Patents

Literature

35results about How to "Meet high-precision measurement requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

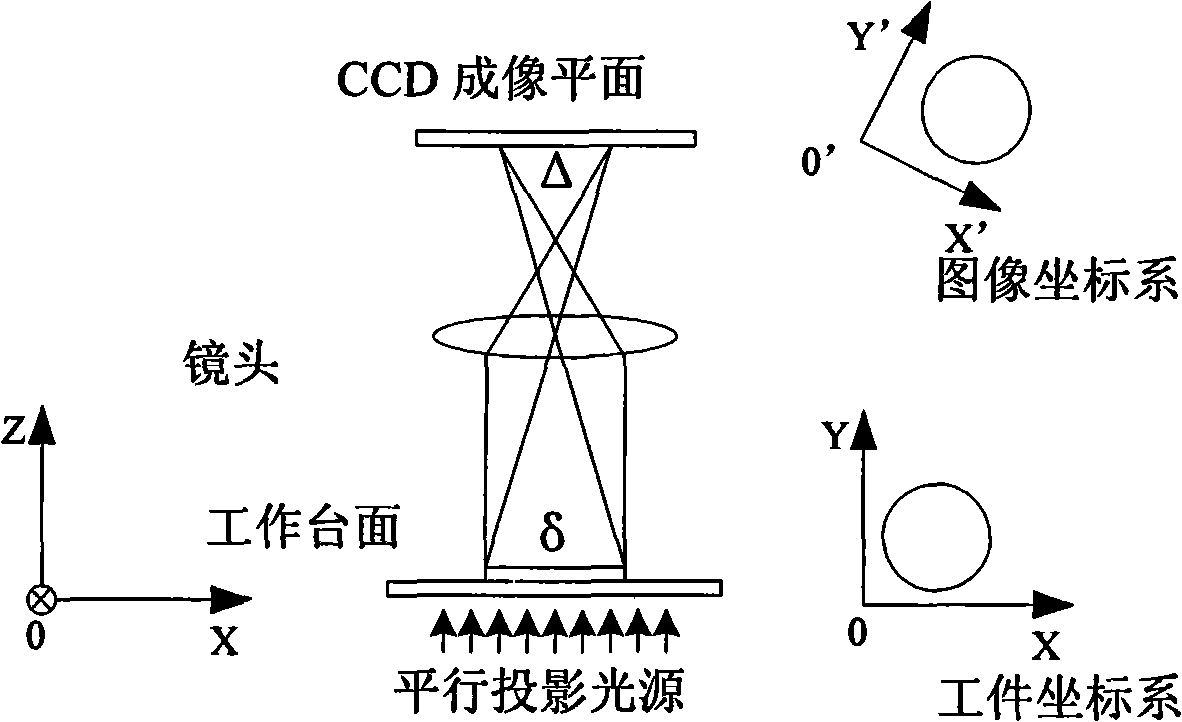

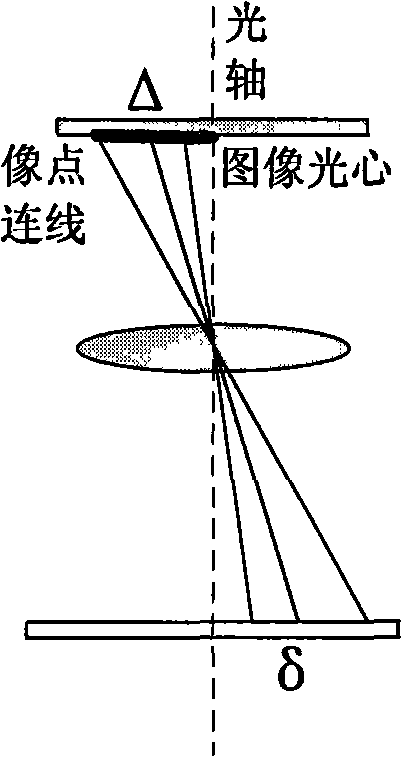

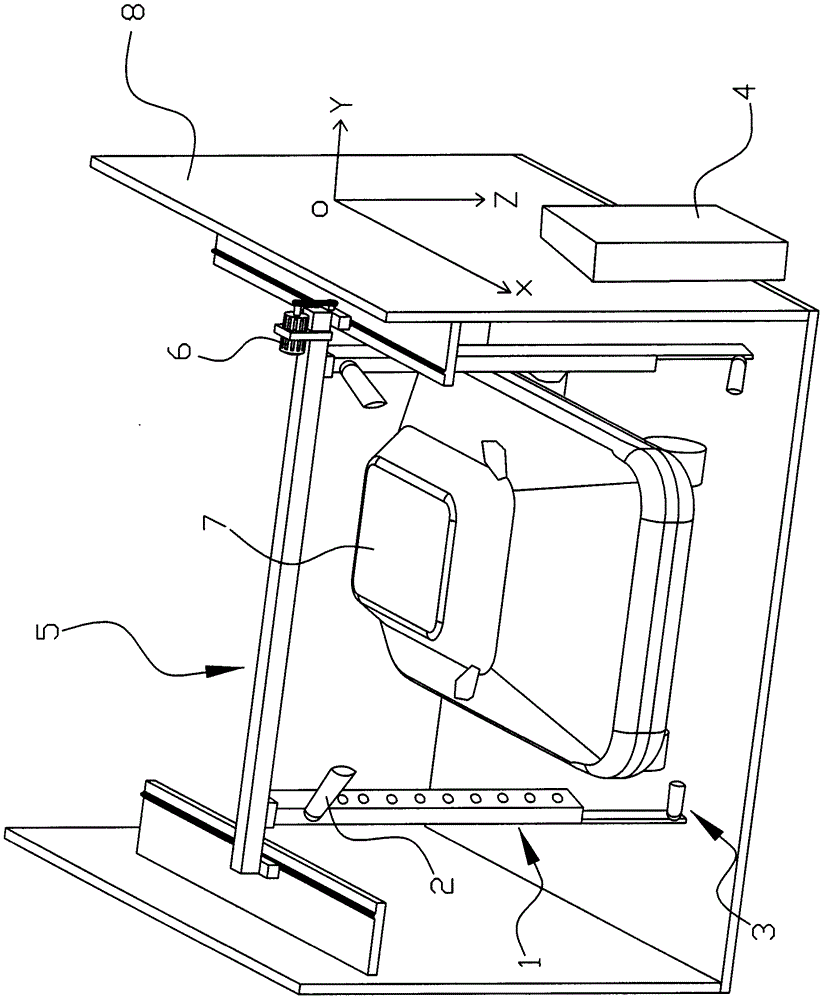

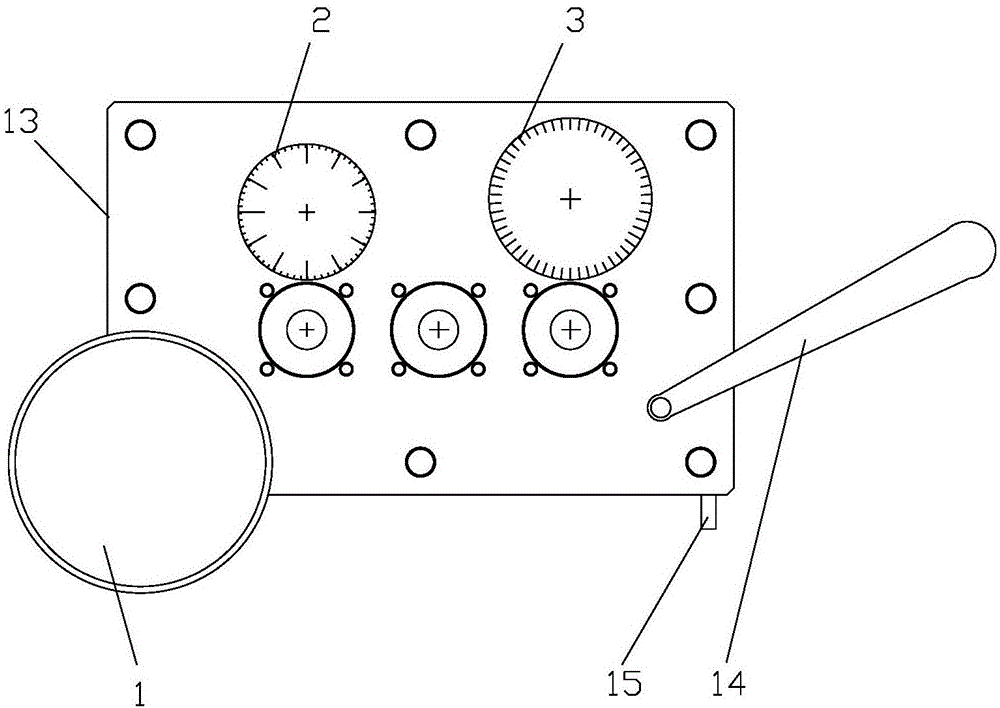

Digital image feeler vector coordinate transform calibration and error correction method and its device

InactiveCN101334267AAccurate measurementMeet high-precision measurement requirementsUsing optical meansObservational errorOperability

The invention discloses a method for the calibration of vectorial coordinate transformation and the modification of errors of a digital image probe, and a device thereof; the noncontact optical measurement principle is adopted to realize the precise calibration and accurate modification of errors of the image probe in high-accurate two-dimensional measurement and ensure an accurate measurement result. The method of calibration is realized completely on the basis of the measuring principle of the image probe, without the existence of the errors of calibration principle. The process of calibration is based on the self-calibration principle, a virtual calibration point is formed by fixing a target object and moving the probe, then the calibration operation is fulfilled by constructing a vector, therefore, the operability of equipment is improved; by calculating the position of the image optical centre of an probe image sensor to be taken as the calibration origin, a new measurement error caused by the offset of a coordinate system is avoided to be introduced after the multiplying power of the probe is adjusted, the requirements of measurement in different application situations are ensured, and as the probe self-calibration technology is adopted, the calibration of the probe is ensured to have very high accuracy; the error self-modification is realized by moving a precise three-dimensional moving mechanical device to extract error meshes.

Owner:XI AN JIAOTONG UNIV

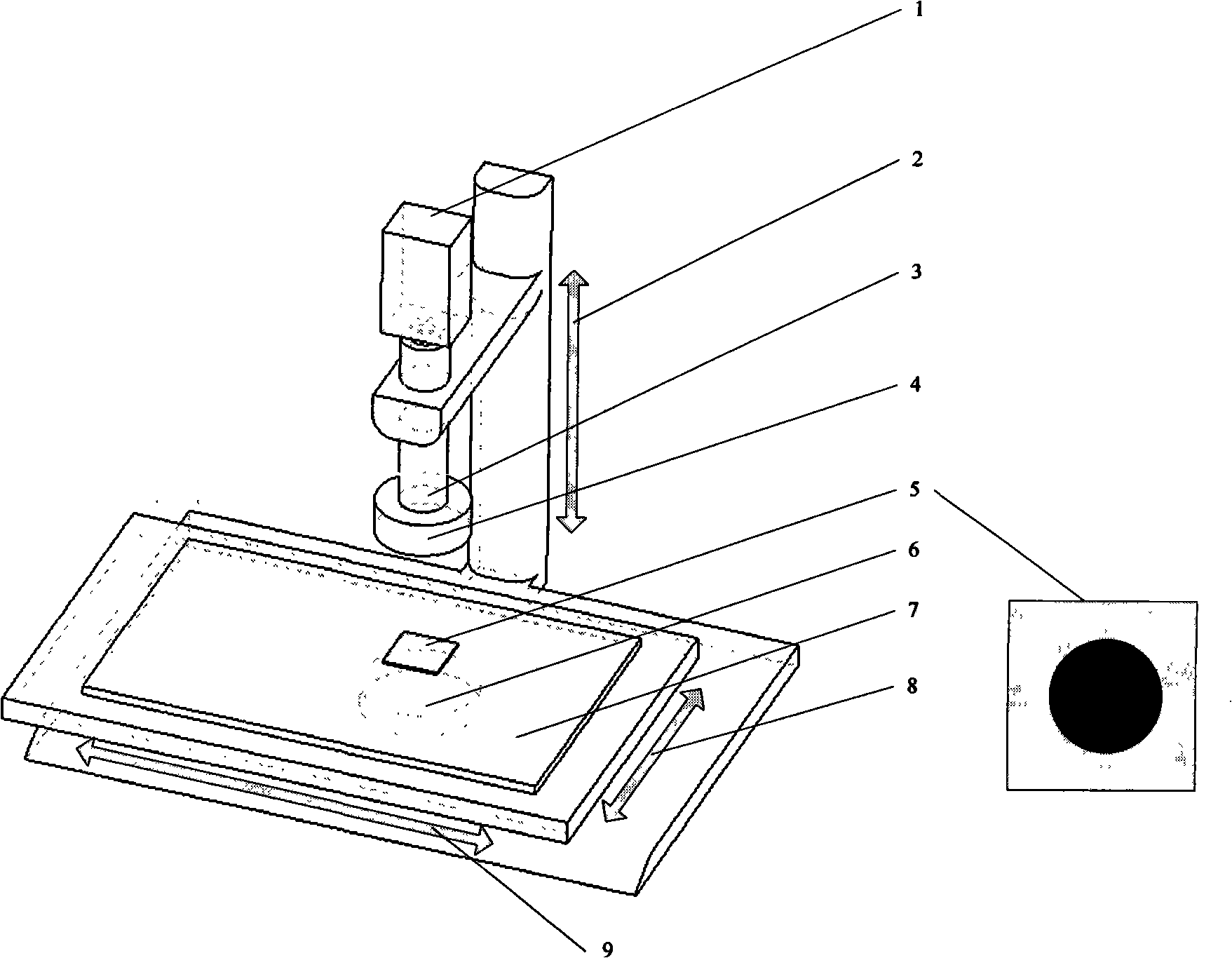

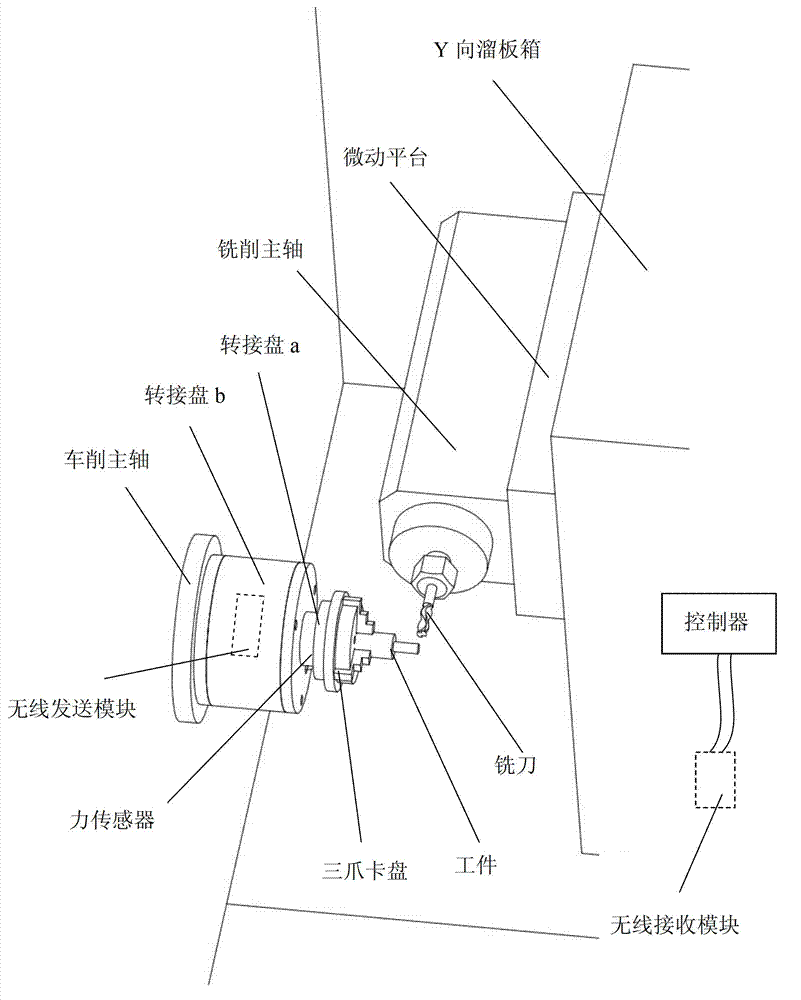

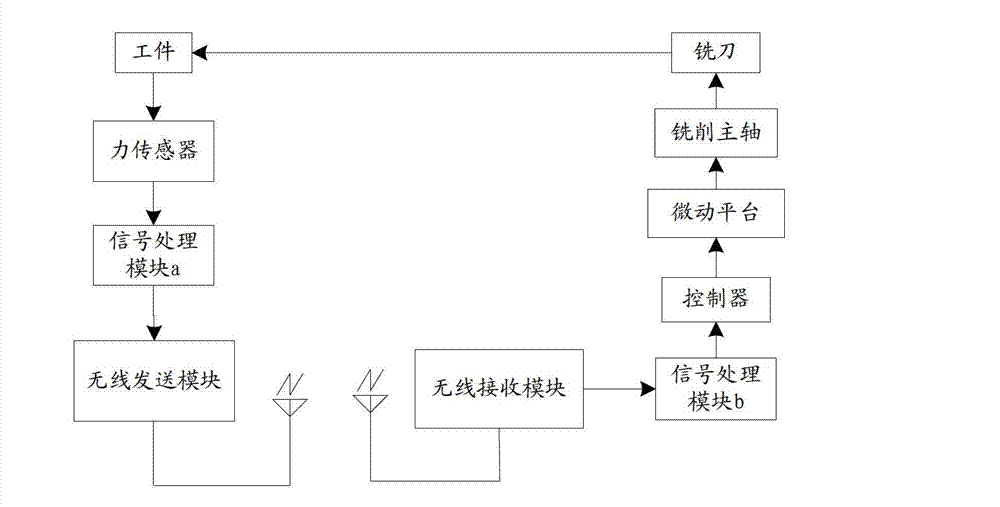

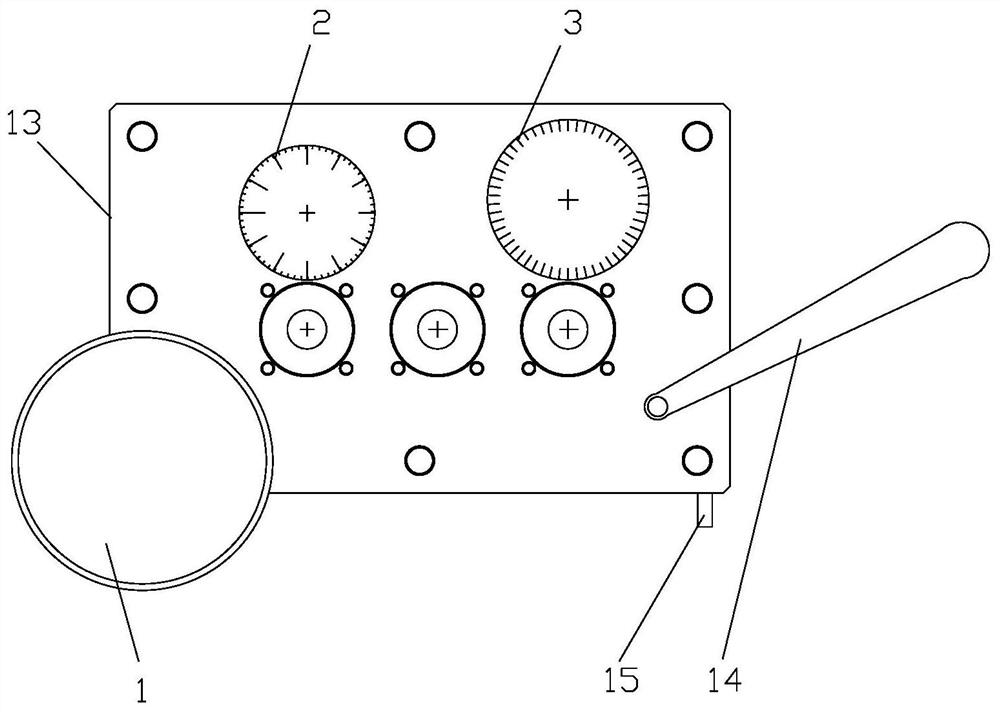

Microminiature machining cutting force real-time wireless detection and control system

ActiveCN102785127AEasy to detectEasy to controlAutomatic control devicesMeasurement/indication equipmentsWireless transmissionMilling cutter

The invention provides a microminiature machining cutting force real-time wireless detection and control system. A force sensor of the system collects an mN-level cutting force applied on a work-piece, and converts the force signal to an electric signal to be outputted to a signal processing module a and to be outputted to a signal processing module b through a wireless transmission module and a wireless receiving module, a controller converts the received electric signal to the cutting force and compares the cutting force with a standard cutting force so as to generate a control order to be outputted to a micro-motion platform, the micro-motion platform adjusts micro displacement of a milling main shaft respectively in an x-axis direction, a y-axis direction and a z-axis direction according to the control order, and further controls a milling cutter to realize the adjustment of the micro displacement, so that the real-time adjustment of cutting parameters can be realized, and the real-time control on the cutting force can be realized. The cutting force is detected through a six-dimensional force sensor and is transmitted to the controller through the wireless module, and further different cutting parameters are controlled, so that the real-time detection and control of the cutting force are realized, and thereby the machining precision and the surface quality of a precise and micro complicated structural member can be improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

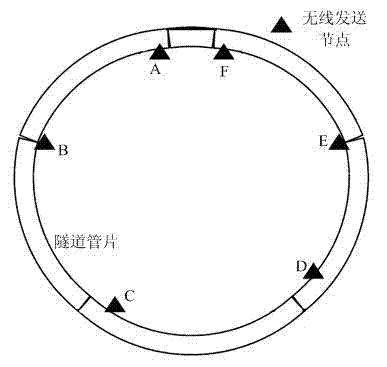

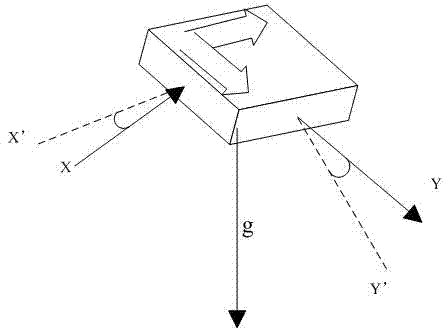

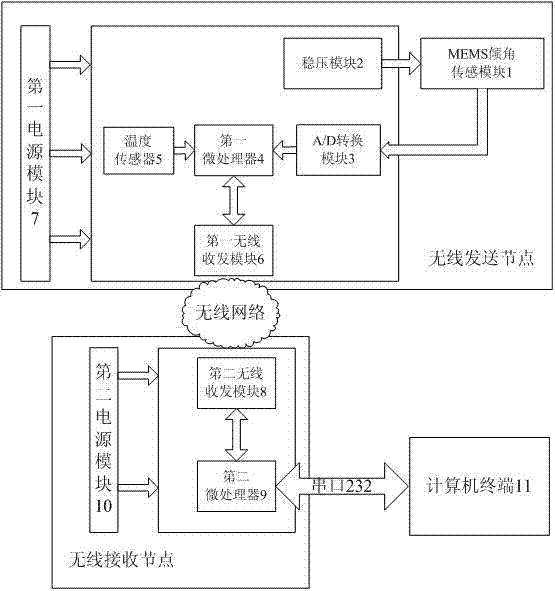

Wireless inclination angle measurement system applied to underground tunnel detection

InactiveCN103035109AMeet high-precision measurement requirementsEffective real-time monitoringTransmission systemsIncline measurementInterference resistanceUnderground tunnel

The invention belongs to the field of underground tunnel environments, and in particular relates to a wireless inclination angle measurement system applied to underground tunnel detection. The wireless inclination angle measurement system comprises at least one wireless sending node and a wireless receiving node, wherein the wireless sending node consists of a micro-electromechanical system (MEMS) inclination angle sensing module, a pressure stabilizing module, an analog-to-digital (A / D) conversion module, a first micro processor, a temperature sensor, a first wireless transmitting and receiving module and a first power module; the wireless receiving node consists of a second wireless transmitting and receiving module, a second micro processor and a second power module; and the first wireless transmitting and receiving module is connected with the second wireless transmitting and receiving module through a wireless network. The wireless inclination angle measurement system can meet a measurement requirement on high precision by performing temperature compensation, filtration and interference resistance on inclination angle information in the wireless inclination angle measurement system; and tunnel structure change can be monitored accurately and effectively in real time by data transmission by the wireless network.

