Patents

Literature

114 results about "Anode effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrolytic apparatus for producing fluorine or nitrogen trifluoride

InactiveUS20070215460A1Avoid it happening againSuppression amountCellsMachining electric circuitsHigh current densityHydrogen fluoride

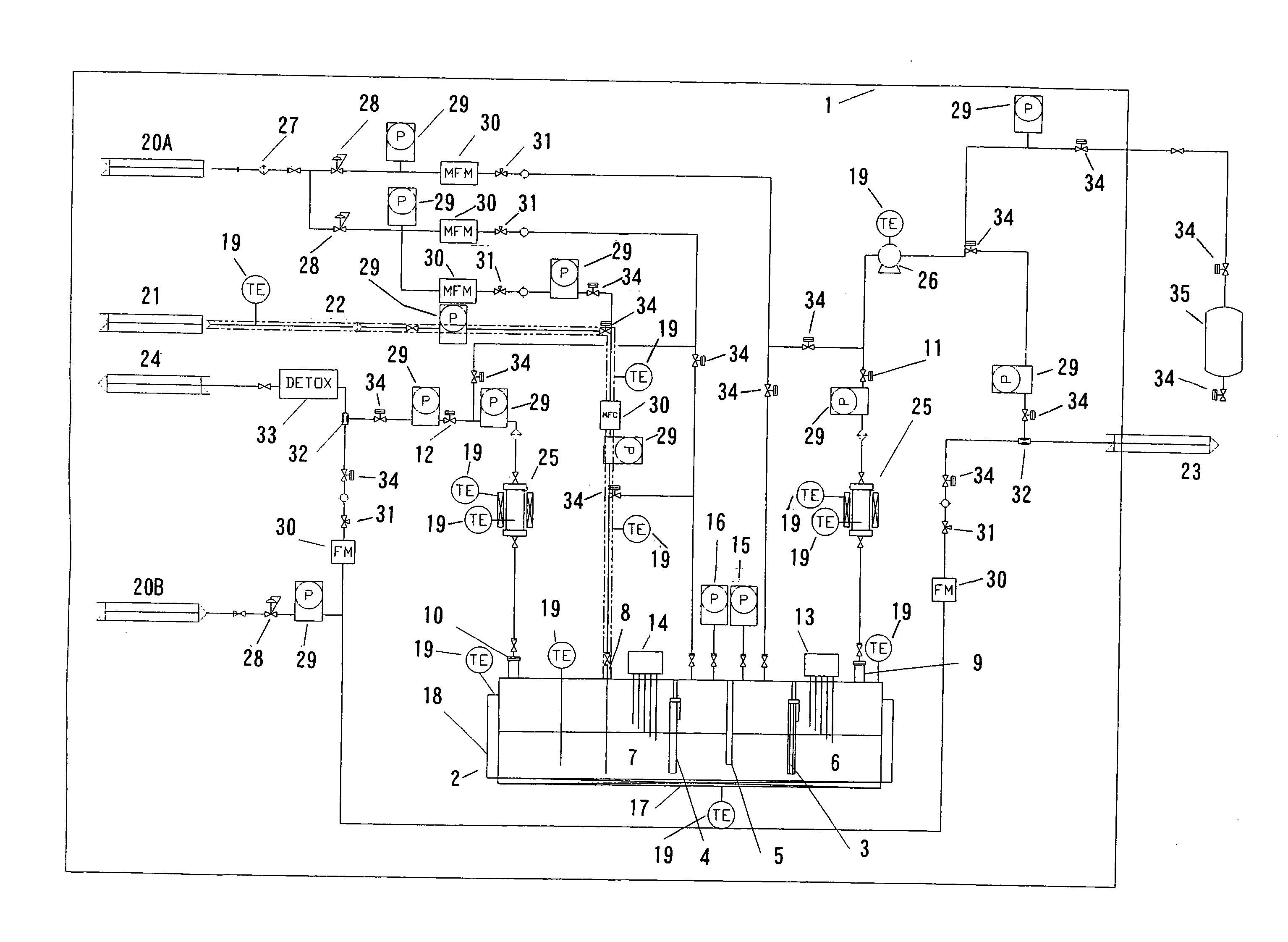

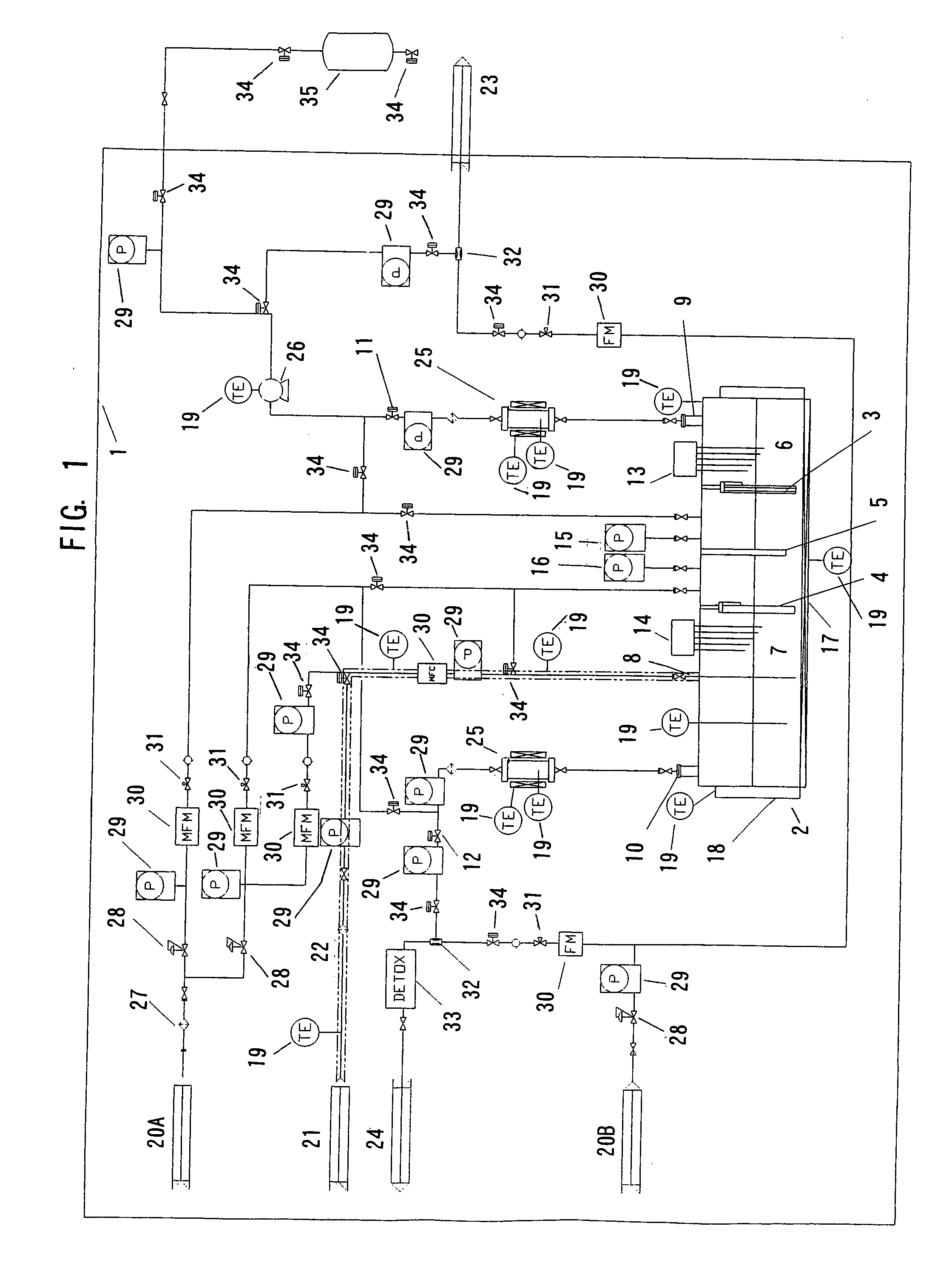

It is a task of the present invention to provide an electrolytic apparatus for producing fluorine or nitrogen trifluoride by electrolyzing a hydrogen fluoride-containing molten salt, the electrolytic apparatus being advantageous in that the electrolysis can be performed without the occurrence of the anode effect even at a high current density and without the occurrence of an anodic dissolution. In the present invention, this task has been accomplished by an electrolytic apparatus for producing fluorine or nitrogen trifluoride by electrolyzing a hydrogen fluoride-containing molten salt at an applied current density of from 1 to 1,000 A / dm2, the electrolytic apparatus using a conductive diamond-coated electrode as an anode.

Owner:TOYO TANSO KK

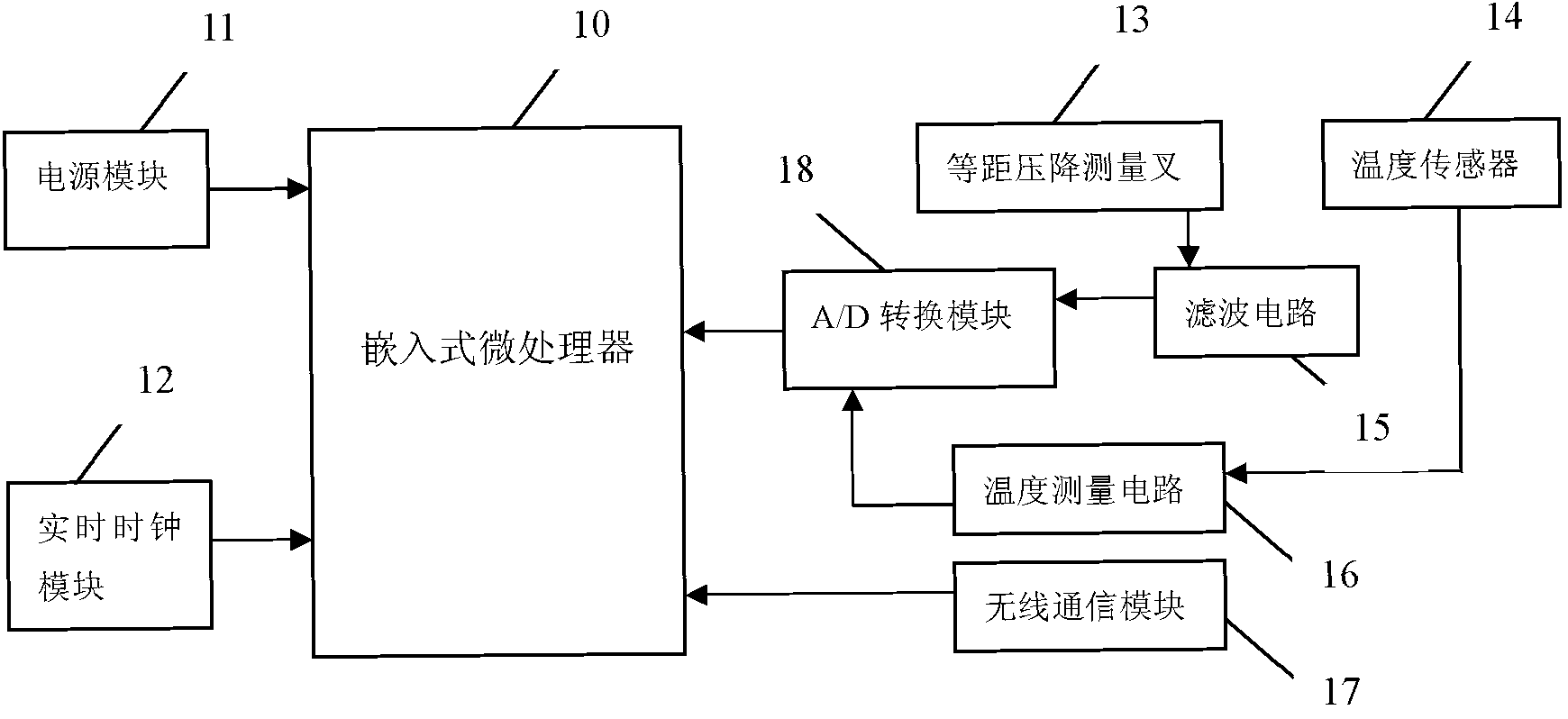

Aluminum cell anode effect prediction device

The invention discloses an aluminum cell anode effect prediction device belonging to the technical field of aluminum electrolysis. The device comprises an isometric pressure drop measuring fork, a temperature sensor, a current distribution on-line monitor for processing output signals of a measuring fixture, a ZIGBEE wireless network for signal transmission, and a control device for warning processing according to the received signals. The invention also discloses an aluminum cell anode effect prediction method which comprises the following steps: correcting isometric pressure drop values based on measured temperature values to obtain the current value of each aluminum cell anode rod, normalizing the difference between the current value and an ideal current value, comparing the normalizing result with a preset threshold, and judging whether the measured aluminum cell anode rod is subjected to the anode effect. The invention can monitor the distribution of current in the normal production process of the aluminum cell in real time and give an early warning, thereby effectively ensuring that the effect can be eliminated and harm caused by the effect can be reduced as early as possible.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

