Patents

Literature

143 results about "Fluorohydrocarbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic compound that contains carbon and hydrogen, with fluorine atoms substituting for one or more hydrogens.

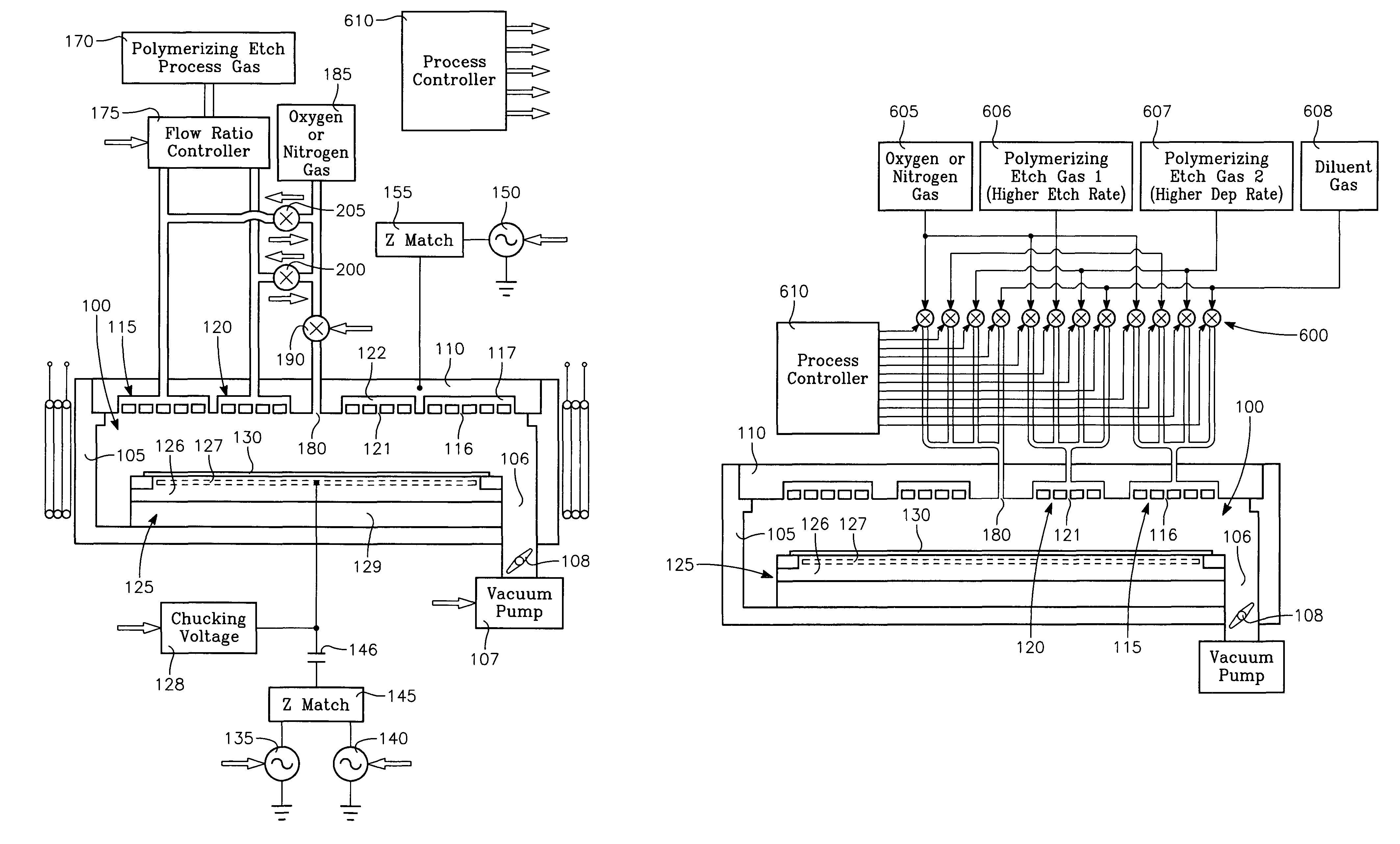

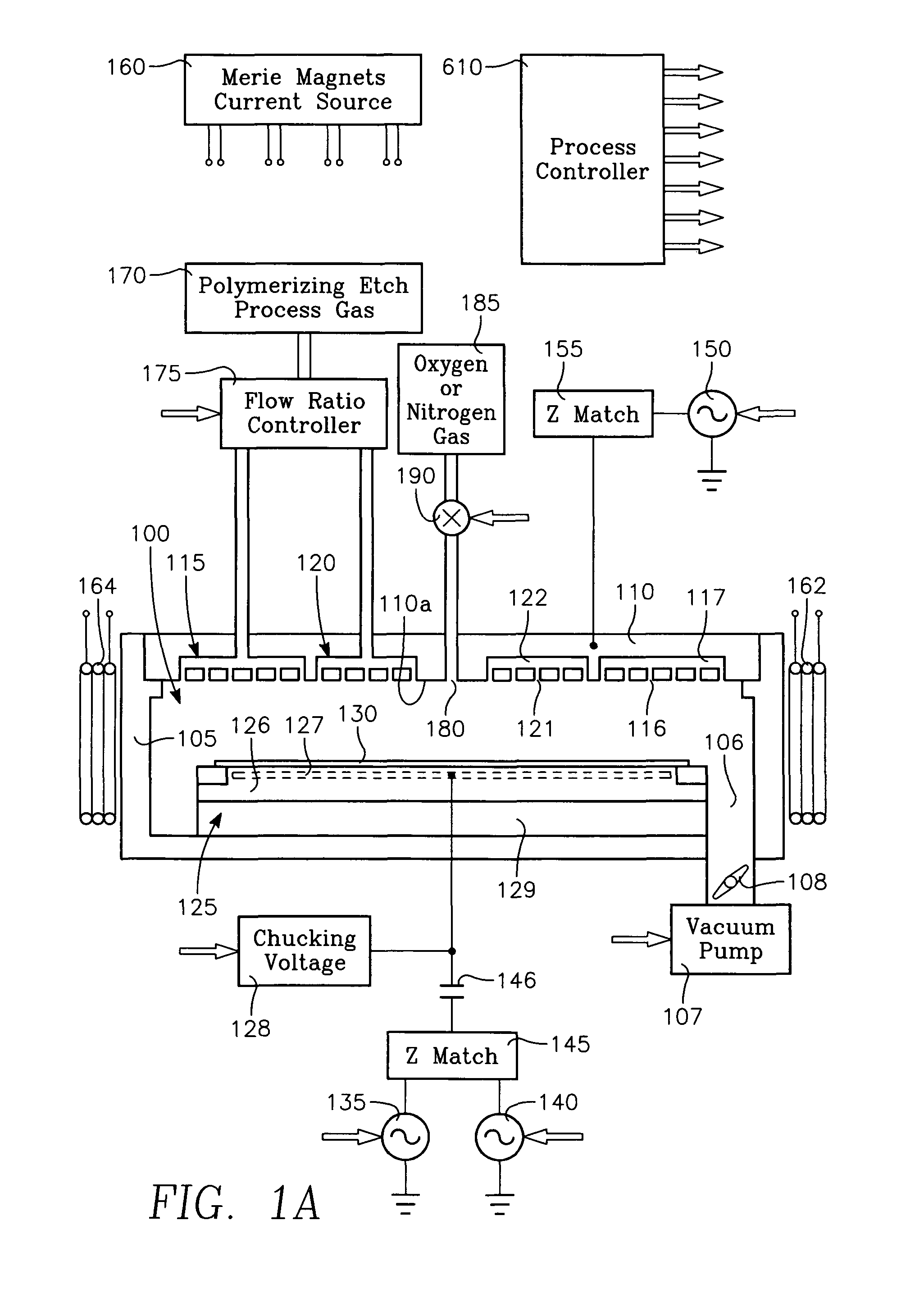

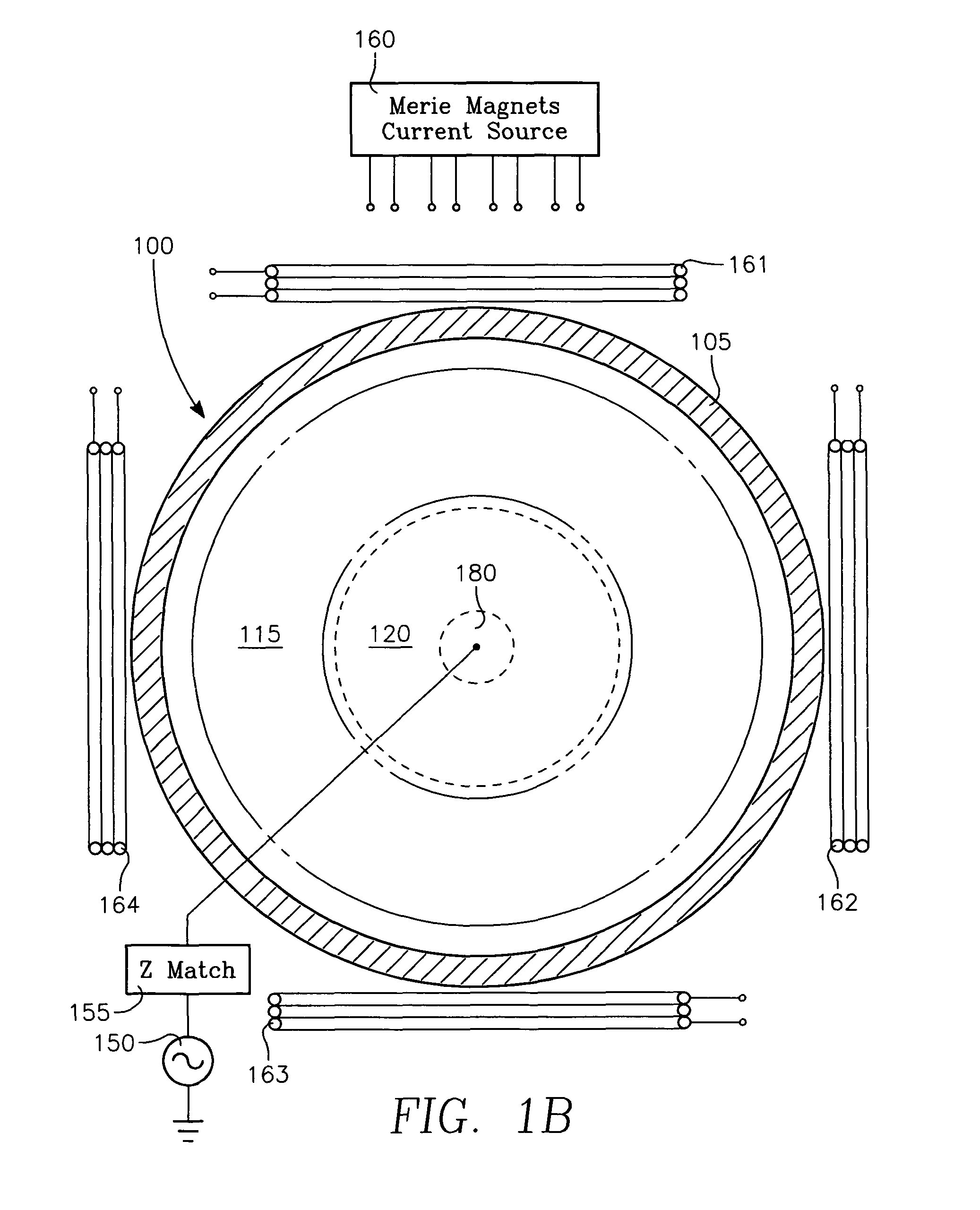

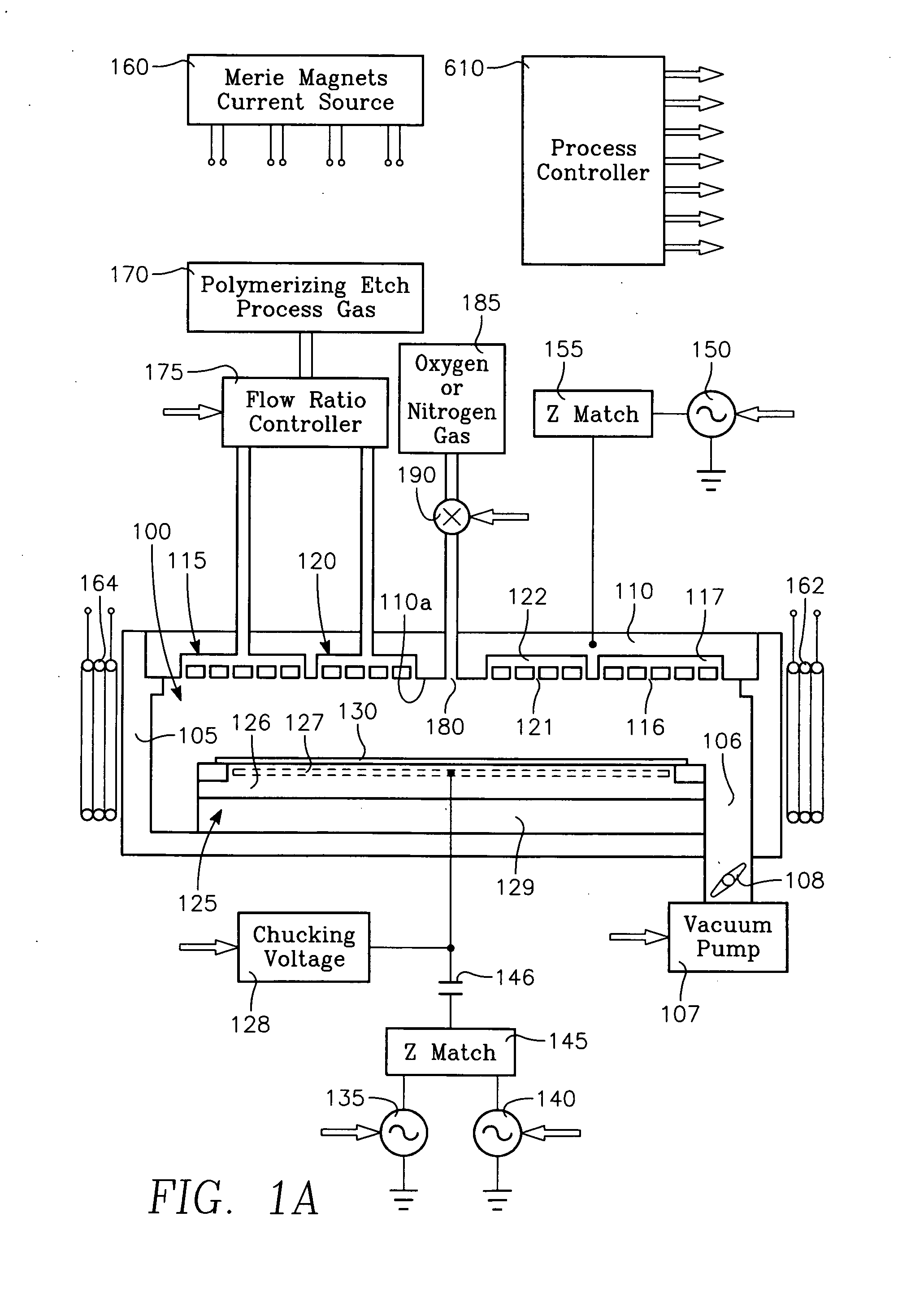

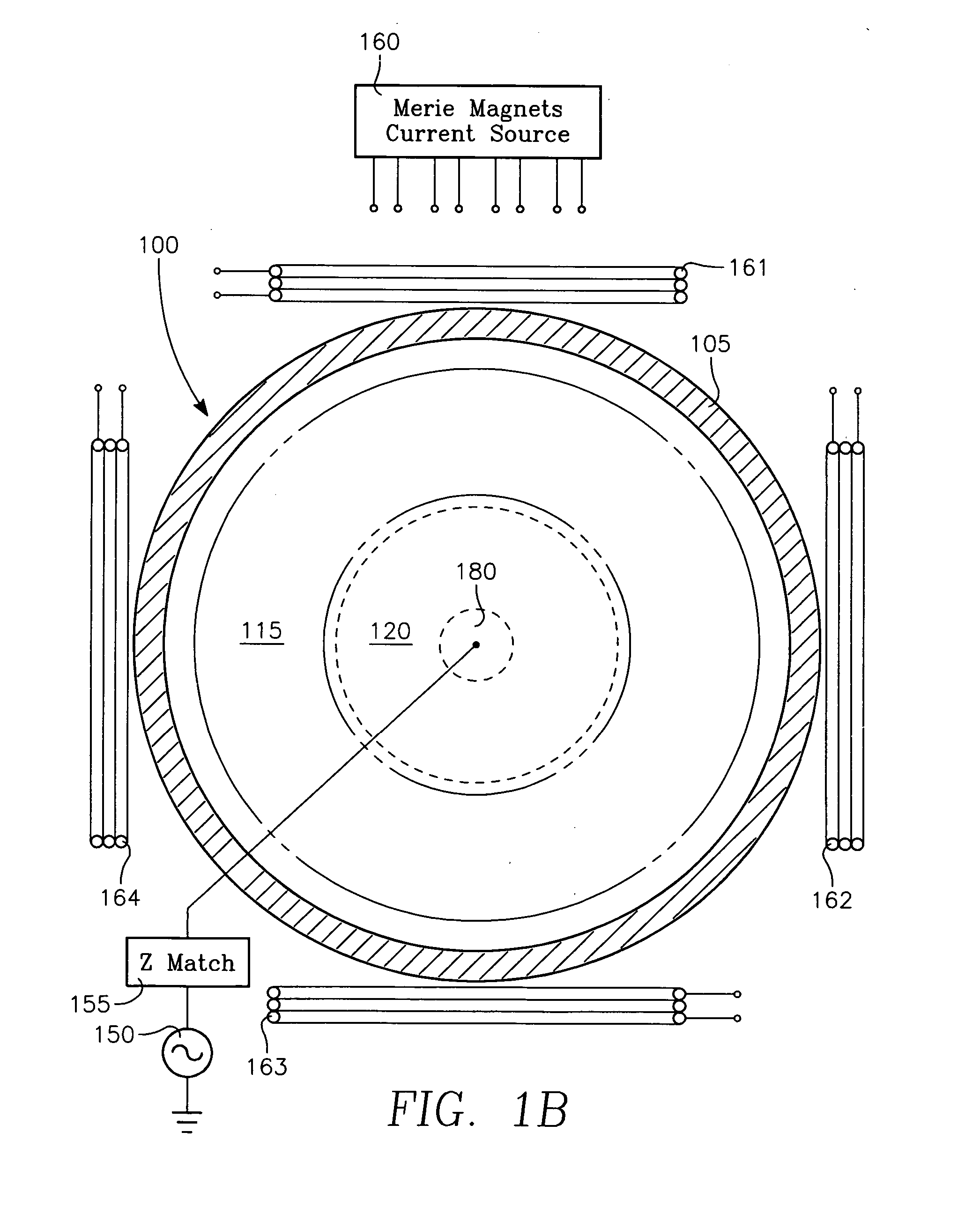

Plasma reactor apparatus with multiple gas injection zones having time-changing separate configurable gas compositions for each zone

ActiveUS8231799B2Electric discharge tubesVacuum gauge using ionisation effectsGas compositionEngineering

