Patents

Literature

824 results about "Metallic foil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

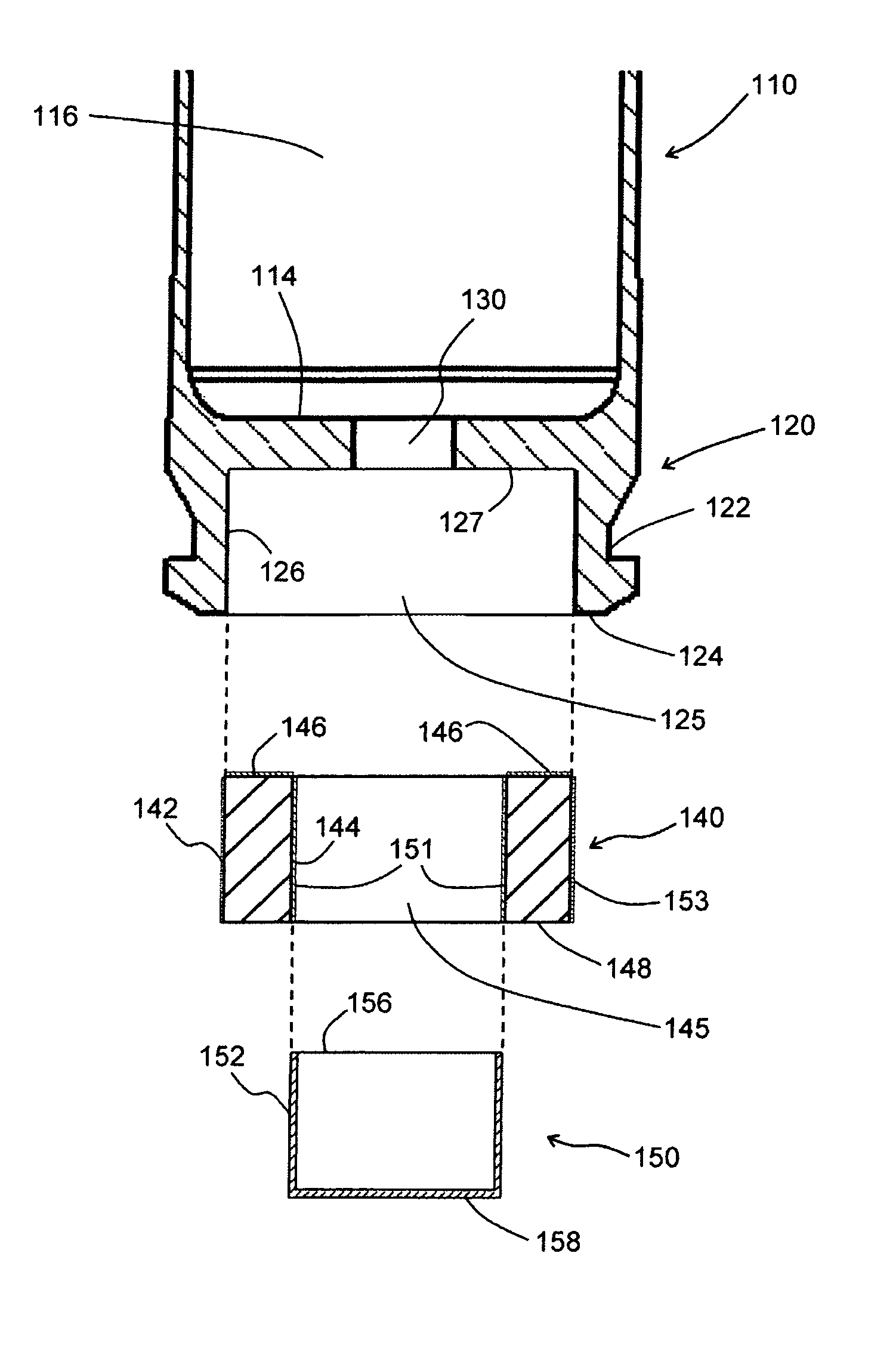

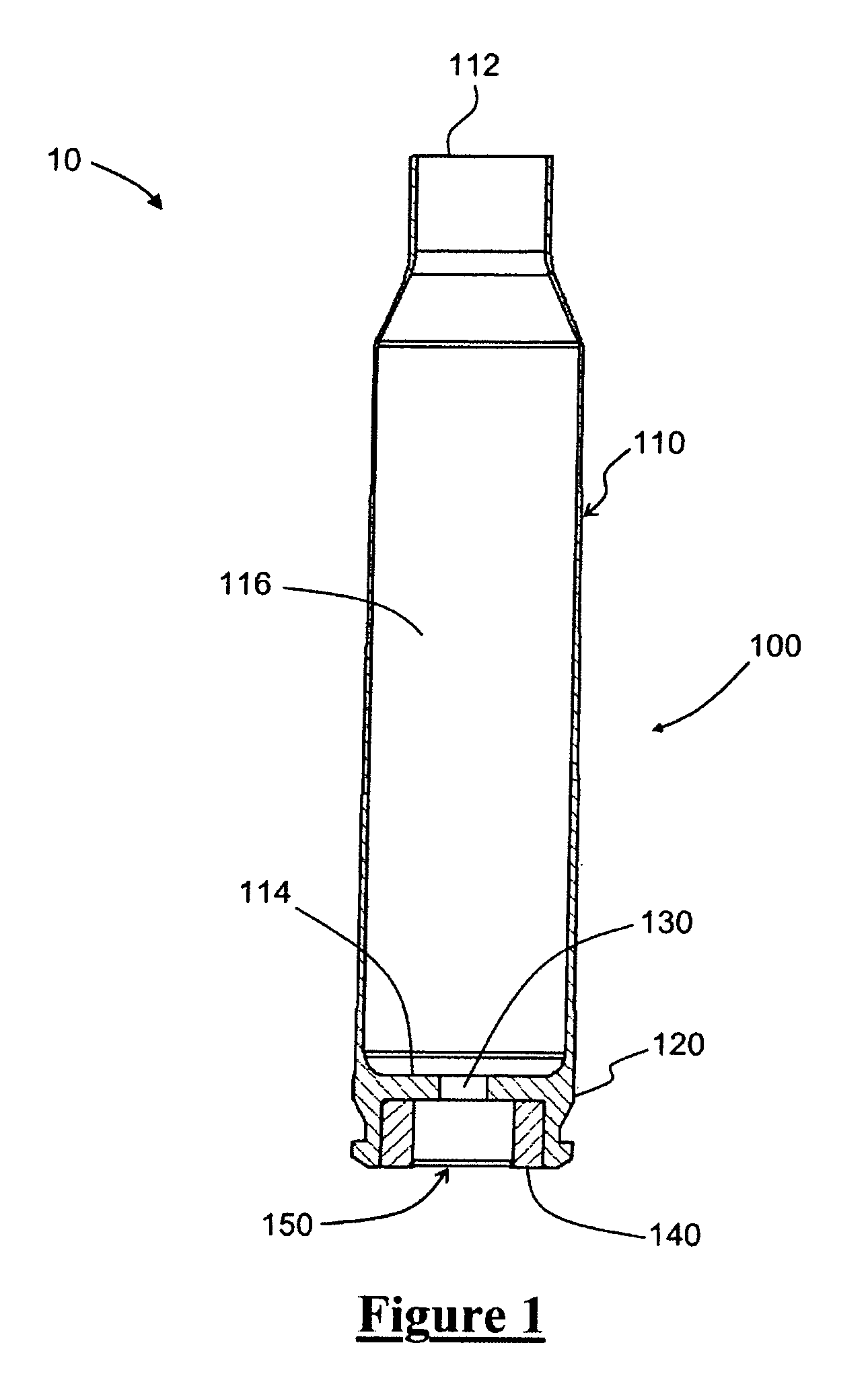

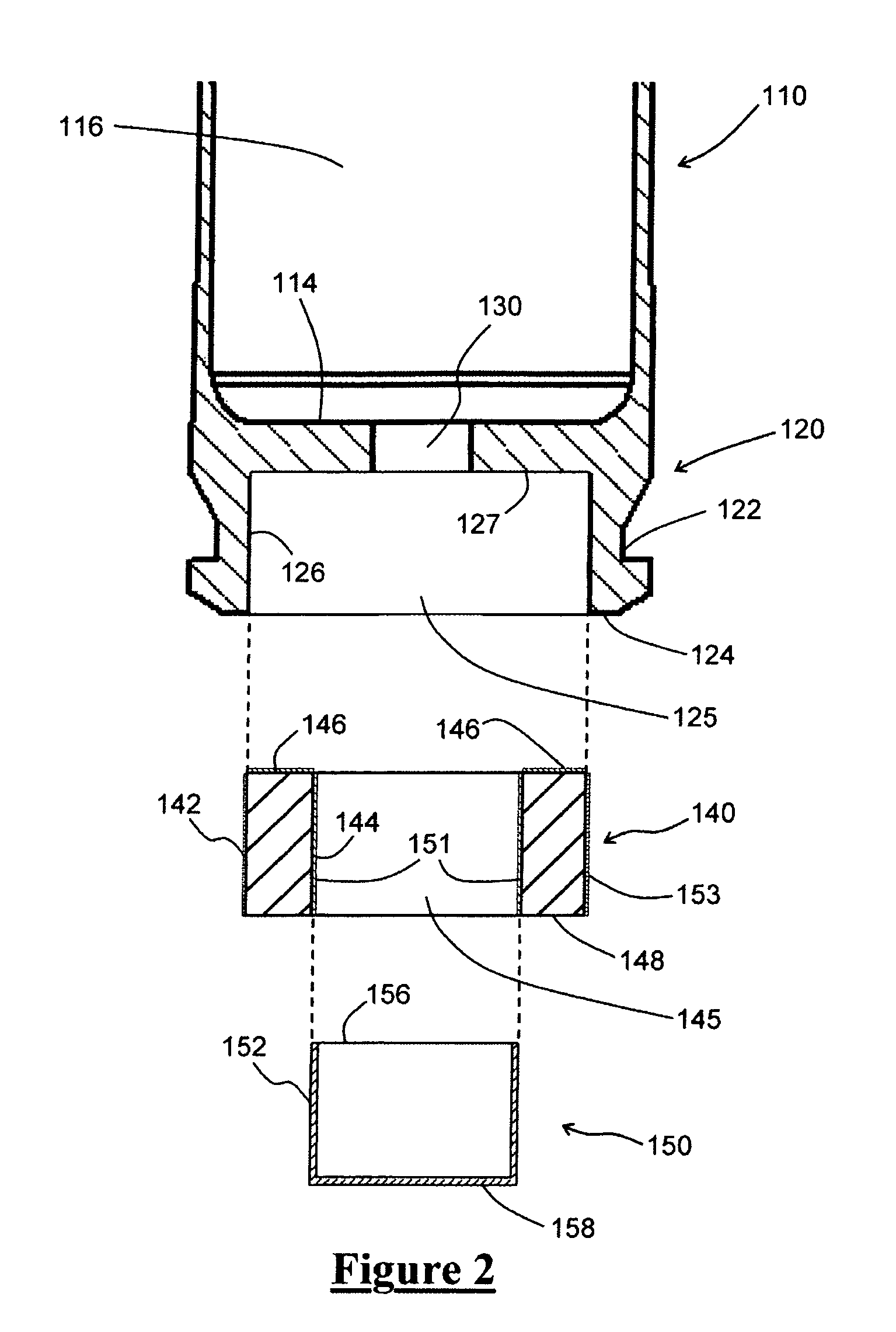

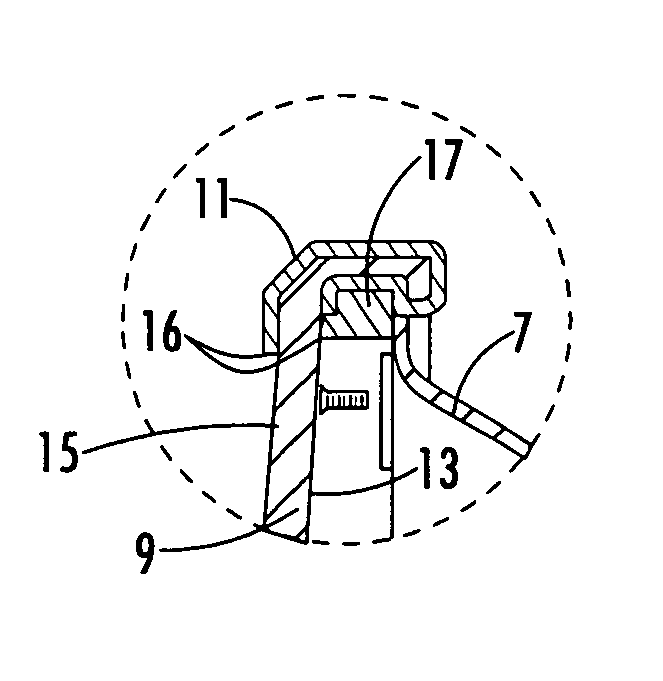

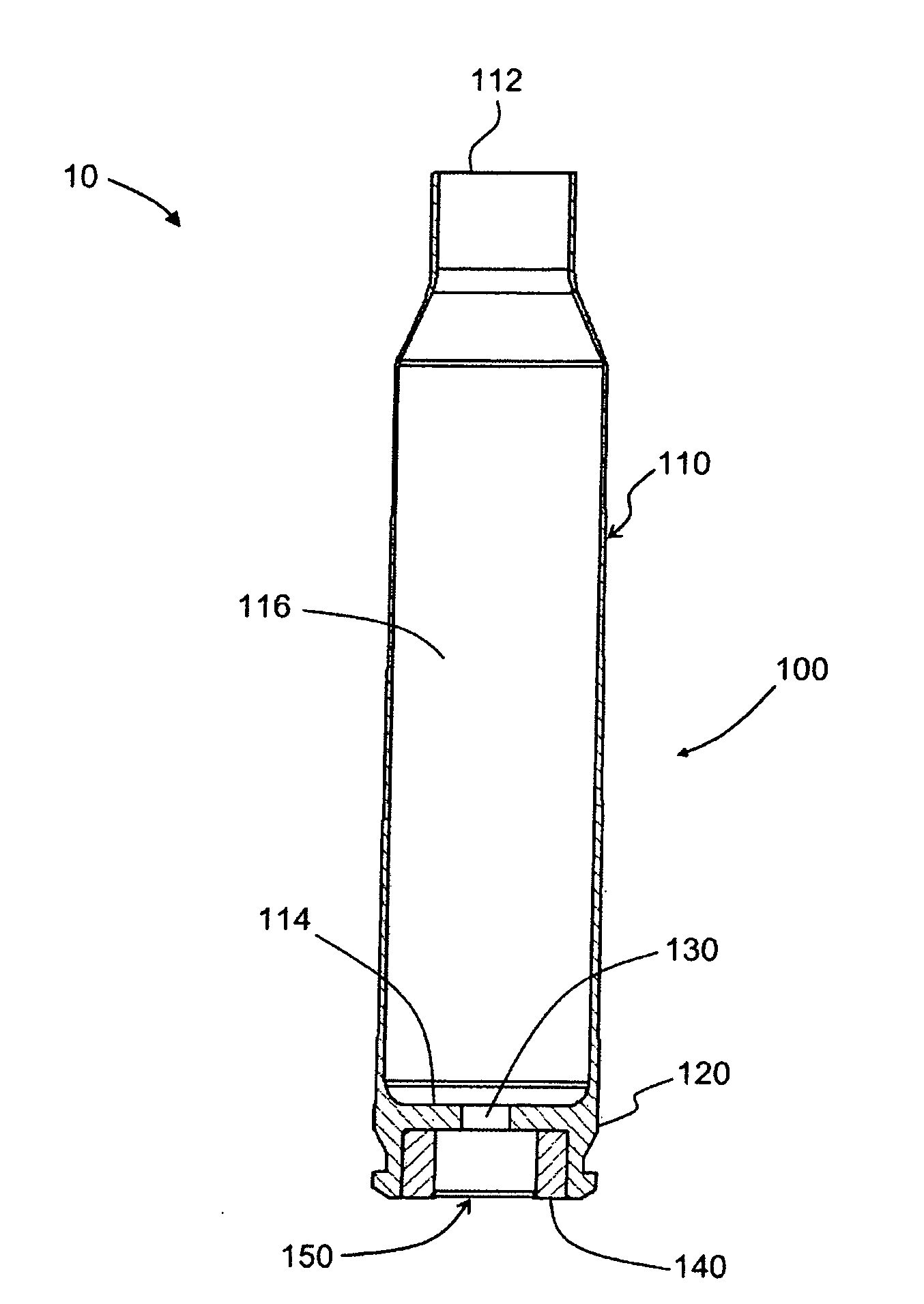

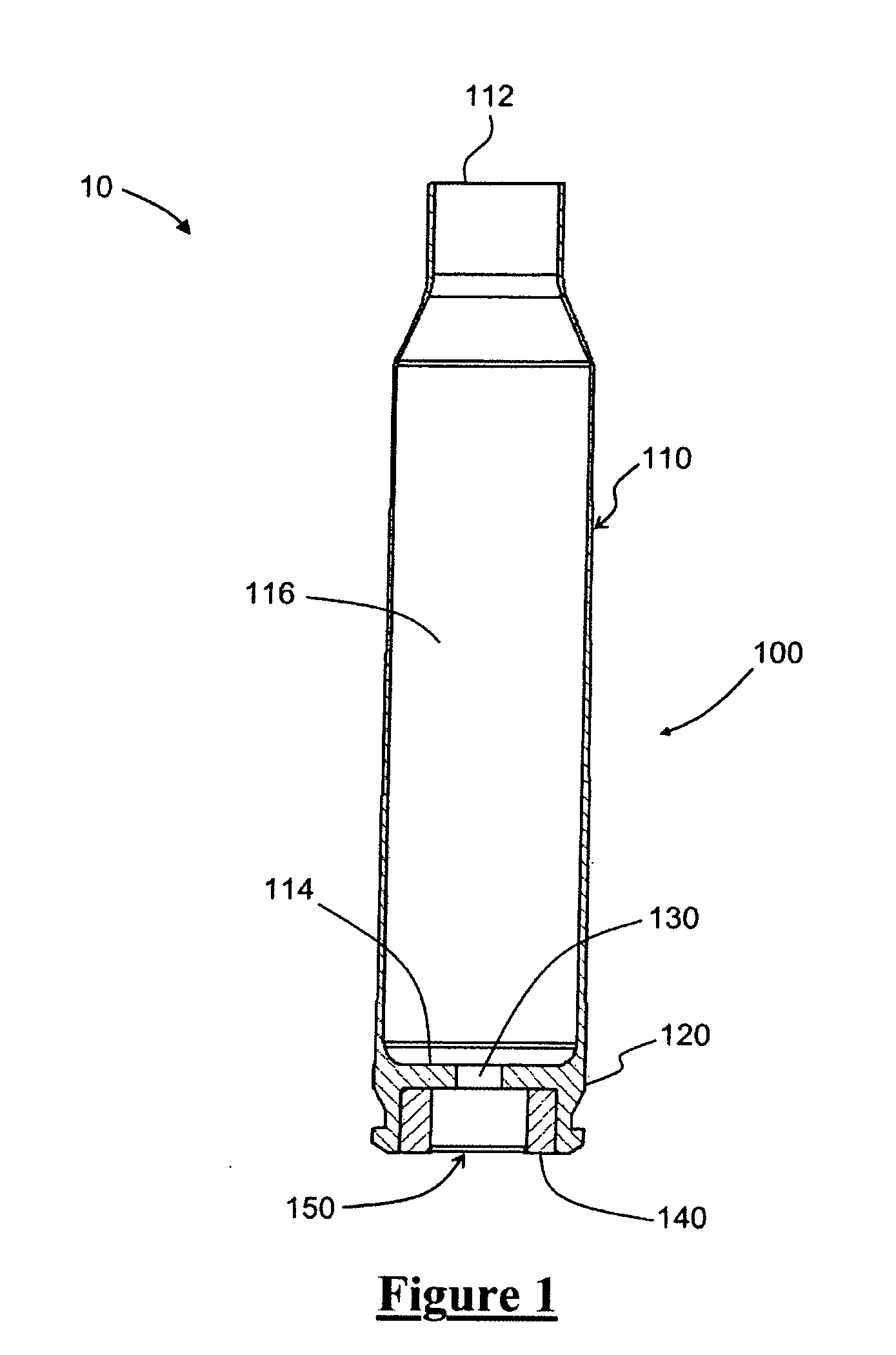

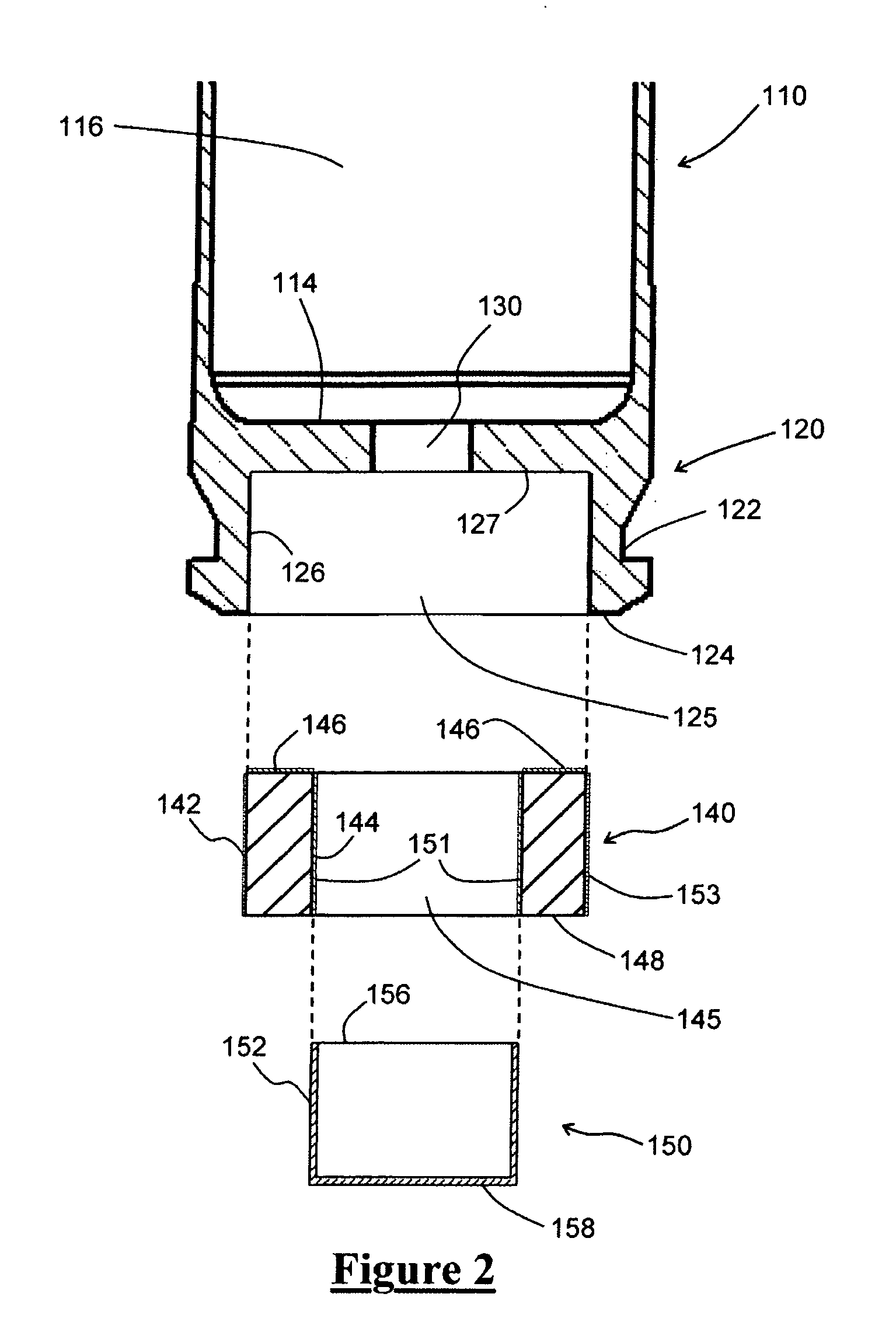

Lightweight cartridge case

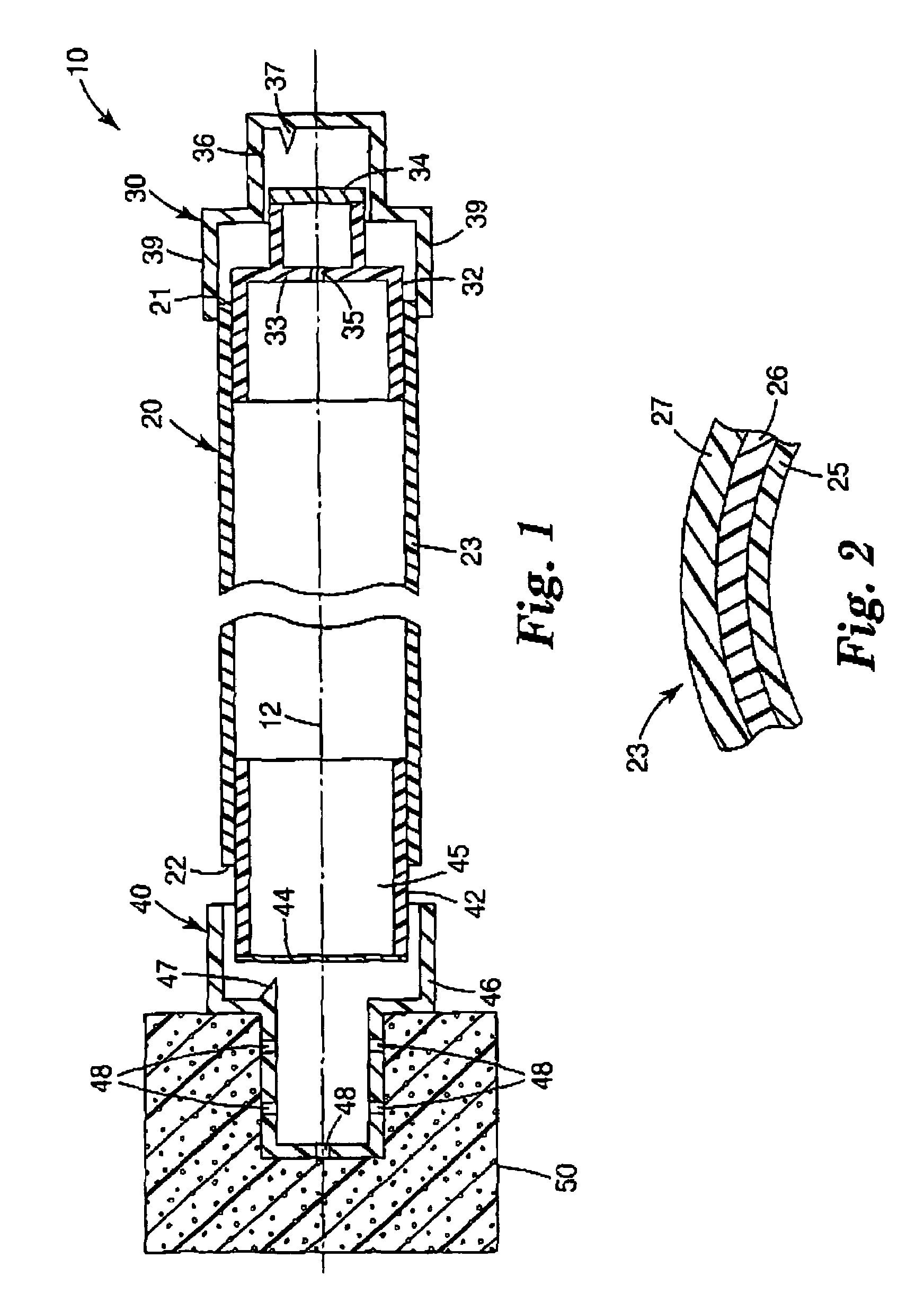

Disclosed is an ammunition cartridge case that includes a sleeve, a base fixedly attached to the sleeve and a fiber reinforced polymer composite annulus that is at least partially within the base. In certain embodiments, the sleeve and the base are formed partly or entirely from a metal, for example steel or stainless steel. The base has a central aperture that affords for the annulus ring to fit within. The annulus is dimensioned such that it fits securely within the central aperture of the base and has a center aperture wherein a primer can be located. The annulus ring contains a volume of composite fibers ranging from 10 to 90 volume percent. The annulus isolates the primer from the cartridge case and thereby prevents galvanic corrosion between the primer and case. In addition, a metallic foil can be present between the annulus and the cartridge case in order to assure proper securement of the annulus therewithin.

Owner:ARMY US SEC THE THE

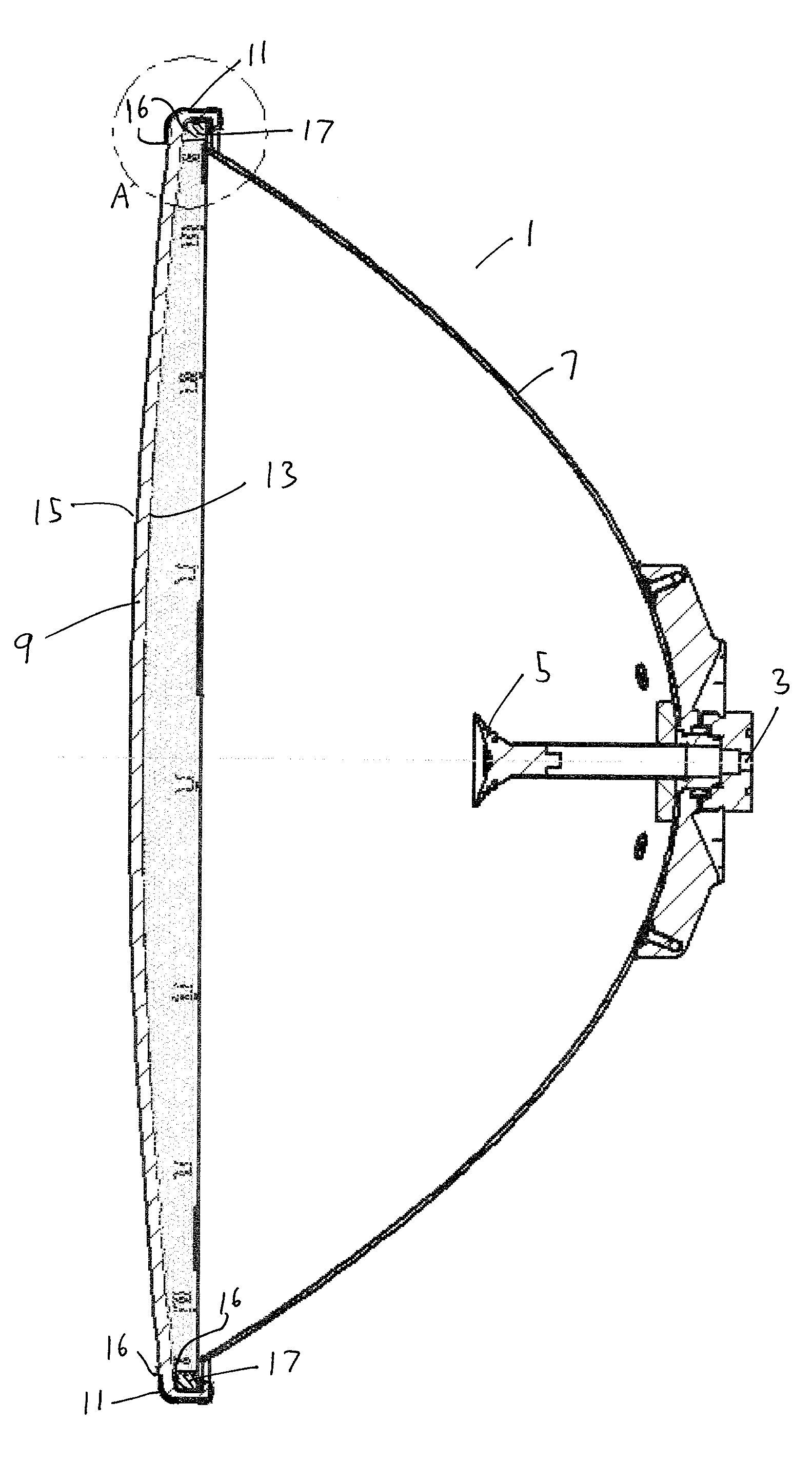

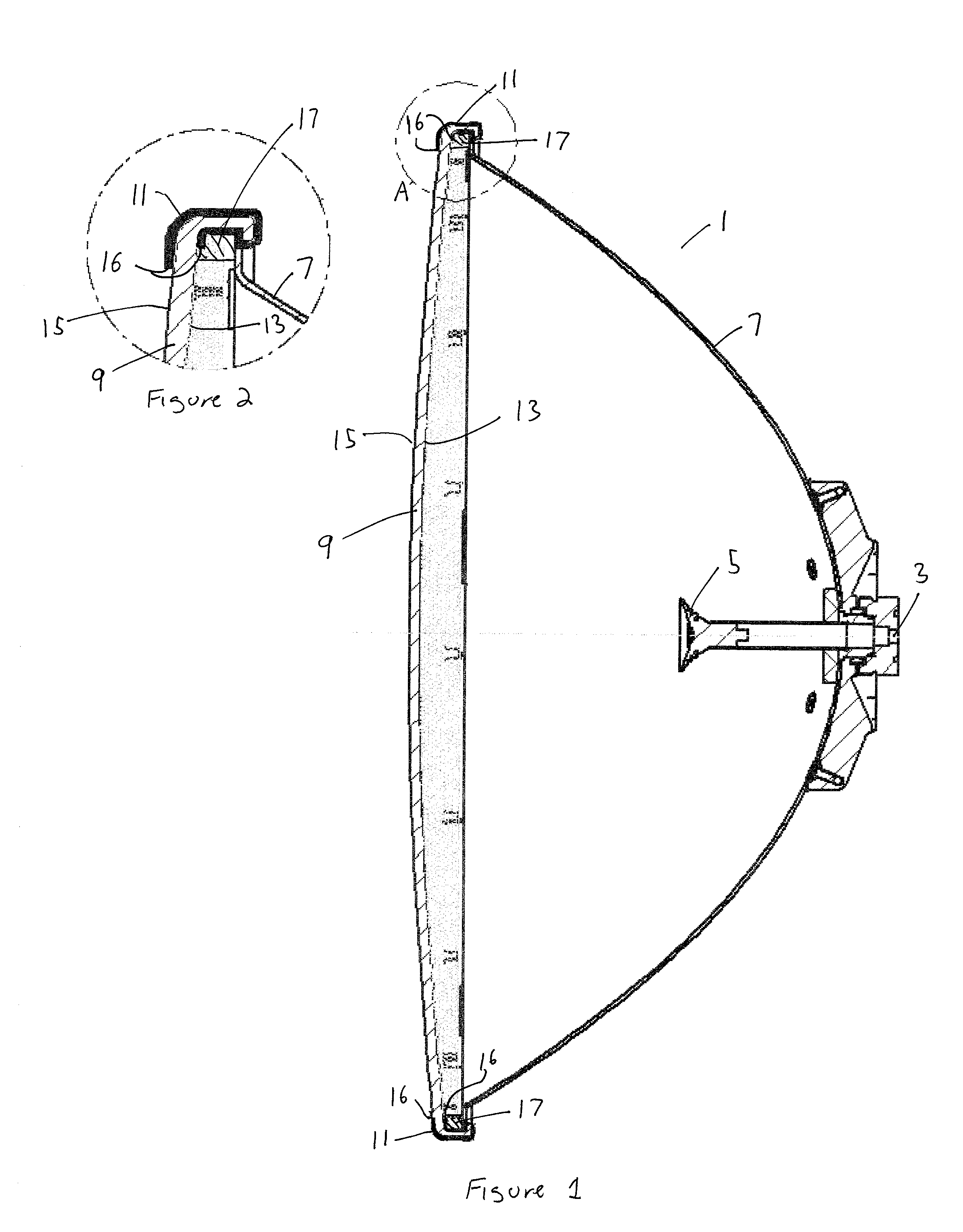

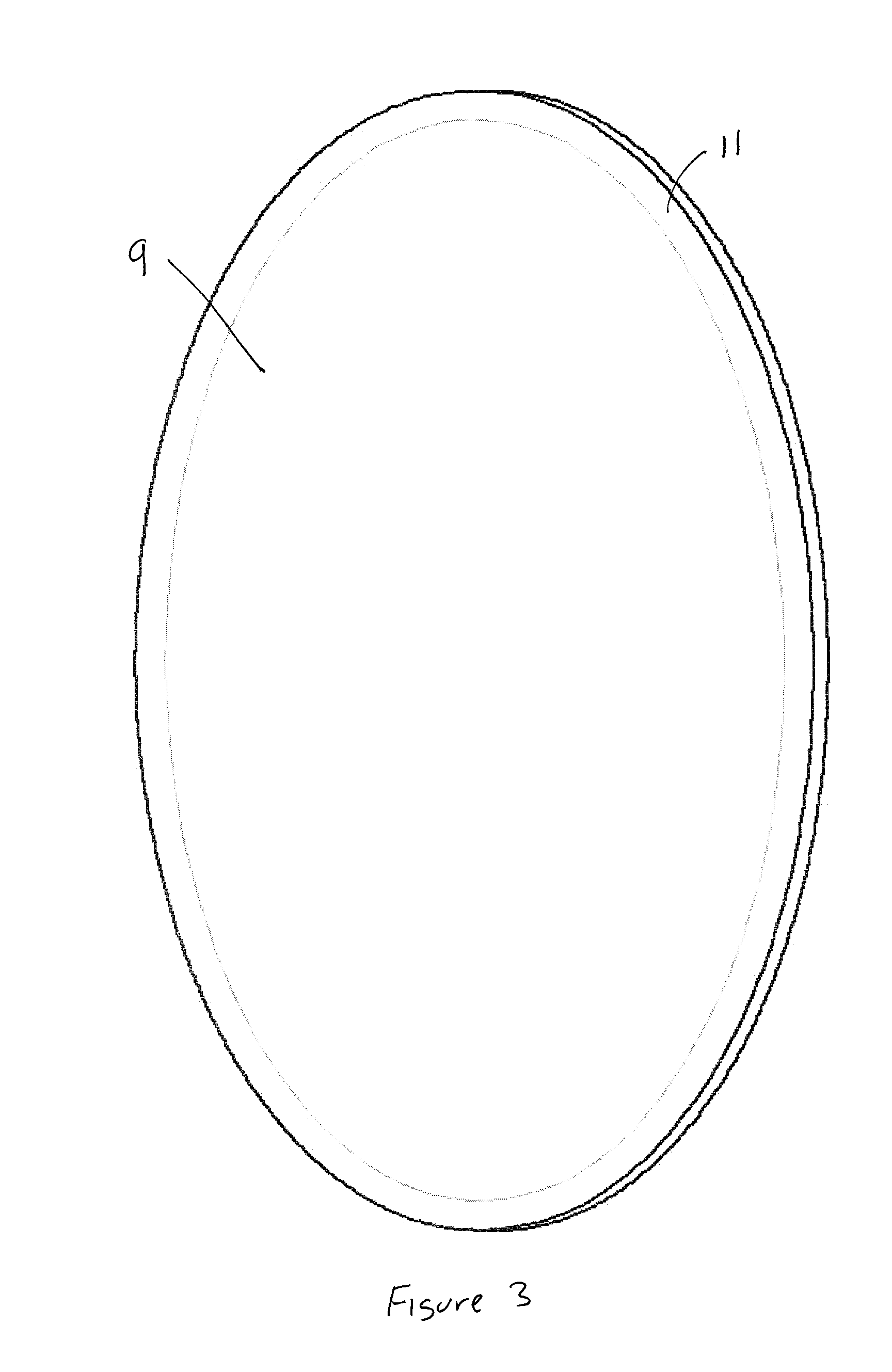

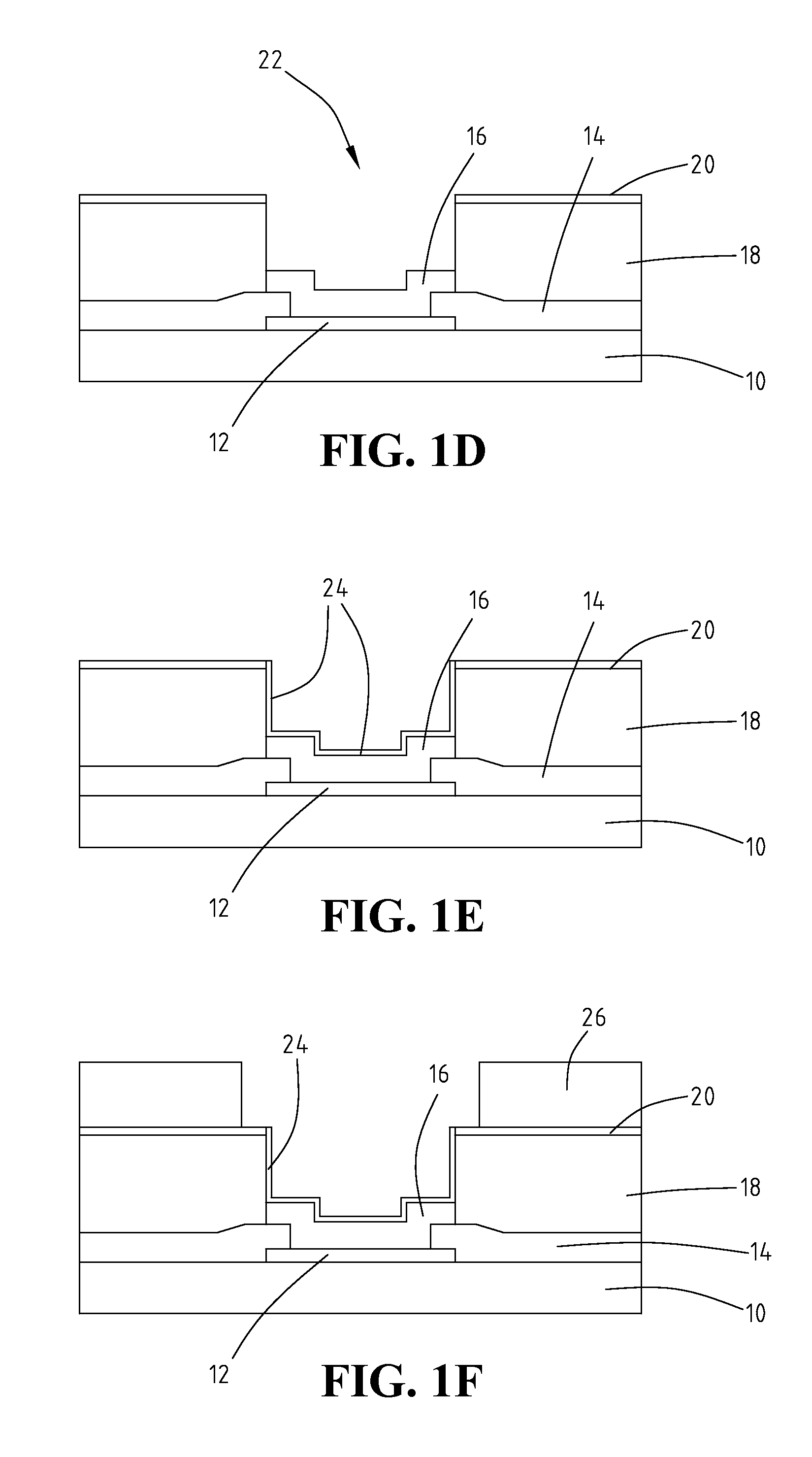

Reflector antenna radome with backlobe suppressor ring and method of manufacturing

