High-temperature and high-speed metal particle generator

A technology of metal particles and generators, which is applied in the direction of weapon types, rocket launchers, combustion ignition, etc., can solve the problems of not being able to prevent gas explosions, and achieve the effect of eliminating large areas of gas, eliminating gas, and spraying long distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

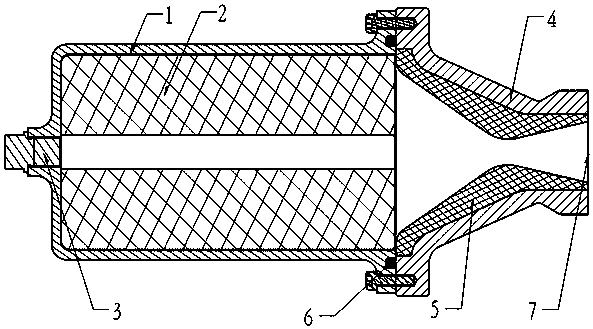

[0020] figure 1 Among them, the present invention includes a combustion chamber 1, a fuel-rich generator grain 2, a nozzle, and an igniter 3. The nozzle includes a nozzle base 4 in a horn-shaped structure, and a throat liner 5 mounted on the inner wall of the nozzle base 4 for forming a narrow throat in the nozzle base 4 to increase the injection velocity. The fuel-rich generator grain 2 includes a thermal insulation layer, a lining layer placed on the inner wall of the thermal insulation layer, and a fuel-rich generator filled in the lining layer. The fuel-rich generator is a butylated hydroxyl generator with high metal content, which can produce a large number of high-temperature and high-speed metal particles when burned under a certain working pressure. Pour the rich fuel generating agent into the combustion chamber 1 which is uniformly coated with a heat insulating layer and a liner of a certain thickness, and wait for it to be completely cured; the throat liner 5 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com