Owner:APPLIED MATERIALS INC

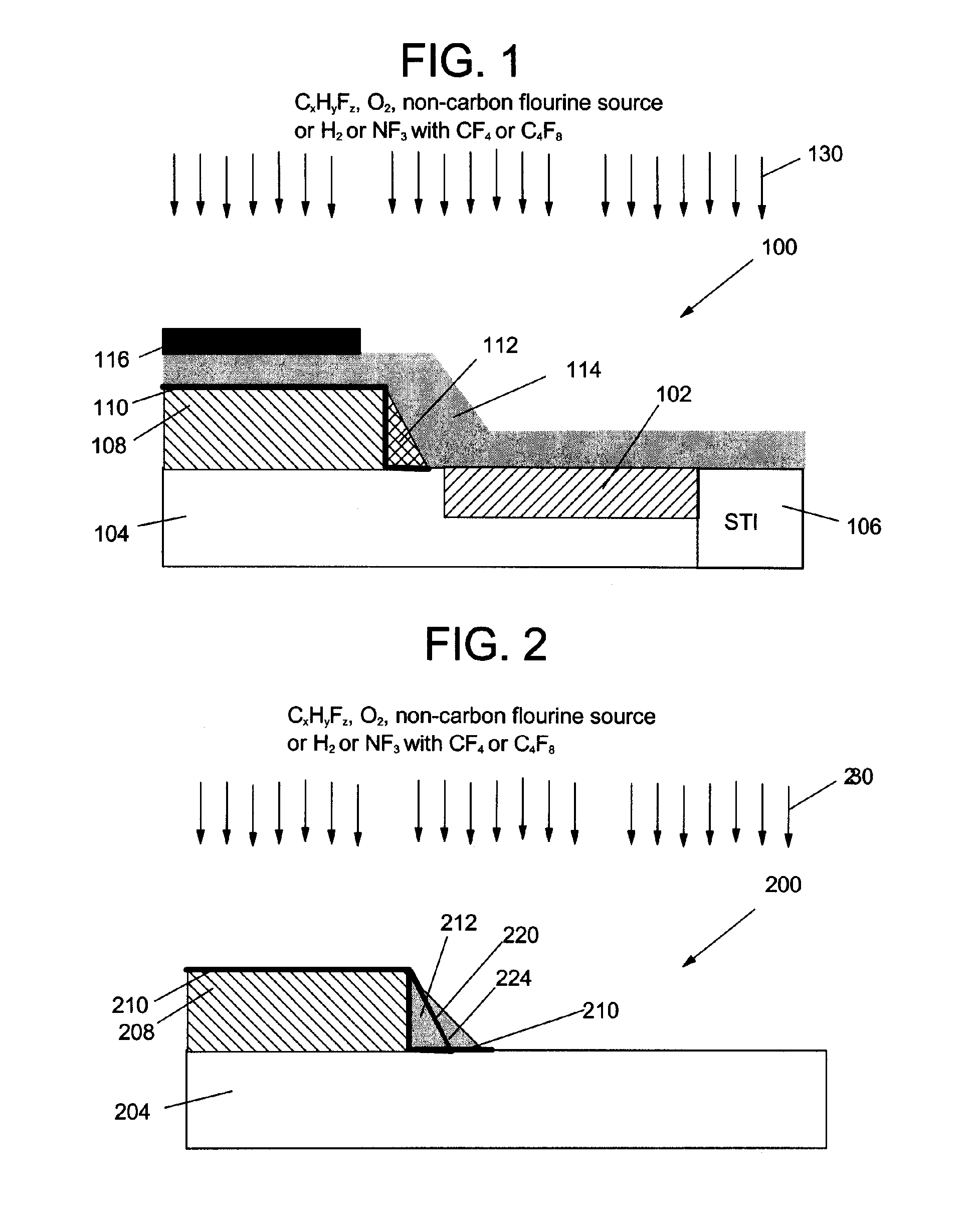

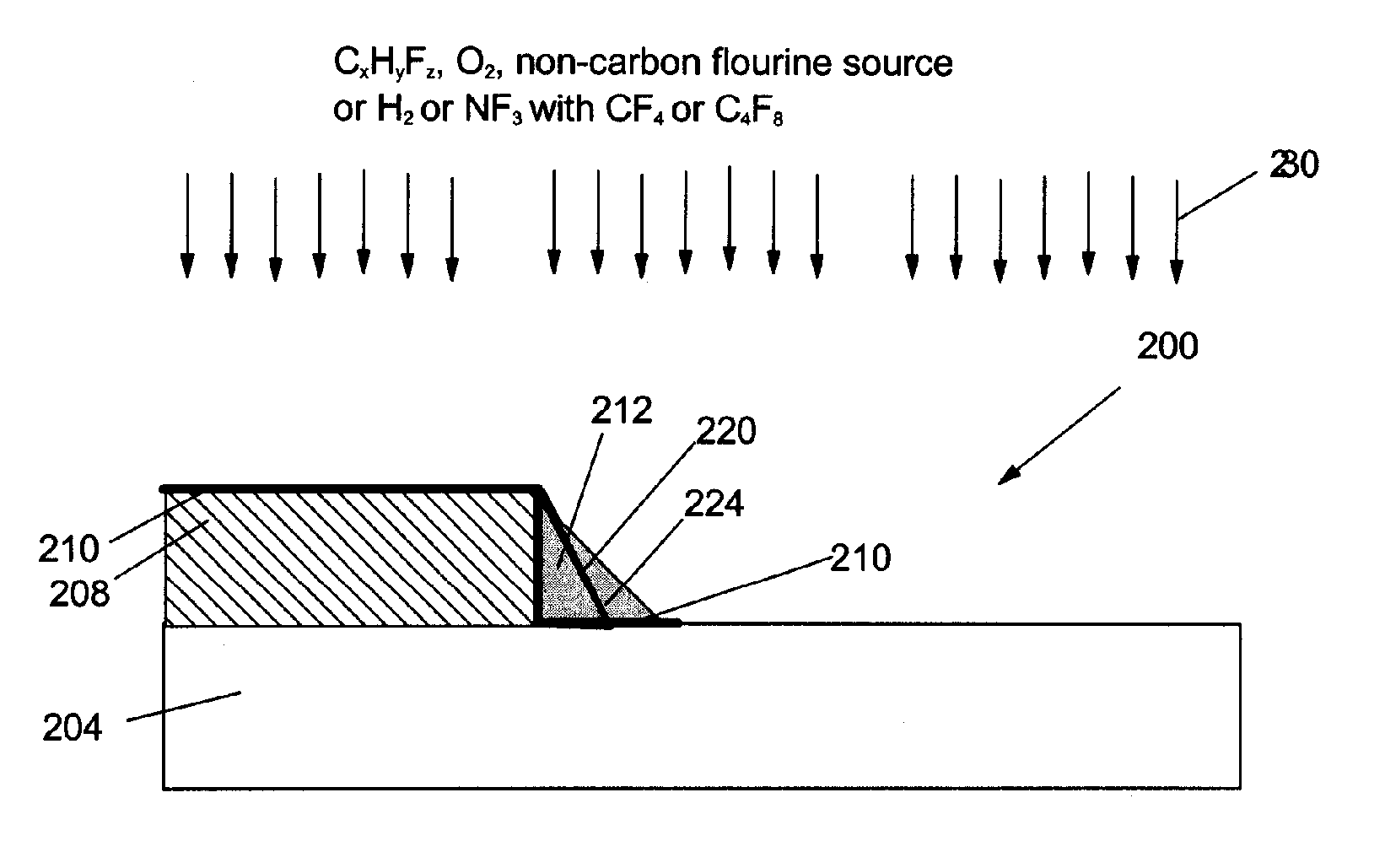

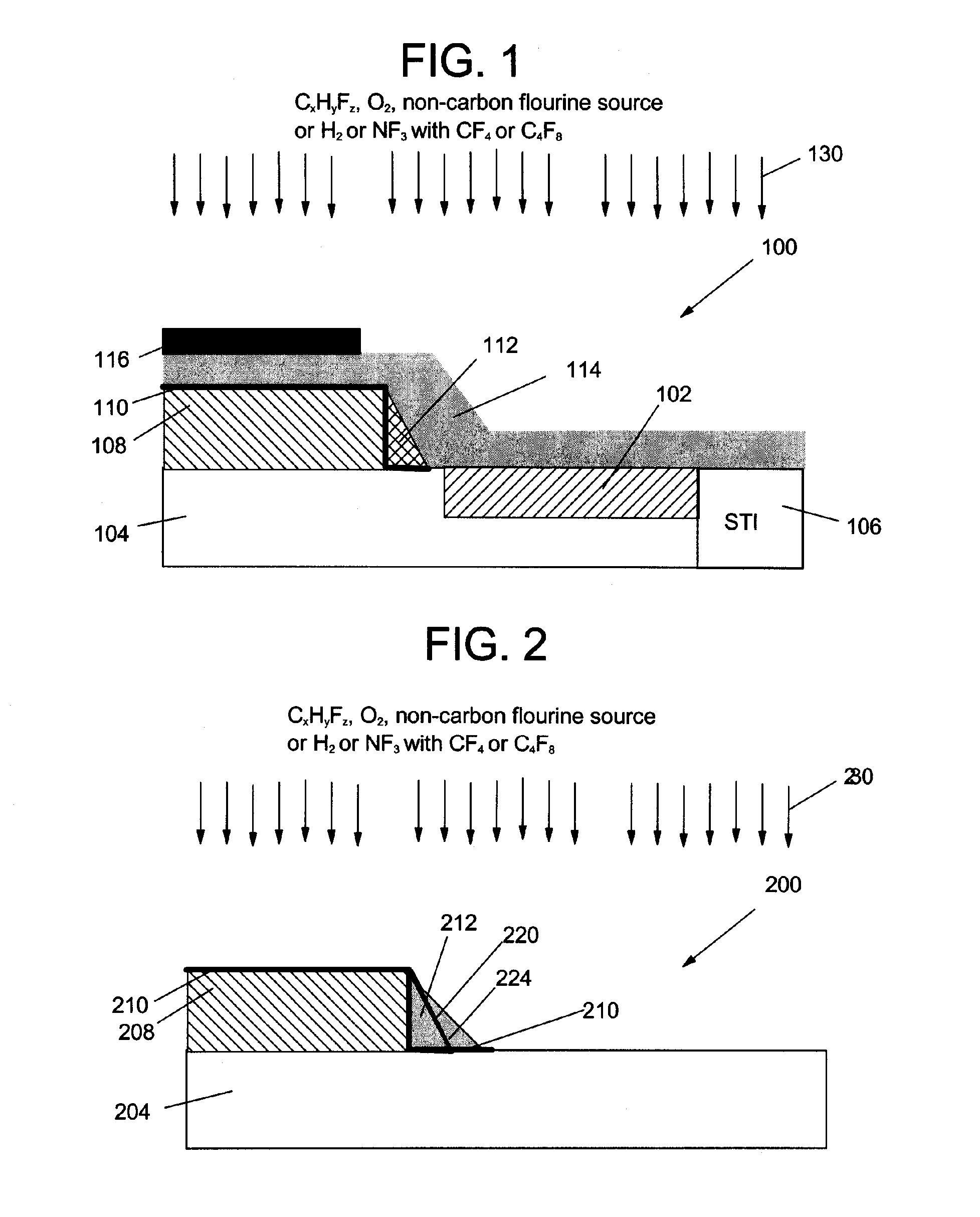

Silicon nitride etching methods

ActiveUS7288482B2Semiconductor/solid-state device manufacturingSulfur hexafluorideOctafluorocyclobutane

Methods of etching silicon nitride material, and more particularly, etching nitride selective to silicon dioxide or silicide, are disclosed. The methods include exposing a substrate having silicon nitride thereon to a plasma including at least one fluorohydrocarbon and a non-carbon containing fluorine source such as sulfur hexafluoride (SF6). The plasma may also include oxygen (O2) and the fluorohydrocarbons may include at least one of: trifluoromethane (CHF3), difluoromethane (CH2F2), and methyl fluoride (CH3F). In an alternative embodiment, the plasma includes one of hydrogen (H2) and nitrogen trifluoride (NF3) and one of tetrafluoromethane (CF4) and octafluorocyclobutane (C4F8). The methods are preferably carried out using a low bias voltage, e.g. <100 V.

Owner:IBM CORP +1

Method for Laterally Trimming a Hardmask

ActiveUS20150064918A1Reduce decreaseReduced dimensionSemiconductor/solid-state device manufacturingDielectricFluorocarbon

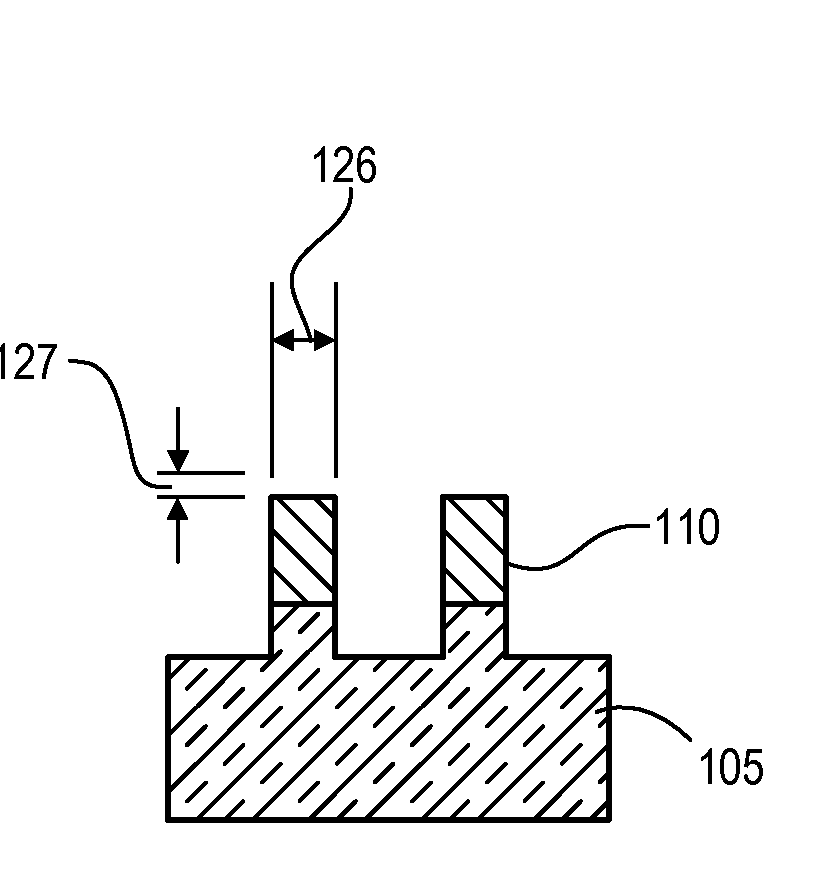

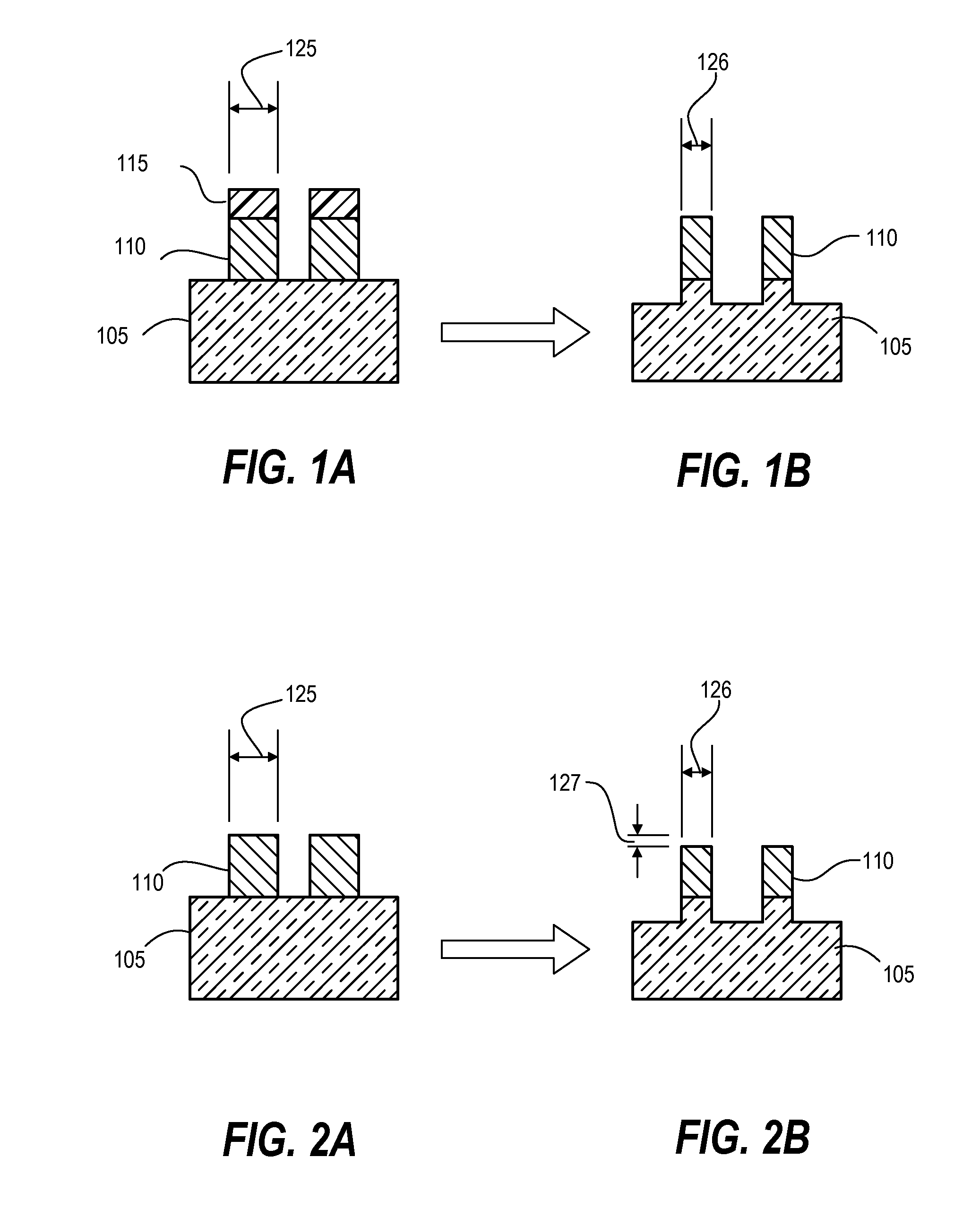

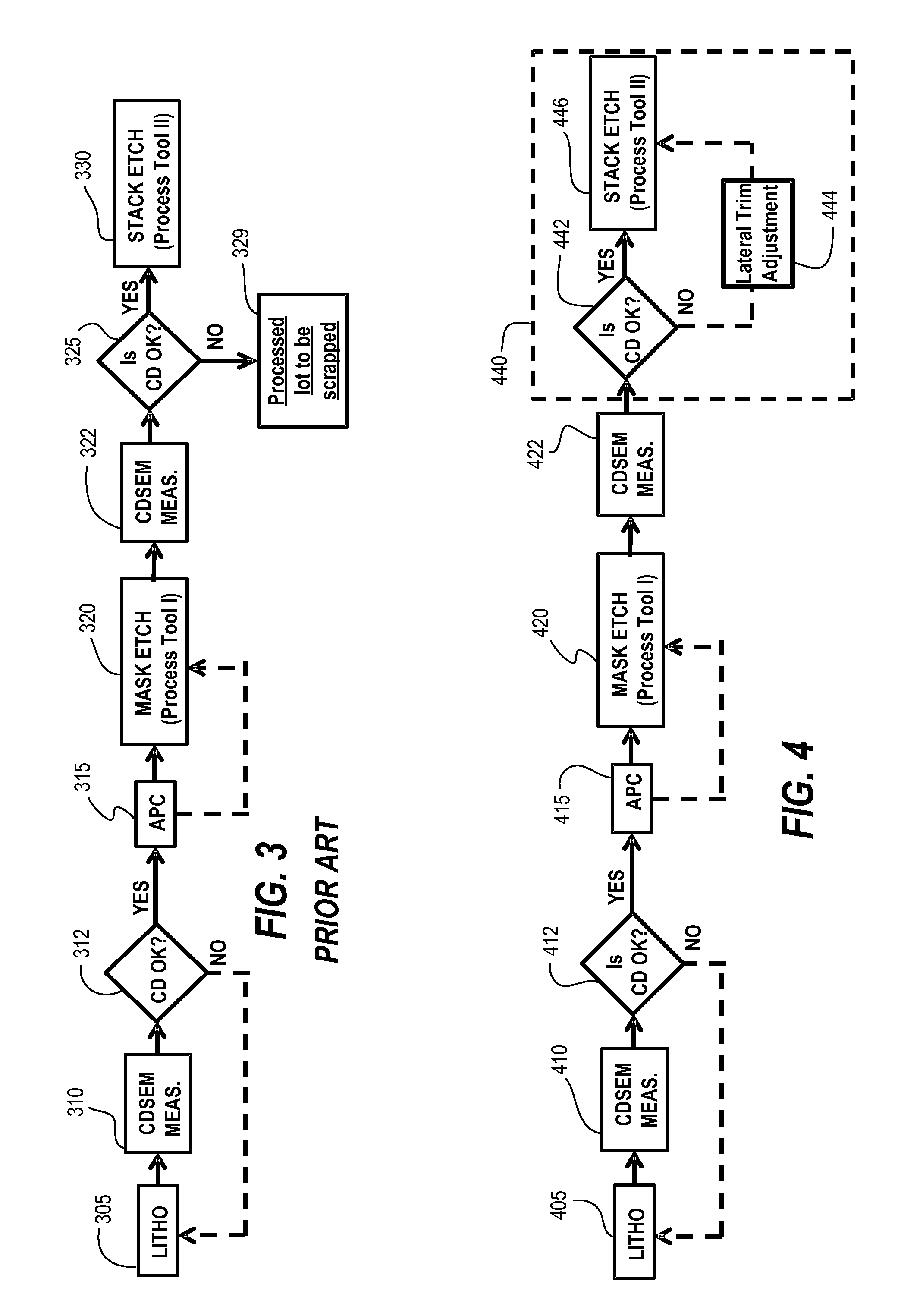

Techniques herein include methods for controllable lateral etching of dielectrics in polymerizing fluorocarbon plasmas. Methods can include dielectric stack etching that uses a mask trimming step as part of a silicon etching process. Using a fluorocarbon mixture for dielectric mask trimming provides several advantages, such as being straightforward to apply and providing additional flexibility to the process flow. Thus, techniques herein provide a method to correct or tune CDs on a hardmask. In general, this technique can include using a fluorine-based and a fluorocarbon-based, or fluorohydrocarbon-based, chemistry for creating a plasma, and controlling a ratio of the two chemistries. Without the hardmask trim method disclosed herein, if a hardmask CD is not on target, then a wafer is scrapped. With hard-mask trim capability in silicon etch as disclosed herein, a given CD can be re-targeted to eliminate wafer-scraps.

Owner:TOKYO ELECTRON LTD

Plasma reactor apparatus with multiple gas injection zones having time-changing separate configurable gas compositions for each zone

ActiveUS20070251642A1Electric discharge tubesVacuum gauge using ionisation effectsGas compositionOxygen

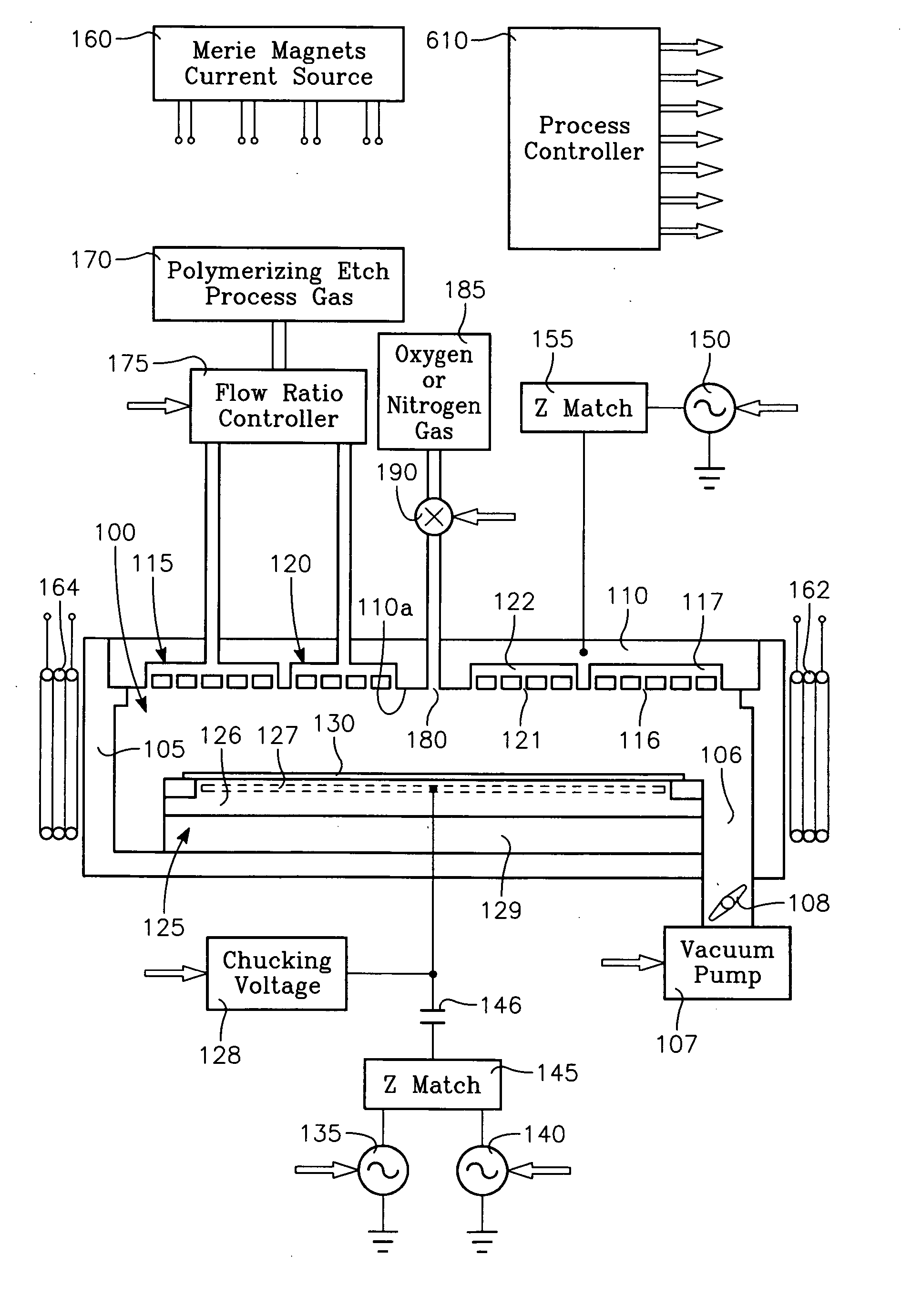

A plasma reactor for processing a workpiece such as a semiconductor wafer has a housing defining a process chamber, a workpiece support configured to support a workpiece within the chamber during processing and comprising a plasma bias power electrode. The reactor further includes plural gas sources containing different gas species, plural process gas inlets and an array of valves capable of coupling any of said plural gas sources to any of said plural process gas inlets. The reactor also includes a controller governing said array of valves and is programmed to change the flow rates of gases through said inlets over time. A ceiling plasma source power electrode of the reactor has plural gas injection zones coupled to the respective process gas inlets. In a preferred embodiment, the plural gas sources comprise supplies containing, respectively, fluorocarbon or fluorohydrocarbon species with respectively different ratios of carbon and fluorine chemistries. They further include an oxygen or nitrogen supply and a diluent gas supply. The controller is programmed to produce flow of different process gas species or mixtures thereof through different ones of said plural gas injection zones. The controller is further programmed to change over time the species content of the gases flowing through different ones of said plural gas injection zones.

