Patents

Literature

11578 results about "Fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluoride (/ˈflʊəraɪd, ˈflɔːr-/) is an inorganic, monatomic anion with the chemical formula F⁻ (also written [F]⁻), whose salts are typically white or colorless. Fluoride salts typically have distinctive bitter tastes, and are odorless. Its salts and minerals are important chemical reagents and industrial chemicals, mainly used in the production of hydrogen fluoride for fluorocarbons. Fluoride is classified as a weak base since it only partially associates in solution, but concentrated fluoride is corrosive and can attack the skin.

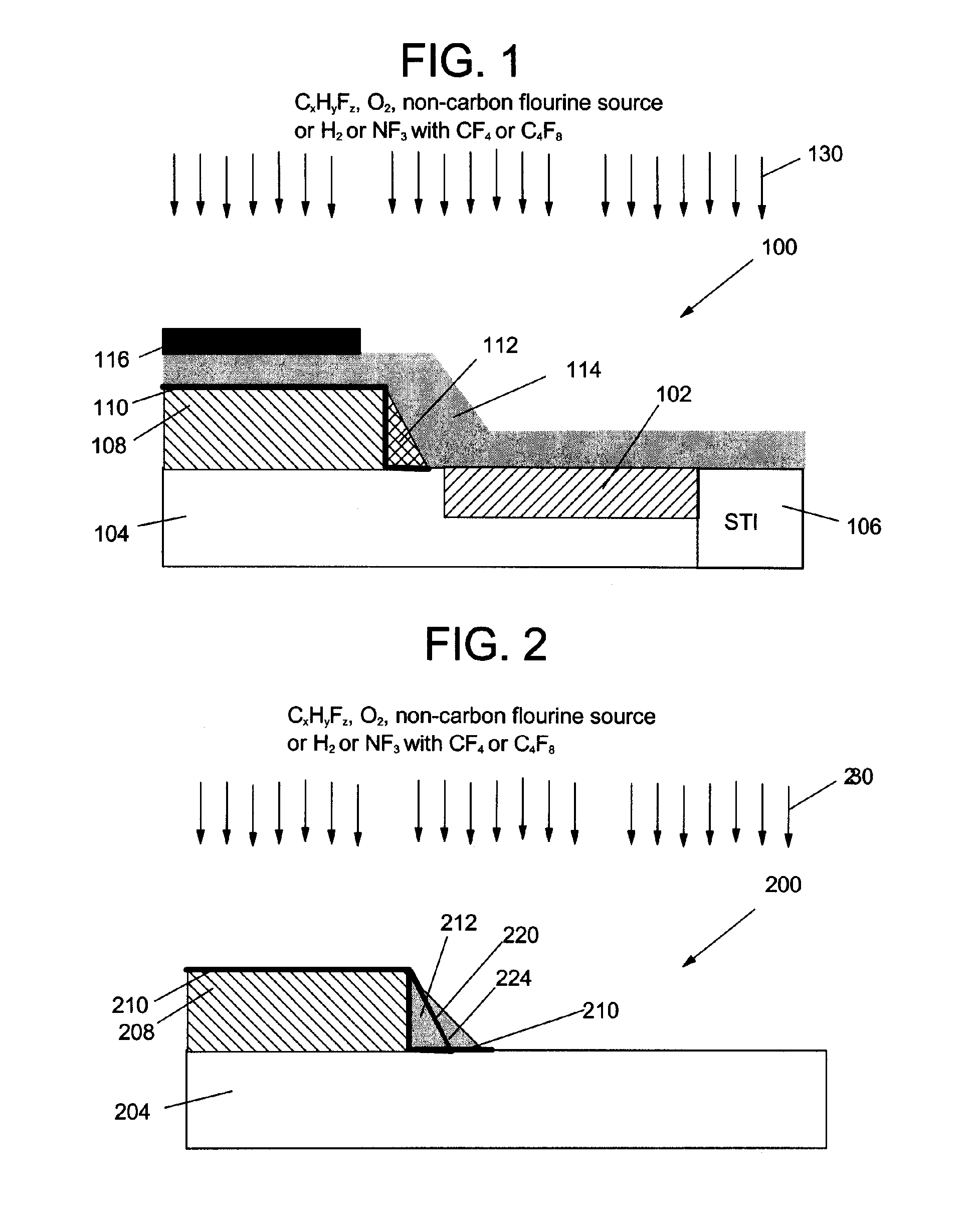

Silicon nitride etching methods

ActiveUS7288482B2Semiconductor/solid-state device manufacturingSulfur hexafluorideOctafluorocyclobutane

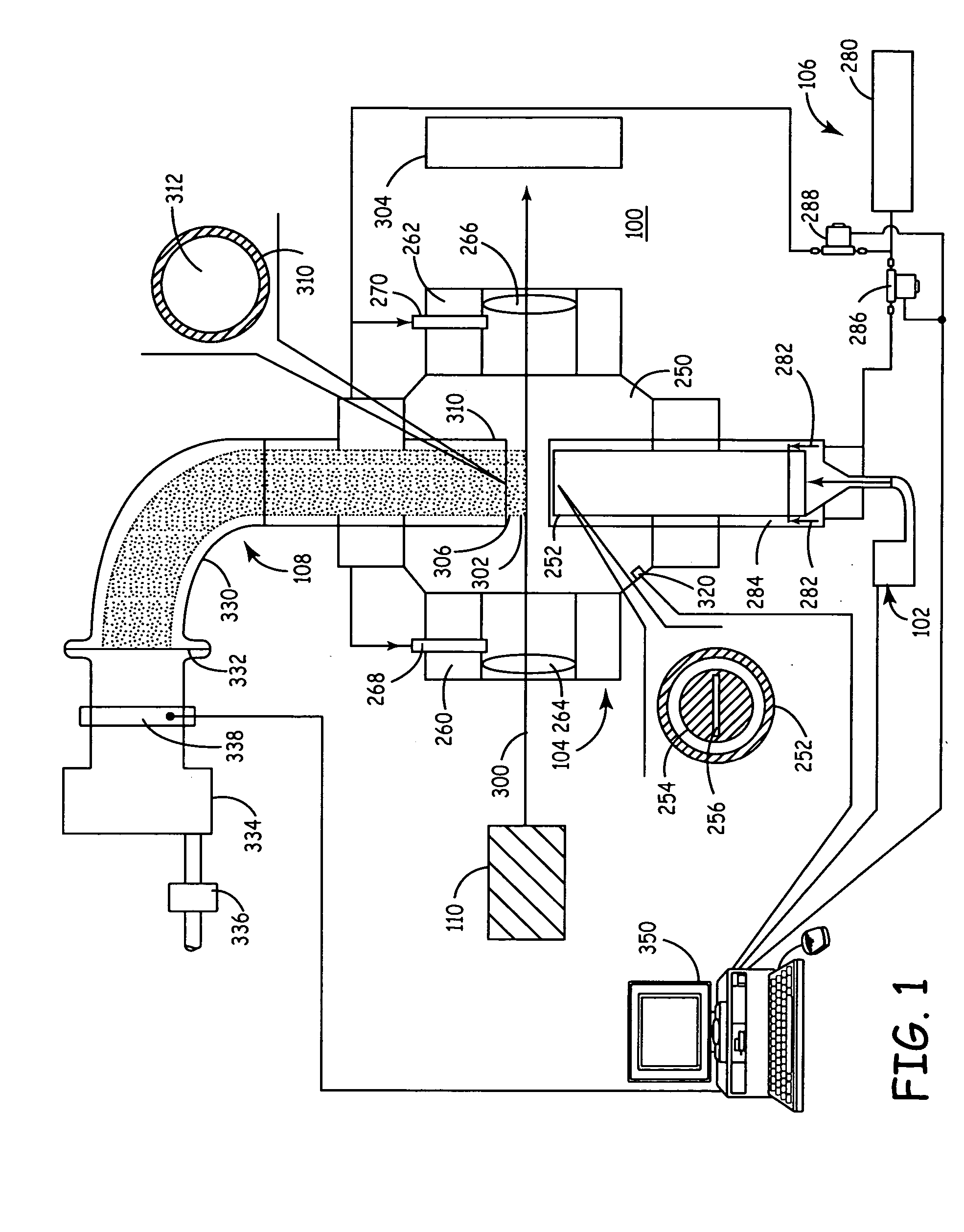

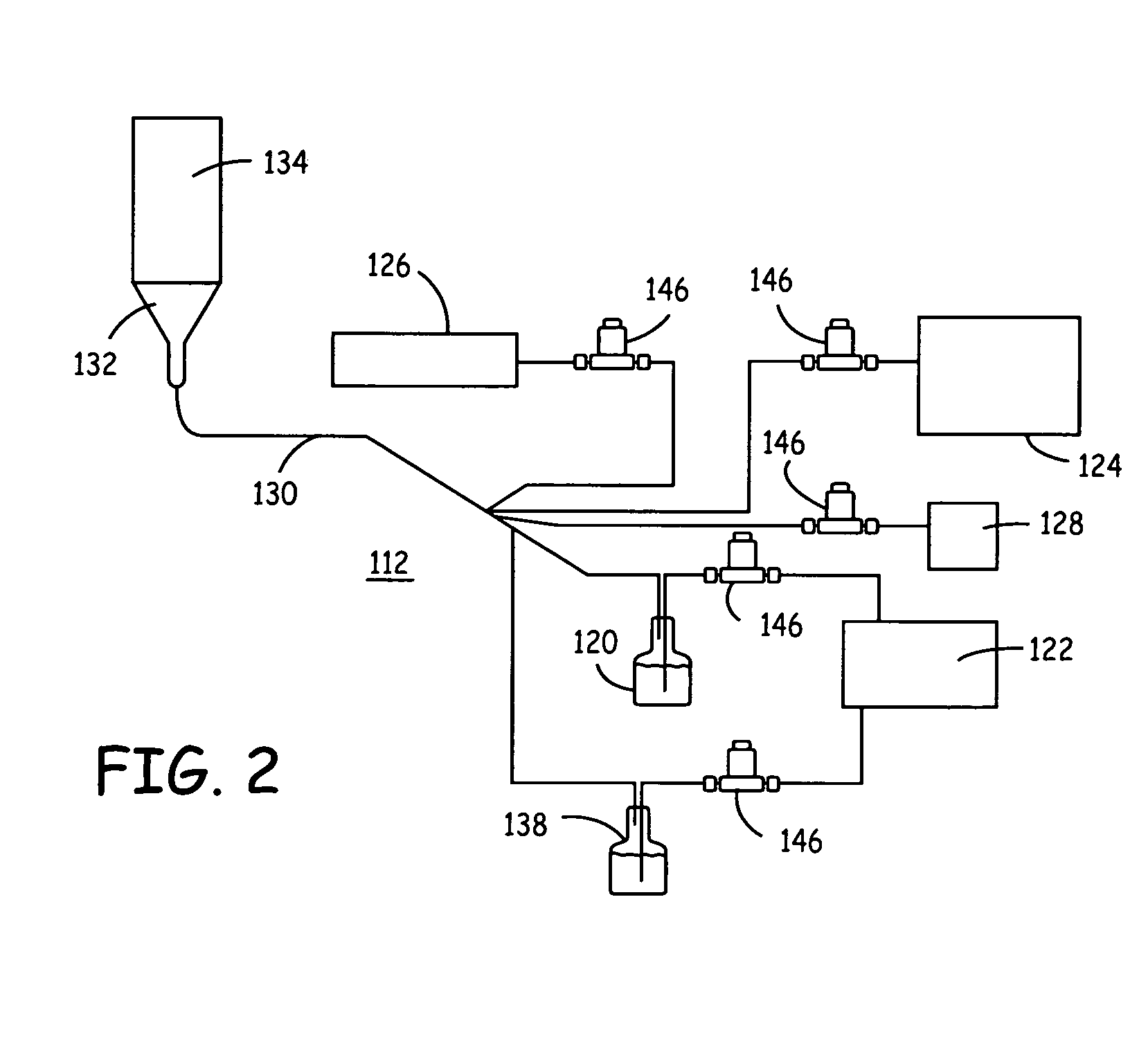

Methods of etching silicon nitride material, and more particularly, etching nitride selective to silicon dioxide or silicide, are disclosed. The methods include exposing a substrate having silicon nitride thereon to a plasma including at least one fluorohydrocarbon and a non-carbon containing fluorine source such as sulfur hexafluoride (SF6). The plasma may also include oxygen (O2) and the fluorohydrocarbons may include at least one of: trifluoromethane (CHF3), difluoromethane (CH2F2), and methyl fluoride (CH3F). In an alternative embodiment, the plasma includes one of hydrogen (H2) and nitrogen trifluoride (NF3) and one of tetrafluoromethane (CF4) and octafluorocyclobutane (C4F8). The methods are preferably carried out using a low bias voltage, e.g. <100 V.

Owner:IBM CORP +1

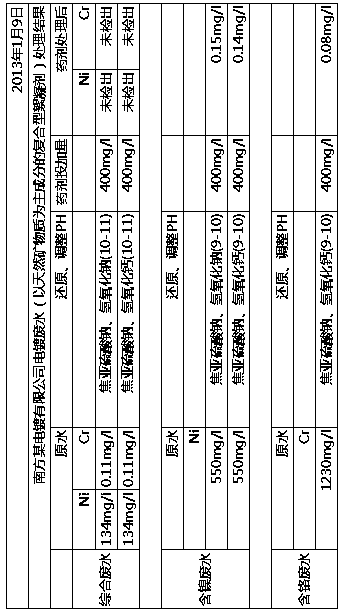

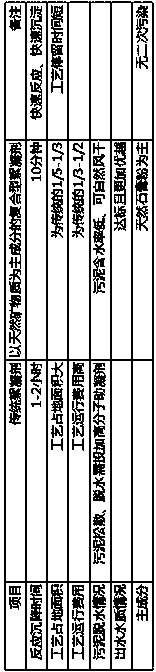

Compound flocculant taking natural minerals as main components

InactiveCN104229957AEfficient removalApplicable to a wide range of PHWater resource protectionWater/sewage treatment by flocculation/precipitationDry weightNatural mineral

The invention discloses a compound flocculant taking natural minerals as main components. The compound flocculant is mainly prepared from the following components by weight percent: 60%-85% of natural minerals, 8%-38% traditional inorganic flocculant and 3%-10% of organic polymer flocculant. According to the invention, key points are as follows: in the compound flocculant taking natural minerals as main components, the weight of the natural minerals, the inorganic flocculant and the organic polymer flocculant is dry weight; and the compound flocculant is implemented to purification of civil engineering wastewater, natural water, industrial wastewater, oily wastewater, fluoride wastewater, food processing wastewater, auto parts processing wastewater, colored wastewater, clean wastewater, semiconductor processing wastewater, restaurant waste water, mine water, slaughter wastewater, grinding wastewater, sewage effluent and the like.

Owner:张家领

Coatings for enhancement of properties and performance of substrate articles and apparatus

PendingUS20180044800A1Avoid reactionGood semiconductor performanceSemi-permeable membranesVacuum evaporation coatingCoated surfaceReactive gas

Coatings applicable to a variety of substrate articles, structures, materials, and equipment are described. In various applications, the substrate includes metal surface susceptible to formation of oxide, nitride, fluoride, or chloride of such metal thereon, wherein the metal surface is configured to be contacted in use with gas, solid, or liquid that is reactive therewith to form a reaction product that is deleterious to the substrate article, structure, material, or equipment. The metal surface is coated with a protective coating preventing reaction of the coated surface with the reactive gas, and / or otherwise improving the electrical, chemical, thermal, or structural properties of the substrate article or equipment. Various methods of coating the metal surface are described, and for selecting the coating material that is utilized.