ActiveUS7138958B2Reduce wind loadsCost efficientRadiating element housingsCollapsible/retractable loop antennasMetallic foilSuppressor

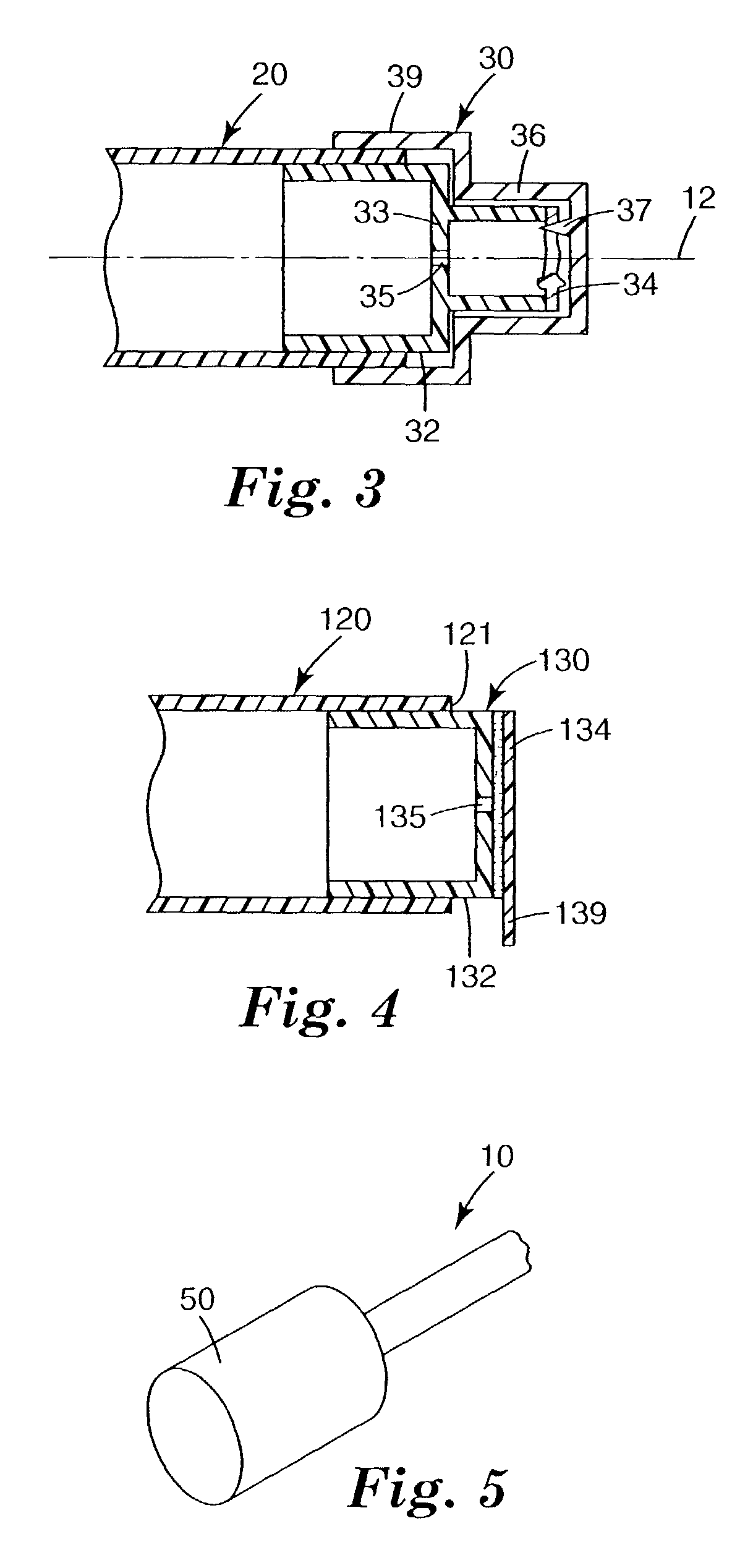

A radome adapted to reduce backlobes of an associated reflector antenna via application of a conductive ring with an inward facing edge about the periphery of the radome. The conductive ring may be applied extending around the radome periphery to an inside and or outside surface of the radome. The conductive ring may be formed upon the radome by metalising, electrodaging, over molding or the like. Further, the conductive ring may be a metal, metallic foil, conductive foam or the like which is coupled to the radome. An absorber in the form of a ring or a surface coating applied to the radome and or the distal end of the reflector may also be added between the radome and the reflector.

Owner:COMMSCOPE TECH LLC

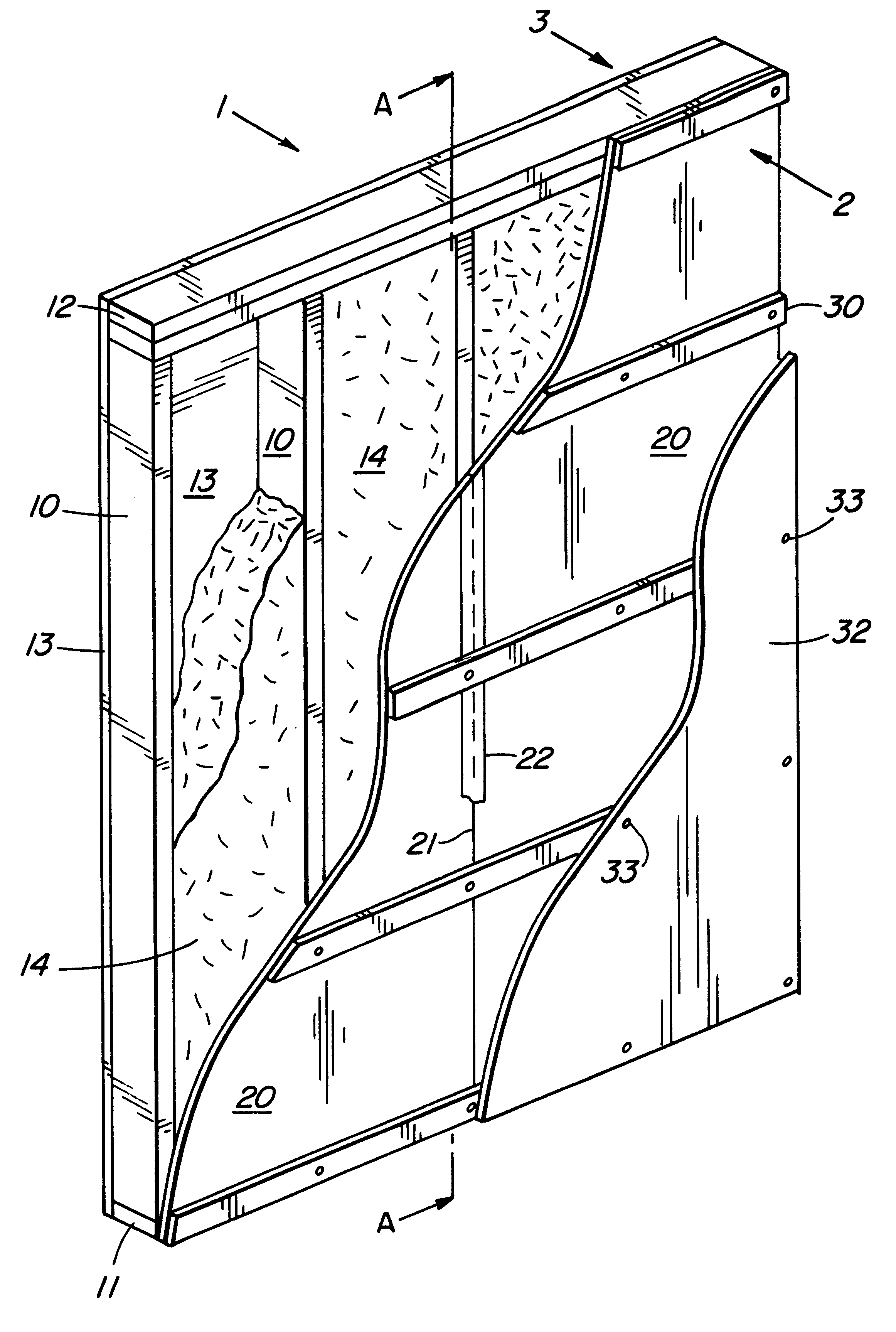

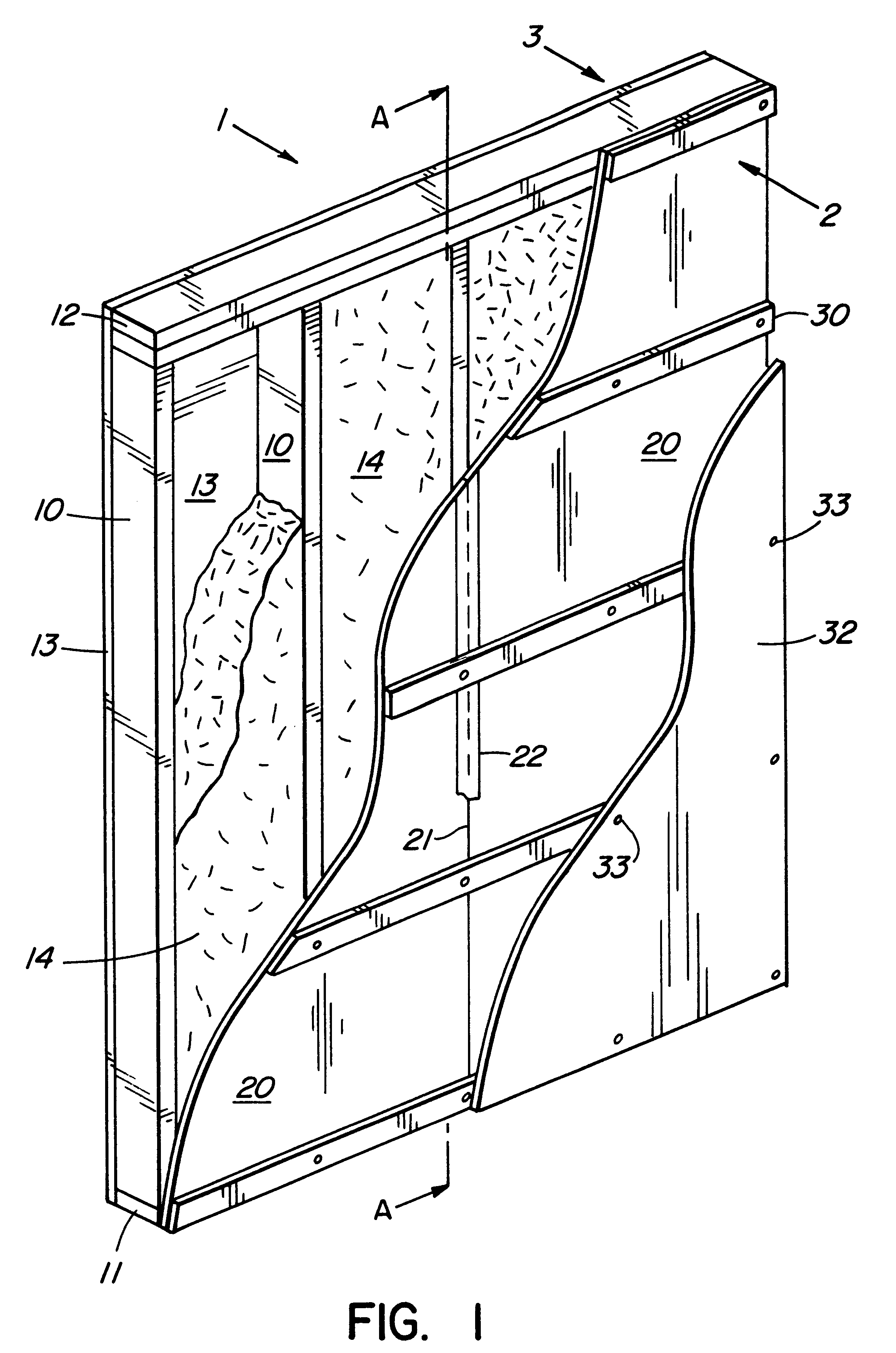

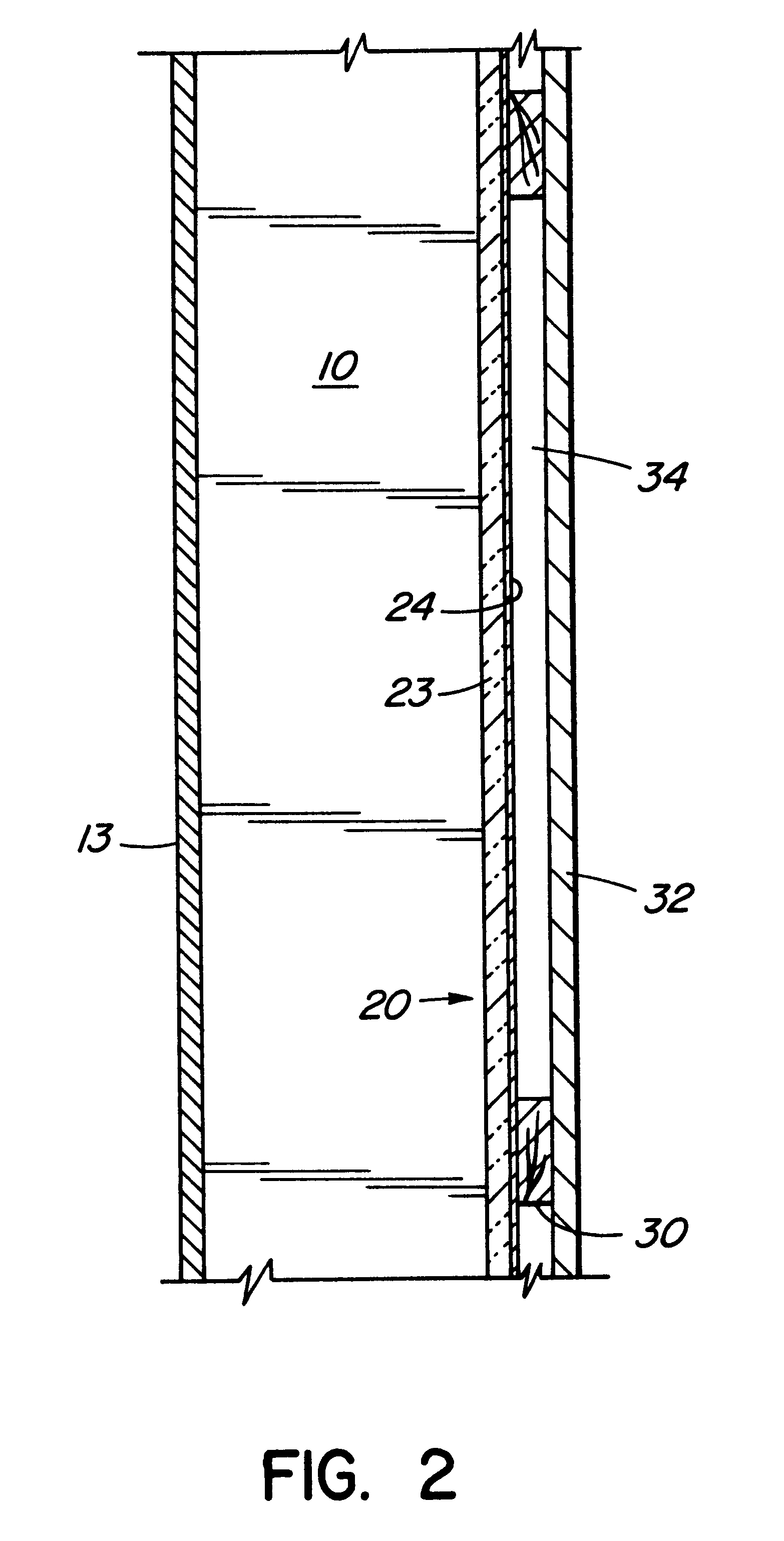

Composite vapor barrier panel

A fibreboard, insulating, wall panel includes an integral air and vapor barrier of metal foil or metallized plastic film adhered to one surface of the panel. Panels are attached to a stud wall frame. Abutting panel joints are taped to provide a continuance vapor barrier. Increased thermal and acoustic insulation as well as structural integrity of the barrier is provided by the panel.

Owner:BUILDING PROD OF CANADA CORP

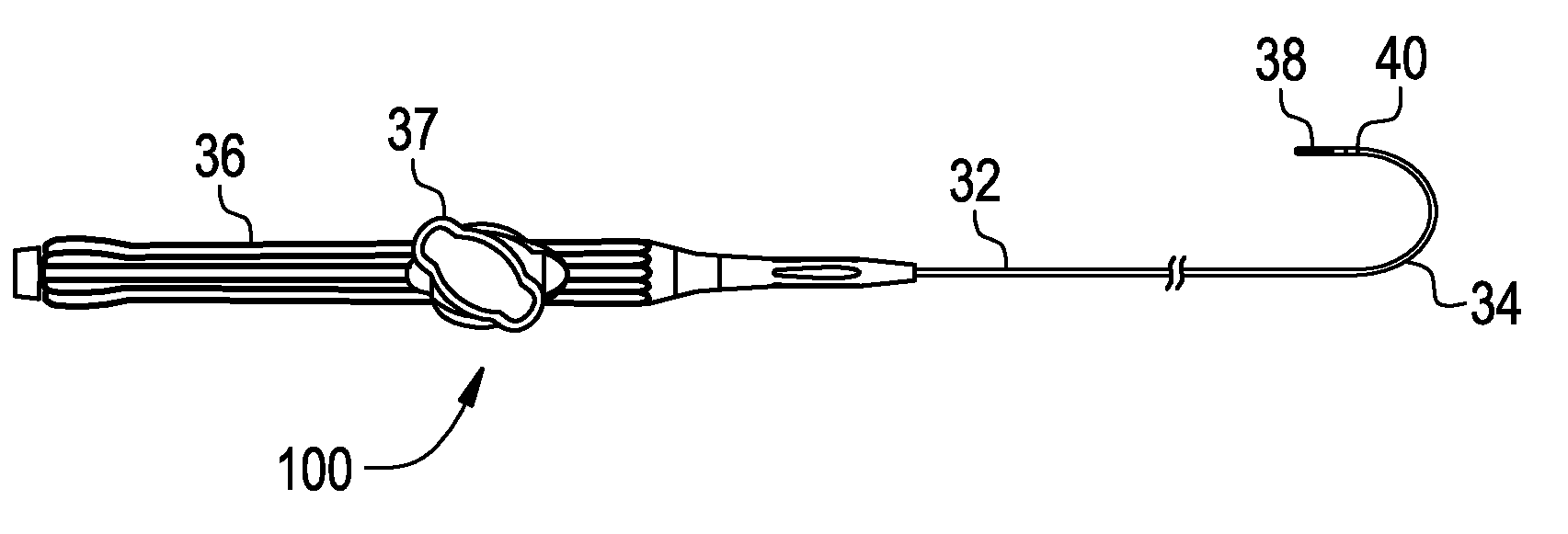

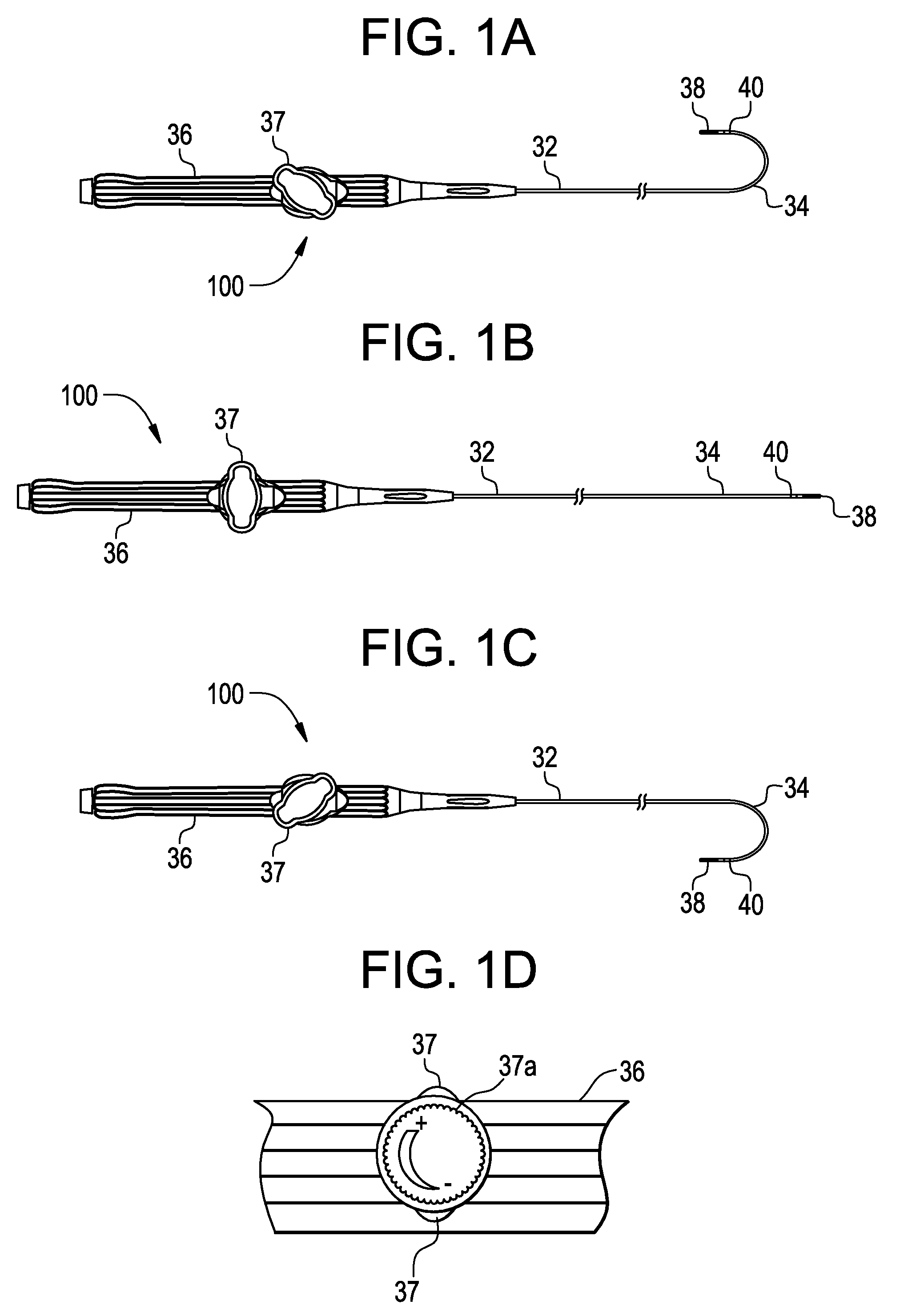

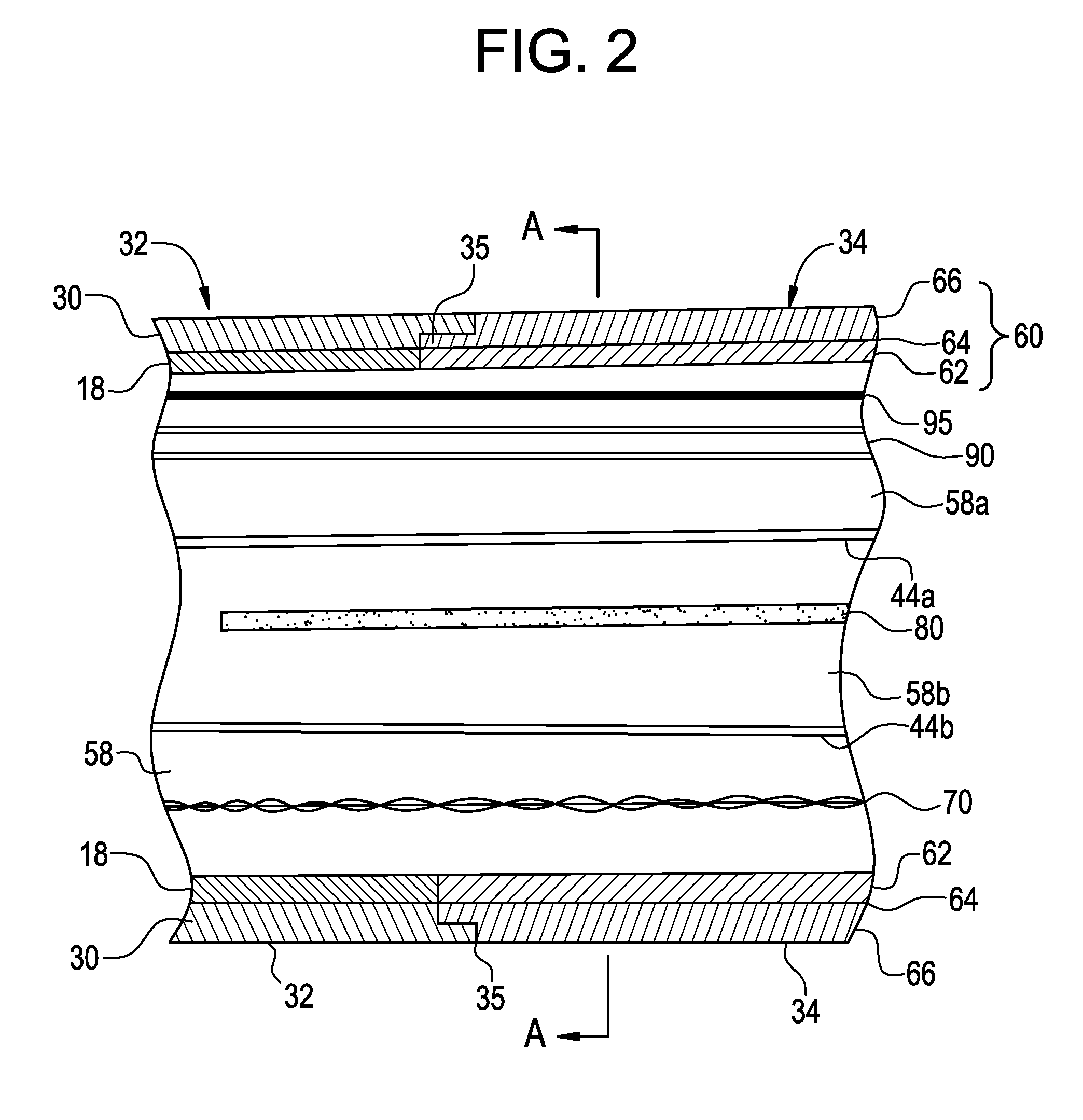

Force-sensing catheter with bonded center strut

ActiveUS20100063478A1Quick assemblyMaximize cross-sectional areaElectrocardiographyStrain gaugeMetallic foilEngineering

A force-sensing catheter for diagnosing or treating the vessels found within a body or body space includes a center strut that is bonded, preferably thermally, along its longitudinal axis with the thermoplastic tubular member within which it is housed. The tubular member preferably has three layers: an inner layer, a braided layer and an outer layer. One or more semiconductor or metallic foil strain gages are affixed to the center strut in order to provide a measure of the bending and torsional forces on the distal tip of the catheter. Temperature compensation is achieved by having a temperature sensor near the strain gages and calibrating the catheter over a range of temperatures.

Owner:BIOSENSE WEBSTER INC

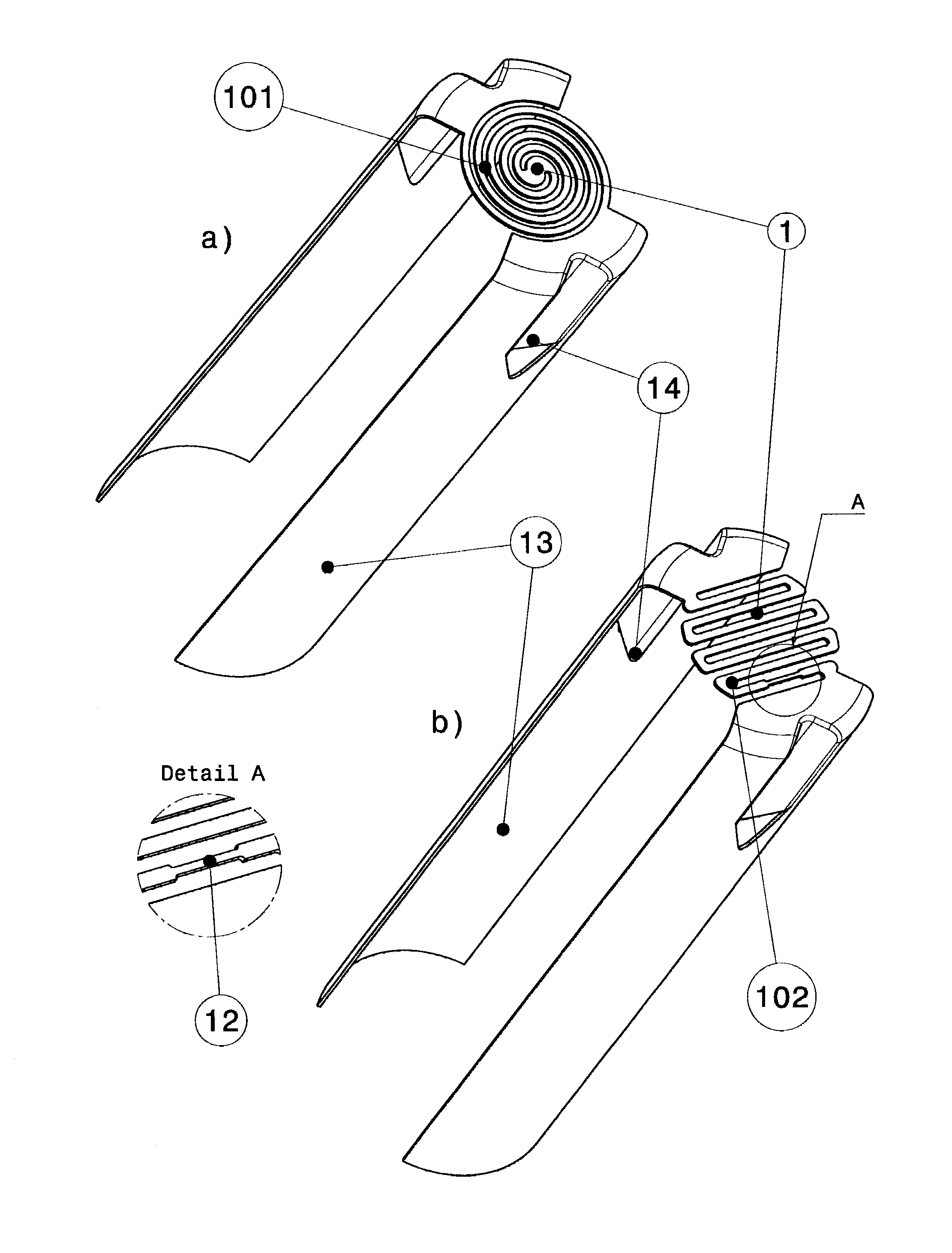

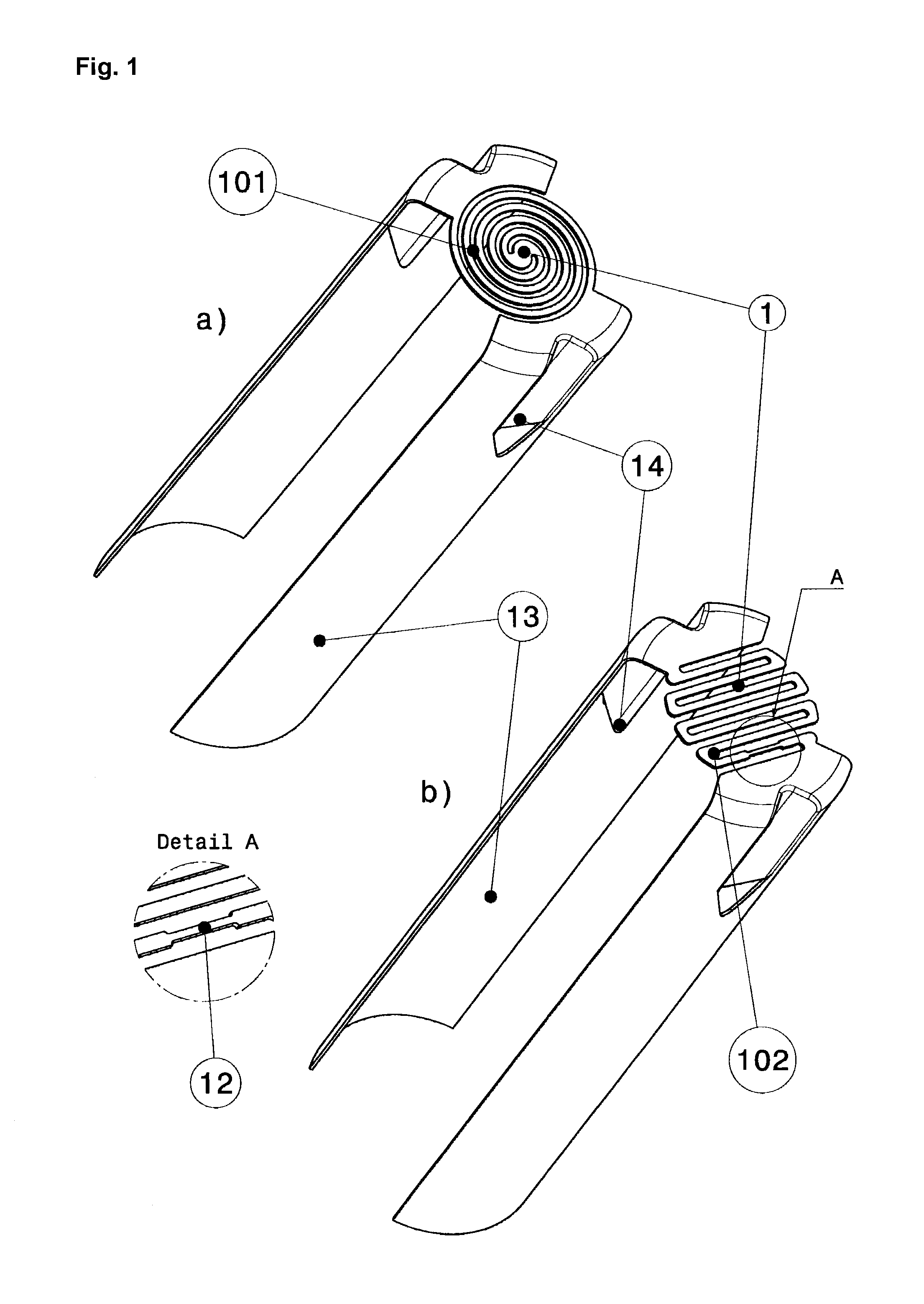

Permeable electric thermal resistor foil for vaporizing fluids from single-use mouthpieces with vaporizer membranes

ActiveUS20140305454A1Low costReduce material usageTobacco pipesTobacco devicesMetallic foilDual coil

A vaporizer device for vaporizing substances is provided, containing active and / or aroma materials, including a mouthpiece with a fluid inlet and a fluid outlet, and including: a heating device with a thermal resistor being a metallic foil or a thin sheet configured as a dual coil and / or sinuous line with two ends and dimensions of the cross-section of a cigarette or a small cigar, wherein the interspaces of the dual coil and / or sinuous line allow fluid flow therethrough, contact tabs are connected to respective opposed ends of the dual coil and / or sinuous line and are not in direct contact with one another, and at least one permeable and wettable vaporizer membrane in large-area contact with the thermal resistor, wherein the thermal resistor and the at least one vaporizer membrane are arranged orthogonally or at an angle to the direction of the fluids passing through the mouthpiece.

