Patents

Literature

1013results about How to "Reduce material usage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

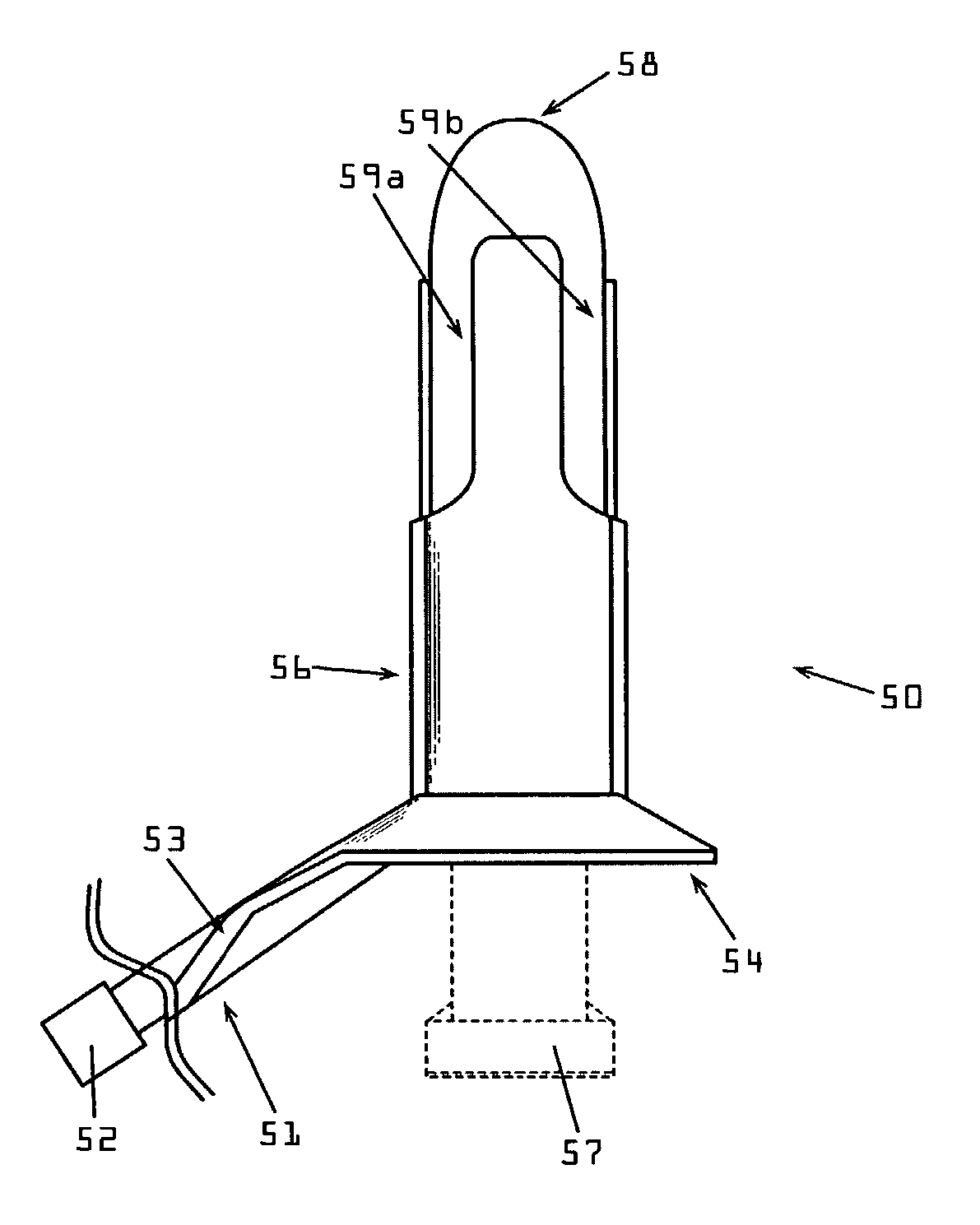

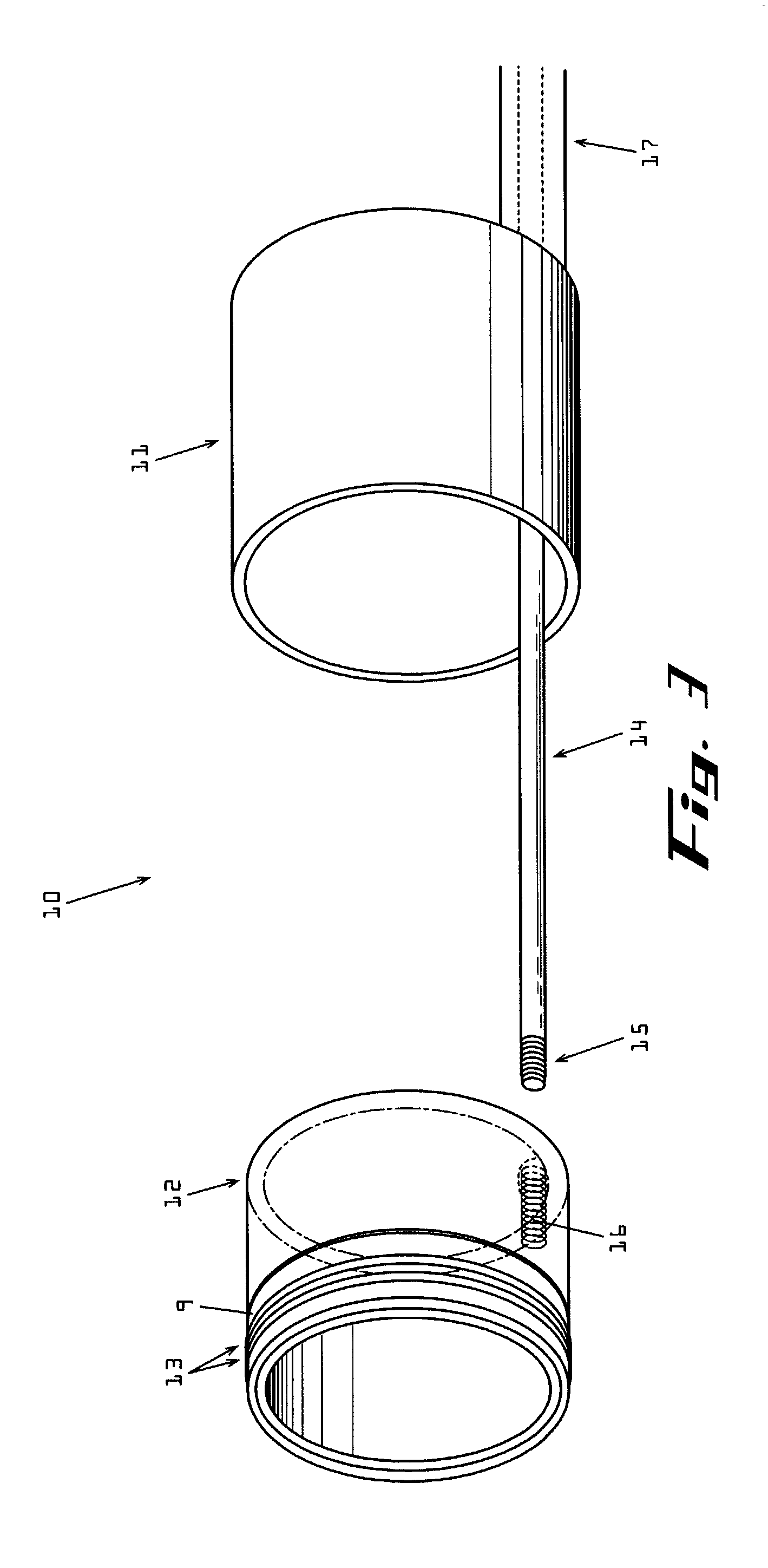

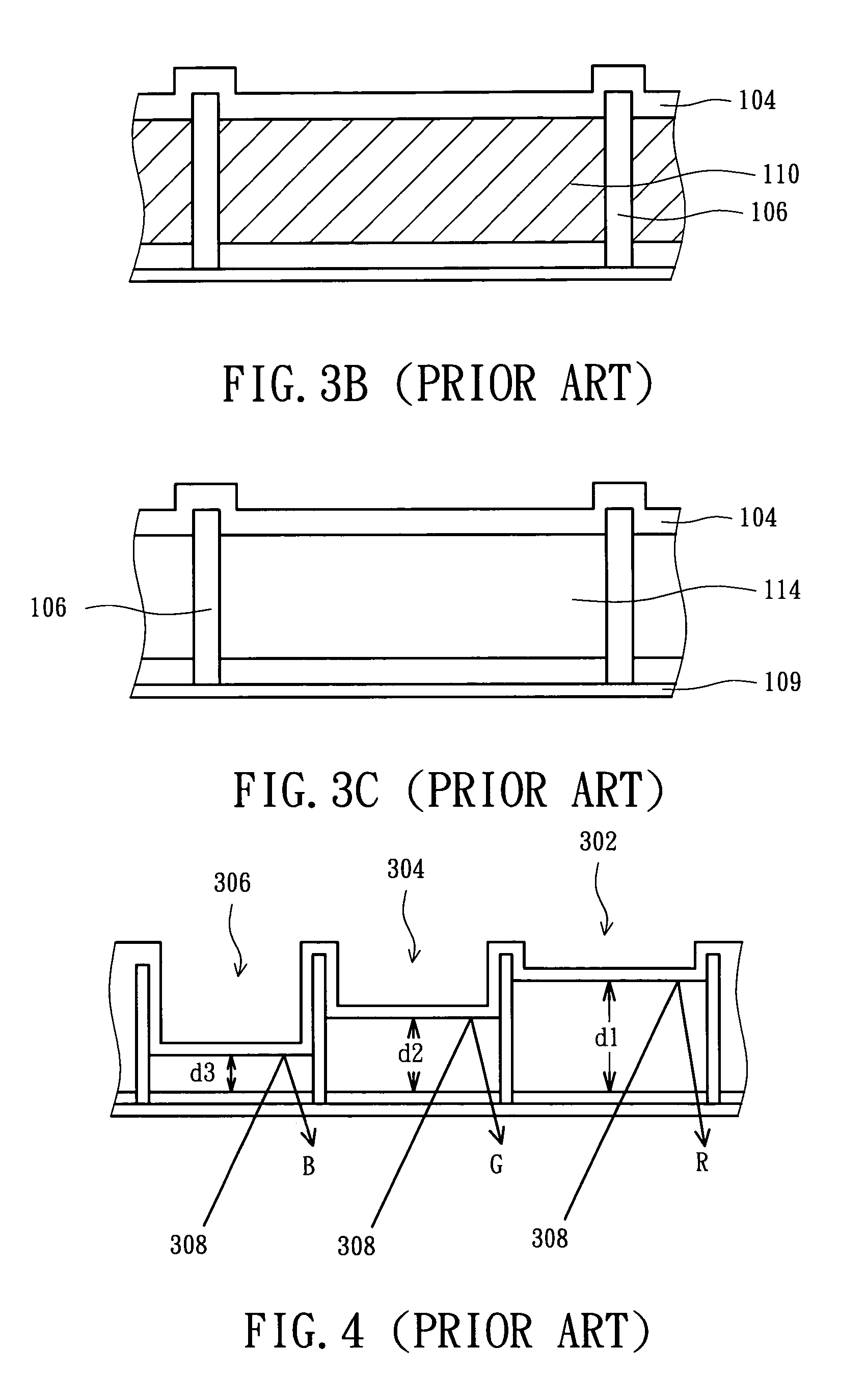

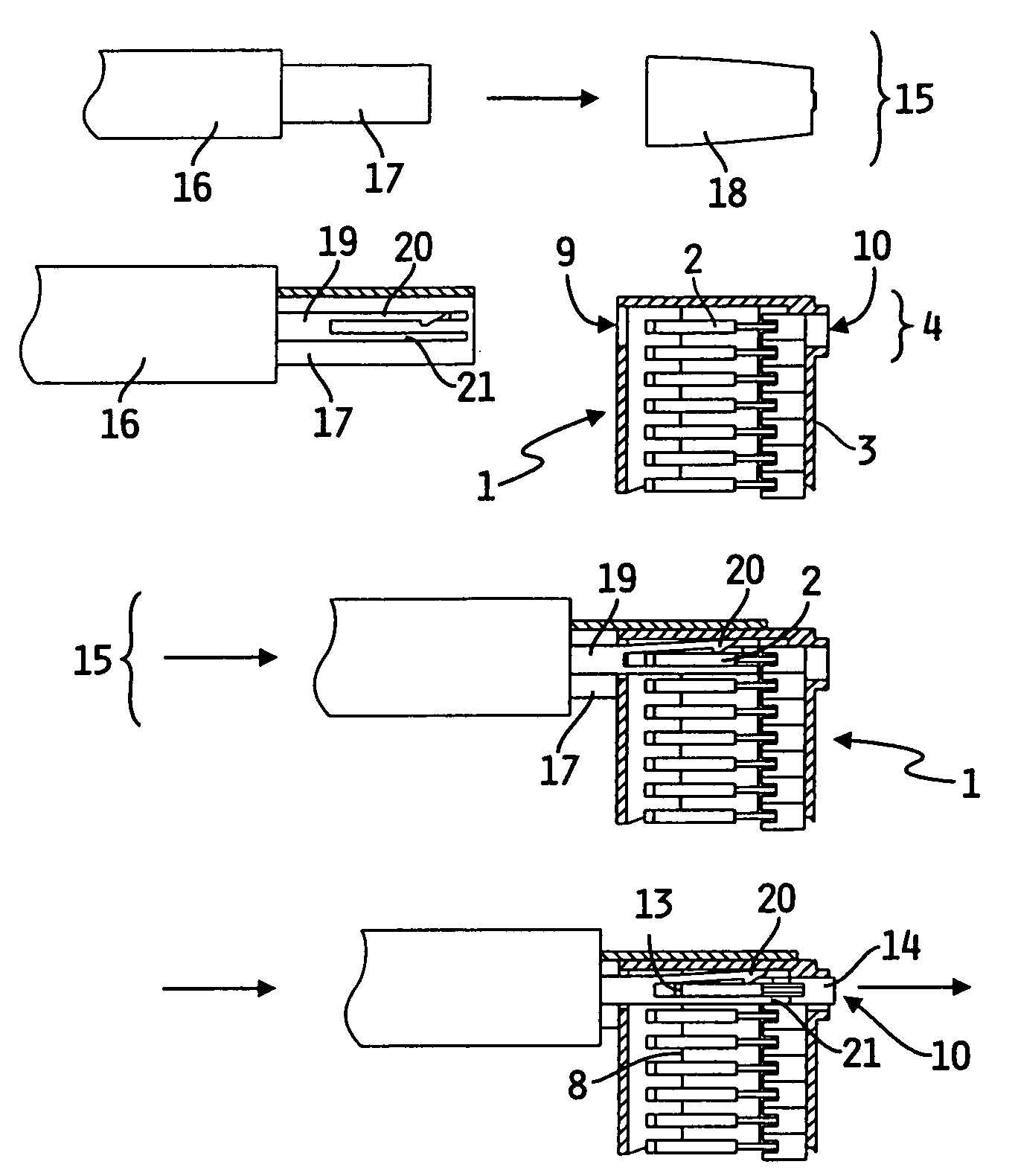

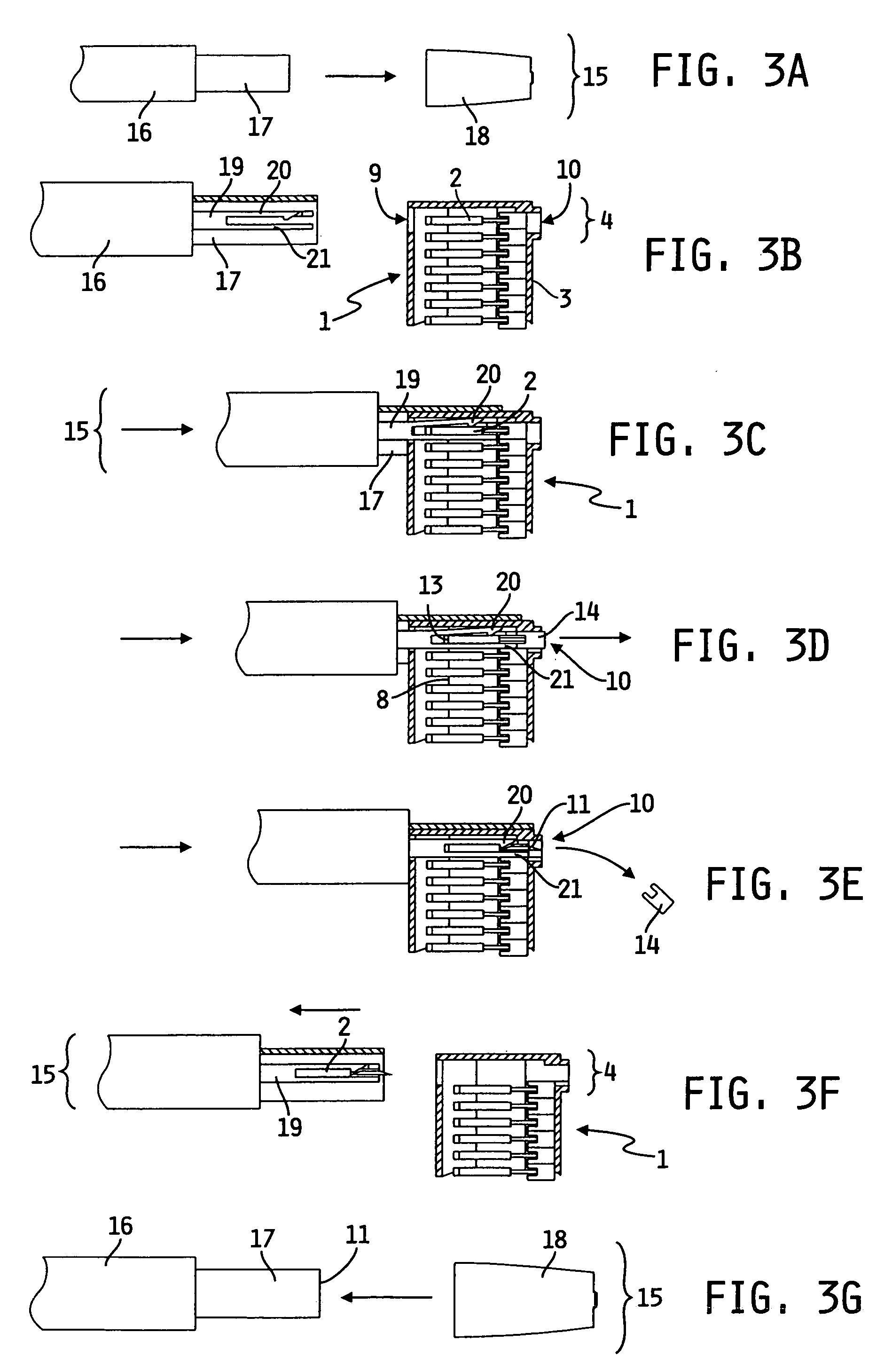

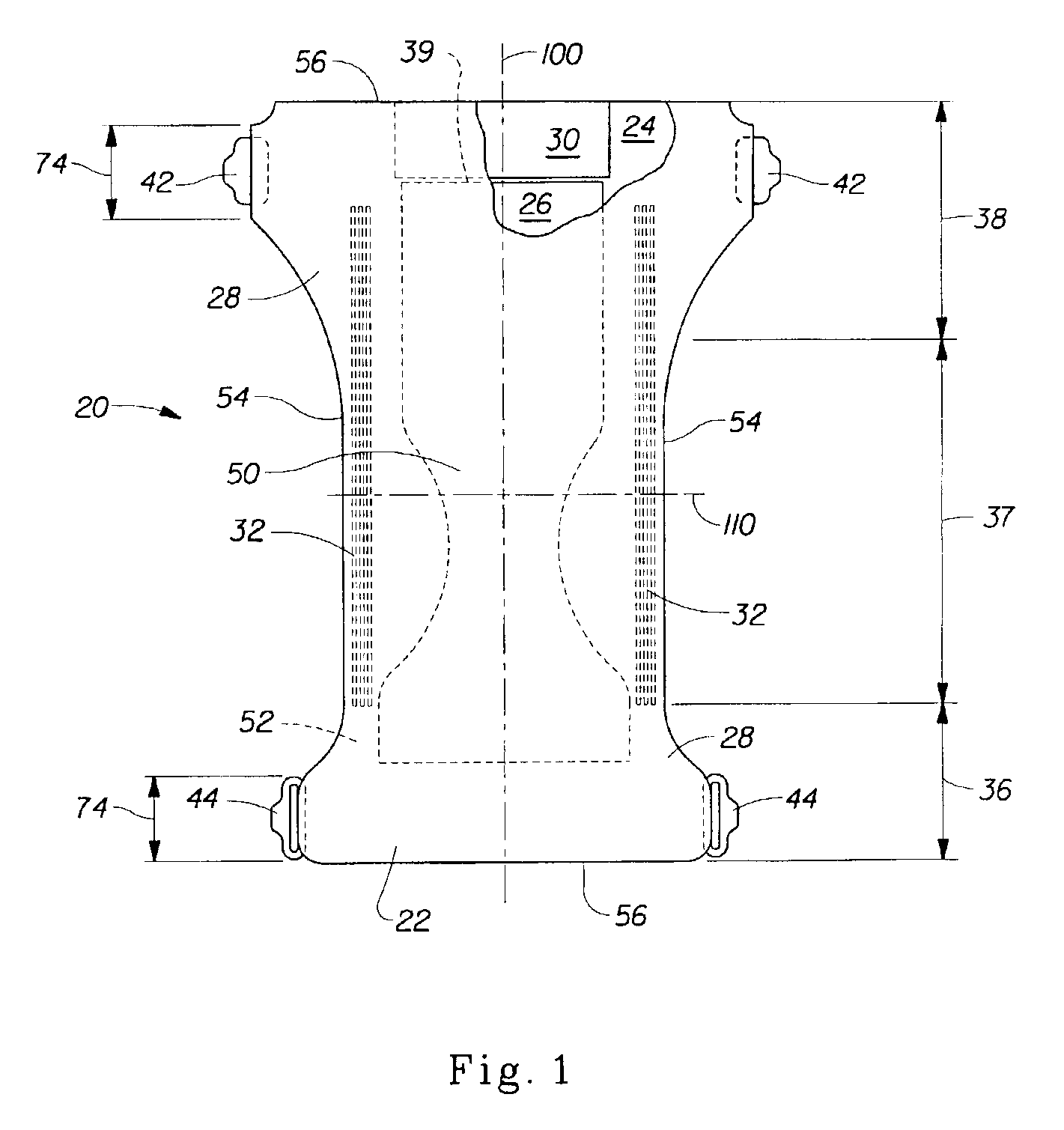

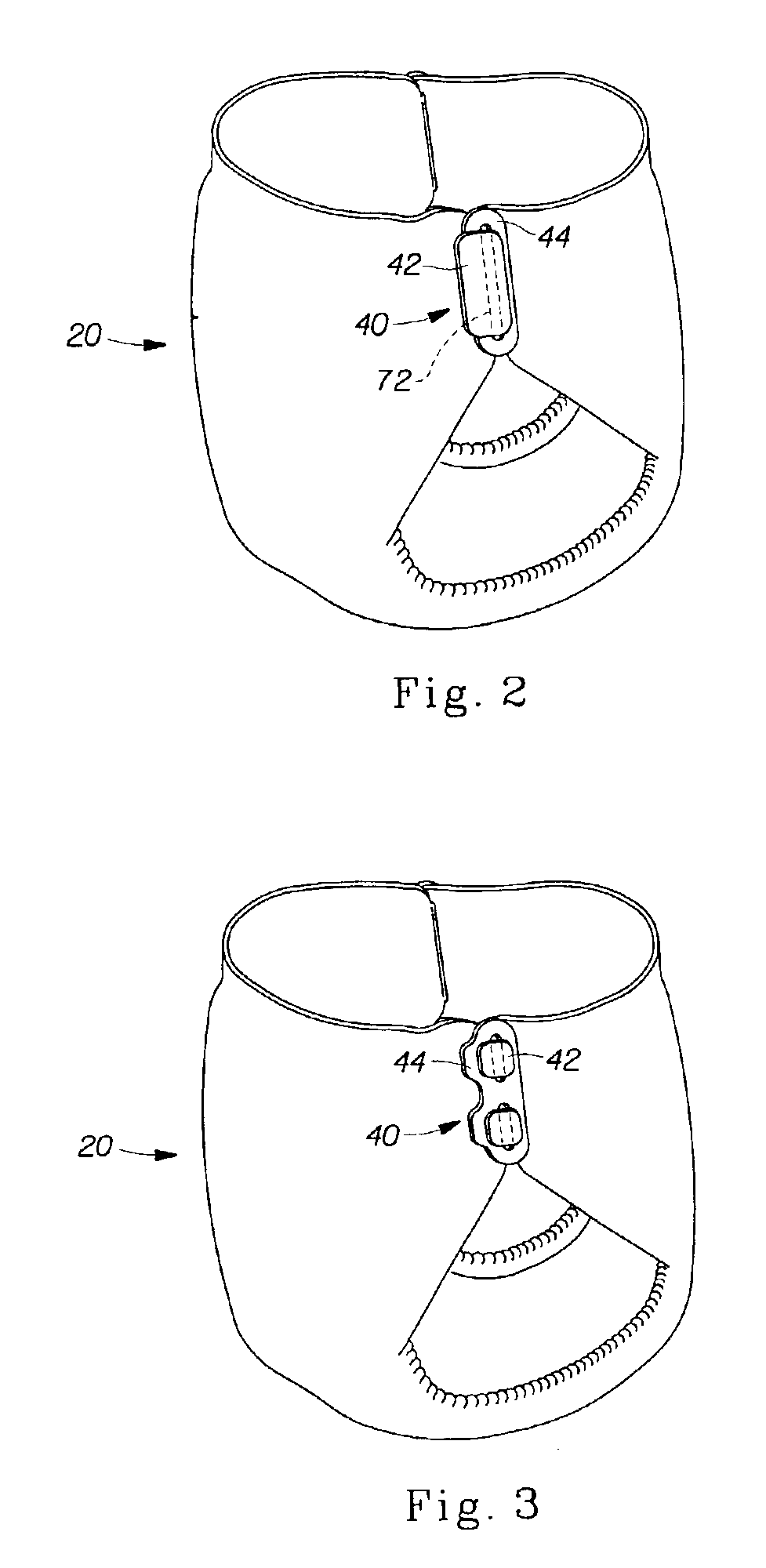

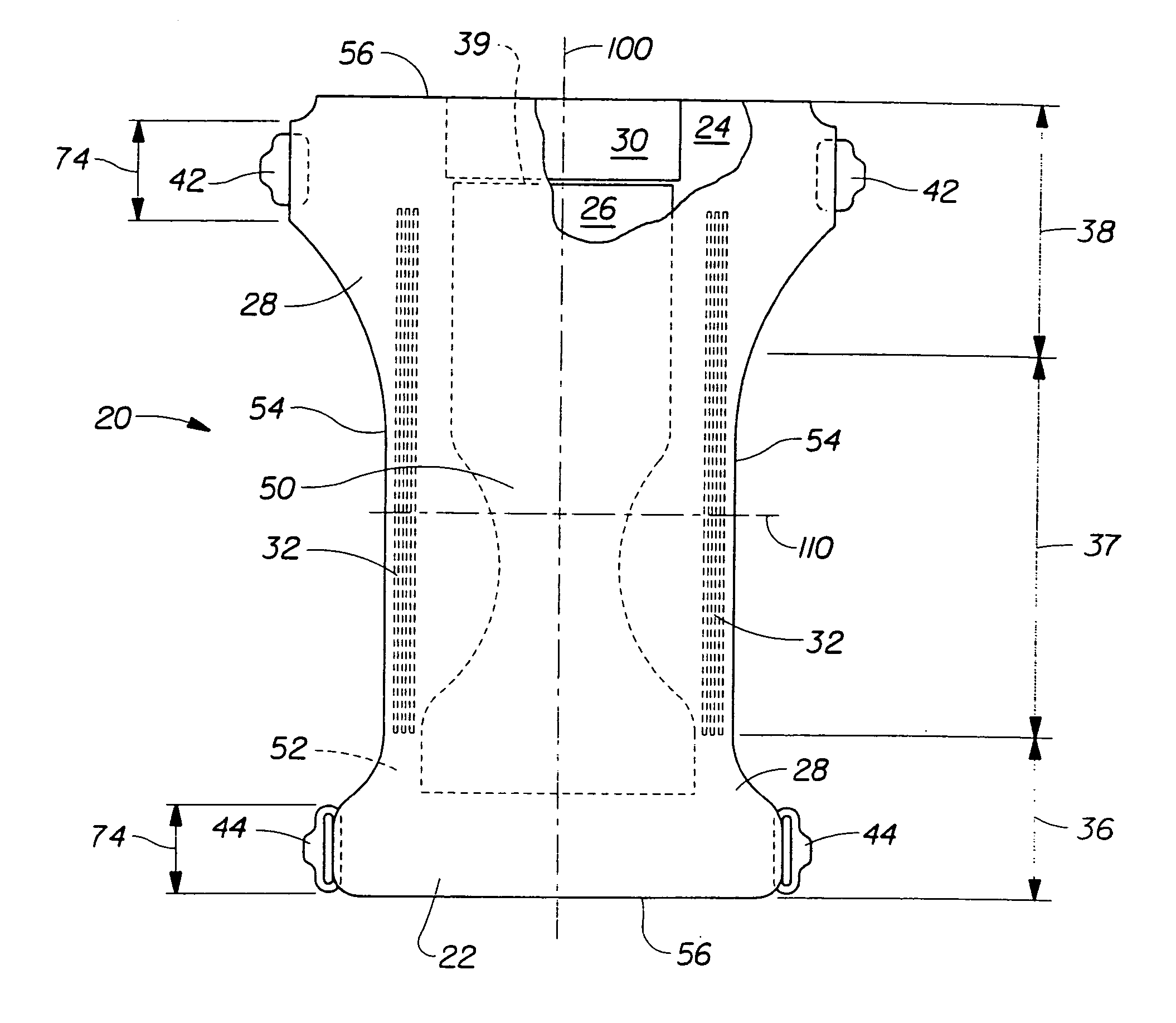

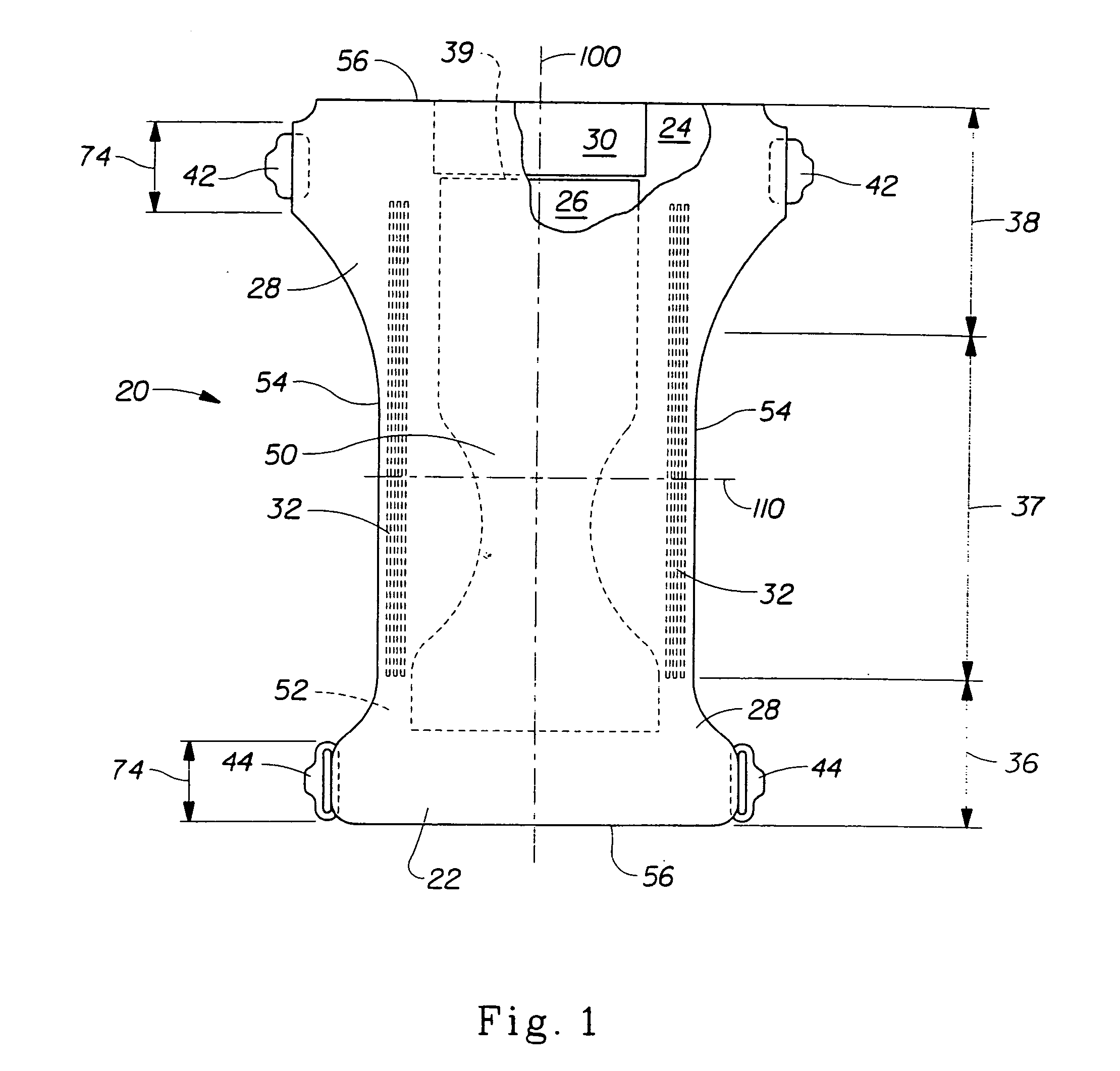

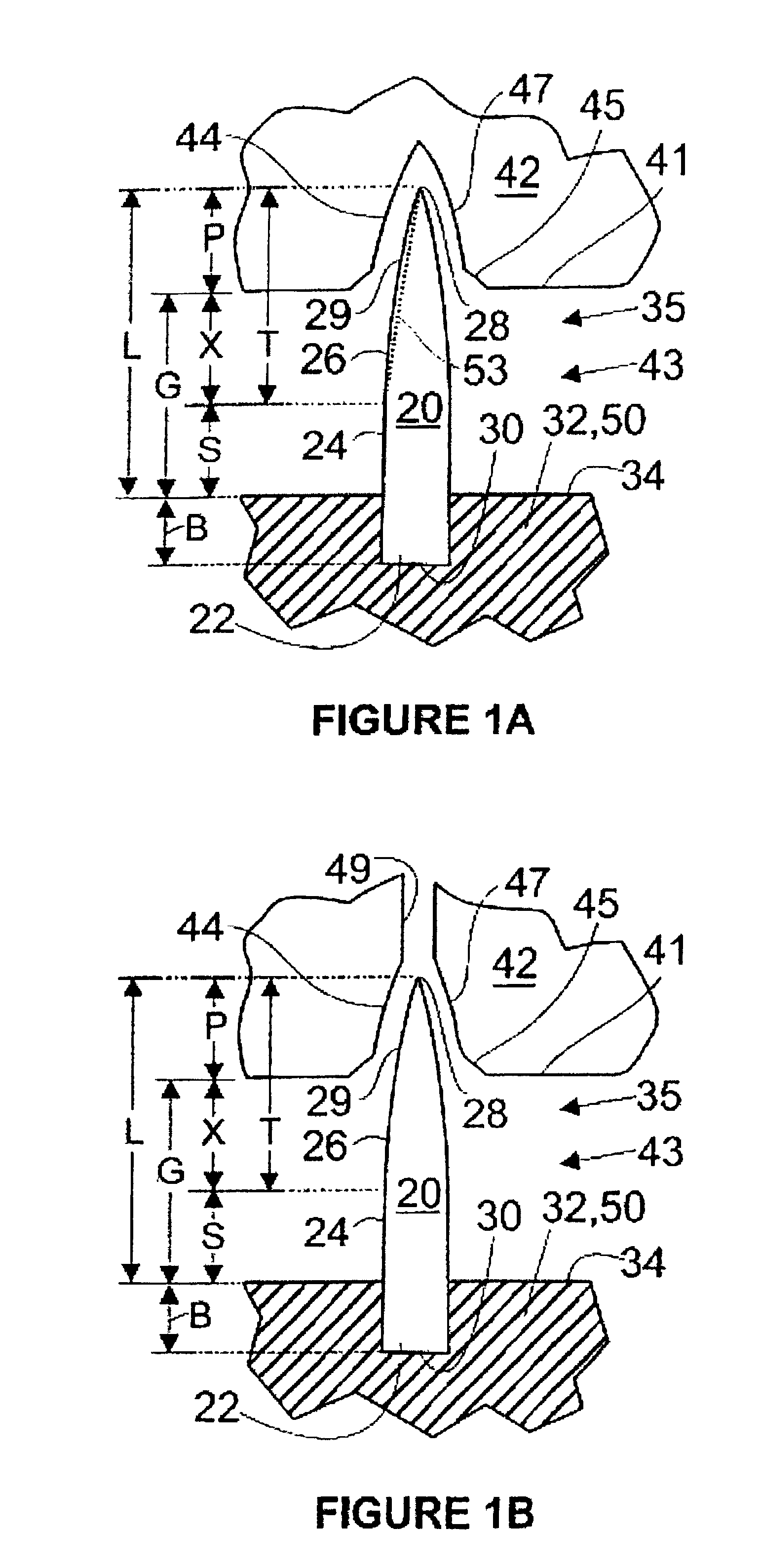

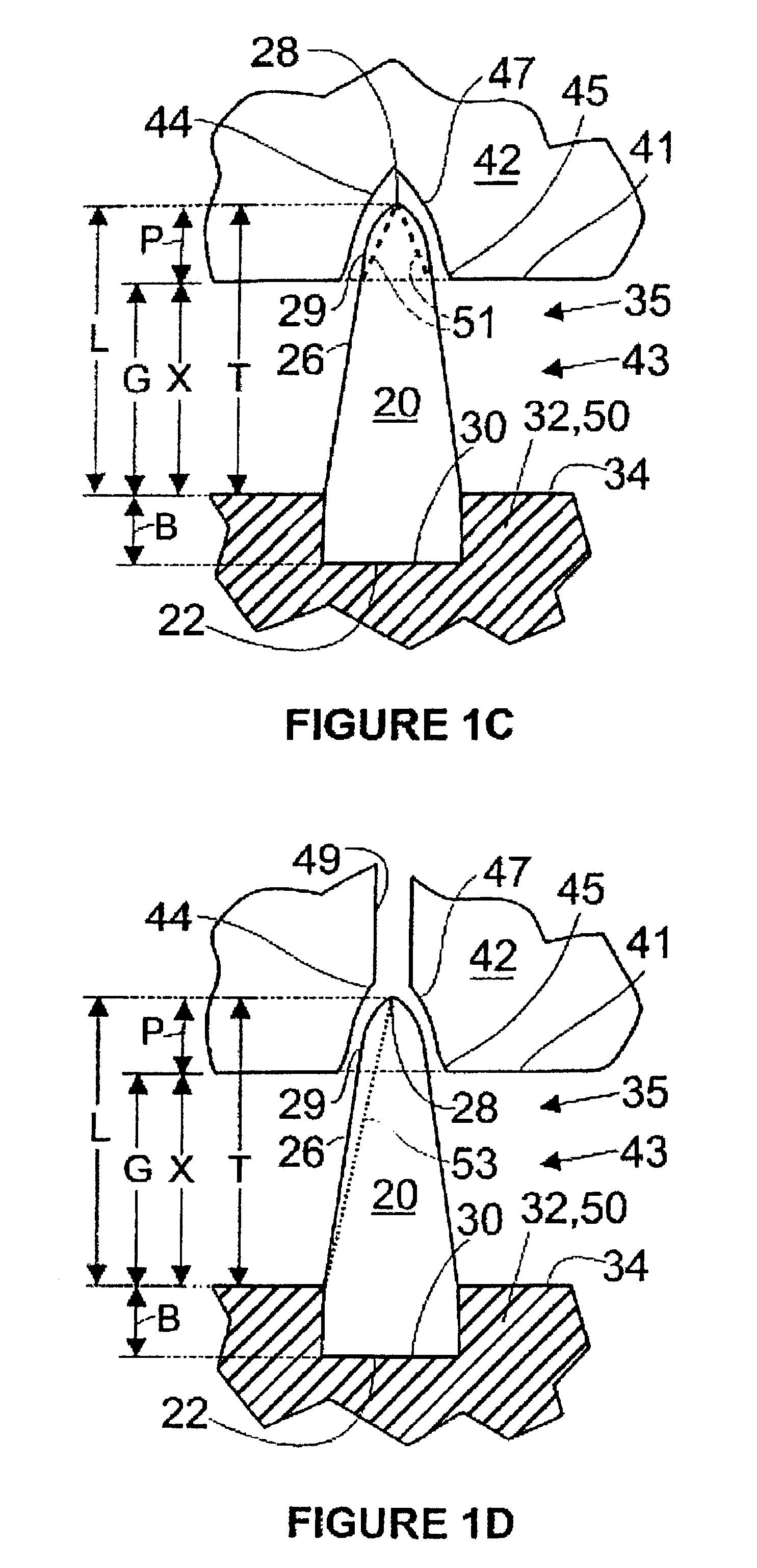

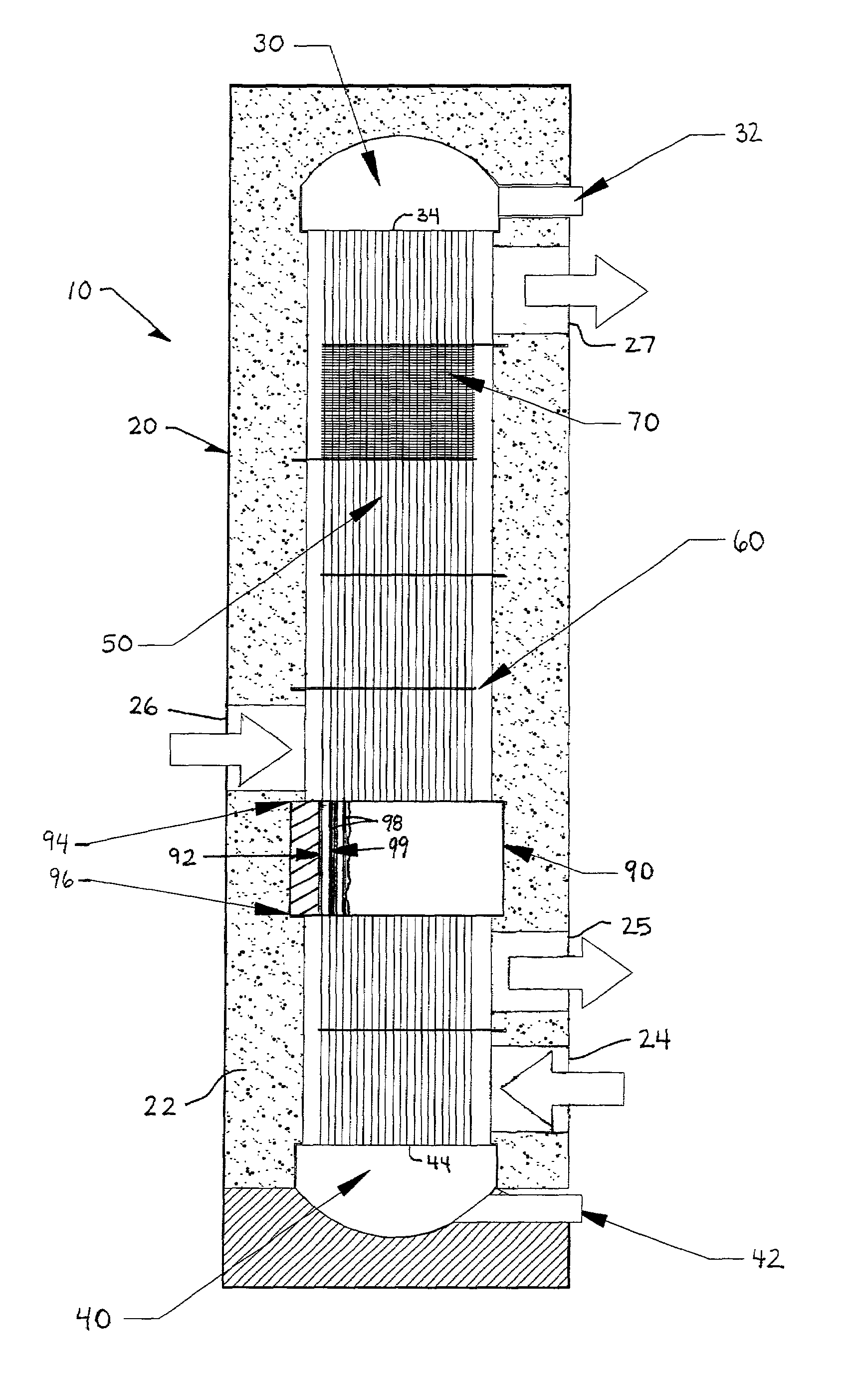

Multiple band ligator and anoscope system and method for using same

InactiveUS7037314B2Facilitate ligationReduce material usageSuture equipmentsRectum colonoscopesInternal HemorrhoidBiomedical engineering

A hemorrhoidal ligator and anoscope system used to facilitate ligation of internal hemorrhoids. The ligating device consists of head, shaft and firing handle assemblies and is capable of storing and releasing multiple rubber bands singularly. The ligating device comprises an inner cylinder that is removable for disposal or reloading for reuse. The inner cylinder may also be configured with a disposable sleeve, the sleeve being disposable or capable of reloading. A modified loading cone is provided for facilitating loading of the rubber bands onto the inner cylinder or the inner cylinder sleeve 9. The anoscope is configured with three lateral apertures that coincide with the anatomic locations of the internal hemorrhoids in man and thus, simultaneously expose all three hemorrhoids for ligation and grading.

