Patents

Literature

1421 results about "Deep drawing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

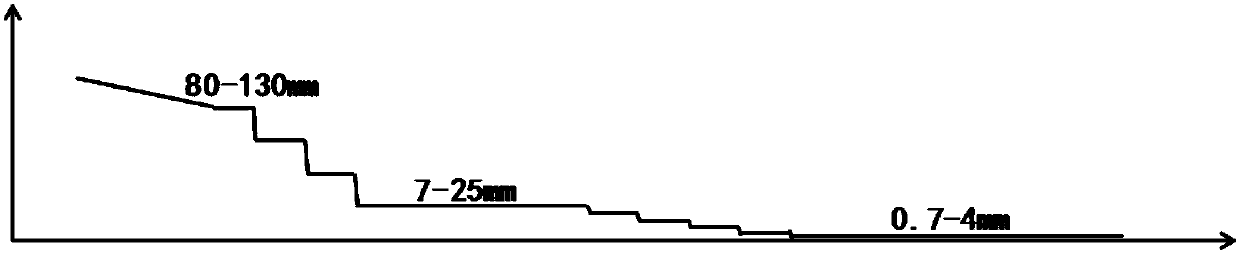

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter. This is achieved by redrawing the part through a series of dies. The flange region (sheet metal in the die shoulder area) experiences a radial drawing stress and a tangential compressive stress due to the material retention property. These compressive stresses (hoop stresses) result in flange wrinkles (wrinkles of the first order). Wrinkles can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius.

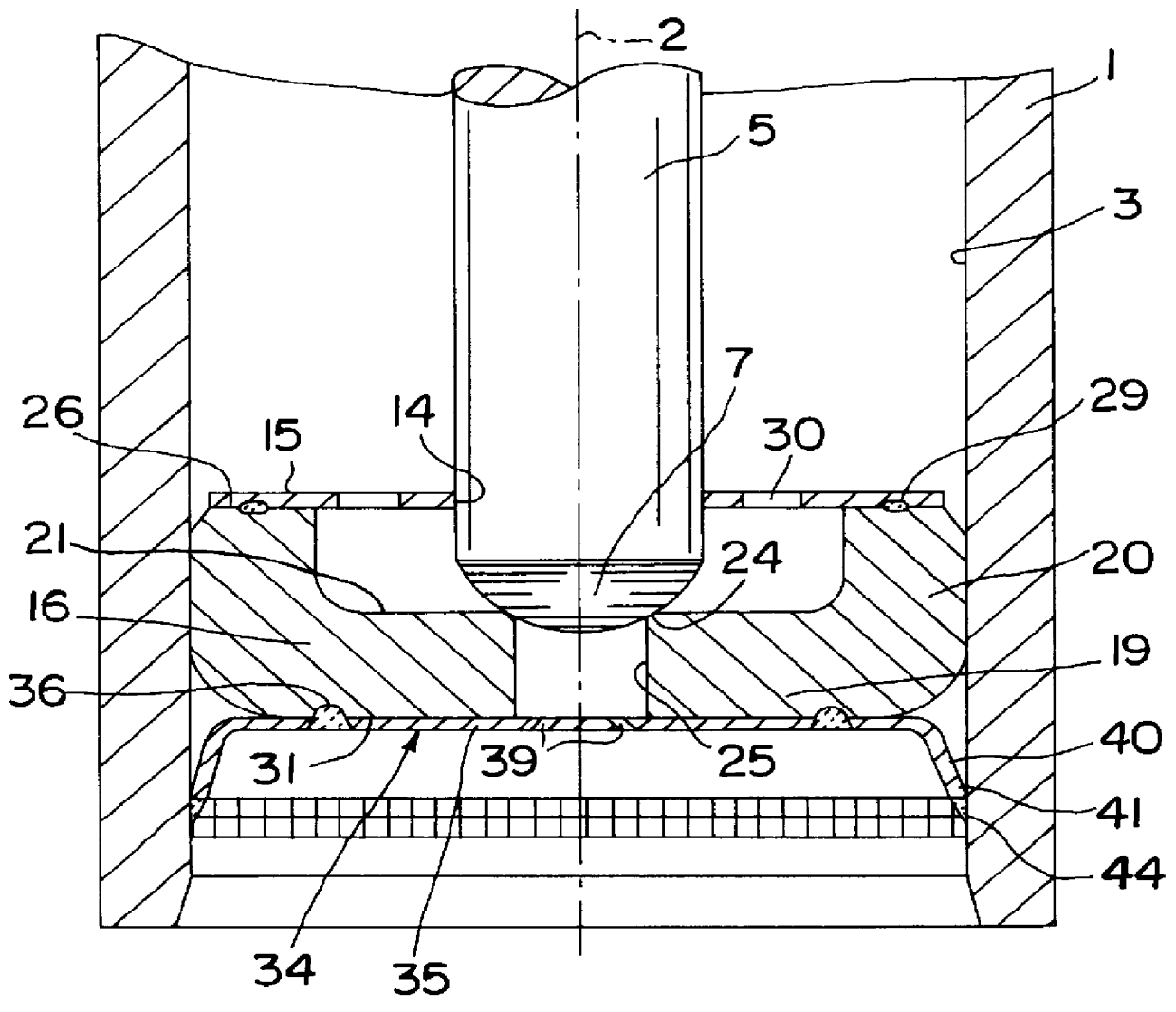

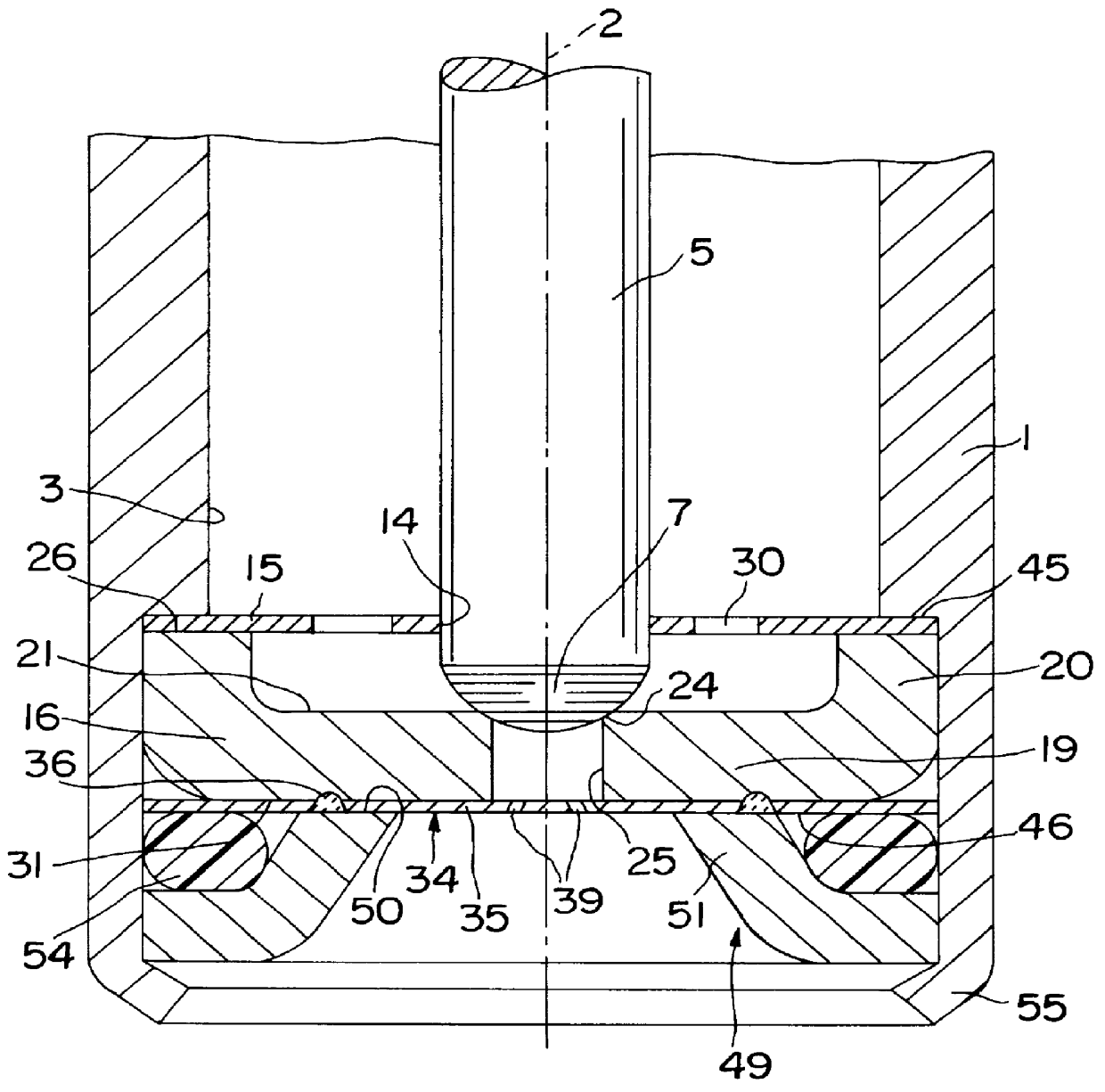

Fuel injection valve

InactiveUS6039271AReduce weightReduce material usageSpray nozzlesFuel injection apparatusCombustionInjection port

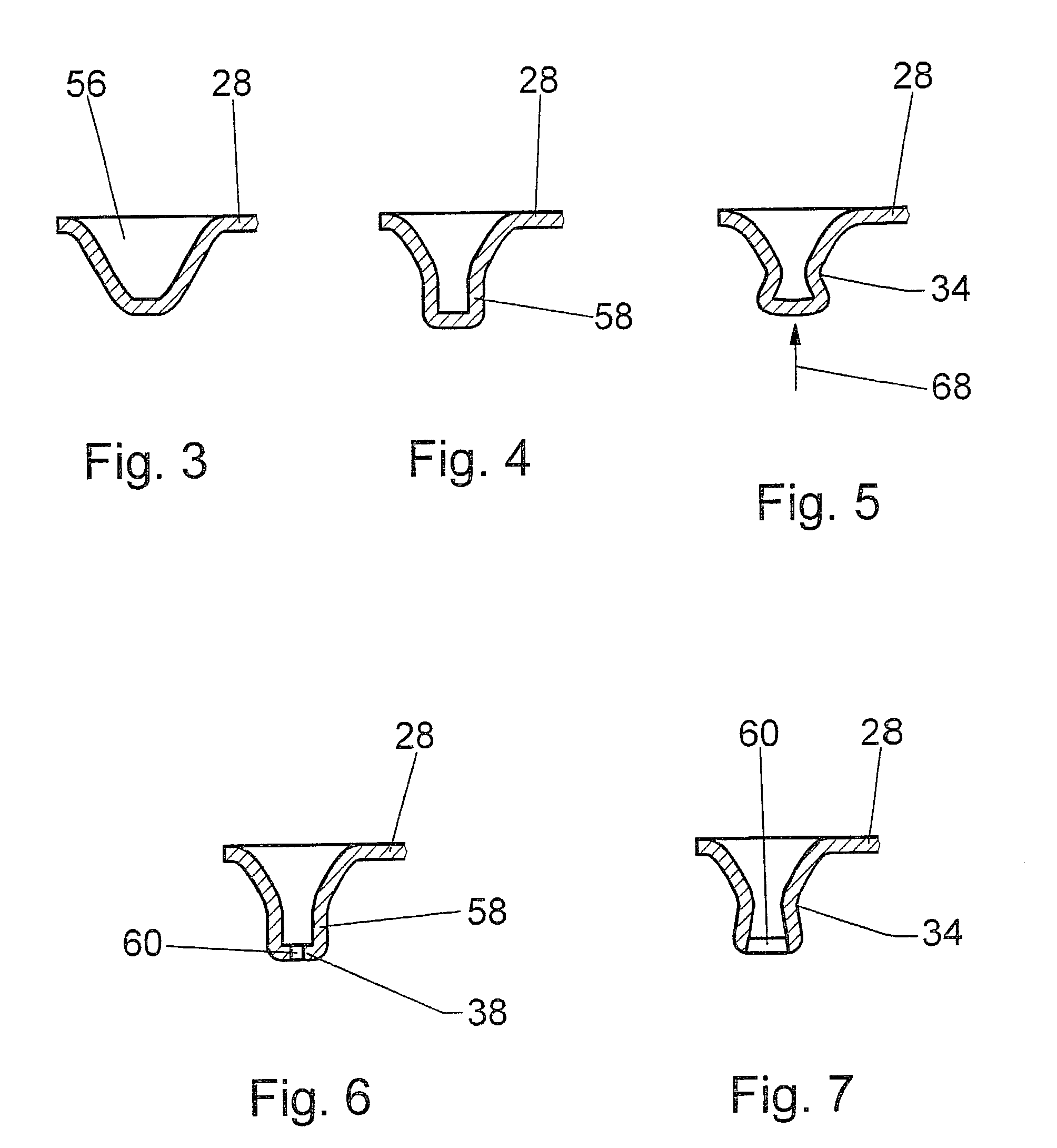

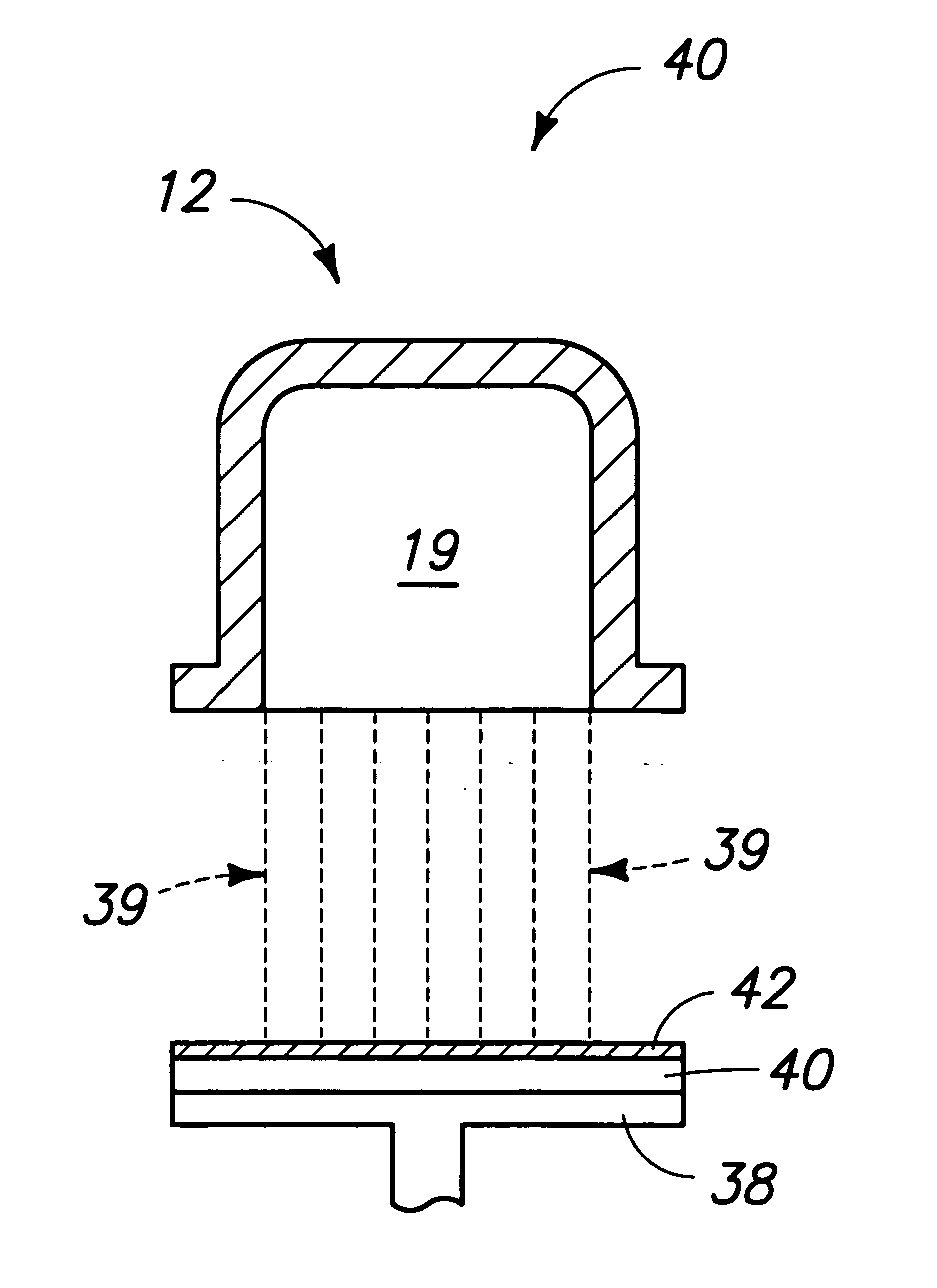

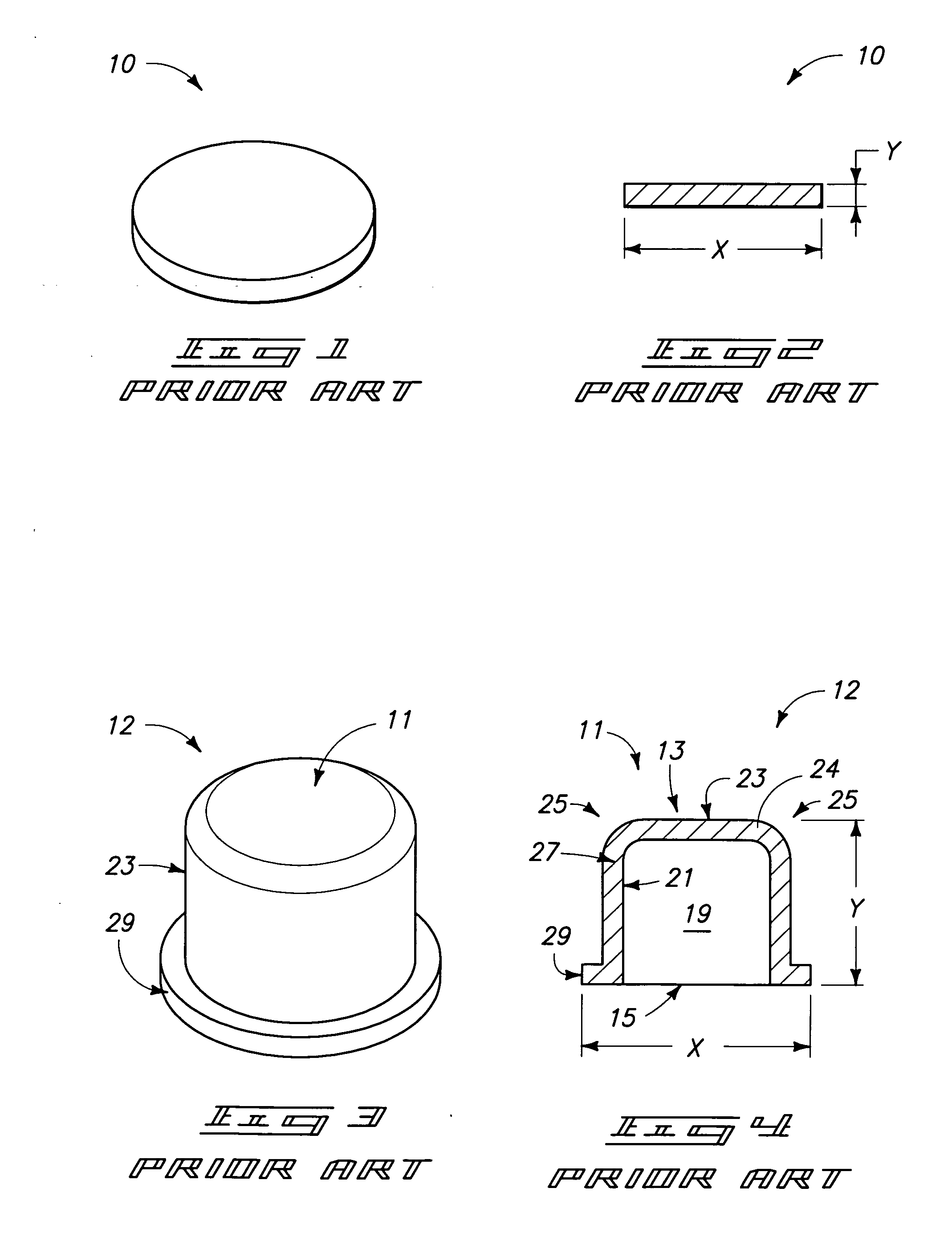

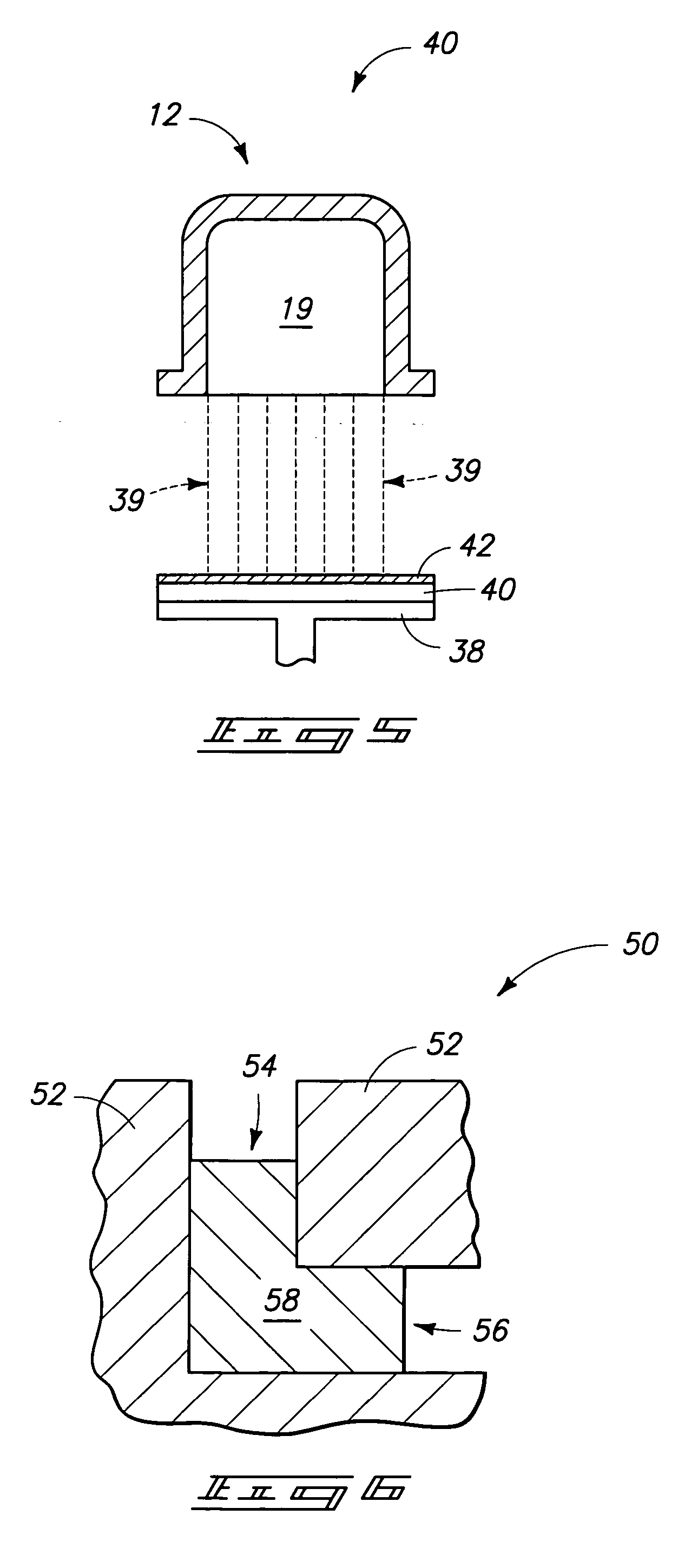

PCT No. PCT / DE97 / 00533 Sec. 371 Date Apr. 1, 1998 Sec. 102(e) Date Apr. 1, 1998 PCT Filed Mar. 15, 1997 PCT Pub. No. WO98 / 05859 PCT Pub. Date Feb. 12, 1998A fuel injection valve for internal combustion engines is already known in which the valve seat body is produced by multiple complicated work processes. In the novel valve, a valve seat body of simple design that can be made economically is used. The valve seat body (16) is made from sheet metal by stamping and deep drawing and has a cup shape with a bottom (19) of the seat body and an annular edge (20) of the seat body. A valve seat (24) is formed in the bottom (19) of the seat body. An injection port disk (34) is joined by welding to the valve seat body (16). The fuel injection valve is especially suitable for fuel injection systems of mixture-compressing internal combustion engines with externally supplied ignition (FIG. 1).

Owner:ROBERT BOSCH GMBH

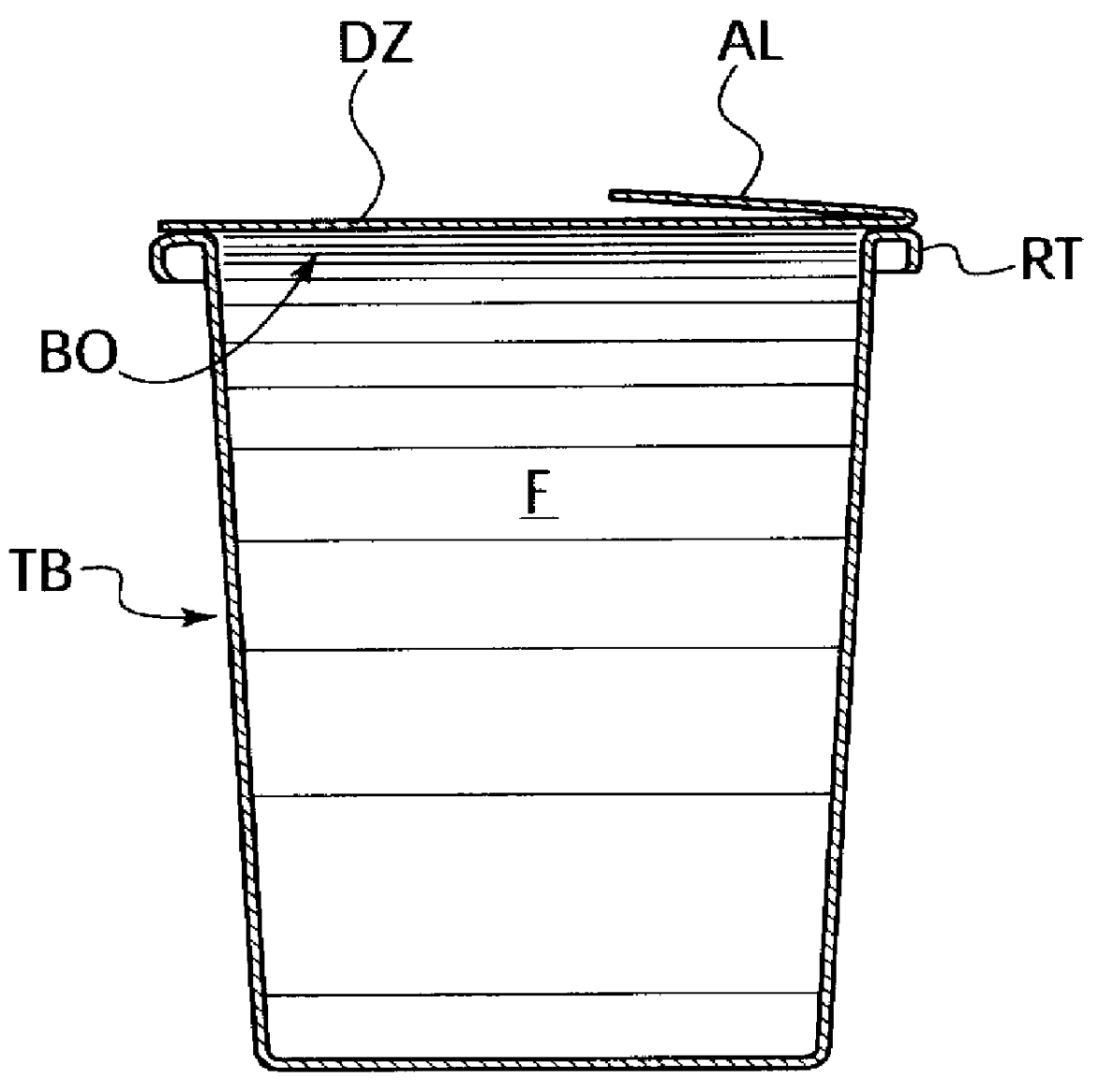

Process and packing machine for manufacturing filled drinking cups

InactiveUS6161367AReduce mechanical forceMinimized cover foil wasteCapsFlanged caps applicationPack materialEngineering

The invention is concerned with a process of manufacturing filled drinking cups closed by cover foil blanks heat-sealed thereto and formed by deep-drawing from a thermoplastic packing material strip, comprising a beaded peripheral flange, with the cover foil blanks being provided with a pull flap. According to the invention the method includes the following steps: cyclically feeding the packing material strip loaded with the deep-drawn and filled cups underneath a cover foil blank transfer means; taking up the cover foil blanks from the transfer means, with the pull flaps, during transfer of the cover foil blanks to the packing material strip, being positioned in a direction substantially vertical to the extension plane of the blanks, and the blanks with the upright pull flaps above the cup openings being applied to the packing material strip; sealing the margins of the cover foil blanks to the unmolded areas of the packing material strip about the cup openings; bending the upright flaps during the advance movement of the packing material strip; punching the cups from the packing material strip along a punching contour line extending in parallel to and at a space from the circumferential contour of the cover foil blanks; and transferring the punched cups into a beading means wherein the peripheral flange portion projecting relative to the cover foil blanks is downwardly beaded.

