Patents

Literature

39results about How to "Avoid necking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

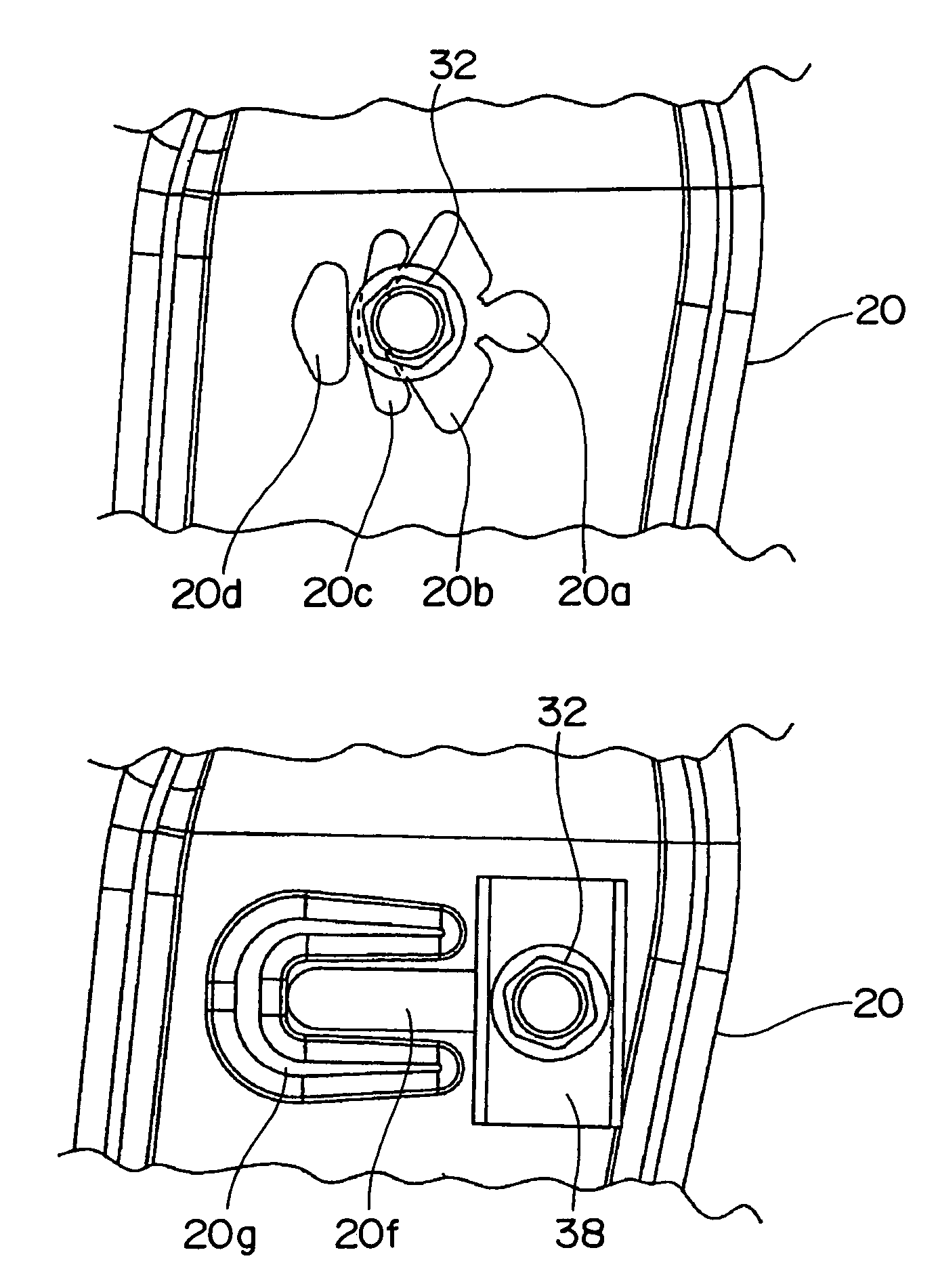

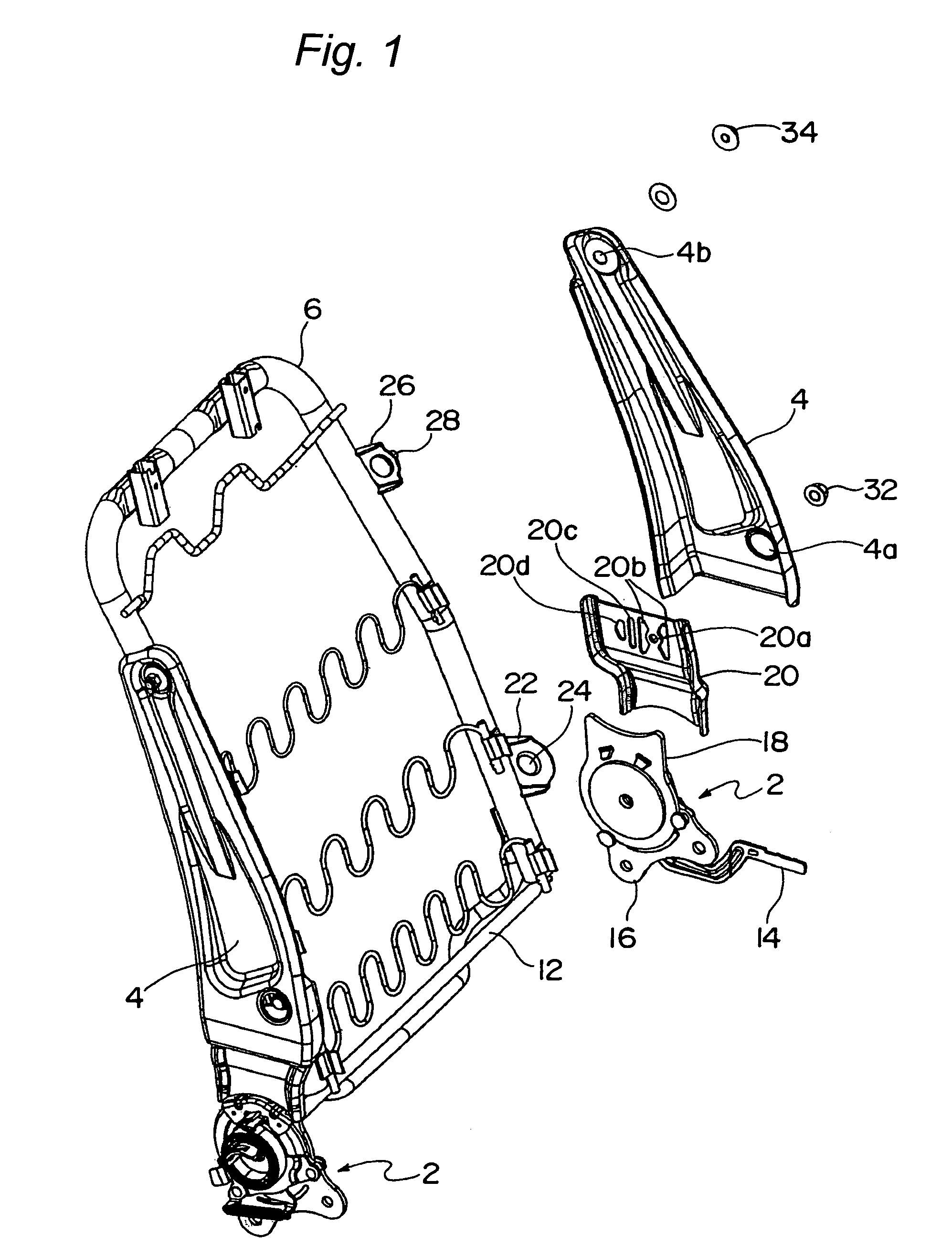

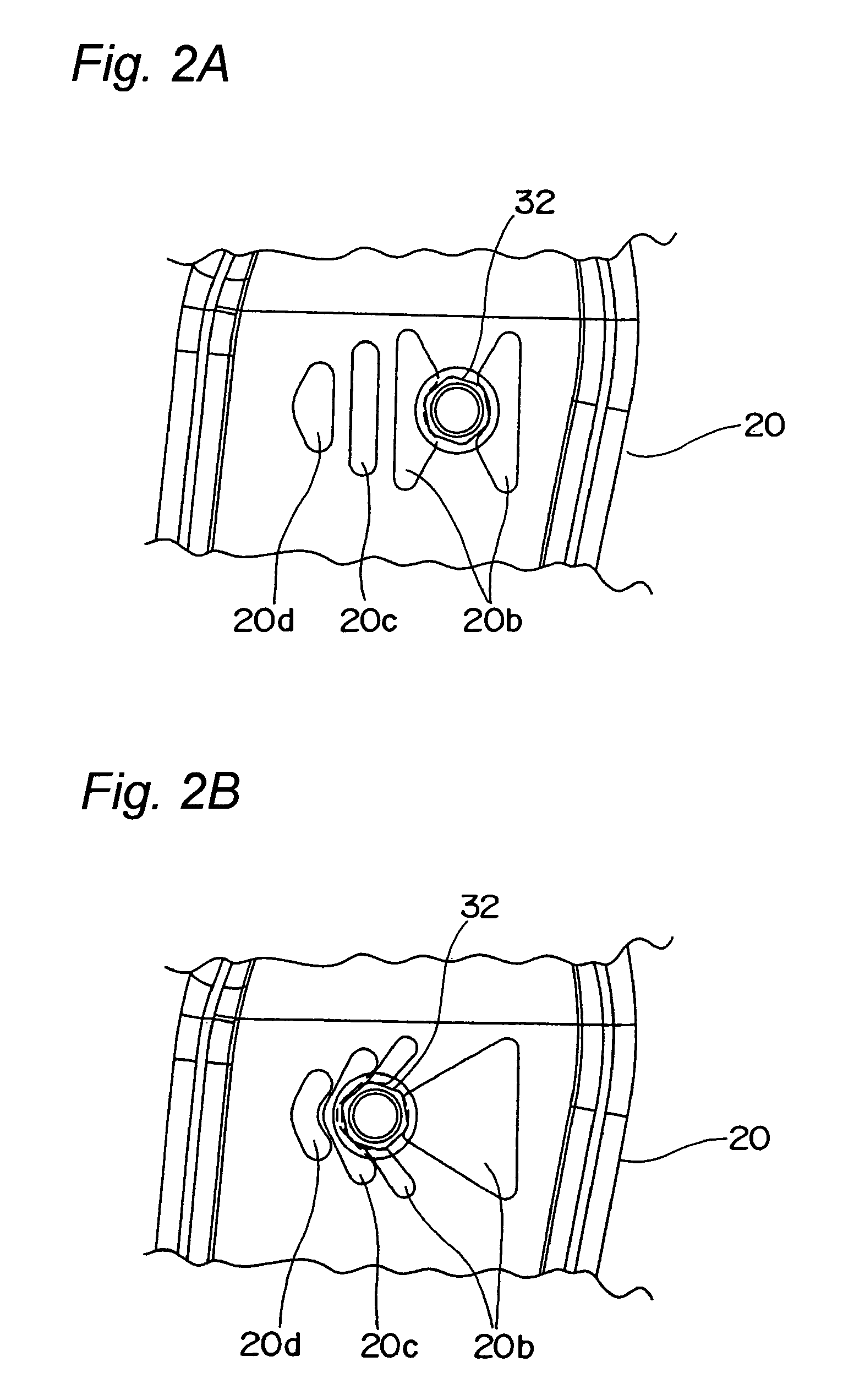

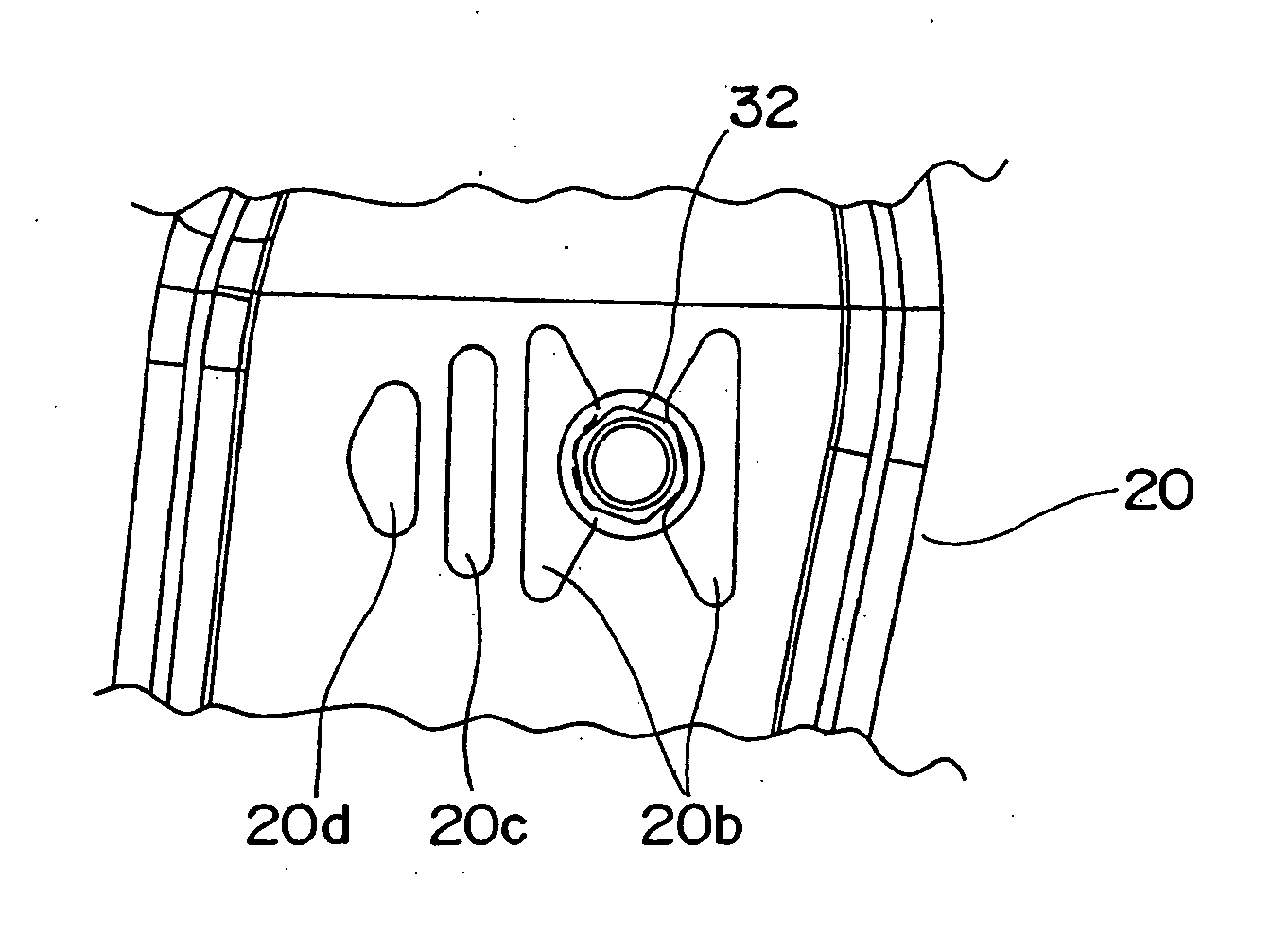

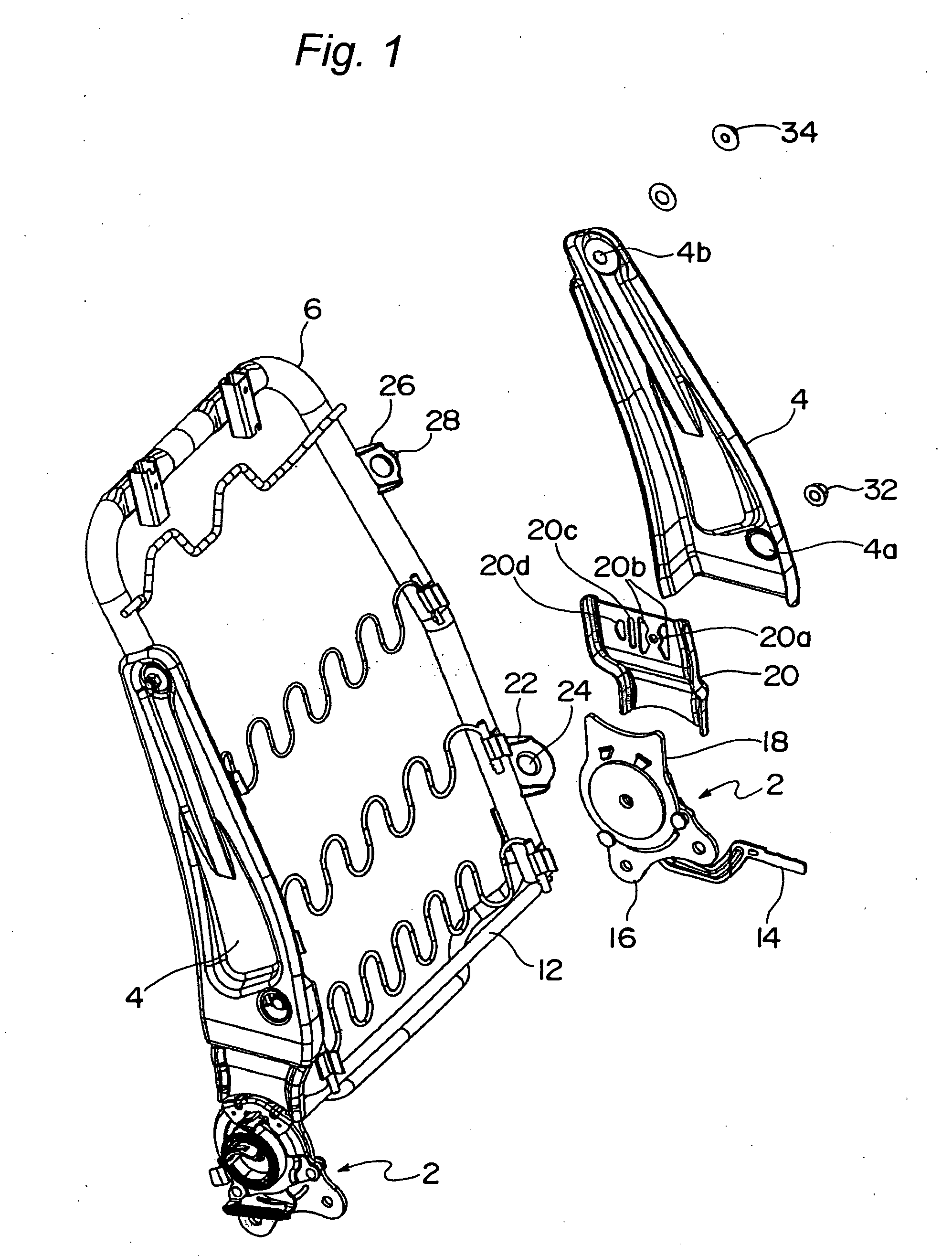

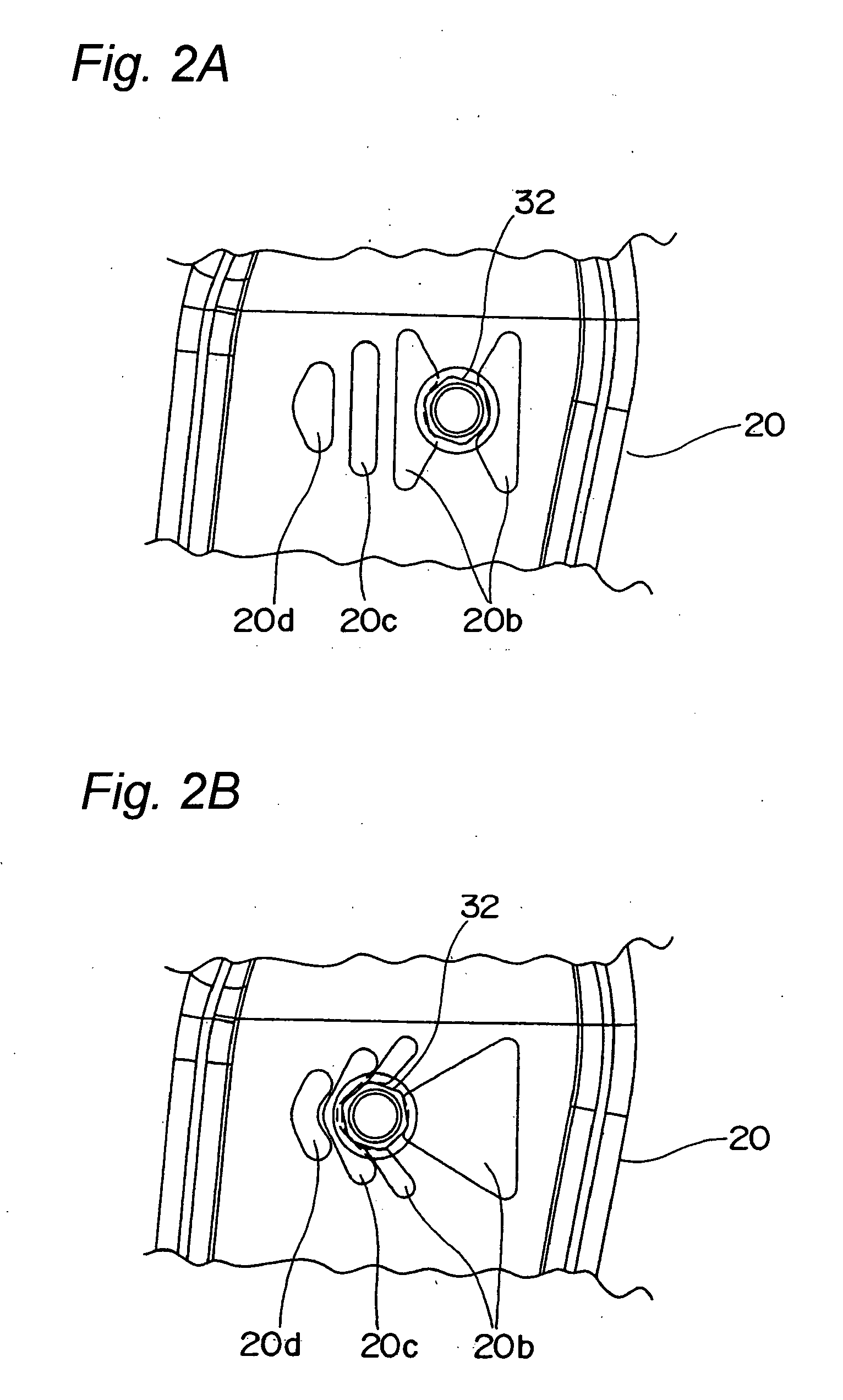

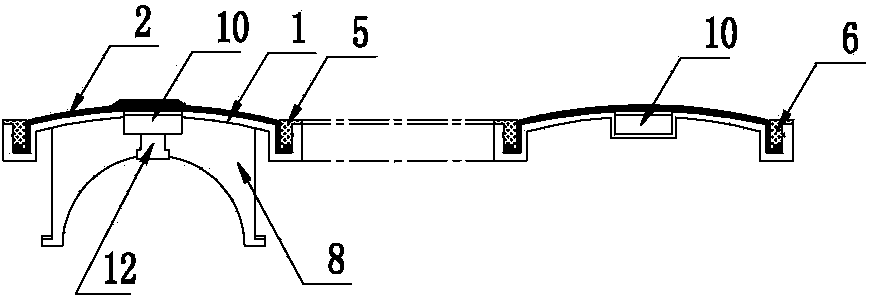

Automobile seat

InactiveUS7070236B2Easy constructionImprove securityVehicle seatsPedestrian/occupant safety arrangementEngineeringBack rests

An automobile seat includes a seat cushion and a seat back tiltably mounted on the seat cushion. The automobile seat also includes a seat cushion frame, a side frame mounted on the seat cushion frame, a seat back frame mounted on the side frame so as to be rotatable within a limited angle, and a fastening member mounted on the seat back frame. The side frame has an insertion hole defined therein in which the fastening member is inserted and also has an impact absorbing structure. When a load greater than a predetermined value is inputted to the seat from behind, a lower portion of the seat back frame is pushed upon a rearward movement of a seat occupant to thereby cause the fastening member to move rearward while deforming the impact absorbing structure. As a result, the seat back frame rotates with respect to the side frame, and an impact is absorbed by deformation of the impact absorbing structure.

Owner:DELTA KOGYO CO LTD

Automobile seat

InactiveUS20050140190A1High impact energyEasy constructionVehicle seatsPedestrian/occupant safety arrangementEngineeringBack rests

An automobile seat includes a seat cushion and a seat back tiltably mounted on the seat cushion. The automobile seat also includes a seat cushion frame, a side frame mounted on the seat cushion frame, a seat back frame mounted on the side frame so as to be rotatable within a limited angle, and a fastening member mounted on the seat back frame. The side frame has an insertion hole defined therein in which the fastening member is inserted and also has an impact absorbing structure. Where a load greater than a predetermined value is inputted to the seat from behind, a lower portion of the seat back frame is pushed upon a rearward movement of a seat occupant to thereby cause the fastening member to move rearwards while deforming the impact absorbing structure. As a result, the seat back frame rotates with respect to the side frame, and an impact is absorbed by the deformation of the impact absorbing structure.

