Non-contact type measuring system for train axle wheel seat and measuring method thereof

A measurement system and a technology for train axles, applied in the field of measurement, can solve the problems of difficult system measurement accuracy, low measurement accuracy, and inability to select and match.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

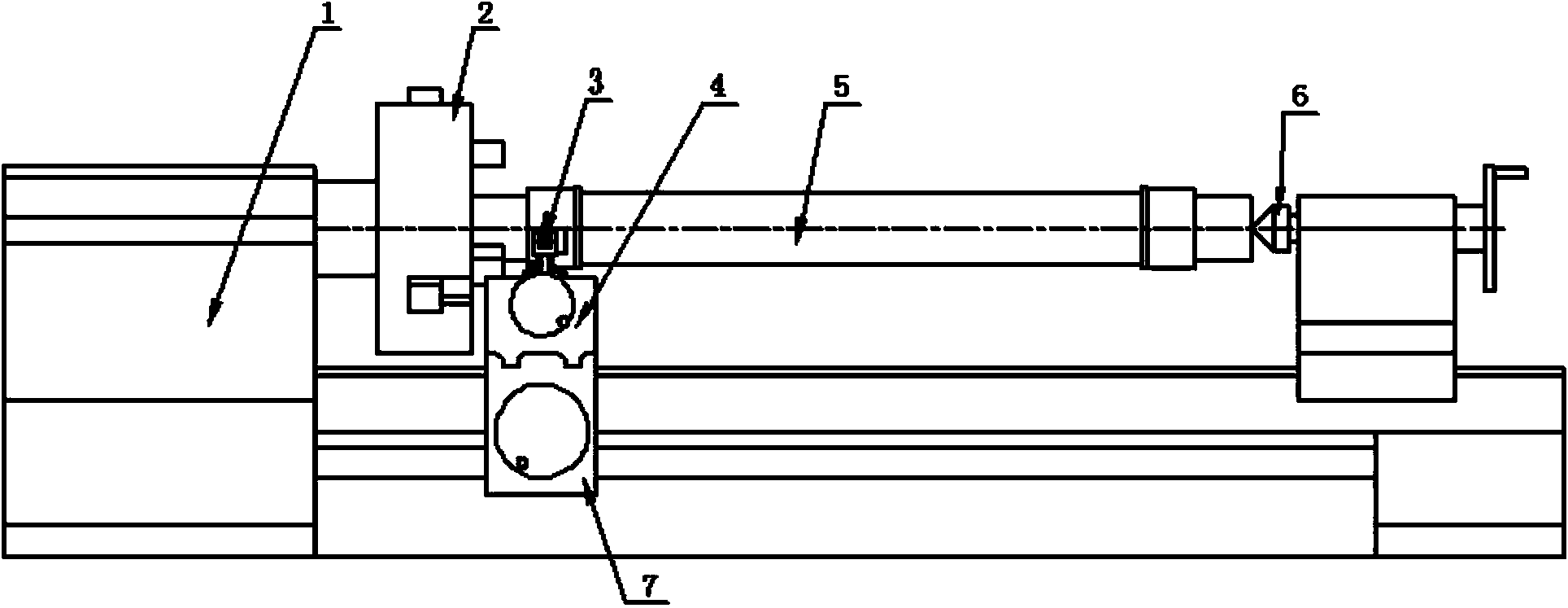

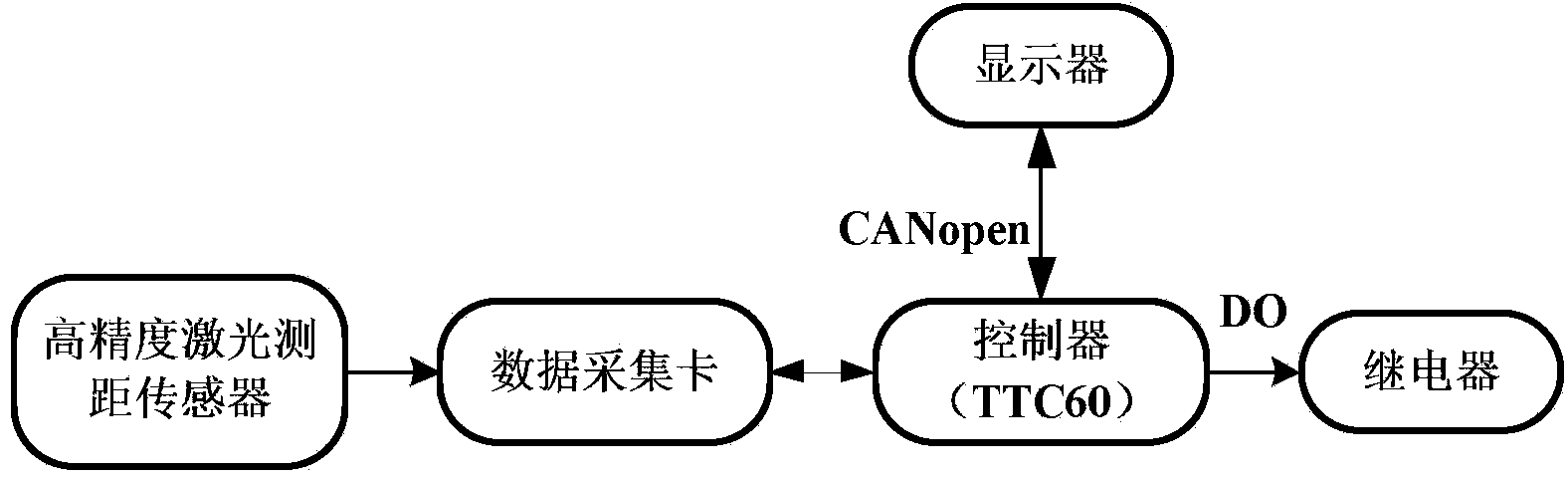

[0042] like figure 1 , 3 As shown, a non-contact measuring system for the diameter of the wheel seat of a train axle consists of a hardware part and a software part. The hardware part consists of a C6180 lathe and a laser distance measuring sensor of the German SICK model OD5-85W20 (see the main technical parameters