Method and system for controlling addition of powdery materials to the bath of an electrolysis cell for the production of aluminium

A control method and technology for powdery materials, which are applied in the field of dry electrolysis to produce aluminum, and can solve problems such as sensitivity to voltage fluctuations in electrolytic cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

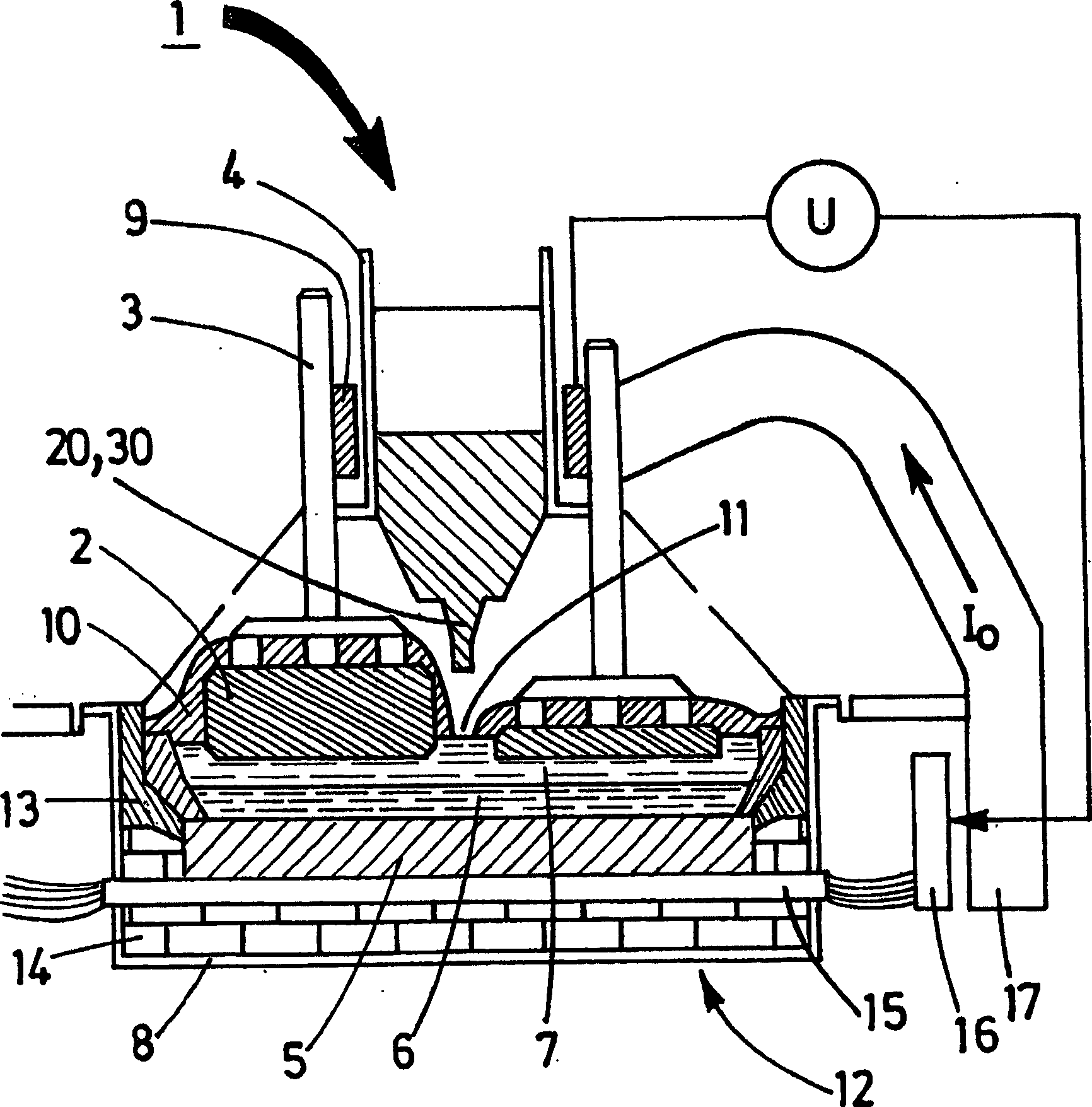

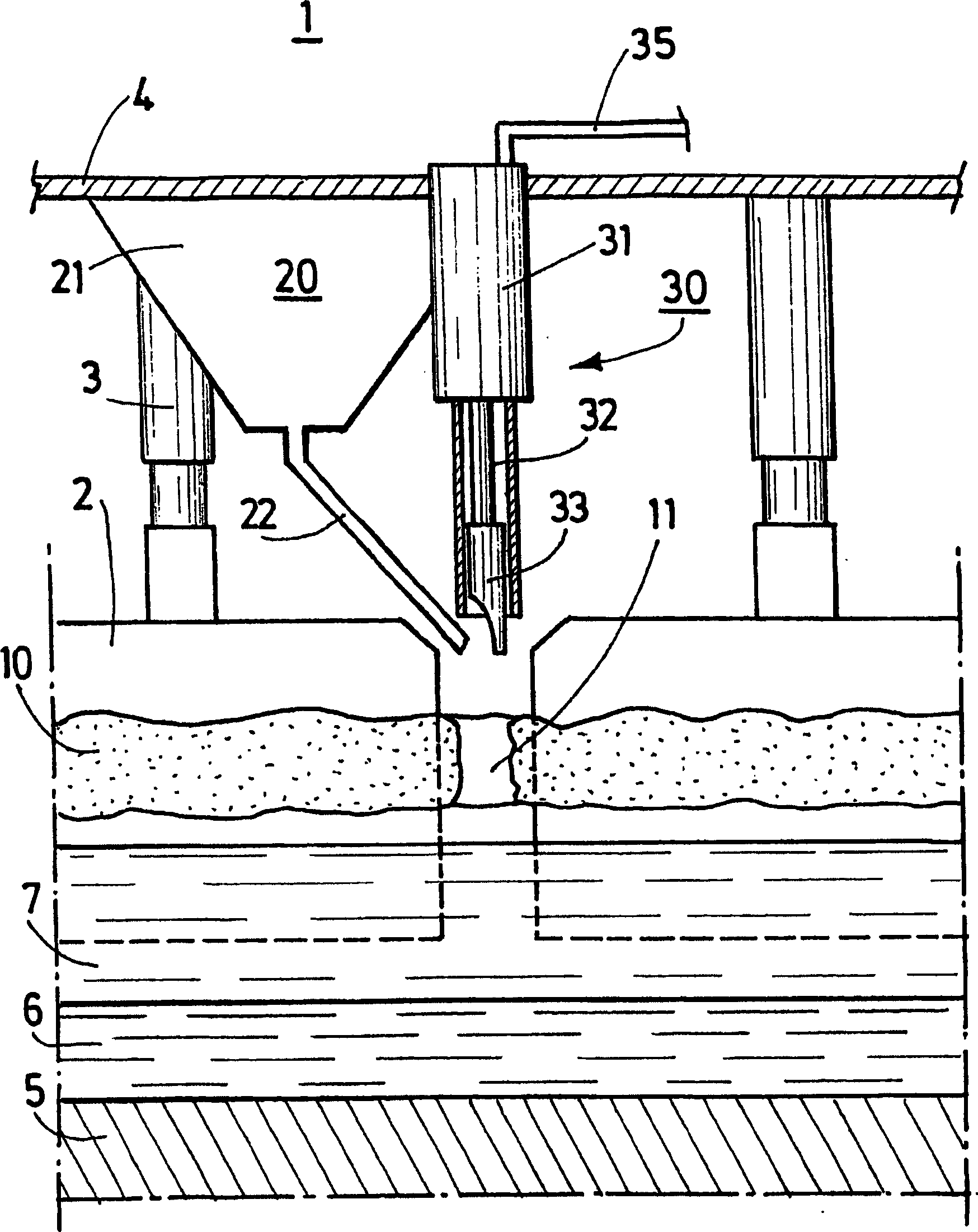

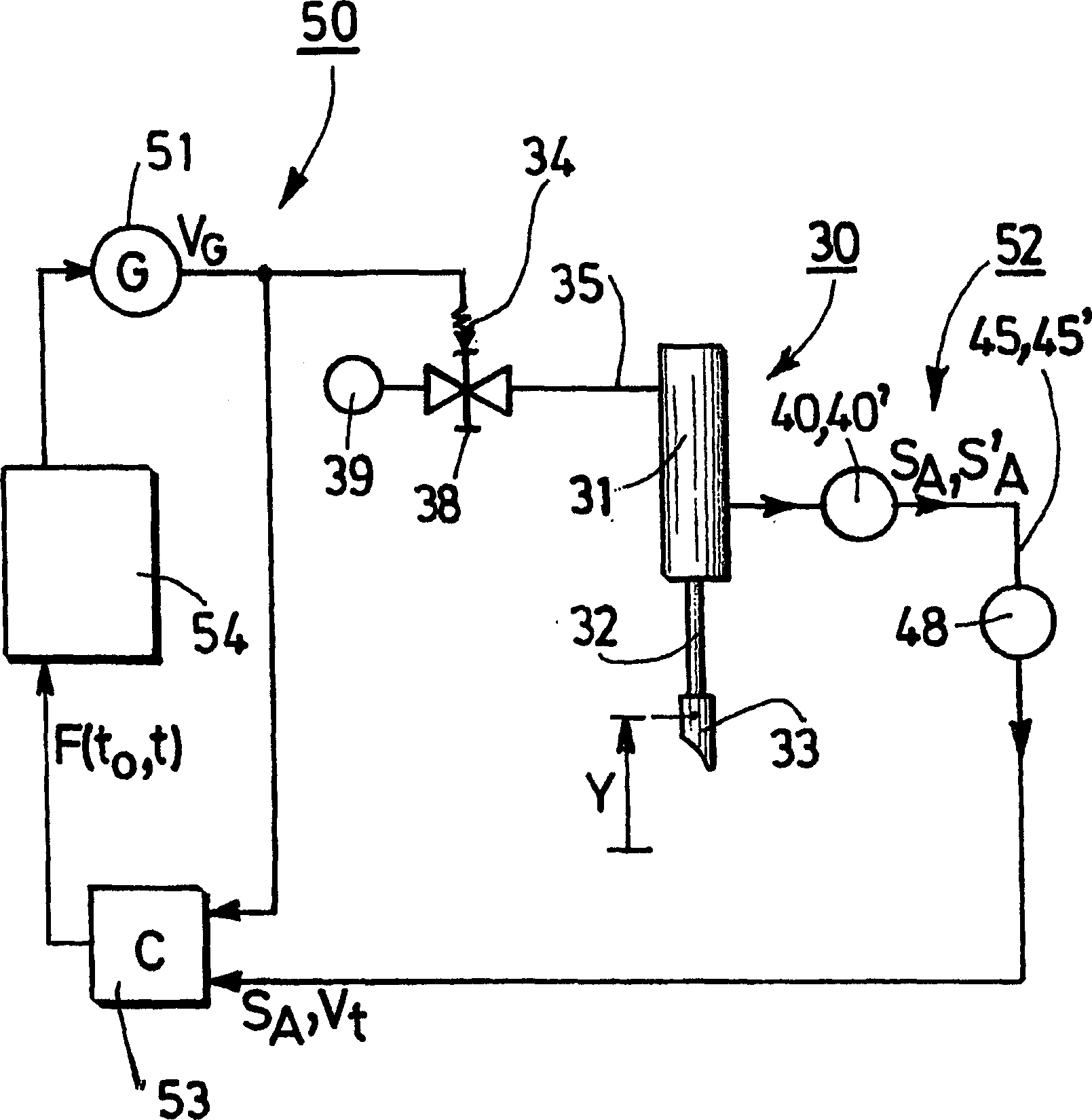

[0027] [27] As in figure 1 As shown above, an electrolytic cell 1 for producing aluminum by dry electrolysis, that is, molten salt electrolysis, includes: a tank 12, an anode 2 and powdery material supply devices 20,30. The anode 2 , usually a prebaked anode made of carbonaceous material, is supported by a rod 3 on an anode beam 9 . The electrolytic cell 12 includes a metal shell 8, usually steel, inner liners 13, 14 and a cathode assembly 5-15. The cathode assembly 5-15 includes a connecting rod 15, called a cathode rod, on which are fixed electrical conductors 16, 17 for delivering electrolysis current Io. The liners 13, 14 and the cathode assembly 5-15 form a crucible inside the tank (12), which is adapted to contain the electrolyte 7 and a layer 6 of liquid aluminum when the cell is in operation.

[0028] [28] A plurality of electrolytic cells are generally arranged in a line and are electrically connected together in series by means of connecting conductors 16,17. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com