Owner:APPLIED MATERIALS INC

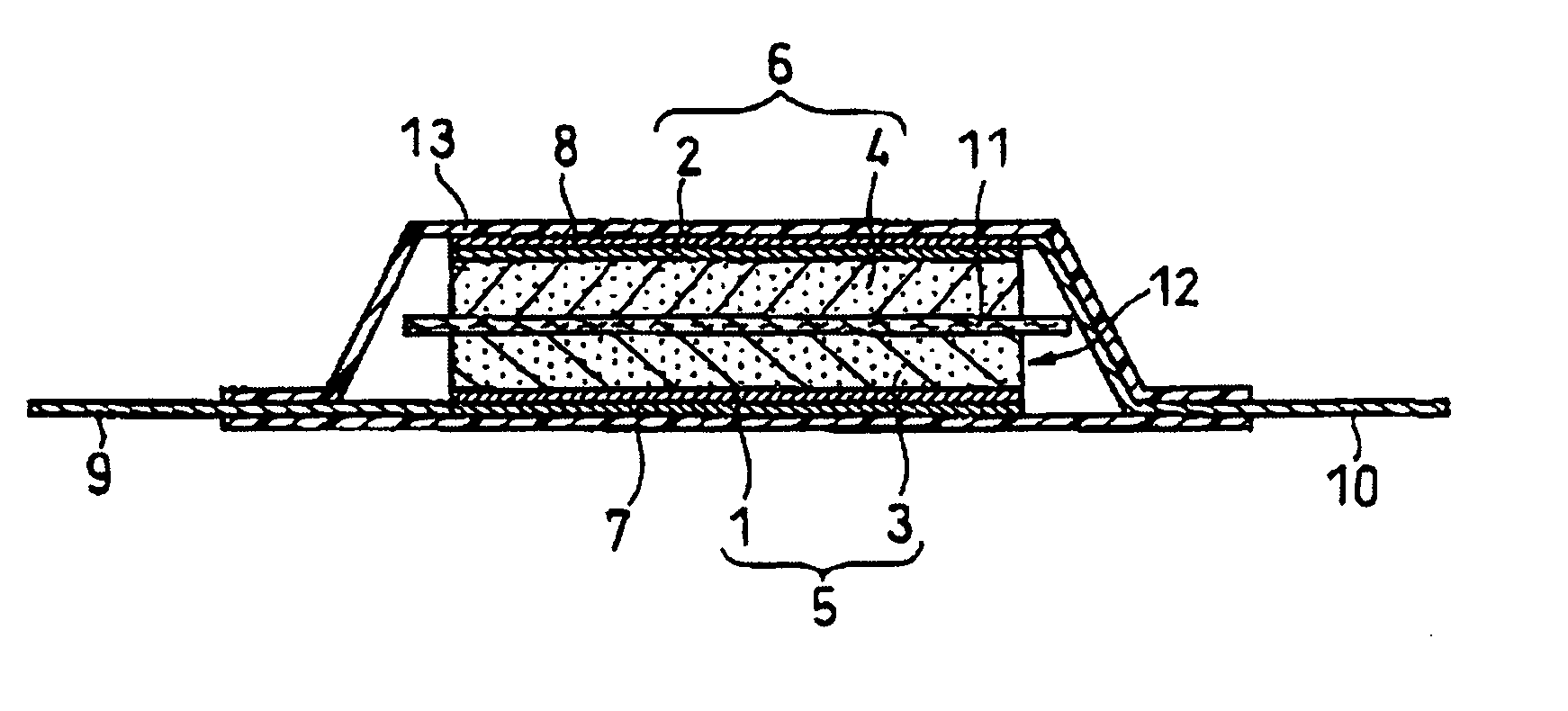

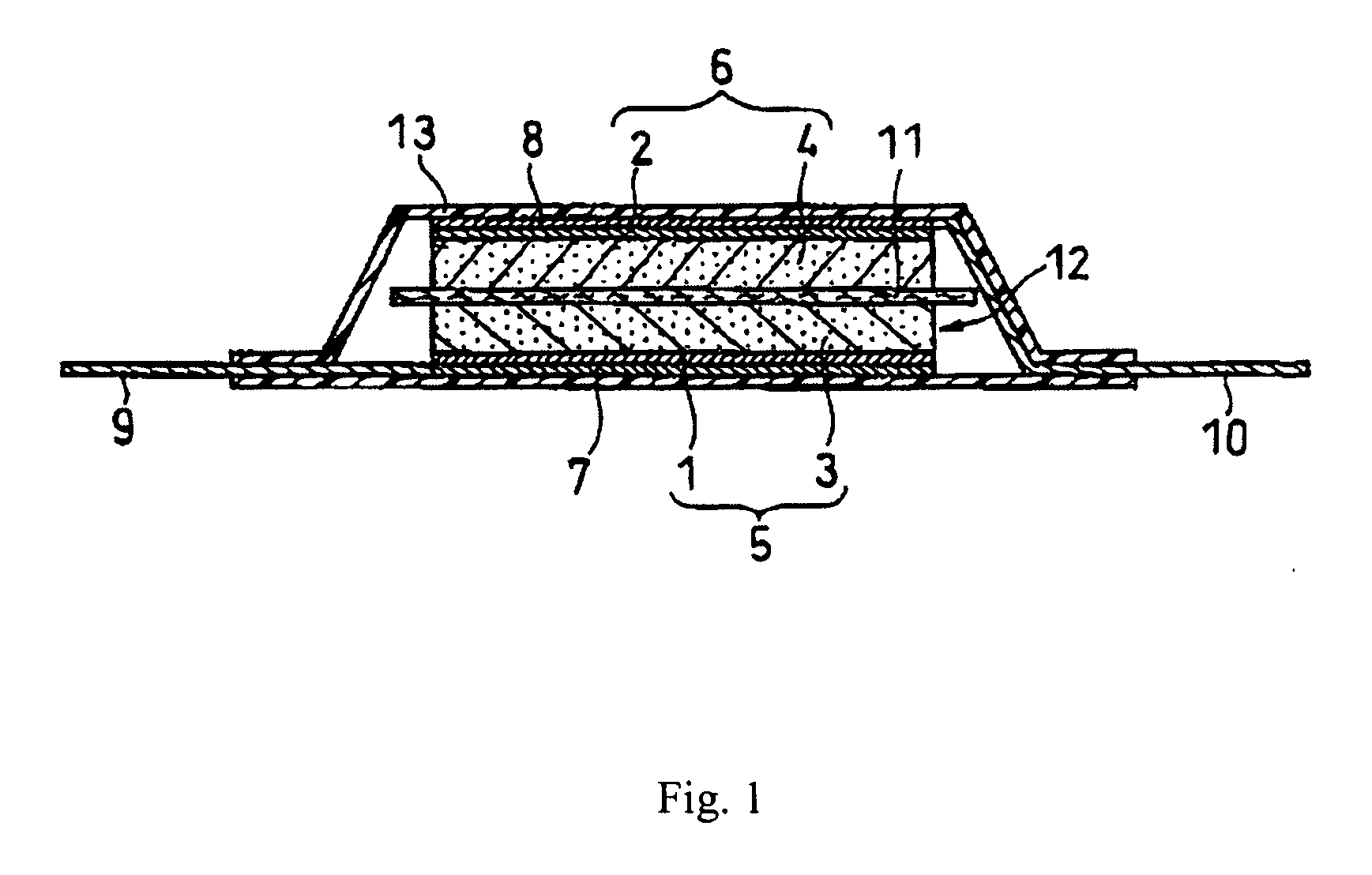

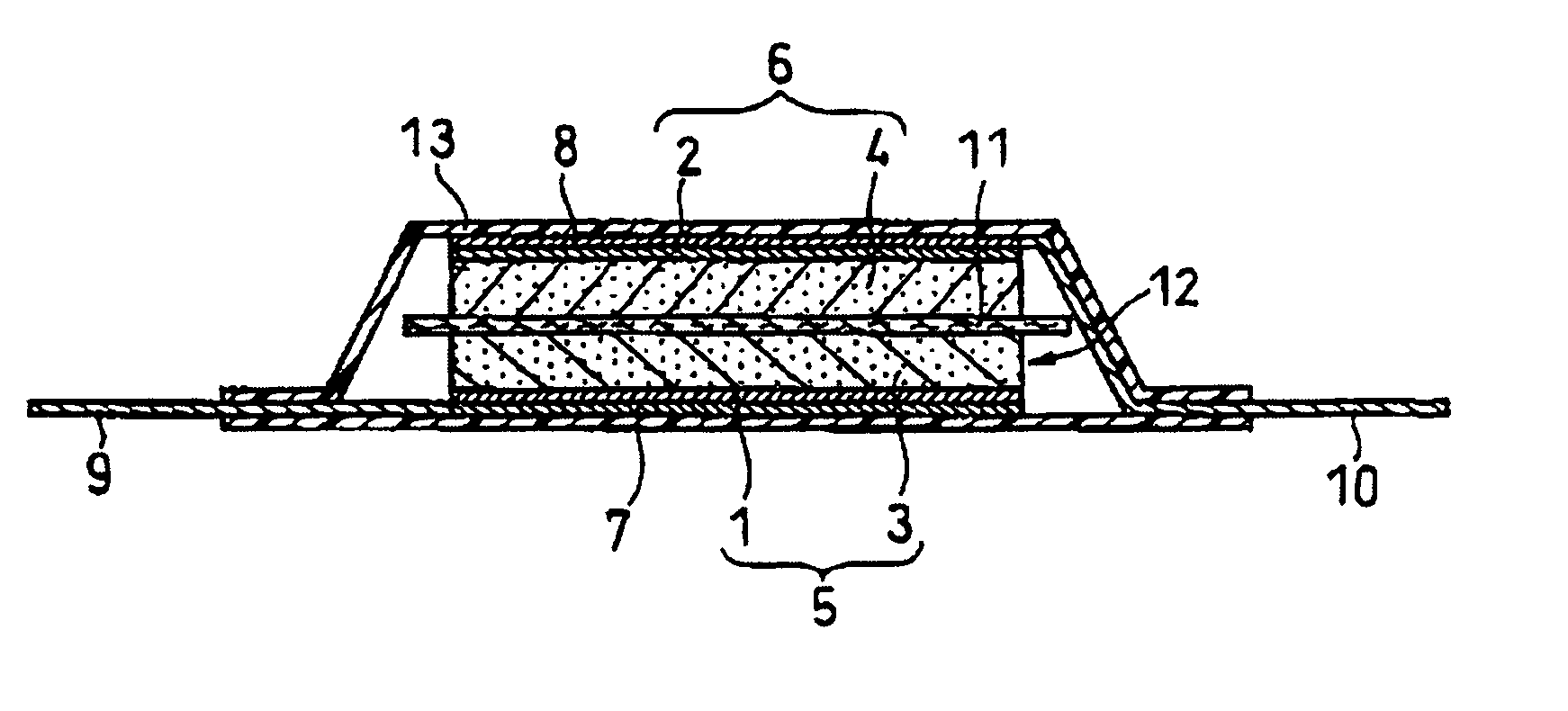

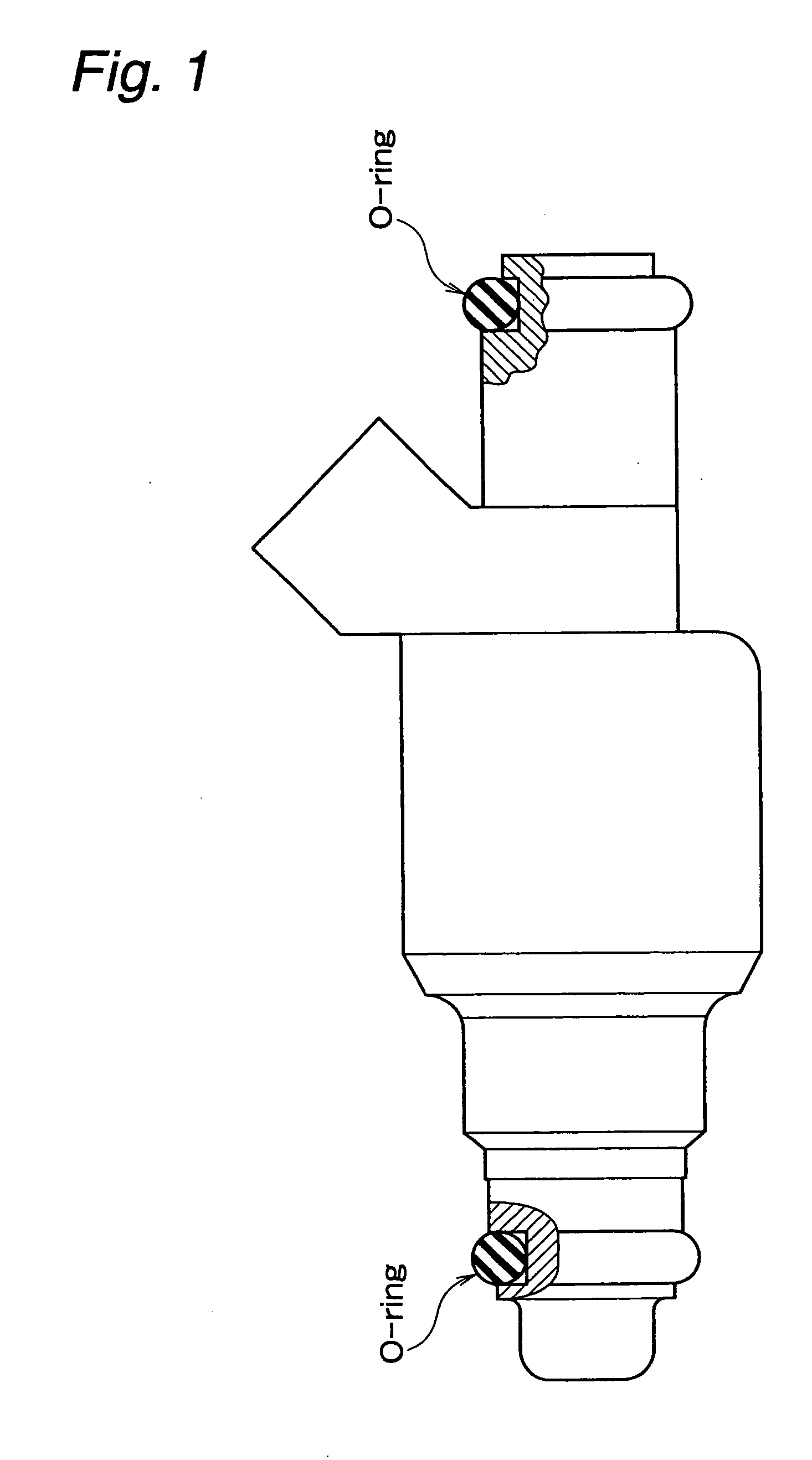

Pharmaceutical formulations for aerosols with two or more active substances

The present invention relates to new pharmaceutical formulations for aerosols with at least two or more active substances for administration by inhalation or by nasal route. Specifically, the invention relates to pharmaceutical preparations for propellant-driven metered dose aerosols using a fluorohydrocarbon (HFC) as propellant, which contain a combination of active substance of two or more active substances, wherein at least one active substance is present in dissolved form together with at least one other active substance in the form of suspended particles.

Owner:BOEHRINGER INGELHEIM PHARMA INC

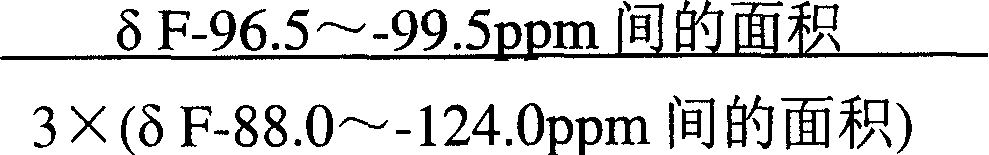

Plasma etching method

InactiveUS20110068086A1Increase etch rateDecorative surface effectsSemiconductor/solid-state device manufacturingSilicon oxidePlasma etching

A plasma etching method includes etching an etching target under plasma conditions using a process gas, the process gas including a saturated fluorohydrocarbon shown by the formula (1): CxHyFz, wherein x is 3, 4, or 5, and y and z are individually positive integers, provided that y>z is satisfied. When etching a silicon nitride film that covers a silicon oxide film formed on the etching target, the silicon nitride film can be selectivity etched as compared with the silicon oxide film by utilizing the process gas including the specific fluorohydrocarbon under the plasma conditions.

Owner:ZEON CORP

Lubricant composition for refrigerator and compressor using the same

ActiveUS20100175421A1Low global warming potentialImprove stabilityWork treatment devicesHeat-exchange elementsAir conditioningBase oil

Provided is a lubricant composition for a refrigerator, which is characterized by using a substance mainly containing a polyoxyalkylene glycol derivative and having a hydroxyl number of 5 mgKOH / g or less, as a base oil. Also provided is a compressor using such the lubricant composition for a refrigerator. The lubricant composition for a refrigerator is used for a refrigerator which uses a refrigerant having a specific structure such as an unsaturated fluorohydrocarbon and being usable in current air-conditioning systems for cars or the like. The lubricant composition for a refrigerator exhibits excellent compatibility with the refrigerant, while having excellent stability. The compressor uses such the lubricant composition for a refrigerator.

