Patents

Literature

2591 results about "Intercooler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

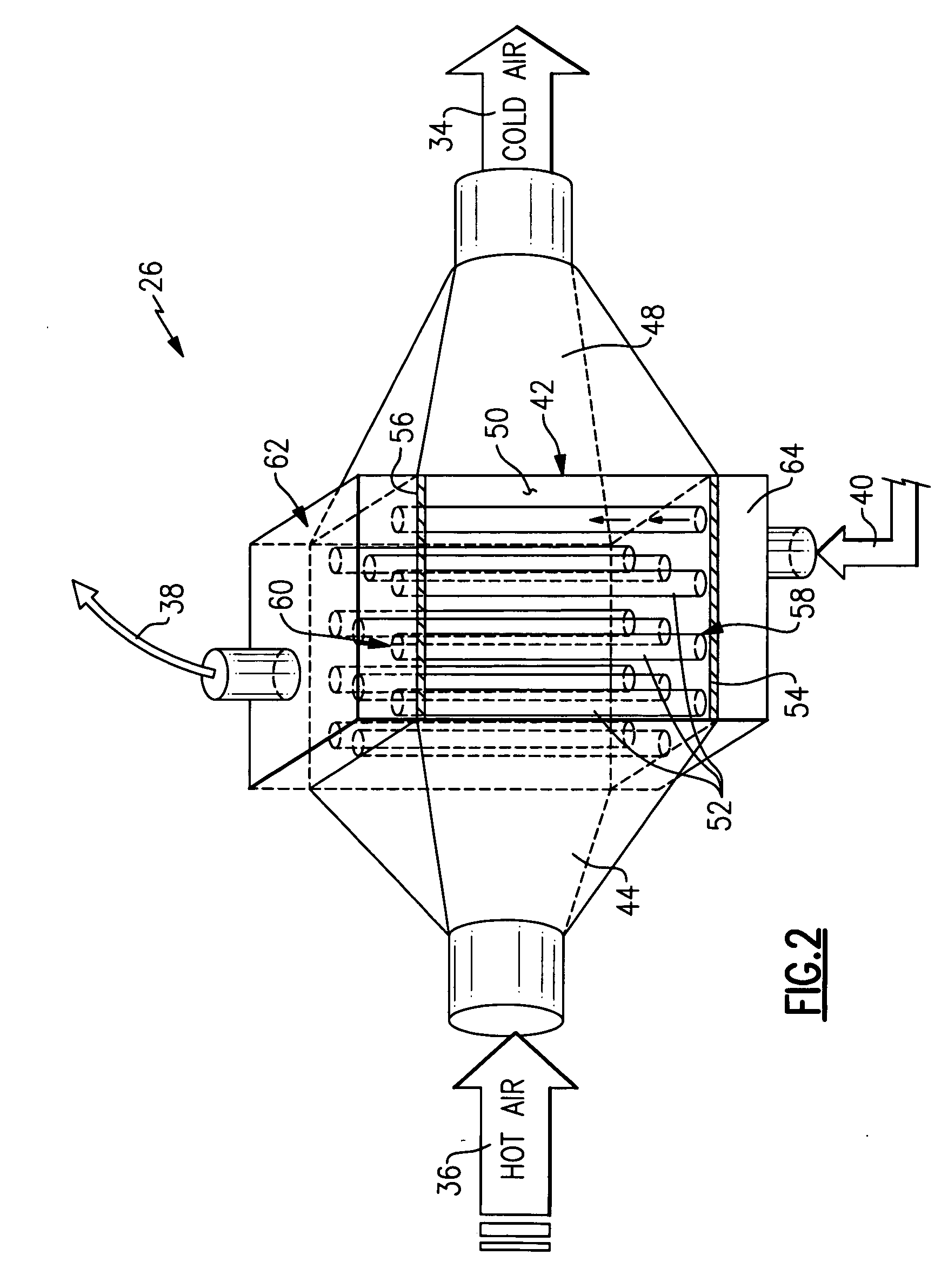

An intercooler is a mechanical device used to cool a gas after compression process. Compression process increases the internal energy of the gas which in turn raises its temperature and reduces the density. In other words intercooler is a device used in compression process, typically a heat exchanger that removes waste heat in a gas compressor. They are used in many applications, including air compressors, air conditioners, refrigeration, and gas turbines, and automotive engines. Here they are widely known as an air-to-air or air-to-liquid cooler for forced induction (turbocharged or supercharged) internal combustion engines to improve their volumetric efficiency, which they do by increasing intake air density through nearly constant pressure cooling. First introduced in 1977 on the Porsche 911, although these were the first cars to use intercoolers they were not the first cars to use turbochargers; in fact they weren’t even the first 911’s to use turbochargers.

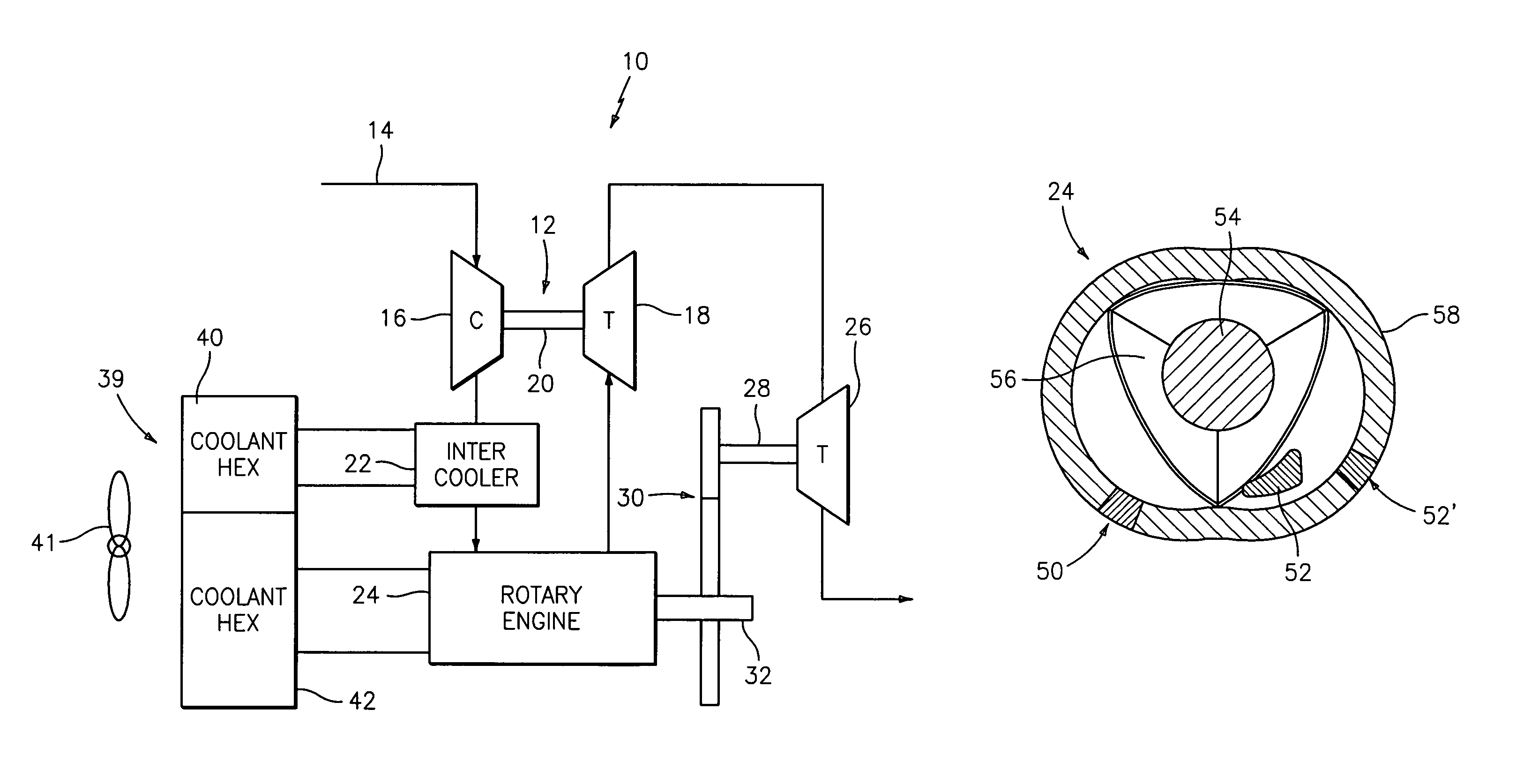

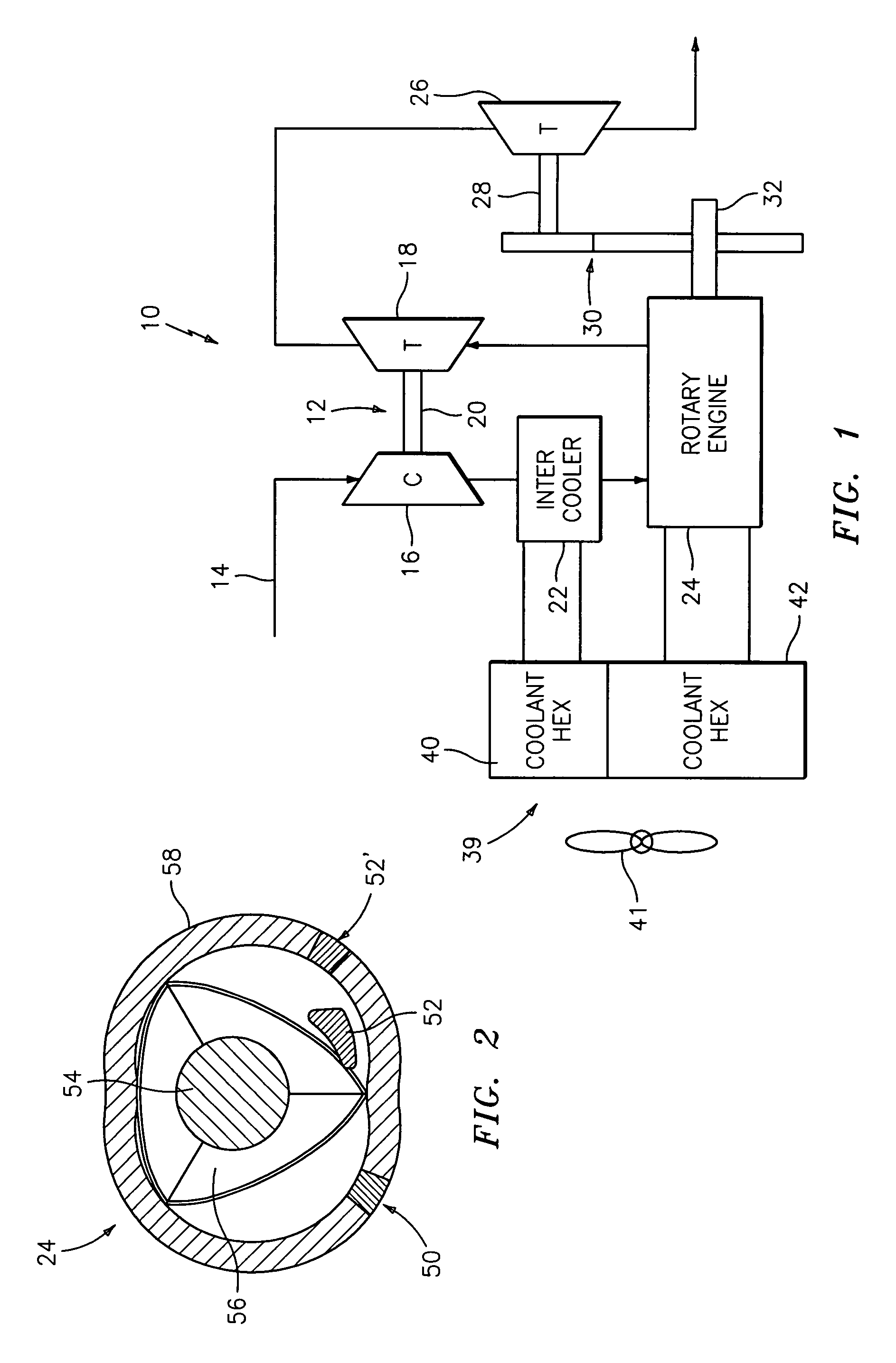

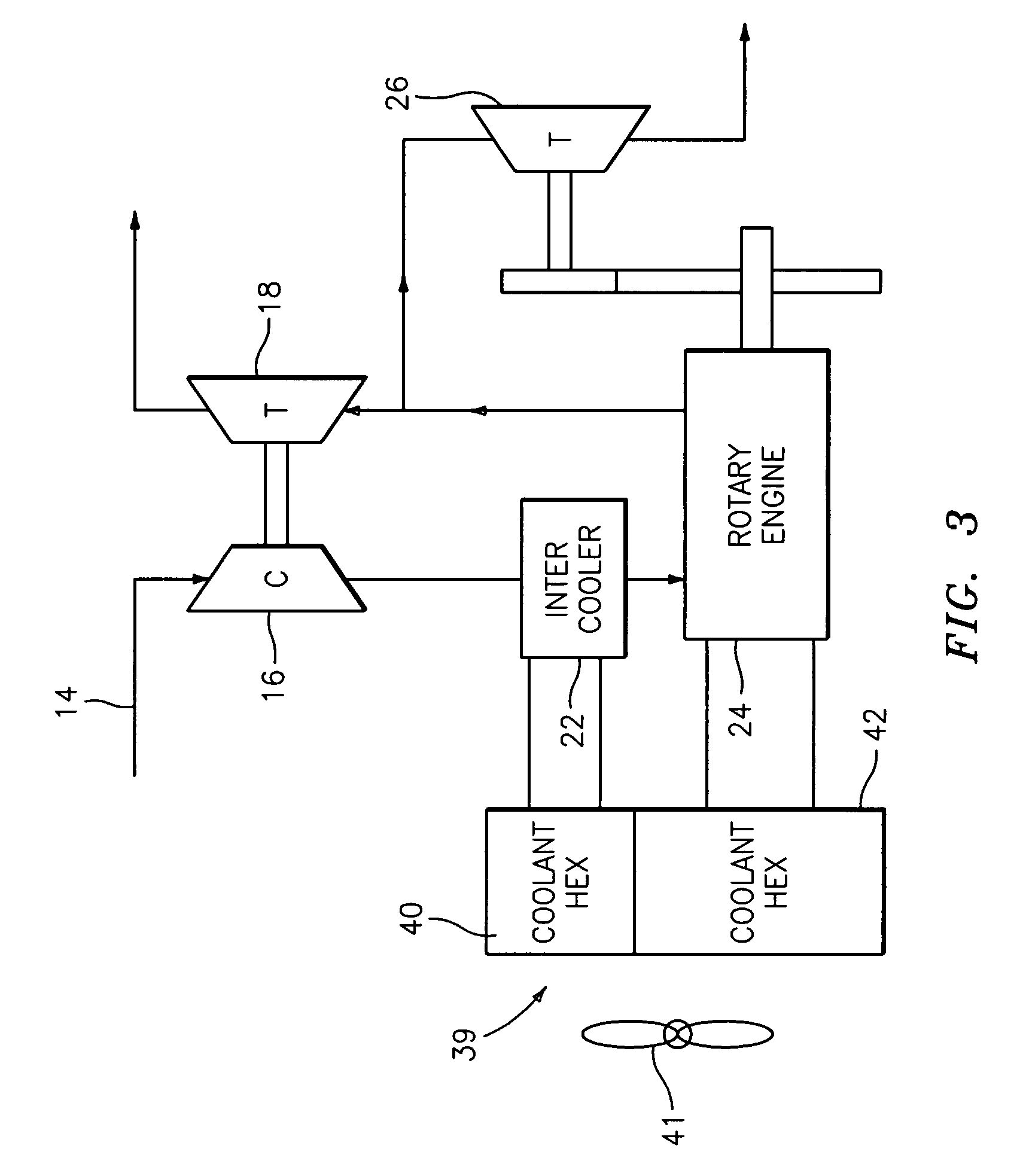

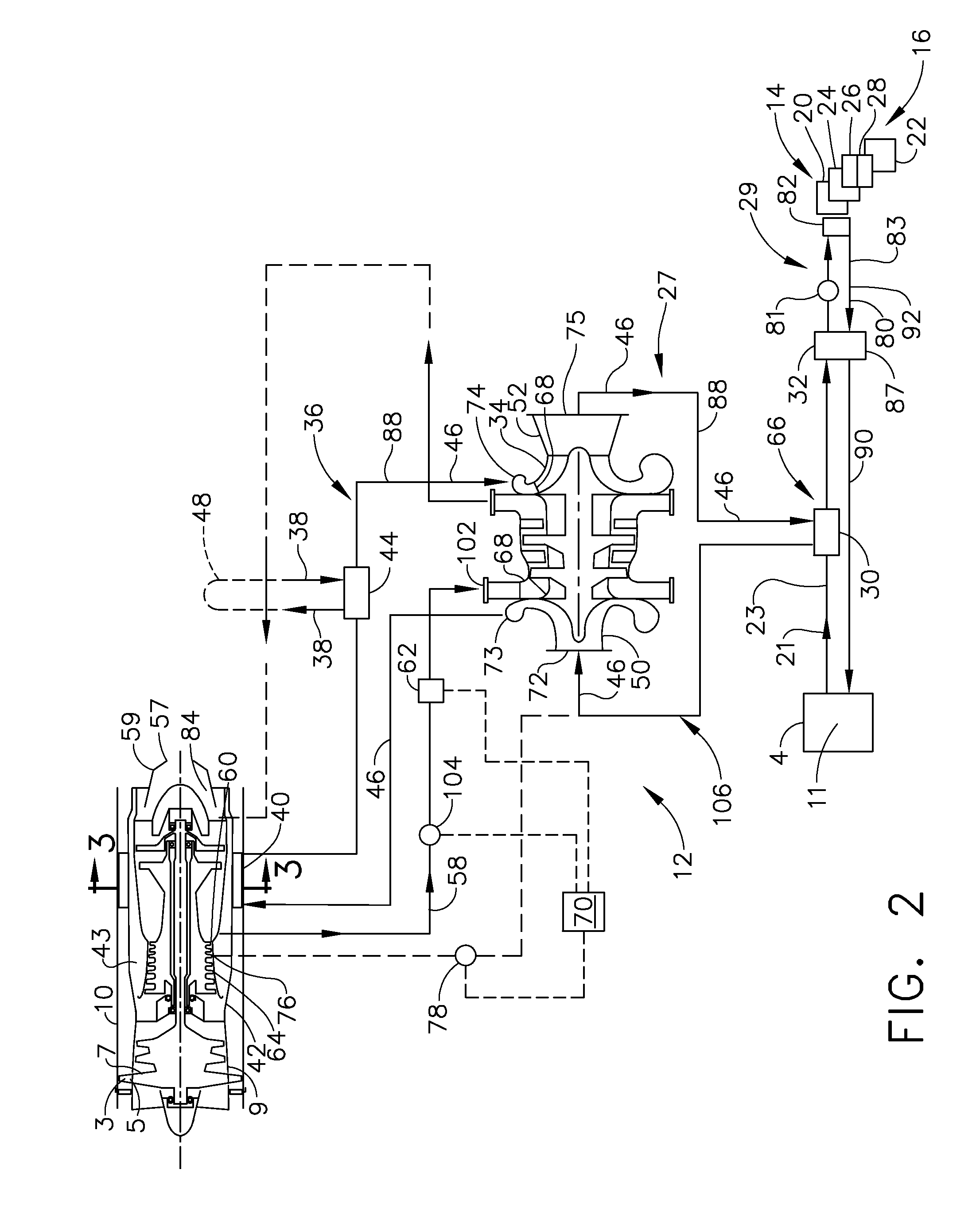

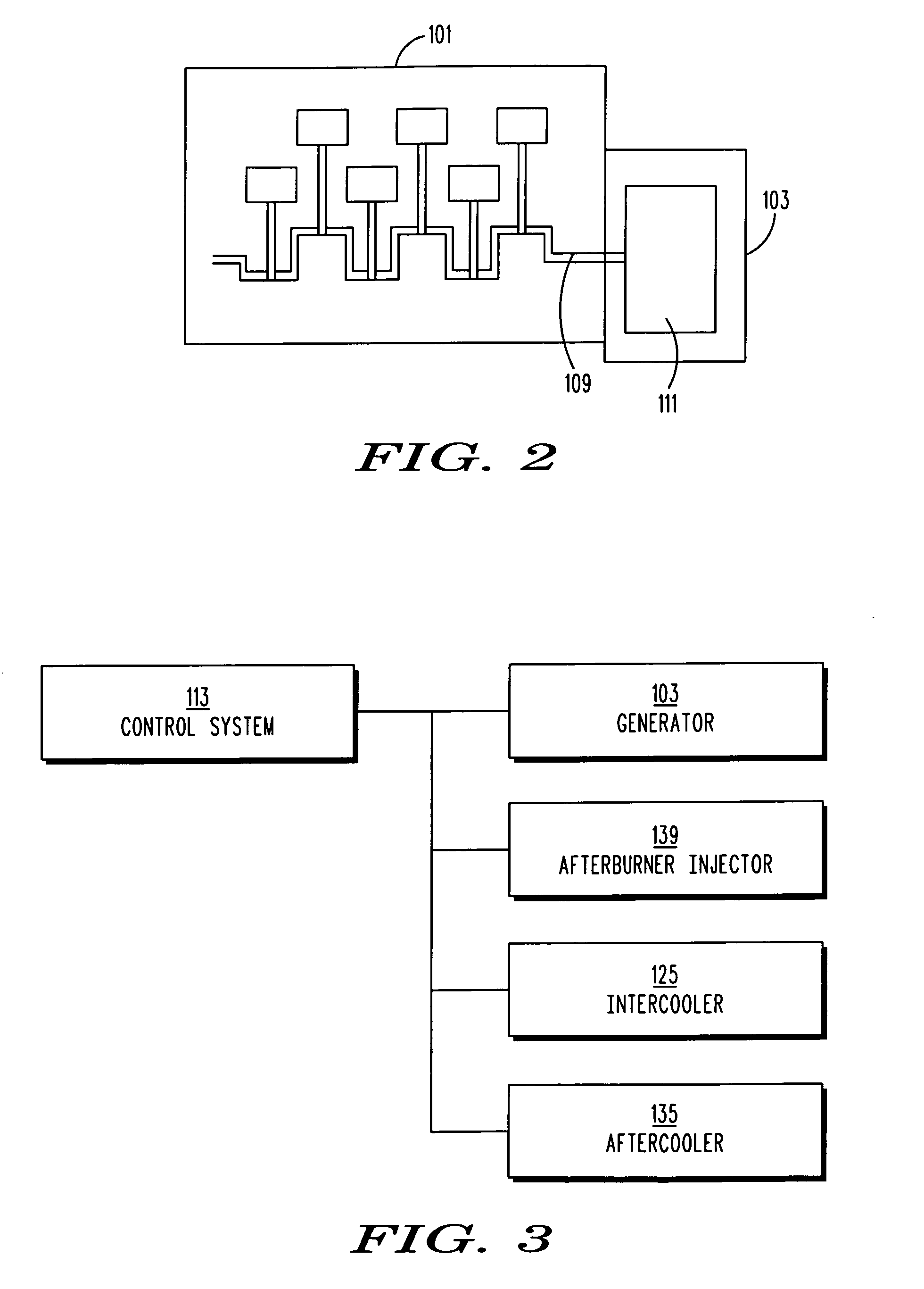

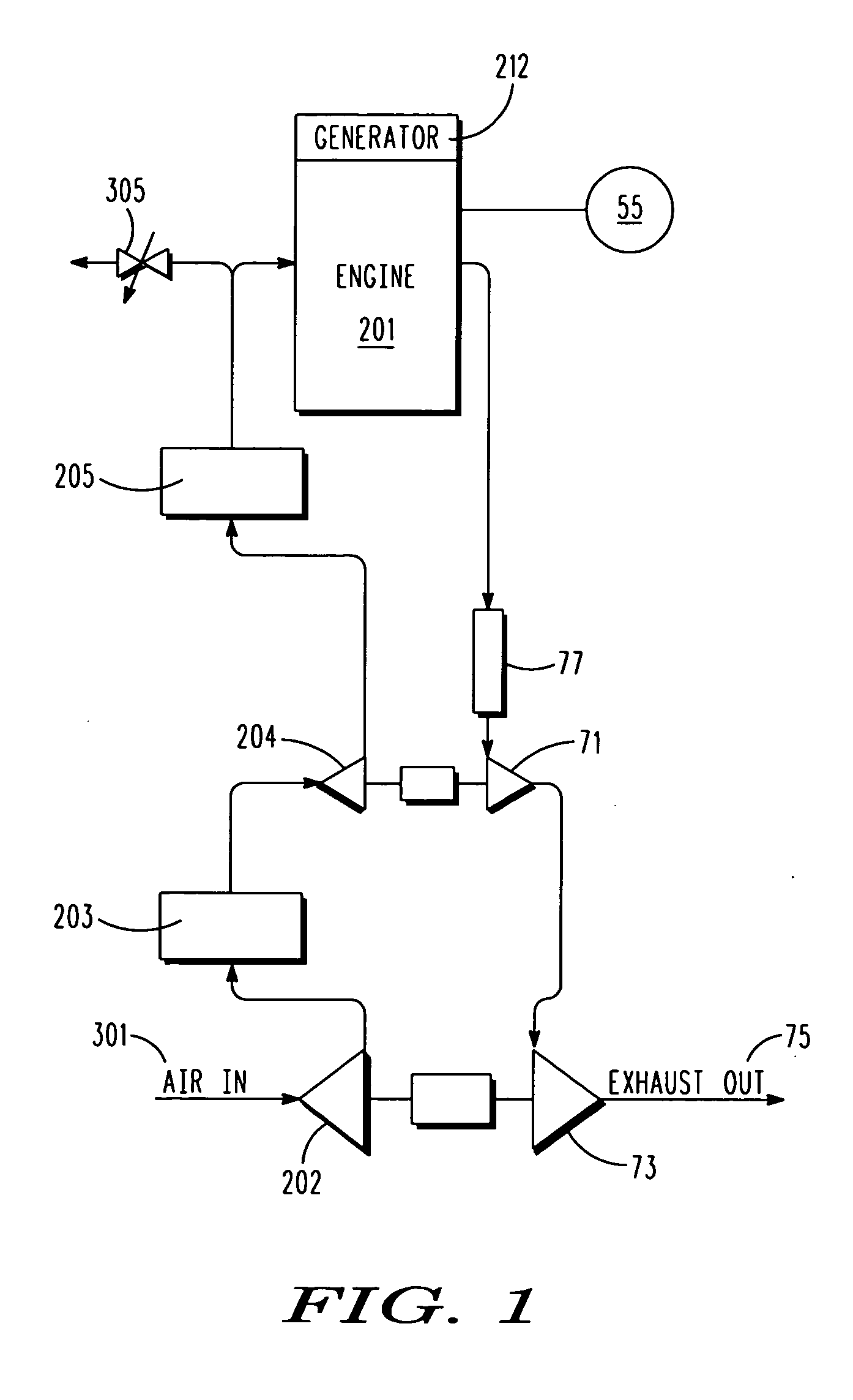

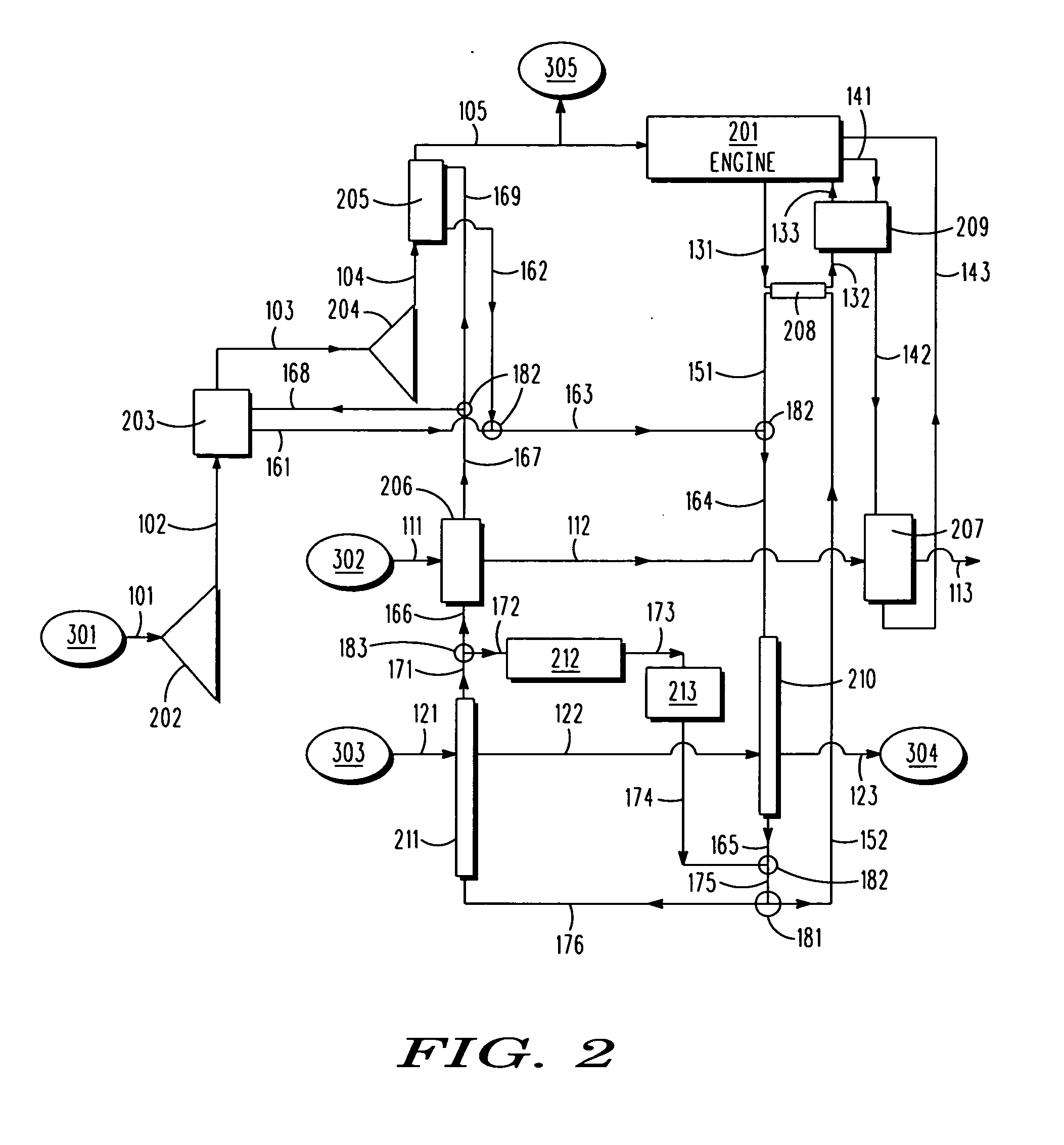

Compound cycle rotary engine

ActiveUS7753036B2High power to weightReduce fuel consumptionInternal combustion piston enginesCombination enginesRotary engineIntercooler

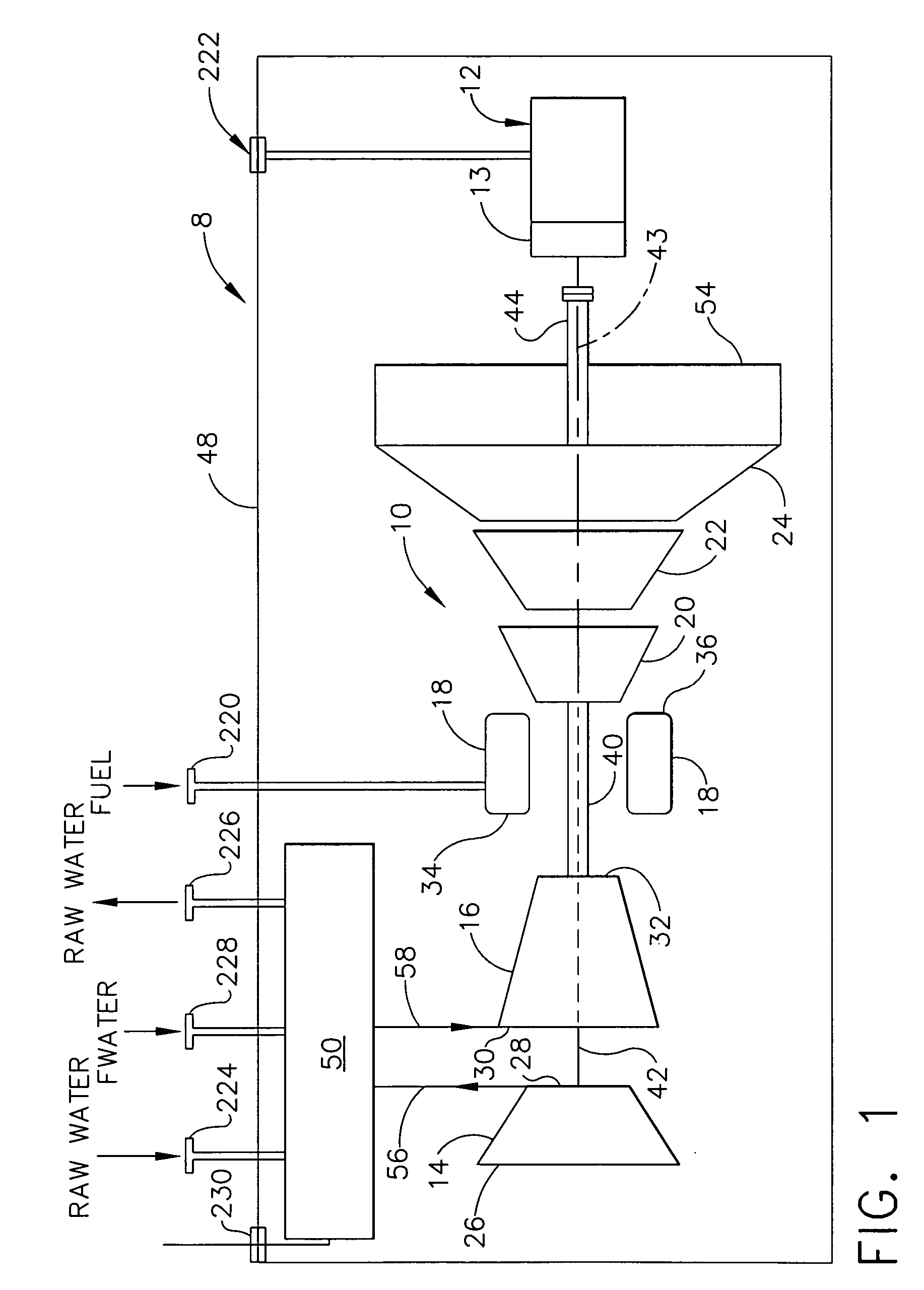

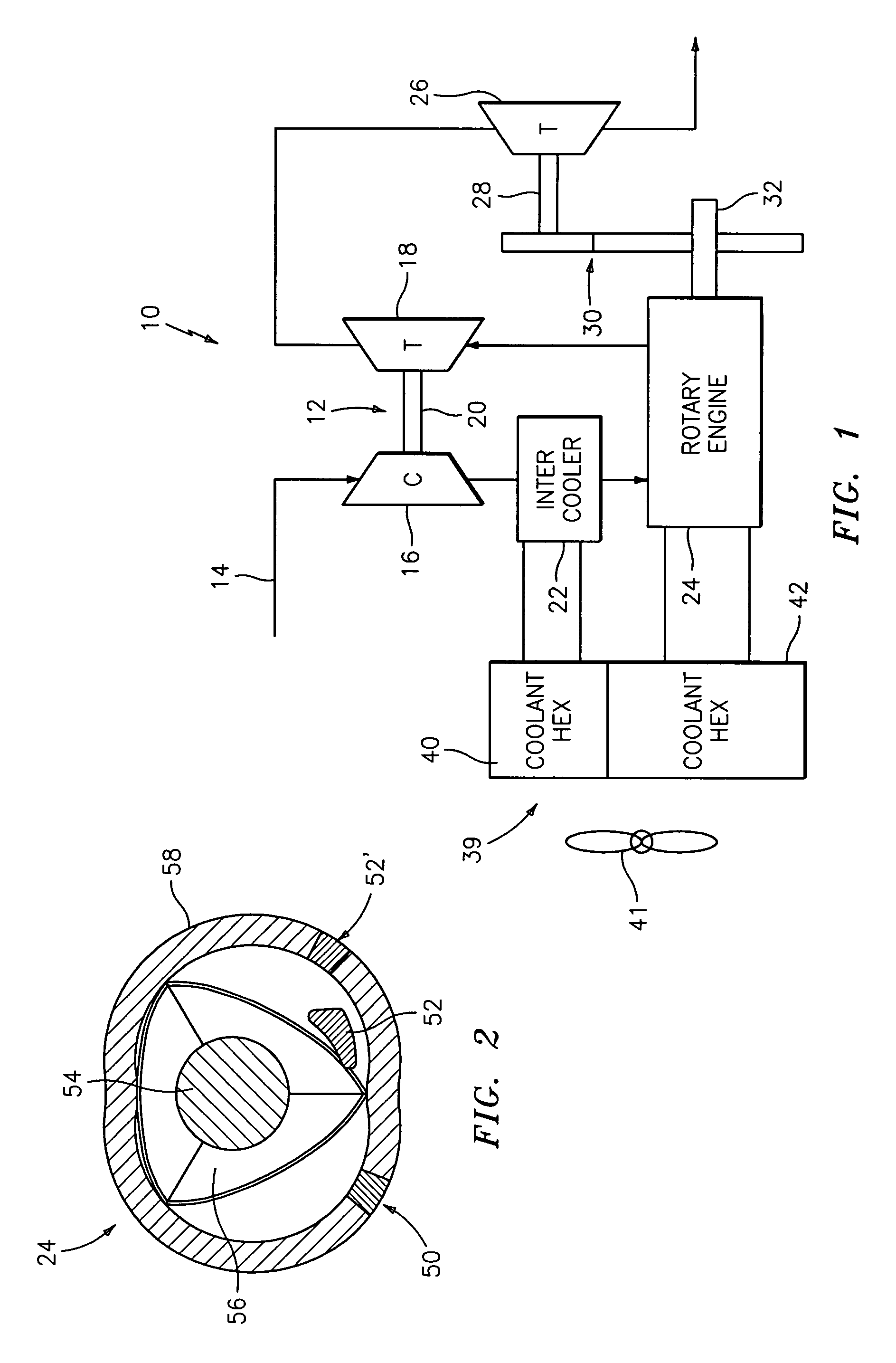

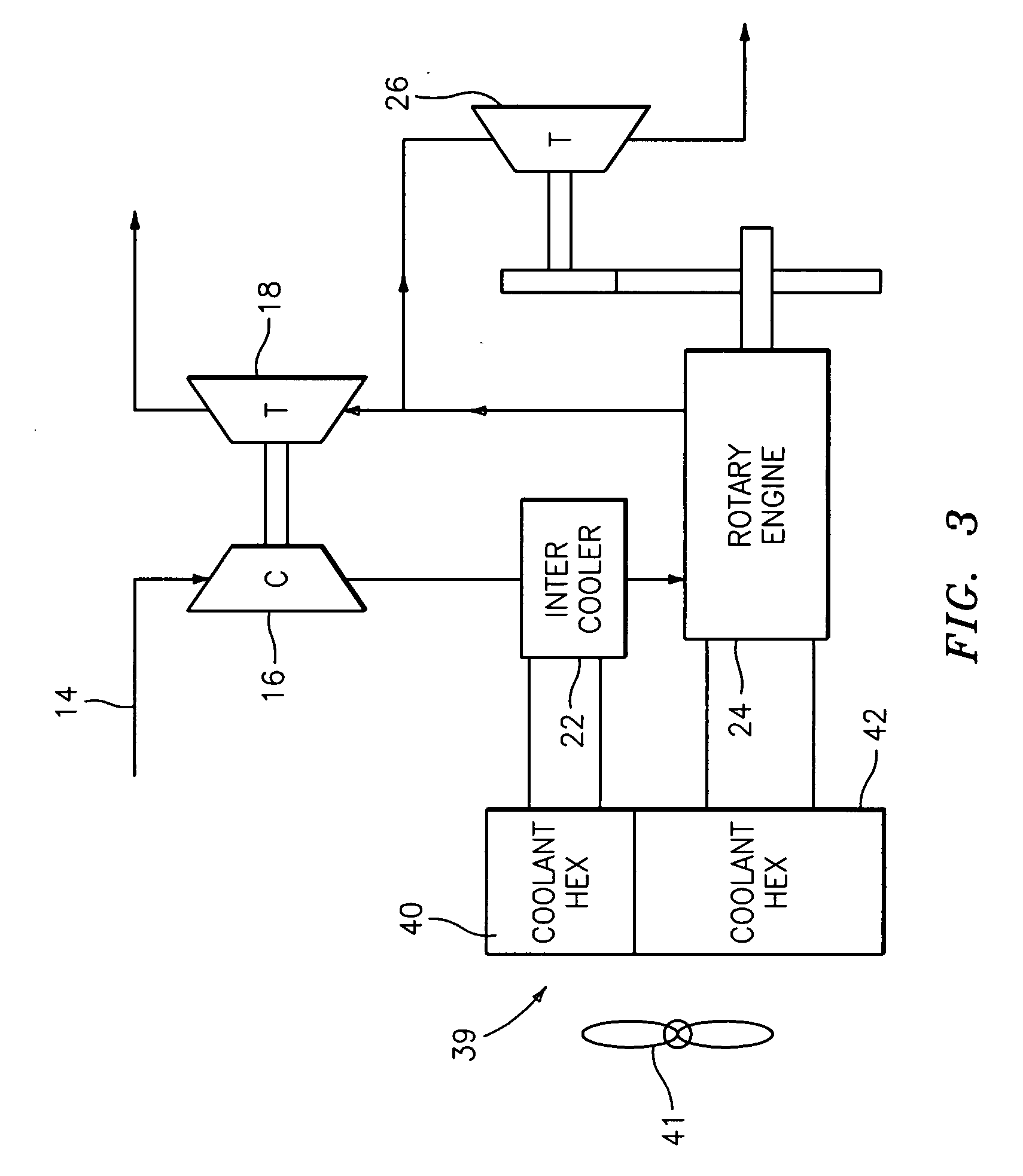

A compound cycle engine system has a rotary engine, which rotary engine generates exhaust gas. The system further has a compressor for increasing the pressure of inlet air to be supplied to the engine to a pressure in the range of from 3.0 to 5.0 atmospheres and an intercooler for providing the inlet air to the engine at a temperature in the range of from 150 to 250 degrees Fahrenheit. The system further has one or more turbines for extracting energy from the exhaust gas. The Miller Cycle is implemented in the rotary engine, enabling the compression ratio to be lower than the expansion ratio, allowing the overall cycle to be optimized for lowest weight and specific fuel consumption.