Owner:ARMSTRONG DAVID N

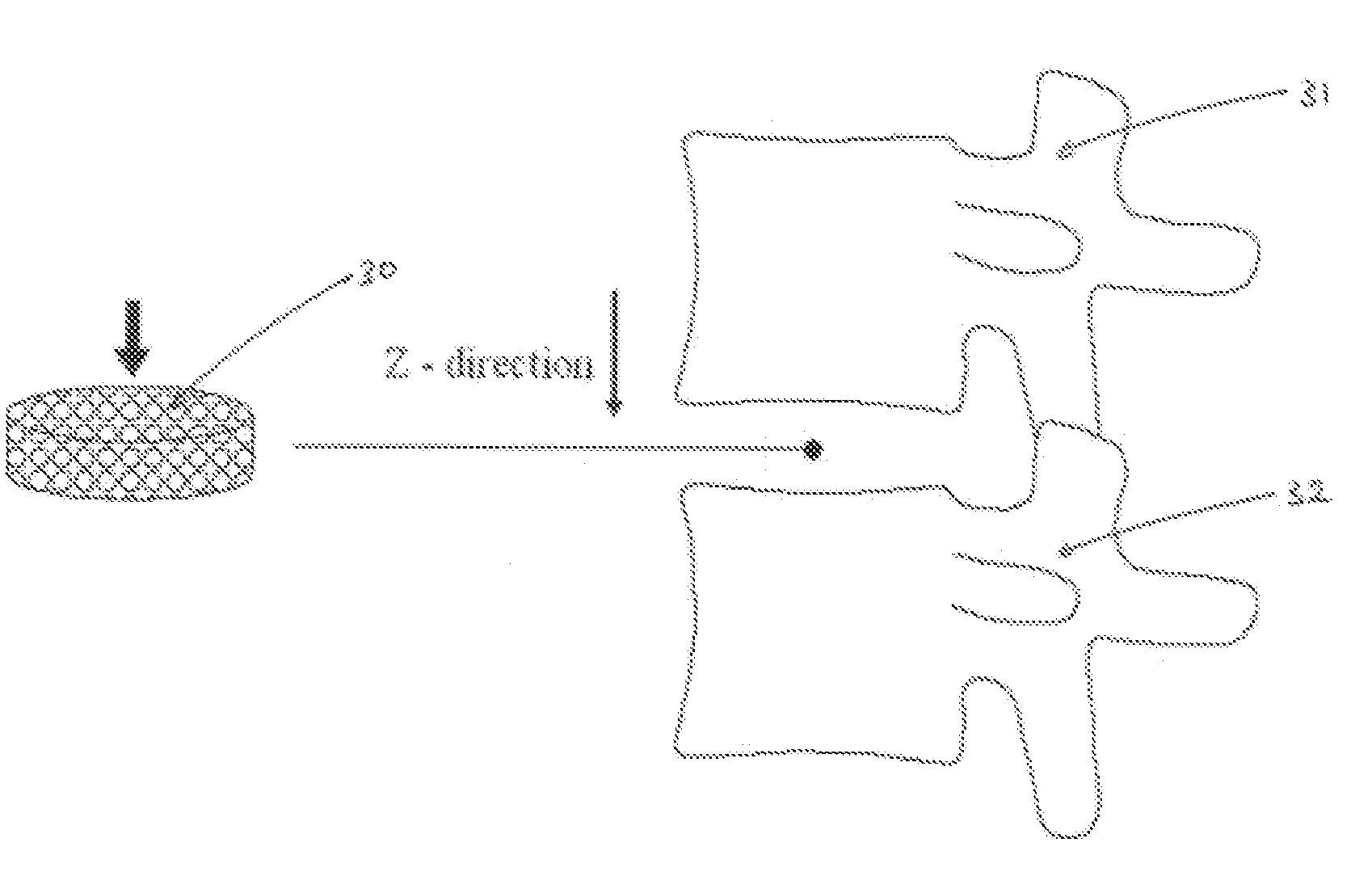

Porous Substrates for Implantation

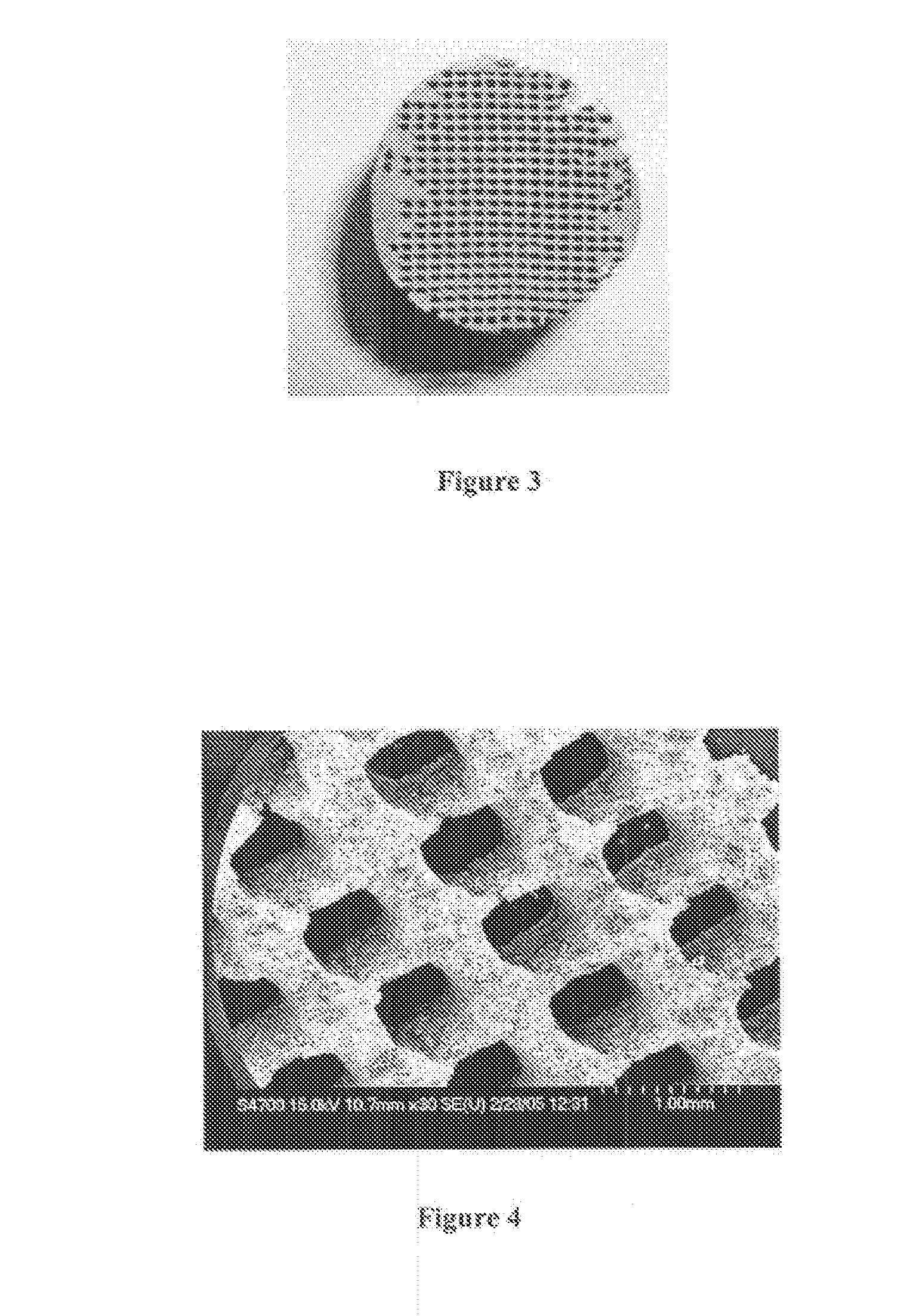

InactiveUS20100137990A1Easy to integrateGood biocompatibilitySuture equipmentsDental implantsPorous substrateAnimal body

A porous substrate or implant for implantation into a human or animal body constructed from a structural material and having one or more regions which when implanted are subjected to a relatively lower mechanical loading. The region(s) are constructed with lesser mechanical strength by having a lesser amount of structural material in said region(s) relative to other regions. This is achieved by controlling pore volume fraction in the regions. A spacer is adapted to define an open-cell pore network by taking a model of the required porous structure, and creating the spacer to represent the required porous structure using three-dimensional modelling. Material to form the substrate about the spacer in infiltrated the scaffold structure formed.

