Cooling module

a technology of cooling module and condenser unit, which is applied in the direction of indirect heat exchanger, light and heating apparatus, transportation and packaging, etc., can solve the problems of deteriorating cooling performance, noise generated by expansion valve, and extremely reduced so as to achieve positive heat exchange performance of condenser unit 200

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

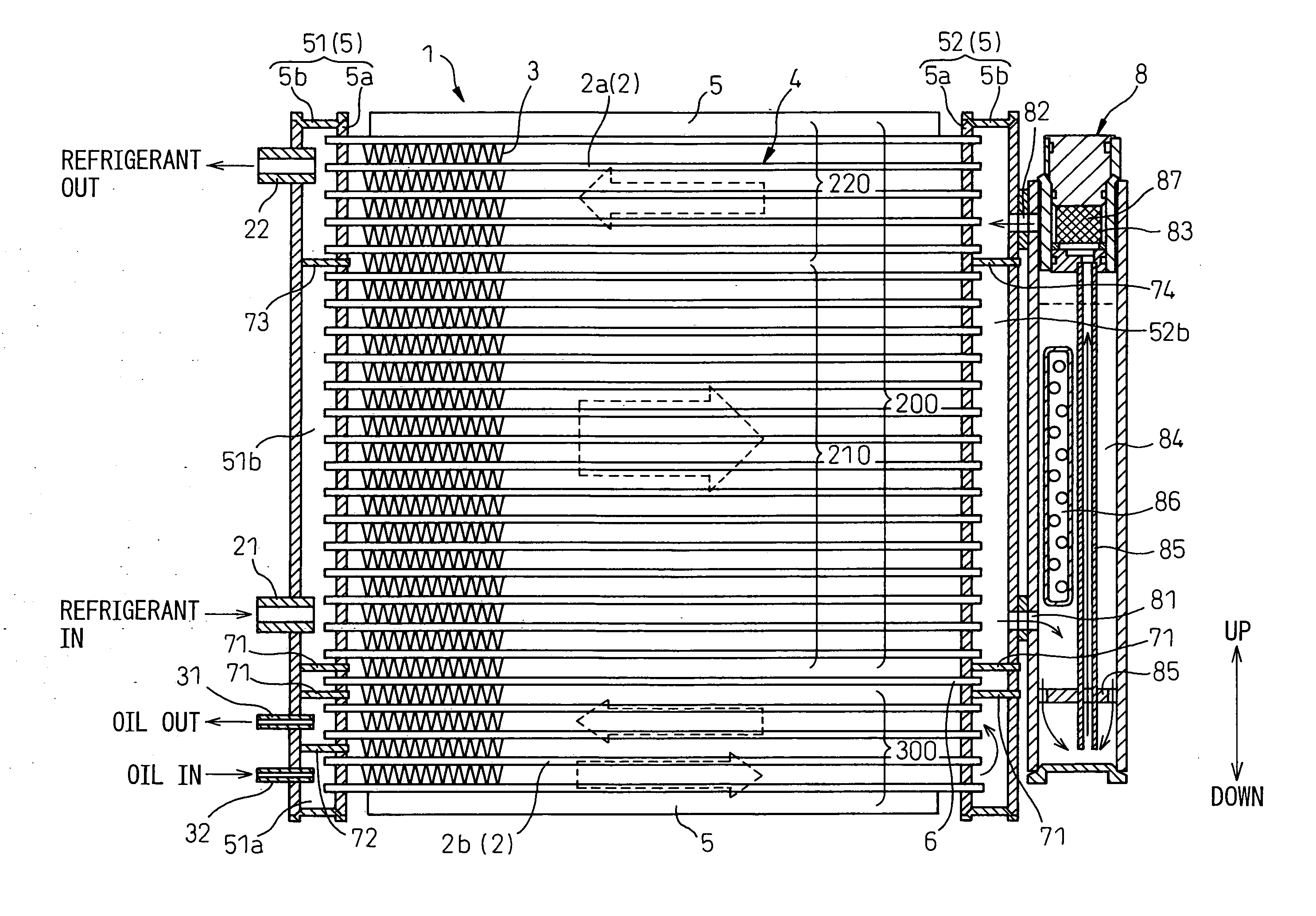

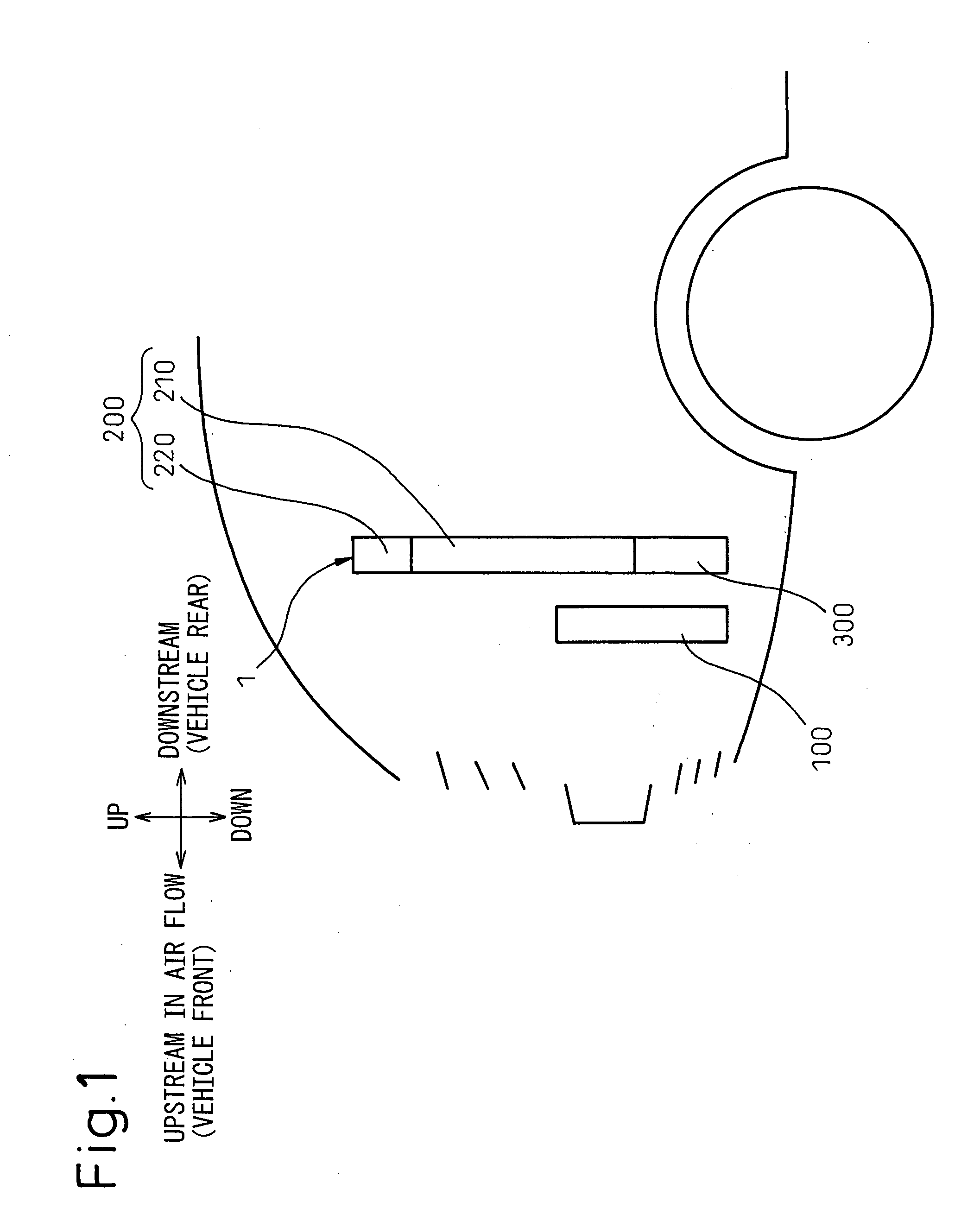

