Patents

Literature

33results about How to "To achieve the welding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

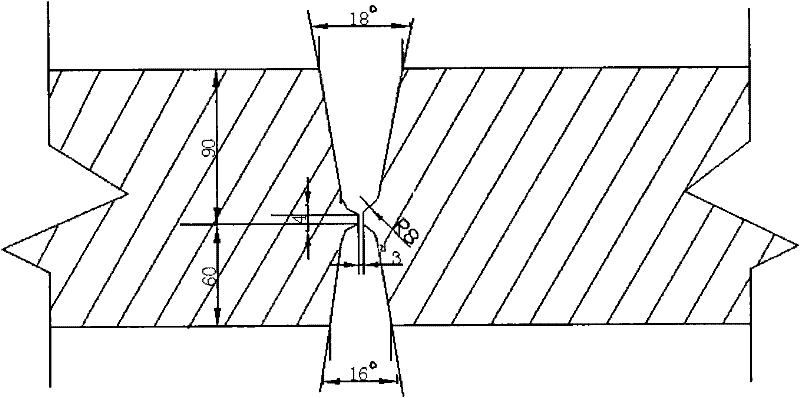

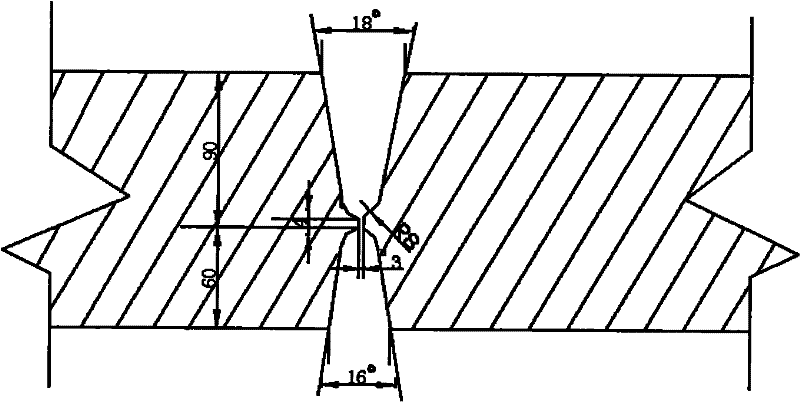

Welding method of ultra-thick and high-strength water-power steel

ActiveCN101905365ATo achieve the welding effectReduce fillingArc welding apparatusWorkpiece edge portionsEngineeringWelding defect

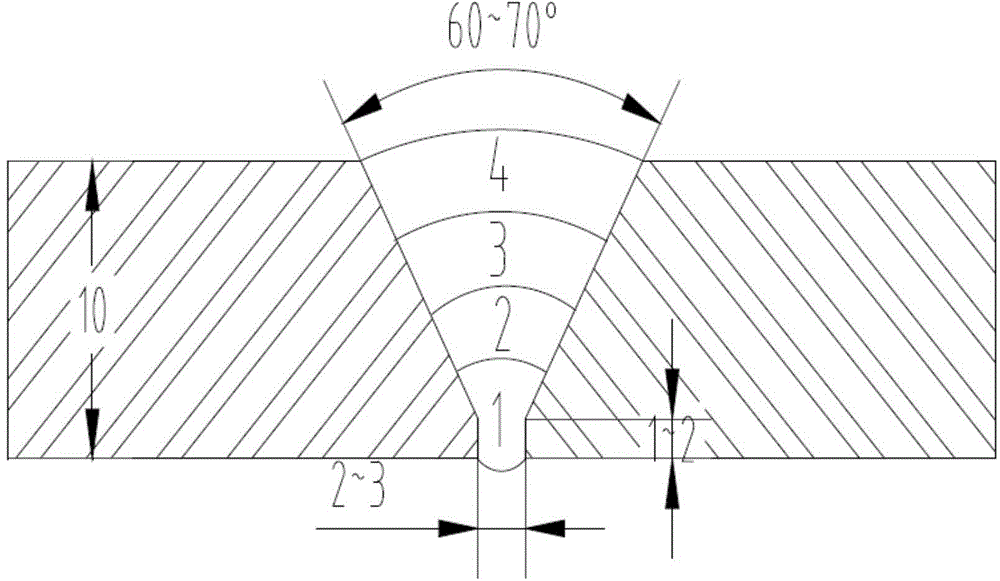

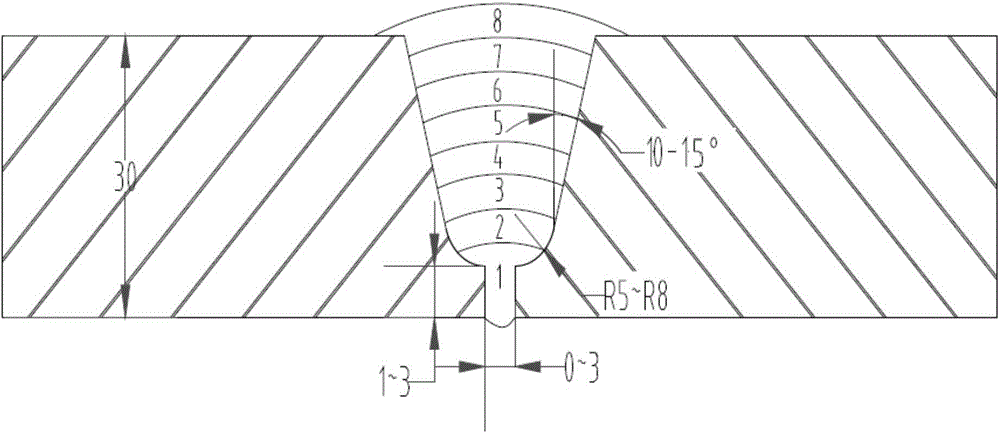

The invention relates to a welding method of ultra-thick and high-strength water-power steel, belonging to the welding field. Welding is realized by adopting a mixed welding mode, i.e. hand welding is adopted as a basis for filling the bottom, and gas shielded welding is adopted for a middle layer and a cover part, multilayer and multi-pass welding are adopted, a carbon arc is cropped out after a single side is filled, and the input of welding heat is controlled within 65 kJ / cm. A welding bevel adopts an asymmetric U-shaped bevel, a thick steel plate of 145-155 mm is preheated to 100 DEG C before welding, the inter-layer temperature is kept between 100 DEG C to 160 DEG C, and heat treatment stress is not carried out after welding, and the problem of reheat embrittlement of a welding joint of the high-strength water-power steel is solved. The invention needs simple welding equipment, realizes welding through a combined welding process on the basis of the traditional equipment, reduces the filling amount of welding metal, and achieves the welding effect of a narrow gap. Compared with the hand arc welding, the invention greatly improves the welding efficiency of the thick steel plate and lowers the possibility of welding defects easily generated on the hand arc welding of an ultra-thick steel plate, such as cold cracks, incomplete fusion, crisp fusion, and the like.

Owner:SHOUGANG CORPORATION +1

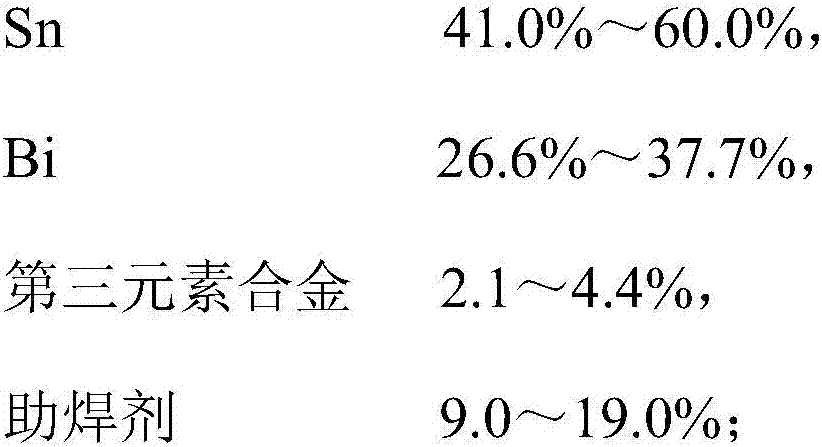

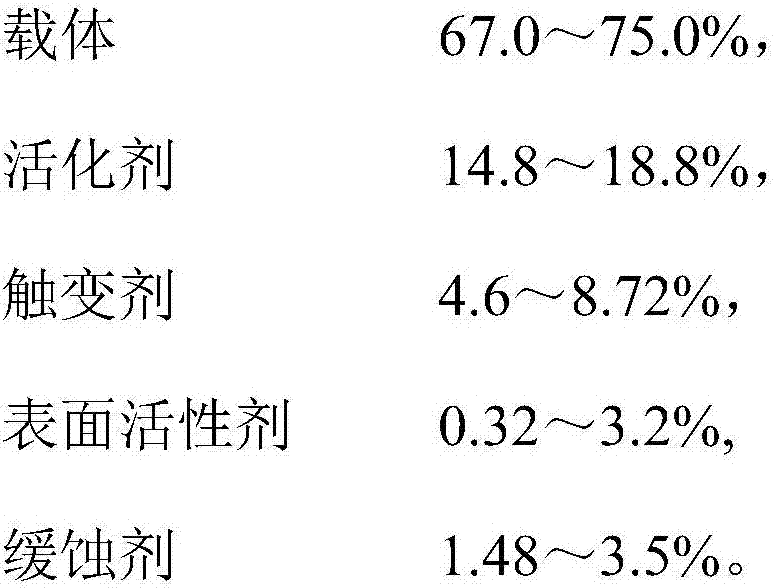

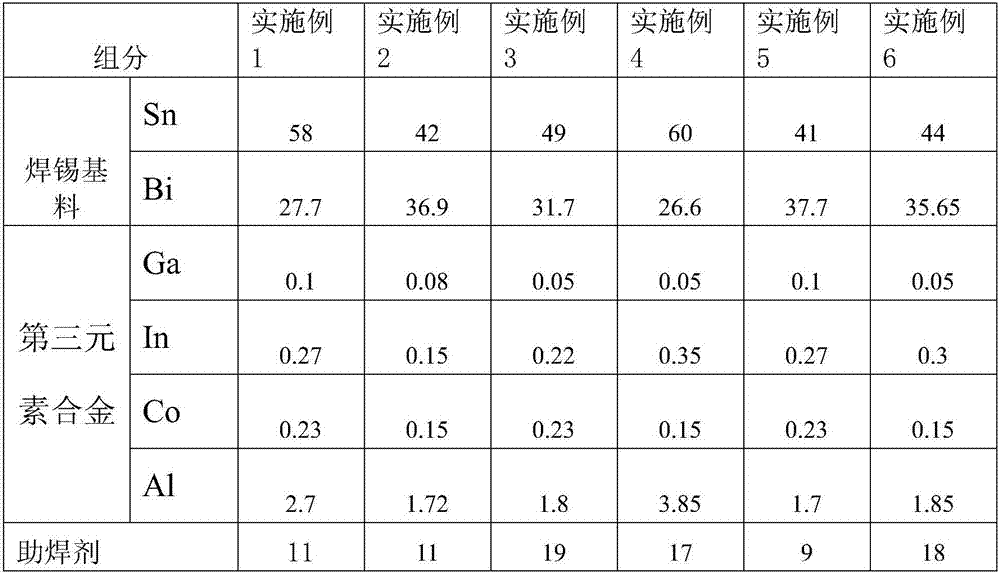

Environment-friendly and low-temperature residue-free solder paste and preparing method thereof

ActiveCN107088716AMeet welding needsHigh insulation resistanceWelding/cutting media/materialsSoldering mediaAlloySolid solution

The invention relates to environment-friendly and low-temperature residue-free solder paste and a preparing method thereof. According to the technical scheme, the environment-friendly and low-temperature residue-free solder paste is characterized in that the solder paste comprises, by weight, 41.0%-60.0% of Sn, 26.6%-37.7% of Bi, 2.1%-4.4% of a third element alloy and 9.0%-19.0% of scaling powder; and the scaling powder comprises, by weight, 67.0%-75.0% of a carrier, 14.8%-18.8% of an activating agent, 4.6%-8.72% of a thixotropic agent, 0.32%-3.2% of a surface active agent and 1.48%-3.5% of corrosion inhibitor. The environment-friendly and low-temperature residue-free solder paste is provided, halogen-free components are adopted in a formula, volatile components are avoided in the tin paste, and smells are avoided during using. After welding, residues are colorless and transparent, and the effect of replacing Pb containing tin paste or halogen-containing tin paste is achieved. Under the low-temperature welding condition, nano aluminum powder is added, a high-temperature solid solution is formed during welding to serve as an auxiliary part for supplementary welding, poor welding of a Sn-Bi alloy is effectively improved, and the welding requirement for aluminum components on the surface of an electronic component can be met; and meanwhile, the storage period of the tin paste is prolonged, and better wettability is brought.

Owner:中山翰华锡业有限公司

Austenitic stainless steel welding technology

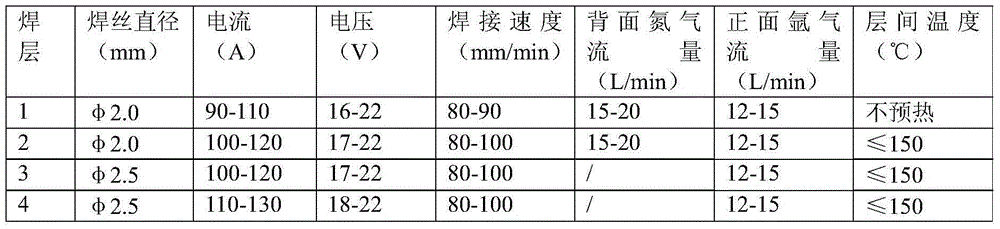

InactiveCN104785902ATo achieve the welding effectLow costArc welding apparatusWelding/soldering/cutting articlesOperating instructionNitrogen

The invention relates to an austenitic stainless steel welding method. The mode that high-purity nitrogen is blown to the back of a welding joint takes the place of the mode that when argon arc welding is performed in the prior art, the back of the welding joint is filled with argon, and backing weld of austenitic stainless steel can be completed. For a base material with the thickness larger than 20 mm, after the backing weld ends, other welding modes, such as electric arc welding, are adopted for completing later welding work. According to the method, due to the fact that the operating instruction is seriously controlled, the argon arc welding effect adopting full-argon shield can be obtained finally. Because the source of nitrogen is wide and the nitrogen is free of pollution, easy to prepare and low in cost, when the method is adopted for welding the austenitic stainless steel, and welding cost can be effectively saved.

Owner:ZHEJIANG BOFAN POWER EQUIP CORP

Electronic component welding method

InactiveCN103192150APromote absorptionAvoid offsetPrinted circuit assemblingSoldering apparatusProduction lineEngineering

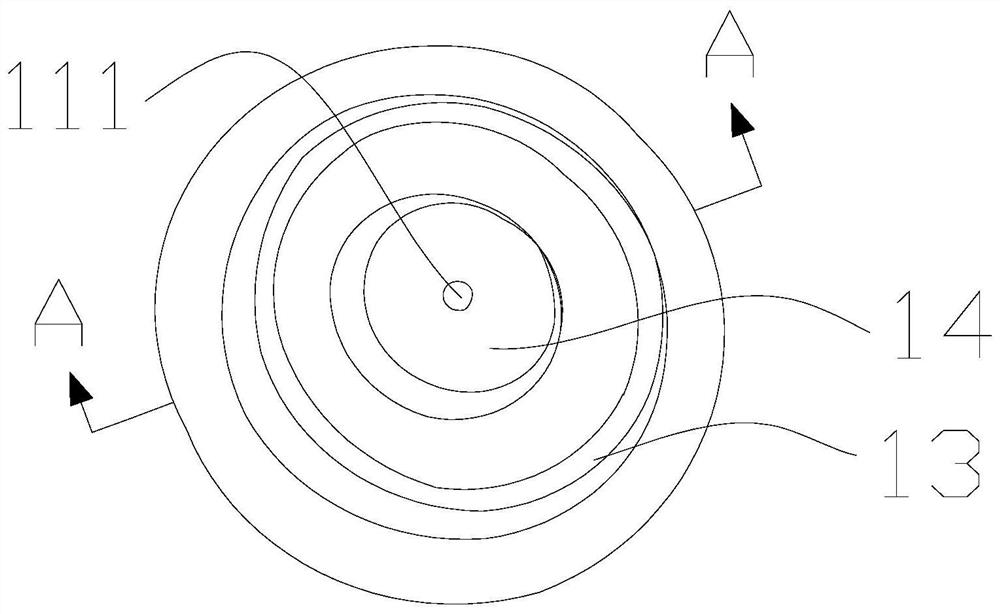

The invention discloses an electronic component welding method. The method comprises the following steps: firstly, subjecting the carrier of an electronic component to the pit structural processing to obtain a pit which is matched with the structure of the electronic component; secondly, placing the electronic component inside the pit and coating solder paste on the top of the electronic component and between the electronic component and the side wall of the pit; and thirdly, heating the solder paste to be melted to complete the welding process. By forming the pit structure on the carrier, defects such as excursion and tombstoning can be avoided due to the structure limit when the electronic component is placed inside the pit; without the blocking of the electronic component, the solder paste can absorb heat easily to be melted for welding; and by means of the top welding, a production line operator can be facilitated to detect and judge the welding quality.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

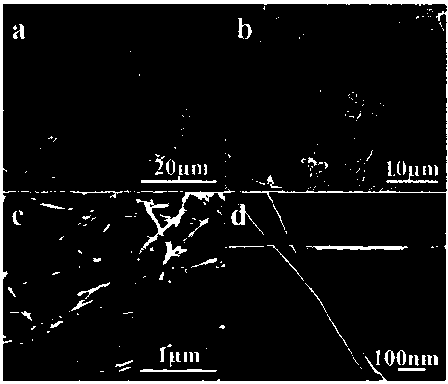

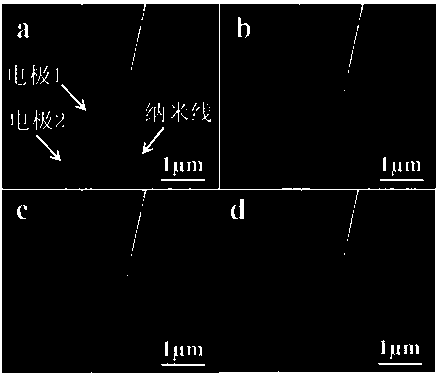

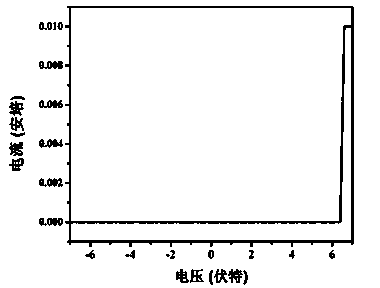

One-dimensional nanomaterial welding method based on electrically-induced heating effect

InactiveCN103624388ATo achieve the welding effectCreate pollutionNanostructure manufactureWelding/cutting media/materialsHeating effectUltimate tensile strength

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Quick-heating electric soldering iron heating head

InactiveCN101062528AGood workmanshipThe process is easy to stabilizeHeating appliancesSoldering ironIsolation layerHeating temperature

The quick heating electric iron is low in energy consumption, long in durability, heating the electric iron to the required temperature, with isolation base on the heating thread formed as the heating core, isolation layer outside the heating core, outside metal conductor outside isolation layer, end of the outside metal conductive body being the iron head, with the heating core, isolation layer, metal conductive body closely bonded together to form a seamless structure. There is a temperature sensor controlling the heating temperature on the heater, formed into the controllable temperature and quick heating electric heater. Between the outside metal conductor and isolation layer forms the link and quick conductive force of the inner metal conductor. The invention relates to a quick heating electric iron with quick heating speed, small in size, low in energy, long in durability, high in efficiency.

Owner:SOUTHEAST UNIV

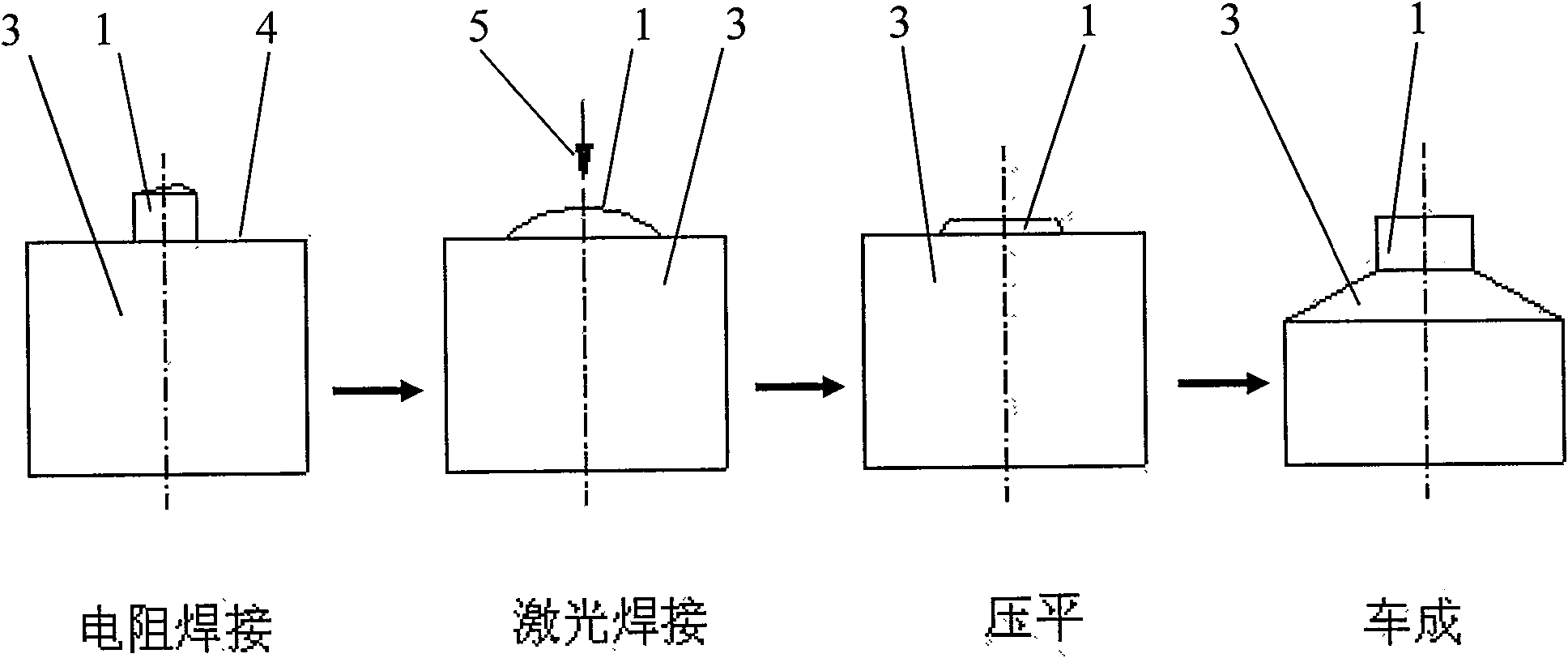

Laser welding method of noble metal spark plug electrode

InactiveCN101670488ASmall spotSmall thermal deformationLaser beam welding apparatusTime sequenceNoble metal

The invention relates to a laser welding method of a noble metal spark plug electrode. The end face of a base material of the electrode is a plane, the melting point of the base material is lower thanthat of a noble metal material, the noble metal material is directly put on the plane of the end face of the electrode of the base material, noble metal is fixed on the plane of the end face of the electrode by common resistance welding, the material is locally heated in a tiny area by laser pulse from the top of the material, and the noble metal and the plane of the end face of the base materialare respectively molten according to different time sequences. The method comprises the following steps: firstly, the central part of the plane of the end face of the electrode which is used for holding the noble metal is molten step by step, and a molten pool which is sunken inwards formed at the central part of the plane of the end face; the noble metal falls into the formed molten pool; then,the molten pool is continuously heated, and the noble metal is molten in the formed molten pool and is molten and welded together with the base material which is already molten; and after the noble metal which is molten and welded together is cooled, the noble metal is shaped and processed by common machine processing, the surface is flattened and compacted, and a spark plug electrode compoundingthe noble metal and a common material is formed.