Owner:ENTEGRIS INC

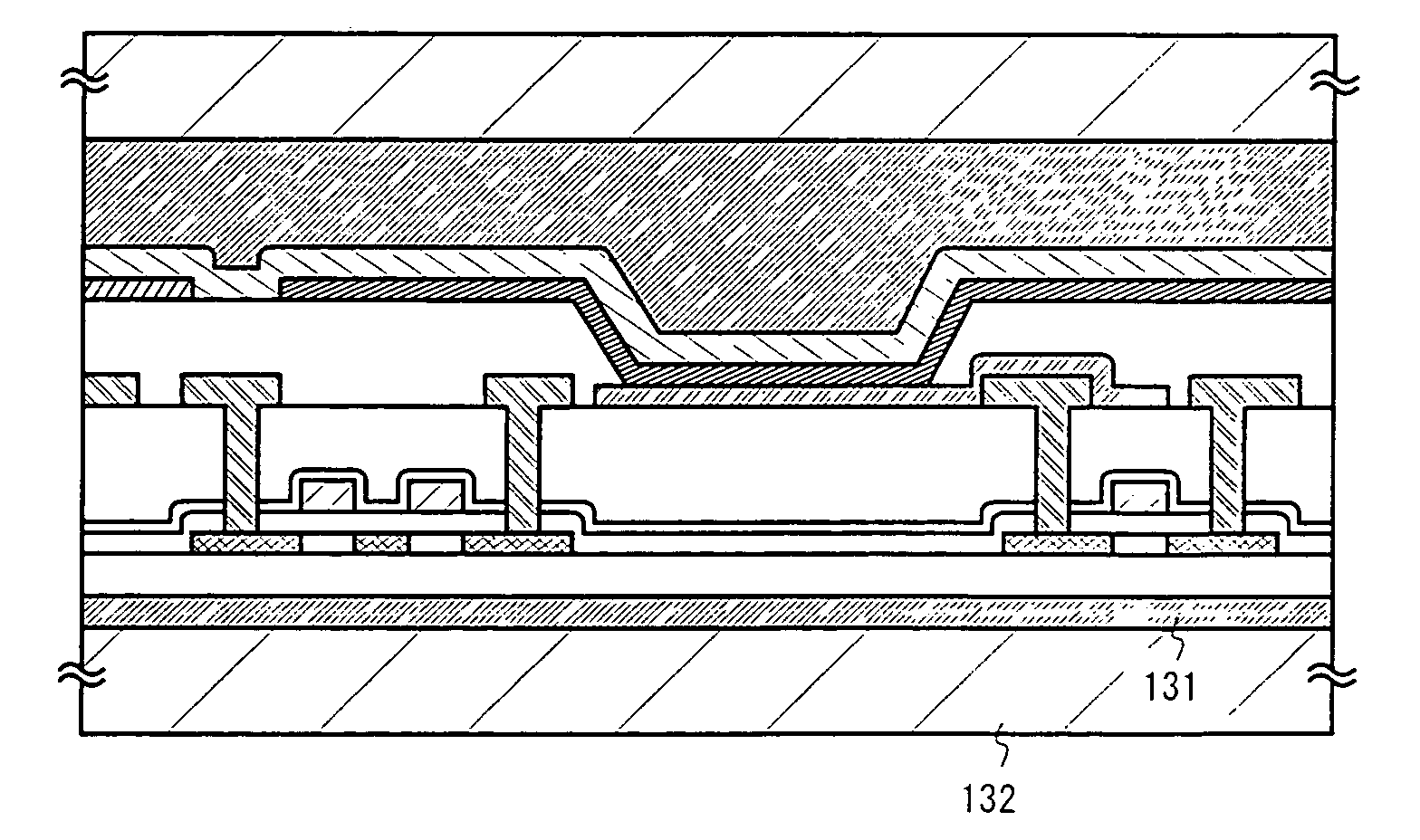

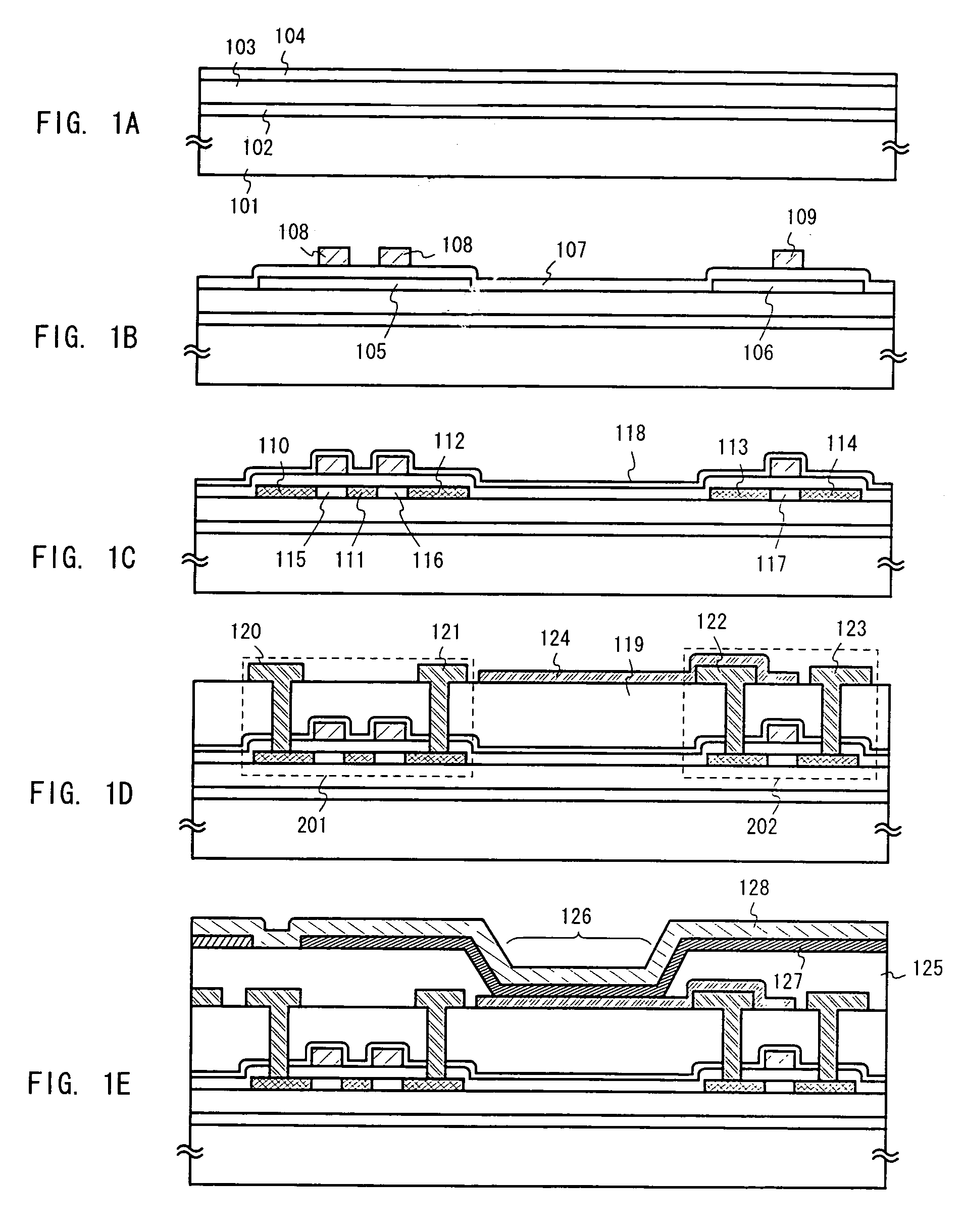

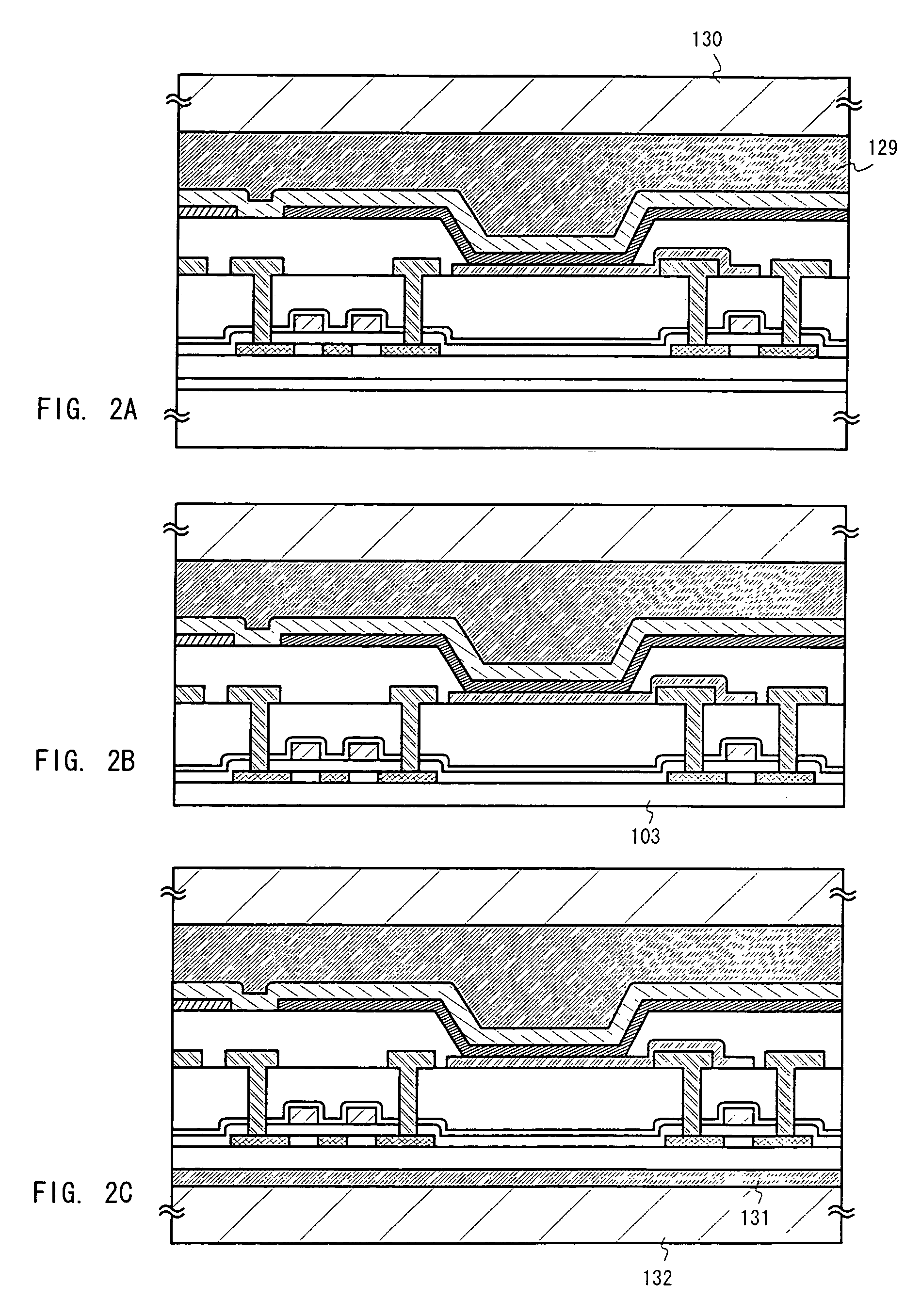

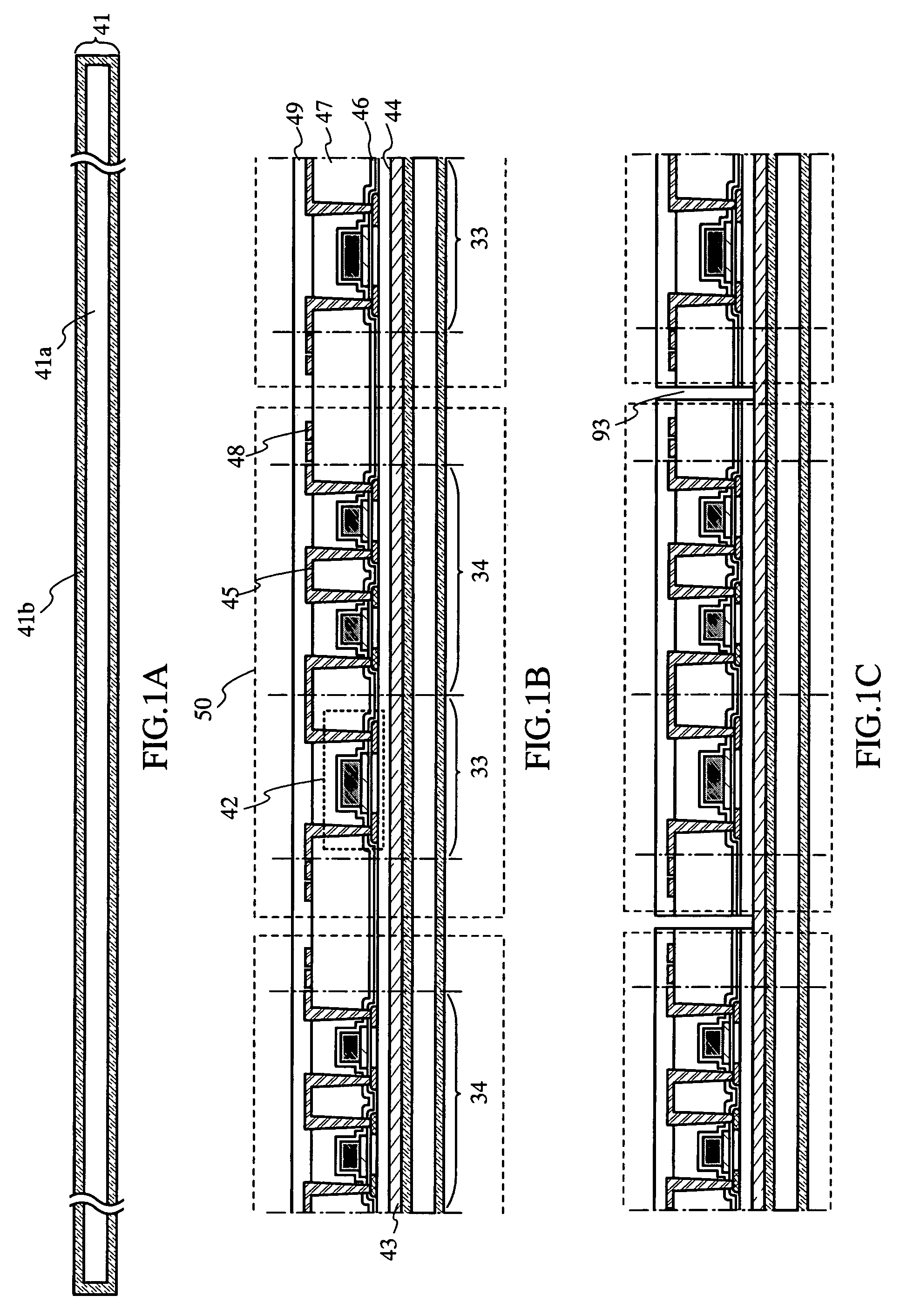

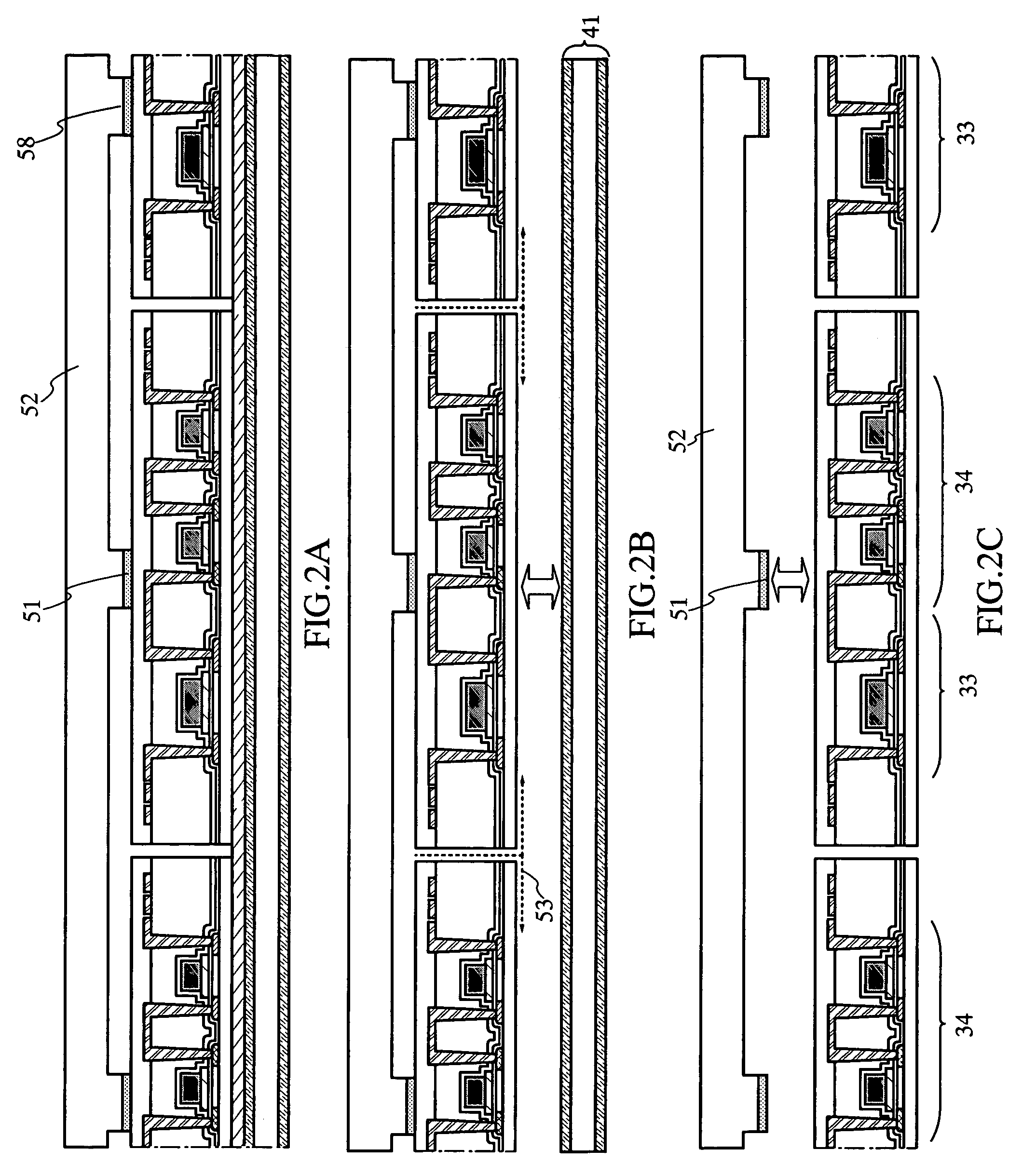

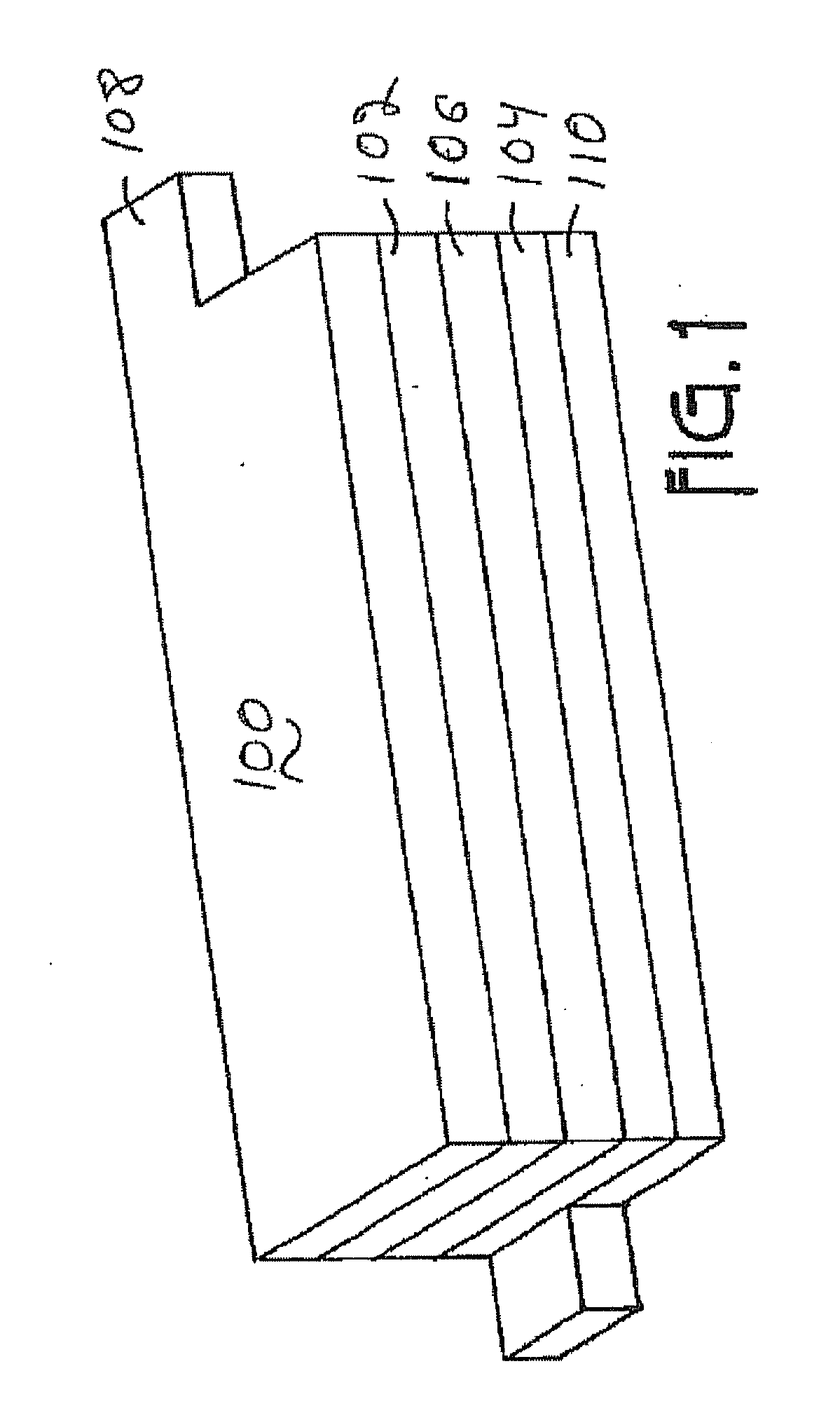

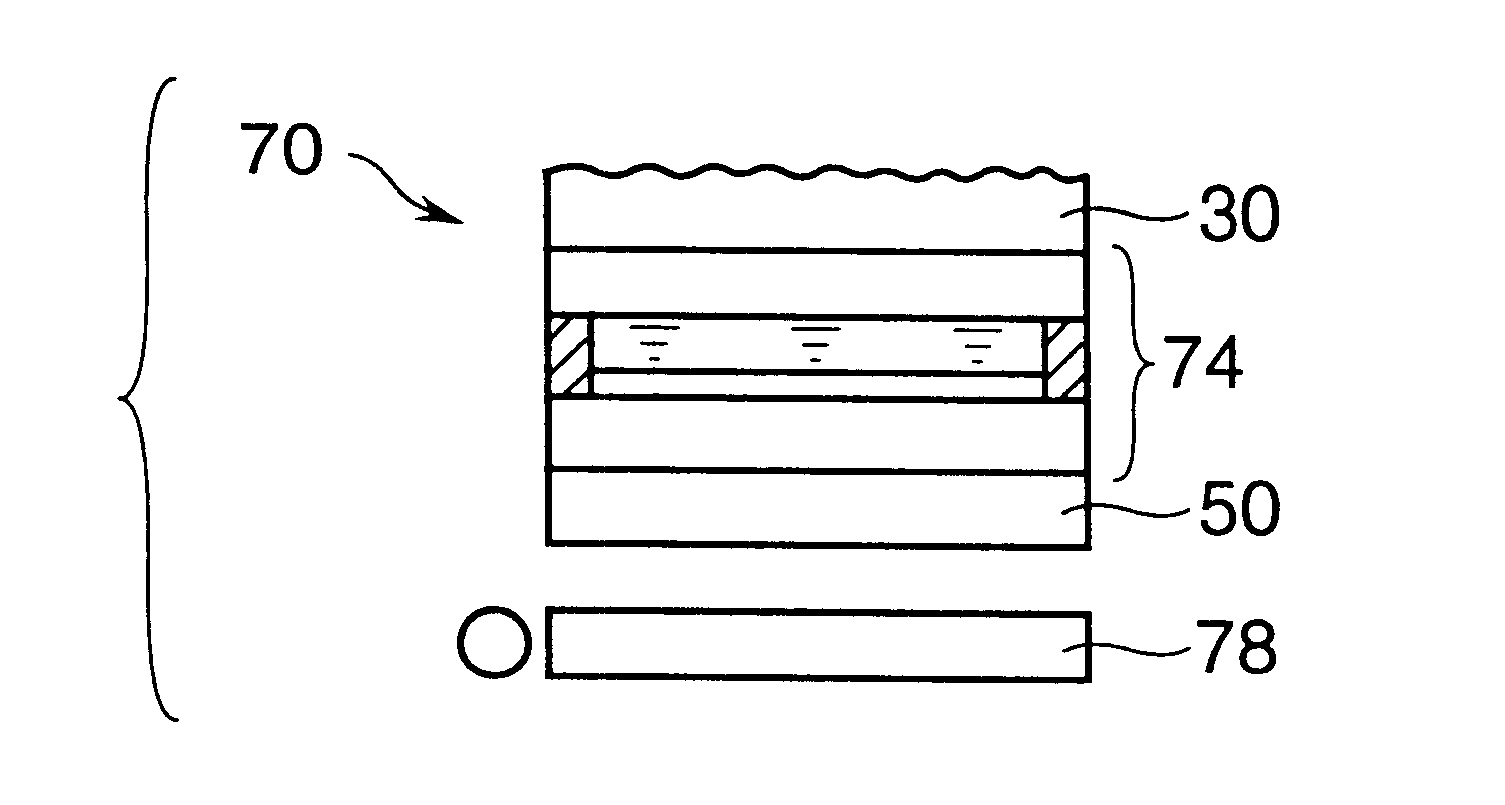

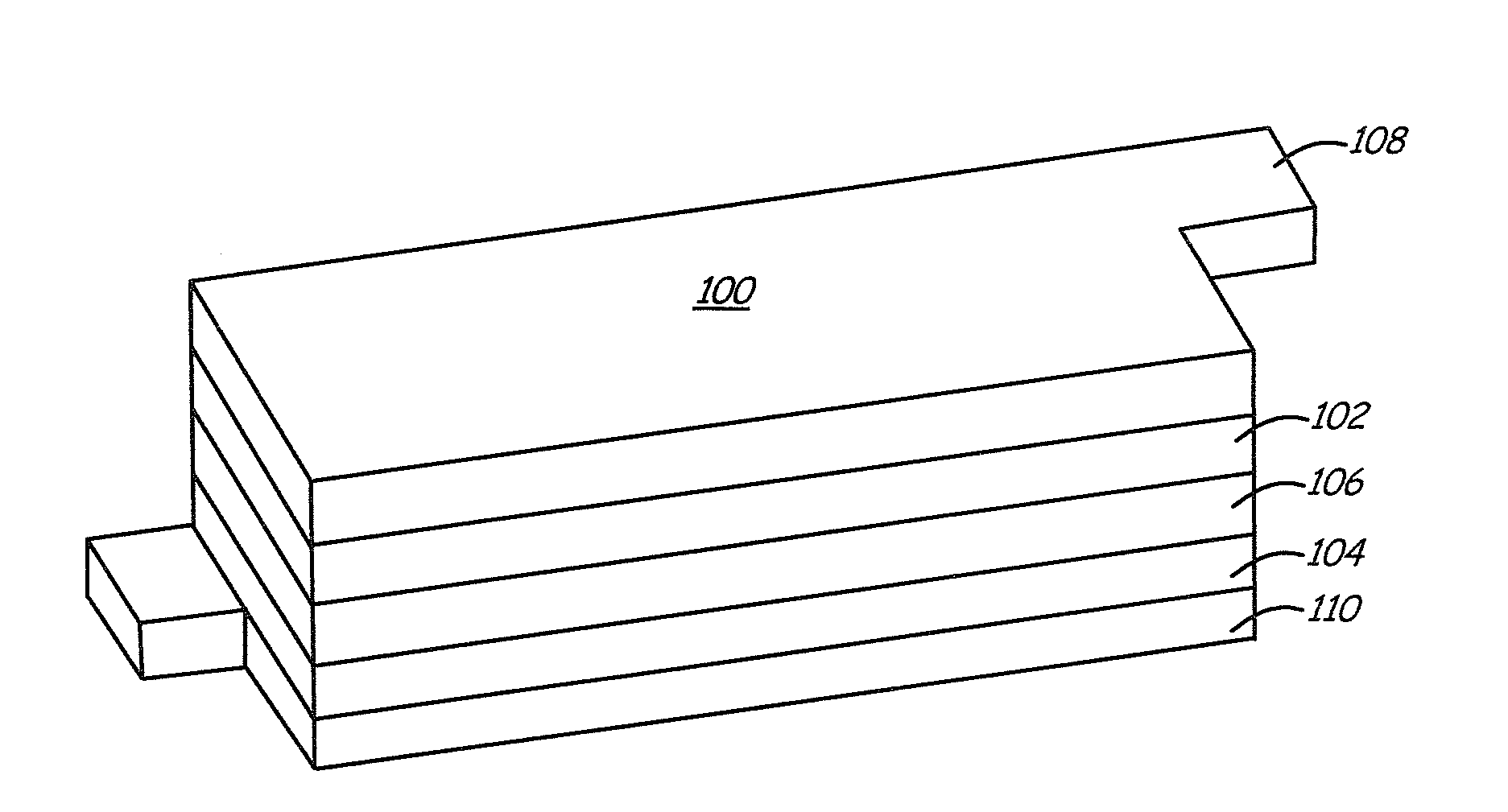

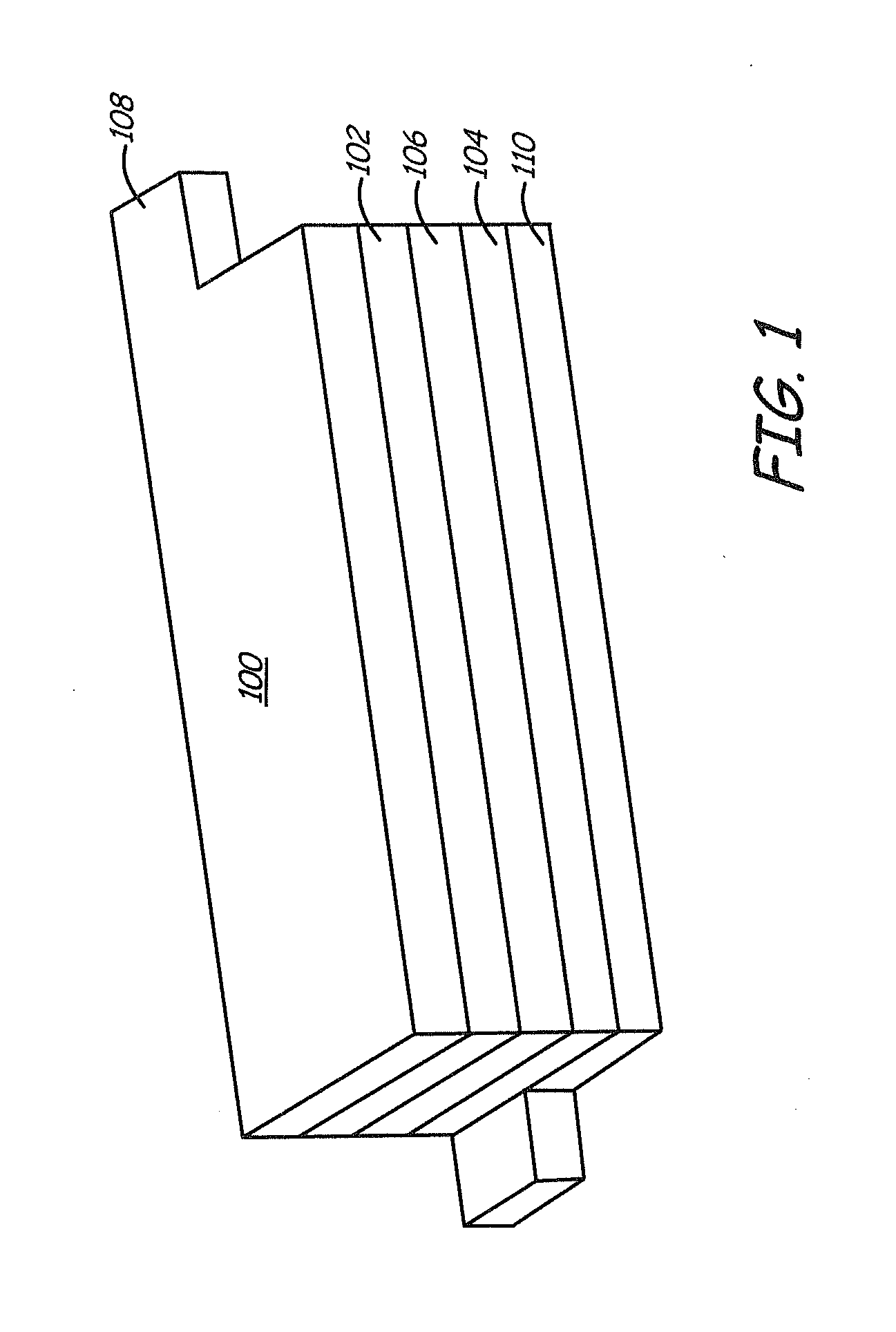

Display device and method of manufacturing the same

InactiveUS7060153B2Low heat resistanceLamination ancillary operationsSolid-state devicesAdhesiveDisplay device

To provide a technique for manufacturing a high-performance display device by employing a plastic substrate. A peeling layer is formed on an element-forming substrate, and a semiconductor element and a luminous element are further formed thereon. Then, a fixed substrate (130) is bonded on the luminous element by using a first adhesive (129). The entire substrate in this state is exposed in a gas containing halogen fluoride to thereby remove the peeling layer and separate the element-forming substrate. Thereafter, a bonding substrate (132) that comprises a plastic substrate is bonded in place of the separated element-forming substrate.

Owner:SEMICON ENERGY LAB CO LTD

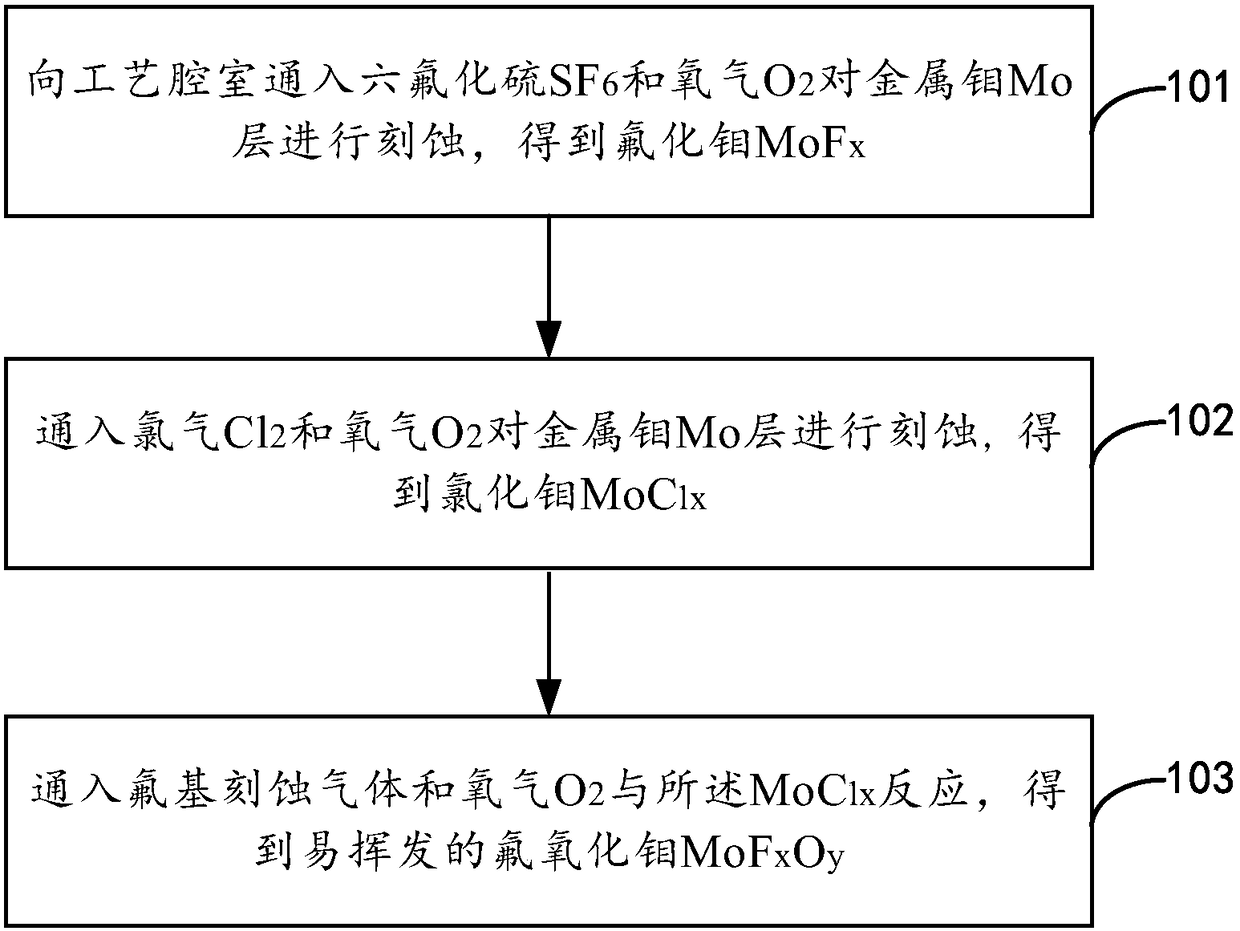

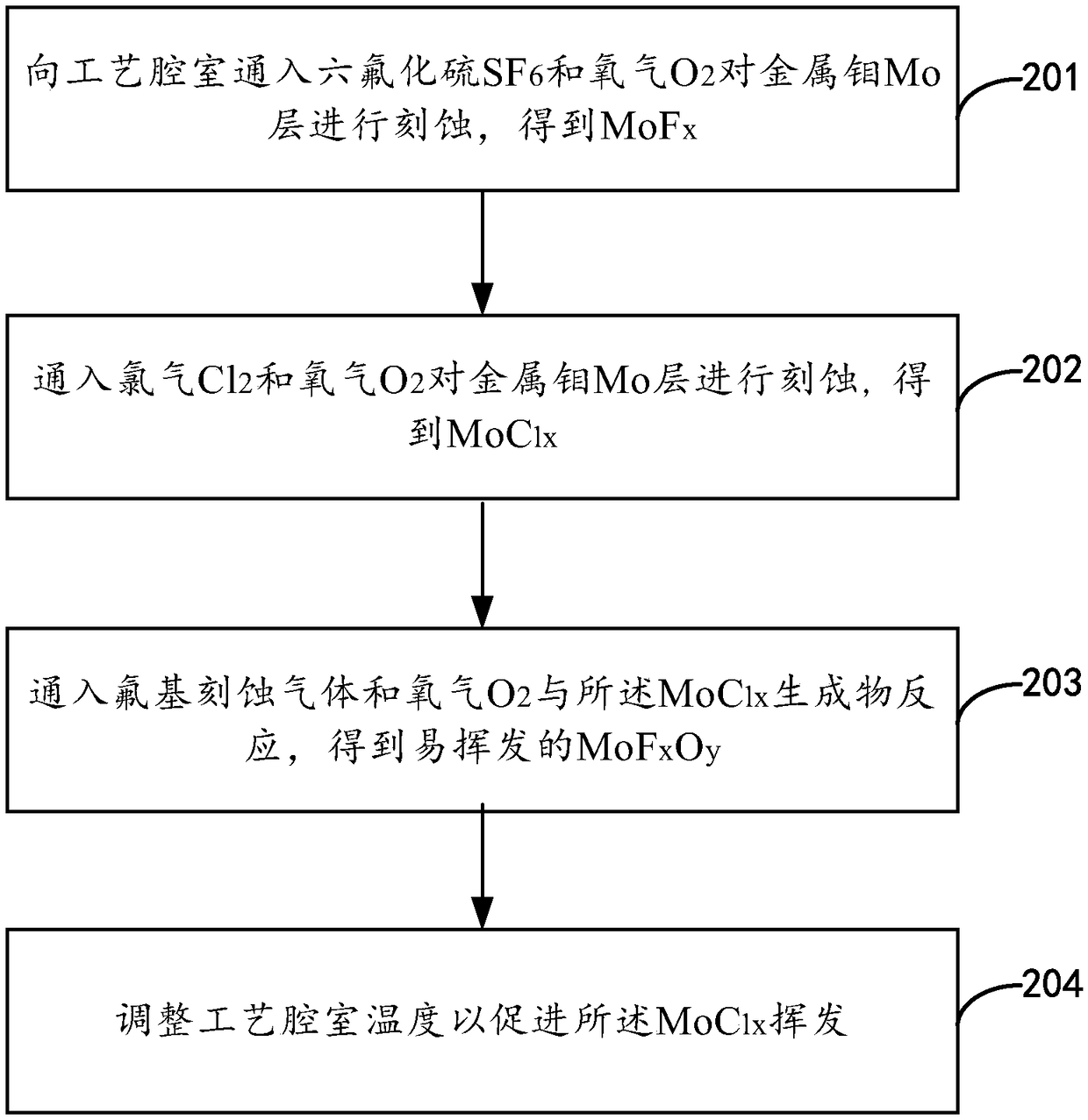

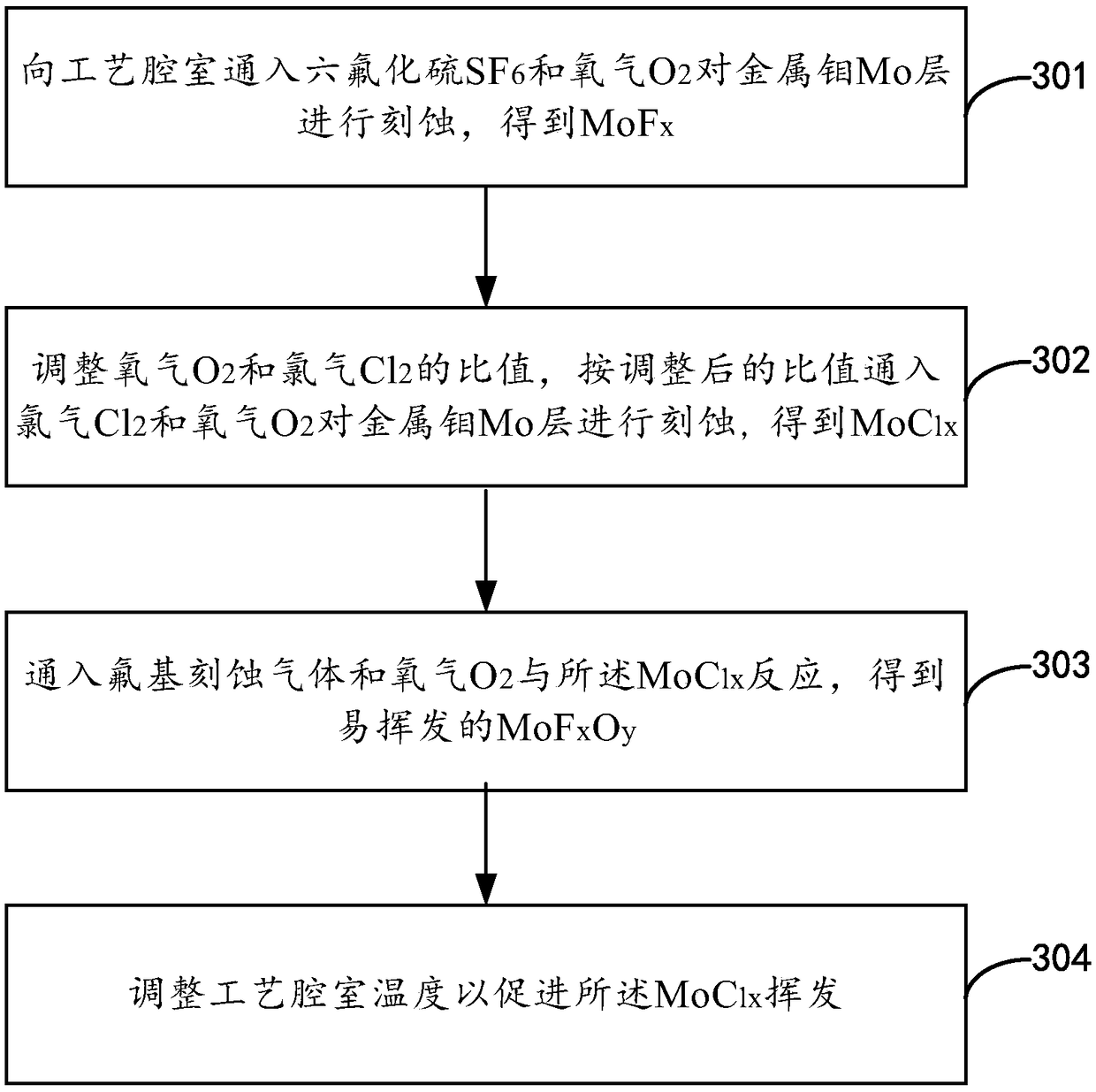

Etching method, low-temperature polysilicon thin film transistor and AMOLED panel

ActiveCN108389798AEasy to handlePrevent dark spotsTransistorSolid-state devicesSulfur hexafluorideOxygen

Owner:TRULY HUIZHOU SMART DISPLAY

Positive electrode materials for lithium ion batteries having a high specific discharge capacity and processes for the synthesis of these materials

ActiveUS20100086853A1Electrode manufacturing processesAlkali metal oxidesDischarge rateLithium-ion battery