Owner:IDEMITSU KOSAN CO LTD +2

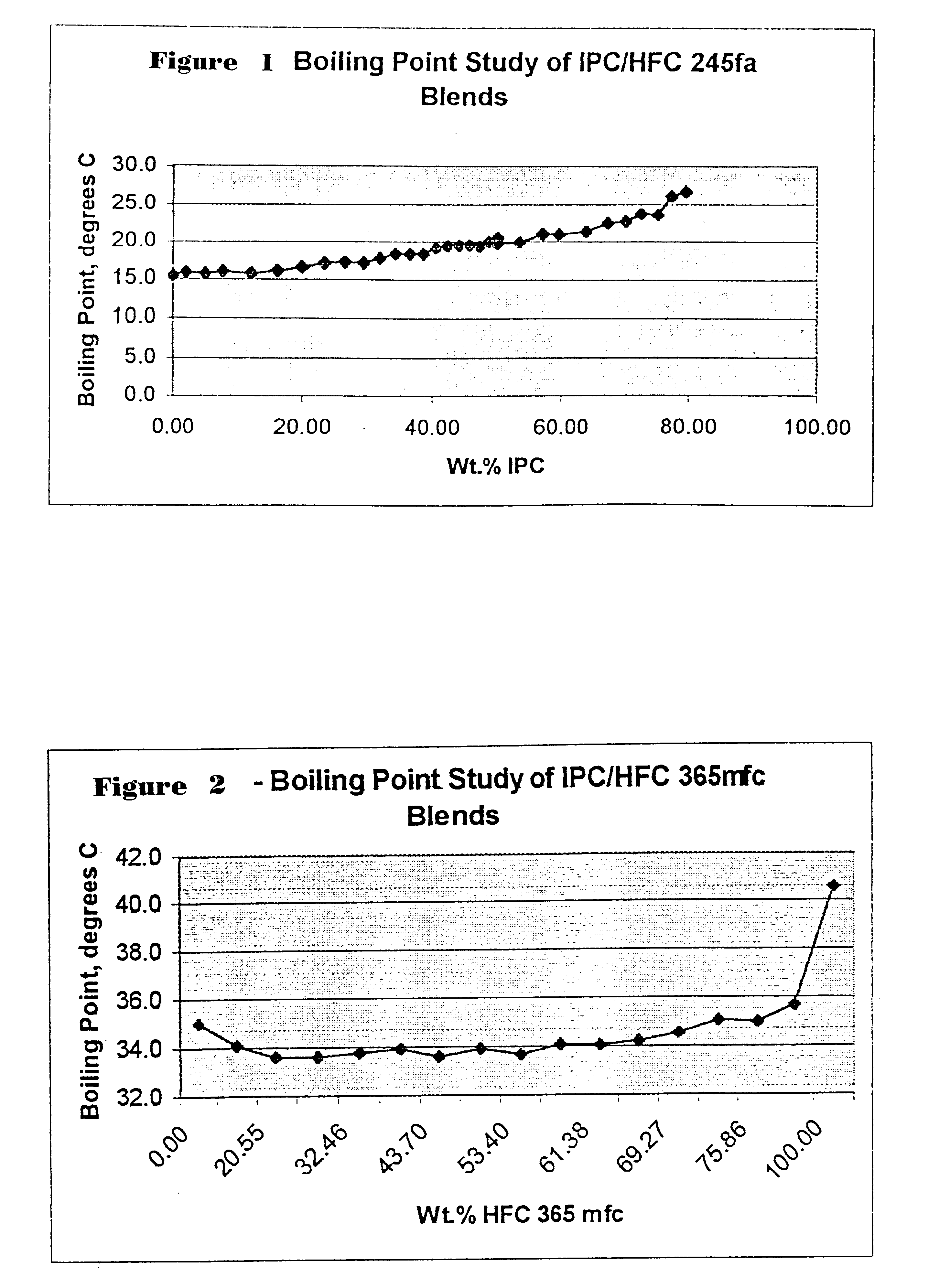

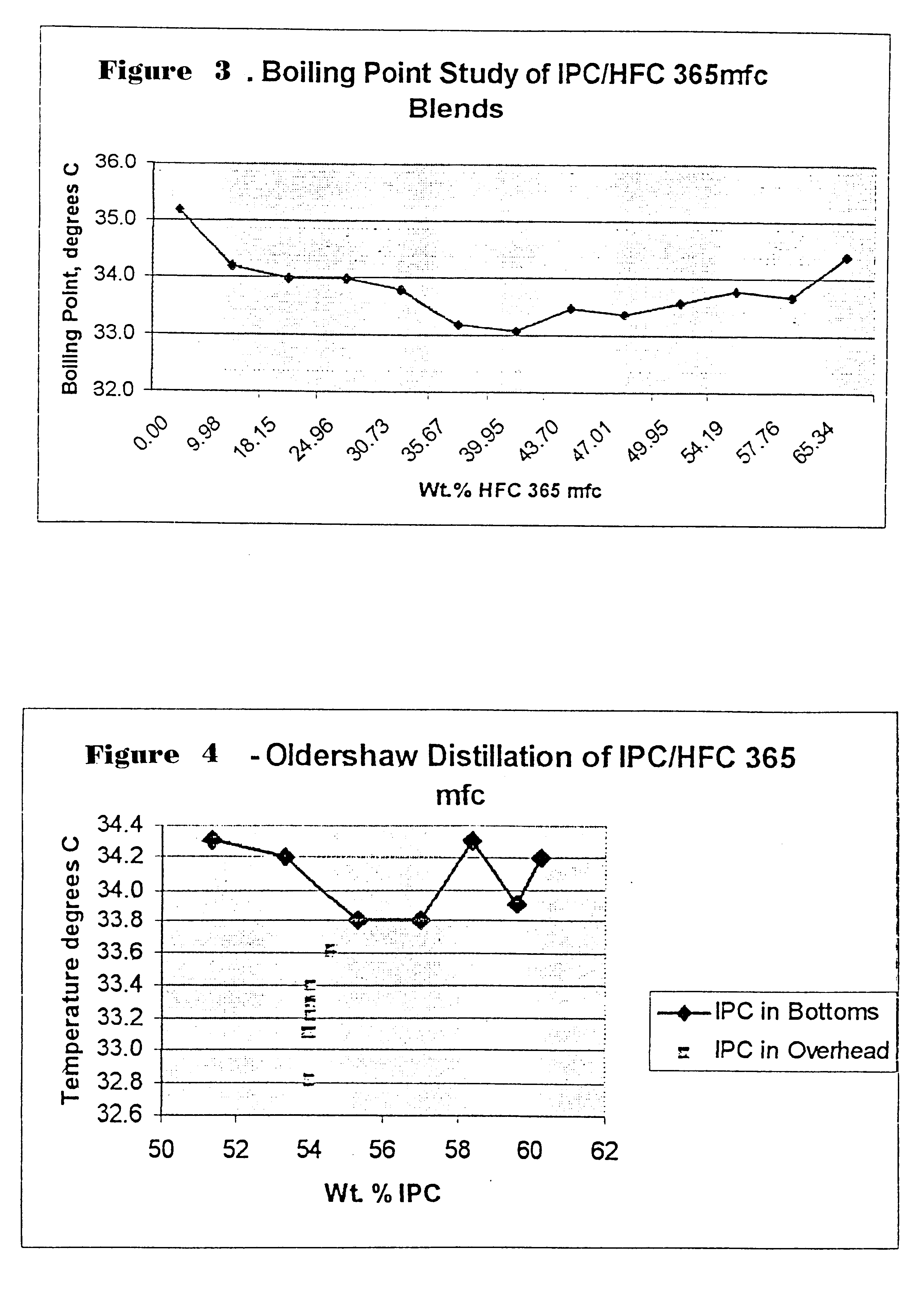

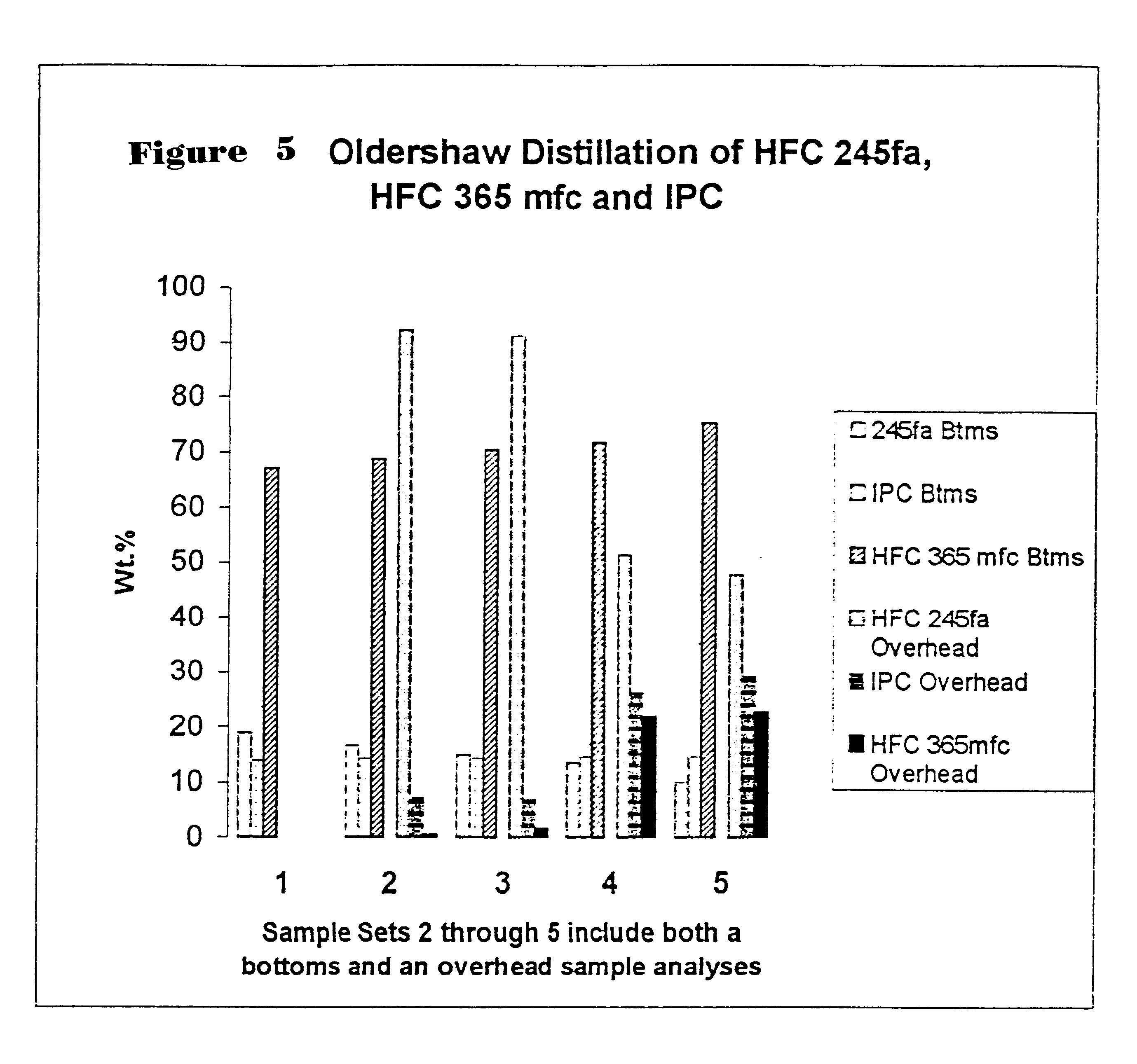

Isopropyl chloride with hydrofluorocarbon or hydrofluoroether as foam blowing agents

InactiveUS6646020B2Combustibility is reduced and eliminatedReduce flammabilityHeat-exchange elementsLiquid soapsPolyisocyanurateHydrofluoroether

A composition useful as a blowing agent having no flash point or reduced combustibility comprising 2-chloropropane and a gas selected from the group consisting of a fluorohydrocarbon, perfluorocarbons, fluoroethers, hydrofluoropolyethers and mixtures thereof is disclosed. A polyisocyanurate foam or a polyurethane modified polyisocyanurate foam having a mainly closed cell structure and also a method for preparing this foam, the latter comprising closed cells wherein a foam blowing agent consisting of a mixture of 2-chloropropane and one or more HFC compounds including pentafluoropropane, pentafluorobutane, heptafluoropropane, hexafluoropropane or pentafluoroethane are disclosed. Pentanes can be added if desired. Azeotropic mixtures in which 2-chloropropane is an ingredient are disclosed.

Owner:OCCIDENTAL CHEM CORP

Preparation method for fluorine-contained emulsifier

The invention provides a preparation method for fluorine-contained emulsifier, comprising the steps: initiating by ultraviolet light with the wavelength of 100nm to 400nm at the temperature lower than-25DEG C; oxidizing and polymerizing a polymerizing monomer in fluorohydrocarbon compounds or a fluorine-contained solvent of a perfluoroether compound and hydrolyzing a photopolymerization product to obtain the fluorine-contained emulsifier. The preparation method has the advantages of less discharge of toxic and harmful matter in the synthesizing process, easy treatment, low production cost andsmall risk. The prepared emulsifier has strong surface activity and can be better applied for producing fluorine resin, fluorine rubber and the like.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

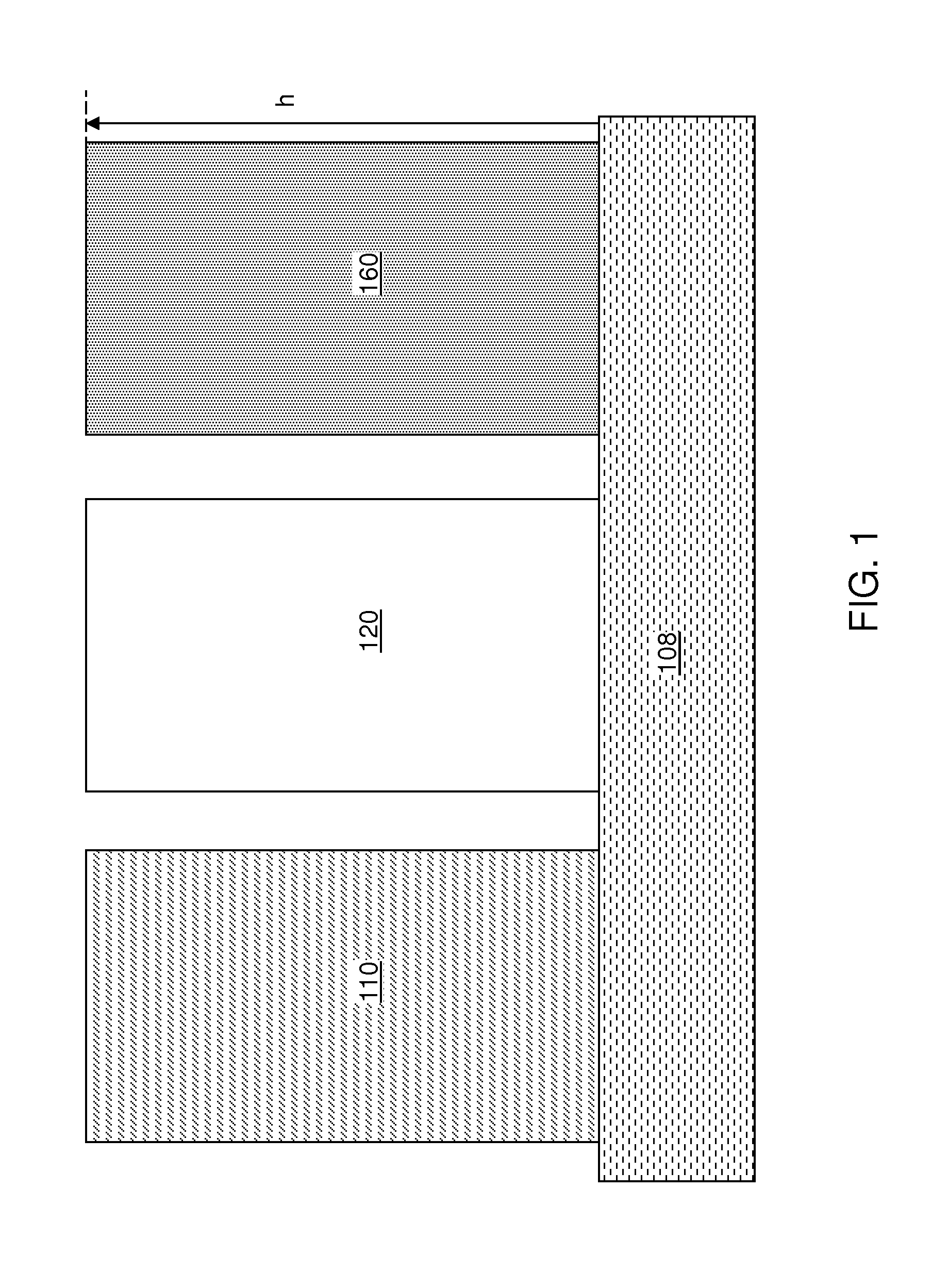

Low energy etch process for nitrogen-containing dielectric layer

InactiveUS20130105996A1Reduce harmPlasma energy can be decreasedSemiconductor/solid-state device detailsSolid-state devicesDielectric layerFluorine containing

A stack that includes, from bottom to top, a nitrogen-containing dielectric layer, an interconnect level dielectric material layer, and a hard mask layer is formed on a substrate. The hard mask layer and the interconnect level dielectric material layer are patterned by an etch. Employing the patterned hard mask layer as an etch mask, the nitrogen-containing dielectric layer is patterned by a break-through anisotropic etch, which employs a fluorohydrocarbon-containing plasma to break through the nitrogen-containing dielectric layer. Fluorohydrocarbon gases used to generate the fluorohydrocarbon-containing plasma generate a carbon-rich polymer residue, which interact with the nitrogen-containing dielectric layer to form volatile compounds. Plasma energy can be decreased below 100 eV to reduce damage to physically exposed surfaces of the interconnect level dielectric material layer.

Owner:ZEON CORP +1

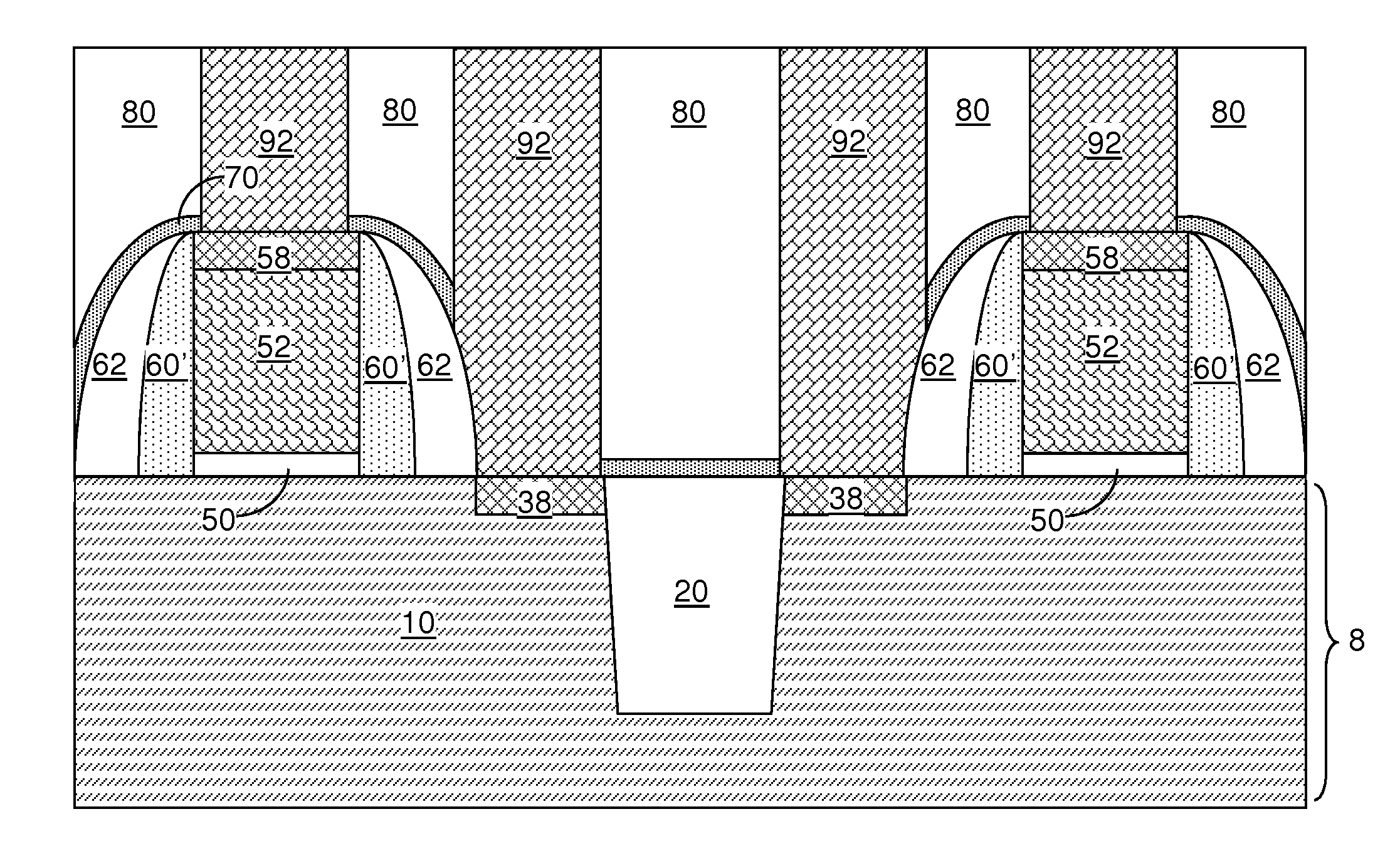

High selectivity nitride etch process

ActiveUS20130105916A1Reduce the probability of reactionTransistorSemiconductor/solid-state device manufacturingEtchingReaction rate

An anisotropic silicon nitride etch provides selectivity to silicon and silicon oxide by forming a fluorohydrocarbon-containing polymer on silicon surfaces and silicon oxide surfaces. Selective fluorohydrocarbon deposition is employed to provide selectivity to non-nitride surfaces. The fluorohydrocarbon-containing polymer interacts with silicon nitride to form a volatile compound, thereby enabling etching of silicon nitride. The fluorohydrocarbon-containing polymer interacts with silicon oxide at a low reaction rate, retarding, or completely stopping, the etching of silicon oxide. The fluorohydrocarbon-containing polymer does not interact with silicon, and protects silicon from the plasma. The anisotropic silicon nitride etch can be employed to etch silicon nitride selective to silicon and silicon oxide in any dimension, including small dimensions less than 50 nm.

Owner:ZEON CORP +1

Plasma etching method

InactiveUS20100264116A1High aspect ratioComplicated operationDecorative surface effectsSemiconductor/solid-state device manufacturingFluorohydrocarbonChemistry

A plasma etching method includes plasma-etching a silicon oxide layer through a mask using a process gas, the process gas containing oxygen gas and a fluorohydrocarbon shown by the formula (1), CxHyFz, wherein x is an integer from 4 to 6, y is an integer from 1 to 4, and z is a positive integer, provided that (y+z) is 2x or less. A contact hole having a very small diameter and a high aspect ratio can be formed in a substantially vertical shape without necking by plasma-etching the silicon oxide layer using a single process gas.

Owner:ZEON CORP

Nonaqueous electrolyte for electrochemical devices

InactiveUS20050158623A1Curb riseQuality improvementHybrid capacitor electrolytesElectrolytic capacitorsLithiumMolten salt

The present invention relates to a nonaqueous electrolyte for electrochemical devices, and to electric double-layer capacitor and secondary battery using the said nonaqueous electrolyte. The nonaqueous electrolyte according to the present invention comprises a room temperature molten salt and a fluorohydrocarbon. The nonaqueous electrolyte is flame resistant and can suppress the rise in its viscosity. Therefore, high quality electrochemical devices can be obtained by using the nonaqueous electrolyte. The electric double-layer capacitor according to the present invention comprises a pair of polarizable electrode plates, a separator interposed between the pair of electrode plates, and the inventive nonaqueous electrolyte. The secondary battery according to the present invention comprises a positive electrode, a negative electrode, a separator interposed between the positive electrode and the negative electrode, and a nonaqueous electrolyte, wherein the nonaqueous electrolyte comprises the inventive nonaqueous electrolyte, and further comprises a lithium salt and a cyclic carbonate.

Owner:GK BRIDGE 1

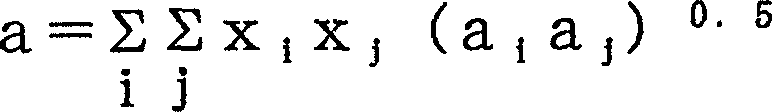

Fluorine-containing elastic copolymers, curable composition containing the same and sealant made therefrom

PCT No. PCT / JP96 / 03732 Sec. 371 Date Jun. 24, 1998 Sec. 102(e) Date Jun. 24, 1998 PCT Filed Dec. 20, 1996 PCT Pub. No. WO97 / 24381 PCT Pub. Date Jul. 10, 1997A fluorine-containing elastomeric copolymer comprising 55 to 62 mole % of repeating units derived from tetrafluoroethylene and 38 to 45 mole % of repeating units derived from perfluoro(methyl vinyl ether) which is obtained by radically polymerizing the monomers in the presence of a diiodide compound of the formula: RI2 in which R is a saturated fluorohydrocarbon or chlorofluorohydrocarbon group having 1 to 16 carbon atoms, or a hydrocarbon group having 1 to 3 carbon atoms and which has a Mooney viscosity (ML1+10100 DEG C.) in the range between 20 and 150. This copolymer has an excellent compression set at high temperature, which is an important property for sealing members.