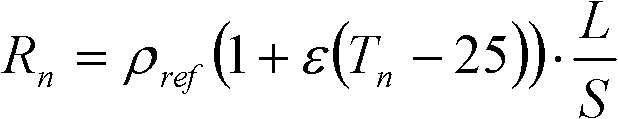

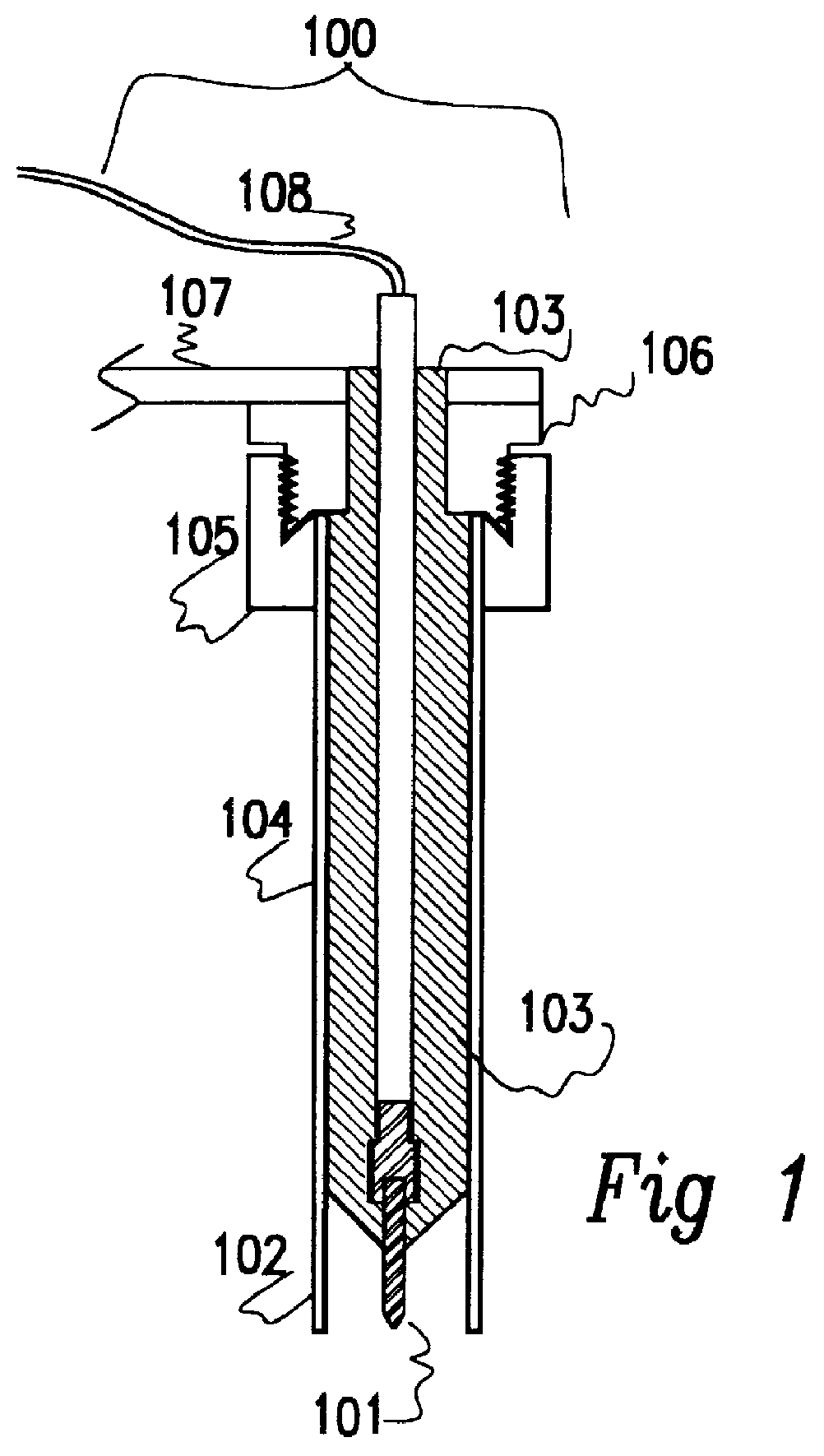

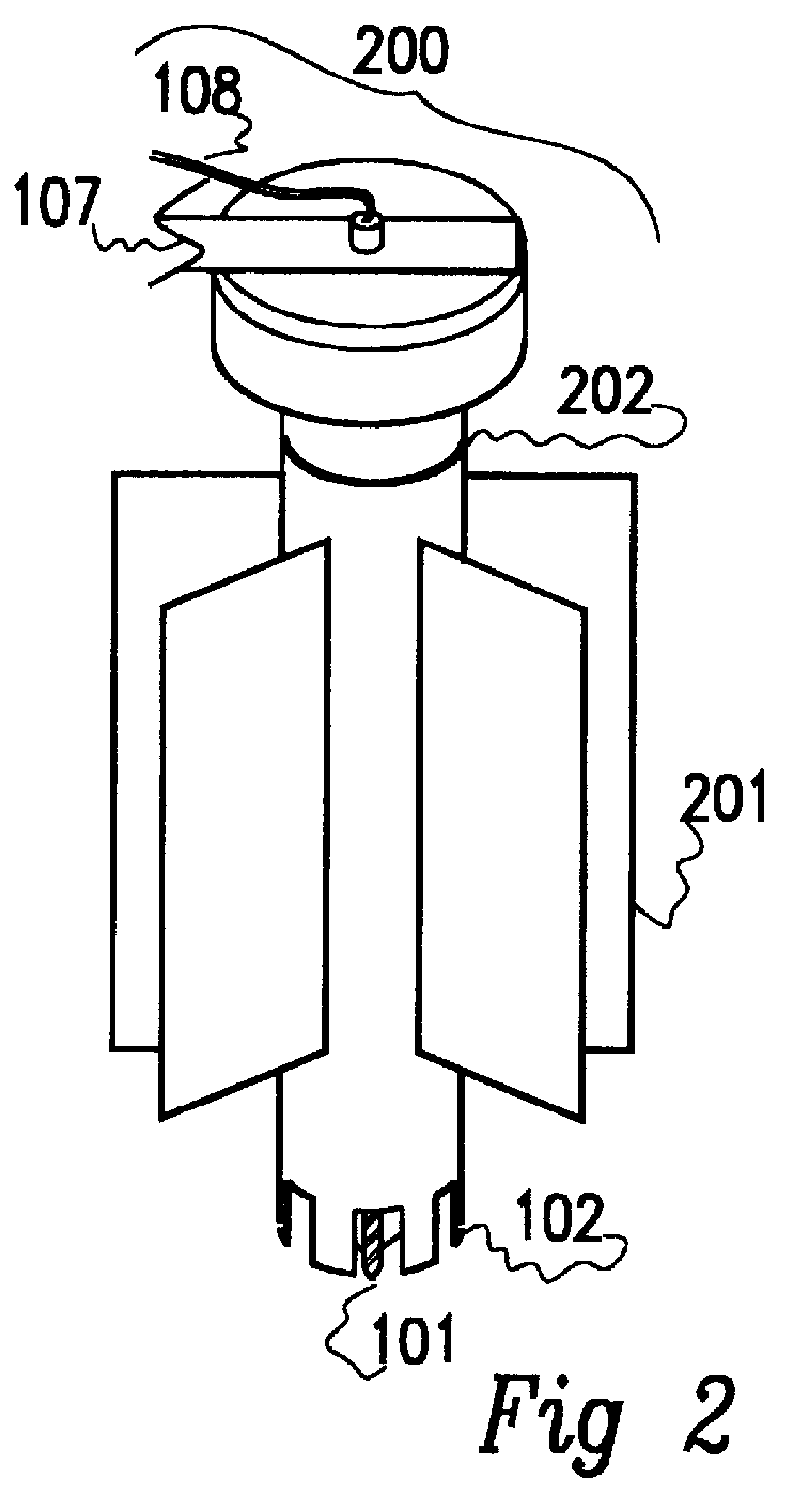

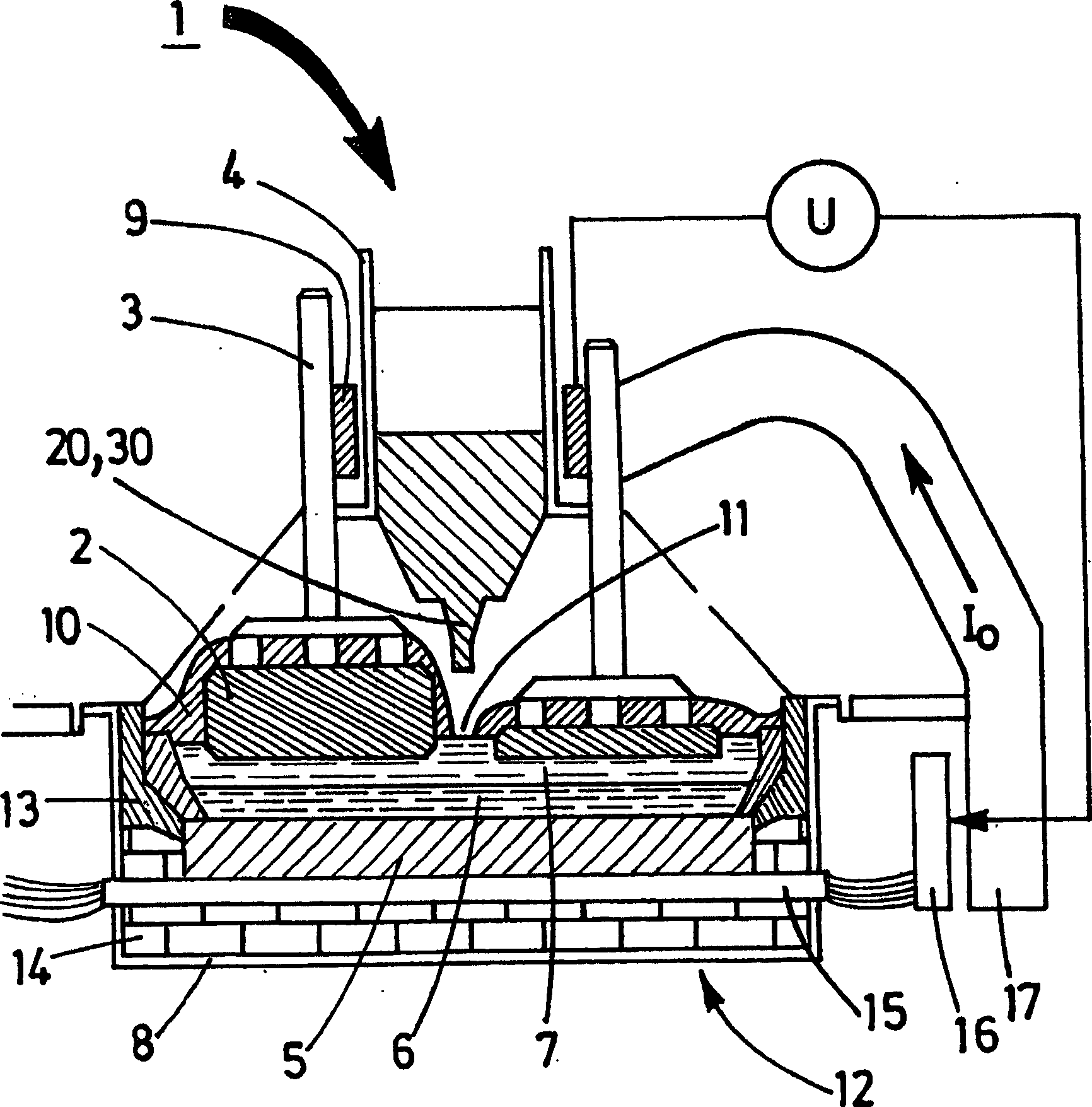

Measurement of alumina in reduction pots

InactiveUS6010611ASimple methodPhotography auxillary processesWeather/light/corrosion resistanceAnode effectVoltage source

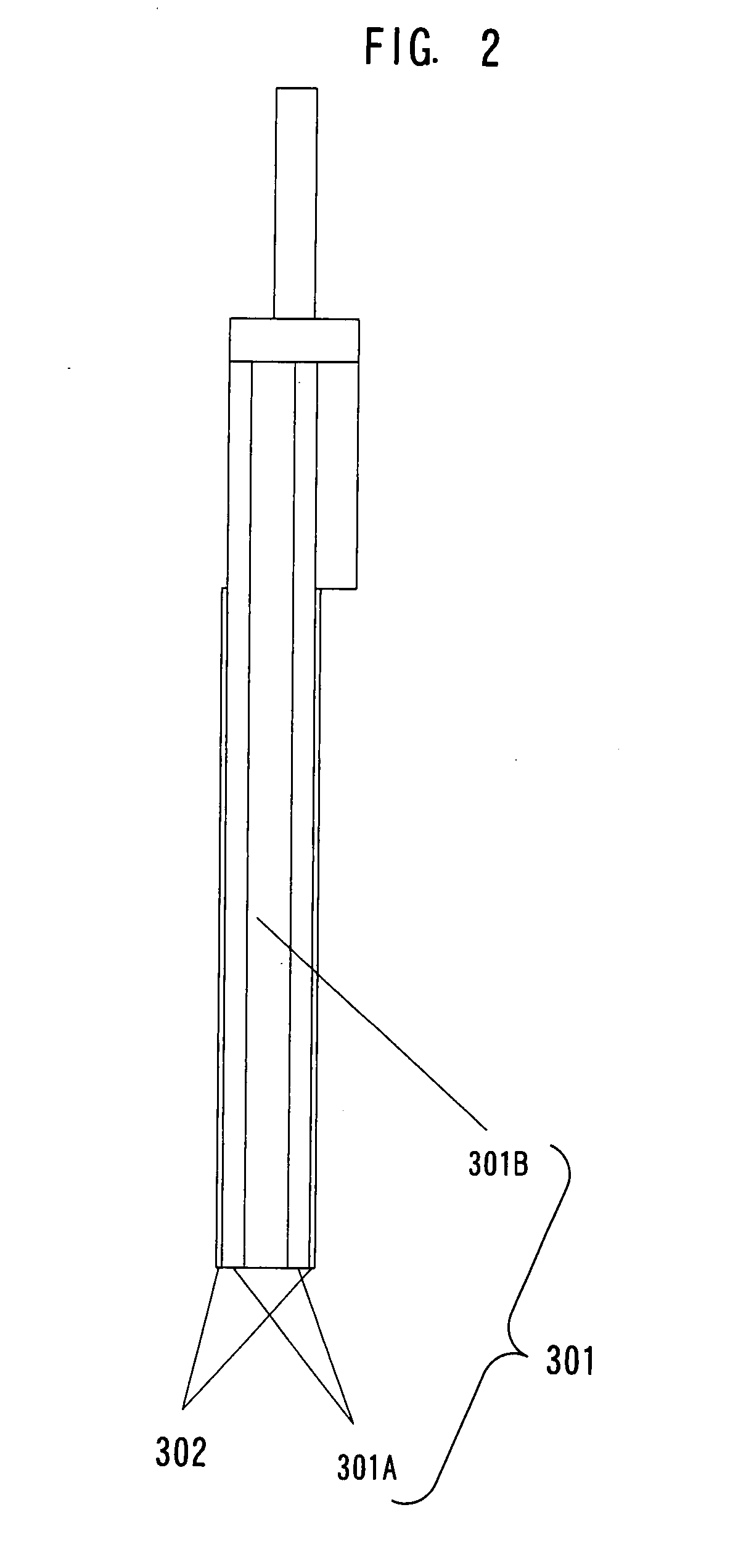

PCT No. PCT / NZ96 / 00088 Sec. 371 Date Apr. 14, 1998 Sec. 102(e) Date Apr. 14, 1998 PCT Filed Aug. 28, 1996 PCT Pub. No. WO97 / 09468 PCT Pub. Date Mar. 13, 1997This invention provides apparatus and a method for measuring the concentration of alumina in a molten electrolyte in a smelter. A test anode (101) (a mimic of the actual cell anode) supplied from a computer-controlled voltage source (303) with several to about (100) rapid cyclic voltammetry sweeps the voltage at which the anode effect occurs, as sensed by current measurement (305). In order to derive a measurement the voltage is compared within the computer (301) to previous measurements made from a calibration set of alumina samples in known concentrations. Brief rapid cycles and an improved electrode configuration help to provide results from the invention which are reproducible and accurate, and in addition the test electrode has a long life.

Owner:AUCKLAND UNISERVICES LTD

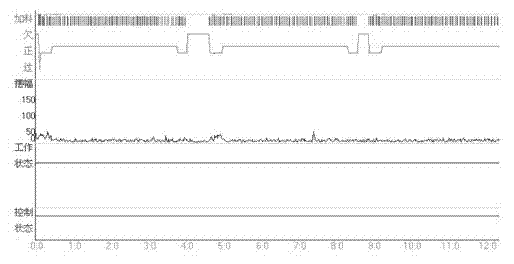

Constant value control method for alumina concentration of aluminum cell

The invention discloses a control method for the alumina concentration of an aluminum cell and relates to a control method for an aluminum electrolysis process. The method is characterized by comprising the following steps of: measuring the alumina concentration of electrolyte by performing soft measurement by using a cell control system, wherein the alumina concentration is taken as a feedback value for the alumina concentration control of the cell control system; obtaining an alumina concentration target value serving as a switching condition for the normal blanking period of alumina; controlling the alumina blanking period by using the cell control system; running the normal blanking period for a period of time, running an excessive blanking period to suppress the generation of anode effect and perform concentration verification, running an insufficient blanking period, verifying the alumina concentration once again, running the excessive blanking period once again and returning to the normal blanking period; and realizing constant value control over the alumina concentration in a blanking control mode in which the normal blanking period is run mainly. By adopting the method, the alumina concentration of the aluminum cell can be kept in a basically constant range, and efficient and stable running of the aluminum cell is realized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

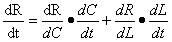

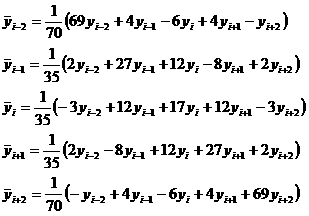

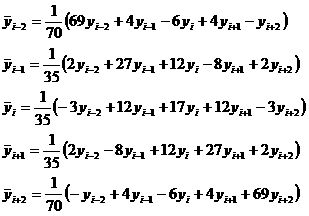

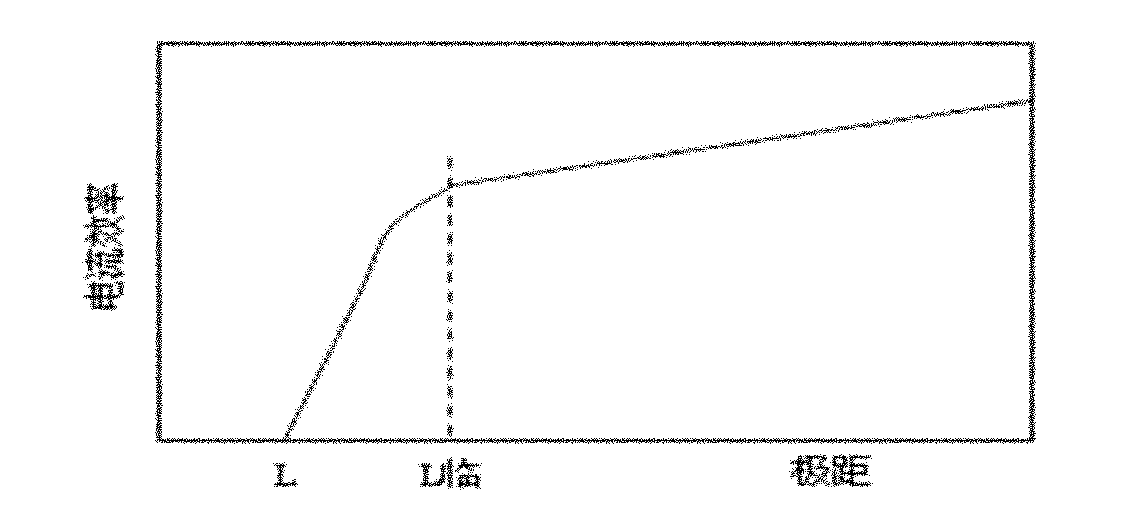

On-line identification method for concentration signal of aluminum oxide in electrolyte in aluminum electrolysis cell

The invention relates to an on-line identification method for a concentration signal of aluminum oxide in an electrolyte in an aluminum electrolysis cell, and relates to an on-line identification method for a concentration signal of aluminum oxide for controlling the charging quantity of the aluminum oxide in the aluminum electrolysis production process. The method is characterized in that: in the on-line identification process, polar distance is used as an excitation signal, and the concentration of the aluminum oxide is identified by a response signal of cell resistance in the adjustment process of the polar distance. The method has the advantages of high identification speed, small influence on the condition of the electrolysis cell and the like, the accurate control over the blanking of the aluminum oxide can be realized, anode effect coefficients can be reduced effectively, current efficiency can be improved, the stable running of the electrolysis cell can be realized, and energyconsumption can be reduced.

