Patents

Literature

376 results about "Plastic welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

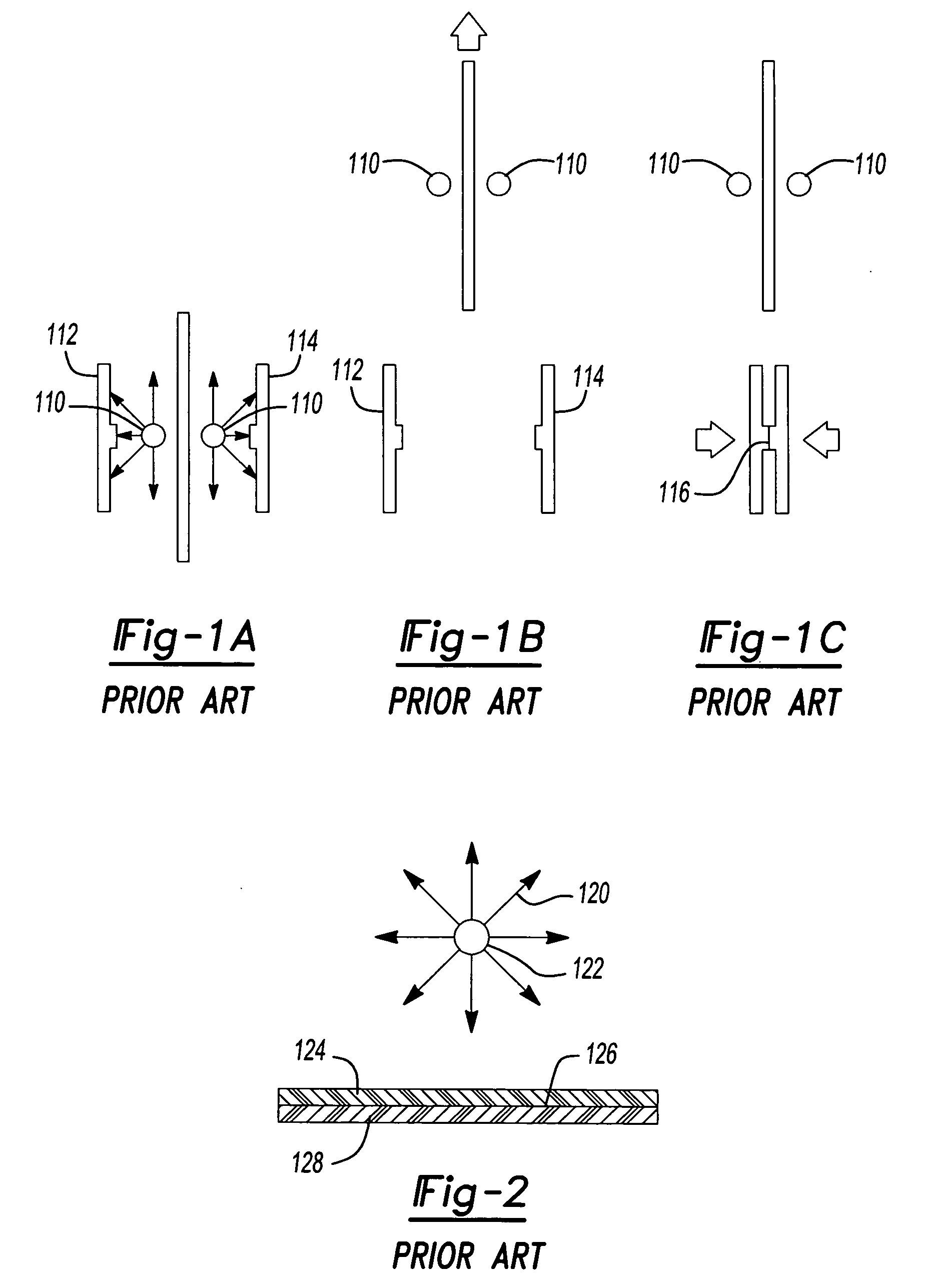

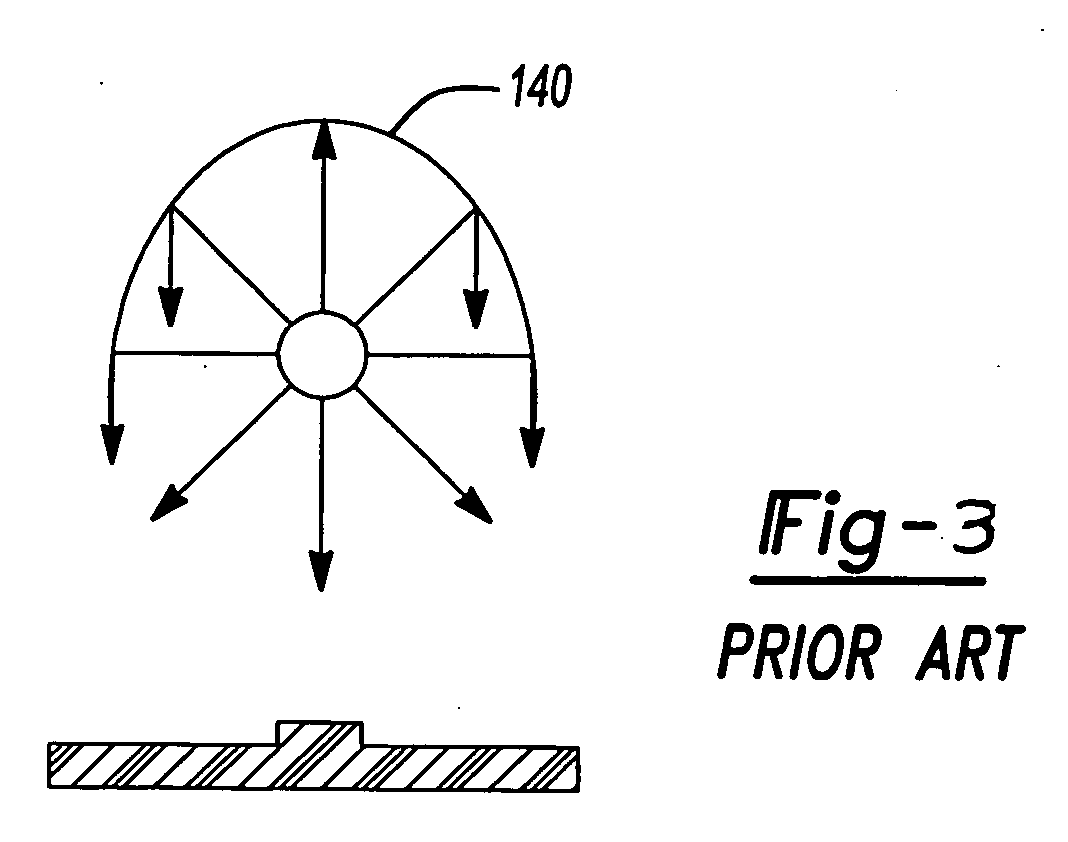

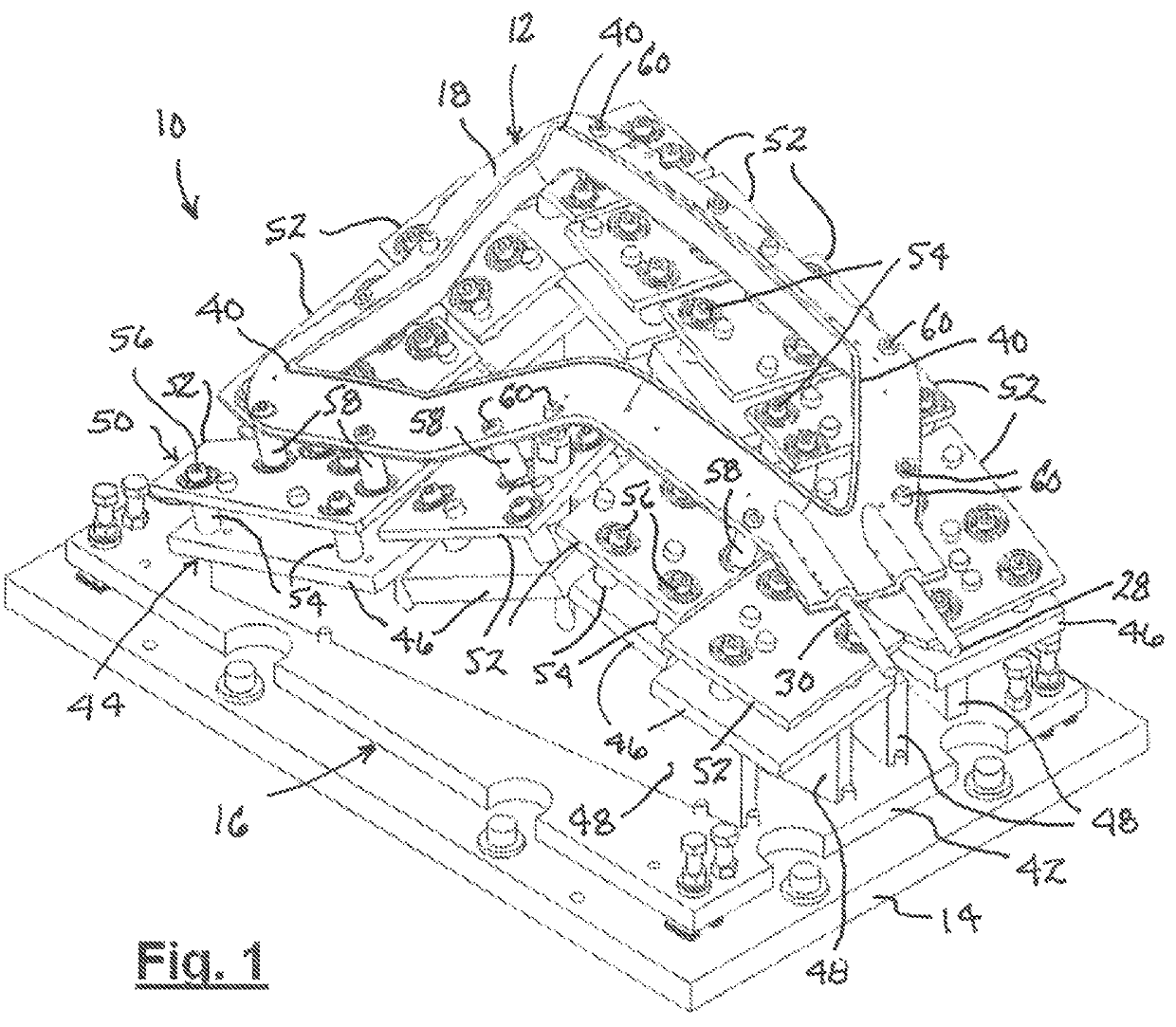

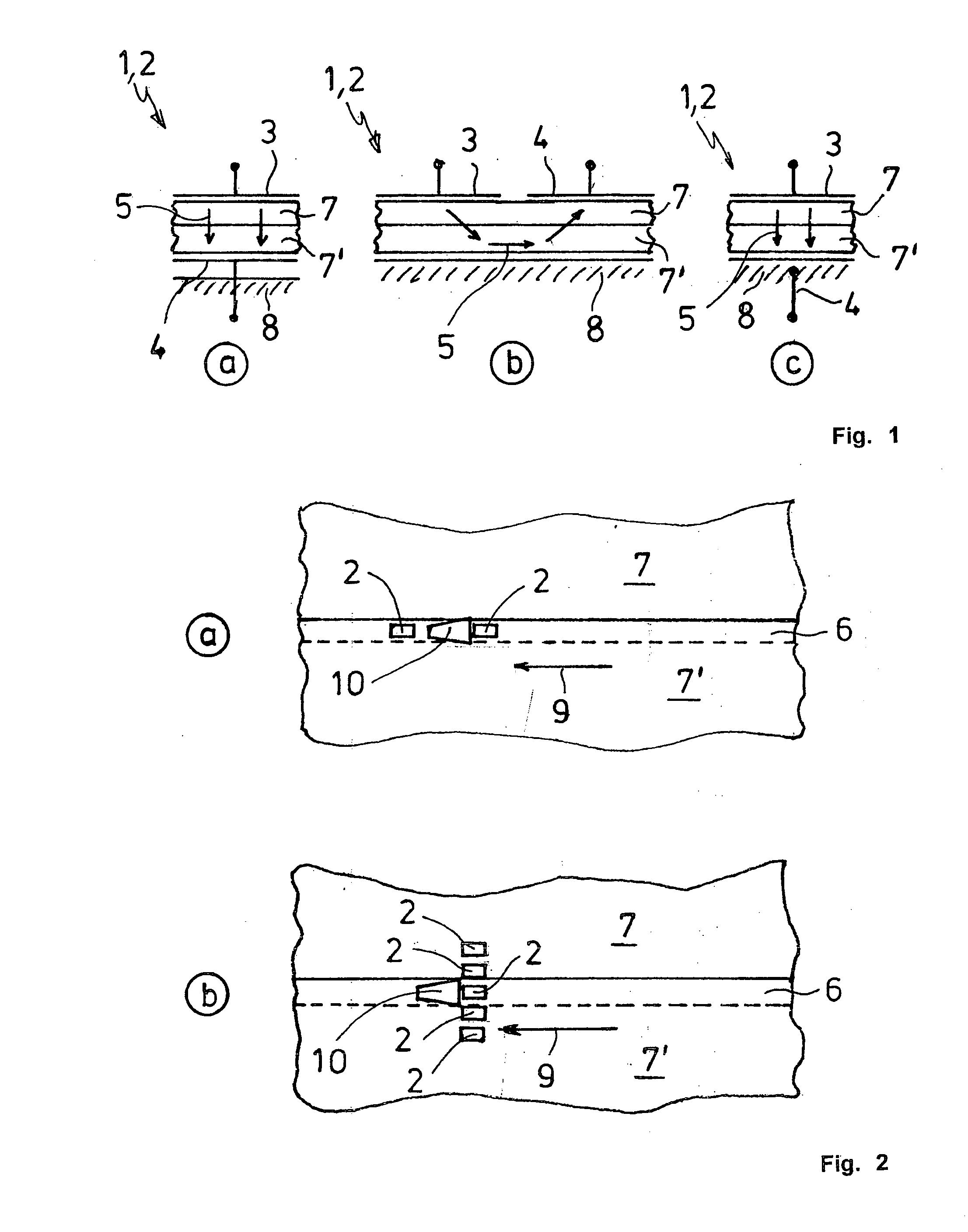

Plastic welding is welding for semi-finished plastic materials, and is described in ISO 472 as a process of uniting softened surfaces of materials, generally with the aid of heat (except solvent welding). Welding of thermoplastics is accomplished in three sequential stages, namely surface preparation, application of heat and pressure, and cooling. Numerous welding methods have been developed for the joining of semi-finished plastic materials. Based on the mechanism of heat generation at the welding interface, welding methods for thermoplastics can be classified as external and internal heating methods, as shown in Fig 1.

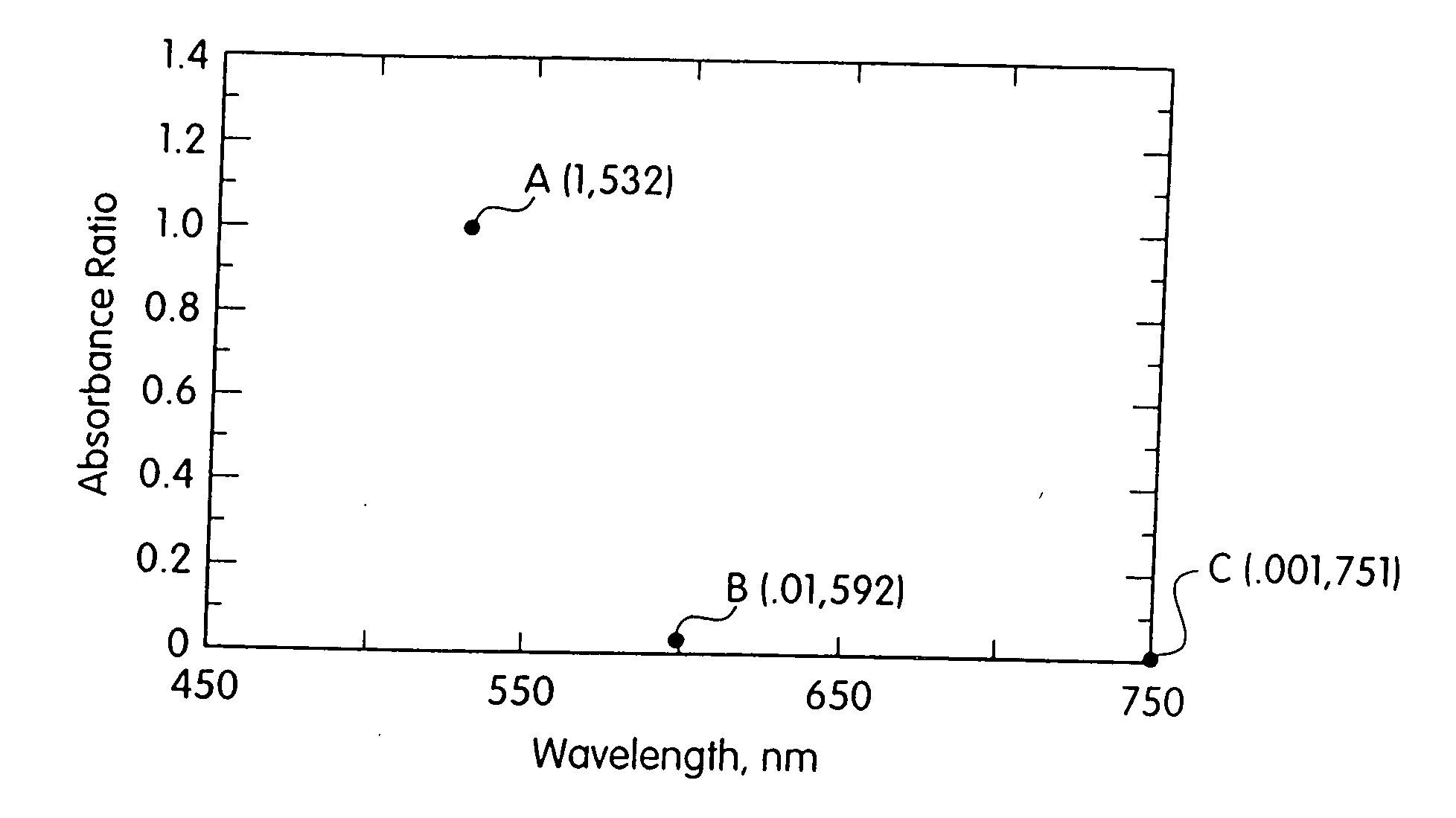

Visibly transparent dyes for through-transmission laser welding

InactiveUS6911262B2Add little or no light scatteringEffective radiationMechanical working/deformationLamination ancillary operationsSelection criterionThrough transmission

Owner:GENTEX CORP

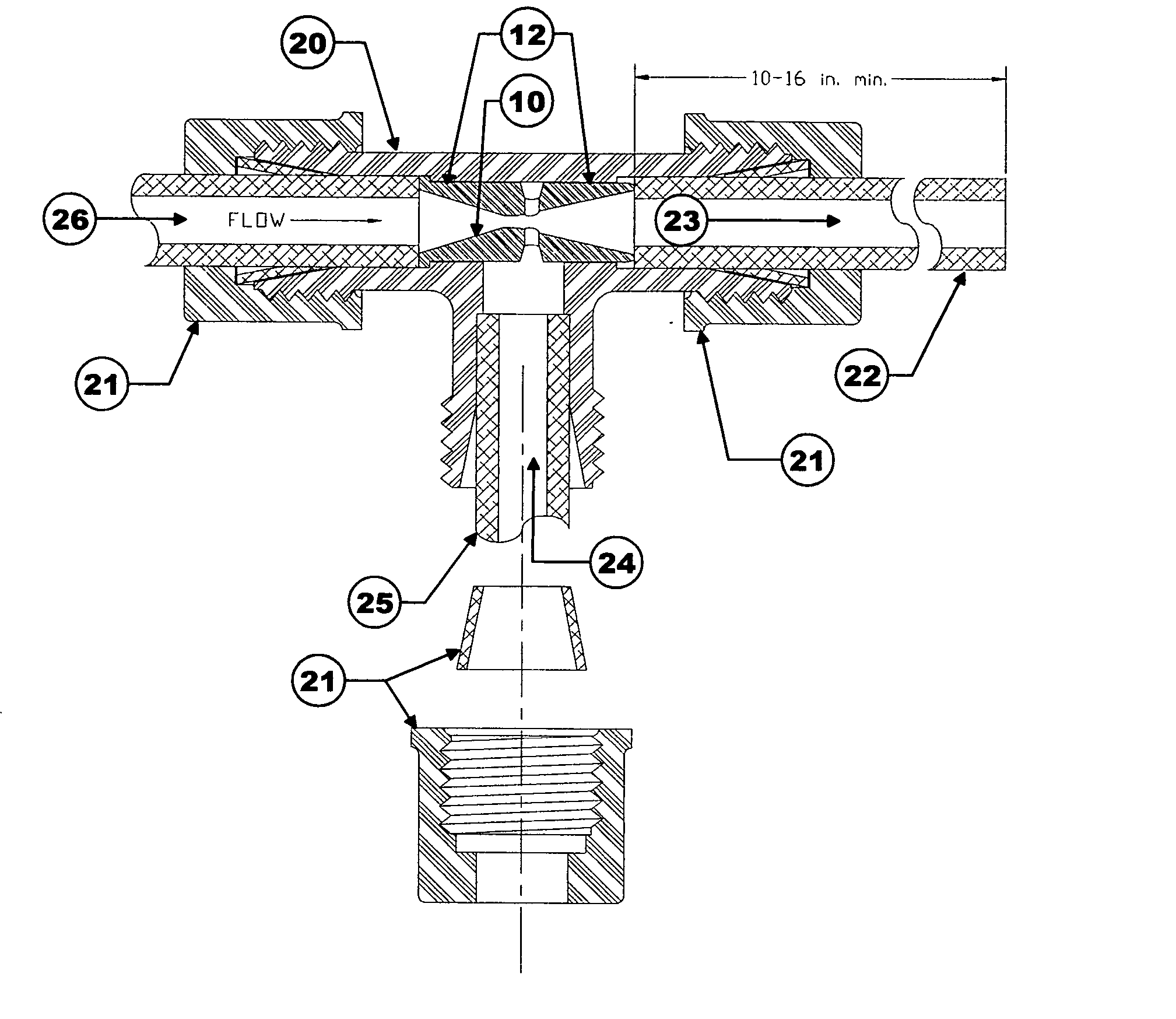

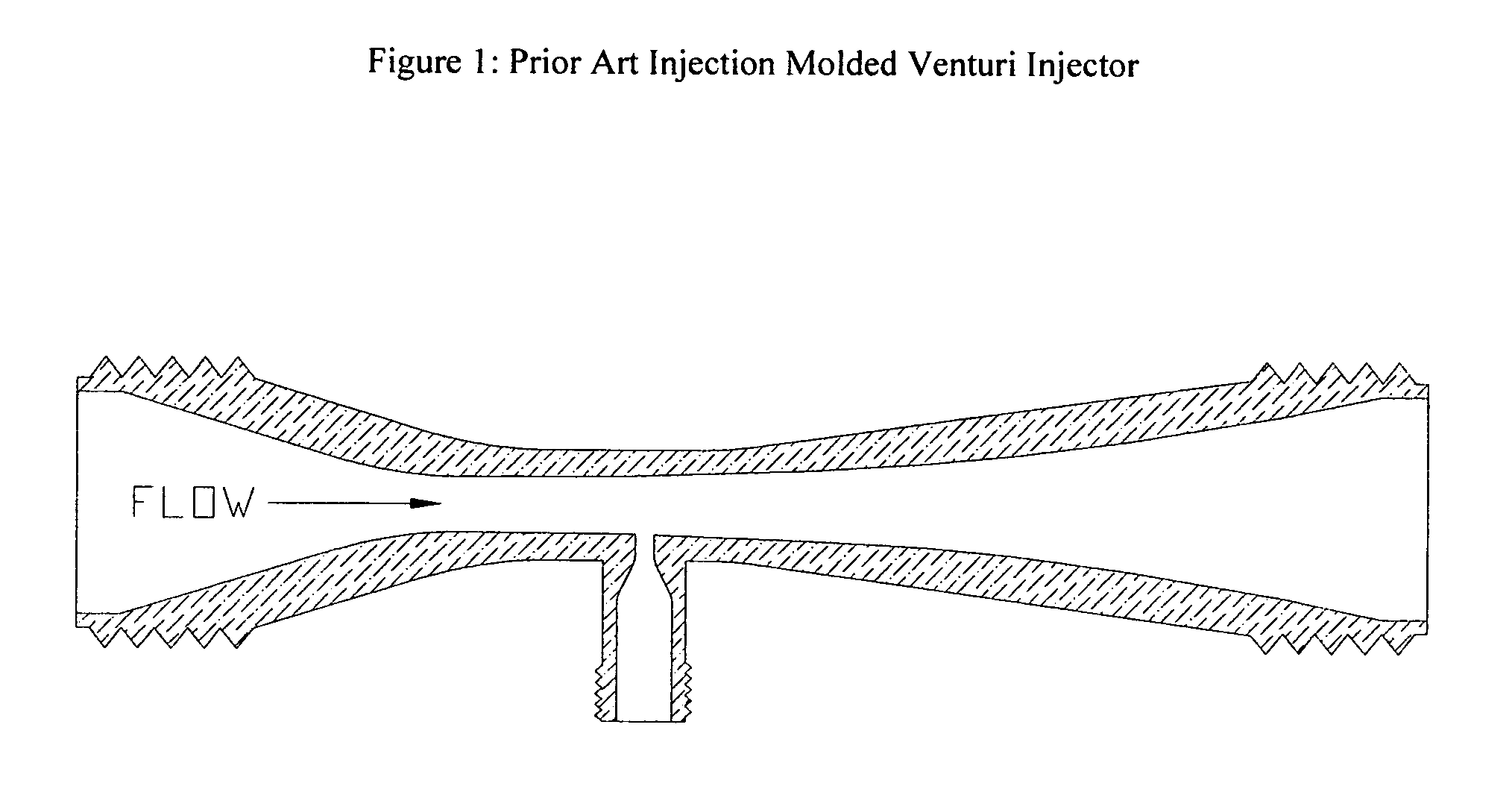

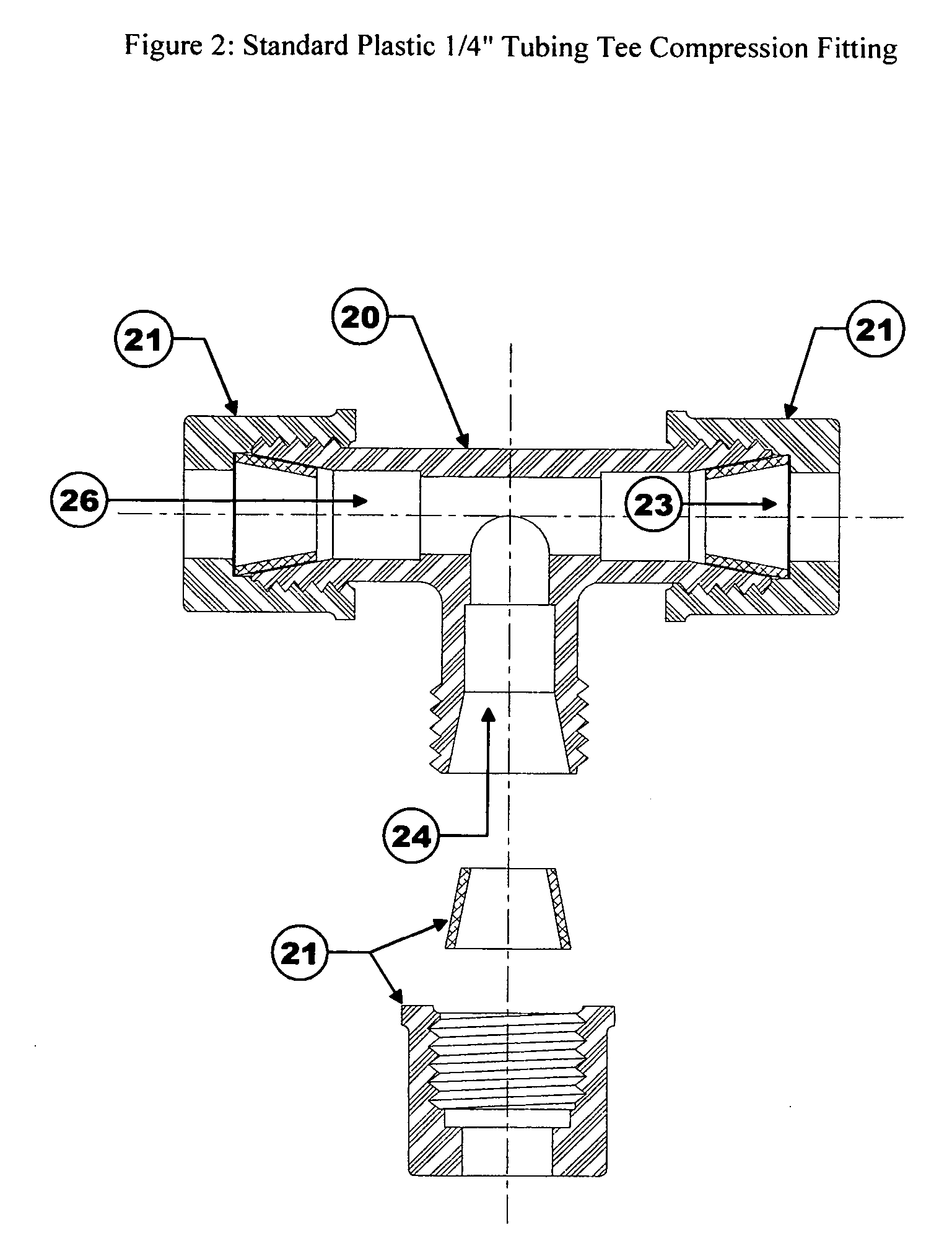

Cylindrical insert fluid injector / vacuum pump

InactiveUS20070152355A1Less-expensive to produceProduces different injector/vacuum pump performanceFlow mixersTransportation and packagingEpoxyCavitation

A method of producing a hydrodynamic cavitation fluid injector, hydrodynamic vacuum pump, venturi fluid injector, or similar device in which a special cylindrical insert is combined with a suitable body, such as one of any number of common off-the-shelf or purpose built pipe and tube “tee” fittings. In its various embodiments, the insert has features, geometry, dimensions, and material characteristics suitable to the intended application, and is installed into the body through any of a variety of methods including threads, epoxy, press-fit, barbed press fit, plastic welding, solder, O-ring, bushing, flange, clamp, etc. to produce the complete injector / vacuum pump assembly. While the term hydrodynamic ordinarily applies only to liquid fluids, for the purposes of descriptions and claims of the present invention it should also be taken to include gaseous fluids. The injector / vacuum pump insert concept works just as well with gaseous fluids as with liquid fluids.