Owner:NATIONAL UNIVERSITY OF IRELAND

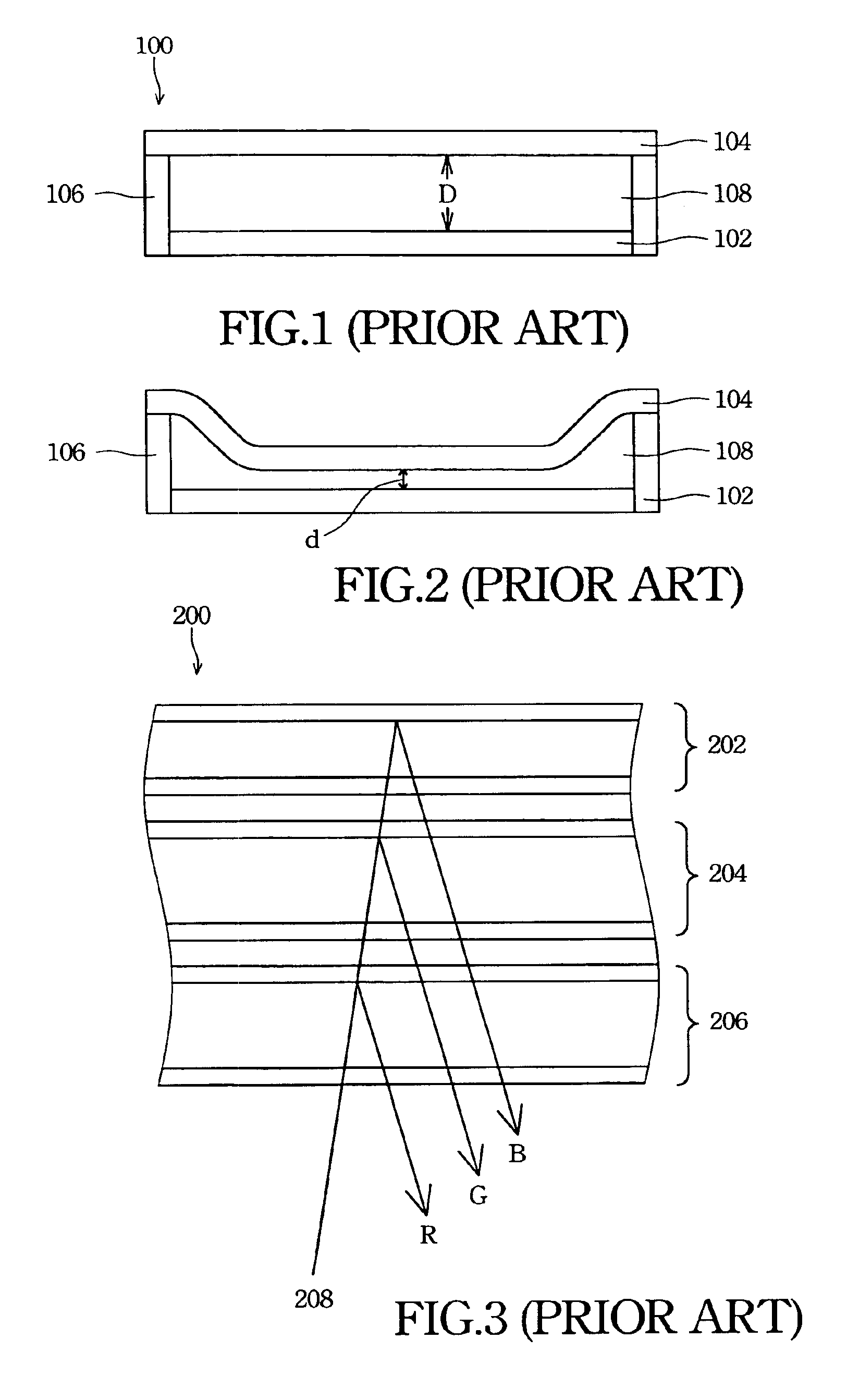

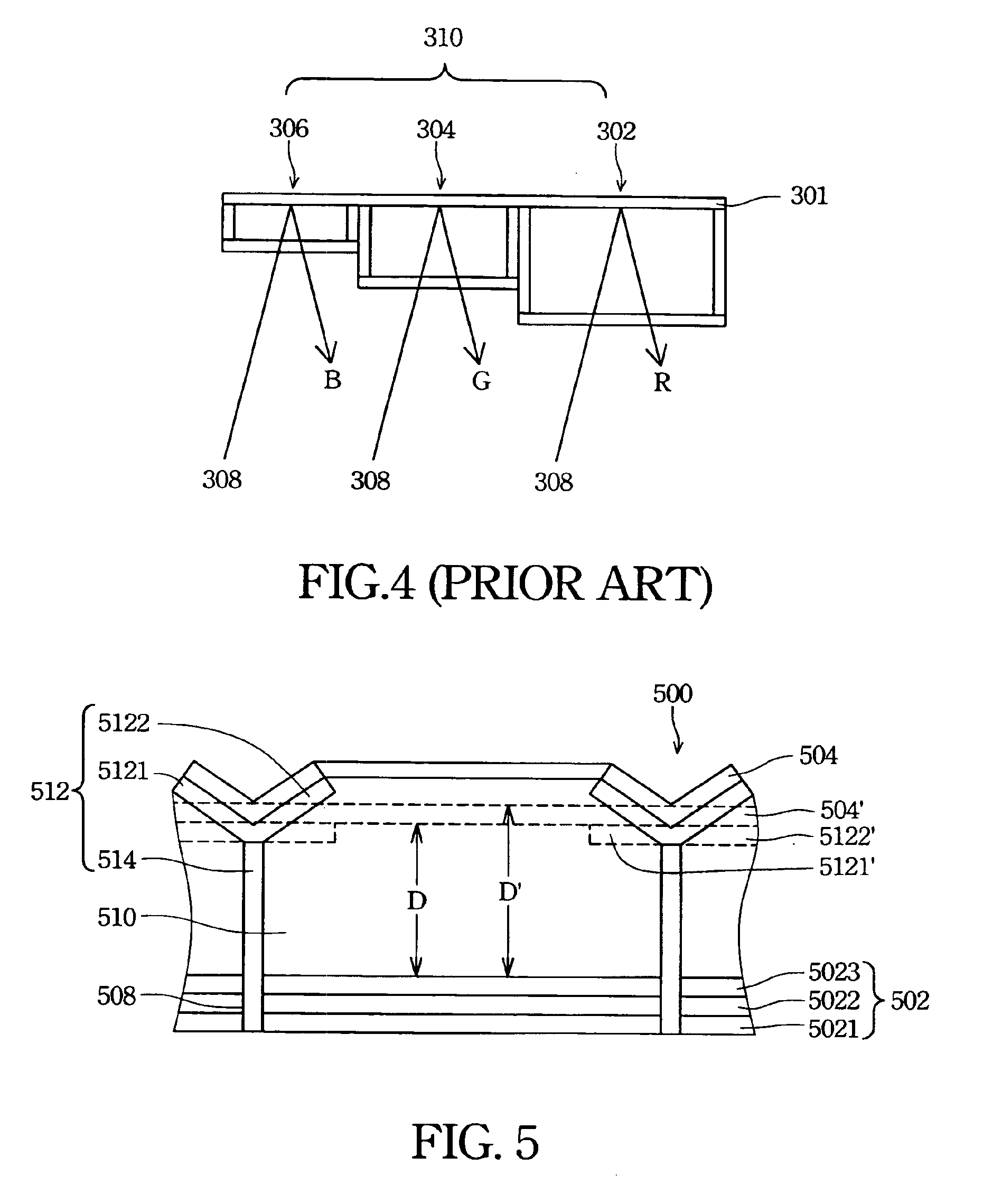

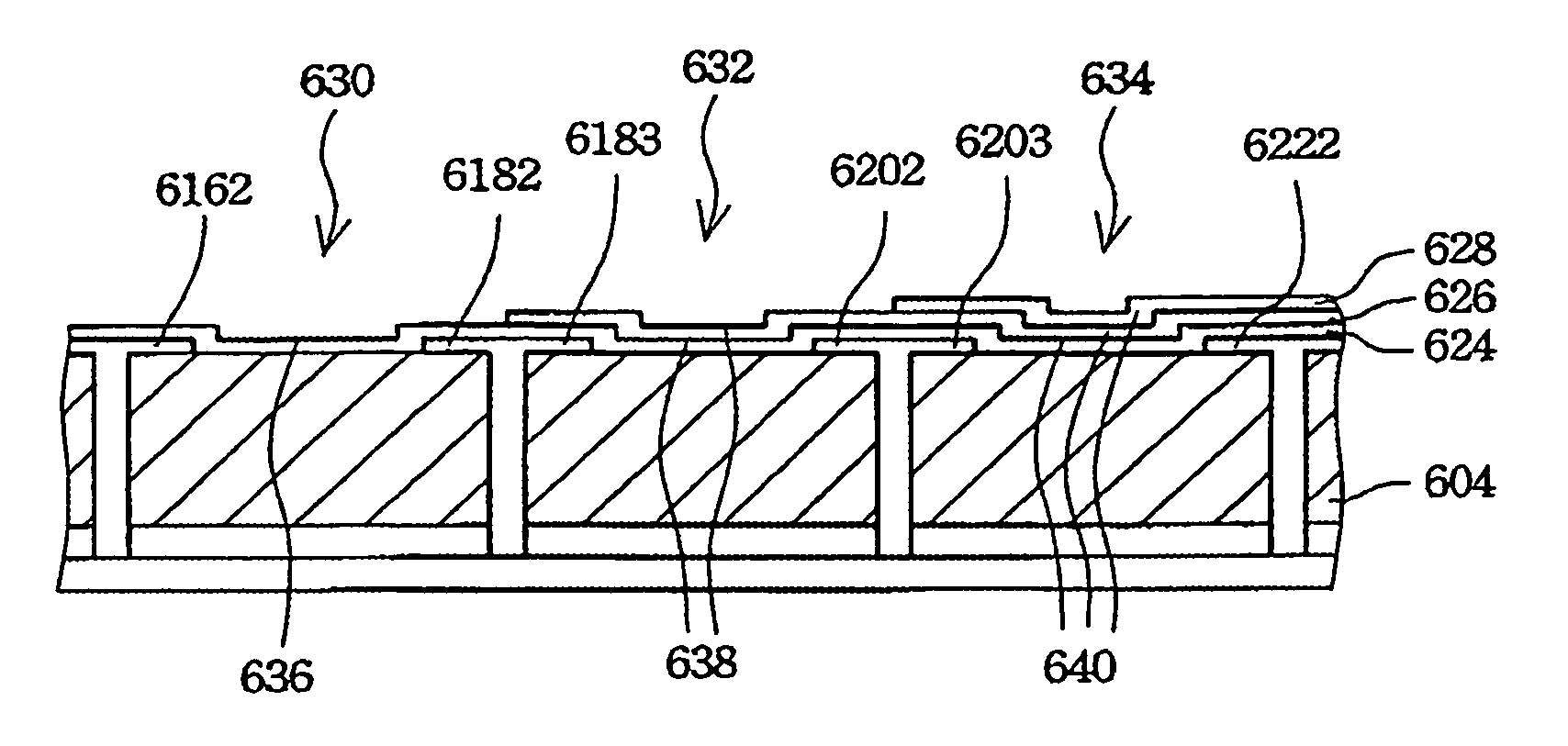

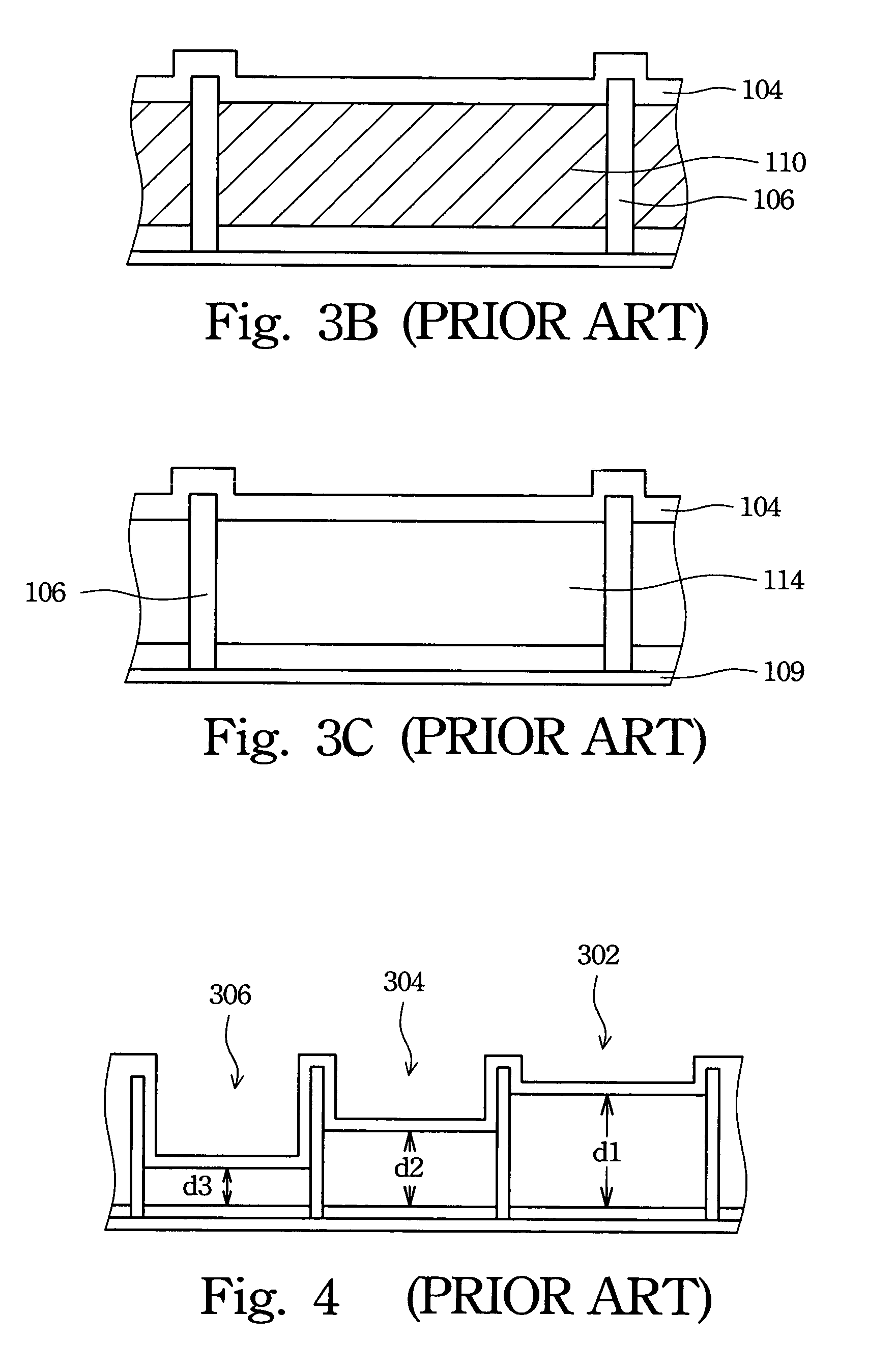

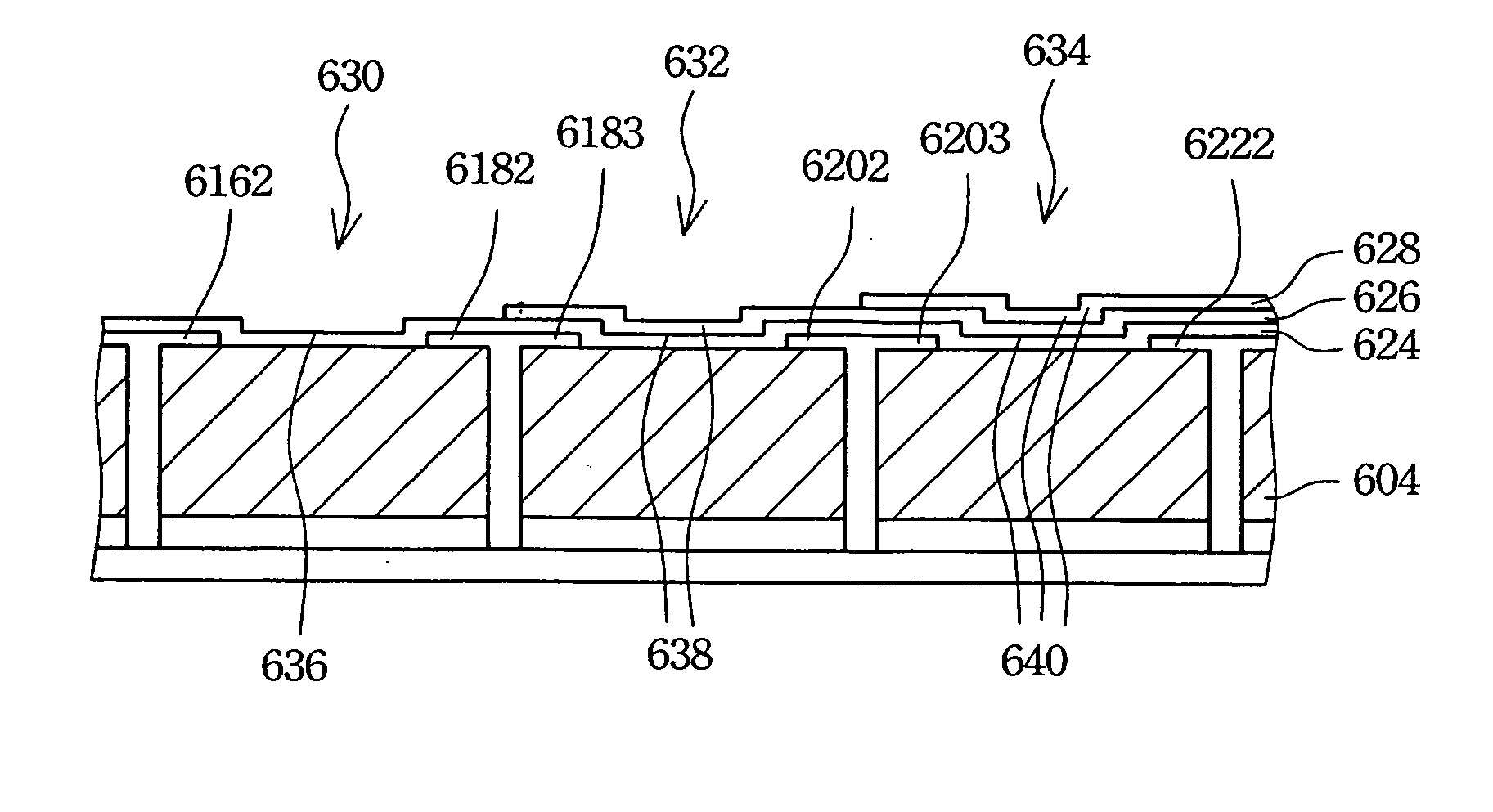

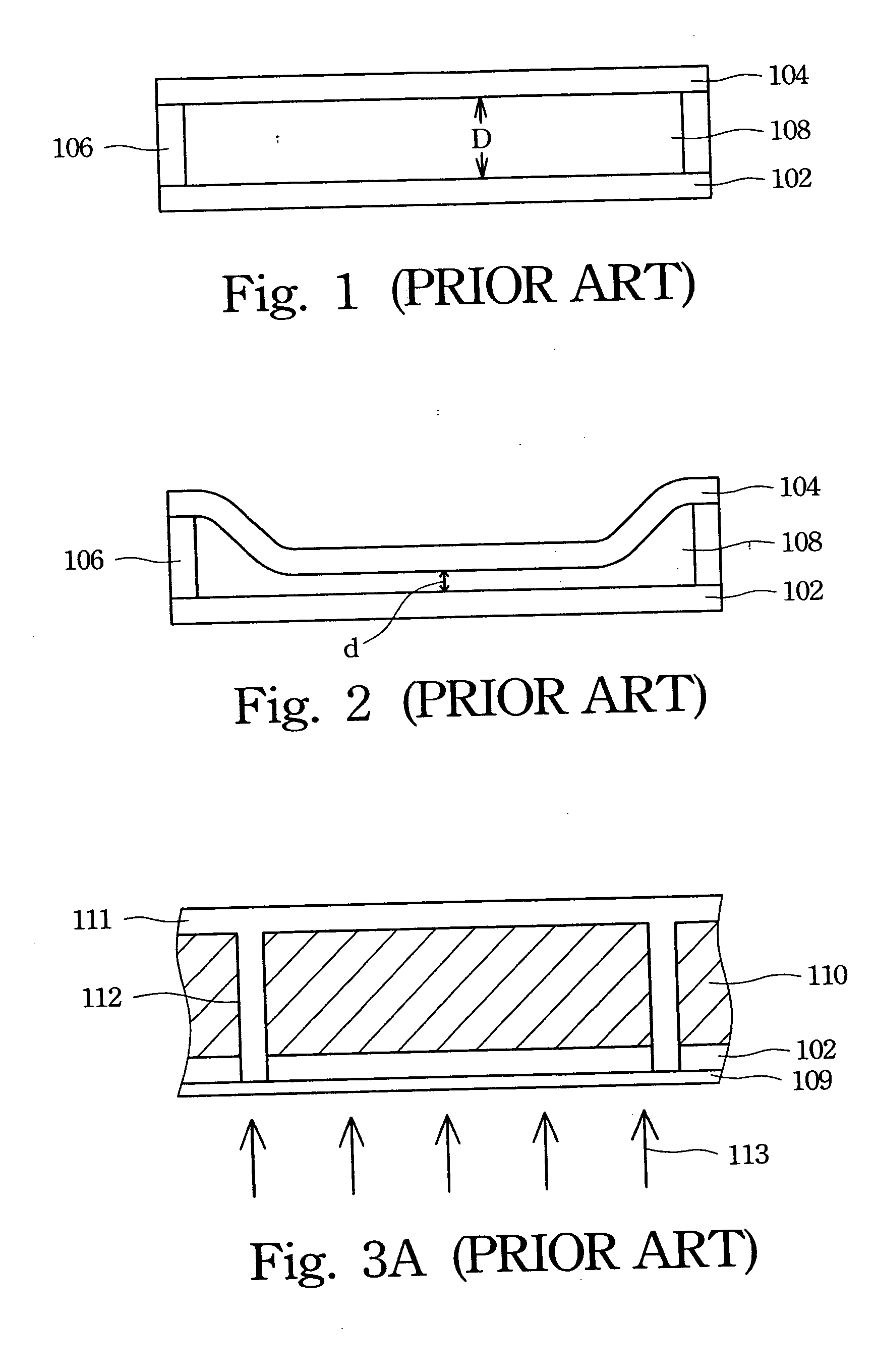

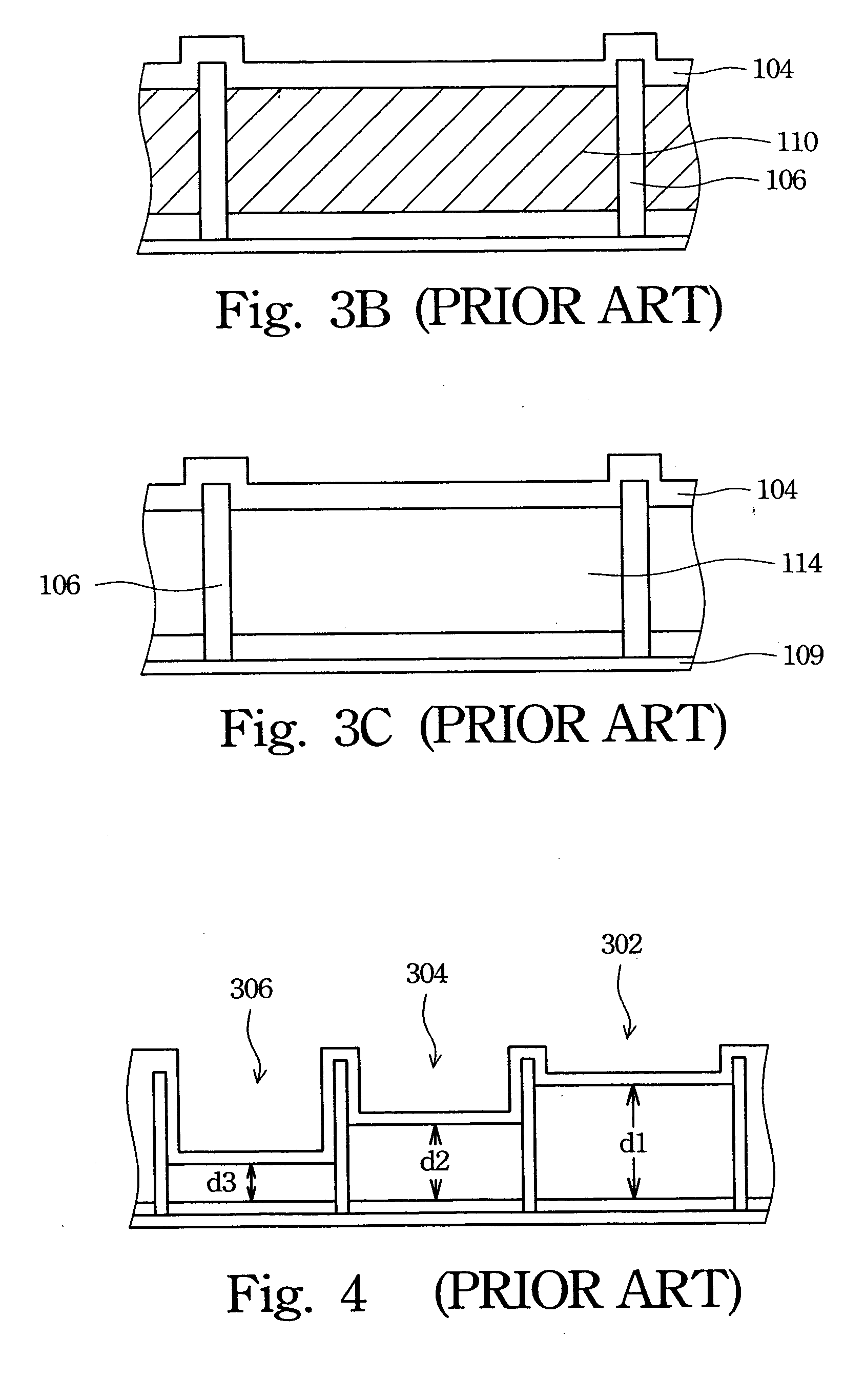

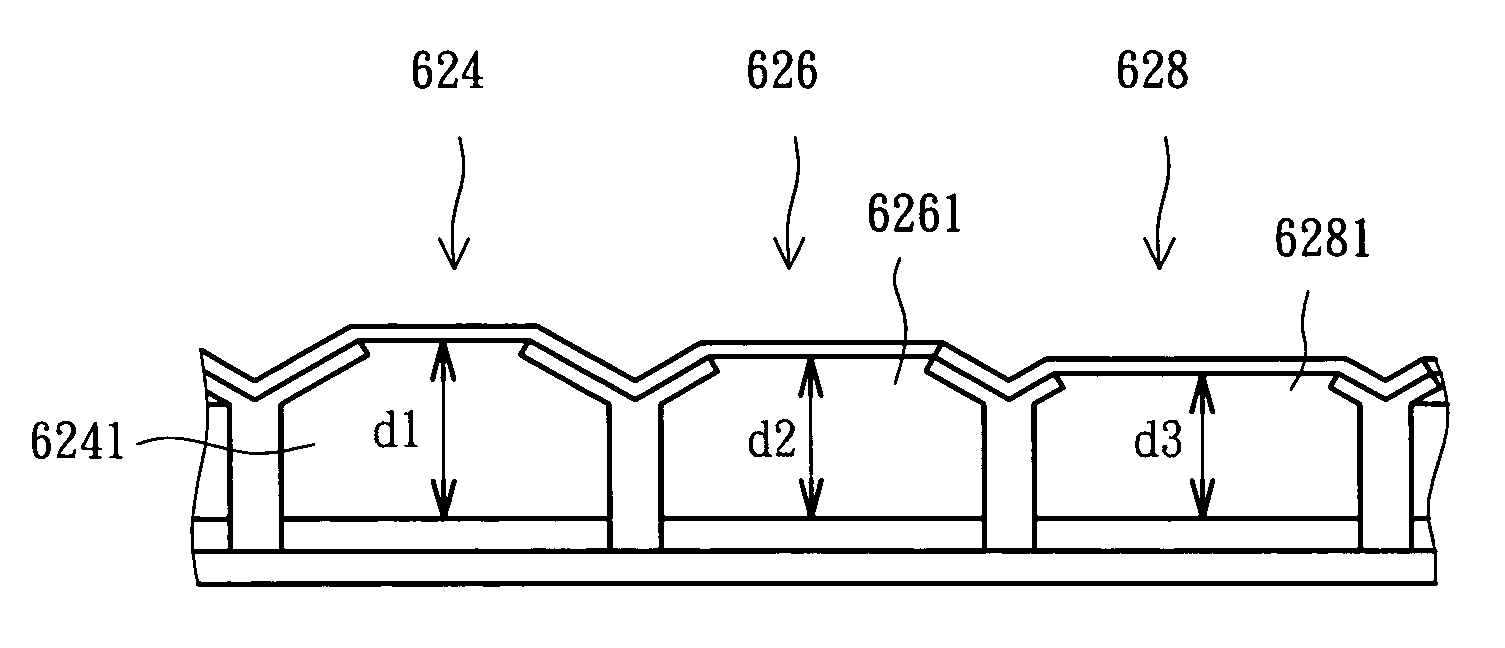

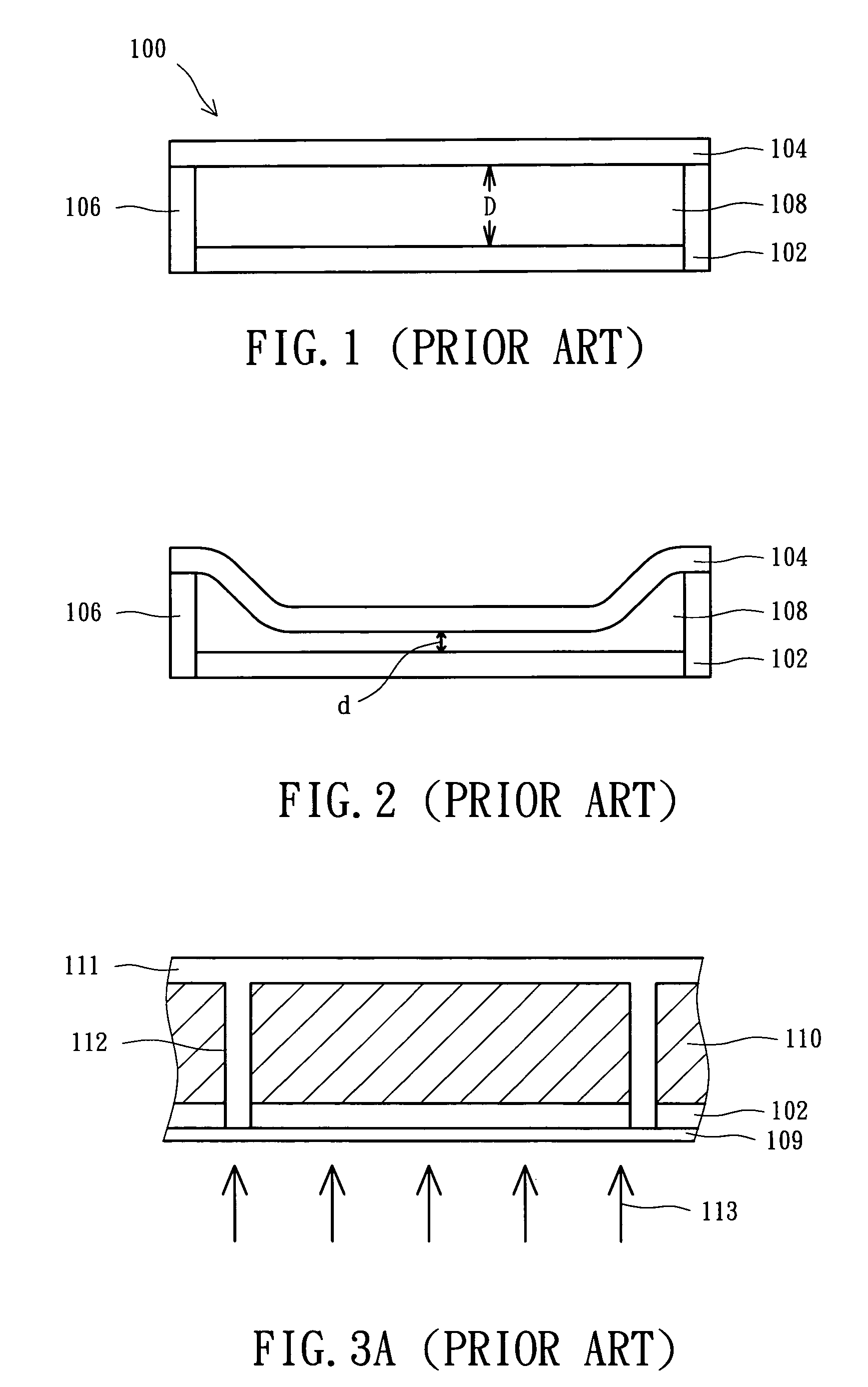

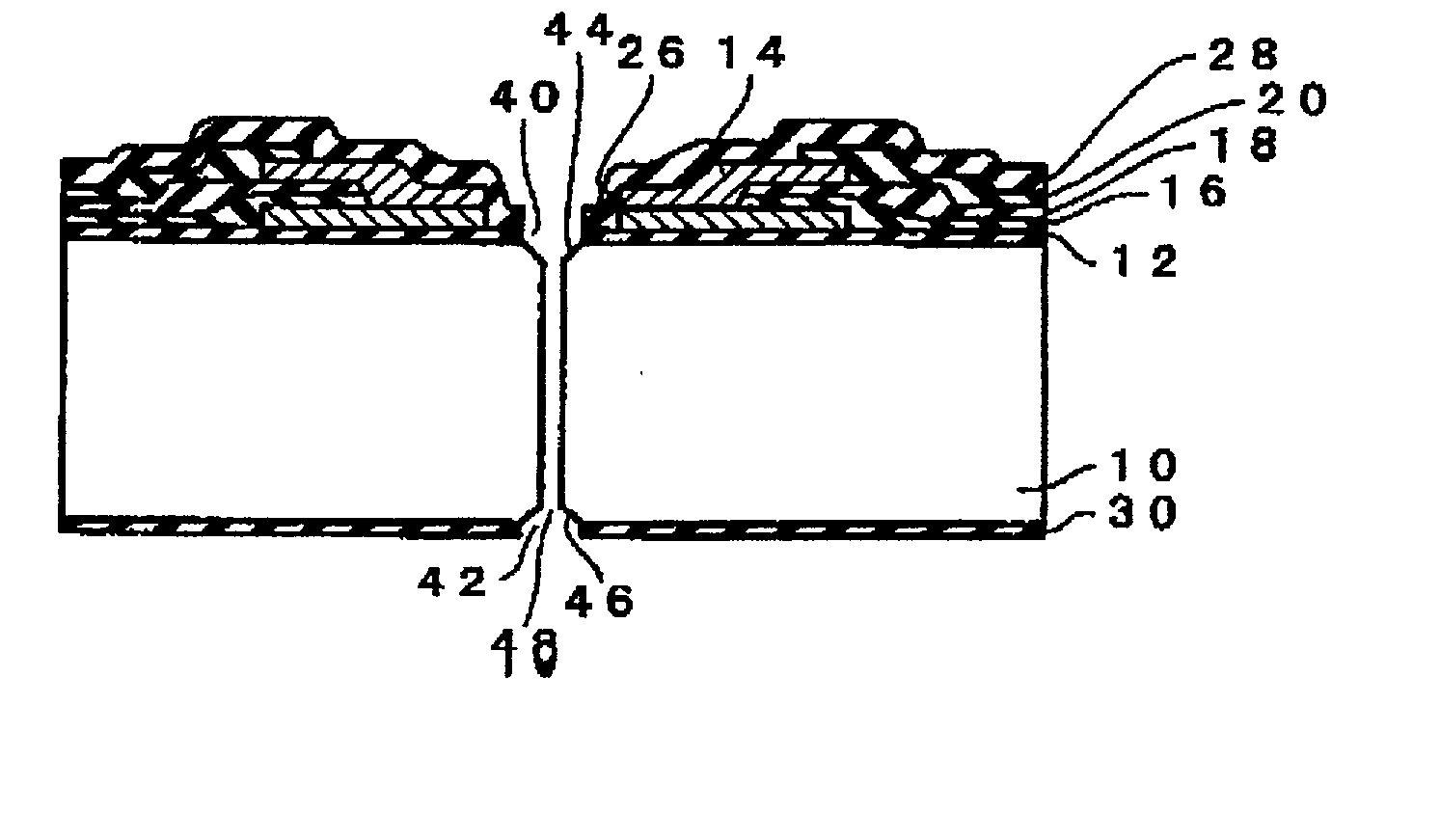

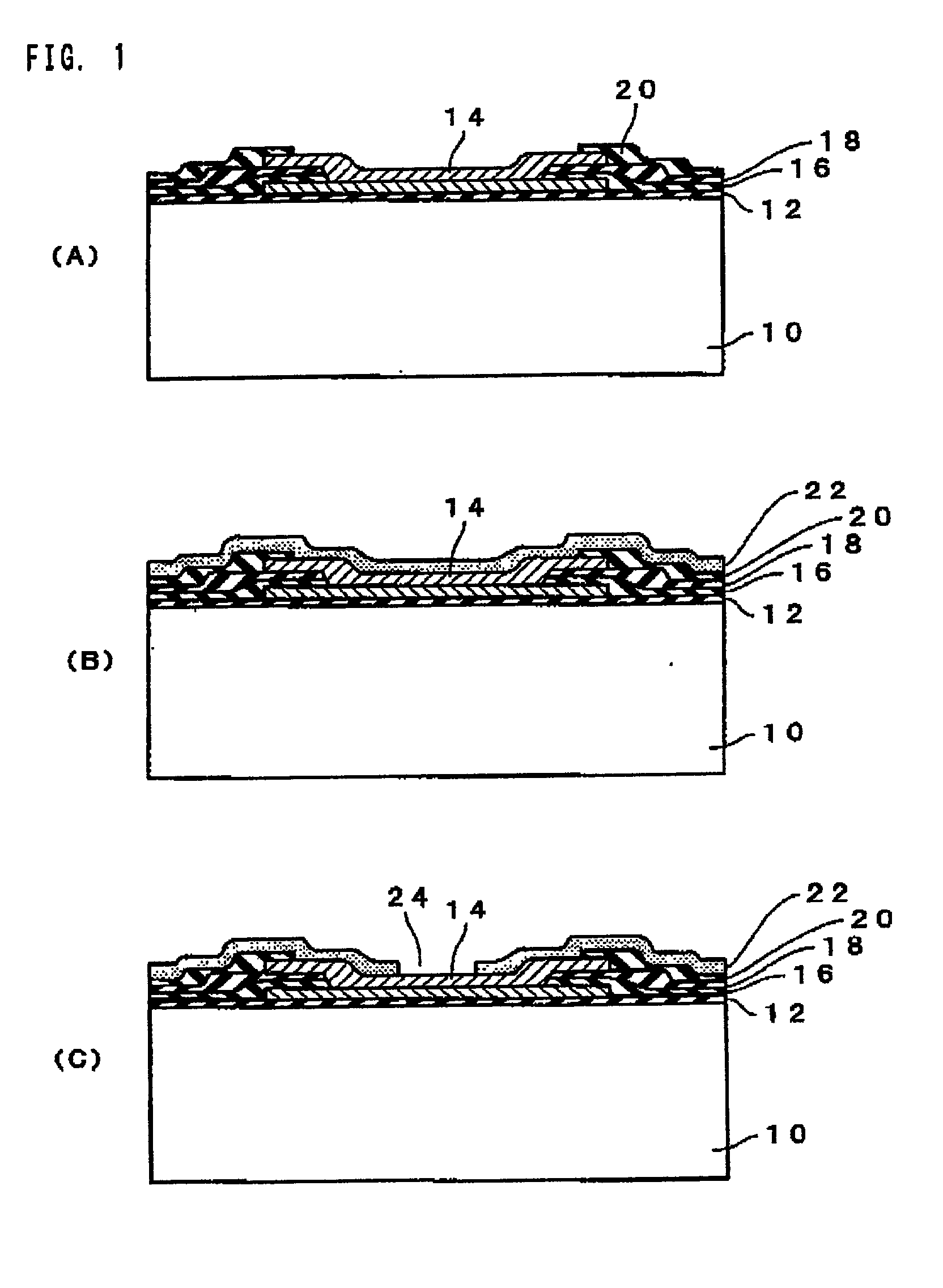

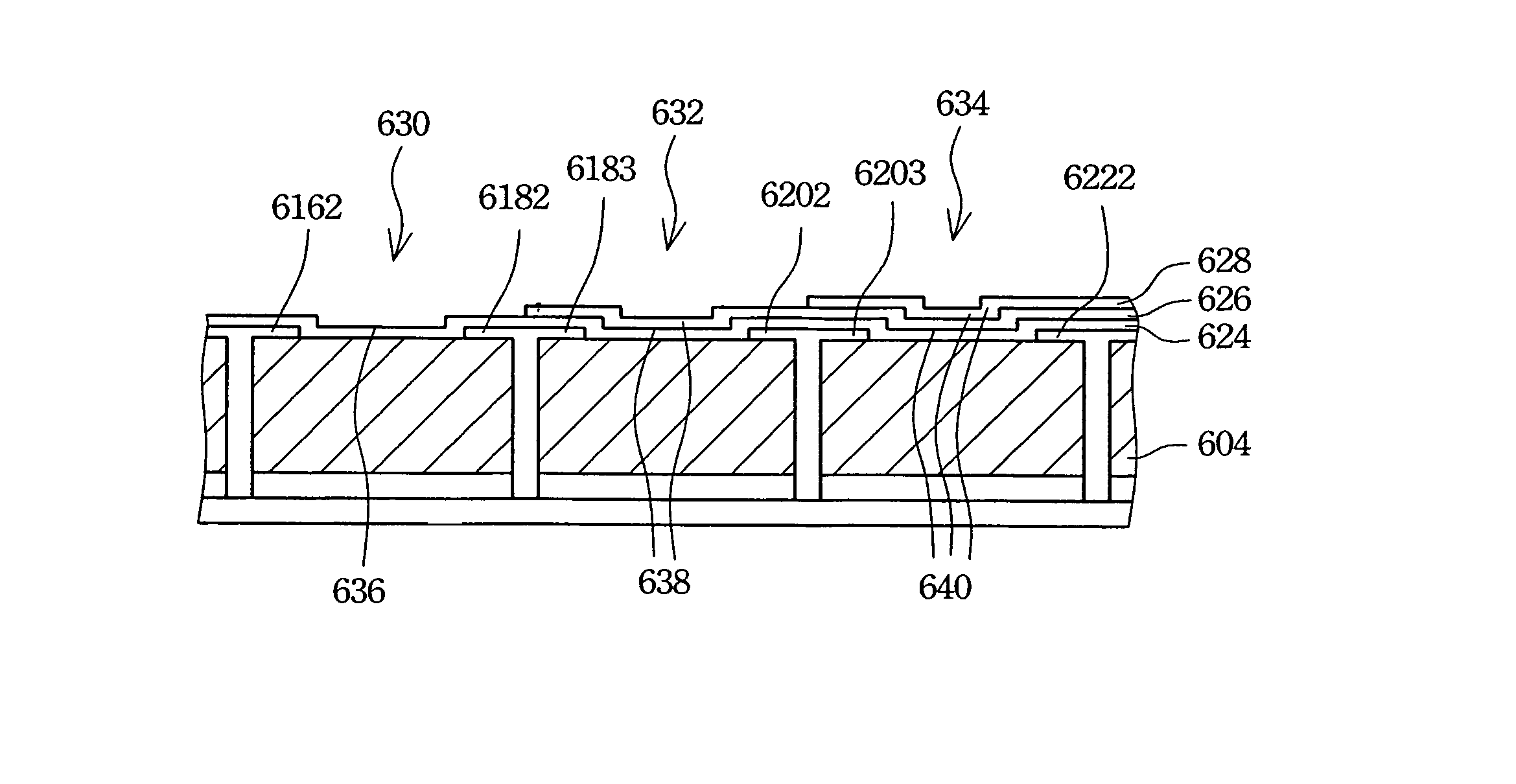

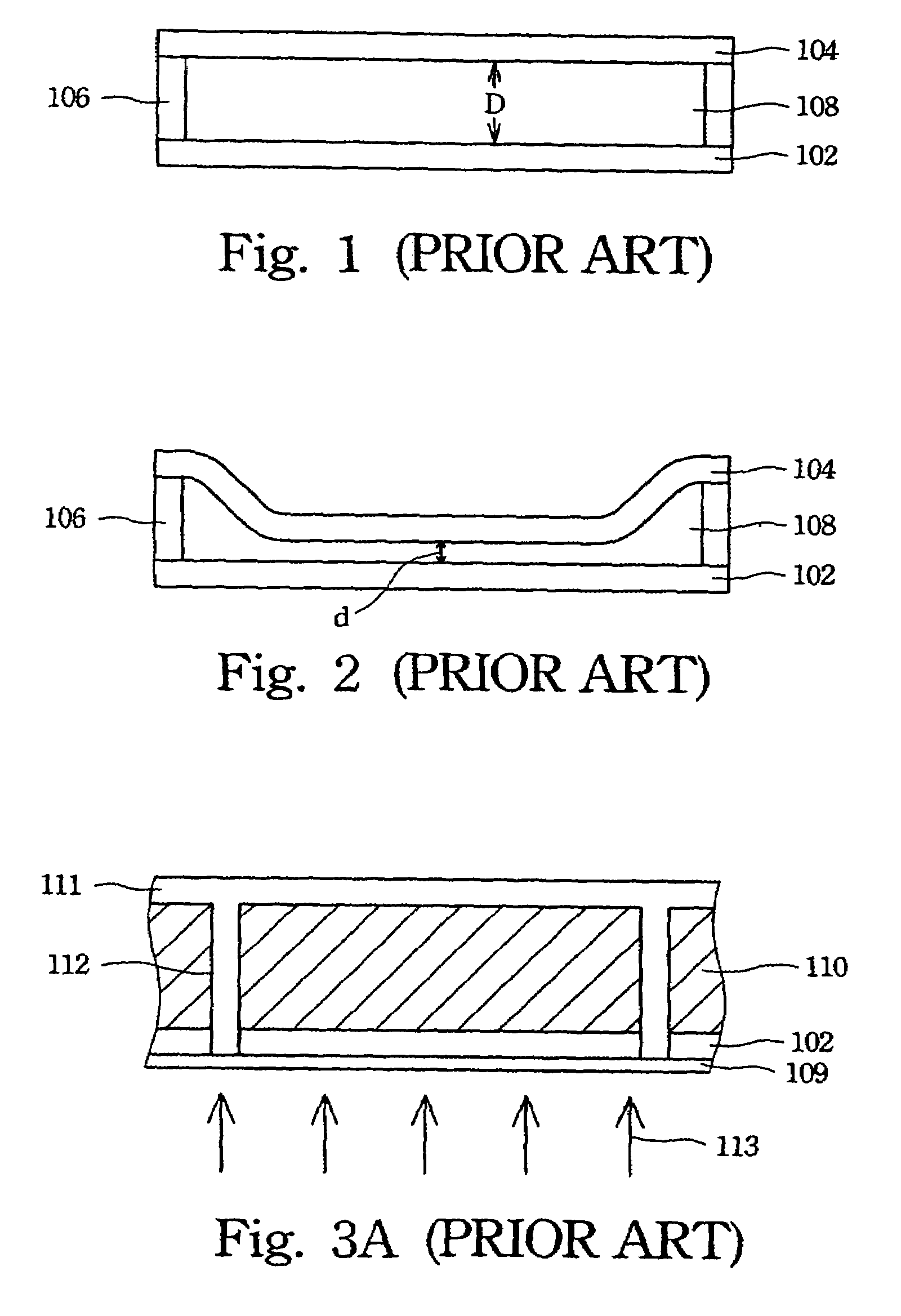

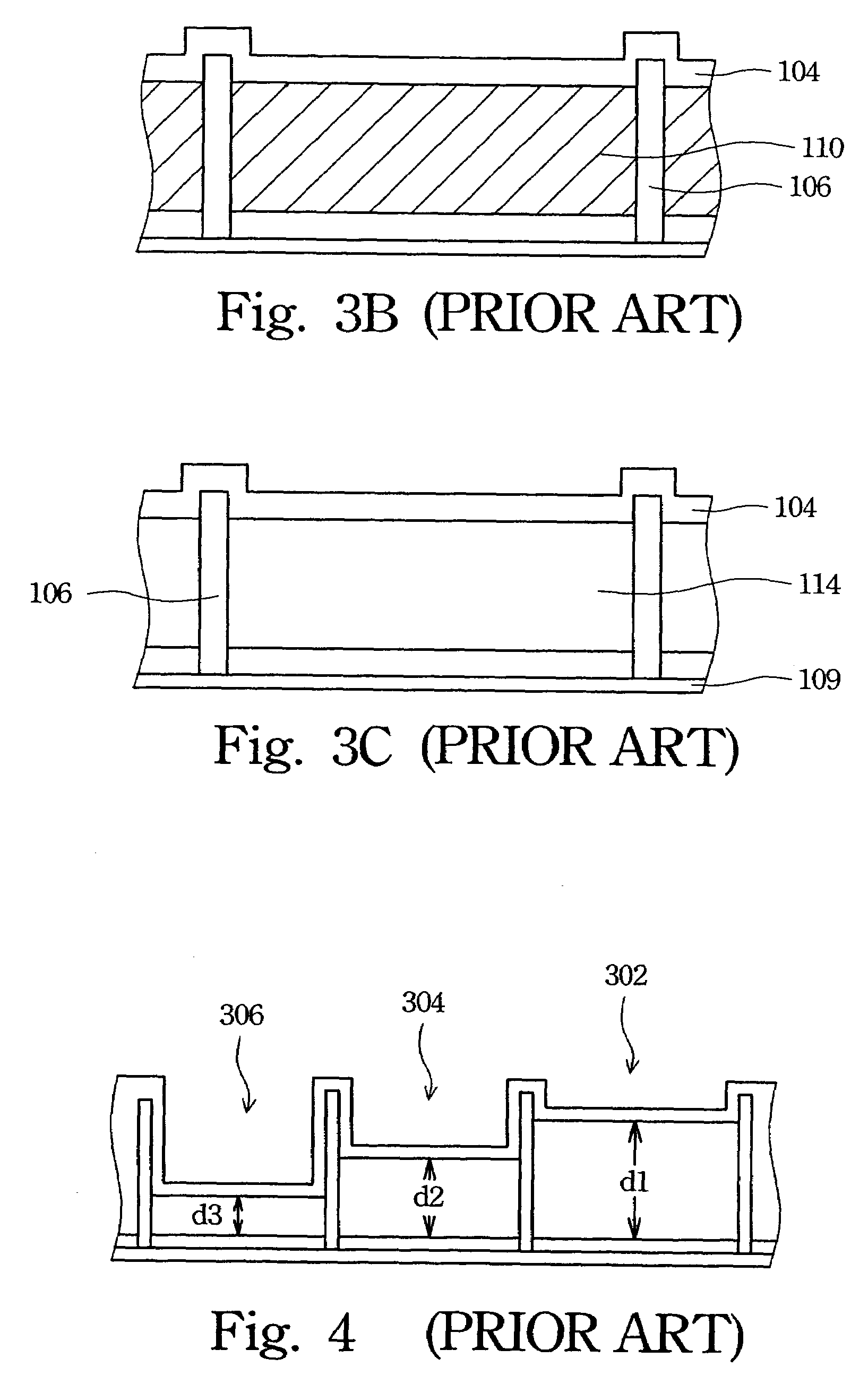

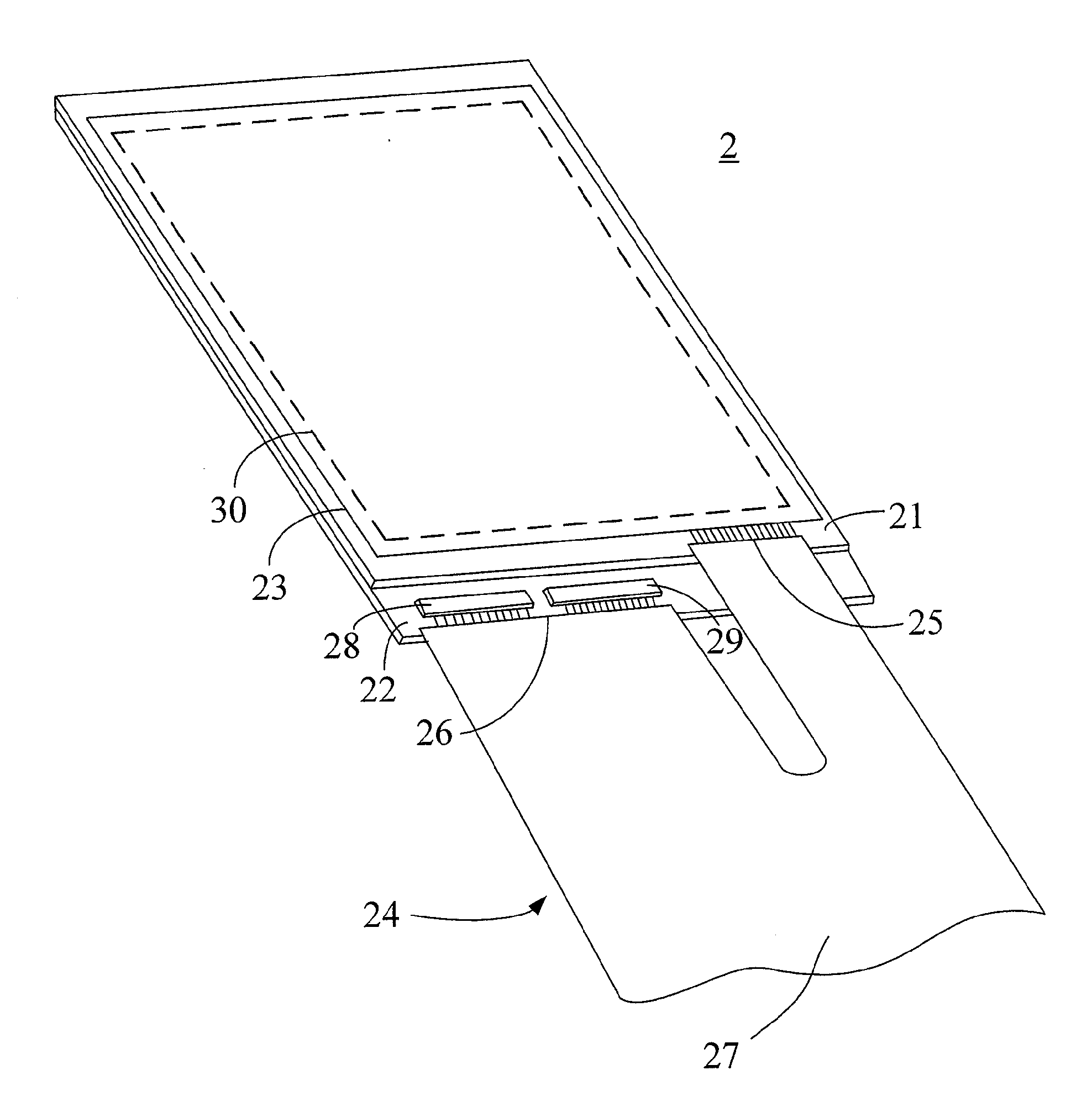

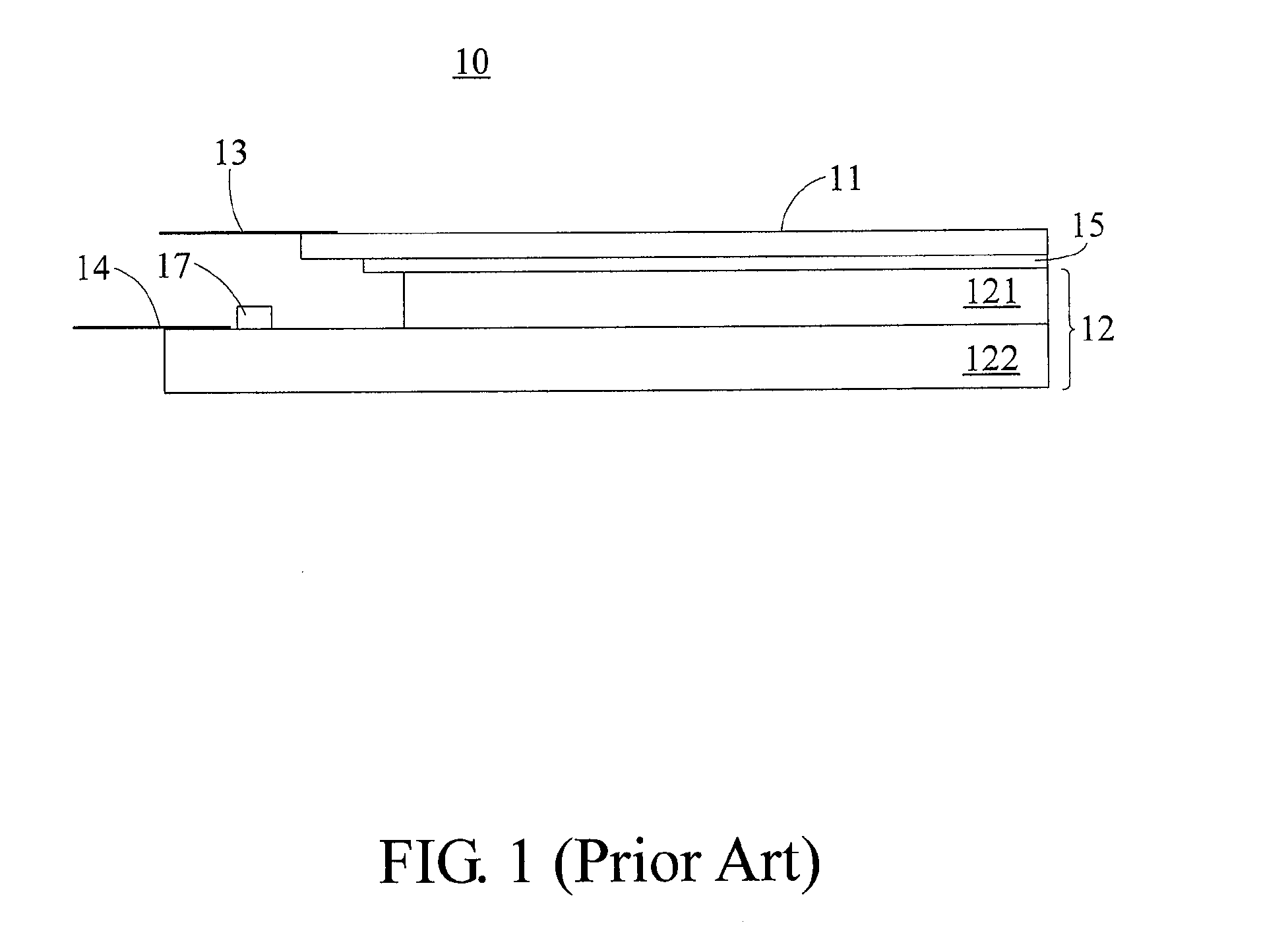

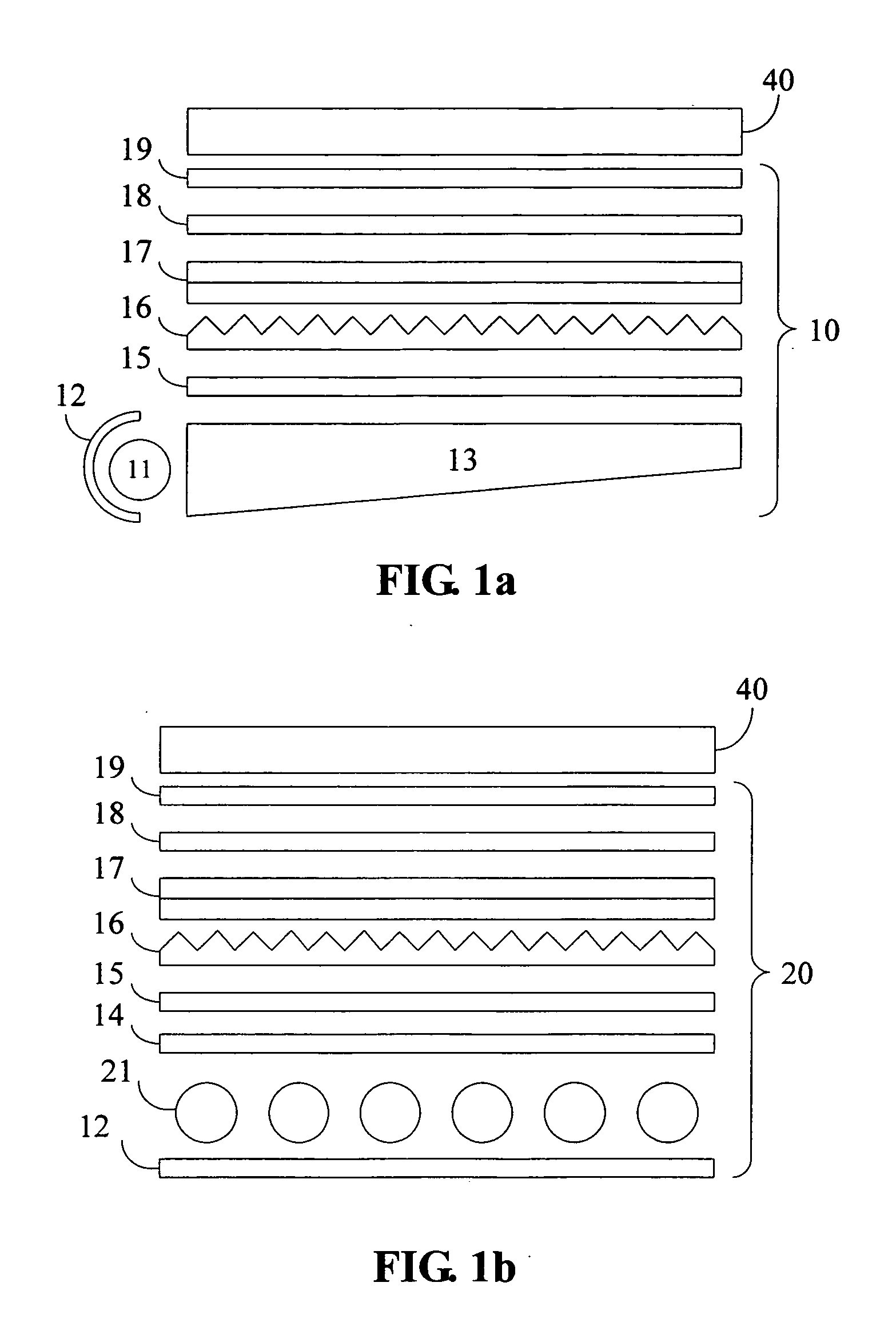

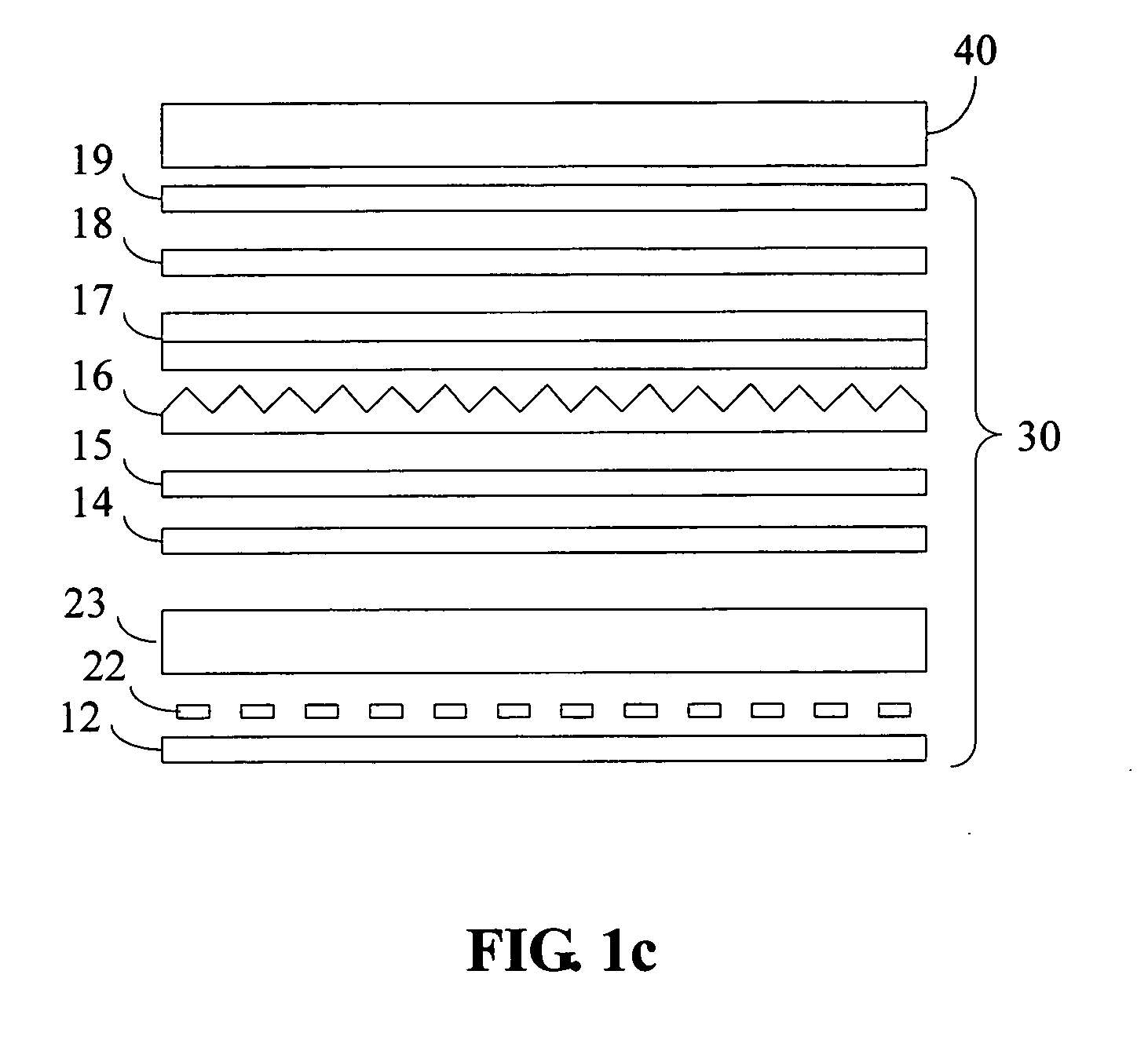

Structure of an optical interference display cell

A structure of an interference display cell is provided. The cell comprises a first plate and a second plate, wherein a support is located between the first plate and the second plate. The second plate is a deformable and reflective plate. An incident light from one side of the first plate is modulated and only specific frequency light reflects by the second plate. The frequency of the reflected light is related to the distance between the first plate and the second plate. The support has at least one arm. The arm's stress makes the arm hiking upward or downward. The distance between the first plate and the second plate is also changed. Therefore, the frequency of the reflected light is altered.

