Multiple dimension plastic welding laser device

A technology of laser welding and plastics, applied in the field of laser welding devices, multi-dimensional laser welding plastic devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

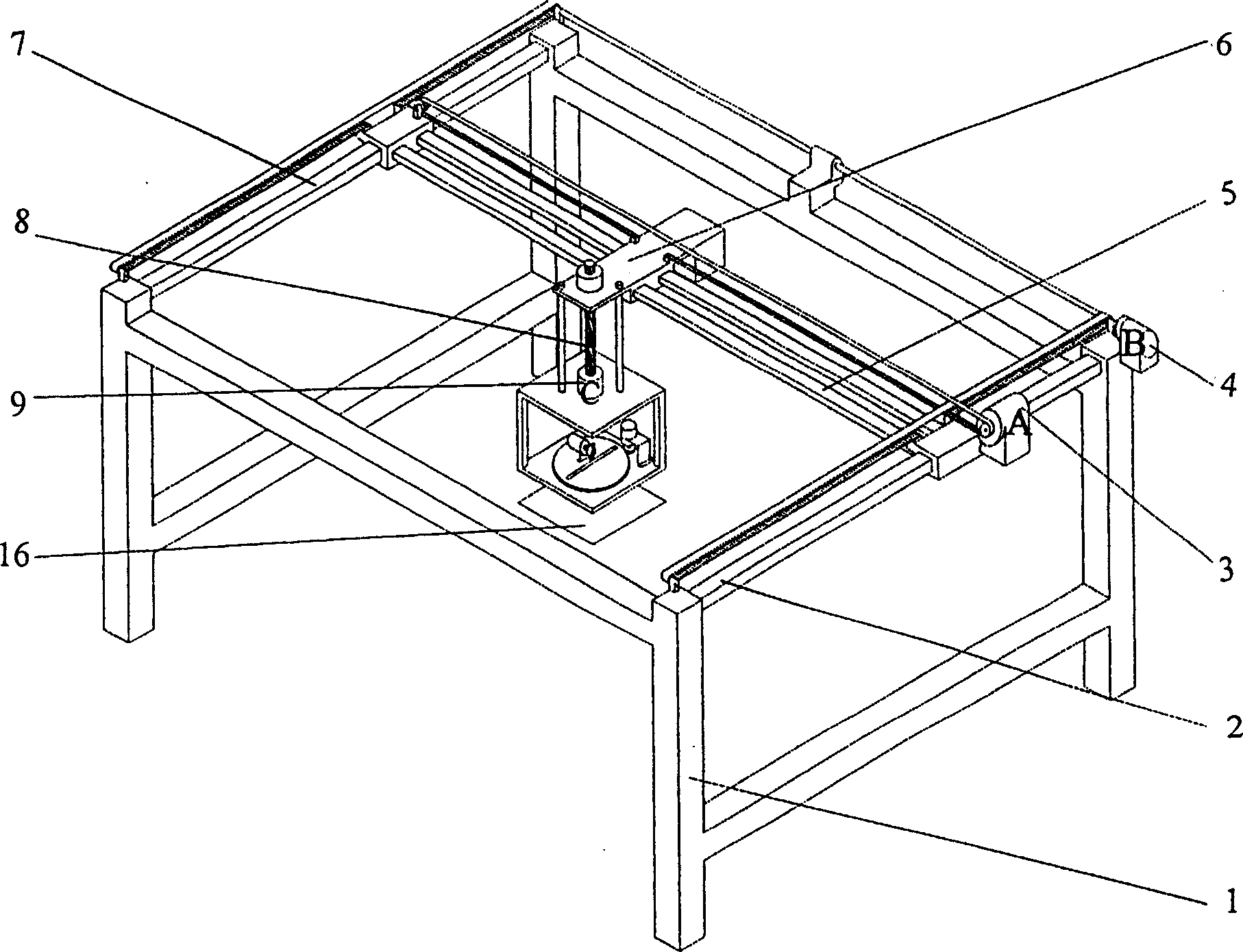

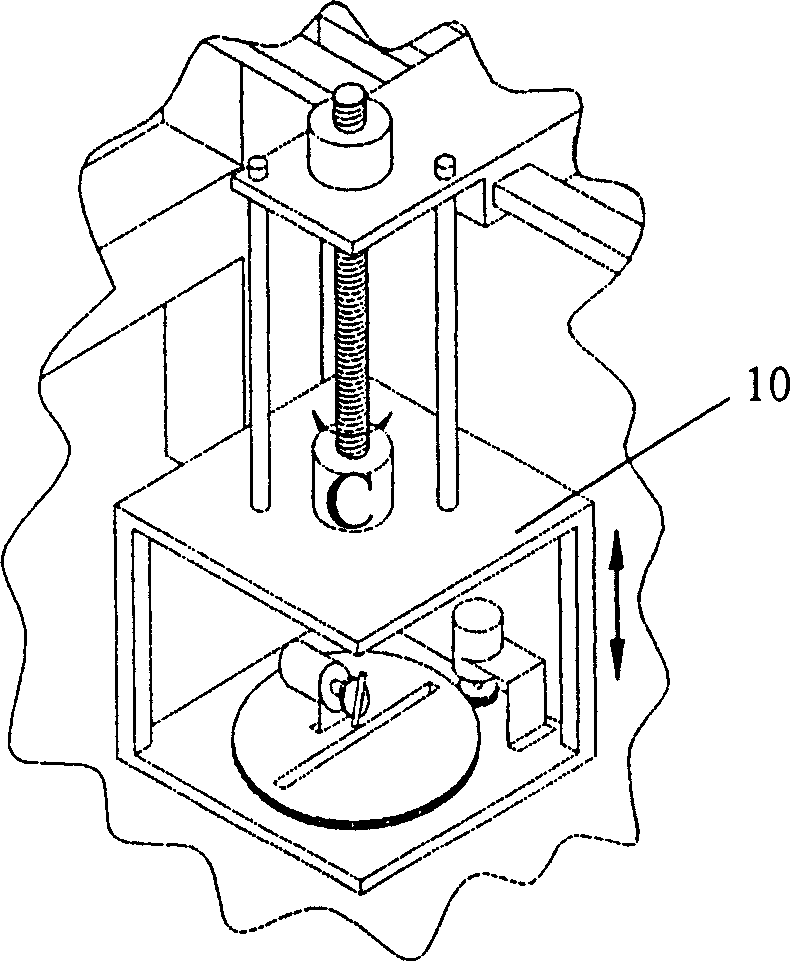

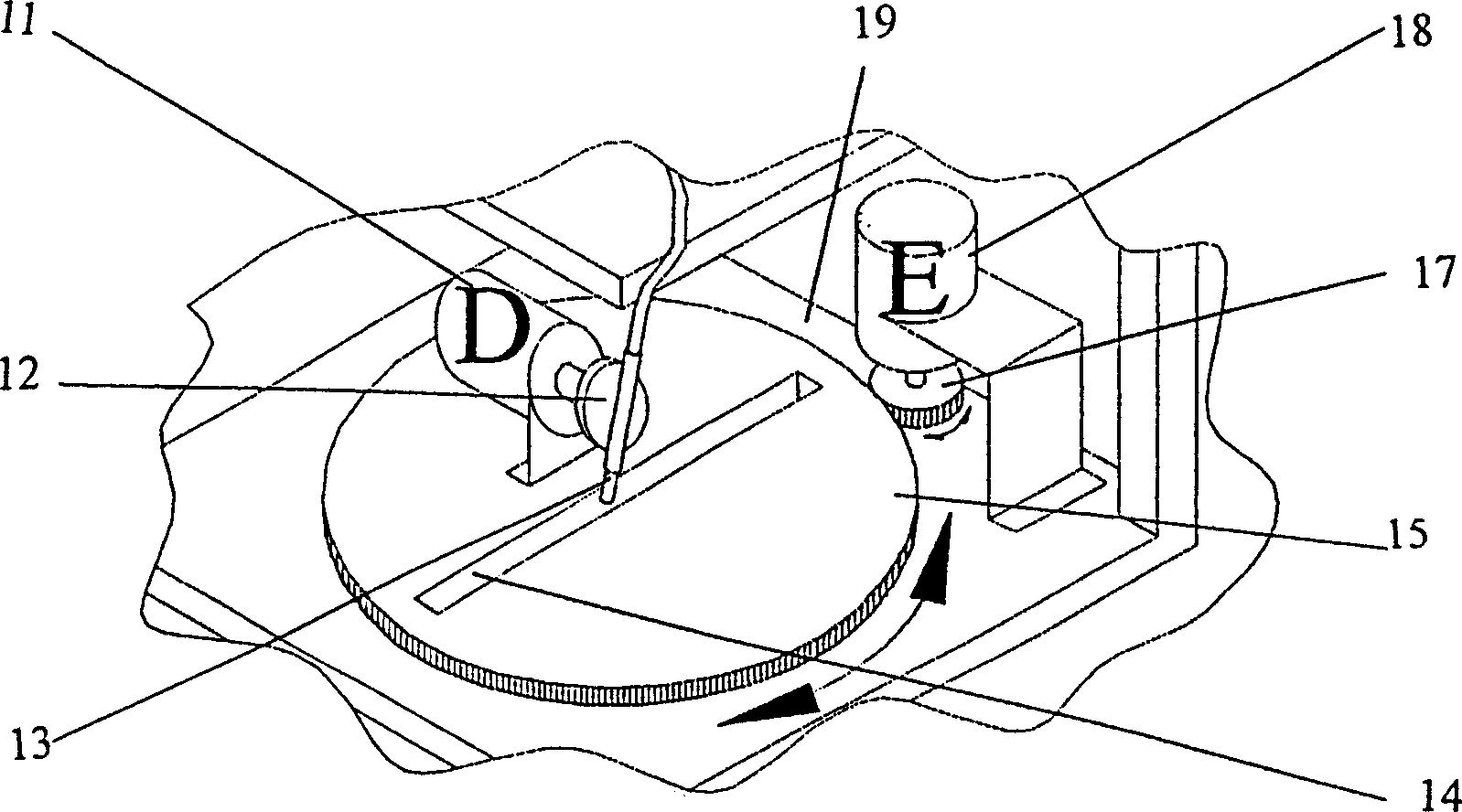

[0018] Depend on Figure 1-Figure 4 As shown, a multi-dimensional laser welding plastic device is characterized in that it includes: laser welding source, X direction guide rail 5, Y direction guide rails 2, 7, workbench 1, fiber optic angle console 10; two Y direction guide rails 2 , 7 are respectively placed on both sides of the workbench 1, the two ends of the X-direction guide rail 5 are respectively connected with the Y-direction guide rail 2 and the Y-direction guide rail 7, and the X-direction guide rail 5 is connected with the moving screw rod 8 in the Z-axis direction through the connecting plate 6, and the Z-axis The direction moving screw 8 is connected to the fiber optic angle console 10; the X direction guide rail 5, the Y direction guide rails 2, 7, and the Z axis direction moving screw 8 are respectively connected with the A motor 3, the B motor 4 and the C motor 9 to control the X axis , Y-axis and Z-axis welding movement; the optical fiber output head 13 used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com