Owner:ZHUZHOU TORCH SPARK PLUG CO LTD

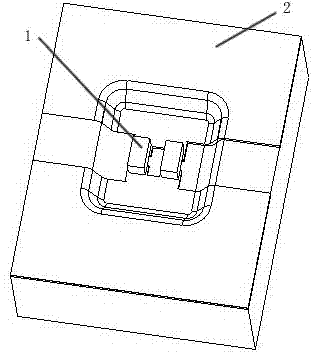

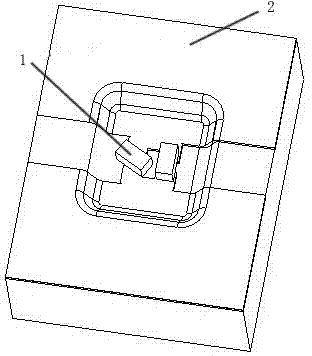

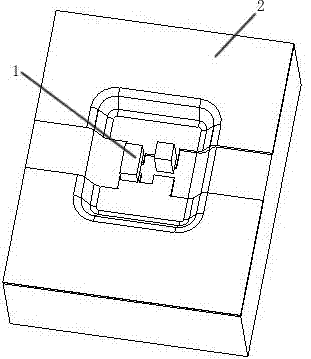

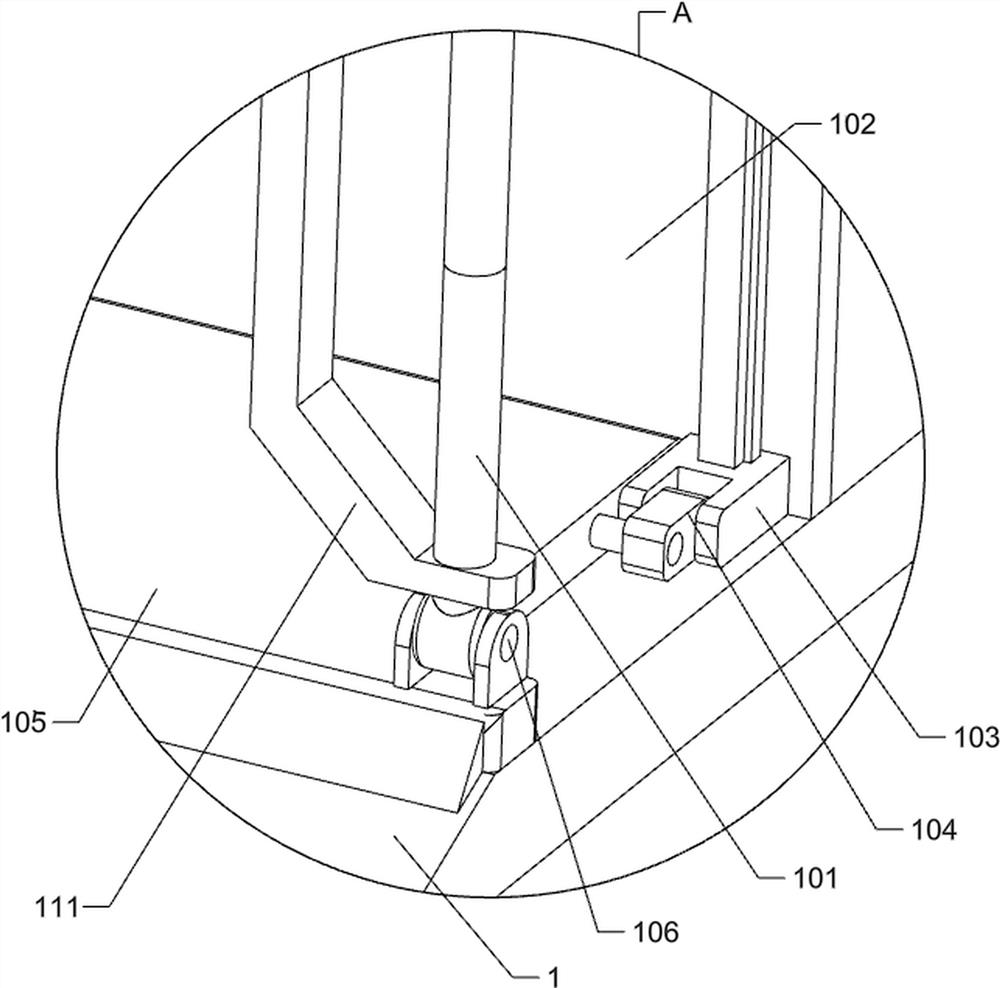

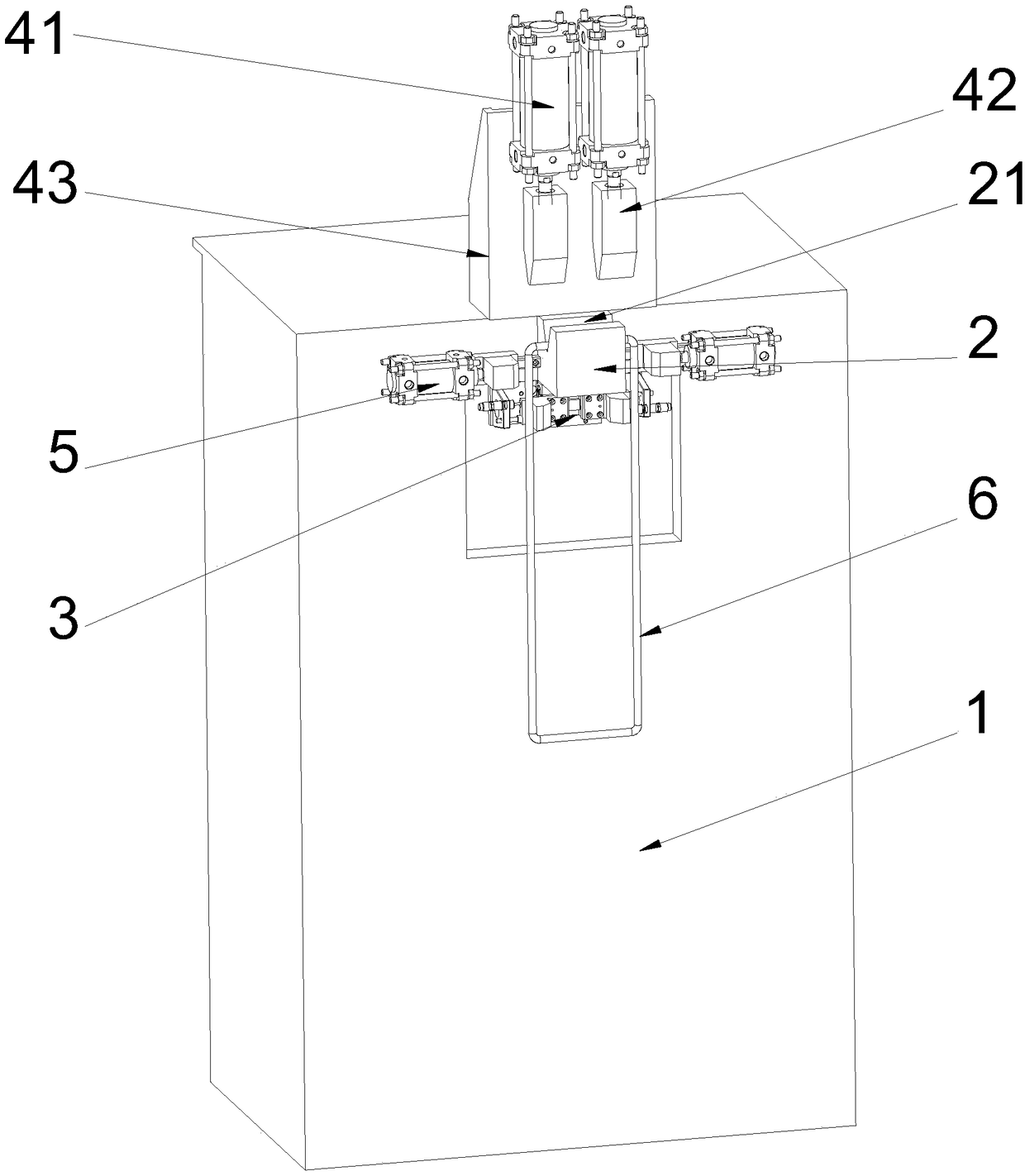

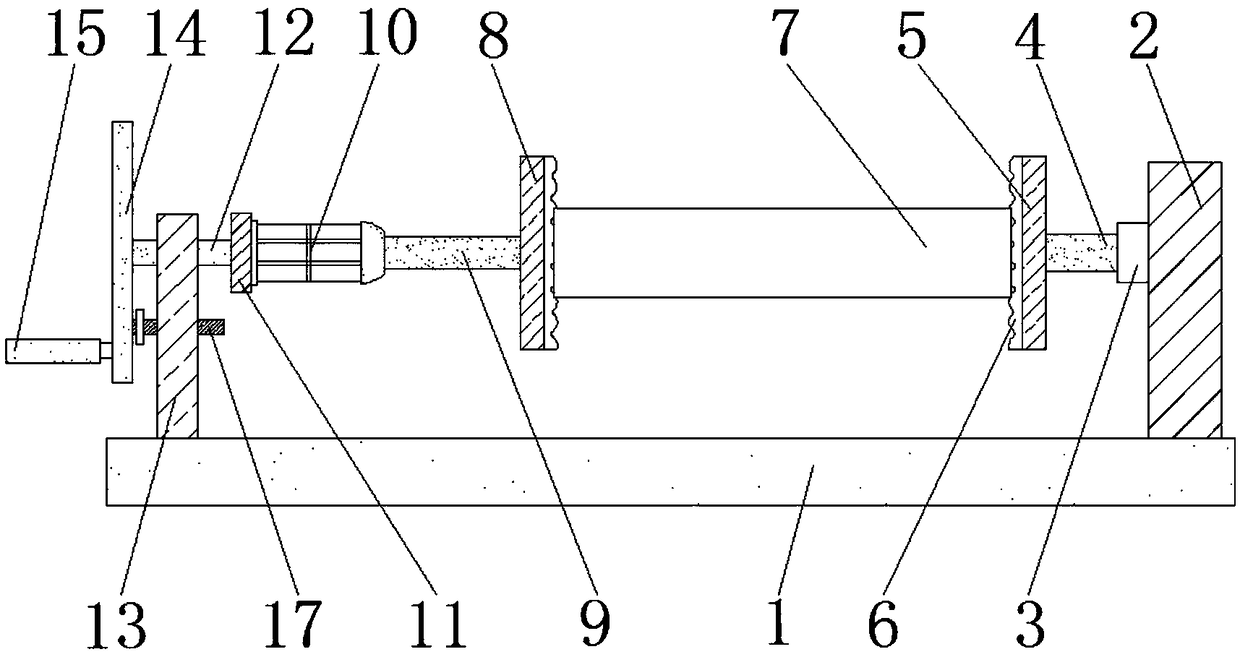

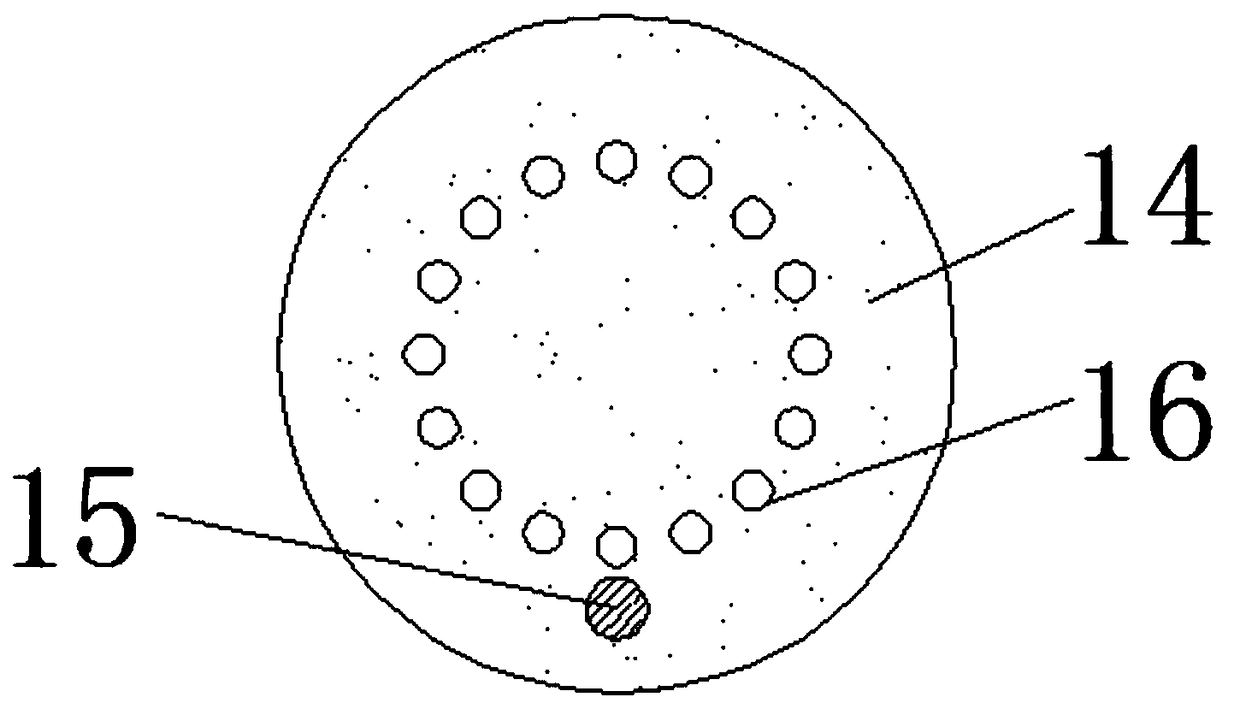

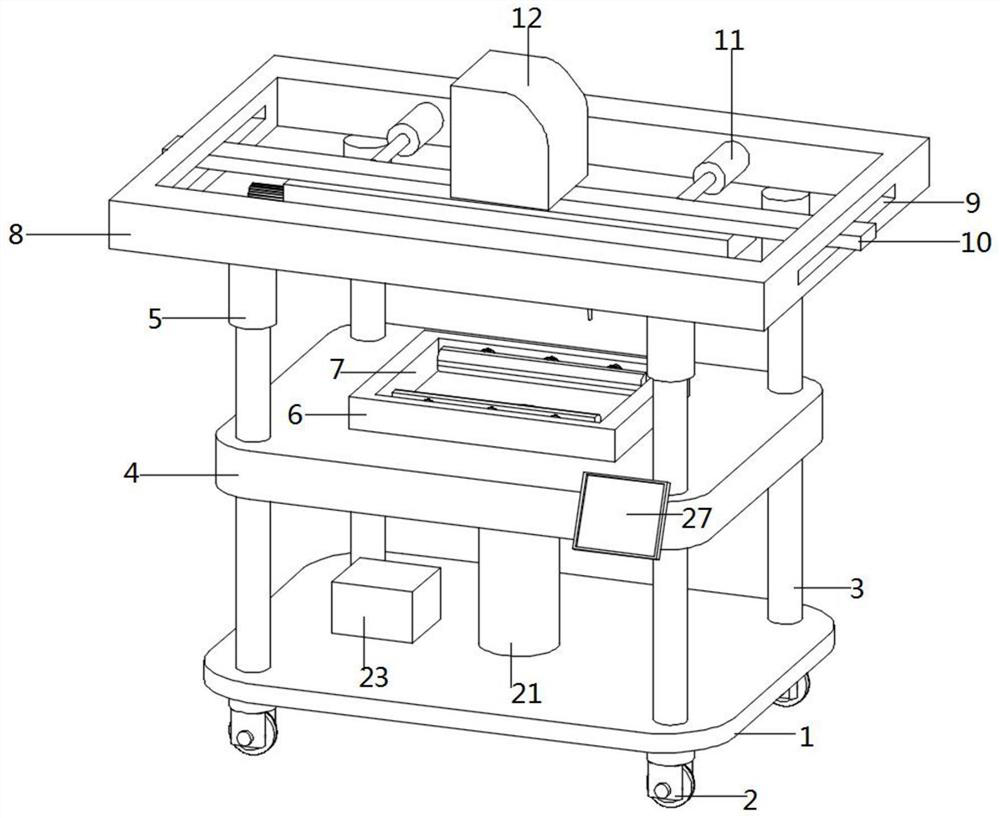

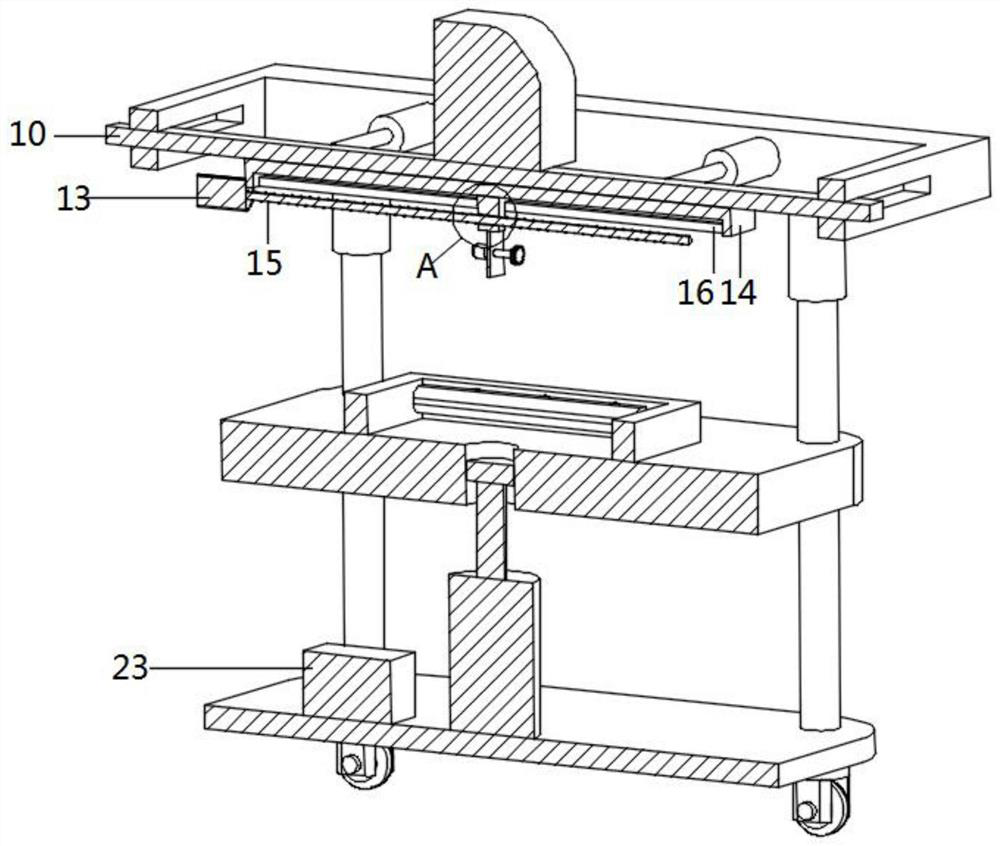

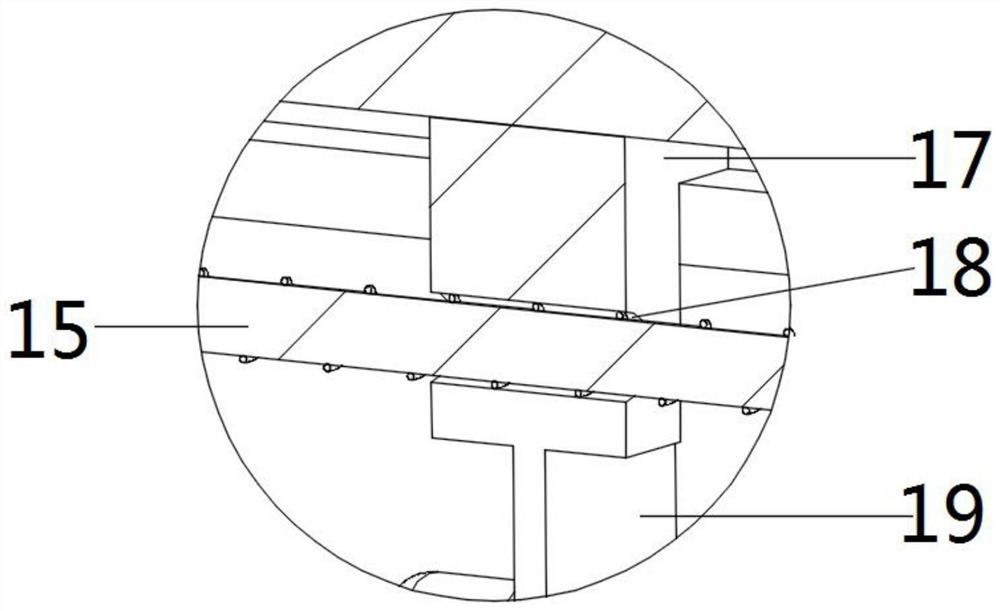

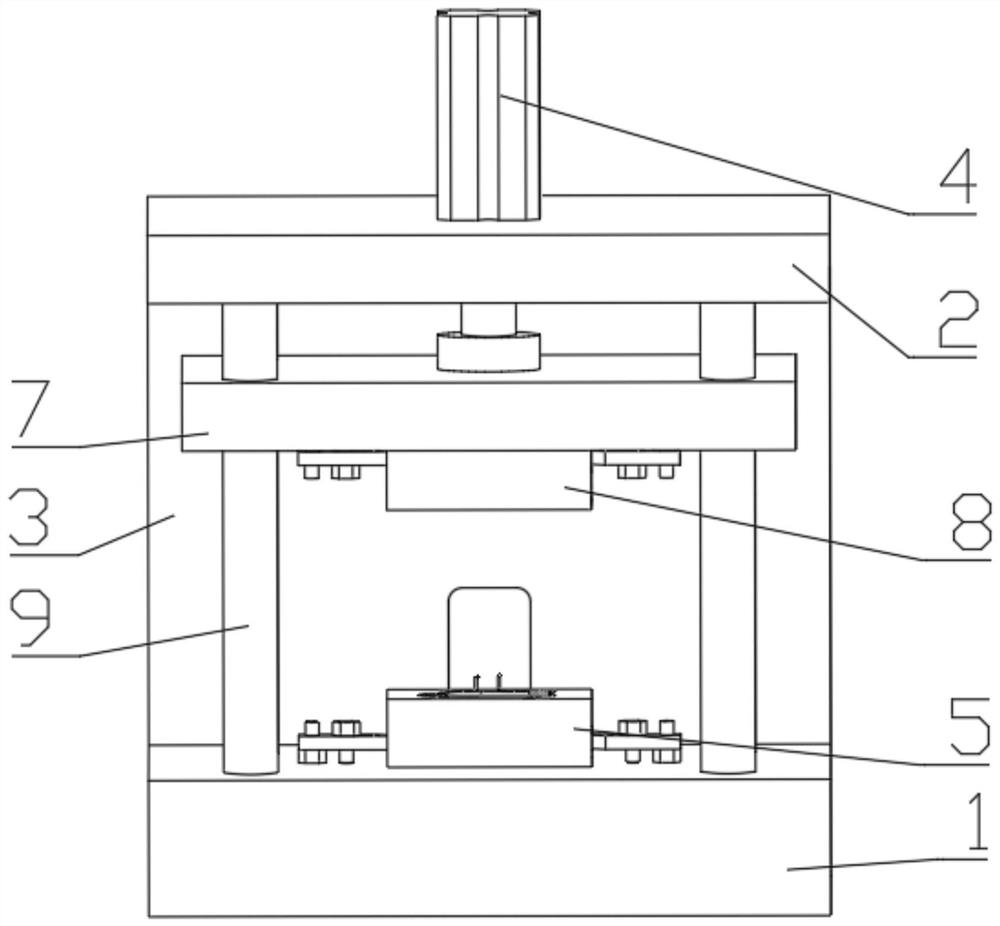

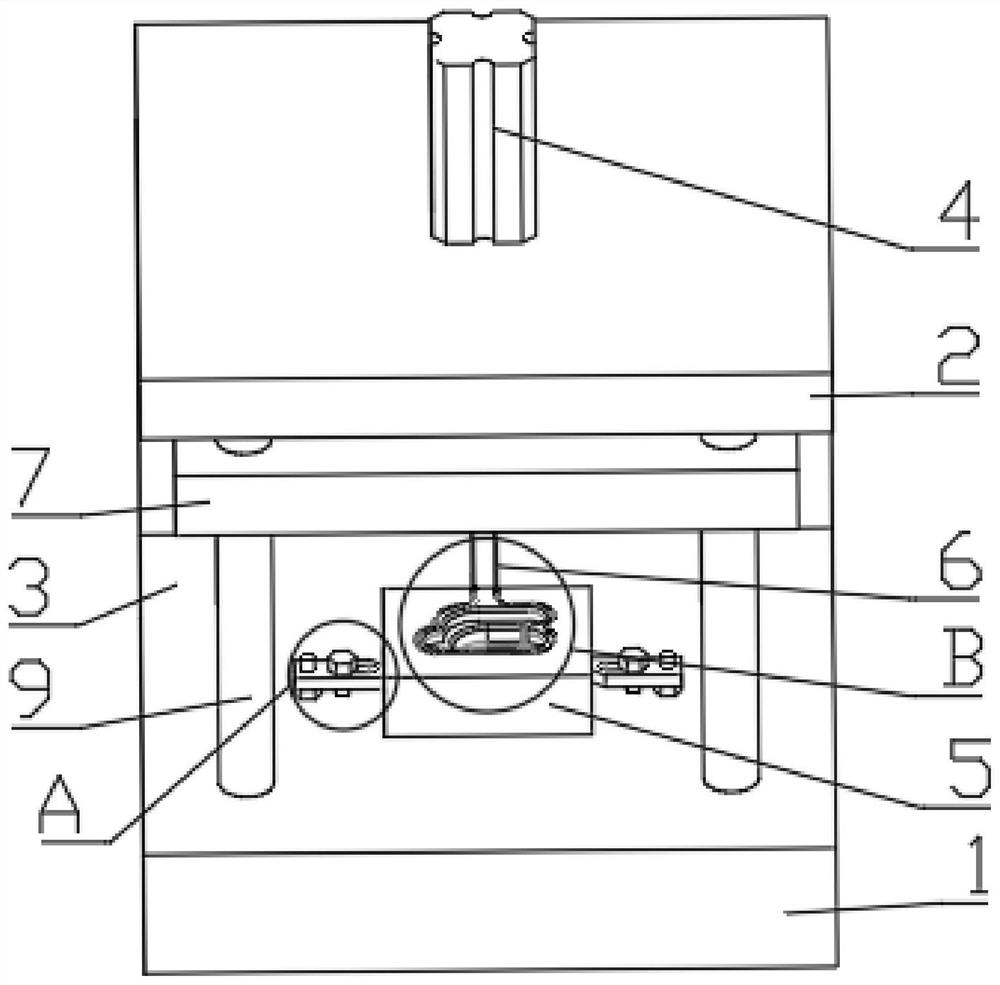

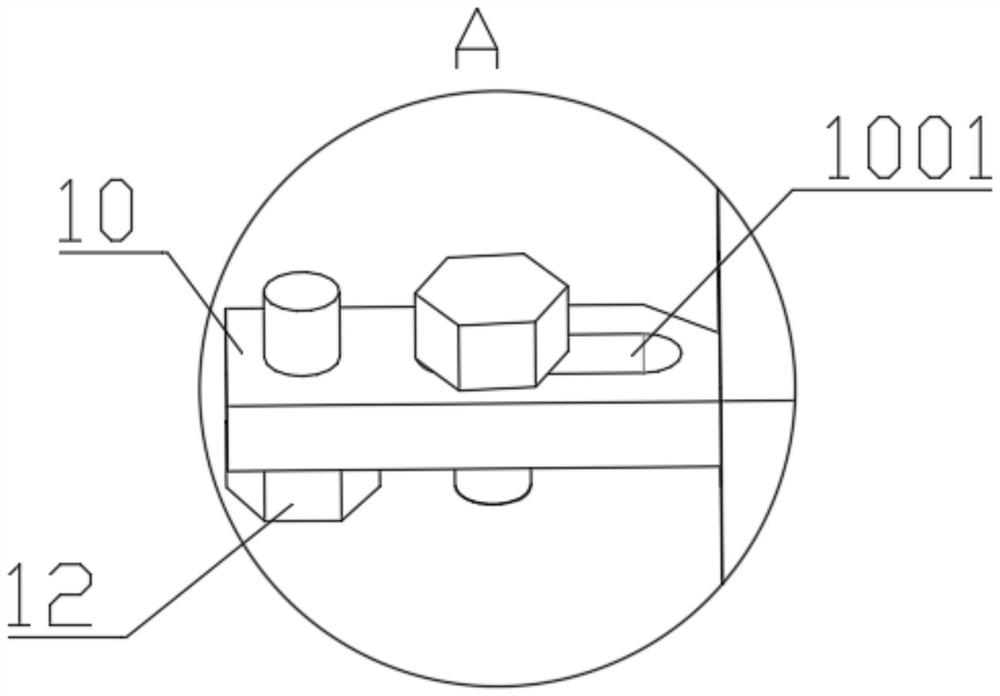

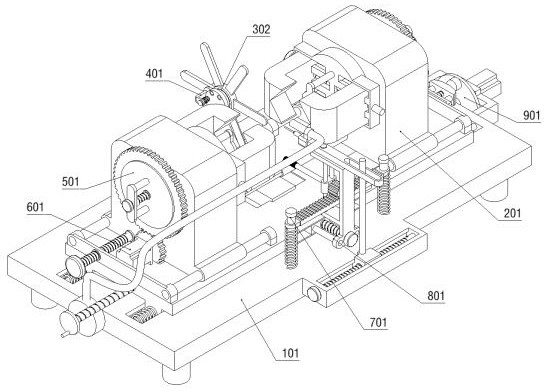

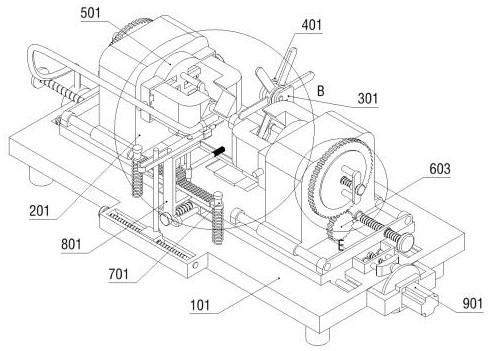

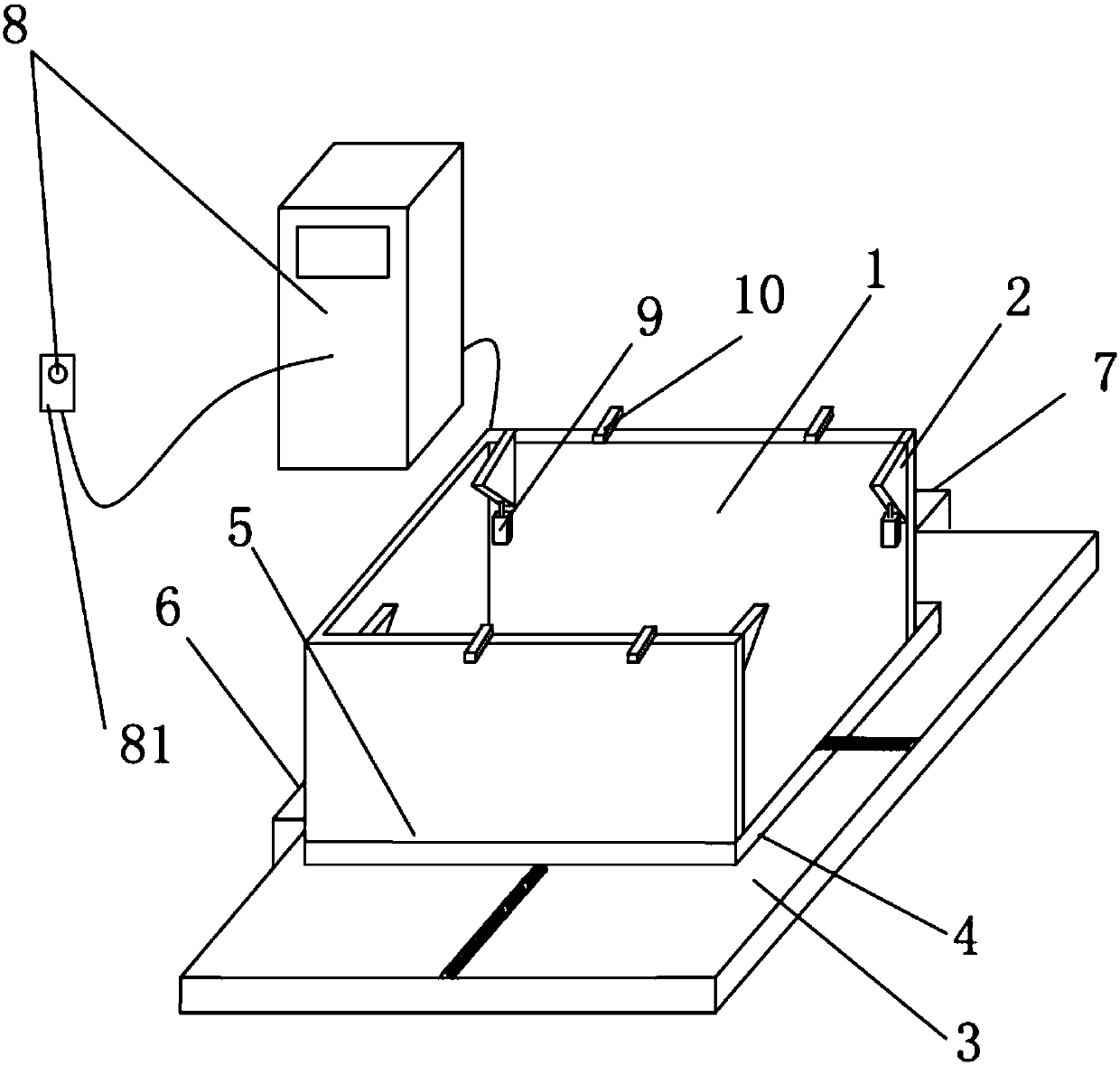

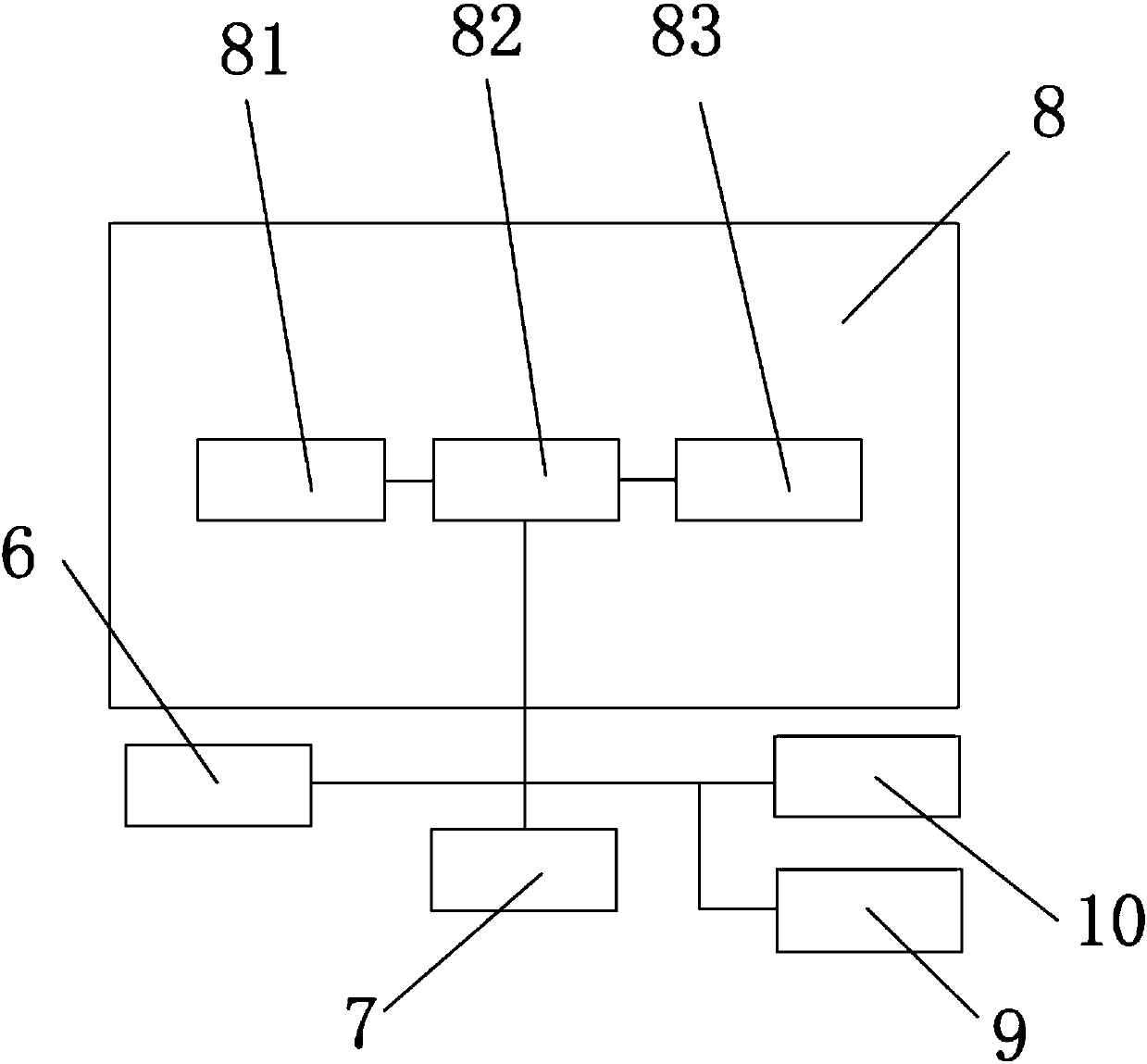

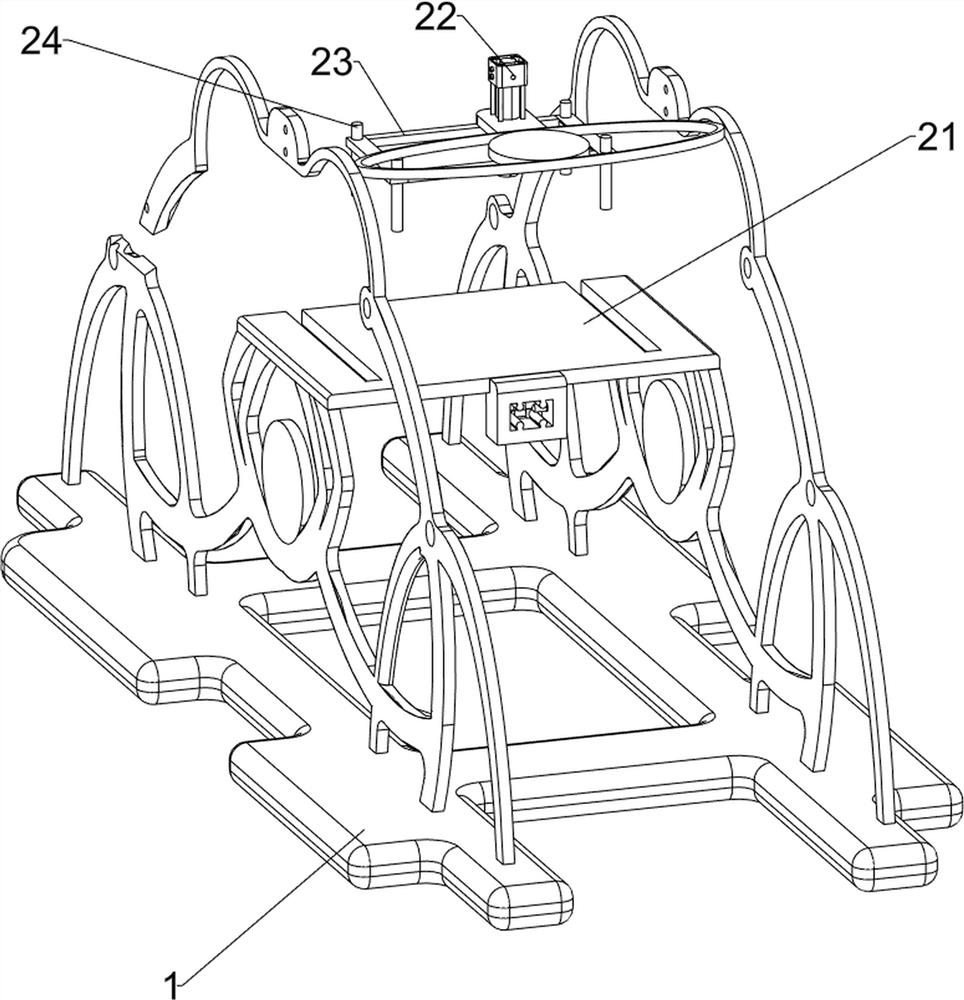

Part welding and clamping device for high-end equipment manufacturing

PendingCN113953727ASave human effortEnsure safetyWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringIndustrial engineering

The invention relates to a welding device, in particular to a part welding and clamping device for high-end equipment manufacturing, and aims to solve the technical problem about how to design the part welding and clamping device which is used for high-end equipment manufacturing and is easy to operate and capable of improving the working efficiency and ensuring the safety of a user. The part welding and clamping device for high-end equipment manufacturing comprises a bottom plate, a central control panel mounted in the middle of a support, a first guide rod connected to the top in the support, a welding gun connected to the first guide rod in a sliding mode and matched with the central control panel, and a driving mechanism arranged on the support; and the support is connected to the top of the bottom plate. According to the part welding and clamping device, the driving mechanism and the welding gun work cooperatively to weld parts, so that the effect of welding the parts is achieved.