Owner:TONGJI UNIV

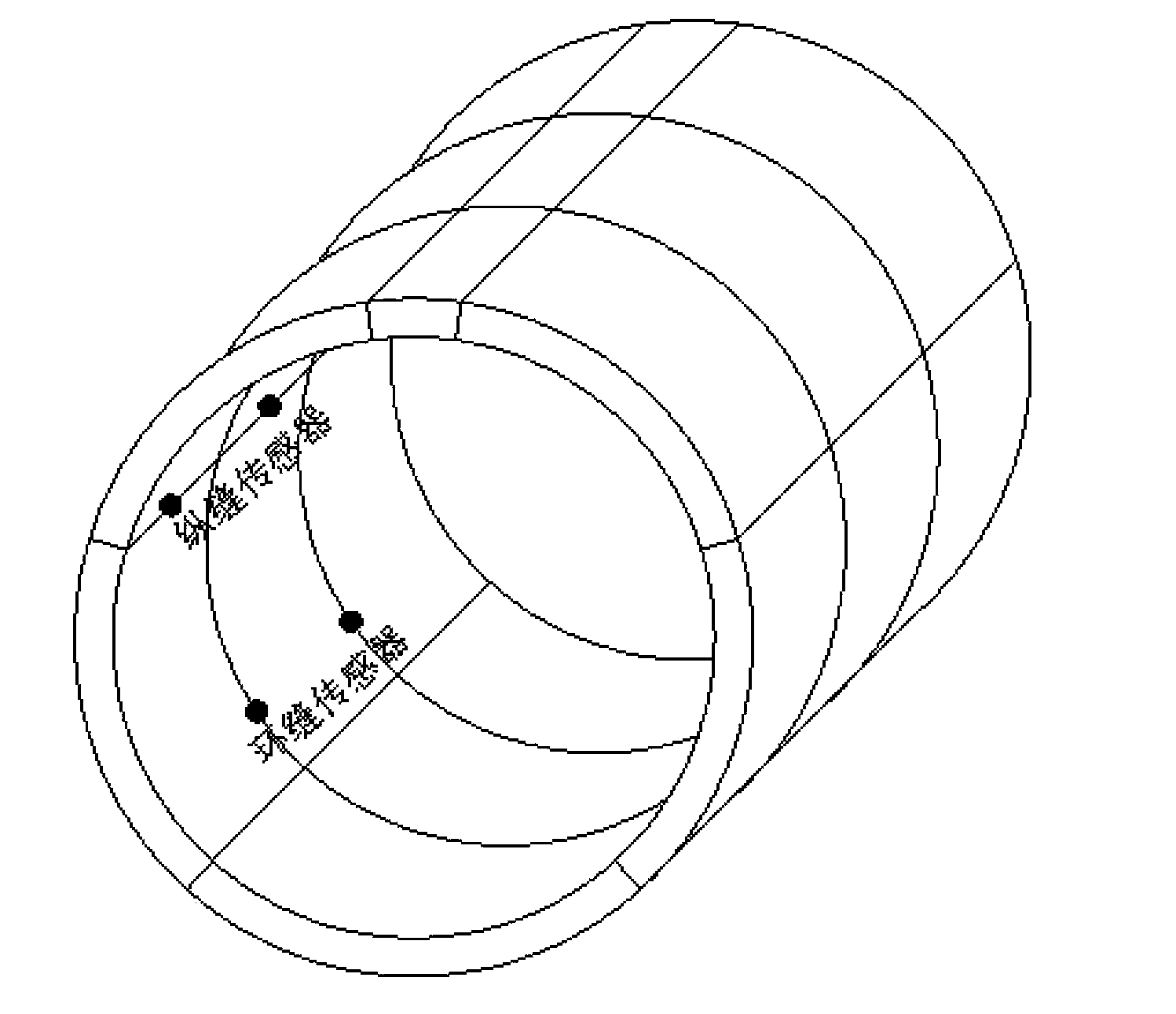

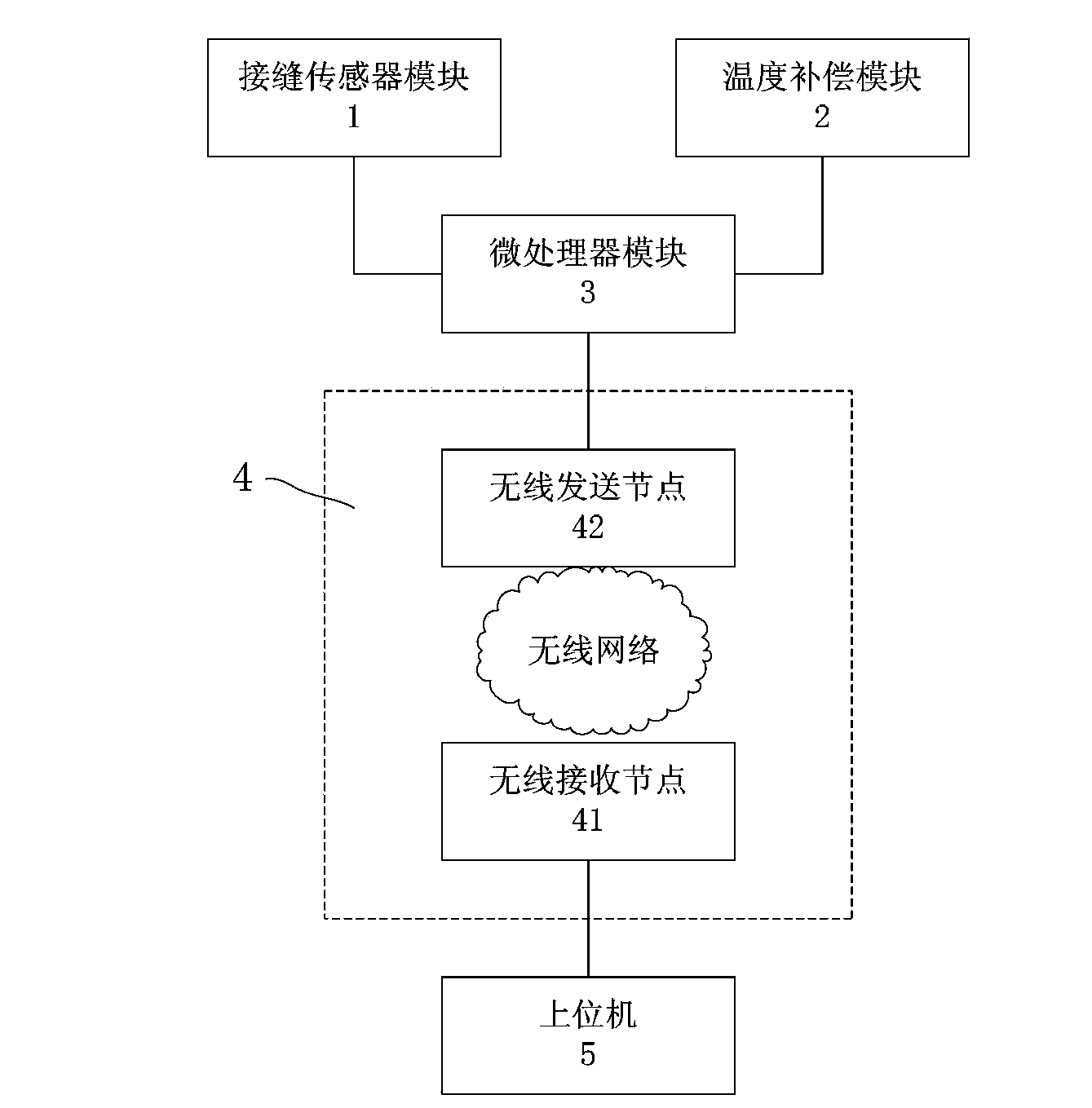

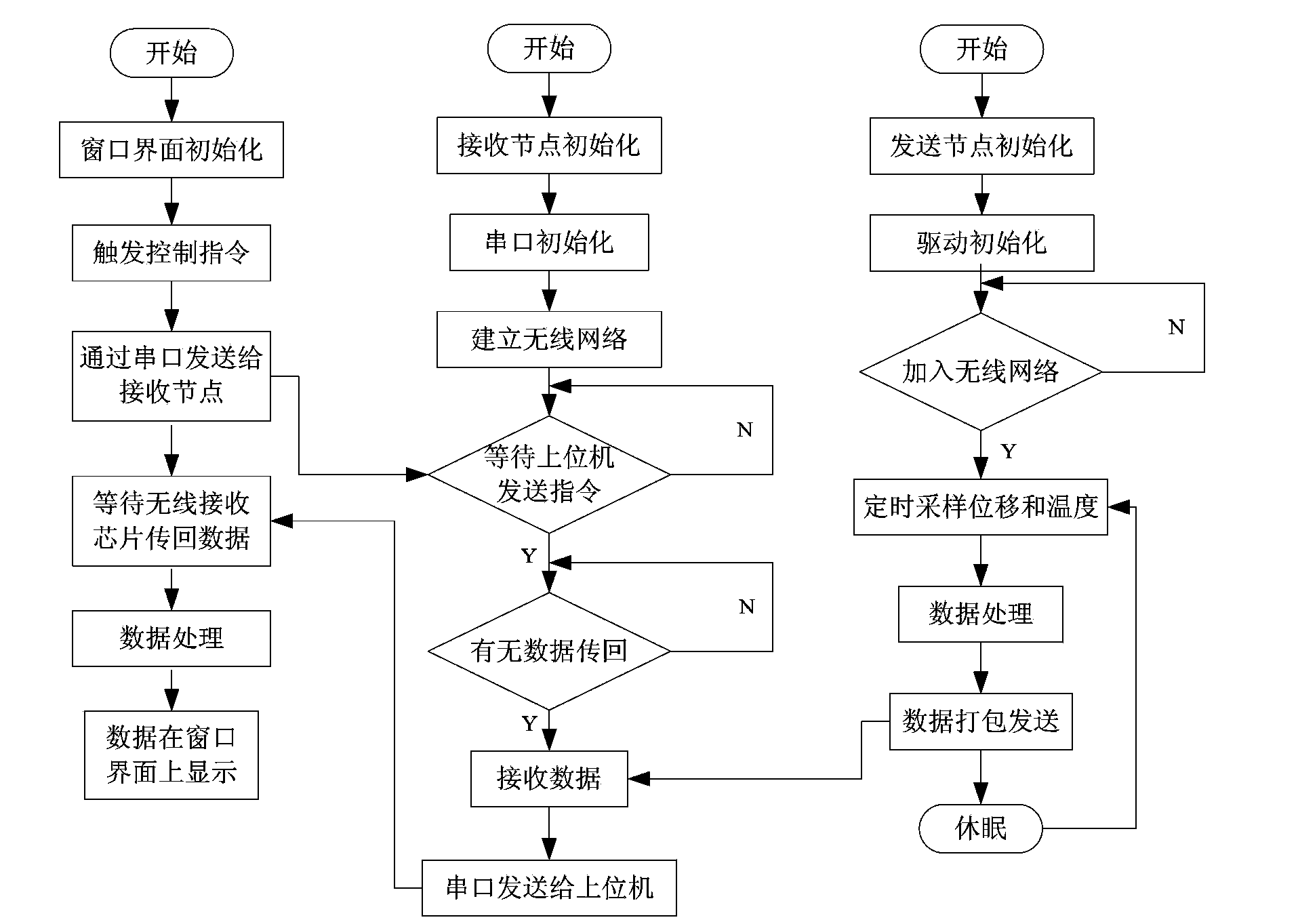

Wireless joints displacement measuring system for metro shield tunnel

InactiveCN104240470AMeet high-precision measurement requirementsAccurate real-time monitoringTransmission systemsNetwork topologiesWireless transceiverUnderground tunnel

The invention relates to a wireless joints displacement measuring system for a metro shield tunnel. The system comprises a displacement sensor module, a temperature compensation module, a microprocessor module, a wireless transceiver module and a host computer. Through the displacement sensor module, width variation of tunnel joints can be detected at real time; and through filtering, anti-interference processing and temperature compensation, metro vibration noise and temperature influence are eliminated so as to achieve high-precision measurement requirements. In addition, by the use of a wireless network for data transmission, wiring requirements are simplified. Thus, the system is more suitable for the complex environment of an underground tunnel, and accurate, effective and real-time monitoring of tunnel structure changes is realized.

Owner:TONGJI UNIV

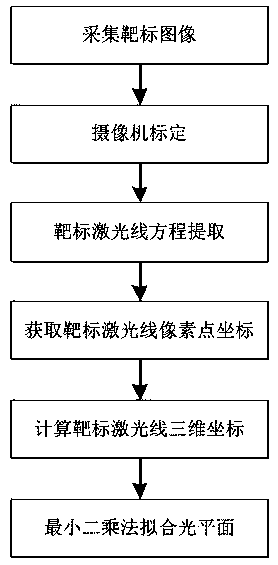

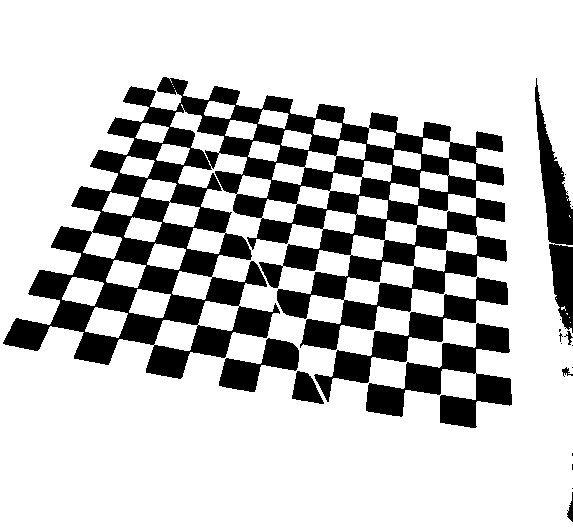

Laser line key point extraction method based on plane target

PendingCN111402330AImprove computing efficiencyIncrease success rateImage enhancementImage analysisGray level imageKey images

The invention relates to the technical field of calibration methods of line structured light vision systems, in particular to a laser line key point extraction method based on a plane target. The method is characterized by comprising the following steps: S1, binarization of a target image: converting a gray level image obtained by a CCD black and white camera into a binary image; S2, morphologicalimage processing: respectively carrying out corrosion and opening operation processing on the target binary image, and subtracting the result of the opening operation and the result of the corrosionoperation to remove useless information interference in the target image so as to obtain laser ray key image information; S3, Hough linear transformation: acquiring a laser line two-dimensional equation; S4, extracting of two-dimensional coordinates in the image coordinate system on the target laser line. The method has the advantages that the laser line equation extracted through the method can accurately calculate the image coordinate points on the laser line, and the measurement accuracy of the system is greatly improved.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI +1

