Patents

Literature

55 results about "Necking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Necking, in engineering or materials science, is a mode of tensile deformation where relatively large amounts of strain localize disproportionately in a small region of the material. The resulting prominent decrease in local cross-sectional area provides the basis for the name "neck". Because the local strains in the neck are large, necking is often closely associated with yielding, a form of plastic deformation associated with ductile materials, often metals or polymers. Once necking has begun, the neck becomes the exclusive location of yielding in the material, as the reduced area gives the neck the largest local stress. The neck eventually becomes a fracture when enough strain is applied.

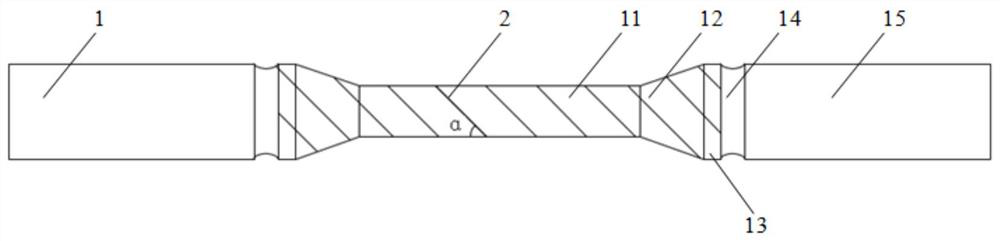

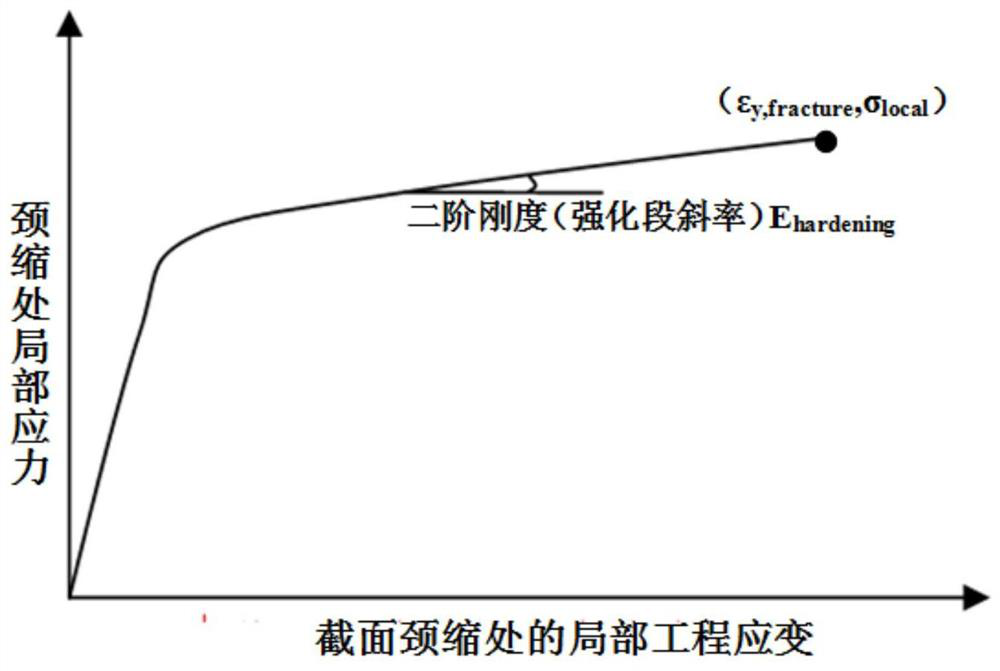

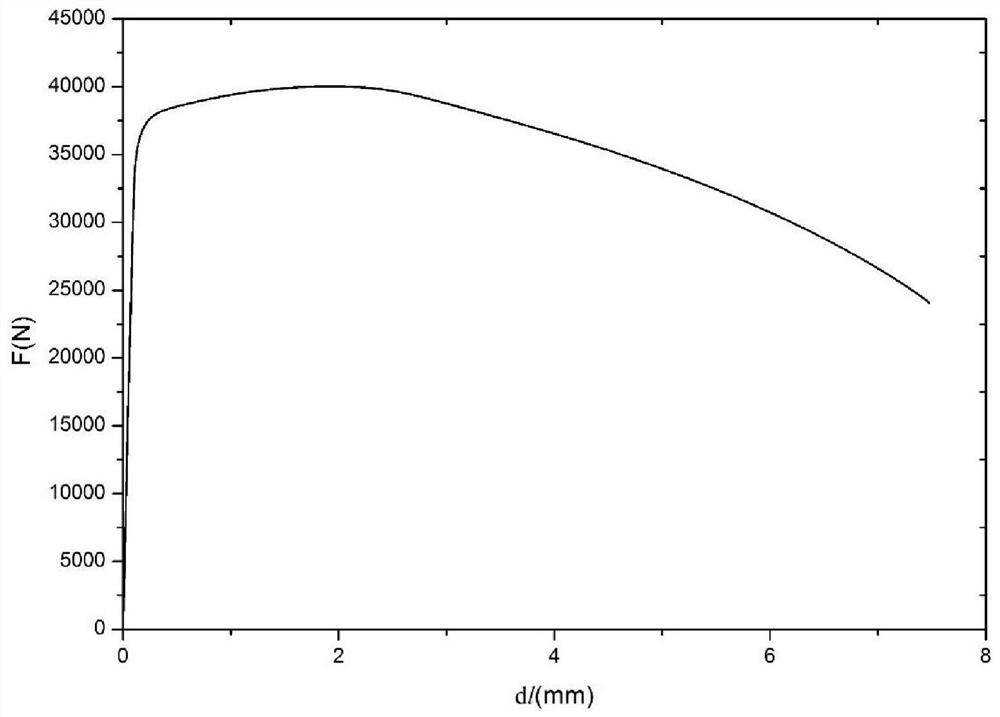

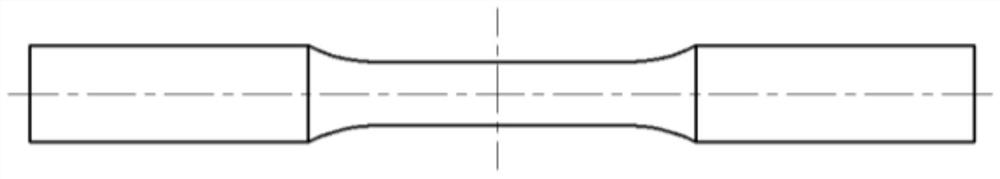

Material tensile real constitutive curve testing technology

InactiveCN103175735AOvercome the disadvantages of large number of iterations and high computational costGood effectMaterial strength using tensile/compressive forcesClassical mechanicsMetallic materials

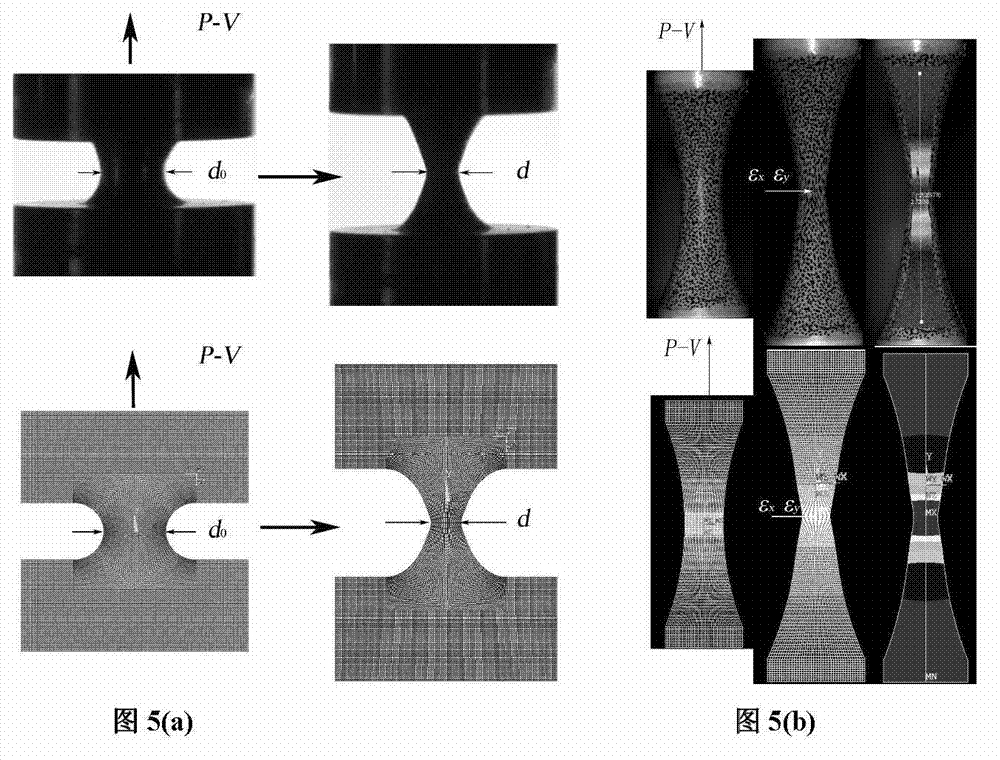

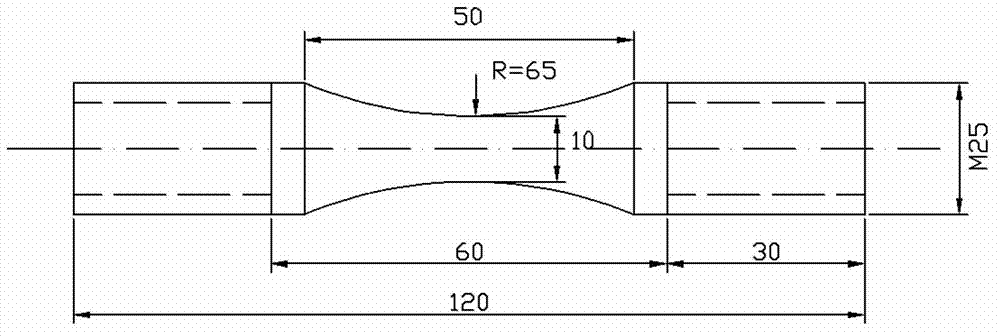

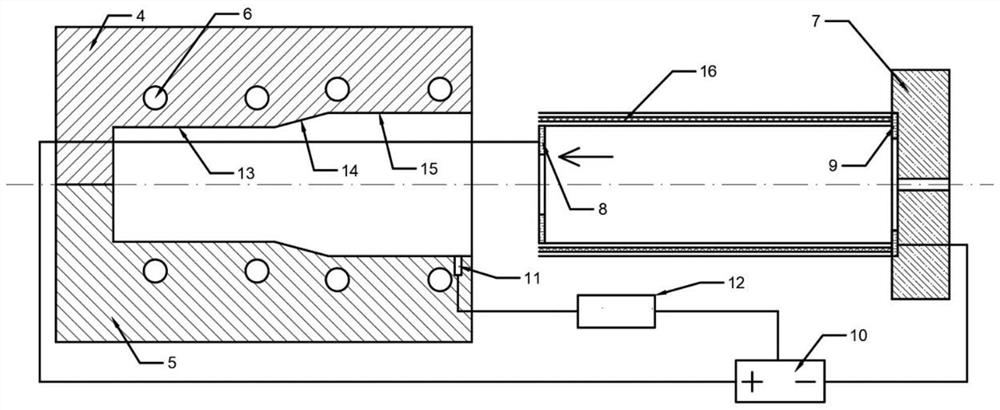

The invention discloses a material tensile real constitutive curve testing technology for obtaining an engineering stress-engineering strain curve and a load-displacement curve. The technology comprises the following steps of: obtaining a necking distortion profile curve and a stress strain field by non-contact optical measurement, establishing a finite element analytical model of a funnel round bar sample, stimulating the whole process that the sample is stretched until the necking is broken, and demarcating the real constitutive curve in an iteration solution mode. The technology disclosed by the invention overcomes the defects that the construction defect mode cannot precisely simulate a necking phenomenon of all metal material, the iteration times in the finite element iteration computation are more, and the computation cost is high; and the technology is combined with a non-contact optical distortion measurement system to monitor the tensile so as to obtain the load-displacement curve of the full-course sample tensile and the distortion field.

Owner:SOUTHWEST JIAOTONG UNIV

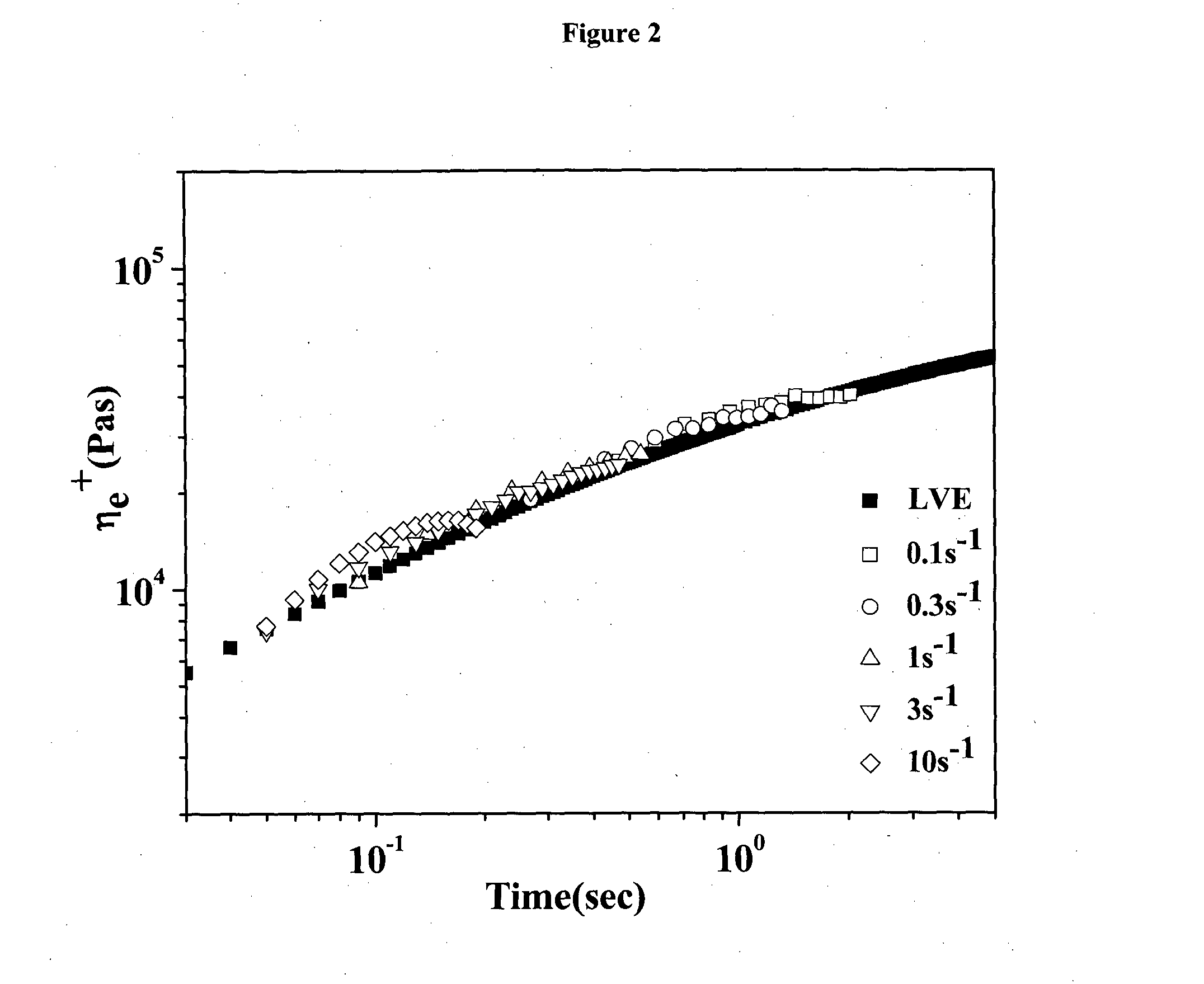

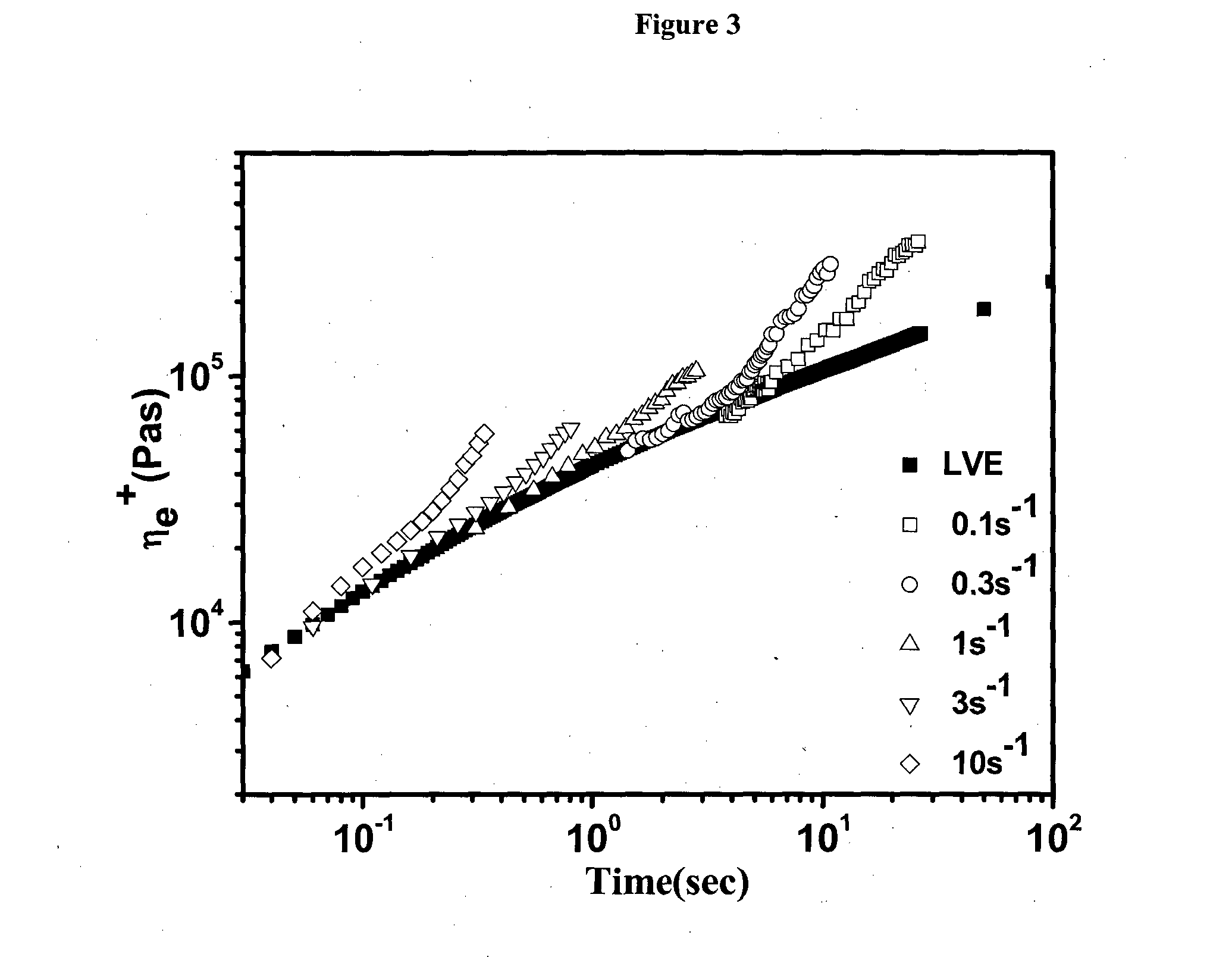

Modified polypropylene compositions for reduced necking in extrusion film casting or extrusion coating processes

ActiveUS20150018463A1Reduced necking tendencyHigh flow activation energyGroup 5/15 element organic compoundsPolymer scienceActivation energy

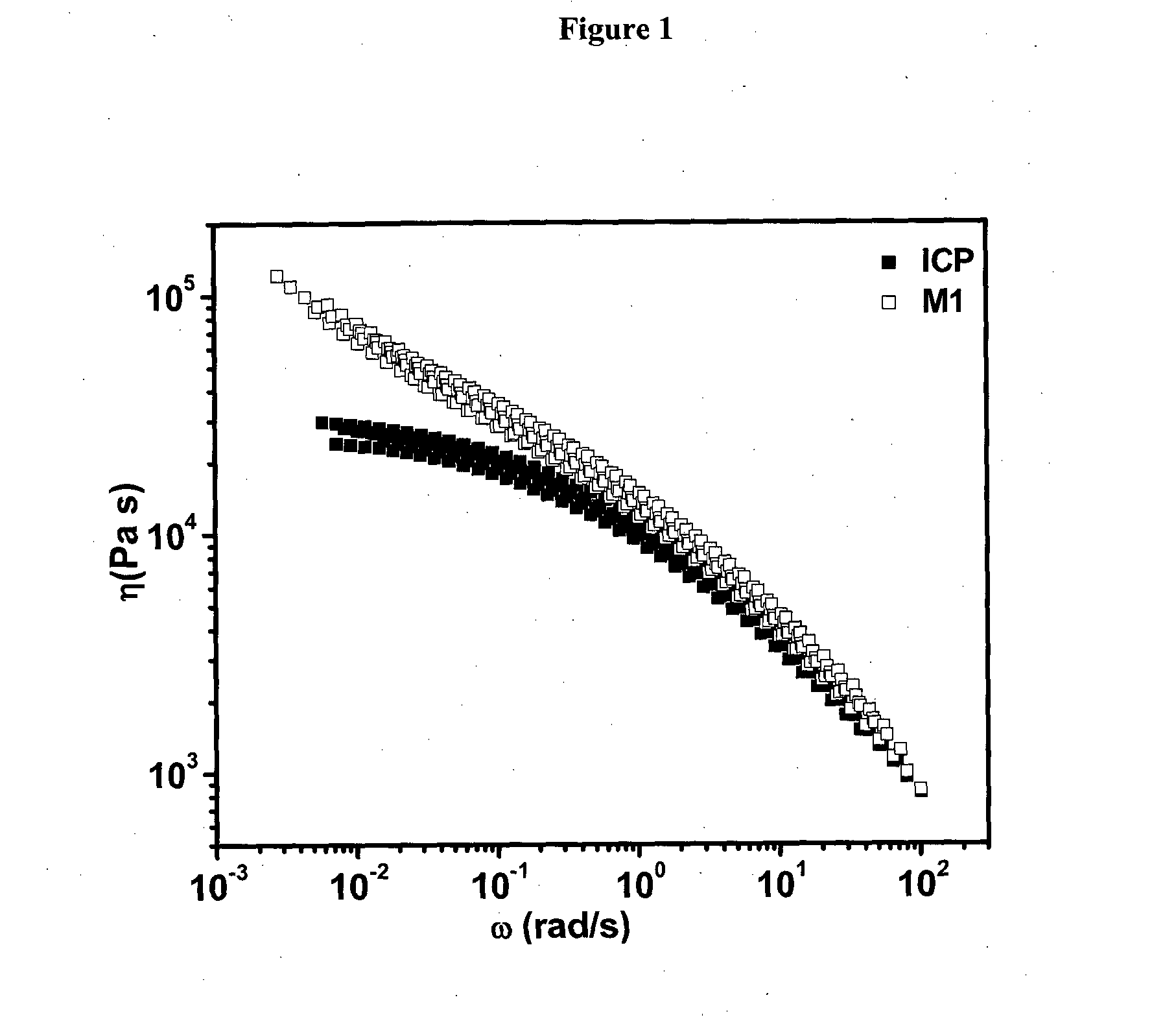

The present invention discloses modified polypropylene composition with higher flow activation energy and reduced necking in extrusion film / coat, wherein composition comprises long chain branch of polypropylene; free radical initiator; primary antioxidant; secondary antioxidant; acid neutralizer; optionally multifunctional monomer. Further the said composition of polypropylene shows higher sensitivity of viscosity to temperature, with improved stretchability.

Owner:COUNCIL OF SCI & IND RES

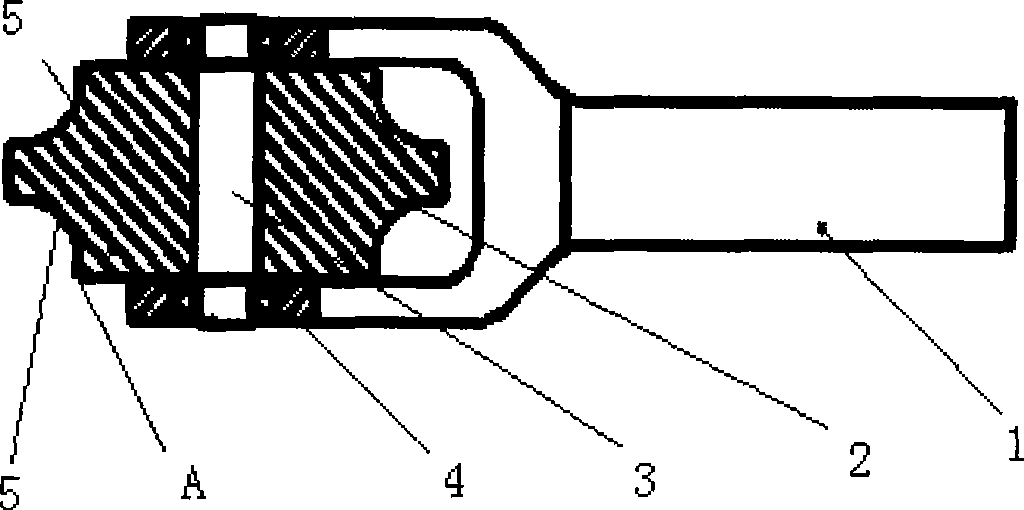

Method for processing spherical closing-in of thin-wall alloy steel delivery tube and special-purpose hob cutter

The invention belongs to the mechanical processing technique and relates to an improved method for processing a thin-wall alloy steel pipeline spherical necking. The method is characterized in that a common lathe and a special hobbing cutter are used for processing the pipeline spherical necking through a rotary extrusion method, and the method adopts the processing following steps of clamping, tool setting, pipe heating, vertical rotary extrusion and horizontal rotary extrusion. The special hobbing cutter is characterized in that working surfaces (5) with the circular-arc cross sections are respectively arranged at two sides of a rolling wheel (2), and are connected with the lateral side and the cylindrical surface of the rolling wheel. In the invention, the common lathe is used for processing; thereby the processing cost is greatly reduced.

