Patents

Literature

71results about How to "Eliminate aggregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

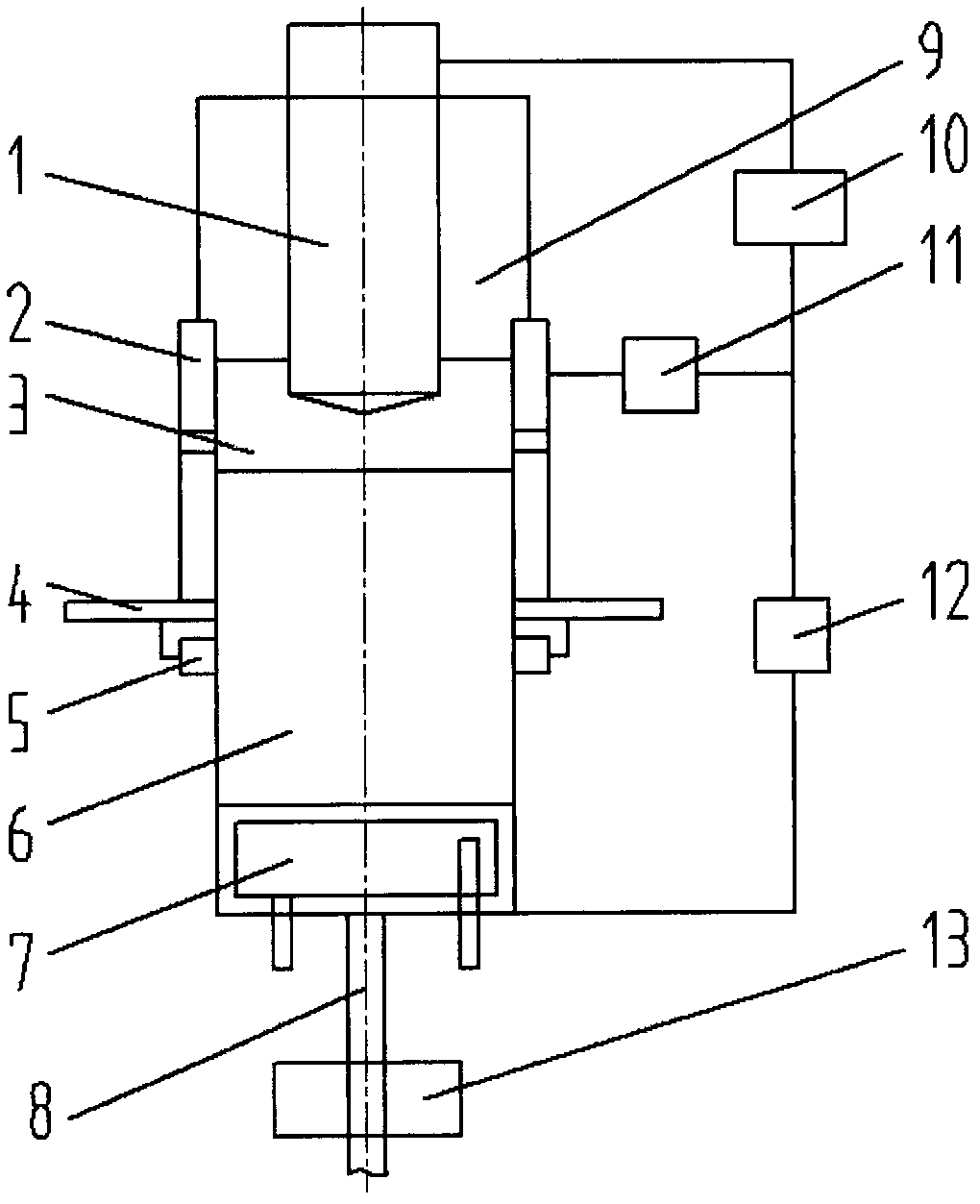

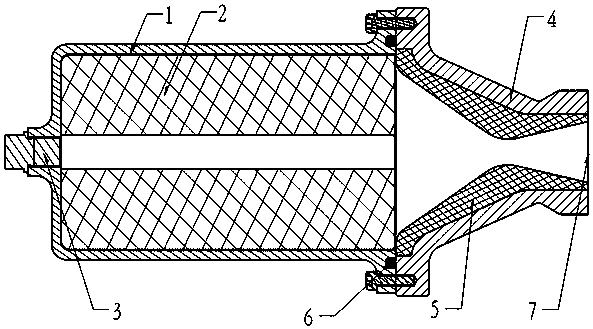

Vacuum/gas shield electroslag remelting continuous directional solidification device and method

ActiveCN102021348AEliminate aggregationEliminate coagulation and looseningElectricityHigh volume manufacturing

The invention relates to an electroslag remelting technique, in particular to a vacuum / gas shield electroslag remelting continuous directional solidification device and method. The device comprises a power supply, a consumable electrode (1), a water-cooling crystallizer (2) and a gas shield system, wherein the lower part of the water-cooling crystallizer (2) is provided with a water-cooling chassis (7) and a stripping device (13), and a two-circuit control mode is adopted by the consumable electrode (1) to make the stripping speed equivalent with the solidification speed of a cast ingot. The invention has simple operation and low cost, is convenient to control, can be used for producing large-dimension low-segregation directional solidification cast ingots and is suitable for mass production and application.