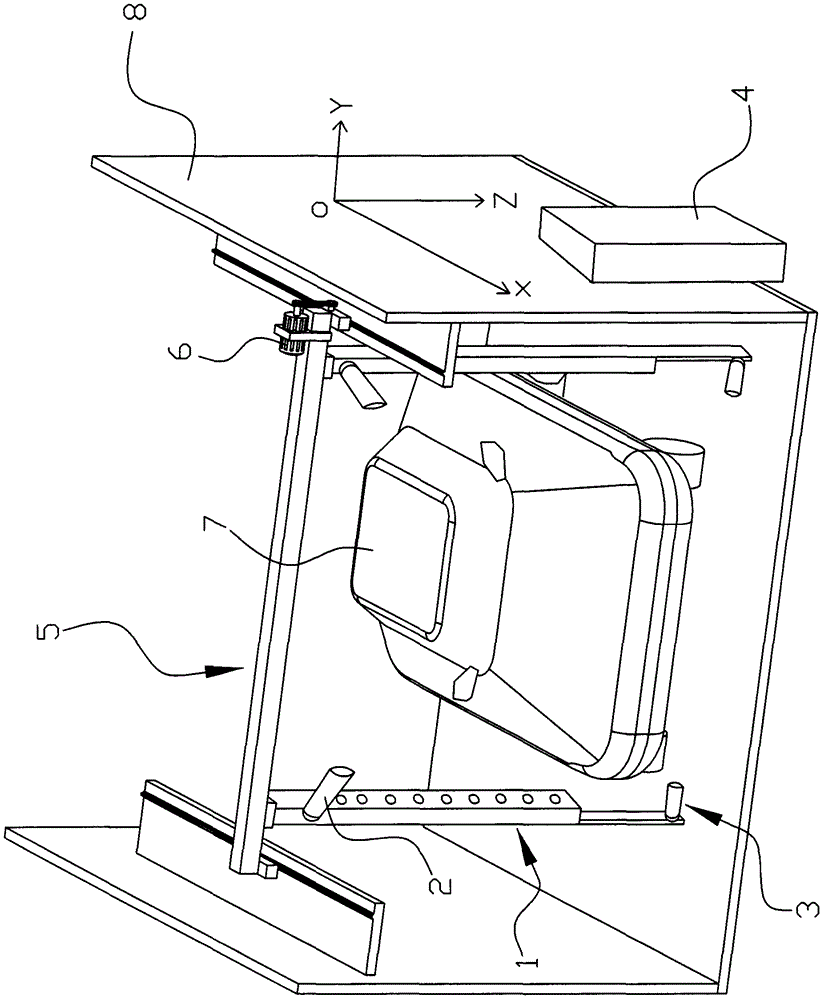

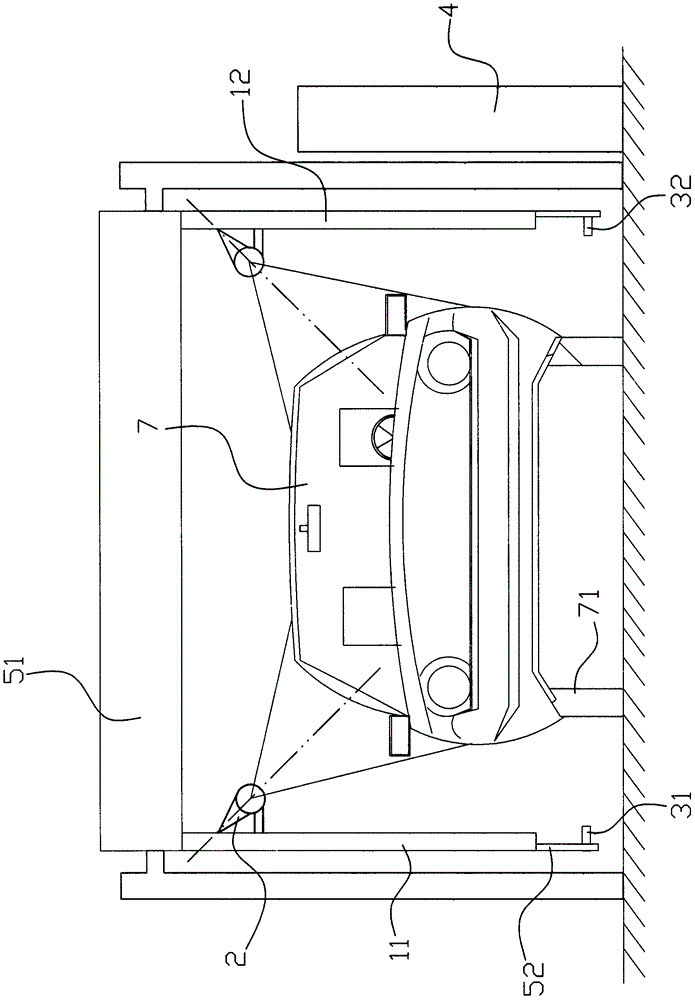

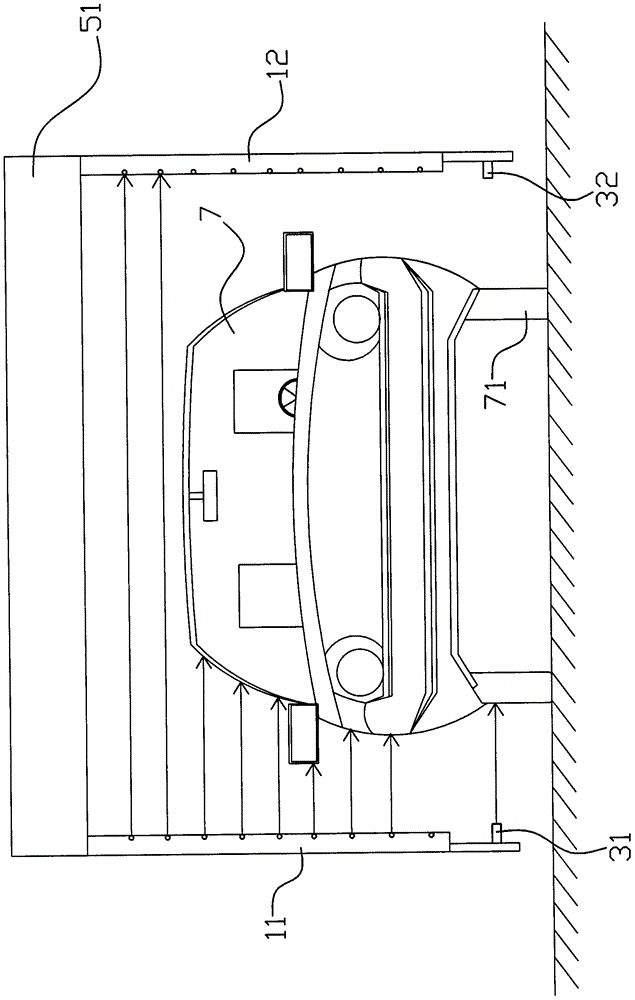

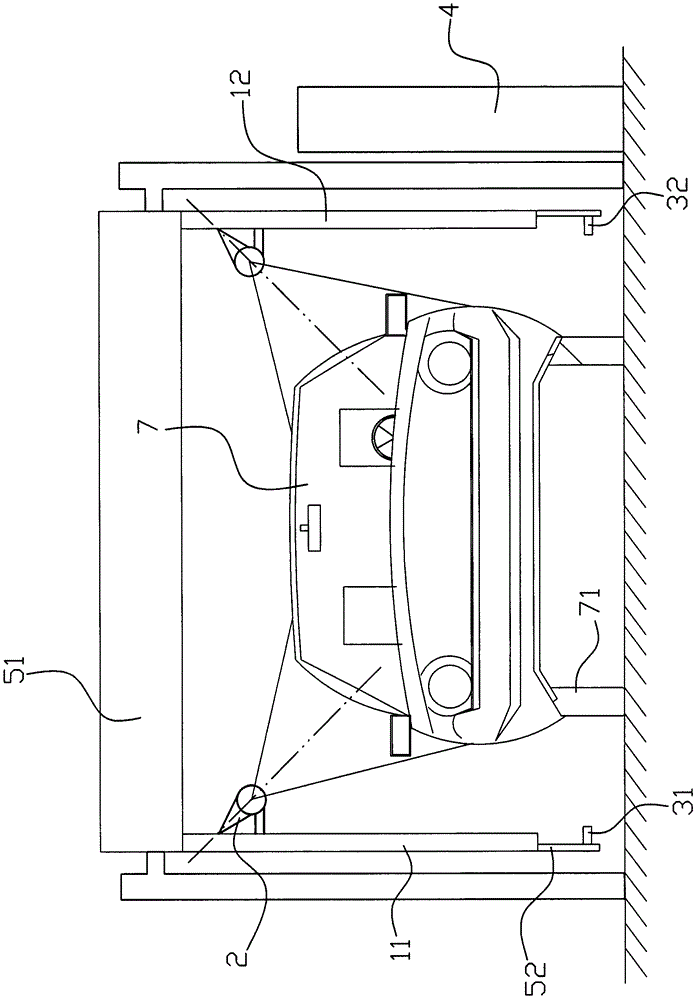

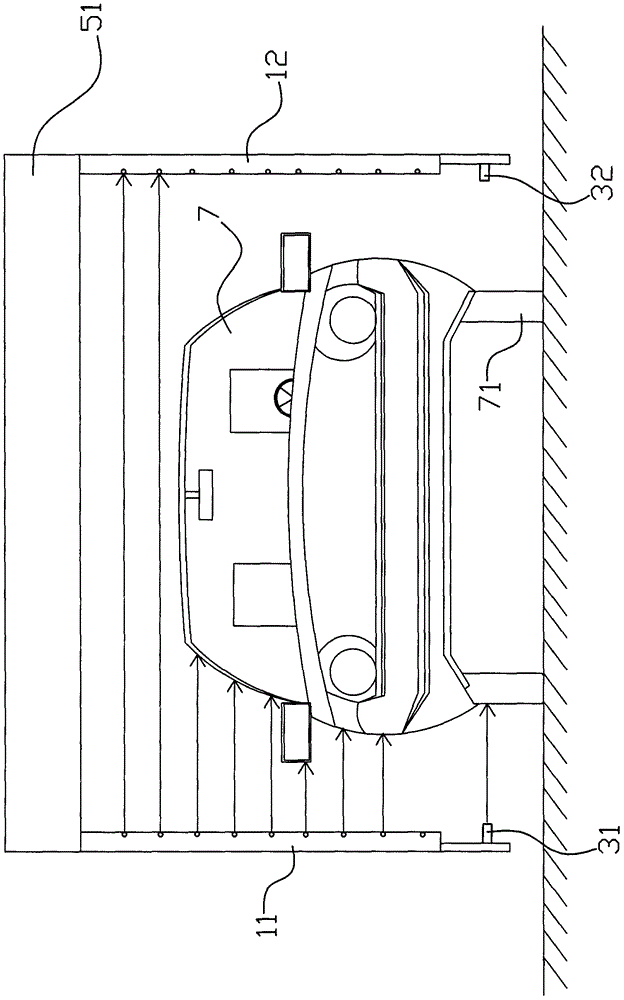

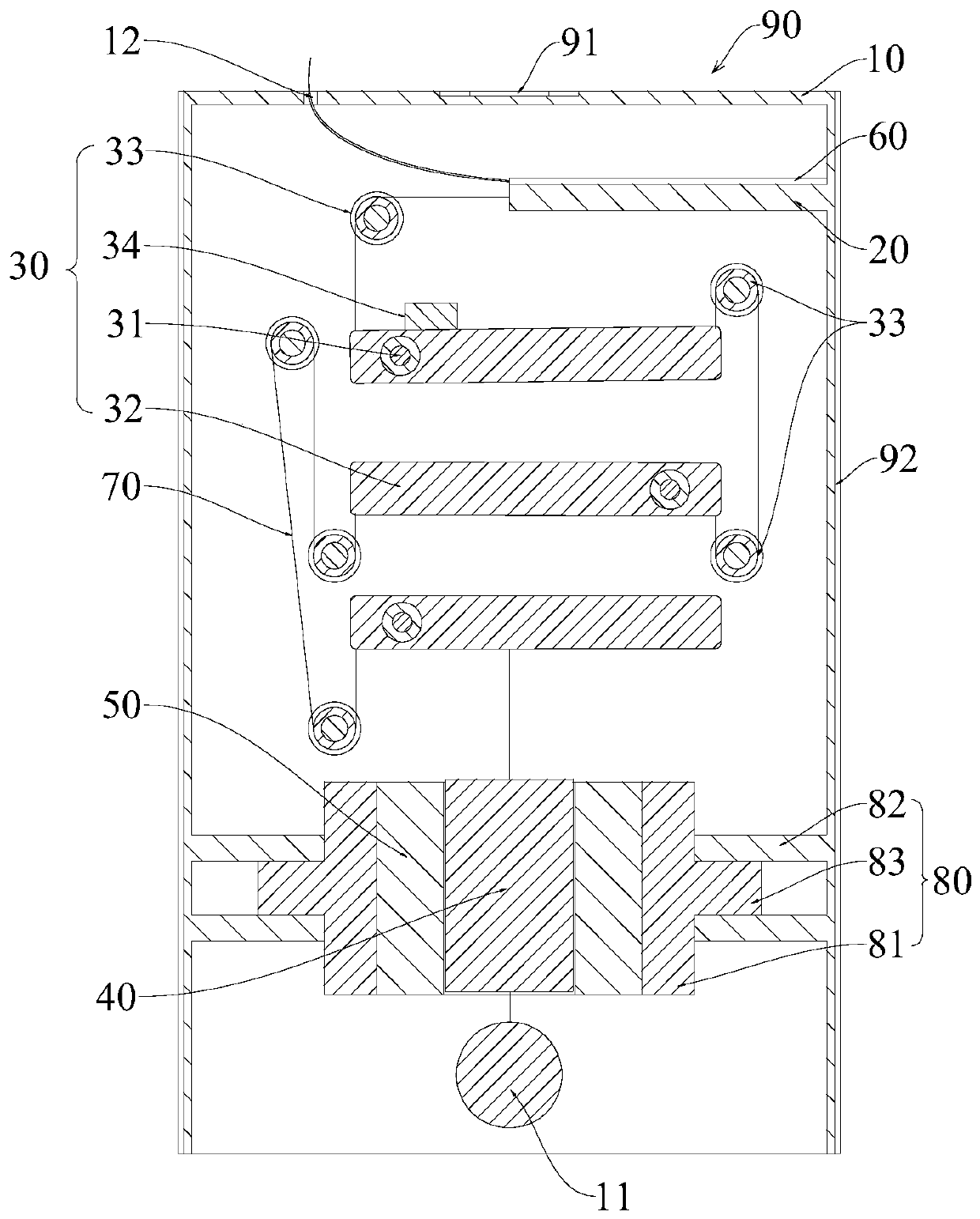

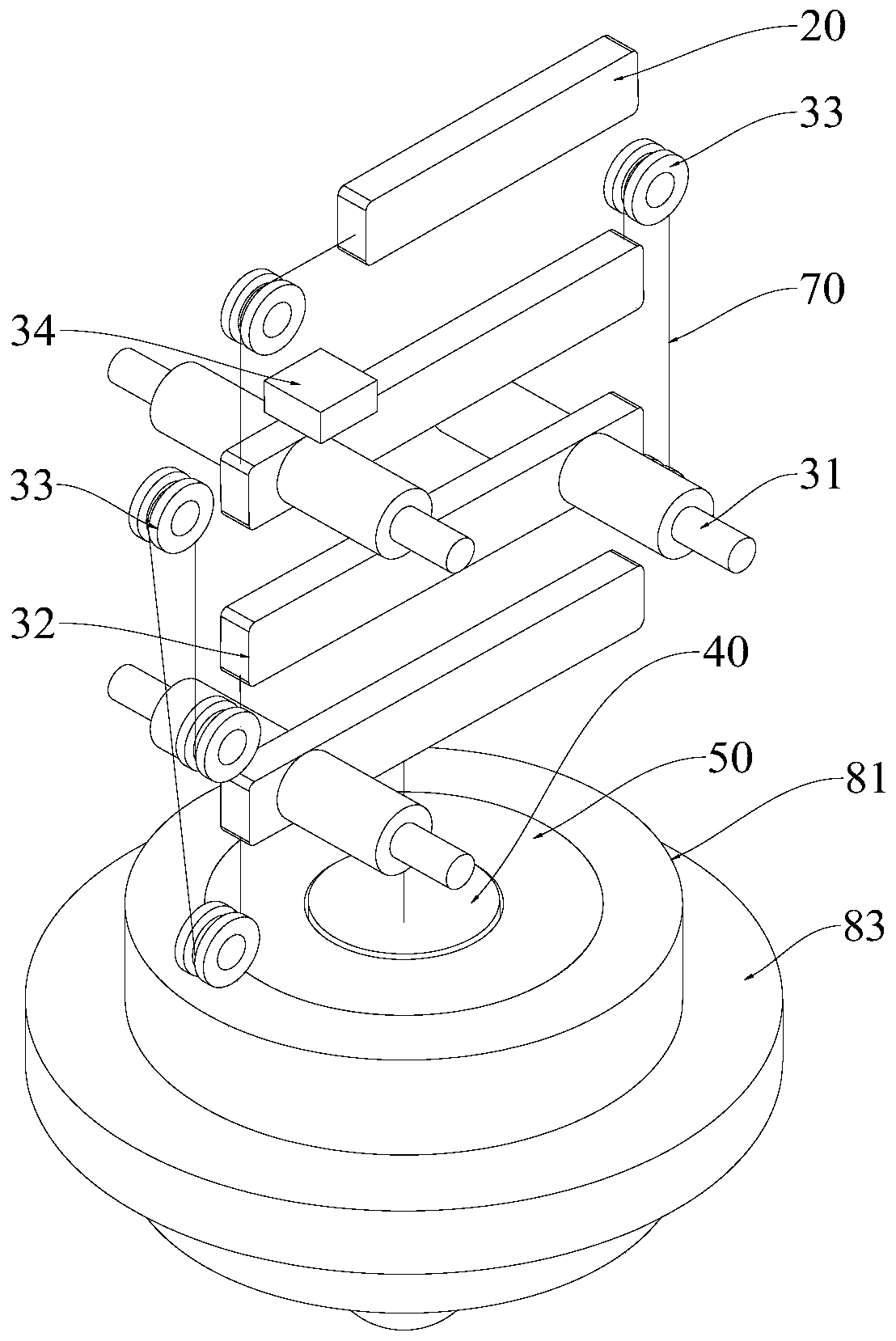

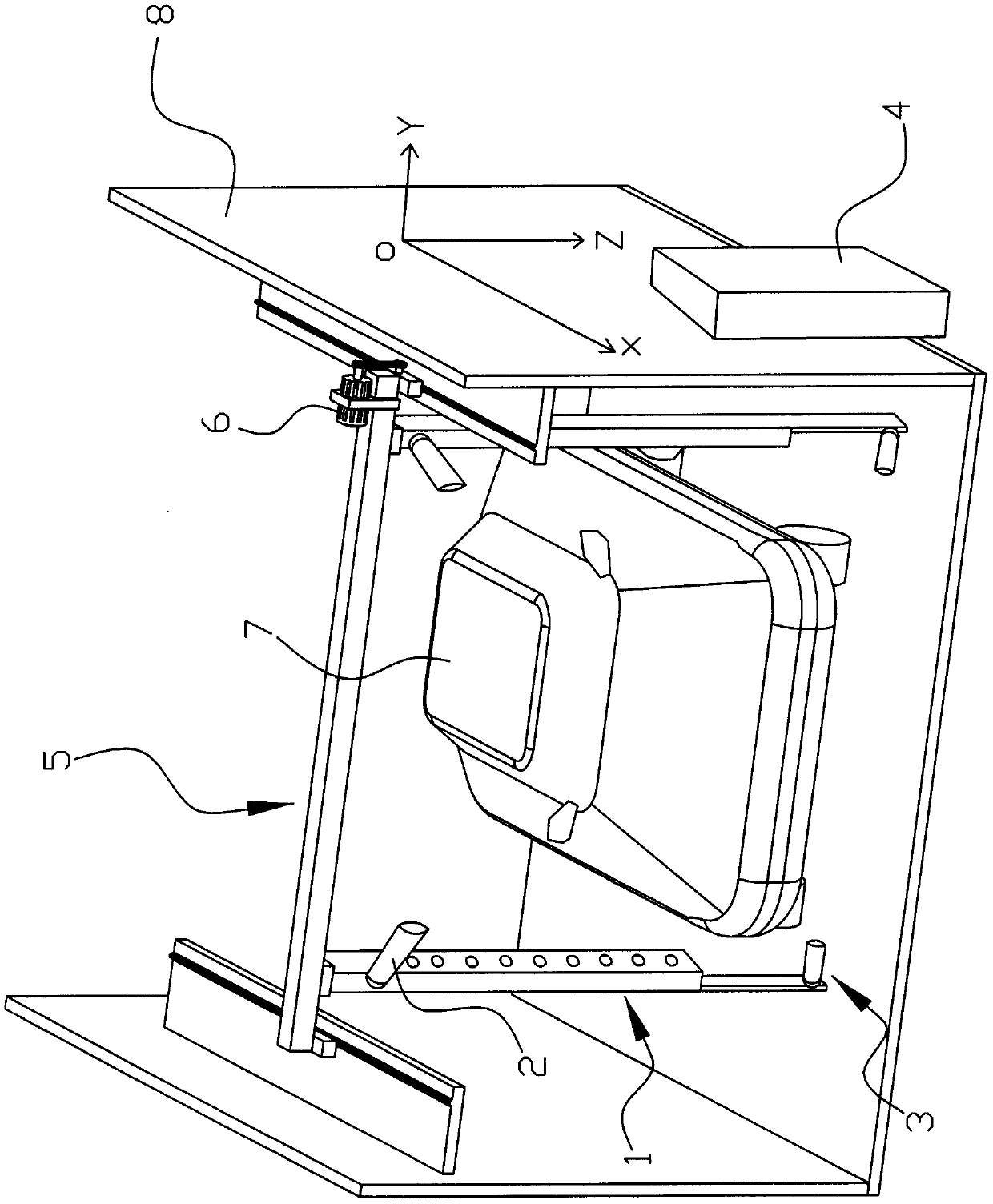

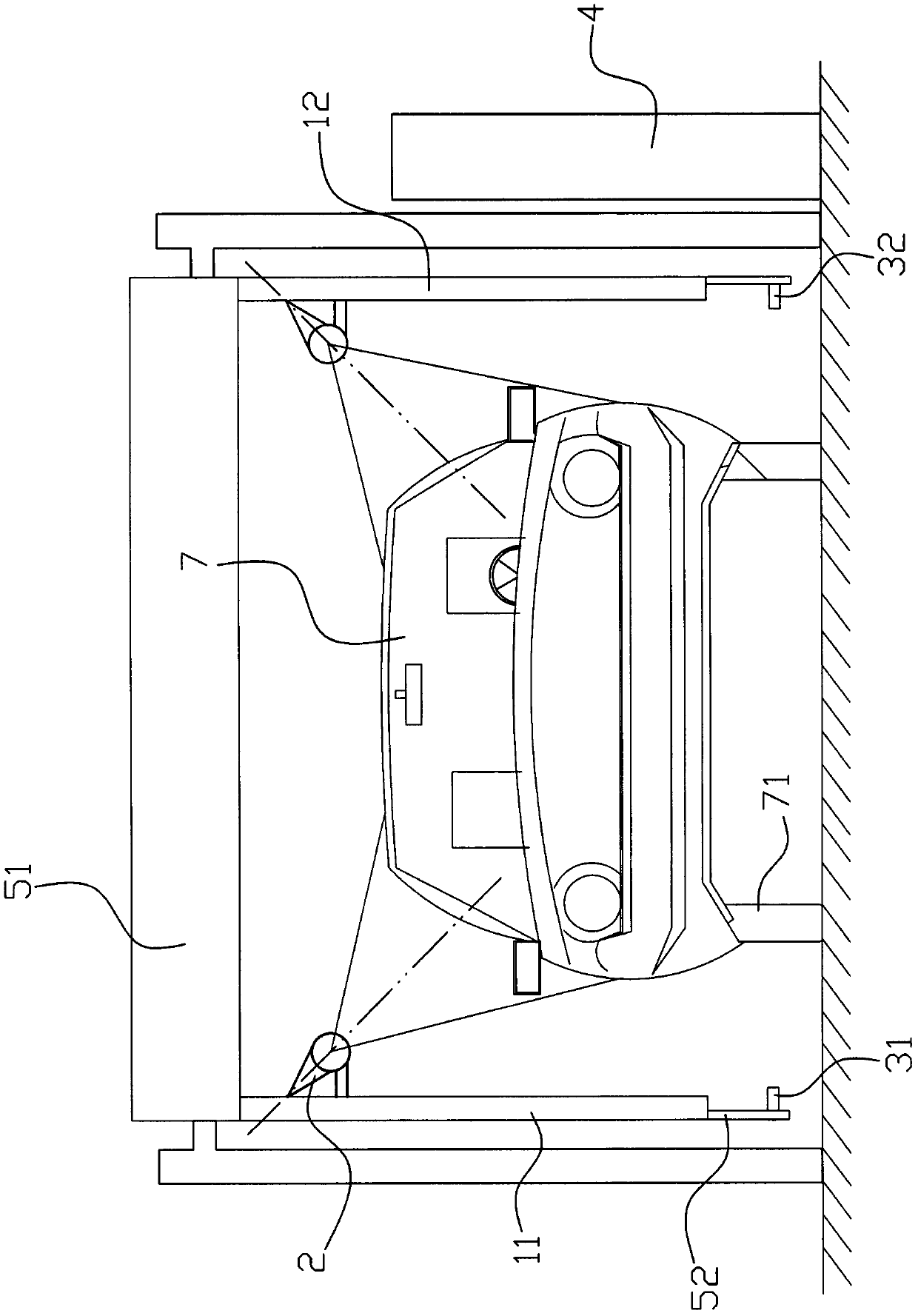

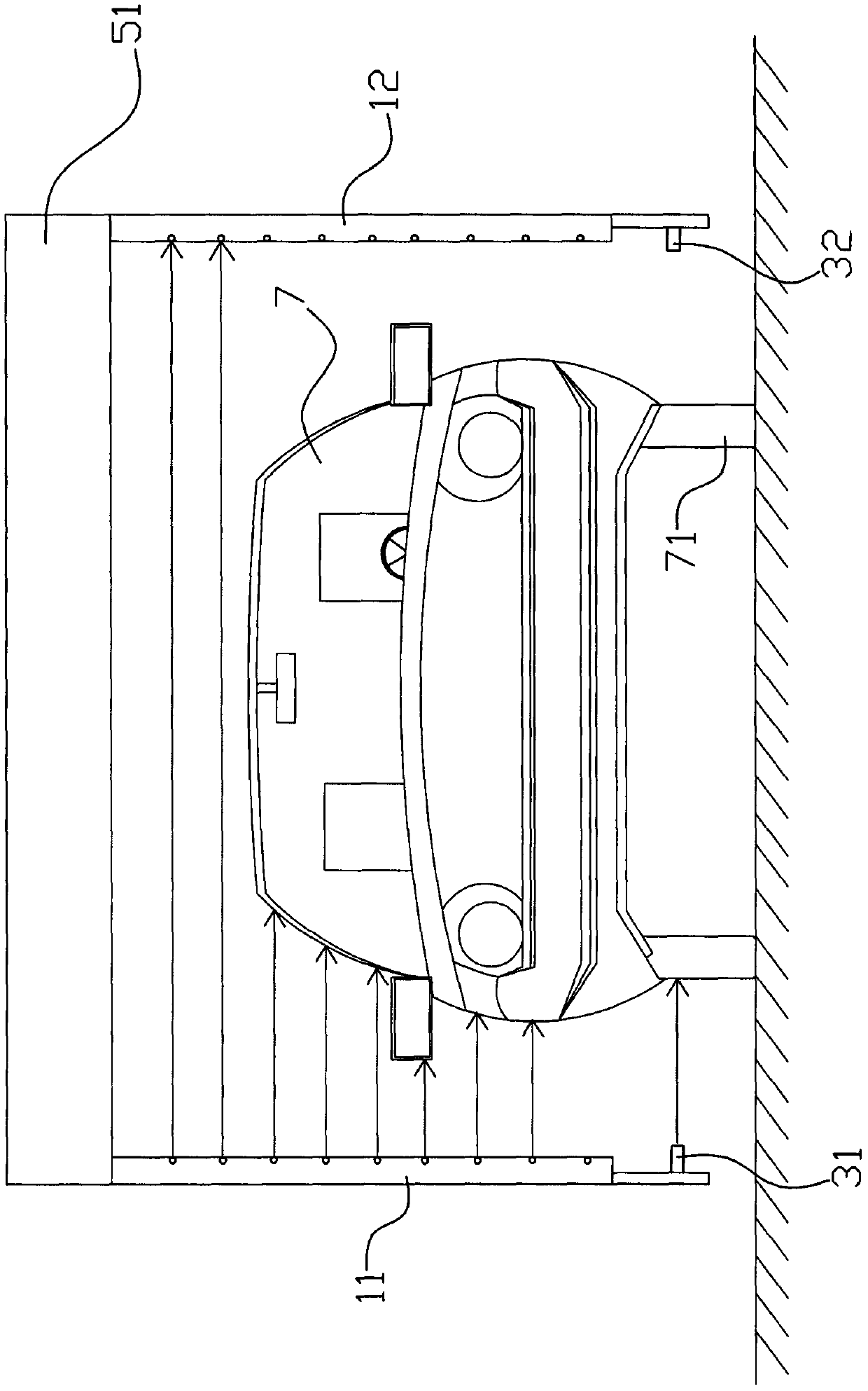

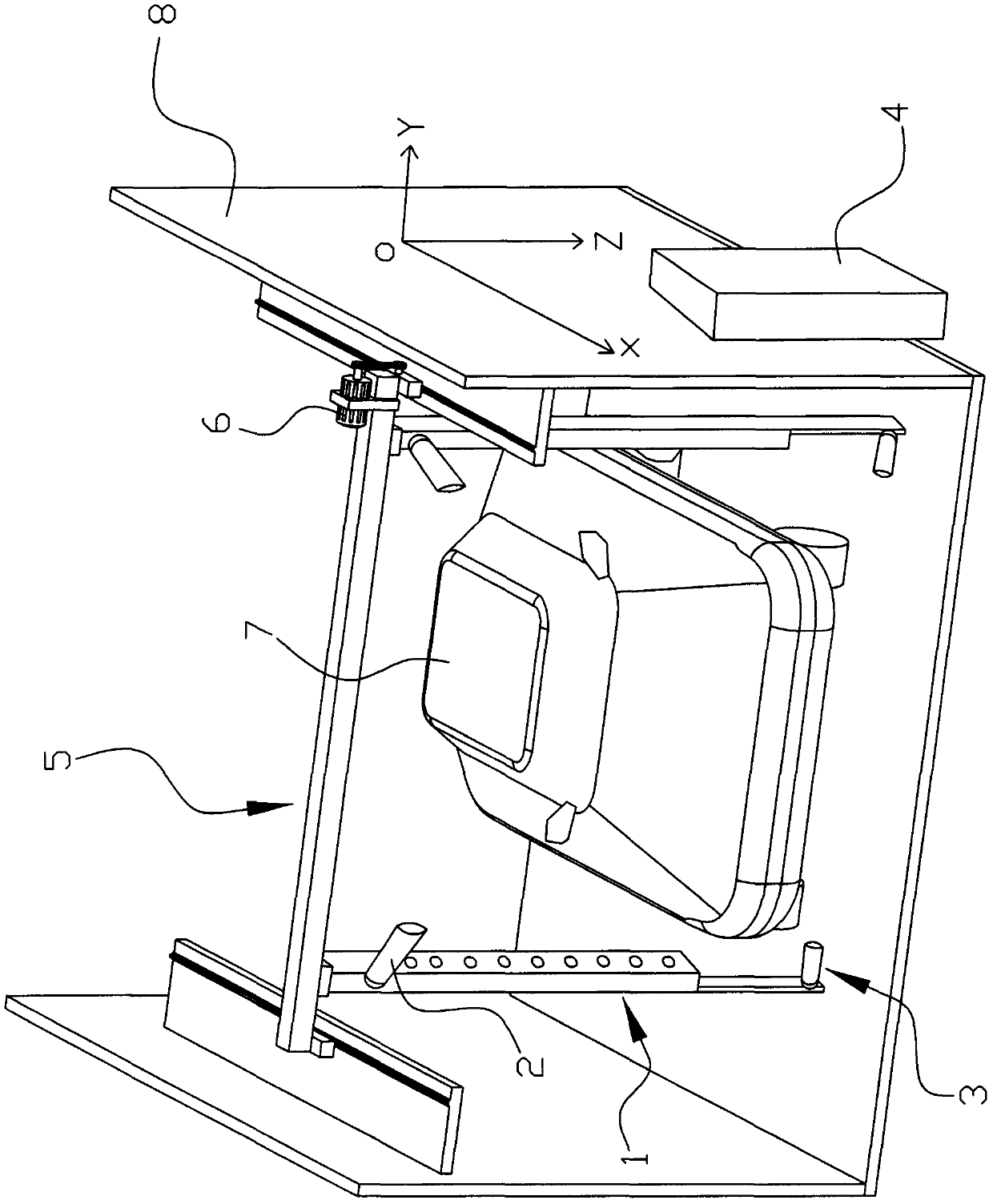

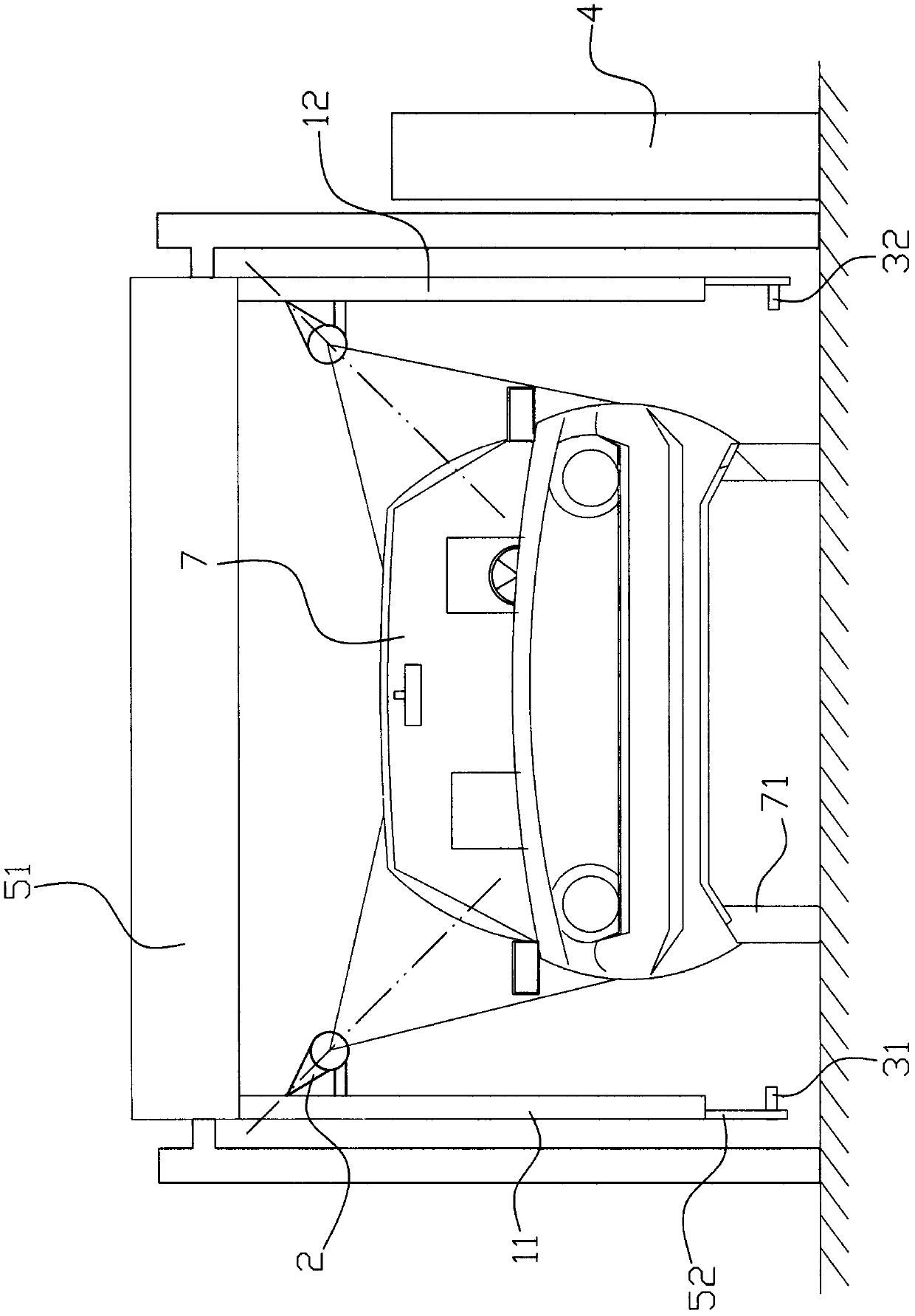

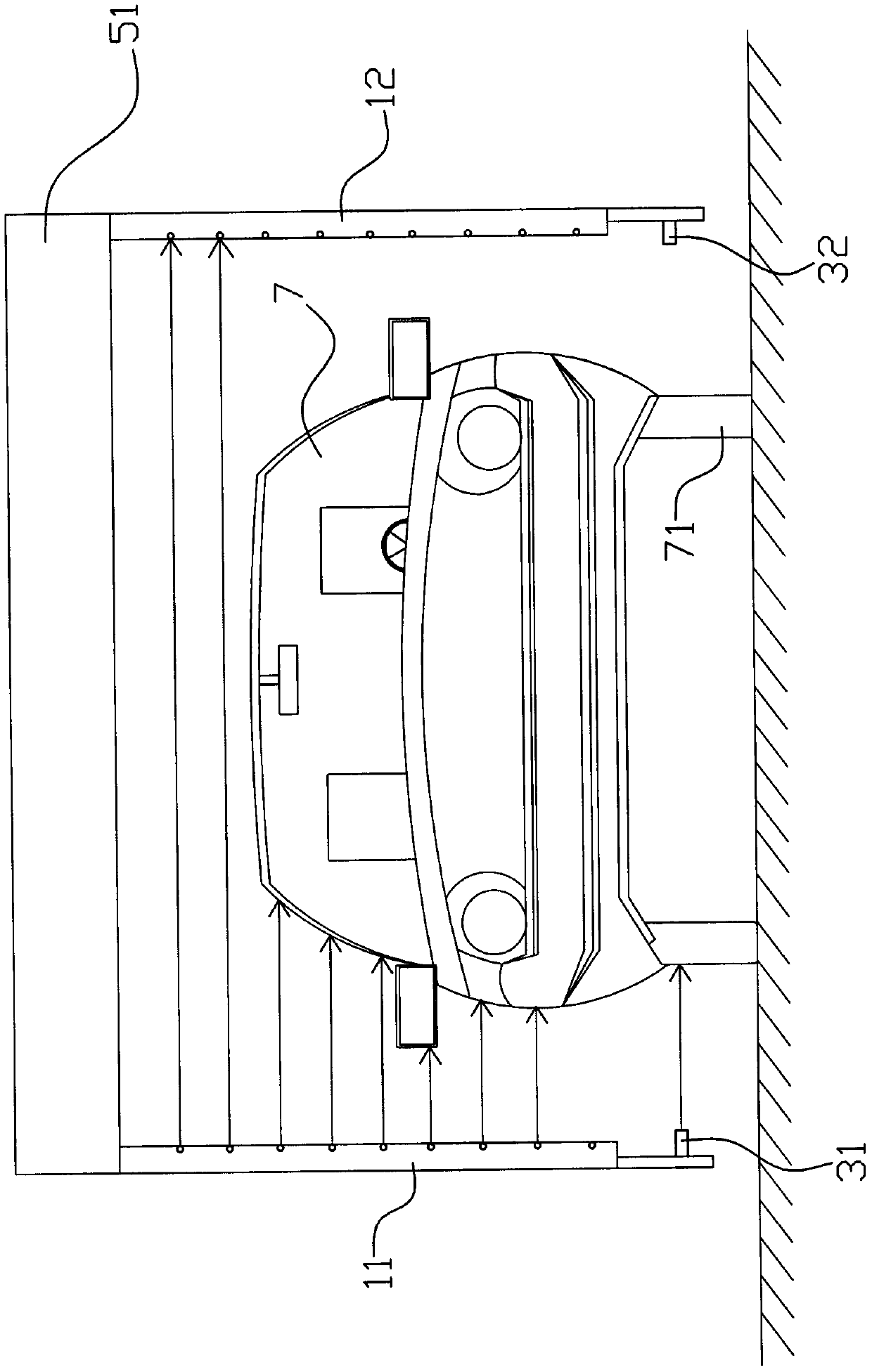

Car body position detection device for car washing

ActiveCN106705842AAccurate measurementMeet high-precision measurement requirementsUsing optical meansLocation detectionElectrical control

The invention relates to a car body position detection device for car washing, which comprises a measuring device 1, a detector 3, an image processor and an electrical control module 4, and is characterized in that the measuring device 1, the detector 3 and the image processor are connected with the electrical control module 4 through lines, the measuring device 1, the detector 3 and cameras 2 in the image processor are fixed on a frame body 5, the frame body can be placed on a car washing frame 8 in a back-and-forth moving manner through a driving mechanism, and the driving mechanism 8 is connected with the electrical control module 4; the measuring device 1 comprises a transmitter 11 and a receiver 12, the image processor comprises the cameras 2 and an image recognition and operation module, the cameras 2 are fixed at the upper parts of the frame body 5 and located at two sides above an automobile 7. The advantages lie in that position values of protruding parts such as reflectors and a luggage rack on the car body contour can be measured, and measurement is performed quickly in a non-contact and automated manner; and meanwhile, the tire azimuth and the wheelbase are measured, special cleaning can be performed on tires accordingly, the head, the tail and inlet and outlet conditions of the automobile are judged, and model judgment is assisted.