Owner:HASSIA VERPACKUNGSMASCHEN

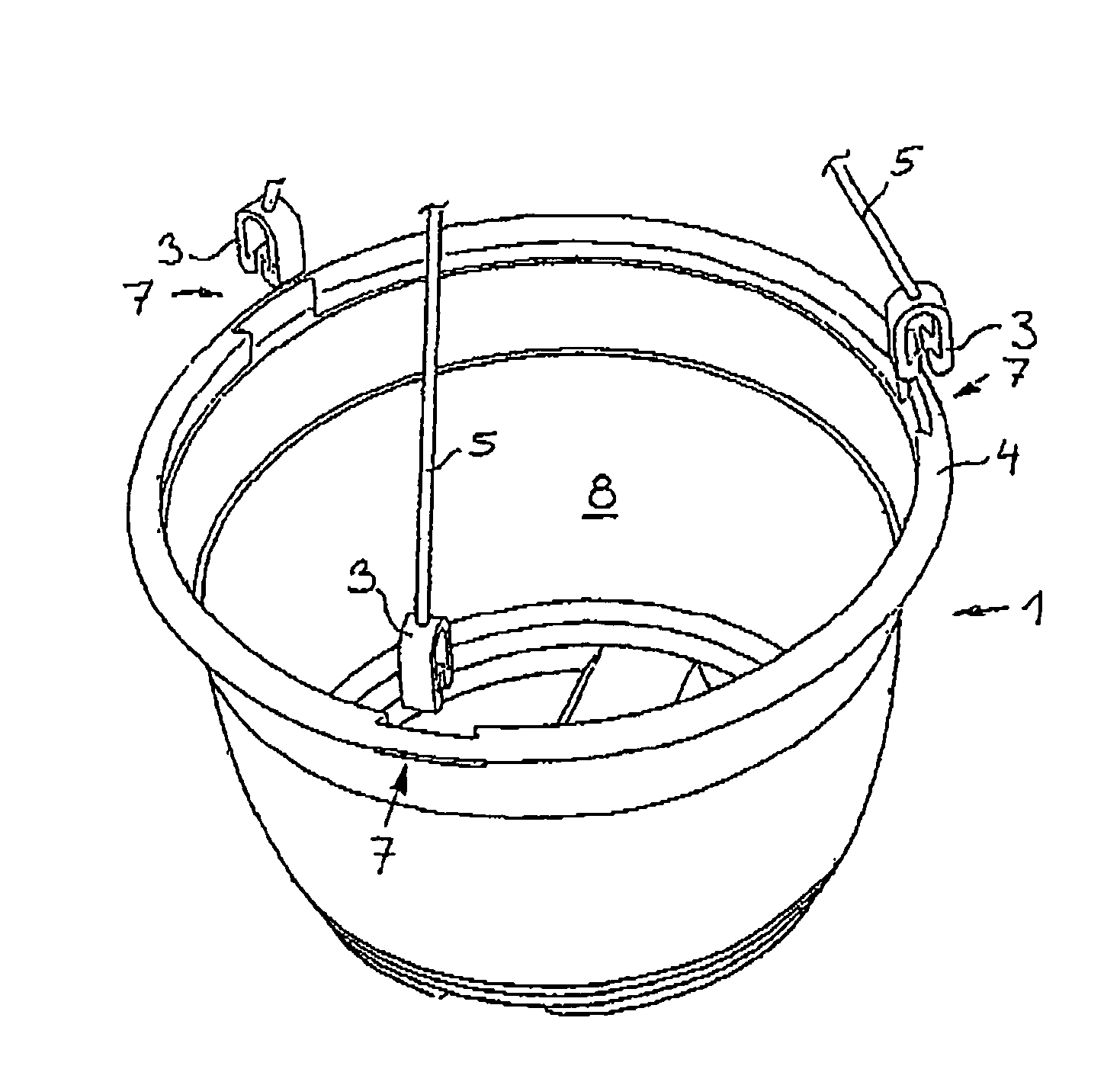

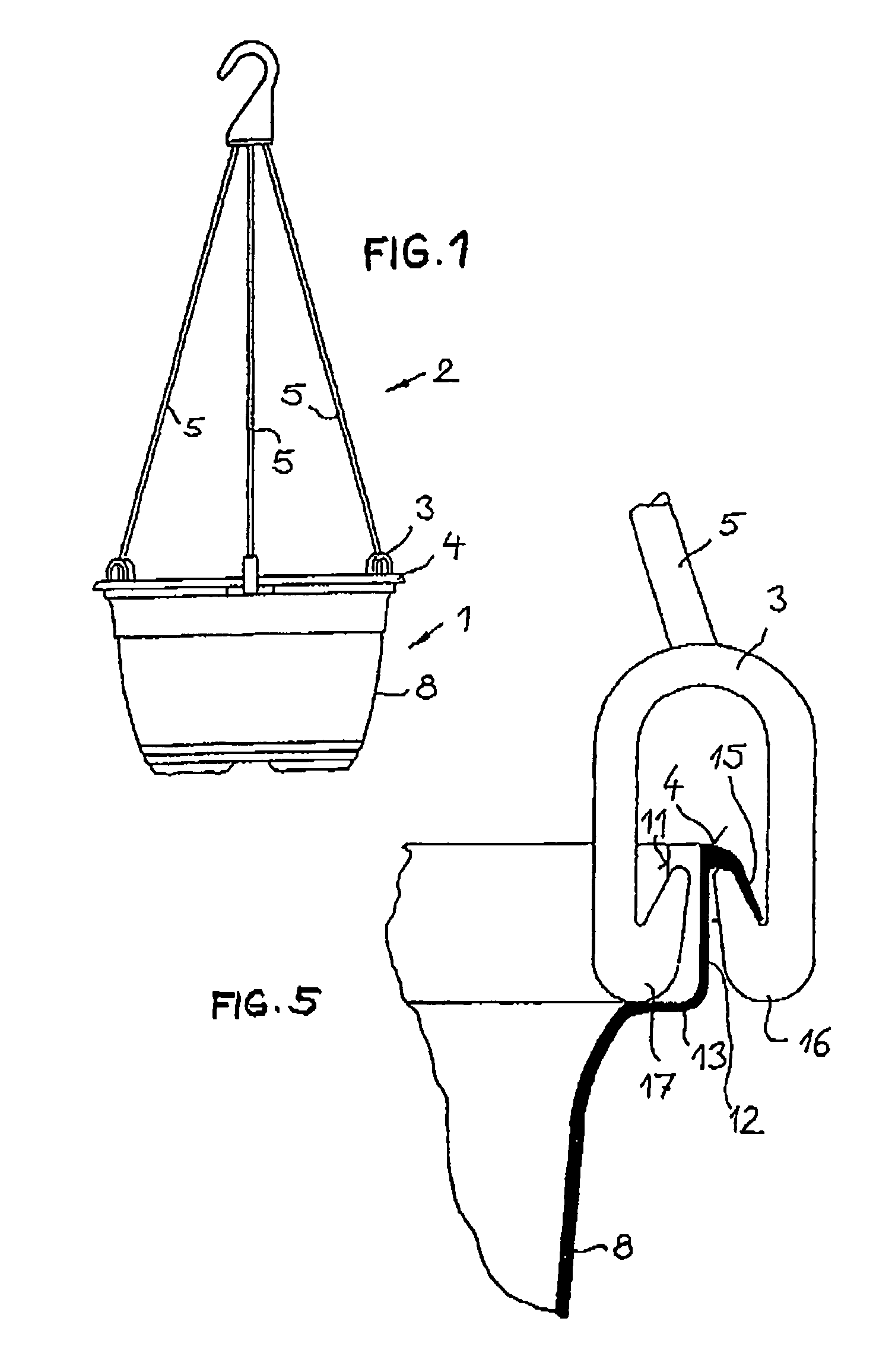

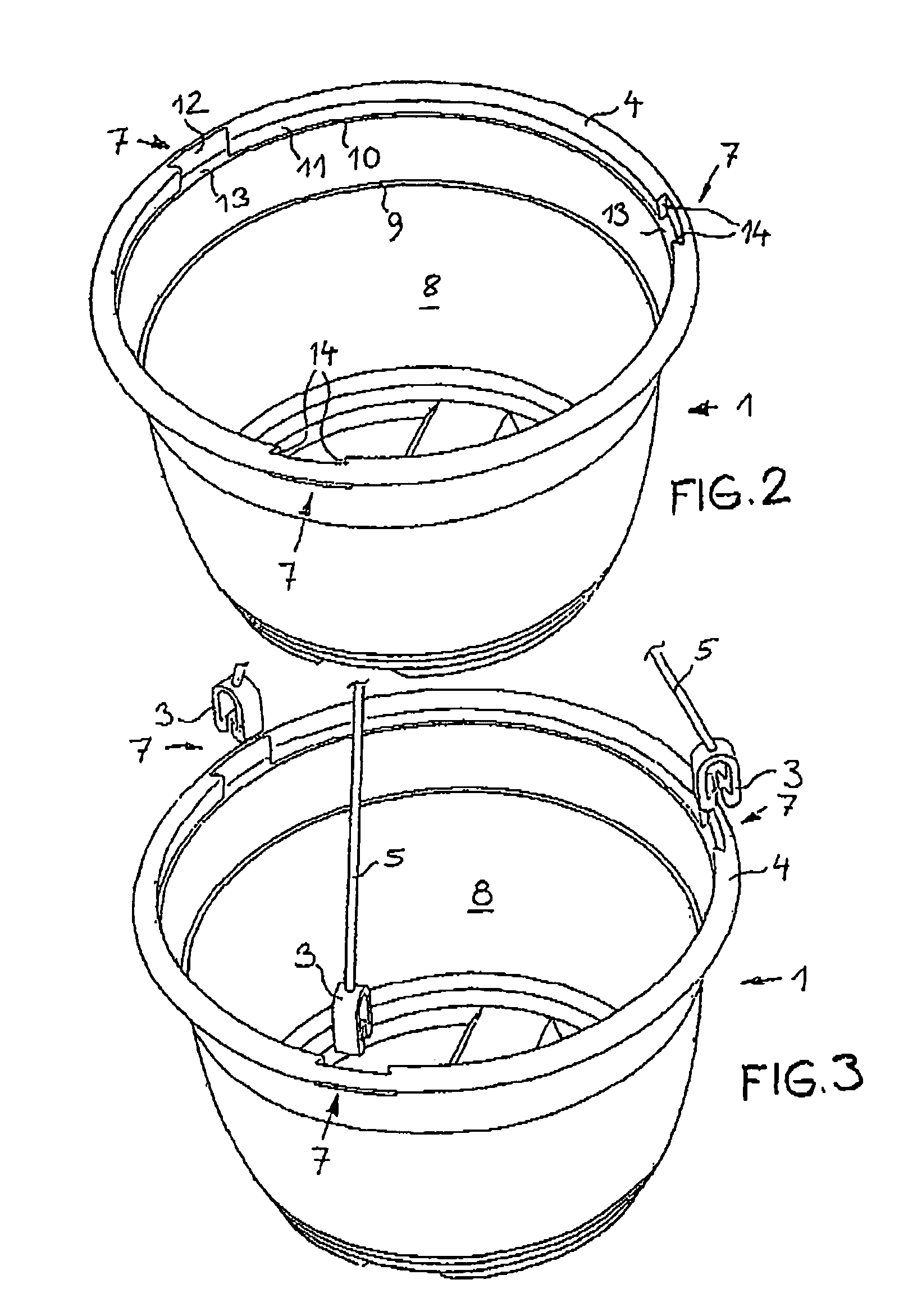

Flower pot

InactiveUS7610717B2Easy transferEasy to handleSnap fastenersStands/trestlesPlastic materialsEngineering

The invention relates to a flower pot (1) made of deep drawn plastic material and provided for a hanging flower pot wherein a suspension part (2) comprises a plurality of strands (5) that are linked via hook clips (3) with the pot rim (4) that has an outer continuous contour. The aim of the invention is to provide a flower pot that, in accordance with the special technical conditions during the deep drawing, is provided with a fixation of the seat (7) of the hook clips (3), while maintaining a good distribution of suspension loads between the pot and the hook clips and safeguarding an appealing yet easy to handle shape. To achieve this aim, the pot rim (4) has tapered sections extending inwards towards a wall contiguous with the bottom. These tapered sections form a seat (7) for the hook clips (3).

Owner:GEBR POPPELMANN KUNSTSTOFFWERK WERKZEUGBAU

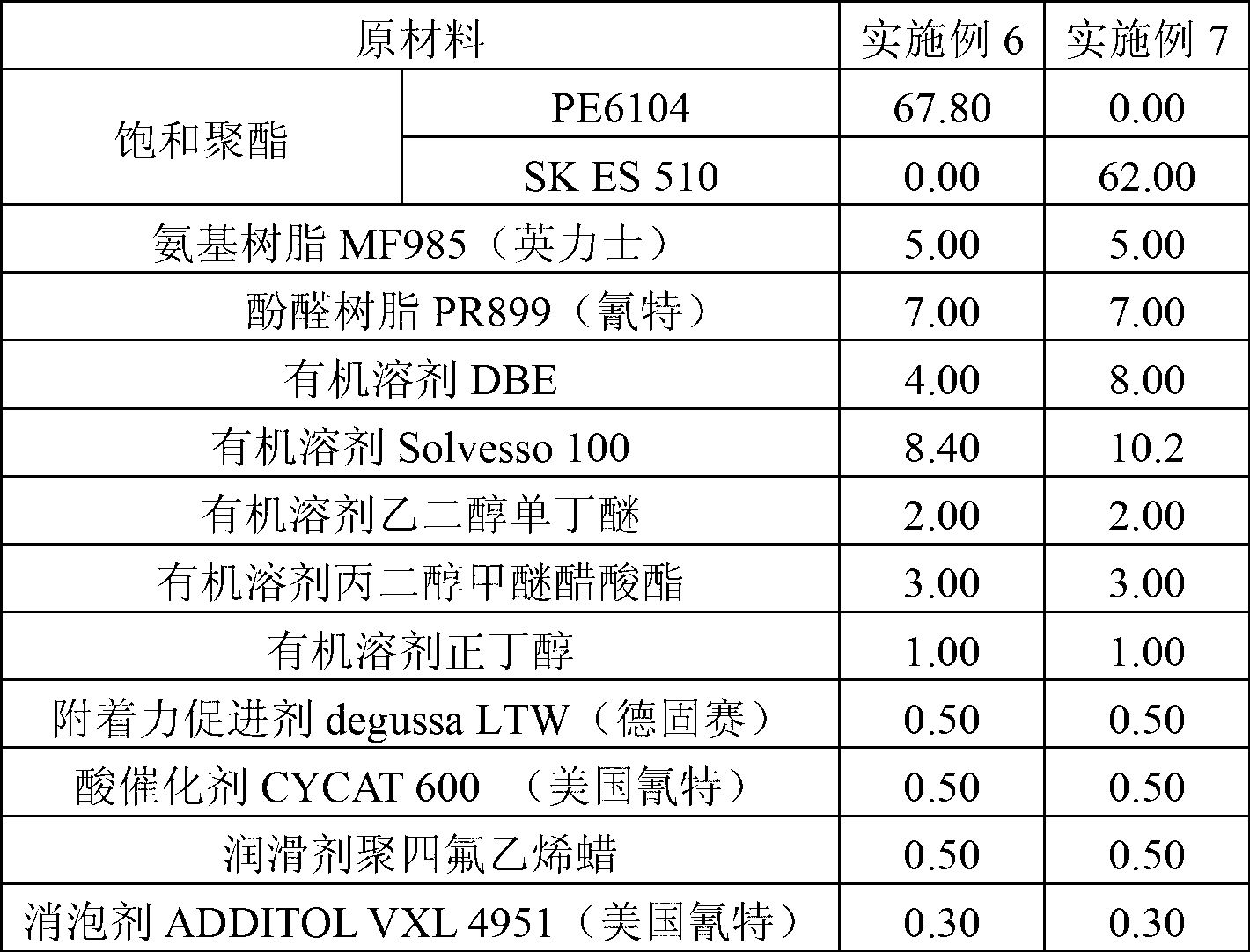

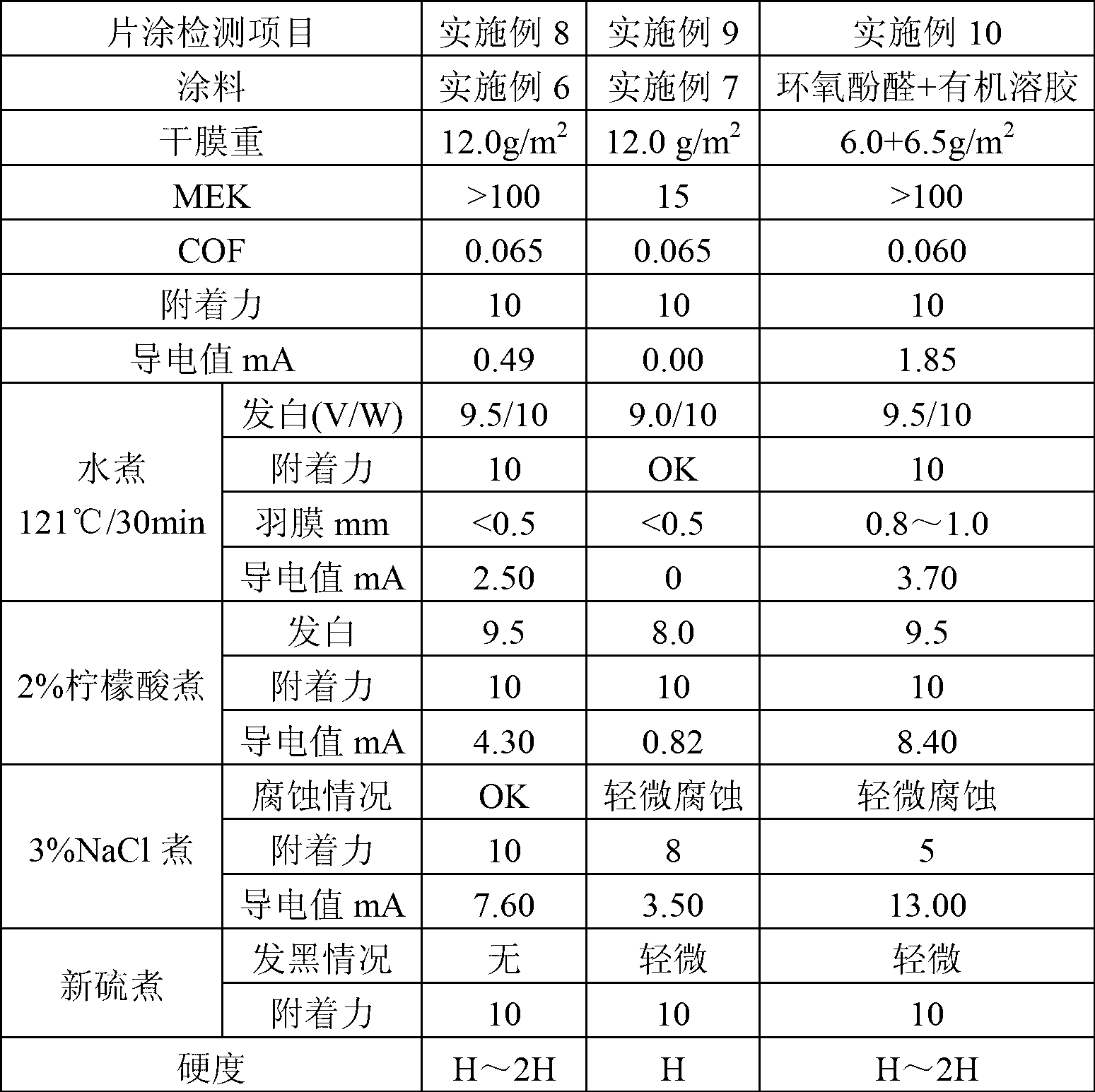

Inner paint of metal beverage food can and preparation method and application thereof

ActiveCN103013303AGood flexibilityCook without turning whiteAnti-corrosive paintsLinings/internal coatingsPolyesterEpoxy

The invention discloses inner paint of a metal beverage food can, a preparation method and an application thereof. The paint comprises the following components by mass: 35-70% of saturated polyester, 1-15% of amino resin, 3-20% of phenolic resin, and 1.8-2.5% of an additive. The components are mixed to obtain the paint provided by the invention. The paint has the following advantages that: no toxic monomer is contained; a coating prepared by the paint can resist high-temperature sterilization and acid boiling, has very good flexibility, thus can be used as an inner coating of easy-drawing lids, an inner coating of two-sheet deep drawing food cans, and an inner wall coating of three-sheet beverage cans, is suitable for storage of carbonated beverages, beer, sardine, pork luncheon meat, tomato sauce, and the like; the paint realizes a single coating weight of up to 13 g / m2, can replace double coating process by epoxy primer and organosol finish in a sheet coating mode, does not turn white during boiling, has excellent adhesive force, and cause no feather film.

Owner:清远慧谷新材料技术有限公司

Hot-dip aluminizing zincium steel plate/belt for deep drawing and method for producing the same

ActiveCN101352946AImprove corrosion resistanceImprove high temperature resistanceHot-dipping/immersion processesFurnace typesChemical compositionSheet steel

The invention provides a deep drawing hot-dipped al-zn steel plate / strip and a production method thereof. The deep drawing hot-dipped al-zn steel plate / strip comprises an IF steel substrate and an alloy coating and the chemical constituents of the substrate (wt percent) are that C is less than or equal to 0.01, Si is less than or equal to 0.12, Mn is less than or equal to 0.6, P is less than or equal to 0.1, S is less than or equal to 0.045, Ti is less than or equal to 0.3 and the allowance is Fe and inevitable impurities. The production method comprises substrate degreasing treatment, annealing treatment and hot dipping, and the annealing treatment is carried out in a continuous annealing furnace and protective gas contents in the annealing furnace are 10 to 60 percent. The yield strength of the steel plate / strip of the invention reaches 140 to 220 MPa, the tensile strength is 260 to 350 MPa and the elongation is more than 30 percent; the production method of the invention is simple in production process and strong in operability.

Owner:BAOSHAN IRON & STEEL CO LTD

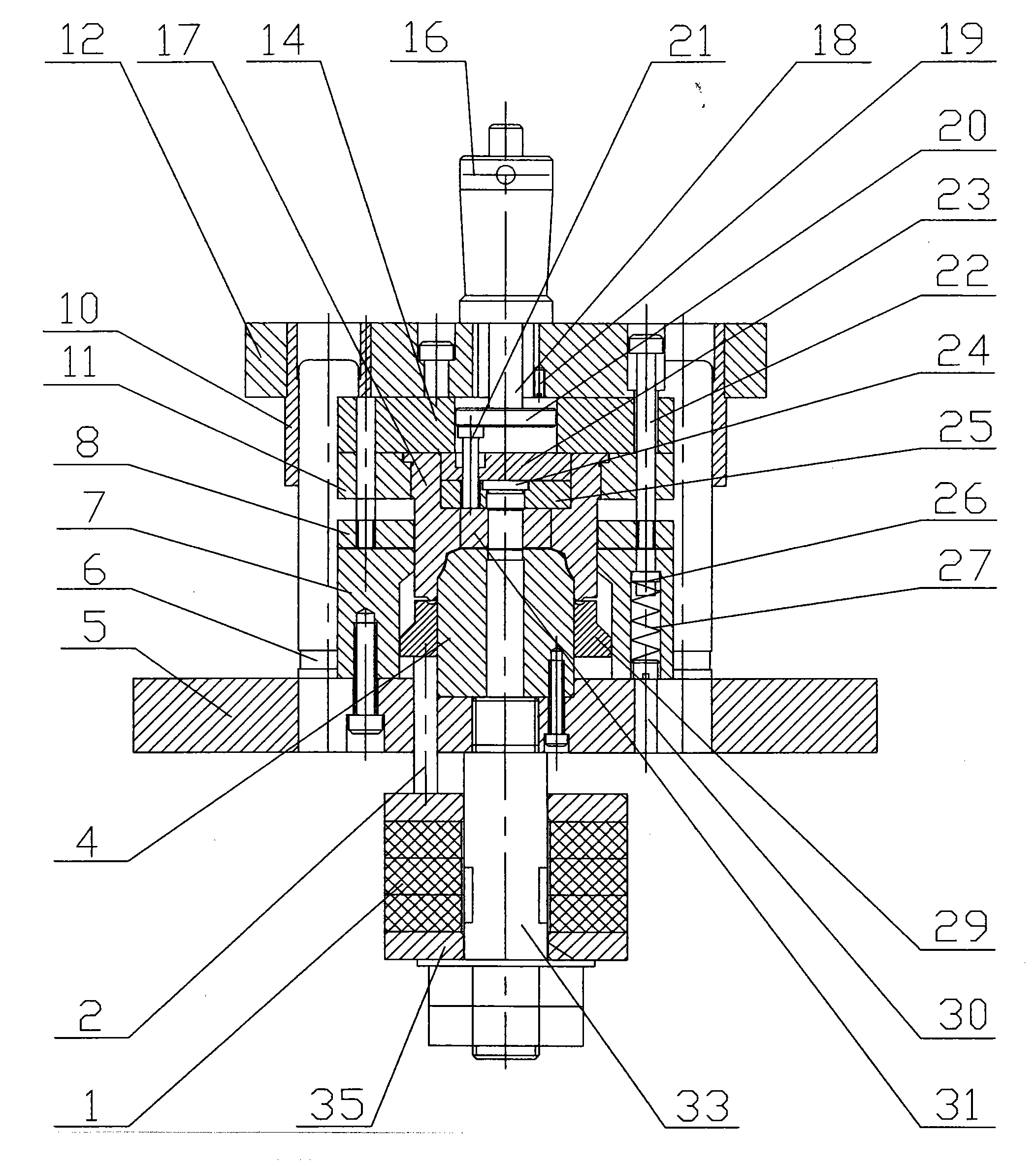

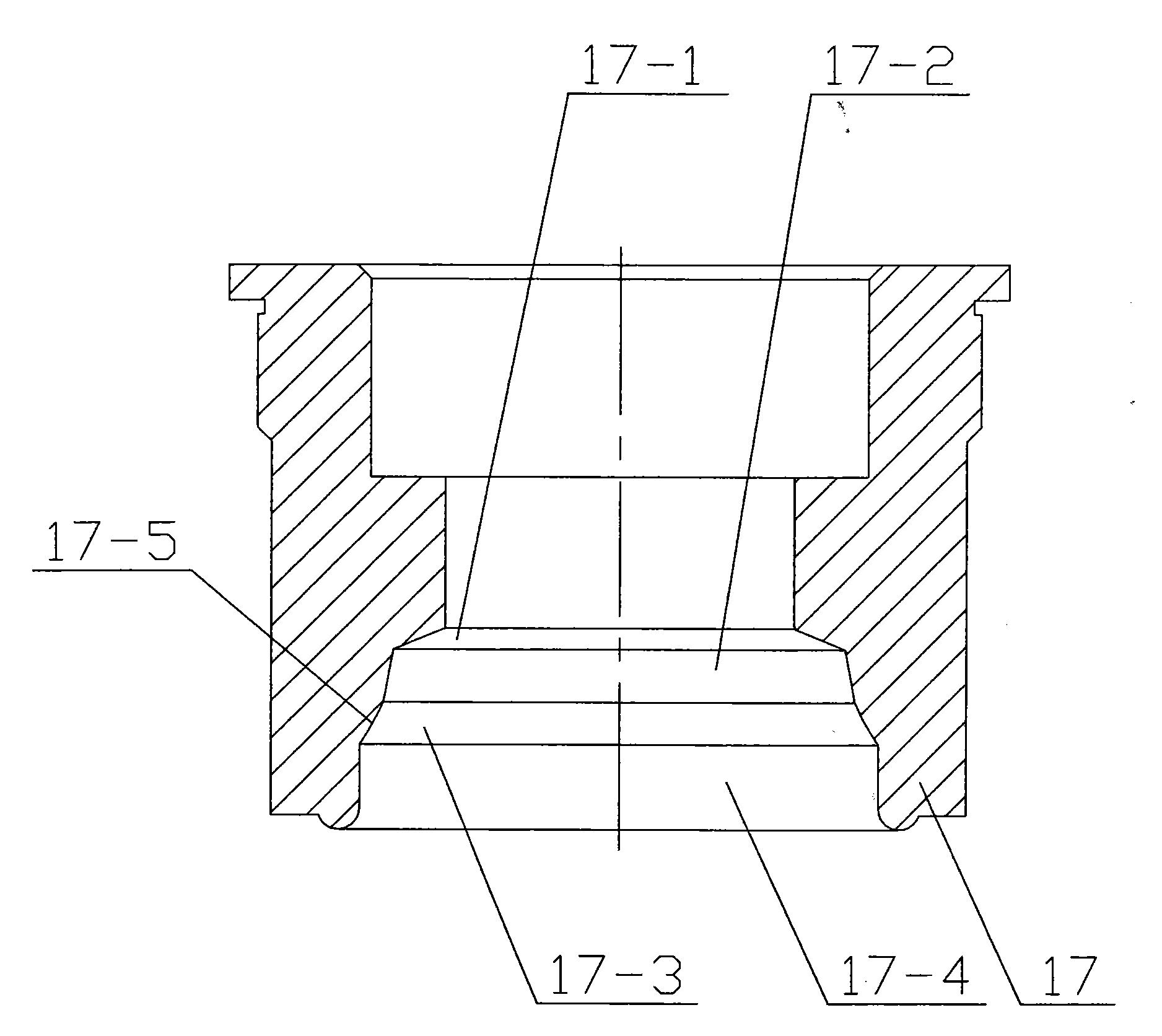

Deep drawing forming composite die for shallow conical pieces with sunken side walls

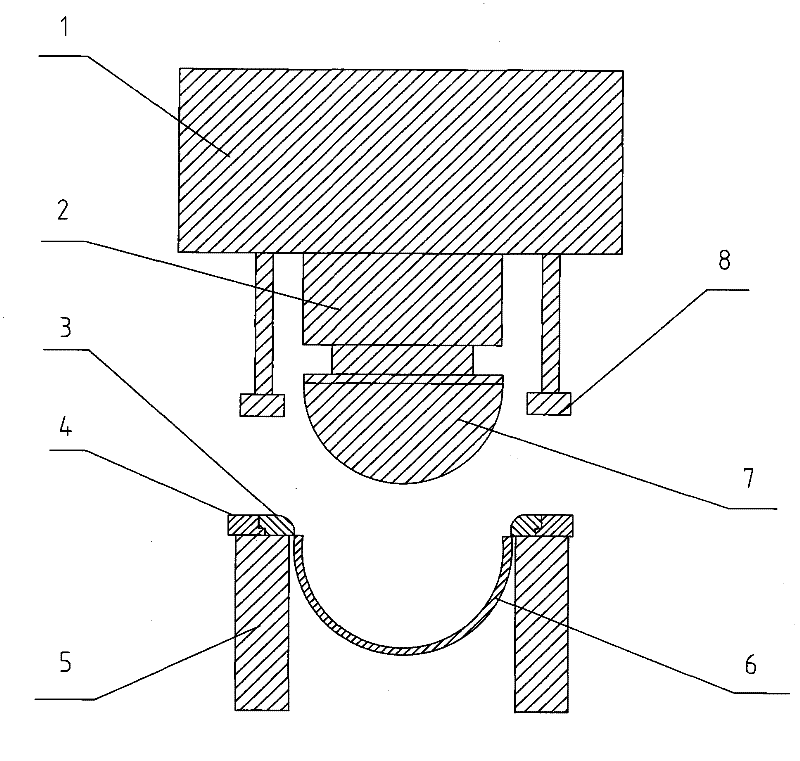

ActiveCN102371309AIncrease productivityGuarantee product qualityShaping toolsInterference fitPunching

The invention discloses a deep drawing forming composite die for shallow conical pieces with sunken side walls, and relates to a deep drawing forming composite die. The problem that the conventional die is difficult in forming the shallow conical pieces with the sunken side walls is solved. The upper end of a guide sleeve is in sliding fit with a guide post, and the lower end of the guide sleeve is in interference fit with a lower guide post hole of a lower template; a blanking female die is arranged on the lower template; an upper convex-concave die is connected with a fixed plate; a backingring is positioned between an upper template and the fixed plate; the upper convex-concave die is placed in the blanking female die; a spring and a baffle pin are arranged in circular bead through holes of the blanking female die; a limiting screw is arranged on the lower template; an ejection plate is arranged in the backing ring; a stripping rod is arranged on the backing ring; a punching male die fixed plate and a shim plate are arranged in the upper convex-concave die; a punching male die is arranged in a lower convex-concave die; the lower convex-concave die is arranged in a profile holeof the upper convex-concave die; a return plate is sleeved on the punching male die; a blank holder is sleeved on the lower convex-concave die; and a side pressing rubber pad and a supporting plate are sleeved on a solenoid. The die is used for deep drawing forming of the shallow conical pieces with the sunken side walls.