Owner:BEIJING CISRI GAONA TECH

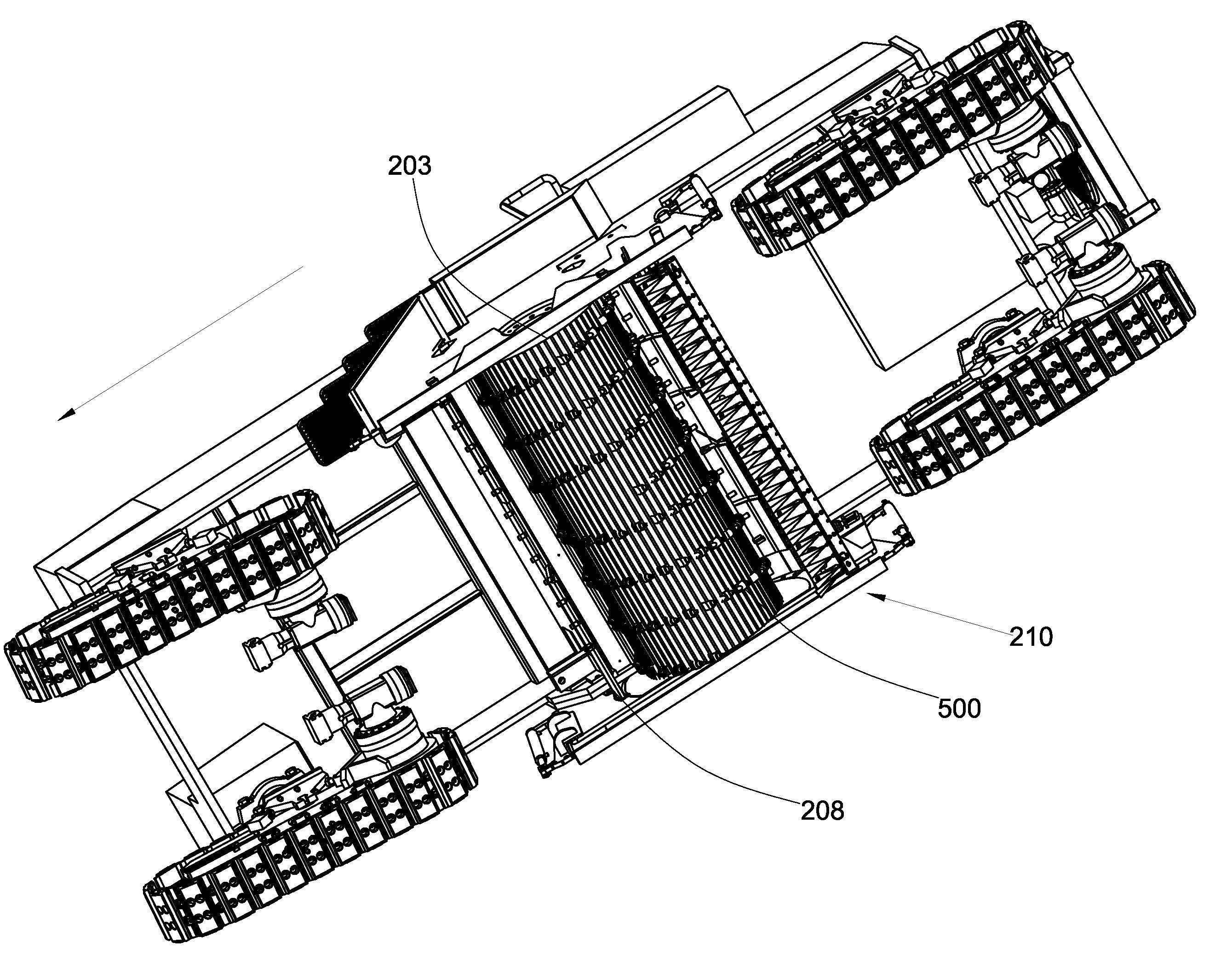

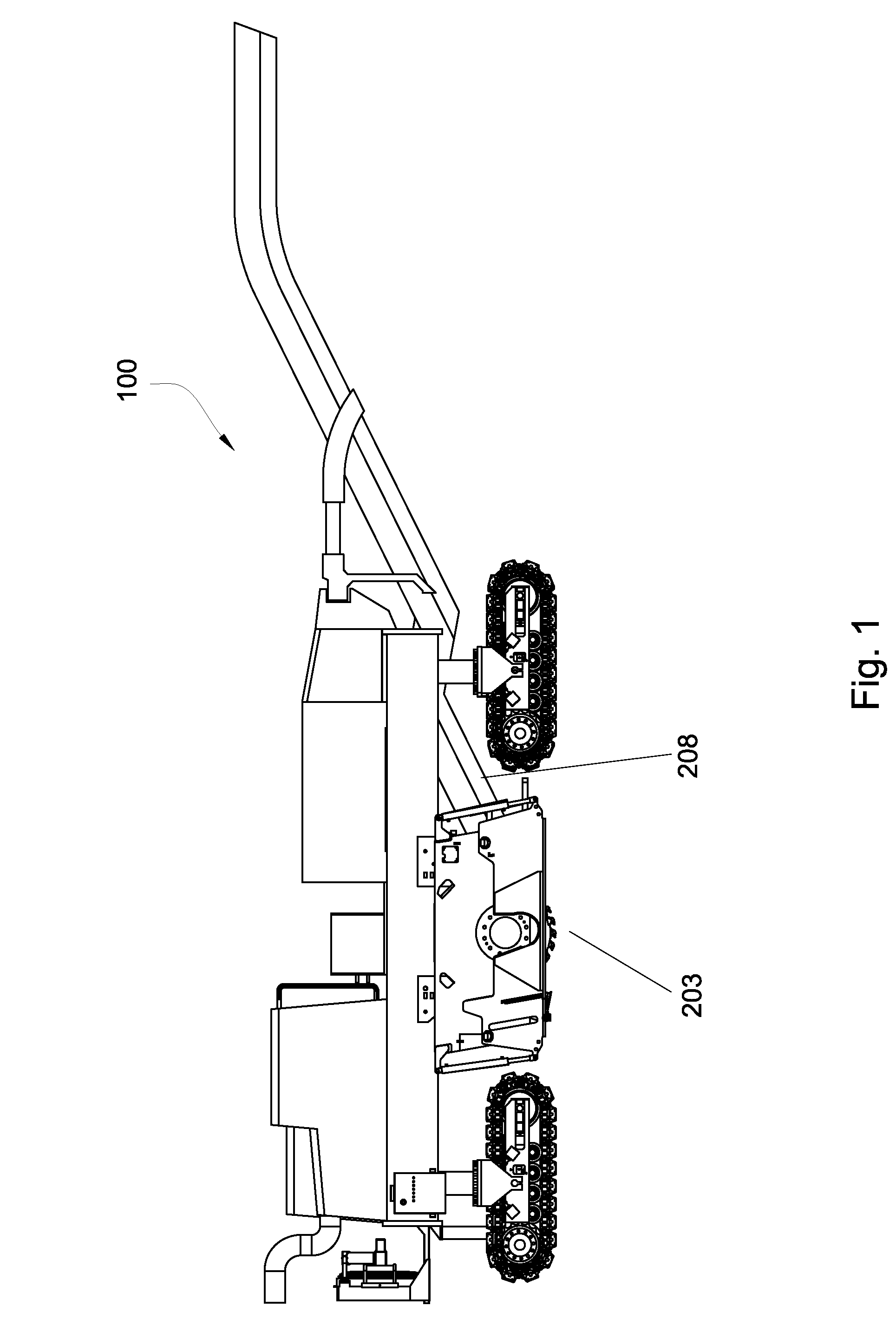

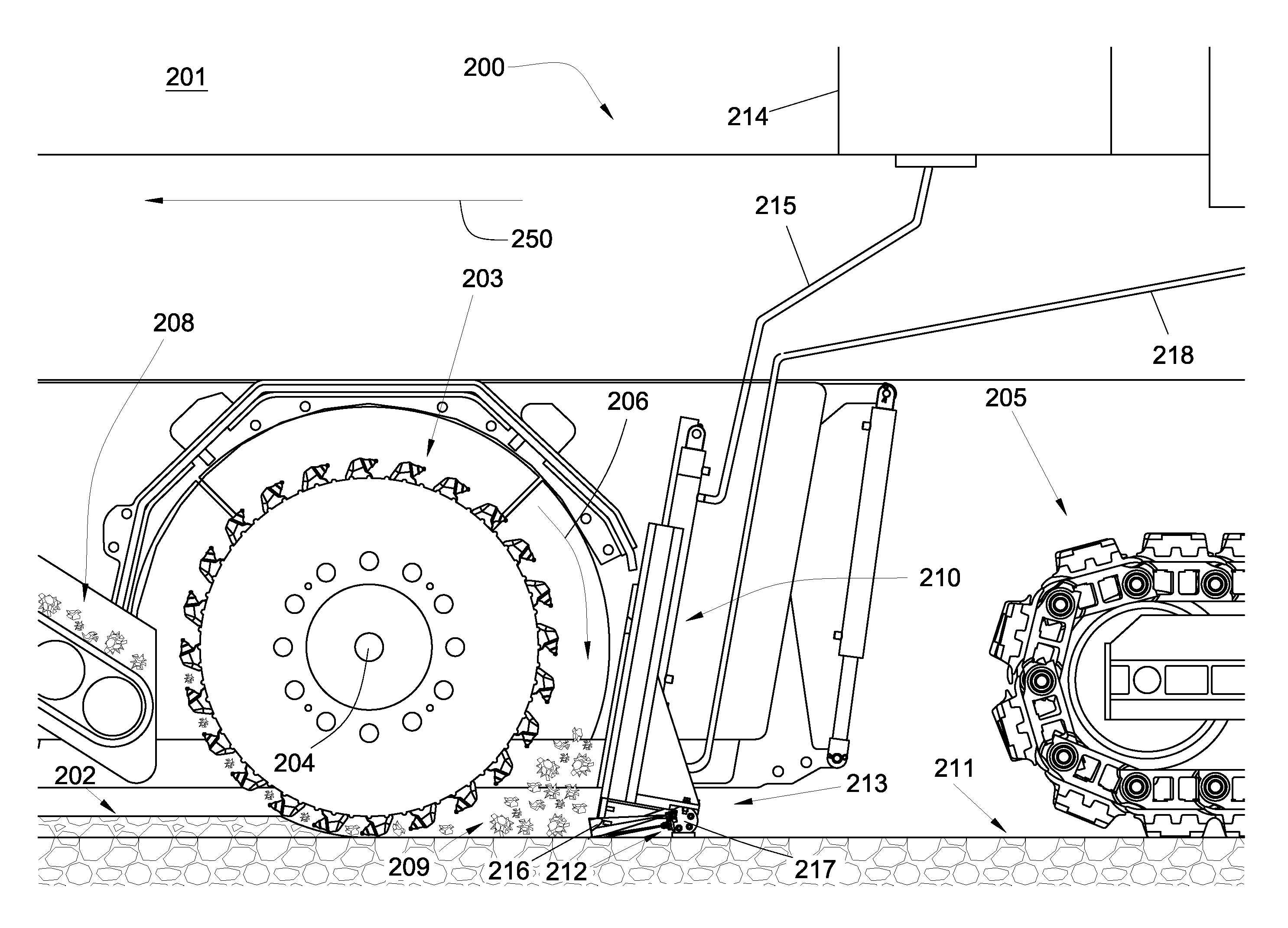

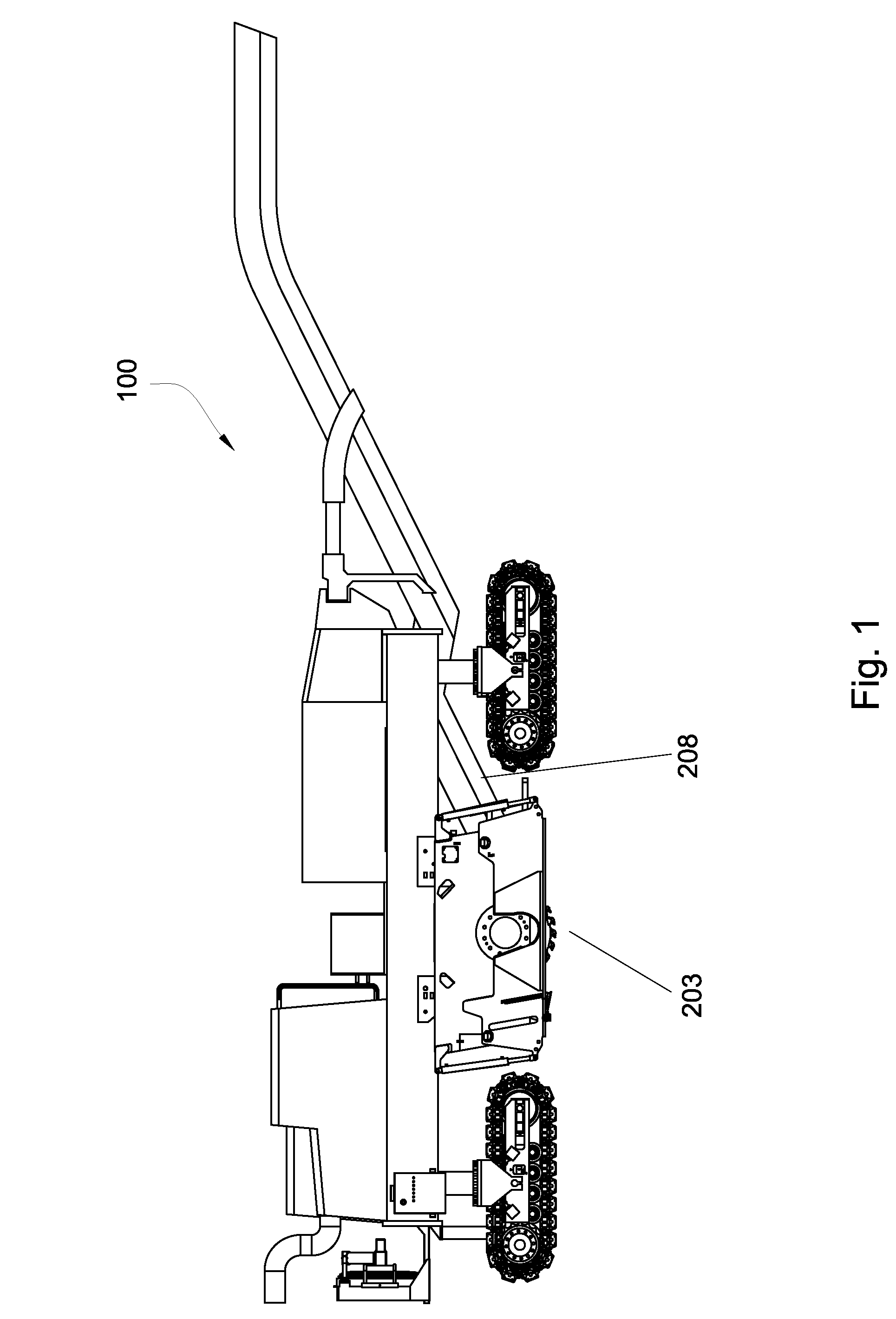

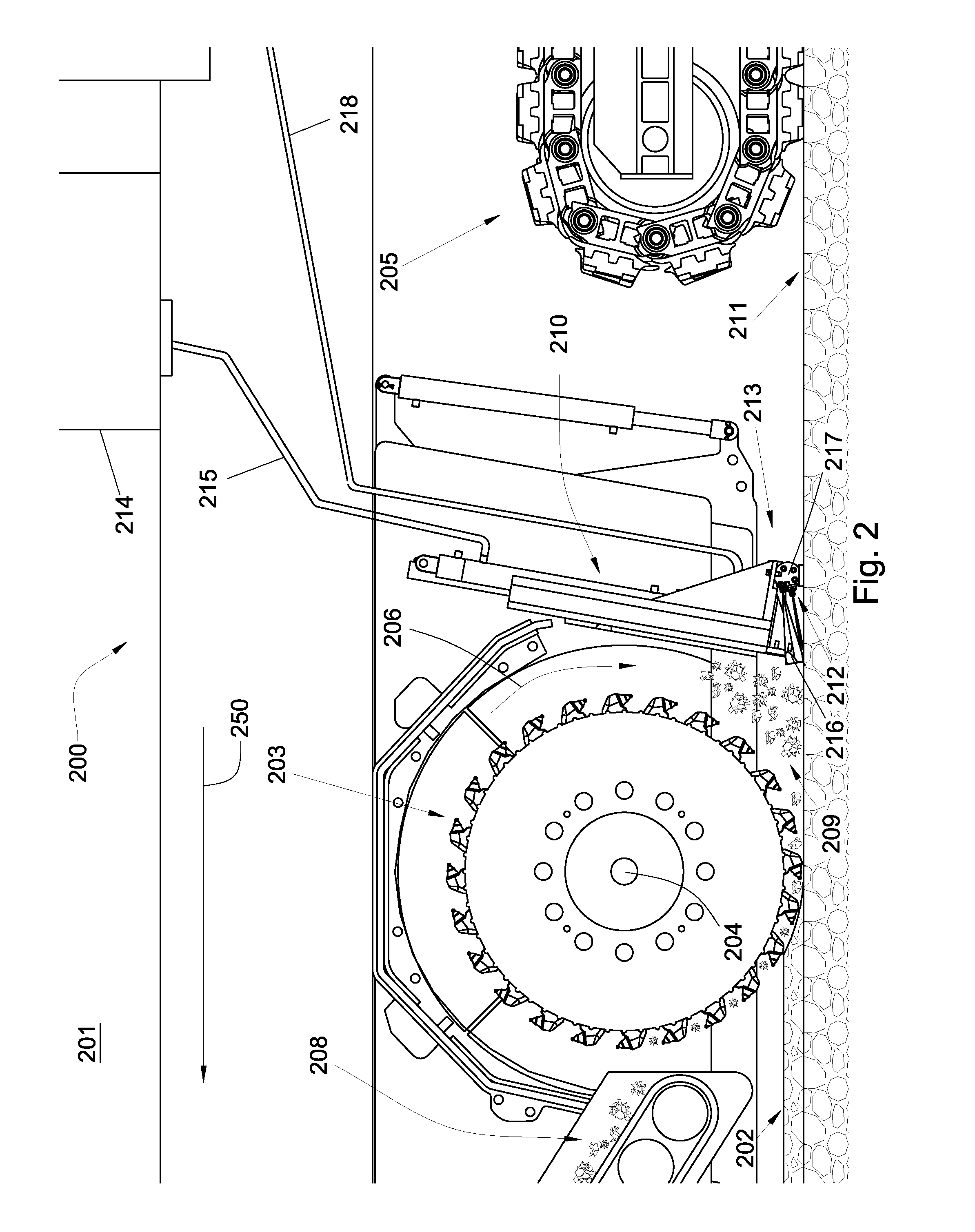

Milling Machine with Cleaning Moldboard

InactiveUS20080129103A1Reduced form requirementsImprove bindingPaving detailsRoads maintainenceEngineeringMechanical engineering

In one aspect of the invention, a system for removing a layer of a paved surface includes a vehicle adapted to traverse a paved surface in a selected direction. A milling drum attached to the vehicle may be adapted to rotate around an axle substantially normal the selected direction of the vehicle. A moldboard may be positioned rearward of the milling drum and also connected to the vehicle. The moldboard may comprise an end that is adapted to push aggregate removed from the paved surface in the selected direction. A plurality of nozzles may be disposed proximate the end of the moldboard which may also be in communication with a fluid reservoir through a fluid pathway.

Owner:NOVATEK IP

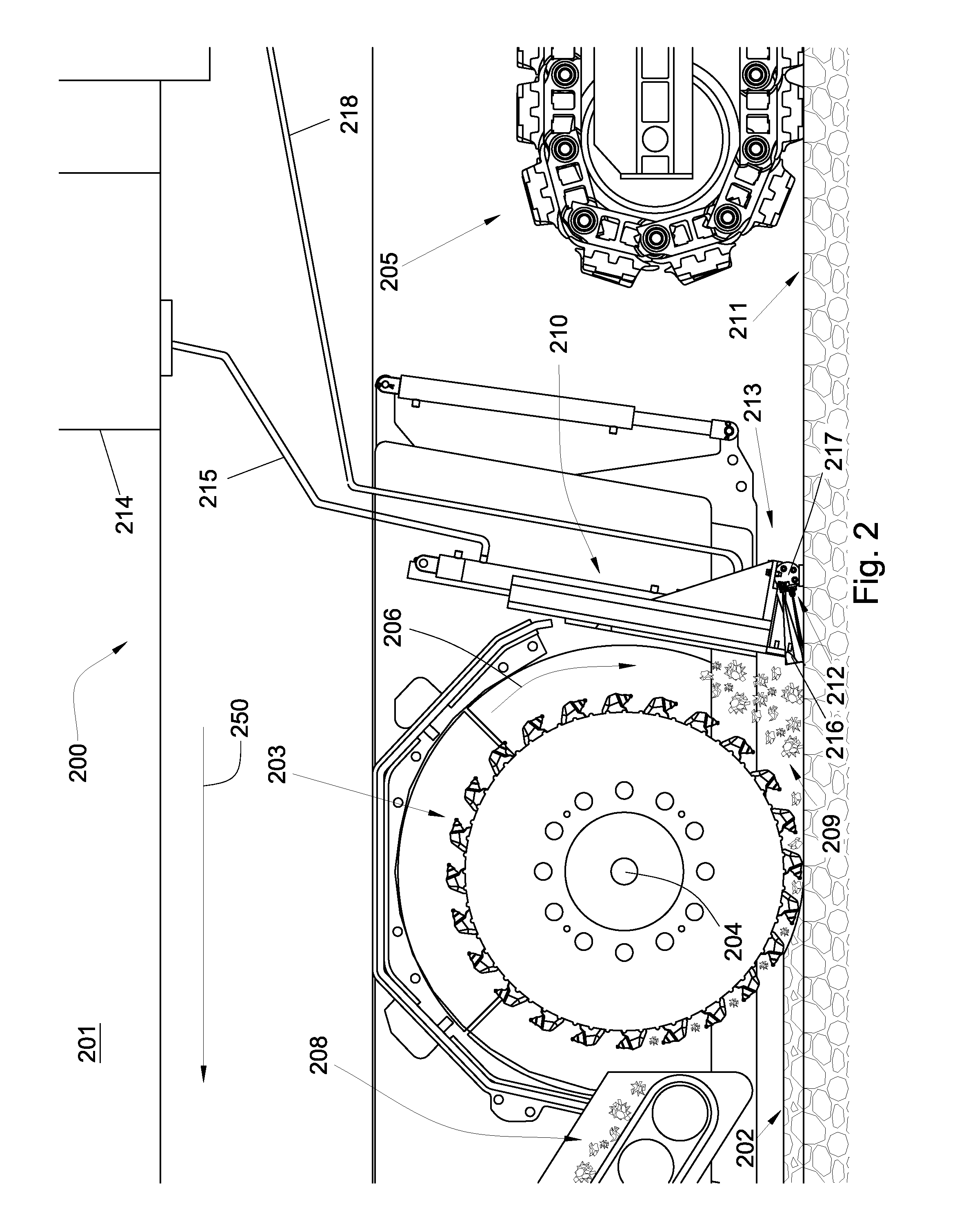

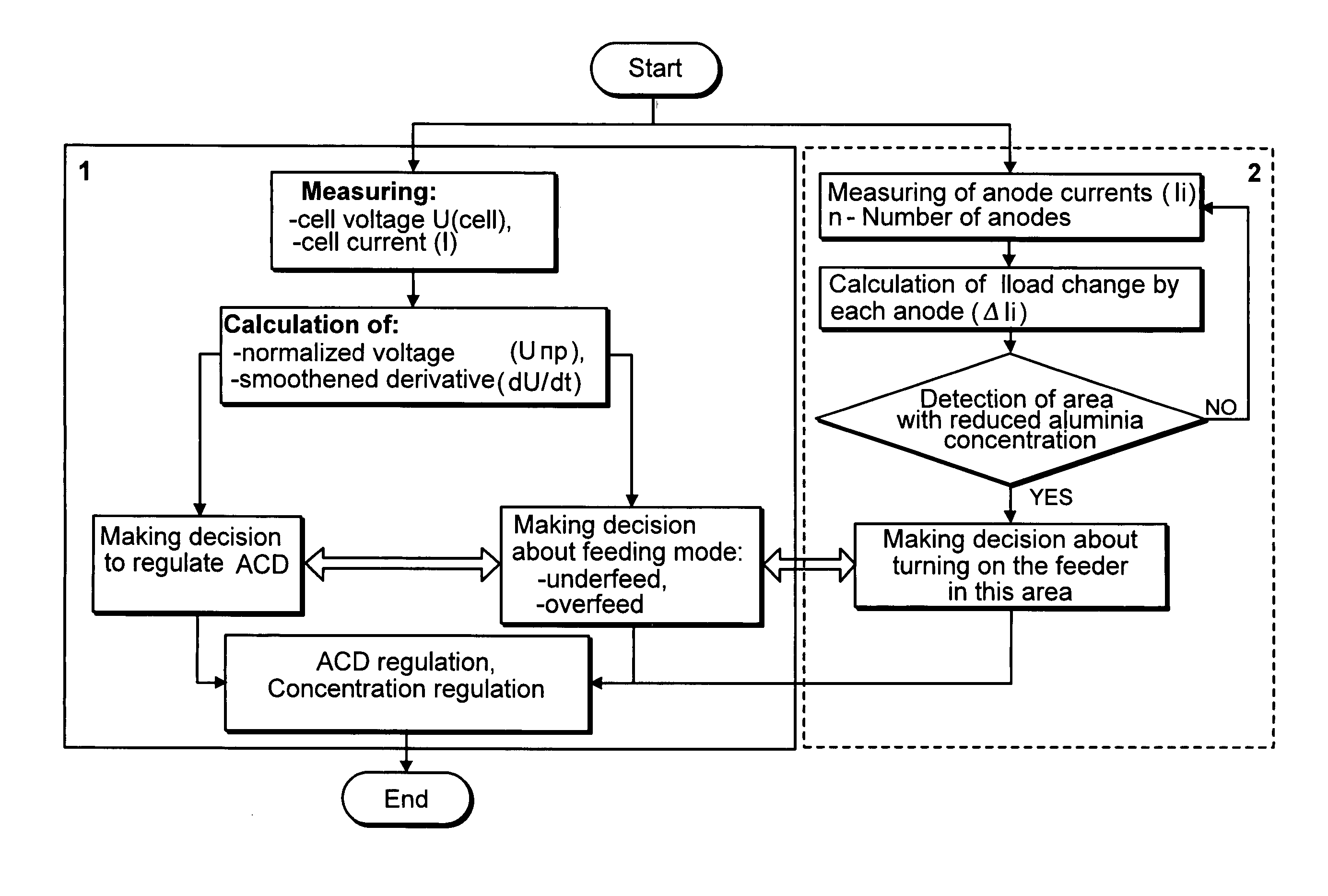

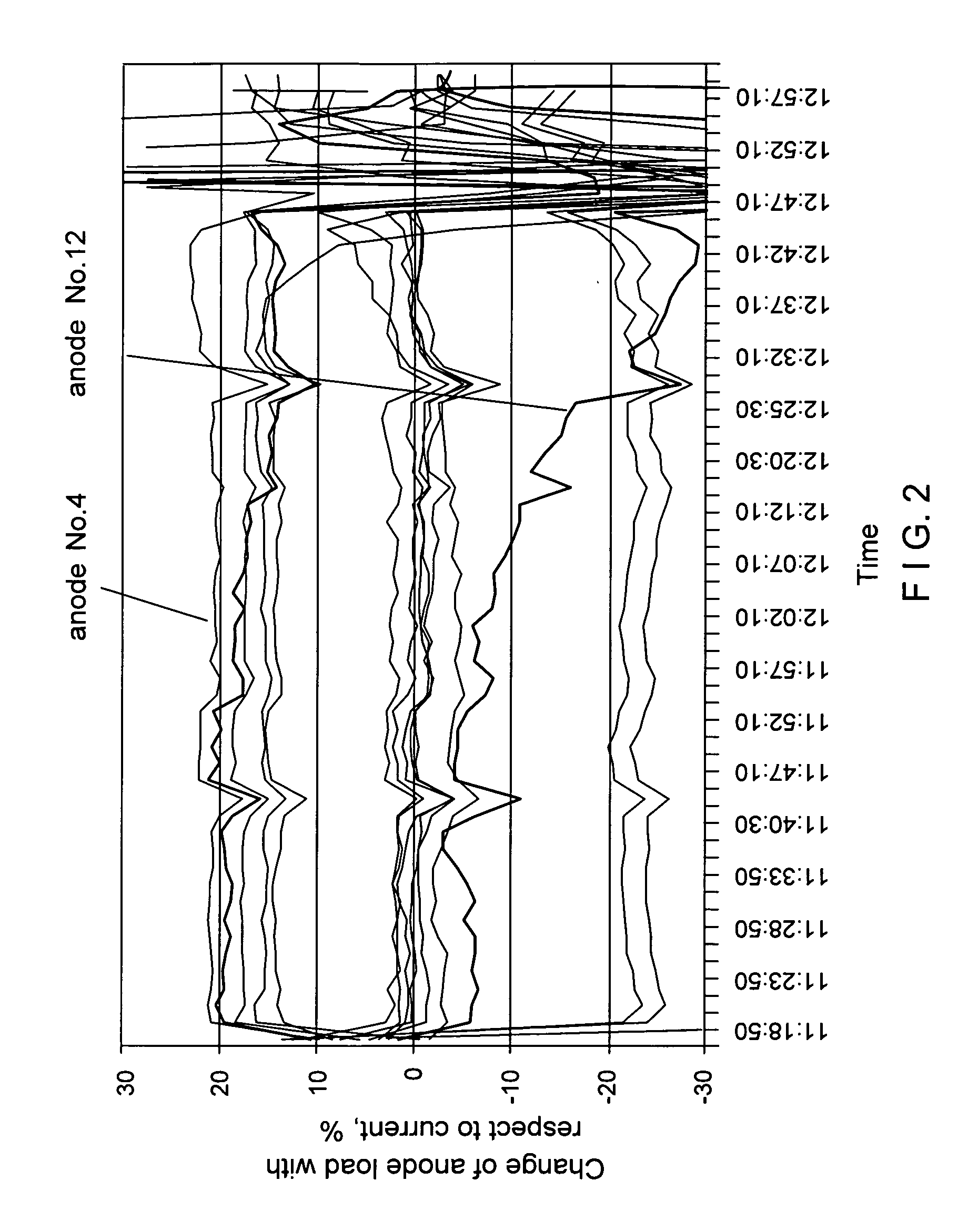

Method of controlling aluminum reduction cell with prebaked anodes

InactiveUS20070095672A1Quality improvementReduce concentrationPhotography auxillary processesElectrolysis componentsElectrolysisCurrent electric

In the method of controlling an aluminum reduction cell with prebaked anodes an area of reduced alumina concentration is defined in the cell by measuring the present electrical current values in at least one anode of the cell independently of other anodes. Upon detection of the electric current reduction in this anode, the rate of alumina feeding is increased into a bath of the cell at the area of reduced alumina concentration.