Owner:HARTLEY JOHN DOW

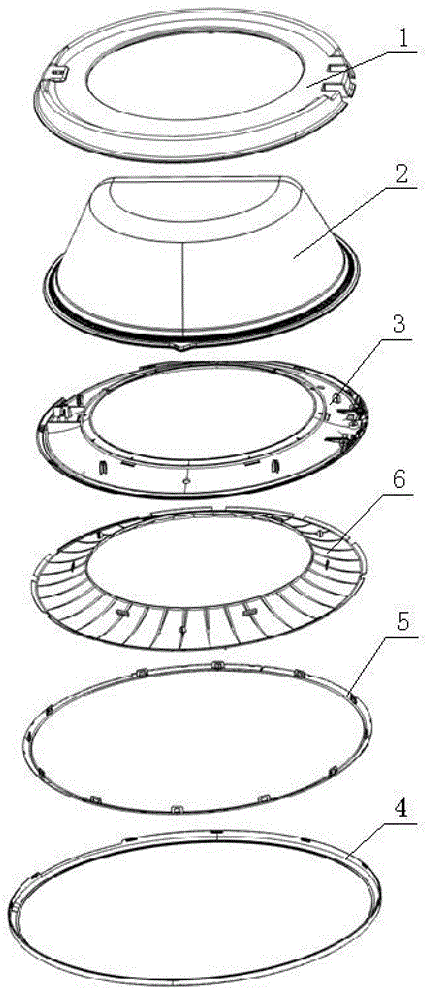

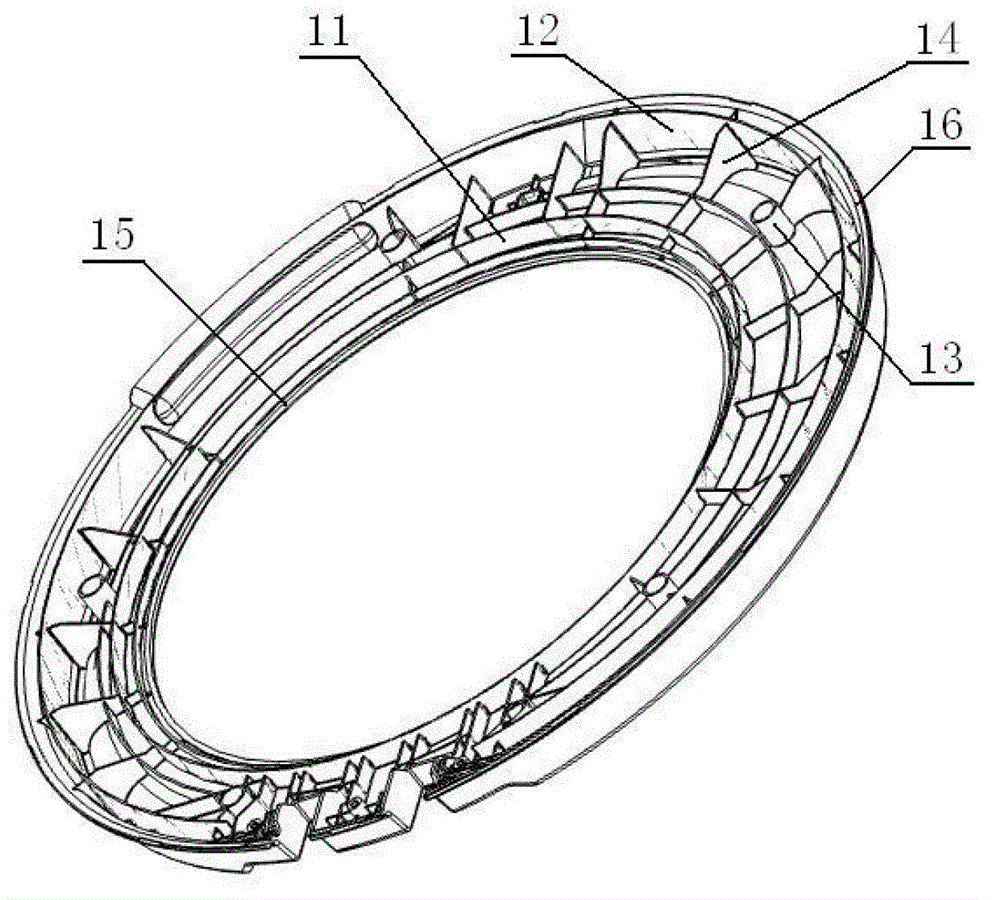

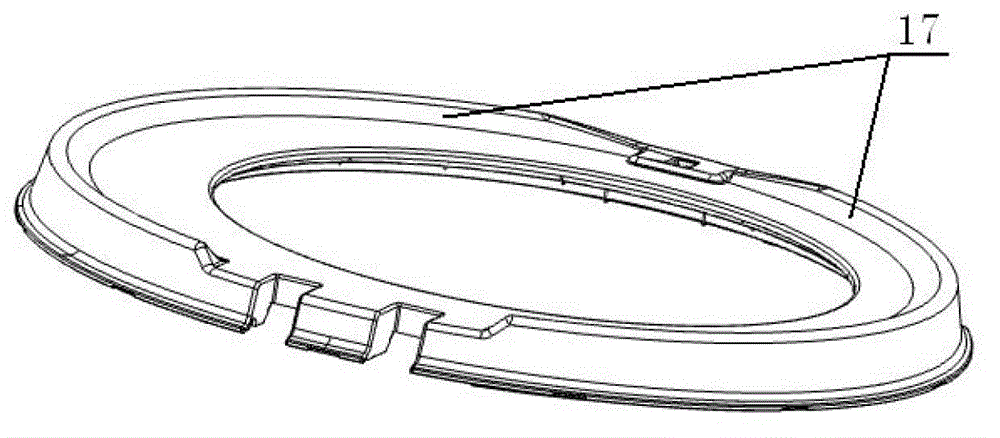

Door of front-loading washer and assembly method thereof

ActiveCN104372569AImprove reliabilityIncreased durabilityOther washing machinesTextiles and paperEngineeringFront loading

The invention discloses a door of a front-loading washer and belongs to the field of parts for front-loading washers. The door comprises an inner frame, a transparent basin, a middle frame and an outer frame which are arranged in order from inside of the door to the outside of the door; a window screen is disposed between the outer frame and the middle frame; the middle frame is in welded connection with the inner frame; the outer frame and the window screen are fastened to the middle frame; a decoration is provided between the window screen and the middle frame. The door is compact in structure and convenient to mechanically assemble; parts of the door are flexible to combine and select; personalized needs of different users can be met. An assembly method of the door includes assembling the parts of the door by plastics welding; production is highly effective; products are more reliable and durable.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD

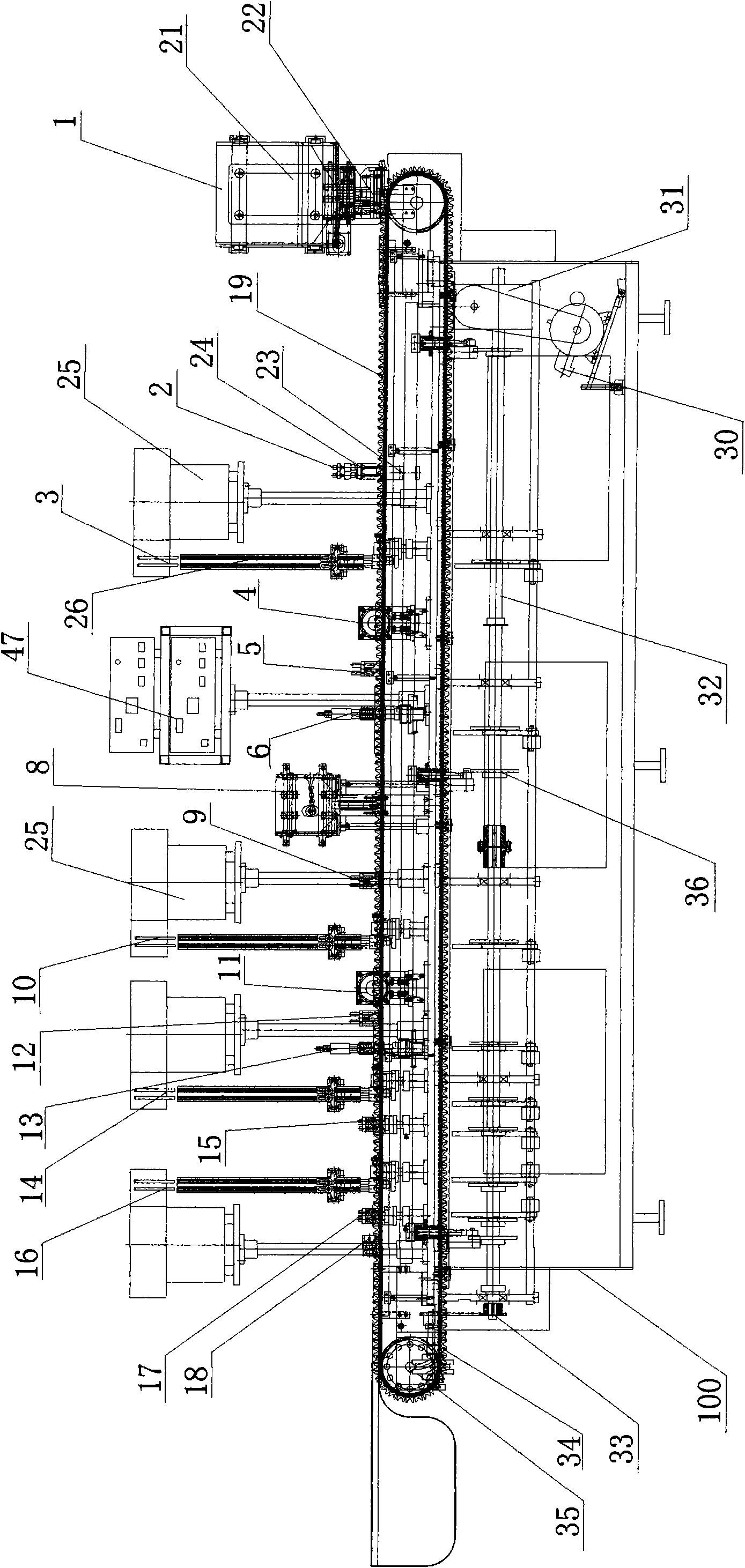

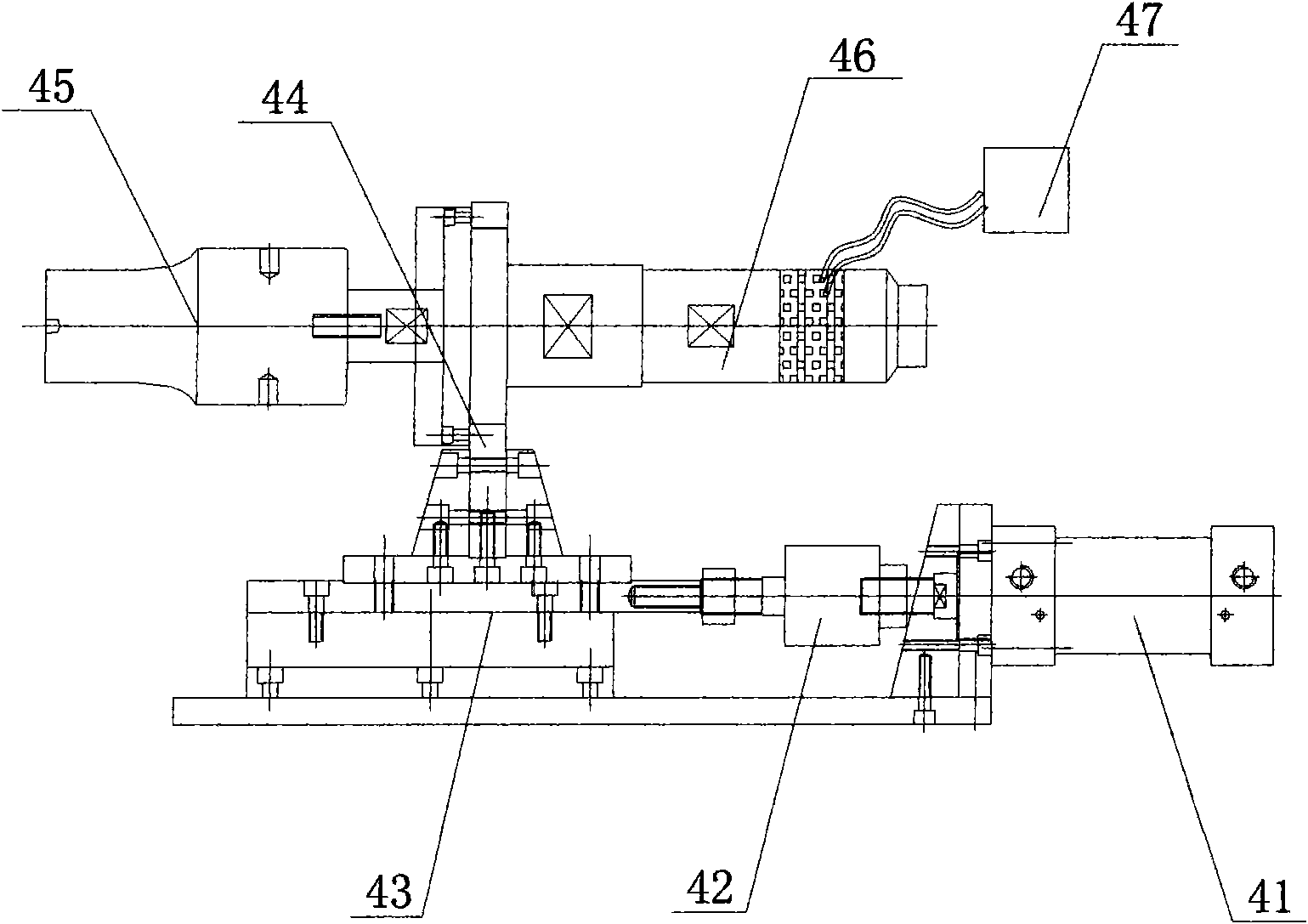

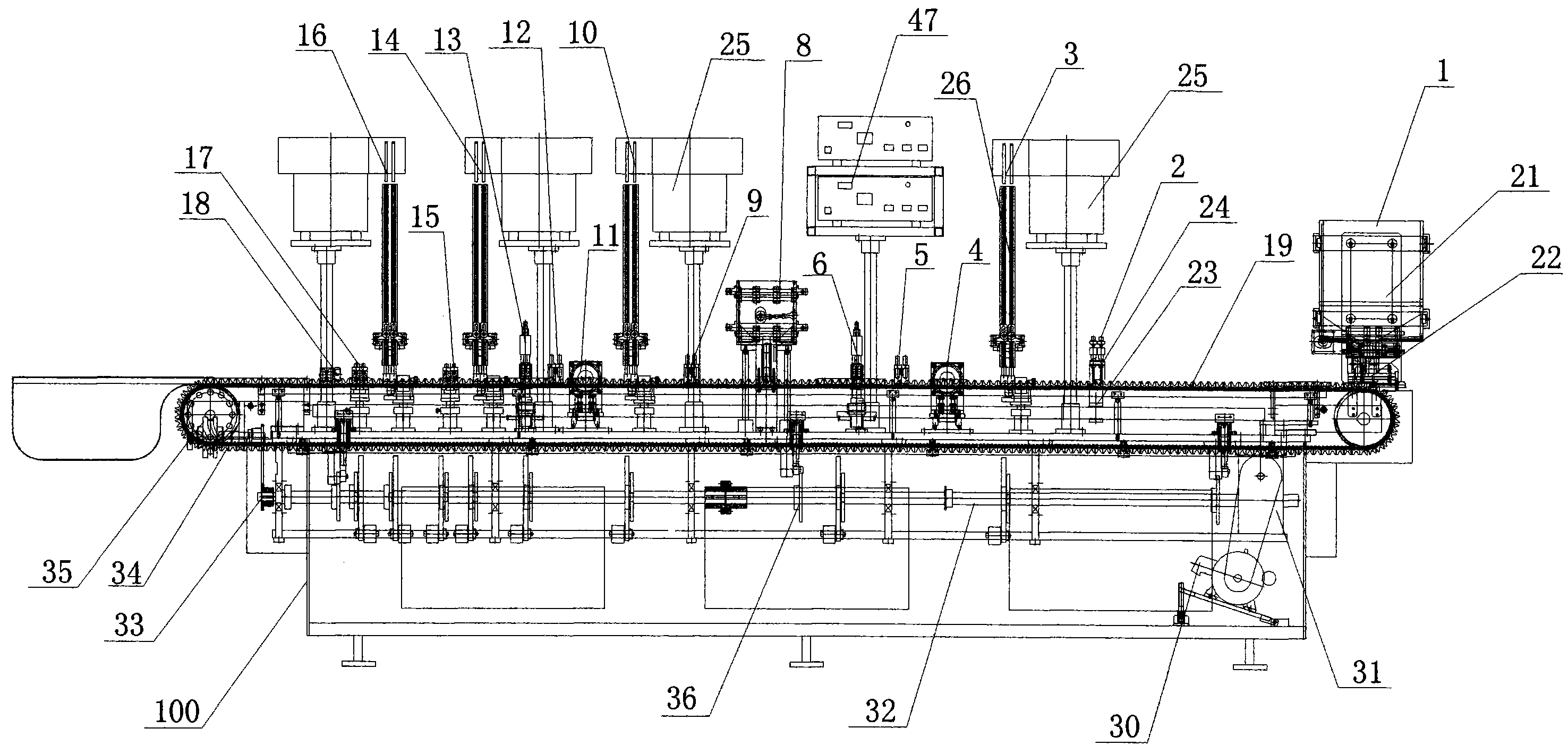

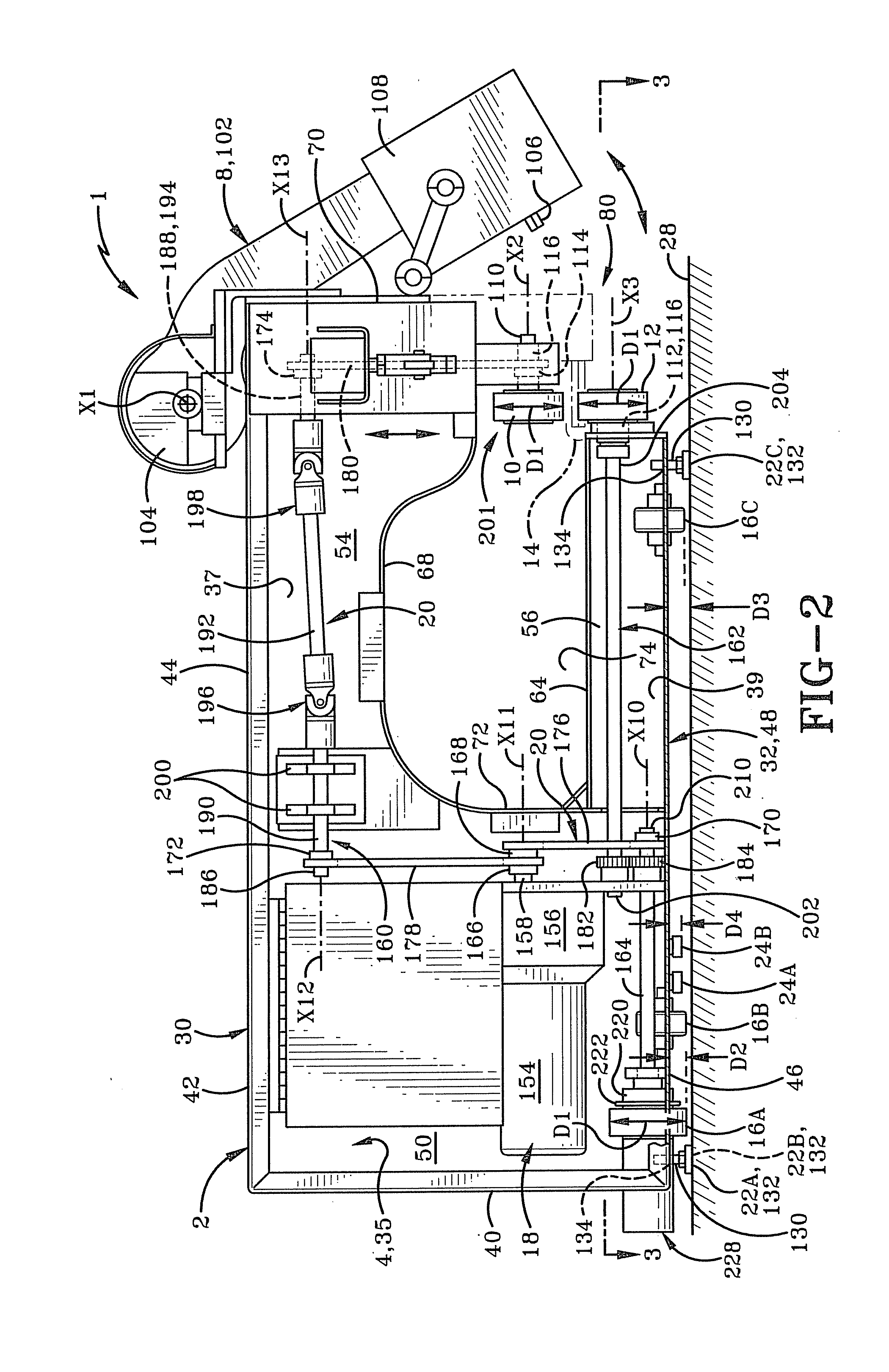

System and method for automatically assembling fountain pen

InactiveCN101830137AIncrease productivityImprove product qualityPen repairingMachine partsSoftware system

The invention relates equipment and method for assembling a fountain pen. The equipment comprises a plurality of operation units consisting of an electric machine part, a pneumatic machine part, a sensing element, a measuring element, an ultrasonic plastic welding electrical appliance and the like. The method comprises: simulating the manual operation methods of each working procedure in a manufacturing process flow; compiling an operational program software system; sending operation instructions to each operation unit; assembling all required fountain pen parts in sequence by adopting barrel cam control and a conveying chain stepping mode; automatically detect and screening the results of all operation units; and automatically segregating quality field products and non-qualified products. Thus, the method improves production efficiency, saves labor and cost, reduces labor intensity and improves product quality.

Owner:张汉平

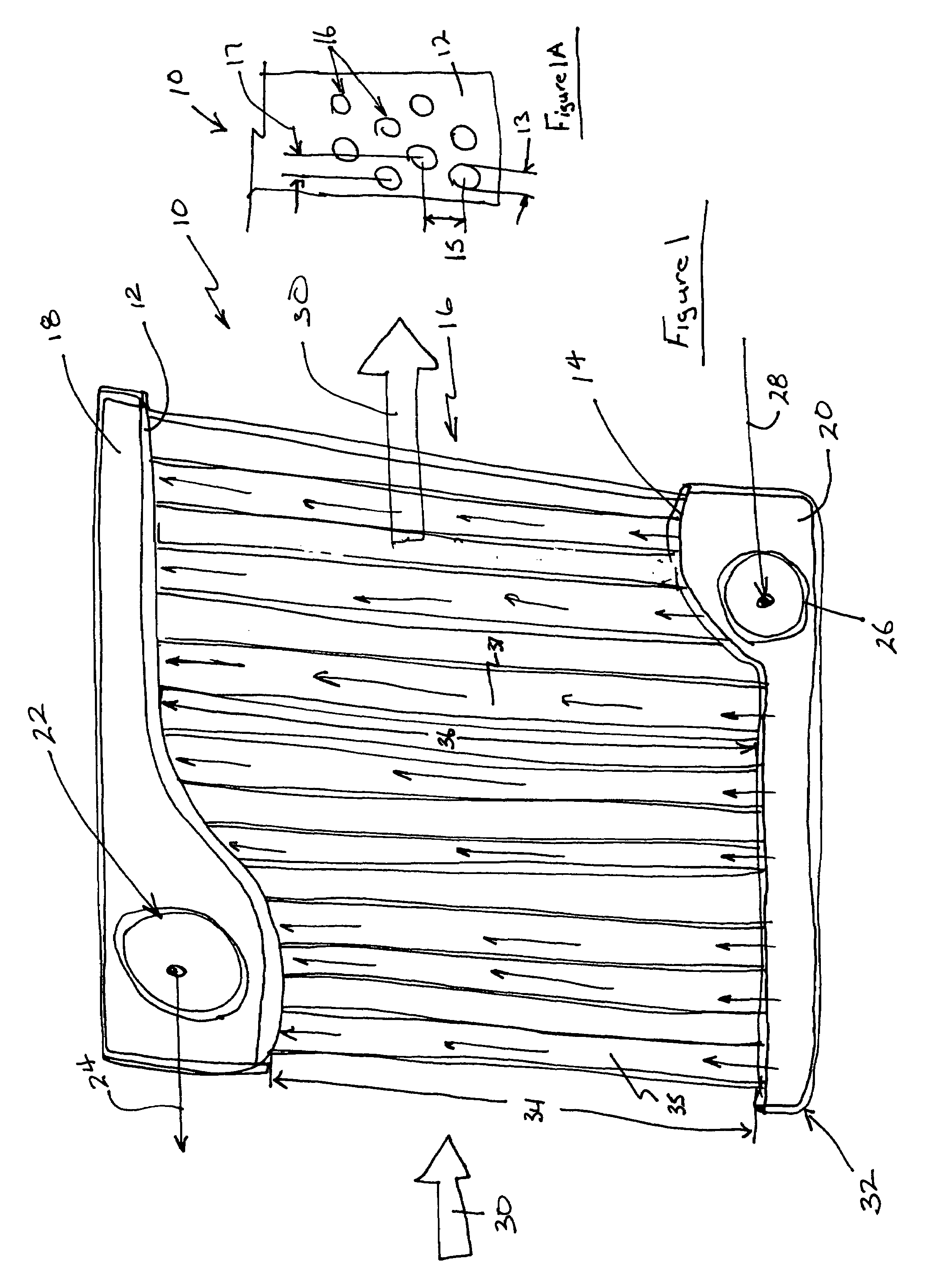

Plastic intercooler

InactiveUS20080000625A1Takes significant amountEasy to assembleInternal combustion piston enginesMetal-working apparatusIntercoolerEngineering

A plastic intercooler assembly includes a plurality of plastic tubes that extend between plastic end plates. The plastic tubes are secured to the end plates to provide the desired seal between the end plates and the ends of the tubes. The plastic tubes are attached utilizing plastic welding methods that reduce assembly time and cost.

Owner:SIEMENS VDO AUTOMOTIVE CORP

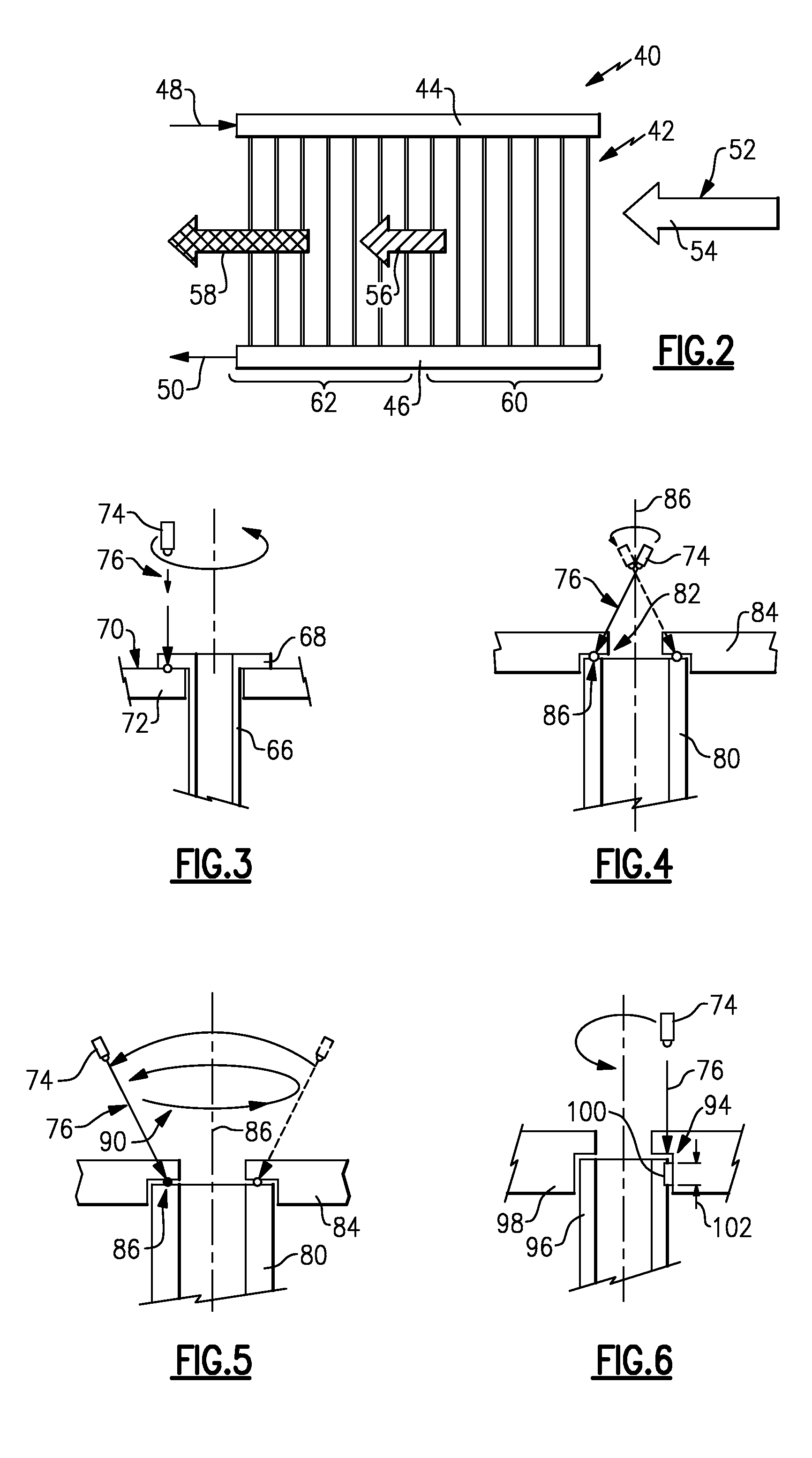

Waveguide for plastics welding using an incoherent infrared light source

An assembly for producing a weld coupling a first part of a workpiece to a second part of the workpiece. The assembly comprises a first incoherent light source that generates incoherent light energy and a first negative waveguide having an input end and an output end, the incoherent light energy from the first incoherent light source and that reflected by the first reflector entering the first negative waveguide at the input end, passing through the first negative waveguide and exiting the first negative waveguide at the output end. The first negative waveguide having a non-conical longitudinal cross section producing a non-circular weld zone

Owner:BRANSON ULTRASONIC CORP

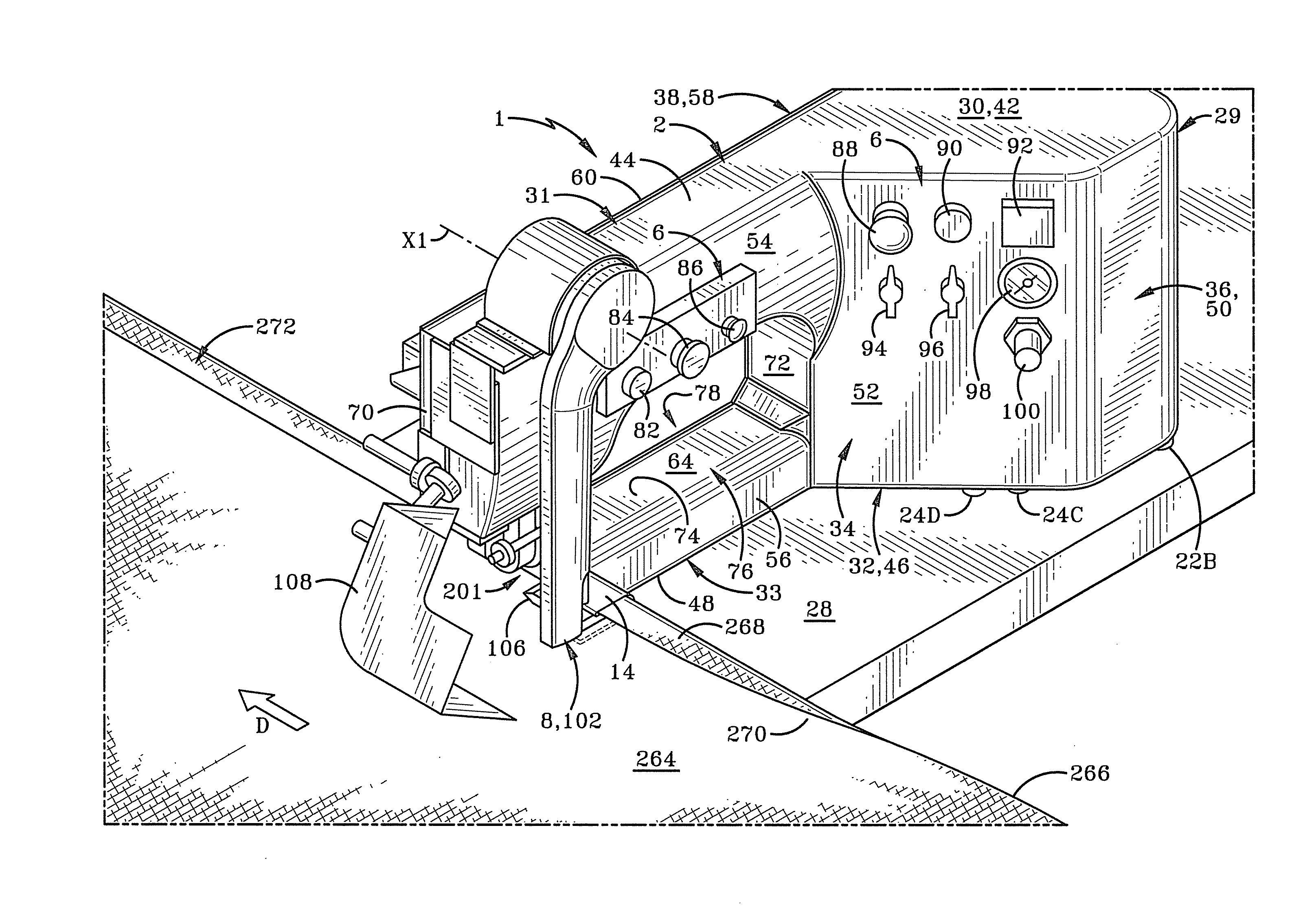

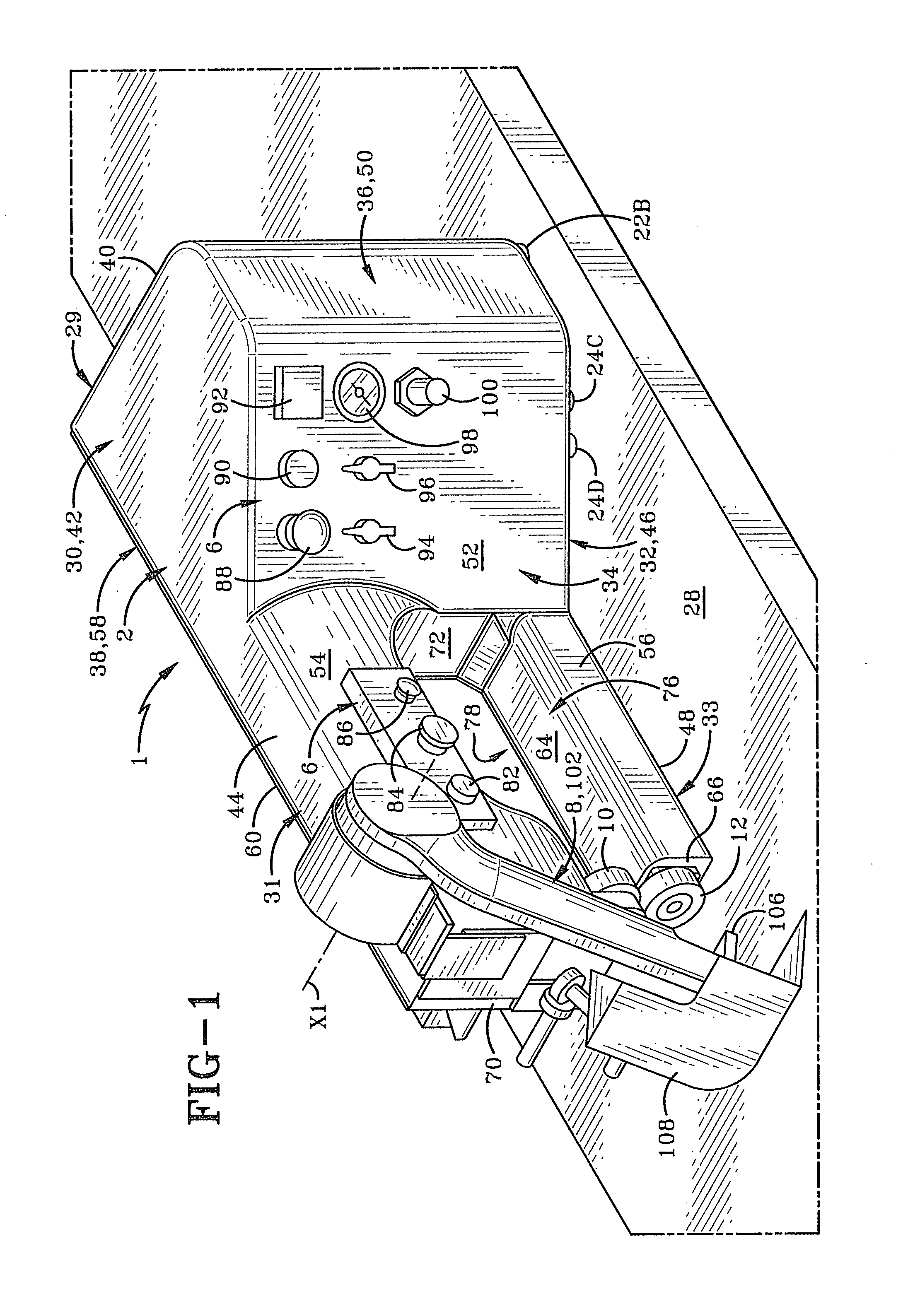

Portable heat welding machine

ActiveUS20130098887A1Ohmic-resistance heatingHigh frequency current welding apparatusTravel modeDrive wheel

A relatively small and lightweight portable plastic welding machine is suitable for use on a table top. The welding machine has stationary and traveling modes for welding one or more sheets of flexible plastic material. A single motor is provided for driving rotation of pinch rollers adjacent a welding tip and rotation of a drive wheel to cause travel of the machine. A clutch provides the ability to easily switch between the stationary and traveling modes.