Owner:RTX CORP

Mobile gas turbine engine and generator assembly

InactiveUS20060254281A1Promote lowerLower operating temperatureTurbine/propulsion engine coolingGas turbine plantsIntercoolerGas turbines

A method for supplying power to a remote load includes coupling a gas turbine engine to a vessel that is not used to provide propulsion for the vessel, coupling a generator to the gas turbine engine, coupling an intercooler system downstream from a first compressor such that compressed air discharged from the first compressor is channeled therethrough, the intercooler system includes an intercooler and a first heat exchanger, channeling a first working fluid through the intercooler to facilitate reducing an operating temperature of air discharged from the intercooler to a second compressor, channeling a second working fluid flowing through the first heat exchanger to extract energy from the first working fluid to facilitate reducing an operating temperature of the first working fluid, and operating the gas turbine engine and generator to supply power to a load that is located remotely from the vessel.

Owner:GENERAL ELECTRIC CO

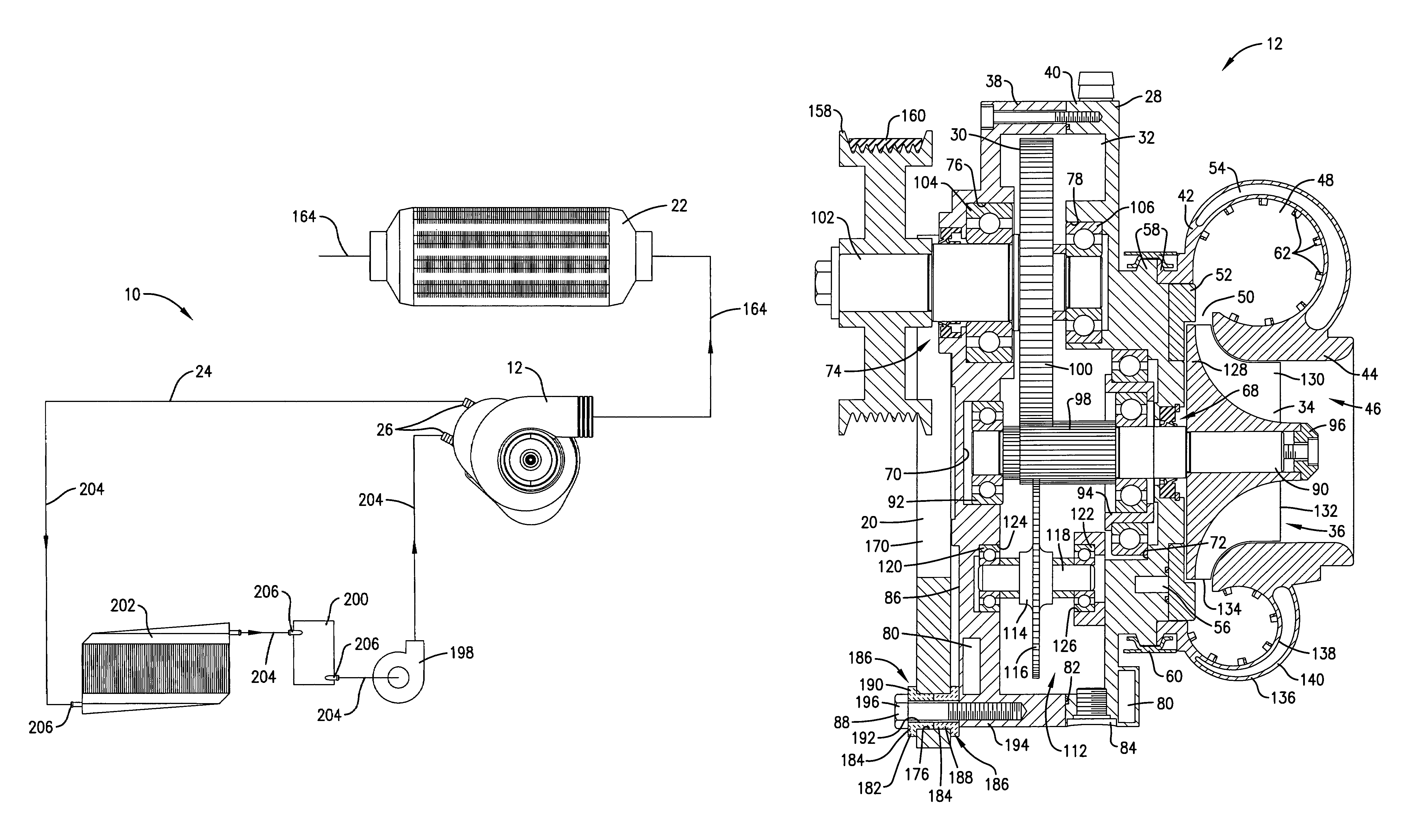

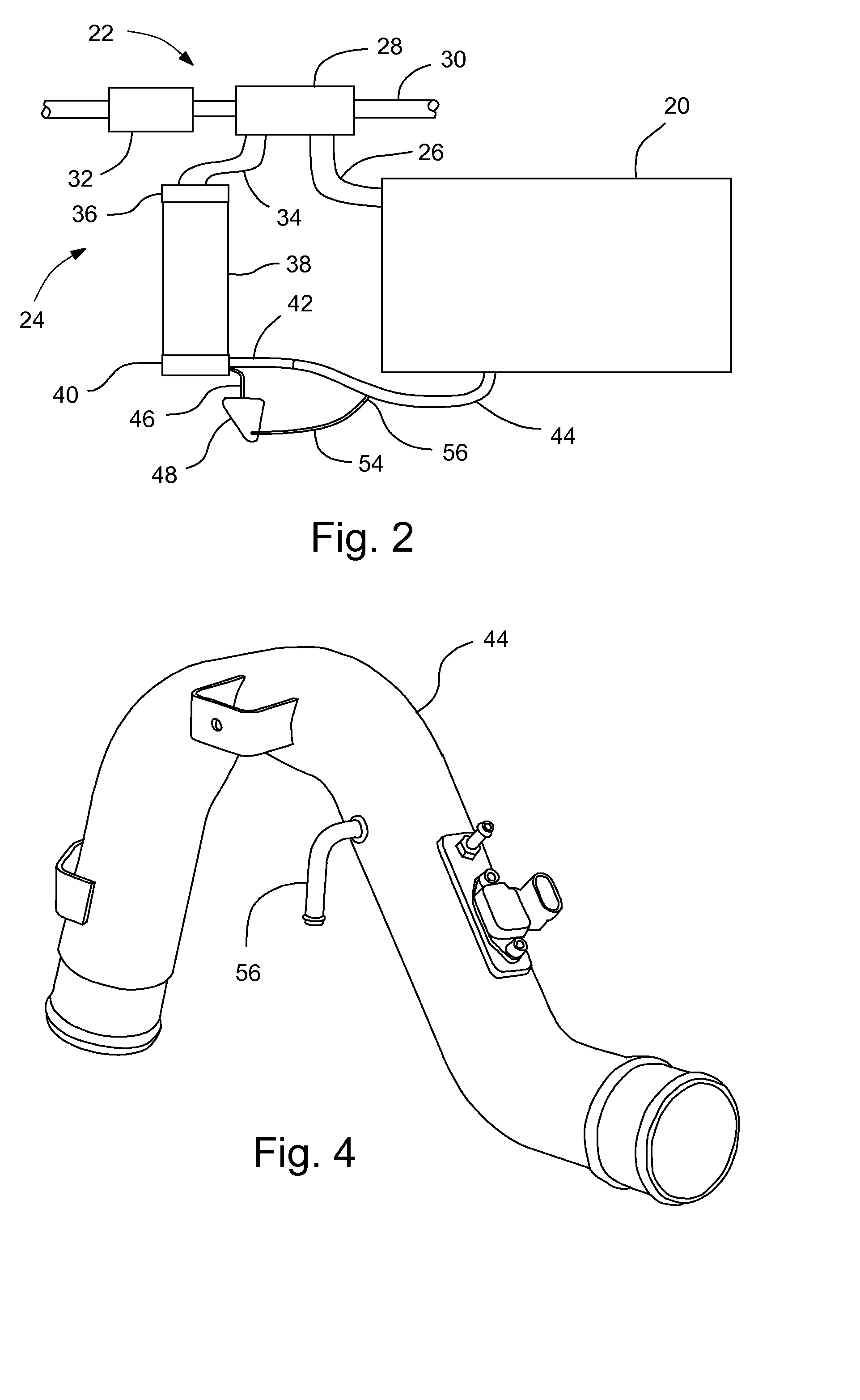

Fluid cooled supercharger

InactiveUS7469689B1Promotes an increase in inductionRaise transfer toPump componentsCombustion enginesForced-airIntercooler

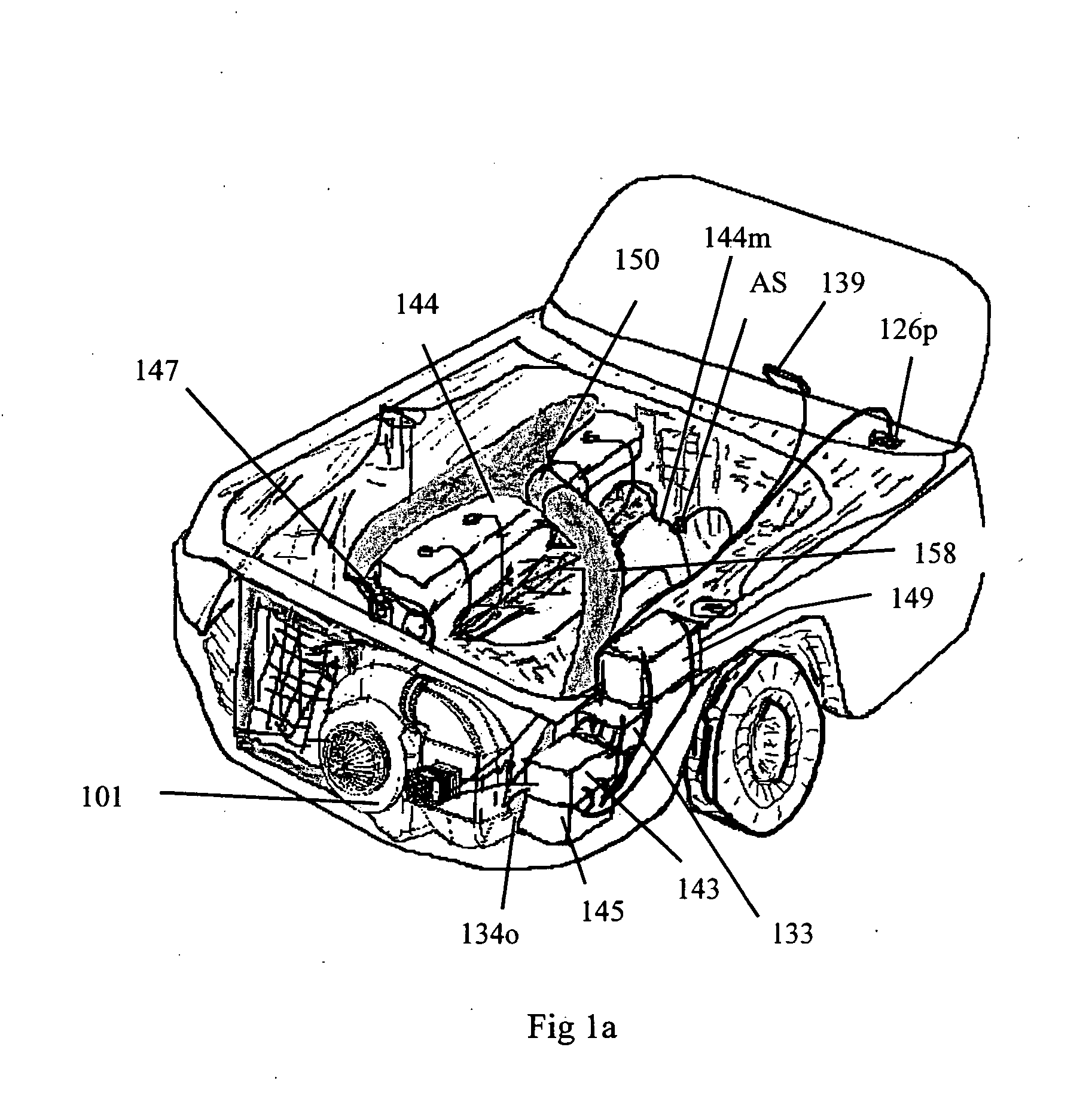

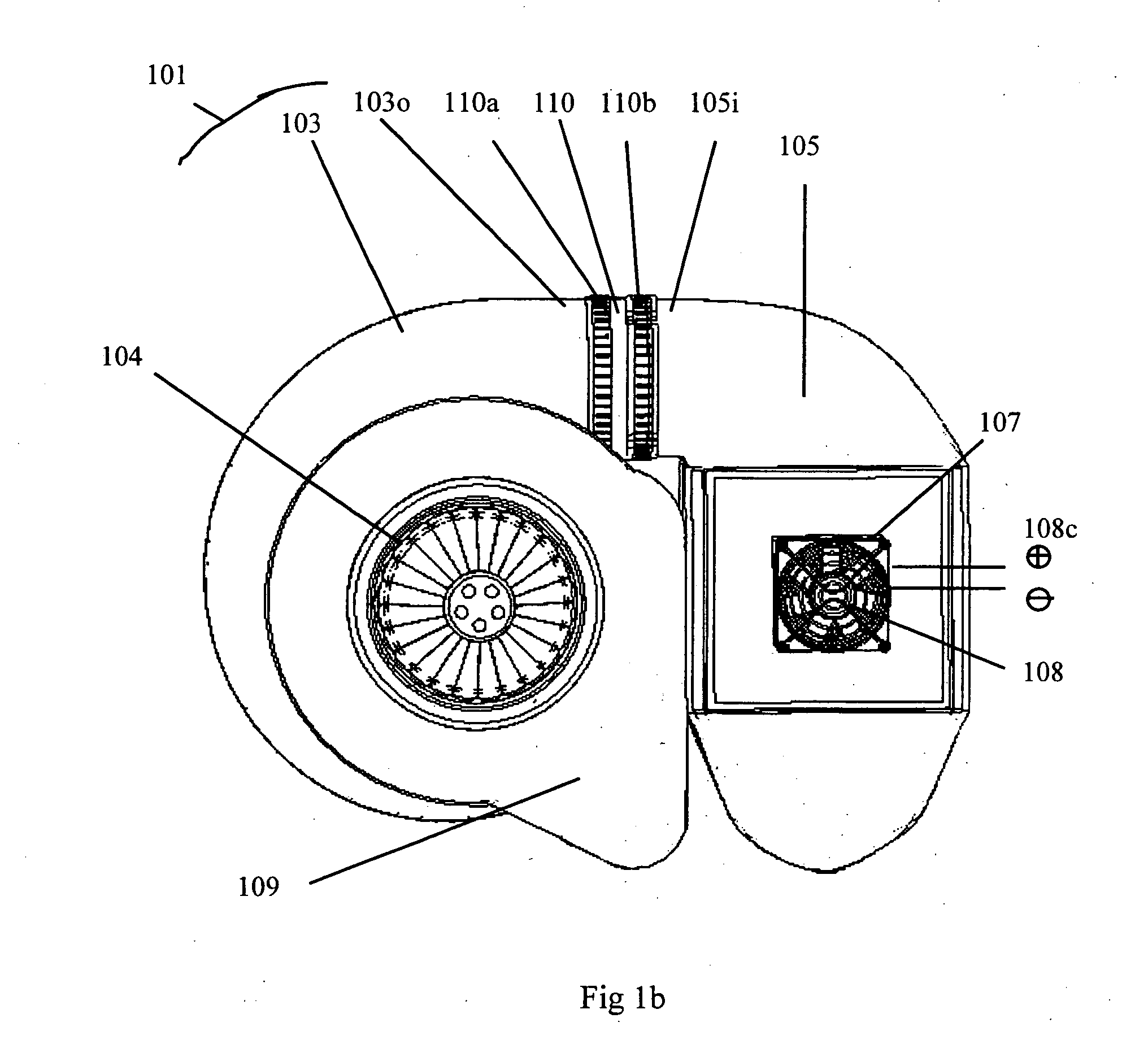

A forced air induction system for use with a powered vehicle is disclosed as including a centrifugal supercharger supported by the vehicle's engine and a recirculating induction coolant system that cools the supercharger and the compressed induction fluid provided by the supercharger. The induction coolant system operates by providing coolant to the supercharger and to an intercooler of the forced air induction system. The supercharger case includes internal passageways for cooling the transmission and compressor. The forced air induction system further includes spacers and radiant heat shields for rejecting heat transferred conductively and radiantly from the engine.

Owner:ACCESSIBLE TECHONOLOGIES

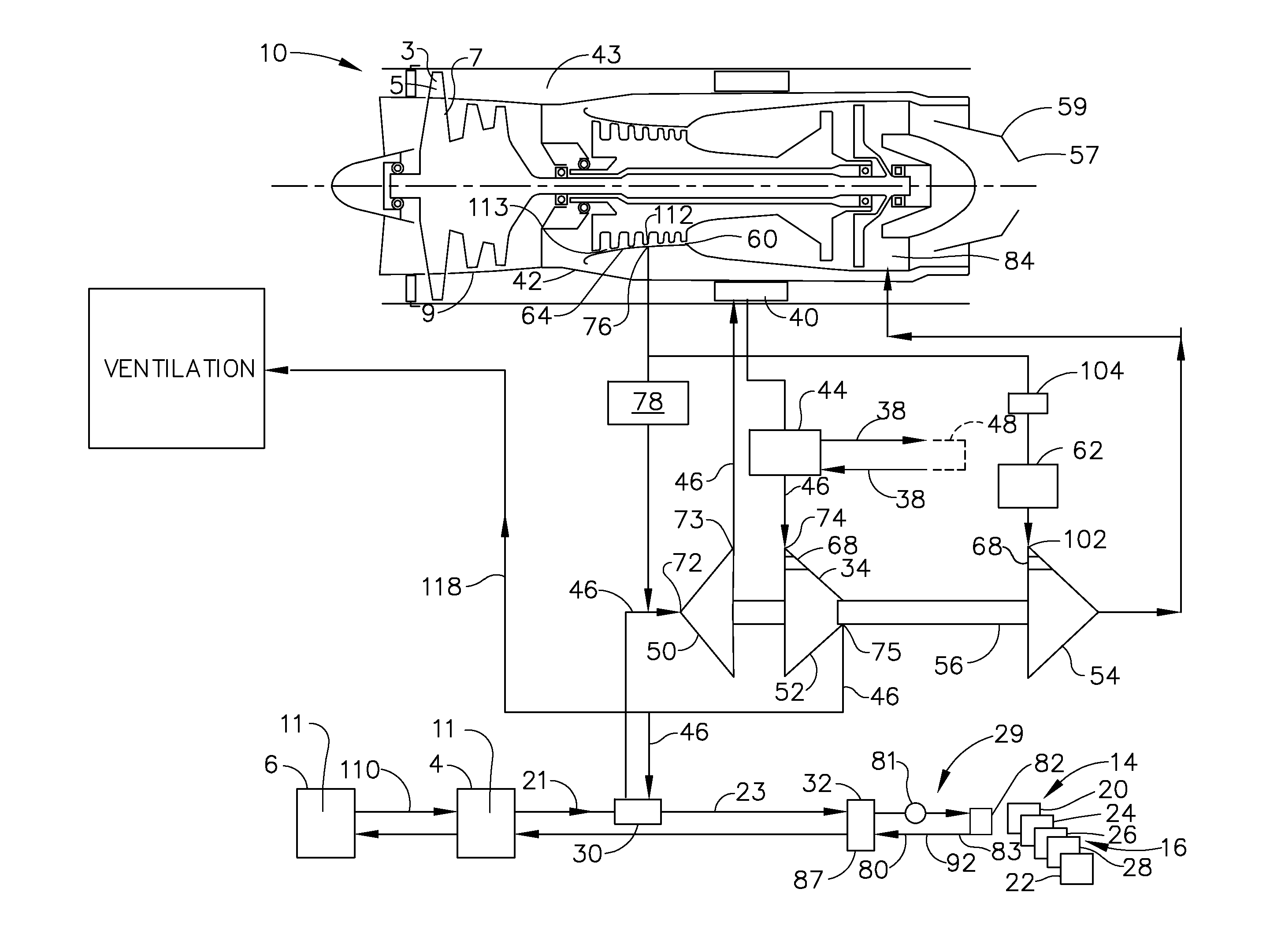

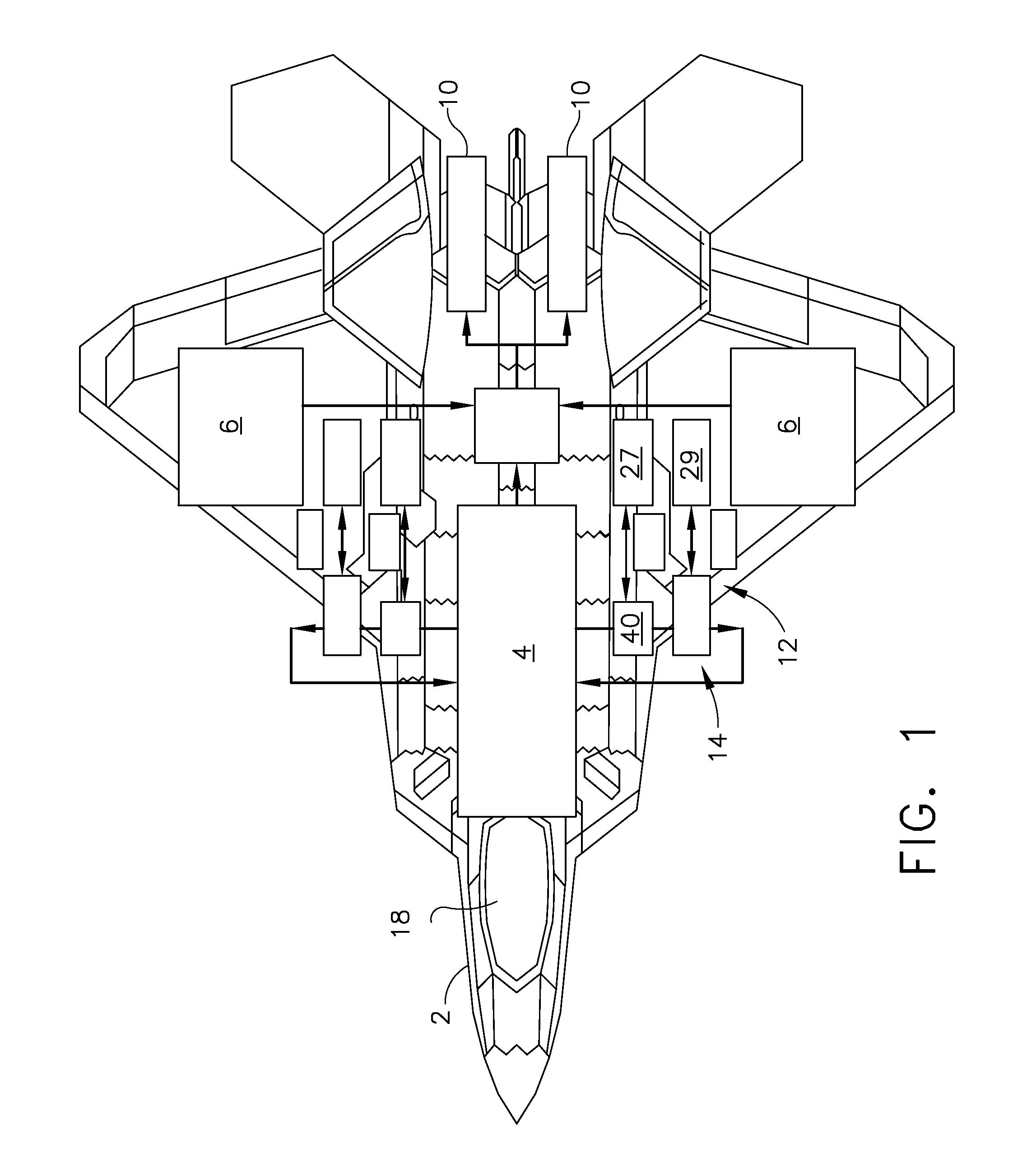

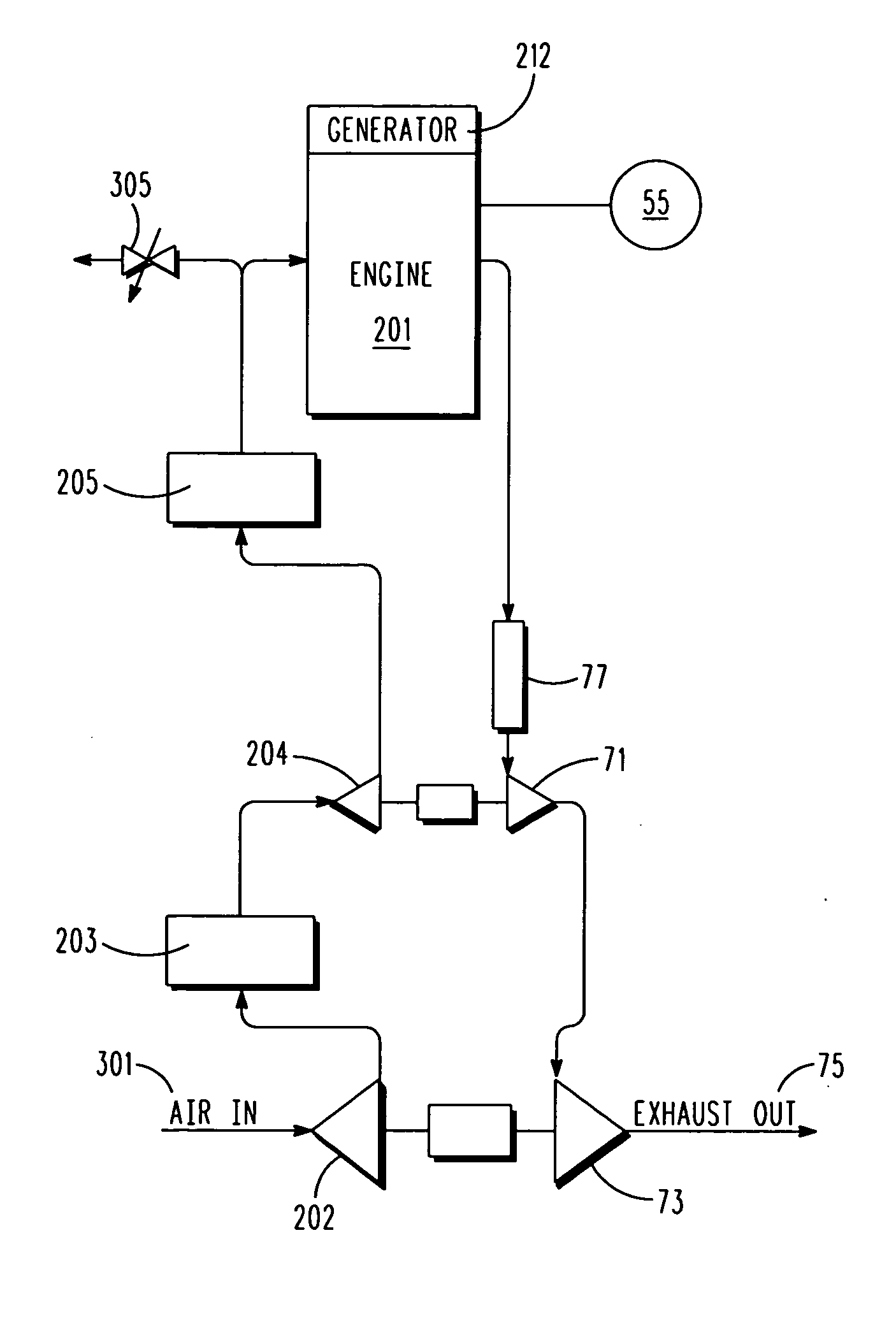

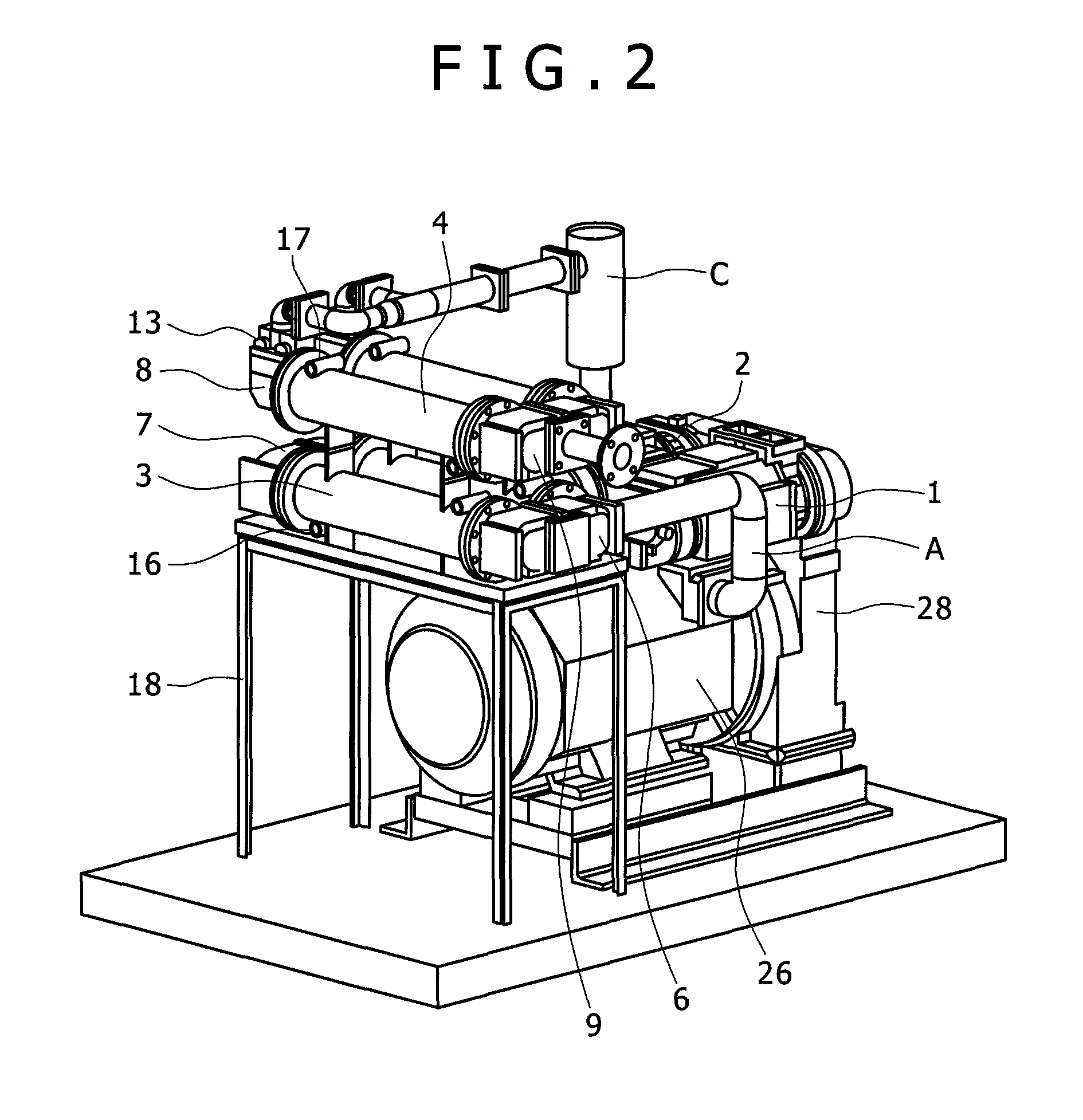

Compound cycle rotary engine

ActiveUS20090007882A1Reduce fuel consumptionHigh power to weightInternal combustion piston enginesCombination enginesRotary engineIntercooler

A compound cycle engine system has a rotary engine, which rotary engine generates exhaust gas. The system further has a compressor for increasing the pressure of inlet air to be supplied to the engine to a pressure in the range of from 3.0 to 5.0 atmospheres and an intercooler for providing the inlet air to the engine at a temperature in the range of from 150 to 250 degrees Fahrenheit. The system further has one or more turbines for extracting energy from the exhaust gas. The Miller Cycle is implemented in the rotary engine, enabling the compression ratio to be lower than the expansion ratio, allowing the overall cycle to be optimized for lowest weight and specific fuel consumption.