Owner:宁波中令清洁技术有限公司

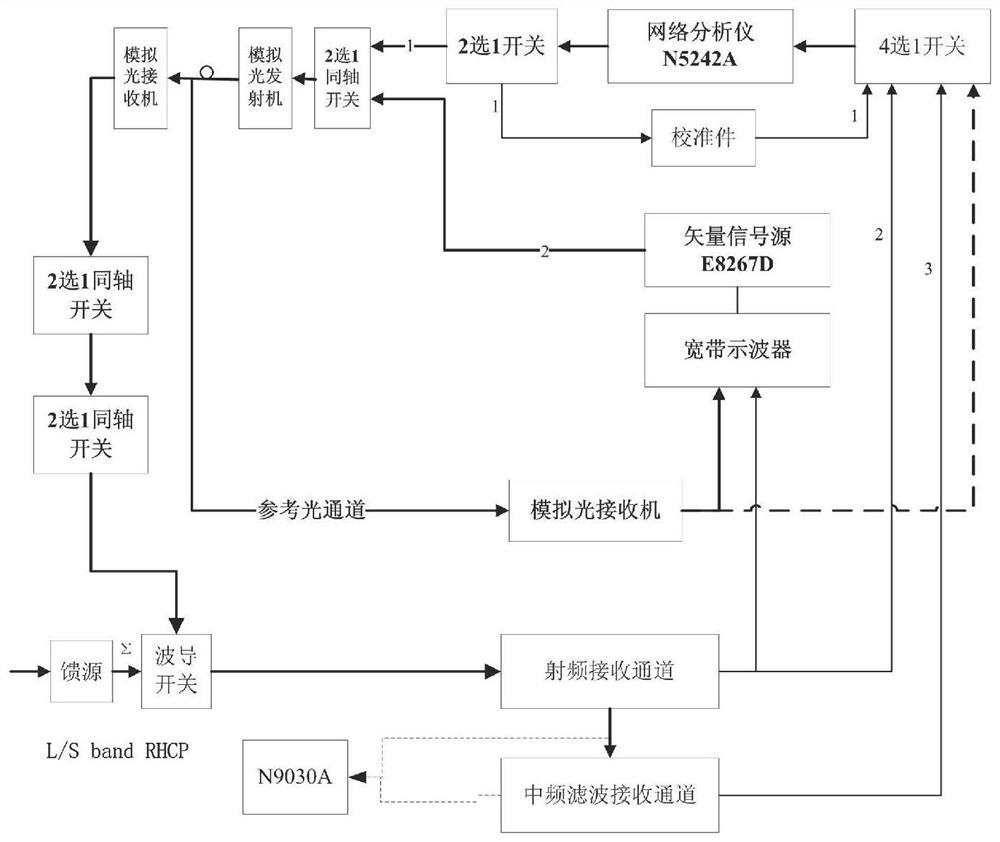

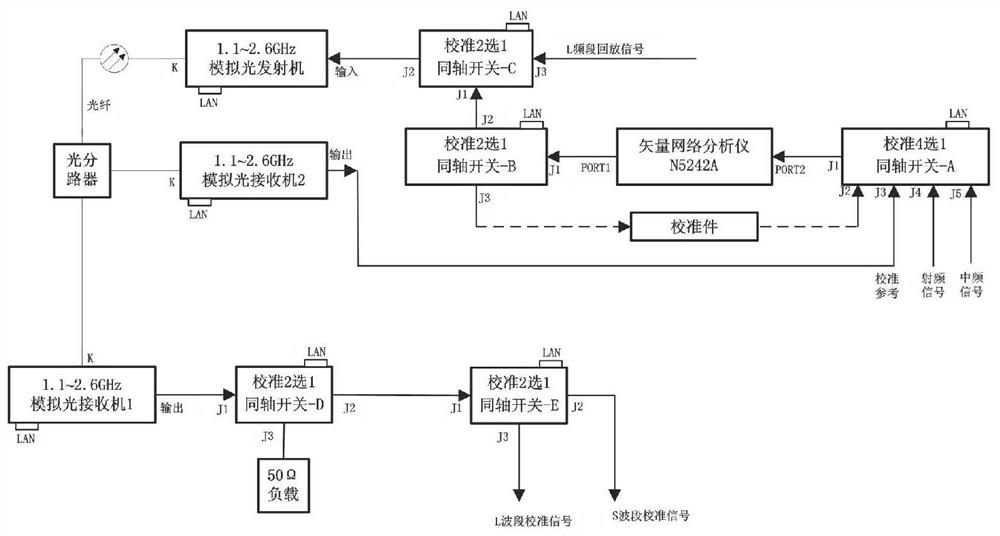

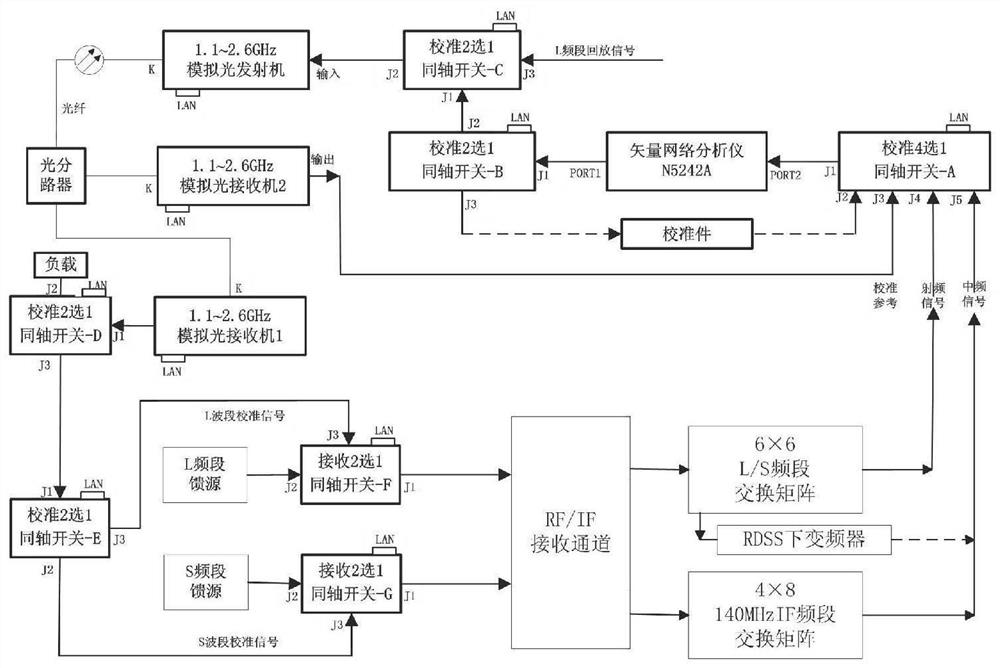

System calibration test method based on GNSS signal quality evaluation

ActiveCN111913146AReduce the effects of harmonic clutterMeet high-precision measurement requirementsReceivers monitoringSatellite radio beaconingSignal qualityTime delays

The invention relates to a system calibration test method based on GNSS signal quality evaluation, which comprises a calibration device test and a receiving channel absolute time delay and variable quantity test; the calibration device test comprises a vector network analyzer time delay measurement precision test and a broadband oscilloscope time delay precision test; a vector network analyzer time delay measurement precision test specifically comprises the following steps: S1, enabling a vector network analyzer to carry out a self-calibration test; s2, according to different RF frequencies and bandwidths, straight-through vector calibration is carried out; s3, connecting the tested piece, and testing the group delay characteristic of the standard delay line; the broadband oscilloscope time delay precision test specifically comprises the following steps: generating a pulse-modulated radio frequency signal by using a vector signal source; dividing pulse-modulated radio frequency signalto two paths, wherein the one path is sent to an oscilloscope as a reference channel, and the other path is connected with a standard delay line for testing; and eliminating the influence on the stability of the whole system instrument by adopting a comparison method; The method has the advantages of being high in precision, easy to operate and high in efficiency.

Owner:NAT TIME SERVICE CENT CHINESE ACAD OF SCI

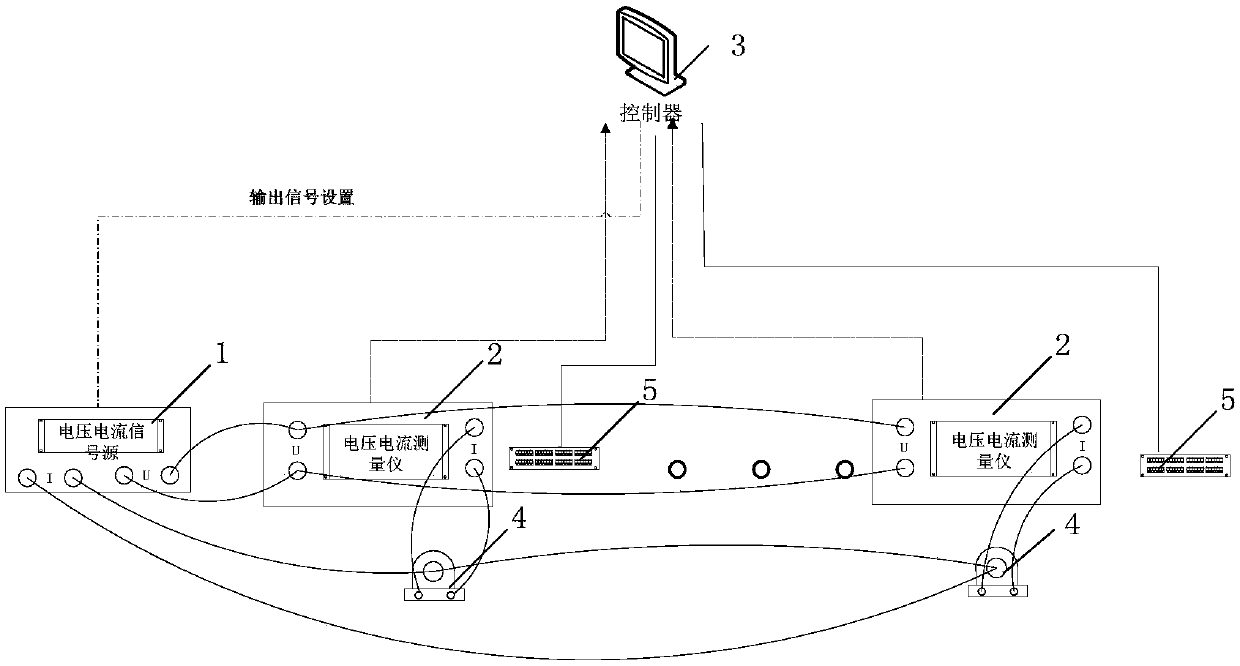

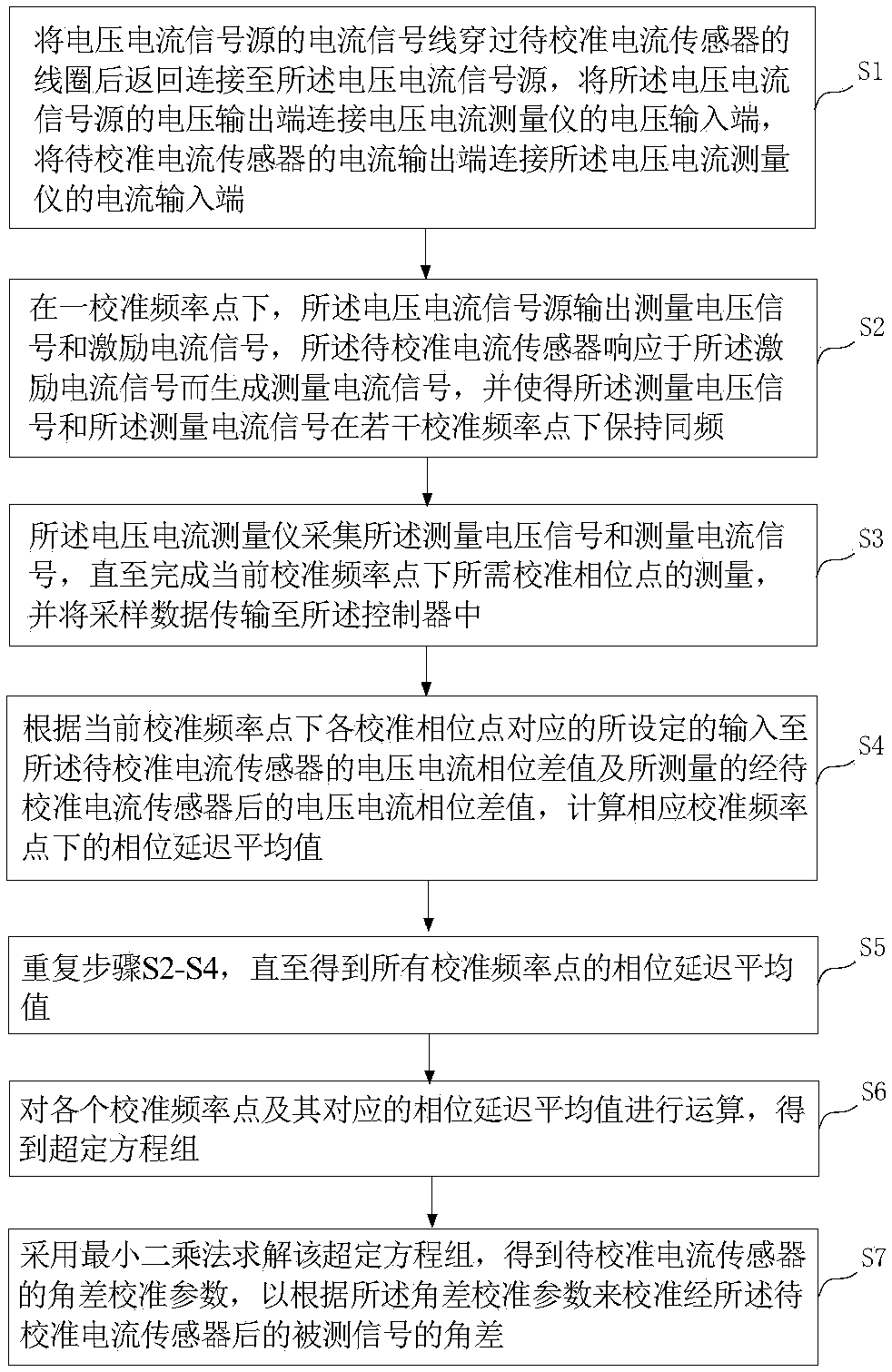

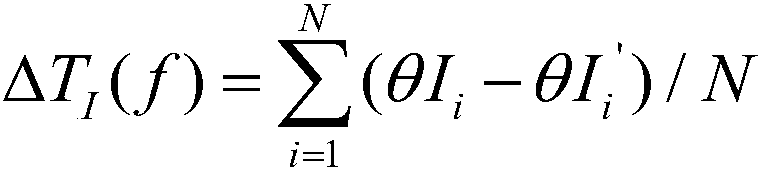

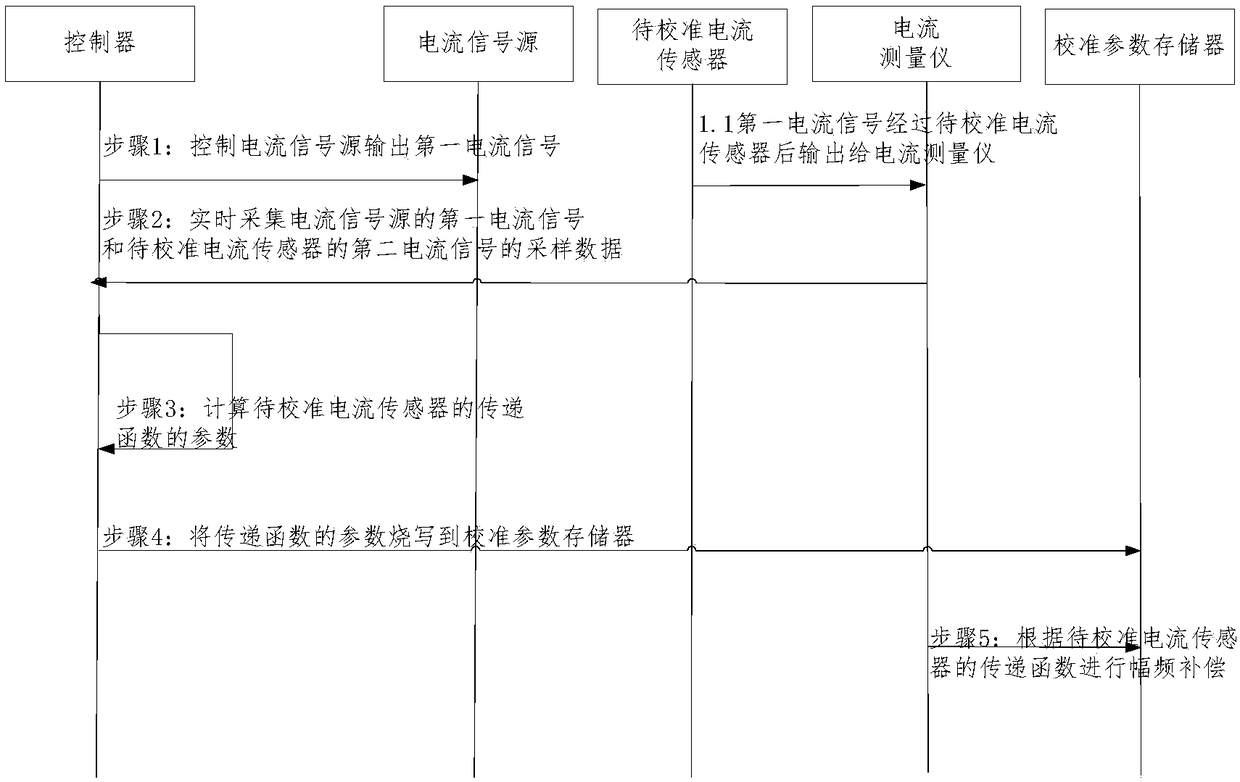

System and method for calibrating angle difference of current sensor

InactiveCN108169700ASolving Current AccuracyImprove calibration efficiencyElectrical measurementsMeasuring instrumentExcitation current

The invention presents a system and a method for calibrating the angle difference of a current sensor. The method comprises the following steps: a voltage and current signal source outputs a measurement voltage signal and an excitation current signal, a current sensor to be calibrated generates a measurement current signal in response to the excitation current signal, and the measurement voltage signal and the measurement current signal are kept at the same frequency at some calibration frequency points; a voltage and current measuring instrument collects signals to complete the measurement ofphase points needing to be calibrated at the calibration frequency points; the average phase delay value of each calibration frequency point is calculated according to the input voltage and current phase difference value and the measured voltage and current phase difference value of the current sensor to be calibrated, and then, the average phase delay value of all the calibration frequency points is obtained; operation is carried out to obtain an over-determined equation group; and the over-determined equation group is solved to obtain the angle difference calibration parameters of the current sensor to be calibrated, and the angle difference is calibrated according to the angle difference calibration parameters. The problem that the precision of current measurement by a current sensor is poor due to angle error is solved.

Owner:INNO INSTR (CHINA) INC

Vehicle body position detection method for washing vehicles

ActiveCN106643496AAccurate measurementMeet high-precision measurement requirementsUsing optical meansElectrical controlBody positions

The present invention provides a vehicle body position detection method for washing vehicles. The vehicle body position detection method comprises the following steps: a measurer (1) measures the height of a vehicle body, a detector (3) measures the position of a tire (71), the contour line of the vehicle body is measured through an image processor, the measurer (1) and the detector (3) are connected with the image processor through a line and an electrical control module (4), the measurer (1), the detector (3) and a camera (2) in the image processor are fixed on a frame body (5), the frame body (5) is arranged on a vehicle washing frame (8) and can move back and forth by means of a driving mechanism, and the driving mechanism is connected with the electrical control module (4). The vehicle body position detection method for washing vehicles can measure the position values of the projecting portions such as retroreflectors, a baggage holder and the like on the vehicle body contour, and the measurement is rapidly performed in a non-contact and automation mode. Besides, the vehicle body position detection method for washing vehicles measures the tire orientation and the wheelbase so as to perform special cleaning of tires, determine the head and tail and in-out position condition of the vehicle and assist to determine the type of the vehicle.

Owner:宁波中令清洁技术有限公司

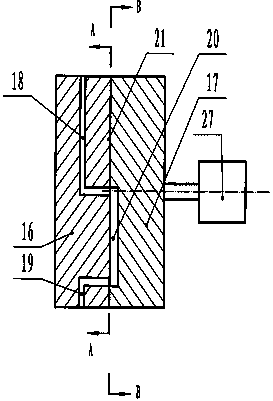

Fiber bragg grating clinometer

InactiveCN110595395ARealize measurementReduce measurement biasUsing optical meansIncline measurementStructural deformationFiber

The invention provides a fiber bragg grating clinometer, and belongs to the field of sensing technology. The fiber bragg grating clinometer comprises a shell, and an elastic beam, a force amplification component, a first magnet and a second magnet, which are disposed in the shell; the elastic beam is located at the upper part of the shell and is placed horizontally, one end of the elastic beam isconnected to an inner wall of the shell, and the other end of the elastic beam is a free end; a fiber bragg grating for monitoring the elongation of the elastic beam is attached to the elastic beam; the force amplification component is located below the elastic beam; the first magnet is located below the first magnet and is connected with the free end of the elastic beam through a rigid wire bypassing the force amplification component; the second magnet is arranged at the outside of the first magnet in a sleeving manner and is in clearance fit with the first magnet; and the second magnet is fixedly arranged in the shell and is magnetically repulsive with the first magnet. The fiber bragg grating clinometer provided by the invention has high measurement accuracy, a large measurement range,a simple structure and convenient use, and is of great significance for the structural deformation monitoring of civil engineering.

Owner:SHIJIAZHUANG TIEDAO UNIV

Combined antenna

ActiveCN111786073AStrengthen mutual influenceGuaranteed stabilityAntenna supports/mountingsSatellite radio beaconingCarrier signalRadio frequency

The invention relates to the technical field of radio frequency antennas, in particular to a combined antenna which comprises a first mounting plate, a second mounting plate and a circuit board, the second mounting plate is arranged on the upper surface of the circuit board, the first mounting plate is arranged on the upper surface of the second mounting plate, and the second mounting plate is larger than the first mounting plate, so that mounting positions are formed in the periphery and / or the side face of the upper surface of the second mounting plate. The upper surface of the first mounting plate is provided with a positioning antenna, and the mounting position of the second mounting plate is provided with at least two mobile communication antennas. According to the combined antenna, the positioning antenna is arranged in the center, the mobile communication antennas are arranged surrounding the positioning antenna; mutual influence between the mobile communication antennas and thepositioning antenna can be effectively enhanced; therefore, the stability of the phase center of the positioning antenna is ensured, the positioning antenna can be assisted by using the mobile communication antennas, an accurate positioning signal can be obtained in real time through a carrier phase difference technology, the high-precision measurement requirement in the industry is met, and theoperation efficiency is improved.