Owner:PHILIP MORRIS PROD SA

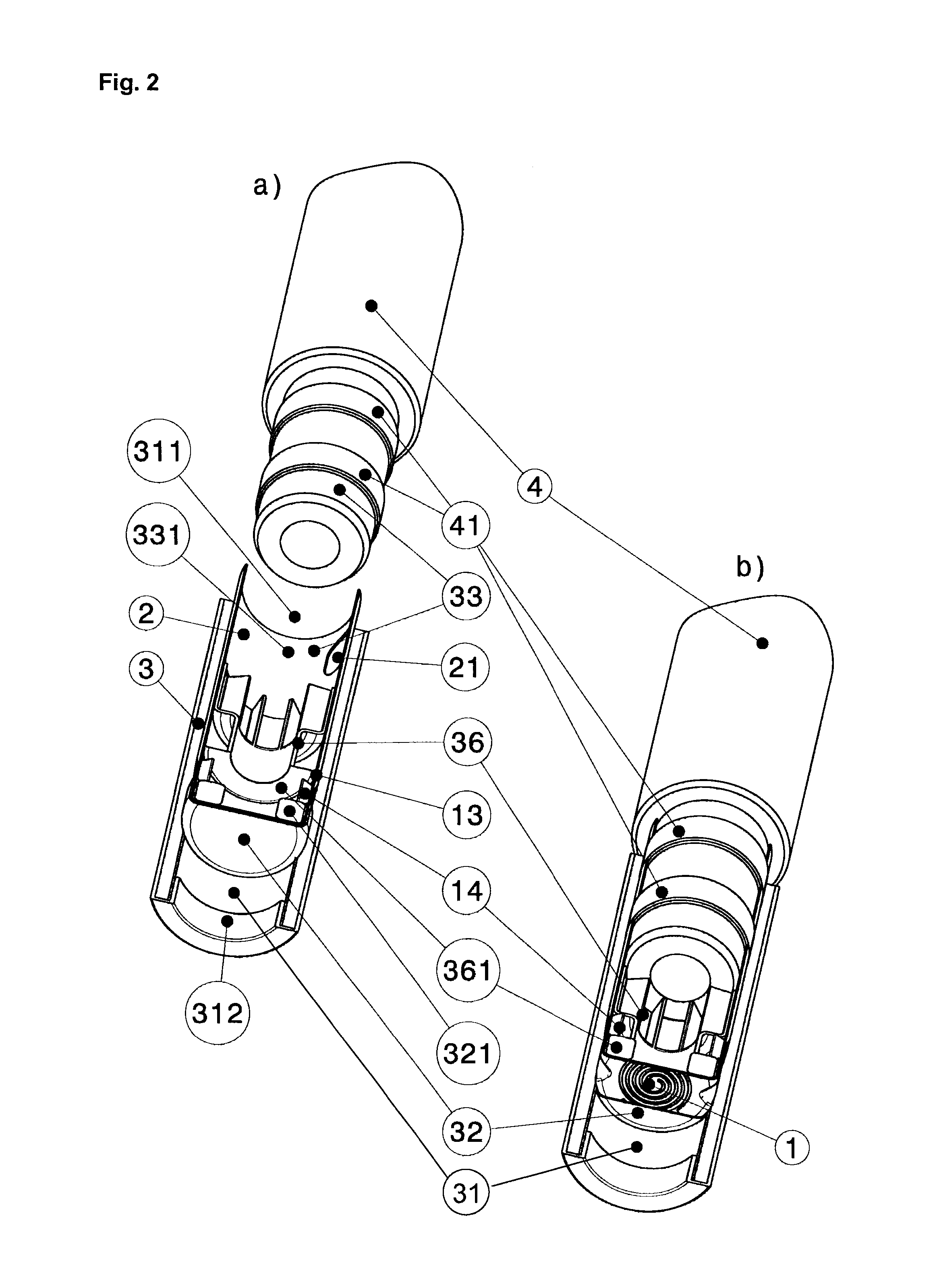

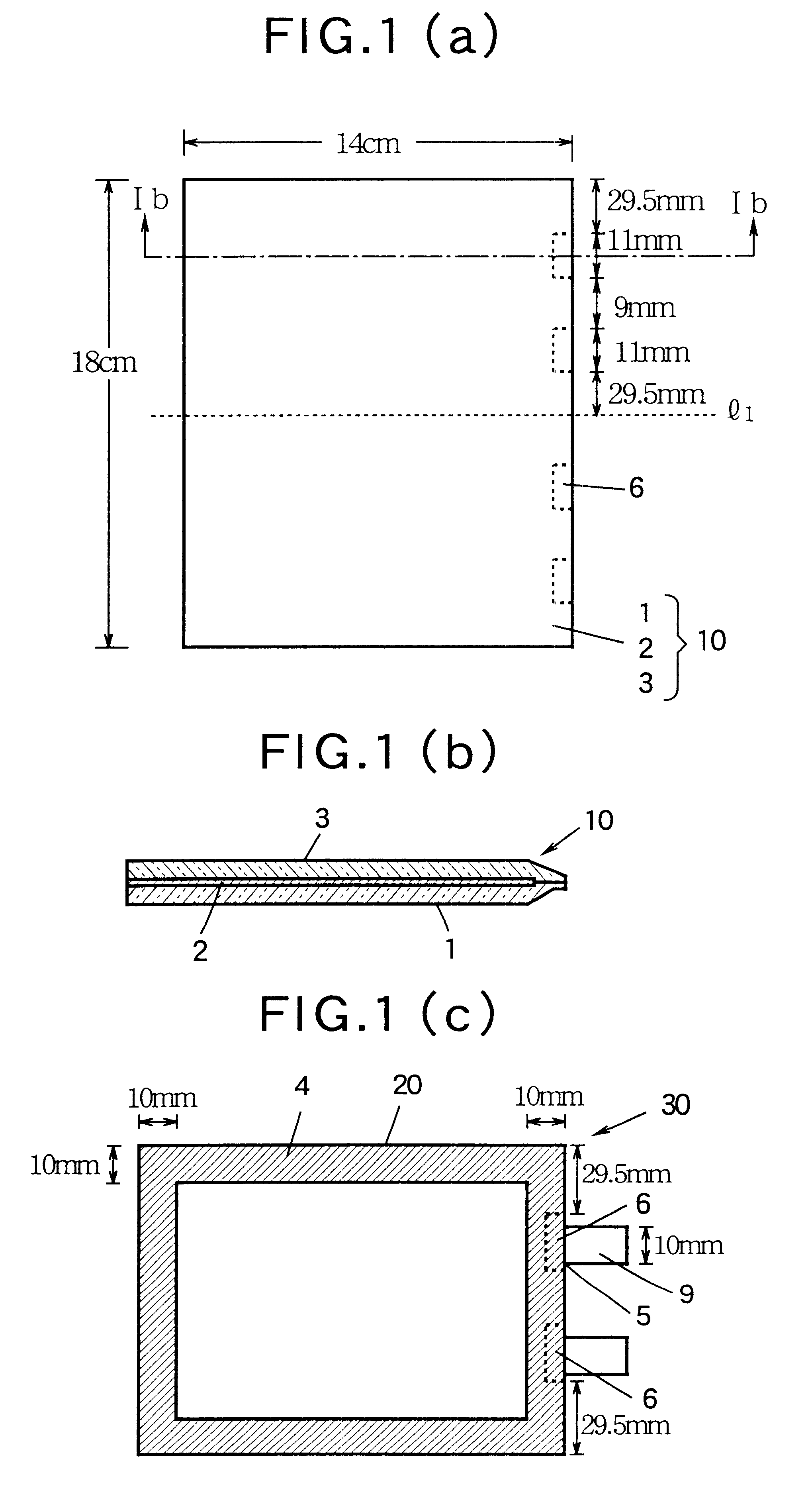

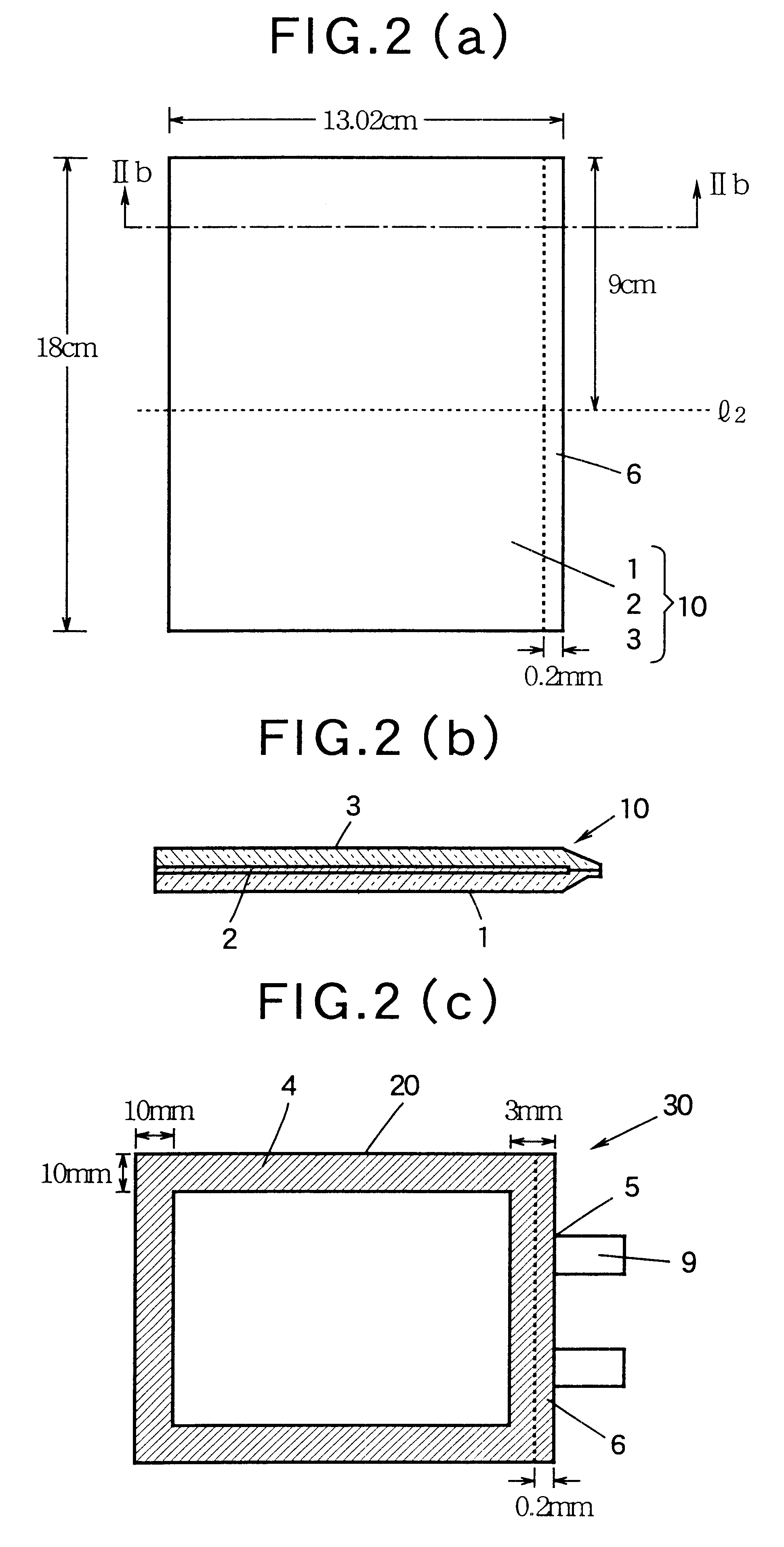

Non-aqueous battery of a thin configuration

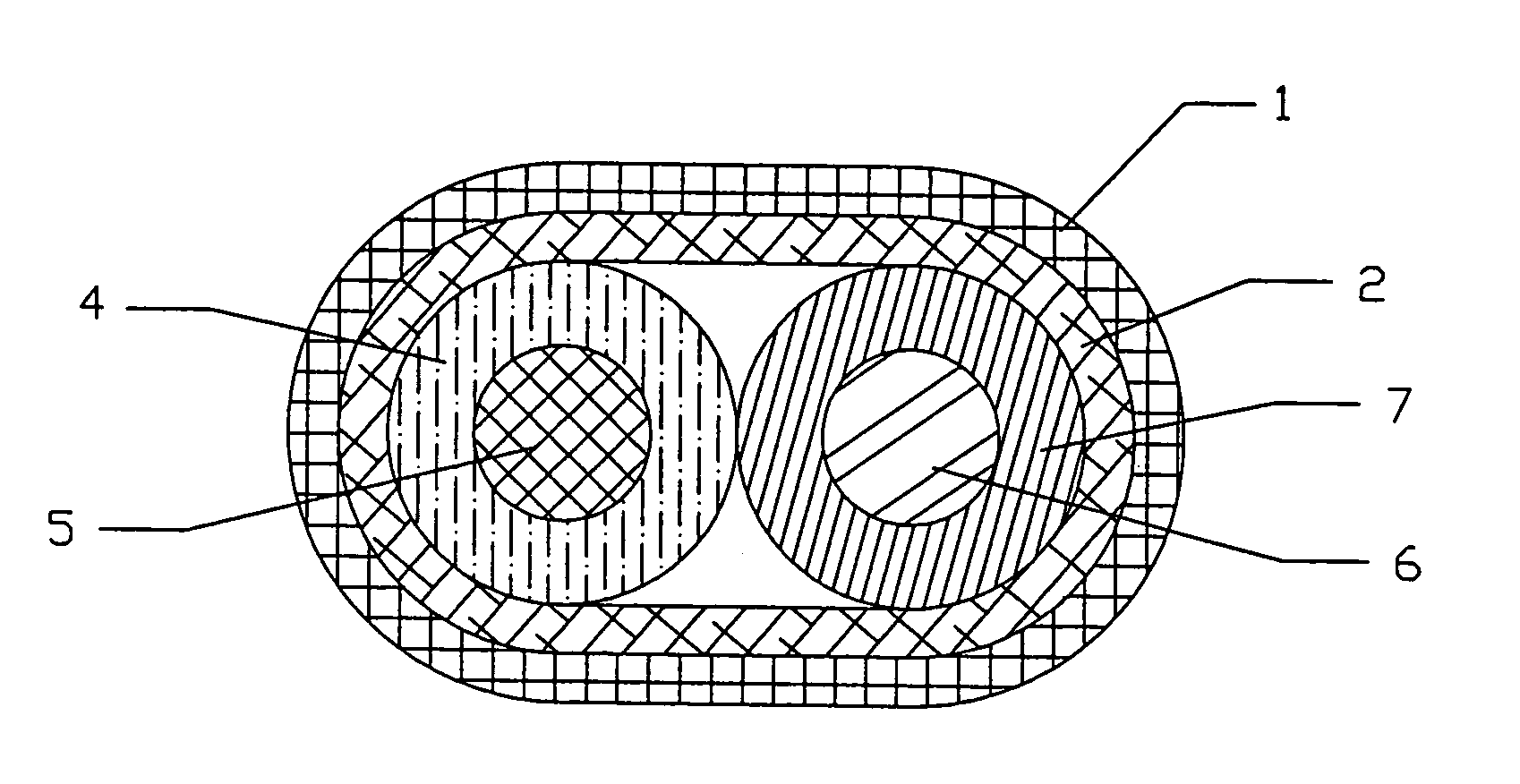

InactiveUS6461757B1Small-sized cells cases/jacketsActive material electrodesMetallic foilElectrical battery

A non-aqueous battery is provided in a pouchy casing comprising opposing sheets of at least three-layer laminates, each laminate comprising (1) an inner thermoplastic resin layer, (2) a middle metal foil layer, and (3) an outer electrically insulating material layer, wherein the pouchy casing has an elongated, hermetic adhesion area along a periphery of the pouchy casing, and the middle metal foil layer has a peripheral elongated region in the elongated, hermetic adhesion area of the pouchy casing, and at least a pair of terminals electrically connected to the cathode and anode of the battery extends through and protrudes from the terminal-withdrawal sites in the elongated, hermetic adhesion area toward the outside of the pouchy casing, and the battery has at least one of the following features: (i) the peripheral elongated region of the middle metal foil layer has cut-out portions around the terminal-withdrawal sites and (ii) the surface of the peripheral edge of the pouchy casing is provided with electric insulation at least at portions around the terminal-withdrawal sites.

Owner:ASAHI KASEI ELECTRONICS CO LTD

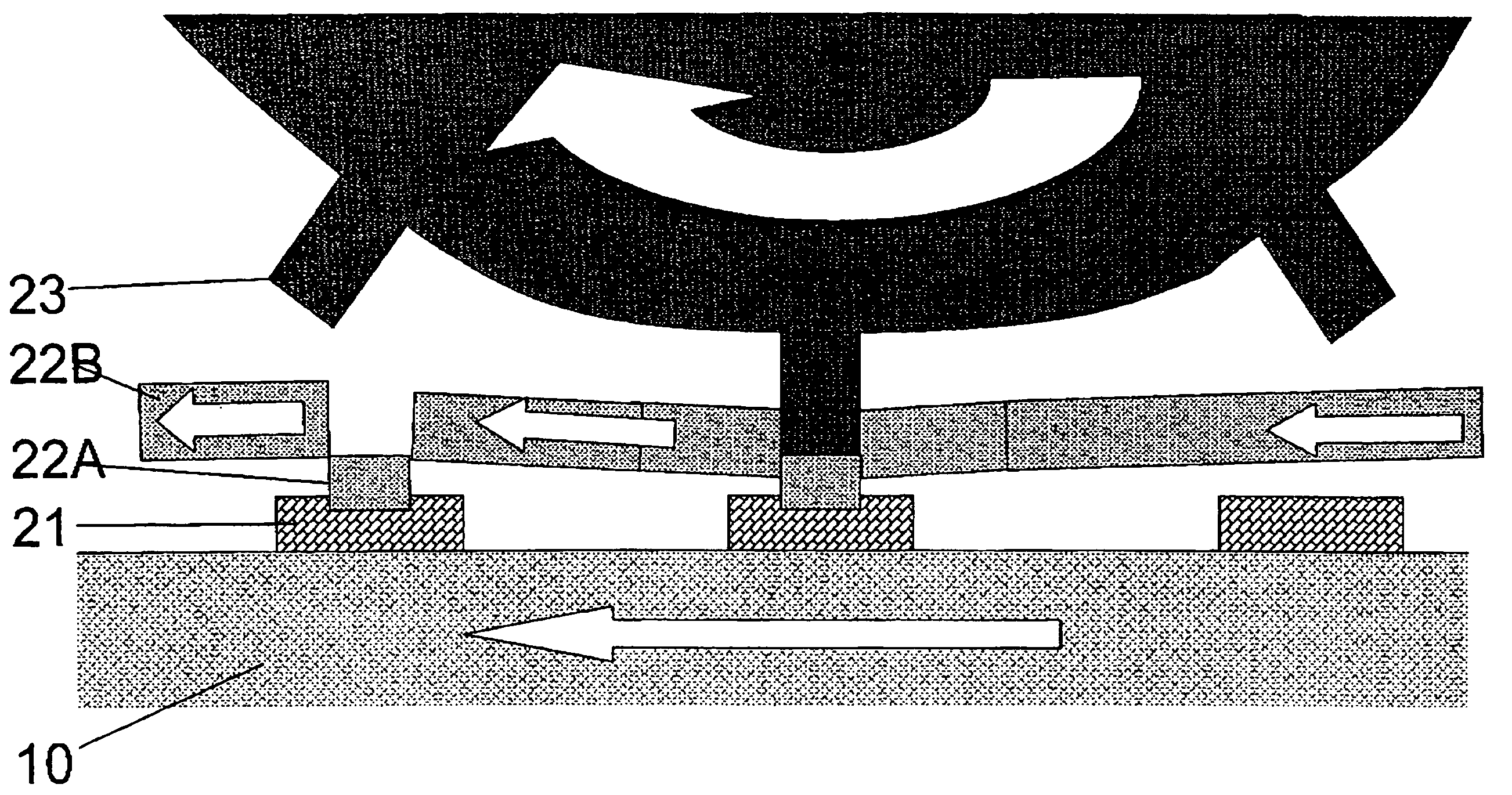

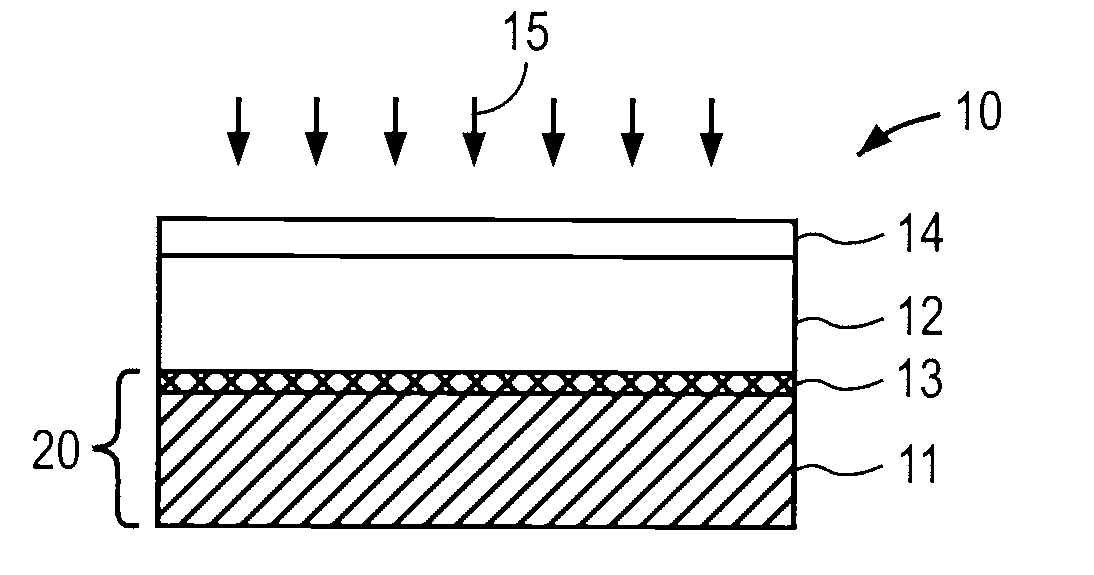

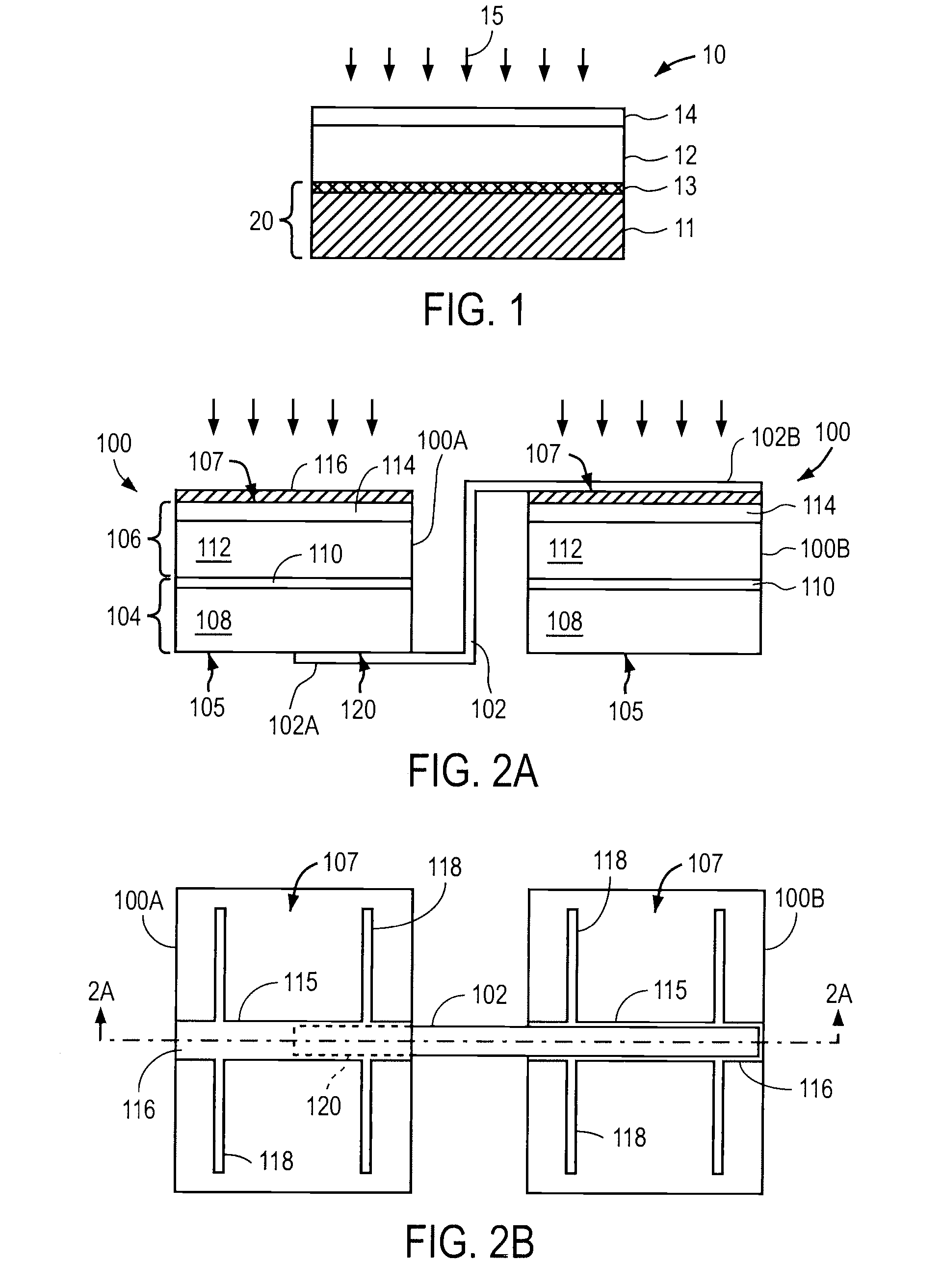

Thin film photovoltaic module manufacturing methods and structures

InactiveUS20100147364A1Reduce effective series resistance of devicePV power plantsSemiconductor/solid-state device manufacturingMetallic foilAmorphous silicon solar cell

Owner:SOLOPOWER

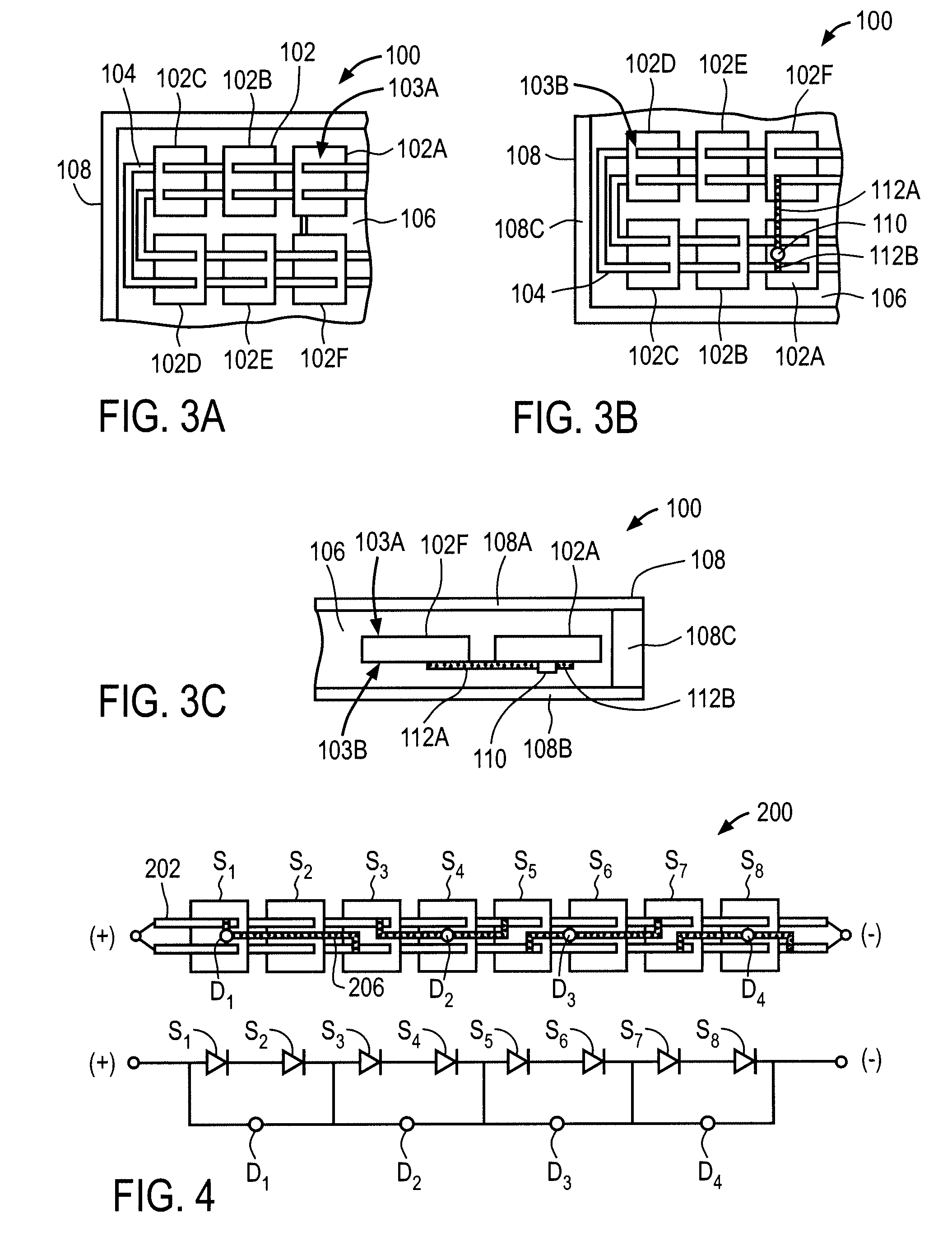

Planar solid oxide fuel cell stack with metallic foil interconnect

A solid oxide fuel cell stack having a plurality of integral component fuel cell units, each integral component fuel cell unit having a porous anode layer, a porous cathode layer, and a dense electrolyte layer disposed between the porous anode layer and the porous cathode layer. The porous anode layer forms a plurality of substantially parallel fuel gas channels on its surface facing away from the dense electrolyte layer and extending from one side to the opposite side of the anode layer, and the porous cathode layer forms a plurality of substantially parallel oxidant gas channels on its surface facing away from the dense electrolyte layer and extending from one side to the opposite side of the cathode. A flexible metallic foil interconnect is provided between the porous anode and porous cathode of adjacent integral component fuel cell units.

Owner:VERSA POWER SYST

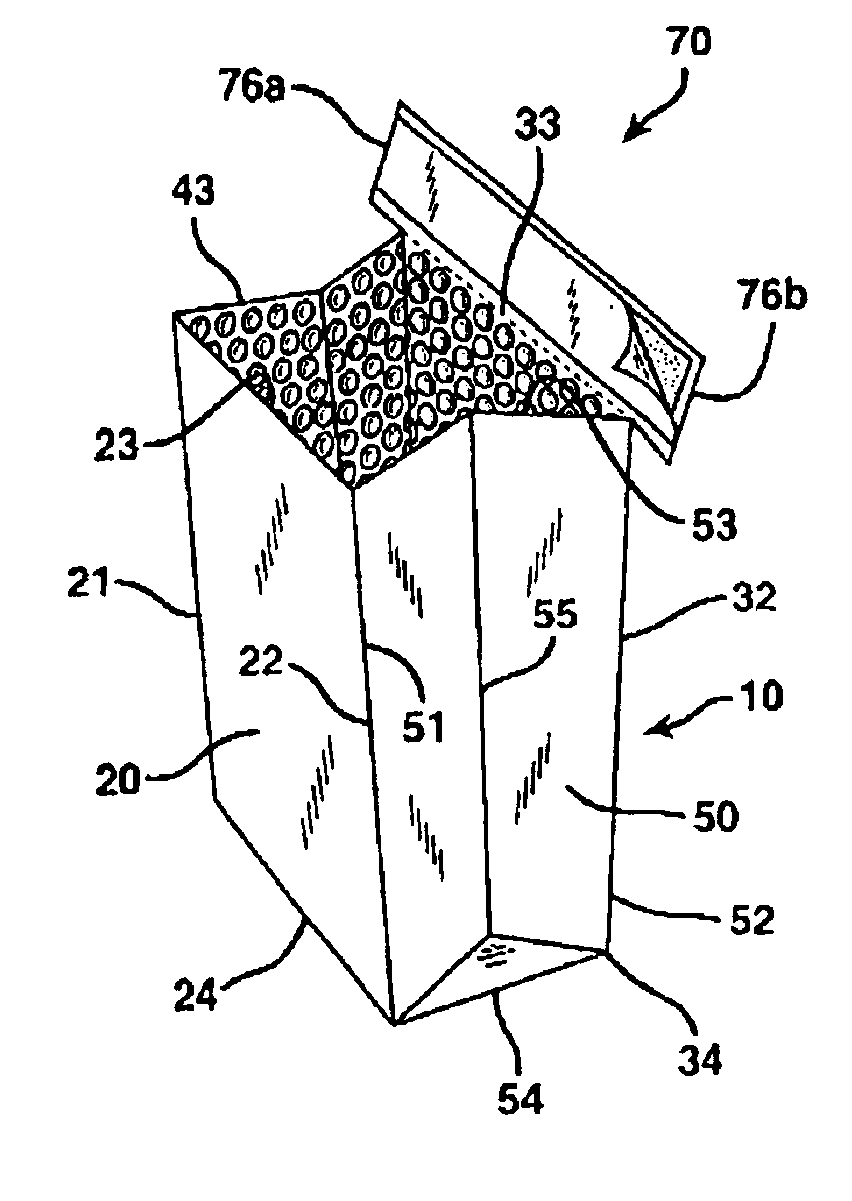

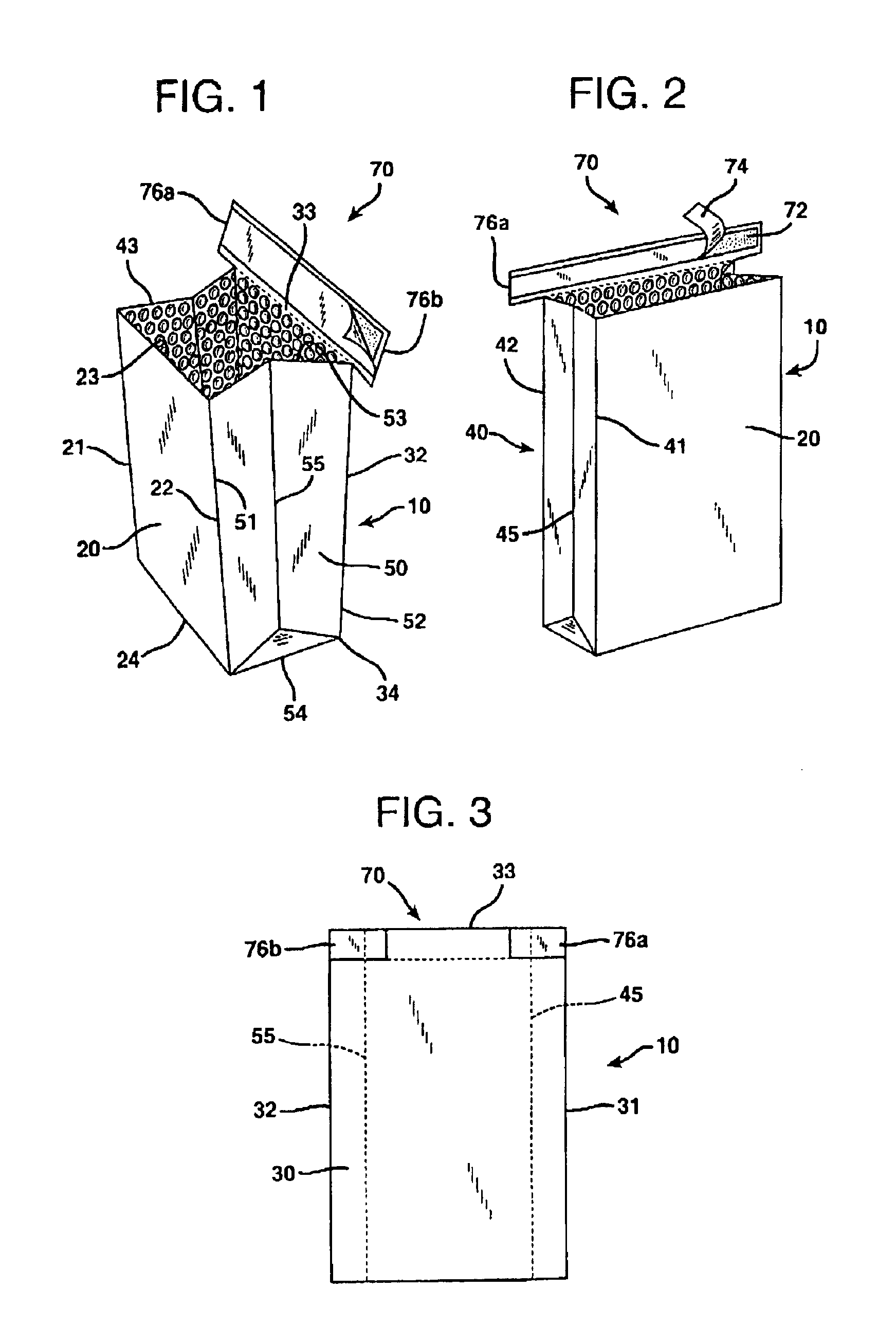

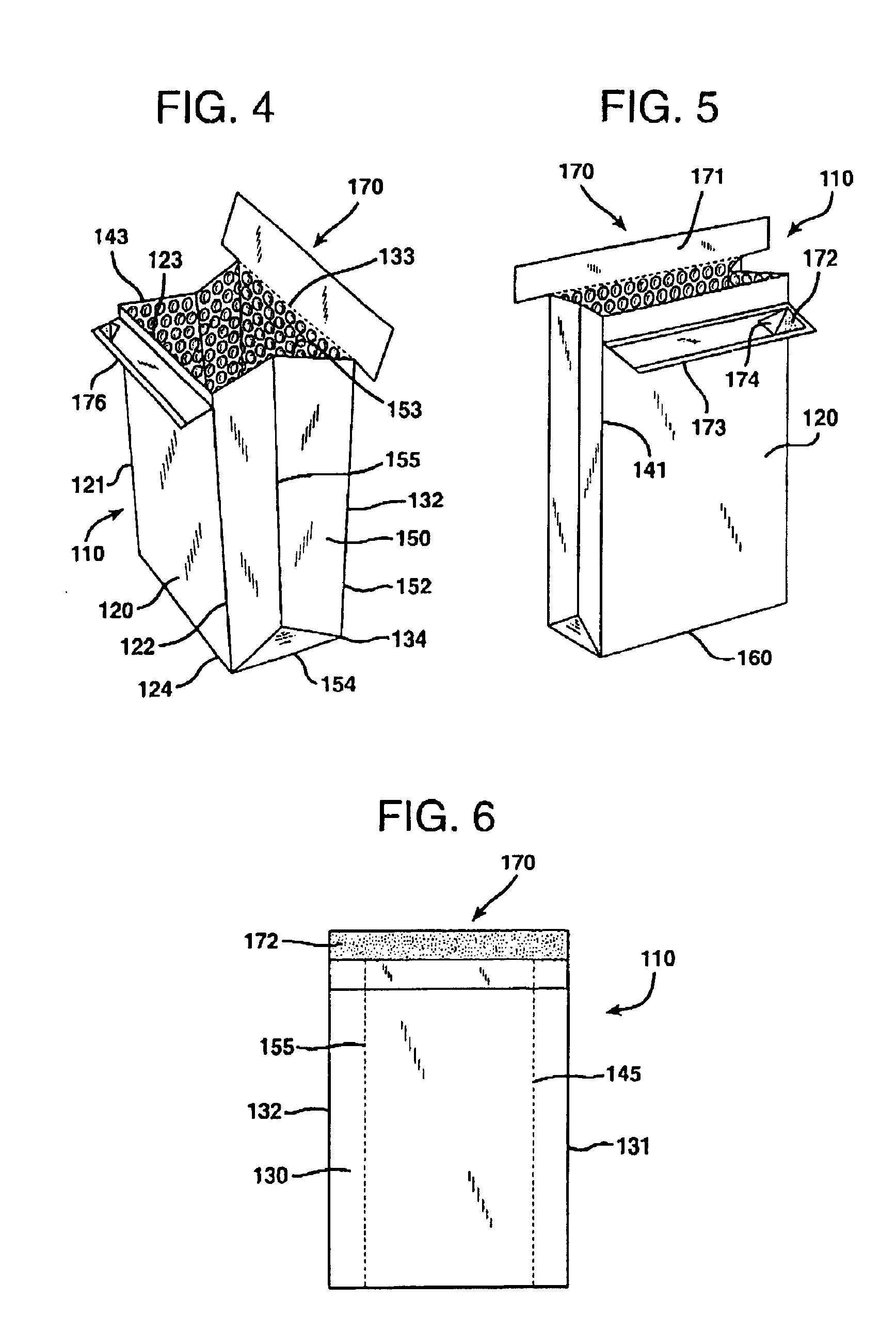

Metallic laminated gusseted insulated bag

A metallic laminated gusseted insulated bag includes a front and rear wall each having two lateral edges, a top edge, and a bottom edge; first and second side walls; a bottom member; and a means for hermetically closing the bag; wherein the front and rear walls are joined along their respective lateral edges to the first and second side walls; either or both of the side walls and bottom member are gusseted; and the front and rear walls are joined along their respective bottom edges to the bottom member; and the front and rear walls each include an outer ply including a metallic foil or metallic coated web, and an inner ply having an inner and outer surface, including a thermal insulating layer; the metallic foil or metallic coated web being adhered to the outer surface of the inner ply.