Owner:HARBIN JIANCHENG GRP

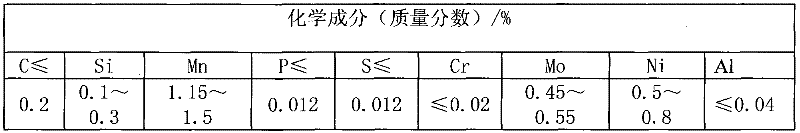

Ultra-low carbon cold-rolling deep-punching glassed steel and method of production

InactiveCN101082107ADoes not affect deep drawabilityImprove deep drawing performanceTemperature control deviceProfile control deviceChemical compositionPunching

The present invention relates to ultralow carbon cold rolled deep drawing glass-lined steel and its production process. The glass-lined steel has the chemical components including C 0.002-0.005 wt%, Si 0.004-0.020 wt%, Mn 0.08-0.13 wt%, P 0.006-0.020 wt%, S 0.01-0.035 wt%, Als 0.010-0.040 wt%, Ti 0.05-0.09 wt%, N not more than 0.004 wt%, and Fe and inevitable impurities for the rest. The steel of the present invention is superior to IF steel, and has raised Ti and S contents for effective separation of biphase Ti4C2S2 particle, and effective fixing of H atom to avoid scale burst of enamel. It has excellent deep drawing performance and excellent enameling performance.

Owner:武汉钢铁有限公司

Method for producing deep drawing skin-passed hot-dip galvanizing sheet steel

ActiveCN101036968AGrain refinementReducing the Effect of Grain SizeTemperature control deviceFurnace typesExtensibilitySheet steel

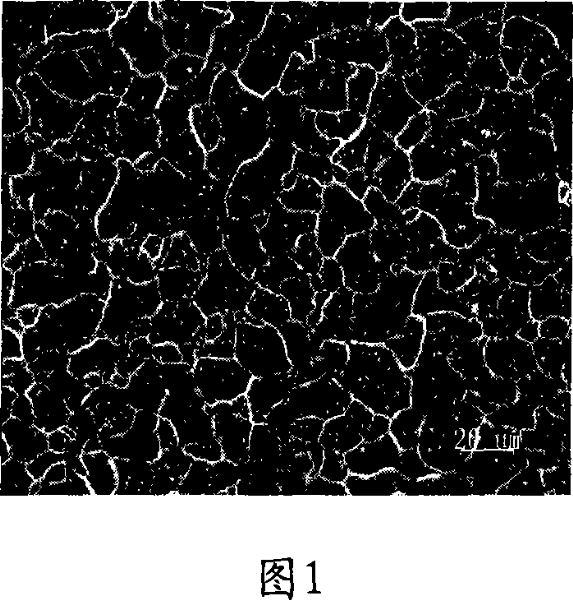

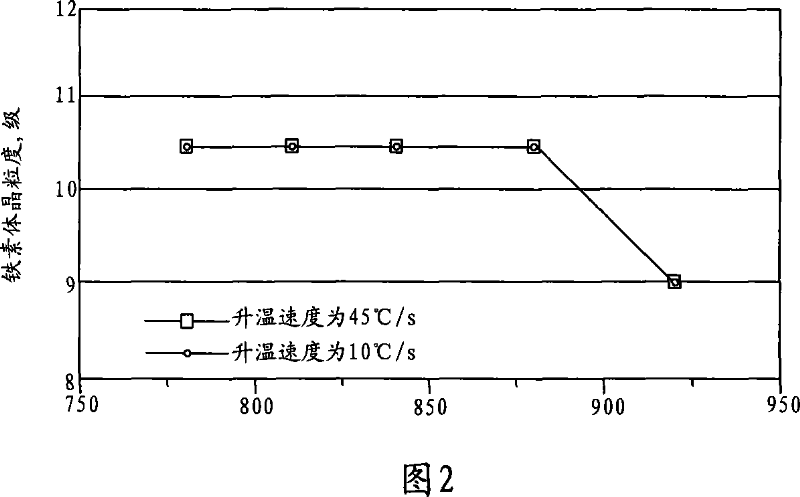

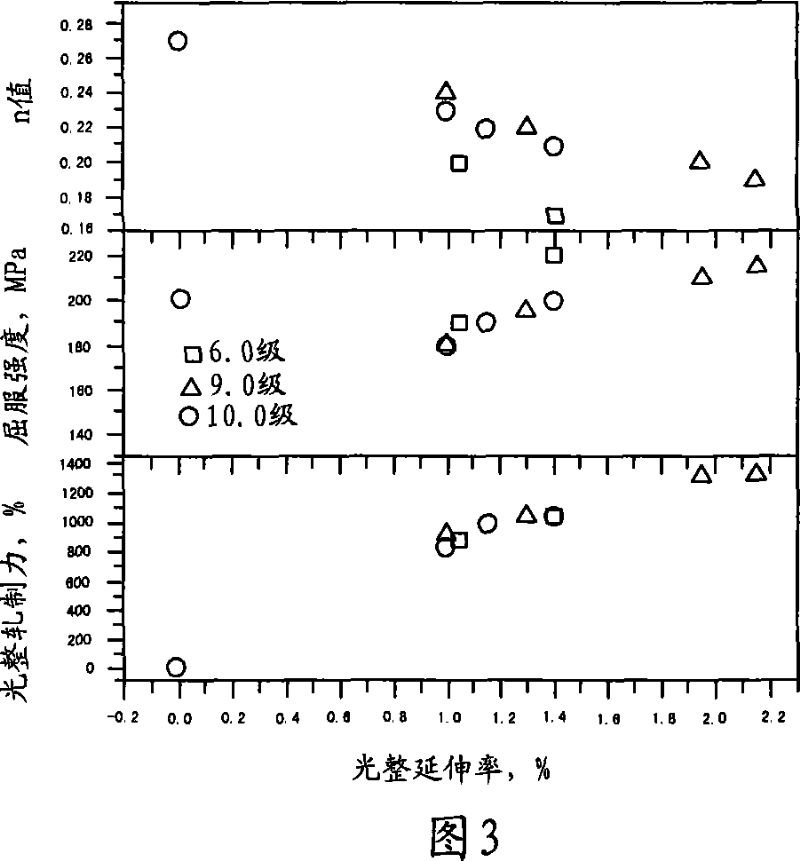

The invention discloses a manufacturing method of deep drawing finish heat galvanized steel sheet, capable of producing the deep drawing finish heat galvanized steel sheet on the continuous heat galvanized line for building materials. The method on the continuous heat galvanized line for building materials uses following technique measures: carbon content of the substrate is controlled in 0.0030 to 0.0060 % by weight percent, Ti* content is controlled in 0.02 to 0.04 % by weight percent; the heat rolling is closed in austenite area near Ar3, after rolling, quickly cooling to 700-780 DEG C, and coiling after cooling 10-15s; annealing in 780-880 DEG C temperature range. Under condition of ensuring r value, the product crystal grain is thinned and the influence of annealing temperature fluctuation to the product crystal grain size is reduced, thereby reducing influence of finish extensibility to the product yield strength and the n value to obtain the deep drawing finish heat galvanized steel sheet with stable and excellent synthesis forming performance.

Owner:PANZHIHUA IRON AND STEEL

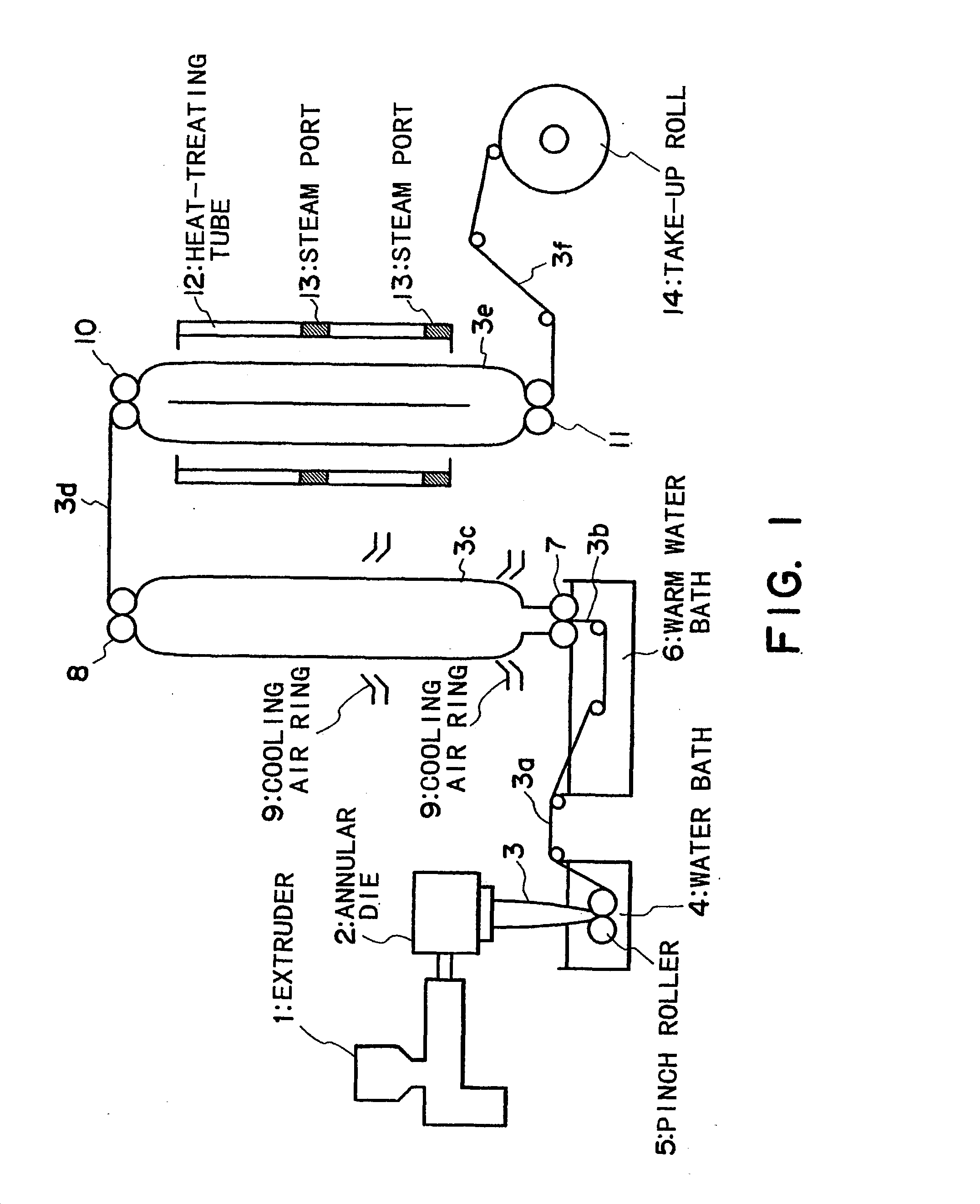

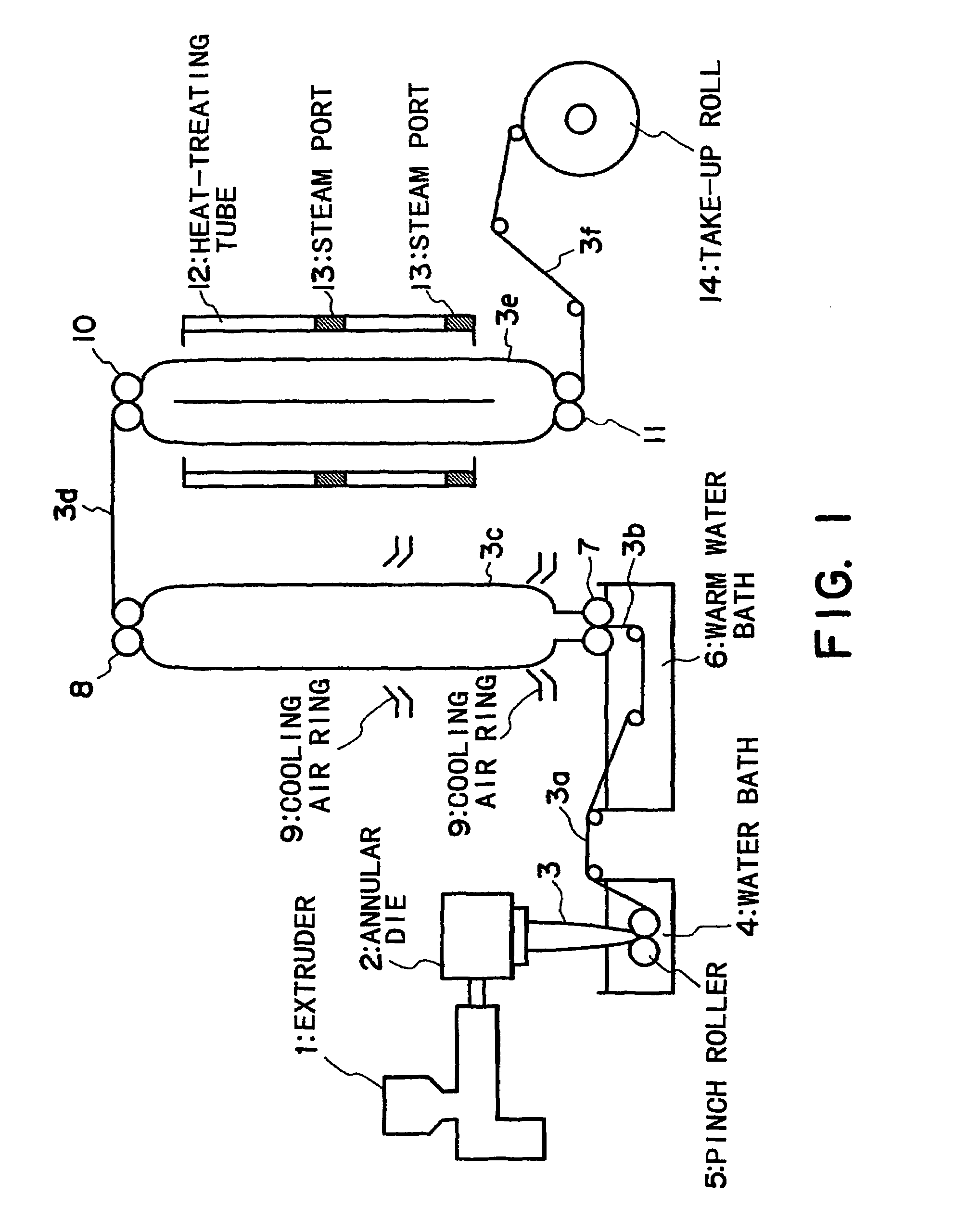

Low-temperature impact-resistant polyamide-based stretch-oriented mutilayer film

InactiveUS20030157350A1High low temperature impact resistanceIncrease elasticityFlexible coversWrappersSurface layerPolyamide

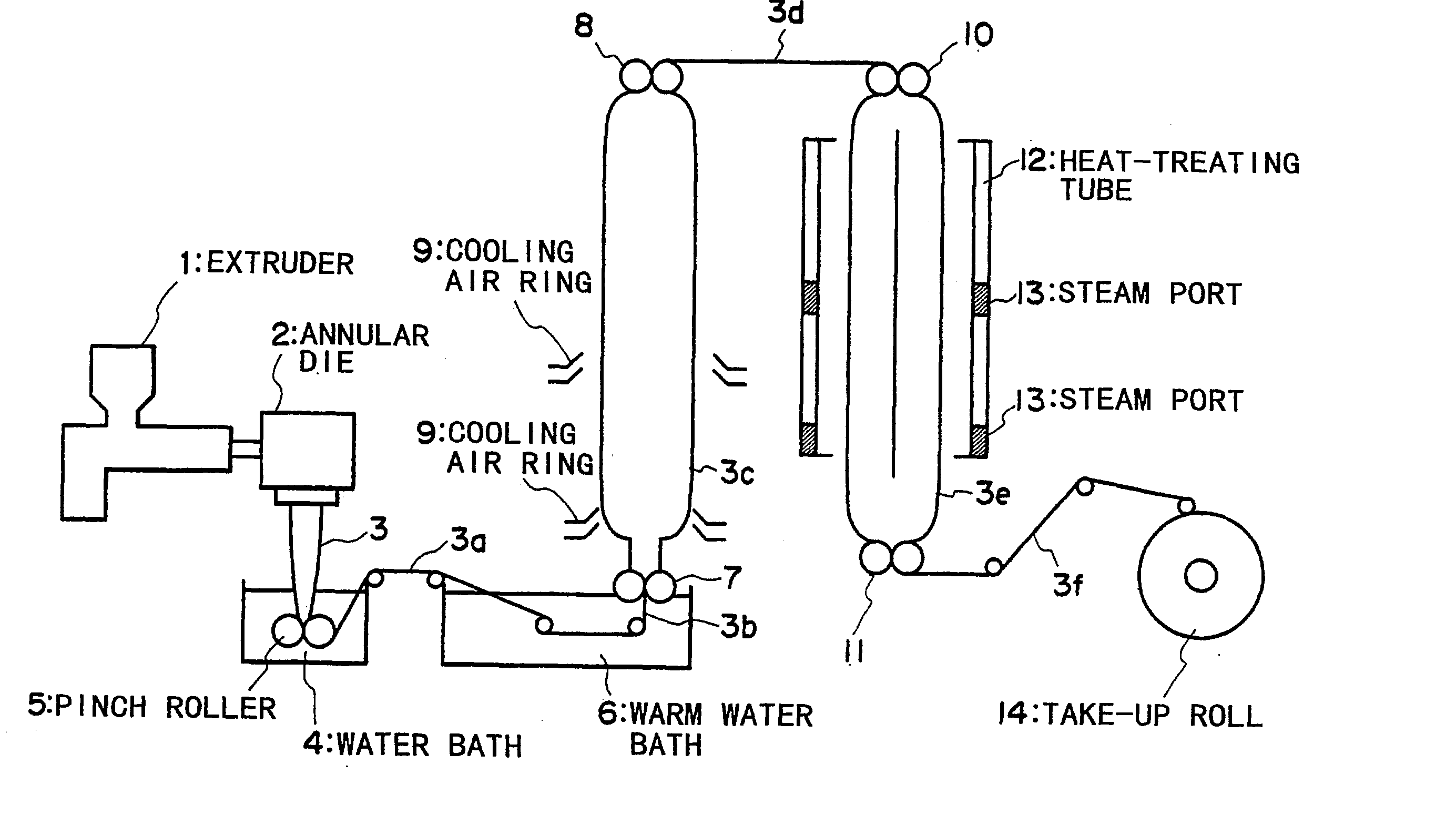

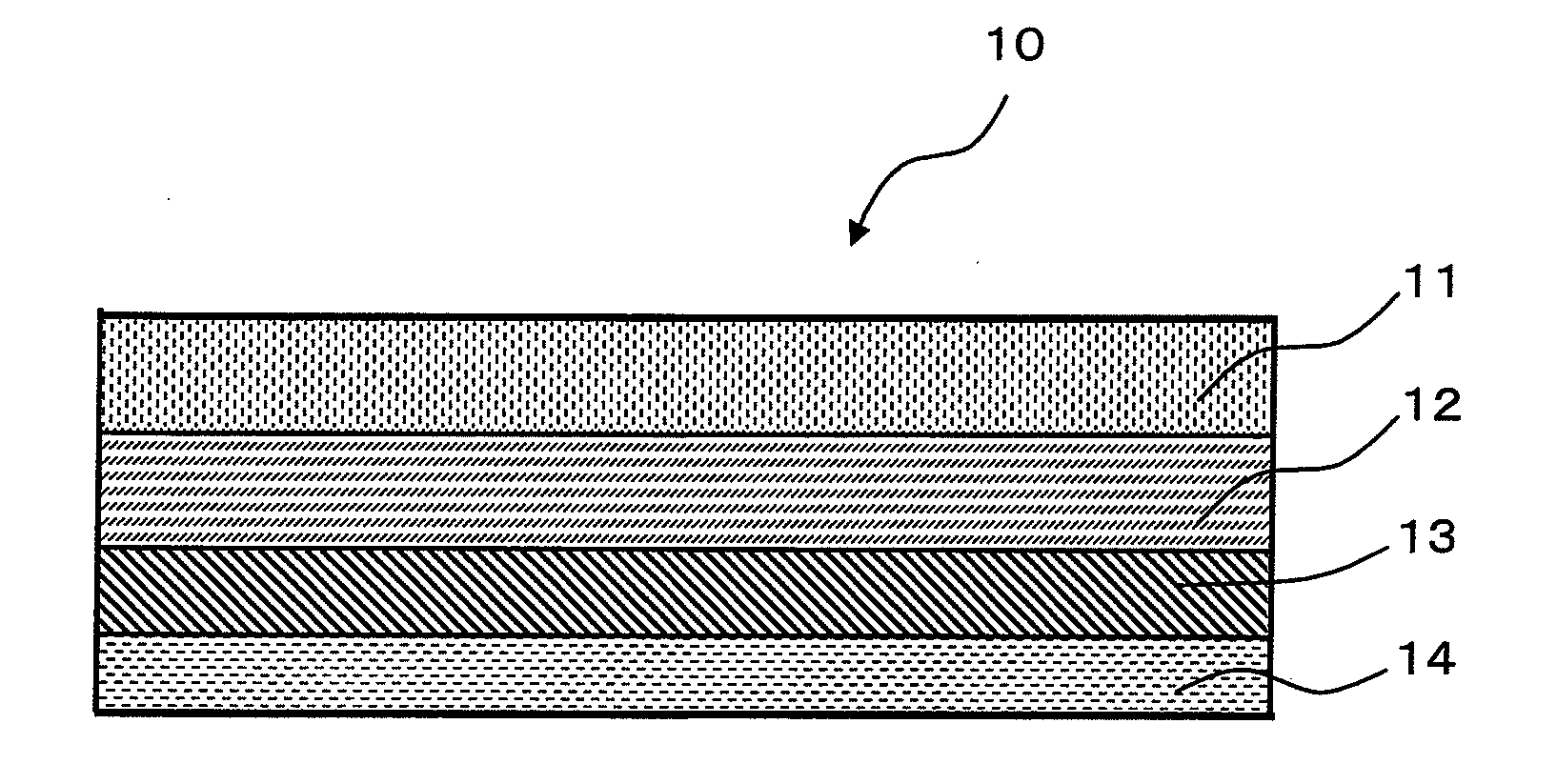

A stretch-oriented multilayer film suited for use as a freeze packaging material, a deep drawing packaging material, a vertical pillow packaging material, etc., is provided as a stretch-oriented multilayer film, comprising at least three layers including a surface layer (a) comprising a thermoplastic resin, an intermediate layer (b) comprising a polyamide resin and a surface layer (c) comprising a sealable resin, said multilayer film exhibiting an impact energy of at least 1.5 Joule at a conversion thickness of 50 mum at -10° C. The multilayer film is produced through an inflation process using water having a large capacity as a cooling and a heating medium and including a combination of a high degree of stretching and a high degree of relaxation heat treatment not exercised heretofore.