Owner:SHENZHEN DINGYAO SCI & TECH

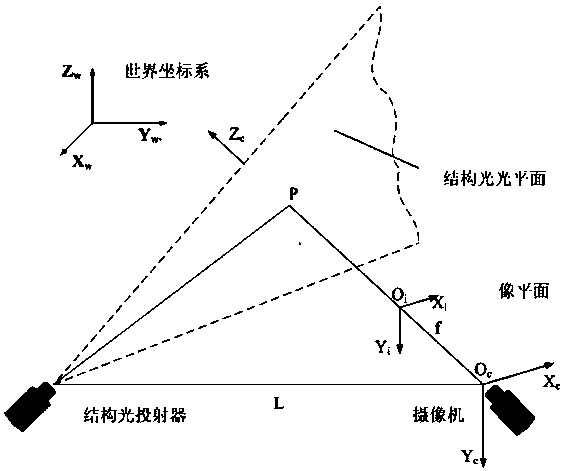

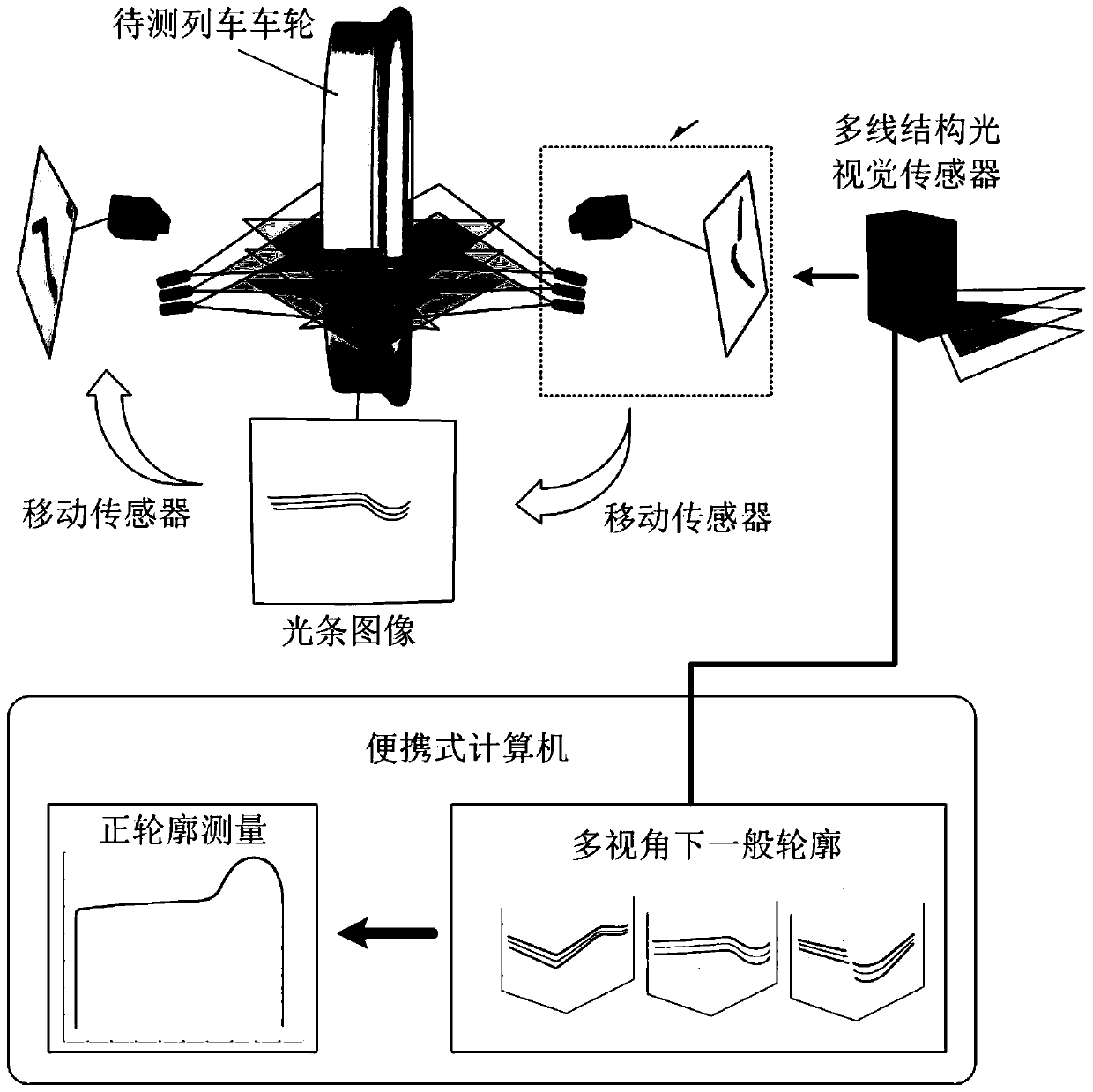

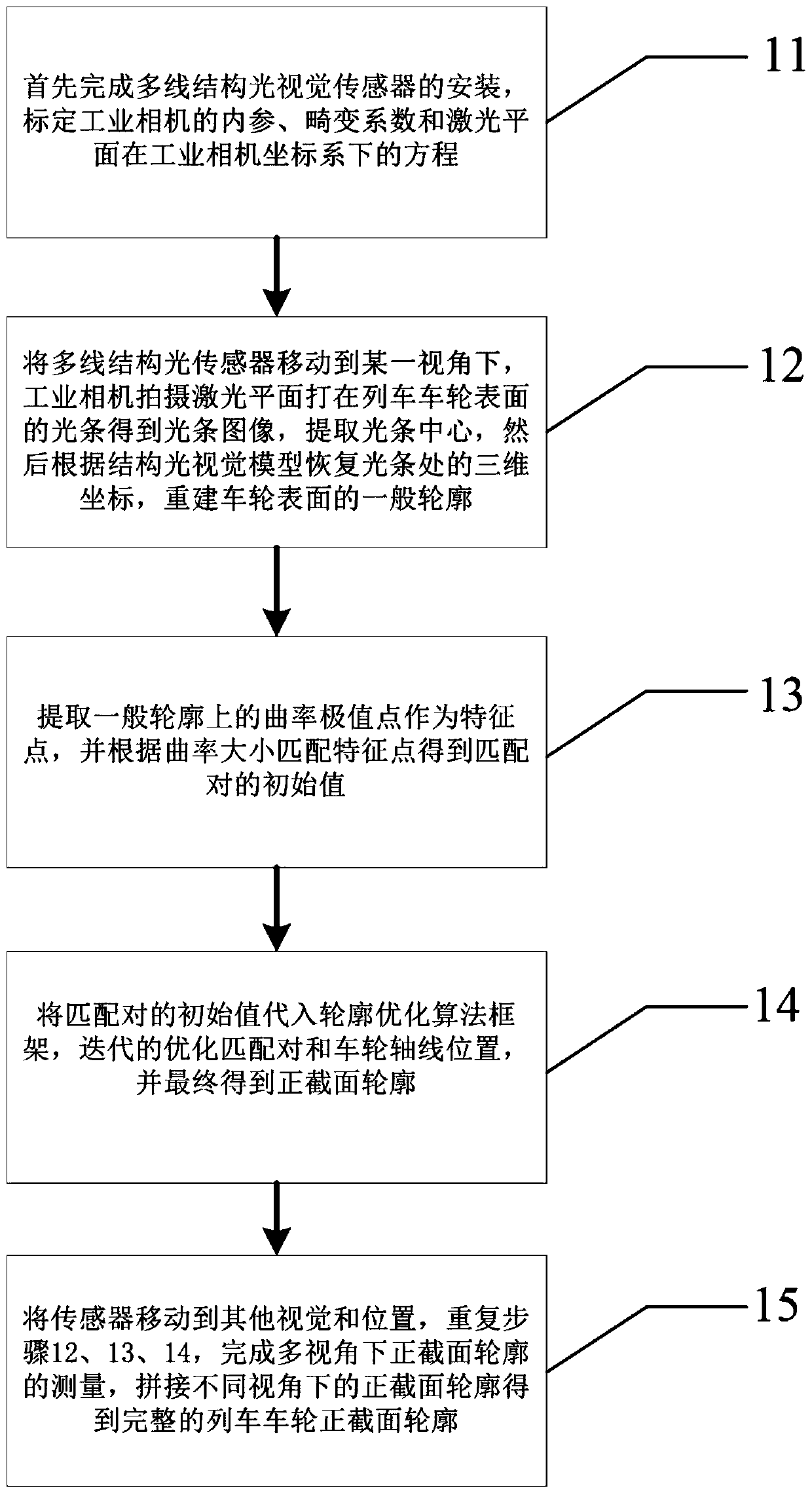

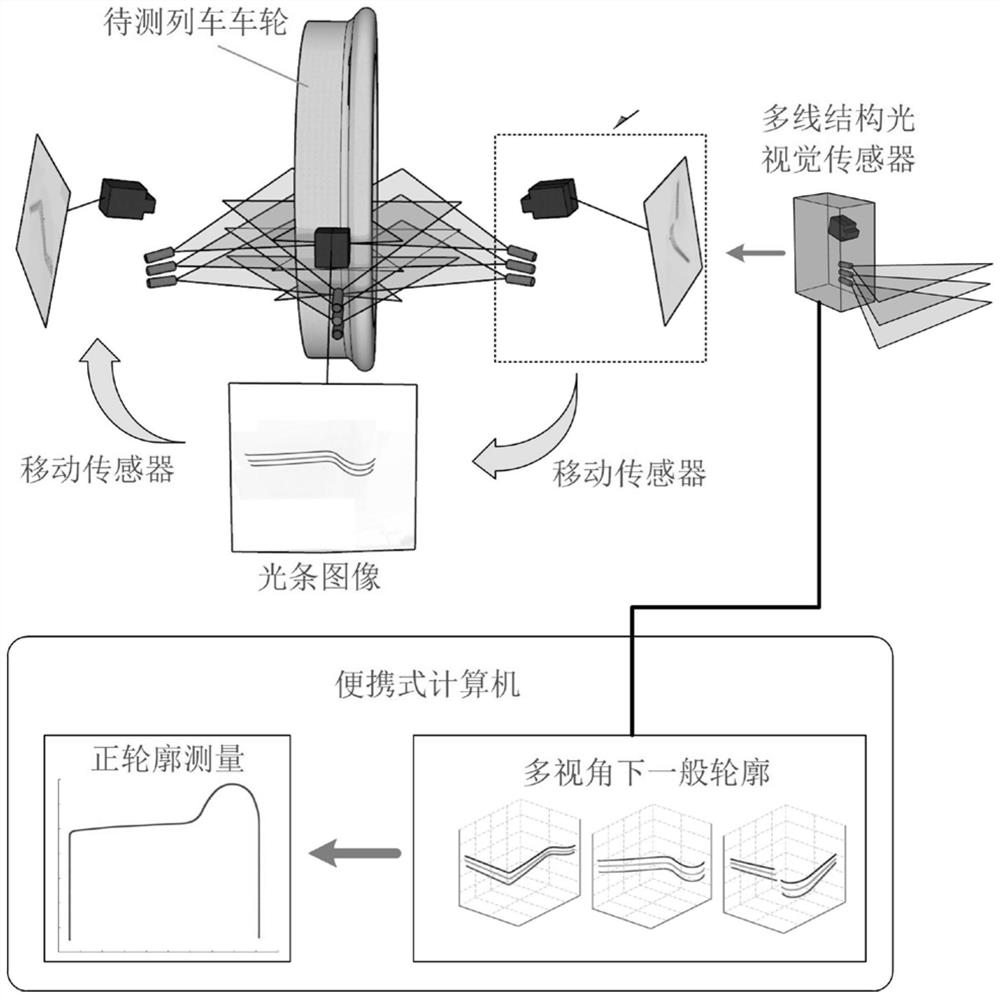

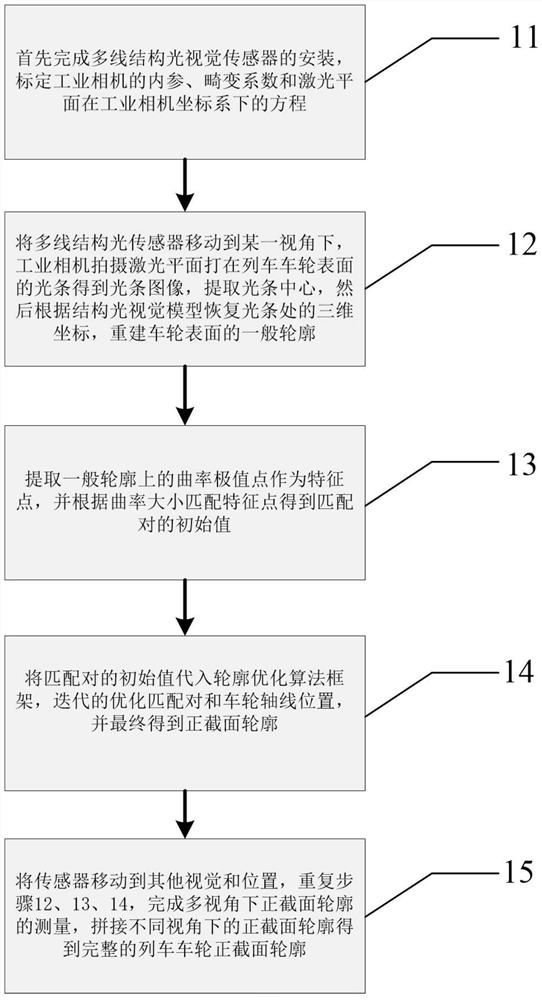

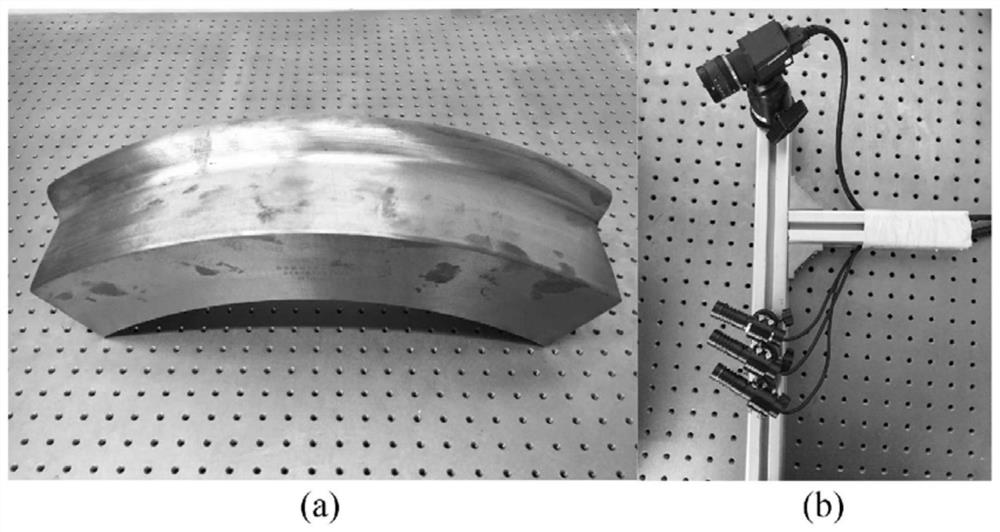

Portable train wheel normal section contour structured light vision measurement system and method

The invention discloses a portable train wheel normal section contour structured light vision measurement system and method. According to the method, a multi-line structured light vision sensor reconstructs general contours of train wheels at different visual angles, the general contours are rotated around an axis and projected to an axis passing plane, so that a normal section contour is obtained, and the complete normal section contour of the train wheels can be obtained by splicing measurement results at the multiple visual angles. The invention provides a train wheel normal section profilemeasurement method which is not constrained by the position and attitude of a sensor. The method has the characteristics of high measurement precision, high operation flexibility, high automation degree, strong robustness and the like.

Owner:BEIHANG UNIV

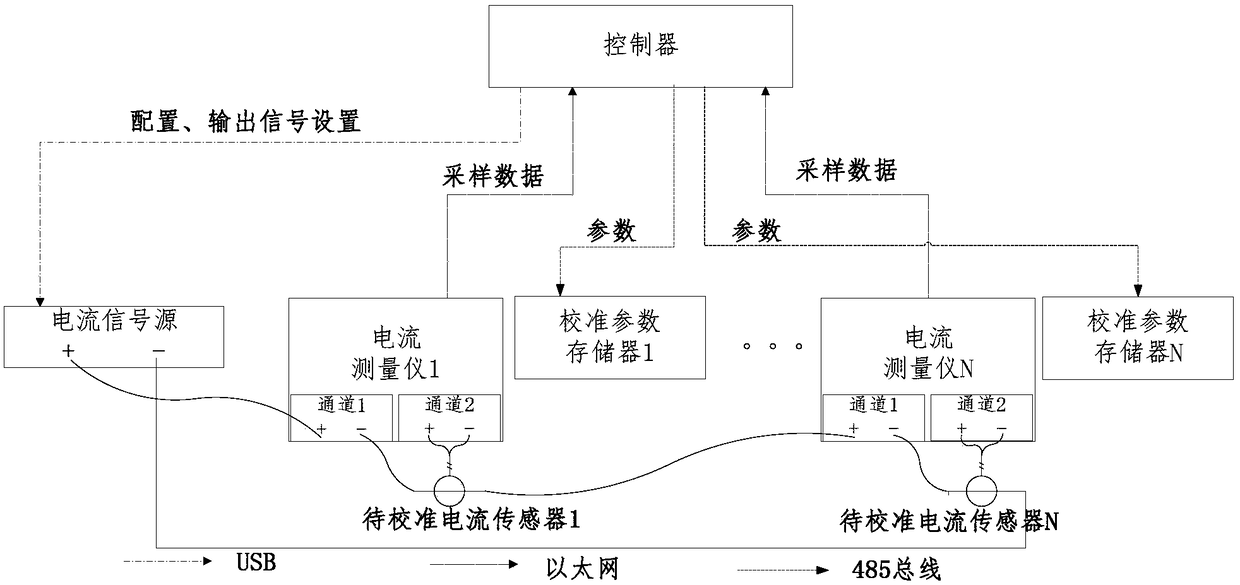

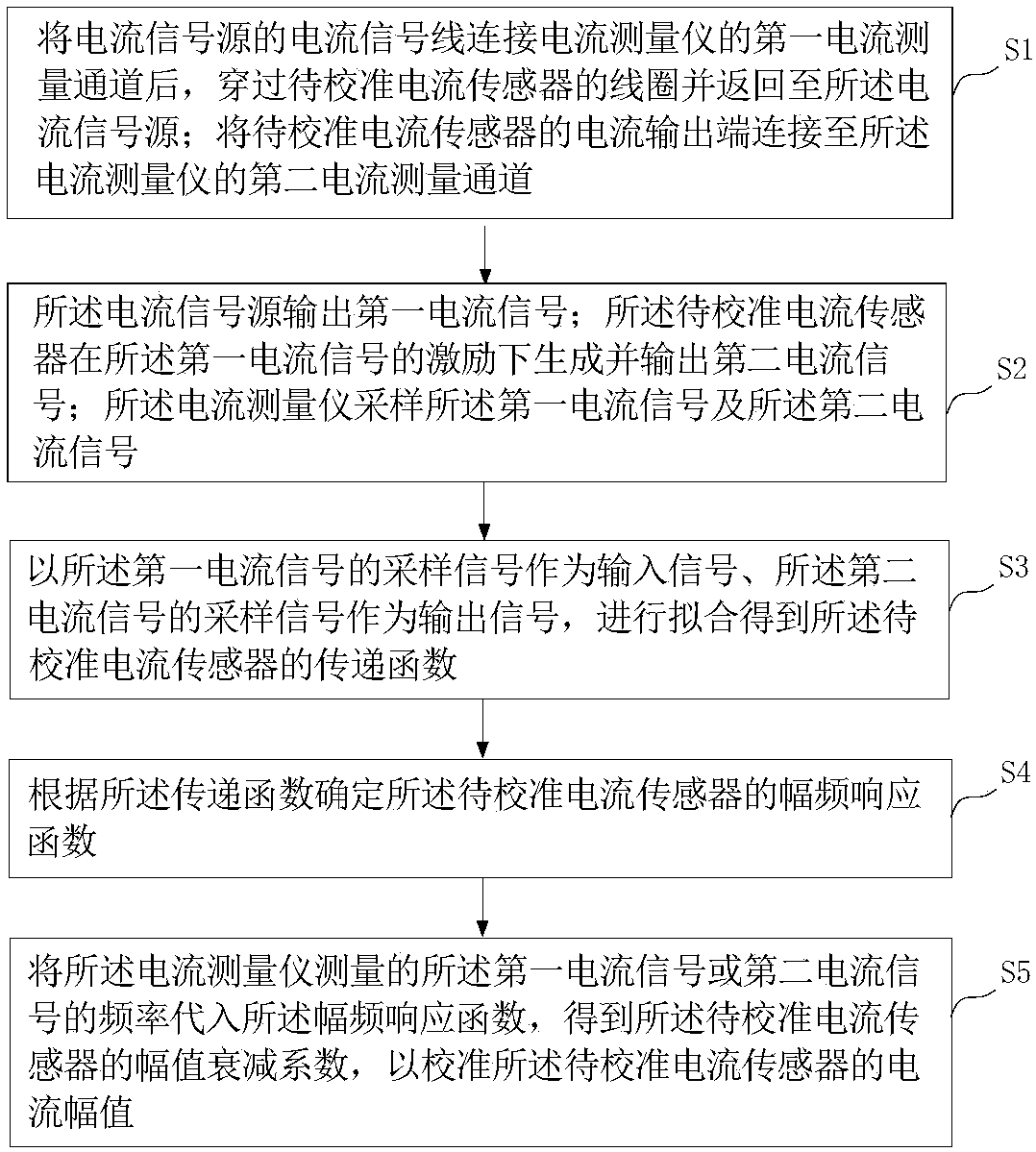

Amplitude frequency calibration system and method of current sensor

InactiveCN108226842AHigh accuracy of amplitude frequency calibrationImprove calibration efficiencyElectrical measurementsObservational errorAttenuation coefficient

The invention provides amplitude frequency calibration system and method of a current sensor. A current signal line of a current signal source is connected with a first current measurement channel ofa current measurement apparatus, then passes through a coil of a to-be-calibrated current sensor and returns to the current signal source; a current output end of the to-be-calibrated current sensor is connected to the current measurement apparatus; the current signal source outputs a first current signal; the to-be-calibrated current sensor generates and outputs a second current signal under excitation of the first current signal; the current measurement apparatus samples the first current signal and the second current signal, and performs fitting to obtain a transfer function of the to-be-calibrated current sensor; an amplitude frequency response function is determined; and the frequency of the measured second current signal is substituted into the amplitude frequency response function to obtain an amplitude attenuation coefficient, so as to calibrate the current amplitude of the to-be-calibrated current sensor. The technical problems of insufficient current accuracy and power measurement accuracy, resulting from the amplitude measurement error introduced by the current sensor when the current measurement apparatus measures current by using the current sensor, are solved.

Owner:INNO INSTR (CHINA) INC

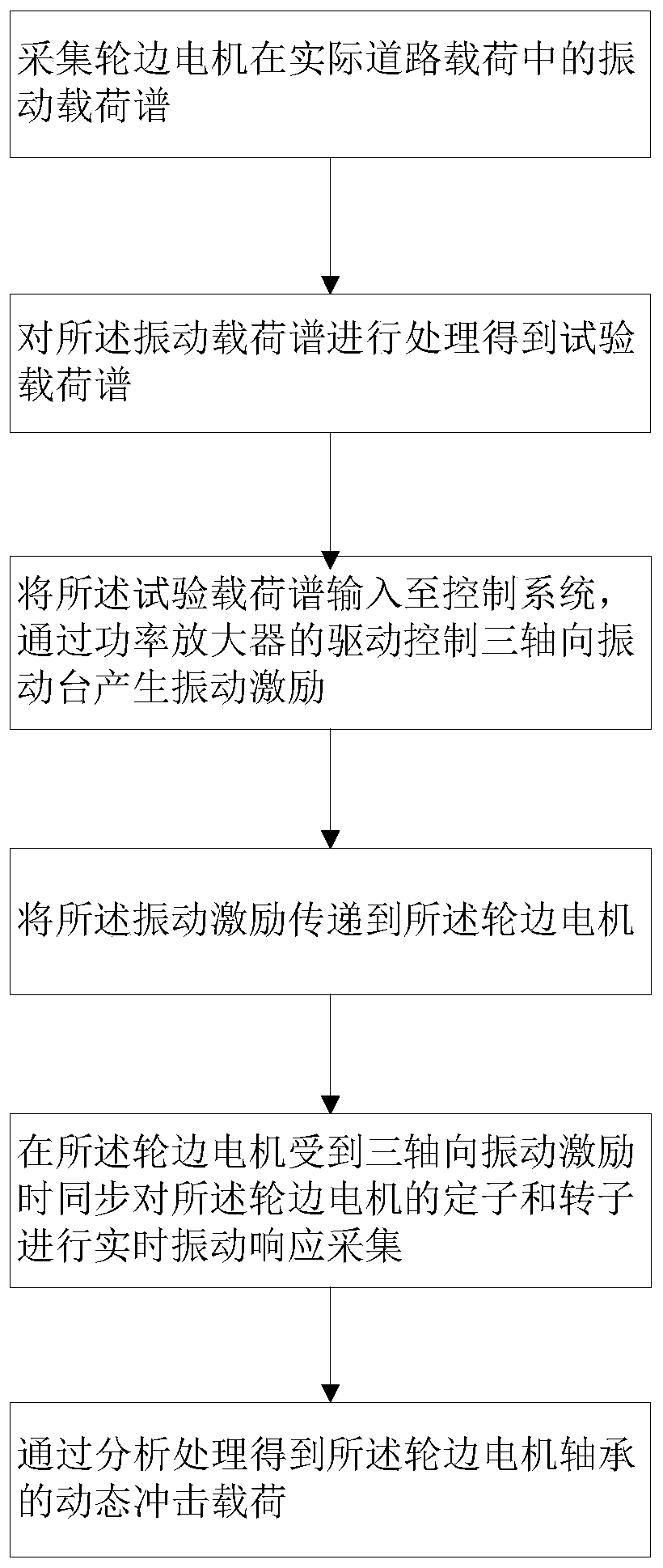

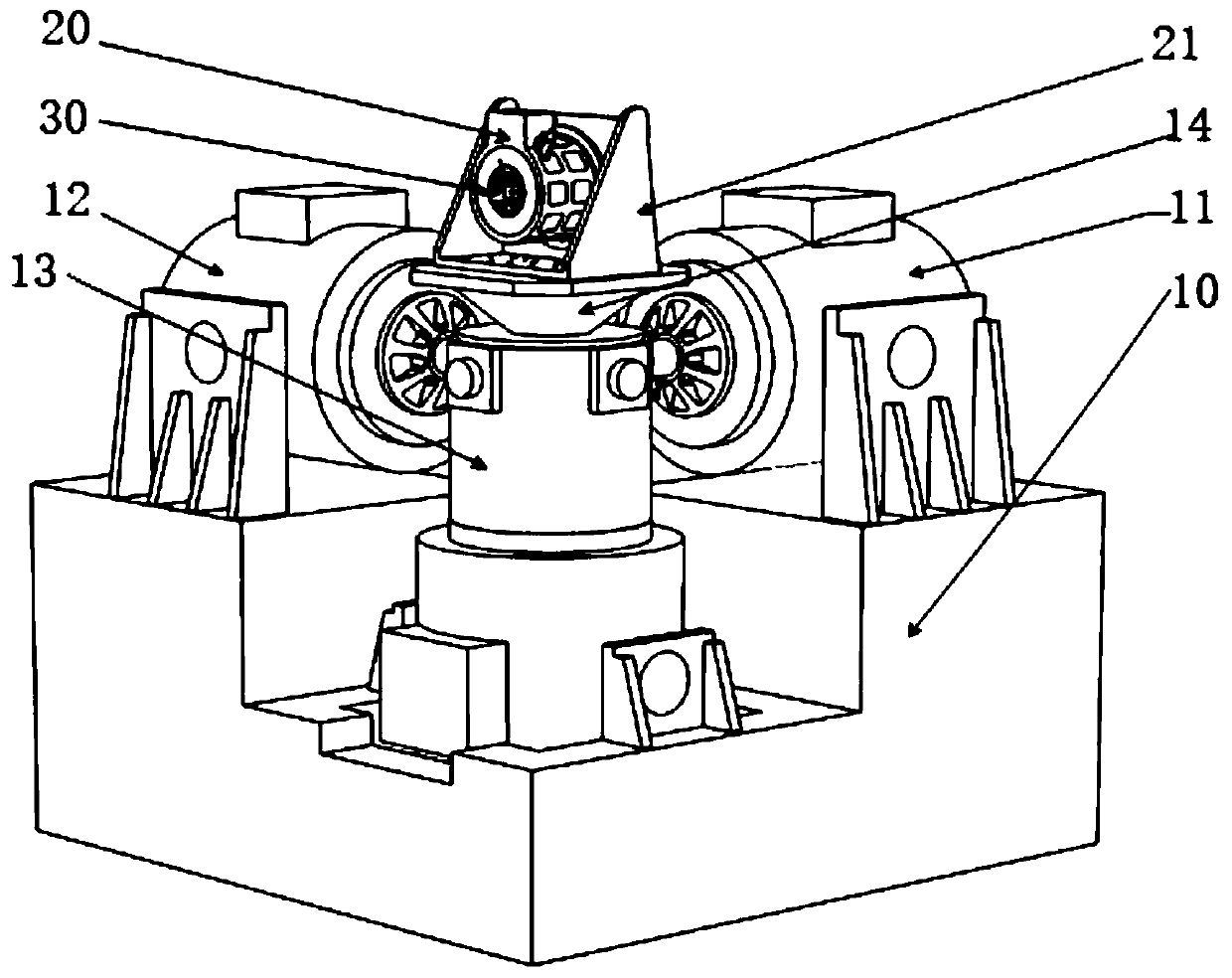

Method and device for measuring dynamic impact load of wheel-side motor bearing

PendingCN111076935AEffective simulationSimulation is accurateMachine part testingControl systemSimulation

The invention relates to a method and a device for measuring a dynamic impact load of a wheel-side motor bearing. The method comprises the steps: collecting a vibration load spectrum of a wheel-side motor in an actual road load, and processing the vibration load spectrum to obtain a test load spectrum; inputting the test load spectrum into a control system, fixing the wheel-side motor on a triaxial vibration table, and using the test load spectrum to drive the triaxial vibration table through a power amplifier to simultaneously generate a triaxial vibration load consistent with an actual roaduse vibration environment; and acquiring vibration responses of a stator and a rotor of the wheel-side motor in real time, and analyzing, processing and obtaining the dynamic impact load of the motorbearing. The method is high in collection precision and high in operability, a multi-axis vibration stress environment in the real use environment is ensured to be effectively simulated, and a high-precision measurement requirement of a complex environment can be well met.