Owner:RTX CORP

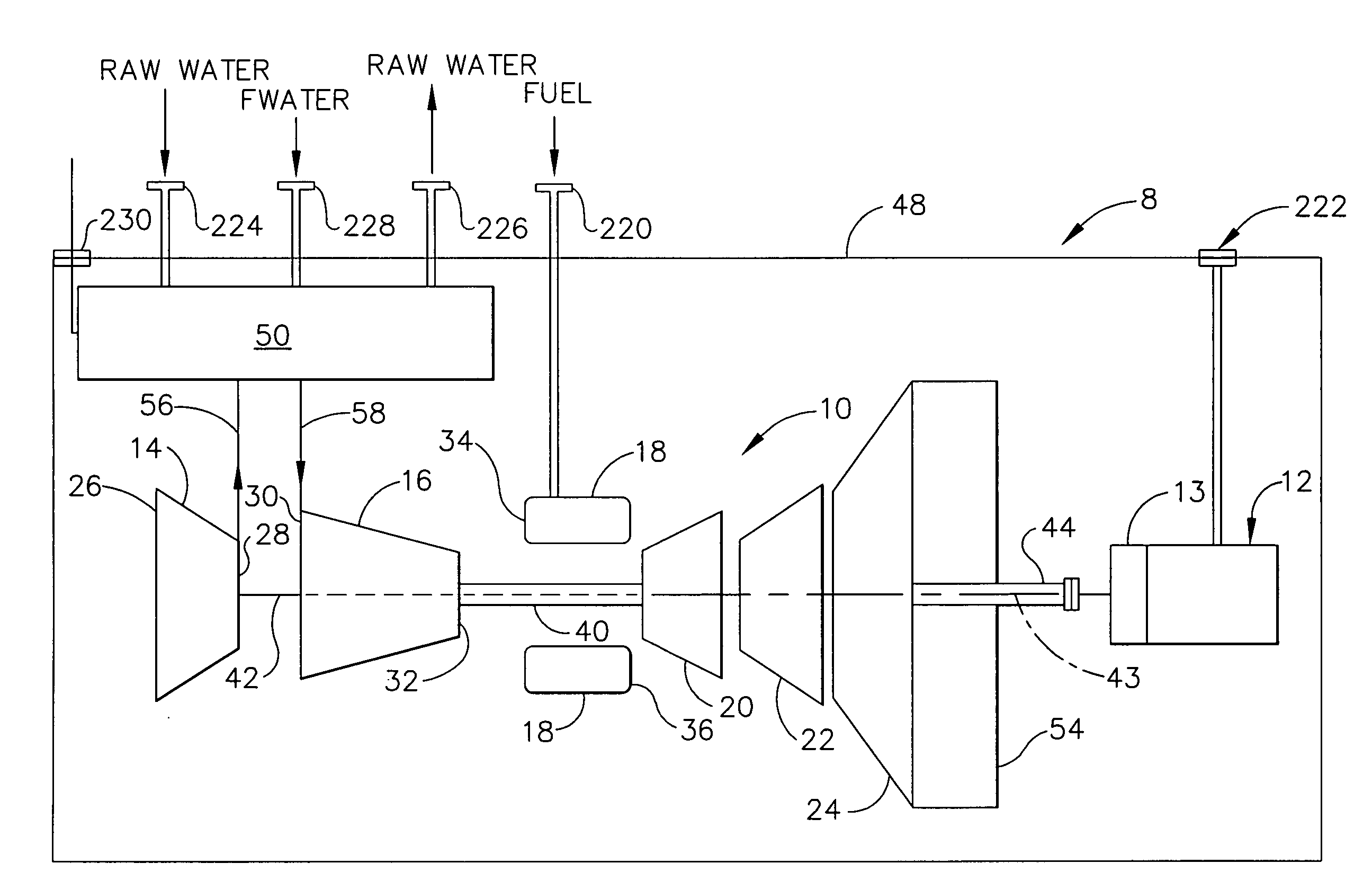

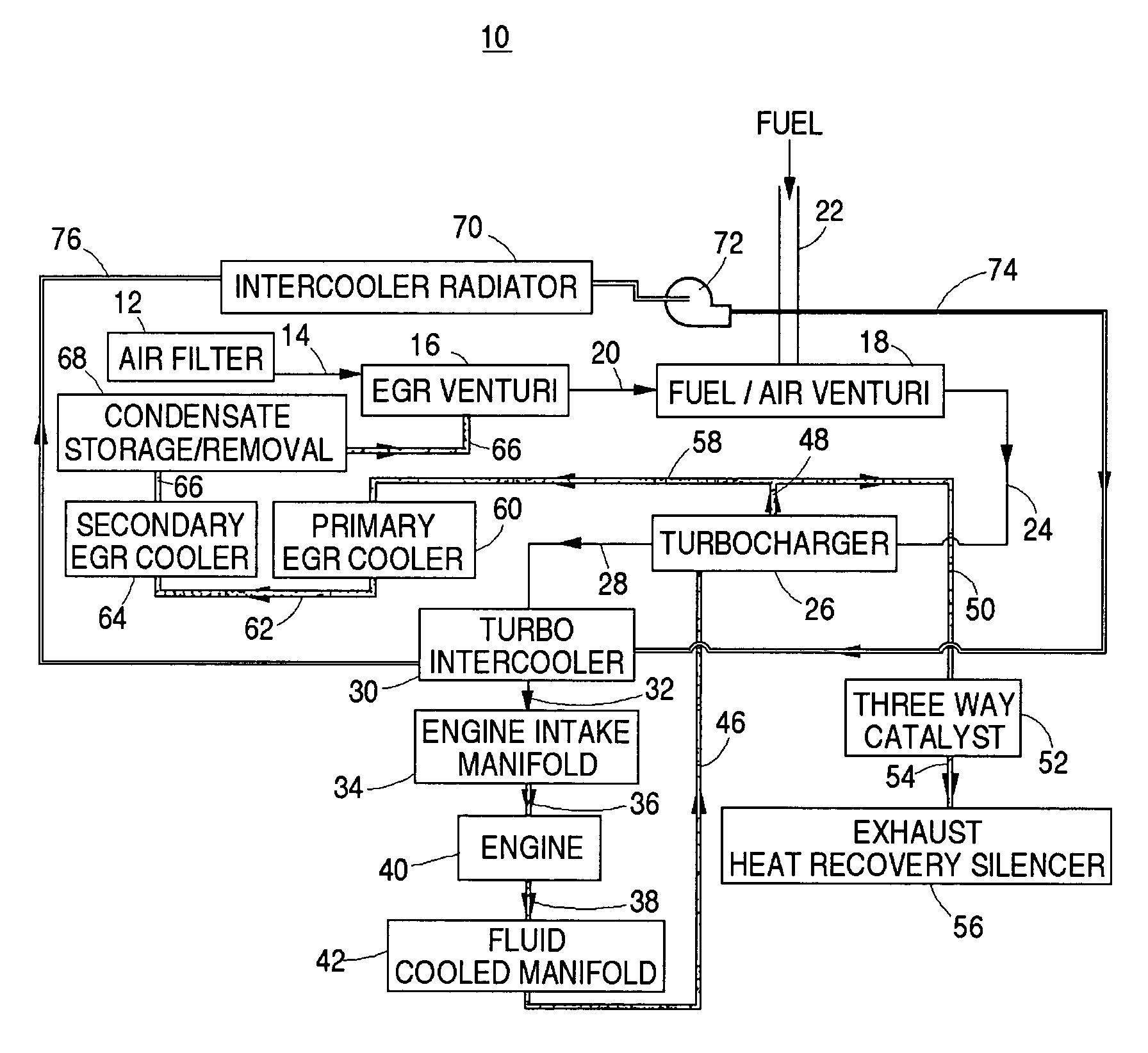

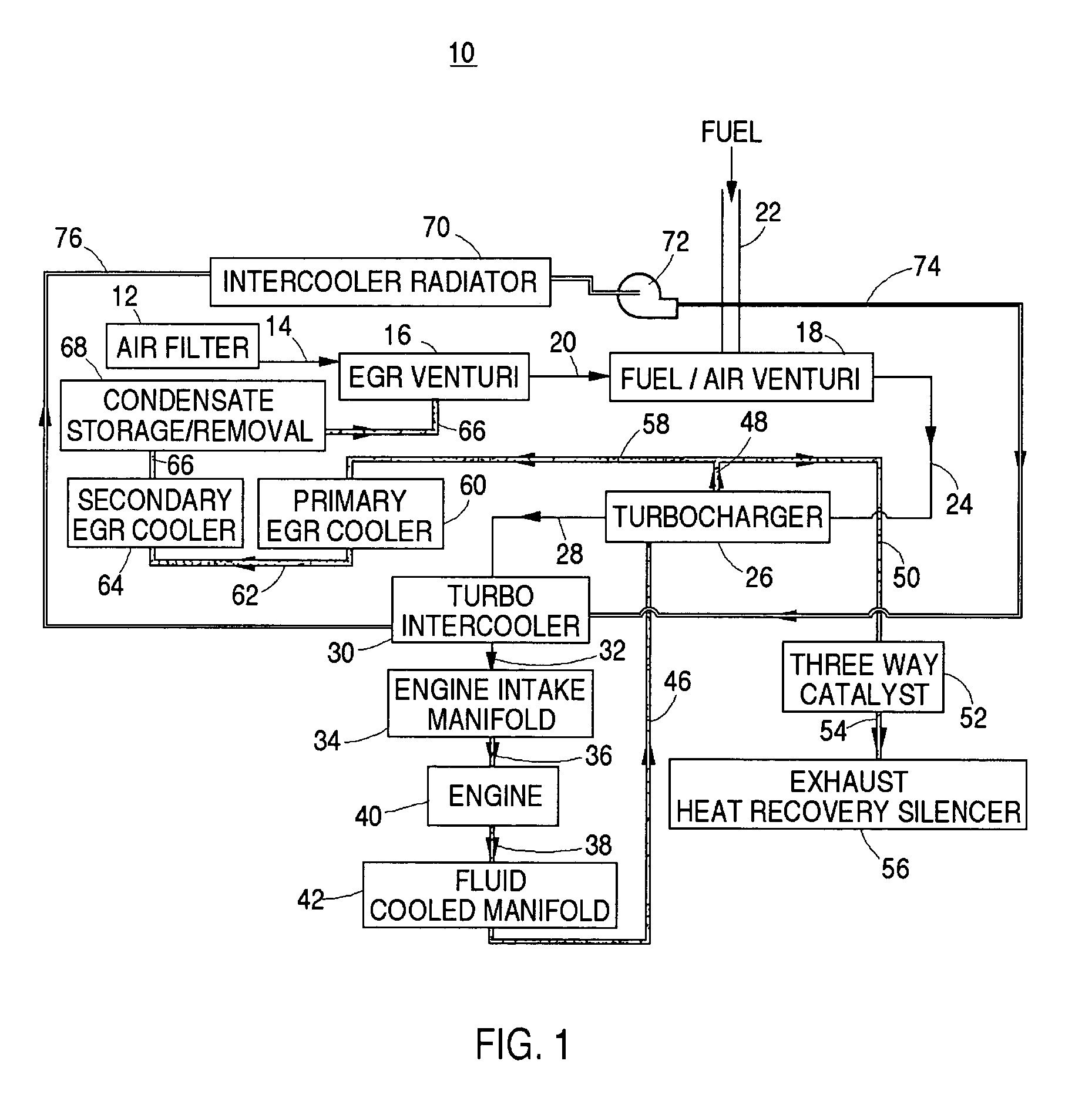

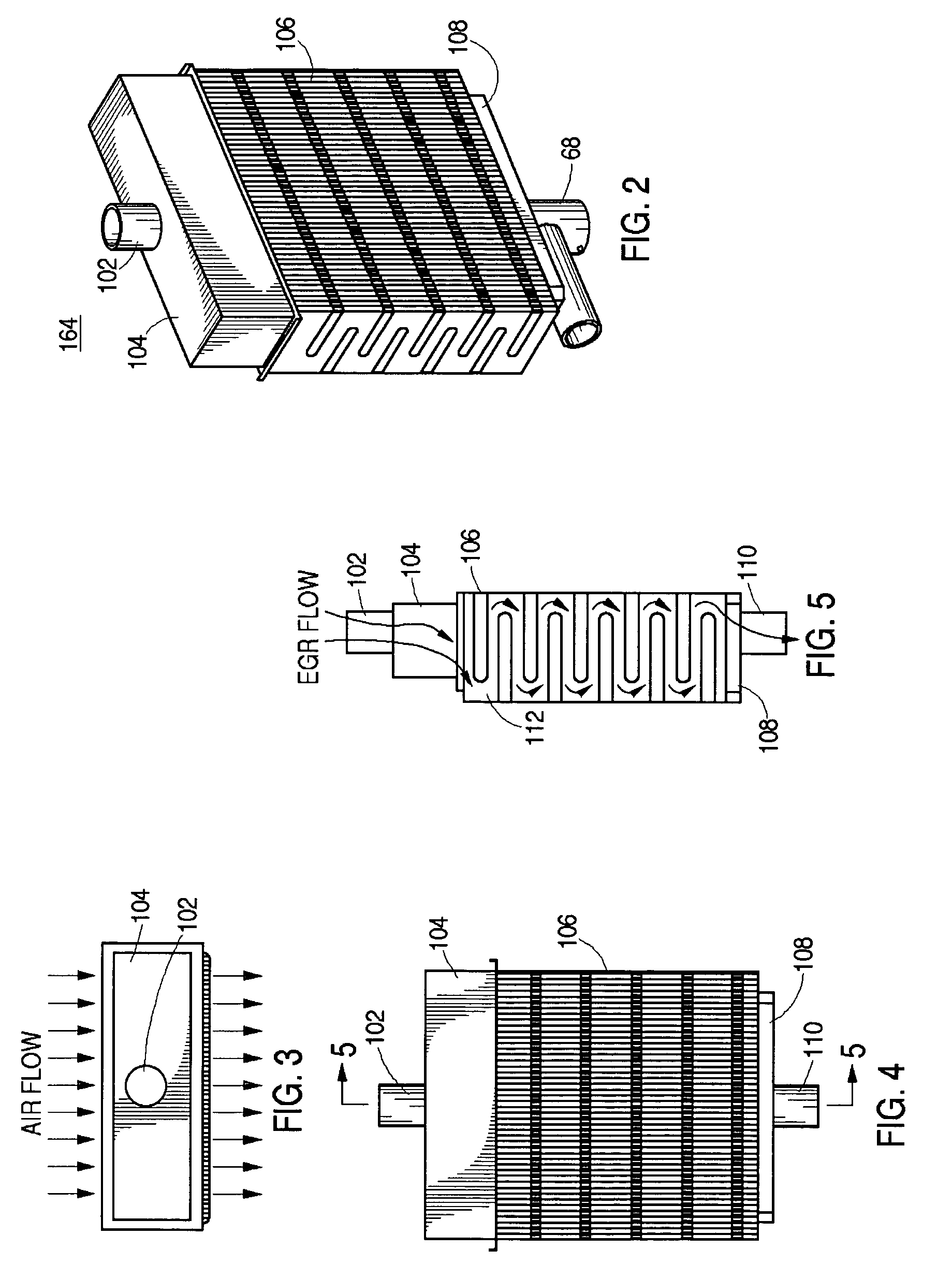

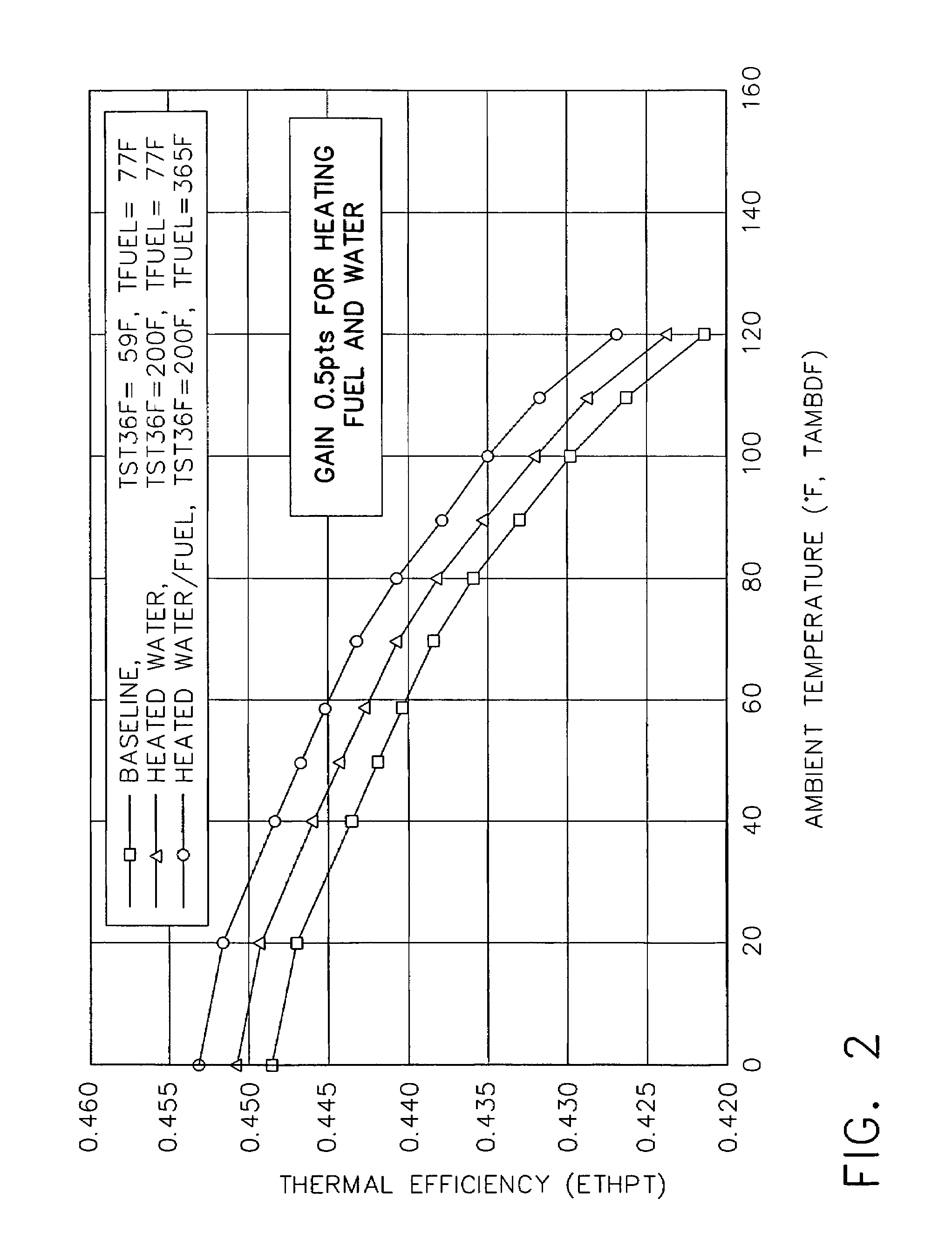

EGR cooling and condensate regulation system for natural gas fired co-generation unit

InactiveUS6978772B1Improve efficiencyReduce condensationNon-fuel substance addition to fuelInternal combustion piston enginesWater vaporCogeneration

A recycled exhaust gas cooling and condensate regulation system for a natural gas fired internal combustion engine driven co-generation plant, which allows efficient exhaust recycled gas combustion while maintaining lower head temperatures to reduce thermal NOx emissions and delivering increased process / utility heat to a proximate co-generation client, is provided. The recycled exhaust gas cooling and condensate regulation system has primary and secondary, air-to-gas, exchanger units, coupled in series, such that the first unit, designed to take exhaust gas exiting the engine, cools the gas to a first exhaust gas temperature effectively super saturating the water vapor in the cooled exhaust gas; and, the second unit, designed to handle lower inlet temperatures, condenses the water vapor and super cools the exhaust gas to <130 F. In one embodiment, the engine intake mixture including the exhaust gas is supercharged. In another embodiment, a separate intercooler circuit is used to cool the compressed intake charge containing the recycled gas prior to entry into the intake engine manifold to further reduce head temperatures and control thermal NOx emissions.

Owner:CHAPEAU

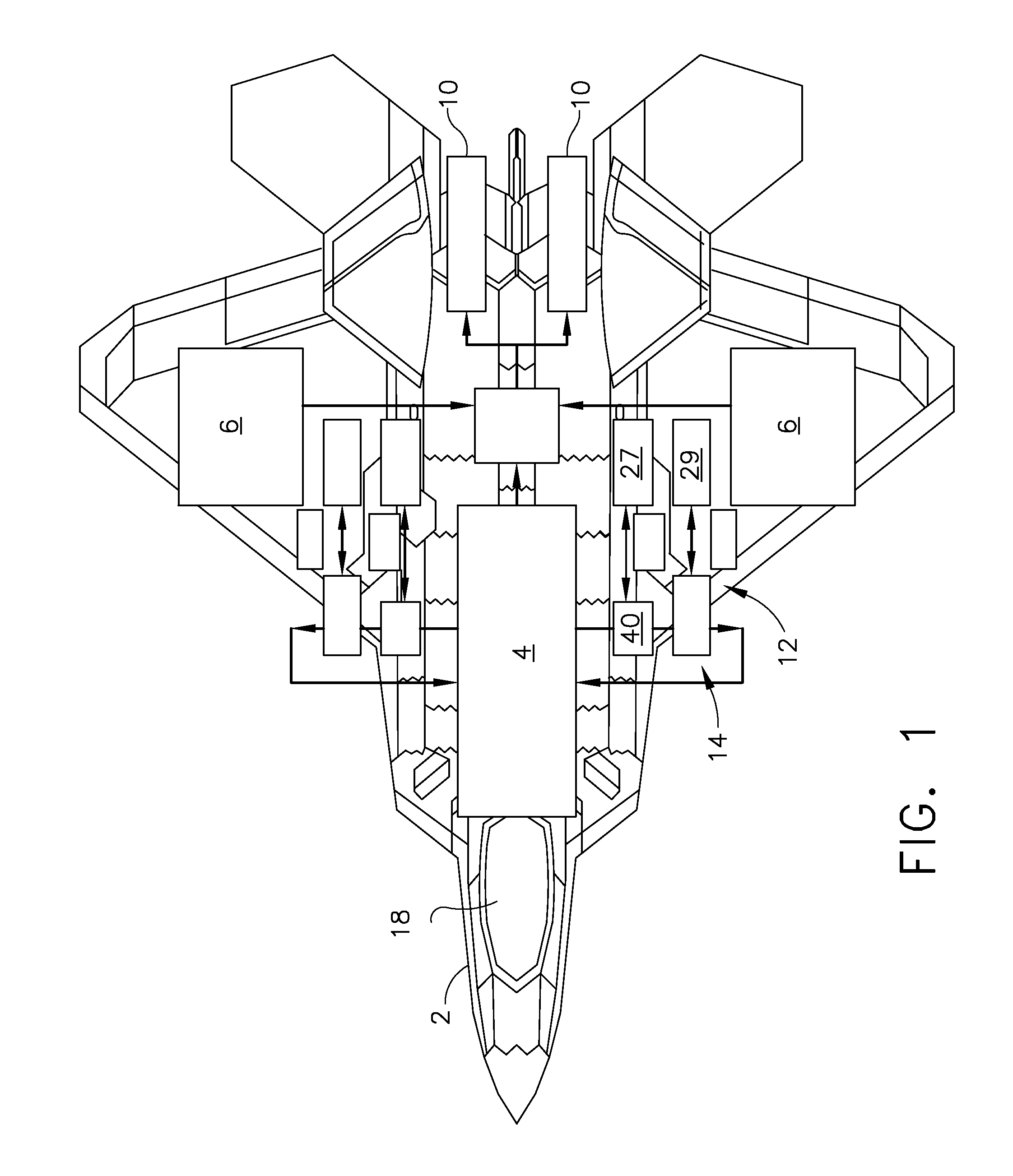

Adaptive power and thermal management system

ActiveUS20120000205A1Improve cooling effectDomestic cooling apparatusTurbine/propulsion engine coolingAir cycleFuel tank

An aircraft adaptive power thermal management system for cooling one or more aircraft components includes an air cycle system, a vapor cycle system, and a fuel recirculation loop operably disposed therebetween. An air cycle system heat exchanger is between the air cycle system and the fuel recirculation loop, a vapor cycle system heat exchanger is between the vapor cycle system and the fuel recirculation loop, and one or more aircraft fuel tanks are in the fuel recirculation loop. An intercooler including a duct heat exchanger in an aircraft gas turbine engine FLADE duct may be in the air cycle system. The system is operable for providing on-demand cooling for one or more of the aircraft components by increasing heat sink capacity of the fuel tanks.

Owner:GENERAL ELECTRIC CO

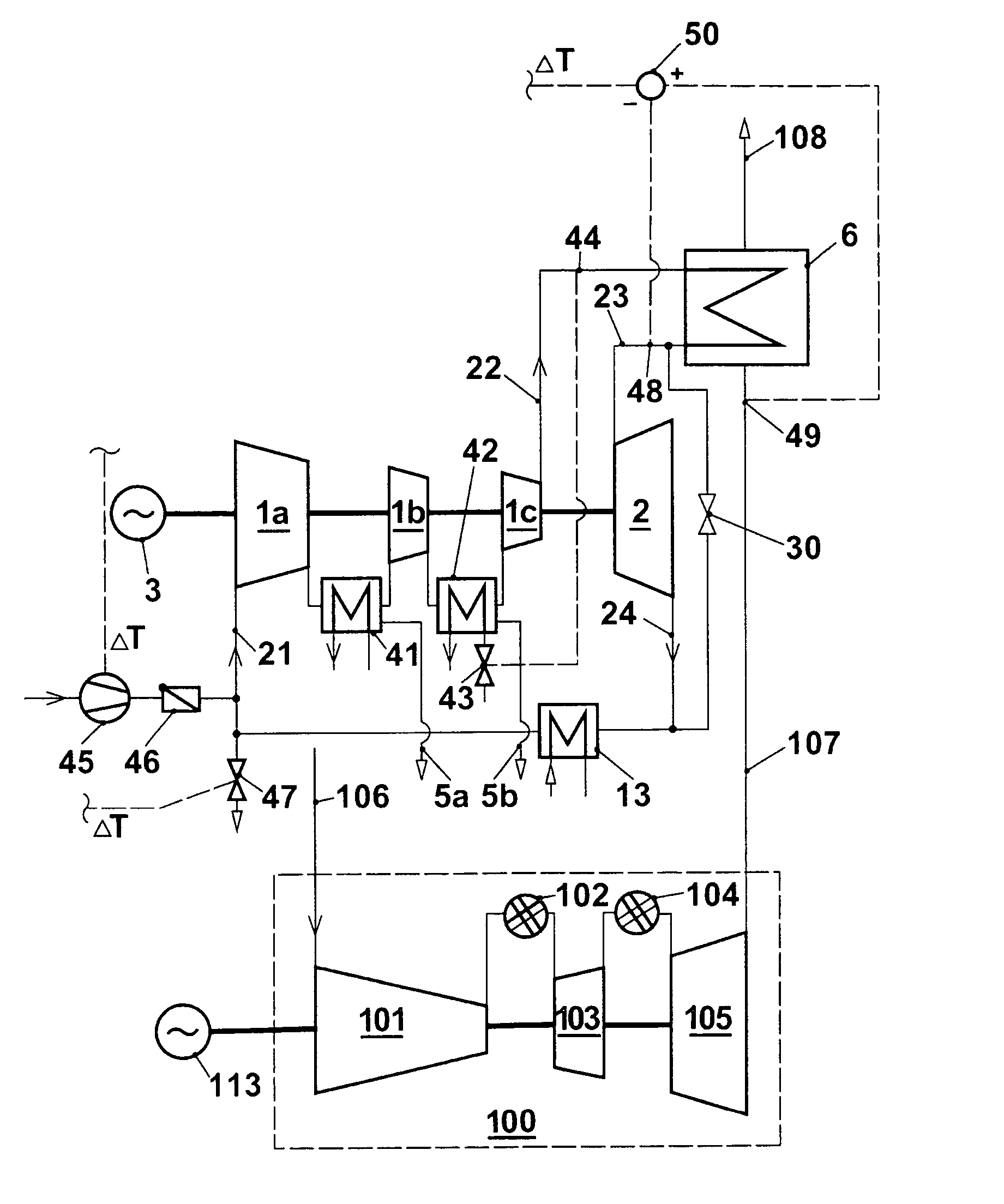

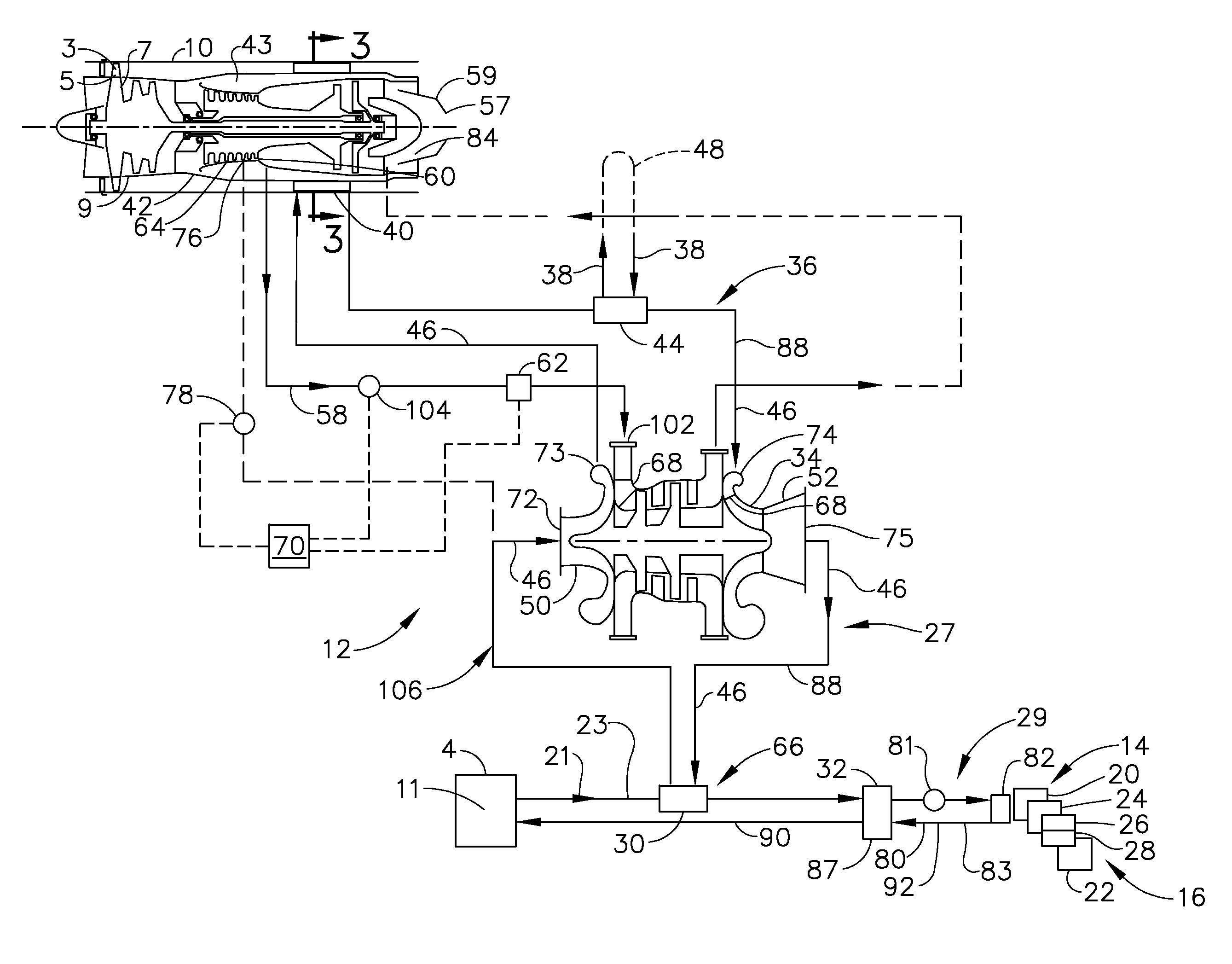

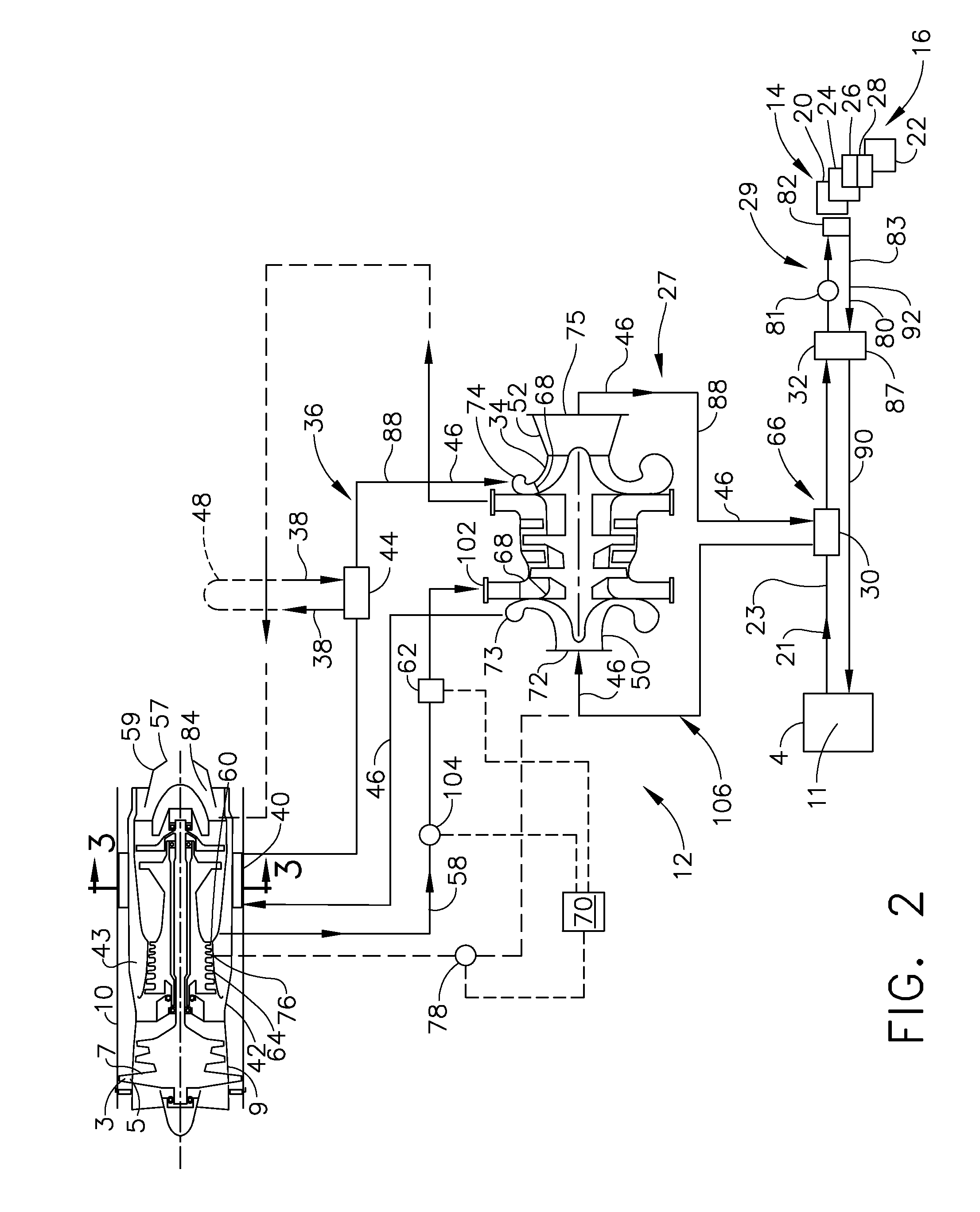

Powerplant and related control system and method

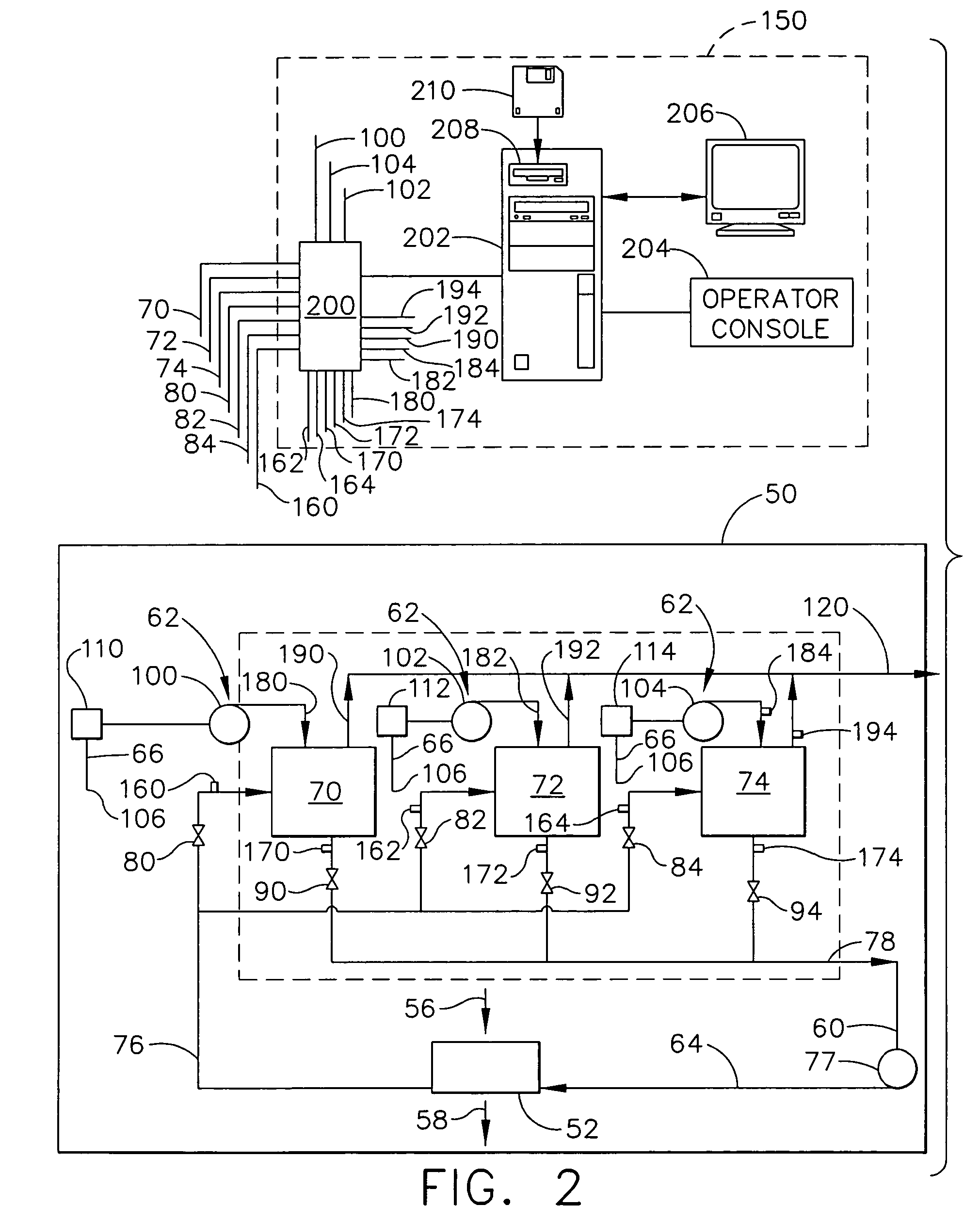

ActiveUS20100100300A1Efficient powerImprove reliabilityInternal combustion piston enginesDigital data processing detailsEquivalence ratioControl system

A hydrogen fueled powerplant including an internal combustion engine that drives a motor-generator, and has a two-stage turbocharger, for an aircraft. A control system controls the operation of the motor-generator to maintain the engine at a speed selected based on controlling the engine equivalence ratio. The control system controls an afterburner, an intercooler and an aftercooler to maximize powerplant efficiency. The afterburner also adds power to the turbochargers during high-altitude restarts. The turbochargers also include motor-generators that extract excess power from the exhaust.

Owner:AEROVIRONMENT INC

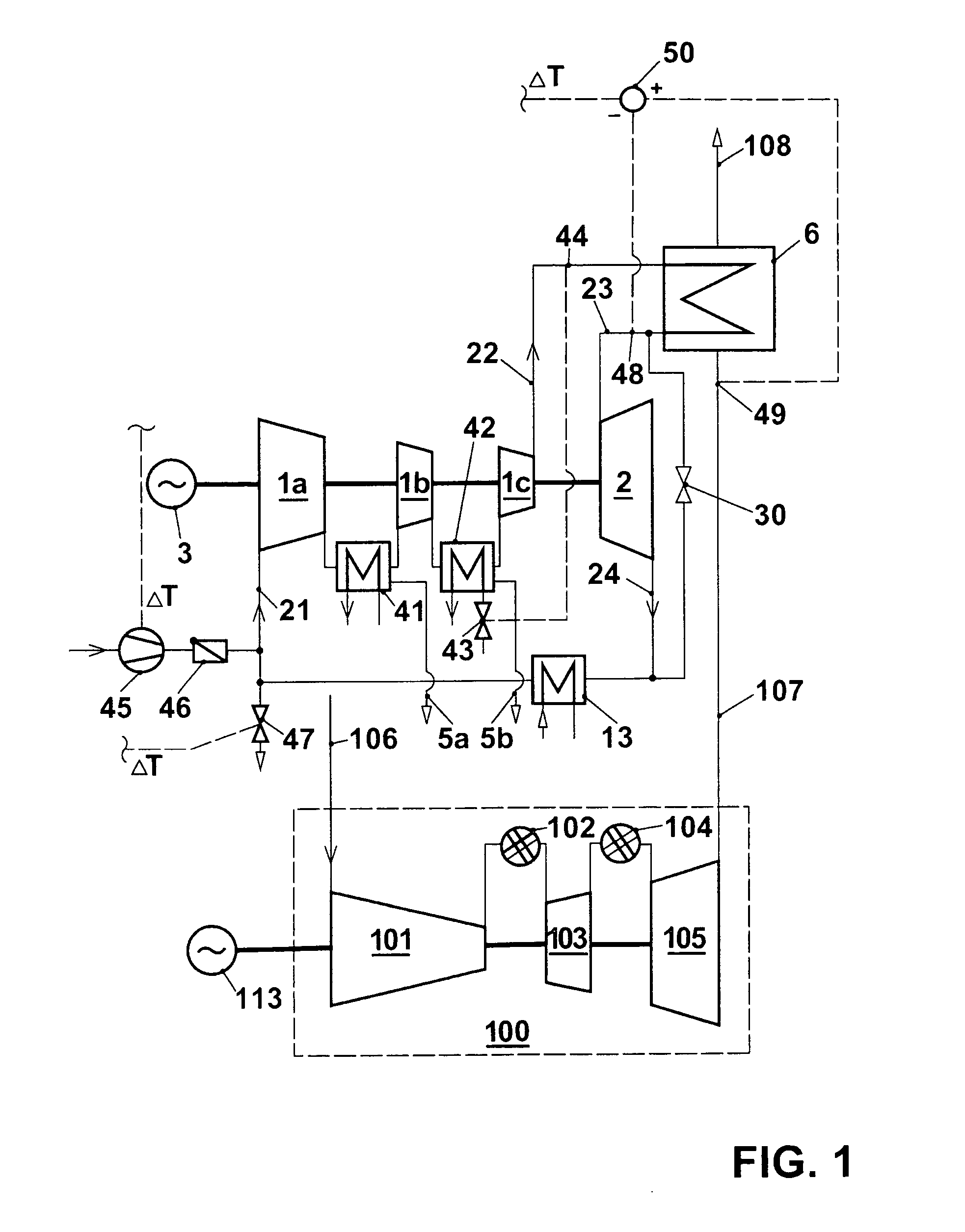

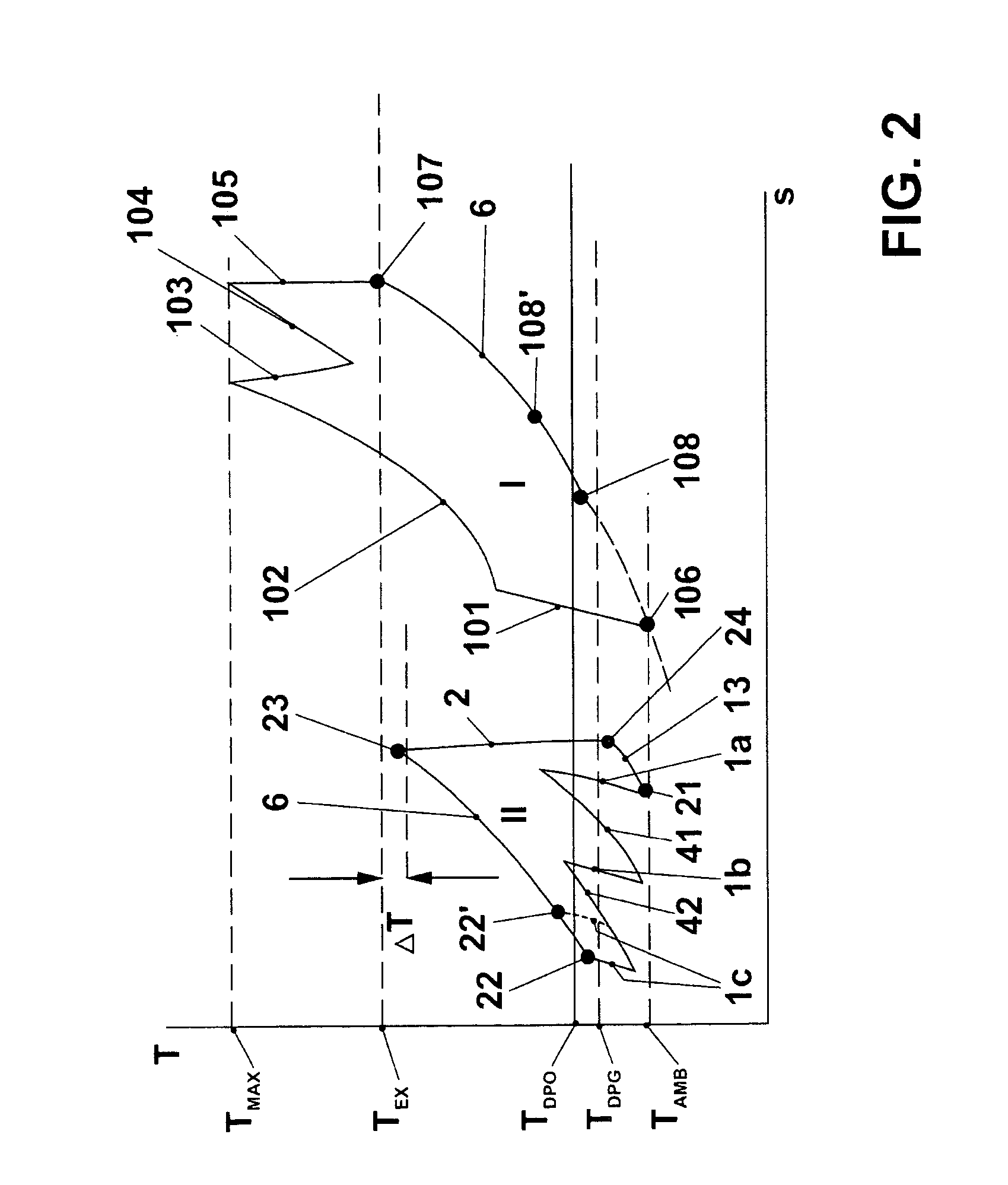

Power generation plant

InactiveUS20050056001A1Increase flexibilityAvoid disadvantagesEfficient propulsion technologiesGas turbine plantsElectricityPower station

In a power generation plant, for example a power station plant for the generation of electricity, a secondary machine (1a, 1b, 1c, 2) is connected downstream of an open-cycle gas turboset (100) for the utilization of the waste heat of the exhaust gases (107). The secondary machine is a machine working in a closed cycle with a gaseous process fluid, for example a closed-cycle gas turboset having a compressor (1a, 1b, 1c), a device for heating the compressed gas (6) which utilize the waste heat of the exhaust gas (107) of the primary gas turboset (100), a turbine (2) and at least one heat sink (13). In one embodiment, intercoolers (41, 42) are arranged during the compression process. A variable cycle charge of the secondary machine permits superior flexibility in the utilization of greatly varying supplies of waste heat available.