Owner:陈贵招

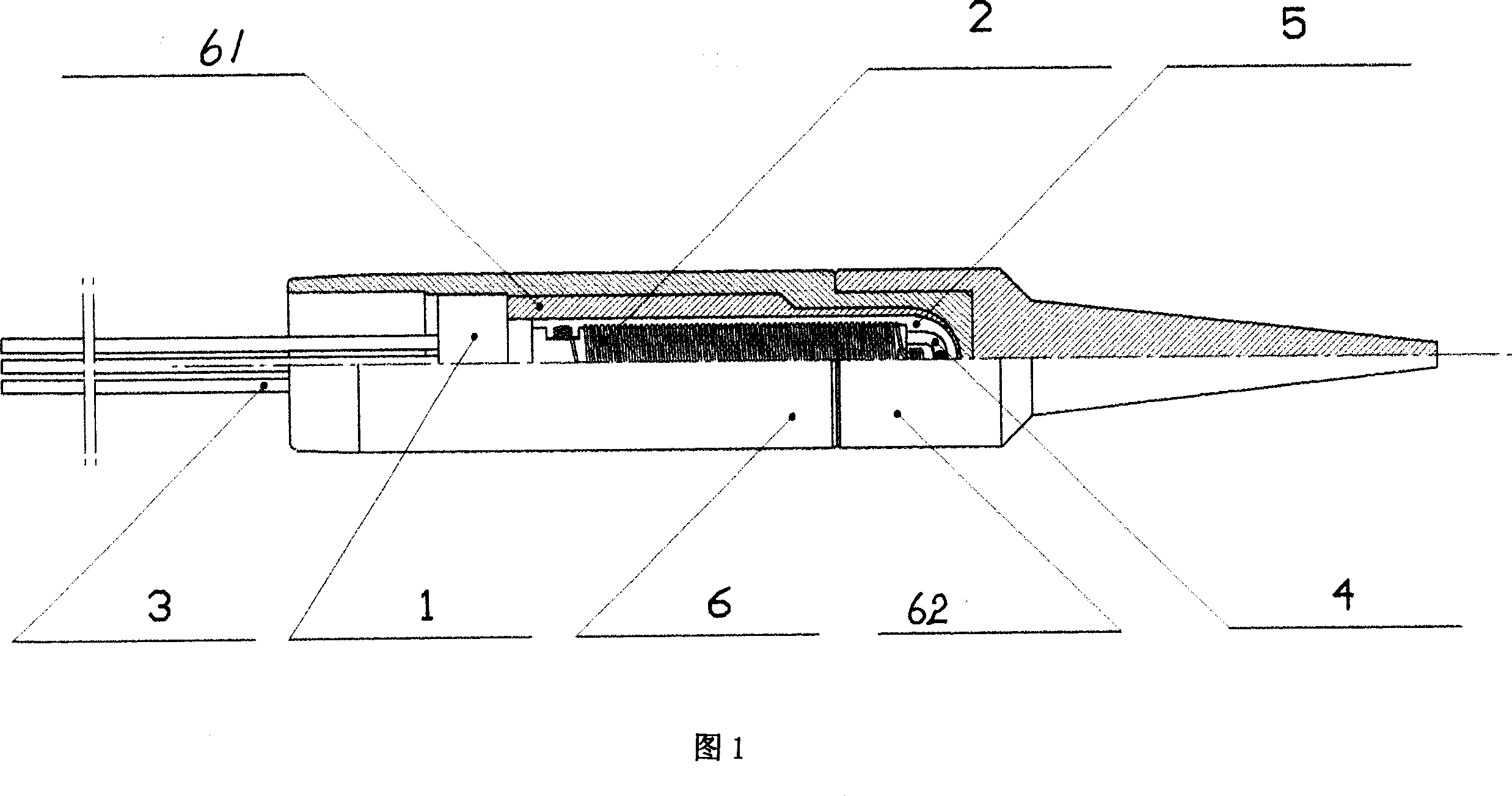

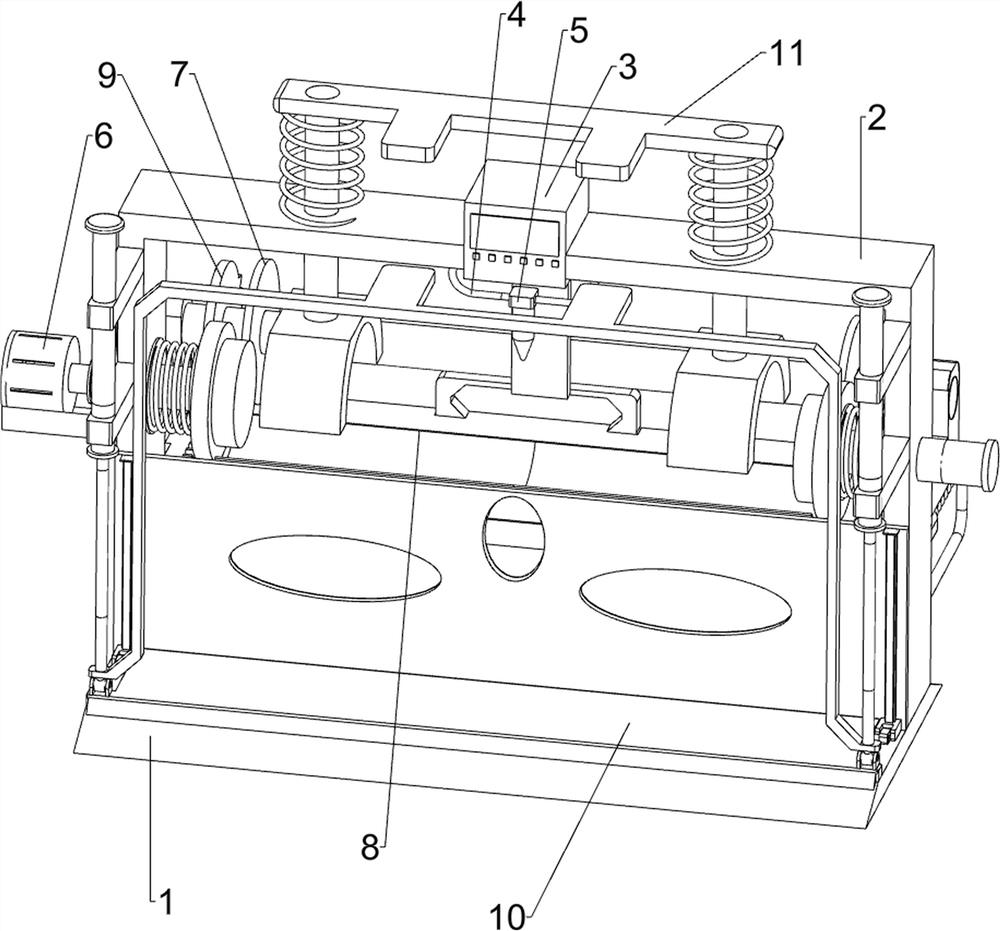

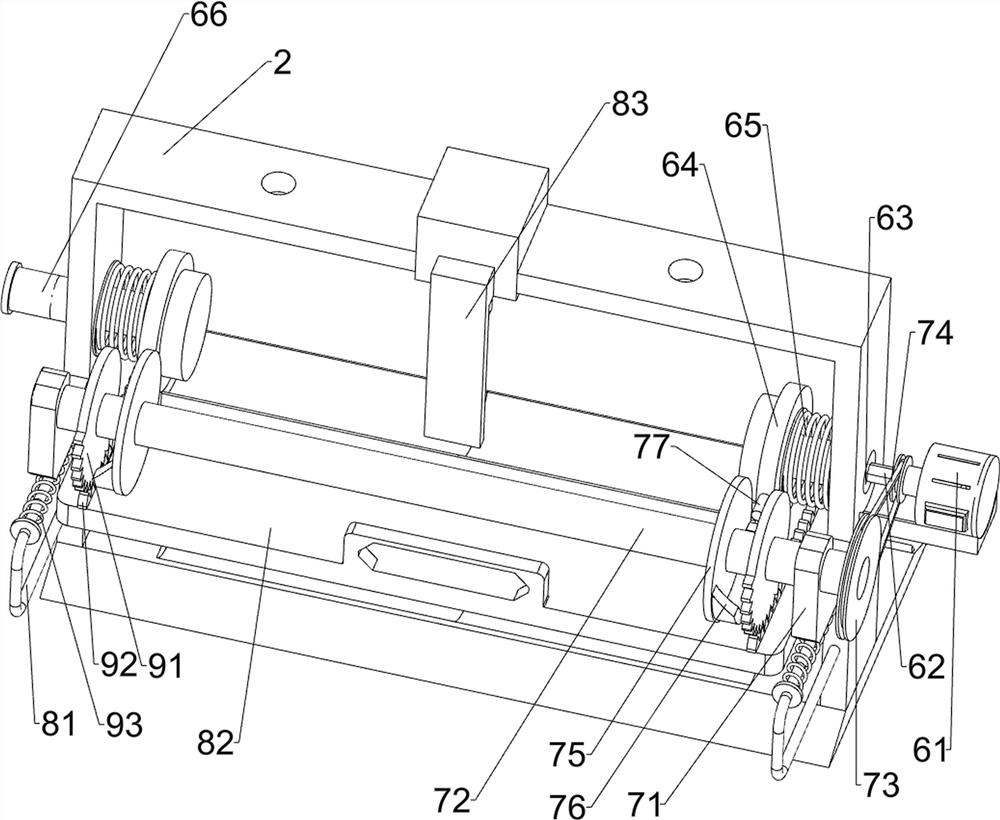

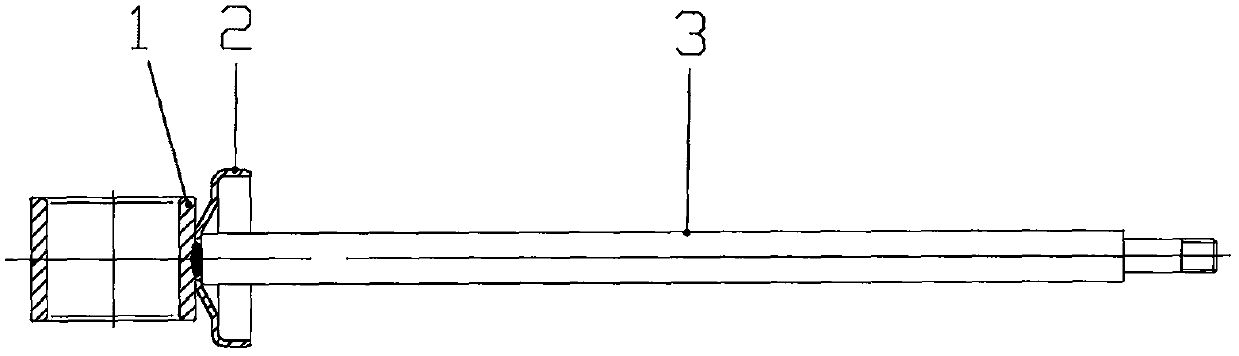

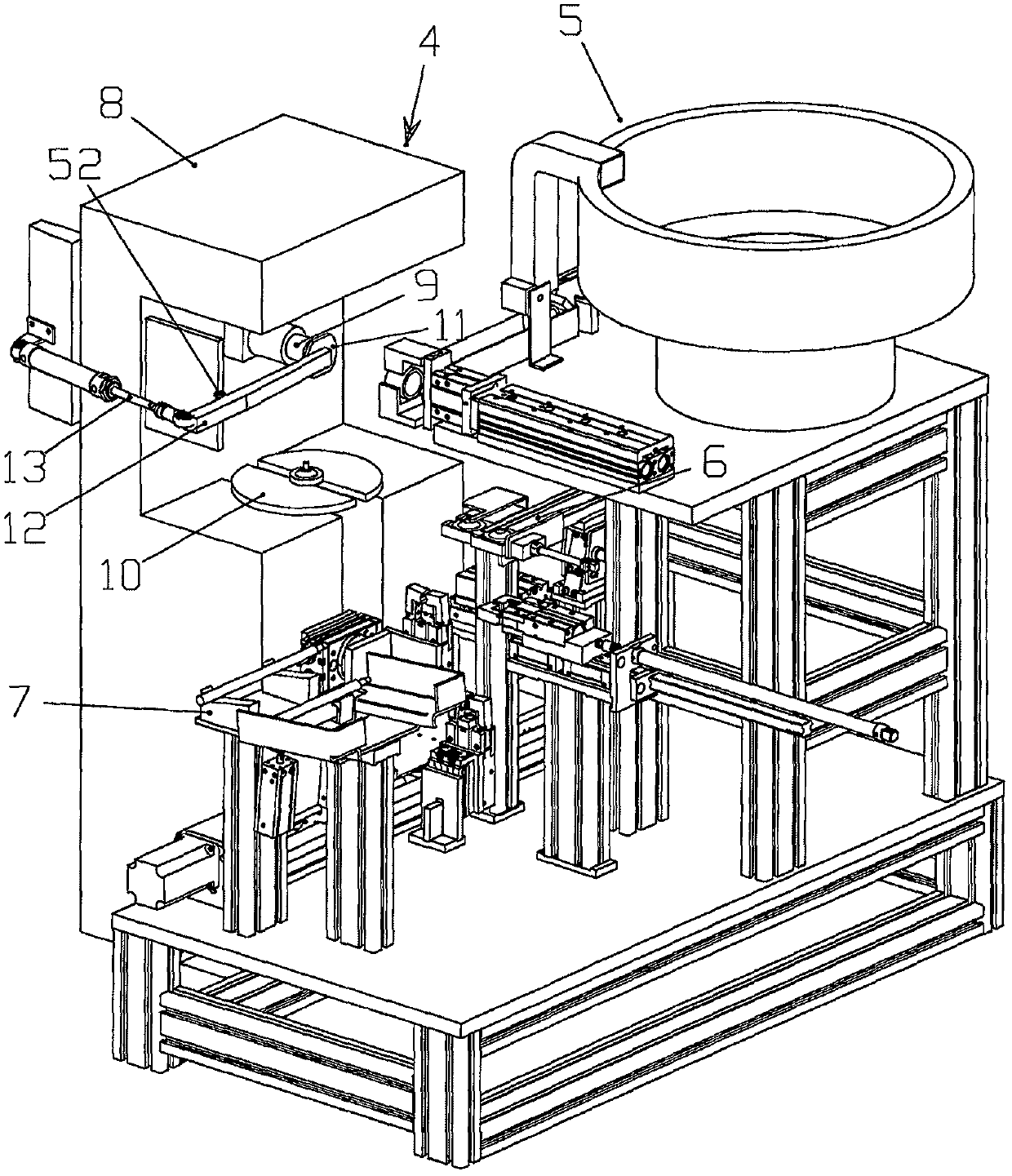

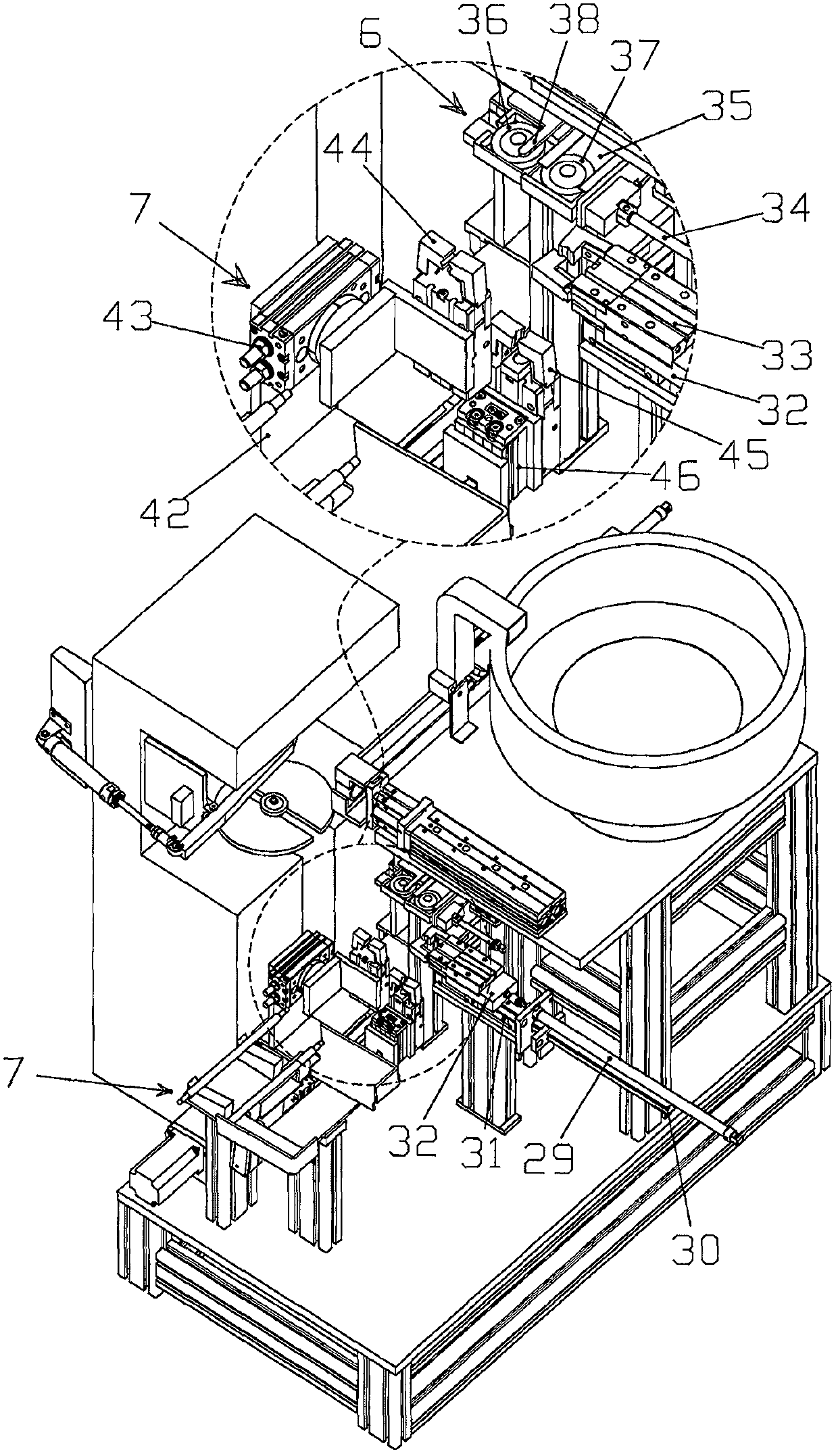

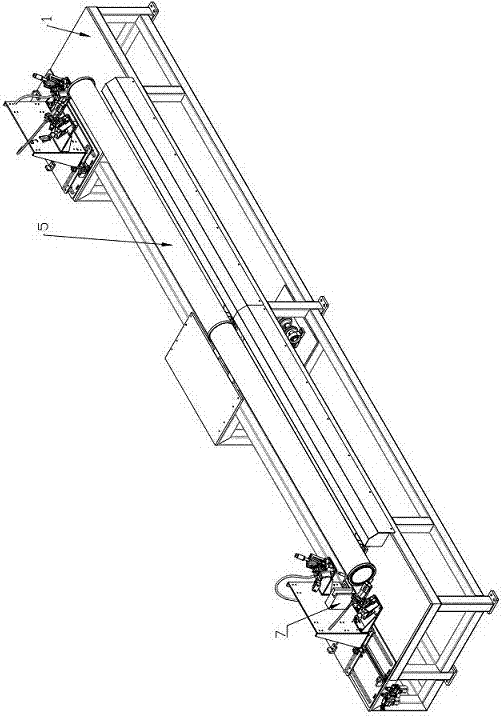

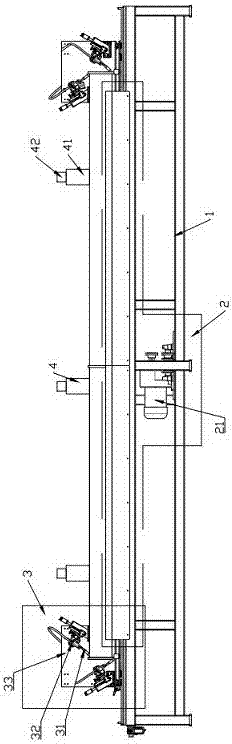

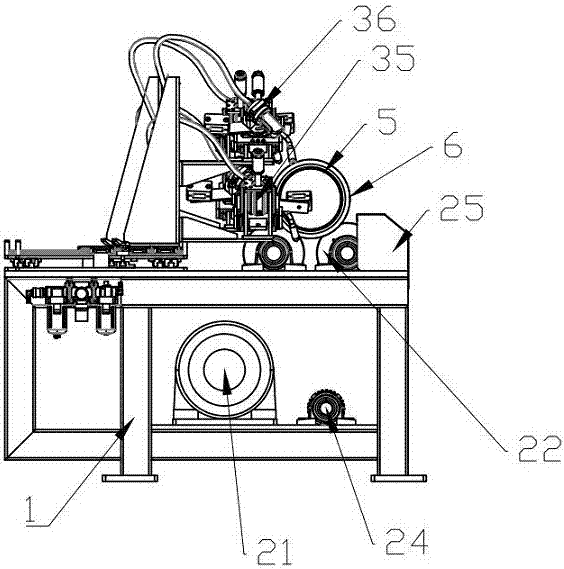

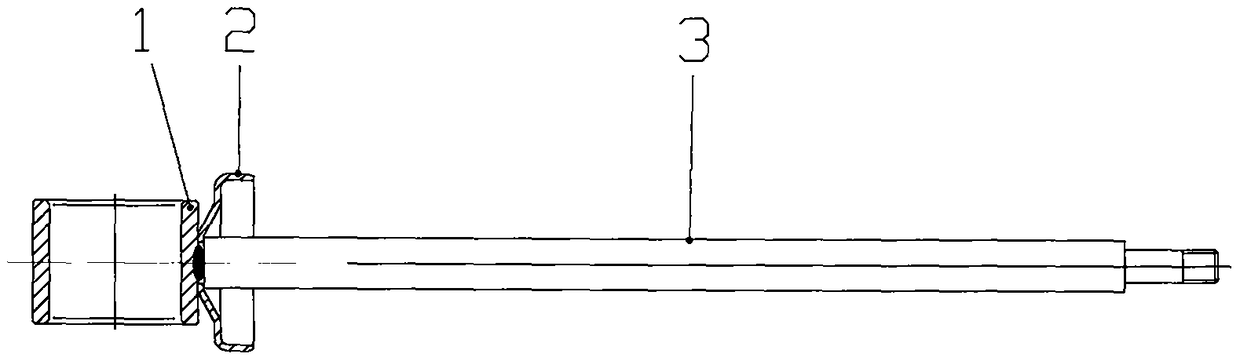

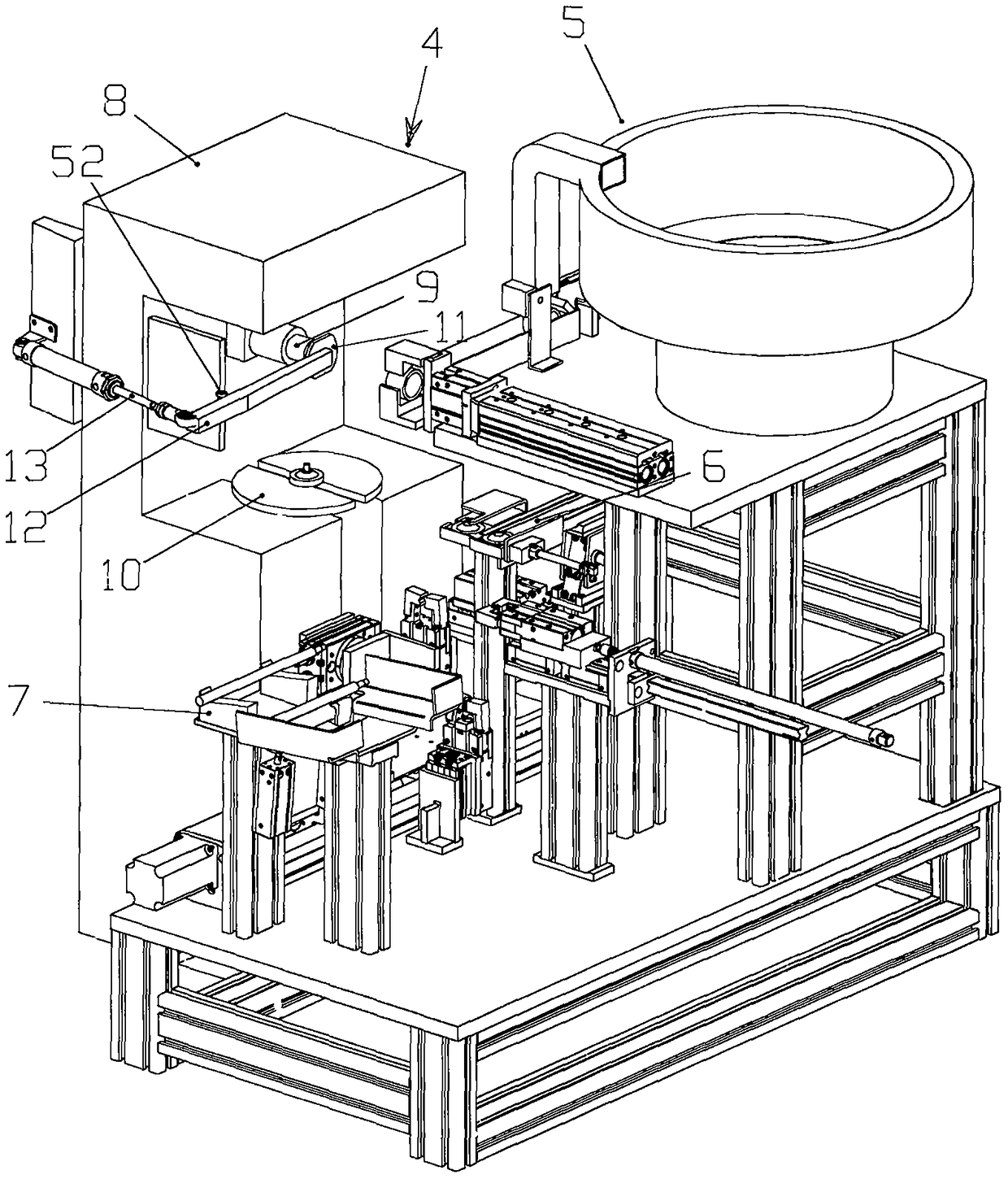

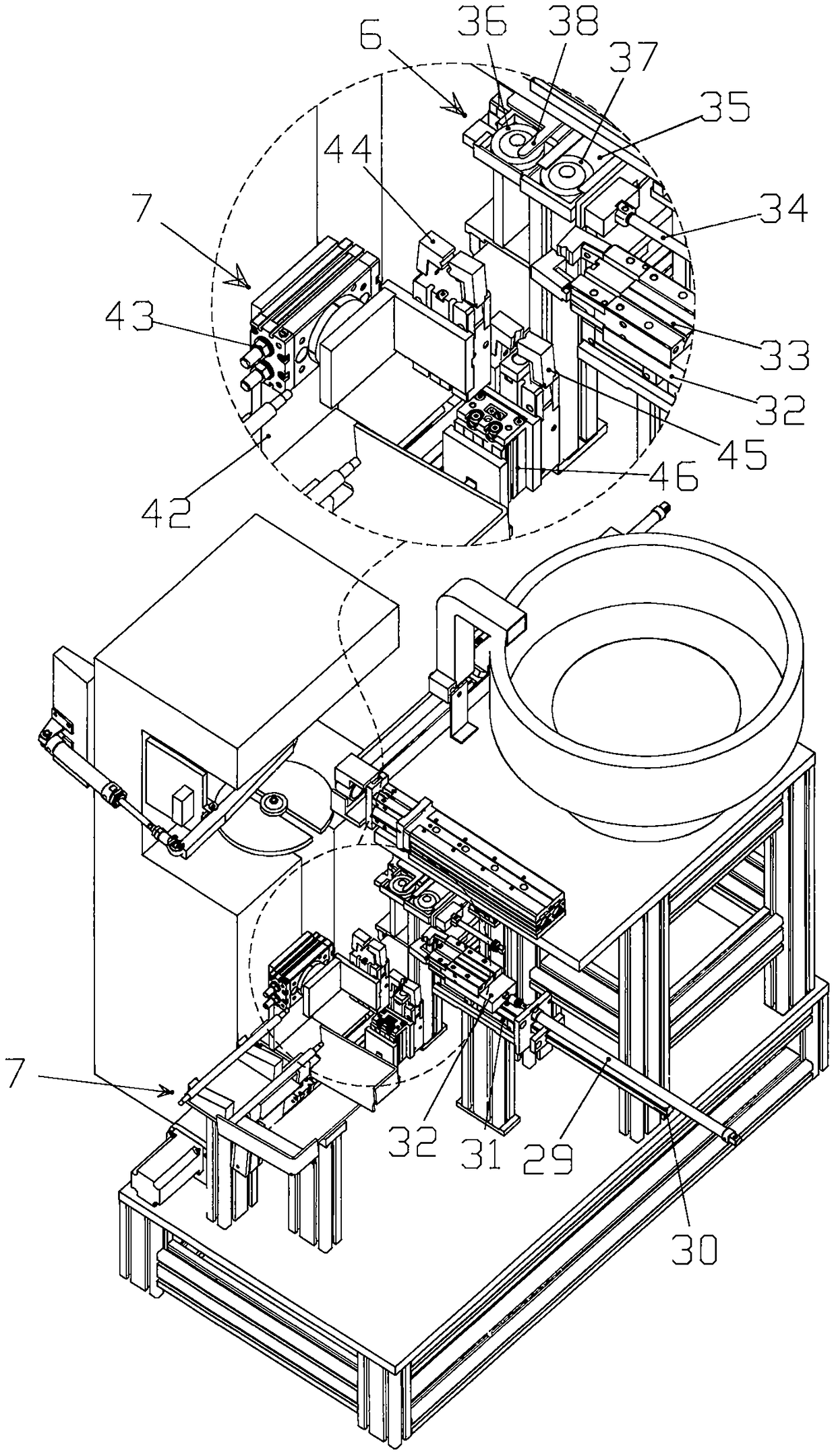

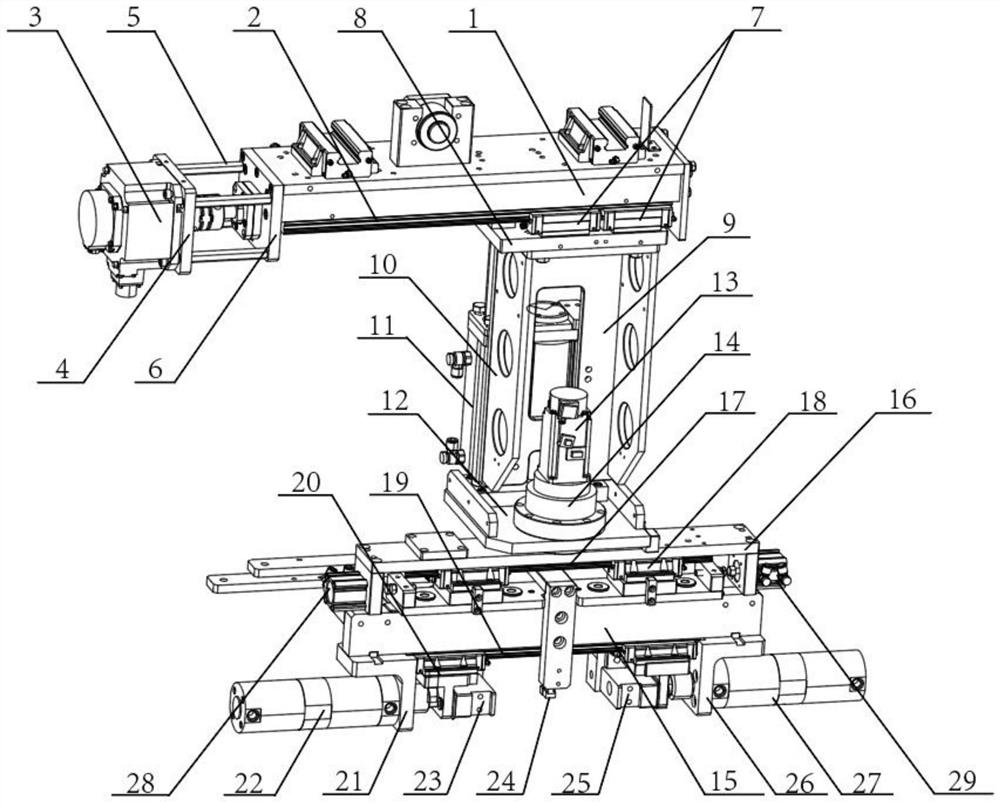

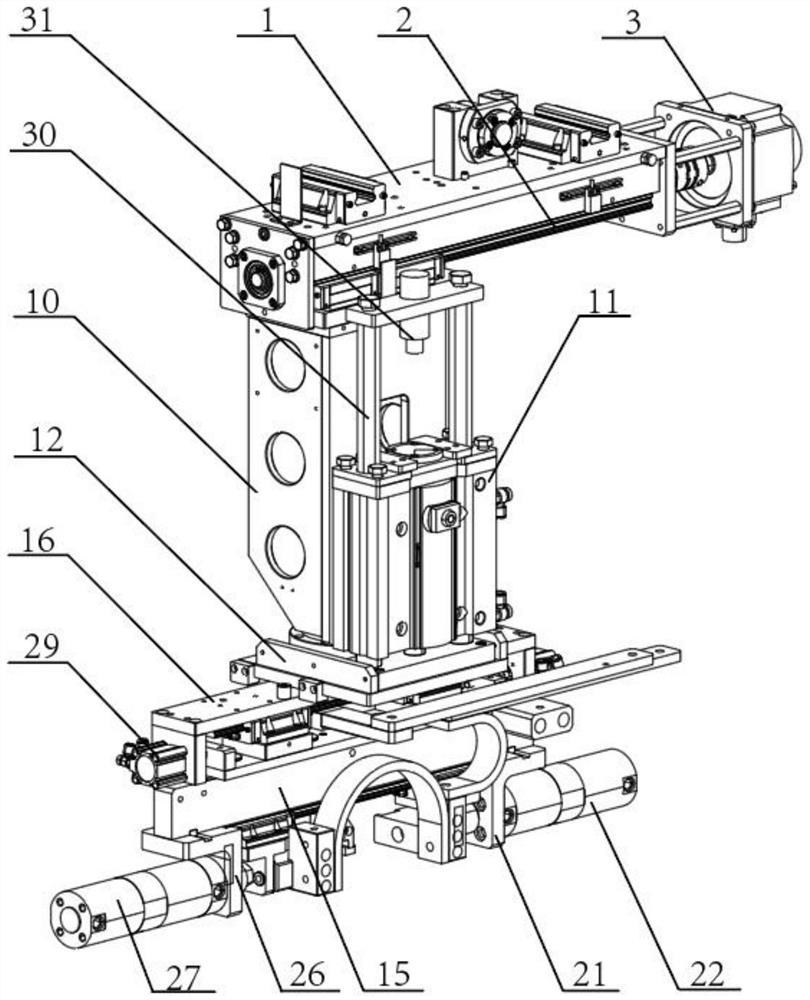

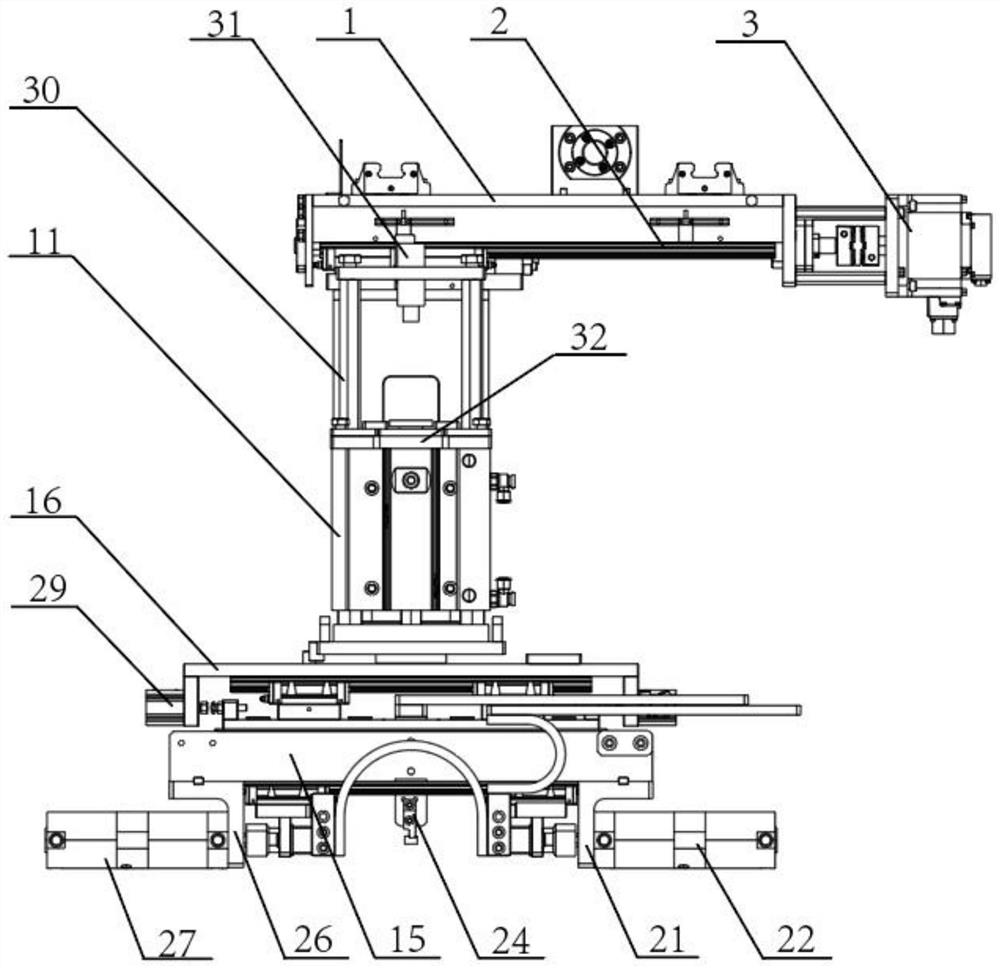

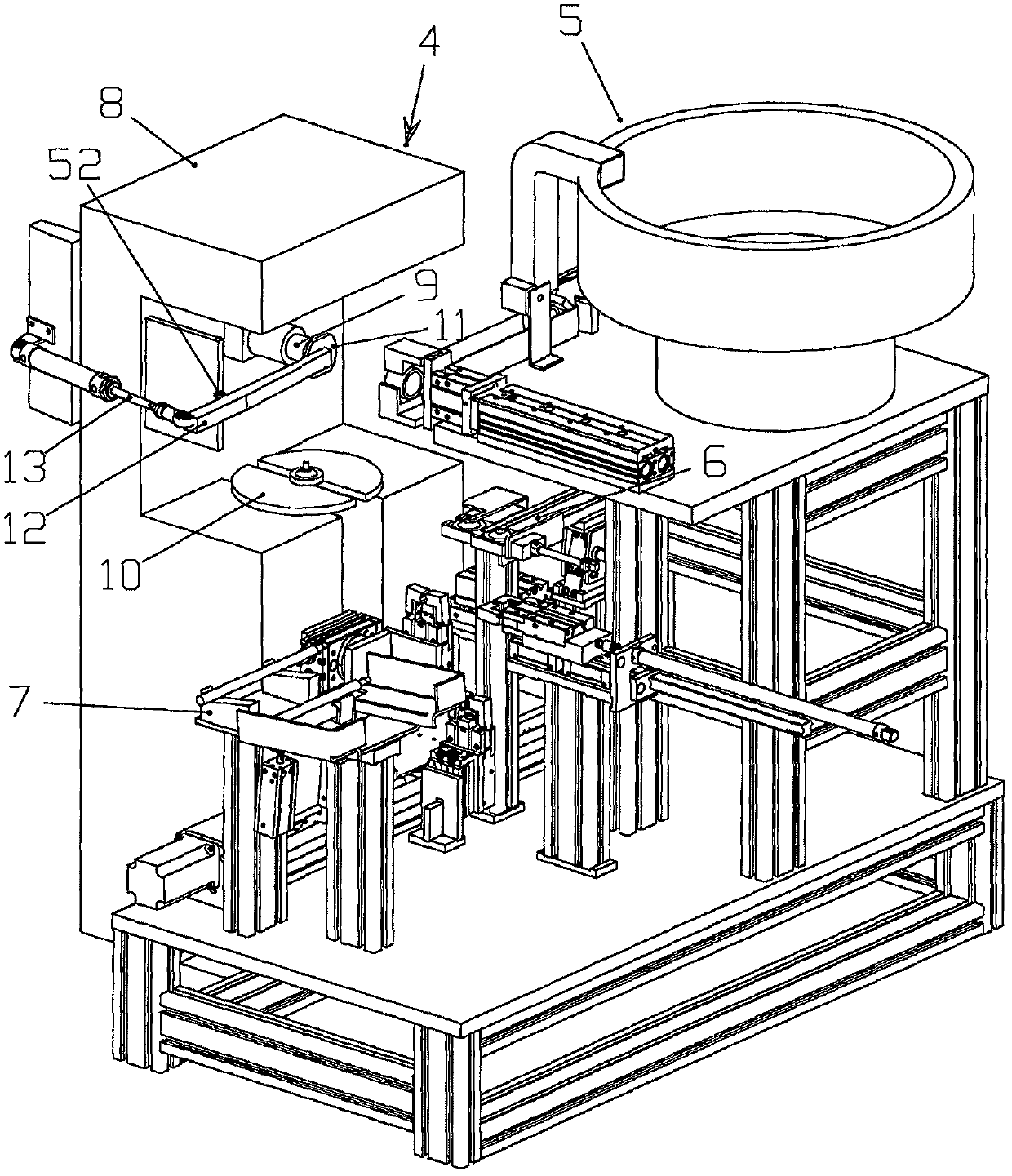

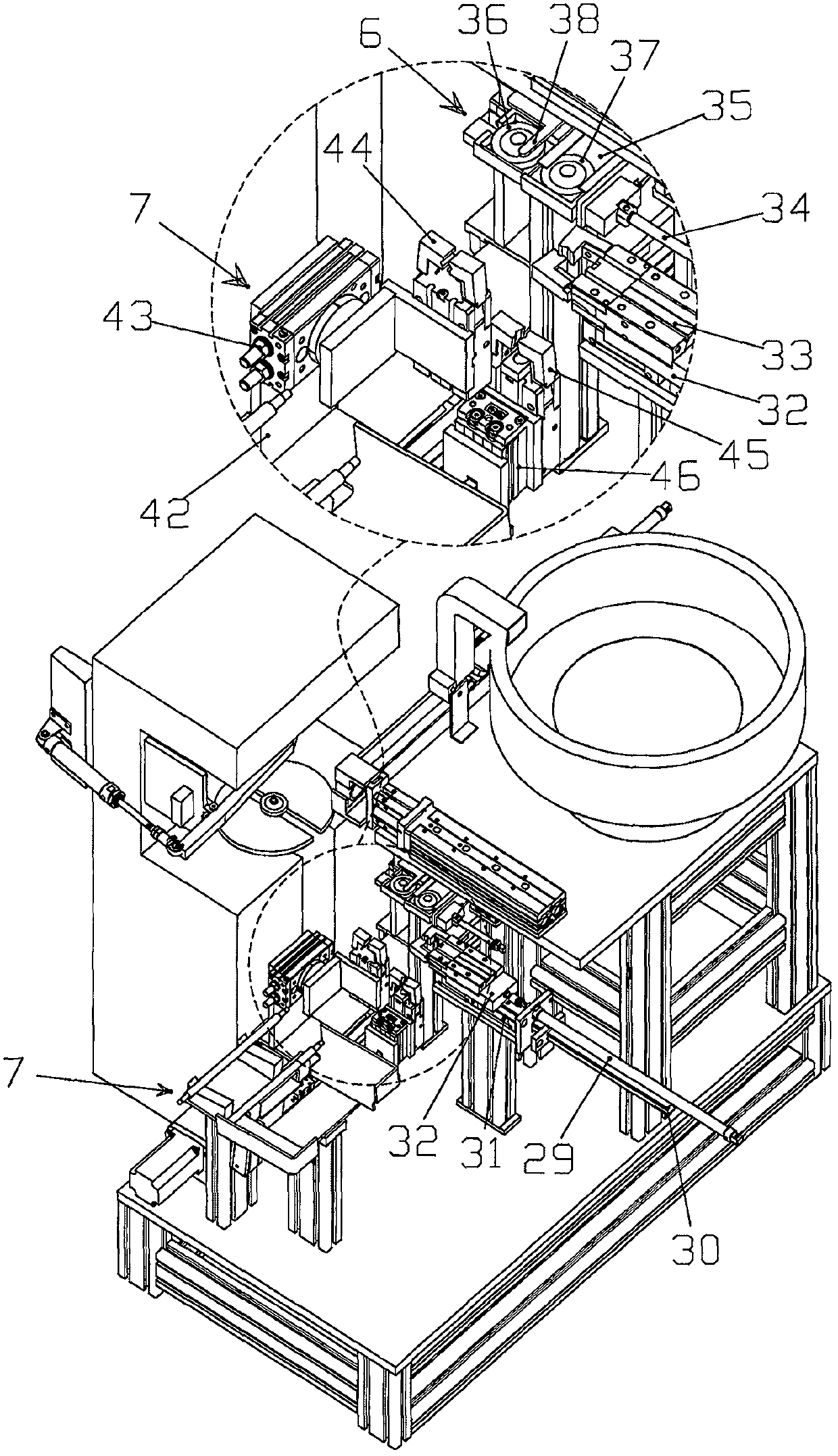

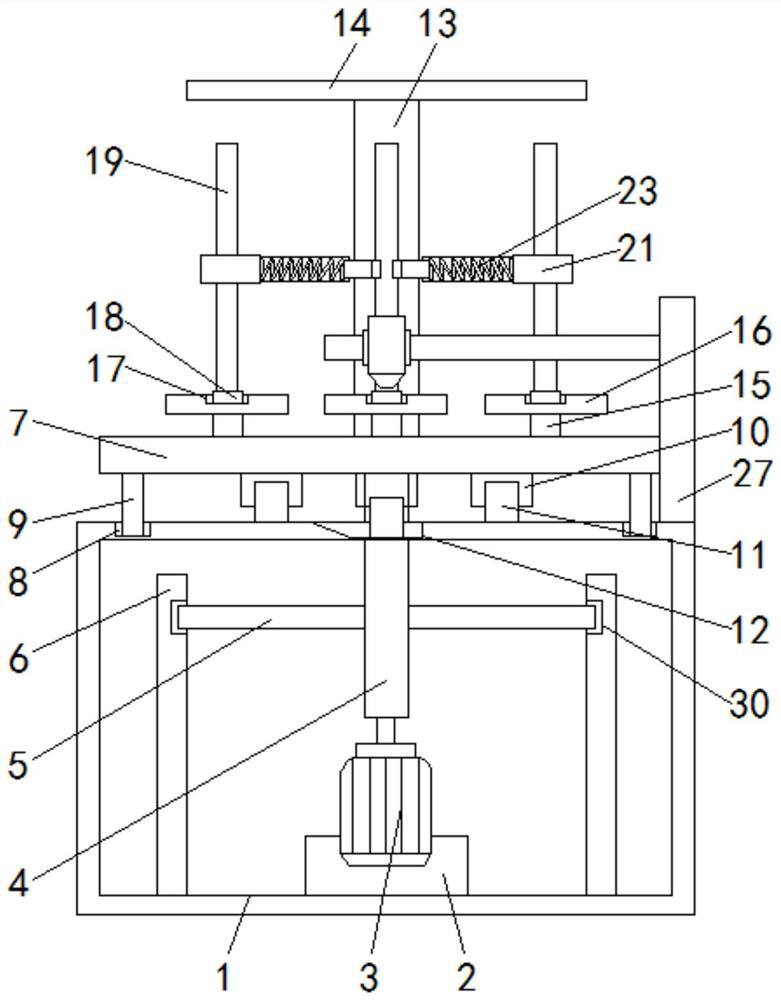

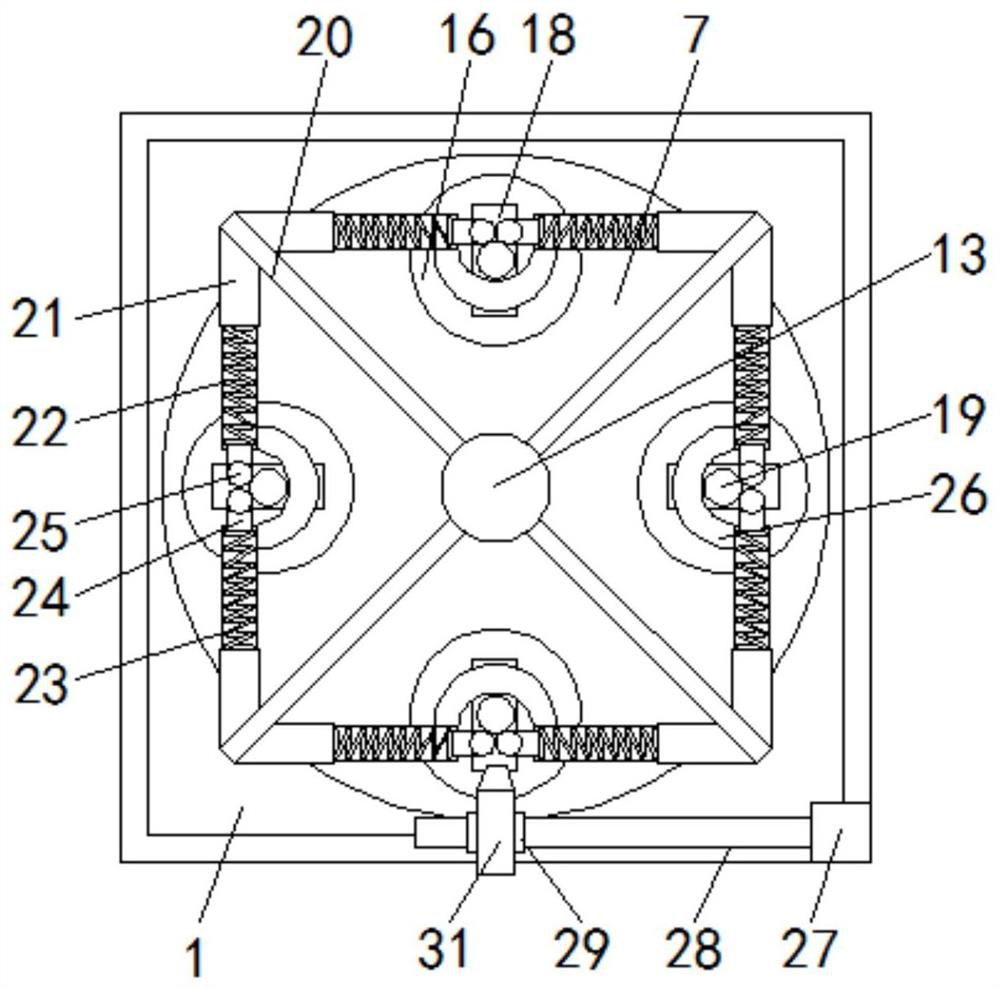

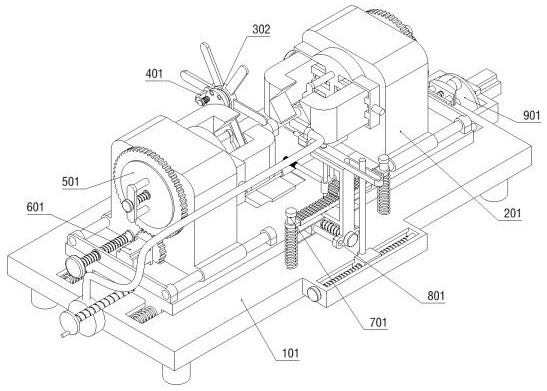

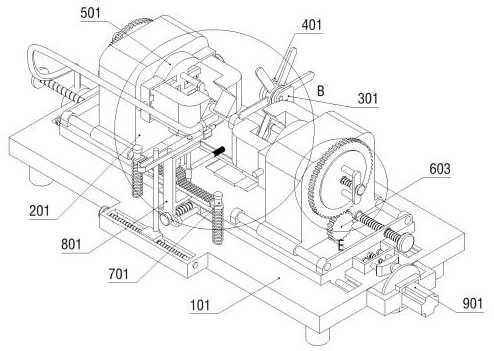

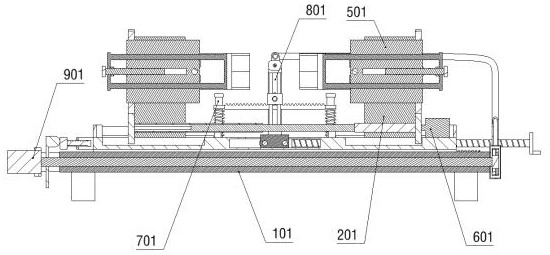

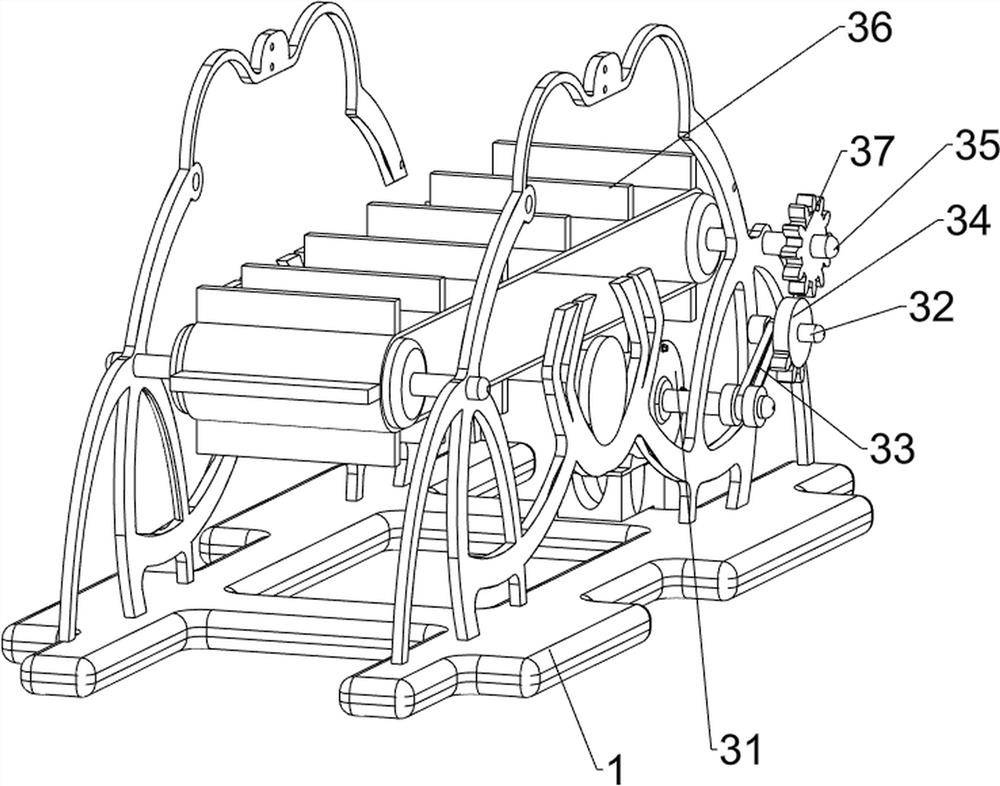

Full-automatic welding device for piston rod assembly of shock absorber

ActiveCN107891233ATo achieve the welding effectWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical equipment

The invention relates to mechanical equipment, more specifically, the invention relates to an automatic production device for manufacturing a piston rod assembly of a shock absorber, in particular toa full-automatic welding device for the piston rod assembly of the shock absorber. The full-automatic welding device comprises an automatic welding machine used for realizing welding operation, a lifting ring feeding mechanism used for conveying a lifting ring, a dustproof cover feeding mechanism used for conveying the a dustproof cover, a piston rod feeding mechanism used for conveying a piston rod, and a feeding mechanical hand used for conveying the dustproof cover and the piston rod to the automatic welding machine. According to the full-automatic welding device for the piston rod assemblyof the vibration absorber, in the automatic production process of the piston rod assembly of the vibration absorber, the lifting ring feeding mechanism is used for achieving automatic conveying of the lifting ring, the