Owner:MILLER WELDMASTER CORP

Plastic and metal permanent direct connection method

The invention relates to the technical field of metal and plastic welding, in particular to a plastic and metal permanent direct connection method. A plurality of connecting holes distributed in a cellular manner are ablated in the surface of a metal component by utilizing laser beams to irradiate at the surface of the metal component. A connecting surface of a plastic component is attached with the surface of the metal component, molten liquid plastic enters the connecting holes, and after the plastic entering the connecting holes is cooled, the welding connection of the metal component and the plastic component is fully realized. The welding method utilizes high-peak power, high beam quality and short-pulse laser beams to treat the metal surface and form the microstructural cellular holes in the surface, micro-hole diameter, depth and filling density can all be flexibly controlled, corresponding adjustment can be carried out according to actual requirements, and the adaptability is better.

Owner:WUHAN LINGYUN PHOTOELECTRONICS SYST

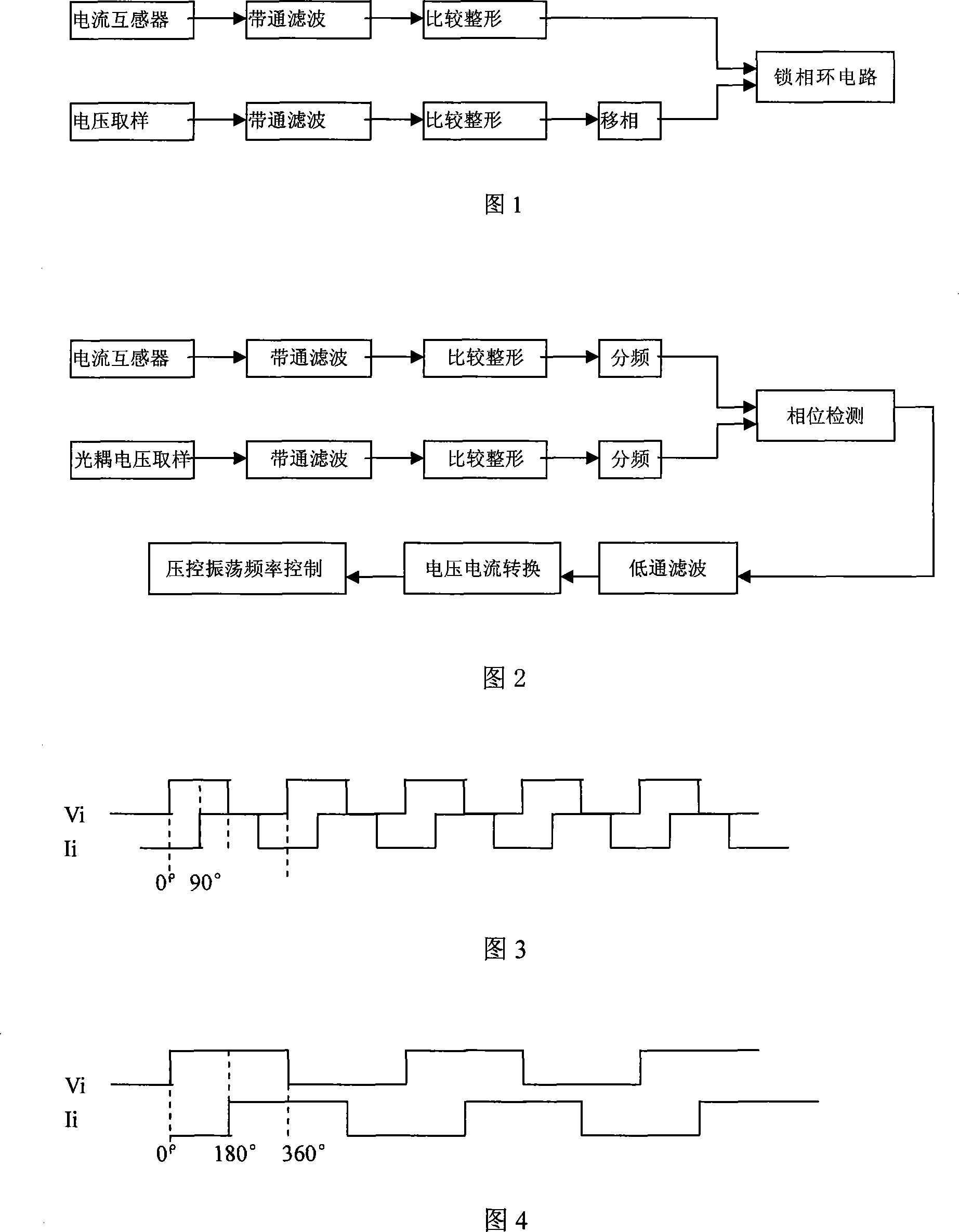

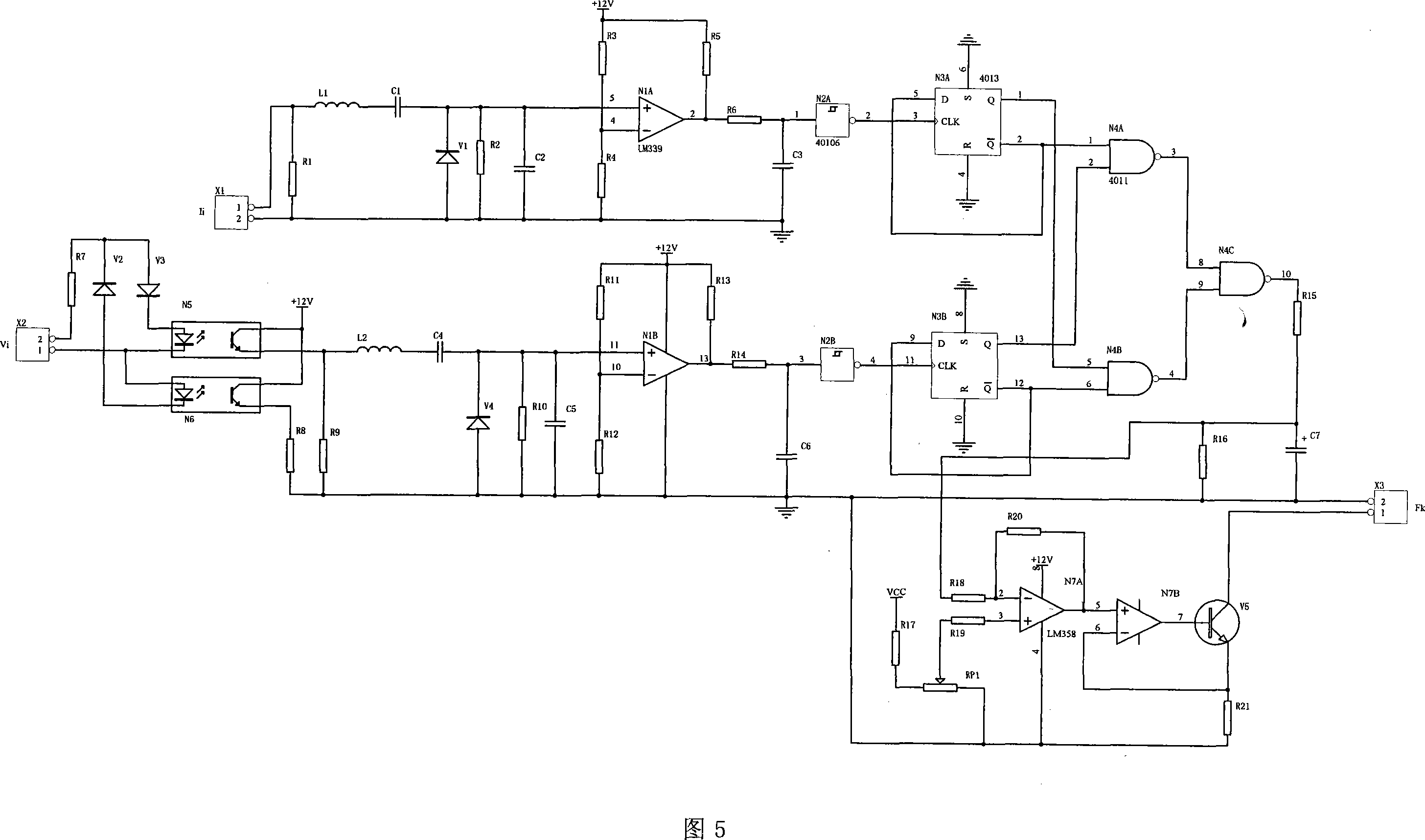

Frequency tracking circuit structure in ultrasonic power

The invention relates to a frequency tracking circuit structure for an ultrasonic power supply, specifically, which is used for ultrasonic screening, ultrasonic plastic welding, ultrasonic metal welding, ultrasonic machining and other application domains. The frequency tracking circuit comprises a current transformer, a photocouping voltage sampling circuit, a first bandwidth limited circuit, a second bandwidth limited circuit, a first comparing and shaping circuit, a second comparing and shaping circuit, a first frequency dividing circuit with output terminal connected with the input terminal of a phase-detecting circuit, and a second frequency dividing circuit with output terminal connected with the input terminal of the phase-detecting circuit, wherein the output terminal of the phase-detecting circuit is sequentially connected with a low-pass filter circuit, a voltage current switching circuit, and a voltage-controlled oscillation frequency control circuit. The invention uses frequency dividing circuit, so that when operating at resonant frequency, the voltage and current in transducer circuit are at the same state, thereby achieving the purpose of automatic frequency tracking.

Owner:JIANGSU WELM TECH

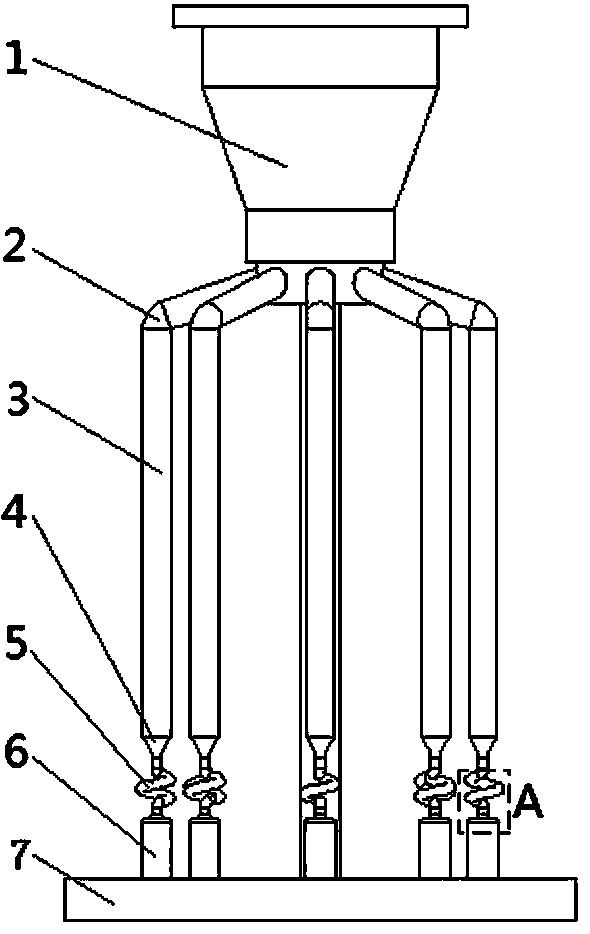

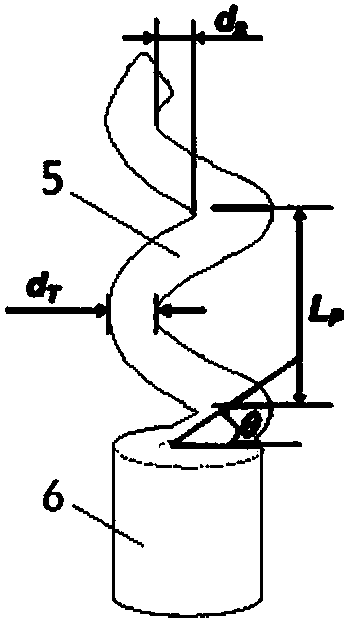

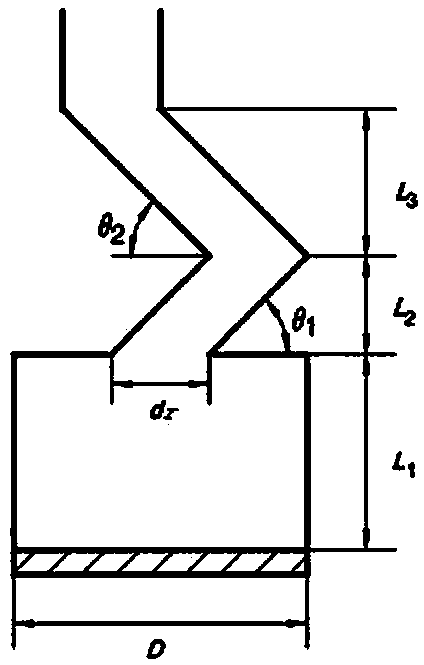

Method for preparing wax mold of monocrystal spiral crystal selector

The invention provides a method for preparing a wax mold of a monocrystal spiral crystal selector. The wax mold of the monocrystal spiral crystal selector comprises a seeding section wax mold, a spiral crystal selecting section wax mold and a transition section wax mold which are sequentially connected from bottom to top. The method comprises the following steps: firstly, manufacturing the seeding section wax mold and the transition section wax mold; winding on a screw corresponding to the size of the required spiral crystal selecting section by a plastic welding rod, sizing for a moment, immersing into 58# refined paraffin liquid at 68 DEG C, taking out after 4-7 seconds so as to obtain the spiral crystal selecting wax mold; connecting two ends of the spiral crystal selecting wax mold with the bottom of the transition section wax mold and the top of the seeding section wax mold respectively by utilizing bonding wax which is heated to be 130 DEG C. According to the invention, the crystal selector wax mold which meets the requirement can be prepared rapidly; compared with the traditional method using a wax injector and a wax mold, the method has the characteristics of no need of wax injector equipment, no need of machining the wax mold, low expense, simplicity in operation, short consumption time, high efficiency, high yield and the like.

Owner:DONGFANG TURBINE CO LTD

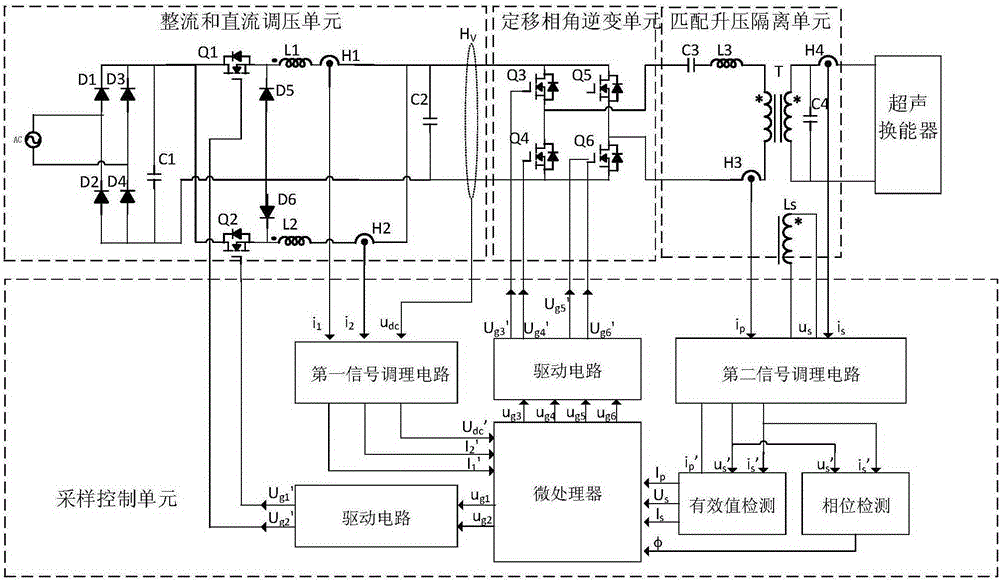

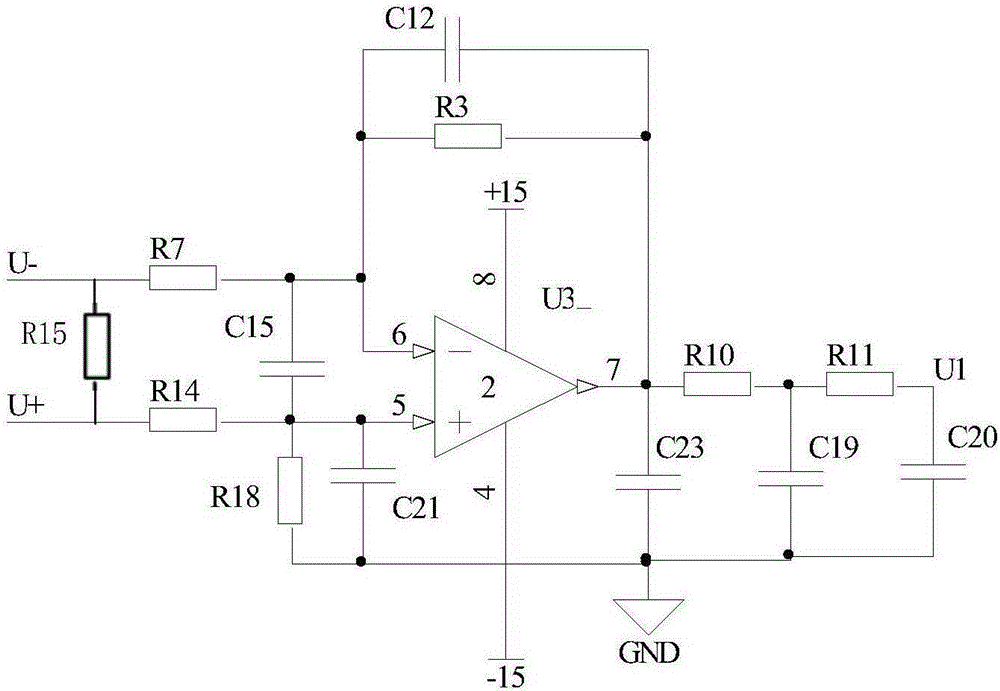

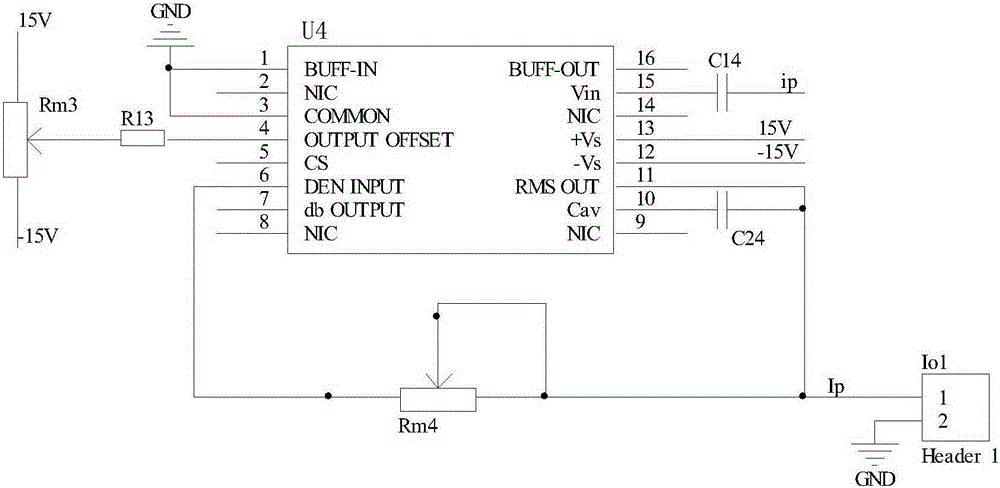

Voltage-regulating variable-frequency hierarchical control ultrasonic plastic welding power supply

InactiveCN105226984ANo distortionSmall waveform THDAc-dc conversionDc-dc conversionVibration amplitudeSignal conditioning circuits

The invention discloses a voltage-regulating variable-frequency hierarchical control ultrasonic plastic welding power supply, which comprises a sampling control unit, a rectifying and DC voltage-regulating unit, a fixed phase-shift angle inversion unit, a matching boosting isolating unit and an ultrasonic transducer. The sampling control unit comprises a microprocessor, a first signal conditioning circuit, a second signal conditioning circuit, a driving circuit, an effective value detection circuit and a phase detection circuit, wherein the first signal conditioning circuit and the driving circuit are connected with the microprocessor; the second signal conditioning circuit is respectively connected with the effective value detection circuit and the phase detection circuit; and the effective value detection circuit and the phase detection circuit are both connected with an AD sampling port of the microprocessor. The voltage-regulating variable-frequency hierarchical control ultrasonic plastic welding power supply has the advantages that output voltage and current waveform THD is small, the voltage-regulating range is wide, large-power ultrasonic welding can be realized, the voltage-regulating or power-regulating response is quick, the voltage ripple is small, the transducer has a small vibration amplitude fluctuation, the frequency tracking precision and the accuracy are high, the electric conversion efficiency is high and the like.

Owner:ZHEJIANG UNIV +1

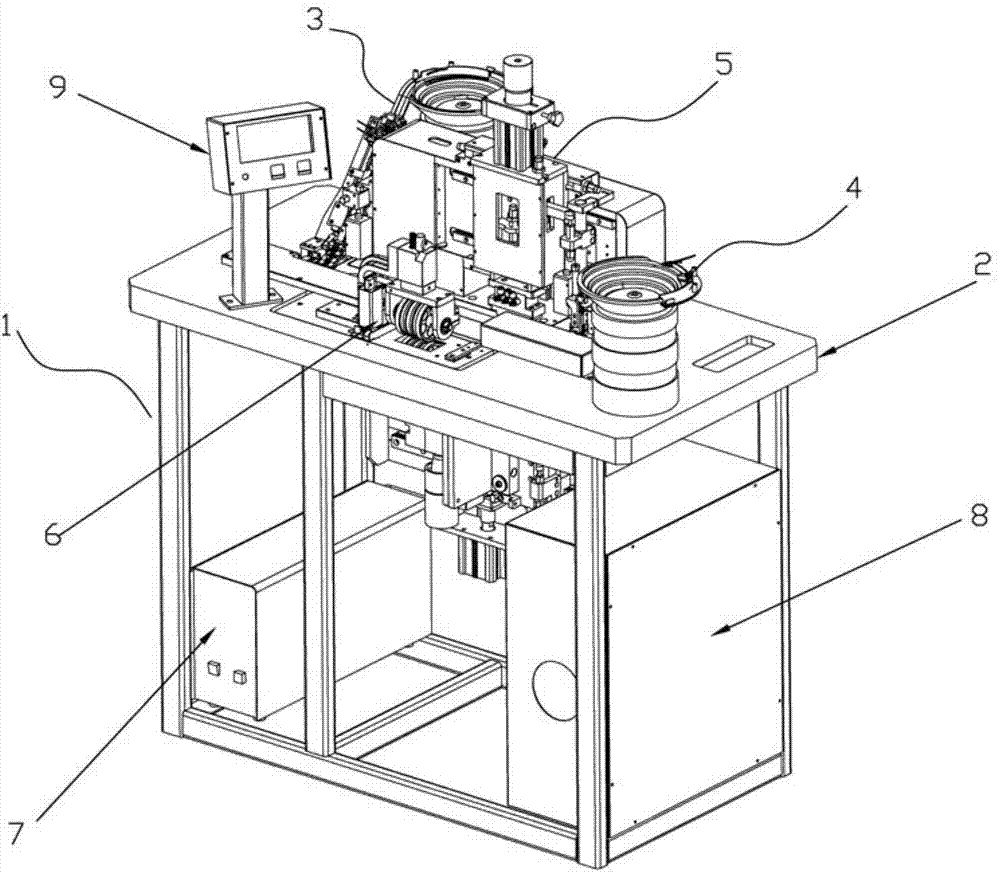

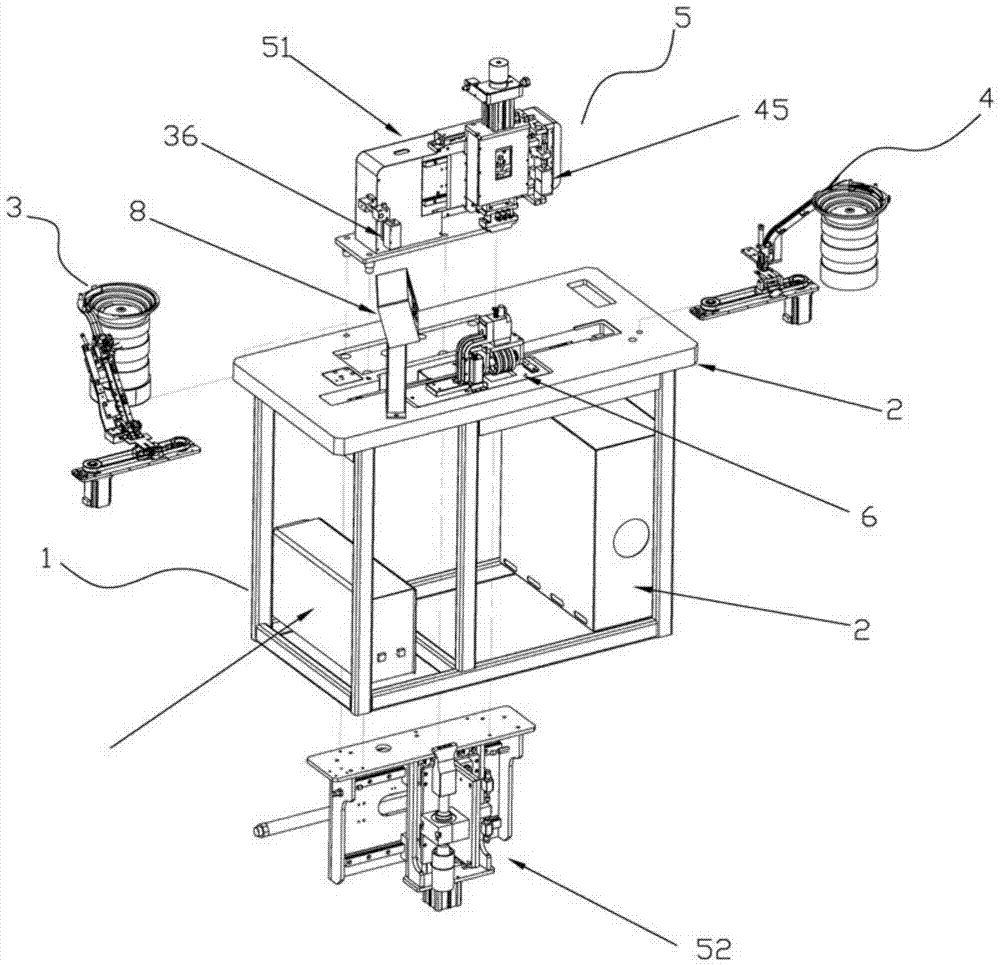

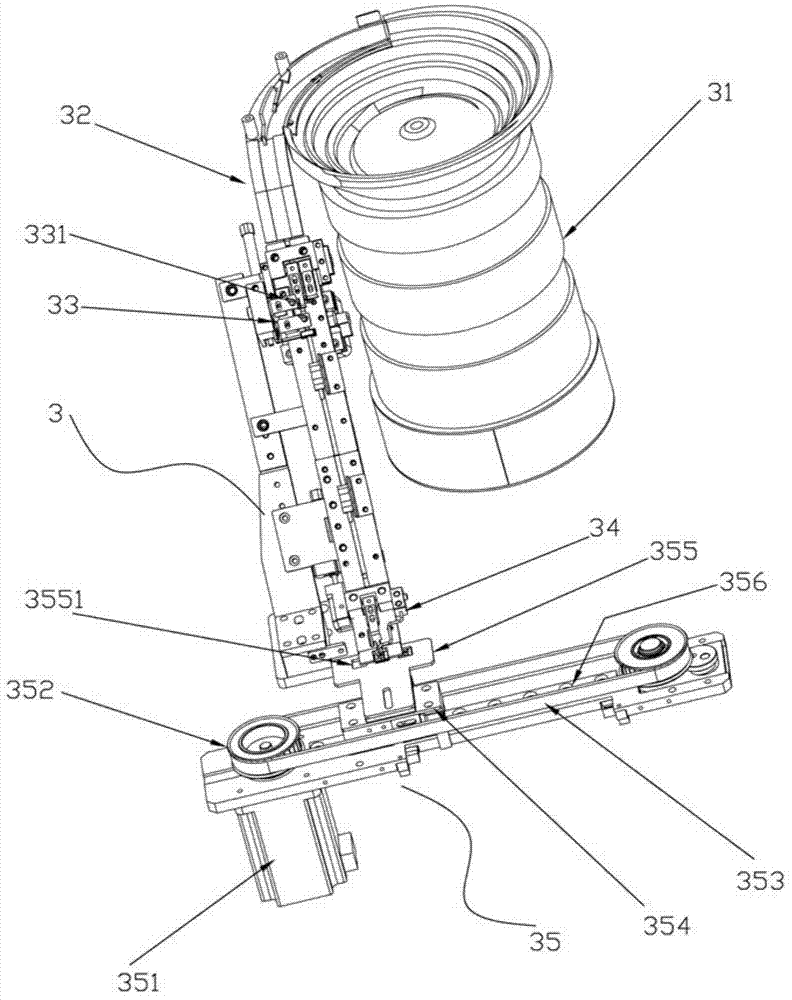

Automatic mounting machine of bra back fasteners

ActiveCN104842553ARealize fully automatic mechanical productionQuality improvementHuman–machine interfaceProgrammable logic controller

The invention discloses an automatic mounting machine of bra back fasteners. The automatic mounting machine comprises a machine frame, a work table board, a lower butterfly-shaped fastener mold feeding device, an upper butterfly-shaped fastener mold feeding device, an ultrasonic plastic welding device, a cloth belt dragging device, an ultrasonic power source, a programmable logic controller and an operating display screen. The work table board is horizontally placed on the top of the machine frame. The lower butterfly-shaped fastener mold feeding device is fixed to the left end of the work table board, the upper butterfly-shaped fastener mold feeding device is fixed to the right end of the work table board, and the ultrasonic plastic welding device is arranged in the center of the work table board and located between the lower butterfly-shaped fastener mold feeding device and the upper butterfly-shaped fastener mold feeding device. The cloth belt dragging device is arranged at the front end of the work table board and located in front of the ultrasonic plastic welding device. The operating display screen is in circuit connection with the programmable logic controller and provides man-machine interface programming operation. According to the invention, the butterfly-shaped fasteners of bras can be automatically produced, the production efficiency is greatly improved, material loss is reduced, and the quality of the fasteners of the bras is improved.