Owner:ALSTOM TECH LTD

Cold fuel cooling of intercooler and aftercooler

ActiveUS20130074812A1Reduce power consumptionNone have achieved superiorInternal combustion piston enginesPower plant arrangements/mountingTurbochargerNuclear engineering

Owner:AEROVIRONMENT INC

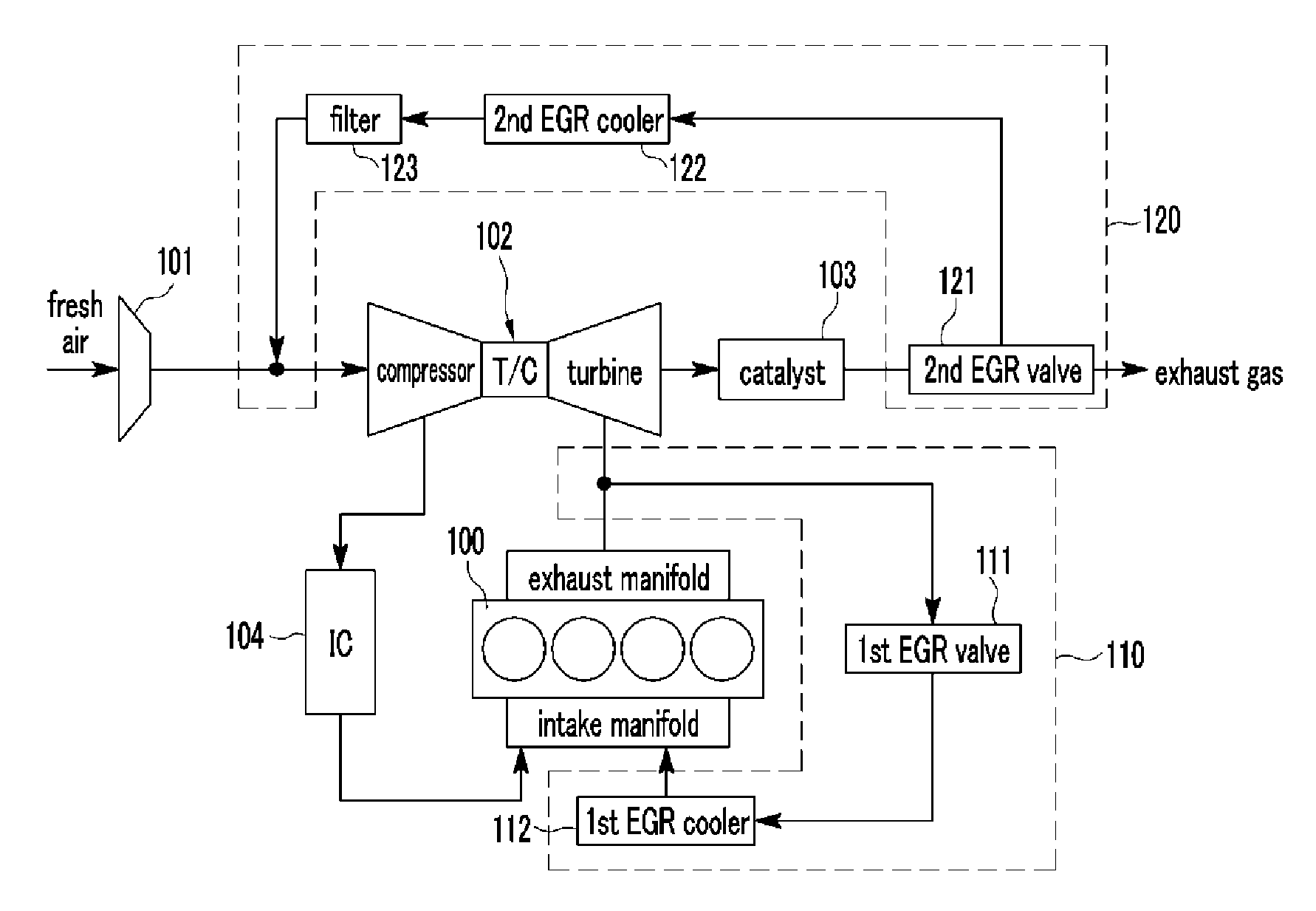

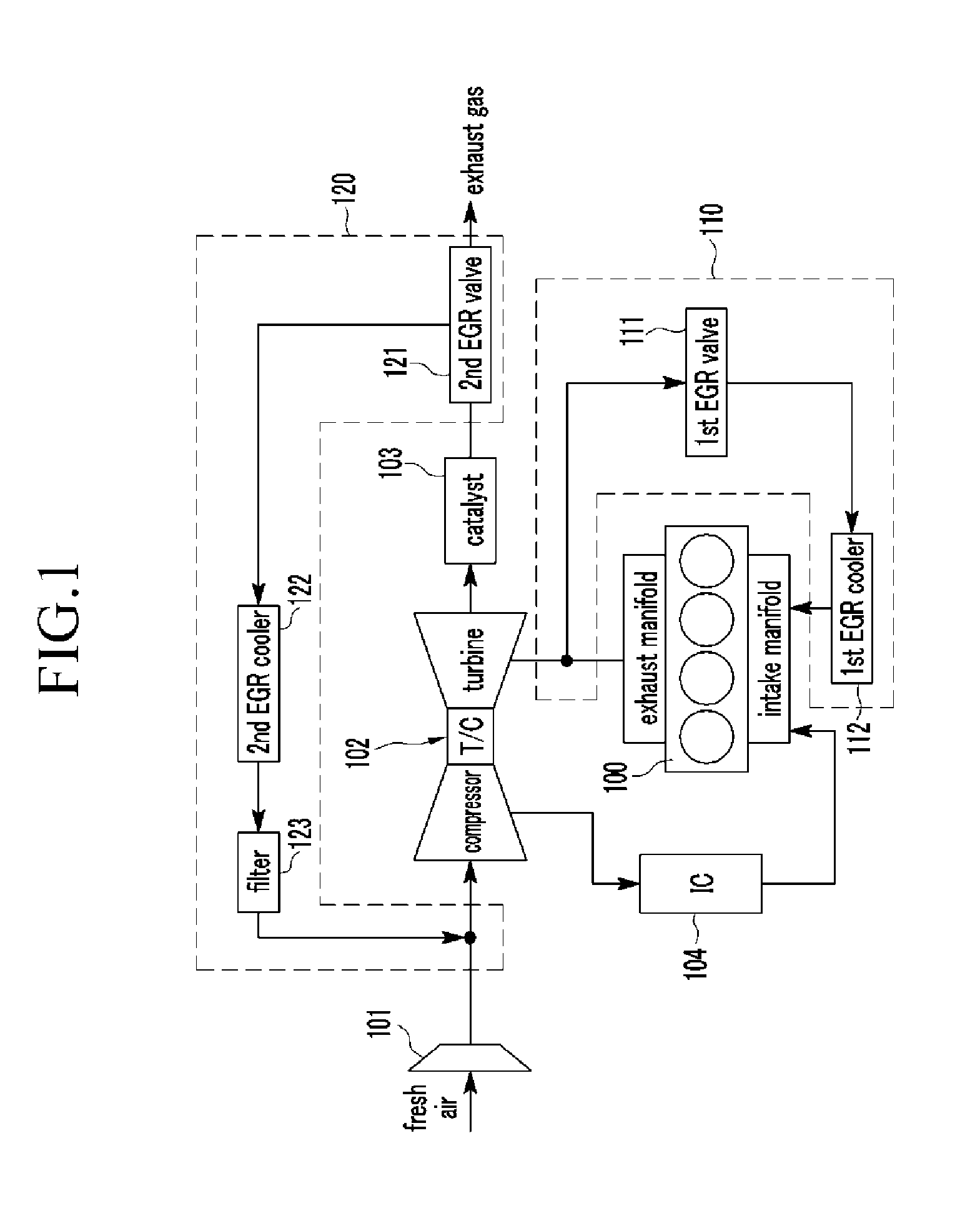

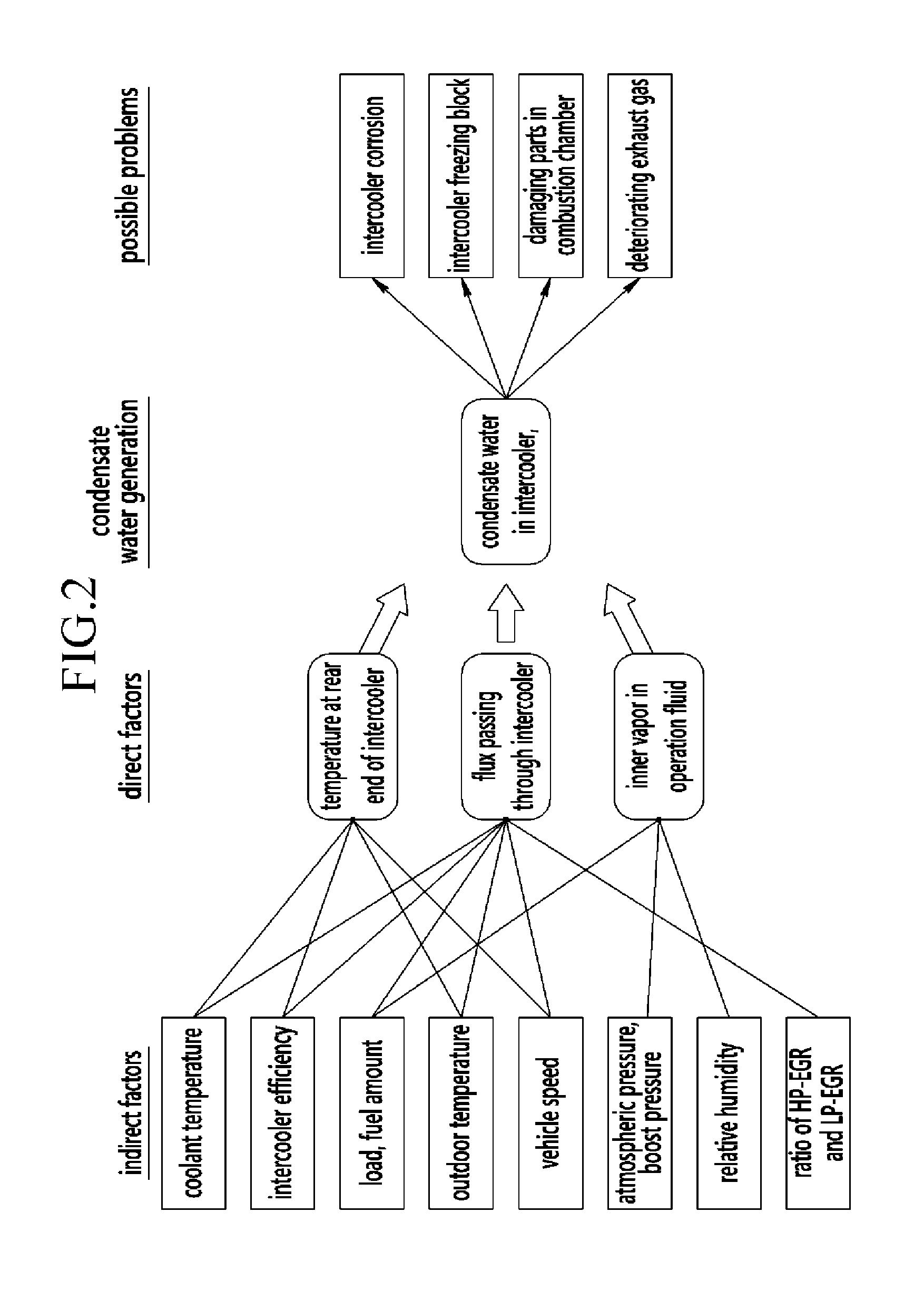

Apparatus and method for controlling low pressure exhaust gas recirculation system

InactiveUS20120090584A1MinimizationStable and reliableElectrical controlInternal combustion piston enginesExhaust fumesIntercooler

An apparatus and a method for controlling a low pressure exhaust gas recirculation system has advantages including minimizing condensate water generation in an intercooler and a low pressure EGR cooler by controlling EGR gas amount through optimally mapping many control variables influencing direct factors instead of controlling the EGR gas amount according to direct factors.

Owner:HYUNDAI MOTOR CO LTD +1

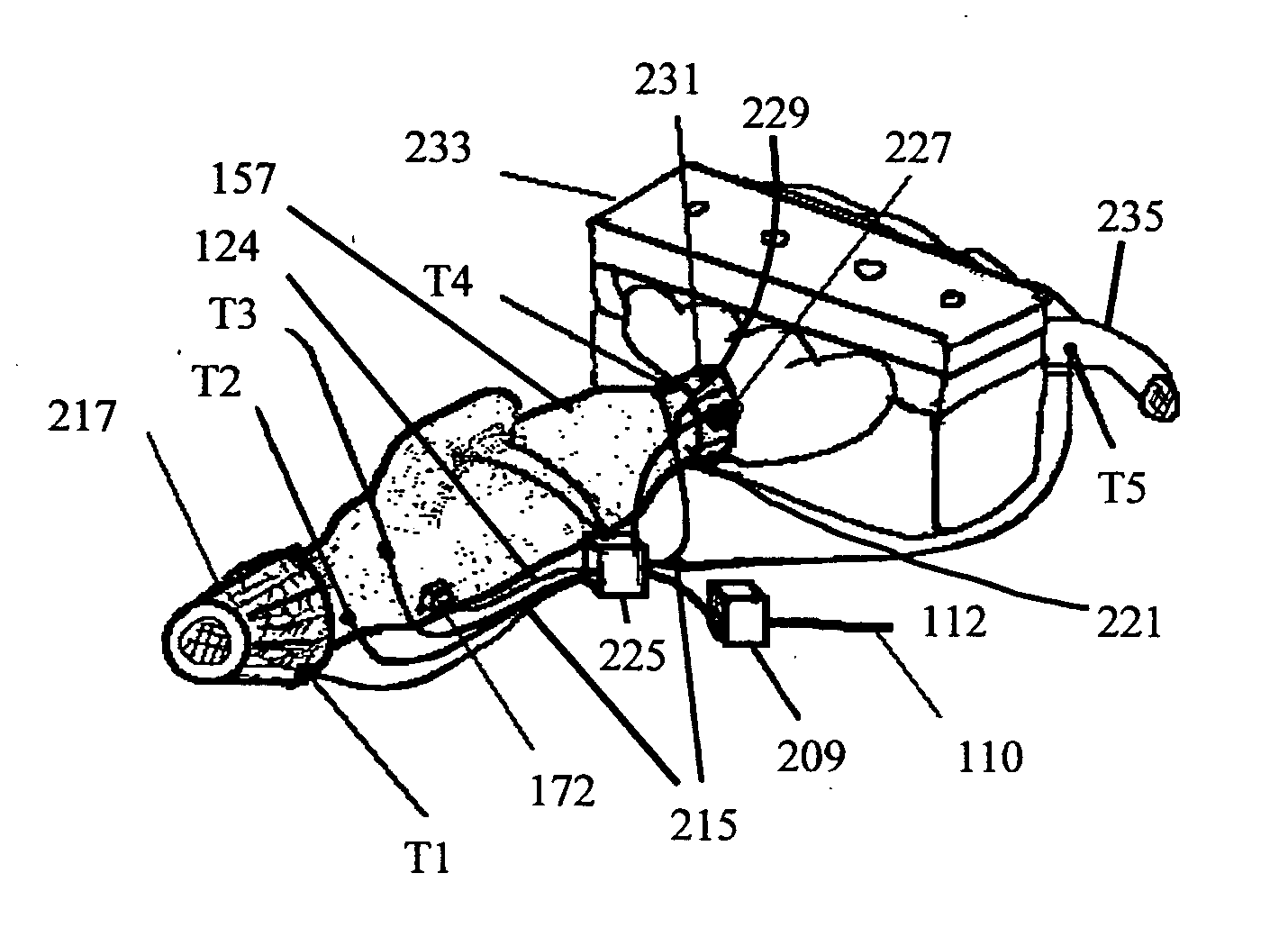

Flowing fluid conditioner

InactiveUS20050081834A1Reduce fuel consumptionEmission reductionTemperature measurement in motorsElectrically conductive connectionsTemperature conditioningIntercooler

A method and system for temperature conditioning of engine intake air by use of controllable intercooler which consists of an active thermoelectric device and a controllable valve system which optimally directs the path of airflow through a plurality of chambers in response to signals from a controller in order to optimally provide temperature conditioned air to the engine. System features temperature storage isolated from heat soaked engine components allowing immediate and efficient conditioning of airflow into an internal combustion engine. Intelligent control of this device removes parasitic power drains during high demand situations.

Owner:PERKINS MICHAEL T

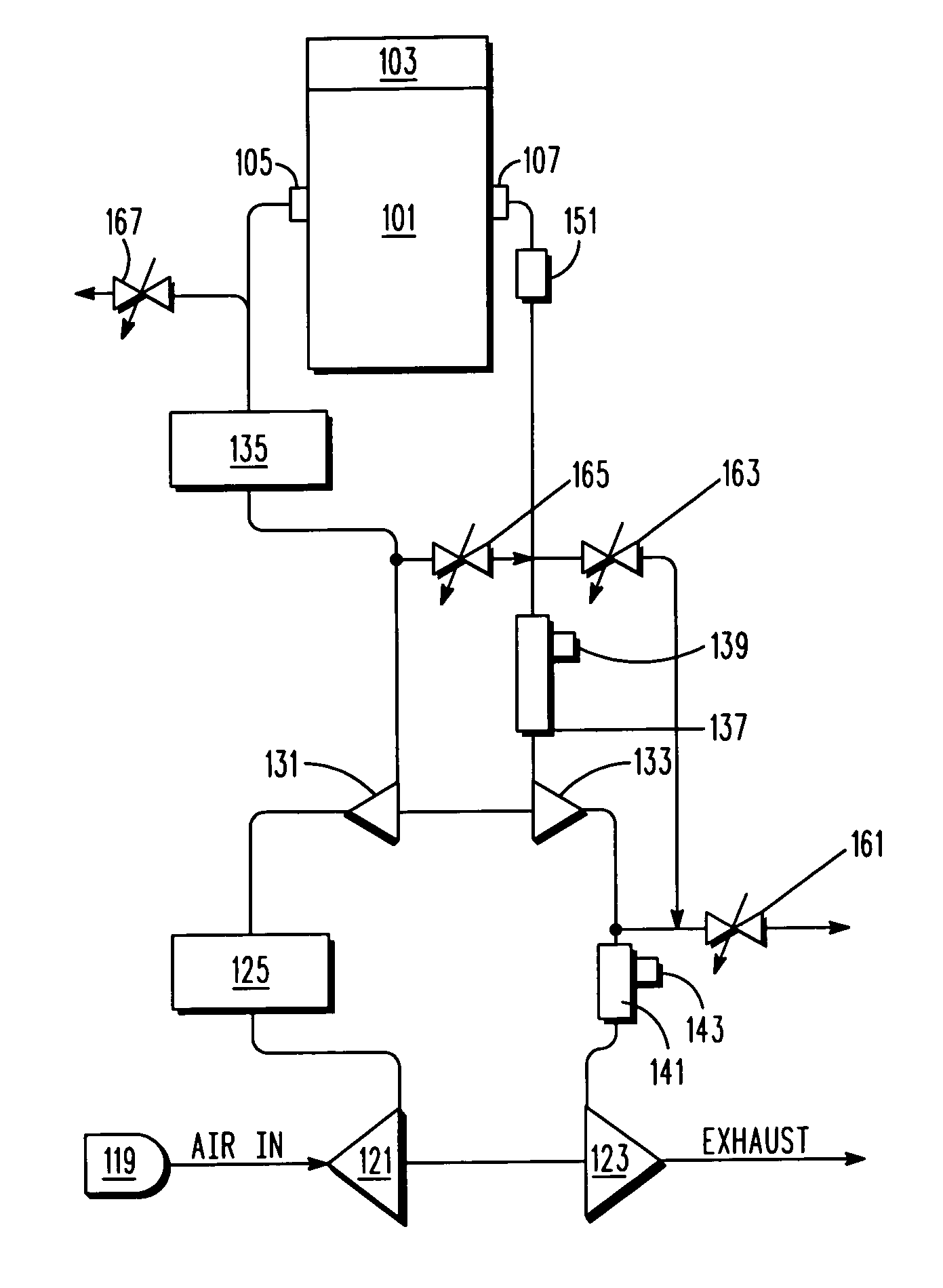

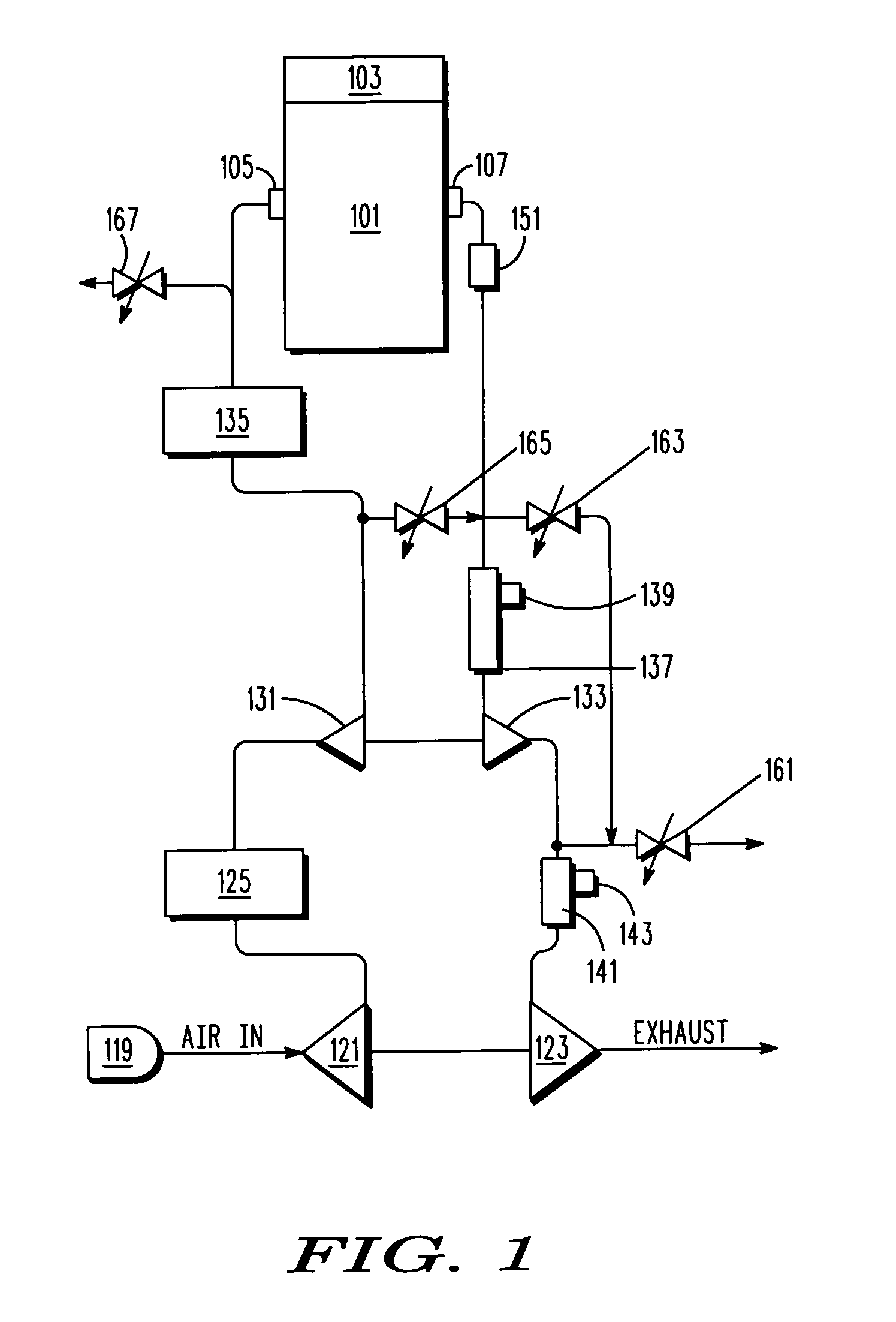

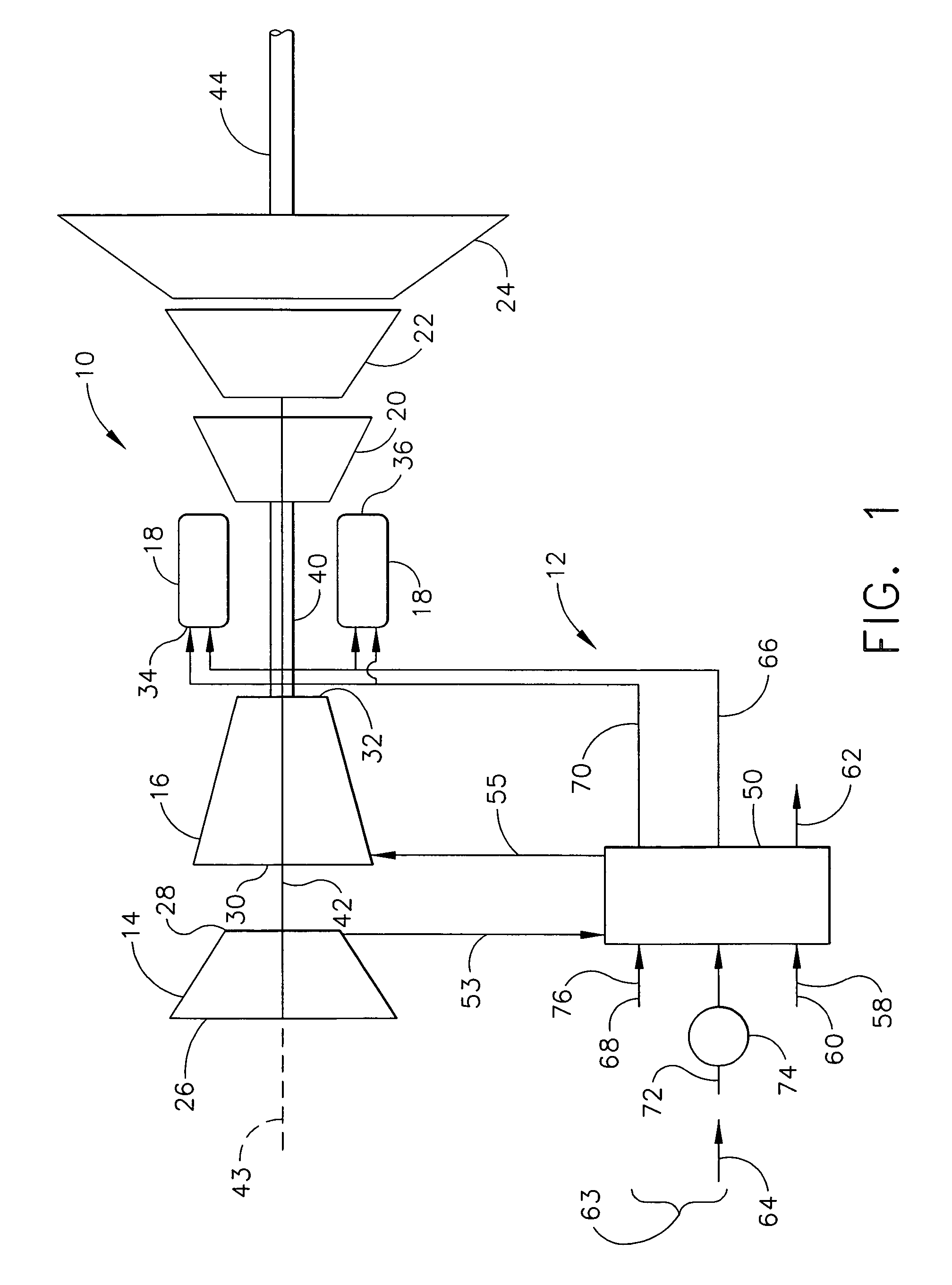

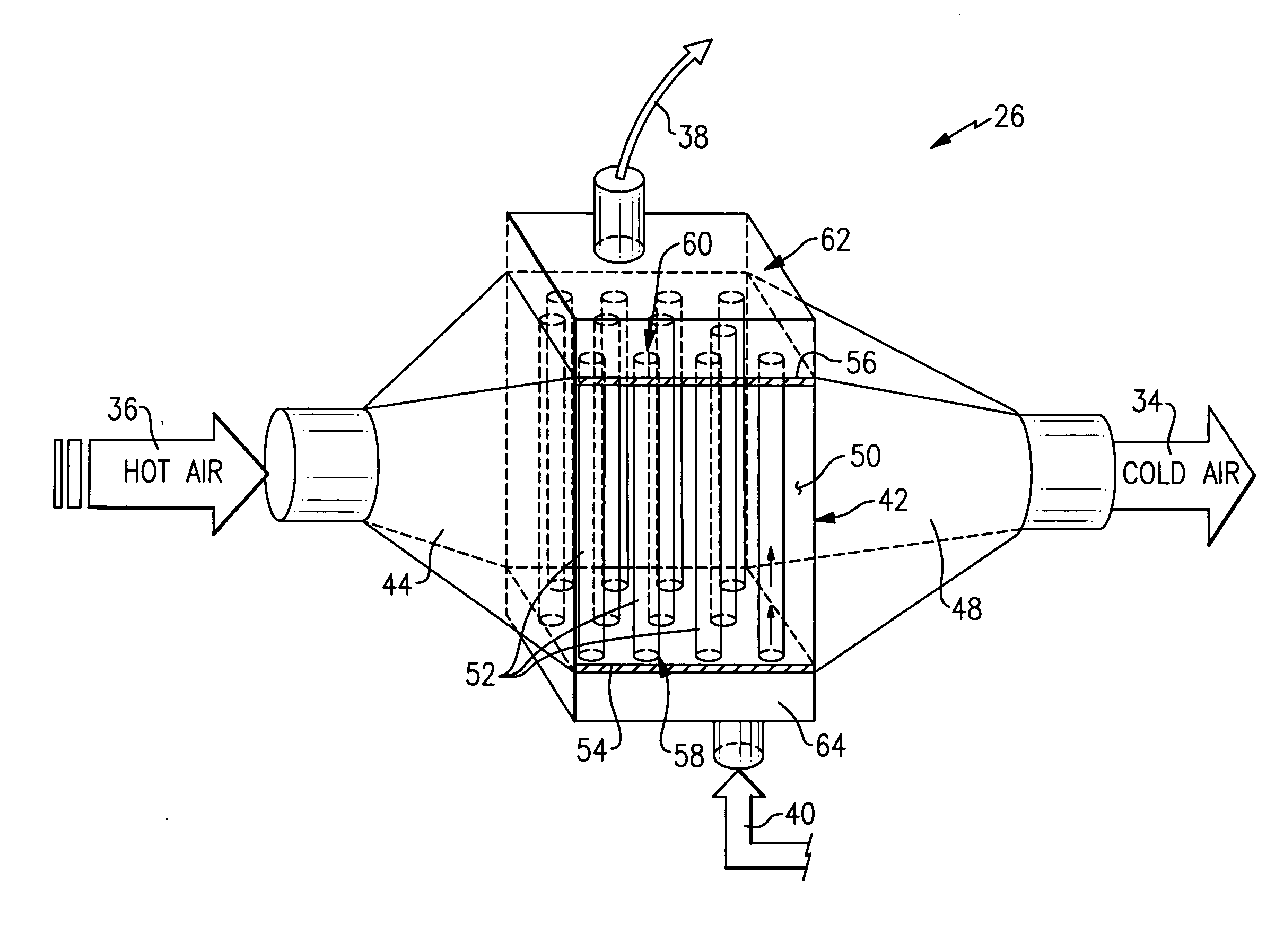

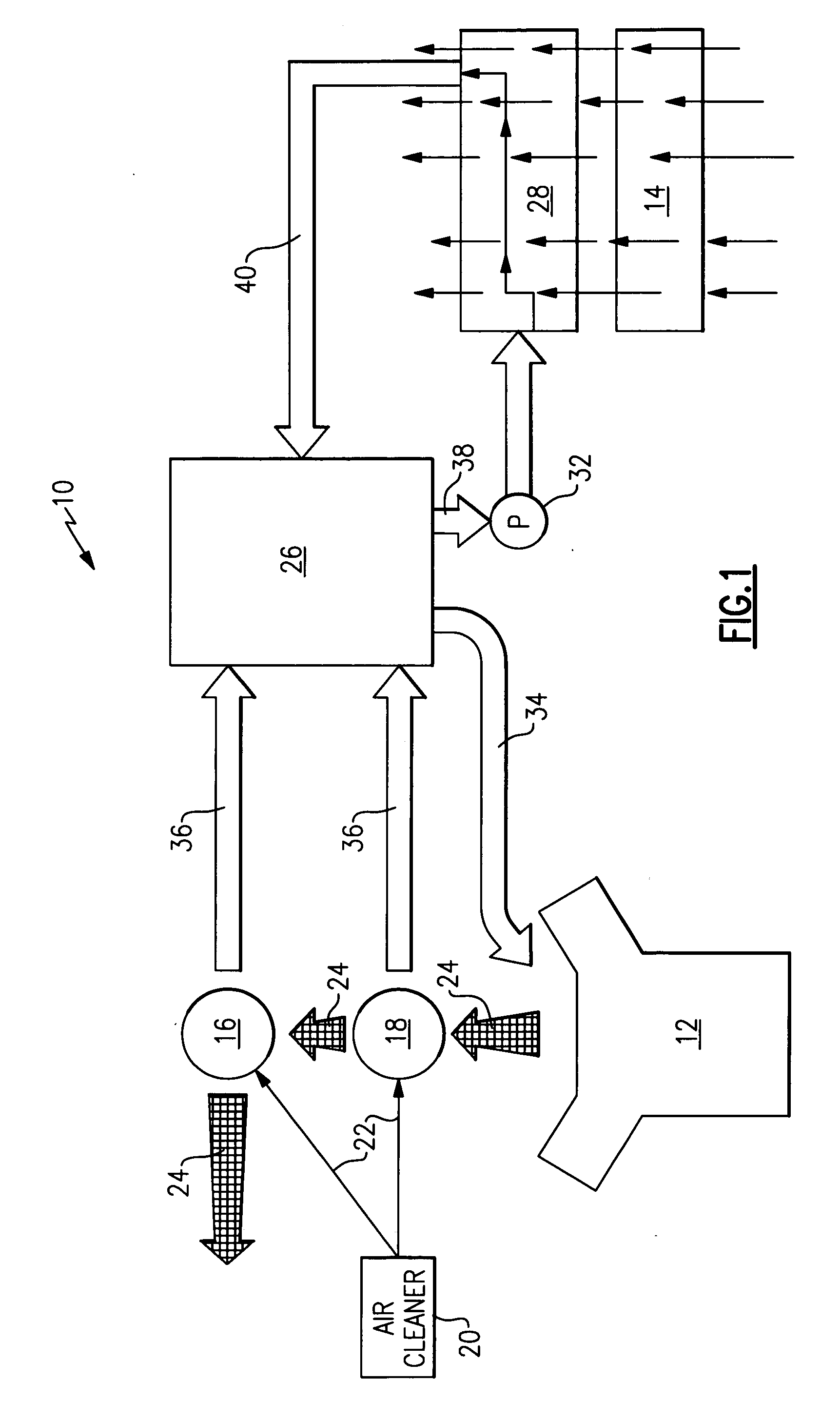

Method and apparatus for operating an intercooler for a gas turbine engine

ActiveUS7284377B2Easy to operateImprove efficiencyEfficient propulsion technologiesGas turbine plantsWorking fluidCombustor

A method for operating a gas turbine engine includes channeling compressed airflow discharged from a first compressor through an intercooler having a cooling medium flowing therethrough, channeling a working fluid through the intercooler to facilitate increasing an operating temperature of the working fluid, and channeling the discharged working fluid to a combustor to facilitate increasing an operating efficiency of the gas turbine engine.

Owner:GENERAL ELECTRIC CO

Adaptive power and thermal management system

ActiveUS8522572B2Improve cooling effectDomestic cooling apparatusTurbine/propulsion engine coolingAir cycleFuel tank

An aircraft adaptive power thermal management system for cooling one or more aircraft components includes an air cycle system, a vapor cycle system, and a fuel recirculation loop operably disposed therebetween. An air cycle system heat exchanger is between the air cycle system and the fuel recirculation loop, a vapor cycle system heat exchanger is between the vapor cycle system and the fuel recirculation loop, and one or more aircraft fuel tanks are in the fuel recirculation loop. An intercooler including a duct heat exchanger in an aircraft gas turbine engine FLADE duct may be in the air cycle system. The system is operable for providing on-demand cooling for one or more of the aircraft components by increasing heat sink capacity of the fuel tanks.

Owner:GENERAL ELECTRIC CO

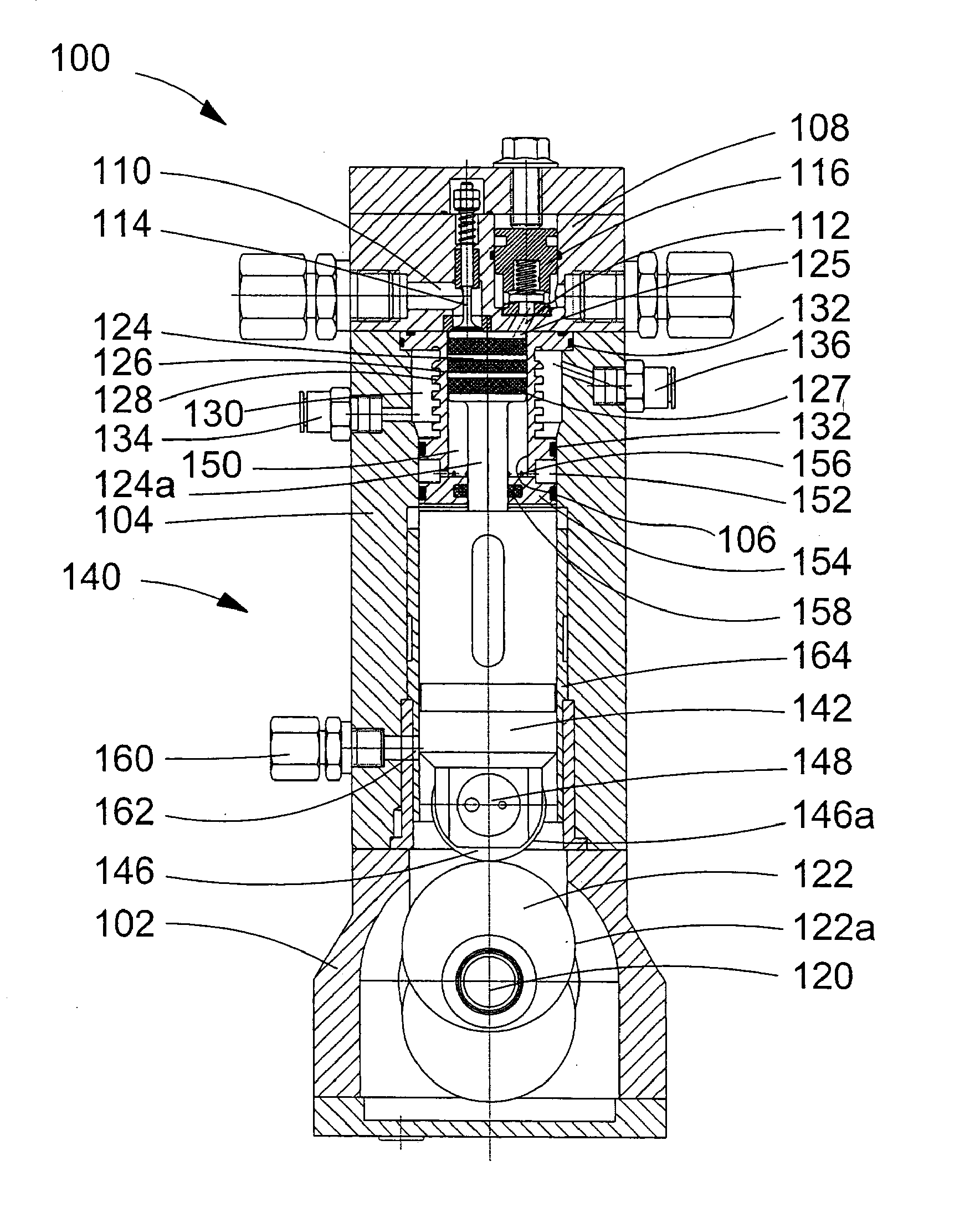

High-Pressure Gas Compressor And Method Of Operating A High-Pressure Gas Compressor

ActiveUS20080213115A1Reduce in quantitySimple manufacturing processPositive displacement pump componentsFlexible member pumpsFriction reductionInlet valve

A high-pressure gas compressor comprises a single-acting cam driven piston with a pressure compensation chamber disposed between the piston and the cam. A roller tappet assembly transmits reciprocating motion from the cam to the piston. A pressurized gas directed to the pressure compensation chamber offsets forces acting on the piston from the compression chamber gas pressure, thereby reducing Hertzian pressure between the tappet roller and the cam. Overall efficiency and durability can be improved by reducing friction between compressor components, for example by employing thin film coatings to reduce friction, pressurized oil lubrication systems and higher cylinder bore diameter to piston stroke ratios. The service life of gas seals and compression efficiency can be improved by thermal management strategies, including liquid-cooled compressor cylinder liners and intercoolers between compression stages. Employing a poppet-style intake valve and reducing parasitic volume in the compression chamber can improve compressor volumetric efficiency.