Owner:DELTA KOGYO CO LTD

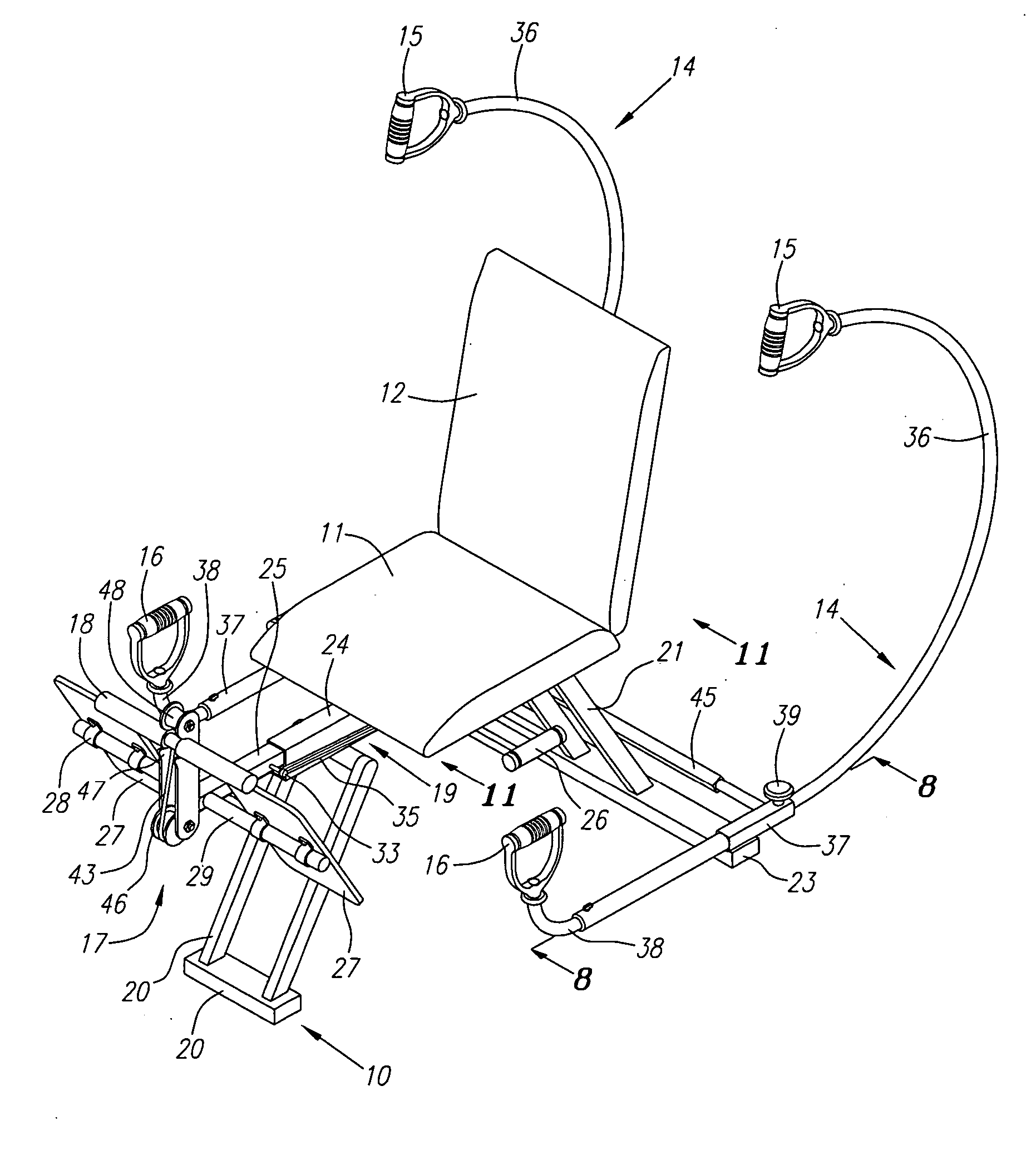

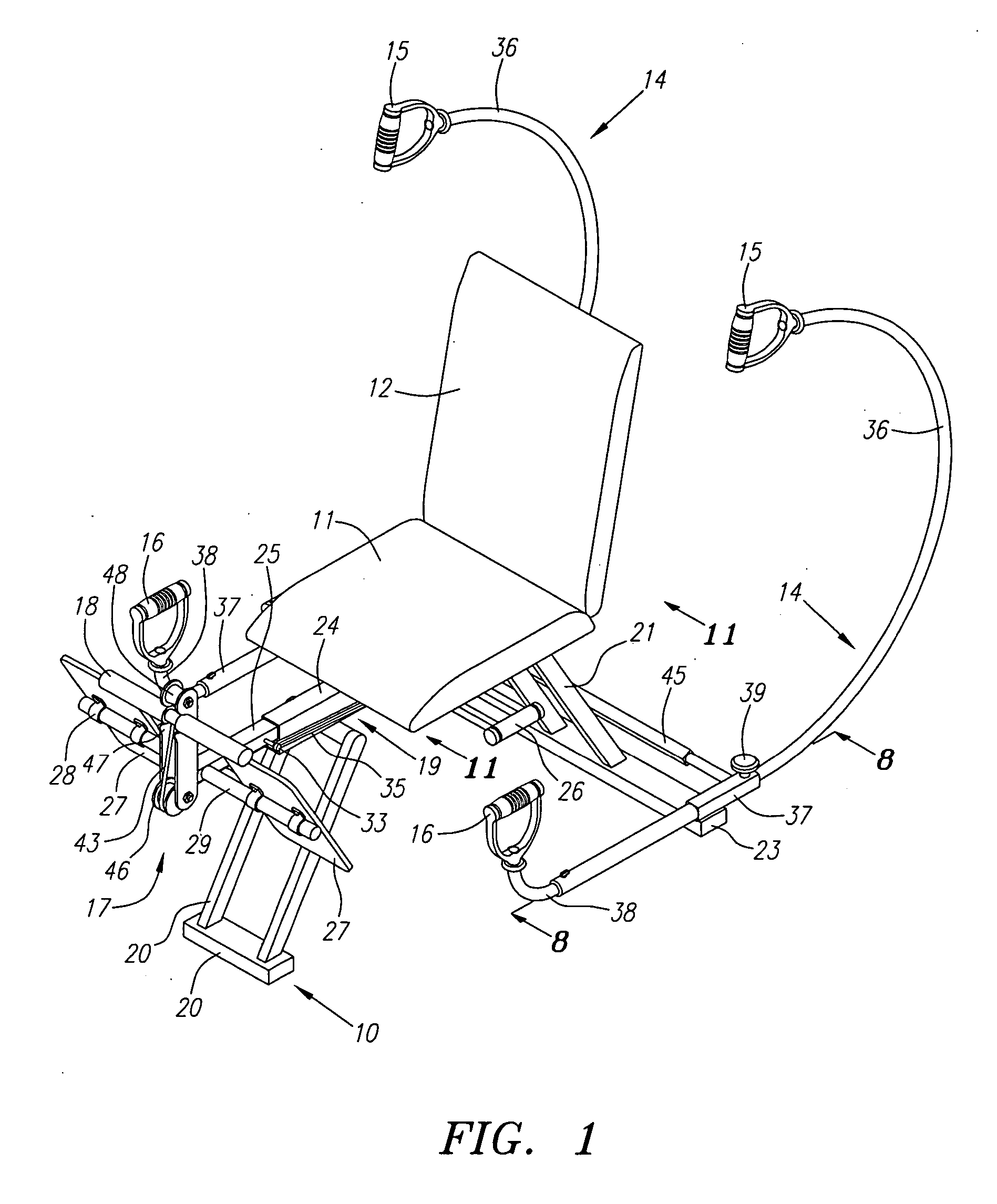

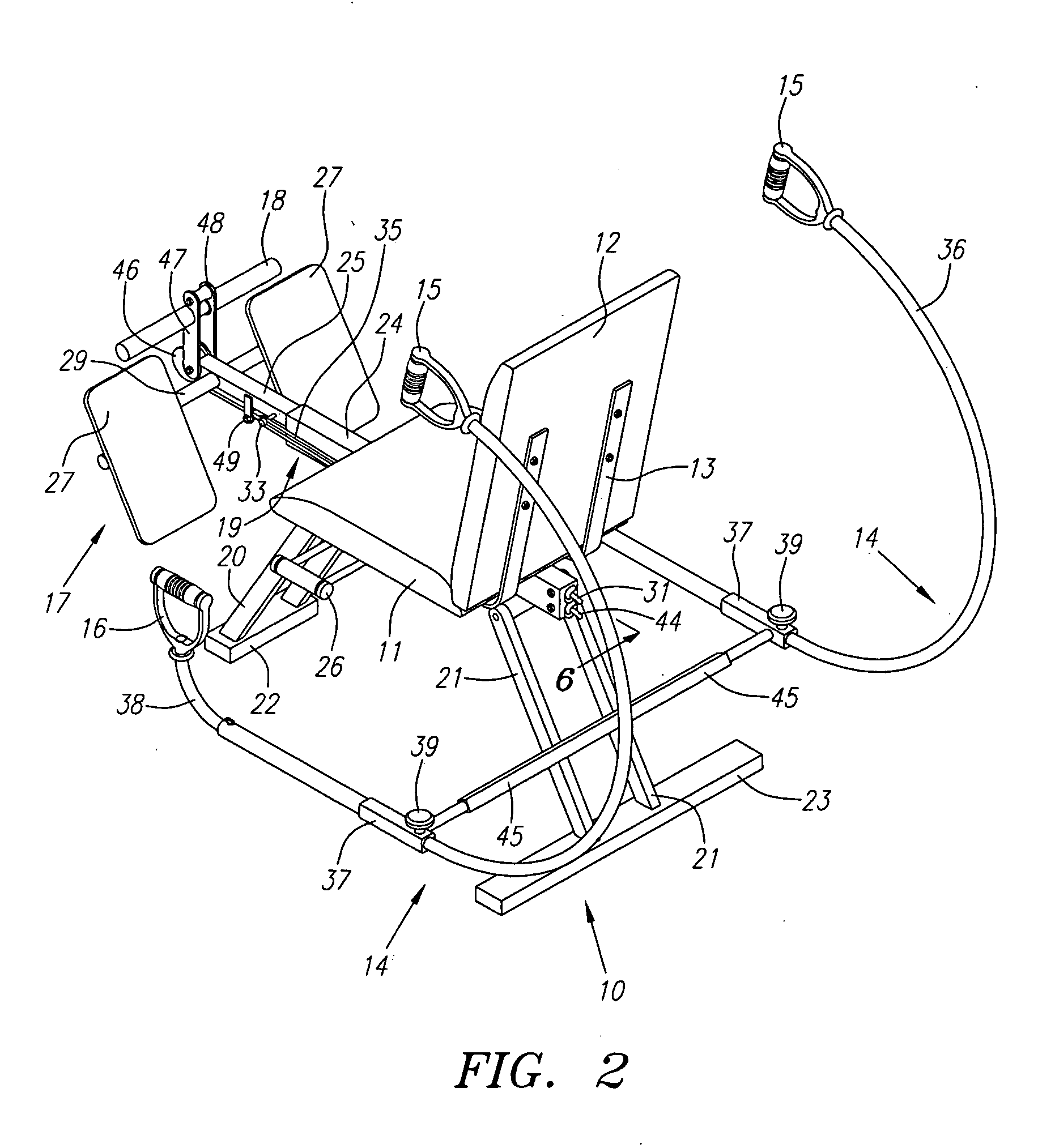

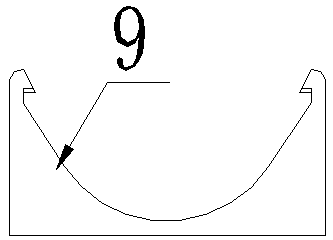

Multi-purpose exercise device

InactiveUS20060025289A1Increase lateral distanceHigh level of operation efficiencyResilient force resistorsSpace saving gamesMuscle groupEngineering

An exercise device capable of simultaneously exercising a plurality of muscle groups, which includes an exercise chair mounted to a base, the exercise chair having a pivotally-resistant seat back. The exercise device further includes large, curvilinear conduits through which pass adjustably-resistant elastic bands with grips fixedly attached to the elastic bands proximate the upper and lower ends of the curvilinear conduits, which curvilinear conduits are laterally spaced, one on each side of the exercise chair. The exercise device further includes a resistive foot platform positioned at the front end of the base, which resistive foot platform is moveably engaged with the exercise chair. The exercise device further includes a resistive seated-row grip positioned at the front end of the base that permits cardiovascular exercise.

Owner:WALLACH MARK

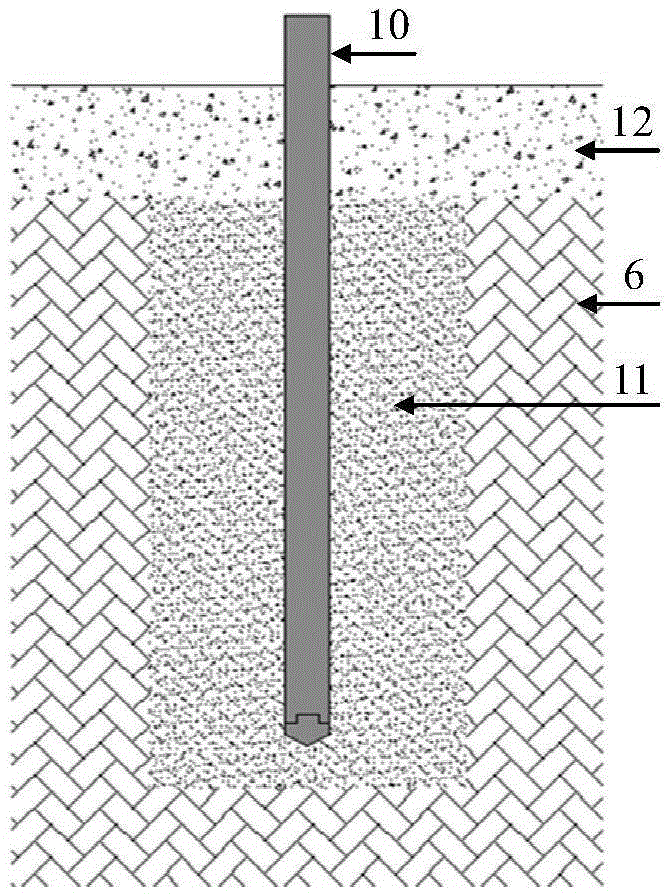

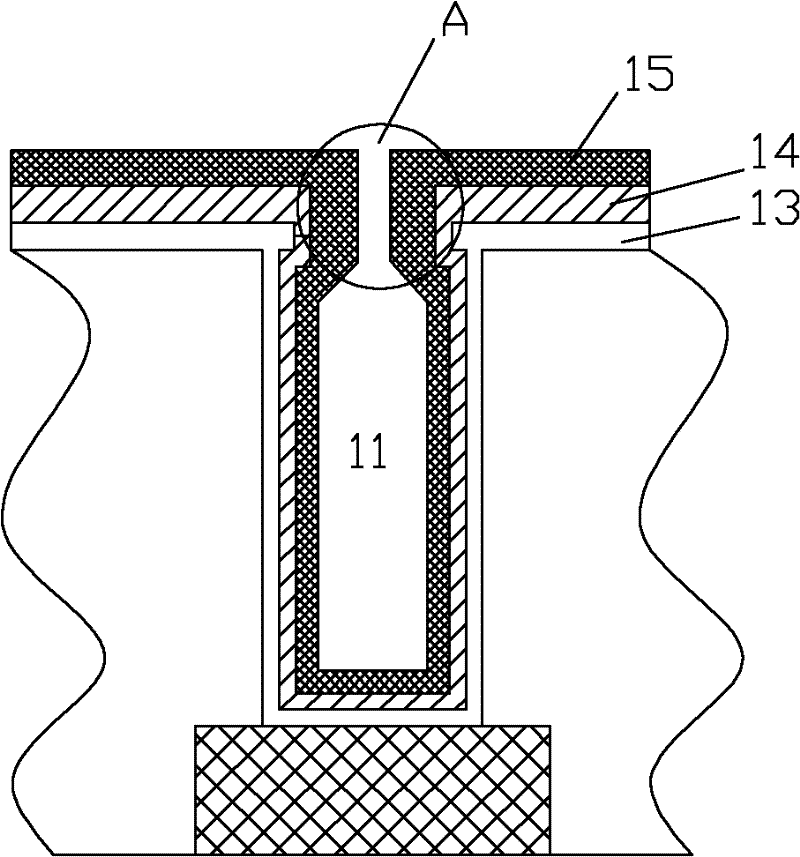

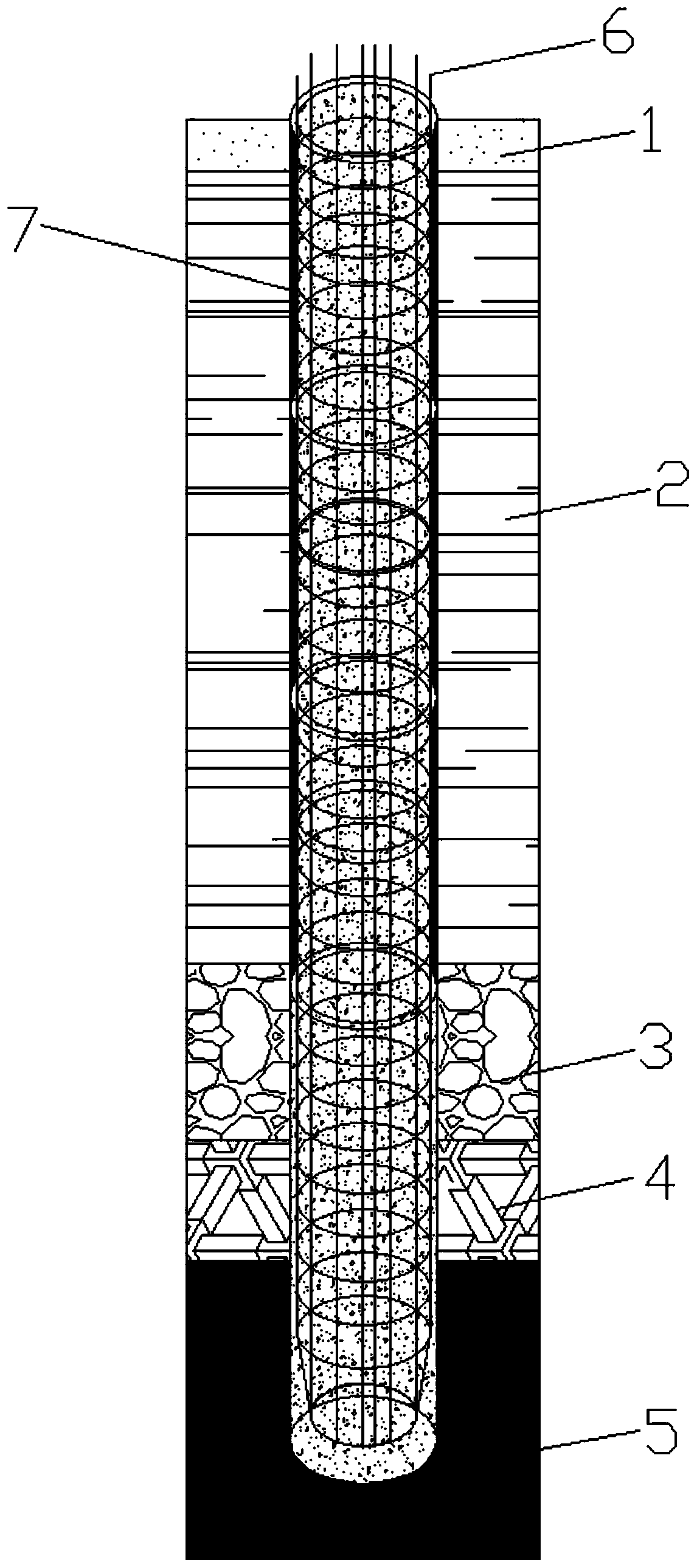

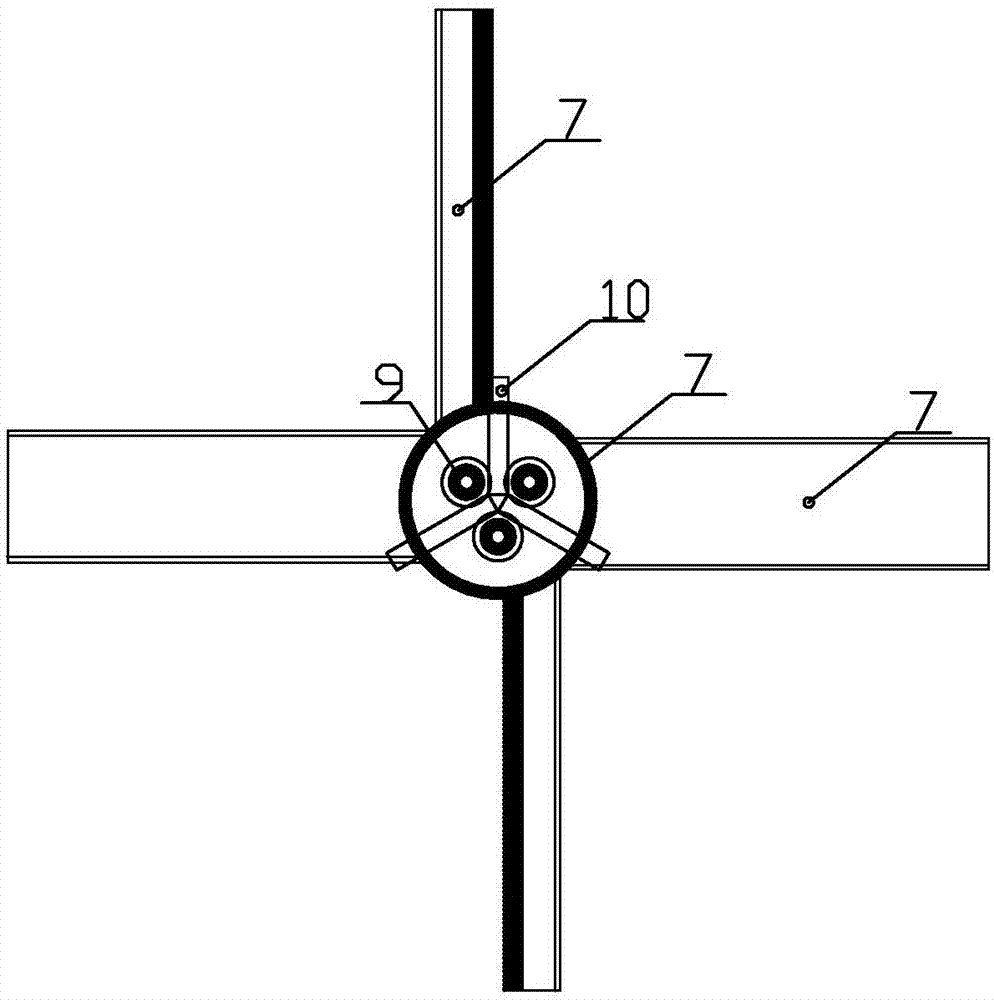

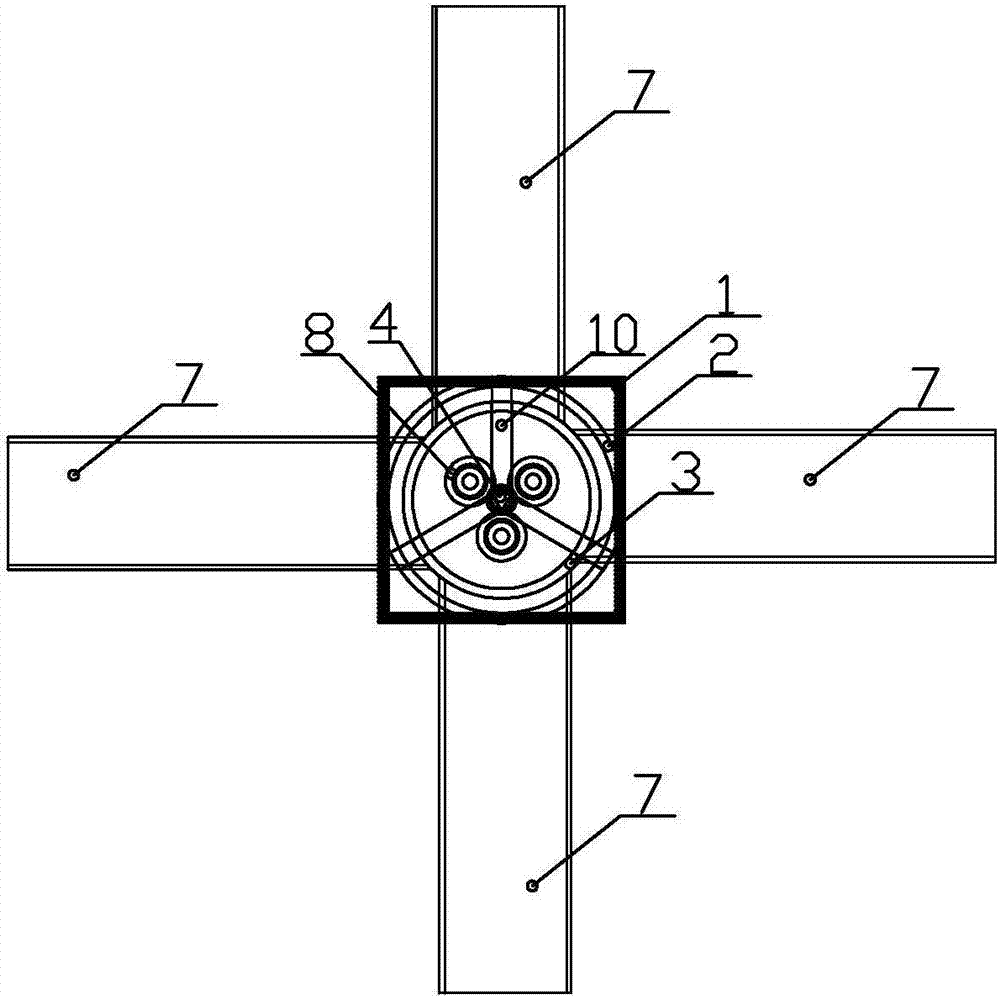

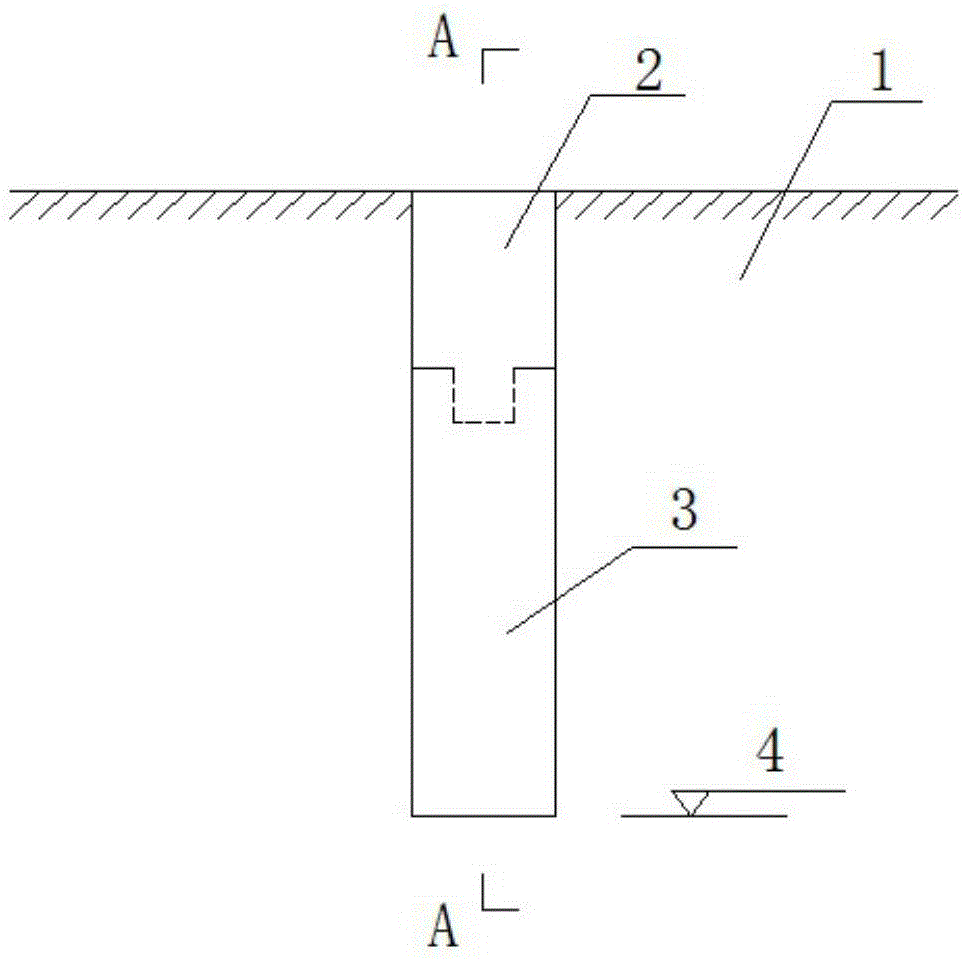

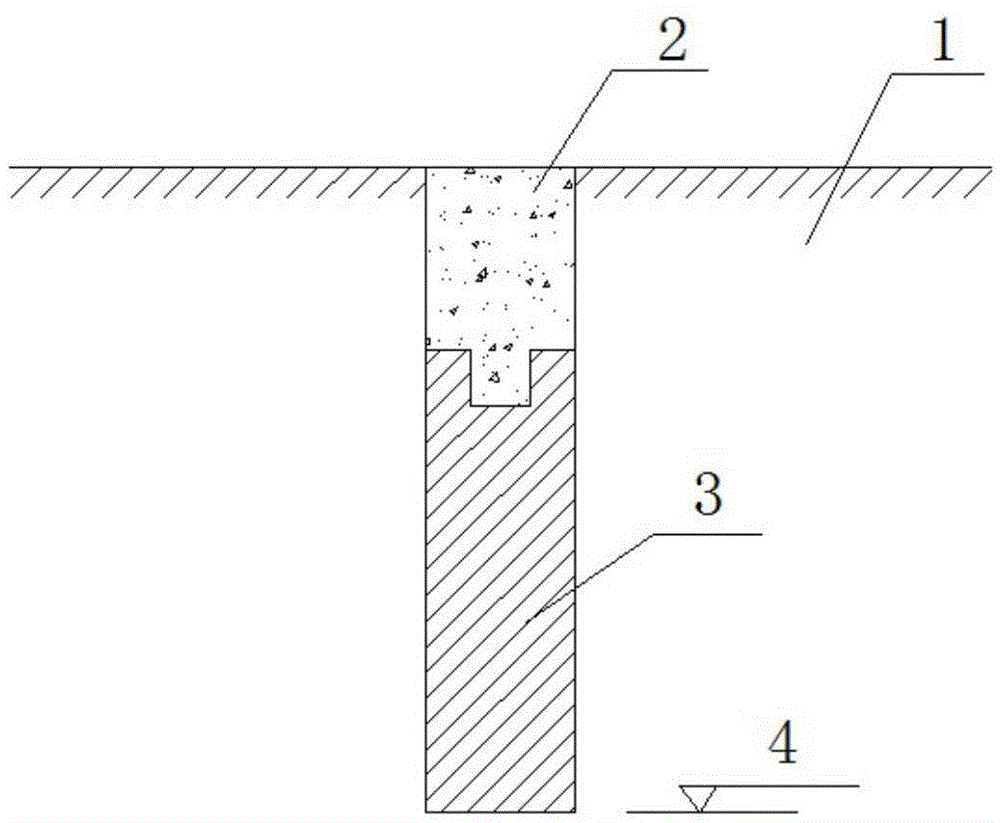

Microorganism soil-reinforcement cement fly-ash gravel (CFG) pile composite foundation and construction method

ActiveCN105386433AHigh strengthImprove bearing capacityBulkheads/pilesSoil preservationMicroorganismAggregate (composite)

The invention discloses a microorganism soil-reinforcement cement fly-ash gravel (CFG) pile composite foundation and a construction method. The construction method comprises the steps that a, a pile pipe is pressed into a foundation; b, microorganism bacterium liquid is injected into the pile pipe at the same time, and the microorganism bacterium liquid is made to diffuse towards the foundation around the pile pipe; c, the microorganism bacterium liquid is pumped out, and a cementing solution is injected into the pile pipe and made to diffuse to the foundation around the pile pipe and reacts with the microorganism bacterium liquid to generate calcium carbonate crystals, and incompact sandy soil or floury soil is cemented; d, the step b and the step c are executed repeatedly till the soil around the pile pipe meets the reinforcement requirement; e, pipe-drawing pile formation is conducted while cement-ash stabilized aggregates are poured; and f, a bed course is laid, so that the CFG pile composite foundation is formed. According to the microorganism soil-reinforcement CFG pile, the soil around the pile pipe is reinforced through calcium carbonate generated through reaction between the microorganism bacterium liquid and the cementing solution, so that the strength of the soil around the pile pipe is improved, and the quality problems of necking, pile breakage, soil carrying and the like in the pile forming process are solved; in addition, a reinforced soil body can be combined with a pile for bearing, and the bearing capacity of the single pile is effectively improved.