Owner:IONBLOX INC

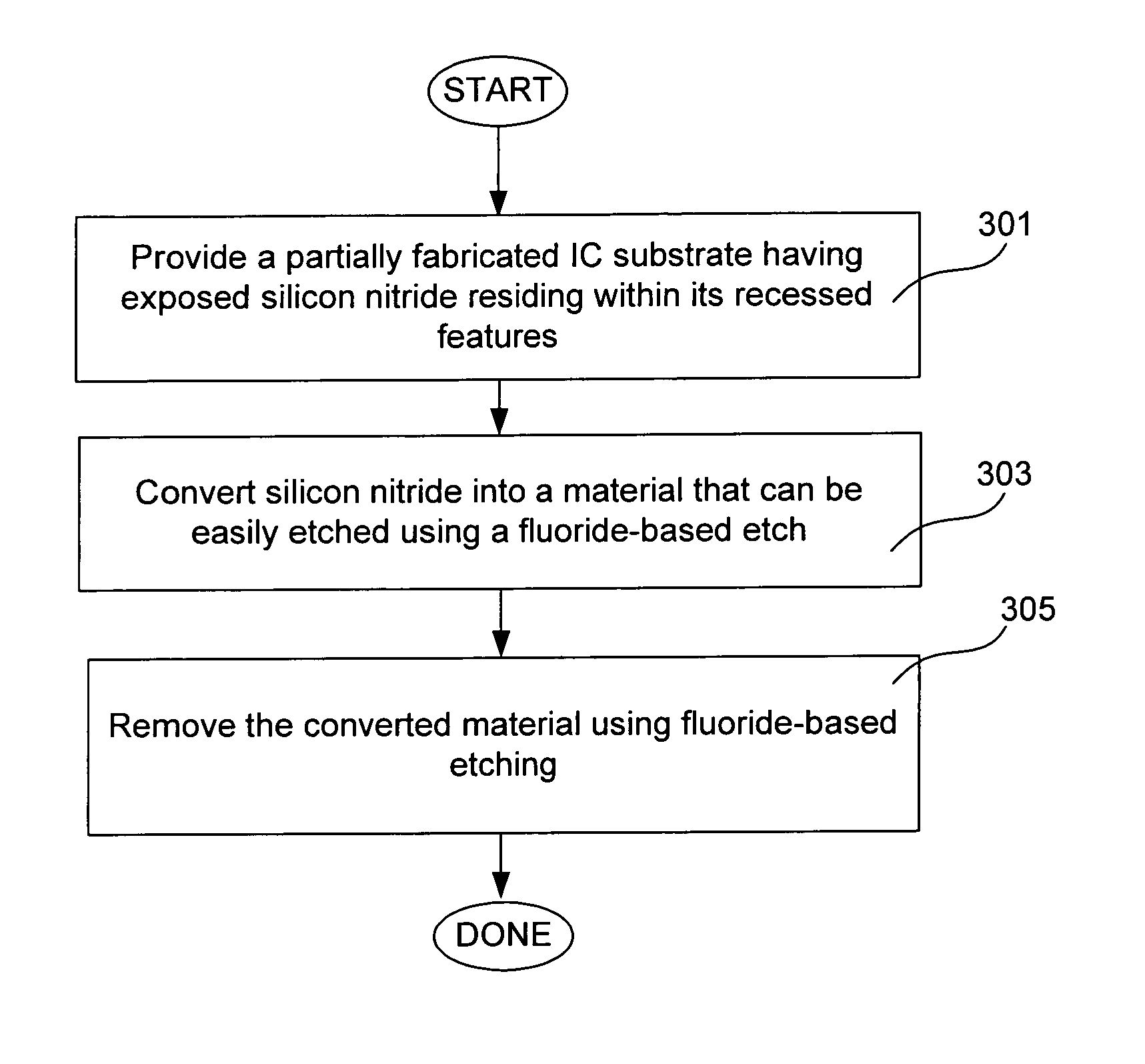

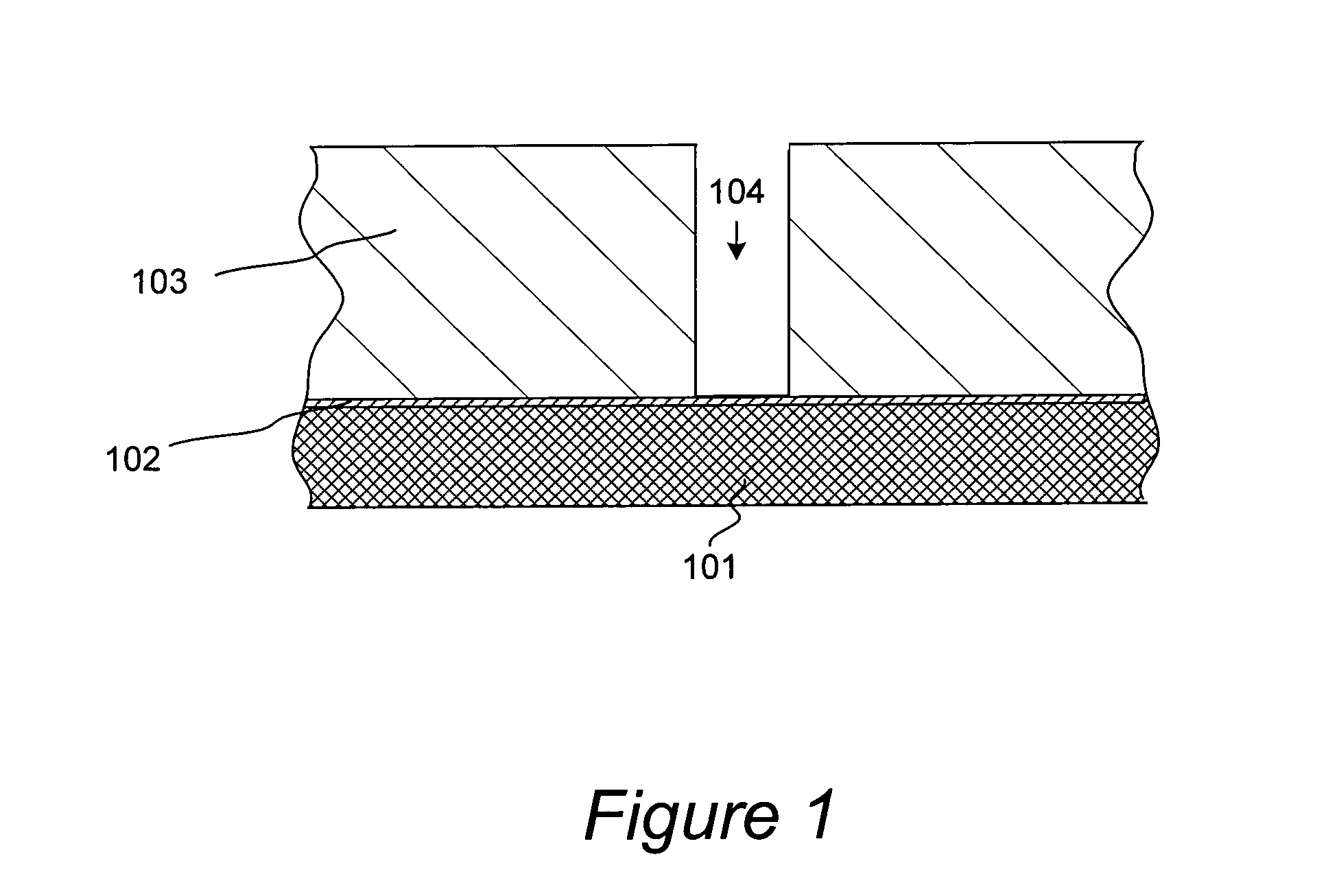

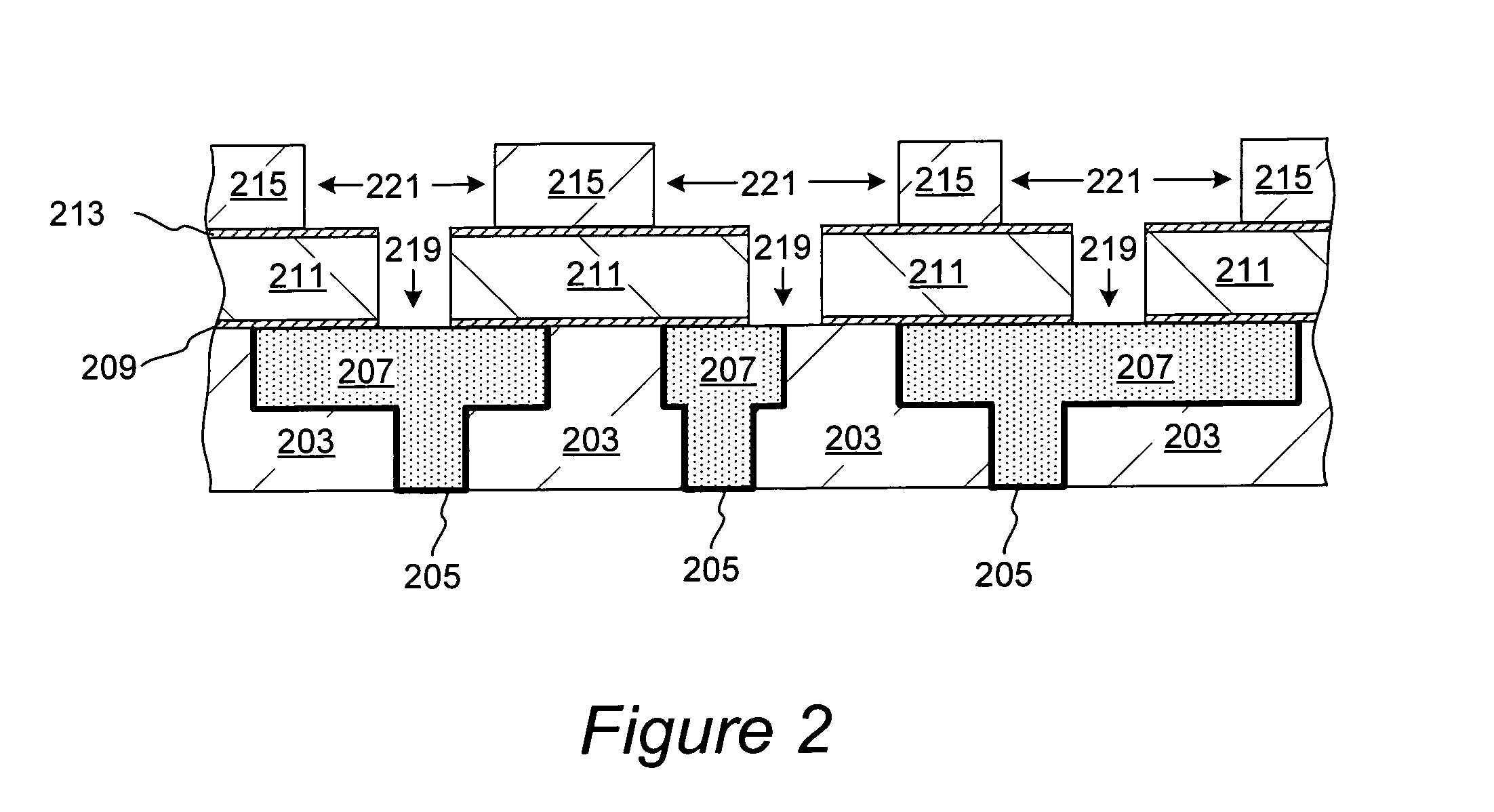

Methods for removing silicon nitride and other materials during fabrication of contacts

ActiveUS7977249B1Easy to etchMinimizes unwanted increaseDecorative surface effectsSemiconductor/solid-state device manufacturingHydrogenContact method

Methods for removing silicon nitride and elemental silicon during contact preclean process involve converting these materials to materials that are more readily etched by fluoride-based etching methods, and subsequently removing the converted materials by a fluoride-based etch. Specifically, silicon nitride and elemental silicon may be treated with an oxidizing agent, e.g., with an oxygen-containing gas in a plasma, or with O2 or O3 in the absence of plasma to produce a material that is more rich in Si—O bonds and is more easily etched with a fluoride-based etch. Alternatively, silicon nitride or elemental silicon may be doped with a number of doping elements, e.g., hydrogen, to form materials which are more easily etched by fluoride based etches. The methods are particularly useful for pre-cleaning contact vias residing in a layer of silicon oxide based material because they minimize the unwanted increase of critical dimension of contact vias.

Owner:NOVELLUS SYSTEMS

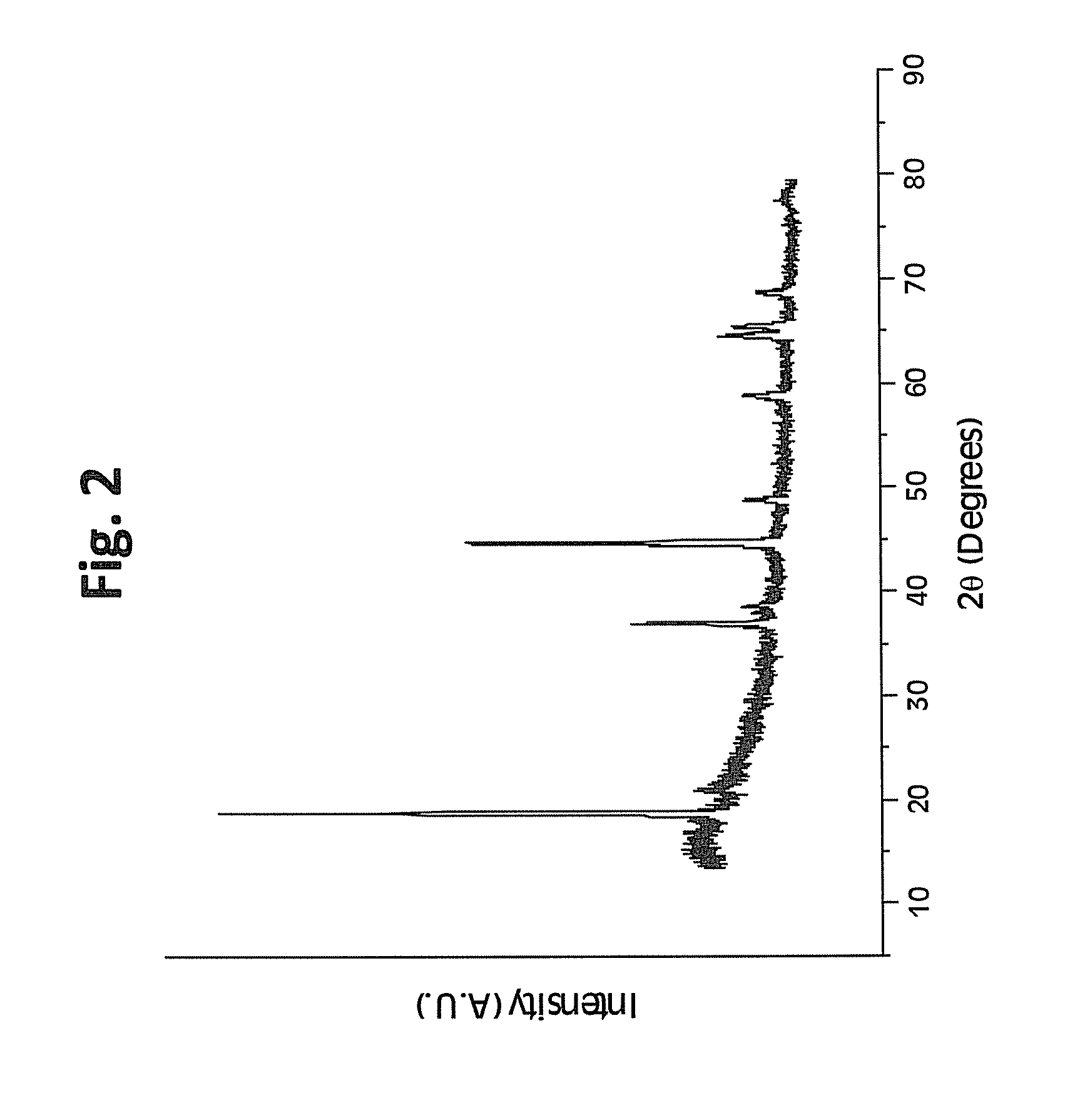

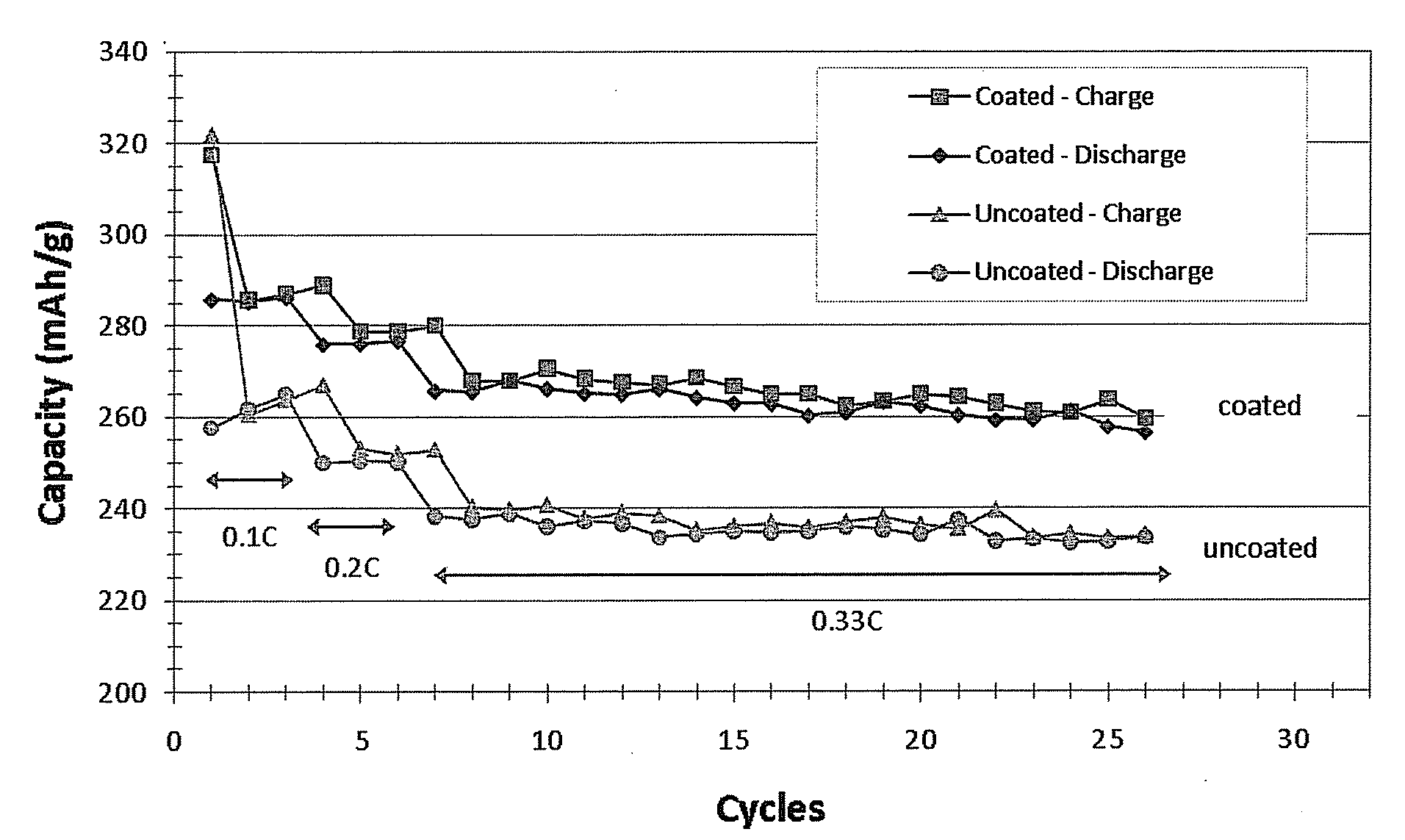

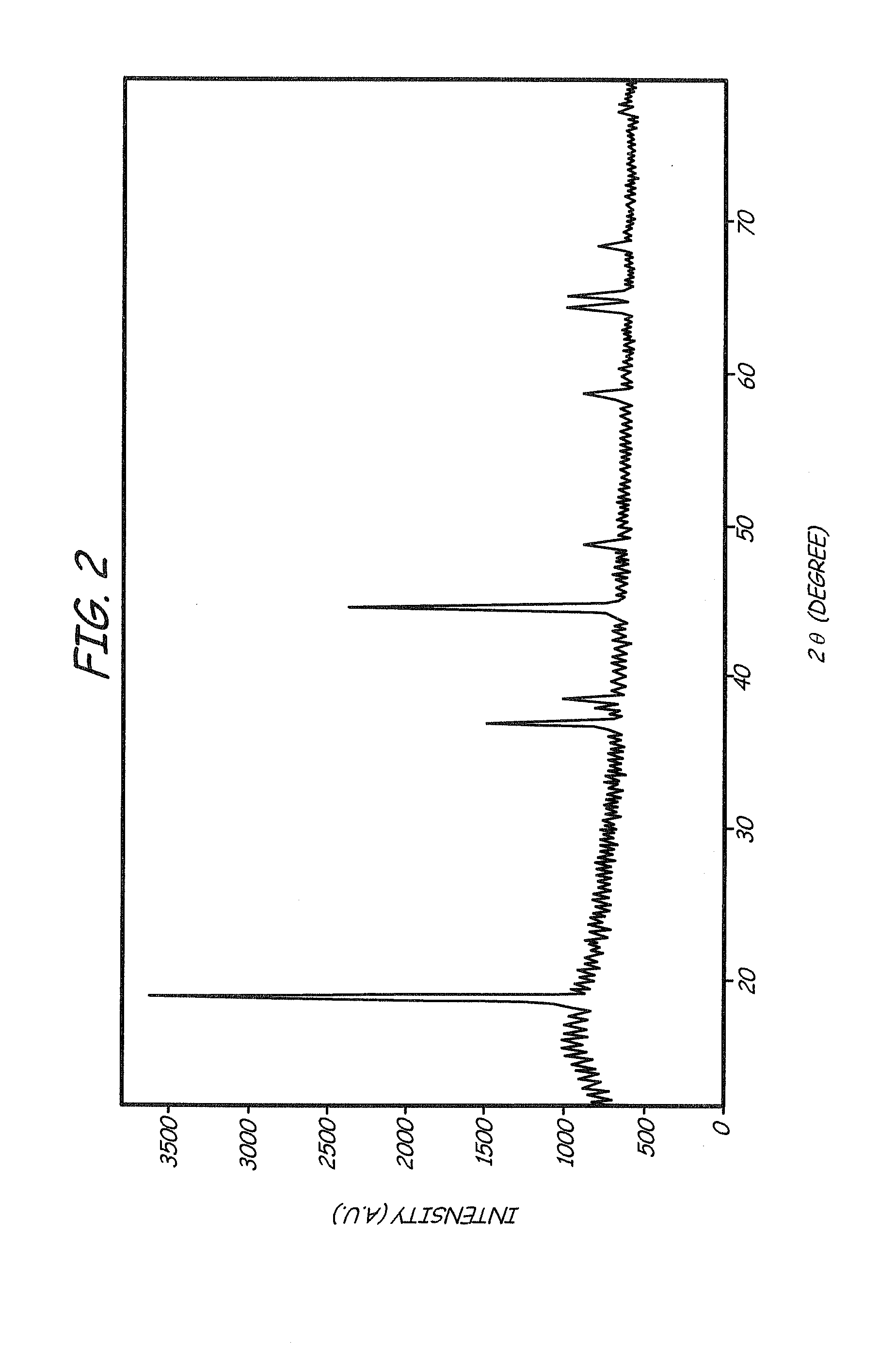

Coated positive electrode materials for lithium ion batteries

ActiveUS20110111298A1Secondary cellsNon-aqueous electrolyte accumulator electrodesLithium metalInorganic composition

High specific capacity lithium rich lithium metal oxide materials are coated with inorganic compositions, such as metal fluorides, to improve the performance of the materials as a positive electrode active material. The resulting coated material can exhibit an increased specific capacity, and the material can also exhibit improved cycling. The materials can be formed while maintaining a desired relatively high average voltage such that the materials are suitable for the formation of commercial batteries. Suitable processes are described for the synthesis of the desired coated compositions that can be adapted for commercial production.