Owner:KUREHA KAGAKU KOGYO KK

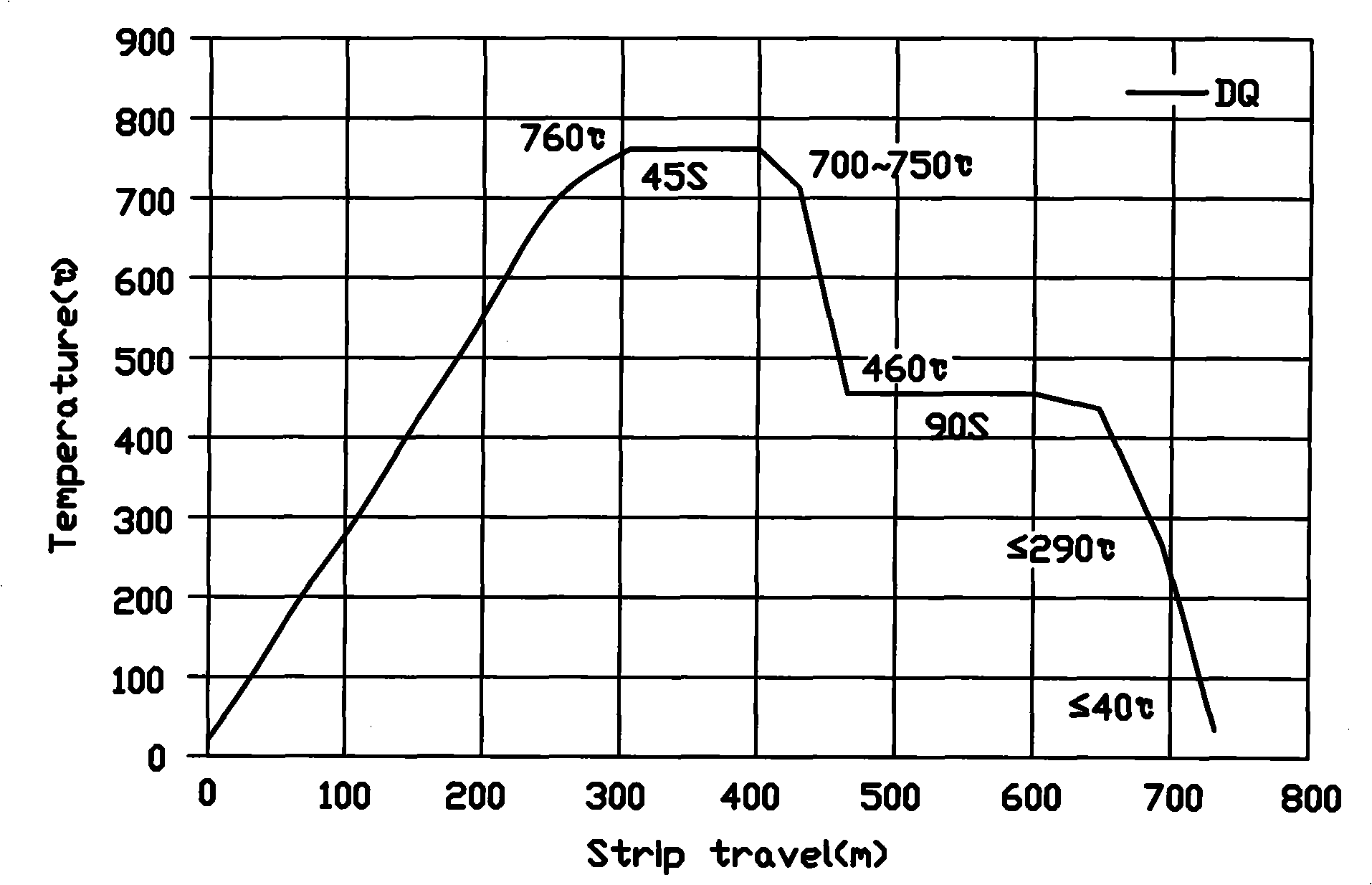

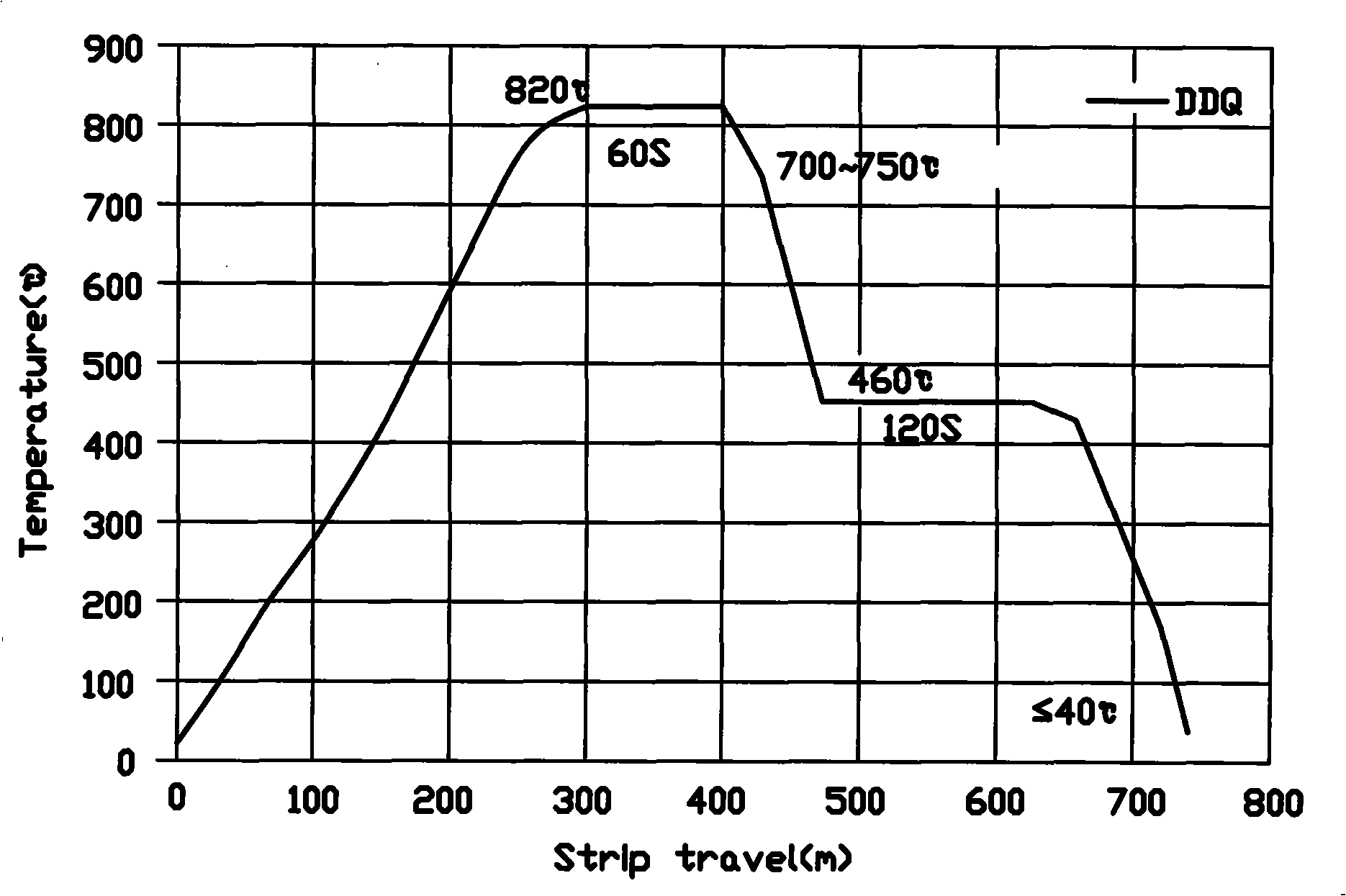

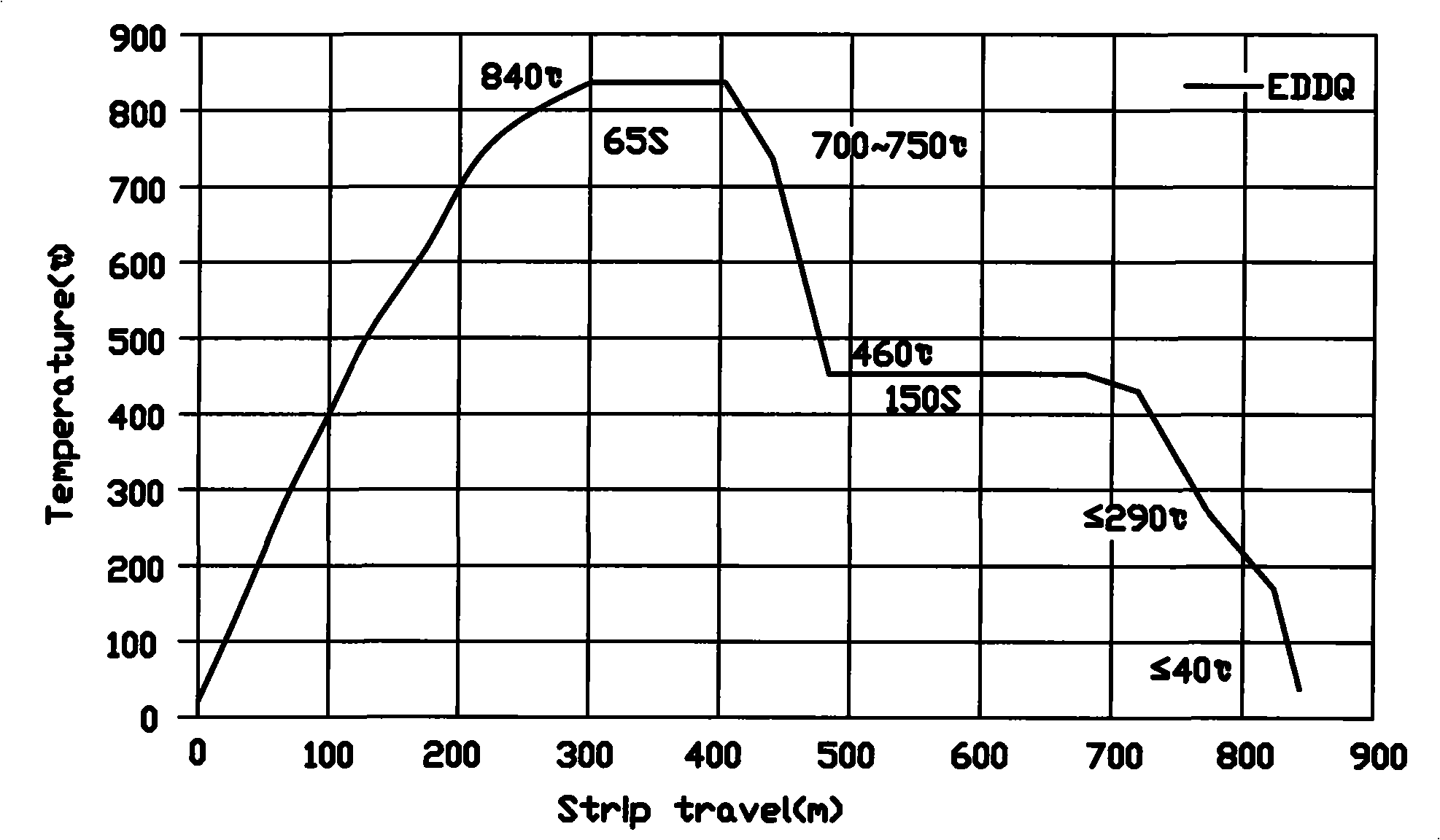

Continuous annealing process of deep drawing and extra-deep drawing steel plates

InactiveCN101514392AGuaranteed stamping effectGuaranteed ultra-deep drawing performanceFurnace typesHeat treatment process controlSheet steelHydrogen

The invention relates to a continuous annealing process of deep drawing and extra-deep drawing steel plates. The steel plate is washed before annealing to cause the contents of rolling oil and iron power on the surface of the steel plate are less than 20mg / m; the steel plate is put into a continuous annealing furnace and walks at the speed of 150-350m / min, mixed gas of nitrogen and hydrogen is used to blow the surface of the steel plate to protect and prevent the steel plate from oxidation, and the steel plate is heated to 120-180DEG C; and then the steel plate is heated again to 750-880 DEG C and the heat is preserved for 40-70 S; then, the steel plate is cooled to 400-460 DEG C and the heat is preserved for 60-300 S to carry out overaging treatment; finally, the steel plate is cooled to normal temperature. Owing to the employment of overaging annealing process, carbide in the steel is fully precipitated, thus guaranteeing the needs of drawing properties and extra-deep drawing properties of plates for household electrical appliances and of automobile plates.

Owner:耿凯

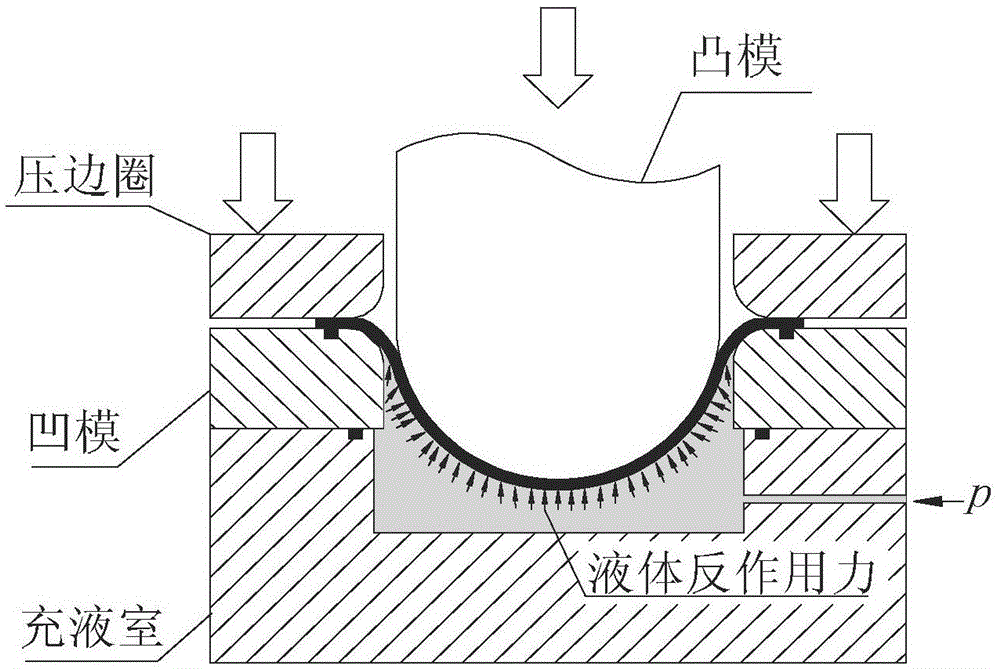

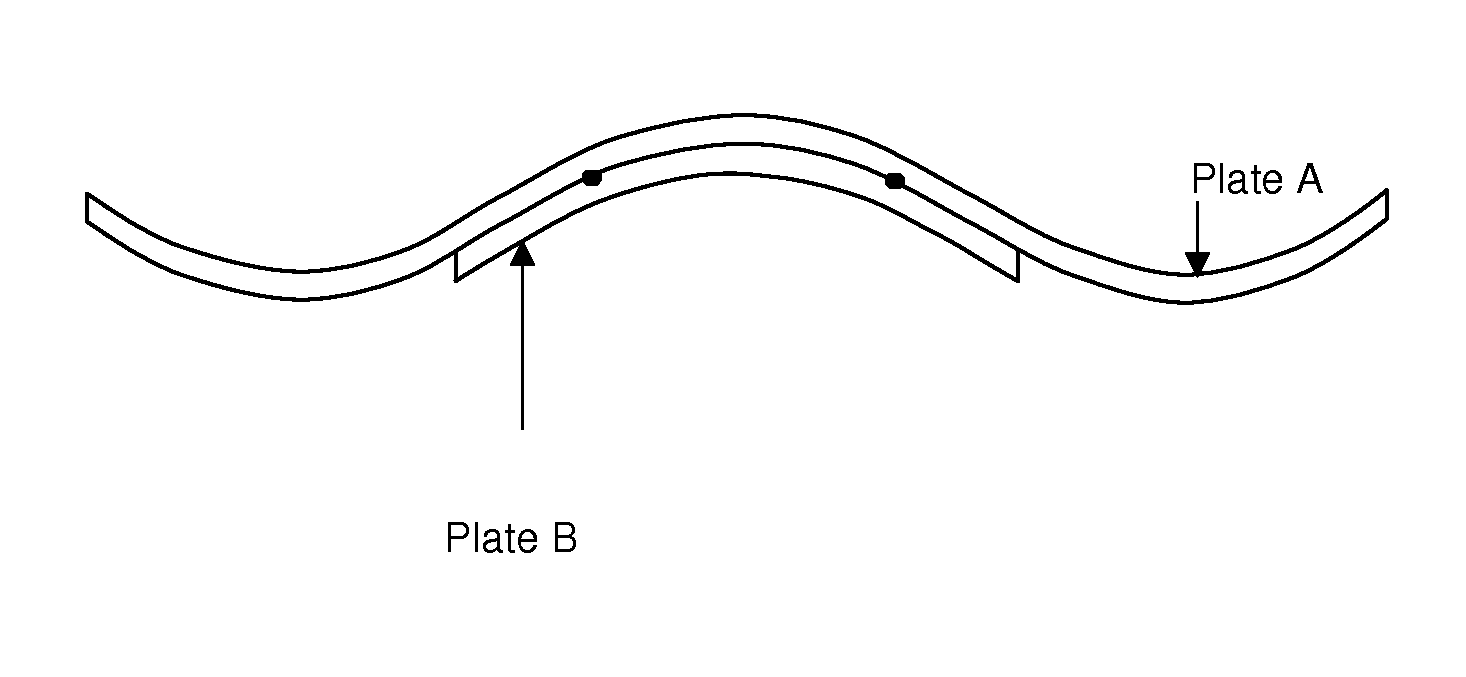

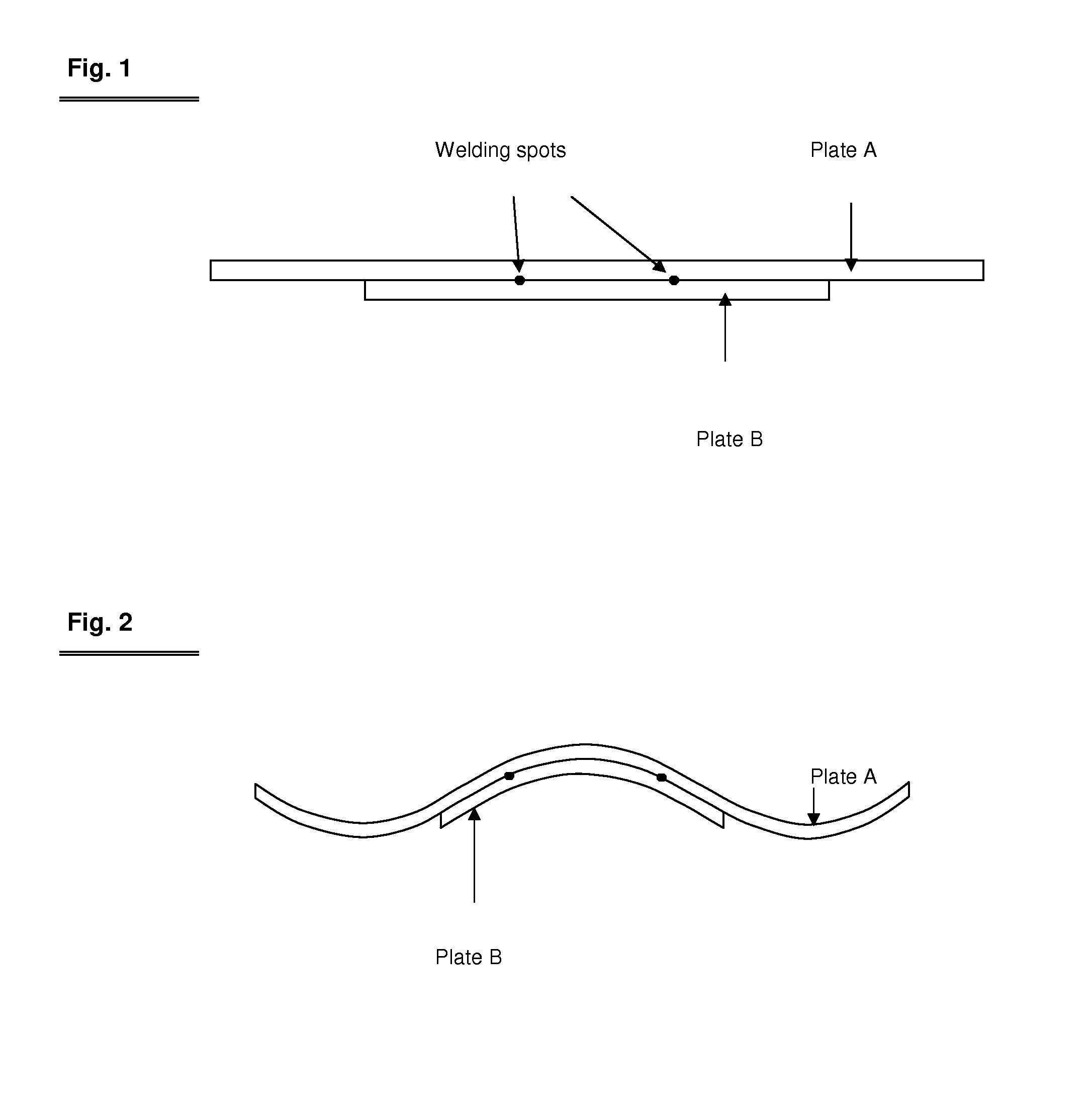

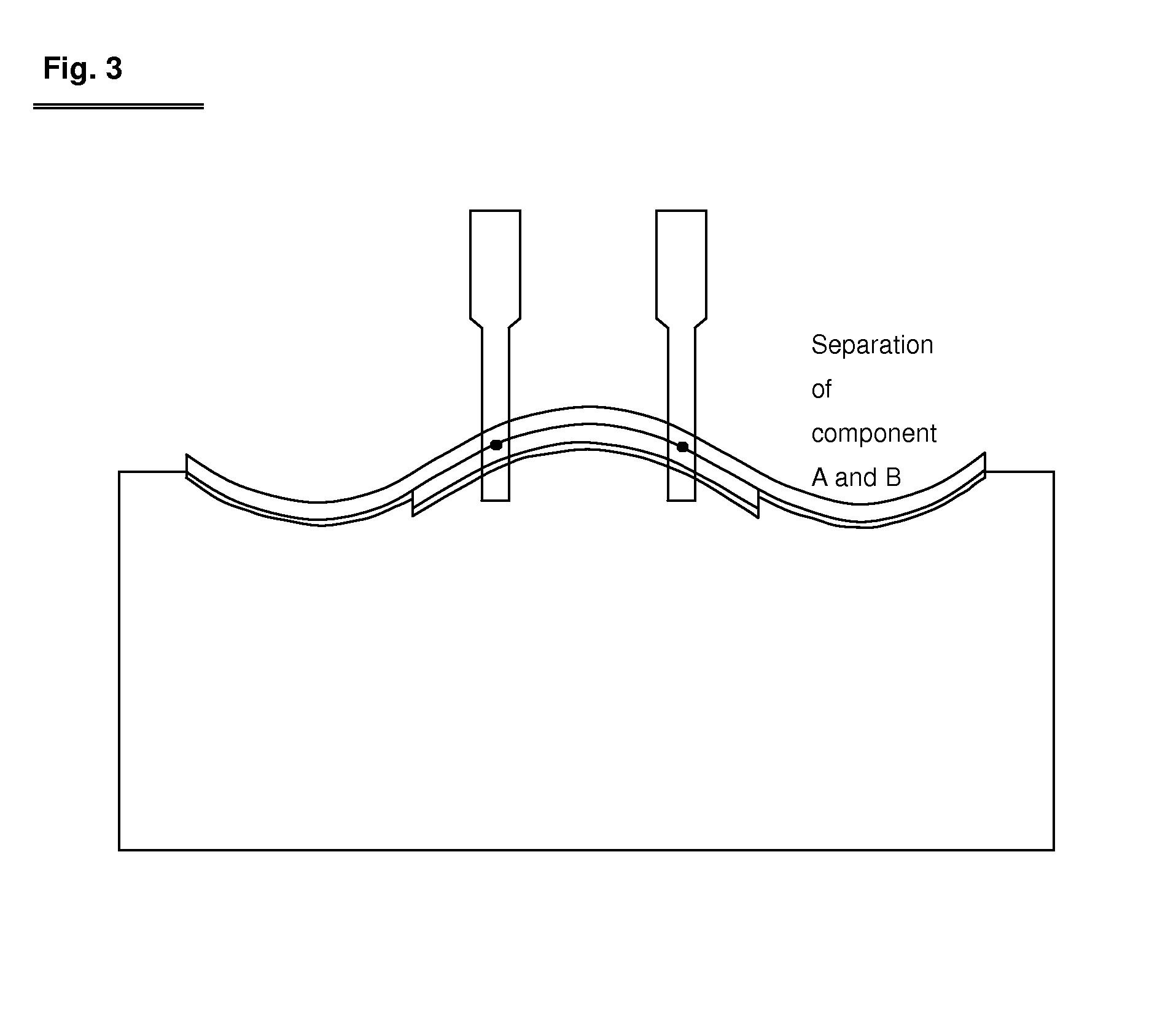

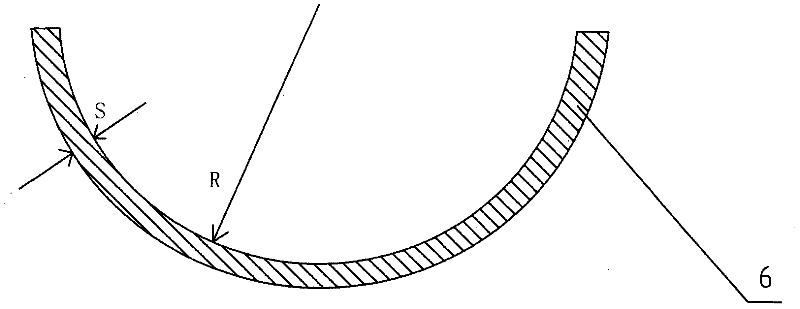

Hydro-mechanical deep drawing forming method capable of improving surface precision of large-scale thin-wall curved-surface part

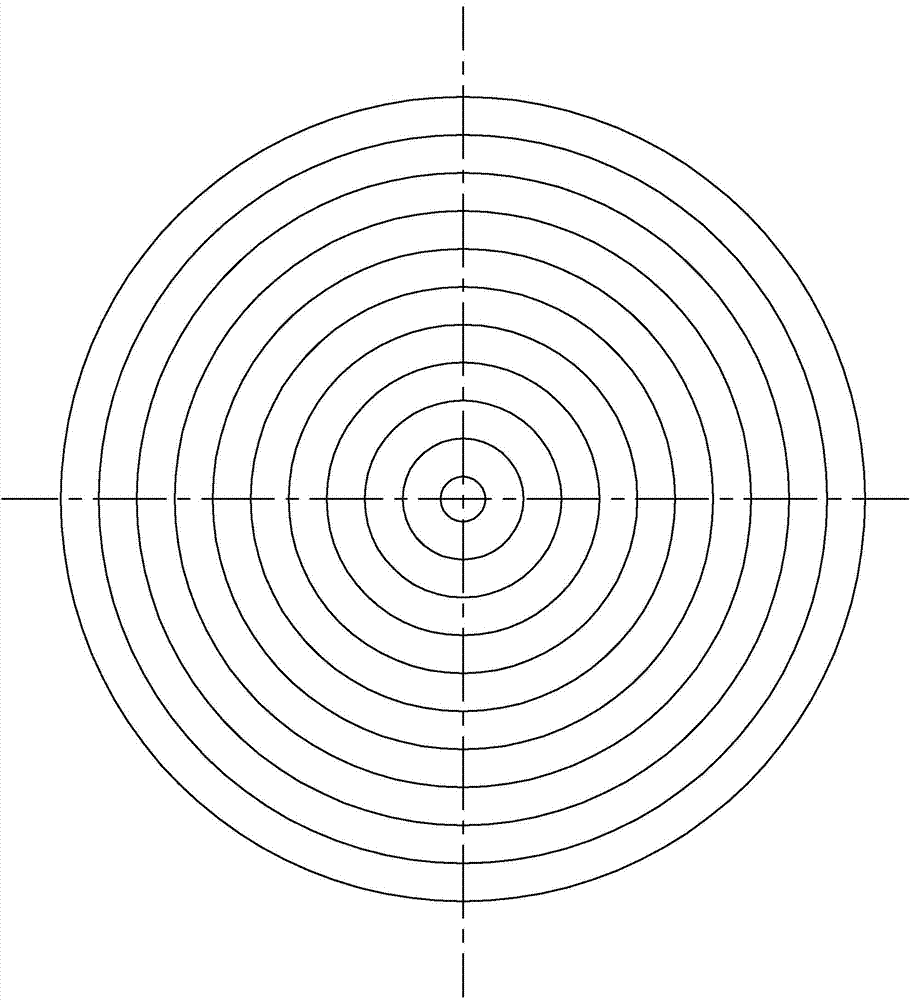

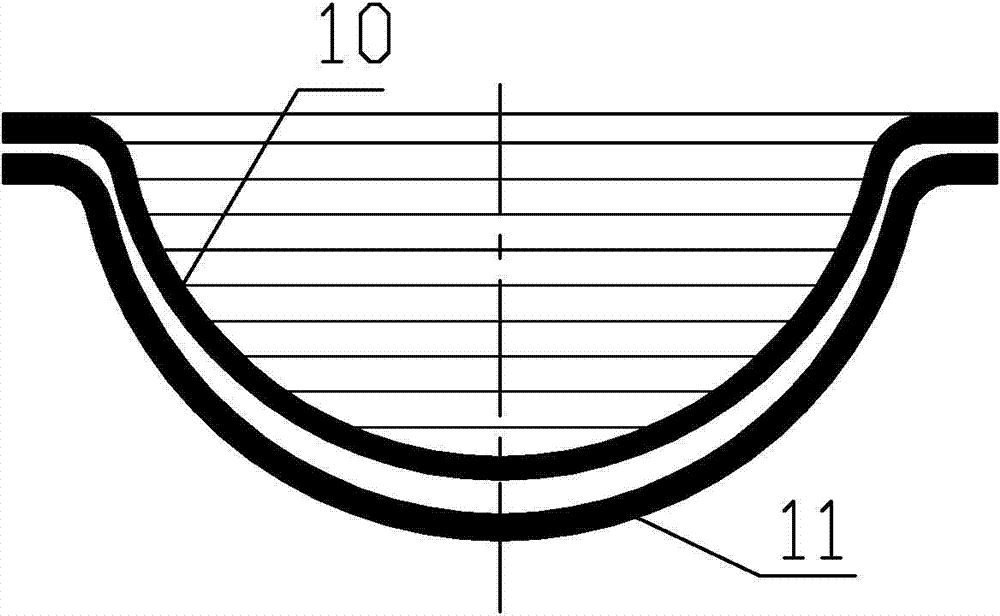

The invention discloses a hydro-mechanical deep drawing forming method capable of improving surface precision of a large-scale thin-wall curved-surface part, and relates to hydro-mechanical deep drawing forming methods. The problems that the curved-surface part is prone to be locally wrinkled and the surface precision is affected in the deep drawing process are solved. Concentric circles with certain distances are carved in the upper surface of an auxiliary forming sheet, the auxiliary forming sheet and a target forming sheet are stacked on a female die, and deep drawing forming is carried out on the auxiliary forming sheet and the target forming sheet. A gap generated by resilience of the auxiliary forming sheet and resilience of the target forming sheet is utilized for separating a deep drawing piece. The diameters and the thicknesses of the concentric circles of the deep drawing piece of the auxiliary forming sheet are measured. Normal inside offsetting is carried out on a molded surface generatrix of an initial deep drawing male die at the corresponding position. Fitting is carried out on an offset point, and the surface generatrix considering deformation and thinning of the auxiliary forming sheet can be obtained. According to the fitted surface generatrix, the initial deep drawing male die is finished, and an ideal deep drawing male die surface is obtained. Deep drawing forming and separation of the auxiliary forming sheet and the target forming sheet are carried out again, and the large-scale thin-wall curved-surface part with improved surface precision can be obtained.