Owner:DAIKIN IND LTD

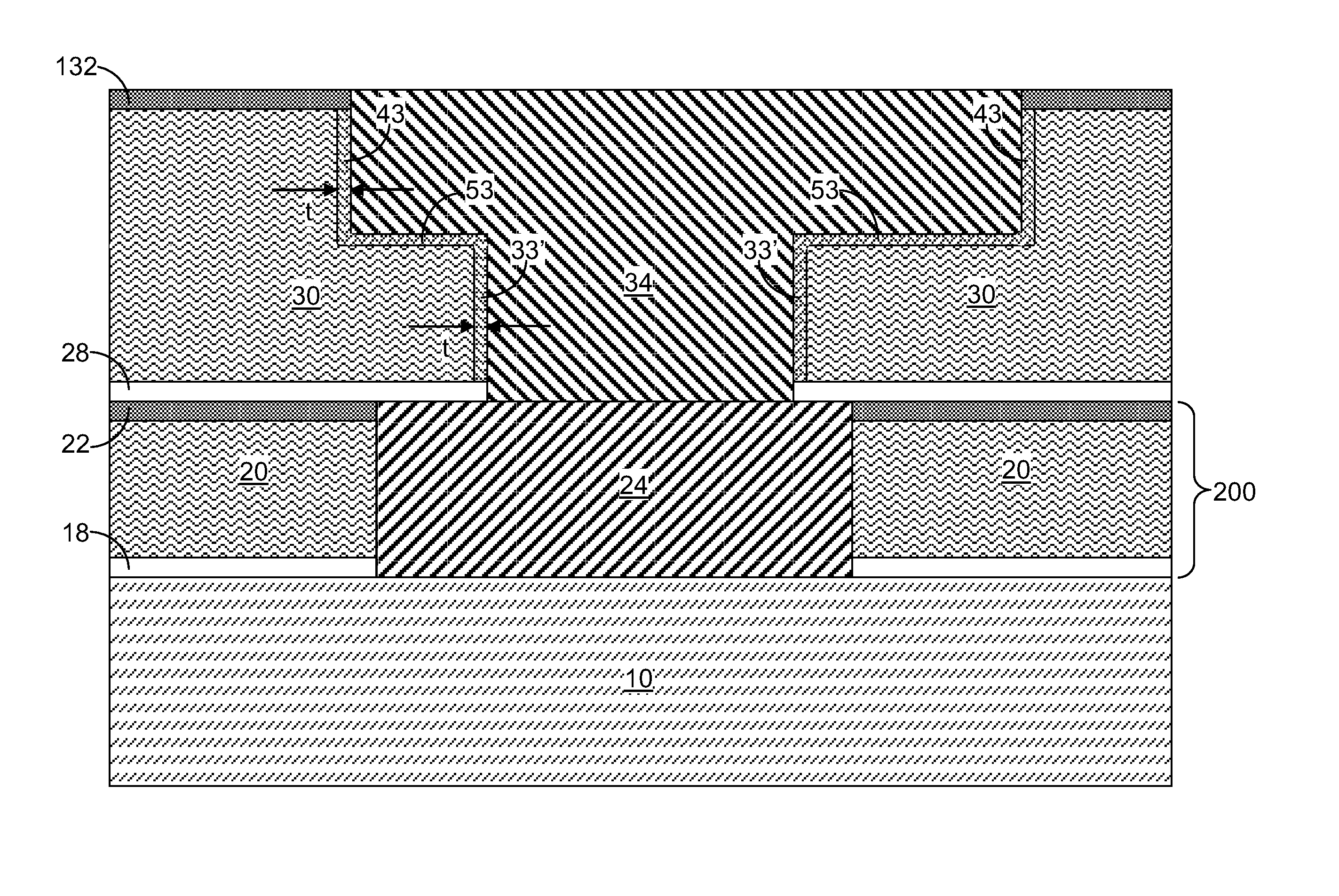

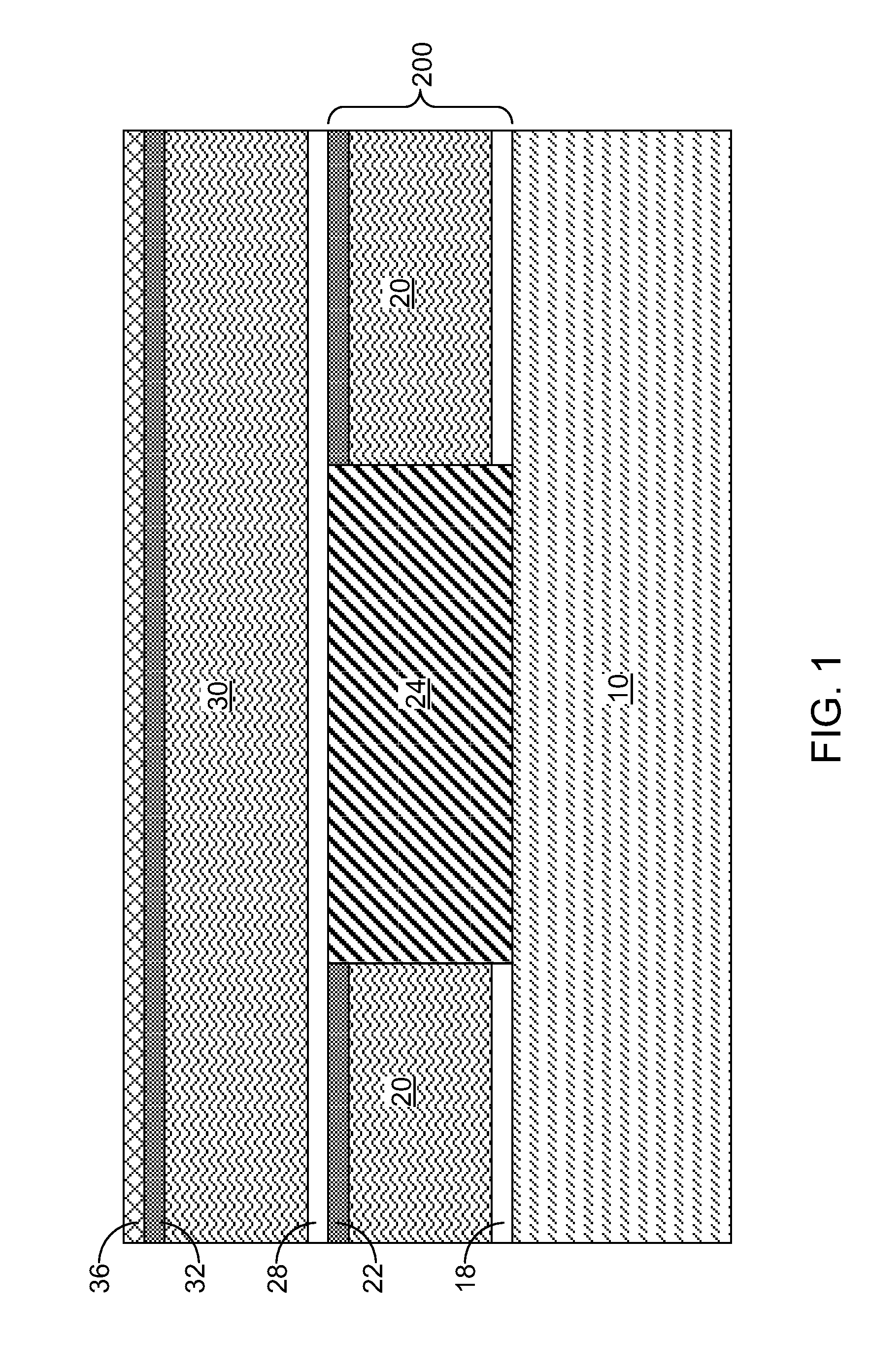

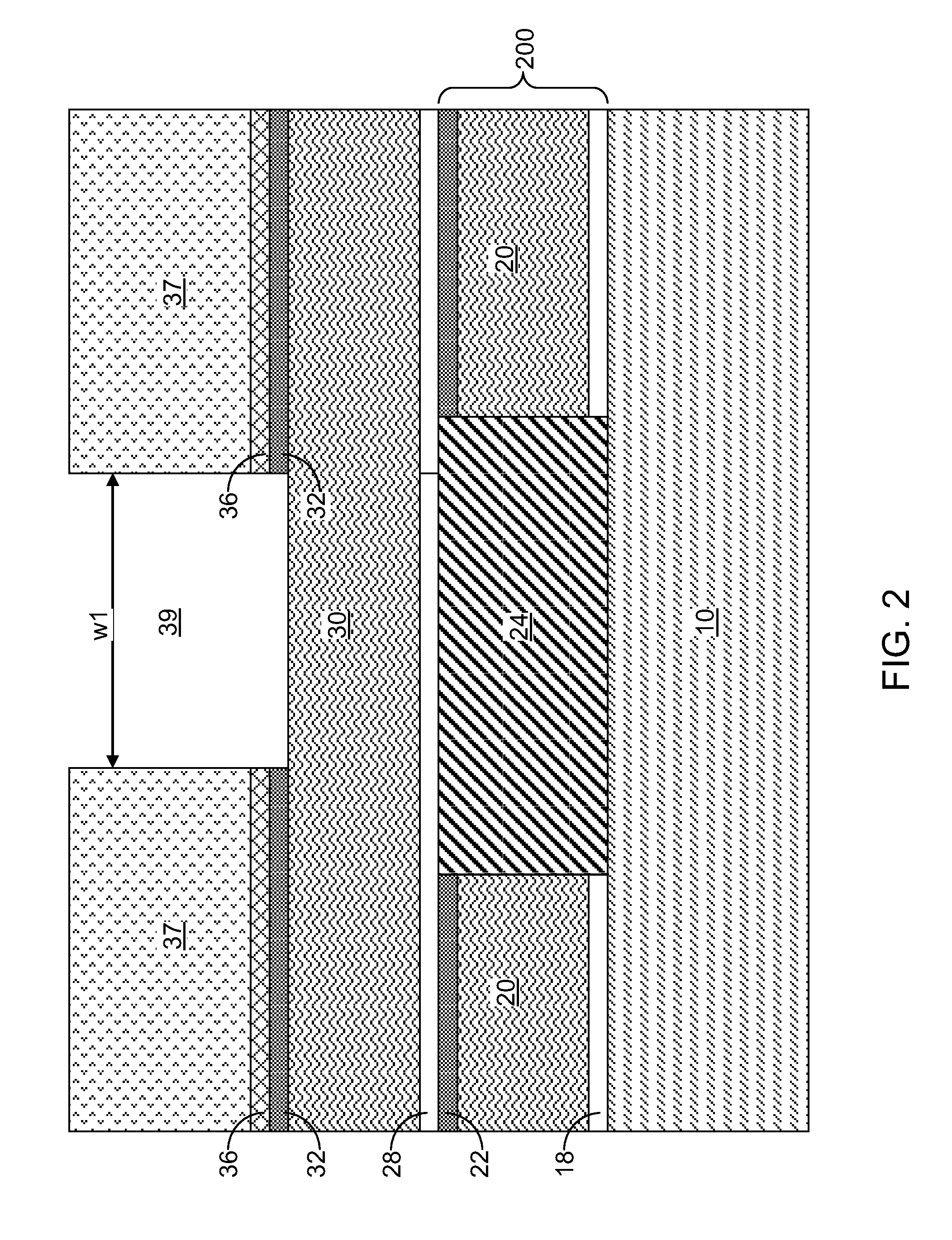

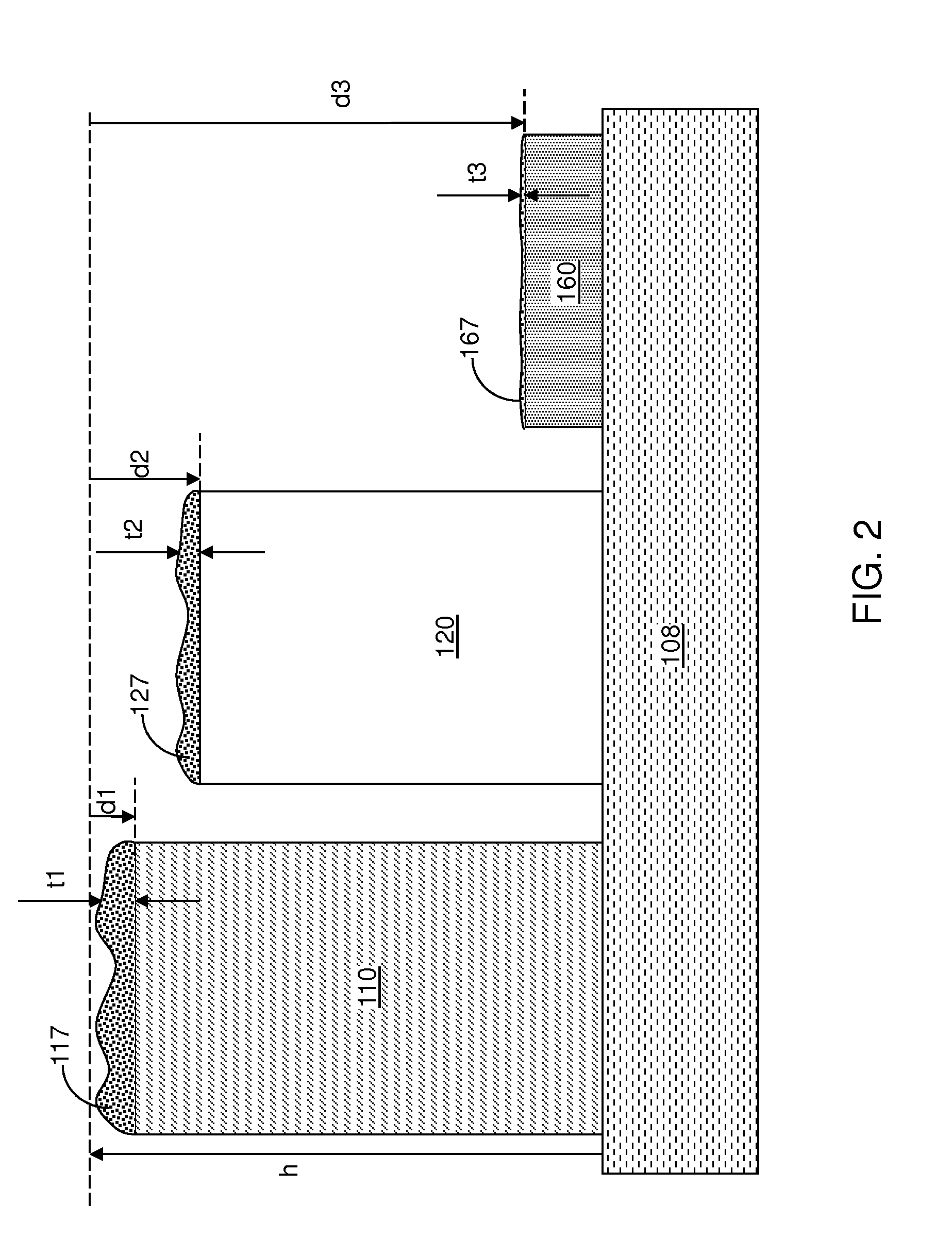

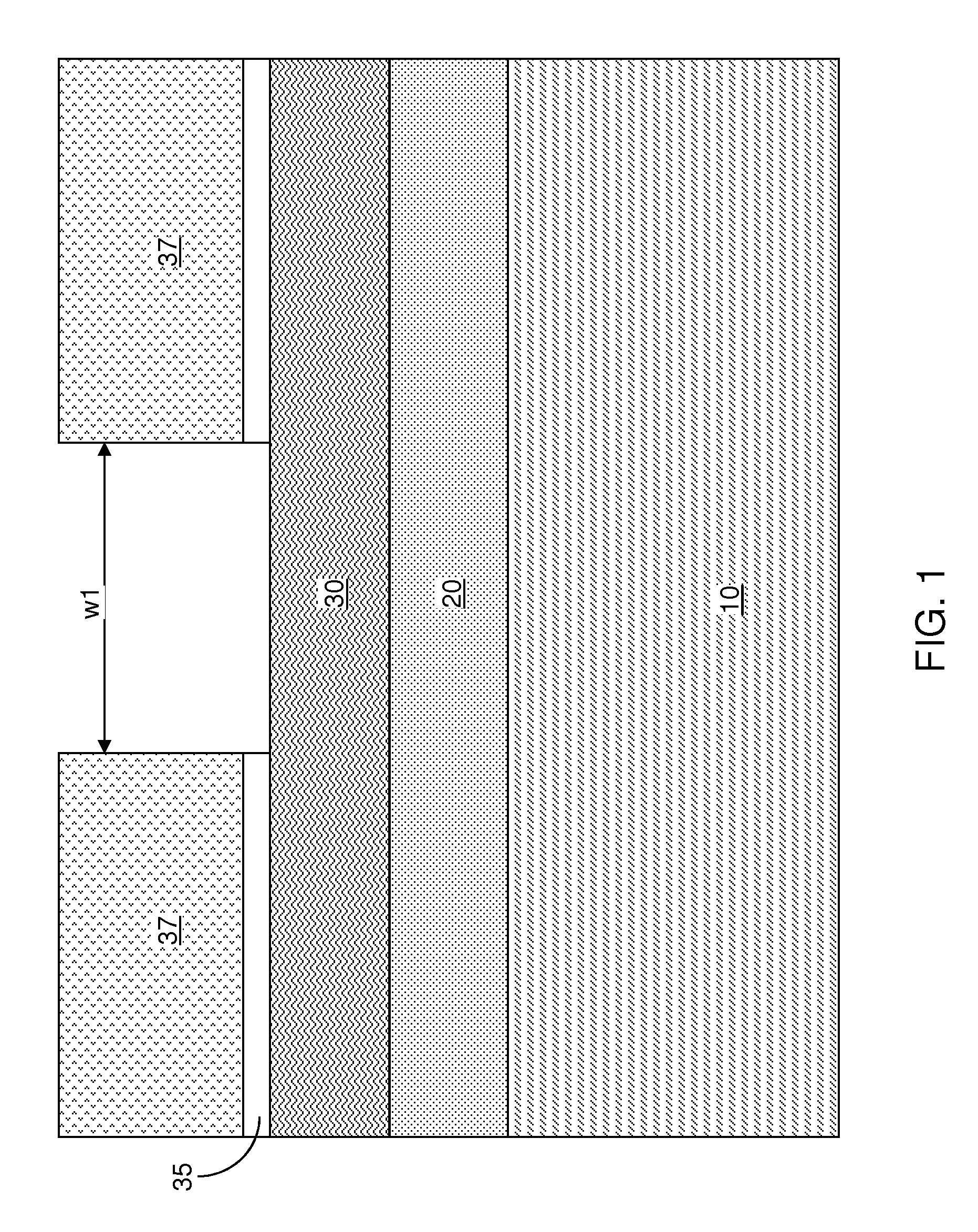

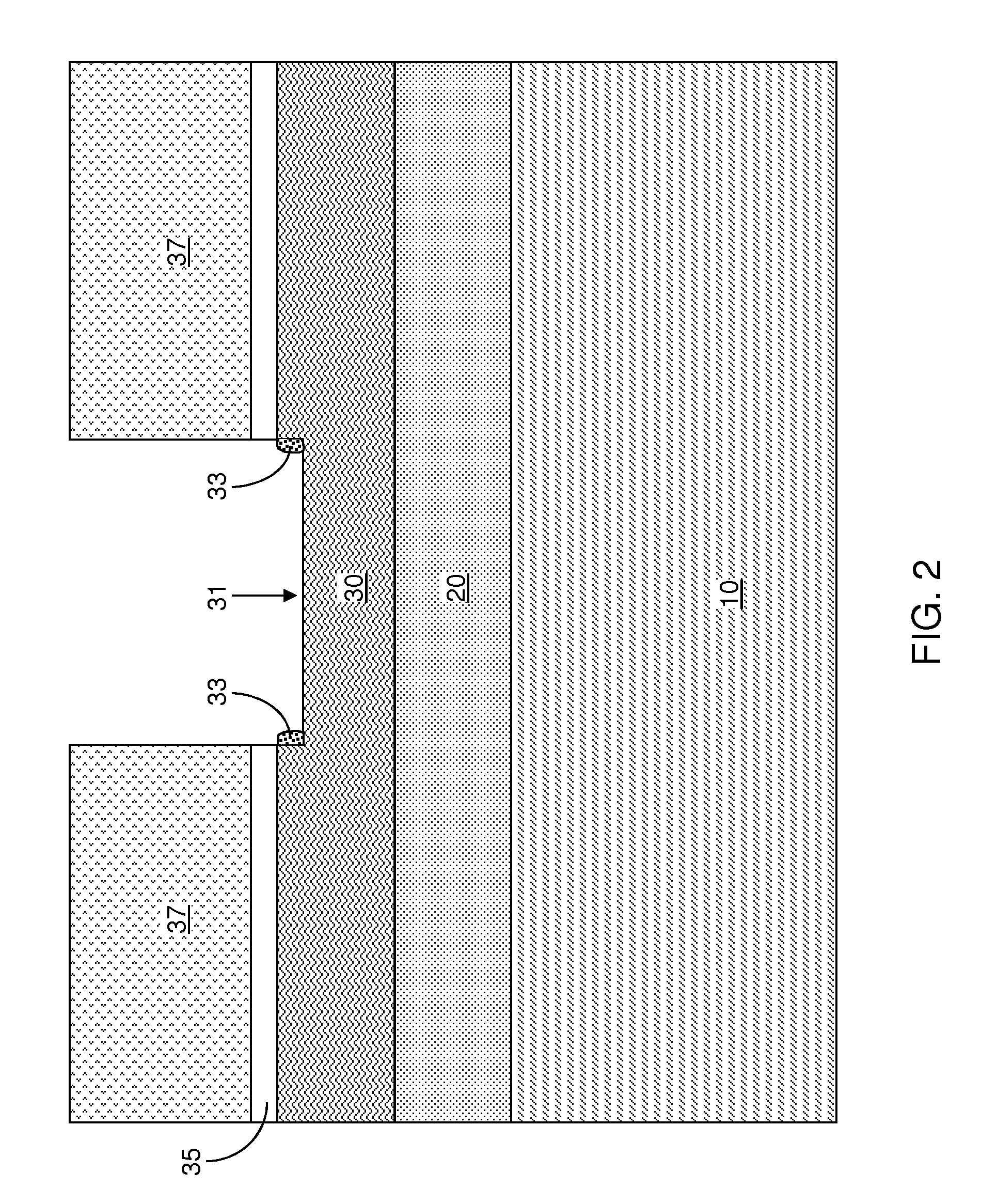

High fidelity patterning employing a fluorohydrocarbon-containing polymer

InactiveUS20130108833A1High pattern transferAvoid elevationLayered productsDecorative surface effectsResistHydrogen

A stack of a hard mask layer, a soft mask layer, and a photoresist is formed on a substrate. The photoresist is patterned to include at least one opening. The pattern is transferred into the soft mask layer by an anisotropic etch, which forms a carbon-rich polymer that includes more carbon than fluorine. The carbon-rich polymer can be formed by employing a fluorohydrocarbon-containing plasma generated with fluorohydrocarbon molecules including more hydrogen than fluorine. The carbon-rich polymer coats the sidewalls of the soft mask layer, and prevents widening of the pattern transferred into the soft mask. The photoresist is subsequently removed, and the pattern in the soft mask layer is transferred into the hard mask layer. Sidewalls of the hard mask layer are coated with the carbon-rich polymer to prevent widening of the pattern transferred into the hard mask.

Owner:GLOBALFOUNDRIES INC +1

Lubricating oil composition for refrigerating machine

ActiveUS9493694B2Low global warming potentialImprove stabilityHeat-exchange elementsRefrigeration componentsChemical compositionAir conditioning

Provided is a lubricant composition for a refrigerator having the following characteristics: the composition being used for a refrigerator using a refrigerant having a specific structure such as an unsaturated fluorinated hydrocarbon compound serving as a refrigerant having a low global warming potential and usable particularly in current air-conditioning system for cars; the composition having excellent stability as well as excellent compatibility with the refrigerant; the composition including a base oil containing a polyoxyalkylene glycol derivative as a main component and 1 to 20% by mass of a monoepoxy compound based on the total amount of the composition; and the refrigerator using a refrigerant containing at least one kind of fluorine-containing organic compound selected from compounds represented by the molecular formula (A) CpOqFrRs or including a combination of the fluorine-containing organic compound and a saturated fluorinated hydrocarbon compound.

Owner:IDEMITSU KOSAN CO LTD

Nonaqueous electrolyte for electrochemical devices

InactiveUS7998615B2Curb riseQuality improvementHybrid capacitor electrolytesElectrolytic capacitorsLithiumMolten salt

The present invention relates to a nonaqueous electrolyte for electrochemical devices, and to electric double-layer capacitor and secondary battery using the said nonaqueous electrolyte. The nonaqueous electrolyte according to the present invention comprises a room temperature molten salt and a fluorohydrocarbon. The nonaqueous electrolyte is flame resistant and can suppress the rise in its viscosity. Therefore, high quality electrochemical devices can be obtained by using the nonaqueous electrolyte. The electric double-layer capacitor according to the present invention comprises a pair of polarizable electrode plates, a separator interposed between the pair of electrode plates, and the inventive nonaqueous electrolyte. The secondary battery according to the present invention comprises a positive electrode, a negative electrode, a separator interposed between the positive electrode and the negative electrode, and a nonaqueous electrolyte, wherein the nonaqueous electrolyte comprises the inventive nonaqueous electrolyte, and further comprises a lithium salt and a cyclic carbonate.

Owner:GK BRIDGE 1

Fluorine-containing elastomer for molding fuel system parts and composition thereof

InactiveUS20100068436A1Uniform physical propertiesImprove compression set characteristicLiquid fuel feeder/distributionLayered productsHexafluoropropyleneIntrinsic viscosity

A fluorine-containing elastomer for molding fuel system parts, which has a copolymer composition comprising 10-40% by weight of tetrafluoroethylene (TFE), 80-30% by mole of vinylidene fluoride (VdF), and 10-30% by mole of hexafluoropropylene (HFP), as copolymerized in the presence of an iodine and bromine-containing compound represented by the following general formula: RBrnIm (where R is a fluorohydrocarbon group, a chlorofluorohydrocarbon group, or a hydrocarbon group, each having 1-10 carbon atoms, and n and m each are 1 or 2), and has an intrinsic viscosity of 20-180 ml / g, Mw (weight average molecular weight) / Mn (number average molecular weight) ratio of 2-20, and a molecular weight distribution of monopeak or multipeak type, and a fluorine-containing elastomer composition, which comprises the fluorine-containing elastomer, at least one of a polyol vulcanizing agent and a polyamine vulcanizing agent, an organic peroxide, and a polyfunctional unsaturated compound. The composition is suitable for use in molding fuel system parts to give fluorine-containing elastomer moldings with distinguished moldability, vulcanizate physical properties, chemical resistance, photostability and economy.