Owner:IONBLOX INC

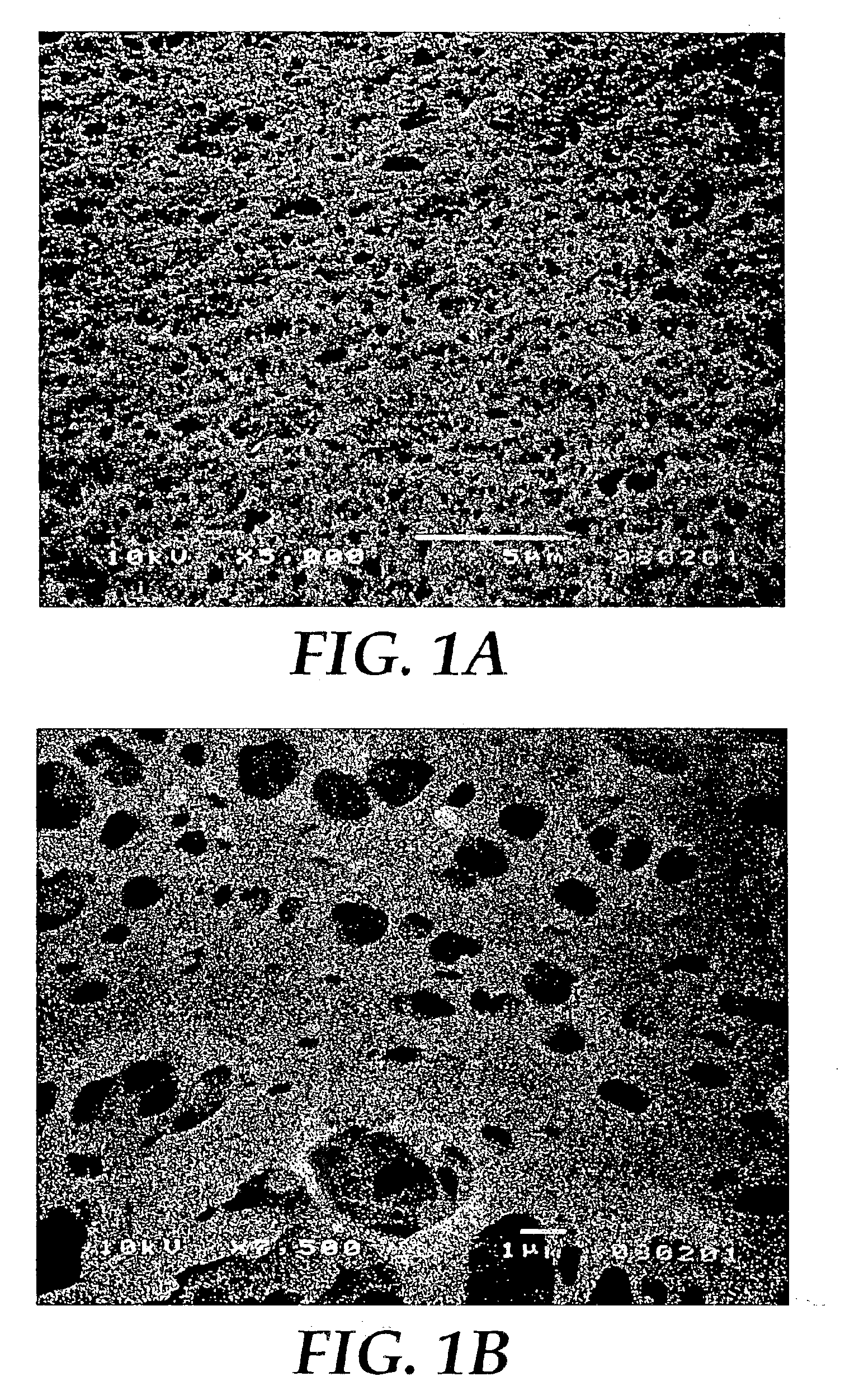

Clean, dense yttrium oxide coating protecting semiconductor processing apparatus

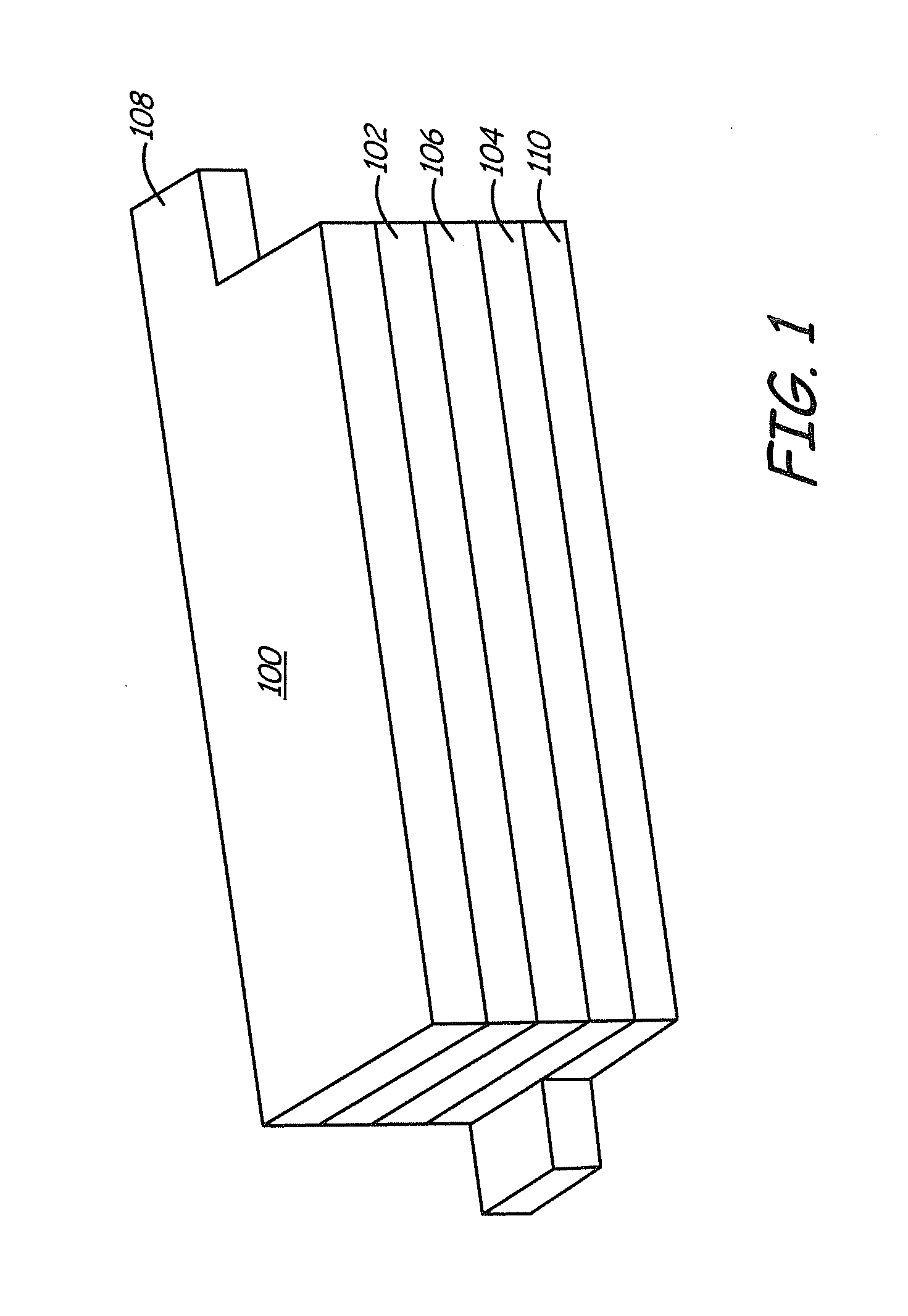

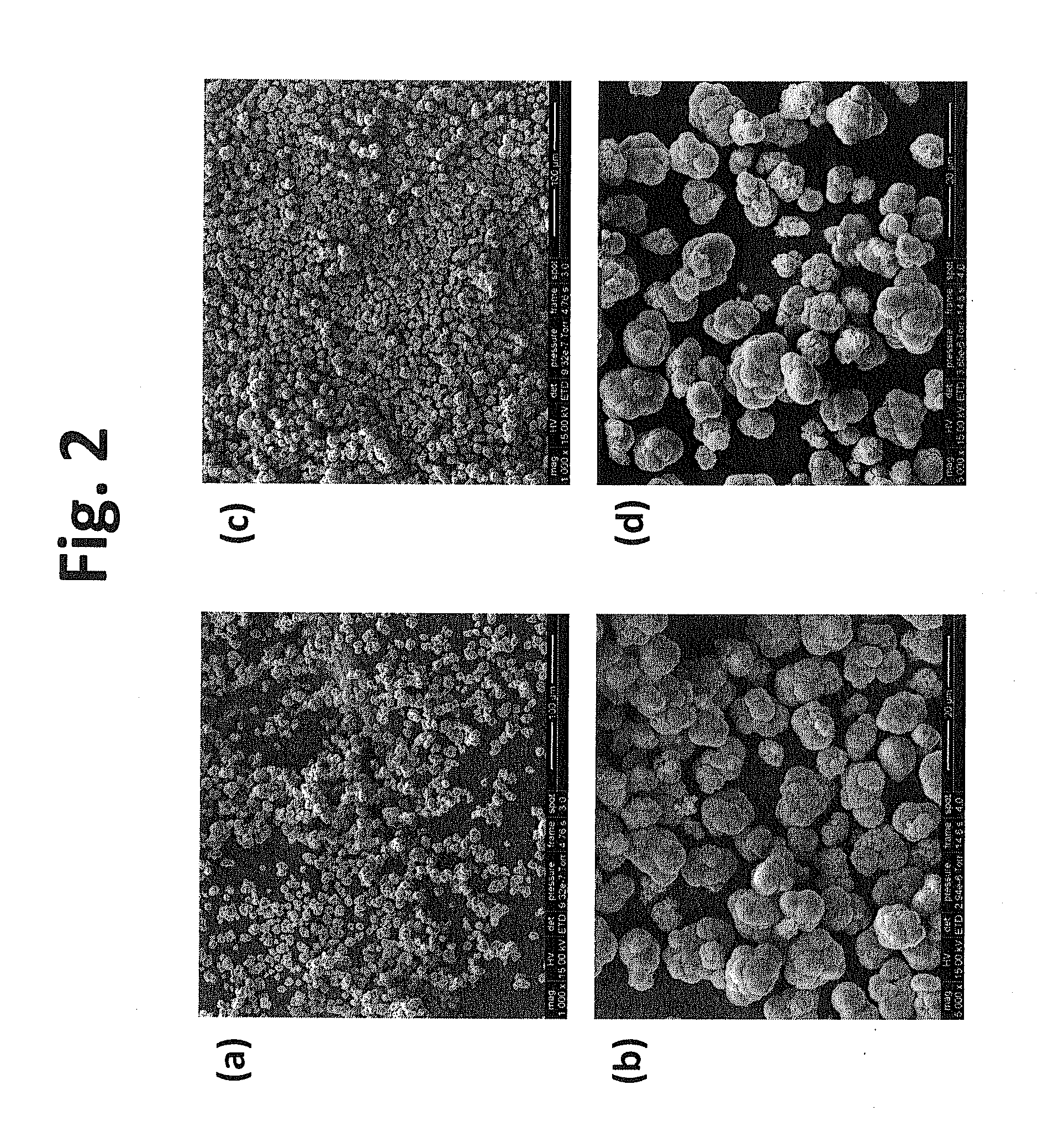

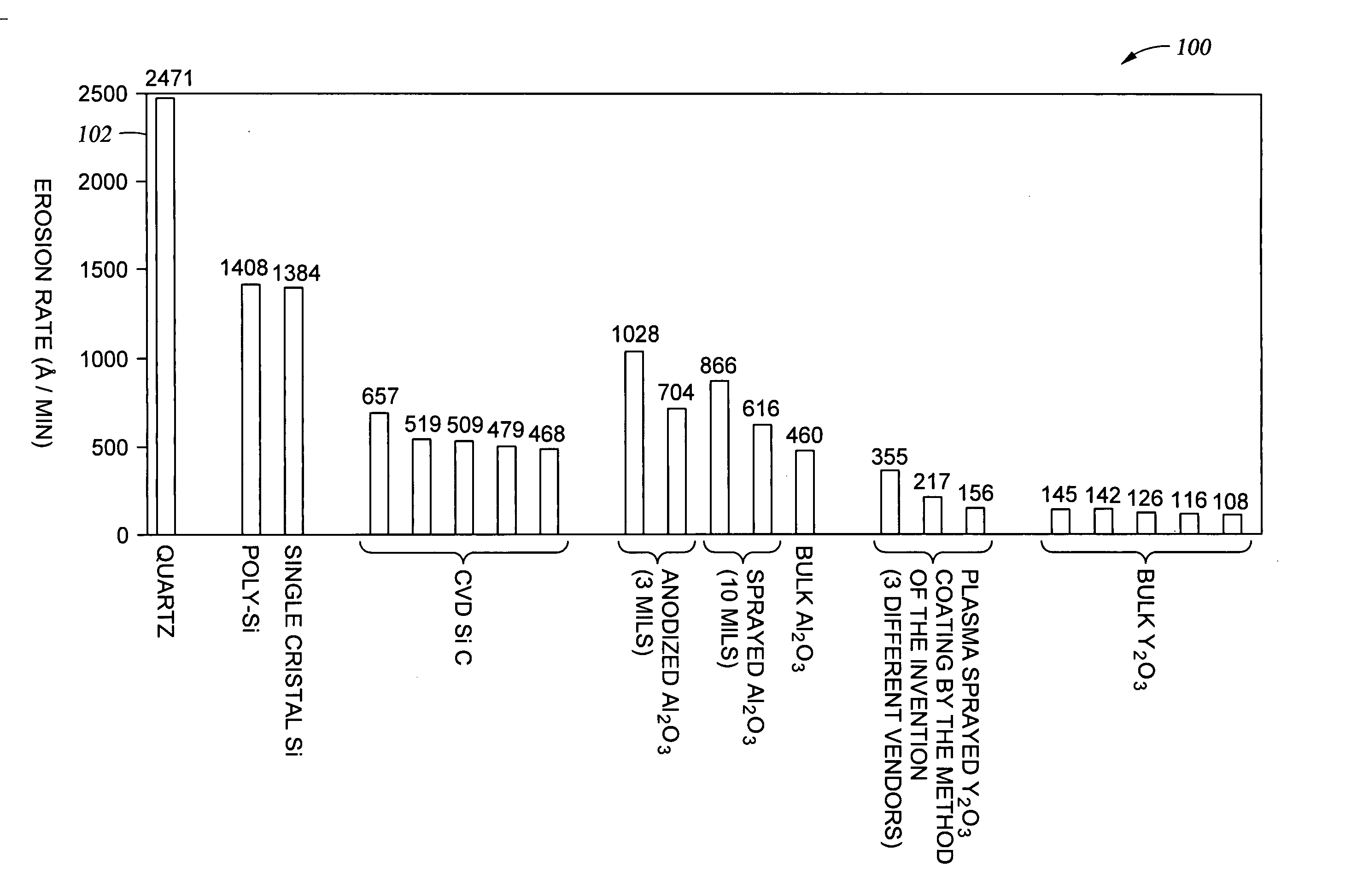

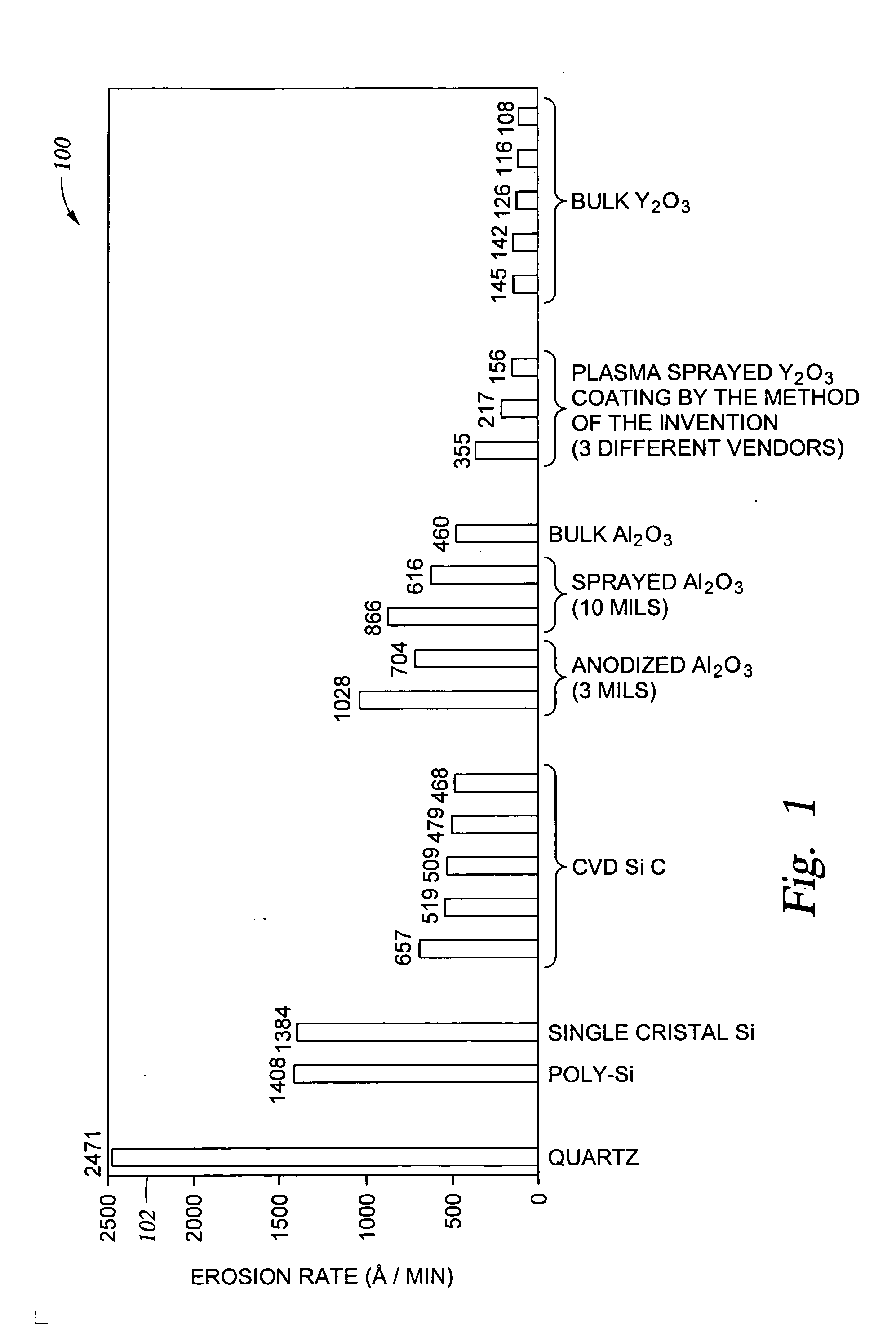

ActiveUS20050037193A1Extended service lifeExcellent plasma corrosion-resistanceLiquid surface applicatorsMolten spray coatingPlasma coatingChemical vapor deposition

Disclosed herein is a method for applying plasma-resistant coatings for use in semiconductor processing apparatus. The coatings are applied over a substrate which typically comprises an aluminum alloy of the 2000 series or the 5000 through 7000 series. The coating typically comprises an oxide or a fluoride of Y, Sc, La, Ce, Eu, Dy, or the like, or yttrium-aluminum-garnet (YAG). The coating may further comprise about 20 volume % or less of Al2O3. The coatings are typically applied to a surface of an aluminum alloy substrate or an anodized aluminum alloy substrate using a technique selected from the group consisting of thermal / flame spraying, plasma spraying, sputtering, and chemical vapor deposition (CVD). To provide the desired corrosion resistance, it is necessary to place the coating in compression. This is accomplished by controlling deposition conditions during application of the coating.

Owner:APPLIED MATERIALS INC

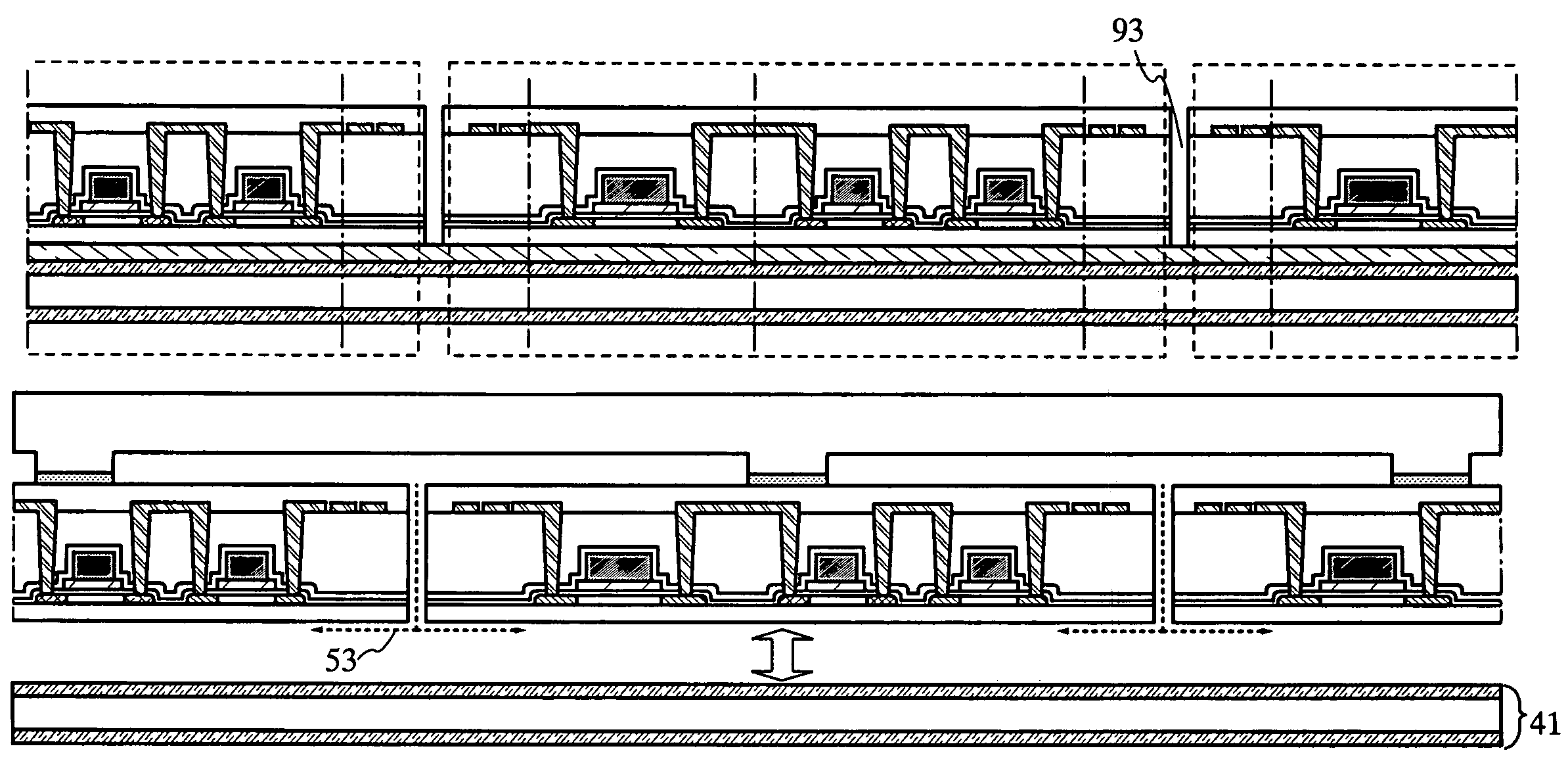

Manufacturing method of thin film integrated circuit device and manufacturing method of non-contact type thin film integrated circuit device

InactiveUS7271076B2Low costSemiconductor/solid-state device detailsSolid-state devicesEngineeringContact type

A method of manufacturing a thin film integrated circuit device according to the present invention includes steps of forming a peel-off layer over a thermally oxidized silicon substrate, forming a plurality of thin film integrated circuit devices over the peel-off layer with a base film interposed therebetween, forming a groove between the plurality of thin film integrated circuit devices, and separating the plurality of thin film integrated circuit devices by introducing one of a gas and a liquid including halogen fluoride into the groove to remove the peel-off layer.

Owner:SEMICON ENERGY LAB CO LTD

Battery electrolytic solution with fluoride-ion-dissociating salt and battery using the same

InactiveUS6306540B1Improve stabilityAvoid conductivitySolid electrolyte cellsLi-accumulatorsSupporting electrolyteDecomposition

The present invention relates to an electrolytic solution excellent in stability, and also relates to a battery excellent in battery performance and having an outer structure having light weight. The electrolytic solution contains a supporting electrolyte and a gas formation inhibitor in the solvent. The gas formation inhibitor contains a decomposition product of the supporting electrolyte with formation of a gas in the solvent. It functions as controlling to solution equilibrium in the electrolytic solution participating in decomposition reaction of the supporting electrolyte. A battery is obtained by filling the electrolytic solution between a positive electrode and a negative electrode.

Owner:MITSUBISHI ELECTRIC CORP

Positive electrode materials for high discharge capacity lithium ion batteries

Positive electrode active materials are described that have a high tap density and high specific discharge capacity upon cycling at room temperature and at a moderate discharge rate. Some materials of interest have the formula Li1+xNiαMnβCoγO2, where x ranges from about 0.05 to about 0.25, α ranges from about 0.1 to about 0.4, β ranges from about 0.4 to about 0.65, and γ ranges from about 0.05 to about 0.3. The materials can be coated with a metal fluoride to improve the performance of the materials especially upon cycling. Also, the coated materials can exhibit a very significant decrease in the irreversible capacity lose upon the first charge and discharge of the battery.

Owner:IONBLOX INC

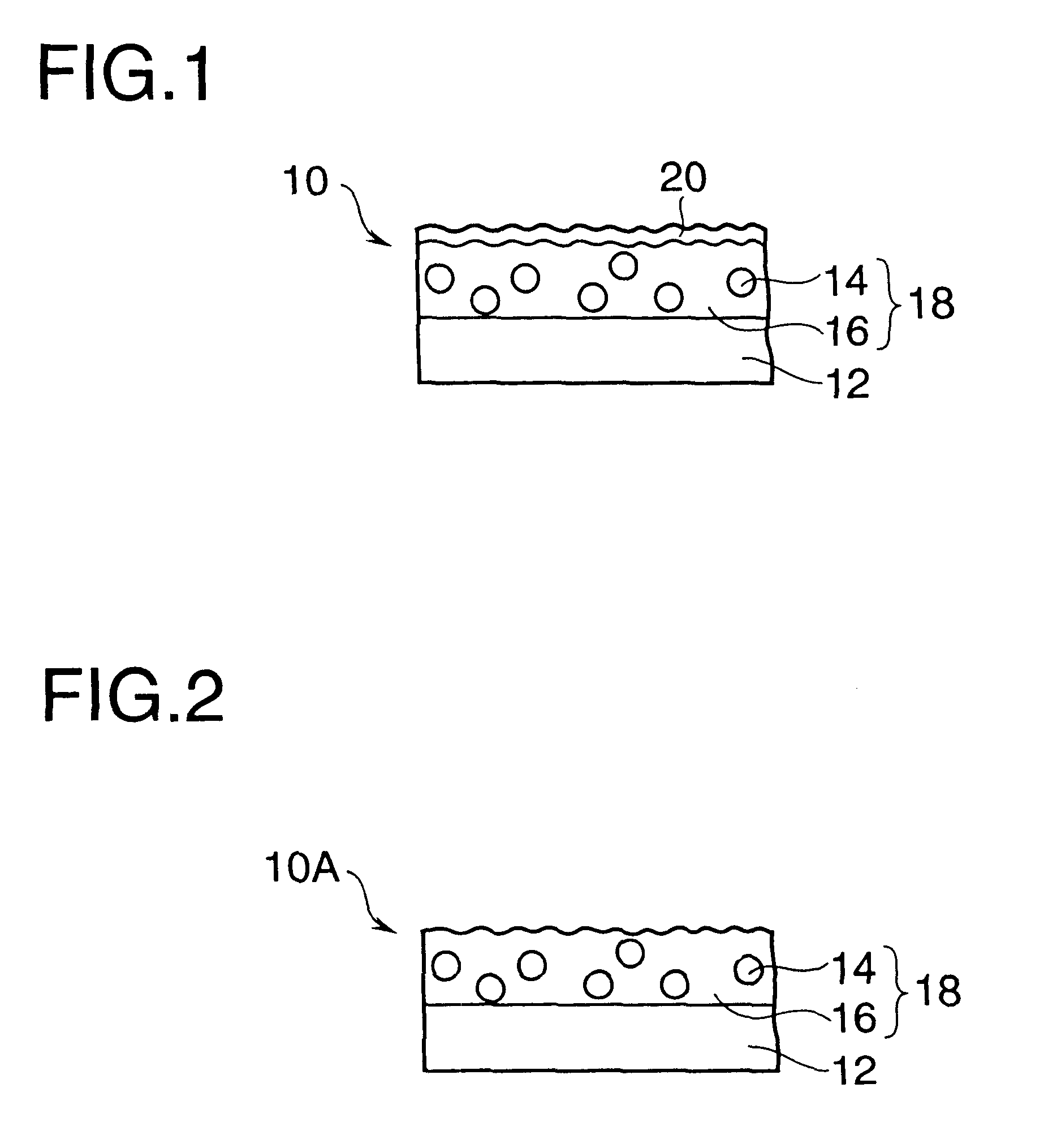

Non-glare film, polarizing device and display device

InactiveUS6343865B1Small particle sizeImprove display qualityMirrorsDiffusing elementsRefractive indexDisplay device

A non-glare film 10 is composed of a non-glare layer 18 formed by coating a transparent base film 12 of TAC or the like with a coating material obtained by mixing a light transmissive diffusing material 14 of resin beads and the like in a light transmissive resin 16, and a low refractive index layer 20 composed of a silicon-containing vinylidene fluoride copolymer, said low refractive index layer 20 being laminated onto the surface of the non-glare layer, in which the haze value on the surface of the non-glare layer 18 is 7 to 30 and the haze value inside the non-glare layer 18 is 1 to 15, and when the non-glare film is attached onto the surface of a display panel, it suppresses degradation in contrast and furthermore prevents face-glare, reflecting-in and whitening.

Owner:DAI NIPPON PRINTING CO LTD

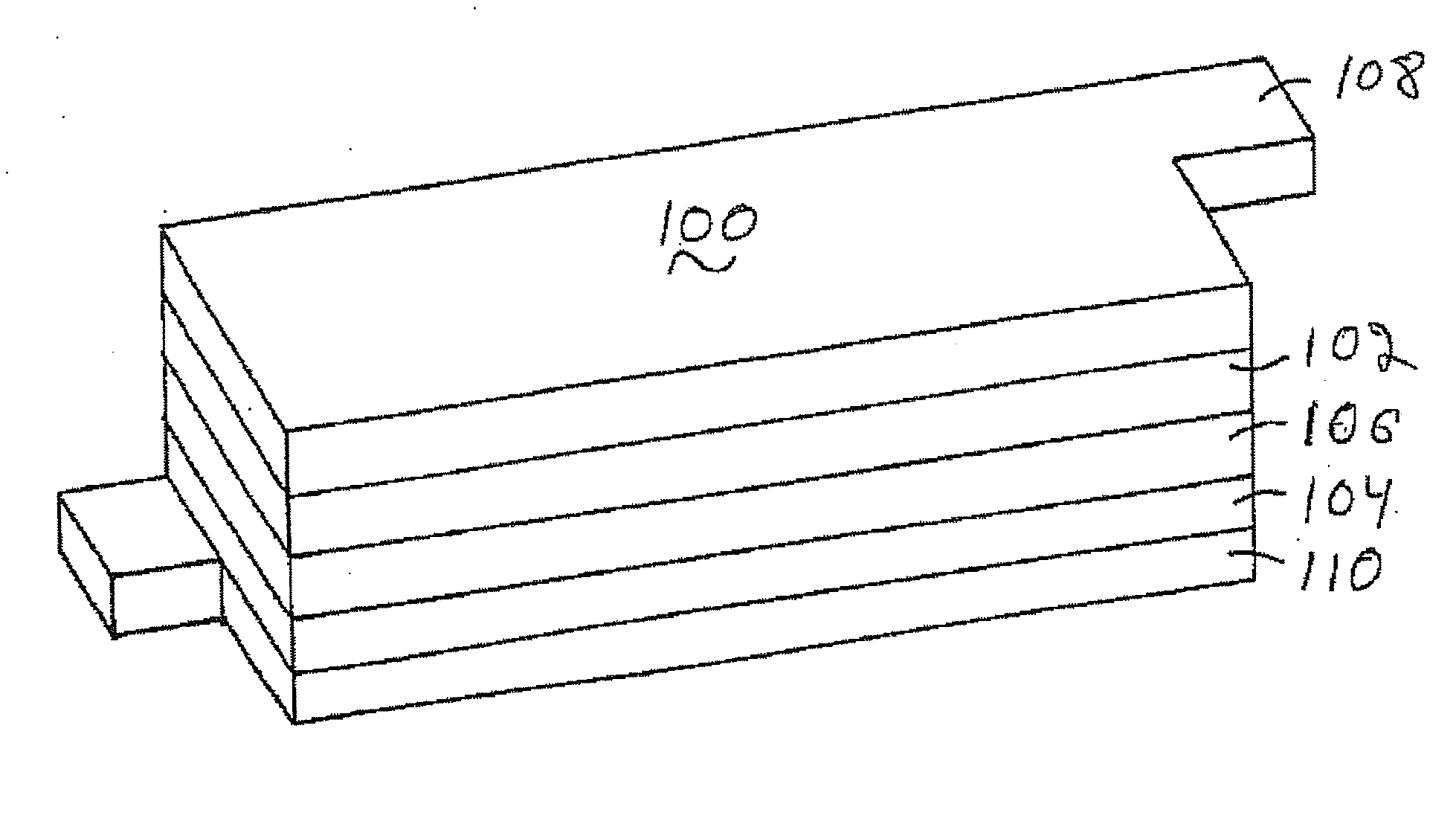

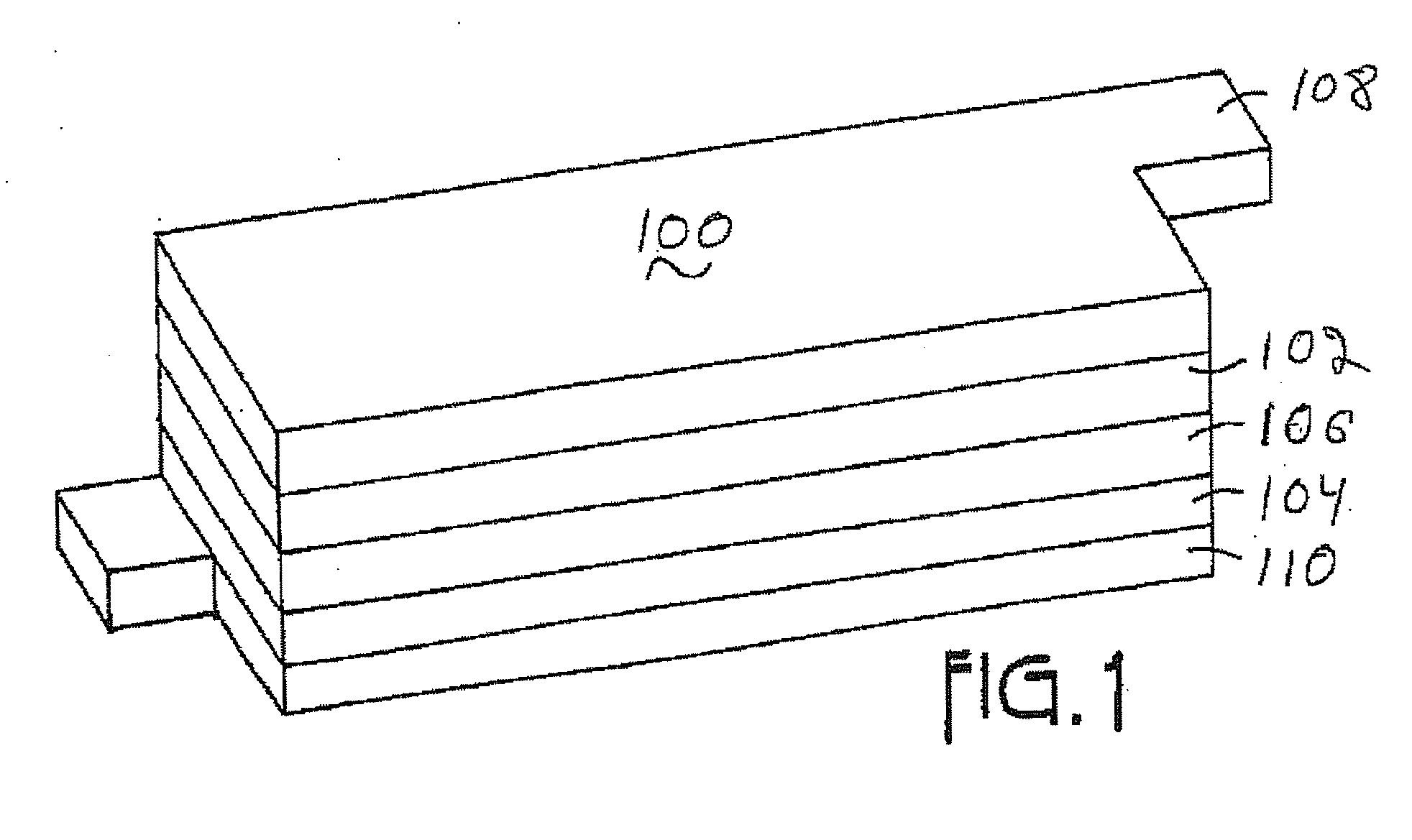

Microelectronic mechanical system and methods

InactiveUS20040053434A1Decorative surface effectsSemiconductor/solid-state device detailsNoble gasSilicon oxide

The current invention provides for encapsulated release structures, intermediates thereof and methods for their fabrication. The multi-layer structure has a capping layer, that preferably comprises silicon oxide and / or silicon nitride, and which is formed over an etch resistant substrate. A patterned device layer, preferably comprising silicon nitride, is embedded in a sacrificial material, preferably comprising polysilicon, and is disposed between the etch resistant substrate and the capping layer. Access trenches or holes are formed in to capping layer and the sacrificial material are selectively etched through the access trenches, such that portions of the device layer are release from sacrificial material. The etchant preferably comprises a noble gas fluoride NGF2x (wherein Ng=Xe, Kr or Ar: and where x=1, 2 or 3). After etching that sacrificial material, the access trenches are sealed to encapsulate released portions the device layer between the etch resistant substrate and the capping layer. The current invention is particularly useful for fabricating MEMS devices, multiple cavity devices and devices with multiple release features.

Owner:SILICON LIGHT MACHINES CORP

Fluoropolymer coated films useful for photovoltaic modules

ActiveUS20070154704A1Strong adhesionIncreased durabilitySynthetic resin layered productsRecord information storageEpoxyPolymer science

A fluoropolymer coated film comprising polymeric substrate film and fluoropolymer coating on the polymeric substrate film. The fluoropolymer coating comprises fluoropolymer selected from homopolymers and copolymers of vinyl fluoride and homopolymers and copolymers of vinylidene fluoride polymer blended with compatible adhesive polymer comprising functional groups selected from carboxylic acid, sulfonic acid, aziridine, anhydride, amine, isocyanate, melamine, epoxy, hydroxy, anhydride and mixtures thereof. The polymeric substrate film comprises functional groups on its surface that interact with the compatible adhesive polymer to promote bonding of the fluoropolymer coating to the substrate film.