Owner:ZHONGSHAN STEP AUTOMATION EQUIP

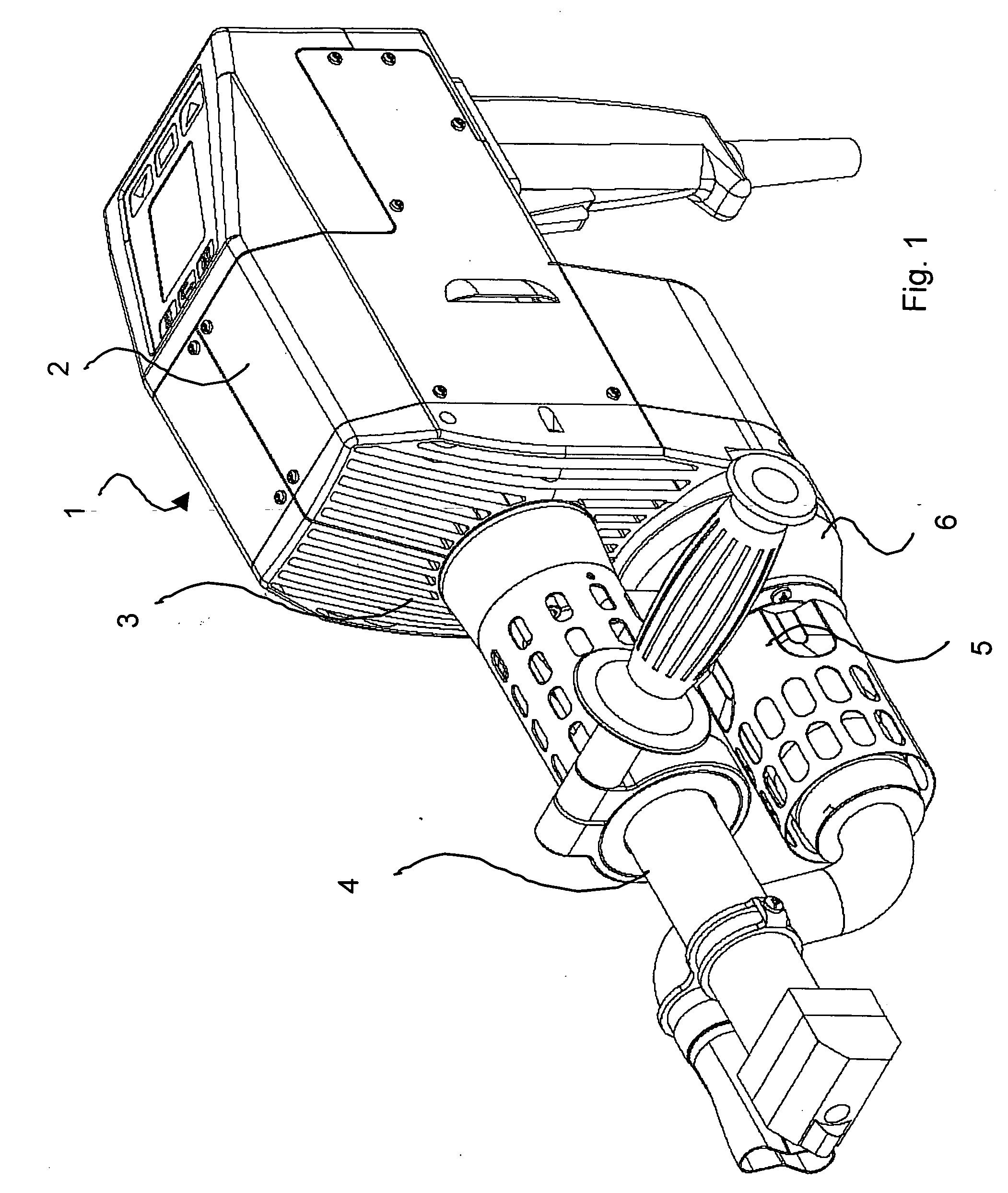

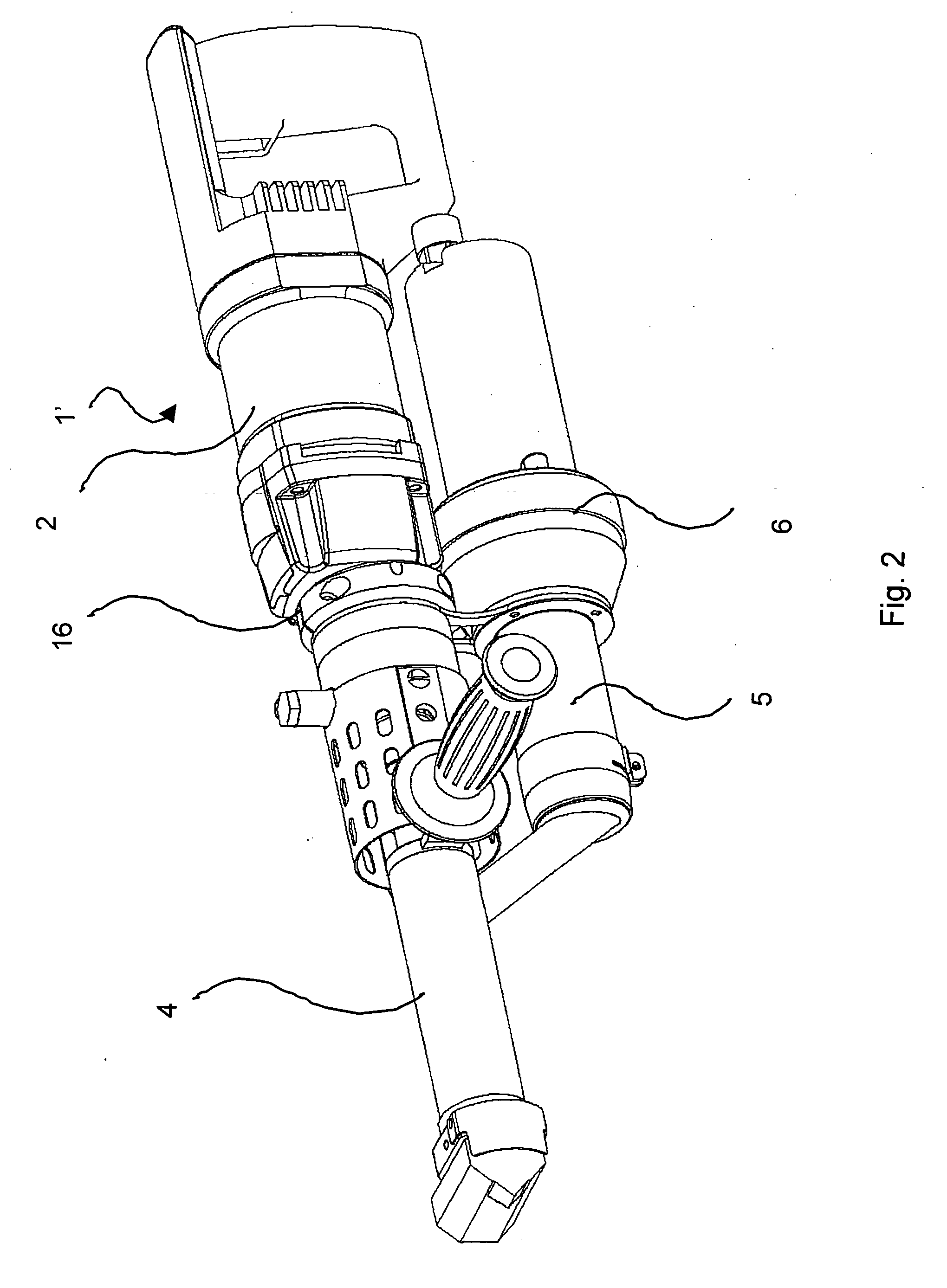

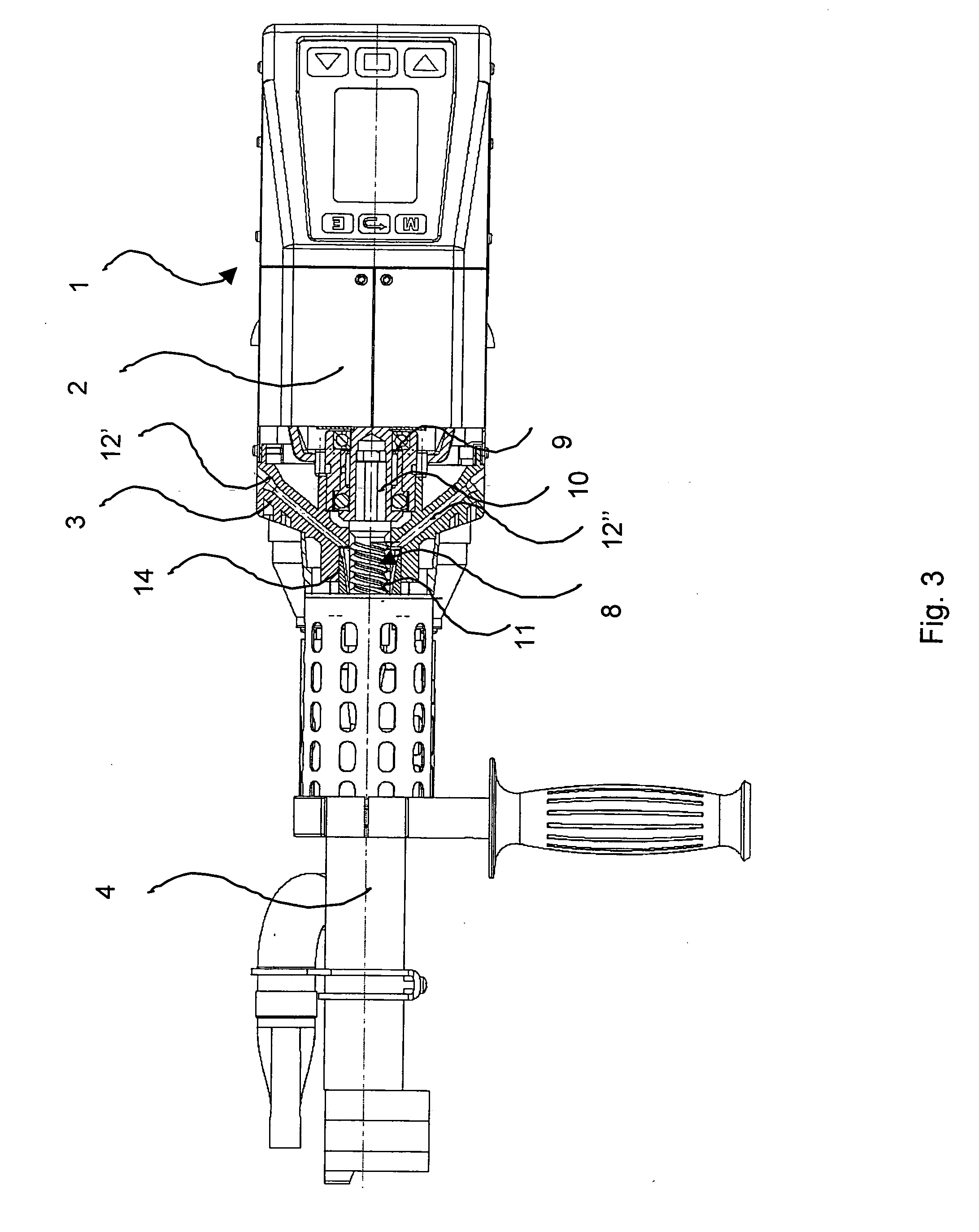

Handheld extruder welding device

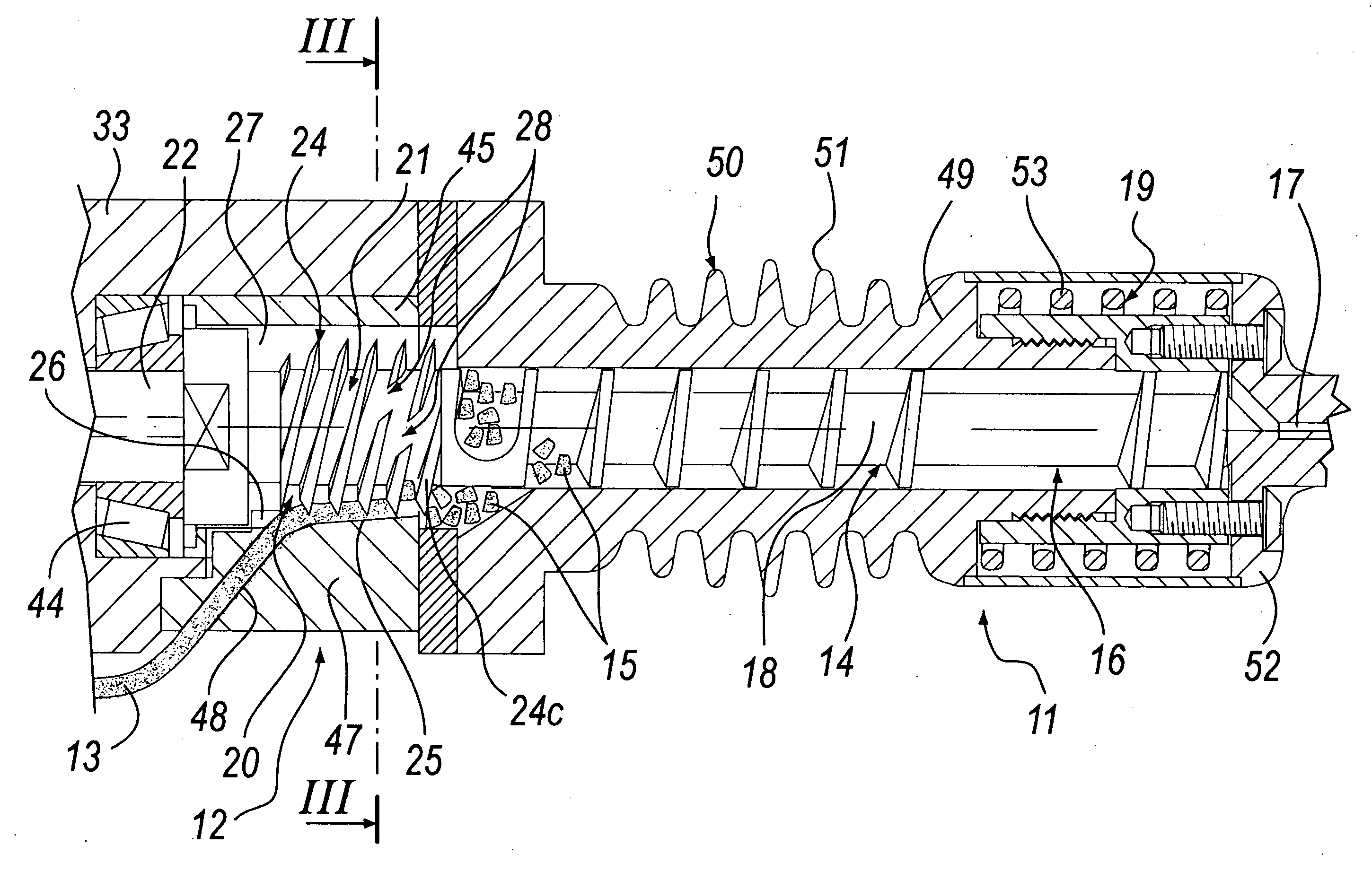

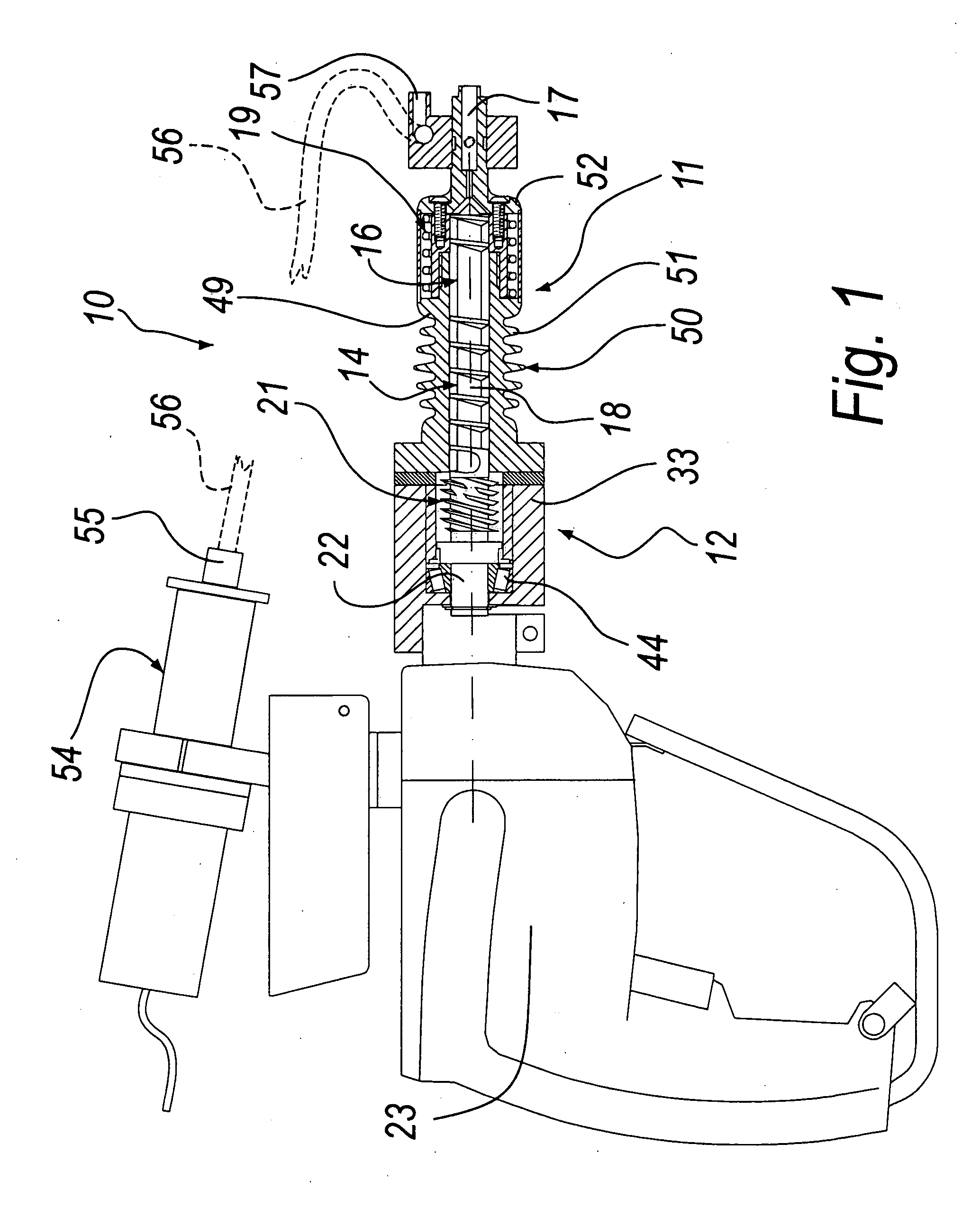

ActiveUS20060054661A1Avoid distortionAvoid friction lossCooking-vessel materialsSynthetic materialsHand held

A handheld extruder welding device is provided for welding thermoplastic synthetic materials by means of an extrusion screw with a feed zone and a conveying / plasticizing zone. In the area of the feed zone, a feed channel with a ridge running in longitudinal direction is located in a sleeve. This ridge prevents the inserted plastic welding wire from twisting and looping inside and especially outside the handheld extruder welding device.

Owner:LEISTER TECHNOLOGIES

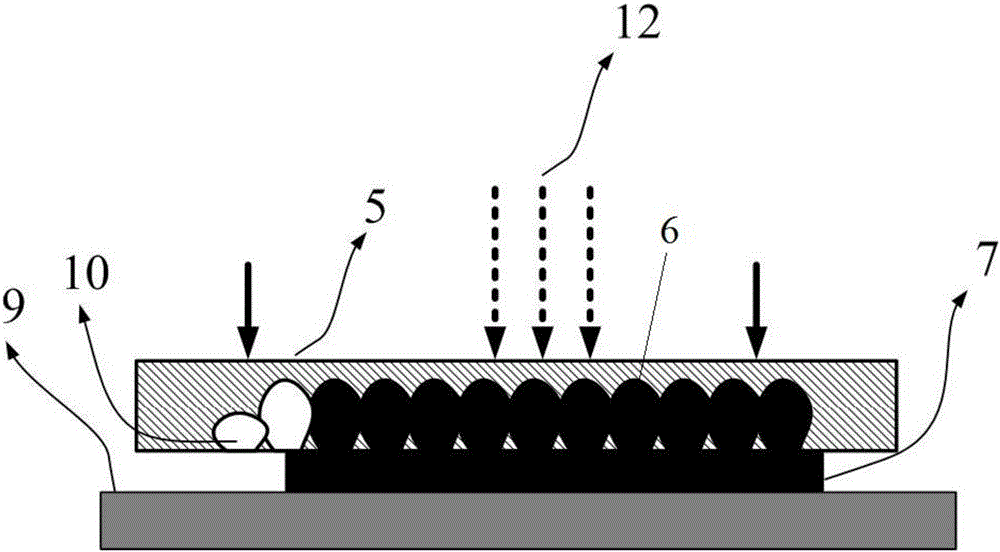

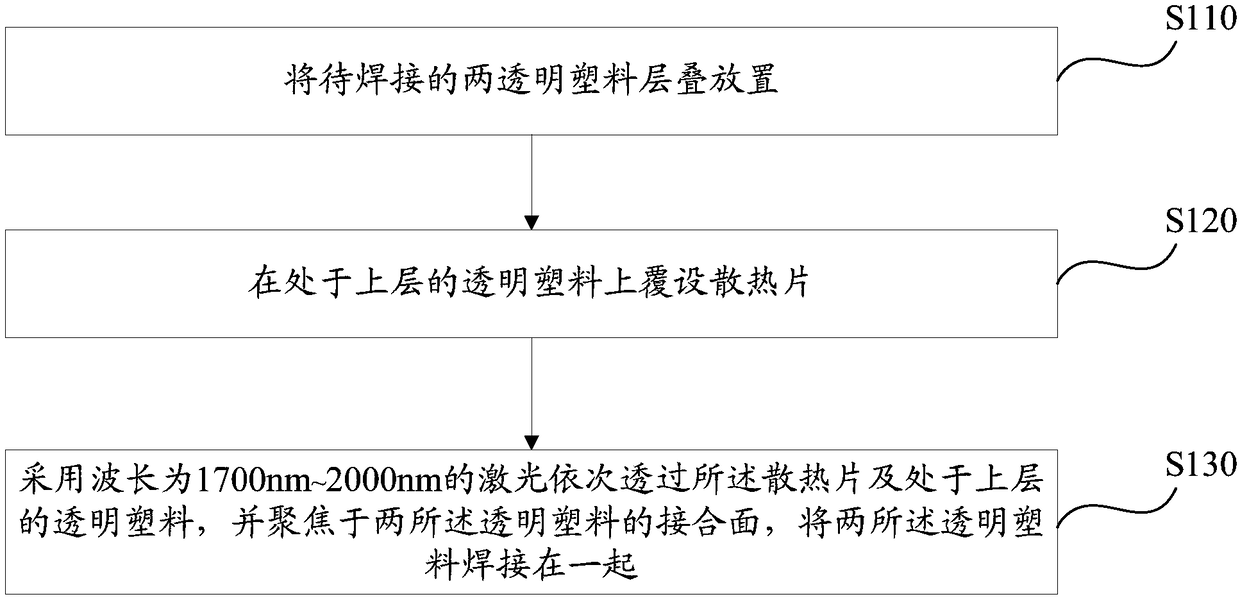

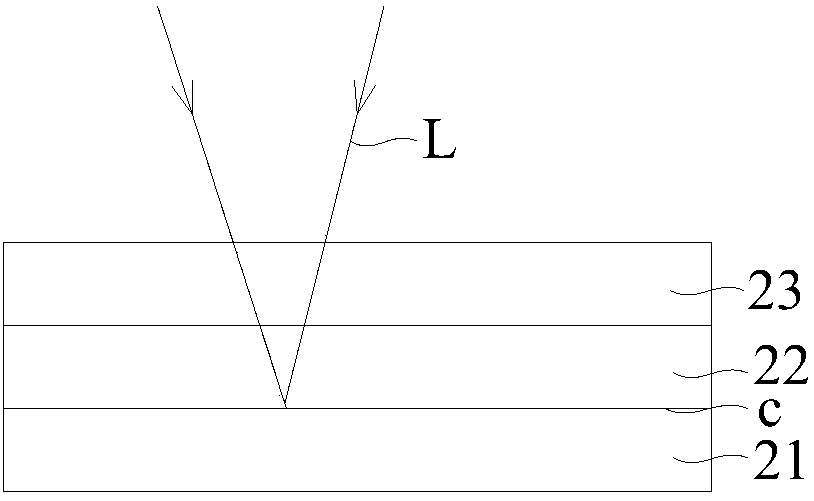

Transparent plastic welding method

The invention relates to a transparent plastic welding method. The method comprises the following steps: stacking two transparent plastics to be welded; covering the transparent plastic at the upper layer with a radiating fin; and enabling the laser of which the wavelength is 1700nm-2000nm to sequentially penetrate through the radiating fin and the transparent plastic at the upper layer and focuson the joint surface of the two transparent plastics so as to weld the two transparent plastics together. In the transparent plastic welding method provided by the invention, the laser of which the wavelength is 1700nm-2000nm is adopted for welding the transparent plastics, and the transparent plastics have lower light transmittance to the laser of which the wavelength is 1700nm-2000nm, so that when the transparent plastics are welded, an absorbent does not need to be added so as to improve the welding efficiency; and furthermore, the radiating fin is adopted for performing heat dissipation onthe transparent plastic at the upper layer so as to avoid the transparent plastic at the upper layer from being burnt out due to too high temperature.

Owner:HANS LASER TECH IND GRP CO LTD

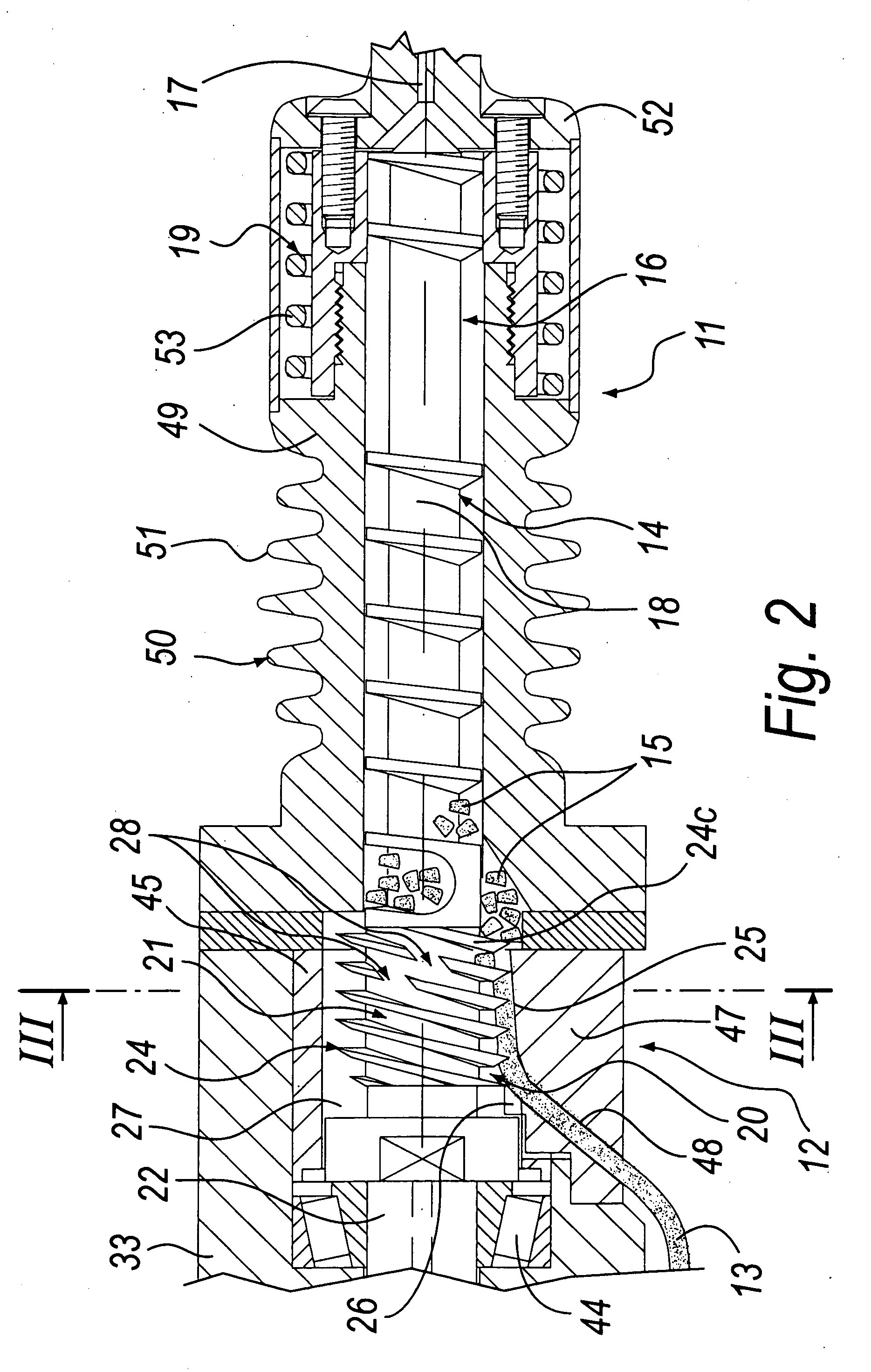

Extruder for welding plastic components

InactiveUS20050129796A1Drawback can be solvedAccurate toleranceLiquid surface applicatorsRotary stirring mixersPlastic materialsEngineering

An extruder for welding plastic components, comprising a front part for plasticizing and ejecting additional plastic welding material, and a rear part, for feeding and breaking up a continuous filament made of the additional plastic material. The rear part comprises a feed channel that cooperates with a worm screw for the advancement of the filament. The feed channel is delimited by the thread of the worm screw on one side and by a sliding surface for the filament on the opposite side. The distance between the sliding surface and the crest of the thread decreases in the direction in which the filament is fed, in order to provide scoring of increasing depth on the filament. The thread comprises at least one discontinuity of the worm that has a sharp discontinuity end for cropping the filament at the scoring.

Owner:RITMO SRL

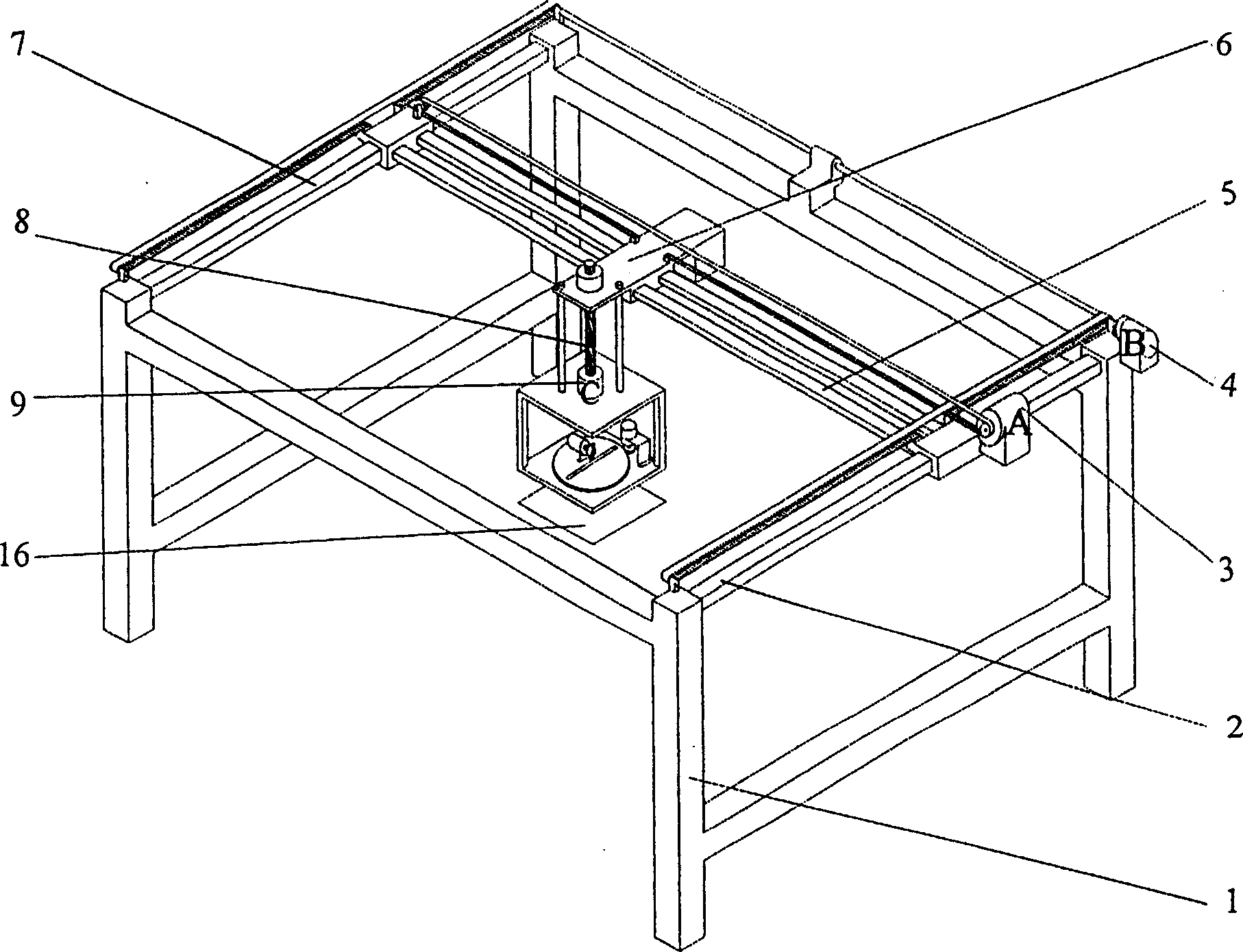

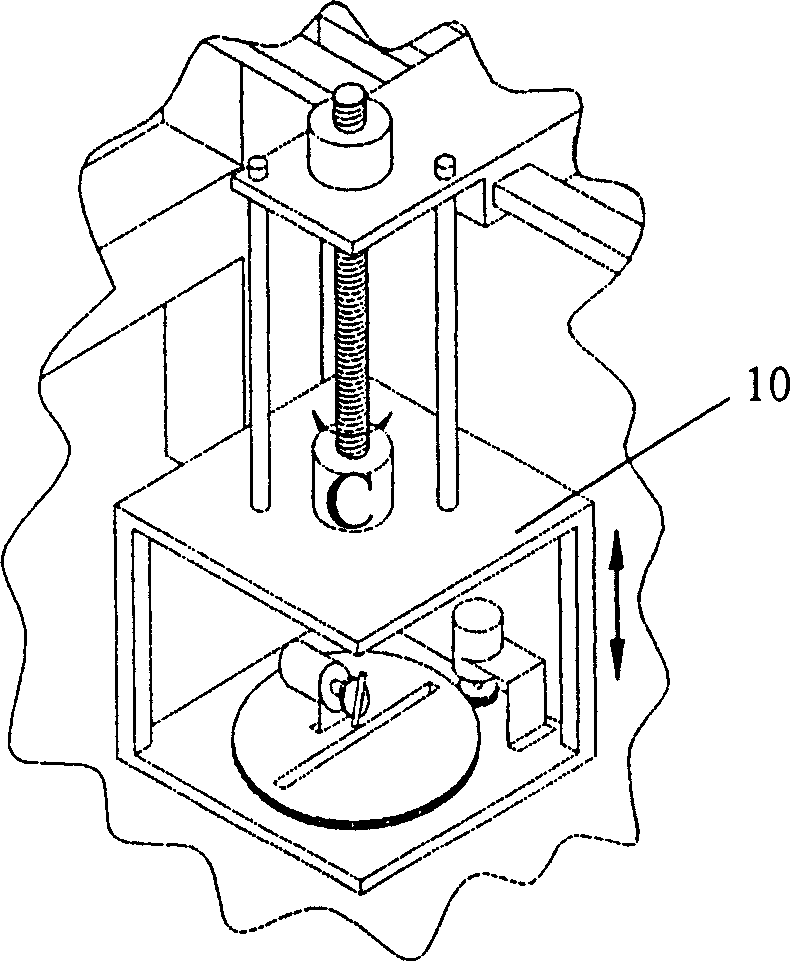

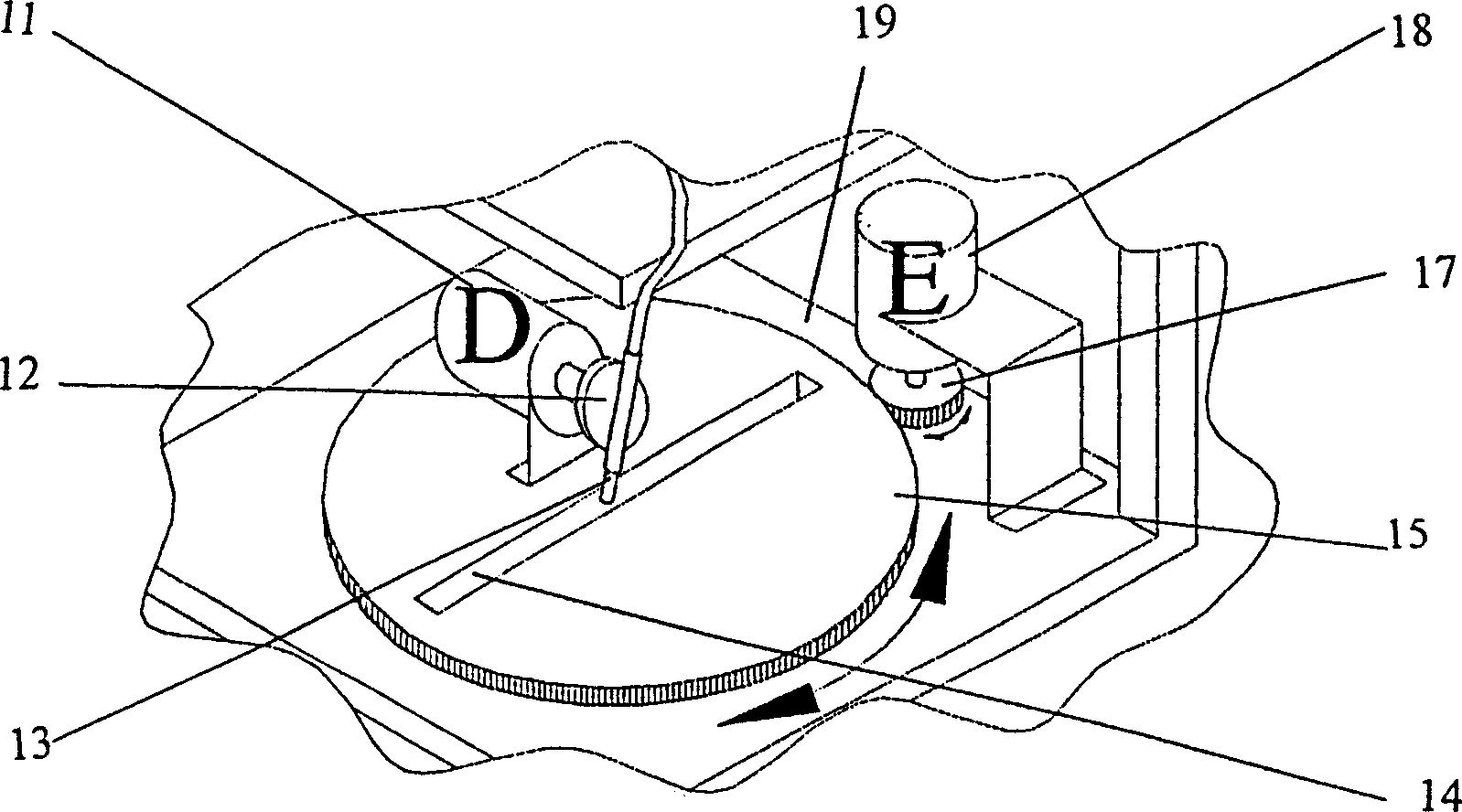

Multiple dimension plastic welding laser device

The multidimensional plastic welding laser device includes welding laser source, X- and Y-guide rails, work bench, fiber angle control console, Z-lead screw connected with X-guide rails, fiber angle controller connected to the Z-lead screw with fiber output head, three motors for the welding shifts of the fiber output head in X, Y and Z directions separately, one fourth motor to drive the fiber output head to swing for deflection output in welding inside Z-X plane, one fifth motor to drive the gear turntable to rotate in X-Y plane for the fiber output head to deflect to required position in welding. The present invention makes it possible for the fiber axis to be always perpendicular to the surface of the work piece, for the laser outputting lens to focus laser beam onto the surface of the work piece, and for the fiber output head to perform six-dimensional motion and to be always in the Z-plane.