Owner:SNAPTRACK

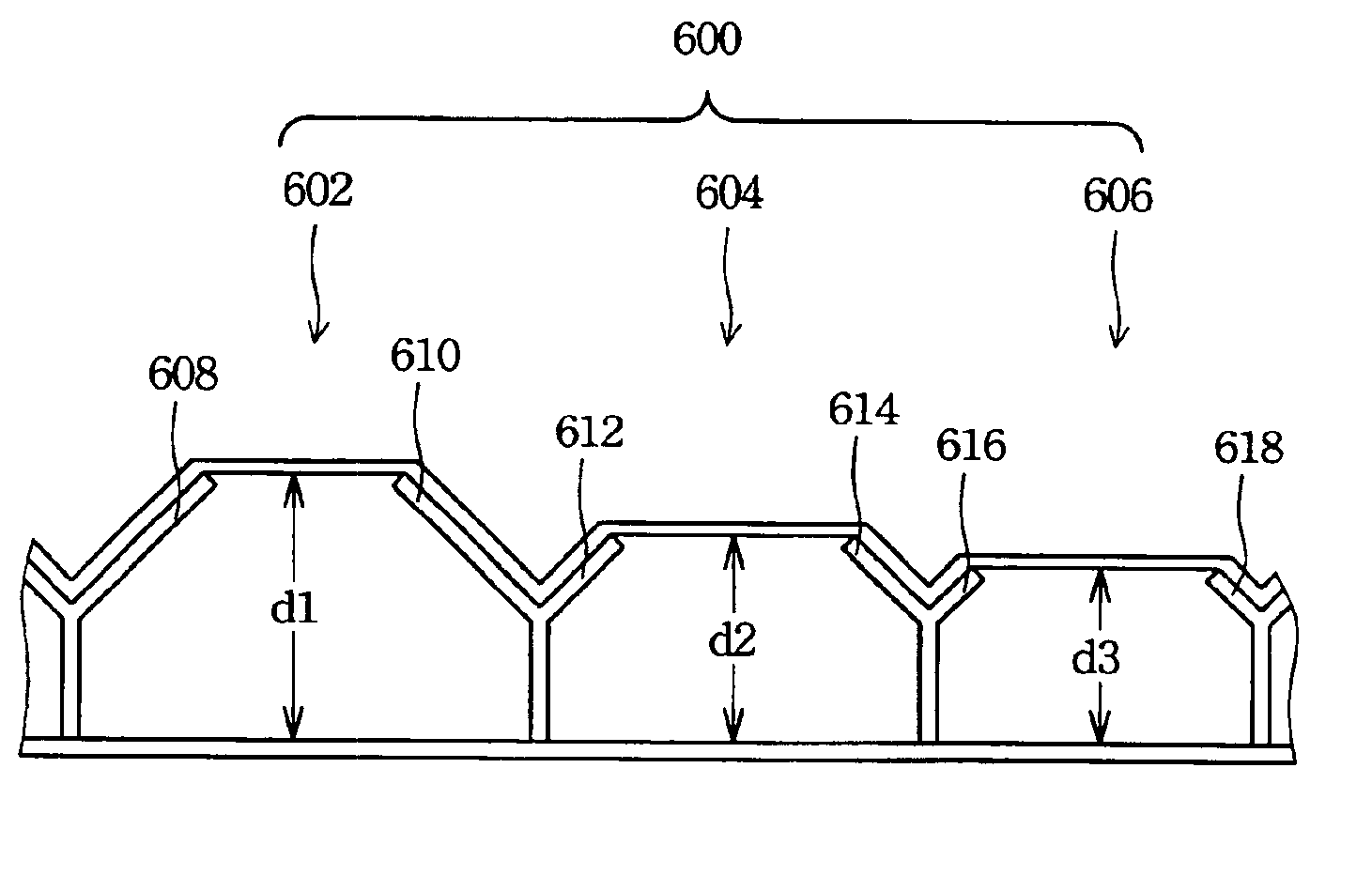

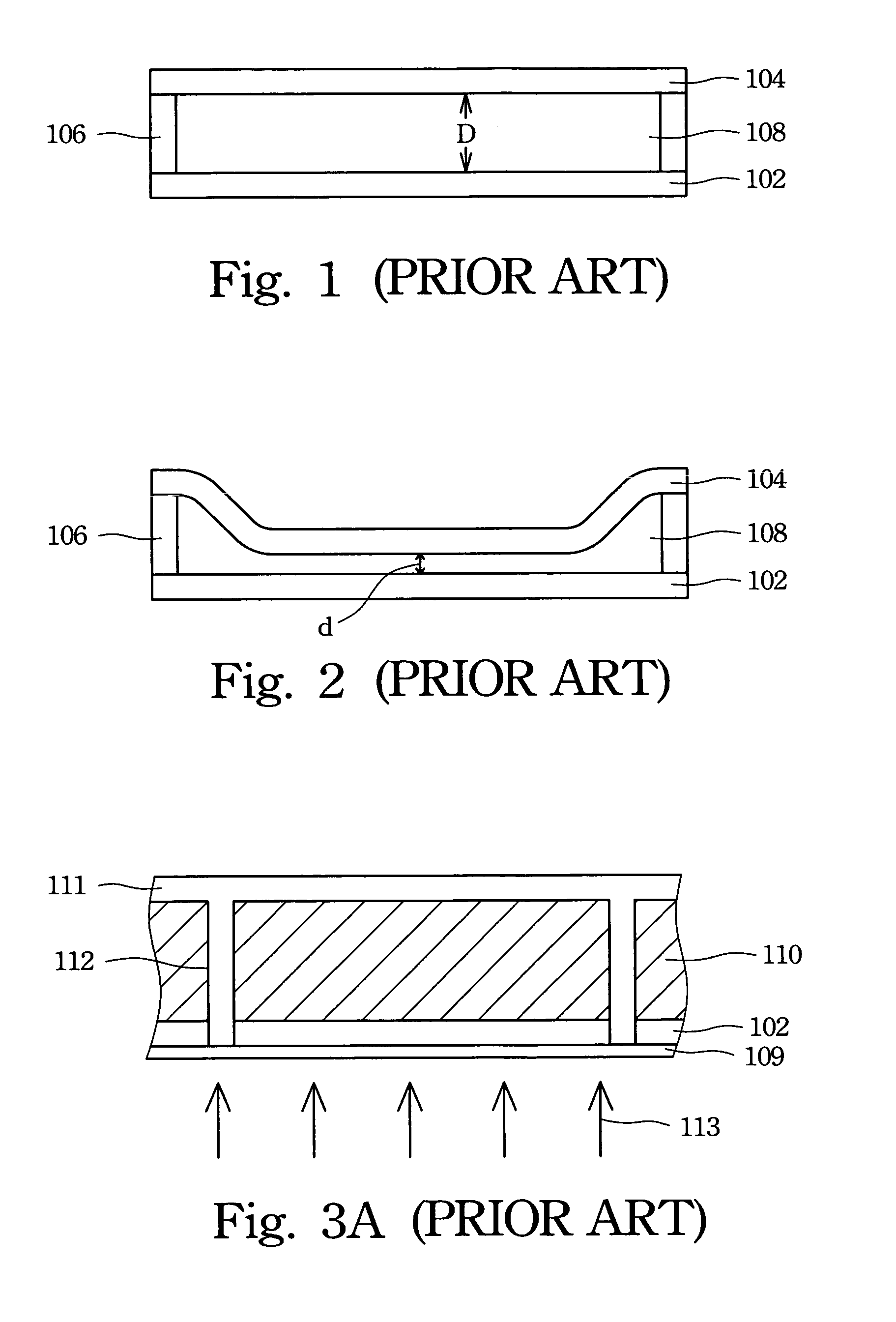

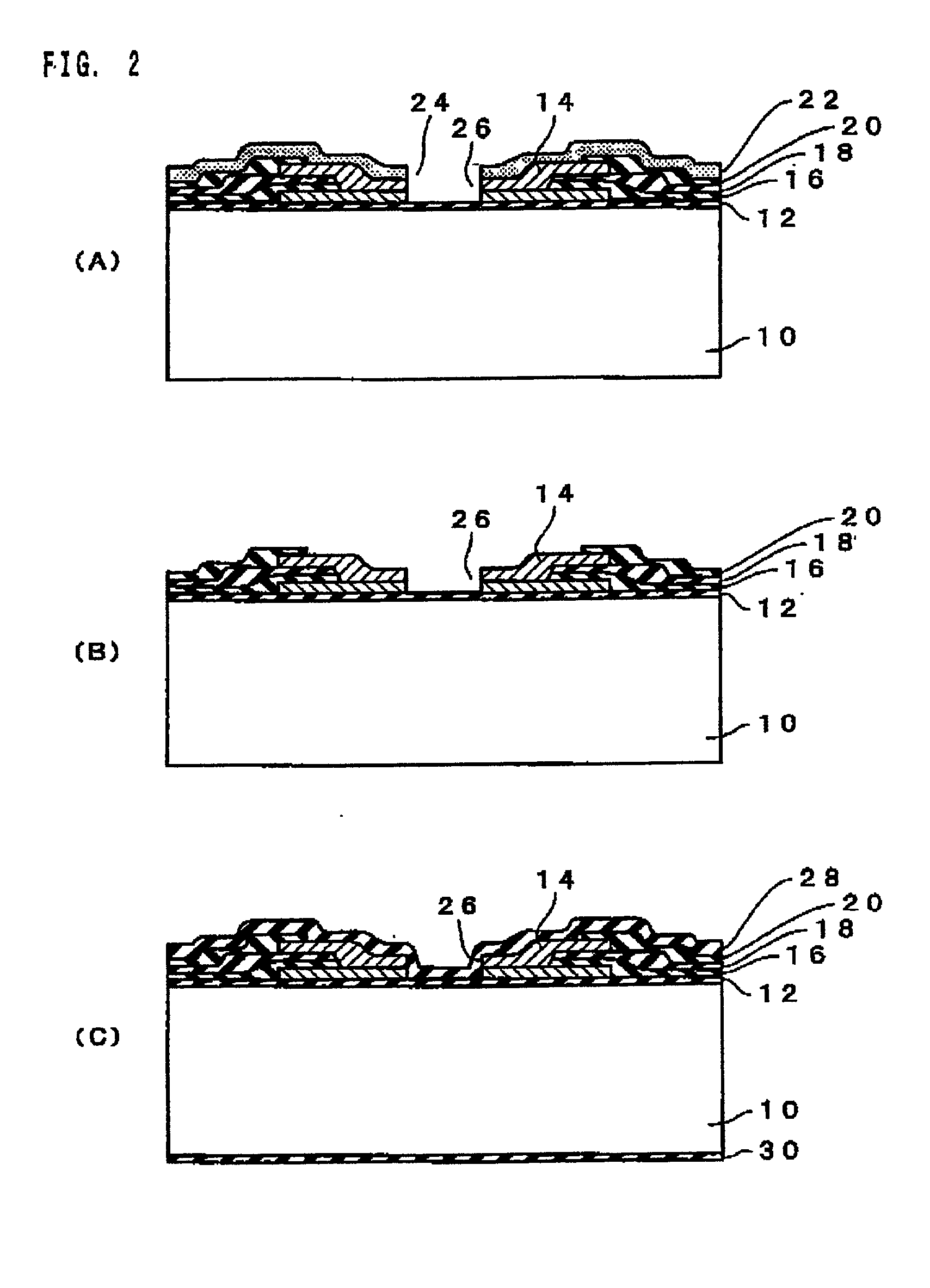

Interference display unit

InactiveUS6995890B2Increase brightnessSimple and easy manufacturing processDecorative surface effectsOptical filtersEngineeringHeat treated

An interference display unit with a first electrode, a second electrode and posts located between the two electrodes is provided. The characteristic of the interference display unit is that the second electrode's stress is released through a thermal process. The position of the second electrode is shifted and the distance between the first electrode and the second electrode is therefore defined. A method for fabricating the structure described as follow. A first electrode and a sacrificial layer are sequentially formed on a substrate and at least two openings are formed in the first electrode and the sacrificial layer. A supporter is formed in the opening and the supporter may have at least one arm on the top portion of the supporter. A second electrode is formed on the sacrificial layer and the supporter and a thermal process is performed. Finally, The sacrificial layer is removed.

Owner:SNAPTRACK

Method for fabricating an interference display unit

InactiveUS20050168849A1Increase brightnessSimple and easy manufacturing processMirrorsDecorative surface effectsEngineeringHeat treated

An interference display unit with a first electrode, a second electrode and posts located between the two electrodes is provided. The characteristic of the interference display unit is that the second electrode's stress is released through a thermal process. The position of the second electrode is shifted and the distance between the first electrode and the second electrode is therefore defined. A method for fabricating the structure described as follow. A first electrode and a sacrificial layer are sequentially formed on a substrate and at least two openings are formed in the first electrode and the sacrificial layer. A supporter is formed in the opening and the supporter may have at least one arm on the top portion of the supporter. A second electrode is formed on the sacrificial layer and the supporter and a thermal process is performed. Finally, The sacrificial layer is removed.

Owner:SNAPTRACK

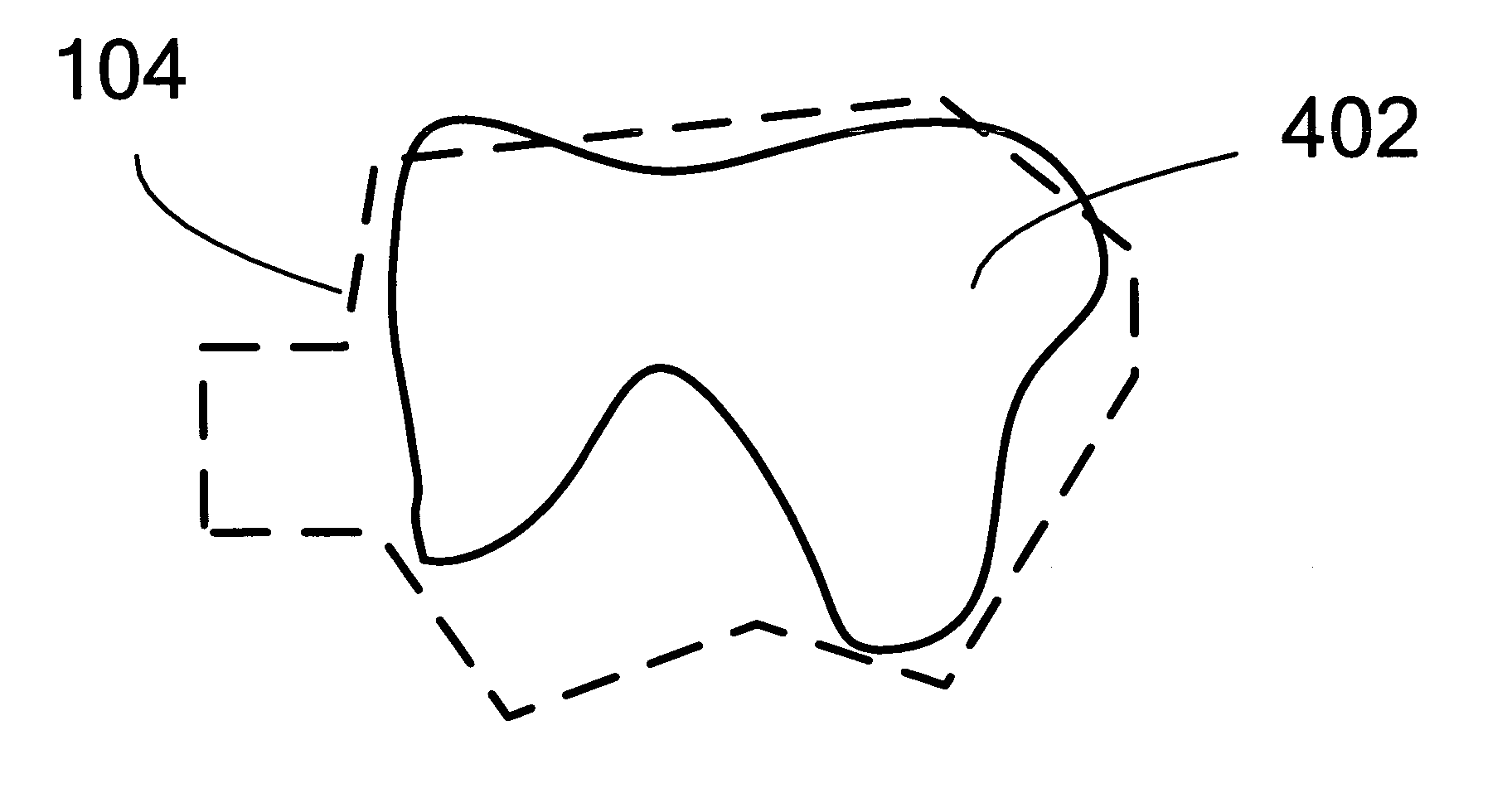

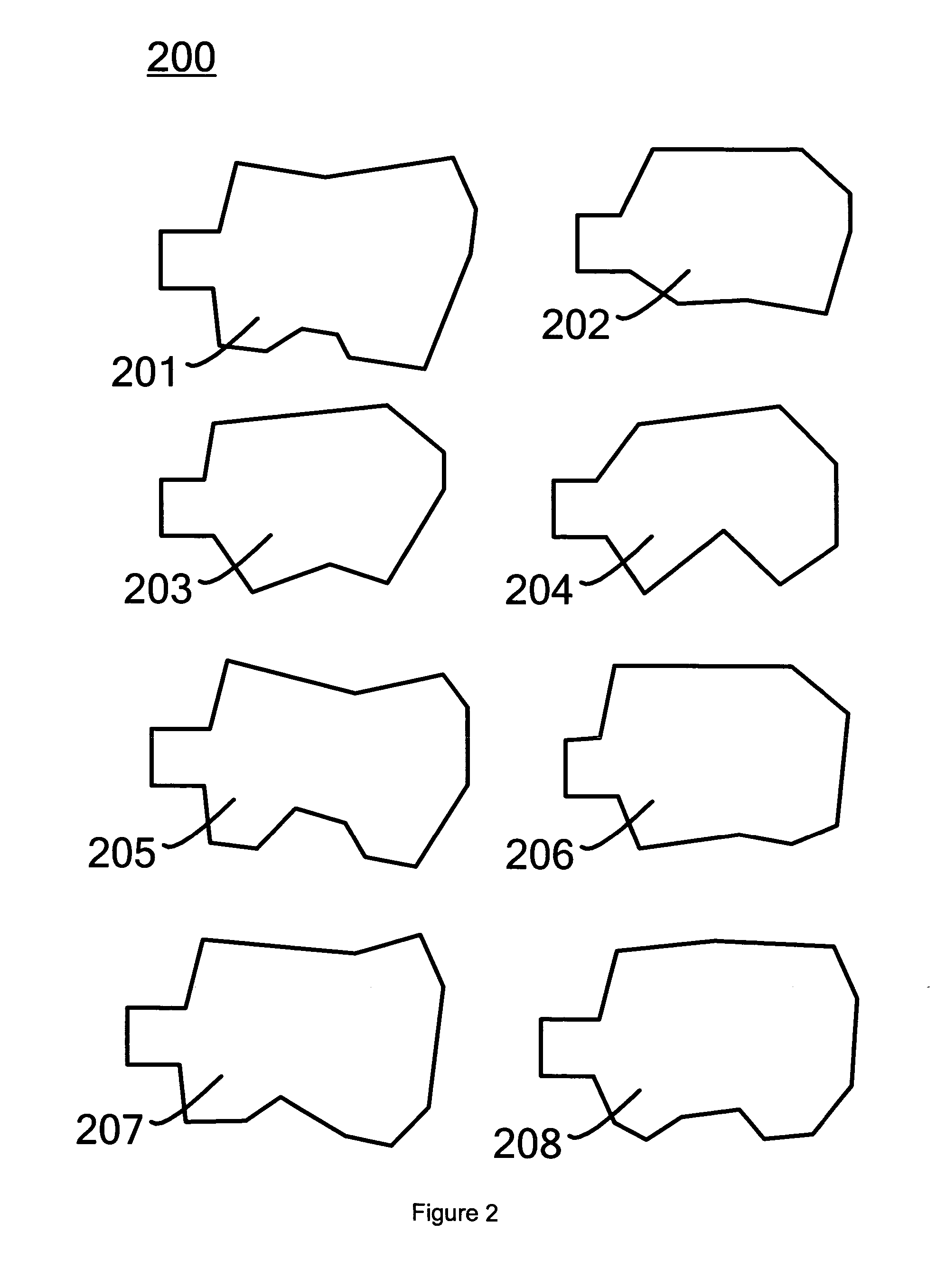

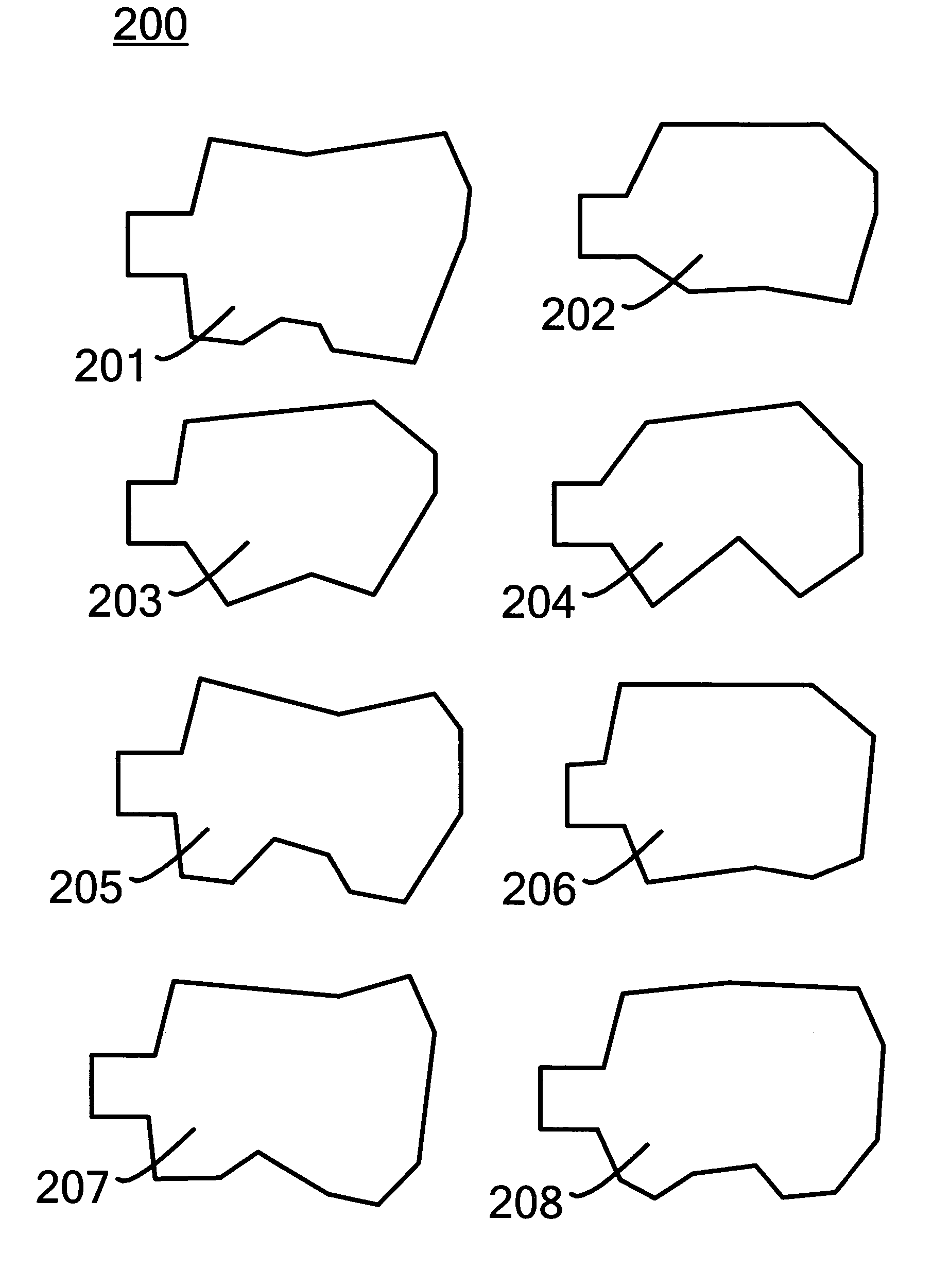

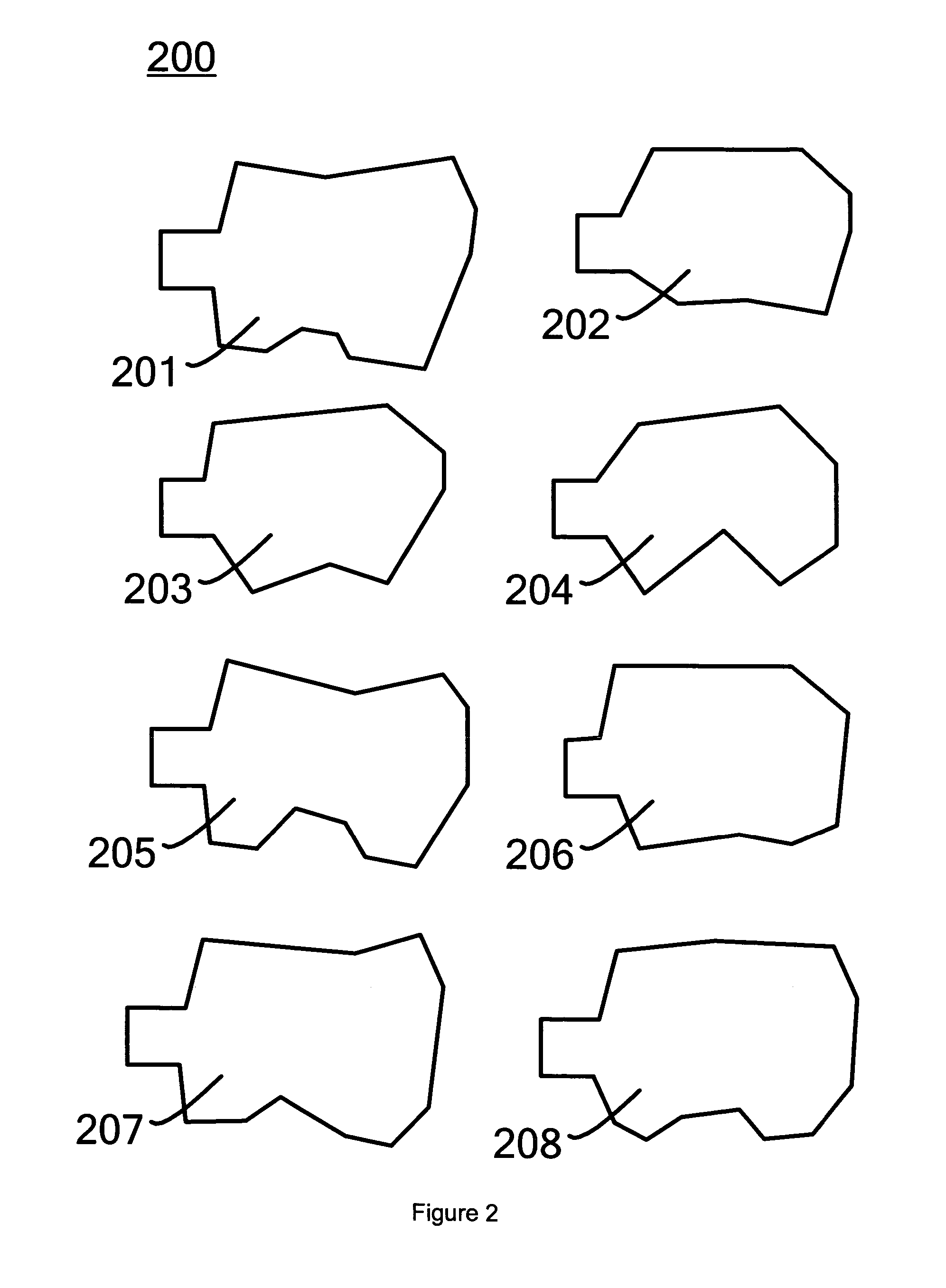

Mill blank library and computer-implemented method for efficient selection of blanks to satisfy given criteria

ActiveUS20050008887A1Easy to manufactureReduce material wasteDental implantsPerson identificationEngineeringInventory management

The present invention relates generally to mill blank constructions to facilitate the manufacture of dental restorations. A given mill blank is formed in a shape (i.e. with a given geometry) that has been predetermined to reduce material waste when the mill blank is machined into the final part. A set of two or more blanks each having such characteristics comprise a smart blank “library.” In one embodiment, a smart blank library includes a sufficient number of unique blanks such that, when the geometry of the designed restoration is known, the smart blank with a highest yield can be selected for use in milling the restoration. The “yield” of a given smart blank represents the amount of material of the smart blank that is actually used in the final restoration. Automated processes for smart blank inventory management and smart blank selection are also described.

Owner:D4D TECH LP

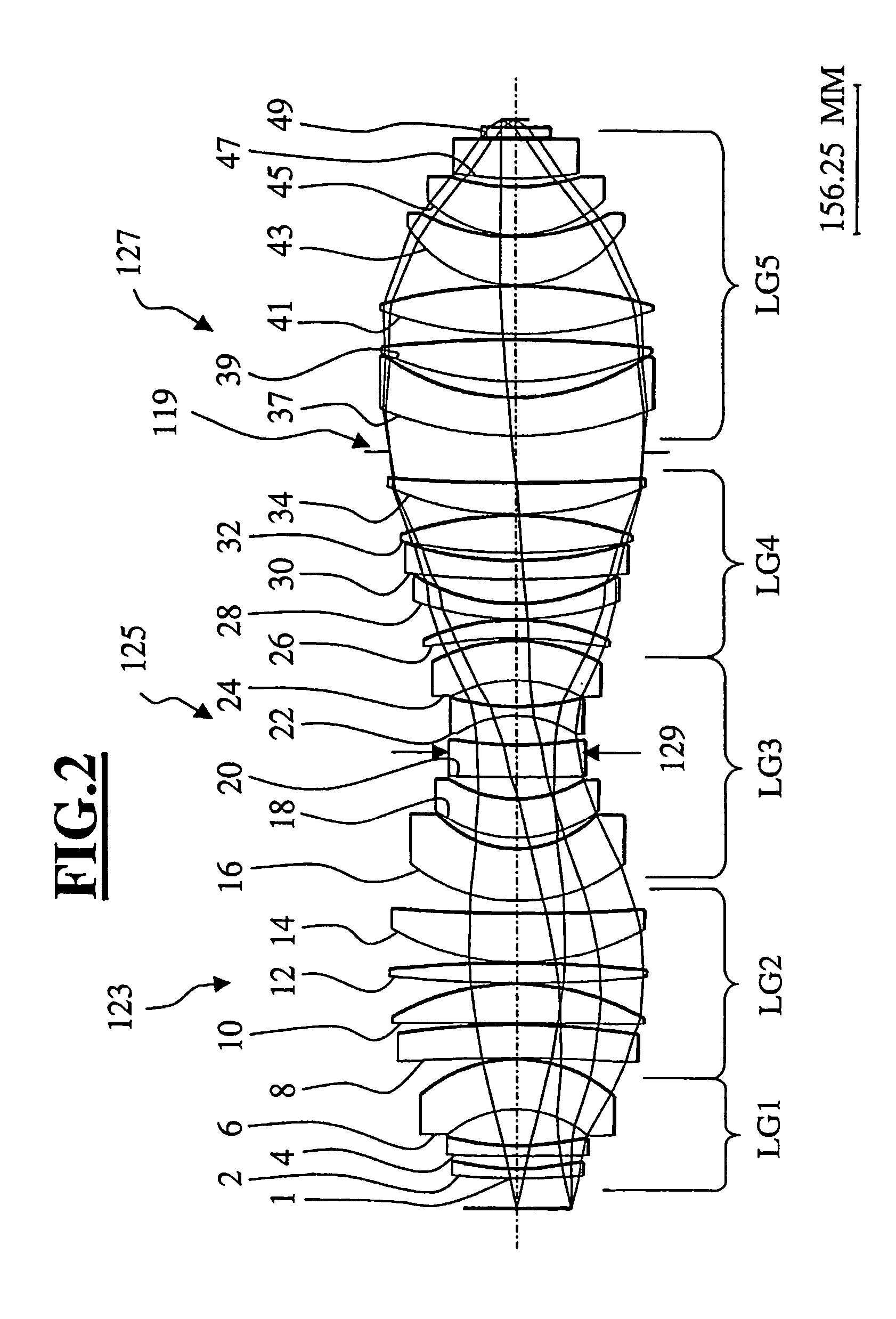

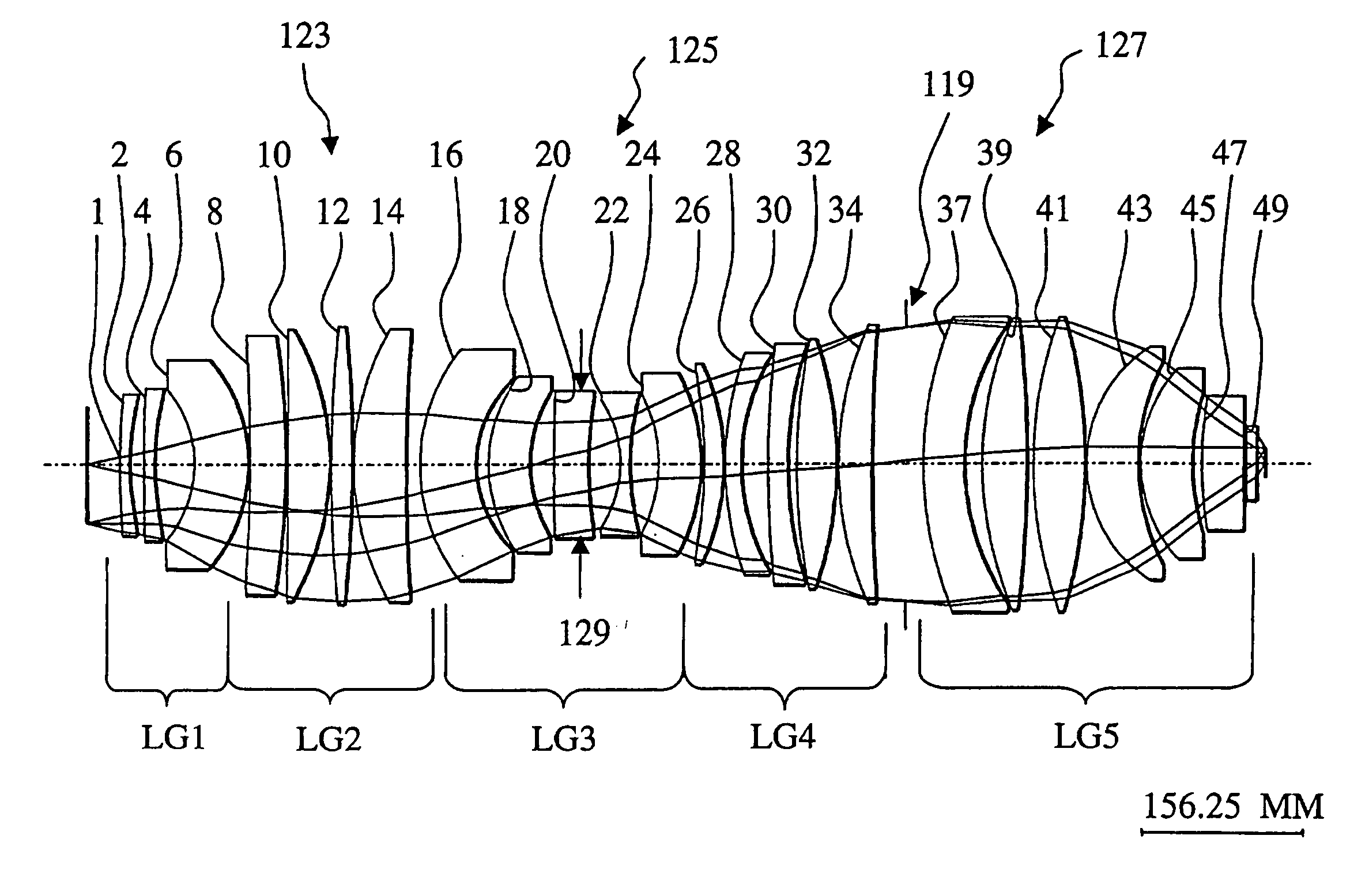

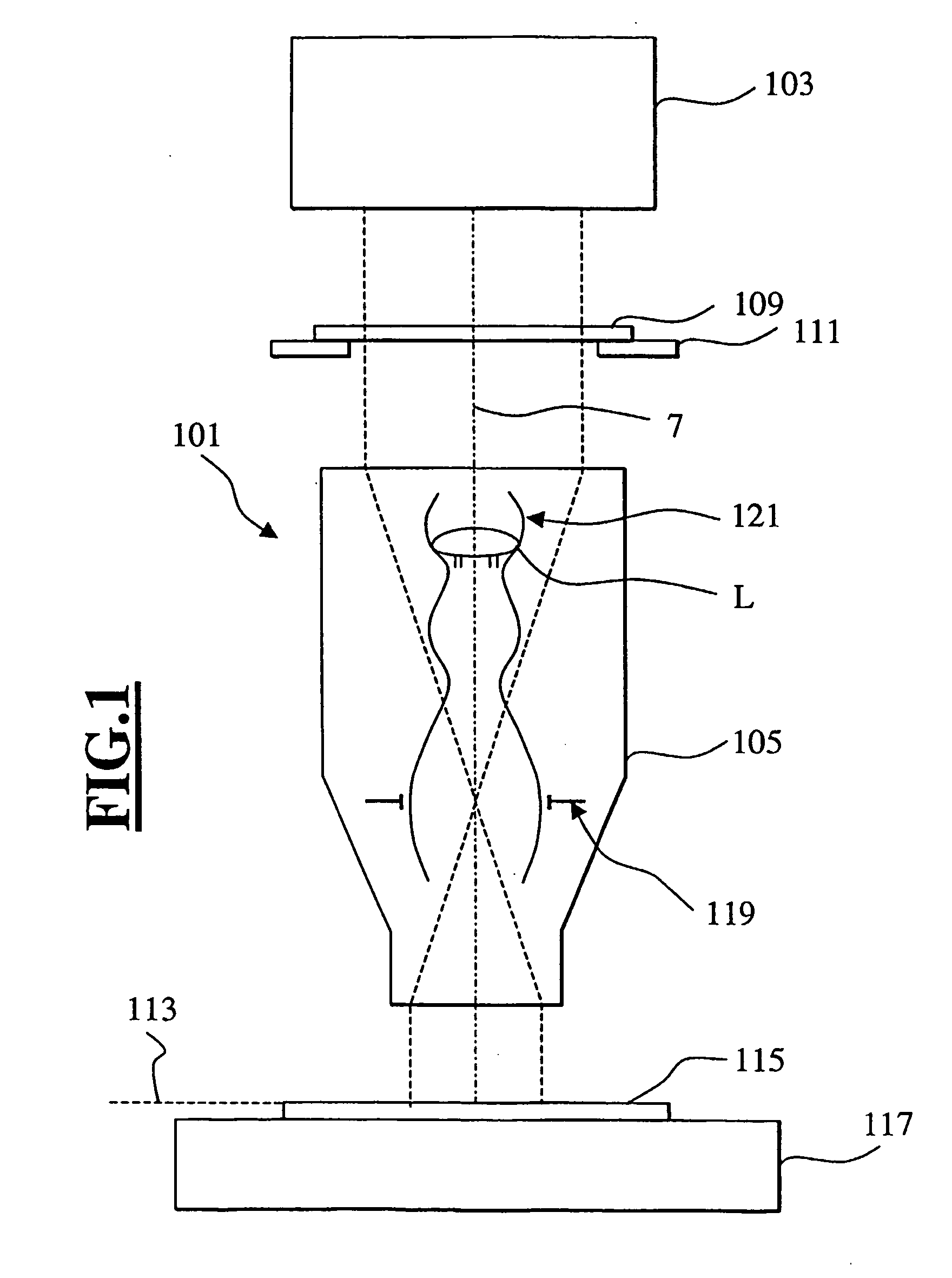

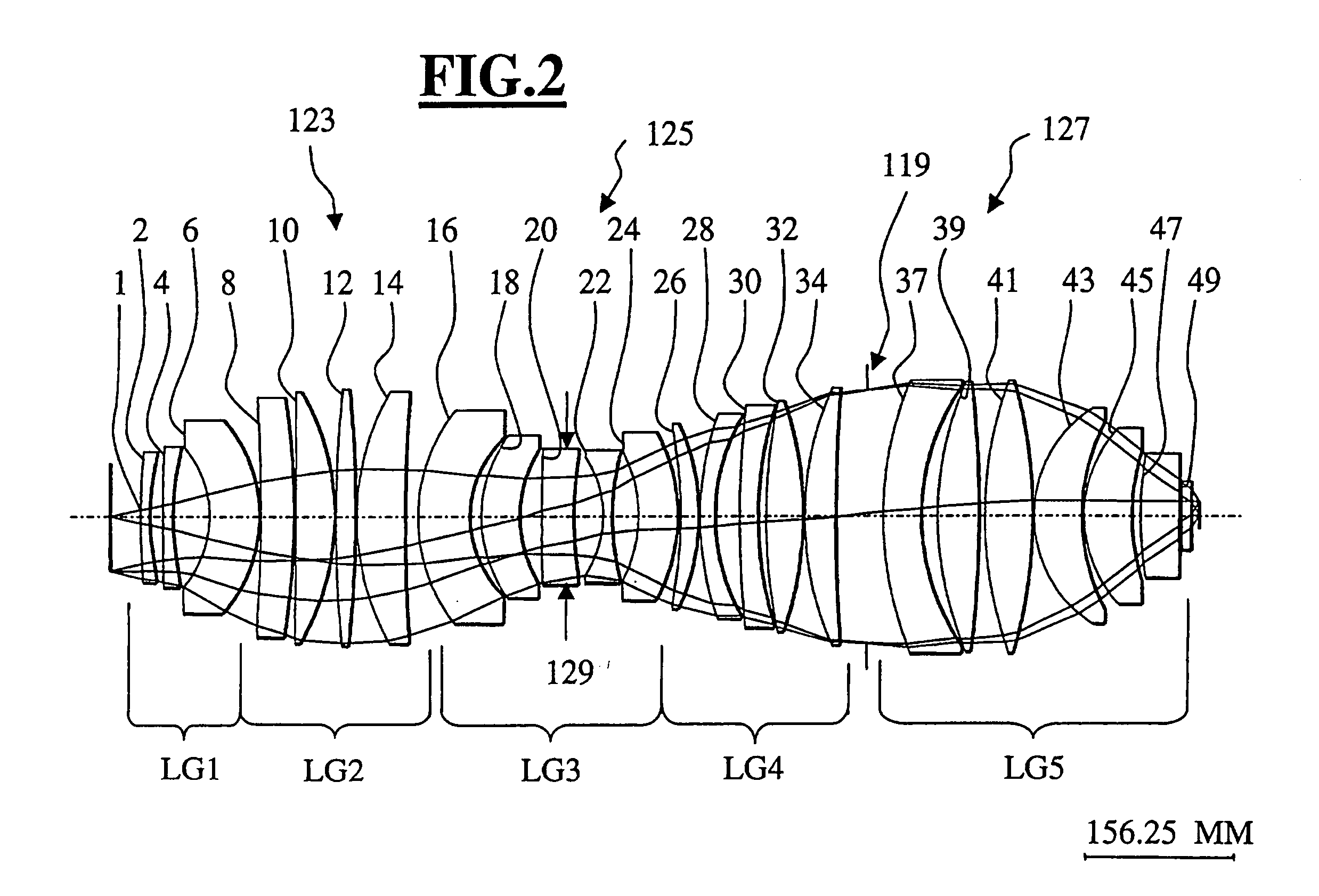

Refractive projection objective

InactiveUS7190527B2Low production costFavorably correctedPhotomechanical exposure apparatusMicrolithography exposure apparatusMaximum diameterSurgery

