Method of controlling aluminum reduction cell with prebaked anodes

a technology of reduction cell and aluminum, which is applied in the direction of electrolysis components, instruments, optics, etc., can solve the problems of reducing metal production, requiring extra energy for operating with alumina or too little alumina being consistently added to the bath, and requiring too little alumina to achieve the effect of reducing alumina concentration, reducing alumina concentration, and improving the quality of controlling alumina feeding systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

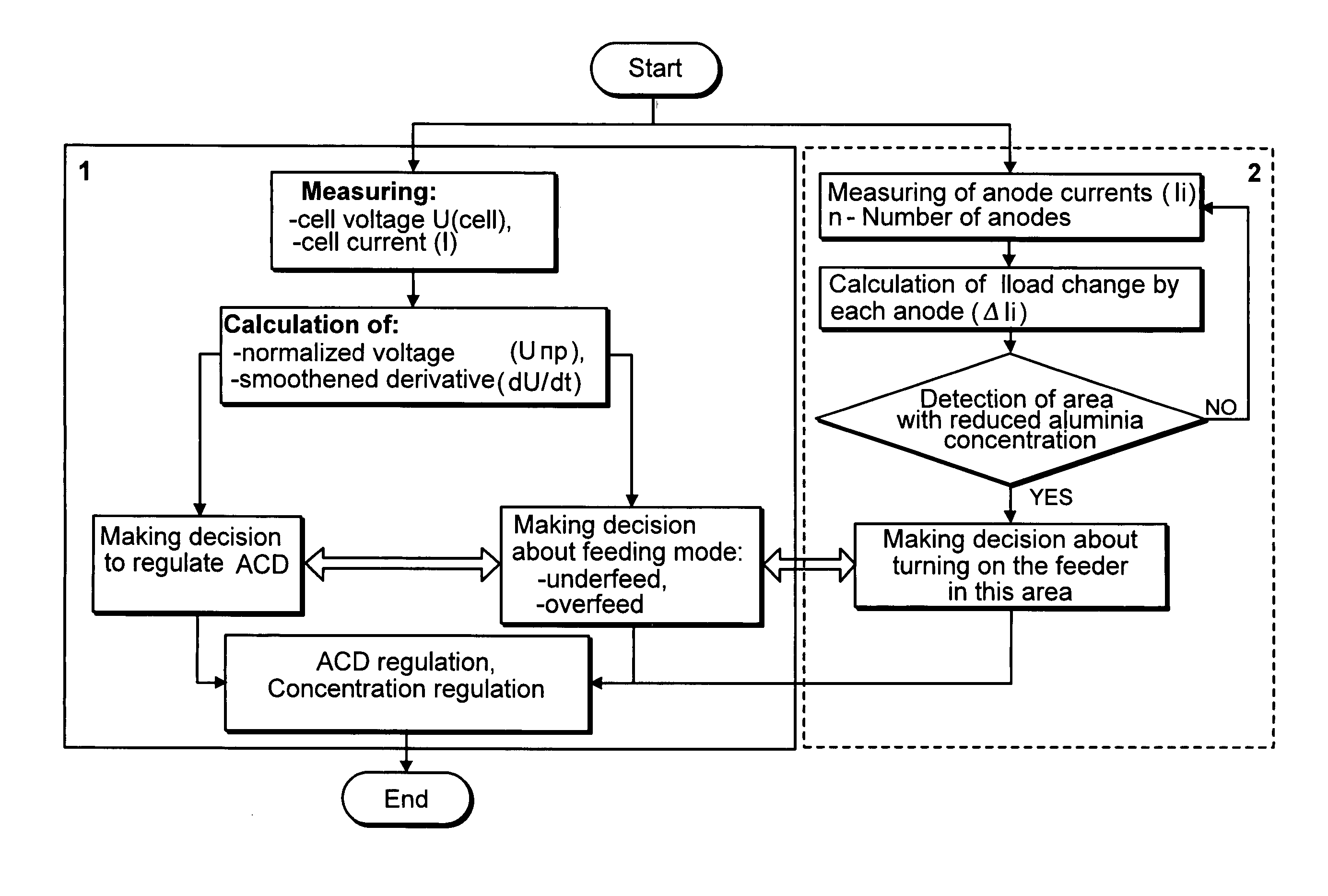

[0023] Frequent and unplanned anode effects are taking place in the prior art aluminum reduction cells utilizing control systems where the level of alumina concentration in the bath melt is controlled by evaluation of changes in the values of Unorm and dUnorm / dt. Such anode effects are typically caused by the lag in response time of the feeding system to reduction in the alumina concentration. This results when the review of the normalized voltage is too close in time to the occurrence of an anode effect and the corrective action taken cannot forestall the anode effect. In other words, such a method does not have the sensitivity to detect an approaching anode effect. By the method of the invention, however, it is possible to predict the occurrence of an anode effect and to anticipate the situation by providing earlier warning signals of the need to change the alumina concentration. Furthermore, the method of the invention is reflected in the improved alumina feeding control algorith...

example 2

[0025] A method of evaluation of the reverse EMF value of the cell based on analysis of the changes in the line current is known in the art. According to this method at the time of considerable changes in the cell current, the values of the cell current and voltage are monitored before and after such changes are taking place. Then, the reverse EMF of the cell is calculated by the following formula: U 1cell-EbackI 1cell(before)=U 2cell-EbackI 2cell(after);where

U1cell, I1cell are the cell voltage and cell current values before to the change of amperage;

U2cell, I2cell are the cell voltage and cell current values after the change of amperage.