Owner:NANJING FORESTRY UNIV

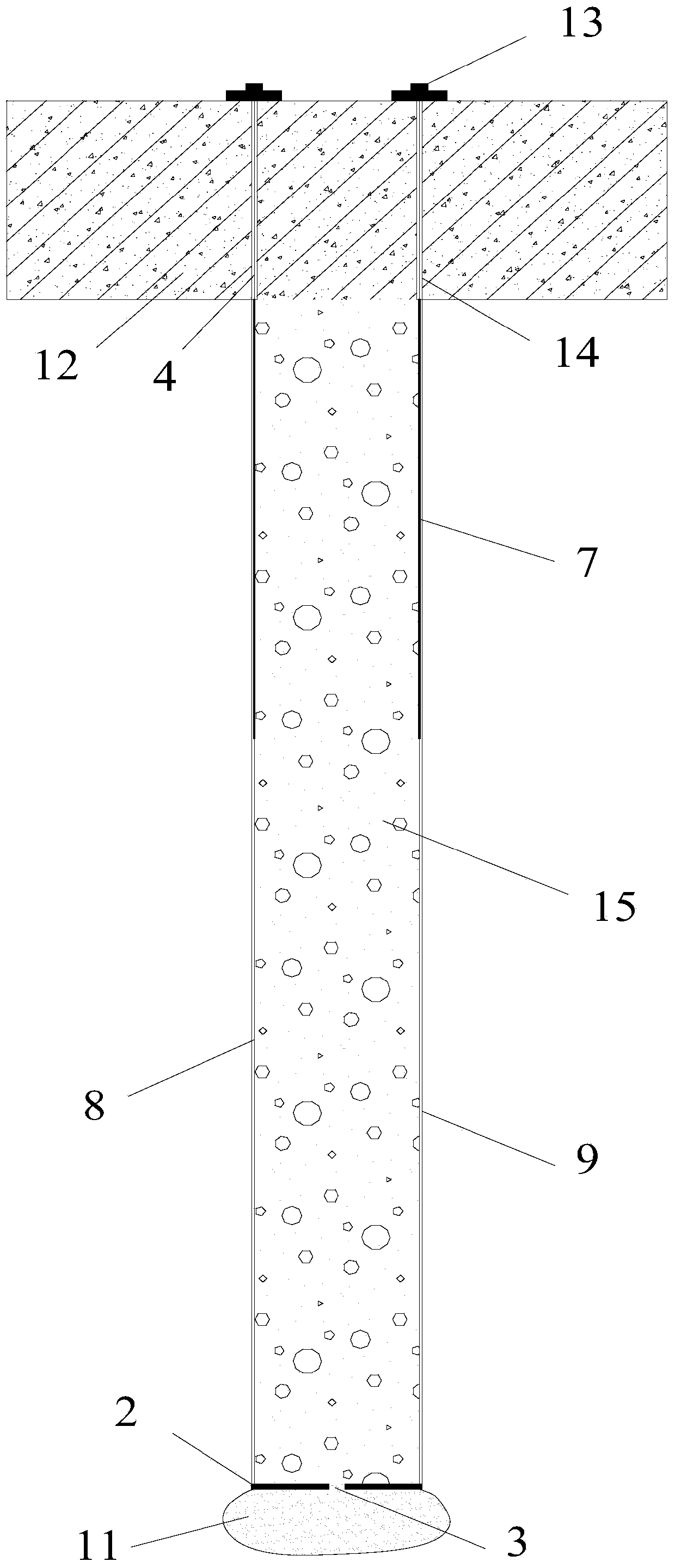

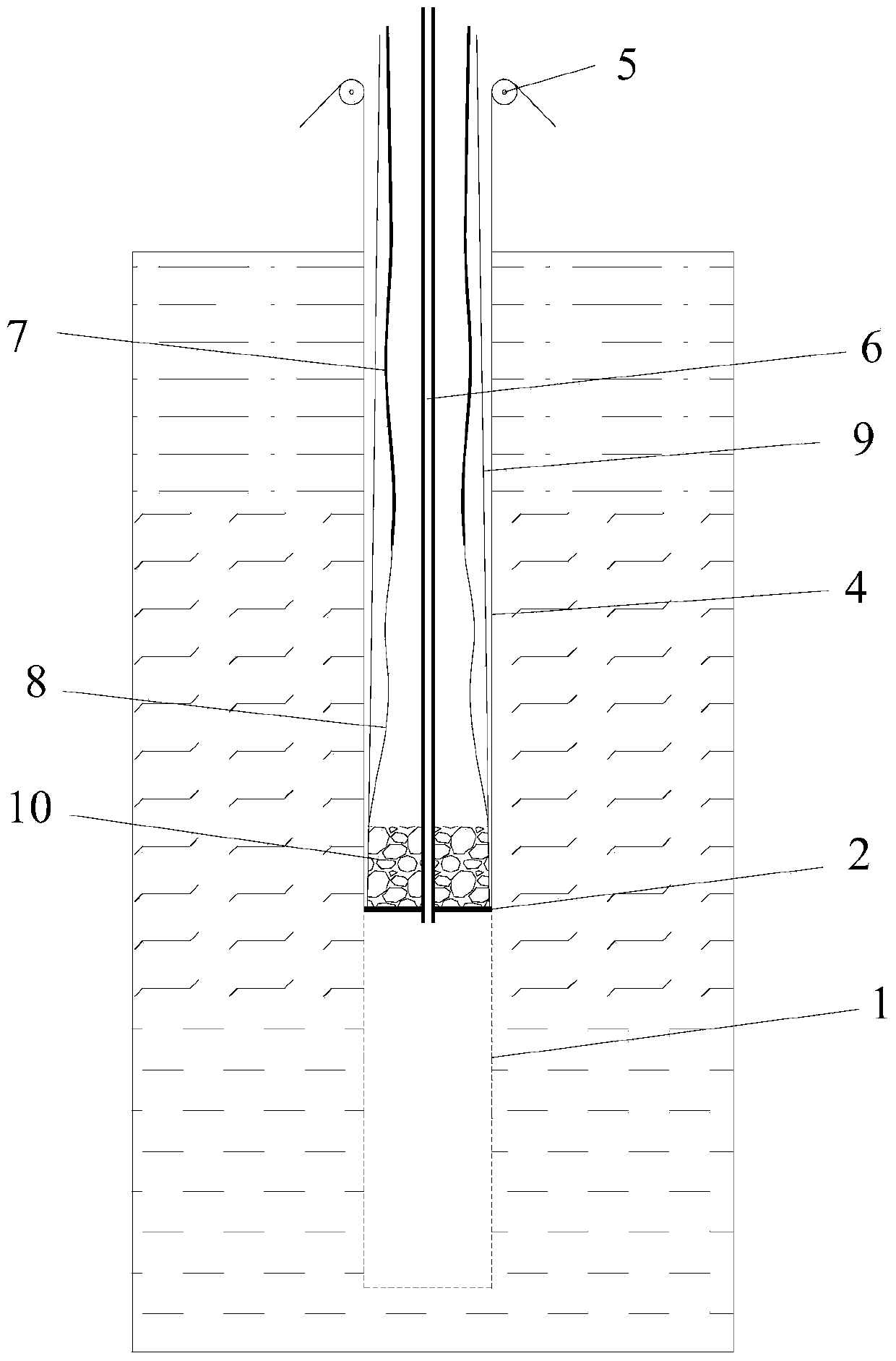

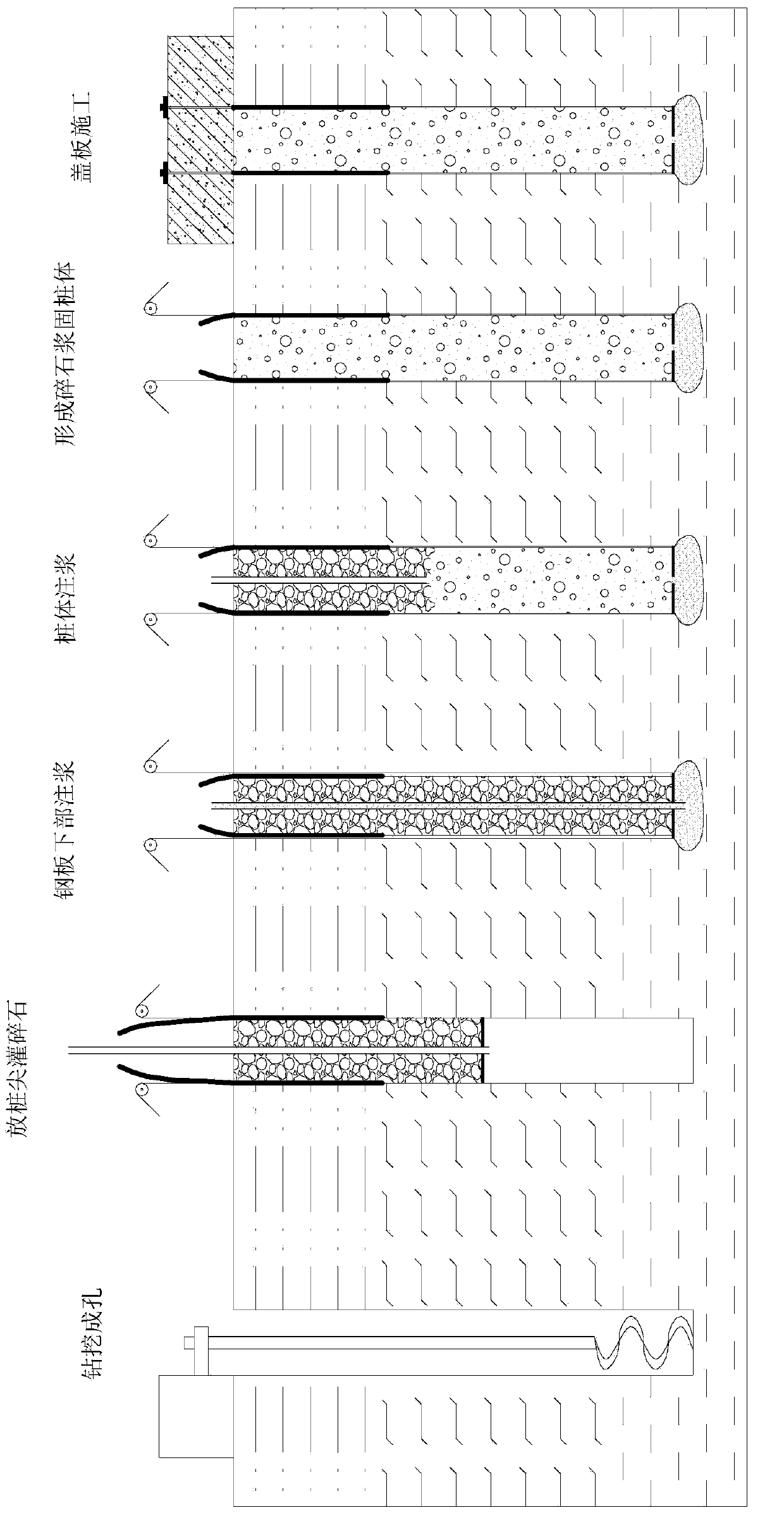

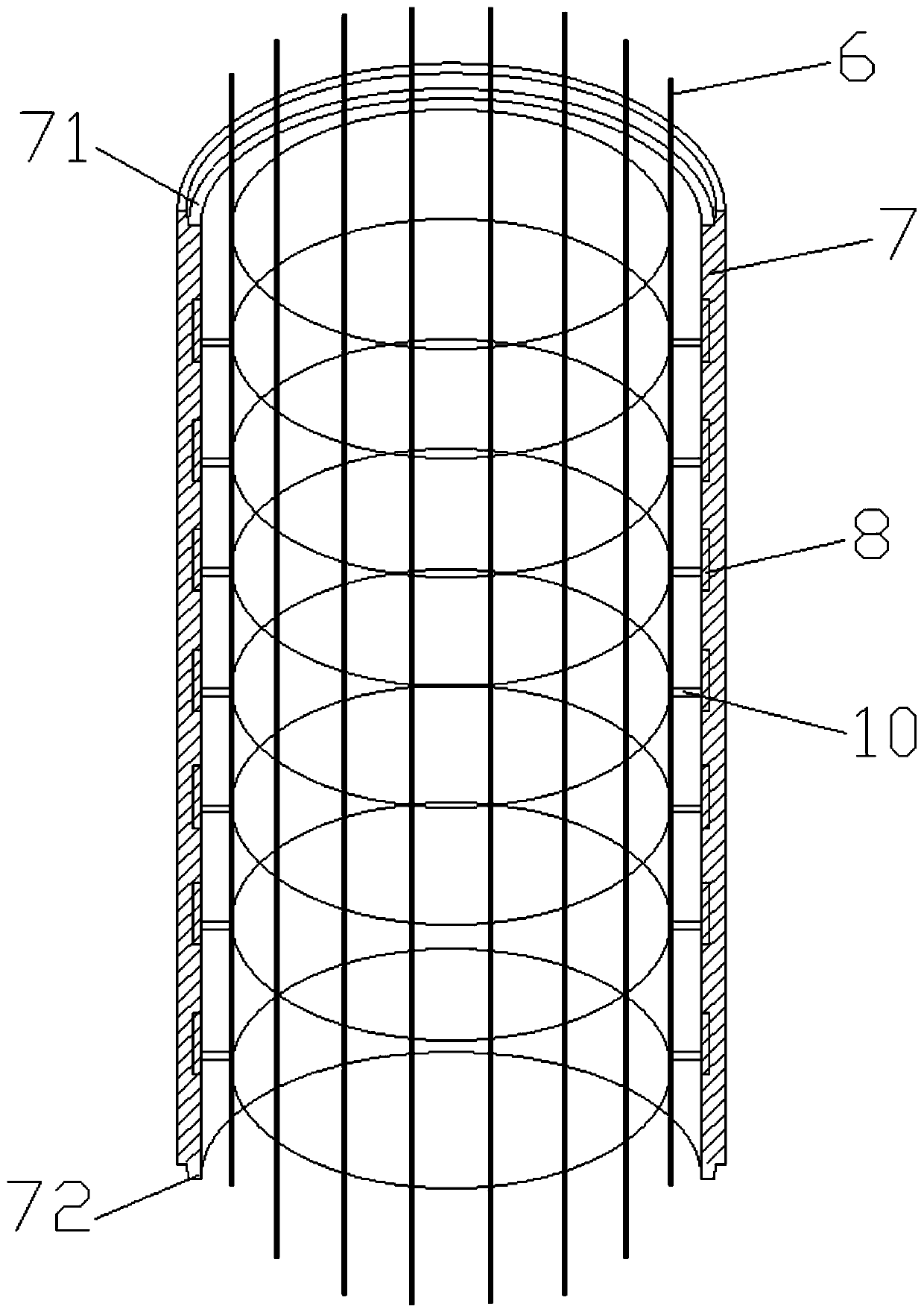

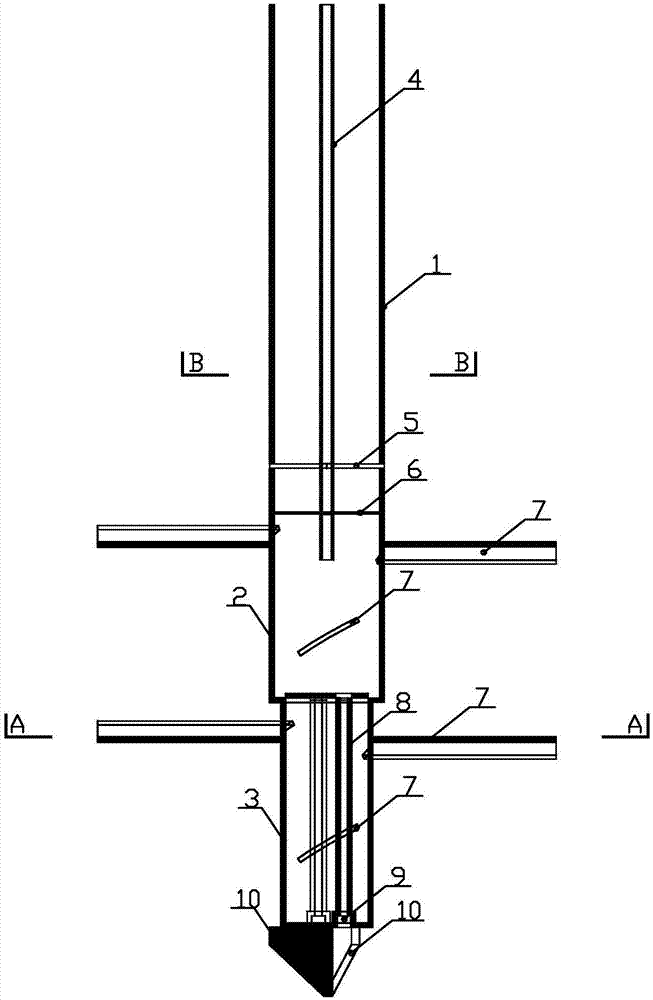

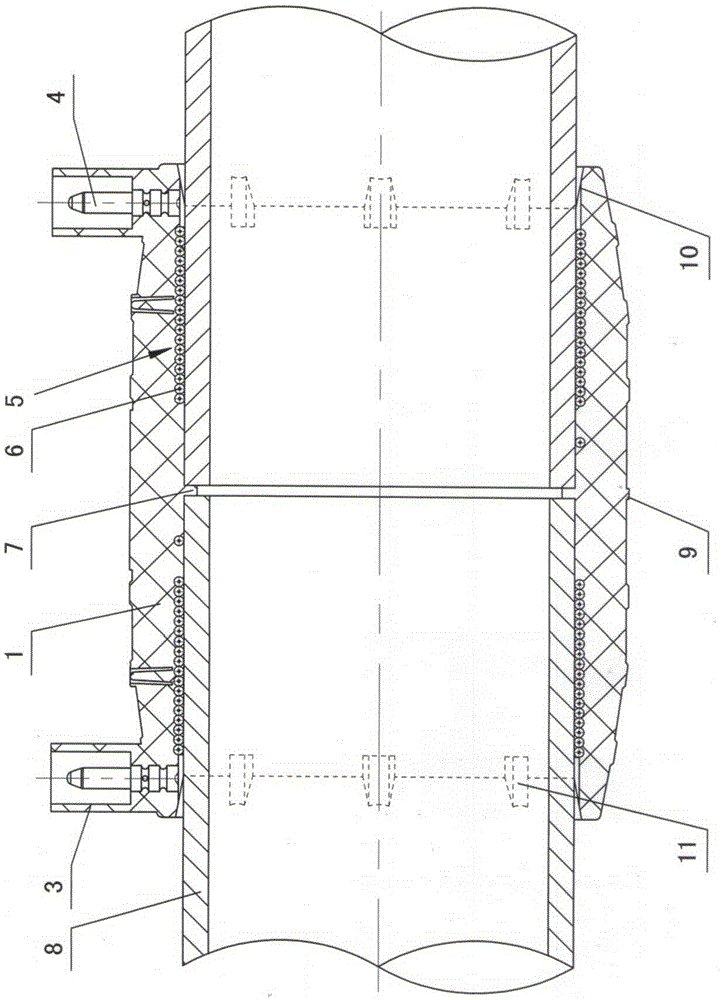

Crashed stone grouting pile with lead holes implanted in cloth bag and construction method

The invention discloses a crashed stone grouting pile with lead holes implanted in a cloth bag and a construction method. The crashed stone grouting pile is mainly composed of a prefabricated pile tip, steel strands, the geotechnical cloth bag, a pile end pulp solidification body, a crashed stone pulp solidification pile body and a cover plate. The fabricated pile tip is arranged at the bottom of the pile body. A reserved hole allowing a grouping pipe to penetrate through is formed in the center of the prefabricated pile tip, and holes allowing the steel strands to penetrate through are formed in the edge of the prefabricated pile tip. The pile tip pulp solidification body is formed at the bottom of the prefabricated pile tip through grouting. The crushed stone pulp solidification pile body is arranged on the upper portion of the prefabricated pile tip, and the geotechnical cloth bag is arranged outside the crushed stone pulp solidification pile body. The cover plate is arranged above the crushed stone pulp solidification pile body. The crashed stone grouting pile has the advantages that performance of bulk solid material is given into full play, the problems of necking, expansion, hole collapse, mud contamination and the like are solved for the pile body, the integrity and the bearing performance of the structure are improved, sedimentation of the pile body is reduced, the improvement of the bearing capacity of the foundation is accelerated, and quality of the pile is improved.

Owner:HANGZHOU JIANGRUN TECH LIMITED

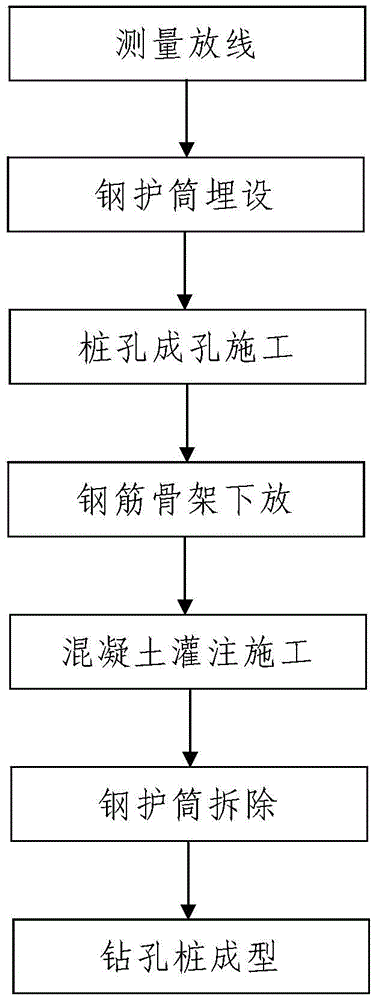

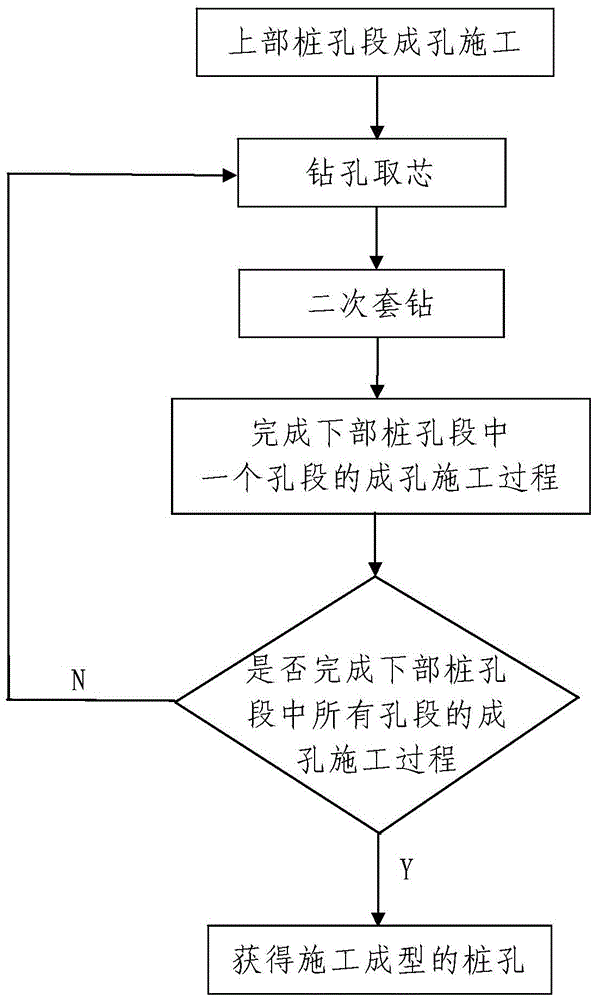

Construction method for bored pile of subway station enclosure structure of upper-soft lower-hard ground

ActiveCN105649012AThe method steps are simpleReasonable designDrill bitsCore removalSubway stationRebar

The invention discloses a construction method for a bored pile of a subway station enclosure structure of upper-soft lower-hard ground. The method includes the steps that firstly, measurement and paying-off are conducted, wherein measurement and paying-off are carried out at a pile position of the bored pile to be constructed, and the bored pile to be constructed is a cast-in-place pile constructed and formed in the upper-soft lower-hard ground; secondly, a steel casing is buried, wherein the steel casing is buried in the soft ground where the bored pile to be constructed is located; thirdly, drilling construction of pile holes is conducted; fourthly, a steel rib frame is laid down; fifthly, concrete pouring construction is conducted; sixthly, the steel casing is detached; seventhly, the bored pile is formed. Drilling construction of the pile holes includes the steps that 301, drilling construction is conducted on an upper pipe hole section and 302, drilling construction is conducted on a lower pile hole section, wherein the lower pile hole section is subjected to drilling construction by being divided into multiple pile hole section bodies from top to bottom, and when any hole section body is subjected to drilling construction, drilling for cores and secondary overcoring are conducted. The method is simple, design is reasonable, construction is easy and convenient, drilling difficulty of the pile holes is low, the use effect is good, and the bored pile construction process of the upper-soft lower-hard ground can be easily, conveniently and quickly completed.