Owner:DUPONT ELECTRONICS INC

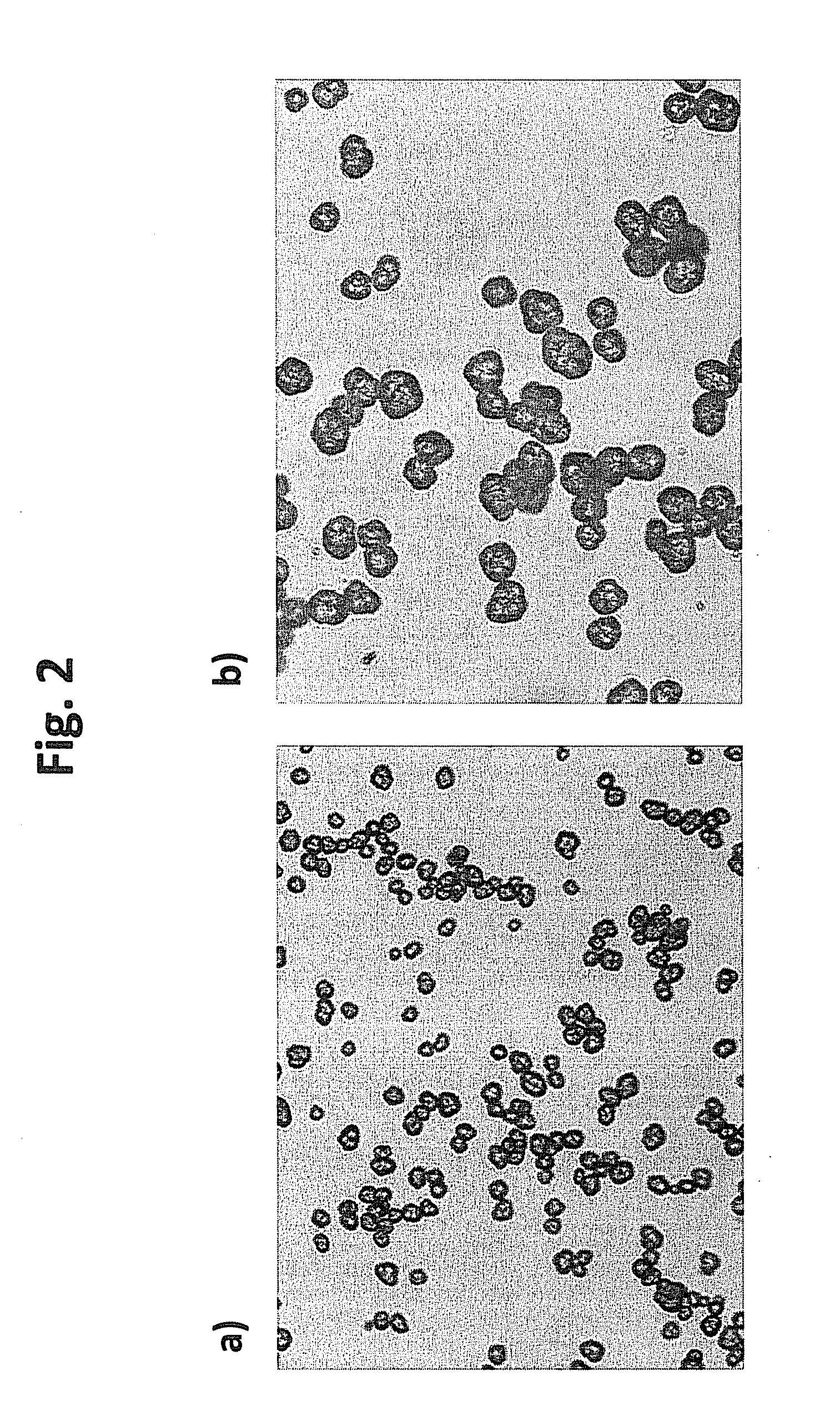

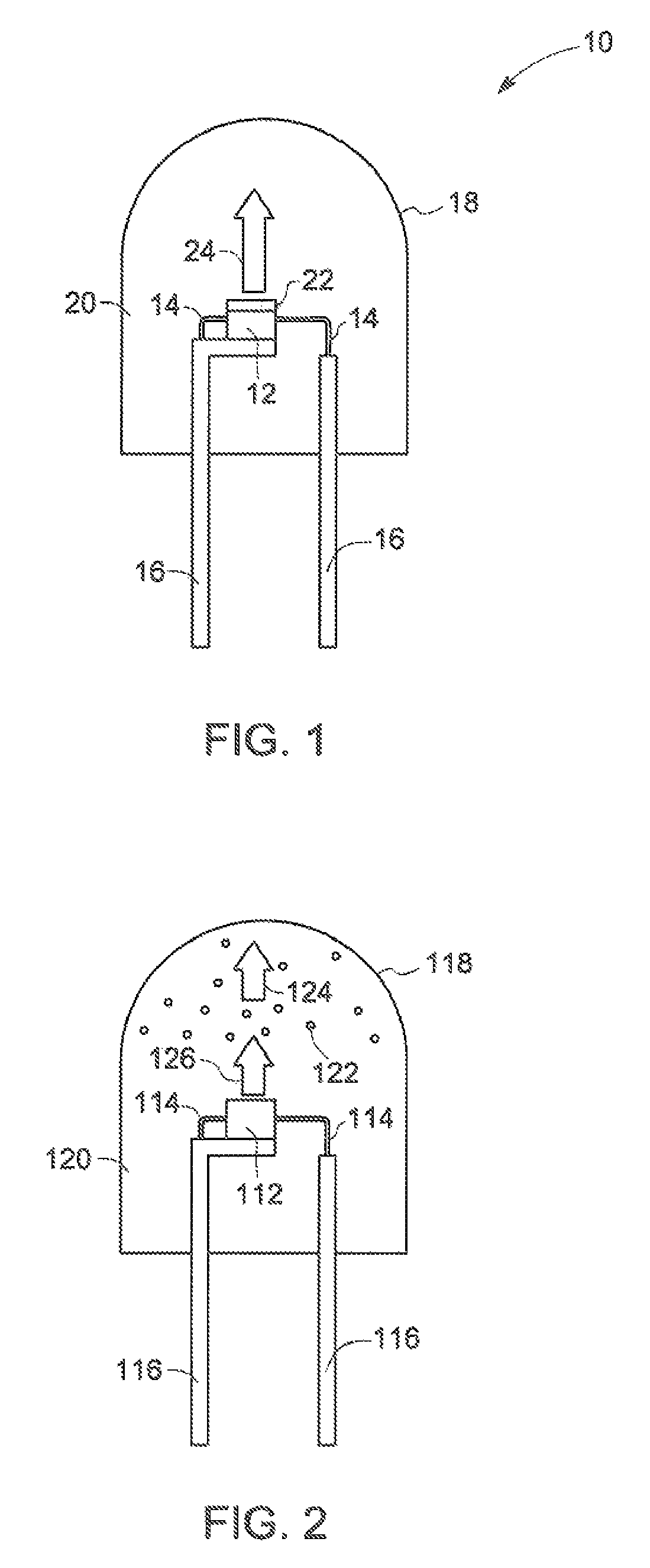

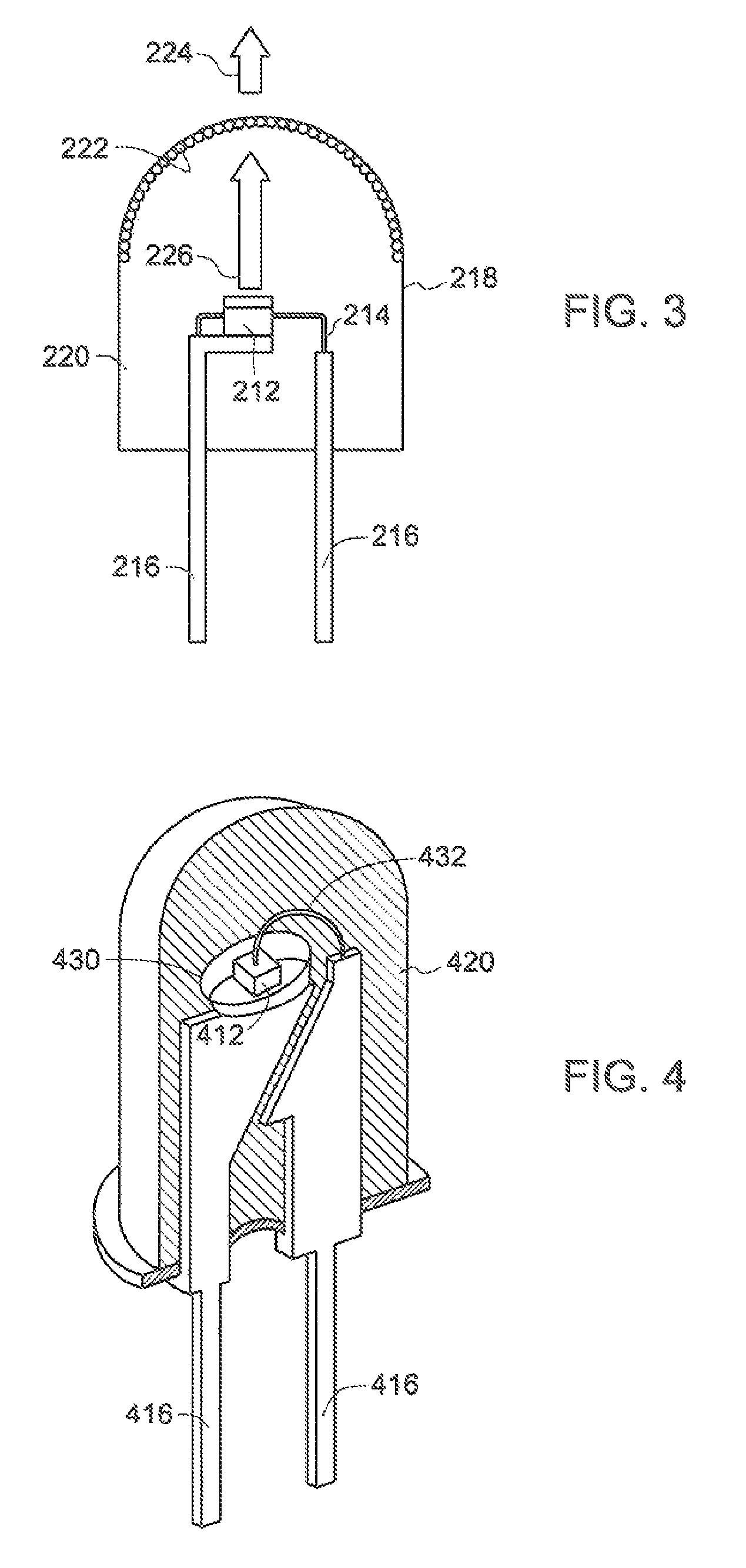

Moisture-resistant phosphor and associated method

A phosphor material contains encapsulated particles of manganese (Mn4+) doped fluoride phosphor. A method of encapsulating such particles is also provided. Each particle is encapsulated with a layer of a manganese-free fluoride phosphor. The use of such a phosphor material in a lighting apparatus results in improved stability and acceptable lumen maintenance over the course of the apparatus life.

Owner:GE LIGHTING SOLUTIONS LLC

Crosslinkable aqueous fluoropolymer based dispersions

Acrylic Modified Fluoropolymers based on vinylidene fluoride polymers are disclosed wherein the acrylic phase is capable of entering into crosslinking reactions. The final cured products provide superior solvent extractability resistance to the fluoropolymer phase.

Owner:ARKEMA INC

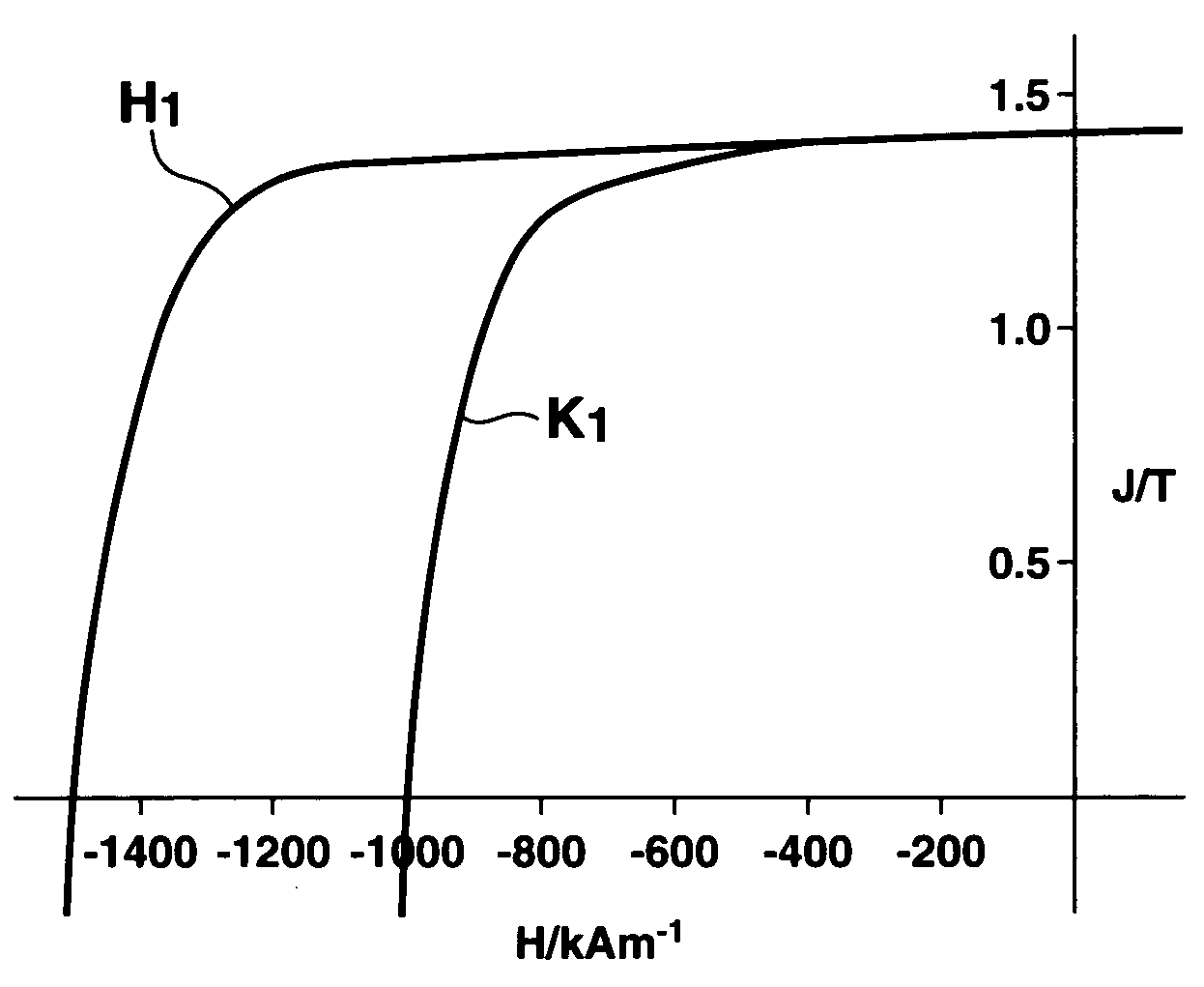

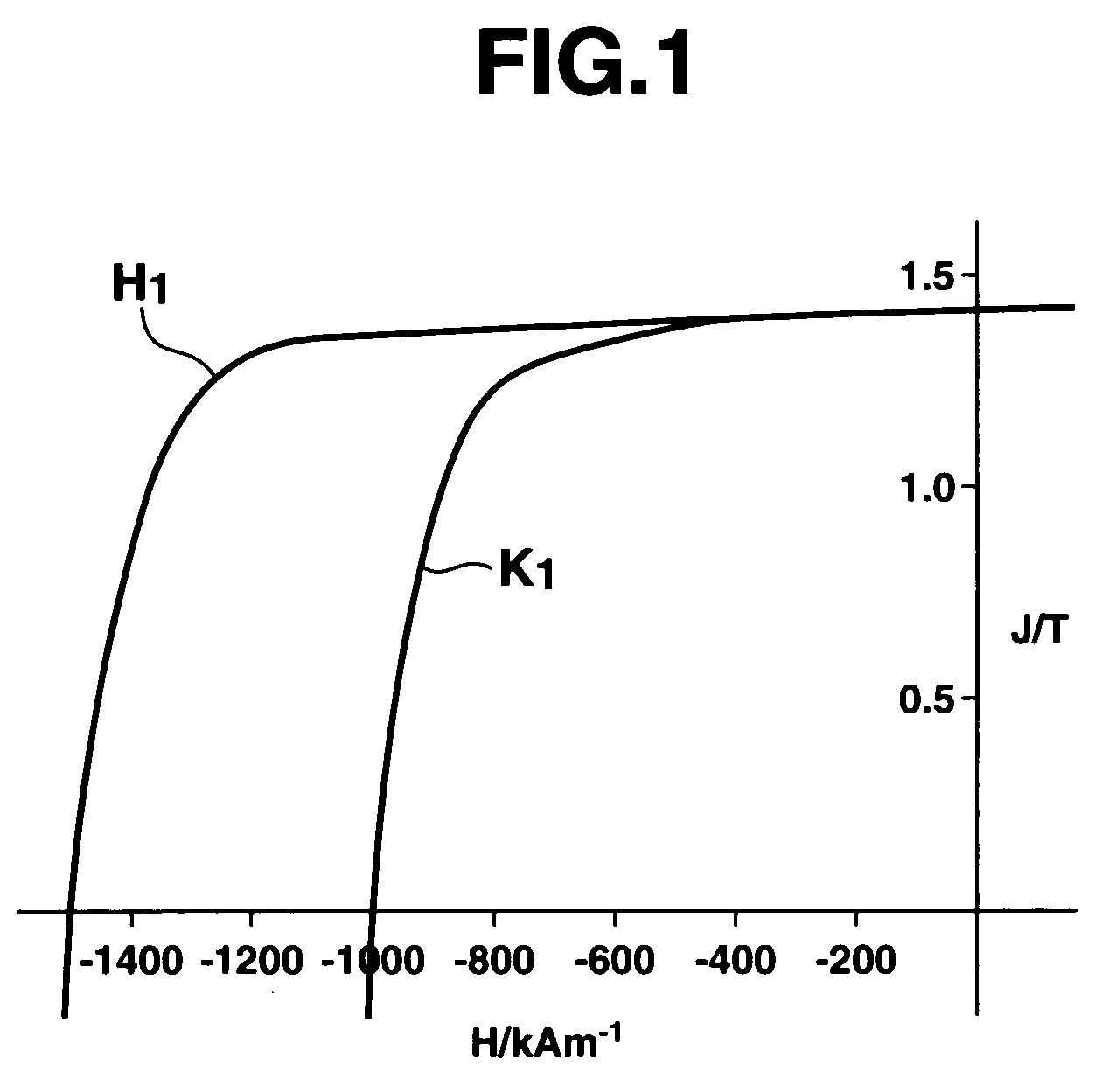

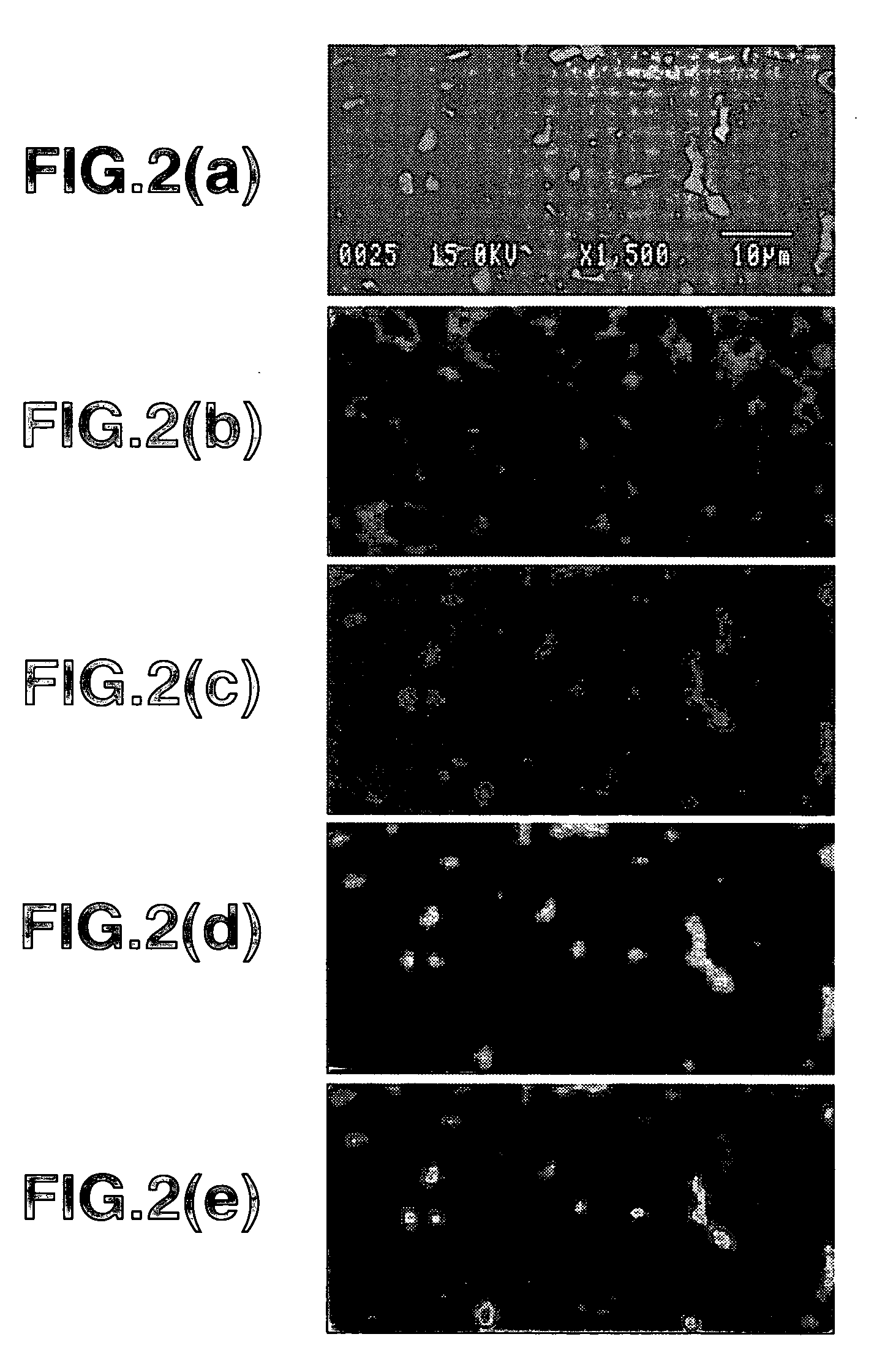

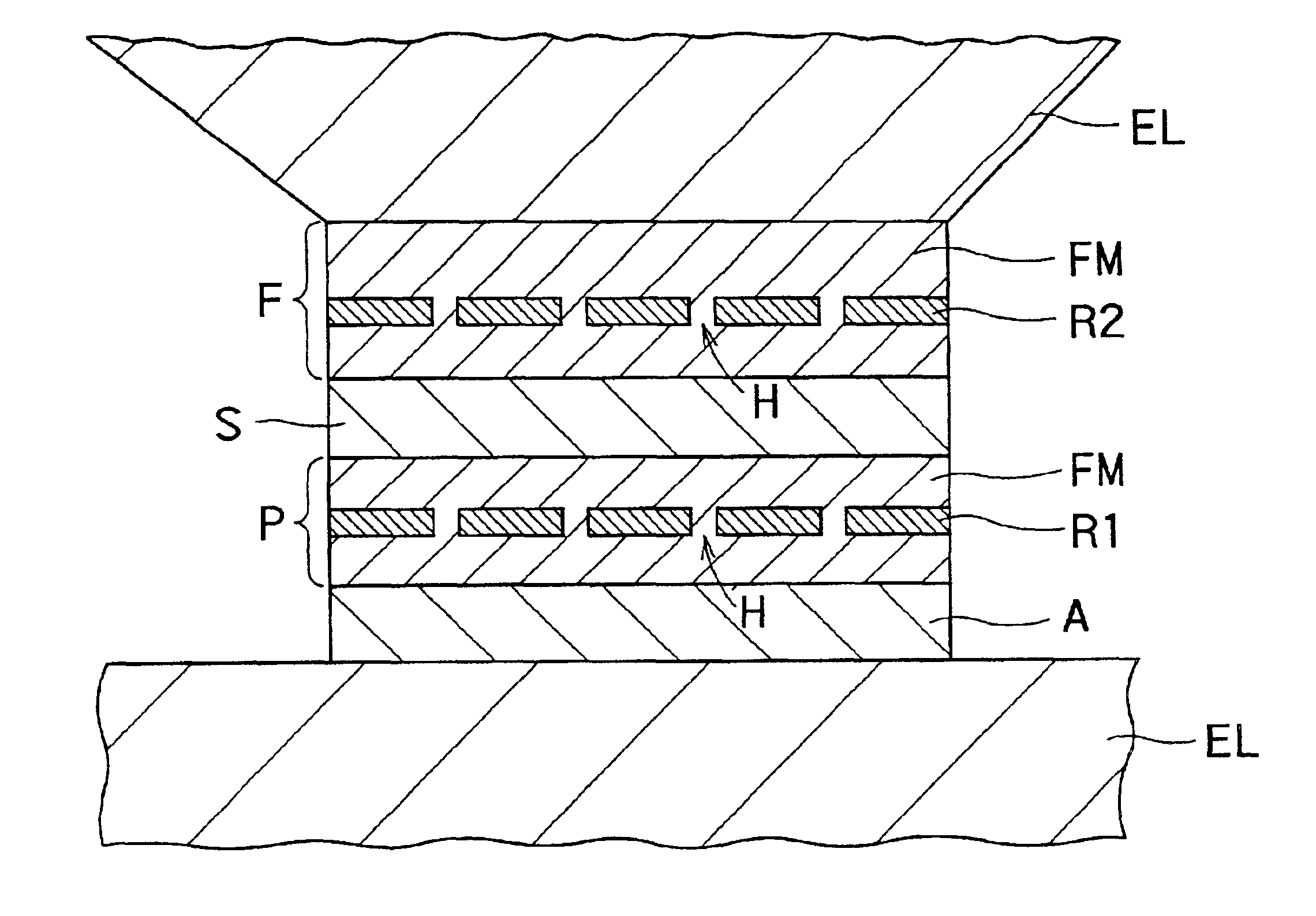

Preparation of Rare Earth Permanent Magnet Material

ActiveUS20080245442A1Improve remanenceImprove coercive forceElectric discharge tubesPermanent magnetsRare-earth elementRemanence

A method for preparing a rare earth permanent magnet material comprising the steps of:disposing a powder comprising one or more members selected from an oxide of R2, a fluoride of R3, and an oxyfluoride of R4 wherein R2, R3 and R4 each are one or more elements selected from among rare earth elements inclusive of Y and Sc on a sintered magnet form of a R1—Fe—B composition wherein R1 is one or more elements selected from among rare earth elements inclusive of Y and Sc, andheat treating the magnet form and the powder at a temperature equal to or below the sintering temperature of the magnet in vacuum or in an inert gas.The invention offers a high performance, compact or thin permanent magnet having a high remanence and coercivity at a high productivity.