Owner:LIMITED LIABILITY COMPANY RUSAL ENG & TECHCAL CENT

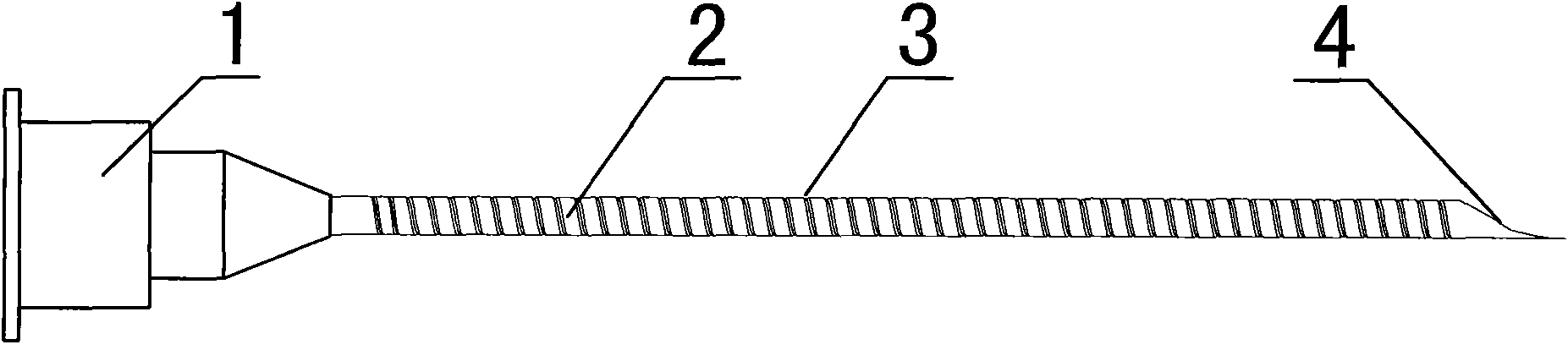

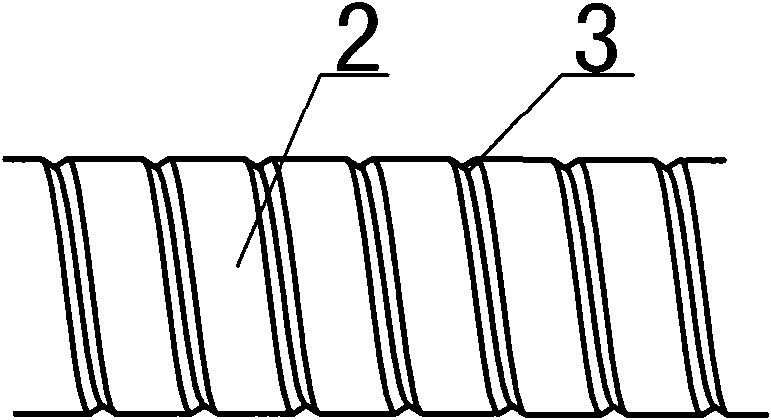

Injection needle with spiral surface

InactiveCN101810897AReduce frictional resistanceReduce contact areaGuide needlesSurgical needlesEngineeringInverted triangle

The invention relates to an injection needle with a threaded surface, which is applied to the field of disposable interventional medical apparatus in the process of clinical transfusion, sampling, puncturing, and the like. The injection needle is characterized in that the surface of the injection needle has a threaded surface with a threaded structure form, wherein a thread adopts an equidistant thread or a variable-distance thread, the depth (c) of a thread groove is 0.01-0.10mm, the width (a) of the thread groove is 0.02-0.50mm, and the thread distance (b) is greater than 1mm. The thread groove can be an inverted triangle, a circular arc, a rectangle, and the like. The threaded form is added on the surface of a needle tube for reducing the continuous friction resistance of the needle tube in the injecting and puncturing process and the stimulation effect of the needle tube to subcutaneous nerve endings in the puncturing process and realizing the pain relieving effect.

Owner:JILIN UNIV

Milling machine with cleaning moldboard

InactiveUS7458645B2Reduced form requirementsImprove bindingRoads maintainenceCutting machinesEngineeringNozzle

Owner:NOVATEK IP

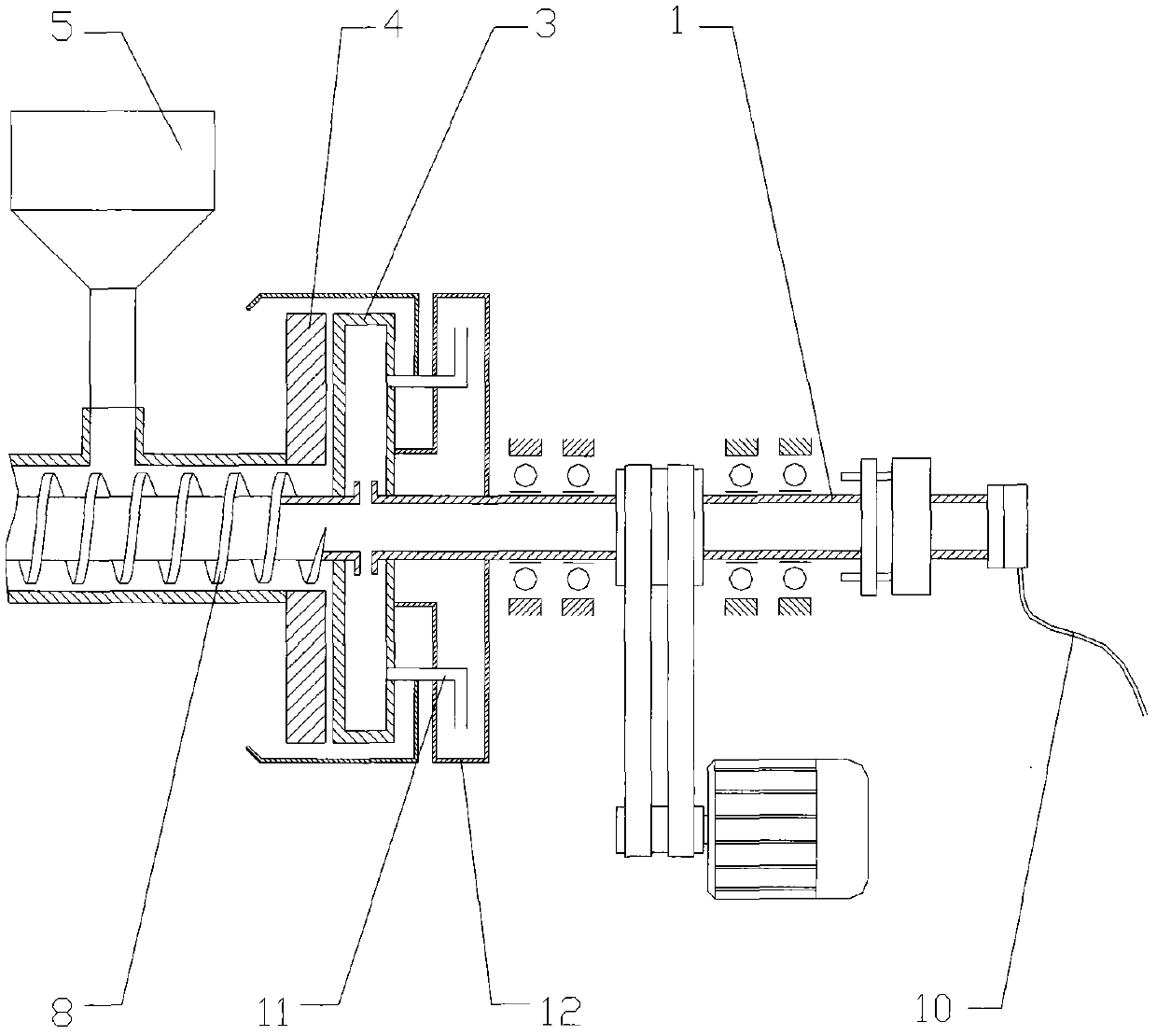

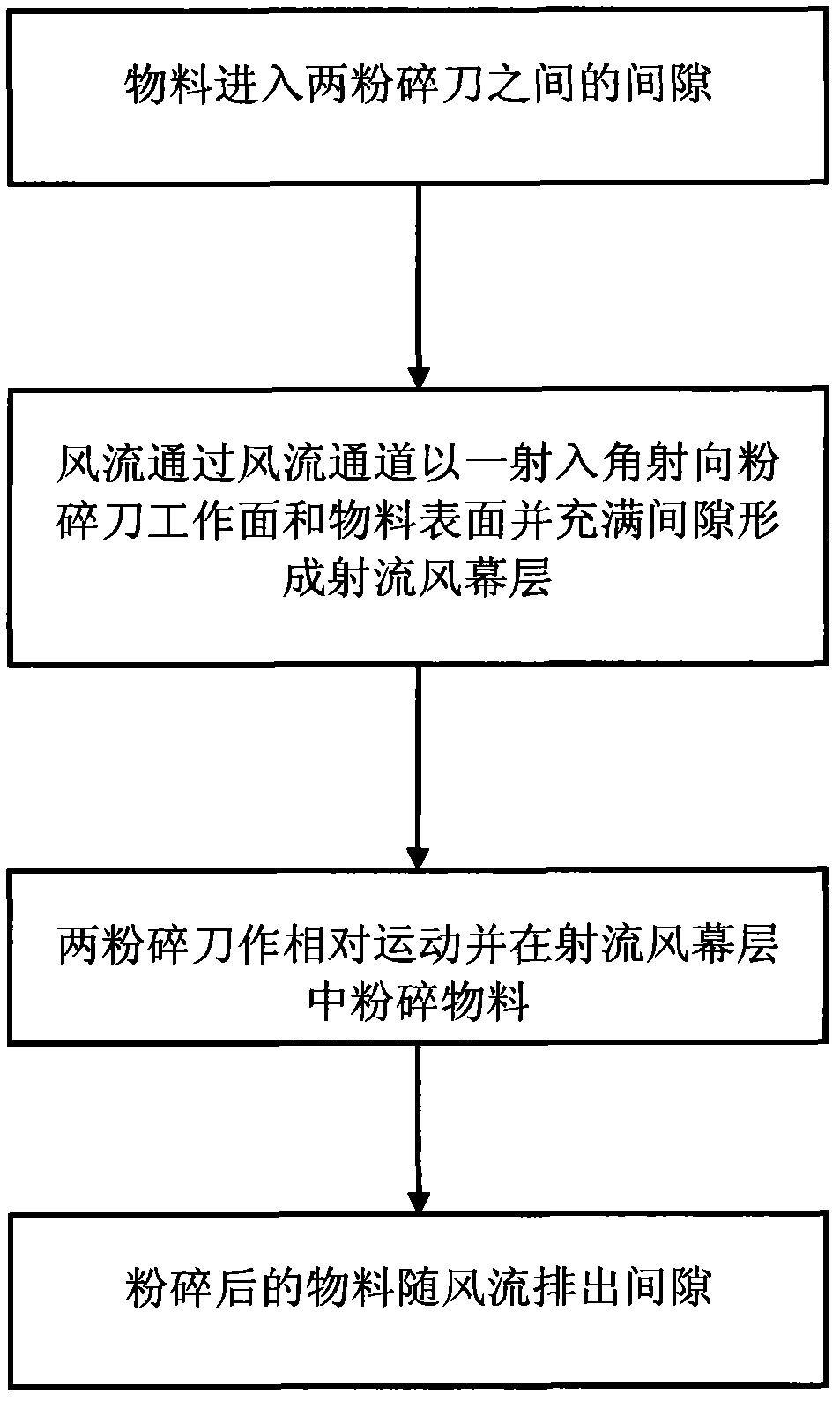

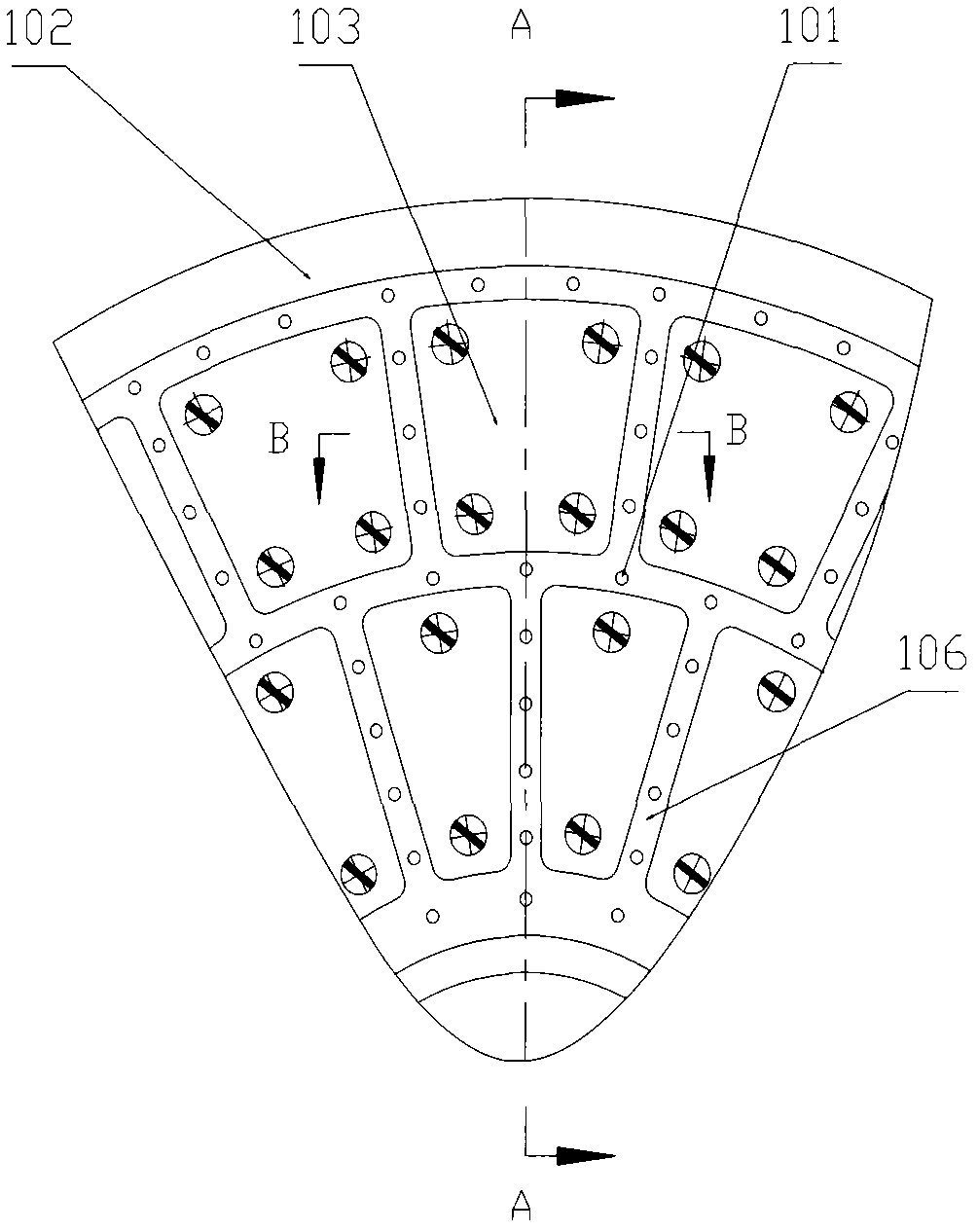

Method and structure for crushing low-temperature materials

ActiveCN102886294AEliminate aggregationReduce surface temperatureGrain treatmentsAngle of incidenceEngineering

A method for crushing low-temperature materials uses a material crushing device which comprises two crushing blades capable of moving relatively and an air flow channel communicated with a gap between the two crushing blades. The method comprises the following steps that: (1) the materials are sent into the gap between the two crushing blades; (2) the air flow passes the air flow channel and goes toward the working face of the crushing blades and the surface of the materials in an angle of incidence, and fills the gaps to form a jet air curtain layer; (3) the two crushing blades move relatively and crush the materials in the jet air curtain layer; and (4) the crushed materials are discharged from the gap with the air flow. By using an air-flow direct cooling way, the method effectively eliminates accumulation of crushing heat and static generated from friction, and prevents occurrence of melting and softening of the materials and degeneration and clustering, thereby meeting crushing requirements of high mesh and fine grain of the low-temperature materials. A structure for crushing low-temperature materials has advantages of large output, low energy consumption and high efficiency, and can be used for crushing the low-temperature materials with relatively low melting temperature, such as rubber, silicone, plastic, protein powder, herbal medicines, etc.

Owner:卢小平 +1

Ceramic base composite material using copper alloy as metal phase and metal phase adding method thereof

The invention provides a ceramic base composite material using a copper alloy as a metal phase and a metal phase adding method thereof, solves the problem of overflow of a pure copper metal phase in a sintering process of the composite materials, and improves the compactness, the electrical conductivity and the toughness of the material. The metal powder of a ceramic-metal composite material is prepared into composite powder by coating a layer of nickel-cobalt alloy or one of nickel and cobalt on the surface of Cu powder, or coating one or several of Ag, Pd, Au and Pt on the surface of Cu powder first and then coating a layer of metal nickel or cobalt or nickel-cobalt alloy. The nickel or cobalt content in the composite powder is 5 to 40 weight percent, and the content of other metal is 0 to 20 weight percent. After the metal composite powder and the ceramic powder are fully and evenly mixed, the mixed powder is prepared into the ceramic-metal composite material through processes of pressure forming, degreasing, sintering and the like. The problems of copper phase aggregation and overflow of the prior material system during the preparing are solved, and the compactness, electrical conductivity, strength, toughness and the like of the material are greatly improved.

Owner:CENT SOUTH UNIV

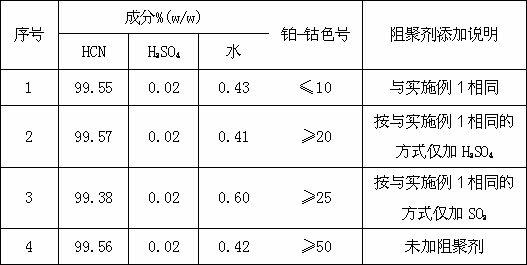

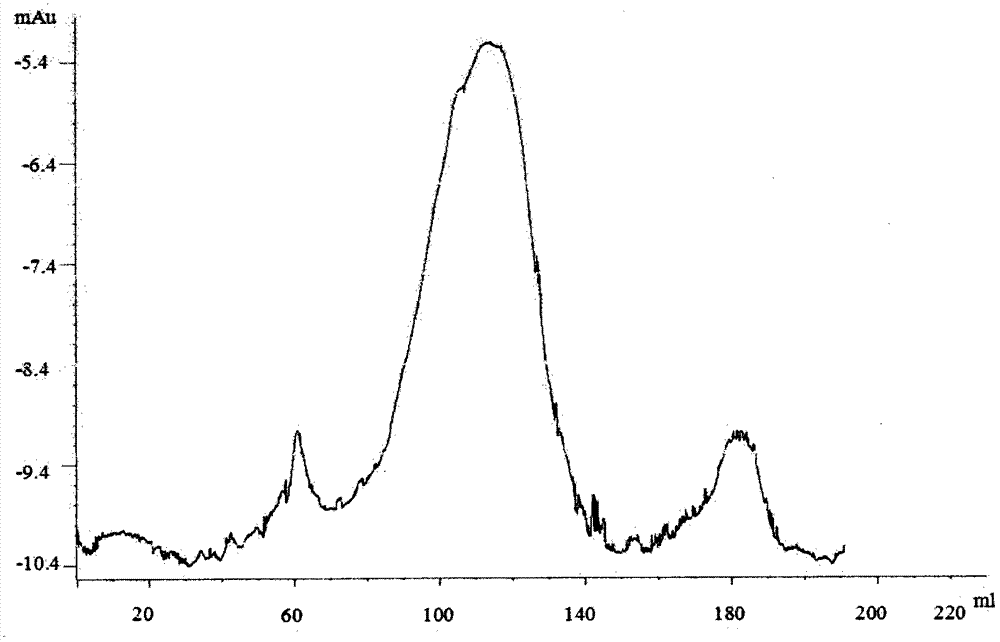

Purification method of hydrocyanic acid

InactiveCN102633283AShort stayEliminate AggregationChemical industryCyanic/isocyanic acidAcid waterPurification methods

The invention relates to a purification method of hydrocyanic acid. In the method, a purification raw material adopts 1-10% by weight of hydrocyanic acid water solution. The purification method comprises the following steps of: preheating the purification raw material to 40-60 DEG C, then introducing into a rectifying tower, adding a polymerization inhibitor, and performing distillation under the conditions that the tower top pressure is 10-90KPa negative pressure, the tower top temperature is 0-25 DEG C, the tower kettle pressure is 20-95KPa negative pressure, the tower kettle temperature is 60-100 DEG C and the reflux ratio is 3-15 so as to realize refining and purification of the hydrocyanic acid. The whole device comprises a vacuum pump which is connected with a reflux tank for operating and used for maintaining the negative pressure in the tower, and the trace hydrocyanic acid contained in exhaust gas of the vacuum pump is sent to an incinerator for incineration treatment. According to the purification method disclosed by the invention, the pressure difference between the tower top and the tower kettle is reduced, the operation temperature is reduced, the corrosion of all the devices can be avoided or reduced, and the polymerization of the hydrocyanic acid is further eliminated, thus the quality of a hydrocyanic acid product and the yield thereof are further improved; and the purification method has the characteristics that the purification method is more economic, energy-saving, environment-friendly and safer.

