Method for precision forming of concave-bottom and thin-wall cylindrical part with large length and diameter ratio

A technology with high slenderness ratio and precision forming, applied in the field of precision forming of parts, which can solve the problems of low forming precision, high forming precision and limited forming limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

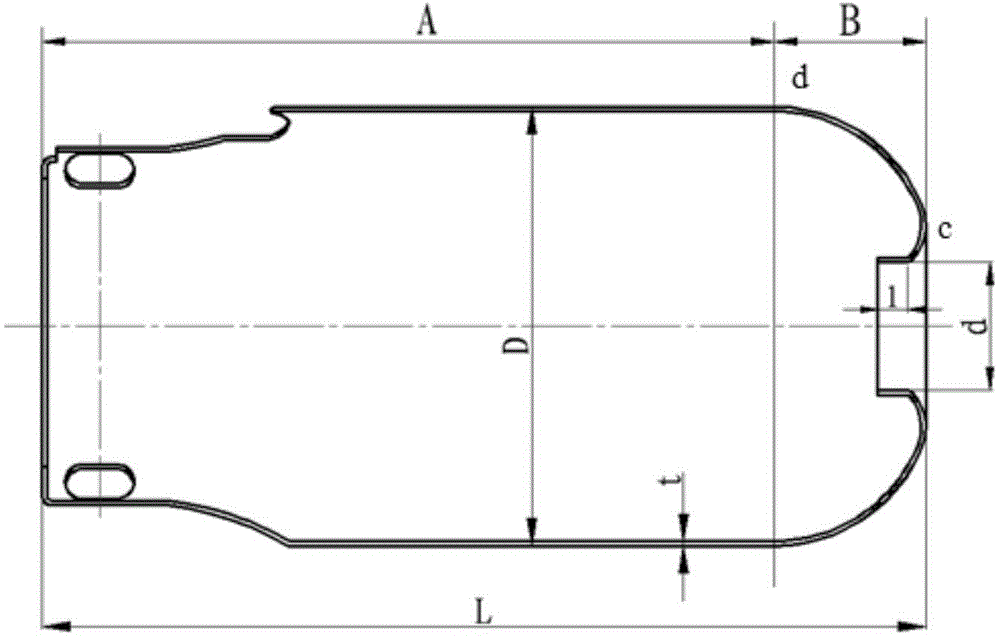

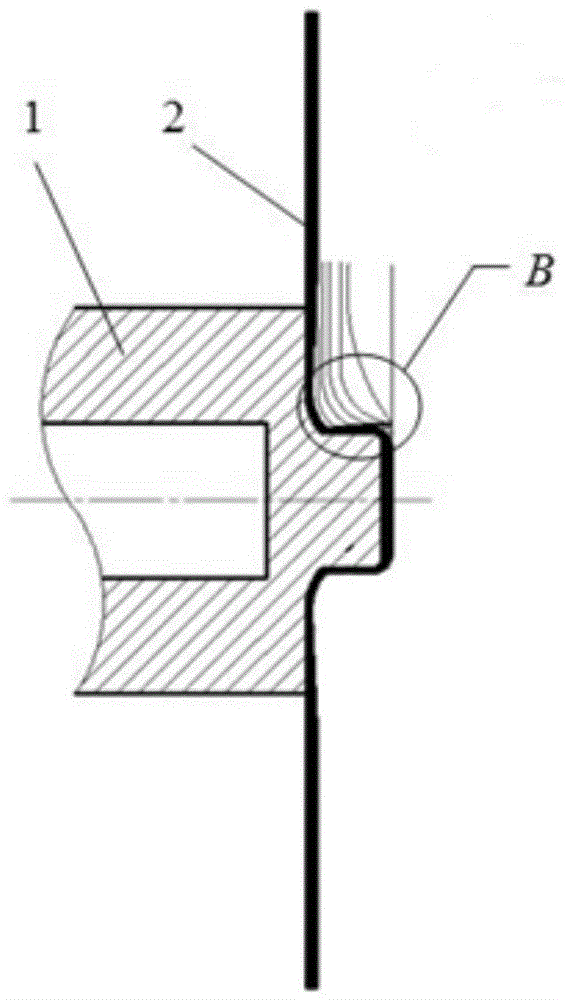

[0071] A high-voltage electrical switch shield, made of 1060 aluminum, shaped like figure 1 As shown, the straight section ( figure 1 Part A) Diameter D=190±1mm, length L=400mm, concave bottom diameter d=56±0.5mm, wall thickness t=2mm, this part is used to shield the external magnetic field and electric field to ensure stable operation of high-voltage electrical switches. The specific steps of spinning forming are as follows:

[0072] 1. Blank calculation: The wall thickness of the part is 2mm. Considering that the wall thickness will be reduced to a certain extent during the processing, the blank thickness should be greater than 2mm. The 1060 aluminum plates currently available on the market mainly have 3mm and 4mm specifications.