Owner:抚顺三方机械制造有限公司

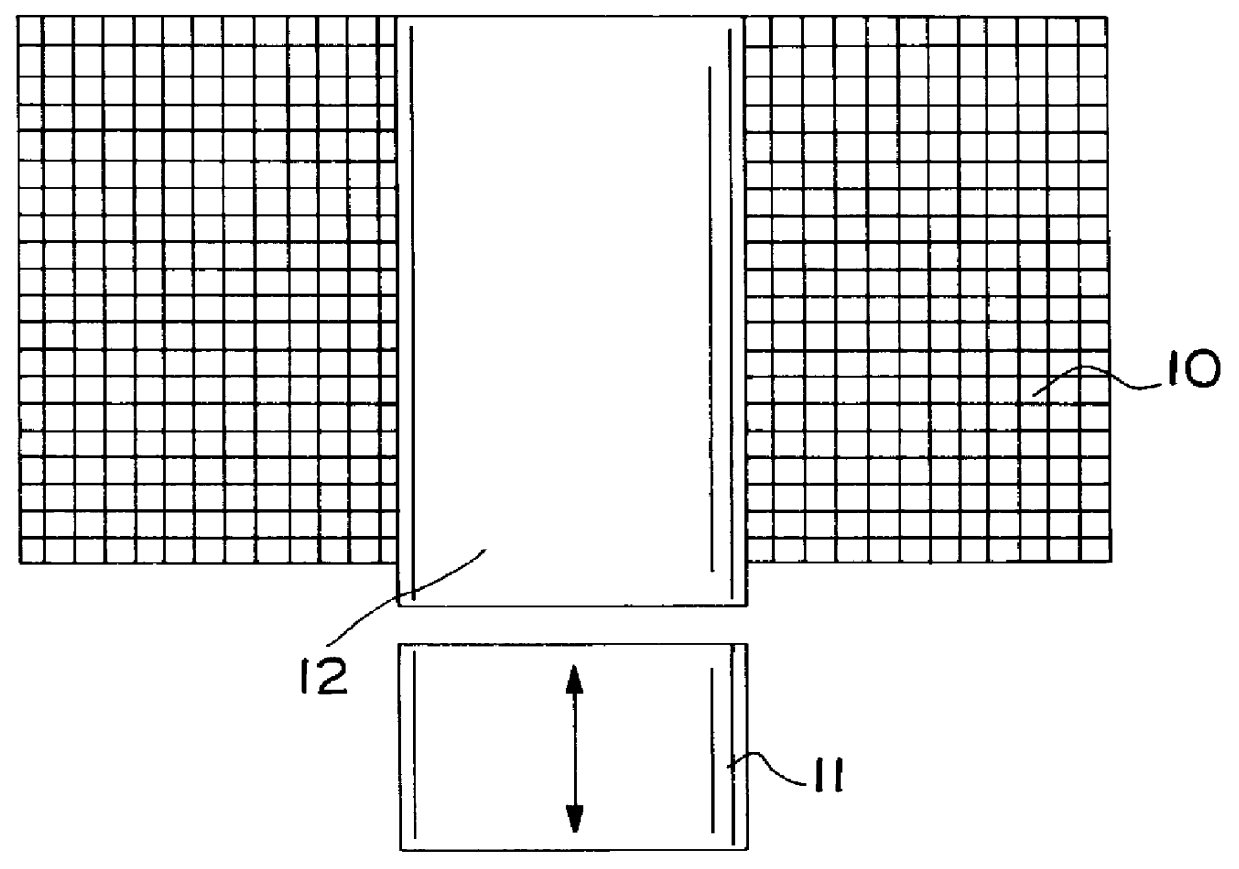

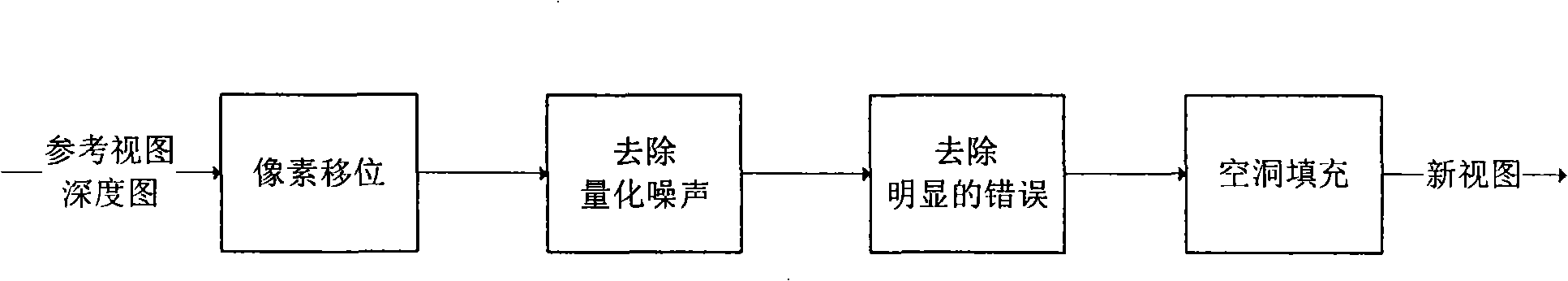

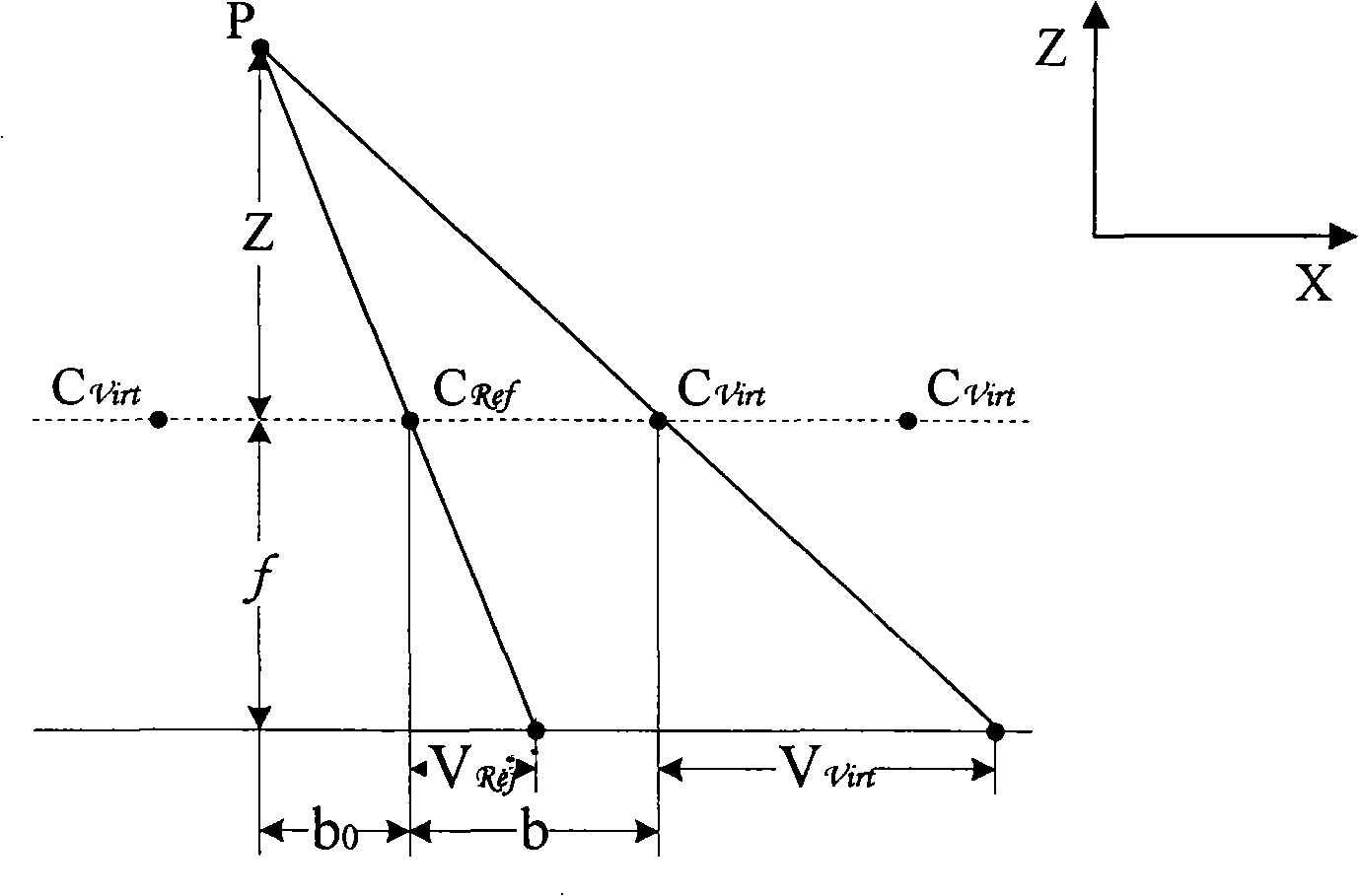

Fast image drafting method based on depth drawing

InactiveCN101271583ASmall amount of calculationFlexible drawing2D-image generationComputer imageDeep drawing

The invention relates to a fast image rendering method based on a depth map, belonging to technical field of the computer image rendering. The method comprises the following steps: all pixels in a two-dimensional reference view are shifted to a two-dimensional virtual view; a shifting distance is in proportion to a depth value in the depth map corresponding to the pixel; the quantization noise in the two-dimensional virtual view is measured and removed; an obvious mistake in the two-dimensional virtual view is removed; an unfilled void area in the two-dimensional virtual view is filled with the pixel of a background area. The invention has the advantages of reducing the calculation amount in the entire rendering course greatly, meanwhile no need to regulate the camera, thereby being convenient and easy, obtaining a satisfactory rendering result, thereby being especially suitable for in some situations where a real-time processing is needed or a system resource is very limited.

Owner:安徽沃孚医疗科技有限公司

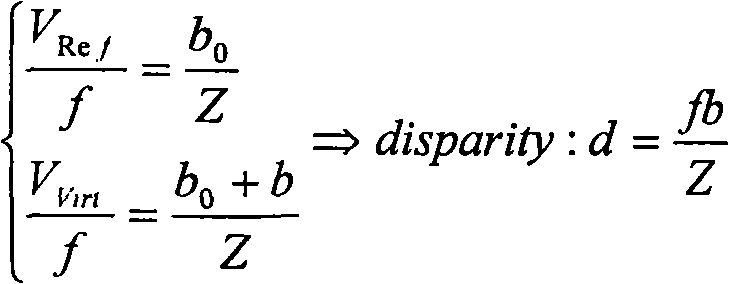

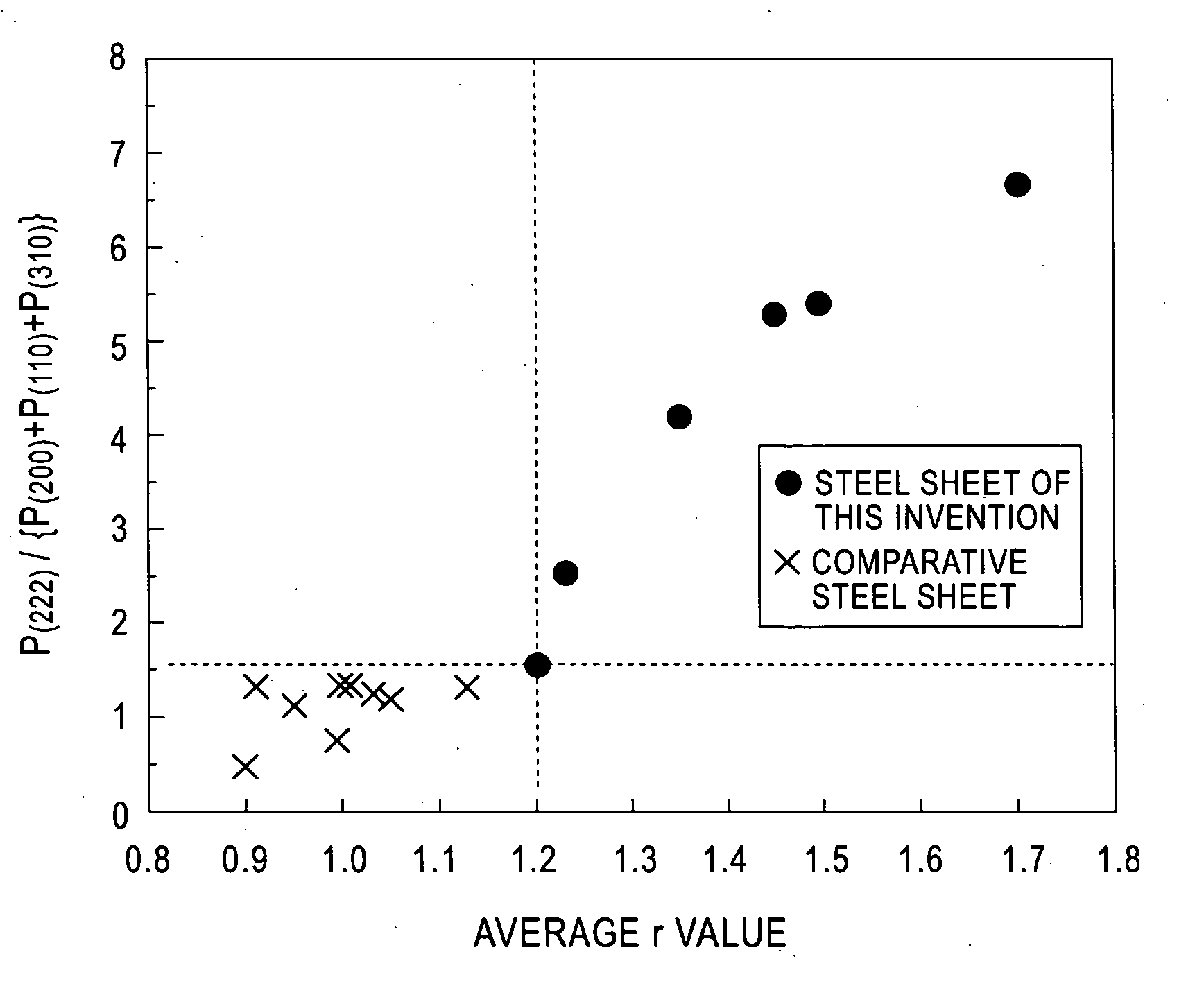

High-strength steel sheet excellent in deep drawing characteristics and method for production thereof

ActiveUS20060191612A1Avoid developmentIncrease valueHot-dipping/immersion processesFurnace typesHigh intensityMartensite

The present invention provides a high-strength steel sheet useful for applications to automobile steel sheets and the like and having excellent deep drawability, a tensile strength (TS) of as high as 440 MPa or more, and a high r value (average r value≧1.2), and a process for producing the steel sheet. The steel sheet has a composition containing, by % by mass, 0.010 to 0.050% of C, 1.0% or less of Si, 1.0 to 3.0% of Mn, 0.005 to 0.1% of P, 0.01% or less of S, 0.005 to 0.5% of Al, 0.01% or less of N, and 0.01 to 0.3% of Nb, the Nb and C contents in steel satisfying the relation, (Nb / 93) / (C / 12)=0.2 to 0.7, and the balance substantially including Fe and inevitable impurities. The steel microstructure contains a ferrite phase and a martensite phase at area ratios of 50% or more and 1% or more, respectively, and the average r value is 1.2 or more.

Owner:JFE STEEL CORP

Aluminum alloy plate type component frozen forming method

InactiveCN107866491AImprove plasticityOvercoming the Difficulty of Forming CrackingShaping toolsEnvironmental resistanceDeep drawing

The invention provides an aluminum alloy plate type component frozen forming method. In the method, by means of the characteristic that plasticity of an aluminum alloy plate is improved under ultralowtemperature, an aluminum alloy plate material 3 is cooled to the ultralow temperature range below 123 K through a cooling agent 1, and a die 2 is adopted for forming a complex thin-wall component. Compared with the prior art, the method has the beneficial effects that the method is executed under ultralow temperature condition, the plasticity of the aluminum alloy material is improved, the problem that plate type components in complex shapes are cracked when formed is solved, the forming limit is remarkably improved, the internal structure of aluminum alloy is not changed, structure propertydamage is not produced, frozen lubricating layers are formed on the working surfaces of the aluminum alloy plate and a die, and plate flow friction resistance can be reduced; and meanwhile, the low-temperature cooling agent is environmentally friendly, and the tonnage and manufacturing cost of equipment can be greatly reduced compared with hot forming and hydrodynamic deep drawing forming.

Owner:HARBIN INST OF TECH

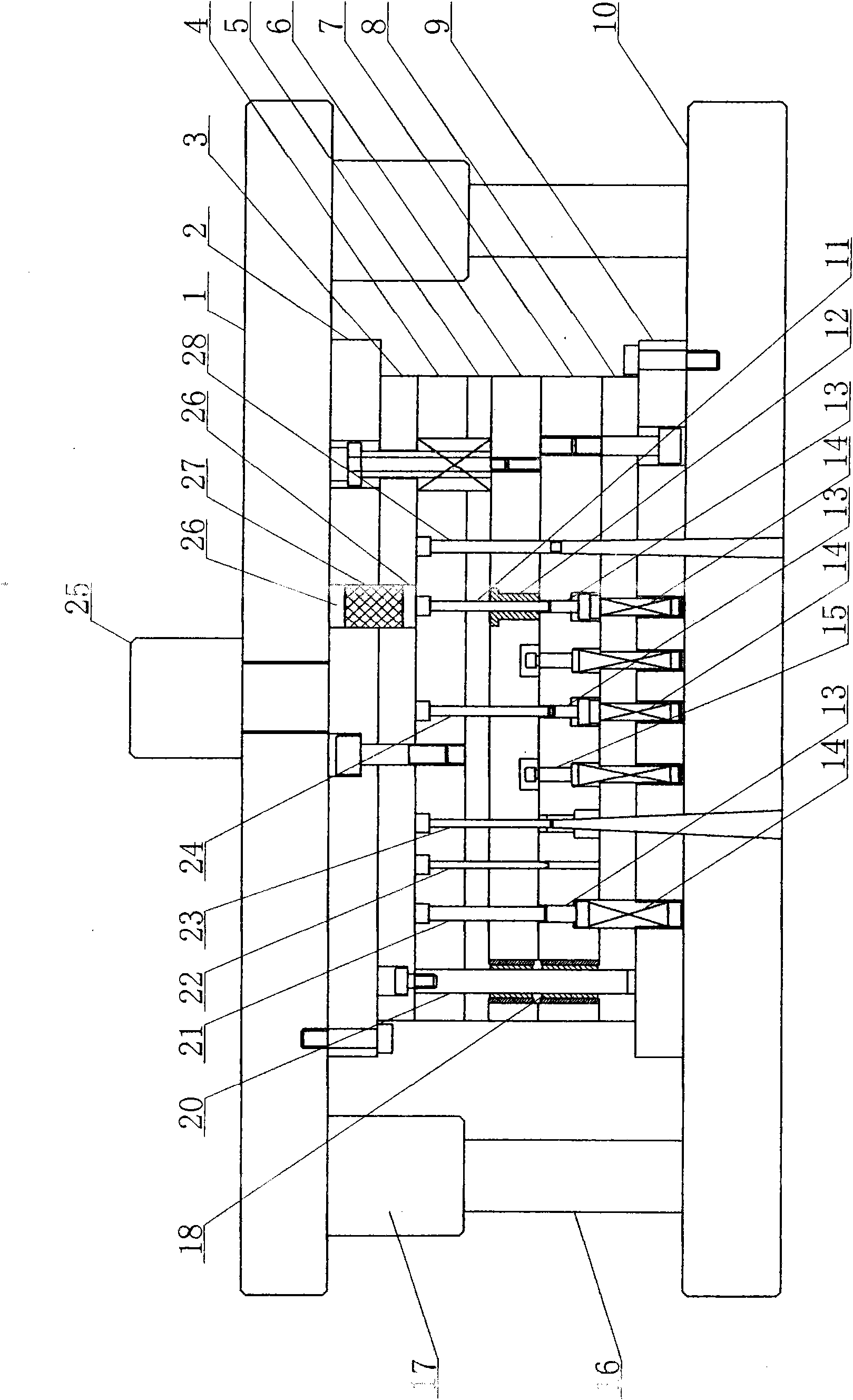

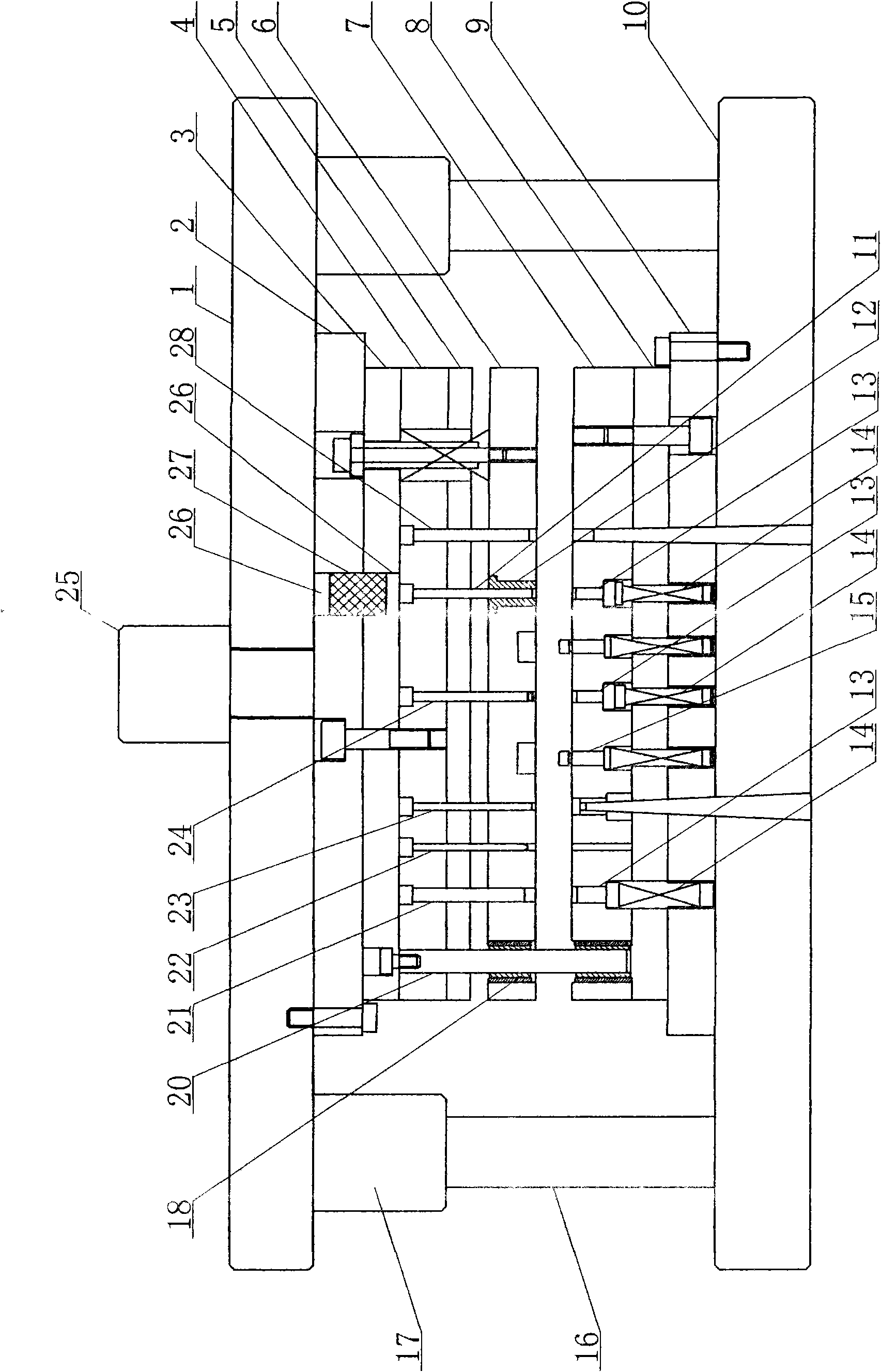

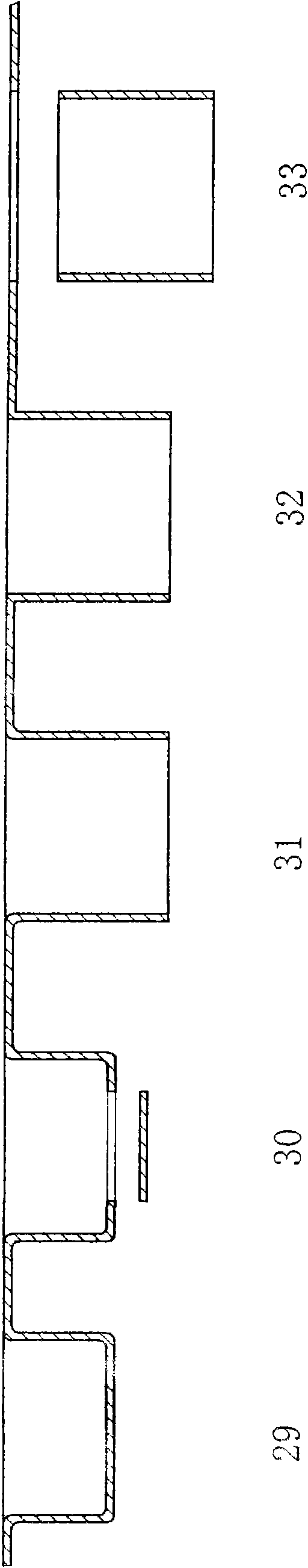

Method for producing thin-wall metal circular ring and grading stamping mould used therefor

ActiveCN101767164AIncrease productivityUniform wall thicknessShaping toolsPunchingElectronic industry

The invention discloses a method for producing a thin-wall metal circular ring, which comprises the steps of deep-drawing, punching, turning up, shaping and blanking plate materials or strip-shaped materials on a grading stamping mould. The grading stamping mould used for implementing the method mainly comprises an upper mould part and a lower mould part, wherein a deep-drawing male mould, a punching male mould, a turning-up male mould, a shaping male mould and a blanking male mould are arranged on the upper mould part sequentially; the male moulds all pass through a discharging plate; an annular convex part is arranged on the part, which surrounds the shaping male part, of the discharging plate; a deep-drawing female mould, a punching female mould, a turning-up female mould, a shaping female mould and a blanking female mould are arranged on the lower mould part sequentially; and spring-ejecting parts are arranged in the cavities of the deep-drawing female mould, the turning-up female mould and the shaping female mould. The method solves the technical problems of low processing precision and low production efficiency of the metal circular ring with two straight end faces. The method has a simple structure and is widely applied to the production manufacturing industry of the metal circular ring in electronic industry.