Owner:SHANGHAI INST OF LASER TECH

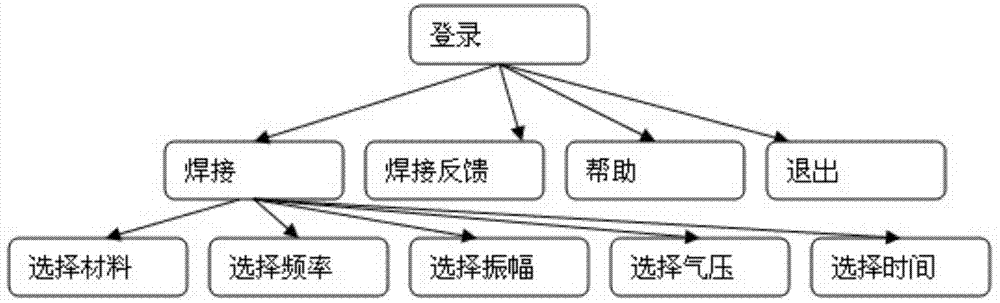

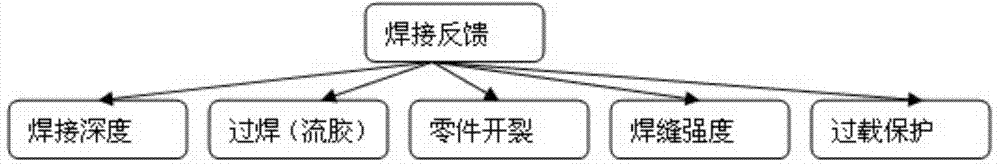

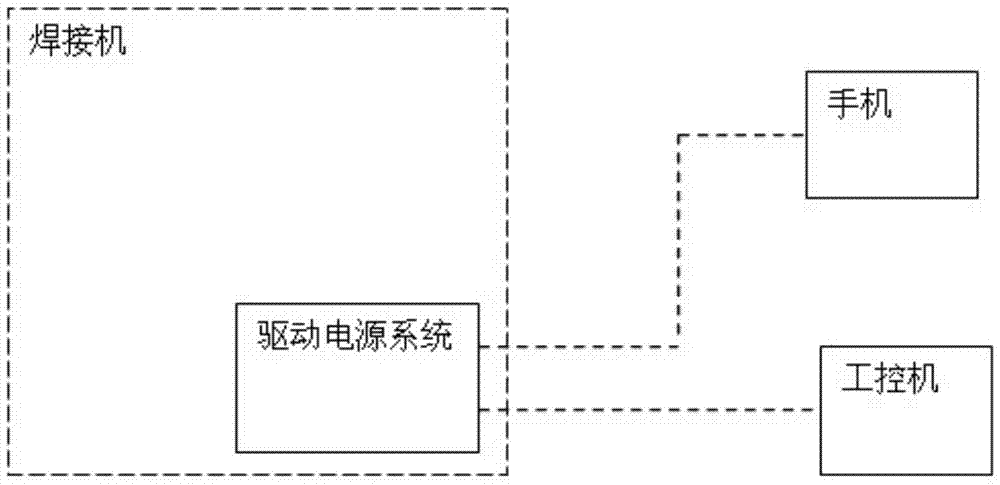

Intelligent adjustment-correction and management method and system for welding parameters of ultrasonic plastic welding machine

The invention relates to the technology of an ultrasonic plastic welding machine and aims at providing an intelligent adjustment-correction and management method and system for welding parameters of an ultrasonic plastic welding machine. The system is characterized in that the welding machine is provided with sensors which are respectively used for monitoring the vibrating amplitude, the power, the welding time or the welding pressure of the welding machine, and all the sensors are respectively connected to a driving power system of the welding machine by a signal line; the system also comprises a mobile phone or an industrial control computer connected with the driving power system. The method and system provided by the invention have the advantages that by data interaction between the mobile phone or the industrial control computer with the driving power system, the acquisition process of the optimal welding parameter is simplified and the consumed time is shortened; in the acquisition process of the optimal welding parameter, the influence of human factors is reduced to a greatest extent; after data of large batches of workpieces is integrated to form a database of the optimum welding parameters of different workpieces, when the welding-parameter adjustment and correction are carried out on a new workpiece, the closest data provided by the database can be utilized to realize fastest adjustment and correction.

Owner:HANGZHOU SUCCESS ULTRASONIC EQUIP

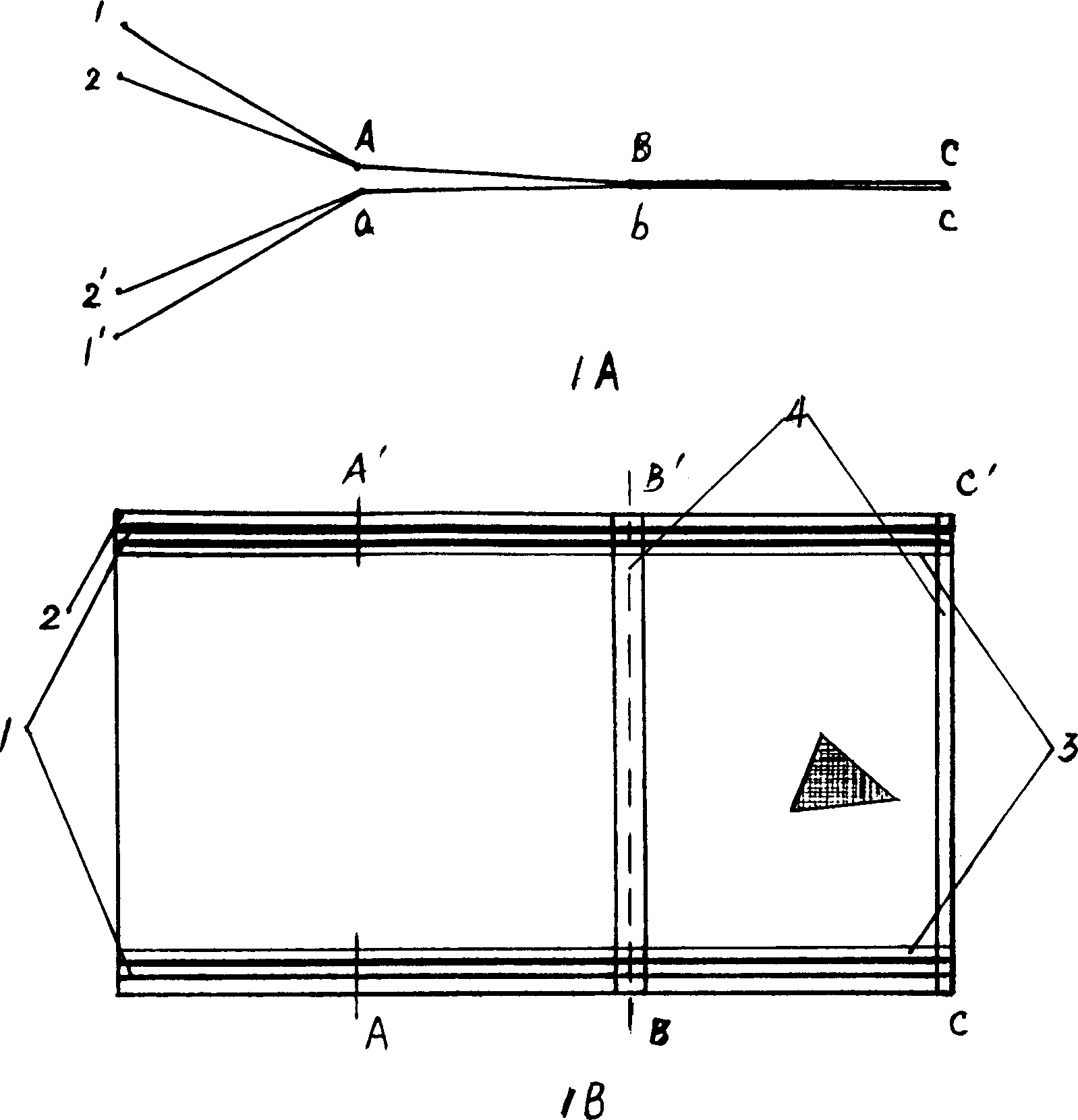

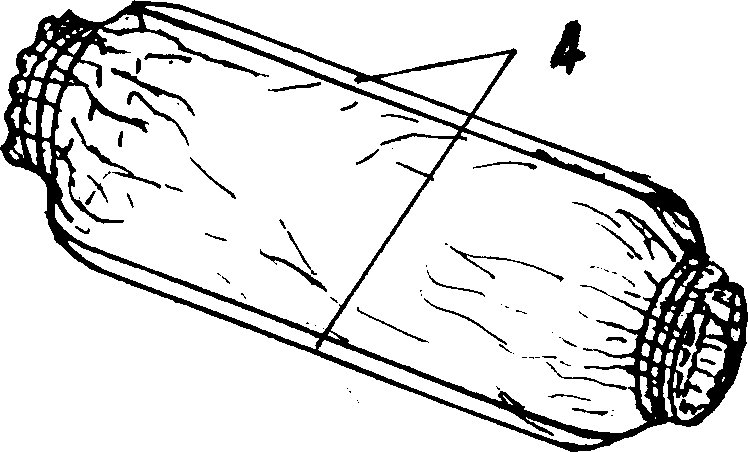

Technology for making oversleeve

The present invention relates to a new production process of sleeve protector, and is characterized by that the rib cuff elastic ring of each of two ends of said sleeve protector is a circular ring synthesized by two symmetrical notched rubber bands, and the number of the rib cuff elastic rings can be one or several bands, and said sleeve is a cylinder synthesized by two symmetric notched plane face fabrics, and the internal side of said sleeve protector has two but-welded seams and four folded selvages, and the rubber band and face fabrics can be adhered and fixed together by adopting the processes of collosed coating and plastic welding, so that the original traditional manual circumferential movement can be changed into the invented mechanical linear movement so as to raise its production efficiency.

Owner:上海蓝岛卫生用品有限公司

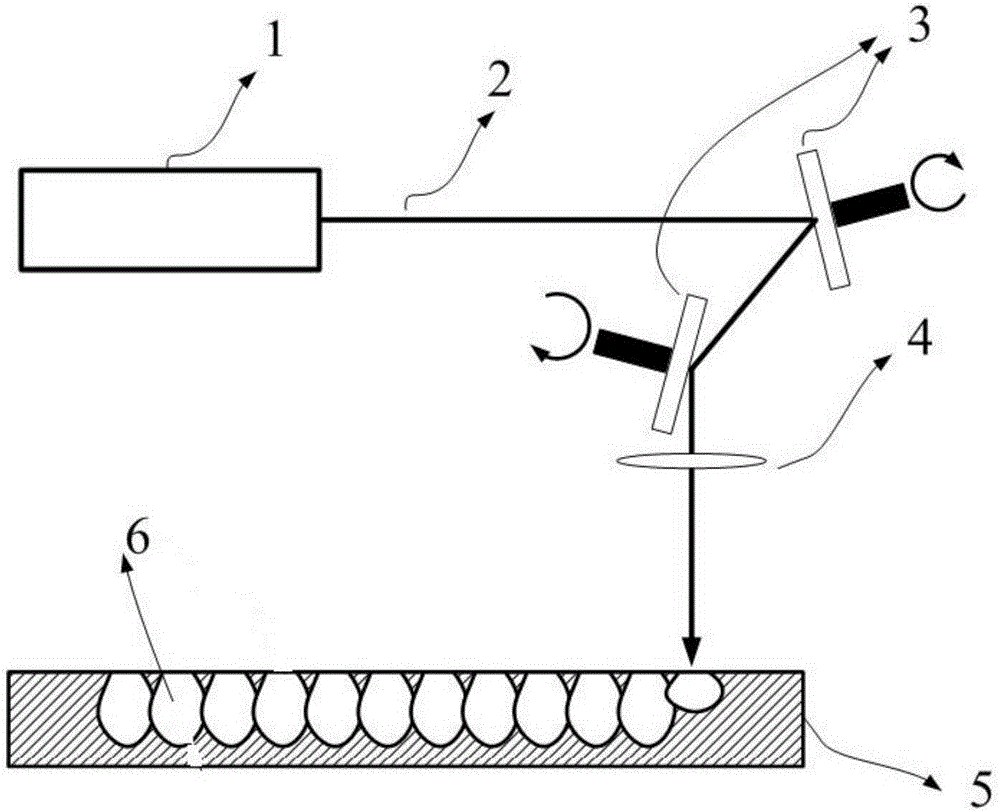

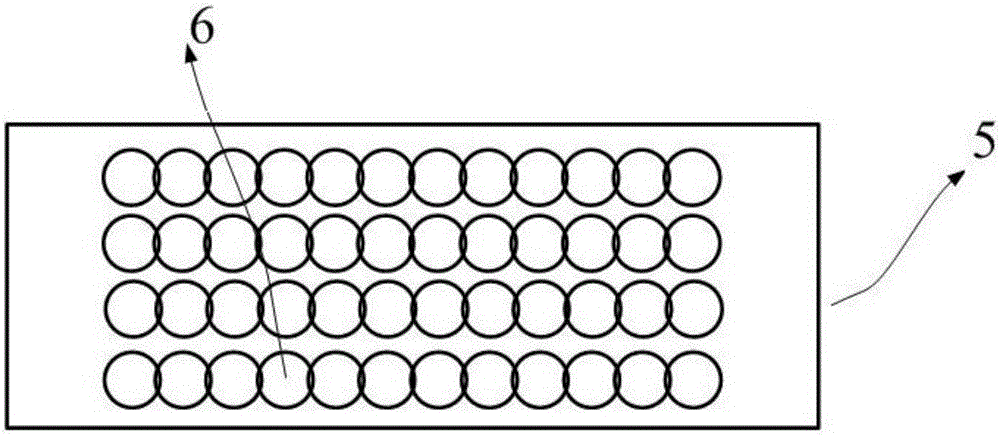

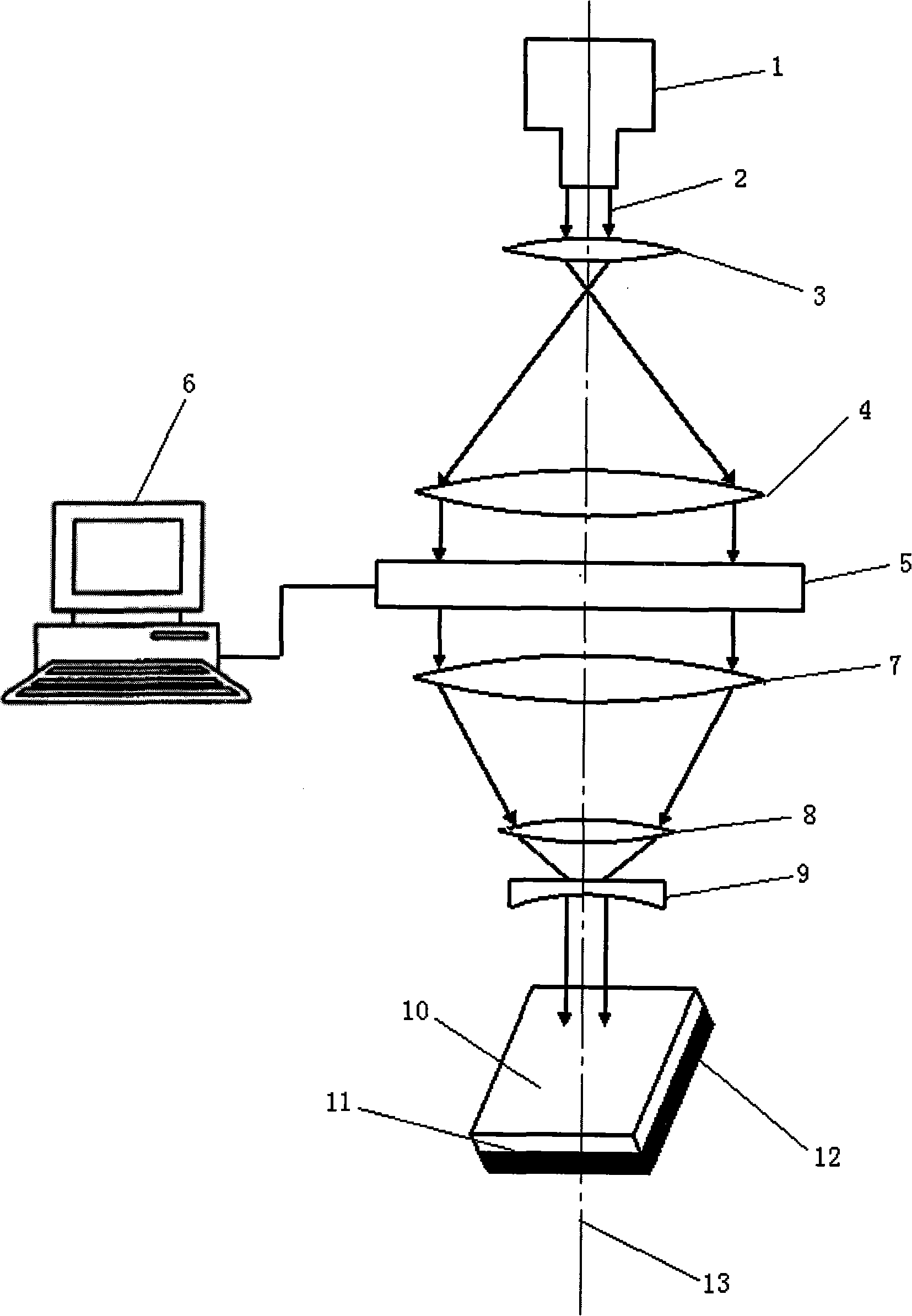

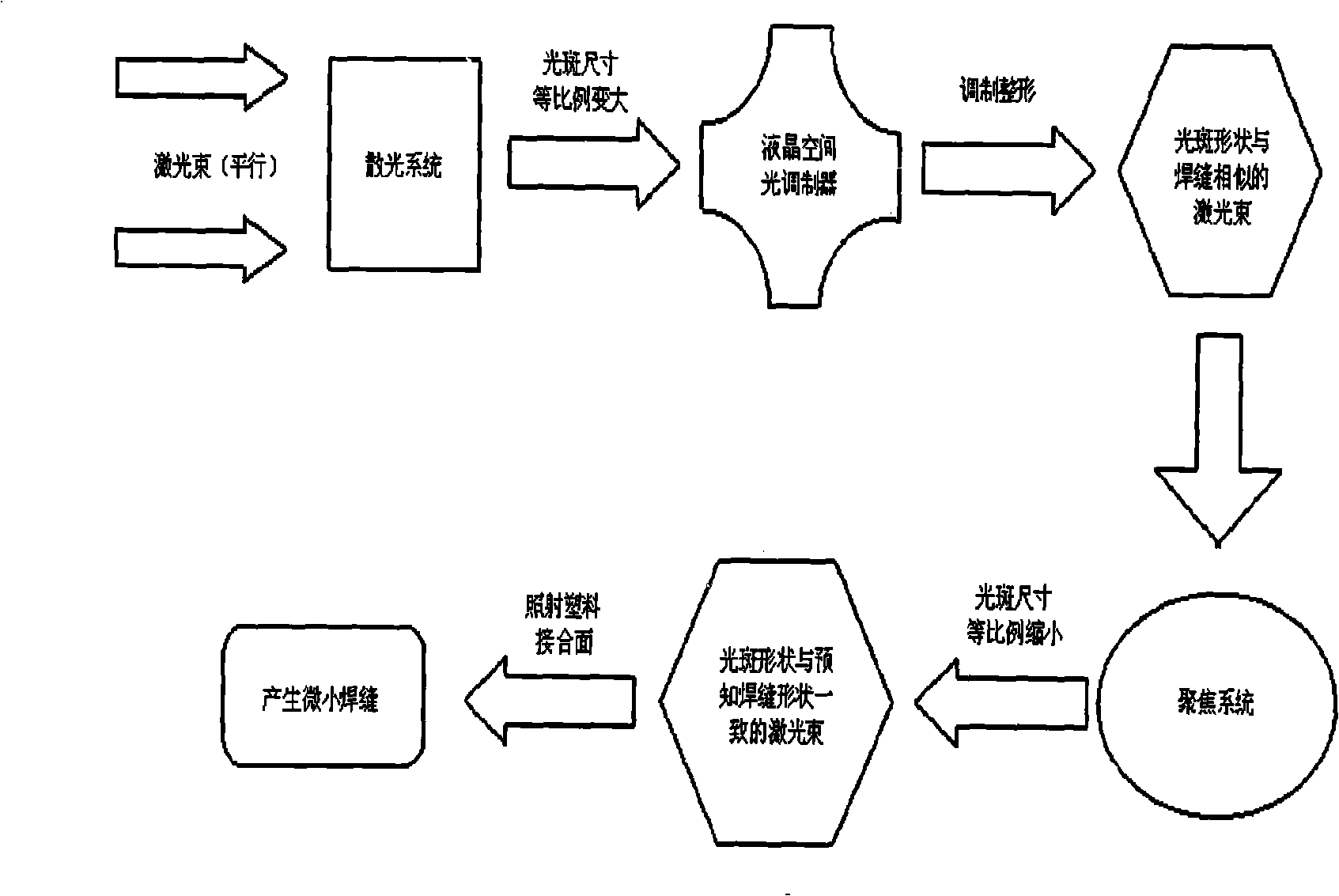

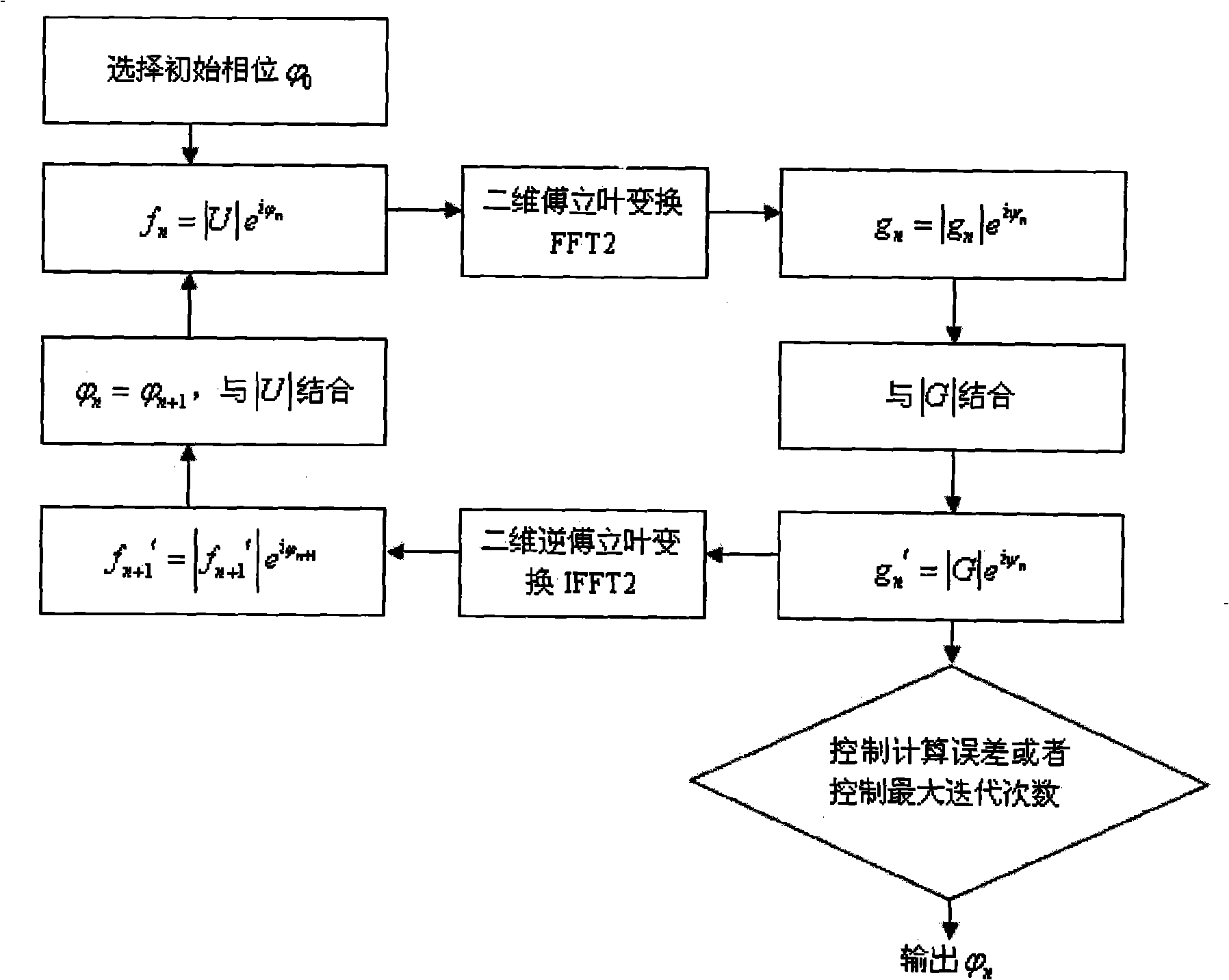

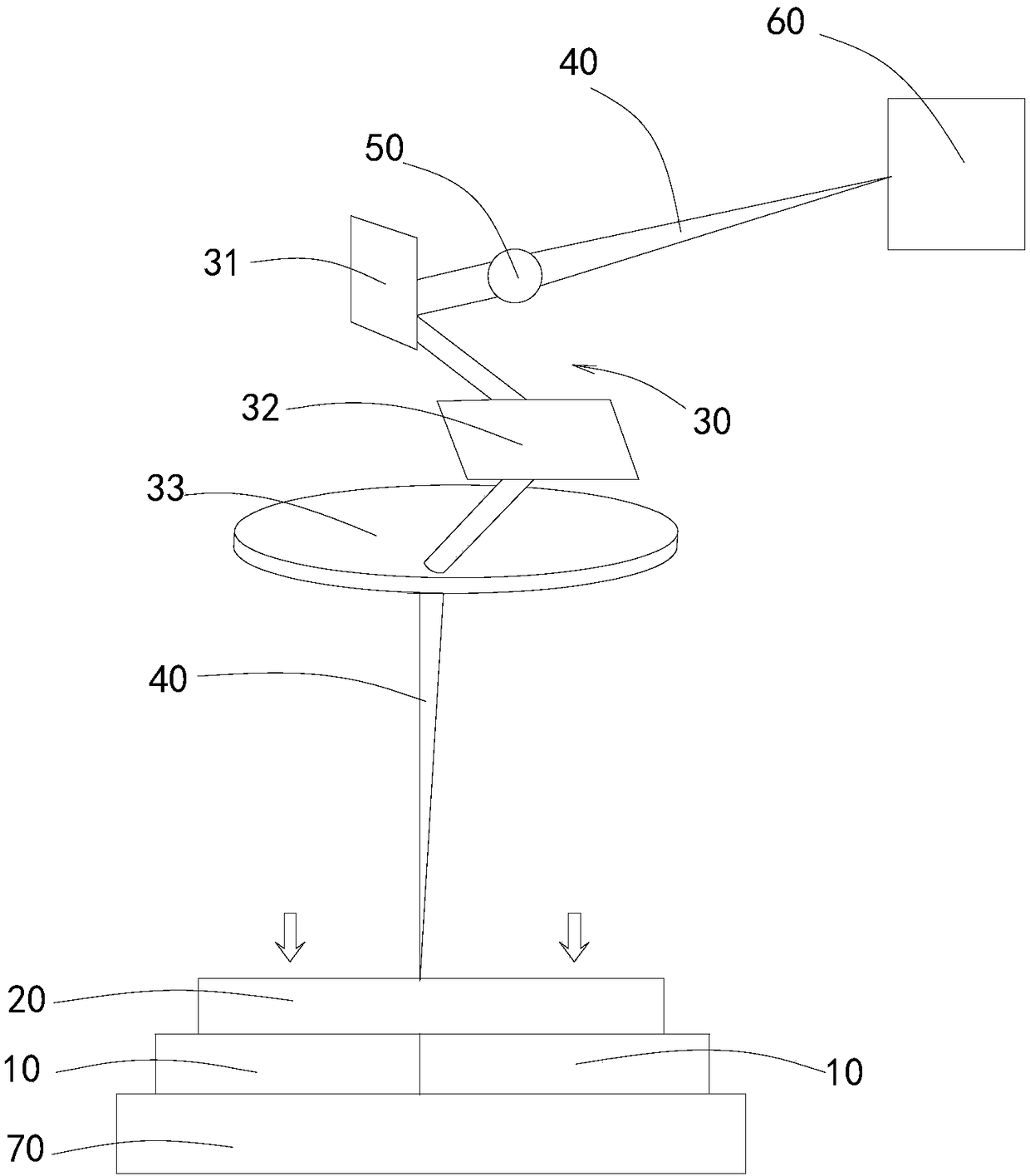

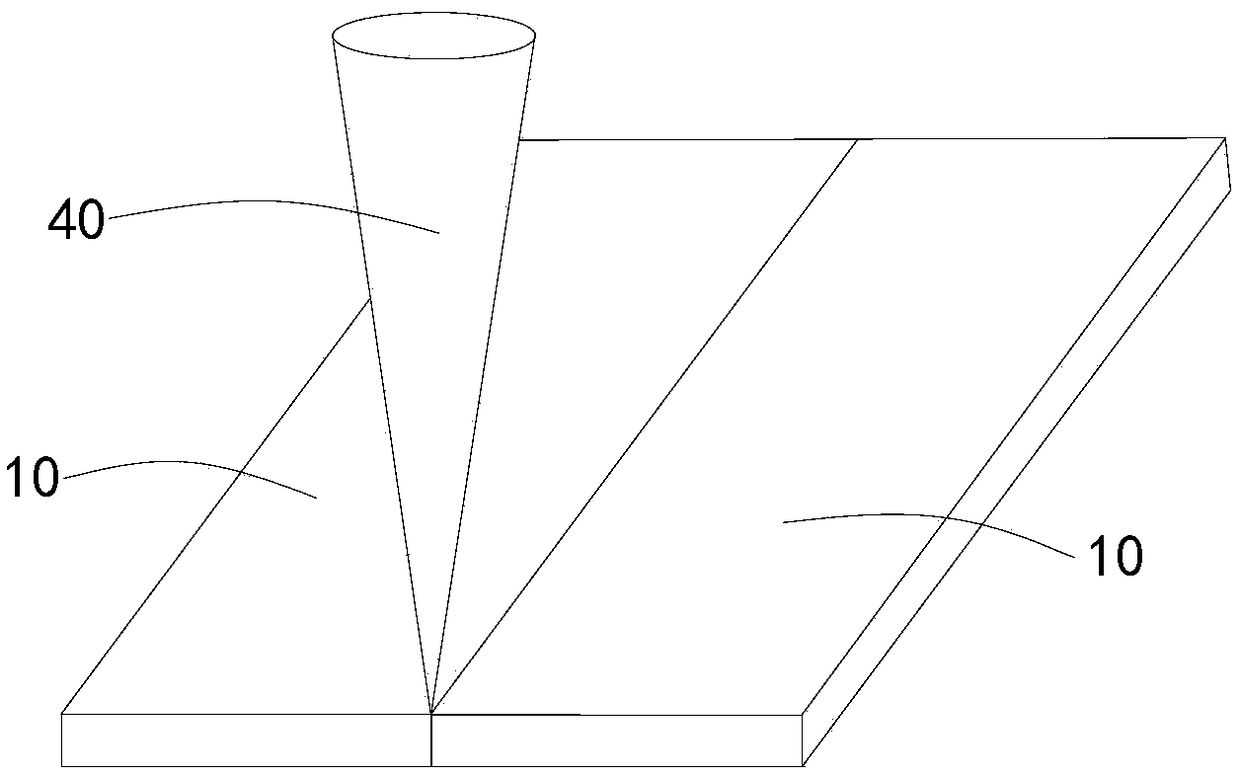

Laser plastic micro-welding method based on LCD space light modulator and device

The invention relates to the field of plastic welding, in particular to a laser plastic micro-welding method and a device based on a crystal space photomodulator. The invention is suitable for the fast welding between plastic materials, in particular to the welding of plastic micro-apparatus. The device includes a laser, an astigmatism system, a crystal space photomodulator, a computer and a focusing system. The micro-welding method includes the following steps of: utilizing the computer to preciously control a phase diagram displayed on the crystal space photomodulator to lead a laser beam to be modulated and shaped after passing through the crystal space photomodulator and obtain a facular with the shape consistent to a welding line after assembled by the focusing system; the facular irradiates on a workpiece so as to realize the synchronous welding of the two plastics. The invention integrates the laser beam shaping technology to the plastic transmission micro-welding technique, thus being capable of adapting the synchronous welding of the welding lines of different shapes and realizing low cost and large batch for welding the micro-apparatuses; besides, the technique is simple and the consistency is good; the invention is suitable for automatization production.