dustproof cover feeding mechanism is used for achieving automatic conveying of the dustproof cover, the piston rod feeding mechanism is used for achieving automatic conveying of the piston rod, and the automatic welding machine is used for carrying out one-step welding forming on the hanging ring, the dustproof cover and the piston rod.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

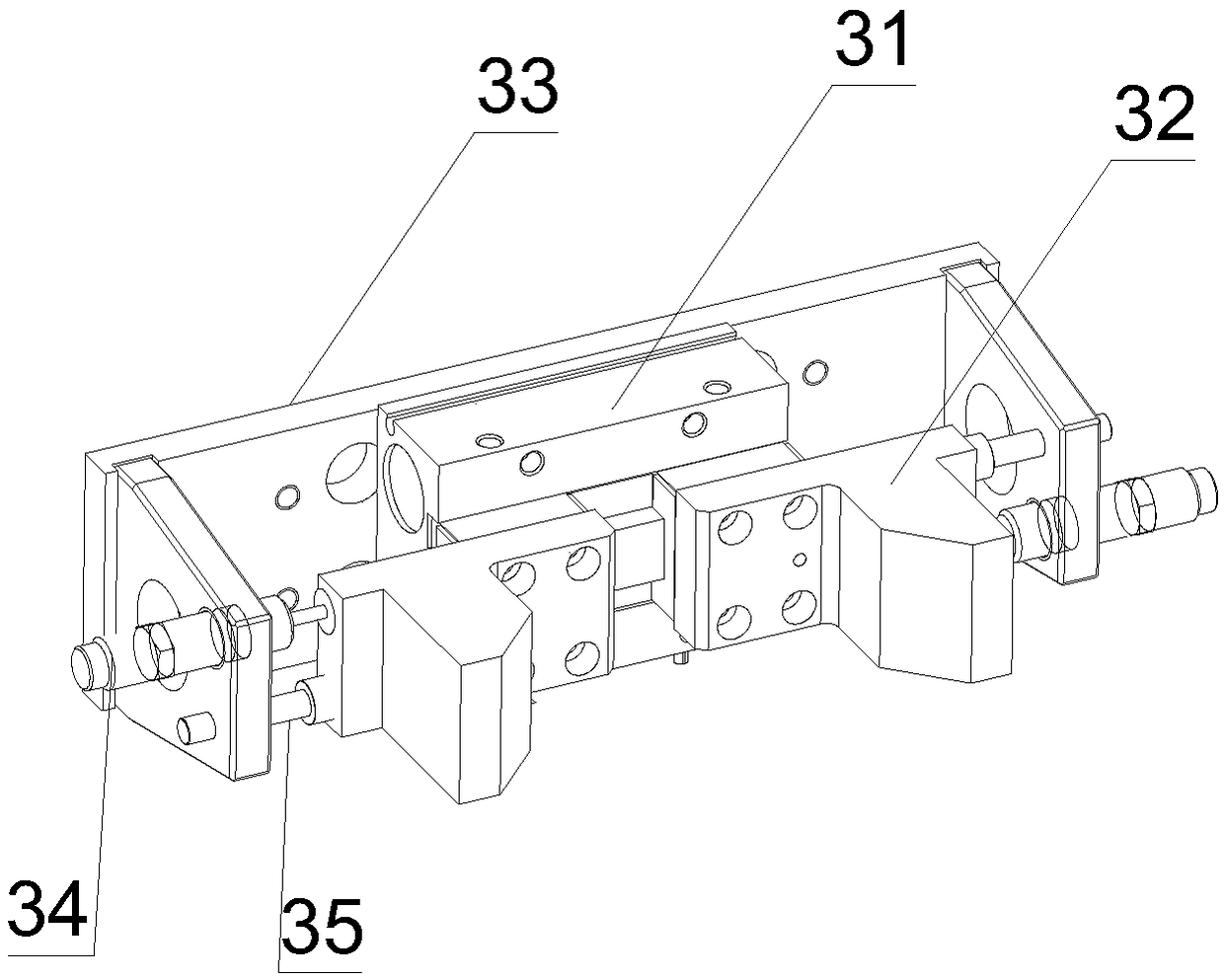

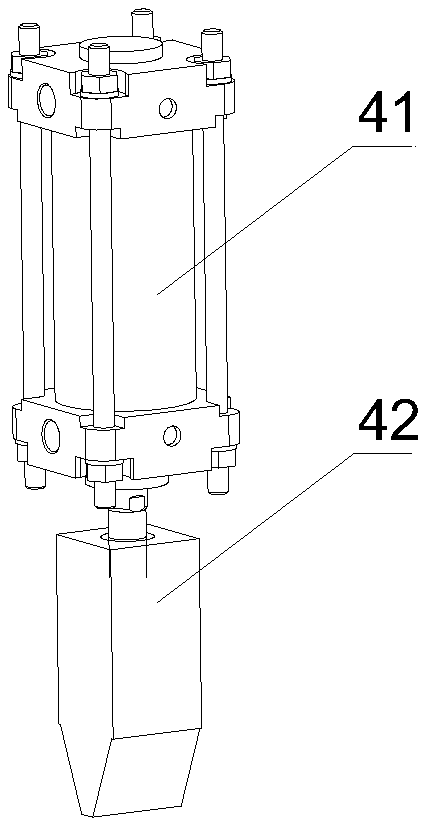

Stirrup centering and welding mechanism, system and method

PendingCN108907428AMeet welding requirementsTo achieve the welding effectResistance welding apparatusEngineeringClose contact

The invention discloses a stirrup centering and welding mechanism. The stirrup aligning and welding mechanism comprises a supporting body, a lower welding electrode, an upper welding electrode, an expanding assembly, a pressing driving member and a centering assembly, wherein the lower welding electrode, the upper welding electrode, the expanding assembly, the pressing driving member and the centering assembly are arranged on the supporting body. A V-shaped groove is formed in the upper surface of the lower welding electrode, and penetrates through the lower welding electrode in the length direction. The expanding assembly is used for expanding side arms on two sides of a stirrup to be welded outwards and ensuring that two joints of the stirrup to be welded are not overlapped. The pressingdriving member is used for driving the upper welding electrode to compact the two non-overlapping joints located in the V-shaped groove and ensuring that the two joints are coaxial. In the process ofwelding the two joints of the stirrup, the centering assembly is used for pushing the two side arms on the two sides of the stirrup to be welded inwards and ensuring that the end portions of the twojoints make close contact with each other until the two joints are coaxially welded together. The invention further discloses a stirrup centering and welding system and method. The stirrup centering and welding mechanism, system and method ensure centering welding of the joints of the stirrup and improve welding quality.