Owner:WESTPORT FUEL SYST CANADA INC

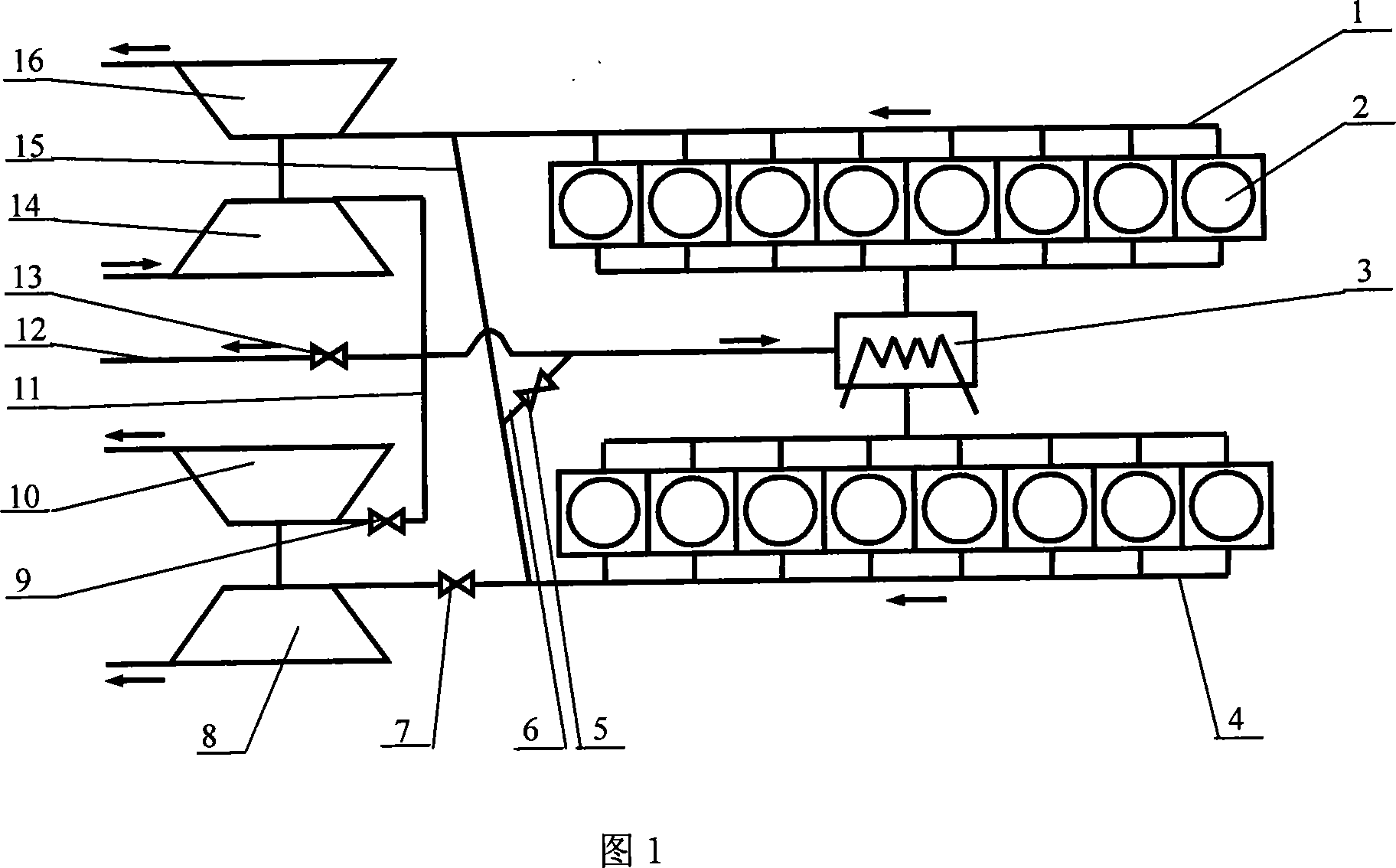

Adjustable high boost system with structure of series-parallel connection of turbochargers in different size

InactiveCN1737346AWide range of changesWide range of operating conditionsInternal combustion piston enginesSingle stageTurbocharger

This invention relates to a turbocharger multiple-series adjustable boost system, which belongs to combustion engine technique field. The system comprises diesel engine air inlet pipe, diesel engine, diesel engine discharge pipe, high-pressure turbine stage by-pass conduit and by-pass valve, high-pressure turbine stage by-pass conduit, high-pressure turbine stage, high and low pressure turbine connecting pipe flow change-over valve, high and low pressure turbine connecting pipe, low-pressure turbine stage by-pass conduit, low-pressure turbine, intercooler, high booster by-pass conduit and by-pass valve, high booster by-pass conduit, high blower, high and low pressure booster connecting pipe flow change-over valve, high and low pressure booster connecting pipe, low pressure booster by-pass conduit and low pressure booster, wherein the diesel engine is connected with diesel engine air inlet pipe and diesel engine discharge pipe separately, and the high pressure turbine outlet is connected with the low pressure turbine through the high and low pressure turbine conduit. By said invention, it can realize single-stage turbocharging, successive turbocharging and two-stage turbocharging.

Owner:SHANGHAI JIAO TONG UNIV

On demand boost conditioner (ODBC)

InactiveUS20060122762A1Analogue computers for vehiclesInternal combustion piston enginesOperator interfaceCombustion

An integrated system for increasing power output from an internal combustion engine. System facilitates an interface for controlling and conditioning of the amount of intake air into an internal combustion engine. The system interfaces to a controller and provides critical data, an active intercooler, power buffer, and an electrically driven supercharger. An operator interface provides monitoring and control to a controller for expanded operator control. A power buffer relieves host power system from loading during high demand operation. A system of advanced sensors and processing from a controller combine to facilitate maximum power output with reduced risks. Active heat removal enables system operation in a vehicle at rest or in traffic. Active conditioning system flexibility facilitates improved implementation of cold temperature environment starting and operation. A low cost option with commercial non-positive displacement blowers implements affordable enhancements for internal combustion engines.

Owner:PERKINS MICHAEL T

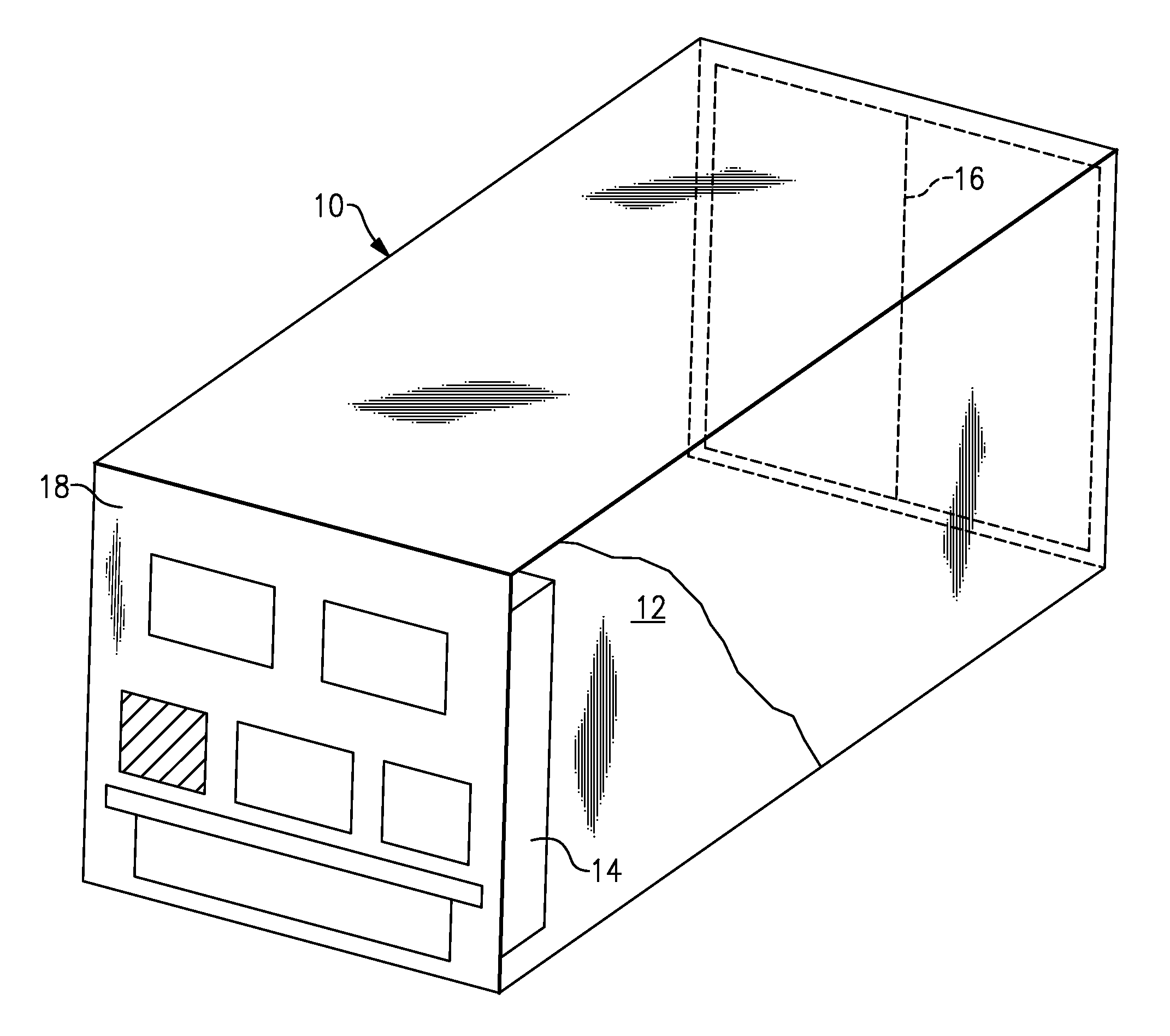

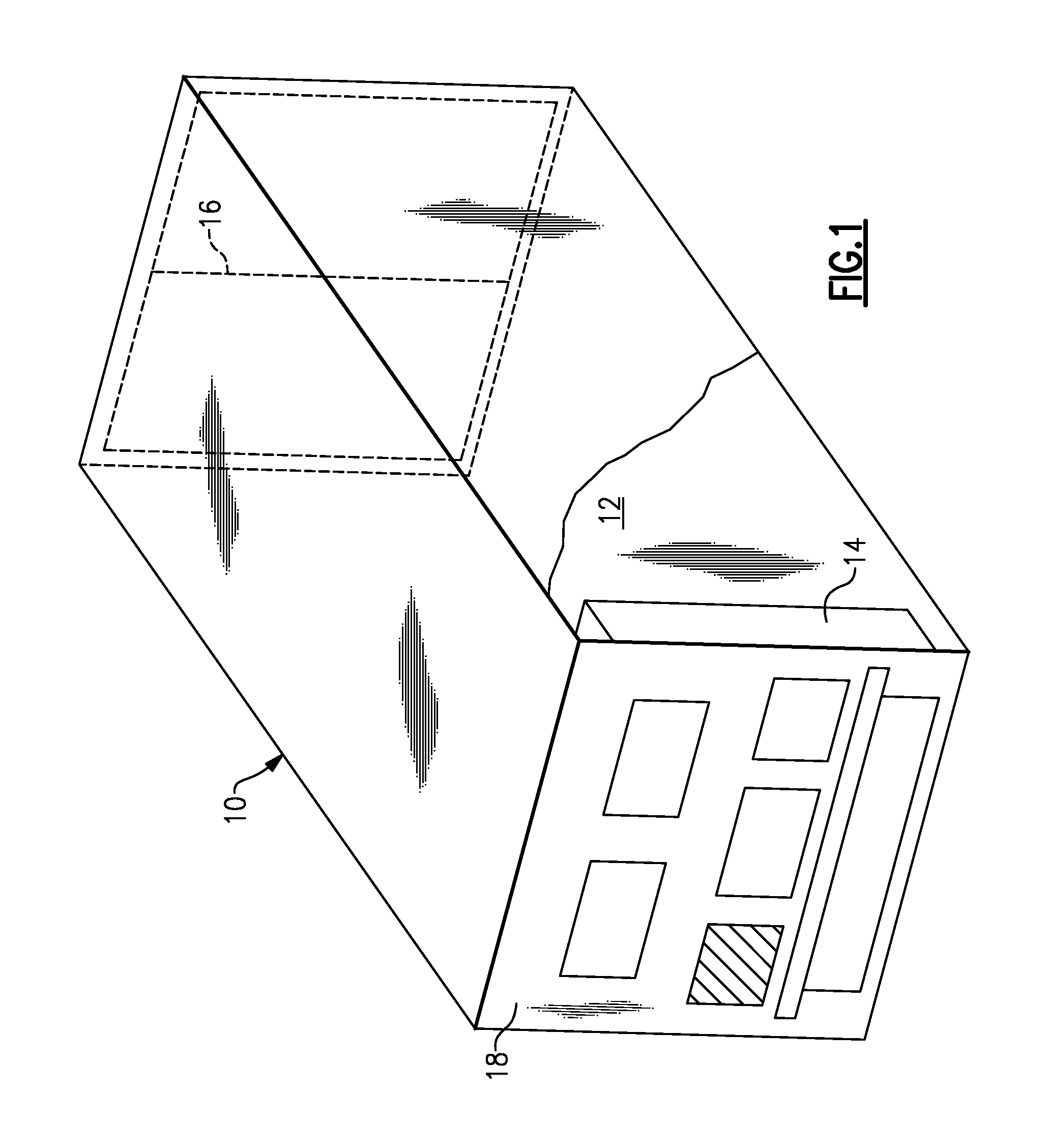

Integrated heat exchanger for use in a refrigeration system

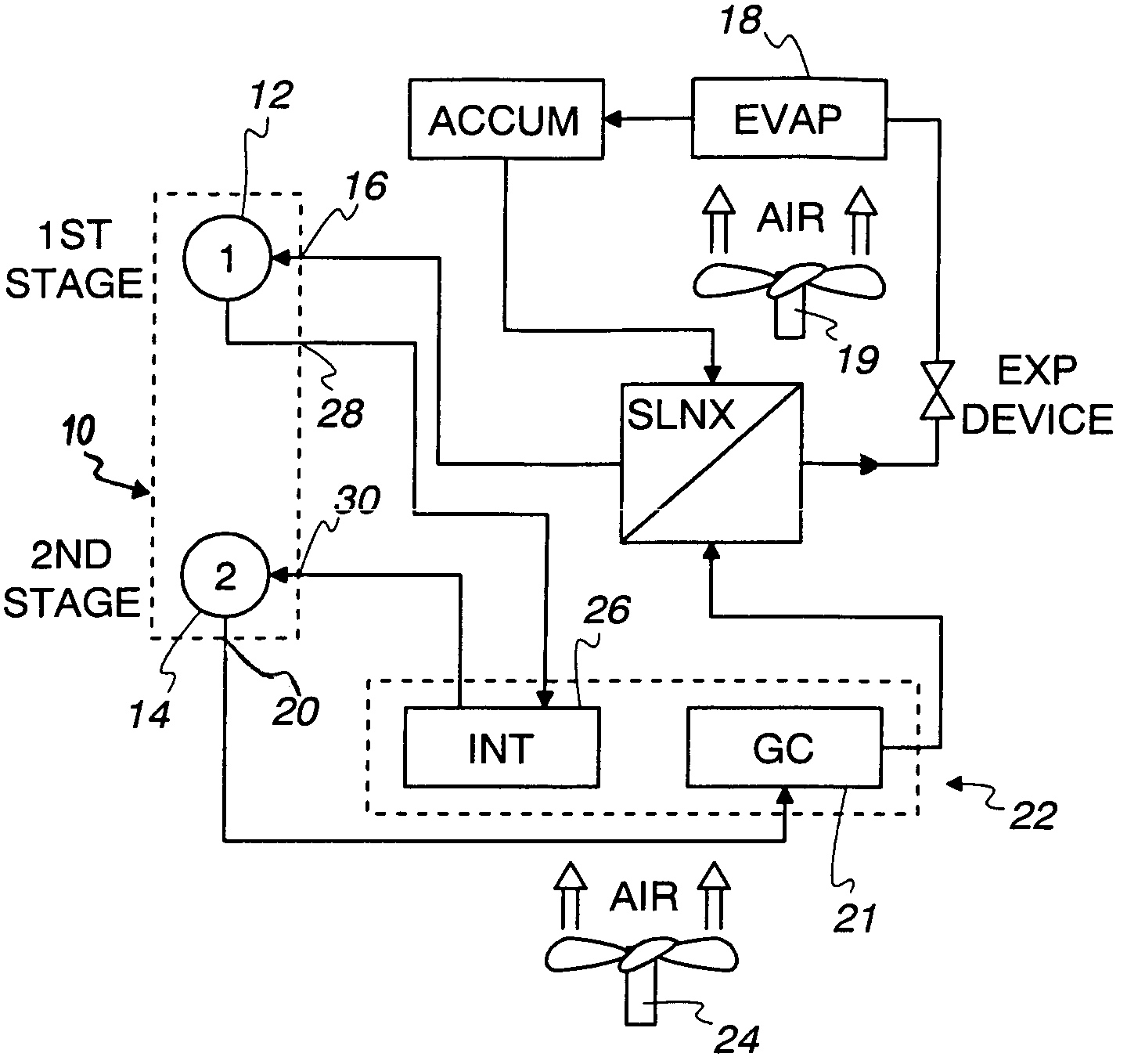

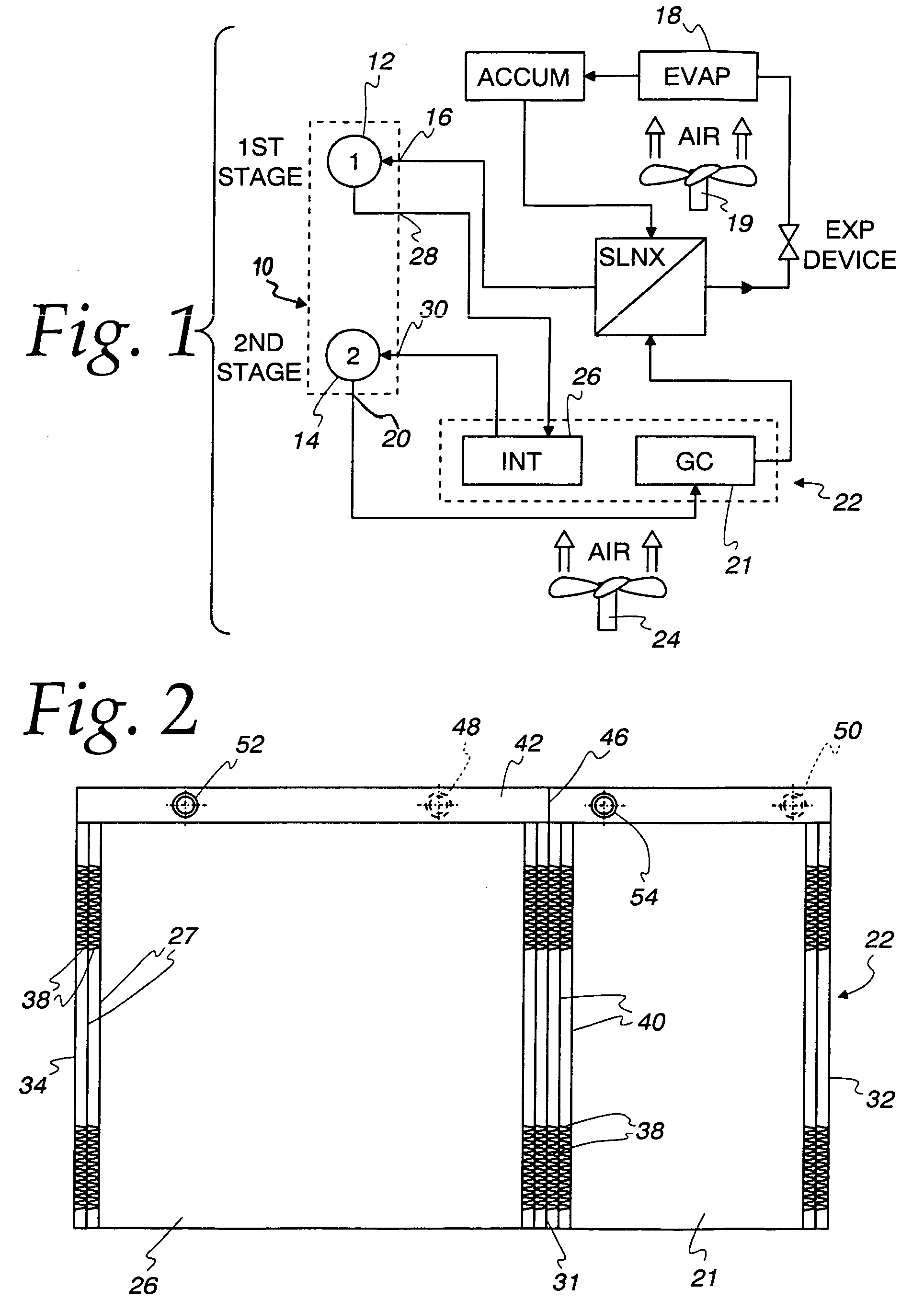

InactiveUS20050279127A1Compression machines with non-reversible cycleEvaporators/condensersGas coolerIntercooler

A refrigeration system includes a multiple stage compressor 10 having at least two stages 12,14 for sequentially compressing the refrigerant together with a gas cooler 21 connected to the compressor 10 for receiving compressed refrigerant from the last stage 14 of the compressor to cool the same. An evaporator 18 is connected to the gas cooler 21 via an expansion device to receive cool refrigerant therefrom and cool the fluid stream passing through the evaporator 18. A return passage connects the evaporator 18 to the first stage 12 of the compressor and an intercooler 26 is connected between the first stage 12 and the last stage 14 of the compressor to cool refrigerant compressed by the first stage 12 and direct the refrigerant cooled thereby to the last stage 14 for further compression. The intercooler 26 and the gas cooler 21 are integrated into a single unit 22 and receive a single cooling heat exchange fluid and the gas cooler 21 has a larger heat transfer surface area than the intercooler 26.

Owner:MODINE MFG CO

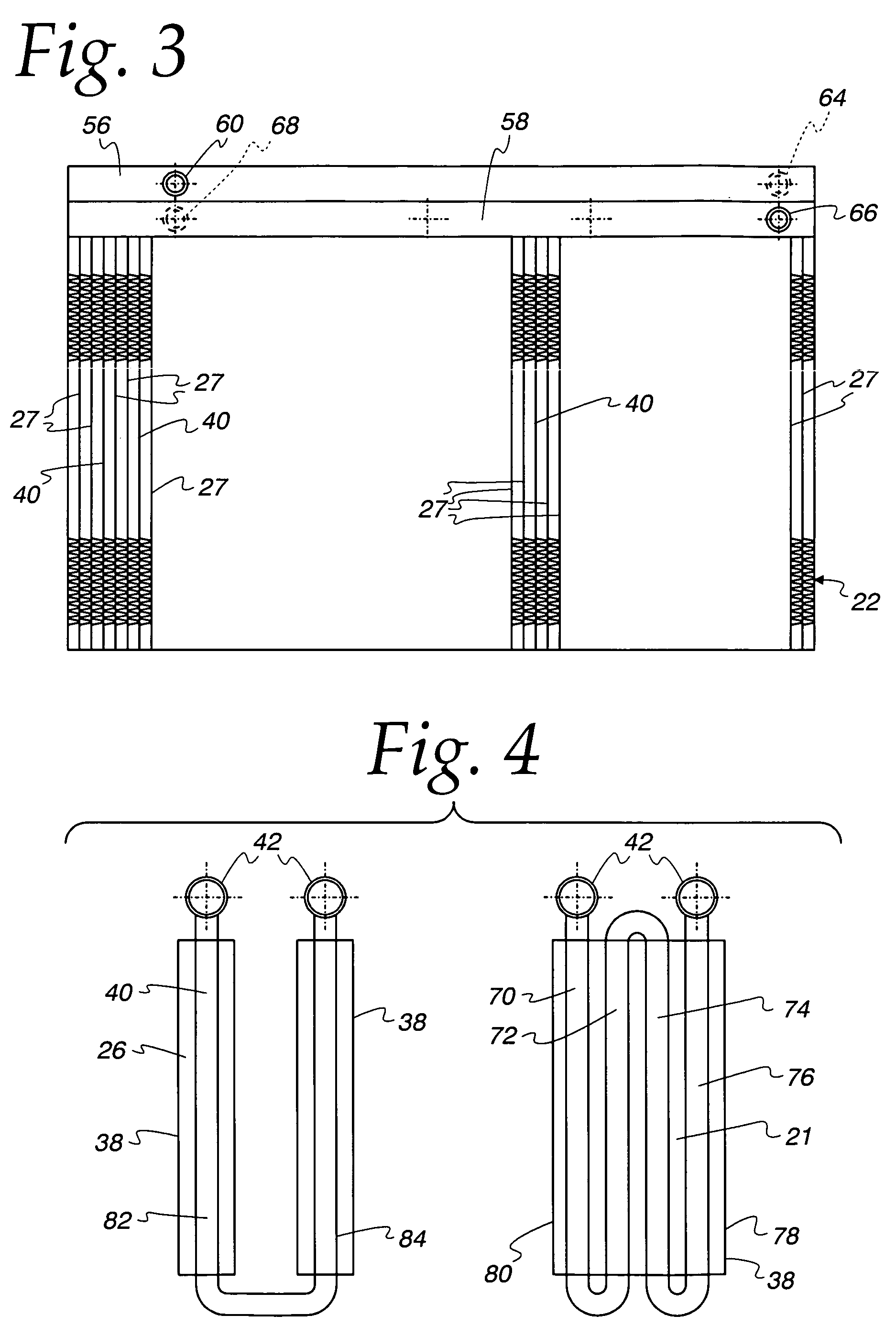

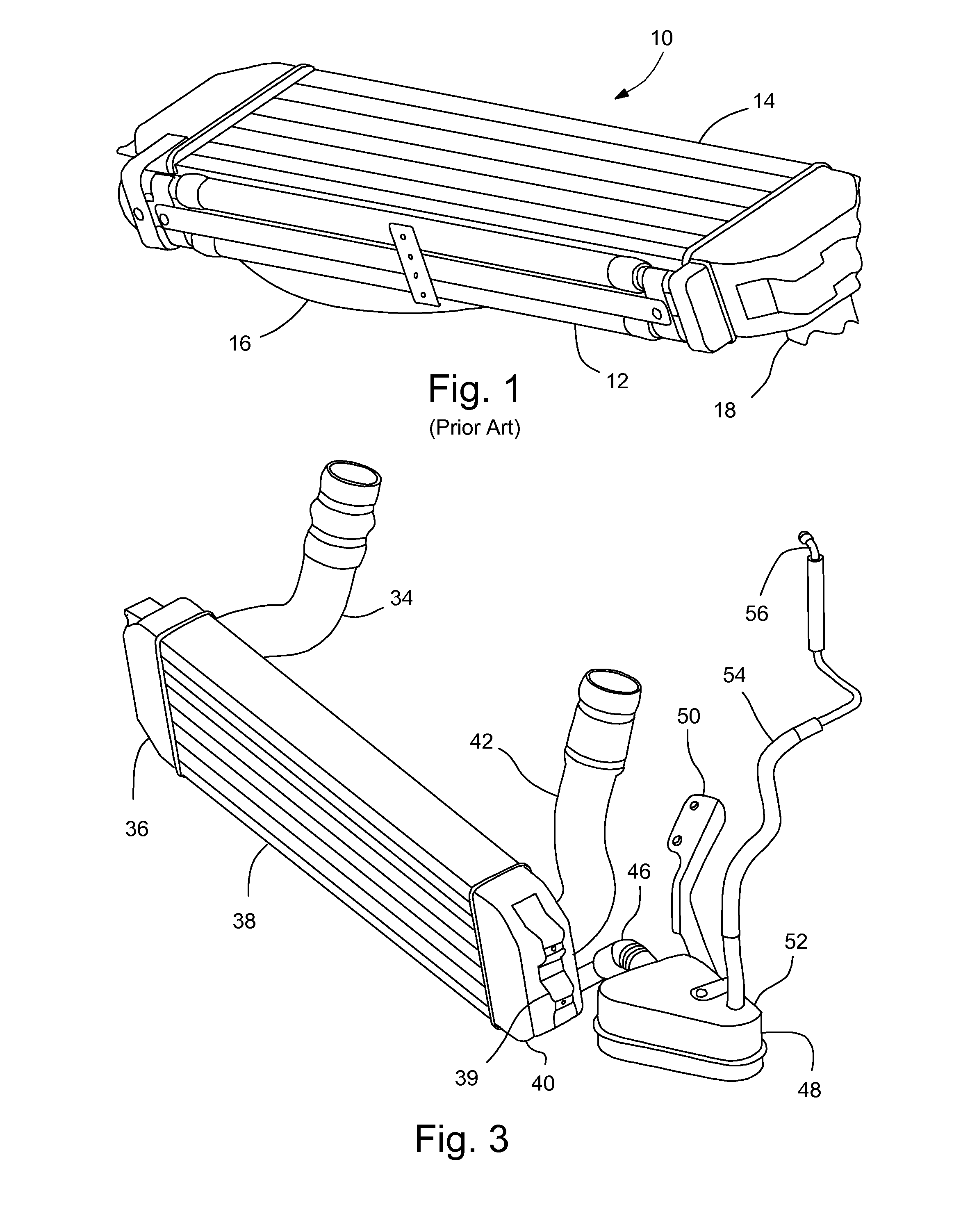

Laser welded plastic intercooler

InactiveUS20070131401A1Low costImprove manufacturabilityLamination ancillary operationsInternal combustion piston enginesInterior spaceEngineering

An intercooler assembly includes a housing that defines an internal space containing a plurality of tubes. A joint between a tube and a tube plate is created by a laser welding process. A form presses the walls of the tube outwardly to form the flange. The downward force of the form not only creates the desired flange, but also exerts a pressure that holds the flange against the tube plate. The form provides for the transmission of laser energy to that the creation of the flange can be performed concurrently with the welding process.

Owner:SIEMENS VDO AUTOMOTIVE INC

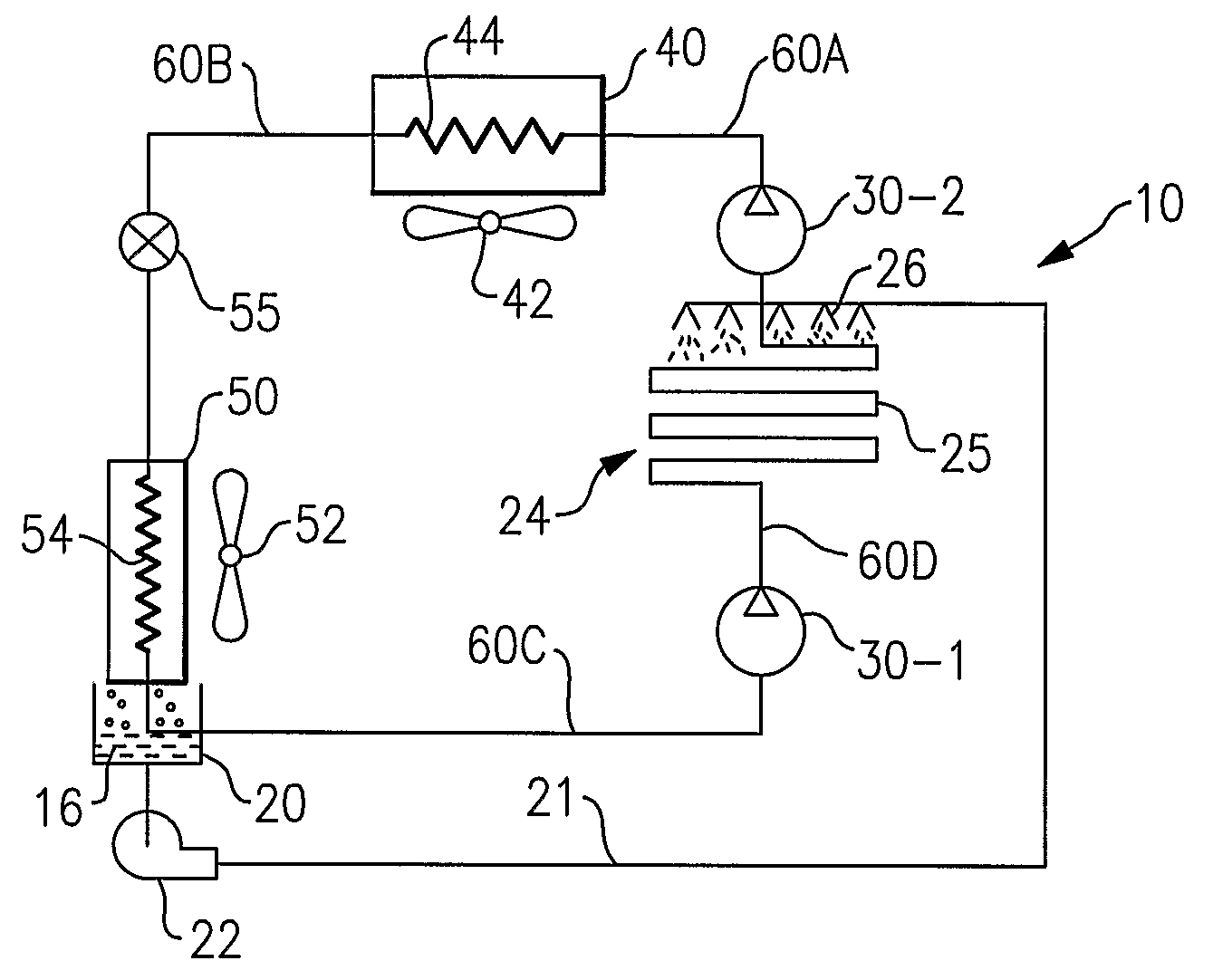

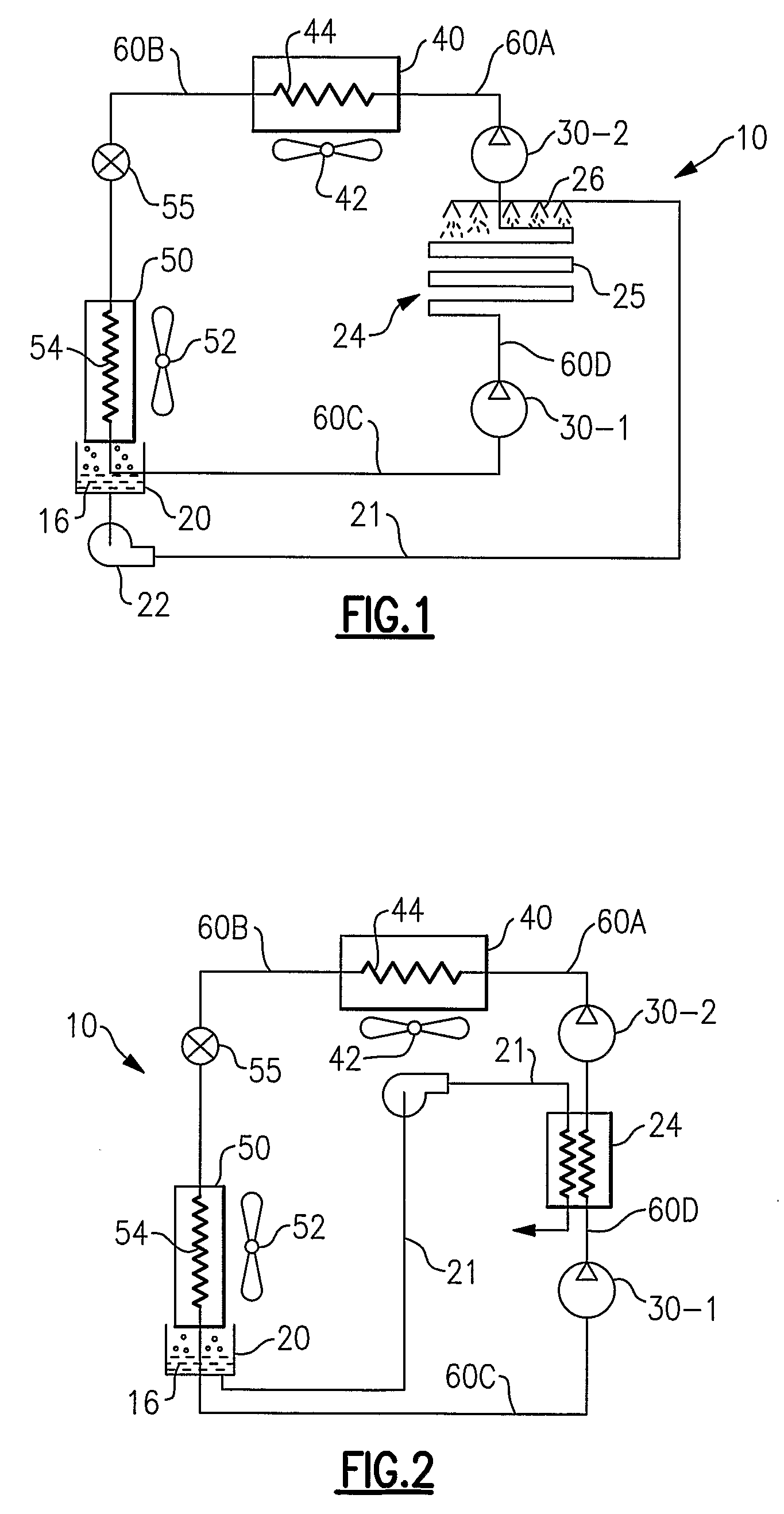

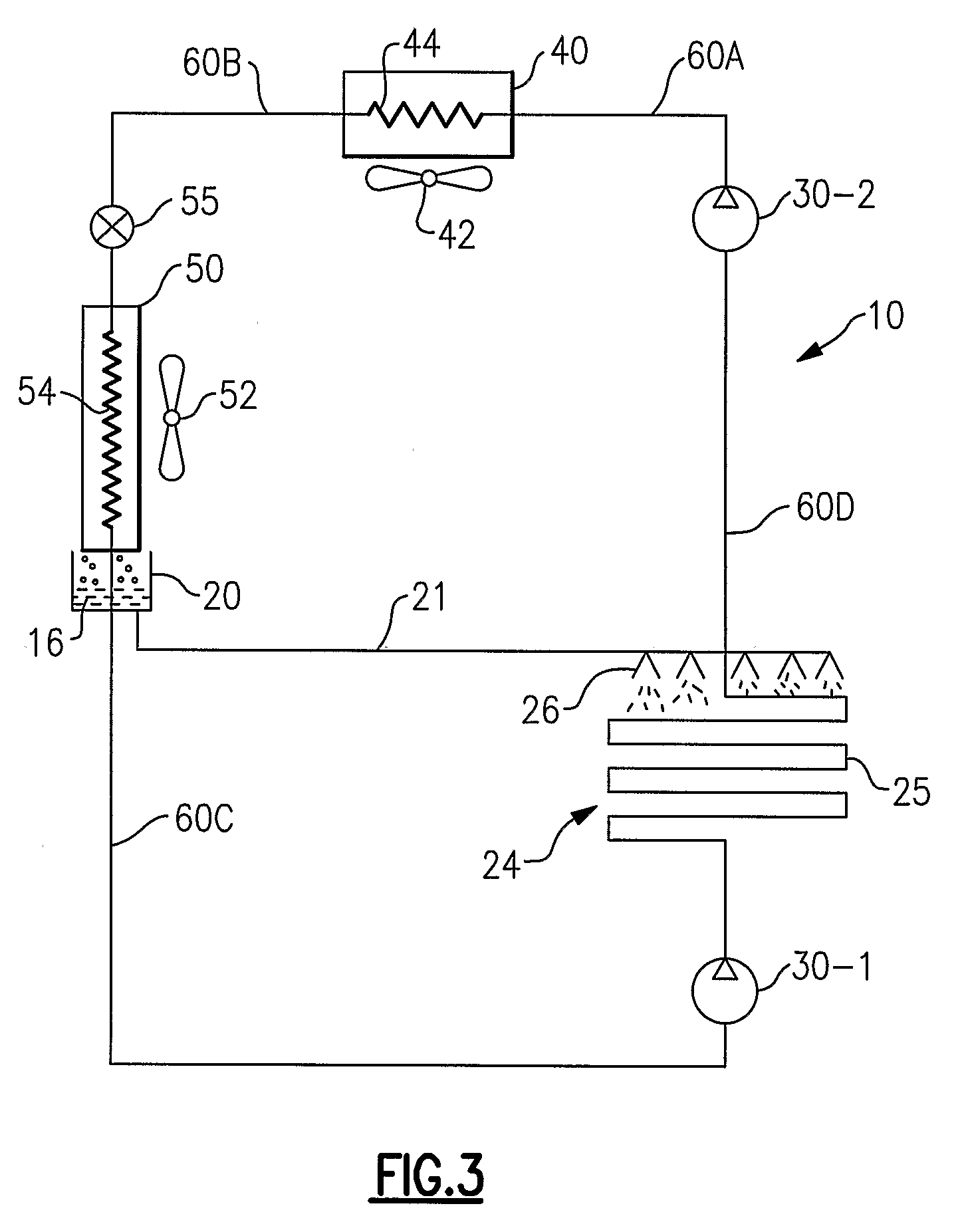

Vapor Compression System With Condensate Intercooling Between Compression Stages

InactiveUS20080256975A1CompressorCompression machines with non-reversible cycleCompression deviceEngineering

A refrigerant vapor compression system includes a first compression device and a second compression device disposed in a refrigerant circuit in series relationship with respect to refrigerant flow and an intercooler adapted to cool the refrigerant passing from the first compression device to the second compression. An evaporator is provided in the refrigerant circuit wherein the refrigerant accepts heat from a moisture bearing gas such as air. Condensate formed of moisture condensing out of the gas is collected and supplied to the intercooler for cooling the refrigerant flowing from the first compression device to the second compression device.