Owner:JIANGSU UNIV

Injection molding method for front frame shell of television or display screen

InactiveCN101746021AImprove mechanical propertiesReduce lossFramesEngineeringInjection molding machine

The invention discloses an injection molding method for a front frame shell of a television or a display screen. In the method, a single gate is adopted to pour, and the method combines the gas-aid injection molding technology to eliminate the defects that multi-point pouring possibly produces plastic welding traces among the flow passages and the like; and the formed product has excellent appearance quality, has no sink mark and buckling deformation, and improves the mechanical property of workpieces. Simultaneously, the method reduces waste loss in the flow passages caused by setting a plurality of gates, reduces the cost, and improves the comprehensive benefit.

Owner:TAICANG QIUJING PLASTIC MOLD

Limiting dispersion of IR radiation from a heater element during plastic welding

Owner:SPM AUTOMATION CANADA

Plastic welding rod

The invention discloses a plastic welding rod and aims to solve the problem that a conventional plastic welding rod cannot meet the welding of all plastic products because the components of the plastic welding rod required in the conventional engineering are different from the components of a welded material. The plastic welding rod comprises the following components in percentage by mass: 50 to 90 percent of plastic and 10 to 50 percent of metal powder with a particle size of between 0.1 and 3 millimeters. During preparation, the plastic is heated and added into the metal powder and the mixture is stirred uniformly and molded according to the preparation process of the conventional plastic welding rod to obtain the plastic welding rod. The plastic welding rod can meet the welding requirements of most plastic products and has the advantages of simple manufacturing process, low price, easy popularization and high market value.

Owner:李红兵

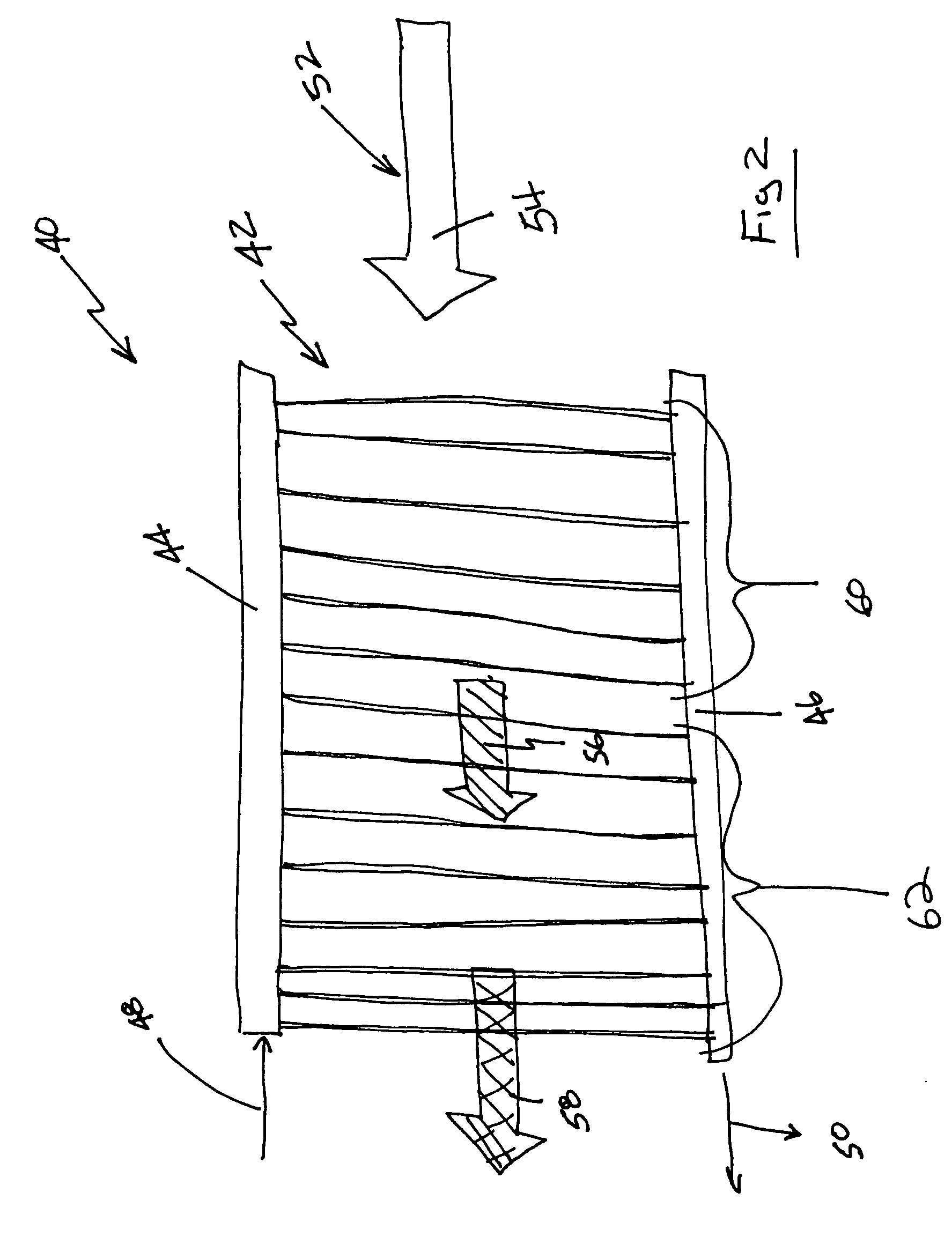

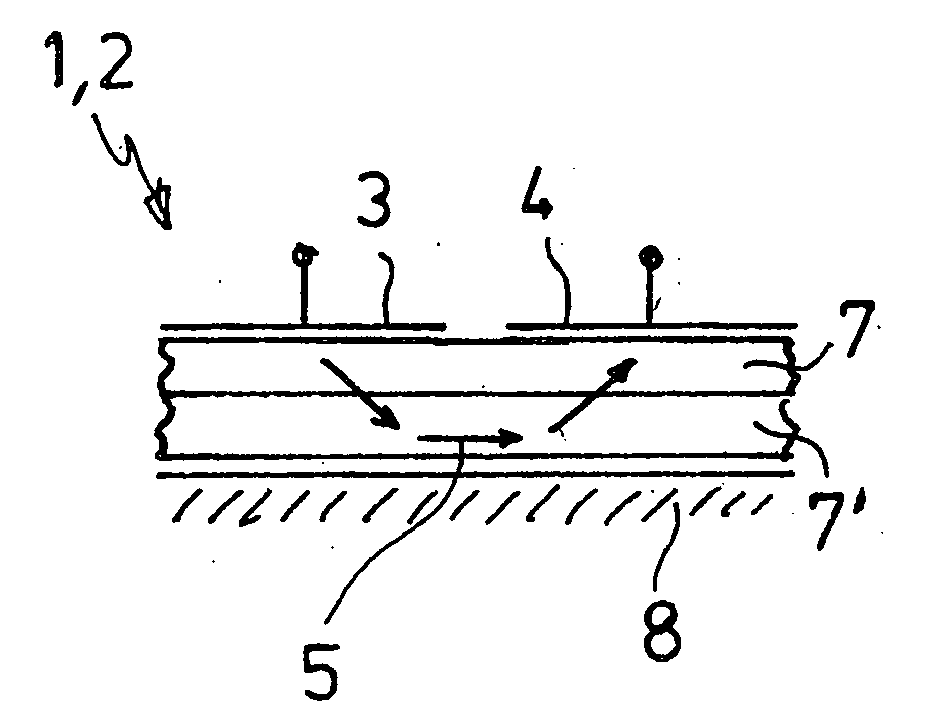

Method for controlling the melt state when producing a plastic weld seam

InactiveUS20120230363A1Quality assuranceAccurately determineThermometers using physical/chemical changesDomestic articlesMolten statePlastic materials

The invention relates to a method for determining the temperature-dependent state, in particular the melt state and / or the melt quantity of thermoplastic material when producing a weld seam (6), for example for joining thermoplastic parts (7, 7′) by means of a plastic welding device. For process control purposes, a temperature-dependent electric state variable of the thermoplastic material of the plastic parts (7, 7′) is measured continuously with and without applying heat to the plastic parts (7, 7′) along the weld seam (6) and compared to a target value or to benchmark values. In the method according to the invention, the electric state variable that is used is preferably the permittivity of the plastic parts (7, 7′). The permittivity is determined by means of the capacitor assembly (1) wherein the plastic material is used as the dielectric between the electrodes (3, 4) of the capacitor assembly (1). The capacitors (2) of the capacitor assembly (1) are preferably operated at different frequencies for the determination of the permittivity.

Owner:LEISTER TECHNOLOGIES

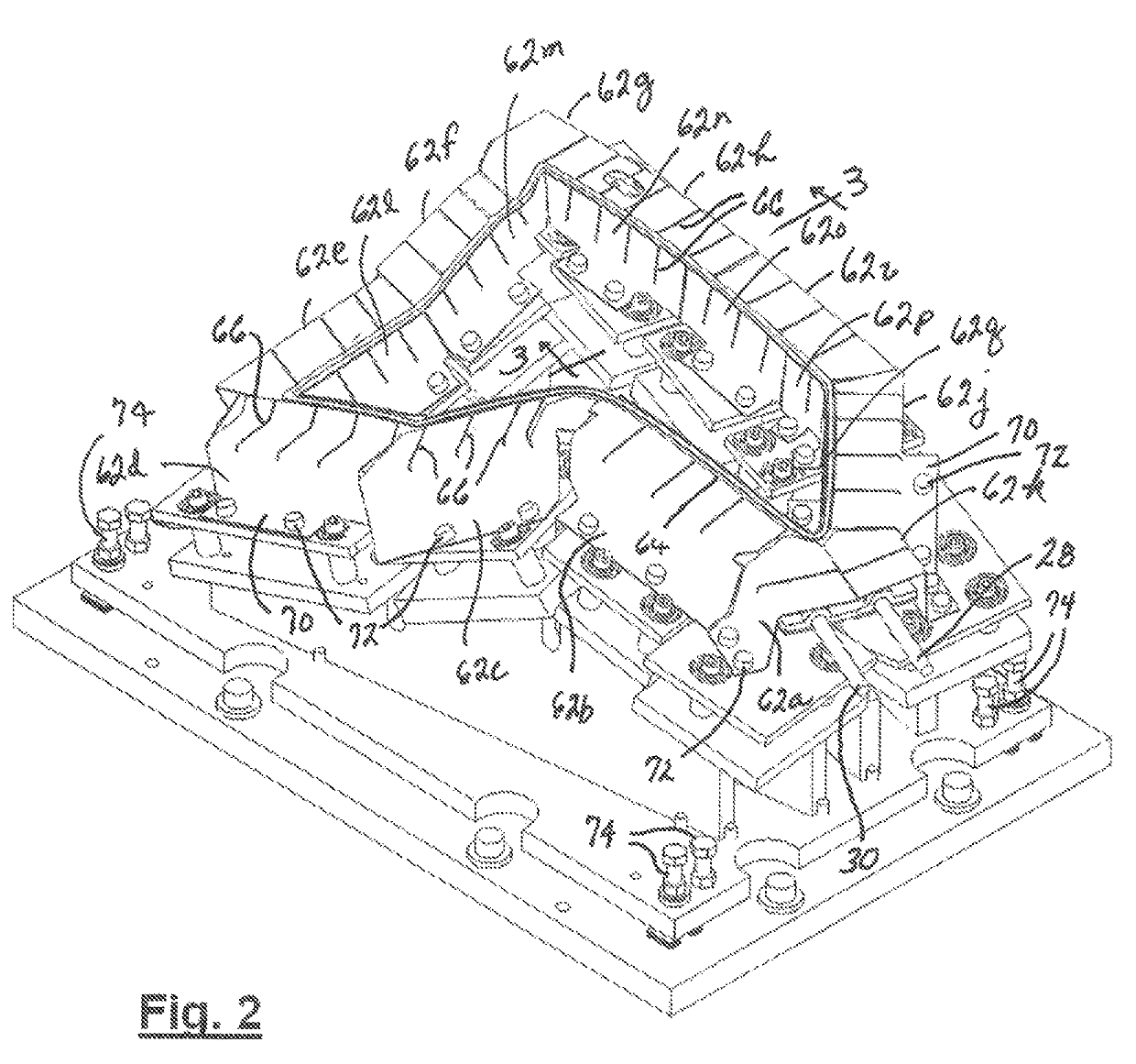

Portable thermo-plastic welding machine and method

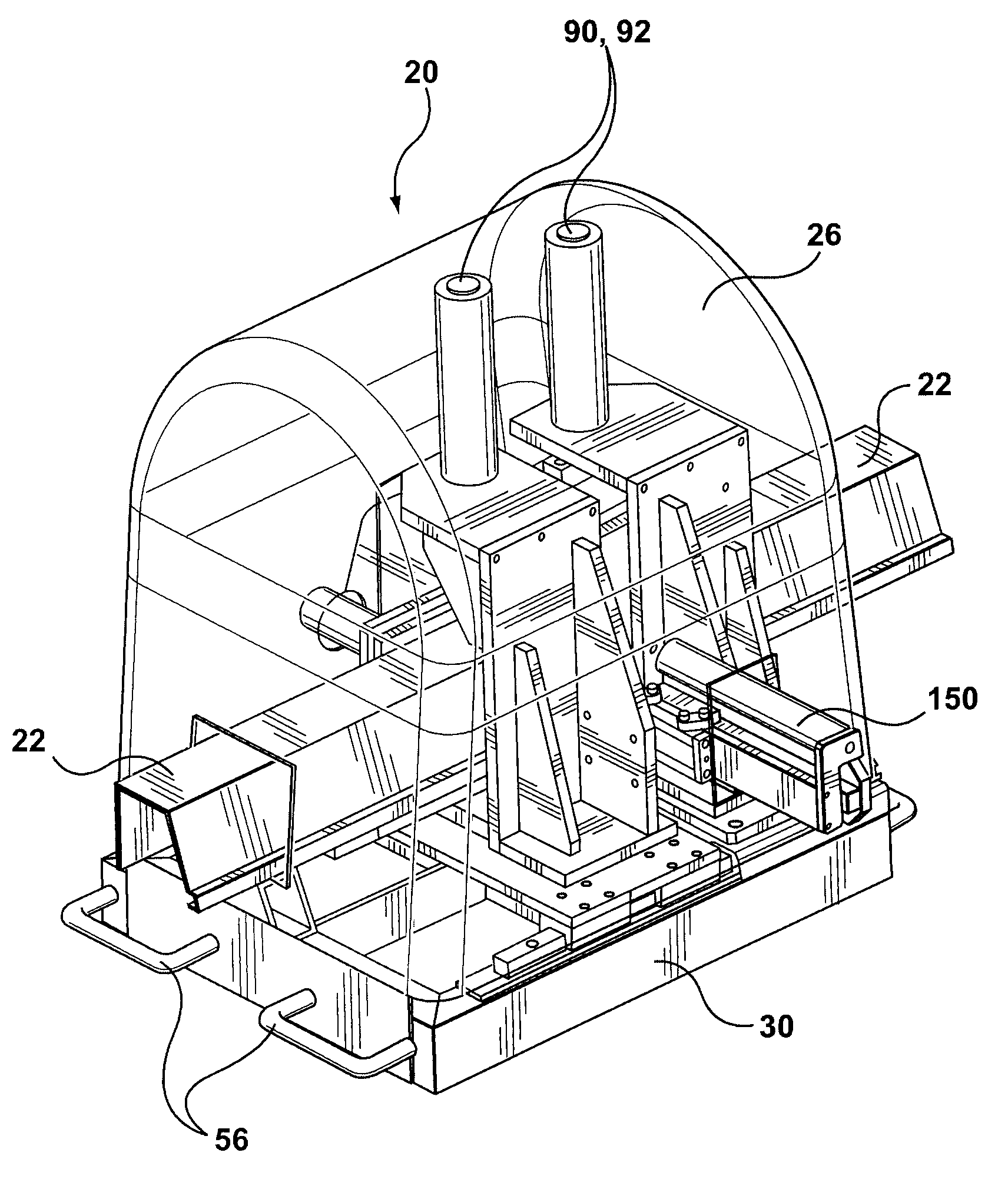

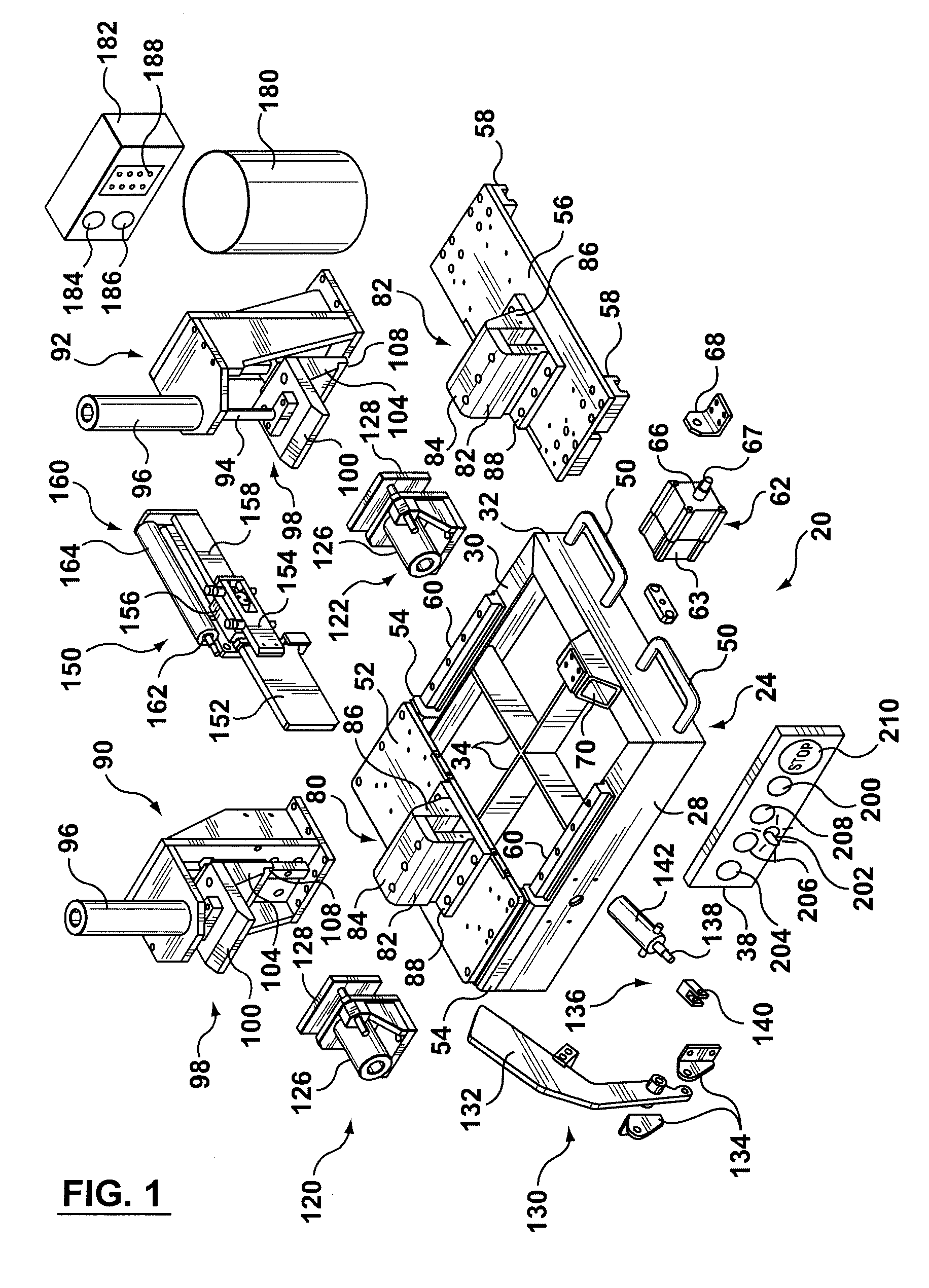

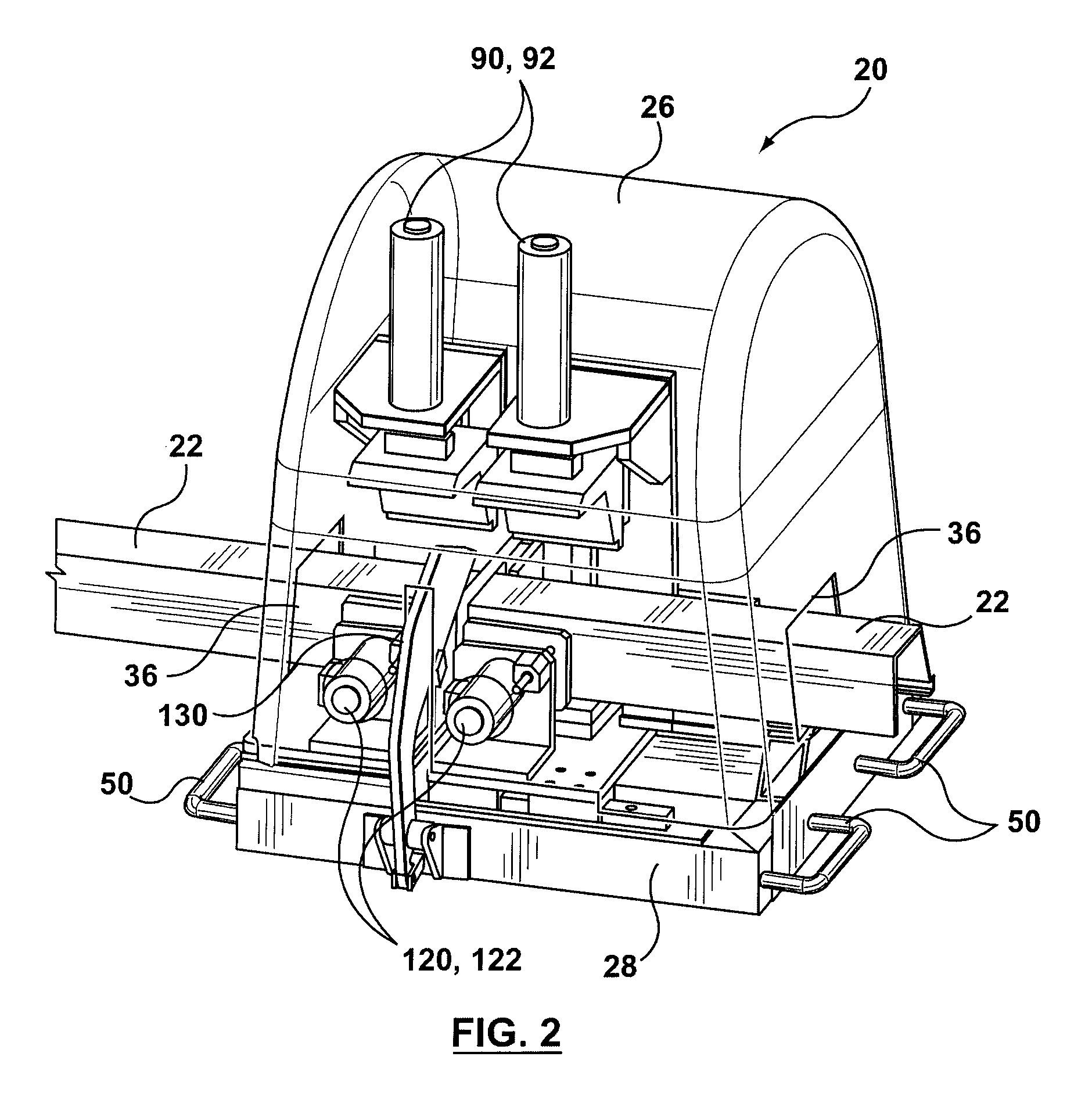

ActiveUS7328734B2Easy to disassembleMechanical working/deformationCovering/liningsEngineeringPlastic welding

A machine and method for welding thermo-plastic rain gutters or other work pieces together. The machine includes a frame assembly and a protective shroud. Handles or a wheeled carriage are provided for transporting the machine to a work site. A stationary plate and a moveable plate are each secured to the frame assembly. Work piece holders and corresponding clamps specially configured for clamping rain gutters or other work pieces are disposed on the stationary and moveable plates together with a spacer plate for positioning and holding the ends of two work pieces in a position for welding the ends together. A heater is provided for heating the ends of the work pieces to a desired welding temperature and a press is provided for pressing and holding the molten ends of the work pieces together for welding.

Owner:GSW BUILDING PRODS

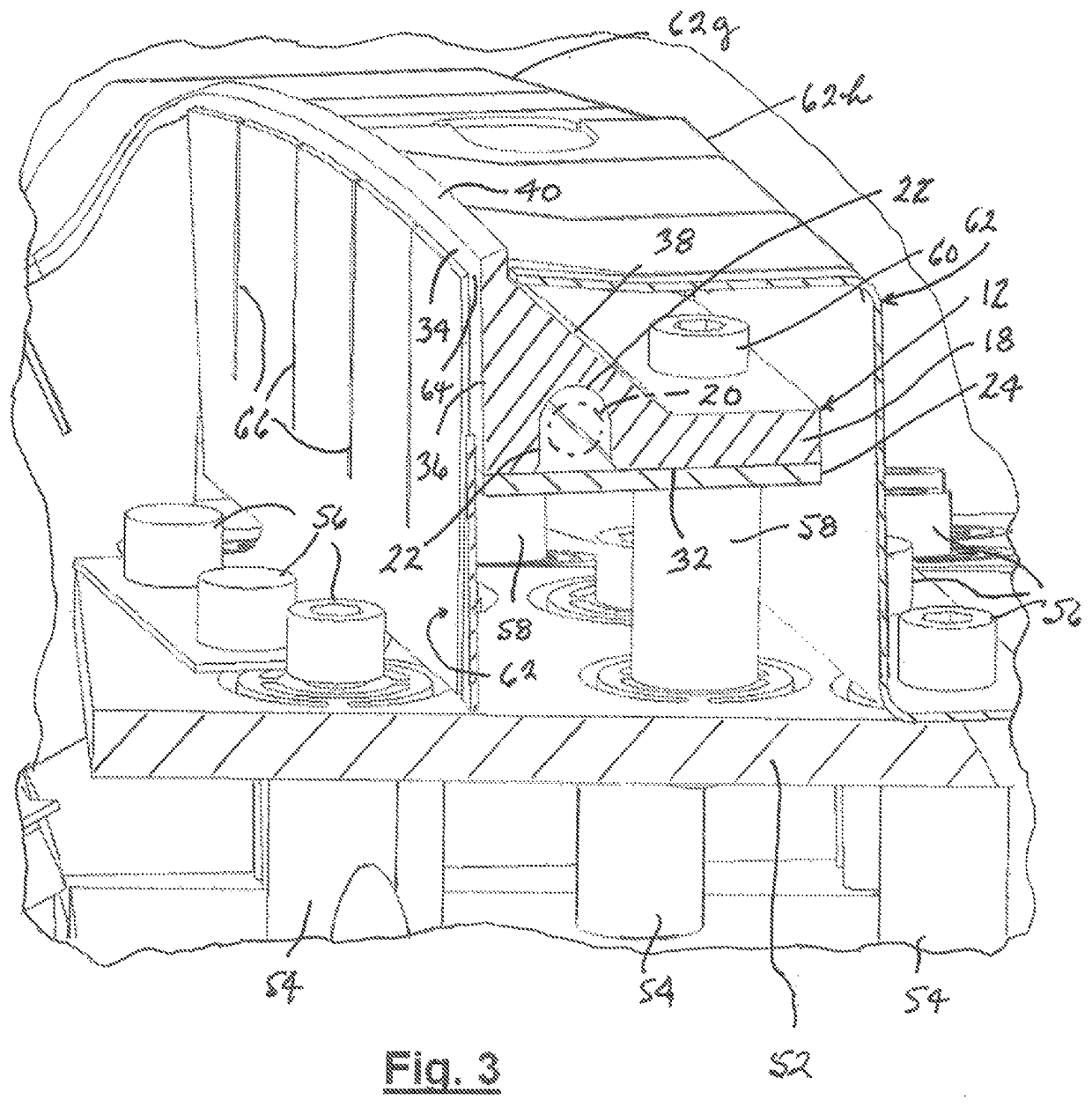

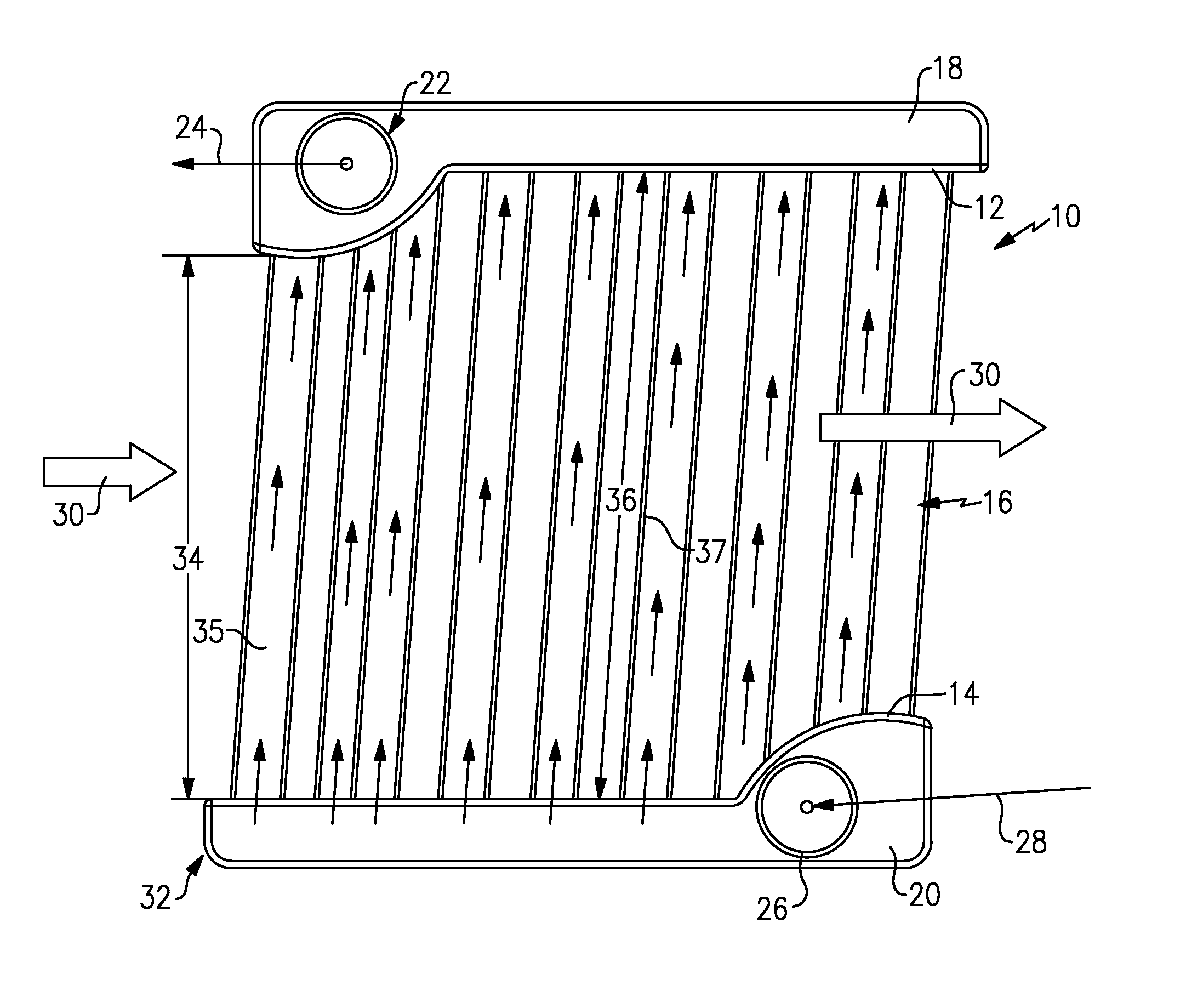

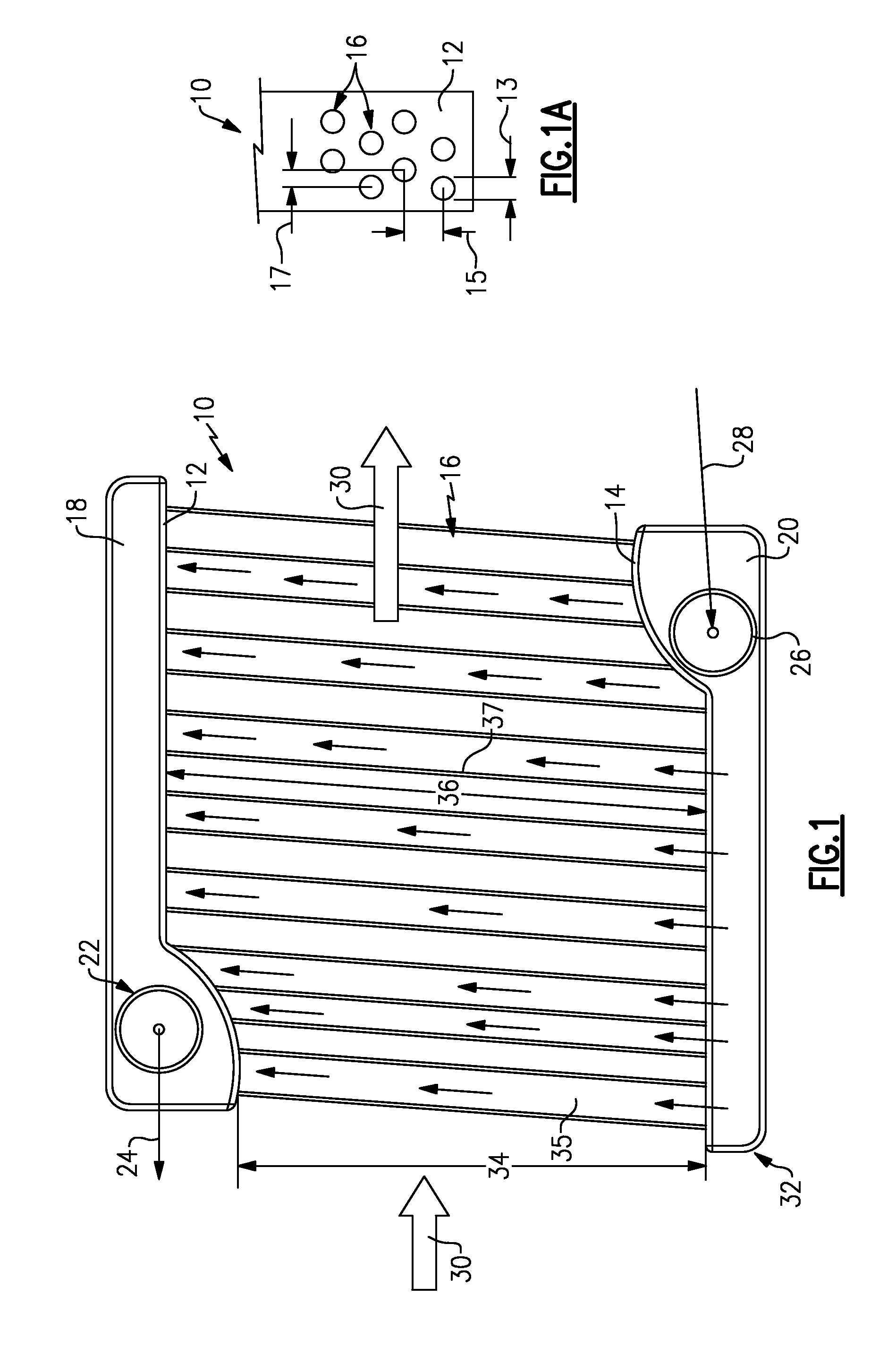

Plastic intercooler

InactiveUS7921905B2Easy to useLow costInternal combustion piston enginesStationary conduit assembliesIntercoolerEngineering

A plastic intercooler assembly includes a plurality of plastic tubes that extend between plastic end plates. The plastic tubes are secured to the end plates to provide the desired seal between the end plates and the ends of the tubes. The plastic tubes are attached utilizing plastic welding methods that reduce assembly time and cost.