Owner:JIANGXI CHANGHE AVIATION IND

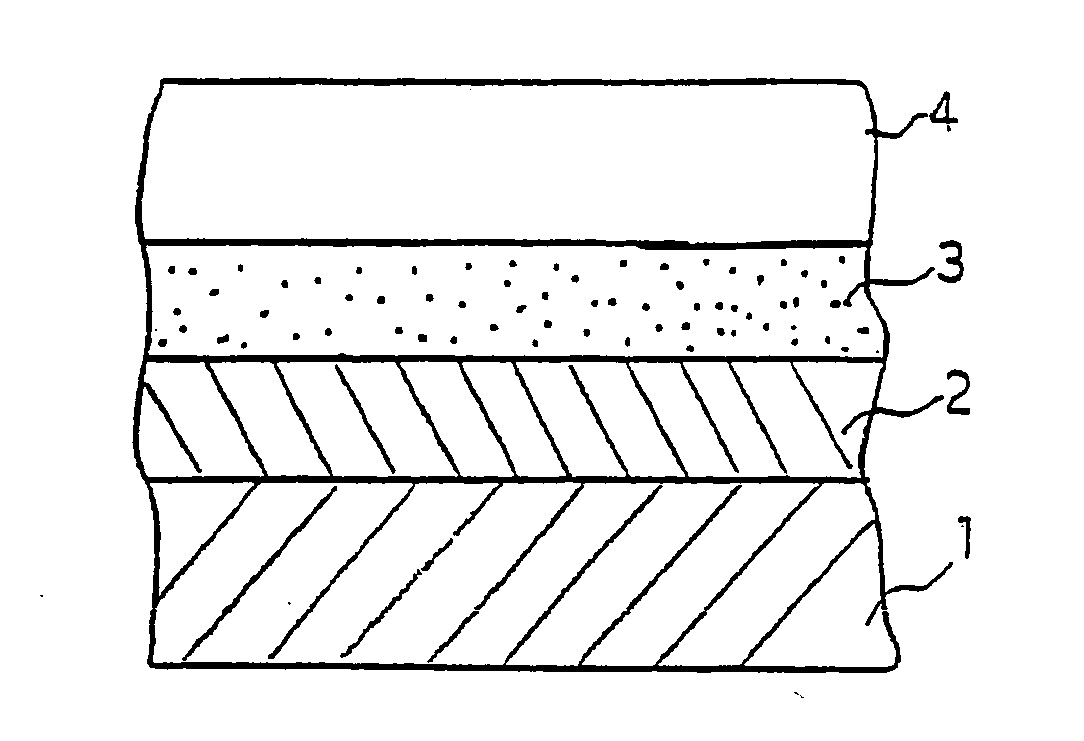

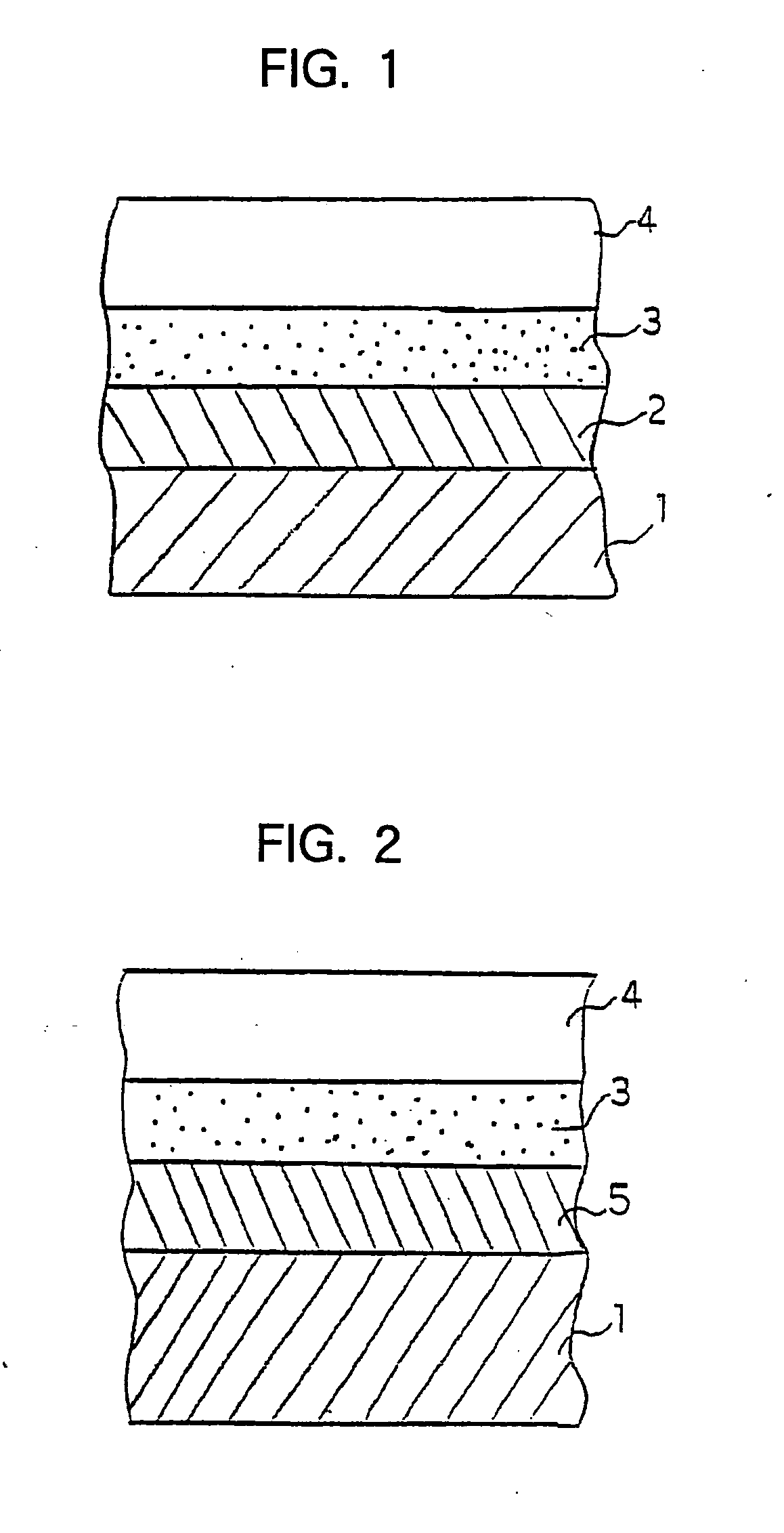

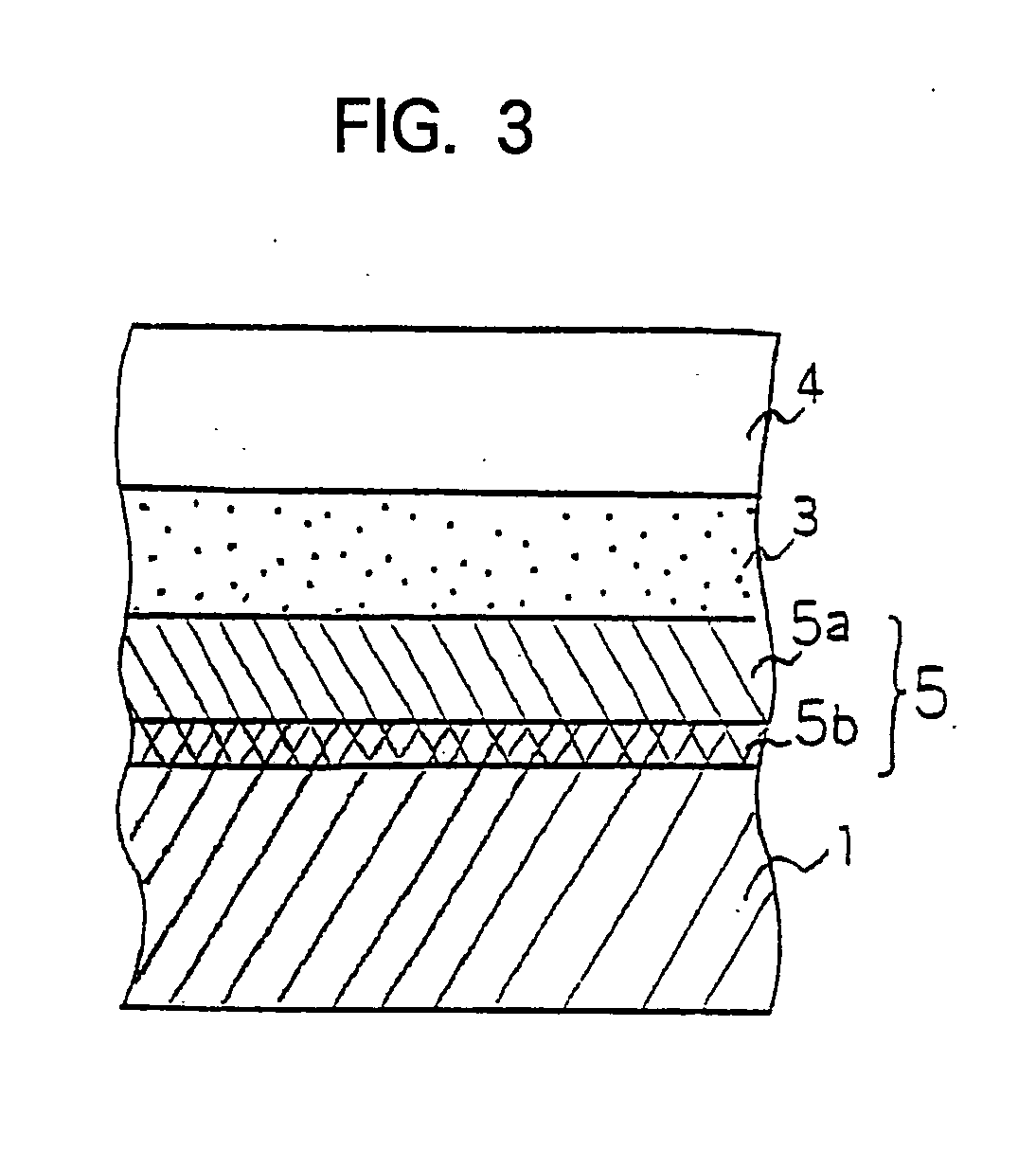

Resin coated steel sheet and can formed by pressing the same

InactiveUS20050153157A1Good film adhesionImprove workabilityLiquid surface applicatorsSuperimposed coating processTinningSilanes

A resin-coated steel plate obtained by providing, on at least one surface of the steel plate, (i-1) an alloy layer of iron and at least one metal selected from tin, zinc and nickel or (i-2) a tin-plated layer containing tin in an amount of not smaller than 0.5 g / m2, (ii) a silane coupling agent-treated layer, and (iii) a thermoplastic polyester resin layer in this order from the side of the steel plate. Despite of not containing chromium, the resin-coated steel plate exhibits excellent work adhesion between the steel blank and the organic resin film even when the thickness is reduced due to a severe working and even at portions subjected to severe working such as flanging and necking. By press-molding the resin-coated steel plate, there are obtained cans featuring excellent corrosion resistance and being adapted to containing even highly corrosive contents.

Owner:TOYO SEIKAN KAISHA LTD

Breathable elastic film/nonwoven laminate

InactiveCN1258327AIncrease elasticitySynthetic resin layered productsAbsorbent padsPolymer scienceWater vapor permeability

A breathable elastic laminate is formed by bonding a film including an elastic water vapor-soluble polymer to a neckable nonwoven web such that when the film is relaxed, the web is in a necked state. The breathable laminate is stretchable in a direction parallel to the narrowing or necking of the web. The laminate possesses excellent water vapor permeability but acts as a barrier to the passage of odor-causing chemicals including ammonia.

Owner:KIMBERLY-CLARK WORLDWIDE INC

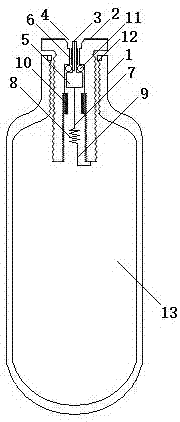

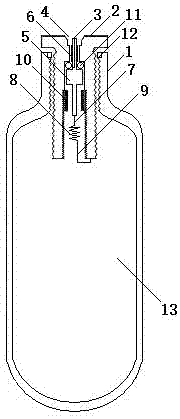

Gas expansion device and machining method and application of neckings of expansion pipe

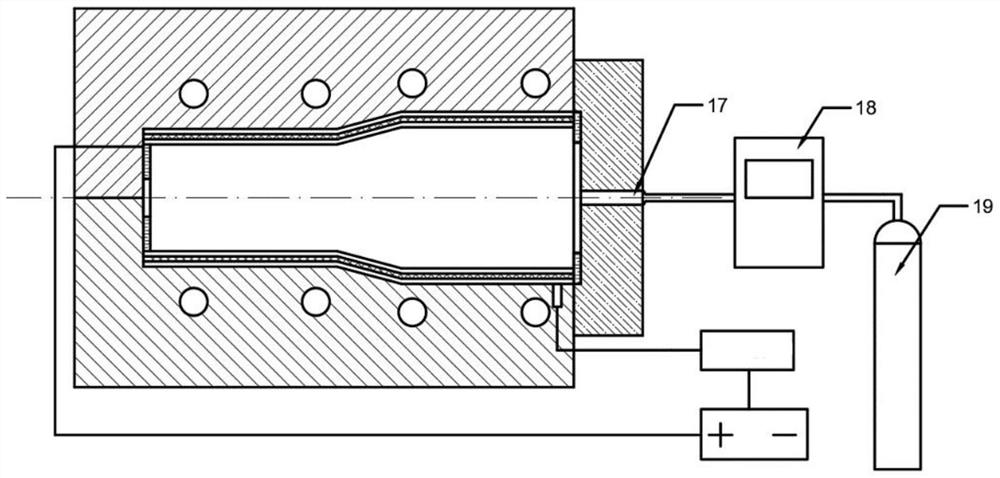

The invention discloses a gas expansion device and a necking processing method and application of an expansion tube. The expansion device includes an expansion tube and an inflatable ignition head. The method is to fix the expansion tube through the clamp first, then rotate the expansion tube and heat the end of the expansion tube through the clamp, heat the end of the expansion tube until it is close to or reach plastic deformation, and after the front part of the shrinking mold touches the end of the expansion tube, The end of the expansion pipe moves from the front to the rear of the shrinking die, and the shrinking die extrudes and thickens the end of the expansion pipe, and the end of the shrinking end is thickened axially outward, and then the end of the expansion pipe is processed with a through-hole knife. Through-hole fixed aperture. The expansion tube is made into a pressure vessel by shrinking. The utility model has the advantages of simple structure, easy processing of structural components, low manufacturing cost, no flying head, no air leakage, safe transportation, no hidden danger of squib, and large expansion force.

Owner:郭远军

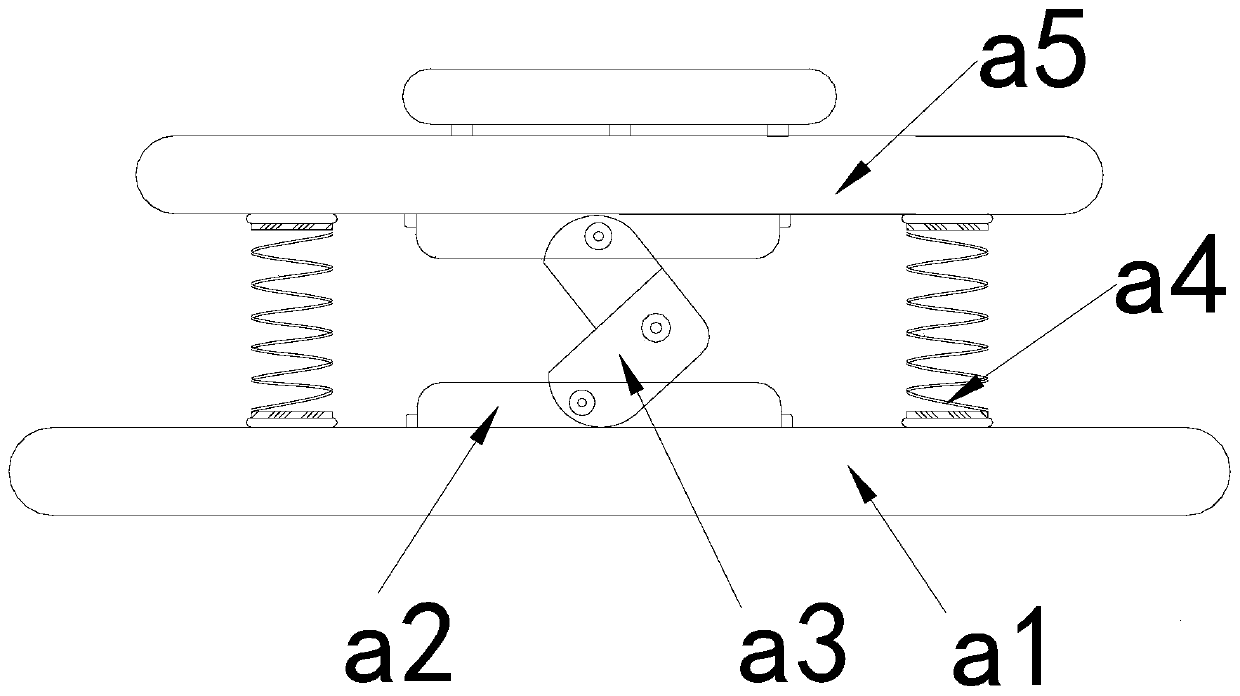

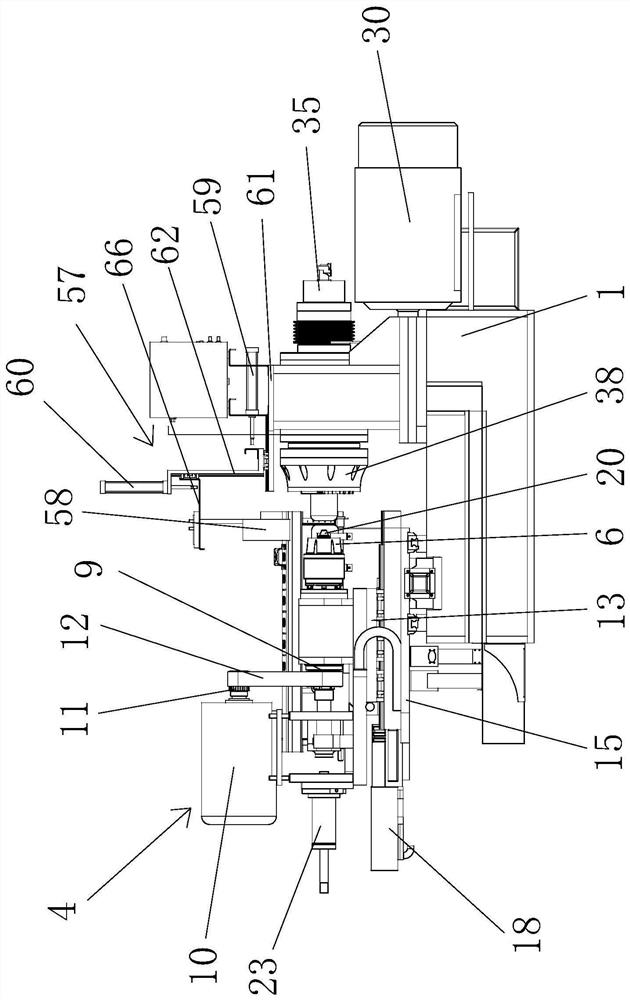

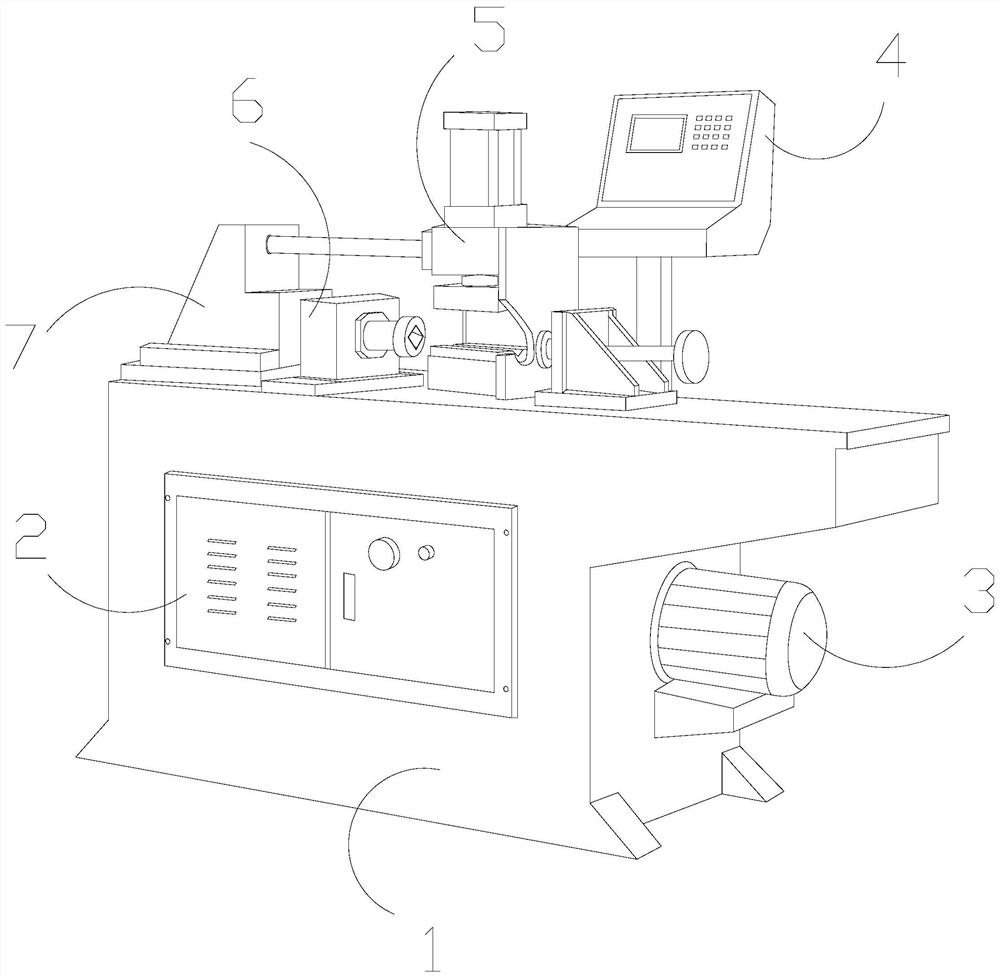

Double-head heating necking method and necking device thereof for thick-wall round tubes

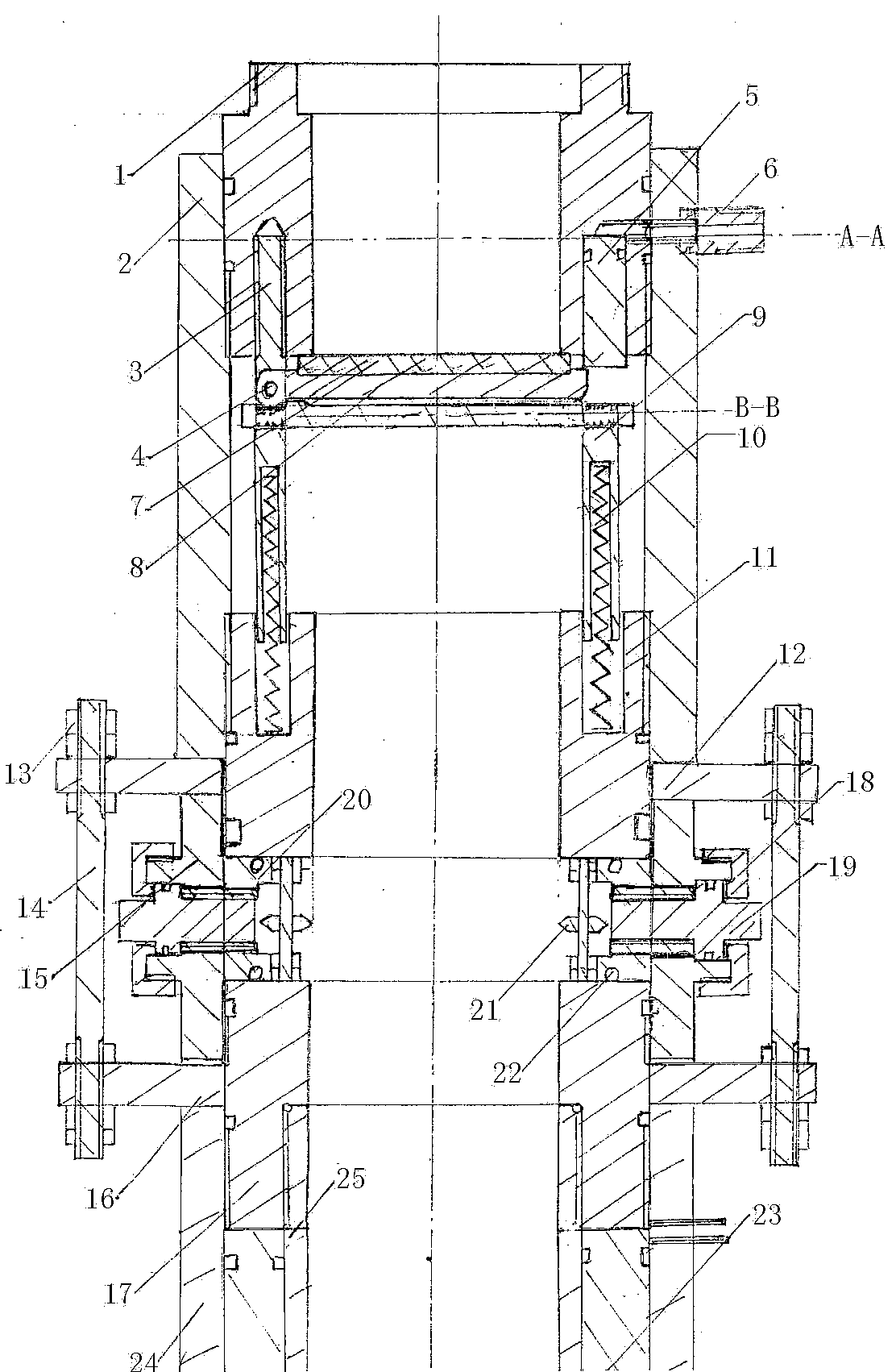

The invention discloses a double-head heating necking method for thick-wall round tubes and a necking device implementing the method. The necking device comprises an automatic control system, a clamping device, heating devices, pressure devices and a material taking device, and the clamping device, the heating devices, the pressure devices and the material taking device are respectively connected with the automatic control system and controlled by the same. The method is simple in work procedure and high in automation degree, and the thick-wall round tubes can be fully automatically and quickly manufactured by the method. The necking device is simple in structure, feeding, heating, necking and discharging procedures are automatically carried out owing to application of mechanical automation, and labor intensity is relieved while production efficiency is greatly improved. In addition, as mold pressing necking processing is adopted, thicker metal wall layers are formed at necking portions under the extrusion effect of a mold, breakage of the necking portions is prevented when the metal tubes are turned, the quality of the products is guaranteed, and competitiveness of an enterprise is strengthened.