Owner:SHIN ETSU CHEM IND CO LTD

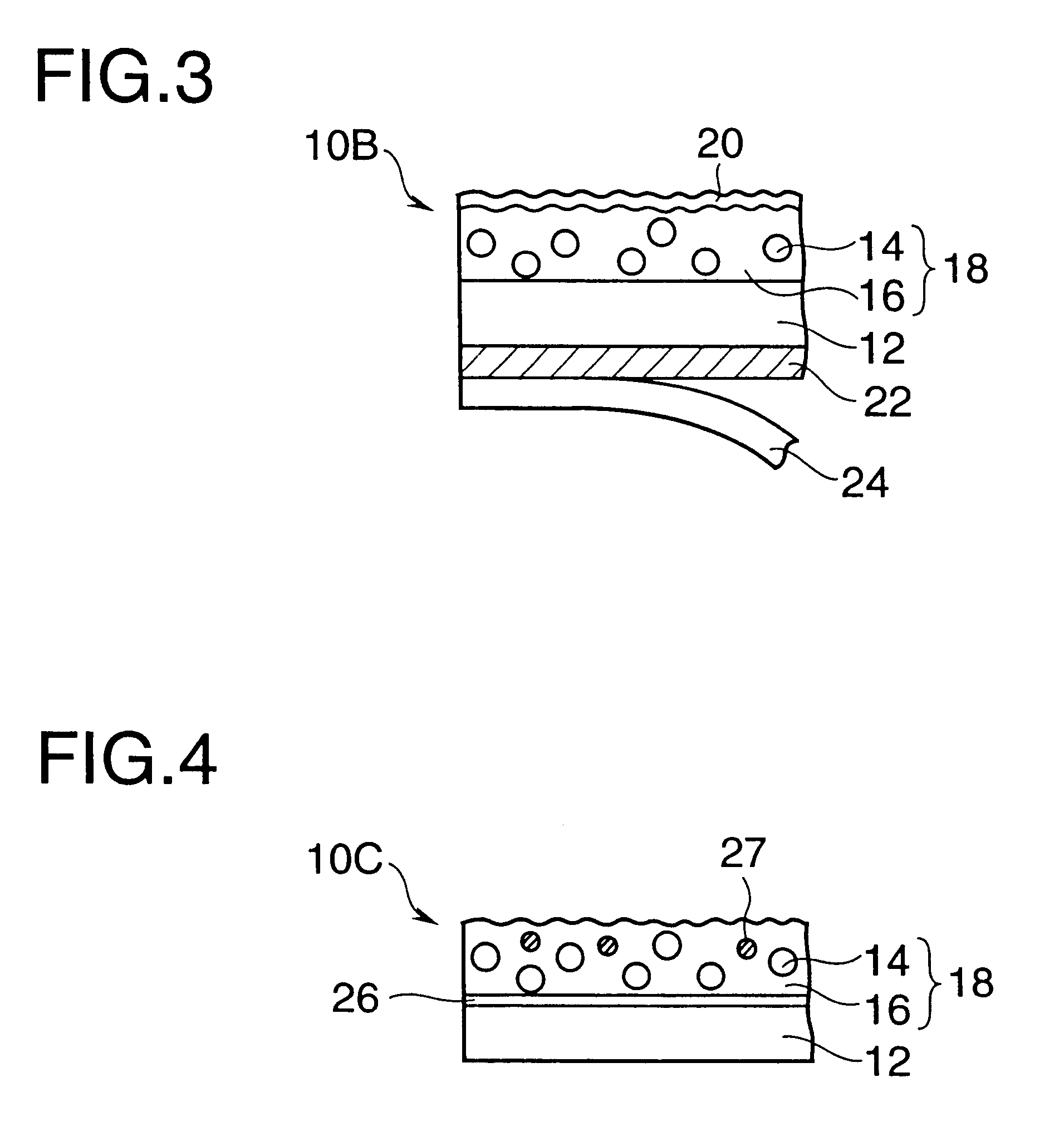

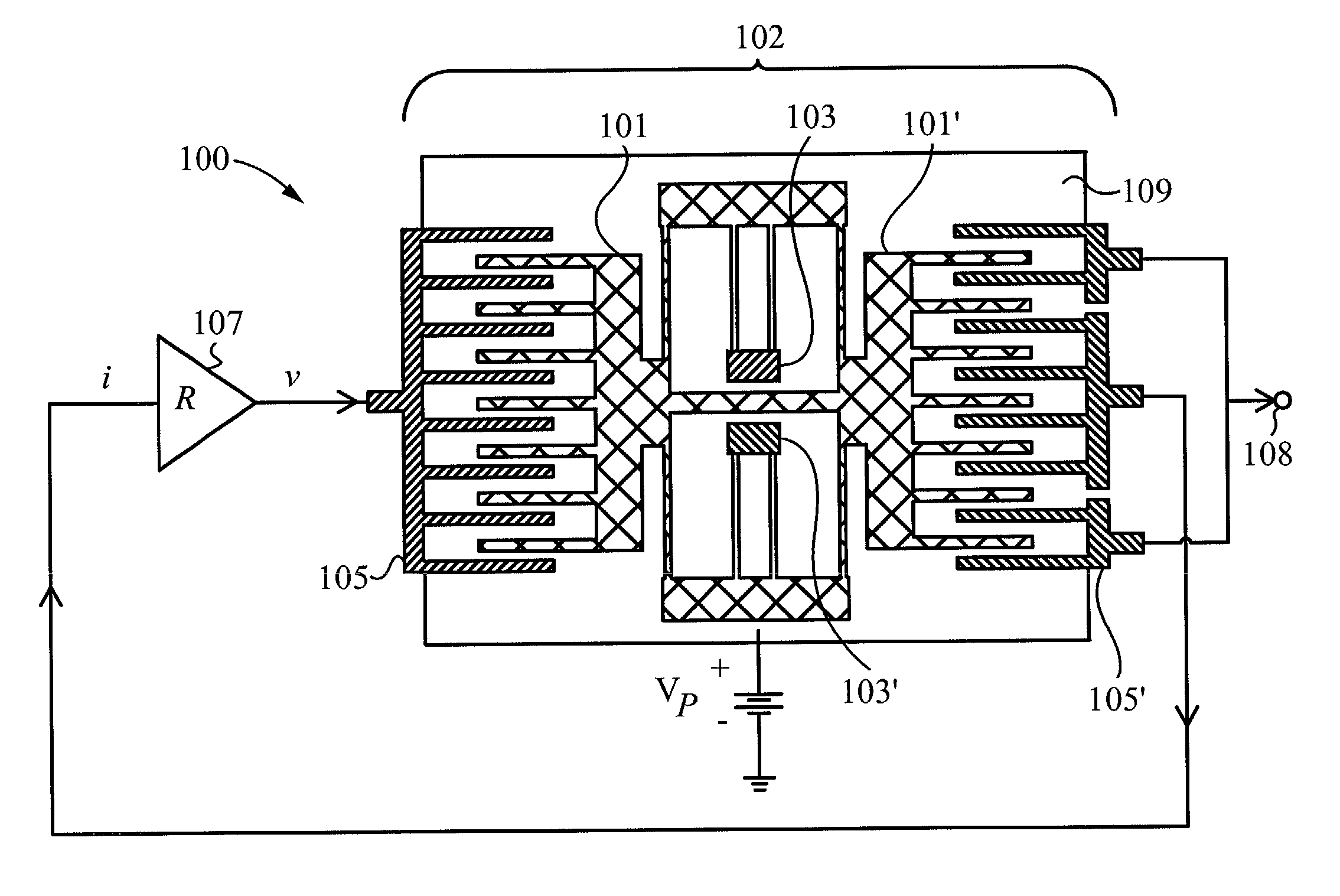

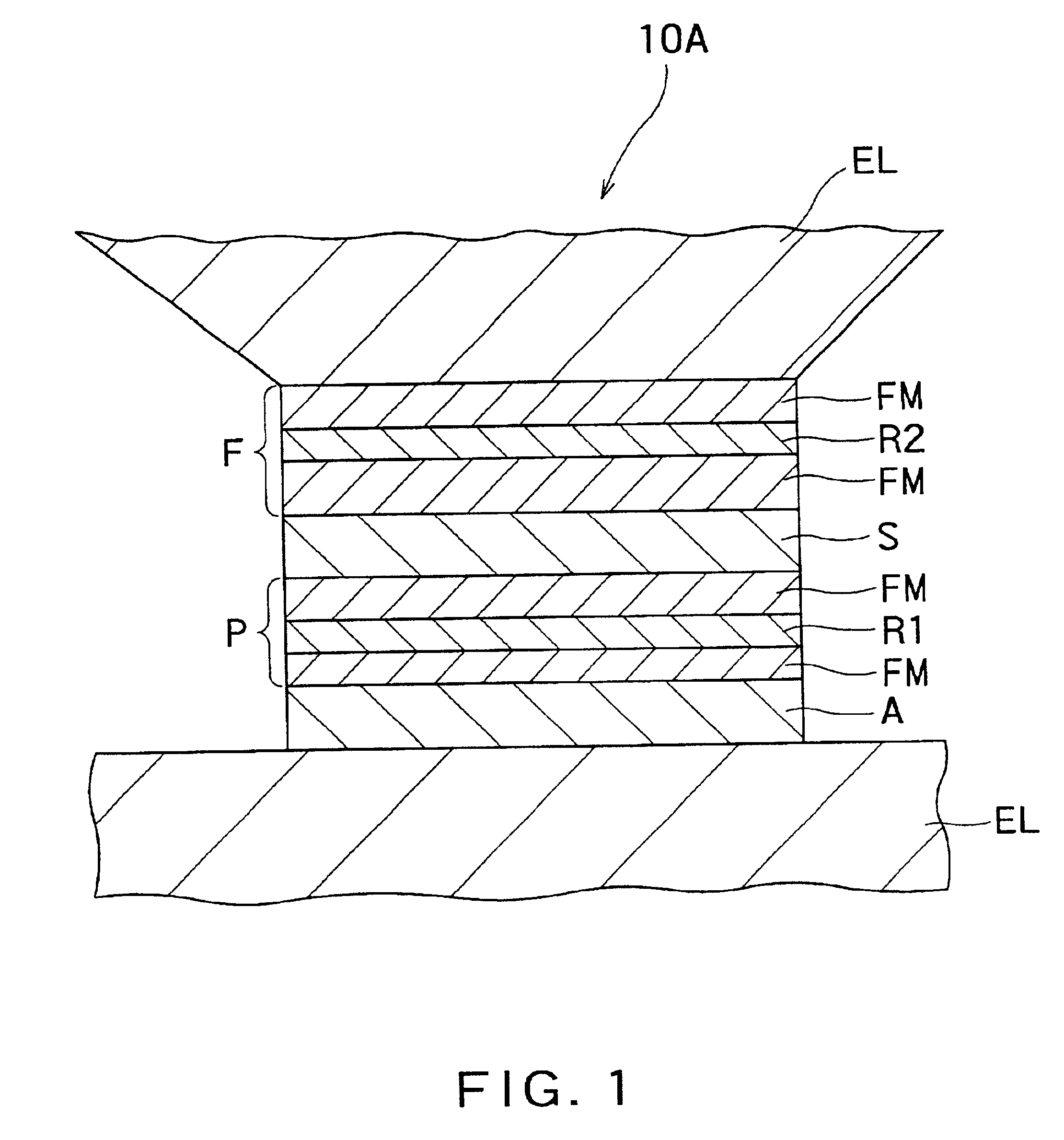

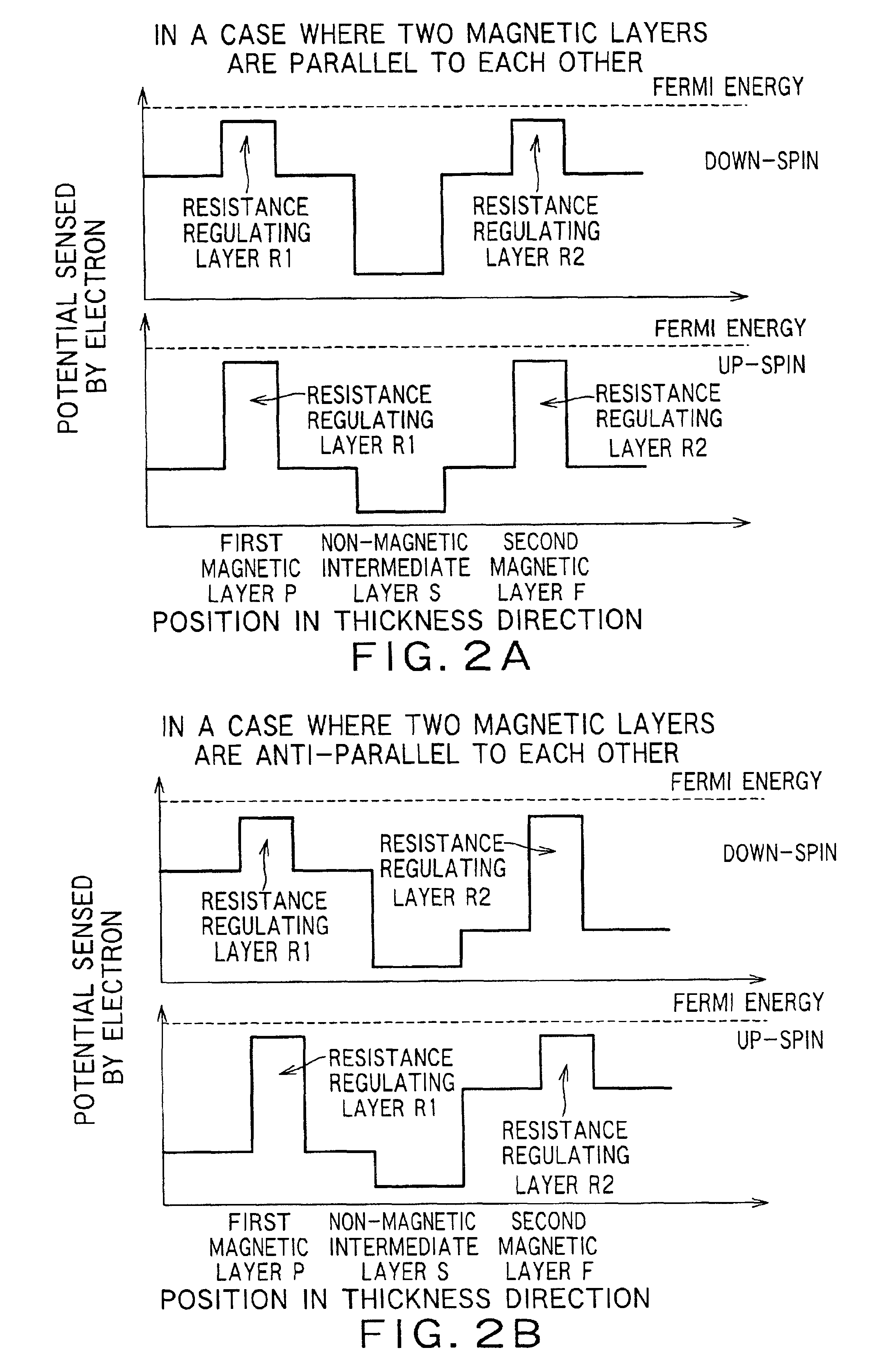

Magnetoresistance effect element, magnetic head and magnetic recording and/or reproducing system

InactiveUS6937446B2Efficient use ofControl quantityNanomagnetismMagnetic measurementsBorideScattering effect

There is provided a practical magnetoresistance effect element which has an appropriate value of resistance, which can be sensitized and which has a small number of magnetic layers to be controlled, and a magnetic head and magnetic recording and / or reproducing system using the same. In a magnetoresistance effect element wherein a sense current is caused to flow in a direction perpendicular to the plane of the film, a resistance regulating layer is provided in at least one of a pinned layer, a free layer and an non-magnetic intermediate layer. The resistance regulating layer contains, as a principal component, an oxide, a nitride, a fluoride, a carbide or a boride. The resistance regulating layer may be a continuous film or may have pin holes. Thus, it is possible to provide a practical magnetoresistance effect element which has an appropriate value of resistance, which can be sensitized and which has a small number of magnetic layers, while effectively utilizing the scattering effect depending on spin.

Owner:KK TOSHIBA

Hydrophobic membrane materials for filter venting applications

The present invention relates to filtration media having both hydrophobic (water-repellent) properties. The filtration media are produced using a fluorothermoplastic material, such as a terpolymer of tetrafluoroethylene, vinylidene fluoride, and hexafluoropropylene. The invention also relates to methods of preparing such filtration media using casting solution phase inversion.

Owner:PALL CORP

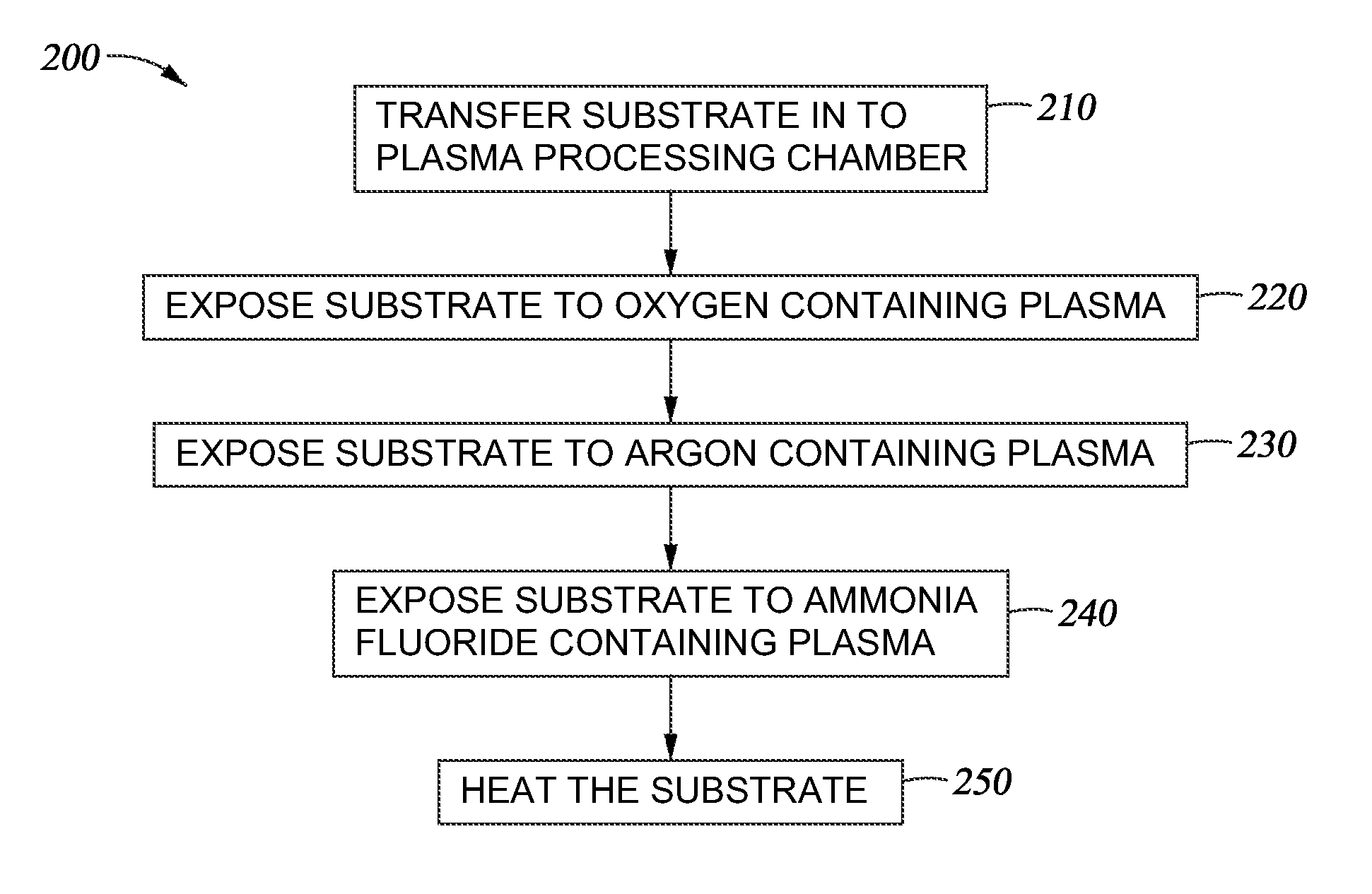

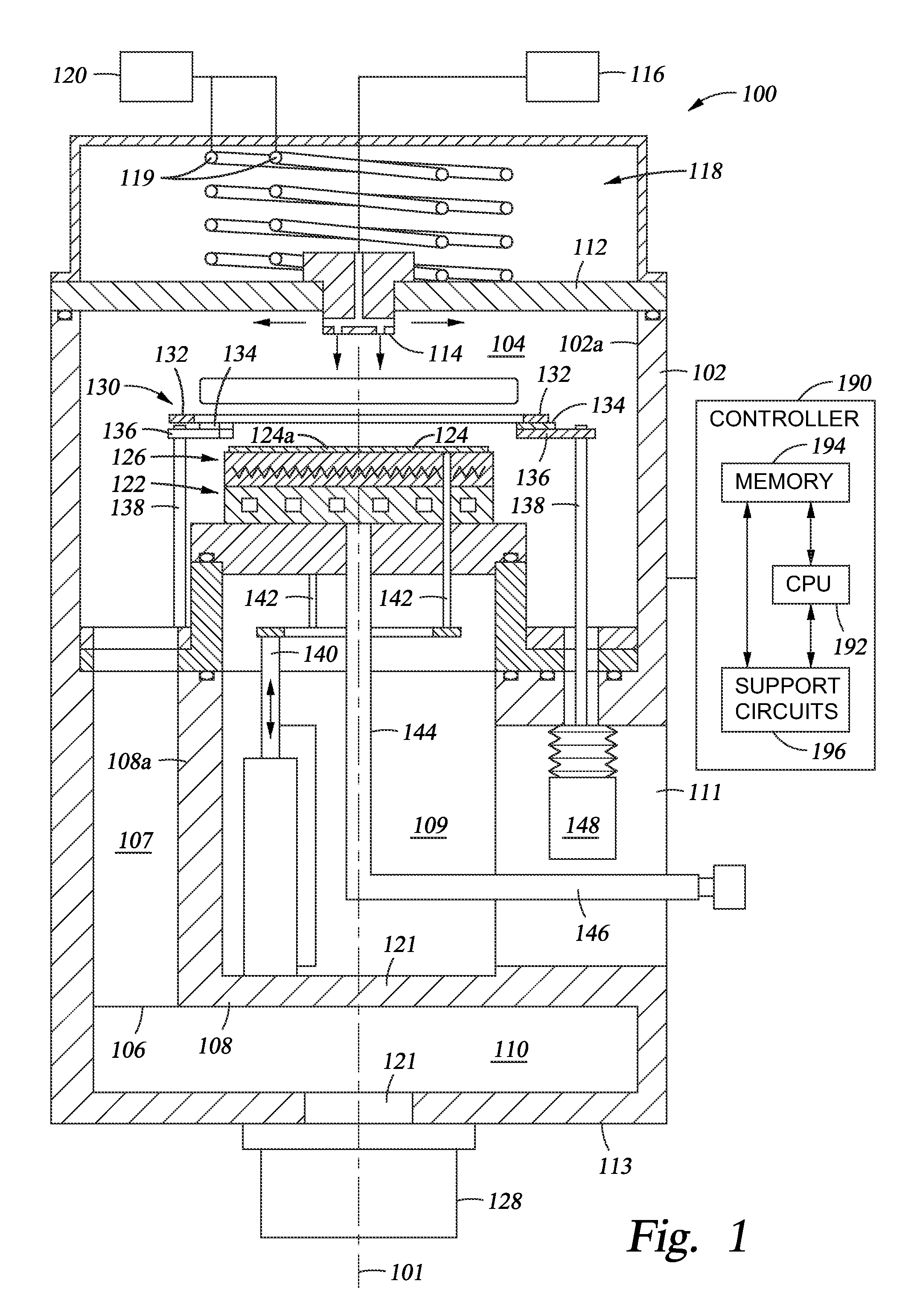

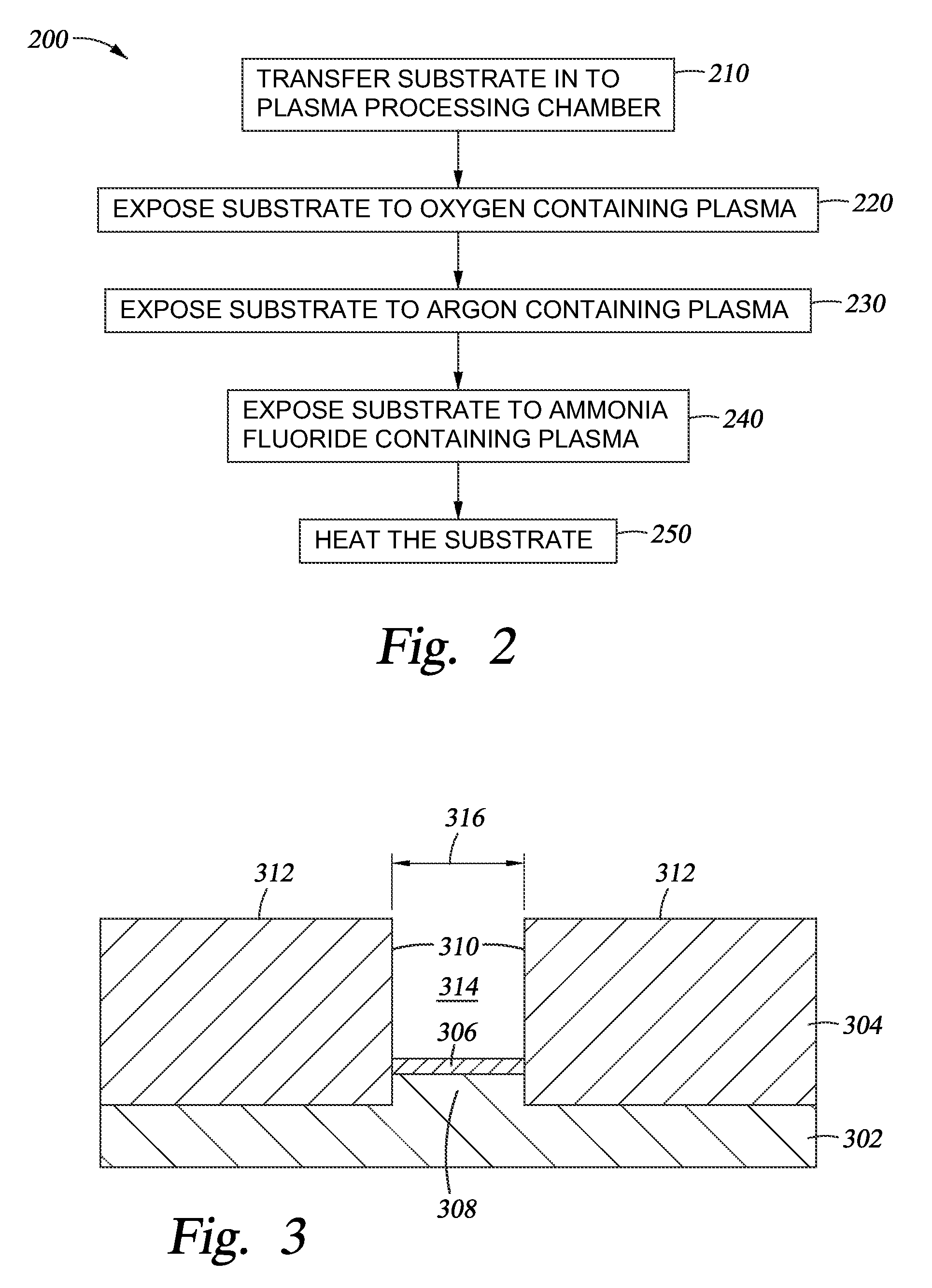

CVD oxide surface pre-conditioning by inductively coupled O2 plasma

A method and apparatus for conditioning an oxide surface during a semiconductor device formation process is provided herein. One or more plasma processing operations are performed on a substrate having a fin structure and shallow trench isolation structure (STI) formed thereon. An oxygen containing plasma process may modify surfaces of the STI structure in preparation for an argon containing plasma process. The argon containing plasma process may form a first layer on the fin structure and STI structure and an ammonia fluoride containing plasma process may form a second layer on the first layer. The first and second layers may be removed from the substrate during a subsequent heating process to provide a cleaned fin structure suitable for subsequent processing operations.

Owner:APPLIED MATERIALS INC

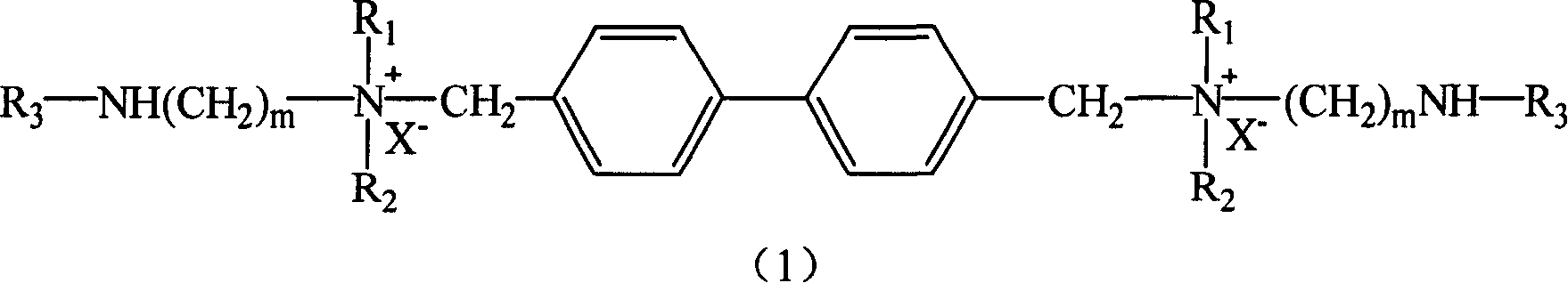

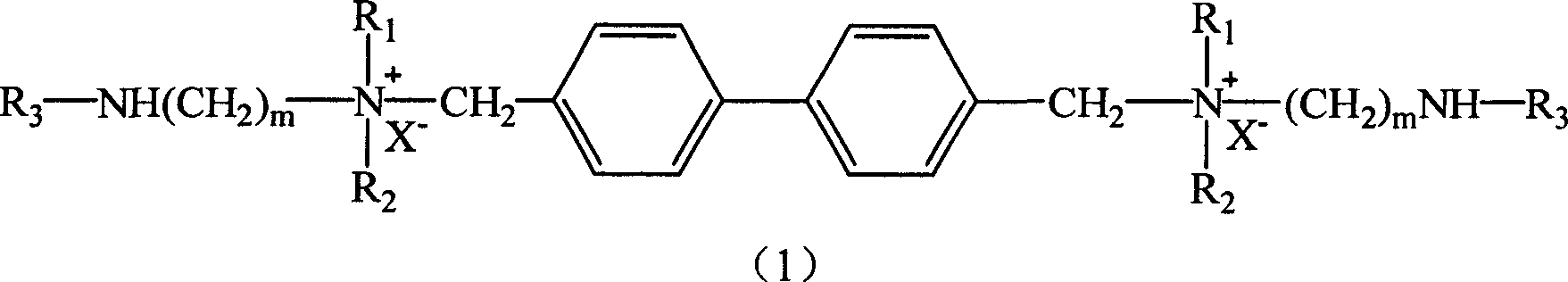

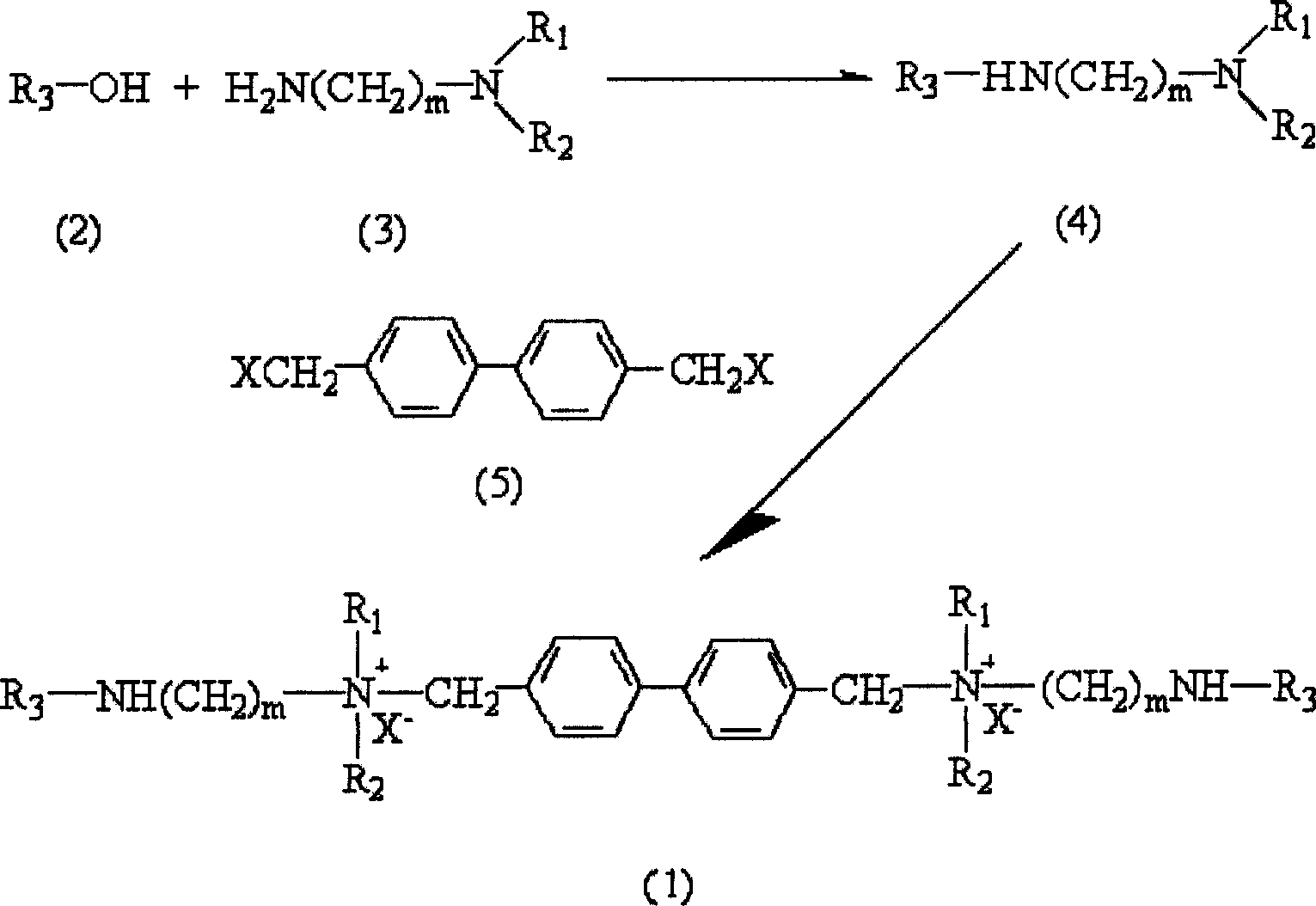

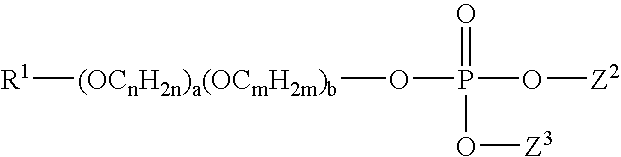

Cation fluoride Gemini surface activator

InactiveCN1817431ALess quantityImprove stabilityTransportation and packagingMixingChemical structureCritical micelle concentration

A cationic fluoric surfactant Gemini and its chemical structure are disclosed. Its advantages are lower critical micell concentration, less consumption, and high dispersity, foam stability, penetrability and wettability.