Owner:SIEMENS VDO AUTOMOTIVE INC

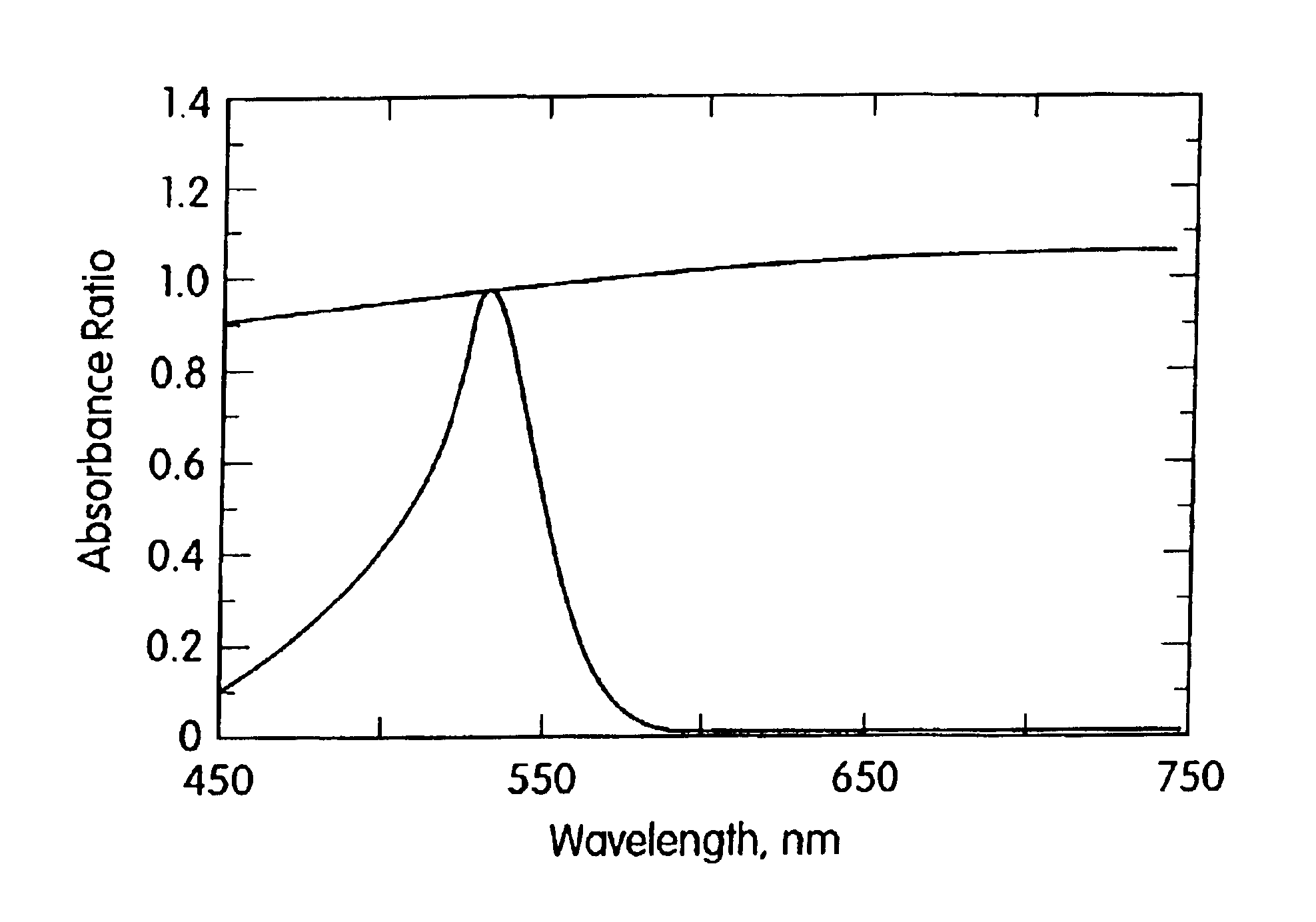

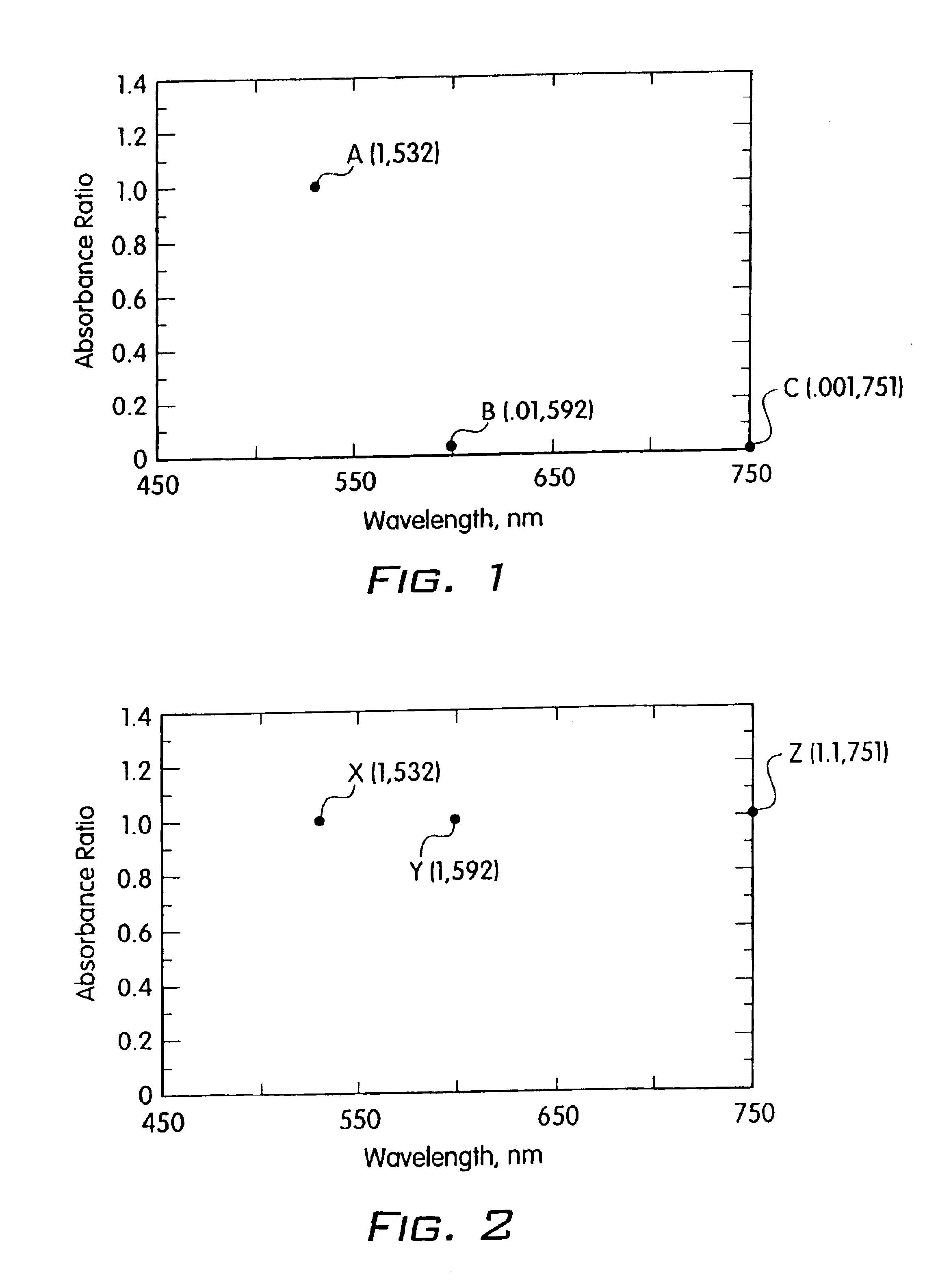

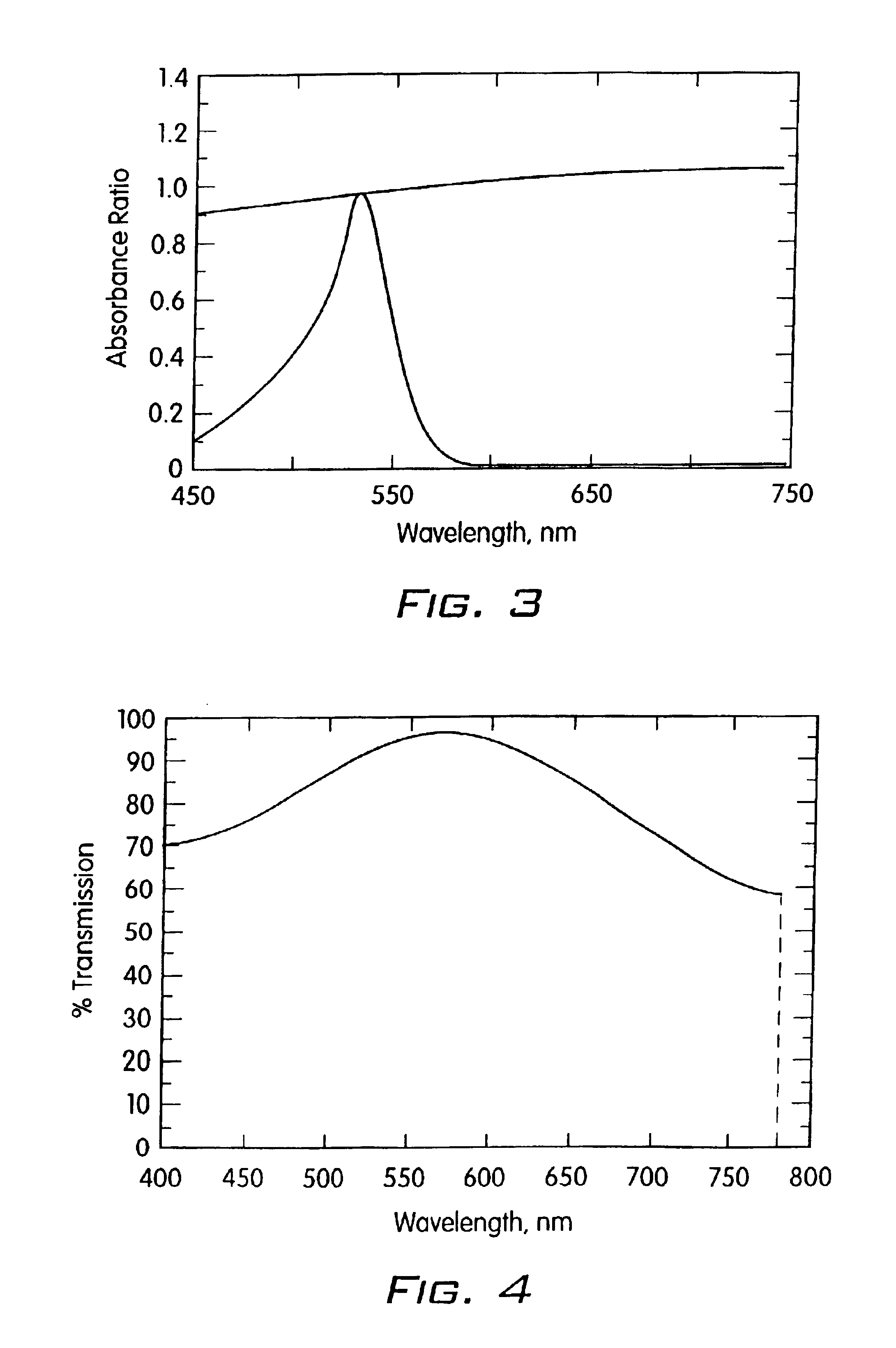

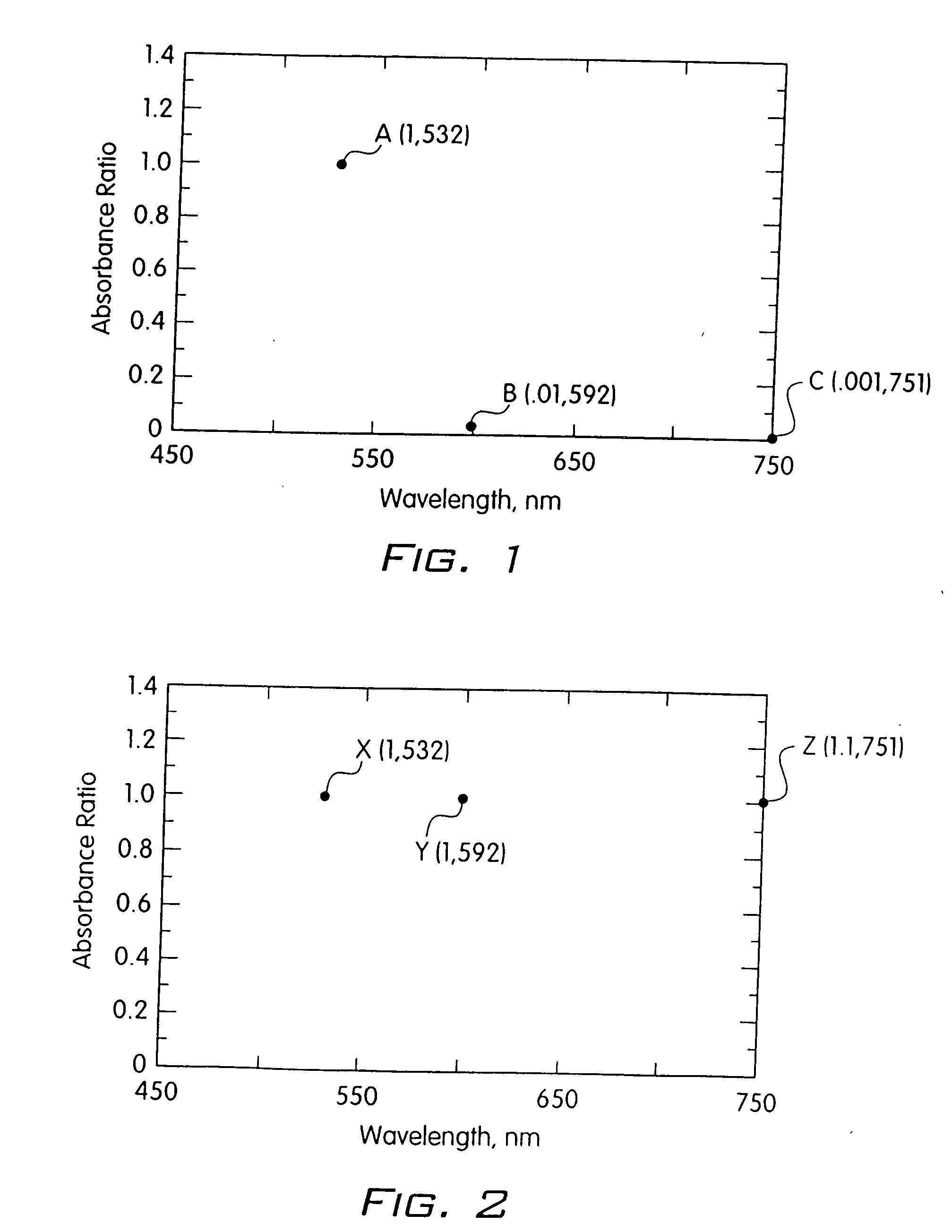

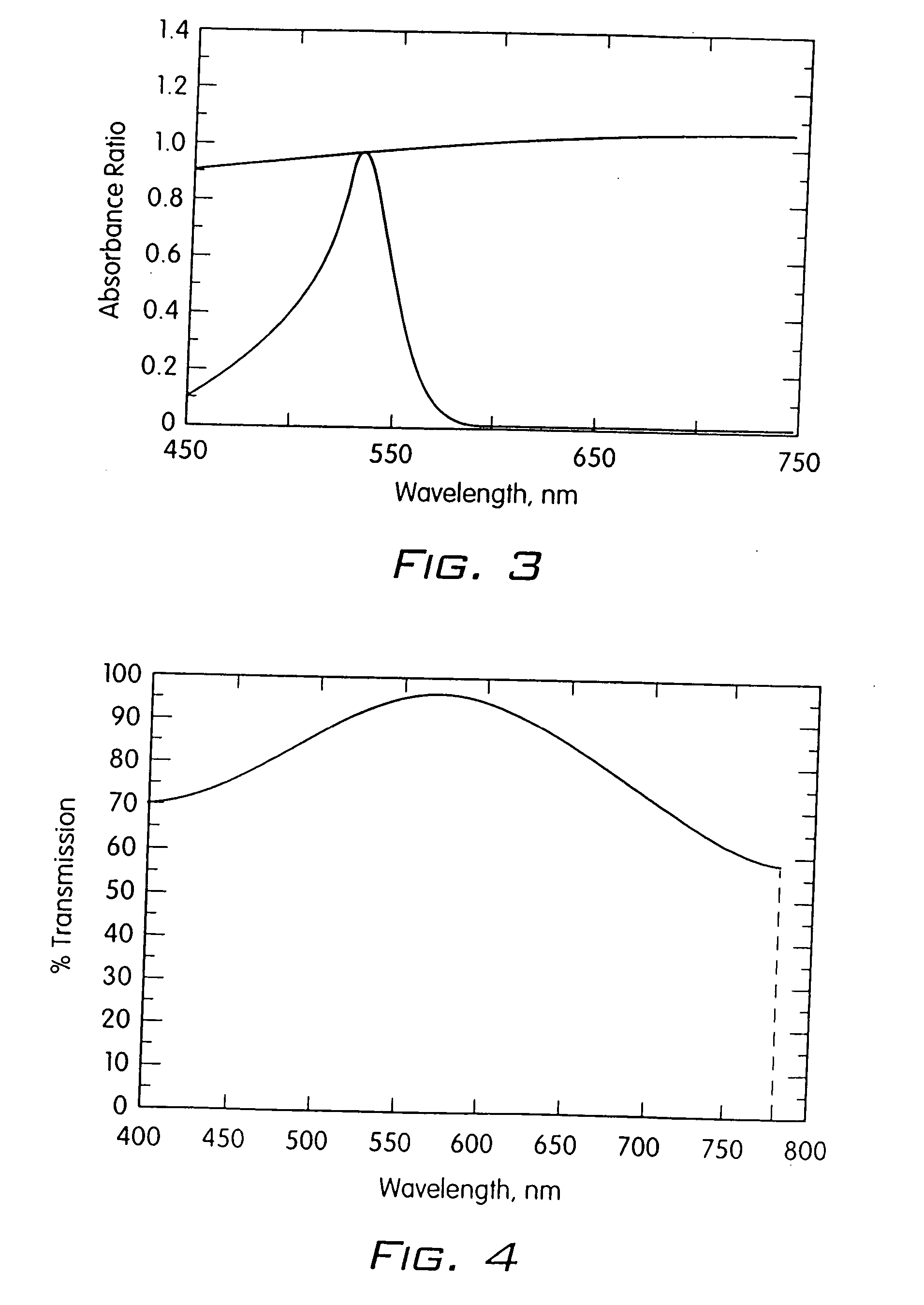

Visibly transparent dyes for through-transmission laser welding

InactiveUS20040244905A1Effective absorptionAdd little or no light scatteringMechanical working/deformationLamination ancillary operationsThrough transmissionSelection criterion

Selection criteria for dyes that predicts efficiency and performance for plastics welding. A first stage quantitative calculation screens dyes that possess an absorption band that can be matched to a laser that is suitable for plastic welding. It also identifies absorption troughs in the visible spectrum and establishes relationships between the relative optical densities of the absorption band and trough. A second stage quantitative calculation screens dyes for their contribution to the transparency of the substrate. By combining these two stages, the usefulness of a candidate dye can be quickly, easily and inexpensively determined.

Owner:GENTEX CORP

Laser plastic welding method and plastic product

The invention discloses a laser plastic welding method and a plastic product. The method comprises the following steps that at least two pieces of plastic are butt-jointed or stacked together, and a heat-conduction cover plate is arranged on the top surfaces of the plastic in a pressing manner; a mid-infrared thulium-doped optical fiber laser with the wavelength being 1,940 nm and a galvanometer are arranged above the heat-conduction cover plate; the optical fiber laser is started and emits a laser beam, the laser beam is transmitted onto the galvanometer and moves along the heat-conduction cover plate according to the preset scanning path after passing through the galvanometer, the plastic absorbs the energy of the laser beam passing through the heat-conduction cover plate, and thus welding is completed; and the plastic product is produced with the laser plastic welding method. With the laser plastic welding method, efficient welding can be realized, additive pollution can be reduced,the welding cost can be reduced, the performance of the welded product is stable, and the surface layers of the plastic can be prevented from being burnt.

Owner:HANS LASER TECH IND GRP CO LTD

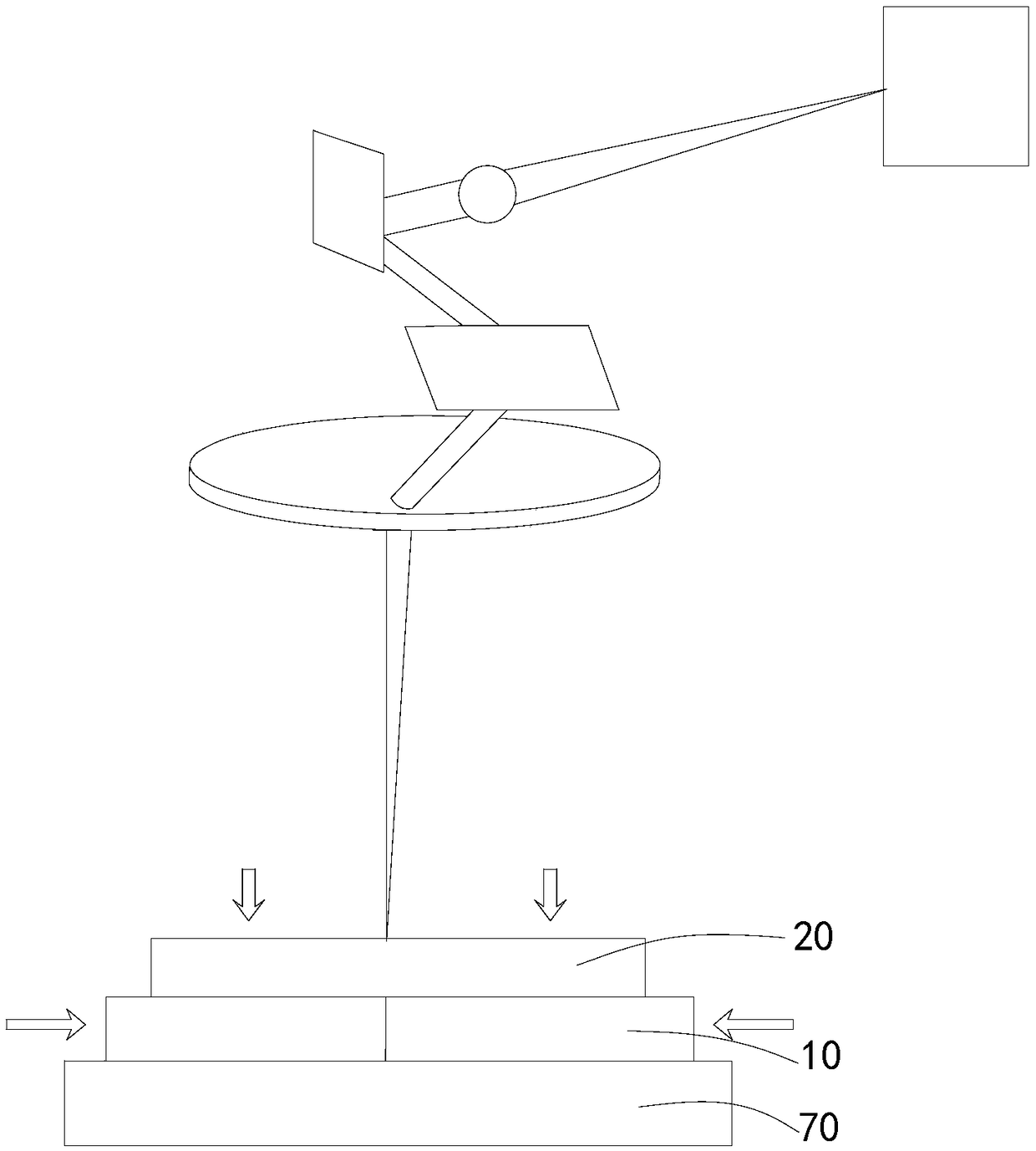

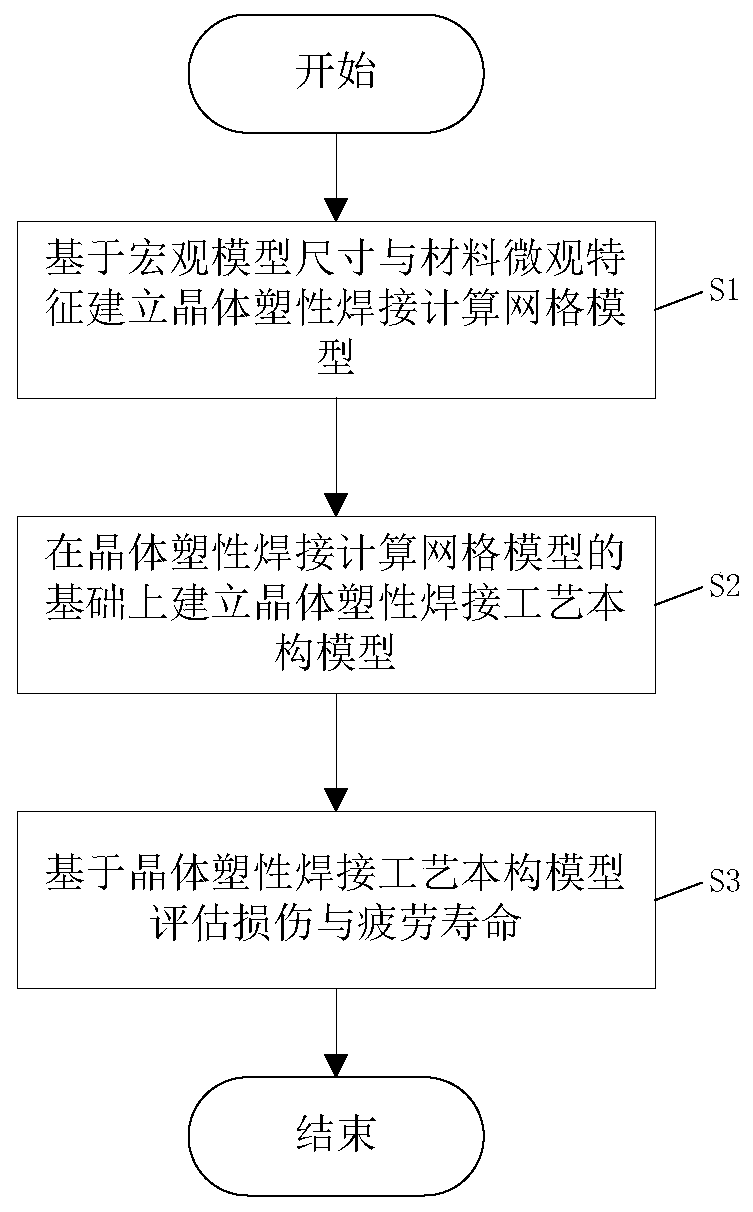

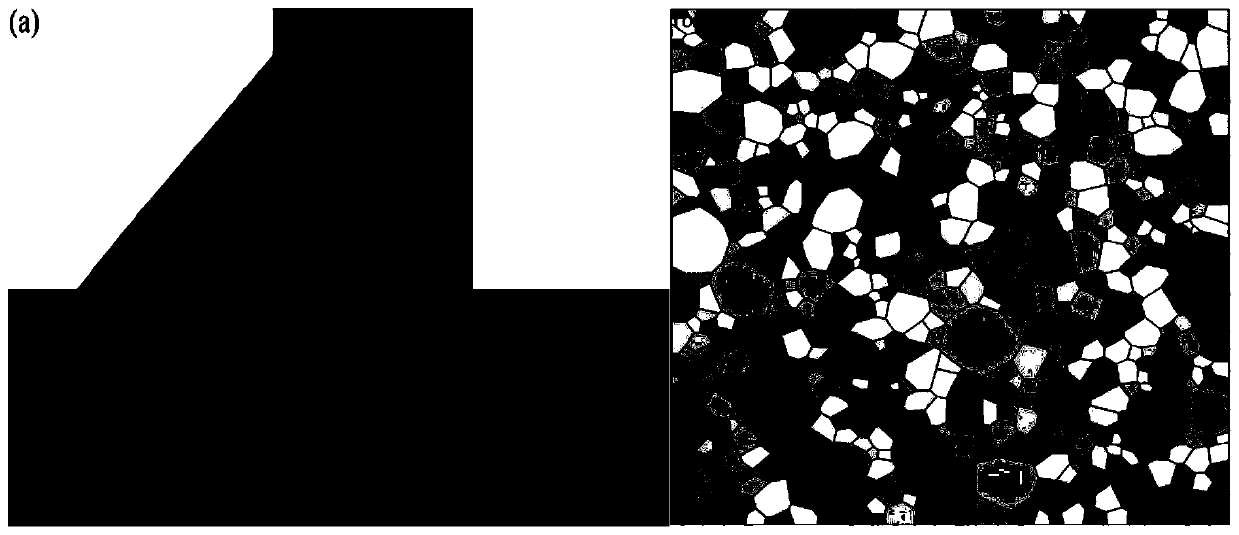

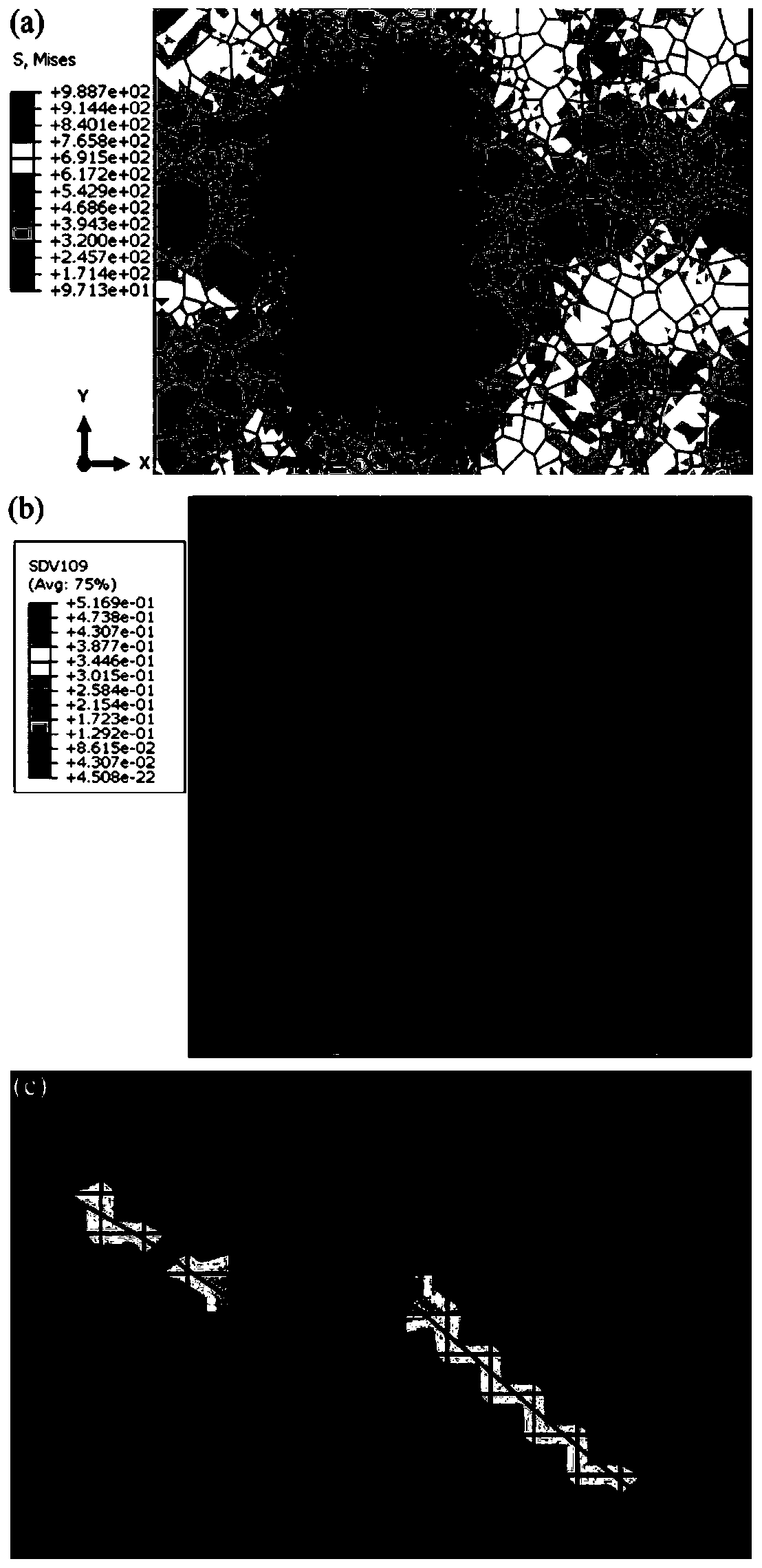

Damage and fatigue life evaluation method based on crystal plastic welding process model

ActiveCN110232243AFix damageSolve the problem of longevityDesign optimisation/simulationSpecial data processing applicationsCouplingEngineering

The invention discloses a damage and fatigue life evaluation method based on a crystal plastic welding process model. According to a crystal plastic constitutive model of the welding process and the calculation method, the influence of a crystal slip system and polycrystalline plastic strain on the welding process performance of the material is considered. A mesoscopic layer welding process damageand fatigue life evaluation model is established. The influence of the microscopic characteristics of the material on the welding process performance and the influence on the damage and fatigue lifeof a welding joint can be researched from the perspective of mesoscopic view. Through a macro-mesoscopic coupling calculation model, the relationship between welding process and material property evolution process is clarified, and the influence and degree of welding process on material damage and fatigue life are further determined, which provides important for studying the damage evolution and fatigue failure process of materials after welding process. The method has important scientific significance and engineering application value.