Owner:CARL ZEISS SMT GMBH

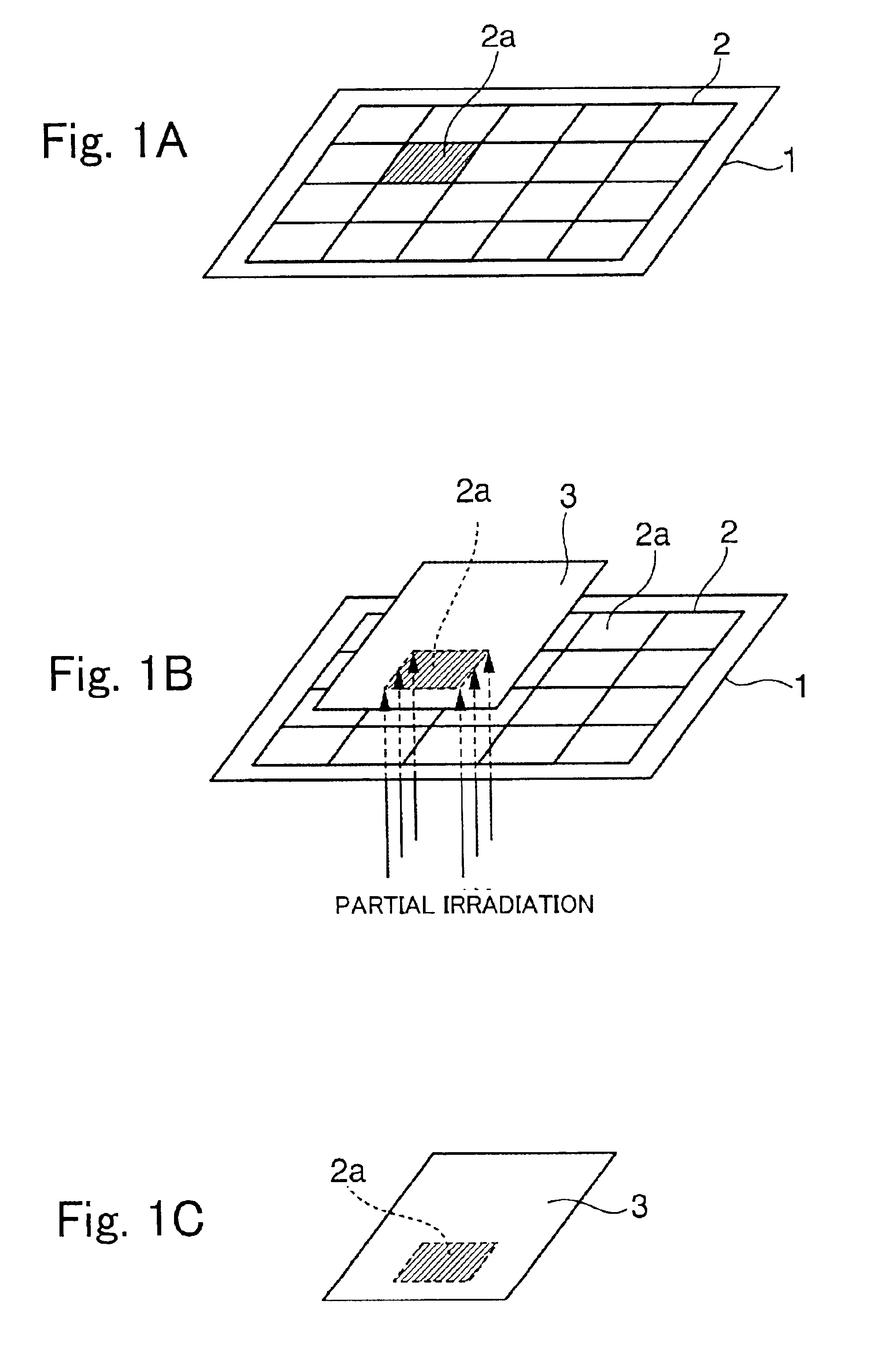

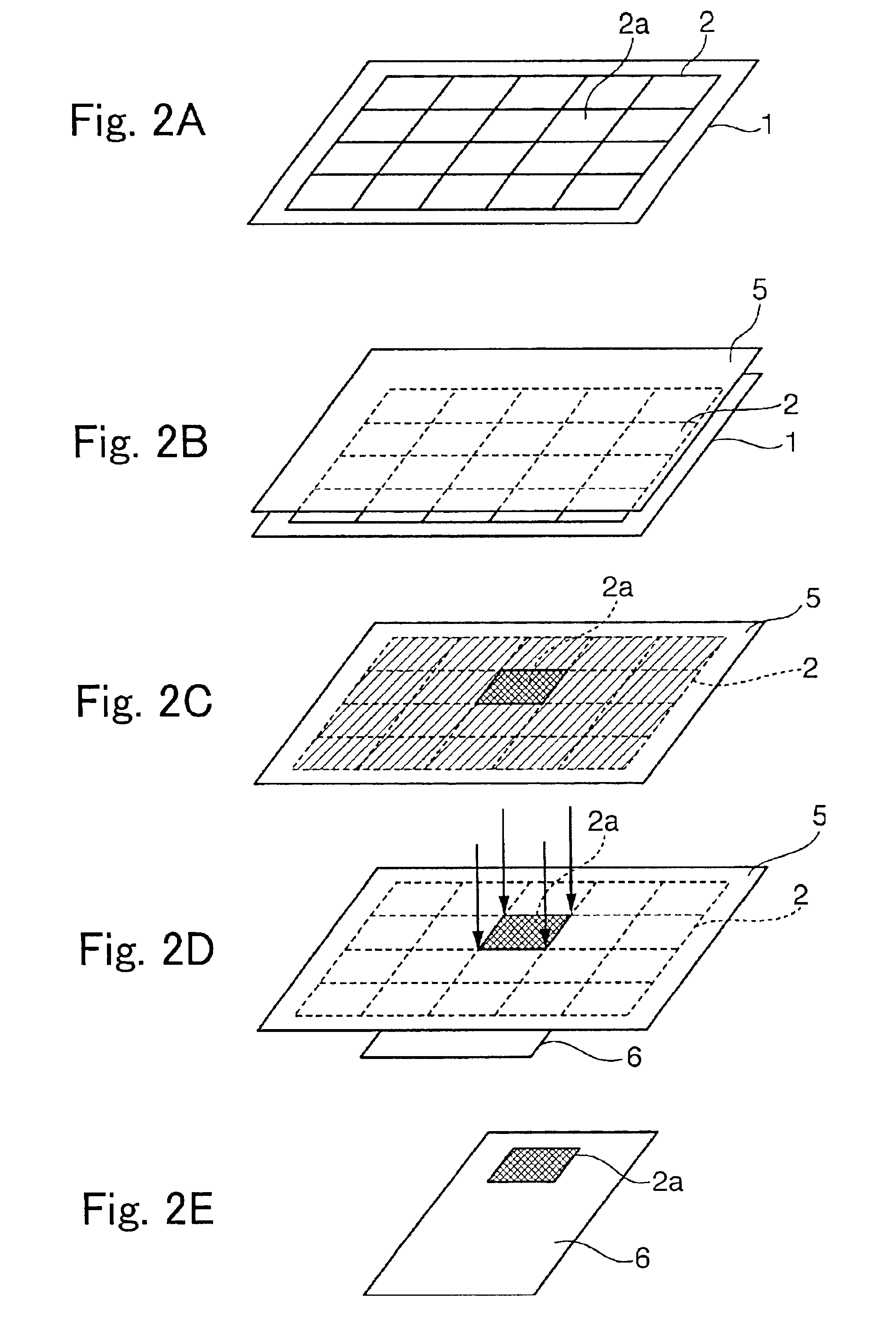

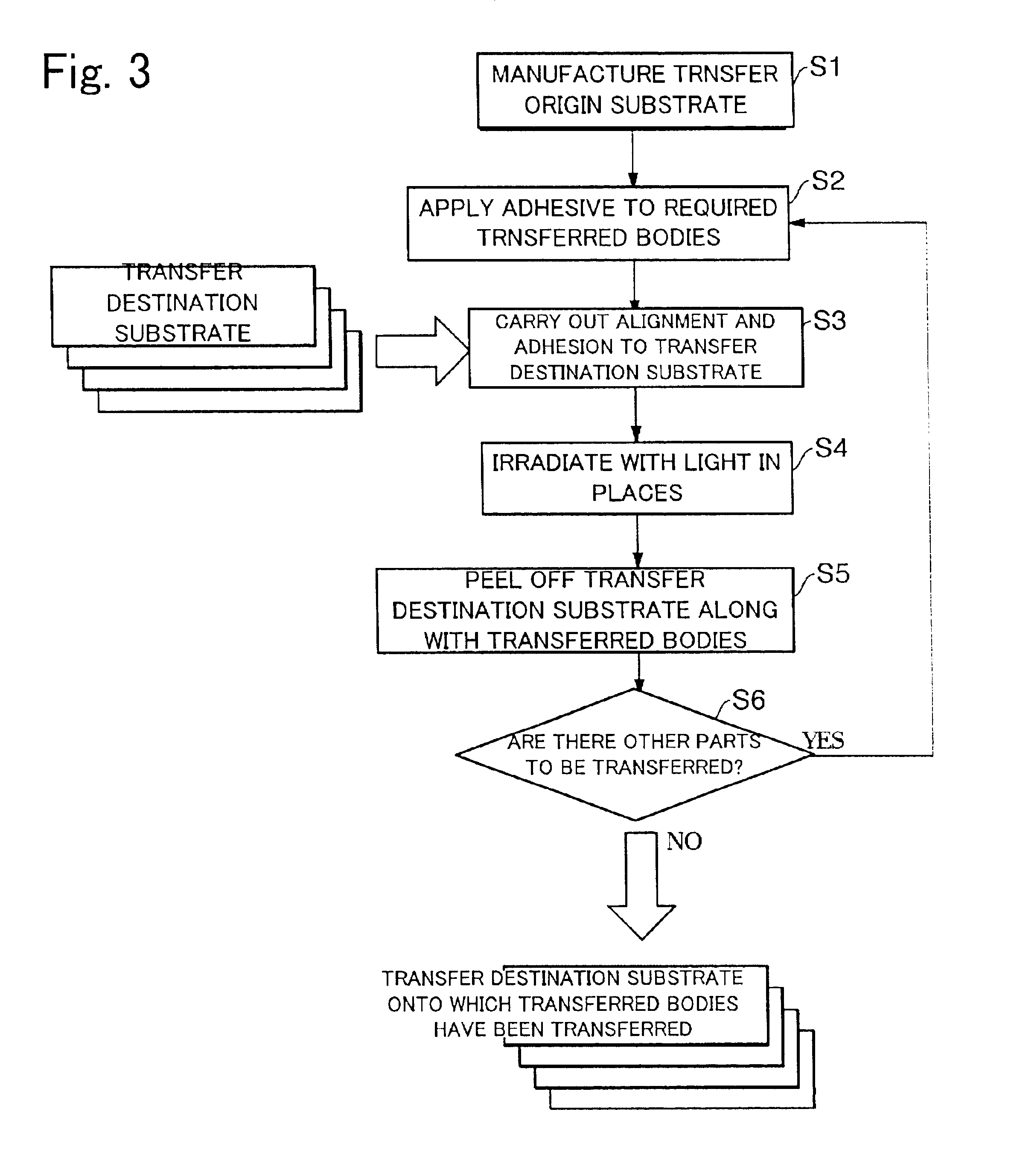

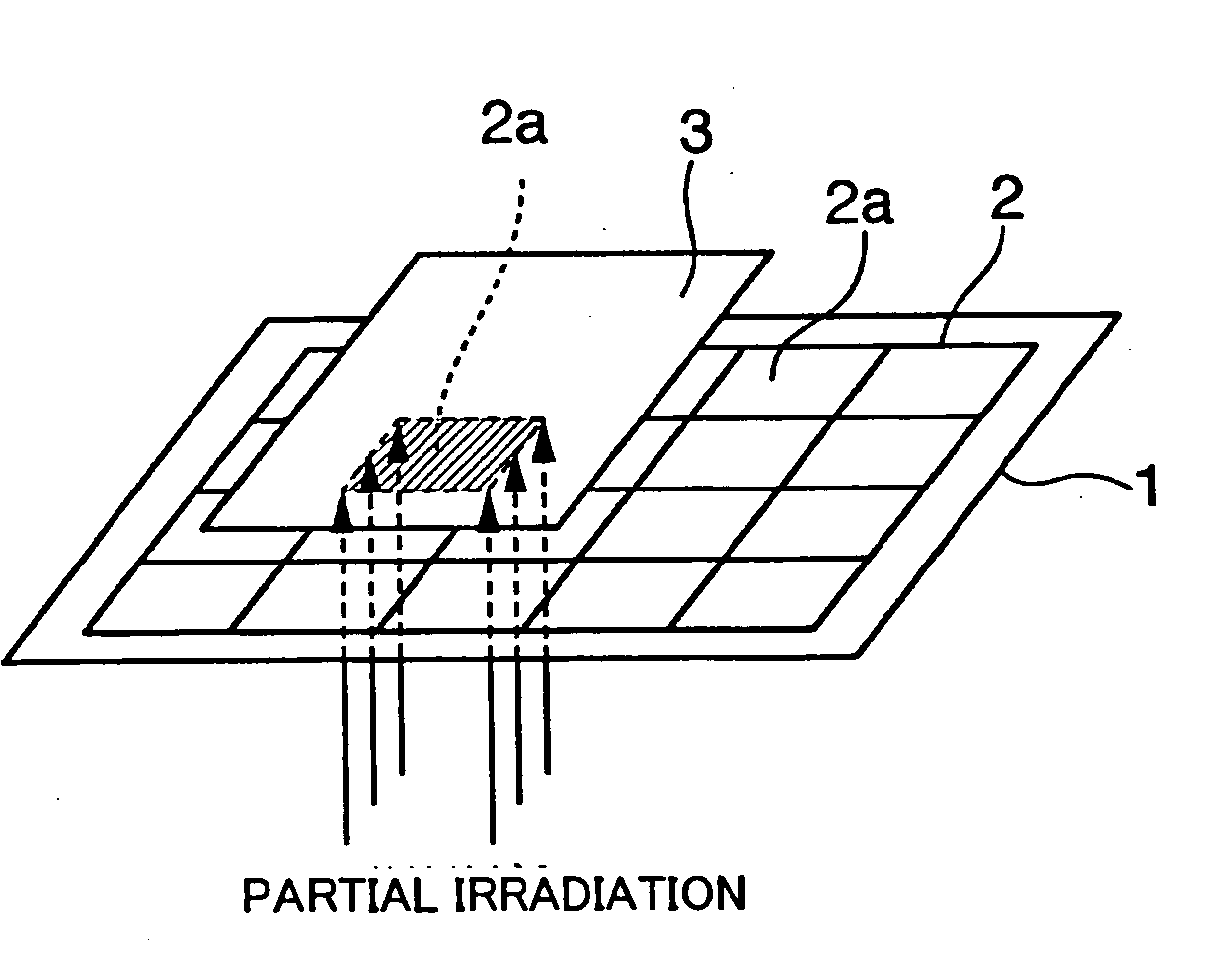

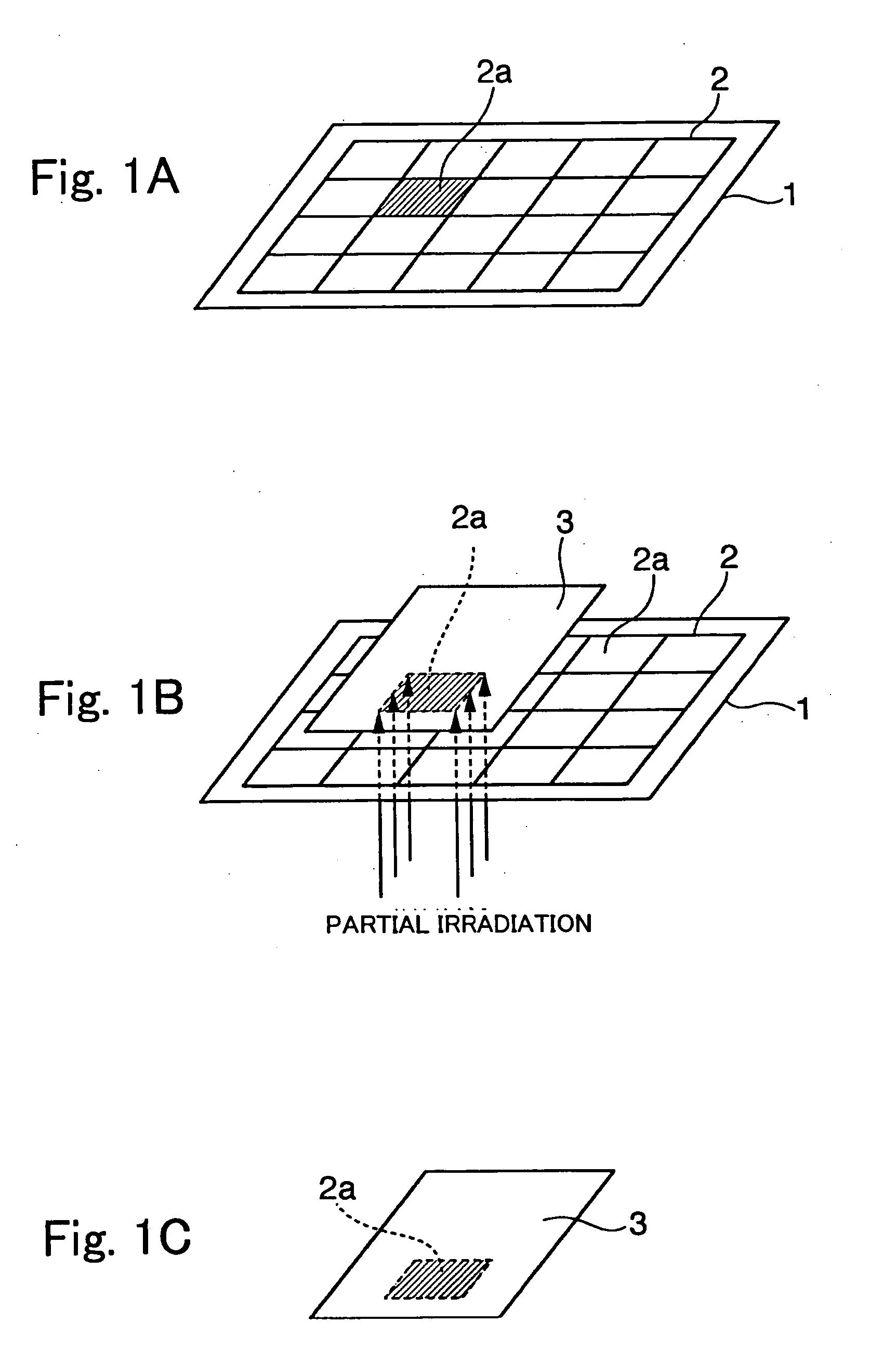

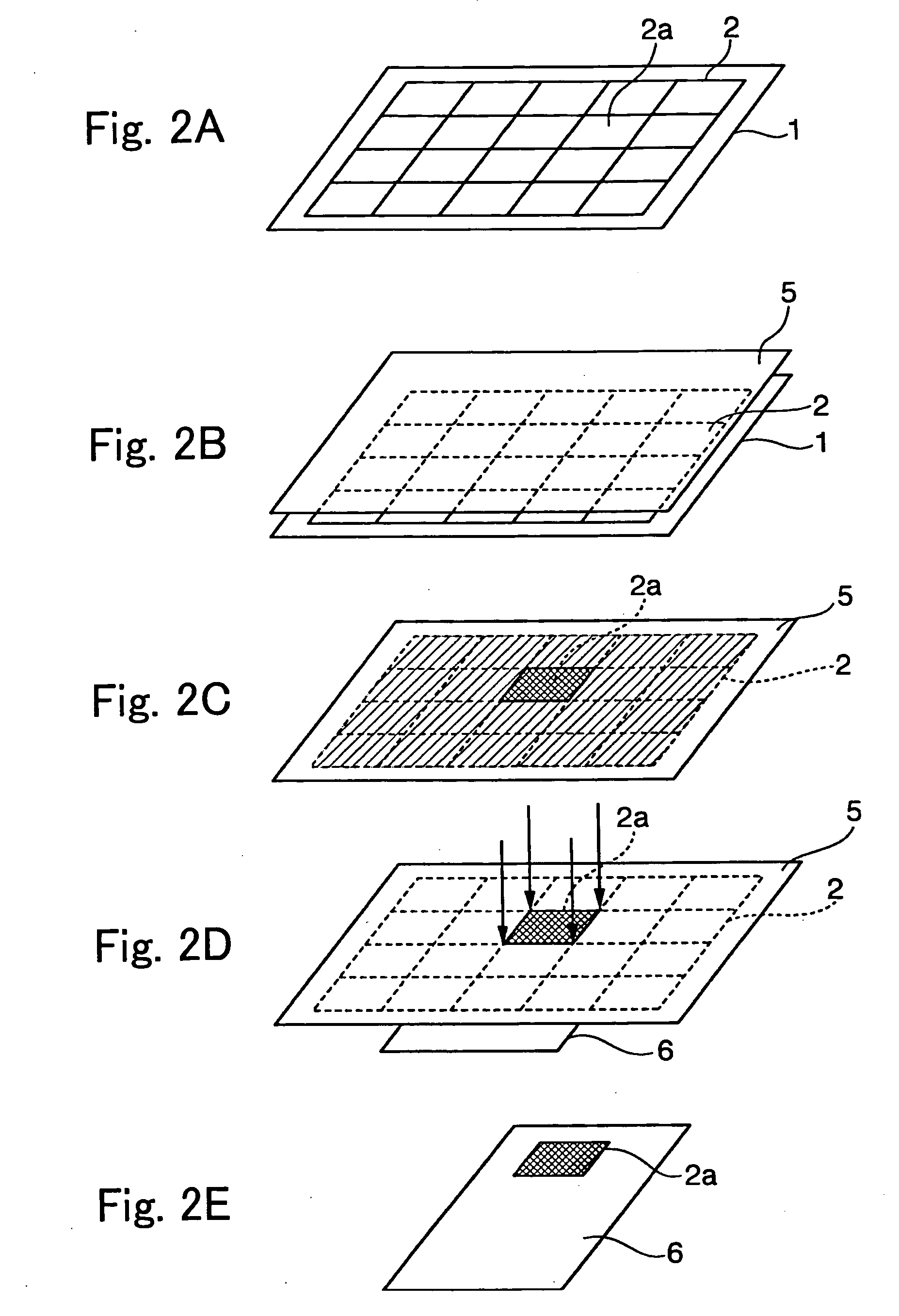

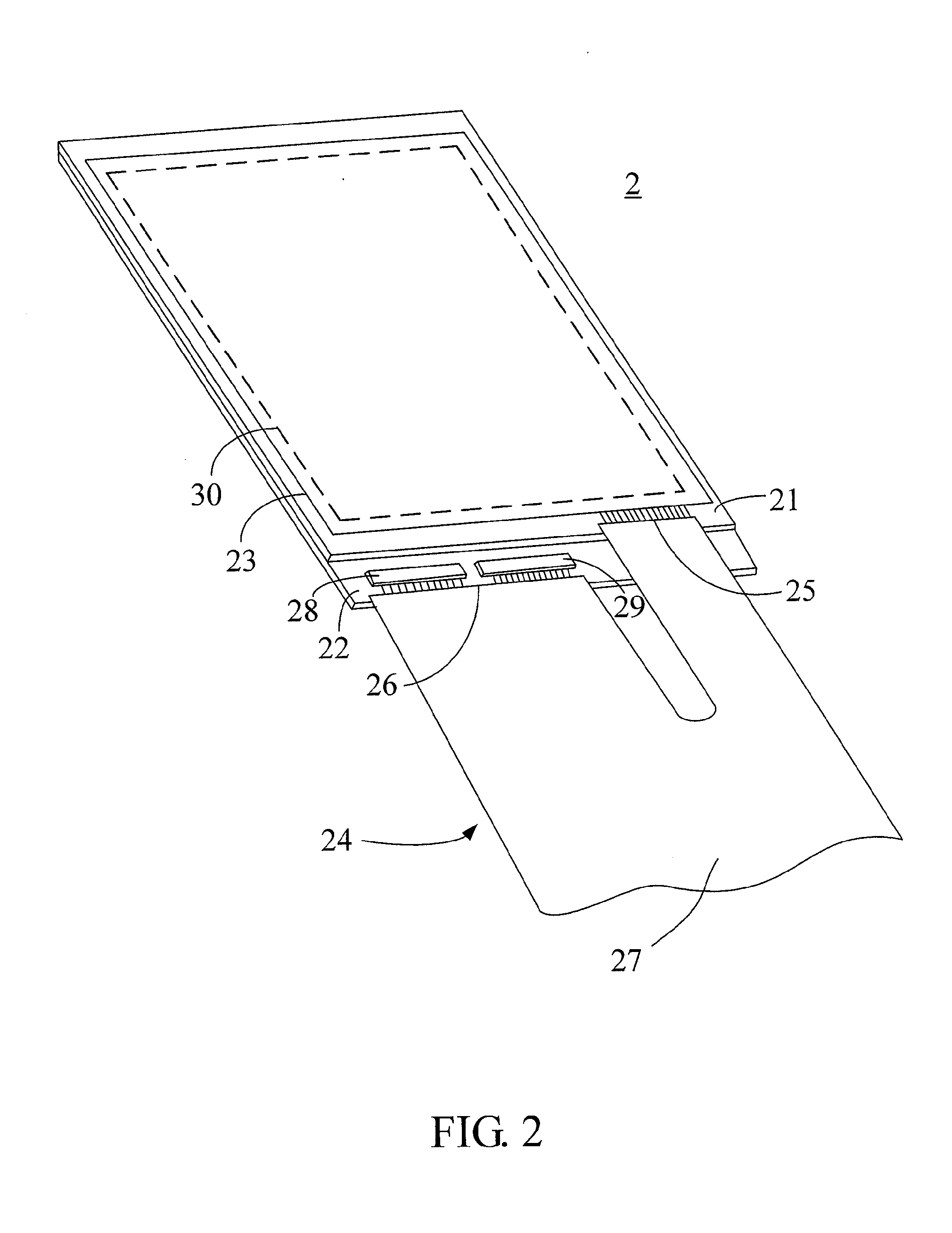

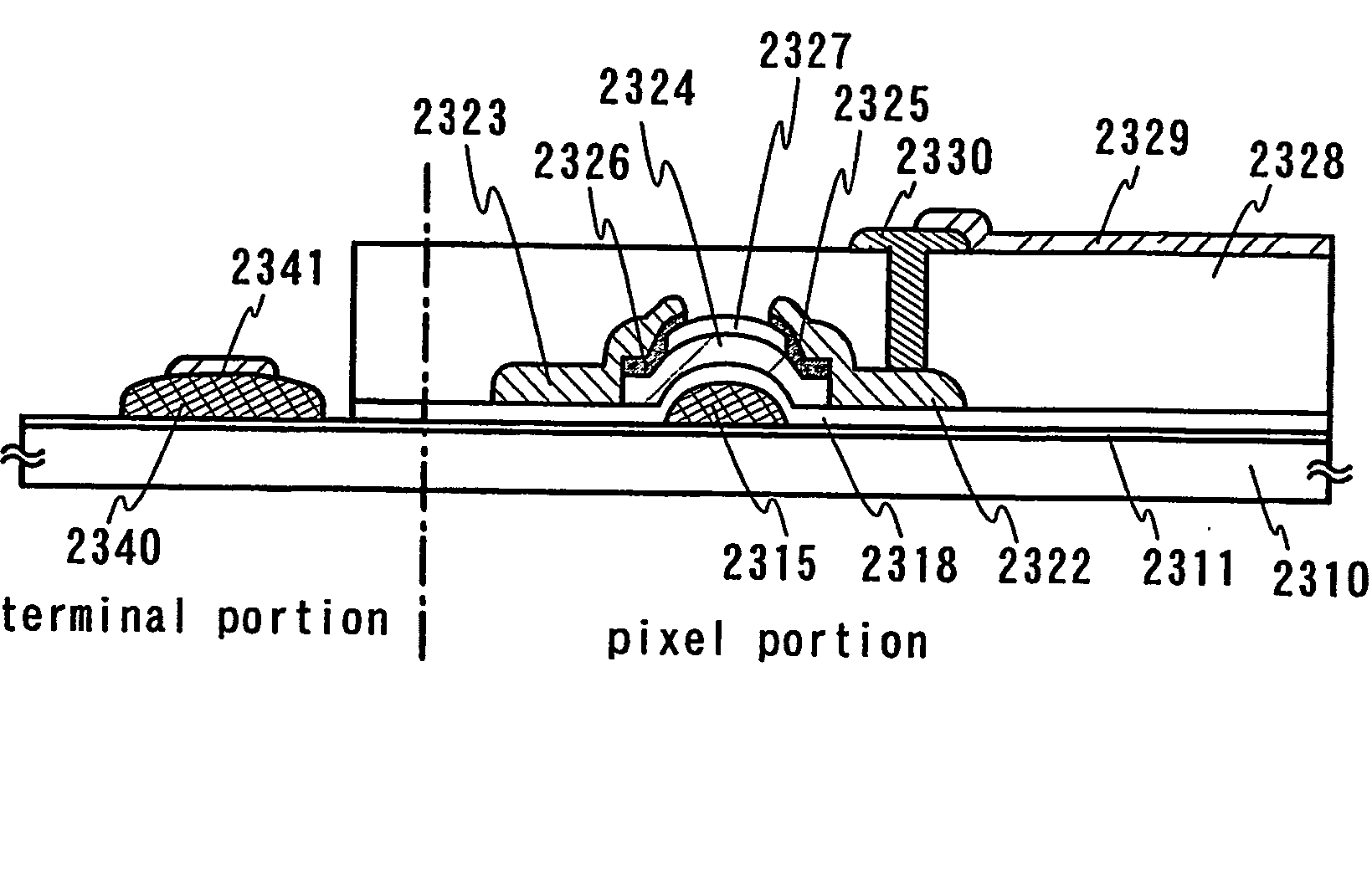

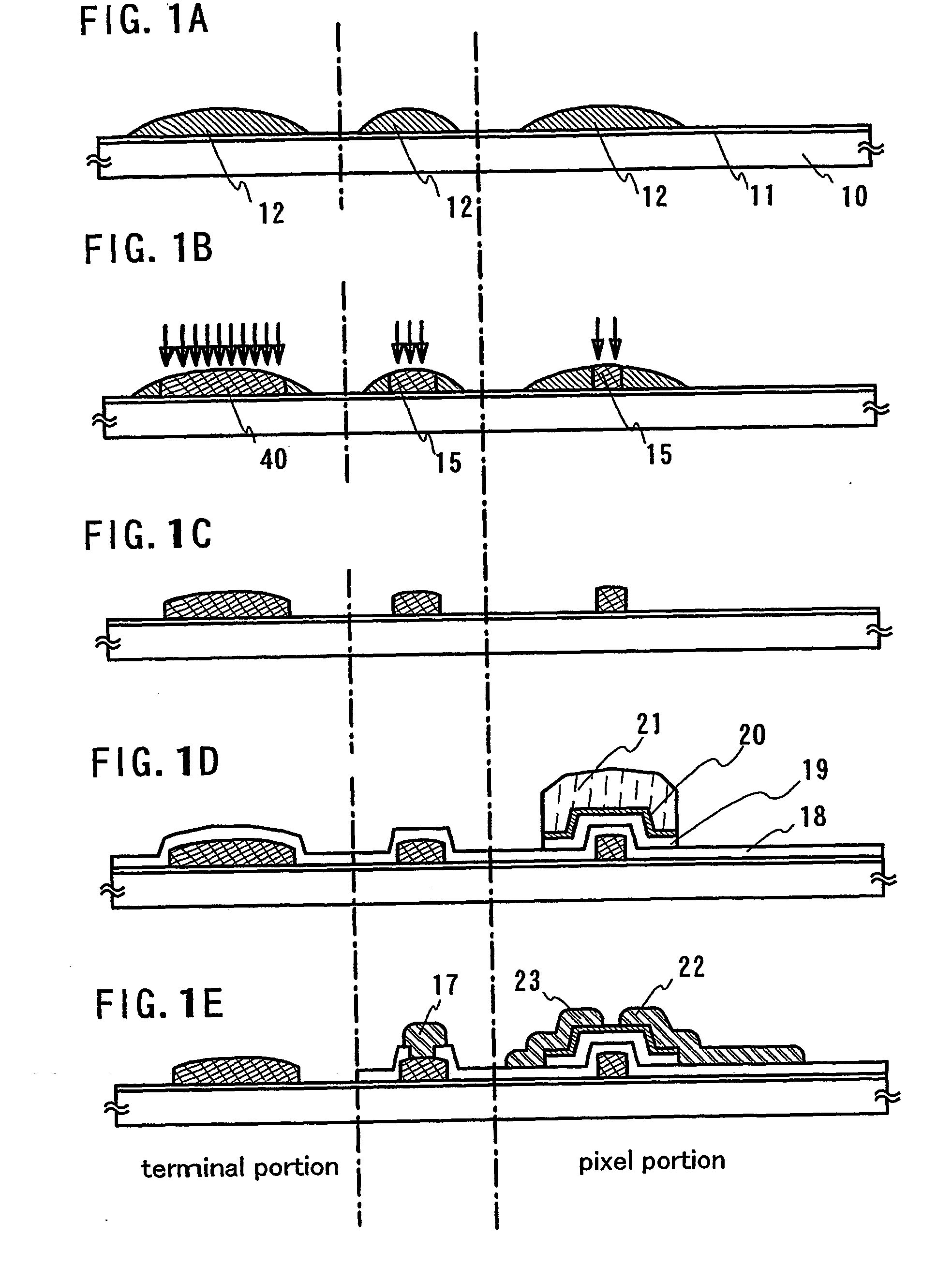

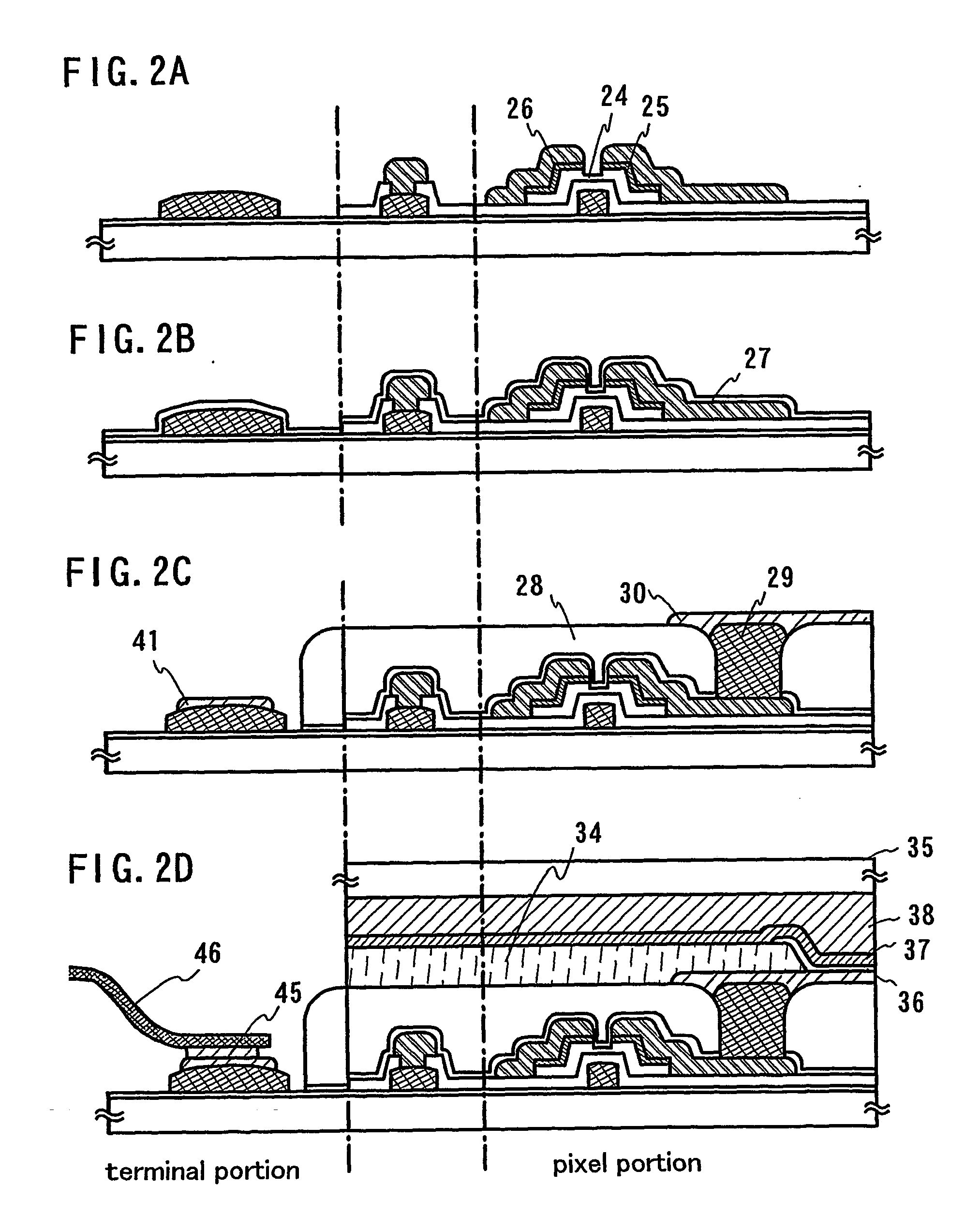

Transfer method, method of manufacturing thin film devices, method of manufacturing integrated circuits, circuit board and manufacturing method thereof, electro-optical apparatus and manufacturing method thereof, IC card, and electronic appliance

InactiveUS6887650B2Reduce material usageImprove area efficiencyMaterial nanotechnologyElectric discharge heatingIntegrated circuitElectronic equipment

Owner:SAMSUNG ELECTRONICS CO LTD

Permeable electric thermal resistor foil for vaporizing fluids from single-use mouthpieces with vaporizer membranes

ActiveUS20140305454A1Low costReduce material usageTobacco pipesTobacco devicesMetallic foilDual coil

A vaporizer device for vaporizing substances is provided, containing active and / or aroma materials, including a mouthpiece with a fluid inlet and a fluid outlet, and including: a heating device with a thermal resistor being a metallic foil or a thin sheet configured as a dual coil and / or sinuous line with two ends and dimensions of the cross-section of a cigarette or a small cigar, wherein the interspaces of the dual coil and / or sinuous line allow fluid flow therethrough, contact tabs are connected to respective opposed ends of the dual coil and / or sinuous line and are not in direct contact with one another, and at least one permeable and wettable vaporizer membrane in large-area contact with the thermal resistor, wherein the thermal resistor and the at least one vaporizer membrane are arranged orthogonally or at an angle to the direction of the fluids passing through the mouthpiece.

Owner:PHILIP MORRIS PROD SA

Method for fabricating an interference display unit

InactiveUS7198973B2Increase brightnessSimple and easy manufacturing processPhotomechanical apparatusSemiconductor/solid-state device manufacturingProcess patternsEngineering

A method for fabricating an interference display unit is provided. A first plate and a sacrificial layer are formed in order on a substrate and at least two openings are formed in the first plate and the sacrificial layer. A photoresist layer is spin-coated on the sacrificial layer and fills the openings. A photolithographic process patterns the photoresist layer to define a support with an arm. A second plate is formed on the sacrificial layer and posts. The arm's stress is released through a thermal process. The position of the arm is shifted and the distance between the first plate and the second plate is therefore defined. Finally, The sacrificial layer is removed.

Owner:SNAPTRACK

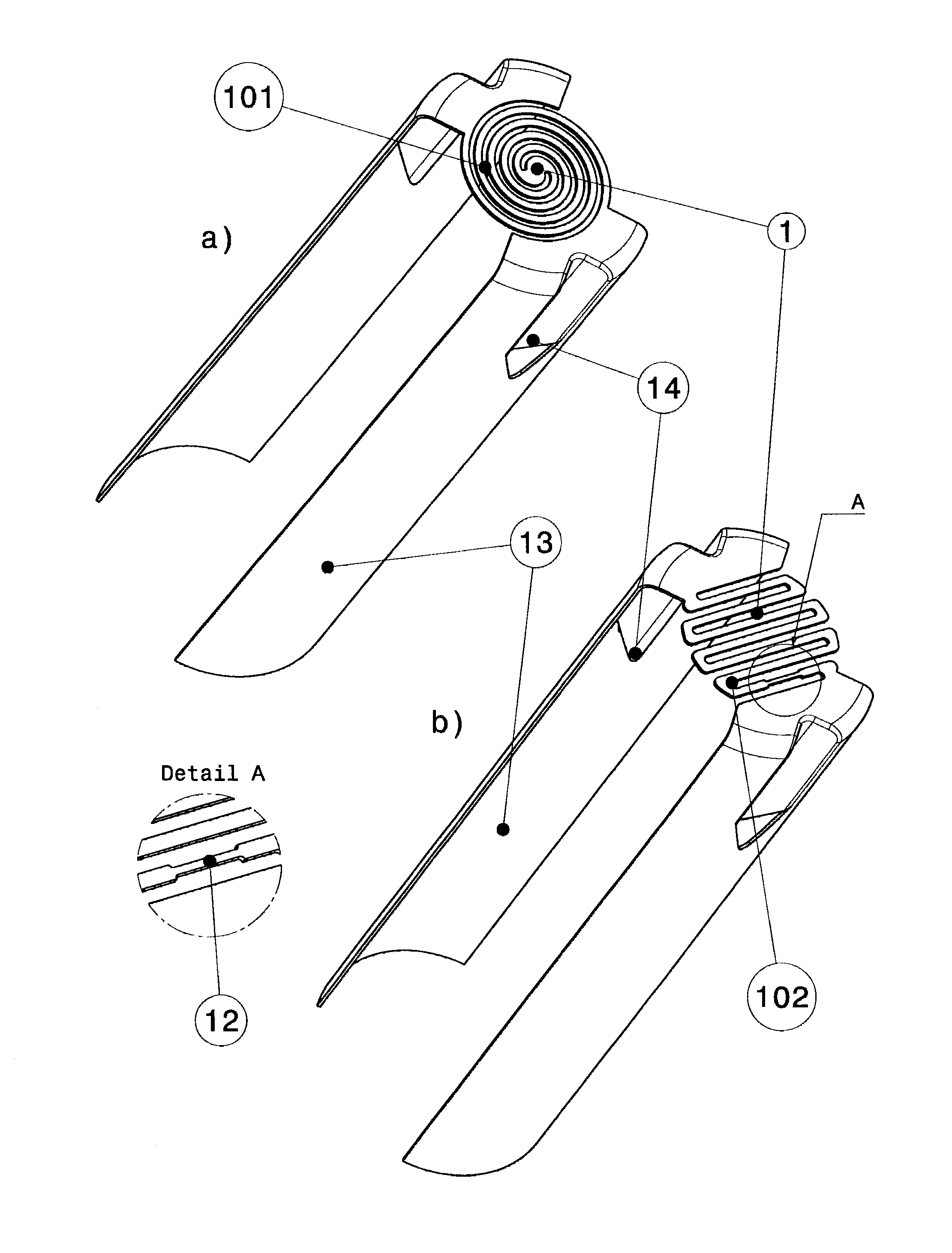

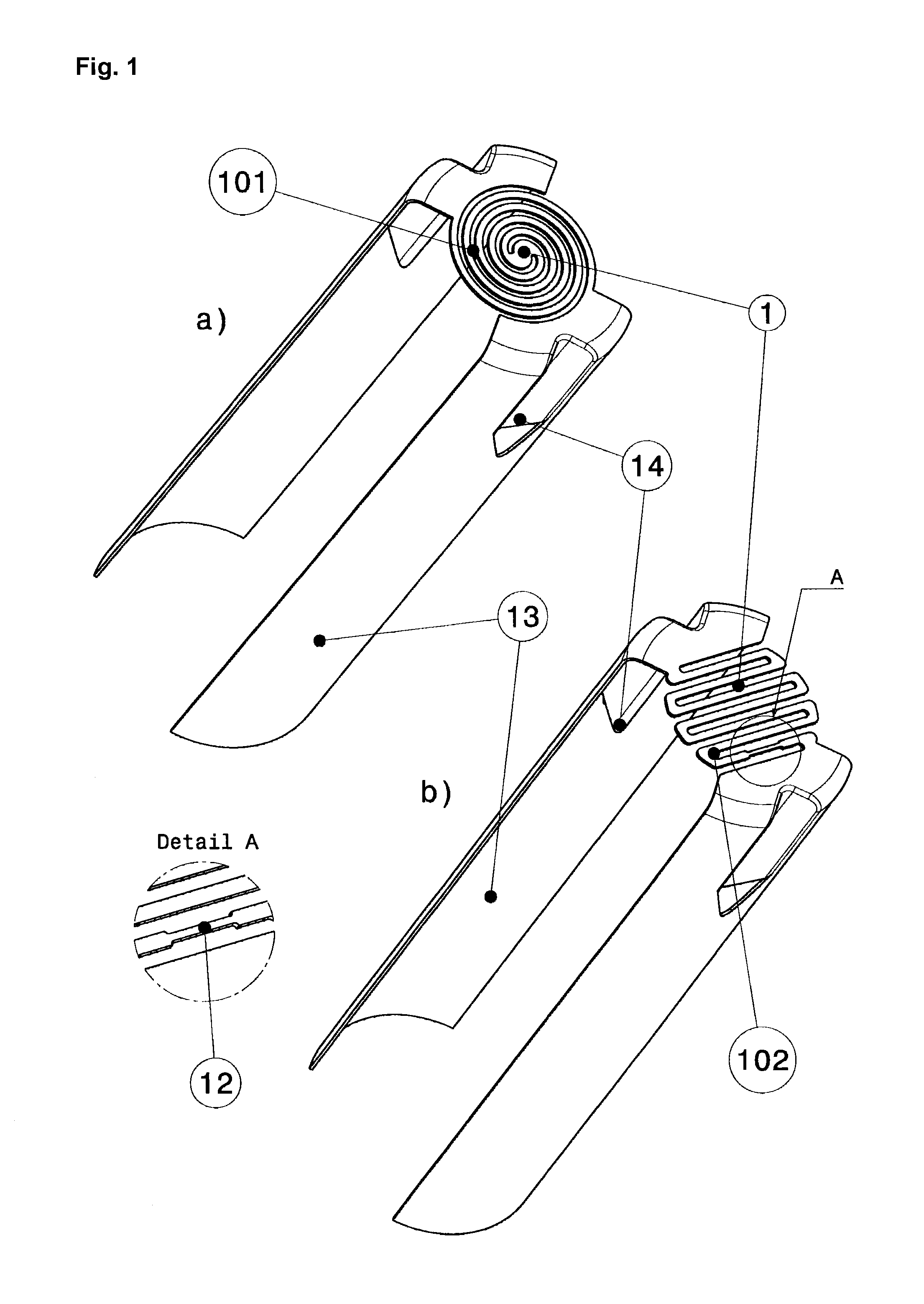

Lancet dispenser

A system suitable for collecting a body fluid, in particular blood from a body region of a person to be examined which comprises a lancing device which is suitable for holding a lancet, a lancet magazine for storing two or several lancets which has a transport device for the lancets and has an opening into which the lancing device can be inserted to remove a lancet from the lancet magazine, and two or several lancets, and which comprises a method for removing a lancet from a lancet magazine in which a lancet located in the lancet magazine is manually or automatically transported into a removal position in the interior of the lancet magazine, a lancing device is partially inserted into the opening provided in the lancet magazine in the process of which the lancing device automatically grips the lancet located in the removal position when it is partially inserted and the lancing device with the gripped lancet is removed from the lancet magazine.