Owner:NORTHEASTERN UNIV

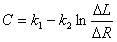

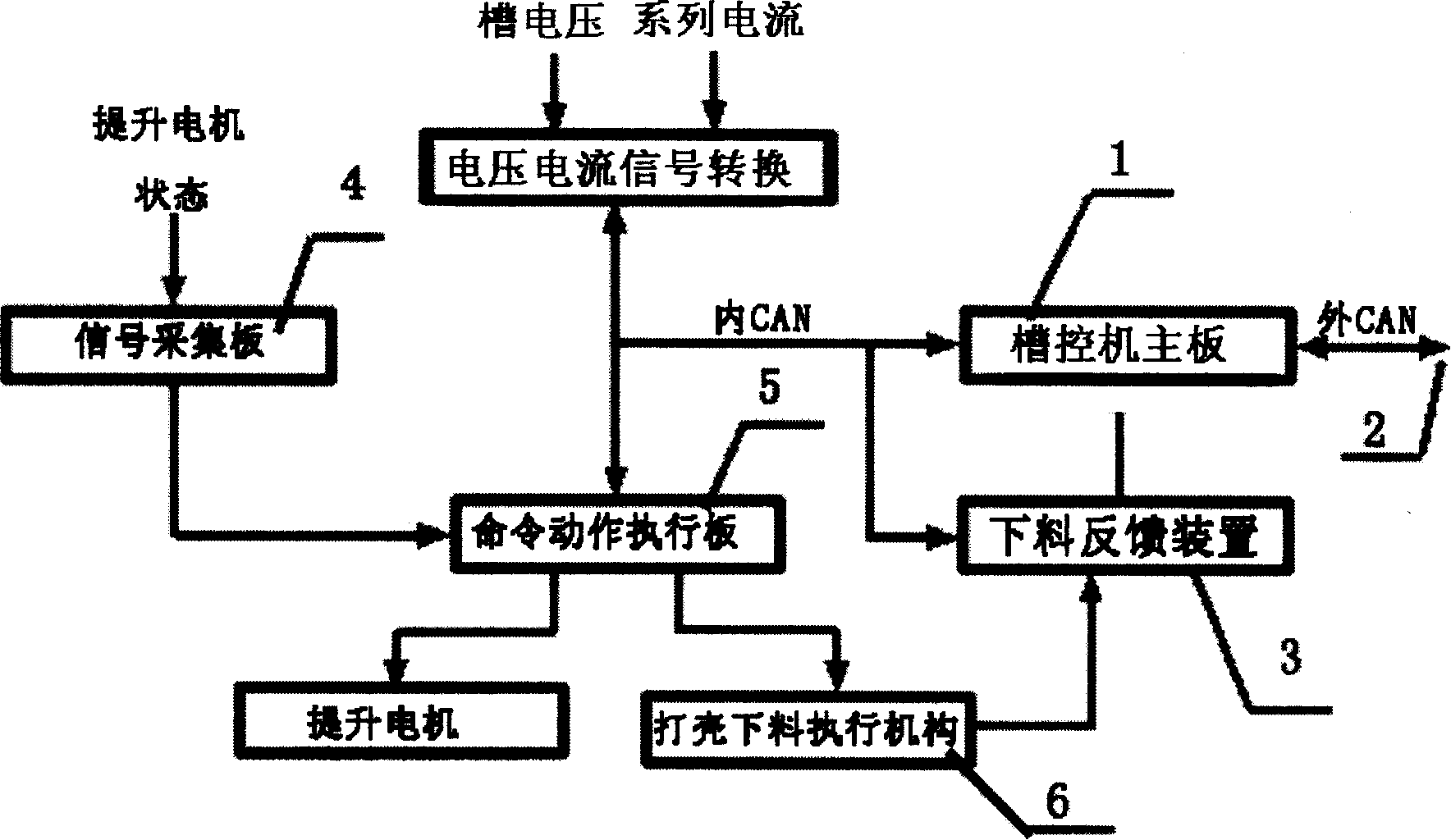

Accurate aluminum cell baiting feedback information control method

InactiveCN101173364AGuarantee unimpededBoost working status signalInformation controlAutomatic control

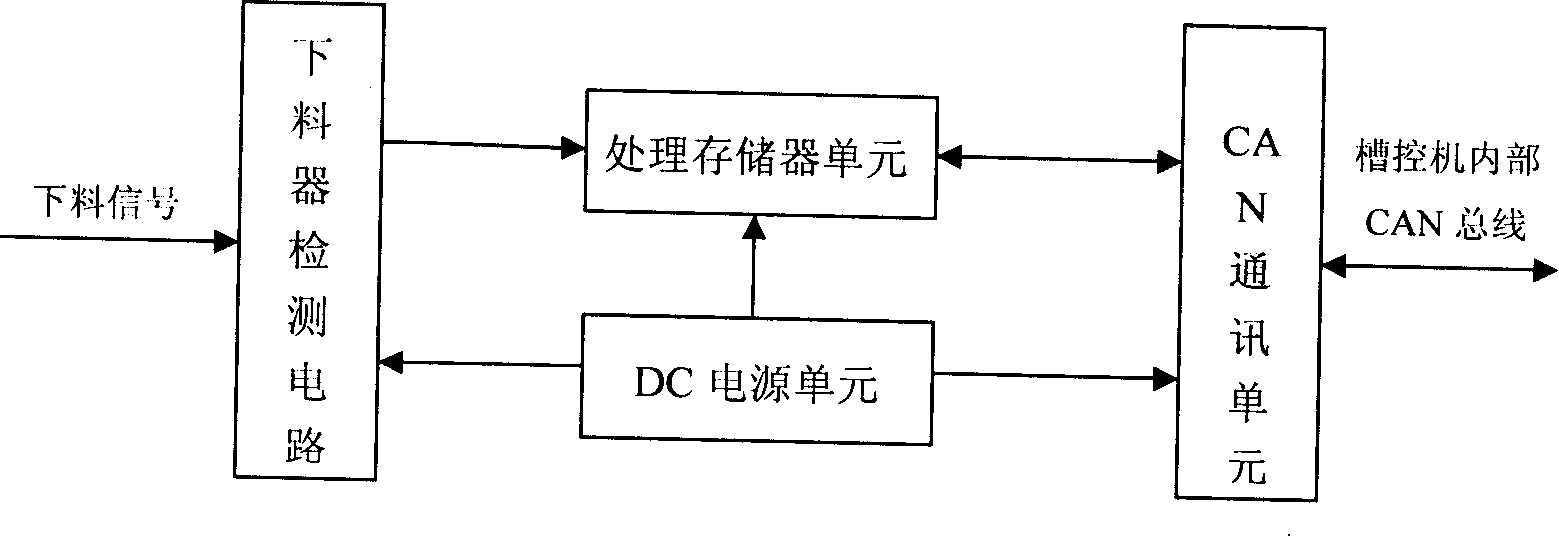

The invention relates to an automatic control system of electrolytic bath in aluminum electrolysis industry, in particular to a feedback information control method of precise feeding of aluminum electrolytic bath. The invention is characterized in that the feedback information control method of precise feeding comprises an electrobath control device, a host computer and a feeding feedback device, wherein, the electrobath control device is connected with the host computer via CAN bus; an output end of a signal collecting plate is connected with an input end of the feeding feedback device via CAN bus; an output end of the electrobath control device is connected with the input end of the feeding feedback device via CAN bus; an output end of the feeding feedback device is connected with an input end of a motherboard of the electrobath control device via CAN bus. The invention has the advantages of effective monitoring be means of feeding and crust breaking instruction sent by electrobath control device due to the added the feeding feedback device, real-time voice alarm for feeding faults, timely maintenance, elimination of interference to electrobath control device during manual inspection of feeding and avoidance of anode effect caused by feeding faults.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

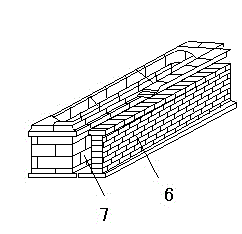

Aluminum oxide breaking and unloading integrated device and aluminum oxide breaking and unloading integrated method for aluminum electrolysis cell

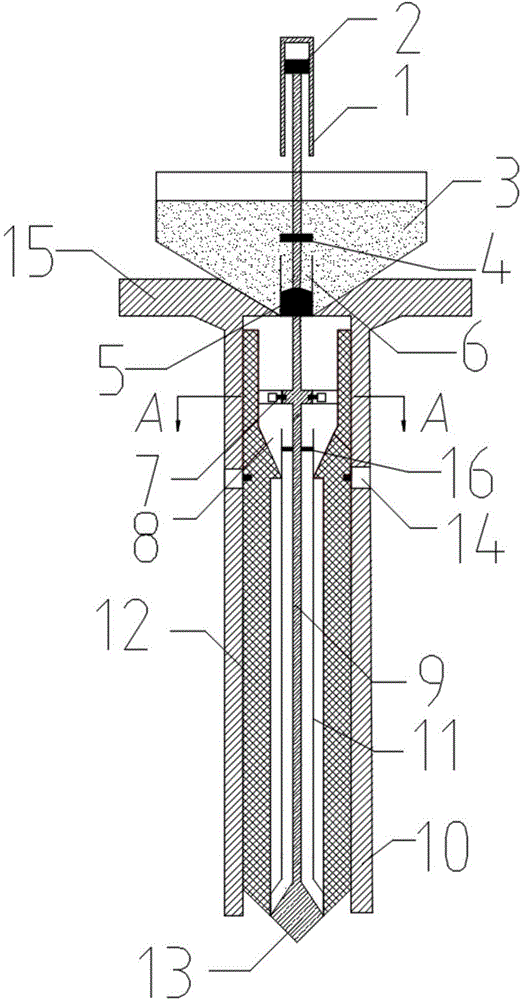

The invention discloses an aluminum oxide breaking and unloading device and an aluminum oxide breaking and unloading integrated method for an aluminum electrolysis cell. The aluminum oxide breaking and unloading device comprises a gas cylinder, a drive piston, a material tank, a charge piston, a discharge piston, a constant volume chamber, a solenoid valve, a material collecting cavity, a hammer head rod, an outer steel sleeve, an unloading tube, a steel barrel, a hammer head, a beam and a bracket. The aluminum oxide breaking and unloading device is characterized in that the hammer head rod and the hammer head which is connected with the hammer head rod are mounted inside the material collecting cavity and the unloading tube, uniform unloading of aluminum oxide is realized, the aluminum oxide is prevented from being unloaded in a stacked manner, and the aluminum oxide is uniformly dispersed into an electrolyte, so that the dissolving capacity of the electrolyte to the aluminum oxide is improved, the anode effects are reduced and the furnace-bottom precipitates are reduced. Meanwhile, the breaking and unloading devices are combined into a whole, so that the equipment cost is reduced and the equipment mounting and maintaining are convenient. The device can scrape off housing package heads which are adhered on the hammer head and the outer steel barrel, so that the labor intensity of a worker is relieved and the service life of the device is prolonged.

Owner:CENT SOUTH UNIV

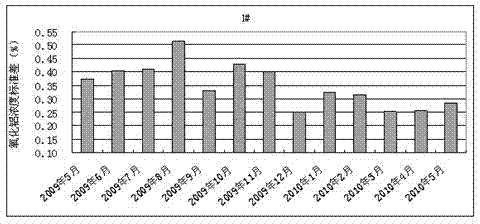

Low effect manufacturing method for aluminum cell

The invention relates to a production process for an aluminum electrolytic tank, in particular to a low-effect production process for aluminum electrolytic tanks, which comprises a tank controller and an up-level unit. The process comprises: 1) adjusting the controlling parameters of the alumina concentration; 2) adjusting the effect-pretreating module and the effect-waiting-period treating module; 3) waiting for eliminating the anode effect. The benefits with the invention are: as the effect-waiting mechanism is canceled in the computer-controlled program, and tech conditions for the electrolytic tank are configured reasonably, steady production of the electrolytic tank is kept; and the low alumina concentration can be kept continuously; while maintaining high current efficiency, occurrence of effect is avoided to the max. extent. The coefficient of effect is reduced to below 0.001 times / tank is multiplied by day at present, the production of low anode-effect coefficient is realized for aluminum electrolytic tank, and null-effect production is realized gradually. The invention is applicable for controlling the low anode-effect system for aluminum electrolytic tank.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

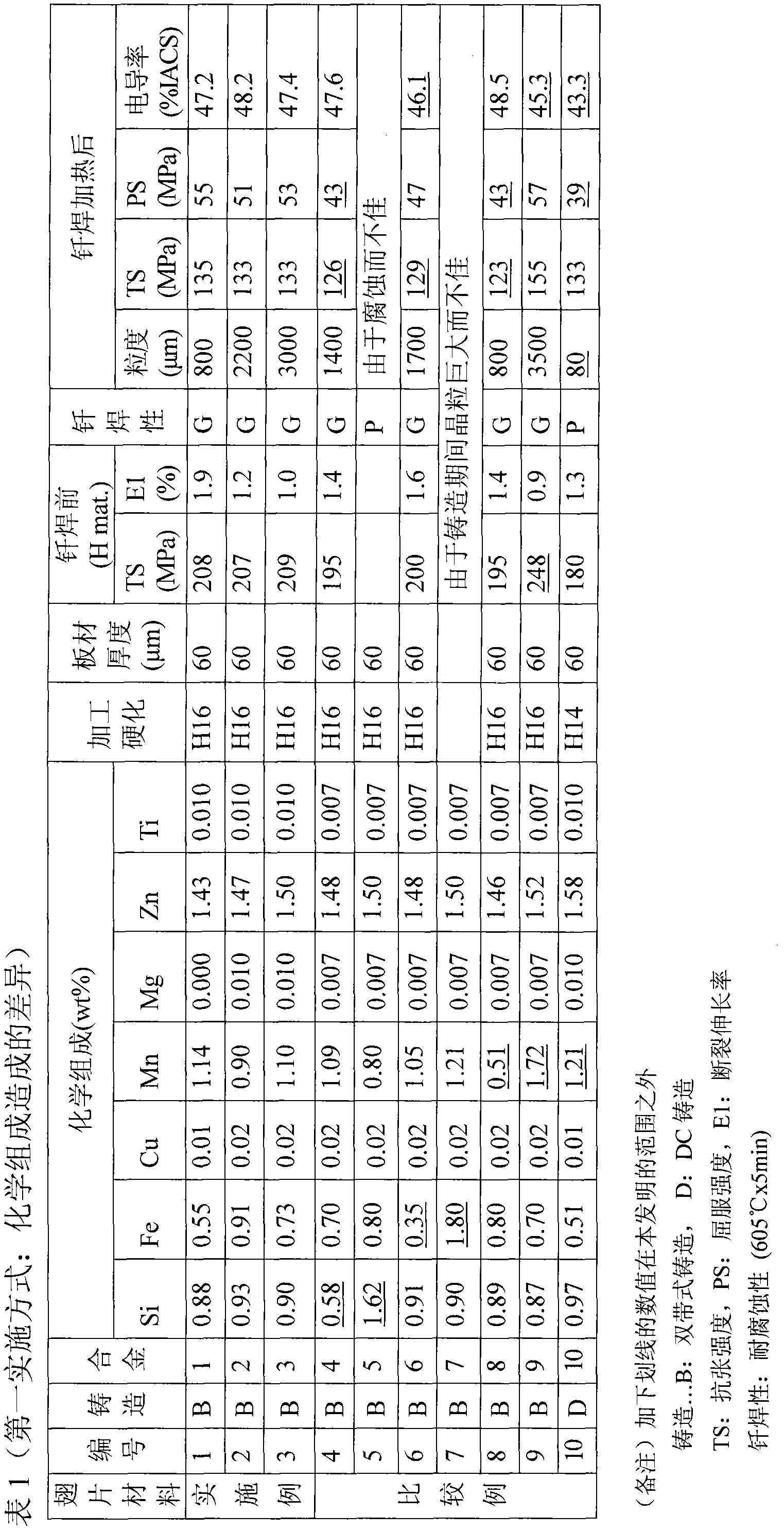

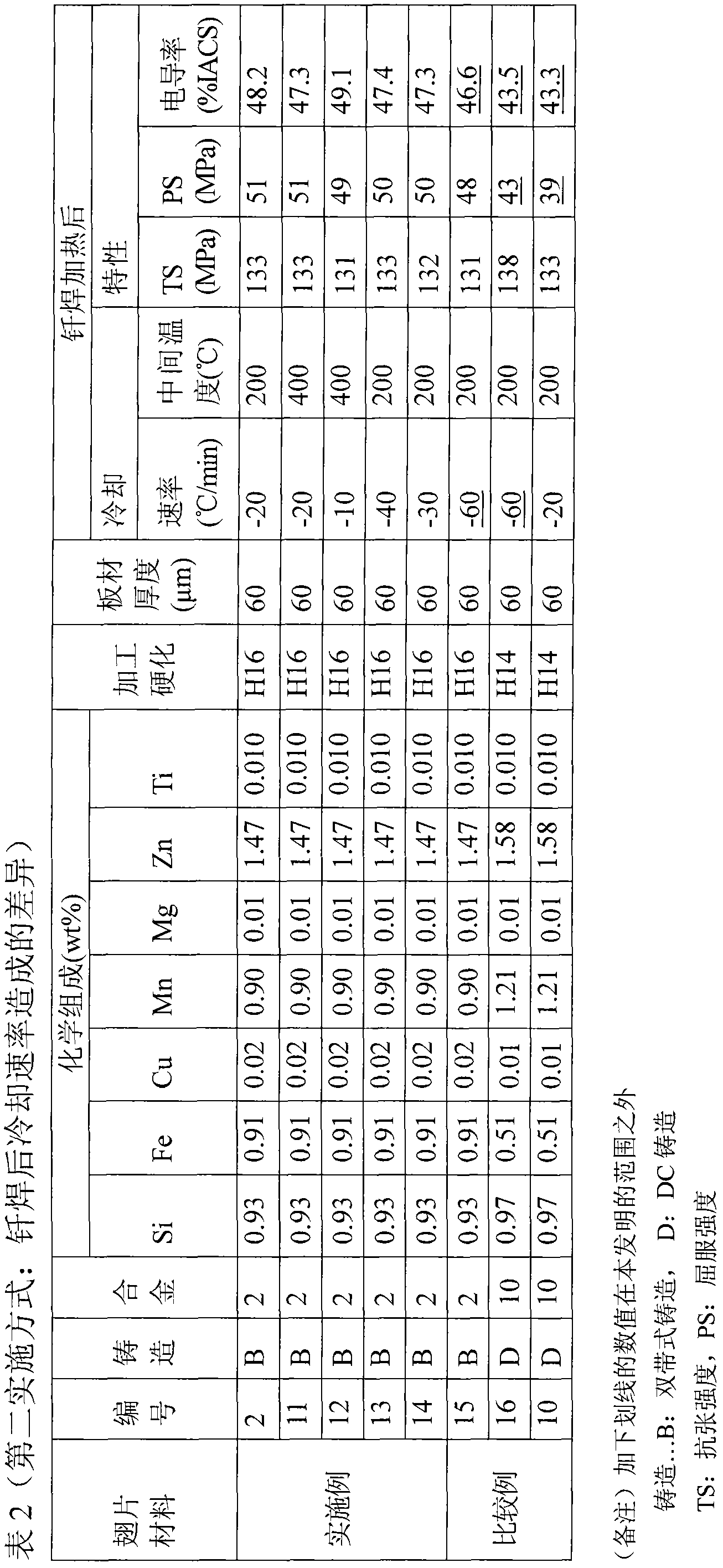

High strength aluminum alloy fin material for heat exchanger and method for production thereof

ActiveUS20070113936A1Well formedHigh strengthHeat exchange apparatusMetal rolling arrangementsAnode effectImpurity

[PROBLEMS] To provide an aluminum alloy fin material for a heat exchanger, which has high strength and high heat conductivity after brazing, and is excellent in the resistance to sagging, erosion and self-corrosion and the in the sacrificial anode effect. [MEANS FOR SOLVING PROBLEMS] A method for producing an aluminum alloy fin material for a heat exchanger which comprises providing a molten aluminum alloy having a chemical composition, in wt %, that Si: 0.5 to 1.5%, Fe: 0.15 to 1.00%, Mn: 0.8 to 3.0%, Zn: 0.5 to 2.5%, with the proviso that the content of Mg as an impurity is limited to 0.05 wt % or less, and the balance: Al and inevitable impurities, casting the molten alloy continuously into a thin slab having a thickness of 5 to 10 mm by the use of a twin belt casting machine, winding up the slab into a roll, cold-rolling the slab into a sheet having a thickness of 0.05 to 2.0 mm, subjecting the sheet to an inter annealing at 350 to 500® C., and cold-rolling the annealed sheet with a cold reduction rate of 10 to 96%, to prepare a sheet having a final thickness of 40 to 200 μm, and optionally subjecting the final sheet to a final annealing (a softening process) at a holding temperature of 300 to 400® C.