Owner:苏州长菱测试技术有限公司

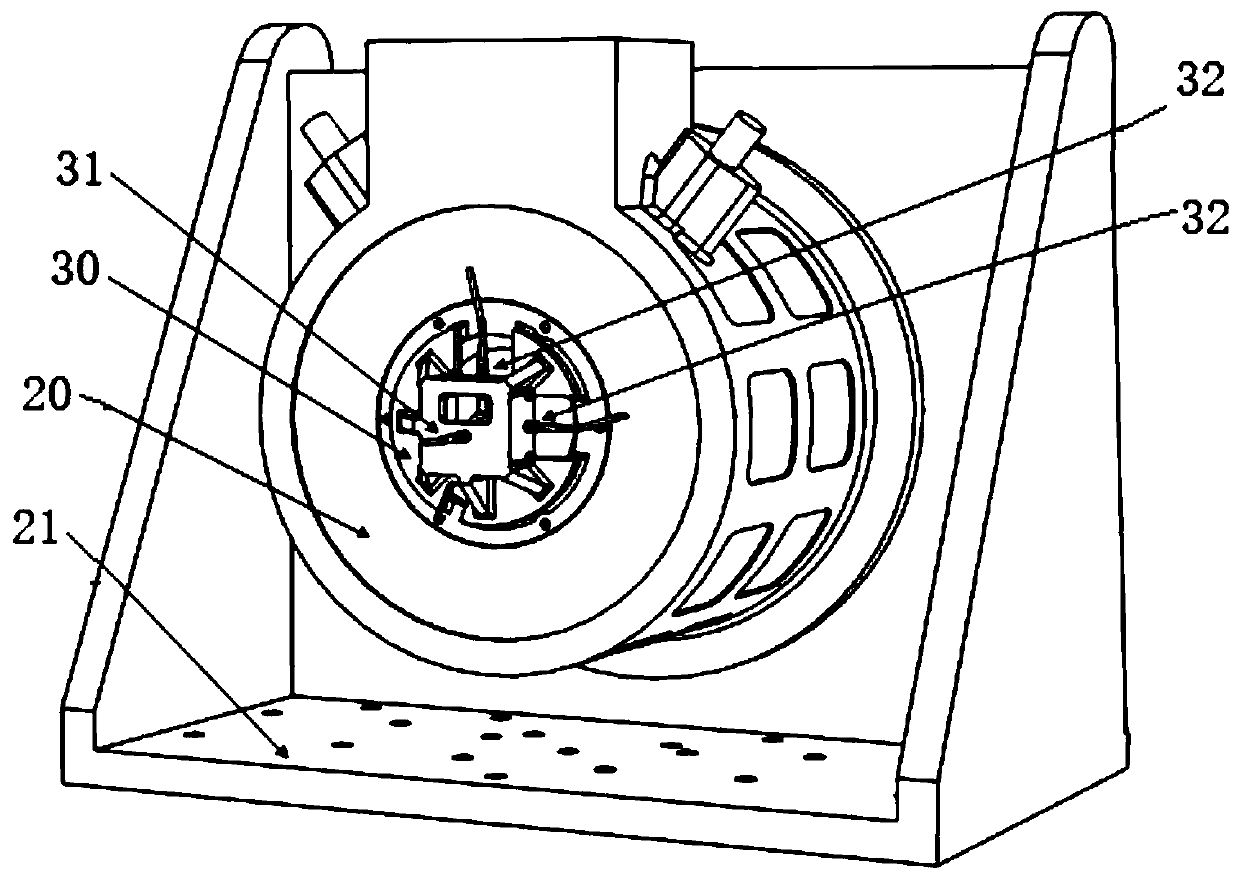

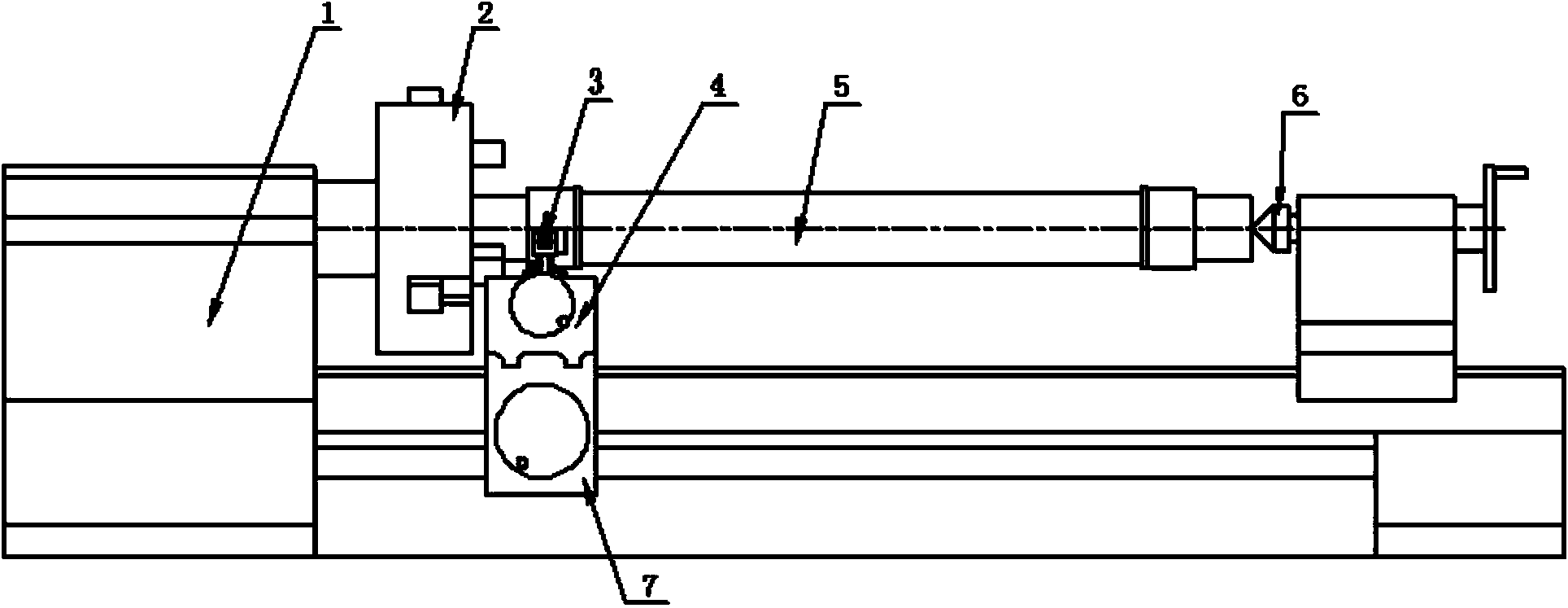

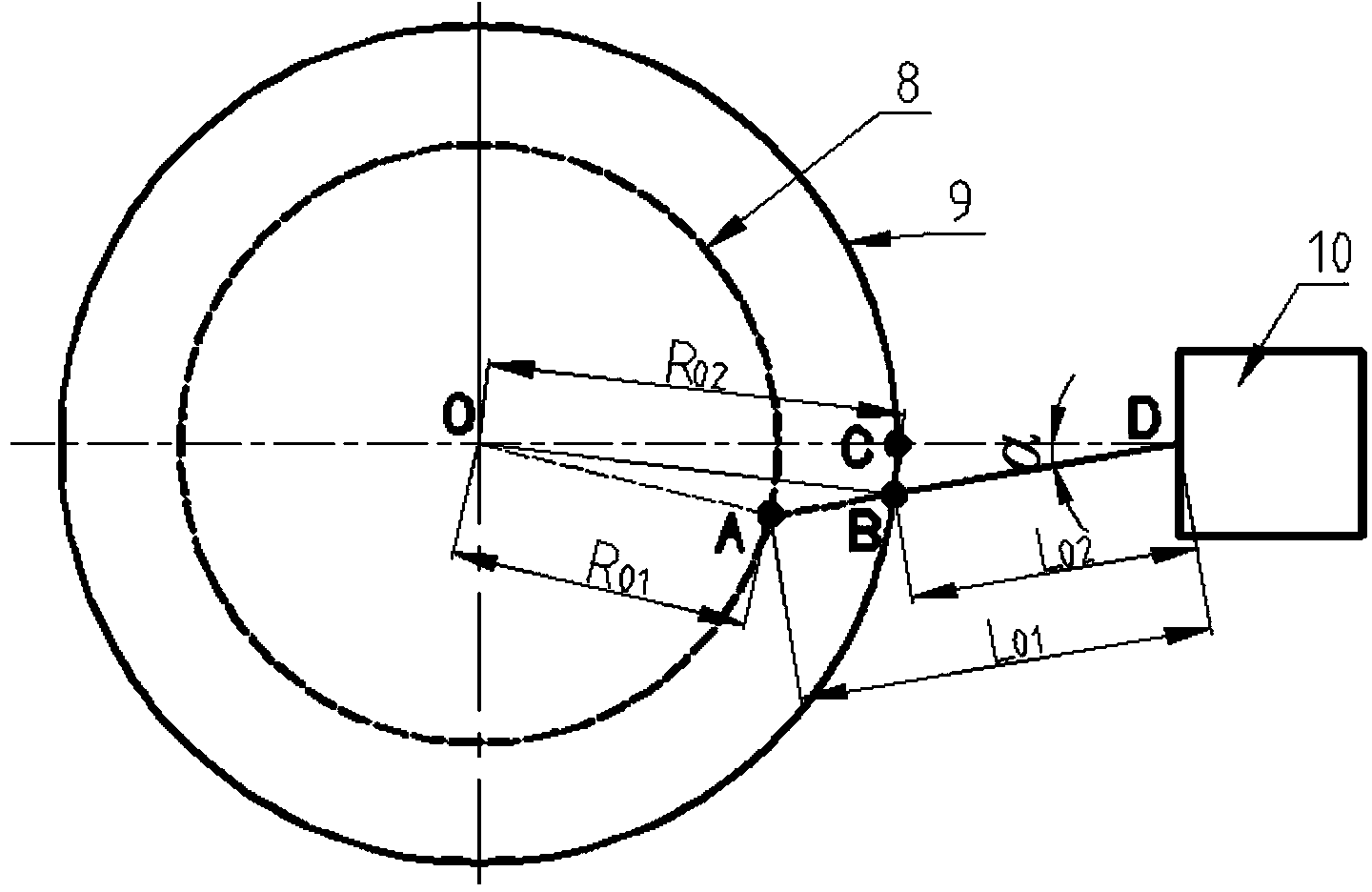

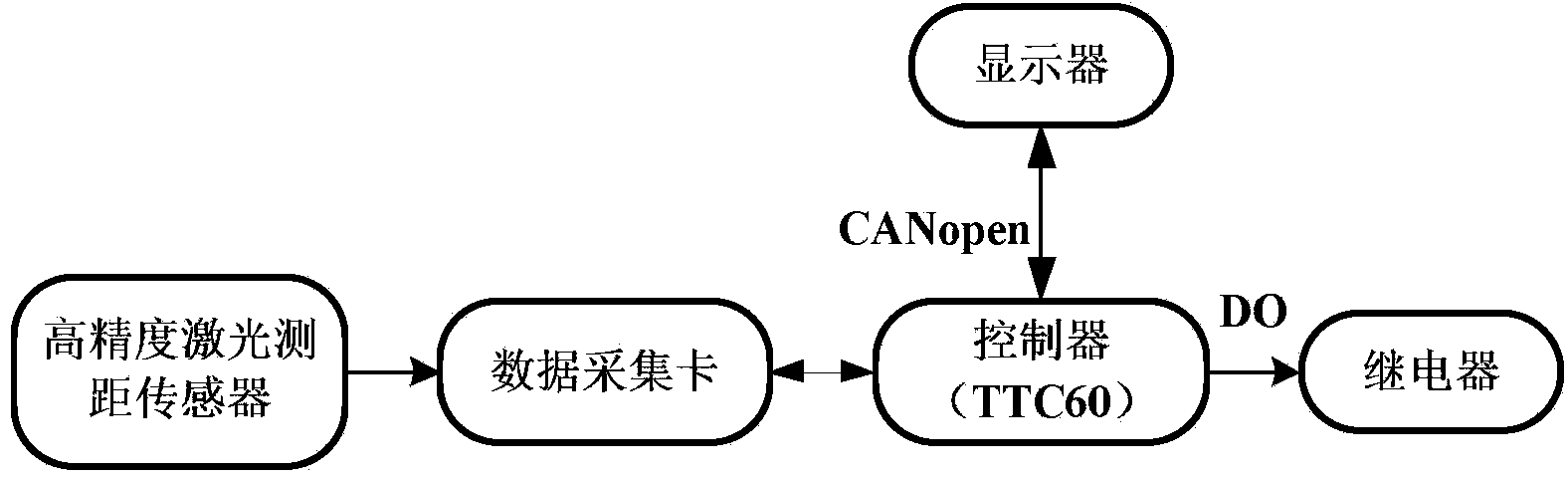

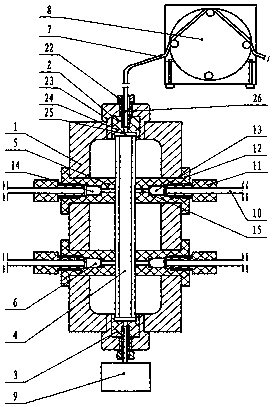

Non-contact type measuring system for train axle wheel seat and measuring method thereof

InactiveCN103586492AEliminate errorsMeet high-precision measurement requirementsAuxillary equipmentLaser rangingDisplay device

The invention discloses a non-contact type measuring system for a train axle wheel seat and a measuring method thereof and belongs to the technical field of measurement. The measuring system comprises a lathe, a laser distance measuring sensor, a fine adjusting device for the laser distance measuring sensor, a data collecting card, a main controller, a displayer, a relay, a cable power supply, a signal communicating module, a driving control module and a data collecting and processing module. The measuring system improves a C6180 lathe, and the high-accuracy laser distance measuring sensor is arranged on a horizontal slide carriage of the lathe. The accurate measurement of the outer diameters of the corresponding positions of large shaft parts on the lathe can be achieved according to the principle that the distance between the laser distance measuring sensor and the axis of the lathe is constant. A layer ray deflection angle alpha which can affect measurement results is calibrated through measurement of two standard measuring rods, so that error generated by the deflection angle is eliminated, and the measuring requirements for higher accuracy are met.

Owner:MAANSHAN MAGANG JINXI RAIL TRANSPORT EQUIP +1

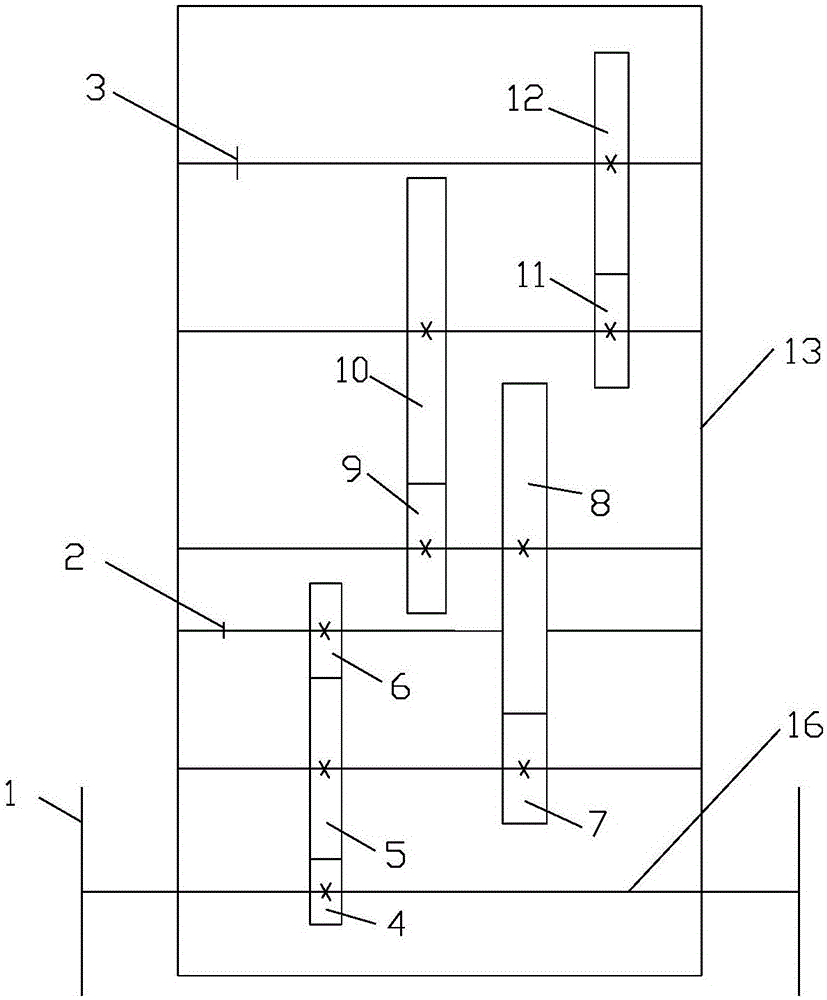

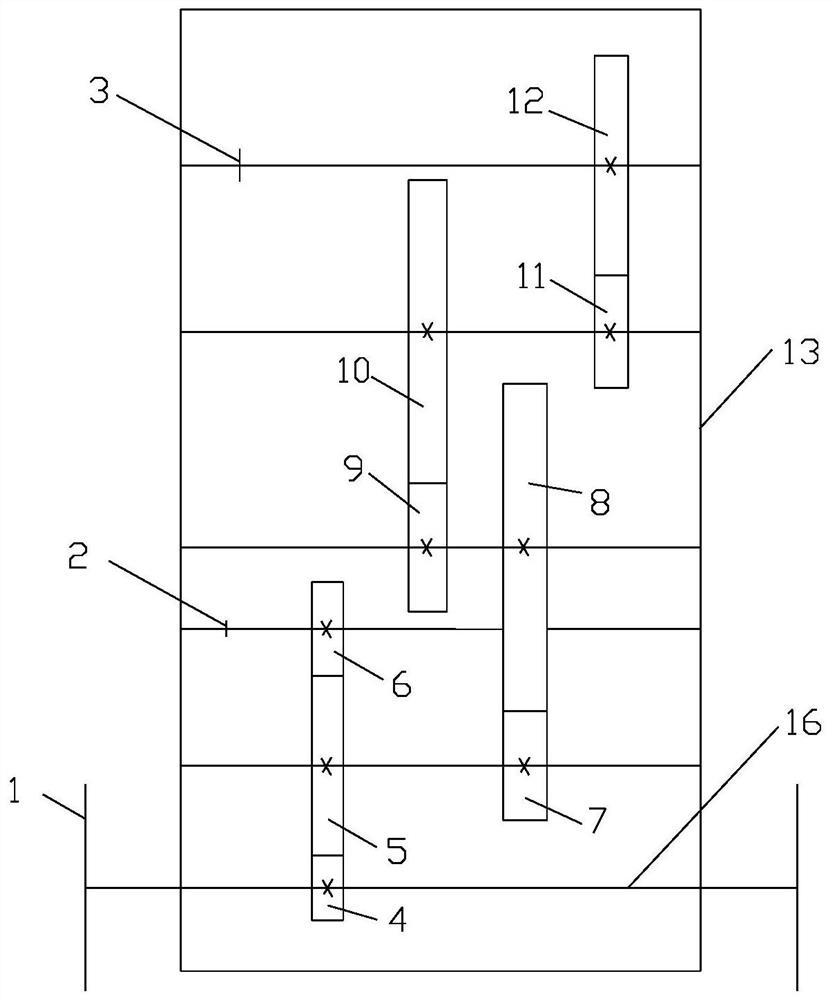

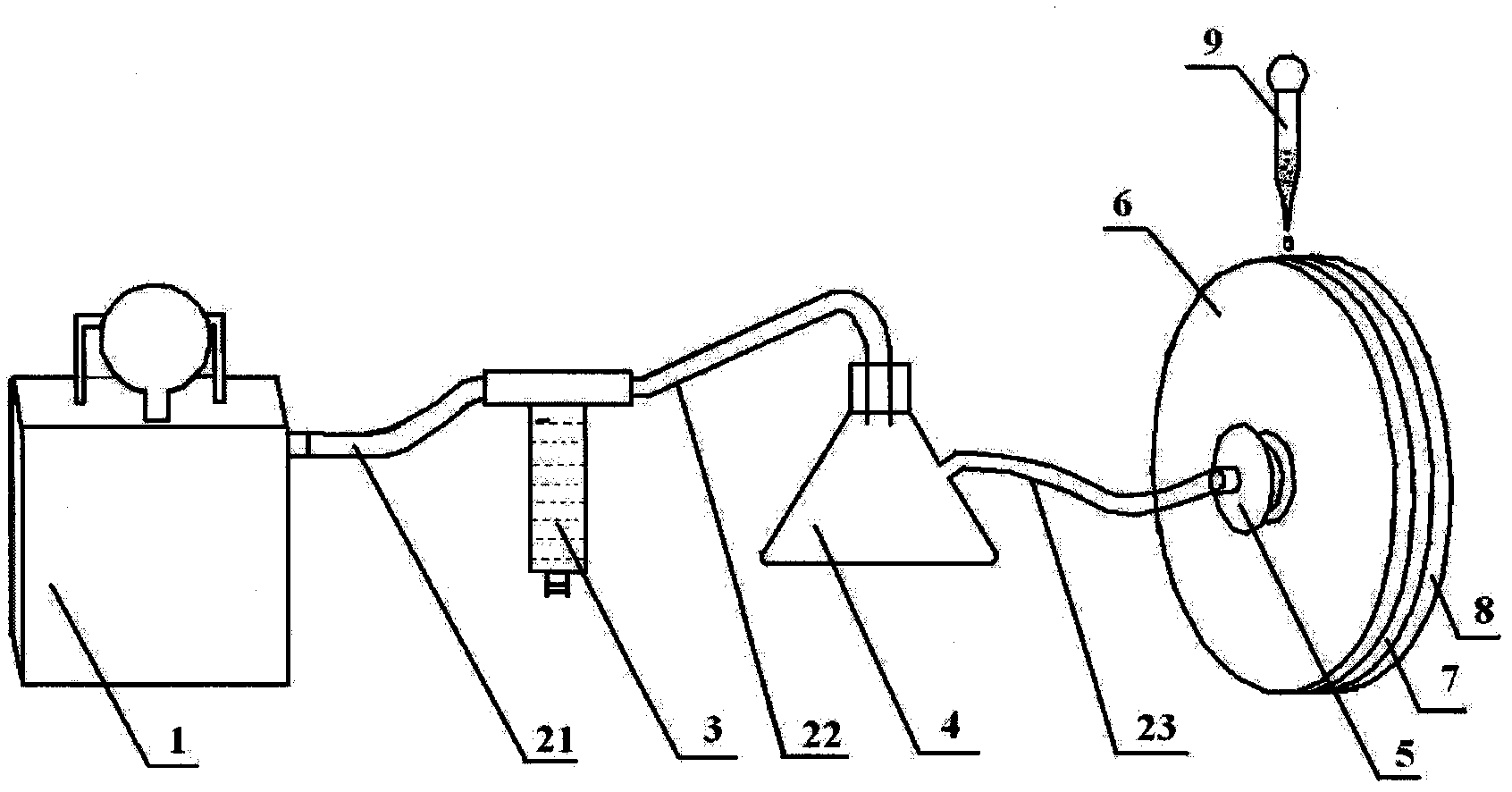

Accurate liquid taking and meteringdevice for water quality analyzer

InactiveCN107764597AAccurate measurementThe metering device adopts peristaltic pump negative pressure to draw accuratelyWithdrawing sample devicesPeristaltic pumpWater quality

The present invention is a precise liquid taking and measuring device for a water quality analyzer, belonging to the technical field of precise liquid taking and measuring devices; the invention overcomes the deficiencies in the prior art, and the problem to be solved is: to provide a precise liquid taking and measuring device for a water quality analyzer, which adopts The solution is: a precise liquid taking and measuring device for a water quality analyzer, including: a measuring bracket, an upper interface, a lower interface, a measuring tube, an upper photoelectric measuring mechanism, a lower photoelectric measuring mechanism, a hose, a peristaltic pump, and a reagent liquid feeding mechanism. The structure is as follows: the top of the metering bracket is provided with an upper interface, the bottom of the metering bracket is provided with a lower interface, a measuring liquid pipe is arranged between the upper interface and the lower interface, the upper interface is connected with a hose and a peristaltic pump, and the lower interface is connected with a reagent inlet. The middle and upper part of the metering bracket is provided with an upper photoelectric measuring mechanism, and the middle and lower part of the metering bracket is provided with a lower photoelectric measuring mechanism; the invention is widely used in the online automatic monitoring system of water quality.

