System and method for automatically assembling fountain pen

A technology of automatic assembly and water pen, applied in the repair of ink pens, printing, writing utensils, etc., can solve problems such as low efficiency, inability to realize complete automation, and affect production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

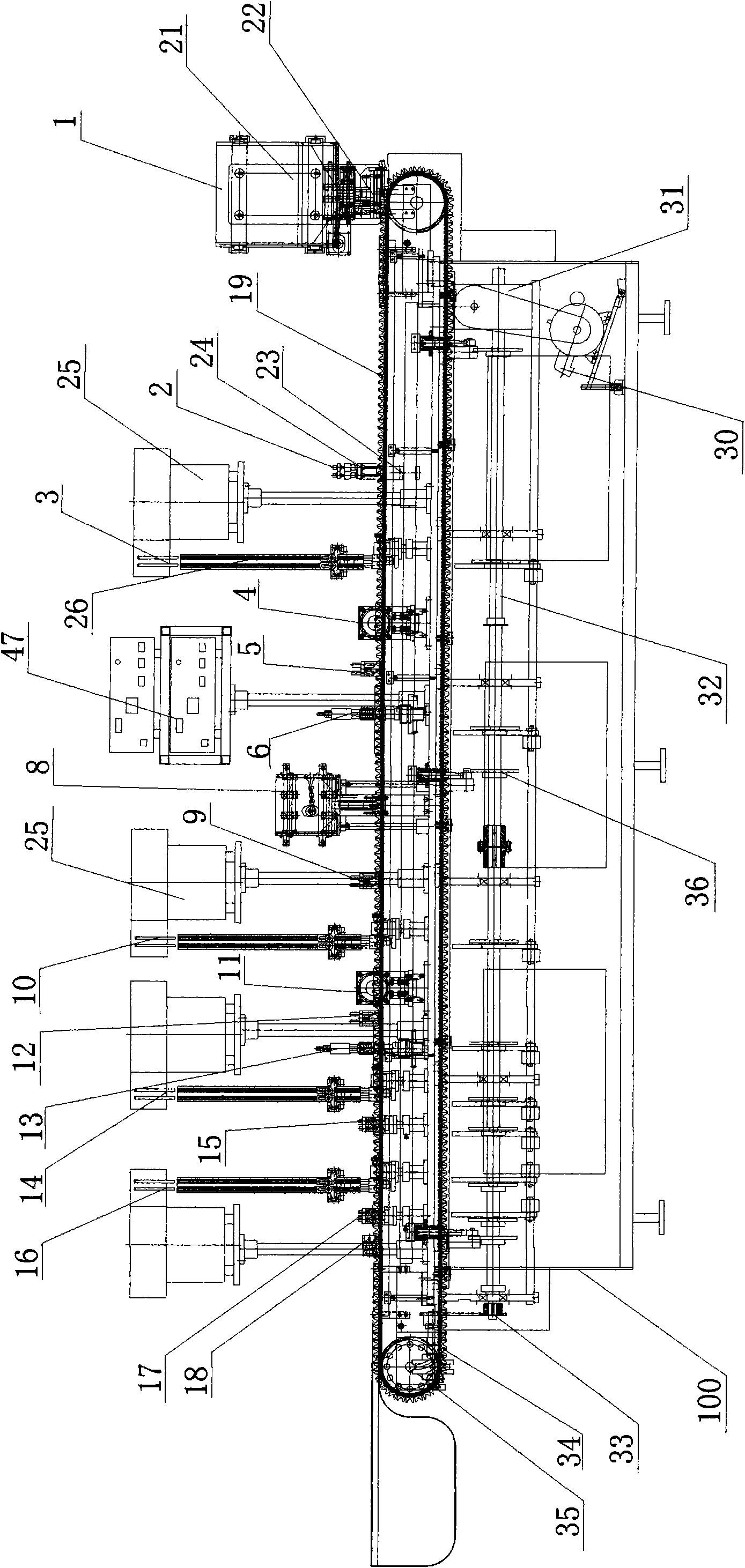

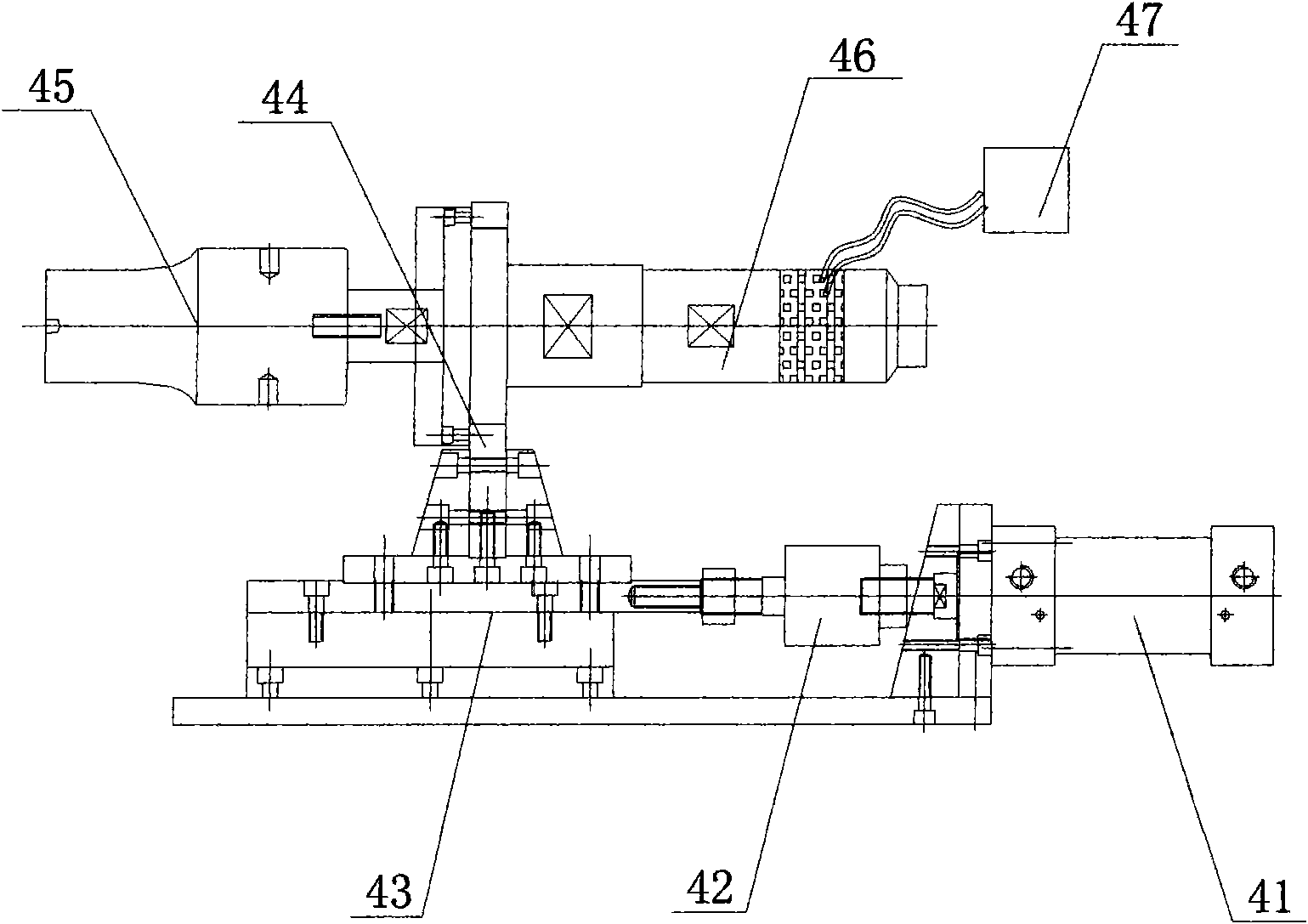

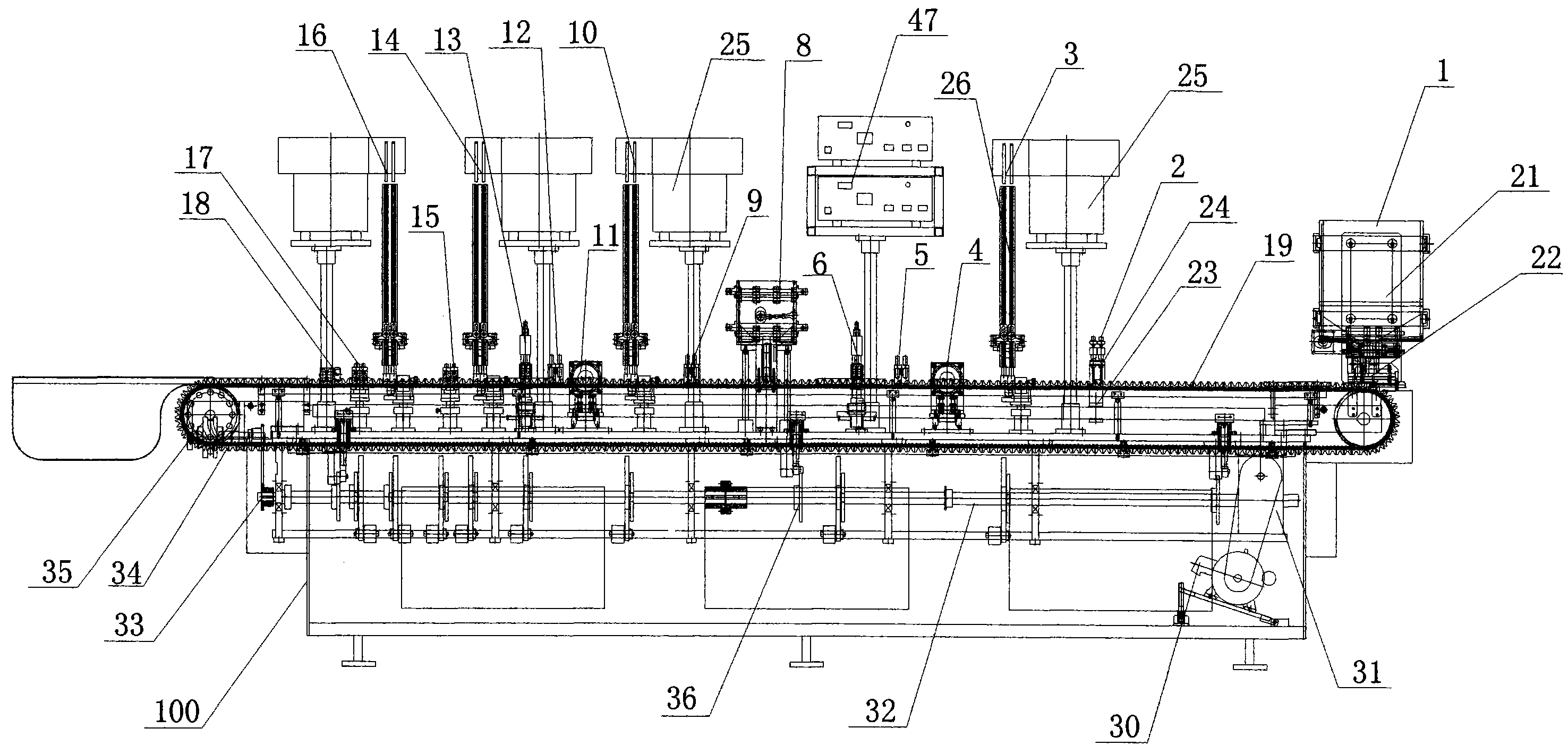

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0030] Such as figure 1 , 2 As shown, a fountain pen automatic assembly system includes a frame 100, a power transmission device is arranged on the frame 100, the power transmission device is connected to a conveying mechanism, and the conveying mechanism is sequentially provided with a pen holder supply mechanism 1, a pen holder detection mechanism 2, Pen nib supply mechanism 3, nib welding mechanism 4, nib detection mechanism 5, the first pen holder transposition mechanism 6, roll core supply mechanism 8, roll core detection mechanism 9, tail plug supply mechanism 10, tail plug welding mechanism 11, Tail plug detection mechanism 12, pen holder transposition mechanism 13 for the second time, water diversion core nib supply mechanism 14, water diversion core nib detection mechanism 15, pen cap supply mechanism 16, pen cap detection mechanism 17, rejecting mechanism 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com