Owner:WEIFANG YUYUAN ELECTRONICS CO LTD

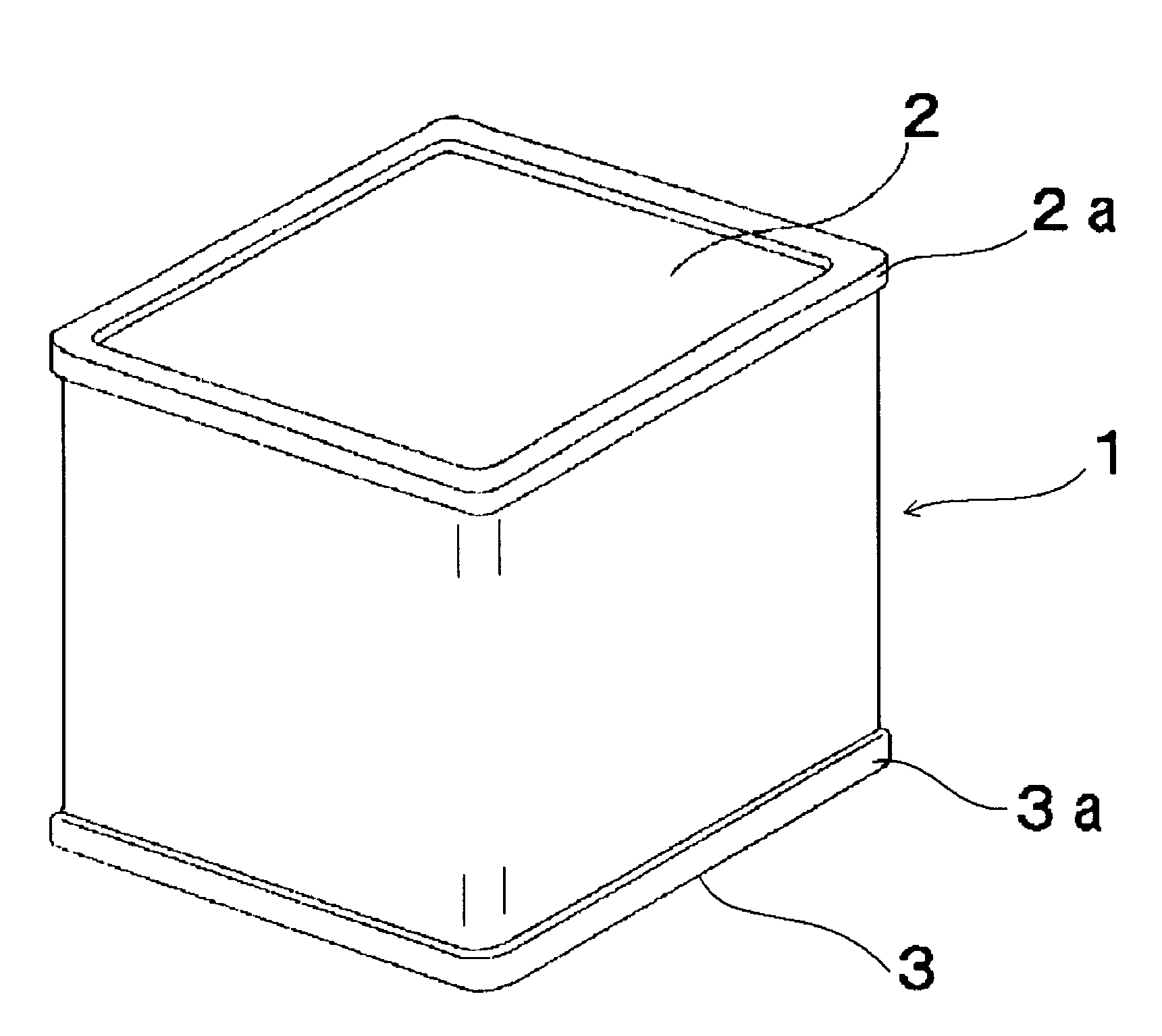

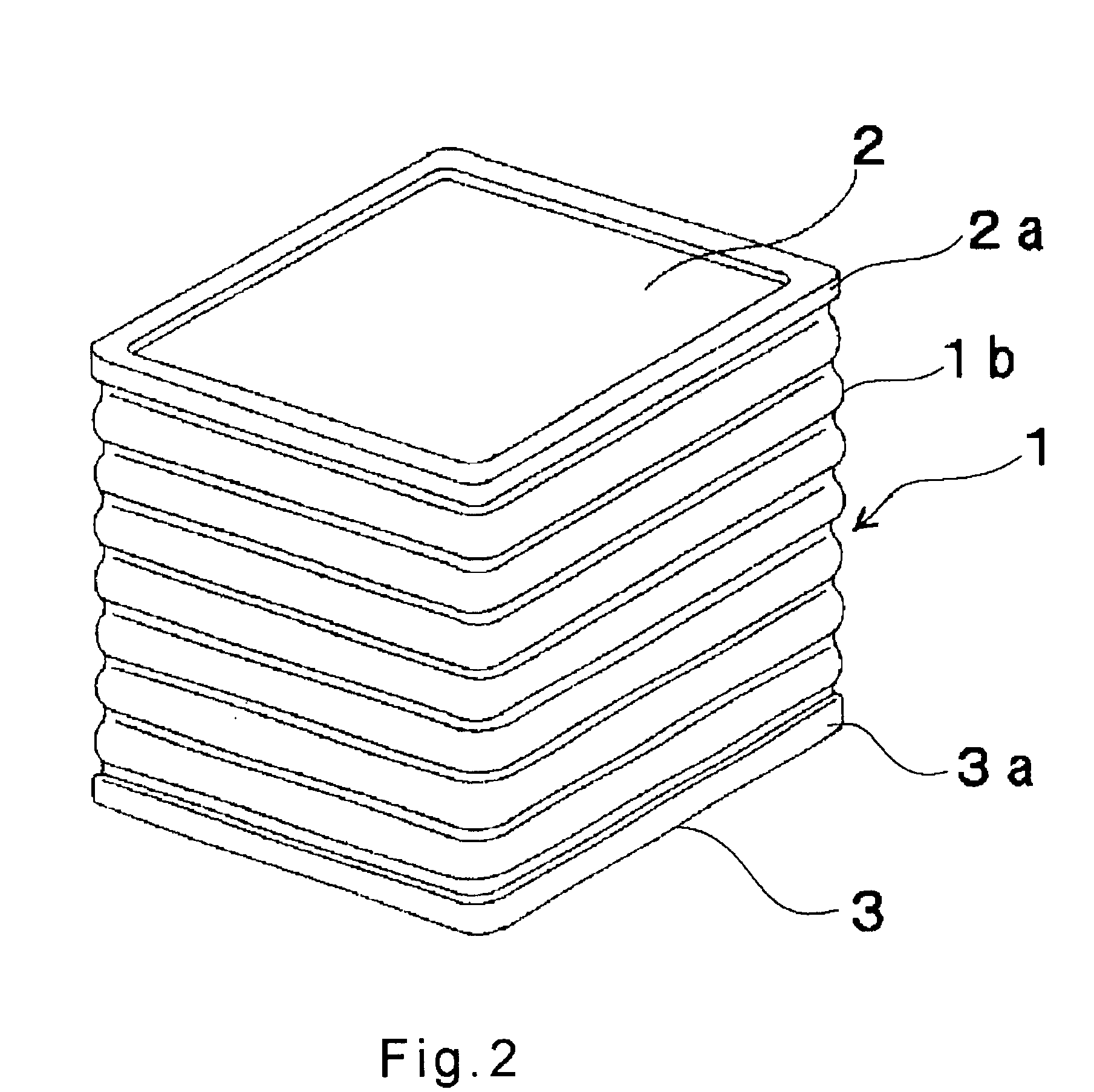

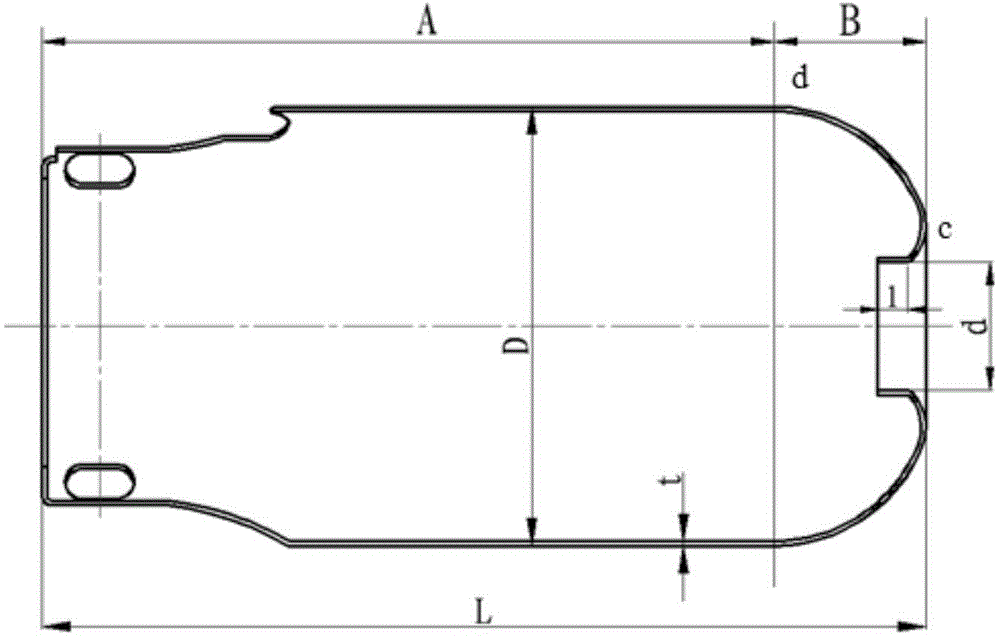

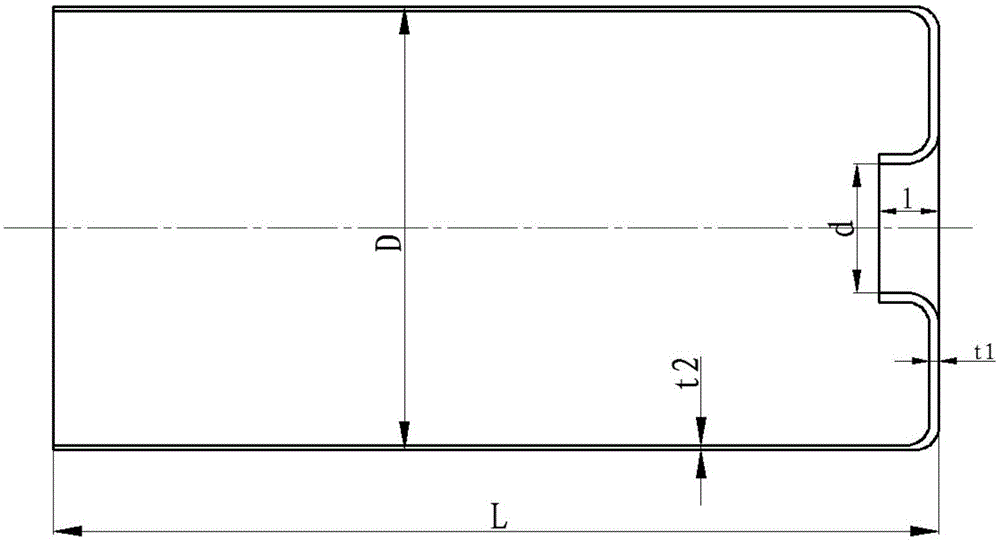

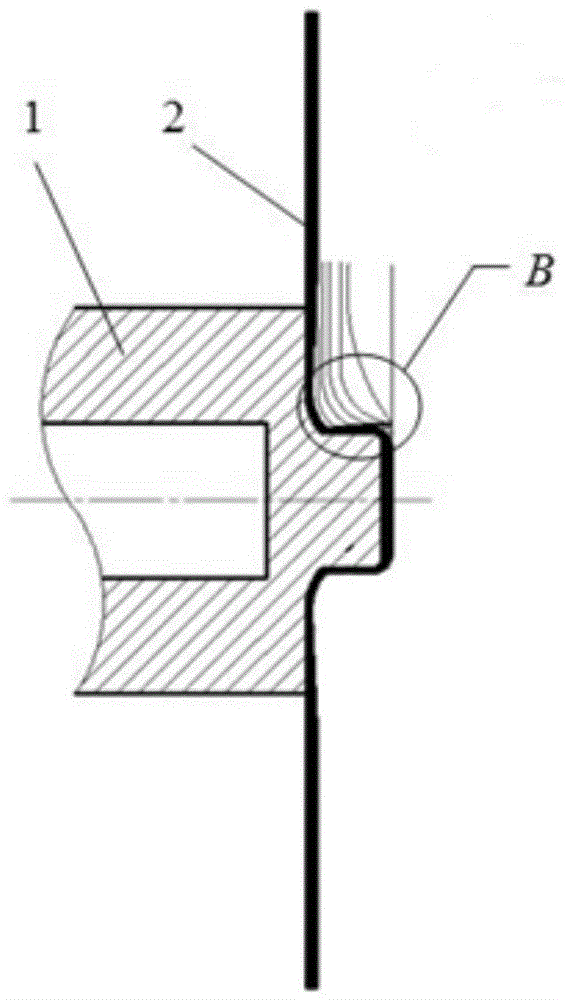

Three-piece square can and method of manufacturing the same

InactiveUS20090206096A1Improve the anti-leakage effectAvoid it happening againAssembling battery machinesSmall-sized cells cases/jacketsOrganic filmBody joints

The present invention provides a three-piece rectangular can which can overcome drawbacks (joint defect) of a can body joint portion of a three-piece can, and is of a new type which overcomes shortage of a can body strength which a two-piece can possesses, and exhibits excellent liquid leakage resistance, excellent can body strength and excellent heat radiation property or the like even when the can is used as a casing of a battery or electric equipment. For this end, the three-piece rectangular can of the present invention is formed such that a circular blank formed of an aluminum plate which forms an organic film on at least one surface thereof is formed into a bottomed circular can by deep drawing such that the organic film forms an inner side of the can, a cylindrical sleeve having no seam on a side surface thereof is formed by cutting a can bottom of the bottomed circular can, a rectangular can body portion having no seam on a side surface thereof is formed by deforming the cylindrical sleeve into a rectangular shape, a necking formed portion is formed by applying necking forming to opening portions at both ends of the rectangular can body, and a top lid and a bottom lid are mounted on the opening portions at both ends of the rectangular can body by double seaming by way of an organic compound.

Owner:TOYO SEIKAN KAISHA LTD +1

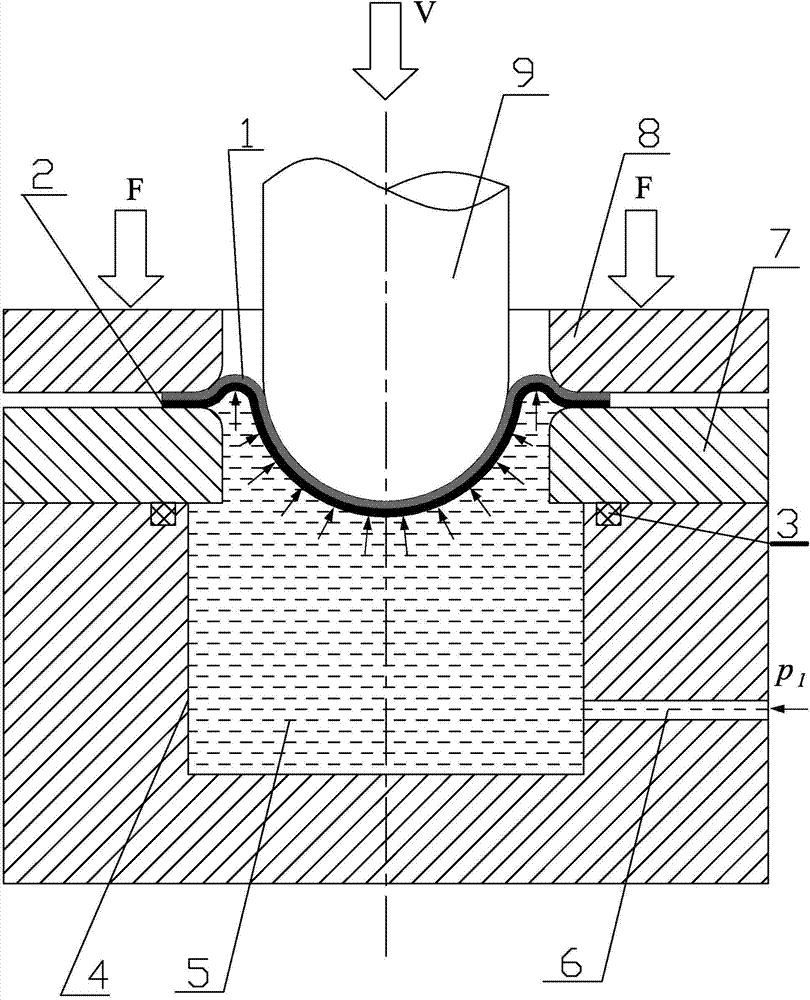

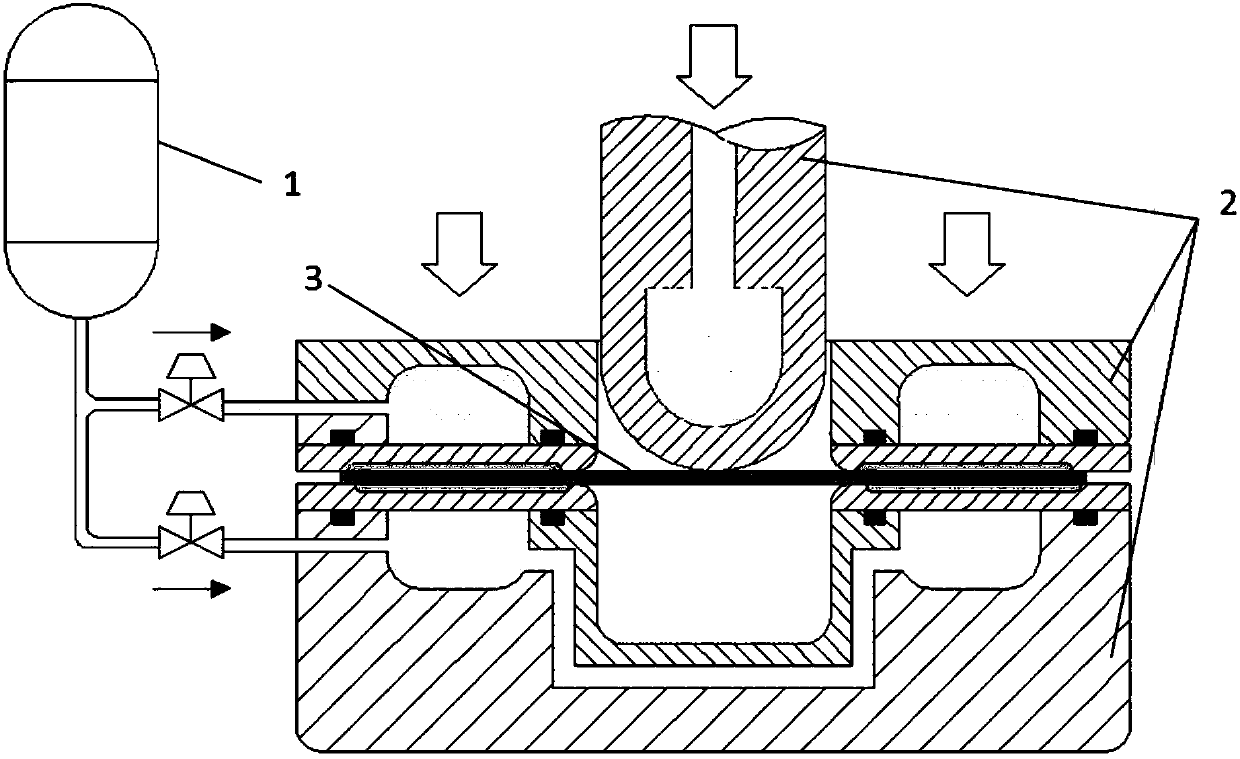

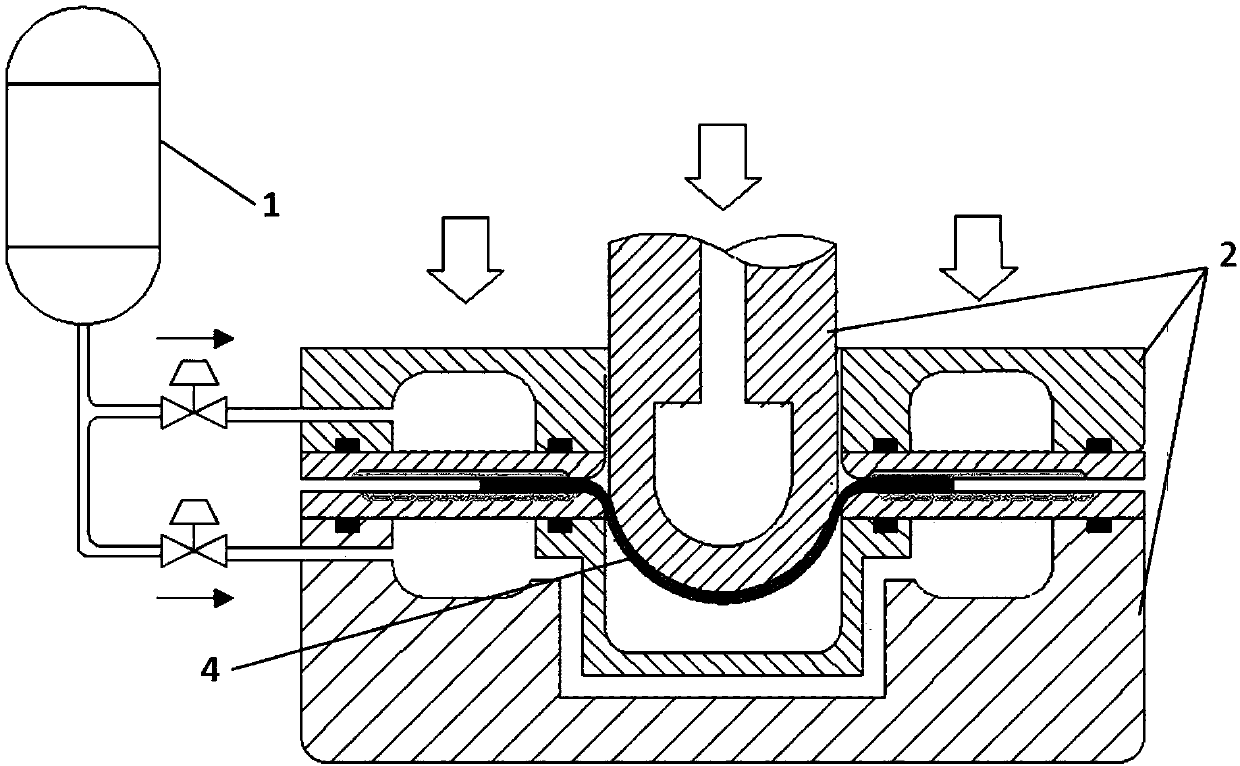

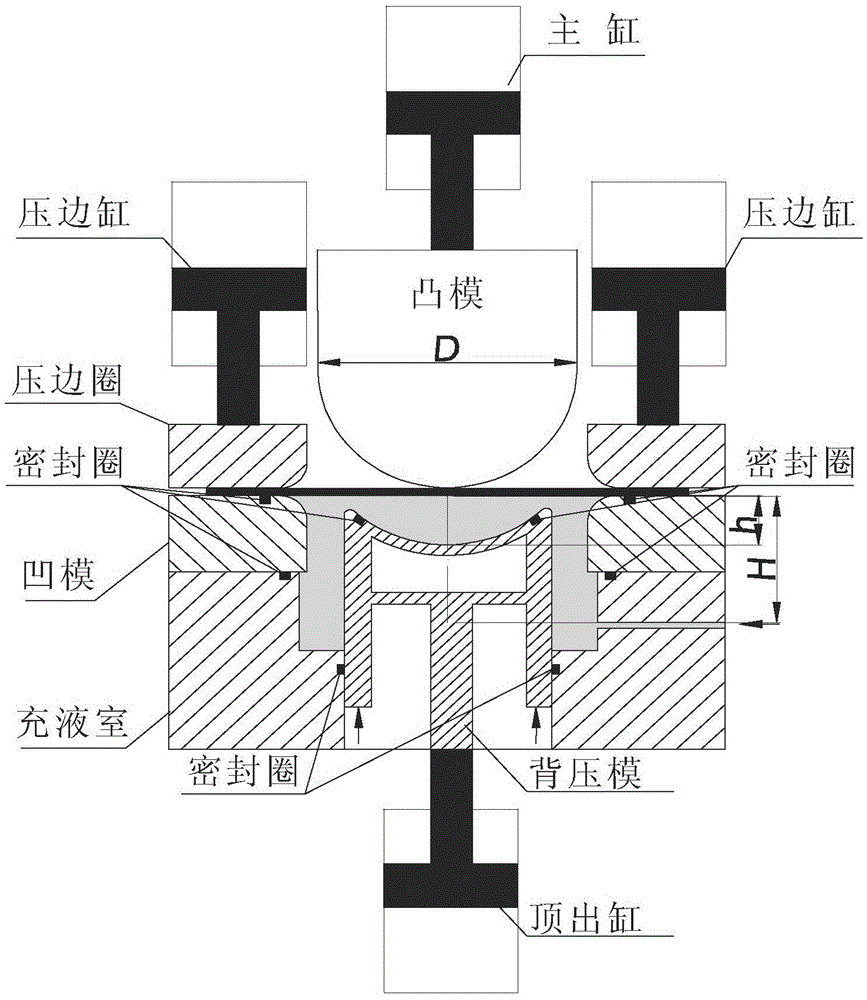

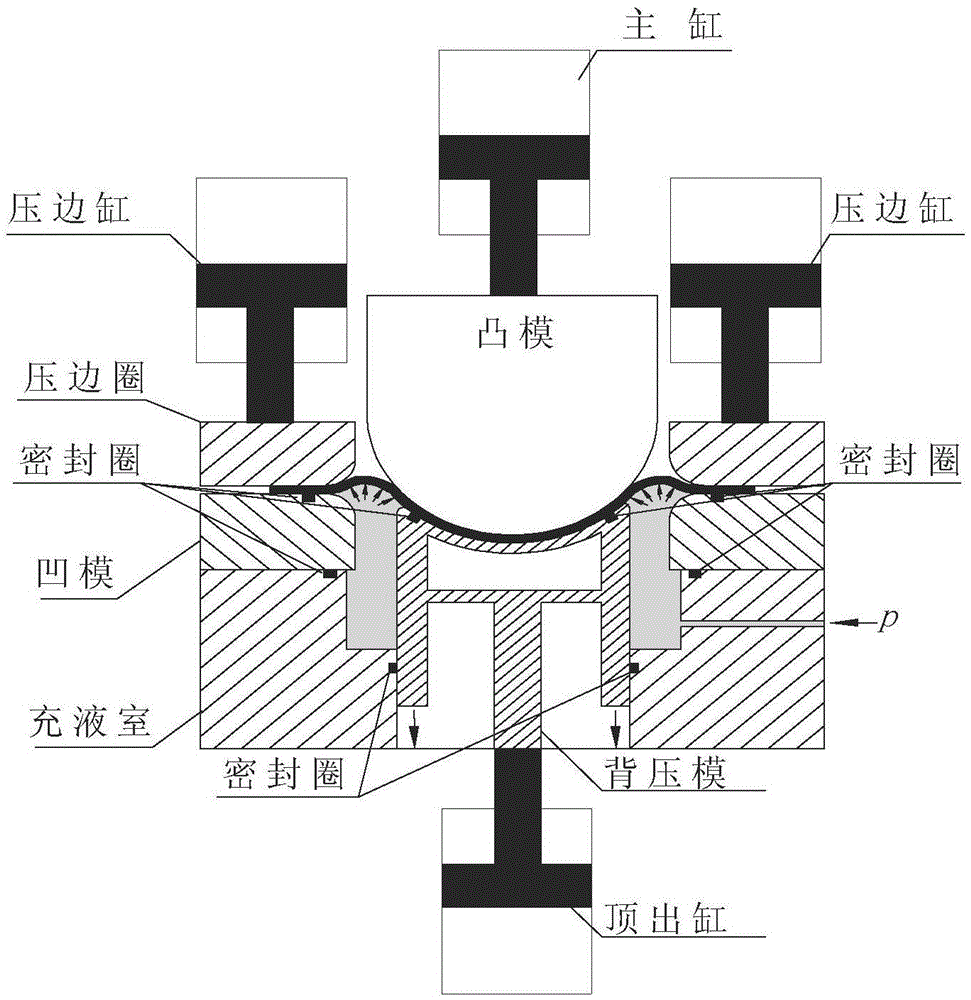

Device and method for reducing hydro-mechanical deep drawing force of large-size plate component

ActiveCN105537362AReduce reaction forceAvoid dependenceMetal working apparatusEngineeringHigh pressure

The invention provides a device and method for reducing hydro-mechanical deep drawing force of a large-size plate component, and relates to a forming device and method for thin-wall deep-cavity curved-surface plate component in order to solve the problems that during hydro-mechanical deep drawing of the large-size plate component, reactive force of liquid media is large, and accordingly equipment tonnage is large and energy consumption is high. The device comprises male die, an edge pressing ring, a female die, a liquid chamber and a back pressing die. The upper surface of the back pressing die is an inwards concave curved face, the curved face and the part, corresponding to the female die above, of the curved face are identical in shape, and the side wall of the back pressing die can slide up and down along the side wall of a large through hole in the bottom of the liquid chamber. When the male die moves downwards to a certain depth, the lower surface of a slab makes contact with the upper surface of the back pressing die and is completely attached to the upper surface of the back pressing die, the back pressing die moves downwards along with the male die and clamps the slab at the same time, the attached portion of the slab is not affected by high-pressure liquid, only the portion, in the annular area of the outer side of the back pressing die, of the lower surface of the slab is subjected to action of the high-pressure liquid, and hydro-mechanical deep drawing force is reduced because the action area of the high-pressure liquid on the male die is reduced.

Owner:HARBIN INST OF TECH

Low-temperature impact-resistant polyamide-based stretch-oriented multilayer film

InactiveUS7018719B2High low temperature impact resistanceImprove mechanical propertiesFlexible coversWrappersSurface layerPolyamide

A stretch-oriented multilayer film suited for use as a freeze packaging material, a deep drawing packaging material, a vertical pillow packaging material, etc., is provided as a stretch-oriented multilayer film, comprising at least three layers including a surface layer (a) comprising a thermoplastic resin, an intermediate layer (b) comprising a polyamide resin and a surface layer (c) comprising a sealable resin, said multilayer film exhibiting an impact energy of at least 1.5 Joule at a conversion thickness of 50 μm at −10° C. The multilayer film is produced through an inflation process using water having a large capacity as a cooling and a heating medium and including a combination of a high degree of stretching and a high degree of relaxation heat treatment not exercised heretofore.

Owner:KUREHA KAGAKU KOGYO KK

Process for producing components having regions of differing ductility

The invention relates to a process for producing sheet steel components having regions of differing ductility, in which either a sheet metal plate composed of a hardenable steel alloy is used to produce a component by deep-drawing and the deep-drawn component is then at least partially austenitized by a heat treatment and subsequently quench hardened in a die or the plate is at least partially austenitized by a heat treatment and shaped in the hot state, and is quench hardened during or after this, with the sheet metal plate having a zinc-based cathodic corrosion protection coating, characterized in that in regions of a desired higher ductility of the component, at least one additional sheet is attached to the plate, situated so that during the heat treatment, the plate is heated to a lesser degree there than in the remaining region.

Owner:VOESTALPINE METAL FORMING

Method for precision forming of concave-bottom and thin-wall cylindrical part with large length and diameter ratio

The invention discloses a method for precision forming of a concave-bottom and thin-wall cylindrical part with large length and diameter ratio. The method comprises the following steps of firstly, calculating the size of a plate blank; then, forming the concave bottom, performing deep drawing and spinning to form a cylindrical blank, and performing spinning and thinning on the blank to reach the specified size; performing subsequent universal processing to meet the requirement of part size; in the deep drawing and spinning process of the cylindrical blank, turning the blank with the formed concave bottom, fixing between a tail jack and a code die, preparing a common spinning track by a common spinning track preparation method, enabling a main shaft to drive the blank to rotate, enabling a rotary wheel to feed according to the prepared track under the drive action of a numerical control system, using the first 6-8 passes of the spinning track as the simple reciprocating spinning, using the subsequent passes of the spinning track as the spinning track combined with the reciprocating travel, and performing the deep drawing and spinning on the blank to form the cylindrical part. The method has the advantages that by utilizing multiple times of deep drawing and spinning, the cylindrical blank is obtained, and then the spinning and thinning are performed on the blank to reach the specified size; by utilizing the characteristics of strong spinning and high accuracy, the wall thickness of the manufactured part is uniform, the surface quality is high, the compactness is good, and the number of defects is fewer.

Owner:SOUTH CHINA UNIV OF TECH

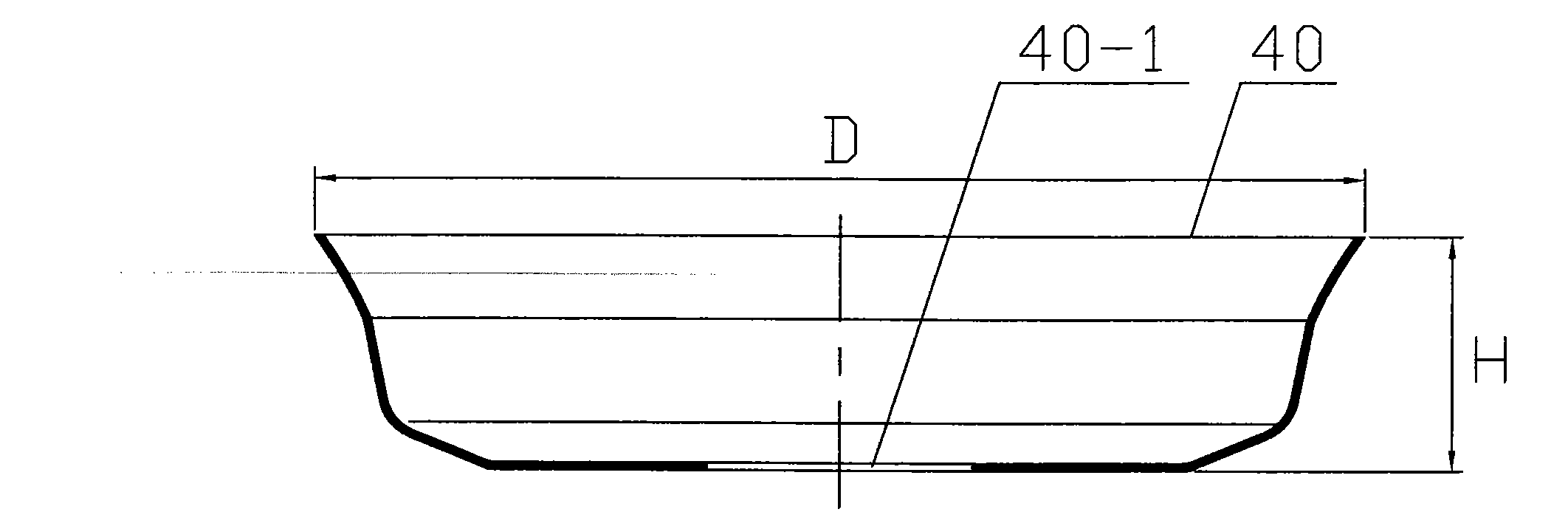

Method for manufacturing end socket of voltage stabilizer for nuclear power

ActiveCN102248362ASize qualifiedQualified shapeFurnace typesHeat treatment furnacesHot stampingNuclear power

The invention discloses a method for manufacturing an end socket of a voltage stabilizer for nuclear power. The integral end socket is subjected to hot stamping deep drawing by a 16MND5 low-alloy steel plate, and is subjected to heat treatment of normalizing and tempering to form the end socket, which is reliable in quality, accurate in size and high in mechanical property, of the voltage stabilizer for nuclear power. In the method, the weight of the end socket manufactured by the low-alloy steel plate can be reduced by about half compared with that of the end socket manufactured by forging piece materials, the manufacturing period is short and the cost is reduced greatly.