Owner:常州耐森环保科技有限公司

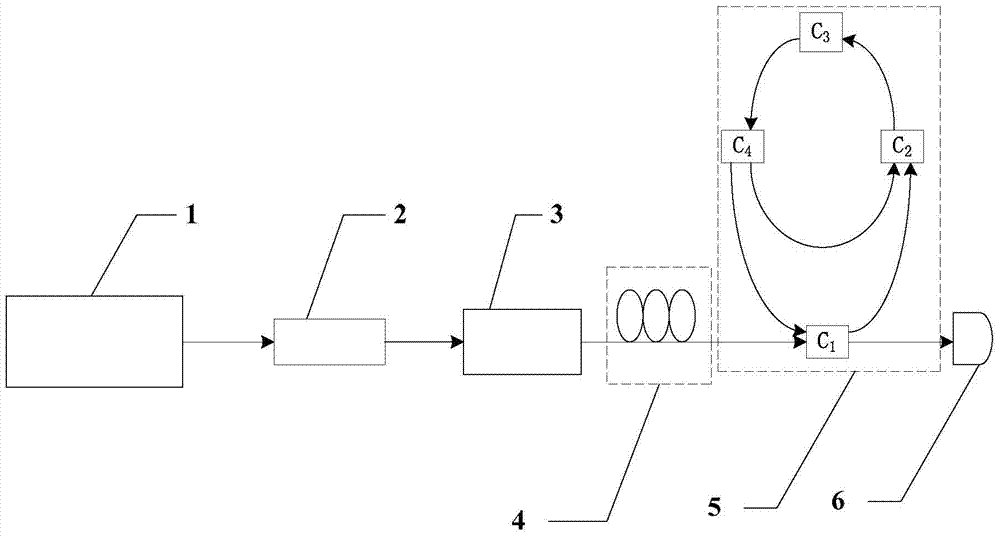

A high-sensitivity resonant system based on straight waveguide-feedback waveguide-ring-straight waveguide

ActiveCN105203135BReduced quality factor requirementsHigh sensitivityConverting sensor output opticallyResonant cavityResonance

Owner:HARBIN INST OF TECH

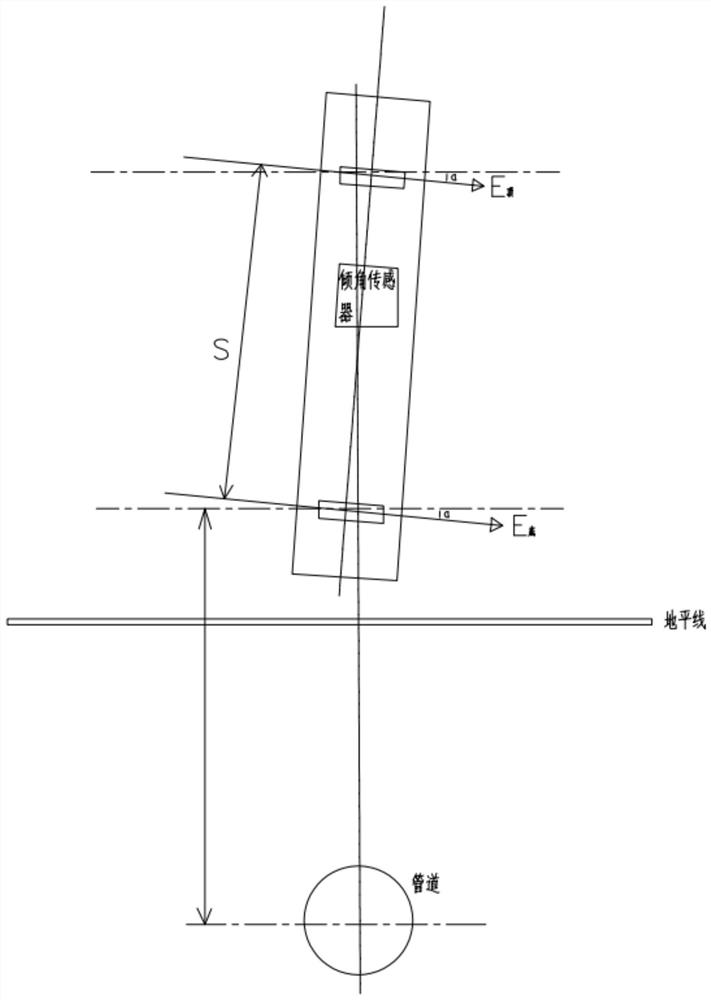

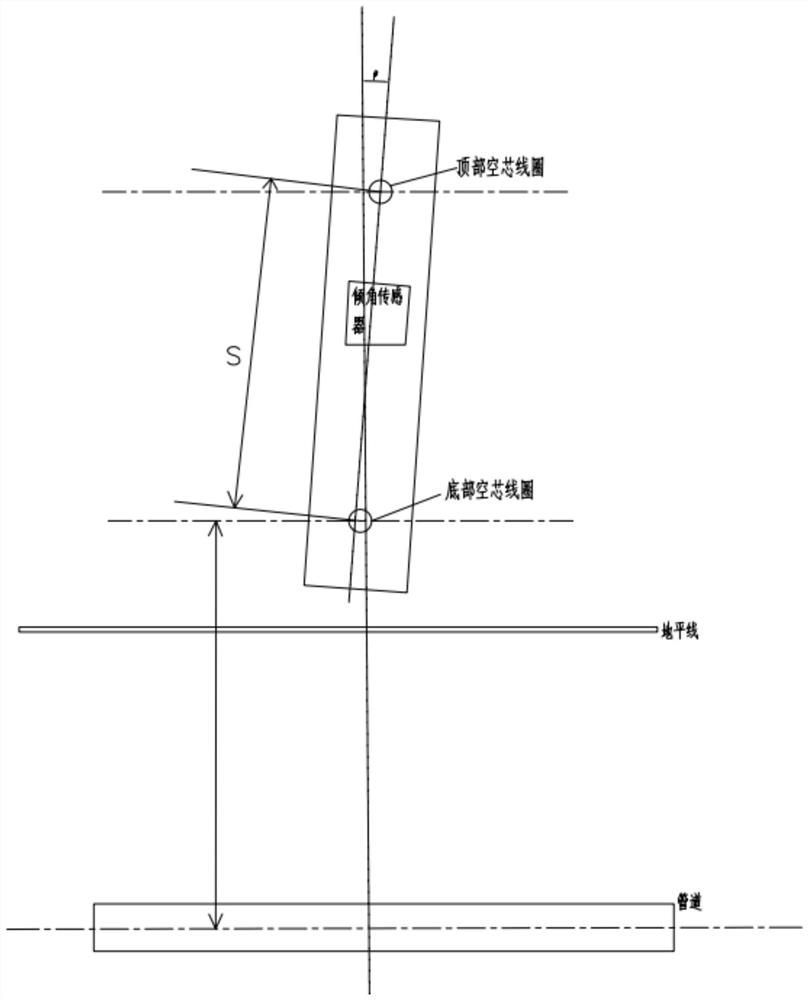

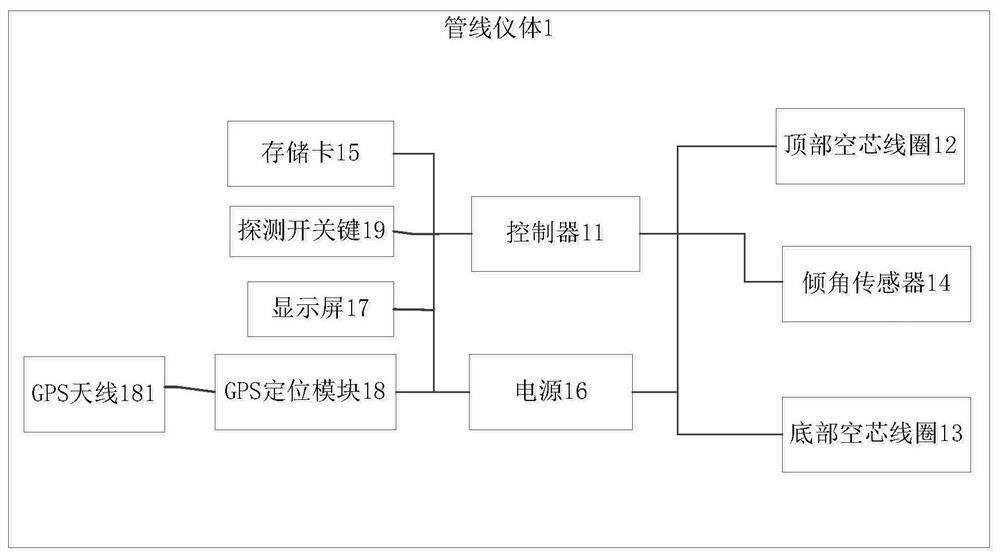

Accurate Electromagnetic Measuring Method and Pipeline Instrument Device of Underground Pipeline Depth

ActiveCN110989012BEasy to operateMeet high-precision measurement requirementsElectric/magnetic detectionAcoustic wave reradiationMagnetic measurementsStructural engineering

The invention discloses an accurate electromagnetic measuring method for the depth of underground pipelines and a pipeline instrument device. The operator holds the pipeline instrument device on the ground directly above the buried pipeline to measure the axis and lead of the top air-core coil and the bottom air-core coil. The included angle in the vertical direction, and the included angle between the central axis of the top air-core coil and the bottom air-core coil and the vertical direction, the inclination sensor in the pipeline instrument device is used to correct the electric current measured by the top air-core coil and the bottom air-core coil respectively. The magnetic induction intensity is the top electromagnetic induction intensity value and the bottom electromagnetic induction intensity value, as well as the distance value between the top air-core coil and the bottom air-core coil, so as to obtain a more accurate buried depth value of the ultra-deep pipeline underground pipeline. The invention is simple to implement, and the measurement deviation caused by the inaccurate measurement position of the locator can be eliminated only by the pipeline instrument device with the inclination sensor, and the measurement accuracy of the buried depth of the ultra-deep pipeline can be greatly improved.

Owner:ZHEJIANG PROVINCIAL SPECIAL EQUIP INSPECTION & RES INST +1

Body position detection method for car wash

ActiveCN106643496BAccurate measurementMeet high-precision measurement requirementsUsing optical meansComputer moduleElectrical control

The present invention provides a vehicle body position detection method for washing vehicles. The vehicle body position detection method comprises the following steps: a measurer (1) measures the height of a vehicle body, a detector (3) measures the position of a tire (71), the contour line of the vehicle body is measured through an image processor, the measurer (1) and the detector (3) are connected with the image processor through a line and an electrical control module (4), the measurer (1), the detector (3) and a camera (2) in the image processor are fixed on a frame body (5), the frame body (5) is arranged on a vehicle washing frame (8) and can move back and forth by means of a driving mechanism, and the driving mechanism is connected with the electrical control module (4). The vehicle body position detection method for washing vehicles can measure the position values of the projecting portions such as retroreflectors, a baggage holder and the like on the vehicle body contour, and the measurement is rapidly performed in a non-contact and automation mode. Besides, the vehicle body position detection method for washing vehicles measures the tire orientation and the wheelbase so as to perform special cleaning of tires, determine the head and tail and in-out position condition of the vehicle and assist to determine the type of the vehicle.

Owner:宁波中令清洁技术有限公司

Point-line form mileage measurement device

ActiveCN106500566AEasy to operateHigh precisionMechanical length measurementsDrive wheelMeasurement device

The invention relates to the distance measurement technology field and particularly relates to a point-line form mileage measurement device. The device comprises a driving wheel rolling on a measurement-needing surface, a decimal scale gear transmission set, an integer scale gear transmission set, a decimal dial arranged at a tail end of the decimal scale gear transmission set, and an integer dial arranged at a tail end of the integer scale gear transmission set, wherein an initial end of the decimal scale gear transmission set, an initial end of the integer scale gear transmission set and the driving wheel are coaxially arranged, the decimal dial has n scale lines distributed around the decimal dial in a circumferential array mode, a radius of the driving wheel is r, a transmission ratio of the decimal scale gear transmission set is a, a transmission ratio of the integer scale gear transmission set is b, 2Pira / n is not greater than 0.1m, the integral dial has t scale lines distributed around the integral dial in a circumferential array mode, 2Pirb / t is not smaller than 1m, and thereby rolling length of the driving wheel can be calculated according to pointer reading of the integral dial and pointer reading of the decimal dial. The device is advantaged in that the device is convenient to operate, and relatively long construction length can be measured by one person.

Owner:JIANGSU UNIV OF TECH

Multilateral measurement calibration method, device and equipment, and medium

ActiveCN114046756AImprove reliabilityGuaranteed Calibration AccuracyMeasurement devicesAlgorithmEngineering

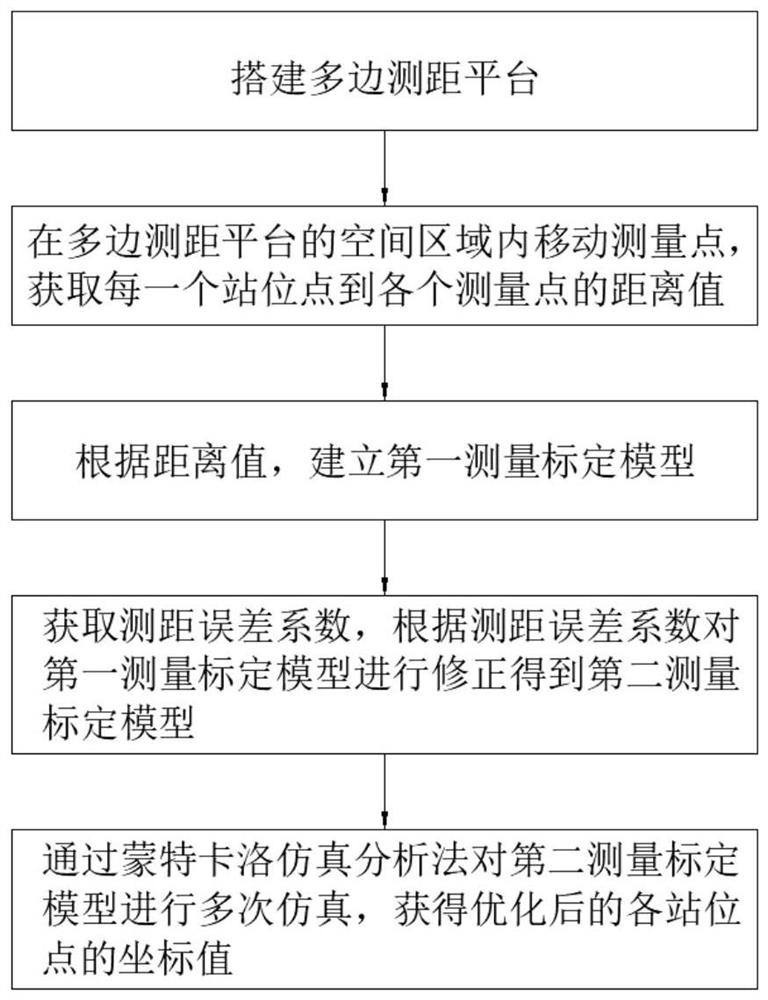

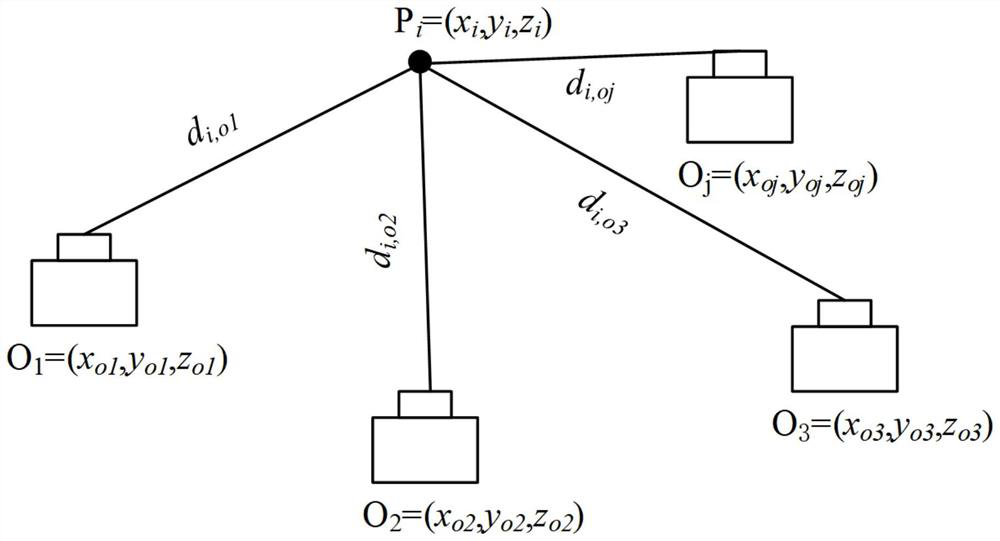

The invention discloses a multilateral measurement calibration method, device and equipment, and a medium. The method comprises the following steps: building a multilateral distance measurement platform, wherein the multilateral distance measurement platform comprises a plurality of distance measuring devices; moving measuring points in the space area of the multilateral distance measurement platform, and obtaining the distance value from each station point to each measuring point, wherein each station point is an original point of a measurement coordinate system of each distance measuring device; establishing a first measurement calibration model according to the distance values; obtaining a distance measurement error coefficient, and correcting the first measurement calibration model according to the distance measurement error coefficient to obtain a second measurement calibration model; simulating the second measurement calibration model for multiple times through a Monte Carlo simulation analysis method, and obtaining the optimized coordinate values of all the station points. According to the method, the influence of distance measurement errors on calibration precision is fully considered, station calibration optimization is conducted through the Monte Carlo simulation analysis method, and therefore the calibration precision of the multilateral measurement method is improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Body position detection device for car washing

ActiveCN106705842BAccurate measurementMeet high-precision measurement requirementsUsing optical meansComputer moduleElectrical control

Owner:宁波中令清洁技术有限公司

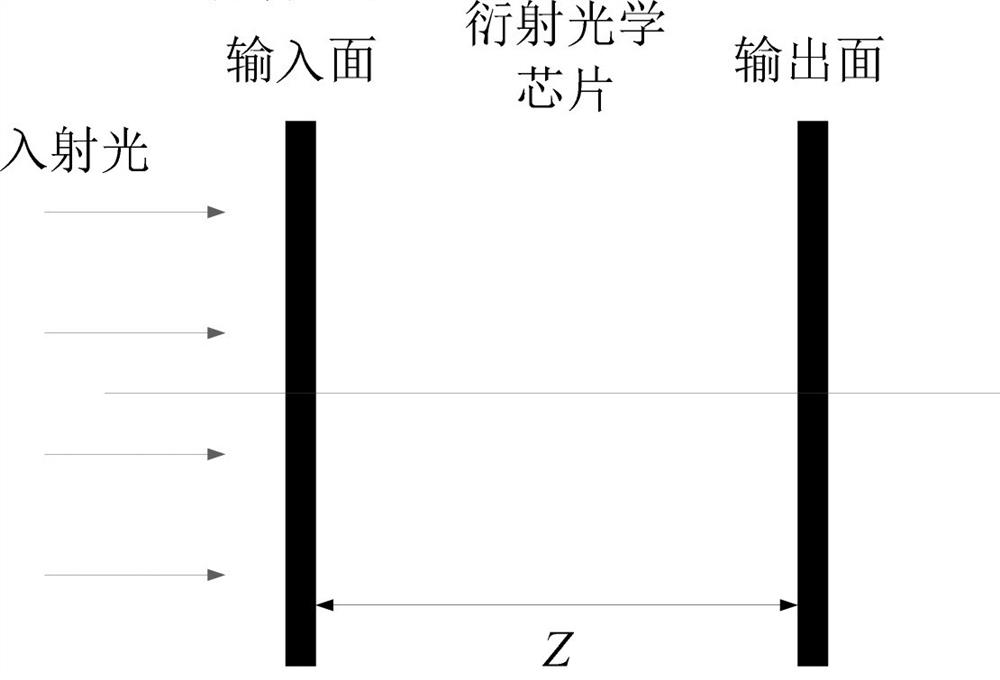

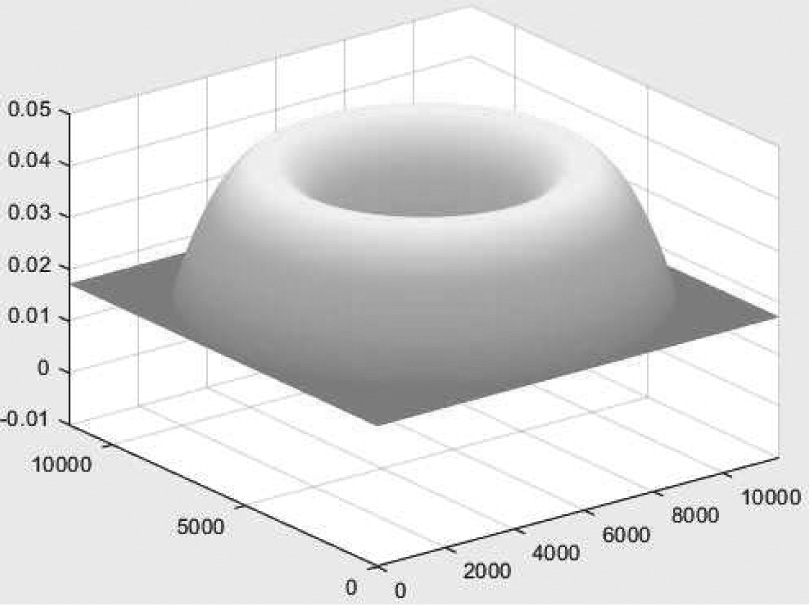

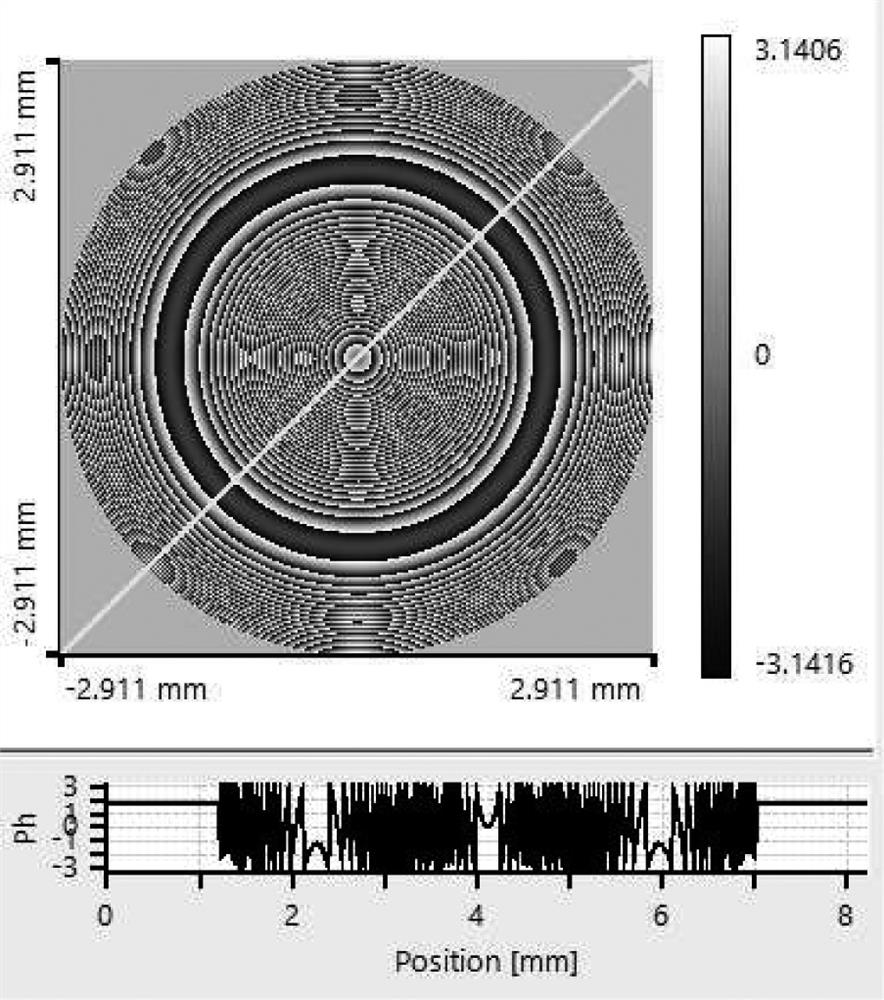

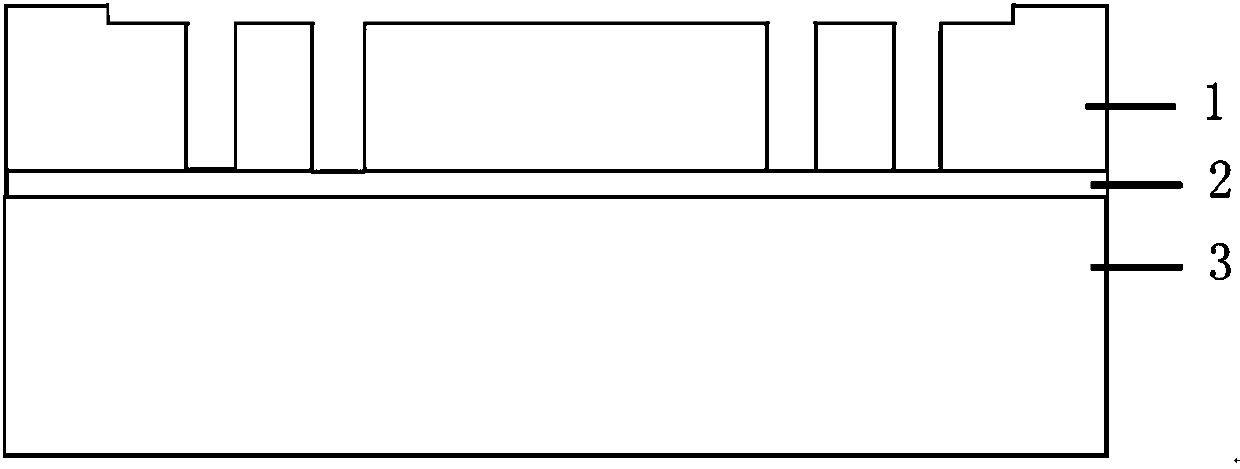

Diffractive optical chip

The invention discloses a diffractive optical chip, which is provided with an incident surface for realizing intensity homogenization and an emergent surface for realizing phase homogenization, the outer diameters of the incident surface and the emergent surface are 25.4 mm, and the incident surface and the emergent surface are symmetrically arranged; fused quartz (JGS1) is used as a substrate material, a laser direct writing gray mask technology is adopted for continuous face type manufacturing, a micro-nano double-face monomer structure or a micro-nano four-face double-body structure with the thickness being 40 mm is formed, and the micro-nano four-face double-body structure further comprises two unstructured planes with the distance being 38 mm. The embodiment of the invention is simple in structure, ingenious in design and convenient to implement, has outstanding substantive features and remarkable progress, and is suitable for large-scale popularization and application.