Owner:CHONGQING UNISPLENDOUR CHEM

Aluminium foil produced by utilization of cast-rolled slabs and used for dynamic functional materials and preparing method thereof

ActiveCN104611616AReduce precipitationUniform grainElectrode carriers/collectorsSurface cleaningSurface roughness

The invention discloses aluminium foil produced by utilization of cast-rolled slabs and used for dynamic functional materials. The aluminium foil comprises following chemical components: more than 99.30% of Al, 0.30-0.5% of Fe, 0.05-0.2% of Si, 0.045-0.1% of Cu, 0.015-0.025% of Ti and 0.006-0.015% of Sr, with the balance being impurities, and the sum of mass percentages of the Al, the Fe, the Si, the Cu, the Ti, the Sr and the impurities being 100%. A preparing method of the aluminium foil is also disclosed. The aluminium foil prepared by the method has advantages of strength, high elongation percentages, good compactness, uniform surface roughness and high surface cleanliness.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

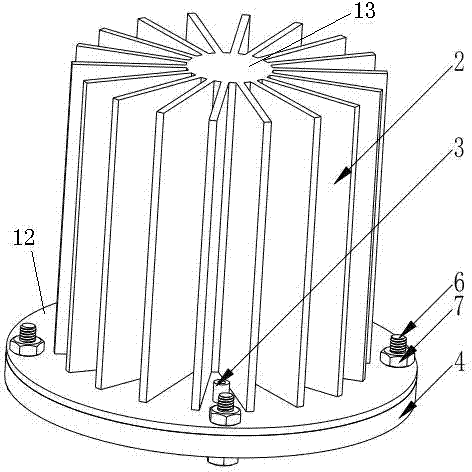

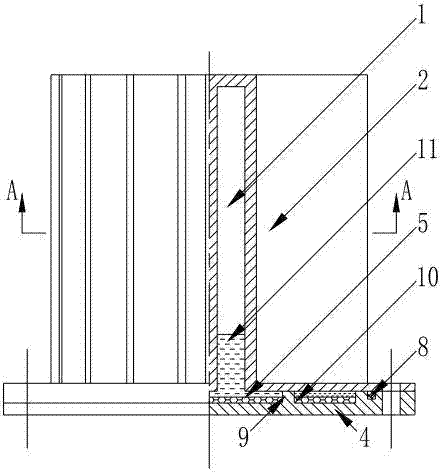

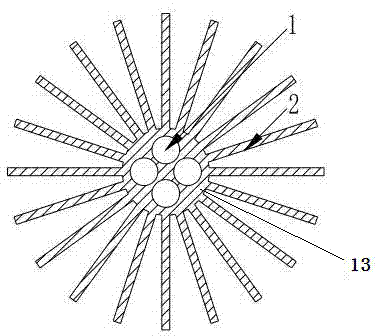

Heat dissipation method and device for integrated heat pipe of large-power LED

ActiveCN103528035AImprove cooling effectExtend working lifePoint-like light sourceLighting heating/cooling arrangementsVapor liquidEvaporation

The invention provides a heat dissipation method and device for an integrated heat pipe of a large-power LED. The method is characterized in that a plurality of cylindrical straight heat pipes are arranged side by side to form a gravity assisted heat pipe array with a small pipe diameter, vertical pipelines of all heat pipes are not communicated, meanwhile, the evaporation ends of all gravity assisted heat pipes share the same evaporator cavity, an upper shell of a heat dissipation device comprising heat pipelines and fins is manufactured in an integrated mode, a clearance between the upper shell and a cover plate forms the evaporation cavity, the upper shell and the cover plate are connected through bolts and sealed by a rubber gasket, and meanwhile the upper shell is provided with a vacuumizing and liquid injection pipe. An LED light source is attached to the heating face of the cover plate under the evaporation cavity, heat of the light source is transmitted to the fins through vapor-liquid phase-change circulation of work media in the evaporation cavity and the heat pipes, and then the heat is dissipated to the environment through the fins in a natural convection mode. The invention further provides the heat dissipation device using the heat dissipation method. The device is simple in structure, convenient to use, and good in heat dissipation effect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

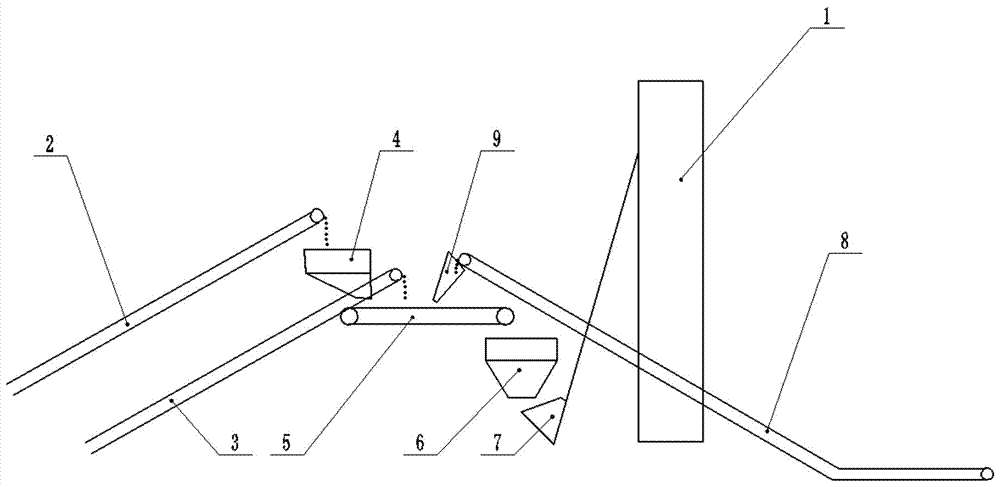

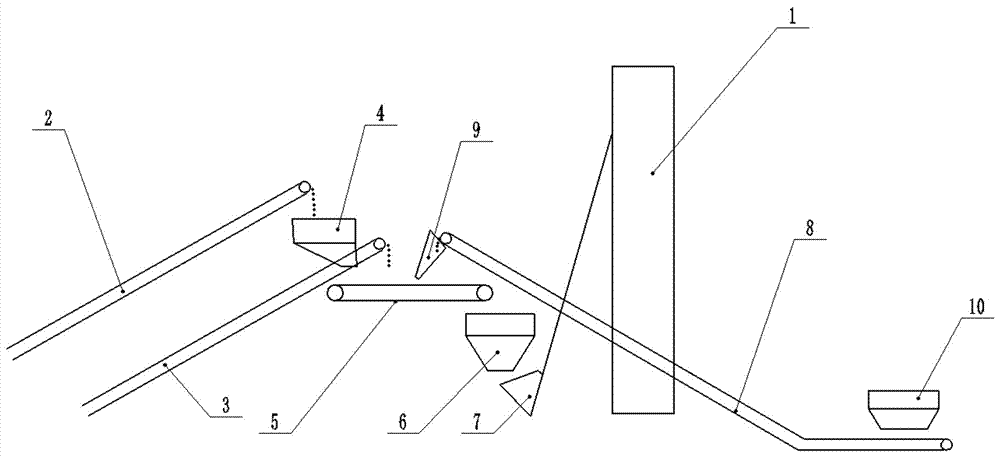

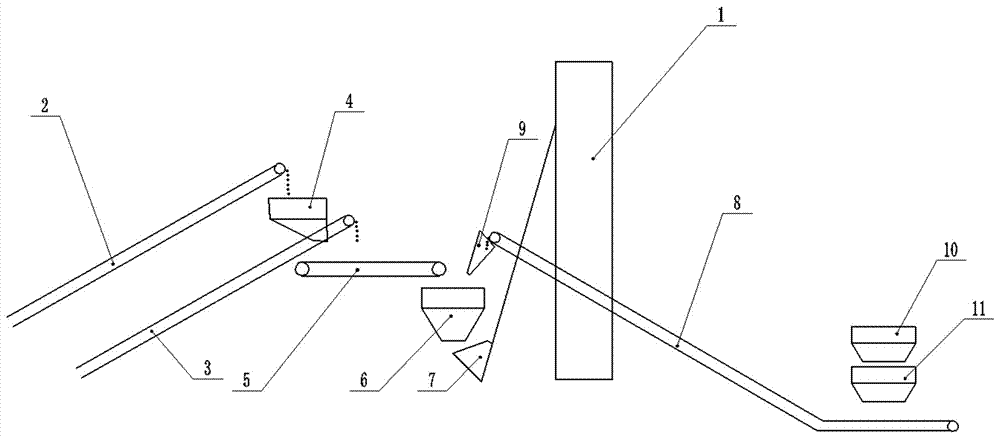

Device and method for feeding steel scraps into blast furnace for iron making

ActiveCN107287373AEliminate cloggingLooseBlast furnace componentsBlast furnace detailsIron oreReducing capacity

The invention discloses a device and a method for feeding steel scraps into a blast furnace for iron making, and belongs to the technical field of smelting. The device comprises an iron making blast furnace and a feeding conveying chain, wherein the feeding conveying chain is arranged on one side of the iron making blast furnace; a steel scrap conveying belt is arranged on the side edge of the feeding conveying chain; and the steel scraps conveyed by the steel scrap conveying belt and iron ore conveyed by the feeding conveying chain together enter the blast furnace for iron making. The device and the method have the advantages that due to the fact that the blast furnace has the relatively strong reducing capacity, the average yield of Fe of the steel scraps can be increased from 84% by an electric arc steel making furnace to 98-99.5% by the blast furnace for iron making, meanwhile, the coke ratio or the fuel ratio for per ton of iron of the blast furnace is lowered, specifically, the coke consumption or fuel consumption can be decreased by 20-35 kilograms every time when 10% of the steel scraps is added, and therefore the yield of the Fe can be obviously improved, and in addition, the coke ratio or the fuel ratio can be obviously decreased.

Owner:HENAN DRAGON INTO COAL TECH CO LTD +1

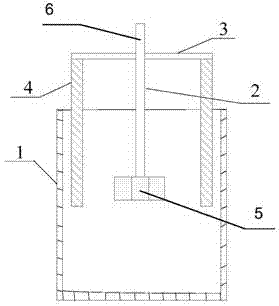

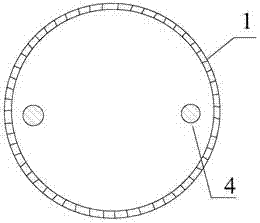

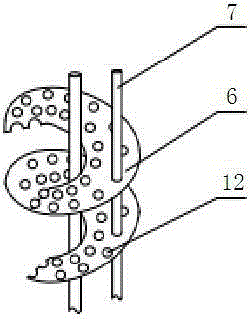

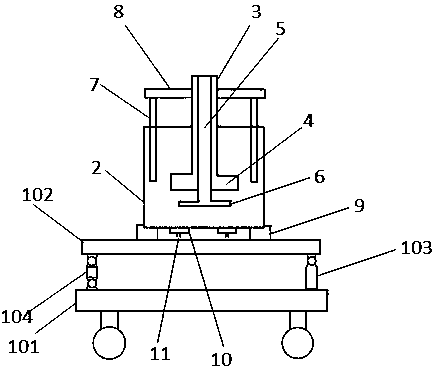

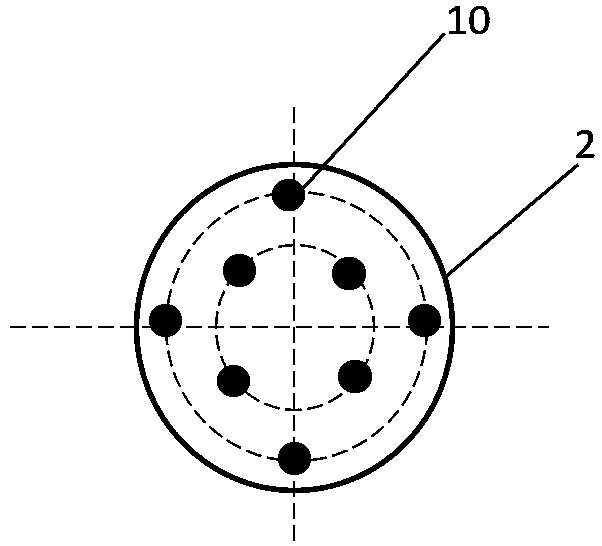

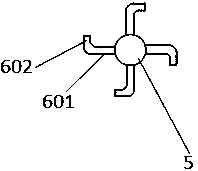

Flow control device in kambara reactor (KR) desulfuration molten iron tank

ActiveCN106987682AInhibition formationImprove desulfurization kinetics conditionsMelt-holding vesselsEngineeringKambara

The invention discloses a flow control device in a kambara reactor (KR) desulfuration molten iron tank. The flow control device comprises a stirring device inserted into the molten iron tank, and the stirring device is composed of a stirring head and a stirring rod. The flow control device further comprises a support and a plurality of stop levers. The support is arranged above the molten iron tank, the upper ends of the stop levers are fixedly arranged on the support, the lower ends of the stop levers are inserted into the molten iron tank, and the stop levers are symmetrically distributed with the stirring rod as an axis. A periodic effect is generated on a stirring flow field of the molten iron tank through the stop levers, formation of a center eddy region is remarkably restrained, the desulfuration dynamic condition of molten iron mechanical stirring is obviously improved, and the utilization rate of a desulfurizing agent is greatly increased.