Owner:ROCHE DIABETES CARE INC +1

Semiconductor device and manufacturing method therefor, circuit substrate, and electronic apparatus

InactiveUS20020151171A1Stress smoothWeaken energySemiconductor/solid-state device detailsSolid-state devicesDevice materialElectrical connection

A semiconductor device and a manufacturing method therefor, a circuit substrate, and electronic apparatus are provided, in which electrical connection can be performed with high reliability and with ease. The manufacturing method for a semiconductor device includes the steps of forming a penetration hole 50 in a semiconductor chip 10 having an electrode 14, and forming a conductive layer 70 in the region including the inside of the penetration hole 50. Regarding the penetration hole 50, an intermediate portion is formed to be larger than an open end portion, and the conductive layer 70 is formed by applying a coating of a liquid containing metal fine particles by an ink-jet method.

Owner:SAMSUNG ELECTRONICS CO LTD

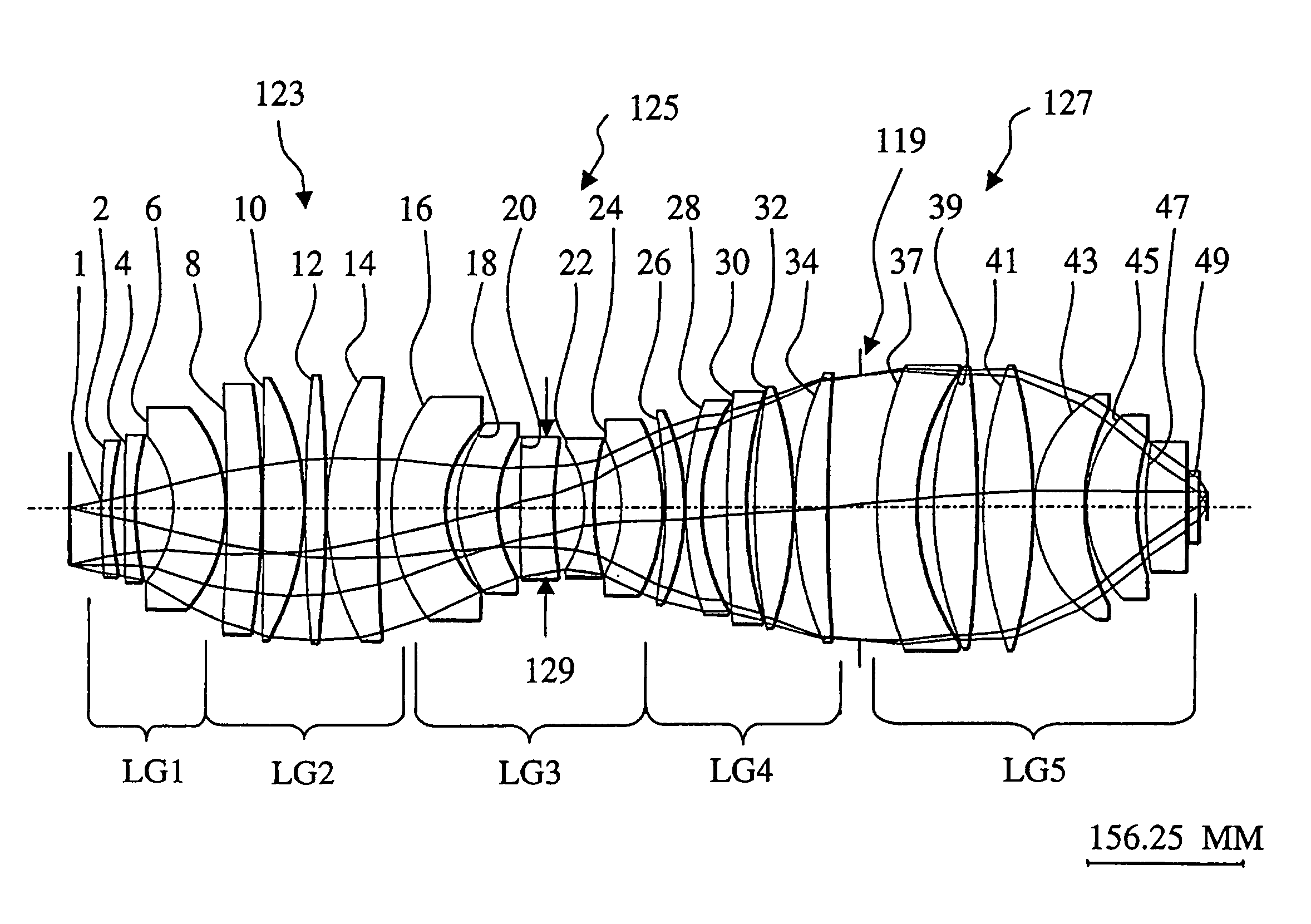

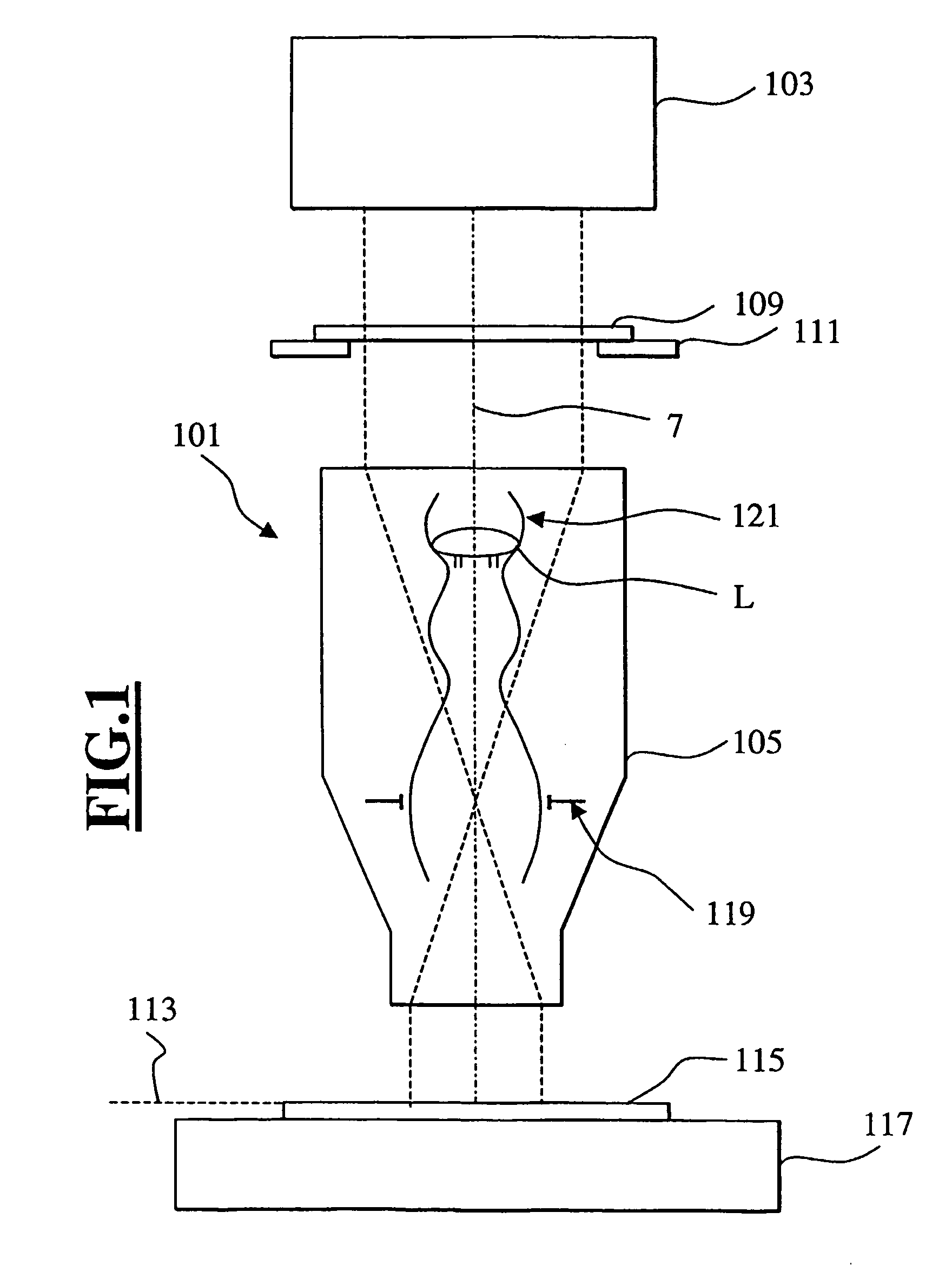

Refractive projection objective

InactiveUS20050231813A1Low production costEasy to correctPhotomechanical exposure apparatusMicrolithography exposure apparatusMaximum diameterNumerical aperture

Refractive projection objective with a numerical aperture greater than 0.7, consisting of a first convexity, a second convexity, and a waist arranged between the two convexities. The first convexity has a maximum diameter denoted by D1, and the second convexity has a maximum diameter denoted by D2, and 0.8<D1 / D2<1.1.

Owner:CARL ZEISS SMT GMBH

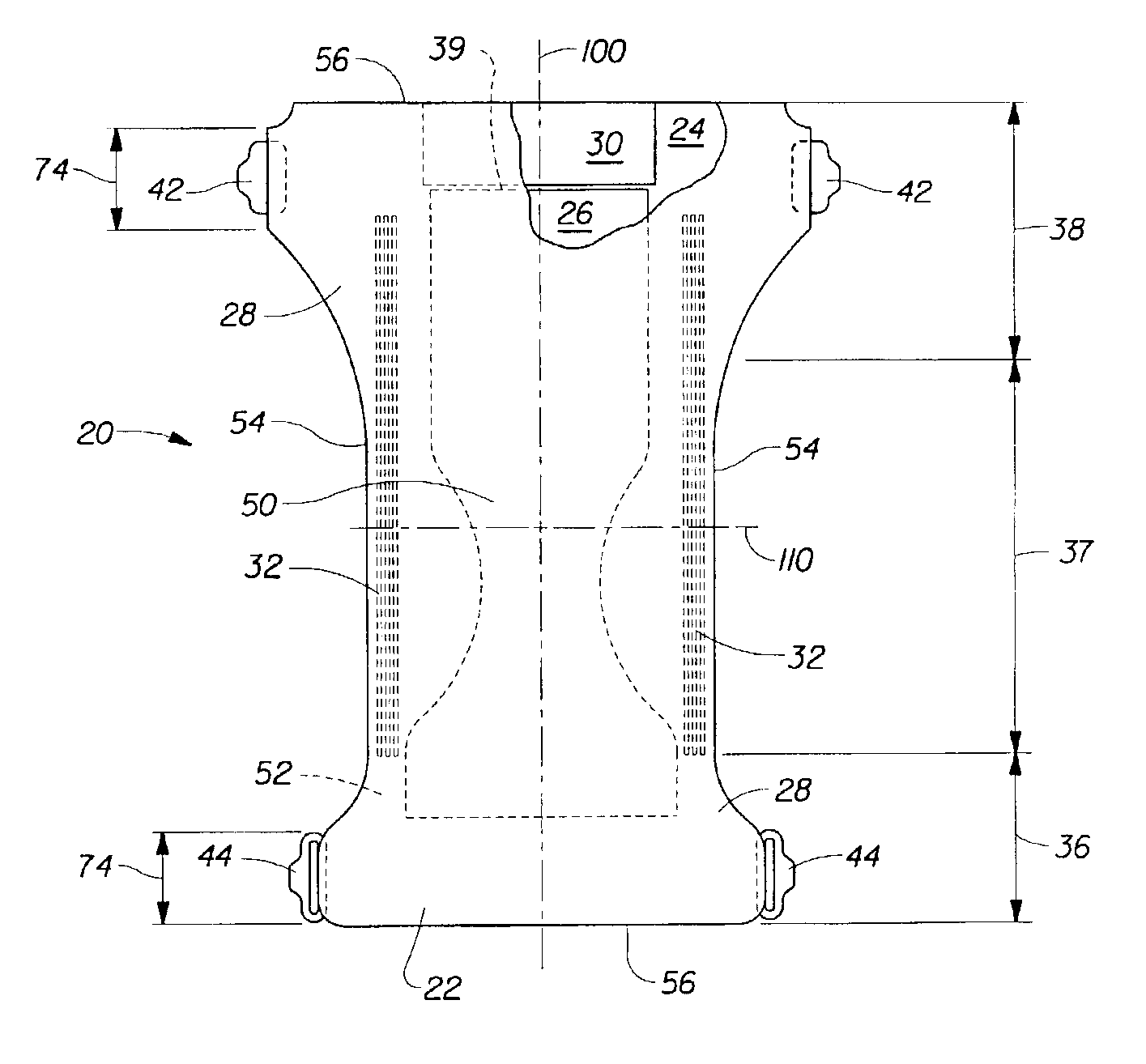

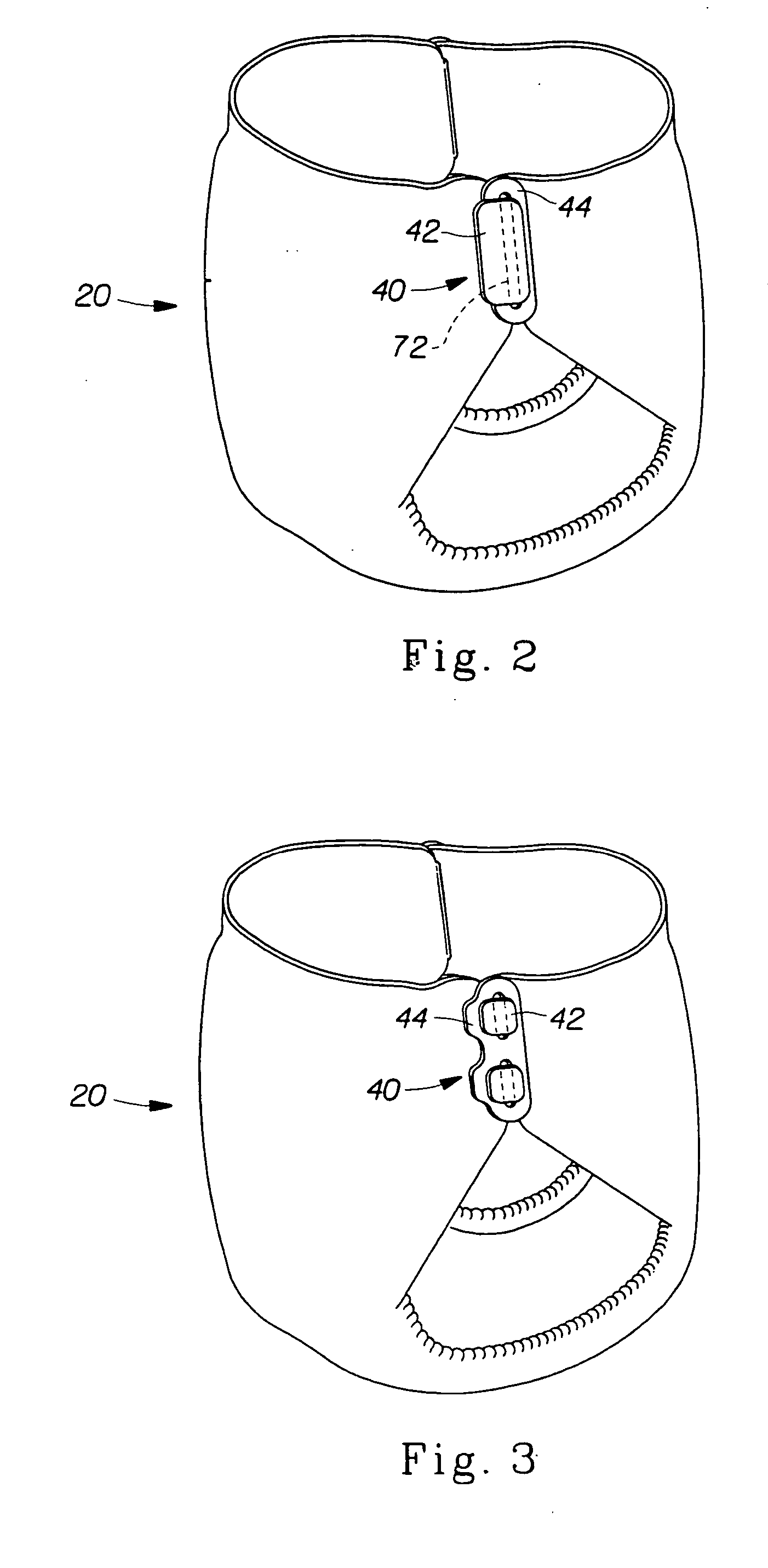

Absorbent article fastening device

Owner:THE PROCTER & GAMBLE COMPANY

Absorbent article fastening device

Owner:THE PROCTER & GAMBLE COMPANY

Transfer method, method of manufacturing thin film devices, method of maufacturing integrated circuits, circuit board and manufacturing method thereof, electro-optical apparatus and manufacturing method thereof, IC card, and electronic appliance

InactiveUS20050106839A1Reduce material usageImprove area efficiencyMaterial nanotechnologySemiconductor/solid-state device detailsEngineeringIntegrated circuit

Owner:SEIKO EPSON CORP

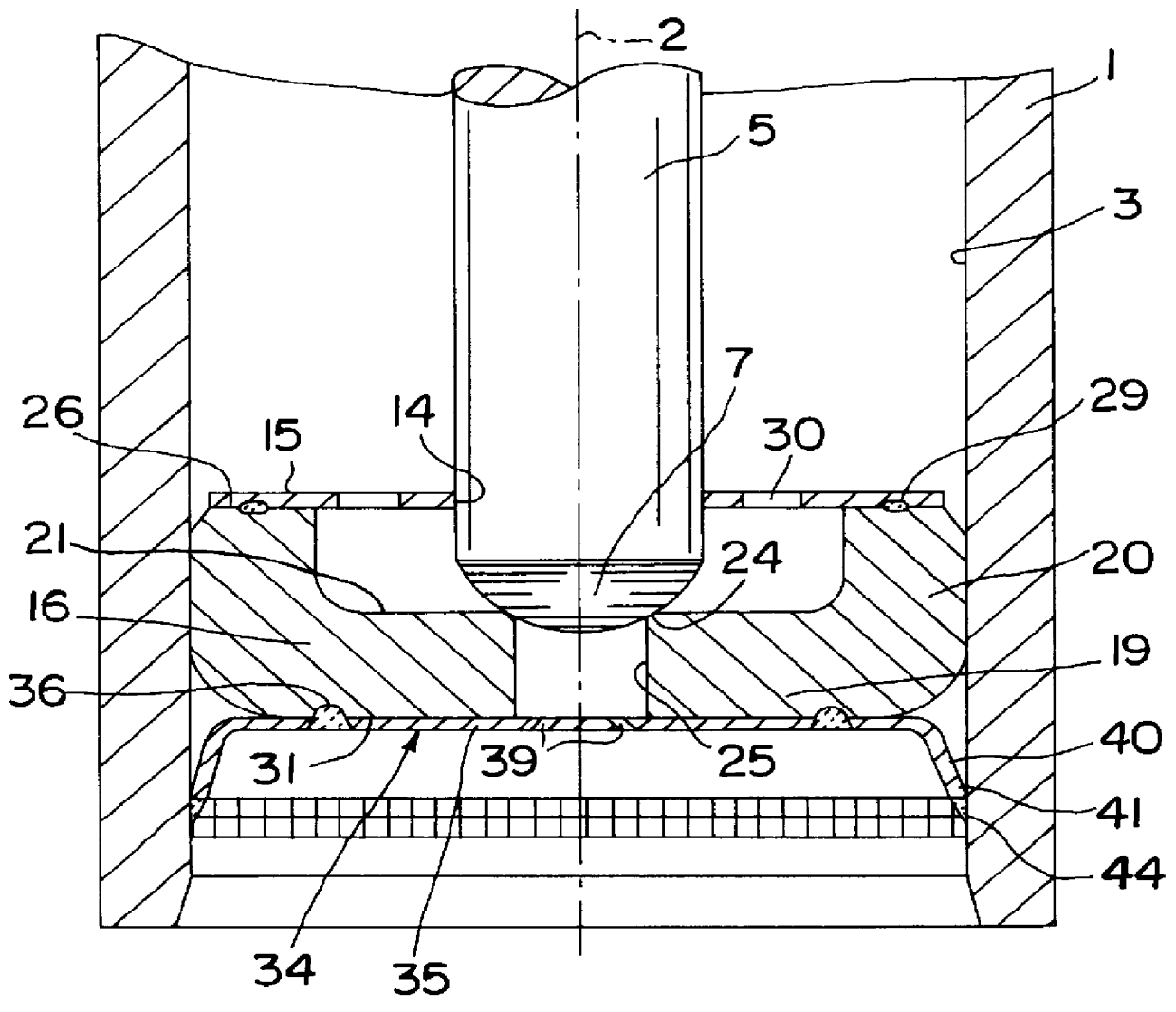

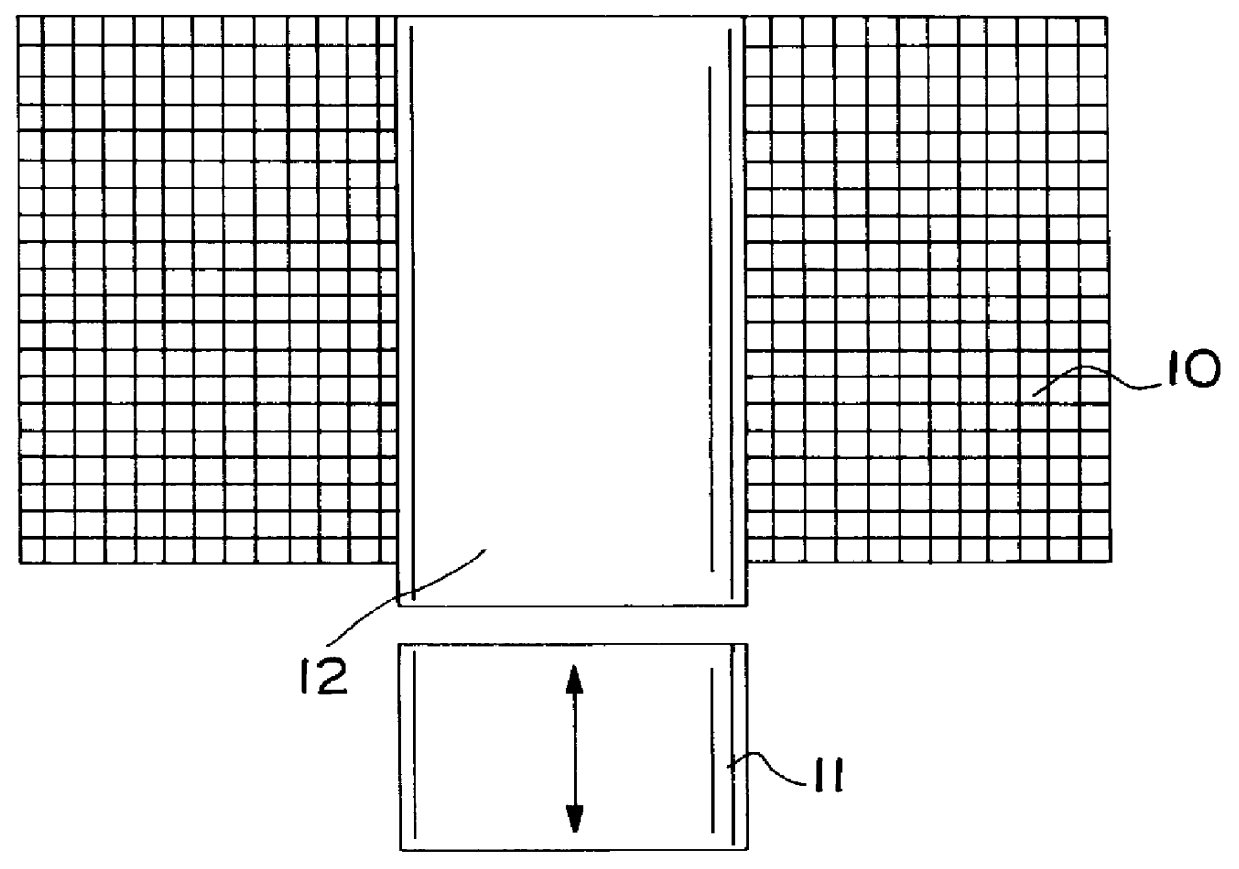

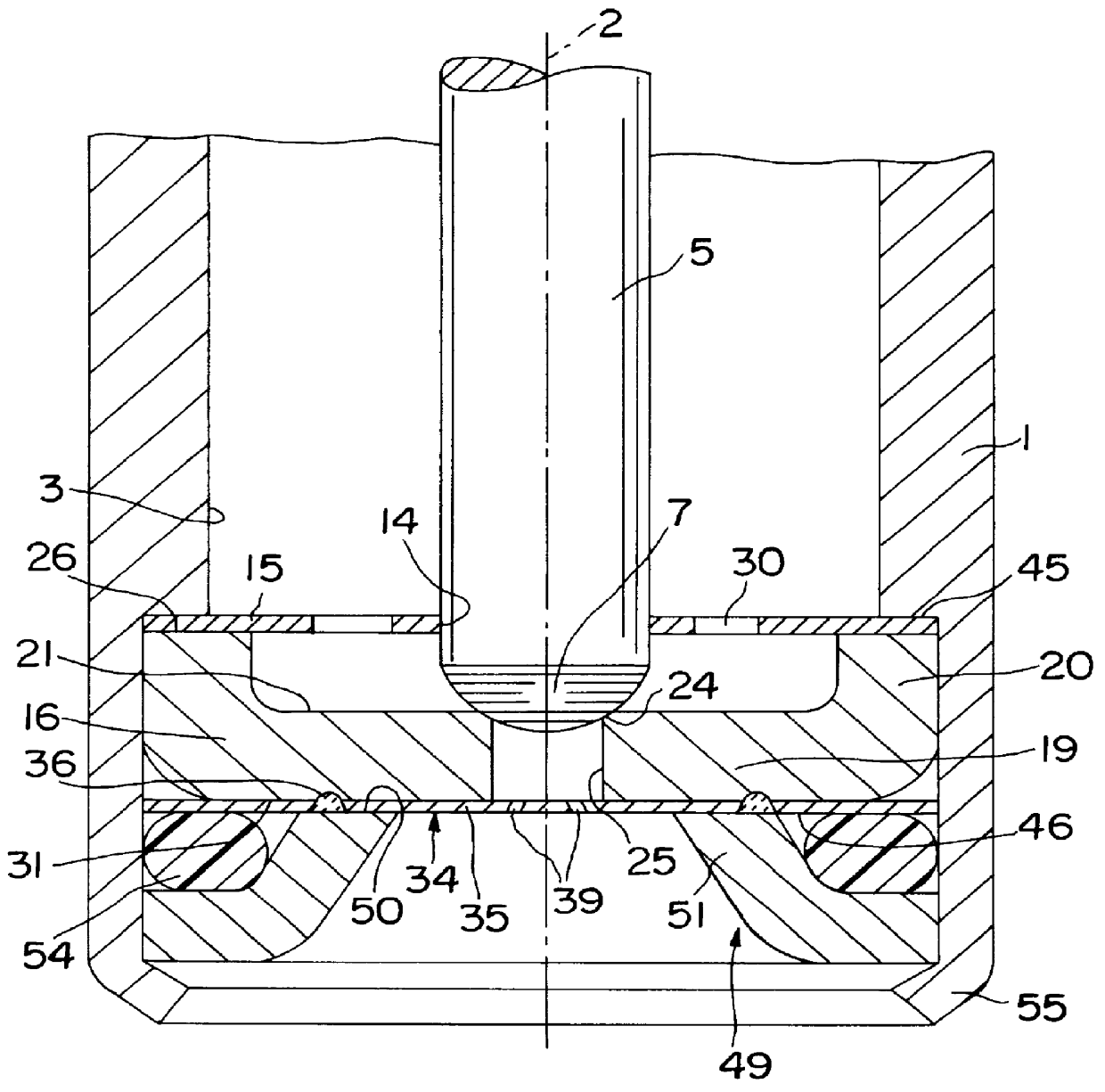

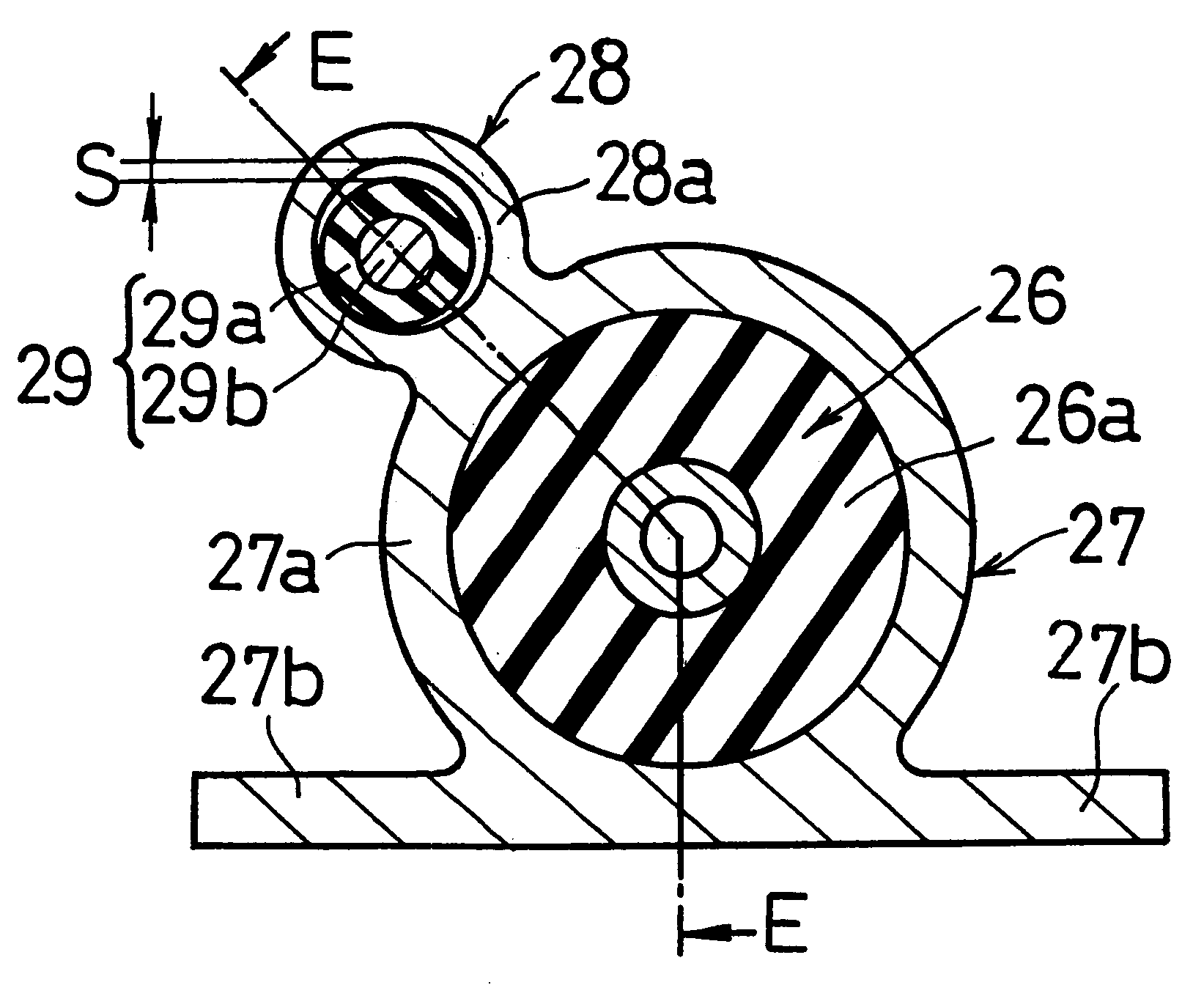

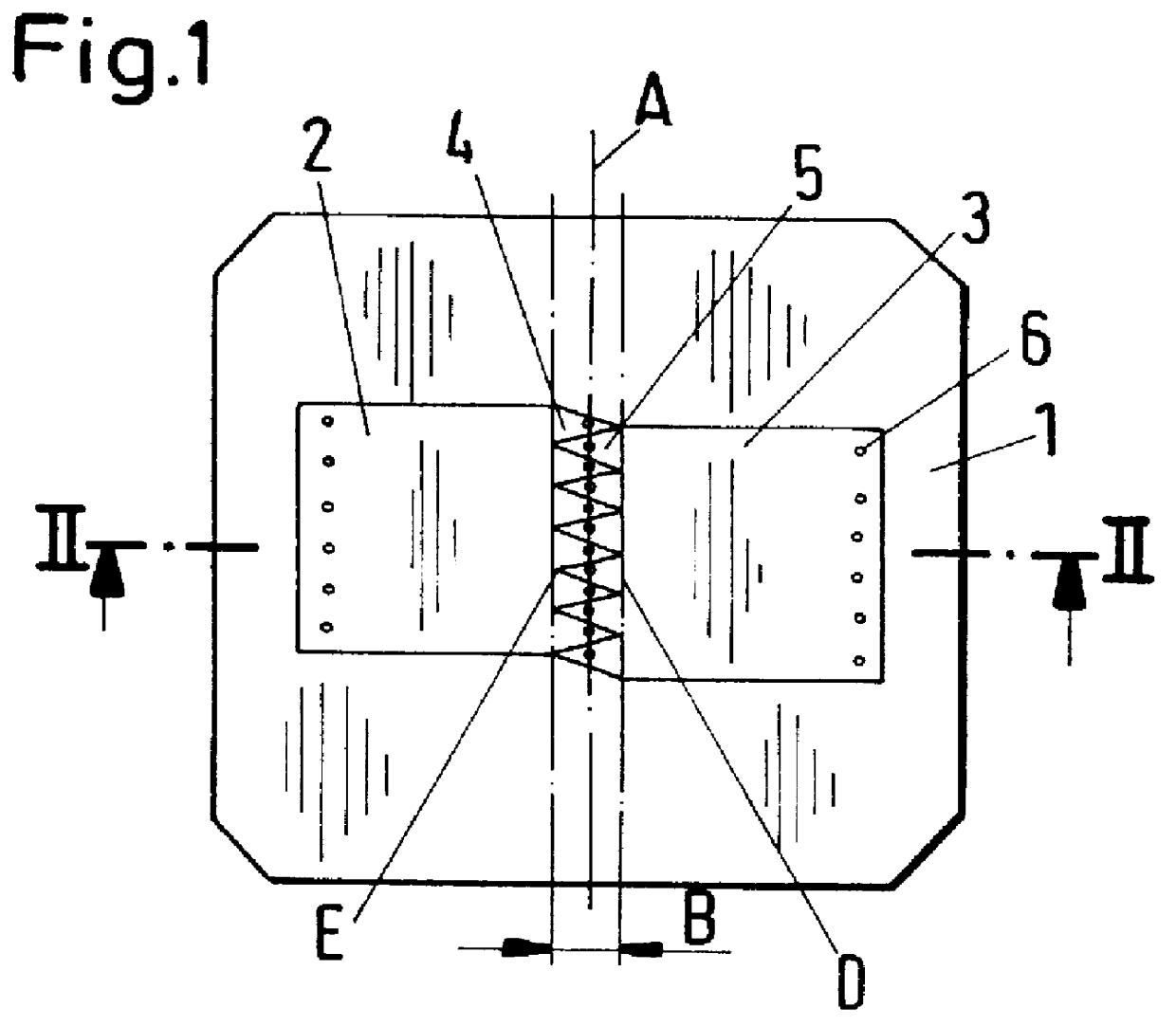

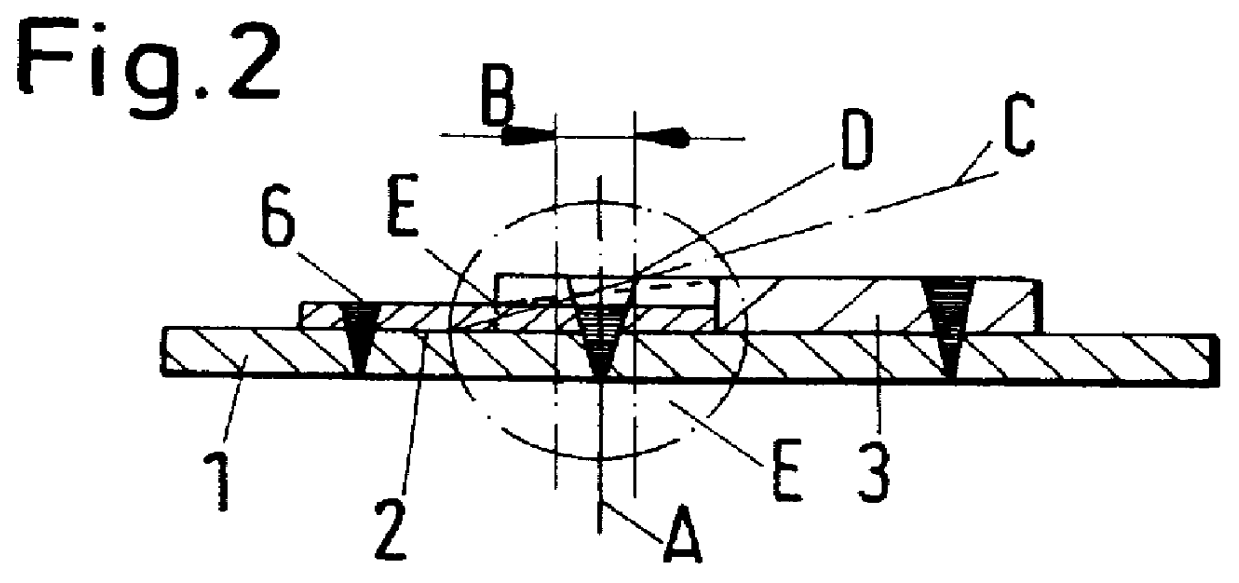

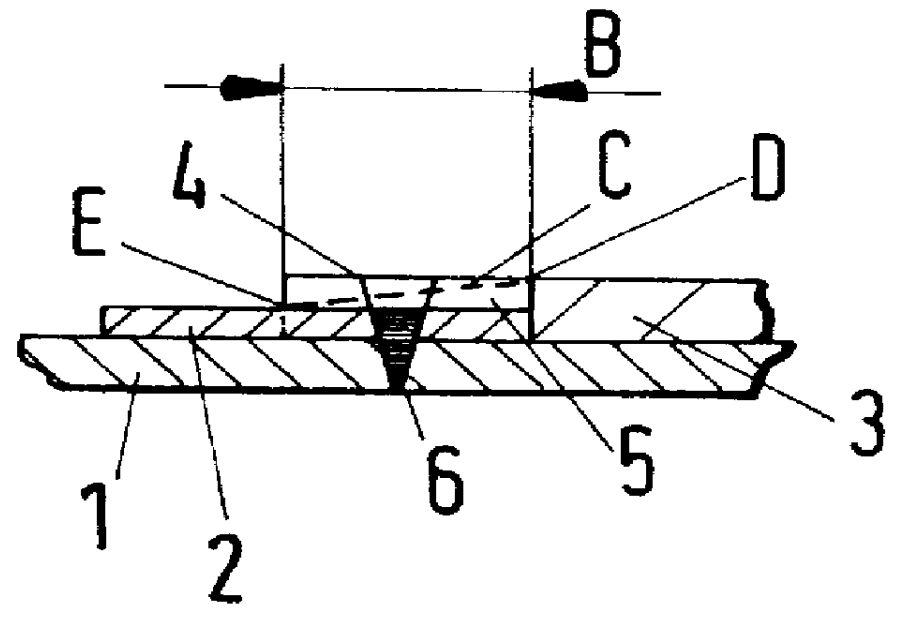

Fuel injection valve

InactiveUS6039271AReduce weightReduce material usageSpray nozzlesFuel injection apparatusCombustionInjection port

PCT No. PCT / DE97 / 00533 Sec. 371 Date Apr. 1, 1998 Sec. 102(e) Date Apr. 1, 1998 PCT Filed Mar. 15, 1997 PCT Pub. No. WO98 / 05859 PCT Pub. Date Feb. 12, 1998A fuel injection valve for internal combustion engines is already known in which the valve seat body is produced by multiple complicated work processes. In the novel valve, a valve seat body of simple design that can be made economically is used. The valve seat body (16) is made from sheet metal by stamping and deep drawing and has a cup shape with a bottom (19) of the seat body and an annular edge (20) of the seat body. A valve seat (24) is formed in the bottom (19) of the seat body. An injection port disk (34) is joined by welding to the valve seat body (16). The fuel injection valve is especially suitable for fuel injection systems of mixture-compressing internal combustion engines with externally supplied ignition (FIG. 1).

Owner:ROBERT BOSCH GMBH

Method for fabricating an interference display unit

InactiveUS7016095B2Increase brightnessSimple and easy manufacturing processMirrorsDecorative surface effectsEngineeringPosition shift

An interference display unit with a first electrode, a second electrode and posts located between the two electrodes is provided. The characteristic of the interference display unit is that the second electrode's stress is released through a thermal process. The position of the second electrode is shifted and the distance between the first electrode and the second electrode is therefore defined. A method for fabricating the structure described as follow. A first electrode and a sacrificial layer are sequentially formed on a substrate and at least two openings are formed in the first electrode and the sacrificial layer. A supporter is formed in the opening and the supporter may have at least one arm on the top portion of the supporter. A second electrode is formed on the sacrificial layer and the supporter and a thermal process is performed. Finally, The sacrificial layer is removed.