Owner:CARRIER CORP

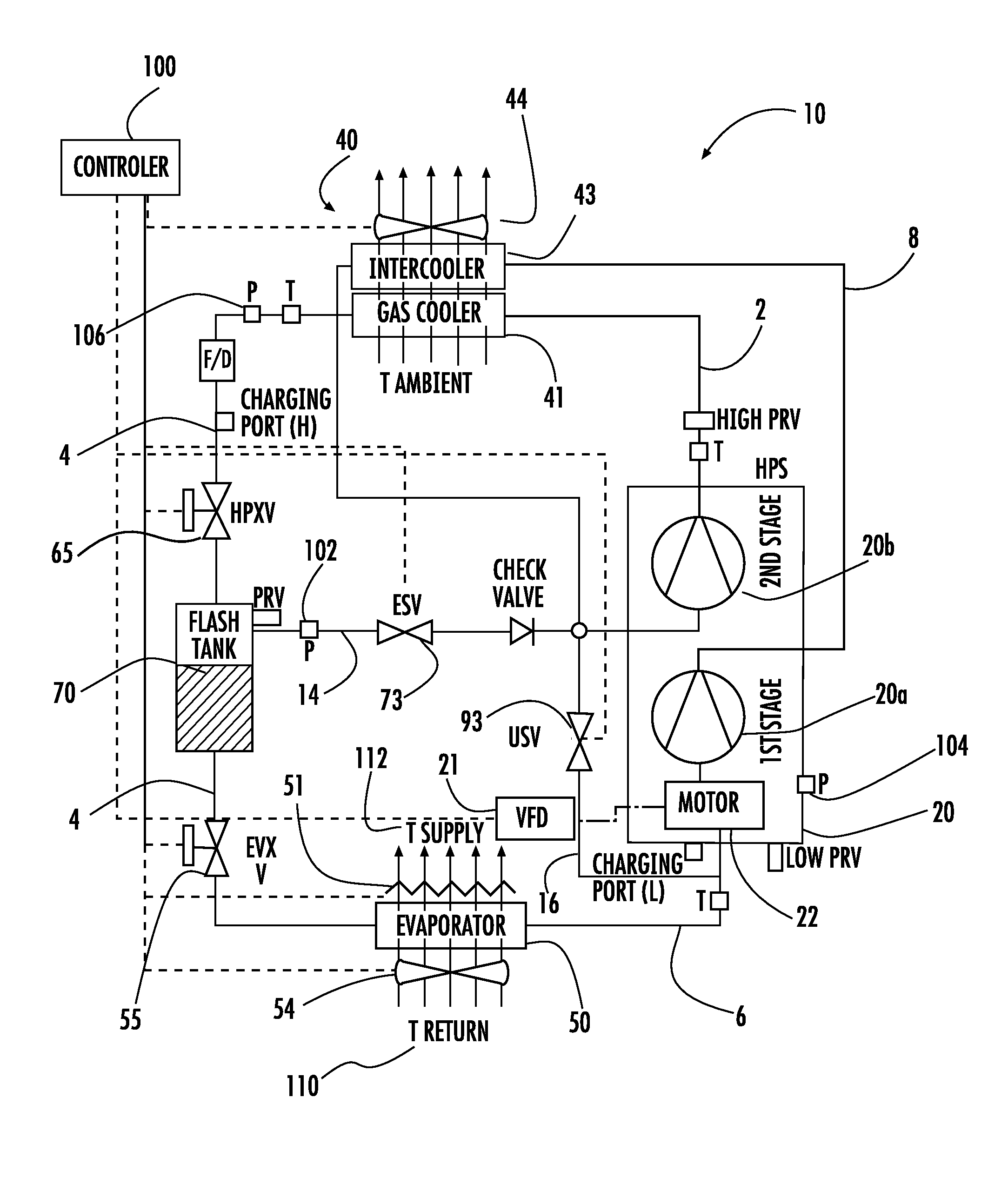

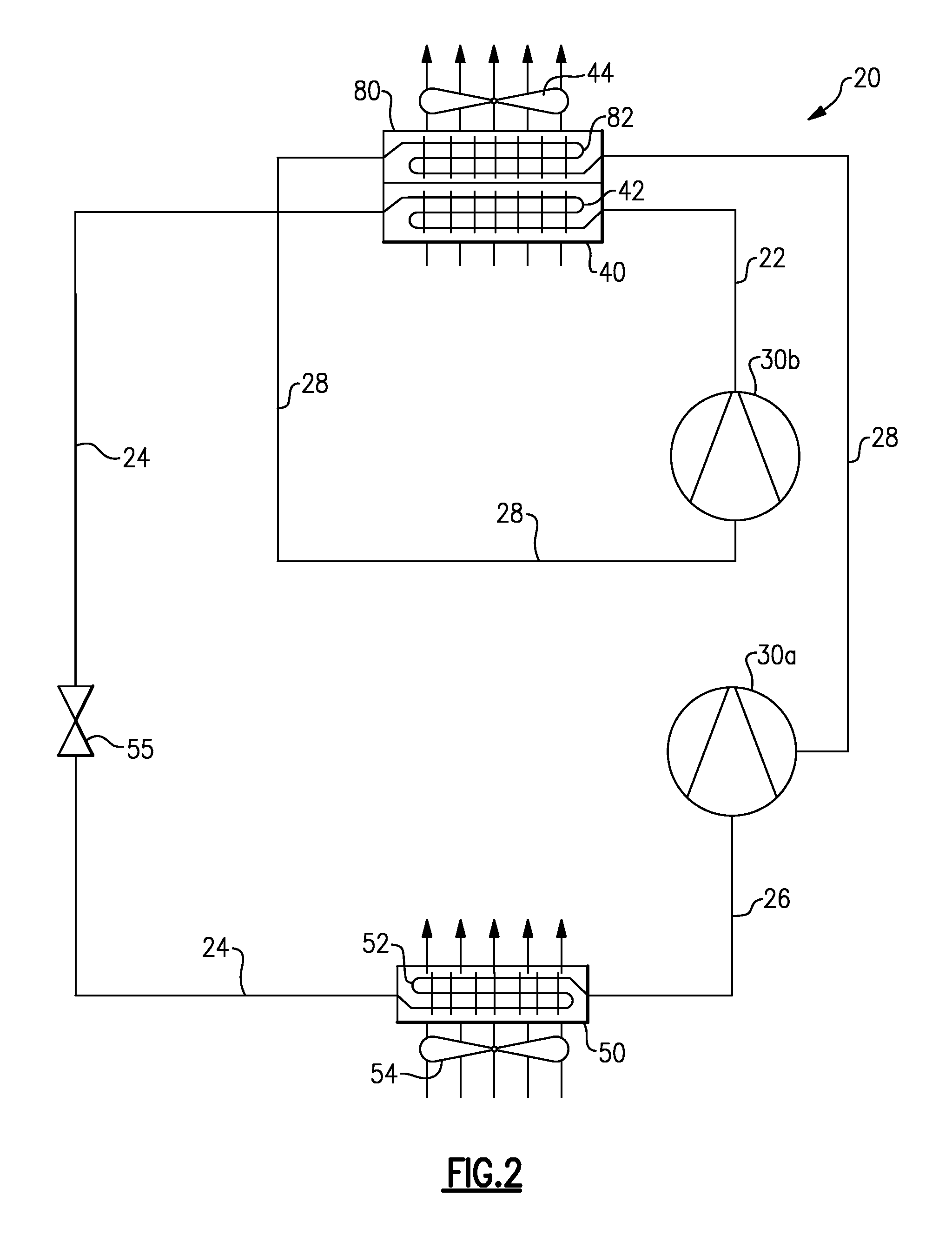

Termperature Control Logic For Refrigeration System

InactiveUS20140151015A1Mechanical apparatusCompression machines with non-reversible cycleTemperature controlProcess engineering

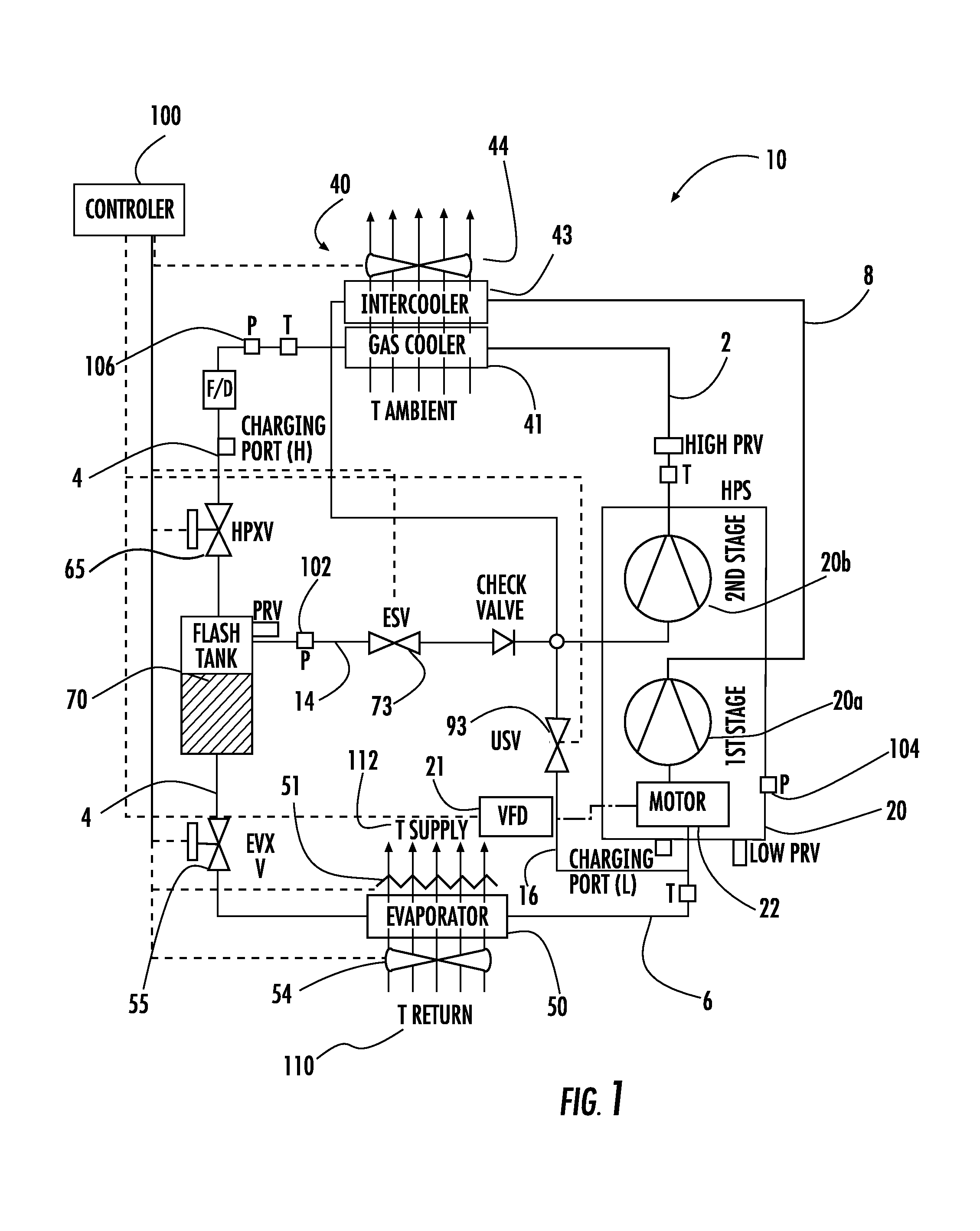

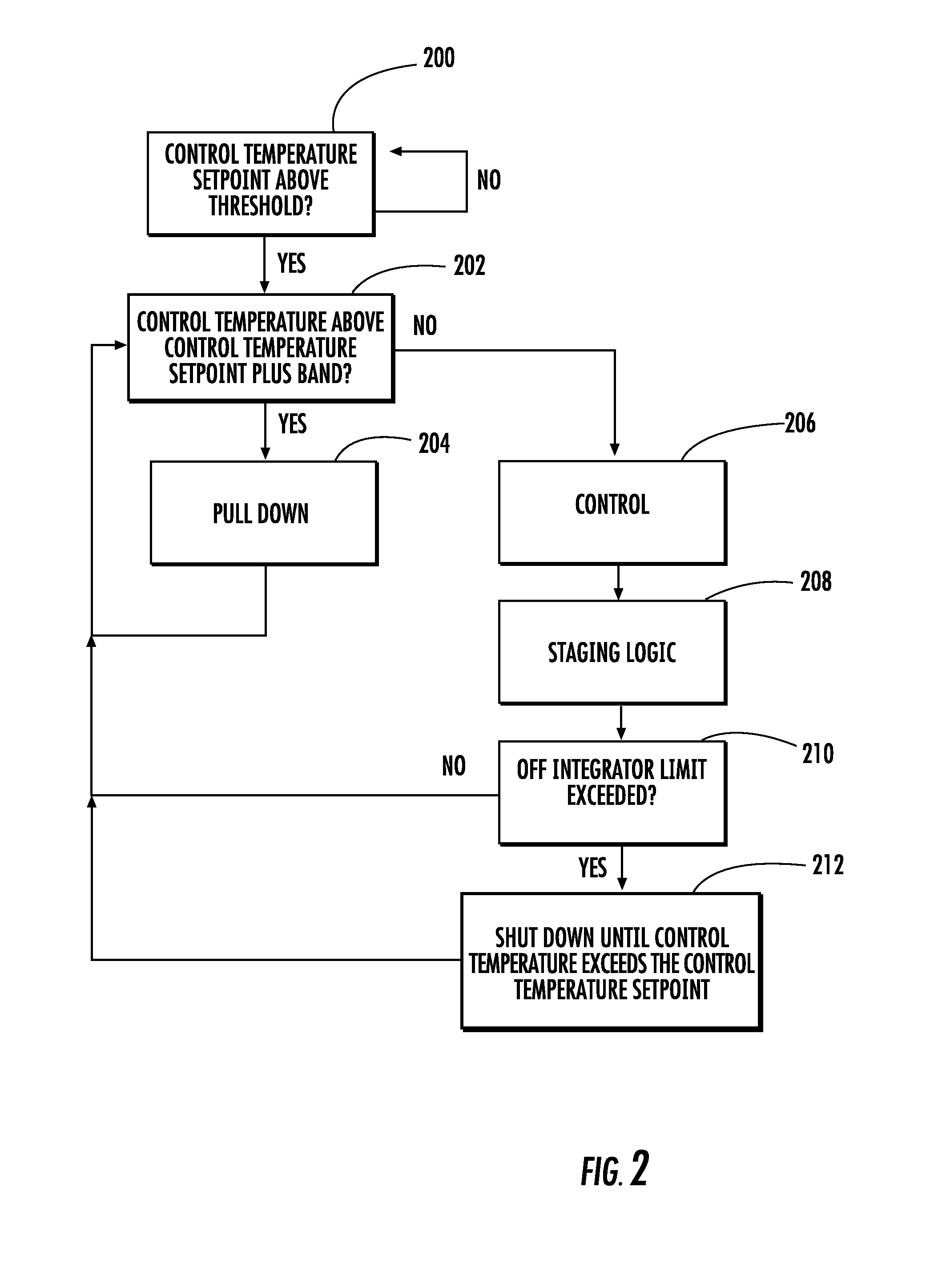

A refrigeration system includes a compressor having a first stage (20a) and a second stage (20b); a motor (22) driving the compressor; a heat rejecting heat exchanger having a fan (44) drawing ambient fluid over the heat rejecting heat exchanger, the heat rejecting heat exchanger including an intercooler (43) and a gas cooler, the inter-cooler coupled to an outlet of the first stage and the gas cooler (41) coupled to an outlet of the second stage; a flash tank (70) coupled to an outlet of the gas cooler; a primary expansion device (55) coupled to an outlet of the flash tank; a heat absorbing heat exchanger (50) coupled to an outlet of the primary expansion device, an outlet of the heat absorbing heat exchanger coupled to the suction port of the first stage; and a controller (100) for implementing a pulldown mode, a control mode and a staging logic mode.

Owner:CARRIER CORP

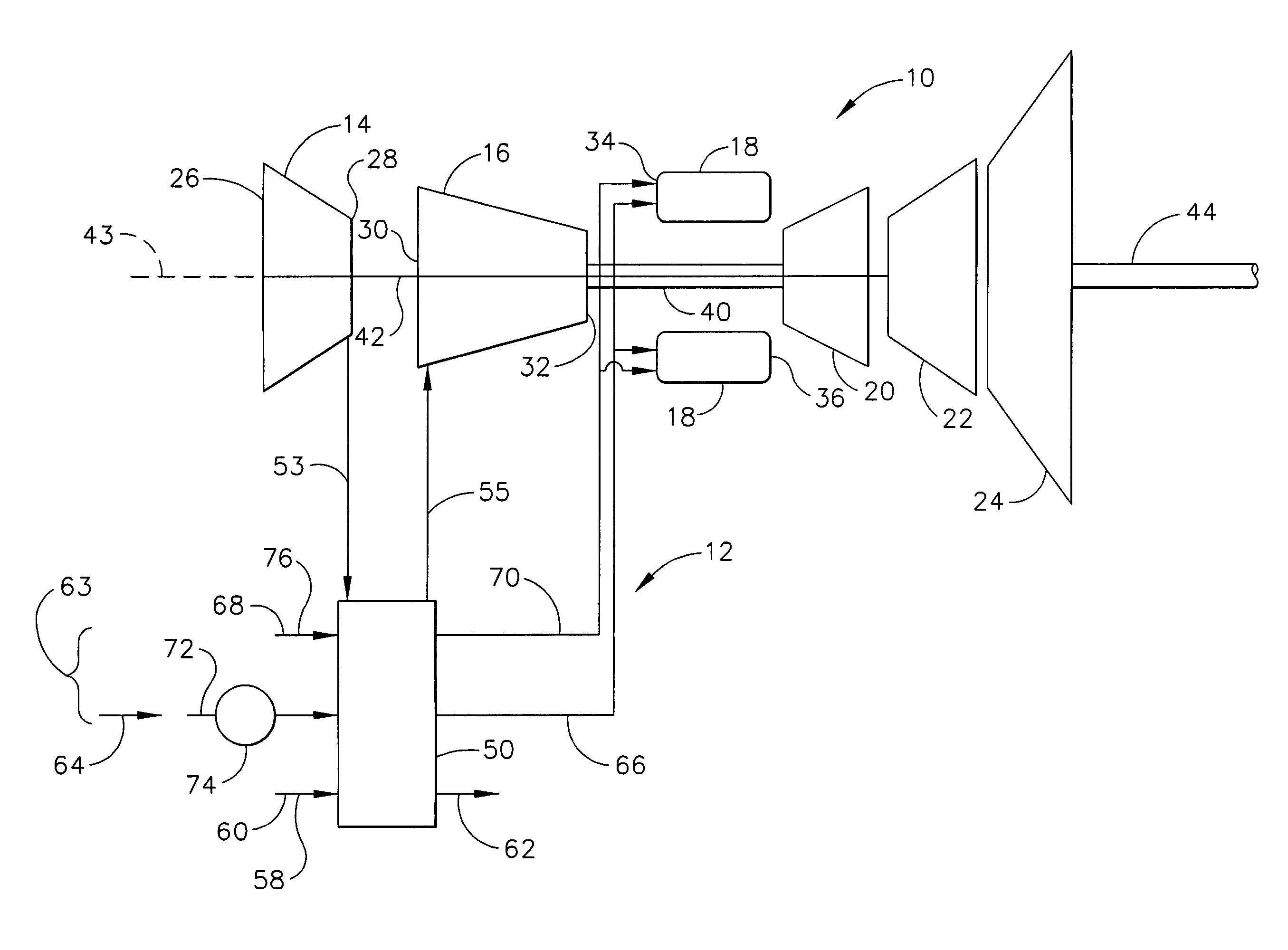

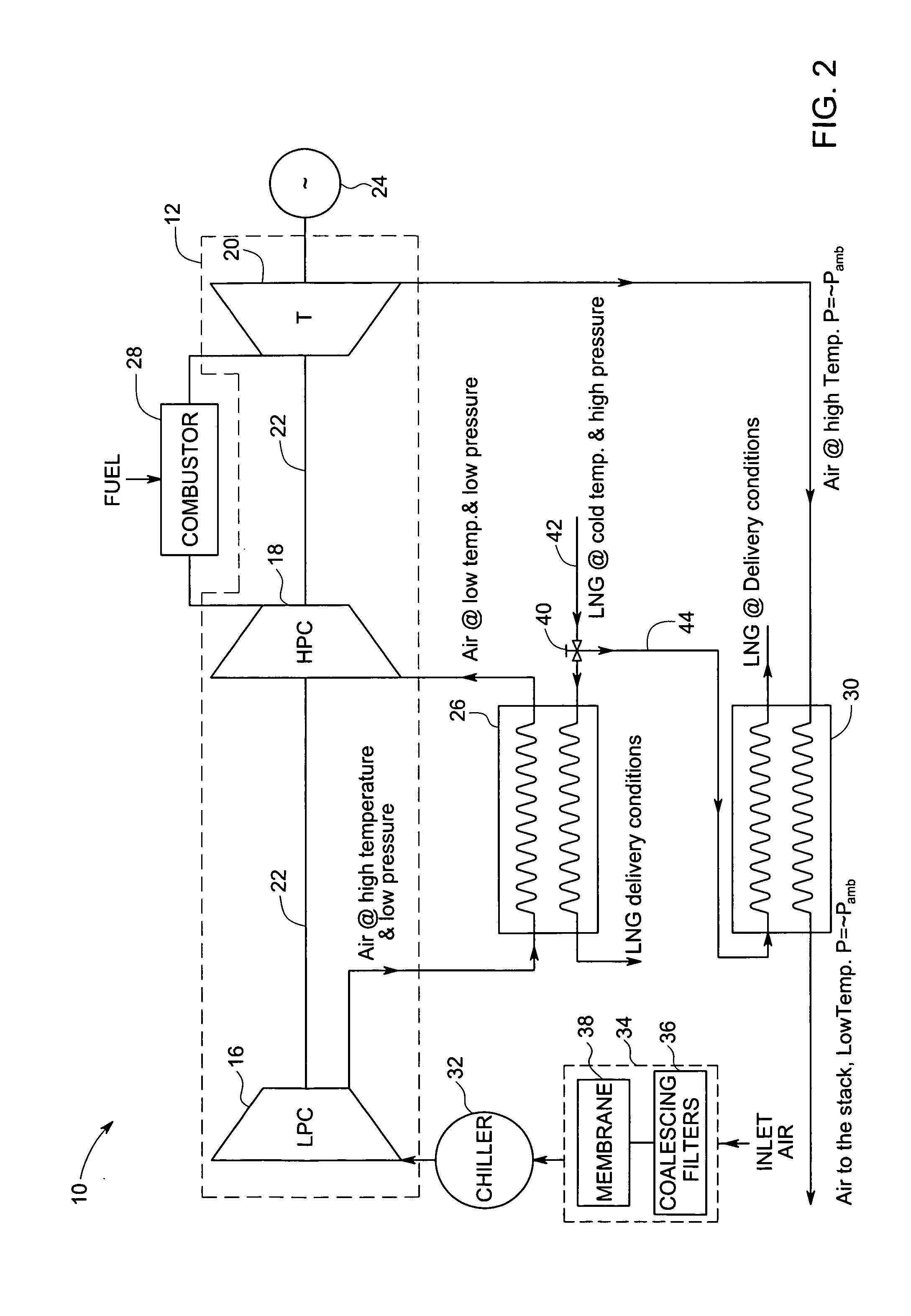

Gas turbine engine system and method of operating the same

InactiveUS20070089423A1Simple systemTurbine/propulsion engine coolingGas turbine plantsCombustion chamberWorking fluid

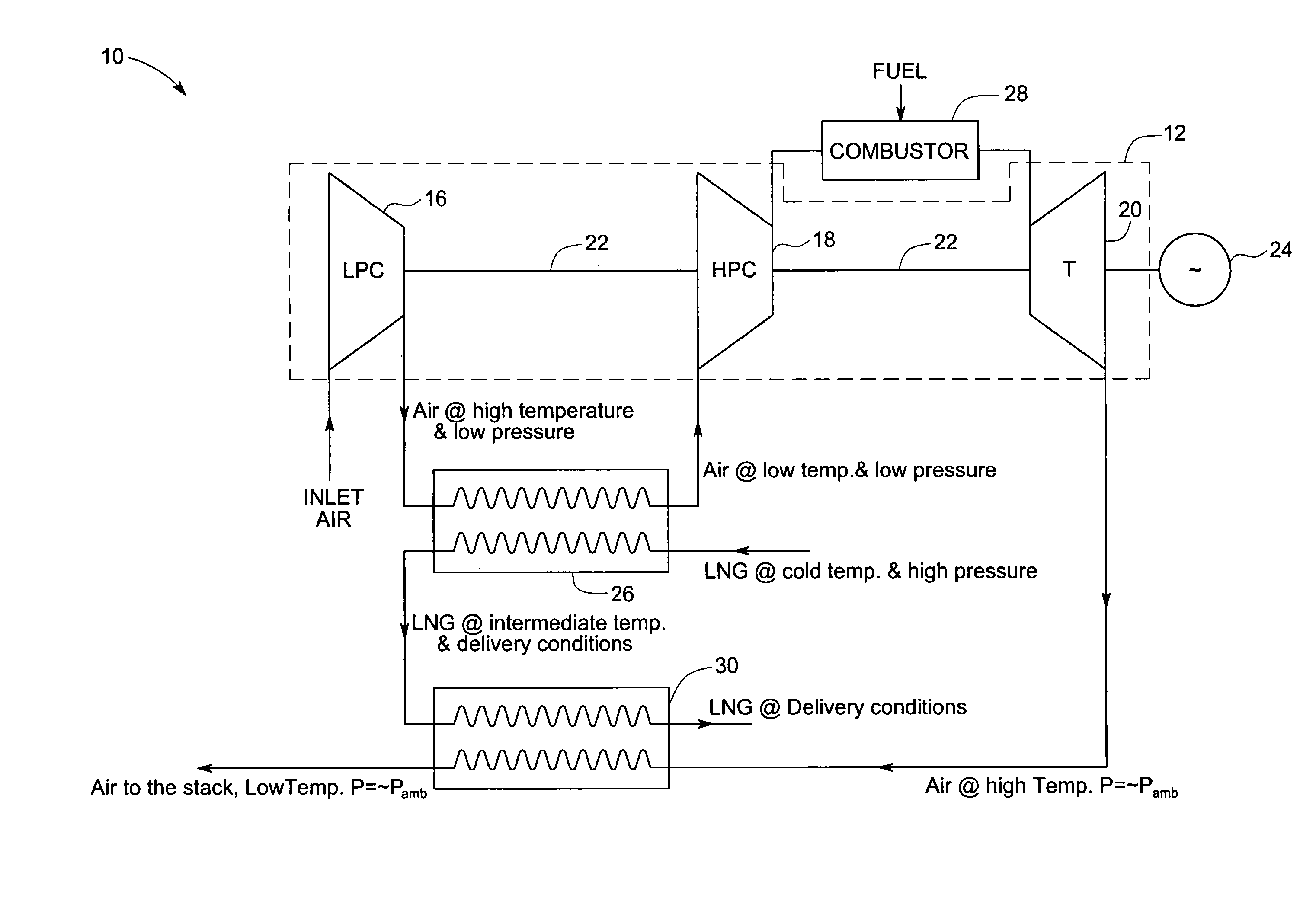

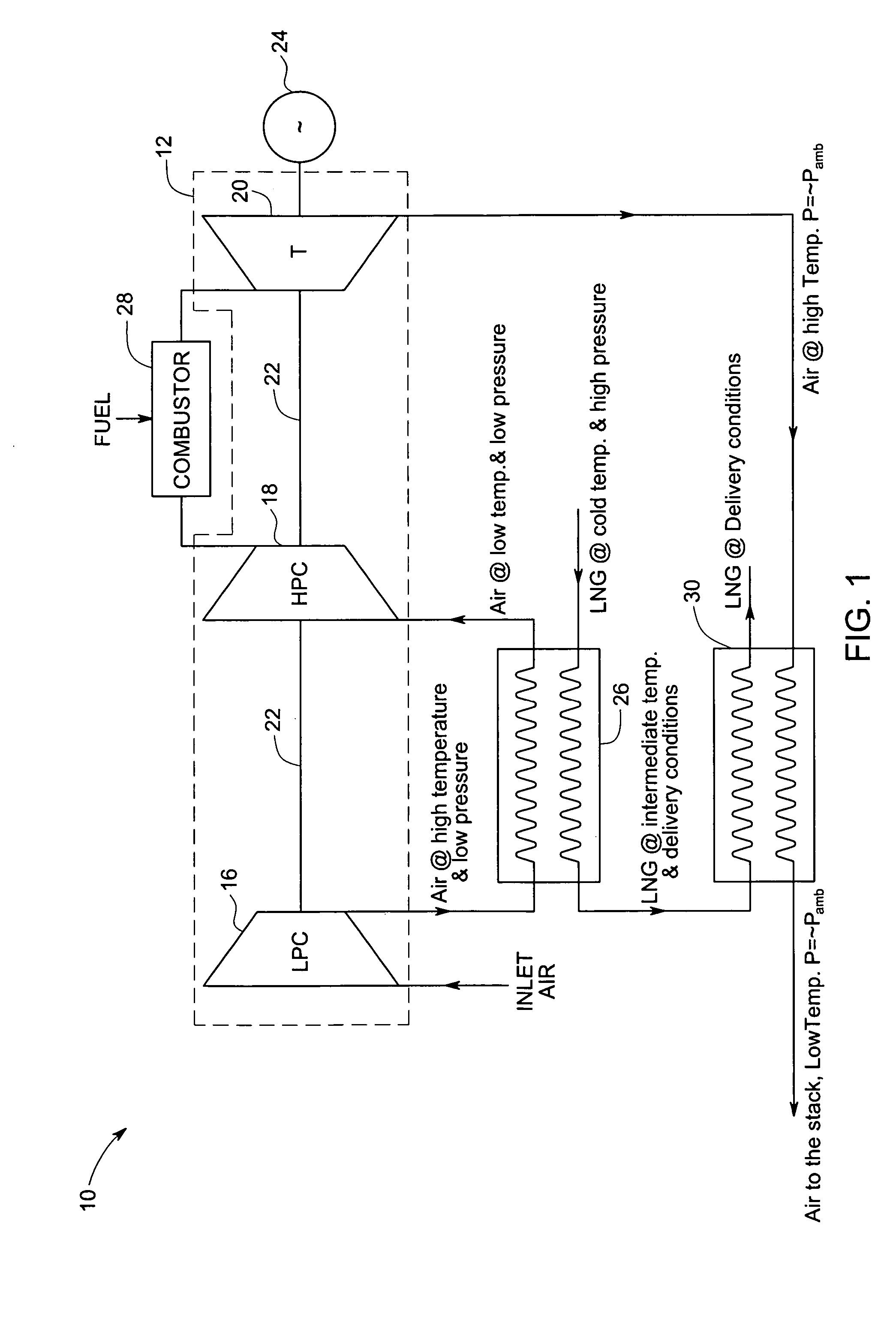

A gas turbine engine system includes an intercooler coupled between a low-pressure compressor and a high-pressure compressor and configured to cool the compressed air exiting the low-pressure compressor. Liquid natural gas or a cooled intermediate working fluid is used in the intercooler to cool the compressed air exiting the low-pressure compressor. A mixture of fuel and compressed air from the high-pressure are combusted in a combustion chamber of an engine. A turbine is coupled to the engine and configured to expand combustion exhaust gas ejected from the engine to generate power. A heat exchanger is coupled to the turbine and the intercooler and configured to re-gasify the liquid natural gas. The exhaust air exiting the turbine or a heated intermediate working fluid is used to gasify the liquid natural gas in the heat exchanger.

Owner:GENERAL ELECTRIC CO

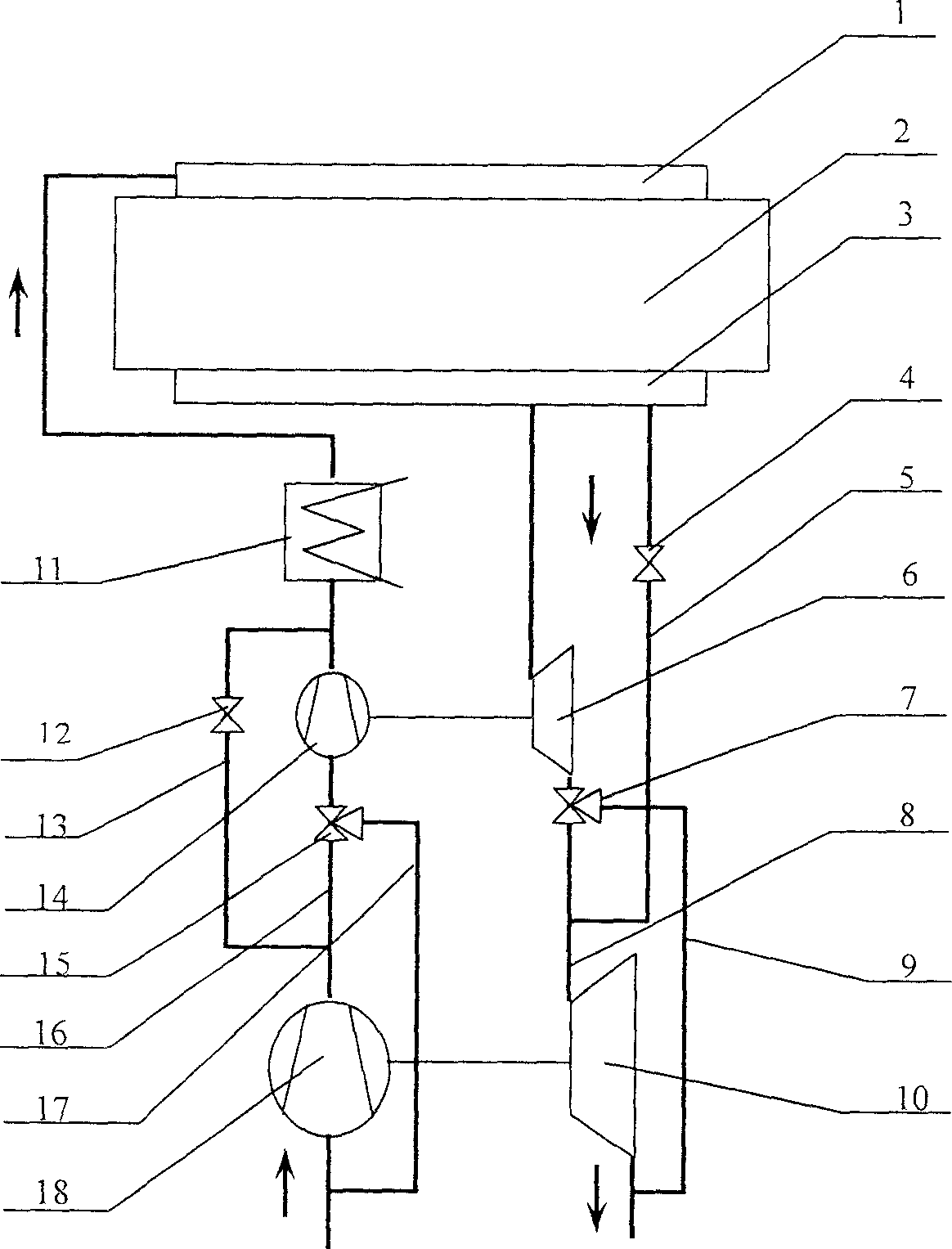

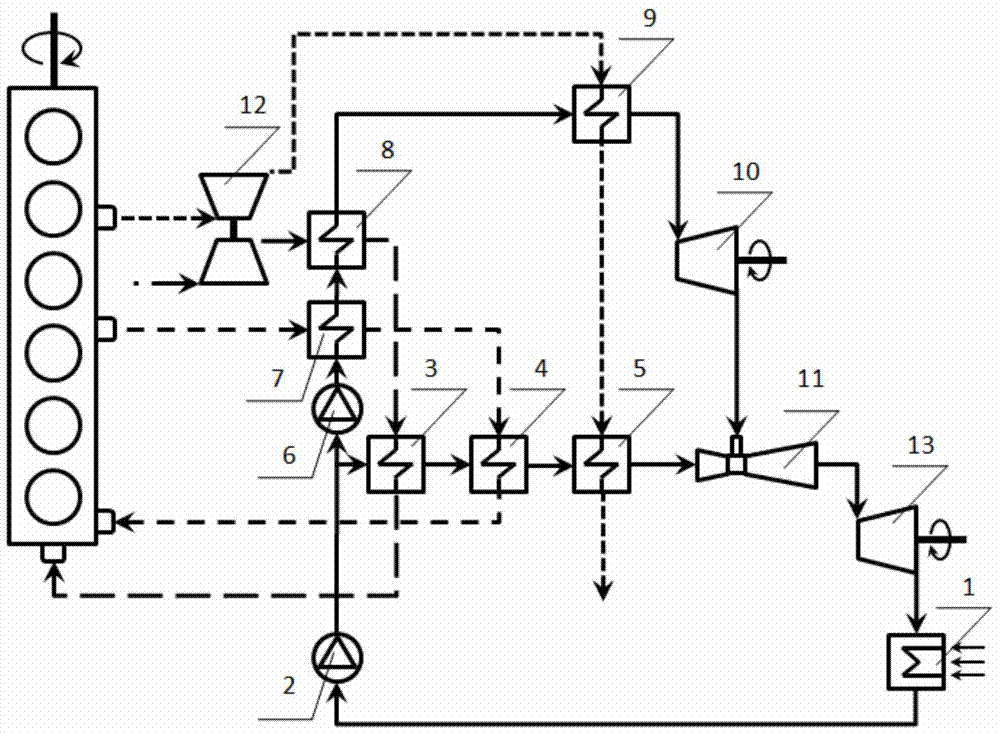

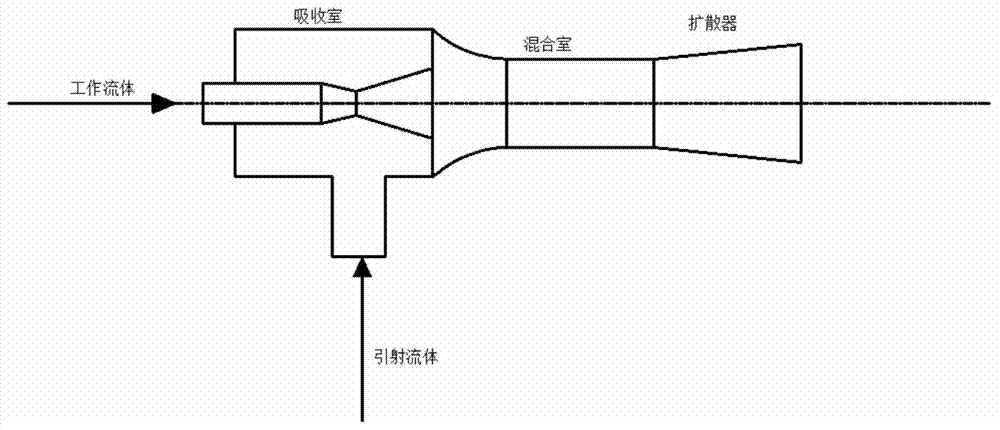

Two-stage expansion jet type waste heat recovery system of internal combustion engine

ActiveCN103670626AImprove the efficiency of waste heat recoveryReduce outlet back pressureInternal combustion piston enginesExhaust apparatusIntercoolerEvaporator