Owner:泰安东润核电装备有限公司

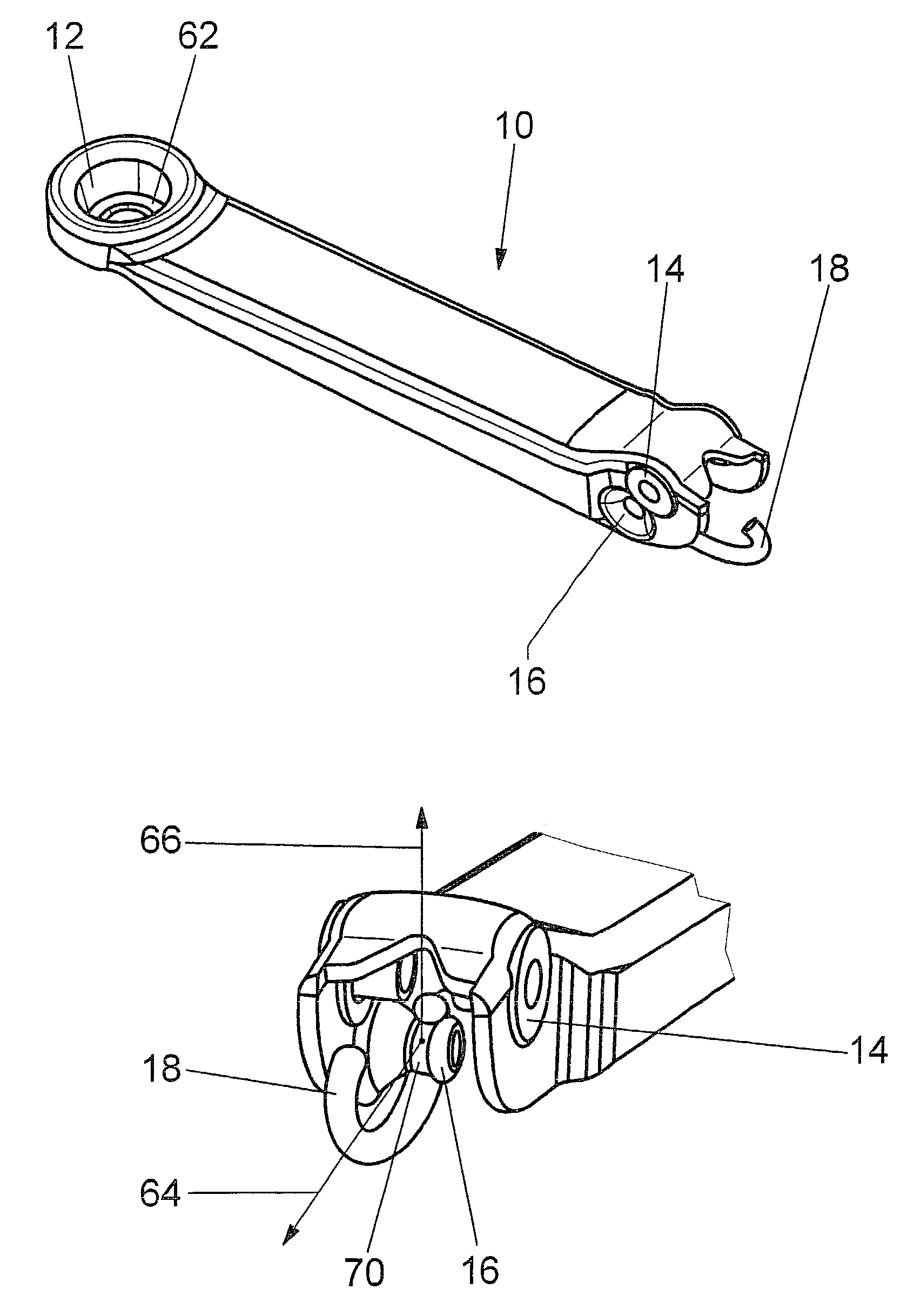

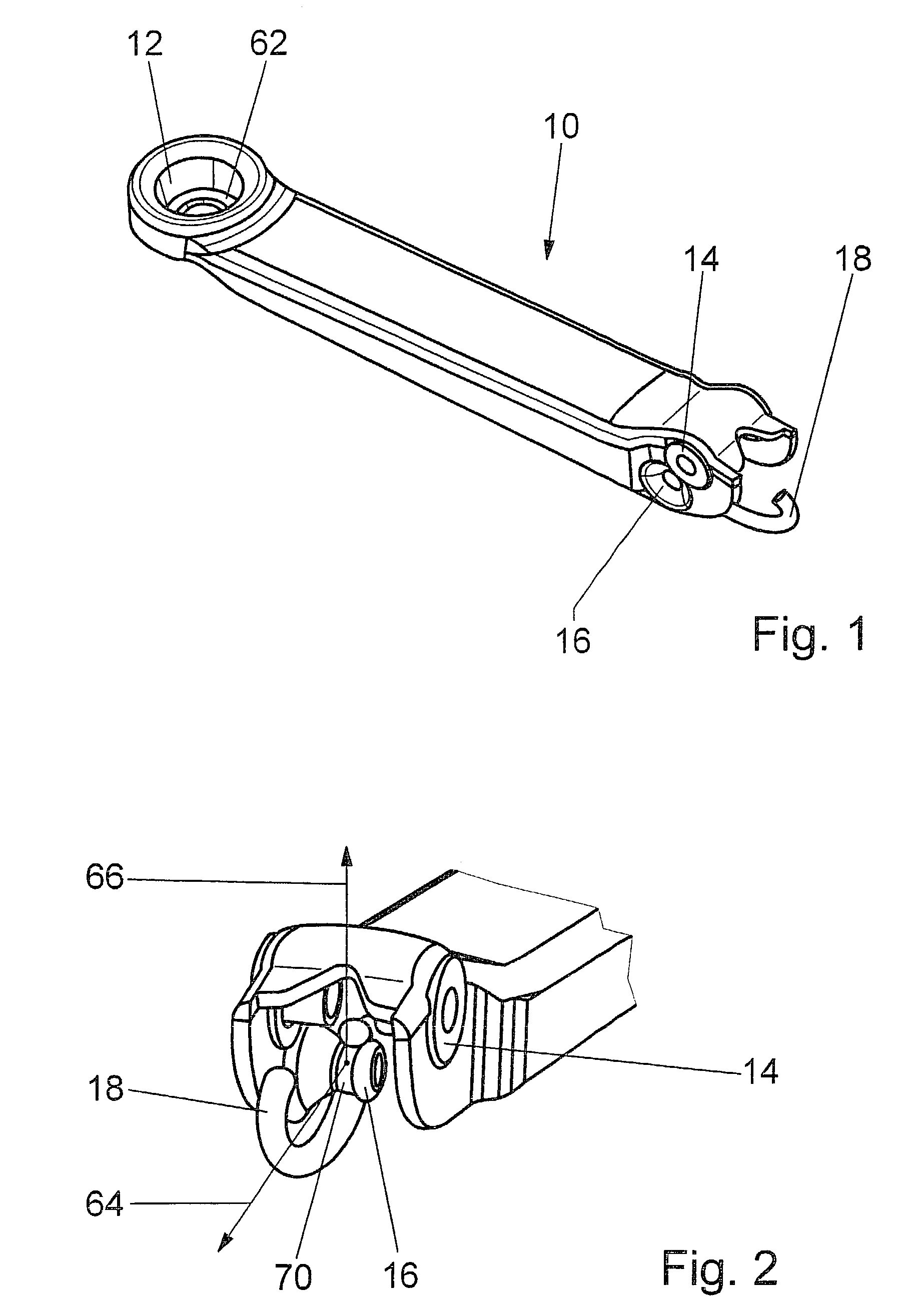

Fixing piece for a windscreen wiper

InactiveUS7036181B2Low costShorten the timeMetal-working apparatusWindow cleanersPunchingEngineering

A mounting part of a windshield wiper, having a receiving opening for a wiper shaft at one end, and forming a part of a fold-away hinge at the other end, and being formed from a flat sheet metal by deep-drawing, punching and bending and having a u-shaped cross-section profile and a spring mount. The spring mount is formed by deep-drawing from a sidewall of the u-shaped cross-section profile.

Owner:ROBERT BOSCH GMBH

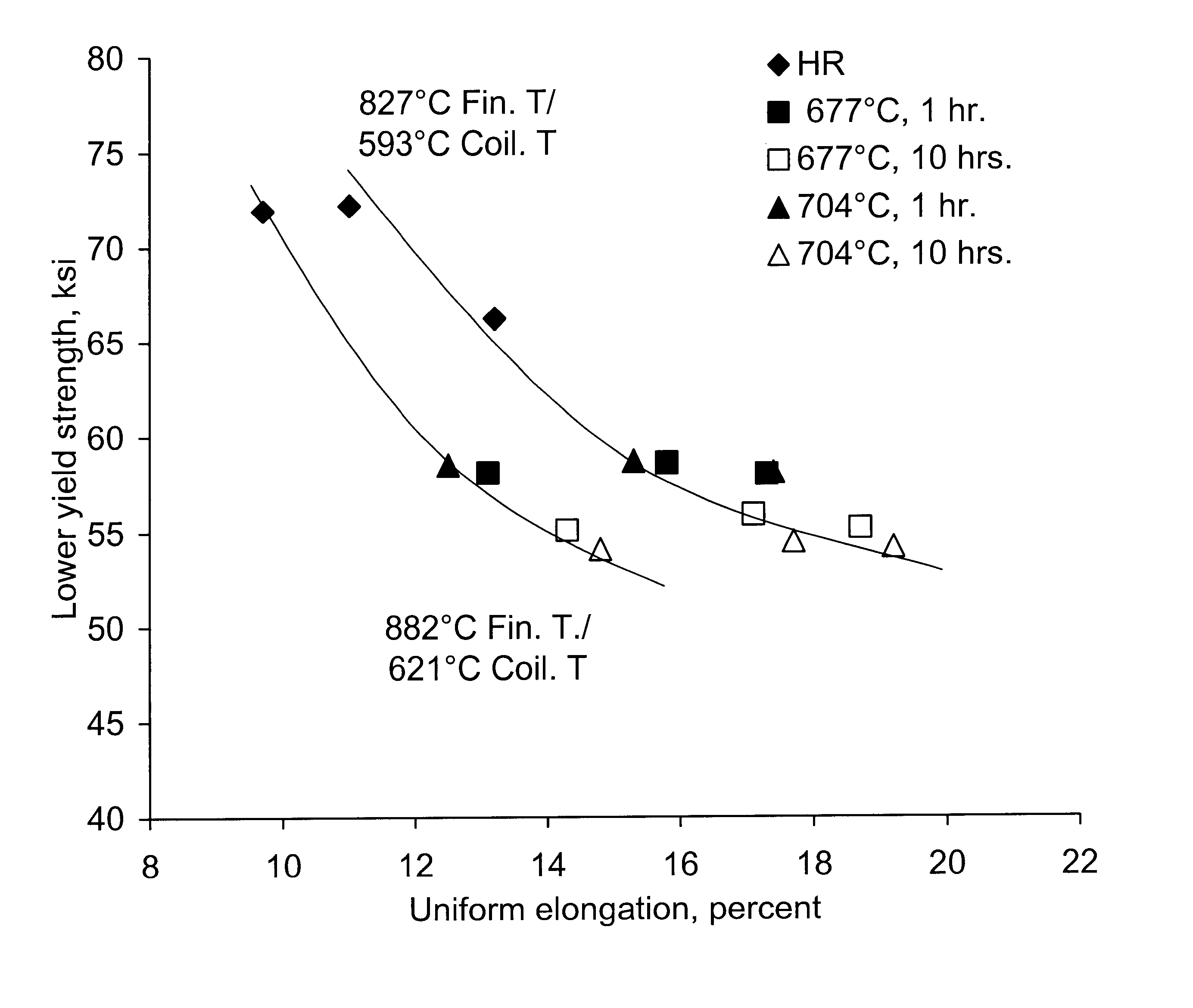

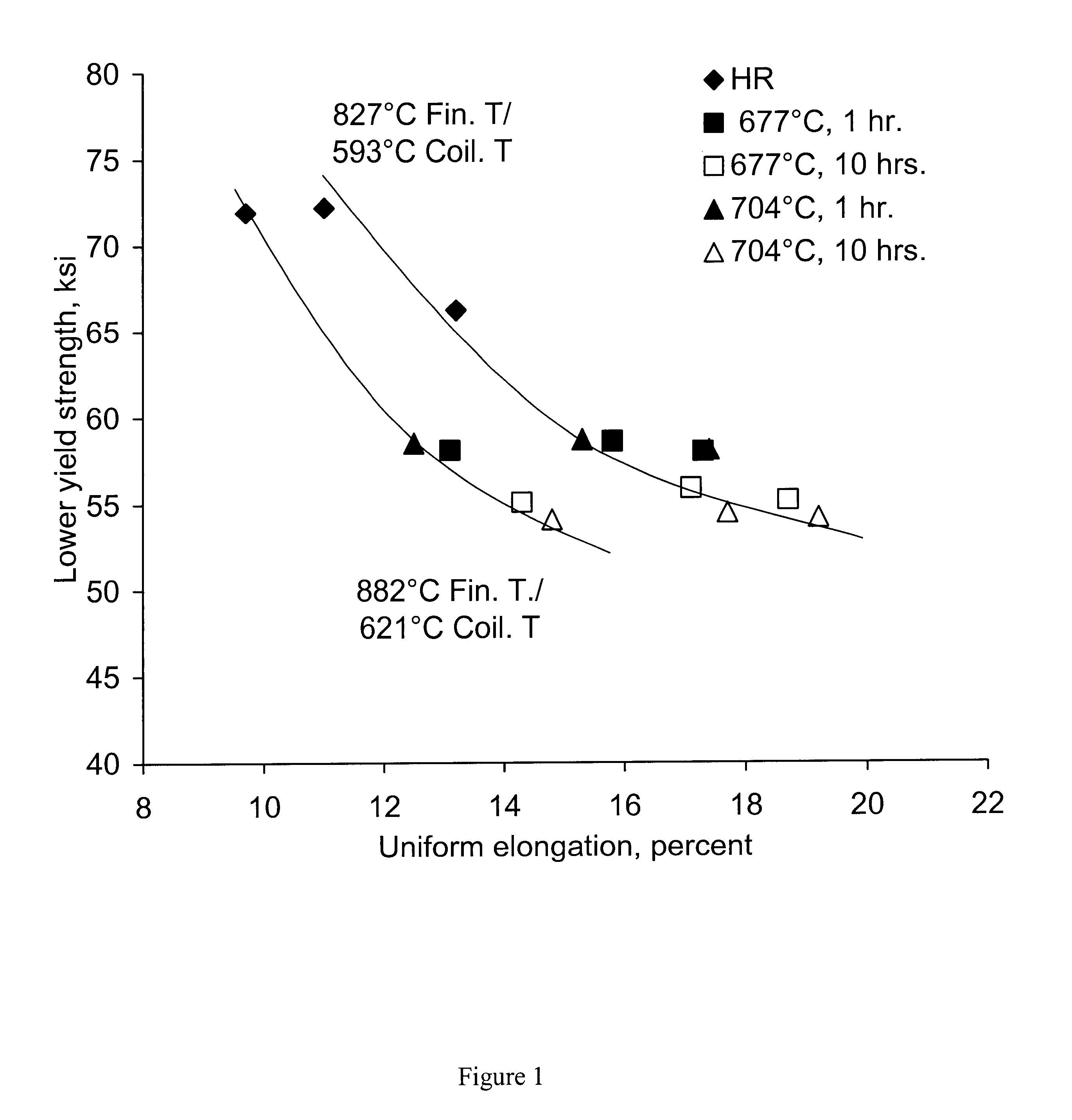

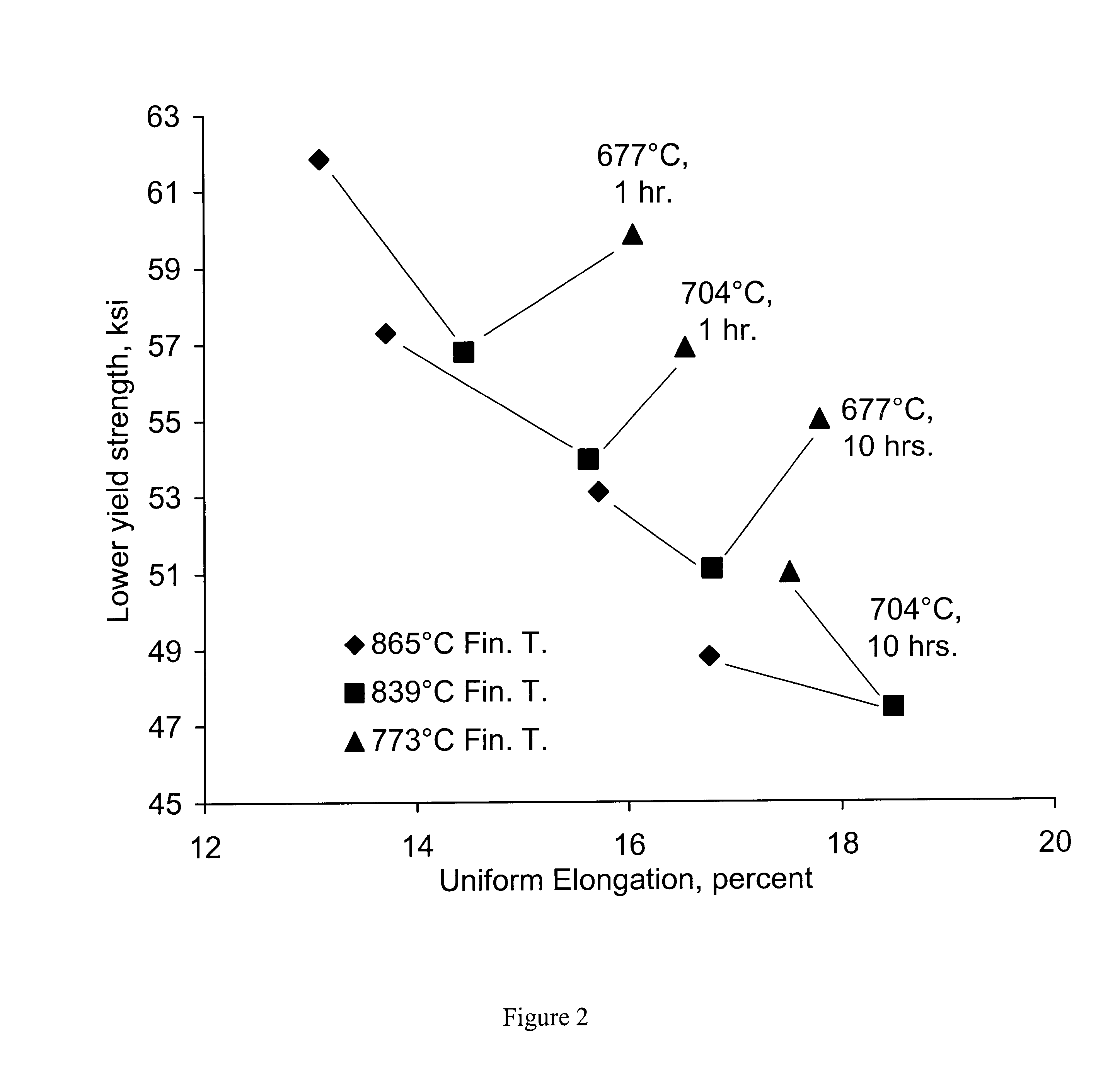

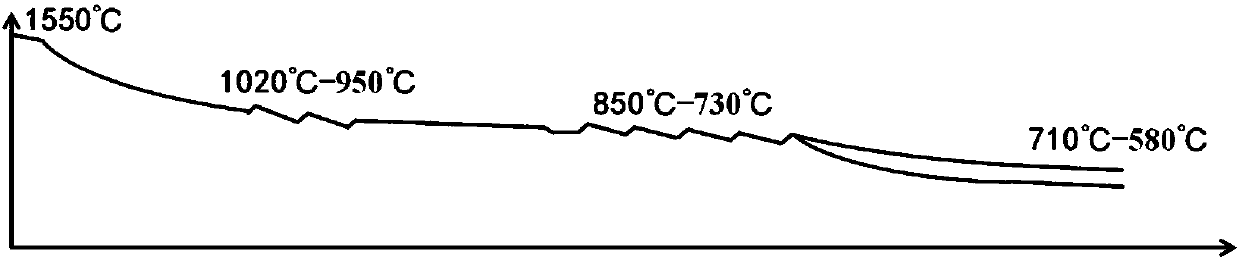

Medium carbon steel sheet and strip having enhanced uniform elongation and method for production thereof

A method is provided for producing medium carbon steel sheet and strip with enhanced uniform elongation for deep drawing applications. In one embodiment, a steel slab containing carbon 0.30 / 0.70%, manganese 0.75 / 2.0%, silicon up to 1.0% max., total aluminum 0.020 / 0.10%, the balance iron and incidental impurities is hot rolled to strip at a finishing temperature within the range of 839° C. (1542° F.) to 773° C. (1424° F.) and spheroidize annealed at a temperature below the A1 temperature. In a second embodiment, a steel slab containing 0.40 minimum / 0.70% maximum carbon, 0.50 / 1.50% manganese, up to 1.0% silicon, 0.020 / 0.10% total aluminum, the balance iron and incidental impurities is hot rolled, cold rolled and spheroidize annealed, with various combinations of manganese and silicon within the above ranges providing lower yield strength at levels of 60 ksi, 70 ksi, and 80 ksi with minimum 14% uniform elongation.

Owner:NITED STATES STEEL CORP

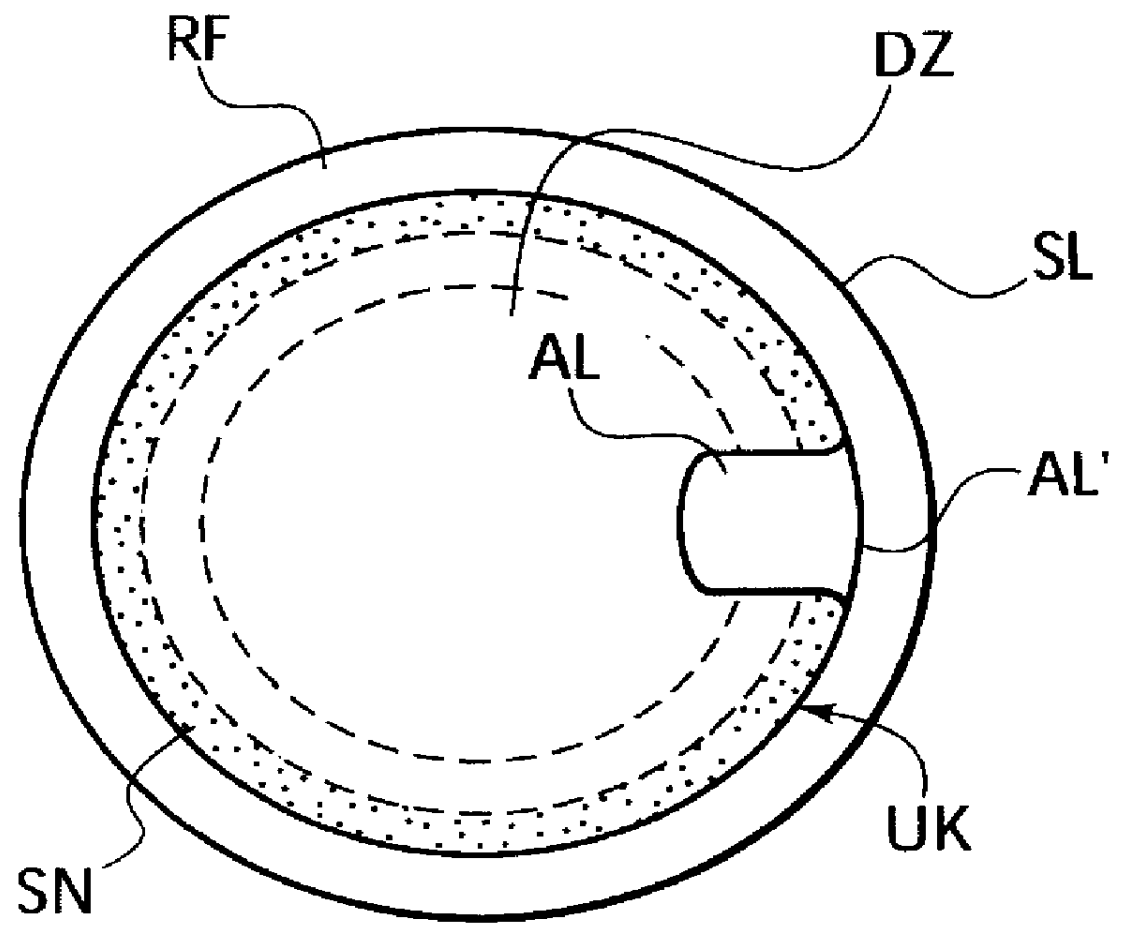

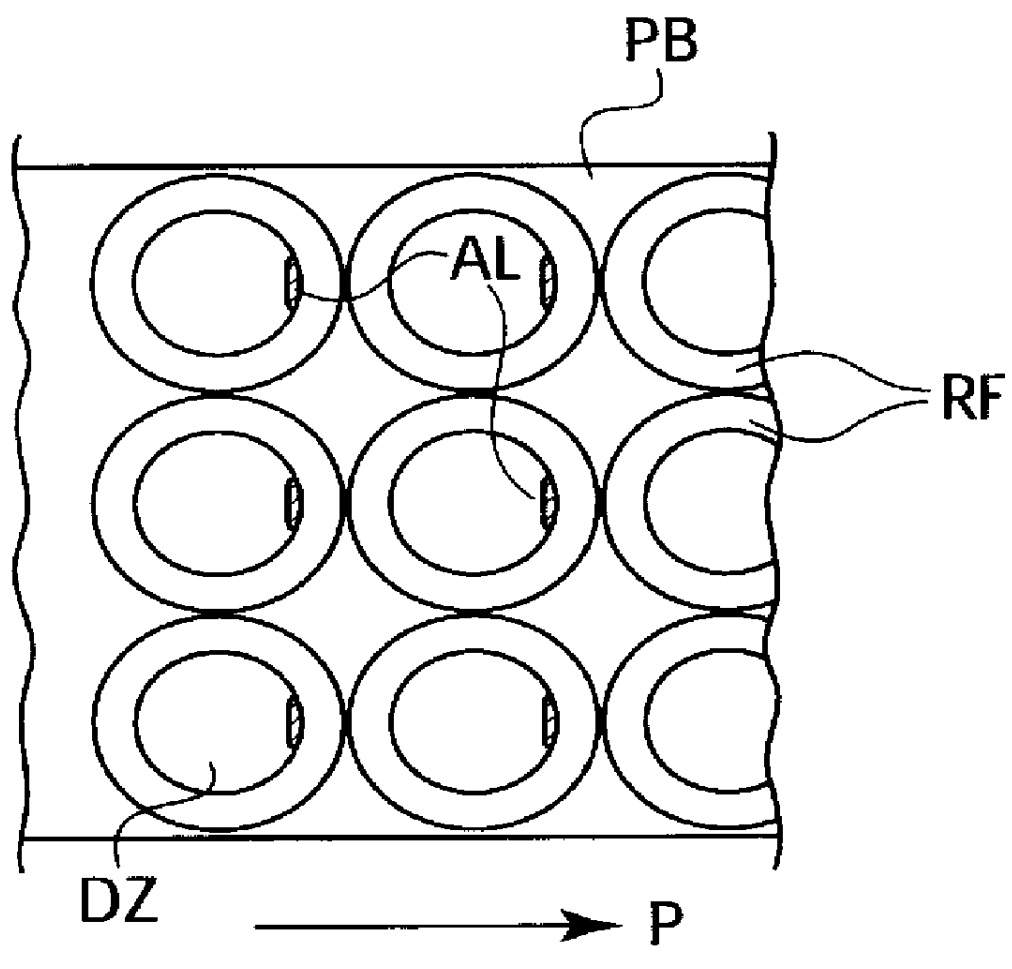

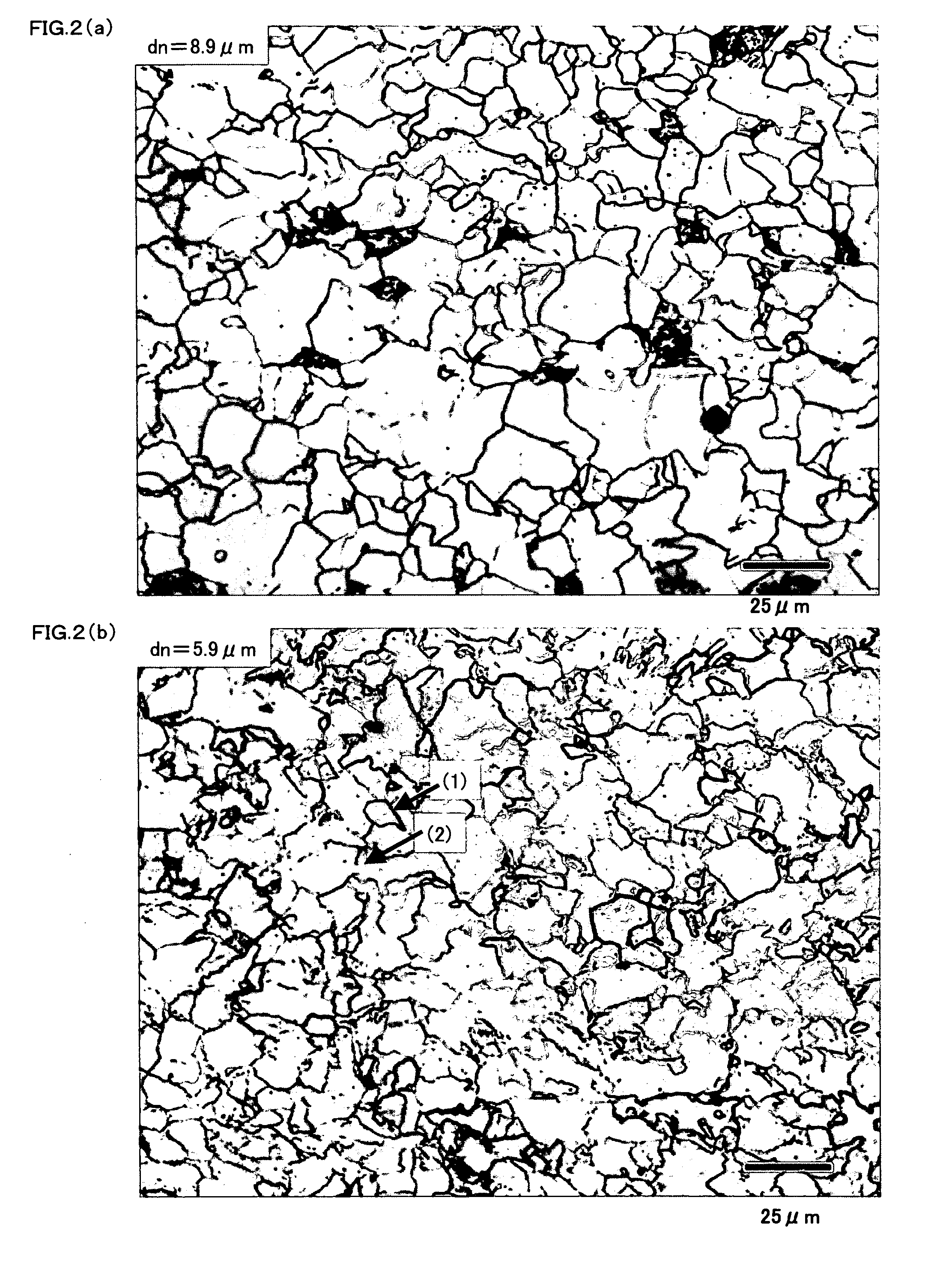

Hollow cathode magnetron sputtering targets and methods of forming hollow cathode magnetron sputtering targets

The invention includes methods of forming hollow cathode magnetron sputtering targets. A metallic material is processed to produce an average grain size of less than or equal to about 30 microns and subsequently subjected to deep drawing. The invention includes three-dimensional sputtering targets comprising materials containing at least one element selected from Cu, Ti, and Ta. The target has an average grain size of from about 0.2 microns to about 30 microns throughout the target and a grain size standard deviation of less than or equal to 15% (1-σ). The invention includes three-dimensional targets comprising Al, having an average grain size of from 0.2 microns to less than 150 micron, with a grain size standard deviation of less than or equal to 15% (1-σ).