Owner:NIPPON LIGHT METAL CO LTD

Aluminum electrolysis carbon pre-baking anode pre-heating method

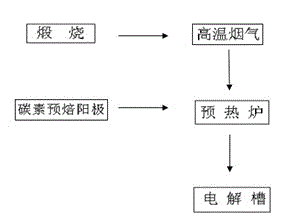

The present invention discloses an aluminum electrolysis carbon pre-baking anode pre-heating method. According to the method, aluminum carbon calcination rotary kiln high temperature flue gas is adopted as a heat source, and the loaded carbon pre-baking anode is pre-heated in a pre-heating furnace, such that the average temperature of the anode can achieve more than or equal to 300 DEG C within 24 h; according to the requirement of the electrolysis bath electrode replacing period, the heated anode is taken out from the pre-heating furnace, is loaded into a special thermal insulation device for conveying the pre-heated anode, is conveyed to an electrolysis workshop, and is loaded into the electrolysis bath to replace the old anode so as to be used; and with the pre-heating, the thermal shock influence on the anode can be reduced, the carbon consumption of the anode is reduced, the fluctuation of the stability and the thermal balance of the electrolysis bath can be reduced, the current efficiency is increased, the current conduction time of the anode is shortened, the furnace bottom precipitate is reduced, the anode effect and the noise generated during the electrode replacing are reduced, and the disordered and harsh conditions of the anode current distribution are reduced so as to provide great benefits for the normal operation of the electrolysis bath.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

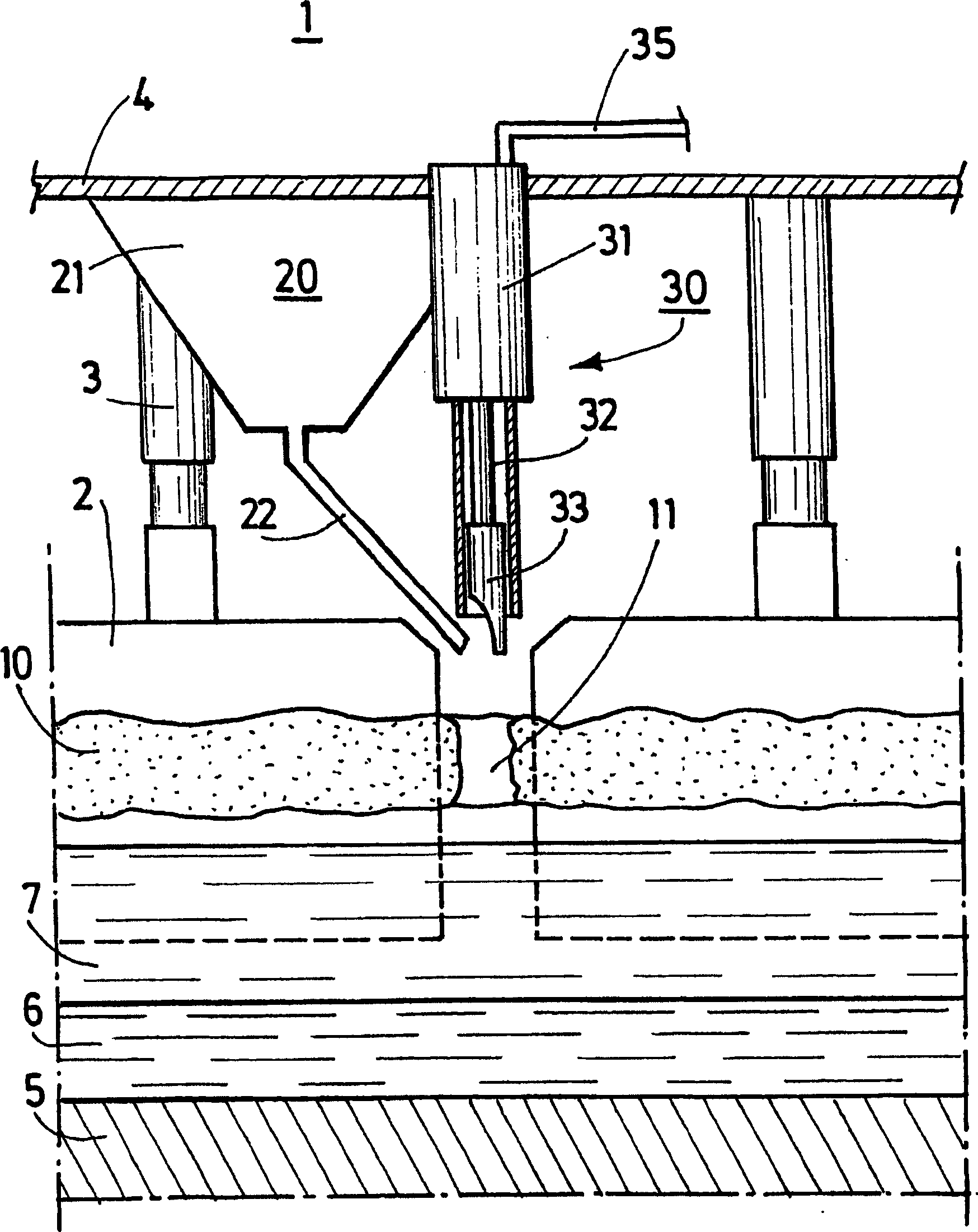

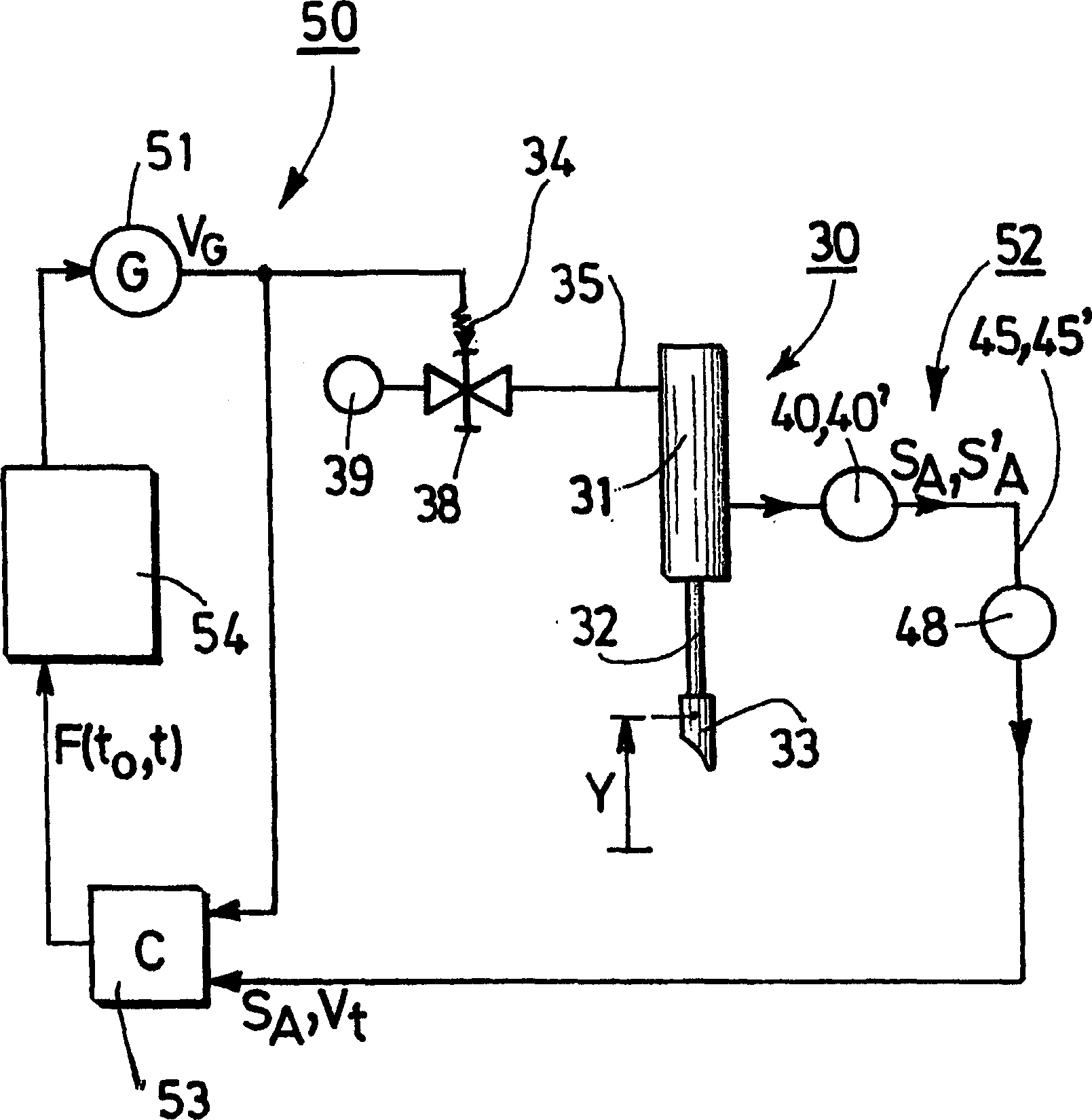

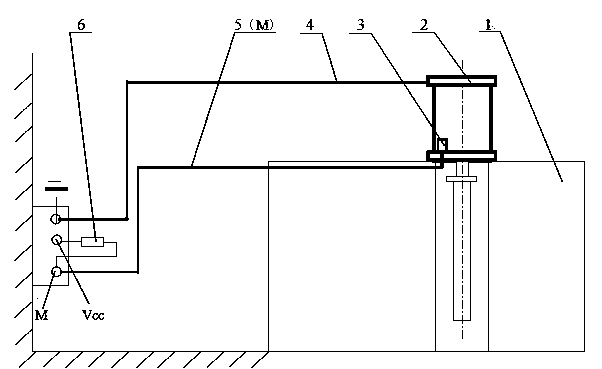

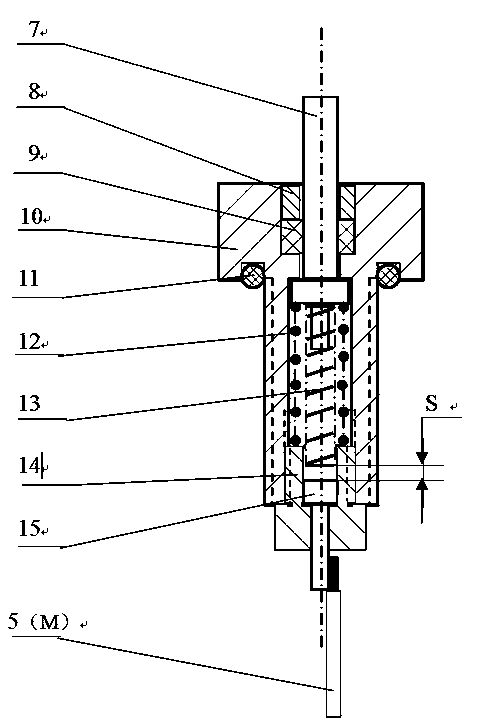

Method and system for controlling addition of powdery materials to the bath of an electrolysis cell for the production of aluminium

The invention relates to a method for controlling the provision of powdery materials to an electrolysis cell used to produce aluminium by fused-salt electrolysis and provided with at least one distributor for powdery materials and at least one piercing device (30) comprising an actuator (31) and a hammer chipper (33) wherein at least one opening is formed in the crust of the solidified bath with the aid of the piercing device and the powdery material is introduced via at least one opening according to a normal supply method wherein, at a given moment to, an electric signal is generated in order to cause the hammer chipper to descend with the aid of the actuator (31) and the moment t, when the hammer chipper assumes a given low position, is measured, the value of at least one operational indicator for supply F is calculated from the value of the value to and the value obtained for moment t, abnormal or normal operation is determined from at least one operational criterion and the value of the operational indicator(s); if operation is not deemed to be abnormal, the normal supply procedure is maintained; if the operation is deemed to be abnormal, at least one corrective procedure (regularization, normalization) is initiated in order to bring the supply of powdery material into line with normal operation. The inventive method can be automated easily and enables operation of the supply to be monitored even during anode effects.

Owner:PECHINEY ALUMINUM

Low-temperature aluminum electrolysis process and electrolyte

InactiveCN101713082AReduced ability to dissolve aluminaIncreased ability to dissolve aluminaAnode effectMaterials science

The invention relates to a low-temperature aluminum electrolysis process and electrolyte. The electrolyte consists of Na3AlF6, K3AlF6, Al2O3, AlF3 and LiF; and the electrolysis temperature is between 850 and 910 DEG C, the coefficient of an anode effect is smaller than 0.1 time / tank day, and the anode current density is 0.5 to 1.2 A / cm2. The primary crystal temperature of the electrolyte adopting the component formula is low and changes comparatively slowly along with the changes of the components in favor of solving the problems of uneven tank bottom current, unstable tank voltage and the like caused by sharp raising of the primary crystal temperature of a melt and cathode crusting due to directional migration of Na+ and cathode enrichment. Besides, The K3AlF6 in the electrolyte can effectively increase the capability of the melt for dissolving the aluminum oxide, and solve the problem of deposition of the aluminum oxide at the bottom of a tank. Because the electrolysis temperature is lower, the heat loss of an electrolytic tank can be greatly reduced, and the energy-saving current efficiency is high. The low-temperature aluminum electrolysis process is simple and is easy to operate, the electrolyte has reasonable components, and the low-temperature aluminum electrolysis process can effectively reduce the aluminum electrolysis temperature, inhibit the cathode crusting in the process of aluminum electrolysis, improve the current efficiency of the aluminum electrolysis and reduce the energy consumption of the aluminum electrolysis, is suitable for industrial production, and can replace the conventional aluminum electrolysis process.

Owner:CENT SOUTH UNIV

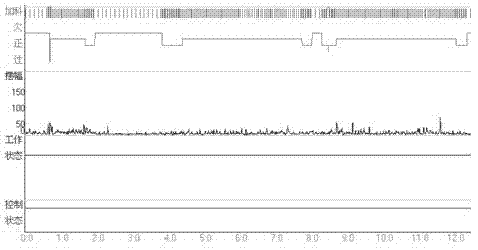

Method for early warning and inhibiting on-line anode effect of aluminum electrolysis cell

The invention provides a method for identifying on-line aluminum oxide critical concentration and early warning and inhibiting an anode effect of an aluminum electrolysis cell. The aluminum oxide critical concentration of the electrolysis cell is identified by monitoring perfluorochemical (PFC) gas content change of smoke in the aluminum electrolysis cell, and the anode effect is predicted and inhibited. The method can be used for identifying the aluminum oxide critical concentration and early warning and inhibiting the effect of the aluminum electrolysis cells with different structures and different current levels under various cell conditions, the effect predicting and inhibiting success rate can reach 100 percent, the effect is inhibited in an initial state, and low-voltage effect-free production of the electrolysis cell is realized. The method is beneficial to accurate control of the aluminum oxide concentration in the aluminum electrolysis production process and beneficial to energy conservation and emission reduction of greenhouse gases in the aluminum electrolysis industry.