Owner:HUAZHONG PHOTOELECTRIC TECH INST (CHINA SHIPBUILDING IND CORP THE NO 717 INST)

Point-line mileage measuring device

Owner:JIANGSU UNIV OF TECH

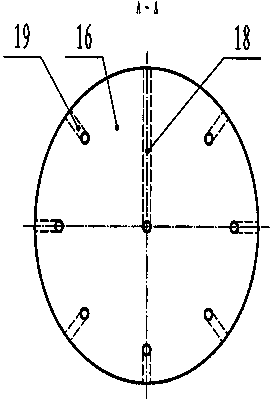

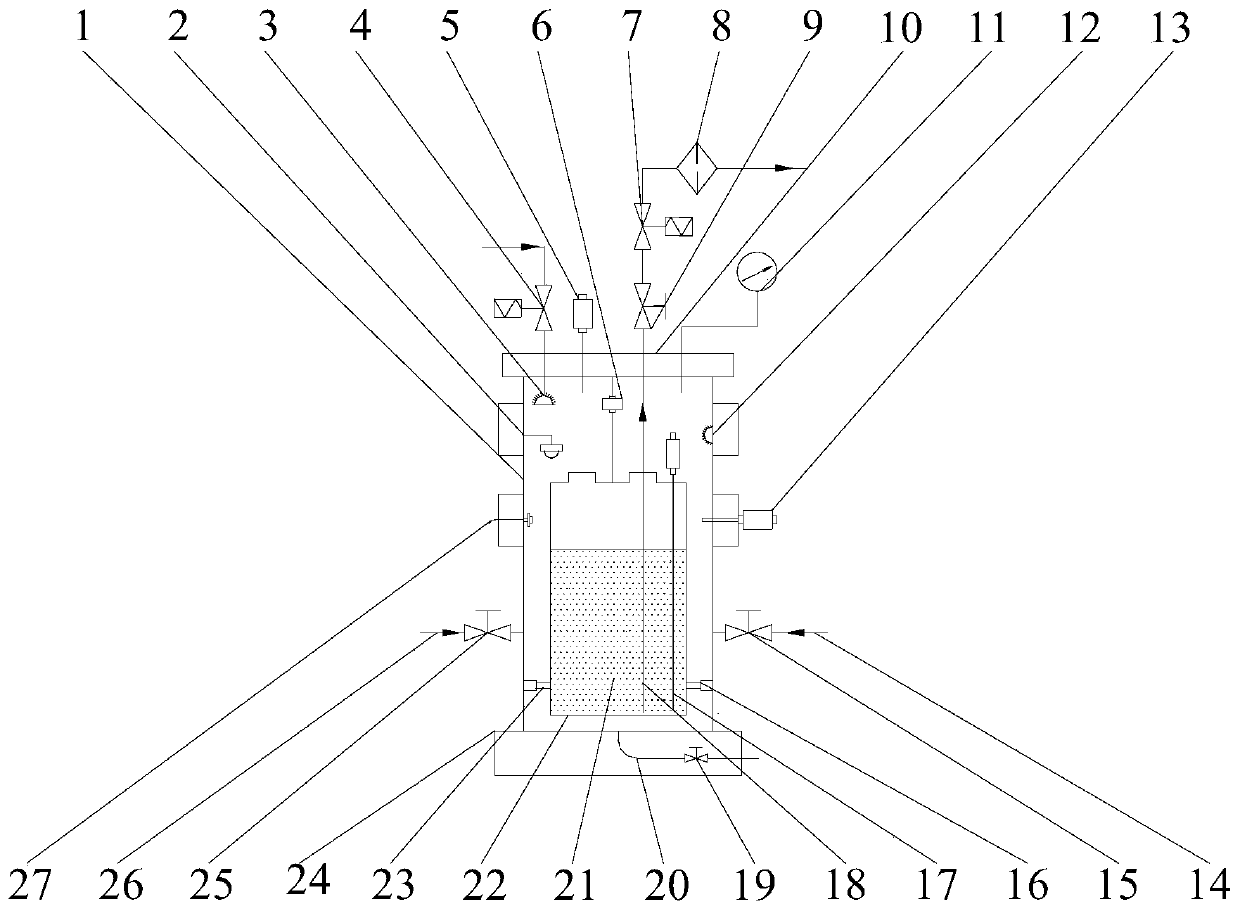

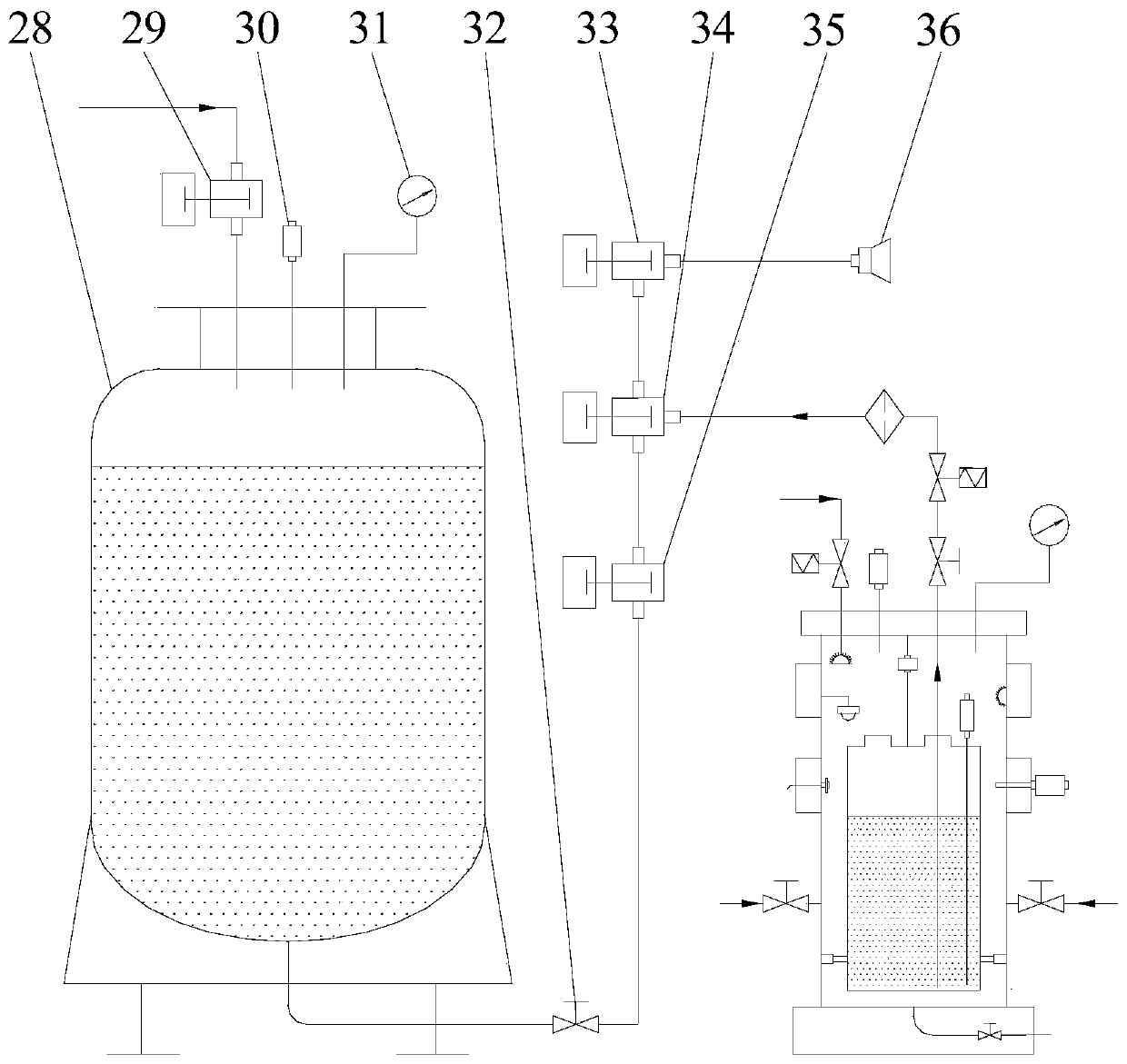

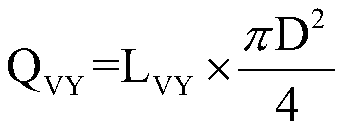

Method and device for dual-mode measurement of engine propellant flow in pulse working condition for fault identification

ActiveCN109307598BImprove stabilityImprove reliabilityEngine testingControl engineeringControl theory

The invention provides a self-feedback intelligent-fault-recognition pulse-working-condition engine propellant flow two-mode measurement device. A function realization auxiliary unit is used for cooperating with propellant flow measurement, and controlling a flowing pipeline of a propellant. A parameter detection module is used for measuring feature parameters of a propellant in a flowing process,and calculating out and deriving a propellant flow value through the feature parameters. A cylinder body support component includes an outer cylinder body and an inner cylinder body. The outer cylinder body is used for enclosing pressurized gas space. The inner cylinder body is used for storing the propellant. Peripheral components are used for ensuring propellant flow measurement stability performance. The cylinder body support component is connected with the function realization auxiliary unit through a propellant liquid discharging pipe. The propellant flows between the inner cylinder bodyand the function realization auxiliary unit through the propellant liquid discharging pipe. Flow measurement under a propellant pulse working condition is realized, the device has the characteristicsof two-mode measurement, good reliability, high stability, intelligent fault recognition and the like, and high-precision measurement requirements of engines on flow can be satisfied.

Owner:SHANGHAI INST OF SPACE PROPULSION

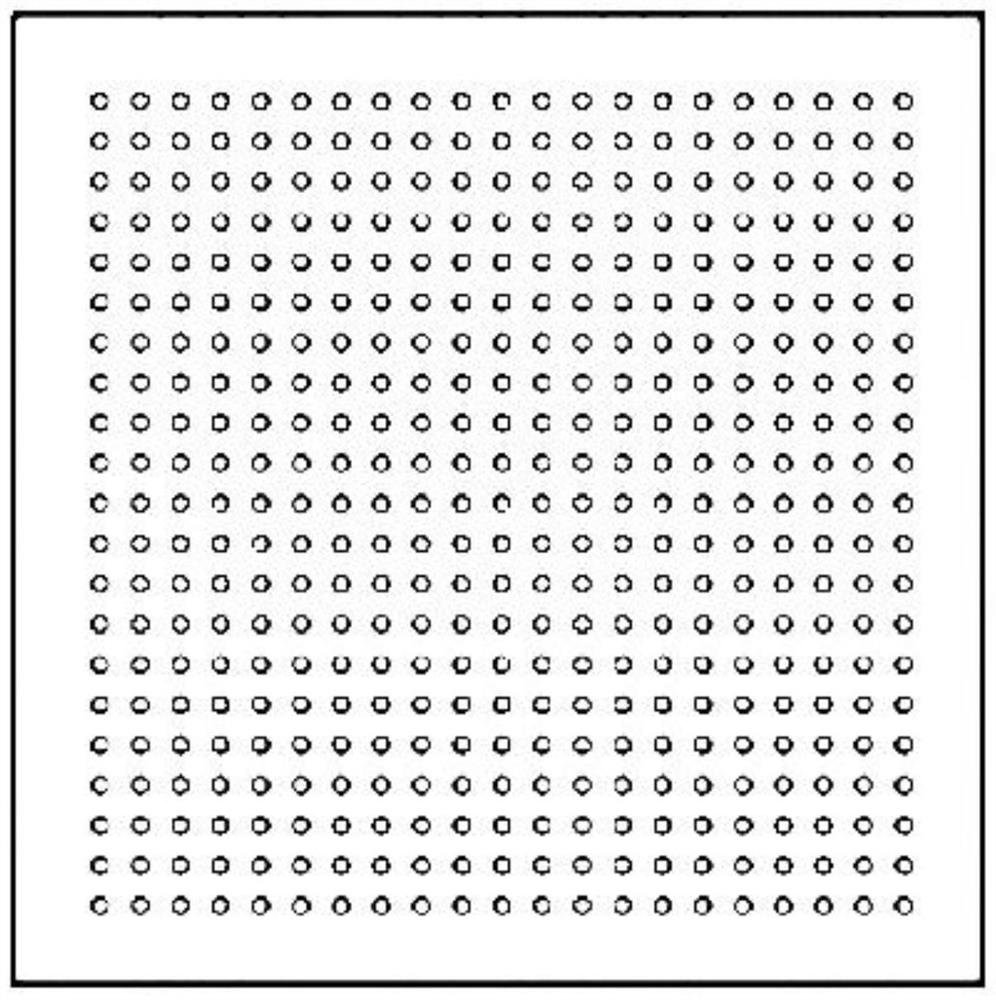

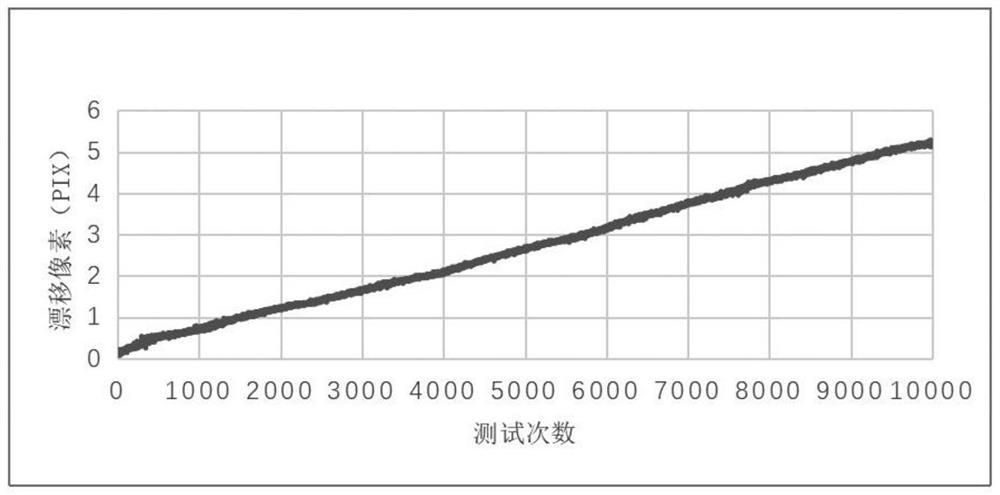

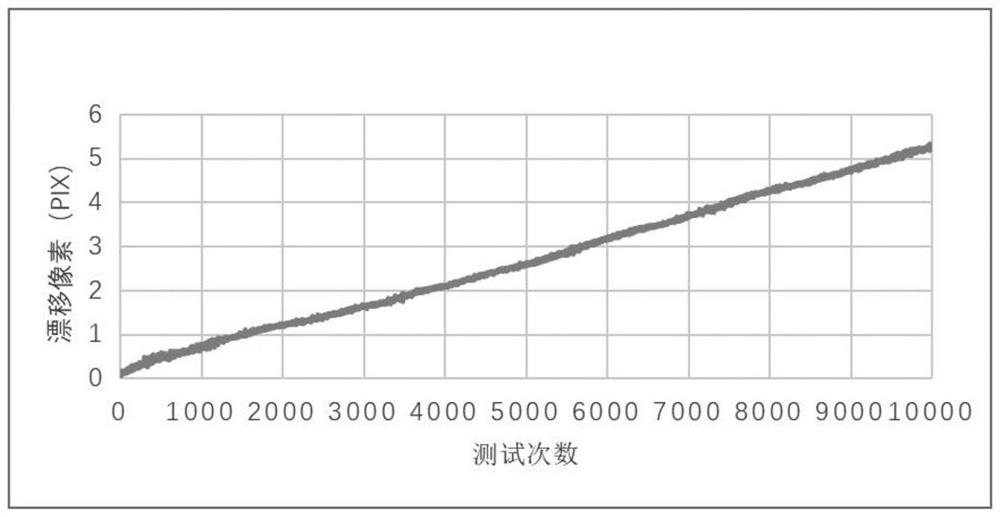

Micron-scale visual displacement calibration method and device

PendingCN113324477ASolve the technical problem of the decrease of measurement accuracyMeet high-precision measurement requirementsUsing optical meansComputer graphics (images)Radiology

The invention relates to a micron-scale visual displacement calibration method, wherein the method comprises the steps: selecting an object space telecentric lens / or a double telecentric lens as an image acquisition tool, selecting two objects to be calibrated as a movable calibration object and a fixed calibration object respectively, acquiring images of the calibration objects by the lens, and calculating to obtain a central pixel coordinate of a mark point; and calculating the actual displacement value of the center pixel coordinate of the mark point after the position of the movable calibration object is moved by combining the displacement of the movable calibration object and the center pixel coordinate offset value of the mark point caused by the influence of the temperature on the fixed calibration object. The invention also relates to a micron-scale visual displacement calibration device comprising a camera, an object space telecentric lens / or double remote lenses, the movable calibration object and the fixed calibration object. The technical problem that the measurement precision is reduced under the influence of environment temperature and camera self-heating is solved, the high-precision measurement requirement of visual displacement calibration in a normal-temperature environment is met, and the measurement precision can reach + / -1 micron.

Owner:济南蓝动激光技术有限公司

A Portable Train Wheel Front Sectional Profile Structured Light Vision Measurement System and Method

The invention discloses a portable train wheel normal section contour structured light vision measurement system and method. According to the method, a multi-line structured light vision sensor reconstructs general contours of train wheels at different visual angles, the general contours are rotated around an axis and projected to an axis passing plane, so that a normal section contour is obtained, and the complete normal section contour of the train wheels can be obtained by splicing measurement results at the multiple visual angles. The invention provides a train wheel normal section profilemeasurement method which is not constrained by the position and attitude of a sensor. The method has the characteristics of high measurement precision, high operation flexibility, high automation degree, strong robustness and the like.

Owner:BEIHANG UNIV

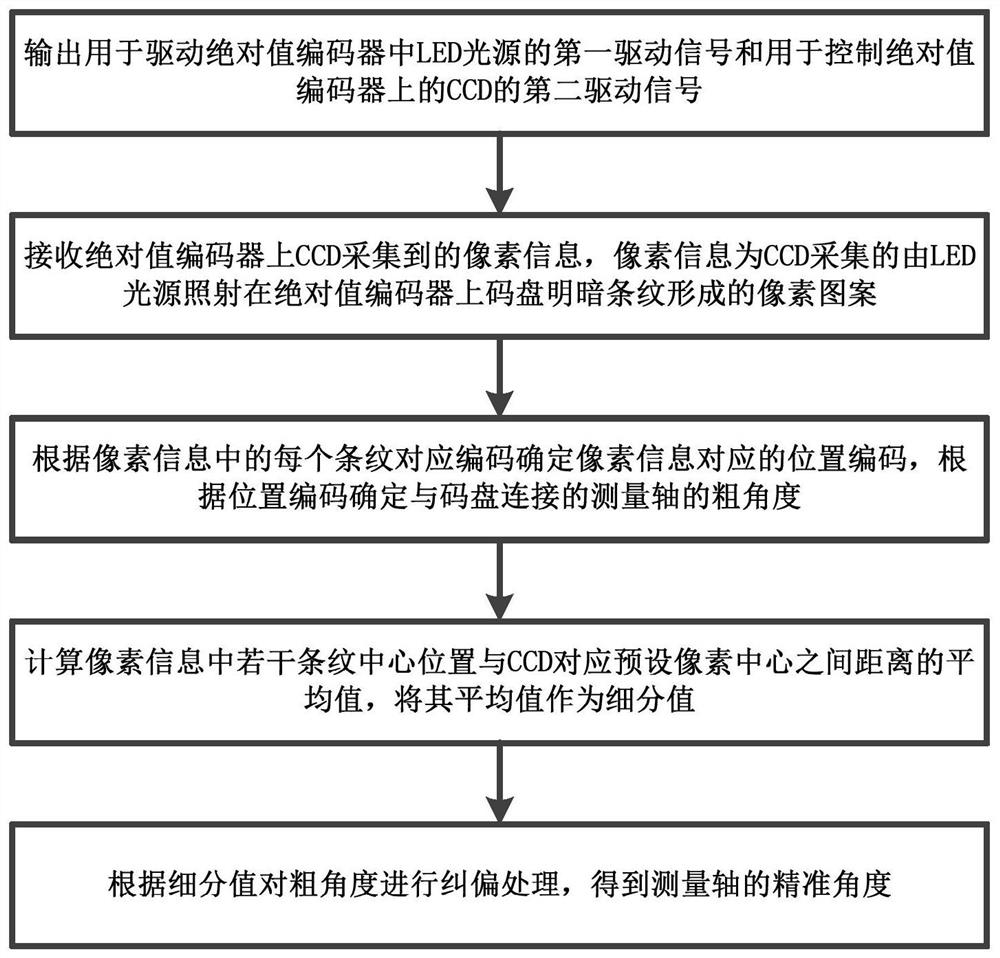

Decoding method of absolute value encoder, equipment medium and product

PendingCN113984094AHigh precisionMeet high-precision measurement requirementsDigital video signal modificationConverting sensor output opticallyEngineeringLight source

The invention relates to the field of absolute value code discs, and discloses a decoding method of an absolute value encoder, which comprises the following steps of: outputting a first driving signal for driving an LED light source and a second driving signal for controlling a CCD (Charge Coupled Device); receiving pixel information collected by a CCDon the absolute value encoder, wherein the pixel information is a pixel pattern which is collected by the CCD and formed by light and dark stripes of a coded disc irradiated by an LED light source on the absolute value encoder; determining a position code corresponding to the pixel information according to the code corresponding to each stripe in the pixel information, and determining a coarse angle of a measuring shaft connected with the coded disc according to the position code; calculating the average value of the distances between the center positions of a plurality of stripes in the pixel information and the center of a preset pixel corresponding to the CCD as a subdivision value; and correcting the rough angle according to the subdivision value to obtain an accurate angle of the measuring shaft. According to the invention, the precision of the output angle of the absolute value coded disc is improved, so that the high-precision measurement requirements of different external measurement devices are met.

Owner:GUANGZHOU SOUTH SATELLITE NAVIGATION INSTR

A processing method for a multi-capacitance comb-tooth micro-accelerometer

InactiveCN105399047BGood size controlSimple processDecorative surface effectsAcceleration measurementCapacitanceAccelerometer

The invention provides a method for machining a multi-capacitor comb micro-accelerometer. The method comprises the following steps: performing shallow slot etching on the surface of a structural layer by means of photoetching; performing photoetching on the surface of the structural layer to define a structural pattern of the micro-accelerometer; etching the structural layer to an insulating layer by adopting deep reactive ion etching (DRIE); corroding the insulating layer by an HF solution; performing photoetching on a glass sheet, corroding glass by a BHF solution, and making a metal electrode and a lead by using a peeling process; bonding the structural layer and the glass sheet; thinning a silicon wafer substrate layer by using a KOH solution; performing photoetching on the surface of the substrate layer, and making a metal electrode by using the peeling process; performing photoetching on the surface of the substrate layer to define the structural pattern of the micro-accelerometer, and etching the substrate layer to the insulating layer by adopting DRIE; and performing splitting, packaging and testing to obtain the required multi-capacitor comb micro-accelerometer. According to the machining method, the detection capacitance area and the masses of mass blocks are increased by the substrate layer, and a produced product has the advantages of high size controllability, simple process, large detection capacitance and capability of meeting the high-accuracy measurement requirement.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

Bubble-free refraction liquid applying device and bubble-free refraction liquid applying method

InactiveCN102507442BApply evenlyMeet high-precision measurement requirementsMaterial analysis by optical meansEngineeringVacuum pump

The invention relates to a bubble-free refraction liquid applying device and a bubble-free refraction liquid applying method. The device is composed of a vacuum pump, multiple air tube segments, a filter, a filter flask, a vacuum chuck, a pasting plate and a piece under test. The vacuum pump, the filter, the filter flask and the vacuum chuck are connected in series by the multiple air tube segments; an adsorption port of the vacuum chuck naturally fits a small hole on the external surface of the pasting plate; two surfaces of the piece under test respectively fit the inner surfaces of two laying plates to form a gap; a dropper is located over the circumferential gap of the piece under test and the pasting plates, and the refraction liquid is continuously added at the edge of the gap through the dropper, so that the refraction liquid is absorbed in the gap between the pasting plates and the piece under test. The method comprises the following steps of: while applying the refraction liquid, starting the vacuum pump to form negative pressure in the gap between the pasting plates and the piece under test, continuously dropping the refraction liquid at the edge of the gap, so as to make the refraction liquid be absorbed in the gap, and finishing the applying of the refraction liquid, until the whole gap is full of the refraction liquid.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com