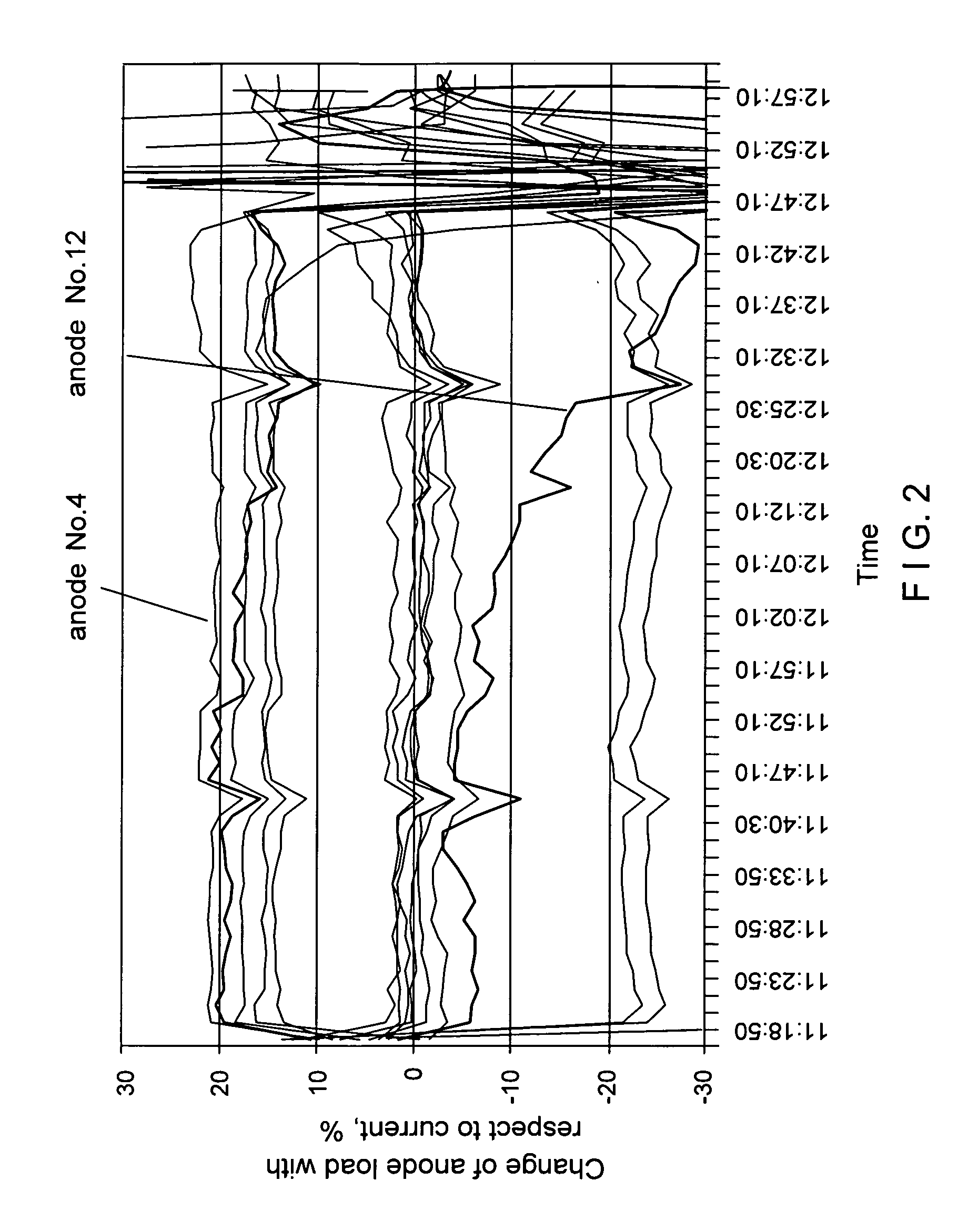

[0026] According to the method of the invention the area with the reduced level of alumina concentration is evaluated according to the change of the reverse EMF which is calculated for each anode of the cell. The reverse EMF values for each individual anode are calculated by the same method as for the entire cell. However, in this ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

| electrical current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com