Owner:CHINA RAILWAY FIRST GRP CO LTD

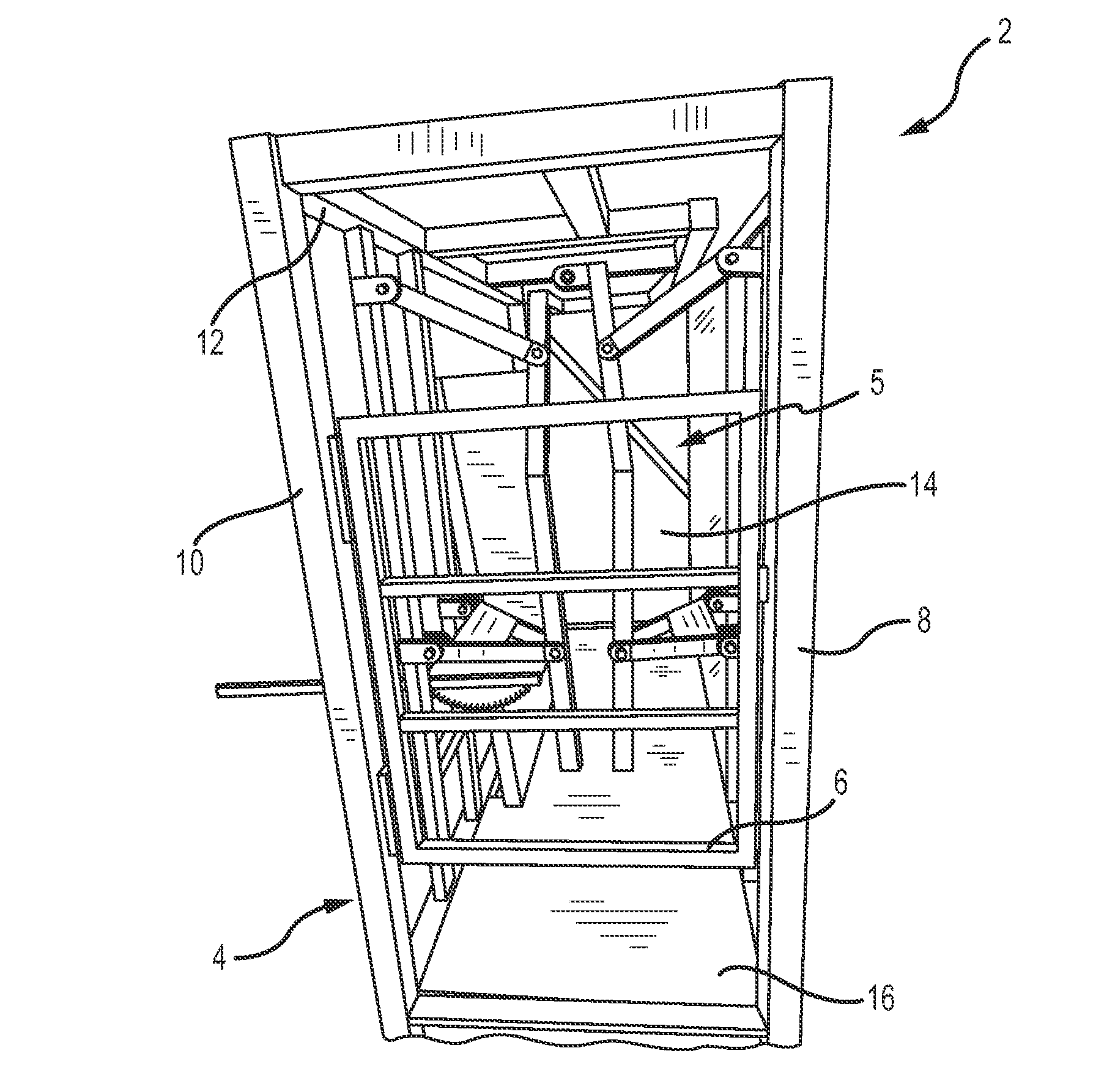

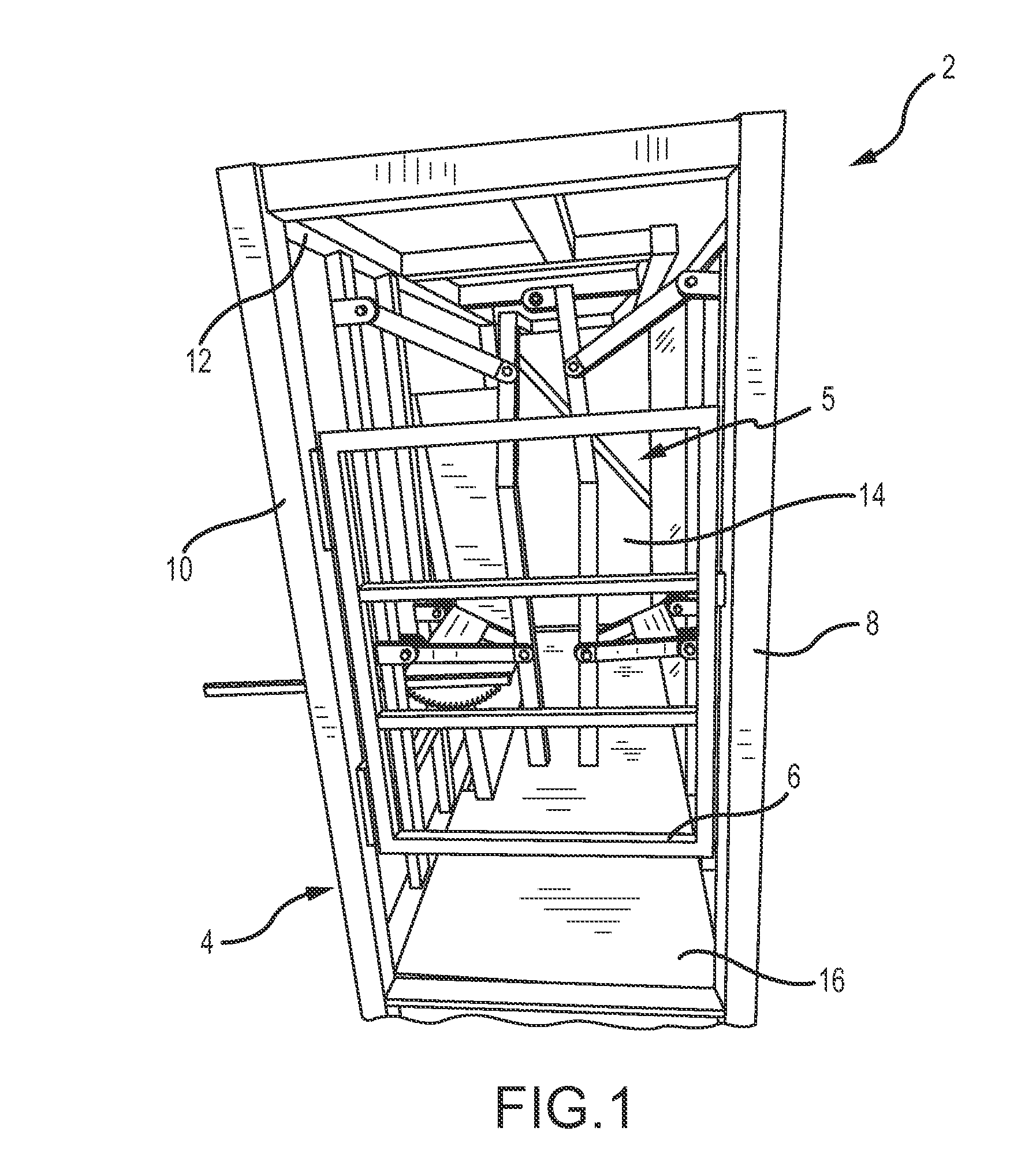

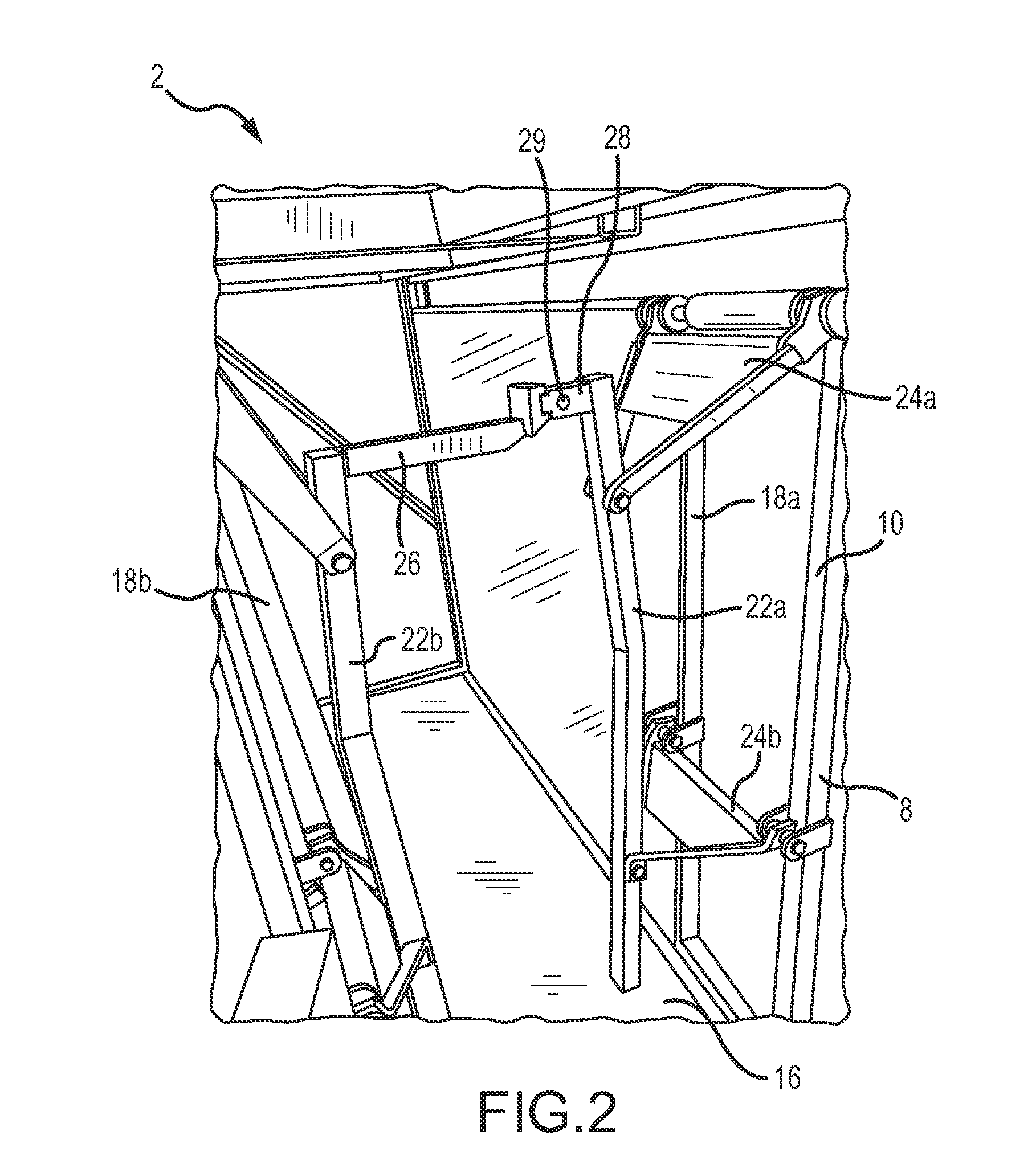

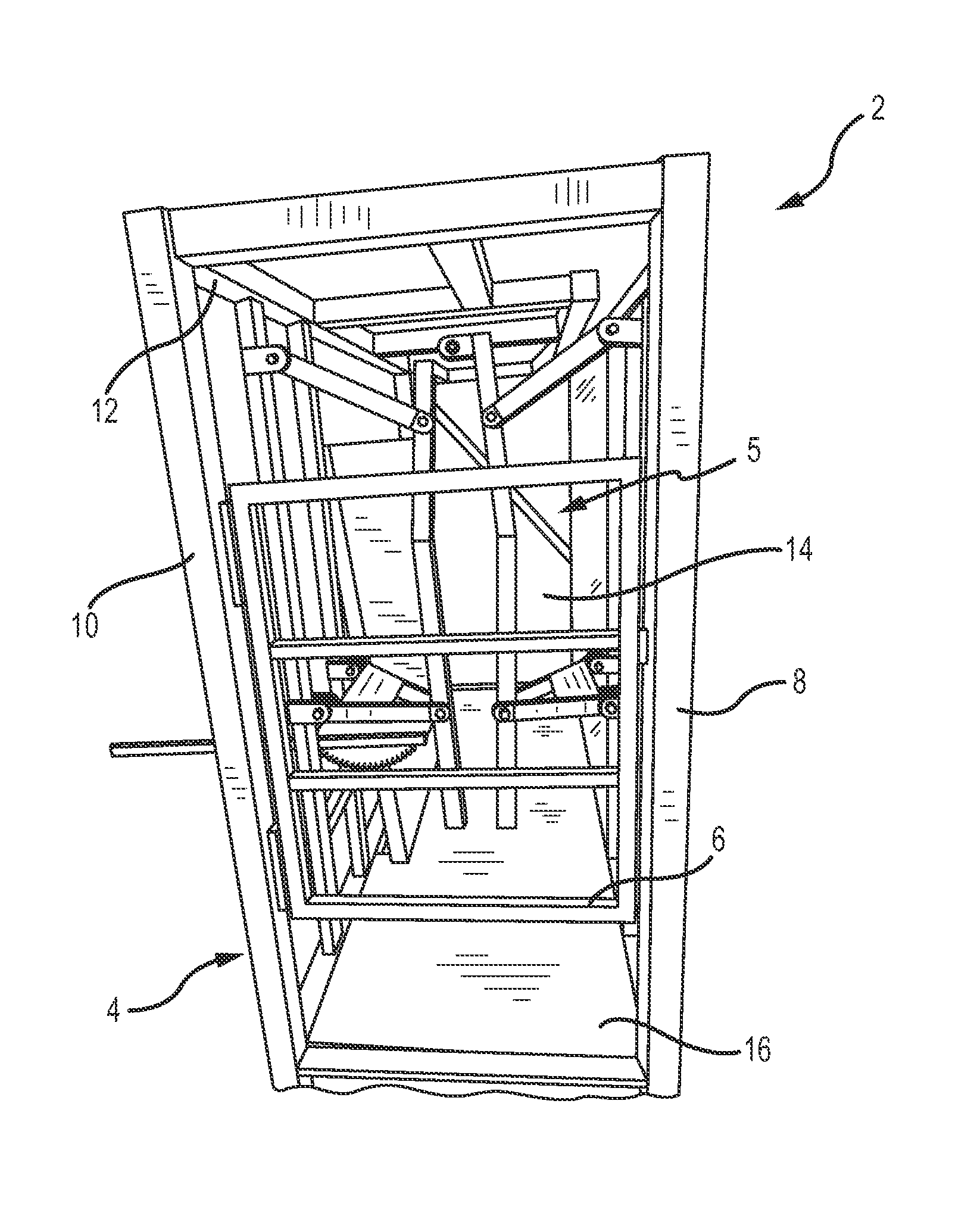

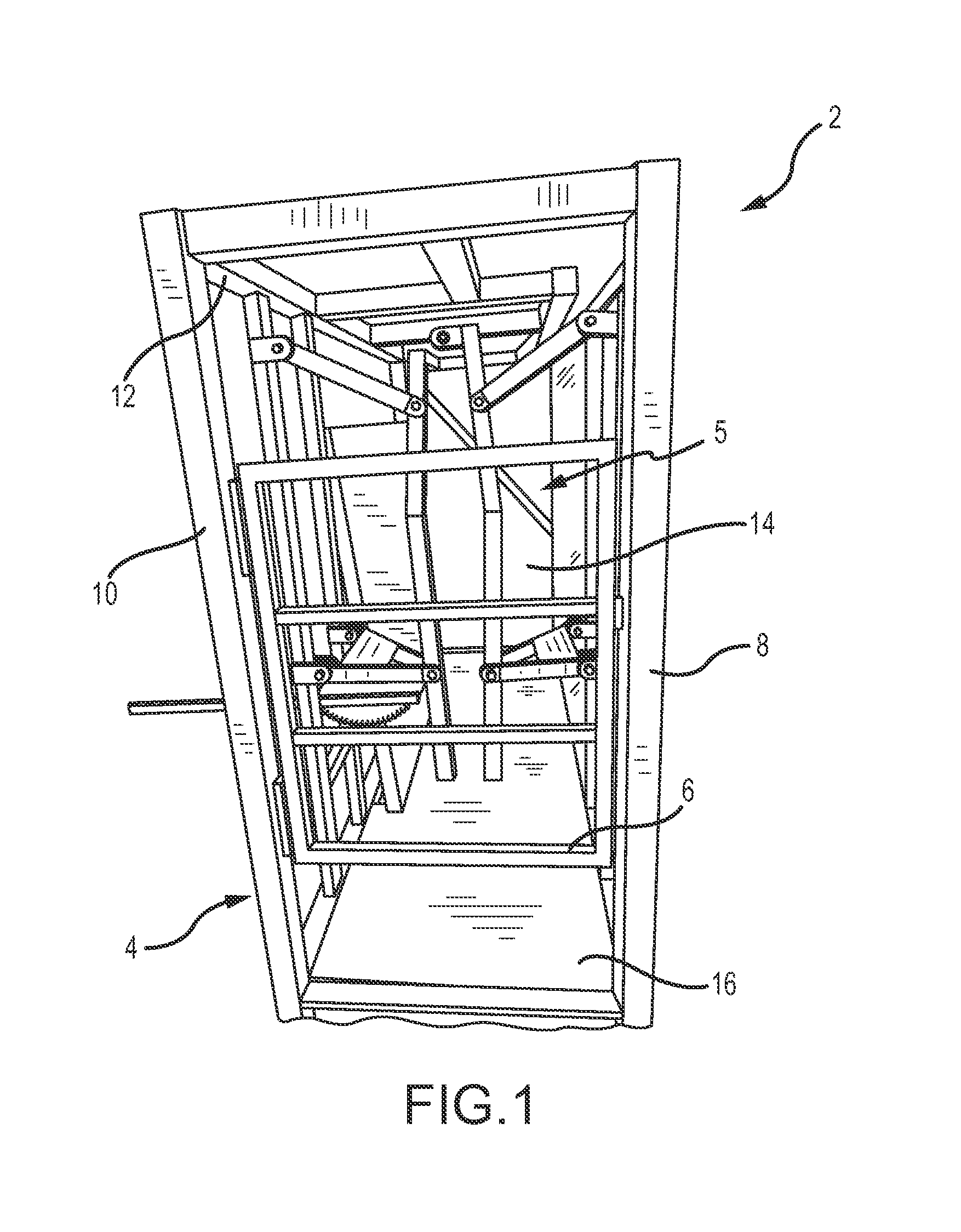

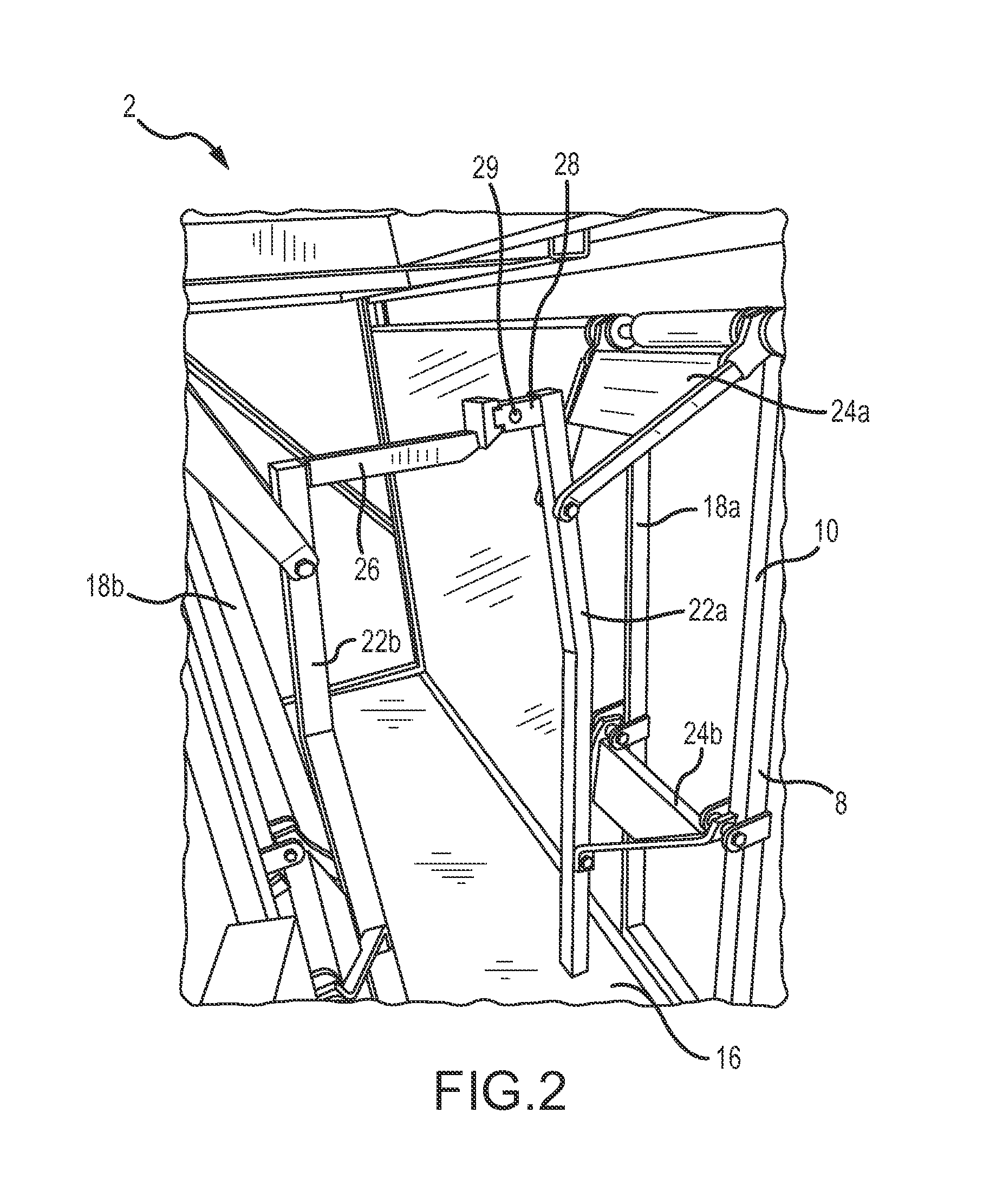

System and method for restraining and handling livestock

InactiveUS20150359233A1Quantity minimizationEfficient loadingSlaughtering animals fettering apparatusSlaughtering stands/spreadersEngineeringHuman operator

A restraining pen for livestock is provided for humane, safe and efficient handling of livestock. A restraining or knocking pen is provided that has features for securely receiving an animal such that the animal may be subject to knocking or veterinary operations and subsequently released from the pen without danger to the animal or human operators. A novel design provides for a compact footprint of the pen and an economical use of space.

Owner:CALLICRATE TEEGAN

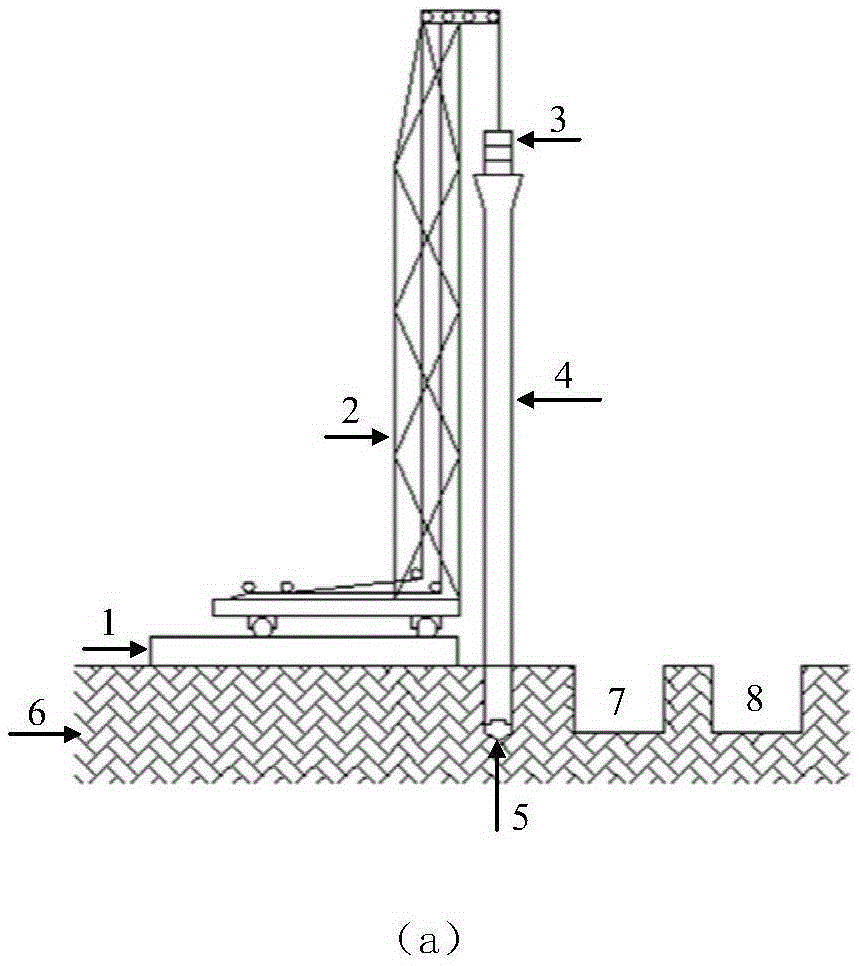

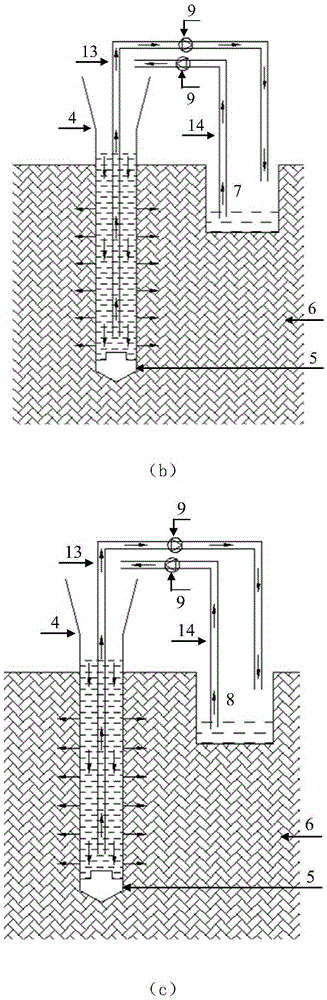

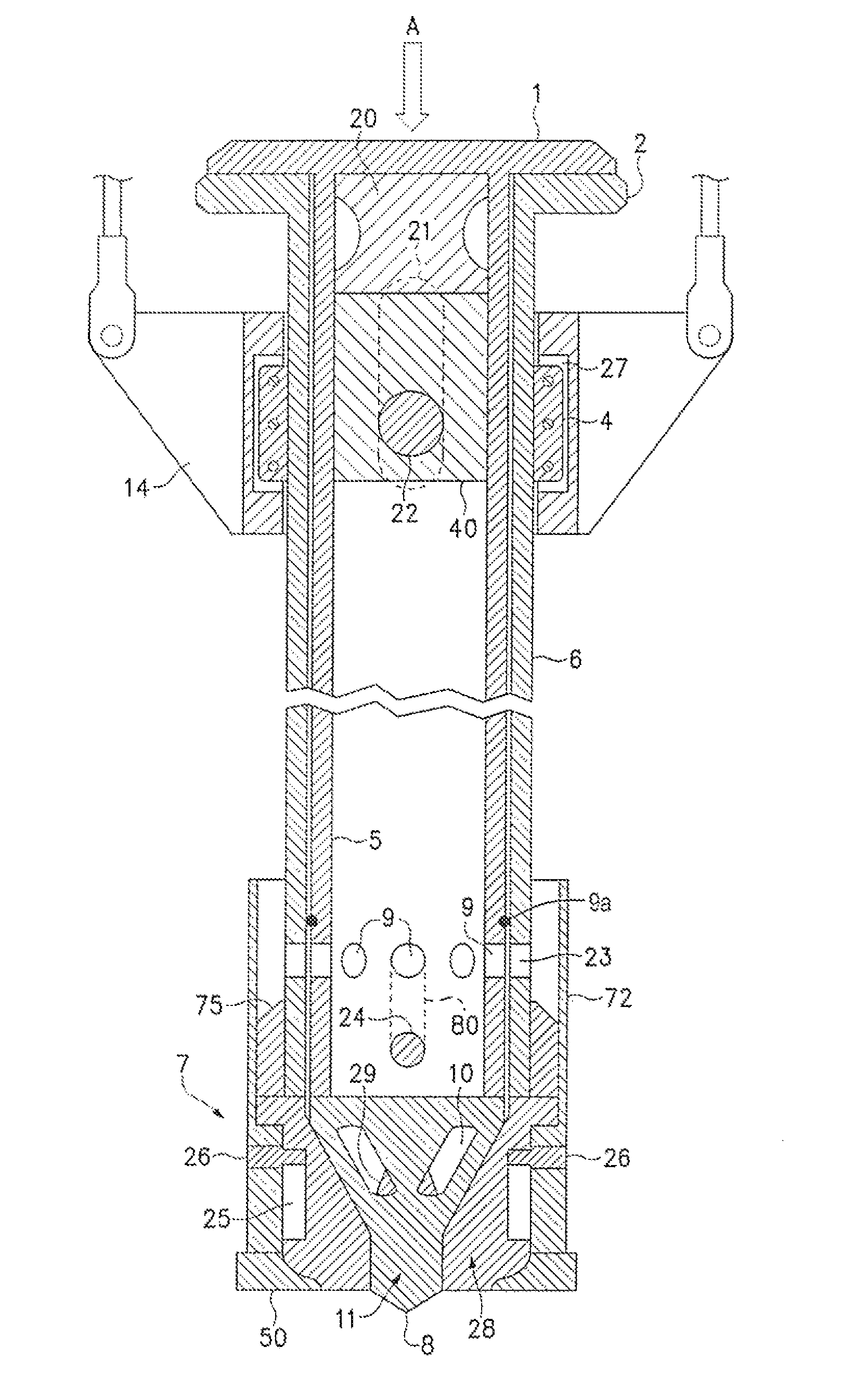

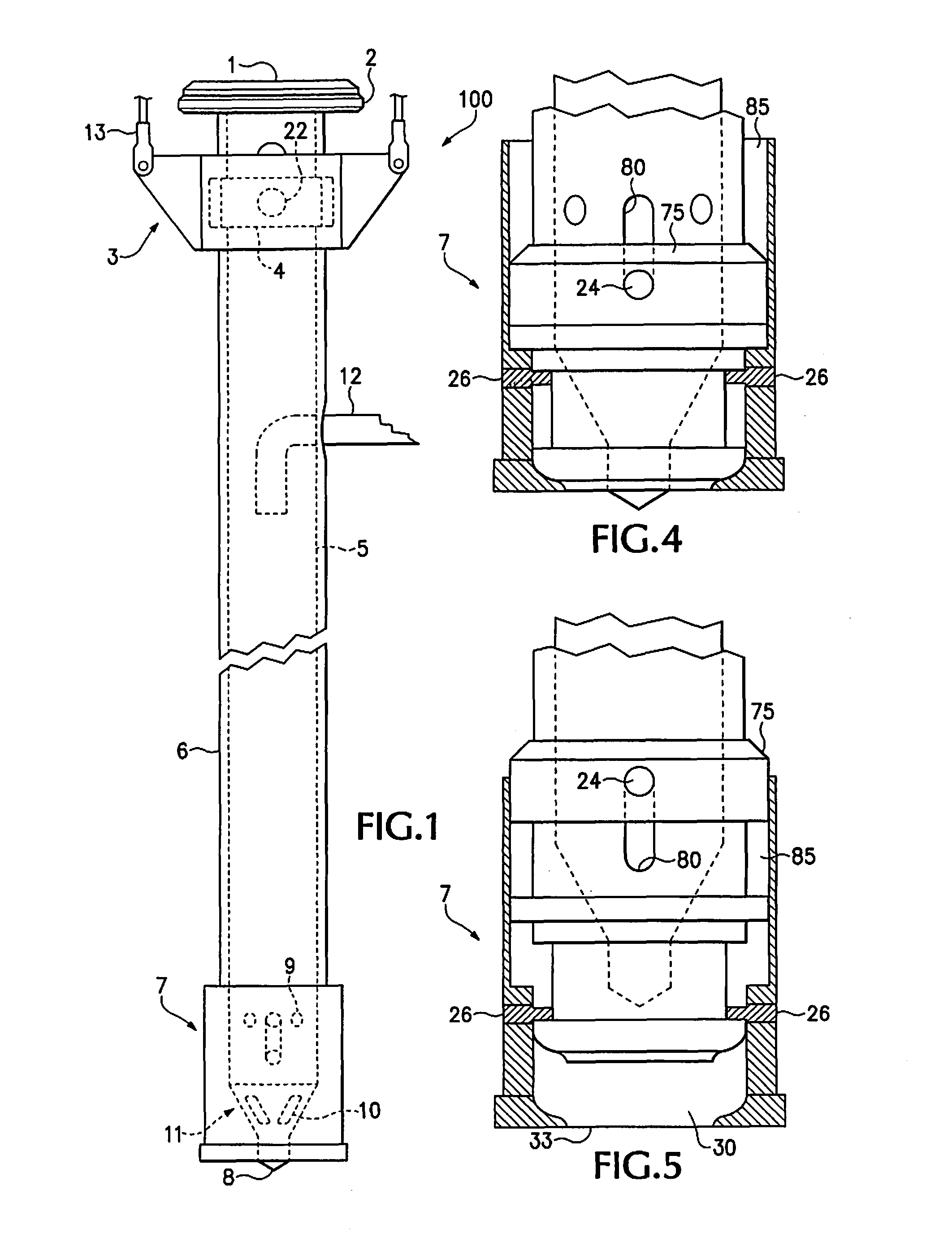

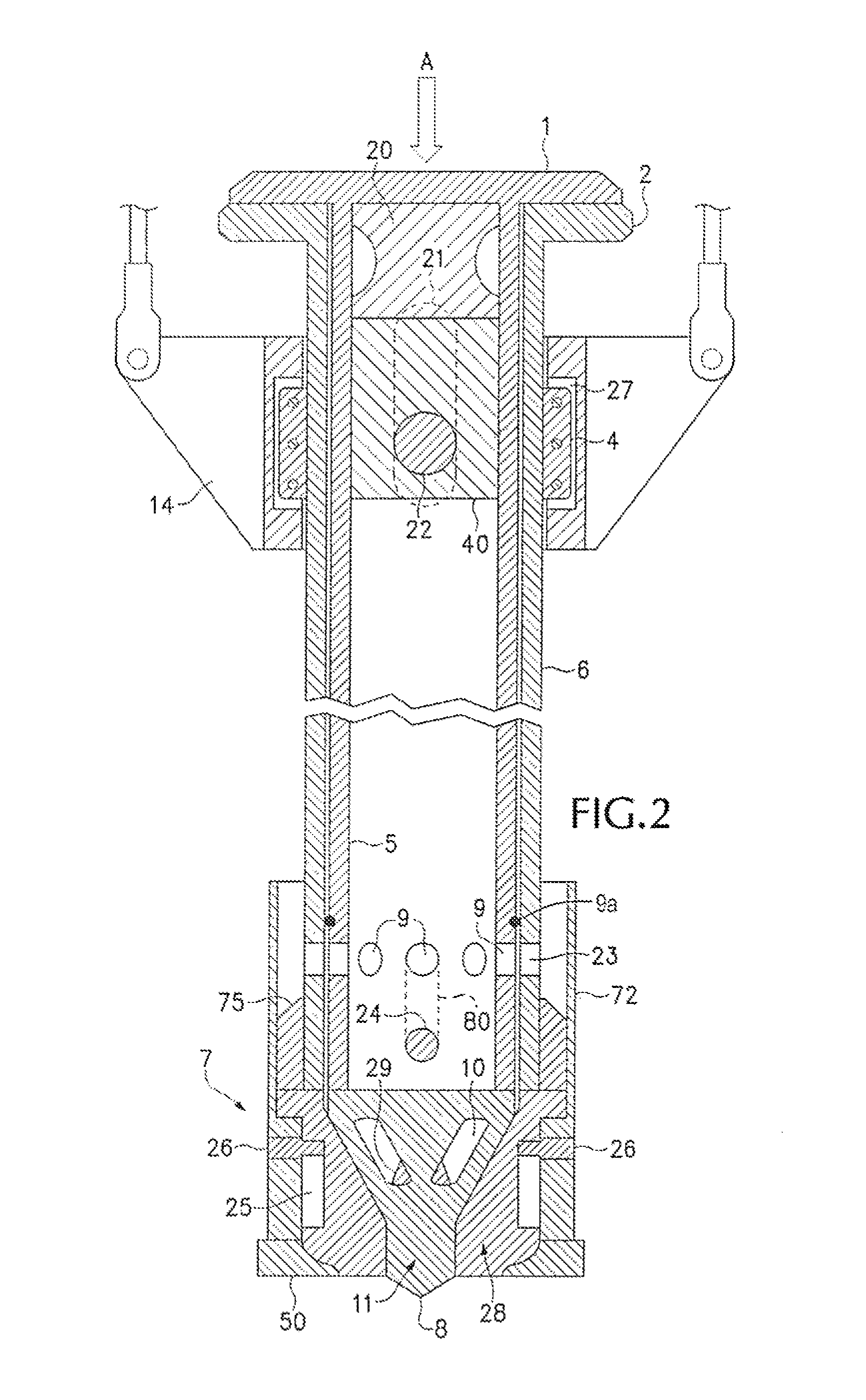

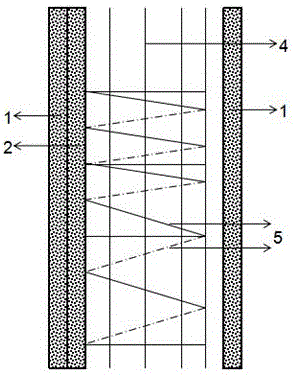

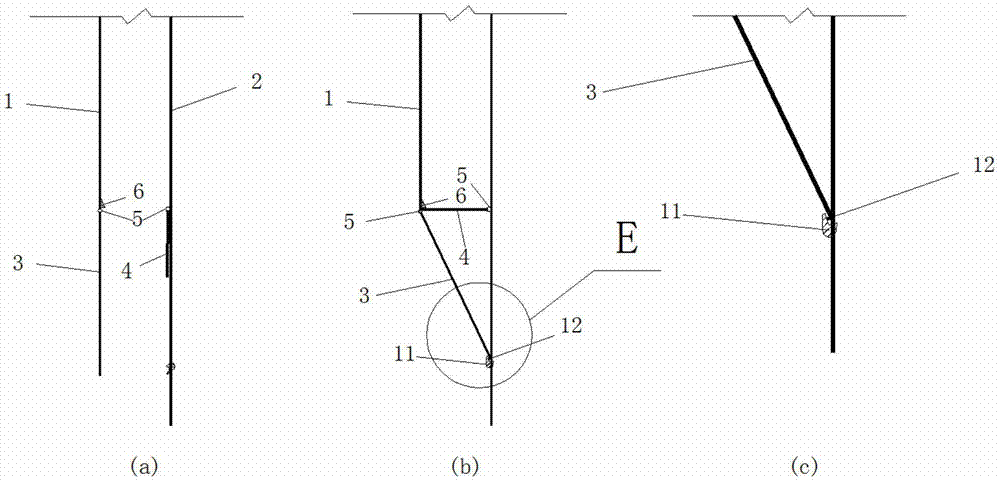

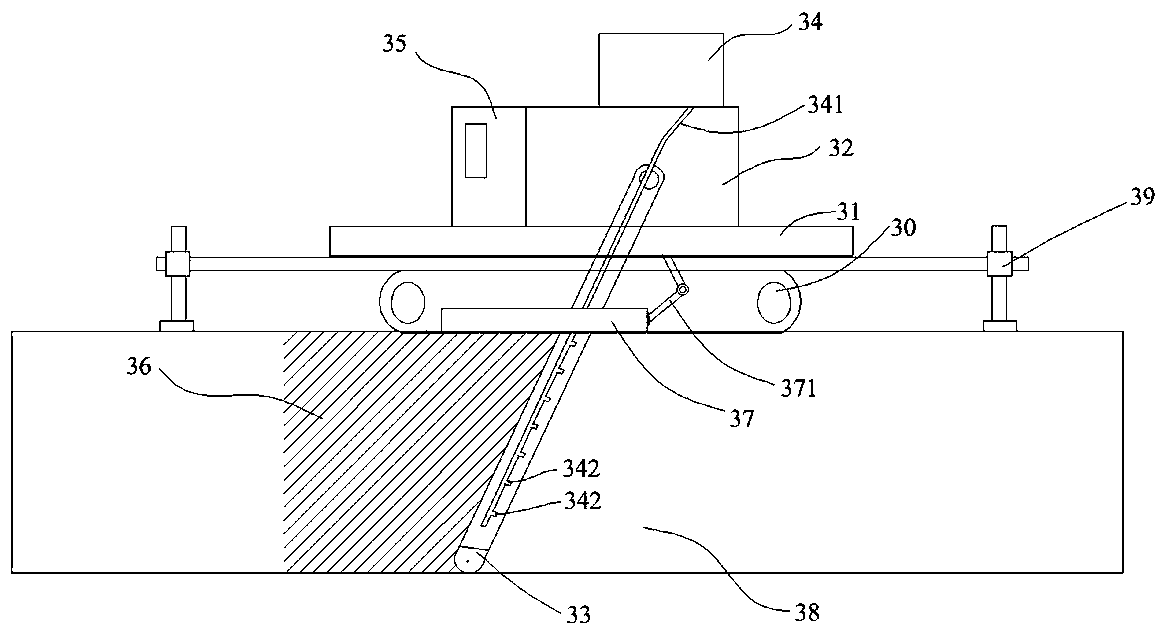

Method and apparatus for forming in ground piles

InactiveUS7726913B1Easy to slideAvoid neckingBarrages/weirsDrilling rodsEngineeringMechanical engineering

The present invention is an apparatus and a method for casting a cementitious or stone pile into the ground. The present invention comprises an exterior driving casing and an interior mandrel acting in cooperation to hold and deliver the pile forming material. A retrievable driving driving shoe is also disclose.