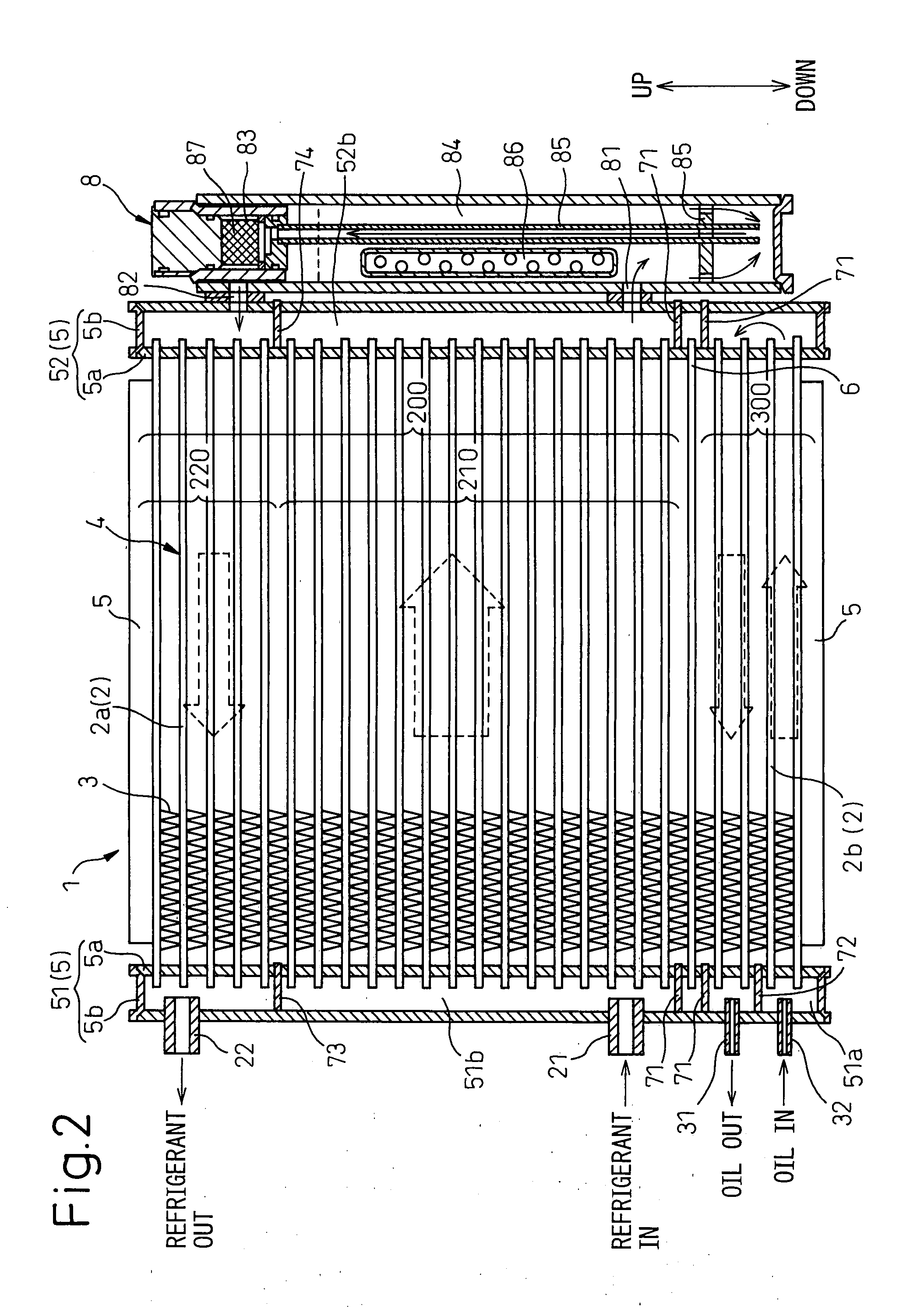

[0024]An embodiment of the invention is explained below with reference to FIGS. 1 and 2. A cooling module according to this embodiment used in a vehicle driven by an internal combustion engine as a drive source is taken as an example. FIG. 1 is a diagram showing the cooling module according to this embodiment mounted on the vehicle.

[0025]As shown in FIG. 1, the cooling module according to this embodiment, mounted at the front end of a vehicle, includes an integrated heat exchanger 1 having a condenser unit 200 and an oil cooler unit 300, and an intercooler 100. The intercooler 100 is an air-cooled heat exchanger arranged downstream of a supercharger (not shown) for pressurizing the intake air of the internal combustion engine to cool the intake air by heat exchange between the intake air and air. Incidentally, the intercooler 100 corresponds to the heat source unit according to the invention.

[0026]The integrated heat exchanger 1 is arranged downstream of the intercooler 100 in the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com