Owner:BAOSHAN IRON & STEEL CO LTD

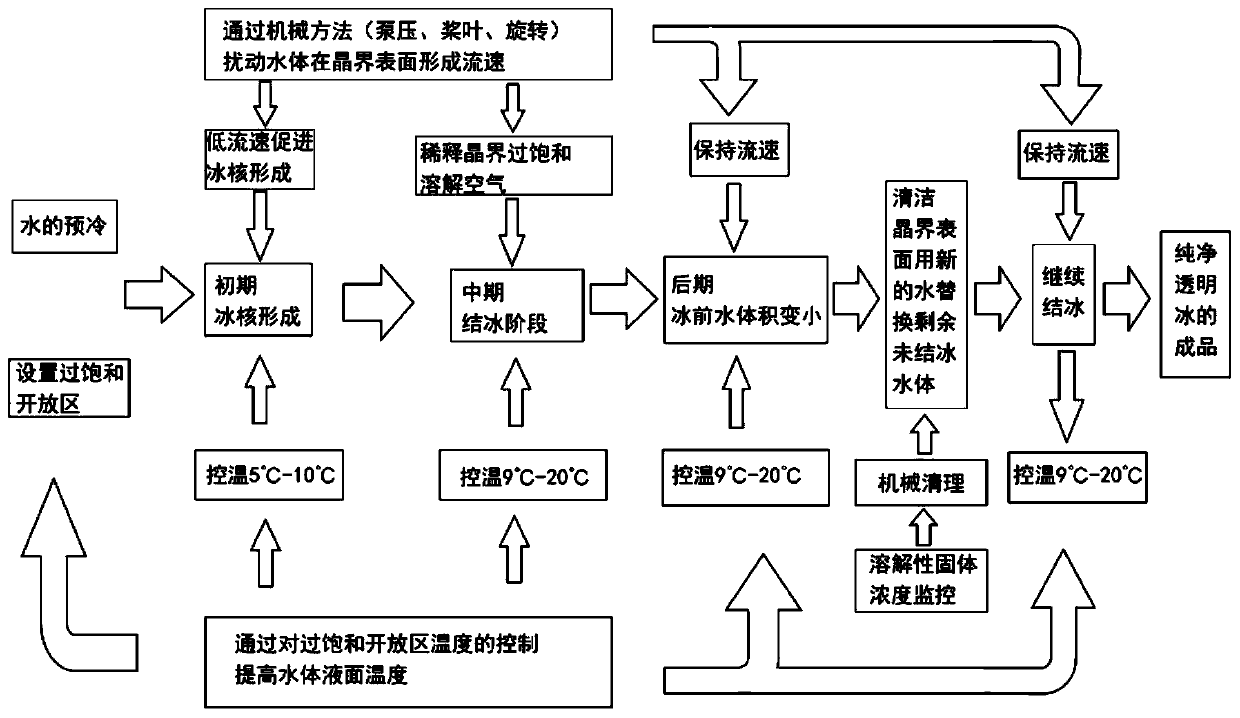

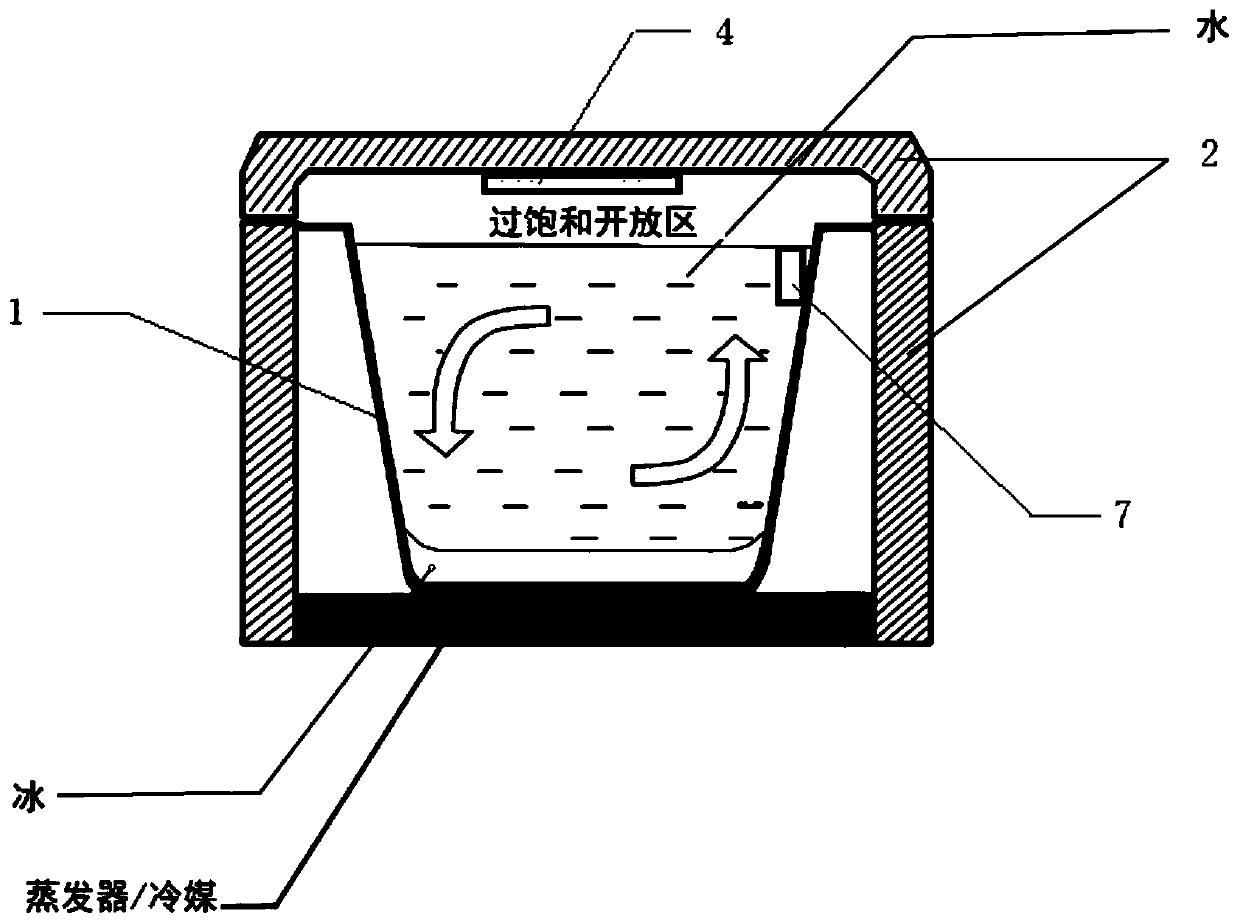

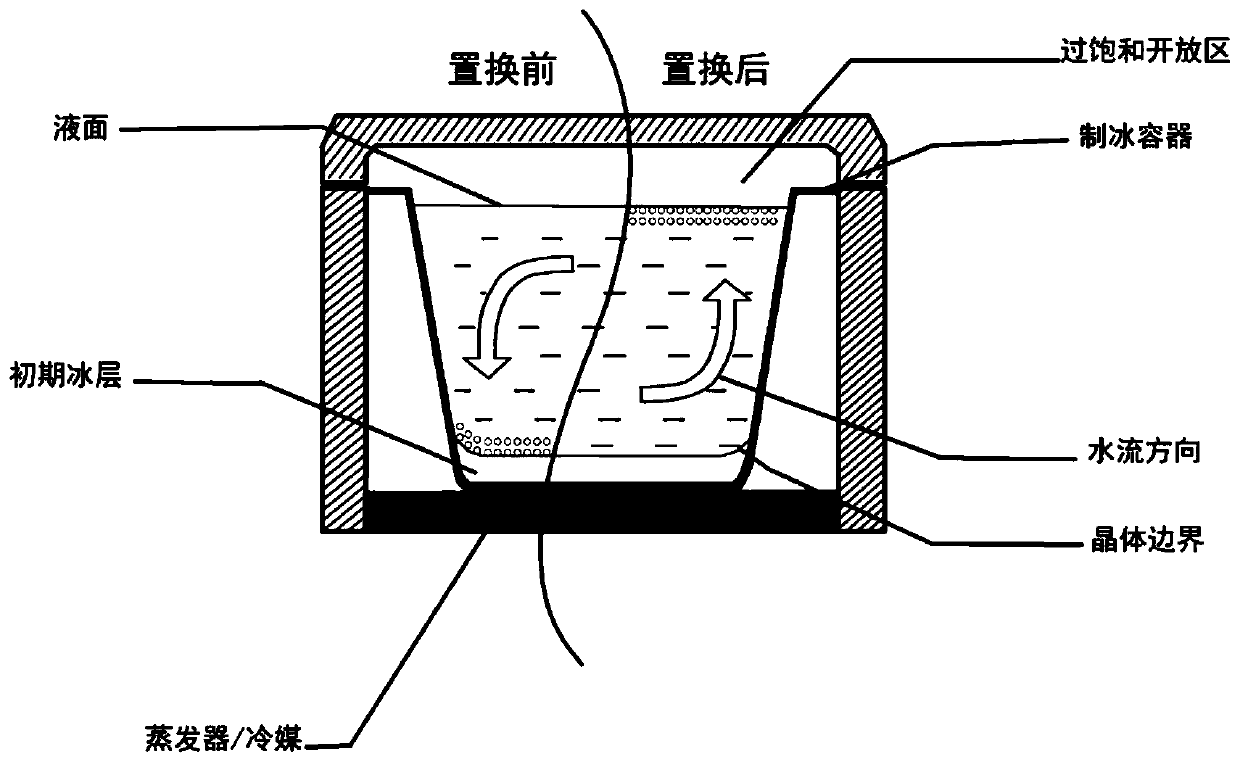

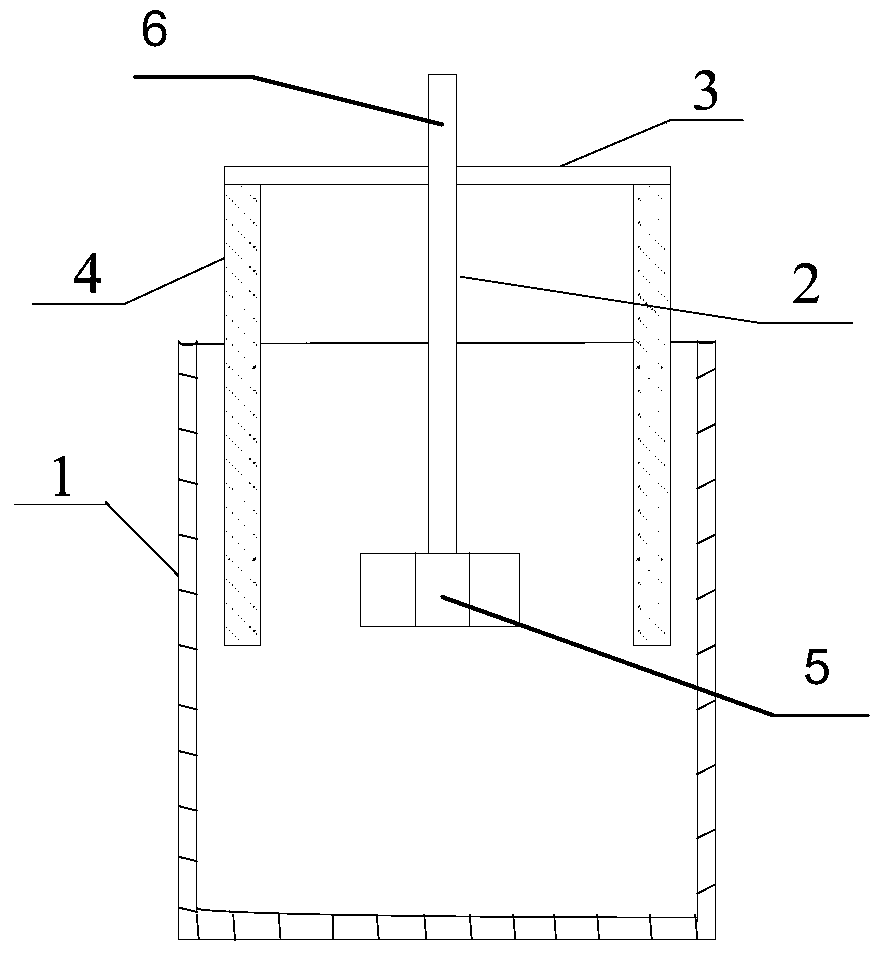

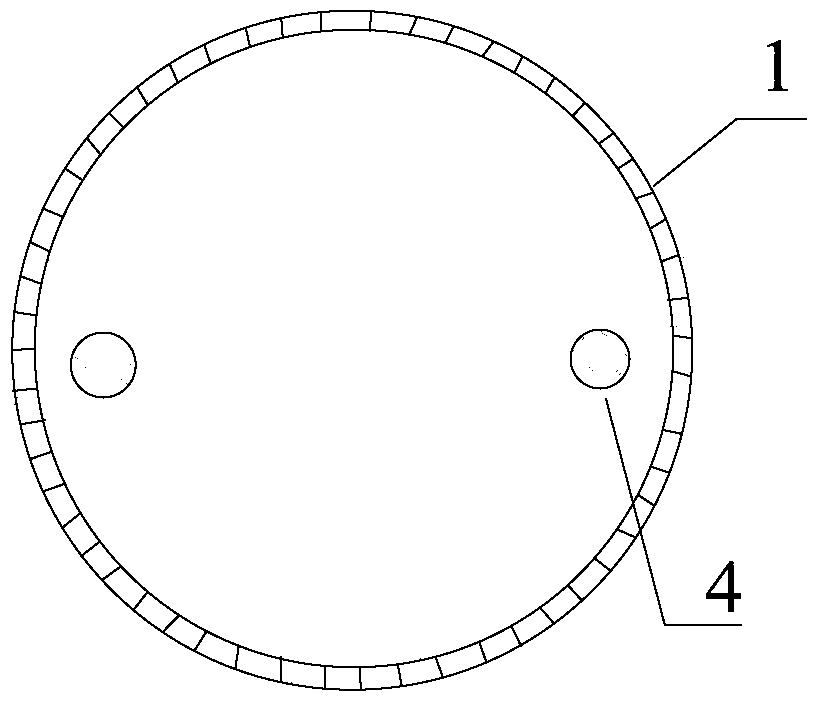

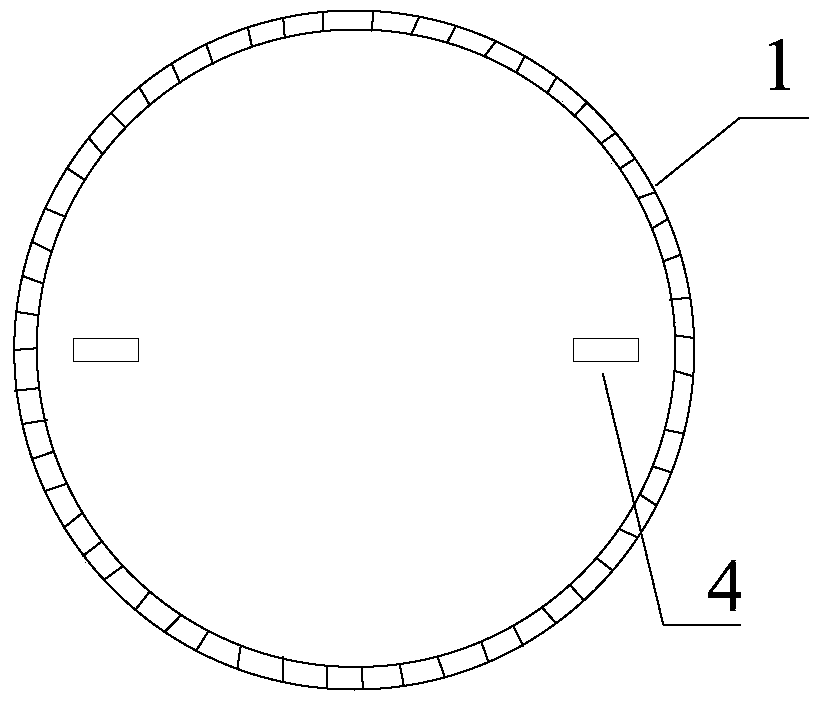

Making method and making device of clean transparent ice

ActiveCN109883097AHigh transparencyImprove purityLighting and heating apparatusIce productionEngineeringImpurity

The invention relates to a making method and a making device of clean transparent ice, and belongs to the field of ice making. The making method and the making device solve the problem that an existing ice making technology cannot discharge air dissolved in water in the freezing process. The making method and the making device are characterized in that a dissolved air supersaturated open area is arranged in an ice making container, in particular, the supersaturated open area is formed between the liquid level in the ice making container and an upper opening of the ice making container, the supersaturated open area keep to communicate with external atmosphere, and the temperature of the supersaturated open area is controlled; a mechanical disturbance mode is selected according to the volumeof the ice making container, the crystal interface is washed at a constant flow rate, the dissolved air supersaturated zone formed by the crystal interface is diluted or replaced, the temperature ofthe supersaturated open area is controlled, and the water body liquid level temperature is improved; and a clean transparent ice body is obtained by controlling the physical conditions in the icing environment. According to the making method and the making device, dissolved air and impurities in water are discharged in the icing process, and meanwhile, the ice making device which is simple in structure and convenient to use is provided for making the clean transparent ice.