Owner:中铝郑州有色金属研究院有限公司

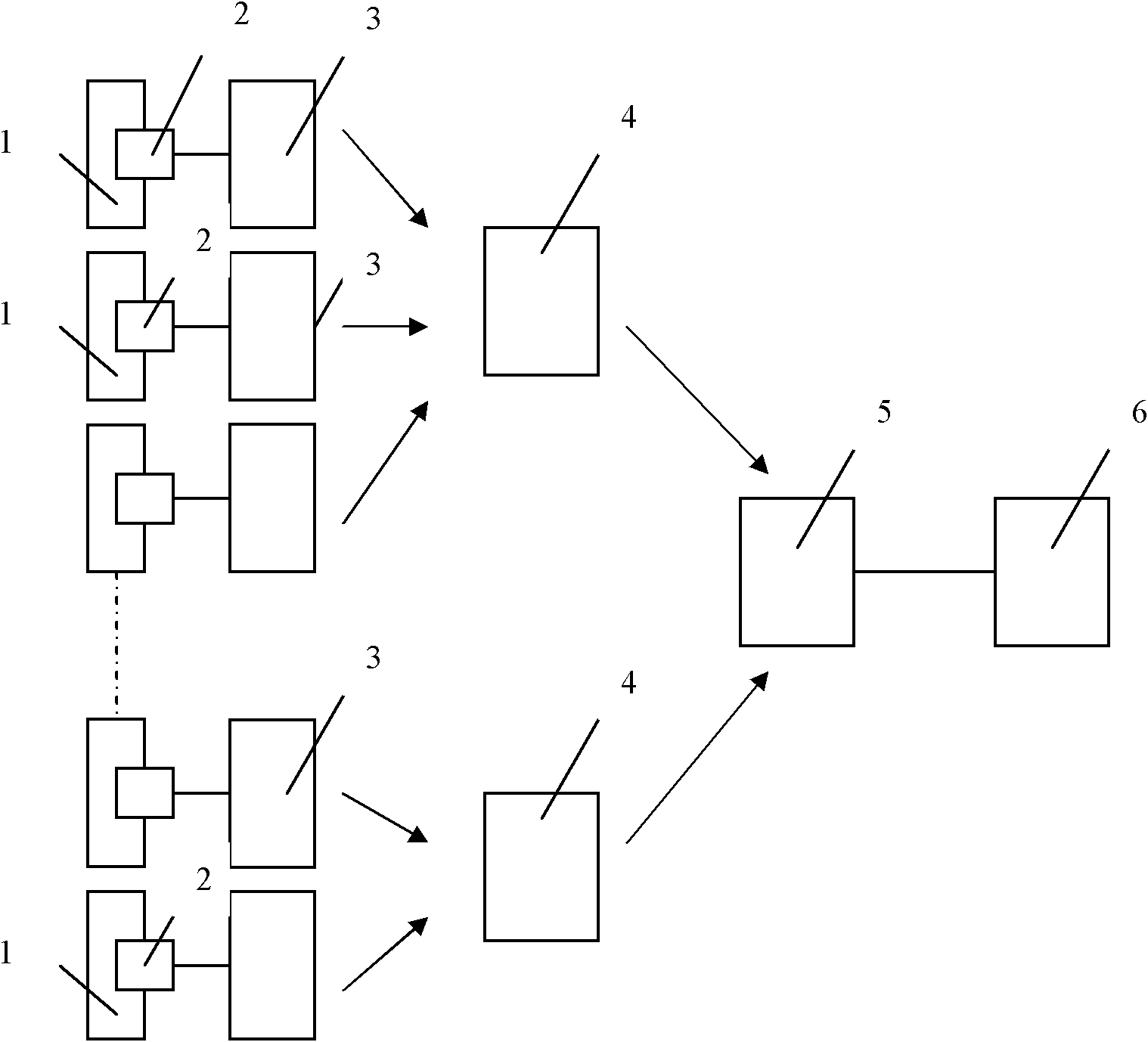

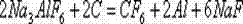

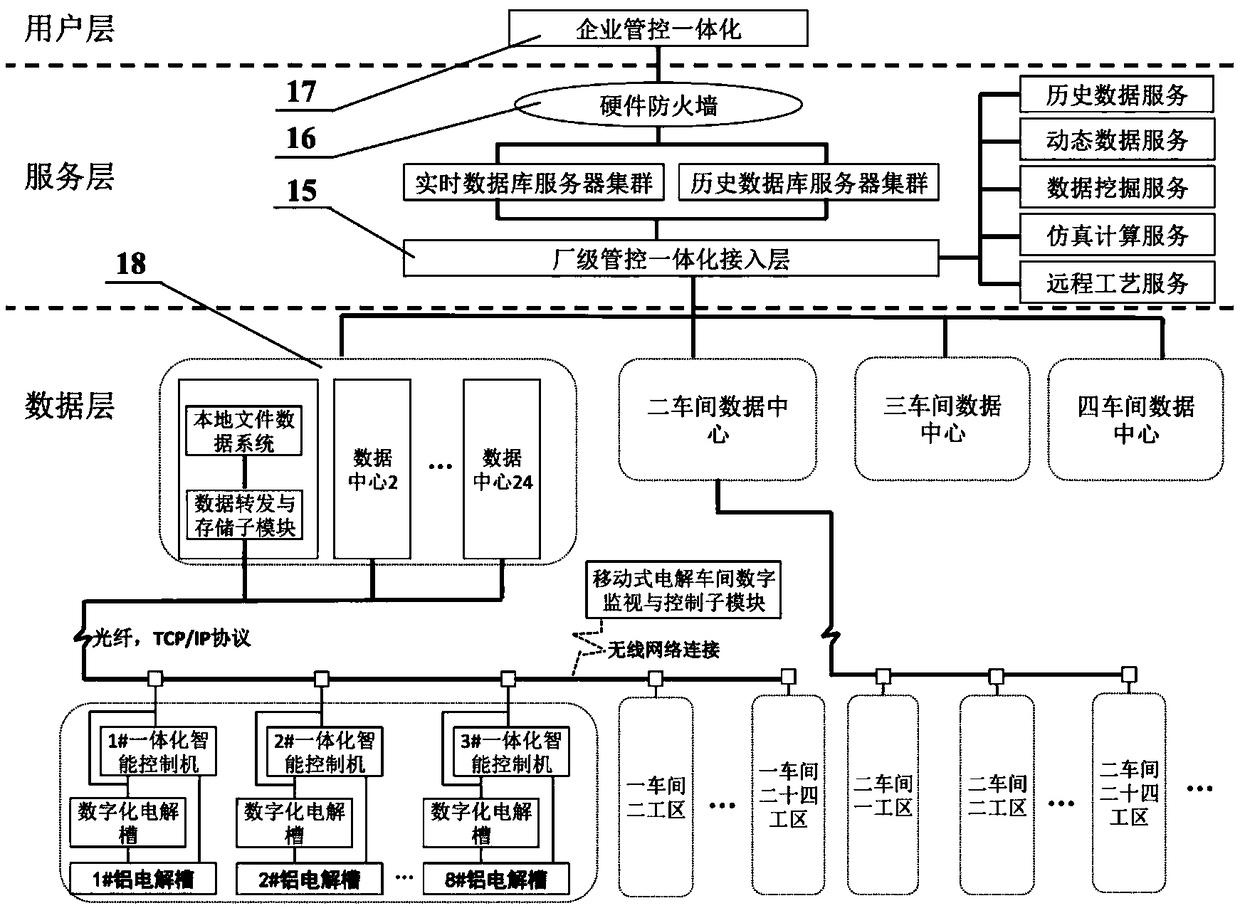

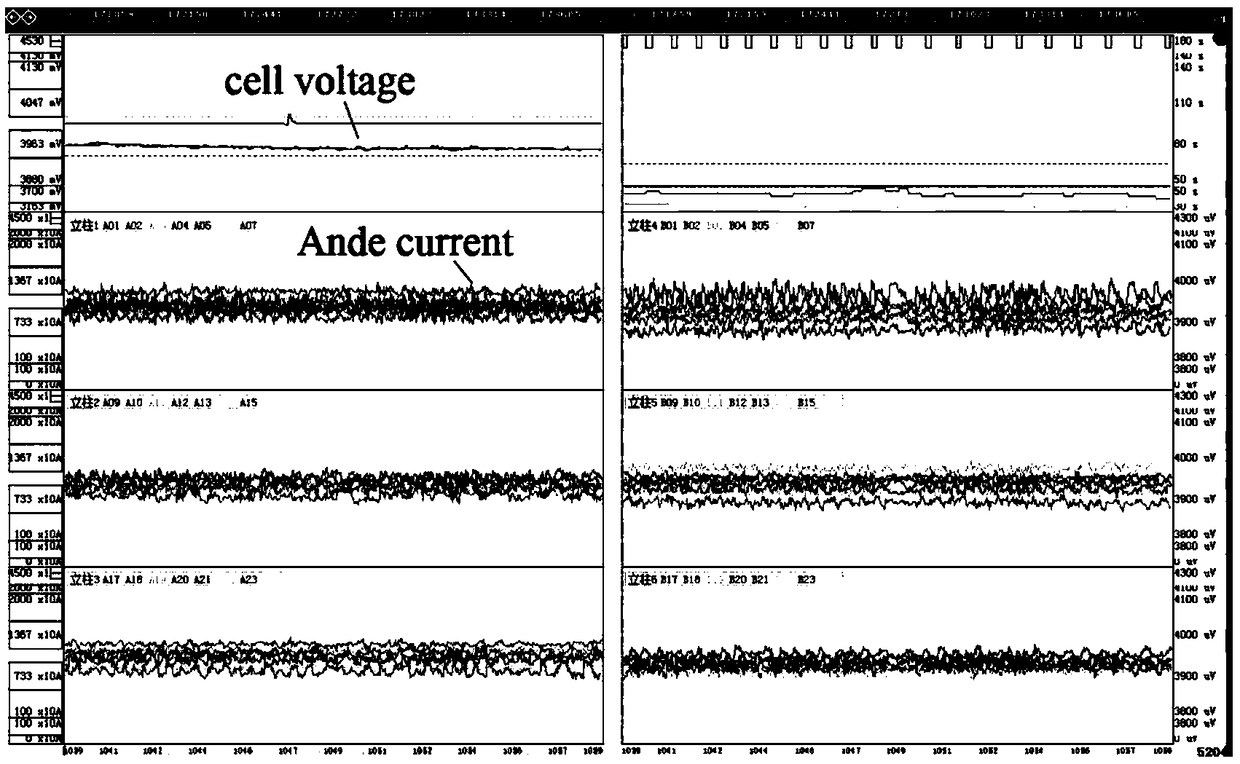

Fully digital electrolytic tank and integrated intelligent control system

The invention discloses a fully digital electrolytic tank and an integrated intelligent control system. The control system comprises a fully digital electrolytic tank (1), an integrated intelligent control unit (2), a movable type electrolytic plant integrated unit (3), and an enterprise grade big data unit (4). Through multiple distribution type sampling systems, electrolytic tank data is collected and multisource information is processed to establish a digitalized electrolytic tank; decision strategy and control commands related with precise effect control, tank stability and overheat control, zone concentration and anode state are formed automatically; the electrolytic tank is controlled, at the same time, mass data is stored in a data center in a text form, and thus people can see theinformation and execute the commands through a mobile terminal in the field. The system is applied to a large aluminum electrolysis system, can save the energy and improve the efficiency, creates an ultralow anode effect, and only needs very few people.

Owner:CENT SOUTH UNIV

Method for forecasting anode effects by isometric voltage drop of anode rods

The invention relates to a method for forecasting anode effects by isometric voltage drop of anode rods. The method includes that anode rod isometric voltage drop signal sensors are respectively mounted on different anode rods of a prebaked anode electrolytic cell and used for transmitting acquired anode rod isometric voltage drop signals to a front-end data analyzer; and the front-end data analyzer is used for analyzing anode rod isometric voltage drop data, forecasting anodes about to have the anode effects, and then sending the forecasting results to an electrolytic cell controller. The method has the advantages that conditions of the anode effect of the single anode of the electrolytic cell can be forecasted intensively, abnormal anodes can be monitored effectively, refined operation of the electrolytic cell is realized, running of the electrolytic cell is stabilized, and effects of saving energy, reducing consumption and improving current efficiency are realized.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

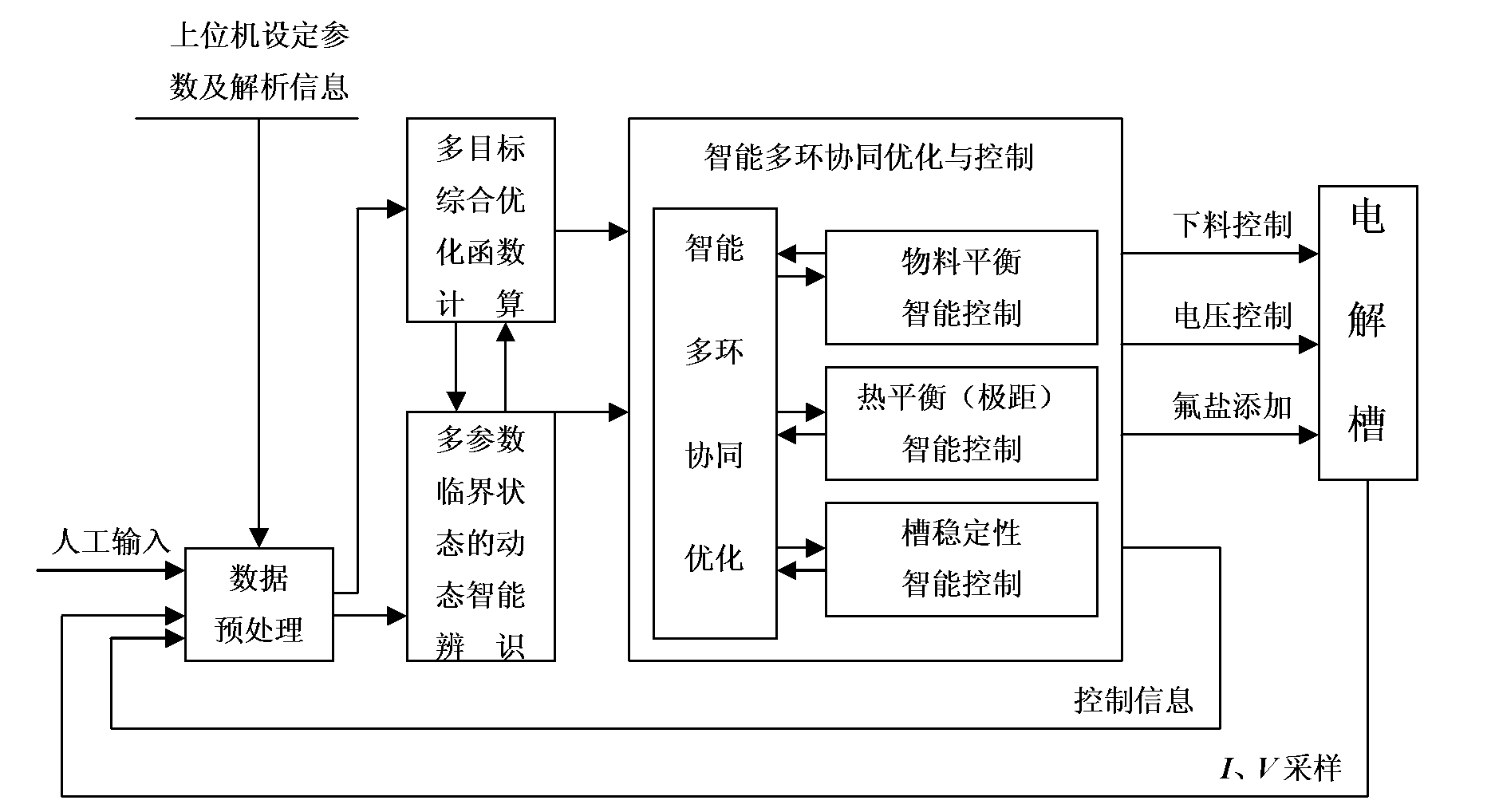

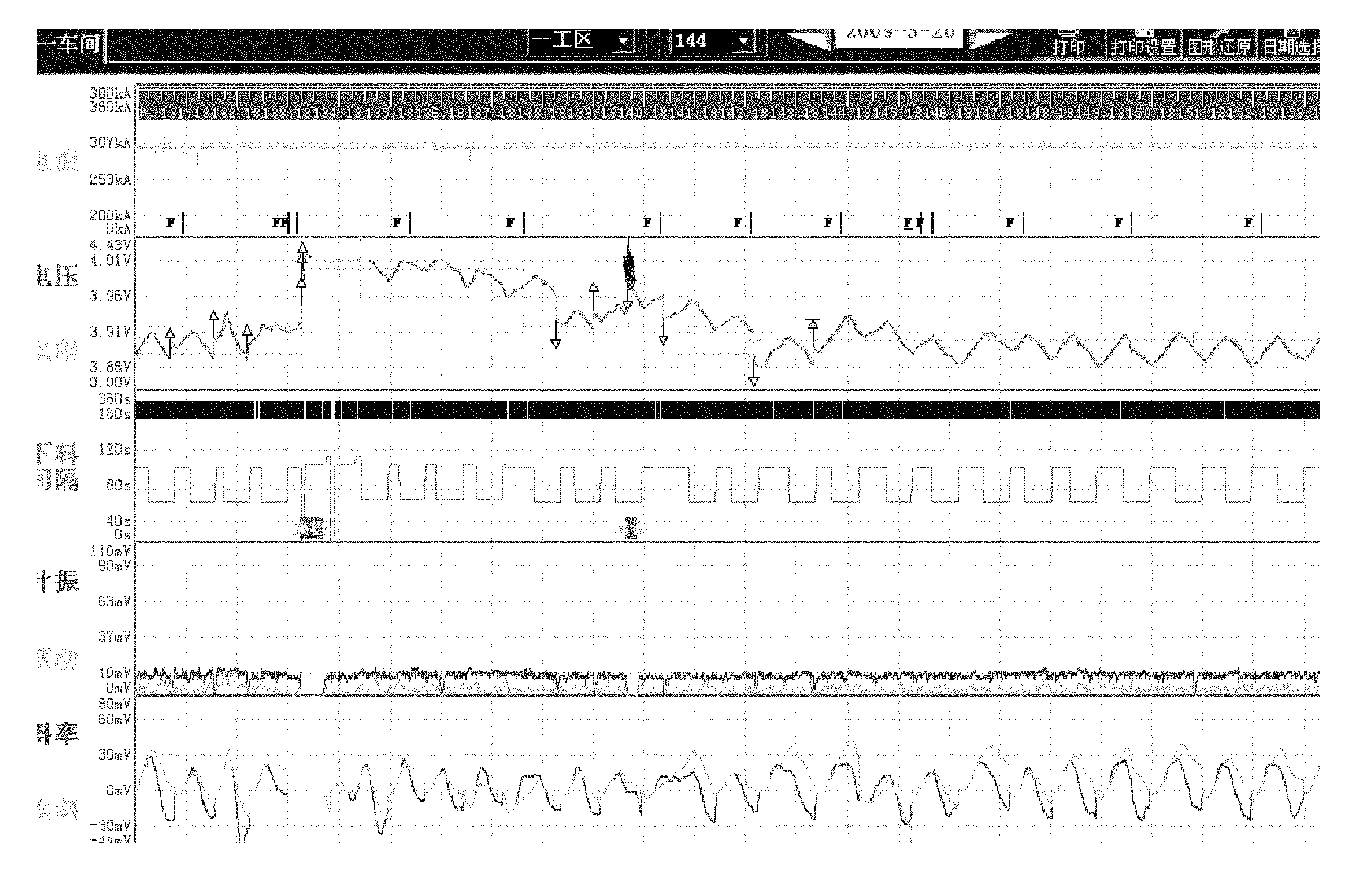

Current strengthening and efficient energy saving method of prebaked aluminium electrolysis cell

The invention discloses a current strengthening and efficient energy saving method of a prebaked aluminium electrolysis cell, comprising the following steps of: adopting a five low, three narrow and one high process in the electrolytic process of the aluminium electrolysis cell, wherein main technical parameters are as follows: electrolytic temperature is 920-935 DEG C, superheat degree is controlled between 8 DEG C and 12 DEG C, the mass concentration of aluminum oxide is 1.8-2.5 percent, anode effect coefficient is less than and equal to 0.02, cell voltage is 3.60-3.90 V, and anodic current density is more than and equal to 0.8 A / cm<2>; and developing an intelligent polycyclic collaborative optimization and control technology matched with the process, therefore the purpose of current strengthening and energy saving of the prebaked aluminium electrolysis cell is achieved. Practices prove that the current strengthening and efficient energy saving method of the prebaked aluminium electrolysis cell can greatly enhance the anode current density and also outstandingly reduces the cell voltage.