Owner:DONGGUAN JIALONG LEATHER MACHIERY

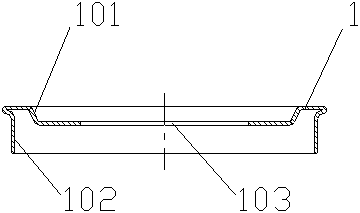

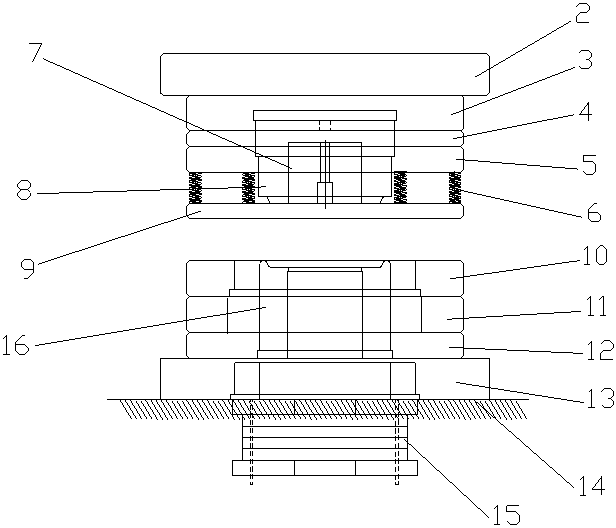

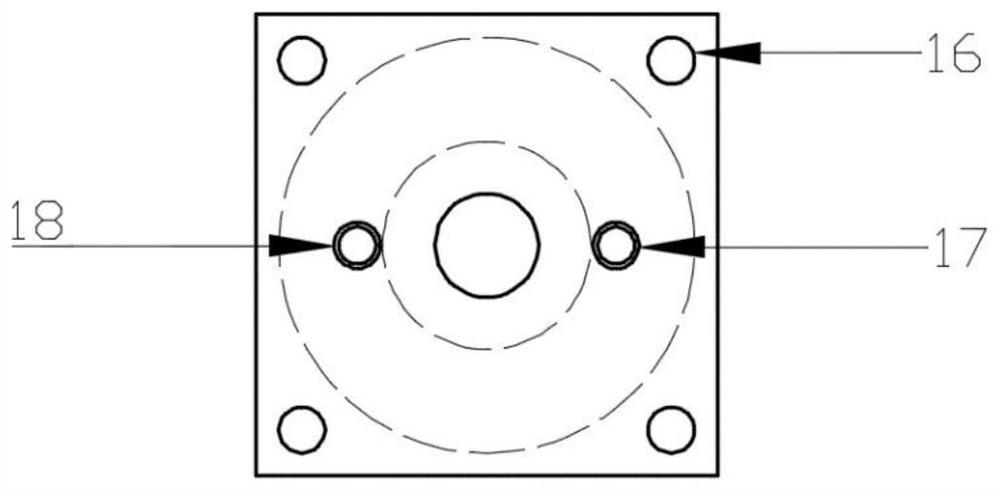

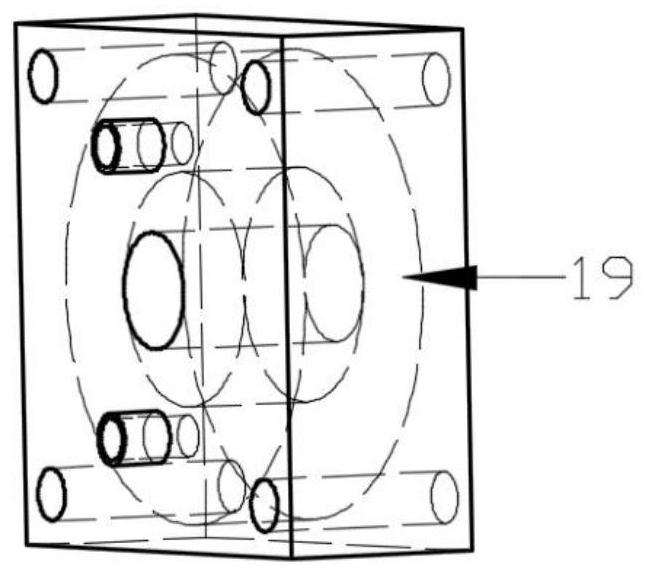

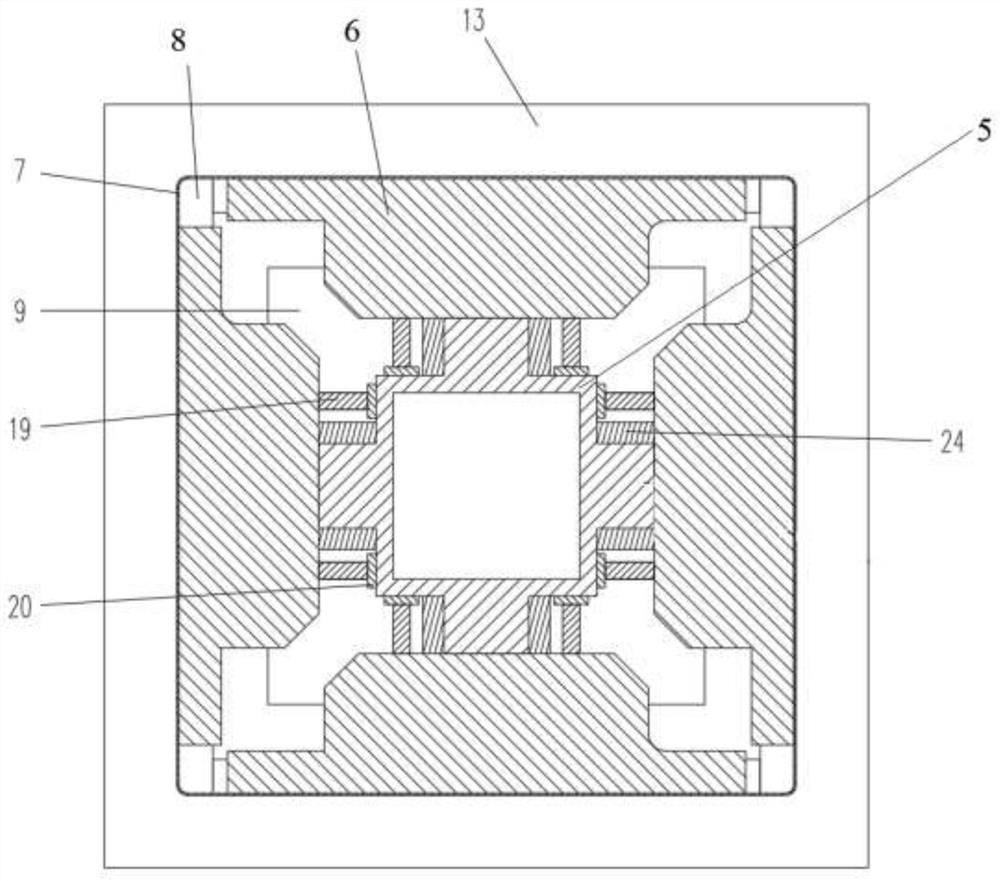

High-necking end cap and machining die thereof

InactiveCN102873226ALarge shrinkagePrecise force controlShaping toolsHollow articlesAdhesiveUltraviolet

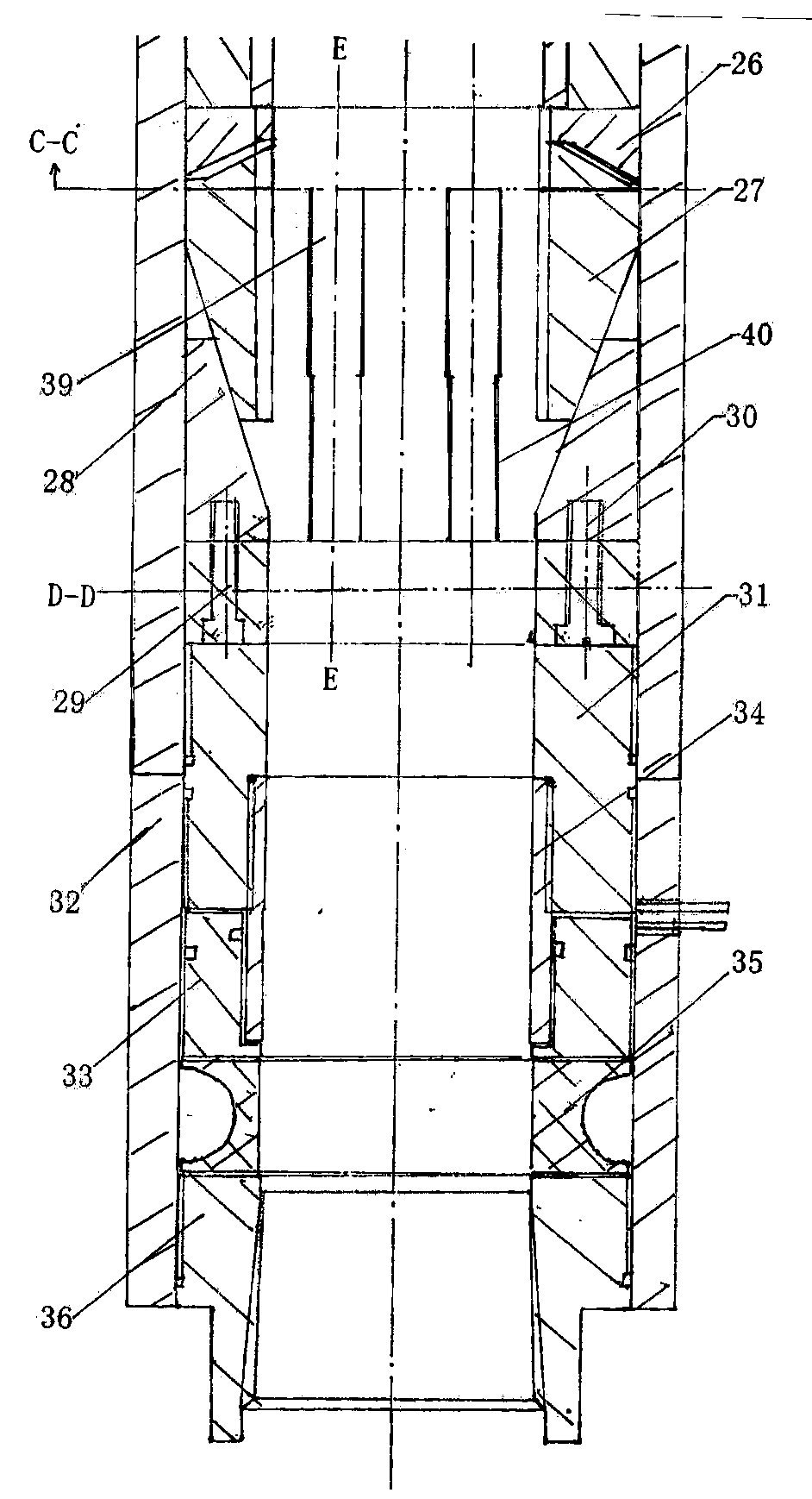

The invention discloses a high-necking end cap and a machining die thereof. The high-necking end cap is provided with a first necking, a second necking and a through hole. The machining die of the high-necking end cap is provided with an upper die holder, an upper die plate, an upper pad, a stop plate, springs, a piercing punch, an upper die drawing punch, a stripper plate, a lower die plate, a lower clamping plate, a lower pad, a lower die holder, a lower table, lower die UV(ultraviolet) adhesives and a lower die drawing punch. The necking quantity of the high-necking end cap is large, and the necking diameter can be larger than the necking quantity. The machining die can be used for completing necking at one step, and the situation of completing necking by multiple steps in the prior art is changed. Spring stress is replaced by elastic UV adhesives on the lower die of the machining die, stress in machining of the high-necking end cap is controlled precisely, the necking size is controlled accurately, excessive machining is avoided, defect of cracking is eliminated, quality of products is stable, production efficiency is high and production cost is low.

Owner:昆山铭佳利电子制品有限公司

Three-way necking machine

InactiveCN111570645APrevent long-term collisionsPrevent burstMetal-working feeding devicesNon-rotating vibration suppressionSilica gelWorkbench

The invention discloses a three-way necking machine. The three-way necking machine structurally comprises a workbench, a power distribution box, a feeder, a necking device, an oil cylinder and an oilpipe. When necking is performed on a three-way pipe, the three-way pipe is horizontally placed on the feeder, the power distribution box is controlled to start the feeder so that the three-way pipe ishorizontally conveyed to the necking device, the pipe is moved towards the interior of a necking pipe to be in tight fit with a buffer device, the three-way pipe is driven to slowly and horizontallyenter the necking pipe, during necking, a stretchable ring is retracted along with the interior of the pipe, the interior of the pipe is buffered, burst caused by sudden necking is avoided, due to thebuffer device, the phenomena that due to the high conveying speed, the surface of the pipe collides with a stop plate inside the device for a long time, the stop plate is sunken, the distance betweenthe stop plate and the necking is enlarged, and the size needed by the butt-joint technology cannot be met are avoided, due to a strip-off device, plated painting remaining on the surface of a silicagel plate is stripped off, and the phenomenon that the buffer effect cannot be achieved due to the fact that elasticity of the silica gel plate is affected when the thickness of the surface of the silica gel plate is increased by long-term stacking is avoided.

Owner:成都佰缇丽贸易有限公司

Tool and method for backfilling deep foundation pit excavation groove

InactiveCN111519681AQuality assuranceSolve the problem of difficult backfillSoil-shifting machines/dredgersArchitectural engineeringNecking

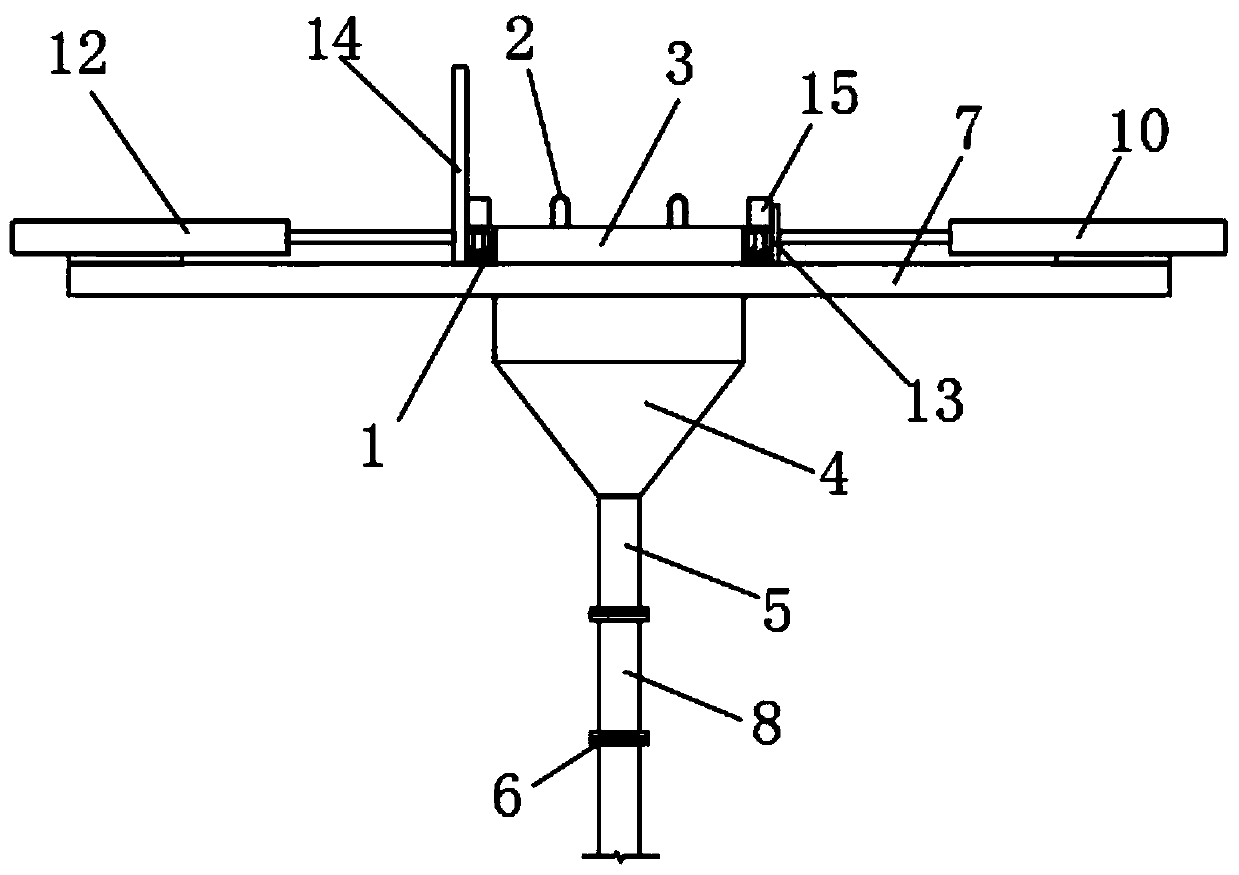

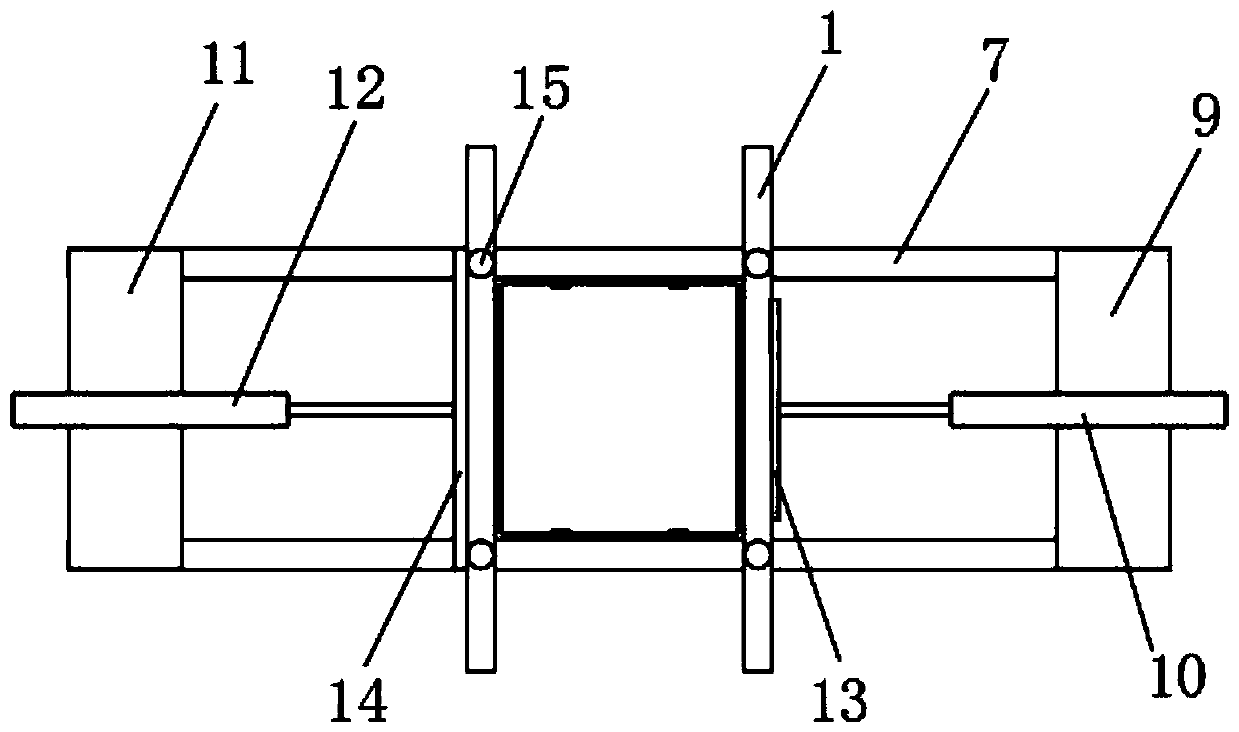

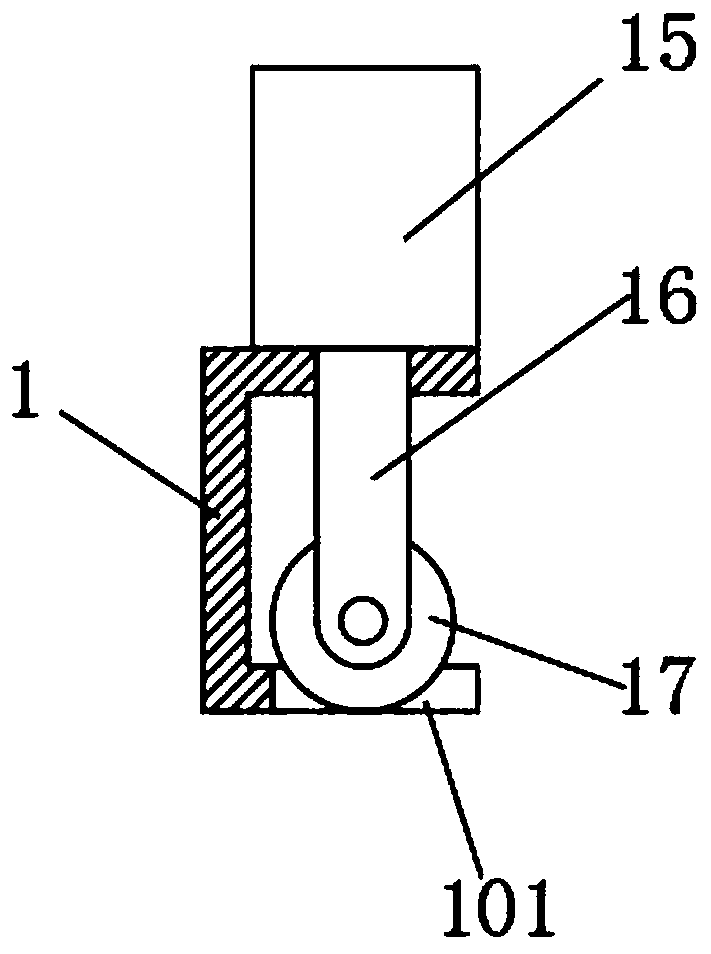

The invention discloses a tool and method for backfilling a deep foundation pit excavation groove. The tool comprises two fixed channel steel which are parallel to each other, and a funnel is arrangedbetween the two fixed channel steel. The funnel comprises a square hopper mouth and necking, a fixed cylinder is fixed to the bottom of the necking by welding, a flange is fixedly installed at the bottom of the fixed cylinder by welding, a plurality of detachable cylinders are arranged at the bottom of the fixed cylinder, and two supporting transverse bars are arranged below the fixed channel steel. A first cylinder is fixed to a first cylinder mounting plate, a first baffle is fixed to the end part of an output rod of the first cylinder, a second cylinder is fixed to a second cylinder mounting plate, and a second baffle is fixed to the end part of an output rod of the second cylinder. According to the tool and method for backfilling the deep foundation pit excavation groove, the cost issaved, the construction period is shortened, the quality of the project and the safety of workers during operation are ensured, safety and stability in the construction process are achieved, and the transportation of the excavation groove backfill tool is facilitated.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH +1