Owner:BEIJING YANTONG BUILDING COMPONENTS PROD +1

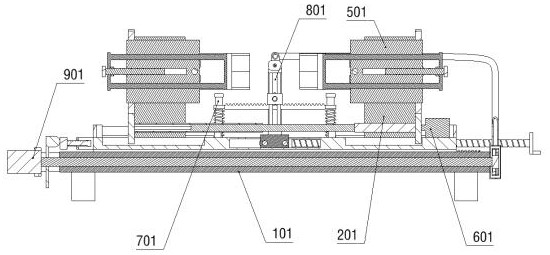

Automatic welding machine for slurry pipe hoops

PendingCN107225335AThe overall structure is compactHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesPhysicsElectric machinery

The invention relates to an automatic welding machine for slurry pipe hoops. By means of the automatic welding machine for the slurry pipe hoops, the problem of poor welding quality in the prior art is solved, and a controller is in electric signal connection with a transmission mechanism, a gun feed mechanism and a pressing mechanism which are installed on a rack. The transmission mechanism comprises a bottom rotating roller set driven by a transmission motor. The bottom rotating roller set comprises two rotating rollers which are arranged correspondingly and are the same in rotation direction. The interval between the rotating rollers is no larger than the outer diameter of a pipeline welded by the automatic welding machine. The pressing mechanism comprises two pressing wheels installed on a pressing frame, and the pressing wheels are installed above the pipeline welded by the automatic welding machine correspondingly. The automatic welding machine for the slurry pipe hoops has the beneficial effects that the automatic welding machine is designed as a vertical four-gun automatic welding machine according to the welding process requirement of the slurry pipe hoops, workpieces can be rotated, welding guns are fixed, and a PLC microcomputer control system is adopted for control, so that the automatic welding machine is stable in performance and reliable.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

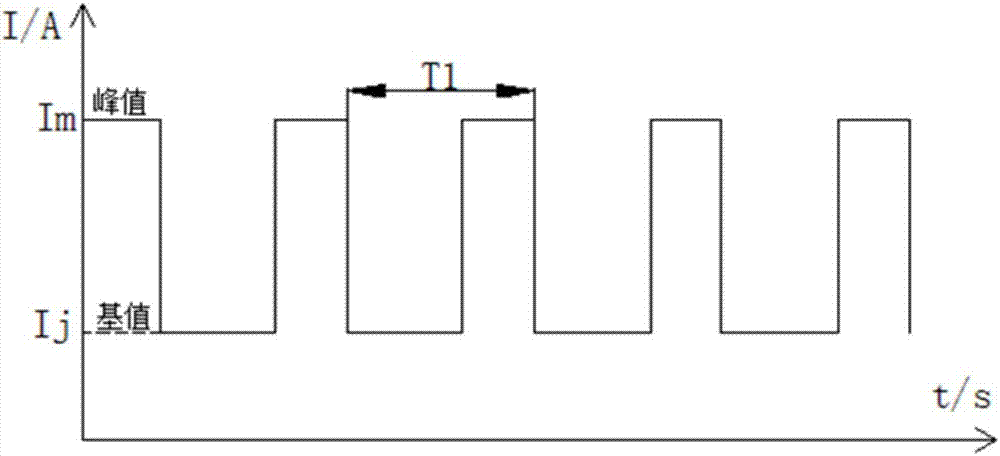

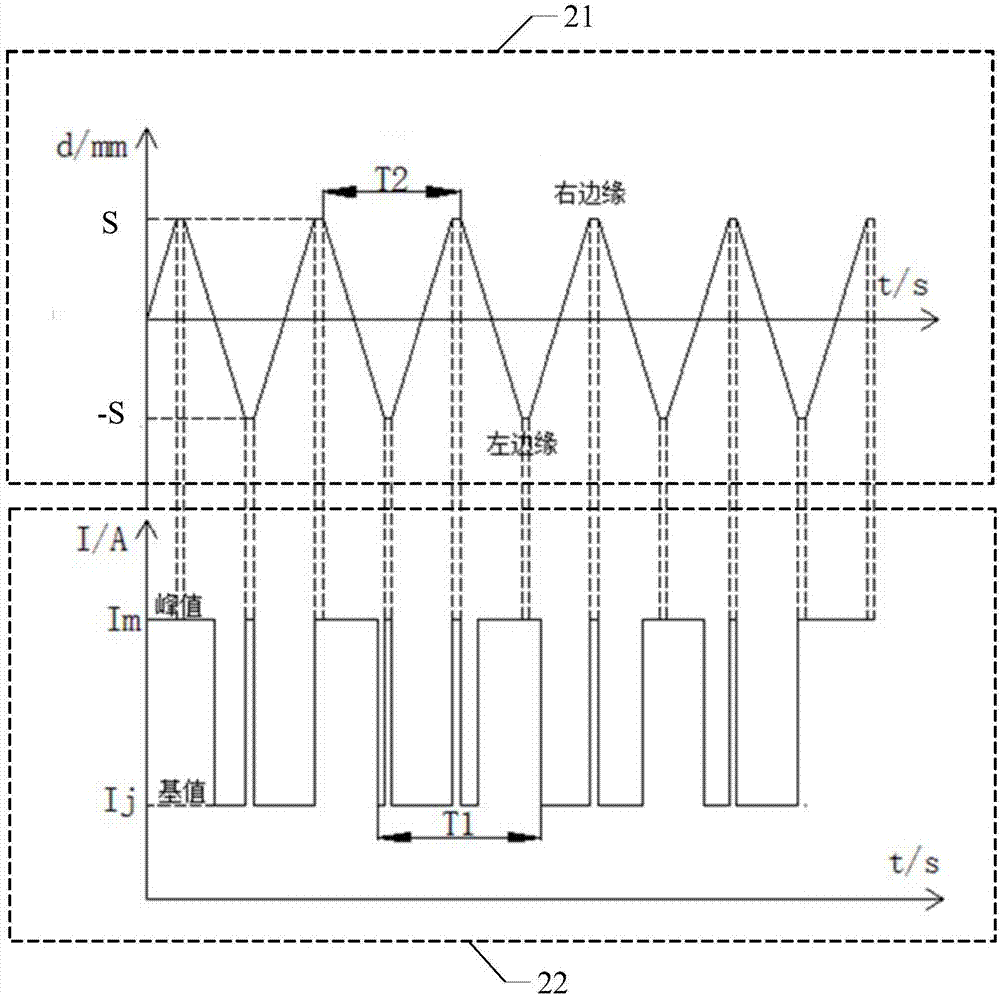

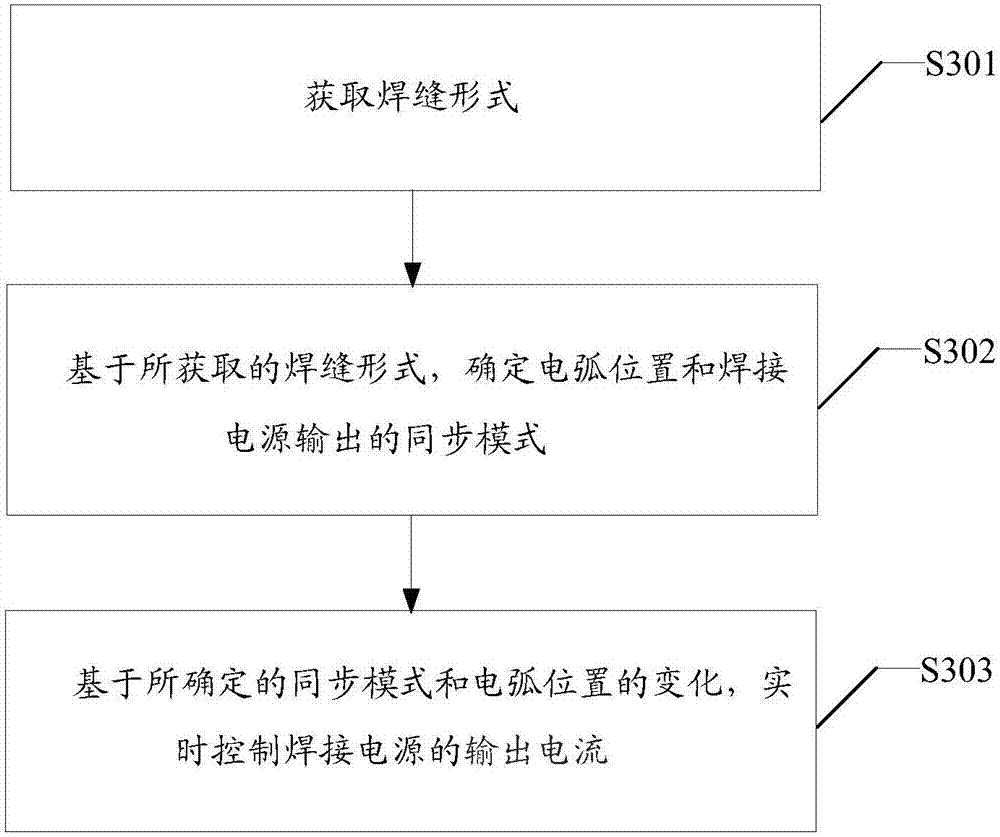

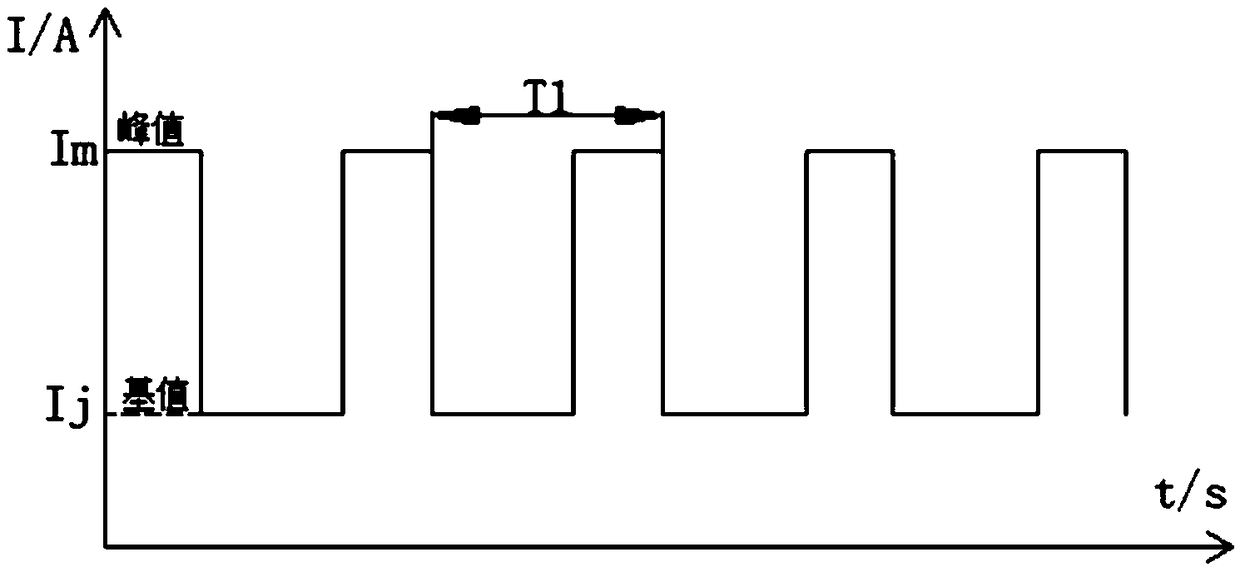

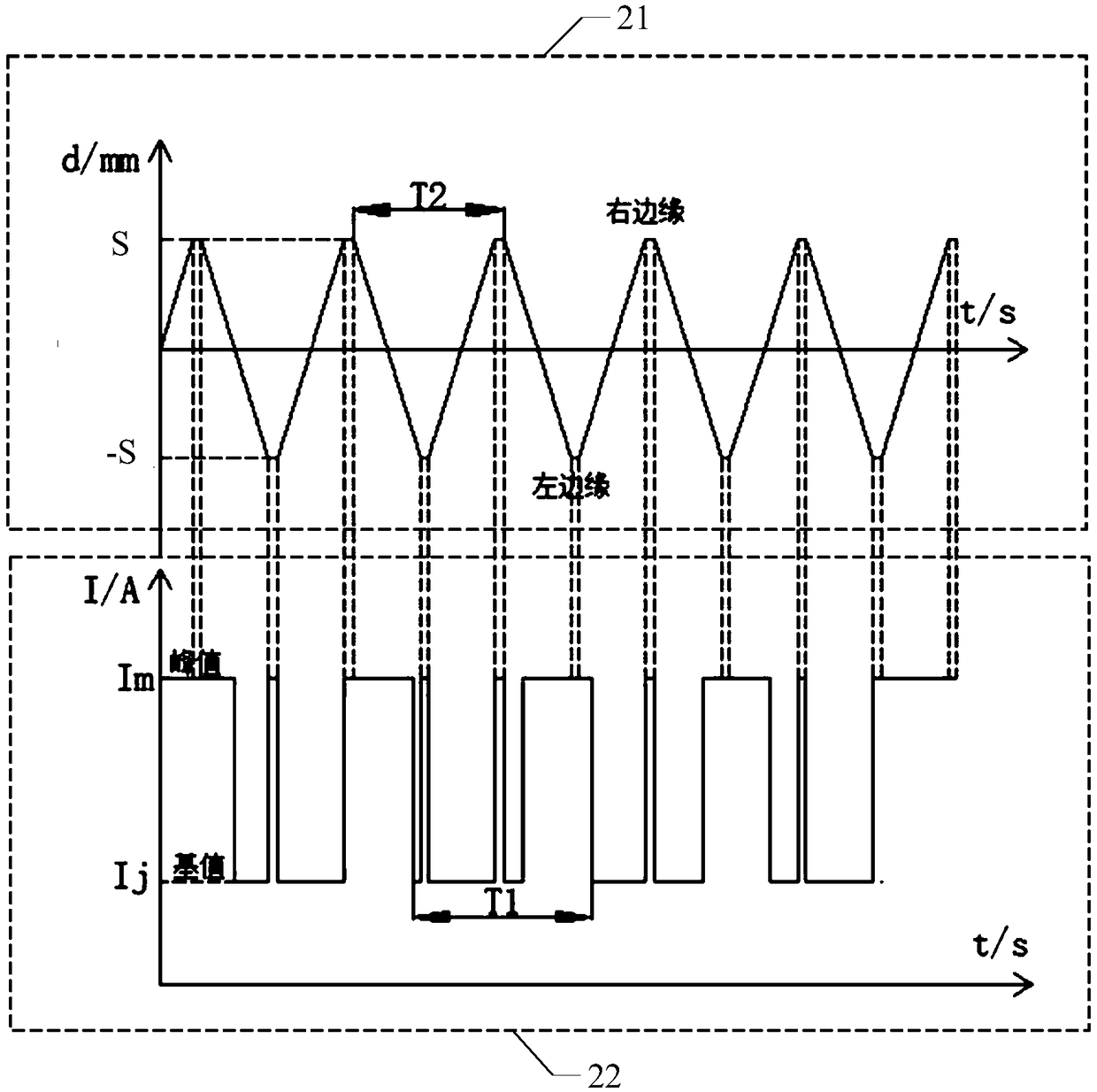

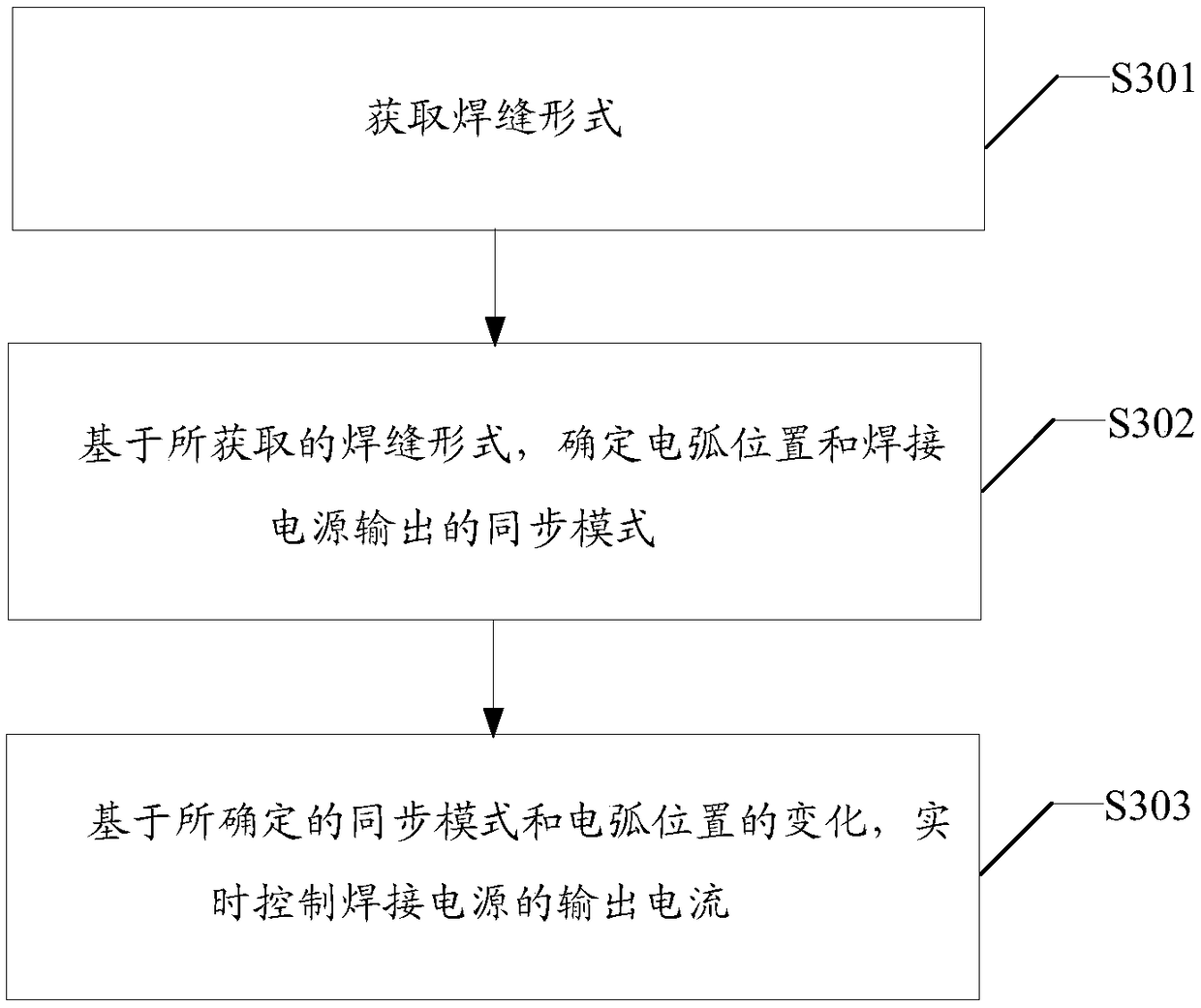

Control method and device for arc energy and computer readable medium

ActiveCN107570841AThe heat input reachesLow heat inputArc welding apparatusPower flowWelding power supply

The invention discloses a control method and device for arc energy and a computer readable medium. The control method for the arc energy includes the steps that a welding joint form is obtained; the arc position and the welding power source output synchronous mode are determined based on the obtained welding joint form; and output currents of a welding power source are controlled in real time based on changes of the determined synchronous mode and the determined arc position. By the adoption of the above scheme, the output currents of the welding power source are controlled in real time basedon the synchronous mode and the arc position, the heat input amount in the arc swing process can be controlled in real time according to the arc position, the expected welding effect can be achieved,in addition, the heat input amount of the arc can be small as much as possible, and therefore a welding connector with better quality is obtained.

Owner:HUAHENG WELDING

Welding assembling clamp

InactiveCN108581349ATo achieve the welding effectAchieving the goal of weldingWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringHydraulic cylinder

The invention discloses a welding assembling clamp which comprises a base. A fixed plate is fixedly connected with the right side of the top surface of the base; a bearing is fixedly connected with the left side face of the fixed plate; a rotary shaft is fixedly connected with the inner ring of the bearing; a first clamping arm is fixedly connected with the end, far away from the bearing, of the rotary shaft; and a fastening pad is fixedly connected with one side face, far away from the rotary shaft, of the first clamping arm. According to the welding assembling clamp, a hydraulic cylinder drives a telescopic rod to stretch out to enable a second clamping arm to extrude and clamp processed material, and a rocking handle is swung to rotate a runner, so that a spindle, the second clamping arm, the processed material and the first clamping arm rotate to enable the bottom surface of the processed material to be exposed; and then, a limiting shaft is inserted in a limiting hole, so that theeffect of welding a plurality of surfaces of a workpiece is realized, the objective that multiple doors of the workpiece can be welded without re-clamping the workpiece is realized, the using efficiency is improved and the welding assembling clamp is more convenient.

Owner:芜湖衡西微量计量科技有限公司

Welding method of ultra-thick and high-strength water-power steel

ActiveCN101905365BTo achieve the welding effectReduce fillingArc welding apparatusWorkpiece edge portionsEngineeringWelding defect

The invention relates to a welding method of ultra-thick and high-strength water-power steel, belonging to the welding field. Welding is realized by adopting a mixed welding mode, i.e. hand welding is adopted as a basis for filling the bottom, and gas shielded welding is adopted for a middle layer and a cover part, multilayer and multi-pass welding are adopted, a carbon arc is cropped out after asingle side is filled, and the input of welding heat is controlled within 65 kJ / cm. A welding bevel adopts an asymmetric U-shaped bevel, a thick steel plate of 145-155 mm is preheated to 100 DEG C before welding, the inter-layer temperature is kept between 100 DEG C to 160 DEG C, and heat treatment stress is not carried out after welding, and the problem of reheat embrittlement of a welding jointof the high-strength water-power steel is solved. The invention needs simple welding equipment, realizes welding through a combined welding process on the basis of the traditional equipment, reduces the filling amount of welding metal, and achieves the welding effect of a narrow gap. Compared with the hand arc welding, the invention greatly improves the welding efficiency of the thick steel plateand lowers the possibility of welding defects easily generated on the hand arc welding of an ultra-thick steel plate, such as cold cracks, incomplete fusion, crisp fusion, and the like.