Owner:UNIMATEC CO LTD

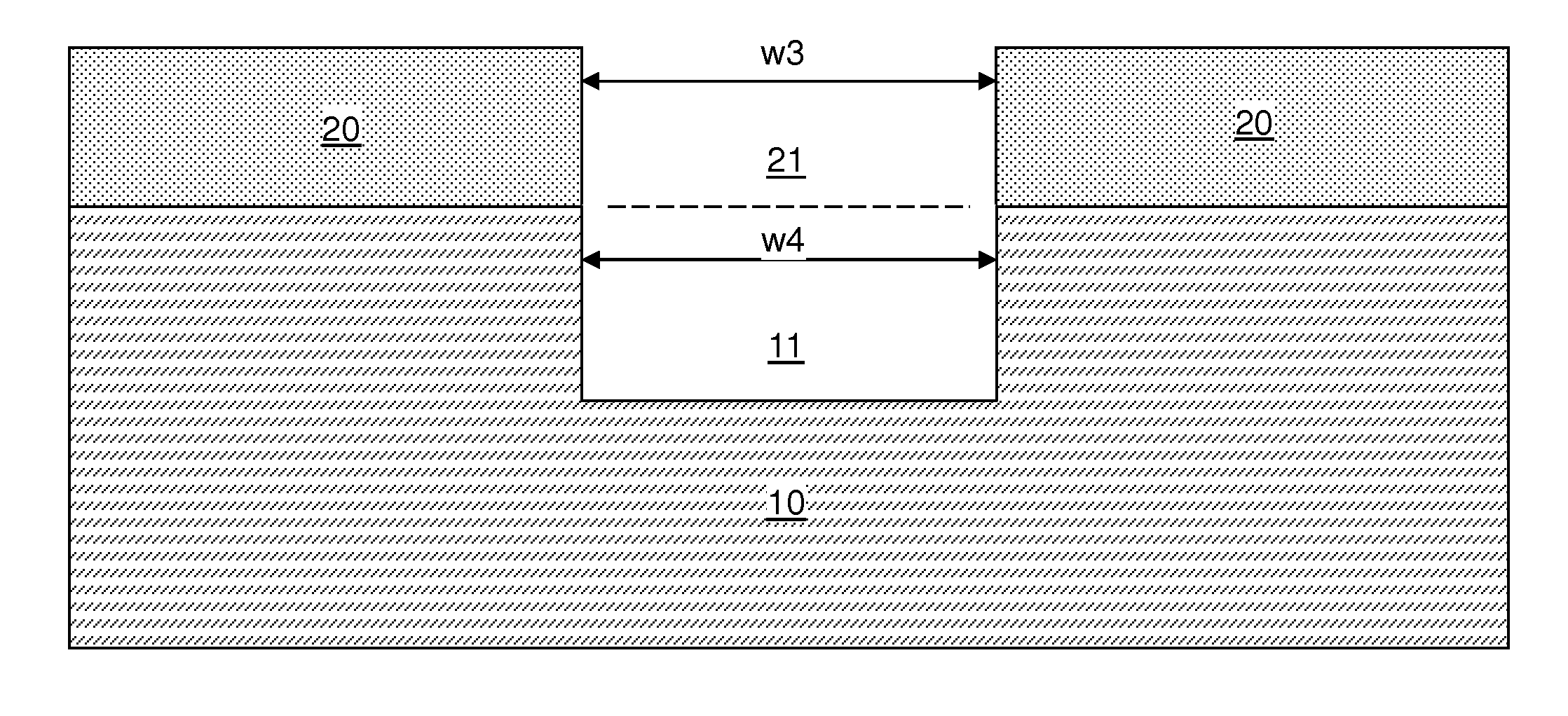

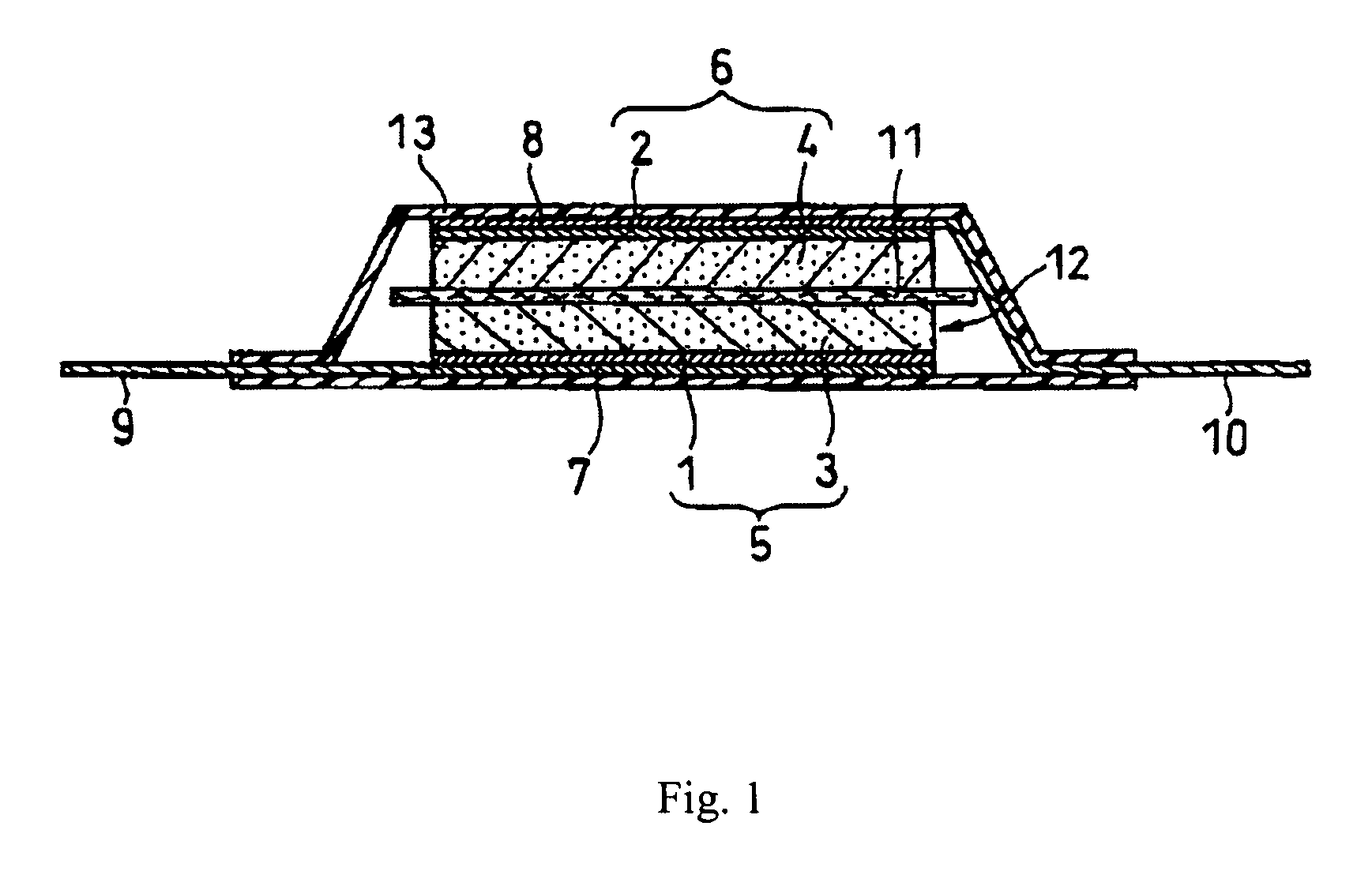

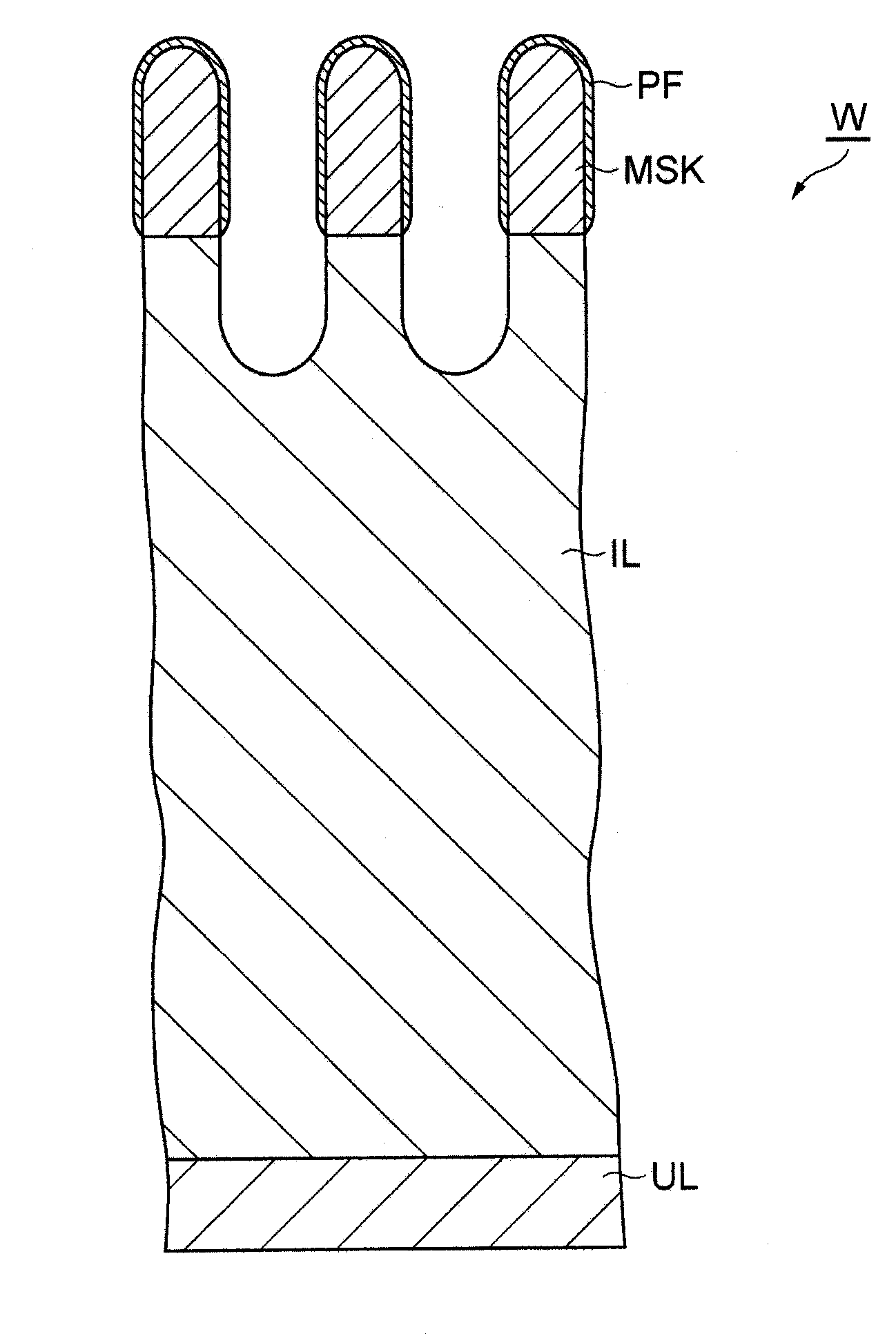

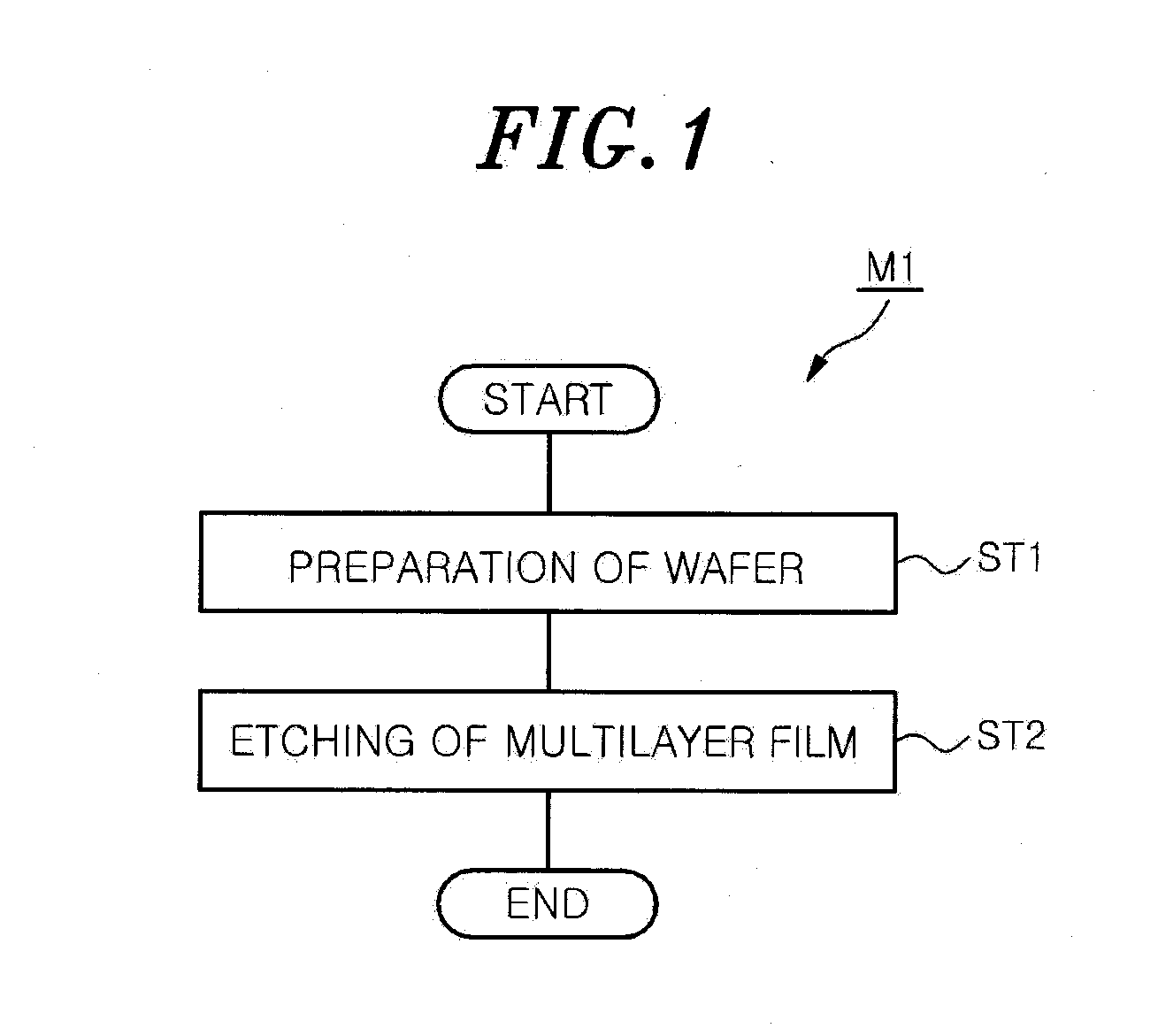

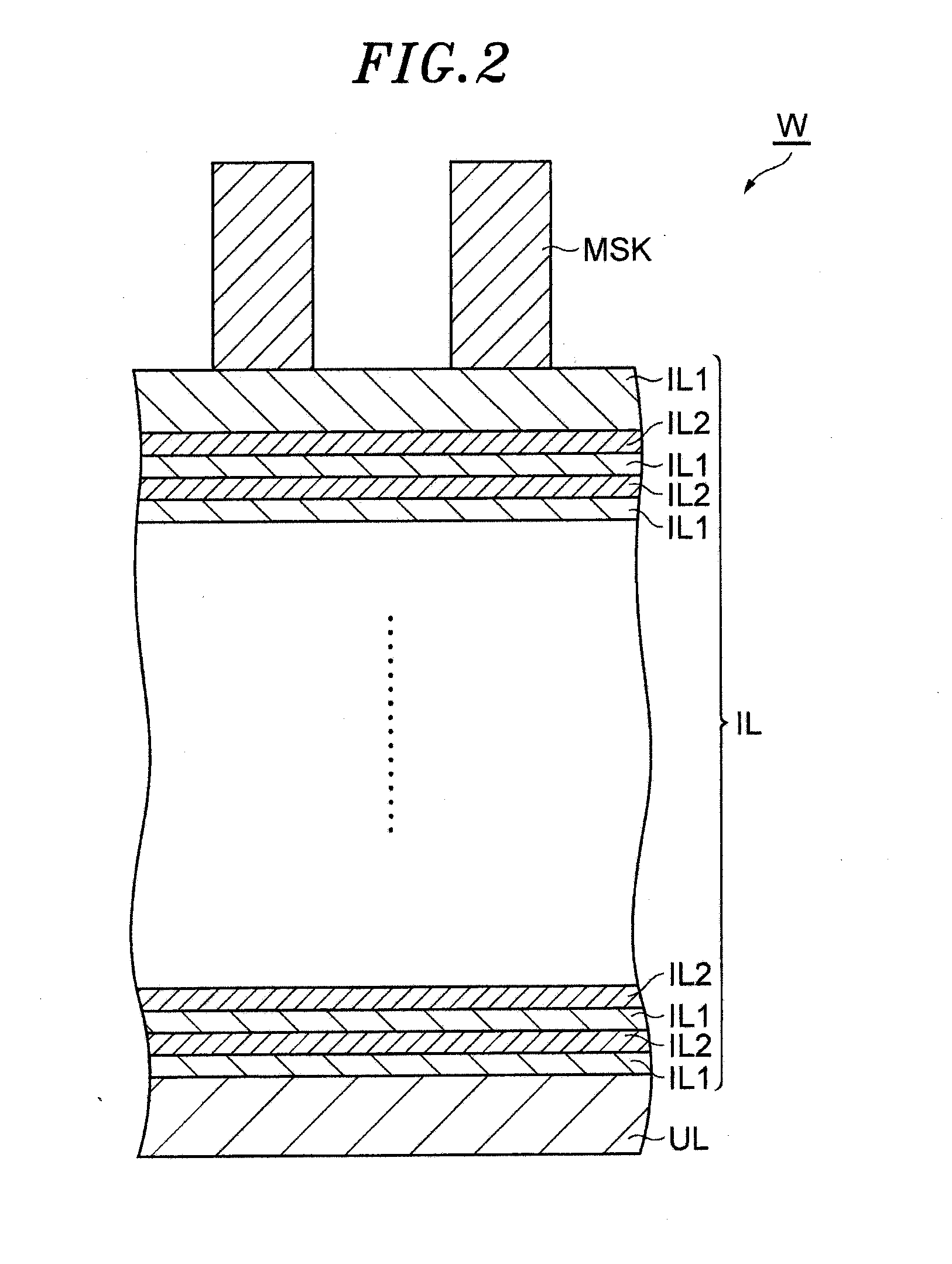

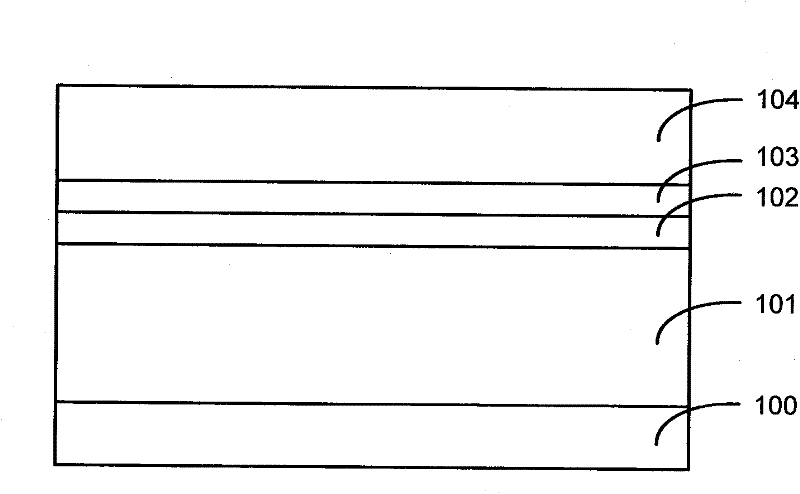

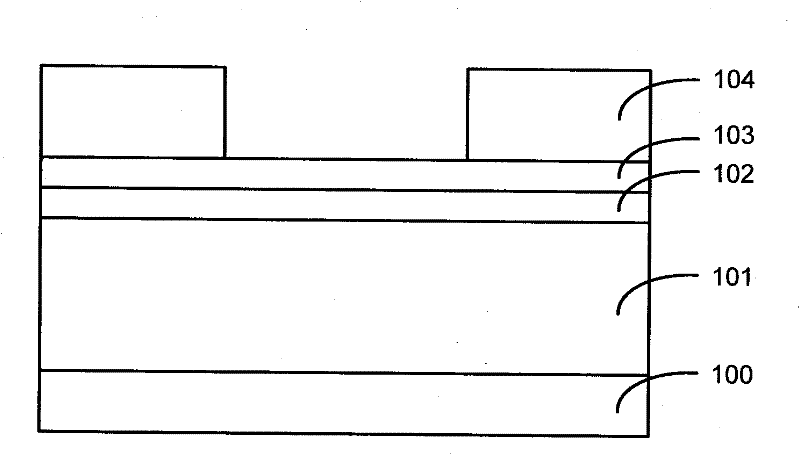

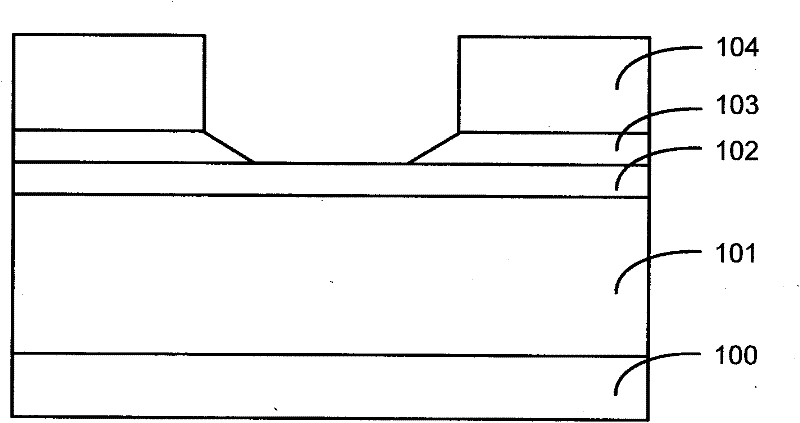

Semiconductor device manufacturing method

ActiveUS20150037982A1Increase widthSmall widthElectric discharge tubesSemiconductor/solid-state device manufacturingSilicon oxideSemiconductor device fabrication

In a semiconductor device manufacturing method, a target object including a multilayer film and a mask formed on the multilayer film is prepared in a processing chamber of a plasma processing apparatus. The multilayer film is formed by alternately stacking a silicon oxide film and a silicon nitride film. The multilayer film is etched by supplying a processing gas containing hydrogen gas, hydrogen bromide gas, nitrogen trifluoride gas and at least one of hydrocarbon gas, fluorohydrocarbon gas and fluorocarbon gas into the processing chamber of the plasma processing apparatus and generating a plasma of the processing gas in the processing chamber.