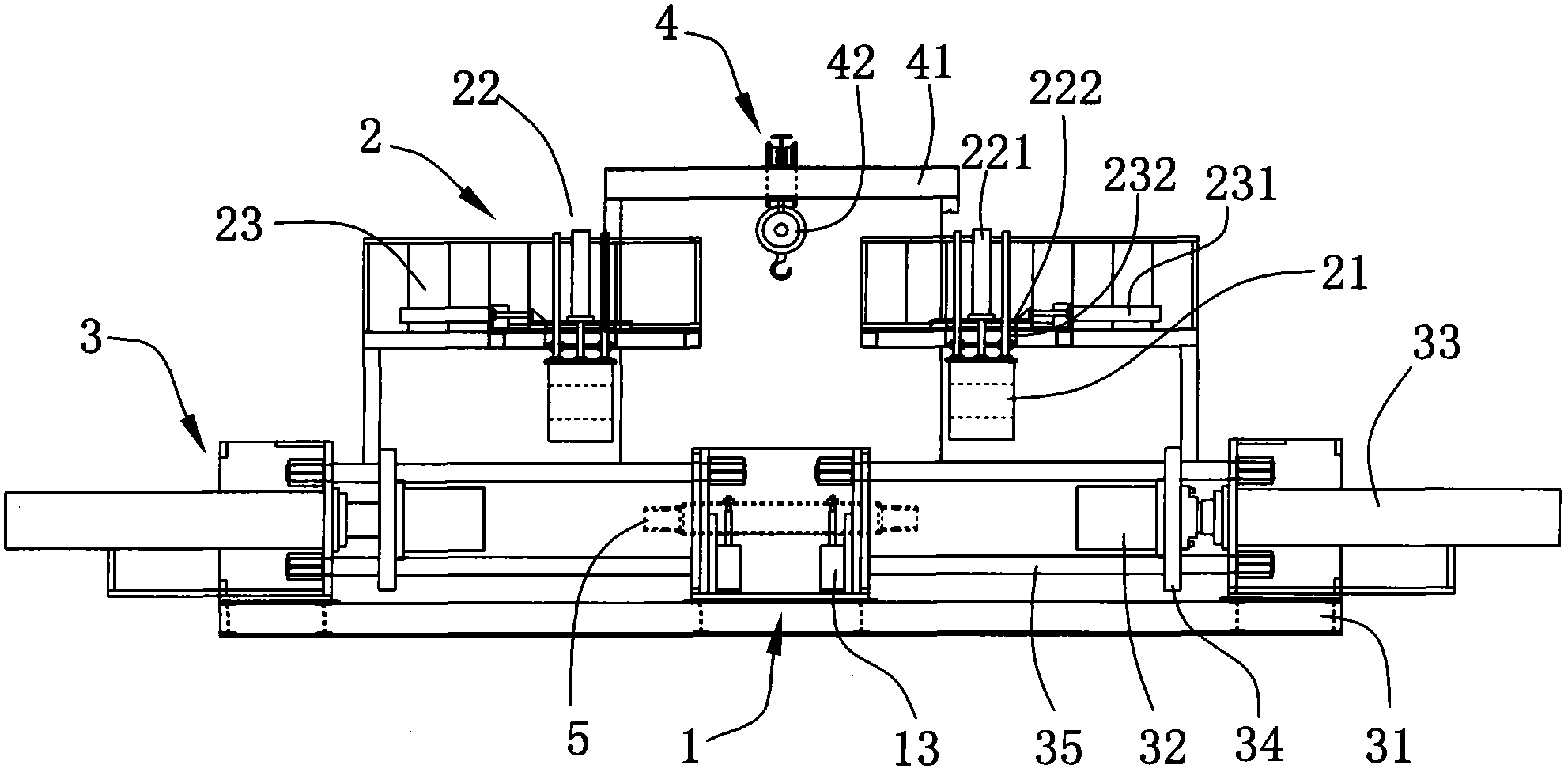

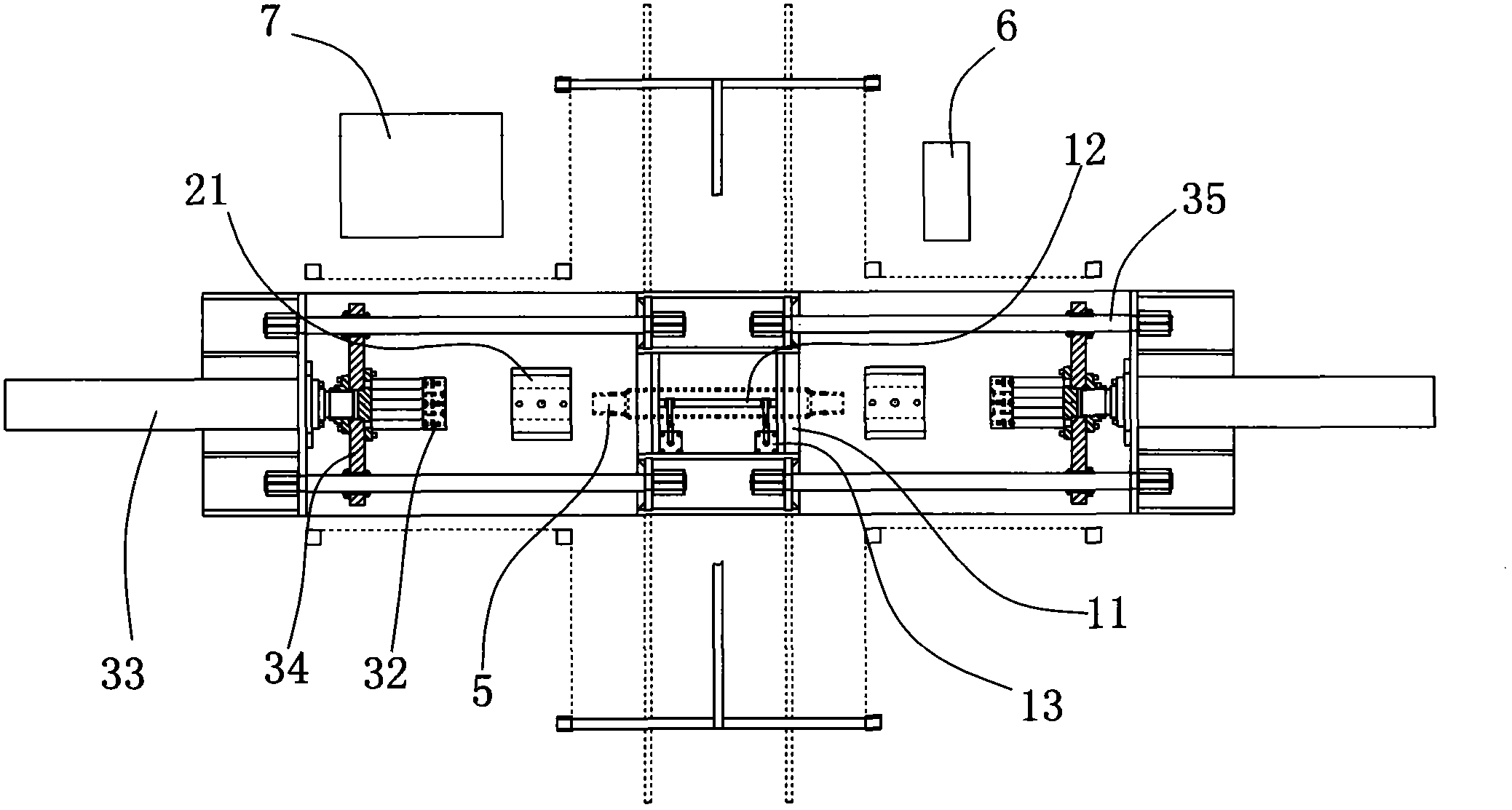

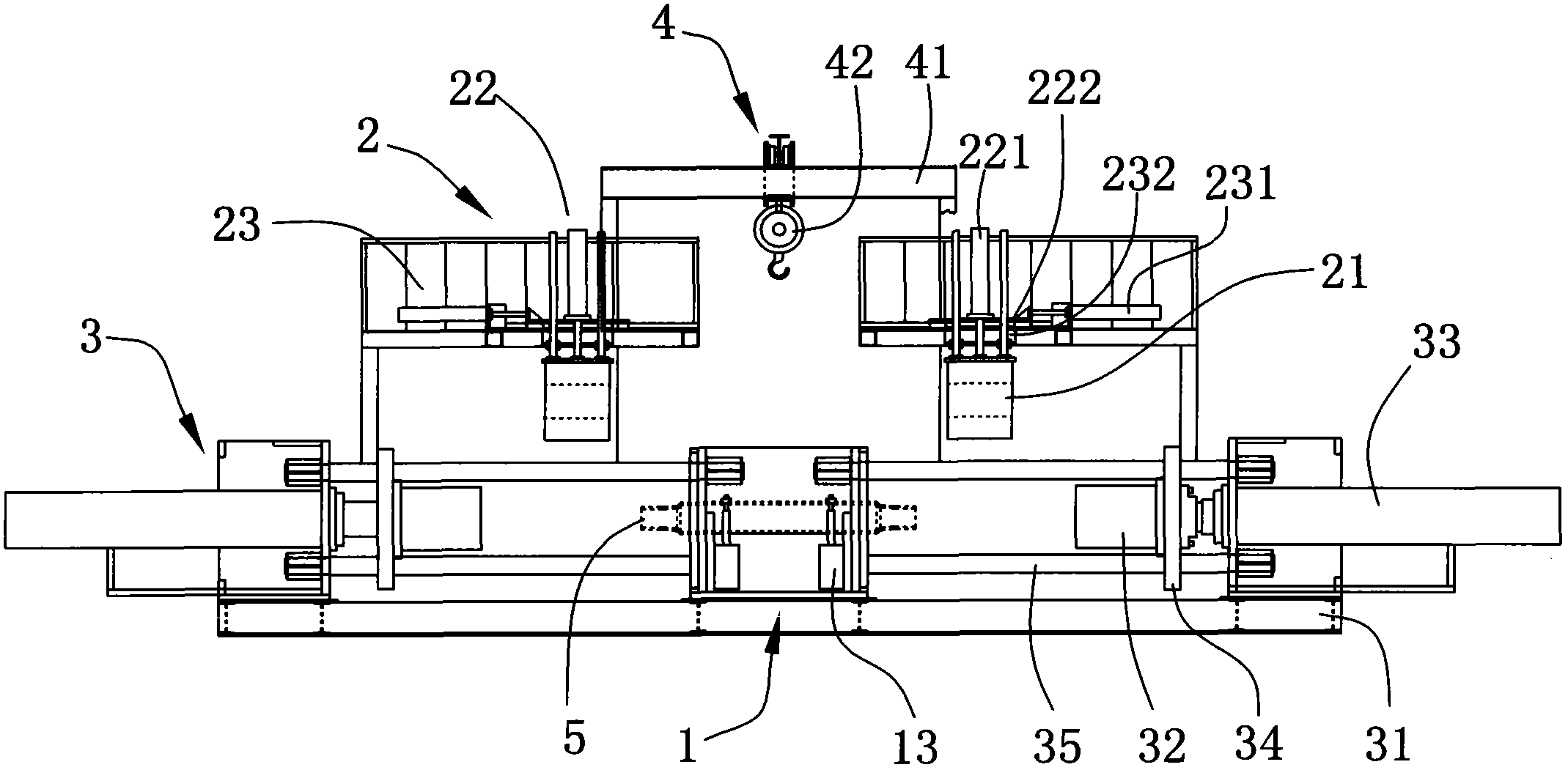

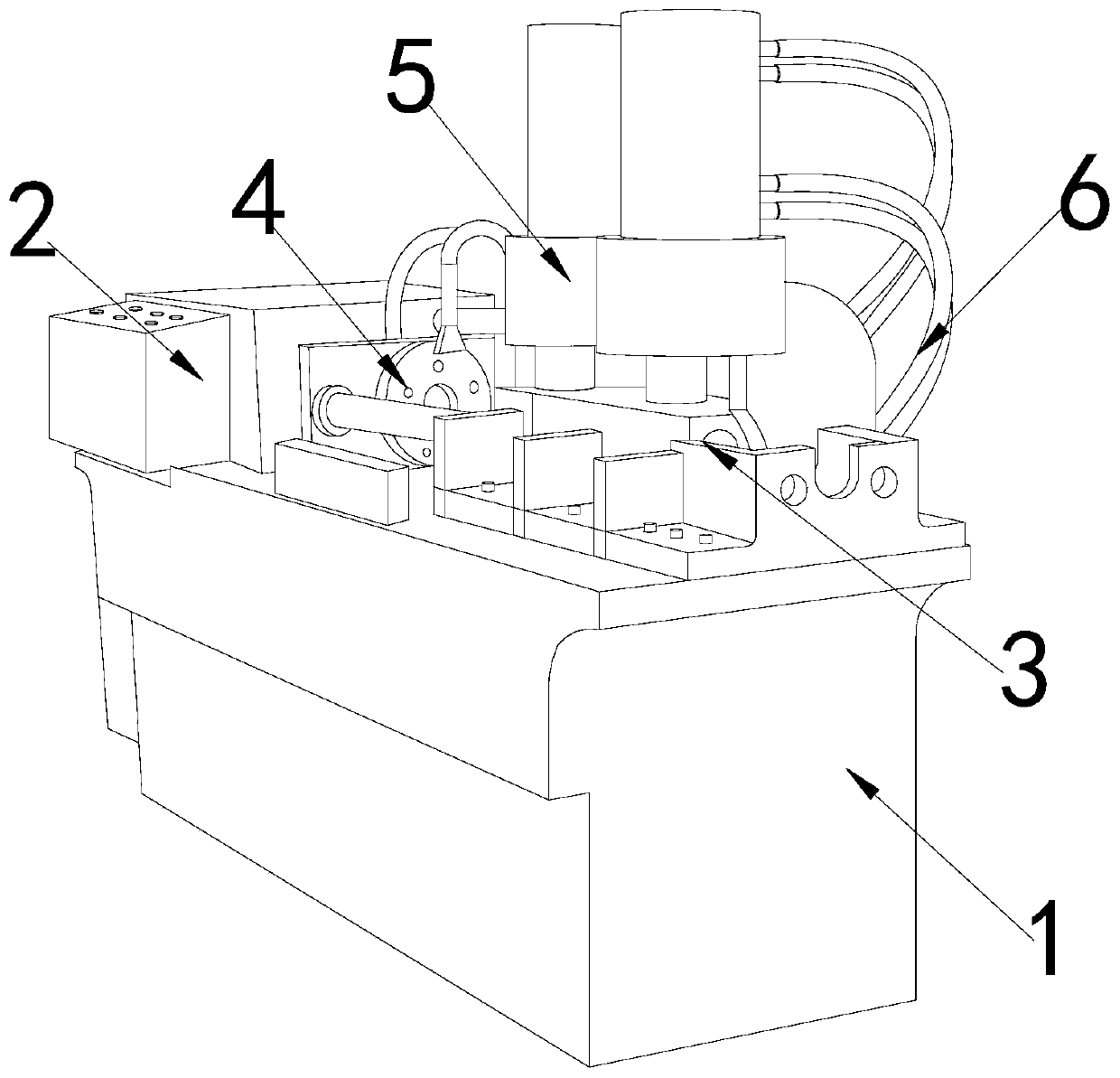

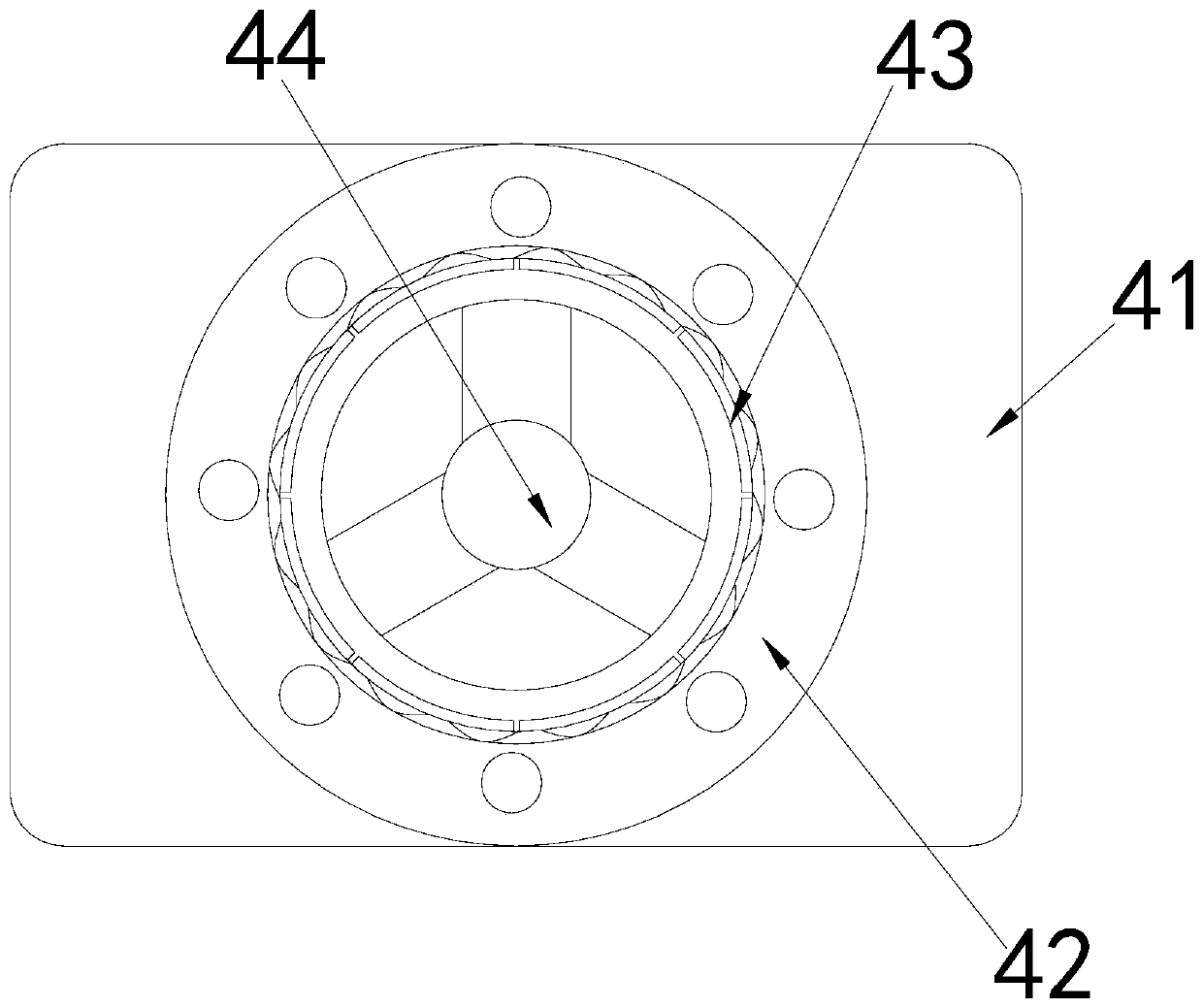

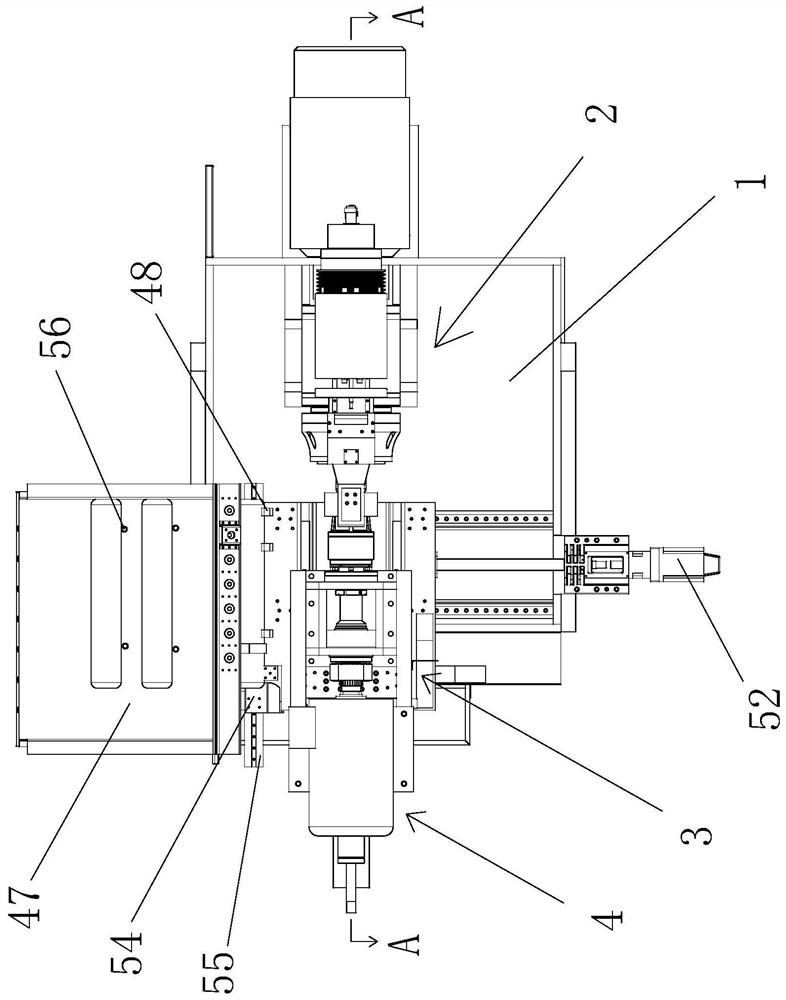

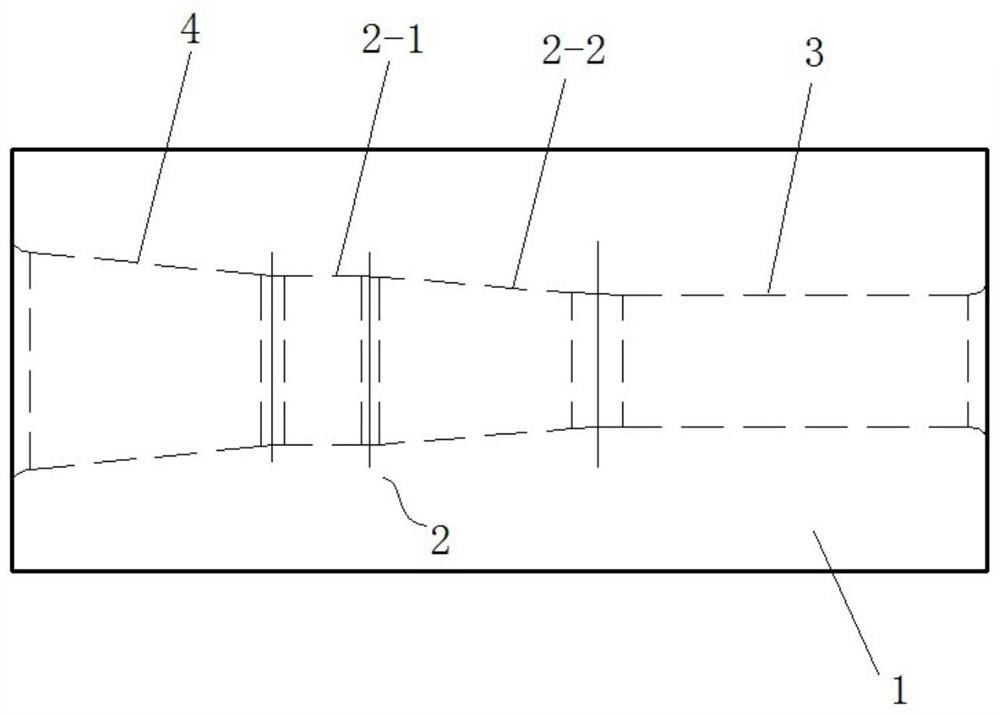

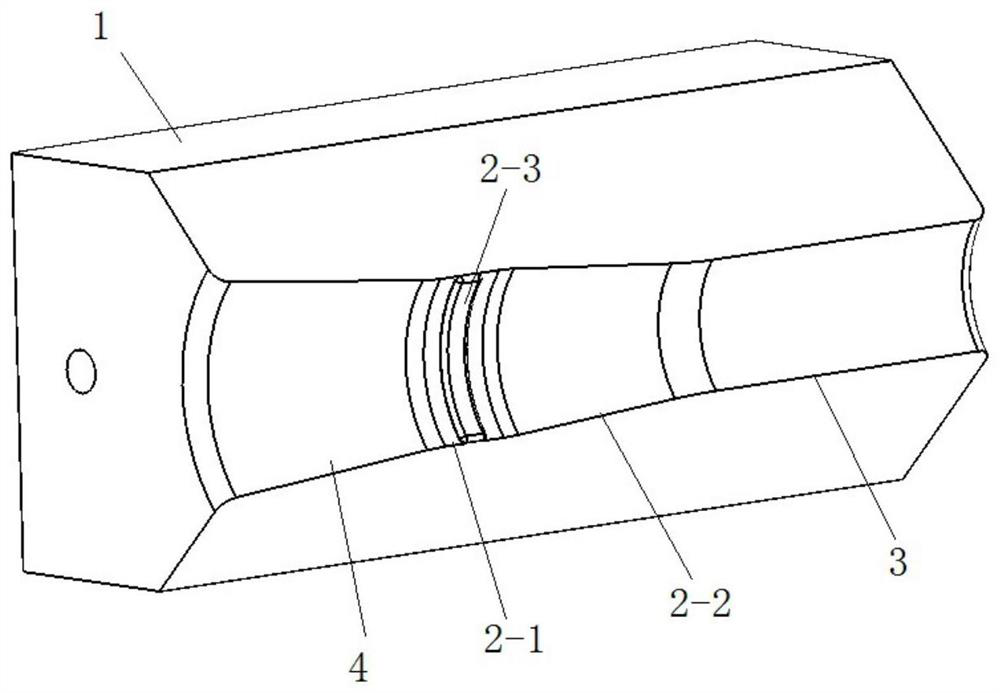

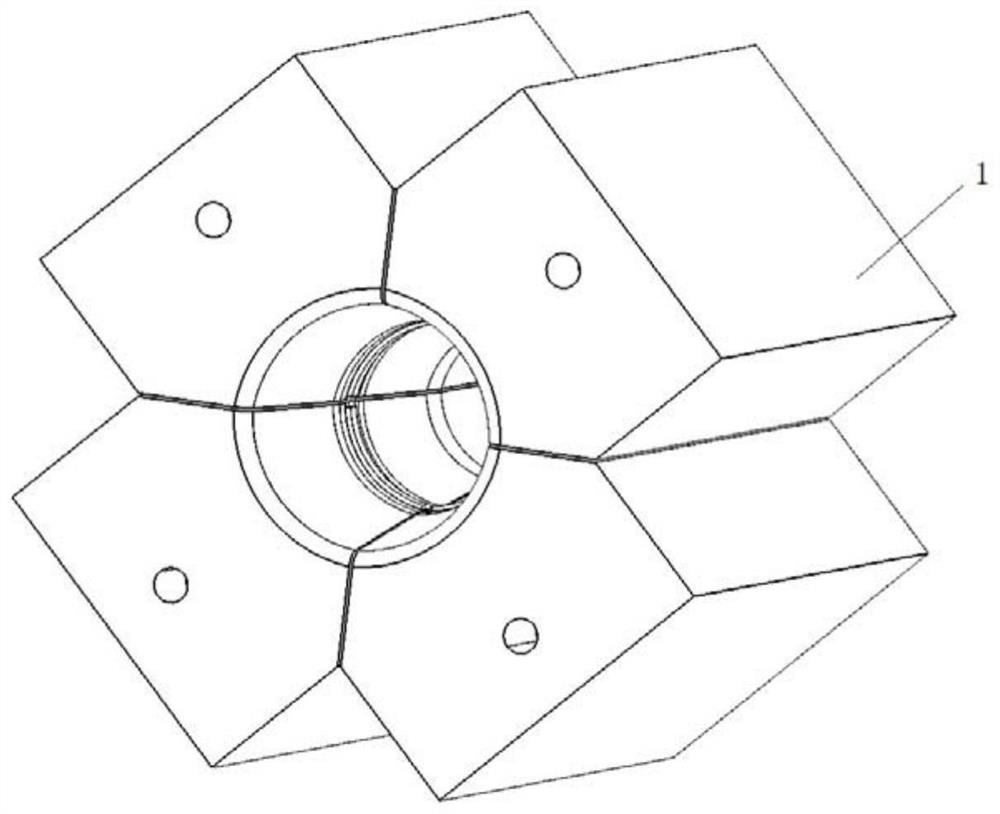

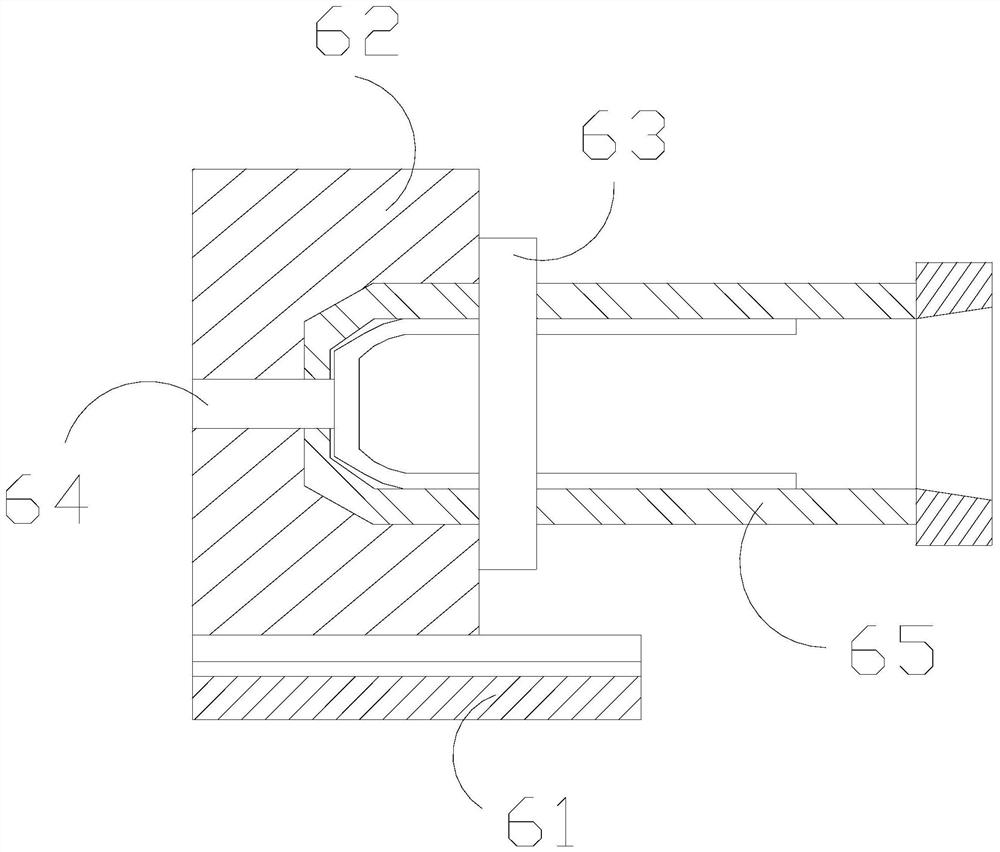

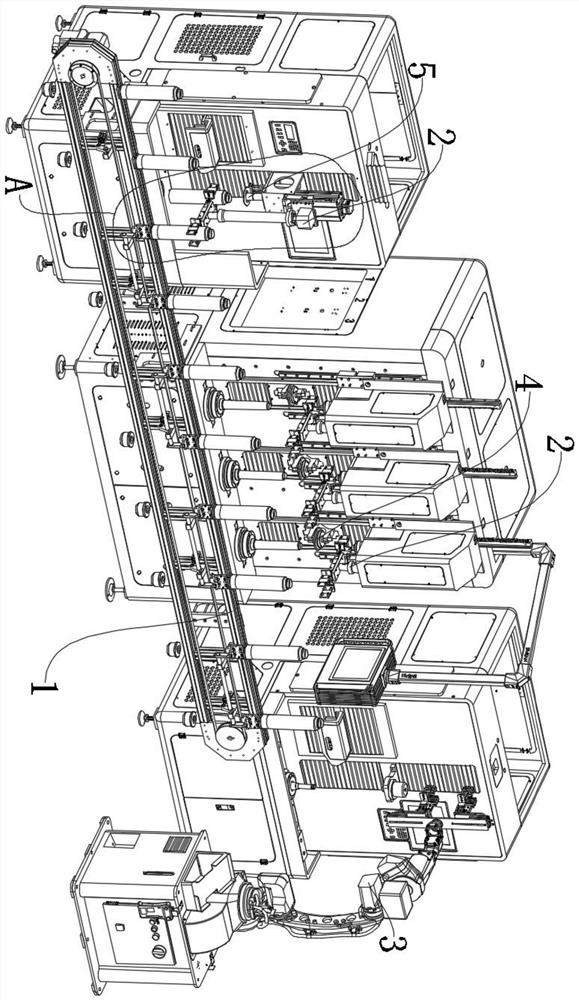

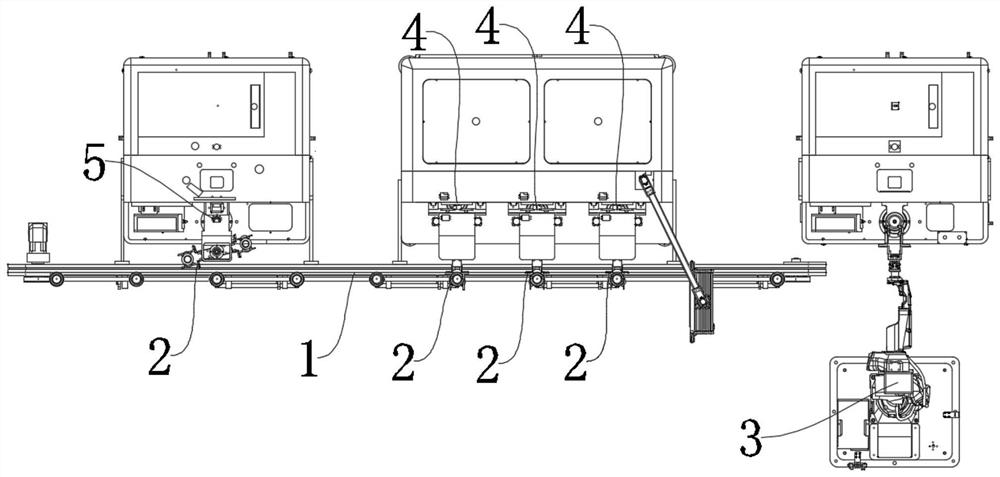

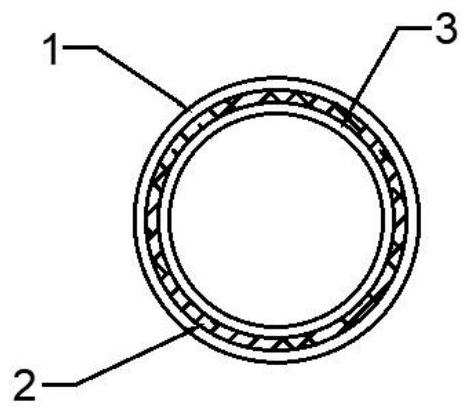

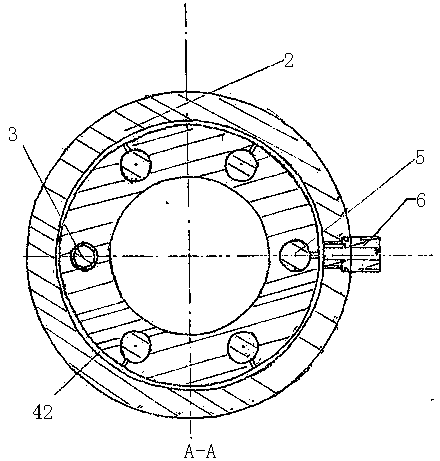

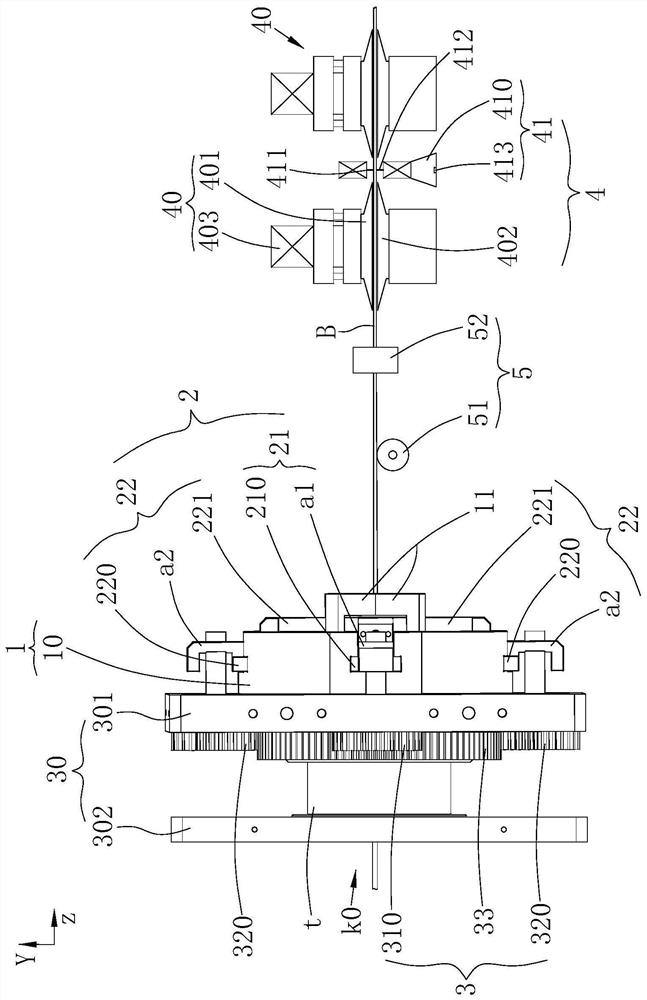

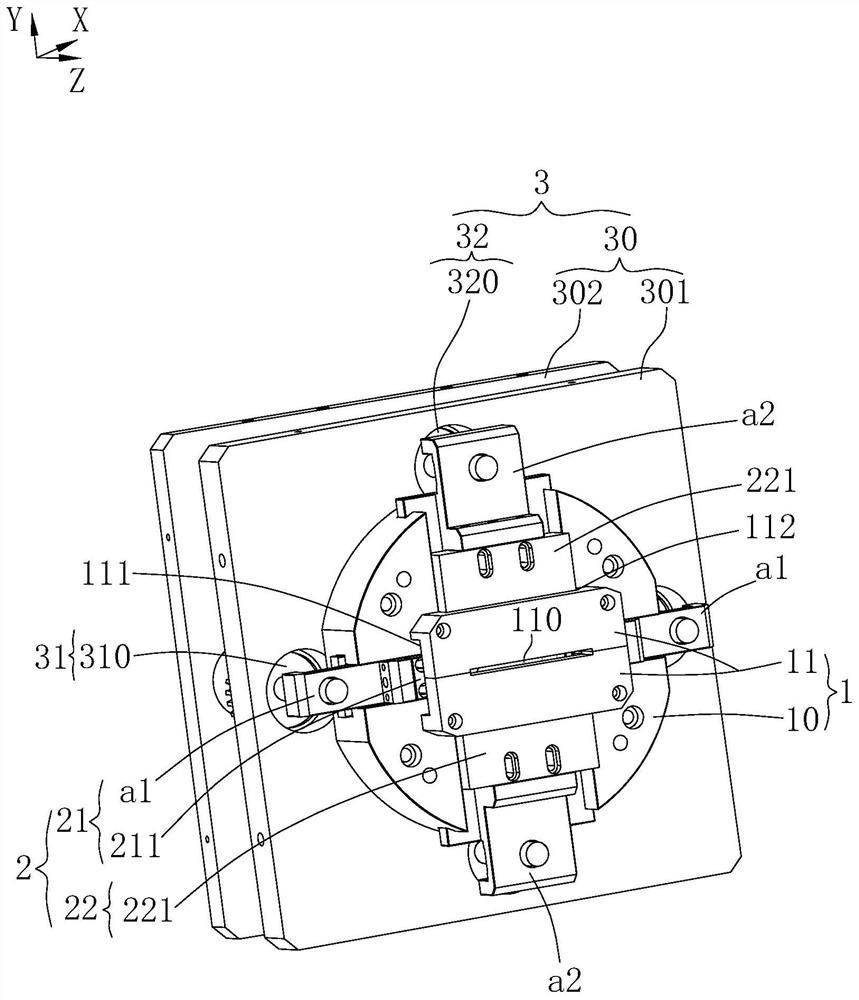

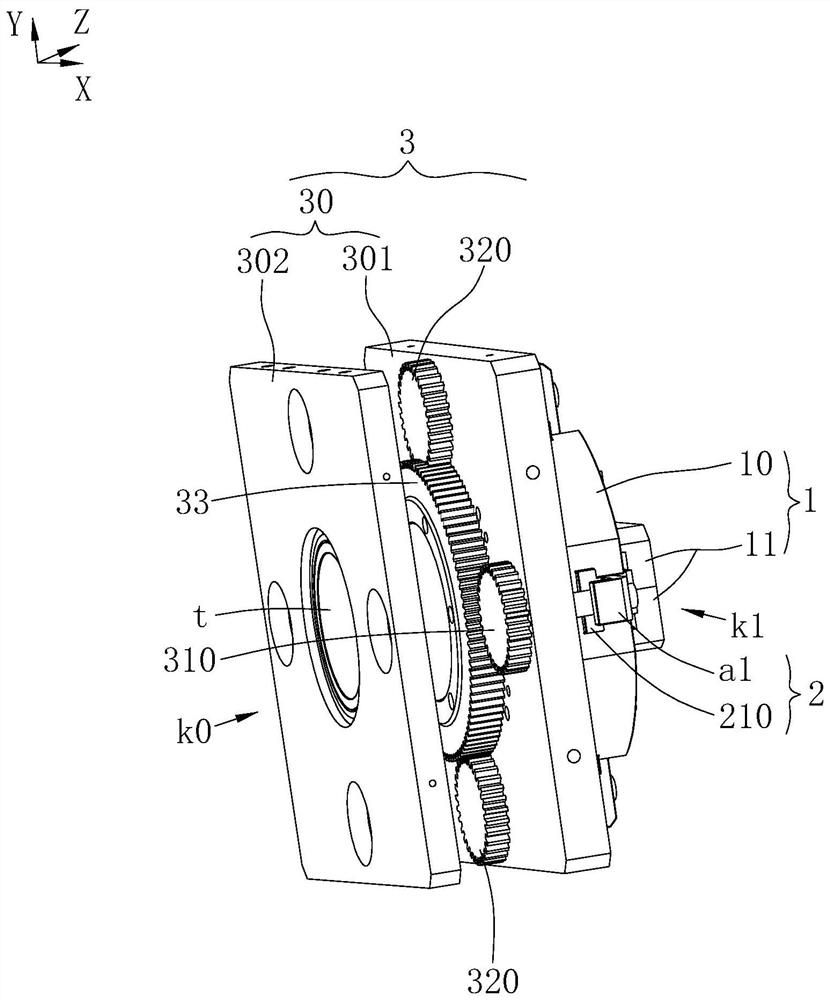

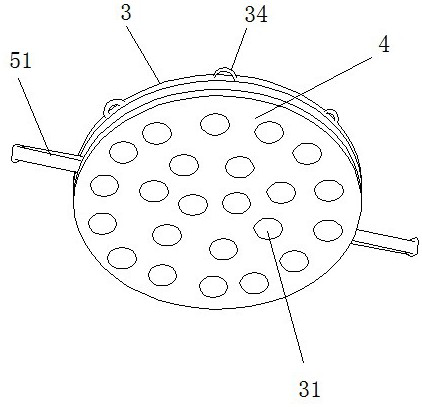

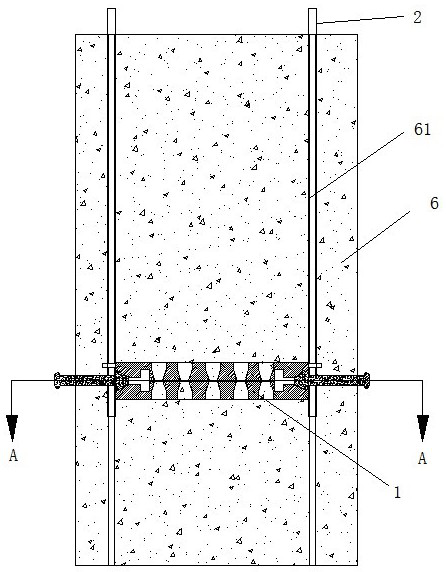

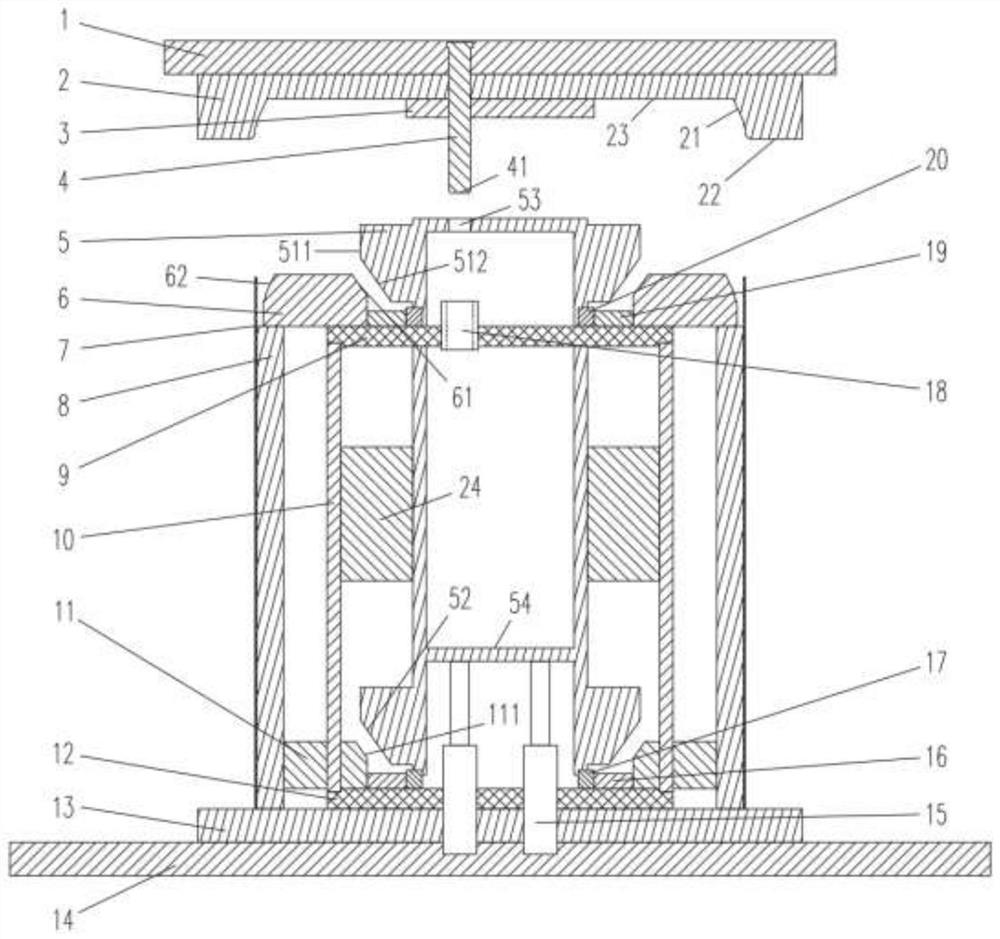

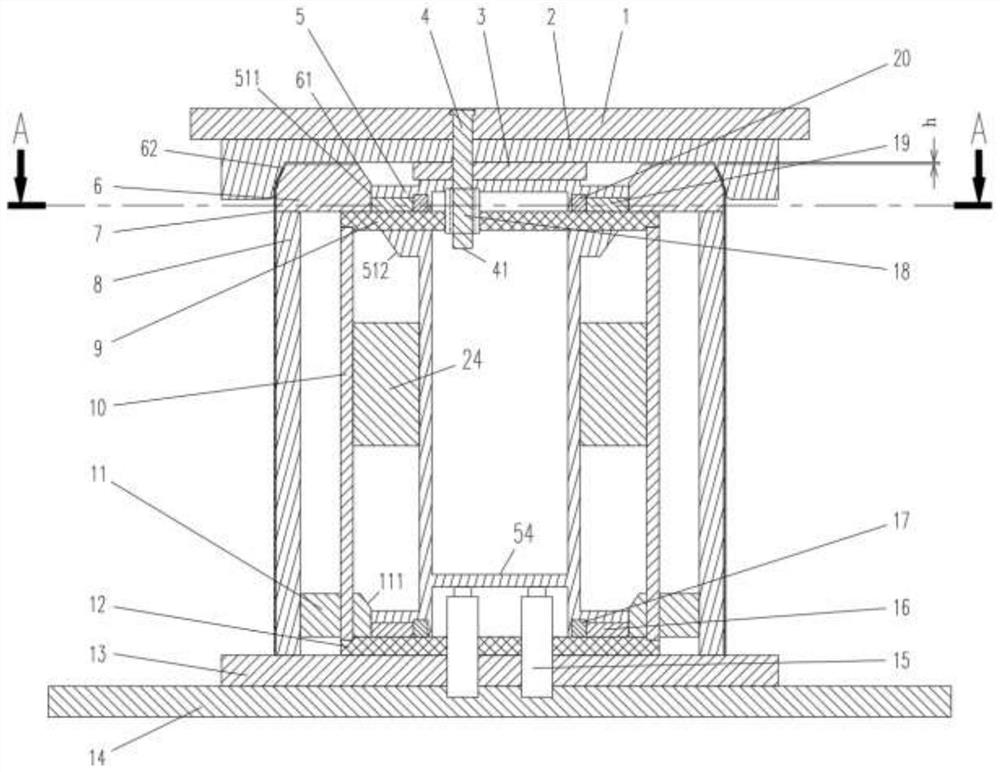

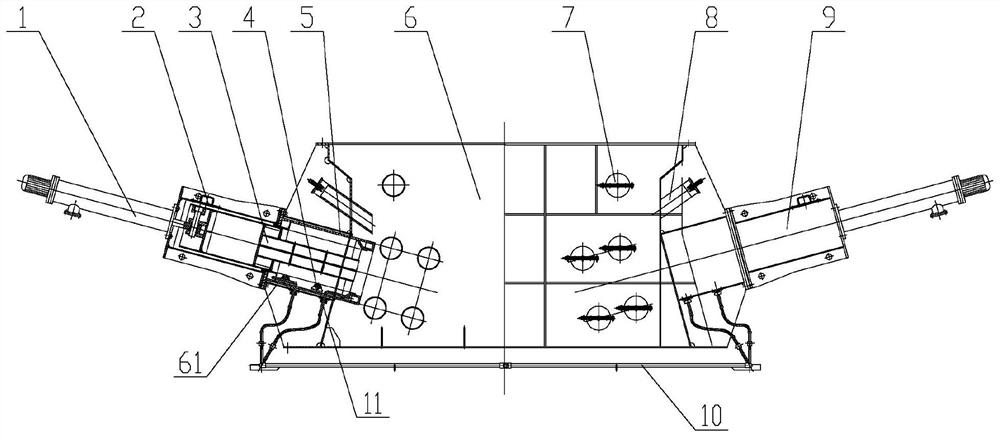

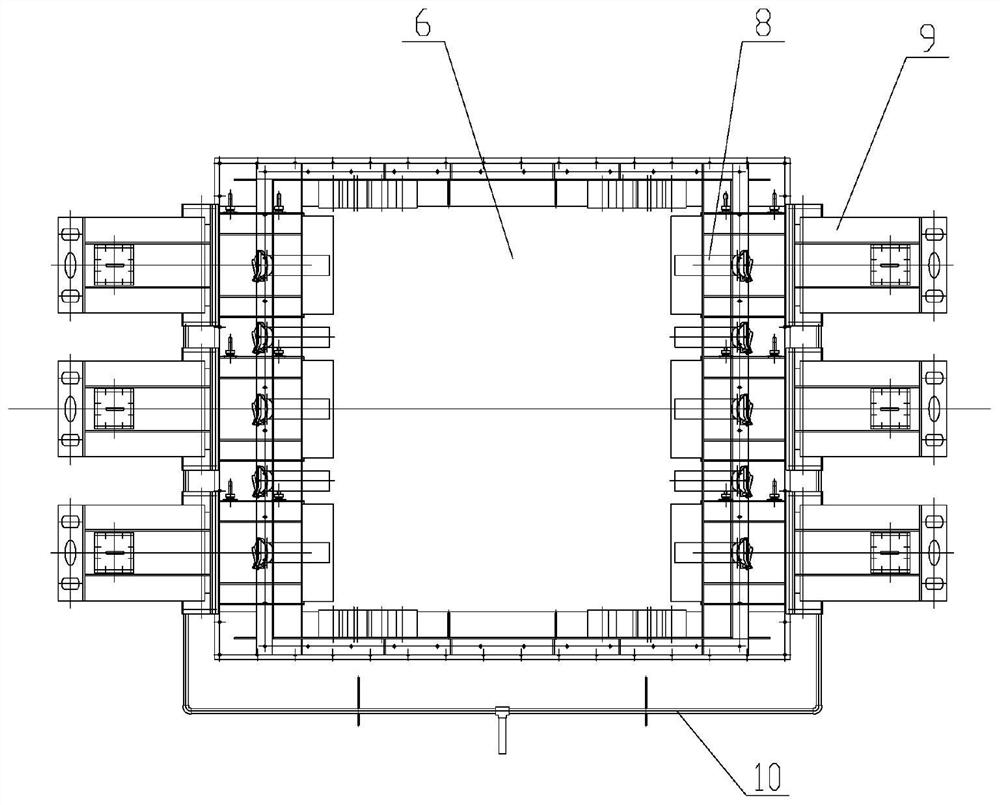

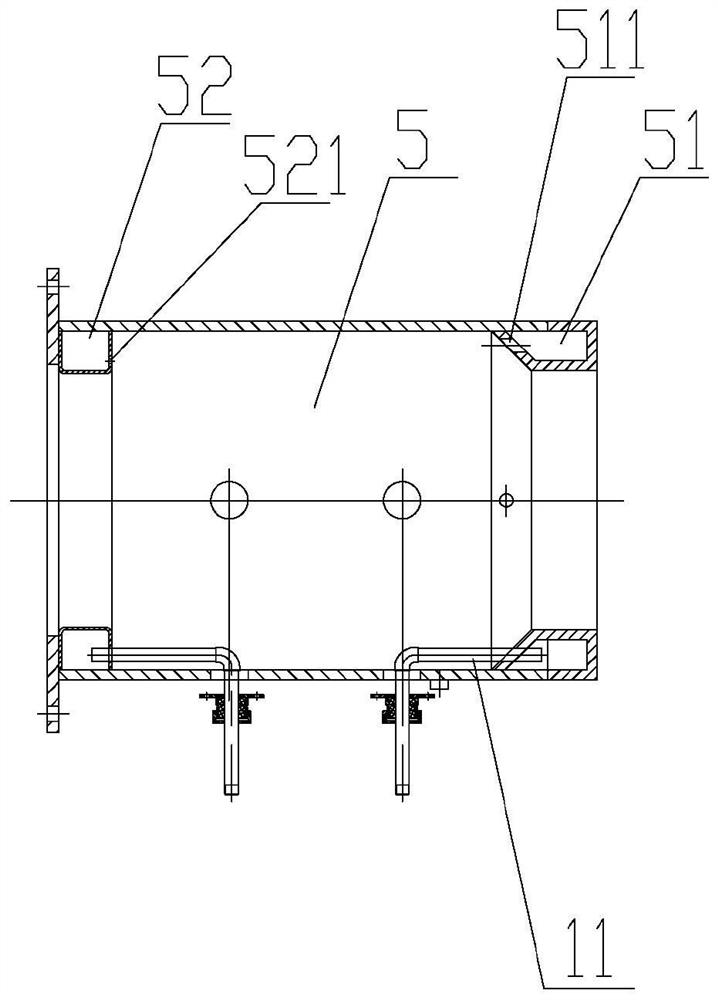

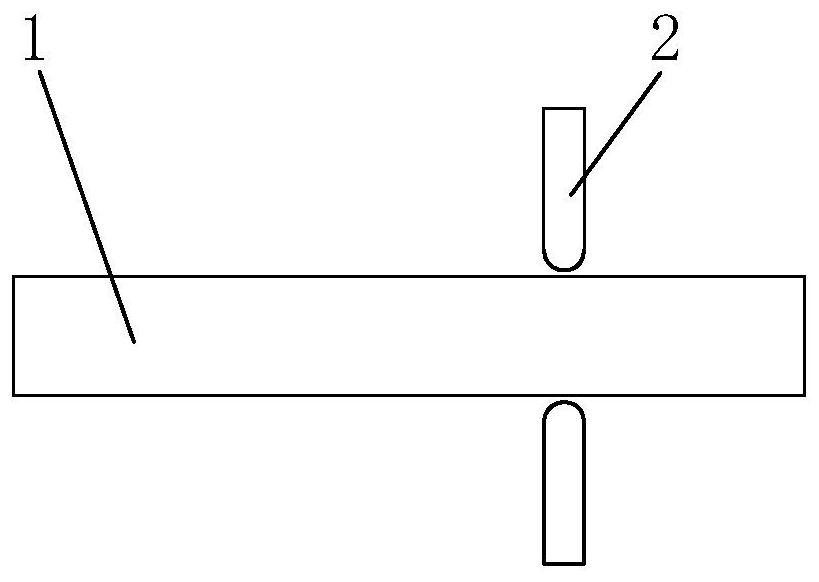

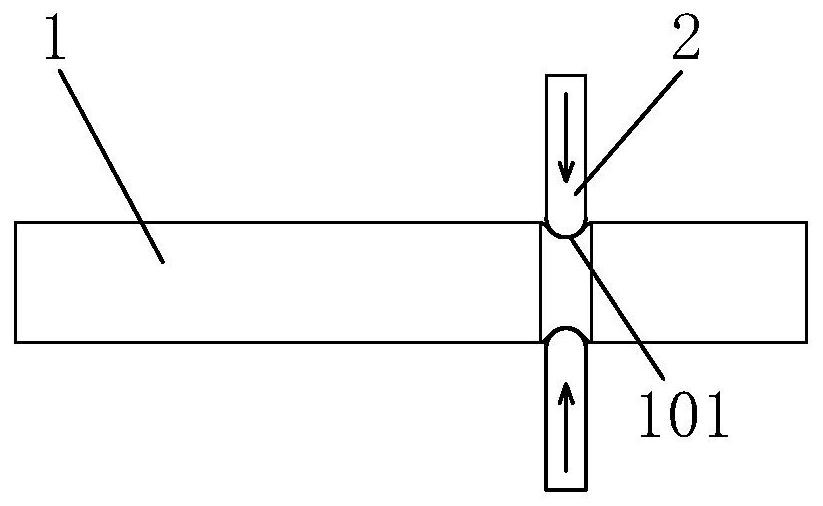

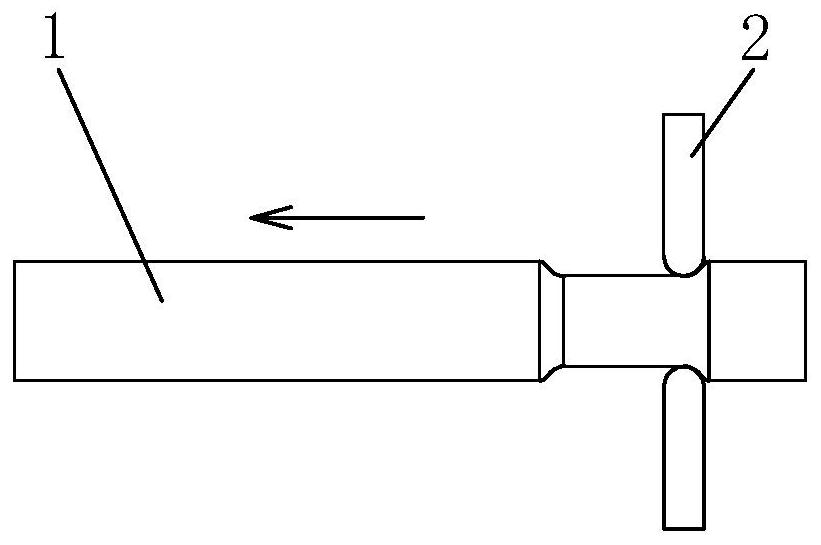

Combined necking and inward turning spinning machine

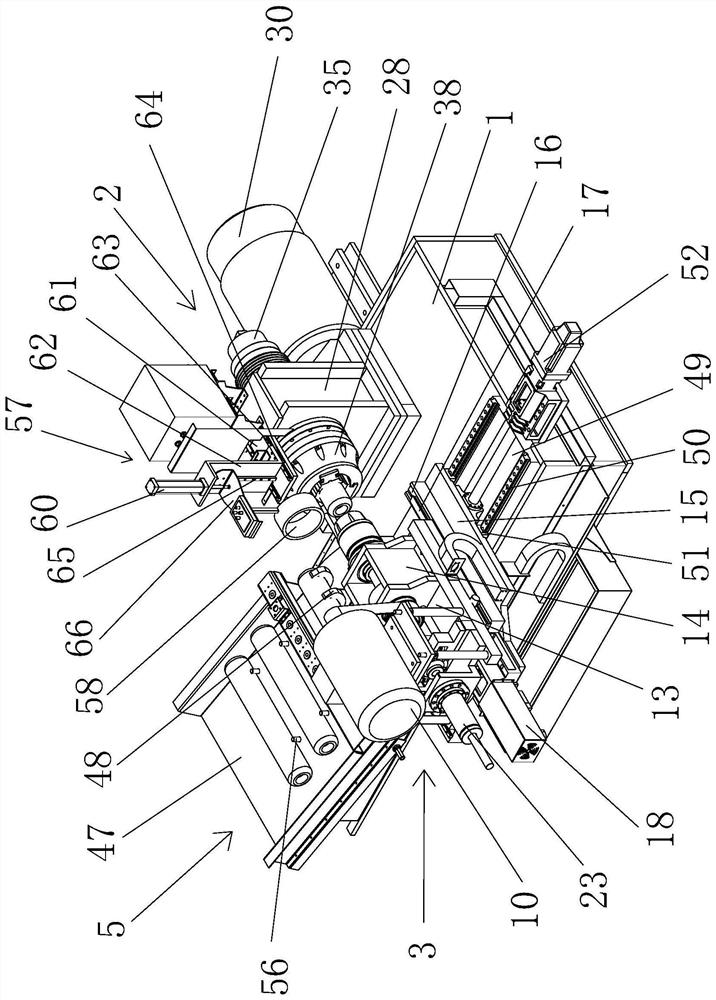

InactiveCN112828116AHigh precisionImprove work efficiencyShaping toolsMetal-working feeding devicesRotational axisSpinning

The invention discloses a combined necking and inward turning spinning machine, and belongs to the technical field of spinning forming. A rack (1) is included, and a workpiece clamping device (2) and a necking, spinning and inward turning device (3) which are opposite to each other are arranged on the rack (1). The necking, spinning and inward turning device (3) comprises a spinning necking mechanism and a spinning and inward turning mechanism, and a first driving device (4) and a second driving device are further arranged on the rack (1). An automatic feeding device (5) is arranged on one side of the necking, spinning and inward turning device (3). A first spinning roller (6) with an arc-shaped groove is adopted to conduct spinning necking on the end portion of one end of a workpiece, a second spinning roller (20) is arranged in a first rotating shaft (8) to conduct spinning and inward turning on the workpiece subjected to necking, necking and inward turning of the end portion of the workpiece are completed in the same spinning machine, the workpiece with a double-layer annular pipeline is machined, the joints of the end portions of the double-layer pipeline are in seamless connection, and the workpiece machining precision and the working efficiency are improved.