Owner:SICHUAN UNIV

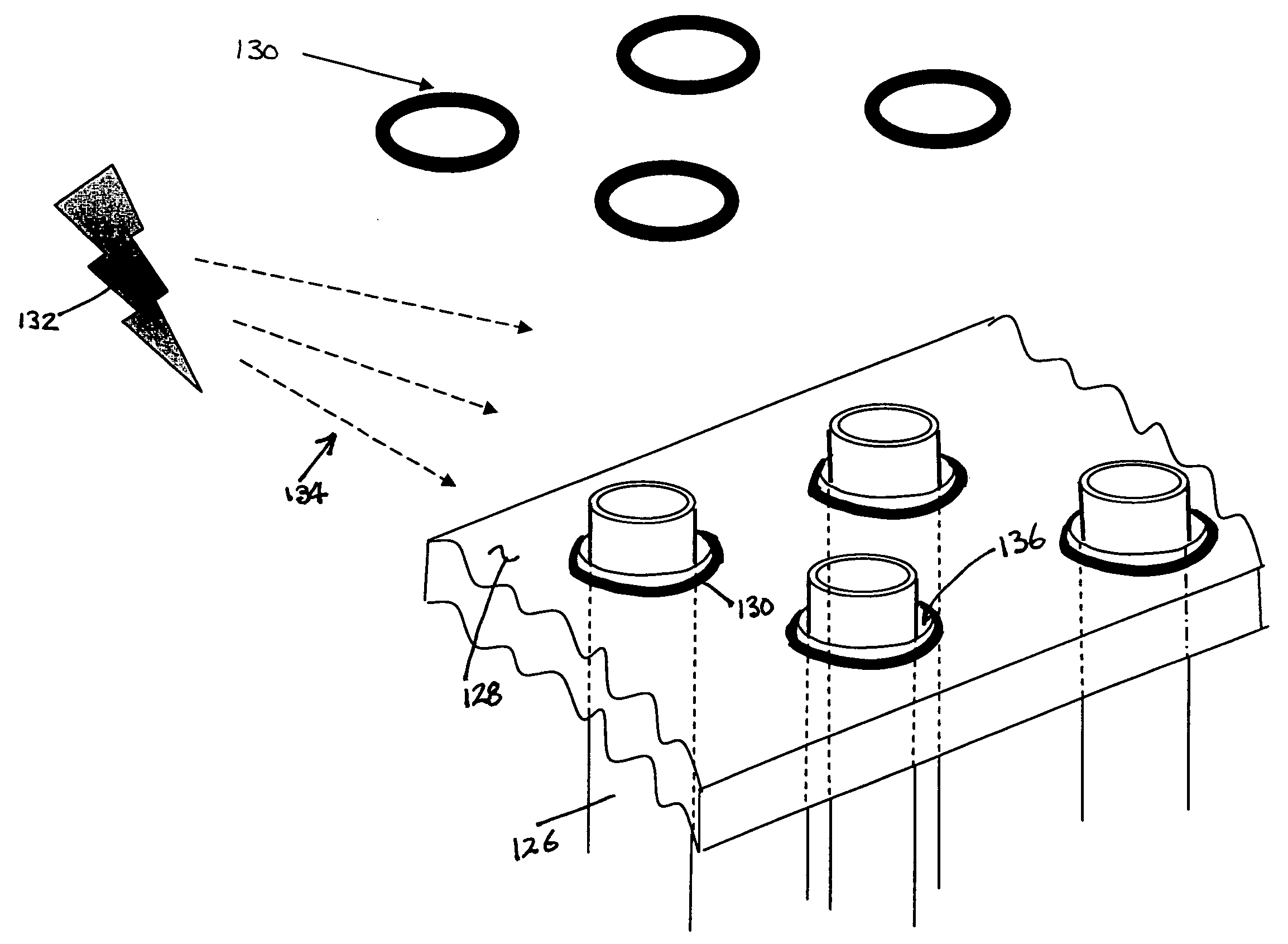

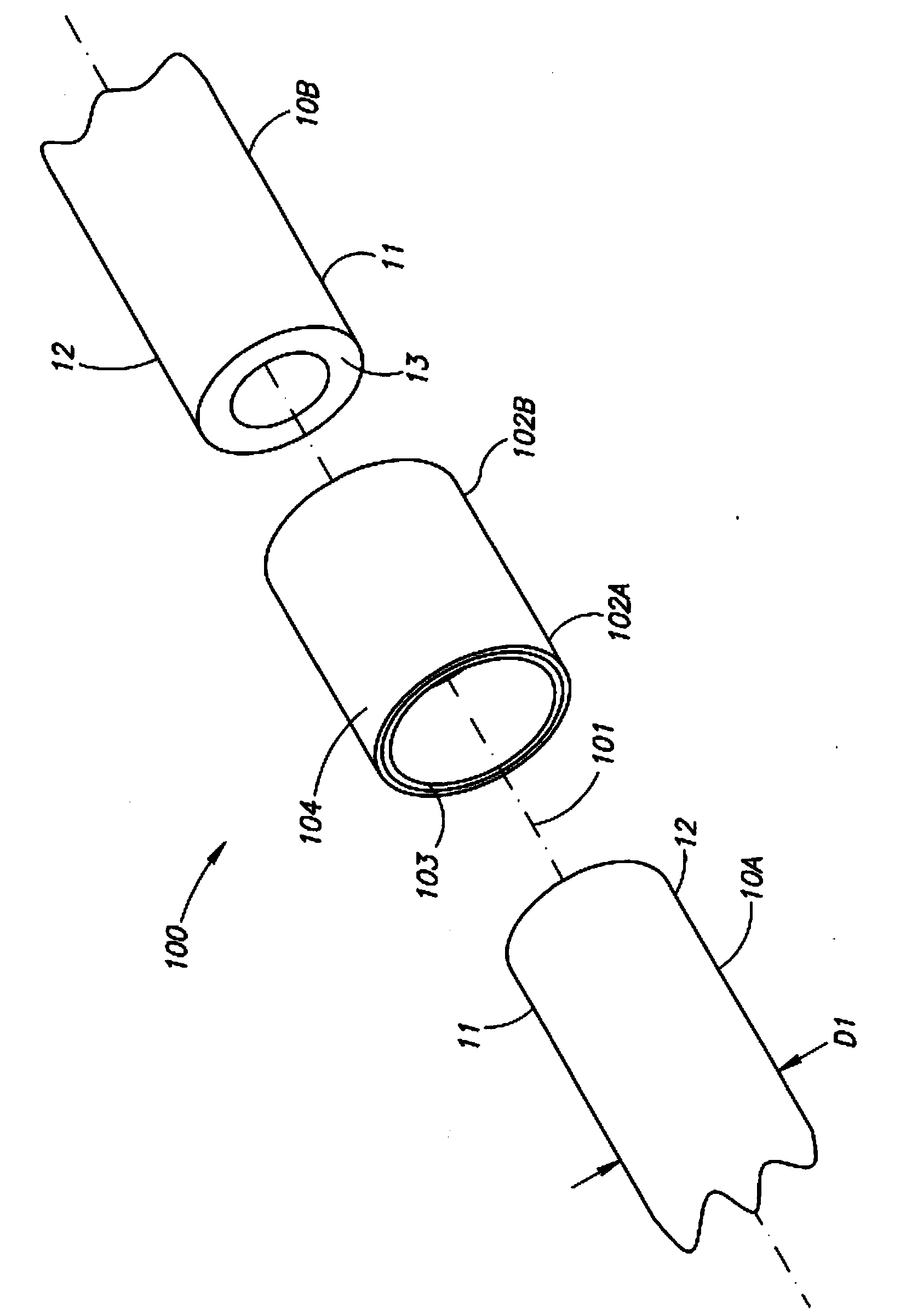

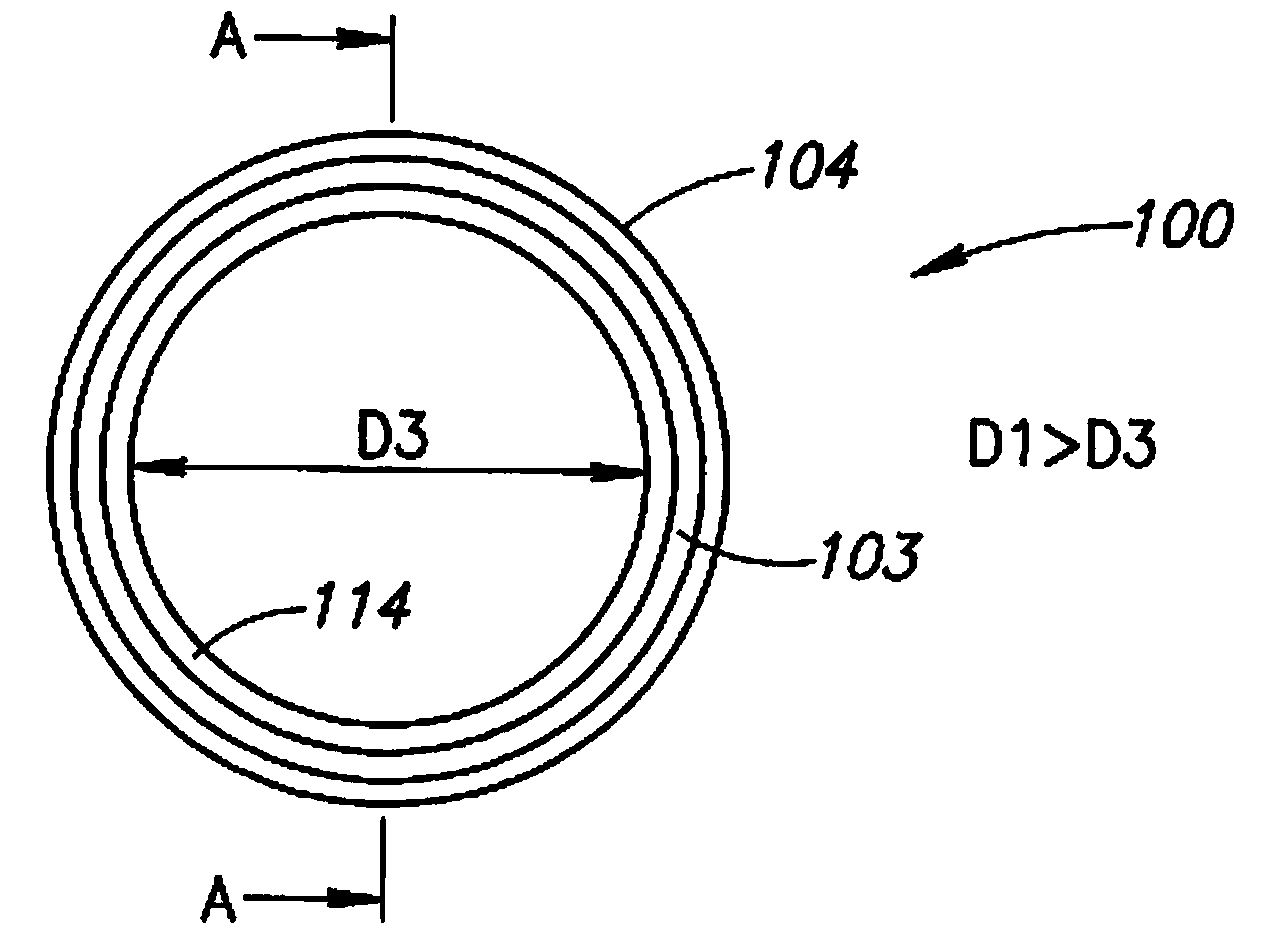

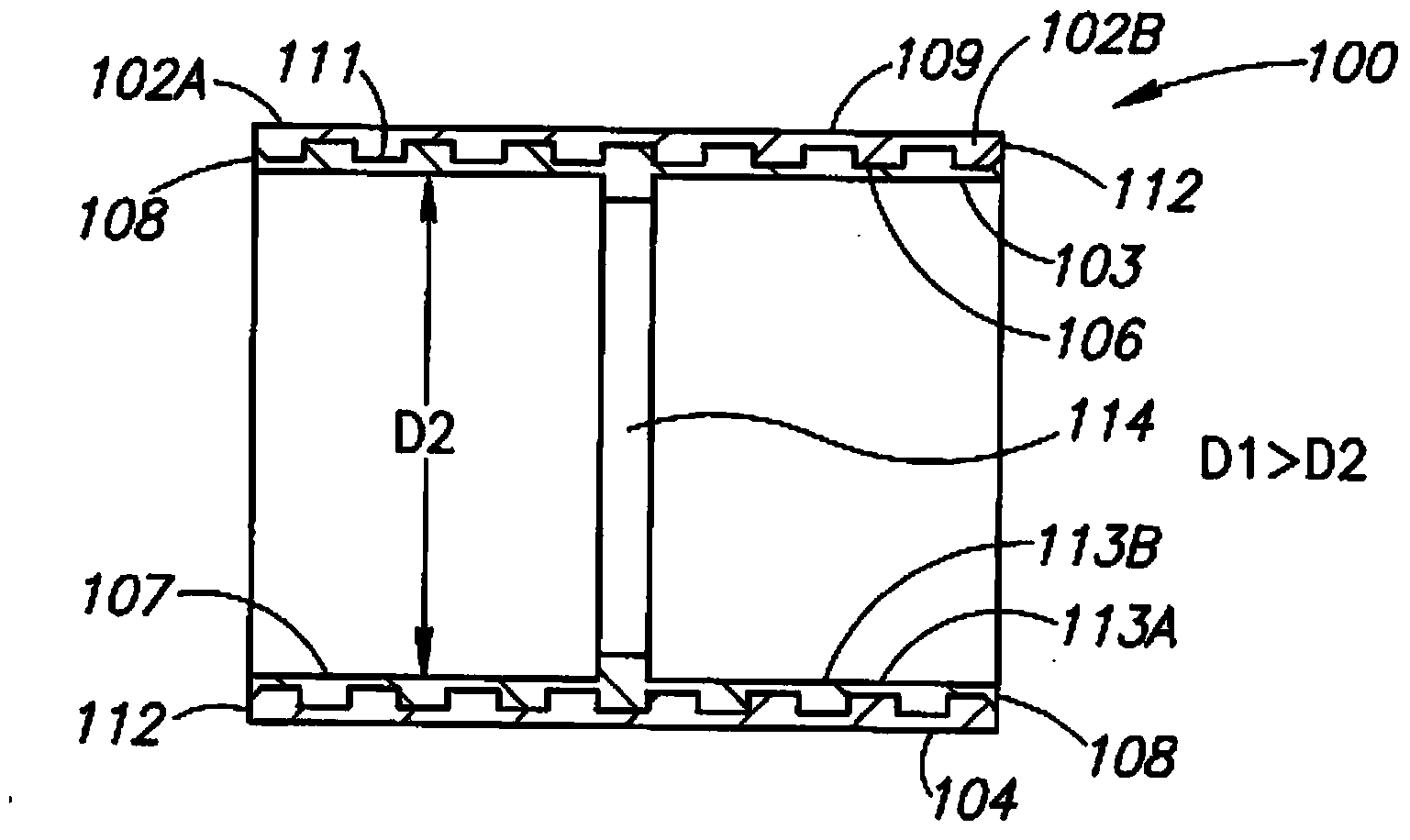

Electromagnetic induction welding of plastic pipe distribution systems

Electromagnetic induction welding of plastic pipe distribution systems including inter alia induction weldable pipe connectors (100) each having at least one induction weldable pipe socket (102). The induction weldable pipe sockets include a solid metal susceptor sleeve (104) enveloping a plastic solder lining (103). Electromagnetic induction coil assemblies (200) for clamping on induction weldable pipe sockets (100).

Owner:HULIOT (A C S) LTD

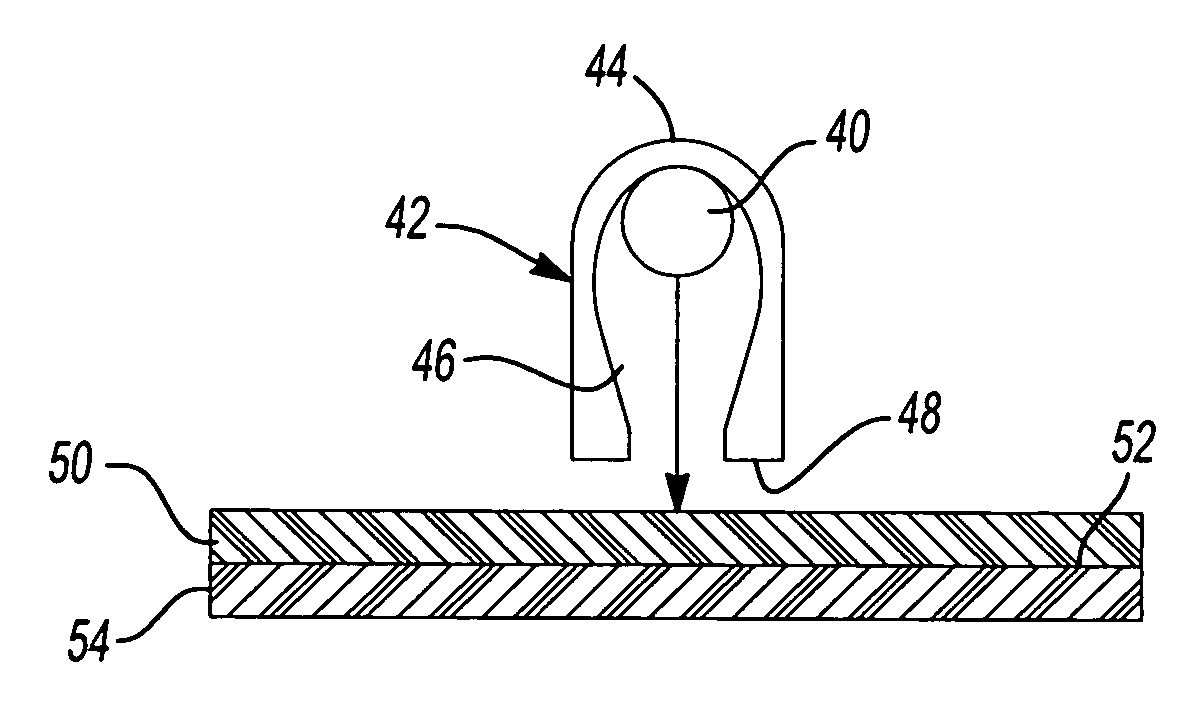

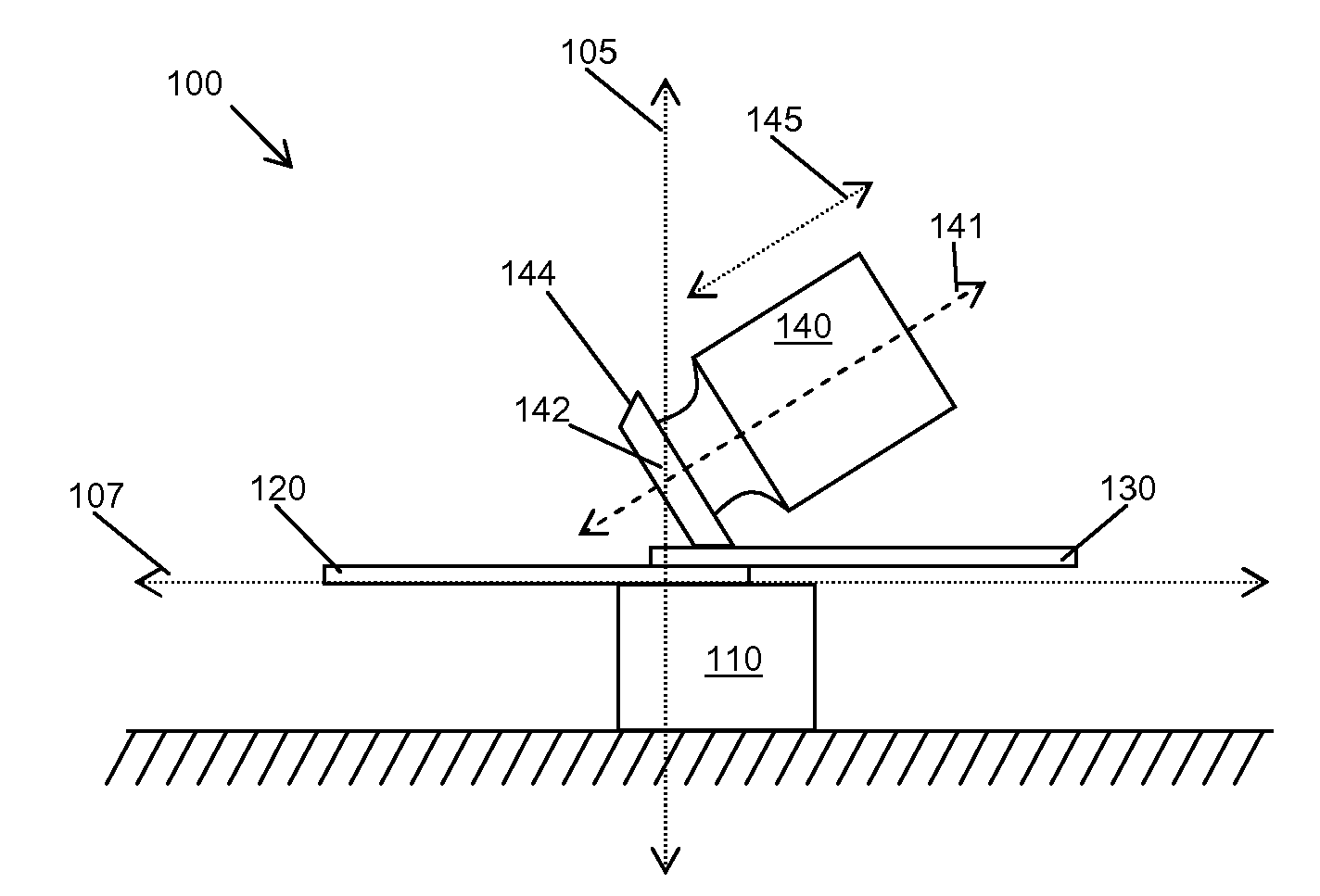

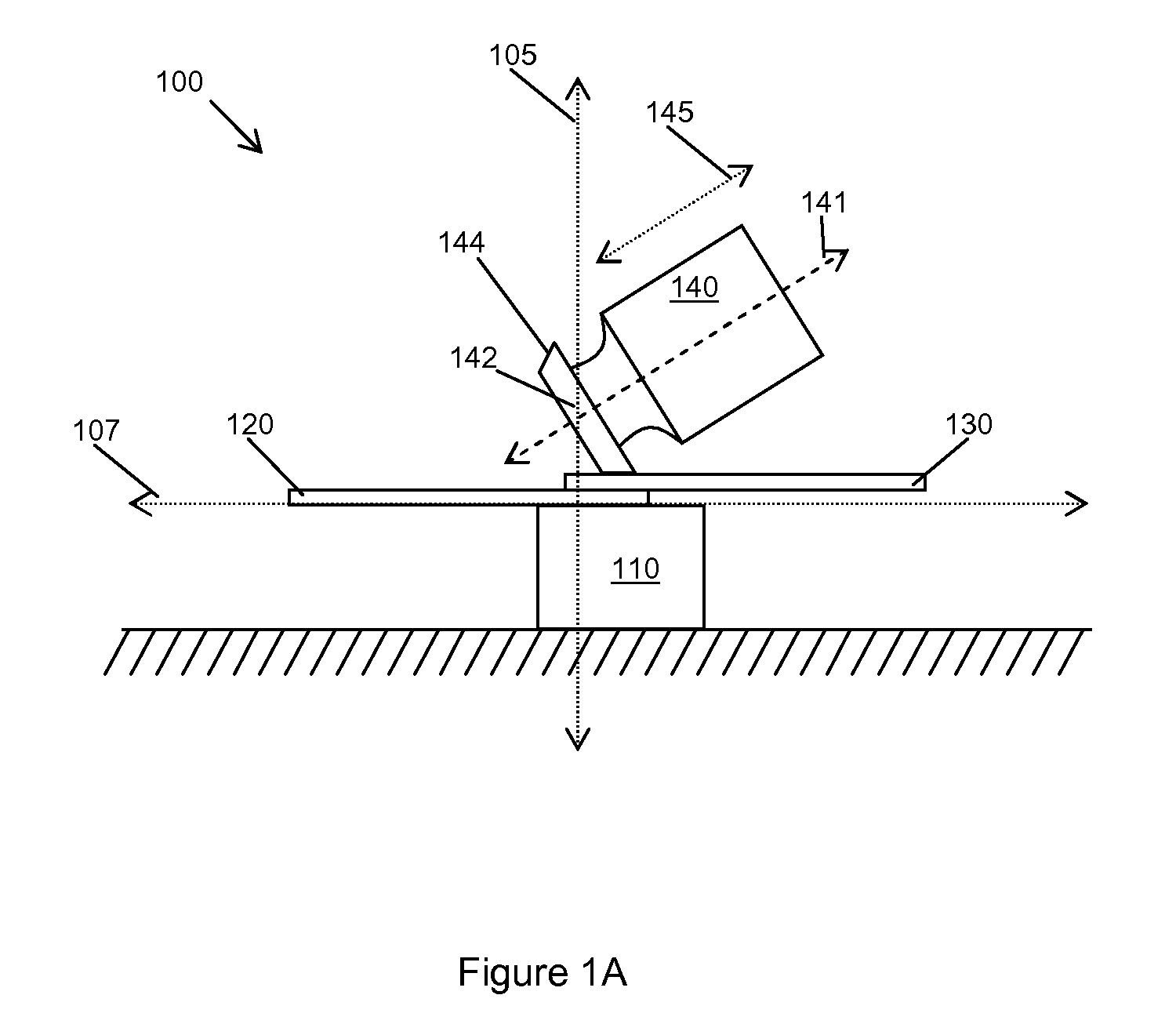

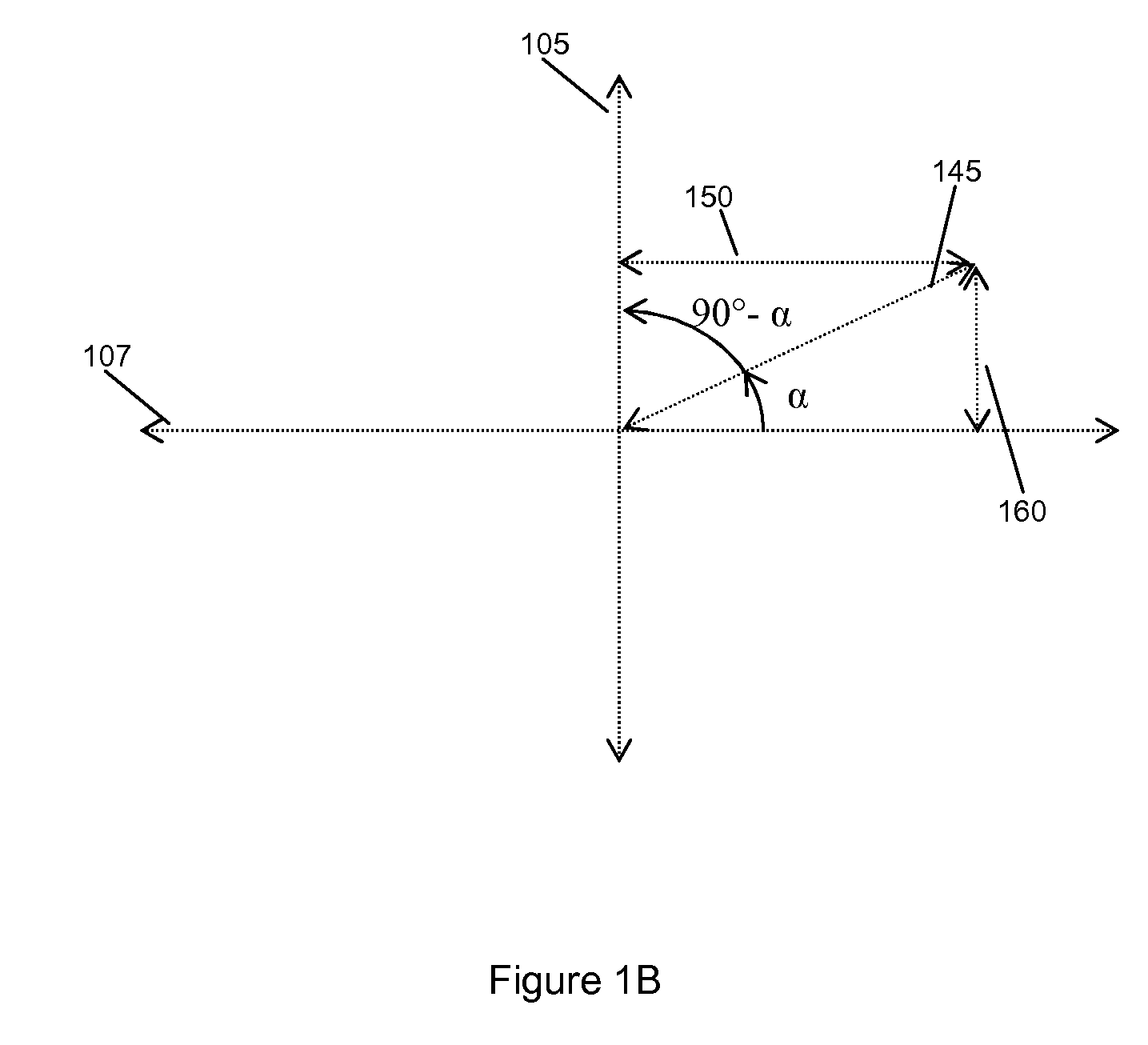

Systems and Methods for Non-Perpendicular Ultrasonic Plastic Welding

Systems for ultrasonically welding described herein include a sonotrode for delivering ultrasonic vibrations to two or more plastic sheets, so as to form a weld between them. The sonotrode and the plastic sheets are arranged such that the ultrasonic vibrations delivered by the sonotrode travel along a path that is oriented at an angle α with respect to a tangent to the surface being welded, wherein the angle α is less than 90 degrees. Methods for ultrasonically welding described herein include providing two or more plastic sheets to be welded together and delivering ultrasonic vibrations to form a weld between them, such that the ultrasonic vibrations travel along a path that is oriented at an angle α with respect to a tangent to the surface being welded, wherein the angle α is less than 90 degrees.

Owner:MOGADAM SAEED +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com