Owner:SHOUGANG CORPORATION +1

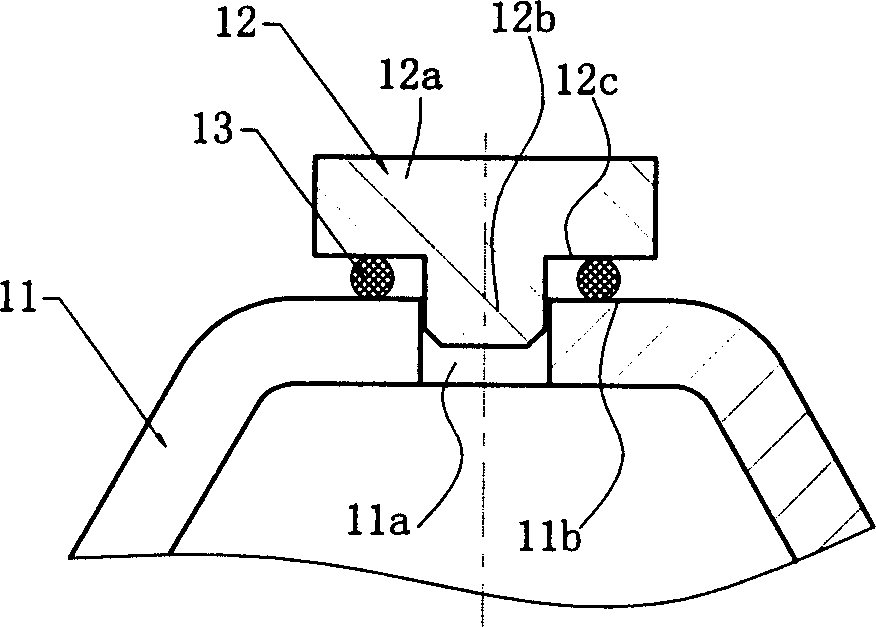

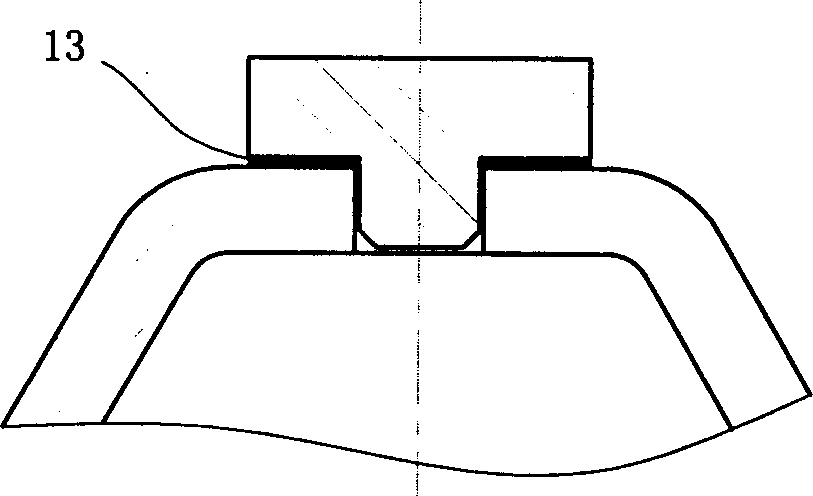

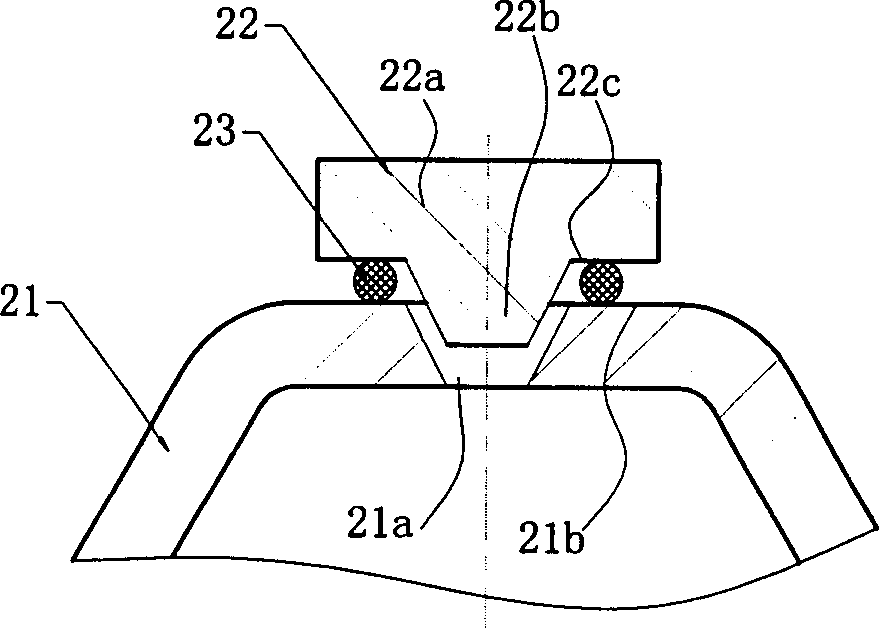

Soldered seal structure of power head part for thermal expansion valve

InactiveCN1814393AAvoid corrosionAvoid formingWorkpiece edge portionsHeat sensitiveThermal expansion

This invention is related to a brazing and sealing structure of dynamic head component of thermal expansion valve. The dynamic head component is consists of a stopper and a cavity which used to accommodate the thermal-sensitive medium. The cavity has holes in its ektexine and the medium can be added into the cavity through the holes. The stopper is used to plug the holes so the medium is sealed in the cavity. Its characteristics are placing brazing filler metal between the stopper and the ektexine and brazing to form a seal, so the thermal-sensitive medium is sealed in the cavity reliably. The program uses the method of brazing to put brazing filler metal between the stopper and ektexine, and melting down the brazing filler metal using the thermal resistance, and make the filler infiltrated into the stopper and the ektexine and realize the connection of the two parts. It is not only helpful for ensuring the seal and preventing the outer wall from being corrupted, but it also can resist the pressure effectively that produced by the heat expansion of the medium, and it is helpful for molding in one time in process.

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

Convenient-to-adjust laser welding head for intelligent home hardware fitting production

InactiveCN113458603ATo achieve the adjustment effectTo achieve the welding effectLaser beam welding apparatusHydraulic cylinderElectric machinery

The invention discloses a convenient-to-adjust laser welding head for intelligent home hardware fitting production in the technical field of hardware fitting production. The convenient-to-adjust laser welding head comprises a first connecting plate, a second connecting plate and a welding head body, each corner of the upper end surface of the first connecting plate is fixedly connected with a lower support column, and the upper end surface of each lower support column is fixedly connected with the second connecting plate; and a first hydraulic cylinder is arranged at each corner of the upper end surface of the second connecting plate, an upper connecting ring is fixedly connected to the upper end surface of each first hydraulic cylinder, moving grooves are formed in the two sides of each upper connecting ring, and moving plates are slidably connected into the moving grooves. The first hydraulic cylinders, moving grooves, moving plates, second hydraulic cylinders, a lower connecting plate, a T-shaped groove, a T-shaped plate, a threaded groove, a first motor and a screw rod are arranged; and a fixing plate and the welding head body can achieve the effects that the height of the welding head body can be adjusted to adapt to welding of hardware fittings with different thicknesses, and the position of the welding head body can be adjusted according to the welding positions of the hardware fittings.

Owner:SHENZHEN SHENPULEI TECH

Flexible manufacturing equipment for piston rods of automobile shock absorbers

PendingCN109014673ATo achieve the welding effectWelding/cutting auxillary devicesAuxillary welding devicesMechanical equipmentEngineering

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

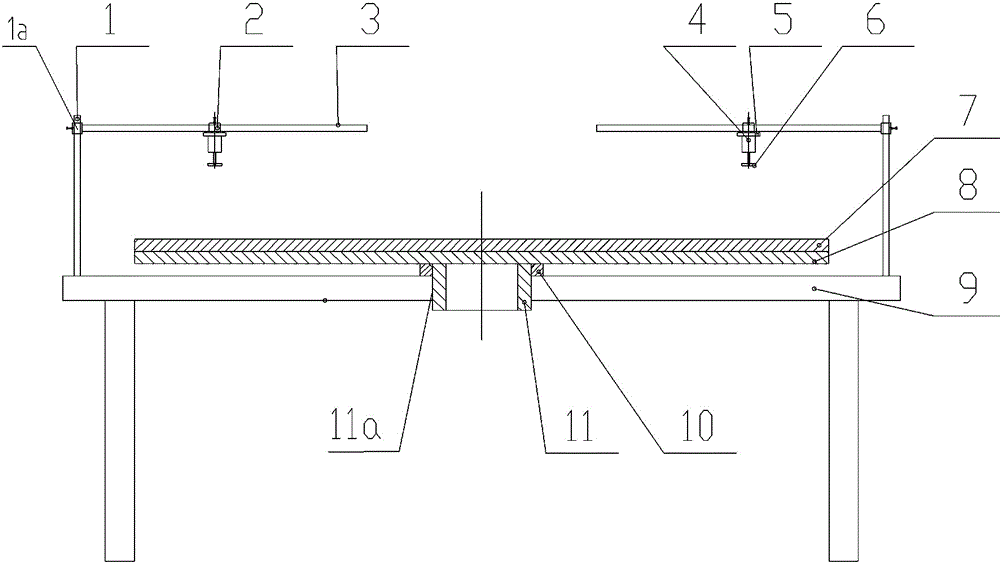

A thin plate welding deformation control device

ActiveCN102814610BGuaranteed flatnessTo achieve the welding effectWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCopper

The invention relates to a sheet welding deformation control device. A welding platform (9) is provided with a rotating hole; a rotating guiding column (11) is arranged in the rotating hole; the upper end of the rotating guiding column (11) is connected with a welding station lining plate (8); the welding station lining plate (8) is connected with a red copper base plate (7); two sets of welding clamping devices are arranged on the welding platform (9); each welding clamping device comprises a fixed arm (1); the fixed arm (1) is connected with an adjusting sleeve (1a); a horizontal adjusting arm (3) is connected in the adjusting sleeve (1a); and an air cylinder (4) and a ballast plates (6) are connected on the adjusting arm (3). The sheet welding deformation control device has the advantages that: the good heat dissipation performance of the red copper base plate is fully utilized, thus the base plate welding effect is achieved, the welding deformation can be controlled to the maximum extent, and the flatness of the welded sheet is guaranteed; and in addition, the air cylinder is used for clamping rigidly, so that the operation is very convenient, and the work efficiency is improved greatly.

Owner:BENGBU SHENZHOU MACHINERY

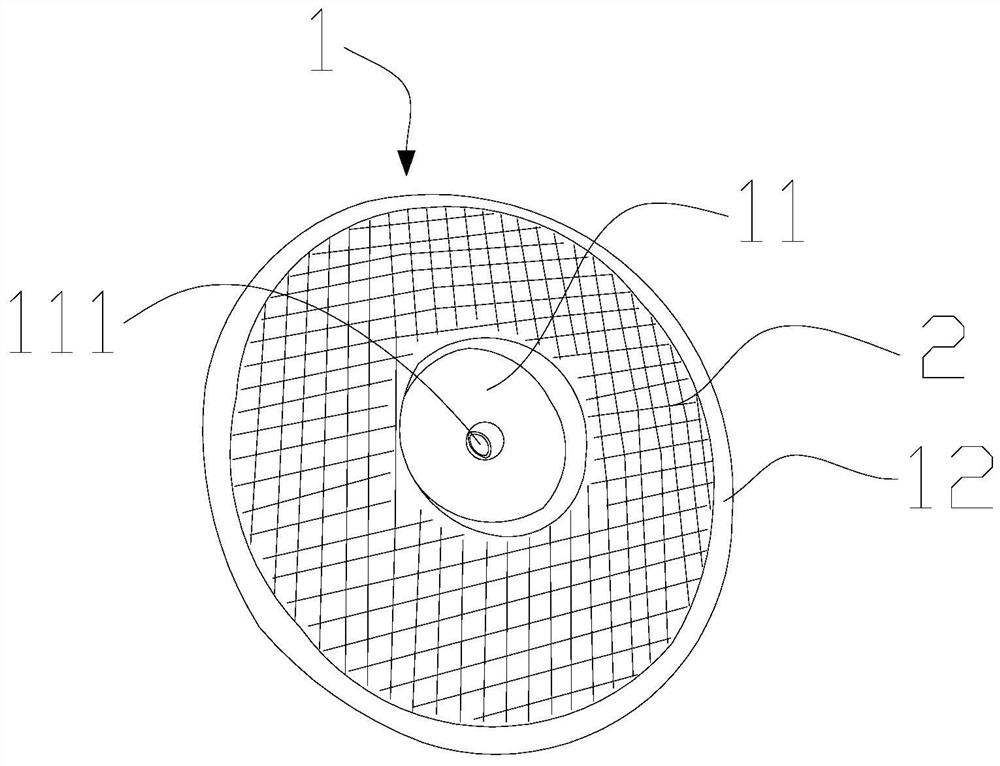

Plastic welding machine for oil-gas separator, and plastic welding method

PendingCN113199765AEvenly heatedFlat and smooth appearanceDomestic articlesEngineeringPlastic welding

The invention relates to a plastic welding machine for an oil-gas separator, and a plastic welding method. The plastic welding machine comprises a base, a top plate and a working cavity, wherein a driving device is arranged on the top plate, and a lower die is arranged on the base; a lower die cavity and a groove are formed in the lower die, and a copper pipe is arranged in the groove, and externally connected with variable high-frequency currents; a movable plate is arranged in the working cavity, and an upper die is arranged on the movable plate; an upper die cavity is arranged on the upper die, and the driving device is connected with the movable plate; the copper pipe is powered on to generate eddy current so that a closed iron wire ring is heated, and a welding wire, located around a second groove, on the lower body of the oil-gas separator is melted; the lower body of the oil-gas separator and the upper body of the oil-gas separator are welded into a whole; and therefore, the technical problems that in the prior art, after the oil-gas separator is welded, welding edges are liable to reserve on the outer surface, and consequently the attractiveness is affected, even the quality is affected due to insecure welding caused by uneven heating are solved.

Owner:宁海县雄达模塑有限公司

Rotary welding gun

PendingCN114473318AMeet welding requirementsTo achieve the welding effectWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSoldering gun

The invention aims to provide a rotary welding gun, which belongs to the technical field of welding equipment and comprises a welding device, a translation device and a lifting device, the welding device is connected to the lower end of the lifting device, the translation device is connected to the upper end of the lifting device, and a rotating device is mounted at the joint of the lifting device and the welding device. The translation device comprises a driving seat A and a servo motor A. The servo motor A is connected to one end of the driving seat A. The lower end of the driving seat A is connected with a guide rail A. The lifting device is slidably connected with the guide rail A. The lifting device comprises a driving seat B, a lifting air cylinder and a lifting lead screw. The lifting air cylinder is connected with the lifting lead screw. Welding of workpieces with different heights and different angles can be achieved, one-time welding forming of the front faces and the rear faces of the workpieces can be achieved, compared with the prior art, another procedure for welding is not needed, welding is convenient and rapid, and the welding efficiency is high.