Owner:SJOGREN DAVID

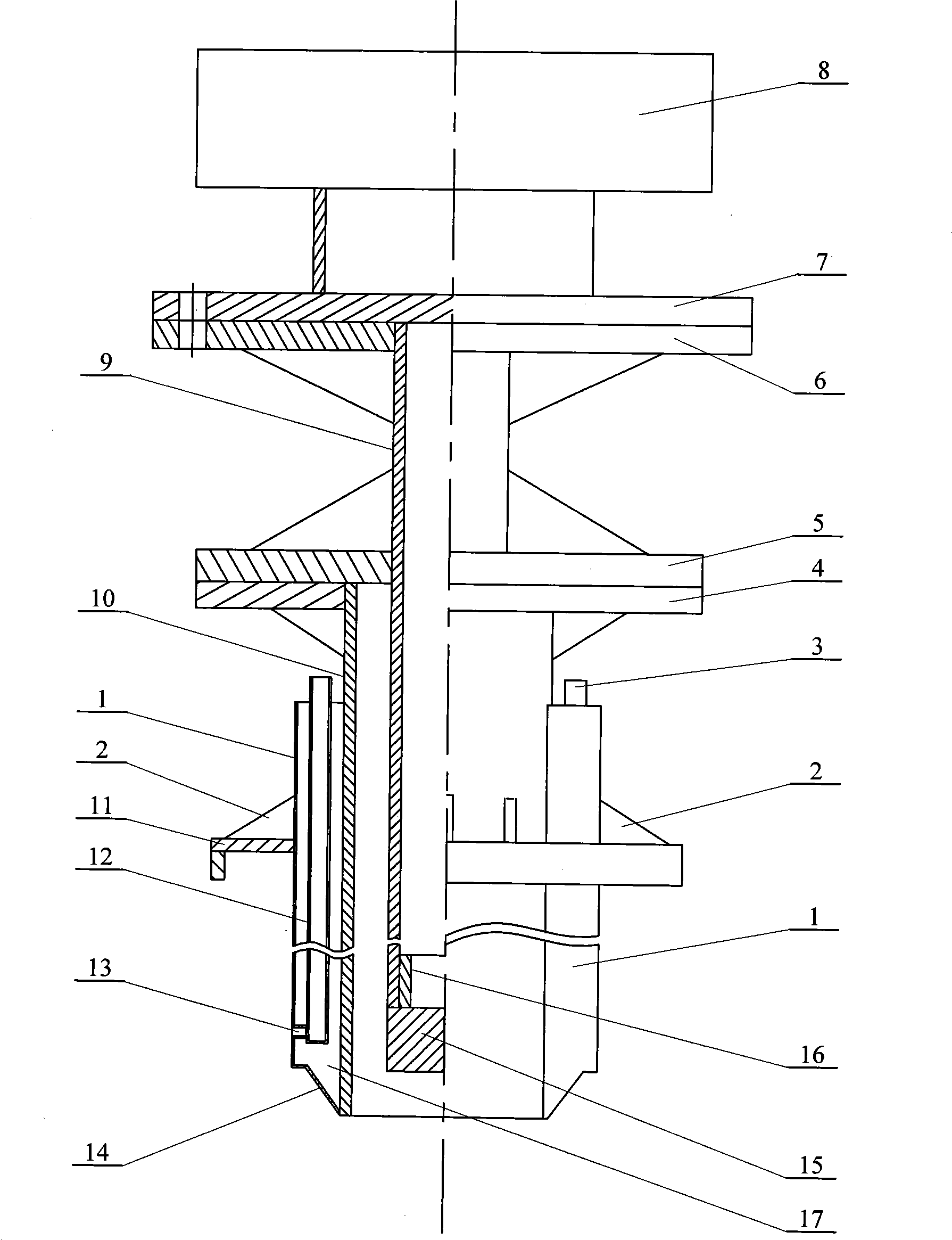

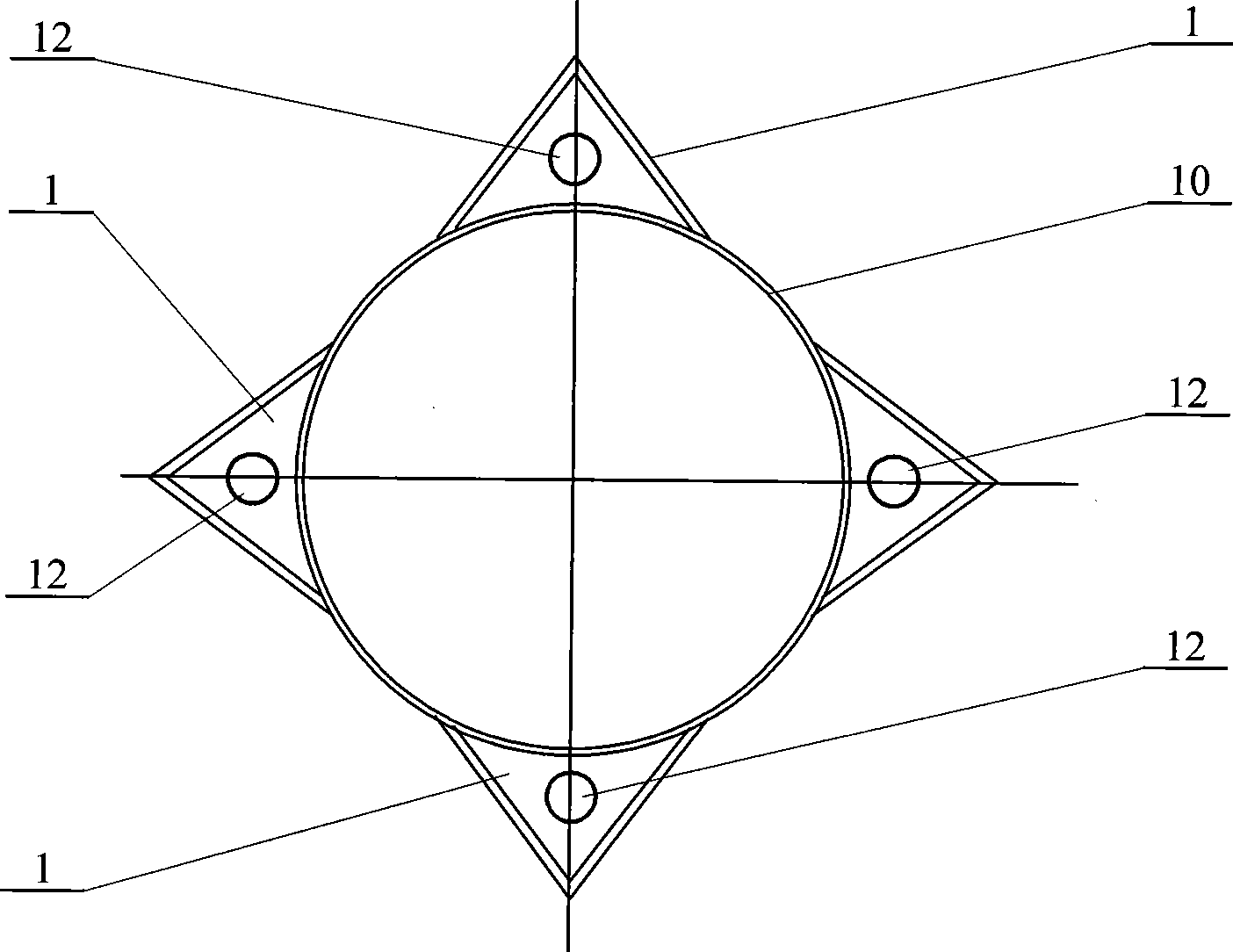

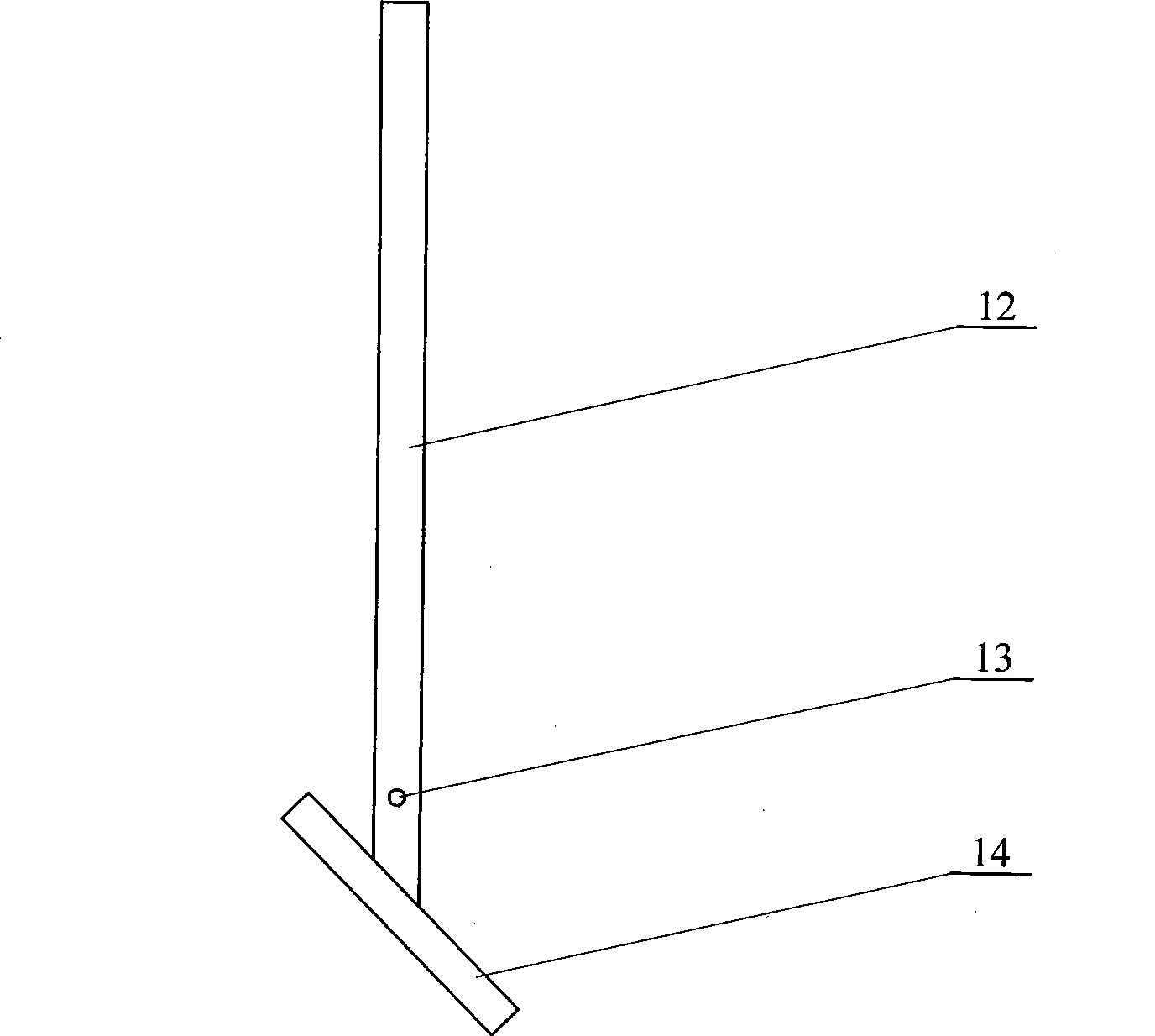

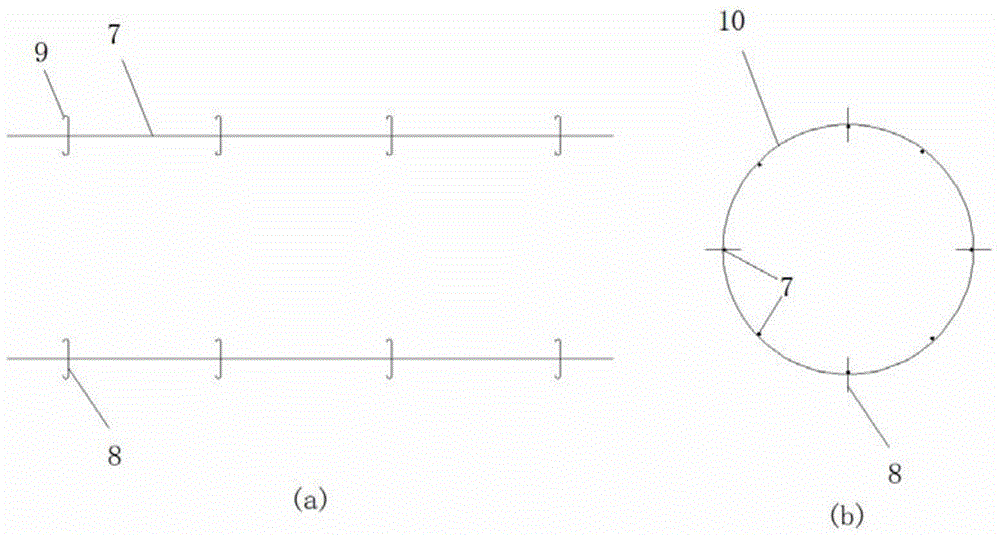

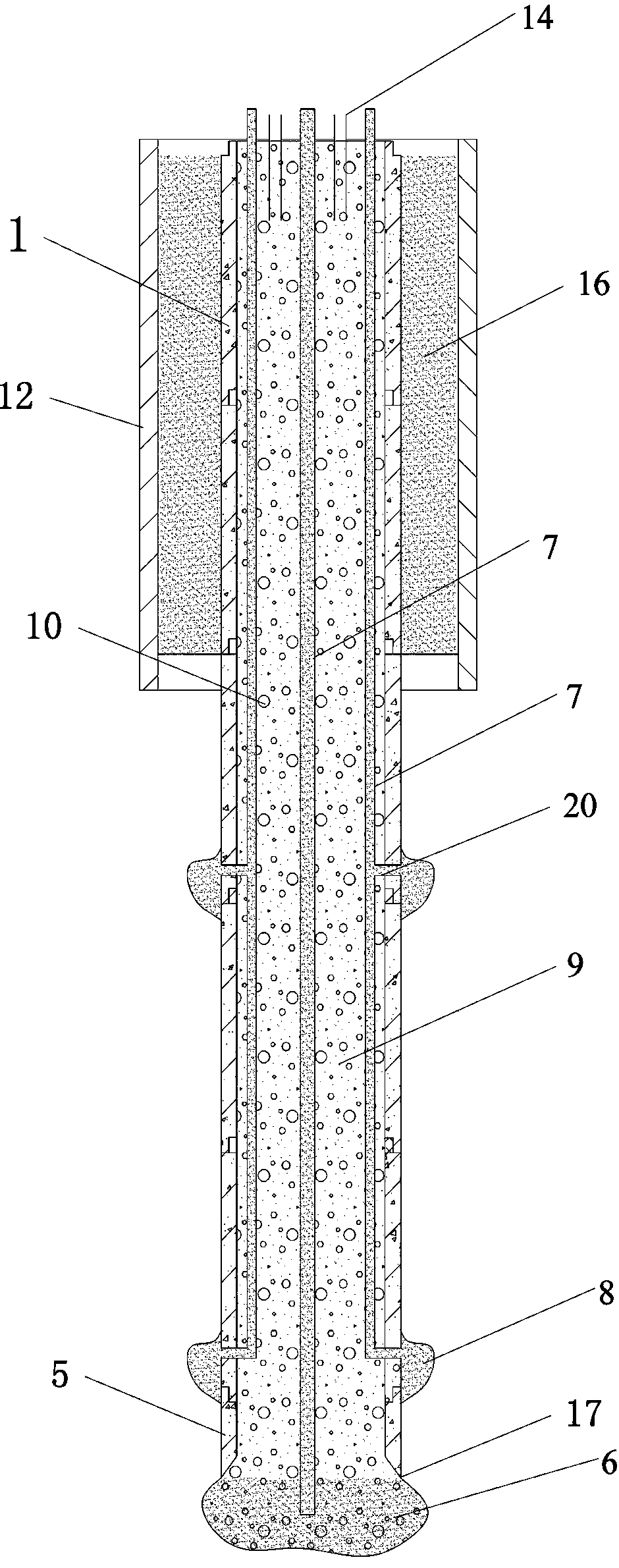

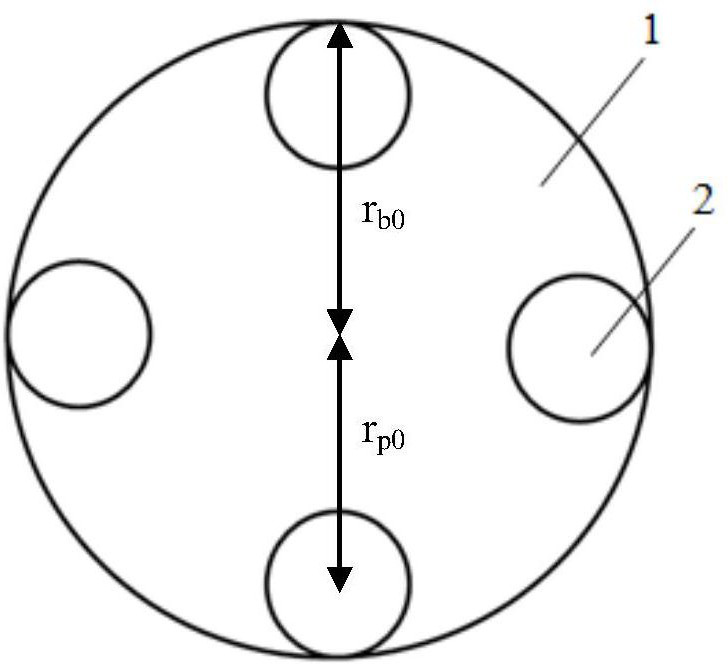

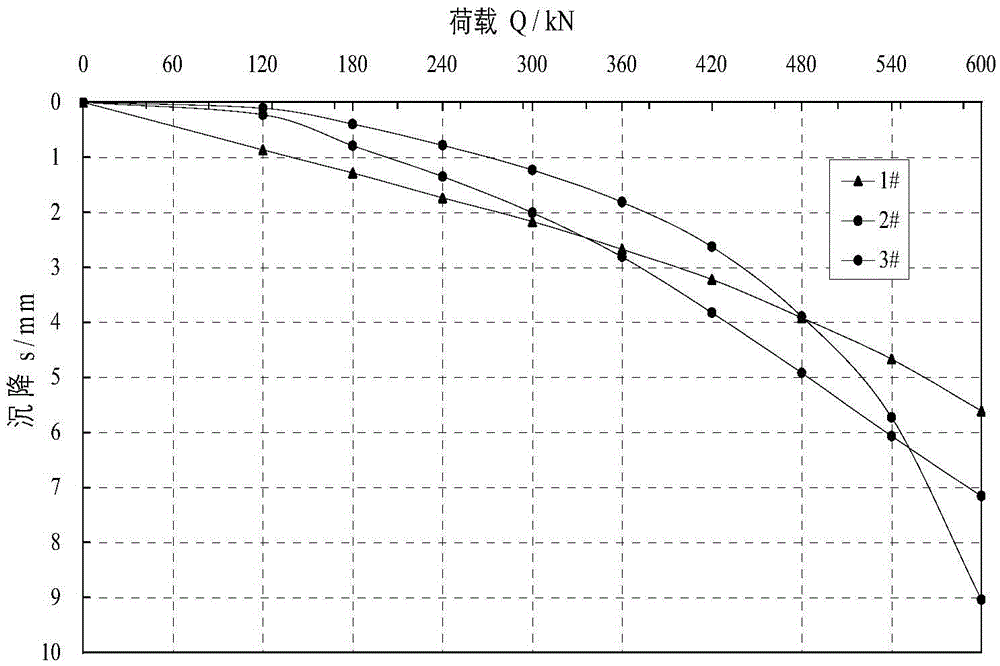

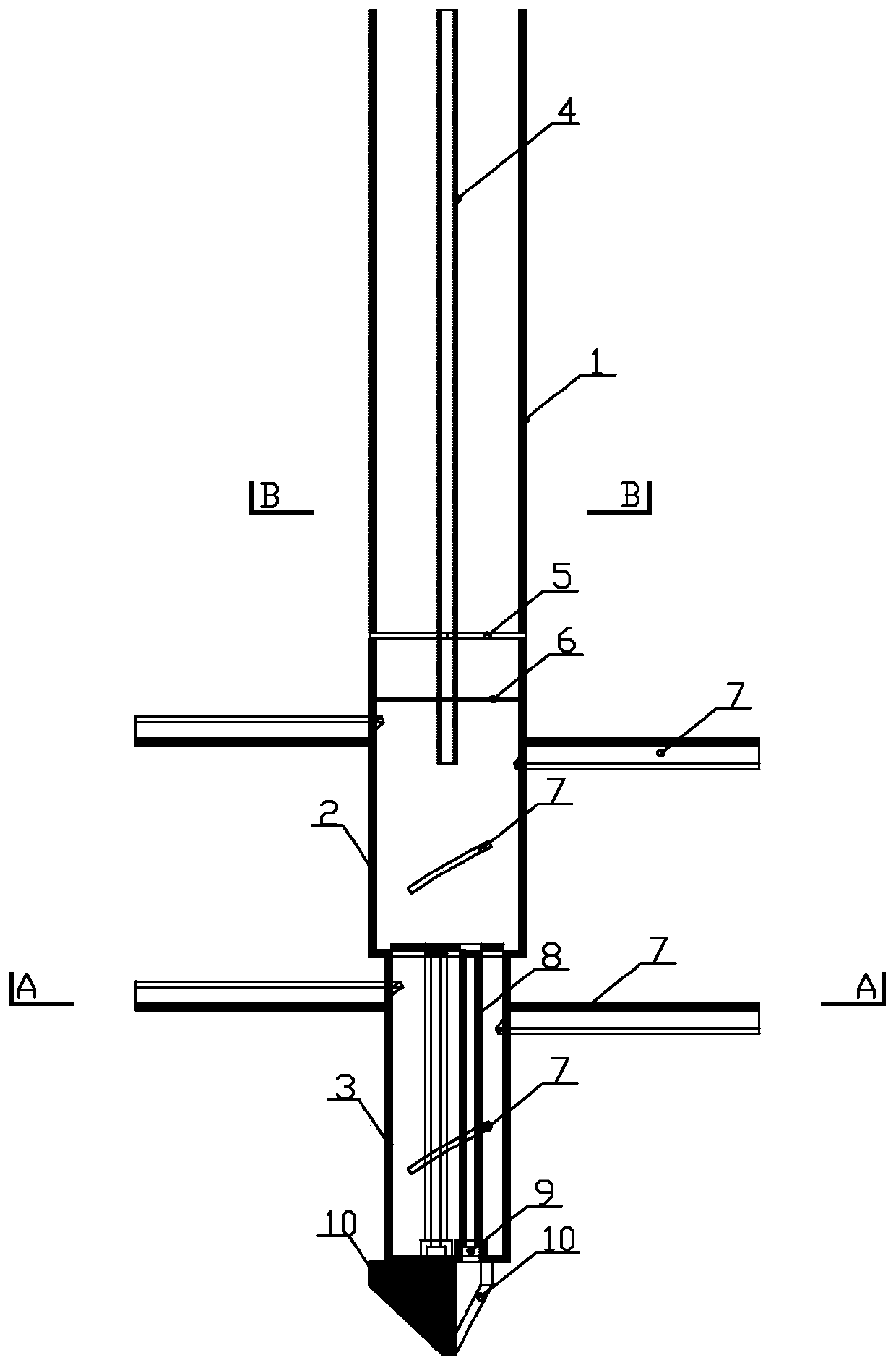

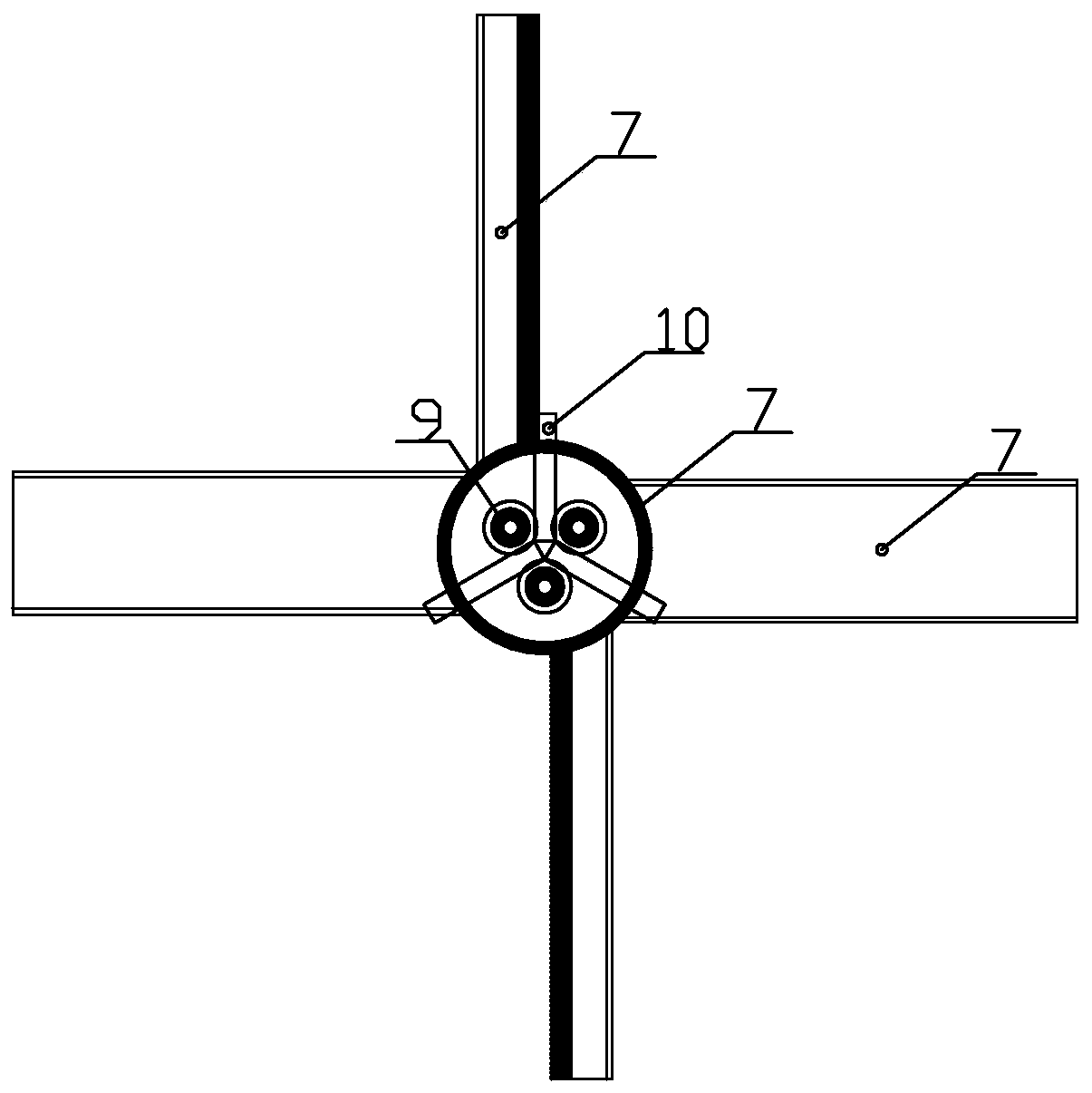

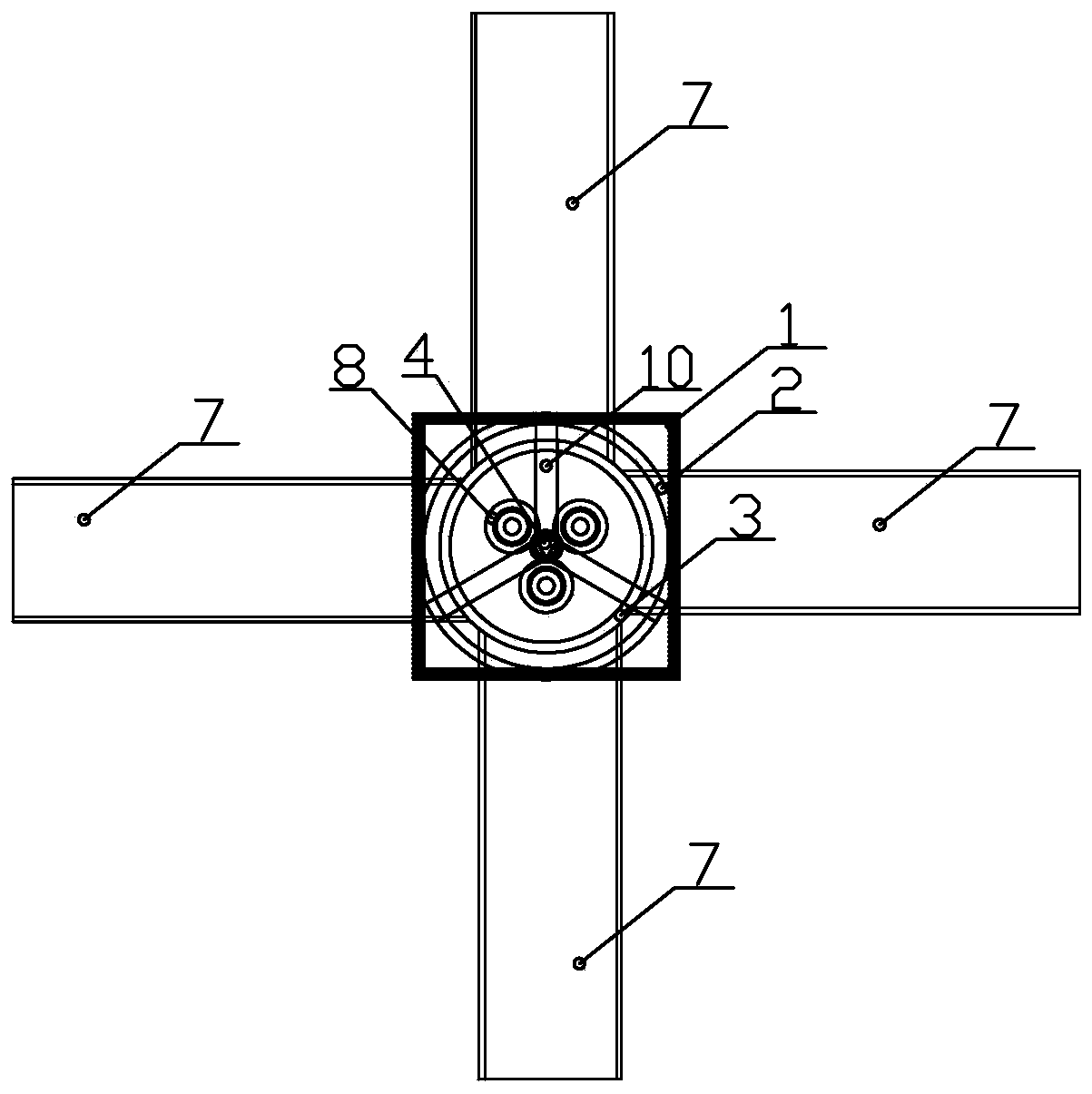

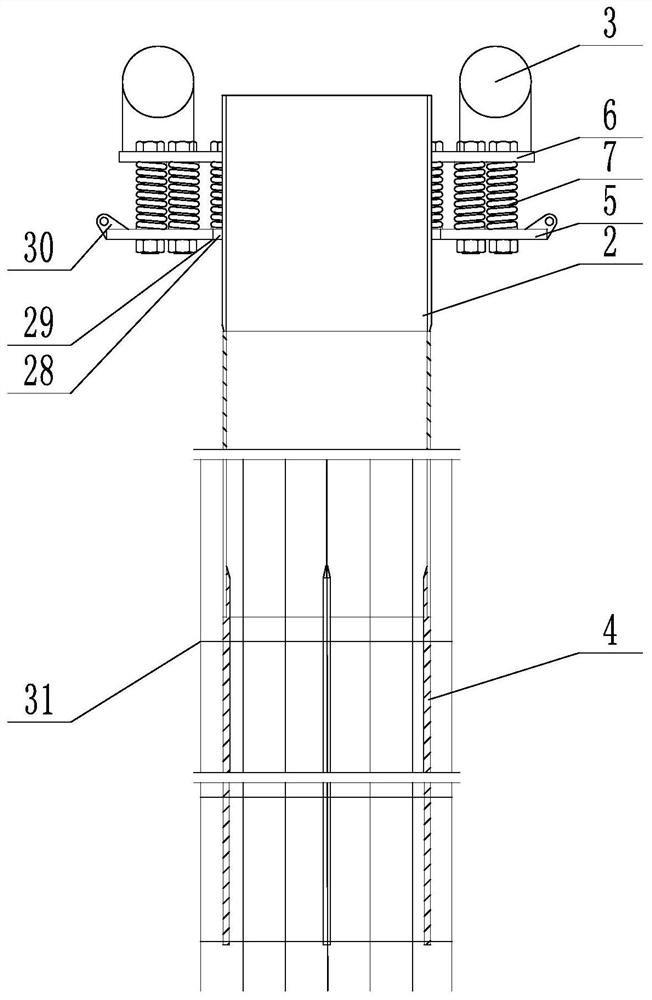

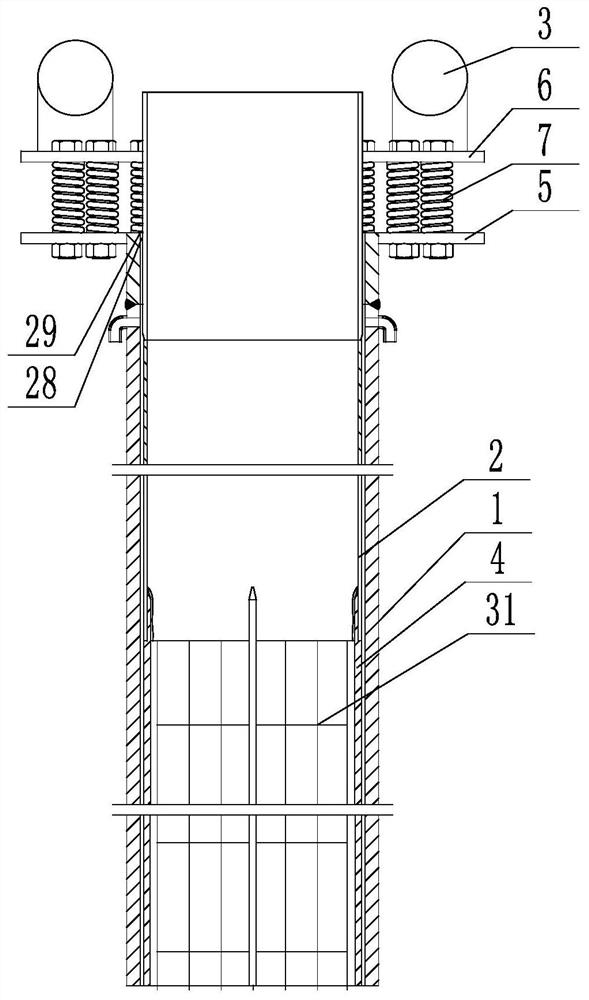

Pile forming apparatus and method for mud-jacking inner-ramming pedestal pile

The invention provides a pile-forming device for a grouting internal-ramming pedestal pile and a pile-forming method thereof, relating to a pile-forming device and a method. The device and the method aim at solving the problems that the existing internal-ramming pile has bad side friction and anti-pulling capability, is easy to generate the necking and breaking problem and has low construction efficiency. The injection pipe of the device is fixed in an external steel plate with a sealed cavity; the bottom end of the external steel plate with the sealed cavity is fixedly provided with a lower sealing plate with a sealed cavity; the invention is provided with four methods as follows: method one: an external pipe is impacted by a hammer, meanwhile, the grout is injected into the injection pipe by a pump, with the injection pressure of 0.3-10MPa; method two: an internal pipe is impacted by a diesel hammer, a hydraulic hammer or a vibration hammer and the filling material is impacted; method three: the external pipe and a pre-fabricated pile are impacted to a design depth by the diesel hammer, the hydraulic hammer or the vibration hammer; method four: the pre-fabricated pile is impacted into the pile hole, wherein, the diameter of the external pipe is less than or equal to the maximum internal tangent round of the pre-fabricating pile. The device has high construction efficiency and is suitable for various soil qualities. The method reduces the generation of necking and breaking, and improves the bearing capability by more than 30%.

Owner:李永刚

System and method for restraining and handling livestock

InactiveUS9259009B2Quantity minimizationEfficient loadingSlaughtering animals fettering apparatusAnimal housingEngineeringHuman operator

A restraining pen for livestock is provided for humane, safe and efficient handling of livestock. A restraining or knocking pen is provided that has features for securely receiving an animal such that the animal may be subject to knocking or veterinary operations and subsequently released from the pen without danger to the animal or human operators. A novel design provides for a compact footprint of the pen and an economical use of space.

Owner:CALLICRATE TEEGAN

Opening filling method

ActiveCN102543835AImprove reliabilityAvoid neckingSemiconductor/solid-state device detailsVacuum evaporation coatingDiffusion barrierDielectric layer

The invention provides an opening filling method, which includes: providing a semiconductor substrate at least comprising an underlying metal wire layer and an isolation dielectric layer above the underlying metal wire layer, wherein an opening is arranged in the isolation dielectric layer; sequentially forming diffusion barrier layers and seed layers on the surface of the isolation dielectric layer inside the opening and outside the opening; forming a mask layer on the surface of each seed layer outside the opening; and covering a metallic layer on the semiconductor substrate with the mask layers, and filling the opening with the metallic layer. As the diffusion barrier layers and the seed layers are sequentially formed on the surface of the isolation dielectric layer inside the opening and outside the opening, and the mask layers are formed on the surfaces of the seed layers outside the opening, under the barrier action of the mask layers, in the follow-up process of depositing the metallic layer on the semiconductor substrate, the metallic layer is not deposited on the surface inside and outside the opening simultaneously but is used for filling the inside of the opening firstly prior to depositing on the outer surface of the opening. Therefore, necking can be avoided, probability of void defects is decreased or eliminated, and reliability of circuits is enhanced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Construction method of hard soil field PCC pile

ActiveCN104929108AReduce side frictionAvoid disturbanceBulkheads/pilesExtrusionBuilding construction

The invention discloses a construction method of a hard soil field PCC pile. A valve pile shoe is arranged in a pile mold inner pipe; the length of a pile mold outer pipe is increased; and after a pile machine is in place, soil having the same section with a pile mold is taken in the center of a pile position. The outer pipe is longer than the closed valve pile shoe; a pile tip formed by the valve pile shoe is inwards inclined; in the vibration mold sinking process, the pile mold mainly generates inward horizontal component force on pile core soil, so that the pile core soil is inwards deformed to fill a reserved cavity, and the disturbance on pile side soil is little; meanwhile, the extrusion stress of the pile core soil on the inner pipe is reduced, and the mold sinking difficulty is reduced in the pile mold driving process; and in the pile mold hoisting process, the side friction resistance of the pile core soil on the inner pipe is reduced, that is, the ascending force of the pile core soil is reduced. The construction method is simple in structure, easy to realize, convenient for operation and low in cost, can effectively reduce the mold dipping difficulty on the hard soil layer and the ascending force of the pile core soil, and is an efficient and practical method in the PCC pile construction.

Owner:江苏斯维尔工程技术有限公司

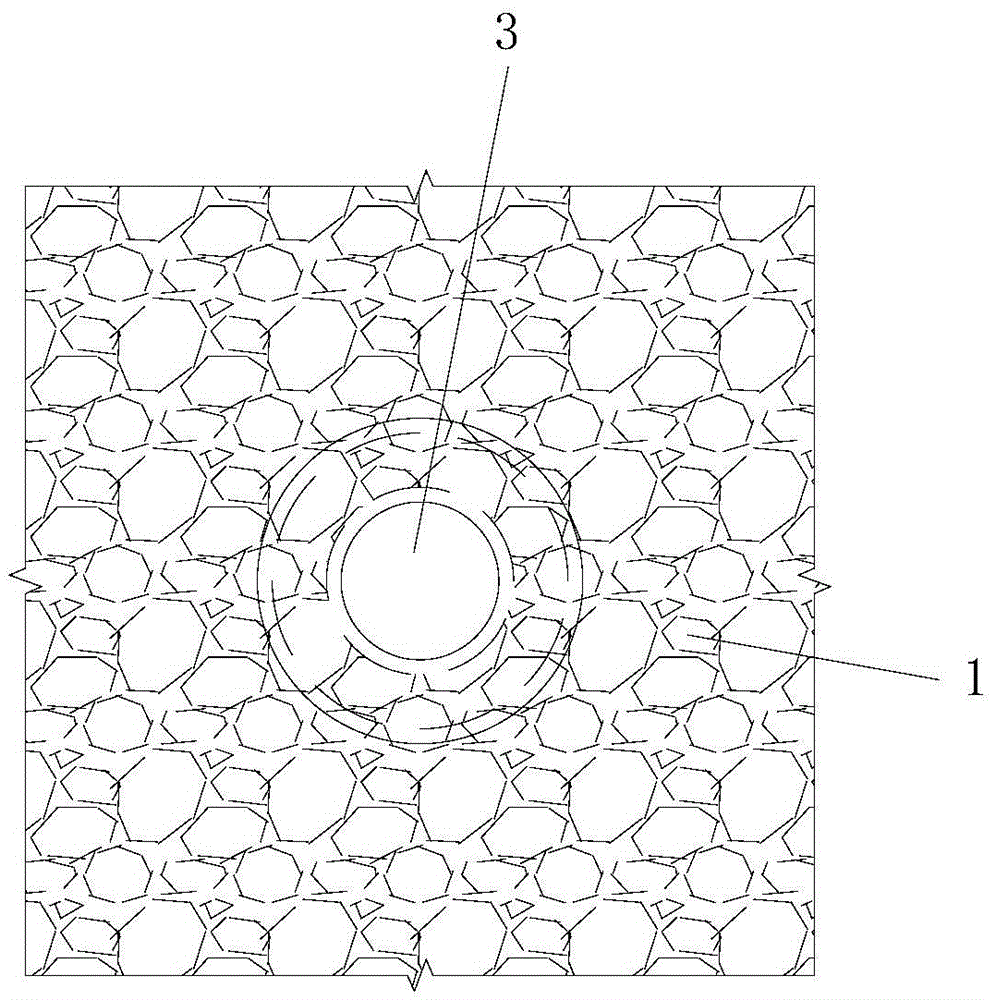

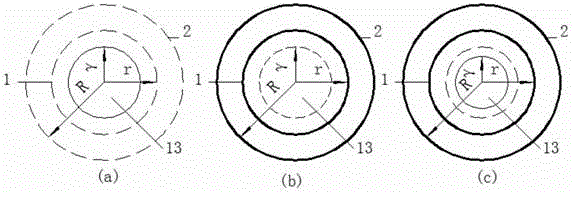

Cast-in-situ bored pile and construction method thereof