Owner:TIANJIN UNIV

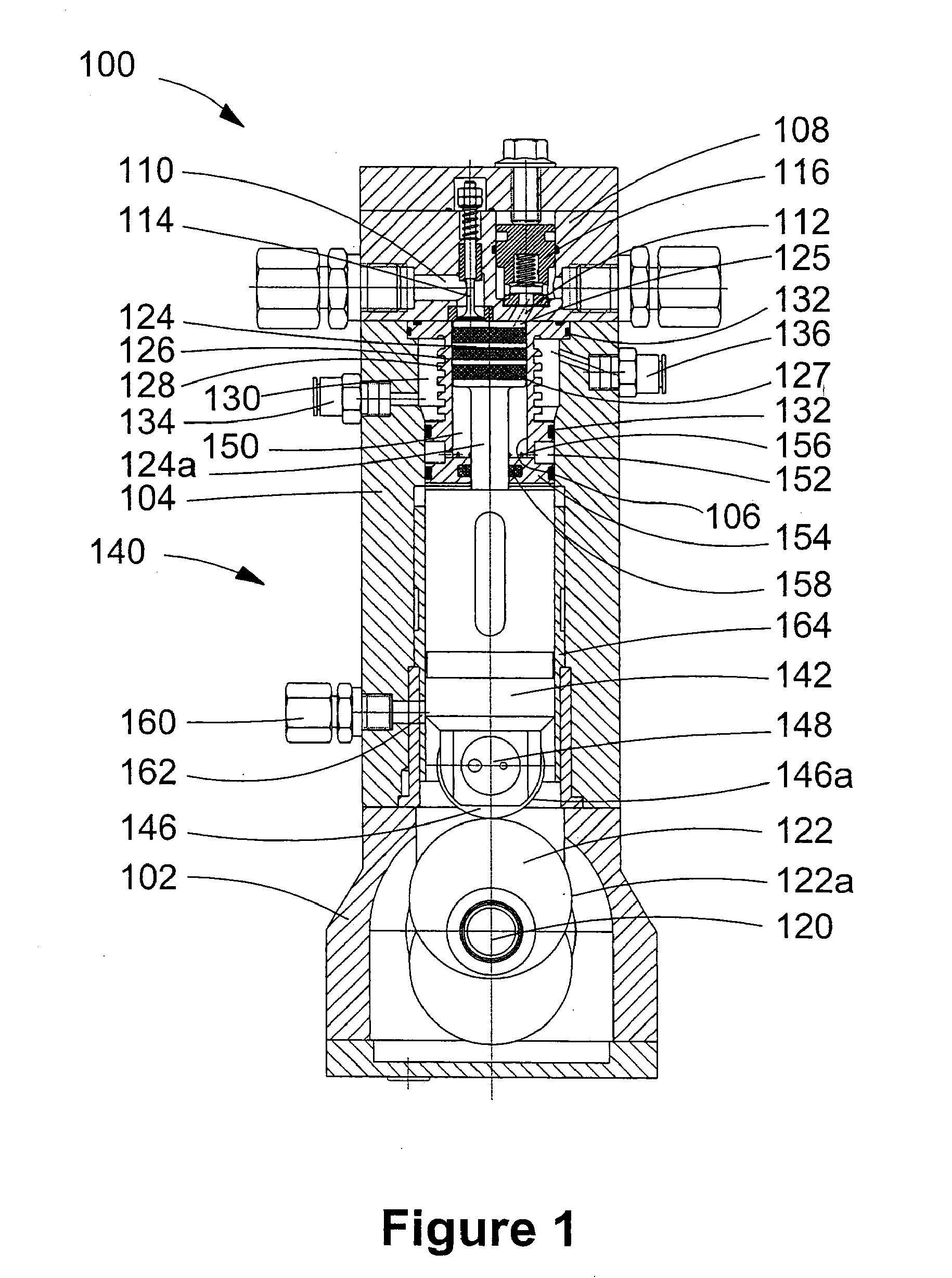

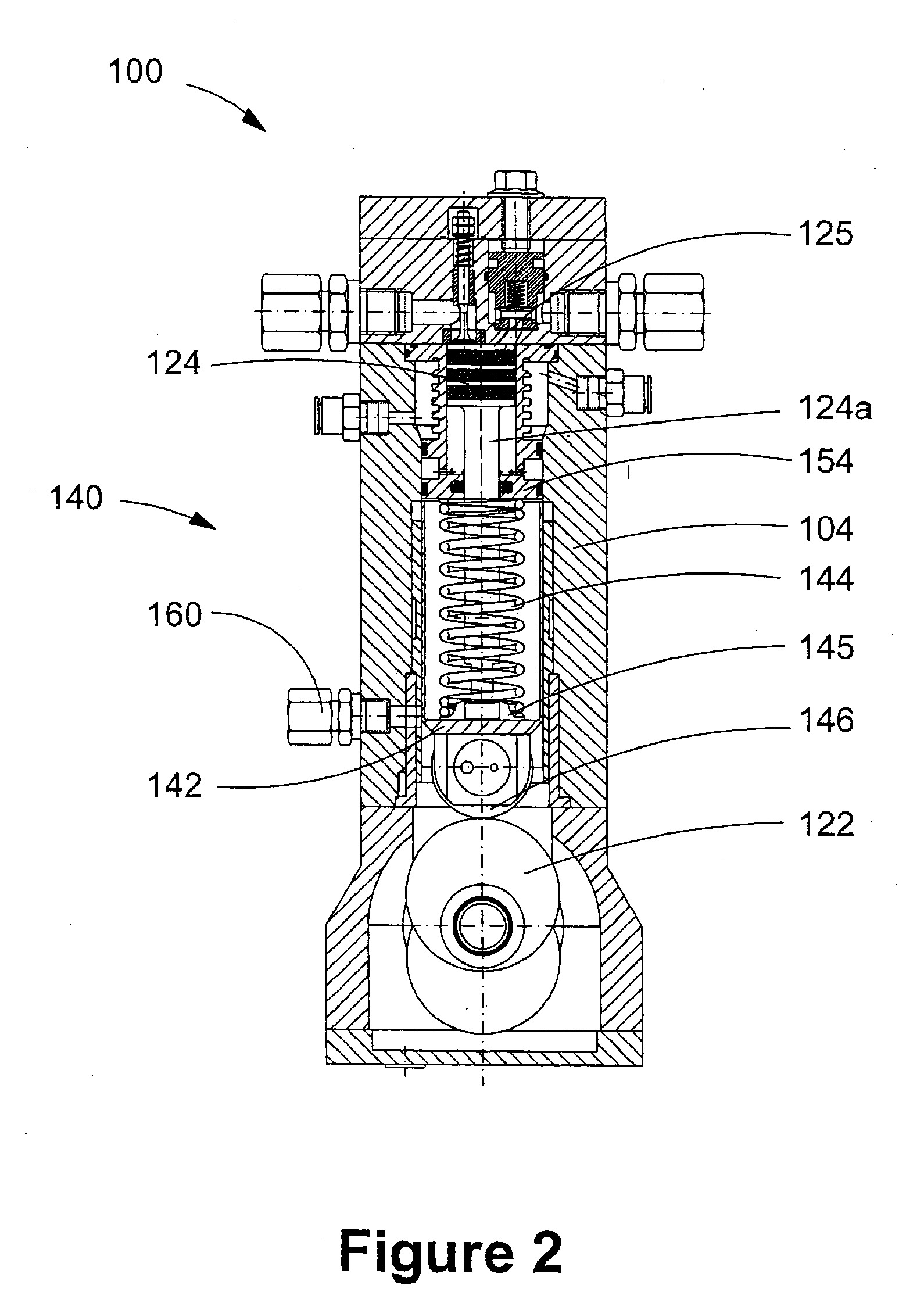

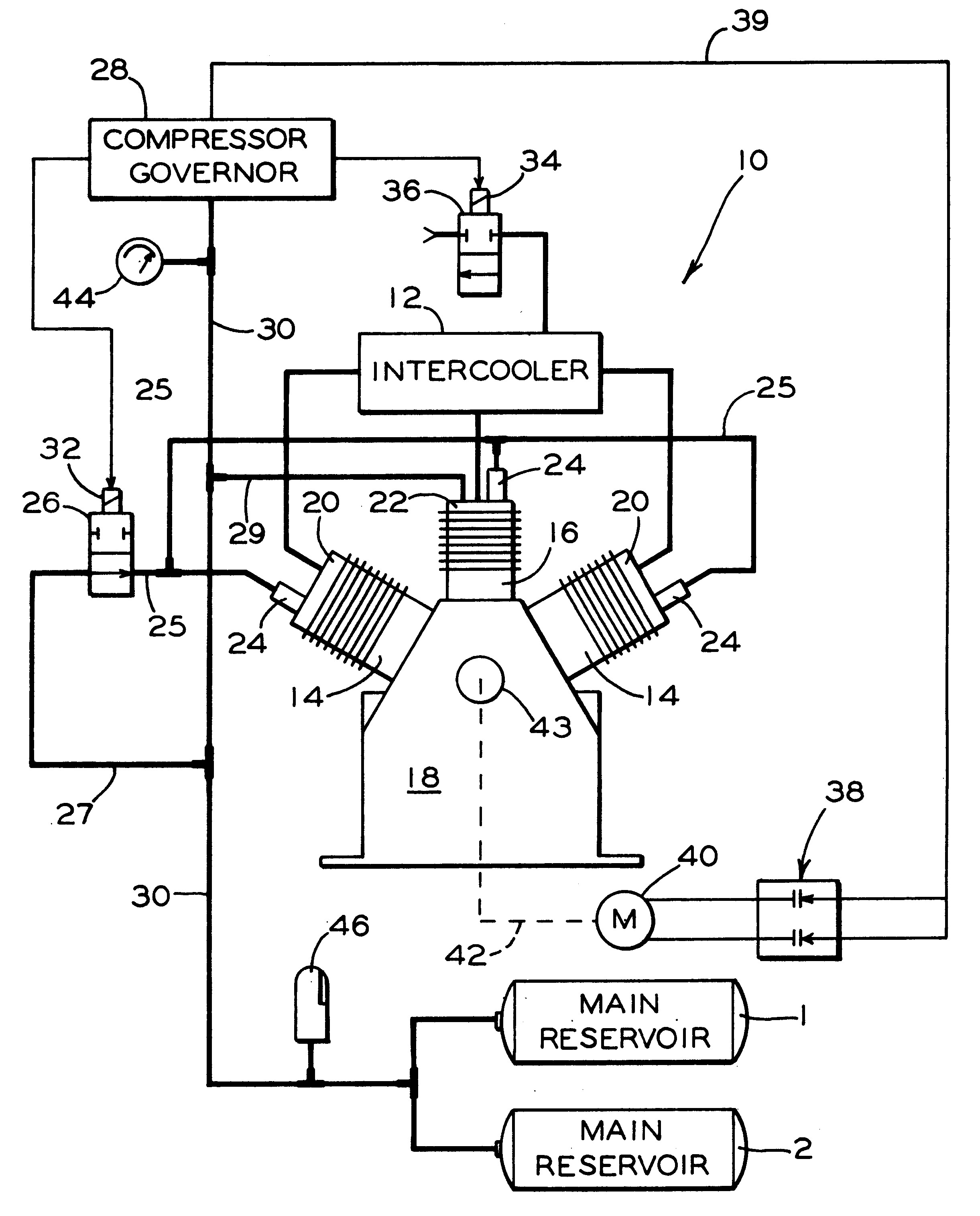

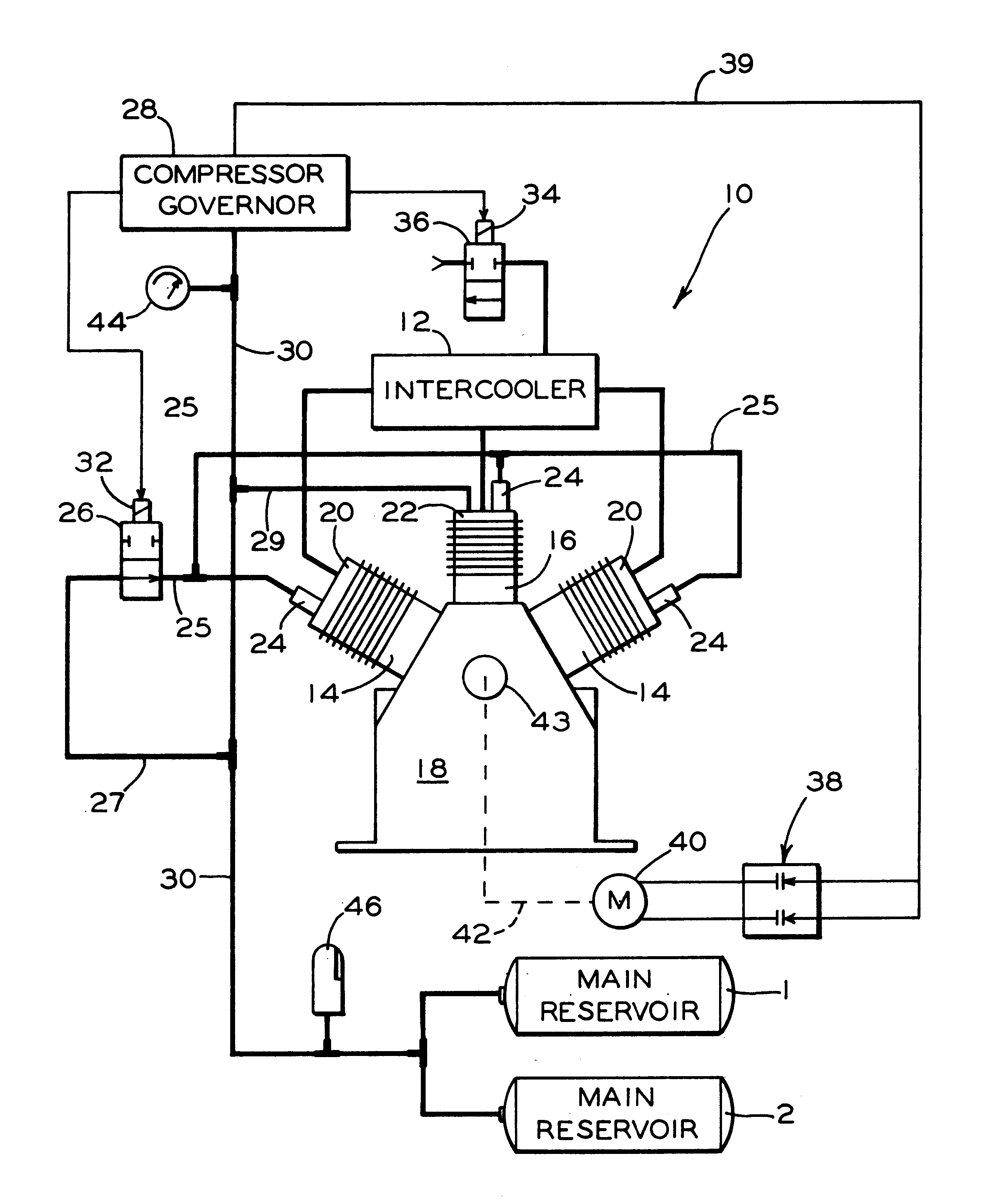

Compressor intercooler unloader arrangement

InactiveUS6203285B1Eliminate compressor motor heat buildupProlong lifePositive displacement pump componentsFlexible member pumpsElectricityLinear compressor

Apparatus for rapidly unloading air pressure in an intercooler to atmosphere when a compressor pneumatically connected to the intercooler is unloaded. The apparatus includes a governor pneumatically connected to a reservoir, that, in turn, is connected to receive pressurized air from the air compressor. The governor has a pressure sensing device operable to order unloading of the compressor when air pressure level in the reservoir tank reaches a preset level. An electrically operated valve is pneumatically connected to the intercooler and connected electrically to the pressure sensing device of the governor, with the electrically operated valve being effective to exhaust air pressure in the intercooler when the valve receives an unload signal from the pressure sensing device. The compressor is driven, by an electrical motor having one or more speed configurations, with transition occurring between one configuration and another when the compressor is unloaded. The electrically operated valve is effective to unload the intercooler at the time of speed configuration transition to reduce undue motor and electrical contactor heat and thus increase life expectancy of the motor and contactors.

Owner:WESTINGHOUSE AIR BRAKE CO

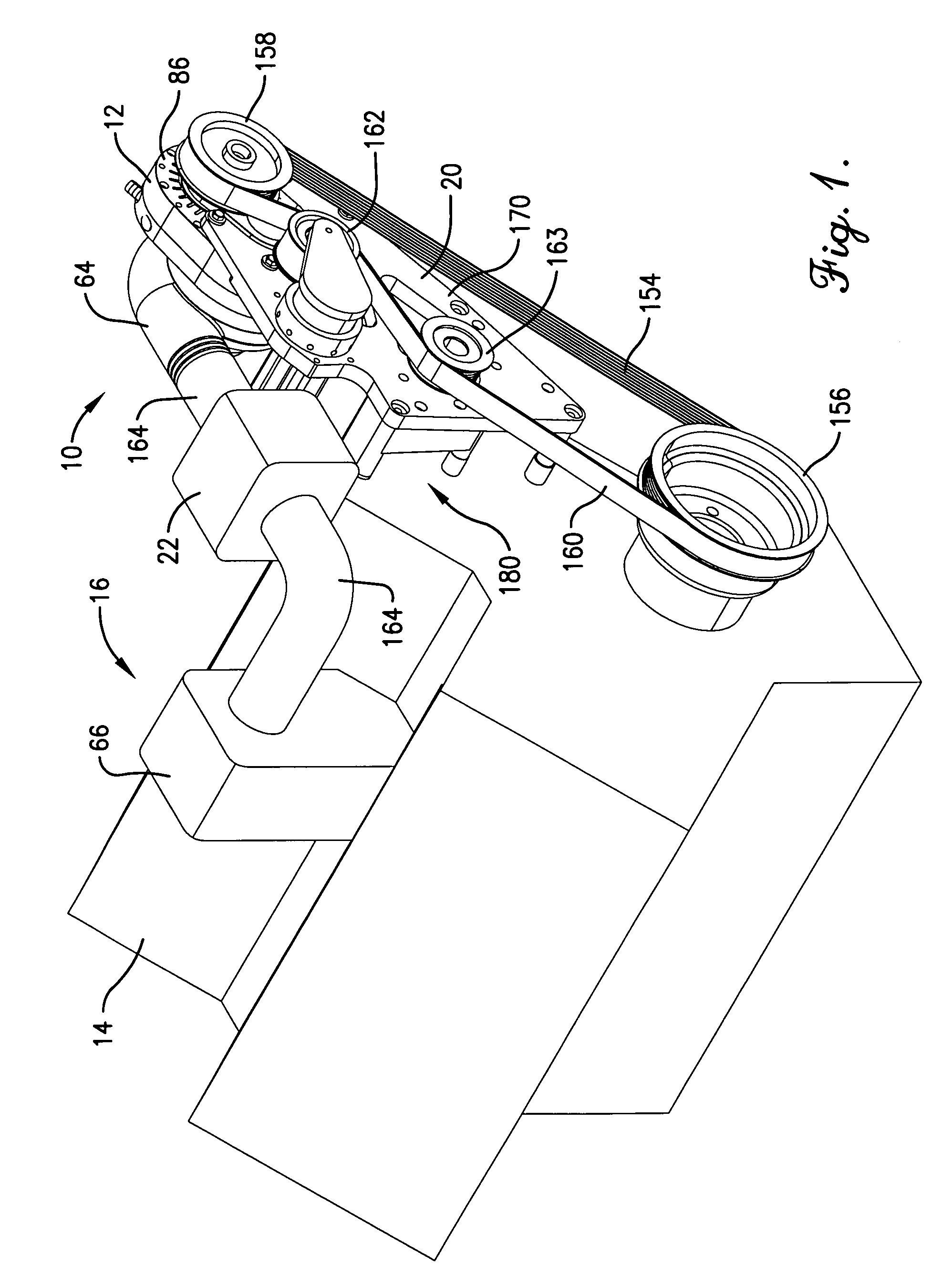

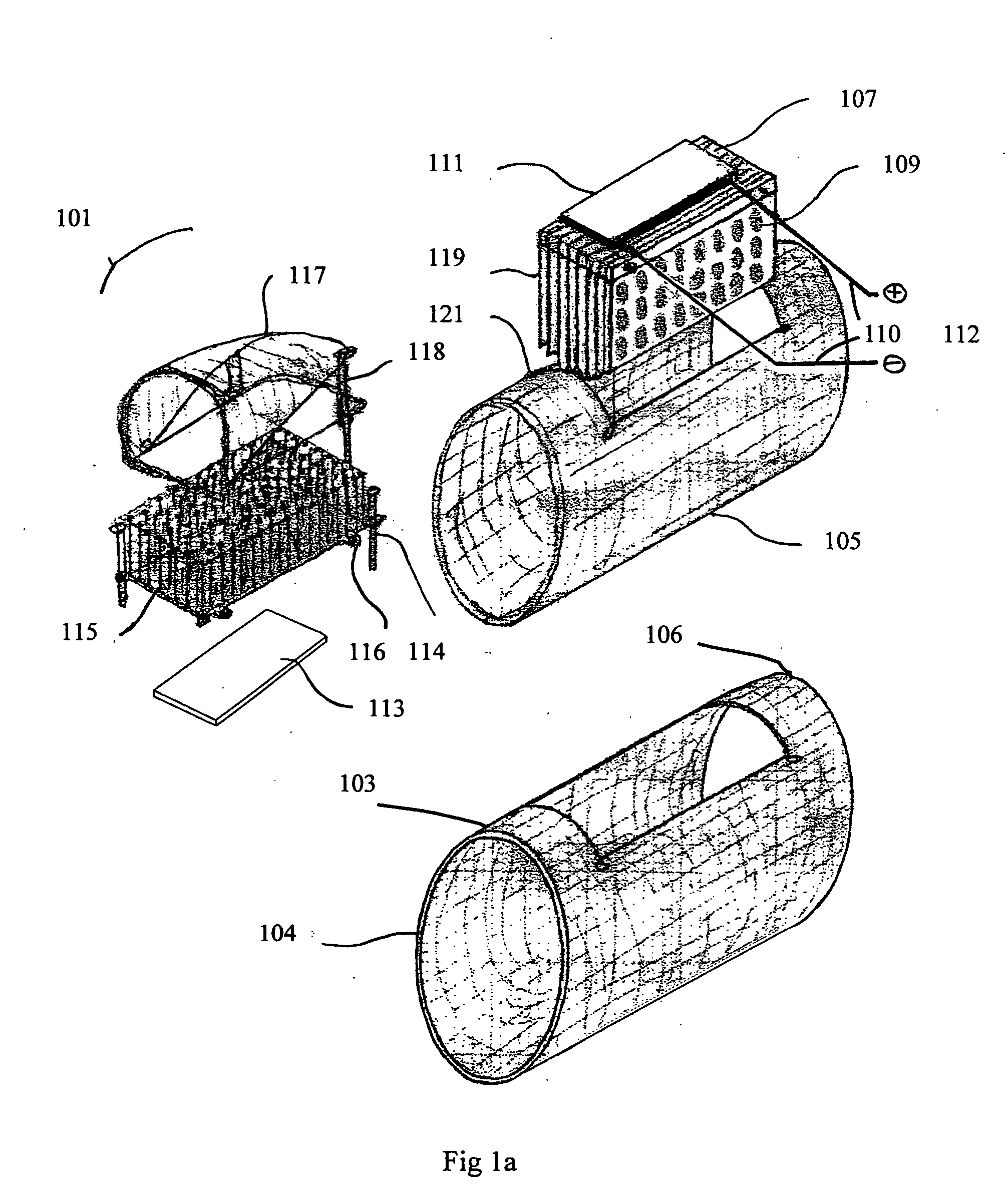

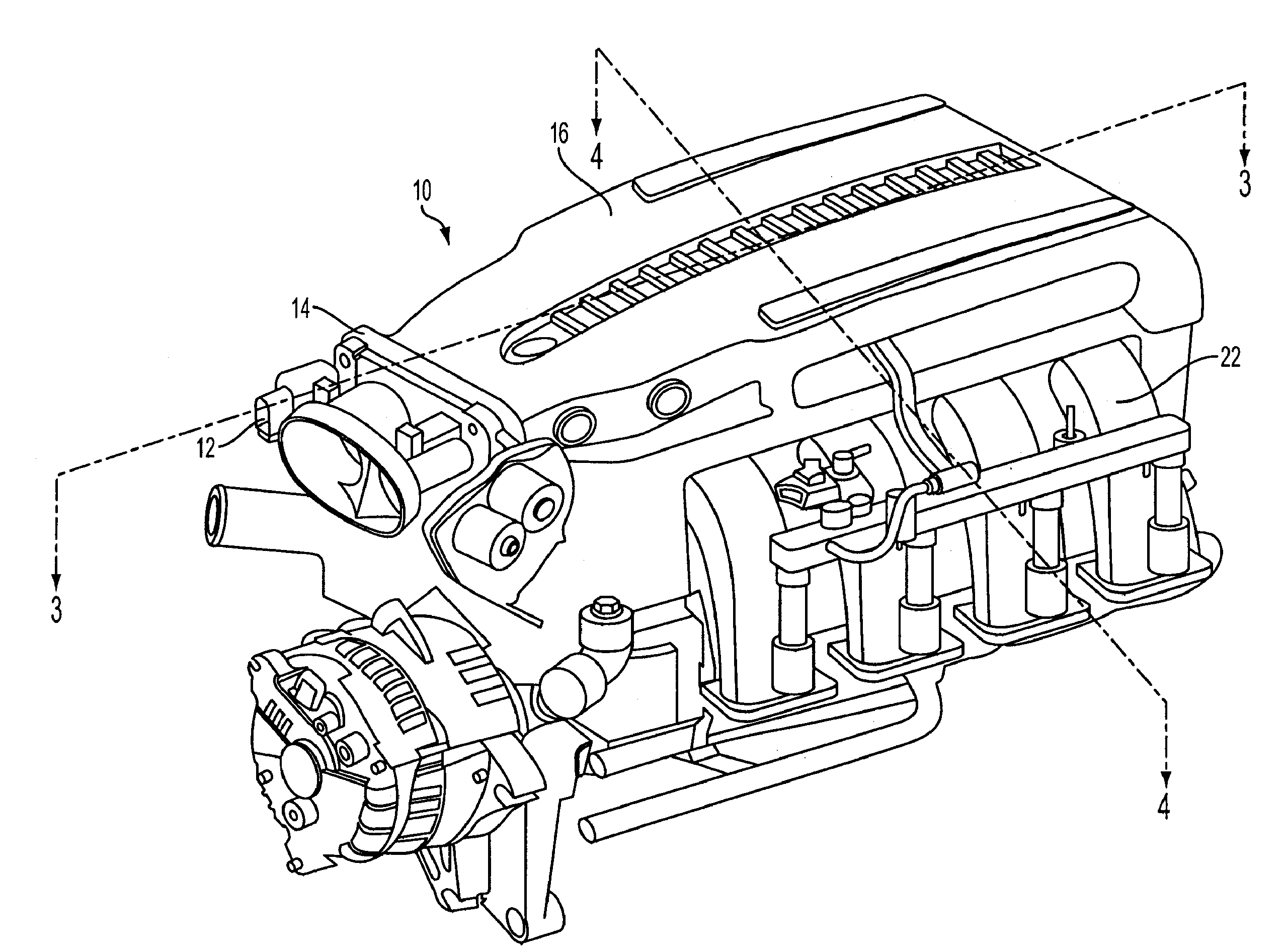

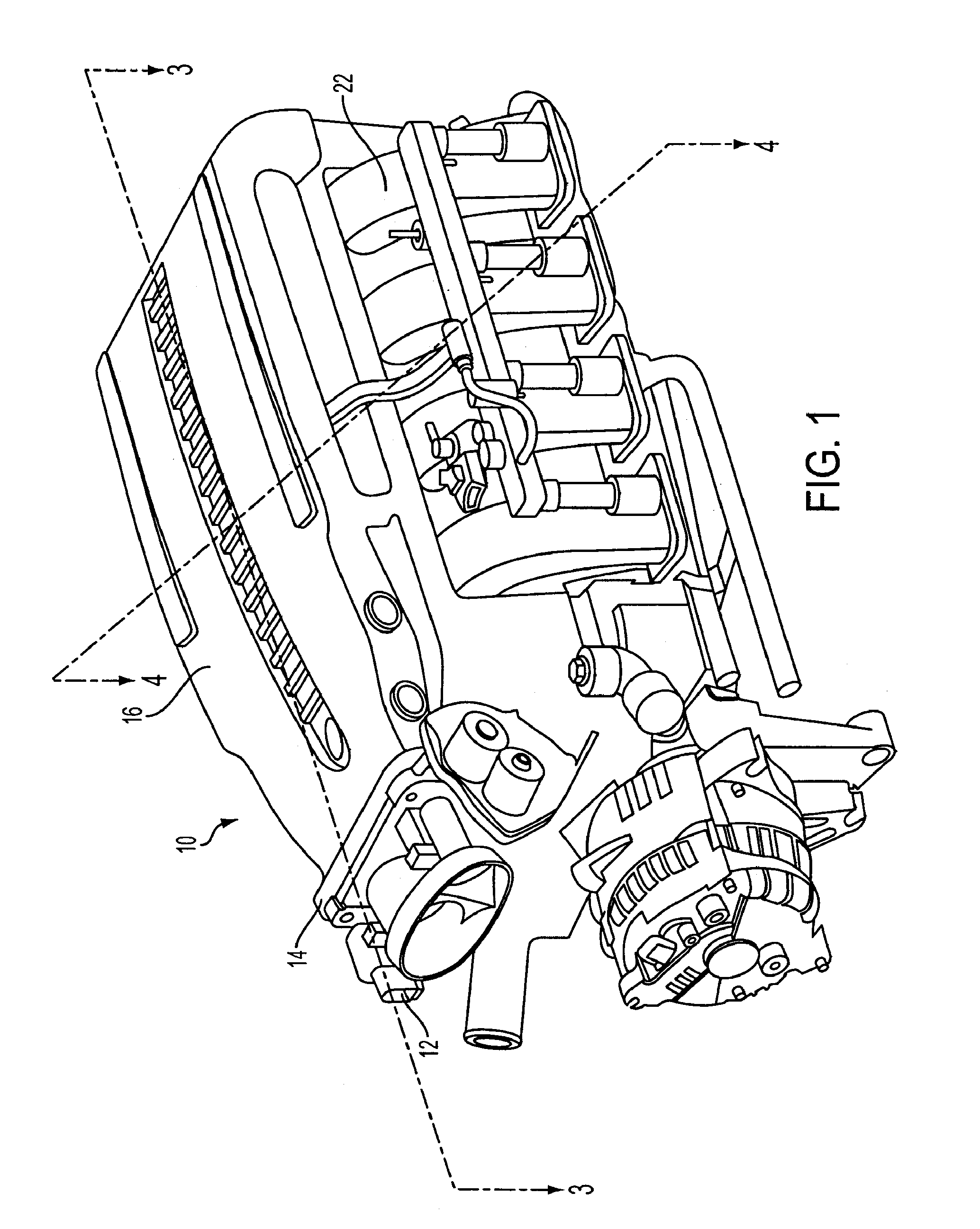

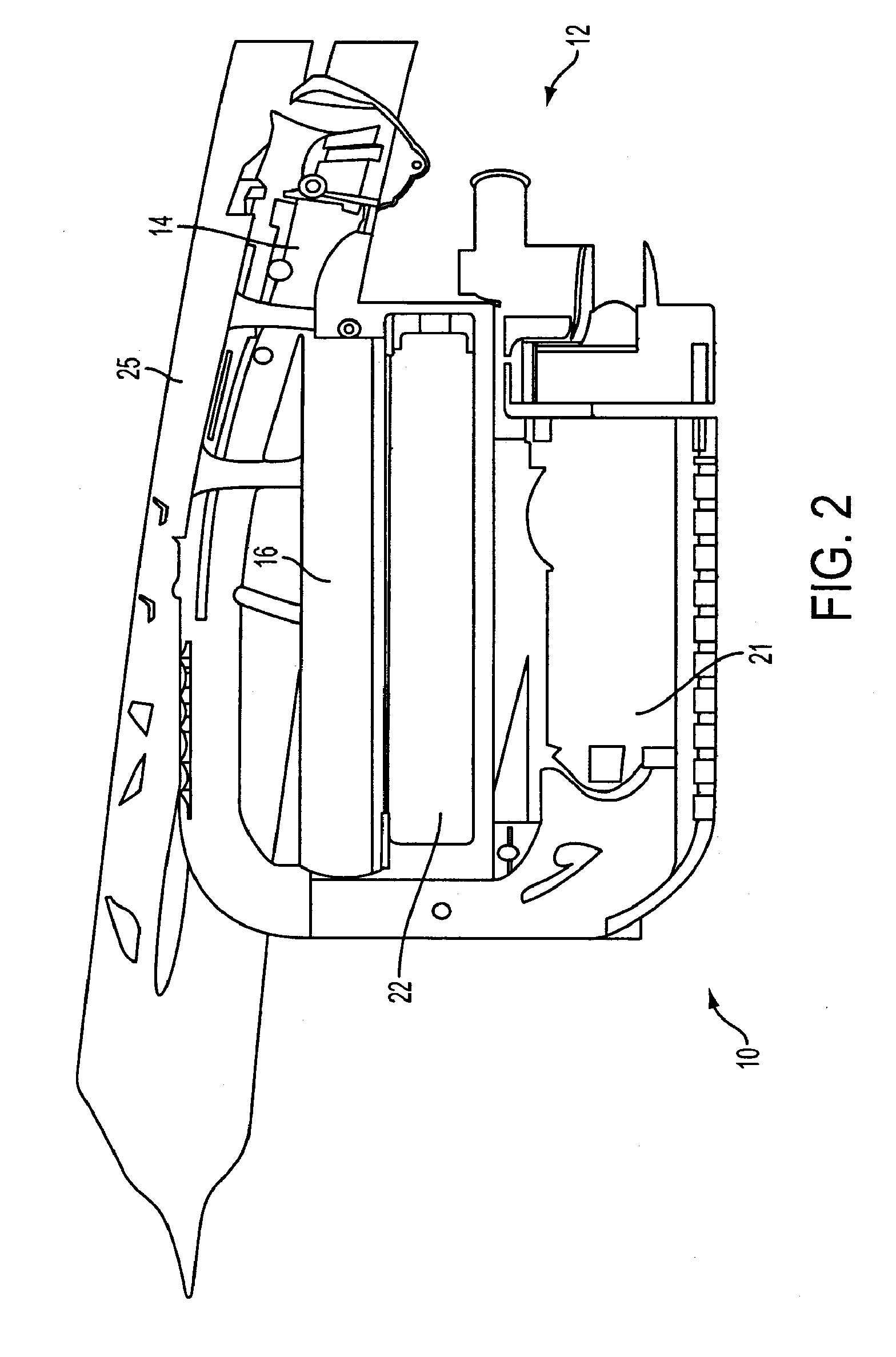

Apparatus and method for boosting engine performance

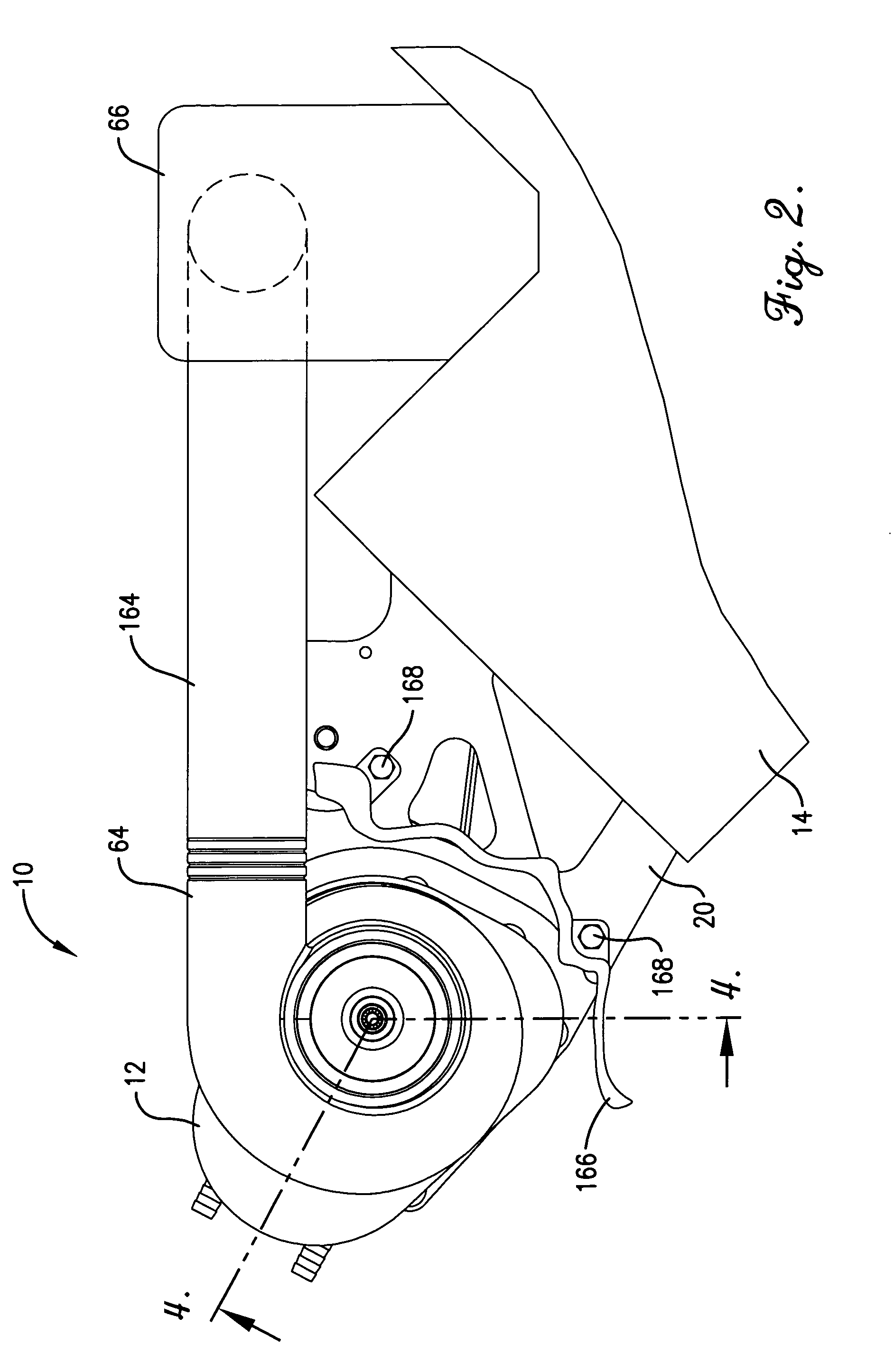

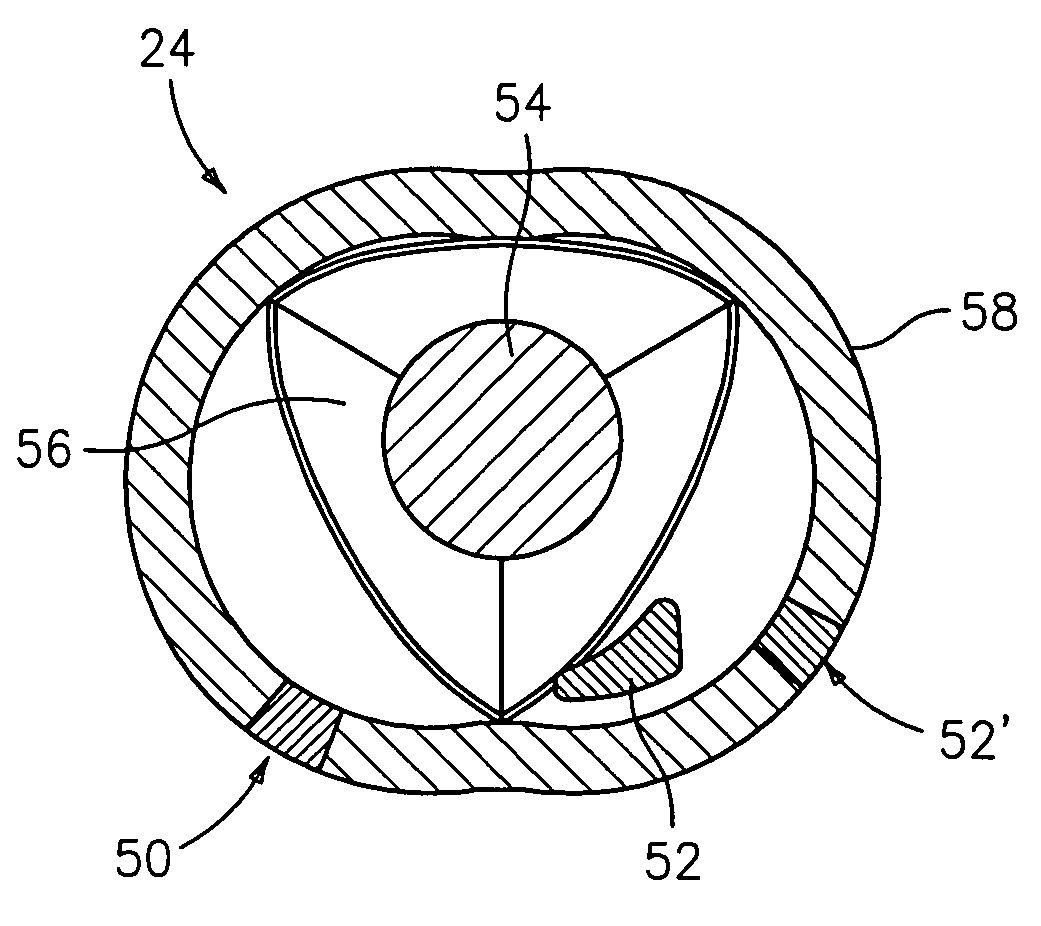

InactiveUS20070175456A1Internal combustion piston enginesCombustion-air/fuel-air treatmentEngineeringIntercooler

A supercharger (10) is positioned in the valley of an automobile engine (60) so that it fits under the engine hood (25). The supercharger (10) has a low profile air inlet (14) at the top that passes air to an inlet tube (16). The height of the inlet tube (16) decreases and its width expands as the inlet tube (16) extends away from the air inlet (14) to keep a low profile while minimizing restrictions to airflow. The inlet tube (16) supplies air to a compressor (18) at the bottom. The pressurized air flows through a large and thin intercooler (24) directly above the compressor (18). The cooled air is fed to long and straight intake manifold runners (28) positioned above the engine heads (61, 62) of the engine (60). The supercharger (10) provides a large volume of low pressure and low temperature air charge to the engine (60).