Owner:SEALED AIR U S

Insulated carrier

InactiveUS20060102497A1Save materialShorten the timeDomestic cooling apparatusLighting and heating apparatusMetallic foilBottle

An insulated carrier for transporting items such as bottles and the like, and retaining them at a predetermined temperature. The carrier is made of a flexible material and includes a pocket-like interior capable of conforming, in a form fitting manner, to the shape of the object to be transported. A flexible insulating film is applied to the pocket-like interior. The insulating layer may be comprised two layers, a first metallic foil layer, facing the item to be transported, and a second, preferably foamed layer.

Owner:FASHION PRODION MARKUS WULF E KFM

Heater with simultaneous hot spot and mechanical intrusion protection

InactiveUS6958463B1Excellent dielectric propertiesPreventing and minimizing current leakageHeating element shapesFiberElectrical conductor

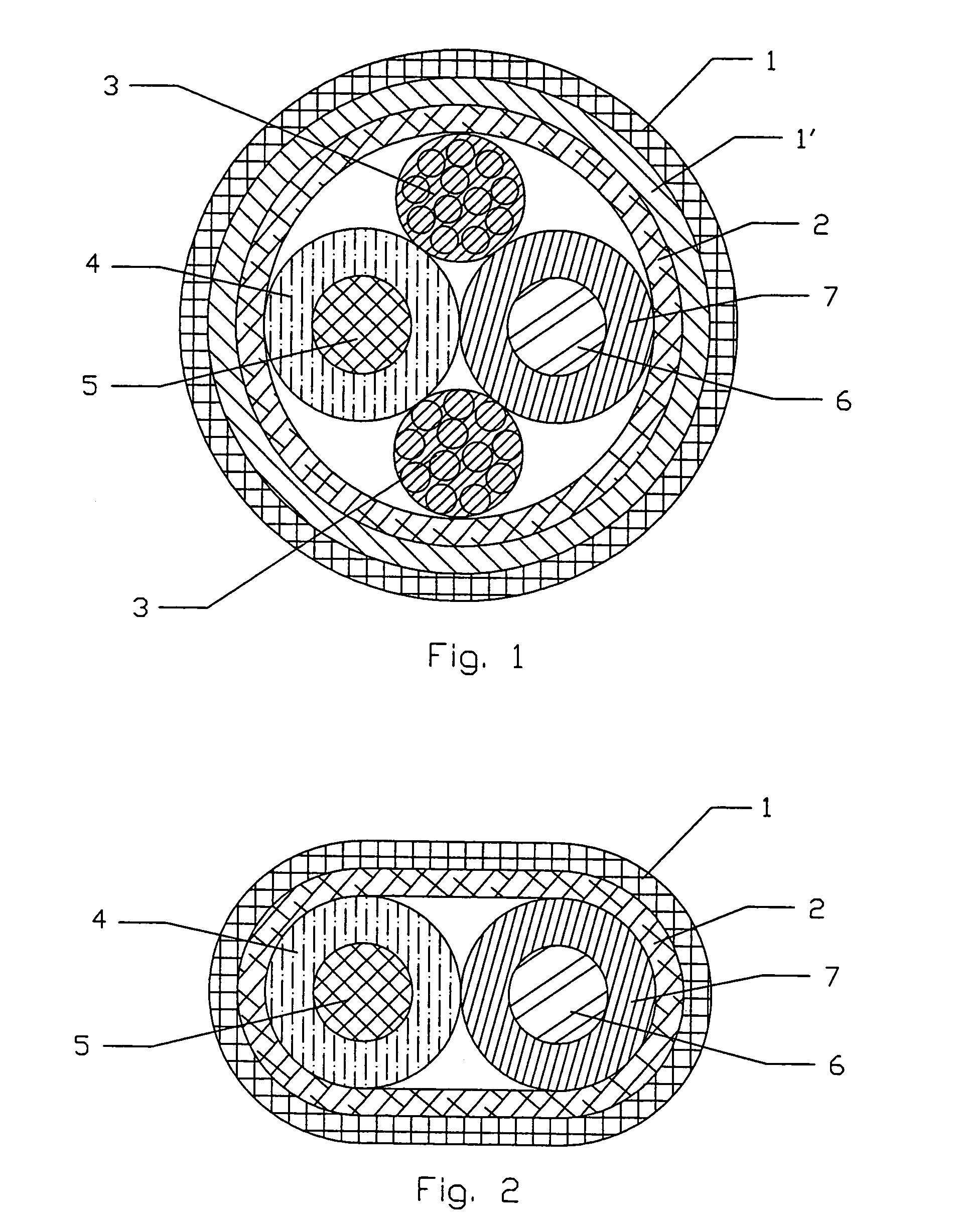

An electrical heater utilizes negative temperature coefficient material (NTC) and current imbalance between live and neutral ends of the heater to simultaneously protect the heater from the hot spot and mechanical intrusion into the heating cable. The NTC layer, separating the heating wire and current leakage conductor, becomes electrically conductive at the temperatures above 60° C., thus “leaking” the current to earth. The hot spot is detected by measuring the current imbalance between line and neutral connections of the heating cable. The mechanical intrusion into the heater, such as cable or insulation damage, water or sharp metal object penetration, is also simultaneously measured by the same current imbalance measuring system such as Ground Fault Circuit Interrupter (GFCI). The optional return conductor and metal foil / mesh hot spot detection shields cancel electromagnetic field. The heater may contain positive temperature coefficient (PTC) continuous sensor to control the temperature in the heater. Such PTC sensor can be made of electrically conductive fibers and / or metal wires.

Owner:THERMOSOFT INT

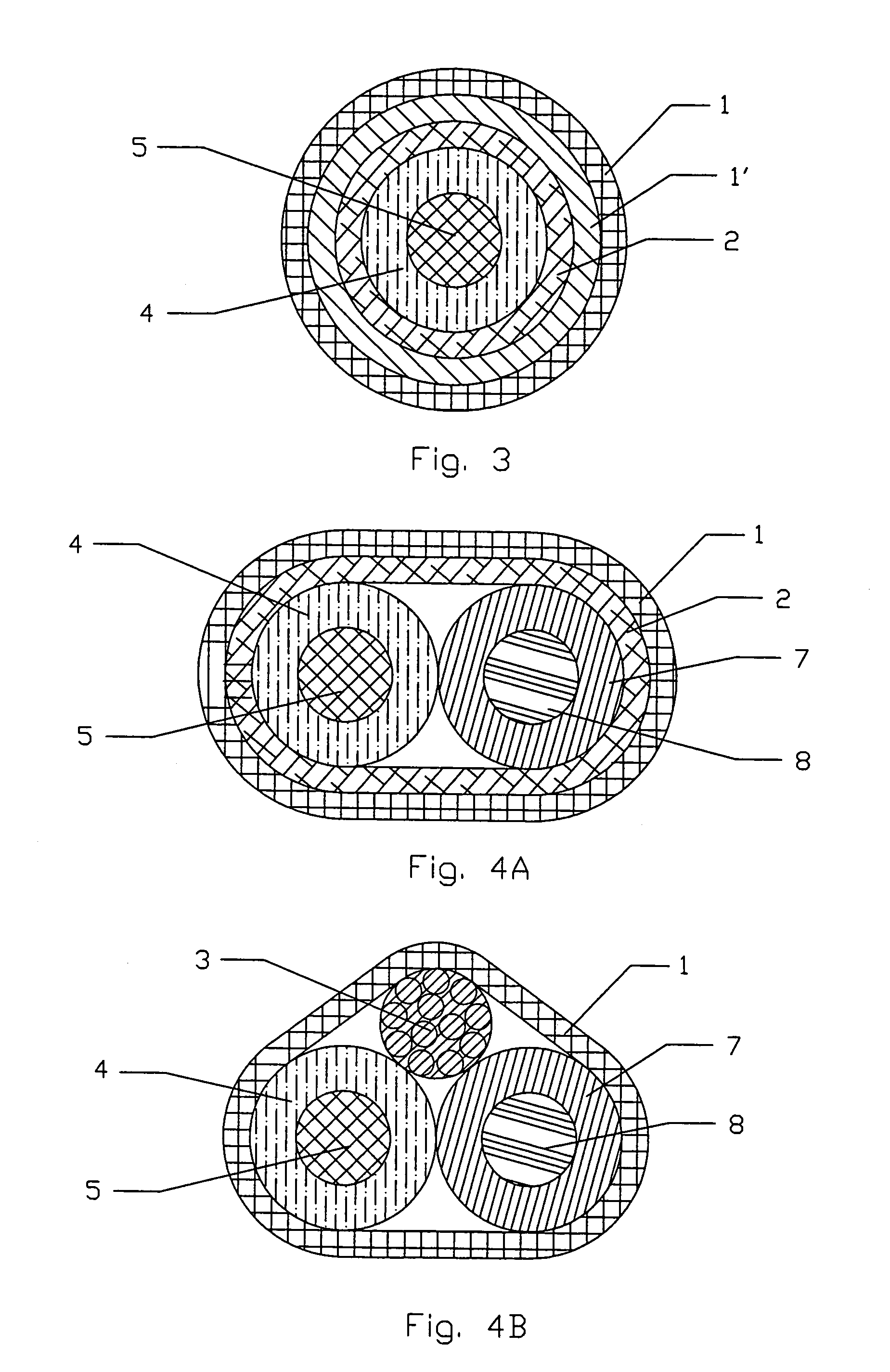

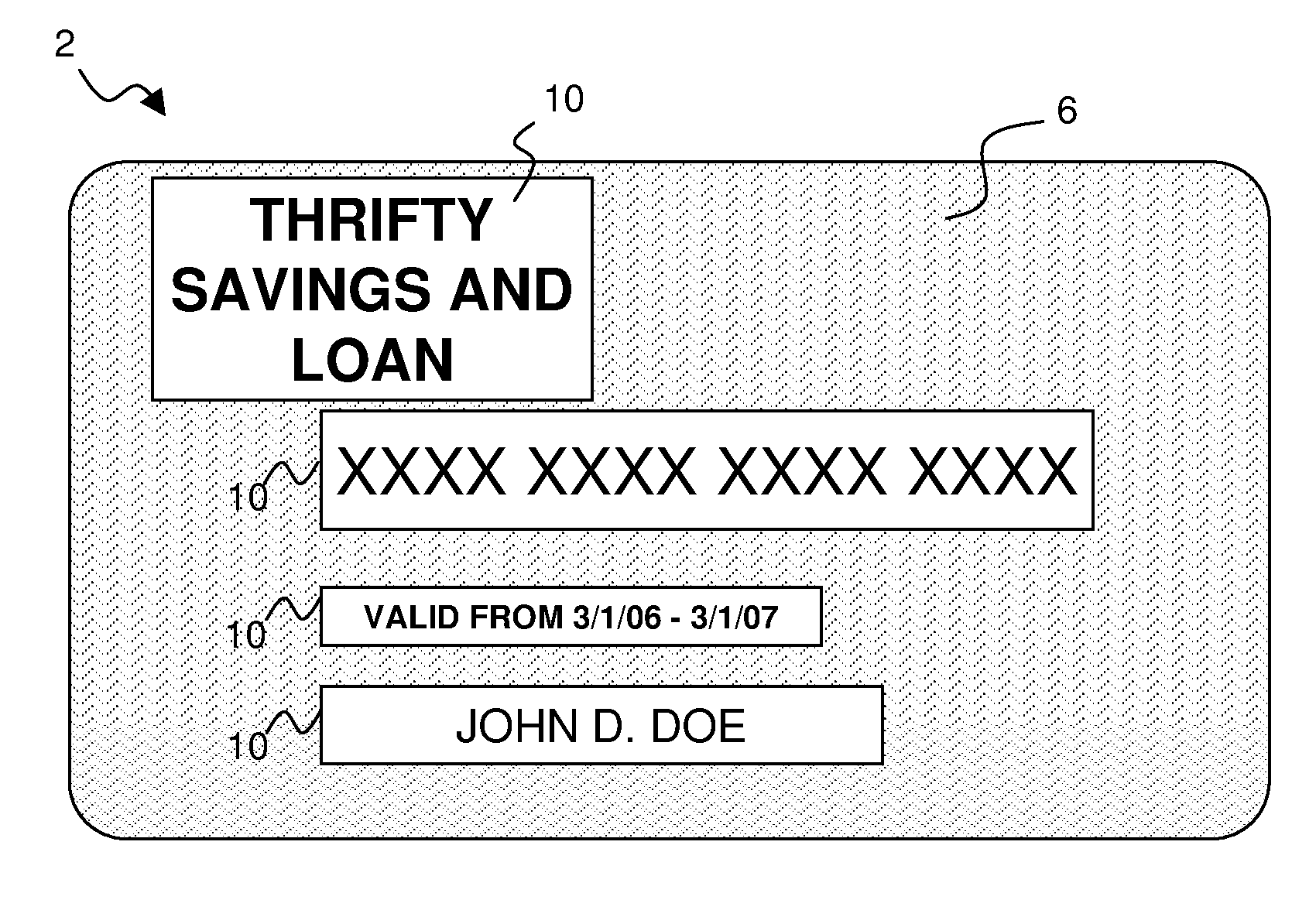

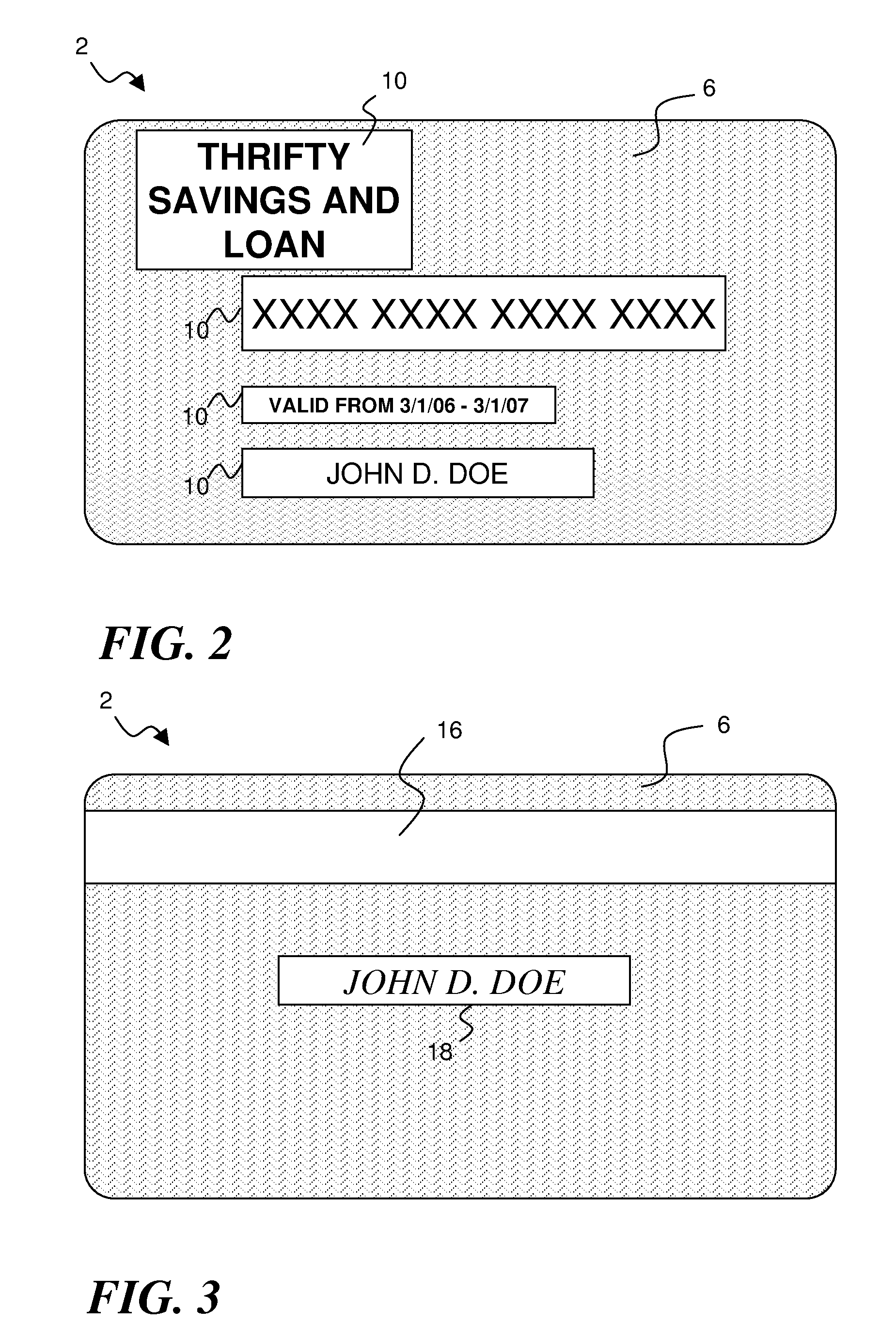

RF Proximity Financial Transaction Card Having Metallic Foil Layer(s)

A contactless financial transaction card includes a plastic inlay having first and second substantially planar surfaces bounded by a continuous peripheral edge. An integrated circuit carried by the inlay stores card-specific data. An antenna carried by the inlay is operatively connected to the integrated circuit. The foil layer provides the financial transaction card with a decorative metallic reflective appearance and is constructed to permit the antenna to inductively couple with the card reader within the maximum coupling distance. Printed graphics or text may be disposed on or above the metallic foil layer. The card is constructed to inductively couple with a card reader that is spaced from the card in order to support limited-range wireless communication between the card and the card reader up to a maximum coupling distance, beyond which it will not couple.

Owner:PERFECT PLASTIC PRINTING

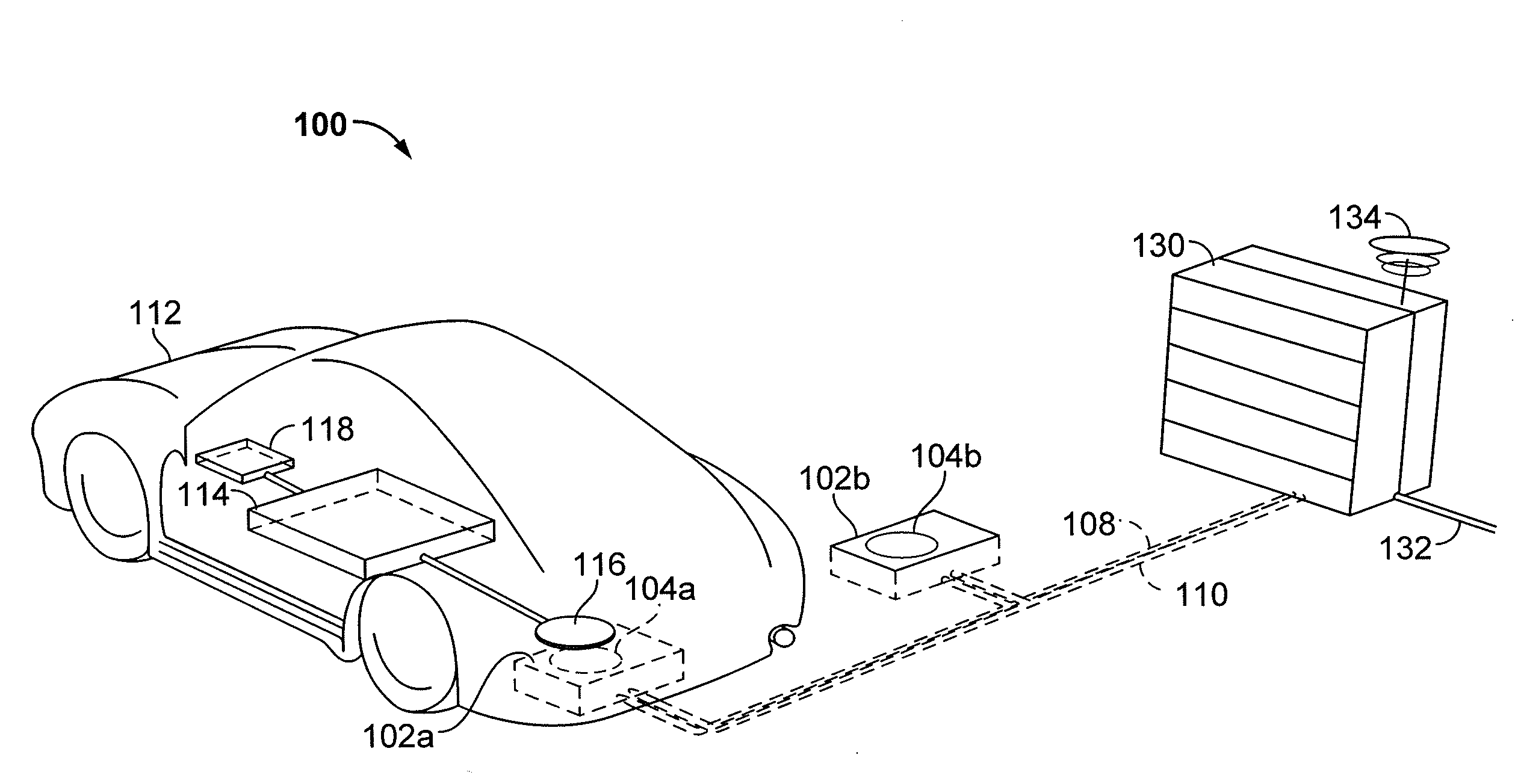

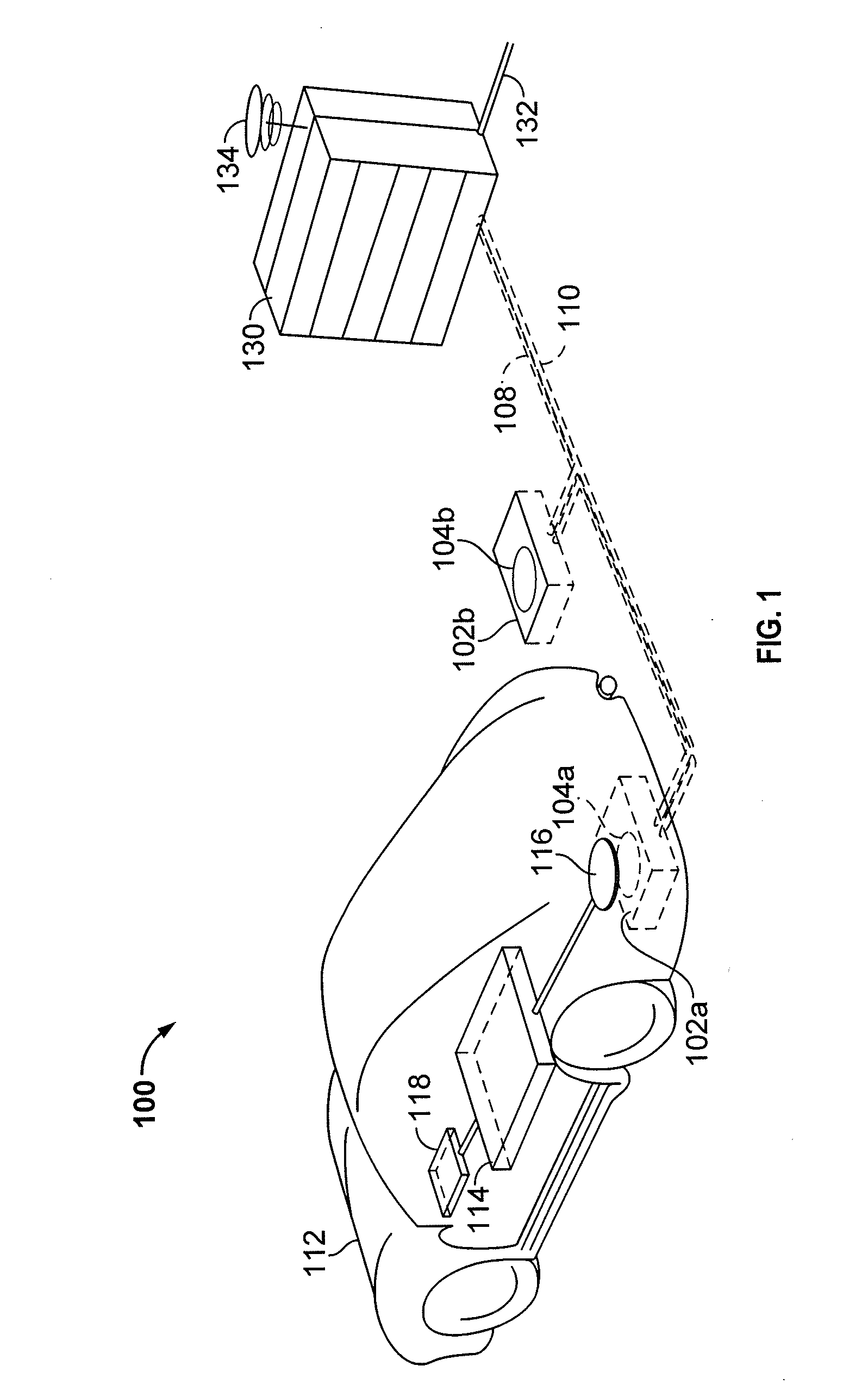

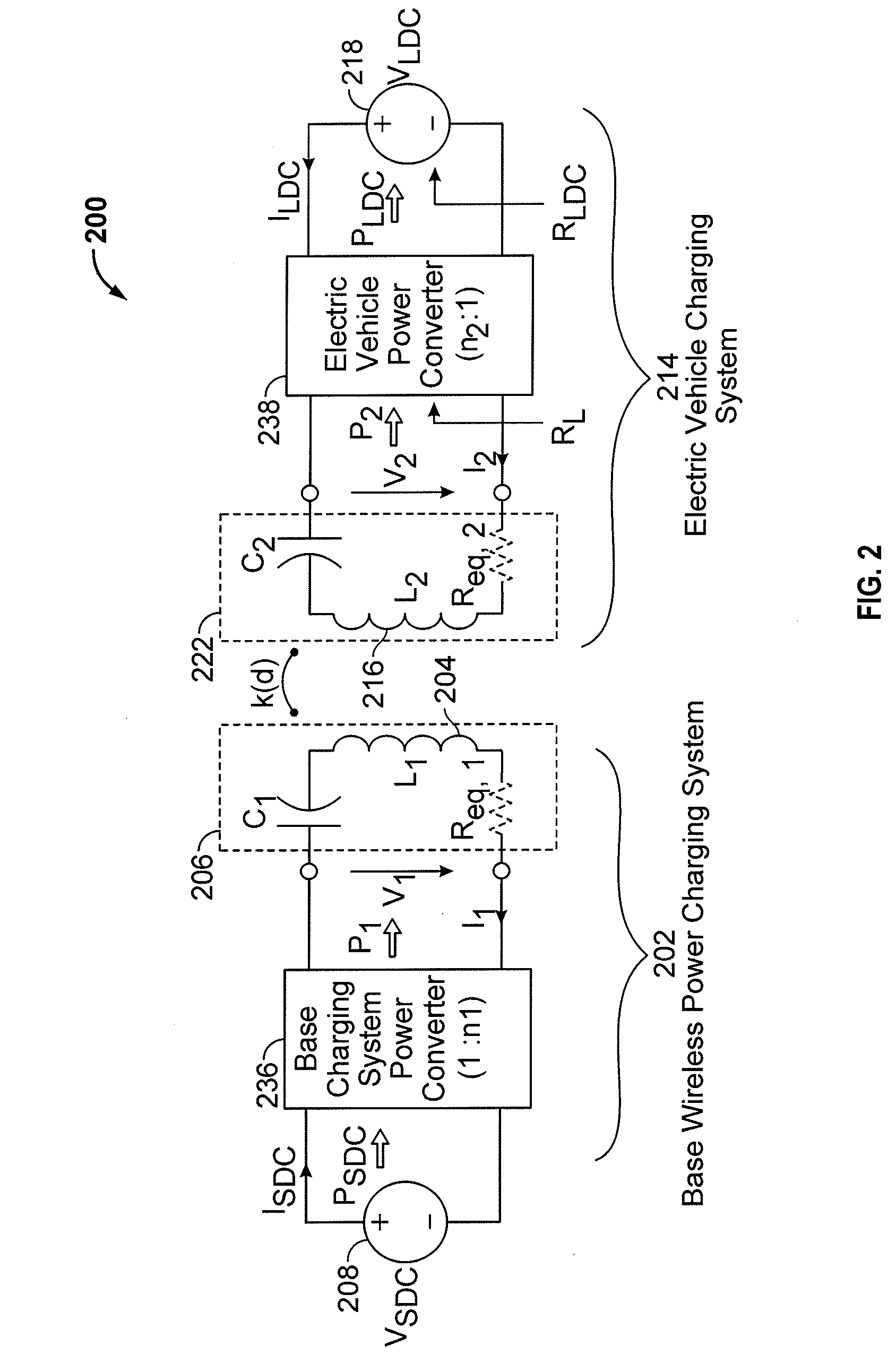

Systems, methods, and apparatus for detecting ferromagnetic foreign objects in a predetermined space

An apparatus for detecting a presence of an object is provided. The apparatus includes an inductive sensing coil that is configurable to generate a first magnetic field. The inductive sensing coil is configured to have an electrical characteristic that is detectable when generating the first magnetic field. The electrical characteristic is configured to vary as a function of a second time-varying magnetic field simultaneously applied to the object. The apparatus comprises a controller configured to detect a change in the electrical characteristic and determine a presence of the object based on the detected change in the electrical characteristic. The electrical characteristic comprises one or more of an equivalent resistance, an equivalent inductance, an equivalent impedance, and an impulse response of the inductive sensing coil. The object comprises one or more of a ferromagnetic object, a metallic film and a metallic foil.