The invention discloses a cast-in-situ bored pile and a construction method thereof. The cast-in-situ bored pile are applied to a geological environment with a sludge layer. Thin-shell concrete roundpipes are arranged at the periphery of a pile column reinforcement cage, so that the phenomenon of expanding or necking when the cast-in-situ bored pile is located at a part of the sludge layer and concrete is poured is avoided, the construction quality is improved, and the construction cost is reduced.

Owner:MCC COMM CONSTR GRP CO LTD

Construction method for swing-injected agitating composite piles

The invention discloses a construction method for swing-injected agitating composite piles. The construction method comprises the following steps of: putting a piling machine in place, and correcting levelness and perpendicularity of the piling machine; pulping, feeding pulp to the piling machine through a high-pressure pump; spraying pulp from a bottom pulp spraying hole of a swing-injected agitating composite drill bit on the piling machine, enabling the swing-injected agitating composite drill bit to agitate and submerge to designed pile bottom elevation, spraying pulp from the bottom pulp spraying hole of the swing-injected agitating composite drill bit on the piling machine, enabling the swing-injected agitating composite drill bit to agitate and lift to the designed pile bottom elevation, and sufficiently agitating a soil body by a first blade on the side wall of the swing-injected agitating composite drill bit; repeating steps 1) to 4) until construction of all swing-injected agitating composite piles is completed, wherein in a construction process, a jet grouting pile jets slurry to cut and damage the soil body under high pressure, and the first blade is utilized for sufficiently agitating the soil body, so that the soil body can be sufficiently mixed with pulp uniformly, and therefore, a phenomenon that jet-grouted solid is not uniform as range is affected by foreign matters when pulp cannot be jetted as a result of the foreign matters in the construction process of the jet grouting piles is avoided.

Owner:广东华隧高科建设有限公司

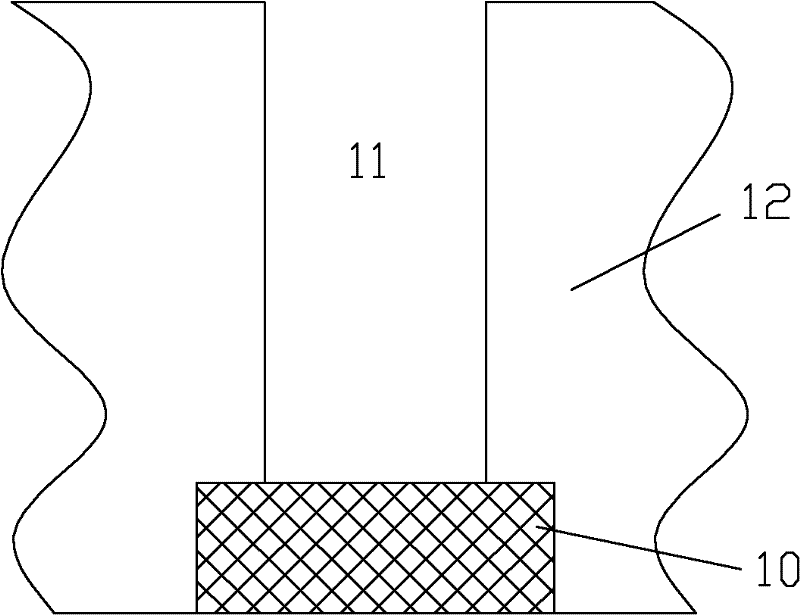

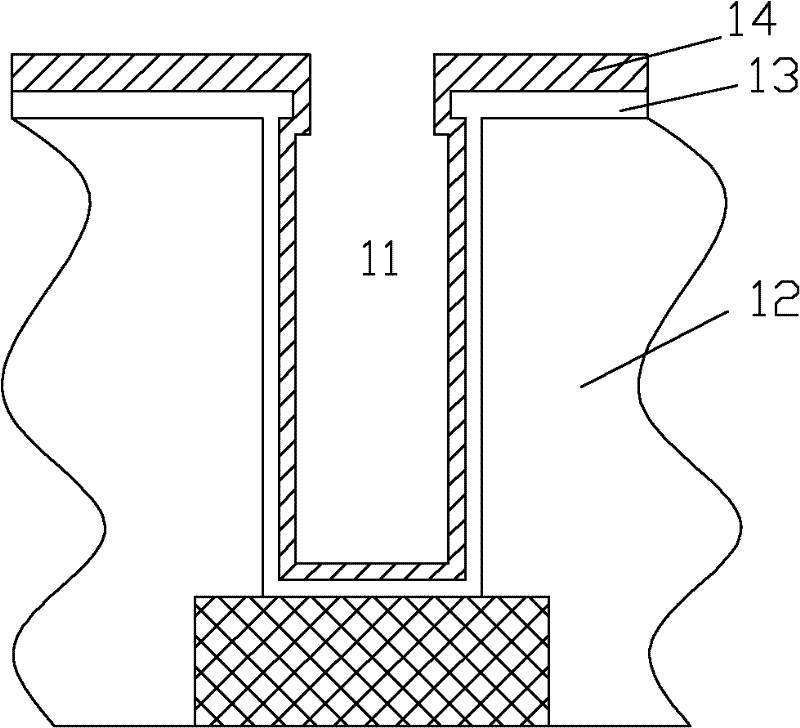

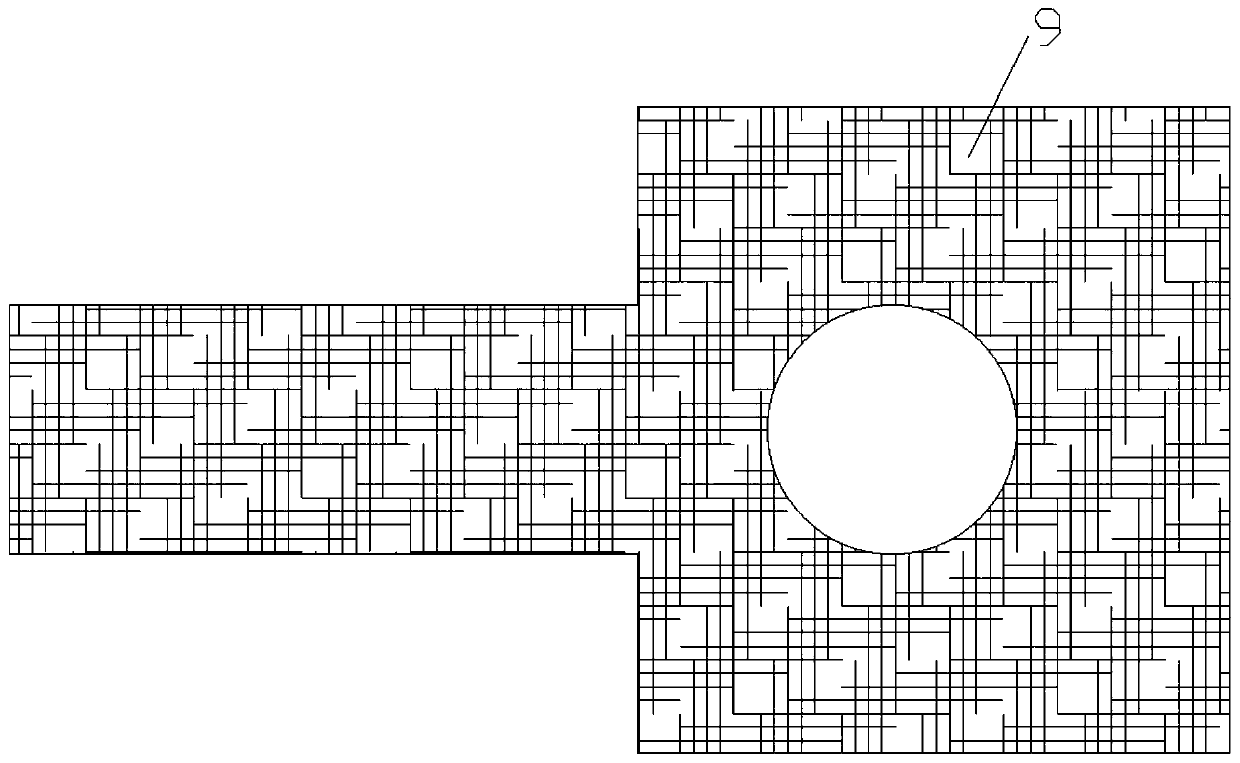

Non-dismantling prefabricated concrete pile protecting die plate and construction method

ActiveCN106049491AOvercome construction neckingOvercome defects such as collapsed holesBulkheads/pilesPrecast concreteEconomic shortage

The invention provides a non-dismantling prefabricated concrete pile protecting die plate and a construction method. The non-dismantling prefabricated concrete pile protecting die plate comprises a prefabricated concrete protecting layer and concave arc shaped concrete bumps arranged at the inner side of the protecting layer, wherein a full-length hole is formed in the prefabricated concrete protecting layer; the concrete bumps are symmetrically arranged at intervals along the circumference of the inner side of the protecting layer. According to the design requirement, the construction method comprises the following steps: prefabricating and transporting the non-dismantling prefabricated concrete pile protecting die plate; levelling a site, and measuring a pile arranging position; hoisting and positioning the non-dismantling prefabricated concrete pile protecting die plate; performing a method combining mechanical soil excavation in the die plate and water injecting on the sidewall; constructing the bottom part of the die plate until the design height is reached, and then hoisting and positioning a reinforced cage; pouring concrete; grouting; maintaining until the pile is formed; and detecting a pile foundation. Compared with the prior art, the non-dismantling prefabricated concrete pile protecting die plate and the construction method have the advantages that the earth mass at the outside of a pile body, the underground water, the outer load and the like can be effectively stopped, so that the safety can be greatly improved; meanwhile, the non-dismantling prefabricated concrete pile protecting die plate is prefabricated in a factory, so that the construction quality can be ensured, and the construction period can be greatly reduced; the shortages such as necking down and hole collapse in traditional pile foundation construction can be overcome.

Owner:浙江长兴市政建设有限公司

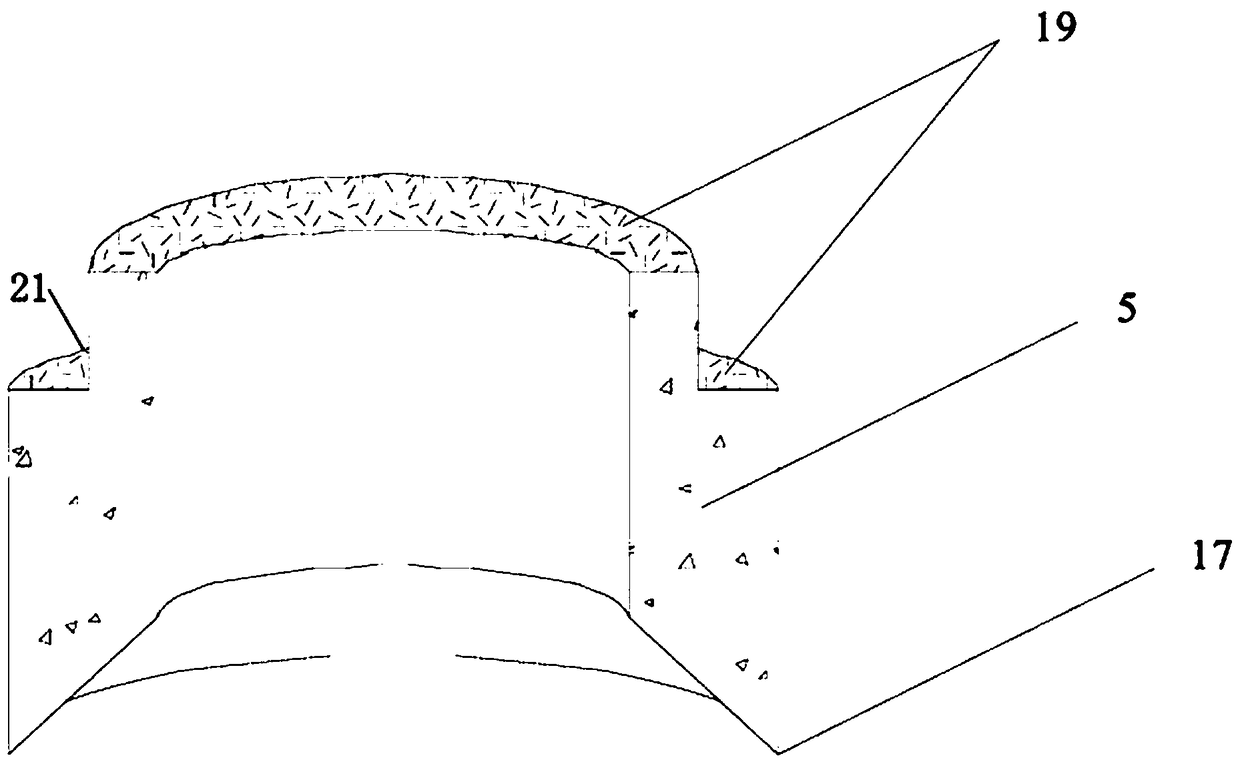

Gravel pile with consolidated sand layer and reinforced concrete pipe joint, and construction method thereof

The invention relates to the field of foundation treatment, which is particularly applicable to soft soil foundation treatment engineering. The invention especially relates to a gravel pile with a consolidated sand layer and a reinforced concrete pipe joint, and a construction method thereof. The gravel pile comprises a central pile body, wherein the consolidated sand layer used for improving theintegrality of the pile body is arranged at the outer side of the central pile body; and a protection layer with a protection function is arranged at the outer side of the consolidated sand layer, andcapable of effectively preventing grout from excessively permeating into the sand layer, thereby reducing the waste of construction materials; a pile foundation is good in forming effect, high in bearing performance, and capable of greatly improving the bearing capacity of foundation soil; with the adoption of the gravel pile with the consolidated sand layer and the reinforced concrete pipe joint, the bearing performance of the sand layer can be exerted, and the side friction of the pile body is improved; and meanwhile, due to the arrangement of the reinforced concrete pipe joint, constrainteffect can be acted on gravels to a certain extent, so that the effect of improving the integrality of the pile body is acted, and due to the arrangement of a pile end grout solid and a pile peripherygrout solid, the bearing performance of the pile foundation can be improved.

