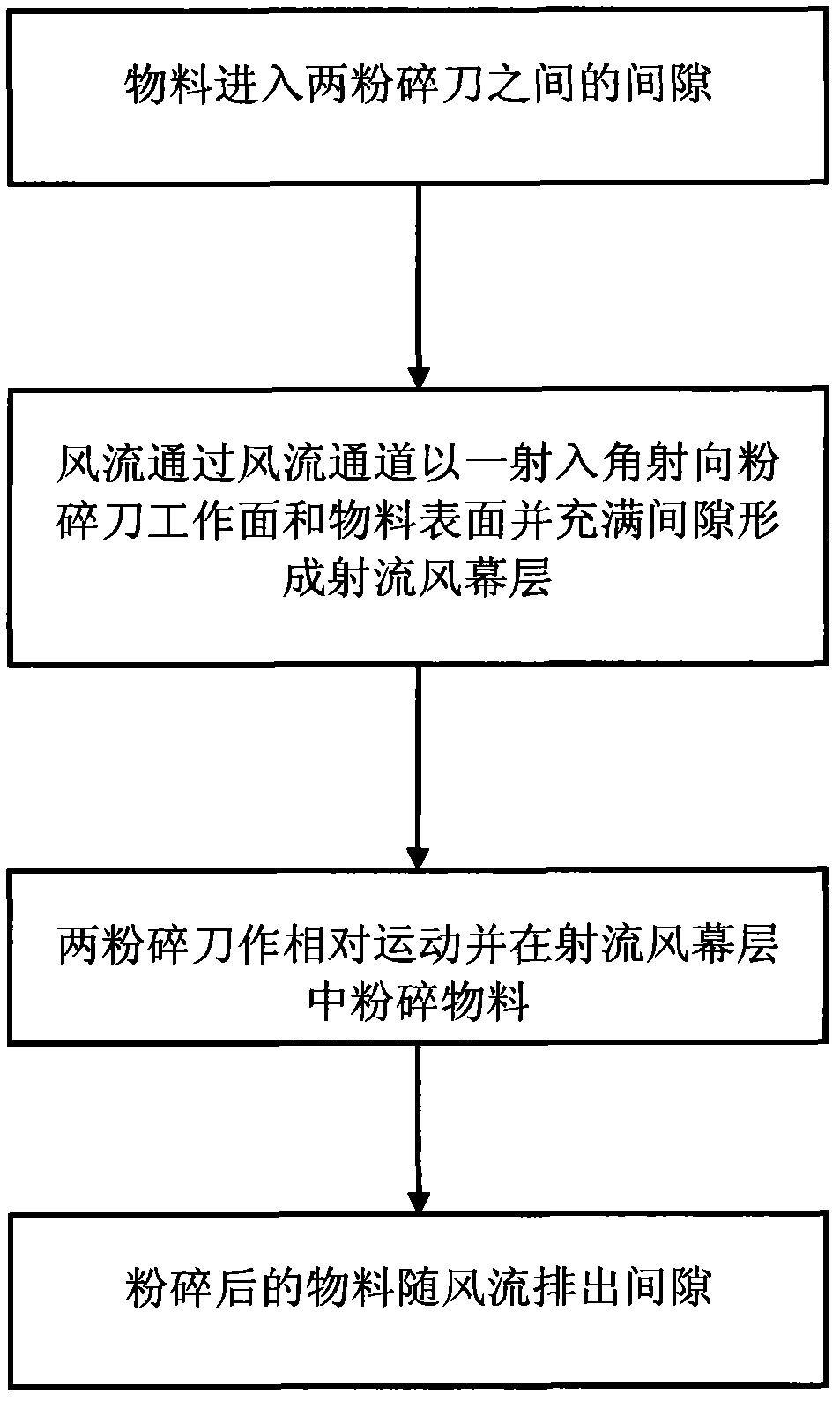

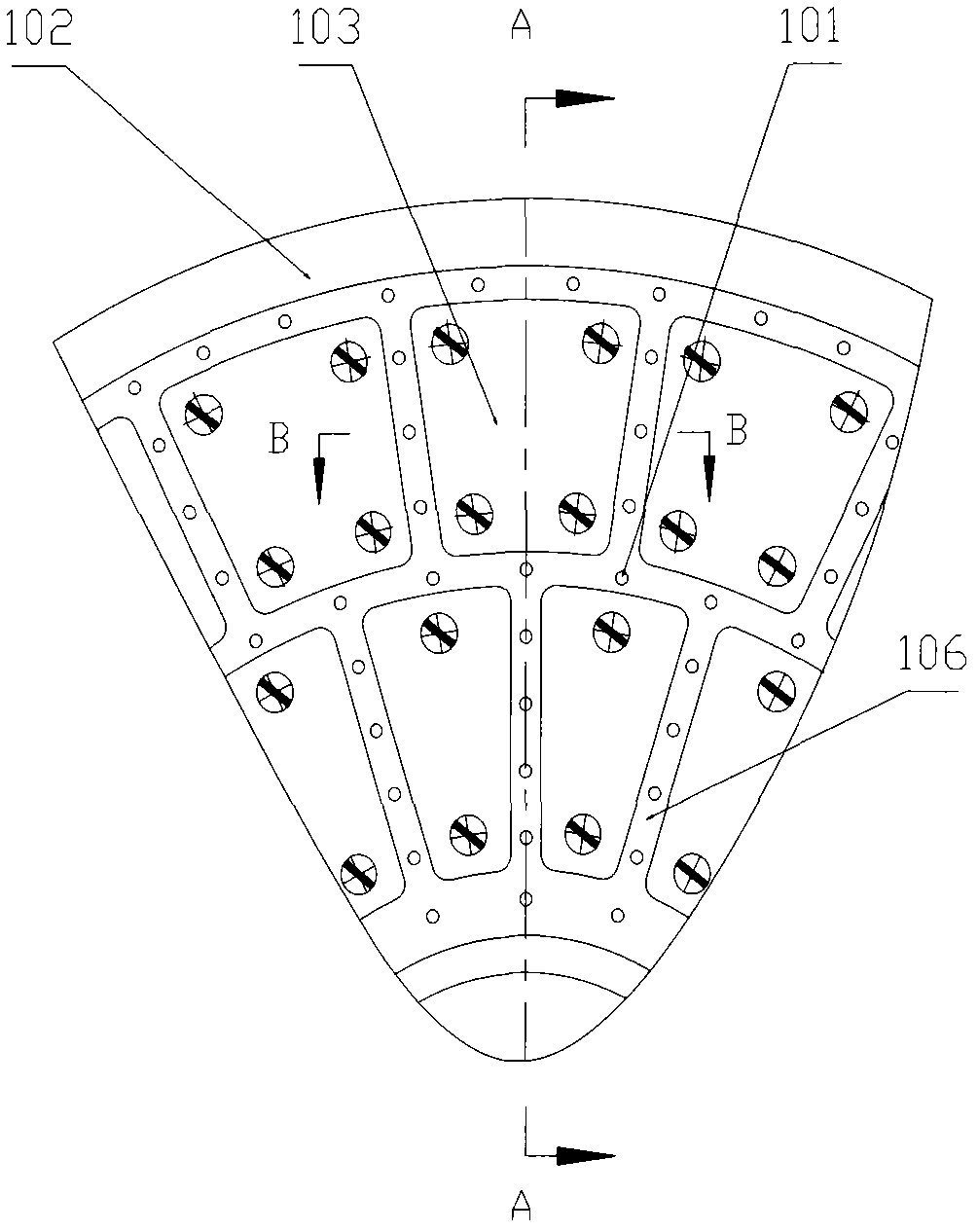

[0069] Please refer to image 3 , 4 And the structural representation of 5 embodiment one. The low-temperature material crushing structure described in Embodiment 1 is set on the material crushing equipment to carry out low-temperature material crushing. The low-temperature material crushing structure shown in the figure includes a cutter capable of crushing materials and an air flow channel capable of introducing air flow. The knives are two crushing knives capable of relative movement, which include a fixed fixed knife and a rotatable moving knife. There is a gap between the moving knife and the fixed knife, and the material is crushed in the gap, so the gap Also called "crushing chamber", the working surface of the moving knife is parallel to the working surface of the fixed knife. The air flow channel is arranged on the crushing blades and communicates with the gap between the two crushing blades. Such as image 3 As shown, the shape of the crushing knife is disc, coni...

Embodiment 2

[0076] Please refer to Figure 6 , 7 And the structural representation of the second embodiment of 8. The low-temperature material crushing structure described in Embodiment 2 is set on the material crushing equipment to carry out low-temperature material crushing. The low-temperature material crushing structure shown in the figure includes a knife capable of crushing materials and an air flow channel capable of introducing air flow. The knives are two crushing knives capable of relative movement, which include a fixed fixed knife and a rotatable moving knife. There is a gap between the moving knife and the fixed knife, and materials are crushed in the gap. The working face of knife is parallel with the working face of fixed knife. The air flow channel is arranged on the crushing blades and communicates with the gap between the two crushing blades. Such as Figure 6 As shown, the shape of the crushing knife is disc, conical or cylindrical, and the present embodiment is dis...

Embodiment 3

[0081] see Figure 9 Schematic diagram of the structure of the third embodiment. The low-temperature material crushing structure described in Embodiment 3 is set on the material crushing equipment to carry out low-temperature material crushing. The low-temperature material crushing structure shown in the figure includes a knife capable of crushing materials and an air flow channel capable of introducing air flow. The knives are two crushing knives capable of relative movement, which include a fixed fixed knife and a rotatable moving knife. There is a gap between the moving knife and the fixed knife, and materials are crushed in the gap. The working surface of the knife is parallel to the working surface of the fixed knife. The air flow channel is arranged on the crushing blades and communicates with the gap between the two crushing blades. Such as Figure 9 As shown, the shape of the crushing knife is disc, conical or cylindrical, and the present embodiment is disc-shaped. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com