Owner:WITRICITY CORP

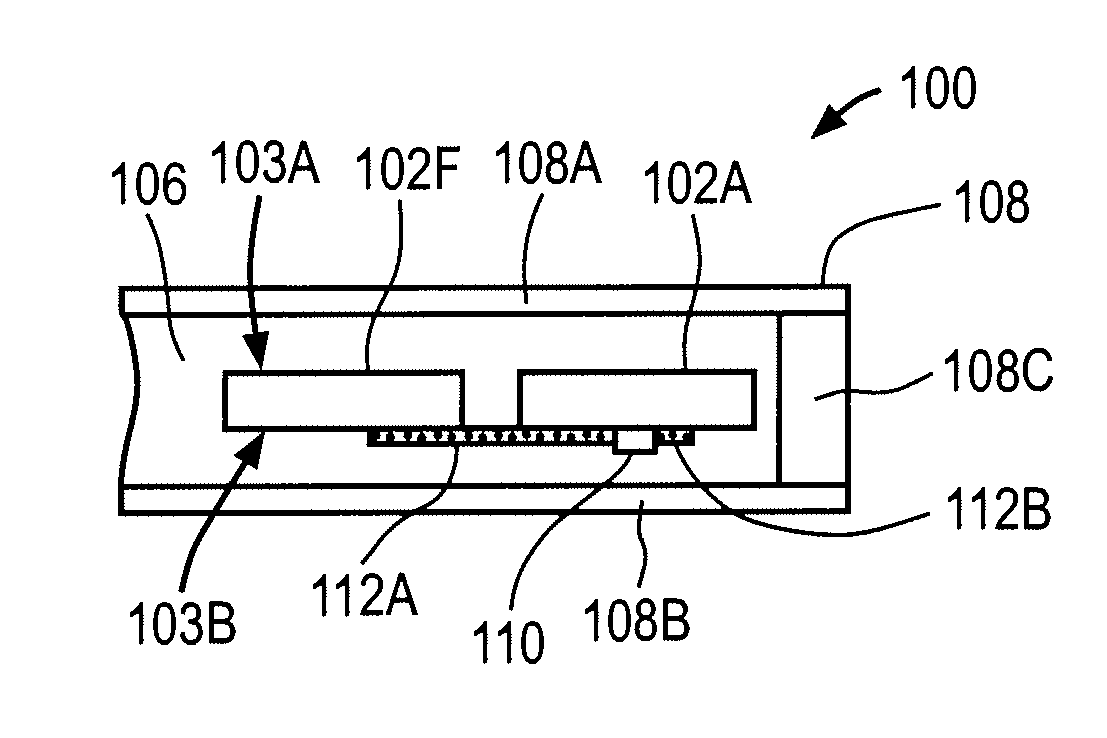

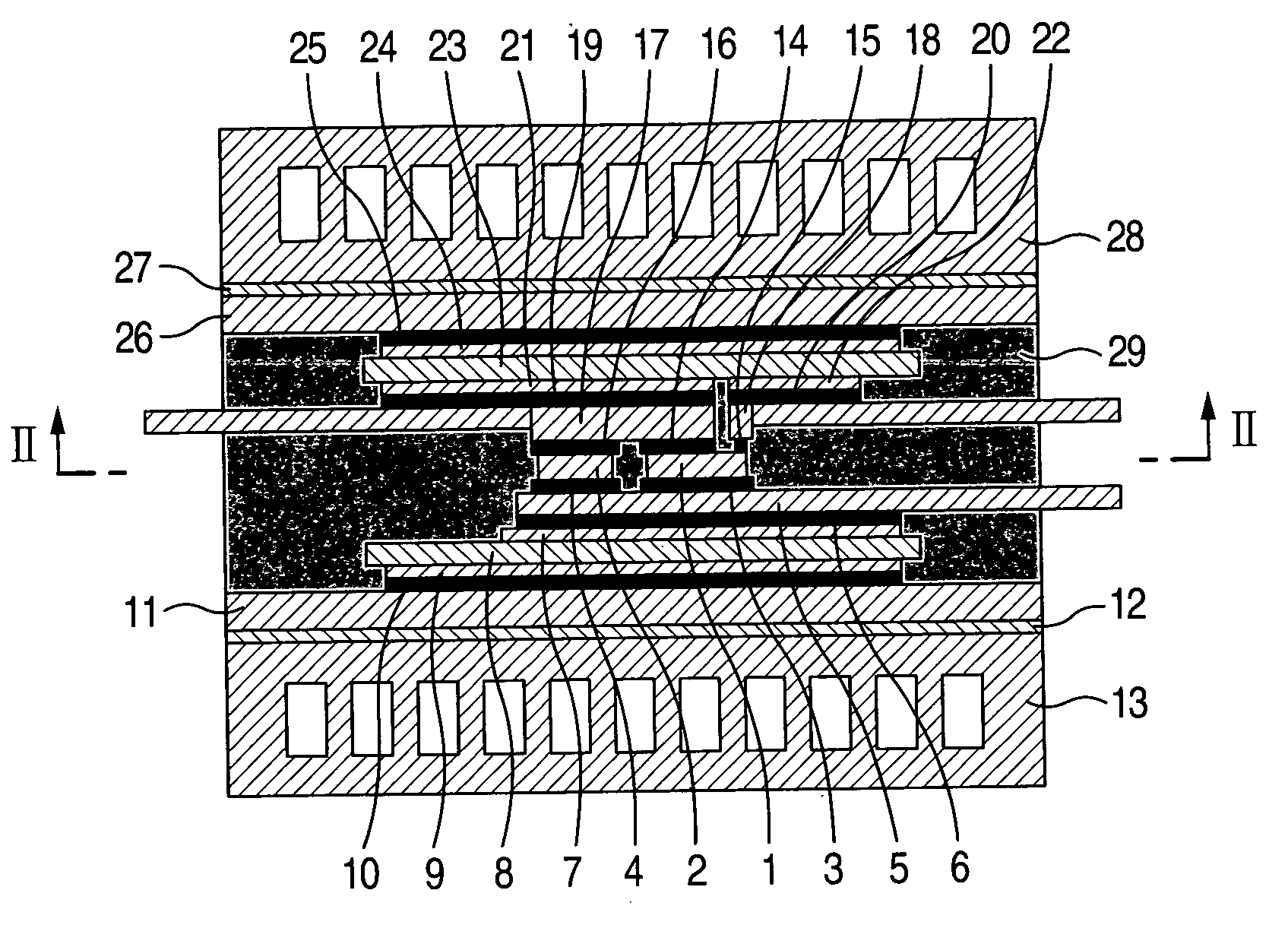

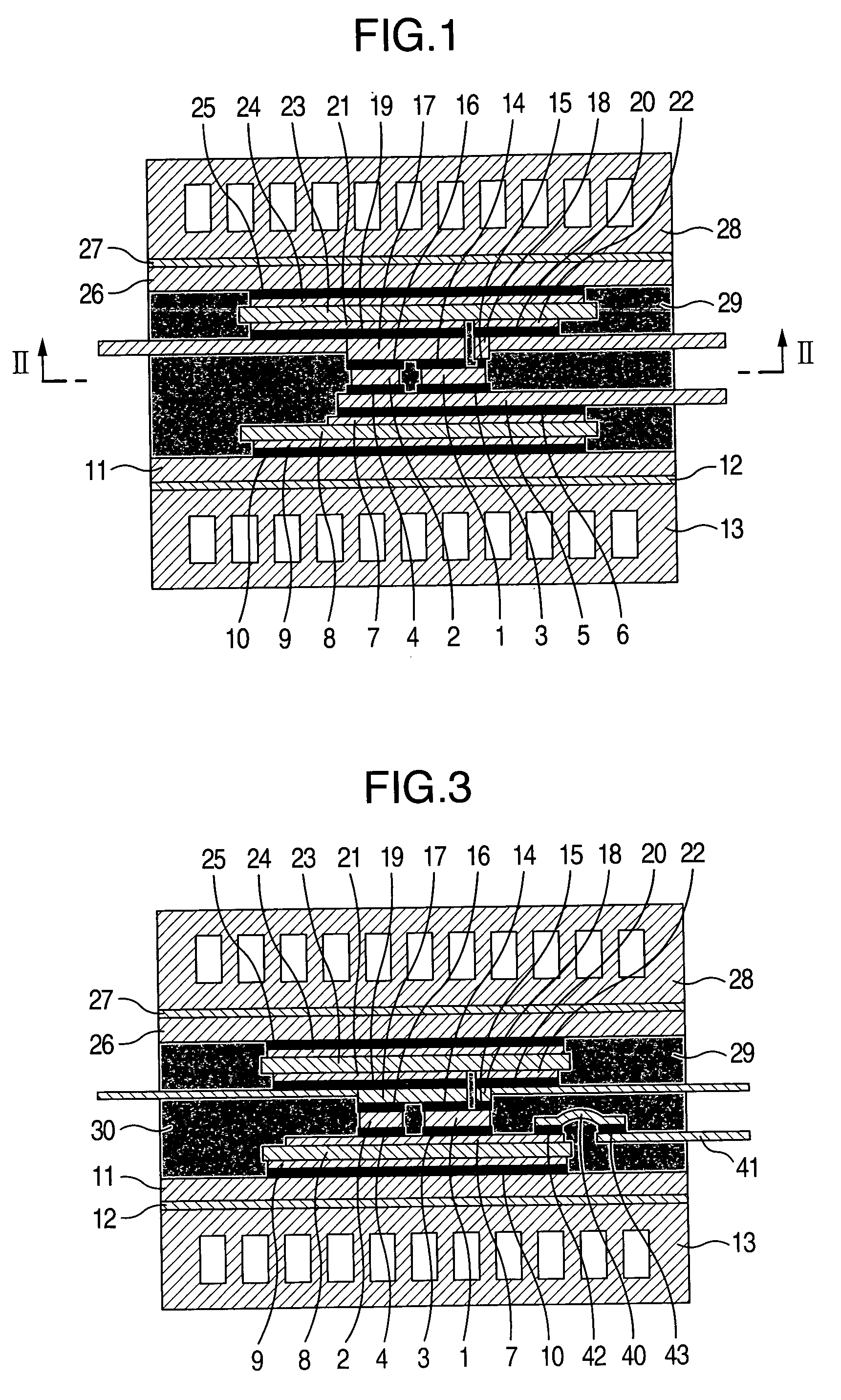

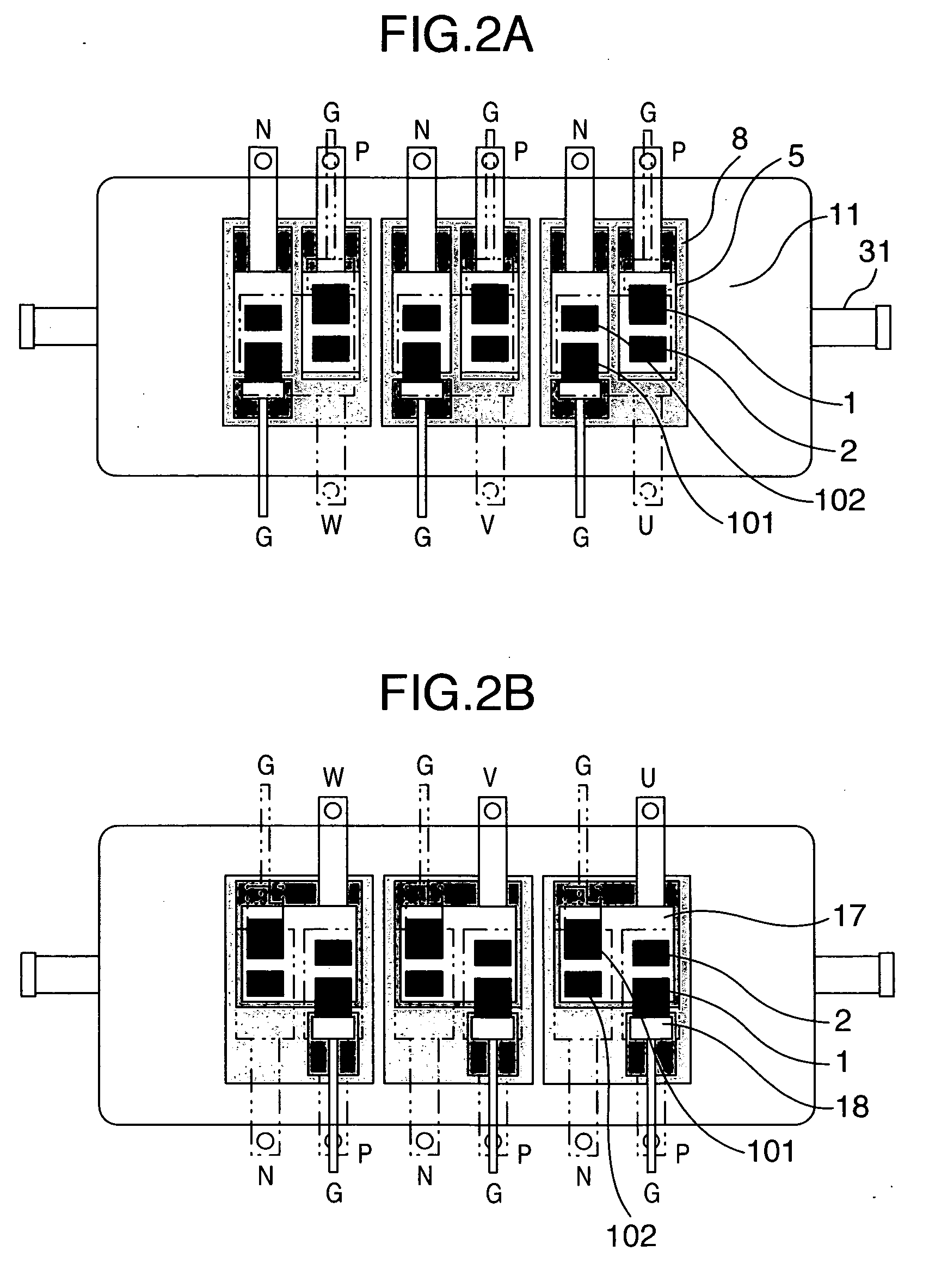

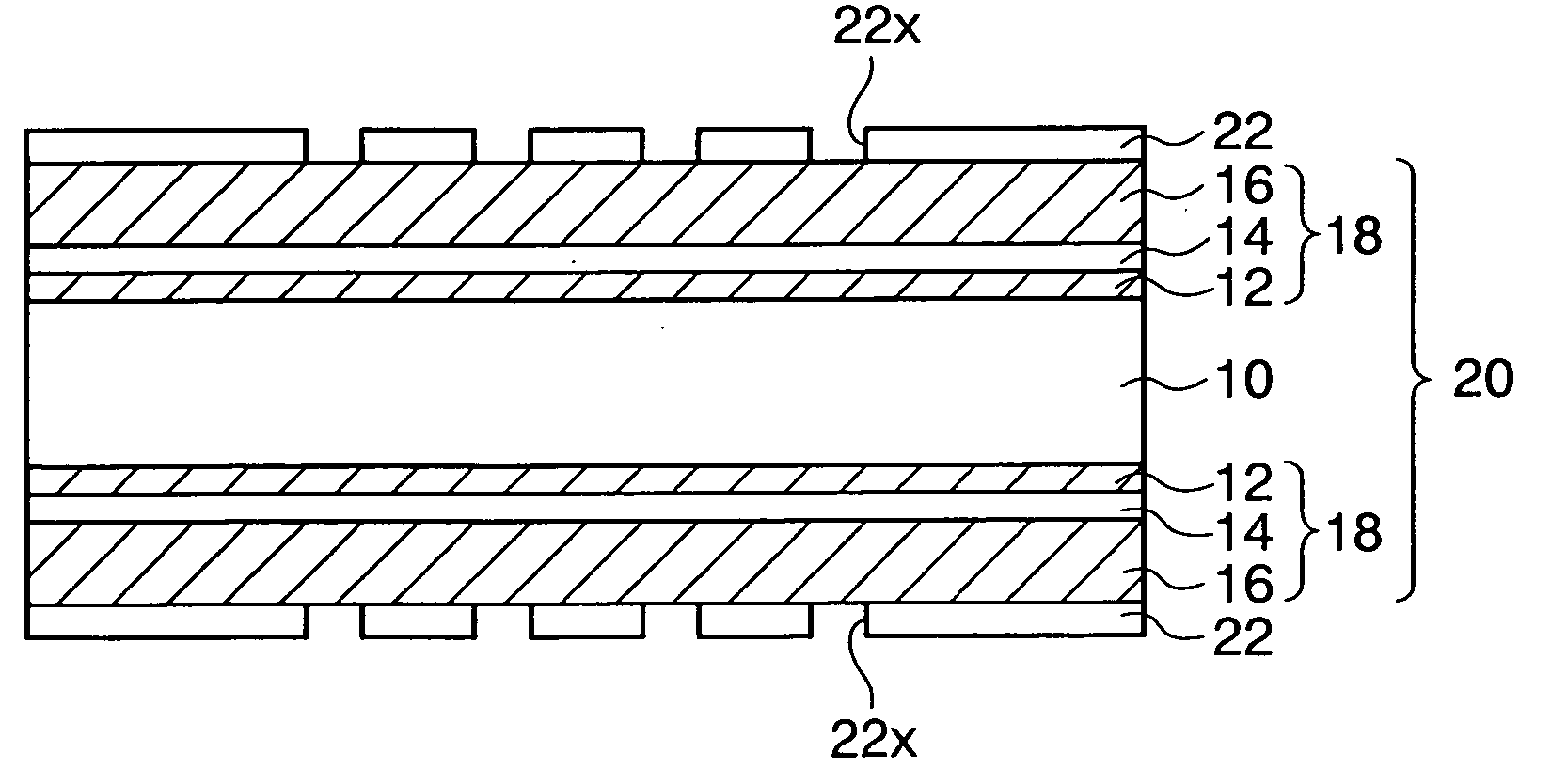

Power semiconductor module

InactiveUS20070216013A1Minimize powerIncreased reliability against thermal fatigueSemiconductor/solid-state device detailsSolid-state devicesMetallic foilThermal fatigue

A power semiconductor module having an increased reliability against thermal fatigue includes a power semiconductor element, a lower-side electrode connected to the lower side of the element, a first insulating substrate connected to the upper side of the lower-side electrode and having metallic foils bonded on both surfaces thereof, an upper-side electrode connected to the upper side of the power semiconductor element, a second insulating substrate connected to the upper side of the upper-side electrode and having metallic foils bonded on both surfaces thereof, a first heat spreader connected to the lower side of the first insulating substrate, and a second heat spreader connected to the upper side of the second insulating substrate. The power semiconductor element and the first and second insulating substrates are sealed with a resin.

Owner:HITACHI LTD

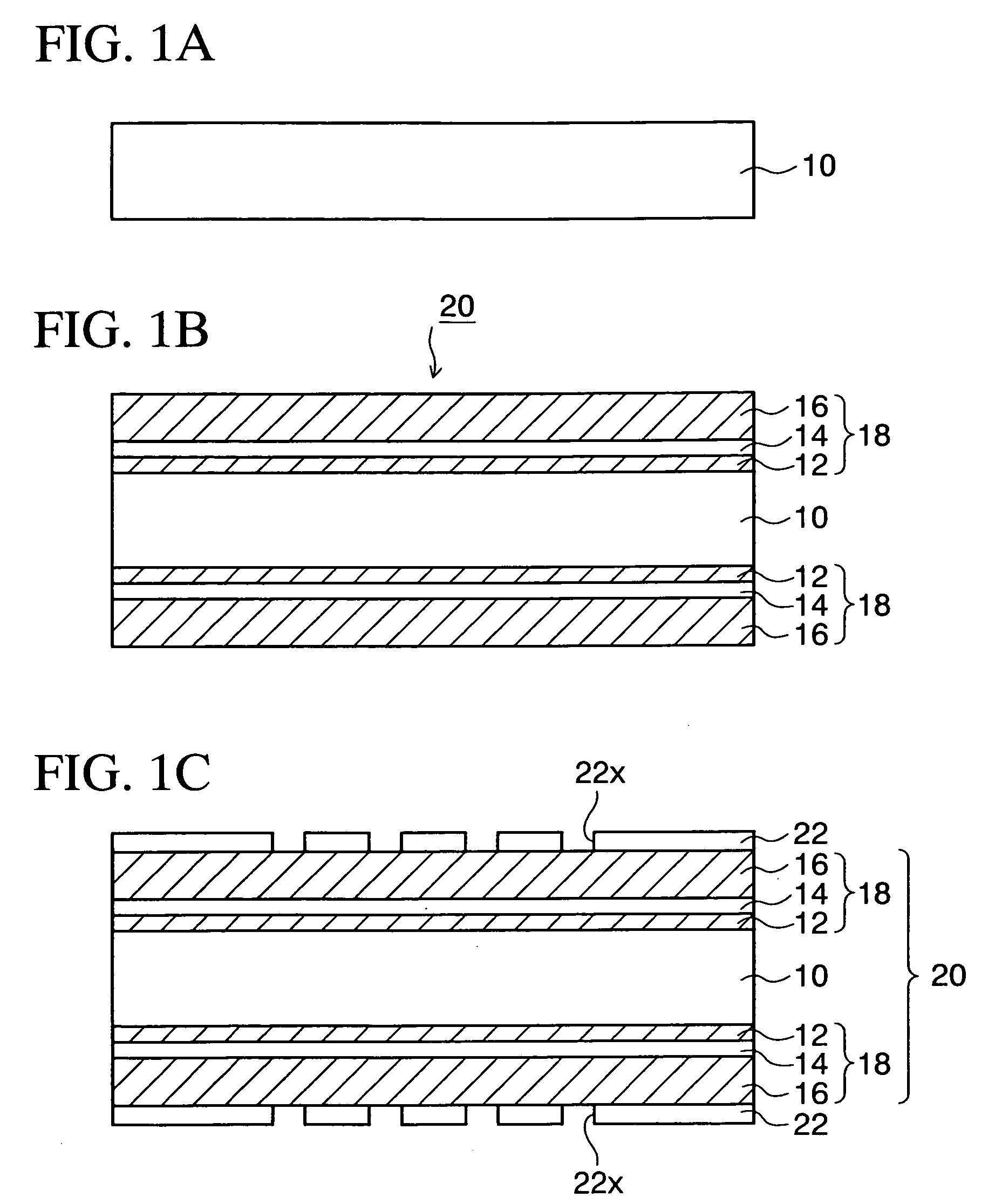

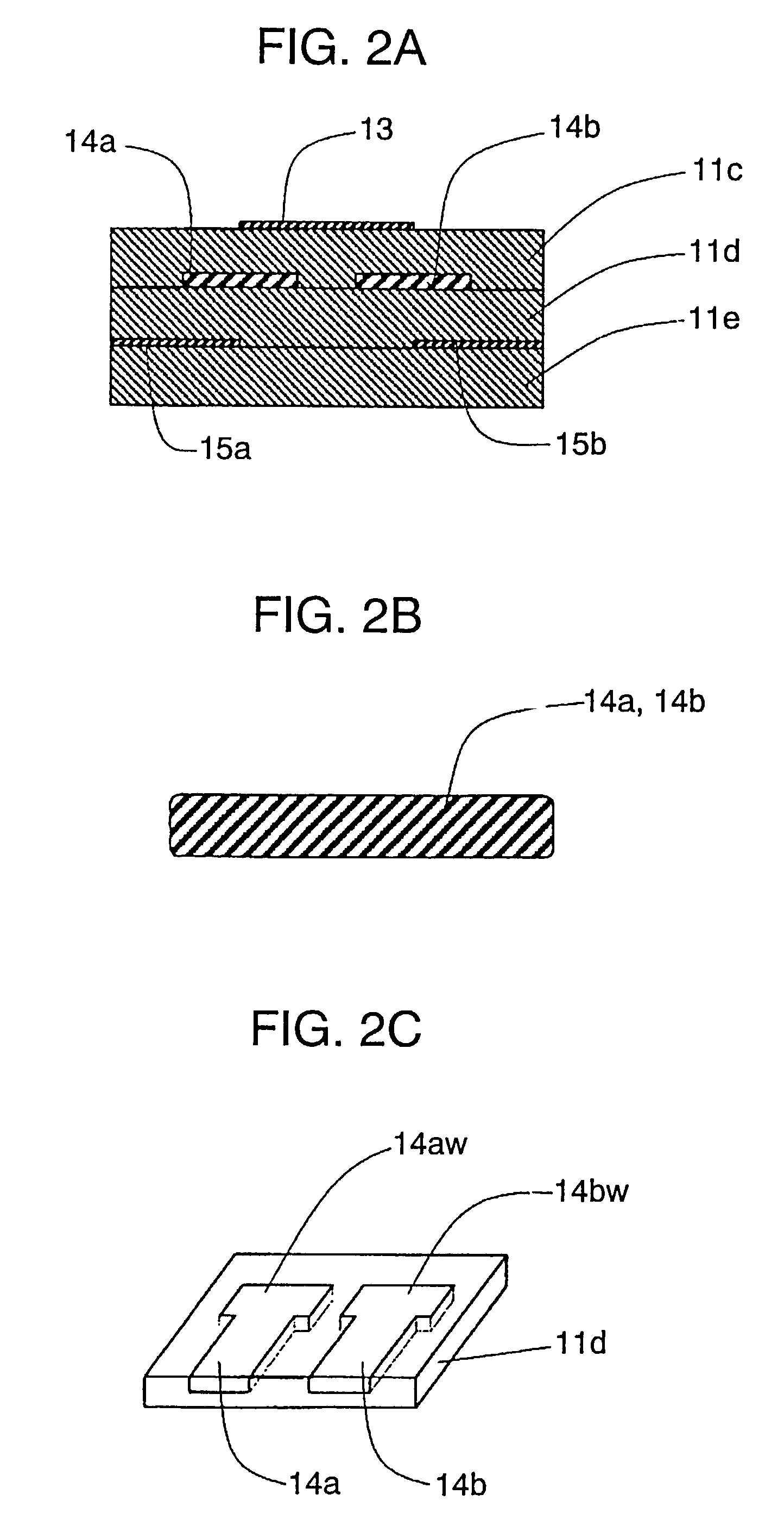

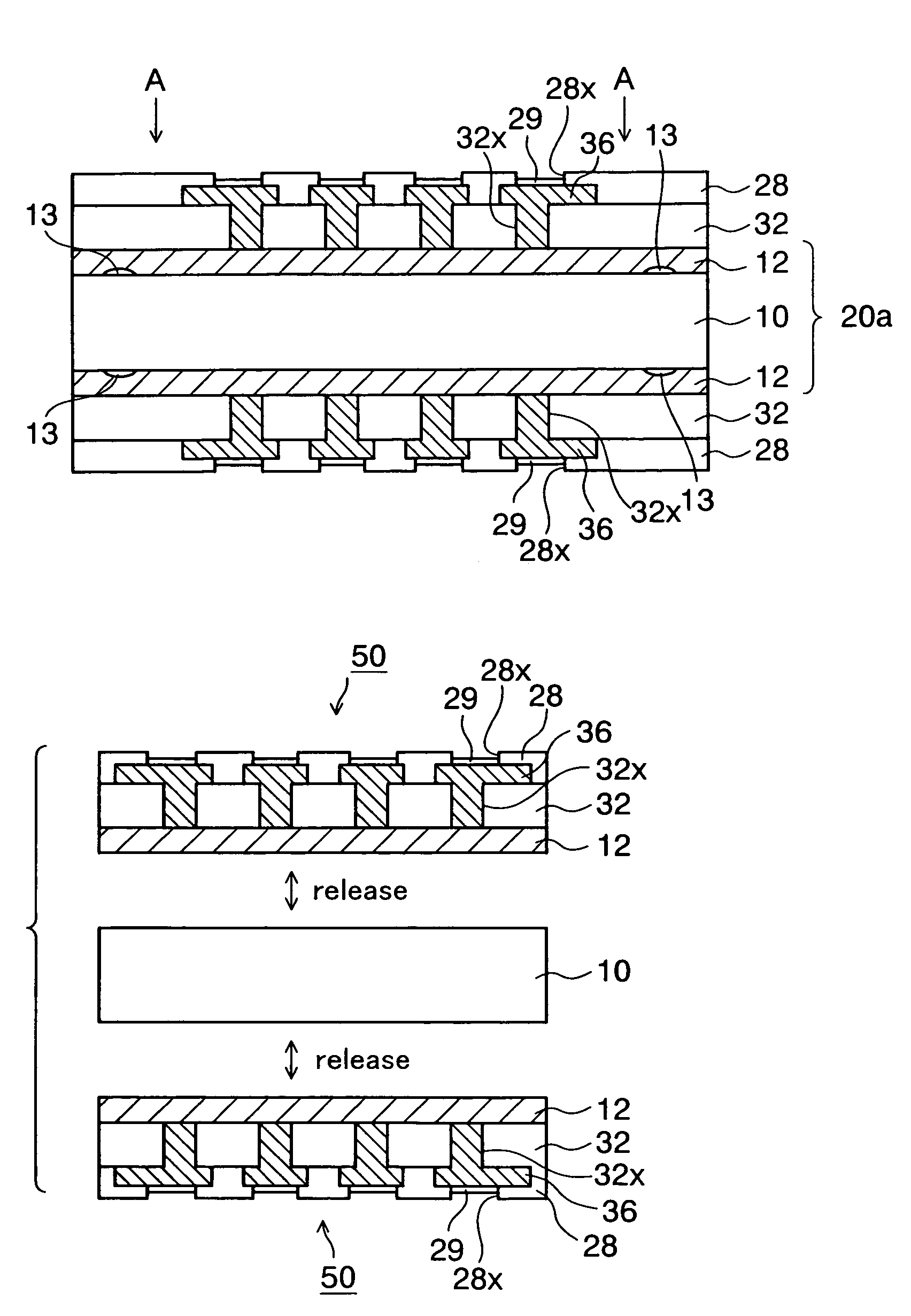

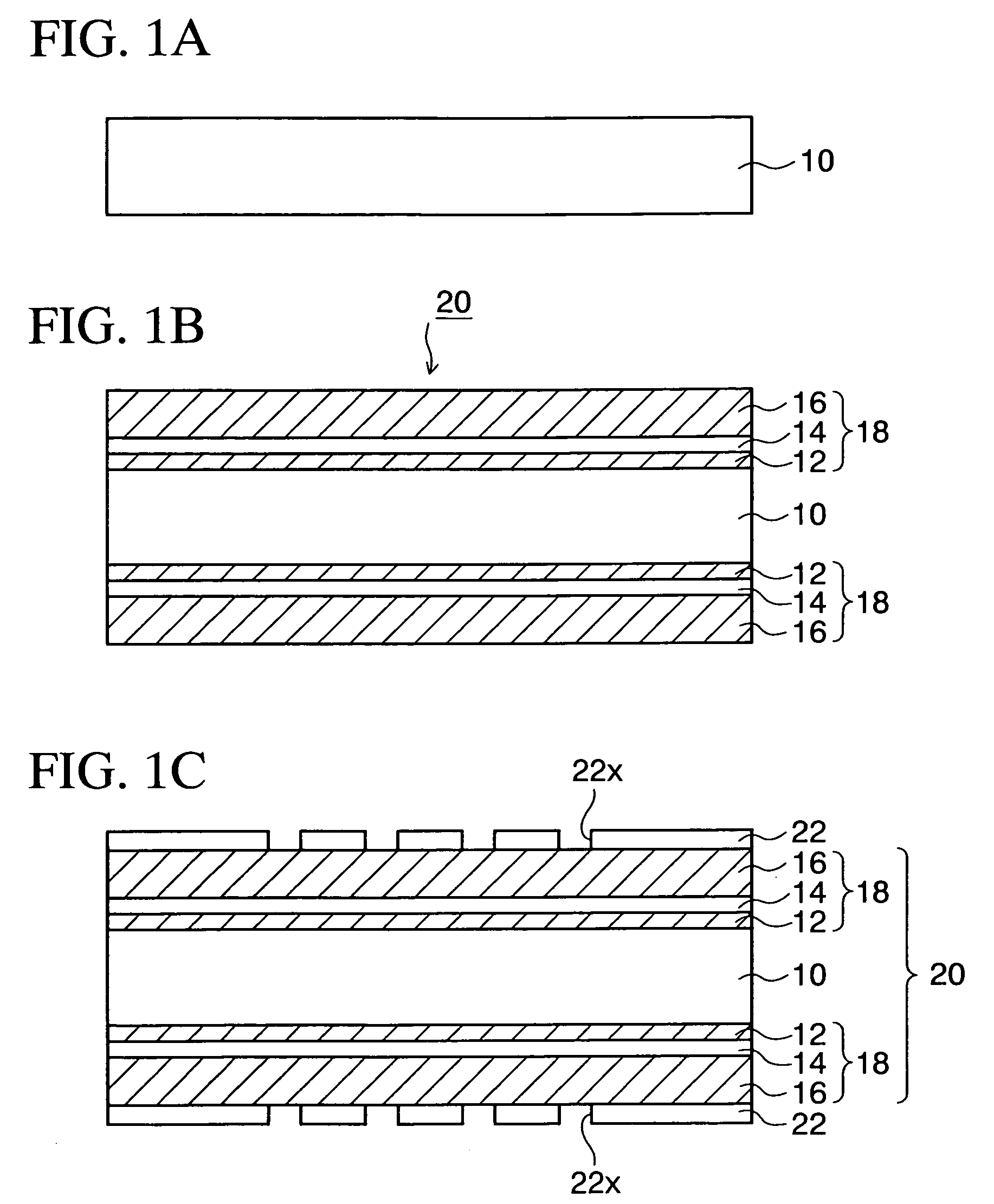

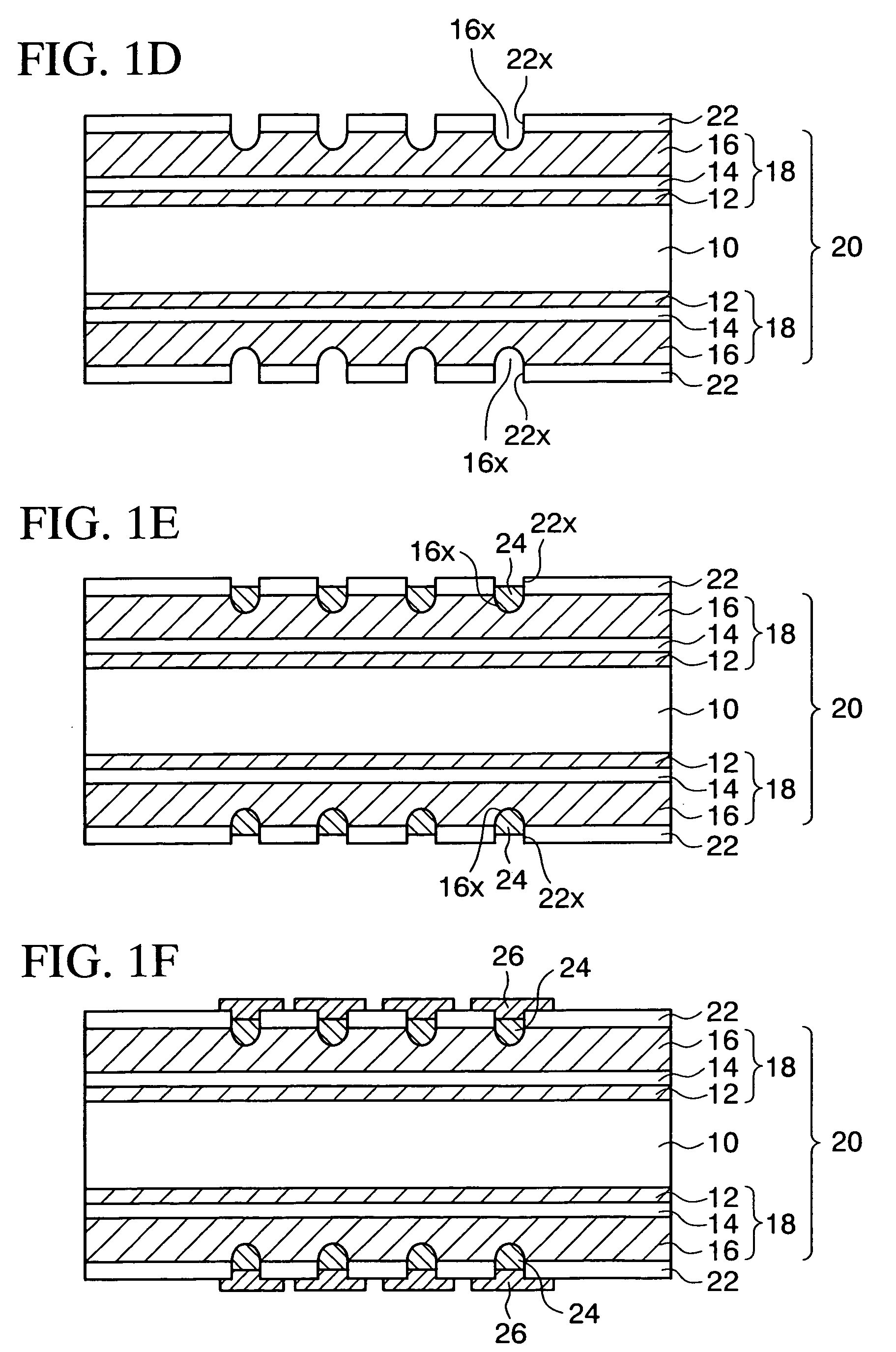

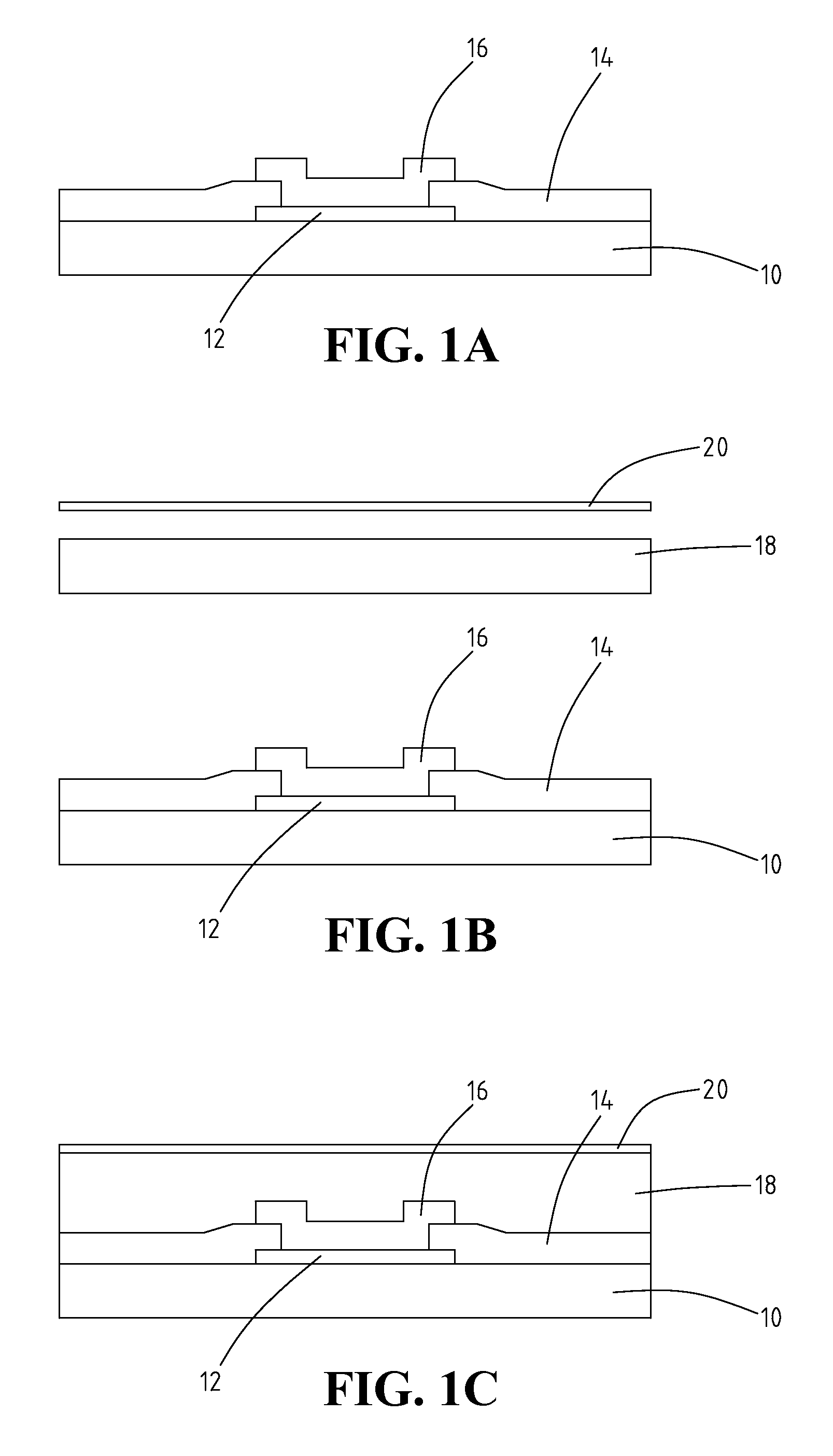

Circuit substrate manufacturing method

ActiveUS20050155222A1Improve workabilityLow costPaper/cardboard articlesLaminating printed circuit boardsMetallic foilOptoelectronics

A circuit substrate manufacturing method of the present invention includes the steps of preparing a substrate on which a metallic foil made of a first metal (copper) is formed in a releasable state, forming a build-up wiring including a metal layer made of a second metal (solder) on the metallic foil, obtaining a circuit member having a structure that the build-up wiring is formed on the metallic foil by releasing the metallic foil from the substrate, and exposing the metal layer by removing selectively the metallic foil of the circuit member with respect to the metal layer.

Owner:SHINKO ELECTRIC IND CO LTD

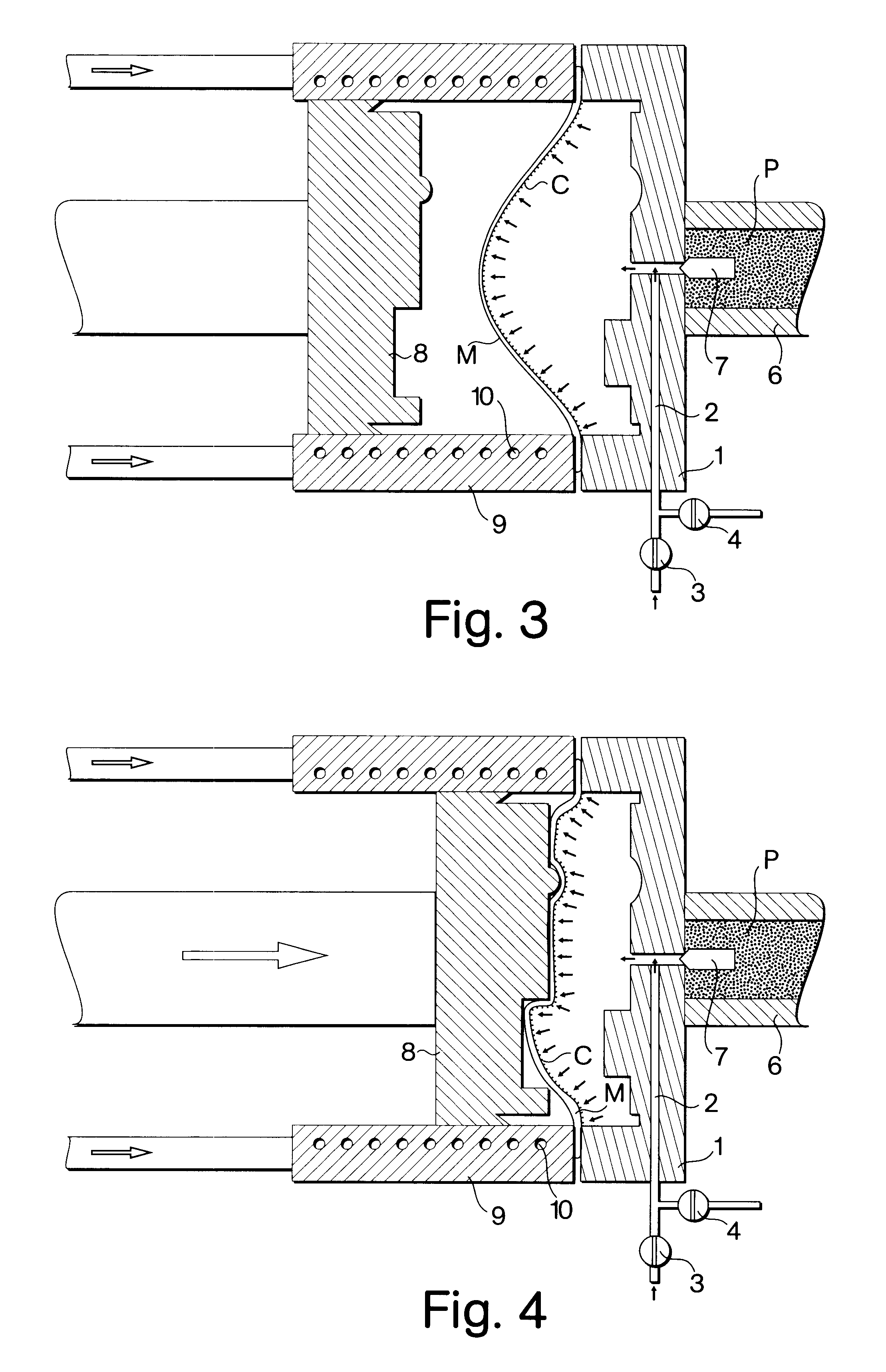

Process for manufacturing an electromagnetic interference shielding metallic foil cladded plastic product

The present invention provides a process and apparatus for manufacturing an electromagnetic interference shielding metallic foil cladded plastic product. The process comprises (a) coating one side of a superplastic alloy plate with a coupling agent or a hot melt adhesive; (b) placing the coupling agent- or hot melt adhesive-coated superplastic alloy plate in a mold, and superplastically forming the superplastic alloy plate to a superplastic alloy foil with a predetermined shape, such that another side of the superplastic alloy foil is attached to the mold and the coupling agent- or hot melt adhesive-coated side of the superplastic alloy foil is spaced apart from the mold to form a mold cavity, wherein an injection machine is attached to the mold cavity, and wherein the injection machine is capable of injecting softened plastic into the mold cavity; (c) introducing softened plastic from the injection machine to the mold cavity, such that plastic adheres on the coupling agent- or hot melt adhesive-coated side of the superplastic alloy foil, and an electromagnetic interference shielding metallic foil cladded plastic product is formed; and (d) removing the plastic product from the mold. The final metallic plastic product can not only have as intricate a shape as an ordinary plastic product, but also has a shielding effectiveness as high as an ordinary metallic shield.