Owner:MJ ACQUISITIONS

Cooling module

InactiveUS20080115528A1Reduce heat transferSuppress noiseEvaporators/condensersVehicle heating/cooling devicesProcess engineeringIntercooler

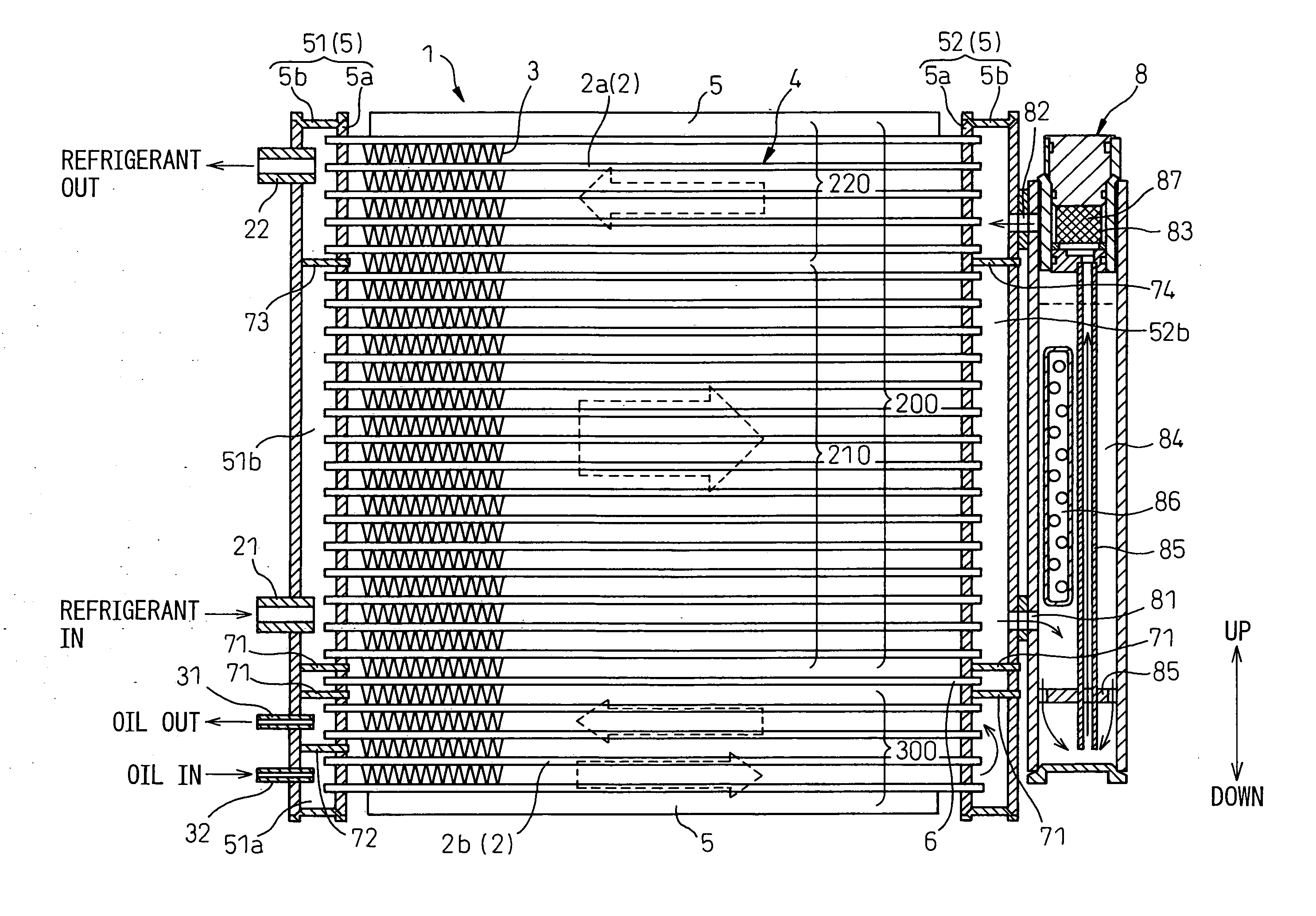

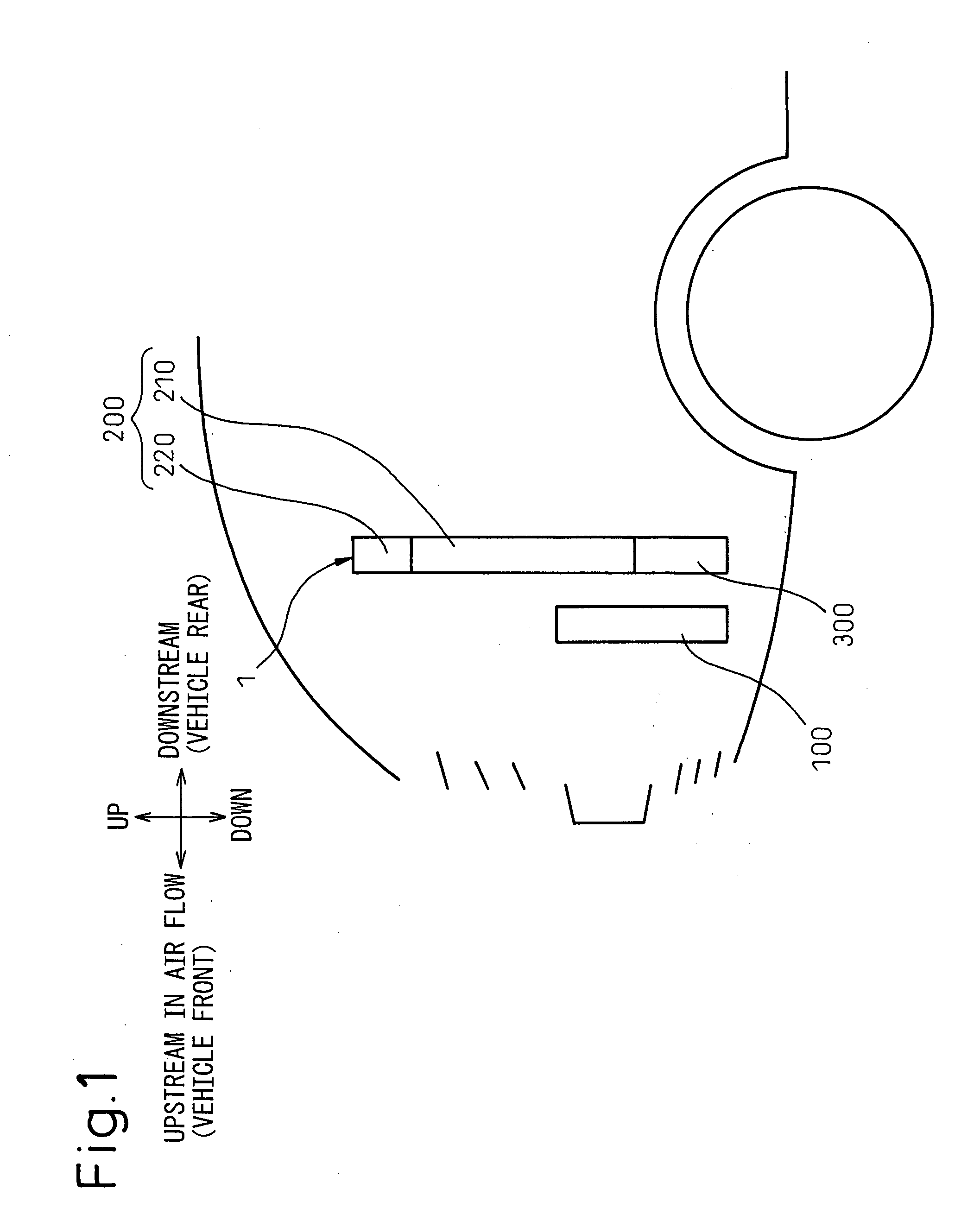

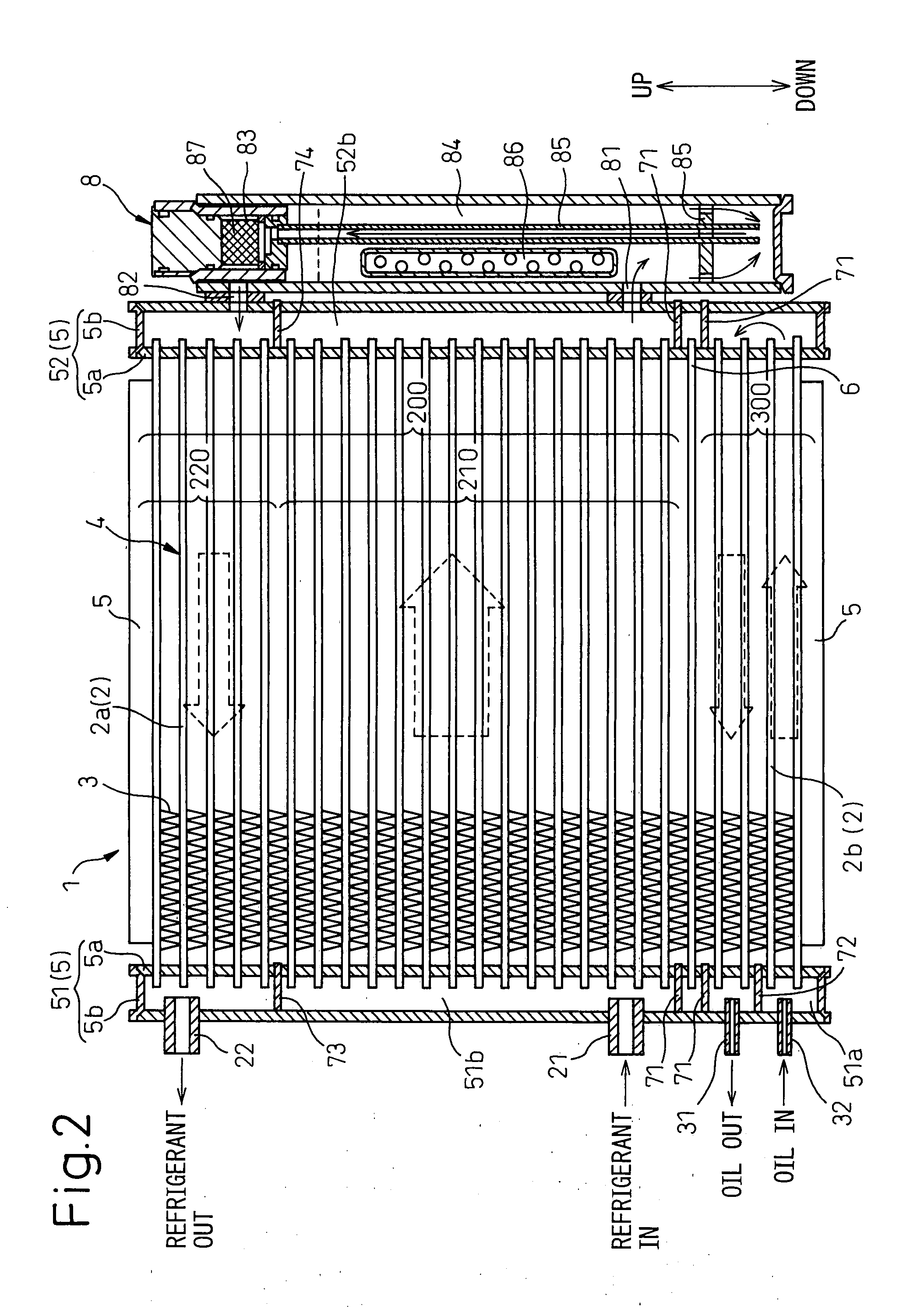

A cooling module comprises an intercooler 100 and an integrated heat exchanger 1 including a condenser unit 200 for cooling a refrigerant circulated in a refrigeration cycle by heat exchange between the refrigerant and air and an oil cooler unit 300 for cooling an oil higher in temperature than the refrigerant by heat exchange between the oil and air. Condenser unit 200 and oil cooler unit 300 are vertically arranged in parallel to each other, and integrated heat exchanger 1 is arranged downstream of intercooler 100 in the air flow. The vertical length of integrated heat exchanger 1 is larger than the vertical length of intercooler 100. Oil cooler unit 300 is arranged in superposition with at least a part of intercooler 100 as viewed from the direction of air flow.

Owner:DENSO CORP

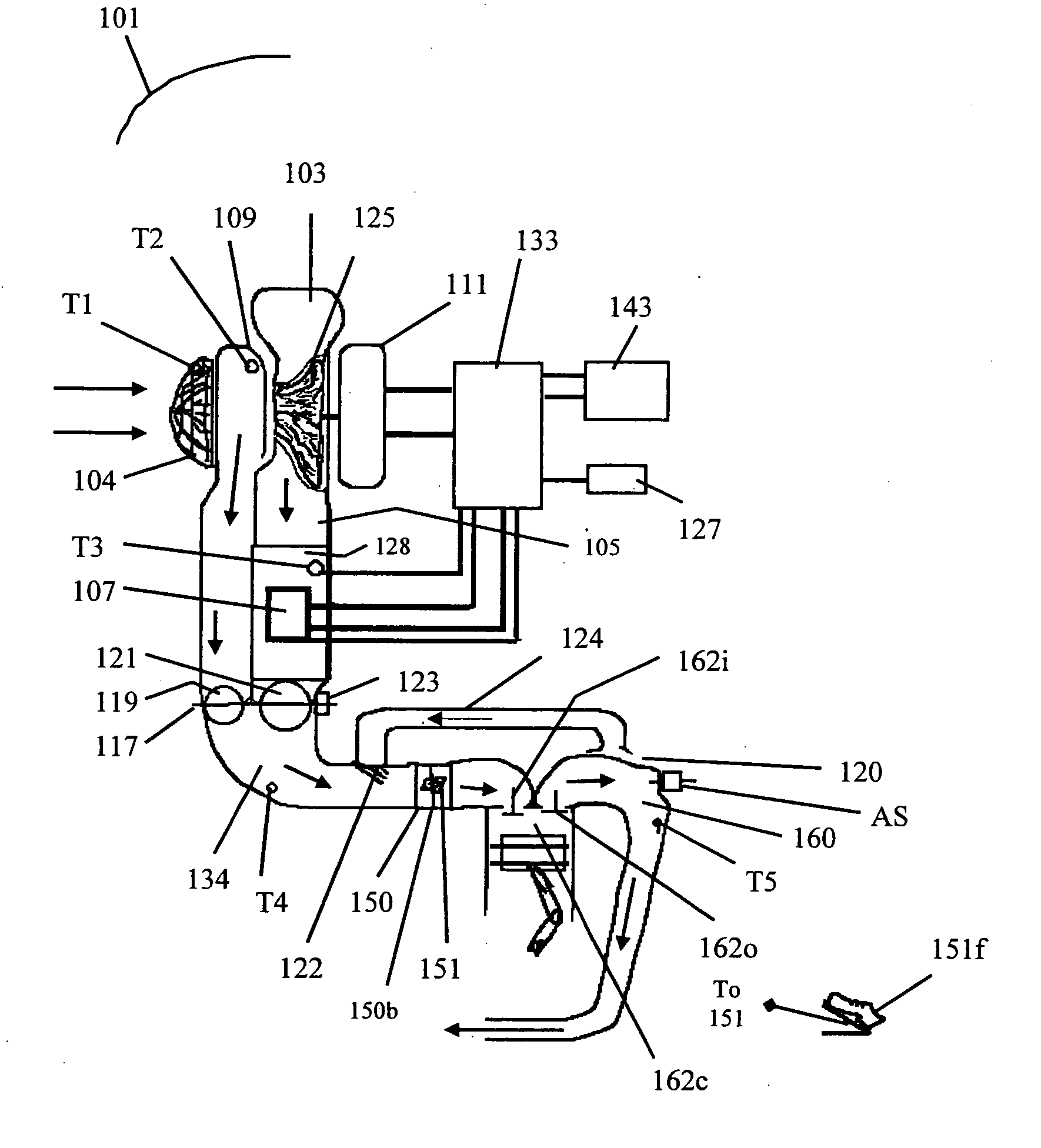

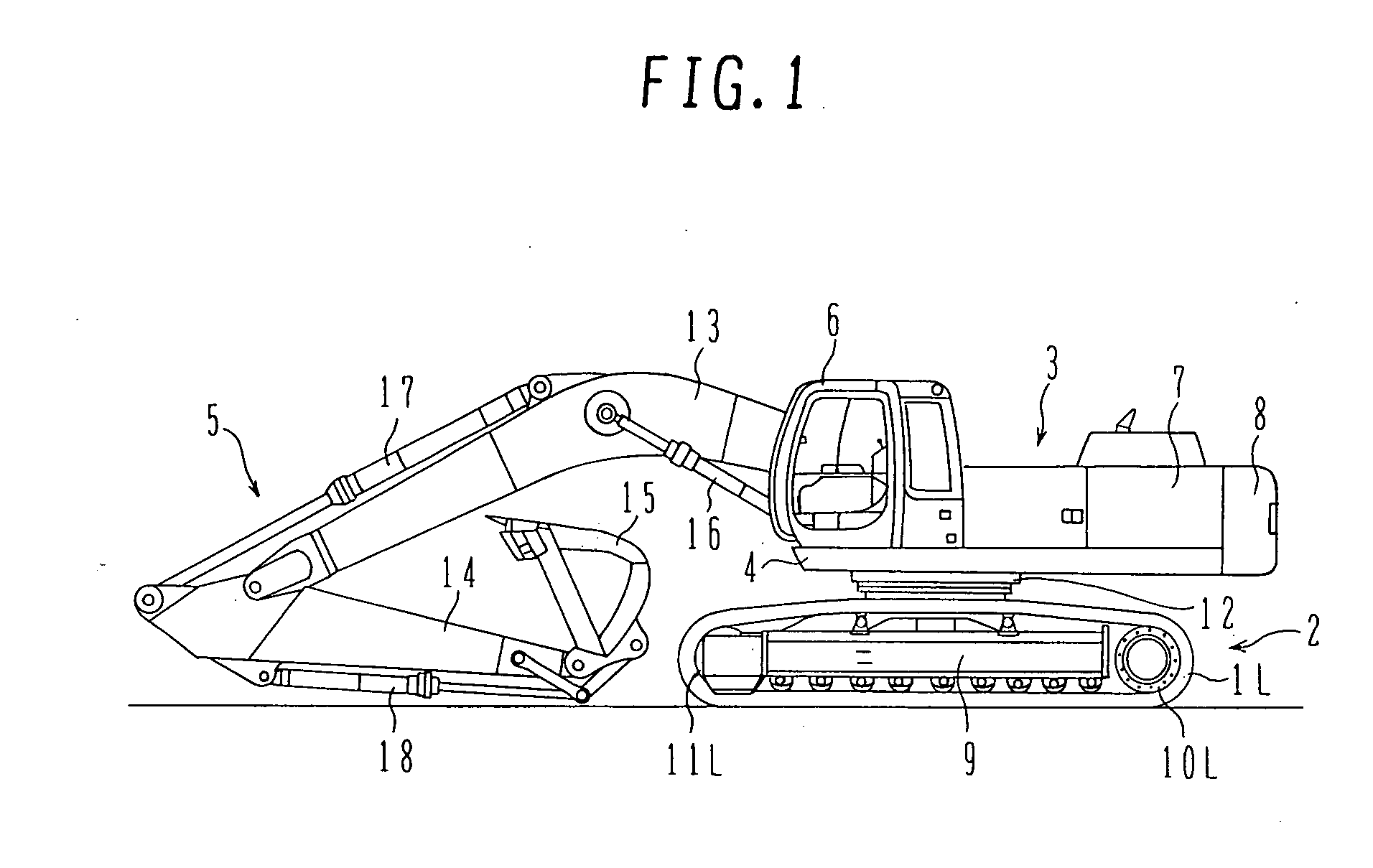

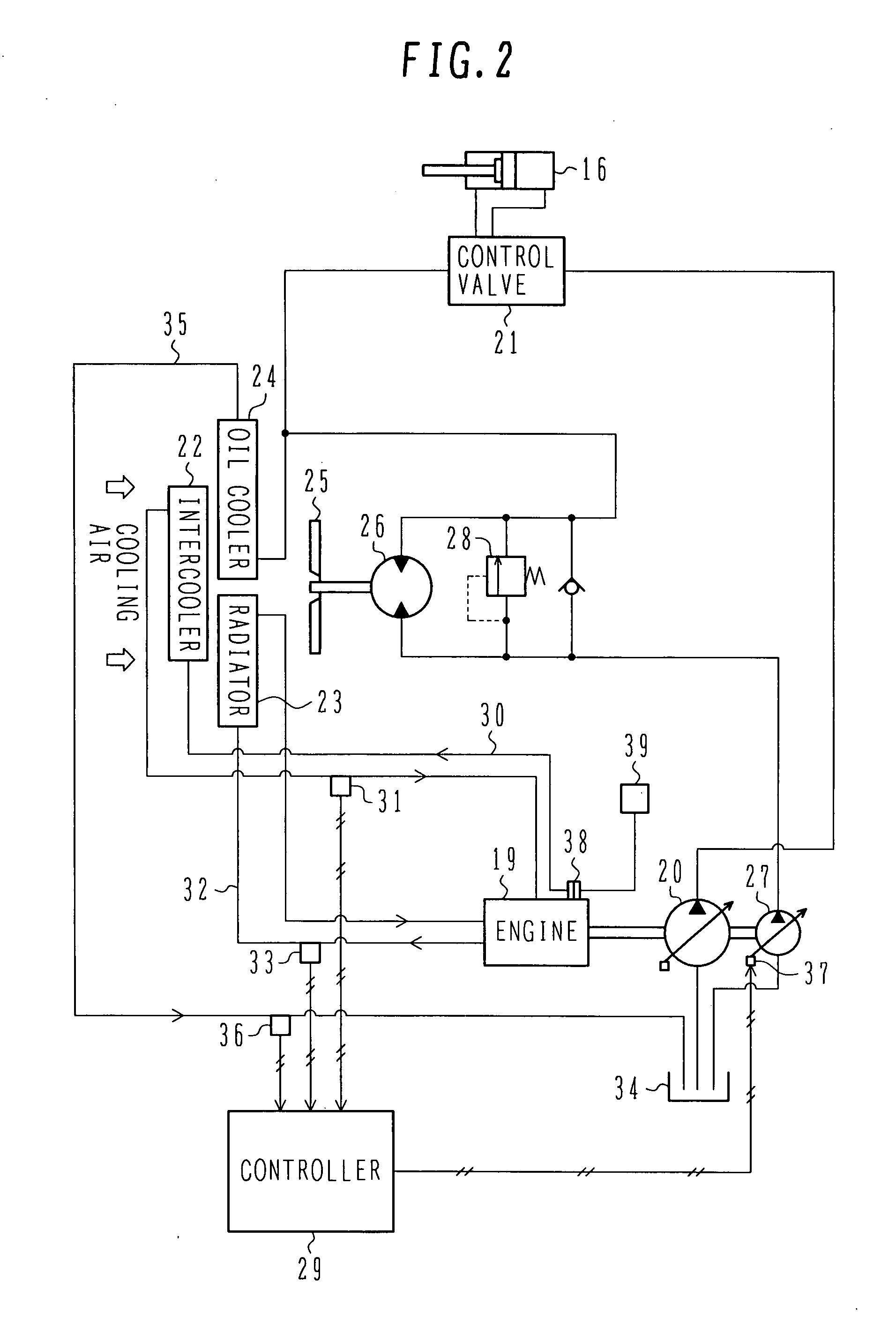

Cooling System for Construction Machine

ActiveUS20090217655A1Reduce noiseReliably producedFluid couplingsCoolant flow controlHydraulic motorControl signal

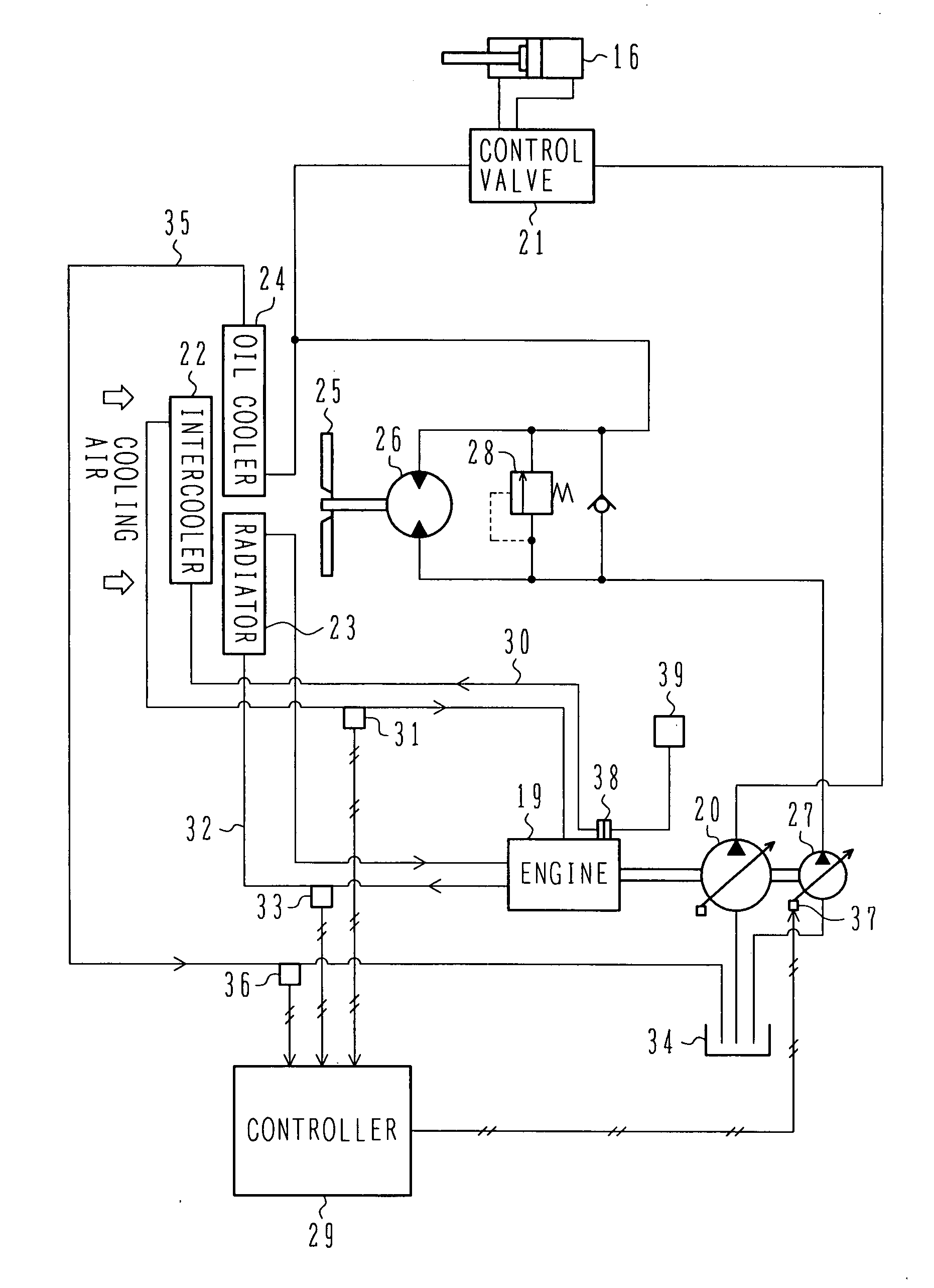

A cooling system for a construction machine, which can reduce noise of a cooling fan and can reliably produce cooling air at a required flow rate.The cooling system comprises a cooling fan 25 for producing cooling air introduced to an intercooler 22, a radiator 23 and an oil cooler 24, a fan hydraulic motor 26 for driving the cooling fan 25, a fan hydraulic pump 27 for delivering a hydraulic fluid to the fan hydraulic motor 26, an air temperature sensor 31 for detecting an air temperature T1 at an outlet of the intercooler 22, a cooling water temperature sensor 33 for detecting a temperature T2 of cooling water for the radiator 23, a working oil temperature sensor 36 for detecting a temperature T3 of working oil for the oil cooler 24, and a controller 29 for outputting a control signal corresponding to a maximum value among calculation values N1, N2 and N3 of cooling fan rotation speed, which correspond respectively to detected values T1, T2 and T3 from the air temperature sensor 31, the cooling water temperature sensor 33 and the working oil temperature sensor 36.

Owner:NIHON KENKI CO LTD

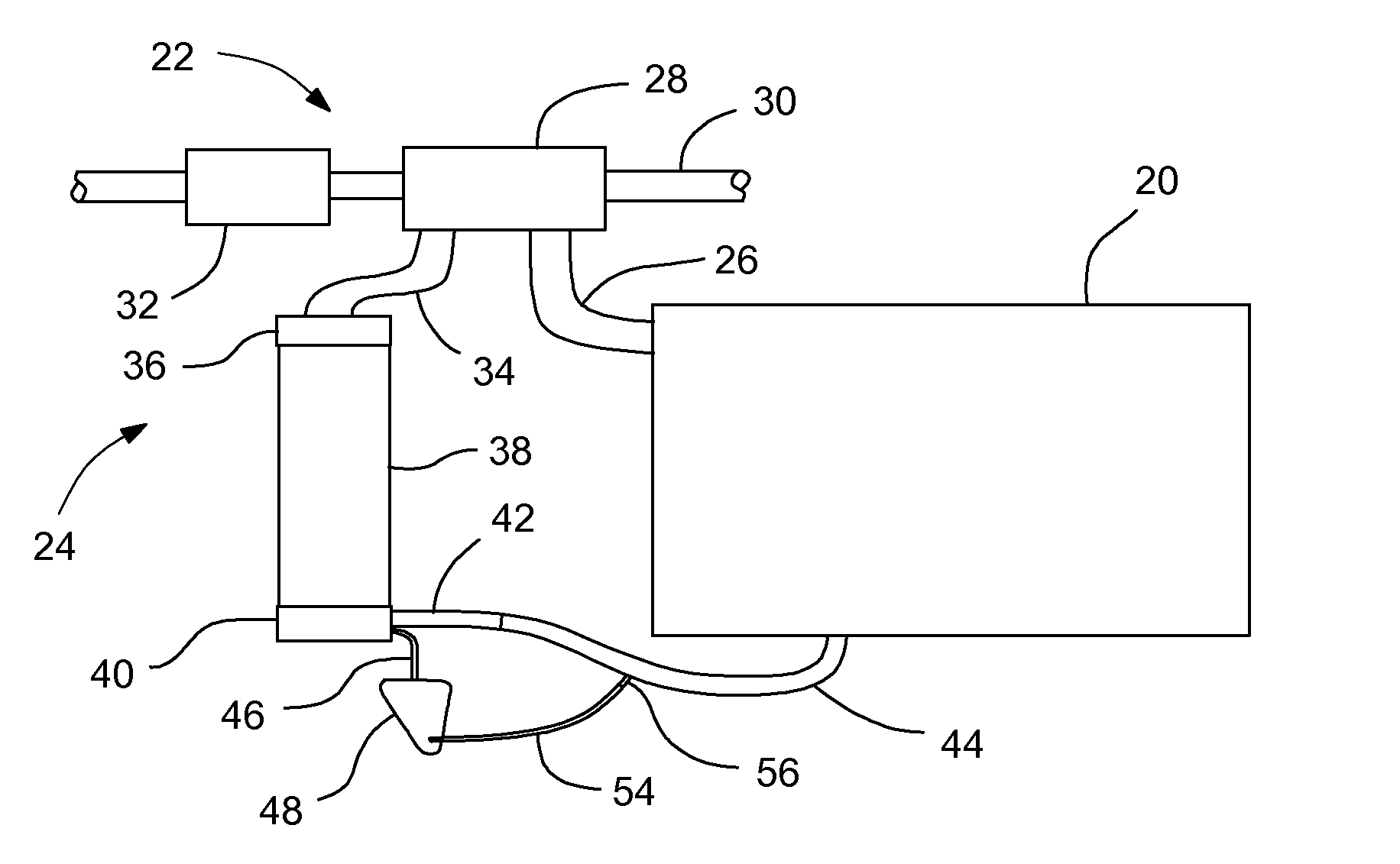

Intercooler Having Condensate Reservoir

InactiveUS20110107760A1Improved intercooler performanceMaximum charge-air-cooler heat exchanger effectivenessNon-fuel substance addition to fuelInternal combustion piston enginesDraining tubeTurbocharger

An engine air intake system for a vehicle having an internal combustion engine may include a turbocharger; a CAC heat exchanger having an inlet end for receiving compressed intake air from the turbocharger and an outlet end; a remote condensate reservoir spaced from the CAC heat exchanger, for storing condensate therein; a condensate drain tube extending from the outlet end to the remote condensate reservoir to allow condensate produced in the CAC heat exchanger to flow into the remote condensate reservoir; an air duct connecting the outlet end to the engine to direct air flow from the outlet end to the engine; and a reservoir outlet hose connected to the remote condensate reservoir at a first end and connected to the air duct at a second end to allow condensate evaporating from the remote condensate reservoir to flow through the reservoir outlet hose into the air duct.

Owner:GM GLOBAL TECH OPERATIONS LLC

Adjustable consecutive composite turbocharging system

InactiveCN101182803AImprove matchExtended operating rangeInternal combustion piston enginesEngine componentsTurbochargerIntercooler

The present invention provides an adjustable successive composite turbine pressurizing system, consisting of a diesel engine, an inlet pipe of the diesel engine, an outlet pipe of the diesel engine, an exhaust communicating pipe, an inlet and outlet communicating pipe, a drain pipe, an air valve arranged on the inlet pipe, a gas valve arranged on the outlet pipe, a bypass valve arranged on the inlet and outlet communicating pipe, a drain valve arranged on the drain pipe, a basic compressor, a basic turbine, a controlled compressor, a controlled turbine and an intercooler. The present invention can achieve single turbine pressurization, two parallel turbines pressurization, inlet and outlet bypass turbine pressurization and high work condition drain turbine pressurization; improve the match between the turbine pressurizing unit and the diesel engine; enlarge the operating range of the turbine pressurizing diesel engine; and increase the performance of the turbine pressurizing diesel engine within the overall work conditions.

Owner:HARBIN ENG UNIV

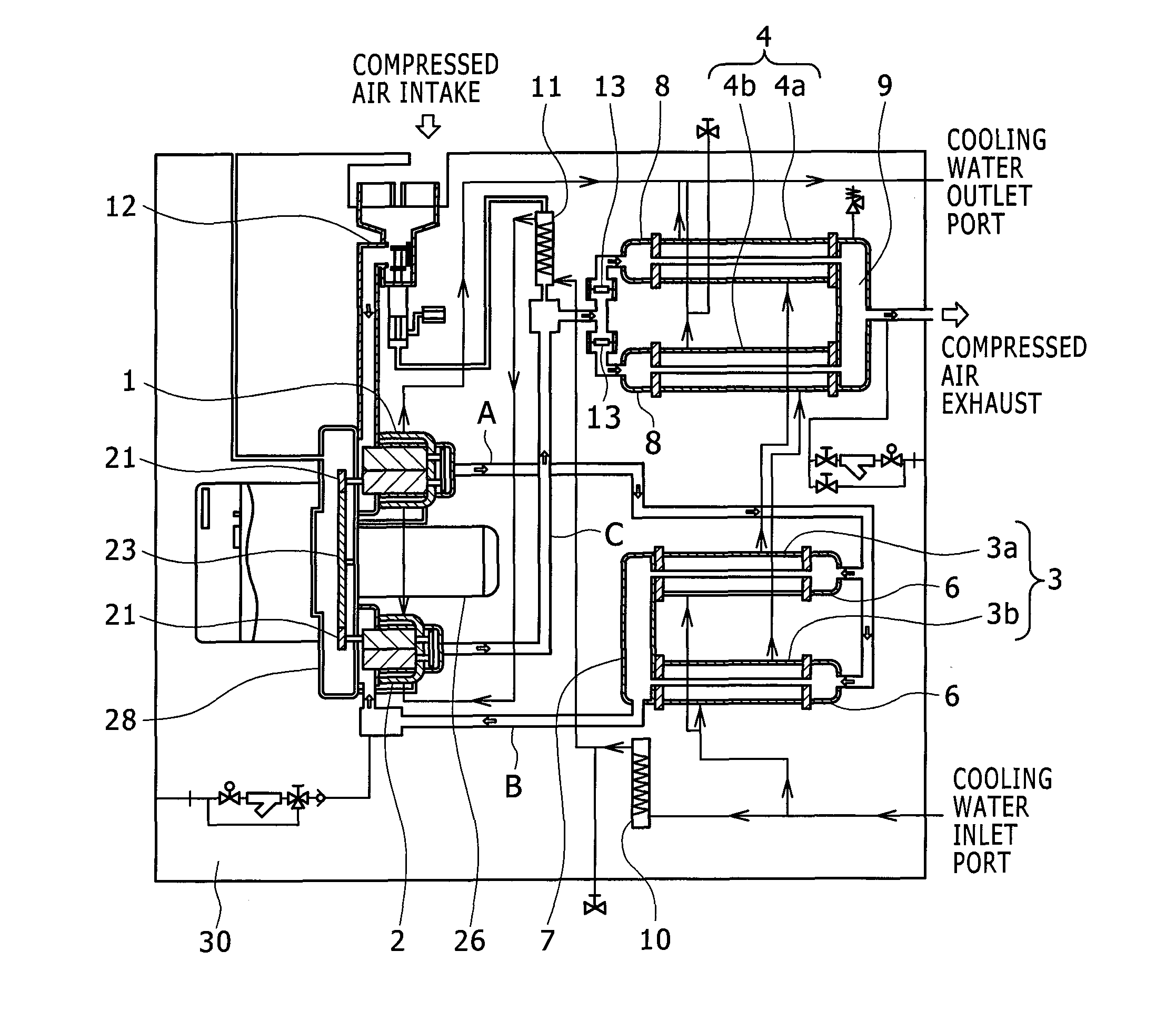

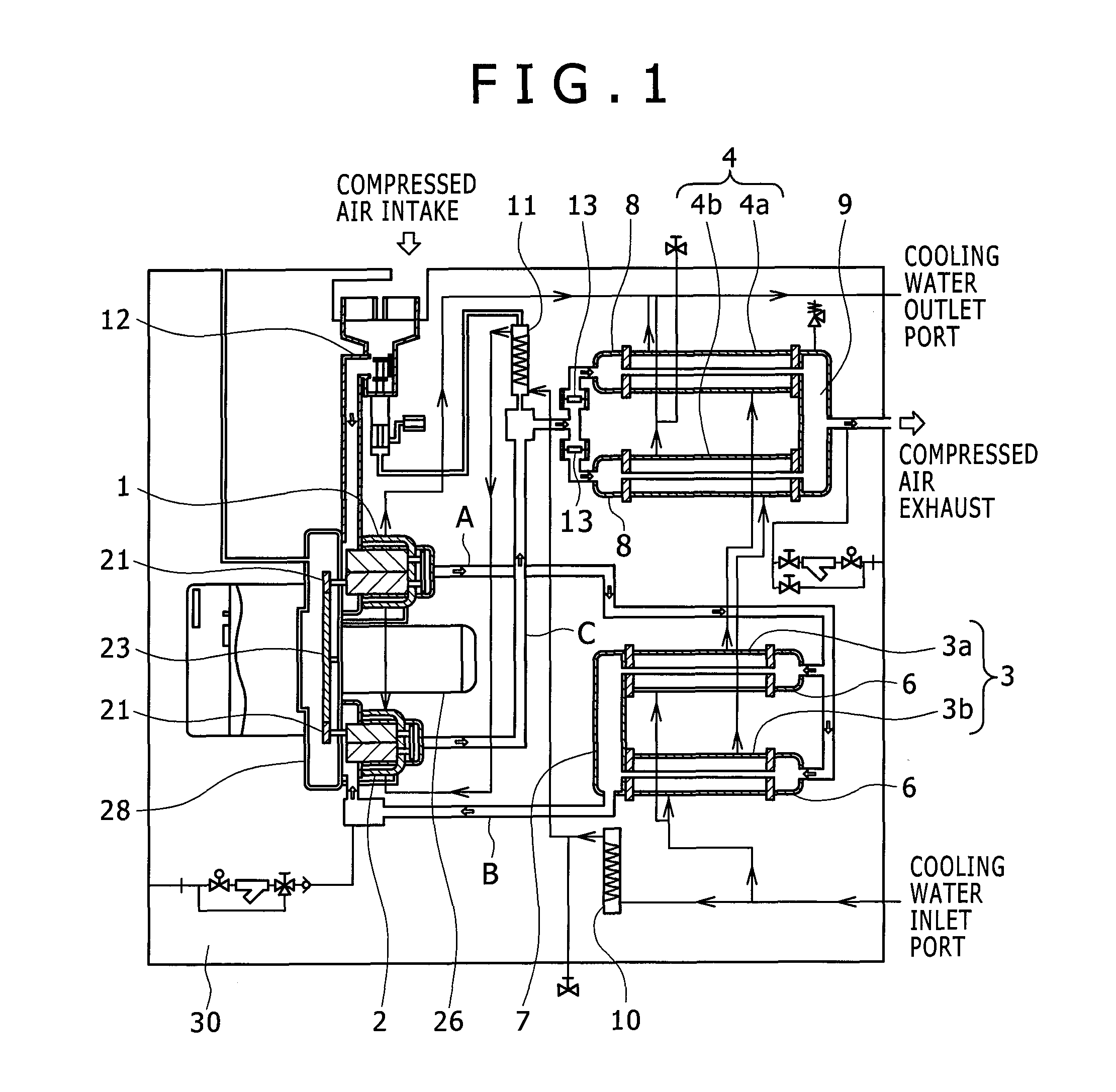

Water-Cooled Oil-Free Air Compressor

InactiveUS20100303658A1Increase productivityImprove maintainabilityRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsProduction rateOil free

A water-cooled oil-free air compressor which features compactness and ensures improved productivity and maintainability. The compressor is an oil-free screw compressor which includes a low pressure stage compressor body, an intercooler for water-cooling the compressed air discharged from the low pressure stage compressor body, a high pressure stage compressor body for further compressing the compressed air cooled by the intercooler, and an aftercooler for water-cooling the air discharged from the high pressure stage compressor body. The intercooler and aftercooler each have a plurality of units, all of which are almost equal in shape. A cooler header on each or either of the inlet and outlet sides for compressed air is shared by the units of each cooler.

Owner:HITACHI IND EQUIP SYST CO LTD

Refrigerant vapor compression system with intercooler

ActiveUS20130031934A1Improve energy efficiencyImprove cooling effectCompression machines with non-reversible cycleStationary tubular conduit assembliesHeat rejectionCompression device

A refrigerant vapor compression system includes a compression device having at least a first compression stage and a second compression stage, a refrigerant heat rejection heat exchanger disposed downstream with respect to refrigerant flow of the second compression stage, and a refrigerant intercooler disposed intermediate the first compression stage and the second compression stage. The refrigerant intercooler is disposed downstream of the refrigerant heat rejection heat exchanger with respect to the flow of a secondary fluid. A second refrigerant heat rejection heat exchanger may be disposed downstream with respect to refrigerant flow of the aforesaid refrigerant heat rejection heat exchanger, and a second refrigerant intercooler may be disposed intermediate the first compression stage and the second compression stage and downstream with respect to refrigerant flow of the aforesaid refrigerant intercooler.

Owner:CARRIER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com