Owner:HARBIN ENG UNIV

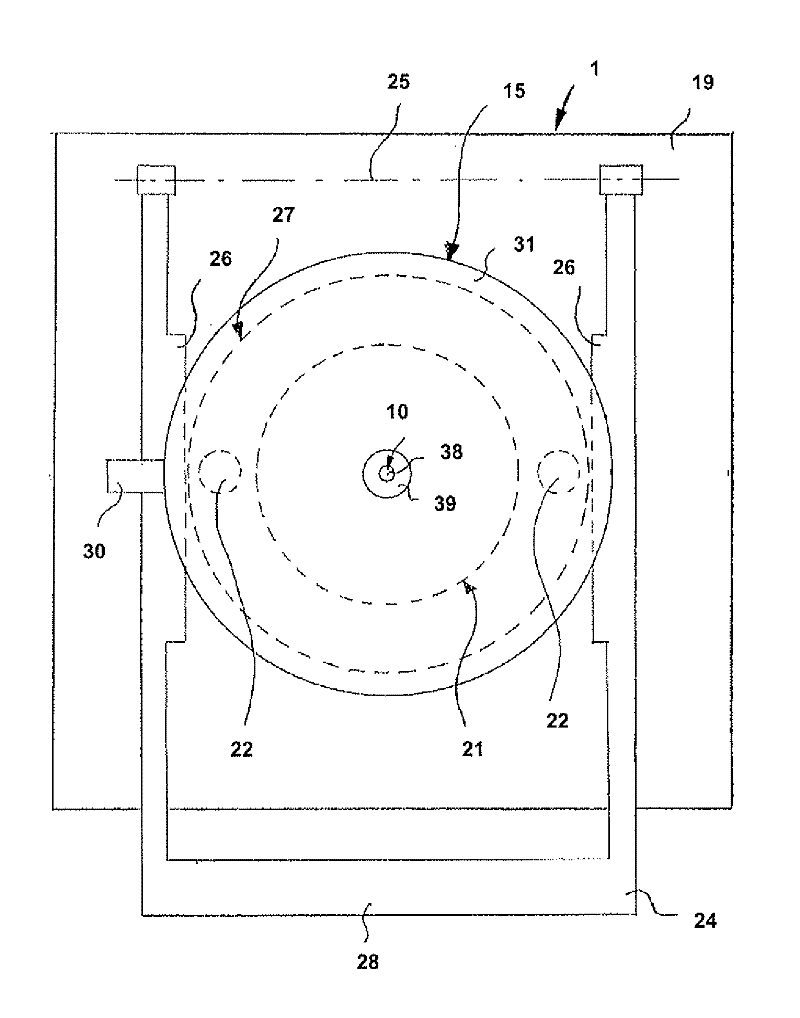

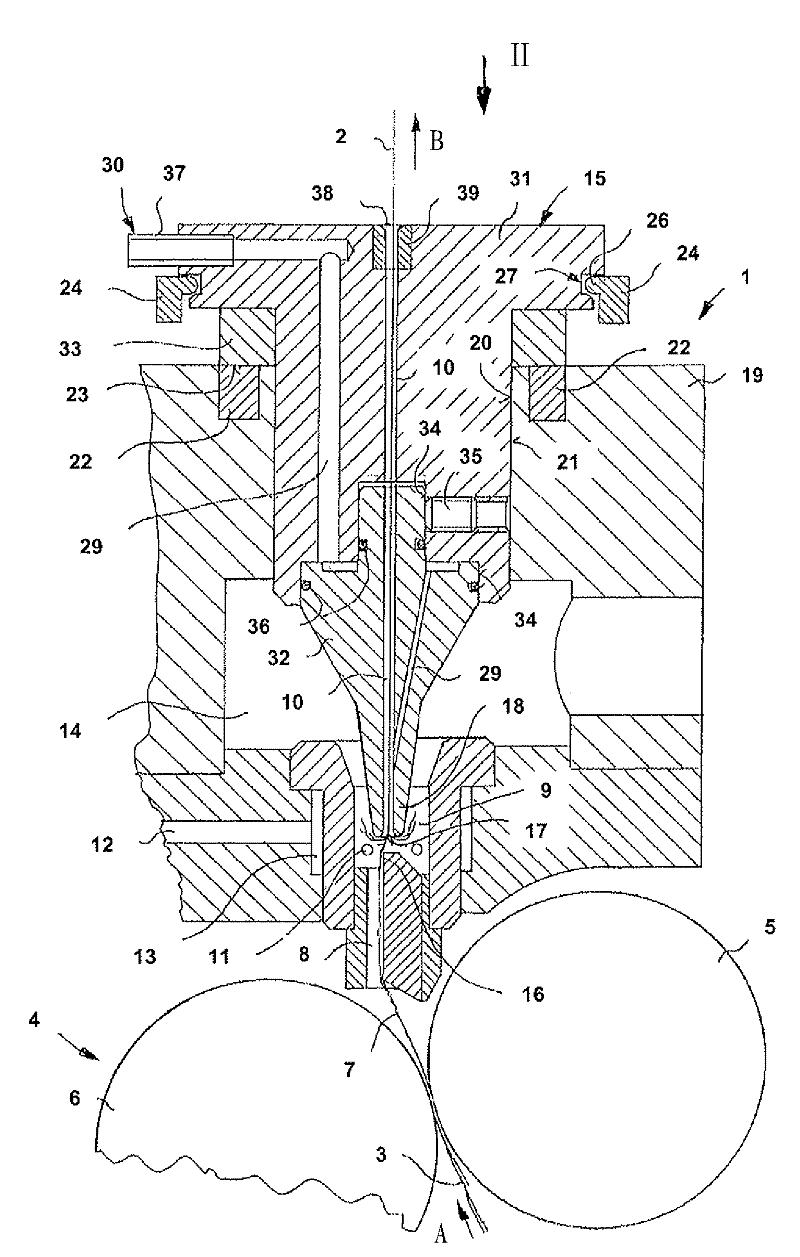

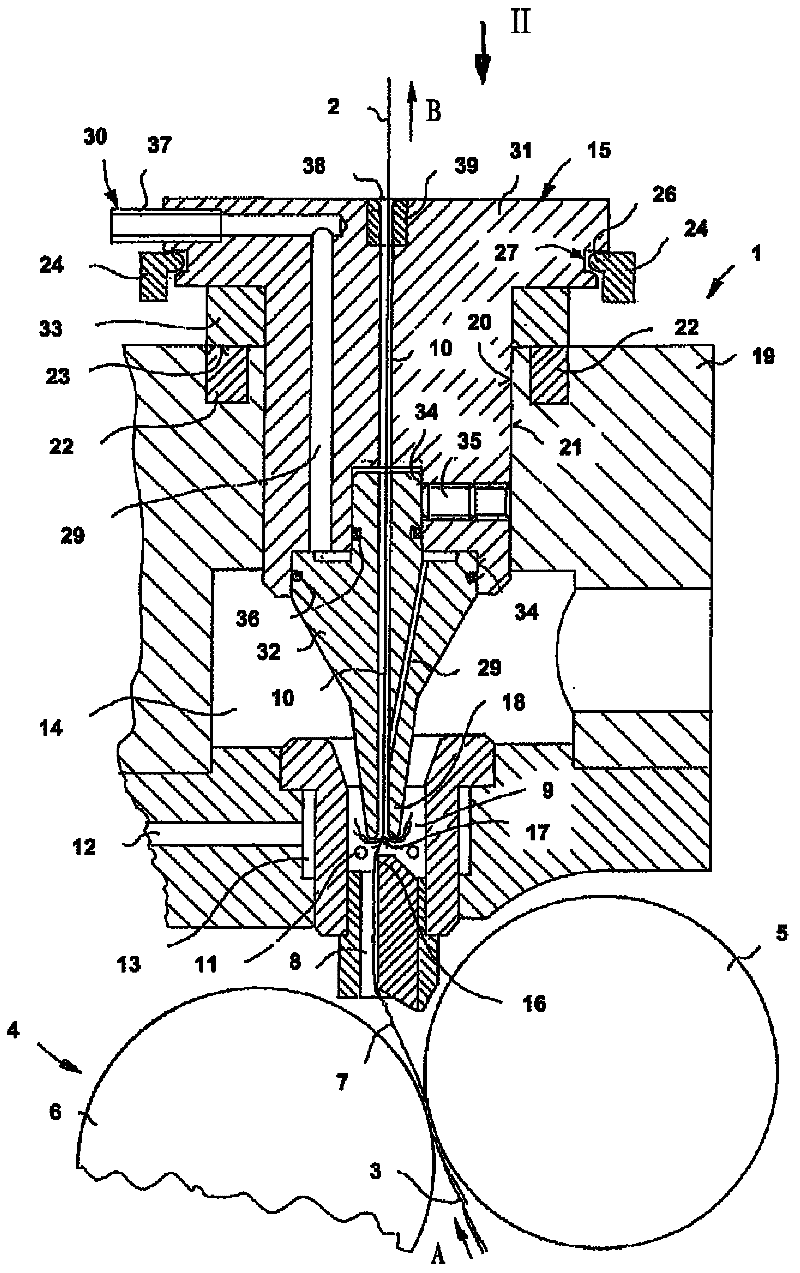

Air jet spinning unit having spindle-shaped component

ActiveCN102165111AEliminate aggregationShorten the lengthContinuous wound-up machinesOpen-end spinning machinesMagnetAerospace engineering

An air jet spinning unit comprises a spindle-shaped component. The spindle-shaped component comprises a thread pulloff channel (10) and can be moved along the thread pulloff channel. The air jet spinning unit comprises at least one magnet (22) for holding the spindle-shaped component in the operating position thereof.

Owner:MASCHINENFABRIK RIETER AG

Method for preparing adjuvant-free haemophilus influenza type b conjugate vaccine lyophilized agent

ActiveCN104491854AEliminate aggregationEliminate degradationAntibacterial agentsPowder deliveryChemistryAdjuvant

The invention discloses a method for preparing an adjuvant-free haemophilus influenza type b conjugate vaccine lyophilized agent. The method comprises forming the formula, preparing the mixture and performing a freeze-drying process. According to the technical scheme in the invention, in the process of performing vacuum sublimation freezing-drying to remove free water in the freeze-drying process, the temperature of the bottled material is controlled to eliminate aggregation of CRM197 proteins below the eutectic point of free water and bound water; in the process of performing vacuum heating desorption drying to remove the free water, the temperature of the bottled material is controlled to eliminate degradation of a Hib capsule structure below the degradation point, so that an adjuvant does not need to be added into a haemophilus influenza type b conjugate vaccine lyophilized agent. The problems and defects such as protein aggregation, structure degradation, adjuvant needs and the like in the prior art are overcome, so that the haemophilus influenza type b conjugate vaccine lyophilized agent achieves the aims of eliminating the protein aggregation and structure degradation and avoiding the adjuvant.

Owner:ZHEJIANG VACIN BIO PHARMA LTD

Saliva pretreatment reagent box and saliva pretreatment process

InactiveCN1492230AEliminate aggregationEffective outflowWithdrawing sample devicesBiological testingSphaerotrichia divaricataSurface-active agents

A pretreatment kit and a pretreatment kit for saliva in identification and quantitative determination of mutans streptococci by immunochromatography utilizing an antigen-antibody reaction, which can remove aggregation caused by mucin and chain formation of mutans streptococci in saliva in a simple operation and can efficiently flow out a complex of a labeled antibody and mutans streptococci from a porous membrane retaining the labeled antibody, contains (A) a 0.01 to 10 mol / L aqueous solution of sodium hydroxide, (B) a 0.01 to 3 mol / L aqueous solution of tartaric acid and / or citric acid, and (C) a nonionic surface active agent and / or an amphoteric surface active agent, in which the component (C) is mixed with the components (A) and / or (B), or is provided separately, and at least one substance selected from the particular metallic salts is contained in at least one of the components (A), (B) and (C) in an amount of 5 to 25% by weight.

Owner:GC CORP

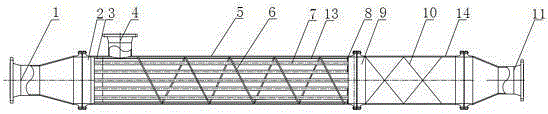

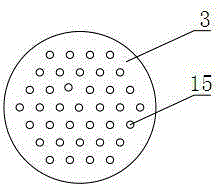

Efficient boiled off gas (BOG) after-condenser

The invention discloses an efficient boiled off gas (BOG) after-condenser. The efficient BOG after-condenser comprises a first shell, a second shell, a liquefied natural gas (LNG) inlet formed in the first shell, a pipe plate and a supporting grid, wherein the pipe plate and the supporting grid are located at the two ends of the first shell respectively; the pipe plate is connected with a BOG inlet; a plurality of micro pore pipes, fixed-interval rods and spiral flow guide plates are arranged between the pipe plate and the supporting grid; the spiral flow guide plates are provided with pipe pores; the pipe plate is provided with pipe plate pipe pores; the surfaces of the micro pore pipes are provided with micro pores; the micro pore pipes and the fixed-interval rods penetrate through the pipe holes in the spiral flow guide plates and are fixed between the pipe plate and the supporting grid in parallel; one end of the second shell is connected with the first shell through a connecting flange, and the other end of the second shell is connected with an LNG outlet; a static mixing unit is arranged inside the second shell. Compared with traditional BOG after-condensation equipment, the efficient BOG after-condenser is high in condensation efficiency, high in processing capacity, easy to operate and convenient to maintain and replace.

Owner:江苏中圣压力容器装备制造有限公司

Preparation method of high-quality aluminum-titanium-boron alloy rods

The invention provides a preparation method of high-quality aluminum-titanium-boron alloy rods and belongs to preparation of refiners. The method is characterized by producing aluminum-titanium-boronalloys through cooperation of a frequency-variable induction electric furnace and a medium-frequency induction electric furnace, refining aluminum liquid before charging, adding a mixture of villiaumite and a diffusion agent, taking the mixture as a nucleating agent of TiAl3 and TiB2 mass points in the alloying process, wherein the TiAl3 and TiB2 mass points formed after completing alloying are fine and are more uniformly distributed; the formation of rod shape of the TiAl3 mass points and the aggregation of the TiB2 mass points are eliminated; the diffusion agent is added into the villiaumitemixture, so that the aggregation of the TiAl3 and TiB2 mass points is effectively controlled; the alloying process is equipped with mechanical stirring, so that the enlargement of the TiAl3 and TiB2mass points is effectively prevented; the separation and purification effect of villiaumite slag and alloys can be improved; through check analysis, the TiAl3 and TiB2 mass points in the produced products are fine, are uniform and dispersive in distribution and are extremely low in slag content; the problems that the TiAl3 mass points in the continuously cast and rolled aluminum-titanium-boron alloy rods in the current market are thick and big, the TiB2 mass points are aggregated, the content of the slag in the alloys is high, and the aluminum-titanium-boron alloy rods are poor in refining capacity in the aluminum alloys are effectively solved.

Owner:河北晶宝新金属有限公司

Method for quickly separating and culturing fibroblast from human skin tissues

InactiveCN107779429AHigh activityShorten digestion timeCell dissociation methodsSkeletal/connective tissue cellsWater bathsFiber

The invention discloses a method for quickly separating and culturing fibroblast from human skin tissues. The method comprises the following steps of cleaning and shearing fresh foreskin tissues afteroperation of adults or children, and sequentially adopting solutions of dispase II and dispase I to digest under the condition of oscillation in a water bath at the temperature of 37 DEG C; and collecting skin tissue blocks through centrifuging; enabling a culture medium to resuspend, and culturing in a culture box with CO2 (carbon dioxide) volume concentration of 5% at the temperature of 37 DEGC. The method has the advantages that the temperature of the digestion function of the dispase I and the dispase II is increased from 4 DEG C to 37 DEG C, the activities of the dispase I and the dispase II are respectively improved, the contact areas between the dispase I as well as the dispase II and a corresponding primer are increased by the oscillation in the water bath, the enzymatic reaction is favorably performed, the digestion time of the dispase I as well as the dispase II is greatly shortened, and the separating and culture speed of the fibroblast is improved; the damage of enzyme to tissue cells is decreased, the wall attaching rate of the cells is improved, and the primary fibroblast can complete passage after culturing for 6 to 8 days.

Owner:陕西九州生物医药科技集团有限公司

Wafer pasting preventing method for silicon wafer

ActiveCN107053503AReduce adsorptionReduce electrostatic adsorption capacityWorking accessoriesFine working devicesWaferingWafer dicing

The invention provides a wafer pasting preventing method for a silicon wafer, and belongs to the field of silicon wafer manufacturing processes. Glue preparation, rod pasting, dispersing agent preparing, mortar preparing, anti-viscidity mortar fluid preparing, wafer cutting and glue removal are sequentially carried out. A dispersing agent with charges capable of being removed is prepared, and therefore the viscidity of overall cutting liquid is guaranteed, the accident of wafer pasting in the silicon wafer cutting process is avoided; and a thick sheet is reserved at each of the two ends of a silicon rod after cutting is completed, it is guaranteed that the two ends of the cut silicon wafer are each provided with a balance weight, silicon wafer slippage caused by swelling caused by pasted silicon powder is avoided, and the stability of the overall production process is improved.

Owner:JA SOLAR

Robot joint part with cooling structure, power joint and robot

ActiveCN111571633AEliminate aggregationHigh speedProgramme-controlled manipulatorJointsEngineeringPhysics

The invention provides a robot joint part with a cooling structure, a power joint and a robot. The joint part is provided with a hollow cylindrical structure and sleeves the outer side of a heat source part, the joint part is provided with multiple phase change cooling units, each phase change cooling unit is distributed in the axial direction of a cylinder wall, each phase change cooling unit comprises a phase change working medium, a capillary material and a seal phase change cavity, the phase change working medium is located in the phase change cavity, the interior of the phase change cavity is in a vacuum or negative pressure environment, the capillary material is located on the inner cavity wall of the phase change cavity, cooling auxiliary ribs are mounted on the periphery of the cylinder wall of the joint part and located on the side, away from the heat source part, of each phase change cooling unit, multiple airflow channels are formed by the cooling auxiliary ribs in a definedmanner, the cross sections of the formed airflow channels are gradually reduced in the airflow direction, the airflow is accelerated to flow in the airflow channels, the joint part is good in coolingeffect, and high in heat conduction efficiency, heat gathering of the joint power source can be rapidly removed, and the power joint of the robot is kept structurally compact.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

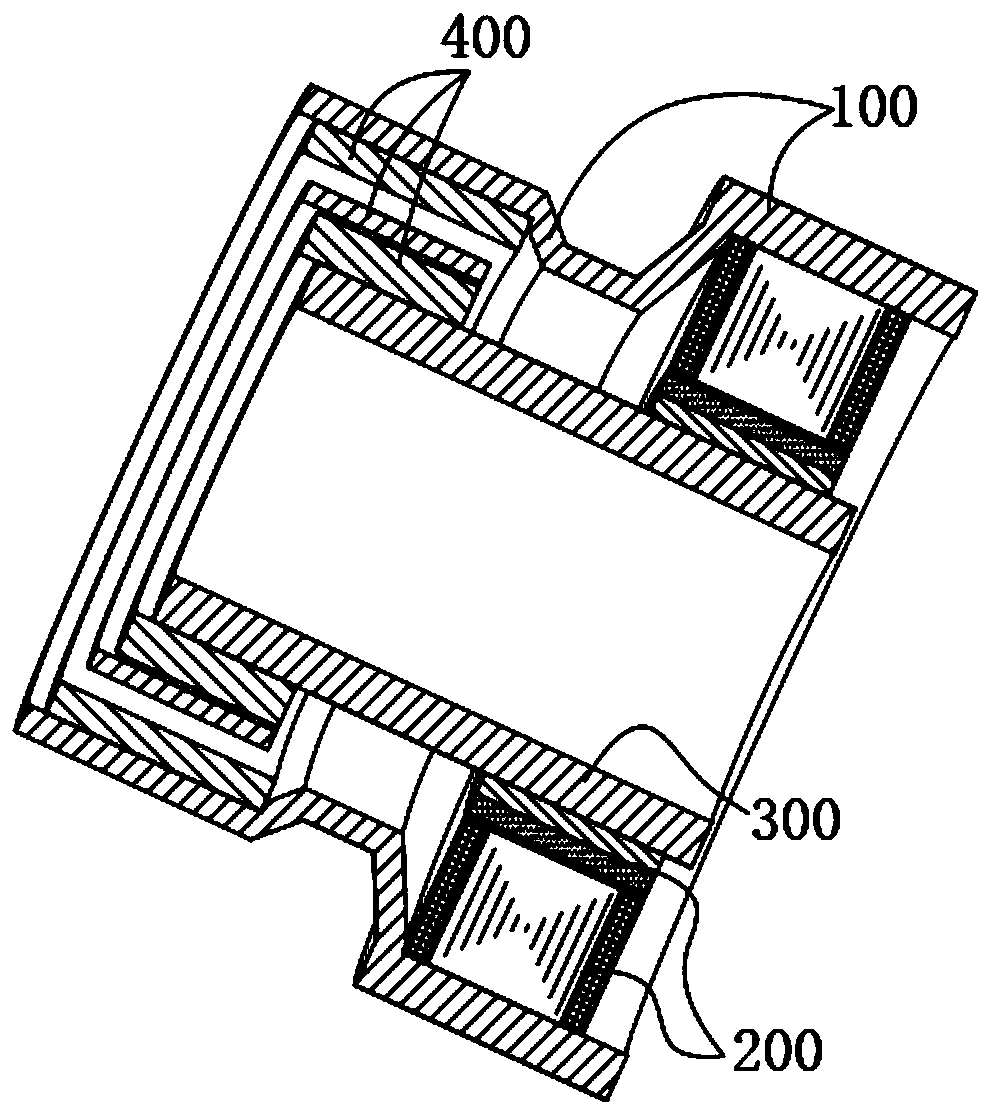

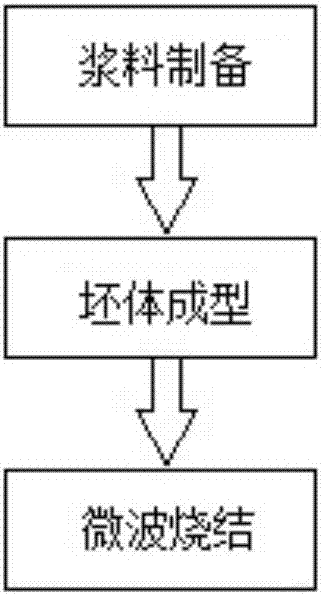

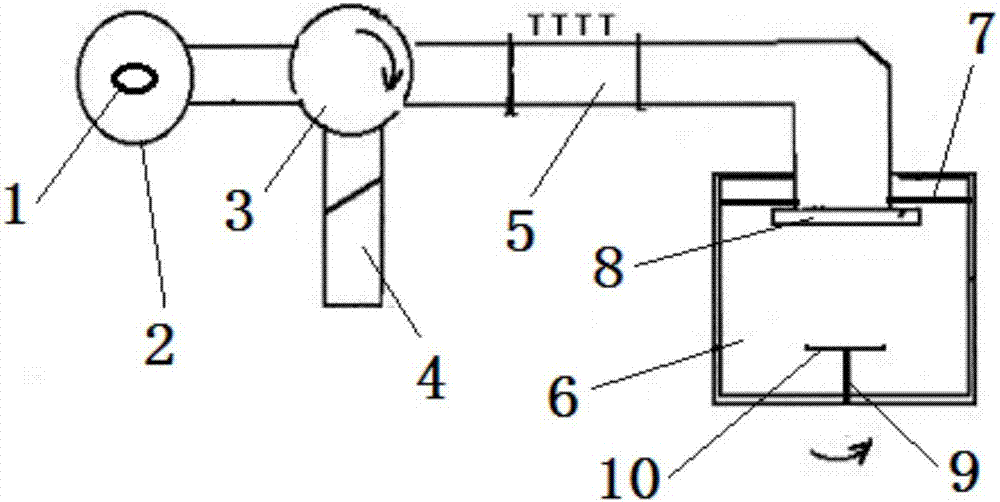

Preparation method of ceramic ring

InactiveCN107021752AImprove yield and finished product reliabilityLow manufacturing costTextiles and paperSolid phasesMicrowave sintering

The invention belongs to the technical field of preparation of new-material rings, and relates to a preparation method of a ceramic ring. The preparation method comprises the technology process with the following steps of slurry preparation, blank forming and microwave sintering. The high-density, uniform and dense ceramic ring is prepared from the slurry with high solid phase content and good fluidity through net size liquid casting in-situ condensing forming and microwave sintering, the density is 6.02g / cm<3>, the hardness is 12.23GPa, the bending strength is 896.86MPa, and the breaking toughness is 11.36Mpaml / 2. The preparation method has the advantages that the metal ring in the prior art is completely replaced; after sintering, the ceramic ring can be used by as long as the surface is polished, so that the grinding procedure after sintering is avoided; the abrasion-resistant property, size stability, self-lubricating property and polishing property are good, the friction coefficient is small, and the ceramic ring is used for replacing the alloy ring in the yarn production; the principle is scientific and reasonable, the operability is strong, the energy consumption is low, the investment is small, the rate of finished yarns is high, the preparation cost is low, the environment-friendly effect in use is realized, and the good industrial application prospect is realized.

