A kind of construction method of cement-soil and concrete composite material pile

A technology of combining materials and construction methods, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of complex stratum conditions of cast-in-place piles, necking and broken piles, and shallow pile damage, etc. Construction period, improve integrity, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

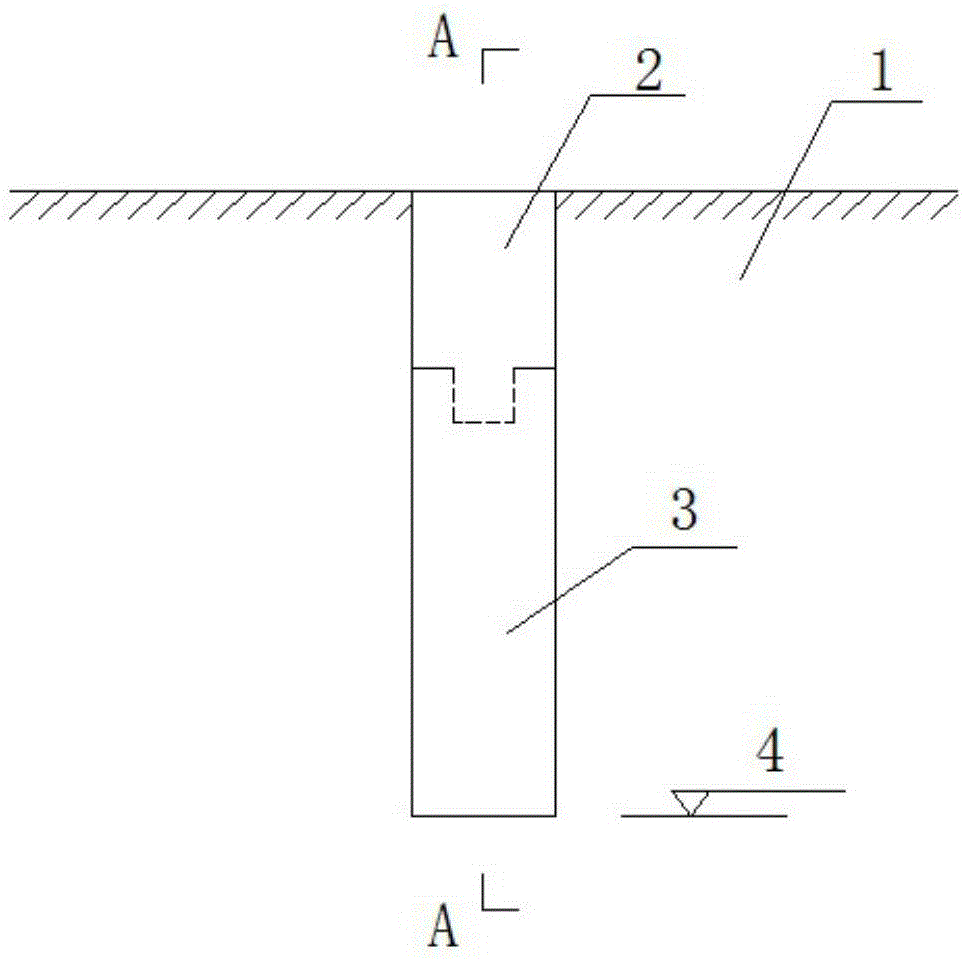

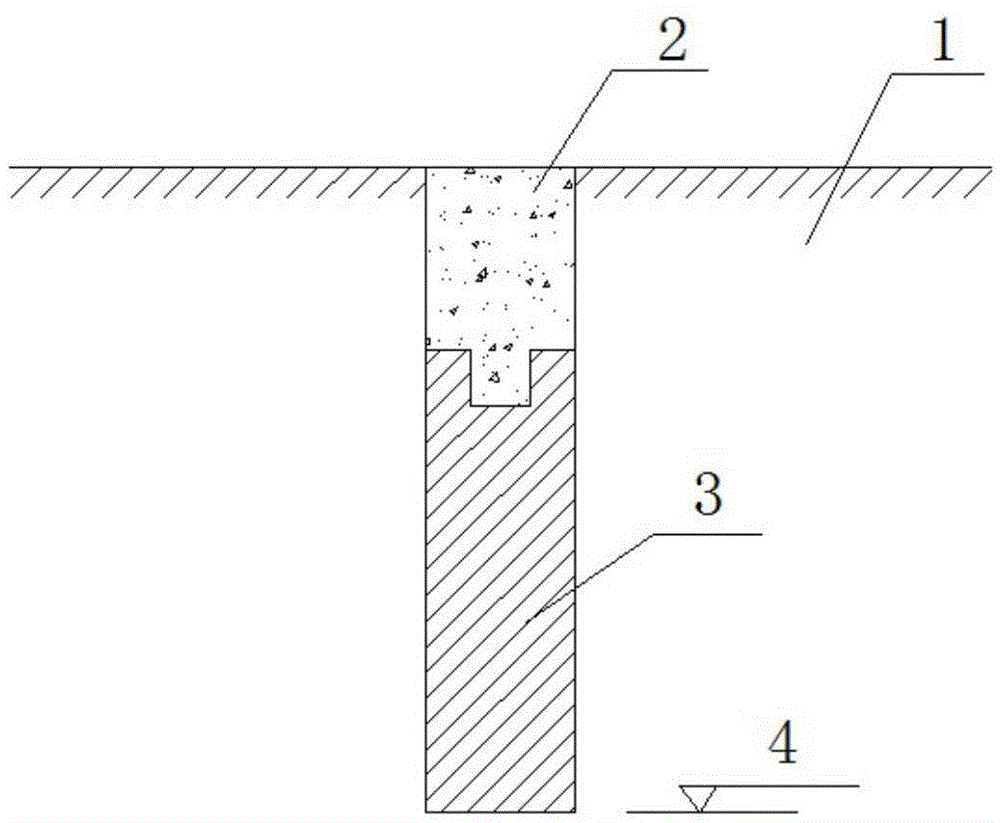

Embodiment 1

[0048] A residential building is 45.1m long and 17.7m wide, with 7 floors above the ground, brick-concrete structure, reinforced concrete raft foundation, and the buried depth of the foundation is -2.5m. The foundation treatment adopts the cement-soil and concrete composite material piles of the present invention, the designed pile diameter is 700mm, the pile distance is 1.7m, arranged in a square, and the design length of a single pile is 6.5m. After the cement-soil and concrete composite pile construction is completed, a 500mm thick natural graded sandstone cushion is laid on it. The characteristic value R of the single pile bearing capacity is required by the design k = 300kN.