Owner:浙江博翔旋压机床有限公司

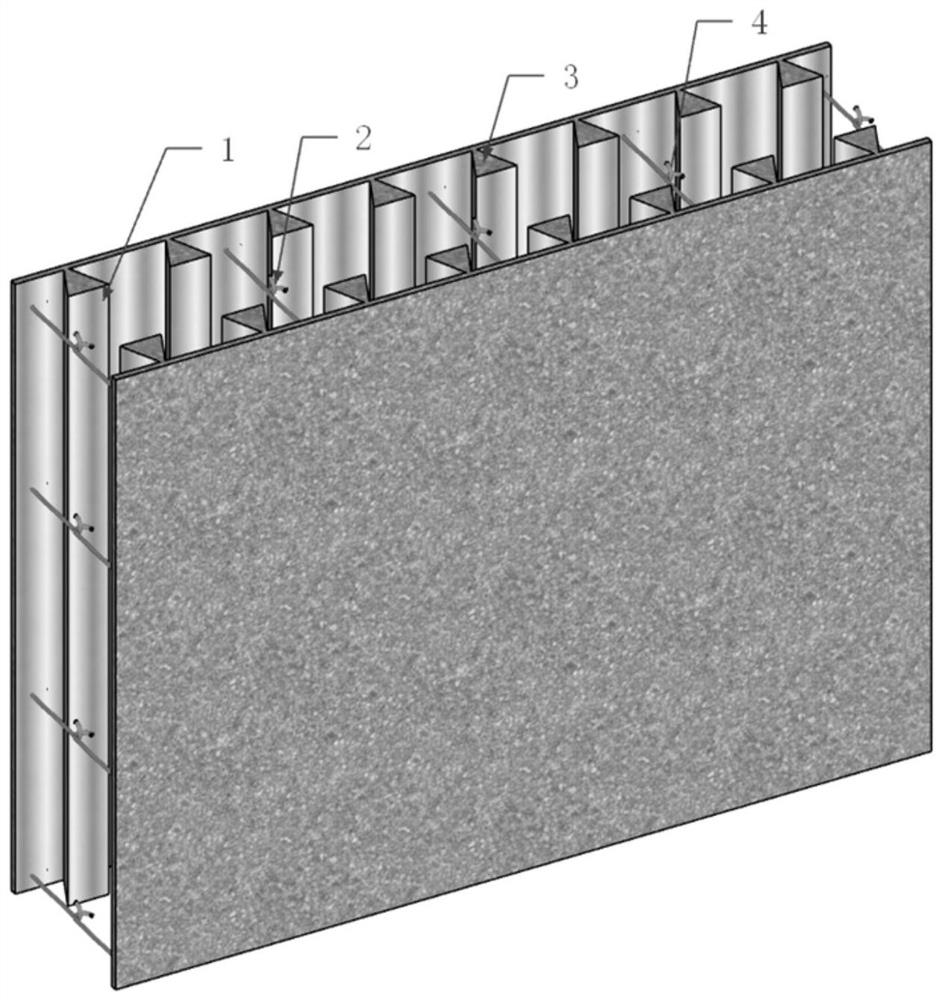

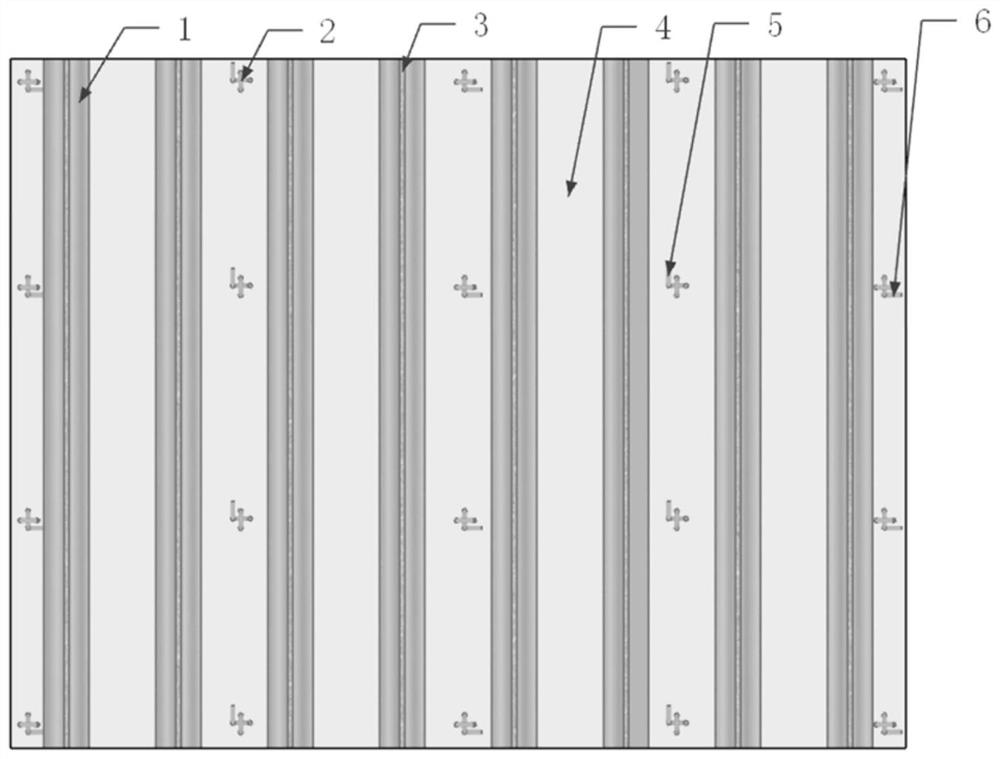

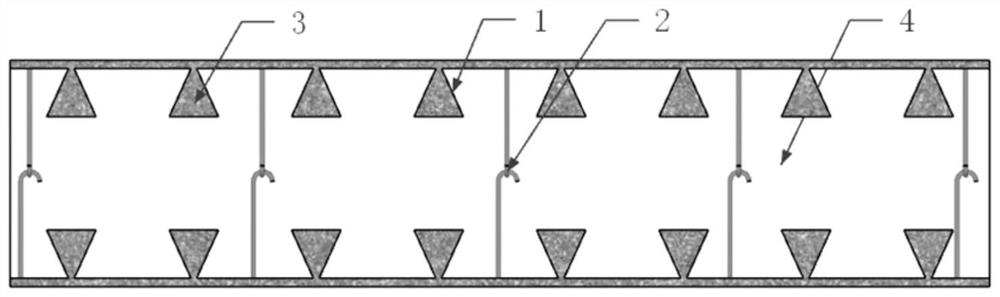

UHPC (Ultra High Performance Concrete)-necking type profiled steel sheet composite template composite shear wall

PendingCN114293688APrevents out-of-plane elastic bucklingWork together wellWallsNeckingTransverse shear

The invention discloses a UHPC (Ultra High Performance Concrete)-necking type profiled steel sheet composite template combined shear wall. The shear wall comprises two necking type profiled steel sheets, the two necking type profiled steel sheets are oppositely distributed, UHPC layers are formed on the outer sides of the two necking type profiled steel sheets in a pouring mode, J-shaped hooks are arranged on the two necking type profiled steel sheets, one ends of the J-shaped hooks are located in the UHPC layers, longitudinal shear keys and transverse shear keys are fixed to the ends of the J-shaped hooks, the other ends of the J-shaped hooks penetrate through the necking type profiled steel sheets, and the longitudinal shear keys and the transverse shear keys are fixed to the UHPC layers. J-shaped hooks are arranged on the two necking-down type profiled steel sheets, the J-shaped hooks on the two necking-down type profiled steel sheets are in one-to-one correspondence, the J-shaped hooks on one necking-down type profiled steel sheet are connected with the corresponding J-shaped hooks on the other necking-down type profiled steel sheet in an opposite pulling mode, and concrete is poured between the two necking-down type profiled steel sheets. And under the action of a horizontal load, the shear failure is not easy to occur.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Metal composite component based on fiber reinforcement and manufacturing method thereof

PendingCN113283037AAvoid neckingAvoid breakingGeometric CADDesign optimisation/simulationMetallic materialsNecking