Owner:CENT SOUTH UNIV

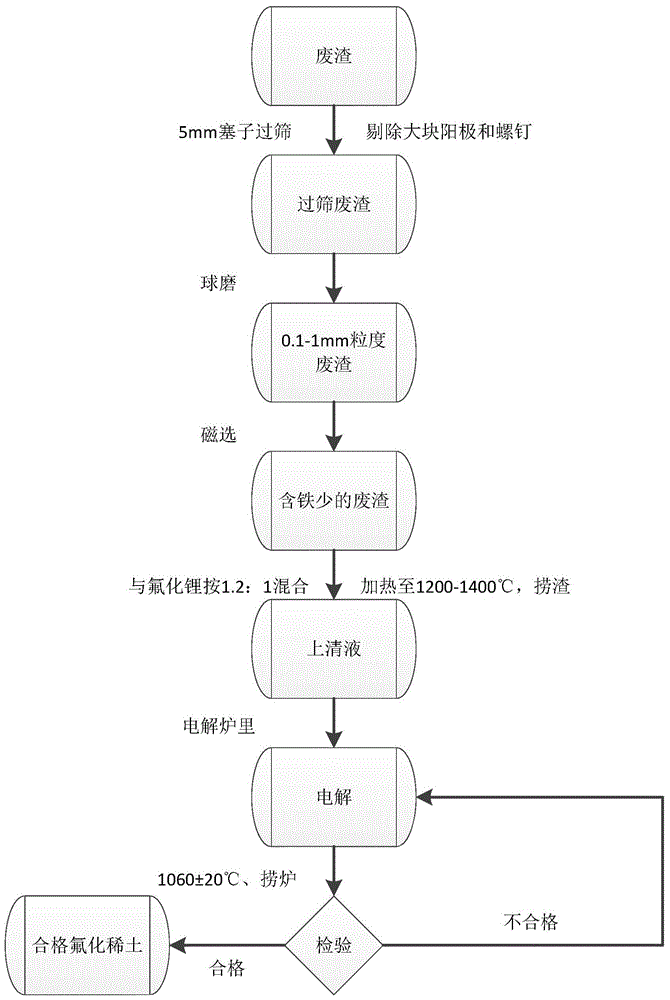

Method for recovering rare earth fluoride from electrode scrap reclaimed material and slag of rare earth

ActiveCN106044833AConvenient and effective purificationSave resourcesRare earth metal fluoridesAnode effectSlag

The invention discloses a method for recovering rare earth fluoride from an electrode scrap reclaimed material and slag of rare earth. The electrode scrap reclaimed material and the slag of the rare earth are taken as raw materials, the massive raw materials are sieved, non-rare-earth impurity blocks are removed, and the materials are subjected to sieving, ball milling and magnetic separation; the materials with most iron removed after magnetic separation are mixed with lithium fluoride; the mixture is heated to be melted until a melted liquid reaches a sufficient liquid level; the melted liquid is stirred and subjected to slag removal through filtering; a filtrate after slag removal is subjected to electrolytic impurity removal, slag is fished after an anode effect occurs in electrolysis, and a supernatant is subjected to cyclic electrolysis; the obtained supernatant is detected and is weighed and packaged after reaching the standard, and the final recovery product is obtained. Rare earth fluoride can be extracted conveniently and effectively from the electrode scrap reclaimed material and the slag of the rare earth, resources are saved, pollution is reduced, and the method has the characteristics of simple process and low cost.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

Computer quenching method for aluminum cell anode effect

The invention discloses a computer extinguishment method for the anode effect of an aluminum electrolytic bath. The method uses a computer to detect and judge the generation of the anode effect, automatically control and execute operations of adding alumina, ascending an anode, waiting and descending the anode and circularly execute the operations of ascending the anode, waiting and descending the anode until the anode effect is extinguished. The invention responds rapidly compared with a manual extinguishment method, can rapidly increase the concentration of alumina in an electrolyte solution below the anode, can impact an air film attached to the surface of the anode, is favorable to the acceleration of anode effect extinguishment and greatly shortens operation time needed for the anode effect extinguishment so as to greatly decrease energy consumption and greatly lighten the labor intensity of operators. The invention can improve the success rate of the anode effect extinguishment, prevents the electrolyte solution from overflowing out of the electrolytic bath, can not waste a great amount of heat and can prevent the high-temperature electrolyte solution from burning a bath cover.

Owner:GUIYANG AL-MG DESIGN & RES INST

Metal substrate corrosion prevention coating and preparation method and anticorrosion member

InactiveCN104928608AImprove closureImprove corrosion resistanceMolten spray coatingNon-pressured vesselsAnode effectStress corrosion cracking

The present invention provides a coating for providing protection for a metal substrate, and the coating comprises a metal component playing the sacrificial anode effect, a component playing the coating stabilizing property, and a component to improve coating stress corrosion cracking resistance. The coating has the advantages that: in addition to a metal and / or alloys thereof, the coating is also added with a coating performance stabilizing component, for example, the coating performance stabilizing component can be a component for filling coating pores to enhance coating sealing effect, and in particular, the coating performance stabilizing component can be a metal oxide. Furthermore, an element binding with the metal substrate is also introduced into the coating, and the coating corrosion resistance is improved. Through integrated use of the technical means, the coating is more stable, and the protective effect on the metal substrate is stronger.

Owner:BEIJING BSS CORROSION PROTECTION IND +1

High strength aluminum alloy fin material for heat exchanger and method for production thereof

ActiveUS20090260726A1Well formedHigh strengthHeat exchange apparatusMetal rolling arrangementsReduction rateChemical composition

Owner:NIPPON LIGHT METAL CO LTD

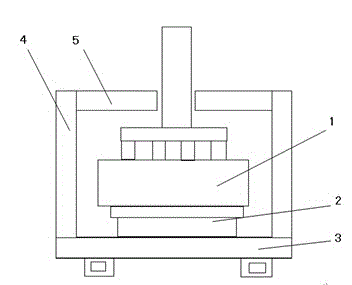

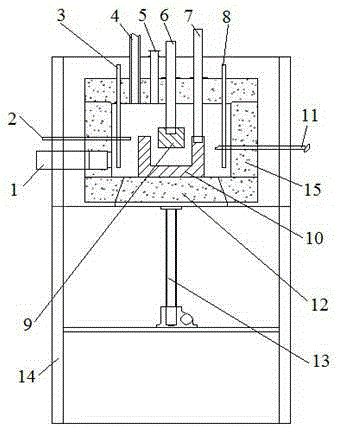

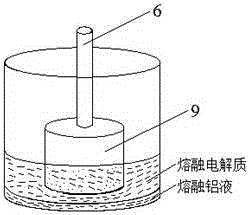

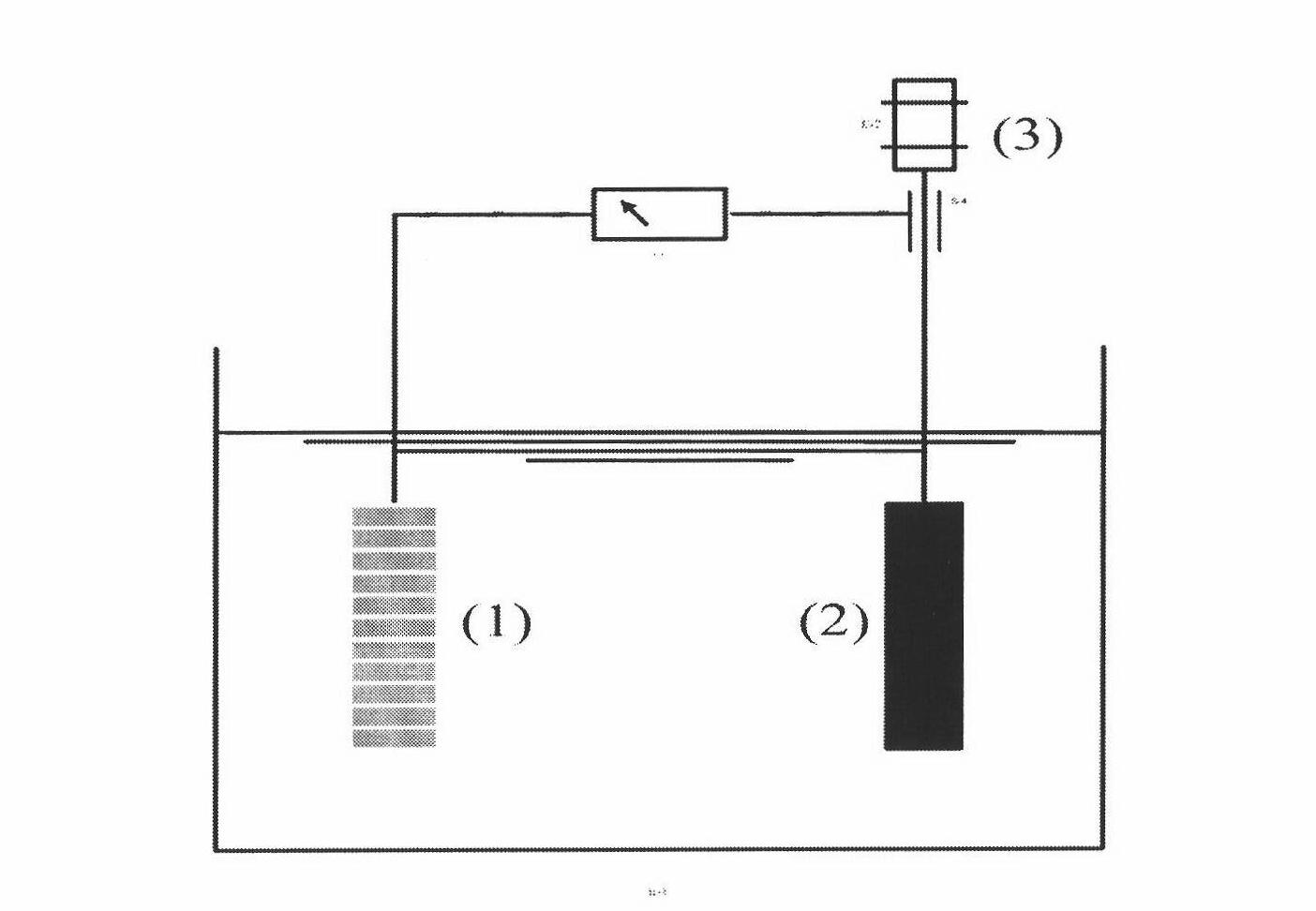

Aluminum electrolytic graphite crucible experimental device and experimental method

ActiveCN105297075ALearn about the variationsRich teaching contentElectrochemical responseFurnace temperature

Provided are an aluminum electrolytic graphite crucible experimental device and experimental method. The device comprises a computer and a heating furnace; a bottom furnace door of the heating furnace is installed at the top end of a lifting mechanism; two silicon carbide rod sets are arranged in the heating furnace, when the device is used, a graphite crucible is located in the heating furnace, an anode conductive rod and a cathode conductive rod are installed, the cathode conductive rod is connected with the graphite crucible, and a graphite anode is installed on the anode conductive rod and located in the graphite crucible. An aluminum ingot is put into the graphite crucible, heating is conducted, after the aluminum ingot and an electrolyte are completely melted, the furnace temperature is kept constant, the heights of melting aluminum and the electrolyte are measured, and data of electric currents changing along with changes of the distance between the anode conductive rod and the bottom face of the graphite crucible are recorded; changes of the electric currents and voltages are observed when an anode effect occurs. The experimental device can simulate an electrochemical reaction in an industrial field device, a good teaching effect is achieved through an early theoretical calculation and arrangement and late experimental phenomenon observation, and meanwhile experimental data can provide guidance and reference data for a production field.

Owner:LANZHOU RESOURCES & ENVIRONMENT VOC TECH COLLEGE +1

Method for improving corrosion resistance of powder coating

InactiveCN112694775AImprove corrosion resistanceImprove general performanceAnti-corrosive paintsPolyurea/polyurethane coatingsInorganic saltsAnode effect

The invention relates to the field of preparation methods of high polymer materials, and particularly discloses a method for improving the corrosion resistance of a powder coating. The method comprises the steps of adding an anti-corrosion auxiliary agent into the powder coating, wherein the anti-corrosion auxiliary agent comprises a first auxiliary agent, or a second auxiliary agent, or a third auxiliary agent, or a mixture of any two of the first auxiliary agent, the second auxiliary agent and the third auxiliary agent, or a mixture of the three auxiliary agents, the first auxiliary agent comprises nano clay, the second auxiliary agent comprises a composition of a barrier type pigment and an inorganic salt antirust pigment, and the third auxiliary agent comprises a composition of a carbon nanotube and a derivative thereof and metal powder with a sacrificial anode effect. According to the invention, a method of adding a special compound anti-corrosion auxiliary agent into a common coating is adopted, the obtained powder coating has higher anti-corrosion performance and wider application fields including common corrosion prevention and heavy corrosion prevention, and the method of directly adding the auxiliary agent is more economical and effective than a method of changing a resin curing agent and has stronger universality.