[0049] According to the site engineering survey report, the stratum structure is as follows: ① plain fill (Q 4 ml+pd ): Brown-yellow, very wet, plastic, mainly silty clay. Layer thickness 0.90 ~ 1.5m. ② gravel sand layer (Q 4 al ): gray, very wet ~ saturated, loose. The thickness of the laye...

Embodiment 2

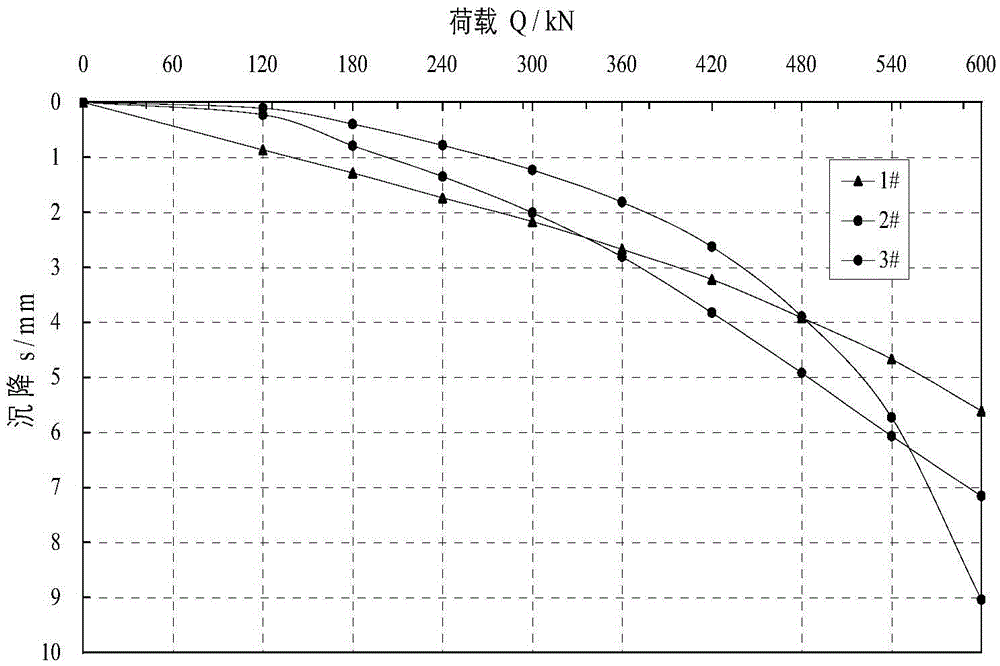

[0061] The site of a residential building to be built in a residential area, the landform unit belongs to the Weihe River I terrace, and the stratum from top to bottom is as follows: 0-5.5m is loess-like soil, 5.5-9.3m is silt soil, 9.3-12.0m is pebble layer , The foundation soil of the site is non-collapsible loess. The foundation treatment of the proposed residential building adopts the rotary grouting pile, the designed pile length of the rotary grouting pile is 12.0m, and the pile diameter is 600mm. Before the construction of engineering piles, a single pile test of 3 jet grouting piles was carried out in the site, and the test pile numbers are D 1 、D 2 and D 3 , the measured pile diameters are 670mm, 480mm and 600mm respectively, and the pile lengths are all 12.0m. The tests were all loaded until the piles were destroyed, and the measured ultimate loads were 720kN, 450kN and 400kN respectively. The load-settlement (Q~s) curves are shown in Figure 4 .

[0062] After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com