Owner:EAST CHINA UNIV OF SCI & TECH +1

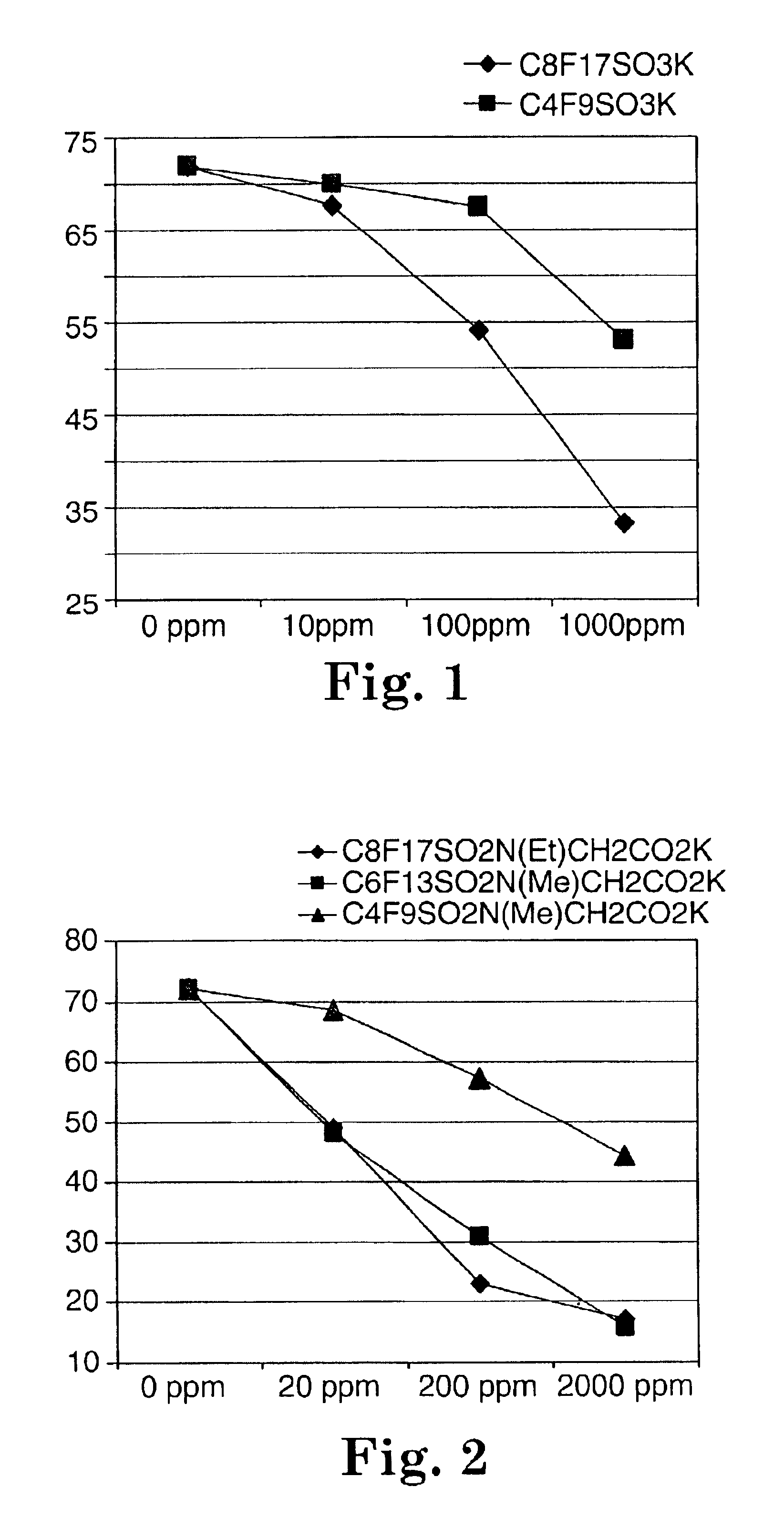

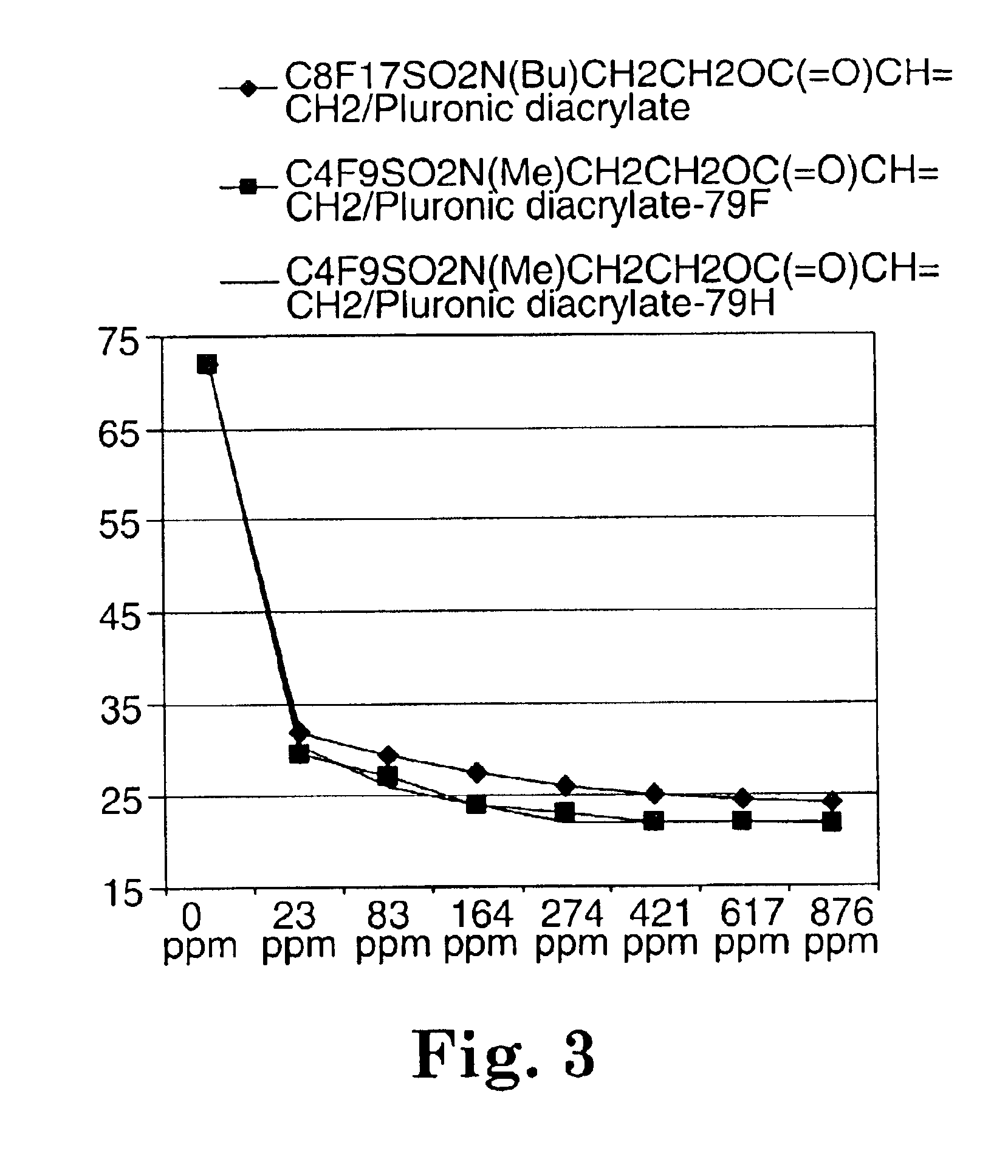

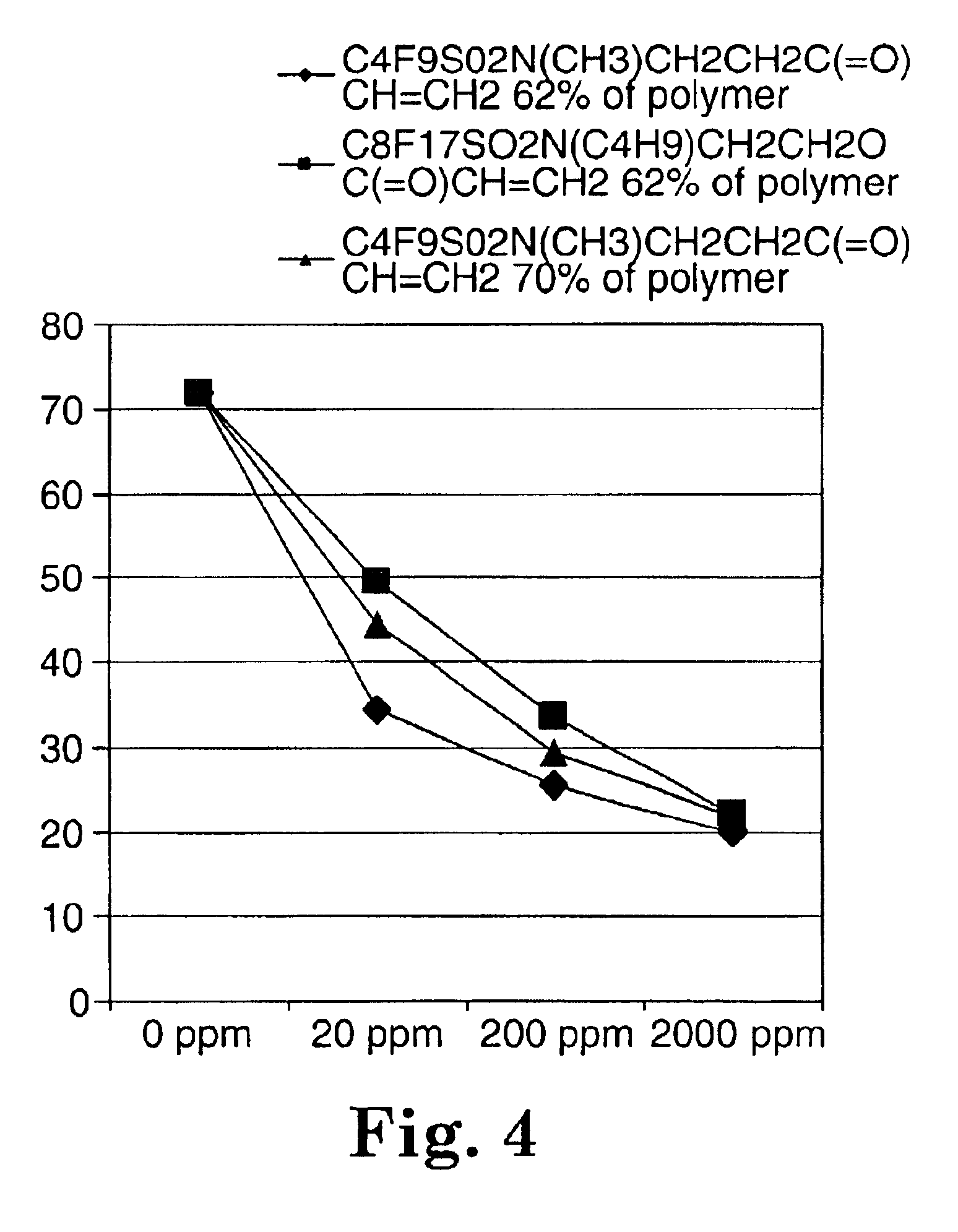

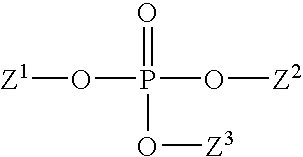

Fluorochemical sulfonamide surfactants

InactiveUS6852781B2High yieldLow costNon-macromolecular adhesive additivesPhotosensitive materialsSide chainSulfonyl fluoride

Described are fluorochemical surfactants derived from nonafluorobutanesulfonyl fluoride that contain polyalkyleneoxy side chains and may be copolymerized with acrylic acid or methacrylic acid to form polyacrylates or polymethacrylates. The surfactants surprisingly lower the surface tension of water and other liquids in the same or similar low values achieved by premier surfactants such as those derived from perfluorooctane sulfonyl fluoride.

Owner:3M INNOVATIVE PROPERTIES CO

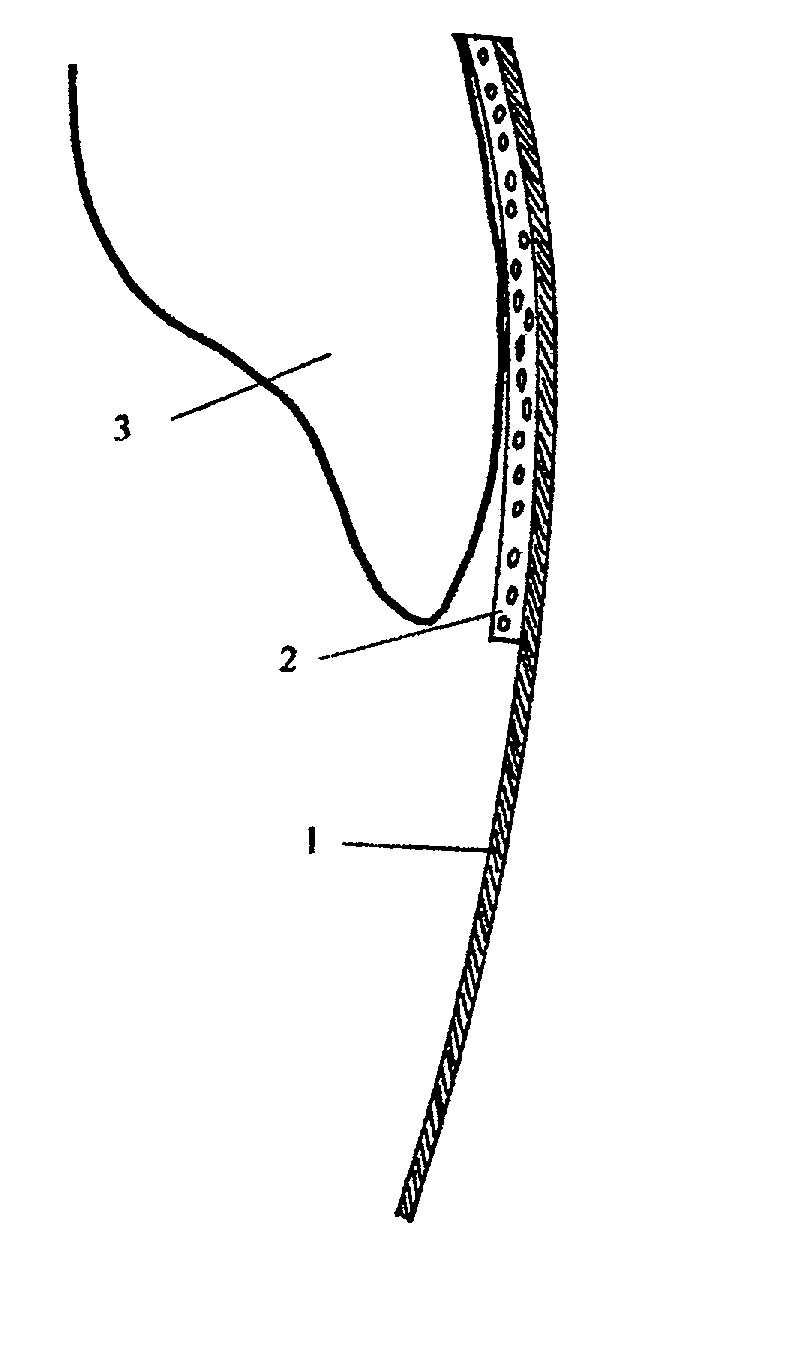

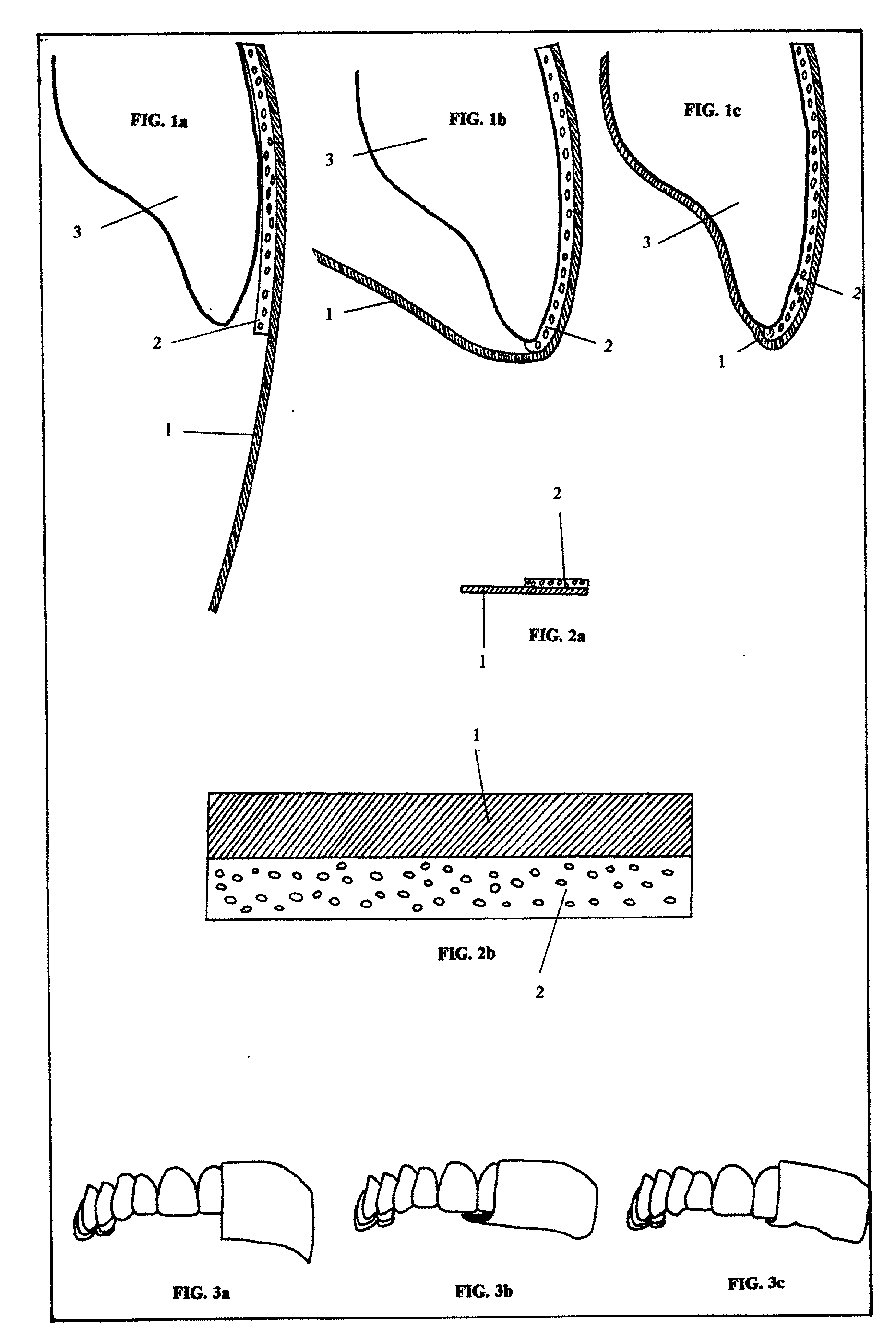

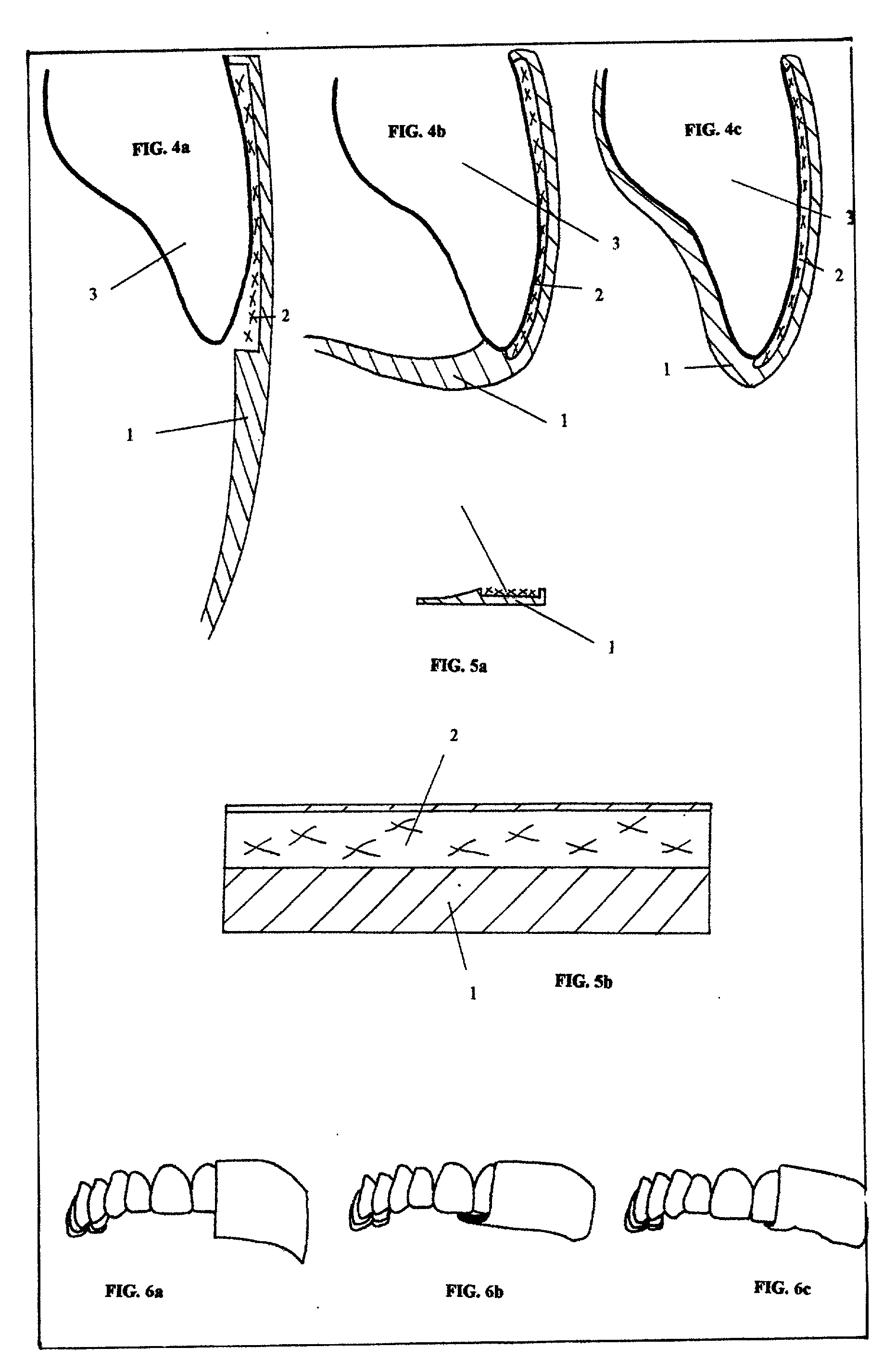

Pre-impregnated disposable dental substance delivery mouthpiece

InactiveUS20030003421A1Increase the patient's comfortPromote healingTeeth fillingCoffinsOral treatmentAdhesive

Disposable dental mouthpiece-strip which has been pre-impregnated with dental substance which can either be placed in the mouth by the user or inserted in the mouth by a dentist for oral treatments, such as teeth whitening treatments, fluoride treatments, or medical treatments, such as the application of anasthetic or antimicrobal / antiseptic treatments. The mouthpiece-strip is made with a foldable structure such as a thin strip of wax with a section of porous material (sponge) that holds the treatment dental product (liquid or gel). The mouthpiece-strip is disposable; the amount of time it is worn is determined by the type of dental treatment. The mouthpiece-strip may be adjusted in size by cutting it with scissors. The wax used for the mouthpiece is non-toxic and allows for a perfect adjustment in the mouth by contouring to the teeth during adjustment by the user. To enhance the fit in the mouth, the inner surface of the mouthpiece-strip may contain a thin layer of non-toxic sticky adhesive. The porous (sponge) strip attached to the wax strip is an inert, nontoxic material which is easy to process and inexpensive. It is attached to the wax strip with a non-toxic adhesive.

Owner:BESTENHEIDER THIERRY +1

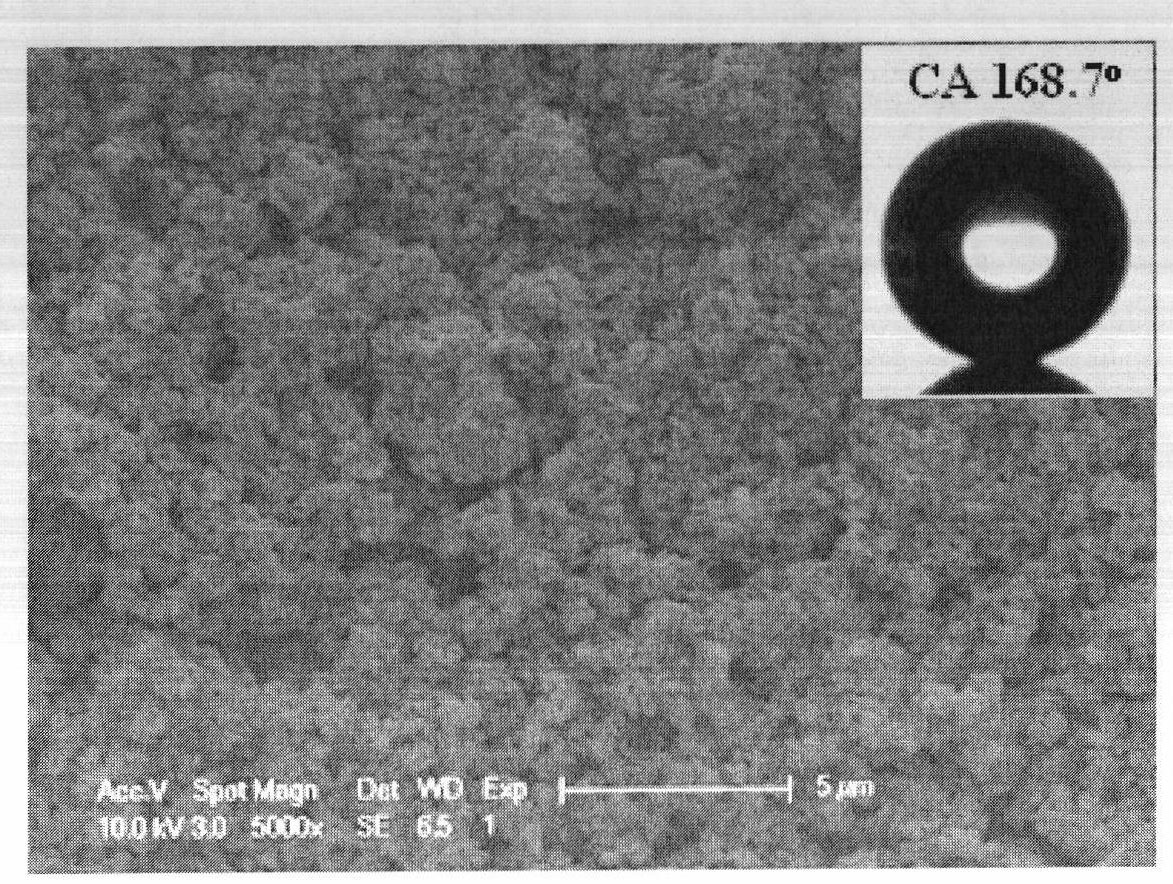

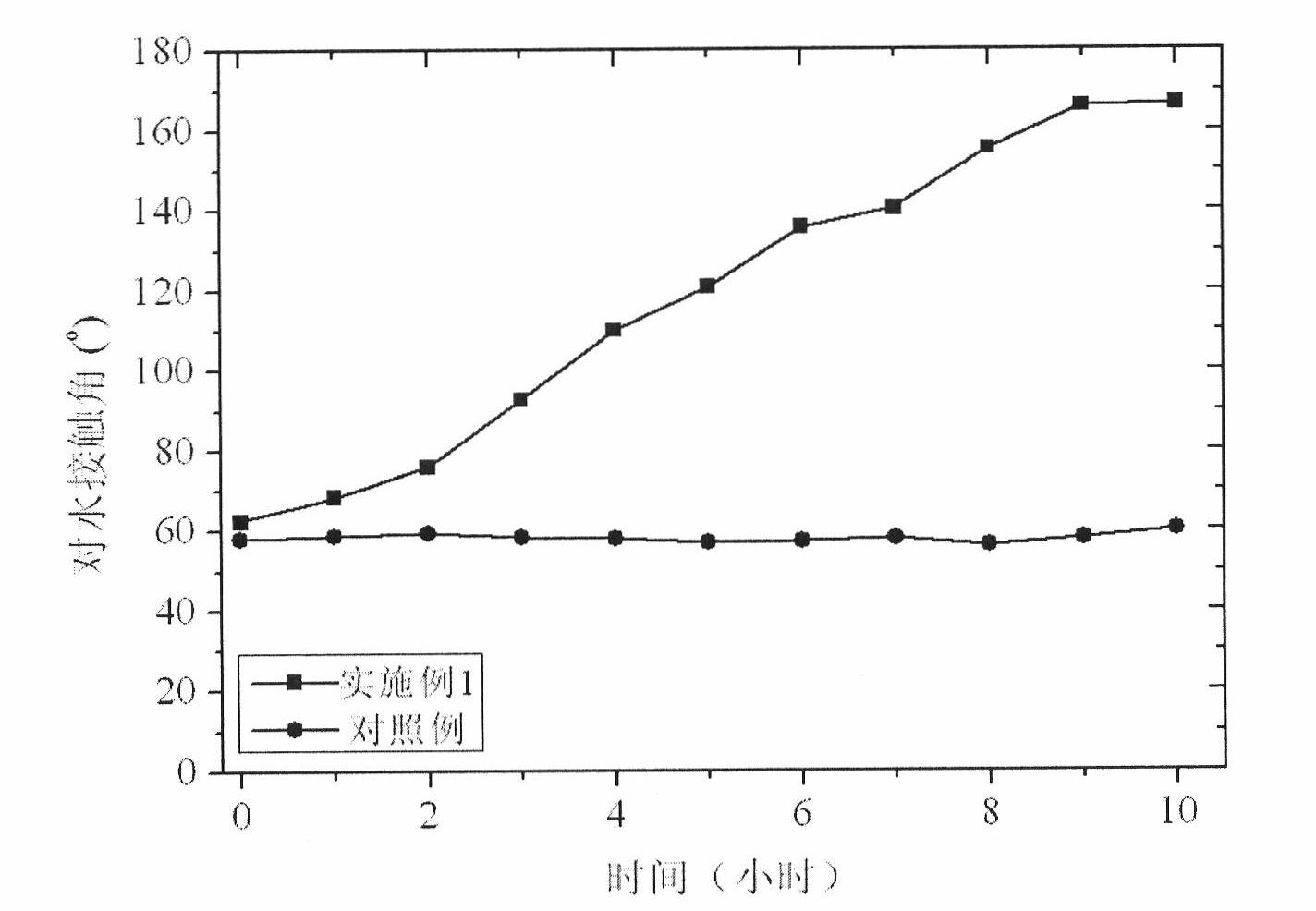

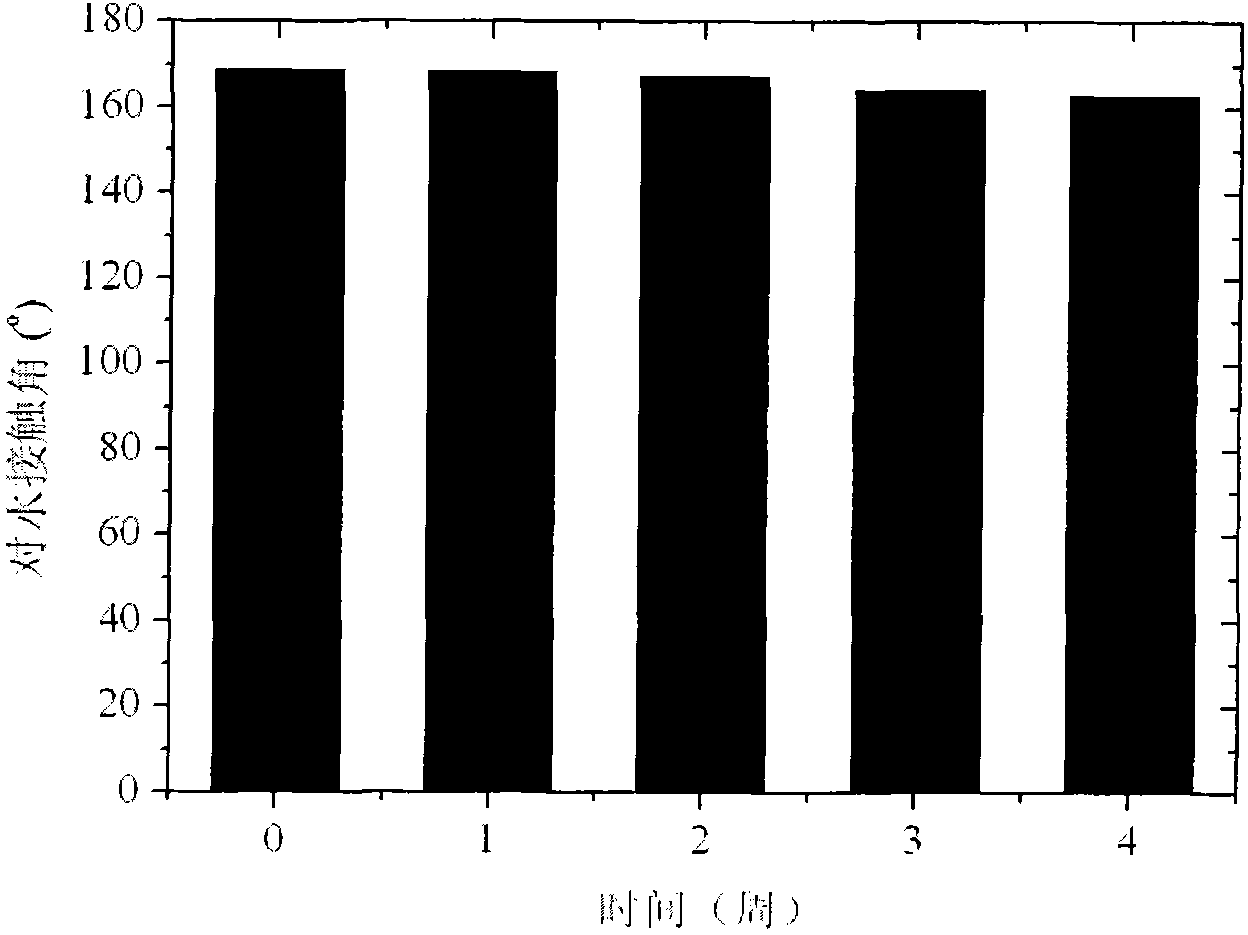

High-durability super-hydrophobic self-cleaning coating material and preparation method thereof

InactiveCN101962514AHas the following advantages: (1) cleanlinessHas the following advantages: (1) has the functionAntifouling/underwater paintsPaints with biocidesDouble bondDimethyl siloxane

The invention belongs to the technical field of a new chemical material, and in particular relates to a high-durability super-hydrophobic self-cleaning coating material and a preparation method thereof. The coating material of the invention is prepared by curing and drying nanoparticles with photo-catalytic activity, a low-surface-free-energy polymer and a cross-linking agent at the room temperature, wherein the low-surface-free-energy polymer consists of one or more of polysiloxane fluoride, dimethyl silicone polymer and polyphenylene methyl siloxane, which contain active groups, such as hydroxyl alkoxy group, carbon-carbon double bond, silanol group, siloxy group, and the like; the cross-linking agent is hydrogen-containing silicone oil or aminosilane; and the mass content of the photo-catalytic nanoparticles in the coating ranges from 10 to 60 percent. The coating is formed into a micro-nanostructure by nanoparticle self-organization; a super-hydrophobic self-cleaning coating with lotus effect is prepared from the coating and a cross-linked filming matrix with low surface energy; the persistence of a lotus-shaped super-hydrophobic characteristic of the coating is realized by using the photo-catalytic decomposition characteristic of an organic pollutant for the nanoparticles; and thus the material is suitable for large-area construction and has high weathering resistance andprominent self-cleaning characteristic.