The invention discloses a metal composite component based on fiber reinforcement and a manufacturing method thereof. The metal composite component comprises a metal matrix, the metal matrix is provided with a plurality of grooves forming a preset angle with the horizontal direction, and the plurality of grooves are filled with a fiber material. According to the invention, based on the characteristics that the deformation at the necking position of the metal material is increased but the tensile bearing capacity is reduced, and the bearing capacity of the fiber material is increased along with the increase of the tensile deformation, the fiber material in the plurality of grooves with the preset angle and the metal jointly bear the tensile force. At a necking generation part, the reduction of the bearing capacity of the metal material is made up by enhancing the bearing capacity of the fiber material, so that the necking is avoided or necking at multiple parts is avoided, the metal composite component is prevented from being fractured due to local necking at one position, and the deformability of the metal composite component is improved.

Owner:SHENZHEN UNIV

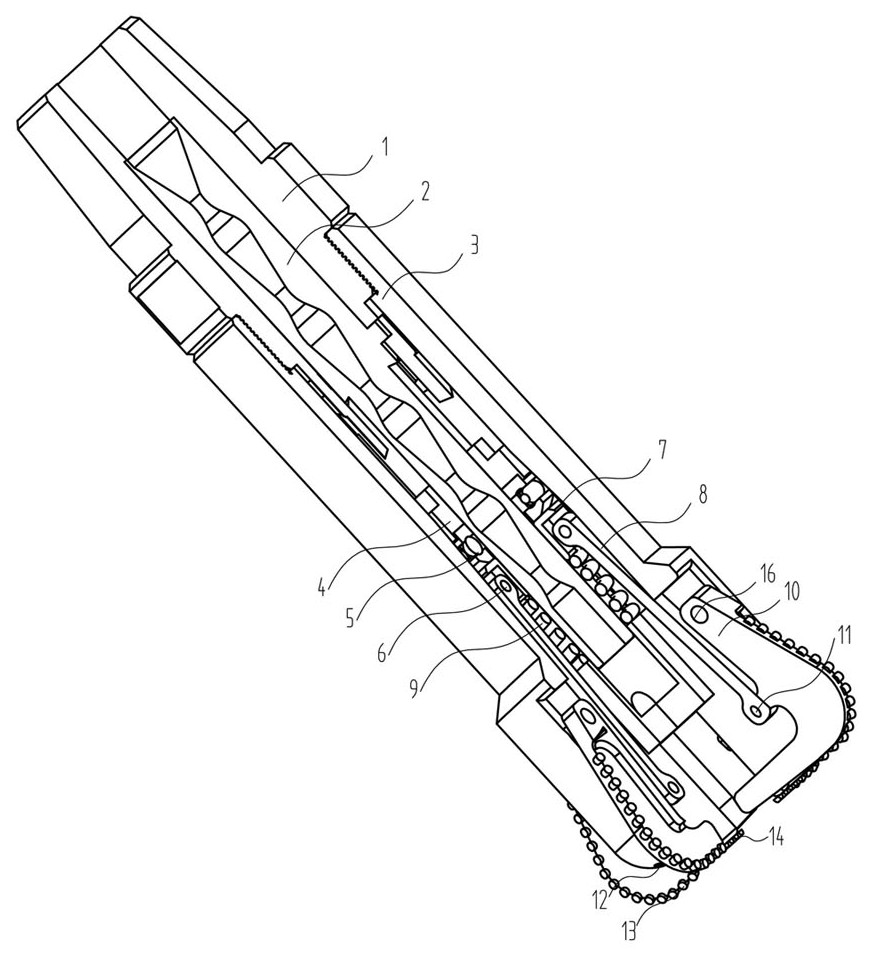

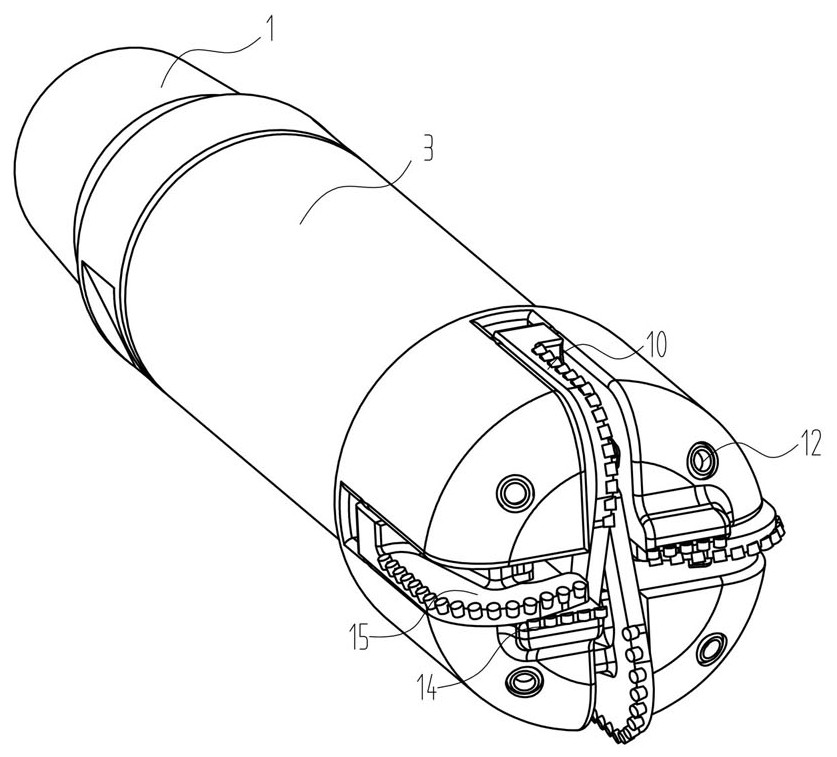

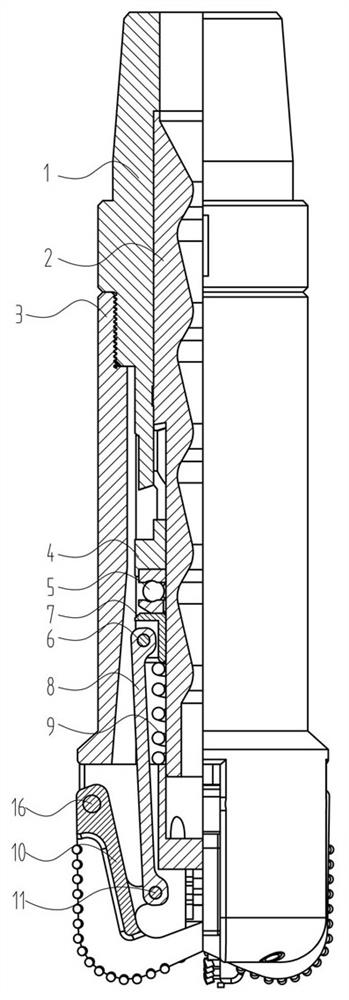

Controllable variable-diameter drill bit

The invention discloses a controllable variable-diameter drill bit. The controllable variable-diameter drill bit is mainly composed of an upper connector, a drill body, combined blades, a pressurizingsliding sleeve, a self-locking mechanism and a telescopic mechanism. The upper connector is connected with the drill body, the telescopic combined blades and a drill bit water hole are formed in thelower part of the drill body, the pressurizing sliding sleeve is arranged in the drill bit, a locking sliding sleeve used for self-locking is arranged below the pressurizing sliding sleeve, and a thrust bearing and a spring are arranged below the locking sliding sleeve. According to the controllable variable-diameter drill bit, the expansion and contraction of the combined blades and the self-locking of the combined blades are controlled by controlling the flow of drilling fluid, and the diameter can be continuously changed, so that the drill bit running into a small casing drills out a largeborehole; and the reasonable annular gap of well cementation is ensured, the problems of drill bit jamming caused by water absorption necking or plastic necking during drilling of a stratum prone to necking and the working stability of the blades after diameter variation of the drill bit are solved, so that production time efficiency is improved, and drilling cost is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