Owner:HONEYWELL INT INC

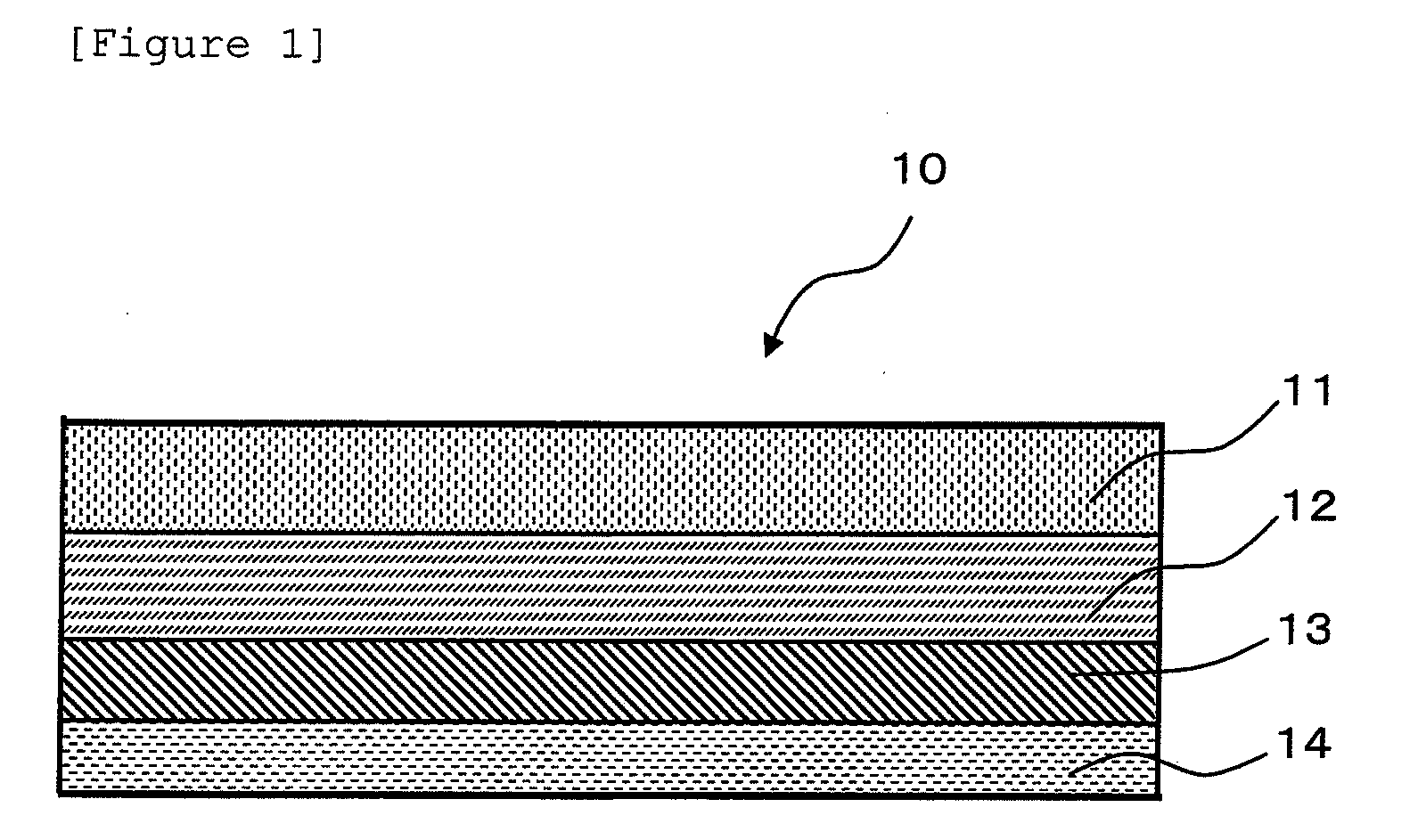

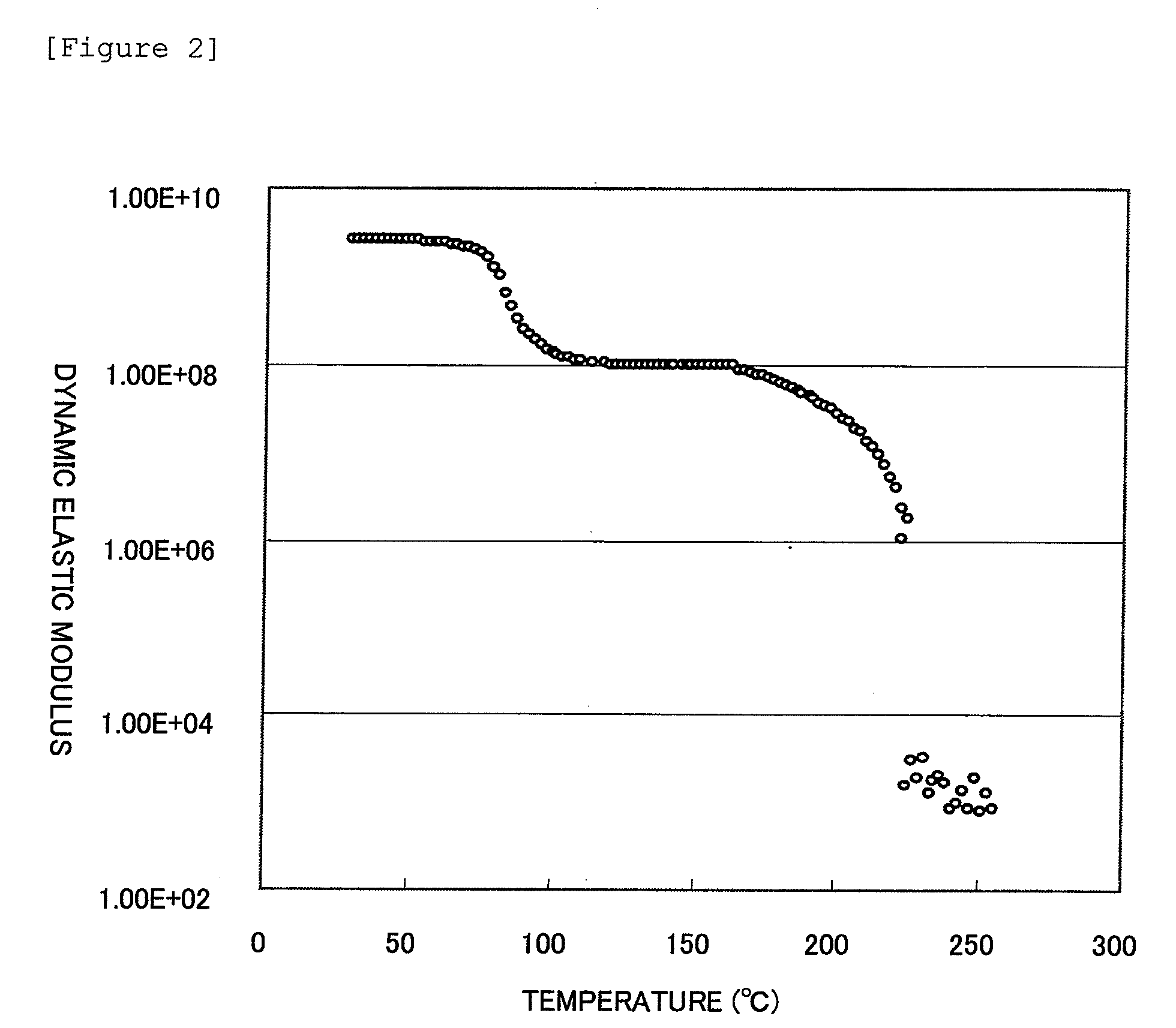

Decorative Sheet

InactiveUS20090286054A1Improve impact resistanceGood followabilityDecorative surface effectsOrnamental structuresPolyesterDynamic elastic modulus

Provided is a sheet for decoration which is excellent in an impact resistance in molding a surface form having a three-dimensional curved surface having a high deep-drawing degree and which has a good followability toward a molding surface of a metal die and is suited to decorated moldings. The above sheet for decoration comprises a peel layer, a picture layer and a heat adhesive resin layer which are laminated in order on the surface of a base film comprising a polyester film, wherein a dynamic elastic modulus of the above base film is 1.0×106 Pa or more at any temperature falling in a range of 190 to 240° C.

Owner:DAI NIPPON PRINTING CO LTD

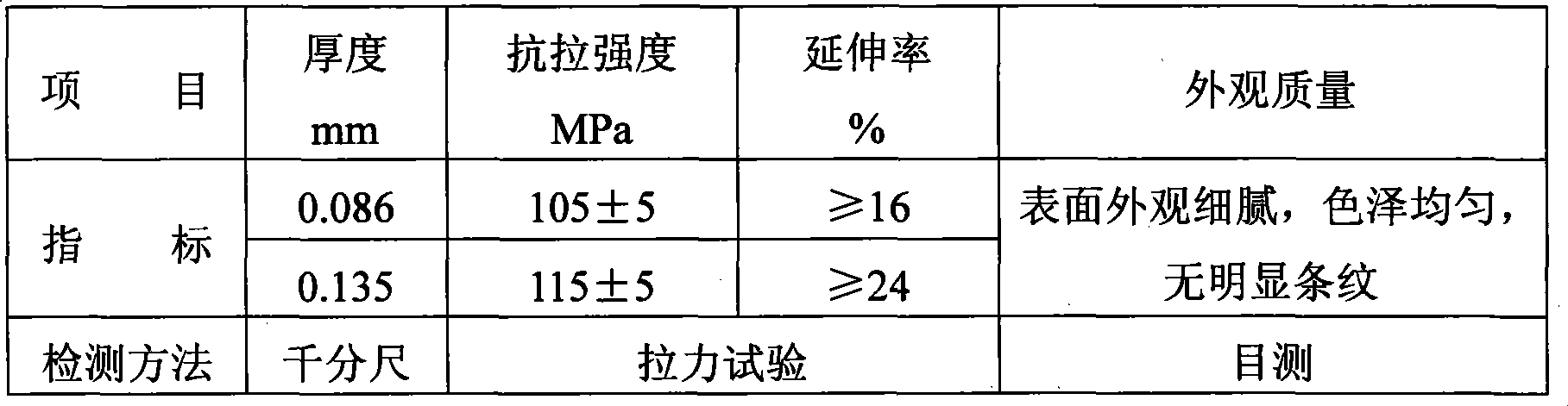

Aluminium alloy foil material for container and method for producing the same

ActiveCN101397622AReduce the influence of plasticityHigh elongationRoll mill control devicesMetal rolling arrangementsManganeseTitanium

The invention discloses an aluminum alloy foil used for containers, which is characterized in that: the components and the weight ratios are: 0.42 to 0.52 percent of iron, 0.05 to 0.20 percent of silicon, 0.04 to 0.13 percent of copper, 1.10 to 1.30 percent of manganese, 0.020-0.040 percent of titanium and the residual quantity of aluminum. The manufacturing method of the aluminum alloy foil used for containers comprises slab casting and rolling, pre-annealing, plank cold rolling, intermediate annealing, cold rolling, finished product annealing, greasing and cutting. Compared with the prior art, the aluminum alloy foil has the remarkable advantages: higher tensile strength and elongation; good deep-drawing performance, formability and stiff and smooth degree, beautiful appearance, uniform color and luster without defect, thus meeting the requirement of the users.

Owner:JIANGSU ALCHA ALUMINUM CO LTD

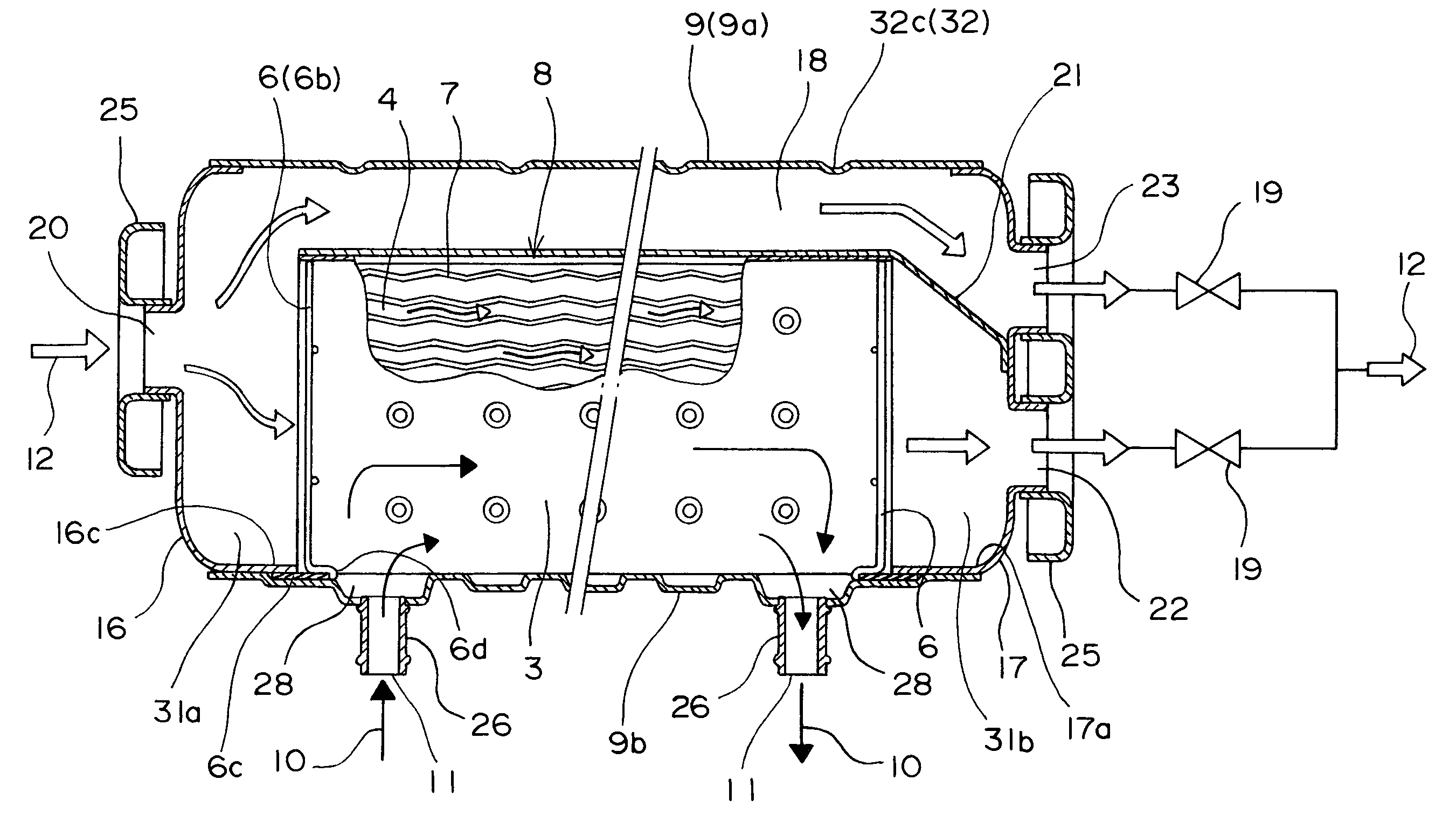

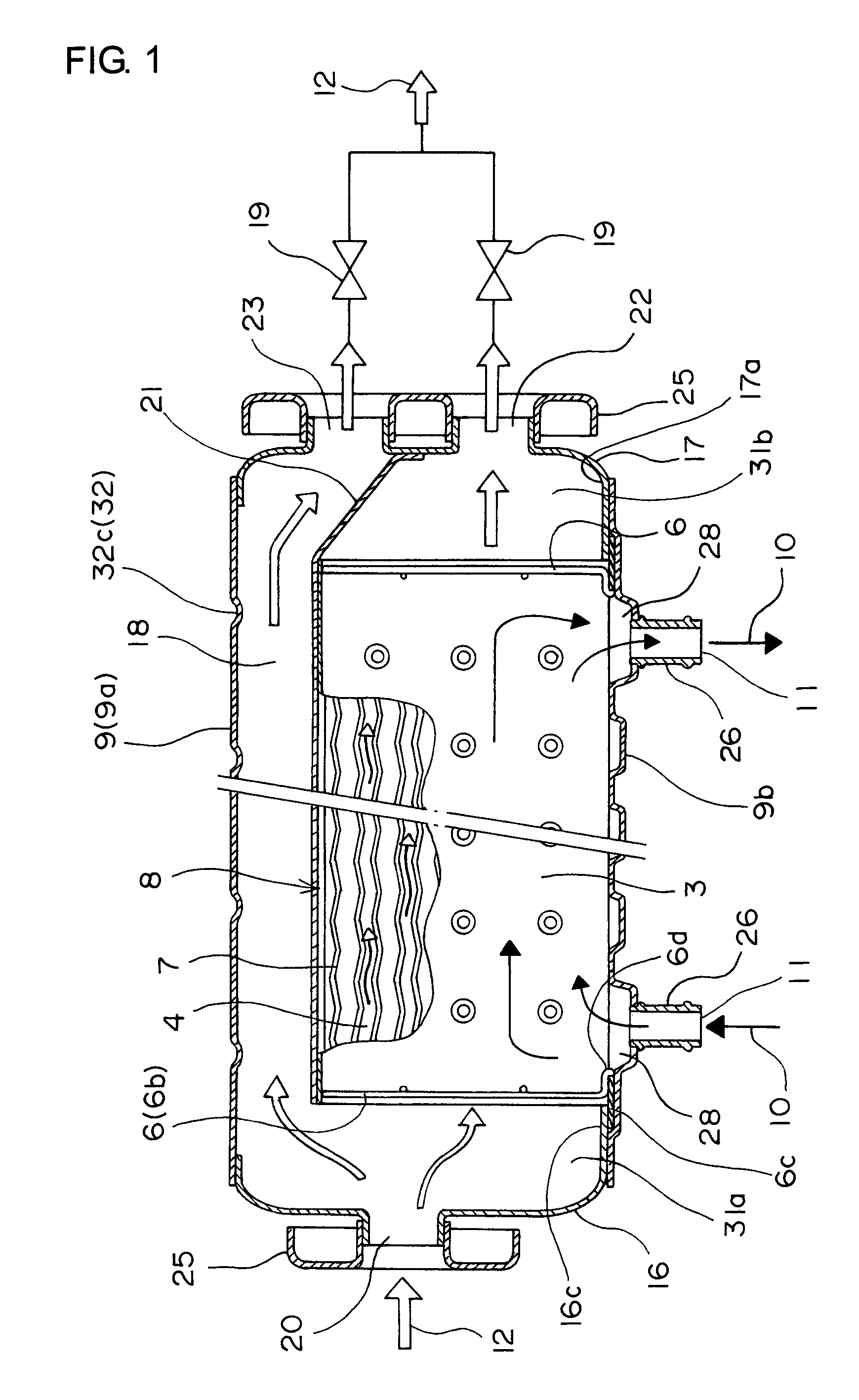

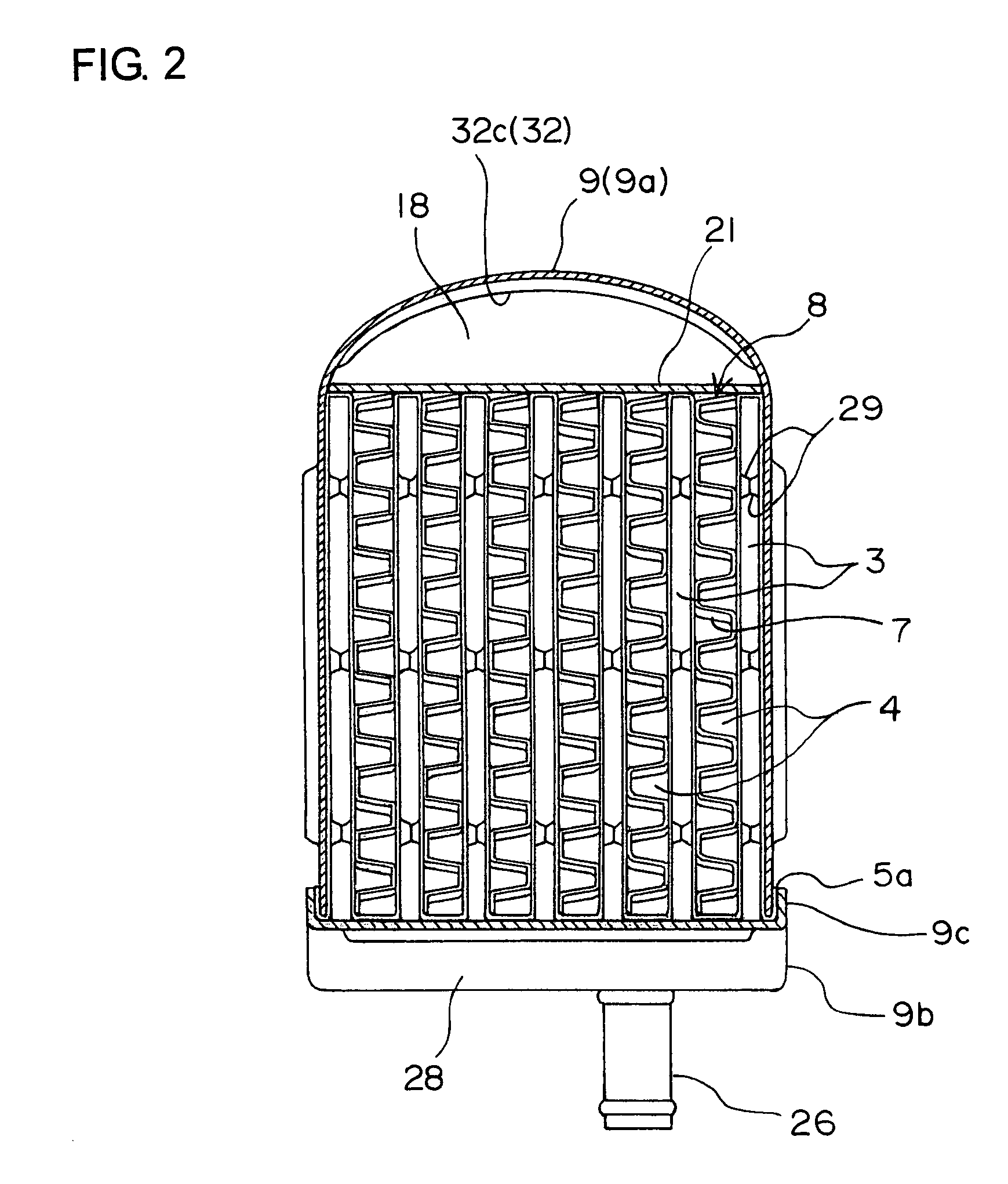

EGR cooler

InactiveUS7661415B2Improve performanceImprove air tightnessNon-fuel substance addition to fuelRecuperative heat exchangersThin metalEngineering

A bypass duct portion is provided in a casing of an EGR cooler so that heat distortion is absorbed, and the EGR cooler body and a valve case are brazed / fixed together so as to improve strength of the valve case, whereby, the bypass duct portion is formed between an inner surface of the casing and the core, a switch is provided for switching and guiding the exhaust gas to either of the core or the bypass duct portion, and a number of outer ribs formed in the circumferential direction respectively are arranged side by side while being separated from each other in the longitudinal direction in the bypass duct portion of the casing to form a heat stress absorbing portion. Also provided is a cylindrical valve case that is integrally formed by deep drawing of a thin metal plate by a press machine, a pair of slits are provided at the rear end of the valve case, both edges of an intra-valve partition plate are inserted into the slits, support projection portions are provided on both faces of the both edge portions of the intra-valve partition plate, and the edge of the slit is supported by the support projection portion. An opening of the valve case is integrally brazed / fixed to an opening of a header portion of the casing.

Owner:T RAD CO LTD

Thermoplastic resin coated aluminum alloy sheet, and method and apparatus for production thereof

InactiveUS6238783B1Cost advantageIncrease speedLiquid surface applicatorsChromatisationShell moldingAlloy

A thermoplastic resin coated aluminum alloy sheet has excellent processing adhesion and high adhesion after retort processing such that laminated thermoplastic resin layers do not peel off even when the alloy sheet is subjected to severe processing such as stretching after deep drawing and furthermore, ironing. A production method and a production apparatus for the alloy sheet are also described. A treatment by an alkaline solution and a treatment by an acidic solution are sequentially applied to bring the surface of an aluminum alloy sheet into a specific surface state and then electrolytic chromic acid treatment is carried out by a known method so as to laminate a thermoplastic resin to an aluminum alloy sheet having a two-layered film which comprises metallic chromium as the lower layer and a chromium hydrate as the upper layer and has a specific surface condition. As a result, a thermoplastic resin coated aluminum alloy sheet having excellent processing adhesion capable of withstanding molding and processing can be obtained.

Owner:TOYO KOHAN CO LTD

Hot roller rolling method for stainless steel/aluminium composite plate

InactiveCN1586751AImprove deep drawing performanceHigh yieldWork treatment devicesAuxillary arrangementsSolution treatmentHeating furnace

The hot roller rolling process of composite stainless steel / aluminum plate includes the main steps of: physical and chemical surface treatment of stainless steel plate and aluminum plate including alkali solution treatment, cold water and hot water flushing, soaking with nitric acid solution, cold water flushing, ultrasonic defatting of stainless steel plate in metal washing agent and cold water flushing and stoving; laminating stoved stainless steel plate and aluminum plate and heating at 250-500 deg.c; composite rolling in rolling mill with roller preheated to 100-400 deg.c; and final diffusion annealing of the composite plate. The present invention has the main advantages of less deformation in total reduction degree of 10-35 %, obviously raised interface combining strength, high qualified product rate and very high deep drawing performance.

Owner:NORTHEASTERN UNIV

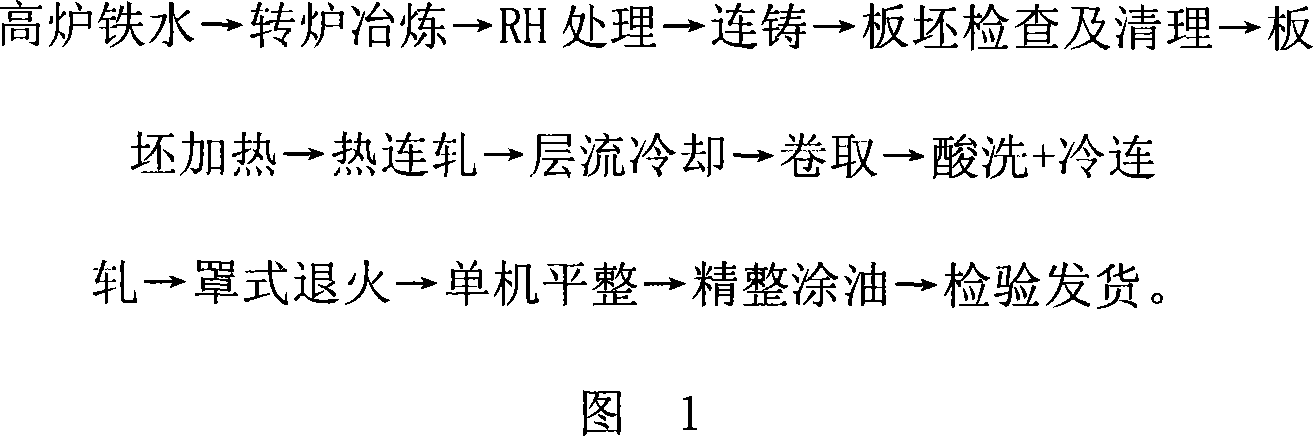

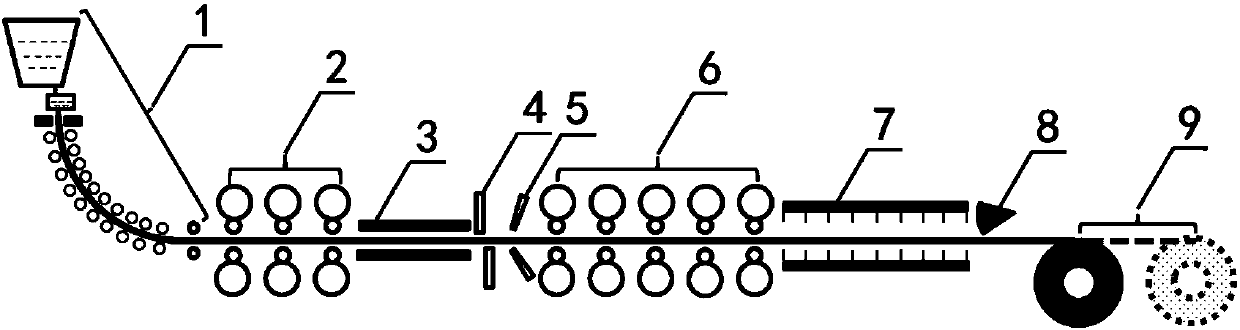

Headless continuous casting and rolling ferrite rolling method and device of low/micro-carbon steel coil for deep drawing

PendingCN107597844AReduce aging phenomenonPromote formationTemperature control deviceWork treatment devicesTemperature controlHigh pressure water

The invention discloses a headless continuous casting and rolling ferrite rolling method and device of a low / micro-carbon steel coil for deep drawing and belongs to the field of metallurgy steel rolling. According to the headless continuous casting and rolling ferrite rolling method and device of the low / micro-carbon steel coil for deep drawing, continuous casting for blank forming, rough rollingof a rough rolling unit, temperature control of a cooling channel, descaling of high-pressure water, ferrite rolling of a finishing mill group, cooling of a layer cooling device, high-speed flying shear and shunt winding and coiling of a reeling machine are carried out. By means of the method and device, the problems that heating / soaking of a heating furnace is needed before rough rolling of a conventional hot rolling process, and cooling with temperature retaining is needed due to the fact that the temperature difference of rough rolling of an austenite zone and finish rolling of a ferrite zone is large and the problems that for thin slab casting and rolling processes with CSP as a respective, heating / soaking or induction heating for temperature supplementing of a heating furnace is needed are solved, the advantages that the arrangement is compact, the investment is small, the production efficiency is high, safety and reliability are achieved, energy is saved, environmental friendliness is achieved, and the cost is reduced are achieved, and the low-carbon / micro-carbon steel coil for deep drawing is produced through headless continuous casting and rolling and ferrite rolling.

Owner:UNIV OF SCI & TECH BEIJING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com