Owner:SNAPTRACK

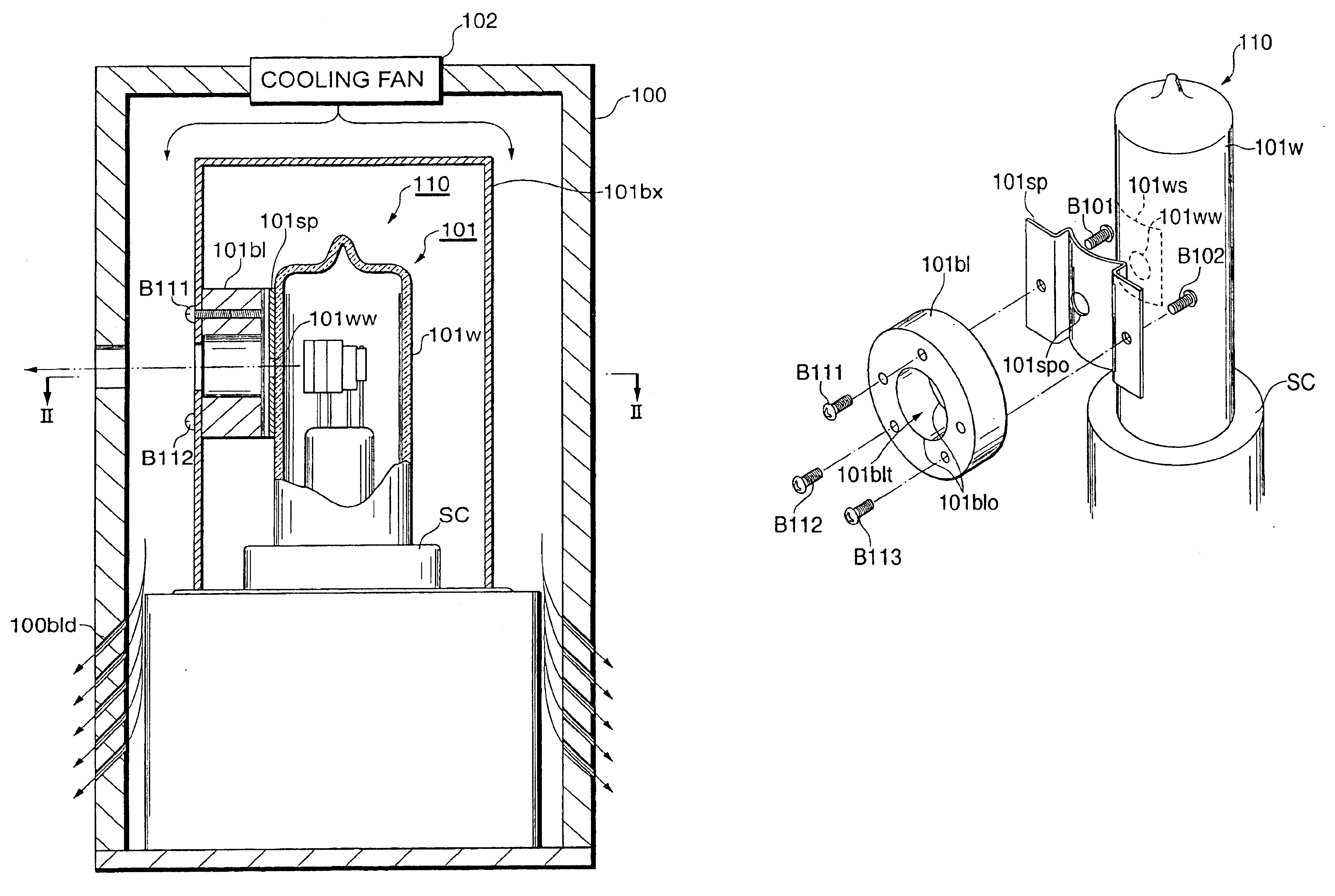

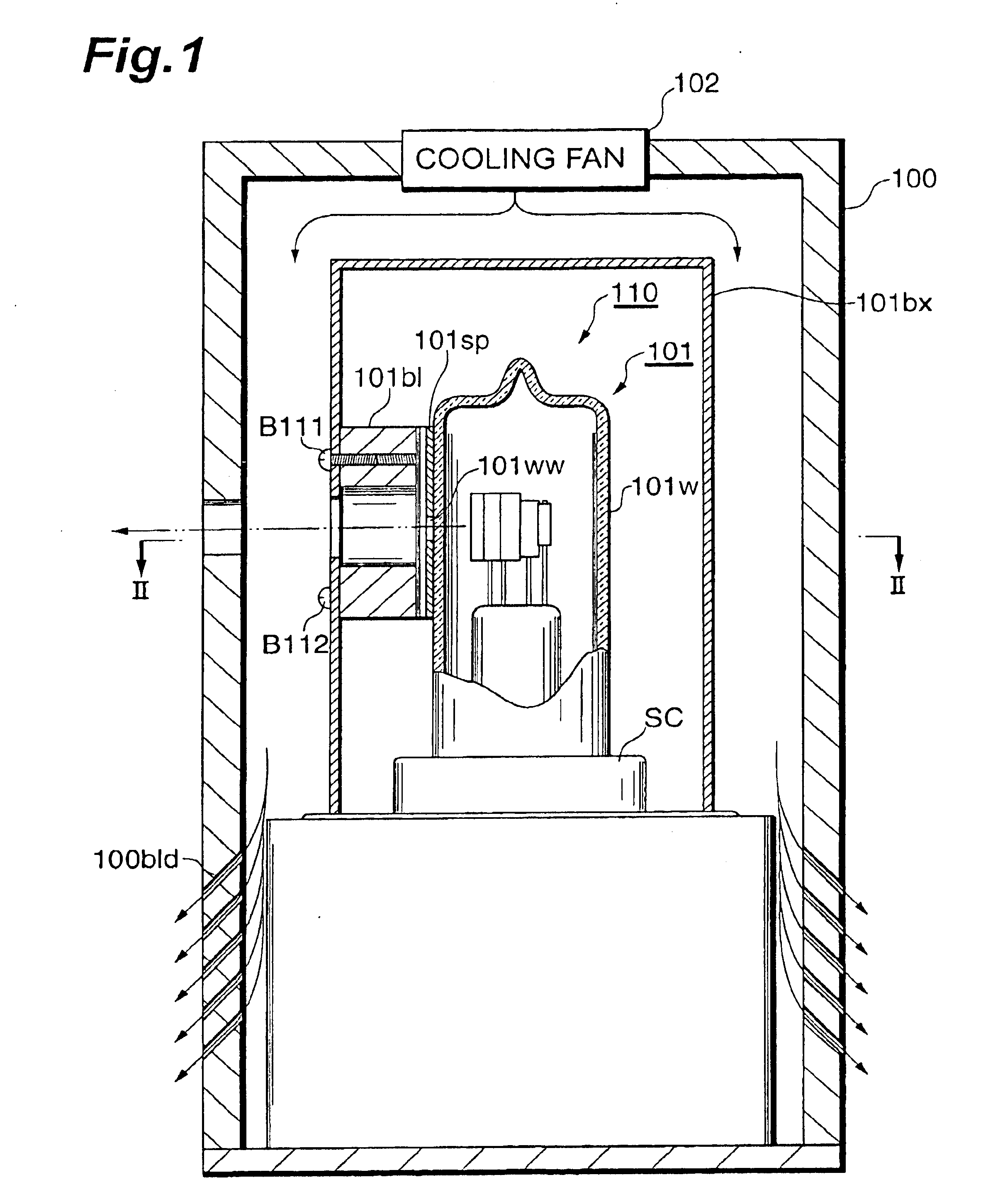

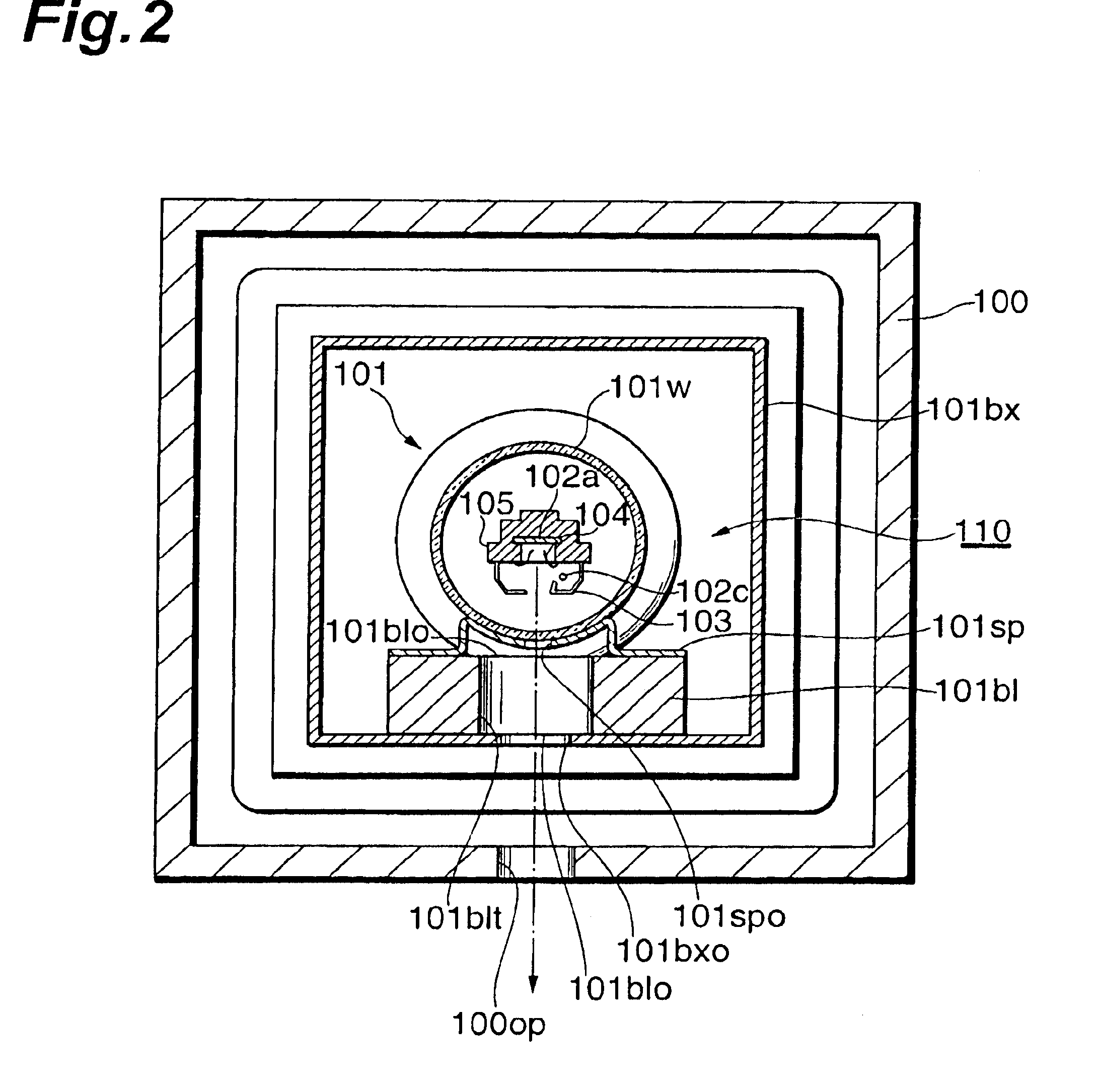

Light source

InactiveUS6885134B2Decrease amount of materialExtended service lifeElectric discharge tubesLighting heating/cooling arrangementsHeat sinkLight source

In a light source, a heat sink is in contact with a side-on type discharge tube 110. The heat sink is in contact with a peripheral region 110ws around an exit window 101ww of the discharge tube 110. The heat sink consists of a spring member 101sp kept in direct contact with the peripheral region 101ws, and a radiating block 101bl which connects the spring member 101sp to a radiator box 101bx. Since materials made by sputtering or the like of electrodes in the discharge tube 110 mostly attach to the peripheral region 101ws of side wall 101w, it is feasible to decrease the amount of materials attaching to the exit window 101ww and, in turn, lengthen the lifetime of the discharge tube. Another light source may be constructed in structure in which the heat sink is in contact with a head-on type discharge tube or in structure in which light is outputted from a projecting portion.

Owner:HAMAMATSU PHOTONICS KK

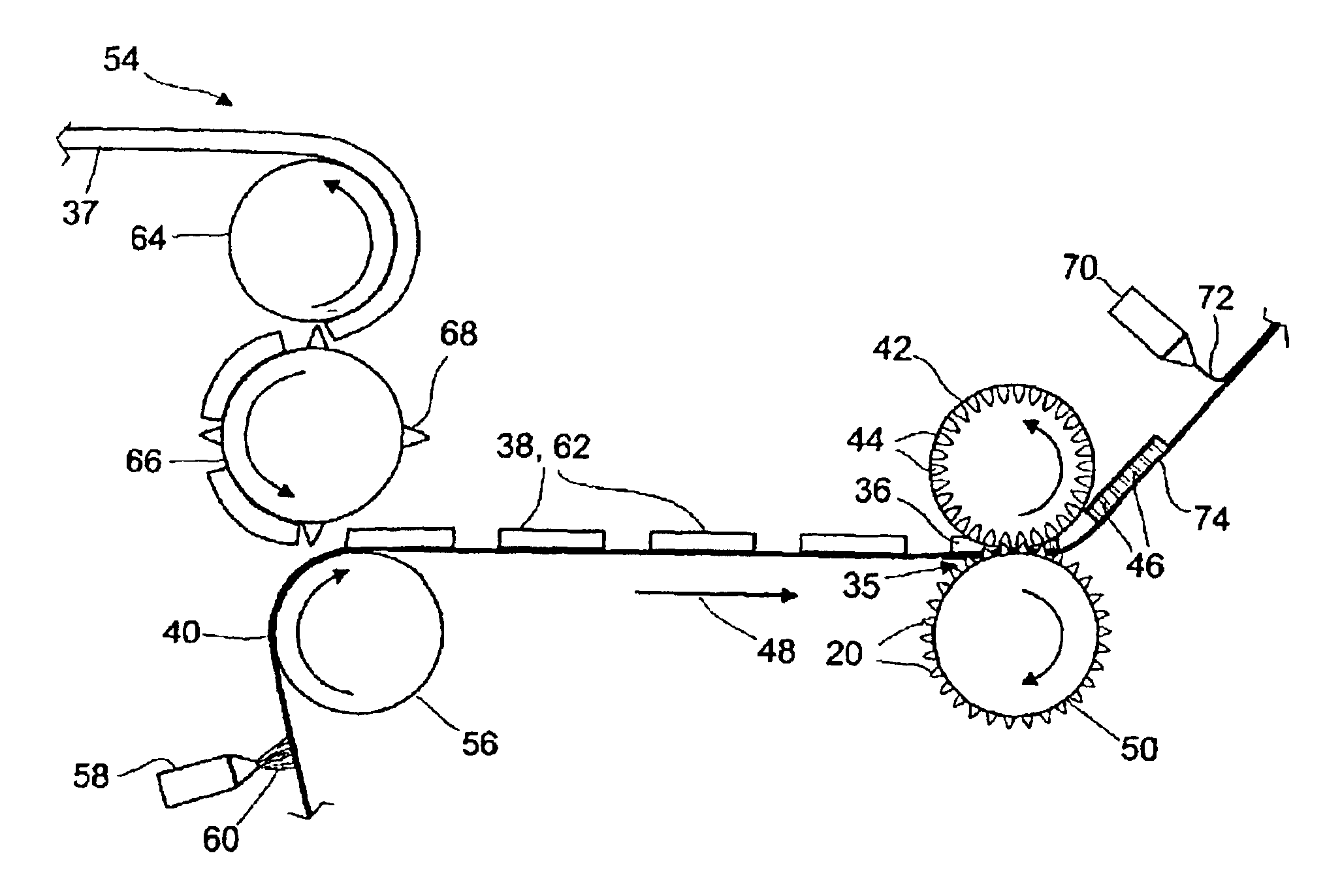

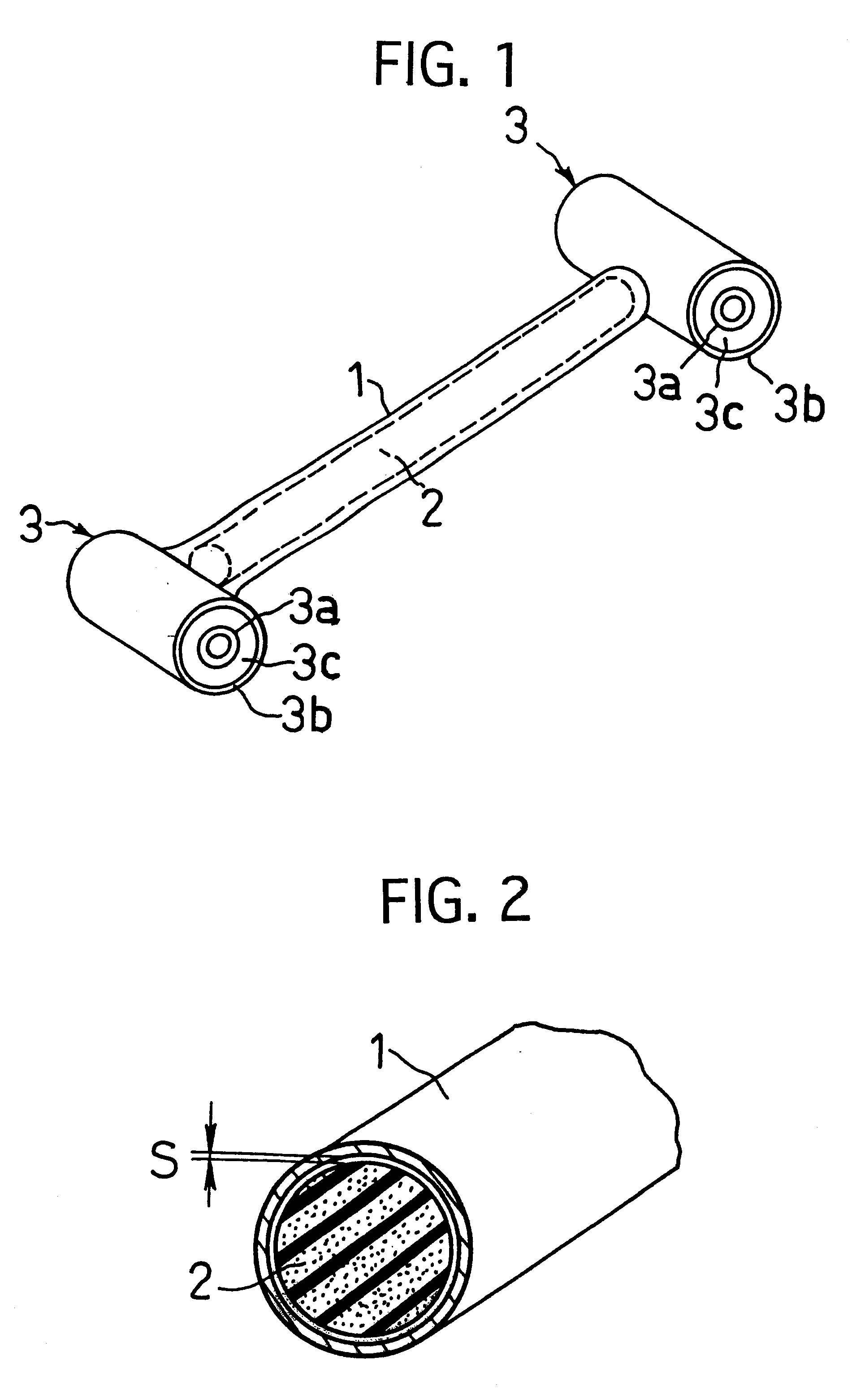

System for aperturing and coaperturing webs and web assemblies

InactiveUS6837956B2Reduce distortionReduce frictionLamination ancillary operationsLaminationEngineeringMechanical engineering

Improved aperturing of a web can be obtained by providing pins with an extended tapered section that is substantially convex in shape. When the tapered section is longer than the penetration depth of the pins into the receiving recesses of a female roll, frictional forces in the nip between layers are reduced. Pins with extended tapered sections can be used in devices for producing apertured composite web assemblies comprising sections of absorbent matter attached to a nonwoven web or other carrier layer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

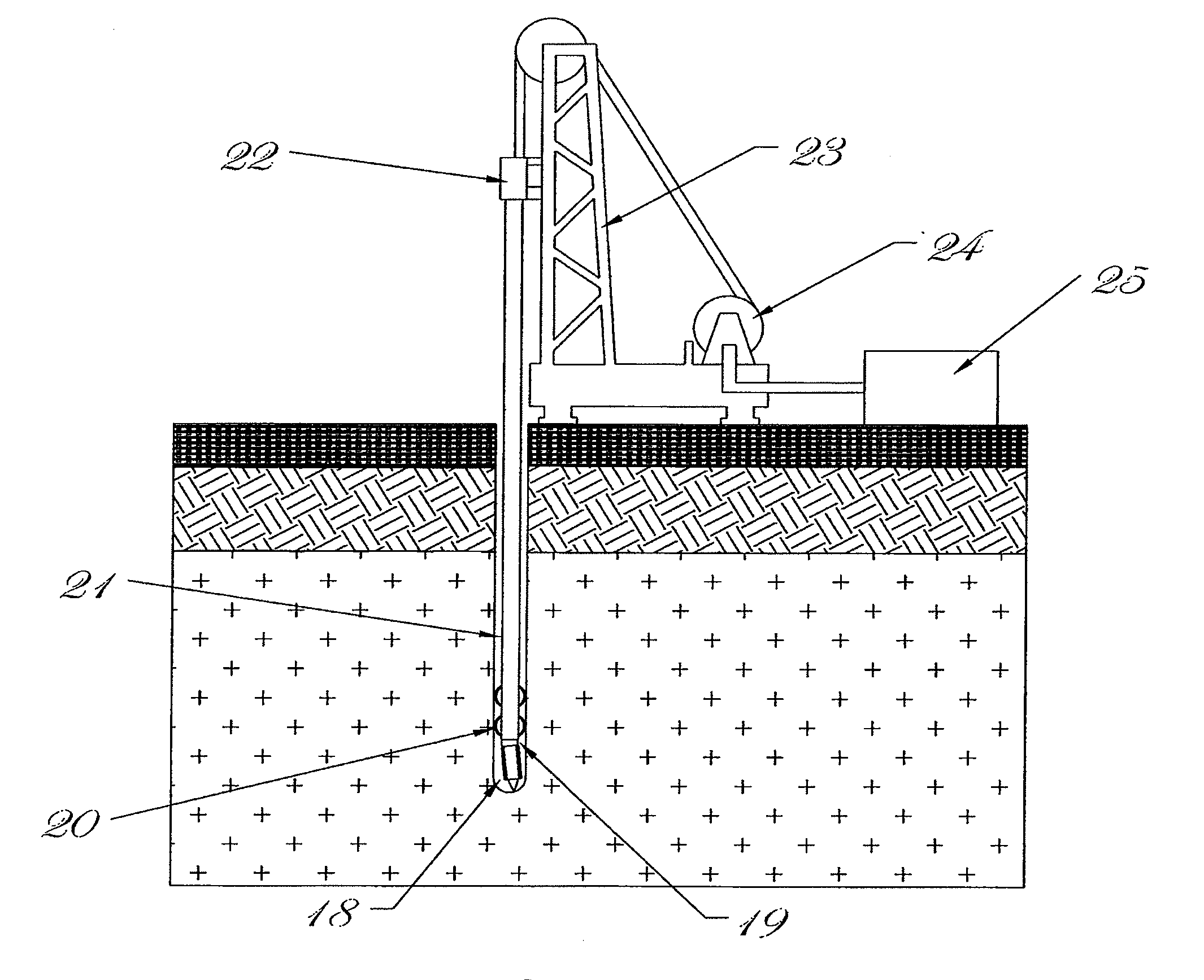

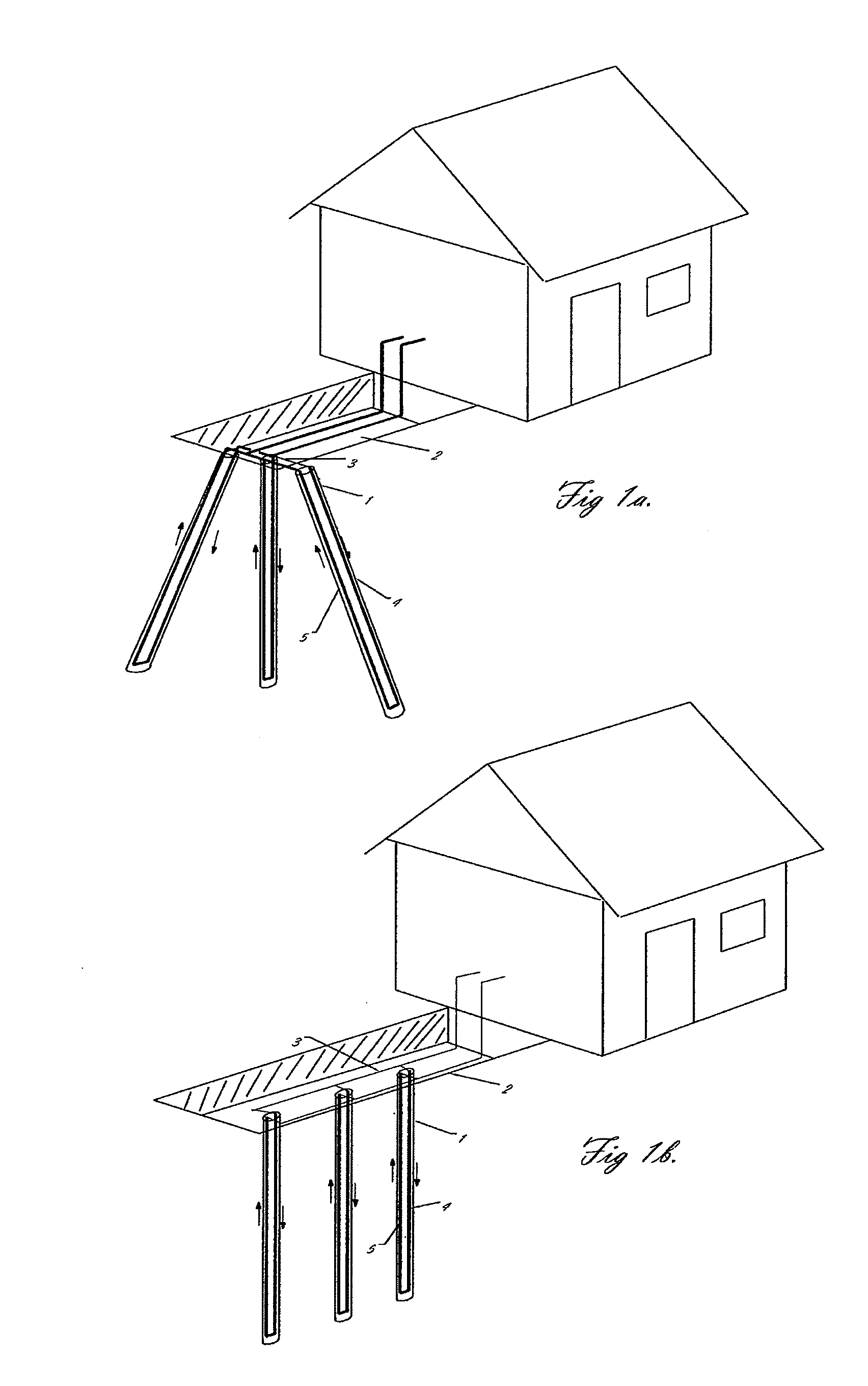

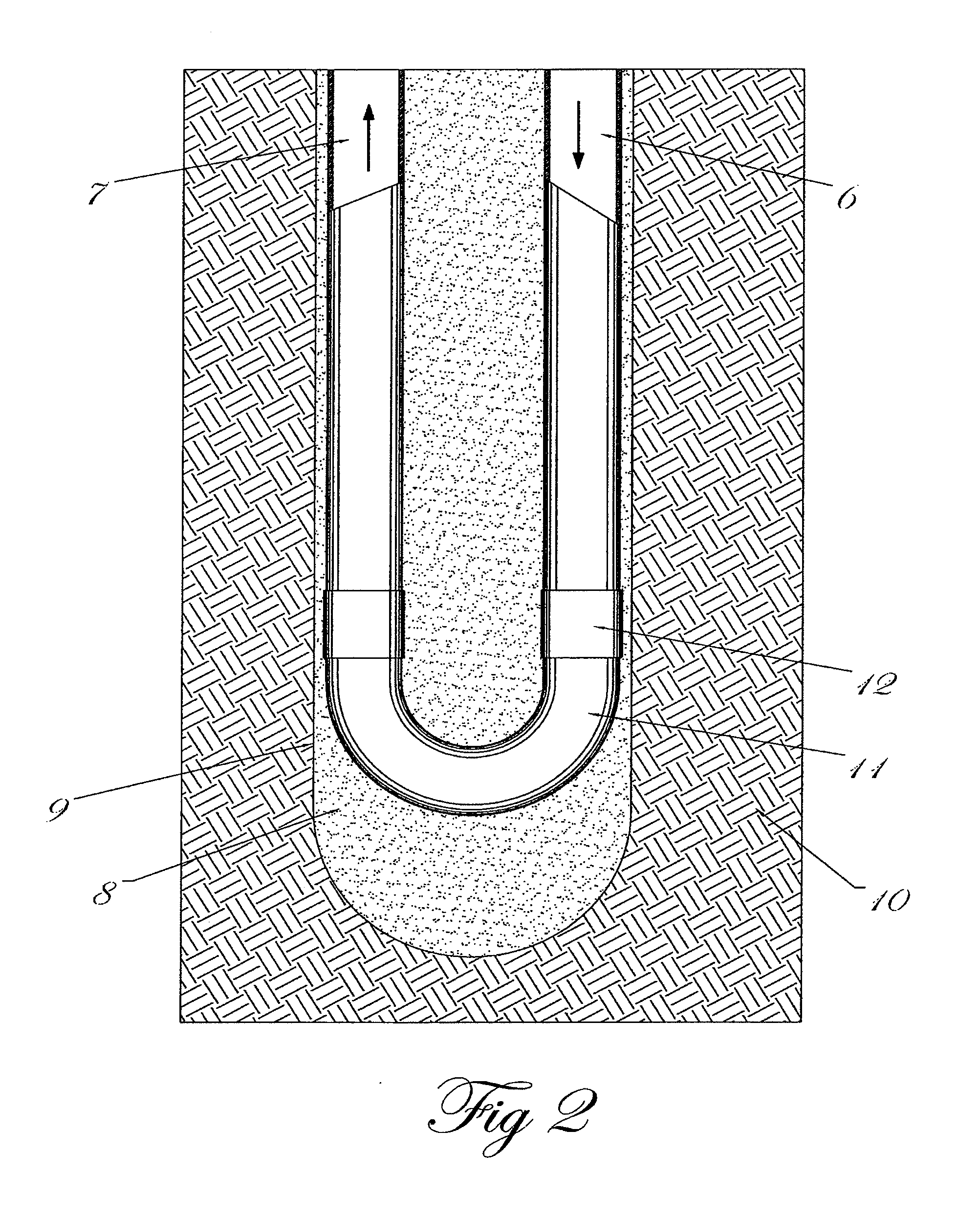

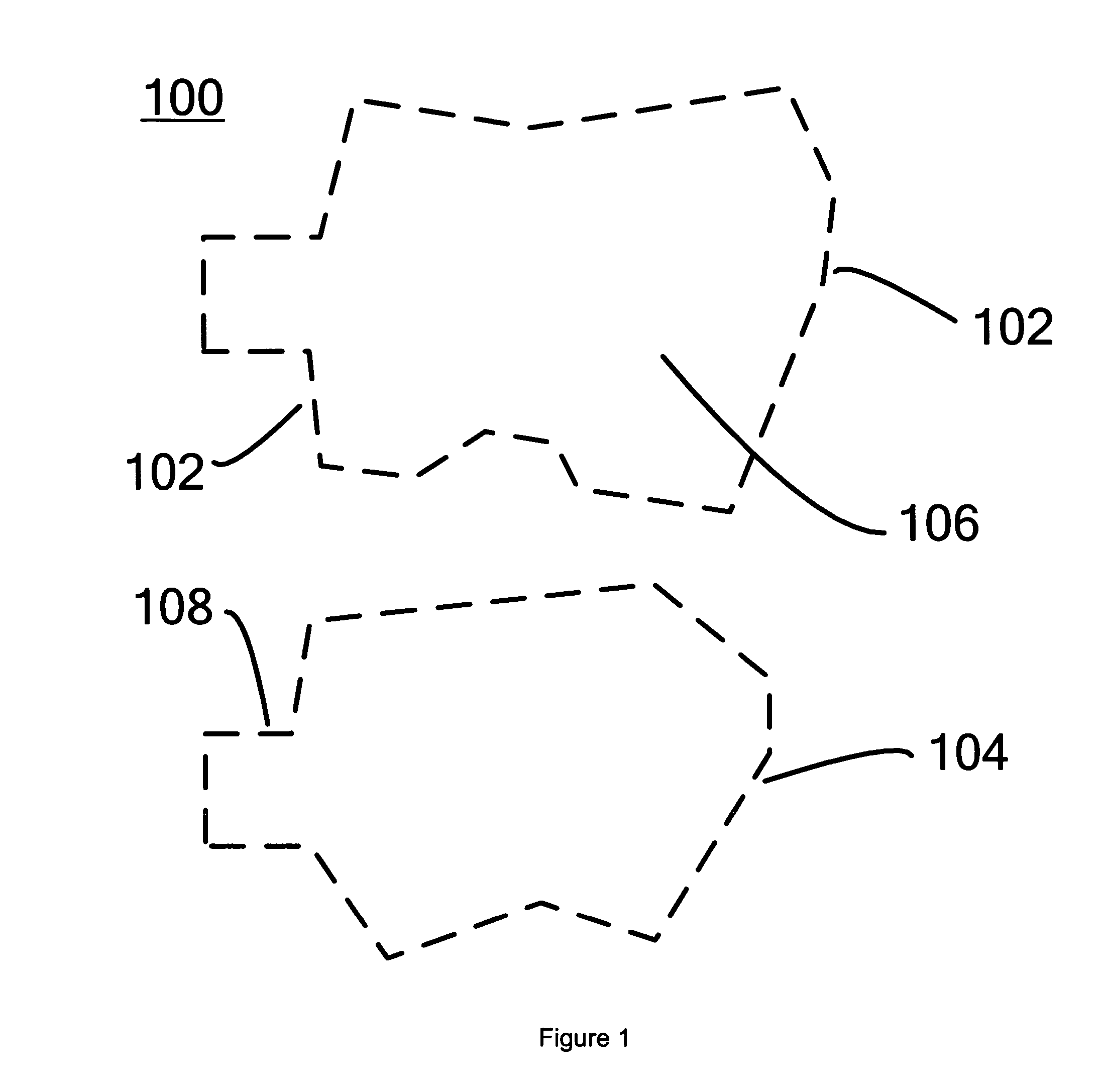

Method and System for Forming a Non-Circular Borehole

InactiveUS20100032207A1Easy to installEasy to operateCollector components/accessoriesLighting and heating apparatusEngineeringDissolution

System and methods for creating shaped, non-circular boreholes in rocks especially for use with geothermal heat pump applications and for increasing wellbore support in applications such as horizontal oil and gas drilling are described. The systems and methods when applied to geothermal heat pumps create an elliptical shaped hole that is optimized for placing heat transfer tubes with a minimum of grout used. The significantly reduced cross-sectional area of the elliptical borehole also increases the overall drilling rate in rock and especially in hard rocks. In horizontal hard-rock drilling, creation of a horizontal non-circular borehole or modification of a circular borehole to a non-circular geometry is used to stabilize the borehole prior to casing insertion, and may also allow the use of lower mud pressures improving drilling rates. The system uses a non-contacting drilling system which in one embodiment uses a supersonic flame jet drilling system with a movable nozzle that swings between pivot points. In a second embodiment the elliptical shaped hole is created by an abrasive fluid or particle bearing-fluid or air jet drill that moves between pivot points. In another embodiment a non-contacting drill can use dual parallel nutating nozzles that create a pair of overlapping circular holes. The non-circular shaped hole is created by either the high temperature flame or water-particle jet or chemically active fluid jet as it removes rock material by erosion, dissolution and or thermal spalling. Modifications of circular boreholes to a generally elliptical shape can also be done using milling or jetting techniques.