Owner:李溯

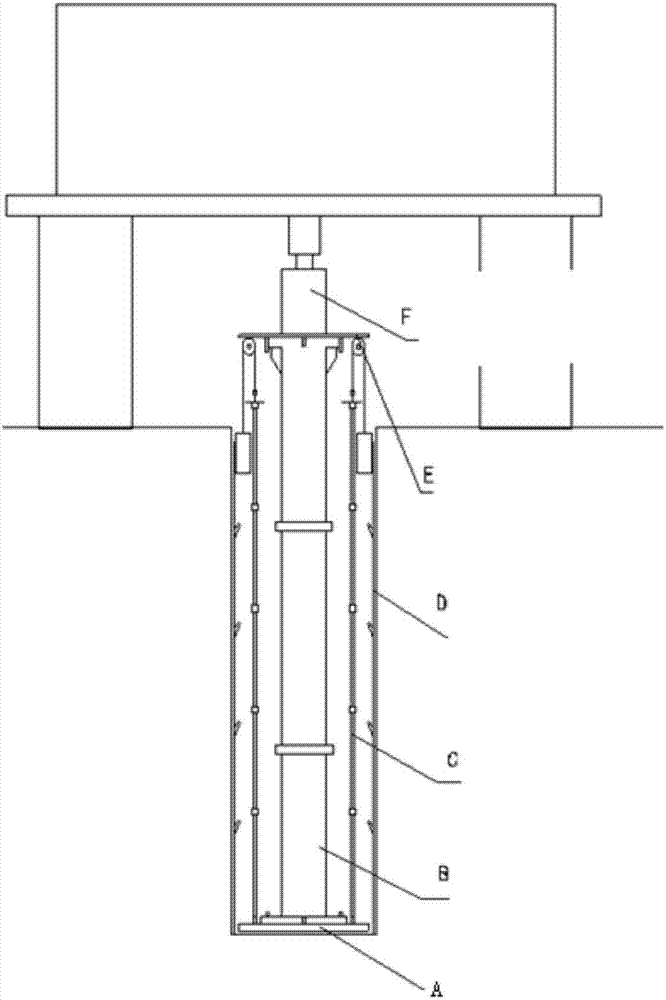

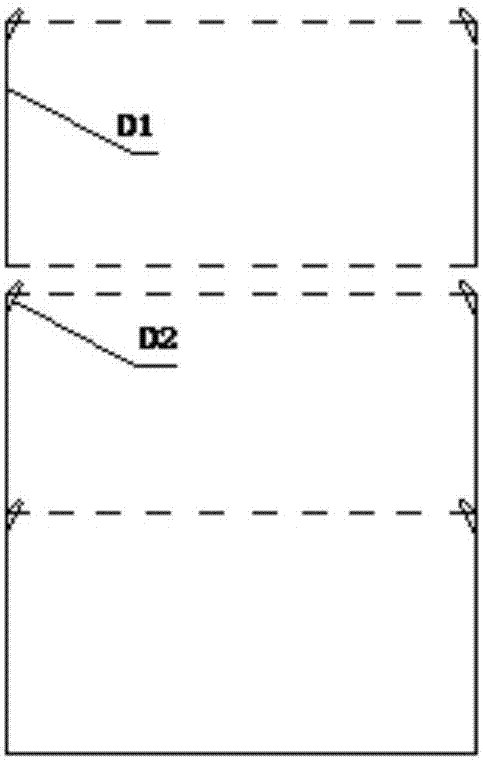

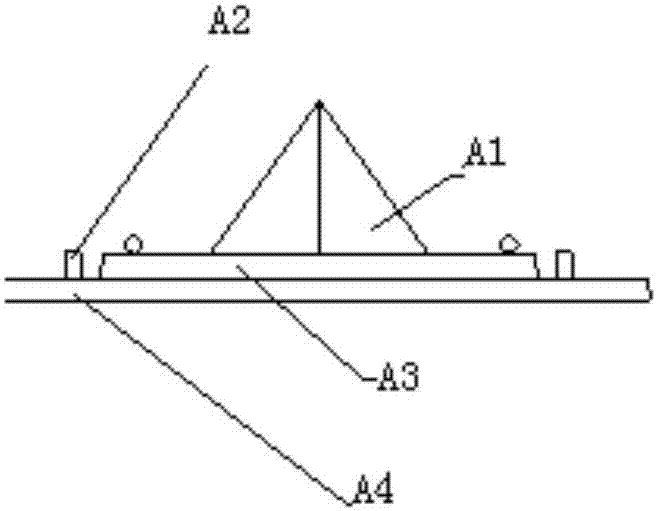

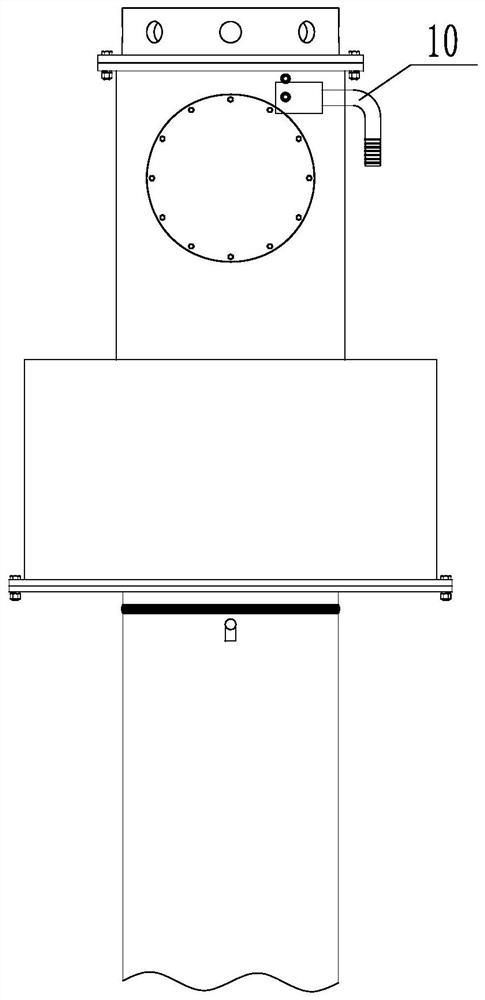

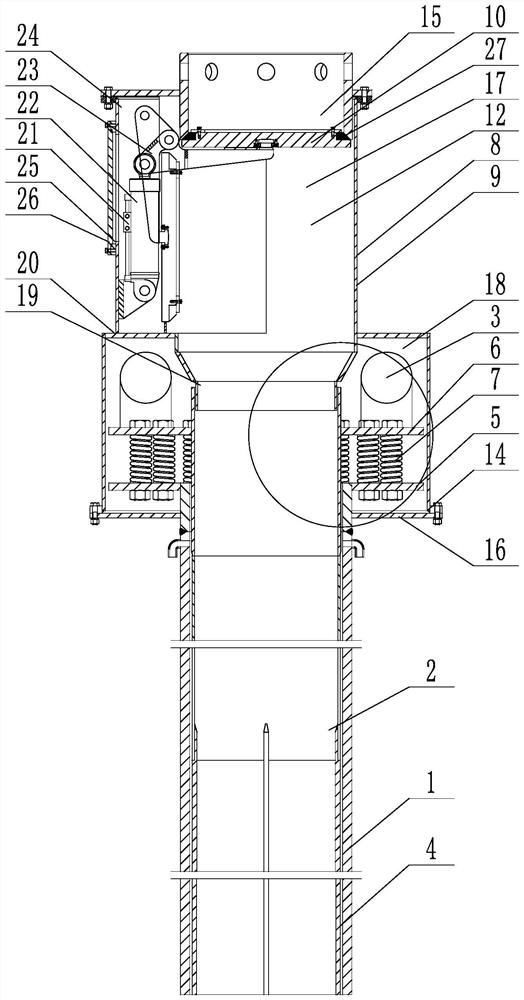

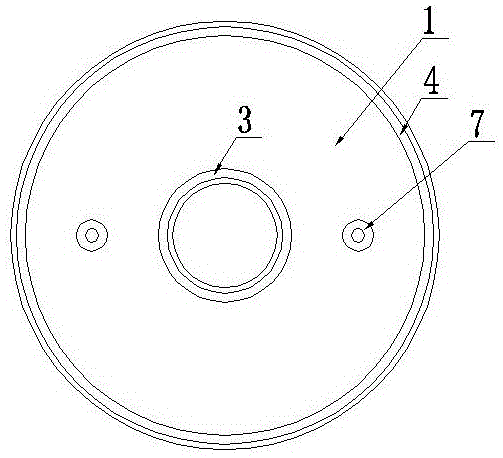

Deep load testing device

The invention discloses a deep load testing device. The deep load testing device comprises a pressure bearing plate arranged at the bottom of a foundation pit; a force transfer column and displacement rods are arranged above the pressure bearing plate; the displacement rods are positioned around the force transfer column; a displacement rod fixed plate is arranged at the top ends of the displacement rods; an automatic numerical control pressing device is arranged at the top end of the force transfer column; a protection arm sleeve is arranged in the foundation pit; the protection arm sleeve is placed after manual or mechanical poring; a disturbance soil layer at the bottom of a well is manually removed for leveling; medium-coarse sand is paved for leveling; after the pressure bearing plate is connected with the displacement rods, the pressure bearing plate is mounted in a testing position at the bottom of the well; after the pressure bearing plate is placed, the force transfer column is put down, and installation is finished through total engaged connection with a conical force transfer column connecting cap; and the deep load testing device provides powerful guarantee to the test safety and precision.

Owner:青海省建筑勘察设计研究院股份有限公司

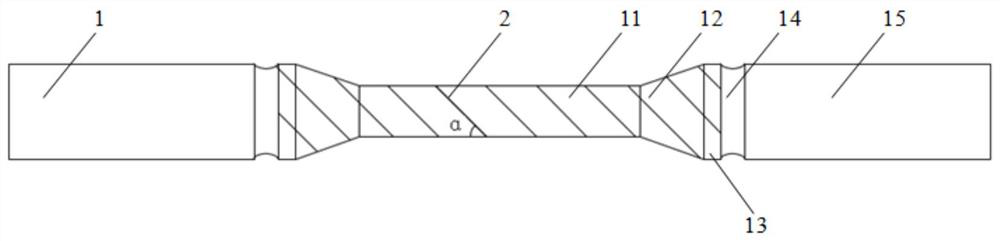

Metal composite component based on fiber reinforcement and manufacturing method thereof

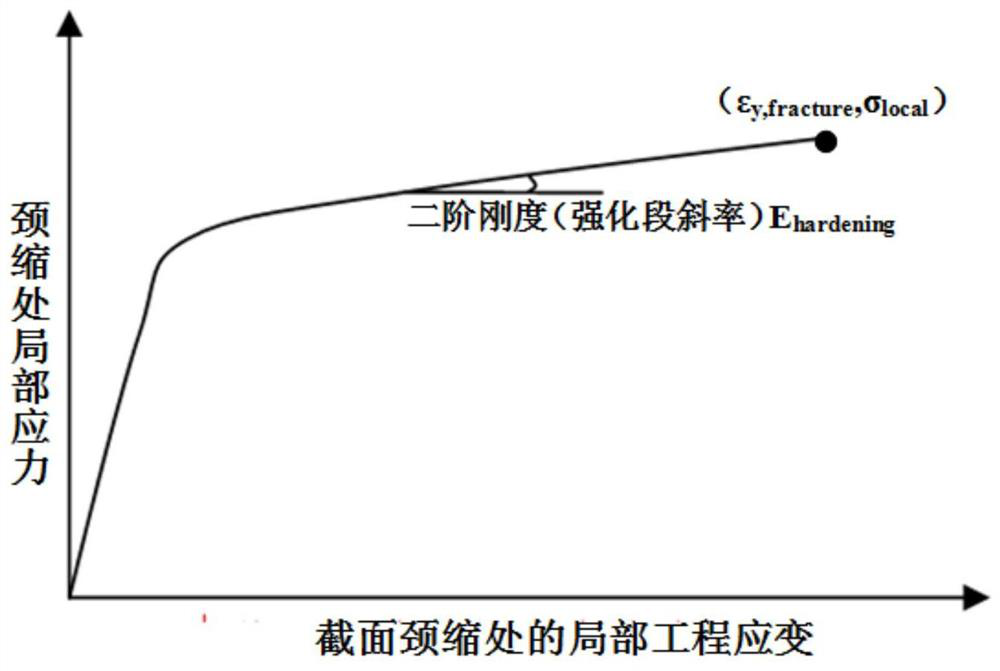

PendingCN113283037AAvoid neckingAvoid breakingGeometric CADDesign optimisation/simulationMetallic materialsNecking

The invention discloses a metal composite component based on fiber reinforcement and a manufacturing method thereof. The metal composite component comprises a metal matrix, the metal matrix is provided with a plurality of grooves forming a preset angle with the horizontal direction, and the plurality of grooves are filled with a fiber material. According to the invention, based on the characteristics that the deformation at the necking position of the metal material is increased but the tensile bearing capacity is reduced, and the bearing capacity of the fiber material is increased along with the increase of the tensile deformation, the fiber material in the plurality of grooves with the preset angle and the metal jointly bear the tensile force. At a necking generation part, the reduction of the bearing capacity of the metal material is made up by enhancing the bearing capacity of the fiber material, so that the necking is avoided or necking at multiple parts is avoided, the metal composite component is prevented from being fractured due to local necking at one position, and the deformability of the metal composite component is improved.

Owner:SHENZHEN UNIV

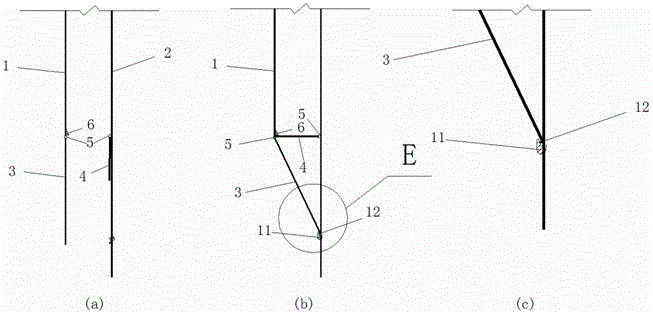

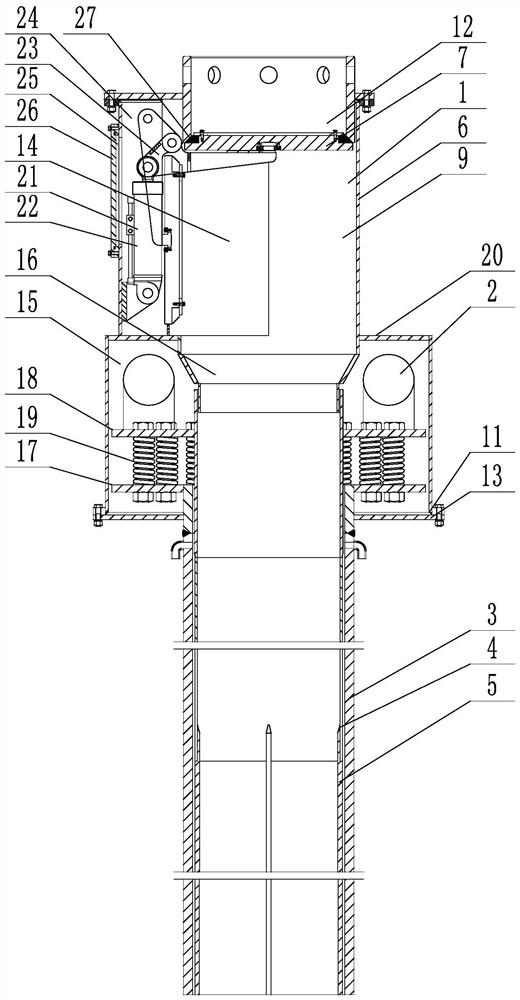

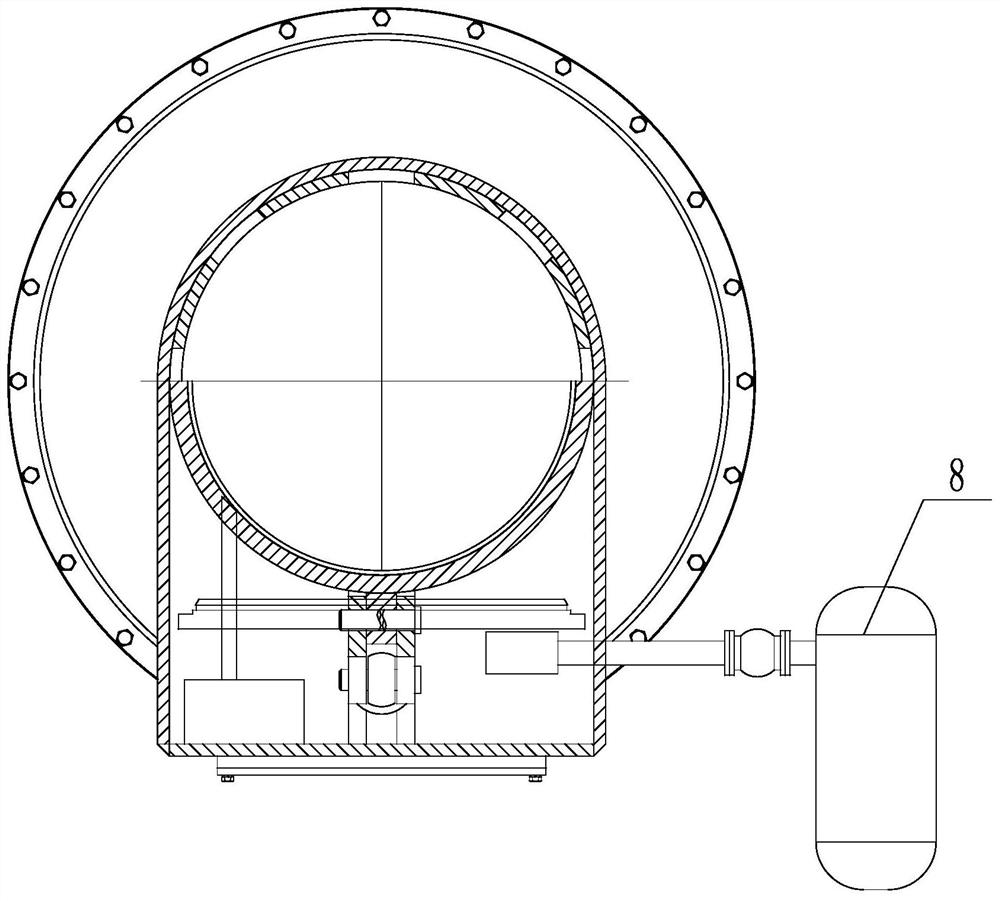

Air pressure pushing and vibrating device

The invention discloses an air pressure pushing and vibrating device. The air pressure pushing and vibrating device comprises an air pressure sealing device, a vibrating device, an outer pipe, an inner pipe and steel chisels. The air pressure sealing device comprises a valve body, a cover plate and a pressurizing mechanism, a valve cavity is formed in the valve body, an air inlet channel is formed in the valve cavity, the air inlet channel communicates with the pressurizing mechanism, an outer pipe connector is formed in the lower part of the valve cavity, an outer pipe is hermetically connected to the lower part of the outer pipe connector, a feeding port is formed in the upper part of the valve cavity, and the cover plate is arranged at the feeding port and seals or opens the feeding port. The vibrating device is arranged in the valve cavity, the inner pipe is inserted into the outer pipe, a gap is formed between the inner pipe and the outer pipe, the multiple steel chisels are annularly arranged on the lower side of the inner pipe along the pipe wall and extend downwards, the vibrating device is fixed above the inner pipe, and the inner pipe and the outer pipe are elastically connected at the upper end of the outer pipe. The concrete is more full and compact during pipe sinking and pouring, the steel pipe is prevented from hanging a reinforcement cage during pipe drawing, the steel pipe is prevented from being blocked by the concrete, and meanwhile necking is prevented.

Owner:陈清贵

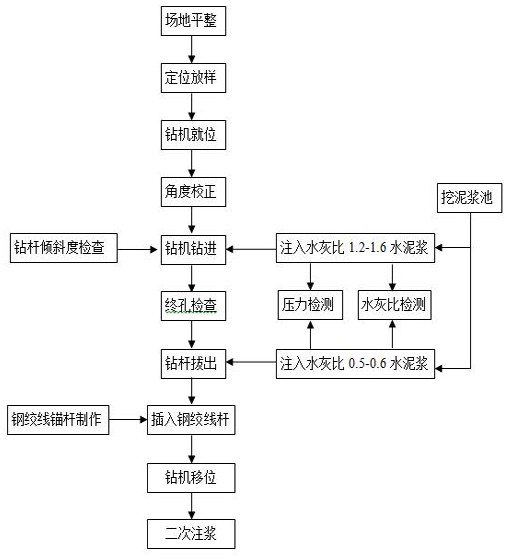

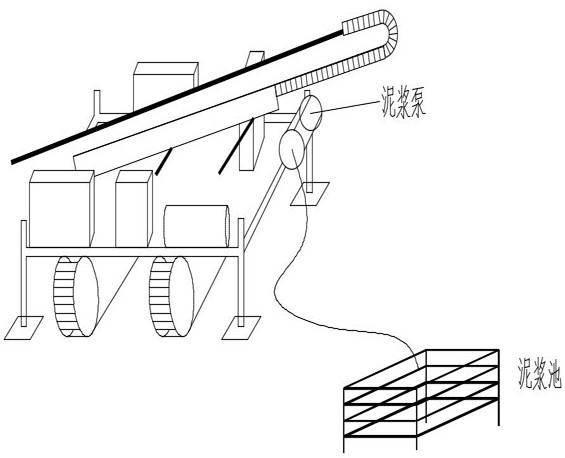

Construction method of full-bonding support anchor rod

InactiveCN111676966AAvoid collapsing holesAvoid neckingExcavationsBulkheads/pilesArchitectural engineeringSlurry

The invention relates to the technical field of building construction, and discloses a construction method of a full-bonding support anchor rod. The construction method of the full-bonding support anchor rod comprises the following operation steps of 1, leveling a site; 2, manufacturing the anchor rod; 3, positioning the position of the anchor rod; 4, preparing a drilling machine; 5, digging a mudpit; 6, enabling the drilling machine to be in place; 7, drilling by the drilling machine; 8, mounting the anchor rod; 9, carrying out hole opening slurry supplementing and secondary grouting; and 10, carrying out tensioning. According to the construction method of the full-bonding support anchor rod, in the support anchor rod construction under the unfavorable geology of silty clay and the like,the phenomena of hole collapse and necking in the anchor rod hole forming process can be effectively avoided, and it is guaranteed that the diameter of an anchor hole meets the design requirement; and the plumpness of cement paste in an anchor rod formed hole is completely guaranteed through the mud replacement technology and the secondary grouting technology, the full length of the support anchor rod is fully bonded with cement mortar, it is guaranteed that an anchor rod body makes full contact with a soil body, the bonding friction resistance between the anchor rod body and the soil body isenhanced, and therefore the foundation pit supporting strength is guaranteed.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

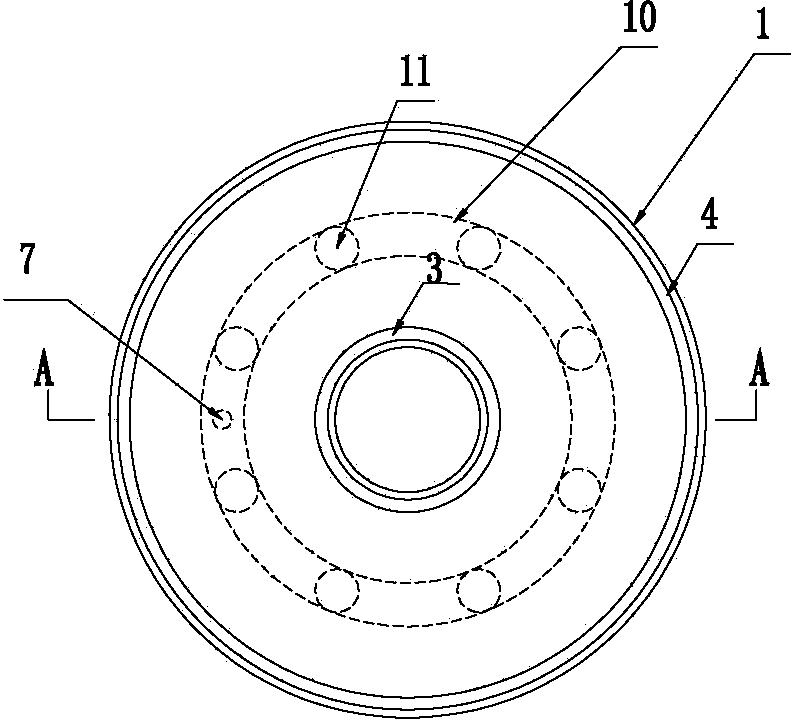

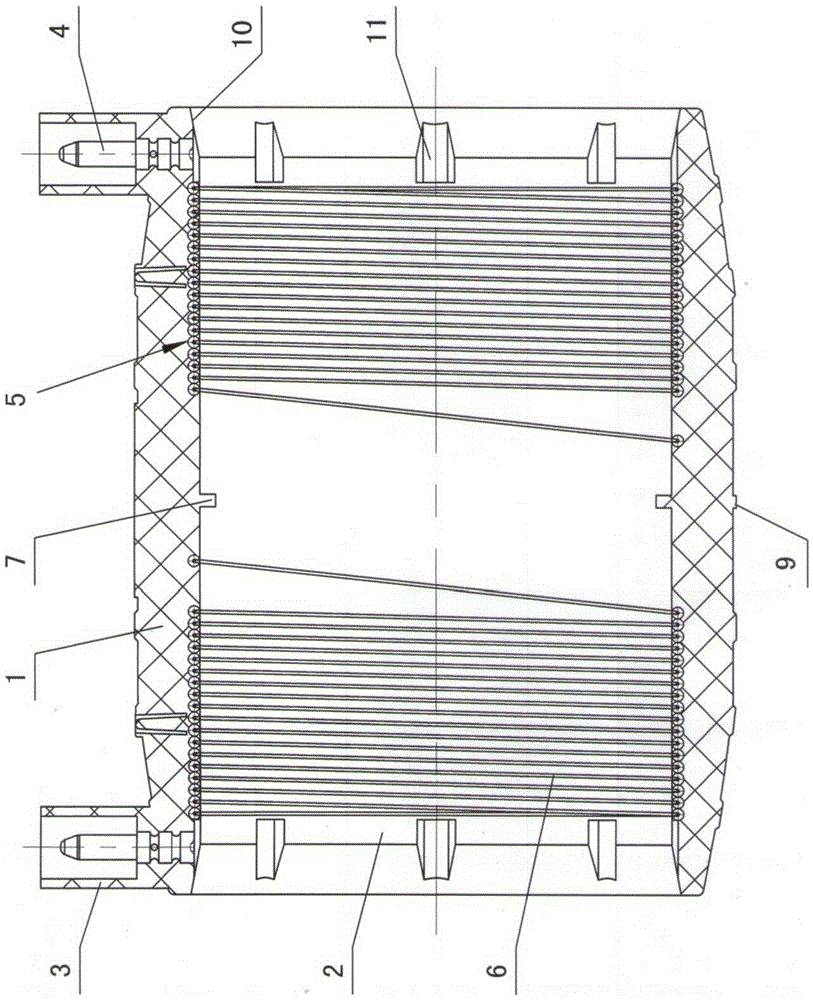

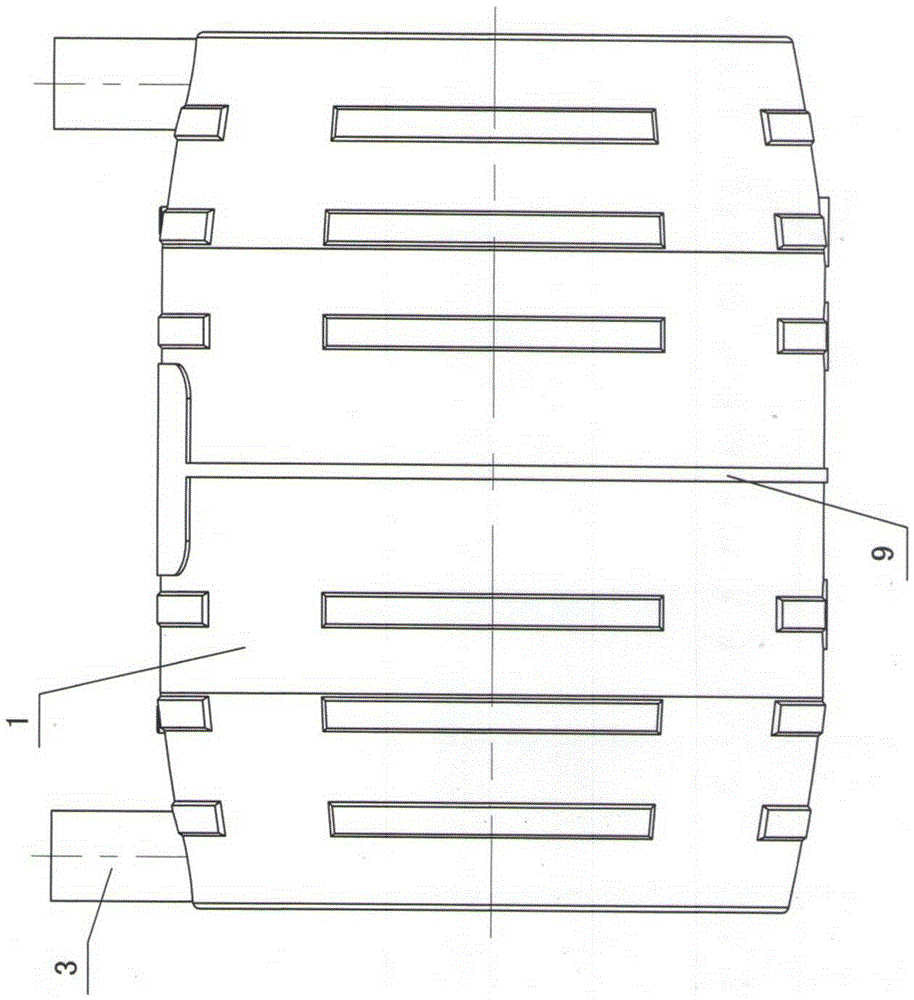

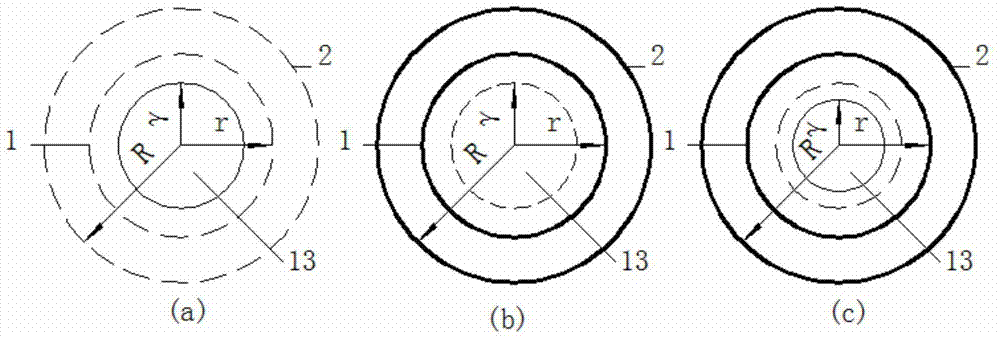

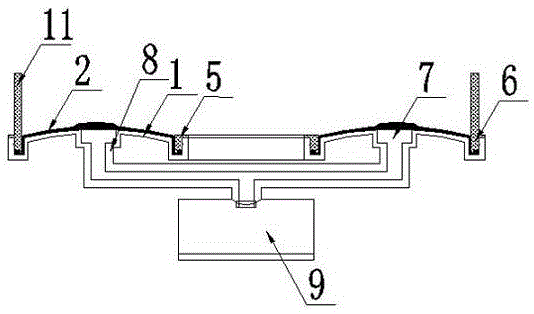

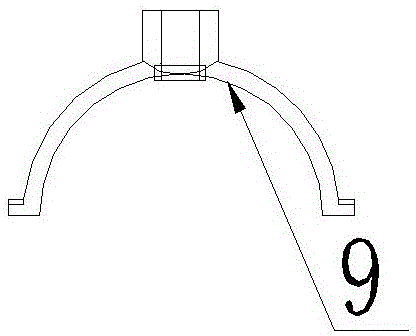

Improved hollow disk-type fine bubble aerator

ActiveCN103803734AReasonable structureEasy to useTreatment using aerobic processesWater aerationEngineeringMechanical engineering

The invention relates to a hollow disk-type fine bubble aerator, which comprises a support disk and a diaphragm covering the support disk, wherein the support disk is a circular cambered disk body being hollow in the center; the diaphragm is provided with micropores, and is fixed to the support disk through a compacting structure; an annular air distribution groove and a plurality of air distribution holes communicated with the air distribution groove are formed in the middle of the support disk; an air inlet hole is formed in the bottom surface of the air distribution groove, and is communicated with a supporting seat arranged below the support disk; the supporting seat is deviated from one side of the support disk, and is prevented from shielding a through water channel in the central hollow position of the support disk. The improved hollow disk-type fine bubble aerator is reasonable in structure, and convenient to use. The supporting seat is deviated from the through water channel in the center of the support disk, so that the propelling action of the through water channel on bubble is ensured, the phenomenon of bubble necking or bubble combination is avoided, and the aeration efficiency is improved remarkably.