Owner:FUDAN UNIV

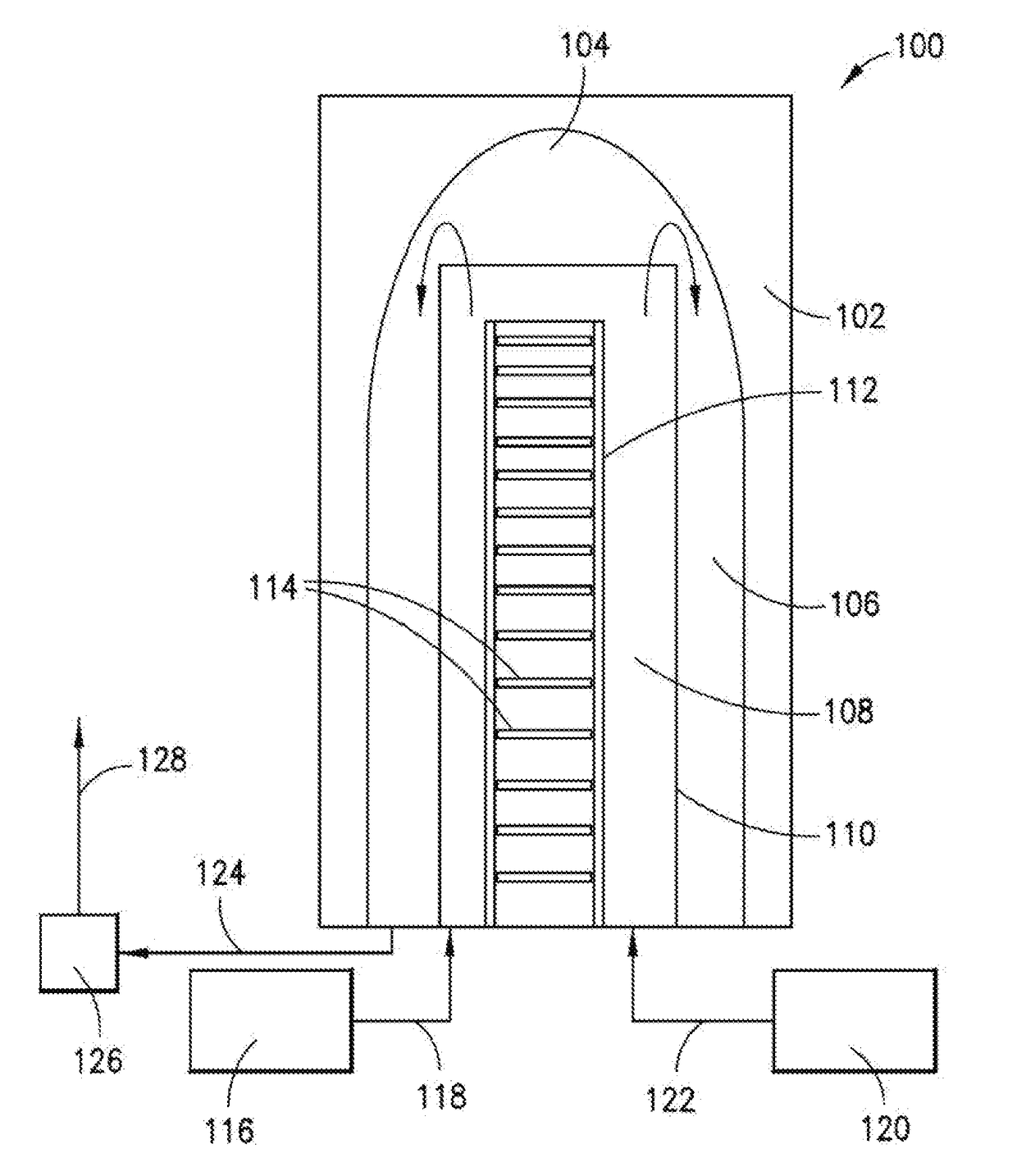

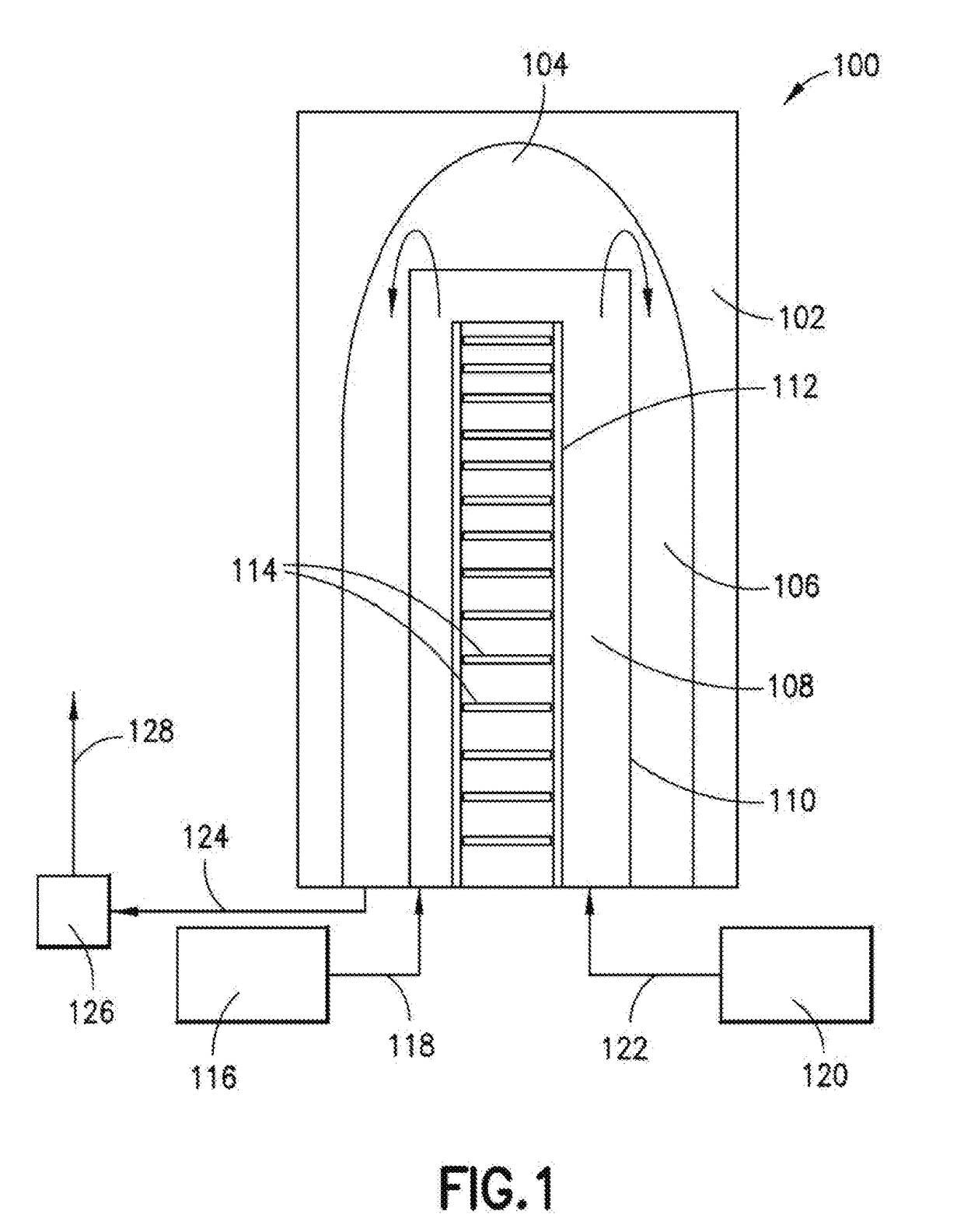

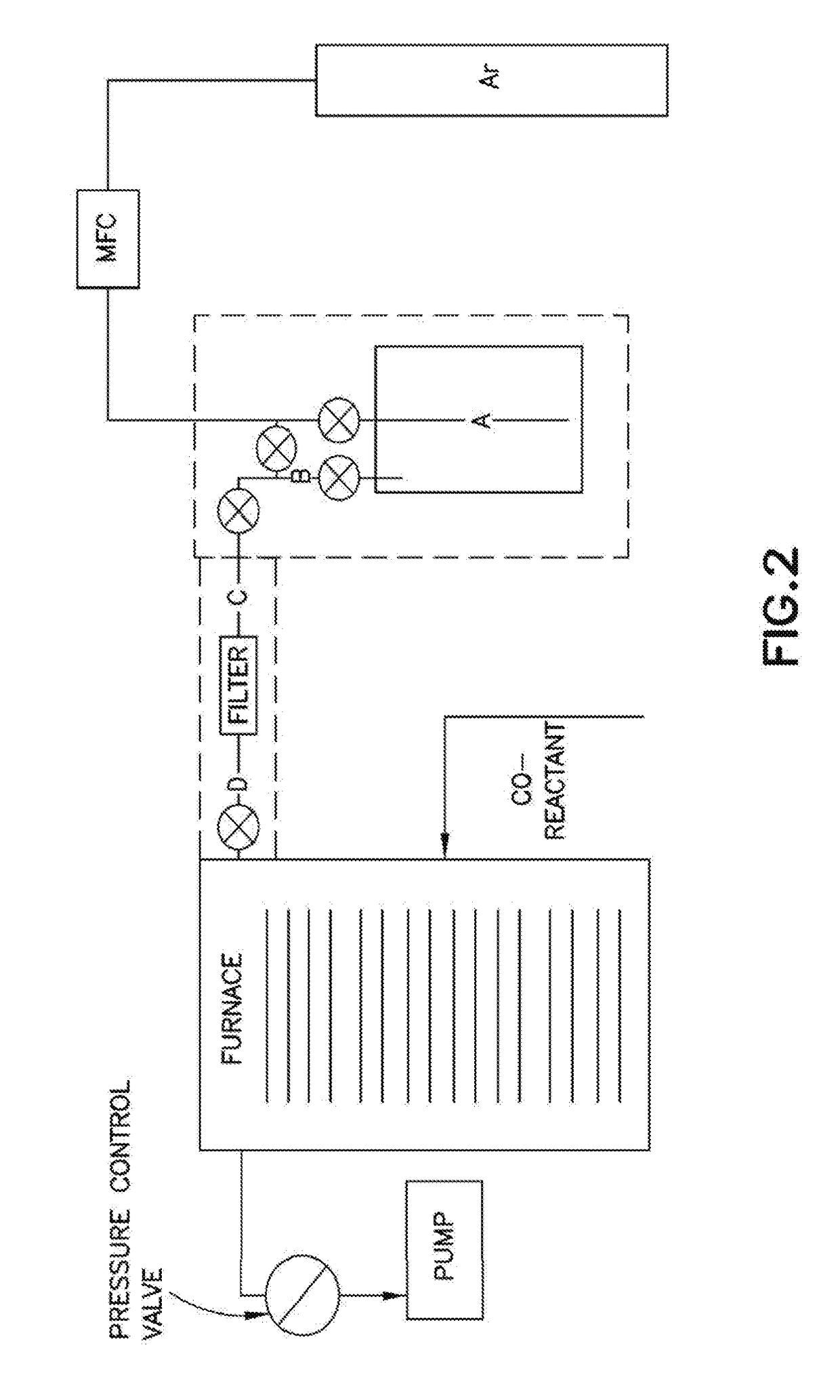

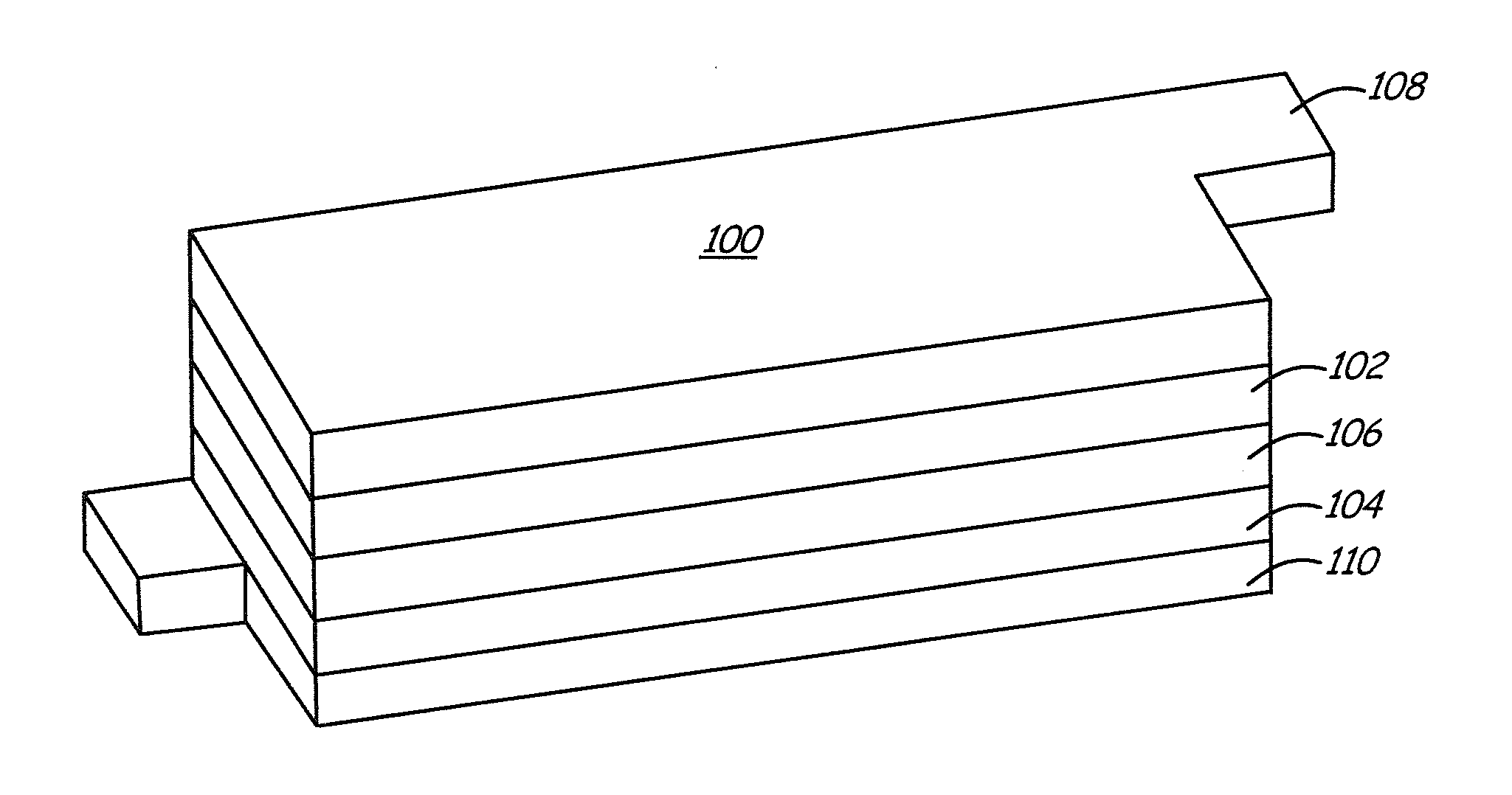

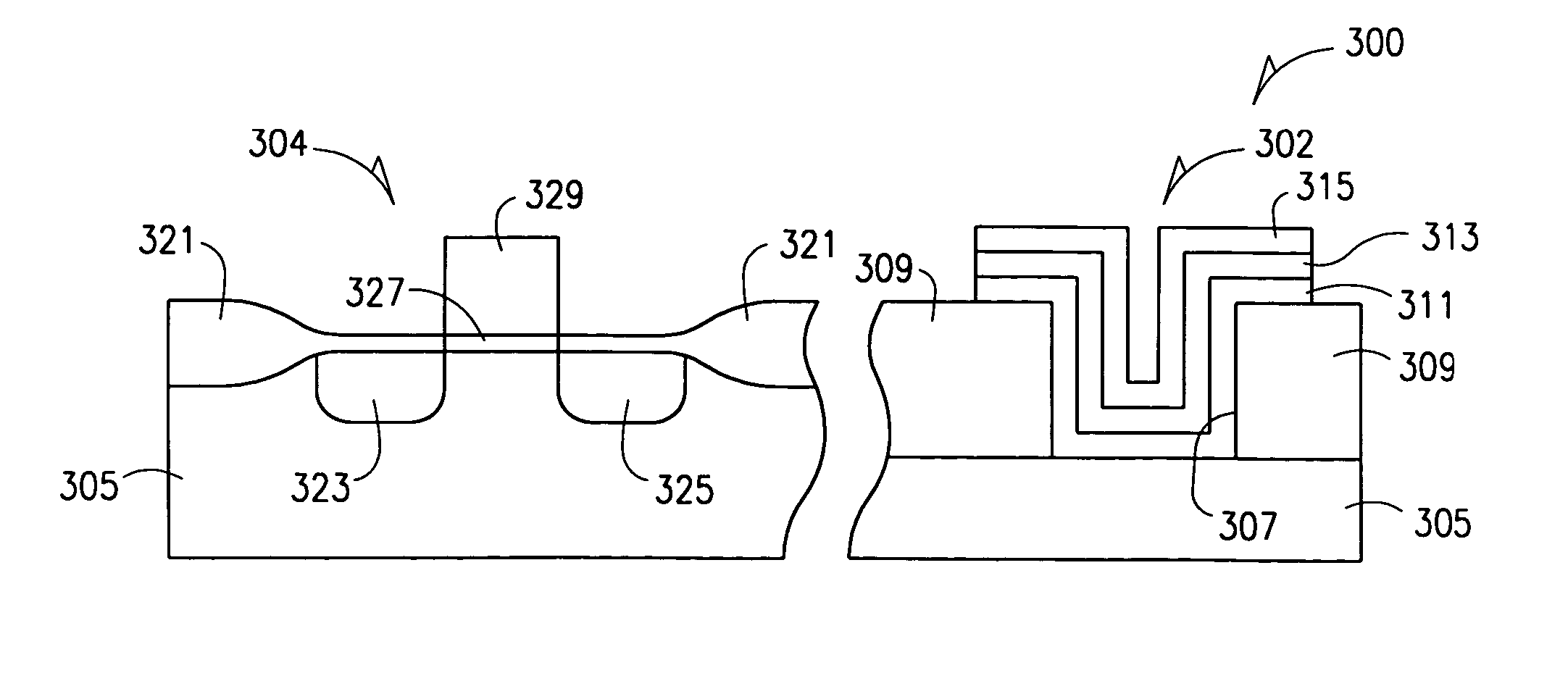

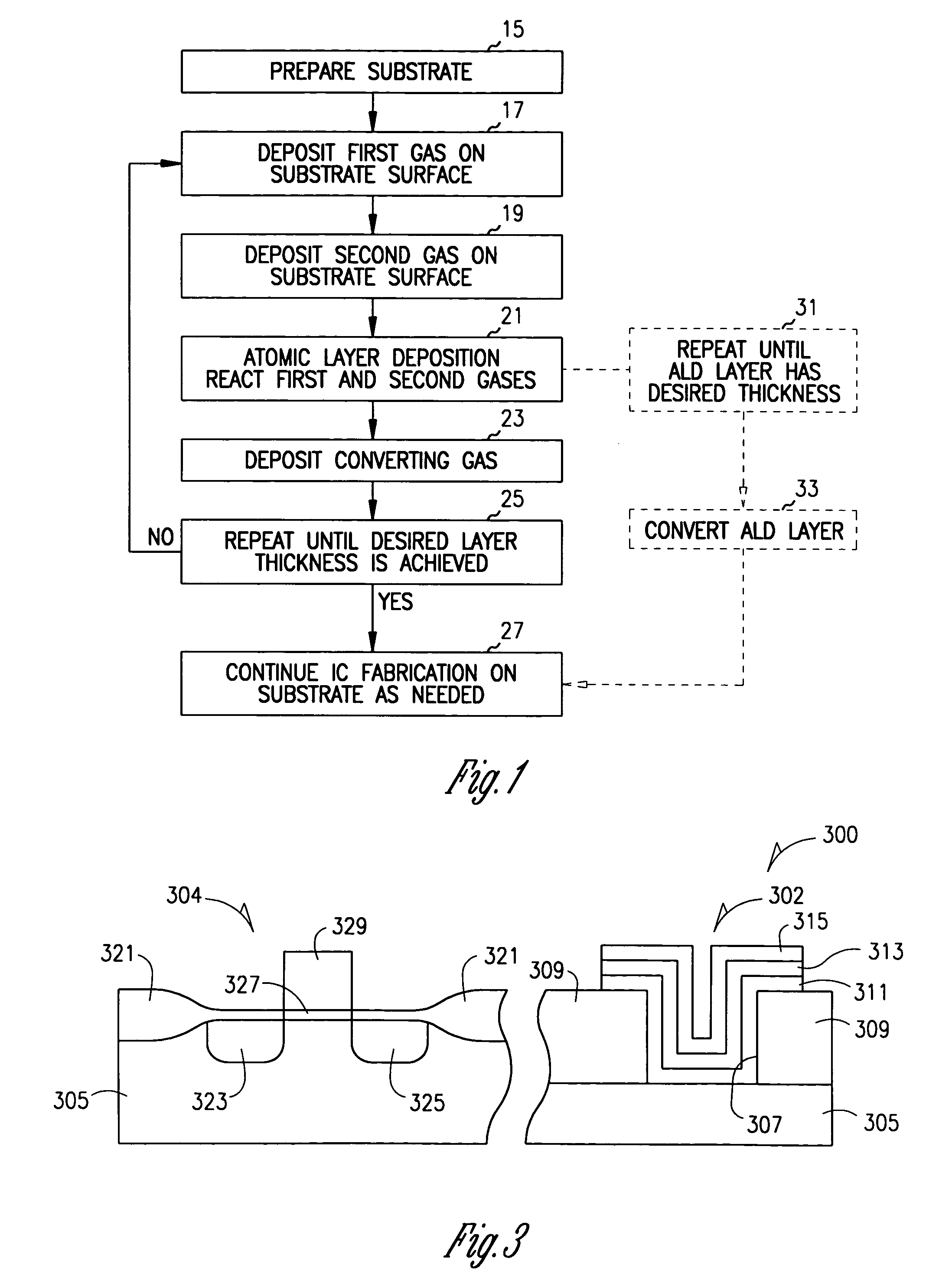

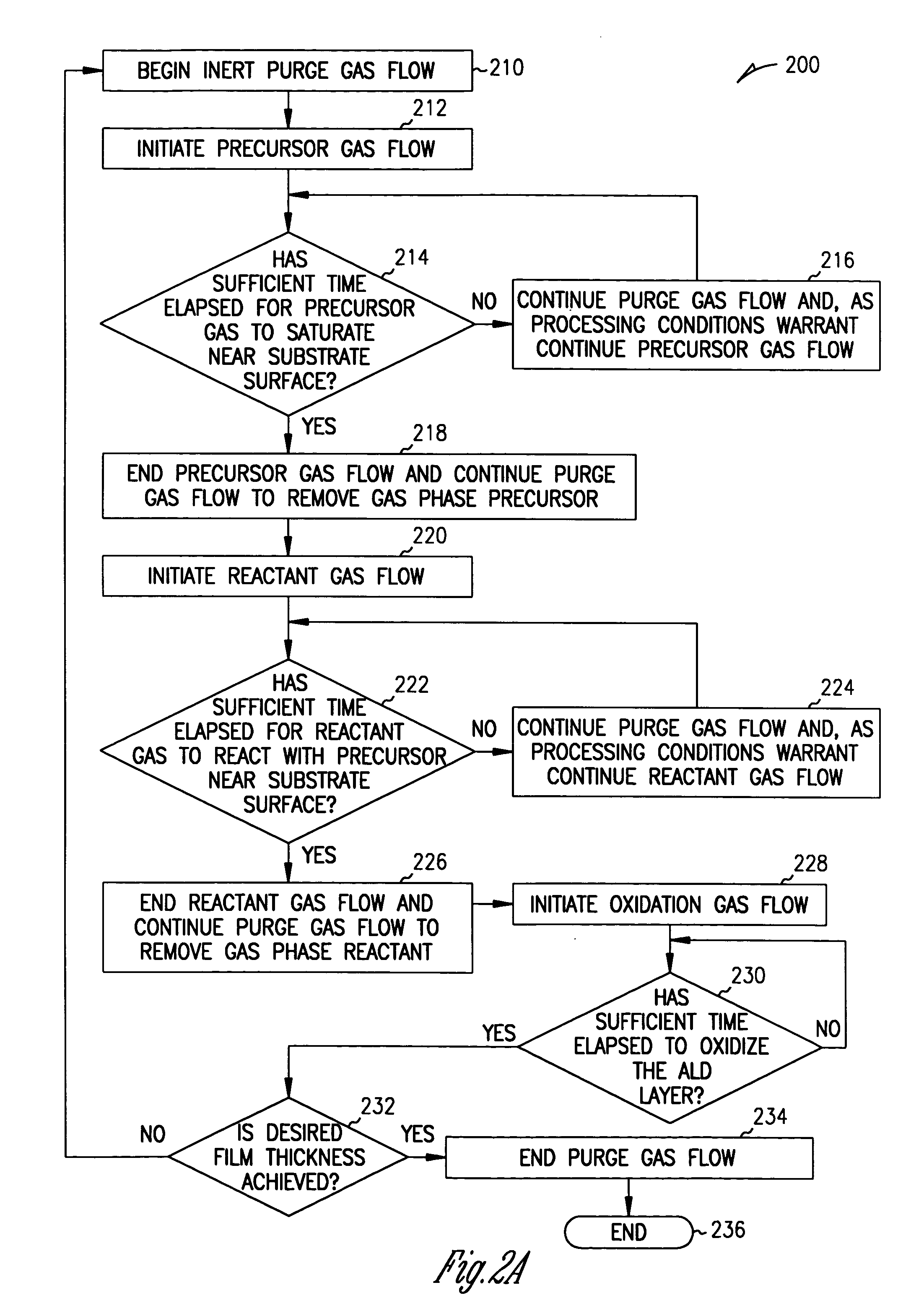

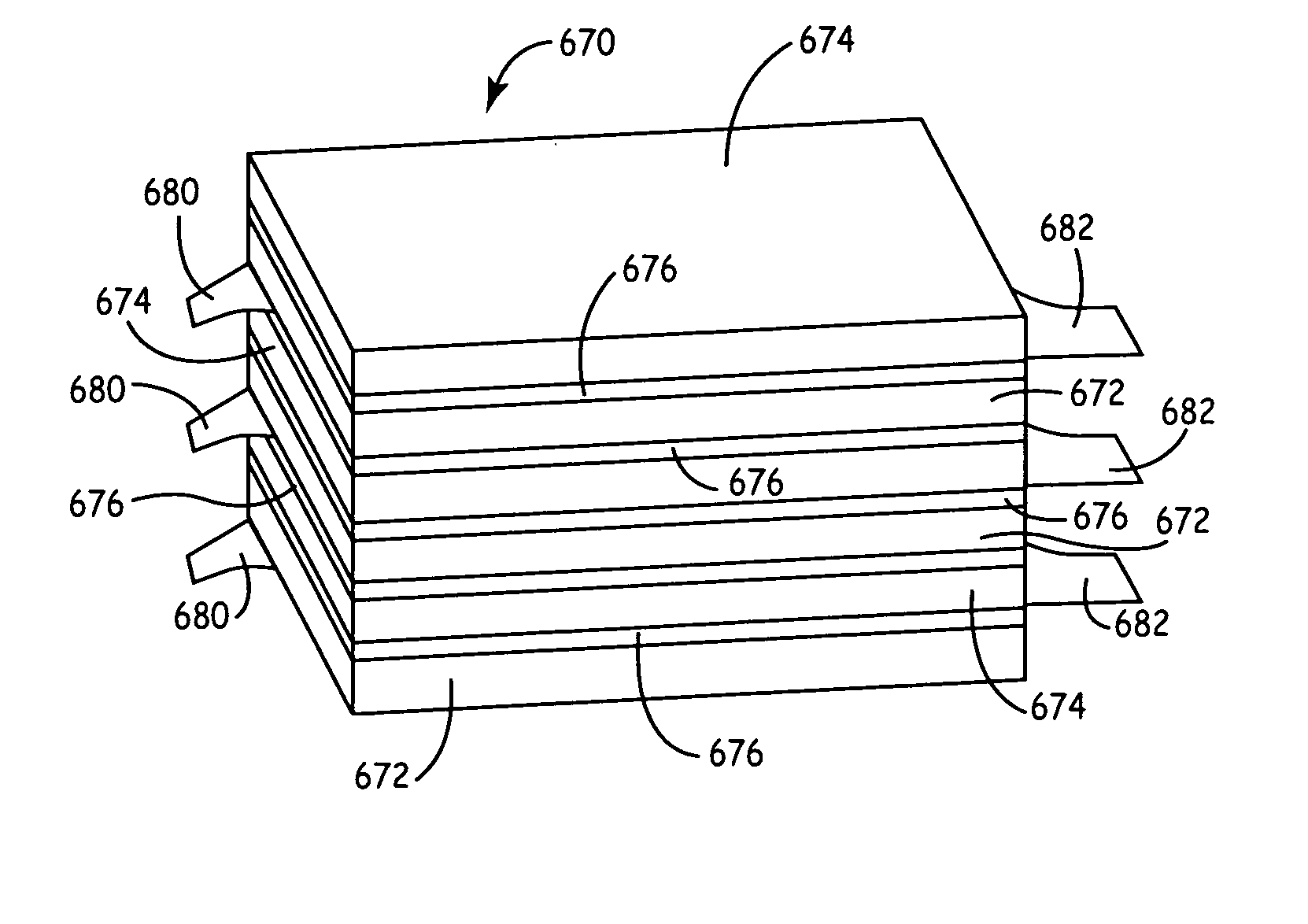

Atomic layer deposition and conversion

A method for growing films for use in integrated circuits using atomic layer deposition and a subsequent converting step is described. In an embodiment, the subsequent converting step includes oxidizing a metal atomic layer to form a metal oxide layer. The atomic layer deposition and oxidation step are then repeated to produce a metal oxide layer having sufficient thickness for use as a metal oxide layer in an integrated circuit. The subsequent converting step, in an embodiment, includes converting the atomic deposition layer by exposing it to one of nitrogen to form a nitride layer, carbon to form a carbide layer, boron to form a boride layer, and fluorine to form a fluoride layer. Systems and devices for performing the method, semiconductor devices so produced, and machine readable media containing the method are also described.

Owner:MICRON TECH INC

Medium rate and high rate batteries

Improved submicron carbon fluoride has increased graphite content and can also have improved uniformity. The increased graphite content and / or uniformity can result in improved battery performance, for example with respect to specific capacity. Desirable battery structures provide for use with implantable medical devices. Suitable batteries can be used for high rate, medium rate, low rate or a combination of rate applications.

Owner:GREATBATCH TECH ADVANCED RES LAB

Compositions and Methods for Improving Overall Tooth Health and Appearance

ActiveUS20080247973A1Avoid lostSuperior anticariesCosmetic preparationsToilet preparationsAmmonium compoundsStaining

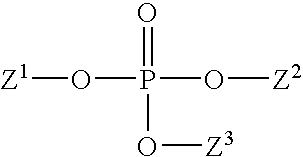

Disclosed are oral care compositions comprising selected surface-active organophosphate compounds and methods of use to provide protection of teeth from erosion caused by the action of chemicals, such as harsh abrasives and acids. The surface-active organophosphate compounds are substantive to teeth, the phosphate groups binding the calcium in teeth and thus preventing loss of calcium from dissolution when contacted with acids. The organophosphate compound may also deposit a protective surface coating that prevents contact of teeth with erosive challenges. Selected organophosphate compounds contain one or more phosphate groups and are combined in the oral care composition with one or more of a fluoride ion agent, an antimicrobial agent preferably selected from quaternary ammonium compounds and polyvalent metal salts, an anticalculus agent and additional surfactant, to provide benefits including superior anti-erosion, anticaries, antiplaque and anti-staining as demonstrated by enhanced fluoride uptake, remineralization, resistance to acid demineralization and antimicrobial activities, resulting in improved overall tooth health, structural integrity and appearance.

Owner:THE PROCTER & GAMBLE COMPANY

Lithium ion batteries with long cycling performance

ActiveUS20110017528A1Maintain discharge capacitySmall-sized cells cases/jacketsElectric propulsion mountingHigh energyEngineering

Batteries with high energy and high capacity are described that have a long cycle life upon cycling at a moderate discharge rate. Specifically, the batteries may have a room temperature fifth cycle discharge specific energy of at least about 175 Wh / kg discharged at a C / 3 discharge rate from 4.2V to 2.5V. Additionally, the batteries can maintain at least about 70% discharge capacity at 1000 cycles relative to the fifth cycle, with the battery being discharged from 4.2V to 2.5V at a C / 2 rate from the fifth cycle through the 1000th cycle. In some embodiment, the positive electrode of the battery comprises a lithium intercalation composition with optional metal fluoride coating. Stabilizing additive maybe added to the electrolyte of the battery to further improve the battery performance. The batteries are particularly suitable for use in electric vehicles.

Owner:IONBLOX INC

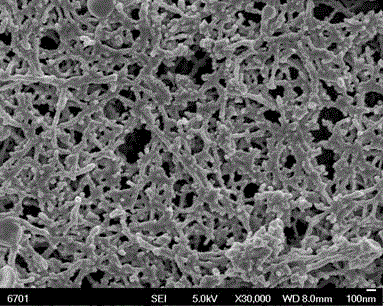

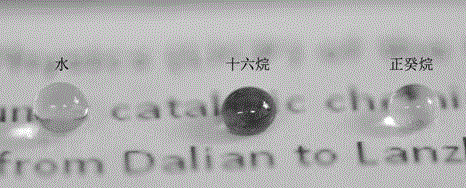

Large-scale preparation method of transparent super-hydrophobic/super-amphiphobic coating

InactiveCN106800885AExcellent superhydrophobic/superamphiphobic propertiesHigh transparencySpecial surfacesCoatingsNanoparticle ComplexAlcohol

The invention discloses a large-scale preparation method of a transparent super-hydrophobic / super-amphiphobic coating. The method comprises the steps of ultrasonically dispersing nano particles into an alcohol-water mixed system and carrying out hydrolysis and condensation reaction on the nano particles and fluoride-free or fluorine-containing organosilane under the acid or alkali catalysis action to prepare a transparent suspension liquid of a fluoride-free or fluorine-containing organosilane polymer-nano particle compound; and applying the transparent suspension liquid of the compound on the surface of a substrate material through spraying or dip-coating to obtain the transparent super-hydrophobic / super-amphiphobic coating with good performance. Preparation of the transparent super-hydrophobic / super-amphiphobic coating of 10-100m<2> can be completed within an hour; large-scale preparation of the large-area transparent super-hydrophobic / super-amphiphobic coating is achieved for the first time; the preparation method is low in cost and simple in process; and the prepared coating has excellent super-hydrophobic or super-amphiphobic property, relatively good mechanical stability, chemical stability and environment stability, and has a wide application prospect.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com