Owner:天津西敦粉漆科技有限公司

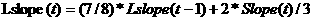

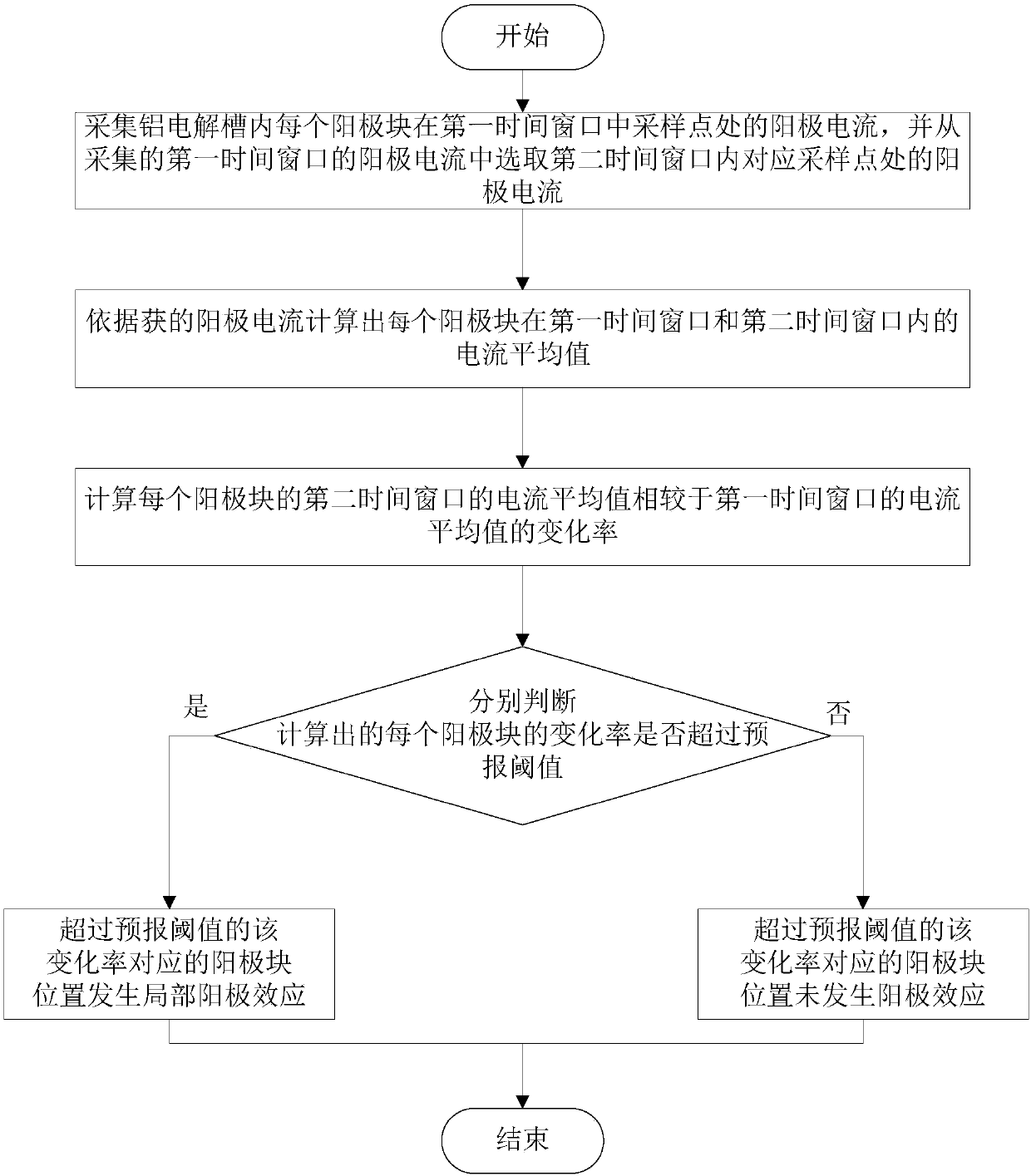

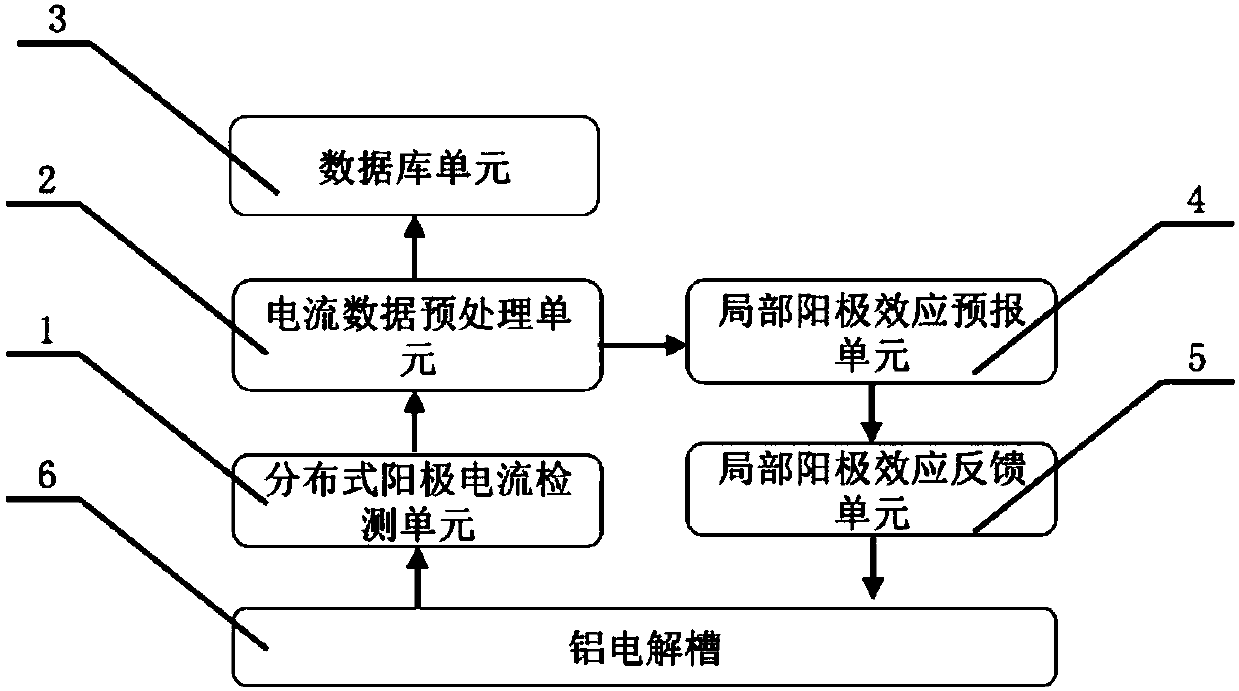

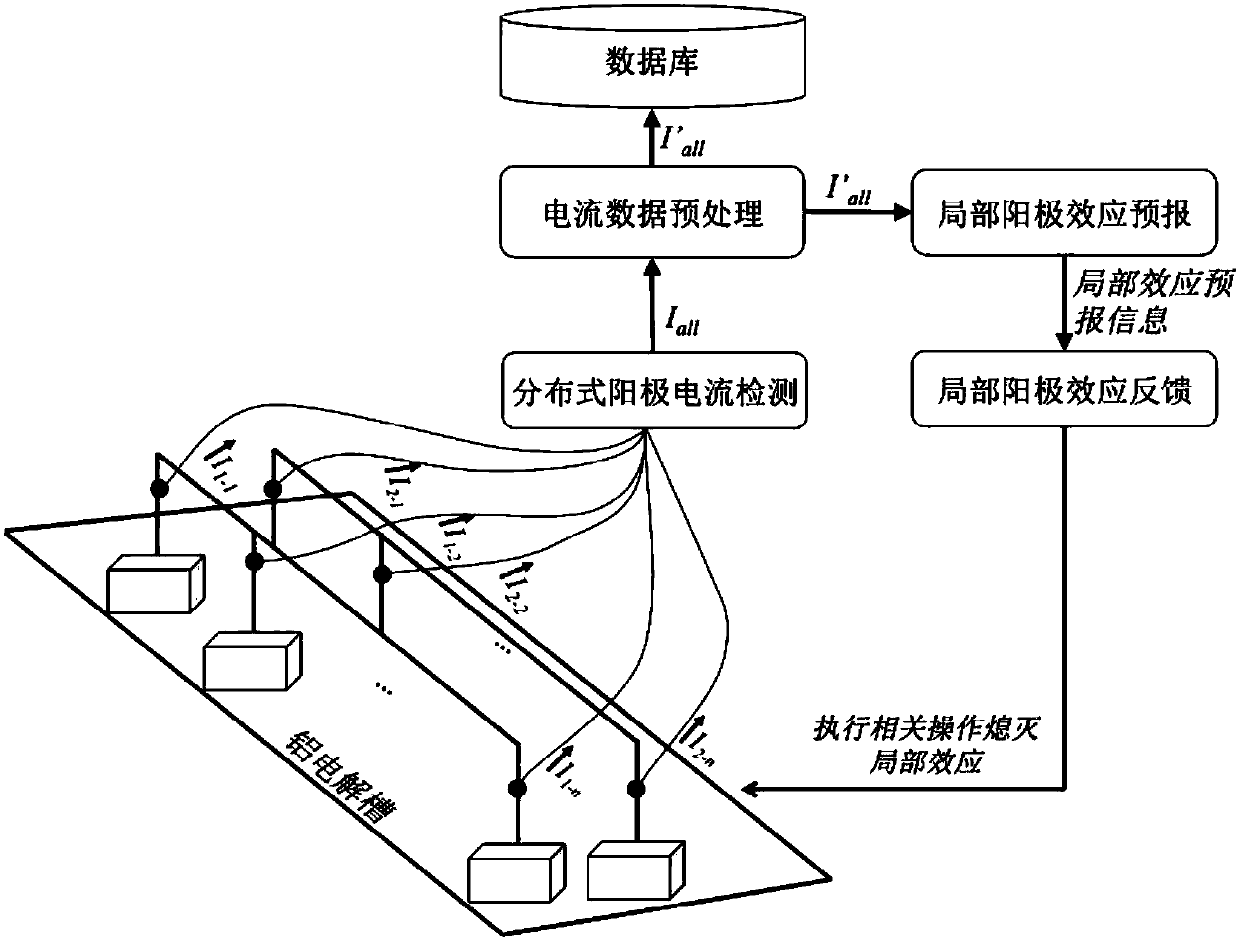

Method and system for forecasting local anode effect in aluminum electrolytic bath

The invention discloses a method and system for forecasting the local anode effect in an aluminum electrolytic bath. The method comprises the following steps of 1, obtaining anode currents of anode blocks in the aluminum electrolytic bath at corresponding sampling points in a first time window and a second time window; 2, calculating the average current values of each anode block in the first timewindow and the second time window according to the anode currents of the step 1; 3, calculating the change rate of the average current value of each anode block in the second time window compared with the average current value of the anode block in the second time window; and 4, judging whether the change rate, figured out in the step 3, of each anode block exceeds the forecasting threshold valueor not, if yes, enabling the anode block positions corresponding to the change rates exceeding the forecasting threshold value to be subjected to the local anode effect, and if not, preventing the anode block positions corresponding to the change rates not exceeding the forecasting threshold value from the anode effect. By means of the method, forecasting of the local anode effect in the aluminumelectrolytic bath is achieved efficiently and accurately.

Owner:CENT SOUTH UNIV

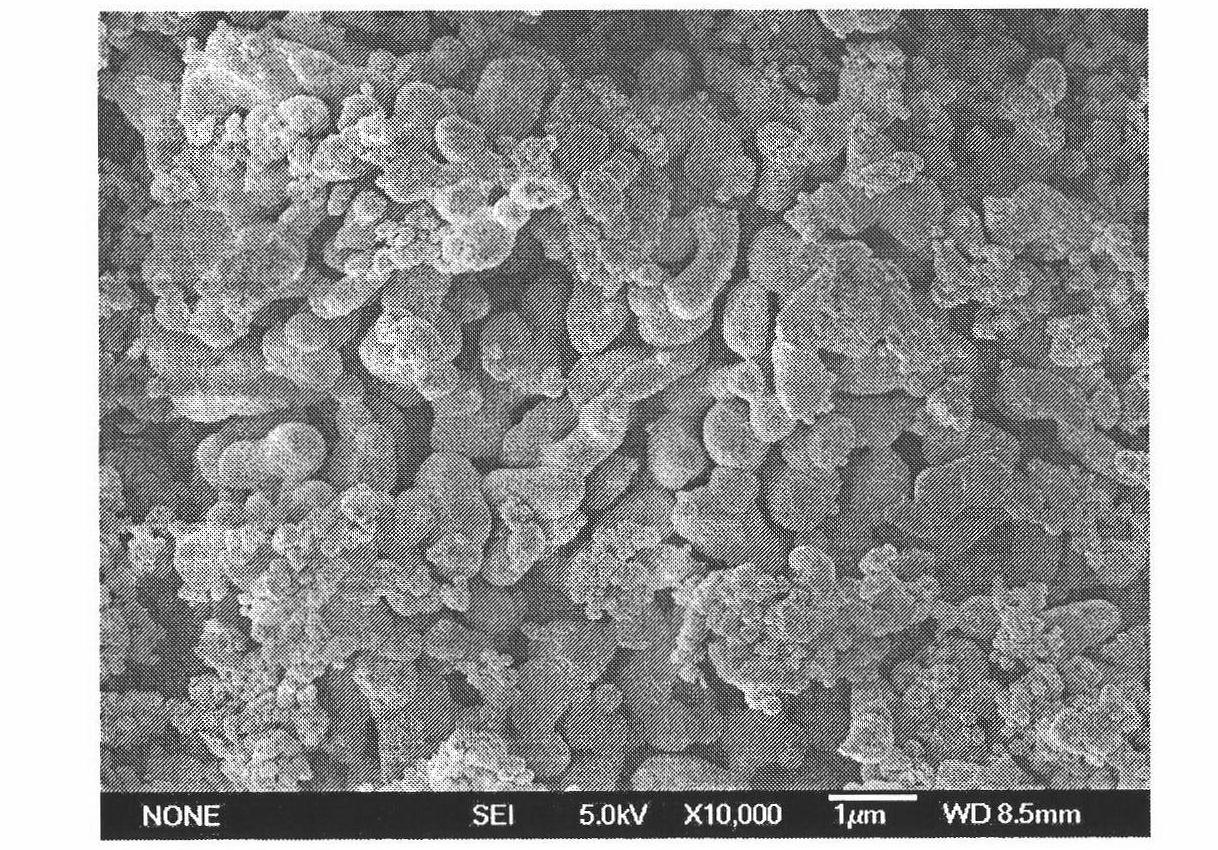

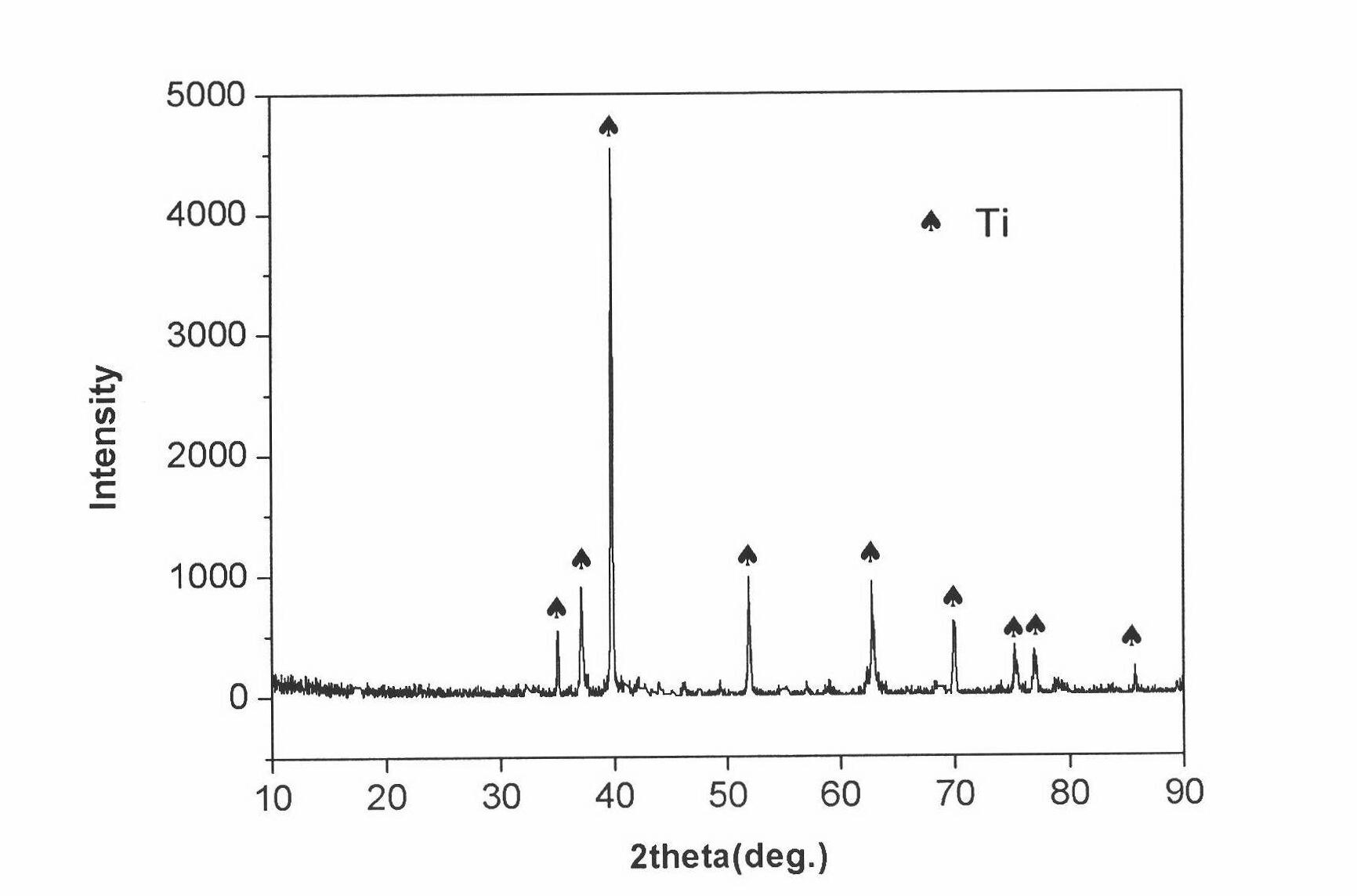

Improved process for smelting metallic titanium by electro-deoxidation method

The invention provides an improved process for smelting metallic titanium by an electro-deoxidation method, which is characterized in that cathode plates used in the process are prepared by mixing titanium dioxide powder, a PVA binder with a carbon powder additive based on a certain ratio, and then sintering at a temperature of 1300 DEG C for 4-6 hours after forming in batch at a pressure of 15-20 MPa. The cathode plates are connected with cathode wires in series to form cathode bars. An anode adopts a rotating graphite anode; the graphite anode can reduce the deoxidation potential in the process of deoxidation; and a rotating electrode can weaken the anode effect on the surface and fast discharge reaction products, wherein the rotating speed is generally in the range of 60-200rpm. The improved process has the advantages of short production cycle, simple structure and low production cost of titanium sponge, and can be applied to manufacturing fields of other metals and alloy products..

Owner:UNIV OF SCI & TECH BEIJING

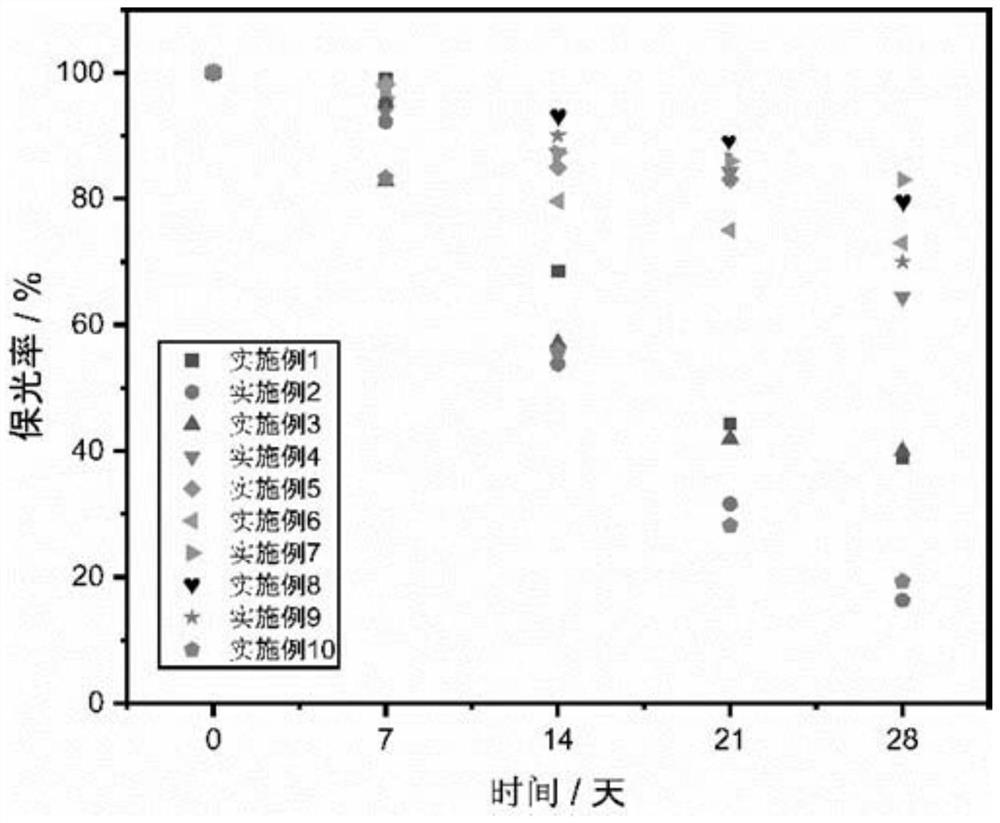

Aluminum product highly-polished anode technology

InactiveCN108747605AAchieve surface finishLarge area anode highlight effectAnodisationAnode effectWax removal

The invention discloses an aluminum product highly-polished anode technology. The aluminum product highly-polished anode technology comprises the following steps that an aluminum product surface is polished with an abrasive belt; a nylon wheel is used for polishing the aluminum product surface; a linen wheel is matched with green wax to conduct initial polishing; a cloth wheel is matched with white wax to conduct finishing polishing; an anodic reaction is made; wax removal, chemical polishing, neutralizing, oxidation, dyeing and hole sealing are carried out; a polishing machine is used, and aconsumable item cloth wheel is matched with white wax to conduct finishing polishing; and the aluminum product surface is wiped and checked. By means of the aluminum product highly-polished anode technology, physical polishing and chemical polishing are combined, a specially-matched chemical polishing agent is used, the large-area highly-polished anode effect can be achieved, the aluminum productanode highly-polished bright face surface machining effect is achieved, dyeing into rich colors can be achieved, a new aluminum product surface machining technology is provided, and the aluminum product highly-polished anode technology is suitable for large-scale industrial production.