Owner:TOKYO ELECTRON LTD

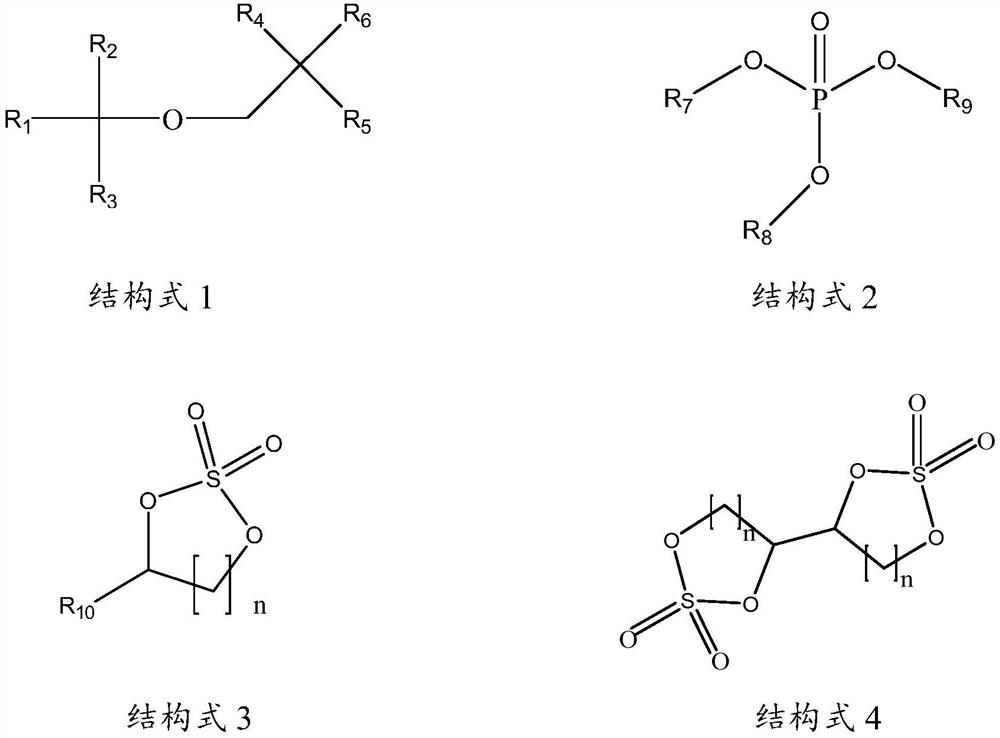

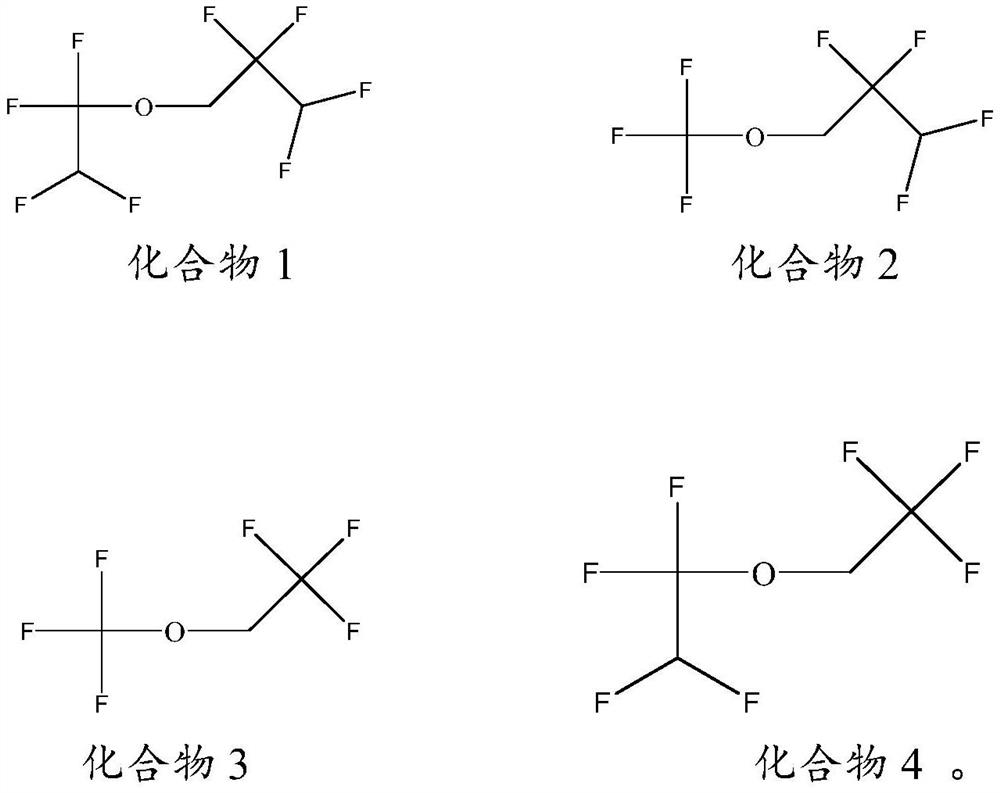

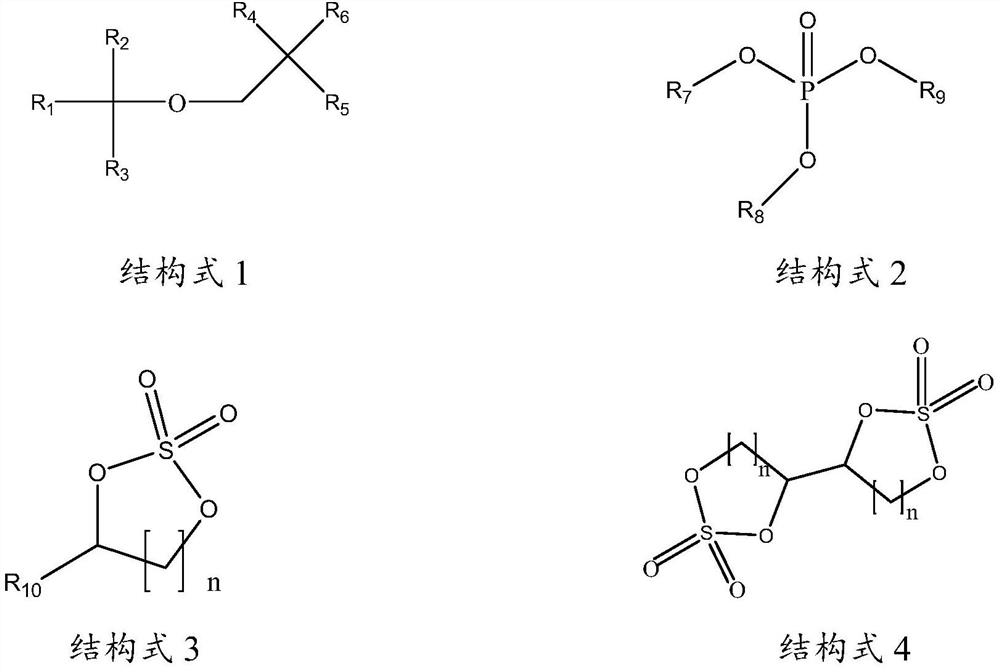

Non-aqueous electrolyte of lithium ion battery and lithium ion battery containing non-aqueous electrolyte

PendingCN111934017AImprove high temperature storage performanceImprove high temperature cycle performanceSecondary cells servicing/maintenanceOrganic electrolytesElectrolytic agentOrganosolv

The invention provides a non-aqueous electrolyte of a lithium ion battery and the lithium ion battery containing the non-aqueous electrolyte. The non-aqueous electrolyte of the lithium ion battery comprises a lithium salt, a non-aqueous organic solvent and an additive. The additive comprises a fluoroether compound with a structural formula 1 and an unsaturated phosphate compound with a structuralformula 2, and further comprises a cyclic sulfate compound with a structural formula 3 or 4, and R1, R2, R3, R4, R5 and R6 are respectively and independently selected from fluorine atoms and C1-C4 fluoroalkyl. R7, R8 and R9 are each independently selected from unsaturated hydrocarbon groups or fluorinated hydrocarbon groups of C1 to C4. R10 is hydrogen or C1-C5 alkyl, and n is an integer from 1 to5. The lithium ion battery prepared from the non-aqueous electrolyte of the lithium ion battery has relatively good wettability, low-temperature charging and discharging performance, high-temperaturestorage performance, high-temperature cycle performance and normal-temperature cycle performance, and low-temperature lithium precipitation can be effectively avoided.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

Silicon nitride etching methods

ActiveUS20060252269A1Reduce bias voltageSemiconductor/solid-state device manufacturingSulfur hexafluorideOctafluorocyclobutane

Methods of etching silicon nitride material, and more particularly, etching nitride selective to silicon dioxide or silicide, are disclosed. The methods include exposing a substrate having silicon nitride thereon to a plasma including at least one fluorohydrocarbon and a non-carbon containing fluorine source such as sulfur hexafluoride (SF6). The plasma may also include oxygen (O2) and the fluorohydrocarbons may include at least one of: trifluoromethane (CHF3), difluoromethane (CH2F2), and methyl fluoride (CH3F). In an alternative embodiment, the plasma includes one of hydrogen (H2) and nitrogen trifluoride (NF3) and one of tetrafluoromethane (CF4) and octafluorocyclobutane (C4F8). The methods are preferably carried out using a low bias voltage, e.g. <100 V.

Owner:IBM CORP +1

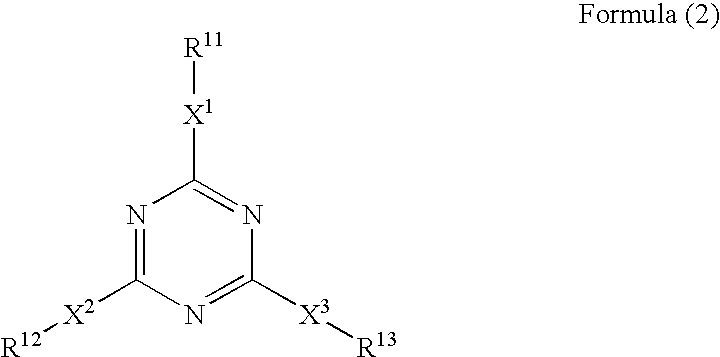

Lubricant composition and triazine ring-containing compound

InactiveUS20060068998A1Improve the lubrication effectReduce frictionOrganic chemistryAdditivesPhotochemistryFluorinated hydrocarbons

A lubricant composition comprising a compound represented by the following formula that can maintain a low friction and a high abrasion resistance on the sliding surface over an extended period of time: wherein D represents a cyclic group; X's each independently represent a single bond, an NR1 group (in which R1 represents a hydrogen atom or a C1-C30 alkyl group), an oxygen atom, a sulfur atom, a carbonyl group, a sulfonyl group or a divalent linking group comprising these groups in combination; R's each independently represent an alkyl group, an alkenyl group, an alkynyl group, an aryl group or a heterocyclic group; m represents an integer of from 2 to 11; and at least one of m groups of R's contains a partly fluorinated hydrocarbon group or a fluorinated carbon group.

Owner:FUJIFILM CORP

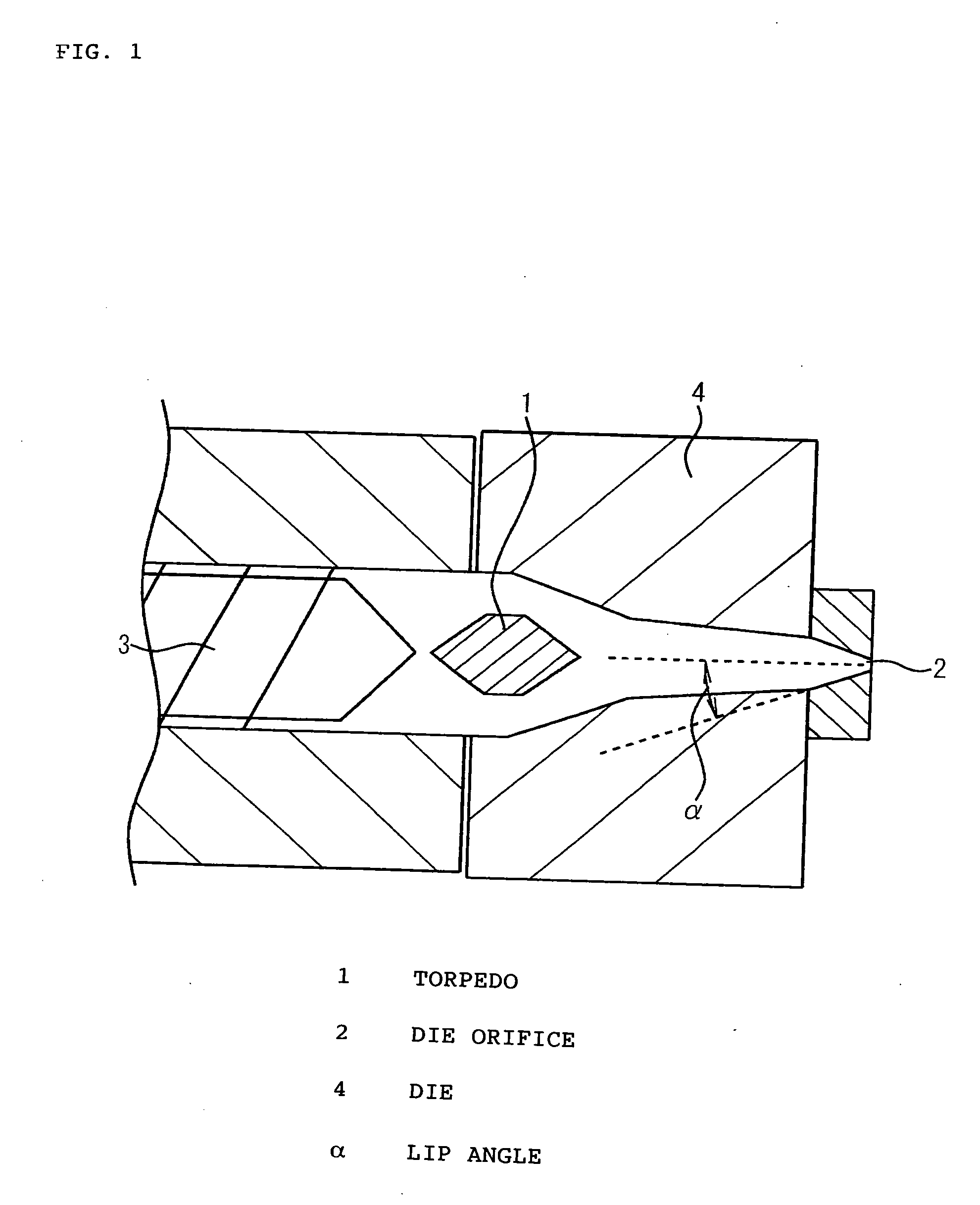

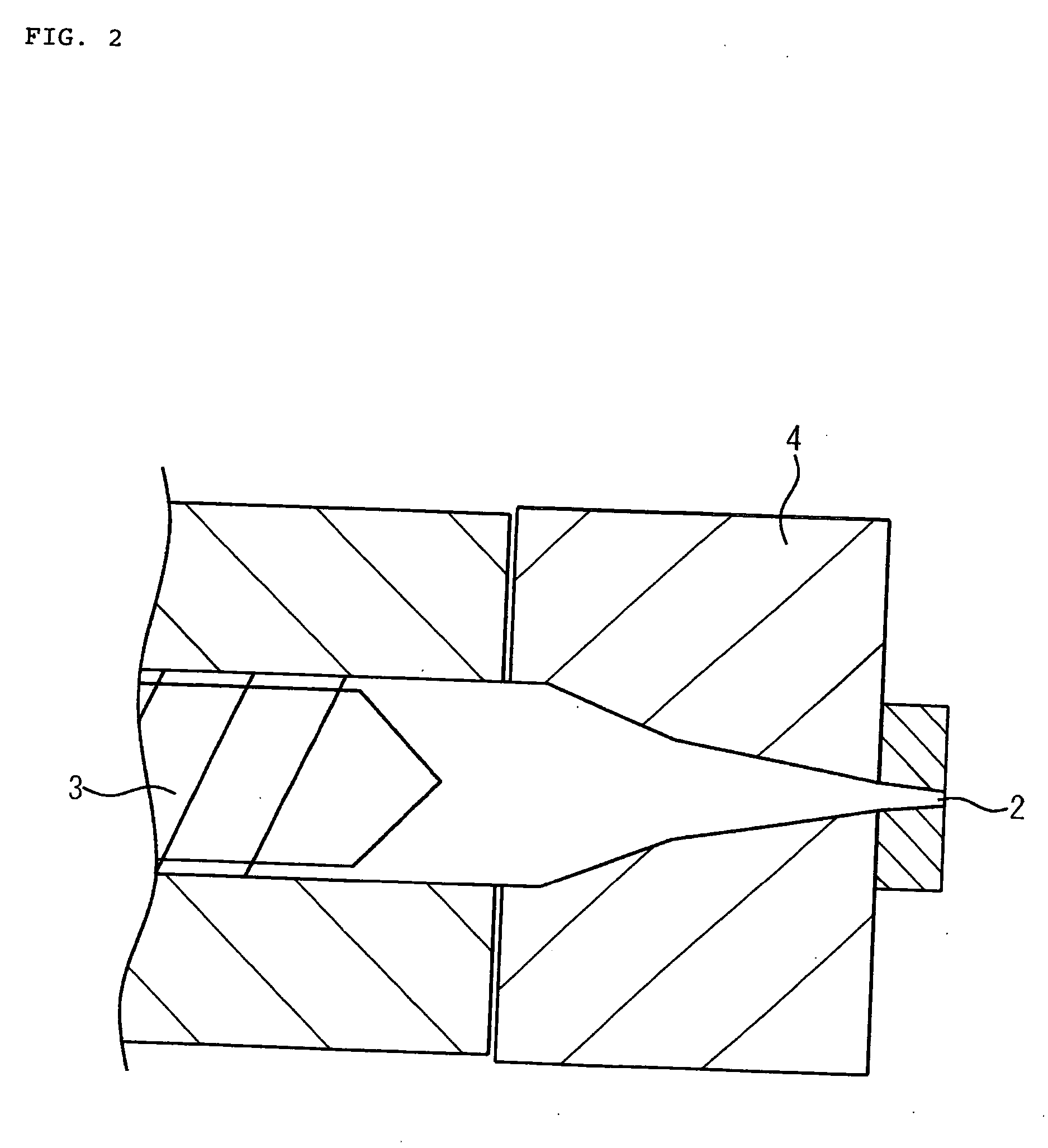

Extruded polystyrene resin foam

A thick extruded polystyrene resin foam which can be obtained without using chlorofluorohydrocarbons has a center portion in which the cells are approximately spherical. The extruded polystyrene resin foam contains a residual gas selected from fluorohydrocarbons, aliphatic hydrocarbons and alicyclic hydrocarbons, and has a thickness of 45 to 150 mm and an apparent density of 0.015 to 0.06 g / cm3. The resin foam includes a center layer, excluding 10% of the foam thickness from each of the two foam surfaces, which is composed of cells with specific shape and compressive strengths in the foam thickness, transverse and machine directions.

Owner:JSP CORP

Method for making contact hole

InactiveCN102194738AGood key dimension uniformitySemiconductor/solid-state device detailsSolid-state devicesOxygenDielectric layer

The invention discloses a method for making a contact hole, which comprises the steps of: forming an etching stop layer on a front-end device layer; forming a dielectric layer on the etching stop layer; forming a contraction layer on the dielectric layer; forming a bottom anti-reflection coating on the contraction layer; coating a photoetching glue layer with patterns on the bottom anti-reflection coating; etching the bottom anti-reflection coating by using the photoetching glue layer with patterns as a mask to form a first opening; etching the contraction layer by using etching gases including fluorohydrocarbon gas and oxygen by using the photoetching glue layer with patterns and the bottom anti-reflection coating as masks to form a second opening with a tapered incline side wall; etching the dielectric layer to the upper layer of the etching stop layer by using the contraction layer as a mask; and removing the bottom anti-reflection coating and the contraction layer to form the contact hole. According to the method disclosed by the invention, 40nm and even larger contraction amount can be effectively realized, and better key size uniformity can be obtained.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Method for Reducing Creep Corrosion

InactiveUS20130240256A1Reduce creep corrosionReducing creep corrosionDielectric materialsCircuit susbtrate materialsSurface finishSolder mask

A method for reducing creep corrosion on a printed circuit board, the printed circuit board comprising a substrate, a plurality of electrically conductive tracks located on at least one surface of the substrate, a solder mask coating at least a first area of the plurality of electrically conductive tracks and a surface finish coating at least a second area of the plurality of electrically conductive tracks, the method comprising depositing by plasma-polymerization a fluorohydrocarbon onto at least part of the solder mask and at least part of the surface finish.