Owner:QINGDAO UNIV

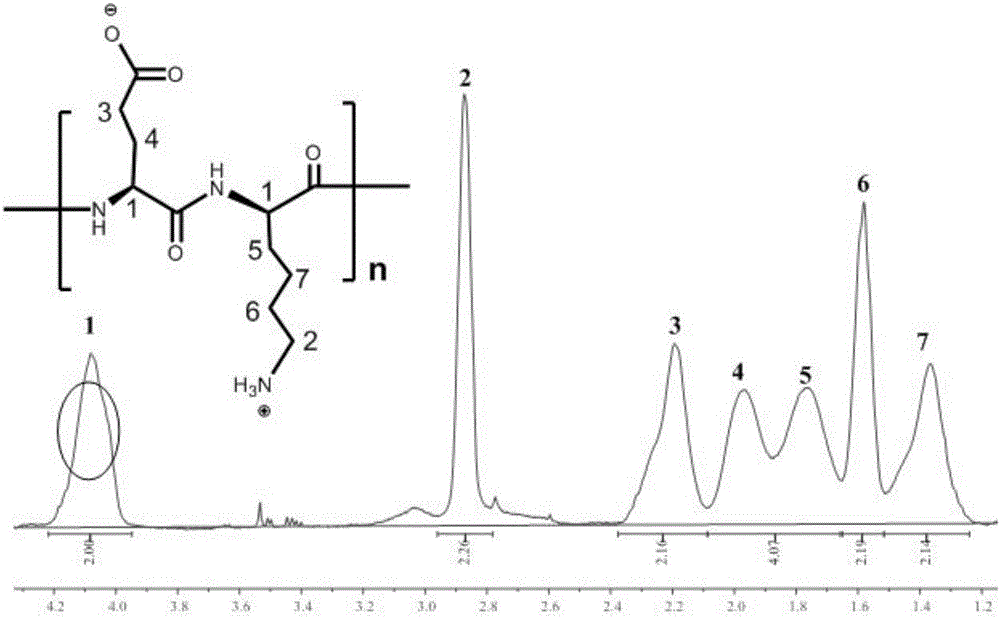

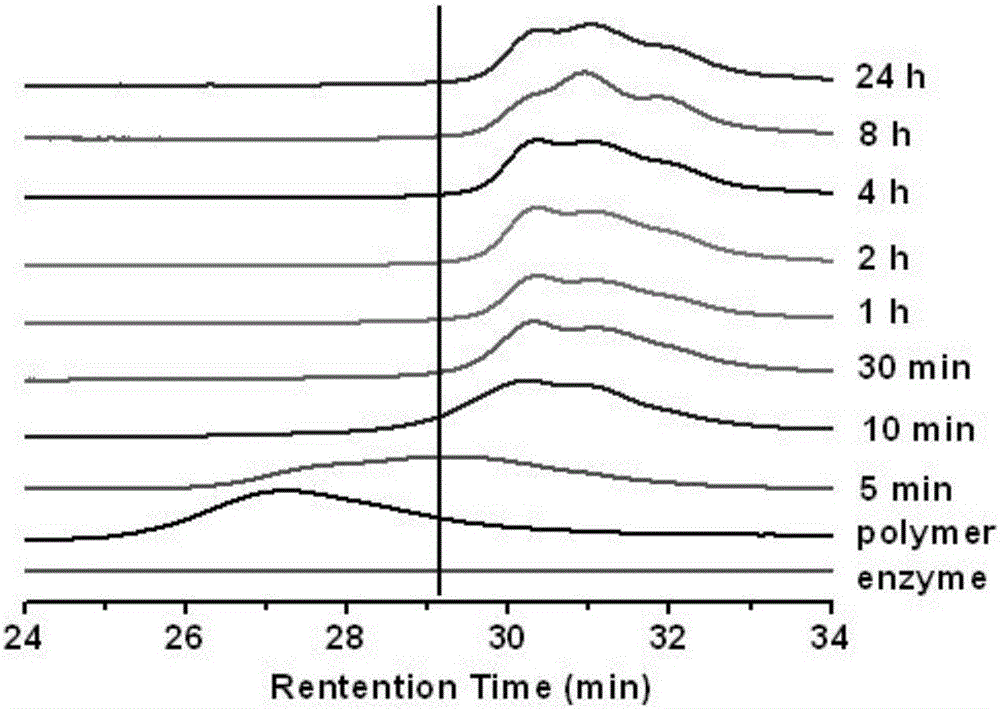

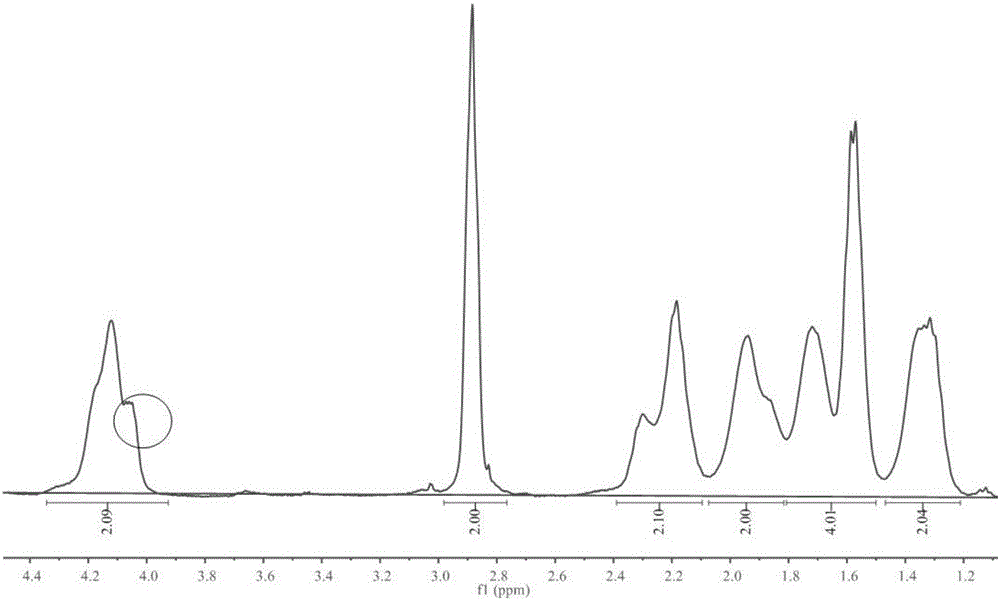

Enzyme degradation-controllable anti-nonspecific protein adsorption polypeptide and monomer and preparation method thereof

PendingCN106565824AEliminate aggregationLittle side effectsCarbamic acid derivatives preparationOrganic compound preparationCrystallographyDipeptide

The invention discloses enzyme degradation-controllable anti-nonspecific protein adsorption polypeptide and a monomer and a preparation method thereof. By means of polycondensation of a dipeptide monomer containing protected carboxyl group and protected amino group at the side chain and subsequent deprotection, polypeptide with perfect repetitive positive and negative charges is prepared, and anti-nonspecific protein adsorption capacity of polypeptide is enhanced. Further, by polycondensation of a dipeptide monomer containing protected carboxyl group and protected amino group at the side chain and an amino acid monomer modified with protected carboxyl group and protected amino molecules simultaneously contained at the side chain at different ratios and subsequent deprotection, anti-nonspecific protein adsorption polypeptide with different enzyme degradation half-life is obtained, and regulation and control of enzyme degradation capability of the anti-nonspecific protein adsorption polypeptide is realized. By controlling the ratio of an end-capping reagent to a monomer, molecular weight of the target polypeptide is regulated and controlled. By the utilization of functional modification groups on the end-capping reagent, modification of different proteins, polypeptide and other polymer and different material surfaces can be realized.

Owner:ZHEJIANG UNIV

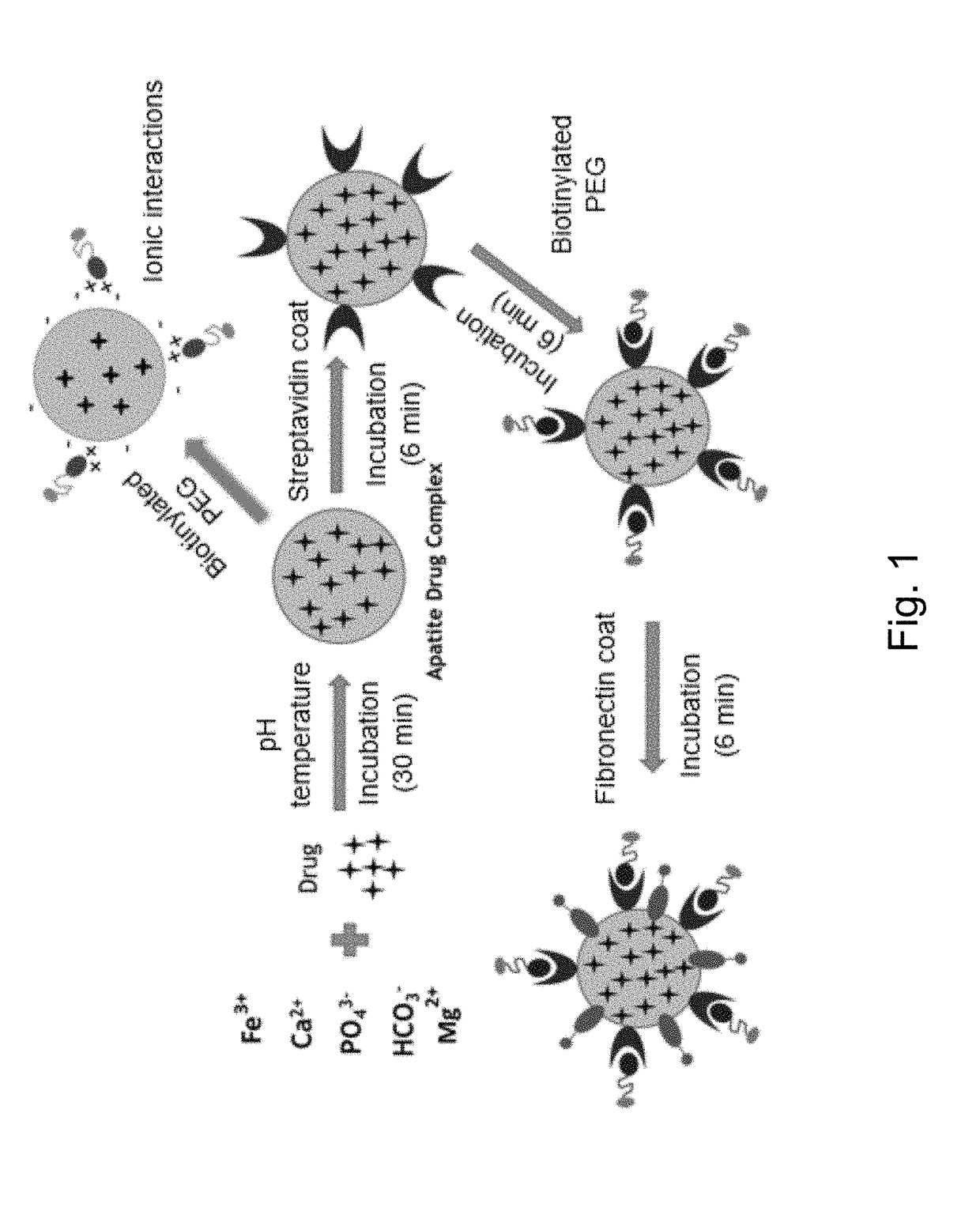

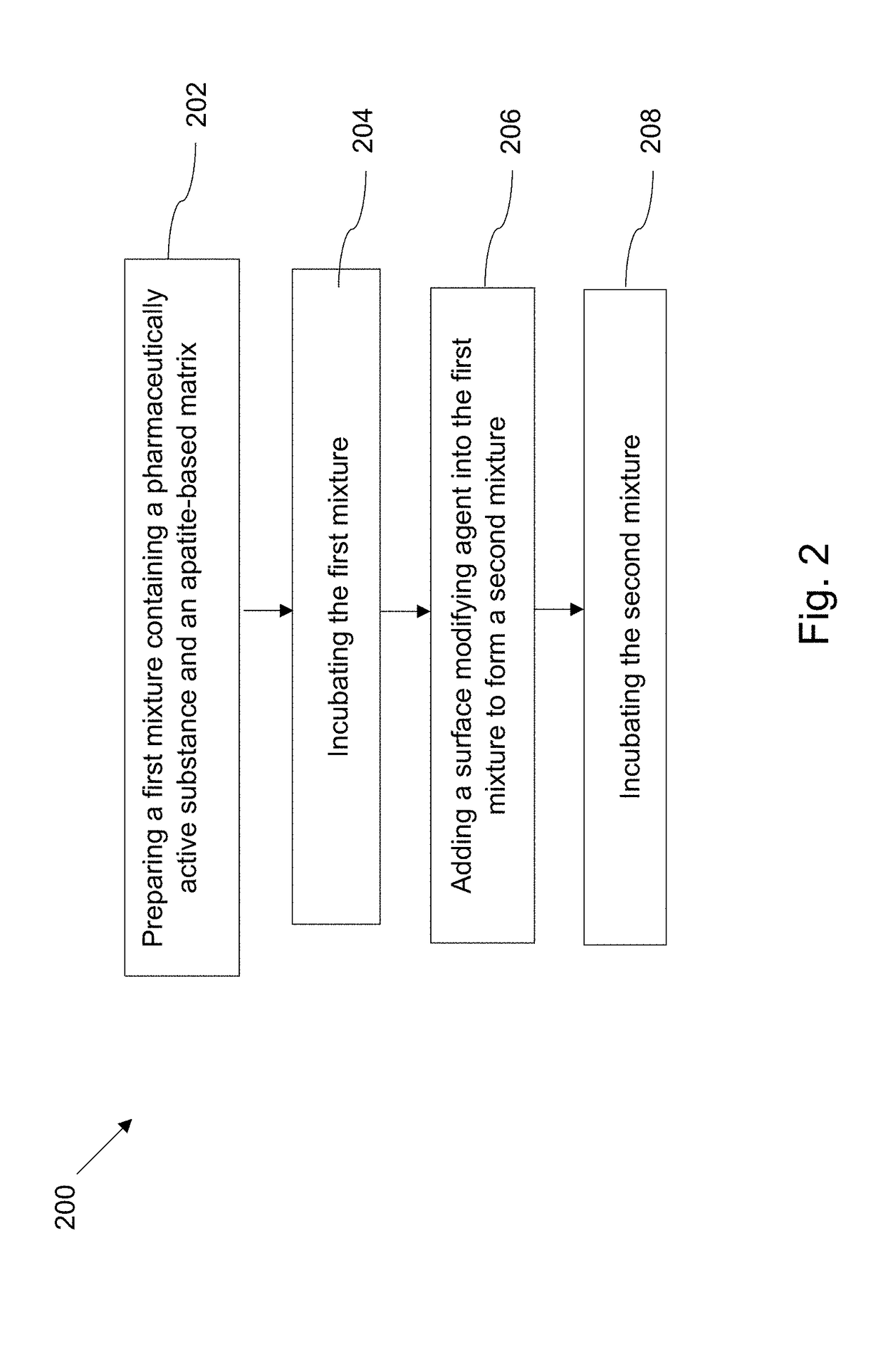

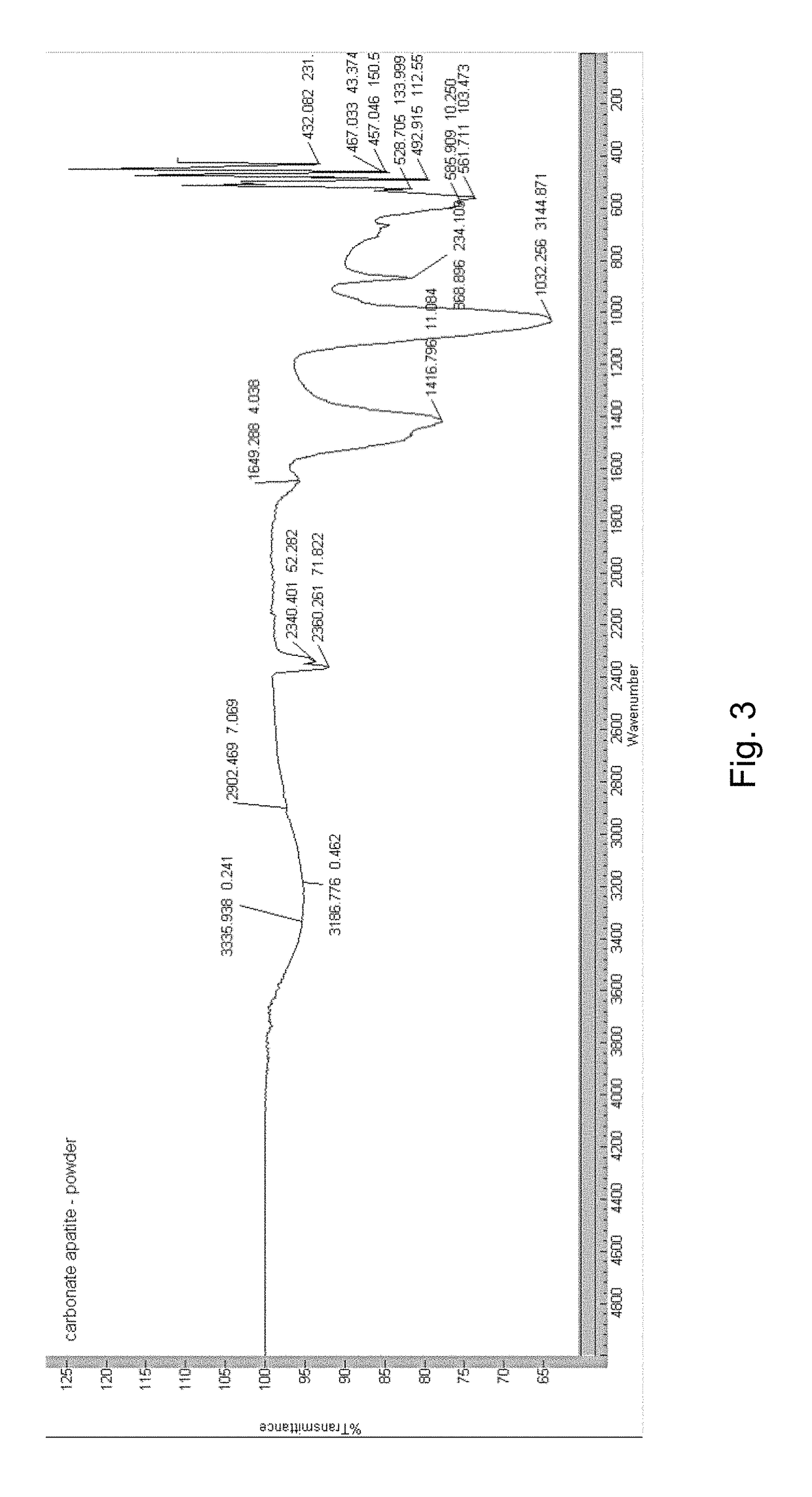

Pharmaceutical composition and a method for producing thereof

InactiveUS20180360964A1Promote absorptionEnhance drug accumulationPowder deliverySpecial deliveryHydrogenPhosphate ion

The present invention provides a pharmaceutical composition, the pharmaceutical composition comprising a pharmaceutically active substance, an apatite-based matrix, and a surface modifying agent. Further, the apatite-based matrix comprises calcium ion, phosphate ion, hydrogen carbonate ion, magnesium ion and iron ion. Also, the surface modifying agent comprises a protein, a polymer or a combination thereof. Further, a method of producing the pharmaceutical composition (200) is disclosed.

