Polyethylene electrofusion socket fittings with external display markings and resistance wire stops

A limit device and resistance wire technology, applied in the direction of pipes/pipe joints/fittings, pipe connection layout, mechanical equipment, etc., can solve the problems of welding failure between welded pipes and pipe fittings, inability to directly observe the internal depth, short insertion of pipes into pipe fittings, etc. , to avoid shrinkage, facilitate construction and reduce resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

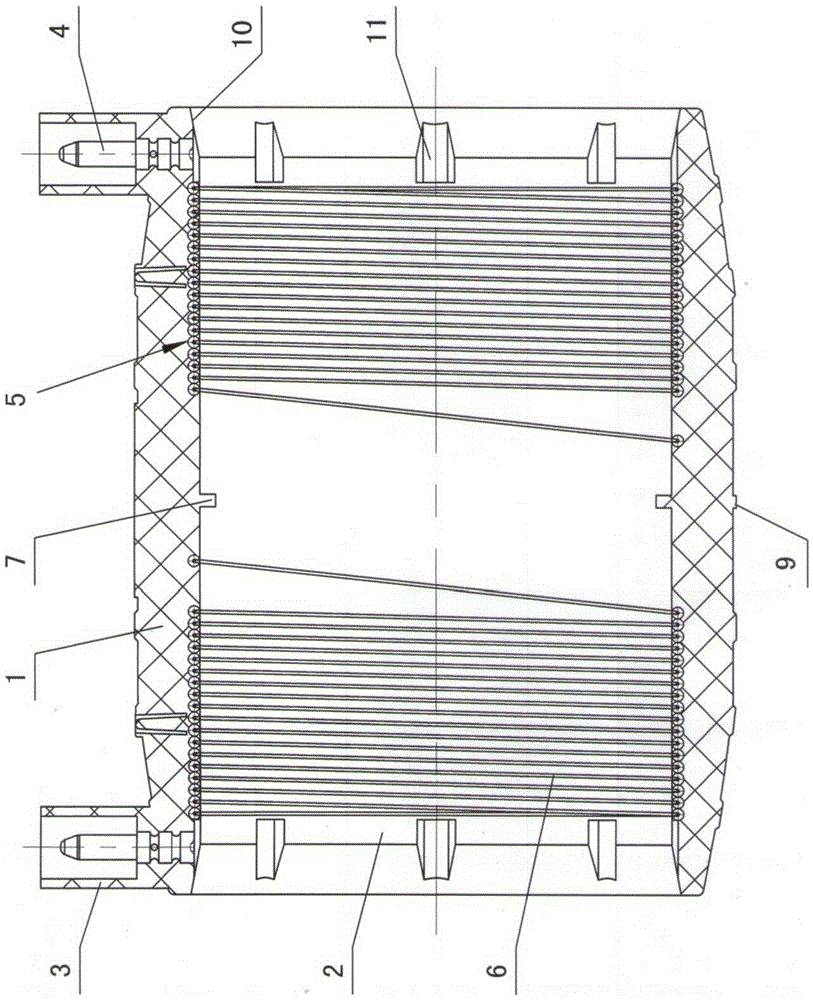

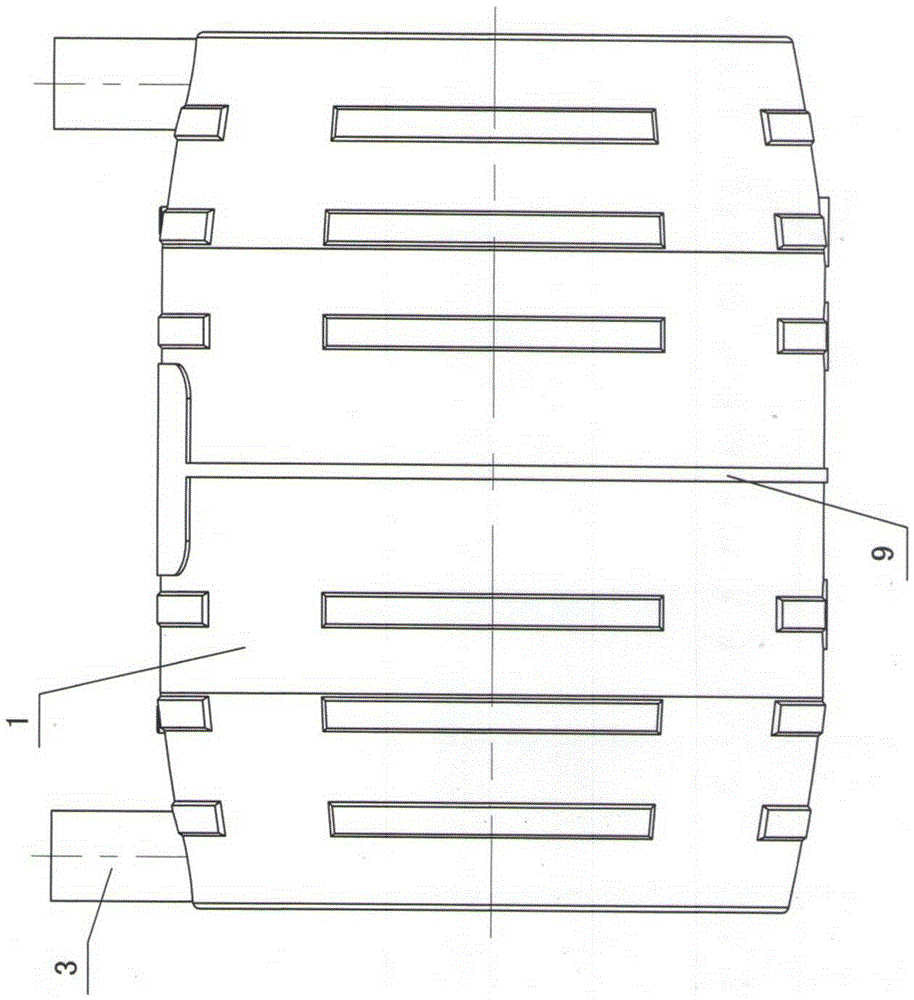

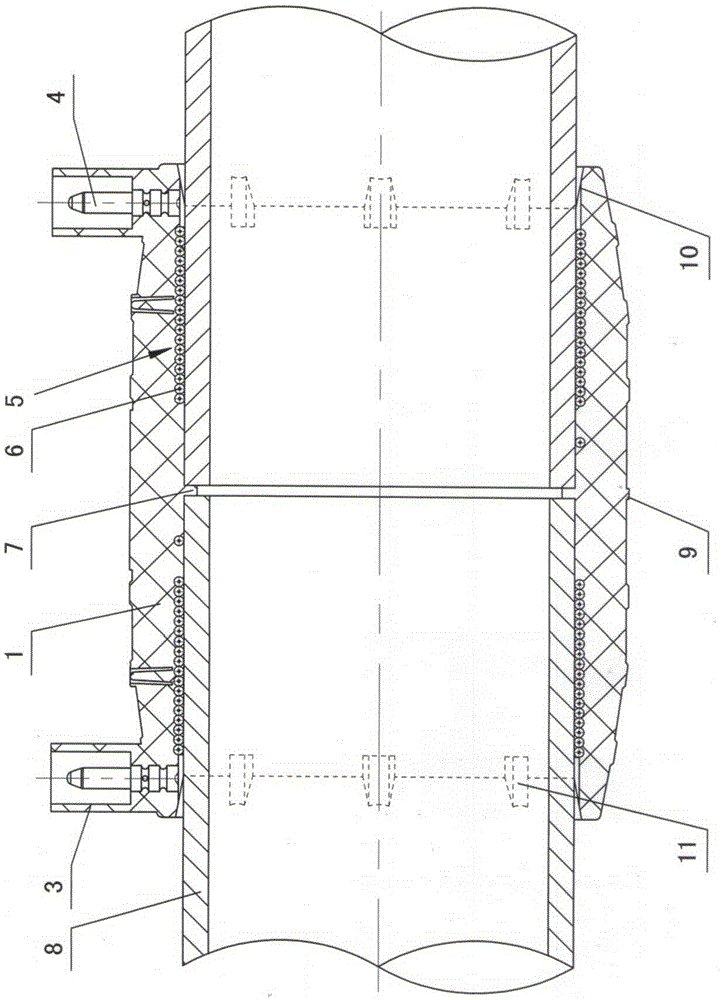

[0011] The invention relates to a polyethylene electrofusion socket pipe fitting with an external display mark and a resistance wire limit device, such as figure 1 — image 3 As shown, it includes a pipe fitting body 1, a socket 2 is formed in the pipe fitting body, a terminal protective cover 3 is formed on the outer wall of the pipe fitting body, a terminal post 4 is set in the body of the terminal protective cover, and a melting zone 5 is set on the inner wall of the pipe fitting body. A resistance wire 6 is set in the melting zone, and one end of the resistance wire is connected to the terminal, and it is characterized in that: the middle part of the inner wall of the pipe fitting body 1 is formed with a stop key 7, and the stop key is in contact with the end face of the inserted polyethylene pipe 8, The outer wall of the pipe fitting body 1 is shaped with a stop key indicating rib 9, which corresponds to the position of the stop key 7, and the inner wall of the socket 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com