Owner:SEMBLANT

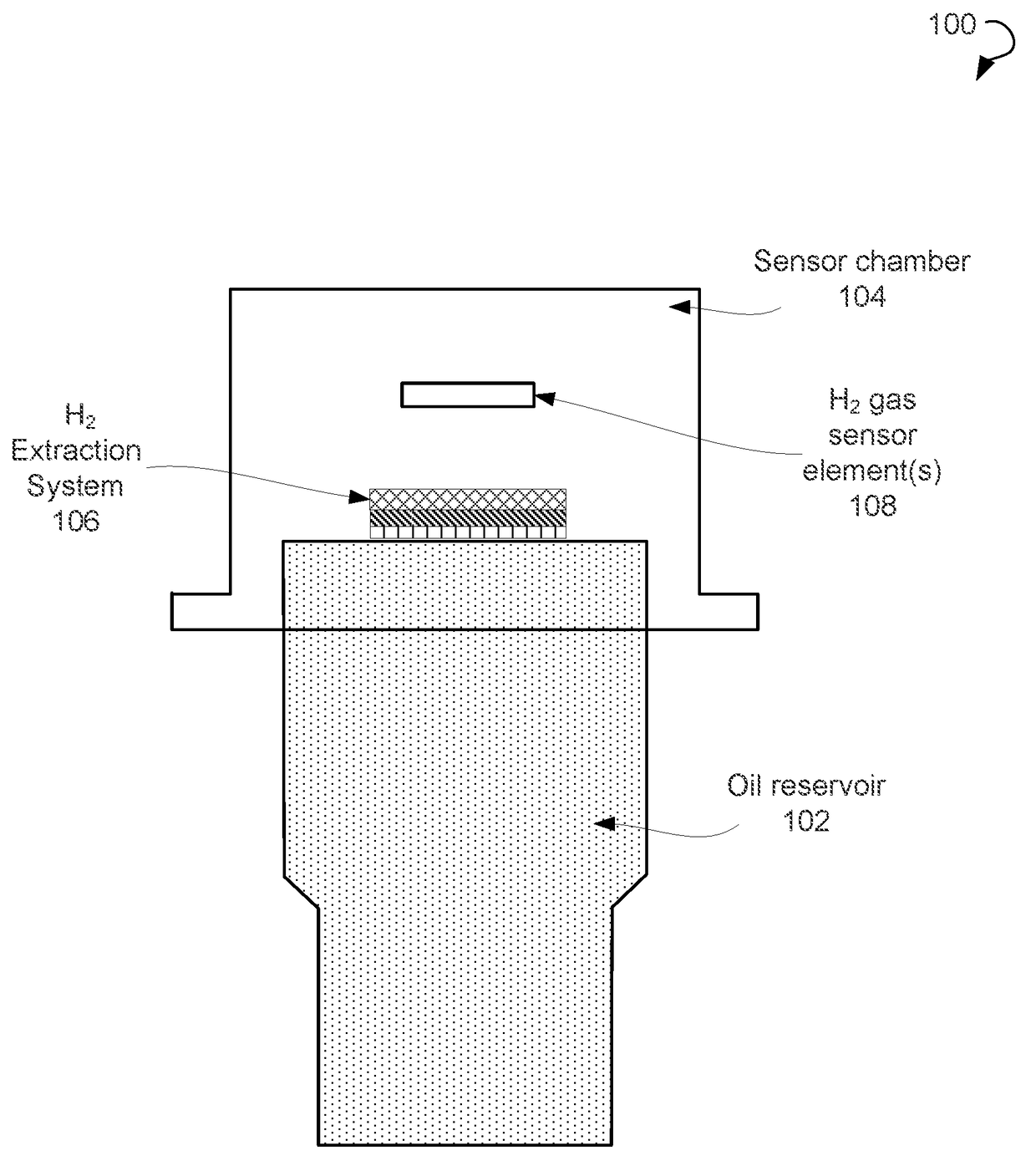

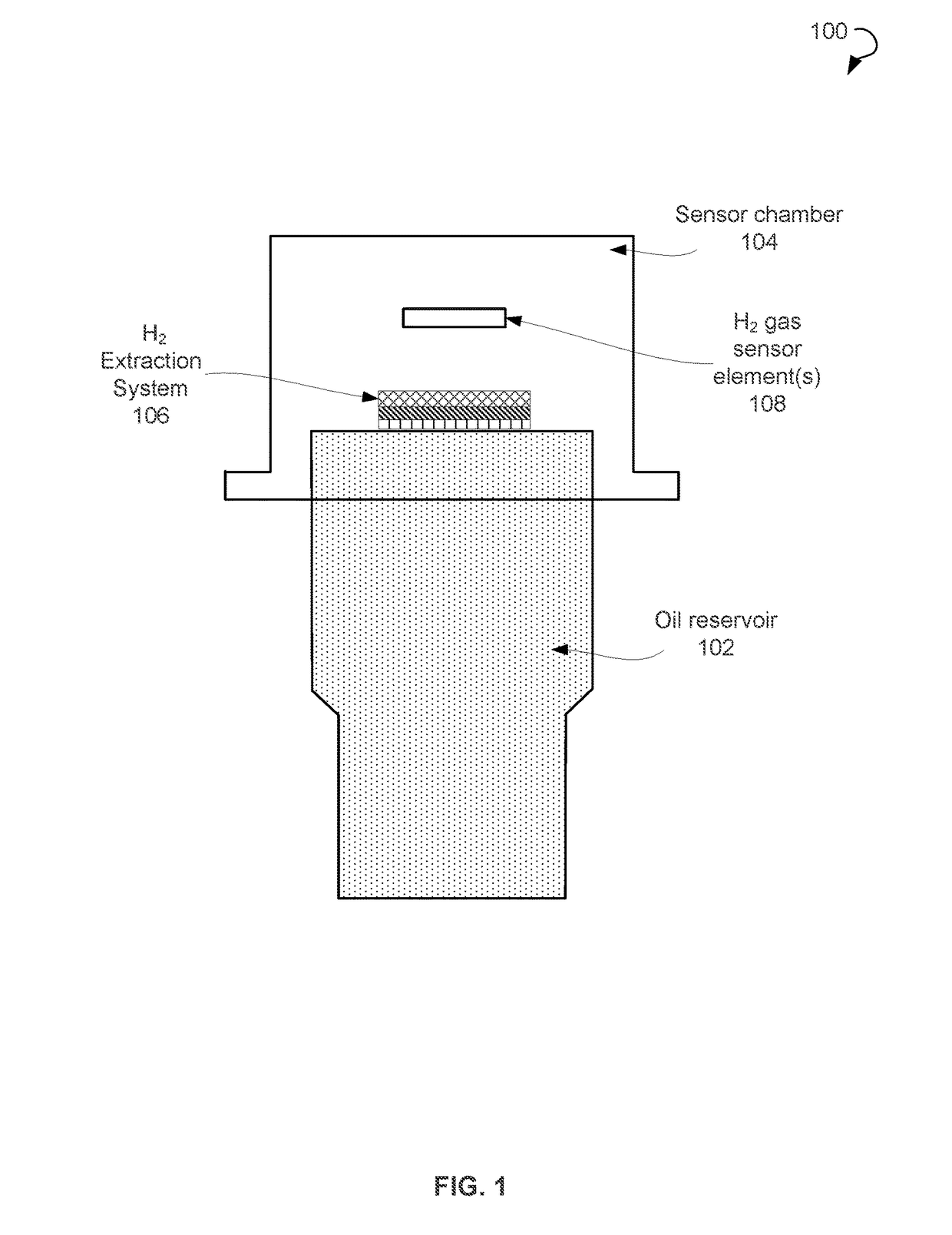

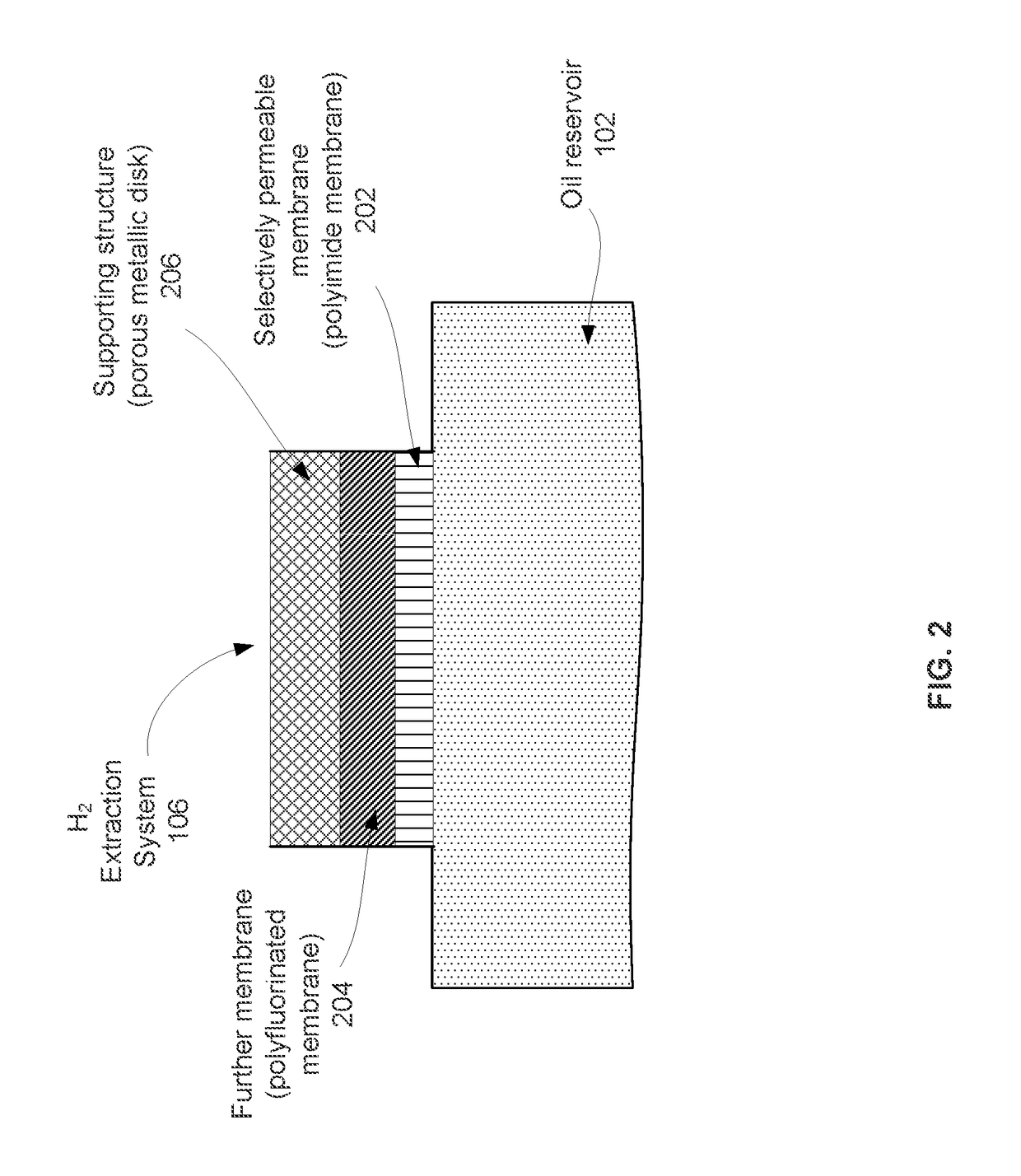

Methods and systems for selective hydrogen gas extraction for dissolved gas analysis applications

ActiveUS9884269B2Accurate measurementMinimizing detectionHydrogenSemi-permeable membranesHydrogenPhysical chemistry

Systems and methods for selectively extracting hydrogen gas dissolved in oil are provided. In one embodiment, a system includes a selectively permeable membrane provided at a point of contact between oil and a sensor chamber. The selectively permeable membrane has a hydrogen specificity and a thickness selected to minimize detection of further gasses dissolved in the oil by a hydrogen gas sensor cross-sensitive to the further gasses. The selectively permeable membrane can include polyimide. The further gasses include carbon monoxide, acetylene, and ethylene. The system can include a further membrane and a porous metal disc. The porous metal disc is bound to the selectively permeable membrane by using the further membrane as an adhesive layer and by applying pressure and temperature. The porous metal disc supports the selectively permeable membrane and the further membrane against pressure of the oil when exposed to a vacuum. The further membrane includes fluorohydrocarbons.

Owner:GE INFRASTRUCTURE TECH INT LLC

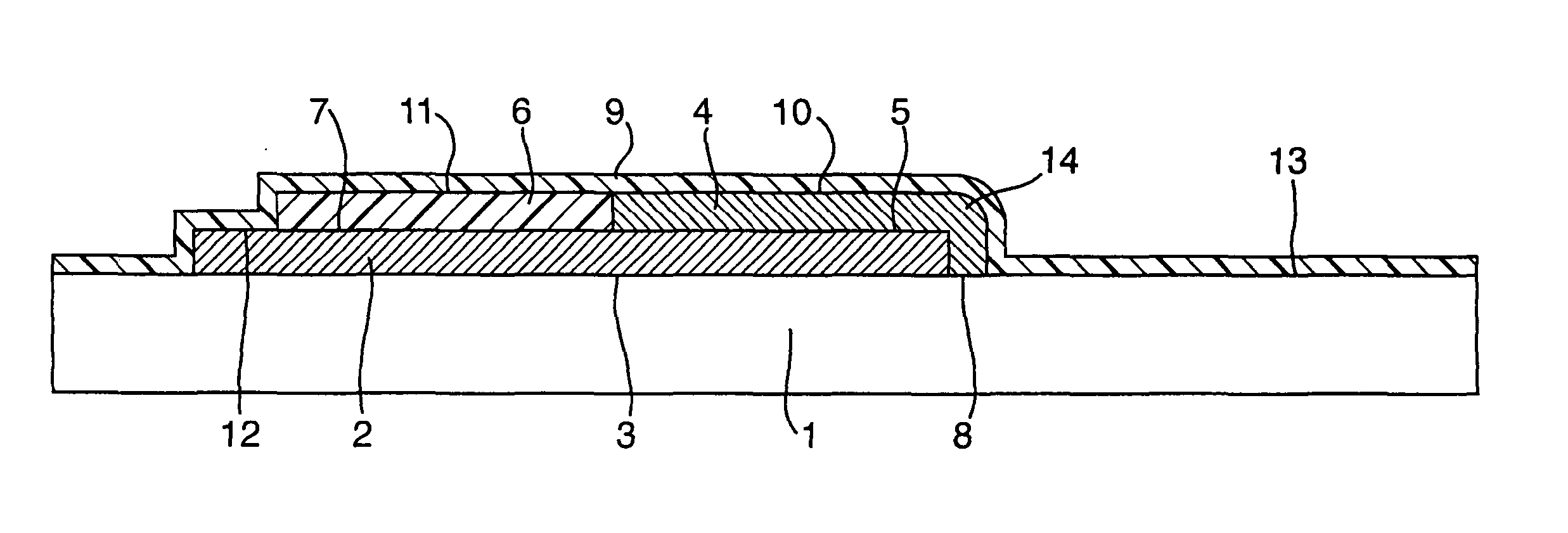

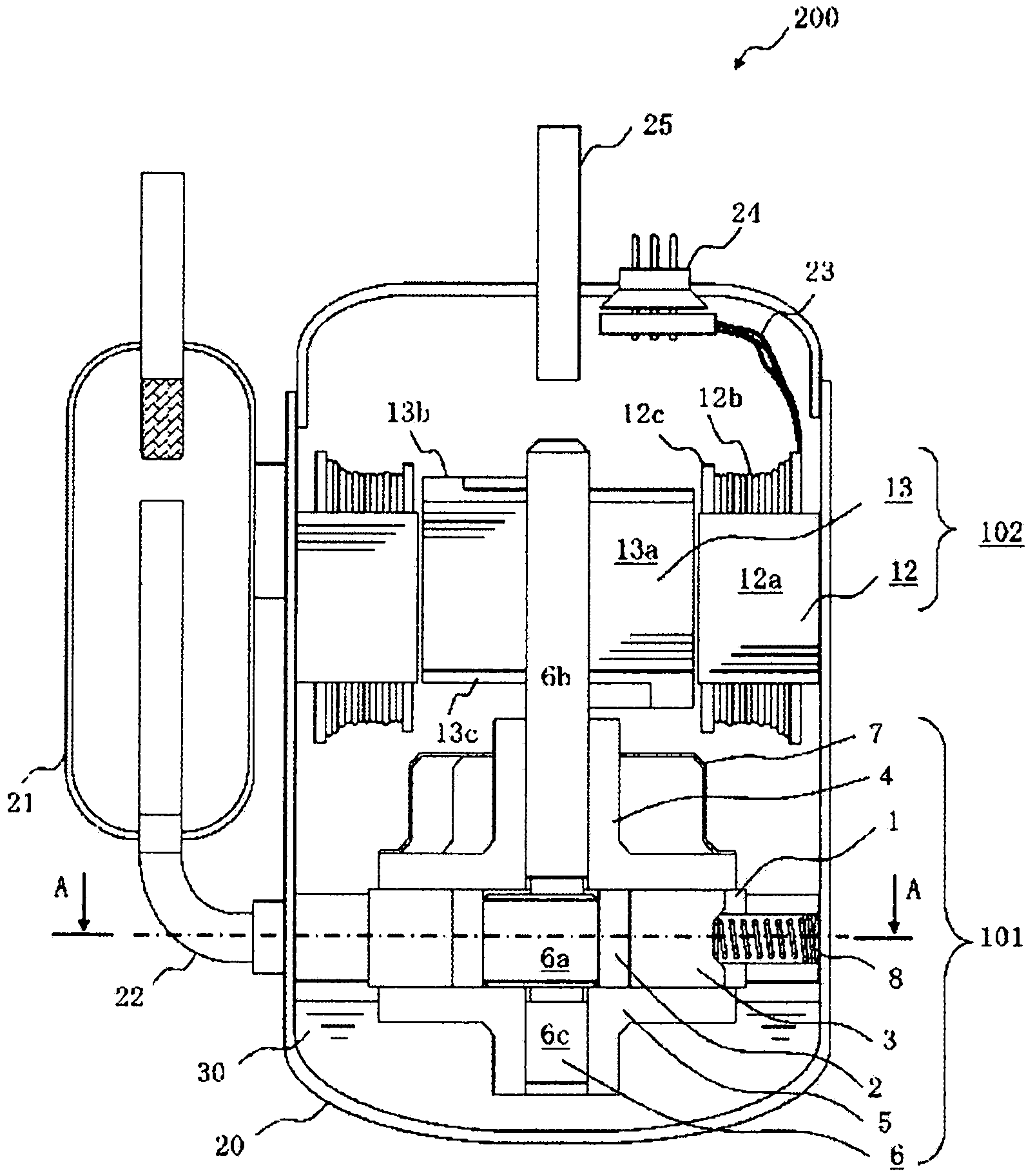

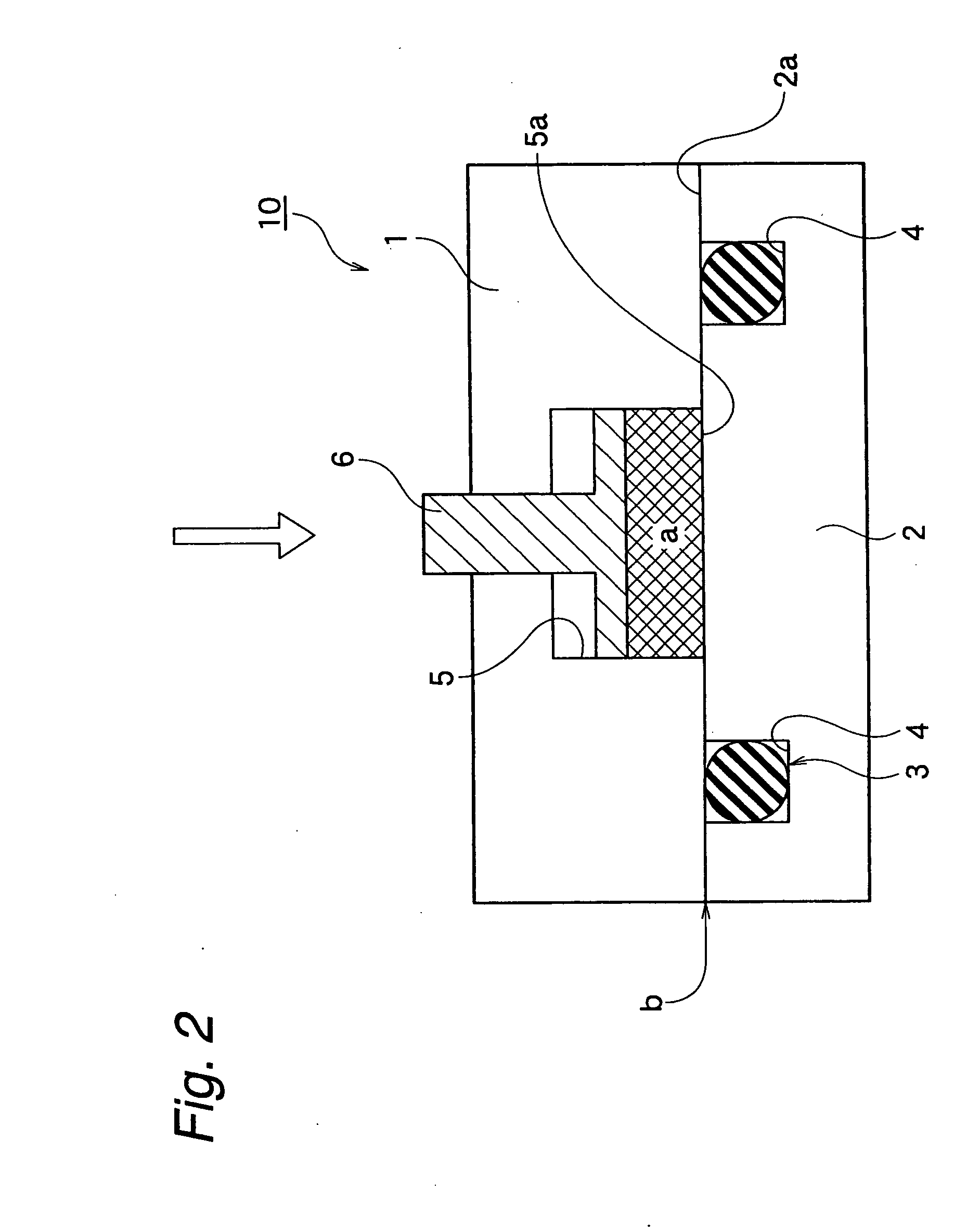

Refrigerant compressor

ActiveCN104110375AInhibition of polymerizationRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringRefrigerant

A refrigerant compressor configured to compress ethylene fluorohydrocarbon or a mixture containing the ethylene fluorohydrocarbon as a refrigerant, the refrigerant compressor including: a compression element configured to compress the refrigerant and including a sliding component that constitutes a sliding portion; and refrigerator oil configured to be supplied to the sliding component so as to lubricate the sliding portion, wherein a polymerization inhibitor configured to suppress polymerization of the refrigerant is contained in the refrigerator oil.

Owner:MITSUBISHI ELECTRIC CORP

Method for producing vulcanizable fluorine-containing elastomer

The present invention provides a process for preparing a fluorine-containing elastomer in a high productivity comparable to that of non-iodine transfer polymerization process by carrying out an iodine transfer polymerization at high pressure. The present invention also provides a fluorine-containing elastomer prepared by this process, and fluorine-containing molded articles. The process is a batch copolymerization process conducted under conditions that the reduced temperature of the critical constant is at least 0.95 and the reduced pressure of the critical constant is at least 0.80 wherein the reduced temperature and the reduced pressure are calculated using the Peng-Robinson formula from the critical temperature, the critical pressure and the composition ratio of each of the monomers in the gaseous phase in a reaction vessel, in which ethylenically unsaturated compounds containing at least one fluoroolefine are copolymerized in the presence of a compound having the formula: Rf<1>.Ix wherein Rf<1> is a saturated or unsaturated fluorohydrocarbon or chlorofluorohydrocarbon group having 1 to 16 carbon atoms, and x is the number of bonds of Rf<1> and an integer of 1 to 4.

Owner:DAIKIN IND LTD

Fluororubber base sealant composition and fluororubber base sealant

InactiveUS20060058450A1Good freezing resistanceImprove heat resistanceOther chemical processesVinyl etherIodide

A fluororubber sealant includes 100 parts by weight of a fluororubber, which is a copolymer having a cross-linking site derived from a bromine-containing and / or iodine-containing compound, capable of crosslinking with peroxide and having a component unit composition comprising 20 to 23% by mol of a perfluoromethyl vinylether component unit, 60 to 70% by mol of a vinylidene fluoride component unit, 10 to 20% by mol of a tetrafluoroethylene component unit, 0 to 10% by mol of hexafluoropropylene component unit (based on 100% of the total of the above component units), and a small amount of a bromide and / or iodide unsaturated fluorohydrocarbon component unit as a crosslinking site based on 100% by mol of the total of the above component units; and further comprising, based on 100 parts by weight of the fluororubber, 2 to 50 parts by weight of a bituminous fine powder; 0.5 to 6 parts by weight of an organoperoxide; and 1 to 10 parts by weight of a polyfunctional monomer. A sealant is prepared by vulcanizing the above composition. The composition has not only excellent ordinary physical properties but also excellent heat resistance, freeze resistance and fuel oil resistance so that it is suitably used as sealants for automobile fuel.

Owner:NOK CORP

Non-combustible aerosol composition

InactiveCN101165135ALow costImprove solubilityBiocideOther chemical processesSolubilityAerosol spray

The non-inflammable aerosol composition consists of dimethyl ether, ethanol and fire retardant. The fire retardant is fluorohydrocarbon, fluorochlorohydrocarbon, ketone fluoride or their mixture. The aerosol composition has high solubility, non-inflammability, low toxicity, adjustable pressure and ODP value of 0-0.1.

Owner:浙江莹光化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com