Owner:RUGAO HUAYANG ALUMINUM PROD

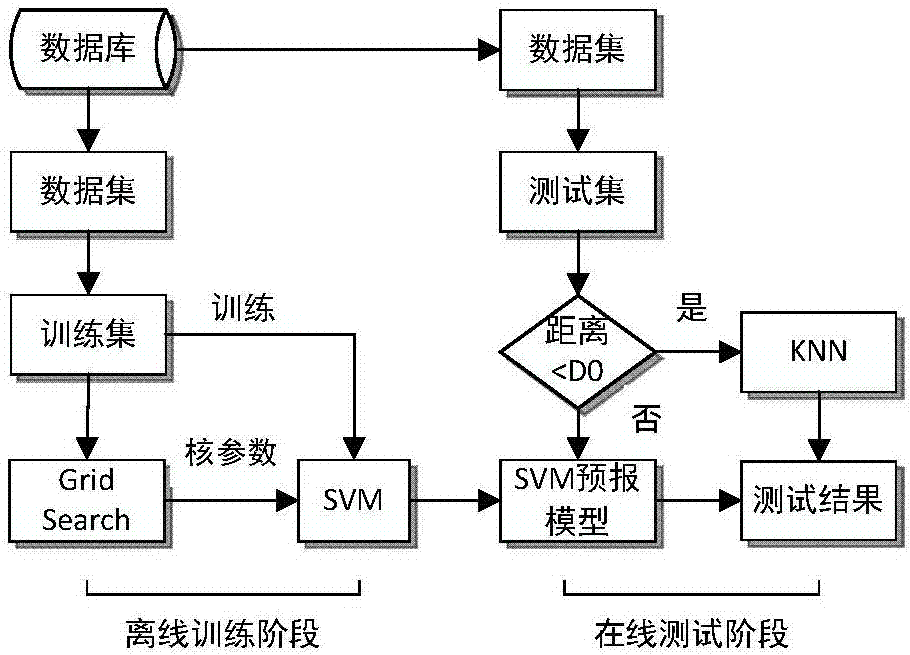

Anode effect prediction method in aluminum electrolysis cell production process

The invention discloses an anode effect prediction method in an aluminum electrolysis cell production process. The method comprises steps of extracting sample data from production data of the aluminumelectrolysis cell; carrying out weighting processing on feature vectors of the sample data by using feature weights; training the sample data by adopting a support vector machine (SVM); obtaining anSVM effect forecast model and model parameters; extracting the feature vectors of the aluminum electrolysis cell to be measured and performing weighting processing; and calculating distance between the feature vectors of the aluminum electrolysis cell to be measured and a optimal hyperplane; if the distance between the feature vectors of the aluminum electrolysis cell to be measured and the optimal hyperplane is larger than or equal to a preset threshold value, the feature vectors are sent to an SVM effect forecast model, and a forecast result is obtained; and otherwise, a nearest neighbor algorithm KNN is adopted to forecast the aluminum electrolysis cell to be measured. According to the anode effect prediction method in the aluminum electrolysis cell production process, the anode effectof different electrolytic cells under various groove conditions can be effectively forecast, the operation of the stable electrolytic cell is facilitated, and the current efficiency is improved.

Owner:HUAZHONG UNIV OF SCI & TECH +2

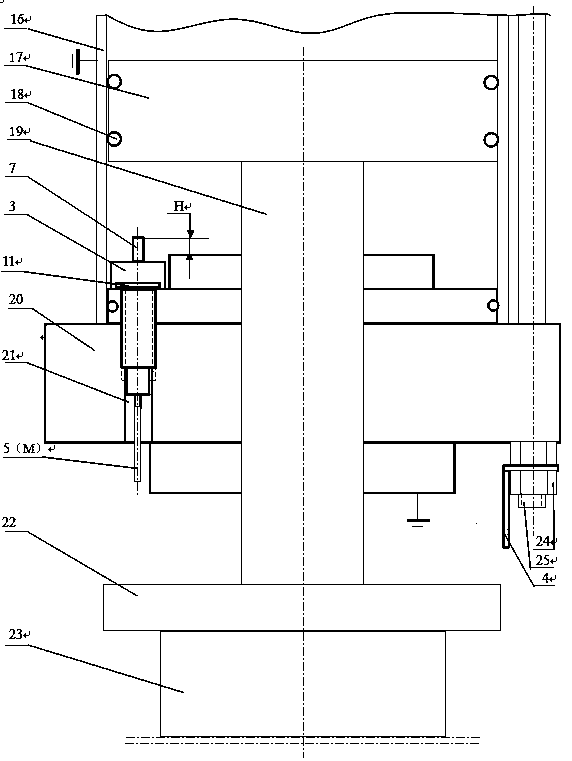

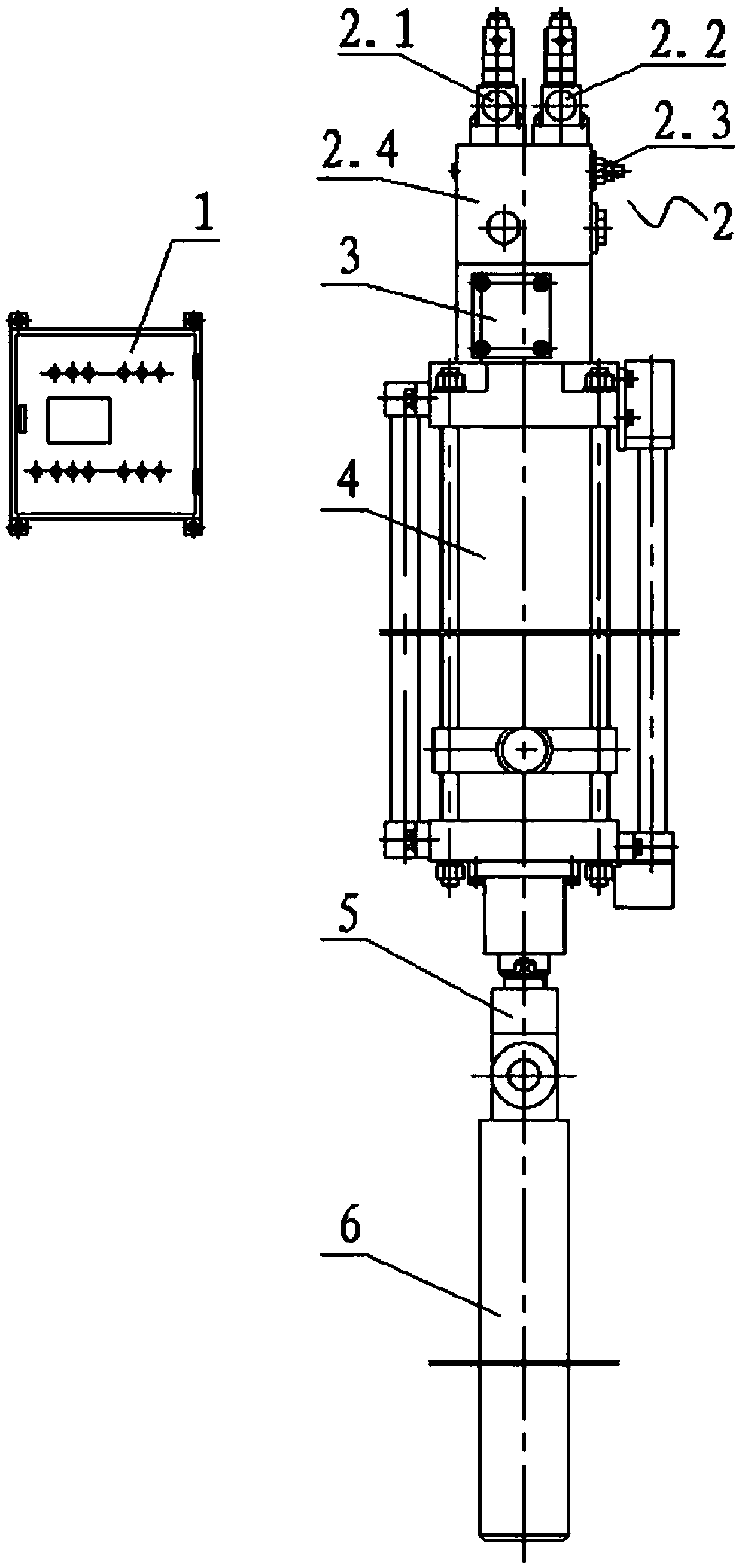

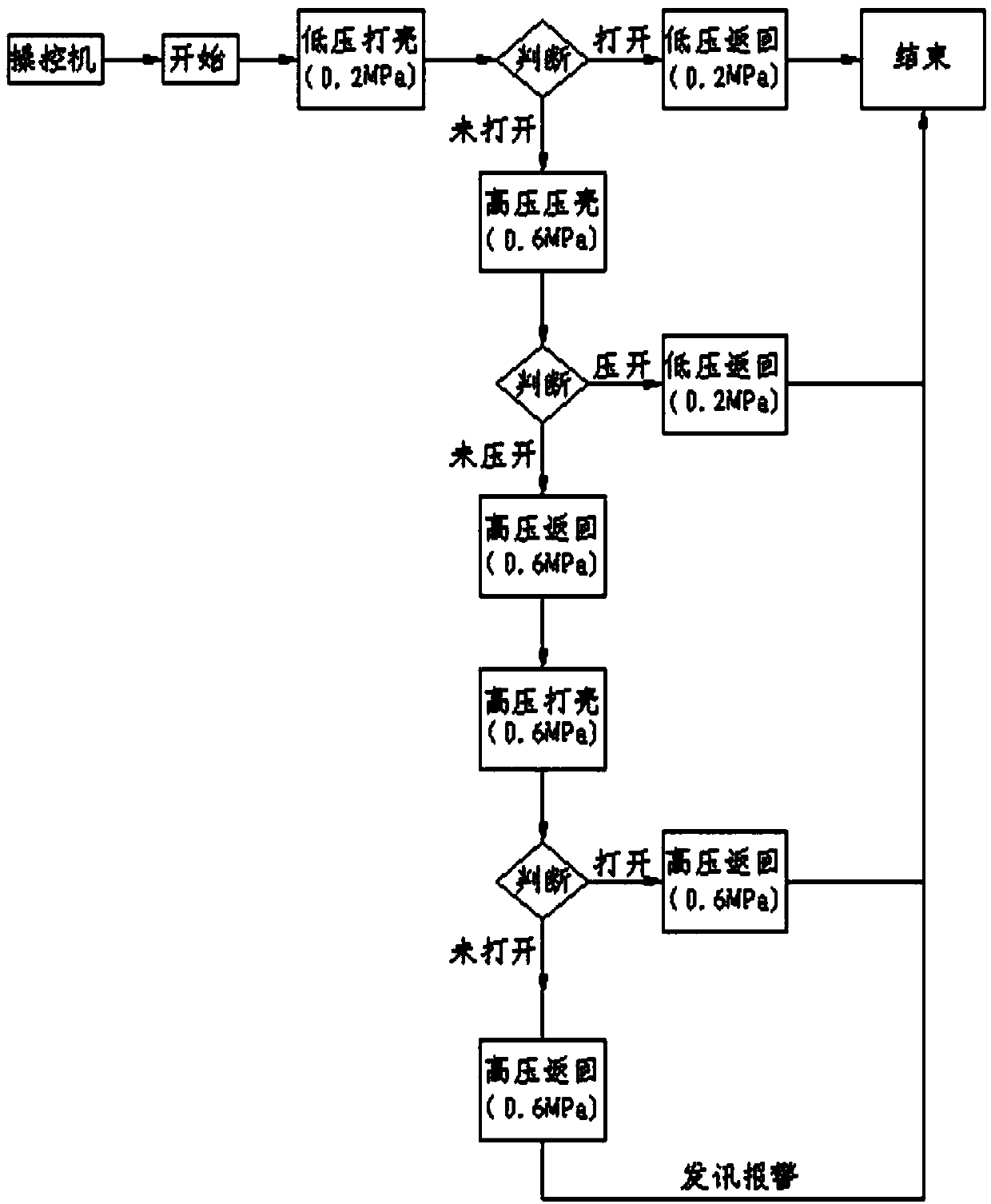

Detecting device for end-reaching of built-in piston of crust breaking cylinder of electrolytic cell

ActiveCN103469254AReduce the number of occurrencesReduce or relieve labor intensityElectrical resistance and conductanceAnode effect

The invention relates to a detecting device for end-reaching of a built-in piston of a crust breaking cylinder of an electrolytic cell. The detecting device comprises the crust breaking cylinder, the electrolytic cell, a built-in detecting sensor and a pull-up resistor, wherein the electrolytic cell comprises a direct-current power supply; a mounting hole is formed in a steel flange at the bottom of the crust breaking cylinder, and the built-in detecting sensor is mounted in the mounting hole; the lower end of the built-in detecting sensor is connected with a high-temperature-resistant pulse conducting wire, the other end of the high-temperature-resistant pulse conducting wire is connected with the pull-up resistor, and the other end of the pull-up resistor is connected with the direct-current power supply; the crust breaking cylinder is connected with a high-temperature-resistant ground wire, and the other end of the high-temperature-resistant ground wire is connected with the grounding terminal of the direct-current power supply. According to the utility model, the built-in detecting sensor is utilized to control a hammer to lift up immediately after a crust breaking hammer head connected with the piston rod of the crust breaking cylinder is broken to the end, so that the crust breaking hammer head is not allowed to stay in electrolyte and seriously adhere the electrolyte; the crust breaking hammer head can break into the electrolyte, so that a discharging opening is unblocked and does not block materials; the frequency of anode effect of the electrolytic cell is effectively reduced, the energy is saved, the consumption is reduced, and the labor strength of electrolytic workers is relieved.

Owner:兰州盛奥电子科技有限公司

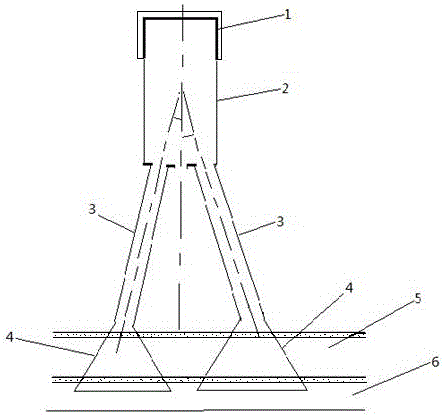

Method for increasing discharging uniformity of aluminum oxide of aluminum cell

The invention provides a method for increasing the discharging uniformity of aluminum oxide of an aluminum cell and relates to the improvement of adischargingmethod of a pre-baked aluminum cell. The method is characterized in that a guide pipe is arranged at a discharging port of an aluminum oxide constant volume blanker in a discharging process; a plurality of branchdischarging pipes are arranged at the lower end of the guide pipe; horn-shaped dischargingfunnels are connected with the lower ends of the branch discharging pipes; and aluminum oxide passes through the guide pipe, the discharging pipes and the dischargingfunnels and then enters electrolyte. According to the method provided by the invention, the discharging uniformity of aluminum oxide of the aluminum cell is increased by increasing the number ofdischarging points, reducing the one-timedischargingvolume of thedischarging points and increasing the dischargingand dispersion area of the aluminum oxide according to the approaching feeding principle. Compared with the present pre-baked cell shell-striking dischargingmethod, the method has the advantages that no shell-striking hammer is arranged, the guide pipe, the dischargingpipes and an opening disperser are directly arranged, the quantity of the discharging points of one cell is above two times of the quantity of the presentdischargingpoints of one cell, thedischarging volume of the dischargingpoints is greatly reduced, the discharginguniformity of aluminum oxide of the aluminum cell is increased, the uniform distribution of the aluminum oxide concentration in the cell is benefited, the generation of sediment and anode effects is avoided, and the energy consumption of the electrolytic cell and the greenhouse gas emission are reduced.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Aluminum alloy fin material for heat exchanger and method ofproduction of same and method of production of heat exchanger by brazing fin material

ActiveCN102051503AImprove conductivityWelding/cutting media/materialsHeat exchange apparatusAnode effectImpurity

Owner:NIPPON LIGHT METAL CO LTD

Intelligent crust breaking system and control method thereof

The invention discloses an intelligent crust breaking system. The intelligent crust breaking system comprises a control cabinet, a combination valve, a signaling adjusting device, a crust breaking aircylinder and a crust breaking chisel. The combination valve comprises a reversing valve, a pressure valve, a pressure adjusting knob and a valve body. The reversing valve and the pressure valve extend out of the top of the valve body. The pressure adjusting knob extends out of one side of the valve body. The signaling adjusting device is installed on one side of the valve body. The valve body isinstalled on a rear end cover of the crust breaking air cylinder. The crust breaking chisel and a piston rod of the crust breaking air cylinder are hinged through a fork rod joint. The combination valve is in wire connection with the control cabinet. According to the intelligent crust breaking system, through several years of research, analysis and trial-production, an on-site experiment in an electrolytic aluminum workshop achieves success, the fact that the crust breaking chisel is non-stick basically is achieved now, the energy-saving effect is obvious, the service life of the crust breaking chisel is significantly improved, the labor intensity and workload of workers are greatly reduced, the anode effect is significantly reduced, the product output and quality are improved, and the enterprise cost is reduced.

Owner:大连怡和工业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com