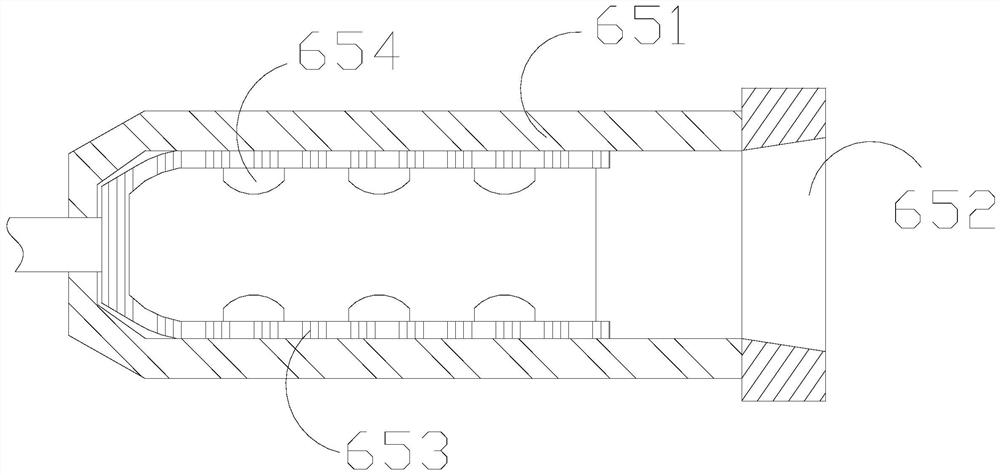

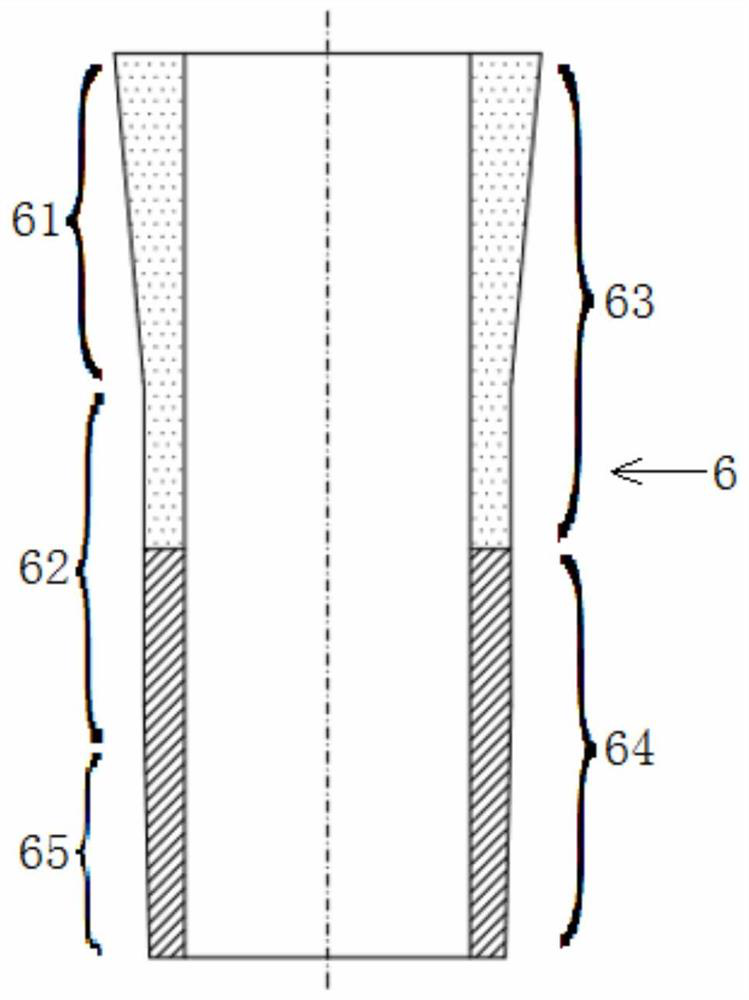

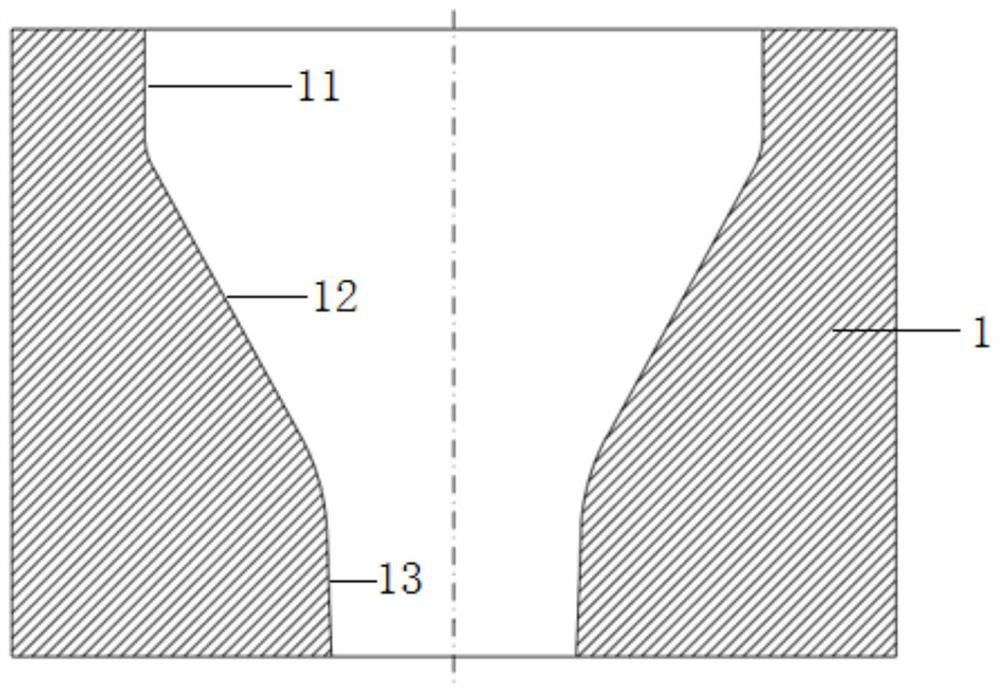

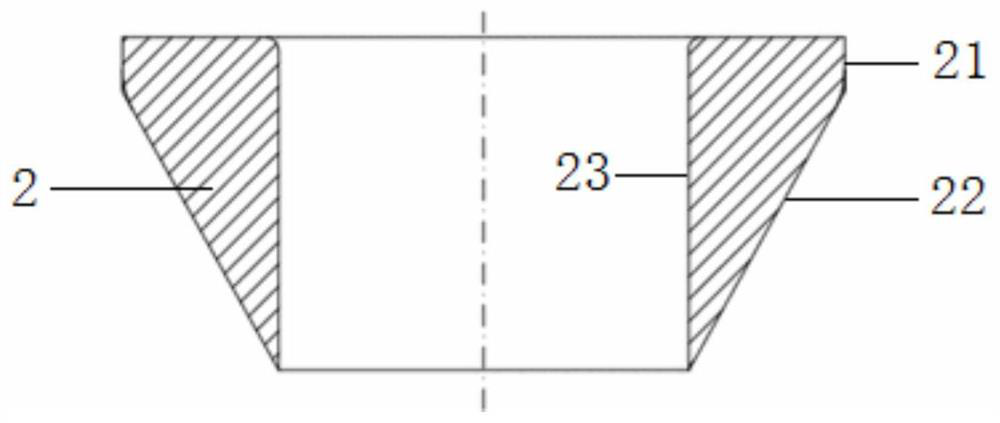

Necking die

The invention relates to the technical field of pipe spinning necking, in particular to a necking die. The necking die comprises a die body, and the die body is internally provided with a die hole; the die hole comprises a sizing part and a necking part; the necking part is provided with a large-diameter end and a small-diameter end; the sizing part and the necking part communicate and are coaxially arranged, and the sizing part is matched with the small-diameter end of the necking part; and the necking part is provided with at least one protrusion. By arranging the at least one protrusion onthe necking part, when smooth pipe sections located at the two ends of an inner pipe and a lining pipe are subjected to necking, concave grooves corresponding to the protrusions in depth are generatedon the surfaces of the smooth pipe sections, it is ensured that the lining pipe and necking parts of at the two ends of the inner pipe after machining are not loosened, and accordingly, the inner pipe and the lining pipe are fixed.

Owner:HANGZHOU SHENSHI ENERGY CONSERVATION TECH

Square pipe joint necking machine

The invention discloses a square pipe joint necking machine. The square pipe joint necking machine is structurally provided with a machine body, a control door, a motor, an adjusting table, a pressingframe, a necking device and a rear driving table, wherein in a clamping process for a pipe joint, an extrusion force is exerted on an elastic ejection device, an ejection body retracts towards the interior of a side ring cavity, and the pipe joint to be necked can make contact with a square necking die conveniently; the elastic ejection device is not subjected to the extrusion force of the pipe joint, and is ejected to the front side end of the square necking die while carrying out concave bending deformation under the springing of spring steel, so that residual chippings are sprung and ejected off, the chippings are prevented from being adhered and accumulated on the wall surface of the square necking die, and after the chippings are ejected off, the necking body is rotated, and the chippings are thrown to a contact port; and a one-way door is extruded to be opened towards the interior of an inner groove chamber, the chippings fall into the inner groove chamber and are collected, then the chippings fall into the bottom of the inner groove chamber through holes in a middle clamping plate and are firmly stuck by a bottom sticking strip, and therefore the situation that in the rotating process, the one-way door is continuously opened and closed, and the chippings fall out is avoided.

Owner:北京亮祥教育咨询有限公司

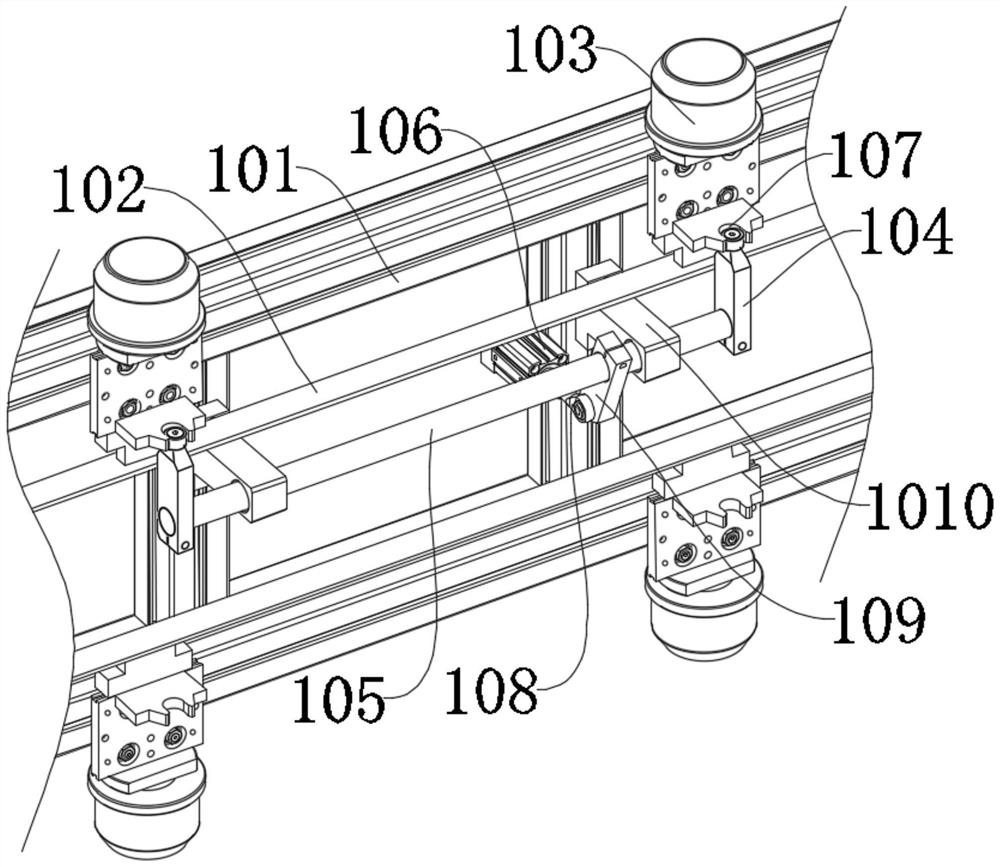

Cup rim processing technology and assembly line

PendingCN114227160AIncrease daily outputImprove work efficiencyPositioning apparatusMetal-working holdersWater flowEngineering

The invention relates to the field of cup automation, and discloses a cup rim processing technology which comprises the following steps: a, assembly line feeding: putting cup bodies on an assembly line capable of conveying the cup bodies in a stepping manner; b, cup body opening necking is conducted, specifically, to-be-machined cup bodies on an assembly line are placed on a cup opening necking device through a feeding and discharging device, and threads are driven to be formed on cup body openings; c, material changing is conducted through the necking device, and through the feeding and discharging device, the positions of the cup bodies to be machined on the assembly line and the positions of the cups with the necked inner cup openings in the necking device are exchanged; d, assembly line conveying is conducted, specifically, the assembly line conveys the cup with the necked cup opening to the next procedure, and the cup body to be machined is aligned with cup opening necking equipment; and e, cup mouth cutting is conducted, specifically, the water flow line is conveyed to the cup mouth cutting device, and the cup mouth of the cup subjected to cup mouth necking is cut through the cup mouth cutting device. The cups on the assembly line and the machining equipment are exchanged through the feeding and discharging device, and the working efficiency is improved.

Owner:浙江明科自动化科技有限公司

Necking and flaring mixed forming method for conical barrel part with straight barrel

ActiveCN113458248AReduce processing timeImprove forming efficiencyWaste based fuelForging/hammering/pressing machinesNeckingIndustrial engineering

The invention belongs to the field of manufacturing, and particularly relates to a necking and flaring mixed forming method for a conical barrel part with a straight barrel. The method can be used for extrusion manufacturing of the conical barrel part. The method comprises the following steps that firstly, a circular-truncated-cone-shaped and cylindrical integrated pipe blank with equal inner diameter and big-end-up outer diameter is prepared through machining; primary hot compression necking is carried out on the pipe blank by utilizing a lower concave die to form the straight barrel with a small diameter at the lower end; and finally, a flaring pressing die is used for performing flaring twice to form the conical barrel part with the large-diameter upper end and the small-diameter lower end. In order to prevent instability during necking of the pipe blank, the upper end of the pipe blank is cooled (the cooling mode is water cooling) before necking deformation, and a protection die is additionally arranged inside the female die; and compared with a traditional free forging process, the forming process is high in forming efficiency, good in size precision and few in forming procedure and heating number, and improves the part structure performance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A kind of necking processing preparation method of fiber-metal tube

ActiveCN112339306BImprove machinabilityImprove heat resistanceFurnace typesTubular articlesFiberCarbon fibers

The invention discloses a fiber-metal tube necking processing preparation method, which relates to the field of material forming; it includes the steps of: (1) pre-treating an alloy plate and a carbon fiber cloth, stacking and then blanking, rolling and forming after blanking, Seamless welding to form circular pipe fittings; (2) Heating the fiber metal pipe fittings in step (1) and extruding them into the variable-diameter shrinking die, so that the pipes are extruded with each other under the action of the variable-diameter shrinking die to produce plastic deformation and fit tightly to obtain the necked composite pipe; (3) apply ultrasonic vibration around the necked composite pipe in step (2) to assist the plastic deformation of the pipe; (4) apply ultrasonic vibration in step (3), Apply air pressure inside the necked composite pipe and heat it; (5) Keep the temperature constant, then release the internal pressure, and finally take it out for air cooling to get the final product. The necking processing and preparation method of the fiber-metal pipe provided by the invention enables the pipe fitting to have high surface quality and good mechanical properties.

Owner:WUHAN UNIV OF TECH

Vertical continuous oil pipe blowout preventer

The invention discloses a vertical continuous oil pipe blowout preventer. The vertical continuous oil pipe blowout preventer sequentially comprises a half seal part, a suspension part, a cutting partand a full seal part from bottom to top. According to the continuous oil pipe blowout preventer of a vertical structure, a transverse structure is changed into a vertical structure, space is saved foroperation construction, operation is facilitated, and operation accidents are reduced. A full seal becomes active closing from passive closing, and the whole blowout preventer becomes safer. A notchbecomes rotary cutting from straight cutting and becomes a circular port from a linear port, and usage becomes smoother. The suspension is controlled by hydraulic pressure, interlocking becomes, and accidents caused by the original necking phenomenon of a continuous oil pipe are relieved. Through the annular half seal design, the half seal is more reliable, adaptability is higher, the situation that due to deformation and the necking phenomenon of an original gate plate type half seal, the half seal is in failure is avoided, and the accident happening probability is reduced.

Owner:王凯

Necking process suitable for multi-duct aluminum alloy flat pipe

The invention relates to a necking process suitable for a multi-duct aluminum alloy flat pipe. The process comprises the following steps of s1, necking of the flat pipe; s2, clamping of the flat pipe; and s3, shearing of the flat pipe. On one hand, synchronous machining of the flat pipe in the width direction and the thickness direction is achieved, deformation of the flat pipe is effectively prevented, the flat pipe necking effect is improved, the product quality is guaranteed, and the production efficiency is improved; and on the other hand, the shearing precision is guaranteed, and rapid shearing after flat pipe necking is achieved.

Owner:杰拉德新能源(江苏)有限公司

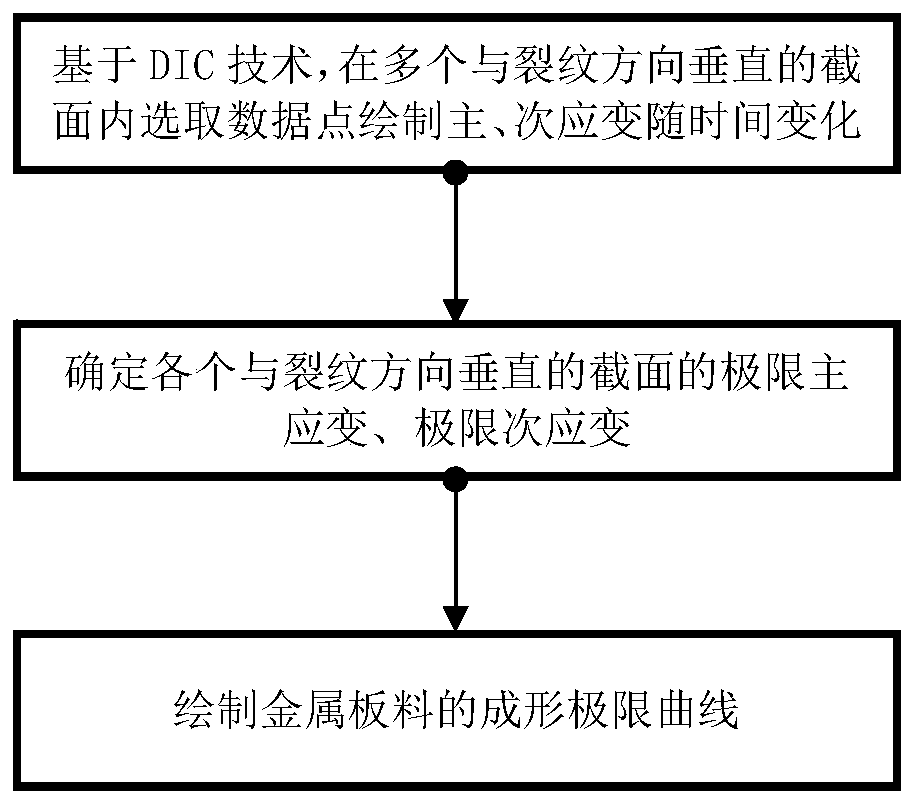

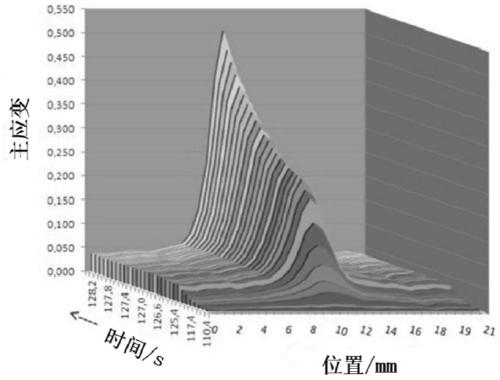

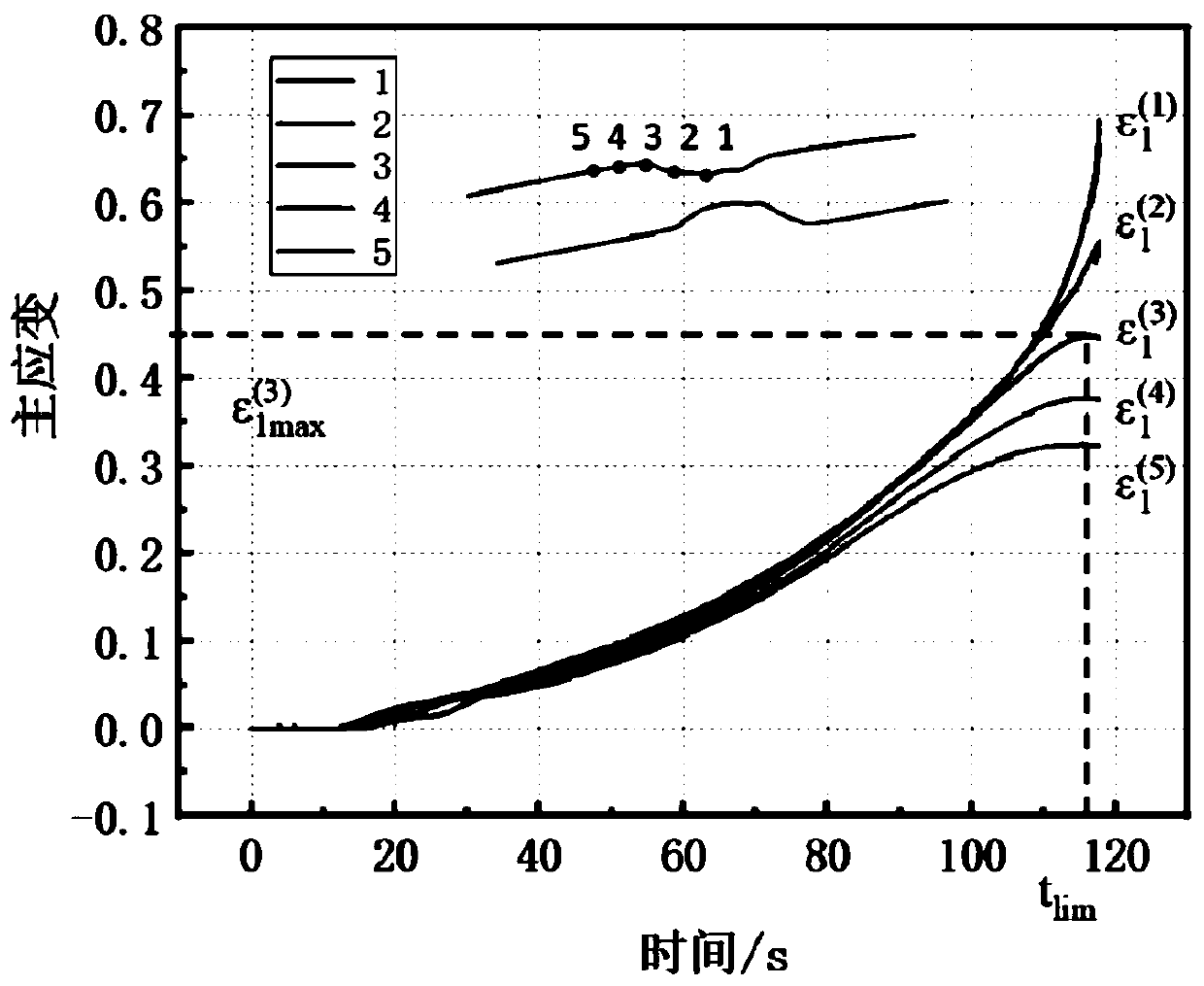

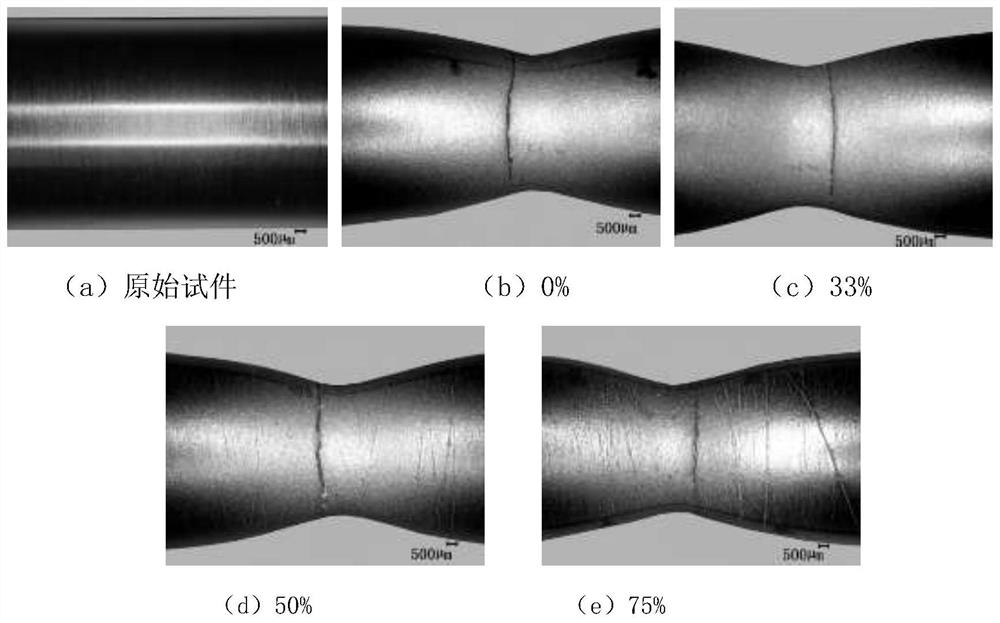

Necking failure limit strain detection method based on dic

ActiveCN109470559BGet results quickly and directlyObtain results concisely and effectivelyMaterial strength using tensile/compressive forcesClassical mechanicsLimit strain

The invention provides a necking failure limiting strain detection method based on DIC. The method comprises the following steps: S1, based on a DIC technique, selecting data points in a plurality ofsections vertical to a crack direction to draw a curve of primary and secondary strains varying along with time; S2, determining the limiting primary strain and the limiting secondary strain of the sections vertical to the crack direction based on the curve of primary and secondary strains varying along with time; and S3, based on the limiting primary strain and the limiting secondary strain of the sections vertical to the crack direction, drawing the limiting primary strain and the limiting secondary strain as vertical axis and cross axis in a coordinate map to obtain a formed limiting curveof a metal panel material, wherein necking failure limiting strain detection of the metal panel material is achieved. The method is quick, direct, concise and effective, and has very good universality.

Owner:SHANGHAI JIAO TONG UNIV

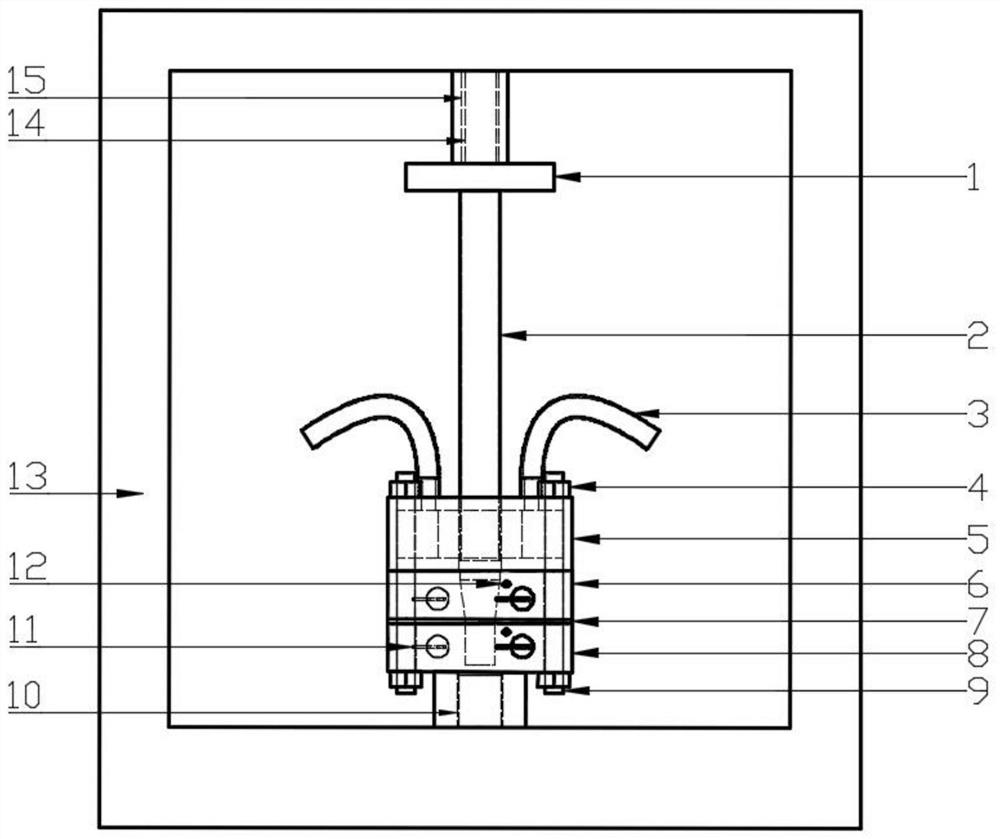

Forming device and method for precise subregional temperature control to realize tube end shrinking and thickening

ActiveCN112570579BAdjust the temperature freelyAvoid wastingShaping toolsNuclear energy generationTemperature controlHeating time

The invention discloses a forming device and a method for accurately controlling temperature in different regions to realize the thickening of pipe end shrinkage, and relates to the technical field of pipe plastic processing. Die and thickening die; the pusher is used to push and extrude the tube blank under the drive of the power source; the shrinking die and / or the thickening die are equipped with a heating structure, and the shrinking die is used for the shrinkage forming of the tube blank to increase the thickness. The thick die is used for thickening and forming of the tube blank; the cooler is used to cool the tube blank temperature outside the necking die and the thickening die. The forming device and method of the present invention can realize the free adjustment of the temperature of the mold necking area and the thickening area, which not only improves the material utilization rate, product quality and connection strength, but also reduces the manufacturing cost of the mold and shortens the heating time of the mold. It is easier to clean after the mold is divided into blocks, and it is more convenient to take out the parts after forming.