Owner:NAT SCI COUNCIL

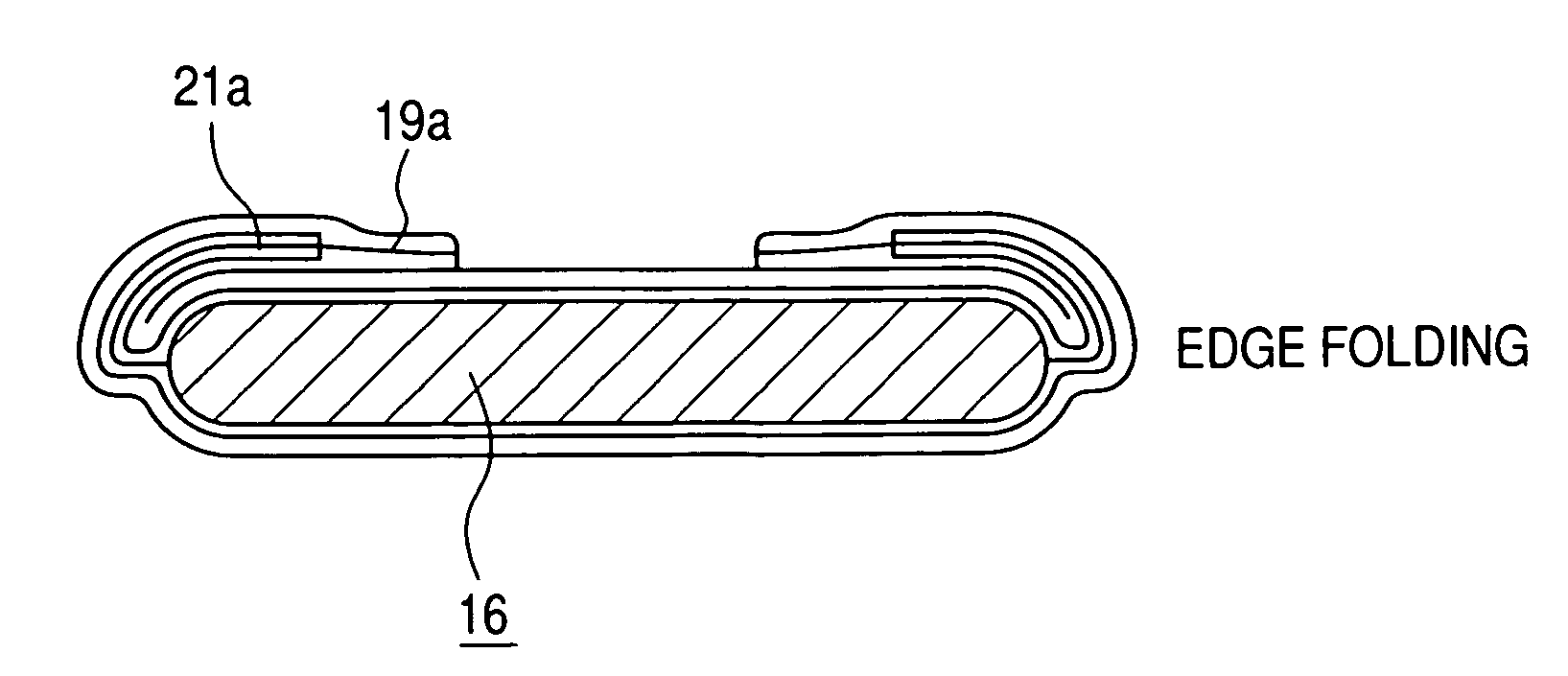

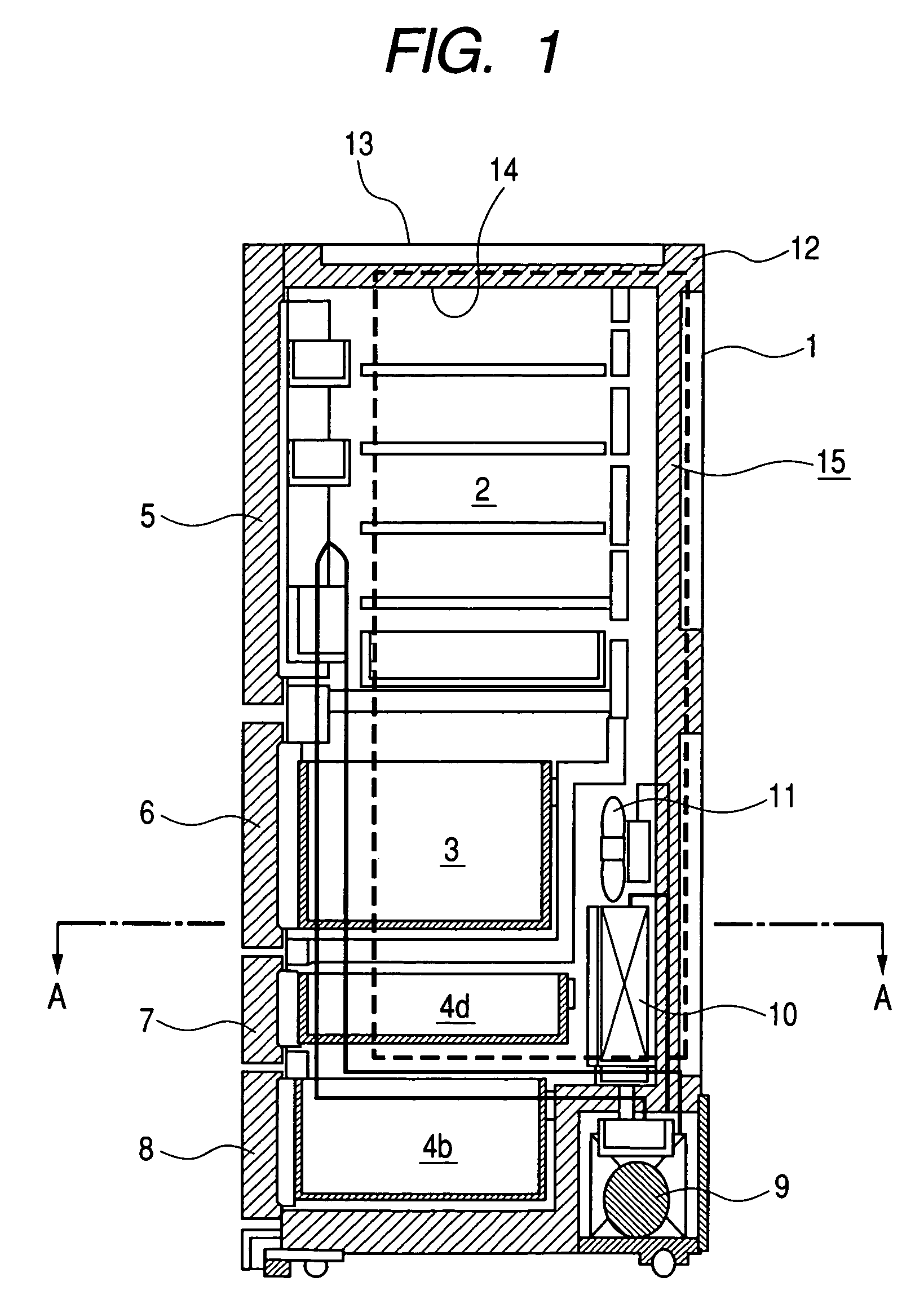

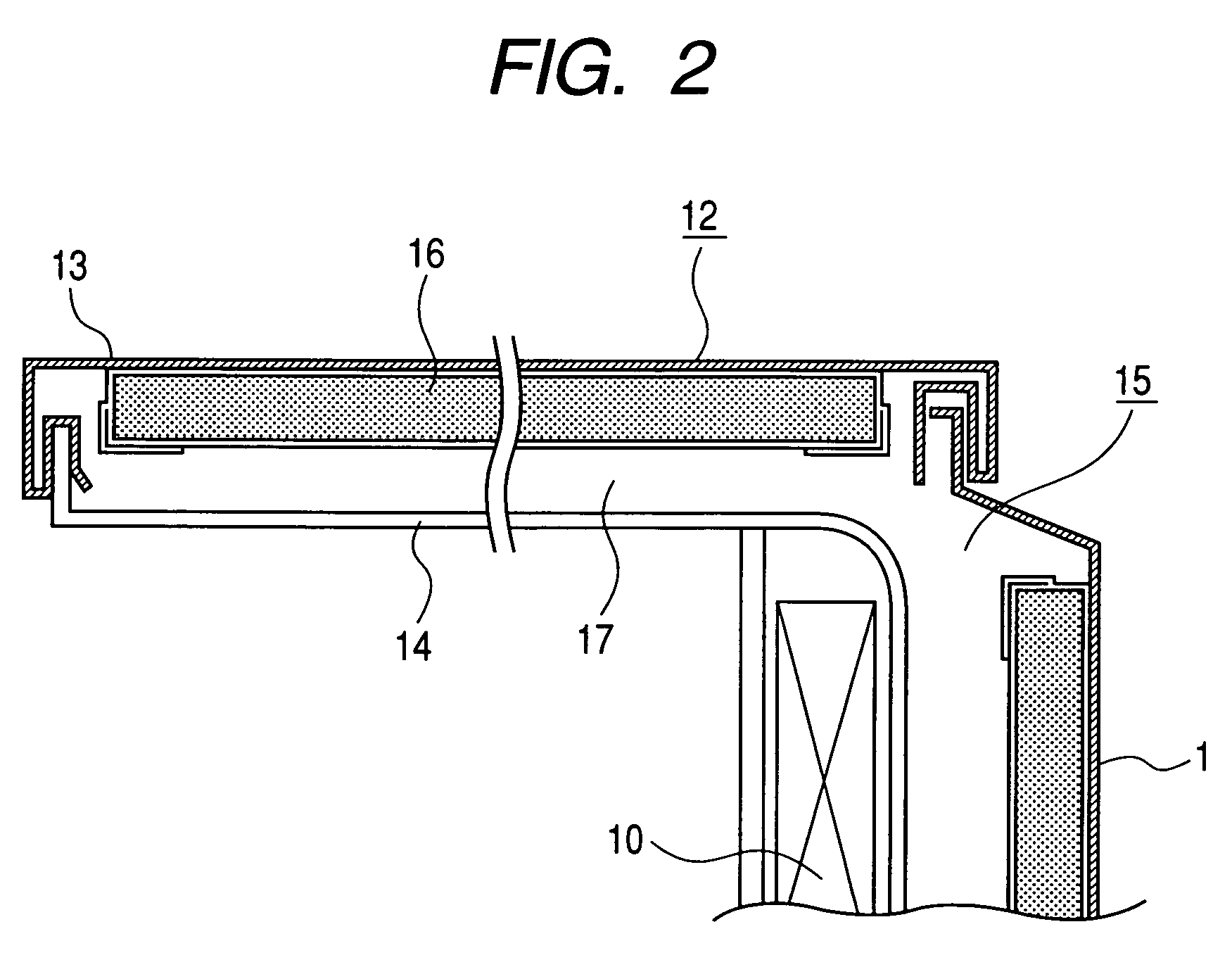

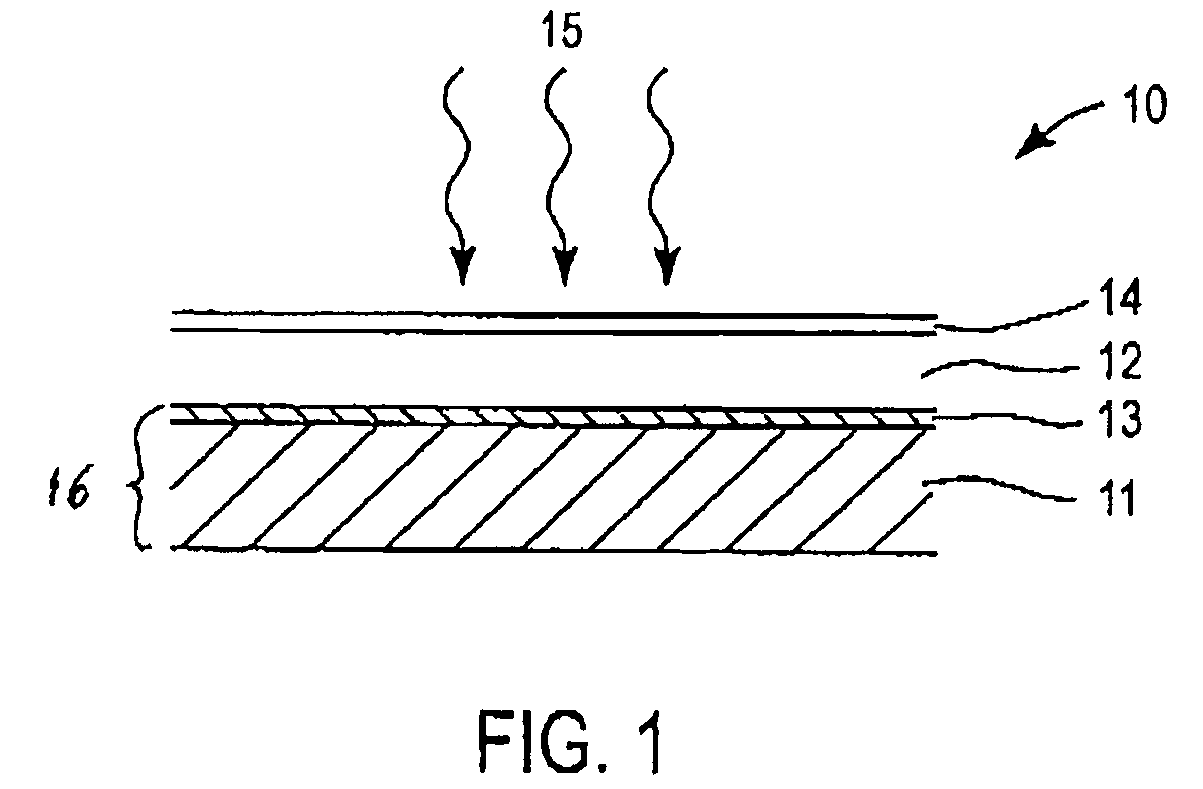

Vacuum insulation panel and refrigerator incorporating the same

InactiveUS7449227B2Reduce heat transferGuaranteed accuracyThermal insulationLayered productsFiberMetallic foil

The invention relates to a vacuum insulation panel which can be used as an insulator for a refrigerator requiring heat insulation to be provided and also to a refrigerator incorporating such a vacuum insulation panel. The invention particularly relates to an arrangement for preventing convection spaces from being formed where an edge of the vacuum insulation panel is folded back. The vacuum insulation panel includes a core which has an inner film bag in which a flexible inorganic fiber laminate is accommodated, and an outer barrier bag which is made of gas-impermeable film such as metallic foil laminated film and which accommodates the core. The inner film bag includes a welded portion and a ventilation portion. The outer barrier bag has a depressurized interior and has been sealed by welding. An edge of the inner film bag is placed in an edge of the outer barrier bag.

Owner:HITACHI APPLIANCES INC

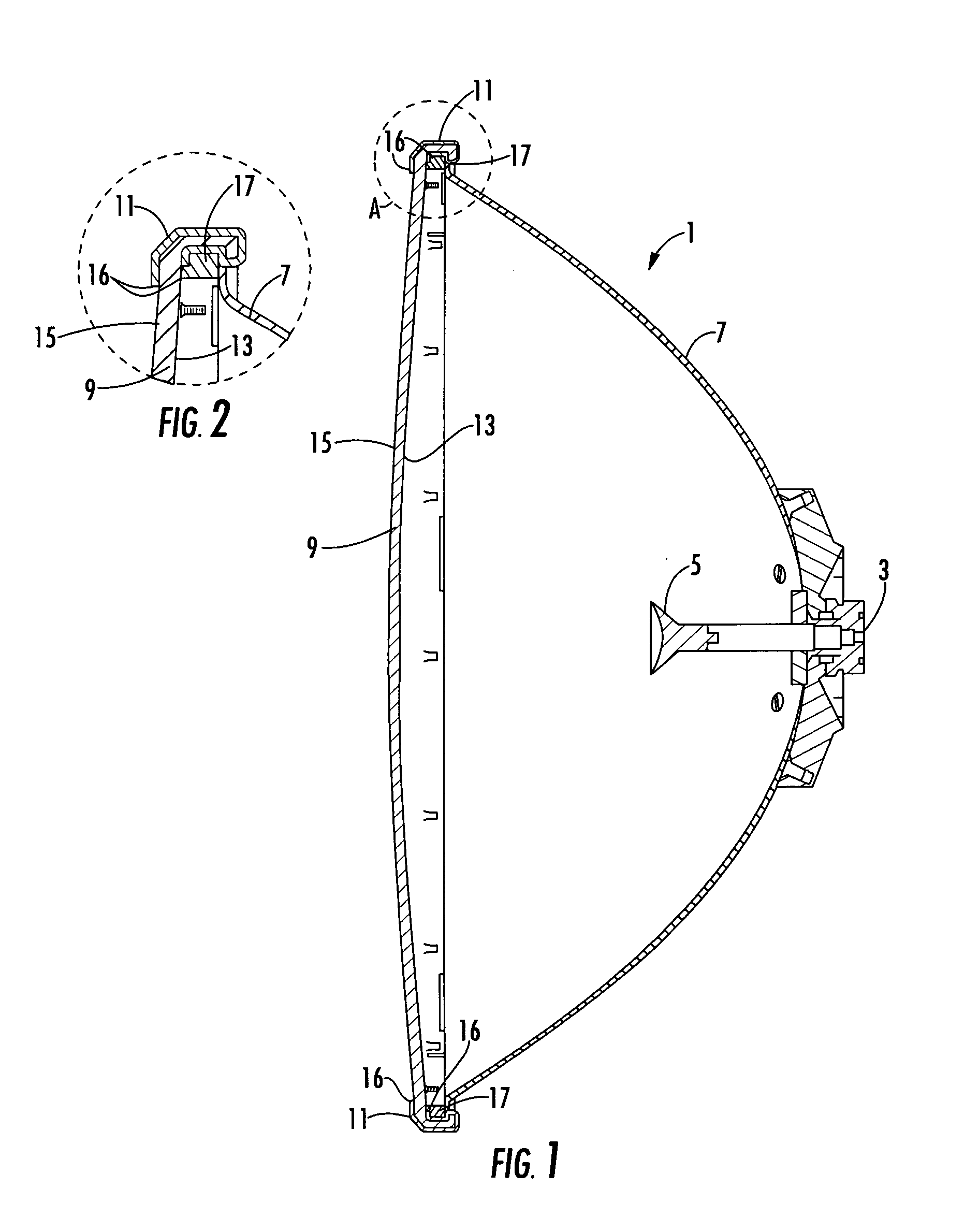

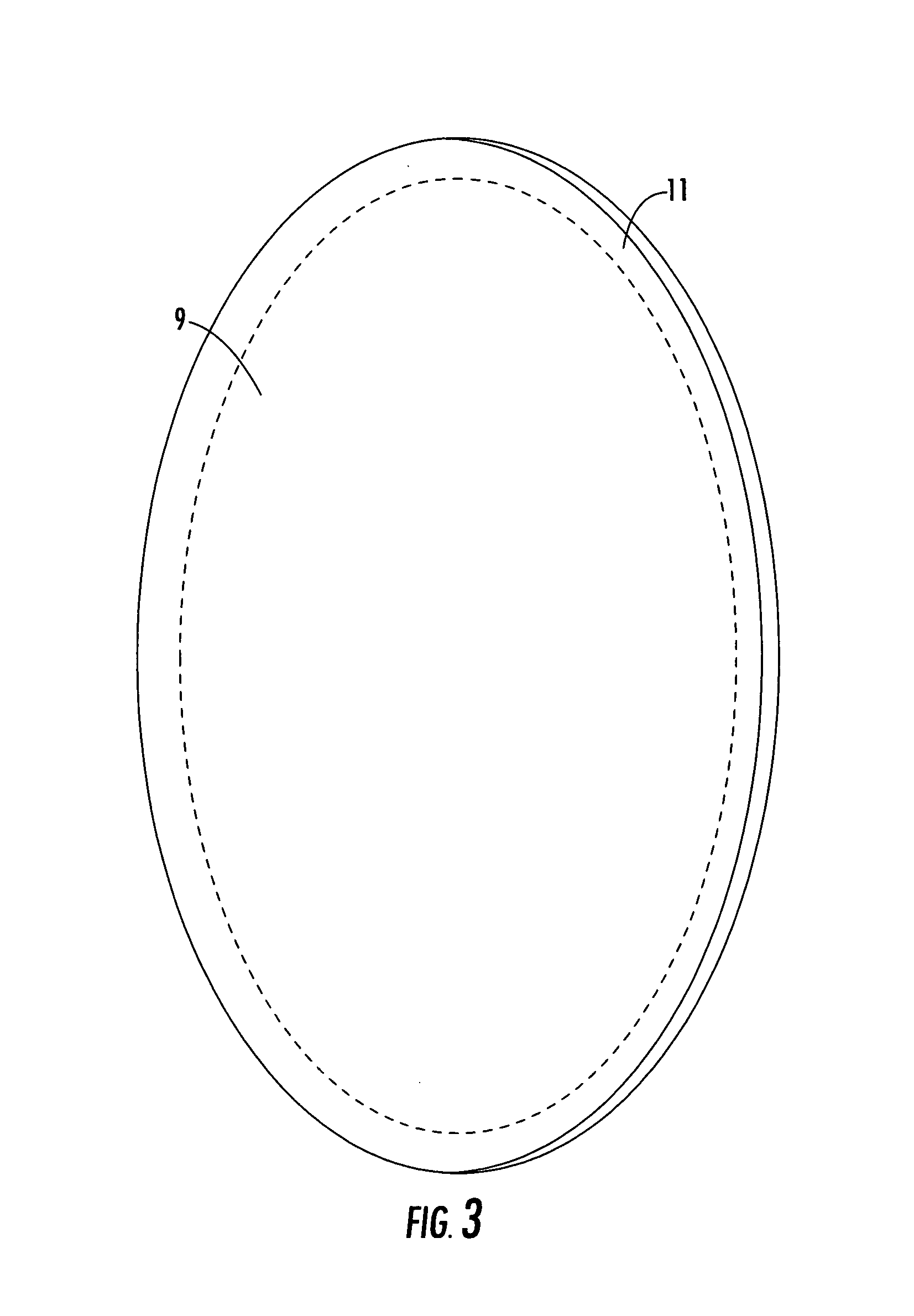

Reflector antenna radome with backlobe suppressor ring and method of manufacturing

A radome adapted to reduce backlobes of an associated reflector antenna via application of a conductive ring with an inward facing edge about the periphery of the radome. The conductive ring may be applied extending around the radome periphery to an inside and or outside surface of the radome. The conductive ring may be formed upon the radome by metalising, electrodaging, over molding or the like. Further, the conductive ring may be a metal, metallic foil, conductive foam or the like which is coupled to the radome. An absorber in the form of a ring or a surface coating applied to the radome and or the distal end of the reflector may also be added between the radome and the reflector.

Owner:COMMSCOPE TECH LLC

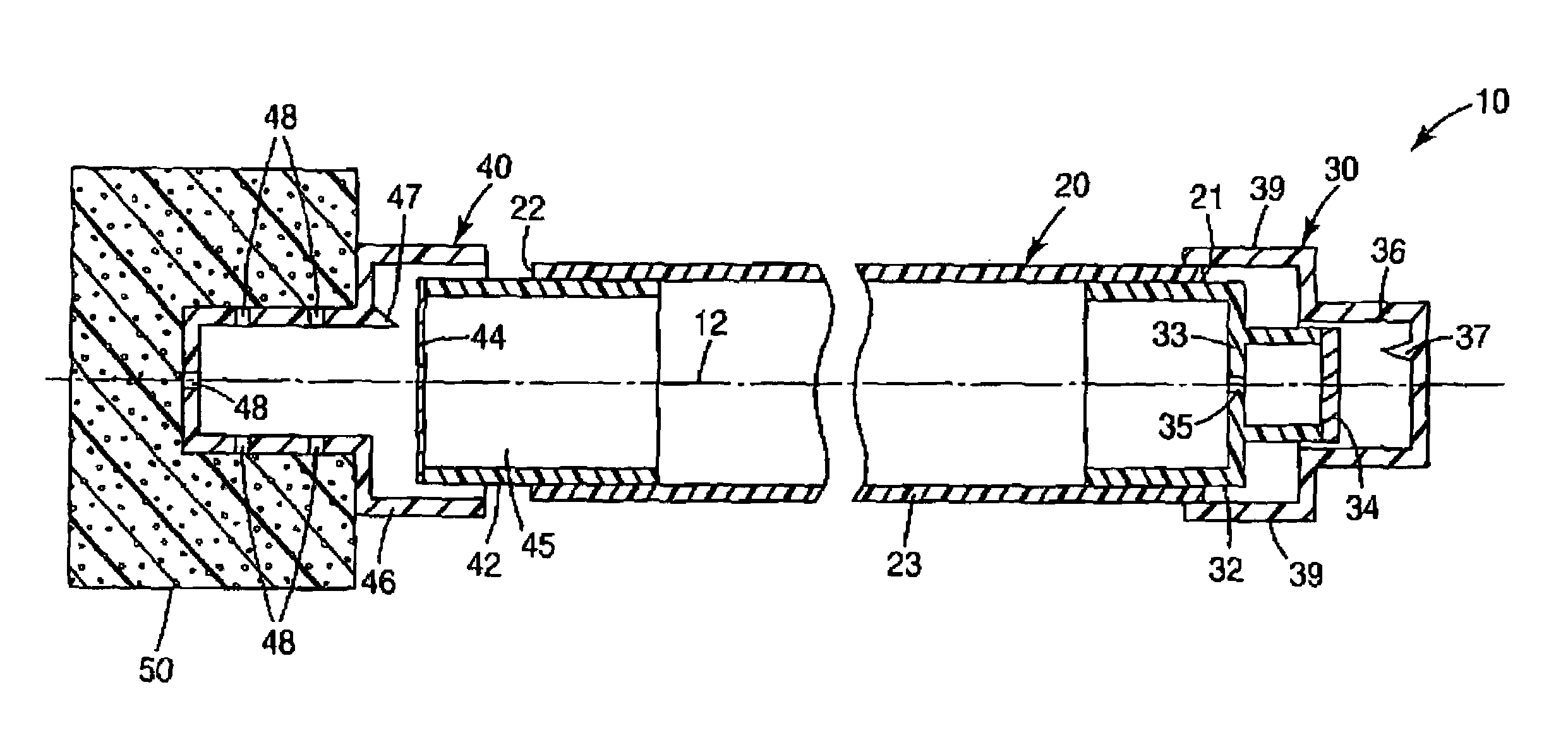

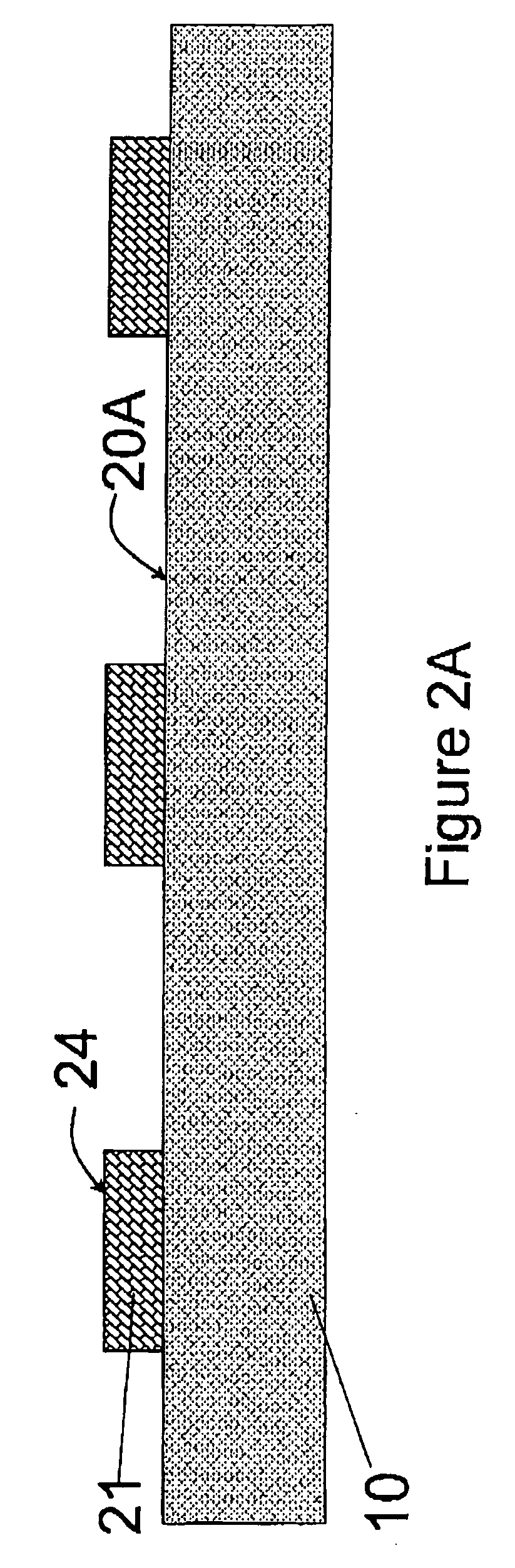

Lightweight cartridge case

Disclosed is an ammunition cartridge case that includes a sleeve, a base fixedly attached to the sleeve and a fiber reinforced polymer composite annulus that is at least partially within the base. In certain embodiments, the sleeve and the base are formed partly or entirely from a metal, for example steel or stainless steel. The base has a central aperture that affords for the annulus ring to fit within. The annulus is dimensioned such that it fits securely within the central aperture of the base and has a center aperture wherein a primer can be located. The annulus ring contains a volume of composite fibers ranging from 10 to 90 volume percent. The annulus isolates the primer from the cartridge case and thereby prevents galvanic corrosion between the primer and case. In addition, a metallic foil can be present between the annulus and the cartridge case in order to assure proper securement of the annulus therewithin.

Owner:ARMY US SEC THE THE

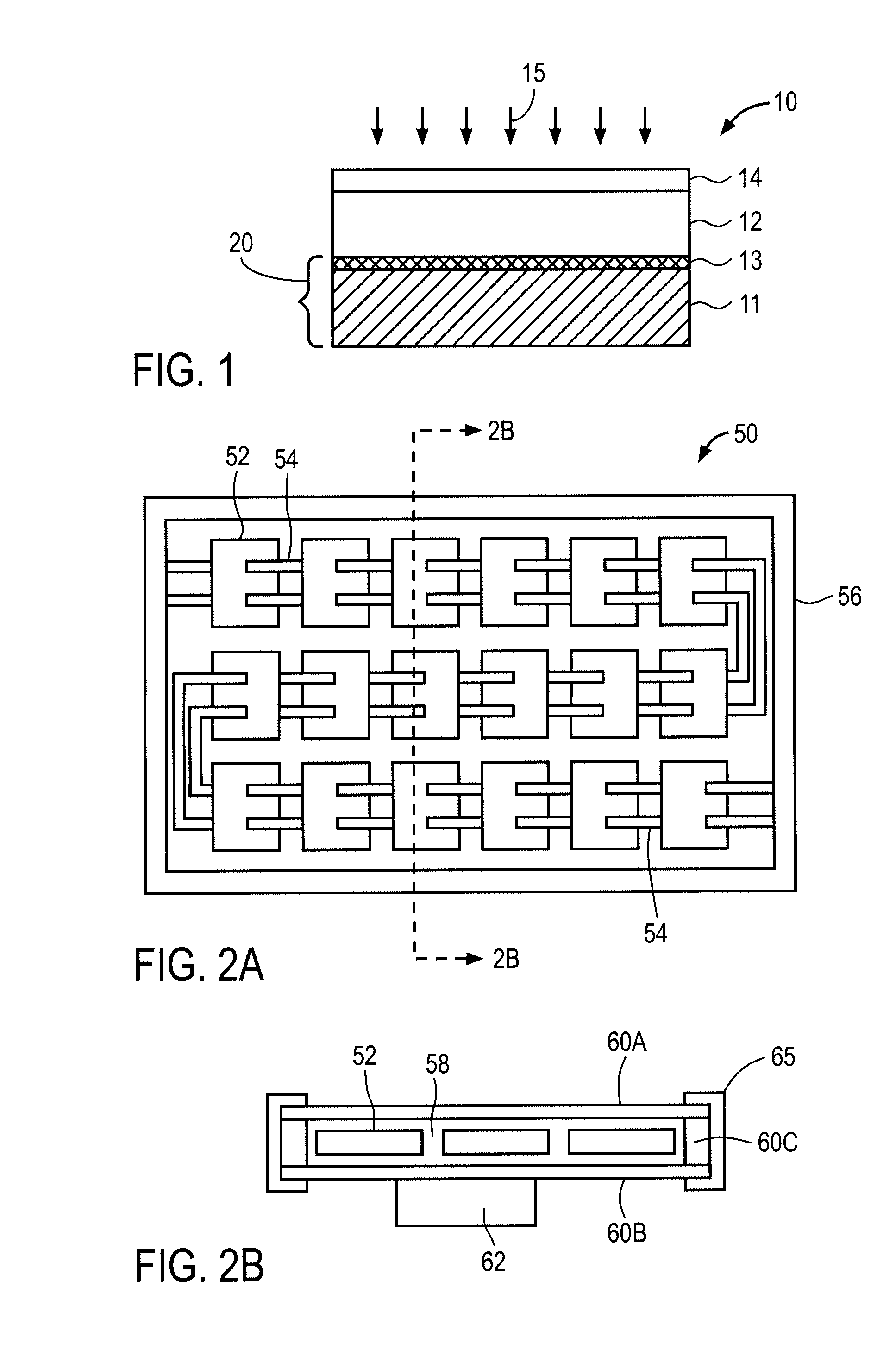

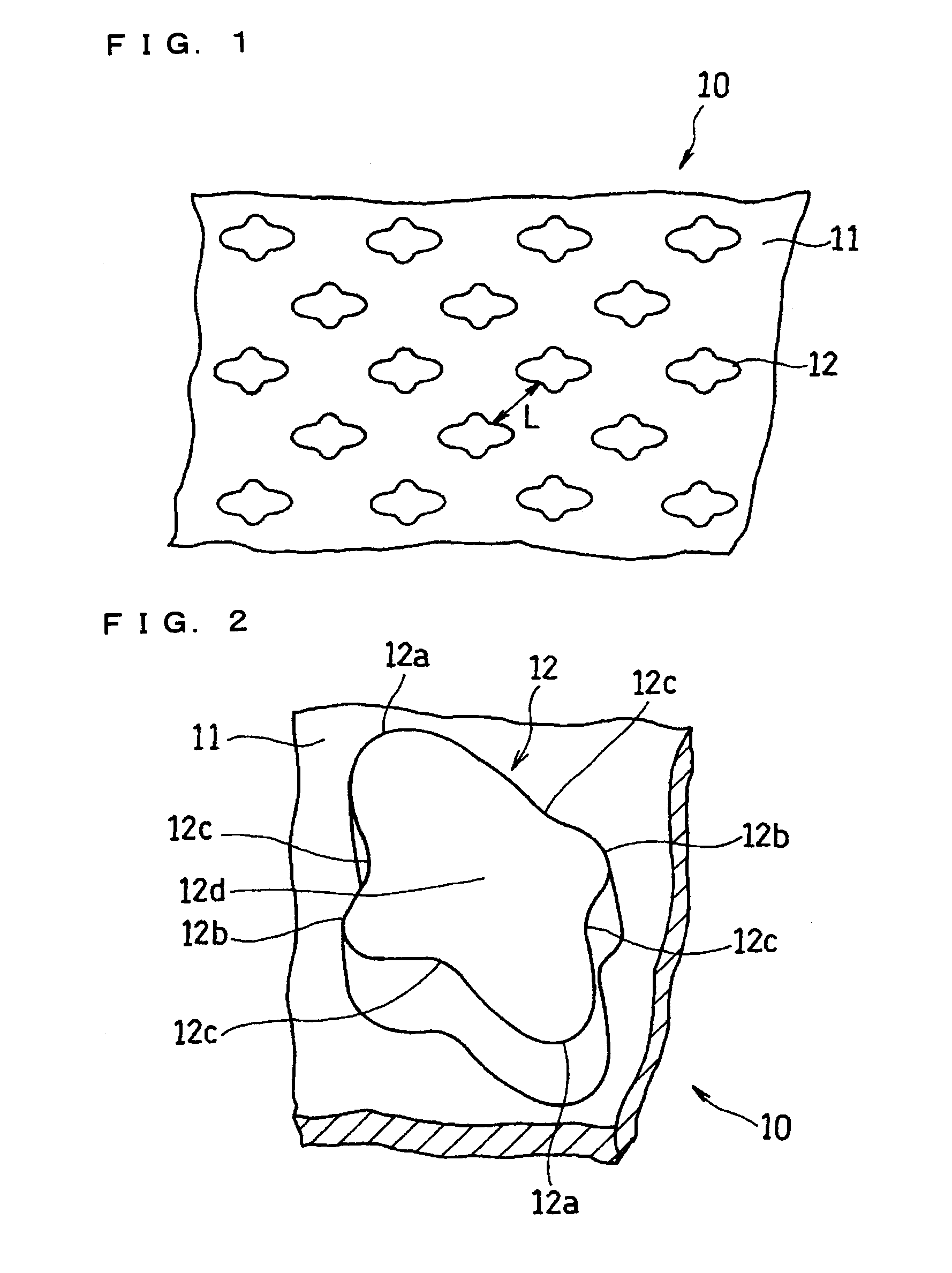

Current collector for non-aqueous electrolyte secondary battery, electrode for non-aqueous electrolyte secondary battery, production methods thereof, and non-aqueous electrolyte secondary battery

InactiveUS20110111277A1Increase flexibilityAvoid problemsFinal product manufactureElectrode carriers/collectorsMetal foilEngineering

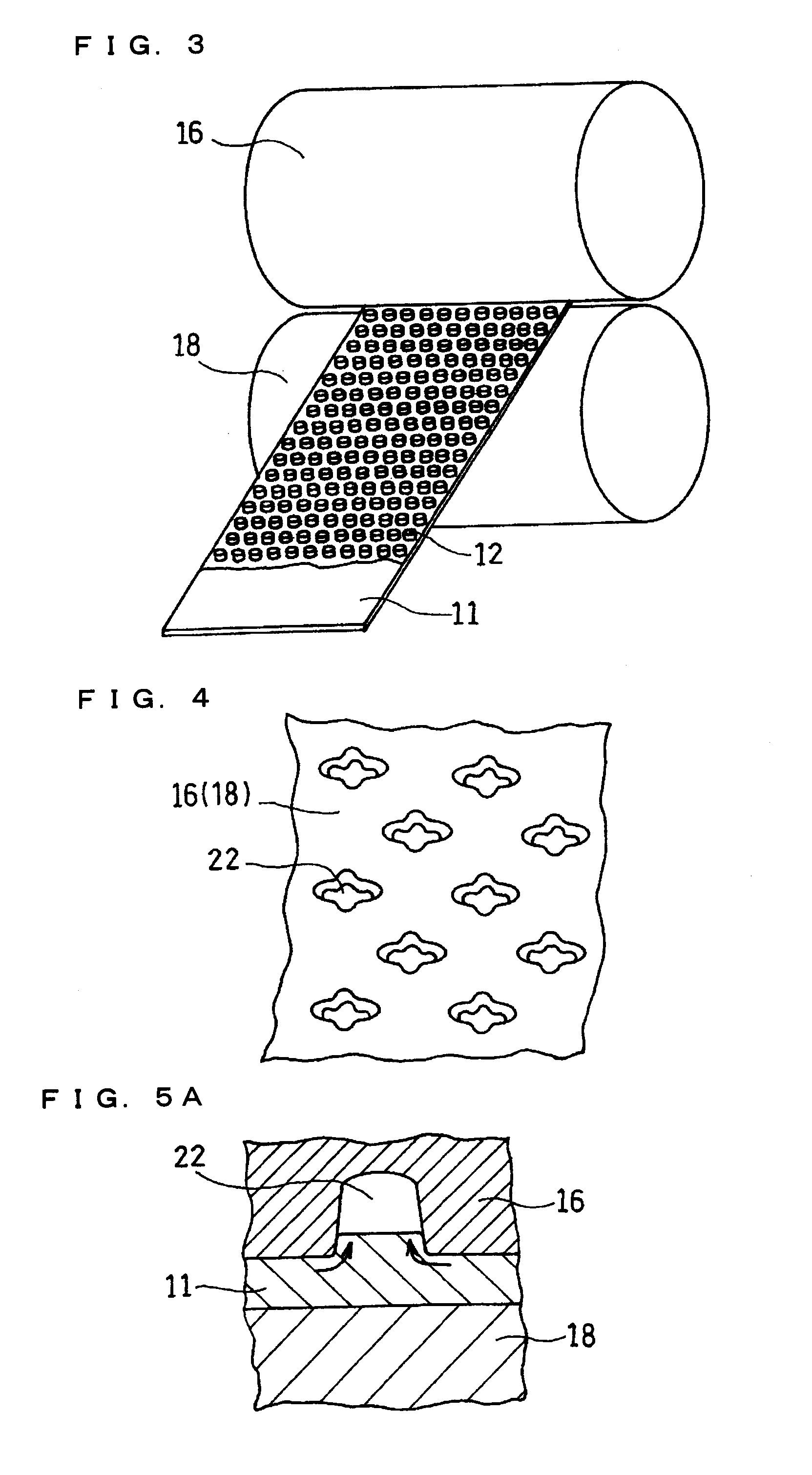

A current collector includes a metal foil and protrusions formed on one face or both faces of the metal foil in a predetermined arrangement. The protrusions are substantially rhombic and aligned in a zigzag. Also, both end portions of each protrusion in each of two orthogonal axial directions protrude outward. Middle portions between the end portions are recessed inward. When columnar blocks of an active material are formed on the protrusions to form an active material layer, the gaps between the protrusions can be increased at portions where the interval between the protrusions is the smallest. As a result, internal stress of the active material layer created by charge / discharge of the battery can be alleviated, and the battery life can be increased.