Owner:MONASH UNIV MALAYSIA

High-humic-acid multi-solid-waste coupling soft soil curing agent in cold region

The invention discloses a high-humic-acid multi-solid-waste coupling soft soil curing agent in a cold region. The curing agent is prepared from the following raw materials in parts by weight: 16-18 parts of Portland cement, 20-22 parts of quicklime powder, 35-38 parts of waste glass powder, 8-10 parts of fly ash, 6-10 parts of an exciting agent, 2-3 parts of an ion replacement agent, 0.9-2 parts of a humic acid degradation agent, 1-2 parts of a water reducing agent, 0.54-1.1 parts of a grinding aid, 0.9-1.9 parts of an early strength agent and 0.5-1 part of an air entraining agent. The curing agent provided by the invention mainly solves the adverse effect of humic acid in high-humic-acid clay soil in northern China on soil curing, and can effectively improve the strength, durability and the like of the cured soil. The curing agent utilizes solid waste to replace part of Portland cement, so that waste utilization is realized.

Owner:吉林建筑科技学院

Aluminum foil for power functional materials produced by cast-rolled slab and preparation method thereof

ActiveCN104611616BReduce precipitationUniform grainElectrode carriers/collectorsSurface roughnessHigh surface

The invention discloses aluminium foil produced by utilization of cast-rolled slabs and used for dynamic functional materials. The aluminium foil comprises following chemical components: more than 99.30% of Al, 0.30-0.5% of Fe, 0.05-0.2% of Si, 0.045-0.1% of Cu, 0.015-0.025% of Ti and 0.006-0.015% of Sr, with the balance being impurities, and the sum of mass percentages of the Al, the Fe, the Si, the Cu, the Ti, the Sr and the impurities being 100%. A preparing method of the aluminium foil is also disclosed. The aluminium foil prepared by the method has advantages of strength, high elongation percentages, good compactness, uniform surface roughness and high surface cleanliness.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

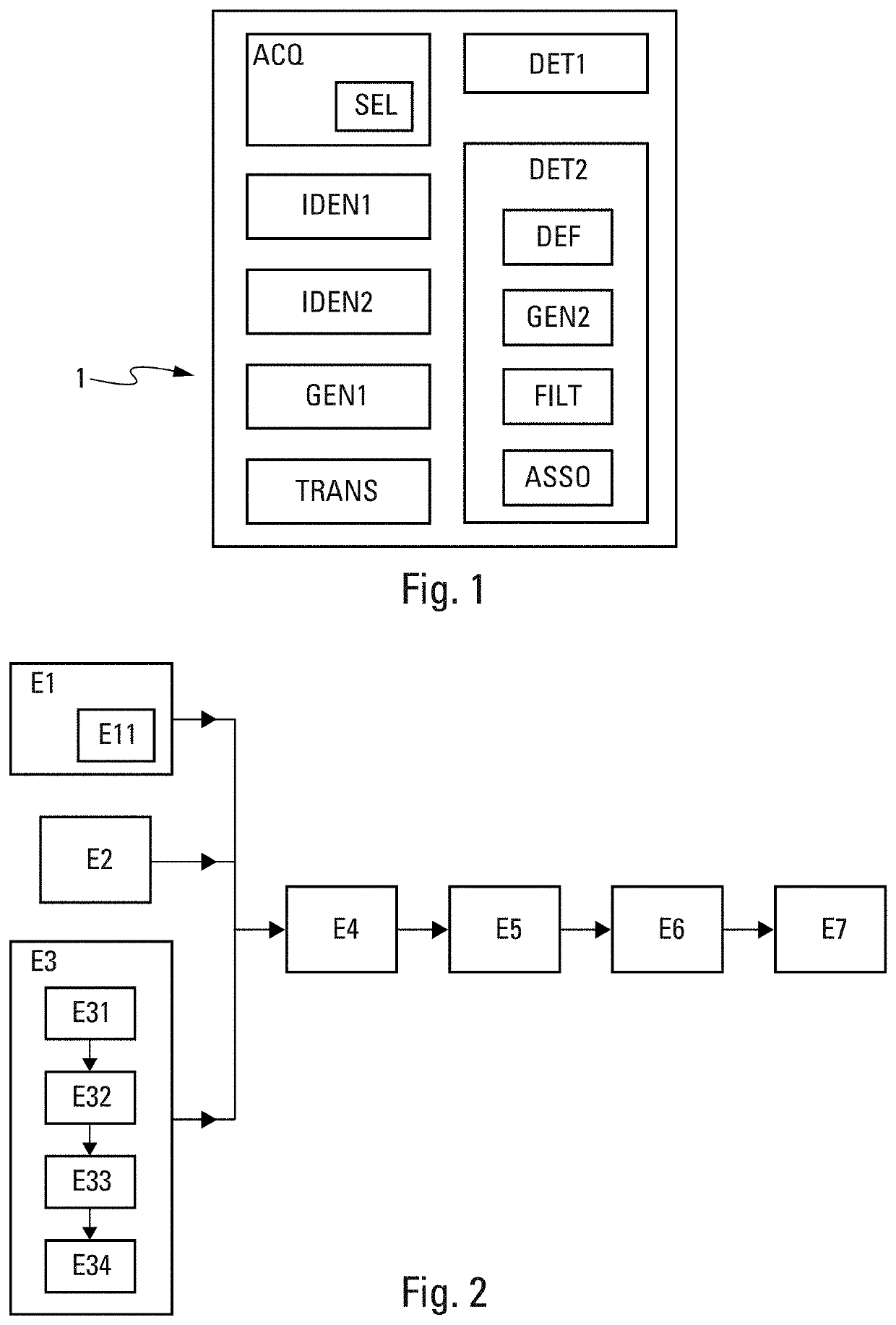

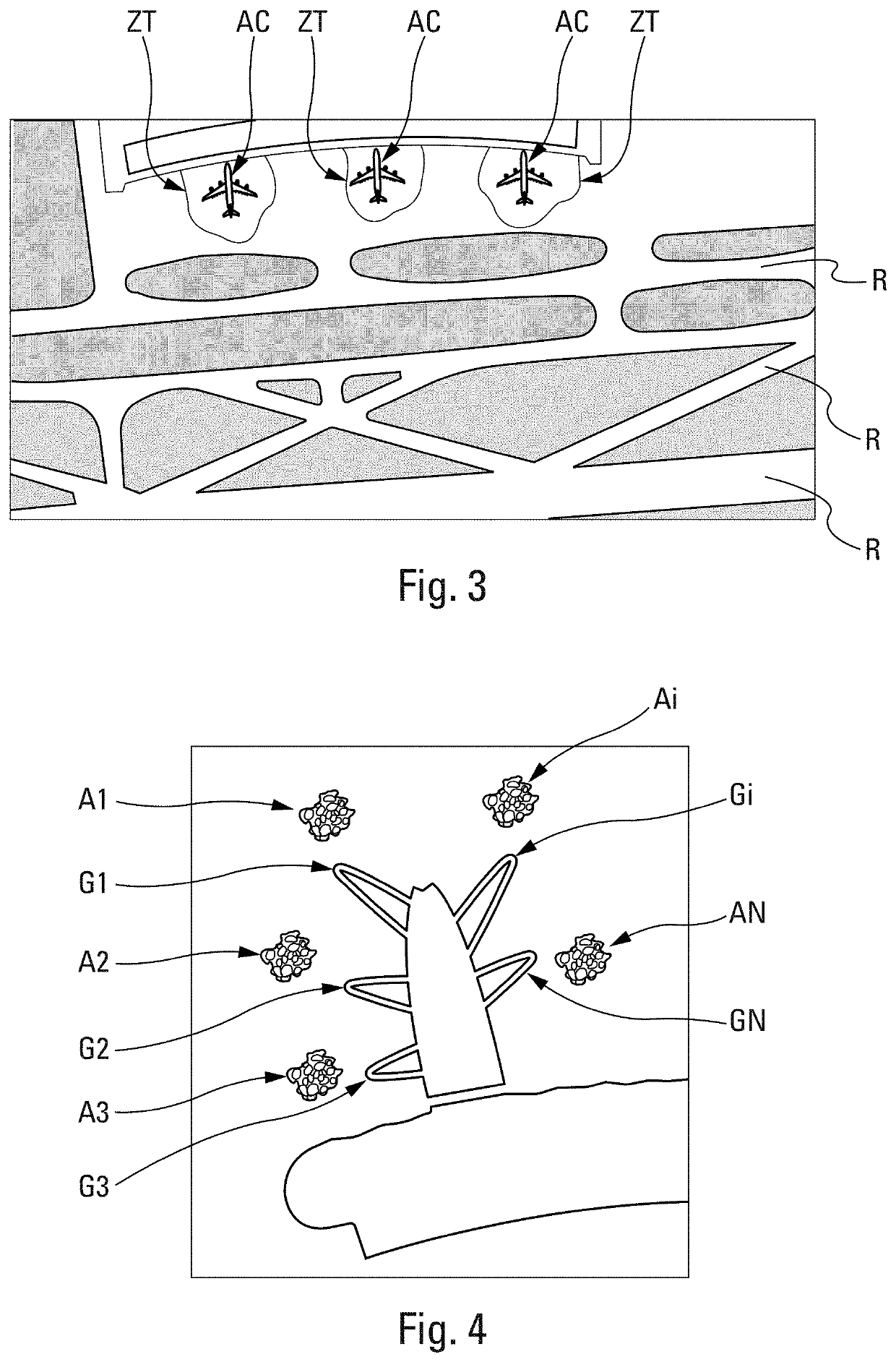

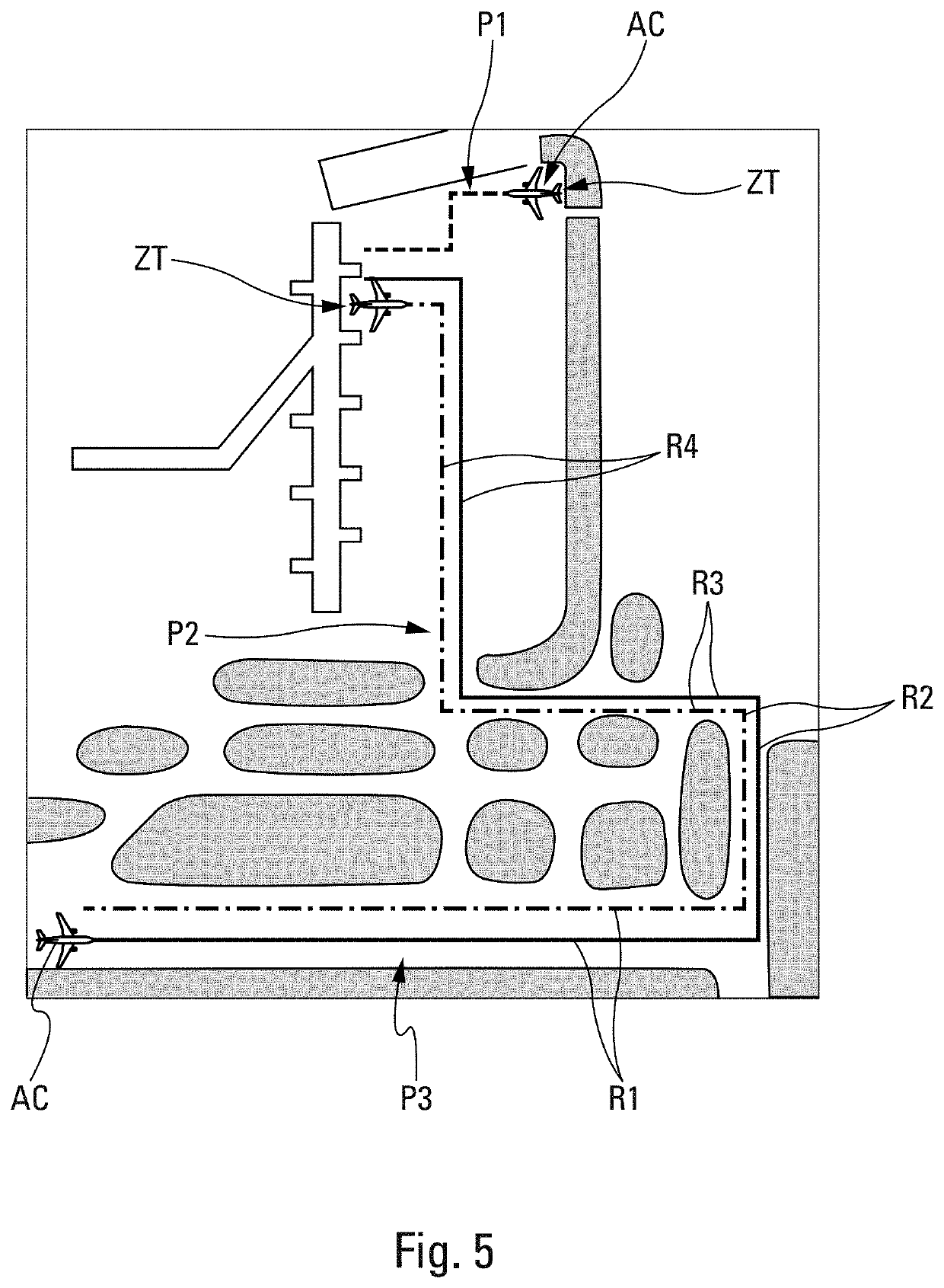

Method And System For Generating Operational Data Relating To Aircraft Movements In An Airport Infrastructure

ActiveUS20200219409A1Accurate dataEliminate aggregationMultiple aircraft traffic managementAircraft ground controlParking areaFlight vehicle

The system for generating operational data includes an acquisition module of sets of aircraft movements tracking, an identification module which identifies a path for each aircraft from sets of movement tracking data, at least one runway and at least one parking zone, an identification module which identifies, for each path, phases associated with phase data, a generation module which generates sets of operational data comprising flight data, position data and phase data of each aircraft, and a transmission module which transmits these sets of operational data to a user system.

Owner:AIRBUS SAS

High-temperature and high-speed metal particle generator

InactiveCN107631322AEliminate in timeHarm reductionRocket launchersIncinerator apparatusCombustion chamberCombustible gas

A high-temperature and high-speed metal particle generator comprises a combustion chamber, a fuel-rich propellant grain with which an inner cavity of the combustion chamber is filled, an igniter arranged at one end of the combustion chamber and used for igniting the fuel-rich propellant grain, a spraying pipe connected with the other end of the combustion chamber in a sealed manner, and a sealingfilm arranged at the position of a spraying port of the spraying pipe. The work of the high-temperature and high-speed metal particle generator is triggered through connection of an outer power sourceand the igniter, the power source is conducted, the igniter is triggered, a large amount of high-temperature and high-pressure gas or particles are ejected to the surface of a fuel-rich propellant sothat the fuel-rich propellant can be ignited, the fuel-rich propellant is combusted, and high-temperature and high-pressure gas and metal particles are generated; expansion is accelerated after compression is conducted through the spraying pipe, the generated high-temperature and high-pressure gas and the metal particles form hot impacts on the sealing film, the sealing film is burnt through, then the high-temperature and high-pressure gas and the metal particles are sprayed out of the spraying port with a certain speed and a certain angle, a high-temperature metal particle combustion area with a certain distance and an enveloping range is formed, the combustible gas in the combustion area can be immediately ignited, and accordingly explosion hidden danger is eliminated in time.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Double-blowing molten iron desulfurization device

InactiveCN110777234AIncrease the length of the moveIncrease contact timeProcess engineeringManufacturing engineering

The invention provides a double-blowing molten iron desulfurization device. The device comprises a molten iron tank and a liftable stirring jetting device, wherein the stirring jetting device comprises a vertical stirring shaft and stirring blades located at the lower end of the stirring shaft; the stirring jetting device further comprises an air intake pipe and a plurality of horizontal L-shapednozzles; the stirring shaft is axially provided with a cavity, and the air intake pipe is embedded into the cavity of the stirring shaft; the plurality of L-shaped nozzles are symmetrically arranged on the periphery of the air intake pipe along the center of the air intake pipe and are all located below the stirring blades; the bottom of the molten iron tank is provided with an annular gasket; thebottom of the molten iron tank is provided with a plurality of air ventilation bricks, wherein each air ventilation brick is connected with a blowing pipe; and a support and a plurality of flow baffle rods are arranged above the molten iron tank, wherein the upper ends of the plurality of flow baffle rods are fixed on the support, and the lower ends are inserted into the molten iron tank and close to the inner wall of the molten iron tank. According to the double-blowing molten iron desulfurization device, the contact time between a desulfurizing agent and molten iron is long, the flow fielddynamics in the blowing process of the molten iron tank is optimized, the using efficiency of the desulfurizing agent is improved, the desulfurization efficiency is high, and the equipment structure is compact.

Owner:ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD +1

A flow control device in kr desulfurization hot metal tank

ActiveCN106987682BInhibition formationImprove desulfurization kinetics conditionsMelt-holding vesselsEngineeringKambara

The invention discloses a flow control device in a kambara reactor (KR) desulfuration molten iron tank. The flow control device comprises a stirring device inserted into the molten iron tank, and the stirring device is composed of a stirring head and a stirring rod. The flow control device further comprises a support and a plurality of stop levers. The support is arranged above the molten iron tank, the upper ends of the stop levers are fixedly arranged on the support, the lower ends of the stop levers are inserted into the molten iron tank, and the stop levers are symmetrically distributed with the stirring rod as an axis. A periodic effect is generated on a stirring flow field of the molten iron tank through the stop levers, formation of a center eddy region is remarkably restrained, the desulfuration dynamic condition of molten iron mechanical stirring is obviously improved, and the utilization rate of a desulfurizing agent is greatly increased.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com