Owner:JIANGSU YULONG ENVIRONMENTAL PROTECTION

Polyethylene electrofusion socket fittings with external display markings and resistance wire stops

ActiveCN103968177BGuarantee welding qualityGuaranteed to be inserted in placePipe connection arrangementsElectrical resistance and conductancePipe fitting

Owner:YONGGAO CO LTD

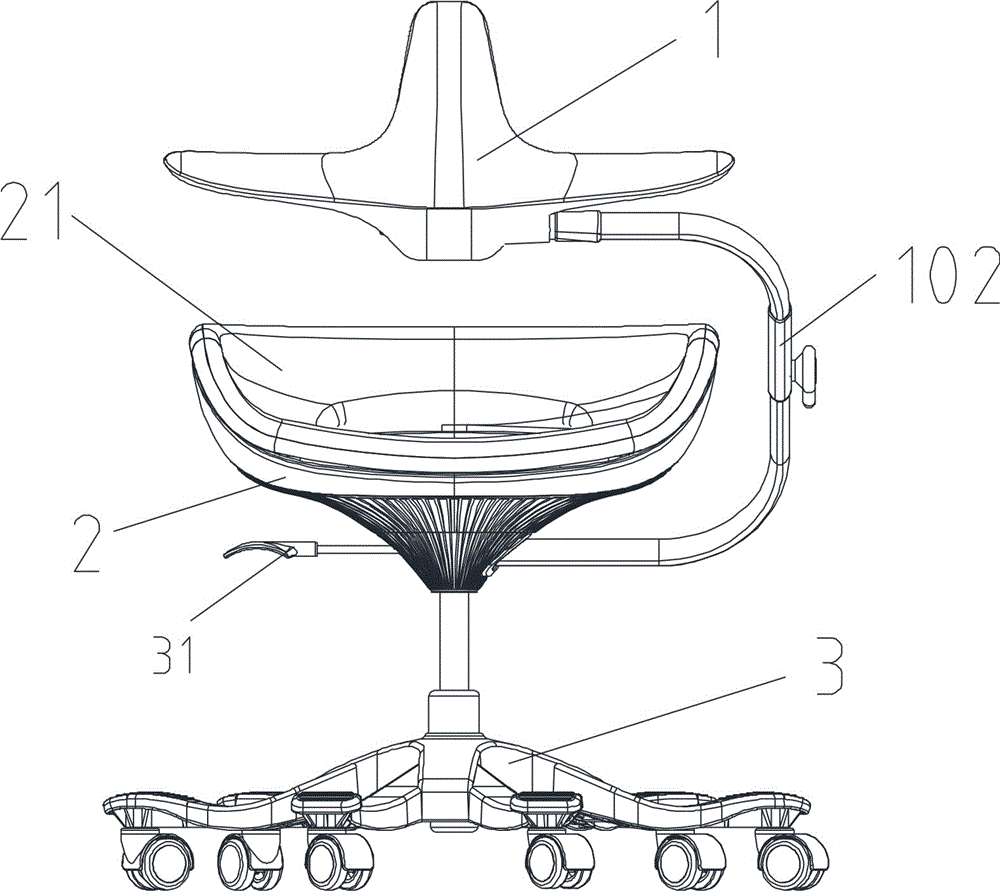

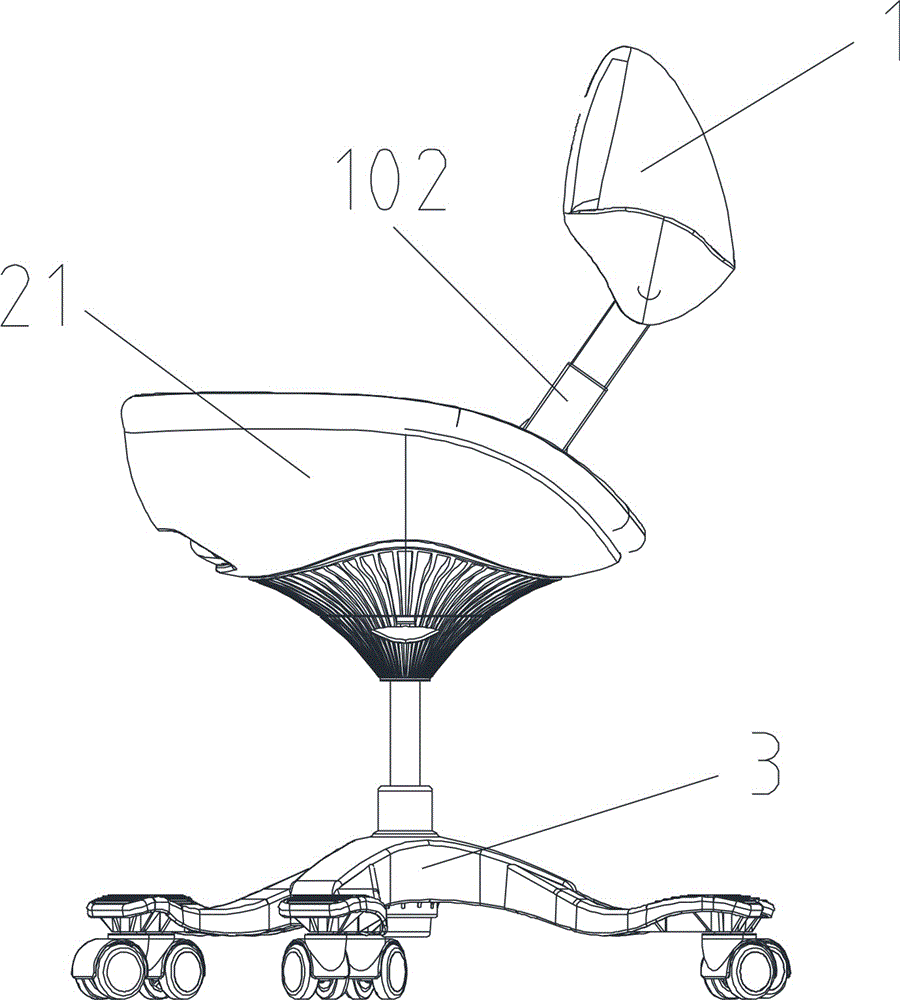

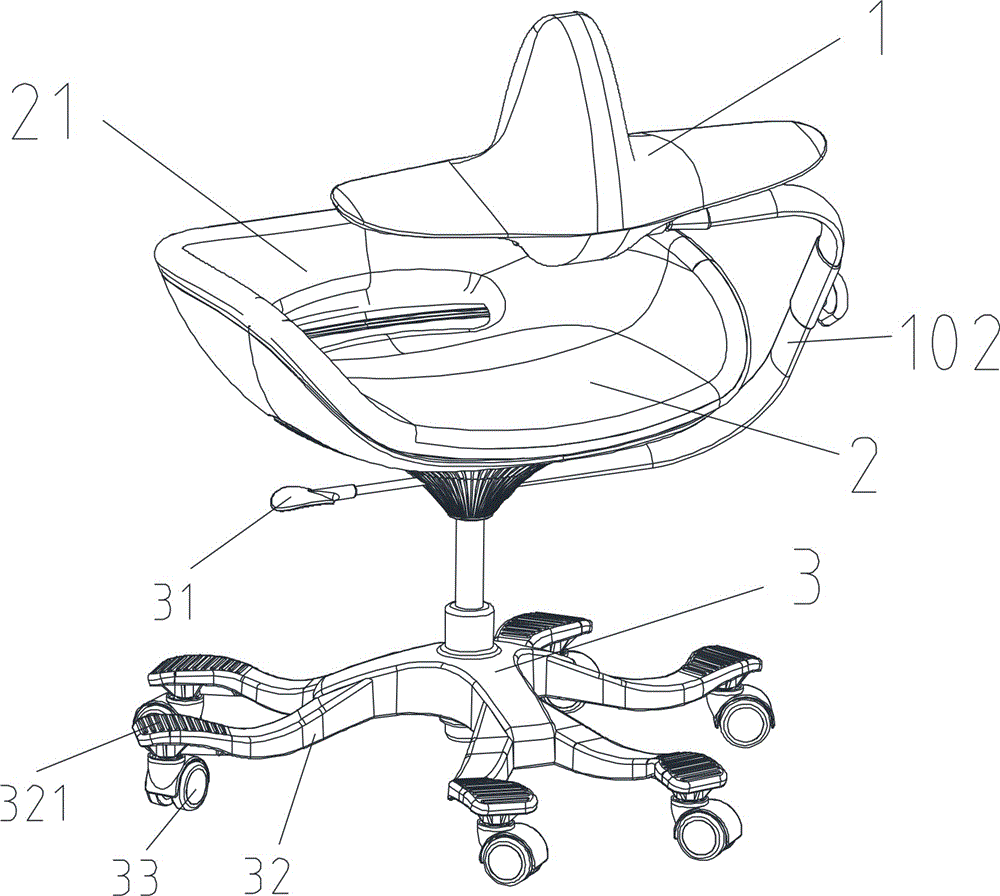

Posture corrective chair

ActiveCN106136652APrevent retractionAvoid neckingStoolsAdjustable chairsPhysical medicine and rehabilitationEngineering

Owner:周建明

A kind of construction method of cement-soil and concrete composite material pile

The invention discloses a cemented soil and concrete composite pile and a construction method thereof. The construction method comprises the following steps: S1, performing setting out positioning according to a designed pile layout; S2, drilling; S3, inserting a spray pipe into a hole to the predetermined depth of the stratum; S4, performing jet grouting; S5, pulling out the pipe and washing to finish jet grouting pile construction; S6, performing cast-in-place concrete pile pore forming on the soil body above the top part of each jet grouting pile after the jet grouting pile construction is finished for 3-5 days; S7, digging the top part of each jet grouting pile to form a mortise; S8, filling plain concrete to the designed elevation of the top of each pile, vibrating and compacting to finish cemented soil and concrete composite pile construction. The composite pile body disclosed by the invention has the advantages that the connection is reliable, the integrality is strong, the vertical bearing capacity and the horizontal shearing resistance are higher, the pile body is not easy to damage under pressure, the adaptability to the stratum is strong, meanwhile, the construction is easy, the environmental pollution is small, the cost is low, and the like.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A kind of construction method of PCC pile in hard soil site

The invention discloses a construction method of a PCC pile in a hard soil site. A movable valve pile shoe is arranged in the pile mold inner tube; the length of the pile mold outer tube is increased, and after the pile driver is in place, the pile mold is taken from the center of the pile position Soil of equal cross-section. The length of the outer tube exceeds the length of the closed spud can, and the pile tip formed by the spud can is inwardly inclined. During the vibration sinking process, the pile form mainly produces an inward horizontal component force on the pile core soil, so that the pile core soil Internal deformation, filling the reserved cavity, little disturbance to the pile side soil, and at the same time reducing the extrusion stress of the pile core soil on the inner pipe during the pile formwork driving process, reducing the difficulty of mold sinking; and reducing the pile formwork lifting During the process, the side frictional resistance of the pile core soil to the inner pipe reduces the rising force of the pile core soil. The invention is simple in structure, easy to realize, easy to operate, low in cost, can effectively reduce the difficulty of sinking molds in the hardened soil layer and the rise of pile core soil, and is an efficient and practical method in PCC pile construction.

Owner:江苏斯维尔工程技术有限公司

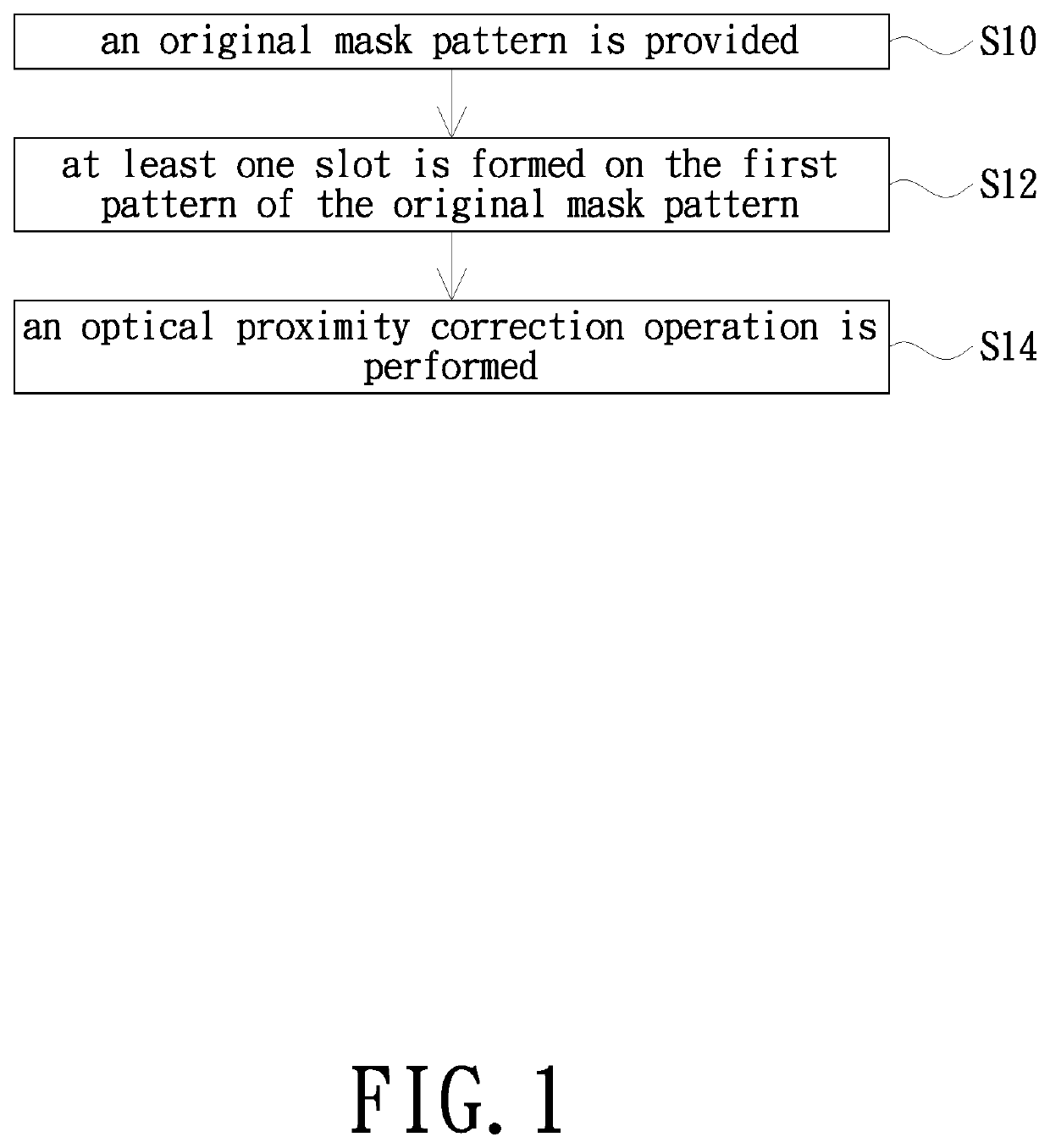

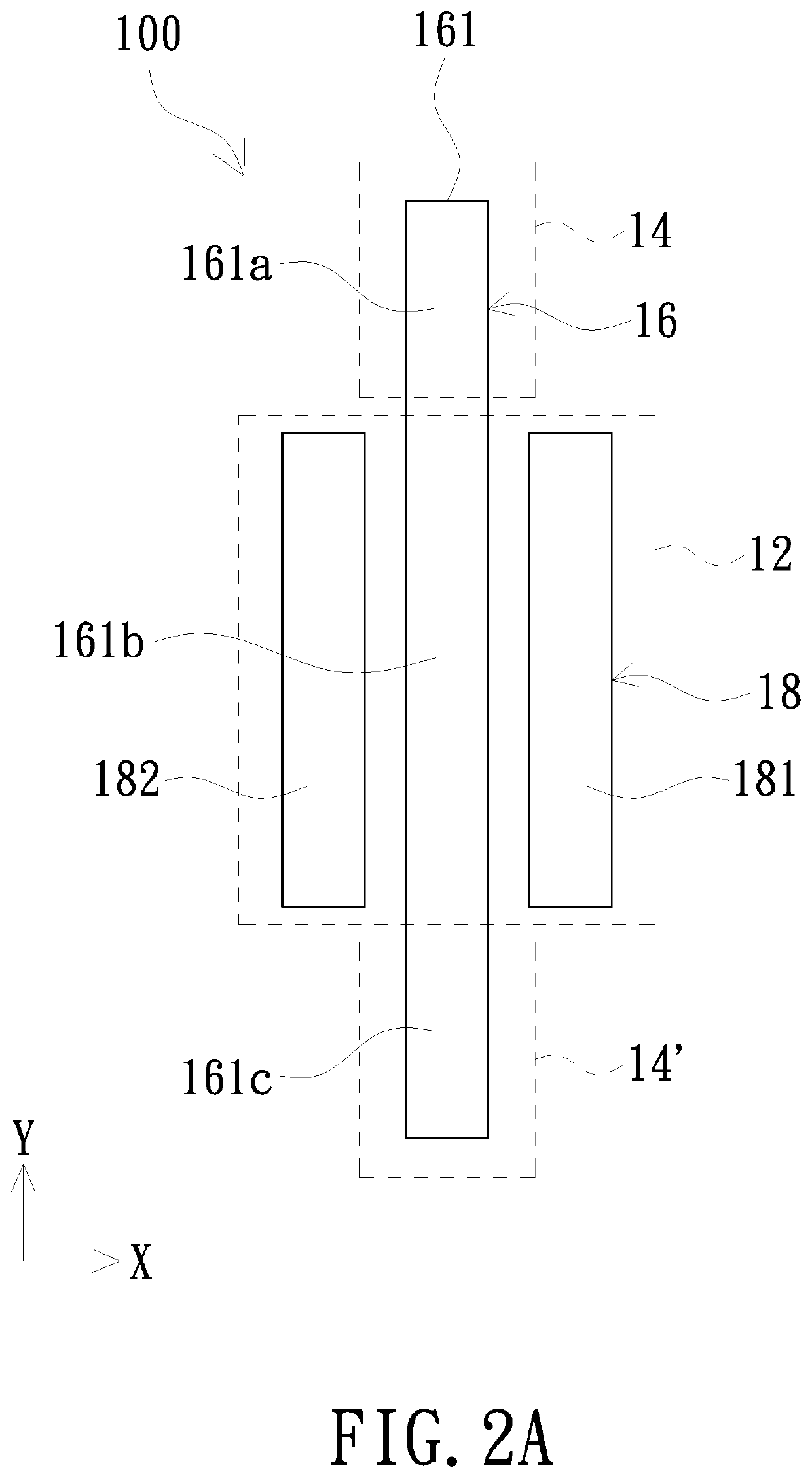

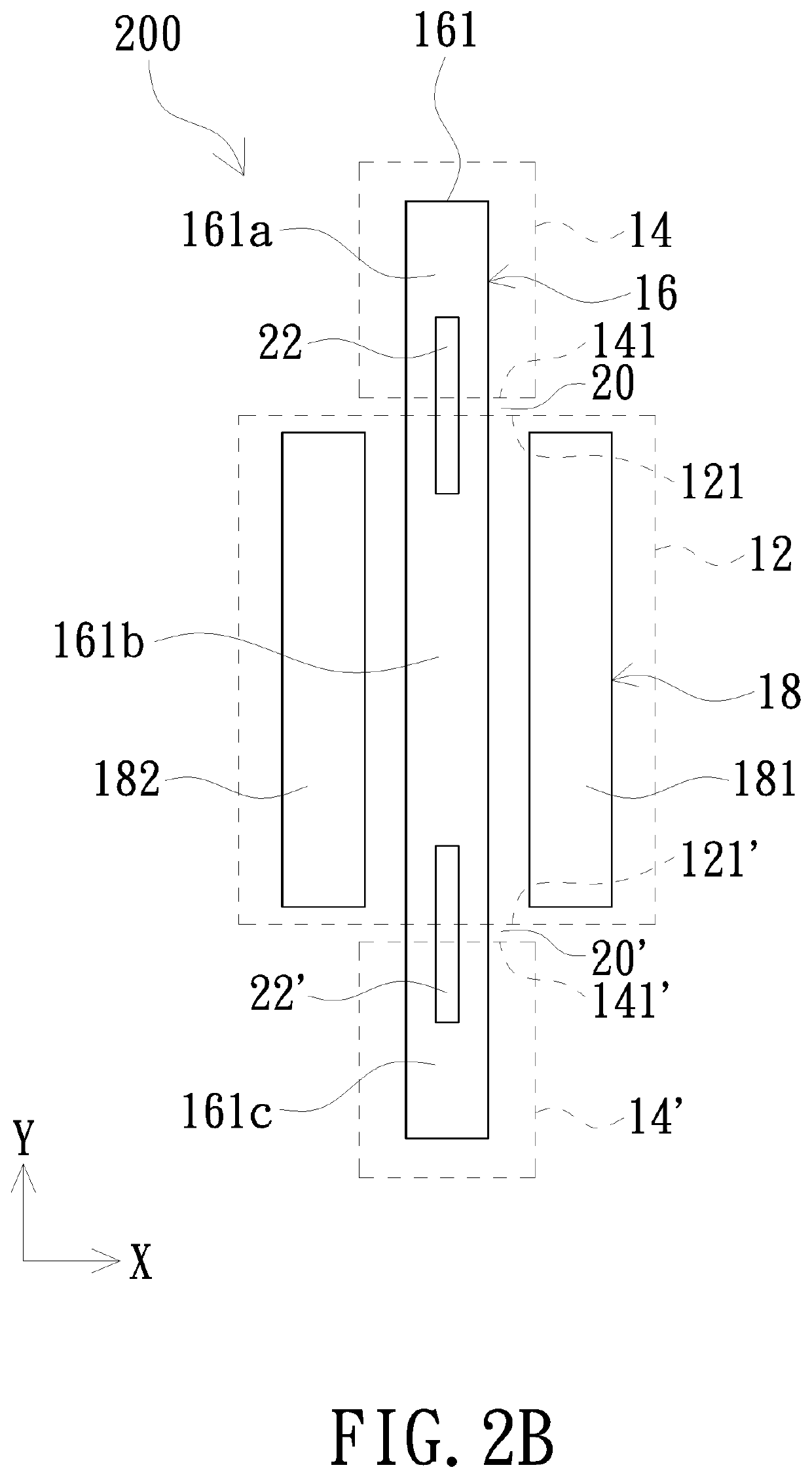

Method for correcting mask pattern and mask pattern thereof

ActiveUS11372324B2Avoid neckingAvoid breakingPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringMaterials science

A method for correcting a mask pattern includes: providing an original mask pattern including at least one dense pattern area and at least one isolated pattern area, and the original mask pattern being divided into a first pattern and a second pattern, wherein the first pattern is formed in the isolated pattern area and extends to the dense pattern area, and the second pattern is formed in the dense pattern area; forming at least one slot on at least one section of the first pattern, and the at least one section of the first pattern is located on at least one transition area between the at least one isolated pattern area and the at least one dense pattern area; and performing an optical proximity correction operation on the first pattern formed with at least one slot and the second pattern. Using the corrected mask pattern may avoid the occurrence of necking or breaking on portion of the post-transfer pattern.

Owner:UNITED MICROELECTRONICS CORP

Construction Method of Rotary Jet Mixing Composite Pile

The invention discloses a construction method for swing-injected agitating composite piles. The construction method comprises the following steps of: putting a piling machine in place, and correcting levelness and perpendicularity of the piling machine; pulping, feeding pulp to the piling machine through a high-pressure pump; spraying pulp from a bottom pulp spraying hole of a swing-injected agitating composite drill bit on the piling machine, enabling the swing-injected agitating composite drill bit to agitate and submerge to designed pile bottom elevation, spraying pulp from the bottom pulp spraying hole of the swing-injected agitating composite drill bit on the piling machine, enabling the swing-injected agitating composite drill bit to agitate and lift to the designed pile bottom elevation, and sufficiently agitating a soil body by a first blade on the side wall of the swing-injected agitating composite drill bit; repeating steps 1) to 4) until construction of all swing-injected agitating composite piles is completed, wherein in a construction process, a jet grouting pile jets slurry to cut and damage the soil body under high pressure, and the first blade is utilized for sufficiently agitating the soil body, so that the soil body can be sufficiently mixed with pulp uniformly, and therefore, a phenomenon that jet-grouted solid is not uniform as range is affected by foreign matters when pulp cannot be jetted as a result of the foreign matters in the construction process of the jet grouting piles is avoided.

Owner:广东华隧高科建设有限公司

Cast-in-place pile concrete vibration device

The invention discloses a cast-in-place pile concrete vibration device. The cast-in-place pile concrete vibration device comprises a base, an inner pipe, a vibration device body and steel chisel bars, the base is provided with an inner pipe insertion opening, the inner pipe penetrates through the base from the inner pipe insertion opening, a gap is formed between the outer wall of the inner pipe and the inner pipe insertion opening, the inner pipe is elastically connected with the base, the vibration device body is fixed to the upper end of the inner pipe, and a plurality of steel chisel bars are annularly arranged at the lower end of the inner pipe along the pipe wall and extend downwards. The concrete in the cast-in-place pile is more full and compact, when the cast-in-place pile is applied to the pipe-sinking cast-in-place pile, the steel pipe can be prevented from being hung with a reinforcement cage, the concrete can be prevented from blocking the steel pipe, necking is prevented, and damage to the steel pipe during pipe drawing is reduced.

Owner:陈清贵

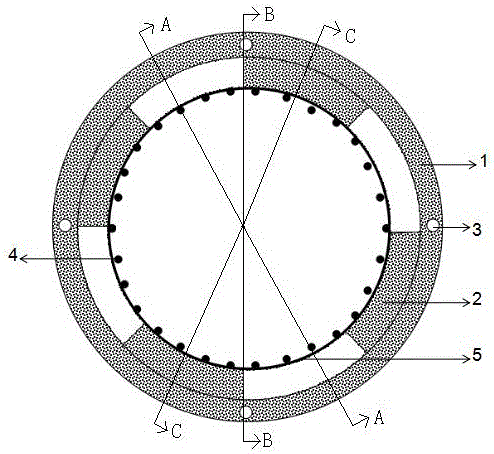

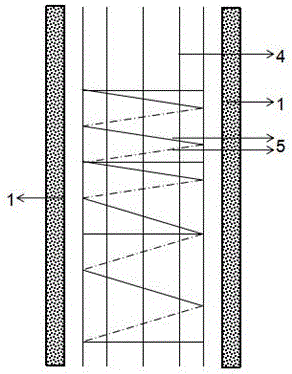

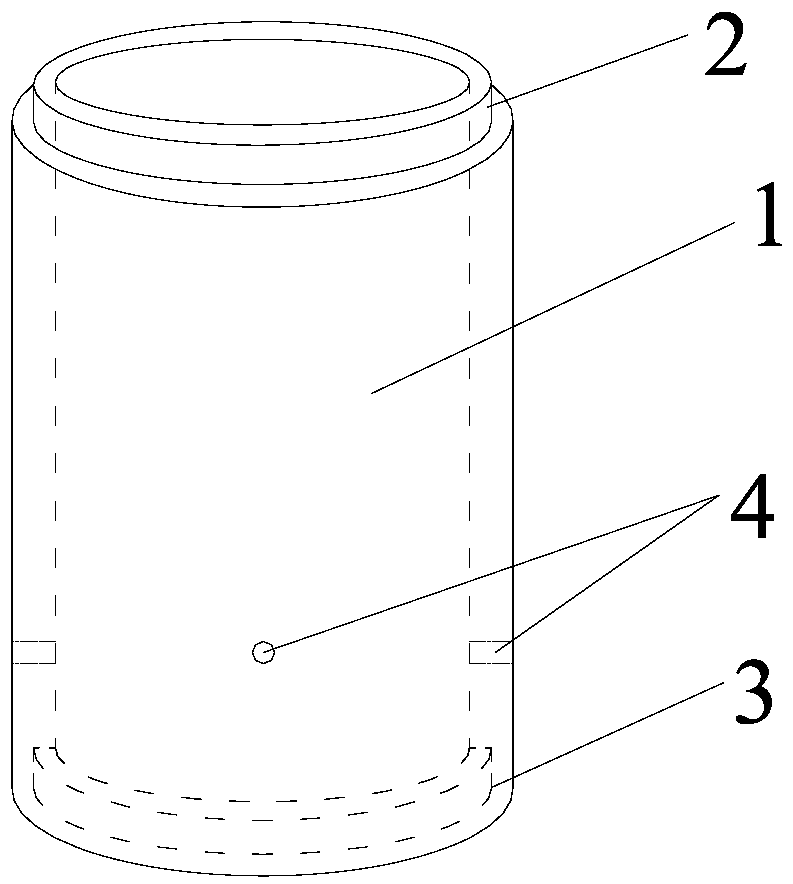

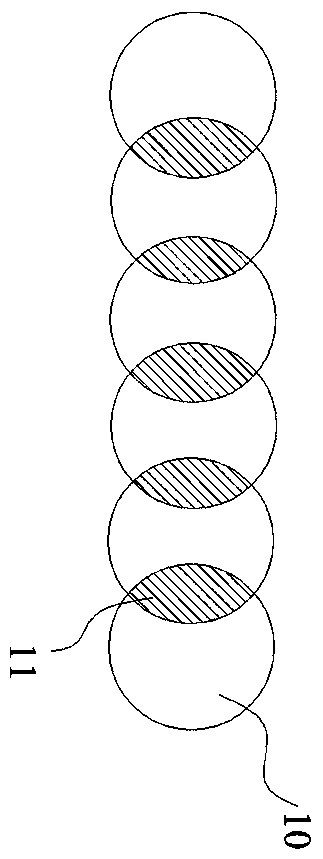

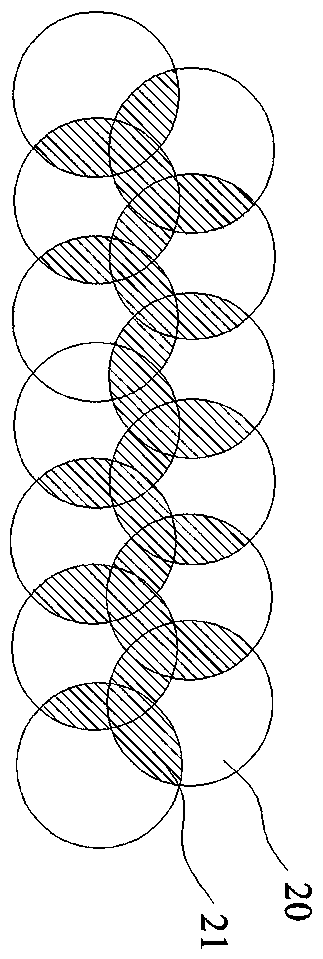

A microporous aerator

ActiveCN103601306BExtended service lifeReasonable designWater aerationSustainable biological treatmentEngineeringMechanical engineering

The invention relates to a micropore aerator which comprises a support disc provided with an air inlet hole and a membrane covering the support disc, wherein the membrane is provided with micropores; the support disc is a circular curved disc body; an inner pressing groove and an outer pressing groove are respectively formed in the edges of an inner ring and an outer ring of the support disc, and an inner pressing ring and an outer pressing ring which are matched with the pressing grooves are respectively arranged on the edges of the inner ring and the outer ring of the support disc; the membrane is shaped as a circle adaptive to the support disc; the edges of the membrane are tightly pressed in the pressing grooves; a baffle plate which is integrally connected with the outer pressing ring is arranged on the outer pressing ring, so that air bubbles on the outmost periphery flow upwards along the baffle plate, so that the necking phenomenon caused by periphery radial water pressure is avoided. The micropore aerator disclosed by the invention is reasonable in design, simple in structure, convenient to use and high in aeration efficiency; the aeration membrane is long in life; the aerator is stable to support and is rapid to mount on the spot.

Owner:JIANGSU YULONG ENVIRONMENTAL PROTECTION

Construction equipment for water-stop curtain

PendingCN110130381ARealize continuous constructionPrevent water leakageSoil-shifting machines/dredgersFoundation engineeringControl systemArchitectural engineering

The invention provides construction equipment for a water-stop curtain. The construction equipment comprises a mounting platform, a control system, a grouting device, a grooving device and a steppingrail; the grooving device, the grouting device and the control system are all mounted on the mounting platform, the control system controls working of the grooving device and the grouting device, andthe stepping rail is detachably mounted below the mounting platform; the grooving device comprises a power device and a chain saw, and the power device drives the chain saw to cut rock soil to form awater-stop curtain groove; the grouting device comprises a grouting pump, a slurry container and a grouting pipeline; and the grouting pump injects slurry stored in the slurry container into the water-stop curtain groove through the grouting pipeline to be mixed with debris of the sawn rock soil, and after solidifying, the water-stop curtain is formed. The construction equipment for the water-stopcurtain has the charactristicss of being concise in structure, complete in function, high in construction efficiency and low in production cost.

Owner:王权民 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com