Owner:天津市奥特威德焊接技术有限公司

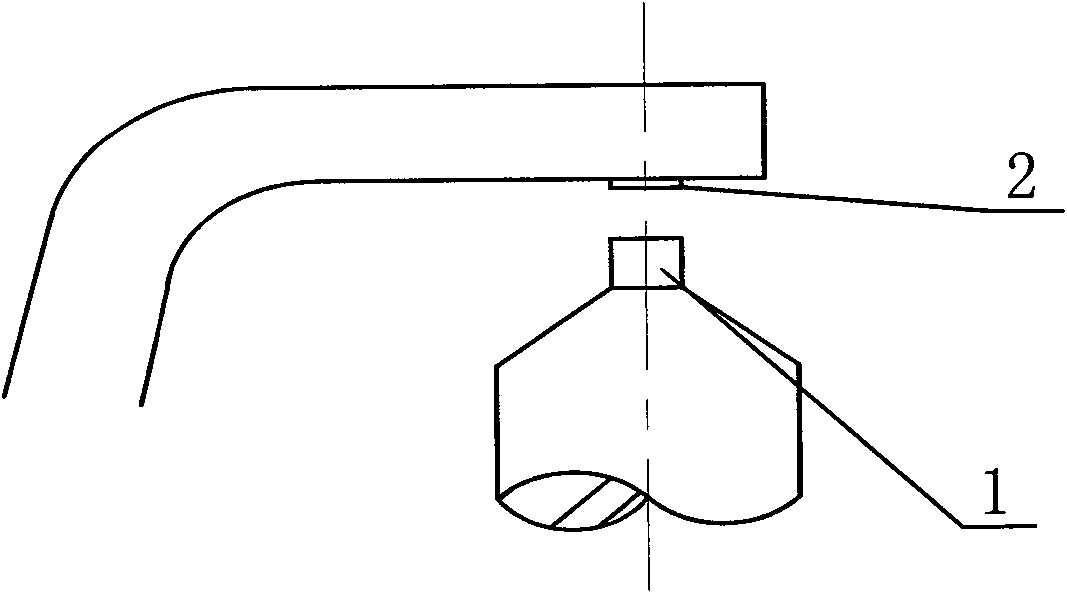

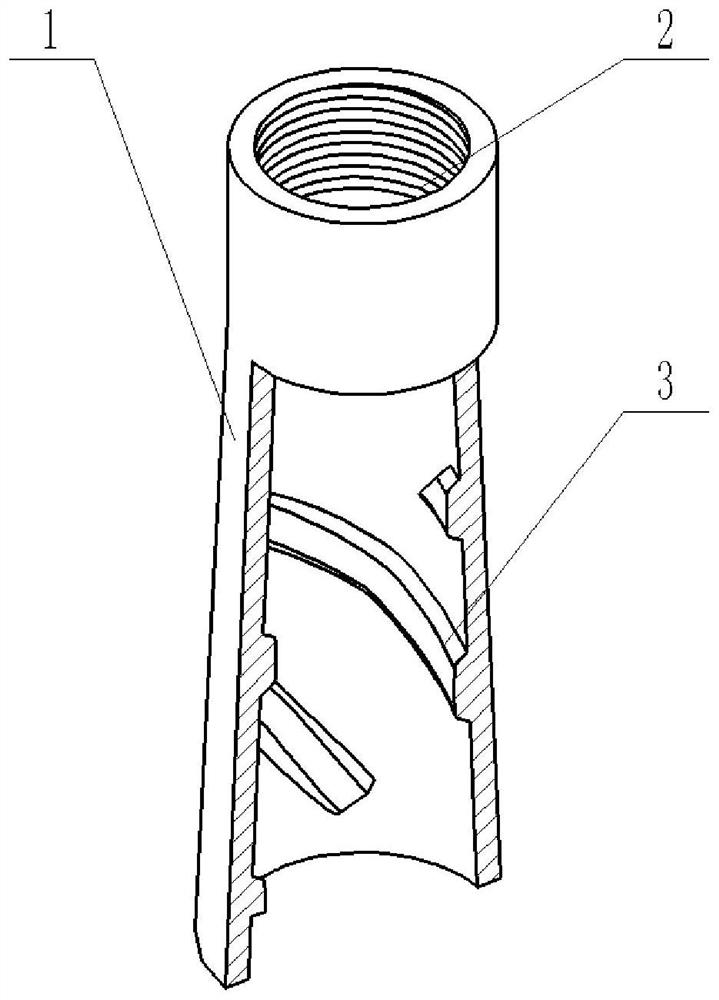

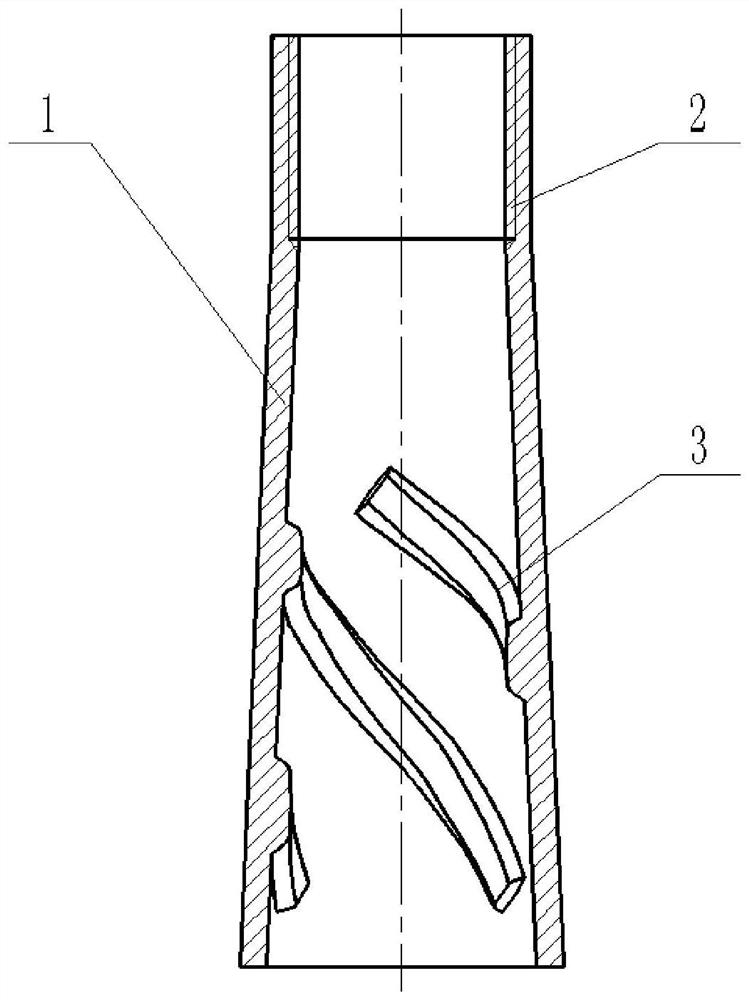

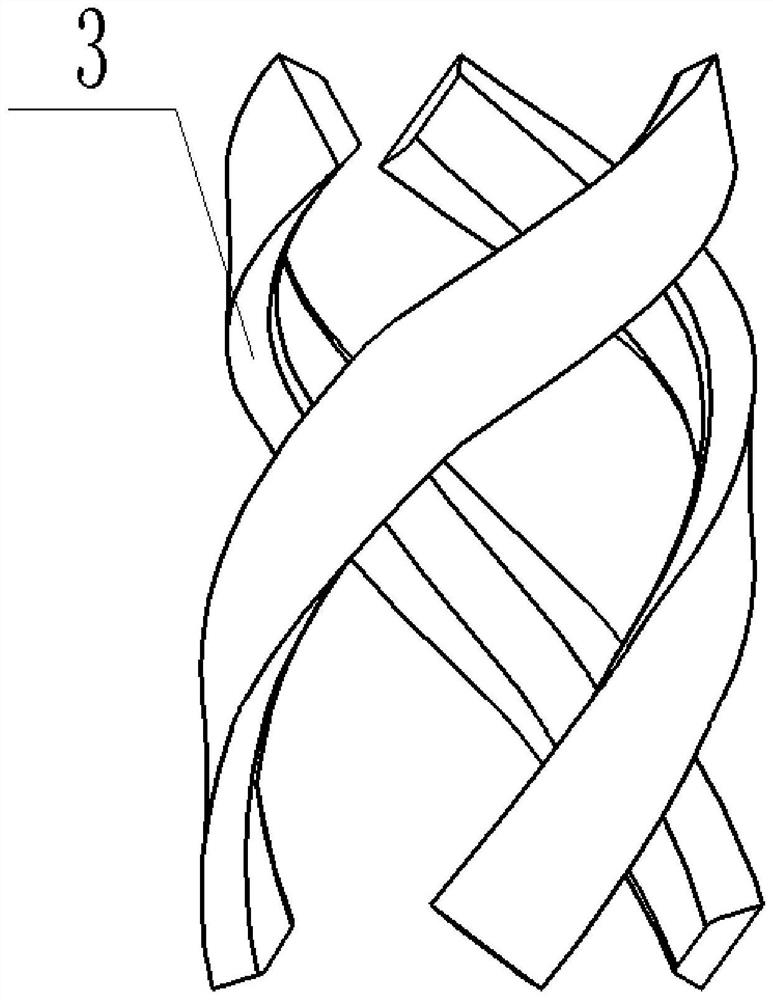

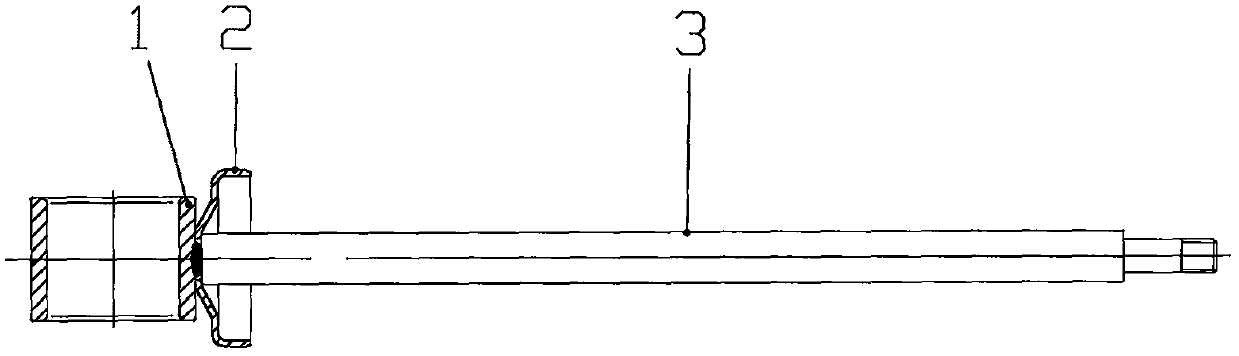

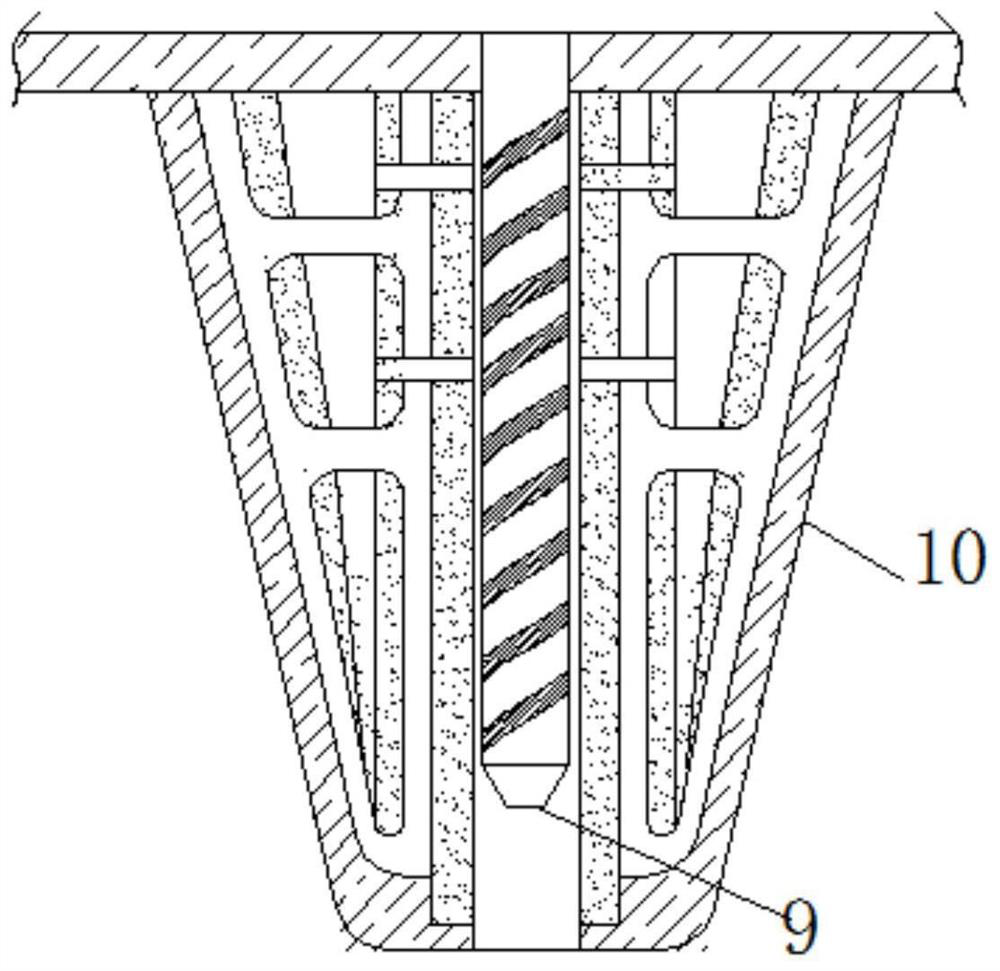

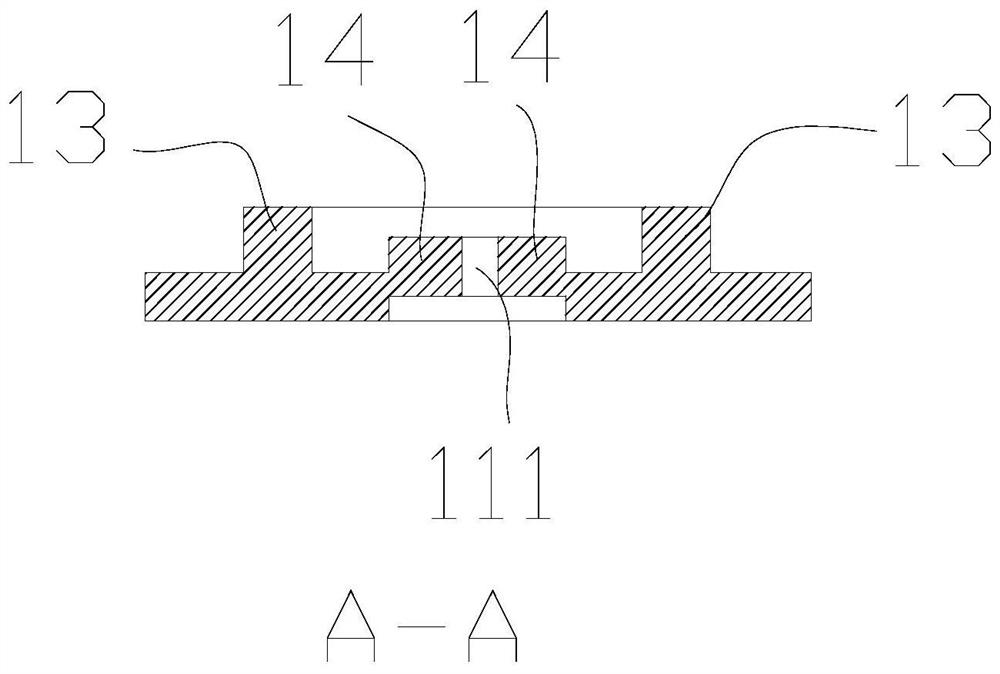

A spiral diffuser nozzle

ActiveCN111701736BImprove crosswind resistanceExpand coverageShielding gas supply/evacuation devicesSpray nozzlesIsosceles trapezoidShielding gas

The invention provides a spiral diffuser nozzle, which includes a nozzle body; the nozzle body includes a cylindrical upper part and a conical lower part; the inner wall of the conical lower part is provided with a plurality of spiral splines, the helix angle of the spiral splines is constant, and the gap between the spiral splines The pitch of the thread decreases linearly from top to bottom. The cross-sectional shape of the spiral spline is an isosceles trapezoid, and the height of the isosceles trapezoid in the cross-section of the spiral spline decreases linearly from top to bottom. During the welding process, the shielding gas passes through the nozzle body under the action of the welding torch, and the shielding airflow forms a spiral diffused airflow under the action of the spiral spline, which acts on the surface of the molten pool to protect the internal arc combustion stability and isolate the air The purpose of impurities. The invention is compact in structure and easy to use. During the welding process, it can improve the ability of shielding gas to resist crosswinds, expand the coverage of shielding gas, reduce the amount of shielding gas, and improve the surface quality of welds. It can meet the requirements of general production sites or large crosswinds, etc. Use in special environment.

Owner:JIANGSU UNIV

Fully automatic welding equipment for shock absorber piston rod assembly

ActiveCN107891233BTo achieve the welding effectWelding/cutting auxillary devicesAuxillary welding devicesMechanical equipmentManipulator

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

Outer edge welding device for hydraulic cylinder manufacturing

ActiveCN114589439AWeld firmlyLow costWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderStructural engineering

The invention provides an outer edge welding device for hydraulic cylinder manufacturing, and relates to the technical field of hydraulic cylinder welding. Two sliding adjusting parts are mounted on the mounting supporting part; the structures on the two sliding adjusting parts are the same; a movable seam clamping device is connected to the mounting supporting part in a sliding manner; the movable seam clamping device is fixedly connected with an elastic positioning device; the two sliding adjusting parts are rotationally connected with rotating mounting parts correspondingly. Arc-shaped swing welding can be achieved, welding is firmer, the overall linkage performance is higher, and auxiliary smoke removal and cleaning work can be achieved; the problems that an existing outer edge welding device for hydraulic cylinder manufacturing is low in overall installation precision, meanwhile, welding is not stable enough, simultaneous rotating welding cannot be achieved, meanwhile, flexible welding line adjustment cannot be achieved, the welding quality is affected, meanwhile, arc swing welding cannot be achieved, and swing adjustment is not convenient and fast enough are solved.

Owner:江苏力速达液压有限公司

An automatic butt welding device for screw bases used in construction

ActiveCN108188538BTo achieve the welding effectAchieve the effect of automatic weldingGas flame welding apparatusCircular discButt welding

Owner:ANHUI FENGYANG LONGXING CONSTR ENG CO LTD

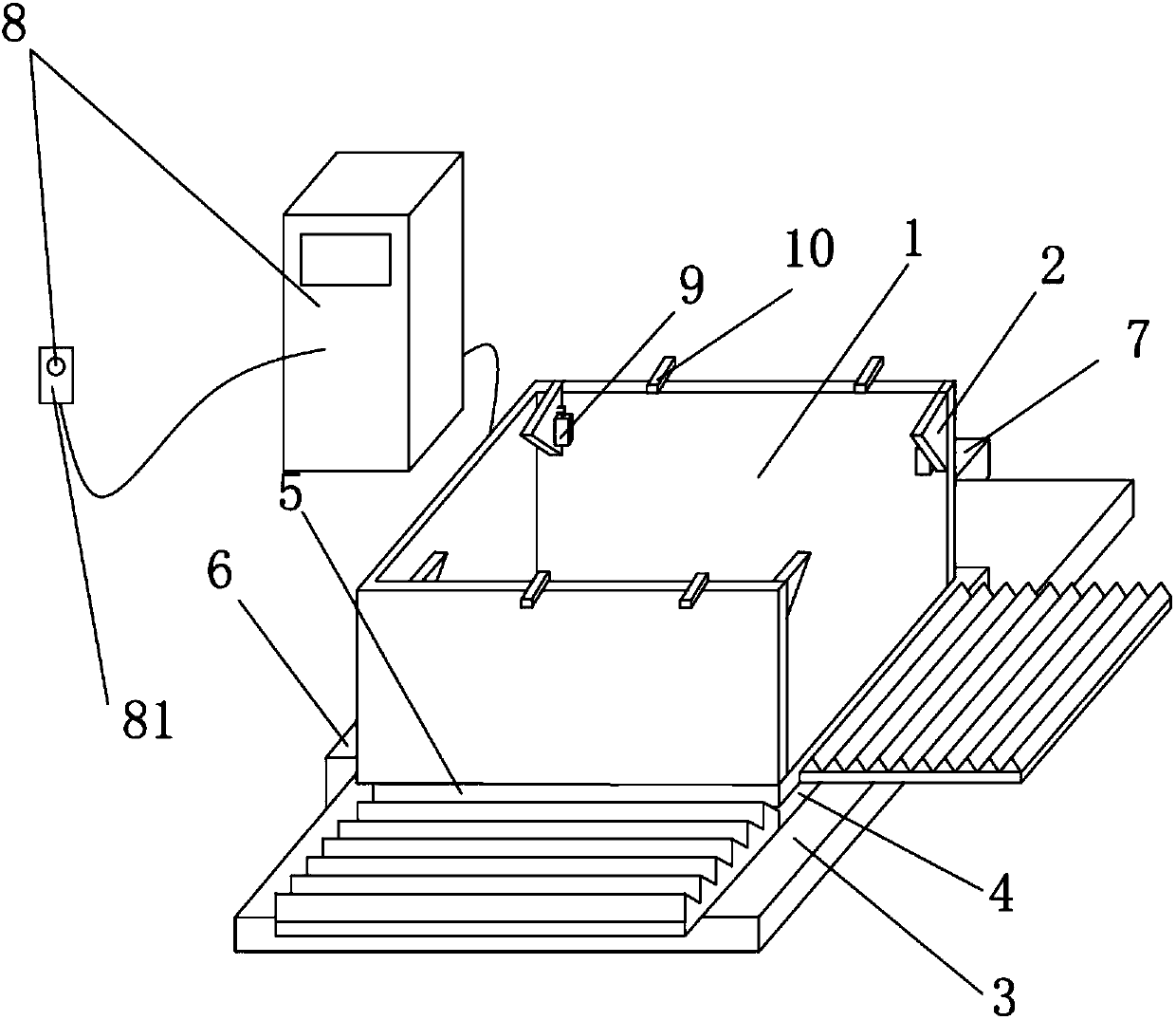

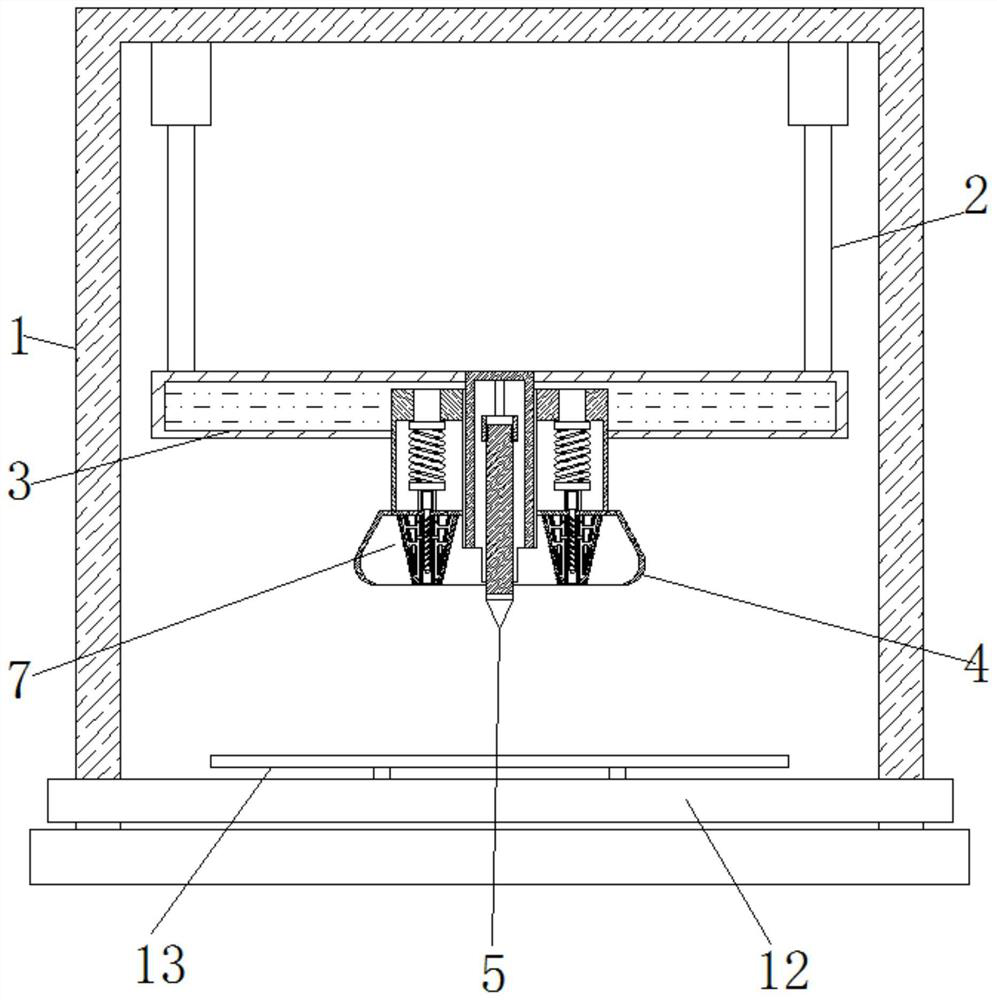

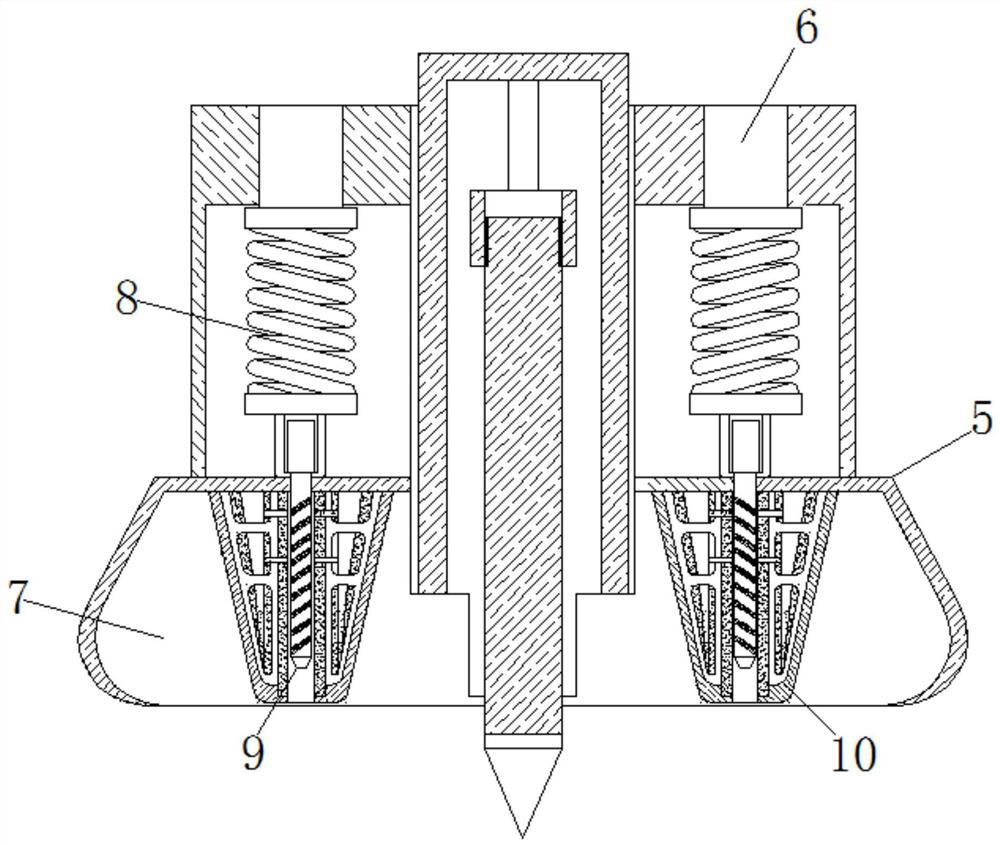

Welding machine operating platform

PendingCN107755871ATo achieve the welding effectWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachine

The invention relates to a welding machine operating platform. The welding machine operating platform is convenient and fast to operate, capable of welding hollowed-out products, safe, stable and efficient. The welding machine operating platform comprises an operating frame, brackets, a base, a first sliding seat, a second sliding seat, a first extending-and-contracting device and a second extending-and-contracting device. The first extending-and-contracting device is mounted on the base. The first sliding seat is in sliding fit with the base, and the extending-and-contracting end of the firstextending-and-contracting device is connected with the first sliding seat and maintains transverse extending and contraction. The second extending-and-contracting device is mounted on the first sliding seat. The second sliding seat is in sliding fit with the first sliding seat, and the extending-and-contracting end of the second extending-and-contracting device is connected with the second sliding seat and maintains longitudinal extending and contraction. The operating frame is mounted on the second sliding seat and is hollow. The multiple brackets are arranged at the top of the inner wall ofthe operating frame. The welding machine operating platform further comprises a control mechanism. The first extending-and-contracting device and the second extending-and-contracting device are eachelectrically connected with the control mechanism.

Owner:无锡市久耐德机械制造有限公司

A device for preprocessing circuit boards using thermal conductivity

ActiveCN110402032BTo achieve the welding effectAchieve the effect of removing dust generated by drillingPrinted circuit assemblingMechanical engineeringThermal conductivity

The invention relates to the technical field of circuit board processing, and discloses a device for preprocessing circuit boards by using thermal conductivity, including a support frame, the inside of which is movably connected with a tin liquid tank through a telescopic rod, and the tin liquid tank The inside is fixedly connected with a shell, and the inside of the shell is movably connected with a drill bit. On the surface of the shell and on both sides of the drill bit, there are inlets. The lower part of the inlet is movably connected to a tin injection mechanism. The tin injection mechanism includes a spring and rotates At the same time, a whirlwind centered on the drill bit will be generated. The whirlwind will drain the liquid tin in the tin liquid tank through the liquid flow channel in the screw. In addition, due to the friction between the two, a certain amount of heat will be generated, and the liquid tin will flow to the circuit. Around the drilled hole, under the action of heat generated by friction, it will not solidify in a short period of time. During this time, the instrument to be installed can be bonded to the surface of the circuit board, thus achieving the effect of welding while the drilling is completed.

Owner:河南拓普艾科技有限公司 +1

An Outer Edge Welding Device for Hydraulic Cylinder Manufacturing

ActiveCN114589439BWeld firmlyLow costWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderStructural engineering

The invention provides an outer edge welding device for hydraulic cylinder manufacturing, which relates to the technical field of hydraulic cylinder welding and includes an installation support part; two sliding adjustment parts are installed on the installation support part; The structure is the same; a movable jamming device is slidably connected to the installation support part; an elastic positioning device is fixedly connected to the movable jamming device; Shape swing welding, the welding is firmer and the overall linkage is stronger, which can realize auxiliary smoke removal and cleaning work; it solves the problem that the overall installation accuracy of the outer edge welding device manufactured by the current hydraulic cylinder is low, and the welding is not stable enough to achieve simultaneous rotation welding. At the same time, it is impossible to realize flexible welding seam adjustment, which affects the welding quality. At the same time, arc swing welding cannot be realized, and swing adjustment is not convenient enough.

Owner:江苏力速达液压有限公司

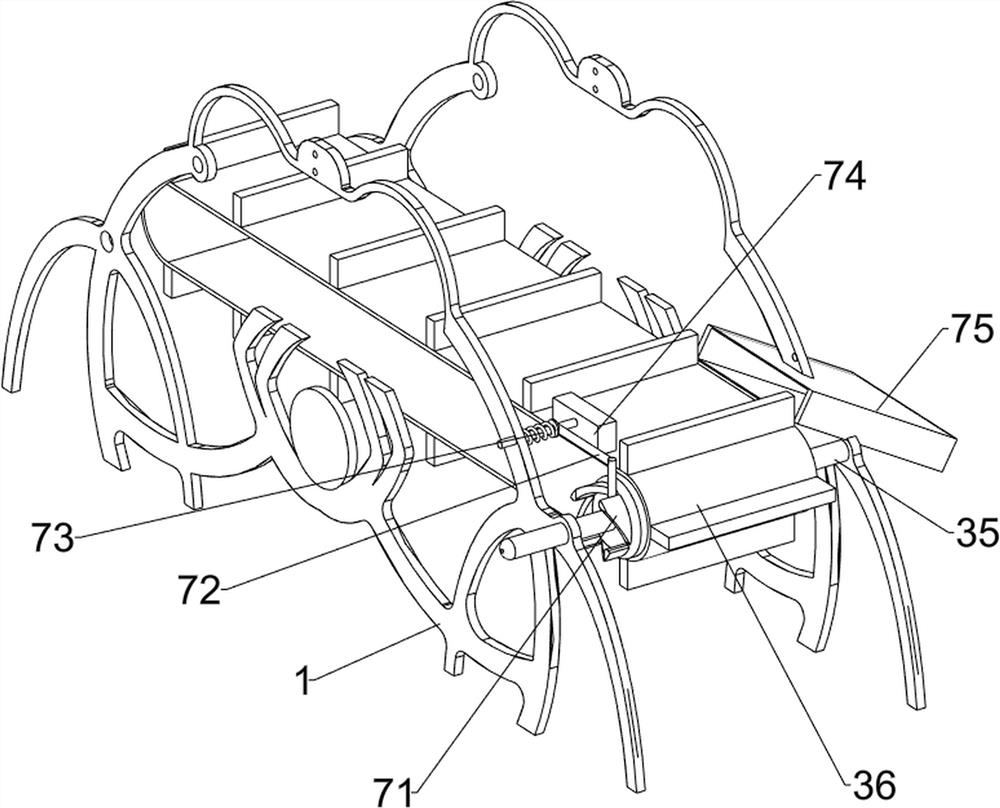

Mucilage glue welding equipment for disposable mask production

PendingCN112690521ATo achieve the welding effectAchieve the effect of automatic feedingProtective garmentClothes making applicancesIndustrial engineeringWelding

The invention relates to welding equipment, in particular to mucilage glue welding equipment for disposable mask production. According to the mucilage glue welding equipment for disposable mask production, automatic viscose welding, automatic feeding and automatic material bouncing can be achieved. The mucilage glue welding equipment for disposable mask production comprises: a bottom plate and a welding mechanism, wherein the welding mechanism is arranged on the bottom plate; and a conveying mechanism which is arranged on the bottom plate, wherein the welding mechanism is matched with the conveying mechanism. A second wedge block is matched with a third connecting rod, the second wedge block moves to enable the third connecting rod to move leftwards, a push block slides out leftwards on a conveying assembly, and after the second wedge block and the third connecting rod are opened in a time-sharing mode, a fifth elastic assembly resets, and then the push block is moved back to the original position; and therefore, the welded disposable mask on the conveying assembly is bounced into the material guide square pipe, and the effect of automatic bouncing is achieved.

Owner:毛益府

An electromagnetic welding method for pre-laid anti-adhesive waterproof membrane

The invention discloses an electromagnetic welding method for pre-laid anti-adhesive waterproof coiled material. The pre-laid waterproof coiled material includes a base material layer made of polyethylene, including: 1) matching the pre-welded waterproof coiled material with the pre-paved waterproof coiled material The gasket is fixed on the substrate, and the gasket is composed of a matrix resin layer and a metal wire inlaid on the upper surface of the matrix resin layer; in terms of mass percentage, the raw materials of the matrix resin layer include: polyethylene 5-30%, polyethylene Propylene 5-30%, ethylene-propylene copolymer 20-50% and ethylene-octene copolymer 20-50%; 2) Lay the pre-laid waterproof membrane on the substrate, so that the pre-laid waterproof membrane and the gasket are attached Then align the electromagnetic welding torch and press it on the pre-laid waterproof membrane at the position of the gasket, and start welding. The invention can quickly fix the pre-laid waterproof membrane on the substrate, and the operation is simple and controllable. It has good performance and firm welding, and also avoids the problem of later leakage caused by nailing and other fixing methods in the prior art.

Owner:JIANGSU CANLON BUILDING MATERIALS

Arc energy control method and control device, computer readable medium

ActiveCN107570841BThe heat input reachesLow heat inputArc welding apparatusElectric variable regulationWelding power supplyEngineering

Owner:HUAHENG WELDING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com