below. Table) and its fine-tuning device, data acquisition card, TTC60 main controller, AT3000 display, relay and cable power supply; the software part is composed of signal communication module, drive control module, data acquisition and processing module.

[0043]

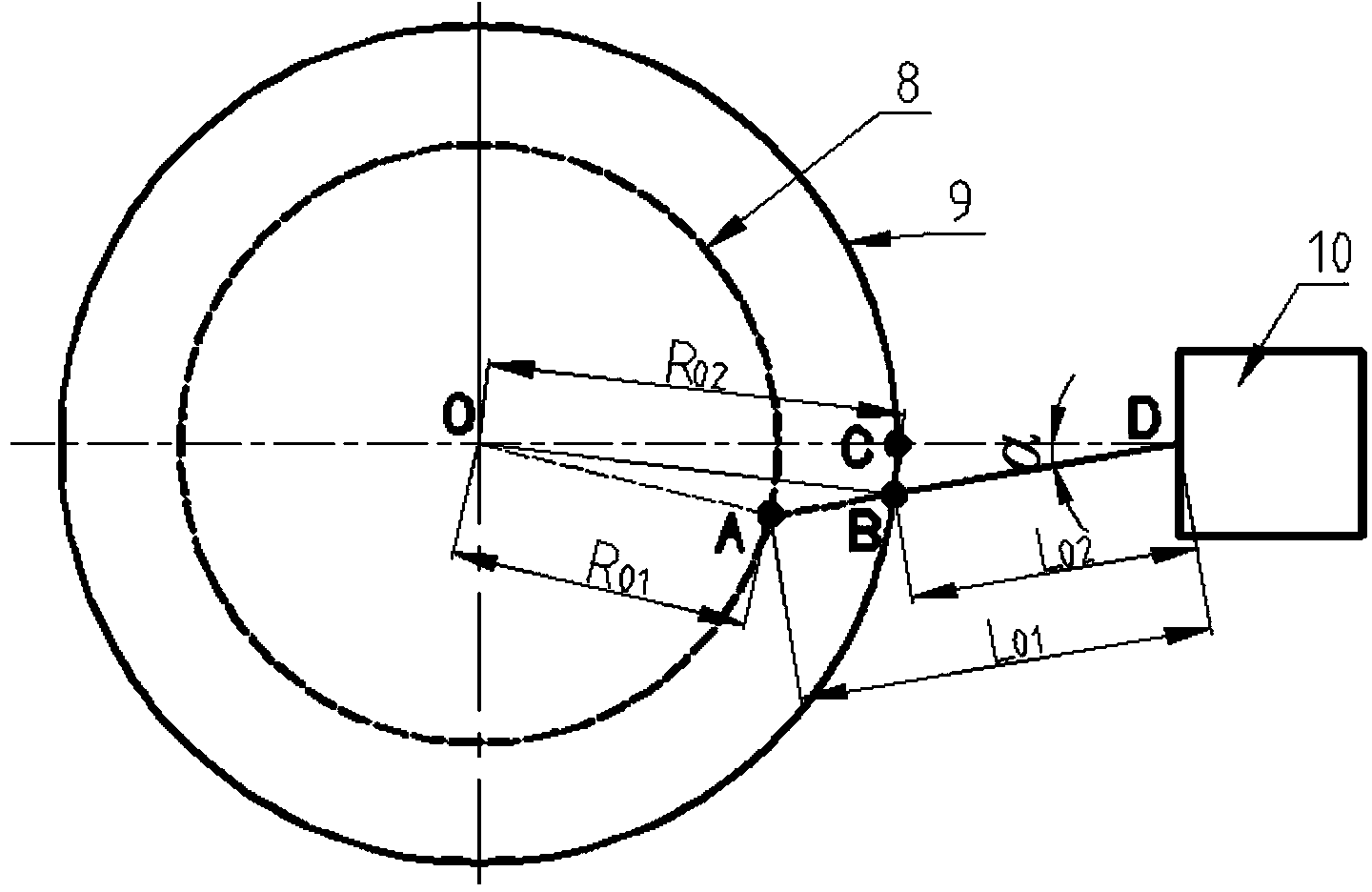

[0044] like figure 1 , 2 , As shown in 4, a simple modification is made to the C6180 lathe, the tool holder on the lathe slide box is removed, and an OD5-85W20 laser ranging sensor is replaced. Will 1 # The standard measuring rod 8 is installed on the lathe to ensure that its axis coincides with the rotation axis of the lathe, and the vertical worm 11 and the horizontal worm 16 are repeatedly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com