Owner:PANASONIC CORP

Electrothermal interface material enhancer

InactiveUS20080236804A1Envelopes/bags making machineryMaterial nanotechnologyMetallic foilCarbon nanotube

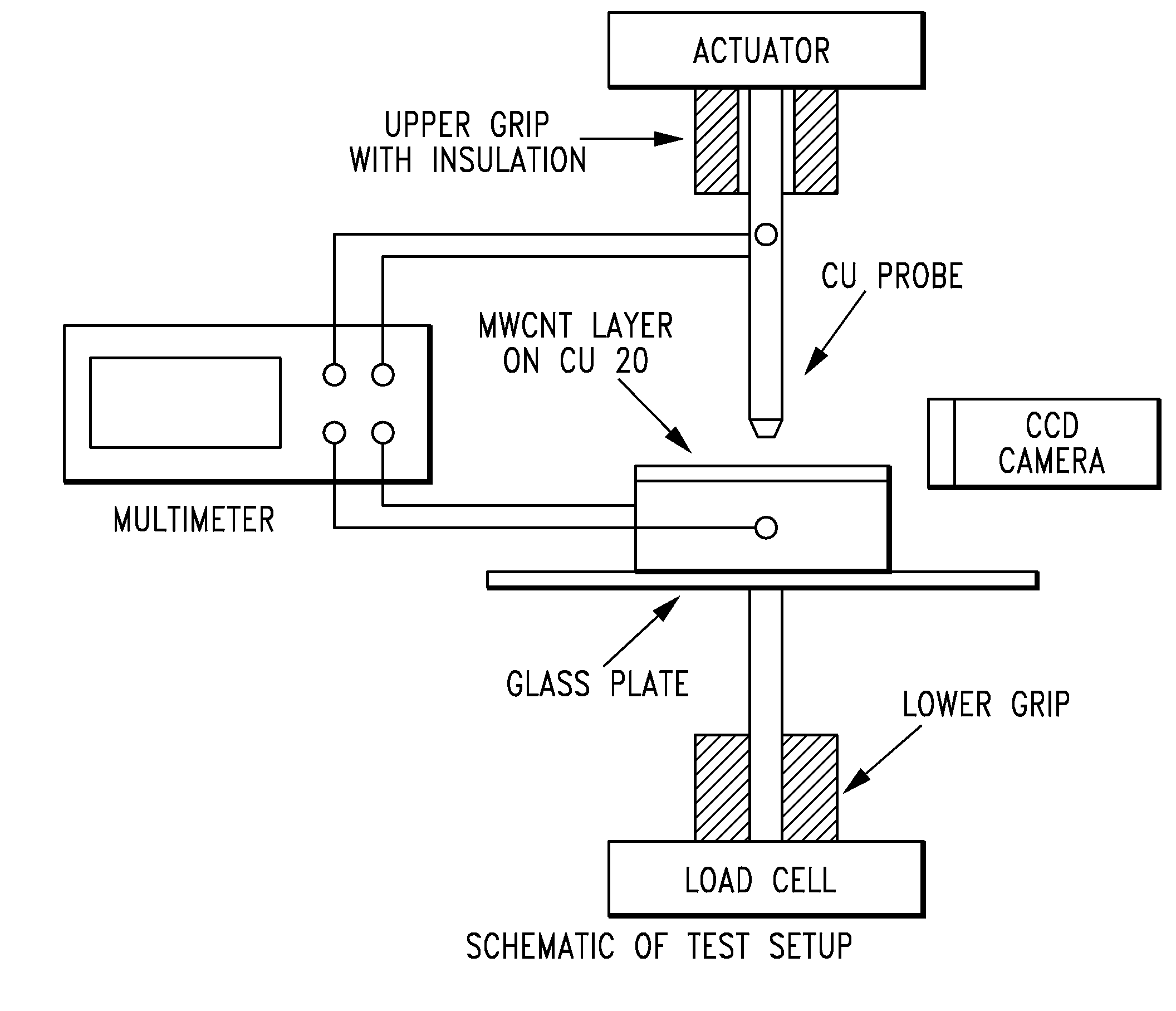

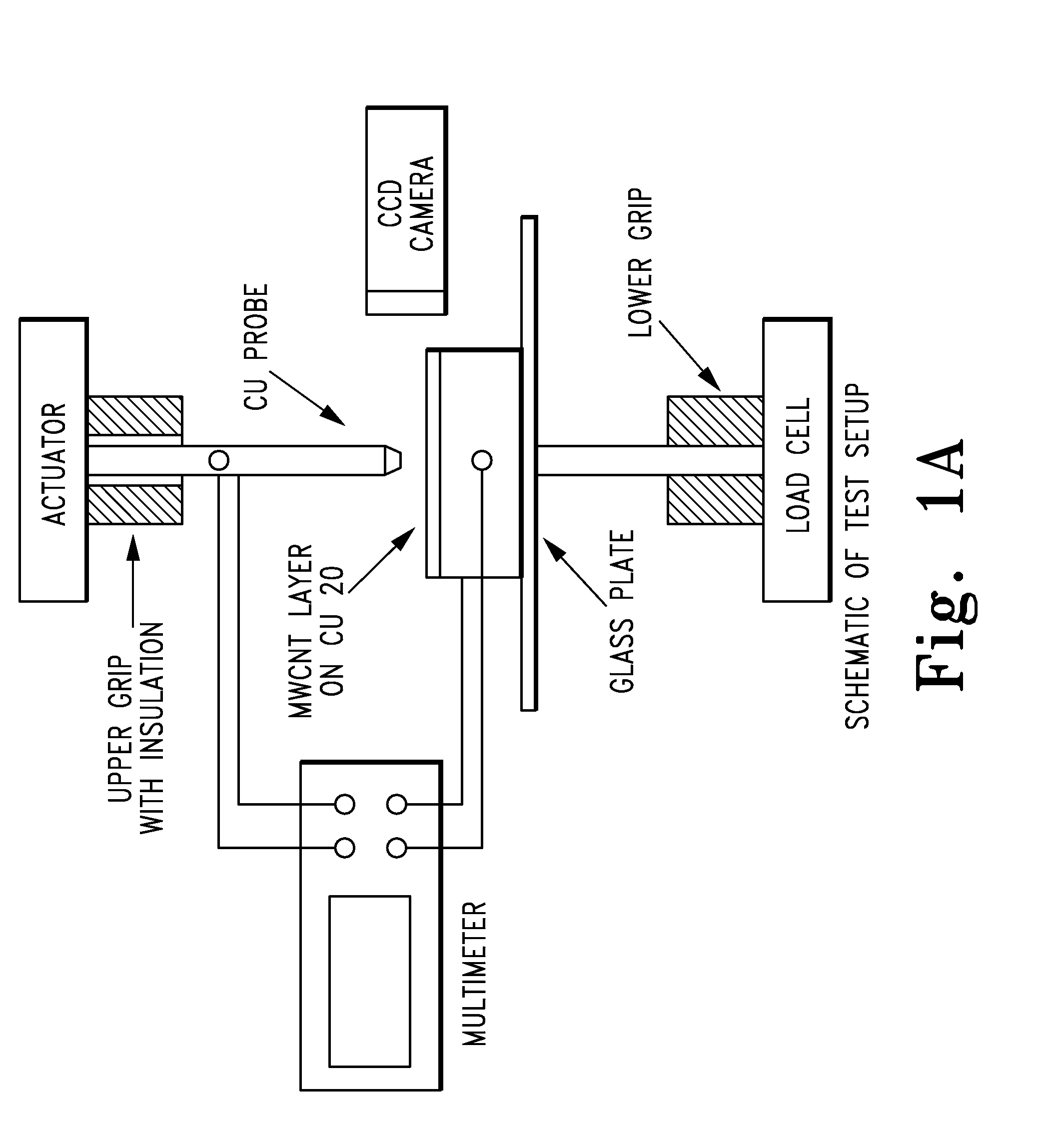

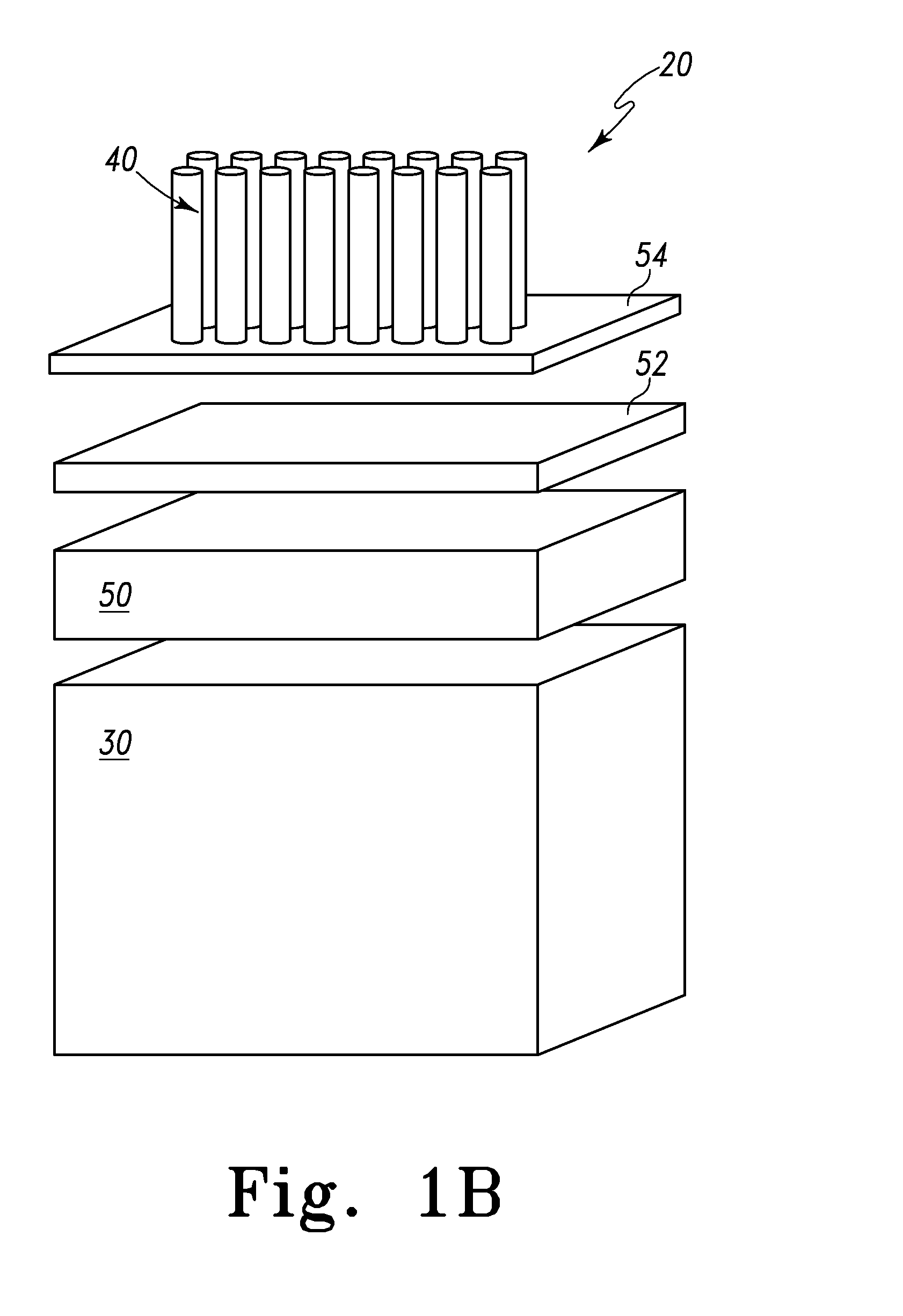

Vertically oriented carbon nanotubes (CNT) arrays have been simultaneously synthesized at relatively low growth temperatures (i.e., <700° C.) on both sides of aluminum foil via plasma enhanced chemical vapor deposition. The resulting CNT arrays were highly dense, and the average CNT diameter in the arrays was approximately 10 nm, A CNT TIM that consist of CNT arrays directly and simultaneously synthesized on both sides of aluminum foil has been fabricated. The TIM is insertable and allows temperature sensitive and / or rough substrates to be interfaced by highly conductive and conformable CNT arrays. The use of metallic foil is economical and may prove favorable in manufacturing due to its wide use.

Owner:PURDUE RES FOUND INC

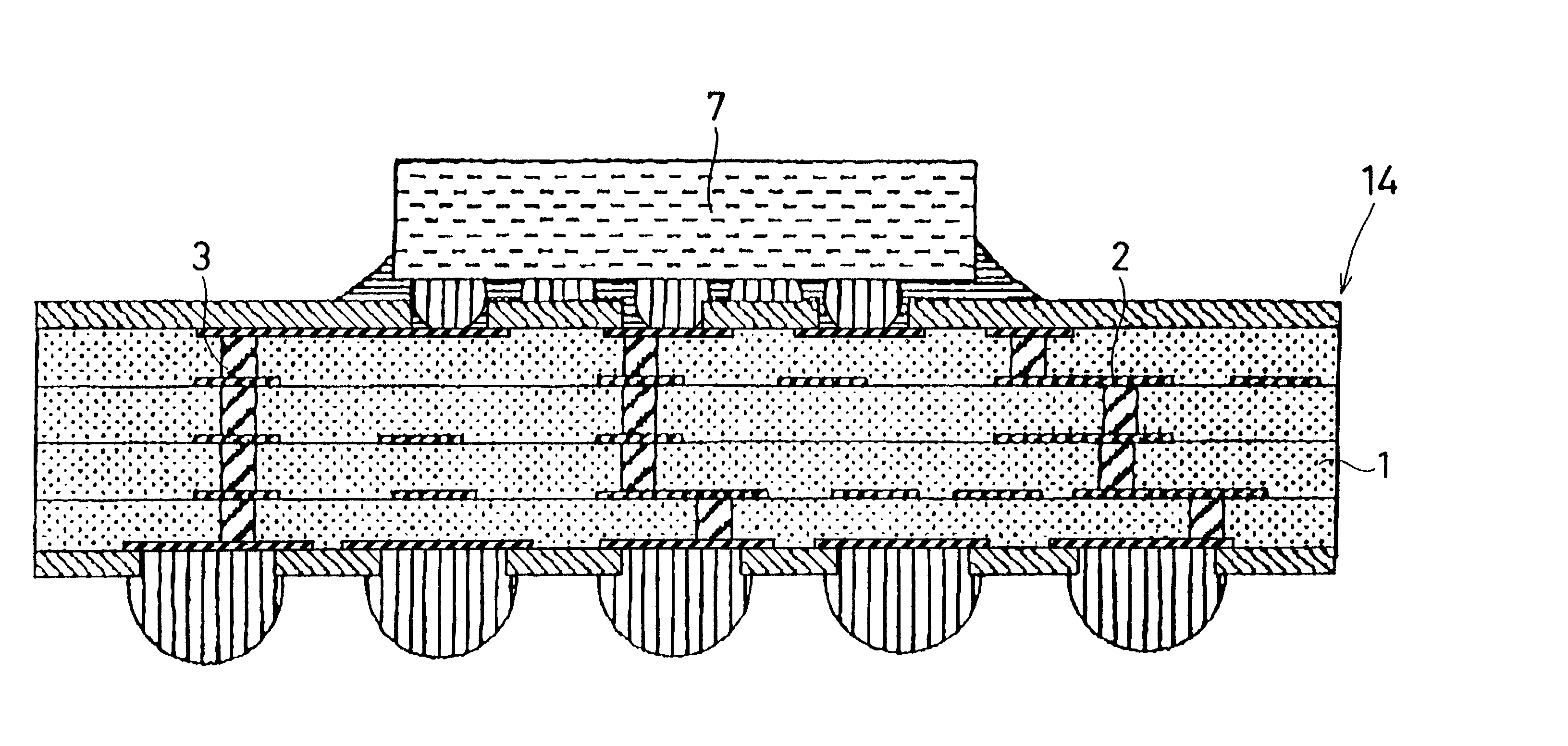

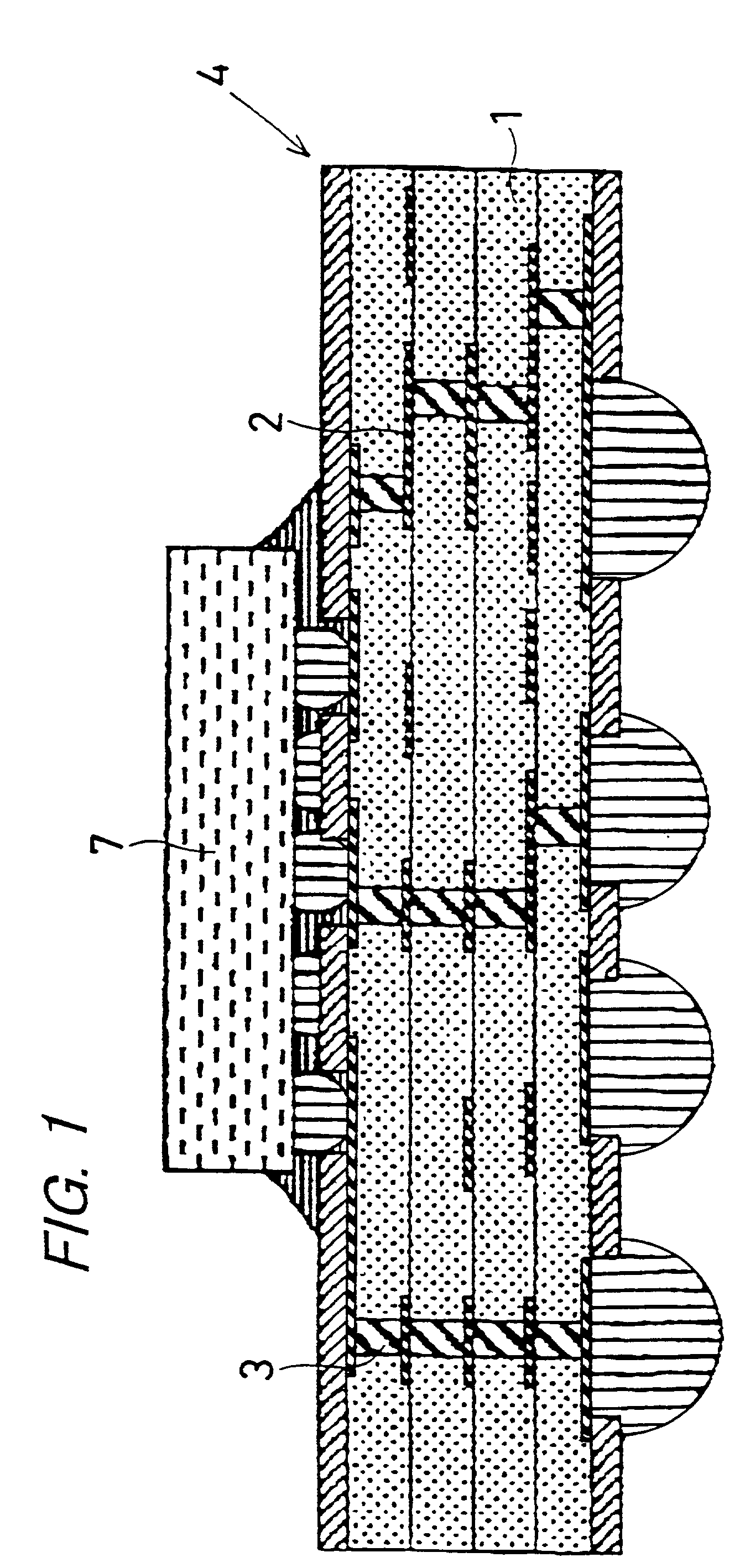

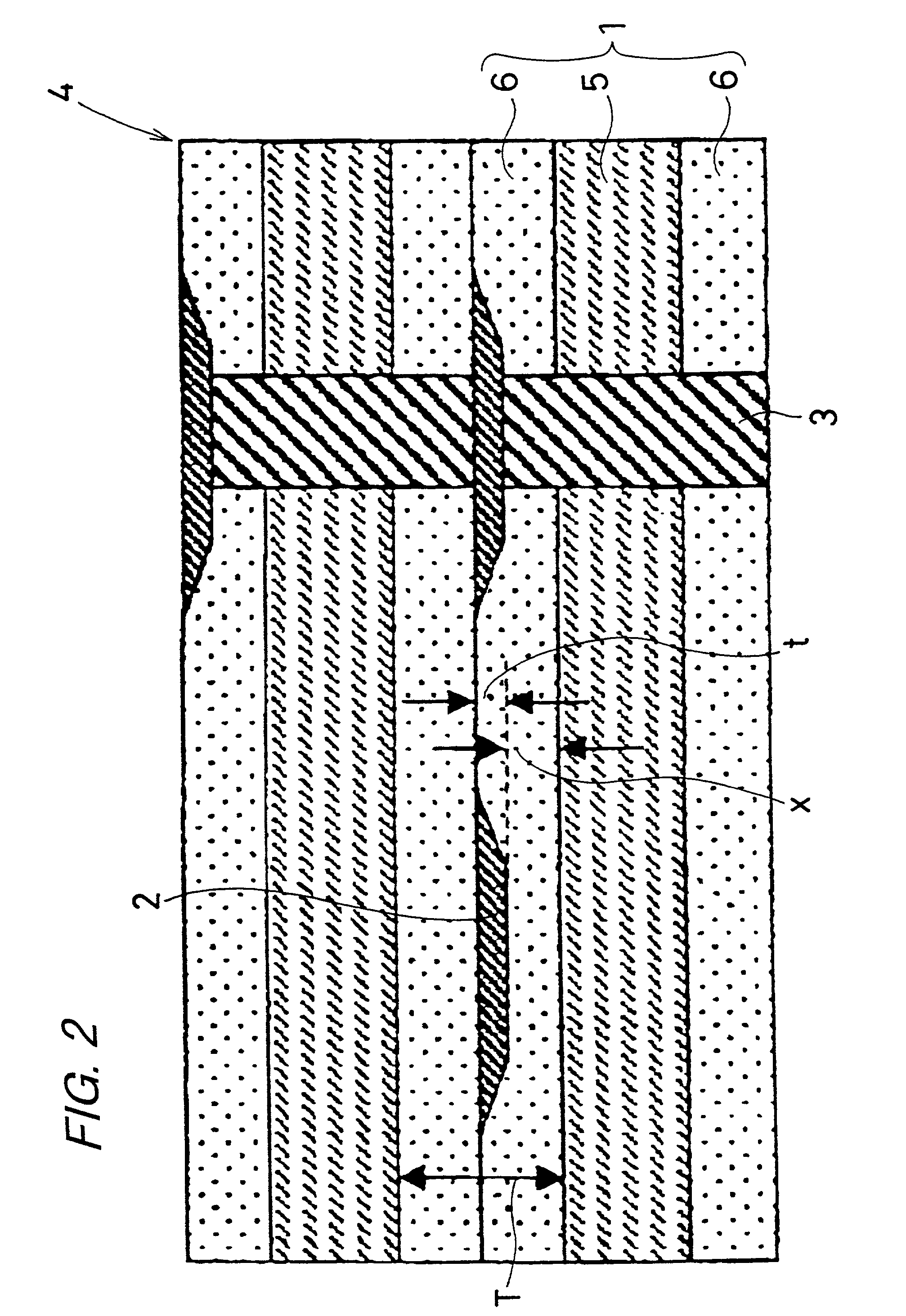

Multi-layer wiring substrate

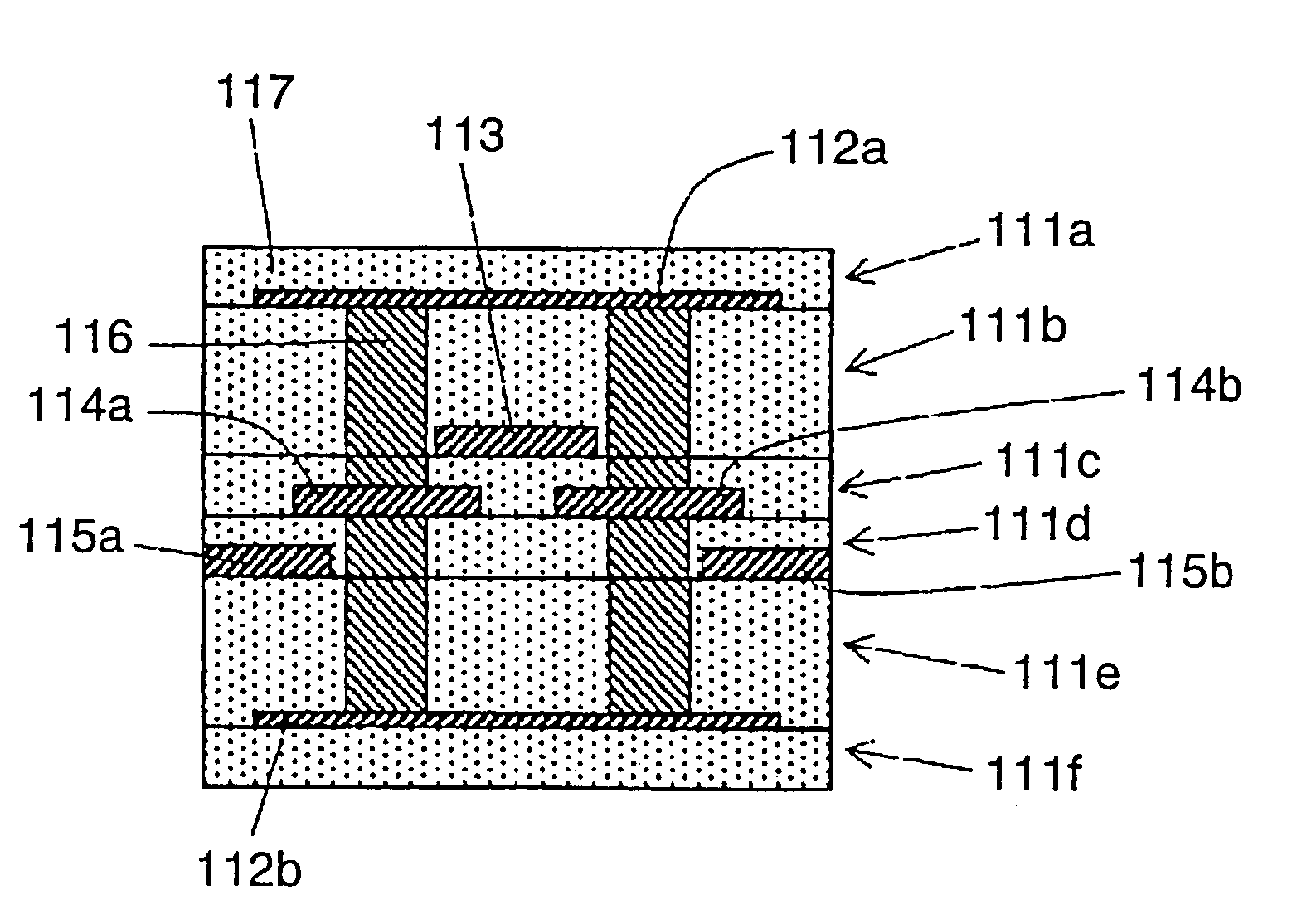

InactiveUS20020172021A1Excellent in high-frequency characteristicAdhesivenessSemiconductor/solid-state device detailsSolid-state devicesMetallic foilHigh density

An object of the invention is to satisfy all of a high-density wiring package, soldering thermal resistance, an insulating property and high-frequency transmission characteristics. The invention is a multi-layer wiring substrate having a lamination of a plurality of dielectric layers which are each provided with a wiring conductor made of a metallic foil on at least one of upper and bottom surfaces of the dielectric layer, the wiring conductors between which the dielectric layer is disposed being electrically connected with each other via a through conductor formed in the dielectric layer; on this occasion, the dielectric layers each individually are composed of a liquid crystal polymer layer and cladding layers made of a polyphenyleneether-type organic substance and formed on upper and bottom surfaces of the liquid crystal polymer layer.

Owner:KYOCERA CORP

Skin antiseptic composition dispenser and methods of use

Skin antiseptic composition dispensers and methods of use are disclosed. The skin antiseptic composition dispenser may include a container with one or more walls that are substantially impermeable to ethylene oxide gas during normal ethylene oxide sterilization processes. In some embodiments, the container may include flexible walls free of metallic foil barrier layers. The containers may also include one or more vents in addition to one or more openings used to dispense the skin antiseptic composition within the container. The dispenser may include an applicator with a hydrophilic foam.

Owner:3M INNOVATIVE PROPERTIES CO

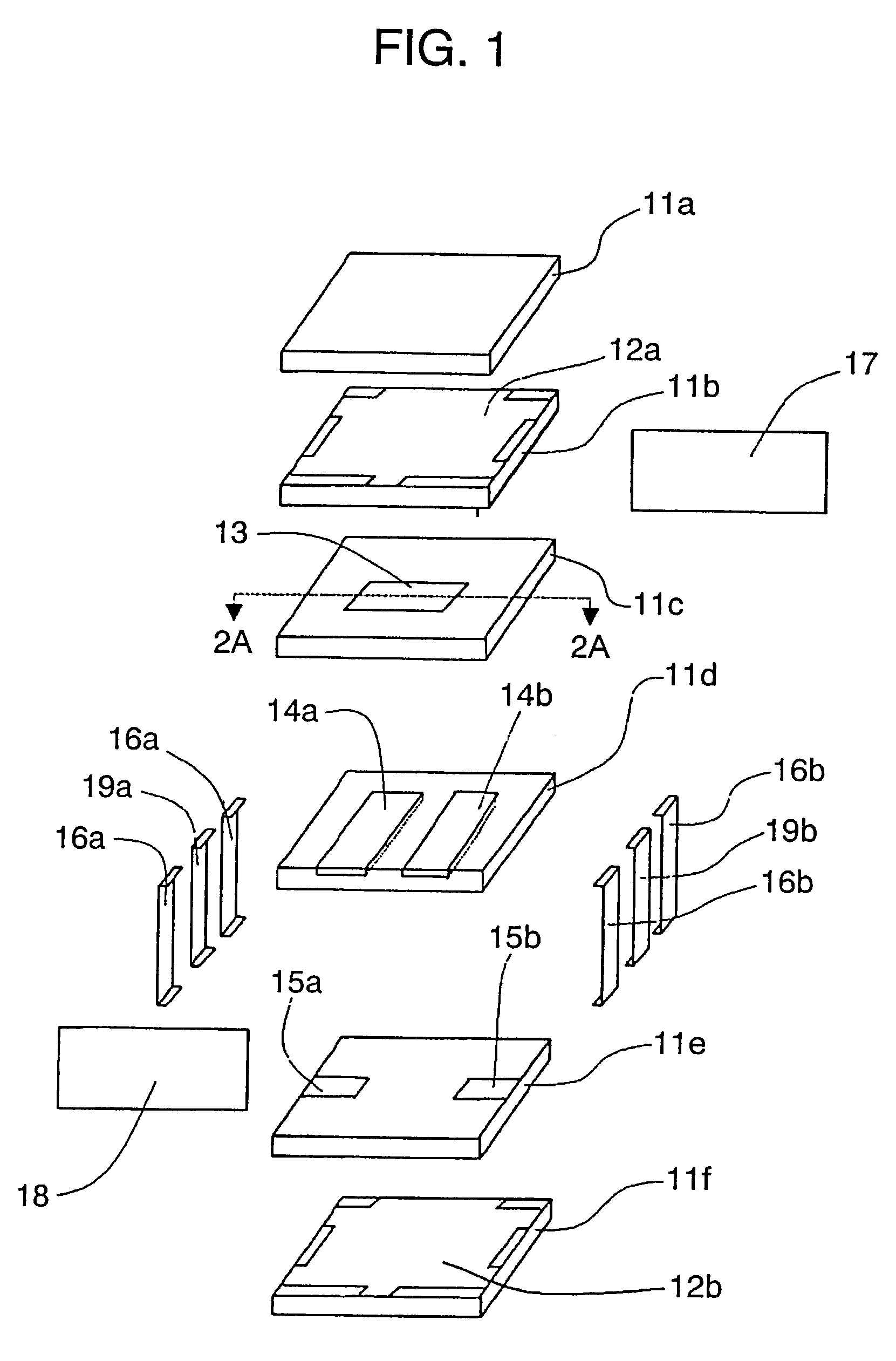

Dielectric filter, antenna duplexer

InactiveUS6965284B2Reduce lossSpeed up the descentMultiple-port networksResonatorsMetallic foilCoupling

A dielectric filter includes resonator electrodes, an inter-stage coupling capacitor electrode, and an input / output coupling capacitor electrode on dielectric substrates, respectively. The resonator electrodes are electro-magnetically coupled to each other to form a tri-plate structure, are made of a metallic foil embedded in a resonator dielectric substrate. Another dielectric filter includes an upper shield electrode dielectric substrate, an inter-stage coupling capacitor dielectric substrate, a resonator dielectric substrate, and an input / output coupling capacitor dielectric substrate which are made of a composite dielectric material including a high-dielectric-constant material and a low-dielectric-constant material. The above described arrangement provides the dielectric filter with an improved Q factor of a resonator, a low loss, and a high attenuation.

Owner:PANASONIC CORP

Circuit substrate manufacturing method

ActiveUS7222421B2Low costImprove workabilityPaper/cardboard articlesLaminating printed circuit boardsMetallic foilOptoelectronics

A circuit substrate manufacturing method including the steps of preparing a substrate on which a metallic foil is formed in a releasable state, forming a build-up wiring on the metallic foil, obtaining a circuit member having a structure that the build-up wiring is formed on the metallic foil by releasing the metallic foil from the substrate, and exposing a lowest wiring layer of the build-up wiring by removing the metallic foil of the circuit member.

Owner:SHINKO ELECTRIC IND CO LTD

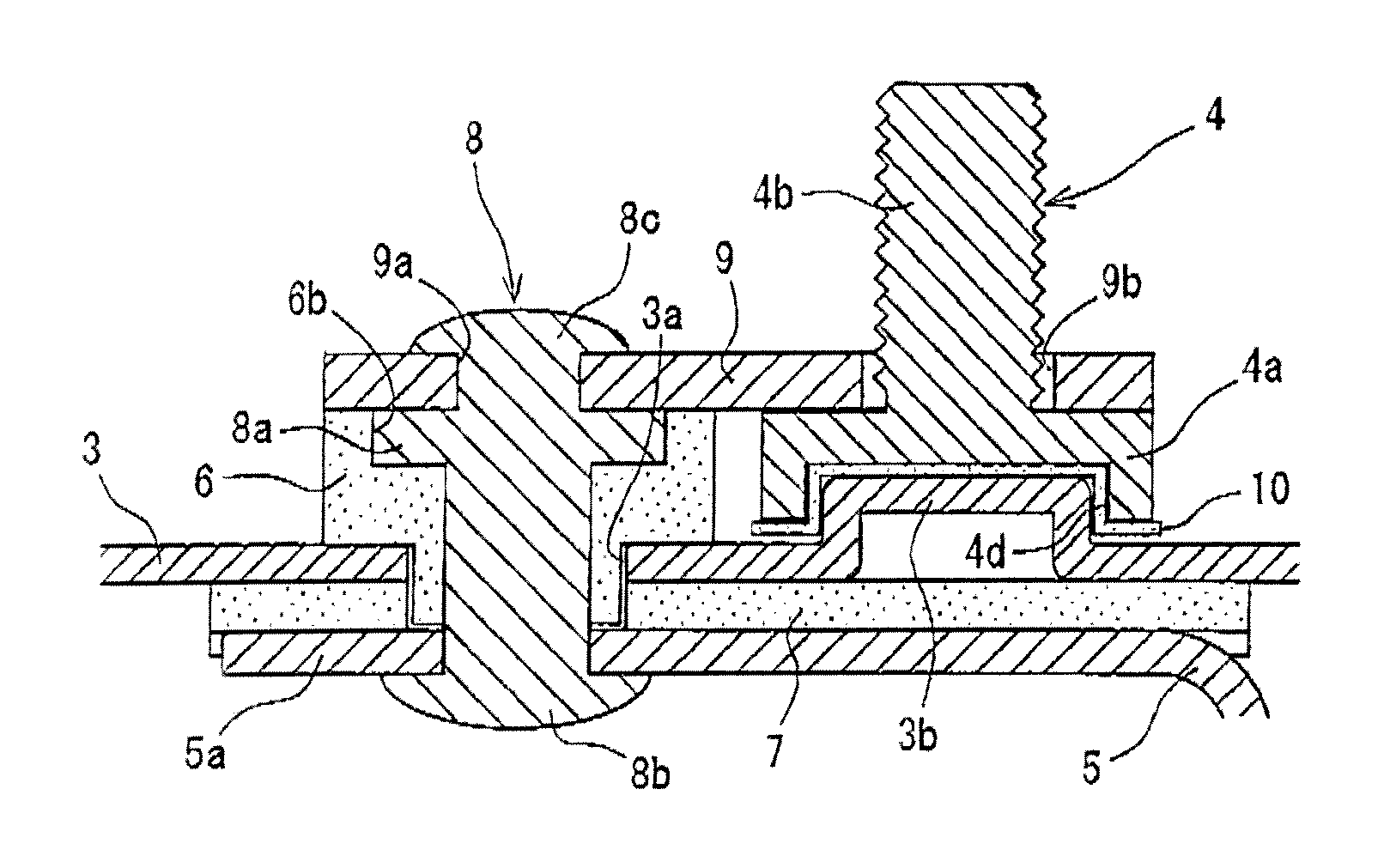

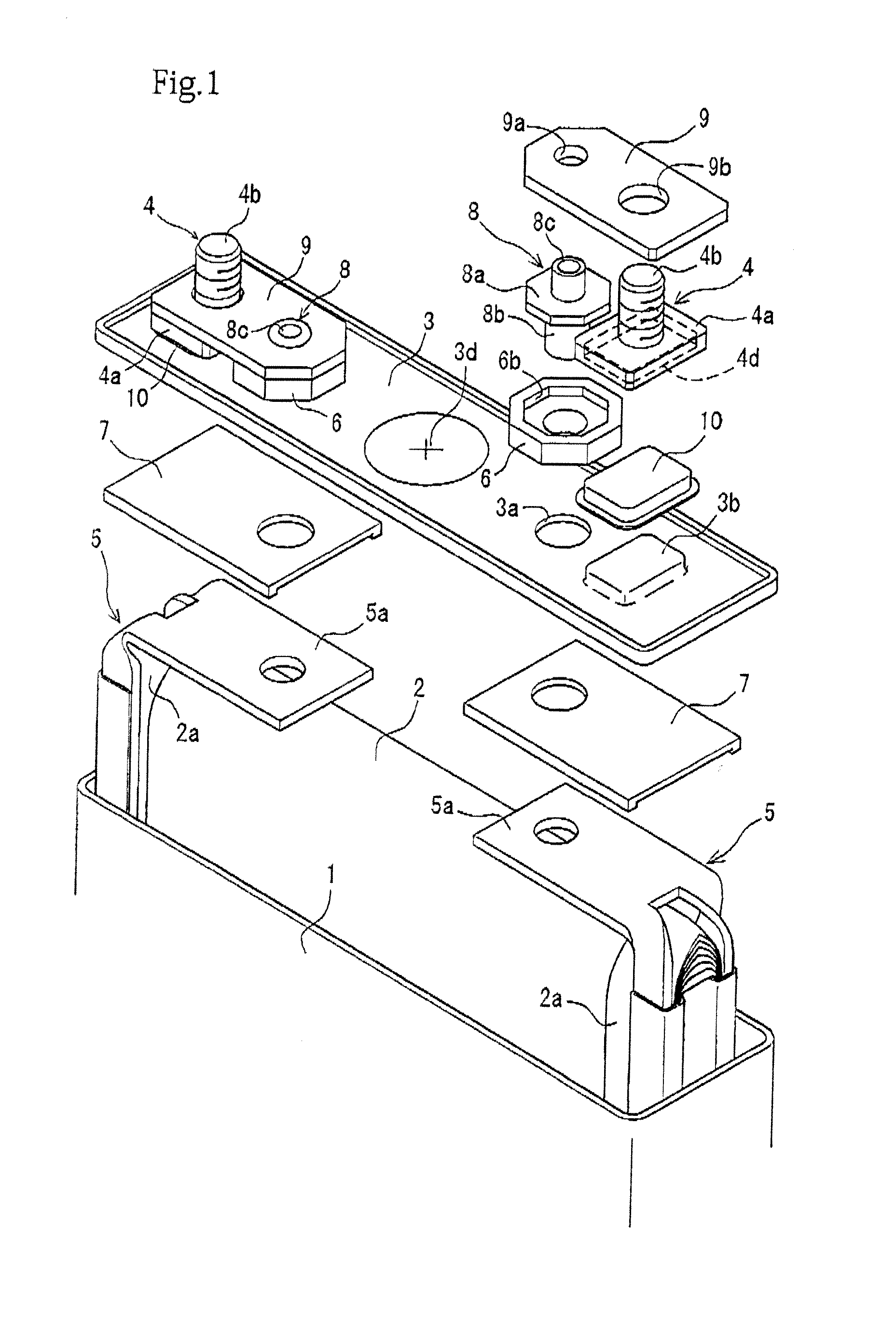

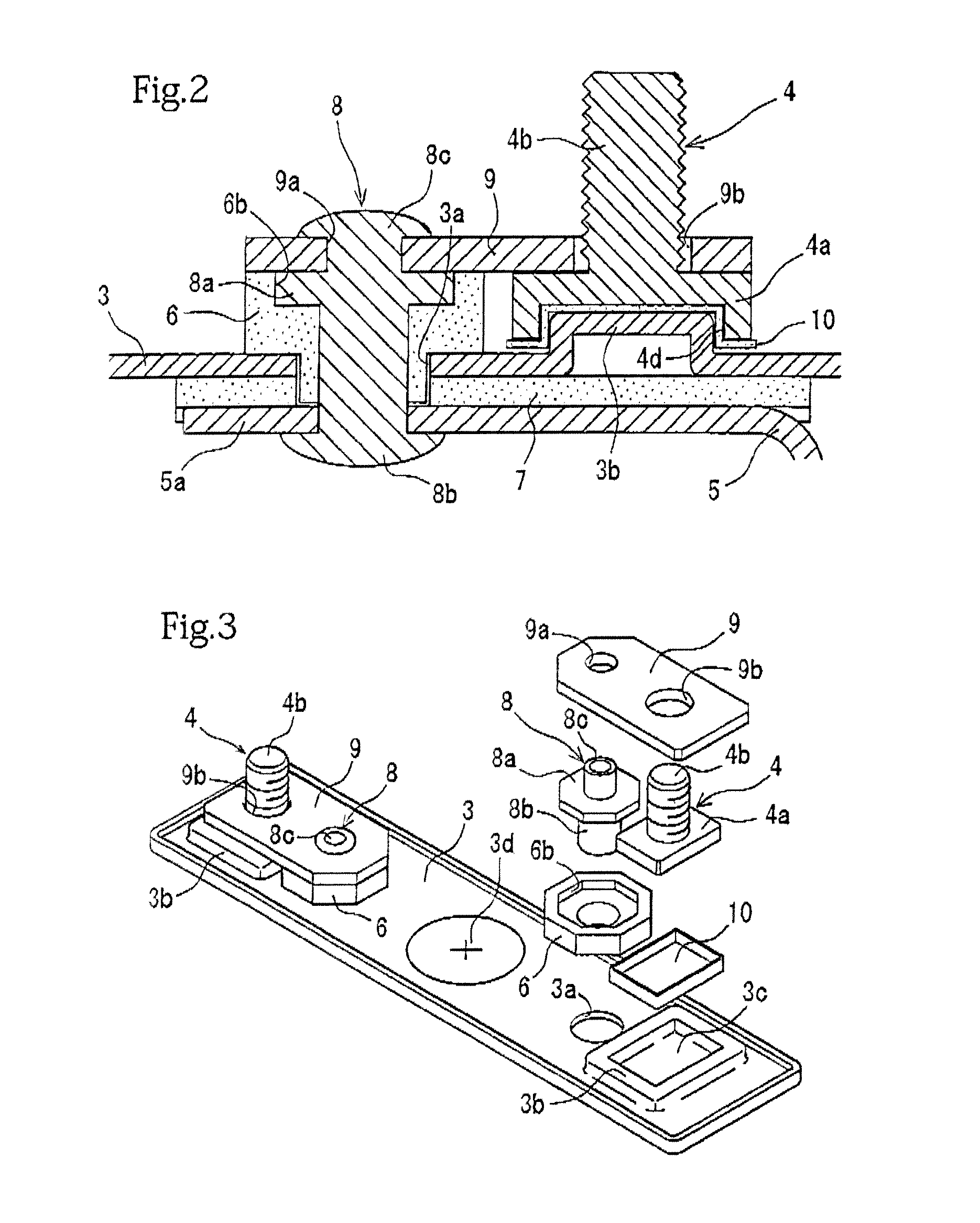

Battery and method of manufacturing the same

ActiveUS20120264007A1Impair airtightnessImpair conductivityCell lids/coversElectric connector introductionMetallic foilElectrical conductor

The present invention provides a battery that includes: a lid plate provided with a terminal pull-out through hole and a baffling portion whose upper surface is configured in a projecting and / or recessed manner; an auxiliary terminal configured such that a lower portion thereof is connected to a metallic foil of a power generating element by being fitted into a battery container through the terminal pull-out through hole, and sealed and fixed to the lid plate by insulating and sealing members; a connecting conductor connected and fixed to an upper portion of the auxiliary terminal; and an external terminal having a bolt portion that projects upward from a base portion, the bolt portion being inserted through the terminal through hole of the connecting conductor from below, and the base portion being engaged with the baffling portion of the lid plate, thereby restricting rotation centering an axial line of the bolt portion.