Owner:POTTER JARED MICHAEL +3

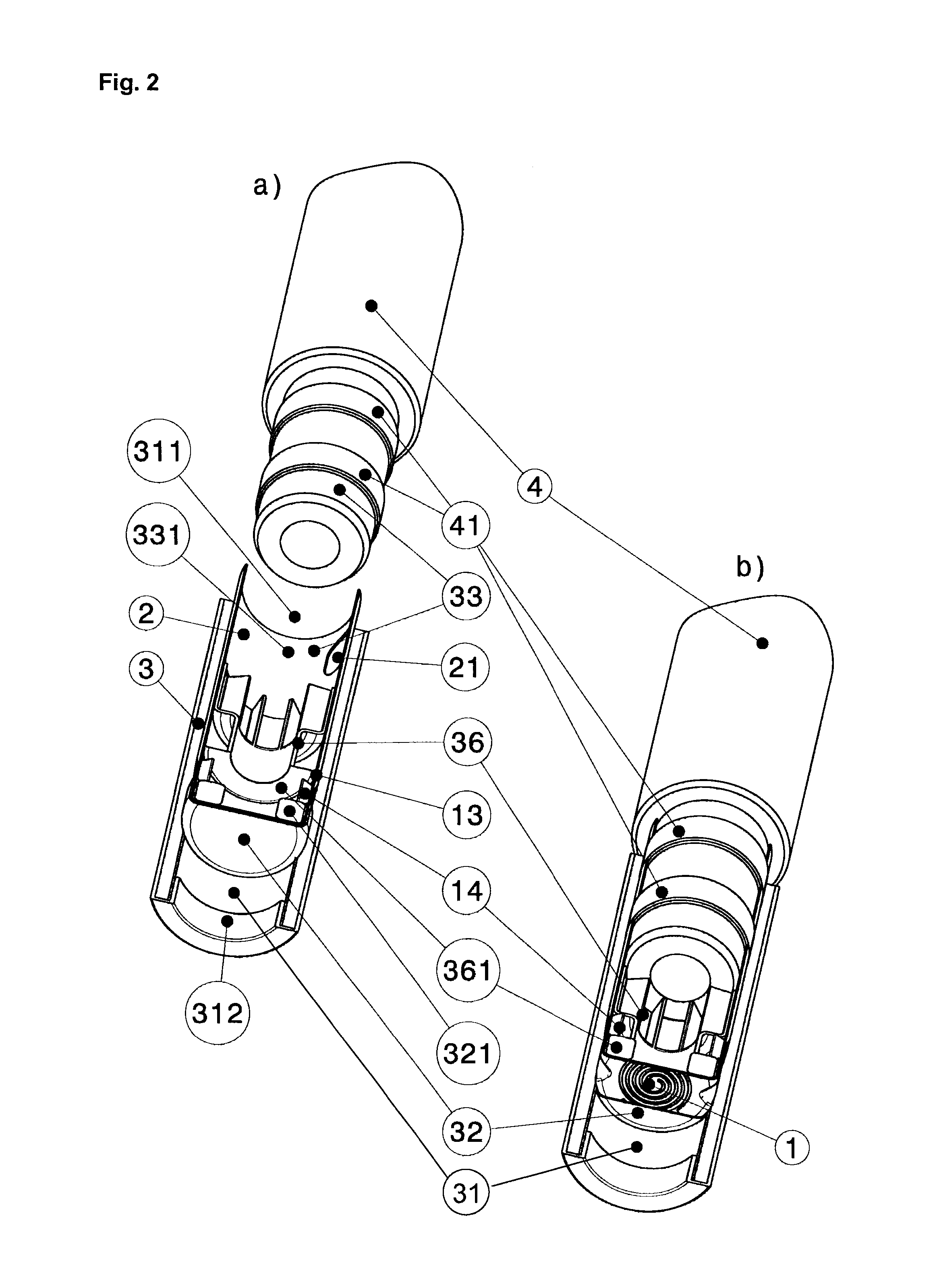

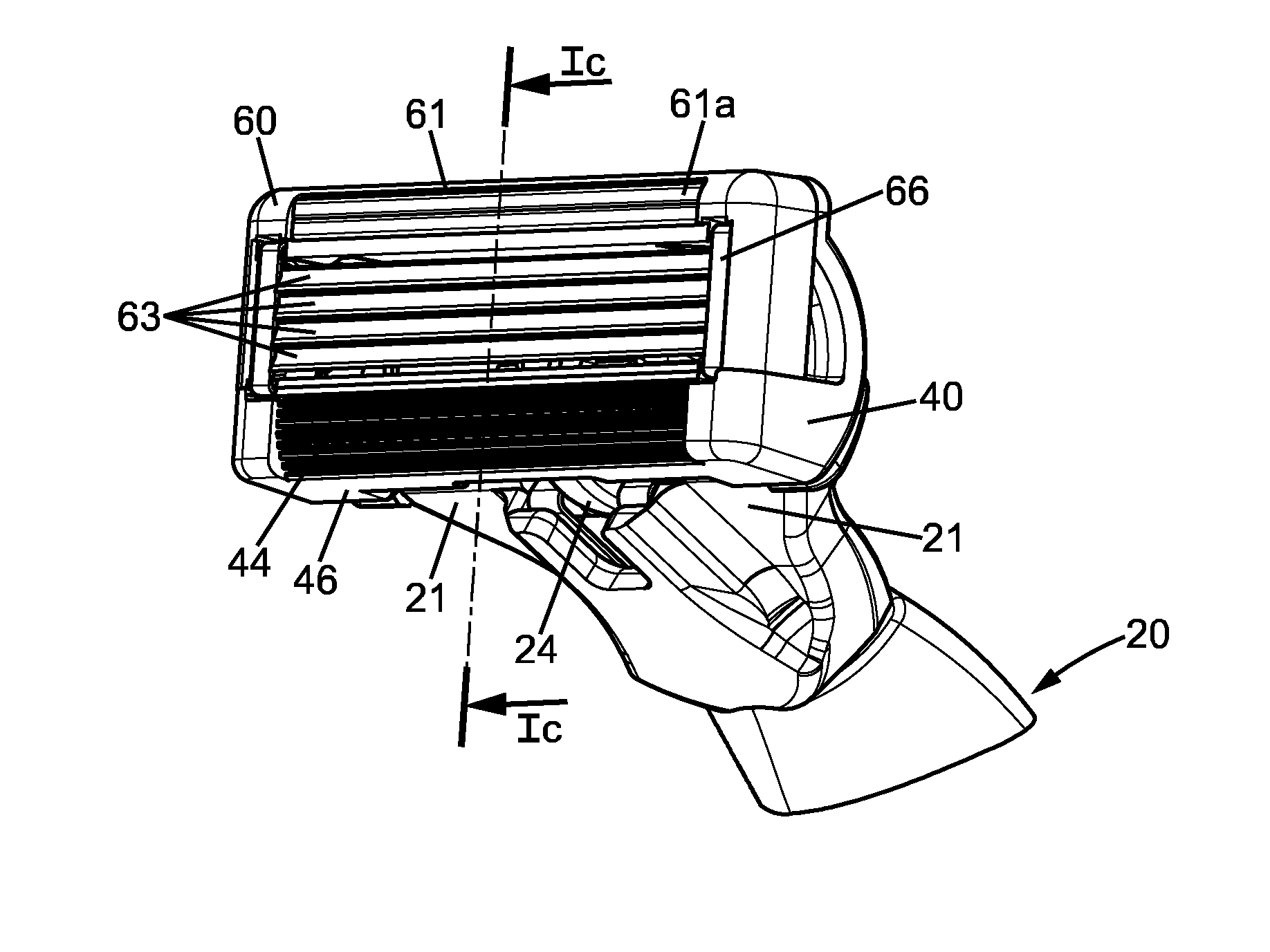

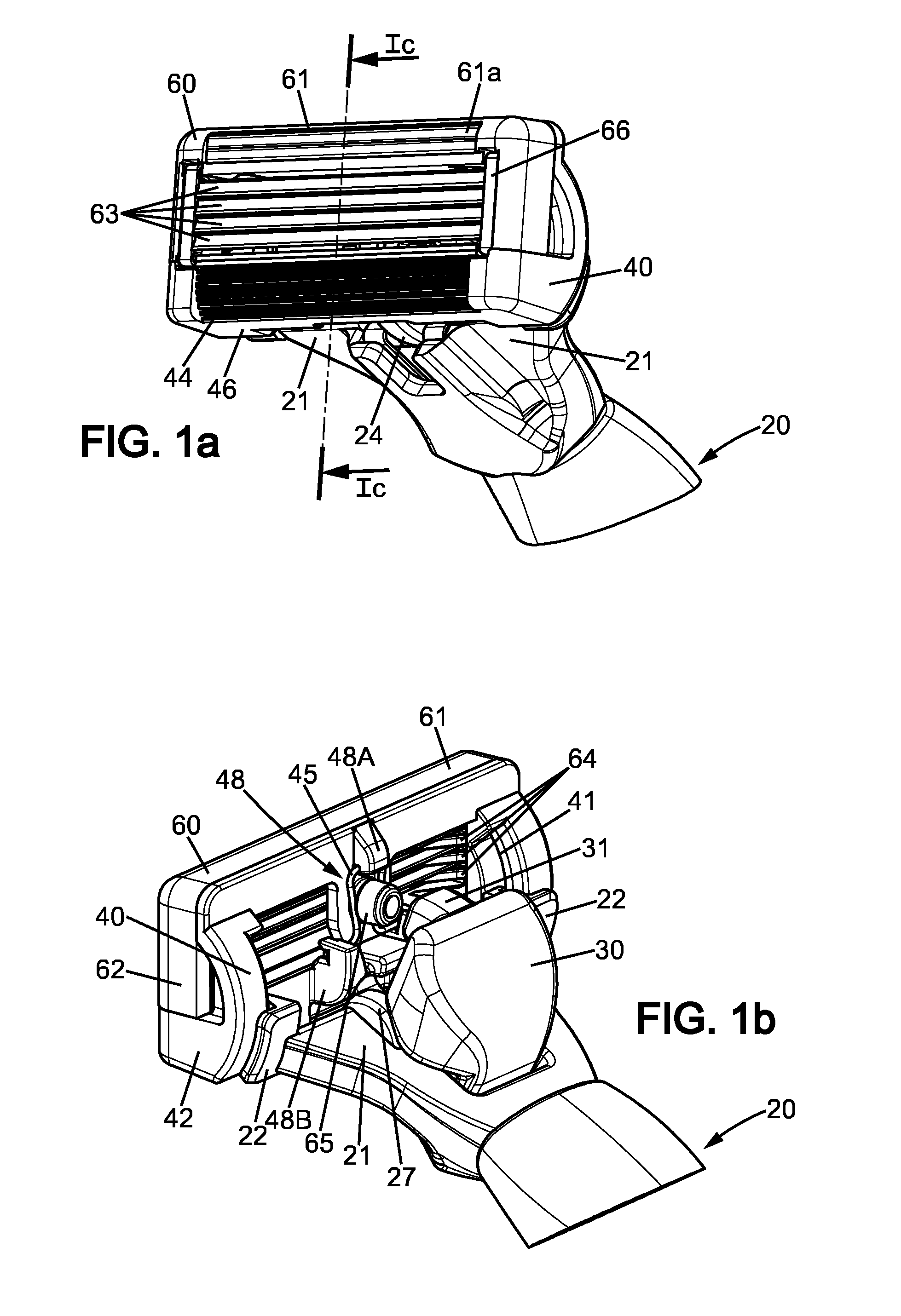

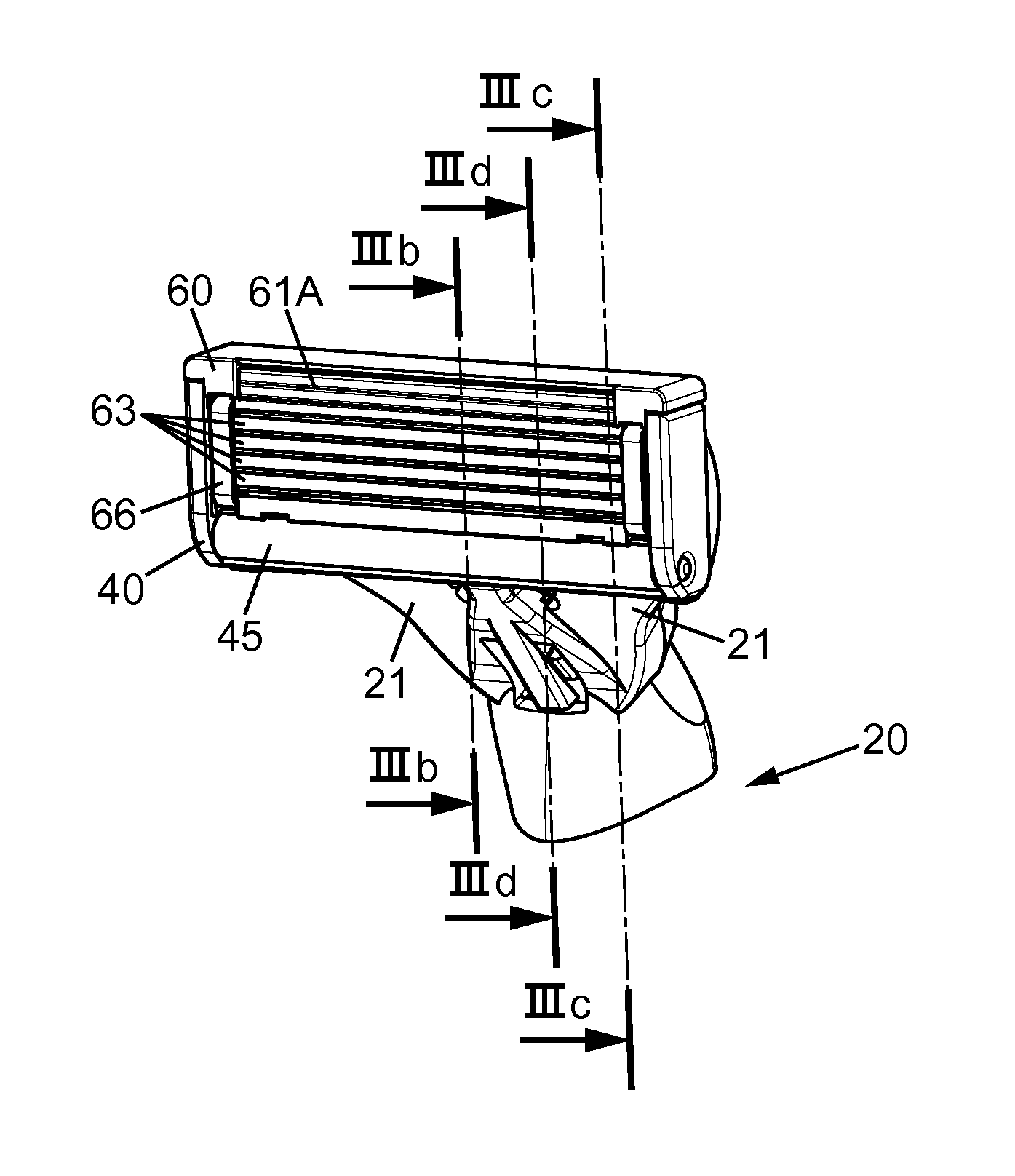

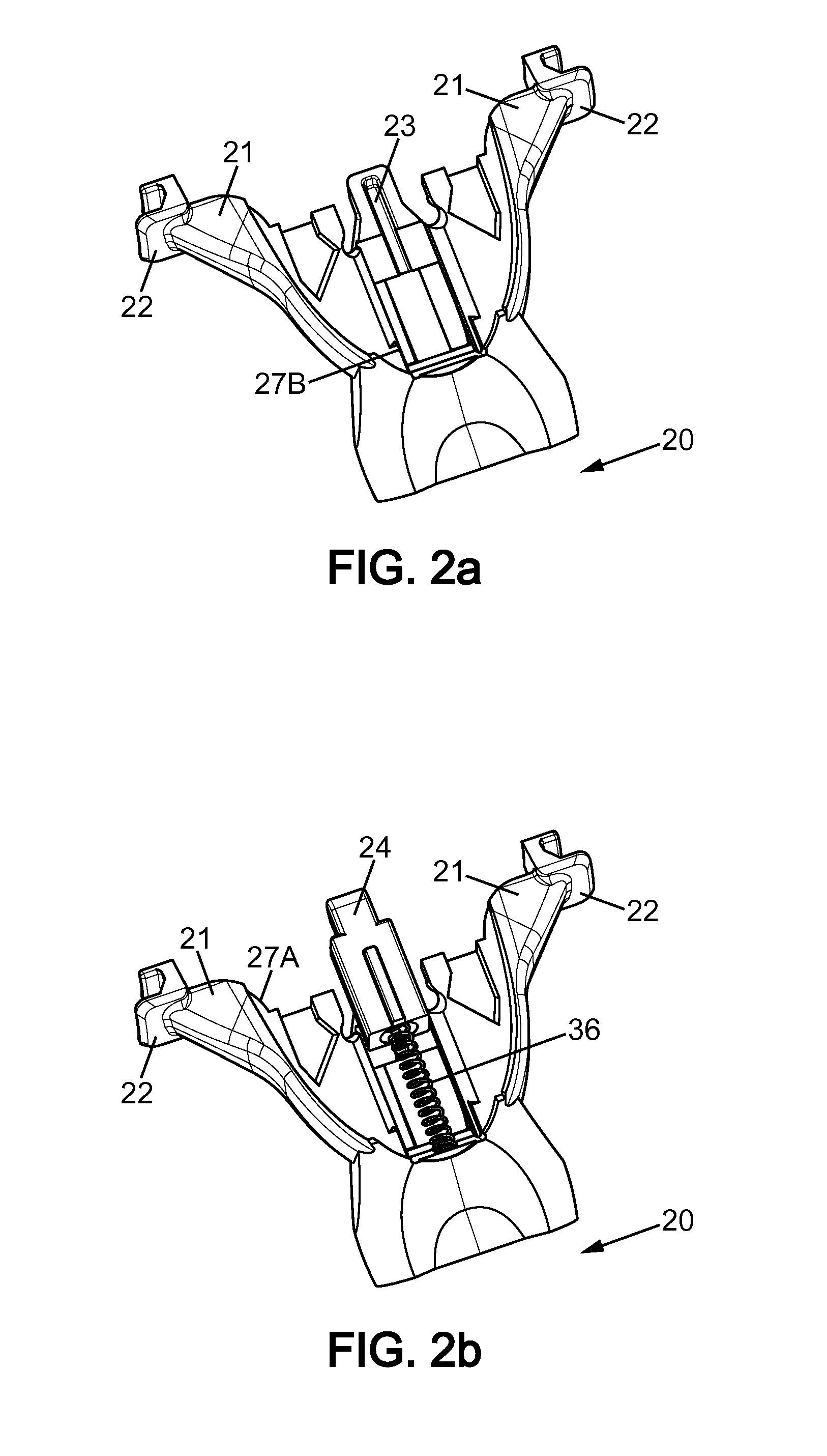

Shaver

ActiveUS20150290819A1Easy to ejectReduce the risk of injuryMetal working apparatusBiomedical engineering

A shaver is provided, the shaver including a handle with an elongated handgrip portion and a mounting portion, a shaver head pivotally attached to the mounting portion, a removable cartridge including at least one blade, the cartridge being adapted to be attached to the shaver head and removed from the shaver head, a pusher, adapted to encounter the cartridge to release the cartridge from the shaver head, and a spring provided on the shaver head, the spring being adapted to attach the cartridge to the shaver head, the spring comprising at least one part which forms a loop.

Owner:BIC VIOLEX SA

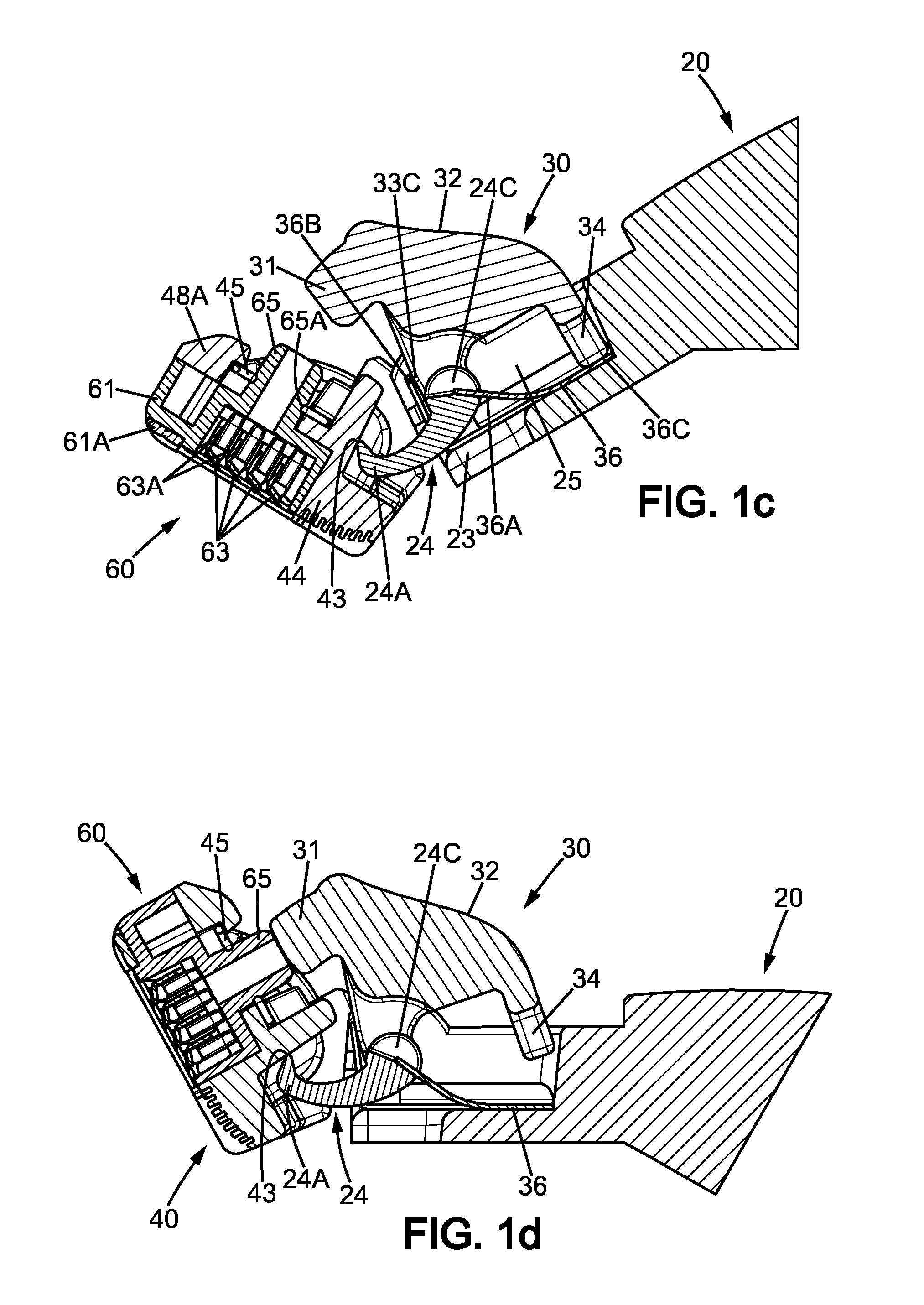

Sensing Structure

ActiveUS20090194342A1Reduce material usageSimple processTransmission systemsPrinted circuit aspectsElectrical and Electronics engineering

A sensing structure is provided. The sensing structure includes a first substrate, a second substrate, a sensing unit, and a flexible printed circuit (FPC). The sensing unit is disposed on the first substrate and adapted to generate a signal when the sensing unit is touched. The FPC has a first end and a second end. The first end includes a first connecting portion and a second connecting portion. The first connecting portion is disposed on the first substrate and electrically connected to the sensing unit, and the second connecting portion connects to the second substrate.

Owner:AU OPTRONICS CORP

Electric appliance, semiconductor device, and method for manufacturing the same

InactiveUS20070093002A1Reduce drastically costReduce material usageTransistorElectroluminescent light sourcesDevice materialConductive materials

In the present circumstances, a film formation method of using spin coating in a manufacturing process is heavily used. As increasing the substrate size in future, the film formation method of using spin coating becomes at a disadvantage in mass production since a mechanism for rotating a large substrate becomes large, and there is many loss of material solution or waste liquid. According to the present invention, in a manufacturing process of a semiconductor device, a microscopic wiring pattern can be realized by delivering selectively photosensitive conductive material solution by droplet discharging, exposing selectively to laser light or the like, and developing. The present invention can reduce drastically costs since a patterning process can be shortened and an amount of material in a process of forming a conductive pattern can be reduced. Accordingly, the present invention can be applied to manufacture a large substrate.

Owner:SEMICON ENERGY LAB CO LTD

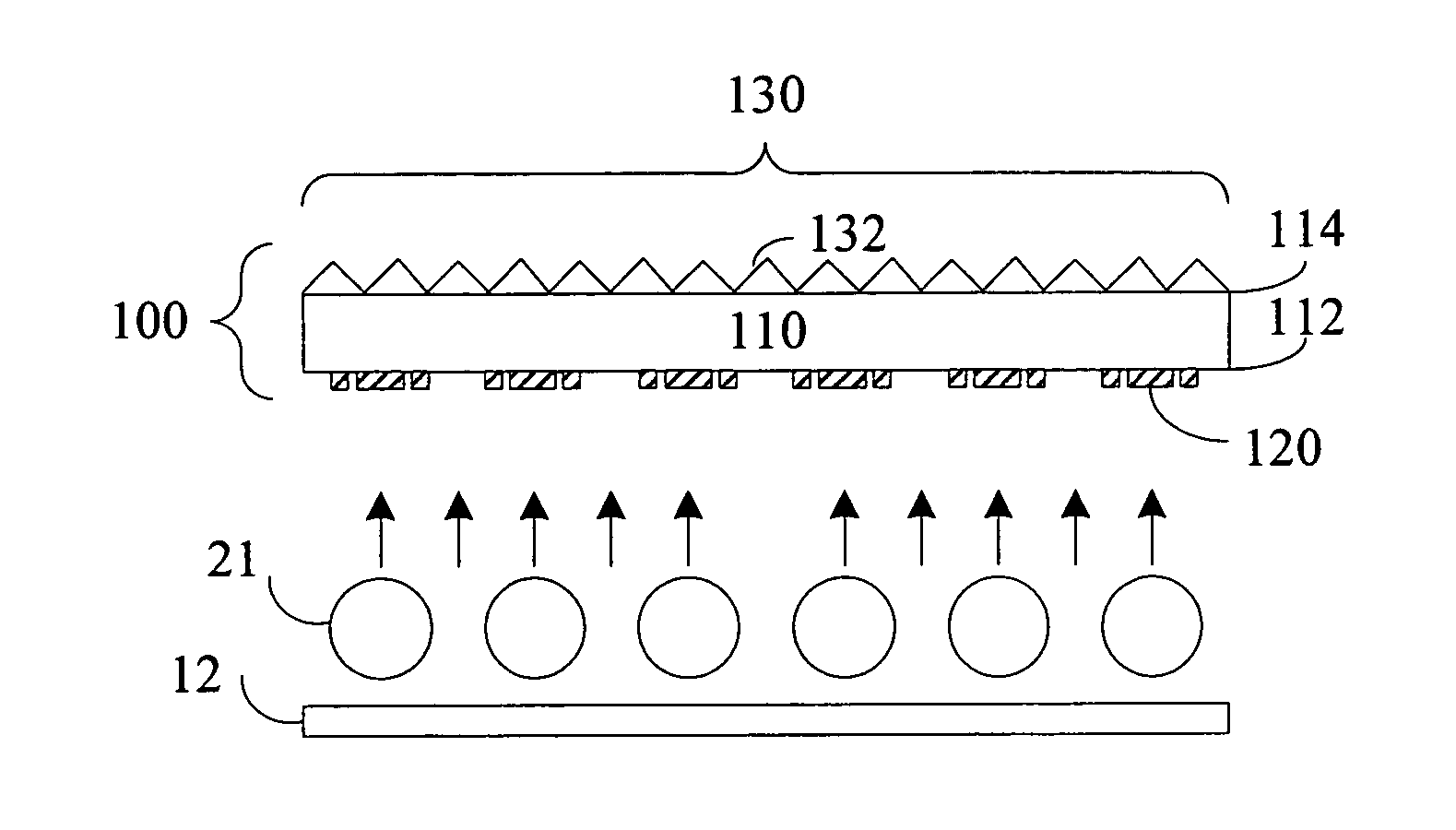

Device having combined diffusing, collimating, and color mixing light control function

InactiveUS20070110386A1High strengthHigh production costOptical light guidesNon-linear opticsDiffusionUltimate tensile strength

A light control device for a light source unit having a specific spatial intensity and / or spectral distribution is provided herein. The light control device is positioned on the path of the light from the light source unit and contains at least one of three light control functions, namely the diffusion, collimation, and color mixing, which has a spatial distribution of its processing power corresponding to the spatial intensity and / or spectral distribution of the incident light. The light control device could also directly or interactively combine two or more of the light control functions into a single device. At least one of the combined light control functions of the device has a spatial distribution of its processing power corresponding to the spatial intensity and / or spectral distribution of the incident light to the device.

Owner:EMPHASIS MATERIALS

Damper for vehicles

InactiveUS6439359B1Reduce weightInhibition effectPortable framesNon-rotating vibration suppressionInterior spaceElastomer

A vibration restraining apparatus for vehicle of the present invention is comprised of a housing formed by a rigid material and having an inner space, and fixed to a vibration transmitting member; a filled member sealed in the inner space of said housing in a non-adhered state with leaving a gap with respect to a vibrating direction of said housing, and formed by an elastic body at least at a surface thereof. When the housing resonates by vibration transmitted from the vibration transmitting member, the filled member contacts inner surface parts located at both sides of the housing in a vibrating direction thereof to exercise a damping character due to an energy loss caused by a sliding friction and a collision. Thus, a large damping character occurs inside of the housing to reduce vibration of the housing effectively. As a result, vibration of the vibration transmitting member is effectively reduced. The vibration restraining apparatus for vehicle of the present invention can be lightened in weight, does not have a temperature dependency, and can exercise the vibration restraining effect for plural resonances having different frequencies.

Owner:SUMITOMO RIKO CO LTD

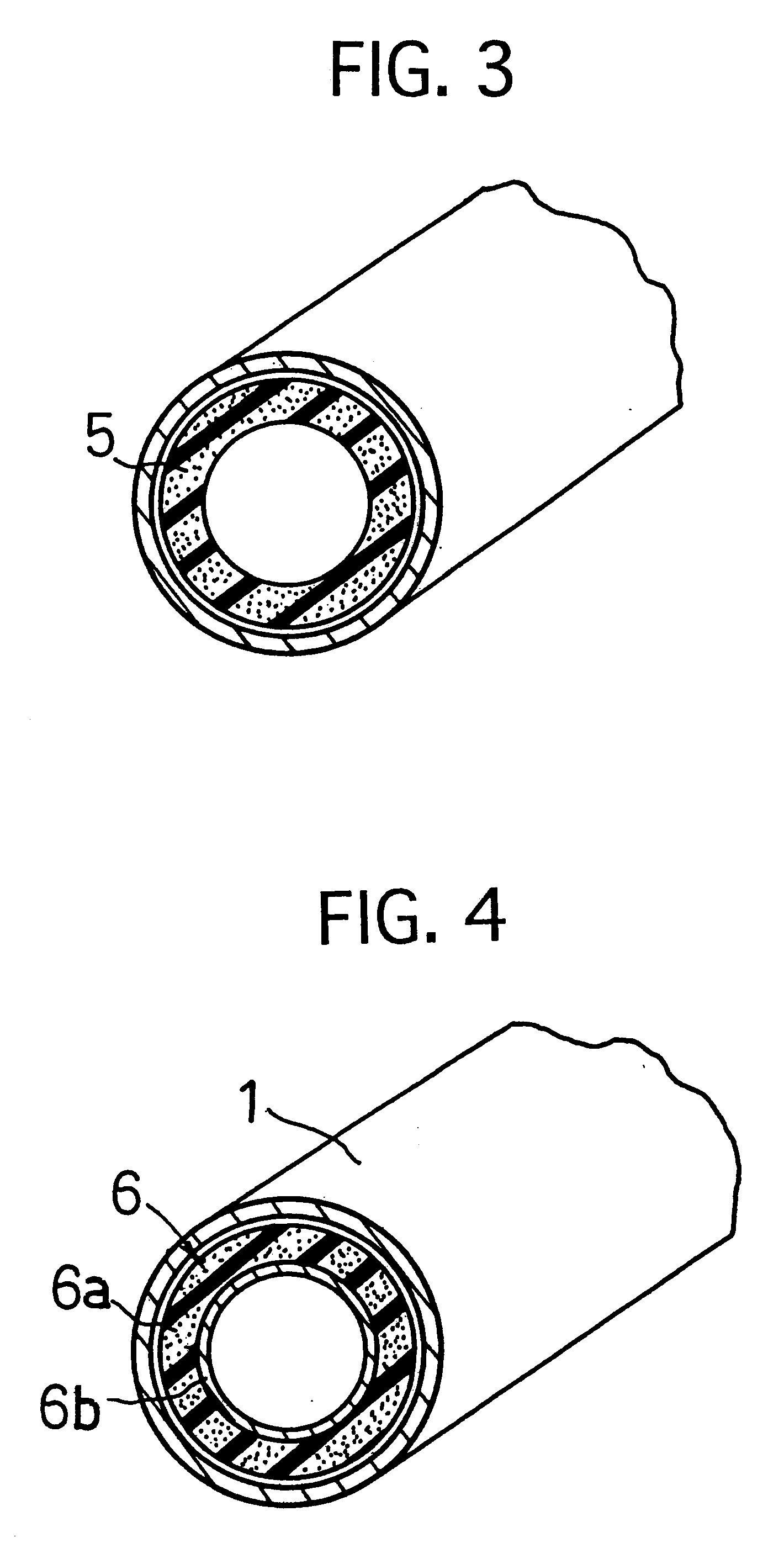

Mill blank library and computer-implemented method for efficient selection of blanks to satisfy given criteria

ActiveUS6979496B2Easy to manufactureReduce material wasteDental implantsPerson identificationInventory managementEngineering

The present invention relates generally to mill blank constructions to facilitate the manufacture of dental restorations. A given mill blank is formed in a shape (i.e. with a given geometry) that has been predetermined to reduce material waste when the mill blank is machined into the final part. A set of two or more blanks each having such characteristics comprise a smart blank “library.” In one embodiment, a smart blank library includes a sufficient number of unique blanks such that, when the geometry of the designed restoration is known, the smart blank with a highest yield can be selected for use in milling the restoration. The “yield” of a given smart blank represents the amount of material of the smart blank that is actually used in the final restoration. Automated processes for smart blank inventory management and smart blank selection are also described.

Owner:D4D TECH LP

Multiple-plate structure of zonal design for a shaped part

InactiveUS6048628ALow production costLow costPig casting plantsExtrusion containersEngineeringLoad profile

A formed part having a multiple-plate structure of zonal design includes a base plate and a plurality of reinforcing plates fastened to the base plate. The multiple-plate structure is configured so that its strength is largely adapted to the load profile to be applied to the formed part and so that its cost of production is reduced. To this end, the thicknesses of the reinforcing plates vary as a function of the load structure to be applied to the formed part and the reinforcing plates engage each other in a positive locking manner so that the abutting edges are provided essentially with regularly arranged projections which are in mutual engagement.

Owner:VOLKSWAGEN AG

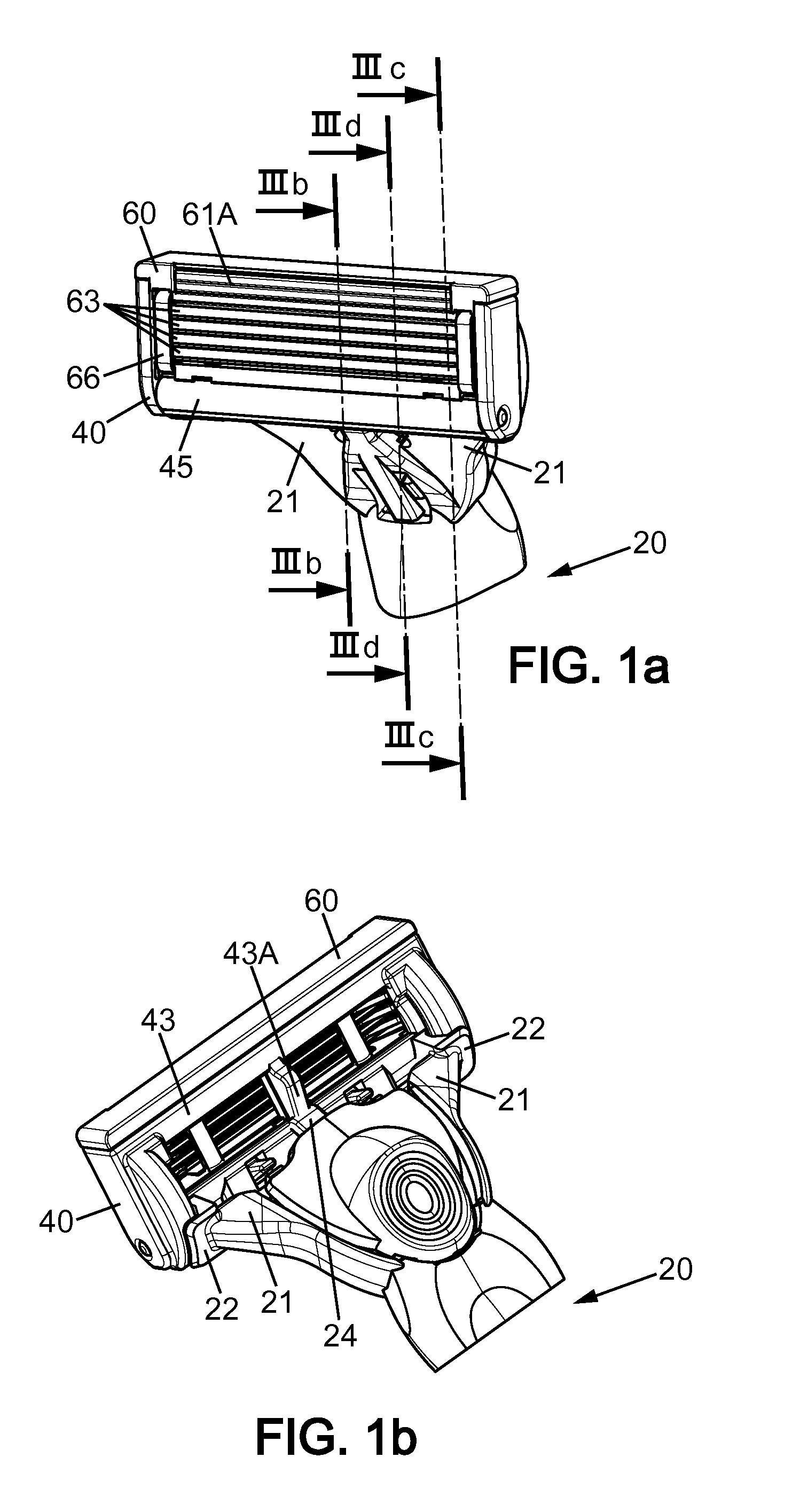

Shaver

ActiveUS20150306777A1Smooth rotationEasy to manufactureMetal working apparatusRazor stropEngineering

A shaver that includes a handle with an elongated handgrip portion and a mounting portion, and a shaver head attached to the mounting portion. A removable cartridge is attached to the shaver head through a rotating lock. The rotating lock is adapted to rotate about an axis parallel to the length of the blades of the cartridge, thus defining a neutral position and a rotated position. The rotating lock in the neutral position attaches the cartridge to the shaver head, and the rotating lock in the rotated position releases the cartridge from the shaver head.

Owner:BIC VIOLEX SA

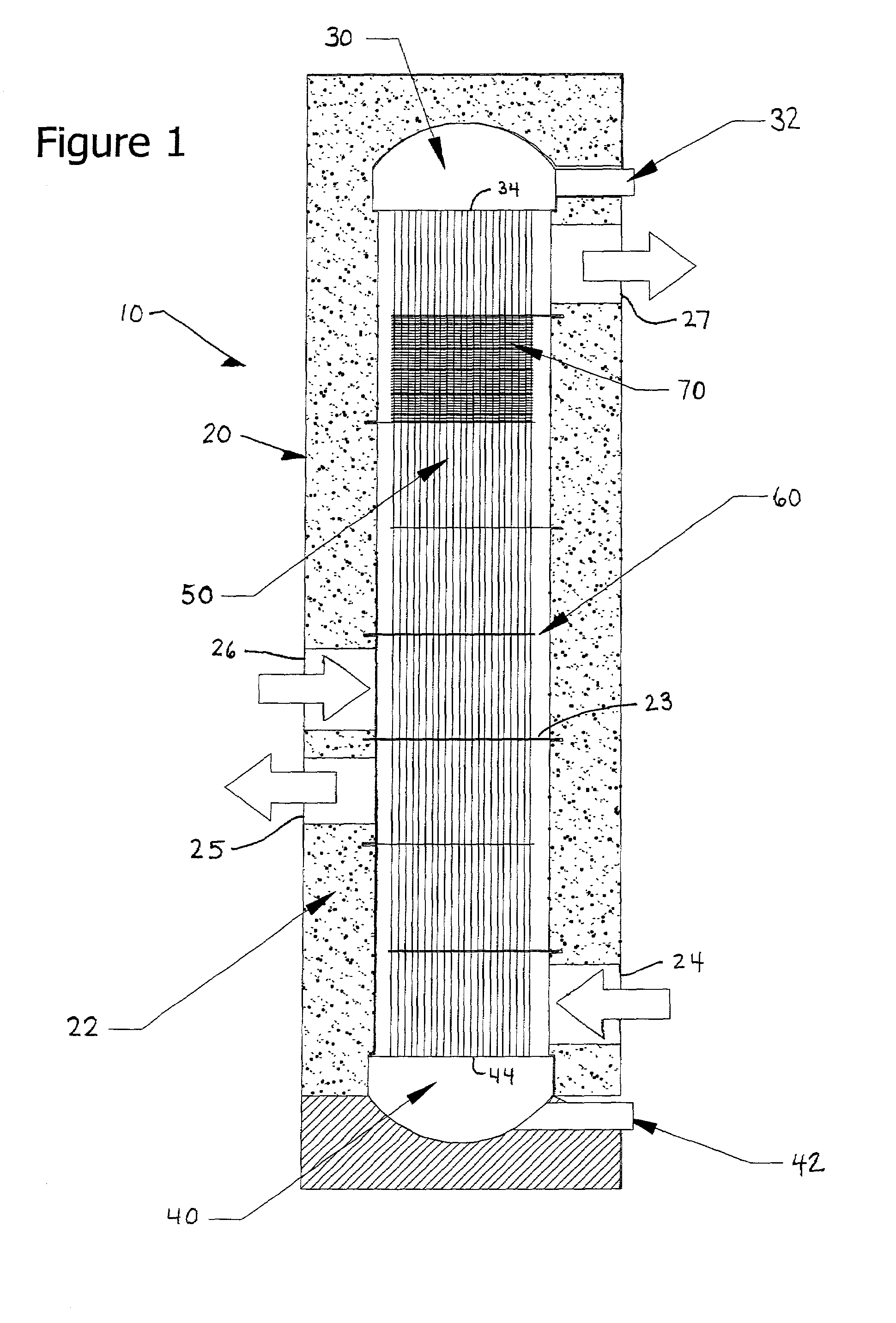

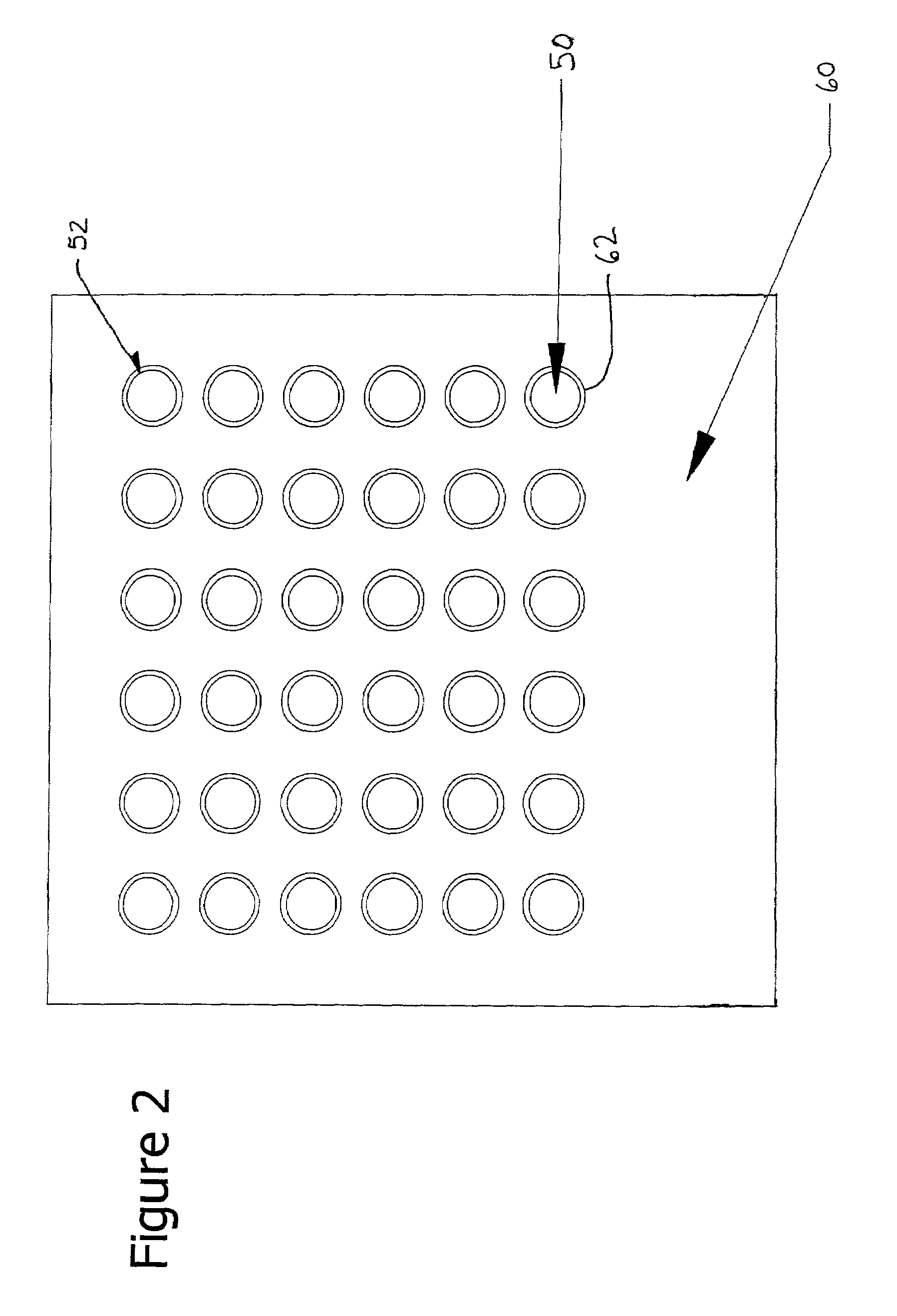

Method and apparatus for minimizing adverse effects of thermal expansion in a heat exchange reactor

InactiveUS7117934B2Improve corrosion resistanceHigh strengthChemical/physical/physico-chemical reactor detailsHydrogen/synthetic gas productionThermal expansionEngineering

A heat exchange reactor including a housing, a plurality of tubes mounted in the housing and configured to carry a first fluid, and a baffle having a plurality of holes receiving the tubes. The baffle is configured to guide a second fluid provided within the housing to flow in a direction generally perpendicular to the tubes. The reactor includes various configurations for minimizing adverse effects of thermal expansion of the baffle and the tubes. The reactor is configured to minimize mechanical interference between the baffle and the tubes in both an operational state and a non-operational state, for example, by shaping the holes in the baffle to take into account thermal expansion. The reactor also includes a thermal insulator along a length of the tubes at a large temperature gradient zone within the reactor. The reactor further includes a heat transfer fin in contact with only one of the tubes.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com