[0073] According to the principle of constant volume, the diameters of the blanks when using 3mm and 4mm slabs are 450mm and 405mm respectively, and the spinning coefficients when using 3mm slabs are 0.418 respectively. 0.45 (i.e. 192 / 405 = 0.464) sa...

Embodiment 2

[0082] A high-voltage electrical switch shield, made of aluminum alloy and shaped like figure 1 As shown, the straight section ( figure 1 Part A) diameter D=240±1mm, length L=300mm, concave bottom diameter d=53±0.5mm, length l=12mm, the overall wall thickness of the part is t=2mm, the specific steps are as follows:

[0083] 1. Billet calculation: According to the principle of constant volume, the diameter of the billet when using 3mm slab is 500mm, and the spinning coefficient is 0.48> 0.45, the thinning rate during powerful spinning is 33%> 10% (1mm / 3mm=33%), which satisfies the principle of deformation distribution.

[0084] 2. Concave bottom spinning forming:

[0085] The forming method is the same as in Example 1. A spinning core mold with the same contour as the concave bottom is designed and installed on the spindle of the machine tool. The specification is The aluminum slab is fixed between the core mold and the tail top with a diameter of 53mm. According to the preparation...

Embodiment 3

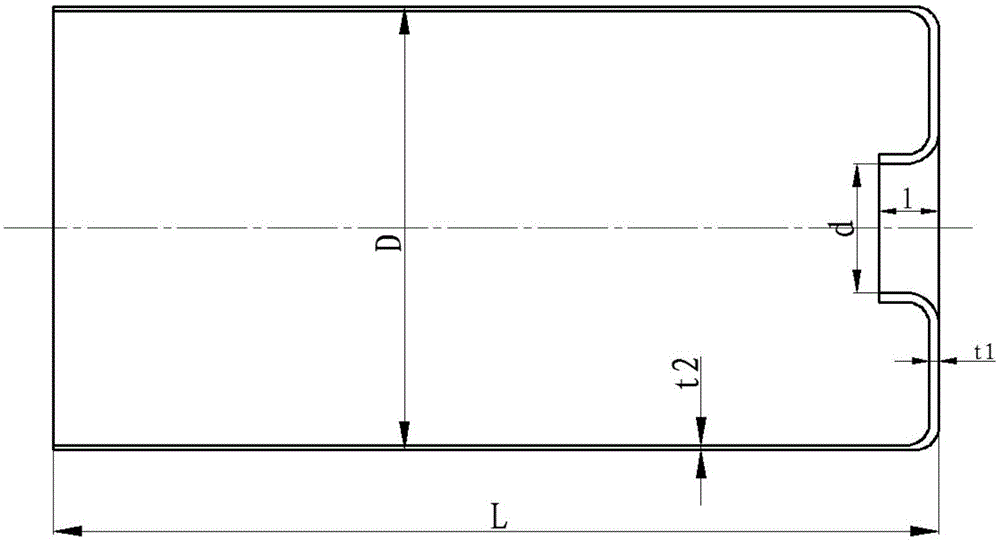

[0092] A high-voltage electrical switch shield, made of aluminum alloy and shaped like figure 2 As shown, the diameter of the straight cylinder is D=250±1mm, the length L=400mm, the wall thickness t1=2mm, the concave bottom diameter d=60±0.5mm, the length l=20mm, and the wall thickness t2=4mm, the specific steps are as follows:

[0093] 1. Billet calculation: According to the principle of constant volume, the diameter of the billet when using 4mm slab is 512mm, and the spinning coefficient is 0.49> 0.45, the thinning rate when strong spinning is 50%> 15% (2mm / 4mm=50%), which satisfies the principle of deformation distribution.

[0094] 2. Concave bottom spinning forming:

[0095] Design a spinning mandrel with the same contour as the concave bottom, install it on the spindle of the machine tool, and set the specification as The aluminum slab is fixed between the core mold and the tail top with a diameter of 60mm. According to the preparation method of the general rotation trajector...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com