Owner:GS YUASA INT LTD

Method Of Forming Metallic Bump And Seal For Semiconductor Device

InactiveUS20090098724A1Improve bindingIncrease productionSemiconductor/solid-state device detailsSolid-state devicesMetallic foilResist

The method mainly contains the following steps. First, an UBM is formed on a top side of a semiconductor's I / O pad. An isolative layer and a metallic foil are sequentially arranged in this order on the UBM. Then, a via is formed to expose the top surface of the UBM. Subsequently, a thin metallic layer is formed in the via and a resist is formed on the metallic foil. Then, by using the metallic foil and the thin metallic layer as an electrode to conduct electrical current, a metallic bump is formed using electroplating in the via on the top side of the UBM. Finally, the resist and the metallic foil are removed and the formation of the metallic bump is completed. Optionally coating on bump may be needed for certain chosen bump materials.

Owner:YU WAN LING

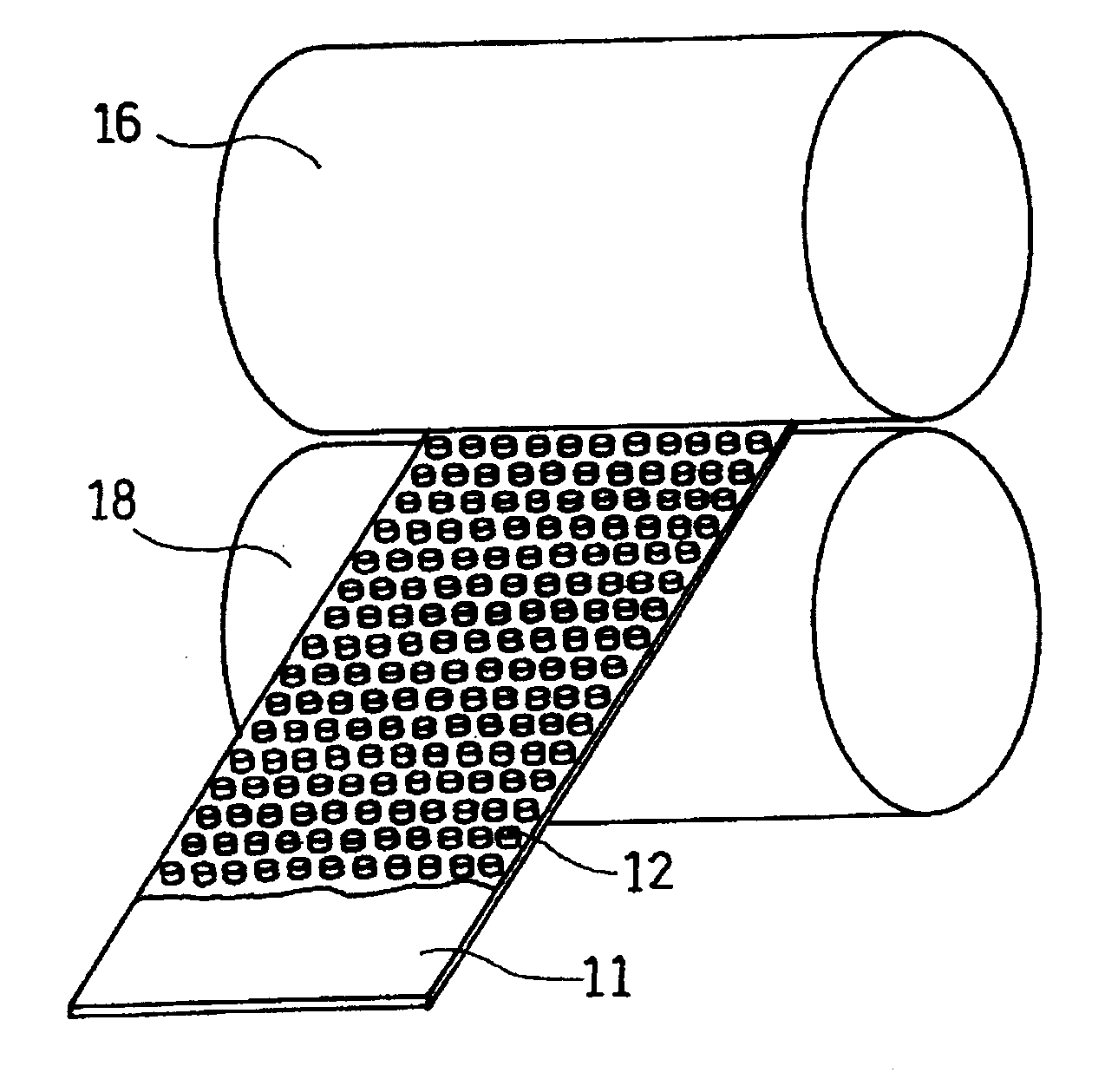

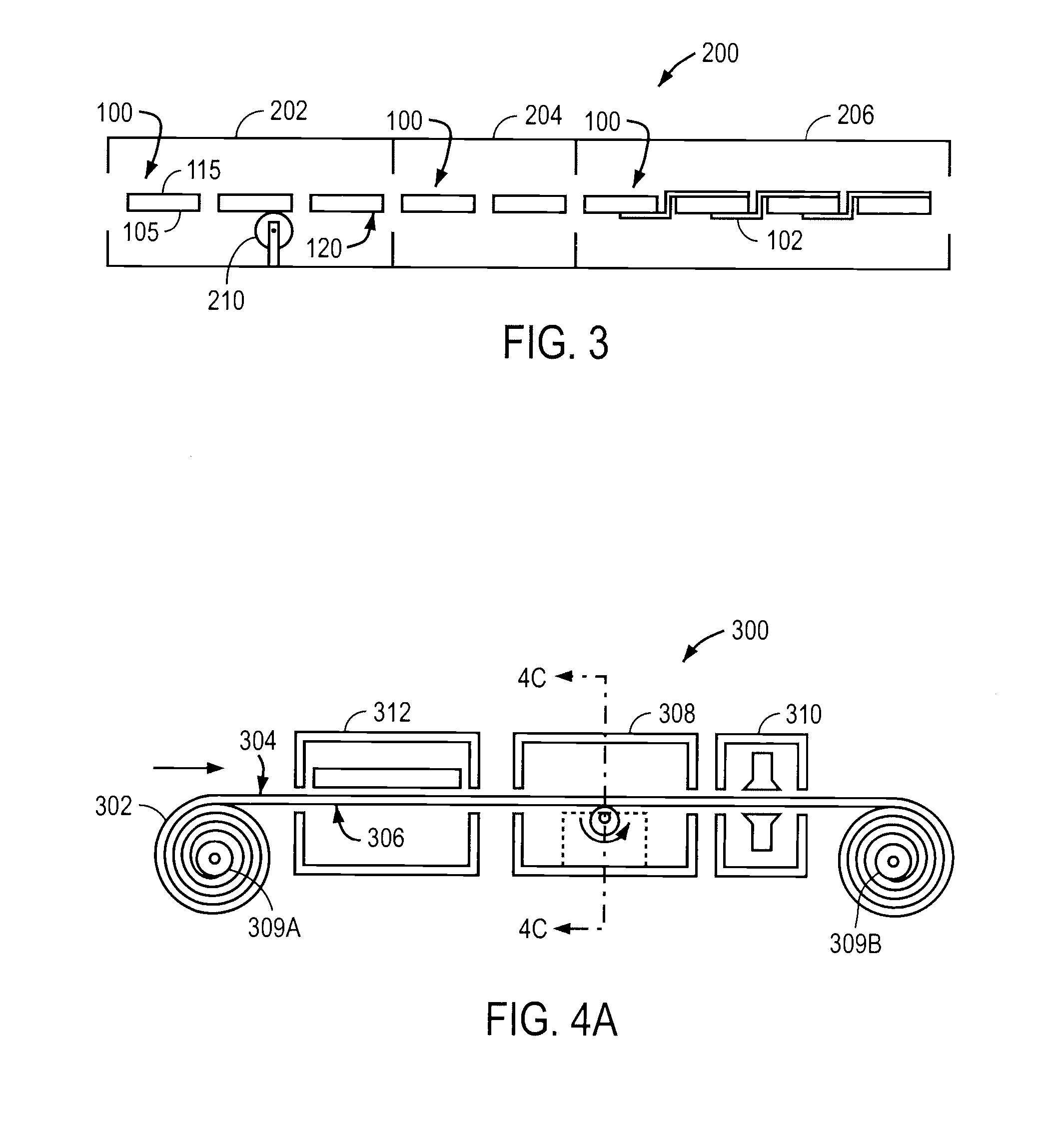

Finger pattern formation for thin film solar cells

InactiveUS20080173390A1Ornamental structuresSpecial ornamental structuresMetallic foilThin film solar cell

A method of forming metallic connector patterns for solar cells, whereby an embosser having raised features shaped in the form of a metallic connector pattern is used to attach a portion of a metallic foil to a transparent conductive layer formed on a top transparent surface of a solar cell structure. The raised surfaces of the embosser press the metallic foil portion against the transparent conductive layer. Heat and pressure directed to the metallic foil portion attach the metallic foil portion to the underlying transparent conductive layer, and then the rest of the metallic foil, which is not attached to the transparent conductive layer, is removed.

Owner:SOLOPOWER

Metallic foil substrate and packaging technique for thin film solar cells and modules

Methods of forming thin film solar cells with a metallic substrate are described, as well as solar cells and solar cells strings. The front surface of the metallic substrate is polished to form a polished front surface so that the average roughness of the polished front surface is less than 50 nm. The back surface of the metallic substrate is roughened to form a rough back surface so that the average roughness of the conditioned back surface is more than 500 nm. A Group IBIIIAVIA compound absorber layer is formed over the polished front surface.

Owner:SOLOPOWER

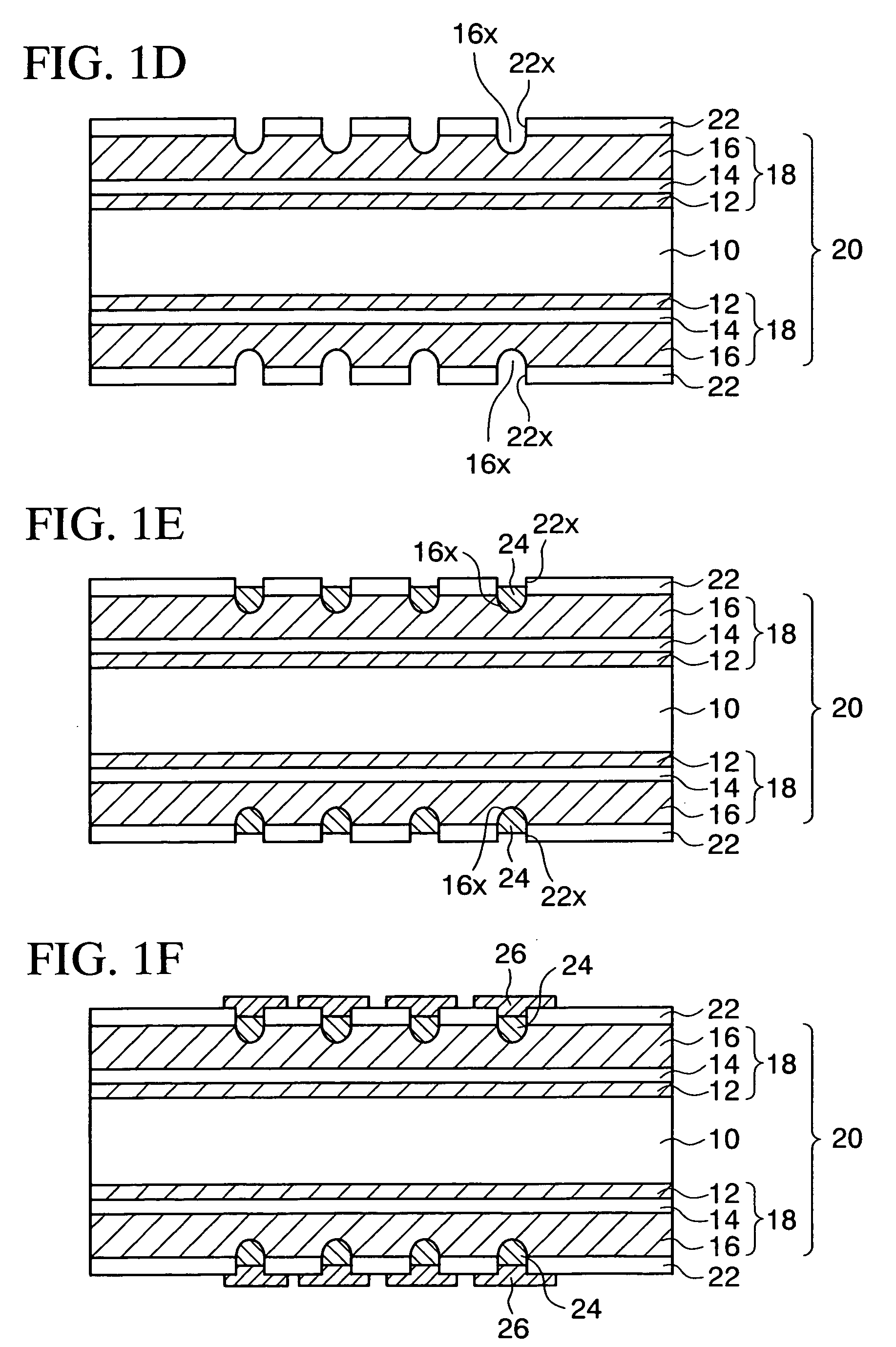

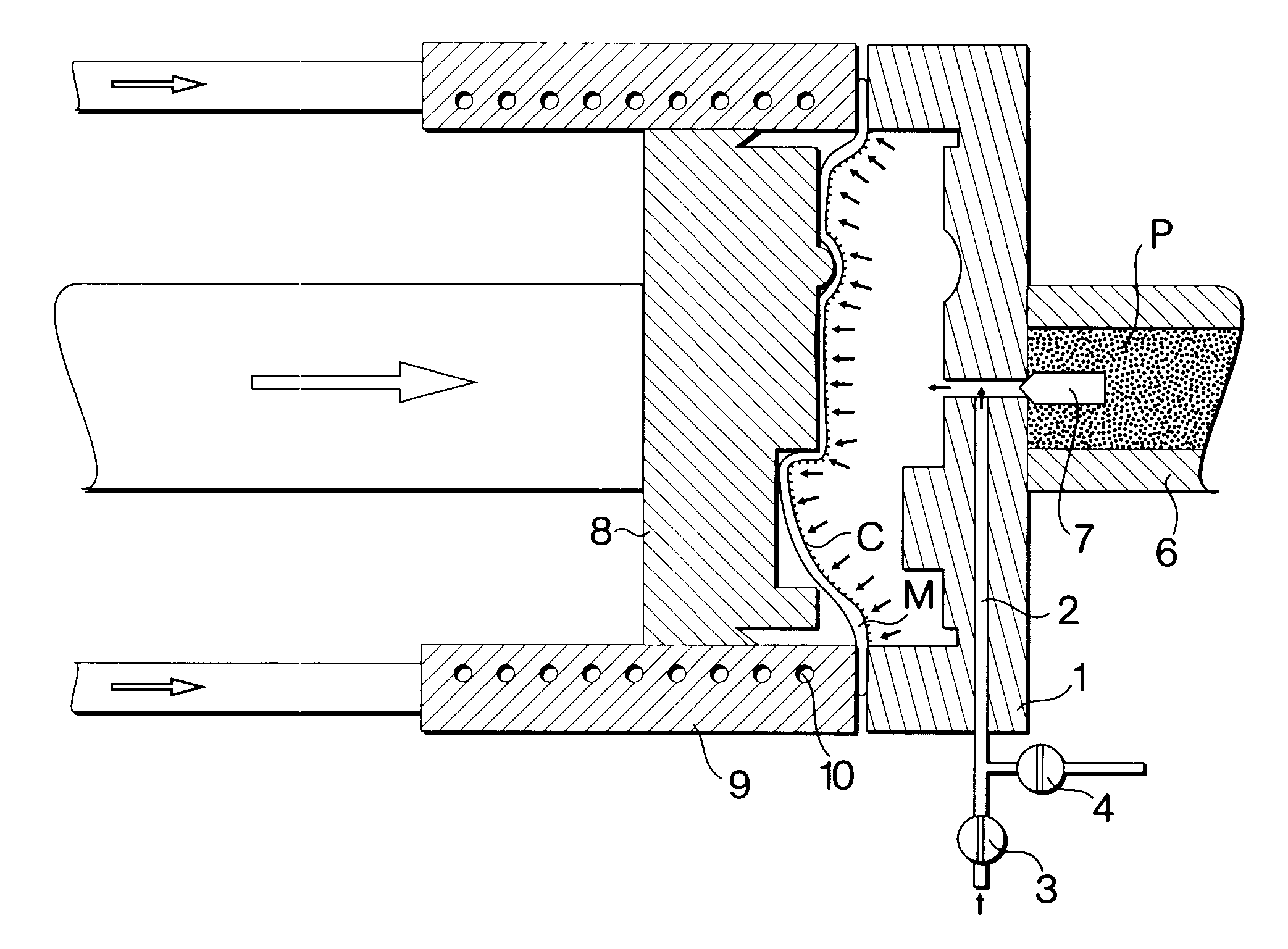

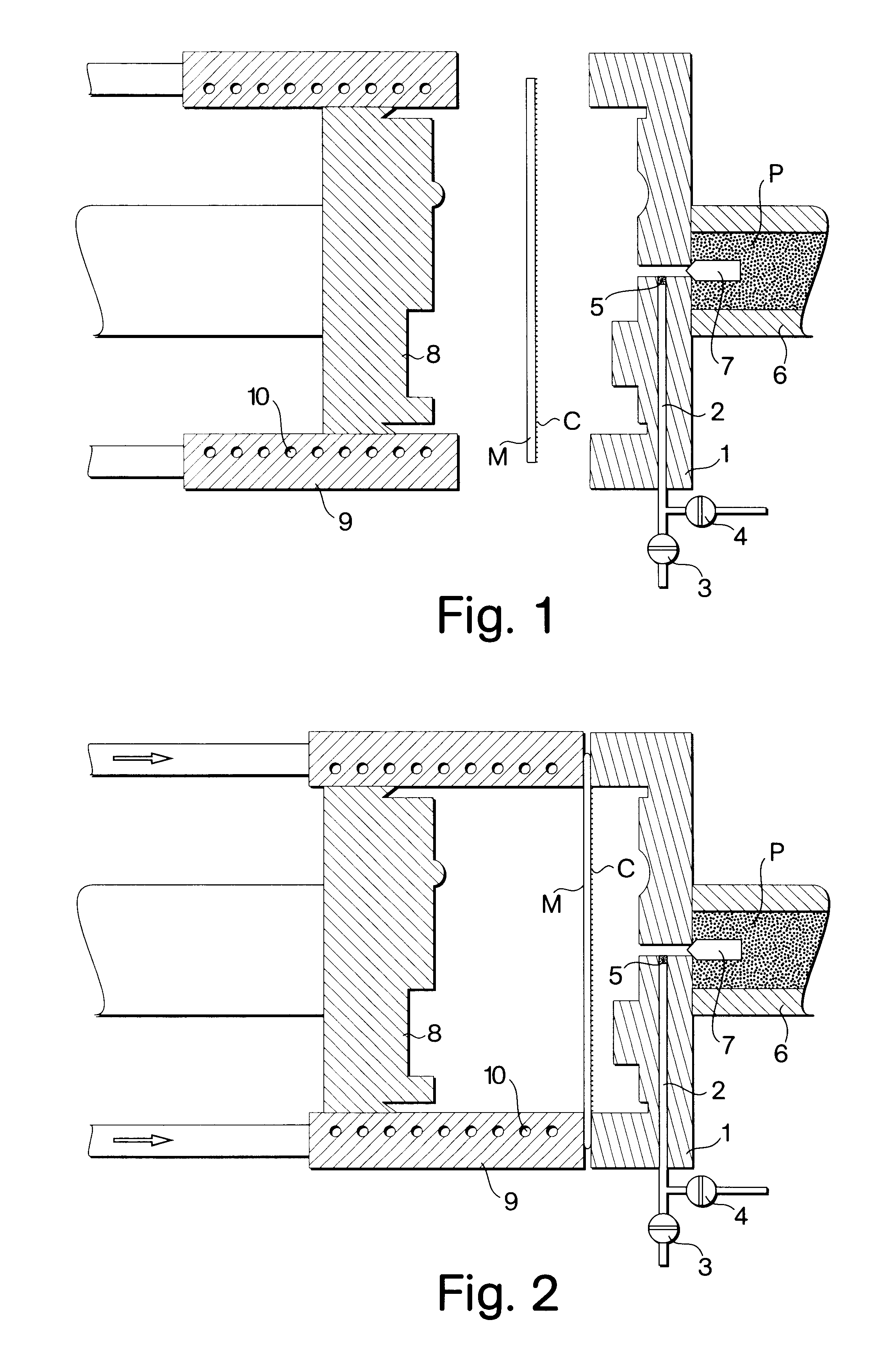

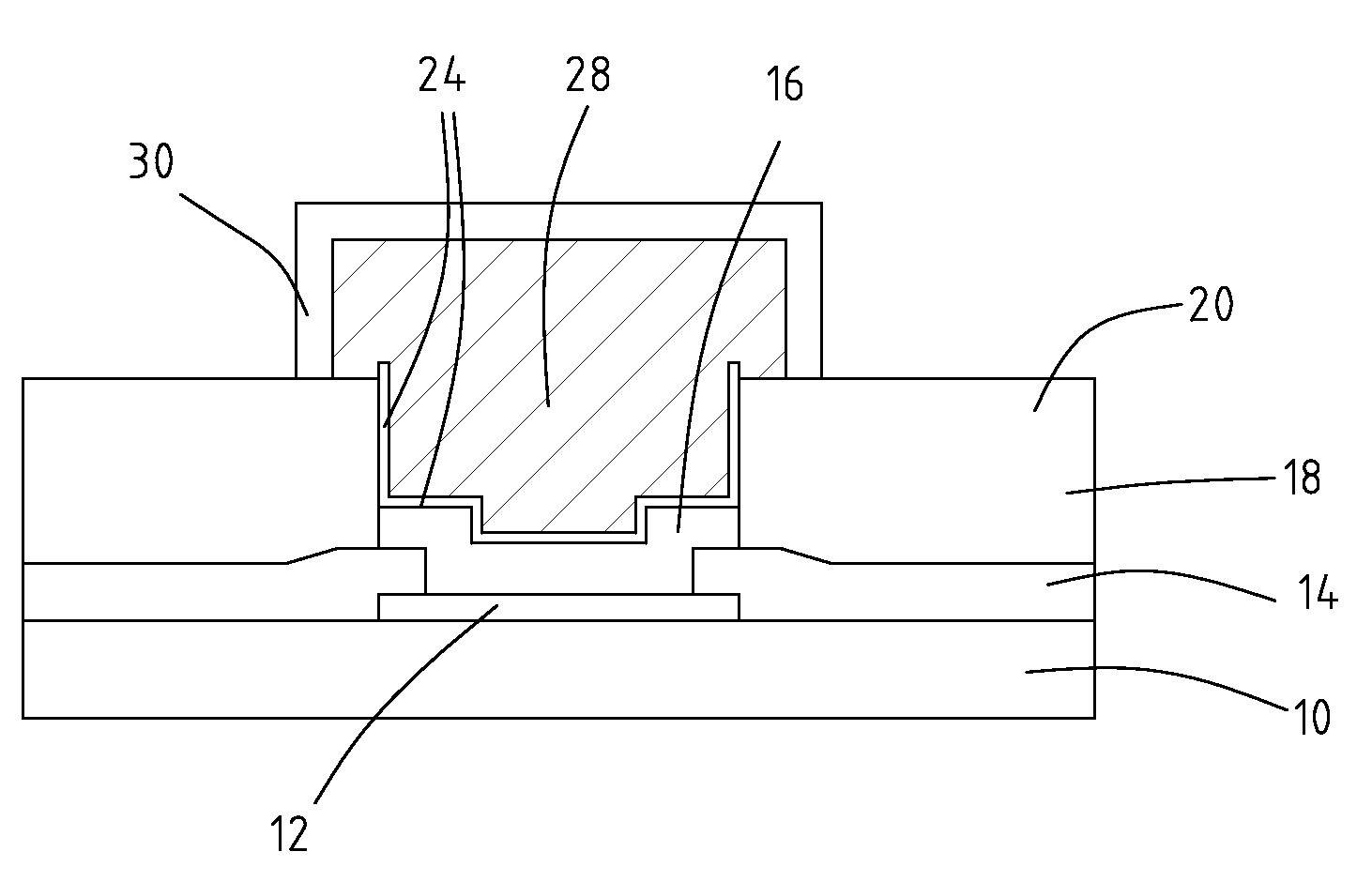

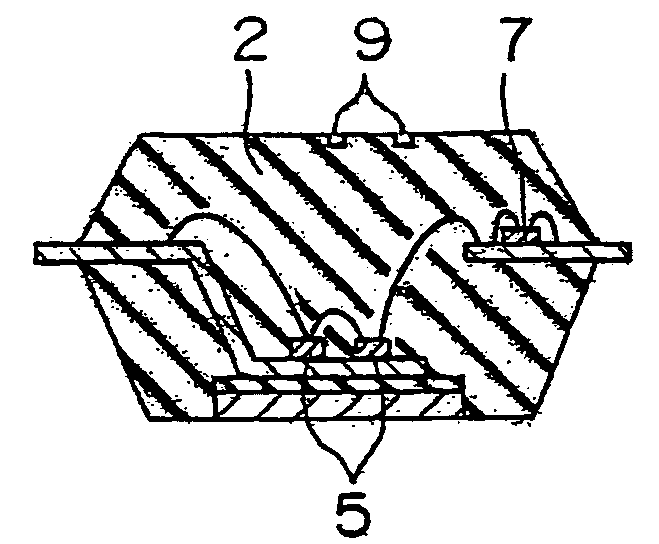

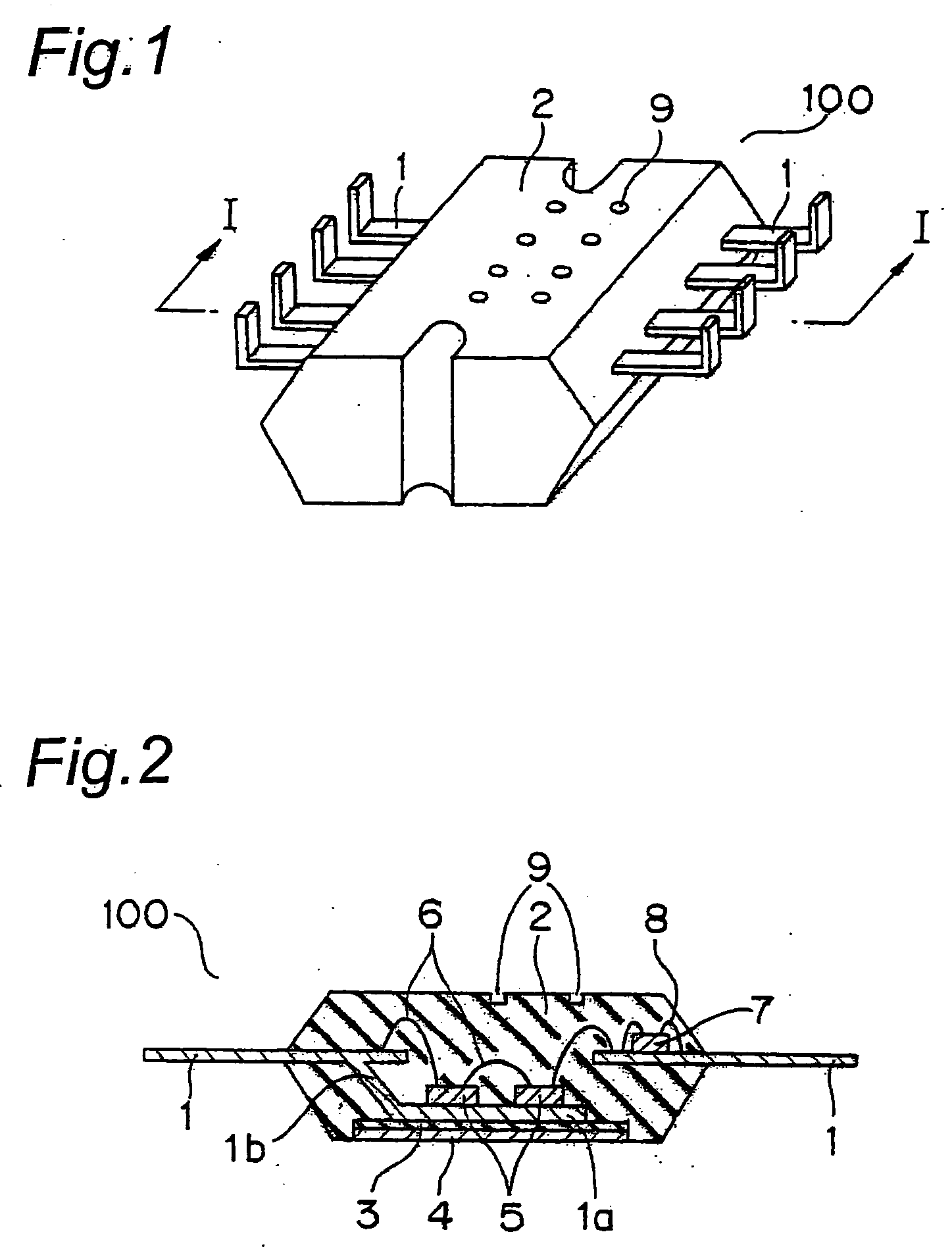

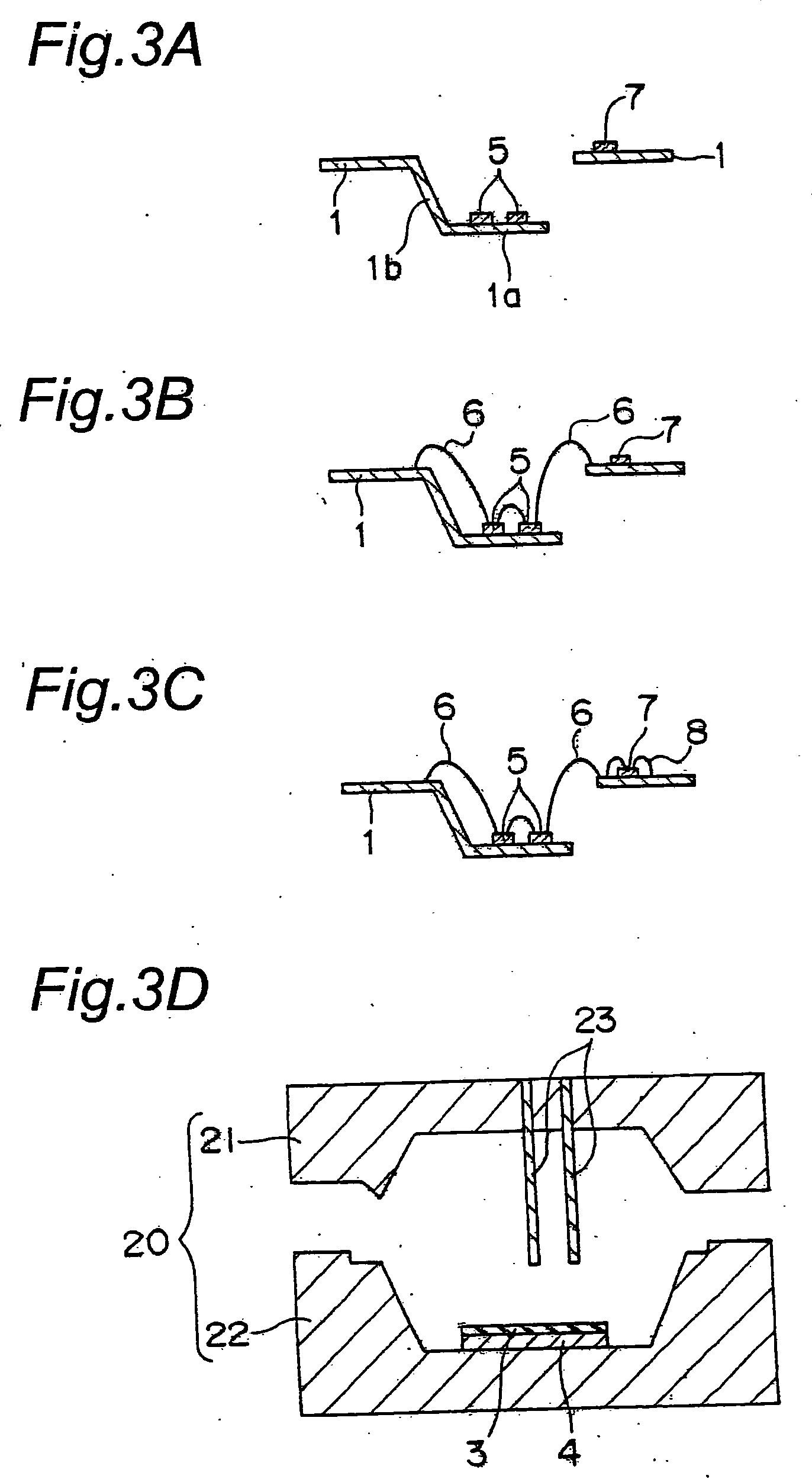

Method for producing semiconductor device and semiconductor device

ActiveUS20050082690A1Improve cooling effectImprove insulation performanceSemiconductor/solid-state device detailsSolid-state devicesDevice materialMetal foil

The method of producing a semiconductor device in which chips are resin-molded, including steps of: preparing frames having front and back surfaces and die pads; preparing an insulation resin sheet having a first and a second surfaces; preparing a resin-sealing metal mold having cap pins; mounting the resin sheet inside the resin-sealing metal mold in such a manner that the second surface of the resin sheet contacts an inner bottom surface of the resin-sealing metal mold; mounting power chips on the surfaces of the die pads; positioning the frames on the first surface of the resin sheet in such a manner that the back surfaces of the die pads contact the first surface of the resin sheet; pressing the die pads toward the resin sheet using the cap pins and fixing the die pads; injecting a sealing resin in the resin-sealing metal mold and hardening the sealing resin; and removing the semiconductor device in which the power chips are molded with the sealing resin out from the resin-sealing metal mold. The resin sheet may include a metal foil which is disposed to the second surface.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com