Owner:NANCHANG HANGKONG UNIVERSITY

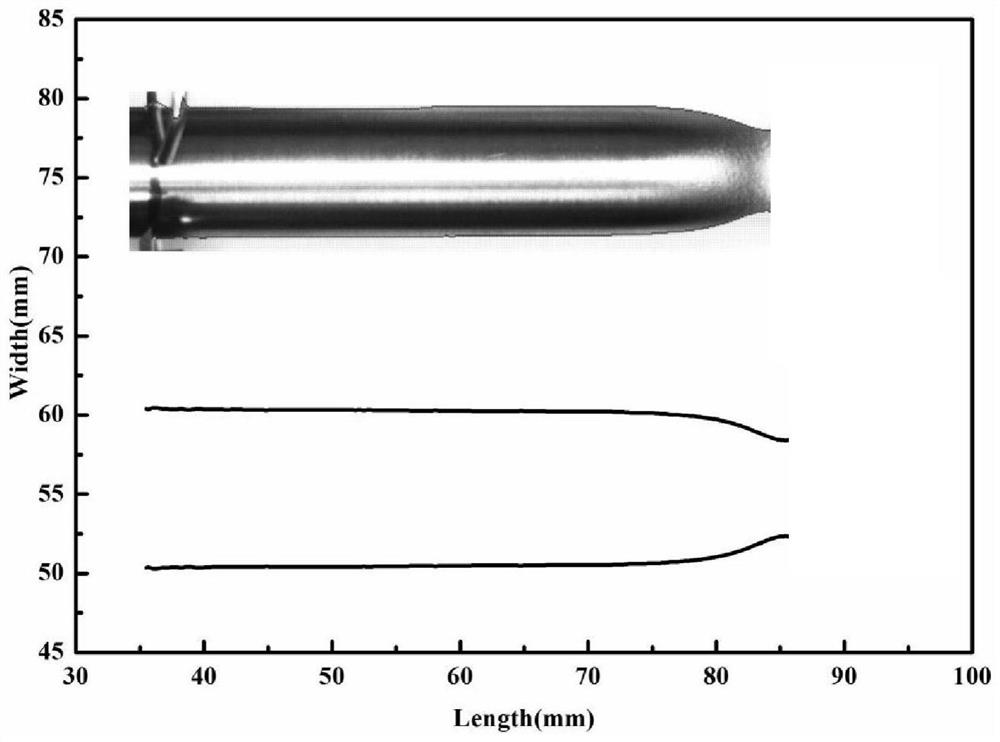

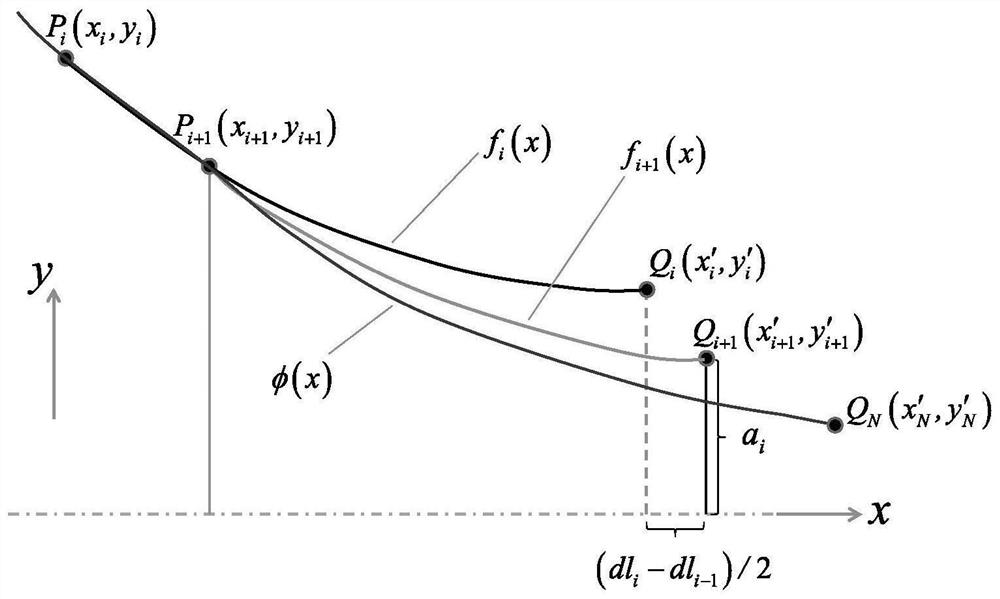

Arc Backward Measurement Method for Uniaxial Tensile Stress-Strain of Metal Round Bar Specimen

InactiveCN109883824BEliminate cumbersome measurement linksSave time and costMaterial strength using tensile/compressive forcesUsing optical meansMetallic materialsRound bar

The present invention relates to the circular arc back-push measurement method of the uniaxial tensile stress and strain of metal round bar samples, and the technical field of testing the mechanical properties of metal materials. The circular arc rotating body model only needs to measure the elongation of the gauge length during the stretching process of the round bar sample, and extract the coordinate information of the outer contour curve of the broken test bar, and calculate the radius of the necking arc and the minimum necking at each moment by back-calculating The section radius is directly substituted into the Bridgman method to calculate the true stress and true strain at this moment. The invention omits the test and measurement link of the minimum section radius of the necking and the curvature radius of the outer contour in the existing method, and improves the measurement accuracy of the stress-strain curve in a large strain range, which is of great significance for the mechanical performance test of metal materials.

Owner:JILIN UNIV

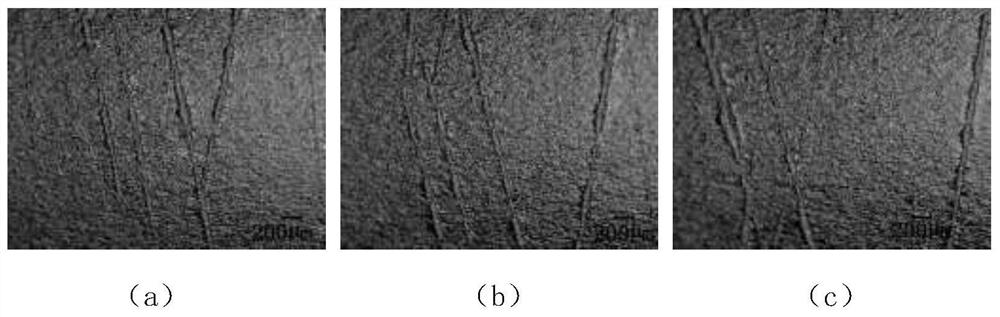

Evaluation method of material remaining life based on image analysis of surface microtopography features

ActiveCN108896562BSimple relationshipPromote engineering applicationOptically investigating flaws/contaminationMaterial strength using repeated/pulsating forcesImage manipulationMetallic materials

Owner:GUANGXI UNIV

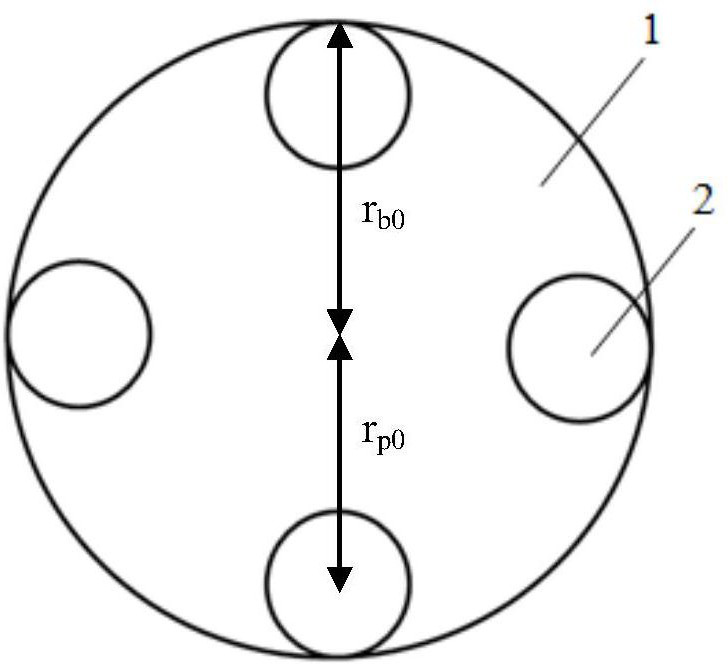

Method for manufacturing rotors

ActiveUS10236755B2Increase productionStructural interferenceManufacturing cage rotorsManufacturing stator/rotor bodiesSlurryEngineering

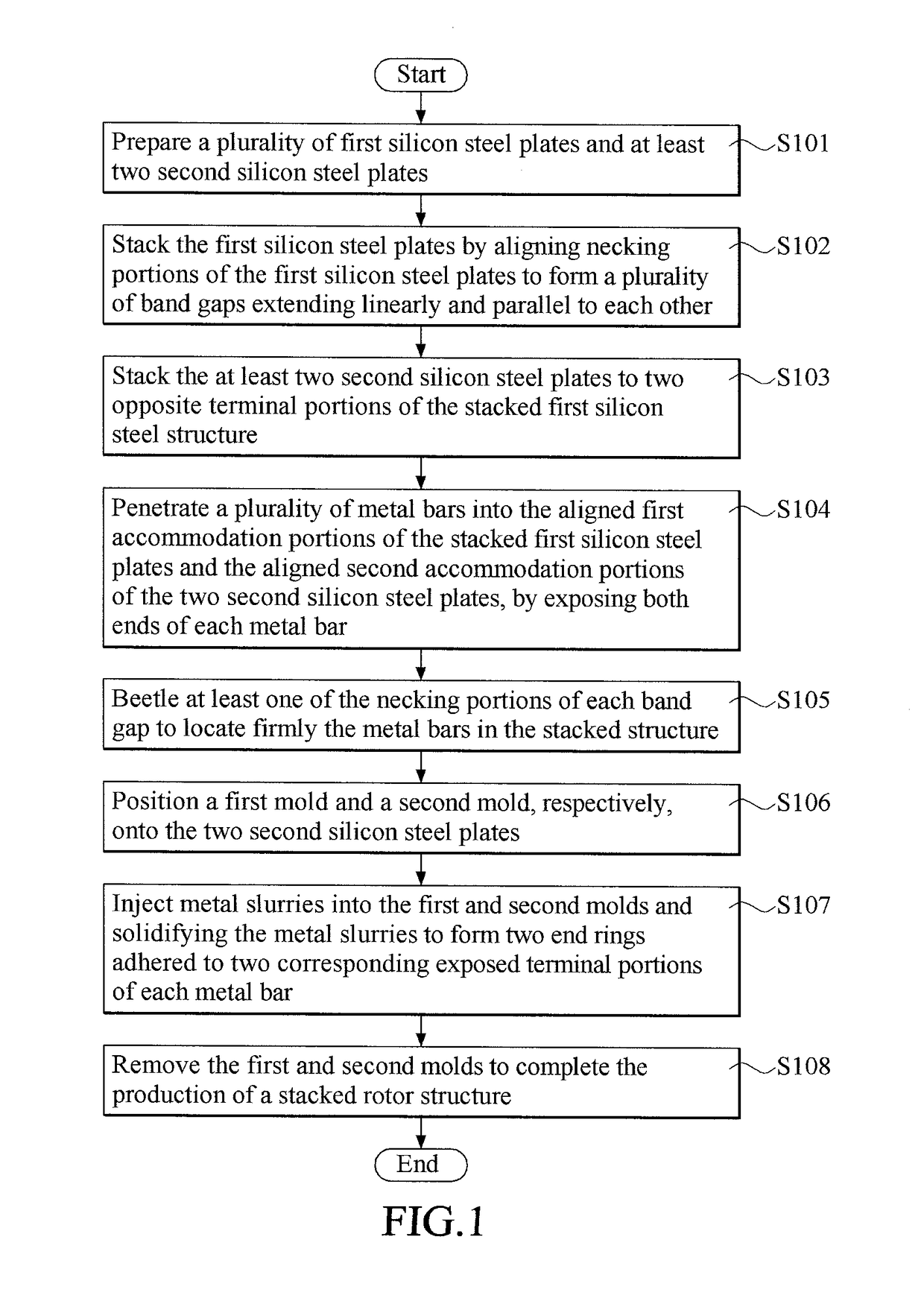

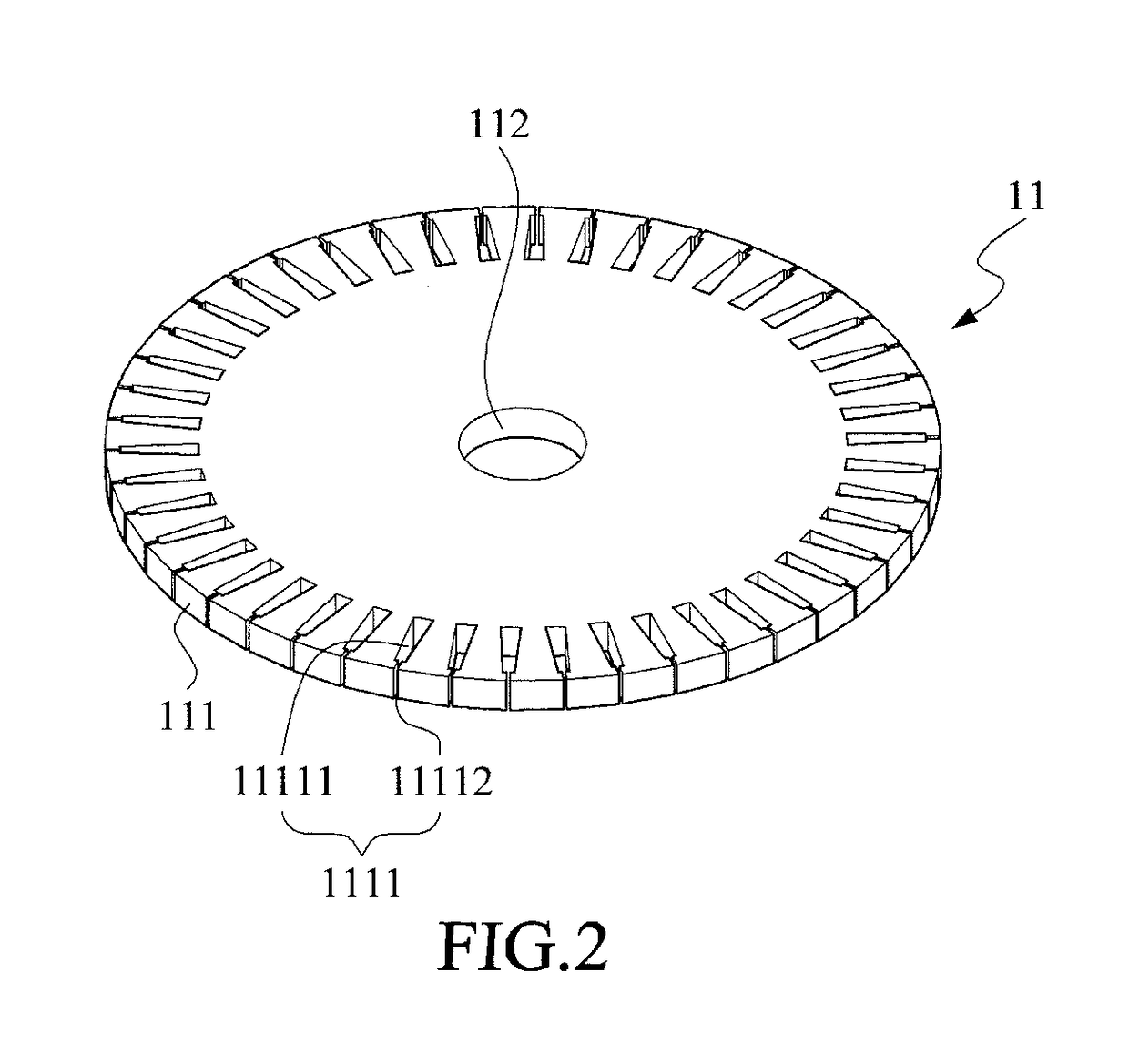

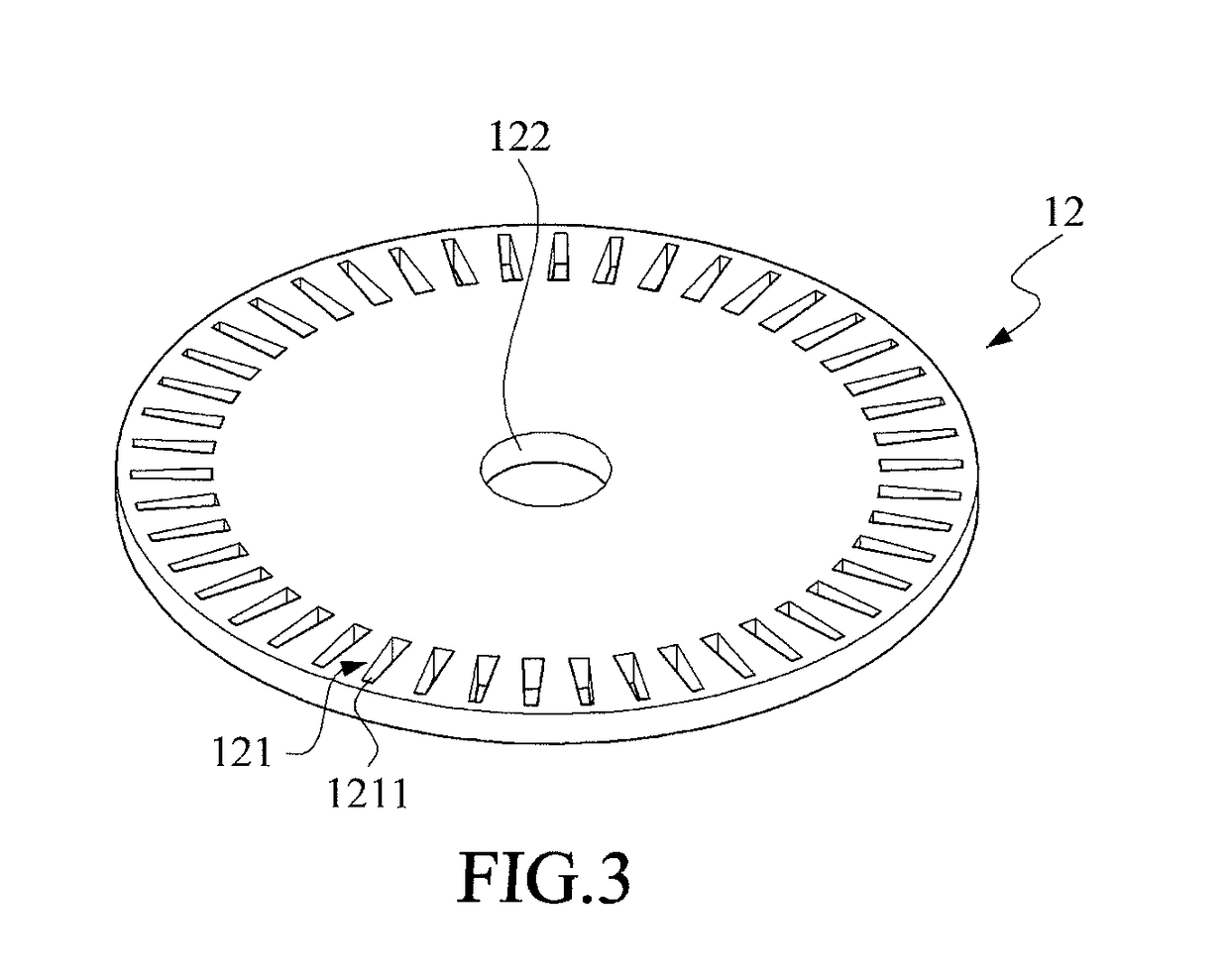

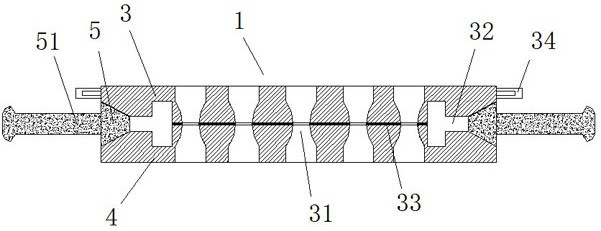

A method includes steps of: preparing first and second plates, each first plate having surrounding apertures, each aperture including a first accommodation portion and an outer necking portion, each second plate having surrounding accommodation portions; stacking the first plates by aligning necking portions to form band gaps extending linearly and parallel to each other; stacking two second plates to two opposing terminal portions of the stacked first plates; penetrating metal bars into the aligned first and second accommodation portions by exposing both ends of each metal bar; beetling the necking portions at each band gap so as to locate firmly the corresponding metal bar; positioning a first mold and a second mold to clamp the stacked plate structure; injecting metal slurries into the first and second molds and then solidifying the metal slurries to form two end rings; and, removing the first and second molds to complete a rotor structure.

Owner:TECO ELECTRIC AND MACHINERY

Concrete pile head breaking device and using method thereof

PendingCN114541396AReduce widthReduce cumbersome operationsBulkheads/pilesNeck structureCement paste

The invention discloses a concrete pile head breaking device and method.The concrete pile head breaking device comprises a steel bar inner ring necking structure, a steel bar sleeve and an annular pile breaker, the steel bar inner ring necking structure comprises an upper necking cover, a lower necking cover and wedge blocks located on the sides of the upper necking cover and the lower necking cover, and a plurality of vertically-through open holes are symmetrically formed in the upper necking cover and the lower necking cover; when the upper necking cover and the lower necking cover are aligned, the upper open hole and the lower open hole are aligned to form a cement paste through hole, the cement paste through hole is narrow in the middle and wide in the vertical direction, slope surfaces are symmetrically arranged on the two sides of the lower surface of the upper necking cover and the two sides of the upper surface of the lower necking cover, and when the upper necking cover and the lower necking cover are aligned, wedge-shaped grooves are formed in the two side faces of the upper necking cover and the two side faces of the lower necking cover, and the wedge blocks are arranged in the wedge-shaped grooves. According to the method, only one-time pile breaking operation needs to be carried out on the bottom of the to-be-broken pile head, existing tedious pile breaking operation on multiple positions of the pile head is omitted, and the pile breaking efficiency can be greatly improved.

Owner:NANJING FORESTRY UNIV

Special-shaped necking die

PendingCN112371849AEasy to useHigh positioning accuracyShaping toolsMetal-working feeding devicesStructural engineeringMechanical engineering

The invention discloses a special-shaped necking die. The die comprises an upper die body and a lower die body which work in cooperation with each other, wherein the lower die body is located under the upper die body, the upper die body comprises a female die, an upper die guide column located in an inner cavity of the female die is fixedly connected with the female die, the top end of the upper die guide column downwards exceeds the top of the female die, the inner cavity of the female die is narrow in bottom and wide in top, the lower die body comprises a lower die base assembly, a square-frame-shaped bottom plate connecting frame is fixedly arranged on the lower die base assembly, an upper end bottom plate is fixedly arranged at the top of the bottom plate connecting frame, a lower dieguide sleeve is arranged in the upper end bottom plate, a special-shaped channel I is formed in the upper end bottom plate, a channel III defined by four slotting tool guide sliding blocks which are symmetrically distributed at four corners correspondingly is formed in an inner cavity of the bottom plate connecting frame, and a push block slotting tool is arranged in the channel III. According tothe special-shaped necking die, stable positioning of a large-size box body or a special-shaped workpiece can be achieved, the positioning precision problem during forming is solved, and meanwhile, the deformation problem of the workpiece is avoided.

Owner:永康市迪迪科技有限公司

Feeding chamber necking adjusting device

PendingCN112902675AGuaranteed spray effectImprove heat transfer efficiencyCharge manipulationPreheating chargesNeck partsEngineering

The invention relates to a feeding chamber necking adjusting device. The feeding chamber necking adjusting device comprises a base, the left side and the right side of the base are each provided with a plurality of necking which are sequentially formed from front to back, each necking is provided with a valve body, each valve body comprises a linear driving mechanism, a valve sleeve, a valve seat and a valve plate, the valve sleeves are obliquely and fixedly inserted into the necking in a sealed mode, the valve seats are obliquely sealed and fixed at openings in the outer ends of the valve sleeves, the valve plates are movably arranged in the valve sleeves and the valve seats, first cooling rings which are annularly distributed are further fixed in openings in the inner ends of the valve sleeves, and the inner ends of the valve plates are matched with the inner walls of the first cooling rings. By means of mutual cooperation of the valve plates and the necking, the size of the necking area is adjusted, then the spouting effect in a decomposing furnace is guaranteed, air, materials and coal in the decomposing furnace are fully mixed, the heat exchange efficiency of the materials is improved, the retention time of the materials is prolonged, the material decomposing rate is increased, and meanwhile, crust at the necking part is effectively avoided, so that great convenience is brought to use.

Owner:NANJING KISEN INT ENG

Thin-wall pipe fitting necking method and necking equipment applying method

The invention relates to a thin-wall pipe fitting necking method and necking equipment applying the method. The necking method comprises the steps that firstly, the necking length of a pipe fitting isdetermined; secondly, the pipe fitting is clamped through a pipe clamping machine, the joint of the necking section and the non-necking section of the pipe fitting is extruded from outside to insidethrough a clamp, and meanwhile, the clamp is rotated till a concave annular groove is arranged in the pipe wall of the pipe fitting; and finally, the clamp is kept rotating, the pipe clamping machineis controlled to drive the pipe fitting to move in the axial direction till the necking section is formed, and pipe fitting necking is completed. The necking equipment mainly comprises a necking clamp, the pipe clamping machine used for clamping the pipe fitting and a first power cylinder driving the pipe clamping machine to move in the axial direction of the pipe fitting, wherein the necking clamp mainly comprises the clamp capable of achieving machining of the annular groove and a mechanism driving the clamp to form clamping and rotating. The necking forming efficiency is high, the size precision is good, the necking caliber is convenient to adjust, and the necking method and the necking equipment are particularly suitable for necking machining of thin-walled pipe fittings with the wallthickness being smaller than 0.25 mm.

Owner:宁波天鑫金属软管有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com